Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

964results about How to "Improve sintering performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

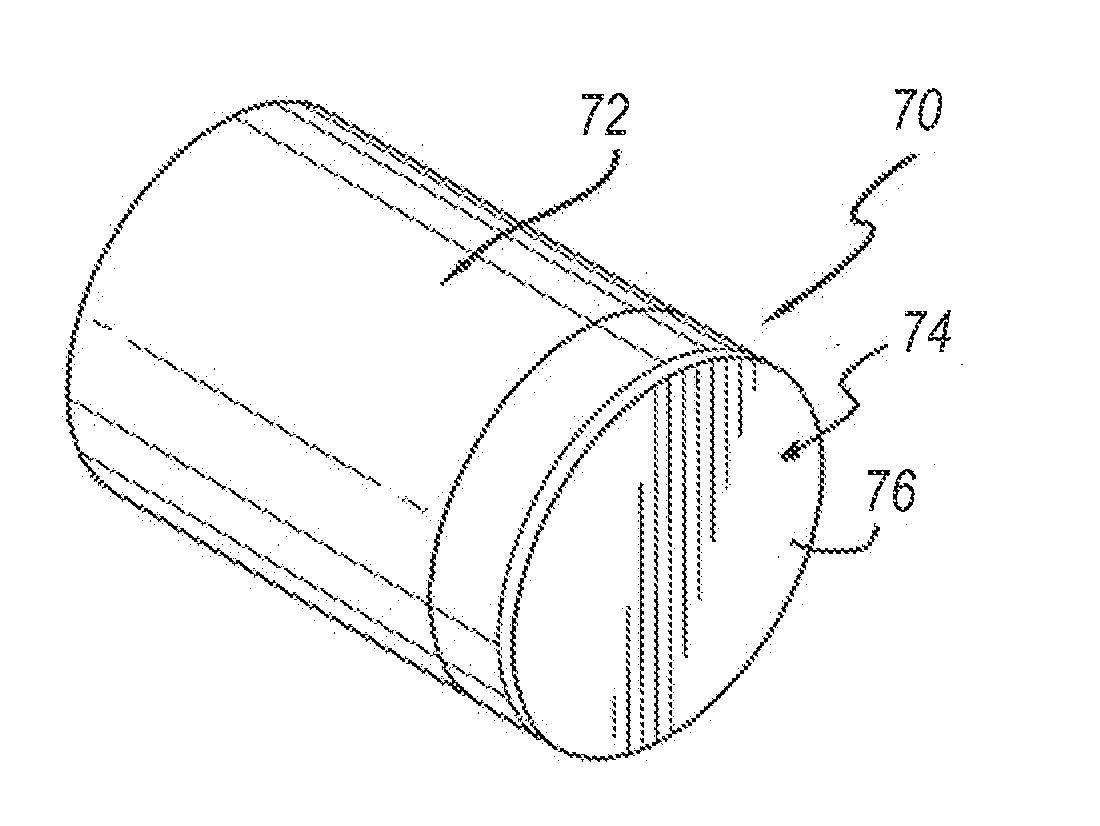

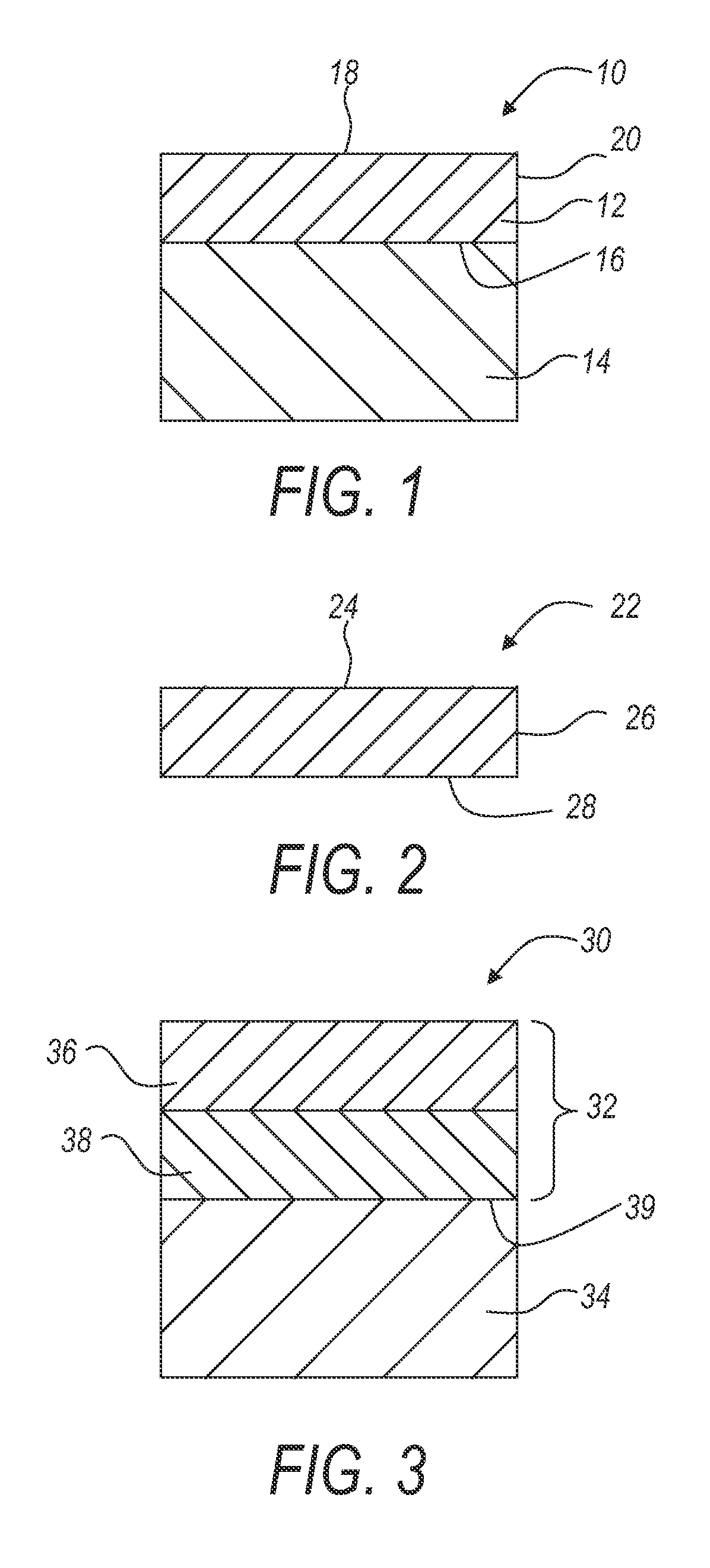

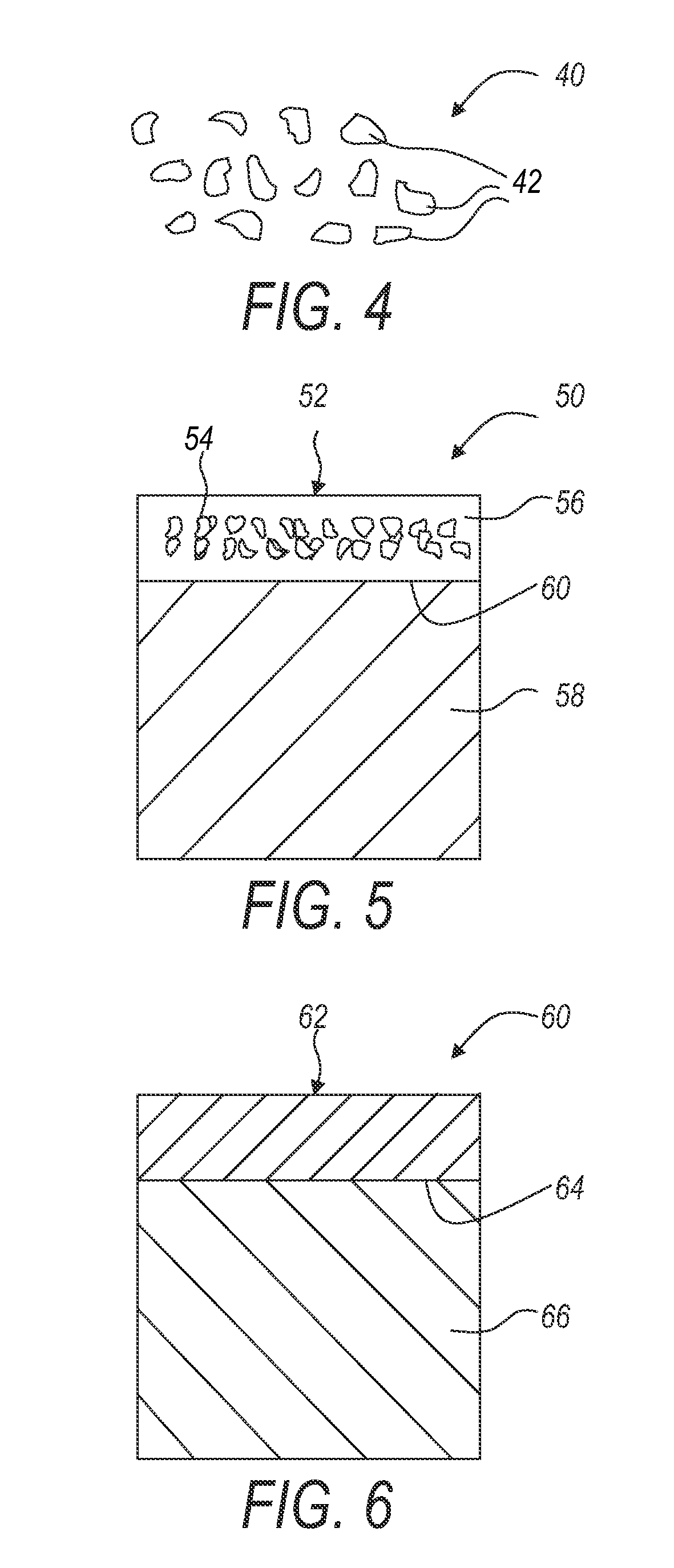

Diamond Bonded Construction Comprising Multi-Sintered Polycrystalline Diamond

InactiveUS20110083908A1Lower Level RequirementsImprove sintering performancePigmenting treatmentDrill bitsPolycrystalline diamondVolume content

Diamond bonded constructions comprise a diamond body attached to a substrate, wherein the body includes a first diamond bonded volume, and a second diamond bonded volume attached thereto. The second volume may be provided in the form of a powder or a presintered mass prior to attachment, and the first volume may be provided in the form of presintered pieces when combined with the second volume. The first volume diamond volume content is greater than about 94 percent, and is the same or greater than that of the second volume. The first volume is sintered during a first HPHT process, and the second volume is sintered and / or attached to the first volume during a second HPHT process. The first HPHT pressure is greater than the second HPHT pressure. The substrate is not an infiltration substrate used to form the first diamond volume. The diamond body may be thermally stable.

Owner:SMITH INT INC

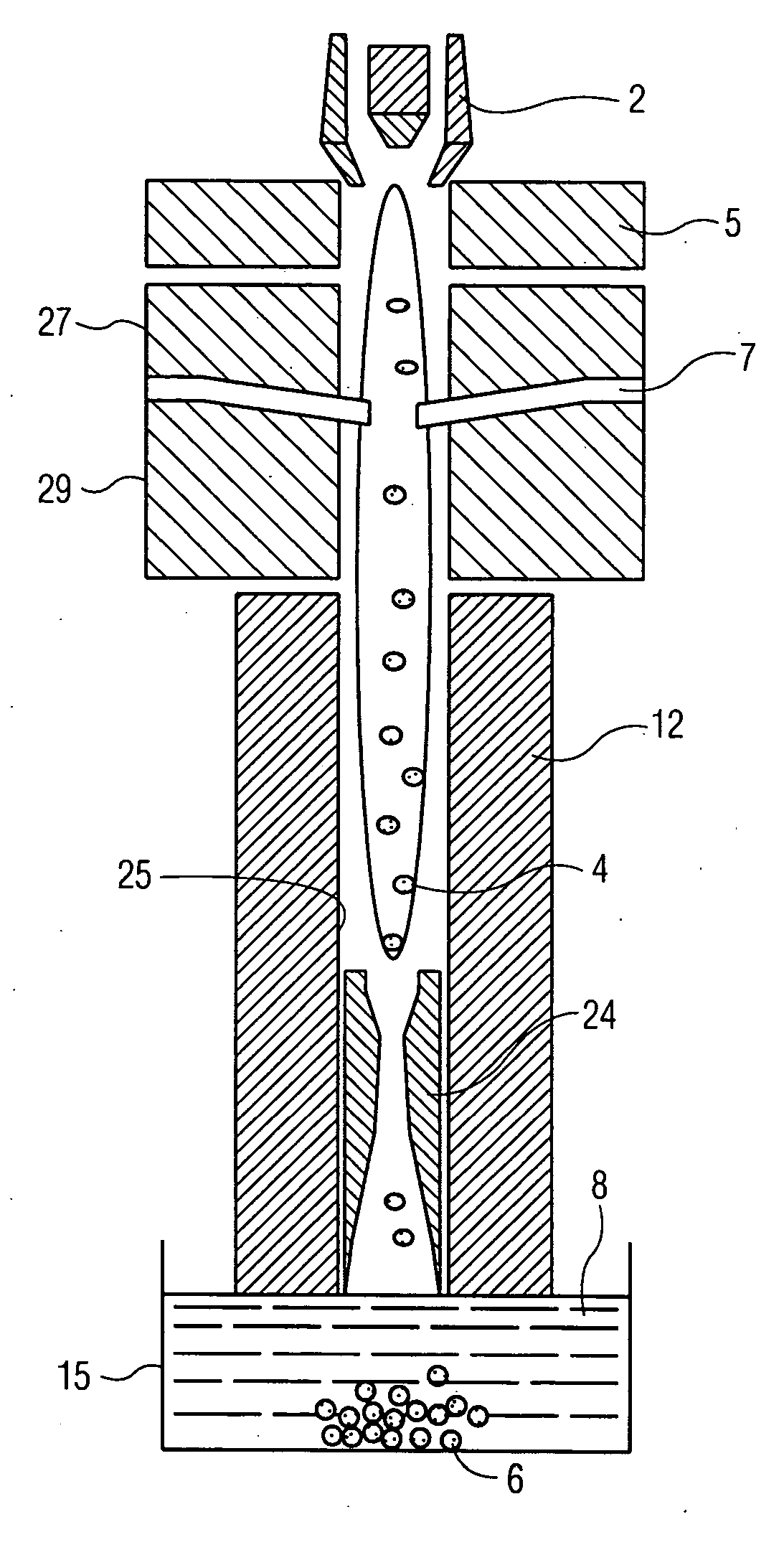

Shrouded-plasma process and apparatus for the production of metastable nanostructured materials

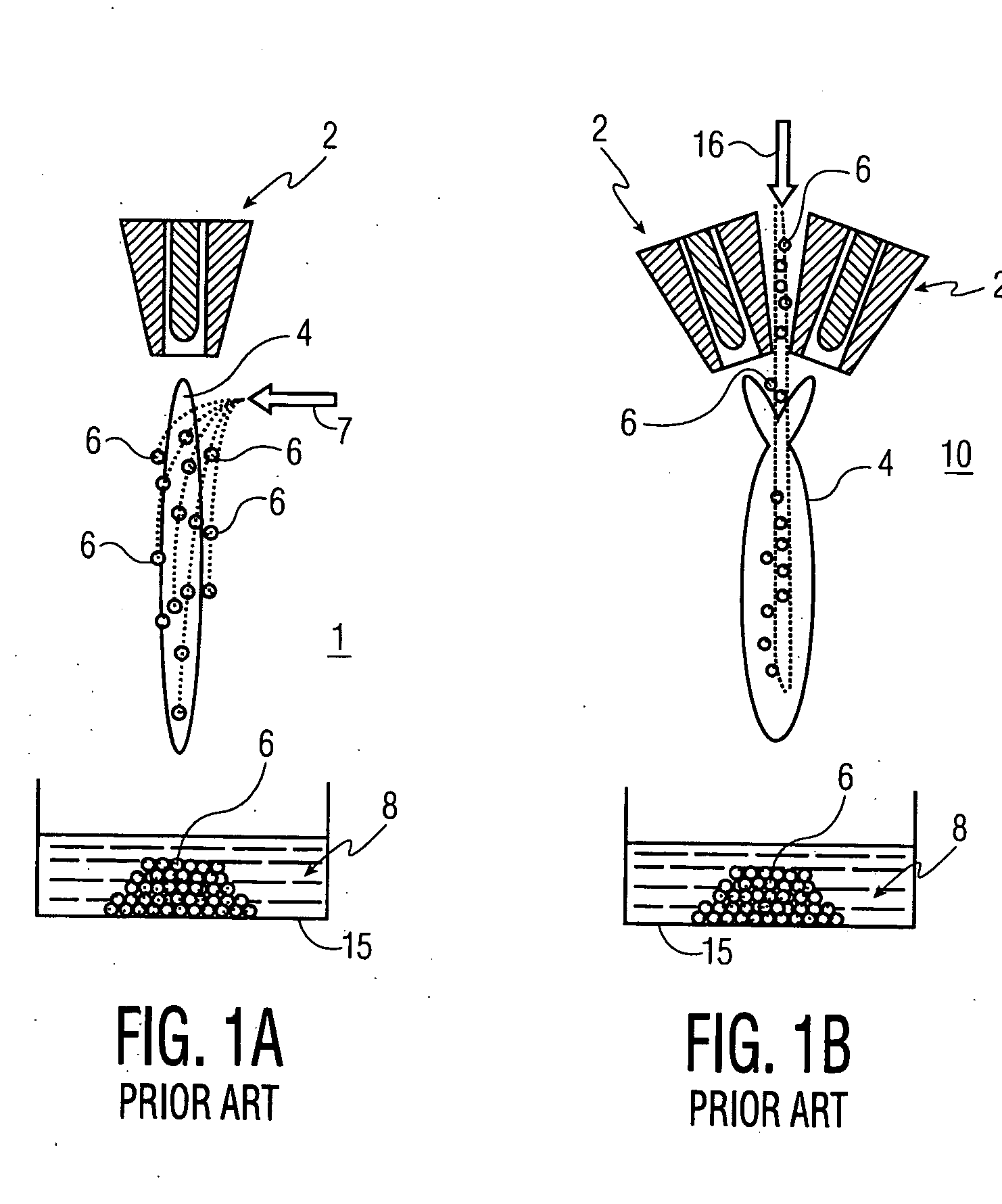

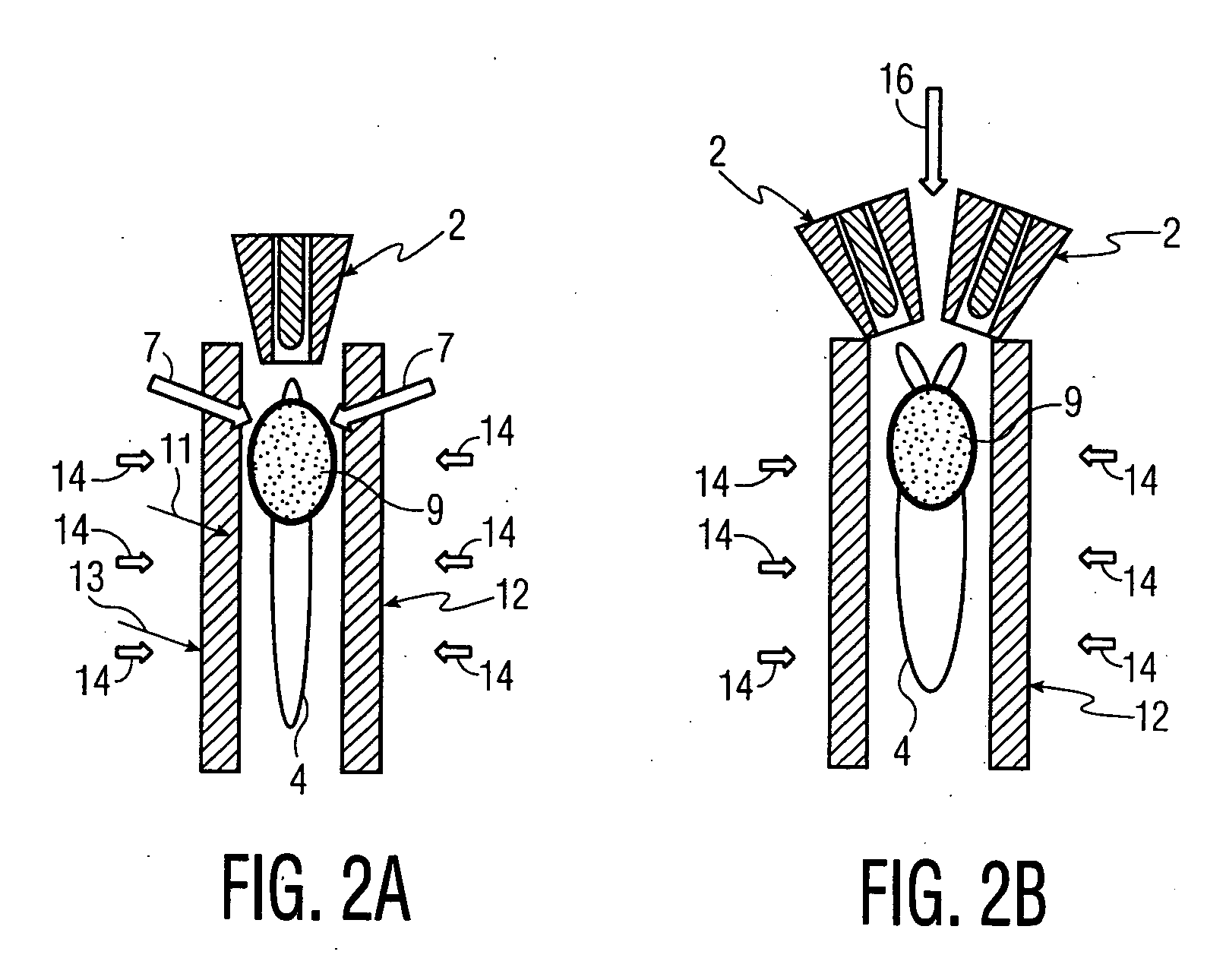

InactiveUS20070044513A1Improve compactnessImprove sintering performanceMaterial nanotechnologyNitrogen compoundsLiquid jetShort range order

A method and apparatus for producing metastable nanostructured materials employing a ceramic shroud surrounding a plasma flame having a steady state reaction zone into which an aerosol or liquid jet of solution precursor or powder material is fed, causing the material to be pyrolyzed, melted, or vaporized, followed by quenching to form a metastable nanosized powder that has an amorphous (short-range ordered), or metastable microsized powder that has a crystalline (long-range ordered) structure, respectively.

Owner:RUTGERS THE STATE UNIV

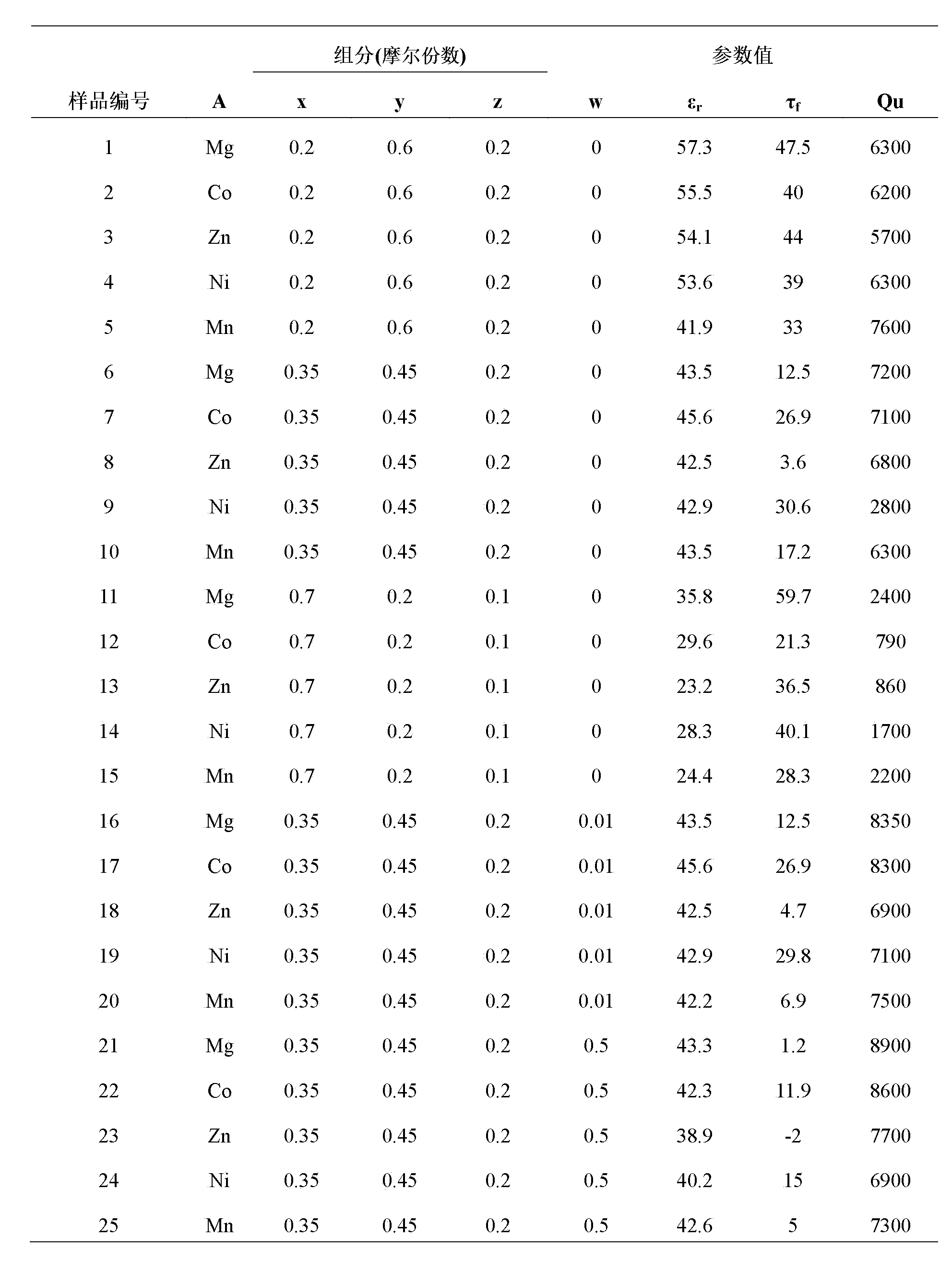

Microwave dielectric ceramic and preparation method thereof

The invention discloses a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic is mainly composed of ZrO2, TiO2 and Nb2O5; the microwave dielectric property of the microwave dielectric ceramic can be improved by selectively adding MgO, CoO, ZnO, NiO and MnO2; the chemical constitution formula of the ceramic is xZrO3-YTiO2-zA(1+W) / 3Nb(2-w) / 2O3; in formula (I), A is one or more elements of Mg, Co, Zn, Ni and Mn; x, y and z are molar ratios, wherein x is between 0.2 and 0.7, y is between 0.2 and 0.6,, z is between 0.1 and 0.2, and, x plus y plus z is equal to 1; numerical range of w is l between 0 and 0.5. According to the microwave dielectric ceramic and the preparation method thereof, the ceramic has the characteristics that the dielectric constant is high, the loss is low, and the temperature coefficient is close to zero, and is liable to sinter; the preparation method has the characteristics that the price of raw materials is low, and a technology during production is simple.

Owner:HEFEI NORMAL UNIV

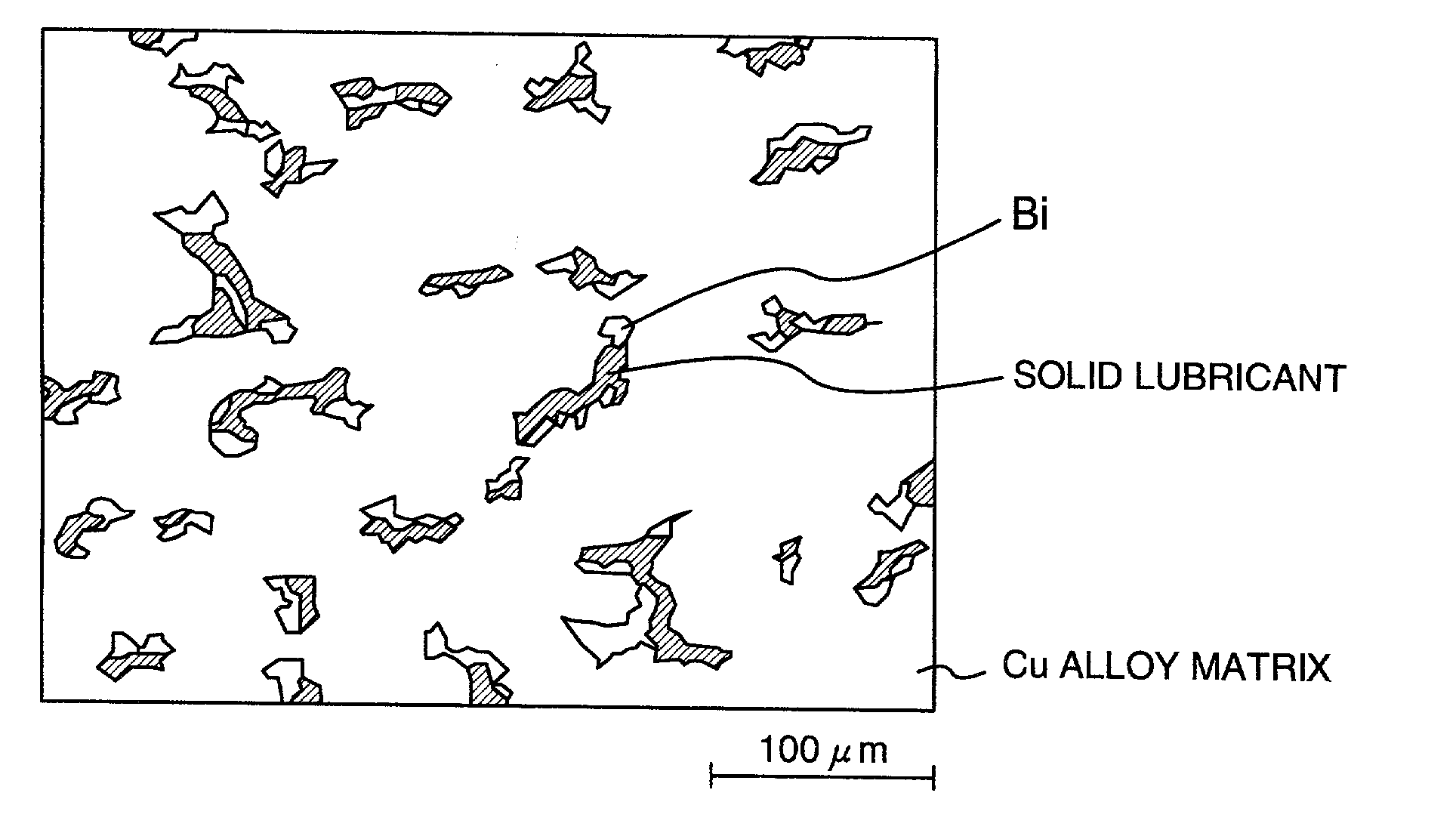

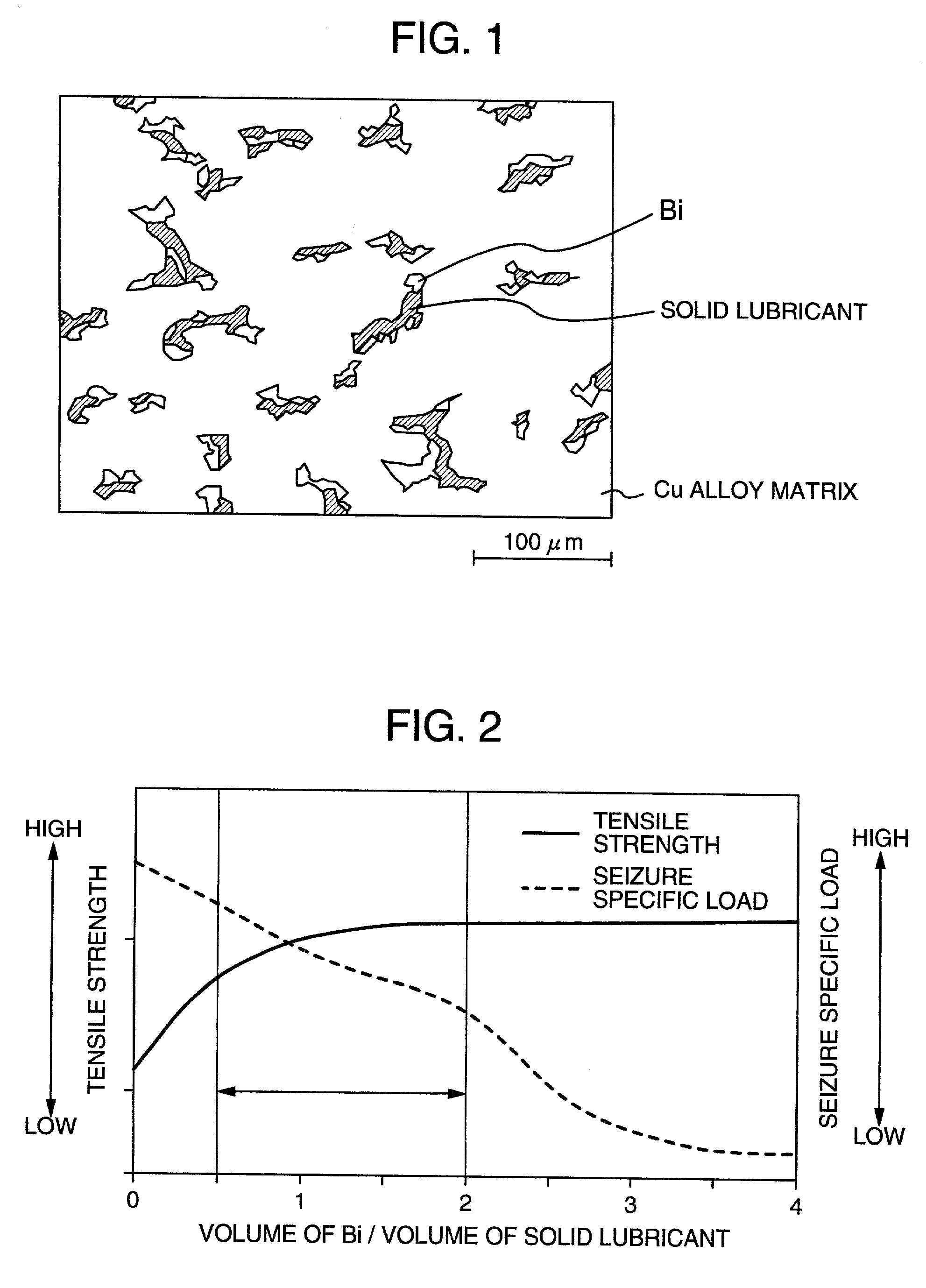

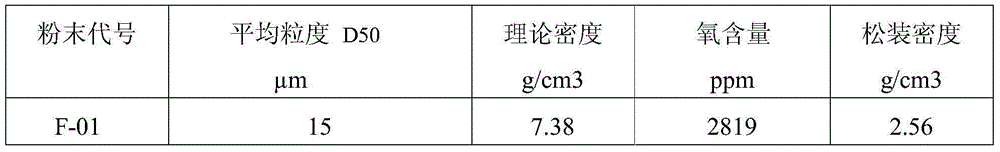

Composite sliding material

InactiveUS20030008169A1Avoid mechanical strengthImprove sintering performanceShaftsBearing componentsSteel platesCopper alloy

Disclosed is a composite sliding material having a steel plate and a sintered copper alloy layer which is bonded to the steel plate. The copper alloy contains, 1.5 to 15 mass % Sn, 1.5 to 15 mass % Bi, 1.5 to 20 volume % of a solid lubricant, and balance of Cu and incidental impurities. The volume ratio of Bi to the solid lubricant is in a range of 0.5 to 2.0. Bi and the solid lubricant improves the copper alloy in sintering property, since Bi melts when sintering because of a low melting point resulting in improved sintering property, and the solid lubricant ensures good anti-seizure property, and deterioration of mechanical strength is prevented by virtue of a phenomenon that the solid lubricant is entrained in Bi.

Owner:DAIDO METAL CO INC

Circular diamond saw blade bit and manufacturing method thereof

The invention discloses a circular diamond saw blade bit and a manufacturing method thereof. The circular diamond saw blade bit is made of diamond particles and matrix powder used for consolidation of the diamond particles. The matrix powder comprises, by mass percent, 40%-80% of Fe, 15%-30% of Cu, 0%-10% of Ni, 2%-8% of Sn, 0%-10% of Co, 0%-5% of Me and the balance inevitable impurities. Me is at least one of Mn, Ti, Si, Cr, P and Al. The manufacturing method comprises the steps of mixing raw materials, conducting cold-press molding and free sintering. The manufacturing method is simple and can effectively avoid the loss of a graphite mould and reduce manufacturing cost. Meanwhile, a volume production requirement can be met, and blade bits in complicated shapes can be produced; production efficiency is prolonged, and the service life of the tool is similar to that of a tool manufactured through a hot-press sintering method; the purpose that high-quality diamond cutting tools are produced under the condition of low cost can be achieved; and the circular diamond saw blade bit and a manufacturing method thereof are easy to popularize in an industrialized manner.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Method of recovery copper, nickel and noble metal in waste water and slag by combined technology of wet method and fire method

A process for recovering the copper, Ni and noble metals from the sewage and dregs by the combination of wet method and fire method includes the wet process including extracting, Cu-Ni separation, removing Fe, extracting, and refining nickel carbonate, and the fire process including sintering and smelting to produce nickel matte and black copper. Its advantages are high recovery rate of Ni, Cu, Au, Ag and Pd, and no secondary pollution.

Owner:孙涛 +1

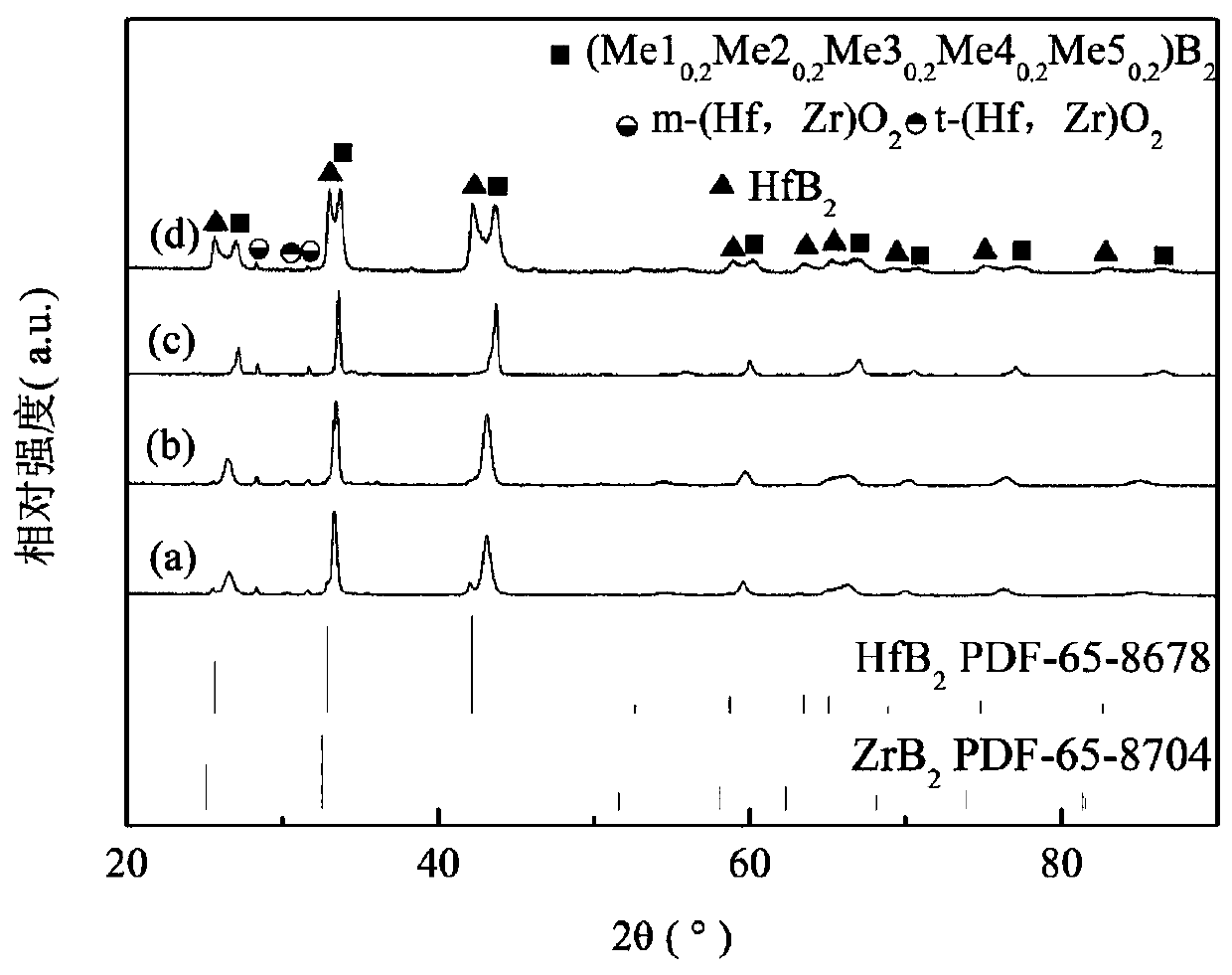

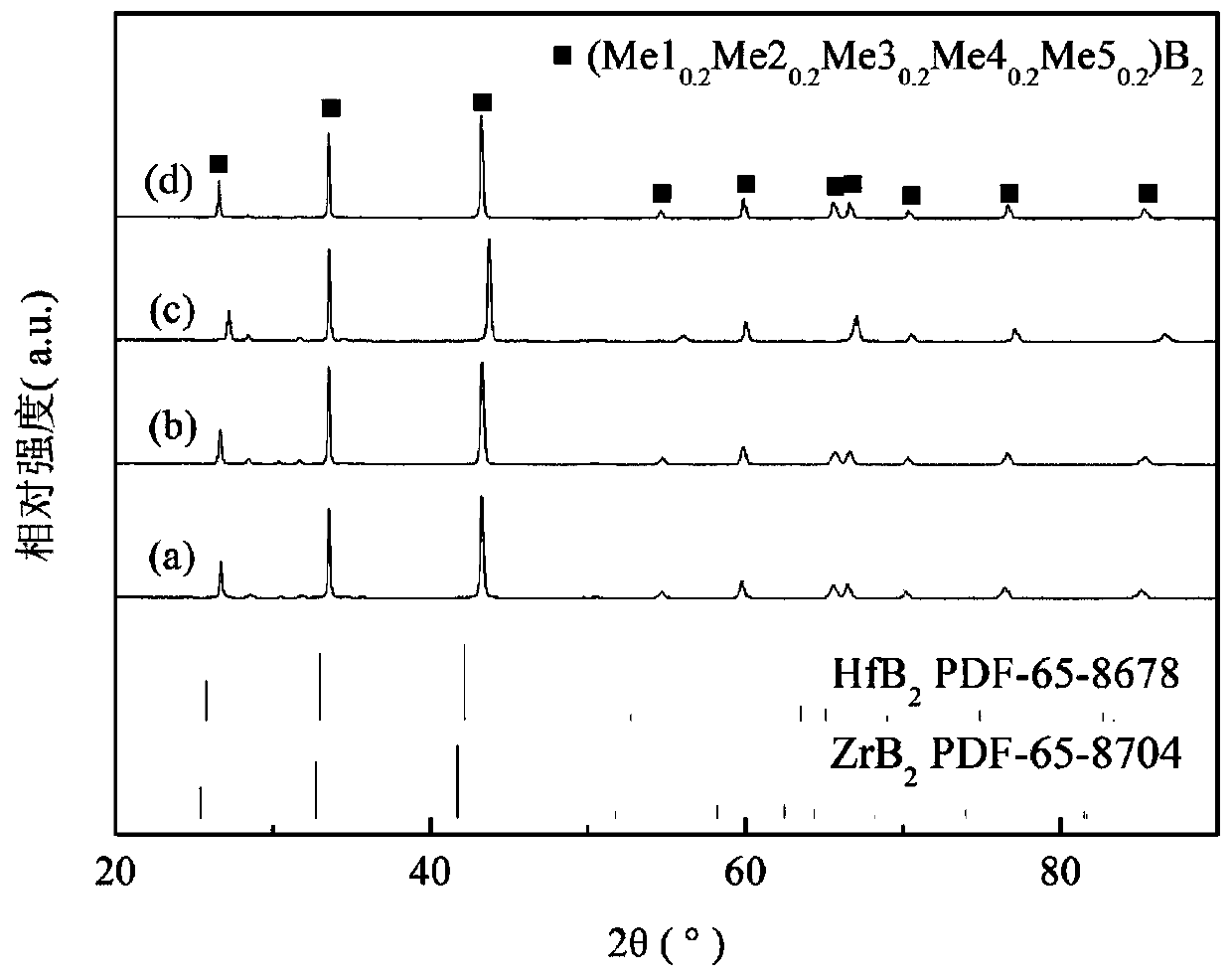

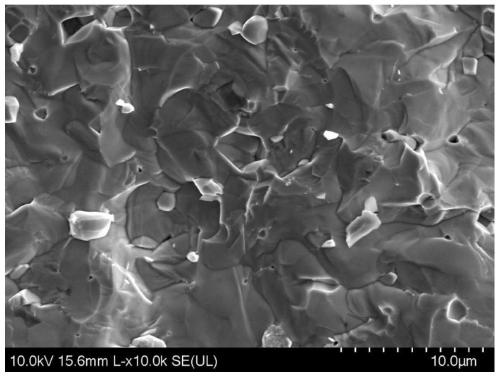

Compact and superhard high-entropy boride ceramic as well as preparation method and application thereof

The invention belongs to the technical field of ceramic materials and discloses novel compact and superhard high-entropy boride ceramic as well as a preparation method and an application thereof. (M1xM2yM3zM4nM5m)B2 ceramic is prepared as follows: metal oxide, B4C and graphite powder are used as raw materials and pressed into a body after ball milling and mixing; high-entropy boride ceramic powderis obtained after thermal treatment; protective atmosphere is charged after the powder is heated to 1,000-1,400 DEG C, then, the powder is heated to 1,800-2,200 DEG C for calcination, and compact andsuperhard (M1xM2yM3zM4nM5m)B2 ceramic is prepared, wherein x is larger than or equal to 0.1 and smaller than or equal to 0.9, y is larger than or equal to 0.1 and smaller than or equal to 0.9, z is larger than or equal to 0.1 and smaller than or equal to 0.9, n is larger than or equal to 0.1 and smaller than or equal to 0.9, m is larger than or equal to 0.1 and smaller than or equal to 0.9, and the sum of x, y, z, n and m is 1. The ceramic material has relative density larger than 98%, hardness of 32-45 GPa, fracture toughness of 3-10 MPa.m<1 / 2 >and carbon content of 0.1wt%-1wt%.

Owner:GUANGDONG UNIV OF TECH

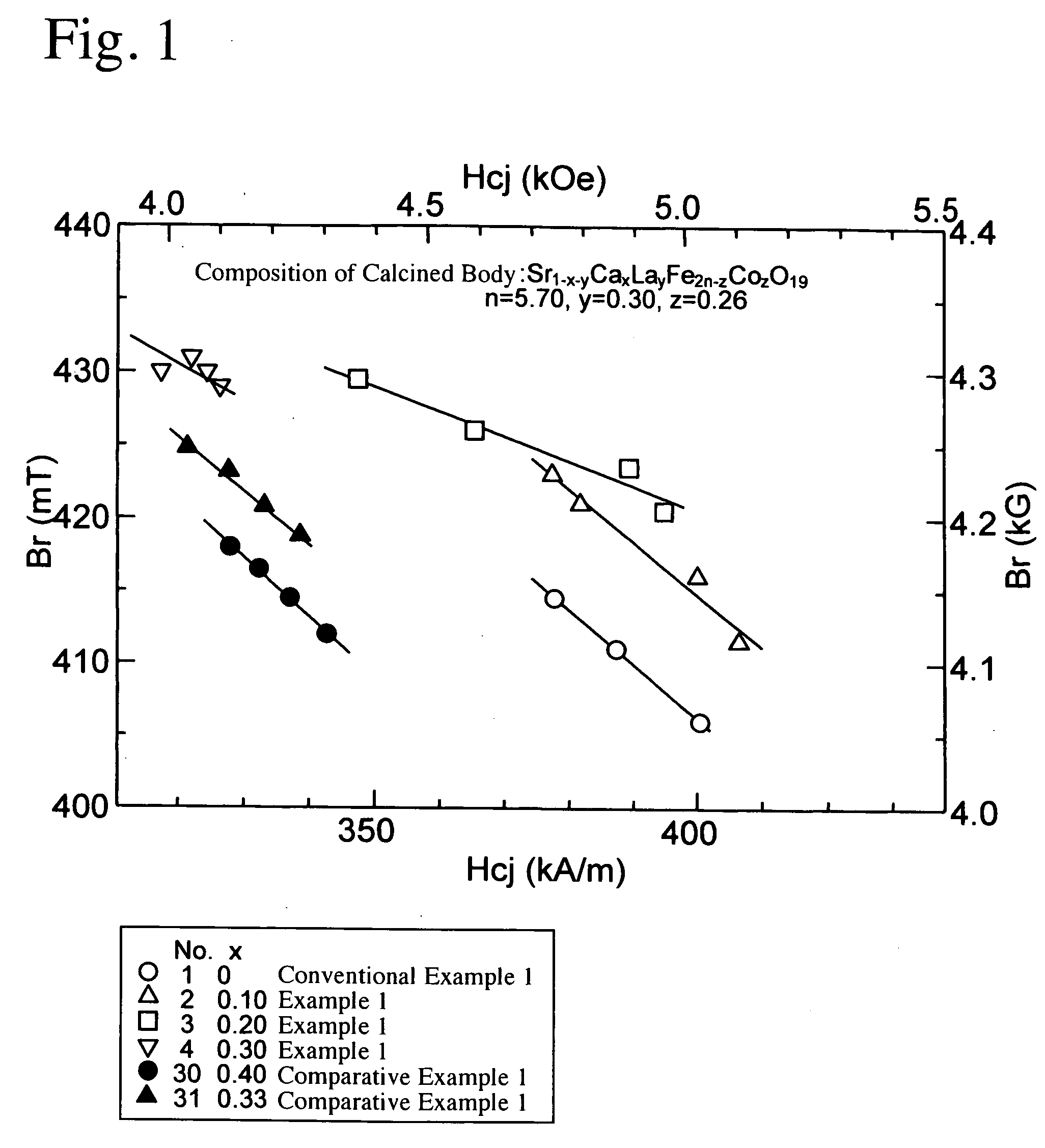

Ferrite sintered magnet

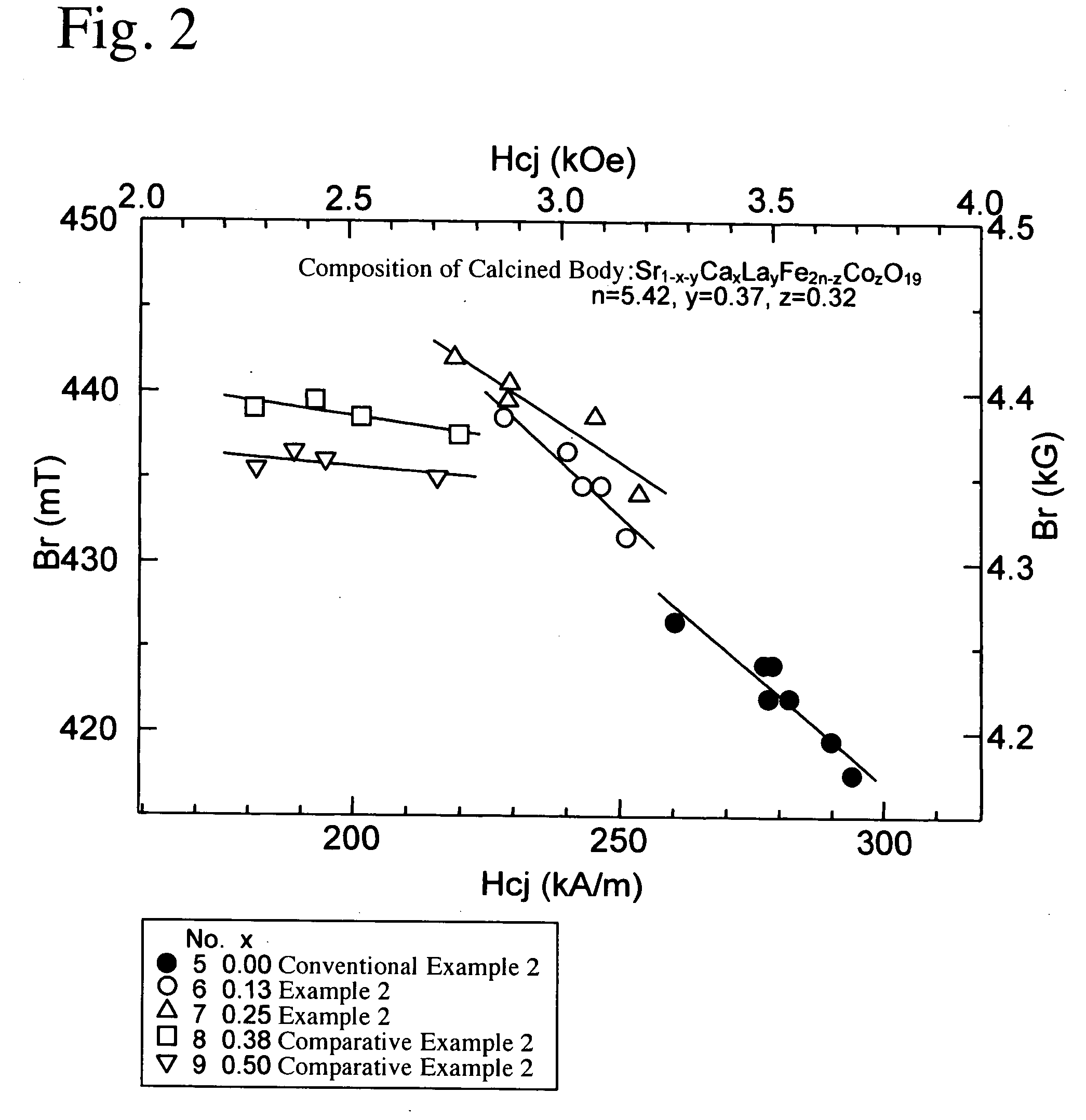

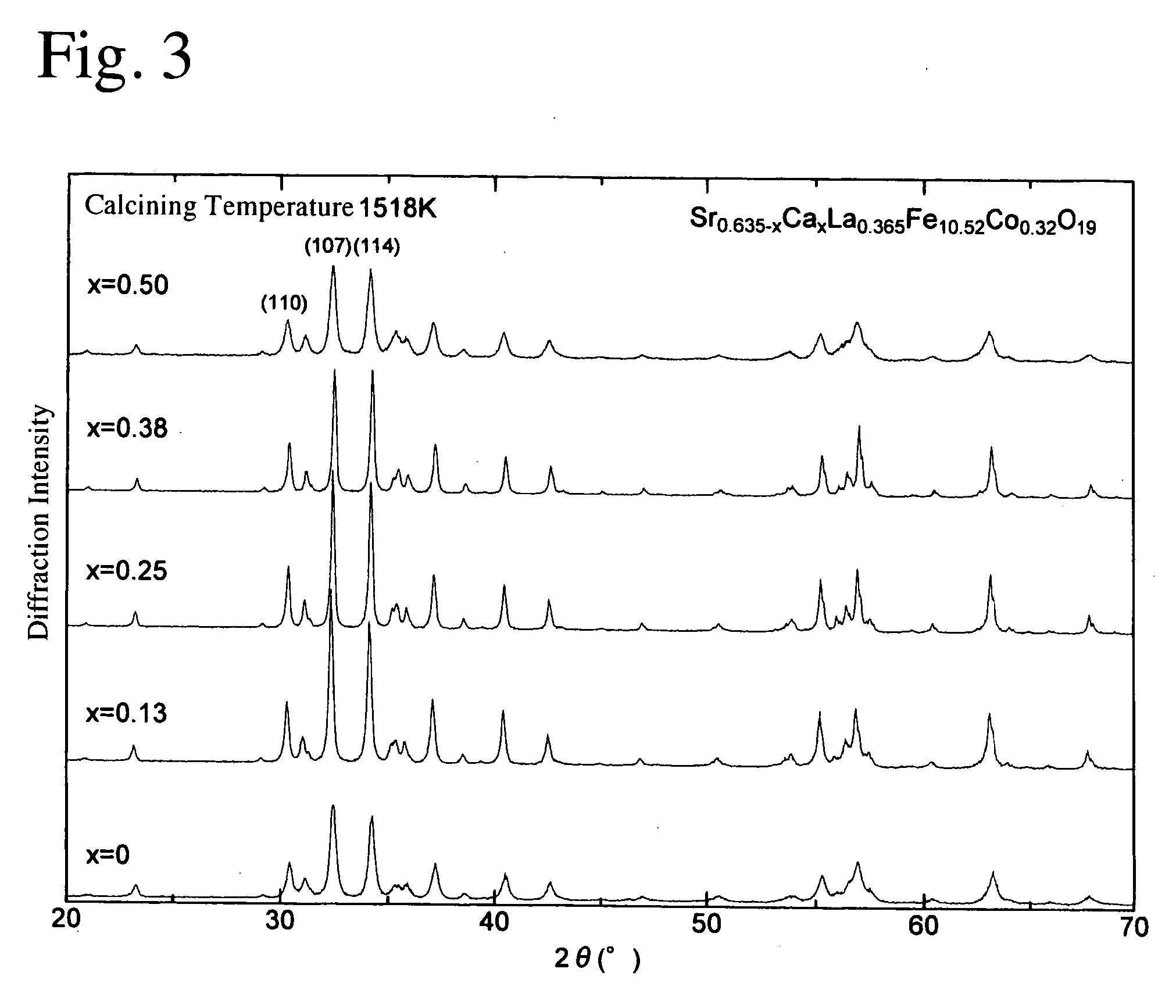

ActiveUS20060284136A1High residual magnetic flux density BrImprove intrinsic coercive forceInorganic material magnetismFerroso-ferric oxidesSintered magnetsFerrite (magnet)

A sintered ferrite magnet having a basic composition represented by the general formula: A1−x−y+aCax+bRy+cFe2n−zCoz+dO19 (atomic ratio), wherein a, b, c and d represent the amounts of an A element, Ca, an R element and Co added in the pulverization step of an oxide magnet material, which are numerals meeting the conditions of 0.03≦x≦0.4, 0.1≦y≦0.6, 0≦z≦0.4, 4≦n≦10, x+y≦1, 0.03≦x+b≦0.4, 0.1≦y+c≦0.6, 0.1≦z+d≦0.4, 0.50≦[(1−x−y+a) / (1−y+a+b)]≦0.97, 1.1≦(y+c) / (z+d)≦1.8, 1.0≦(y+c) / x≦20, and 0.1≦x / (z+d)≦1.2.

Owner:HITACHI METALS LTD

Lightweight vitreous foamed ceramic

The invention discloses improvement to lightweight vitreous foamed ceramics and is characterized in that: a lightweight vitreous foamed ceramic mainly comprises 50 to 95 wt % of ceramic walls, a floor tile grinding wet powder skeleton material, 5 to 50 wt % of china clay and / or talcum and / or bentonite and / or tremolite and / or saponite fine powder matrix material and 0 to 8 wt % of a foaming agent; the above-mentioned materials are mixed and sintered at a temperature equal to or above a vitrification point of the matrix material. According to the invention, composition and ratio are simplified, composing materials basically comprise only two materials, mutual influence between the materials is small, it is easy to control the process of manufacturing, and therefore, a preparation process has good stability and products of different batches have stable performance and good consistency; a main raw material is waste materials generated in the production of ceramics, and the raw material is easily available and enables preparation cost to be substantially reduced and primary minerals to be saved; tangent planes of a prepared product are basically of a uniform noncommunicating subtle enclosed foam structure, the prepared product has volume density (unit weight) of 0.35 to 0.48 g / cm<3>, compressive strength at normal temperature of 9.0 to 9.6 Mpa and a heat conduction coefficient at a temperature of 70 DEG C (on average) of 0.168 to 0.182 W(m.k), and the natural color of the product (without addition of pigments) is white and greenish and appears to be tattletale gray.

Owner:江苏赛宇环保科技有限公司

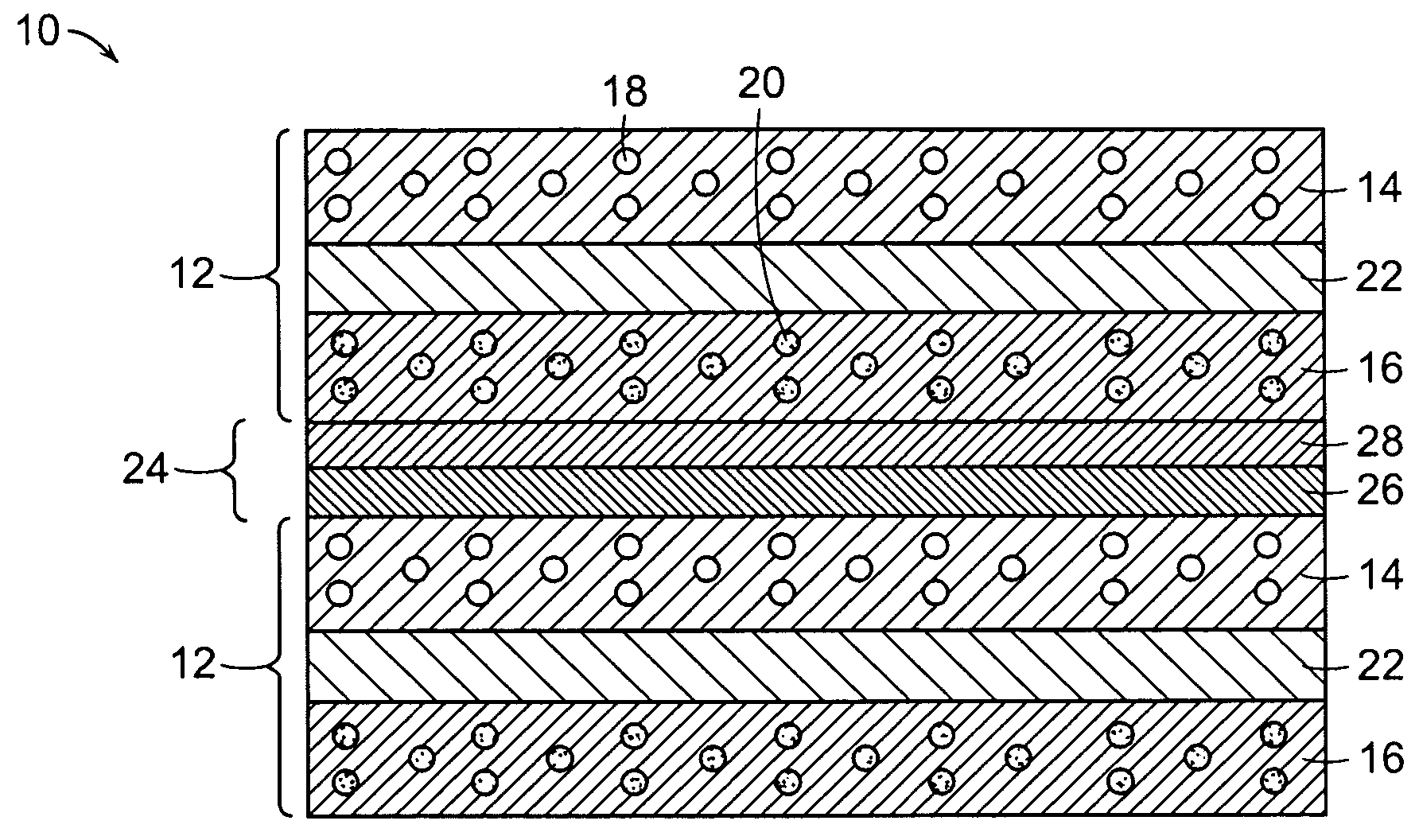

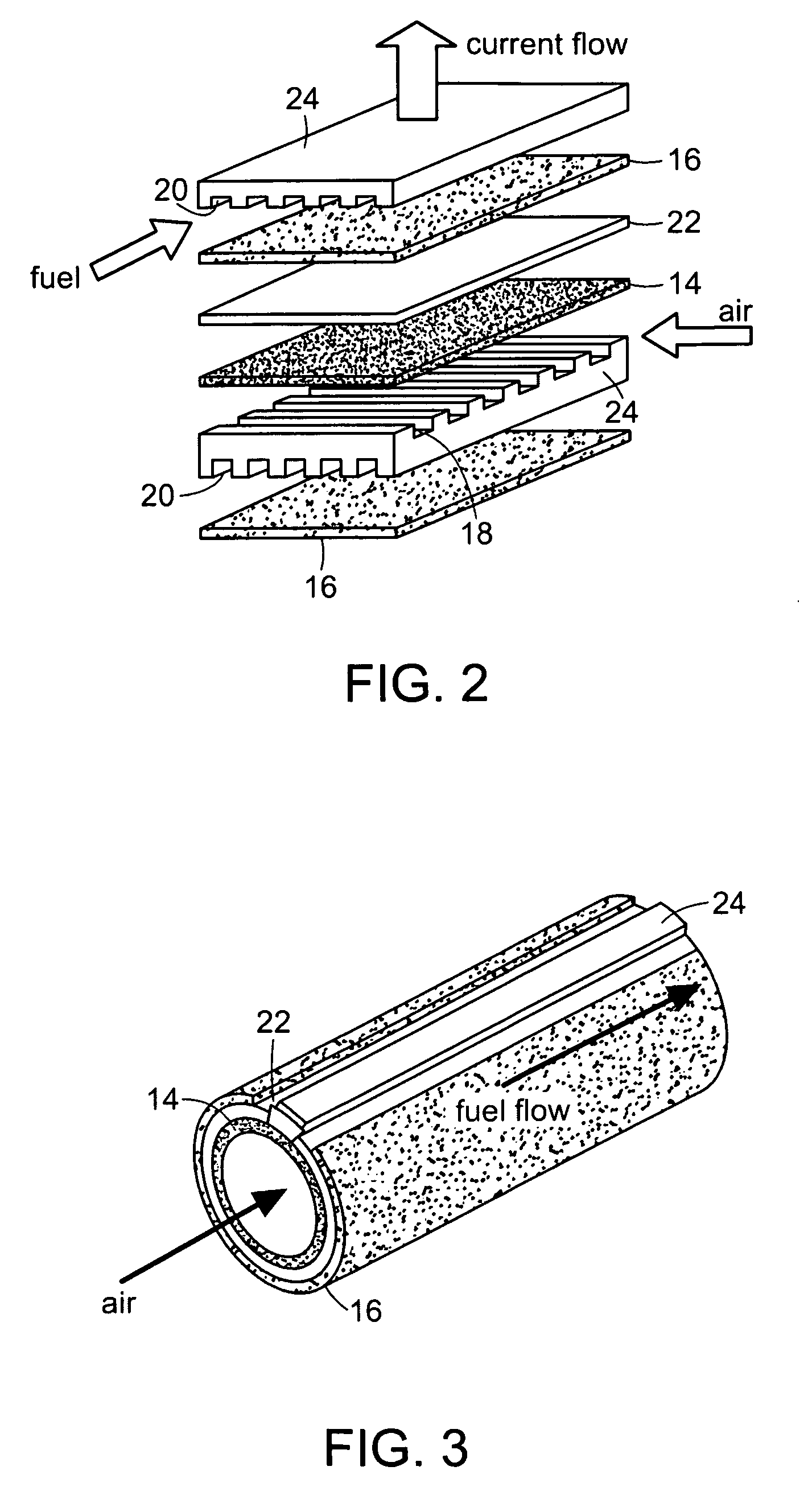

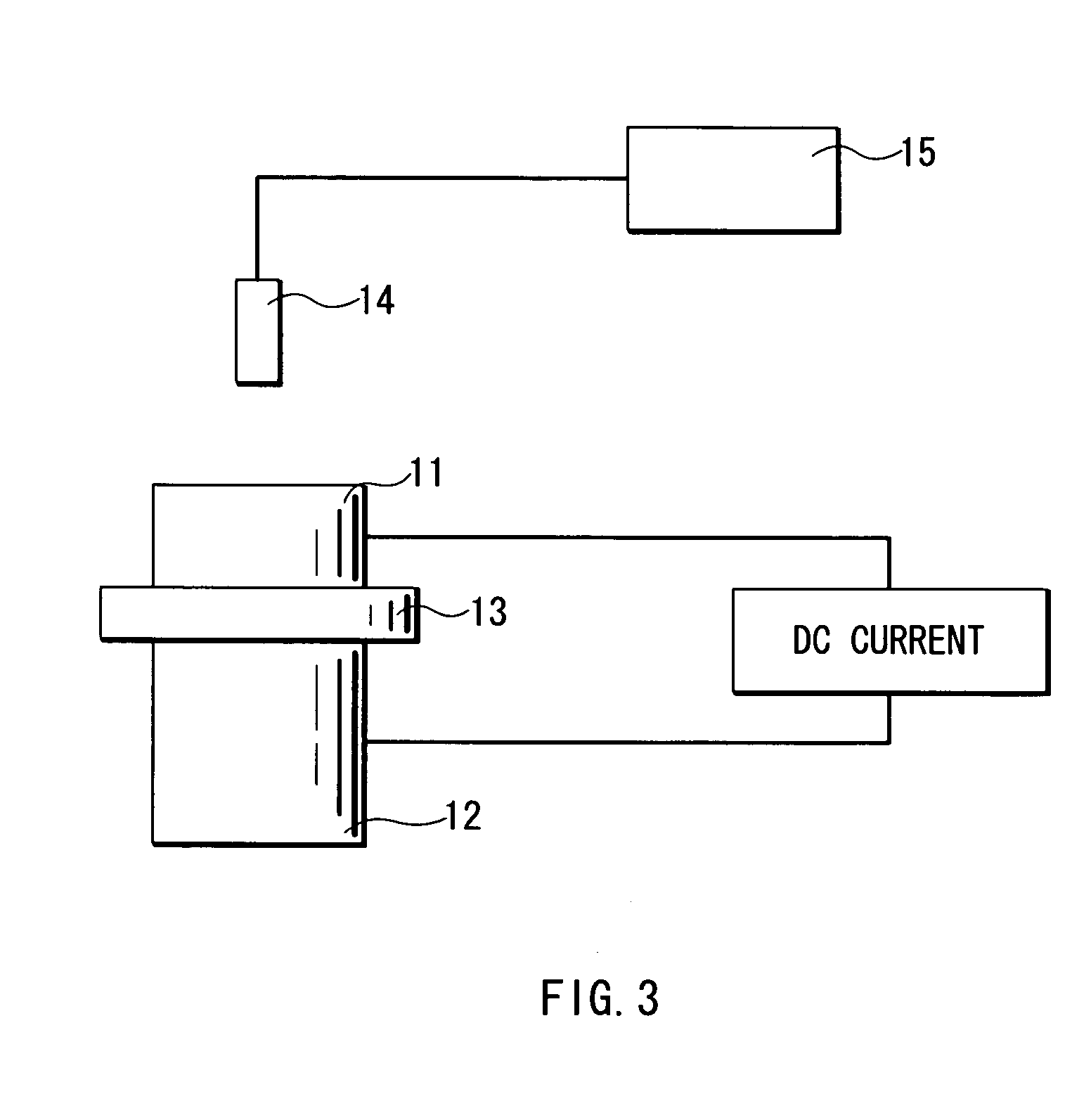

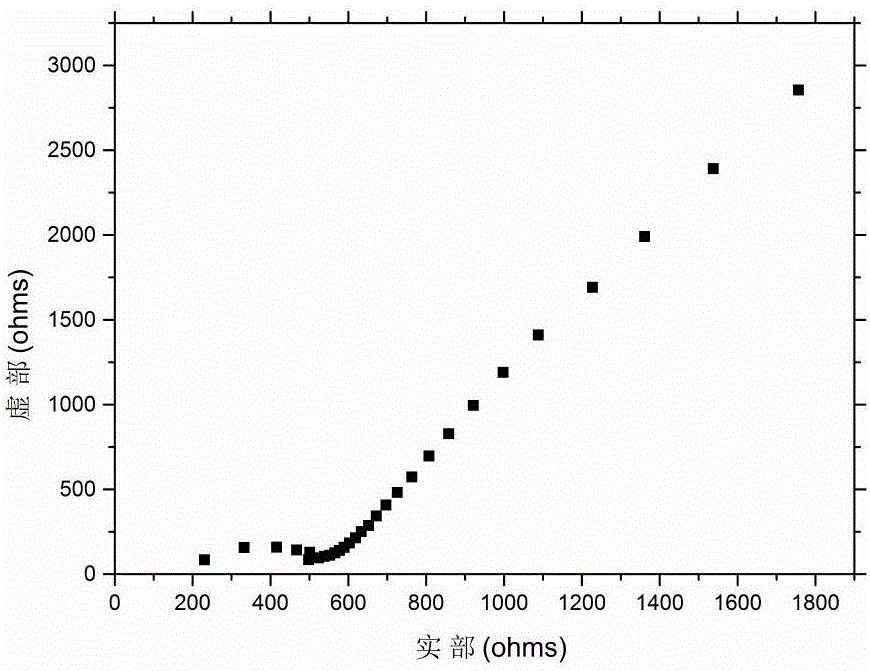

Ceramic interconnect for fuel cell stacks

InactiveUS20090169958A1Low emissionFavorable combination of electrical efficiency and co-generation efficiency and fuel processing simplicityPrimary cellsElectrode carriers/collectorsEngineeringElectrolyte

A fuel cell comprises a plurality of sub-cells, each sub-cell including a first electrode in fluid communication with a source of oxygen gas, a second electrode in fluid communication with a source of a fuel gas, and a solid electrolyte between the first electrode and the second electrode. The sub-cells are connected with each other with an interconnect. The interconnect includes a first layer in contact with the first electrode of each cell, and a second layer in contact with the second electrode of each cell. The first layer includes a (La,Mn)Sr-titanate based perovskite represented by the empirical formula of LaySr(1−y)Ti(1−x)MnxOb. In one embodiment, the second layer includes a (Nb,Y)Sr-titanate perovskite represented by the empirical formula of Sr(1−1.5z−0.5k±δ)YzNbkTi(1−k)Od. In another embodiment, the interconnect has a thickness of between about 10 μm and about 100 μm, and the second layer of the interconnect includes a (La)Sr-titanate based perovskite represented by the empirical formula of Sr(1−z±δ)LazTiOd.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

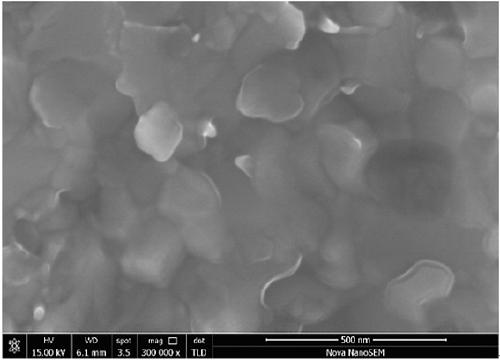

Method for preparing ultra-fine crystal grain tungsten-copper alloy and tungsten-copper alloy

A method to prepare ultra-fine grain tungsten-copper alloy and the tungsten-copper alloy, it belongs to powder metallurgy technology field. The solution of concentrated HNO3 and solution of Cu (NO3)2 will be added into the solution of (NH4)2WO4 at the condition that they are blended, the chemical deposition reaction will occur in the agitator. And then the deposit will be burned and grinded to produce the composite powder of tungsten-copper oxidate. The composite powder will be reduced at low temperature in the pipe furnace, and nanometer tungsten-copper composite powder can be gained, and then they will be pressed to take shape, the pressed compact will be sintered at the protection of H2 and ultra-fine grain tungsten-copper alloy can be gained. The weight percent of copper in a kind of tungsten-copper alloy produced according to the above method is 20%, the relative density of the alloy is 98.0%-99.7%, the average crystal grain size of the tungsten in the alloy is 0.5-1.5 mu m, the electrical resistance of the alloy is 0.035-0.041X10-6omega .m, the heat-transmit index is 200-223W.m-1.k-1. The advantage of it is that. The densification degree of the alloy is high, the tungsten crystal grain is small and uniform, the copper is highly dispersed to compose a compact net. And the flow of it is short, the technology operation is easy and reliable, the production efficiency is high, the energy and production cost is lower, and an industrial production can be carried on according the method.

Owner:UNIV OF SCI & TECH BEIJING

Laser-welding diamond disc and preparation method thereof

ActiveCN101456216AGood self-sharpeningGood edge cutting effectStone-like material working toolsLow speedCobalt

The invention relates to a laser welding diamond round saw blade and a preparation method thereof, which belong to the technical field of powder metallurgy material. The saw blade is used for solving the problem that the laser welding diamond round saw blade has lower speed and easy edge feed when used for cutting hard stones. The material of a cutting head is prepared from the following powder raw materials by weight percentage: 36 to 46 percent of copper, 28 to 38 percent of iron, 10 to 20 percent of cobalt, 3 to 10 percent of nickel, 3 to 9 percent of tin, 1 to 2.5 percent of silicon-chromium alloy, 1 to 1.6 percent of liquid paraffin wax and 1.0 to 2.2 percent of diamond, wherein the silicon-chromium alloy contains 40 percent of silicon, 30 percent of chromium and the balance being iron and small quantities of impurities according to mass proportion. The method adopts a mixed base material of the copper, the iron and the cobalt to improve the service life and the sintering performance of the saw blade and the added silicon-chromium alloy powder is dispersively distributed in a fetal body, thereby effectively improving the sintering performance of the fetal body so as to make the fetal body accelerate an alloying process. At the same time, the self-sharpening performance of the fetal body is improved, the holding force of the fetal body to the diamond is enhanced and the service life and the cutting performance of the saw blade are improved, thereby making the wear performance of the fetal body and the wear performance of the diamond be matched.

Owner:BOSUN TOOLS CO LTD

Paint for continuous casting pouring box work liner and preparing technique thereof

ActiveCN101508586AGood spreadabilityGood application effectMelt-holding vesselsFiberSodium phosphates

The invention discloses a painting for continuously cast pouring basket working lining and a producing technique thereof. The components of the painting is as follows according to parts by weight: 50-90 parts of forsterite raw material, 10-50 parts of magnesia, and 3-5 parts of composite additive, wherein the composite additive is at least one of organic fiber, paper fiber, lime, trimeric sodium phosphate, sodium hexametahposphate, clay or silicate. The producing technique of the painting is evenly mixing and stirring the forsterite raw material, the magnesia and the composite additive according to the parts by weight to lead the mixture to show no evident white trace, thereby obtaining the painting used for the continuously cast pouring basket working lining. The painting has excellent smearing, sintering, anti-scouring, anti-dreg erosion and anti-peeling properties, is free from collapsing and pollution, is environment-friendly, and has long service life, low production cost and simple and convenient preparation method.

Owner:WUGANG REFRACTORY CO LTD

Method for repairing furnace lining of intermediate frequency furnace for steelmaking

InactiveCN1731061ARepair method is simpleQuick and effective patchingLinings repairProcess efficiency improvementSteelmakingIntermediate frequency

The present invention is furnace lining repairing process, and is especially the furnace lining repairing process for steelmaking IF furnace. The furnace lining repairing process includes the following steps: determining repairing time, clearing furnace inside, applying adhesive and furnace building material, setting forming steel mold and starting mold block, applying furnace building material, and sintering furnace building material. The furnace lining repairing process is relatively simple, and has effective repair of furnace lining, organic combination of the repair material and original furnace building material, flat furnace bottom, homogeneous heating of the hearth, good sintering effect and long service life of the repaired furnace lining.

Owner:QINGTONGXIA ALUMINUM IND GROUP

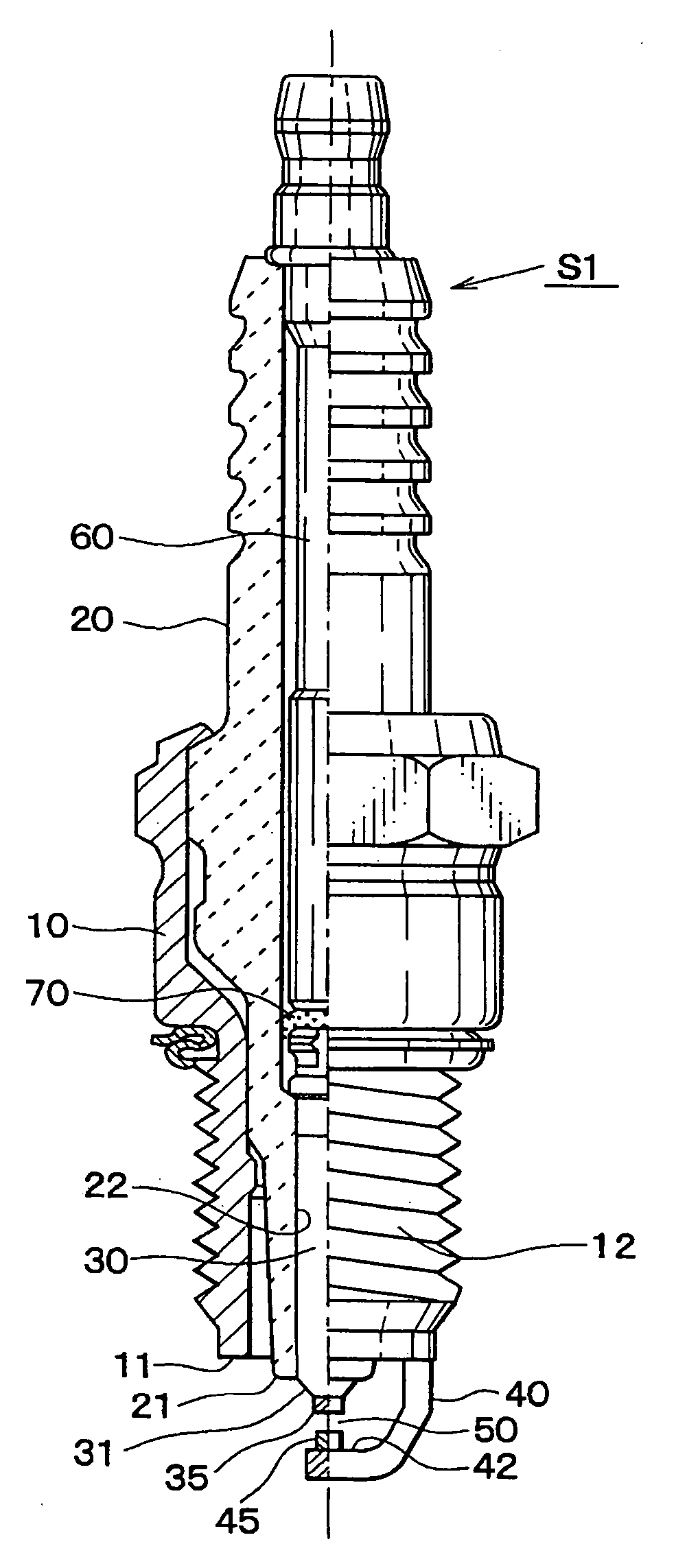

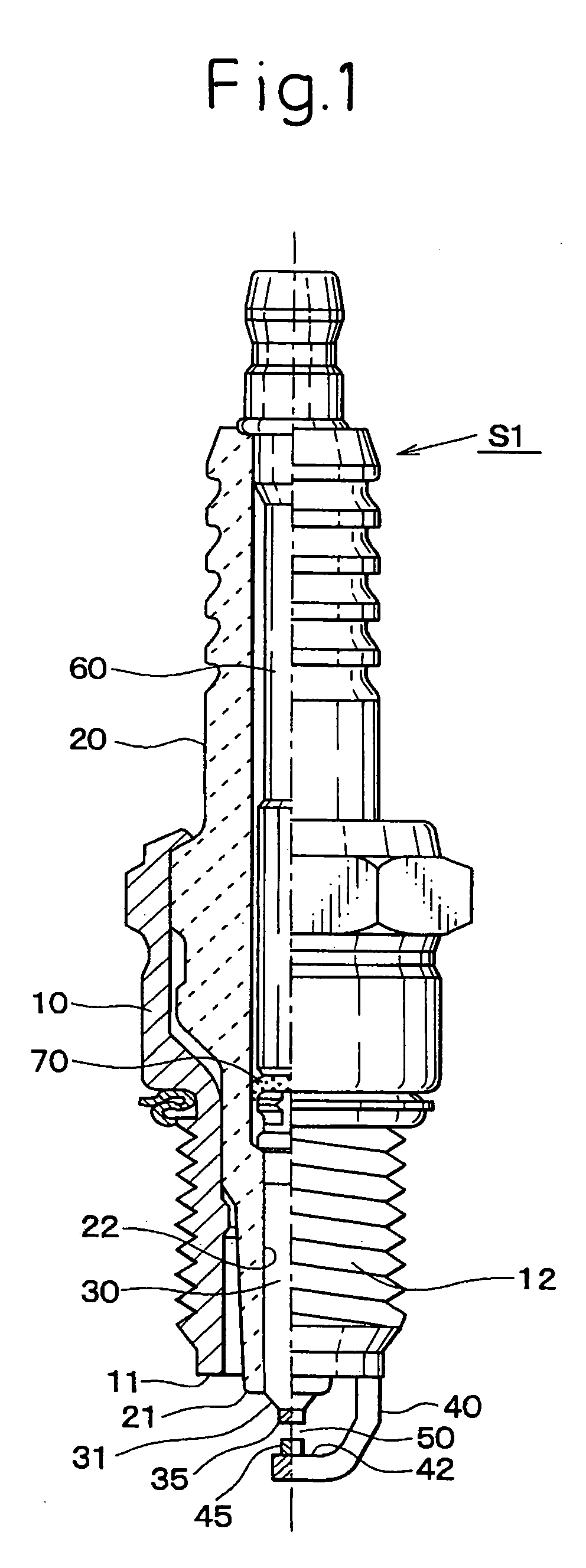

Alumina-based ceramic composition and spark plug using the same

InactiveUS20060186780A1Improve sintering performanceImprove withstand voltage characteristicsSparking plugsFuel injection apparatusRare-earth elementMaterials science

An alumina-based ceramic composition comprising a composite sintered body of alumina as a main component and a composition of at least one element selected from Al, Si, Mg and rare earth elements, wherein an amount of the composition of at least one element selected from Al, Si, Mg and the rare earth elements is not greater than 5 parts by weight on the basis of 100 parts by weight of alumina as the main component, and a spark plug using this alumina-based ceramic composition for an insulator.

Owner:NIPPON SOKEN +1

Manganese slag-solid waste mixed sintering brick making method

The invention discloses a manganese slag-solid waste mixed sintering brick making method, which includes that manganese slag, shale and fly ash which are dried to have constant weight are mixed and ground together or are respectively ground and then mixed in certain ratio, and are sieved according to a certain gradation requirement to obtain preparation materials of solid waste mixed sintering brick, then a certain amount of sodium humate stabilizer is added and uniformly stirred with clear water and is aged for a period of time, then is produced to be samples by an extruder, at last the finished products of solid waste mixed sintering bricks are obtained by the heat treatment processes of drying, roasting, cooling and the like. The invention uses electrolytic manganese dioxide slag as the main material, adopts the shale to replace clay as supplementary raw material, and adds the fly ash to adjust the components on the basis, the manganese slag-solid waste sintering brick is prepared through the processes of proportioning, preprocessing, patternmaking, drying, roasting and cooling, and the utilization of a large amount of solid waste resource is realized.

Owner:CENT SOUTH UNIV

Catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, preparation method and applications thereof

InactiveCN106582652AHigh activityImprove overall lifespanOrganic compound preparationHeterogenous catalyst chemical elementsSal ammoniacCopper salt

The present invention relates to a catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, a preparation method and applications thereof. The catalyst comprises CuO, a metal auxiliary agent oxide and silica, wherein the Cu element accounts for 10-50% of the total weight of the catalyst, and the metal auxiliary agent element accounts for 1-10% of the total weight of the catalyst. The invention further discloses the preparation method of the catalyst. According to the present invention, a soluble copper salt and a metal auxiliary agent soluble salt are used and are added with ammonia water to form an ammonia complex aqueous solution, aging-ammonia evaporation and co-precipitating are performed, and the obtained material and silica form the gel so as to form the stable chemical structure, such that the stability of the catalyst is substantially improved; during the preparation process, the organic modifier is added so as to effectively improve the pore structure and the specific surface area of the catalyst, and improve the activity of the catalyst and the ethylene glycol selectivity; and with the application of the catalyst in the dimethyl oxalate hydrogenation reaction, the service life is more than one year, the average conversion rate of dimethyl oxalate is more than 99.9%, and the ethylene glycol selectivity is more than 95%.

Owner:SHANGHAI HUAYI ENERGY CHEM

Ultra-fine grain high-entropy metal ceramic composite material and preparing method thereof

InactiveCN110423930AUniform particle sizeImprove mechanical propertiesCeramic compositeHigh entropy alloys

The invention discloses an ultra-fine grain high-entropy metal ceramic composite material and a preparing method thereof. The composite material is made with (MoTiWTaZr)C high-entropy ceramic as a hard phase and FeCoCrNiAl high-entropy alloy as a metal bonding phase. Specifically, five kinds of carbide powder of molybdenum carbide, titanium carbide, tungsten carbide, tantalum carbide and zirconiumcarbide are subjected to high-energy ball milling to form high-entropy ceramic powder, five kinds of metal powder of iron, cobalt, chromium, nickel and aluminum are subjected to high-energy ball milling to form single-phase solid solution high-entropy alloy powder, high-entropy ceramic powder and high-entropy alloy powder are mechanically mixed, through discharge plasma sintering, the ultra-finegrain high-entropy metal ceramic composite material is obtained, and the comprehensive performance of the obtained composite is obviously improved.

Owner:FUJIAN UNIV OF TECH

Alumina ceramic composition

Owner:HITACHI METALS LTD

Process for preparing sintered body of aluminum titanate

InactiveUS6403019B1High mechanical strengthImprove stabilityCeramic shaping apparatusTitanium compoundsWet grindingBall mill

The present invention provides a process for preparing a raw material powder for producing a sintered body of aluminum titanate comprising:pulverizing a mixture containing:(1) 100 parts by weight of aluminum titanate crystals pulverized until a maximum grain size of 30 to 50 mum is attained; and(2) 2 to 6 parts by weight of spinel crystals obtained by heating a mixture containing MgO and Al2O3 at 1250° C. to 1290° a molar ratio of MgO to Al2O3 being 1:0.95 to 1:1.05,said pulverizing being conducted by wet grinding process with a ball mill or cylinder mill.

Owner:OHCERA CO LTD

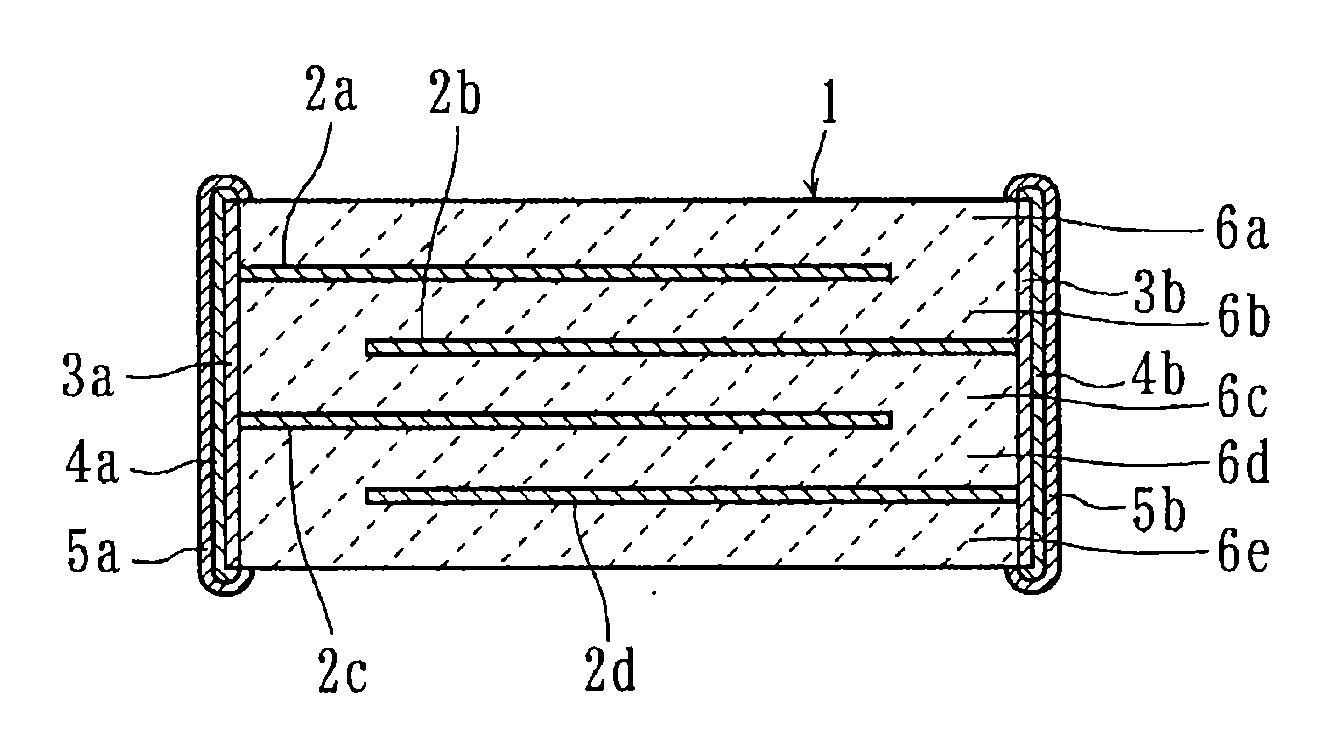

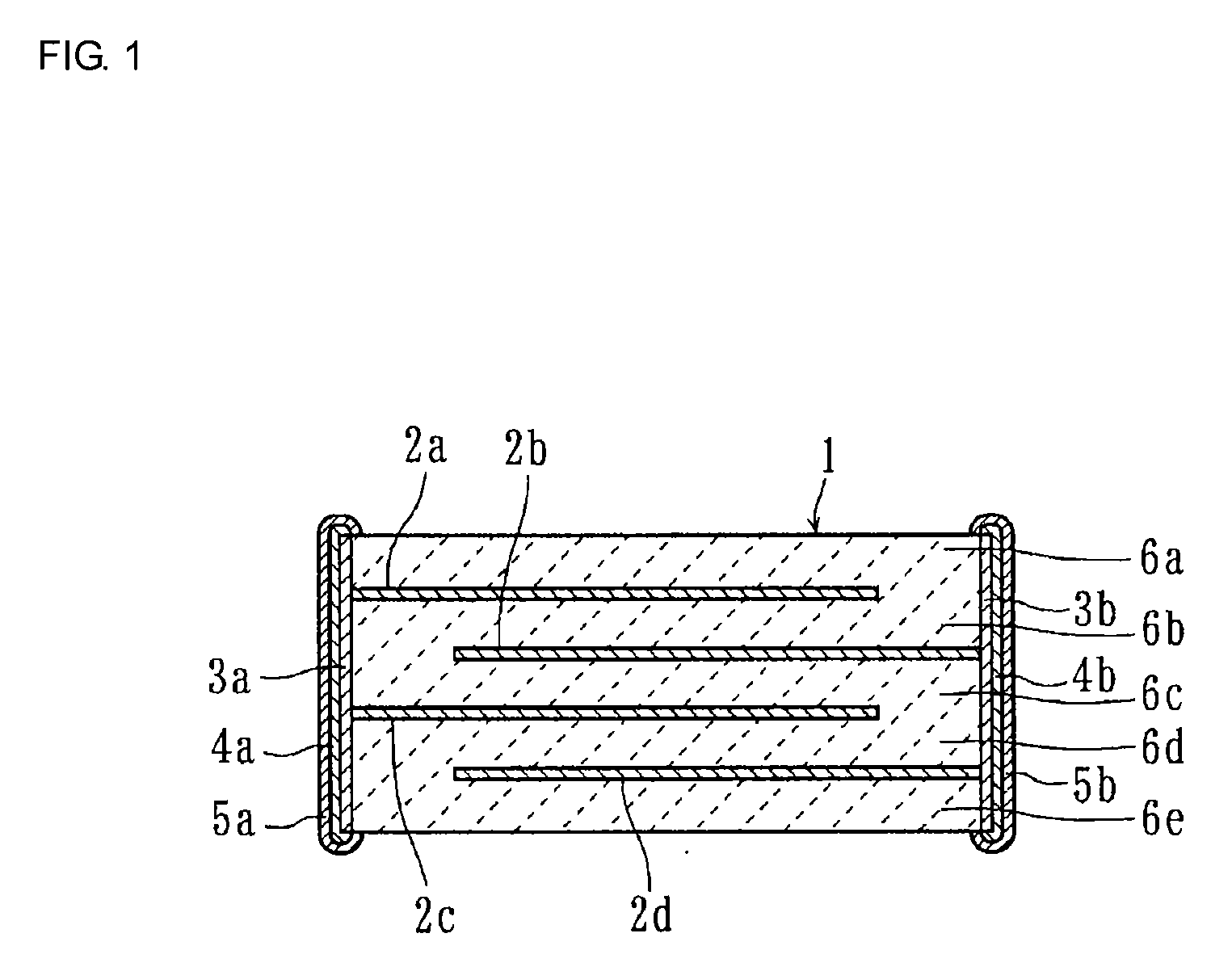

Dielectric ceramic, ceramic electronic element, and multilayer ceramic capacitor

ActiveUS20090128989A1Improve sintering performanceEasy to useFixed capacitor dielectricZirconium compoundsDielectricCeramic capacitor

A dielectric ceramic including a perovskite compound represented by the general formula {(Ba1-x-yCaxSny)m(Ti1-zZrz)O3} as a primary component in which the x, y, z, and m satisfy 0.02≦x≦0.20, 0.02≦y≦0.20, 0≦z≦0.05, and 0.99≦m≦1.1 and is processed by a thermal treatment at a low oxygen partial pressure of 1.0×10−10 to 1.0×10−12 MPa. Accordingly, there are provided a dielectric ceramic which can be stably used in a high-temperature atmosphere without degrading dielectric properties, properties of which can be easily adjusted, and which generates no electrode breakage even when ceramic layers and conductive films are co-fired, and a ceramic electronic element, such as a multilayer ceramic capacitor, which uses the above dielectric ceramic.

Owner:MURATA MFG CO LTD

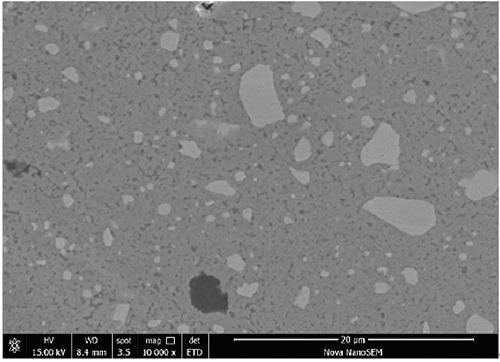

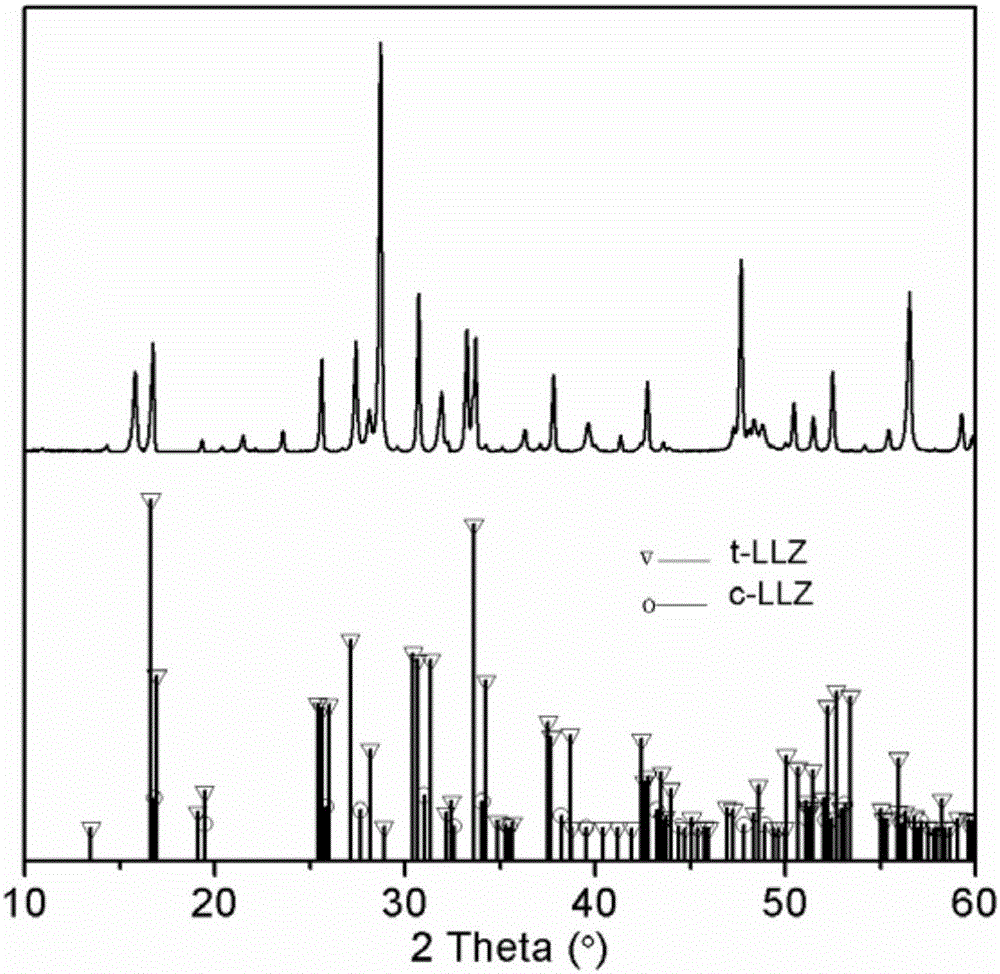

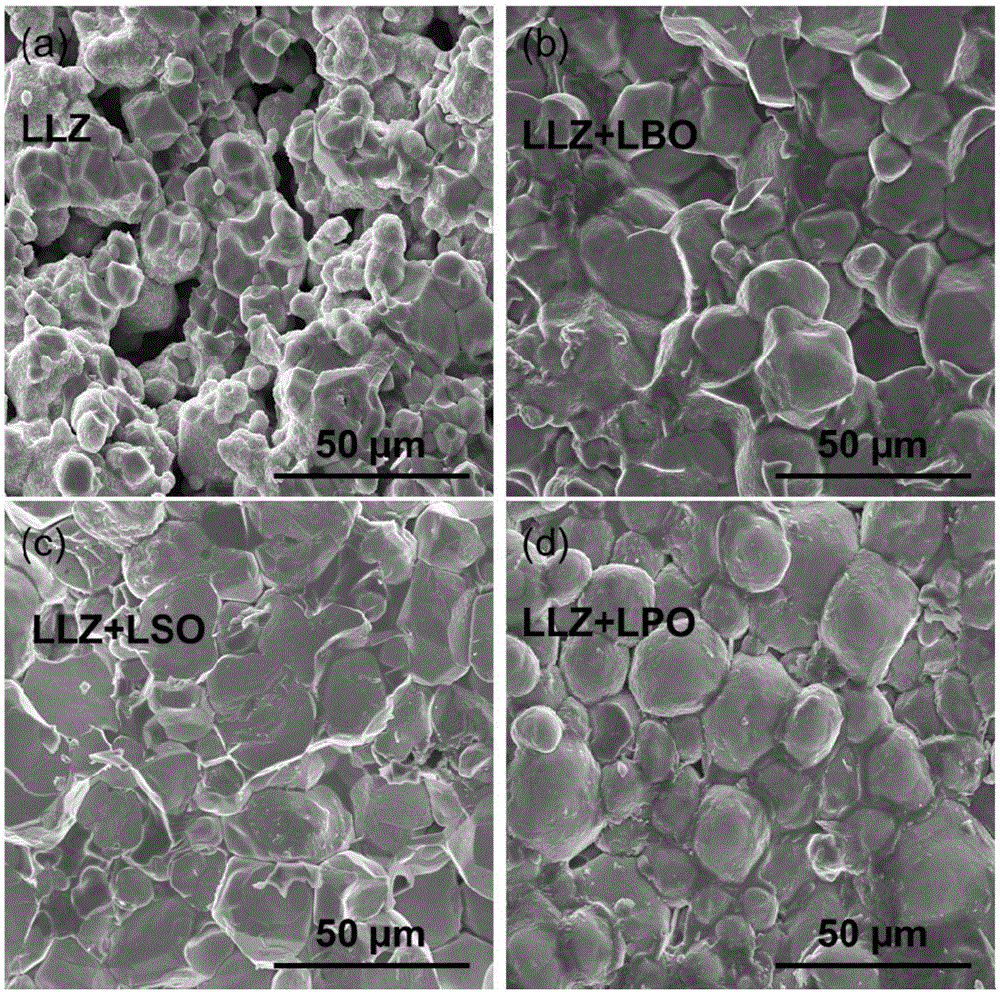

Solid electrolyte for inhibiting lithium dendrites growth in full-solid-state battery, and preparation method thereof

InactiveCN106848392AImprove microstructureImprove sintering performanceSecondary cellsSolid state electrolyteIonic conductance

The invention relates to a solid electrolyte for inhibiting lithium dendrites growth in a full-solid-state battery, and a preparation method thereof. The solid electrolyte is prepared from lithium-lanthanum-zirconium oxide ceramic and 0.1 to 10 weight percent of low-melting-point sintering aid. The preparation method comprises the following steps of dry grinding and uniformly mixing stoichiometric lithium carbonate, lanthanum oxide and zirconium oxide, and then presintering in a muffle furnace at the temperature of 900 DEG C to form a phase; adding the low-melting-point sintering aid into presintering powder, and dry grinding and mixing to obtain a manual pressed sheet sample; densifying during a further high-temperature sintering process to form the solid electrolyte with high ionic conductance, stable performance and high repeatability. Compared with the prior art, without influencing a conductive property of a lithium-contained garnet lithium ion, a low-cost second phase is used so that the conductive property of the lithium ion at a crystal boundary part is improved, the solid electrolyte can better realize lithium ion transmission and plays a role in inhibiting the lithium dendrites growth in the full-solid-state battery, and the safety of the lithium battery is improved.

Owner:SHANGHAI JIAO TONG UNIV

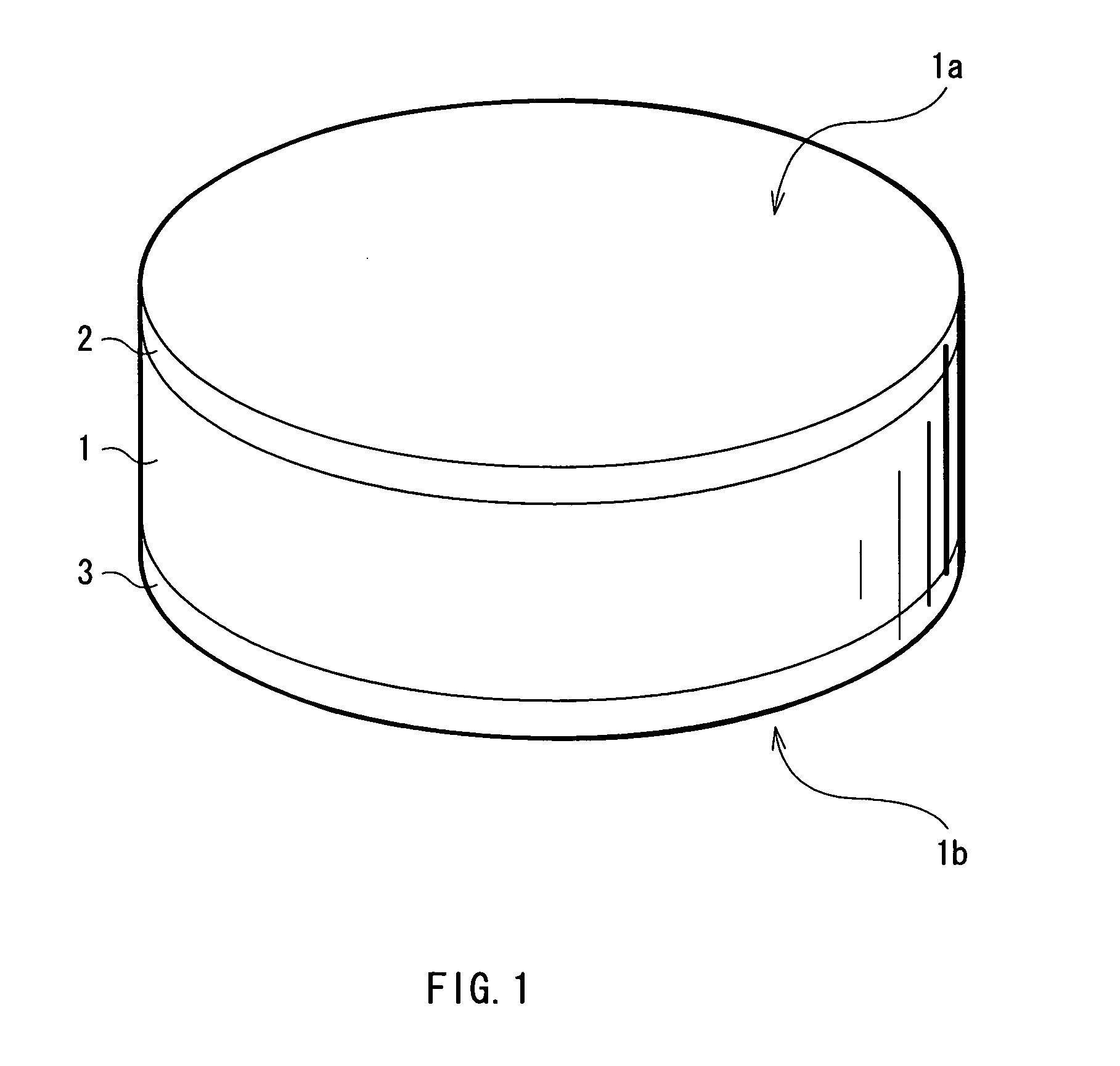

Piezoelectric ceramic and method of manufacturing the same

InactiveUS20070152183A1Improve piezoelectric performanceImprove sintering performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionAlkaline earth metalCurie temperature

There is provided a piezoelectric ceramic having a wider operating temperature range, being capable of obtaining a larger amount of displacement, being easily sintered, and being superior in terms of low emission, environment and ecology. A piezoelectric substrate (1) includes (1−m−n){(Na1-x-yKxLiy)(Nb1-zTaz)O3}+m{(M1)ZrO3}+n{M2(Nb1-wTaw)2O6} as a main component. M1 and M2 each represent an alkaline-earth metal element, and the values of x, y, m and n are preferably within a range of 0.1≦x≦0.9, 0≦y≦0.1, 0<m<0.1 and 0<n≦0.01, respectively. Thereby, a higher Curie temperature and a larger amount of displacement can be obtained, and sintering can be more easily performed. At the time of sintering, after (M1) ZrO3 is formed, other materials are mixed.

Owner:TDK CORPARATION

Rare earth permanent magnet and production method thereof

InactiveUS6159308AResidual magnetic flux density Br is reducedEnhance coercive force iHcInorganic material magnetismRare-earth elementDiffusion methods

A method of producing an R-Fe-B-based, sintered permanent magnet, wherein R is at least one rare earth element including Y, having a small oxygen content. A coarse alloy powder prepared by a reductive diffusion method is milled and recovered into a solvent to form a slurry. The slurry is wet-compacted to form a green body which is then sintered after removing the solvent. The milling, recovering, wet-compacting, solvent-removing and sintering steps are carried out while preventing the powder, slurry and green body from being brought into contact with air to minimize the oxygen content in the final sintered permanent magnet. The sintered permanent magnet produced has a high density and a high magnetic properties due to a low oxygen content.

Owner:HITACHI METALS LTD

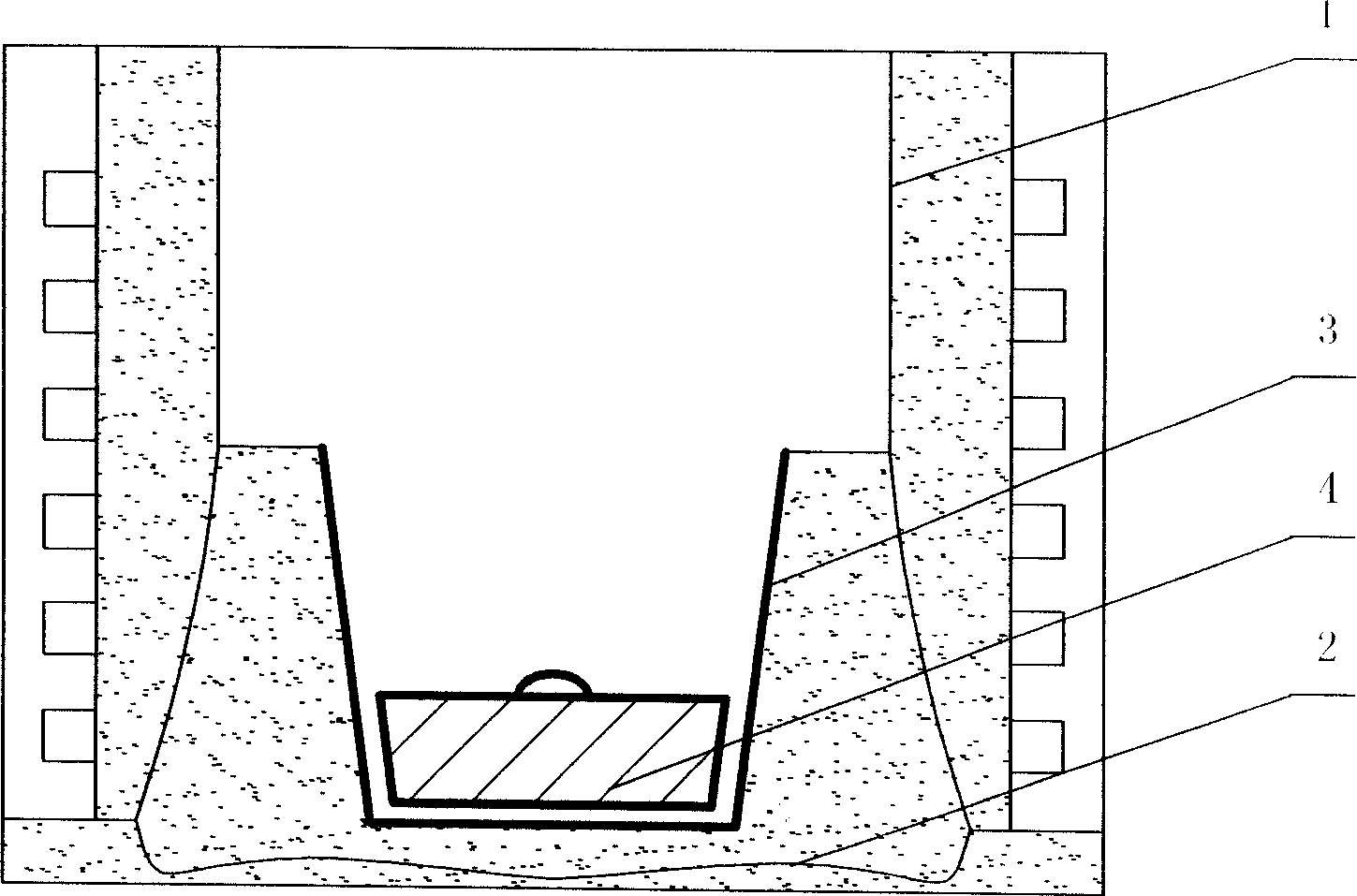

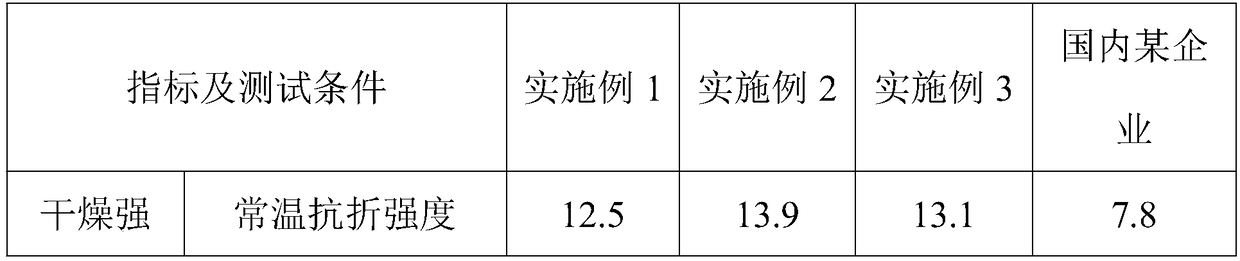

Refractory castable for blast furnace tapping trench and preparation method thereof

InactiveCN109293375AImprove liquidityImprove room and medium temperature strengthAluminiumMicrostructure

The invention discloses method of preparing a refractory castable used for large blast furnace iron runners, and the refractory castable has the advantages of green environmental protection, energy saving and emission reduction, good construction performance, high strength, high temperature volume stability, thermal shock stability and slag corrosion resistance. The method adopts Shanxi high-quality high bauxite (Al2O3 is greater than equal to 88%), fused brown corundum, fused white corundum and 97 silicon carbide as main raw materials, and high bauxite and fused brown corundum are composed ofcertain particles, fused white corundum powder, calcined alumina powder, 95 silicon micropowder, spherical asphalt, metal silicon powder and pure calcium aluminate cement are composition of a matrix,and an appropriate amount of an anti-explosive agent and a high-efficiency dispersant are added for the preparation. The calcined alumina powder used in the long-life environment-friendly tapping trench castable prepared by the method of the invention has uniform microstructure, high fineness, good sinterability and fluidity, and reacts with silicon oxide to form a high-temperature phase of mullite at high temperature, which improves the internal microstructure of the material and improves the thermal shock stability of the material.

Owner:洛阳润昌窑业有限公司

Method for continuous low temperature sintering of high thermal coefficient AIN ceramics and product thereof

ActiveCN101570437AReduce manufacturing costImprove sintering performanceRare earthThermal coefficient

The invention relates to the field of microelectronic packaging material or ceramic material, in particular to a method for continuous low temperature sintering of high thermal coefficient AIN ceramics and a product thereof; the AIN ceramics is prepared from AIN powder and additive by sintering; the AIN powder has an average grain diameter of 1.0-2.0mum and an oxygen content of being equal to or less than 1.0%, the additive is composed of nano AIN powder, sintering auxiliary agent and rare earth metal oxide; wherein the sintering auxiliary agent is selected from CaCO3 and LiCO3, the rare earth metal oxide is selected from Y2O3, Sm2O3, Dy2O3, Nd2O3, Ho2O3 and Er2O3, wherein the content of the sintering auxiliary agent is 1-2wt%, the use amount of the nano AIN powder accounts for 5-10% of the total weight, the content of the rare earth oxide is 1-3wt%. The invention has the beneficial effects that superfine aluminum nitride powder and sintering aid are used to improve sintering property of the aluminium nitride ceramics, lower sintering temperature of the AIN ceramics, so that densification sintering can be carried out with the range of 1450-1600 DEG C and thermal conductivity of the AIN ceramics can reach 170-220W / m.K; in addition, the invention has the advantages of capability of sintering in a continuous hydrogen and nitrogen atmosphere furnace, improved production efficiency, low energy consumption, large output and low cost.

Owner:CHAOZHOU THREE CIRCLE GRP

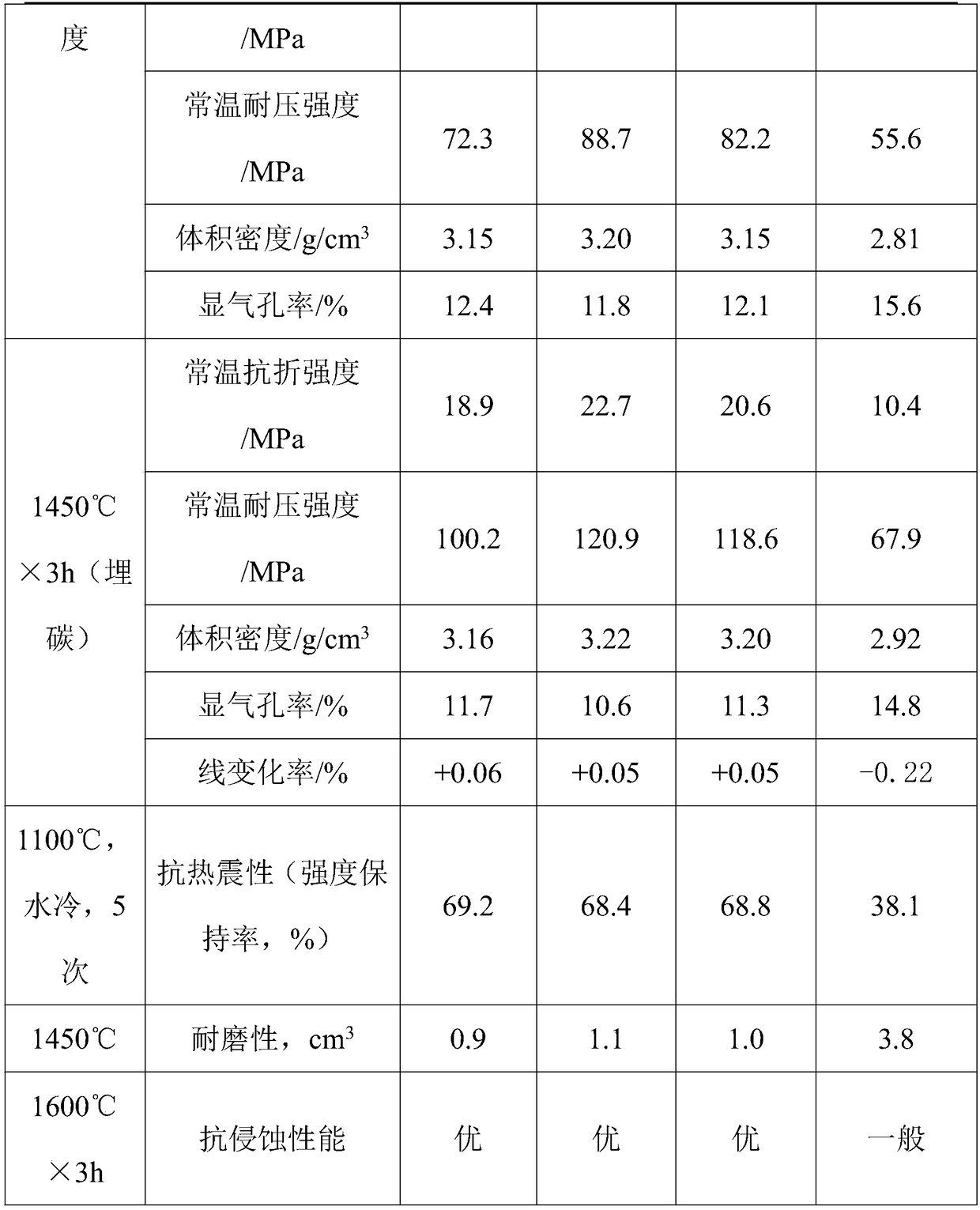

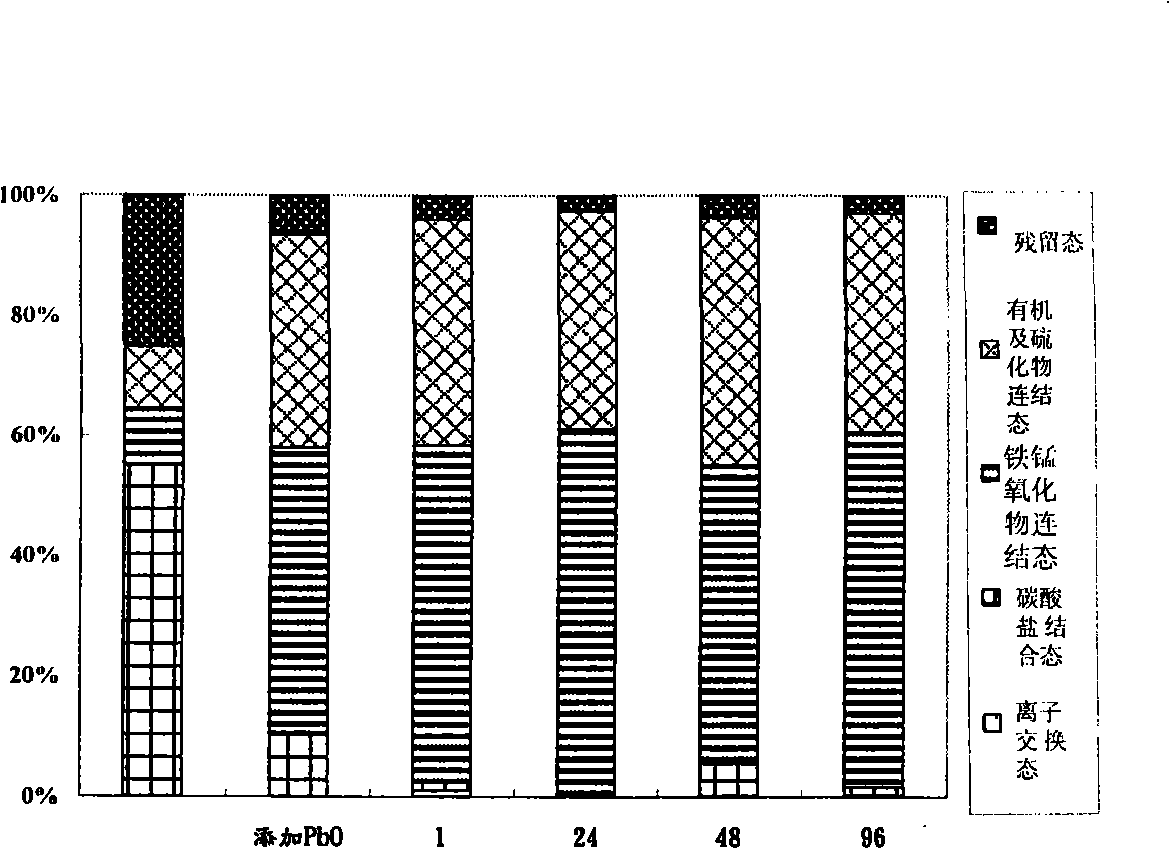

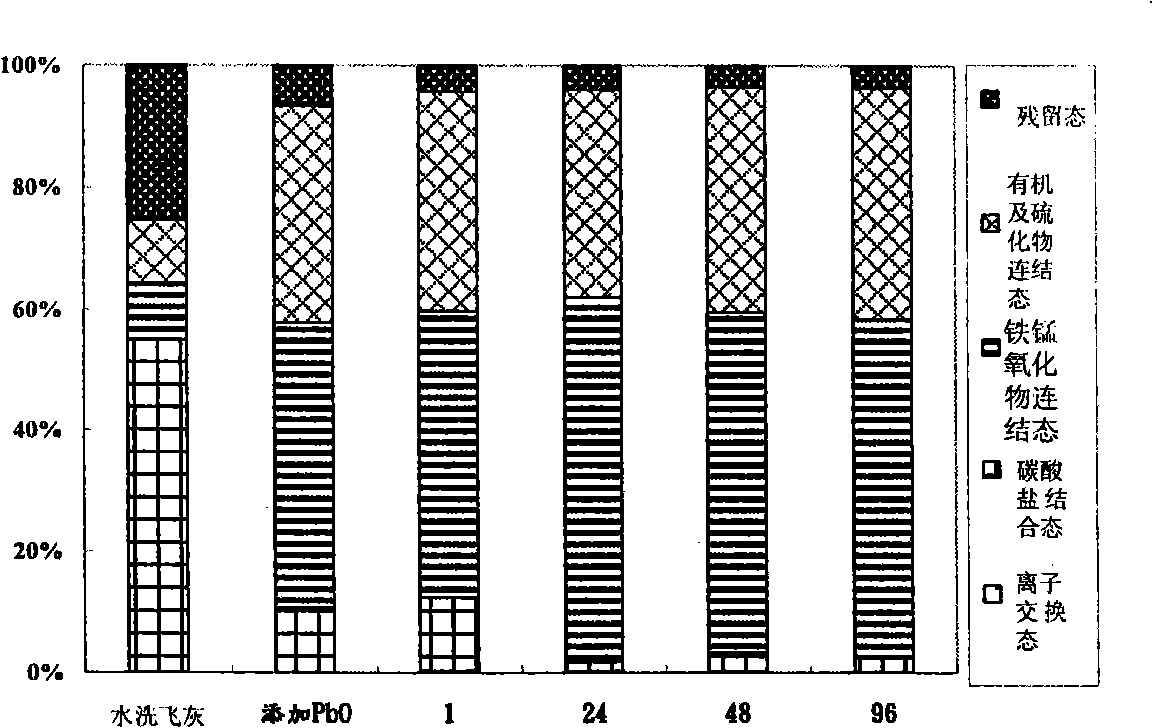

Heavy metal stabilization method in garbage incineration ash

The present invention relates to a method for stabilizing heavy metal in garbage cremated slag. The method comprises a water extraction step for removing soluble salt contained in the garbage cremated slag by water extraction cremated slag and a wet lapping step which ensures that the heavy metal contained in the garbage cremated slag is stabilized, so as to prevent the pollution to the environment caused by the heavy metal, promote the subsequent sintering effect and ensure that the disposed slag can be fired into regrown material by a sintering technology.

Owner:TAMKANG UNIVERSITY

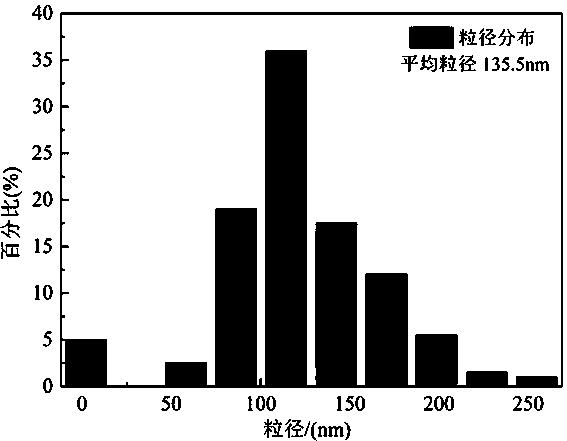

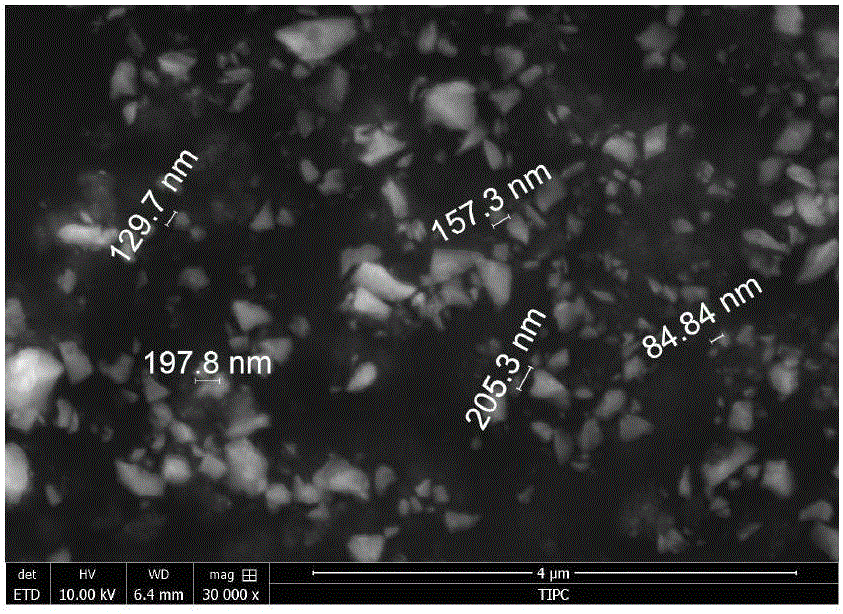

Preparation method for cubic-phase lithium lanthanum zirconium oxide solid-state electrolyte nano material

ActiveCN105932327ARich sourcesLow priceSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteRoom temperature

The present invention provides a preparation method for a cubic-phase lithium lanthanum zirconium oxide solid-state electrolyte nano material. A simple solution combustion synthesis technology is adopted, and a solid-state electrolyte material is obtained after heat treatment, and the solid-state electrolyte material has relatively high room temperature ionic conductivity and can be used as a solid-state electrolyte of a full solid-state battery. The preparation method of solution combustion synthesis is simple, and a prepared precursor is synthesized by one step, and element distribution is uniform. The layer thickness of a precursor particle is 100- 200 nano-meters, and the particle has a big specific surface area, so that element diffusion is facilitated at a high temperature, and a reaction is complete. Compared with other methods such as a sol-gel method and a solid phase method, the method has great technical advantages: low costs, high yield, simple operation and feasible industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Process for producing coated silver fine particles and coated silver fine particles produced by said production process

InactiveUS20150231698A1Low production costPractical and convenientMaterial nanotechnologyTransportation and packagingSolubilityDecomposition

The invention provides a novel and non conventional process for producing coated silver fine particles by the so-called amine complex decomposition process, and also provides coated silver fine particles produced by the process. The process includes a first step of forming a complex compound including a silver compound and an alkylamine by mixing (1) a silver compound capable of generating metal silver by thermal decomposition, (2) an alkylamine, and (3) at least one alcoholic compound having a solubility in water and / or a compound having at least one of a carbon-heteroatom multiple bond and a heteroatom-heteroatom multiple bond in the molecule, and a second step of generating silver fine particles coated with a protecting layer including the alkylamine by thermal decomposition of the complex compound.

Owner:YAMAGATA UNIVERSITY

Ceramic material and the production thereof

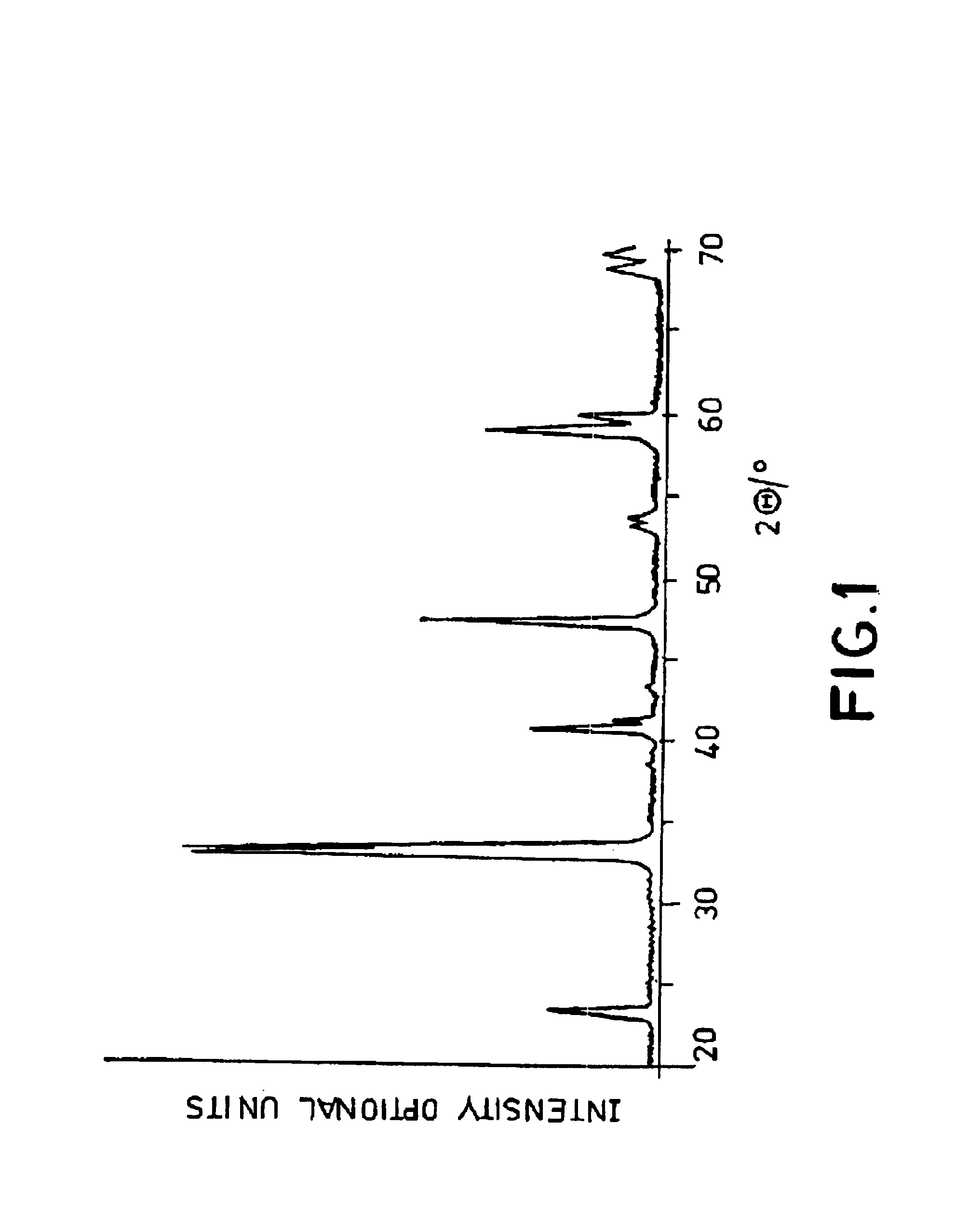

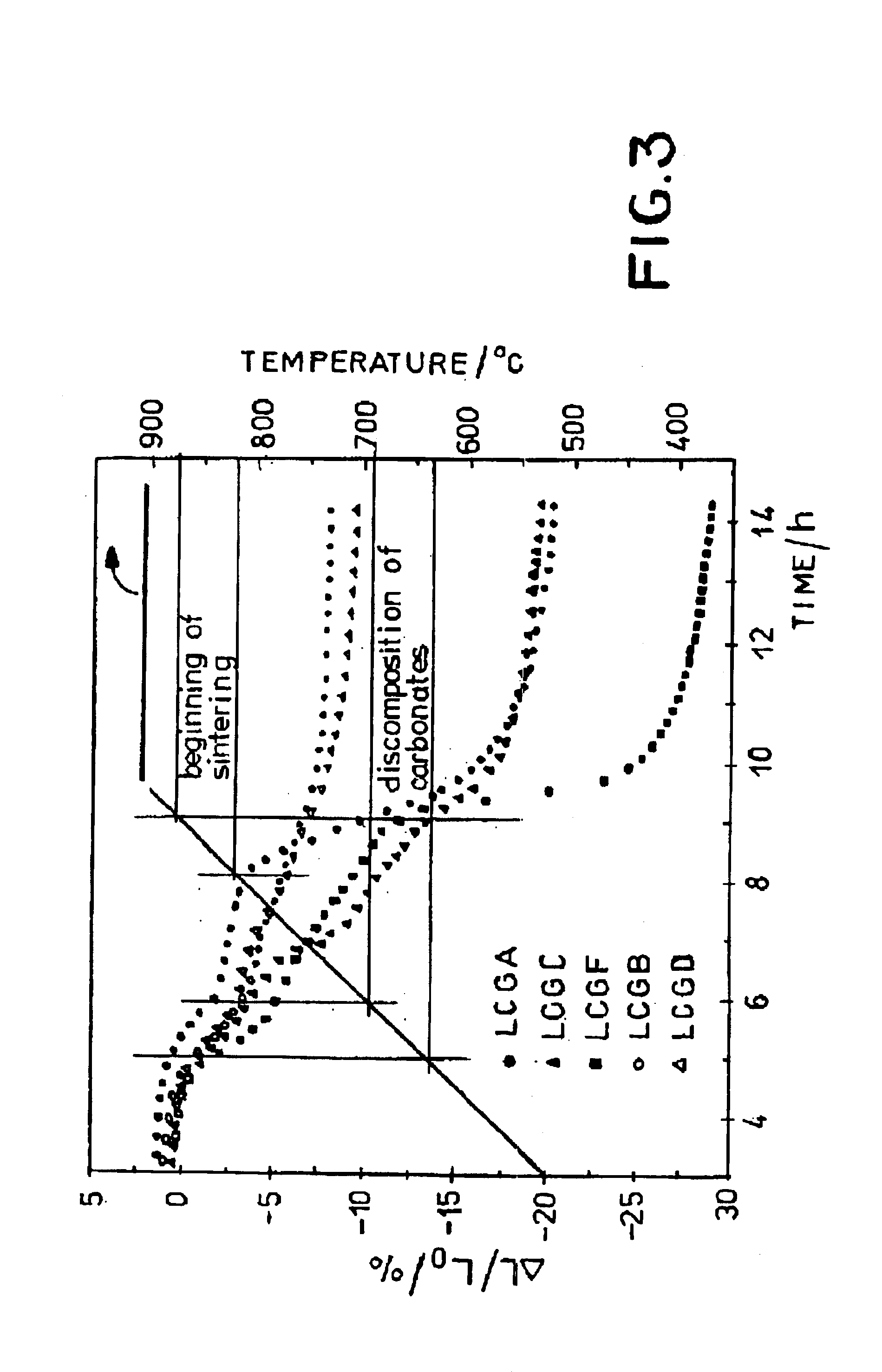

InactiveUS6835684B2Improve electrical performanceImprove sintering performanceOxide/hydroxide preparationFinal product manufactureMetallurgyStoichiometric composition

A ceramic material with a sintering temperature below 1000° C. and a Perovskite Structure with the general stoichiometric composition A'1-x-yA''xB'1-a-bB''aB'''bO3 whereby A'=Y, La, Pr, Nd; A''=Mg, Ca, Sr, Ba; B'=Mn, Ti, V, Cr, Ni, Zn, Pb, Sb, W, Zr; B''=Co; B'''=Cu, Bl; O<x<=0.4; 0<=y<=0.1; 0.09<a<=0.6 and; 0.09<=b<=0.6.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com