Ceramic materials for microwave ceramic capacitor and making method therefor

A technology of ceramic materials and microwave ceramics, applied in fixed capacitor dielectrics, parts of fixed capacitors, ceramics, etc., can solve the problems of high cost of raw materials, and achieve the effects of low preparation costs, low raw material prices, and excellent microwave dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

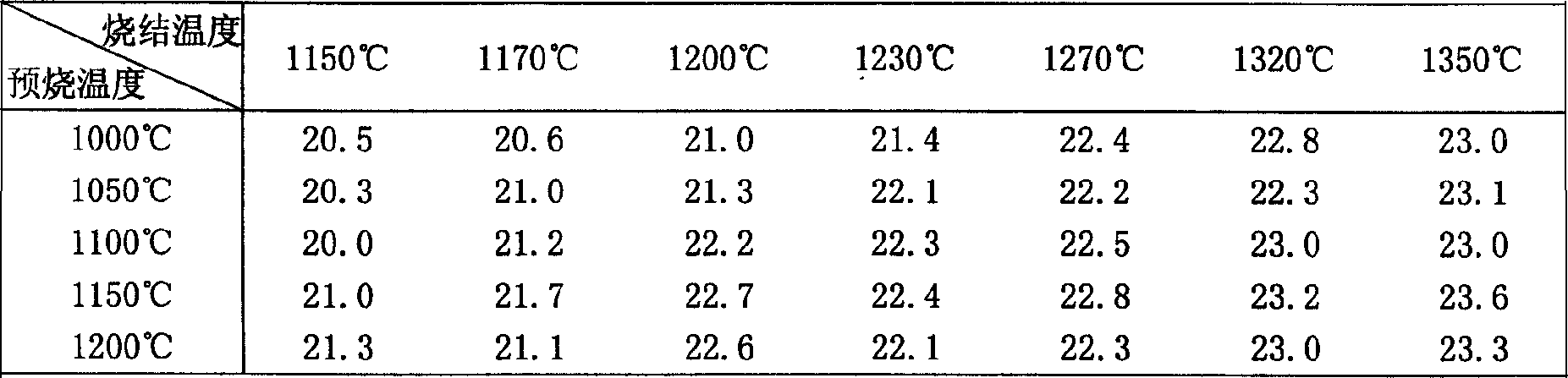

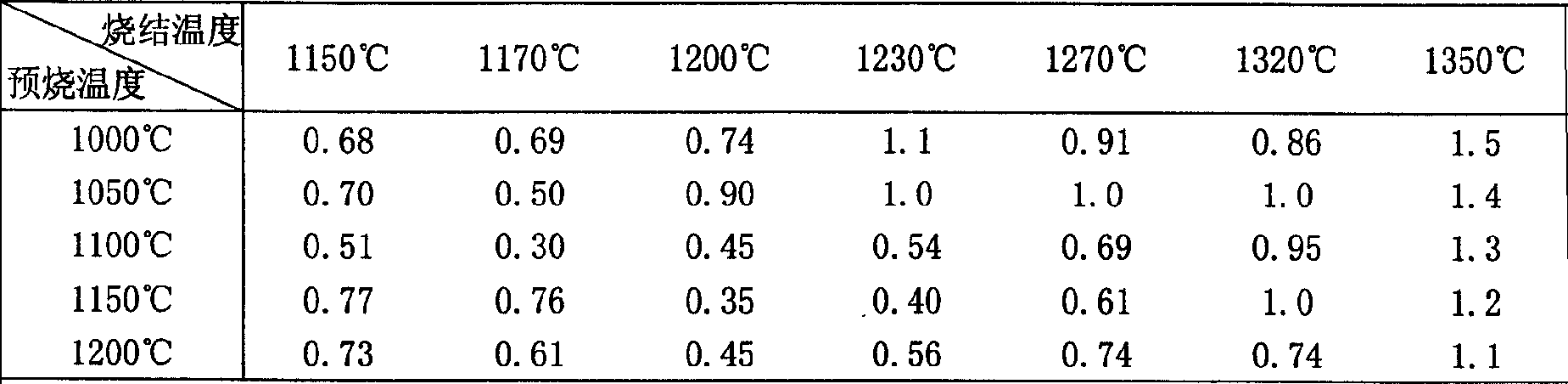

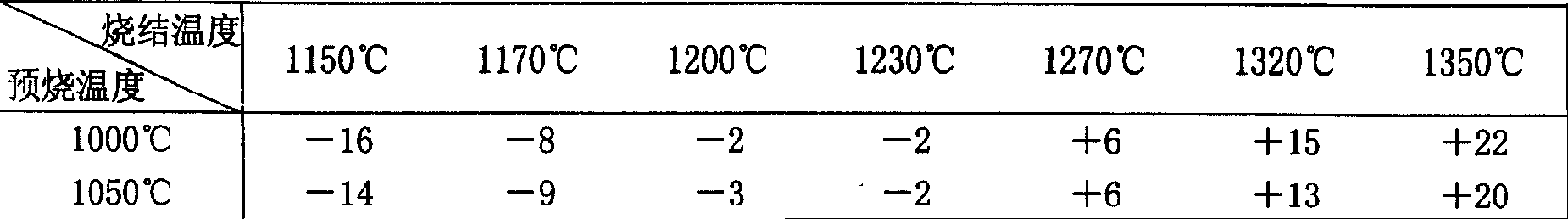

[0009] Using the analysis of soda magnesium carbonate, titanium dioxide, calcium carbonate, and boron pentoxide as raw materials, according to the formula 57g of soda magnesium carbonate, 41g of titanium dioxide, 2g of calcium carbonate, and 2g of boron pentoxide, after mixing these substances, use ZrO 2 The balls were milled with deionized water for 5 hours, dried in an electric drying oven at 120°C, passed through a 40-mesh sieve, and then pre-fired at 1000-1200°C with a heating rate of 6°C / min and kept for 2 hours to obtain molten piece. Reuse ZrO 2 The balls and deionized water were subjected to a second ball mill (4.5 hours). The ball-milled mixture is dried at 120°C, granulated with paraffin wax, and pressed under a pressure of 80 MPa to form a disc-shaped green body with a diameter of about 20 mm and a thickness of about 1 mm. The green body is sintered at 1150-1350°C. The initial heating rate of the sintering process is 3°C / min. After rising to 500°C, the heating rat...

Embodiment 2

[0023] The formulation and preparation process of the sample are all the same as in Example 1, except that xMgTiO is changed between 0.9 and 1.0 3 -(1-x)CaTiO 3 the x-value. That is to change the ratio of basic magnesium carbonate, titanium dioxide, calcium carbonate and boron pentoxide in the raw materials. X=0.90, that is, the weight ratio of basic magnesium carbonate, titanium dioxide, calcium carbonate, and boron pentoxide is 55:41:4:2; X=0.93, that is, basic magnesium carbonate, titanium dioxide, calcium carbonate, and boron pentoxide The weight ratio is 56:41:2.8:2; X=0.95, that is, the weight ratio of basic magnesium carbonate, titanium dioxide, calcium carbonate, and boron pentoxide is 57:41:2:2; X=0.98, that is, basic The weight ratio of magnesium carbonate, titanium dioxide, calcium carbonate, and boron pentoxide is 58:41:0.8:2; X=1.0, that is, the weight ratio of basic magnesium carbonate, titanium dioxide, calcium carbonate, and boron pentoxide is 59:41 :0:2. w...

Embodiment 3

[0027] The formula of sample and preparation process are all identical with embodiment 1 conditions, just change 0.95MgTiO 3 -0.05CaTiO 3 Add B to 2 o 5 weight ratio so that B 2 o 5 The percentage by weight of the compound varies in the range of 0-10%. The calcining temperature is 1100°C, and the sintering temperature is 1200°C. The measurement method of the obtained ceramic material parameters is the same as that of Example 1. Table 6 gives the dielectric properties of the samples as a function of B 2 o 5 The law of content change.

[0028]

[0029] As can be seen from Table 6, increasing MgTiO3 -CaTiO 3 B in dielectric ceramic 2 o 5 The content can significantly reduce the optimum sintering temperature of the sample, while at the same time ε decreases slightly, tanδ remains small, and the temperature coefficient tends to be negative. Within the range given in the table, ρ ν All in 10 13 More than cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature coefficient of dielectric constant | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com