Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

250results about How to "Excellent microwave dielectric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave dielectric ceramic and preparation method thereof

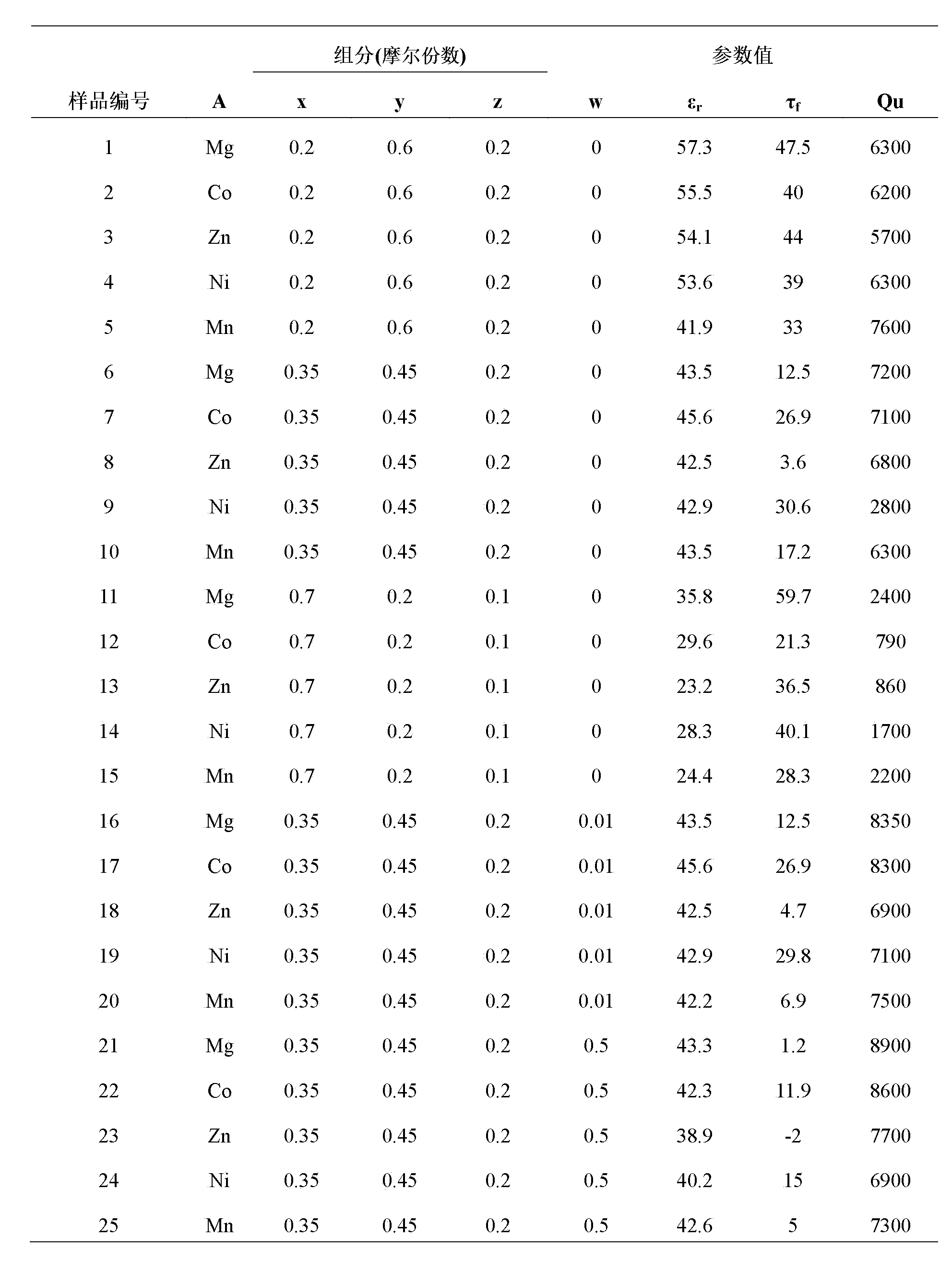

The invention discloses a microwave dielectric ceramic and a preparation method thereof. The microwave dielectric ceramic is mainly composed of ZrO2, TiO2 and Nb2O5; the microwave dielectric property of the microwave dielectric ceramic can be improved by selectively adding MgO, CoO, ZnO, NiO and MnO2; the chemical constitution formula of the ceramic is xZrO3-YTiO2-zA(1+W) / 3Nb(2-w) / 2O3; in formula (I), A is one or more elements of Mg, Co, Zn, Ni and Mn; x, y and z are molar ratios, wherein x is between 0.2 and 0.7, y is between 0.2 and 0.6,, z is between 0.1 and 0.2, and, x plus y plus z is equal to 1; numerical range of w is l between 0 and 0.5. According to the microwave dielectric ceramic and the preparation method thereof, the ceramic has the characteristics that the dielectric constant is high, the loss is low, and the temperature coefficient is close to zero, and is liable to sinter; the preparation method has the characteristics that the price of raw materials is low, and a technology during production is simple.

Owner:HEFEI NORMAL UNIV

Low-temperature sintering microwave dielectric ceramic material with high Q value and preparation method thereof

ActiveCN102531570AExcellent dielectric propertiesExcellent microwave dielectric propertiesCeramic materialsSintering

The invention belongs to the technical field of the material science, in particular to a low-temperature sintering microwave dielectric ceramic material with a high Q value and a preparation method thereof. The low-temperature sintering microwave dielectric ceramic material with a high Q value has the raw material formula composition of Li2(Mg1-xZnx)Ti3O8 and a sintering assistant, wherein x is more than or equal to 0 and less than or equal to 1; and the sintering assistant accounts for 0.5-5wt% of Li2(Mg1-xZnx)Ti3O8 and is one or more of Li2O-B2O3-SiO2 glass powder, ZnO-B2O3-SiO2 glass powder, BaO-O-B2O3-SiO2 glass powder and CuO-Bi2O3-V2O5 sintering powder. The low-temperature sintering microwave dielectric ceramic material provided by the invention has the advantages of low cost, smalladded sintering dose, high quality factor Qf value, simple preparation technology, good reproducibility and great industrial application value.

Owner:JIAXING GLEAD ELECTRONICS CO LTD +1

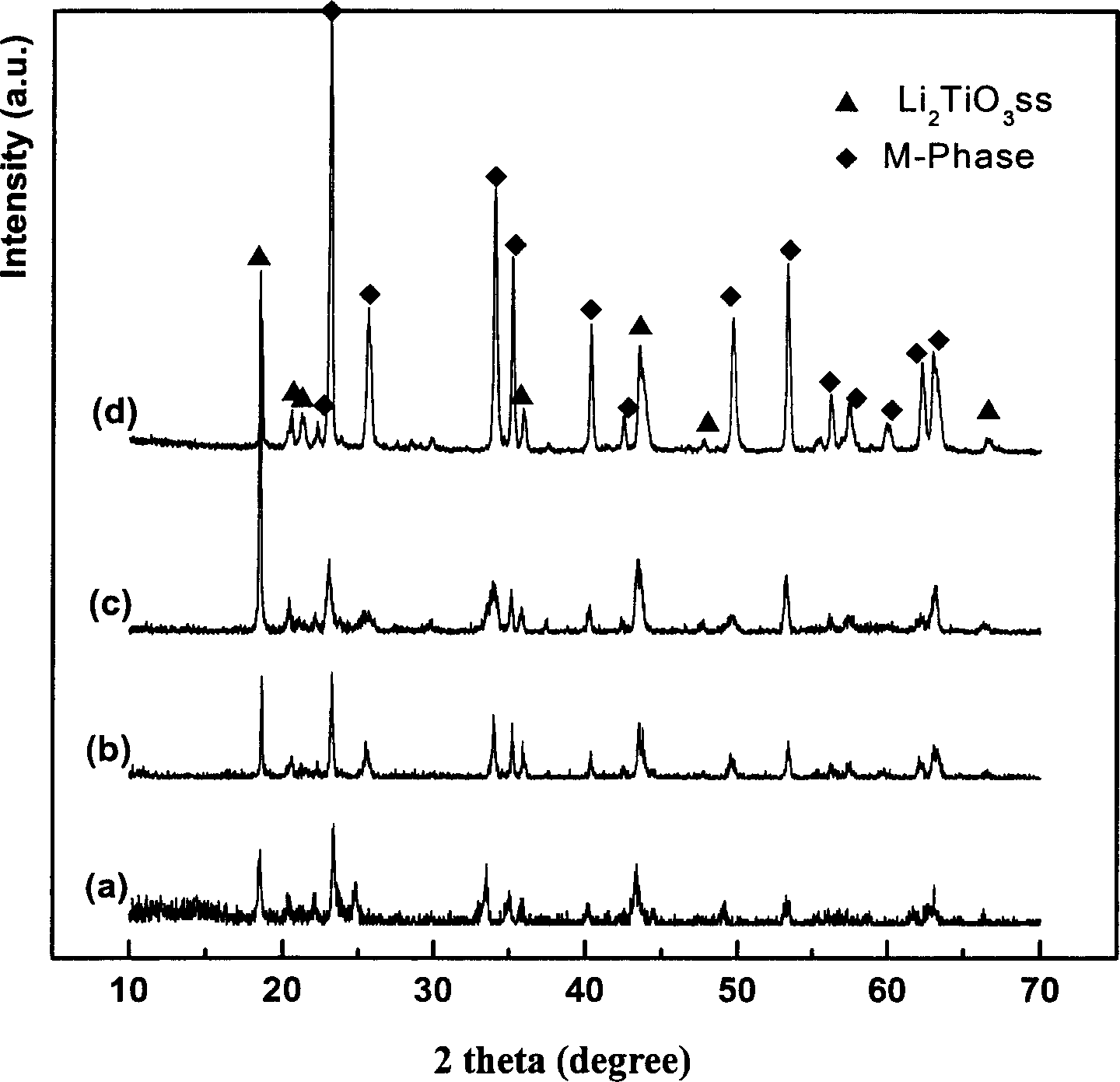

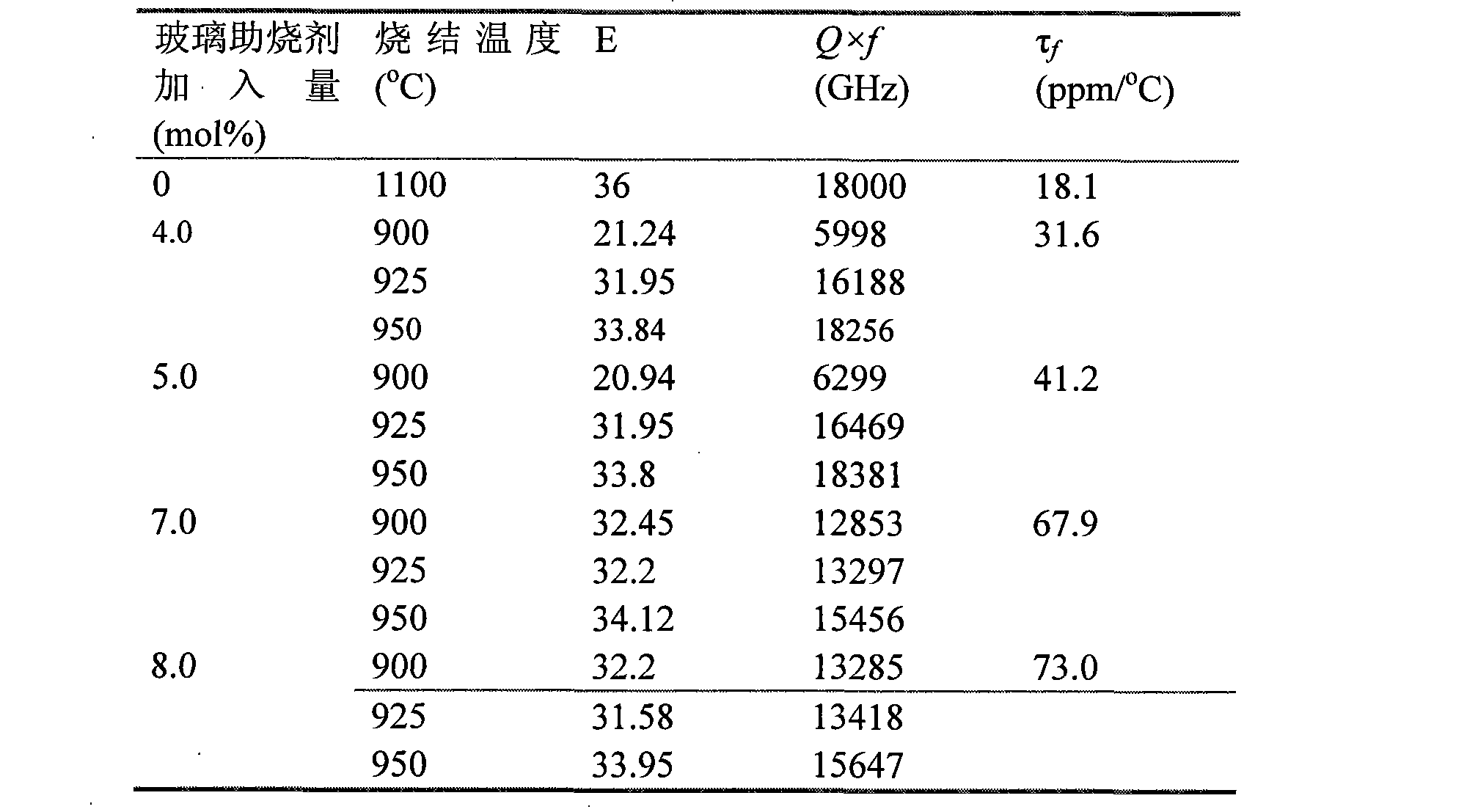

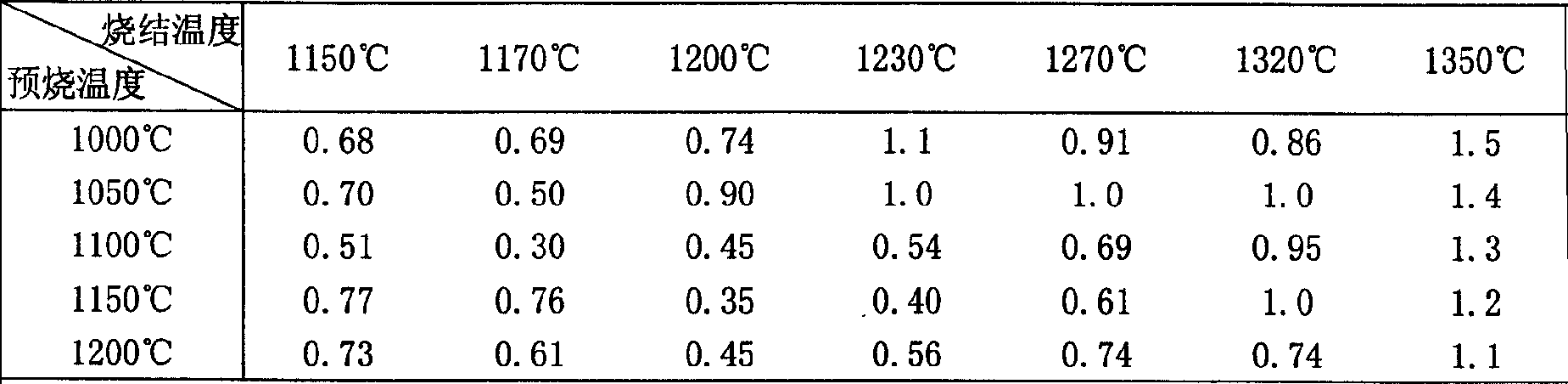

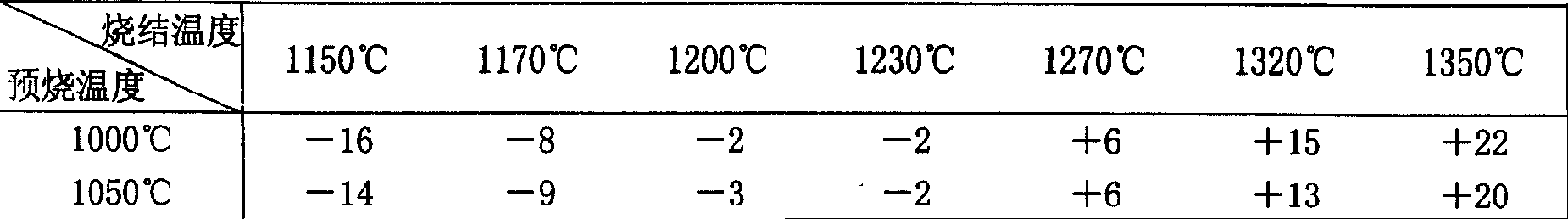

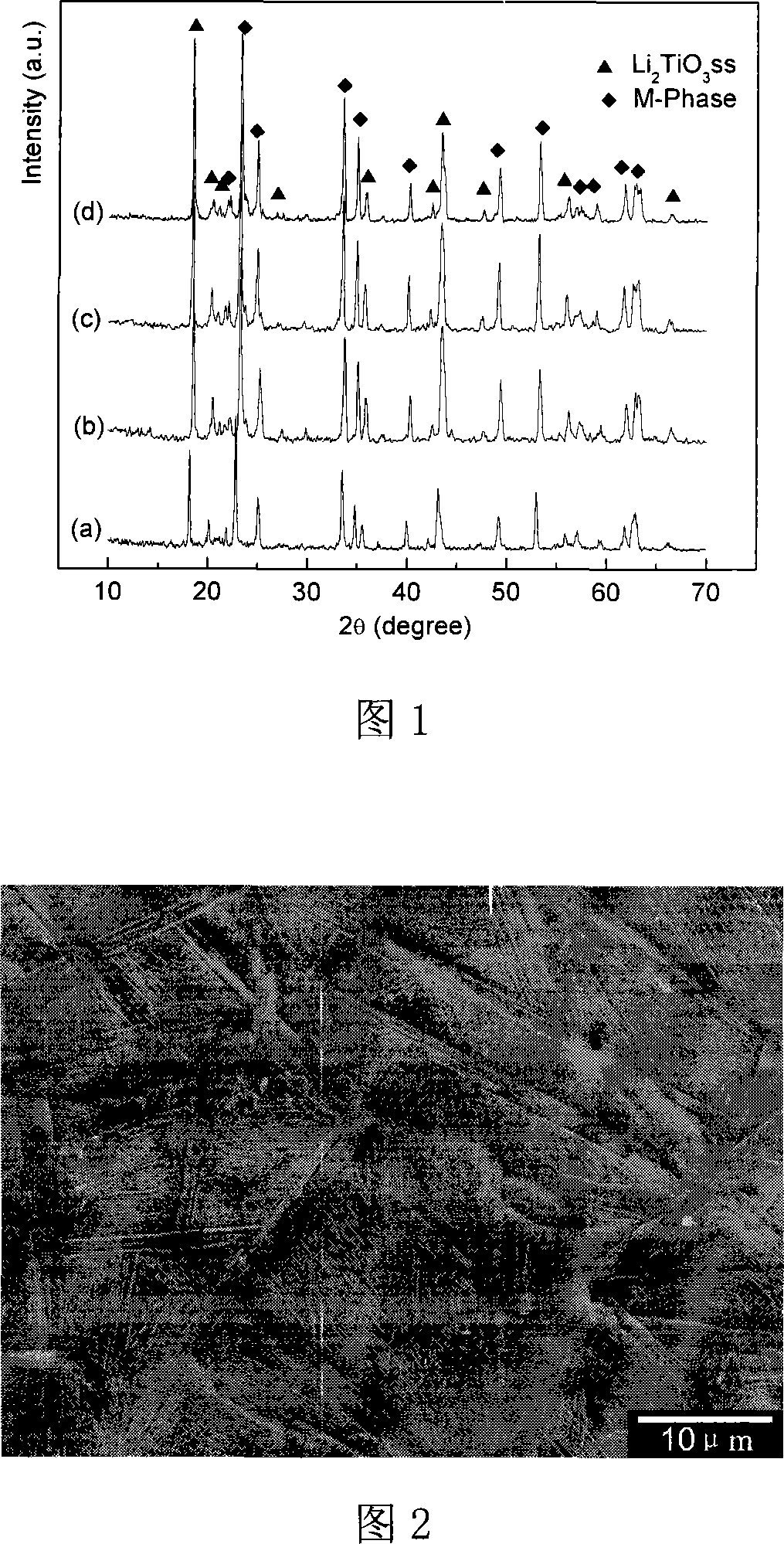

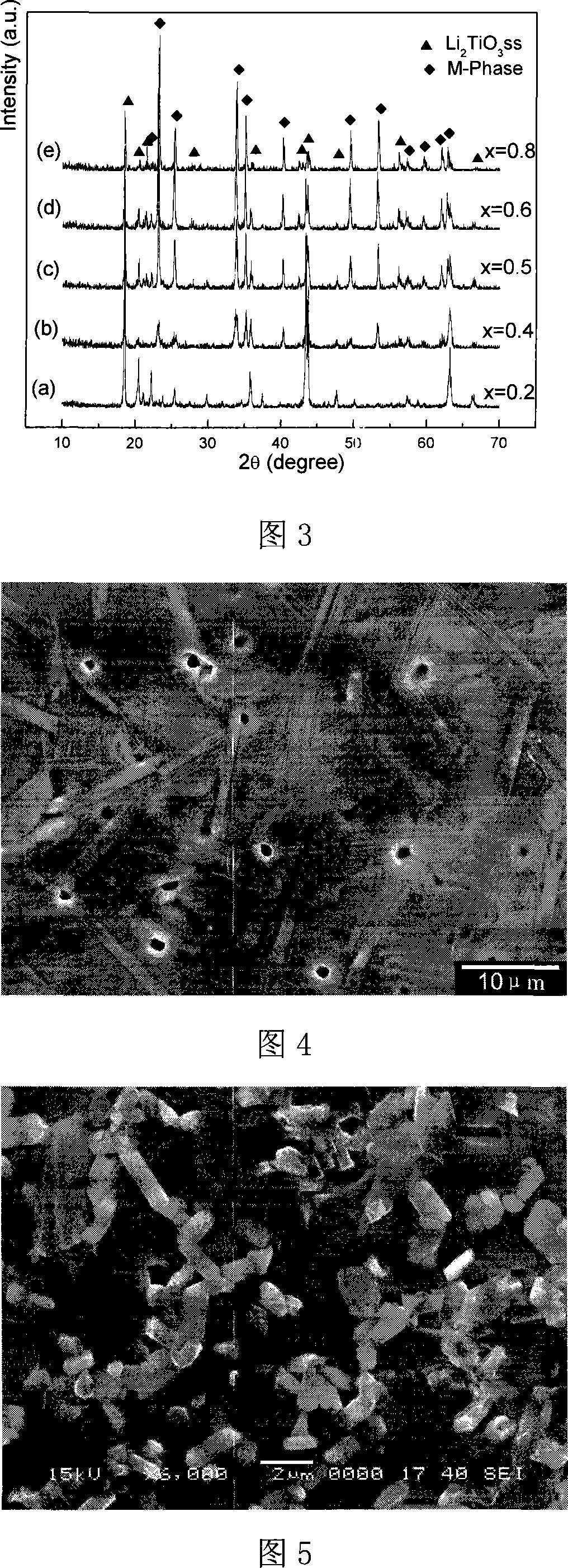

Low temperature sintered composite microwave medium ceramic in series of lithium, niobium and titanium, and prepartion method

This invention relates to a method for preparing low-temperature-sintered lithium-niobium-titanate composite microwave dielectric ceramic, which is composed of Li2TiO3 solid solution and M-phase solid solution. The composite microwave dielectric ceramic is prepared from Li2CO3, Nb2O5 and TiO2 at a mol ratio of 5: x: y (x is in 1-2 and y in 4-6), and B2O3 or V2O5 0-5 wt. % by conventional solid-phase reaction. The composite microwave dielectric ceramic has a low sintering temperature (about 1100 deg.C), good dielectric property with a dielectric constant of 34-50, a high Q*f value (Q is quality factor), and a low resonance frequency temperature coefficient, and can be used in sheet dielectric resonator, filter, antenna, balun, etc. when added with a small quantity of low-melting-point oxide, the composite microwave dielectric ceramic has a lower sintering temperature of about 900 deg.C, while its good microwave dielectric property can be maintained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

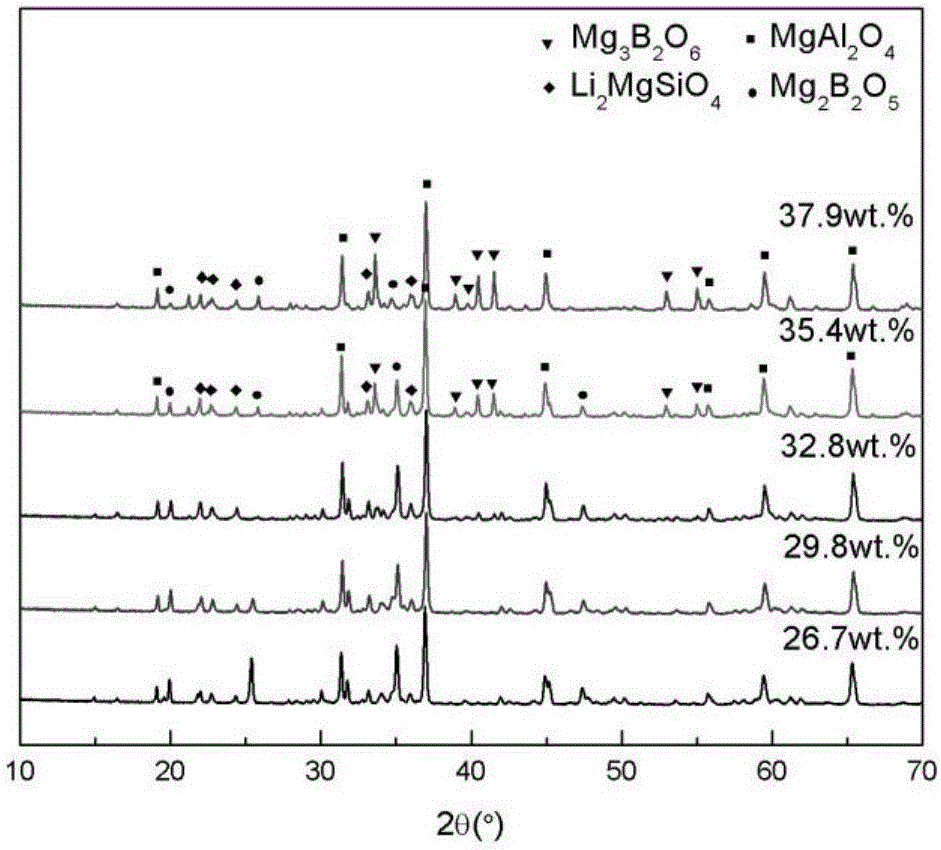

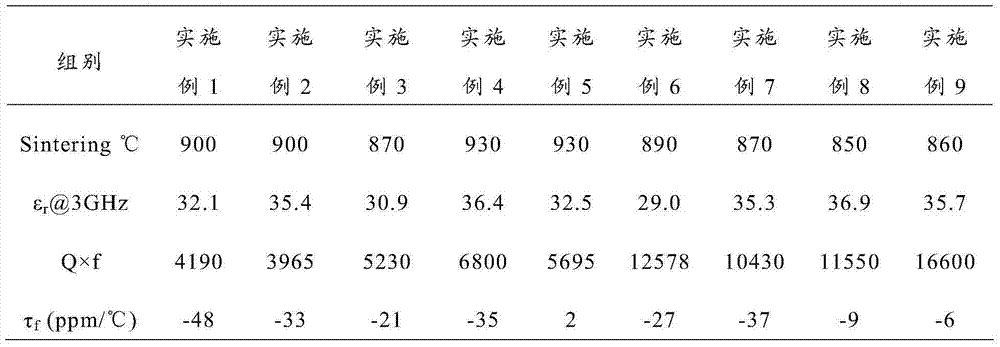

Low-temperature sintered microwave medium ceramic material and preparation method thereof

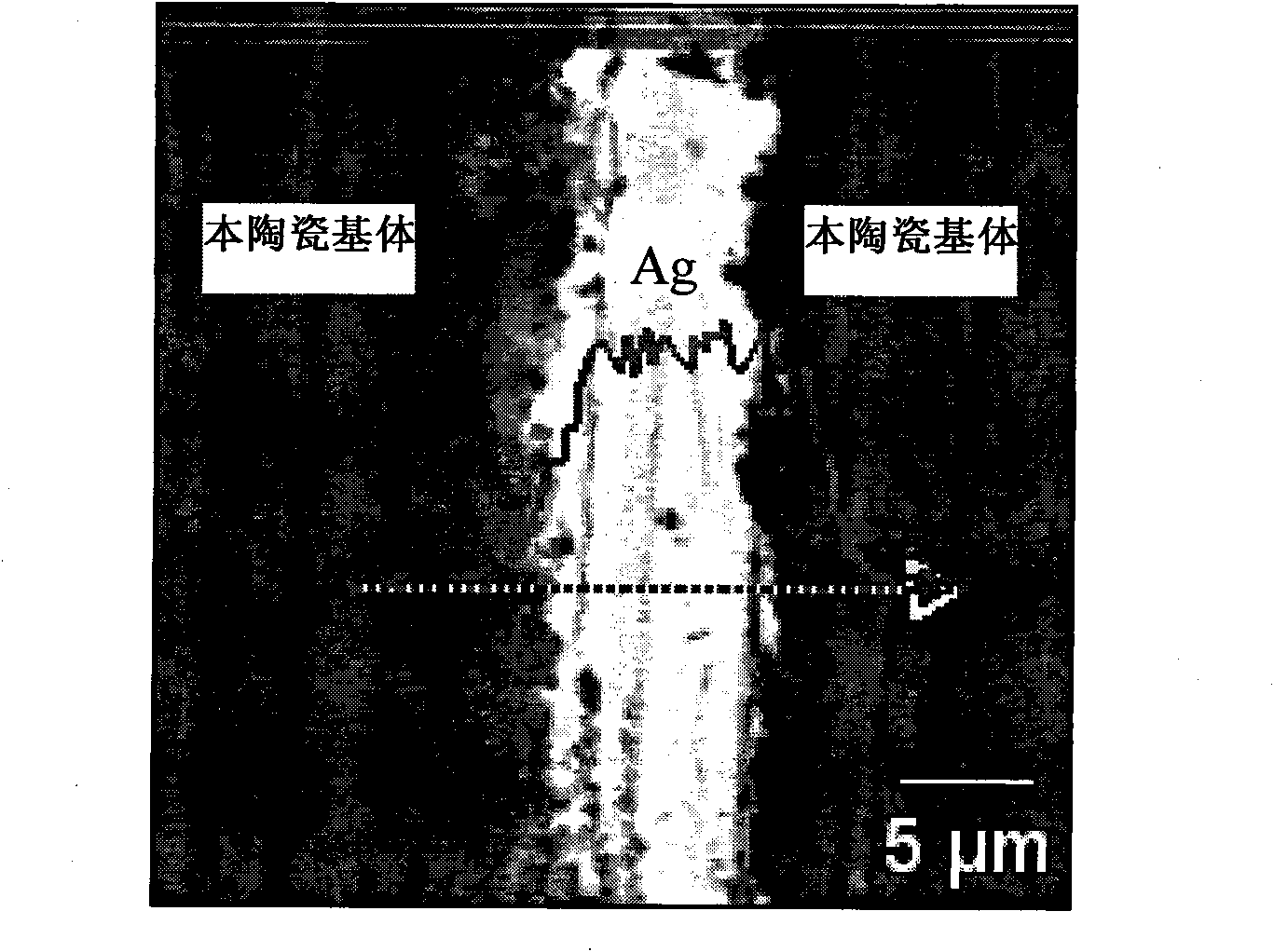

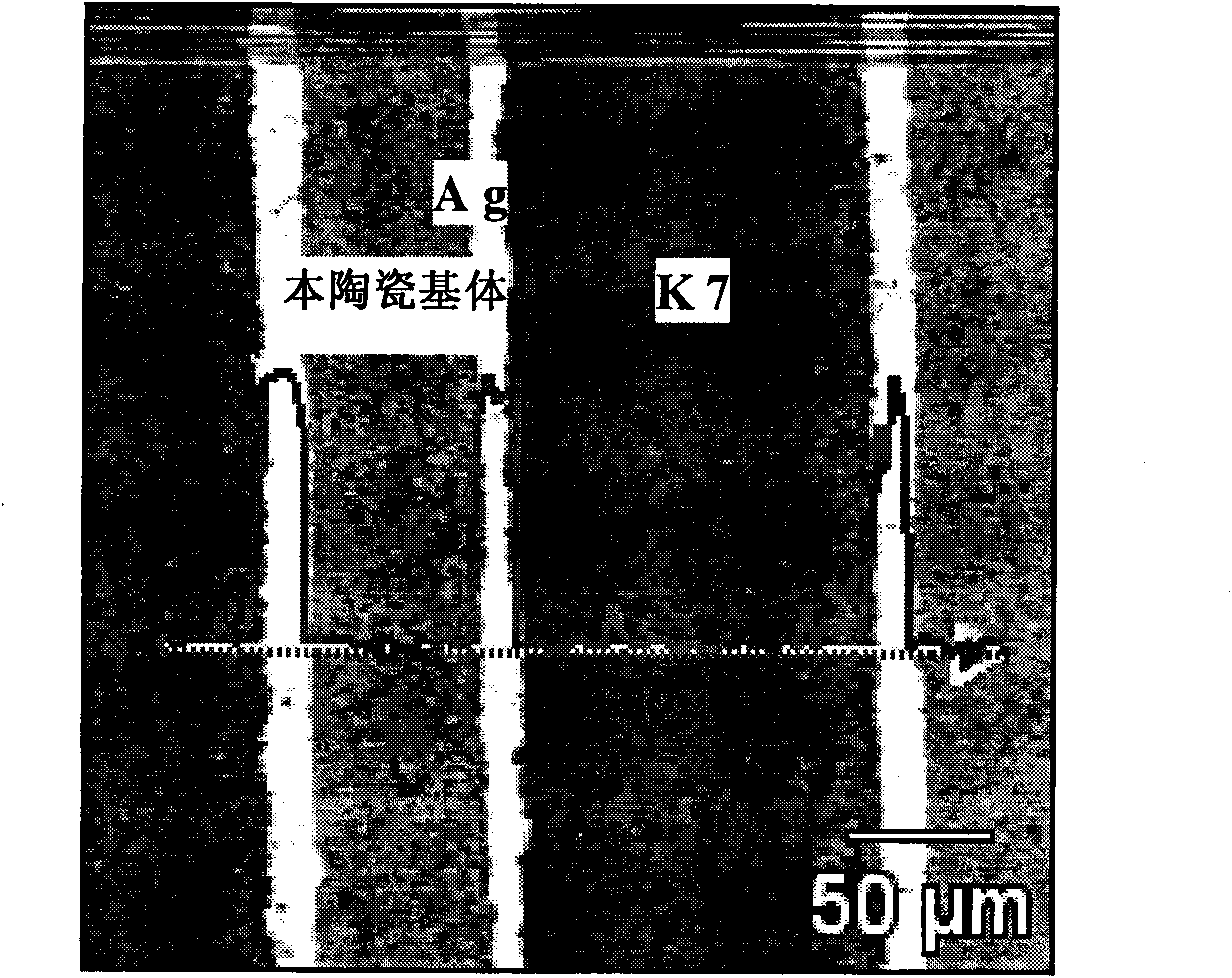

ActiveCN101613200AImprove performanceExcellent microwave dielectric propertiesCeramicsCombustionSilver electrode

The invention discloses a low-temperature sintered microwave medium ceramic material and a preparation method thereof. The material comprises the raw materials with the mol ratio: BaCO3:ZnO:TiO2:Q=1:x:(4+y):z, wherein x=0.01-0.5, y=0.01-0.5, z=0.01-0.1, and Q is glass combustion-supporting agent or BaCu (B2O5); the glass combustion-supporting agent comprises the raw materials with the mol ratio being Li2O:ZnO:B2O3=1:2:7 or Li2O: B2O3-1:2:7=3:2:5. The material can be obtained through traditional solid phase reaction synthesis. The material has lower sintering temperature (is capable of being fired at the temperature below 900 DEG C to form ceramics), is capable of being fired at the temperature of 900 DEG C to form ceramics and has better microwave dielectric property, wherein Epsilon r is equal to 25-35, Q*F is larger than 12,000, and Pi f is equal to -10ppm / DEG C to +30ppm / DEG C; in addition, the material has stable process and good repeatability and can be better co-fired and matched with a silver electrode. The low-temperature sintered microwave medium ceramic material can be used for manufacturing microwave devices, such as lower temperature co-fired ceramic (LLCC) systems, multilayer medium resonators, microwave antennae, wave filters, and the like.

Owner:XI AN JIAOTONG UNIV

Potassium-based vanadium-based low-temperature sintered microwave dielectric ceramic material and preparation method thereof

InactiveCN102249664AImprove performanceLow and low frequency dielectric lossElectricityDielectric loss

The invention discloses potassium-based vanadium-based low-temperature sintered microwave dielectric ceramic materials and a preparation method thereof. Based on the structure of typical scheelite of ABO4, low-valent K+ ions and Bi3+ are selected to occupy an A site jointly, and high-valent Mo6+ and V5+ composite cations are selected to occupy a B site; a series of ceramic materials are obtained by a solid state reaction sintering method, wherein the ceramic materials can be sintered in a temperature range below 800 DEG C, have a high dielectric constant (34<=epsilon r<=80), an adjustable temperature coefficient of resonant frequency (-260 ppm / DEG C<=TCF<=+116 ppm / DEG C), and a low microwave dielectric loss (high quality factor Qf value, 4,000 GHz<=Qf<=9,700 GHz) in microwave frequency band. The specific structure expression is (K0.5xBi1-0.5x)(MoxV1-x)O4, wherein 0.05<=x<=0.99.

Owner:XIAN TECH UNIV

Temperature frequency characteristic regulator of microwave medium ceramic and LTCC material thereof

ActiveCN106927804AStable phase structureExcellent microwave dielectric propertiesAlkaline-earth metal silicatesPrinted circuitsDielectric permittivityMicrowave dielectric properties

The invention discloses a microwave dielectric ceramic, a temperature frequency characteristic regulator of the microwave medium ceramic and an LTCC material thereof. The microwave dielectric ceramic comprises a principal crystalline phase. The chemical formula of the principal crystalline phase is BaSixO2(x+1)(x is greater than or equal to 1.56 but less than or equal to 1.85). The ceramic has a low dielectric constant (epsilon r is equal to 7.1-7.9), a relatively high quality factor (Q*f is equal to 10973-20350GHz) and a relatively wide sintering temperature (750-1250 DEG C). Meanwhile, the principle crystalline phase which is sintered in a reductive atmosphere N2-1vol%H2 still has an excellent microwave dielectric property and is the microwave dielectric material with good reduction resistance. The microwave dielectric material can be used as the temperature frequency characteristic regulator of the microwave medium ceramic and can keep a stable phase structure and a good microwave dielectric property (reduction resistance) in the reductive atmosphere. Compared with a conventional adjustor, the microwave dielectric ceramic has an obvious advantage and is a novel temperature frequency characteristic regulator which can be applied to BME-MLCC.

Owner:HUAZHONG UNIV OF SCI & TECH

Low temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and preparation thereof

InactiveCN101475371ALow costExcellent electrical performanceCeramicsDielectric antennasCeramic capacitor

The invention discloses a low-temperature sintered ZnO-MgO-TiO2 system microwave ceramic material and a preparation method thereof. The formula of raw materials of the ceramic material comprises the following compositions: 30 to 45 percent of zinc oxide, 2 to 14 percent of magnesium oxide, 50 to 60 percent of titania and an auxiliary sintering agent. The preparation method comprises: taking the zinc oxide, basic magnesium carbonate and the titania as raw materials, mixing the raw materials, adding a grinding aid for ball milling, drying, sieving and presintering, and obtaining clinker; and mixing the obtained clinker with the titania, the auxiliary sintering agent and an additive, performing drying, granulation and press forming after secondary ball milling, finally sintering the mixture for 2 to 8 hours at a temperature of between 900 DEG C and 1,000 DEG C, and obtaining the ceramic material. The ceramic material prepared by the method has the advantages of superior microwave dielectric property, low sintering temperature, low cost and the like, and is suitable for microwave devices such as multi-layer ceramic capacitors, filters, resonators and dielectric antennas.

Owner:SOUTH CHINA UNIV OF TECH

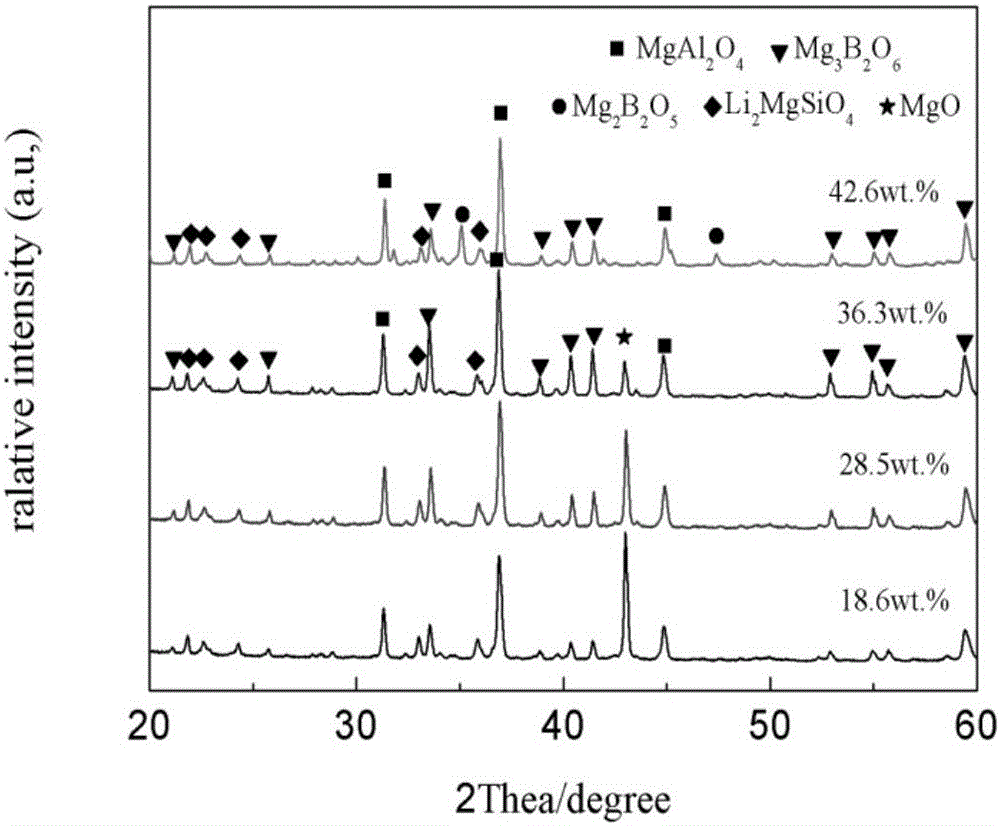

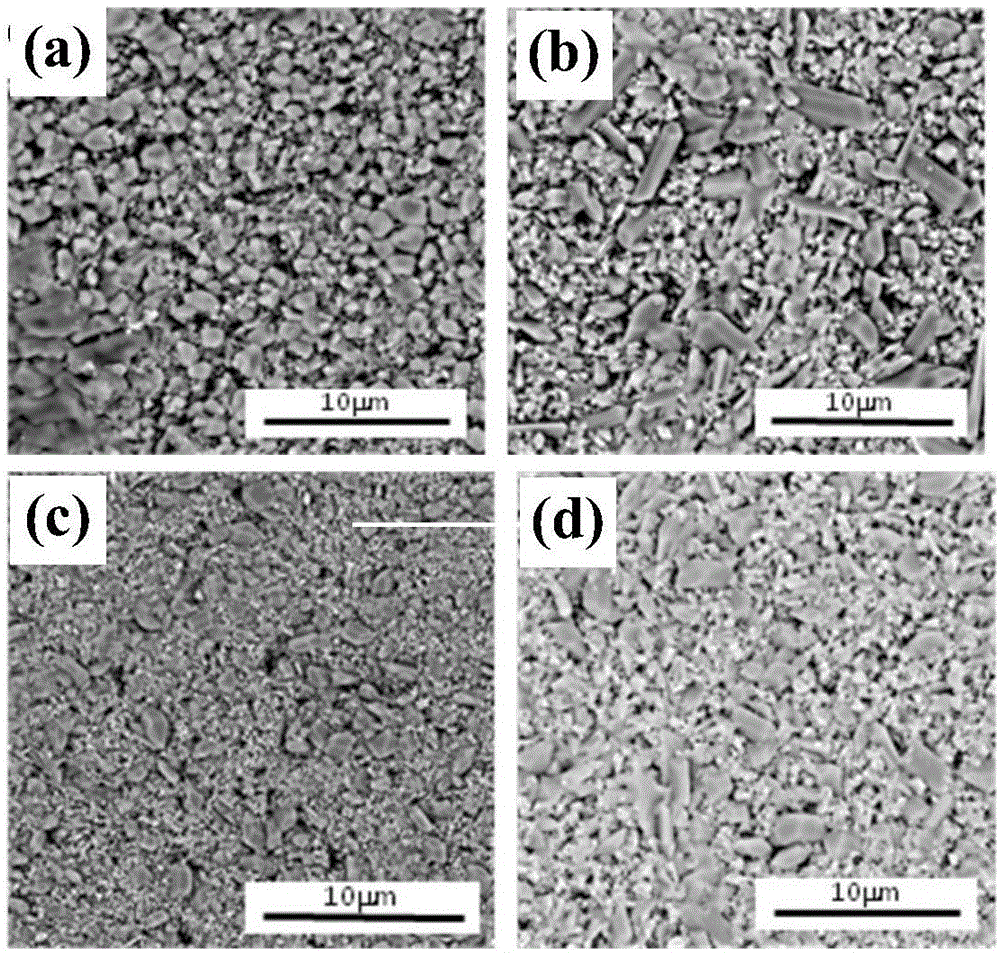

Low-dielectric constant high-quality factor LTCC microwave medium material and preparation method thereof

InactiveCN107434411AExcellent microwave dielectric propertiesLower quality factorMicrowaveCeramic composite

The invention provides a low-dielectric constant high-quality factor LTCC microwave medium material and a preparation method thereof. The material comprises MgAl2O4 ceramic and MgAl2O4 ceramic composite sintering reducer, the MgAl2O4 ceramic is formed by pre-burning MgO and Al2O3; the composite sintering reducer is pre-burned by Li2CO3, H3BO3, SiO2, ZnO, and MgO to form Li2O-MgO-ZnO-B2O3-SiO2 glass, and the pre-burned MgAl2O4 ceramic and the Li2O-MgO-ZnO-B2O3-SiO2 glass are subjected to ball milling mixing according the mass ratio of 1:2, granulation, moulding, rubber discharging and sintering to prepare the low-dielectric constant high-quality factor LTCC microwave medium material. The microwave medium material has low dielectric constant (6-8), the high quality factor (is greater than or equal to 45000), the sintering temperature is 920 DEG C, the process is simple, and the microwave medium material has the advantages of easy industrial production and stable material performance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

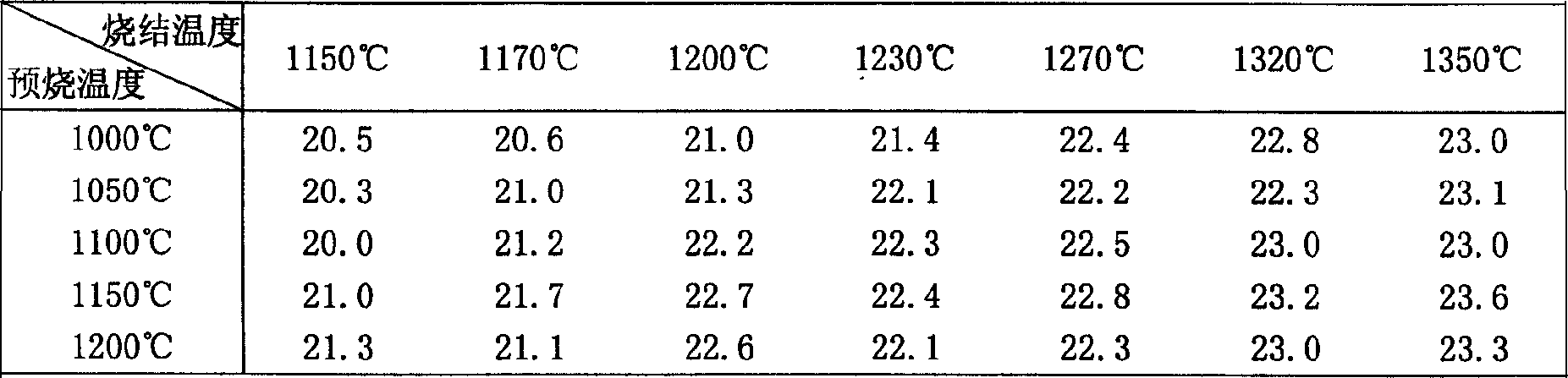

High dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material and preparation method thereof

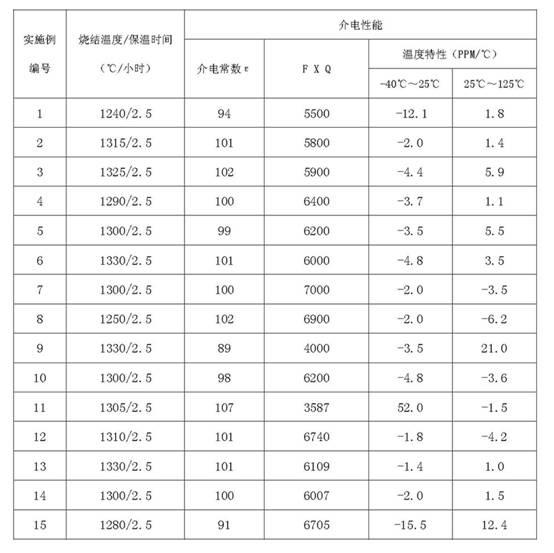

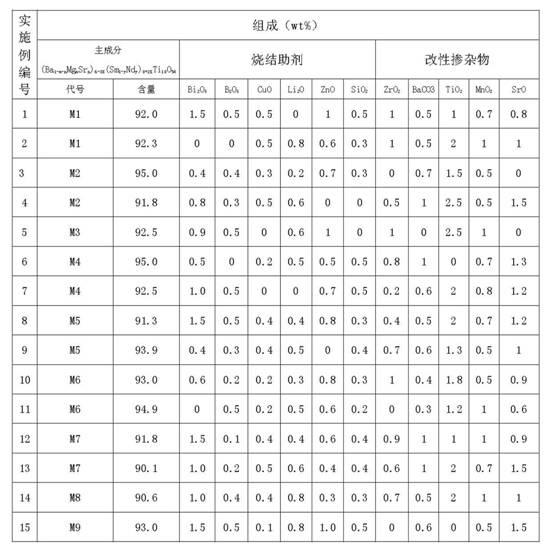

The invention provides a high dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material and a preparation method of the high dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material. The high dielectric constant BaO-Ln2O3-TiO2 system microwave dielectric material is composed of a major component (namely, (Ba1-m-nMgmSrn)6-3X(Sm1-yNdy)8+2XTi18O54), a sintering aid and a modified dopant. The major component, namely the (Ba1-m-nMgmSrn)6-3X(Sm1-yNdy)8+2XTi18O54 is solid solution, wherein the X is equal to 0-0.02; Y is equal to 0-0.05; m is equal to 0.002-0.025; and n is equal to 0.05-0.03. The sintering aid comprises one of or a mixture of more than one of low-melting-point oxides of Bi2O3, B2O3, CuO, Li2O, ZnO, SiO2, and the like and low-melting-point glass dust. The modified dopant comprises different metallic oxides and carbonate, such as one of or the mixture of more than one of ZrO2, BaCO3, TiO2, MnO2, SrO, and the like. The microwave dielectric material finally prepared through reasonable formula, optimized synthesis and ball-milling process can be sintered in the temperature range of 1250 DEG C to 1330 DEG C. The produced microwave capacitor has excellent microwave dielectric properties, wherein epsilon r is equal to 100; Q*f is more than or equal to 5500GHZ(3.5-4.5GHZ); and tau f(-40 DEG C-25 DEG C / 25 DEG C-125 DEG C) is less than or equal to 10PPM / DEG C.

Owner:XIAMEN SUNYEAR ELECTRONICS CO LTD

High-Q-value medium-dielectric-constant microwave dielectric ceramic and preparation method thereof

ActiveCN102531571AExcellent microwave dielectric propertiesResonant frequency temperature coefficient continuous adjustmentCompound aMicrowave dielectric properties

The invention discloses a high-Q-value medium-dielectric-constant microwave dielectric ceramic and a preparation method thereof and relates to a microwave dielectric ceramic. According to the invention, a novel material system is adopted as follows: xCaTiO3-(1-x)LaGaO3 (x is 0.66-0.62) microwave dielectric ceramic is obtained by compounding a calcium titanate (CaTiO3) phase with a lanthanum gallate (LaGaO3) phase; the microwave dielectric ceramic comprises the following components by weight percent: 25-35% of CaCO3, 15-30% of TiO2, 20-35% of La2O3 and 10-25% of Ga2O3, wherein the purities of CaCO3 and TiO2 are more than or equal to 99.0%, and the purities of La2O3 and Ga2O3 are more than or equal to 99.9%. The high-Q-value medium-dielectric-constant microwave dielectric ceramic disclosed by the invention is good in microwave dielectric property, simple in production technical process and good in repeatability, can be widely applied to preparation of good-property microwave devices such as a dielectric resonator, a filter and a duplexer and meets the technical requirements of systems such as a communication base station.

Owner:HUAZHONG UNIV OF SCI & TECH +1

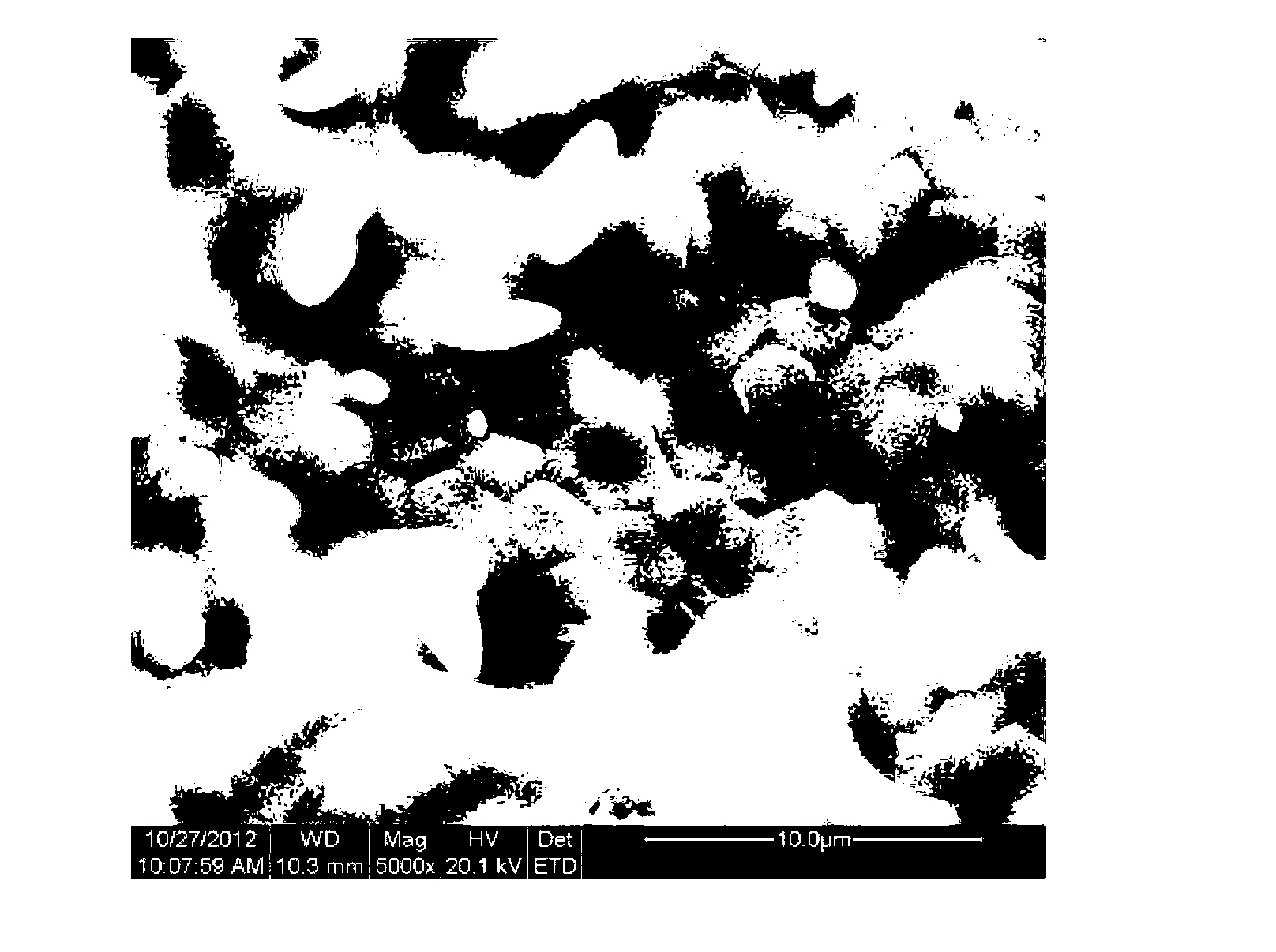

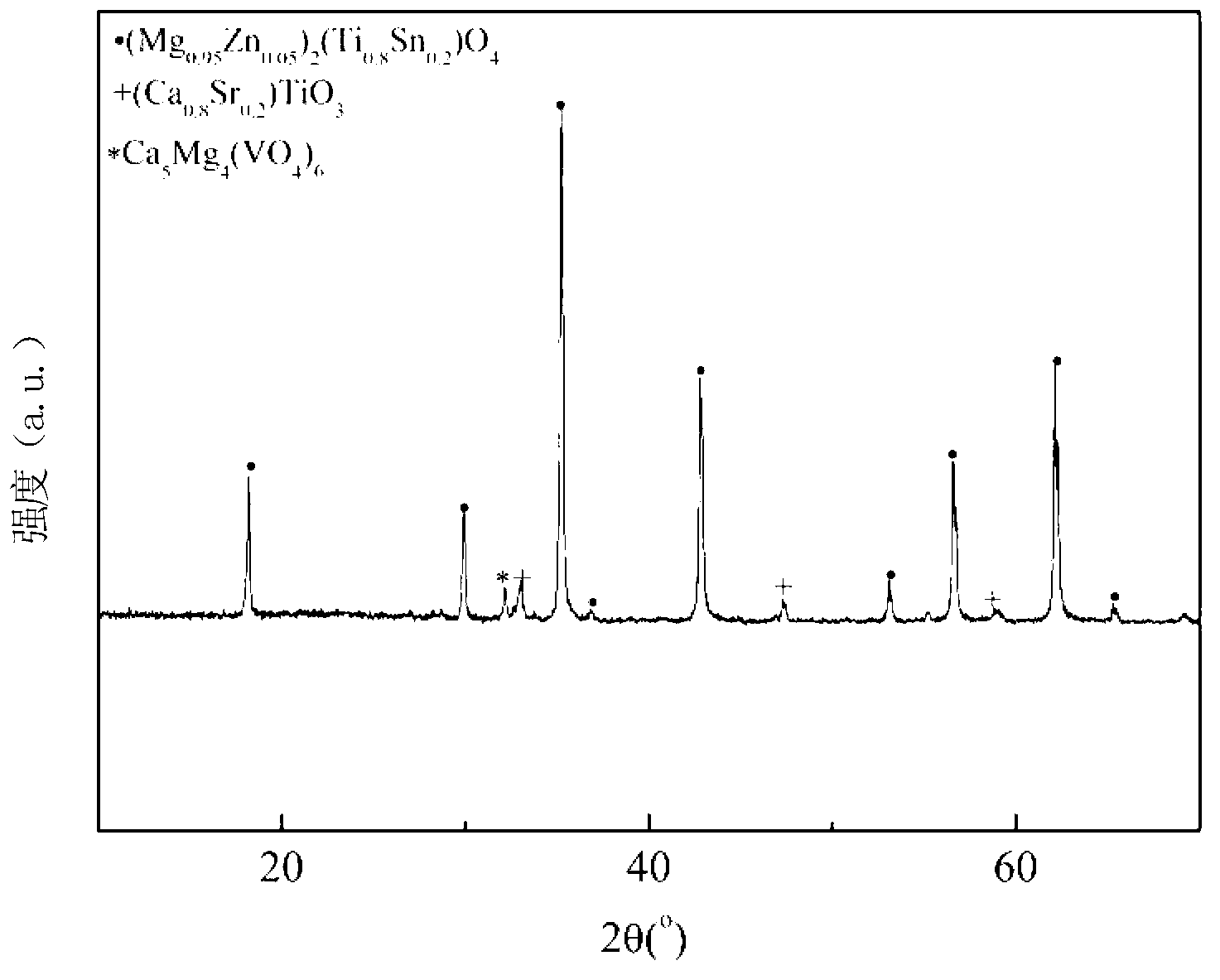

Magnesium titanate based composite ceramic sintered at low temperature and preparation method thereof

The invention relates to magnesium titanate based composite ceramic sintered at low temperature and a preparation method thereof. The magnesium titanate based composite ceramic is composed of the material adopting the following general formula: 0.9 (Mg0.95Zn0.05)2(Ti0.8Sn0.2)O4-0.1(Ca0.8Sr0.2)TiO3-3.0wt%LiF-0.8wt%Fe2O3-xwt%V2O5, wherein x is between 0.5 and 3.0. The sintering temperature of the magnesium titanate based composite ceramic can be decreased to 900 to 975 DEGC, so that the defect of the large temperature coefficient of the resonant frequency of the ceramic material is overcome; and thus the temperature stability of the material is ensured. According to a preparation method, the adopted raw materials are abundant and low in cost, thereby being favorable for industrial production. The magnesium titanate based composite ceramic can be widely used for manufacturing microwave devices such as low-temperature co-fired ceramic systems, GPS (Global Positioning System) antennae, wave filters for wireless local area networks, multilayer dielectric resonators and the like.

Owner:SHAANXI NORMAL UNIV

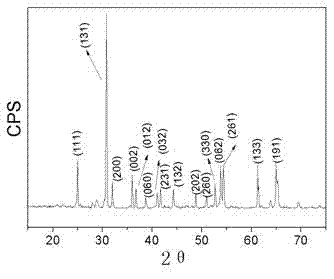

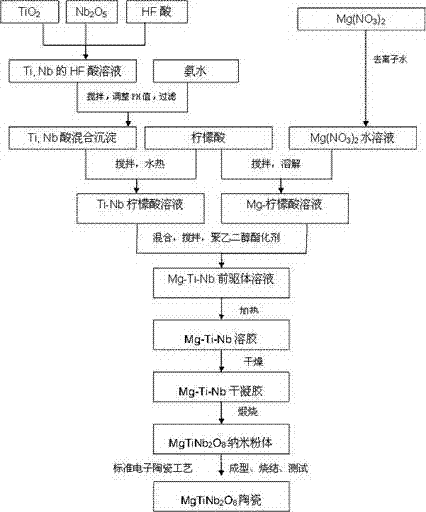

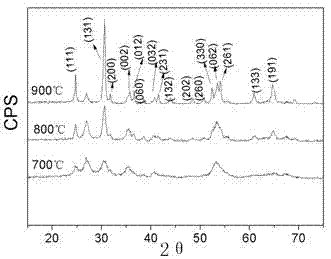

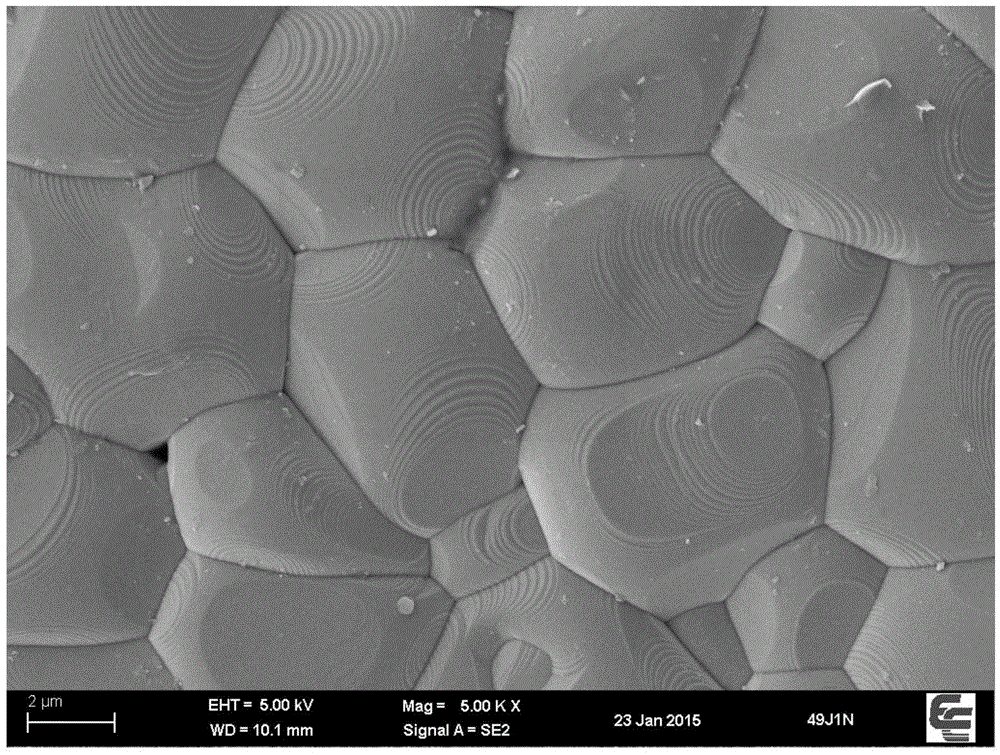

New method for finely preparing ixiolite structure MgTiNb2O8 microwave dielectric ceramic by using chemical process

Owner:UNIV OF JINAN

STLA microwave dielectric ceramic material and preparation method and application thereof

The invention belongs to the field of new materials and microwave communication, and in particular, relates to an STLA microwave dielectric ceramic material and a preparation method and an application thereof. The STLA microwave dielectric ceramic material has main crystal structure of a perovskite structure, and has the chemical expression of aSrO-bTiO2-cCaO-d / 2Ln2O3-e / 2Al2O3, wherein Ln is at least one of rare earths La, Nd and Sm. The preparation method comprises the steps: according to the stoichiometric ratio of the main crystal phase structure, taking strontium carbonate, titanium dioxide, calcium carbonate, rare earth oxide and aluminum oxide, and sanding to mix the raw materials uniformly; then carrying out spray drying, and pre-sintering; smashing, adding a modification additive or adding no modification additive, and again sanding to mix uniformly; carrying out spray granulation, sieving, and carrying out compression molding; and finally, sintering to obtain the STLA microwave dielectric ceramic material. The microwave dielectric ceramic material can be applied to the fields of new materials, microwave communication and the like.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH

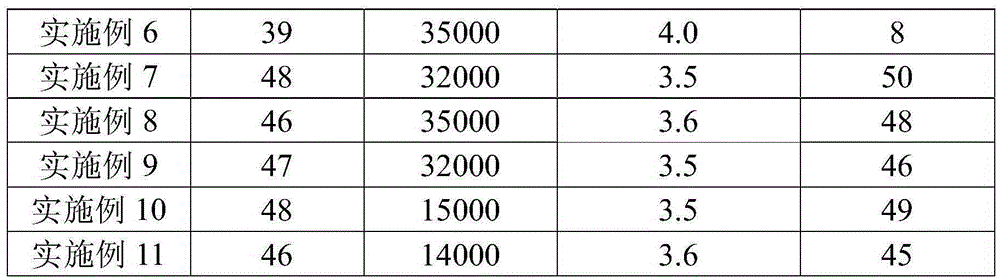

Lithium-zinc-titanium-tin series microwave dielectric ceramics material and preparation method thereof

The invention discloses a lithium-zinc-titanium-tin series microwave dielectric ceramics material and a preparation method thereof. A stoichiometric equation is Li2Zn(Ti(1-x)Snx)3O8, wherein x is larger than 0 and is less than or equal to 1. The preparation method comprises the following steps of: compounding Li2CO3, ZnO, TiO2 and SnO2 according to molar ratio; carrying out ball milling; stoving; carrying out presintering at the temperature of 900 DEG C; carrying out secondary ball milling; and sintering at the temperature of 1040-1120 DEG C finally to obtain microwave dielectric ceramics. When x is equal to 0.2, a dielectric constant is 22.1, a resonant frequency temperature coefficient is -22.5ppm / DEG C, and a quality factor reaches 80500 GHz. The preparation method successfully prepares the lithium-zinc-titanium-tin series microwave dielectric ceramics for the first time, and can be applied in a crossing field of microwave dielectric ceramics and multifunctional ceramics.

Owner:TIANJIN UNIV

Ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material and preparation method thereof

ActiveCN104692795AExcellent microwave dielectric propertiesEasy to prepareRadar systemsDielectric resonator

The invention discloses an ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material and a preparation method thereof. A chemical component of the ceramic material is Li2Mg3TiO6; the dielectric loss is 0.000037-0.000048; Q*f is 123,000-152,000GHz; the dielectric constant is 14.5-15.5; the temperature coefficient of the resonance frequency is -42ppm / DEG C to -36ppm / DEG C; and the ultra-low-loss lithium magnesium titanate microwave dielectric ceramic material is prepared by a high-temperature solid reaction method. The microwave dielectric ceramic material is simple in preparation method, abundant in used raw material, low in cost, and beneficial to industrialized production; and the prepared microwave dielectric ceramic is stable in performance, can be used as a manufacturing material for an electronic circuit substrate, a dielectric resonator, a filter, a high-frequency satellite microwave device substrate and a microstrip line, and has important application prospect and economic value in the fields of electronic circuits, microwave mobile communication, satellite communication and radar systems.

Owner:SHAANXI NORMAL UNIV

Low temperature sintered microwave dielectric ceramic with high dielectric constant and its prepn process

InactiveCN1609049AAdjustable frequency temperature coefficientSpeed up the development processCeramicsSilver electrodeSlurry

The present invention relates to low temperature sintered microwave dielectric ceramic with high dielectric constant and its preparation process. The preparation process includes mixing material including Li2CO3, Nb2O5 and alcohol, stoving, calcining, adding V2O5 and self-made ZnO-B2O3-SiO2 glass, mixing, drying, pressing into disc and sintering. The present invention features the sintering temperature lowered through the synergistic effect of V2O5 and ZnO-B2O3-SiO2 glass, regulated temperature coefficient of material frequency, improved powder and slurry characteristic, excellent co-sintering matching property with silver electrode, good microwave dielectric performance obtained through sintering at about 900 deg.c and stable technological process. The low temperature sintered microwave dielectric ceramic material may be used in various kinds of microwave devices.

Owner:ZHEJIANG UNIV +1

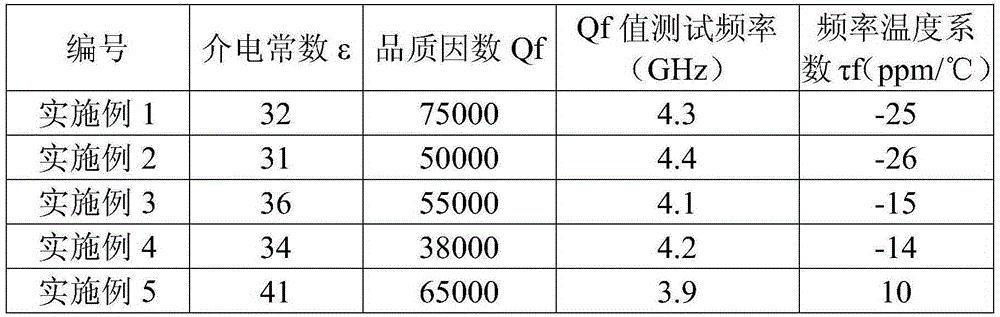

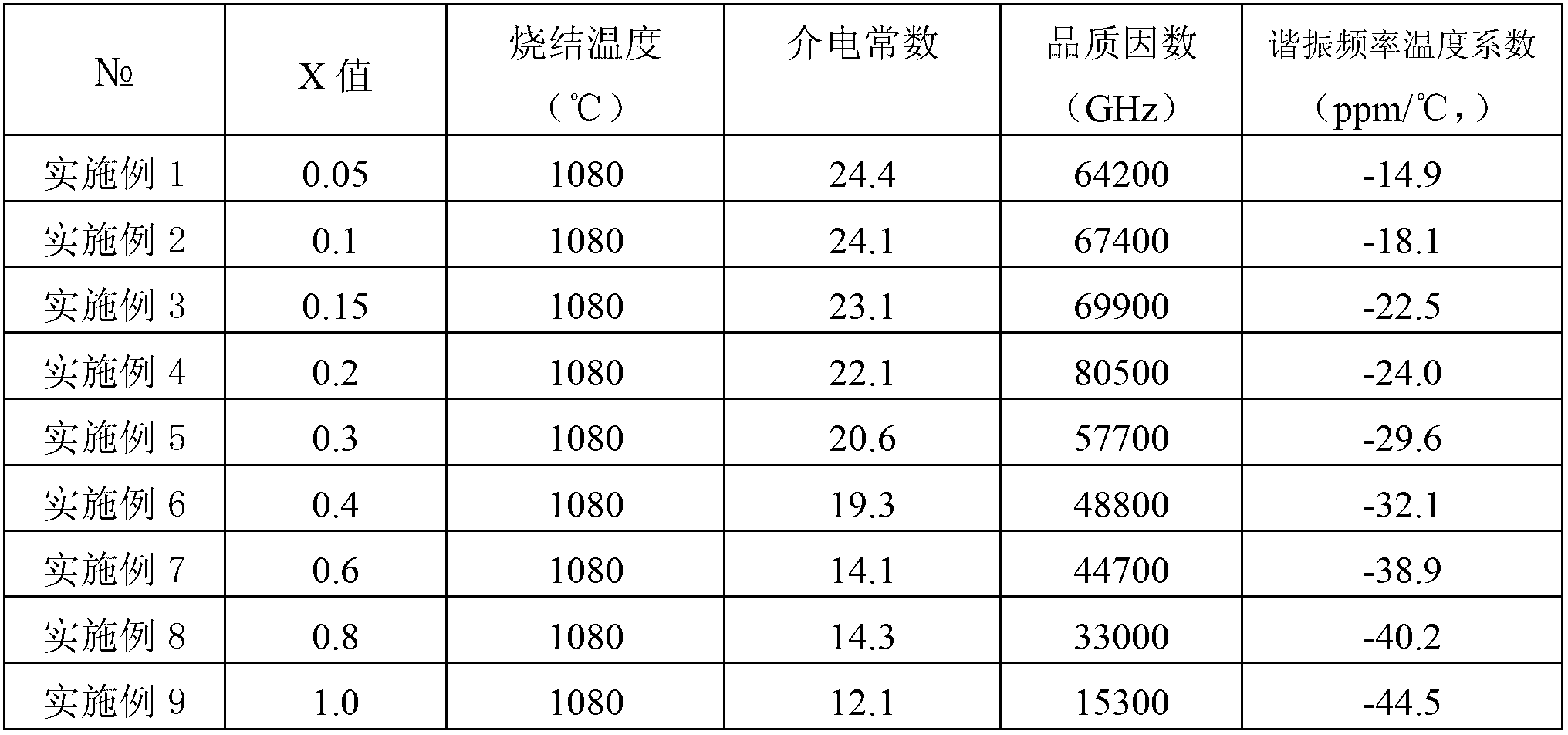

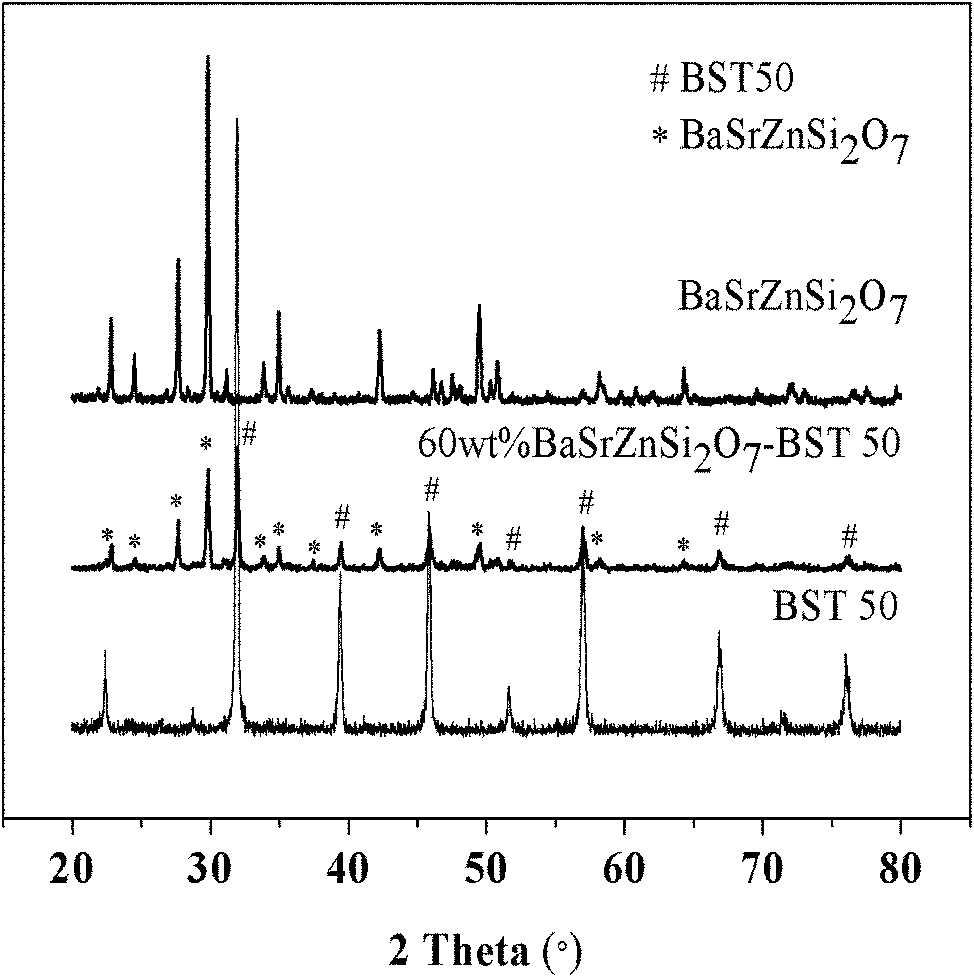

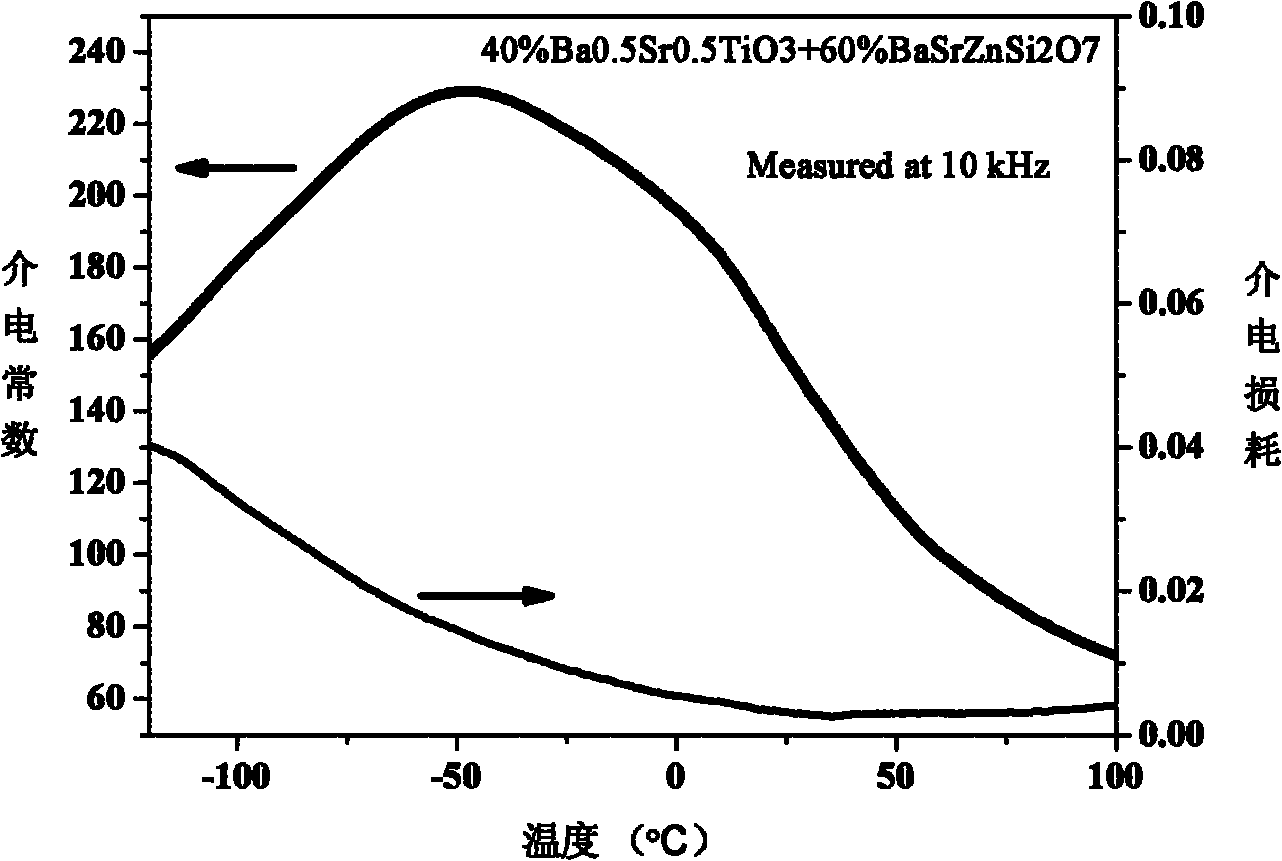

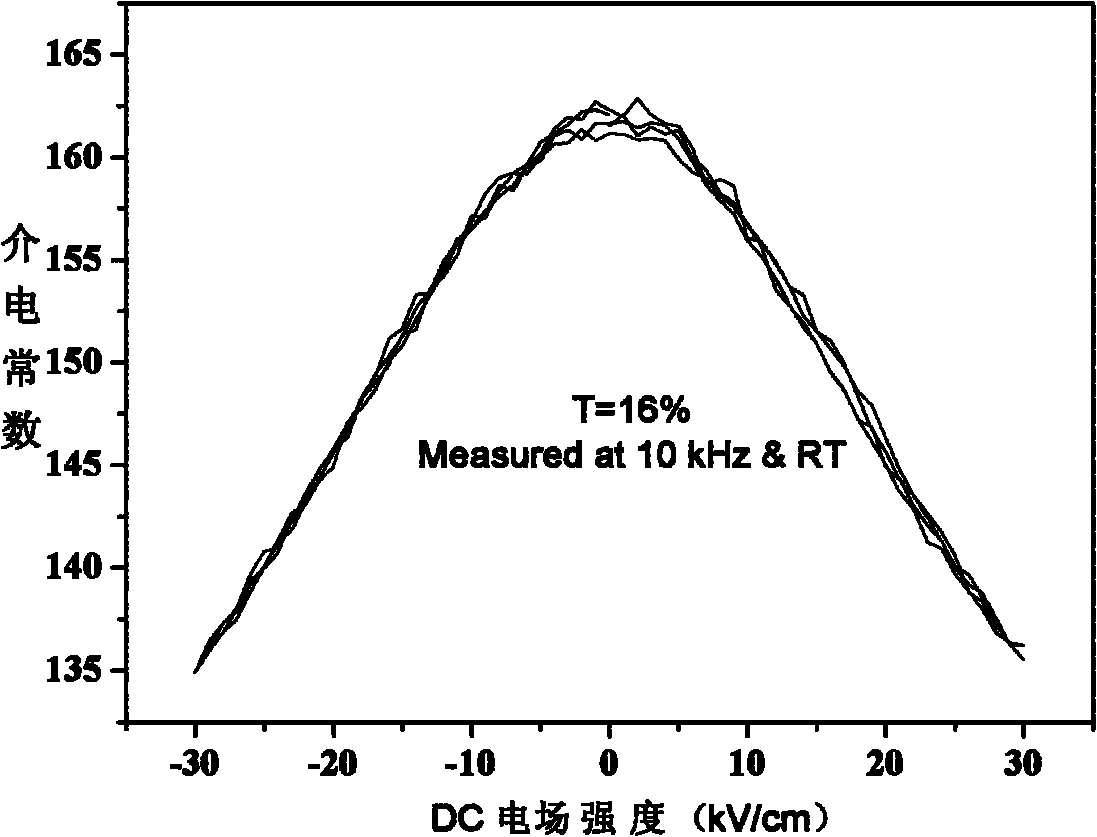

Tunable dielectric barium strontium titanate based composite silicate microwave dielectric material and preparation thereof

The invention belongs to the technical field of electronic materials and devices, and discloses a tunable dielectric barium strontium titanate based composite silicate ceramic dielectric material and preparation thereof. The tunable dielectric barium strontium titanate based composite silicate ceramic dielectric material has a component formula of (1-m%)Ba1-zSrzTiO3+m%(Sr1-xAx)2(Zn1-yBy)Si2O7, wherein A is selected from Ba or Ca; B is selected from Co, Mg, Mn or Ni; the numerical value range of x is not smaller than 0 and not more than 1; the numerical value range of y is not smaller than 0 and not more than 1; the numerical value range of z is not smaller than 0.4 and not more than 0.6; and the numerical value range of m% is more than 0wt% and smaller than 100wt%. The tunable dielectric barium strontium titanate based composite silicate ceramic dielectric material of the invention is high in Q (Quality) value, low in dielectric constant and high in dielectric tunable rate, and can bewidely applied to preparation of tunable microwave elements and devices such as electric tuning microwave tuners, filters, microwave dielectric antennae and the like.

Owner:TONGJI UNIV

Low temperature co-fired ceramic material and preparation method thereof

The invention provides a low temperature co-fired ceramic material. The low temperature co-fired ceramic material comprises the following components: 79-95wt% of ceramics and 5-21wt% of firing aiding glass. Compared with existing ceramic materials, the low temperature co-fired ceramic material has the beneficial effects that BaO, ZnO and TiO2 components are used as the raw materials of the ceramics; the ceramics formed by BaO and TiO2 have excellent microwave dielectric properties but have higher sintering temperatures; the sintering temperatures of the ceramics can be obviously reduced through addition of ZnO, so that the ceramics with better dielectric properties and lower sintering temperatures are obtained; the firing aiding glass has lower sintering temperature and part of atoms in the firing aiding glass are the same as or similar to part of atoms in a ceramic matrix; and meanwhile, the low temperature co-fired ceramic material with middle dielectric constant is obtained by controlling the contents of the ceramics and the firing aiding glass.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

Ceramic materials for microwave ceramic capacitor and making method therefor

InactiveCN1690014AExcellent microwave dielectric propertiesRaw materials are cheapFixed capacitor dielectricCeramicsMicrowave dielectric propertiesTitanium dioxide

The ceramic material for microwave ceramic capacitor has the composition of MgTiO3-CaTiO3, and may be expressed in xMgTiO3-(1-x)CaTiO3, with x being 0.9-1.0. The preparation process includes: mixing basic magnesium carbonate, calcium carbonate and diboron pentoxide in certain proportion, ball milling, stoving, sieving and pre-sintering to obtain fused block; secondary ball milling, stoving, pelletizing, pressing to form and sintering to obtain the ceramic material. The ceramic material for microwave ceramic capacitor has excellent microwave dielectric performance and low cost.

Owner:TIANJIN UNIV

Composite microwave medium ceramic material

This invention relates to a composite microwave medium ceramic material-Li2O-Nb2O5-TiO2 series material. It is composed of Li2TiO3 sosoloid (Li2TiO3ss phase) and M-phase sosoloid. The compositions are: xLi1+a-bNb1-a-3bTia+4bO3+(1-x)Li2+dNb3dTi1-4dO3, wherein: 0<x<1,0.05<a<0.2, 0<b<0.18,0<d<0.2; this inventive material is obtained by traditional preparation method. This inventive product has lower sintering temperature (1100deg.C), excellent microwave medium properties, adjustable dielectric constant (epsilon r=18-70), low resonant frequency temperature coefficient.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

High-permittivity microwave dielectric ceramics capable of being sintered at medium-low temperature and preparation method thereof

InactiveCN103274684ALow sintering temperature into porcelainExcellent microwave dielectric propertiesComposite ceramicResonance

The invention discloses high-permittivity microwave dielectric ceramics capable of being sintered at medium-low temperature and a preparation method thereof. The ceramic material is a composite ceramic material whose main component is composited by (Ca0.8Sr0.2)x(Li0.5Sm0.5)(1-x)TiO3 and any of bi-based compounds Bi4B2O9, Bi2W2O9 and Bi2MoO6 sintering agents. The implementation method comprises the steps that (Ca0.8Sr0.2)x(Li0.5Sm0.5)(1-x)TiO3 powder as well as Bi4B2O9, Bi2W2O9 and Bi2MoO6 sintering agents are synthesized firstly; the (Ca0.8Sr0.2)x(Li0.5Sm0.5)(1-x)TiO3 powder is mixed and ball-milled with any of the Bi4B2O9, Bi2W2O9 and Bi2MoO6 sintering agents; and then the mixed powder containing the sintering agent is compressed into a cylindrical blank body and is subjected to heat preservation for 4 hours at 900 DEG C-1050 DEG C for presintering, so that the high-permittivity (Ca0.8Sr0.2)x(Li0.5Sm0.5)(1-x)TiO3 microwave dielectric ceramics which can be sintered at medium-low temperature and contain the sintering agent. The ceramic material has higher permittivity, smaller resonance temperature coefficient and moderate loss; performance tests prove that better microwave dielectric performances can be obtained: the permittivity Epsilonr is larger than 95, the absolute value of the resonance temperature coefficient Tauf is smaller than 50 ppm / DEG C, the quality factor Qf is larger than 1,500 GHz, the best sintering temperature is lower than 1,050 DEG C, and the 900-DEG C optimum sintering can be achieved; and the whole preparation technology for the microwave dielectric ceramics is relatively simple, stable and easy to implement.

Owner:GUILIN UNIV OF ELECTRONIC TECH

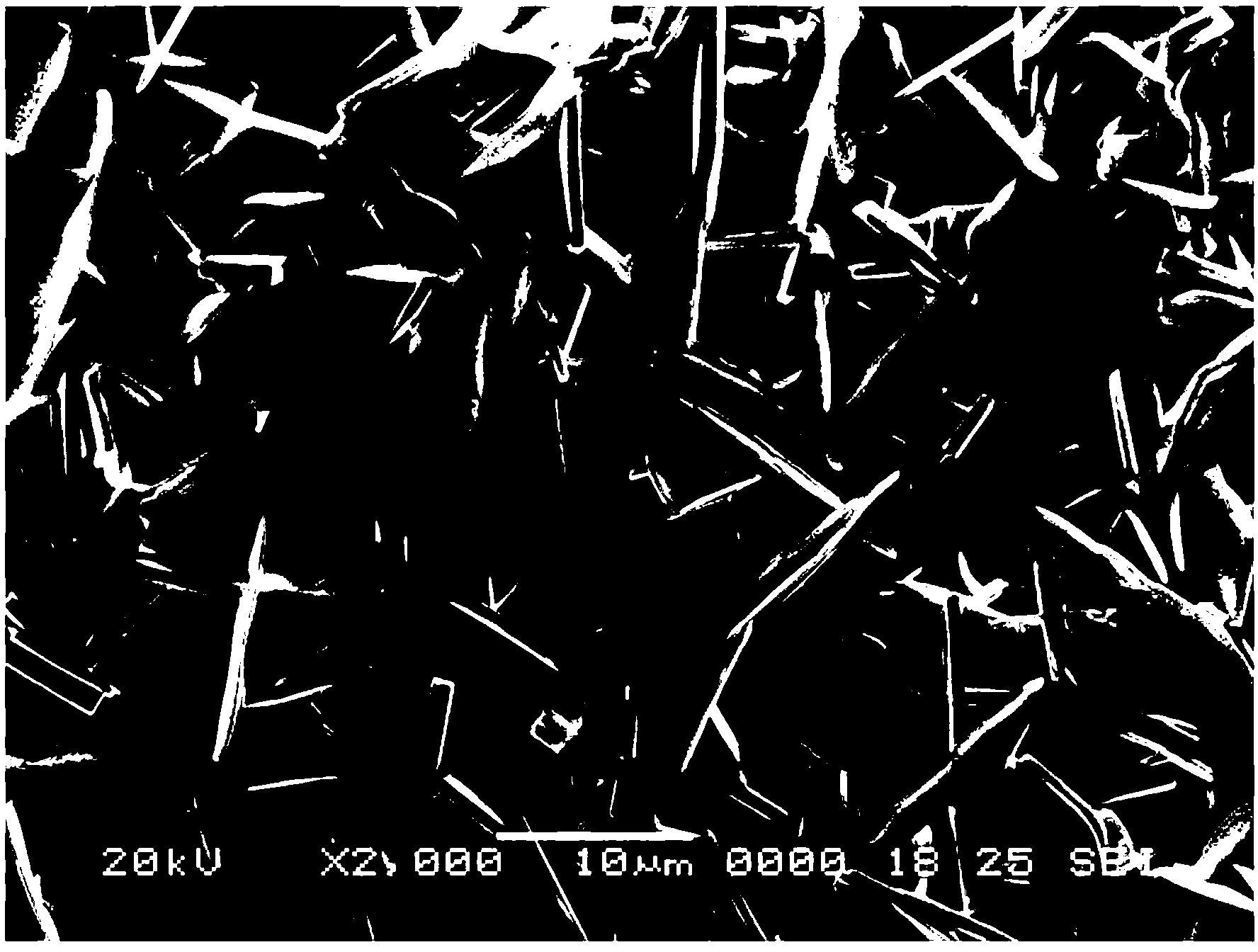

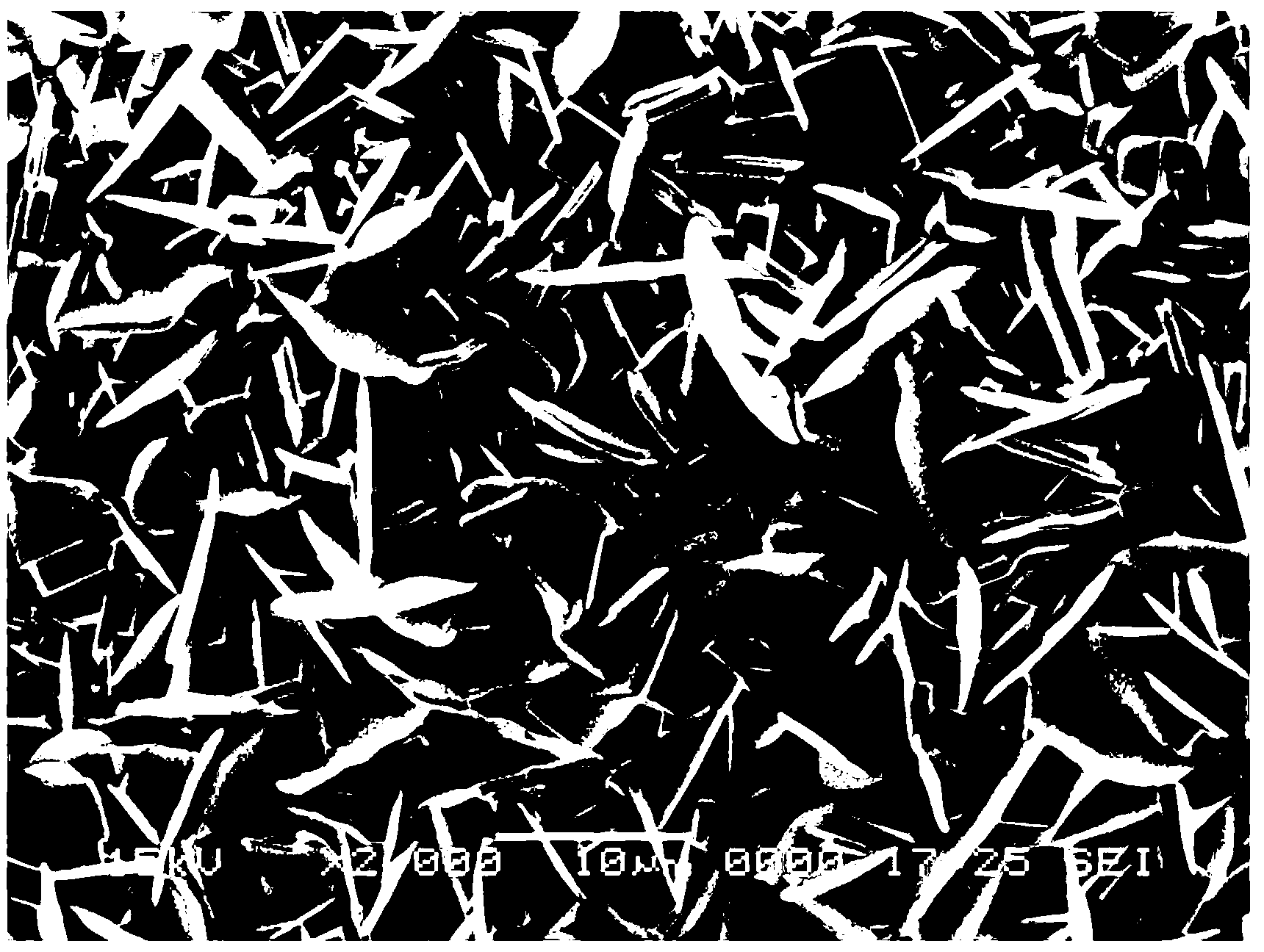

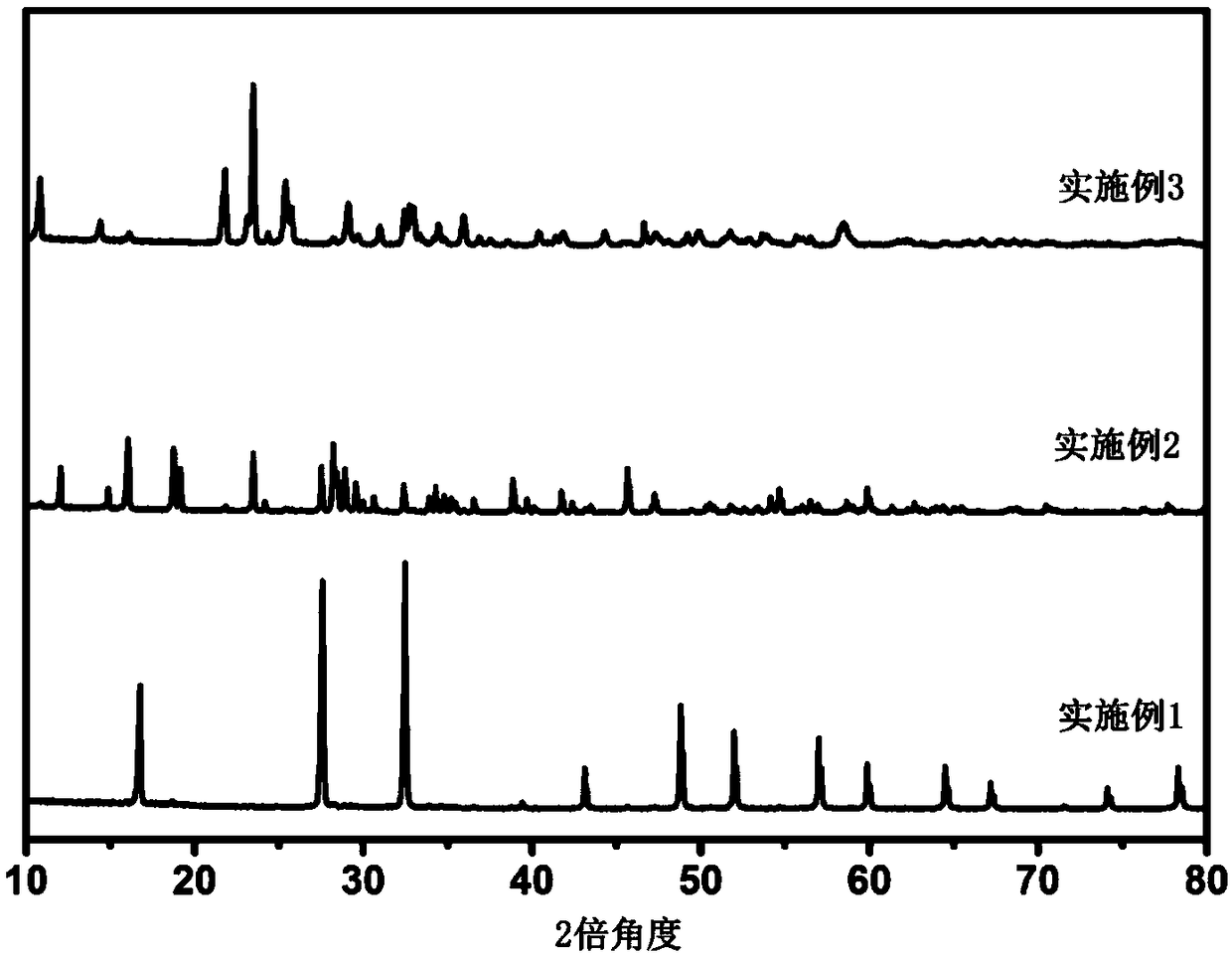

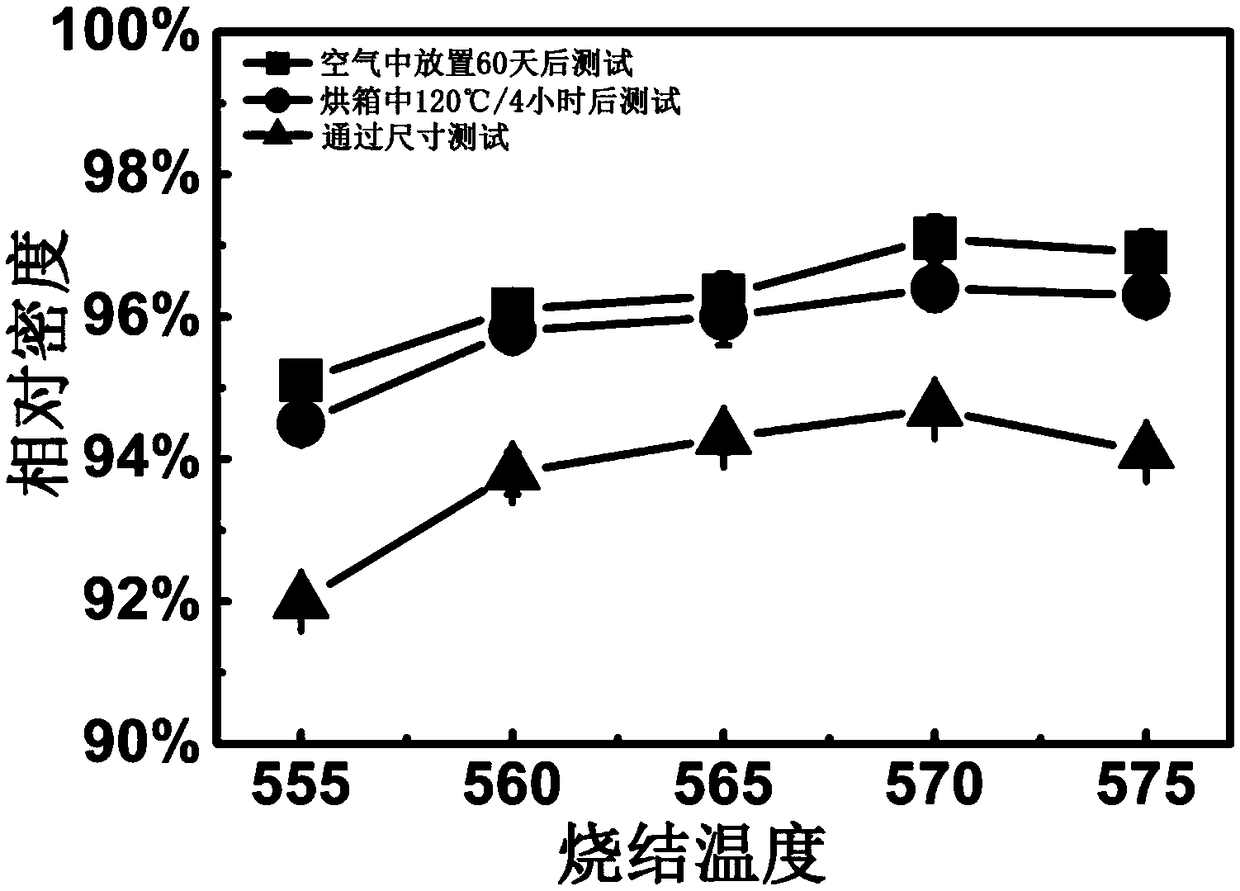

Ultra-low temperature sintering microwave dielectric ceramic material system, and preparation method and application thereof

ActiveCN108911746AExcellent microwave dielectric propertiesGood stabilitySolid phasesMicrowave dielectric properties

The invention discloses an ultra-low temperature sintering microwave dielectric ceramic material system, and a preparation method and application thereof. A structural general expression of the systemis Na2WxO3x+1 (x=1, 2, 4). The system can be sintered at a very low temperature (565 to 740 DEG C) and has excellent microwave dielectric properties (dielectric constant between 5 and 12, quality factor Qf between 10,000 GHz and 124,200 GHz, and temperature coefficient of frequency -60 ppm / DEG C to -80 ppm / DEG C). Powder preparation is carried out by an improved solid phase method, and calciningtemperature is 400 to 550 DEG C. The material system can be co-fired with Ag or Al electrodes and can be used to prepare low-temperature co-fired ceramic (LTCC) substrates for use in microwave resonators, filters, and panel antennas. The ceramic material system meets the requirements of environmental protection, and is non-toxic and pollution-free.

Owner:XI AN JIAOTONG UNIV

Microwave medium ceramic material and preparing method thereof

InactiveCN103159473ARaw materials are cheap and easy to getSimple preparation processCommunications systemMiniaturization

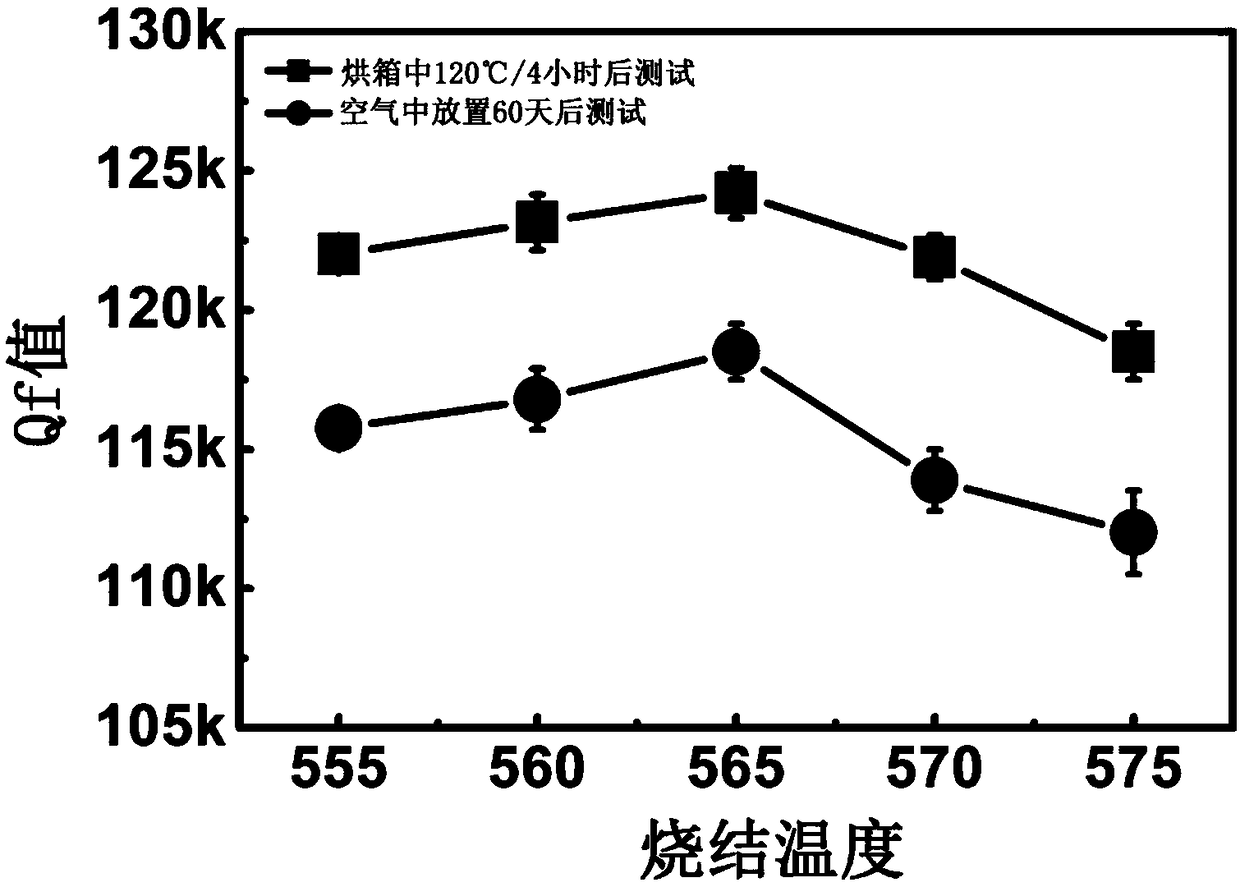

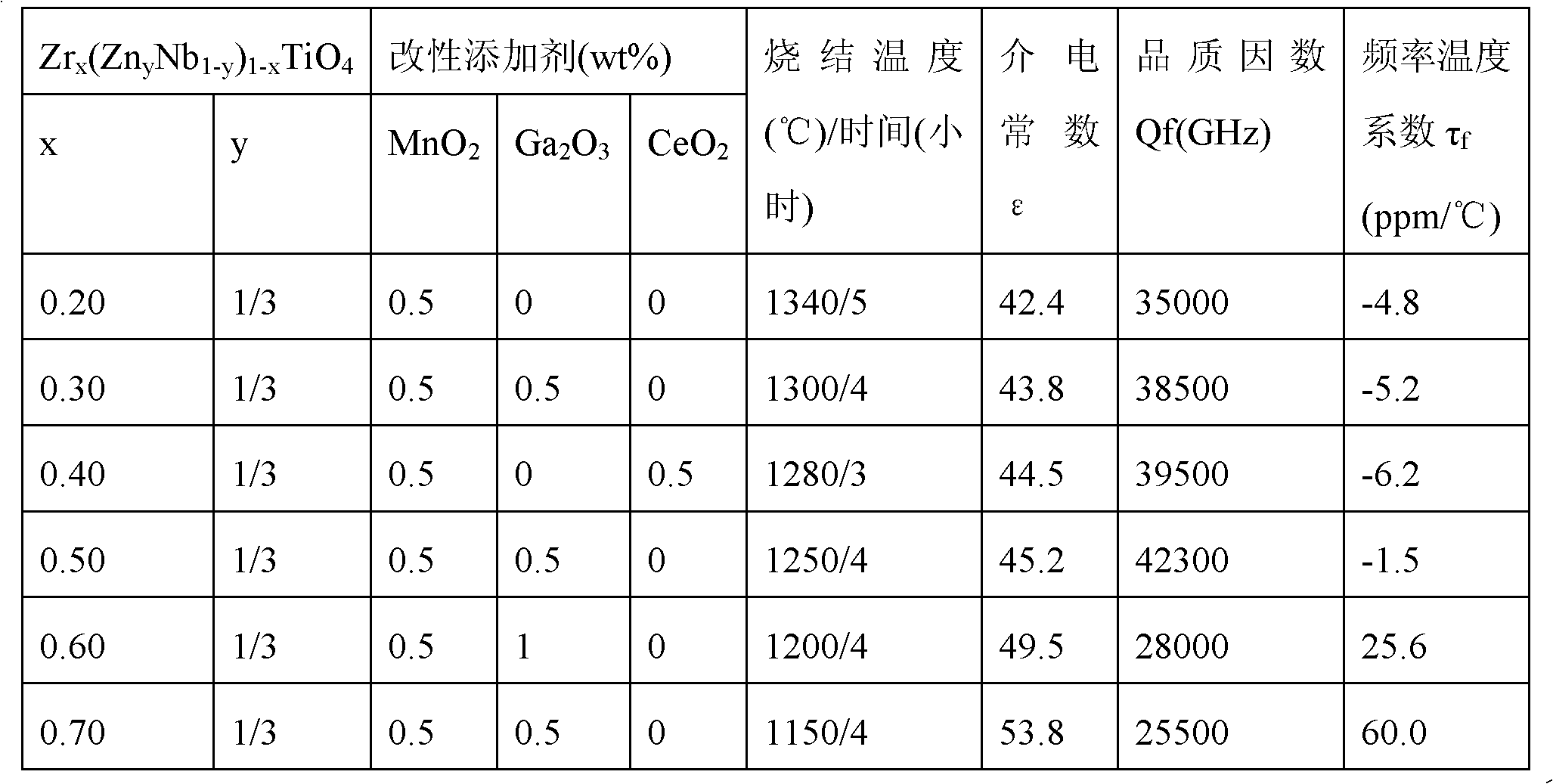

The invention provides a microwave medium ceramic material and a preparing method thereof. The microwave medium ceramic material is composed of principal crystalline phases and property-modifying additives, wherein the structural formula of the principal crystalline phases is Zrx(ZnyNb1-y) 1-xTiO4, 0.2<=x<=0.7, 1 / 3<=y<=2 / 3, and the property-modifying additives are mixture of any one or more than two of MnO2, CeO2 and Ga2O3. The preparing method of the material includes the following steps of burdening, ball-milling, presintering, property-modifying additive adding and ball-milling, prilling, compression moulding, and sintering. The microwave medium ceramic material is low in sintering temperature, and good in microwave dielectricity, has the middle dielectric constant, the high Q and the adjustable frequency temperature factor, can meet development requirements of microwave device miniaturization and high frequency, and can be used for manufacturing medium resonators, filters, oscillators and other microwave devices in communication systems.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

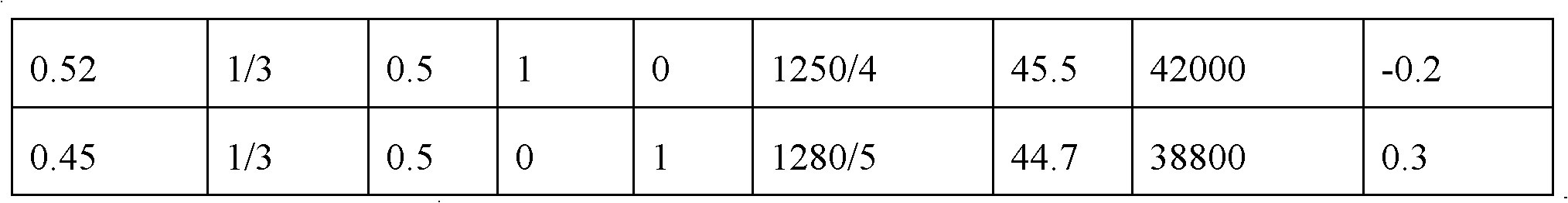

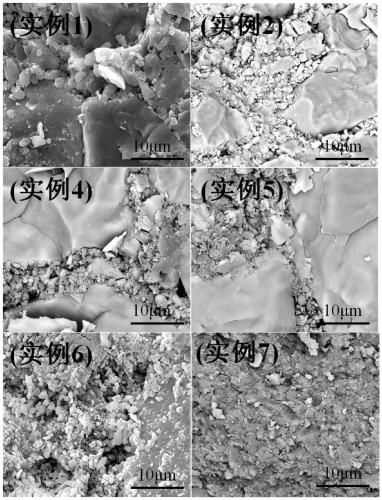

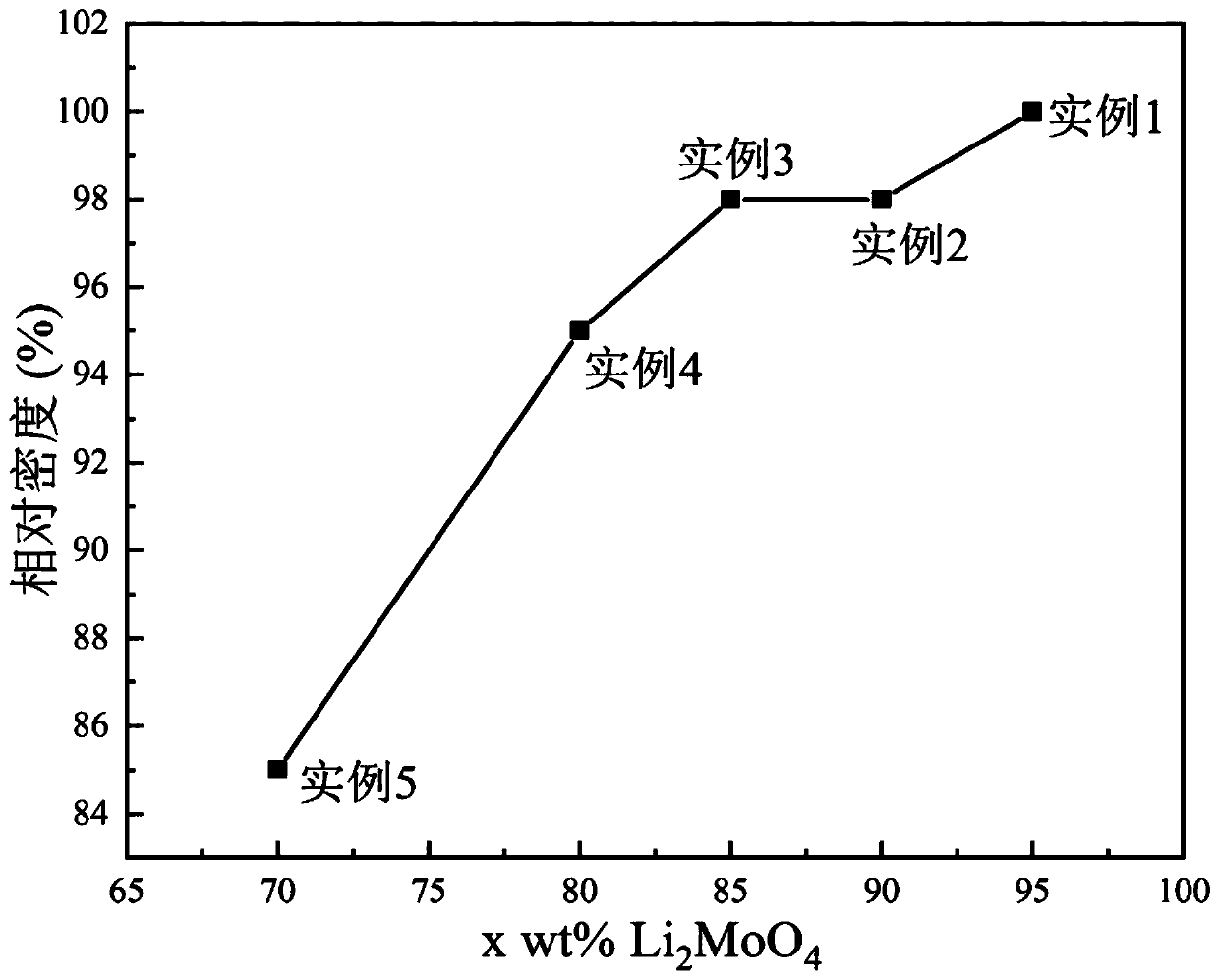

Li2MoO4-Mg2SiO4-based composite ceramic microwave material and preparation method thereof

ActiveCN110183227AExcellent microwave dielectric propertiesHigh dielectric constantComposite ceramicSilicon dioxide

The invention discloses a Li2MoO4-Mg2SiO4-based composite ceramic microwave material and a preparation method thereof. A chemical general formula of the composite ceramic can be written as xLi2MoO4-(1-x)Mg2SiO4, wherein x=10 wt%, 50 wt%, 70 wt%, 80 wt%, 85 wt%, 90 wt% or 95 wt%. The method comprises the following steps: firstly weighing magnesium oxide and silicon dioxide according to a certain stoichiometric ratio, performing ball milling for uniformization, performing drying, and performing pre-sintering to obtain Mg2SiO4; and weighing the prepared Mg2SiO4 and a Li2MoO4 raw material according to a certain weight ratio, adding 15 wt% of deionized water, performing uniform mixing, performing heat pressing on the mixture at 200 DEG C and 500 MPa for 60 min, and performing drying at 120 DEGC for 24 h to remove residual water to obtain the ultra-low-temperature cold sintered xLi2MoO4-(1-x)Mg2SiO4 composite ceramic material. Compared with traditional high-temperature solid-phase sintering(often higher than 1000 DEG C or more), the method provided by the invention has a sintering temperature in the range from room temperature to 200 DEG C; and the method provided by the invention hasa simple process, saves energy and can be widely applied to production of Li2MoO4-Mg2SiO4 composite ceramic substrates.

Owner:HANGZHOU DIANZI UNIV

Microwave dielectric ceramics with lower sintering temperature and preparation method thereof

InactiveCN101570433AExcellent microwave dielectric propertiesLower sintering temperatureCeramicsMaterials preparationDielectric ceramics

The invention discloses a microwave dielectric ceramics with lower sintering temperature, comprising the component of (Mg [1-x] Sn[X]) TiO3, wherein X ranges from 0.03 to 0.08, and the content of the raw materials according to molar percentage is as follows: 50 percent of TiO2, 40 to 50 percent of MgO and 0 to 10 percent of SnO2. The solid phase synthesis technology is adopted and includes the following steps: (1) material preparation; (2) calcination at 1100 DEG C, precursor synthesis, ball milling and drying; and (3) blank preparation and sintering at 1150 to 1250 DEG C. The invention uses Sn[2+] ion to partially replace Mg[2+] ion, thereby improving the microwave dielectric property of MgTiO3 ceramic, reducing the sintering temperature (1150 to 1250 DEG C)of the system, and realizing dense sintering at a lower temperature; and the preparation technology is simple, and the preparation process does not cause pollution.

Owner:TIANJIN UNIV

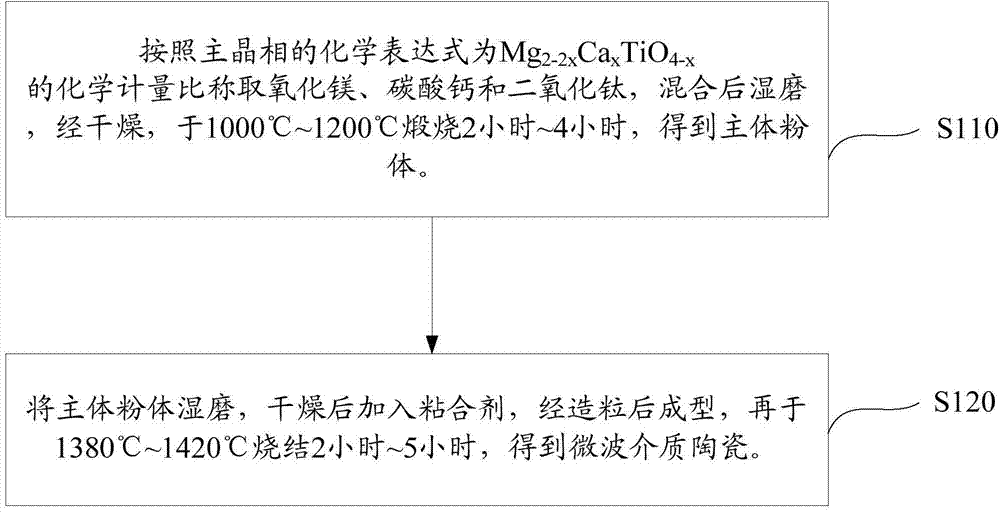

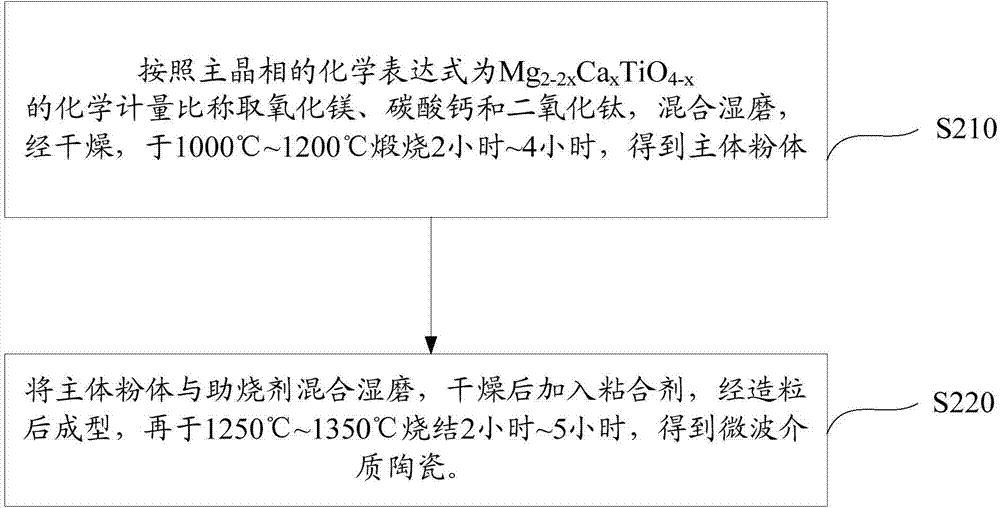

Microwave dielectric ceramic and preparation method thereof

ActiveCN103833351AStable temperature characteristicsExcellent microwave dielectric propertiesMaterials scienceMicrowave dielectric properties

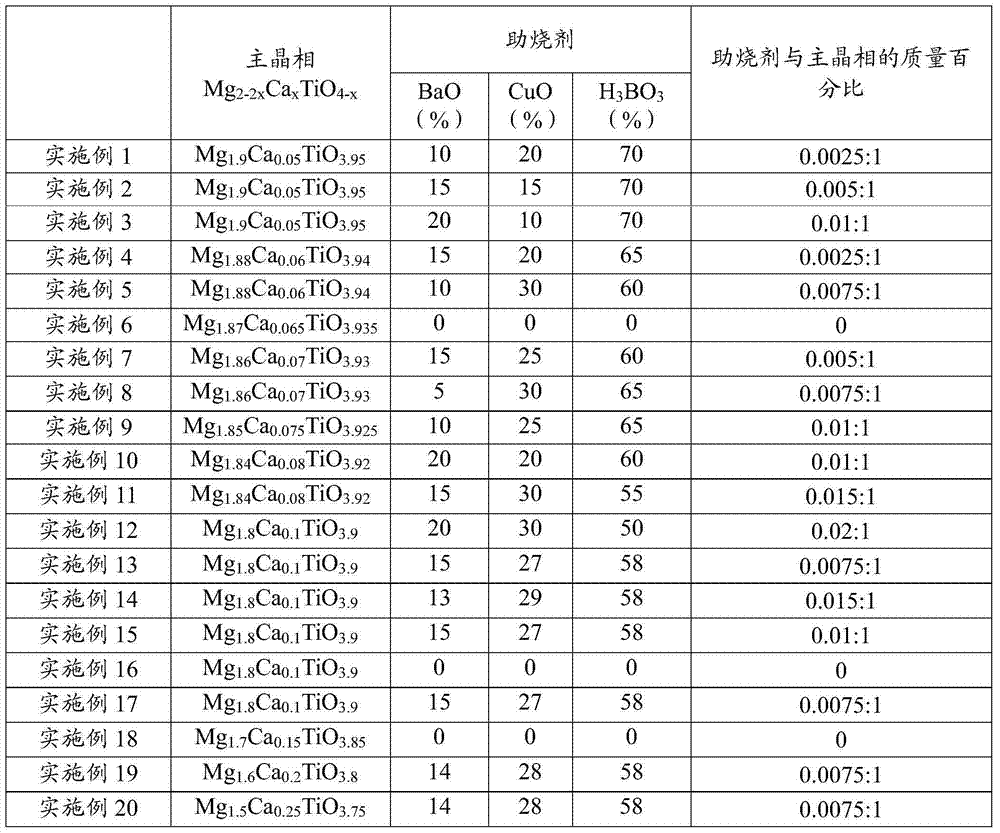

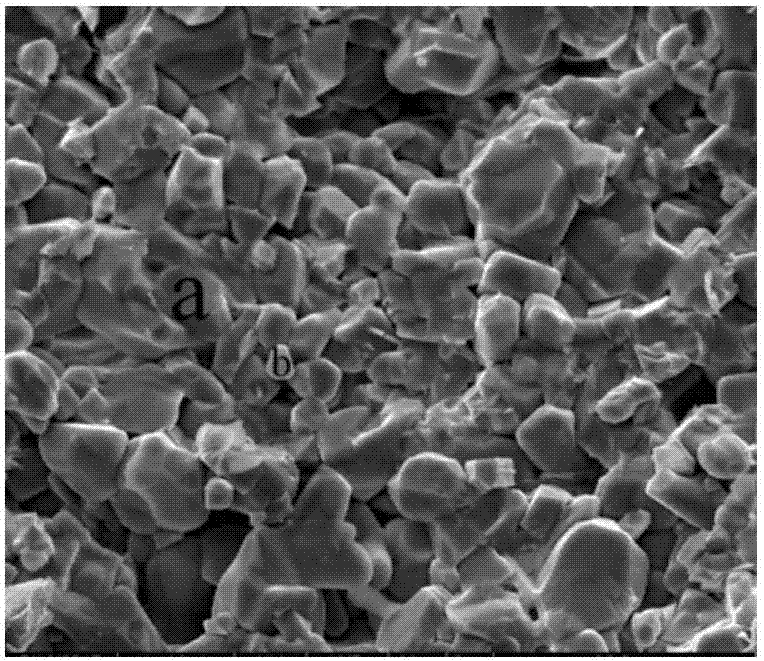

The invention relates to a microwave dielectric ceramic, comprising a main crystal phase. A chemical formula of the main crystal phase is Mg<2-2x>CaTiO<4-x>, wherein x is equal to or larger than 0.05 but smaller than or equal to 0.2. The microwave dielectric ceramic has relatively good microwave dielectric properties. Besides, the invention provides a preparation method of the microwave dielectric ceramic.

Owner:GUANGDONG GOVA ADVANCED MATERIAL TECH +1

Temperature stable type magnesium antimonite lithium base medium microwave composite ceramic and its preparation method

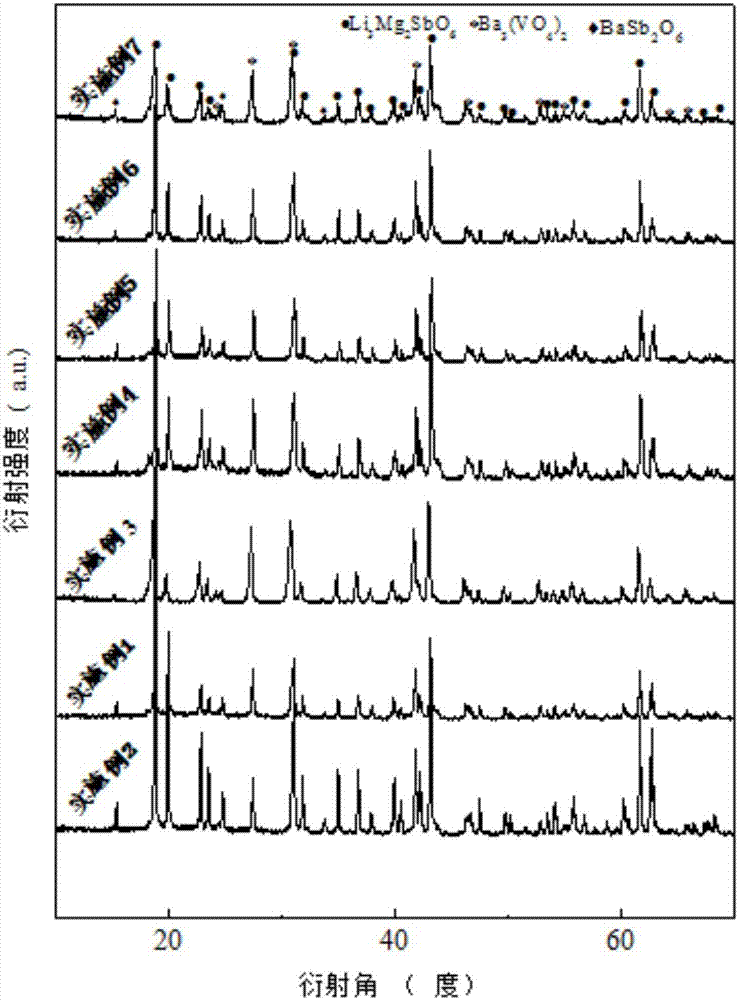

ActiveCN107235711AImprove temperature stabilityExcellent microwave dielectric propertiesElectricityLithium

The invention discloses a temperature stable type magnesium antimonite lithium base medium microwave composite ceramic and its preparation method. A phase of a composite ceramic comprises Li3Mg2SbO6 phase in a rock salt structure, Ba3 (VO4)2 phase in an orthorhombic structure and a BaSb2O6 in a trilateral structure, wherein Li3Mg2SbO6 content is 54wt%-78wt%, Ba3 (VO4)2 content is 13wt%-38wt%, and the rest is BaSb2O6. Through adding Ba3 (VO4)2 presintering powder in the Li3Mg2SbO6 main powder body, the composite ceramic inhibits the rupturing of Li3Mg2SbO6, improves its temperature stability, and acquires a new material with good microwave dielectric property; the dielectric constant is 9.0-12.1, the quality factor is 18400-45100 GHz, and the resonate frequency temperature coefficient is -9.0 to +7.0 ppm / DEG C. The preparation method is rich in raw materials, simple in technique, and good for industrial production.

Owner:XIAN UNIV OF POSTS & TELECOMM +1

Ultralow-temperature-sintered composite microwave dielectric ceramic material and preparation method thereof

ActiveCN103232241AExcellent microwave dielectric propertiesLower sintering temperatureTemperature coefficientDielectric ceramics

The invention discloses an ultralow-temperature-sintered composite microwave dielectric ceramic material and a preparation method thereof. The formula of the ceramic material is (Ag0.5Bi0.5)(MoxW1-x)O4, wherein 0.3<=x<=0.7. The ultralow-temperature-sintered composite microwave dielectric ceramic material has the characteristics of finely adjustable relative dielectric constant (32.2-34.5), favorable microwave behavior microwave dielectric ceramics (Qf=11500GHz-12000GHz), adjustable temperature coefficient of resonance frequency (-32ppm / DEG C to +19ppm / DEG C) and simple chemical composition. By adopting the solid-phase reaction sintering method, the invention is simple in technological operation, environment-friendly and suitable for industrial production.

Owner:北京中科行运科技有限公司

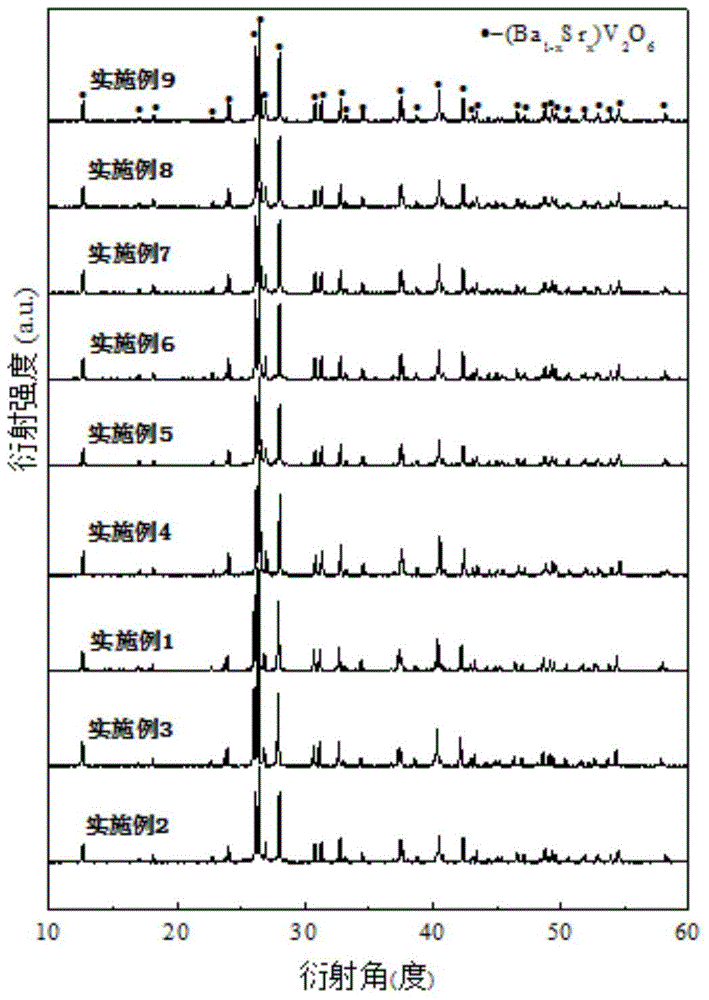

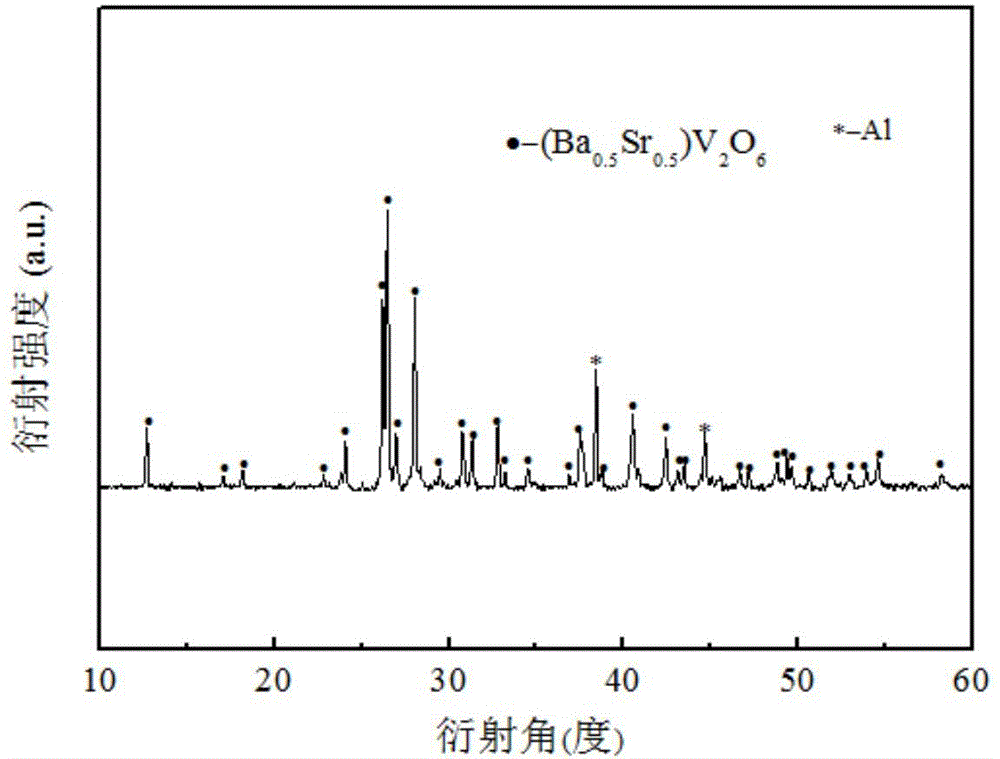

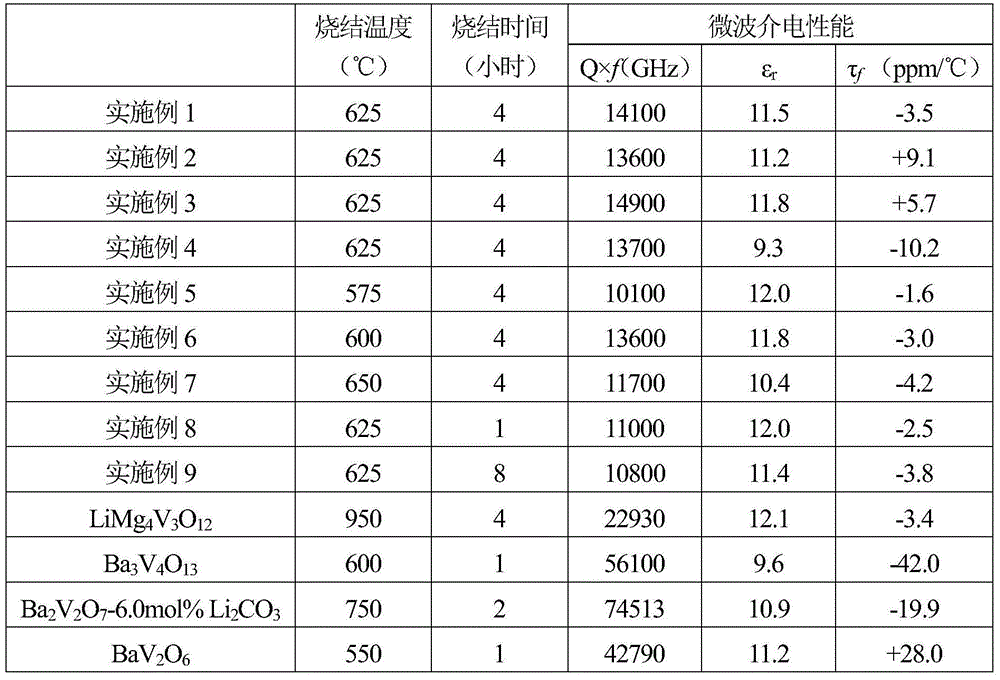

Vanadium-based temperature-stable ultralow-temperature sintered microwave dielectric ceramic material and preparation method thereof

InactiveCN104876568AExcellent microwave dielectric propertiesOvercome the disadvantage of large temperature coefficient of resonant frequencyMicrowave substrateSolid reaction

The invention discloses a vanadium-based temperature-stable ultralow-temperature sintered microwave dielectric ceramic material and a preparation method thereof. The ceramic material consists of a material shown by a general formula (Ba1-xSrx)V2O6, wherein x is 0.35-0.55; and the ceramic material has good microwave dielectric properties (the dielectric constant is 9.3-11.1, the quality factor is 10000-14900GHz, and the temperature coefficient of resonance frequency is -10.2 to +9.1ppm / DEG C), is low in sintering temperature (575-650 DEG C), and can be matched and co-fired with an Al electrode. The vanadium-based temperature-stable ultralow-temperature sintered microwave dielectric ceramic material disclosed by the invention is prepared by virtue of traditional solid phase reaction, is rich in used raw materials, low in cost and beneficial for industrial production, and can be widely applied to the manufacturing of microwave devices including a low-temperature co-fired ceramic system, a multilayer dielectric resonator, a wave filter, a microwave substrate and the like.

Owner:XIAN UNIV OF POSTS & TELECOMM

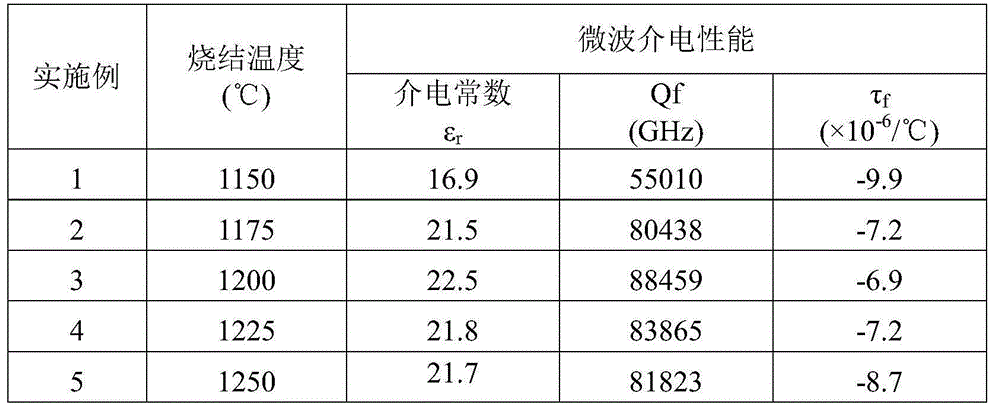

Temperature-stable type low-loss microwave dielectric ceramic and preparing method thereof

InactiveCN104961453ASimple preparation processExcellent microwave dielectric propertiesElectricityResonance

The invention discloses temperature-stable type low-loss microwave dielectric ceramic. The target composition expression of the temperature-stable type low-loss microwave dielectric ceramic is 0.99(0.95(Mg0.97Zn0.03)TiO3-0.05CaTiO3)-0.01LaAlO3. Firstly, MgO, TiO2, CaCO3 and ZnO are mixed according to the stoichiometry equation 0.95(Mg0.97Zn0.03)TiO3-0.05CaTiO3, and presintering is carried out at 900-1150 DEG C after ball milling, drying and screening are carried out; secondly, La2O3 and Al2O3 are mixed according to the stoichiometry equation LaAlO3, and presintering is carried out at 1100-1300 DEG C after ball milling, drying and screening are carried out; thirdly, the two kinds of powder obtained after presintering are mixed according to the mole ratio of 99:1 and pressed into a green body after ball milling, drying, screening and pelleting are carried out, the green body is sintered at 1150 DEG C-1250 DEG C, and the temperature-stable type low-loss microwave dielectric ceramic is prepared. The QF value of the temperature-stable type low-loss microwave dielectric ceramic reaches 55,000-88,500 GHz, and the temperature coefficient (tao f) of resonance frequency reaches -9.9--6.9*10<-6> / DEG C. The temperature-stable type low-loss microwave dielectric ceramic is simple in preparing technology and superior in microwave dielectric performance, saves energy cost, conforms to the low-carbon environment-friendly concept and has wide application prospects.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com