Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201results about How to "Raw materials are cheap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process of preparing PDT copolyester fiber

InactiveCN101046007ASpinning high speedHigh speed spinning equipmentMonocomponent copolyesters artificial filamentFiberAlcohol

The process of preparing PDT copolyester fiber includes the following steps: 1. saccharifying and catalytically hydrogenating corn starch to prepare sorbitol, catalytically hydrogenating to prepare multicomponent mixed alcohol, and fractionating in a fractionating tower at 182-212 deg.c to obtain corn-base ethylene glycol product of 89-99 % content and with ethylene glycol as main component and other diols; 2. detecting the contents of component diols in the ethylene glycol product and adding insufficient components for content fluctuation controlled within 10-30 %; and 3. adding nanometer titania in 0.05-1 wt% into the corn-base ethylene glycol product, and copolymerizing together with terephthalic acid at 280-288 deg.c for 5-7 hr to prepare PDT copolyester. The process is suitable for industrial production.

Owner:DONGHUA UNIV

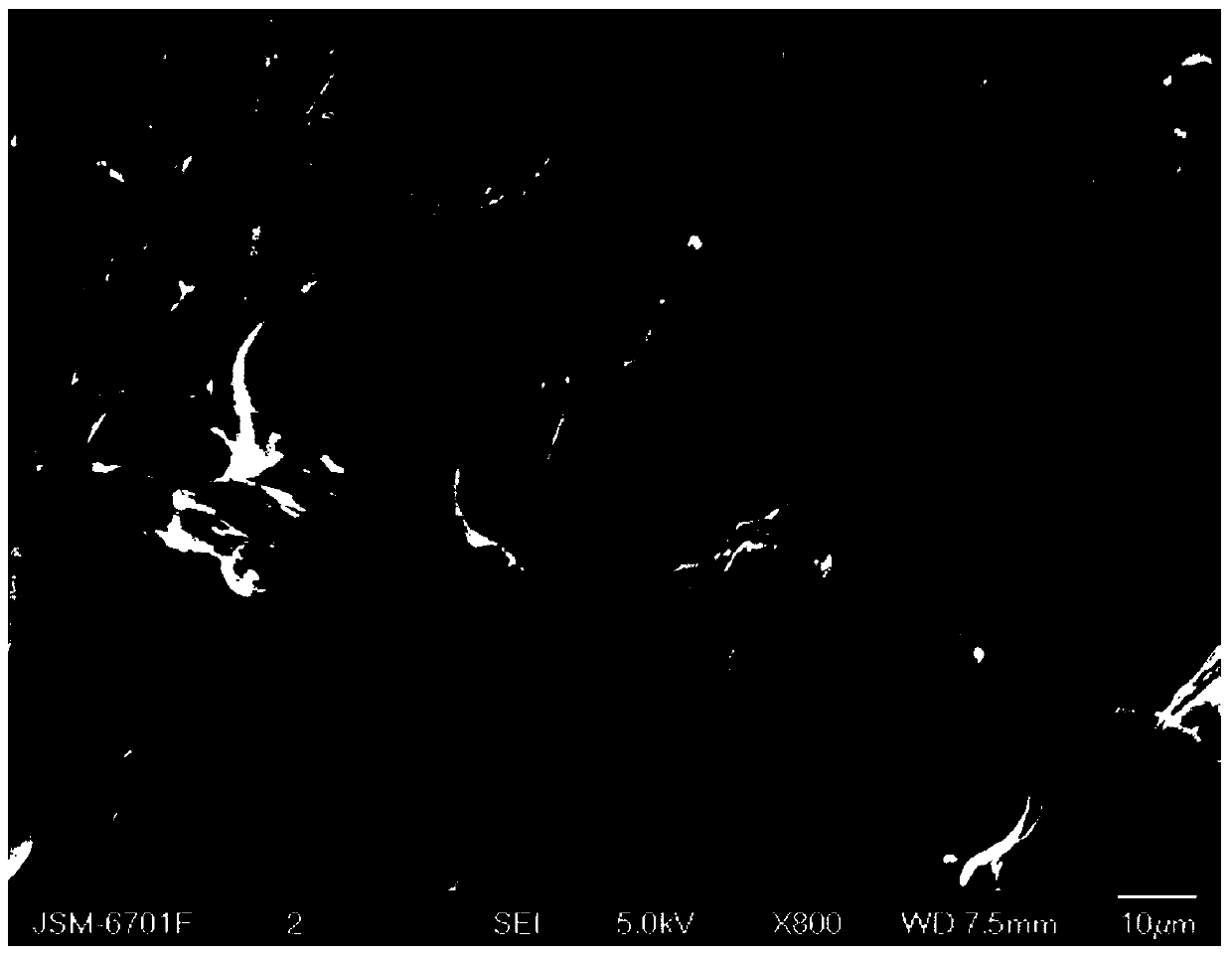

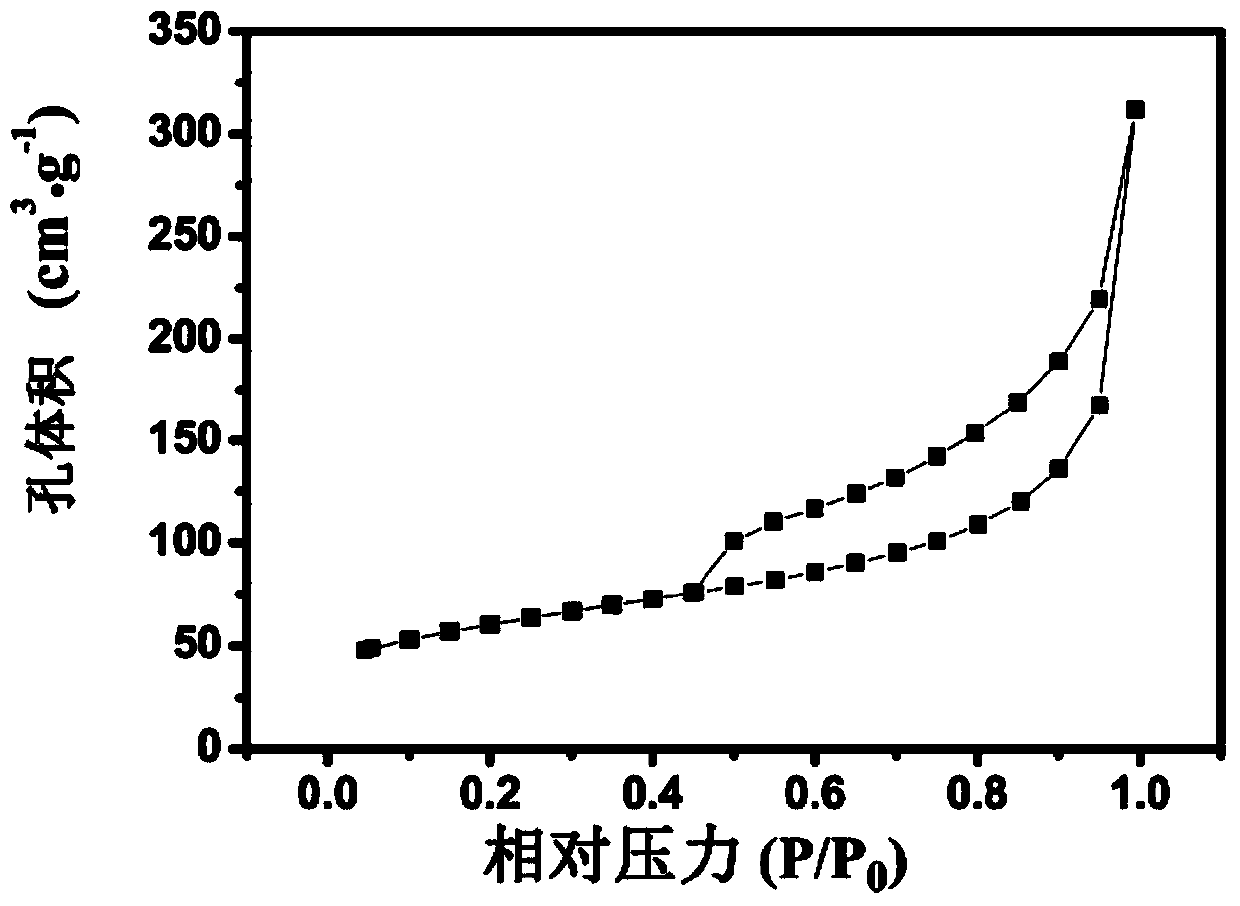

Nitrogen-doped porous carbon fiber material and preparation method and application thereof

ActiveCN103806129AThe synthesis conditions are mild and convenientRaw materials are cheapCell electrodesFibre chemical featuresChemistryTube furnace

The invention discloses a nitrogen-doped porous carbon fiber material and a preparation method and application thereof. The preparation method comprises the following steps: (1) dissolving a nitrogen source and a carbon source in water, standing, precipitating and filtering to obtain a precursor formed by combining the nitrogen source and the carbon source, wherein the nitrogen source is melamine and / or cyanuric acid, and the carbon source is an organic acid and / or organic amine; (2) calcining the precursor in a tube furnace, thus obtaining the nitrogen-doped porous carbon fiber material. The melamine provided by the invention can be dissolved in a hot aqueous solution and can be assembled with the organic acid through the acting force between amino and carboxyl and the acting force of the hydrogen bond, a white precipitate is separated out through cooling treatment and serves as the precursor, the precursor is calcined at high temperature under inert gas conditions after filtering and drying, and thus the black nitrogen-doped porous carbon fiber material is obtained. The material is mild, simple and convenient in synthesis conditions and low in raw material price and has high specific surface area and good electrochemical performance.

Owner:赤峰福纳康生物技术有限公司 +1

Glass compositions

Improved glass fibers compositions, typically useful for fire resistant blankets or containers to provide high burn-through resistance at high temperatures of 2,400° F. and higher, and typically comprising silica, sodium oxide, potassium oxide, calcium oxide, magnesium oxide, ferrous+ferric oxide, and titanium oxide; the improved glass compositions may further include alumina, lithium oxide, and boron oxide.

Owner:GLASS

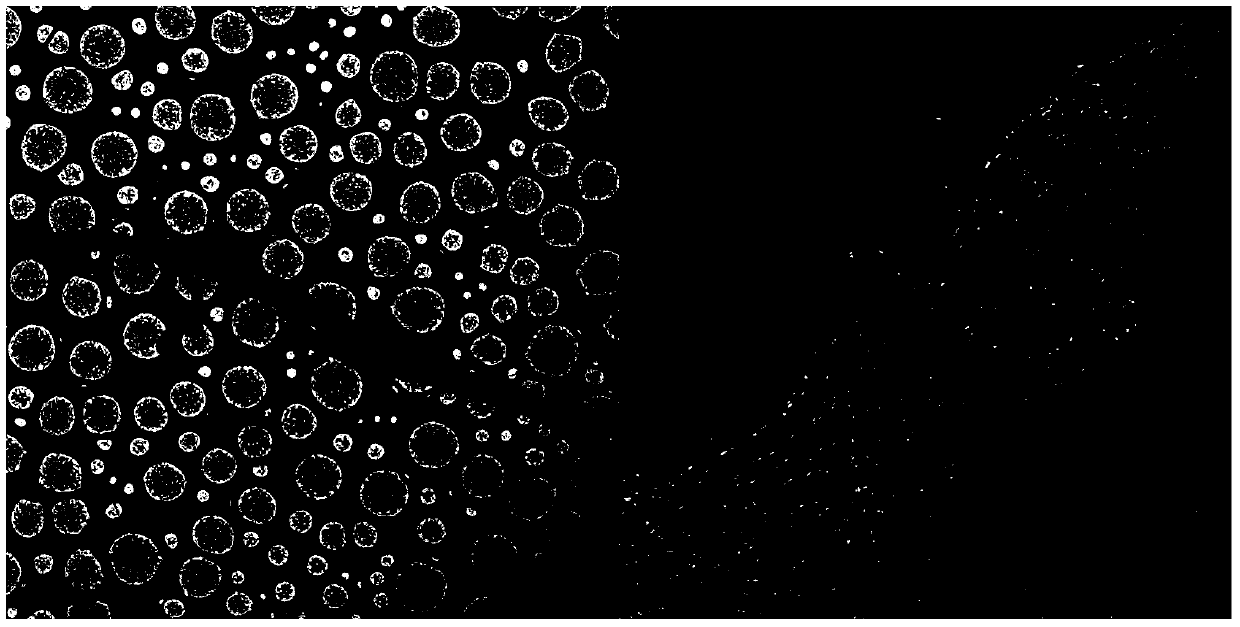

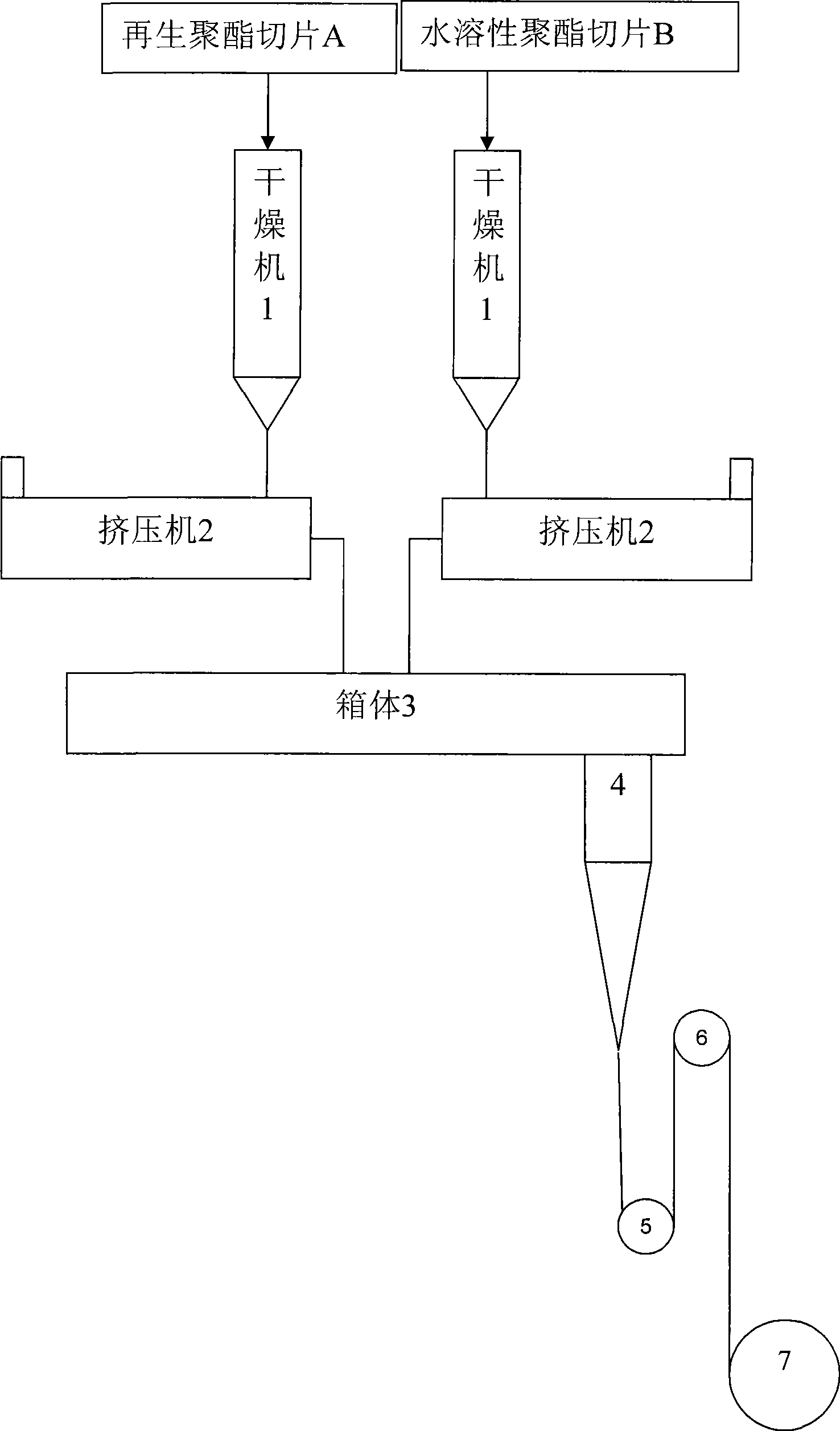

Superfine fibre material and producing method thereof

InactiveCN101429689ARaw materials are cheapSmall fiber finenessFilament forming substance formingSpinning head liquid feederPolyesterMicrofiber

The invention discloses a method for producing regenerated polyester ultrafine fiber based on bicomponent fiber production equipment. The method comprises the following steps: a regenerated polyester slice and a water soluble polyester slice are used as raw materials; after the two raw materials are subjected to crystallizing and drying, extruding and fusing respectively, the two raw materials are fed to a composite spinning manifold, are extruded through an insulated spinning metering pump with accurate measurement, and are distributed to each composite spinning component; the two components are compounded to be shaped according to shapes set by a spinneret component, are extruded to be shaped through side ram cooling and oiled by a nozzle tip, and are wound by a winding head to form a regenerated polyester ultrafine POY spinning cake; and then the spinning cake is processed to obtain an applicable ultrafine fiber through subsequent texturing. After the method is adopted, through adjusting the processing technology, the regenerated polyester raw material can be applied to high grade fiber so as to improve effective application of resource, and save cost. The method has double significances of economy and environmental protection.

Owner:无锡海丝路纺织新材料有限公司

Silicon nitride porous ceramics and its preparing method

The porous silicon nitride ceramic is prepared with C and CO2 in 75-95 wt%, silicon nitride 1-10 wt%, and sintering assistant 2-20 wt%. The C / CO2 weight ratio is 0.4-0.6; and the sintering assistant is at least one the metal oxides Y2O3, Al2O3 and MgO. The preparation process includes the following steps: ball milling the materials, drying and sieving to obtain mixture powder; pressure forming in mold; and sintering in a nitrogen atmosphere furnace through raising temperature at the rate of 600deg.c / hr to 1500deg.c, further raising temperature at the rate of 180deg.c / hr to 1700-1800deg.c, and maintaining at nitrogen pressure of 6-10 atm for 2-8 hr to obtain the sintered body. The porous silicon nitride ceramic may be used as base filter material for separating gas in high temperature and corrosive atmosphere, heat resisting material and reinforcing material in gas turbine, engine, space shuttle, etc.

Owner:XI AN JIAOTONG UNIV

Microalgae cell flocculating and harvesting technology

InactiveCN102604837ARaw materials are cheapLow priceUnicellular algaeMicroorganism based processesEthylene diamineFlocculation

The invention relates to a microalgae cell flocculating and harvesting technology, belonging to the technical field of energy microalgae. The technology is characterized in that chitosan, melamine or EDTA (ethylene diamine tetraacetic acid) and attapulgite are prepared into a flocculating agent; and CaCl2 is added as a flocculation aid to perform flocculating and harvesting of microalgae. The invention provides preparation of a flocculating agent and a flocculating and harvesting technology. The technology comprises the following steps of: drying the flocculating agent, grinding and sieving; adding the flocculating agent into the microalgae culture solution so that the concentration of the flocculating agent is 0.3-0.6g / L, and the concentration of the flocculation aid CaCl2 is 0.01-0.03g / L; adjusting the microalgae culture solution until the pH is 7-9; and stirring uniformly and standing for precipitation, wherein the flocculation degree can be more than 99%. For the flocculating technology provided by the invention, the raw materials are cheap; and the technology is safe and environment-friendly and convenient to operate, has high flocculation efficiency, and can be widely used for harvesting microalgae in the industrial production.

Owner:YANCHENG INST OF TECH

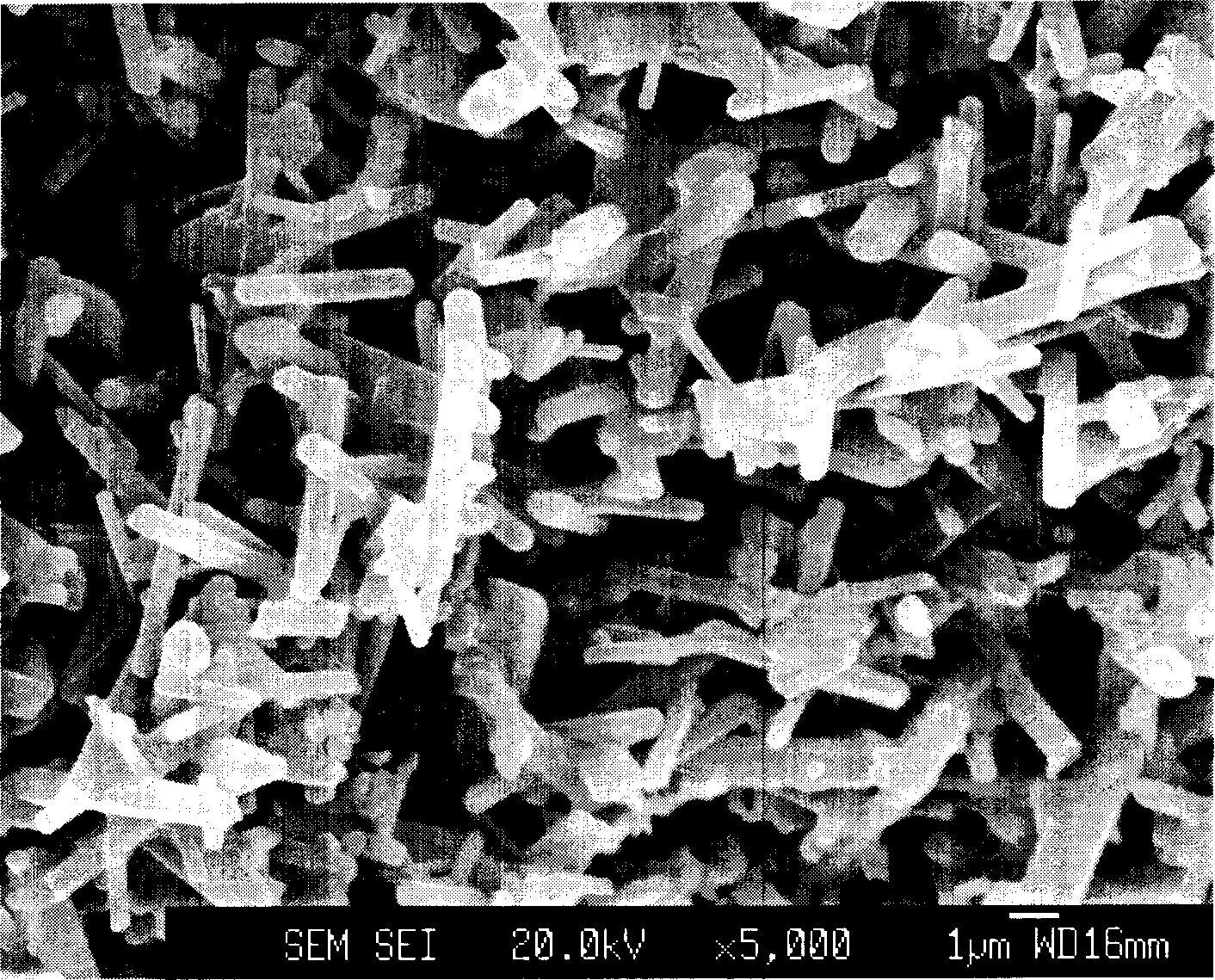

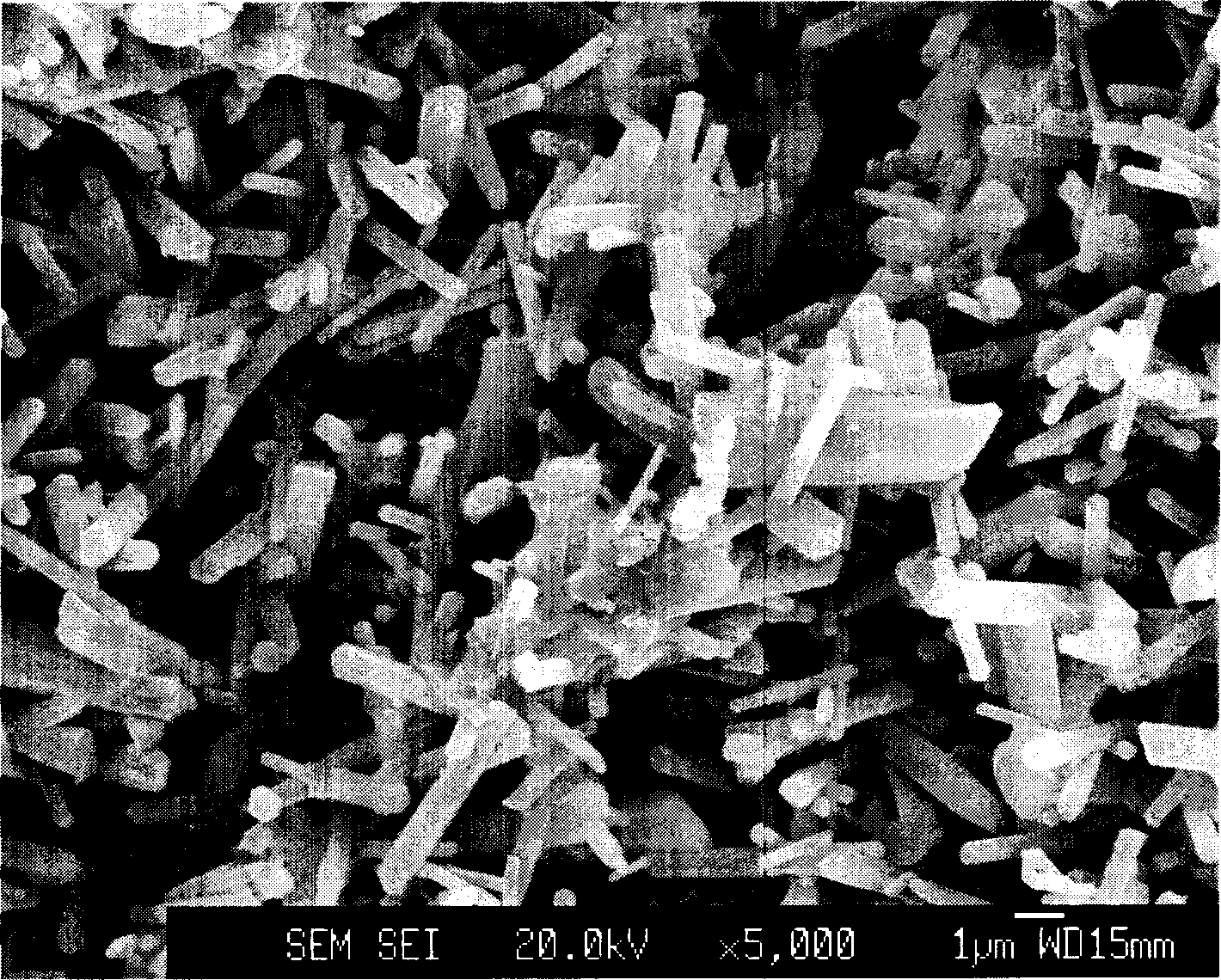

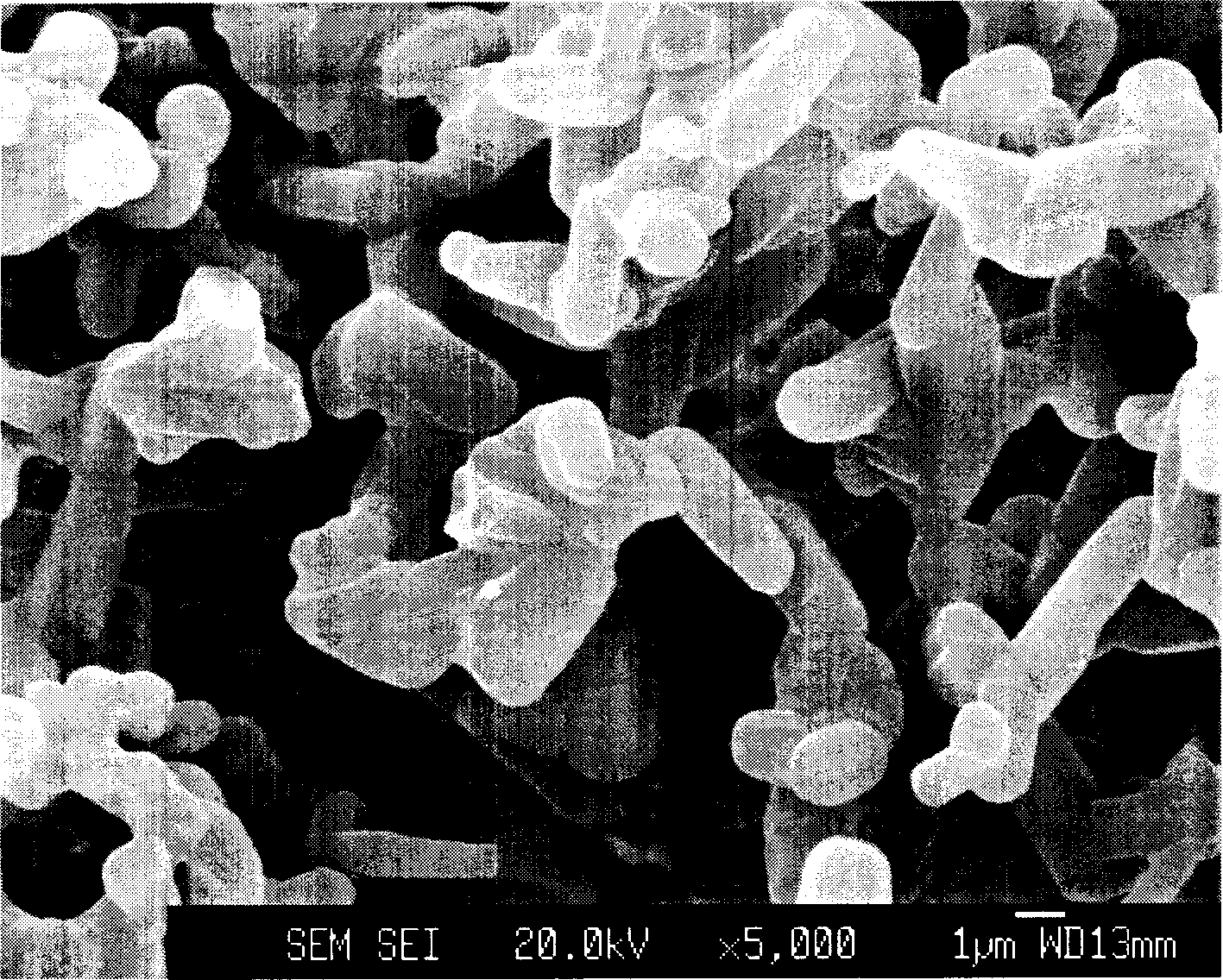

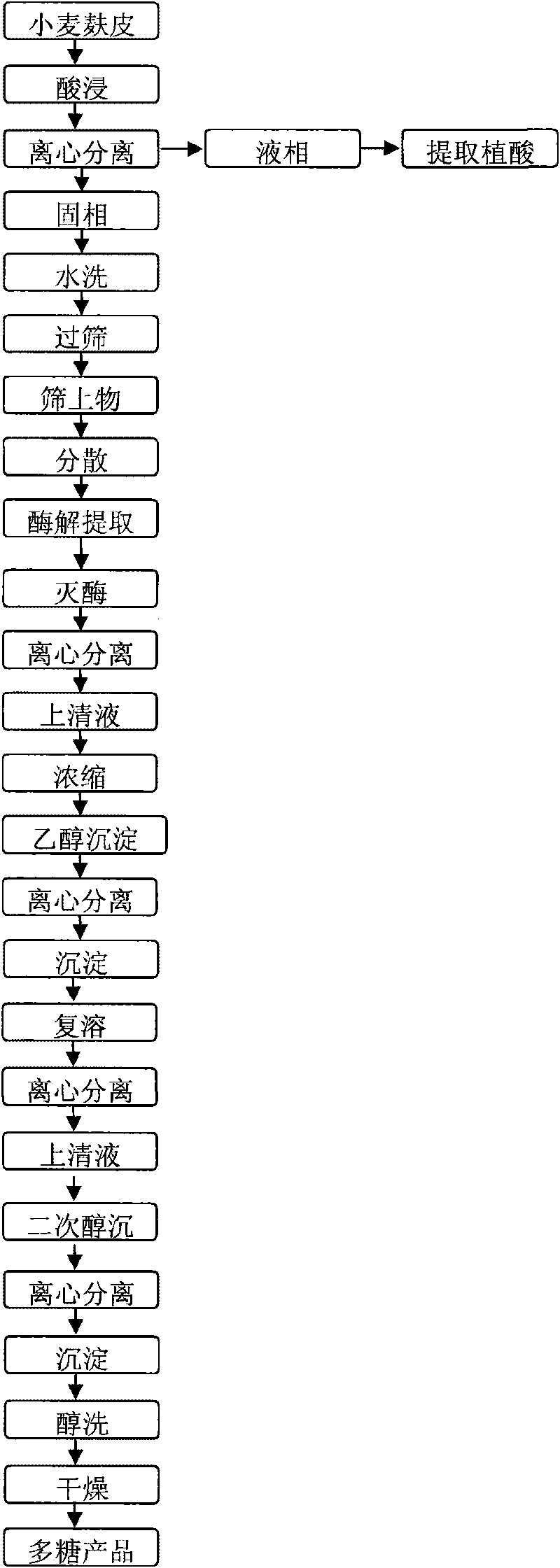

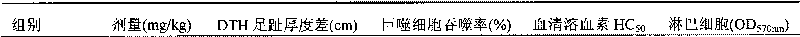

Wheat bran polysaccharide with antitumor and immune regulation activities and extraction method thereof

ActiveCN101705268ALow priceRich sourcesOrganic active ingredientsImmunological disordersArabinoxylanDrug

The invention discloses a wheat bran polysaccharide with antitumor and immune regulation activities and an extraction method thereof. The method for extracting the polysaccharide comprises the following step: performing enzymolysis of wheat bran with xylanase to obtain the polysaccharide, wherein the proportion of xylanase and wheat bran is (5U-12.5U):1g. The method of the invention adopts wheat bran which is a subsidiary agricultural product resource, to largely prepare the polysaccharide product by processing and extracting, the polysaccharide product mainly contains araboxylan (or pentosan); animal experiments show that the polysaccharide has the similar immune regulation and antitumor effects of the antitumor adjuvant drugs which are used in clinic; in addition, the price of raw materials of the polysaccharide is cheap and the sources are wide so that the polysaccharide of the invention has more market competition advantage and wide industrialized development prospect.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for precission shaping ceramic blank by semi-water-base injection-moulding gel process

The invention belongs to the field of inorganic material, relating to the improvement of a ceramic blank precision molding technique. The steps of the invention includes: mixing, blending and ball-milling, eliminating gas, adding in catalyst or reducing agent, adding in initiator, injection molding and gelating, and demolding and drying. The invention uses less water, thoroughly eliminates organic matter, reduces the blank shrinkage and avoids larger-sized ceramic blanks from cracking in the drying course. Besides, the gelated blanks have better machining property before glycol, glycerine, and other solvents are eliminated.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

Method for producing potassium sulphate fertilizer by using phosphogypsum

The invention relates to the technical field of fertilizer production methods, in particular to a method for producing potassium sulphate fertilizer by using phosphogypsum. The method comprises the following steps: fully mixing 20 to 80 percent of the phosphogypsum and 20 to 80 percent of potassium feldspar powder in percentage by weight, and calcining the mixture, wherein the calcination temperature is 800 to 1,800 DEG C, and the calcination time is 2 to 120 minutes. The method has easily-obtained raw materials and low cost; and the whole process flow is smooth, simple, easy and is quite suitable for industrialized production.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

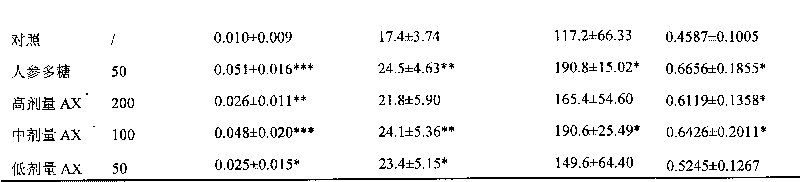

Medicine for preventing and treating bovine rumen flatulence and preparation method thereof

InactiveCN105232704AReduce incidenceEasy to solveDigestive systemBird material medical ingredientsLicorice rootsOfficinalis

The invention discloses medicine for preventing and treating bovine rumen flatulence. The medicine is prepared from, by mass, 170-210 parts of rheum officinale, 50-80 parts of licorice roots, 190-220 parts of pericarpium citri reticulatae, 180-215 parts of endothelium corneum gigeriae galli, 180-210 parts of perilla stems, 80-110 parts of cassia twigs, 130-165 parts of salvia chinensis, 185-215 parts of cape jasmine, 105-135 parts of asarum, 210-245 parts of fructus aurantii, 105-140 parts of gleditsia officinalis, 135-160 parts of white paeony roots and 120-150 parts of Chinese fevervine herbs. No incompatibility between the raw materials in the medicine exists, and the medicine can obviously lower the occurrence rate of bovine rumen flatulence, has an excellent prevention and treatment effect on bovine rumen flatulence and is free of toxic and side effects and harmful medicine residues and safe to use.

Owner:HENGYANG JINFENG LIVE PIG BREEDING SPECIALIZED COOP

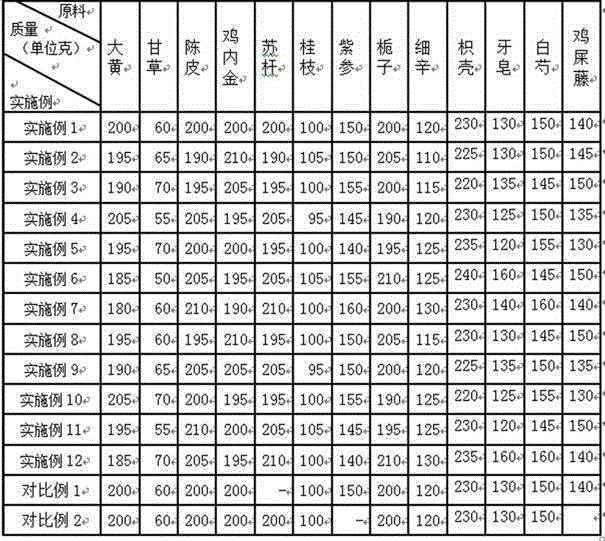

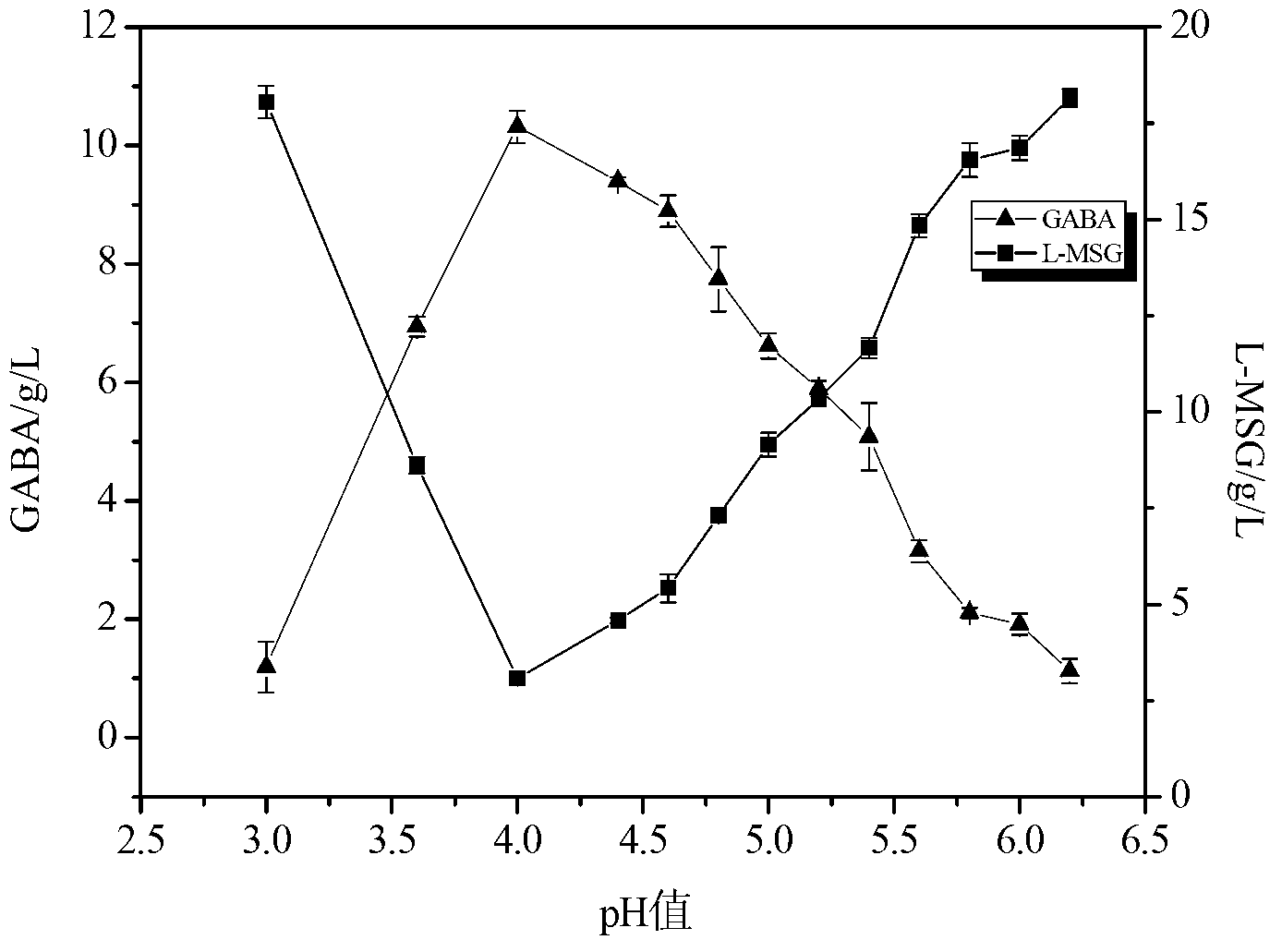

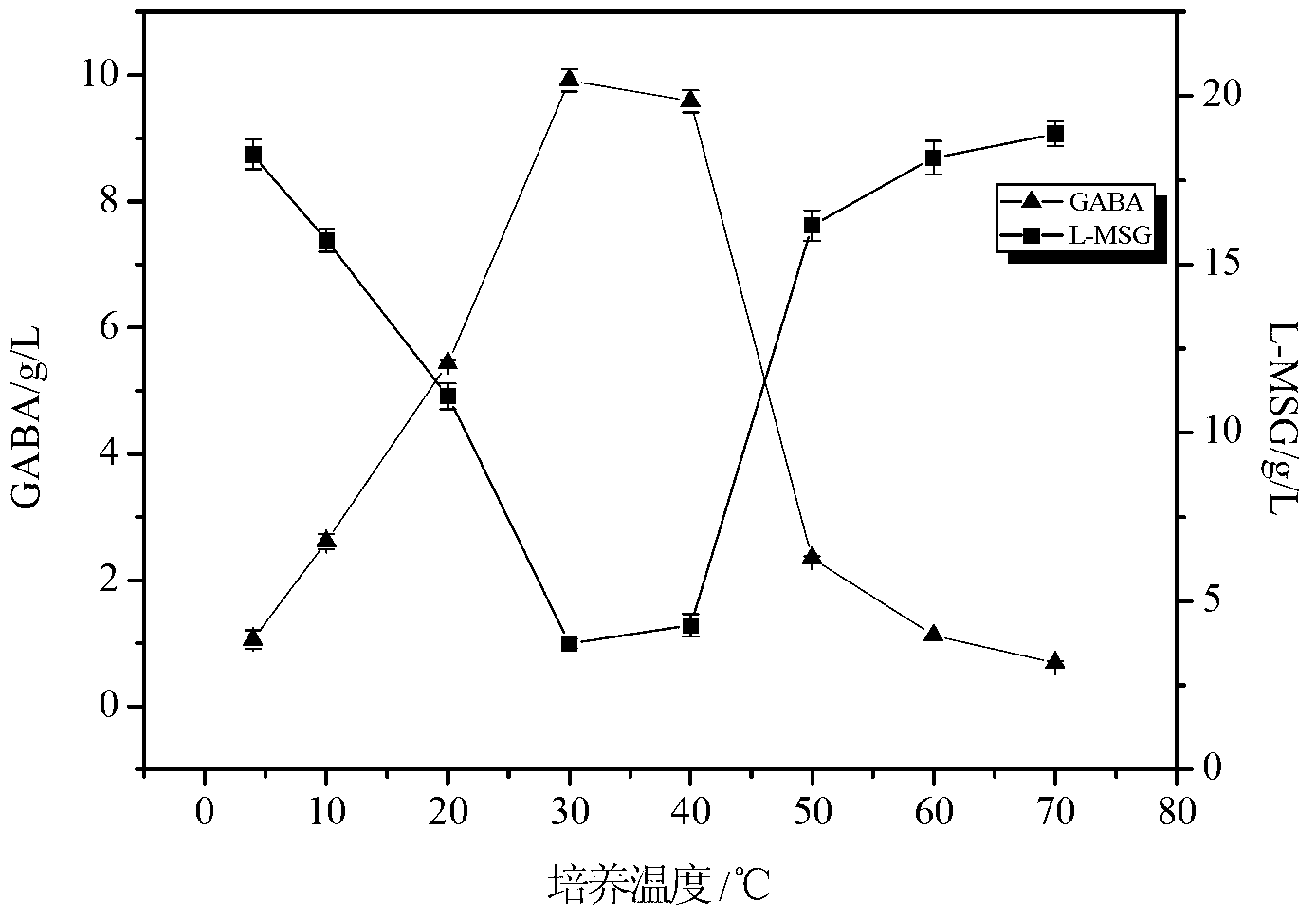

Method and fermentation culture medium used for synthesizing gamma-aminobutyric acid through microbial fermentation

ActiveCN102925504AEasy to prepareRaw materials are cheapMicroorganism based processesFermentationBacilliLactobacillus sp

The invention relates to a microbial fermentation method, and especially relates to a method and a fermentation culture medium used for synthesizing gamma-aminobutyric acid (GABA) through microbial fermentation. The gamma-aminobutyric acid synthesizing method adopts a microbe which is a lactobacillus brevis L2 strain. The lactobacillus brevis L2 strain is subjected to MRS culturing flat plate activation; an obtained strain is transferred into a GYP seed culture medium; seeds used in fermentation are cultured; and the material is inoculated in the culture medium with an inoculation amount of 1-5% by volume. The culture medium comprises 10-100g / L of millet bran, and 30-80g / L of L-glutamic sodium. An initial pH value of the culture medium is regulated to 3.00-5.00. Static culture is carried out for 50-80h under a temperature of 20-45 DEG C, such that a lactobacillus fermentation broth with high gamma-aminobutyric acid content is obtained. The culture medium provided by the invention is pure natural, and has the advantages of simple preparation and low raw material cost. Biosynthesis of GABA has the advantages of simple operation, high yield, easy separation and purification, and no pollution. A product reaches a food safety level.

Owner:北京航天恒丰科技股份有限公司

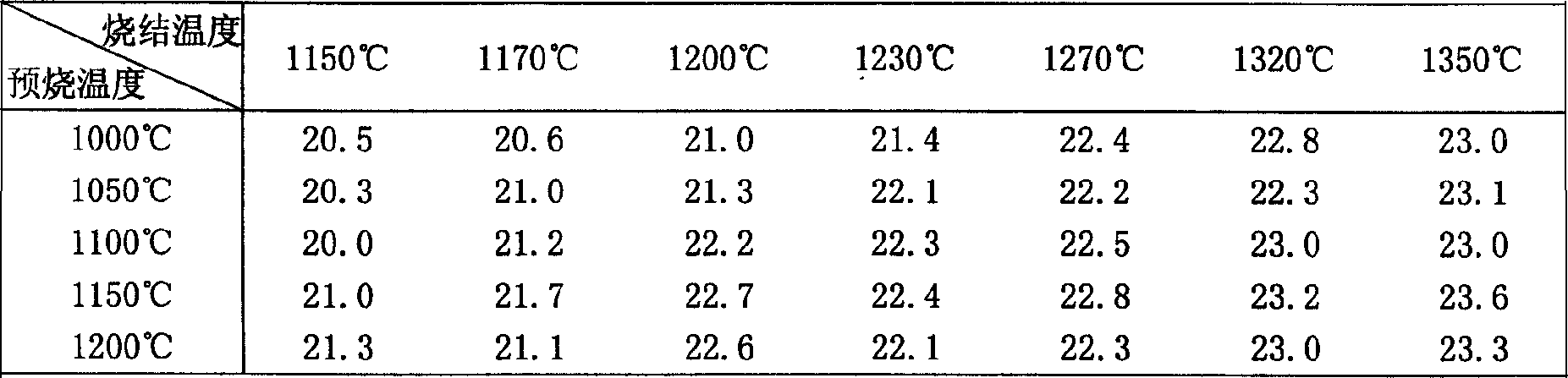

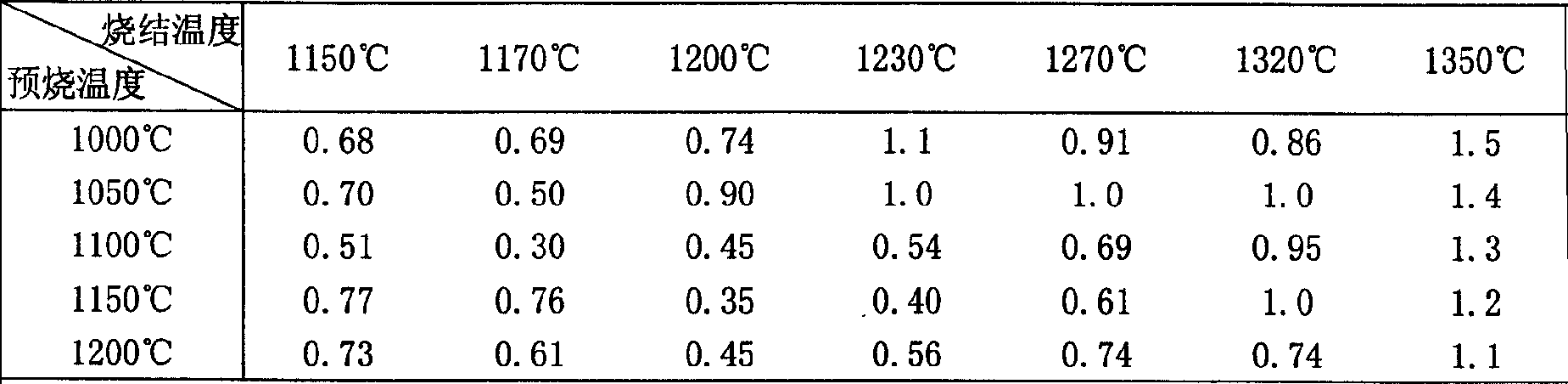

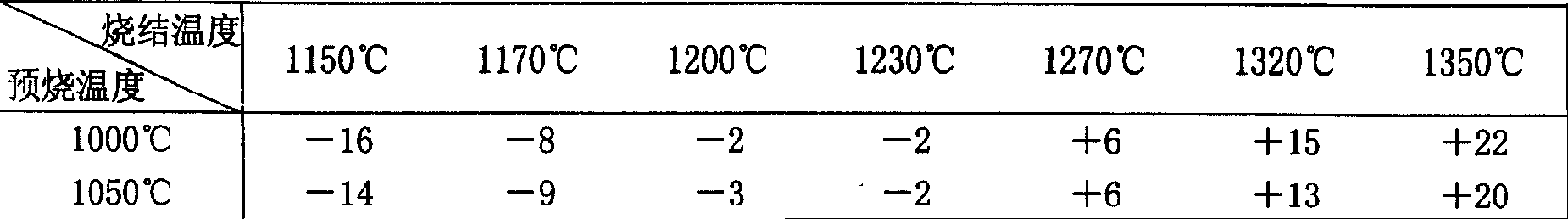

Ceramic materials for microwave ceramic capacitor and making method therefor

InactiveCN1690014AExcellent microwave dielectric propertiesRaw materials are cheapFixed capacitor dielectricCeramicsMicrowave dielectric propertiesTitanium dioxide

The ceramic material for microwave ceramic capacitor has the composition of MgTiO3-CaTiO3, and may be expressed in xMgTiO3-(1-x)CaTiO3, with x being 0.9-1.0. The preparation process includes: mixing basic magnesium carbonate, calcium carbonate and diboron pentoxide in certain proportion, ball milling, stoving, sieving and pre-sintering to obtain fused block; secondary ball milling, stoving, pelletizing, pressing to form and sintering to obtain the ceramic material. The ceramic material for microwave ceramic capacitor has excellent microwave dielectric performance and low cost.

Owner:TIANJIN UNIV

Paper starch adhesive and preparation method thereof

ActiveCN101967355ARaw materials are cheapWide range of usesNon-macromolecular adhesive additivesStarch derivtive adhesivesEpoxyHydrogen Sulfate

The invention discloses a paper starch adhesive and a preparation method thereof. The paper starch adhesive comprises the following components in part by weight: 100 parts of starch, 300 to 600 parts of water, 0.1 to 0.3 part of potassium hydrogen peroxymonosulfate, 5 to 10 parts of caustic soda, 1 to 5 parts of epoxy chloropropane, 0.5 to 1.5 parts of boric acid, 1 to 3 parts of sodium sulfite, 4 to 8 parts of light calcium carbonate and 2.5 to 5 parts of bridging agent. The preparation method comprises the following steps of: adding water into a reaction kettle, heating the water to 38 DEG C, adding the starch into the water, stirring the solution, adding potassium hydrogen peroxymonosulfate solution into the reaction kettle, and reacting the mixed solution for 20 minutes with stirring; diluting the caustic soda, then slowly adding the caustic soda into the reaction kettle twice, stirring the solution for about 20 minutes to form milk white or light yellow transparent colloid, then adding the boric acid, the bridging agent and the light calcium carbonate into the colloid, and stirring the mixture uniformly; and adding the epoxy chloropropane, sodium aliphatate and the sodium sulfite into the reaction kettle with stirring, and stirring the mixture uniformly to obtain the paper starch adhesive. The adhesive has the characteristics of stable viscosity, good adhesiveness, low comprehensive cost, good permeability and the like.

Owner:山东荣工建筑工程有限公司

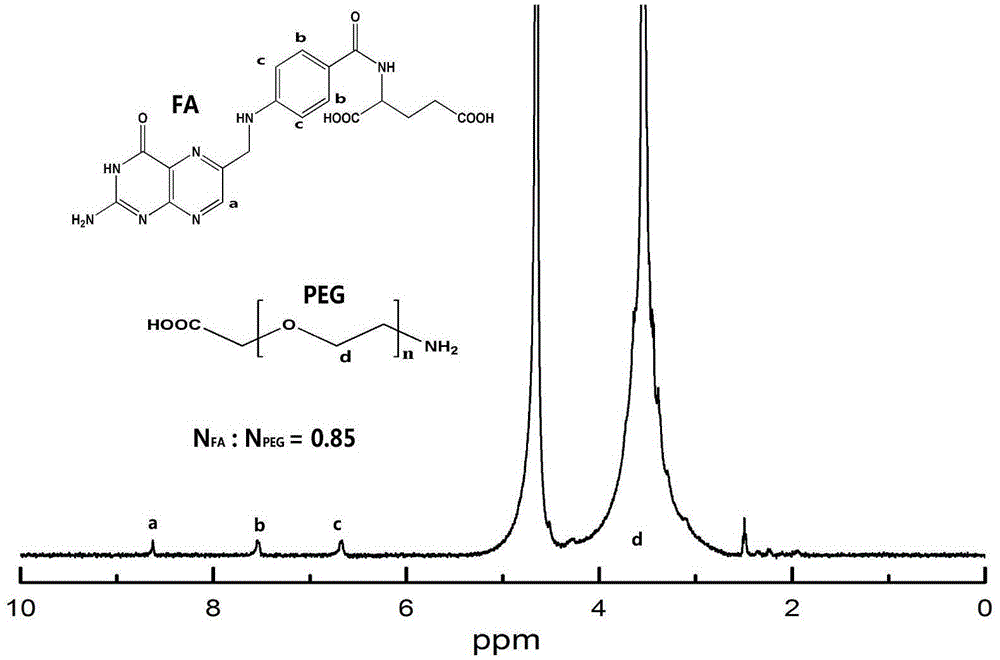

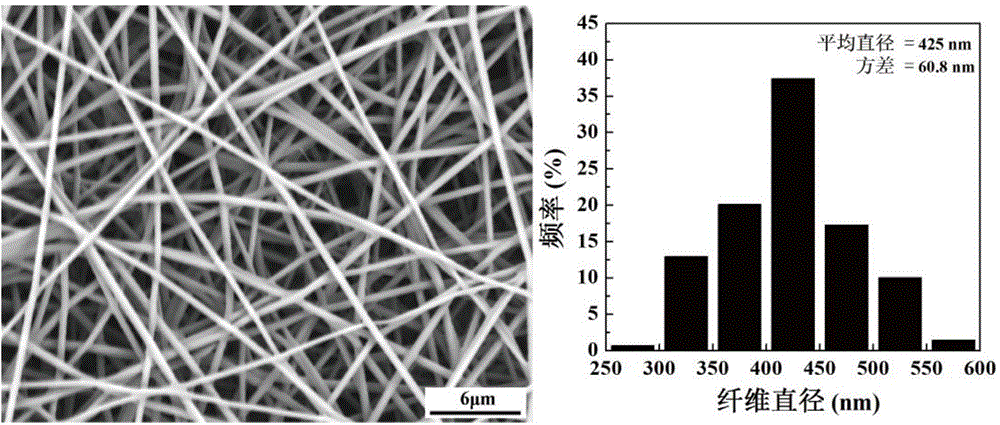

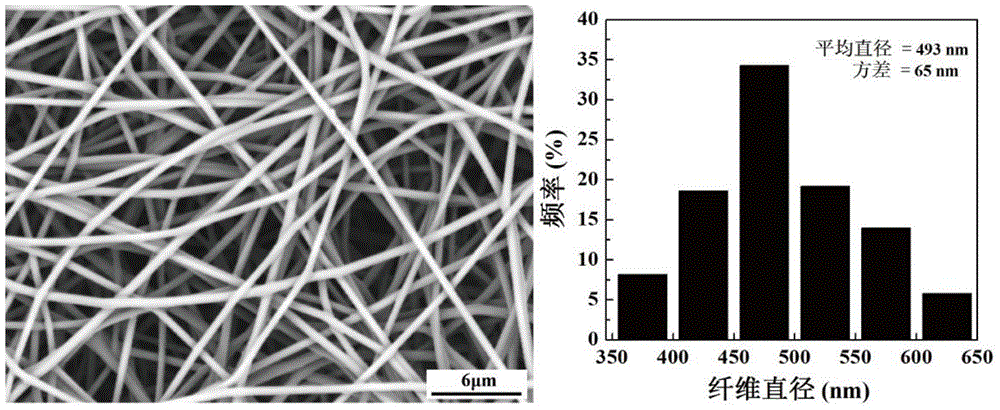

Method for preparing folic acid functional nanofibers for target capture of cancer cells

InactiveCN104790216AImprove capture abilityGood lookingFibre typesFilament/thread formingFiberCancer cell

The invention relates to a method for preparing folic acid functional nanofibers for target capture of cancer cells. The method comprises the following steps: (1) preparing a PVA / PEI nanofiber membrane by electrostatic spinning, and carrying out vacuum drying; (2) after drying, using glutaraldehyde for crosslinking; (3) activating carboxyl of folic acid FA through EDC.HCl and NHS, and reacting the carboxyl-activated FA with polyethylene glycol PEG with carboxyl at one end and amidogen at the other end to obtain FA-PEG-COOH; (4) activating carboxyl of FA-PEG-COOH, adding FA-PEG-COOH into the PVA / PEI nanofiber membrane, and carrying out shaking reaction to obtain the folic acid functional nanofibers; adding triethylamine and acetic anhydride for acetylation treatment, washing and drying. The prepared nanofibers have good biocompatibility and structural stability, is short in time to capture the cancer cells and strong in specificity, and has a wide application prospect.

Owner:DONGHUA UNIV

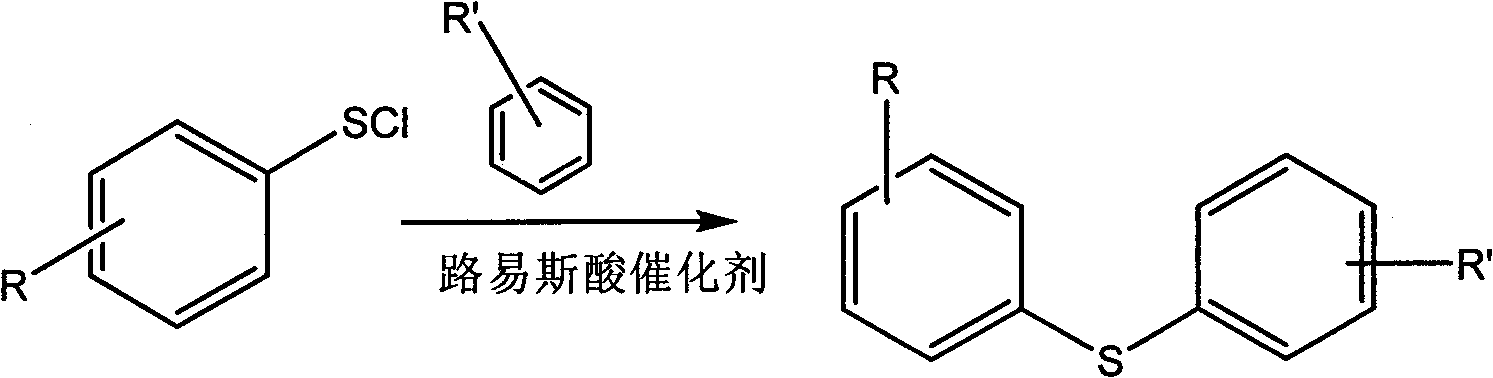

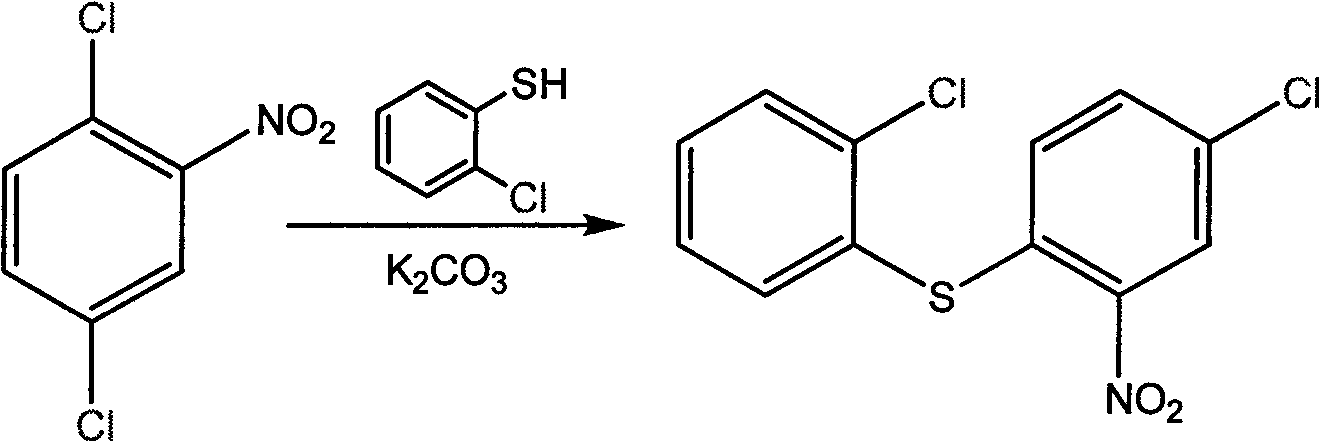

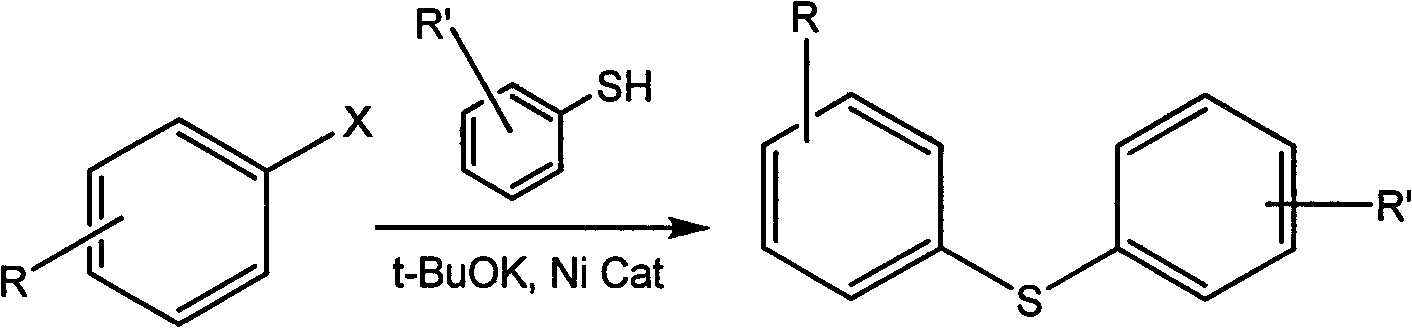

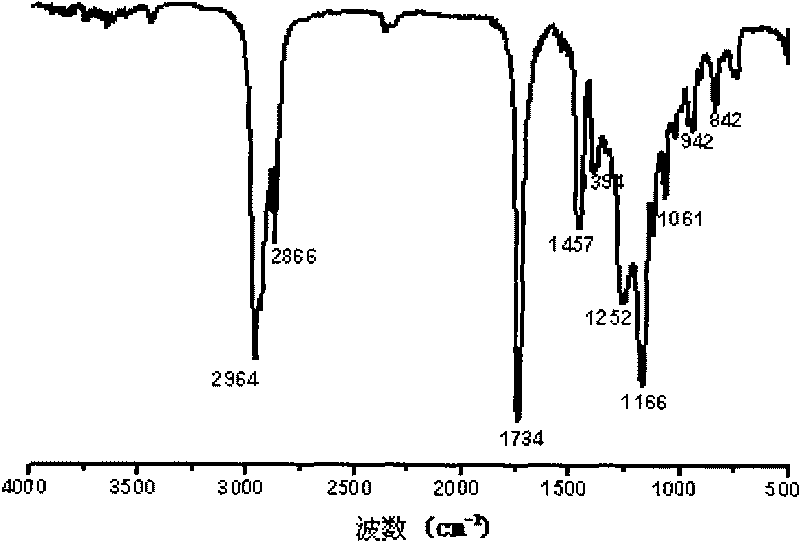

Preparation method for substituted diphenyl sulfide

InactiveCN101774953ARaw materials are cheapThe synthesis reaction is mild and stableSulfide preparationTitanium tetrachlorideDichloromethane

The invention relates to a synthesis method for organic compound, in particular to a preparation method for substituted diphenyl sulfide, belonging to the technical field of organic chemical substance preparation. Under the existence of Lewis acid catalyst, reaction temperature is controlled to be negative 10 DEG C to 70 DEG C to enable substituted benzene sulfenyl chloride and substituted benzene to take place Friedel-Crafts reaction in chloralkane solvent to generate substituted diphenyl sulfide. The used chloralkane solvent is mixed solvent formed by one or more of monochloromethane, dichloromethane, chloroform, carbon tetrachloride, dichloroethane and tetrachloroethane. The used catalyst is mixed catalyst formed by one or more of anhydrous ferric chloride, anhydrous aluminum chloride, titanium tetrachloride and anhydrous boron trifluoride. The invention has the advantages that the price of the raw materials is low, the synthesis reaction is mild and stable, the conversion rate of the raw materials is high, the product selectivity is good, the product can be easily separated from solvent, the product yield is high and the like.

Owner:QINGDAO UNIV OF SCI & TECH

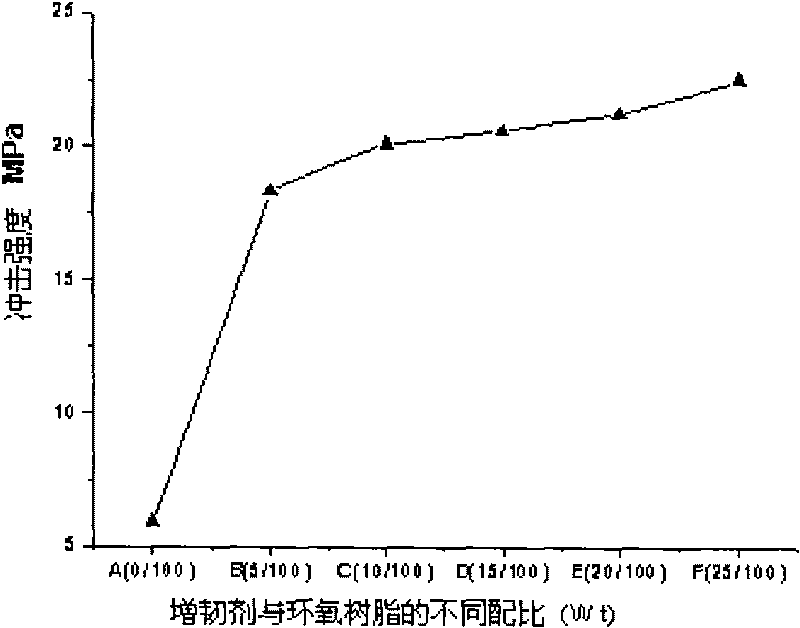

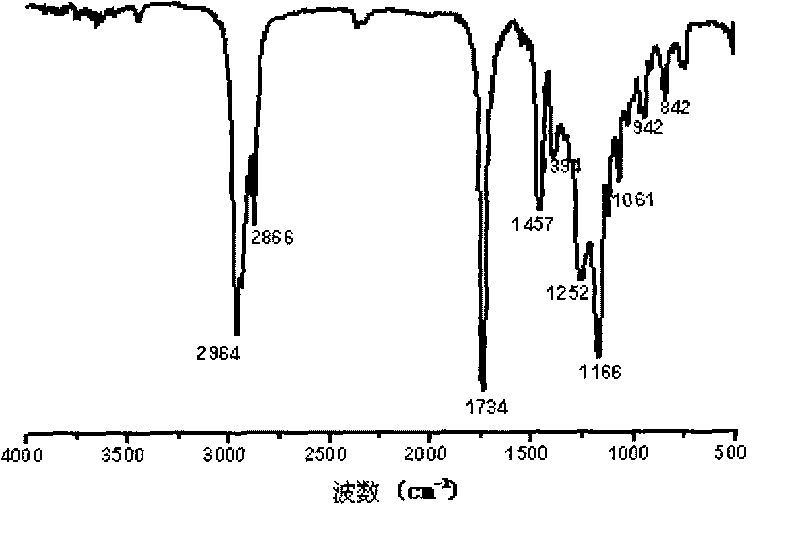

Powdered epoxy resin toughener and preparation method thereof

The invention discloses a powdered epoxy resin toughener and a preparation method thereof, which belong to the technical field of tougheners. The method takes n-butyl acrylate and glycidyl methacrylate as raw materials to prepare an active toughener in solution through a copolymerization reaction. The toughener is blended, cross-linked and cured with a powdered epoxy resin and then can form a cross-linking network with the epoxy resin. A structure of the toughener contains a flexible segment and an active epoxy group, so the toughener has excellent toughening effect on the powdered epoxy resin. When the mass ratio of a polymer to the epoxy resin is 5 to 100, the measured impact resistance is improved to 209.2 percent of a pure epoxy resin. The synthesis of the toughener is only a one-step reaction without side reactions, and has high product yield. The method has the advantages of cheap raw materials, simple reaction, mild conditions, easy control, and convenient industrialization.

Owner:JIANGNAN UNIV

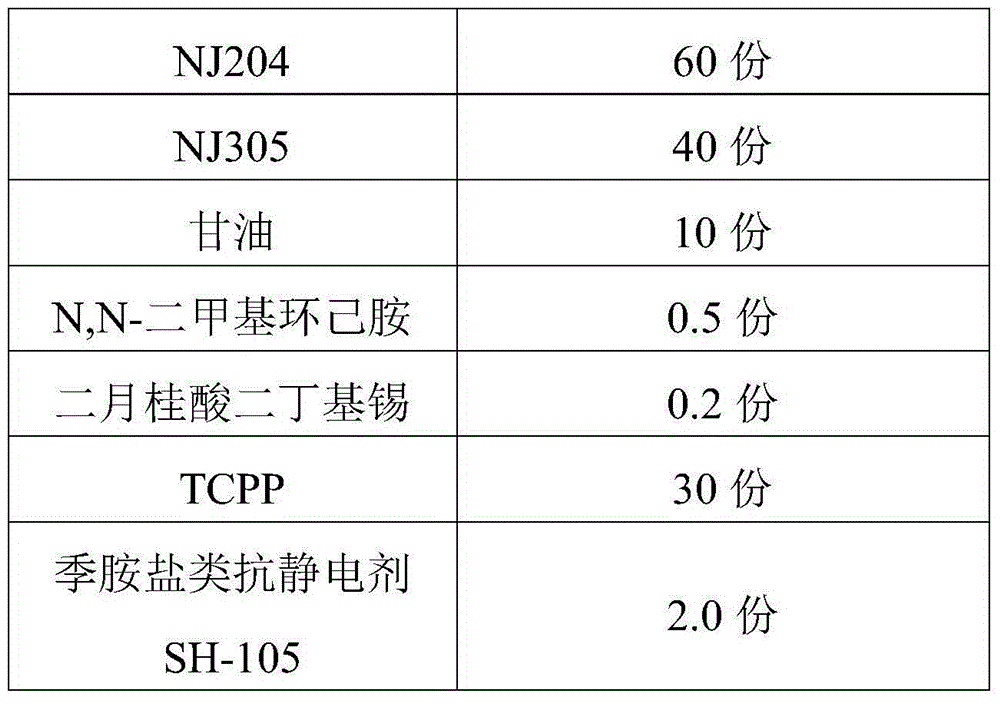

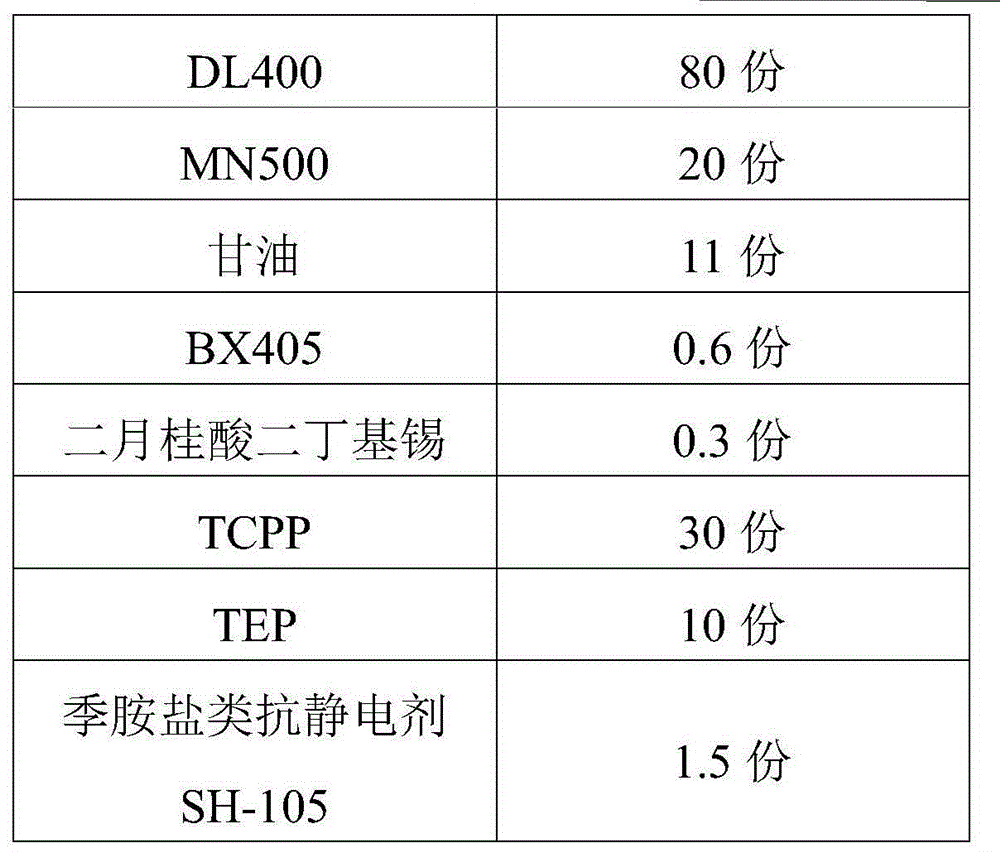

Raw material combination combined by polyether and polyurethane reinforcement materials and preparing method thereof

The invention discloses a combination polyether which comprises, by weight, the components of 60-90 parts of polyether polyol A, 10-40 parts of polyether polyol B, 7-12 parts of cross-linking agents, 0.3-1.0 part of amine catalyst, 0.1-0.3 part of metal catalyst, 20-40 parts of flame retardant agents and 1.5-2.5 parts of antistatic agents. The polyurethane reinforcement materials have solvent-free performance and non-volatilization performance, raw materials are easy to obtain, raw material price is low, flame retardant effect is good, antistatic effect is good, a danger coefficient is small during using in underground, safety and innocuity are achieved on an operator and an environment, and the combination is suitable for industrialization large-scale production. The preparing method of the polyurethane reinforcement materials is easy to operate, and three wastes are low. When the polyurethane reinforcement materials are used in the field of mining reinforcement, operation is easy, using is convenient, flexibility is high, a security coefficient is high, and safety and innocuity are achieved on the operator and the environment.

Owner:SHANGHAI DONGDA CHEM

Photocatalytic concrete material sprayed with titanium dioxide/activated zeolite composite material and preparation method thereof

ActiveUS20170209856A1Improve photocatalytic degradation efficiencyReached efficientlyMolecular sieve catalystsCatalyst activation/preparationMolecular sievePhotocatalytic degradation

The present invention provides a photocatalytic concrete material sprayed with titanium dioxide / activated zeolite composite material and preparation method thereof, and the photocatalytic concrete material sprayed with titanium dioxide / activated zeolite composite material comprises following raw materials in parts by weight titanium dioxide 0.1-20 parts, activated zeolite molecular sieve 0.1-20 parts, dispersant 0.1-5 parts, emulsifier 0.05-2 parts, coupling agent 0.05-2 parts, cement 40-90 parts, fine sand 40-90 parts and water. In the present invention, the activated zeolite molecular sieve can load titanium dioxide photocatalytic material as a carrier, and can easily adsorb gaseous pollutant of automobile exhaust with huge specific surface area (280.1 m2 / g), thereby increasing photocatalytic degradation efficiency and the efficiency can reach 92%, besides, the present invention has advantages of simple preparation technology, cheap raw materials and low preparation cost, so the present invention is suitable for industrial production.

Owner:RUNTAI CHEM TAIXING CO LTD

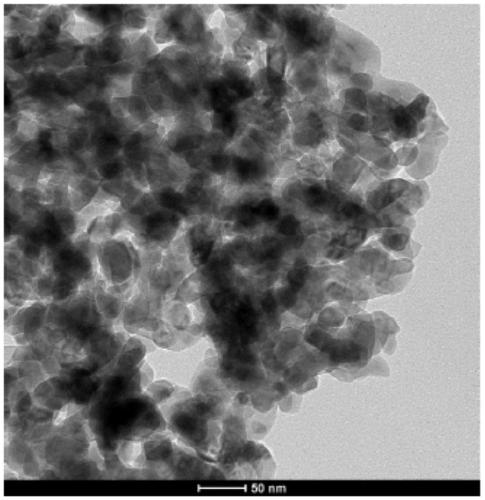

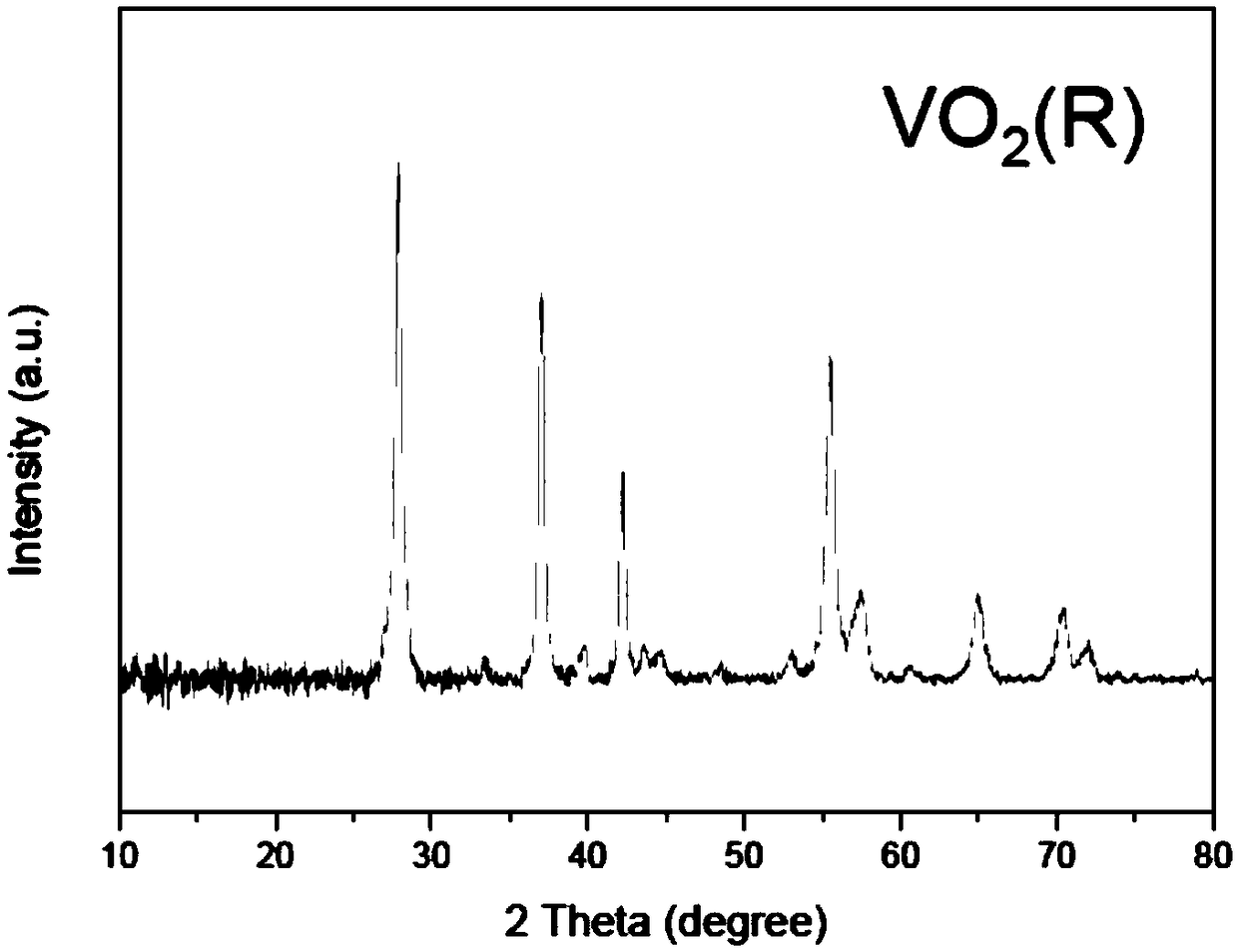

Preparation method for rutile phase vanadium dioxide superfine nano powder

InactiveCN109319838ARaw materials are cheapFast productionNanotechnologyVanadium oxidesSolventAmmonium hydroxide

The invention discloses a preparation method for rutile phase vanadium dioxide superfine nano powder, which comprises the following steps: S1, enabling ammonium hydroxide to quickly react with an acidic tetravalent vanadium solution to obtain turbid liquid B; S2, performing sealing, heat preservation and stirring treatment on the turbid liquid B to obtain a colloidal suspension C, wherein the temperature for heat preservation is not higher than the boiling point of a solvent in the tetravalent vanadium solution; S3, performing solid-liquid separation and cleaning on the colloidal suspension Cto obtain hydrated vanadium hydroxide colloid D; S4, drying the hydrated vanadium hydroxide colloid D and sintering in the protection atmosphere to obtain the rutile phase vanadium dioxide superfine nano powder. The rutile phase vanadium dioxide particles prepared by the process method disclosed by the invention have the advantages of high purity, smaller and even size and good dispersion and canserve as an excellent raw material for high-quality vanadium dioxide intelligent temperature-control coated windows.

Owner:INST FOR PROCESS MODELING & OPTIMIZATION JITRI

Method for preparing aluminum-titanium-carbon intermediate alloy

One Al-Ti-C intermediate alloy preparation method, involves a kind to use in the aluminum alloy production crystal grain thin Al-Ti-C intermediate alloy production method. Its characteristic lies in with the calcium carbide does carbon source, the production craft completely dissolves after the aluminum, melts the body fever to join the electricity stone powder hydrofluotitanic acid armor the mixture, elevates temperature to 950deg.C~~1000deg.C, guarantees the wet 10~~30 minute, after melt body surface liquid state dregs casting.The invention characteristic is the raw material unites is easy, alloy production craft simple, production cost low, produces the alloy thin medicinal preparation thin crystal grain with this craft is incubation period short, specially suits outside the stove is continuously thin.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

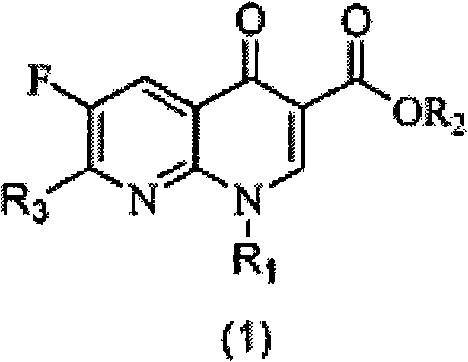

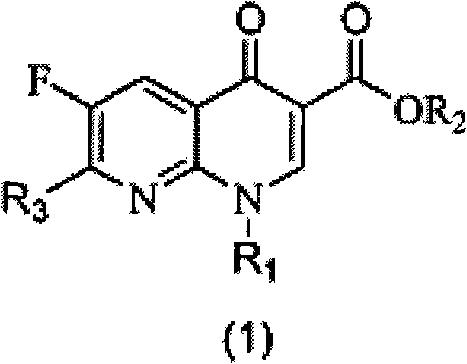

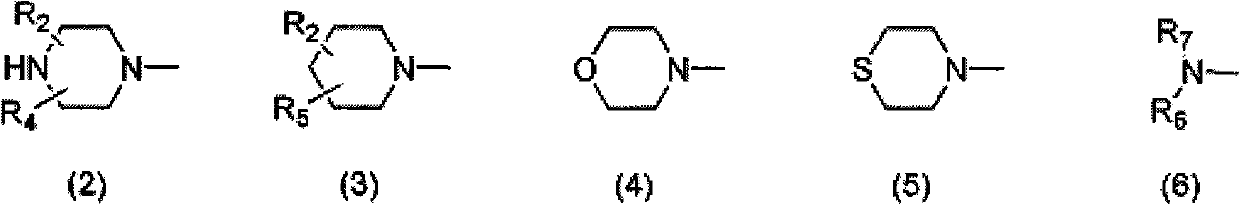

Fluoro-carbostyril derivative as well as preparation method and application thereof

InactiveCN101792443ARaw materials are cheapMild reaction conditionsAntibacterial agentsOrganic active ingredientsStereochemistryReaction step

The invention provides a novel fluoro-carbostyril derivative which is expressed as the following formula (1) and has antibacterial activity and a preparation method thereof. The preparation method has mild reaction condition, few reaction step, high total yield and convenient postprocessing and can realize the purification of a product just by simple filtering and recrystallization, therefore, the method is suitable for industrialized production.

Owner:BEIJING OKEANOS TECH

Method for removing low-concentration heavy metal by embedding heat-inactivation activated sludge with sodium acetylide

InactiveCN1702044AStrong ability to adsorb mixed heavy metalsWell buriedWater/sewage treatment by sorptionActivated sludgeVolumetric Mass Density

The low concentration heavy metal removal method by sodium alginate embedding heat-activated activated sludge, which pertains to heavy metal waste water disposal method, comprises the following steppes: treating the activated sludge from municipal sewage plant with scouring, centrifugal separation and drying under pressurization to deactivate it; embedding it with sodium alginate(CaCl2) to get immobilization calcium alginate ball(CA); filling fixed reactor with CA in certain density; continuously treating low concentration waste water containing mixing heavy metal such as Cd2+, Pb2+, Cu2+ and Zn2+; and selectively washing CA ball by hydrochloric acid to get mixing heavy metal adsorbed on CA ball. Heavy metal is retained while sorbent material revived to reuse. The invention has the advantages of high efficiency and economical and practical property.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

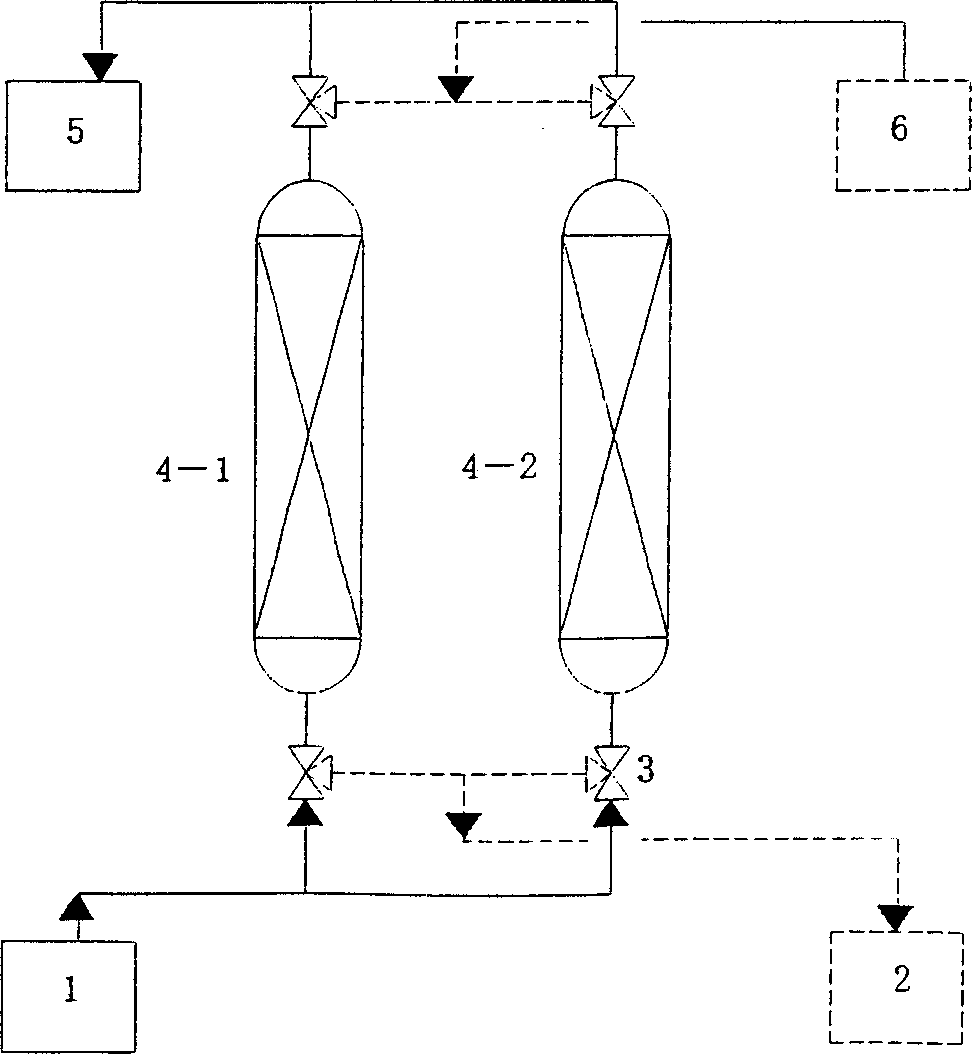

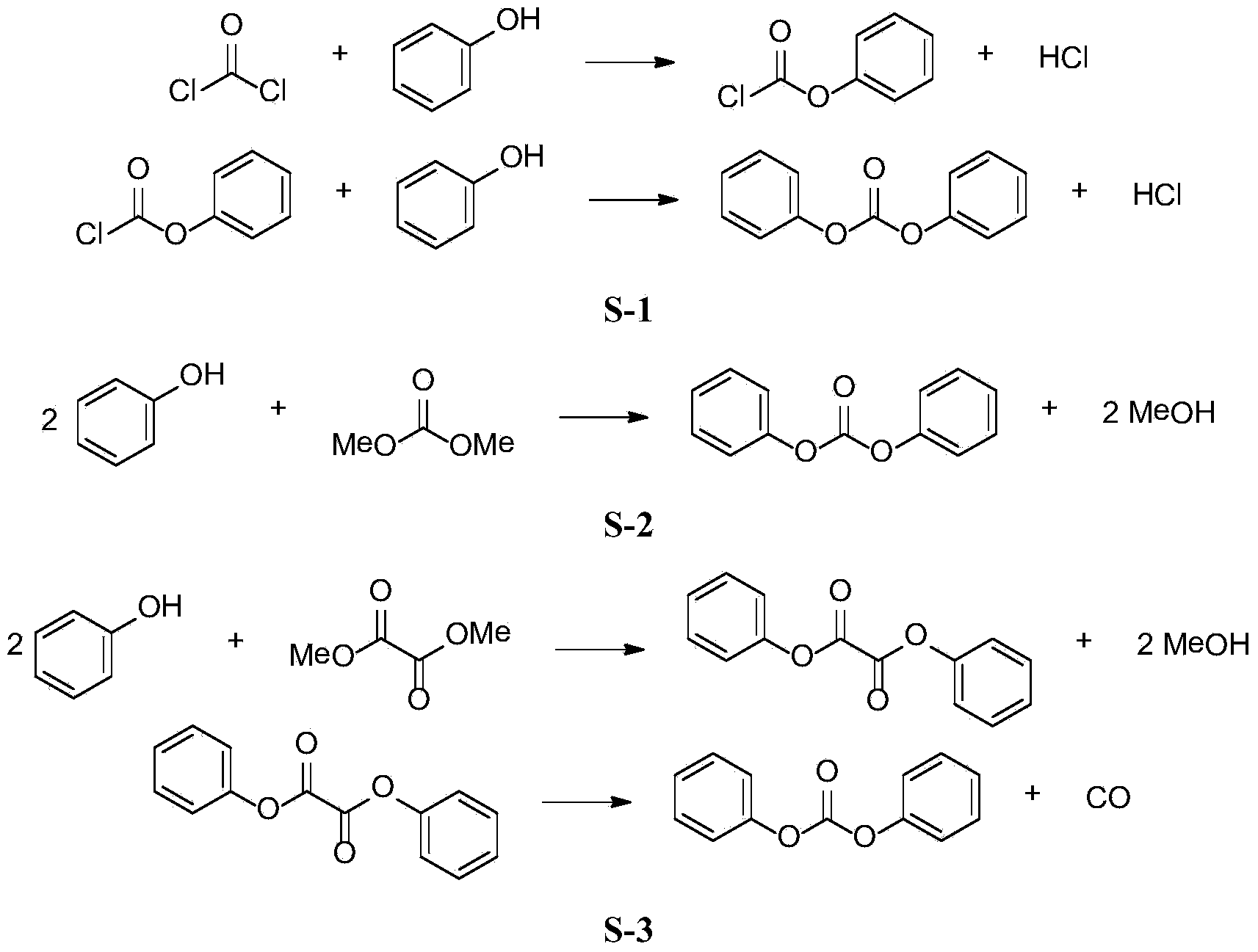

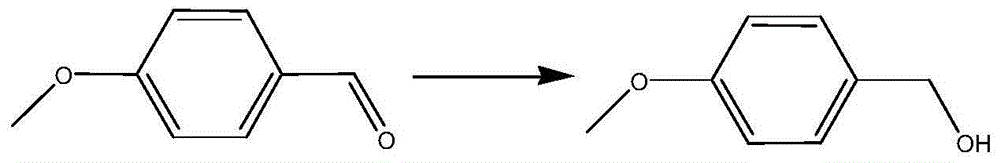

Application of Br phi nsted acid ion liquid to preparation of diphenyl oxalate

ActiveCN103524341AEasy to separateReduce corrosionOrganic compound preparationCarboxylic acid esters preparationTransesterificationReaction temperature

The invention discloses an application of a Bronsted acid ion liquid to preparation of diphenyl oxalate. Phenol and dimethyl oxalate are subjected to transesterification under the catalytic action of the Bronsted acid ion liquid, and the transesterification is carried out under a solvent-free condition, so that a mixture with diphenyl oxalate is obtained, wherein the reaction temperature ranges from 150 DEG C to 250 DEG C, the reaction time ranges from 2h to 5h, the mole ratio of phenol to diphenyl oxalate is (2.0-10.0):1, and the mole ratio of the Bronsted acid ion liquid as a catalyst to dimethyl oxalate as a substrate is 5-20%. By using the method, diphenyl oxalate (namely the mixture with diphenyl oxalate is obtained) can be greenly and safely prepared through the transesterification between phenol and dimethyl oxalate under mild reaction conditions and at high yield and low cost.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

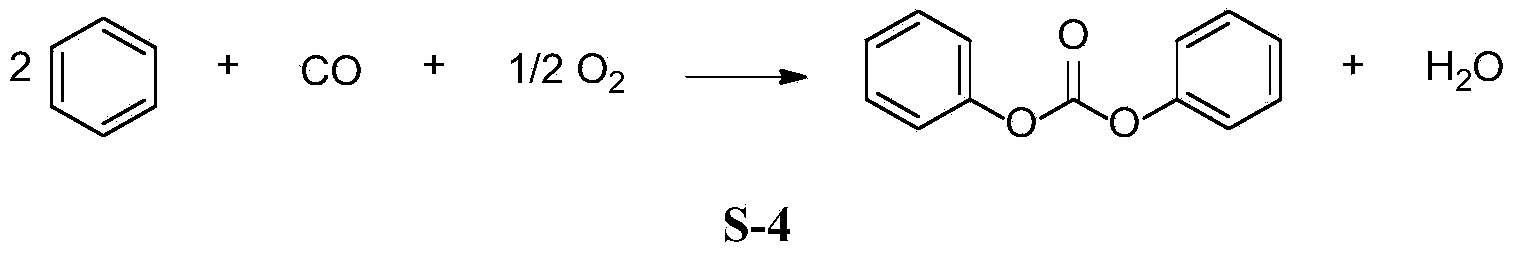

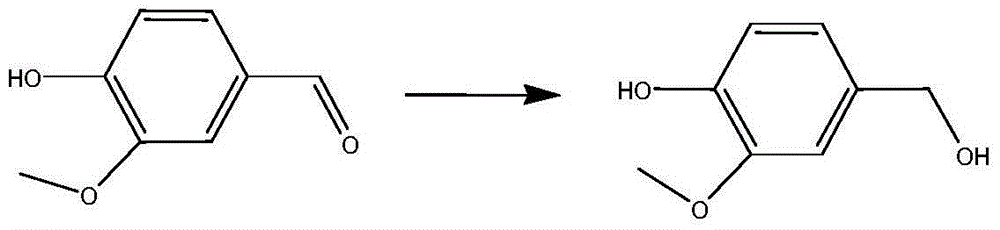

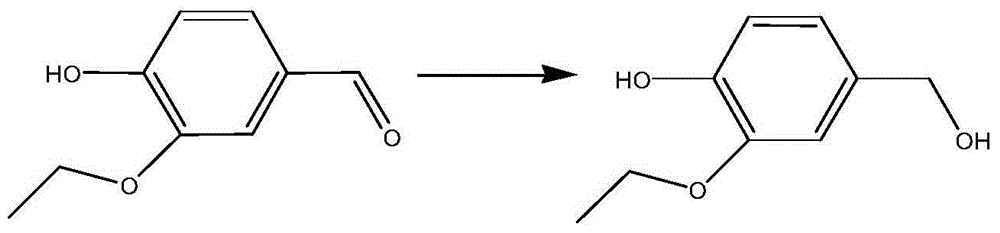

Ru-Co nanocatalyst and application of Ru-Co nanocatalyst in selective hydrogenation reaction of benzaldehyde compound

InactiveCN104475123ASave raw materialsRaw materials are cheapOrganic chemistryOrganic compound preparationNano catalystHydrogen atmosphere

The invention relates to an active carbon loaded Ru-Co nanocatalyst and its application in a selective hydrogenation reaction of a benzaldehyde compound. The Ru-Co nanocatalyst is characterized in that a metallic ruthenium compound and a metallic cobalt compound undergo coprecipitation on an active carbon carrier and then reduction is carried out under a hydrogen atmosphere so as to obtain the Ru-Co nanocatalyst, wherein mass ratio of ruthenium to cobalt to active carbon in the prepared active carbon loaded Ru-Co nanocatalyst is 1: (10-100): (50-500). According to the selective benzaldehyde compound hydrogenation reaction catalyzed by the Ru-Co nanocatalyst, the benzaldehyde compound is converted to obtain corresponding benzyl alcohol. A preparation method of the catalyst is simple; raw materials are cheap and easily available; and the Ru-Co nanocatalyst is suitable for industrial production. In addition, the catalyst shows good activity and selectivity for the hydrogenation reaction of the benzaldehyde compound, and the catalyst is easy to recycle and reuse.

Owner:NANJING UNIV OF TECH

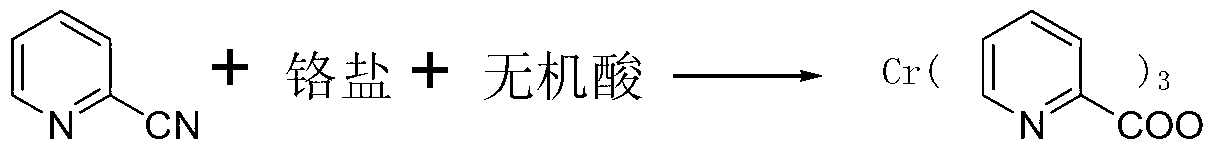

Technology for preparing 2-chromium picolinate through one-step method

The invention relates to a technology for preparing 2-chromium picolinate through a one-step method. The technology comprises the following steps: placing 2-cyanpyridine, an inorganic acid and a water-soluble trivalent chromium salt in a reaction vessel in proportion, carrying out a heating reaction under stirring, filtering after reaction ending to obtain a 2-chromium picolinate solid, and drying to obtain 2-chromium picolinate. The technology which shortens the multi-step reactions of original production technologies to one step has the characteristics of cheap and easily available raw materials, no need of the addition of other substances in the reaction intermediate process, simple operation, low energy consumption and the like. Additionally, there is no need to open the reaction kettle in the reaction process, so the damages to an operator are reduced.

Owner:CHINA ANIMAL HUSBANDRY IND

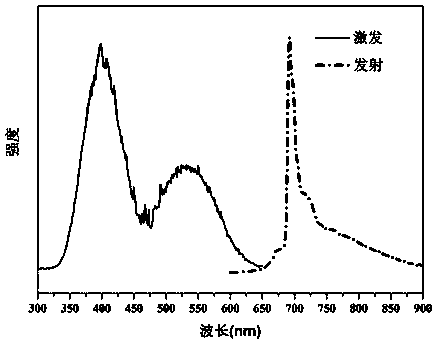

Fluorescent powder capable of promoting plant growth, preparation thereof and light conversion film prepared from fluorescent powder

PendingCN111205868ARaw materials are cheapSource channel is cheapHorticulture methodsLuminescent compositionsPhotosynthesisRed light

The invention discloses fluorescent powder capable of promoting plant growth, preparation of the fluorescent powder and a light conversion film prepared from the fluorescent powder. The fluorescent powder is formed by mixing SrMgAl10O17: Cr<3+> powder and commercial yellow fluorescent powder Y(3-y)Al5O12: yCe<3+>. The preparation method comprises the following steps: mixing the raw materials, adding a fluxing agent to form a mixture, fully grinding the mixture, calcining the ground mixture at high temperature in a nitrogen atmosphere, cooling to room temperature along with a furnace, and carrying out grinding to obtain SrMgAl9.95O17: 0.05 Cr<3+> powder; and mixing the powder with commercial yellow-light fluorescent powder and uniformly grinding the mixed powder to obtain the fluorescent powder capable of promoting plant growth. The two components in the epoxy resin AB glue are uniformly mixed, the fluorescent powder capable of promoting plant growth is added, uniform stirring is carried out, and the obtained substance is applied to a glass mold and dried at constant temperature to obtain the light conversion film capable of promoting plant growth. The light conversion film can effectively convert sunlight into red light capable of being efficiently absorbed by plants, plant photosynthesis can be enhanced, and plant growth is promoted.

Owner:LANZHOU UNIVERSITY

Process for producing non-quenched and tempered N80 steel grade petroleum pipeline

The invention relates to the technical field of metallurgy, in particular to a process for producing a non-quenched and tempered N80 steel grade petroleum pipeline. According to the technical scheme, the non-quenched and tempered N80 steel grade petroleum pipeline comprises the following components in percentage by mass: C: 0.34 to 0.38; Si: 0.25 to 0.40; Mn: 1.45 to 1.70; V: 0.11 to 0.16; P: not more than 0.025; S: not more than 0.025; Als: not more than 0.020; Cu: not more than 0.020, Ni: not more than 0.020; and Cr: not more than 0.25. The steel has good comprehensive mechanical property even at as rolled state, therefore, the on-line normalization or thermal refining process of the non-quenched and tempered N80 steel grade petroleum pipeline is canceled, the production process is simplified, the production efficiency is improved, and the production cost is reduced.

Owner:WUXI SEAMLESS OIL PIPE

Wall surface energy-saving decorative board and manufacturing method thereof

InactiveCN101864828AReduce consumption of mineral resourcesRaw materials are cheapCovering/liningsSolid waste managementSurface energyScrap

The invention relates to a wall surface energy-saving decorative board and a manufacturing method thereof. The wall surface energy-saving decorative board is manufactured by the following raw materials in portions by weight: 10-20 portions of cement, 50-55 portions of pulverized coal ash, 10-20 portions of water, 2-3 portions of fiber glass mesh, 3-5 portions of high polymer, 0.1-0.5 portion of foaming agent, 0.01-0.1 portion of air entraining agent, 0.01-0.5 portion of foam stabilizer and 6-12 portions of auxiliary materials. The manufacturing method of the wall surface energy-saving decorative board comprises the following steps: mixing, pulping, molding, autoclaving, curing and veneering. The invention has the advantages that the consumption of mineral resources is reduced, and simultaneously solid wastes produced by power industry are consumed; the wall surface energy-saving decorative board has relative low material price, simple manufacturing process, saved cost, heat preservation and insulation, water resistance (low water absorption), lighter weight, no burning or gas release on high-temperature open fire, extremely low heat conductivity factor, high shock resistance and wide serviceable range.

Owner:吴钜晓

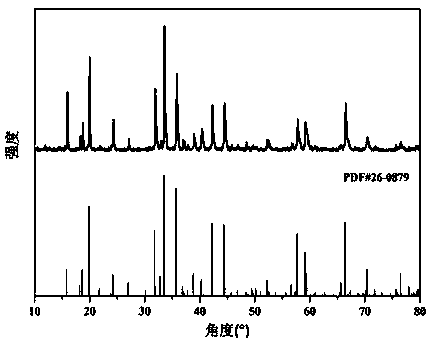

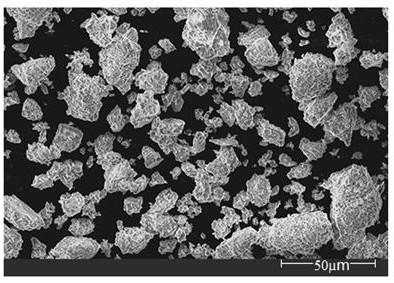

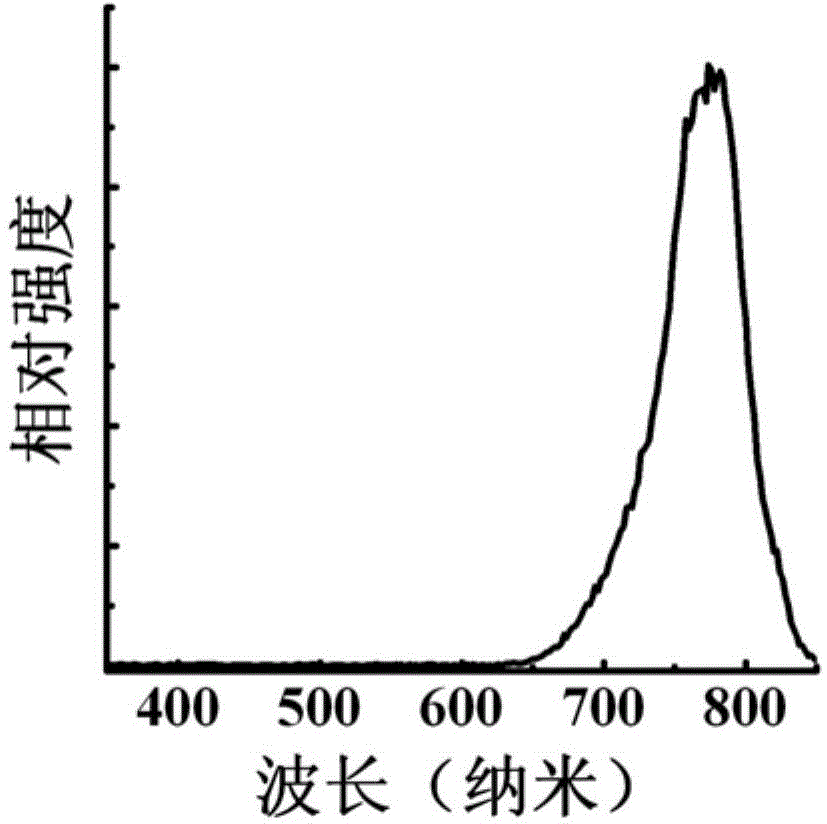

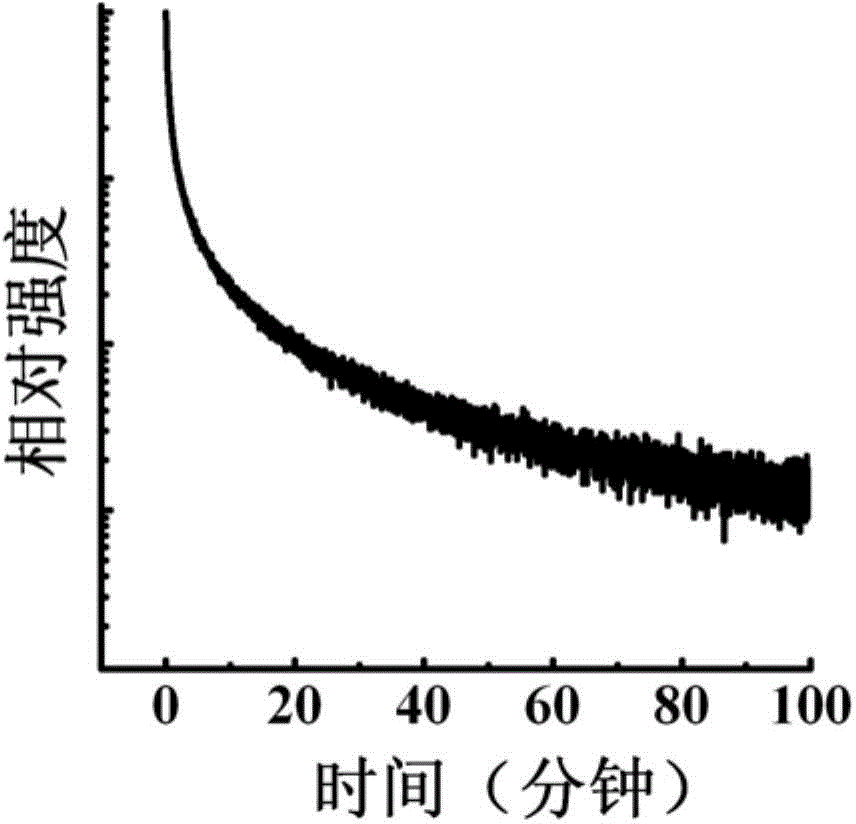

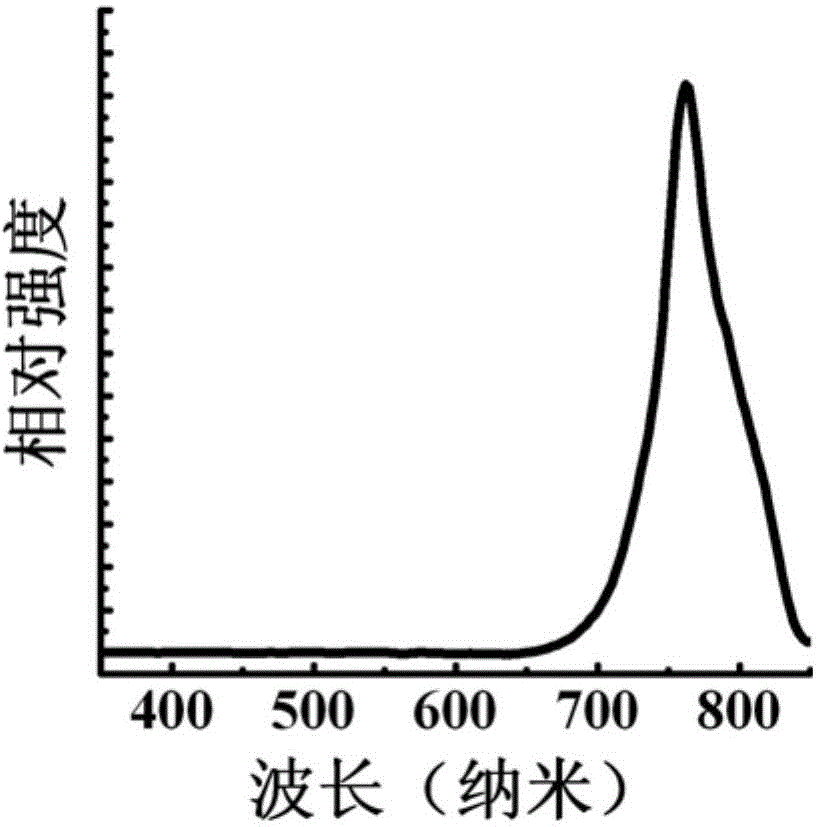

Cr-doped near-infrared long-afterglow luminescent material with perovskite structure and preparation method thereof

ActiveCN104861970AIncrease contentLong afterglow glow enhancementLuminescent compositionsCr dopedLuminescent material

The invention discloses a Cr-doped near-infrared long-afterglow luminescent material with a perovskite structure. A substrate material of the luminescent material is ABO3, wherein A is Ca, Sr or Ba, B is Sn or Ti, and 0.001 to 5 mol% of Cr<3+> is doped in the substrate material. The invention further discloses a preparation method for the near-infrared long-afterglow luminescent material. The method comprises the following steps: (1) separately weighing a compound containing A, a compound containing Ti and a compound containing Cr; and (2) after grinding and uniform mixing of the above compounds, presintering the obtained mixture in the air / reductive atmosphere, then grinding the mixture again and carrying out sintering in the air / reductive atmosphere for a plurality of hours. The near-infrared long-afterglow luminescent material prepared in the invention has an emission band located at 650 to 850 nm, an emission peak at 760 nm and afterglow time of as long as 100 min. The preparation method is simple, uses cheap raw materials and can easily realize large-scale technical popularization.

Owner:SOUTH CHINA UNIV OF TECH

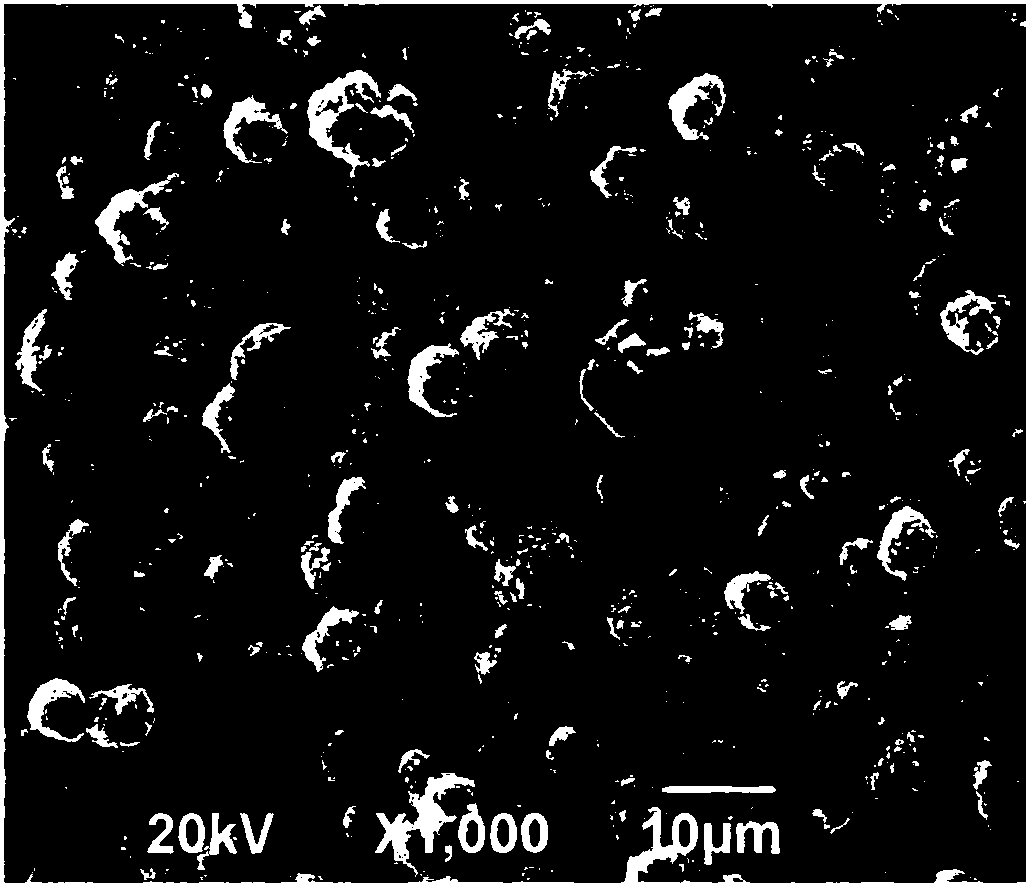

Production method for spherical active carbon

InactiveCN107746056ARaw materials are cheapSimple preparation processCarbon compoundsActivated carbonActive carbon

The invention discloses a production method for spherical active carbon. The production method comprises the following steps: (1) mixing glucose, an anionic surfactant, a cationic surfactant, humic acid and water, carrying out a hydrothermal reaction, and carrying out filtering so as to obtain hydrothermal carbon spheres; (2) carbonizing the hydrothermal carbon spheres prepared in the step (1) under the protection of nitrogen gas so as to obtain carbonized carbon spheres; and (3) mixing the carbonized carbon spheres obtained in the step (2) with an activating agent, and carrying out activationunder the protection of nitrogen gas so as to obtain the spherical active carbon. The spherical active carbon prepared by using the production method provided by the invention has the advantages of small particle size and great specific surface area.

Owner:江苏森森炭业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com