Raw material combination combined by polyether and polyurethane reinforcement materials and preparing method thereof

A technology of combining polyether and polyether polyol, which is applied in the field of raw material composition and preparation of combined polyether and polyurethane reinforcement materials, can solve problems such as health threats to operators, volatile solvents, environmental pollution, etc., and reduce safety accidents The effect of probability of occurrence, easy availability of raw materials, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

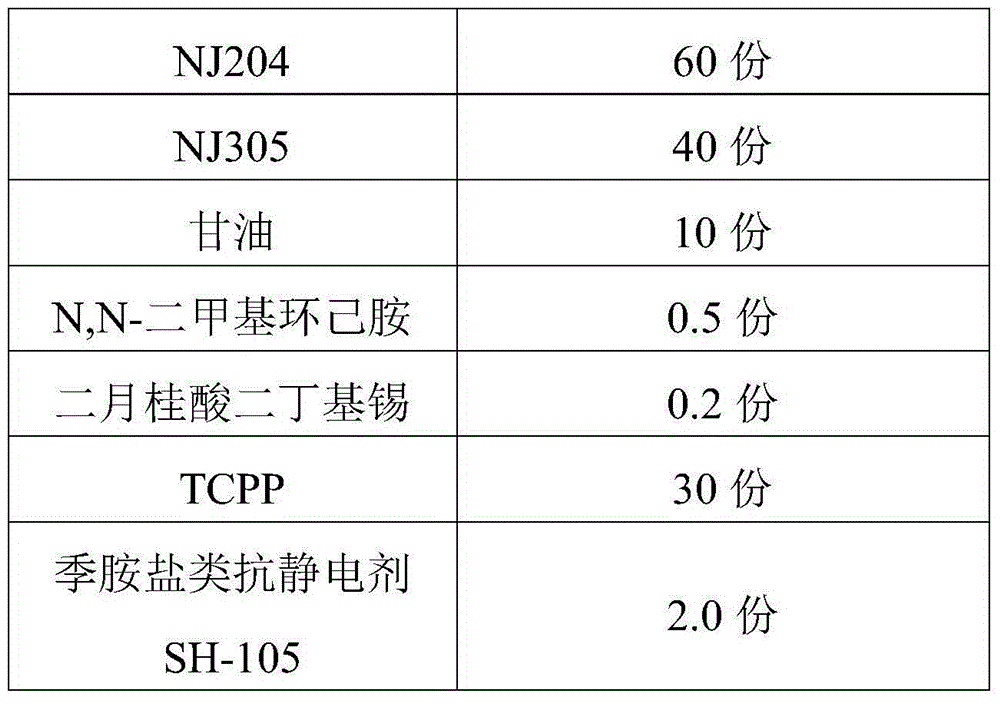

[0052] Prepare Part A according to the ingredients in the table below

[0053]

[0054] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make component A; then pour component A and component B into the container according to the weight ratio of 1:1, and then Use an electric stirrer to stir for 8 seconds, and test the reaction index and physical properties.

[0055] Part of the mechanical performance test reference standard is as follows (embodiments 1 to 5 and comparative examples are the same):

[0056] Free cell density: refer to "GB / T 6343-2009 Determination of Apparent Density of Foamed Plastics and Rubber"

[0057] Compressive Strength: Refer to GB / T 8813-2008 Determination of Compressive Properties of Rigid Foamed Plastics"

[0058] Bond strength: refer to the method in Appendix A of "GB / T 26689-2011 Rigid Polyurethane Foam for Refrigerators and Freezers"

[0059] ...

Embodiment 2

[0063] Prepare Part A according to the ingredients in the table below

[0064] NJ204

[0065] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make component A; then pour component A and component B into the container according to the weight ratio of 1:1, and then Use an electric stirrer to stir for 8 seconds, and test the reaction index and physical properties.

Embodiment 3

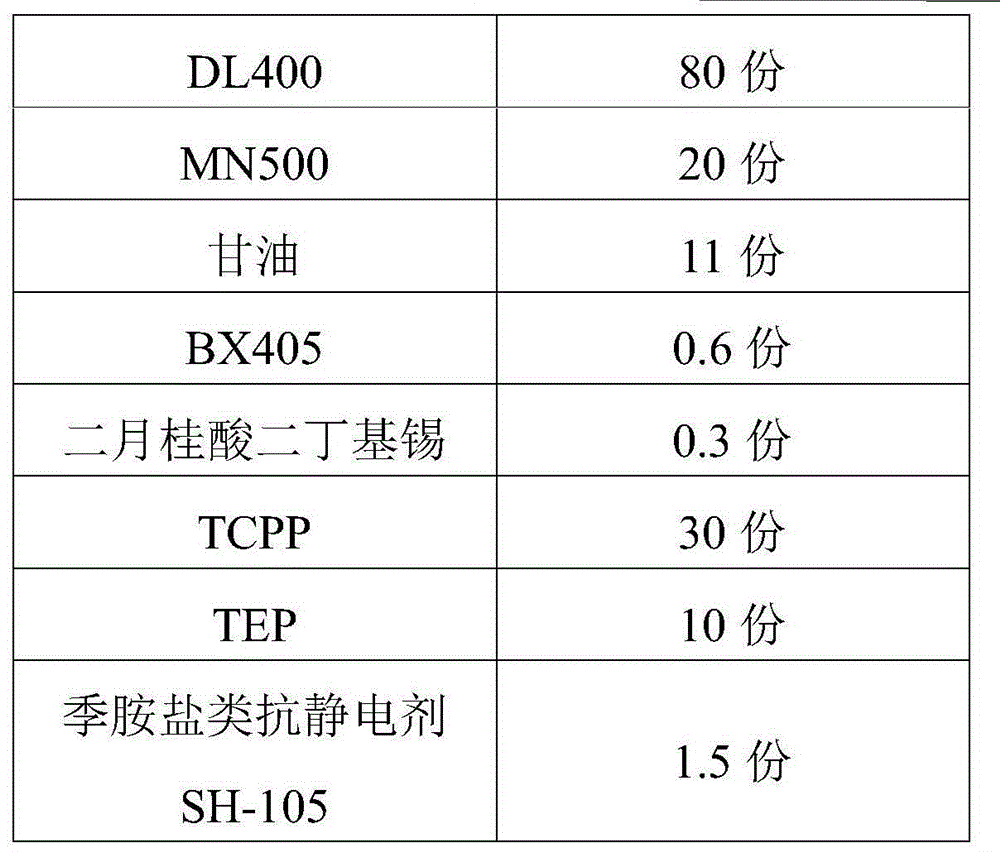

[0067] Prepare Part A according to the ingredients in the table below

[0068]

[0069] Pour the raw materials mentioned in the above table into the container according to the specified ratio, and mix them evenly with an electric mixer to make component A; then pour component A and component B into the container according to the weight ratio of 1:1, and then Use an electric stirrer to stir for 8 seconds, and test the reaction index and physical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com