Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Stable phase structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

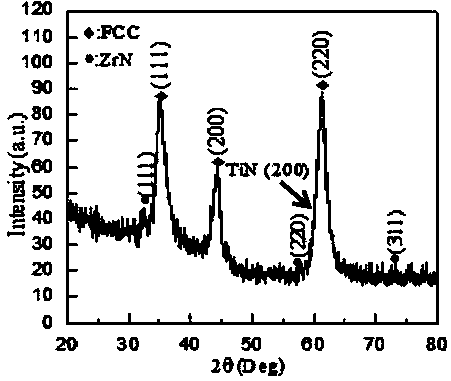

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

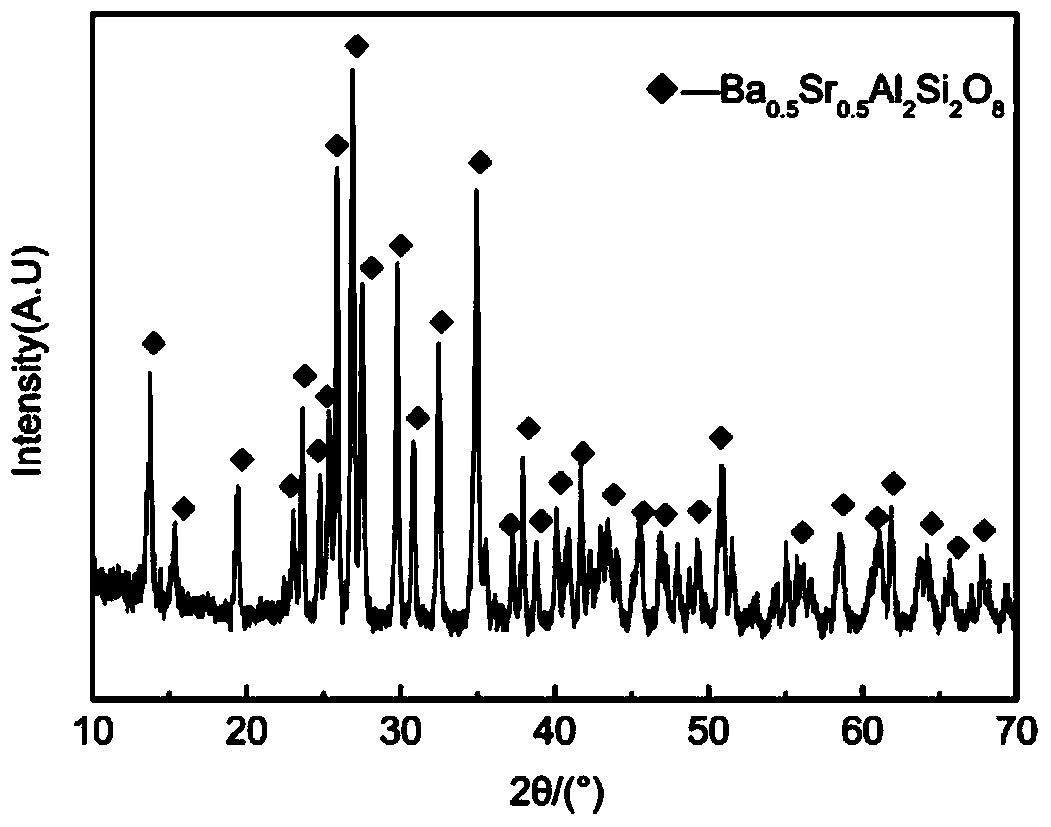

Temperature frequency characteristic regulator of microwave medium ceramic and LTCC material thereof

ActiveCN106927804AStable phase structureExcellent microwave dielectric propertiesAlkaline-earth metal silicatesPrinted circuitsDielectric permittivityMicrowave dielectric properties

The invention discloses a microwave dielectric ceramic, a temperature frequency characteristic regulator of the microwave medium ceramic and an LTCC material thereof. The microwave dielectric ceramic comprises a principal crystalline phase. The chemical formula of the principal crystalline phase is BaSixO2(x+1)(x is greater than or equal to 1.56 but less than or equal to 1.85). The ceramic has a low dielectric constant (epsilon r is equal to 7.1-7.9), a relatively high quality factor (Q*f is equal to 10973-20350GHz) and a relatively wide sintering temperature (750-1250 DEG C). Meanwhile, the principle crystalline phase which is sintered in a reductive atmosphere N2-1vol%H2 still has an excellent microwave dielectric property and is the microwave dielectric material with good reduction resistance. The microwave dielectric material can be used as the temperature frequency characteristic regulator of the microwave medium ceramic and can keep a stable phase structure and a good microwave dielectric property (reduction resistance) in the reductive atmosphere. Compared with a conventional adjustor, the microwave dielectric ceramic has an obvious advantage and is a novel temperature frequency characteristic regulator which can be applied to BME-MLCC.

Owner:HUAZHONG UNIV OF SCI & TECH

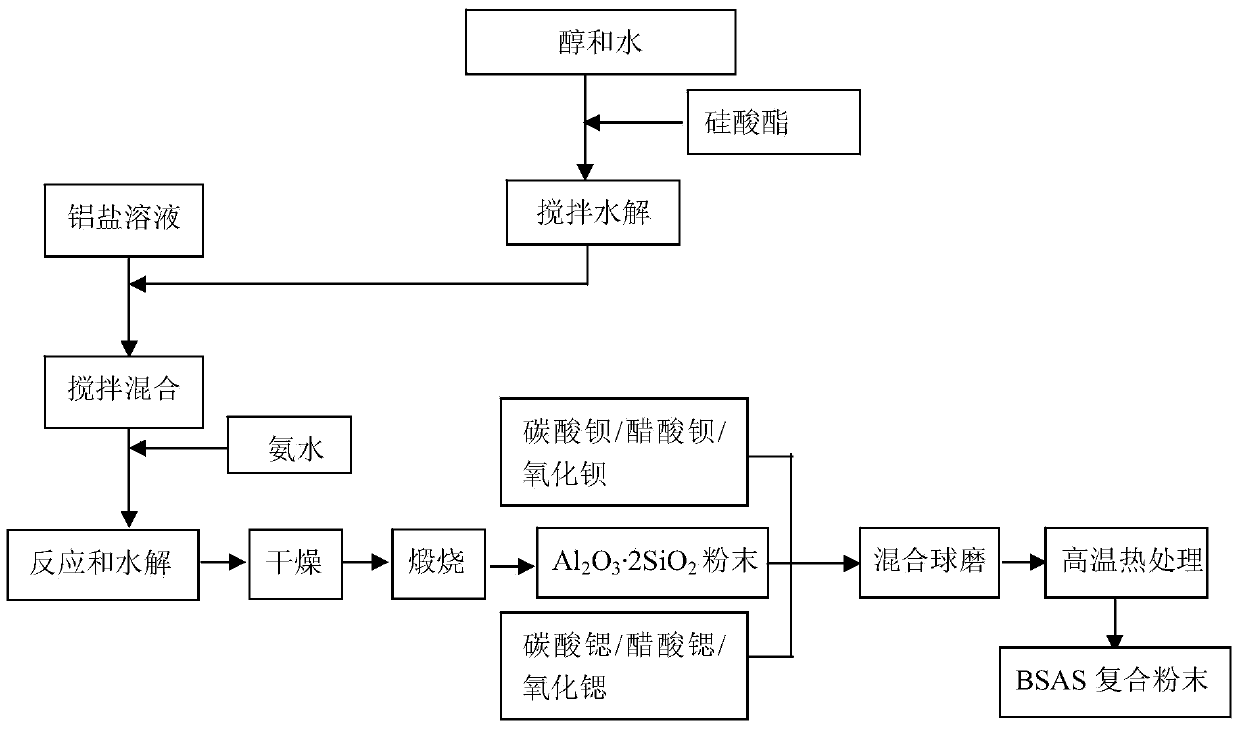

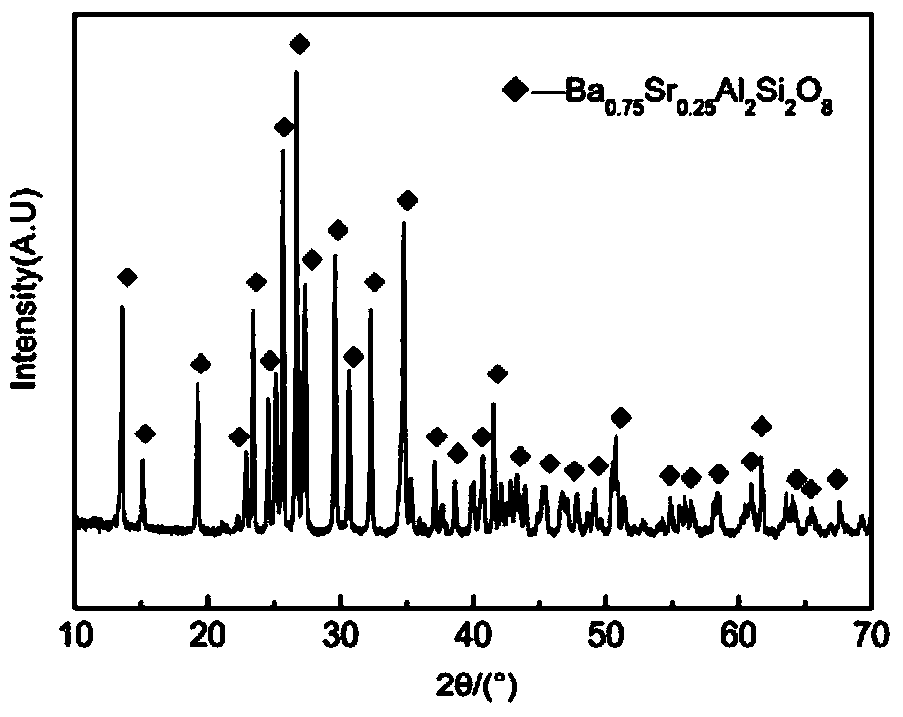

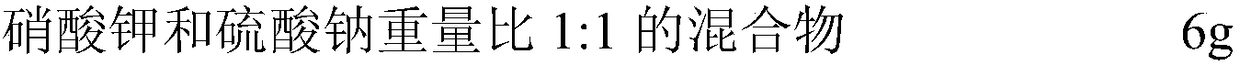

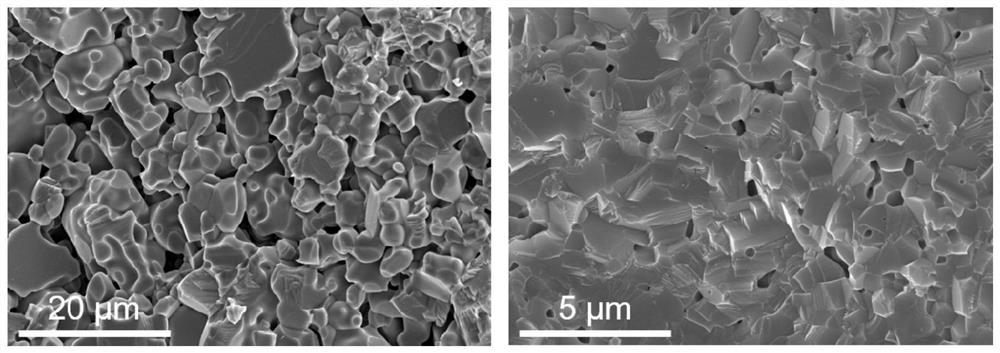

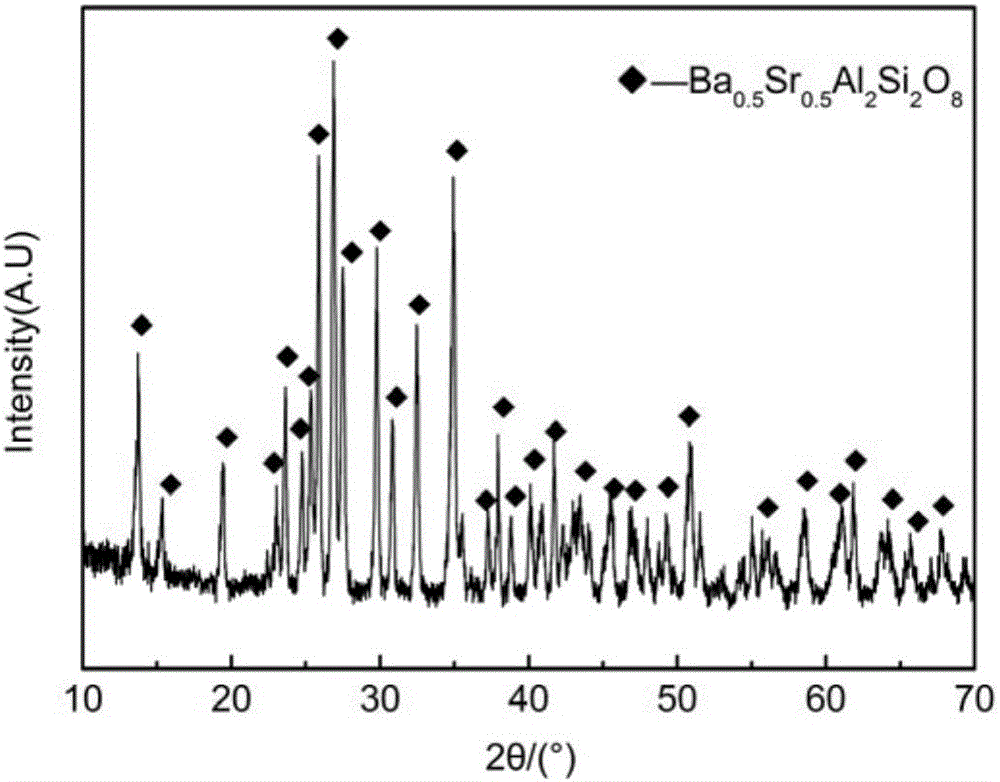

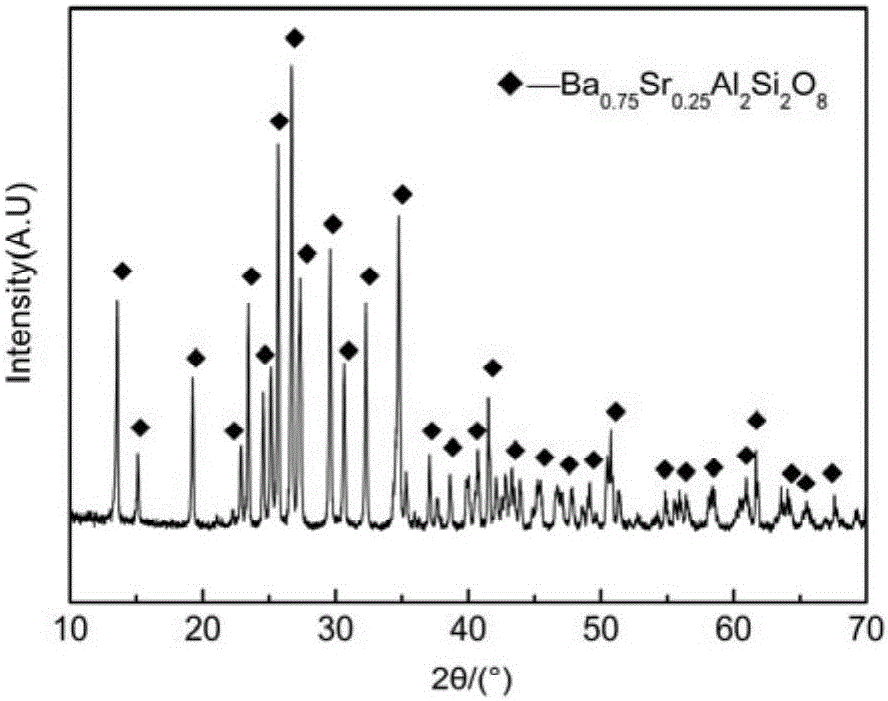

Preparation method of BSAS composite ceramic powder

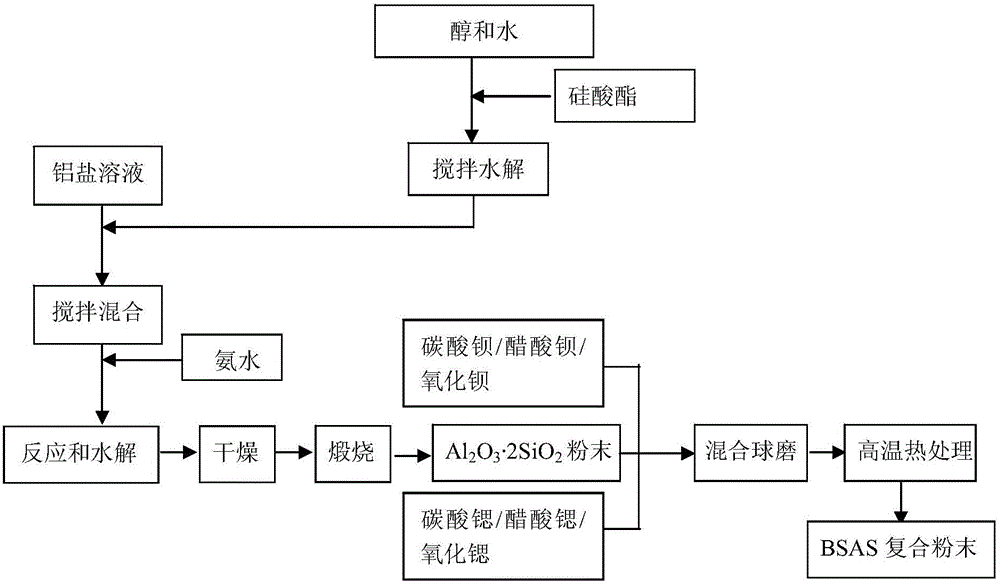

ActiveCN104003697AProcess raw materials are cheapThe process is simple and easy to controlComposite ceramicCrystallinity

The invention discloses a preparation method of a composite ceramic powder material used for an environmental barrier coating. The composite ceramic powder is composed of single phase BSAS (1-xBaO-xSrO-Al2O3-2SiO2, x is more than 0 and less than 1). The obtained BSAS composite ceramic powder has the advantages of easiness for ingredient control, high purity, high crystallinity and low synthesis temperature. The composite ceramic powder can be used for plasma spraying after being subjected to ball milling, agglomeration, pelletizing and high-temperature heat treatment, so that the environmental barrier coating is prepared on the surface of a C / C-SiC composite material, the coating can be used for effectively improving high-temperature water oxygen corrosion resistance performance of a C / C-SiC matrix, is applicable to surface high-temperature protection of other silicon substrate materials, can be used for solving the problem of high-temperature water oxygen corrosion of a silicon substrate composite material and has an important application value.

Owner:CENT SOUTH UNIV

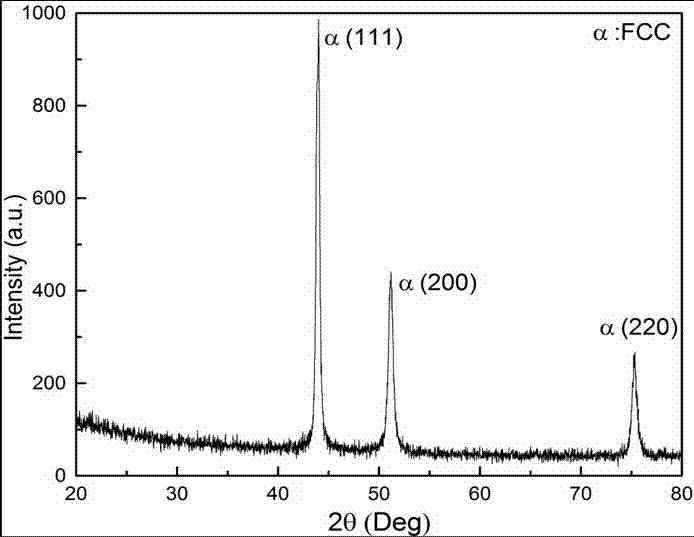

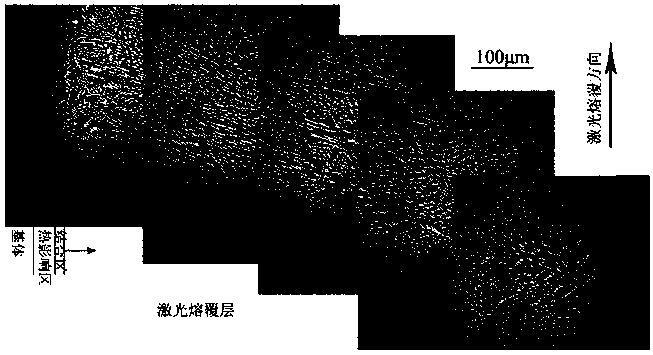

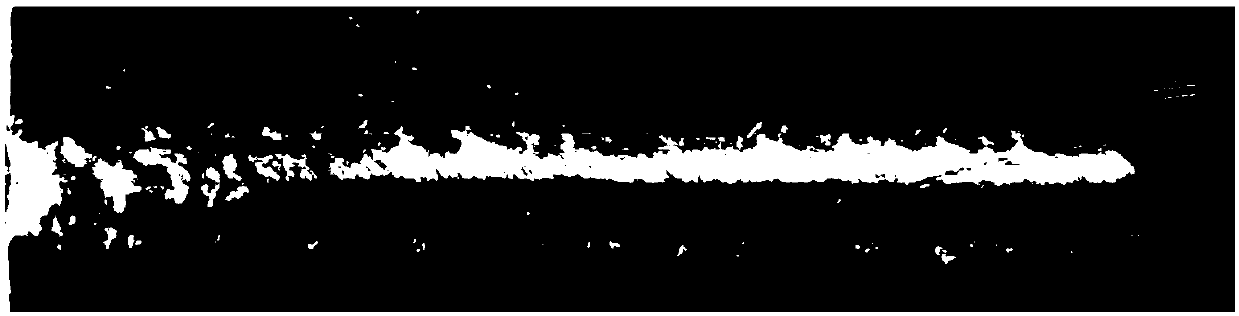

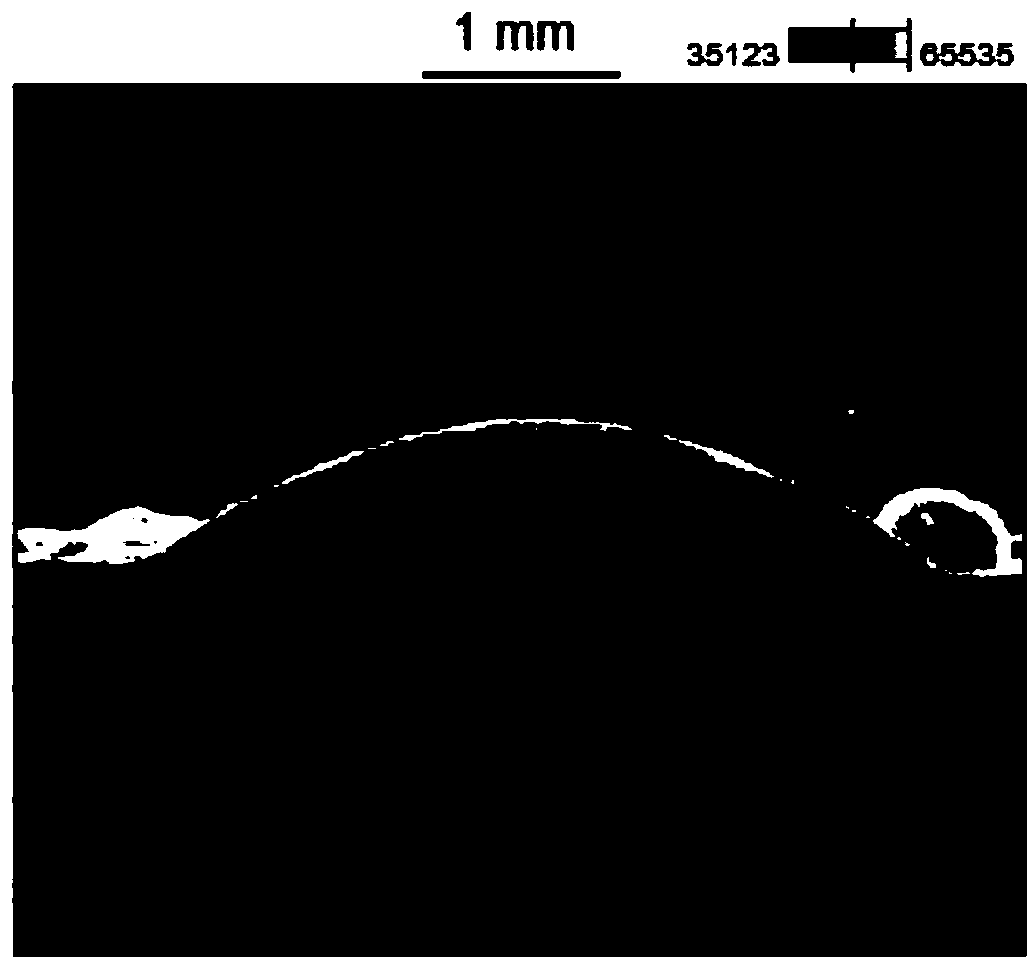

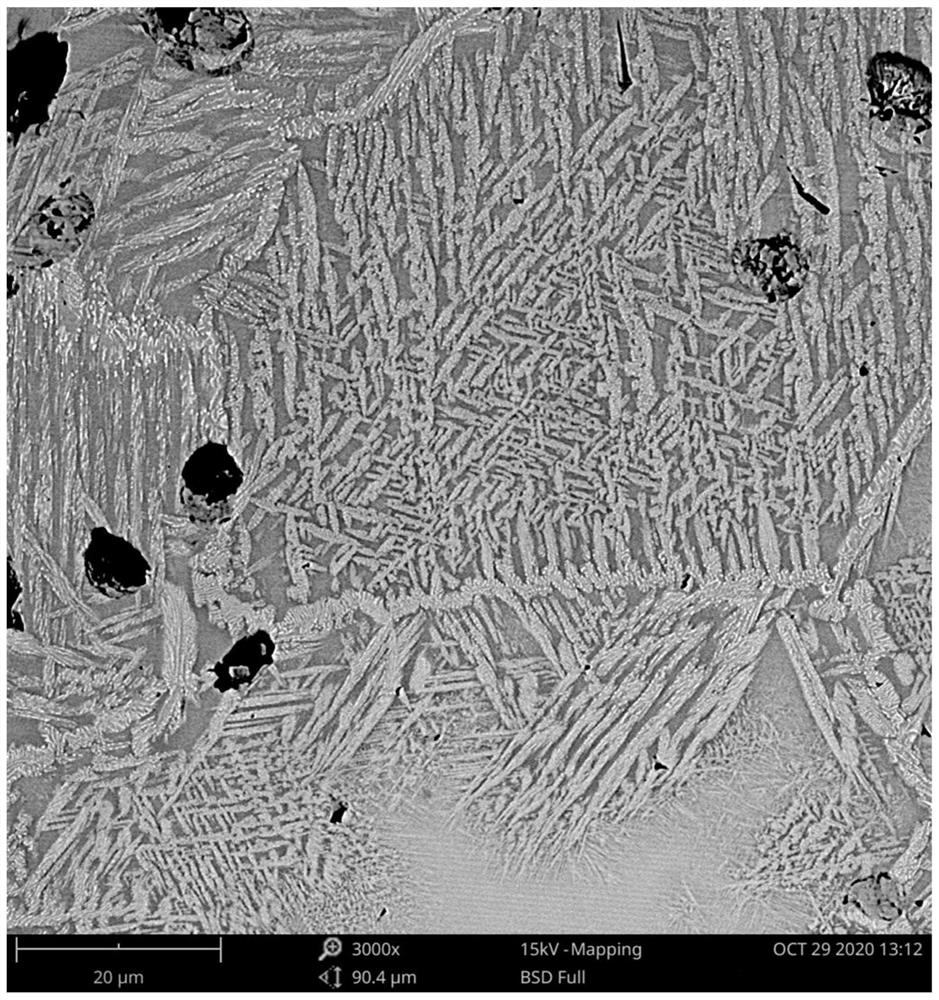

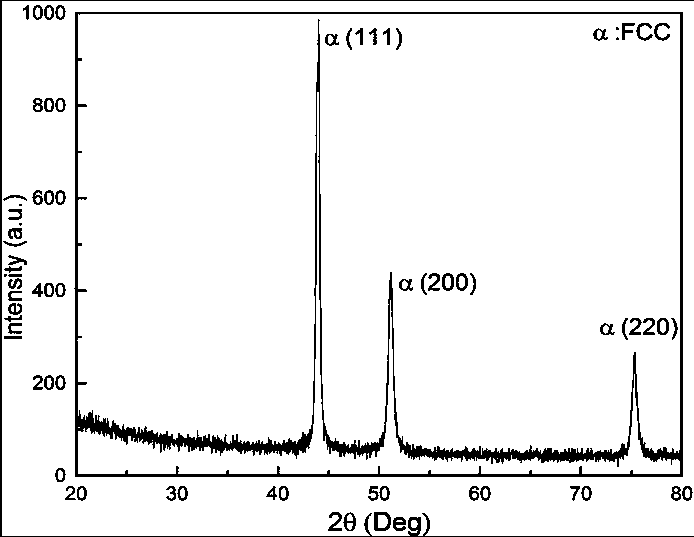

High-entropy alloy powder and preparation method and application of laser cladding layer

InactiveCN110804711AReduce oxidation rateHigh hardnessMetallic material coating processesHigh entropy alloysLight spot

The invention discloses high-entropy alloy powder and a preparation method and application of a laser cladding layer. The high-entropy alloy powder consists of Fe, Co, Cr, Mn, Ni and Al element powderin an equimolar ratio, the alloy powder is applied to laser cladding welding, the high-entropy alloy powder and ethanol are mixed and uniformly coat the surface of a base material, and the cladding layer can be obtained through laser cladding after drying. When laser cladding is carried out, the selected base material is H13 steel, the laser power is 1300-1600 KW, the light spot diameter is 2-4 mm, the scanning speed is 5-7 mm / s, the defocusing amount is 10 mm, and the protective gas flow rate is 20-25 L / min. Due to the fact that the chaos degree of the laser cladding high-entropy alloy coating is large, and becomes larger at high temperature, the high mixed entropy effect obviously reduces the diffusion and redistribution rates among elements, therefore, the phase structure in the coating is stable, the high-temperature hardness basically keeps unchanged, and the laser cladding high-entropy alloy coating has good high-temperature softening resistance.

Owner:TIANJIN UNIV

Rare earth surface modified aluminum nitride powder and preparation method thereof

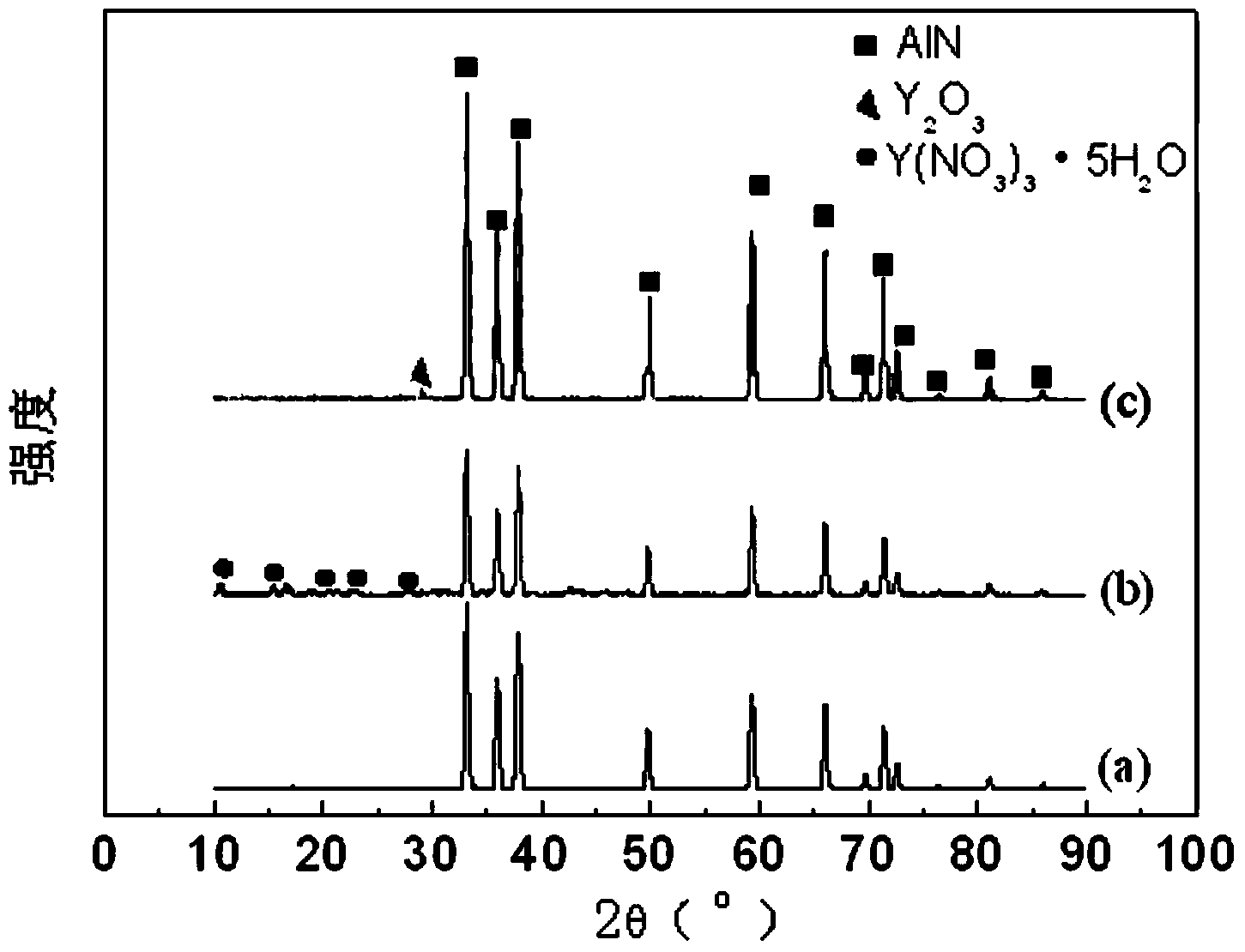

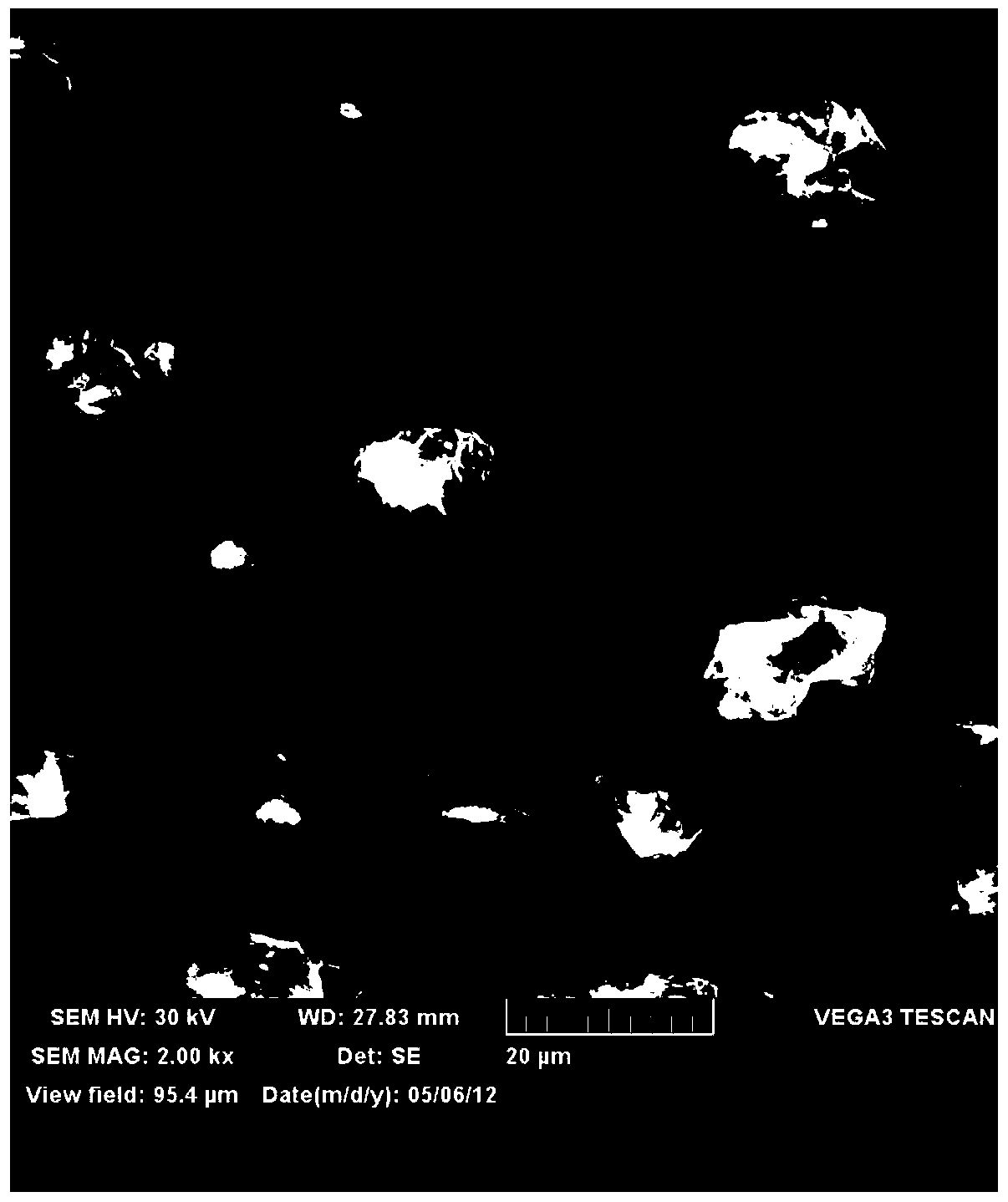

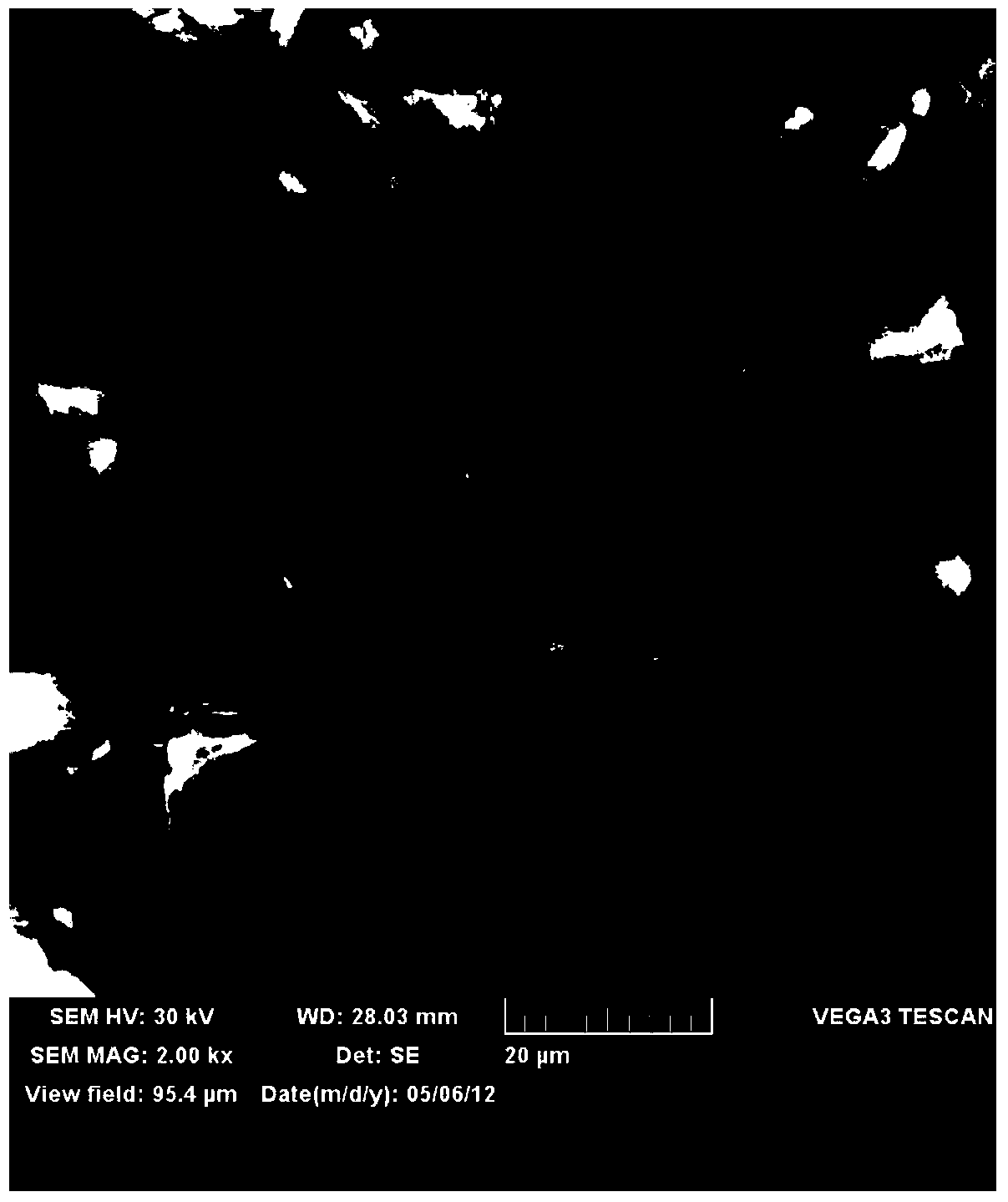

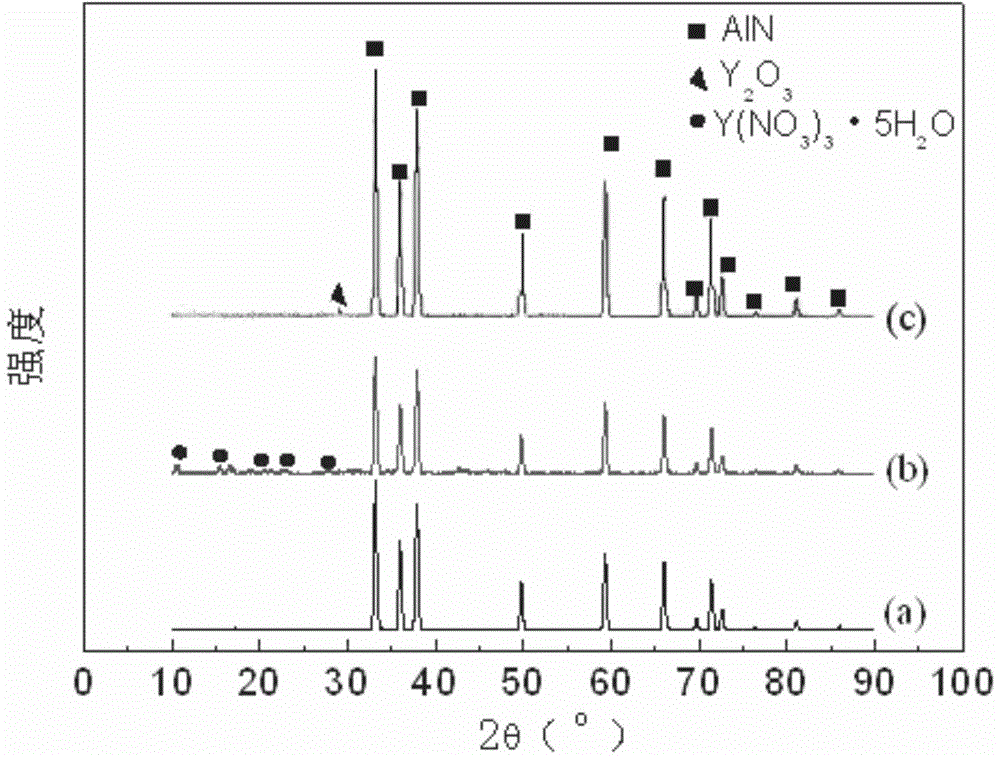

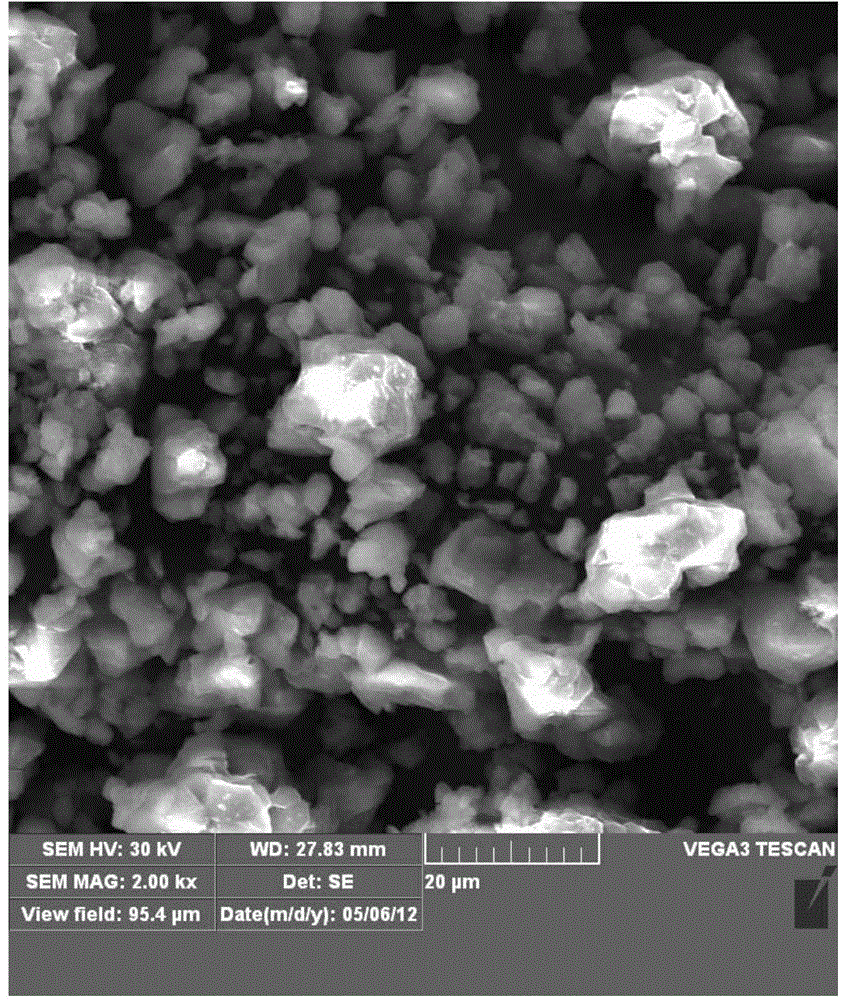

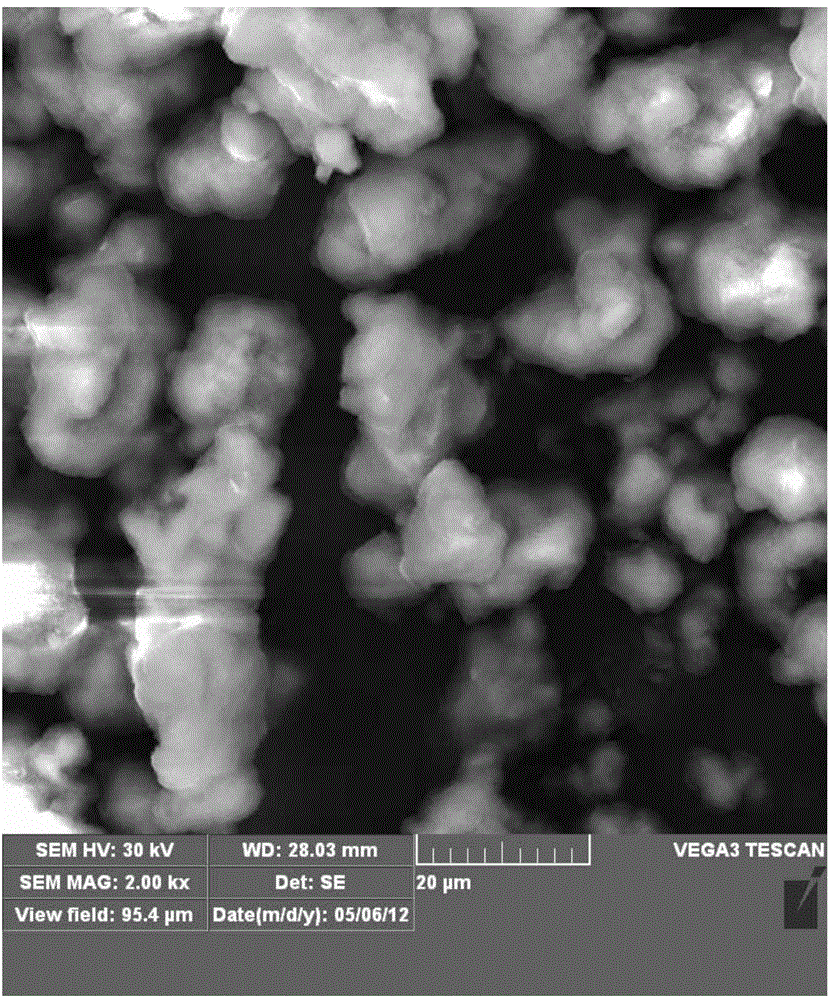

The invention discloses rare earth surface modified aluminum nitride powder and preparation method thereof, and relates to a modifying method of aluminum nitride powder. The rare earth surface modified aluminum nitride powder disclosed by the invention aims at solving the technical problems that the performance of a composite material using AlN as a reinforcement phase is influenced since impurity elements are introduced into the existing modified AlN powder and the modified AlN power and the metal are non-wetting. The rare earth surface modified aluminum nitride powder is aluminum nitride powder coated by rare earth oxide. The preparation method comprises the following steps: step one, preparing a rare earth nitrate solution; step two, adding the AlN powder in the rare earth nitrate solution, dropwise adding strong ammonia water while stirring, so as to obtain a mixed slurry; step three, filtering, washing and drying the mixed slurry; step four, sintering in a muffle furnace to obtain the rare earth surface modified aluminum nitride powder. The powder cannot be hydrolyzed after being soaked in water at 60 DEG.C for 30 hours, and the wetting angle of the powder and the copper at 1200 DEG.C is 85-89 DEG according to a sessile drop method, and the powder can be applied to a metal-based composite material as reinforcement.

Owner:HEILONGJIANG HEIKE TECH CO LTD +1

Regulator for regulating frequency-temperature characteristics of microwave dielectric ceramics and low temperature co-fired ceramic material comprising the same

ActiveUS10017422B1Excellent anti-reductive propertyLow dielectric constantAlkaline-earth metal silicatesPrinted circuitsDielectric ceramicsOxygen

A microwave dielectric ceramic, including a main crystal phase having a chemical formula of BaSixO2x+1, where 1.56≤x≤1.85. A regulator for regulating frequency-temperature characteristics of microwave dielectric ceramics is also provided. The dielectric constant of the microwave dielectric ceramic is smaller than 8, the temperature coefficient of resonate frequency of the microwave dielectric ceramic is positive, and the microwave dielectric ceramic is anti-reductive. A low temperature co-fired ceramic material includes a main crystal phase, the regulator, and a sintering additive. The main crystal phase of the low temperature co-fired ceramic material includes barium, aluminum, silicon, and oxygen.

Owner:HUAZHONG UNIV OF SCI & TECH

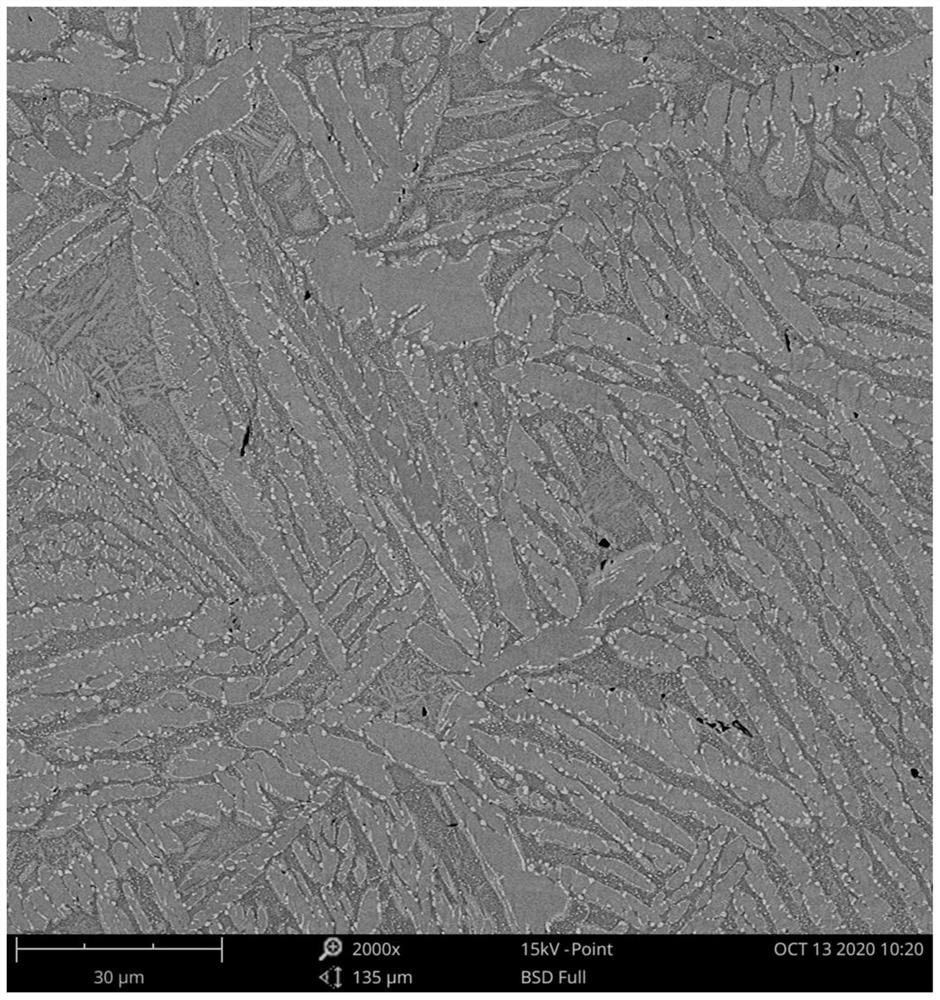

Preparation method of high-strength and high-toughness high-entropy alloy

The invention discloses a preparation method of a high-strength and high-toughness high-entropy alloy, and relates to the technical field of alloy material production. The preparation method comprises the following specific steps that high-entropy alloy powder prepared from the components in atomic percent: 27%-30% of Mn, 8%-12% of Co, 8%-12% of Cr, 0.4%-1.3% of C and the balance of Fe is prepared; the high-entropy alloy powder is subjected to ball milling treatment and then pre-pressed, the pressure ranges from 300 MPa to 500 MPa, the pressure is maintained for 200 seconds to 300 seconds, and a pre-pressed block of the high-entropy alloy is obtained; the pre-pressing block is subjected to vacuum annealing, vacuum hot pressing sintering and cold rolling deformation; and the high-entropy alloy sheet subjected to cold rolling deformation is subjected to constraint carbon distribution treatment at the temperature of 400-550 DEG C, and free carbon elements are diffused. The C-containing unequal-atom FeMnCoCrC high-entropy alloy prepared through the method has excellent strength and plasticity combination, and meanwhile, the problems that a high-entropy alloy prepared through a traditional technology is uneven in component and unstable in structure are solved.

Owner:ZHONGBEI UNIV

Mn-Al-CNTs type alloy as well as preparation method and application method thereof

InactiveCN101775562AStrong adsorptionImprove magnetic propertiesInductances/transformers/magnets manufactureAfter treatmentMagnet

The invention discloses an Mn-Al-CNTs type alloy as well as a preparation method and an application method thereof, relating to a manganese-based alloy. The components of the Mn-Al-CNTs type alloy based on atomic percentage are as follows: Mn50+xAl50-y(CNTs)y-x, wherein the limited ranges of x and y are as follows: x is not less than 1 and not more than 3, y is not less than 4 and not more than 5, and y-x is not less than 1 and not more than 3; the preparation method of the Mn-Al-CNTs type alloy comprises the following steps of: preparing cast alloys after raw materials preparation, melting and smelting, and then preparing final Mn-Al-CNTs type alloy products after treatments of solution and annealing; and the application method of the Mn-Al-CNTs type alloy is as follows: preparing the Mn-Al-CNTs type cast alloy into an annealing Mn50+xAl50-y(CNTs)y-x type alloy thin strip magnet. The invention further improves the magnetization intensity and the coercive force of the Mn-Al type alloy so as to further improve the permanent magnetism performance and the machining property of the Mn-Al type alloy materials.

Owner:HEBEI UNIV OF TECH

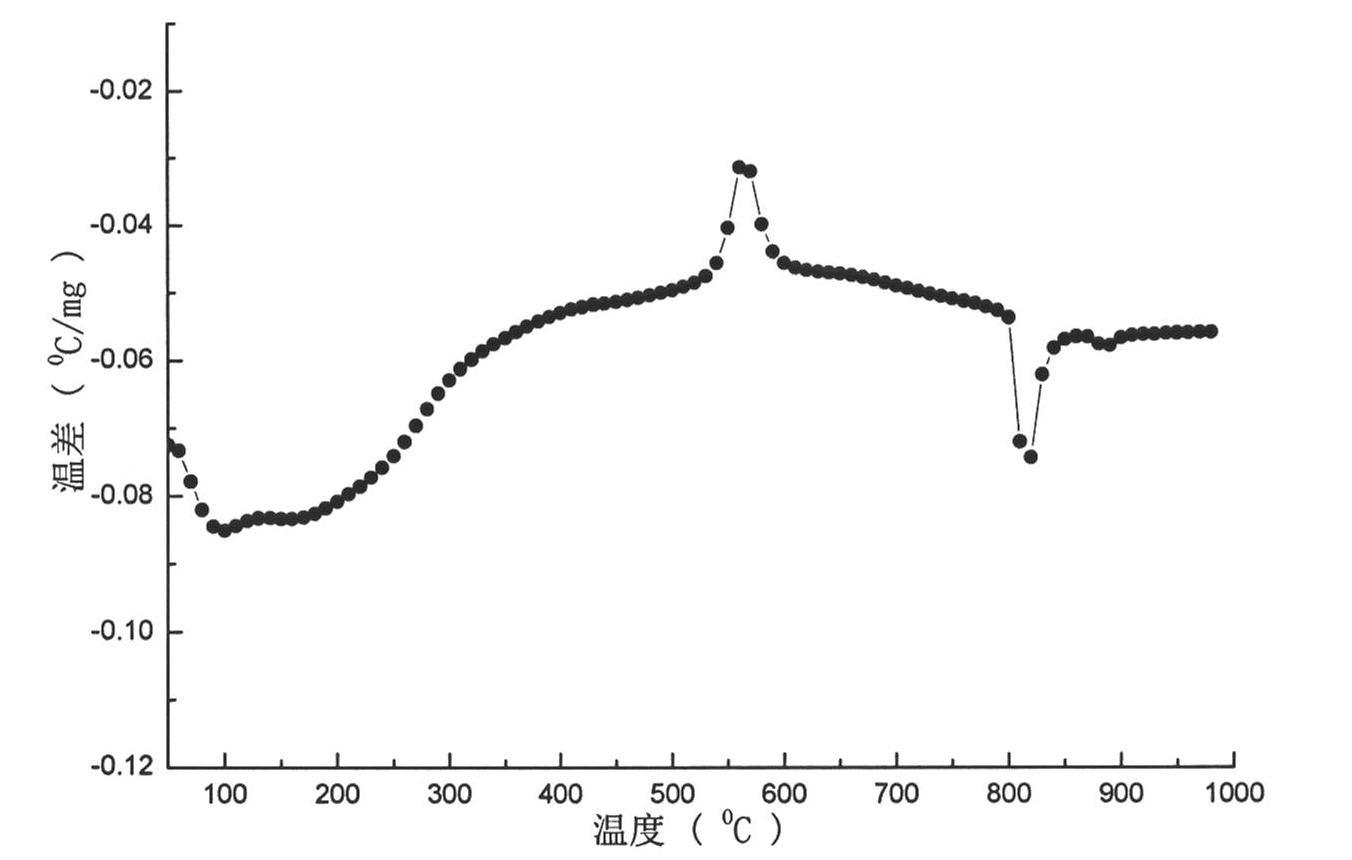

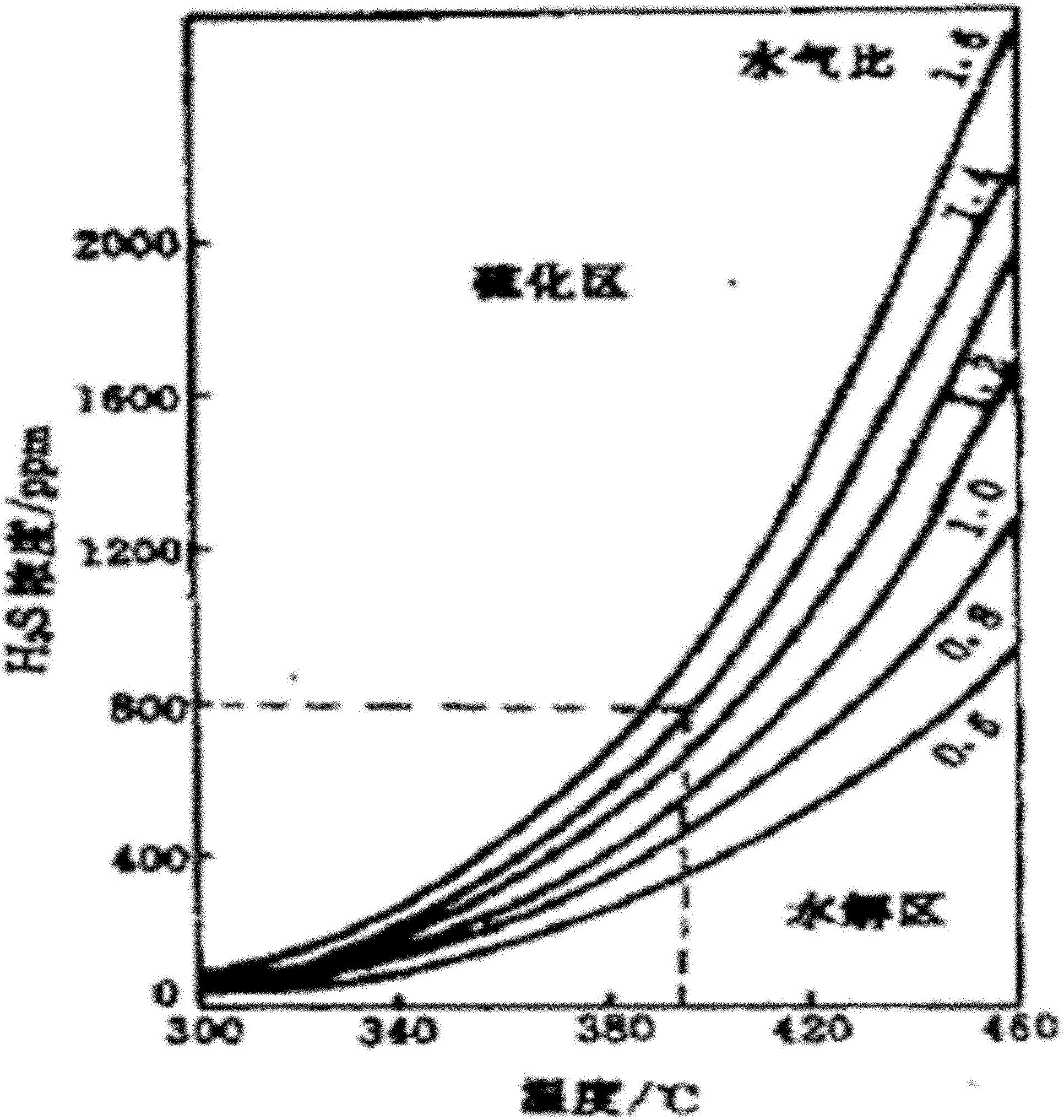

Novel CO sulfur-tolerant shift catalyst and preparation method thereof

ActiveCN102151574AStable vulcanization stateStable phase structureMetal/metal-oxides/metal-hydroxide catalystsCeriumLanthanum

The invention provides a novel CO sulfur-tolerant shift catalyst and a preparation method thereof, and a carrier of the catalyst is titanium dioxide; active ingredients comprise molybdenum and cobalt or / and nickel; and auxiliaries which refer to at least one compound of magnesium, calcium, zinc, zirconium, cerium and lanthanum also can be added in the carrier. The invention further provides the preparation method of the novel CO sulfur-tolerant shift catalyst. The catalyst has high shift activity and particularly has high low-sulfur activity and stable structure; furthermore, the catalyst has very high activity without performing prevulcanization before use, thereby simplifying the operation procedure; when the sulfur content in raw material is low (50ppm), sulfur does not need to be supplemented additionally; in addition, the catalyst further has excellent performances of anti-hydrate phase change and anti-sulfation, and can greatly expand the application range of the CO sulfur-tolerant shift catalyst.

Owner:SHANDONG QILU KELI CHEMICAL RESEARCH INSTITUTE CO LTD

Powder metallurgy refractory multi-principal-element high-entropy alloy and preparation method thereof

The invention relates to the technical field of powder metallurgy preparation of refractory metal materials, and specifically discloses a preparation method of a powder metallurgy refractory multi-principal-element high-entropy alloy. The preparation method of the powder metallurgy refractory multi-principal-element high-entropy alloy specifically comprises the following steps: step S1, refractory metal element powder is sieved through a 300-mesh sieve and mixed in a multi-element powder mixing mode, so that a mixture is obtained; the mixture comprises at least four elements of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W; the atomic percent of each element in the mixture is 5%-35%; and the total percentage is 100%; step S2, pressing forming is carried out, and a pressed blank is obtained; and S3, vacuum high-temperature solid-phase sintering is carried out to obtain a sintered block. The preparation method of the powder metallurgy refractory multi-principal-element high-entropy alloy has the advantages that the components are easy to regulate and control, the production efficiency is high, and near-net forming is achieved; the prepared powder metallurgy refractory multi-principal-element high-entropy alloy is stable in structure and performance and low in cost; and the powder metallurgy refractory multi-principal-element high-entropy alloy has remarkable advantages in research and development of high-performance powder metallurgy refractory multi-principal-element high-entropy alloy and flexible batch production of products of various shapes and varieties.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

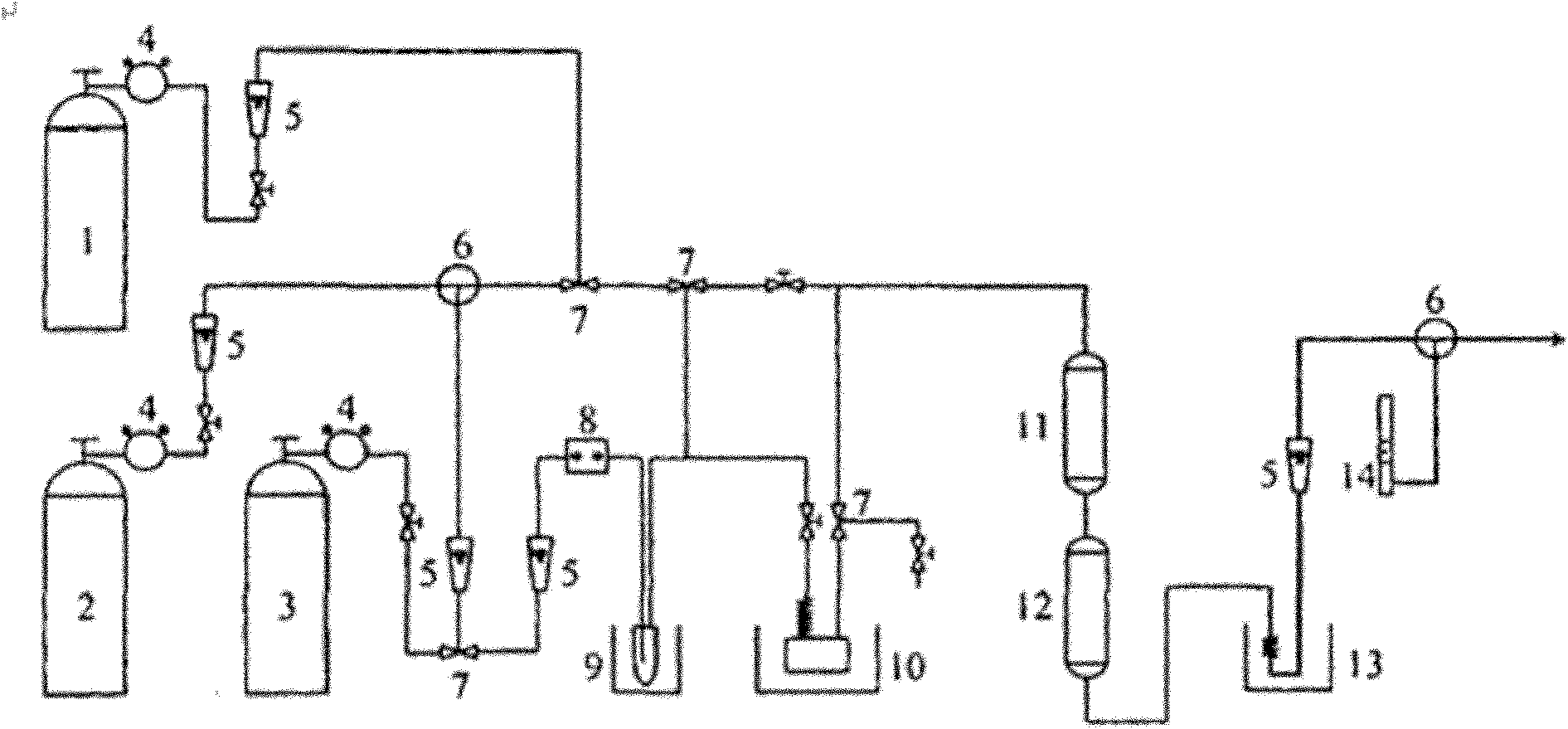

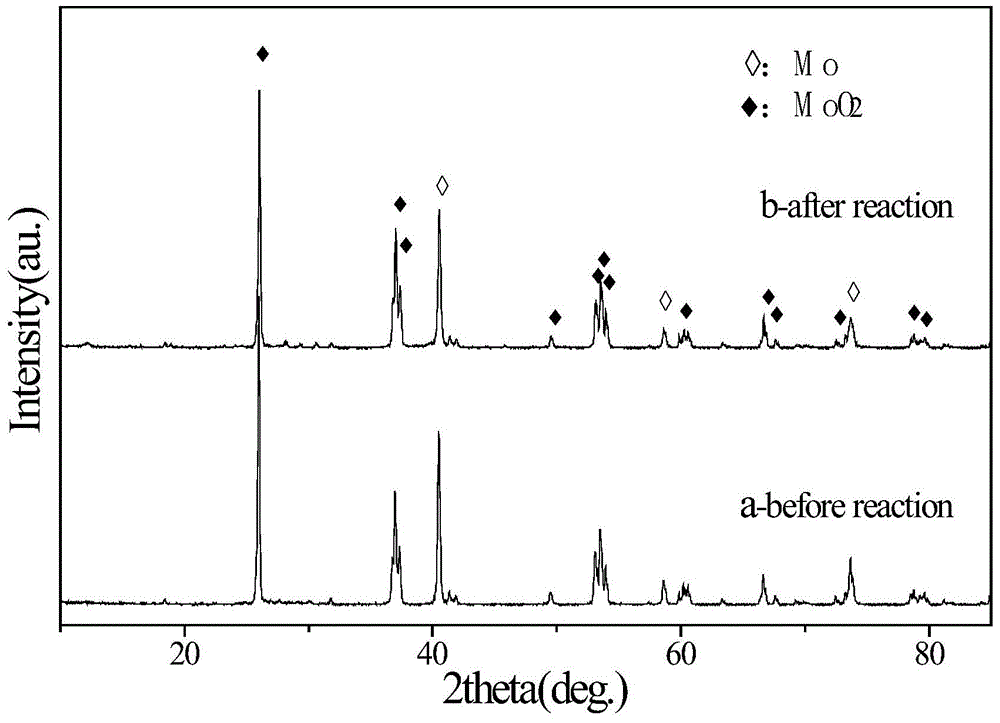

Composite molybdenum-based catalyst and preparation method and application thereof

InactiveCN104399473AHigh catalytic activityHigh selectivityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionActive component

The invention discloses a composite molybdenum-based catalyst. The composite molybdenum-based catalyst consists of an active component Mo and an auxiliary agent K, wherein molar percentages are as follows: 66.7-96.8% of Mo and 3.2-33.3% of K; Mo exists in a composite form of any two or three phases of a metallic state, oxide and carbide. The invention further discloses a preparation method of the composite molybdenum-based catalyst. The preparation method comprises the following steps: firstly, raising the temperature by using a controlled program to reduce and carbonize MoO3 powder; secondly, impregnating by a wet impregnation method; finally, grinding, tabletting and granulating the powder. The composite molybdenum-based catalyst has the benefits as follows: during CO hydrogenation reaction, the composite molybdenum-based catalyst has high catalytic activity and olefin selectivity, the CO single-pass conversion rate being higher than 80% and the olefin-paraffin ratio (O / P) being higher than 4.0, a product mainly comprises light hydrocarbons (C1-C5), C2-C4 olefins account for more than 49% of the total hydrocarbon content and the C5+ selectivity is lower than 15%; before and after the CO hydrogenation reaction, composite molybdenum-based catalyst is stable in phase structure and is suitable for long-term operation. The preparation method of the composite molybdenum-based catalyst is simple in preparation process and easy to control conditions and has relatively high repeatability.

Owner:NINGXIA UNIVERSITY

Phase change heat storage material and preparation method and application thereof

ActiveCN108504336AHigh heat storage densityStable phase structureHeat-exchange elementsInorganic saltsWax

The invention provides a phase change heat storage material. The phase change heat storage material is prepared from, by weight, 3-80% of inorganic salt, 30-50% of heat conduction oil, 3-80% of organic wax, 1-35% of water and 2-30% of a surfactant, wherein a mixture of diaromatic hydrocarbon ether and biphenyl is preferably selected as the heat conduction oil. By introducing a certain amount of heat conduction oil into the phase change heat storage material, the heat storage capacity of the material can be significantly improved, so that the material is higher in heat storage density which isup to 260 kJ / kg, larger in heat conductivity coefficient and more sensitive to the ambient temperature; moreover, the particle size of microemulsion particles in the obtained phase change heat storagematerial is larger and more uniform, and therefore the material is more stable to store.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

A kind of sb‑te‑w phase change target material for phase change storage and its preparation method

ActiveCN103898452BAvoid lossAvoid stabilityElectrical apparatusVacuum evaporation coatingPhase-change memoryHigh density

The invention relates to a Sb-Te-W phase-change target material for phase-change storage and a preparation method thereof. The Sb-Te-W phase-change target material has a general chemical formula of SbxTeyW1-x-y, and in the general chemical formula, x is >0 and <1, y is >0 and <1, the sum of x and y is <1, x / y is >=0.67 and <=4 and a mass fraction of W is <=10%. An intermediate compound is synthesized by a sheath seal vacuum melting synthesis technology and the Sb-Te-W phase-change target material is prepared by a bidirectional compaction vacuum hot-pressing sintering technology. The preparation method can effectively solve the problem that in alloy melting, material components are nonuniform because of difference of component melting points and densities, and can produce the Sb-Te-W phase-change target material having high density, high stability and high purity. Compared with the existing Ge2Sb2Te5 materials used widely, the Sb-Te-W phase-change target material has a high crystallization temperature and a low melting point and has good heat stability and good data retention when being used as a phase-change storage material.

Owner:GRIMAT ENG INST CO LTD

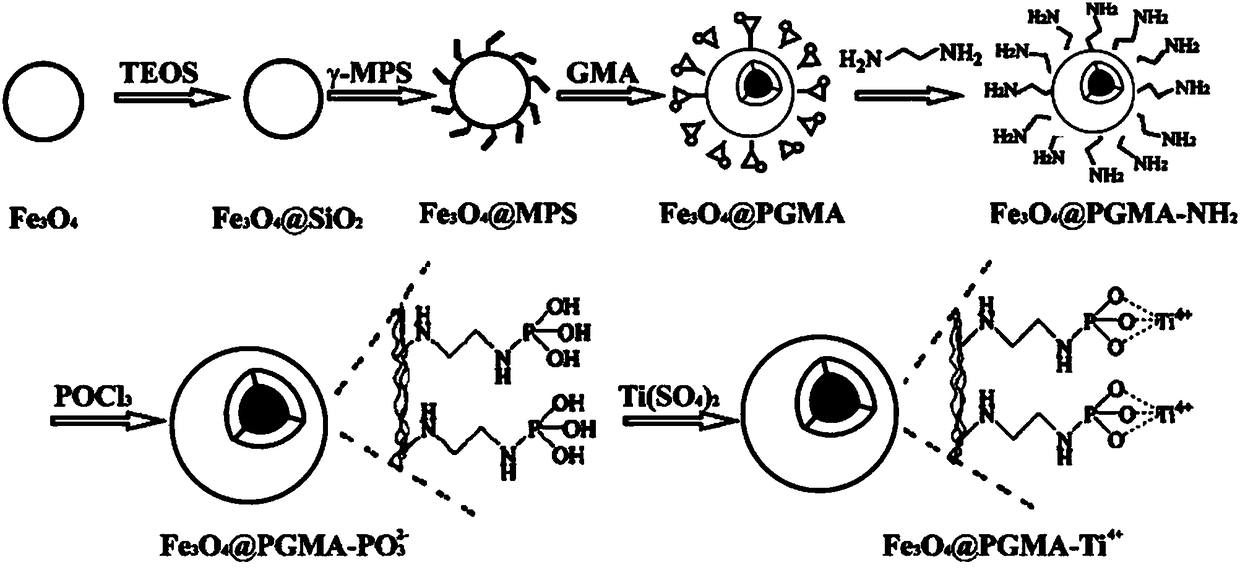

Preparation and application method of combined nano magnetic separating medium

InactiveCN109382076AEasy to prepareLow costOther chemical processesAlkali metal oxides/hydroxidesPretreatment methodDesorption

The invention discloses preparation and application method of a combined nano magnetic separating medium. Nano magnetic separating mediums with different characteristics are combined so as to enrich and separate components with different polarity characteristics in a complicated system at a time. A magnetic nano material matrix with a porous structure or a pore-free structure is modified to prepare nano magnetic separating mediums with different characteristics. Different kinds of separating materials are combined to form a mixed separating medium with special selectivity, and the separating medium has high adsorption selectivity and adsorption capacity on different target components. Through a magnetic separation technology, the nano magnetic separating medium with adsorbed target components is separated from the matrix of a complicated sample, and after heat desorption, quantitative analysis and qualitative analysis are performed by GC / MS. The provided combined nano magnetic separating medium can high-selectively and efficiently collect and enrich target compounds, the preprocessing method is convenient and efficient, the stability of the method is good, and the method can be conveniently and effectively adjusted so as to enrich specific target components in different samples.

Owner:APPLE FLAVOR & FRAGRANCE GRP

Environment-friendly high-tech powder material for ceramic roller and preparation method of powder material

The invention relates to an environment-friendly high-tech powder material for a ceramic roller. The powder material is prepared from the following raw materials in parts by weight: 100 parts of high-purity fused quartz powder, 20-50 parts of aluminum-doped zinc oxide, 25-35 parts of lanthanum strontium manganese oxide, 10-18 parts of titanium diboride, 20-30 parts of boron carbide, 5-8 parts of carbon black and 8-15 parts of aluminum oxide. The preparation method comprises the following steps: weighing the raw materials in parts by weight according to the formula, putting the raw materials into a planetary ball mill for ball milling for 4-5 hours, and drying to obtain a mixed powder; and then putting the mixed powder into a plasma activation calcining furnace to be calcined for 1 to 2 hours so as to obtain the environment-friendly high-tech powder material for a ceramic roller. The powder material disclosed by the invention is a novel functional ceramic powder material and can be used as a powder material for a dielectric and piezoelectric multiphase quartz ceramic roller; and the multiphase quartz ceramic roller disclosed by the invention has the advantages of high temperature resistance, water vapor resistance, good dielectric property and piezoelectric property, stable phase structure, good uniformity, high compactness and stable and superior performance, and has great production benefits and practical values.

Owner:徐州亚苏尔高新材料有限公司

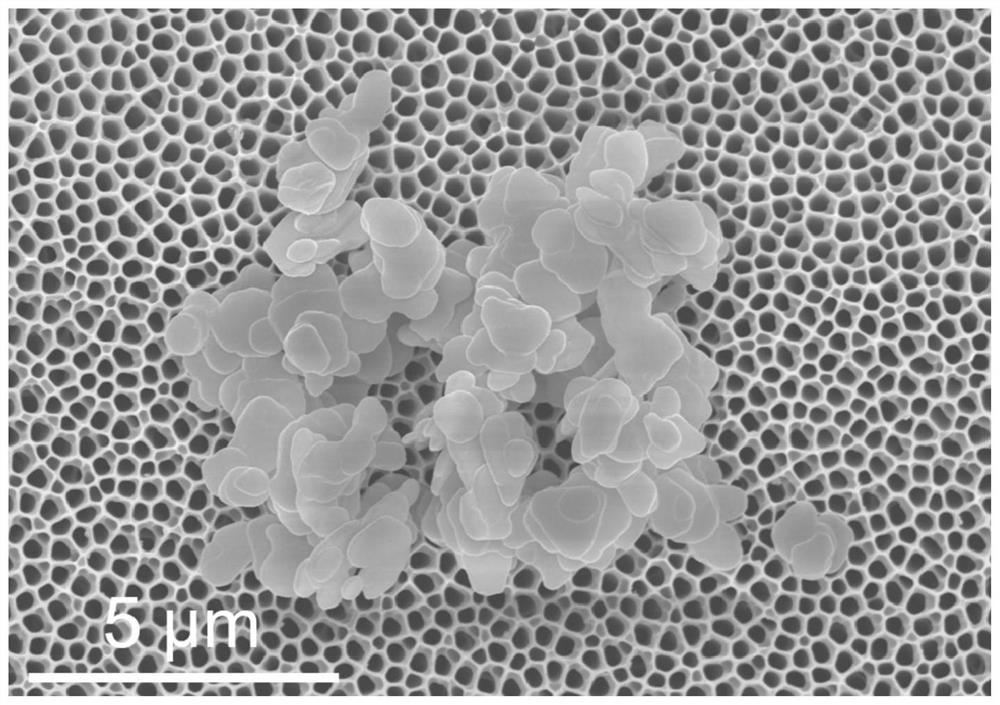

Zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material with layered structure and capable of being operated at medium and low temperature as well as preparation method and application of zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material

ActiveCN113578071AImprove proton conductivityEvenly dopedSemi-permeable membranesDispersed particle separationElectrical conductorPhysical chemistry

The invention discloses a zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material with a layered structure and capable of being operated at medium and low temperatures as well as a preparation method and application of the zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material. The chemical general formula of the mixed conductor hydrogen permeation membrane material is Zr<1-x> MxP2O<7-delta>, wherein M is one of Mg and Cu; and delta is a non-stoichiometric ratio, x is greater than or equal to 0 and less than or equal to 0.5, and delta is greater than or equal to 0 and less than or equal to 1. As the zirconium pyrophosphate-based compound has a stable phase structure in a wide temperature range (200-600 DEG C), the mixed conductor hydrogen permeation membrane material still keeps a local layered structure after being sintered at high temperature, and a rapid proton transfer channel formed between layers further increases the hydrogen permeation amount of the membrane material. The zirconium pyrophosphate-based mixed conductor hydrogen permeation membrane material with the layered structure prepared by the preparation method disclosed by the invention shows very high hydrogen permeation quantity and good chemical stability at medium and low temperatures.

Owner:SOUTH CHINA UNIV OF TECH

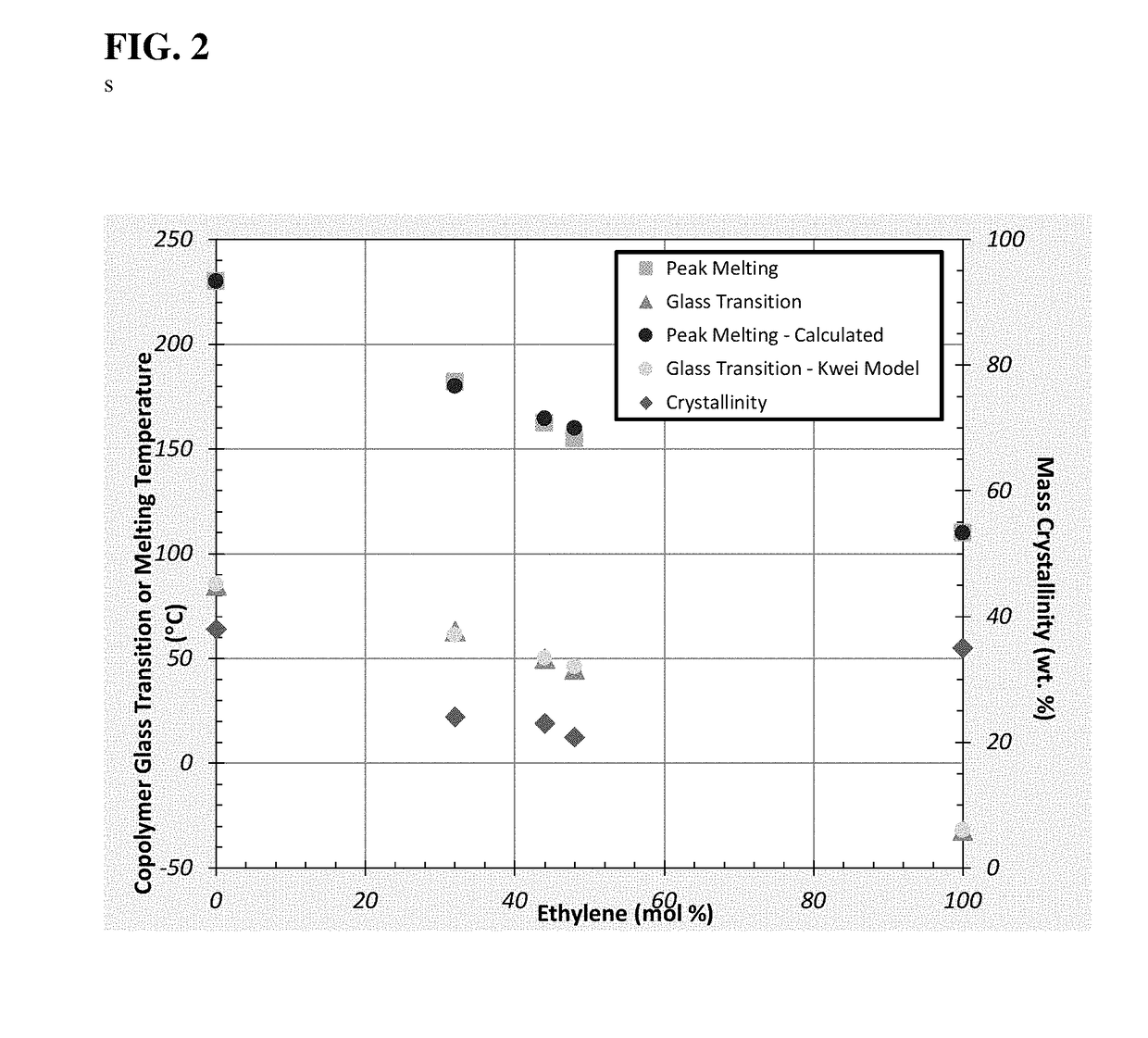

Barrier laminate material with improved heat sealability and reduced flavor scalping

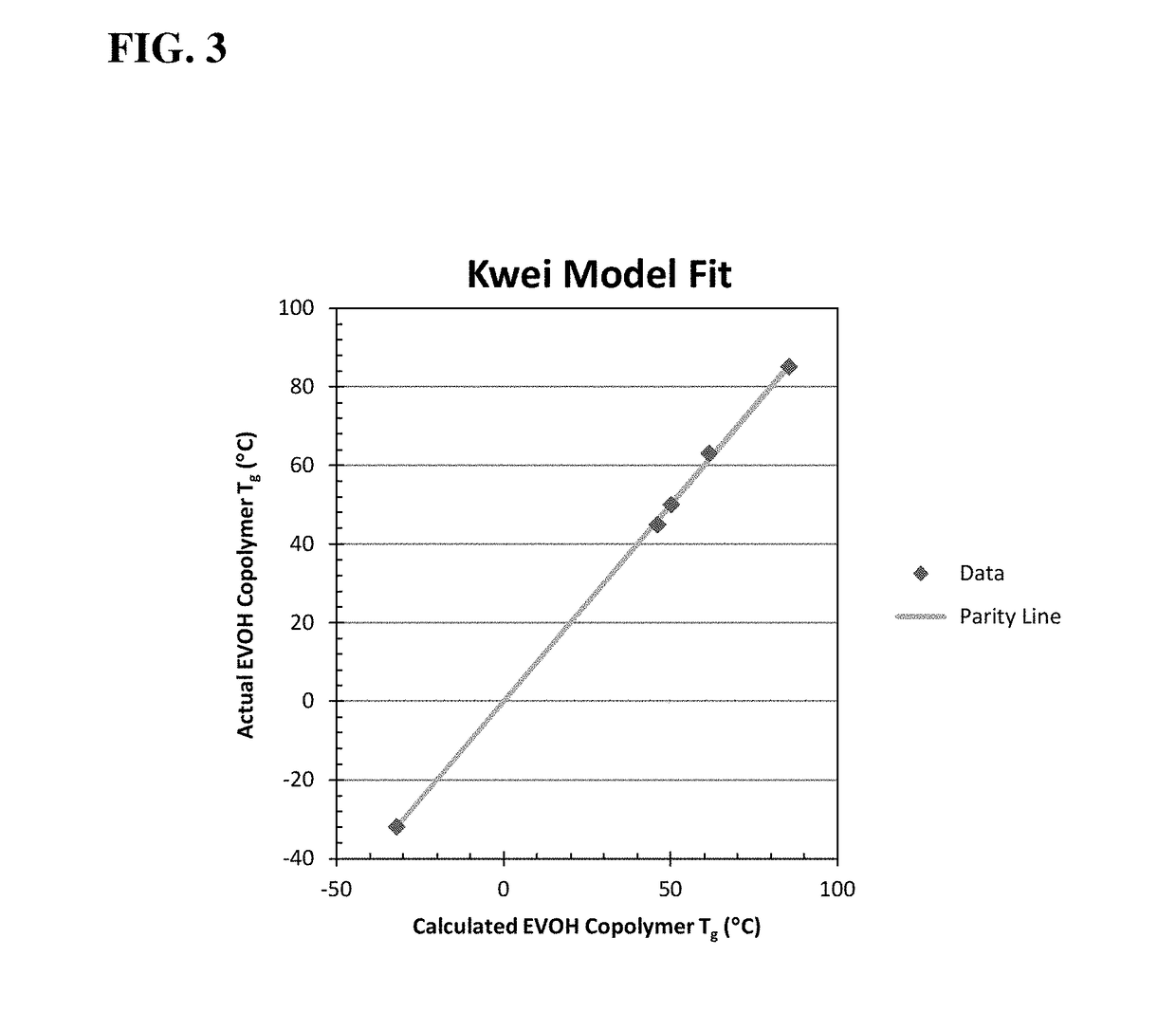

ActiveUS20180281365A1Avoid product qualityLow flavorSynthetic resin layered productsBagsChemical compositionMoisture

This disclosure provides new heat sealable, barrier laminate packaging structures used for beverage component pouches or cartridges, including new structures and chemical compositions of the pouch made to contain the beverage base, component, or component concentrate. These structures and compositions used for heat sealable, barrier laminate packaging balance good heat sealability with improved performance for flavor scalping, oxygen permeability, and / or undesirable moisture ingress or egress, which affect the stability and useful life of the pouch or cartridge and its contents.

Owner:THE COCA-COLA CO

Powder metallurgy refractory multi-principal element high-entropy alloy and its preparation method

ActiveCN113549780BSimple processLow costTransportation and packagingMetal-working apparatusHigh entropy alloysMetallic materials

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

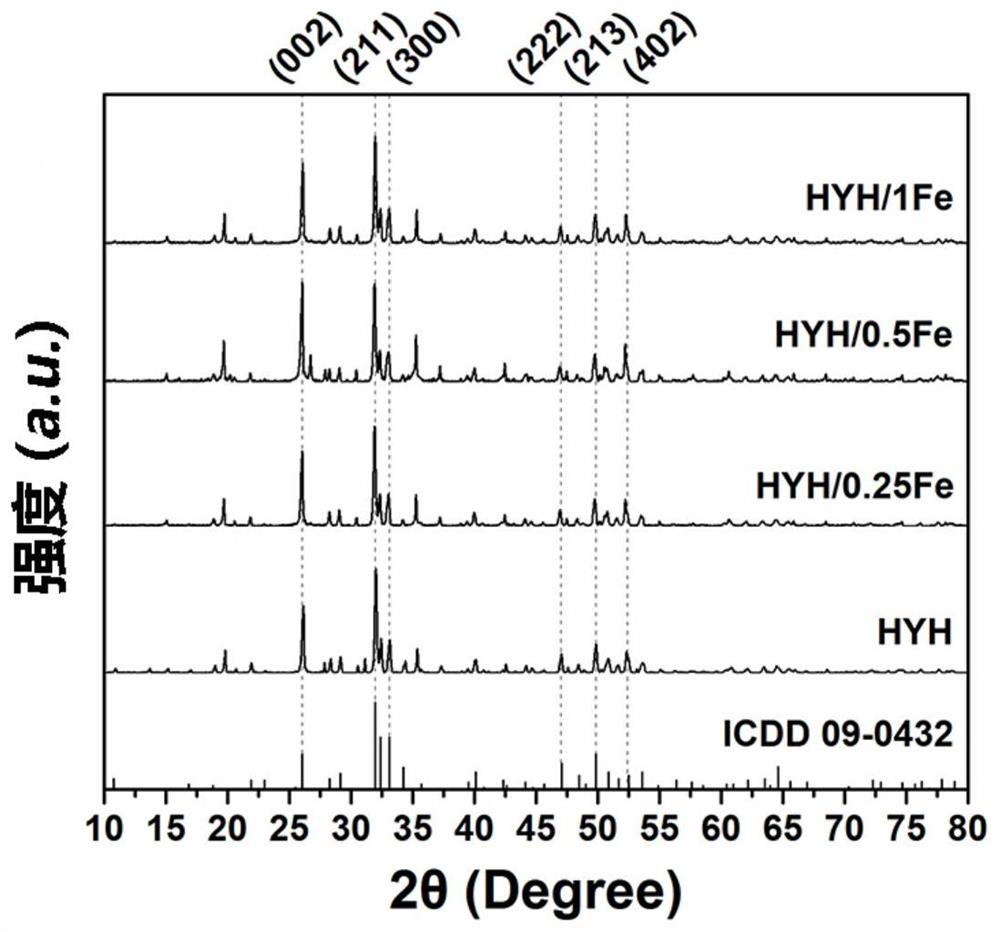

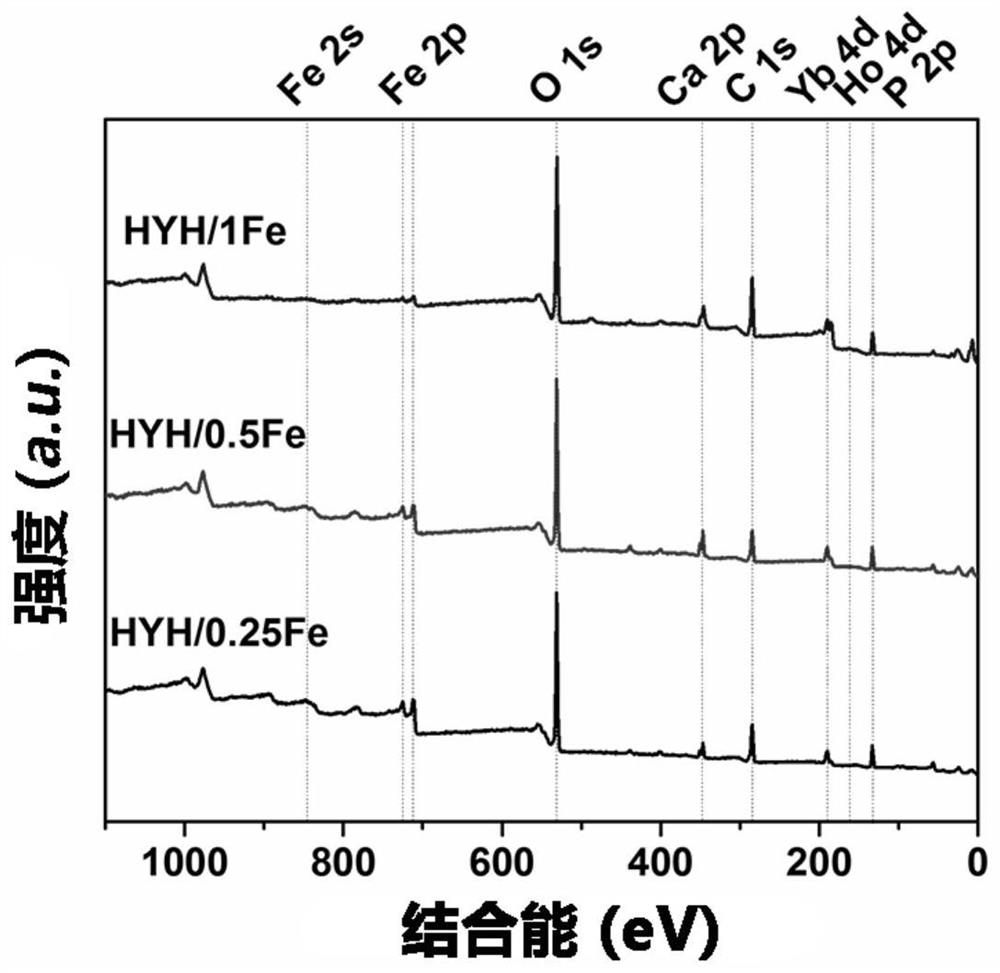

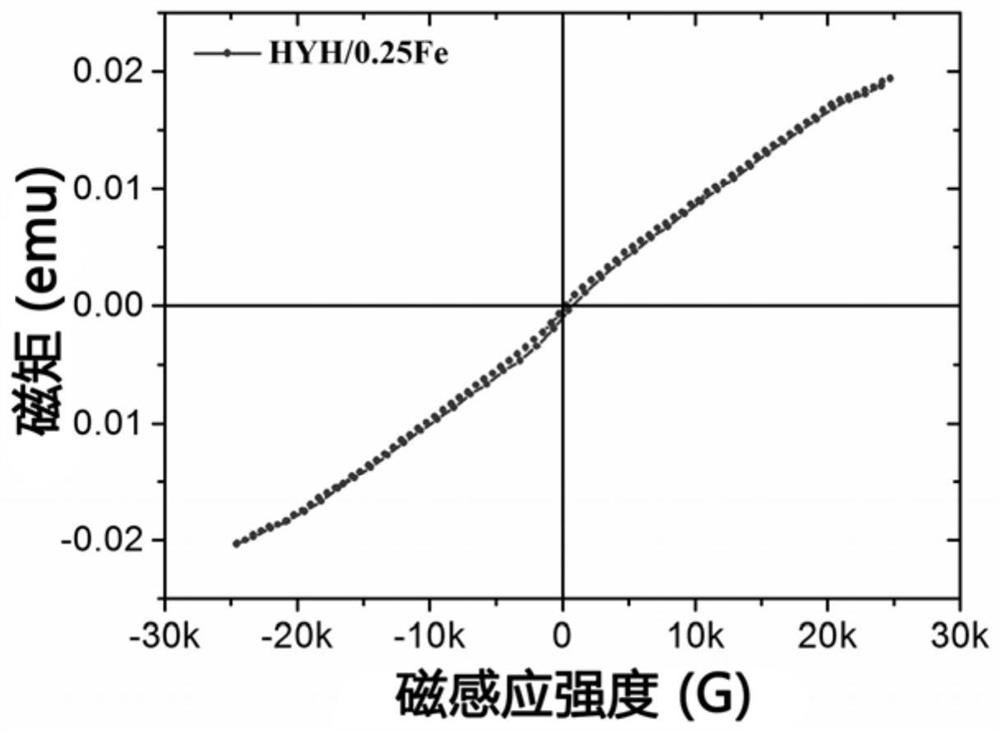

Hydroxyapatite powder with upconversion fluorescence and superparamagnetism and preparation method thereof

ActiveCN108219788BUpconversion fluorescence performance with little interferencePromote proliferationInorganic material magnetismTissue regenerationSuperparamagnetismParamagnetism

The invention discloses hydroxyapatite powder with up-conversion fluorescence and superparamagnetism and a preparation method thereof. The preparation method adopts a step-by-step hydrothermal synthesis technology and specifically comprises the following steps: step 1, preparing hydroxyapatite powder HA:Ln1+Ln2 rich in two or more rare earth ions and up-conversion fluorescence with adjustable luminous color by hydrothermal synthesis; and step 2, performing hydrothermal reaction to realize exchange between iron ions and HA crystal surface cations (Ca<2+> and / or Ln<3+>) so as to obtain HA:Ln1+Ln2 / Fe powder with superparamagnetism. The obtained hydroxyapatite powder has high up-conversion fluorescence intensity and strong penetrability under the excitation of near infrared light and can avoidtissue autofluorescence interference; and furthermore, the obtained hydroxyapatite powder has superparamagnetism under the action of an external magnetic field, thereby being favorable for promotingcell proliferation and osteogenesis. The hydroxyapatite powder has wide application prospects in the aspects of biomedicine fundamental research, development of high-performance bone and tooth repairmaterials, osteogenesis promotion, in vivo tracing research of biological materials, and the like.

Owner:SICHUAN UNIV

A preparation process for zrcrfe/alcrfetizr composite gradient alloy coating for anti-high temperature oxidation on the surface of zirconium alloy

ActiveCN107513694BImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

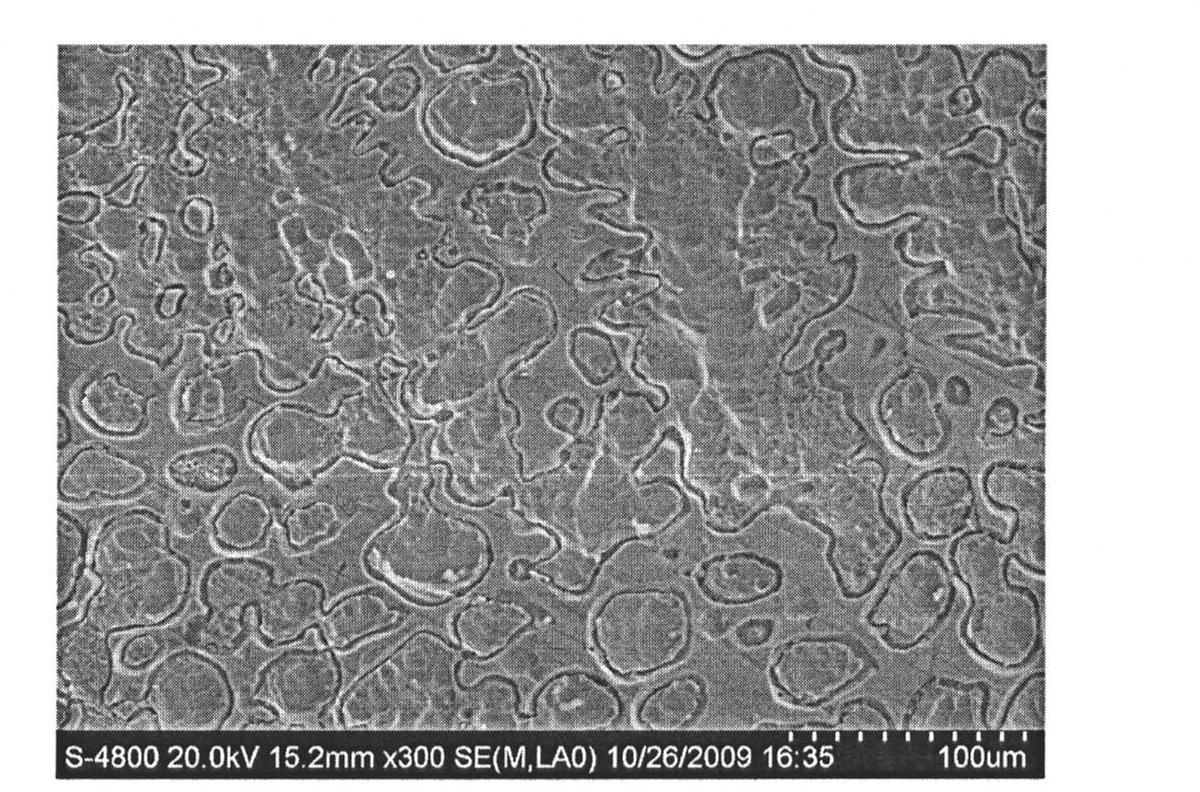

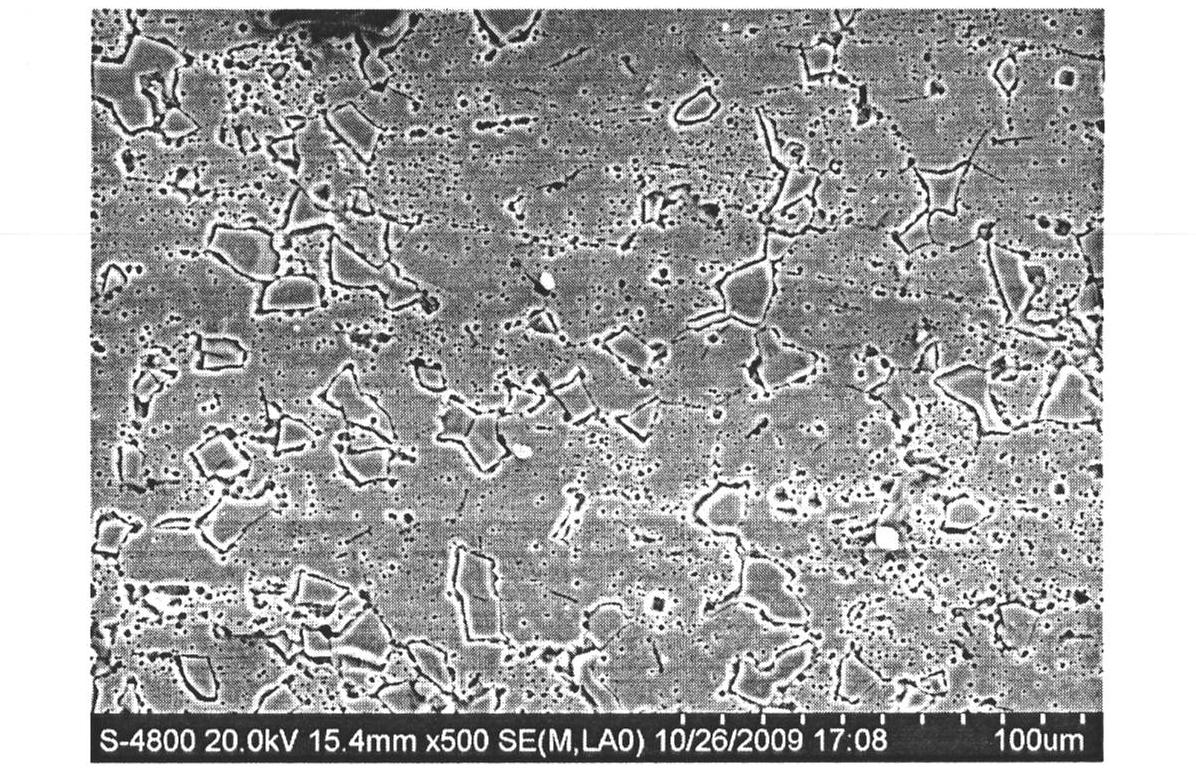

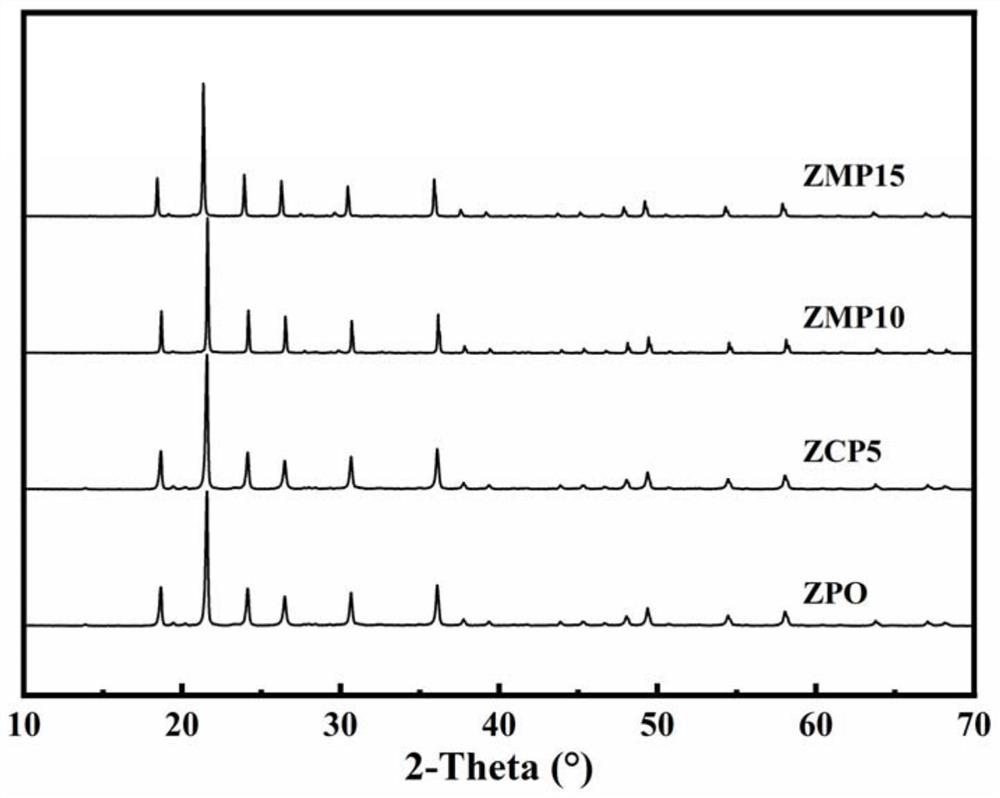

A kind of polyoxymethylene/polylactic acid SERS polymer substrate and its preparation method and application

ActiveCN106498716BFast crystallization rateEffective control of apertureFibre typesRaman scatteringComposite filmRhodamine 6G

The invention discloses a polyoxymethylene / polylactic acid (POM / PLLA) SERS polymer substrate and its preparation method and use. The POM / PLLA SERS polymer substrate comprises a POM / PLLA composite film and metal nanoparticles carried by the surface of the POM / PLLA composite film. The POM / PLLA composite film has a micron-order spherocrystal structure. After an aminolysis reaction, the ring-banded spherulitic structure has nanoscale holes. The POM / PLLA melt blended film and an amino group modifier undergo a reaction so that an amino functional group is introduced and simultaneously, POM / PLLA blended film porous formation is realized. The POM / PLLA SERS polymer substrate can be used in rhodamine 6G and glucose detection. Compared with the existing detection limit, the sensitivity of the polymer substrate is high and the rhodamine 6G detection limit of the polymer substrate can reach 10-19mol / L.

Owner:HANGZHOU NORMAL UNIVERSITY

A kind of preparation method of BSAS composite ceramic powder

ActiveCN104003697BProcess raw materials are cheapThe process is simple and easy to controlMolten spray coatingComposite ceramicCrystallinity

The invention discloses a preparation method of a composite ceramic powder material used for an environmental barrier coating. The composite ceramic powder is composed of single phase BSAS (1-xBaO-xSrO-Al2O3-2SiO2, x is more than 0 and less than 1). The obtained BSAS composite ceramic powder has the advantages of easiness for ingredient control, high purity, high crystallinity and low synthesis temperature. The composite ceramic powder can be used for plasma spraying after being subjected to ball milling, agglomeration, pelletizing and high-temperature heat treatment, so that the environmental barrier coating is prepared on the surface of a C / C-SiC composite material, the coating can be used for effectively improving high-temperature water oxygen corrosion resistance performance of a C / C-SiC matrix, is applicable to surface high-temperature protection of other silicon substrate materials, can be used for solving the problem of high-temperature water oxygen corrosion of a silicon substrate composite material and has an important application value.

Owner:CENT SOUTH UNIV

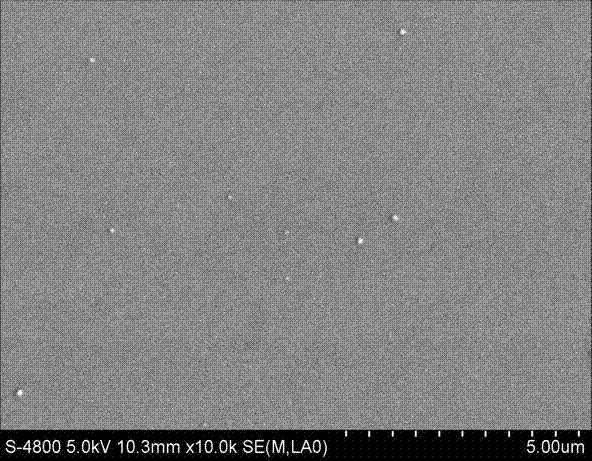

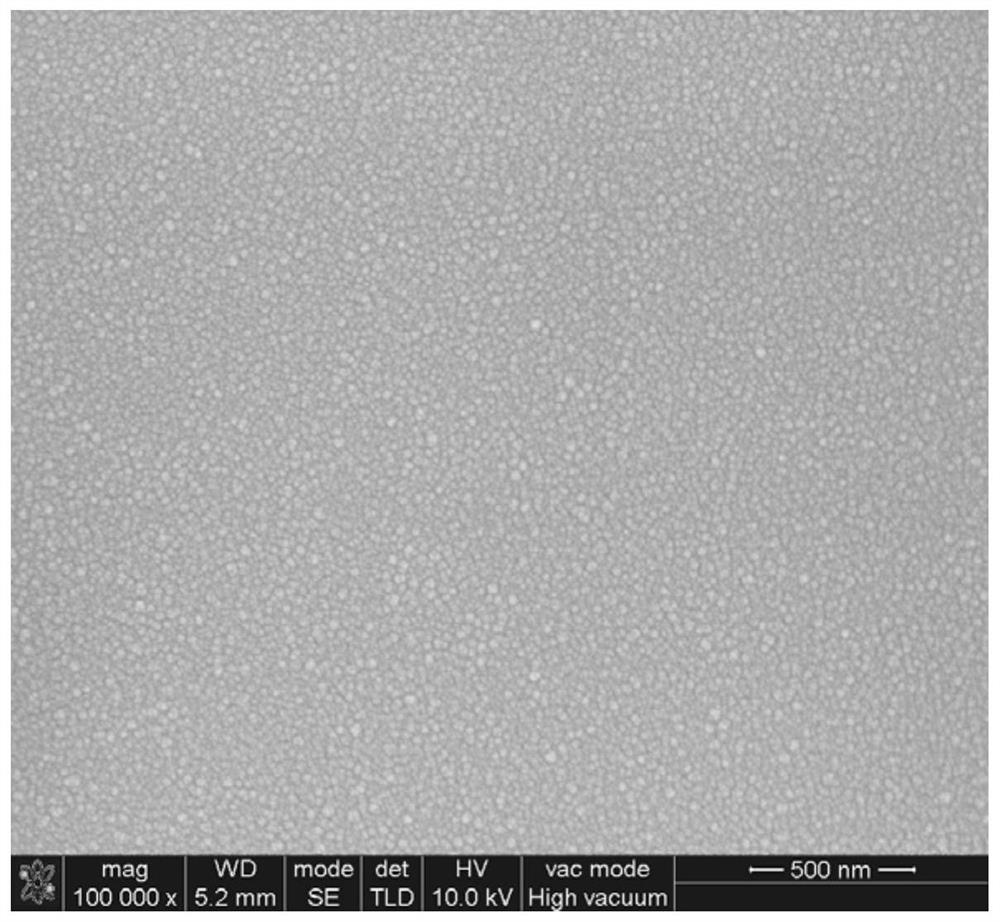

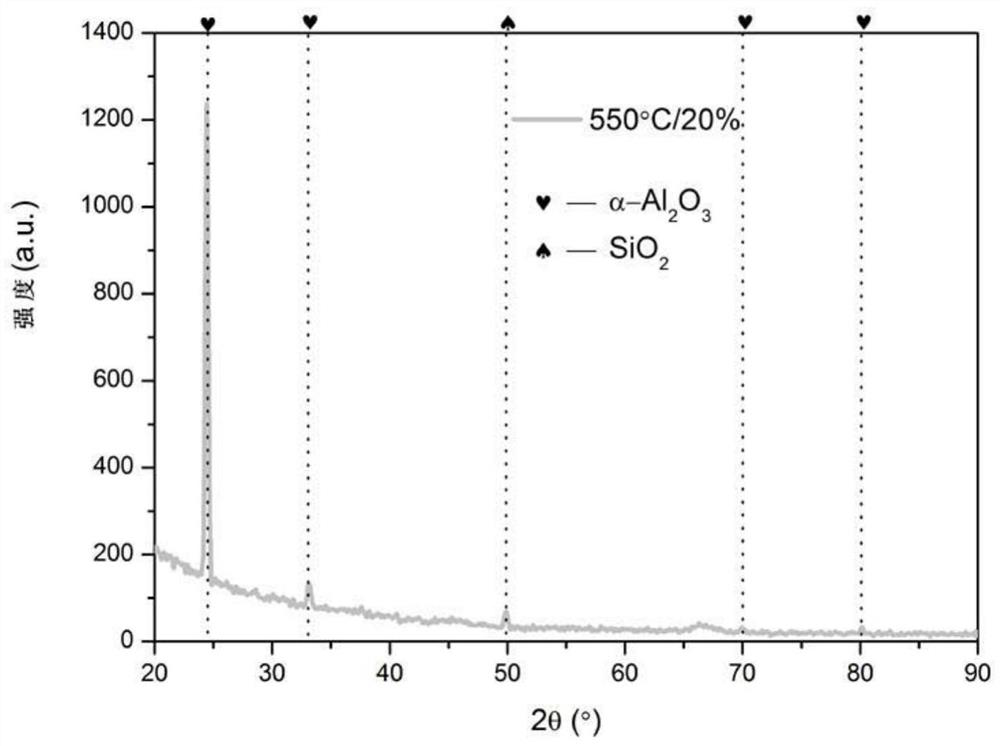

A low-temperature reactive sputtering deposition of nano-α-al 2 o 3 coating method

InactiveCN108411262BStable α-phase structurePrevent Adhesive WearVacuum evaporation coatingSputtering coatingAl powderRadio frequency magnetron sputtering

The invention belongs to the technical field of metal oxide coatings and discloses a method for low-temperature reactive sputtering deposition of a nanometer alpha-Al2O3 coating. The method comprisesthe following steps: manufacturing Al powder and alpha-Al2O3 powder into a composite material through a powder metallurgy method; after cutting the composite material to reach the size required for equipment, mounting the composite material of the required size on a target station for radio frequency magnetron sputtering as a deposition target material, and mounting a workpiece substrate on a sample table in a deposition cavity; after removing residual steam in the deposition cavity, vacuumizing to achieve base pressure, and then injecting a gas mixture of Ar and O2 for pre-oxidation treatment; and adjusting the partial pressure of O2 in the gas mixture of Ar and O2 to reach the range of 15% to 25%, adjusting the temperature of the workpiece substrate to reach the range of 550 DEG C to 750DEG C, starting a radio frequency magnetron sputtering film coating system, and starting reactive deposition so as to obtain the nanometer alpha-Al2O3 coating. The nanometer alpha-Al2O3 coating obtained through the method disclosed by the invention is of a nanocrystalline structure, is high in toughness, can be firmly combined with the workpiece substrate, and has a stable alpha-phase structure at relatively low temperature.

Owner:SOUTH CHINA UNIV OF TECH +1

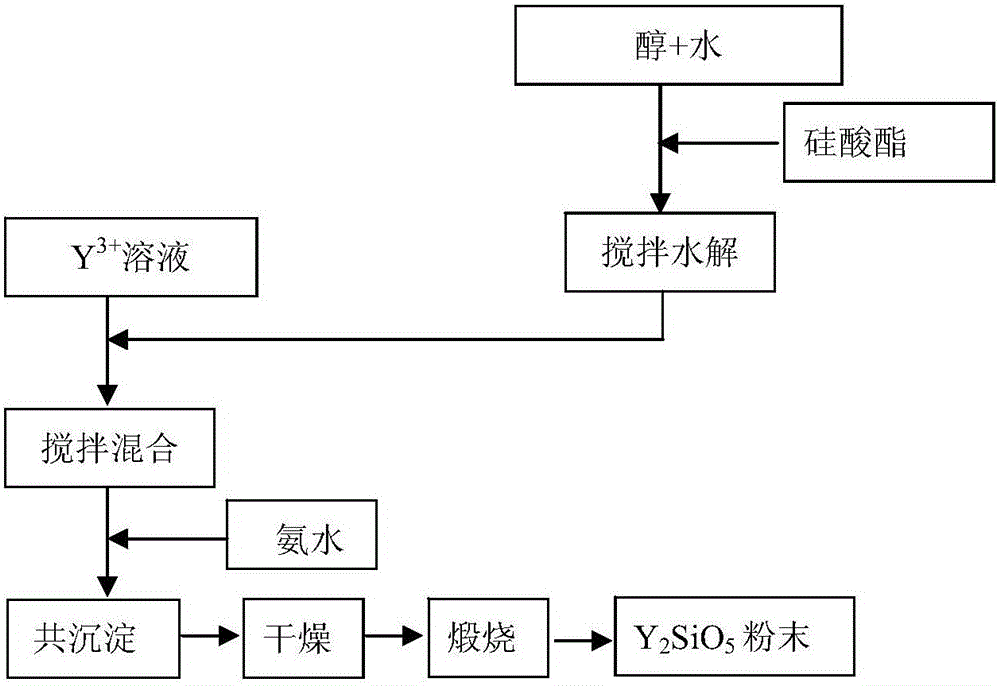

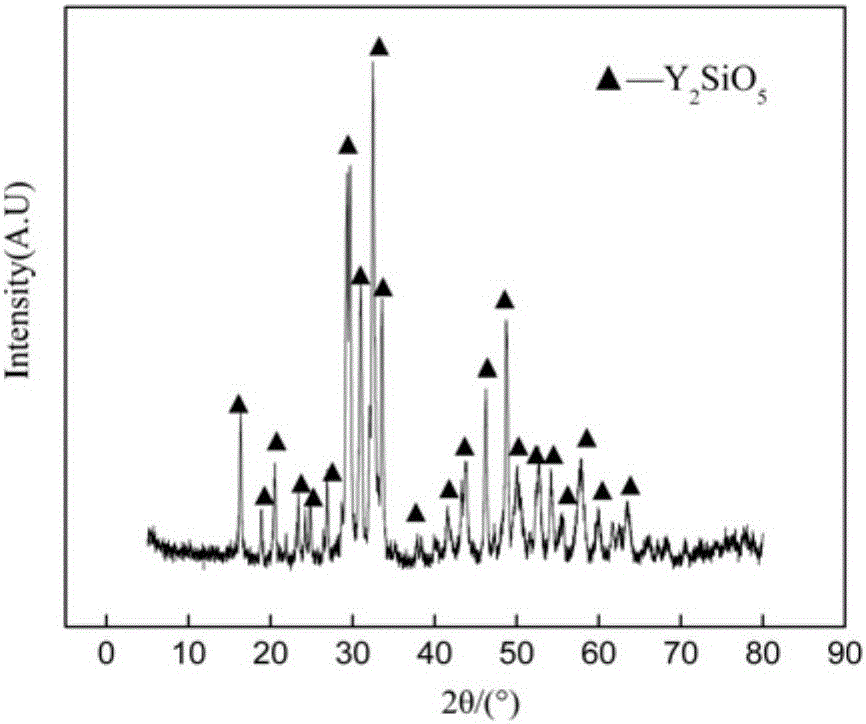

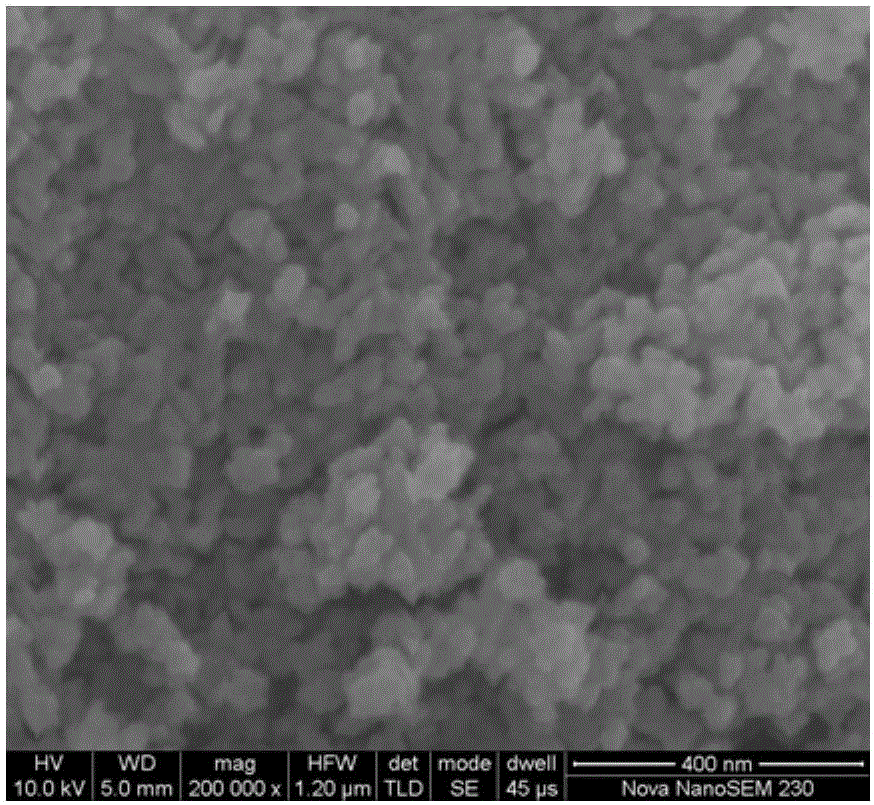

A kind of preparation method of yttrium silicate ceramic powder

ActiveCN104003699BStable pHGuaranteed GranularityMolten spray coatingOxide ceramicMaterials preparation

The invention relates to a preparation method of yttrium silicate ceramic powder, in particular relates to a preparation method of yttrium silicate ceramic powder for environment barrier coating, and belongs to the technical field of oxide ceramic material preparation. The method comprises the following steps: using a yttrium solution with Y<3+> ion concentration of 0.6-1.5 mol / L as solution A; weighing silicate ester according to a molar ratio of Y to Si being 2: 1; adding alcohol and water in the weighed silicate ester according to a volume ratio of the silicate ester to alcohol to water being 1: 1-2: 2-6 to obtain solution B; uniformly mixing the solutions A and B solution to obtain the mixed solution containing aluminum and silicon; adding the mixed solution containing aluminum and silicon into ammonium hydroxide with pH value of 9-10 at a speed of dropwise adding 0.2-0.5 L of the mixed solution containing aluminum and silicon in 1L of precipitator every minute, and stirring to obtain the co-precipitate; after the reaction is finished, standing, filtering, washing and drying the residue, calcining for at least 4 hours at 800-1000 DEG.C to obtain the Y2SiO5 ceramic composite powder. The method provided by the invention is short in reaction period and good in repeatability; and the obtained product is high in purity and is of a single crystal form.

Owner:CENT SOUTH UNIV

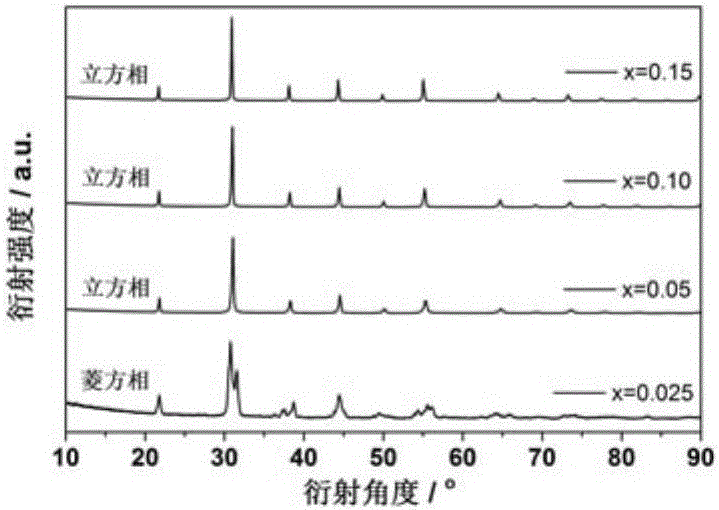

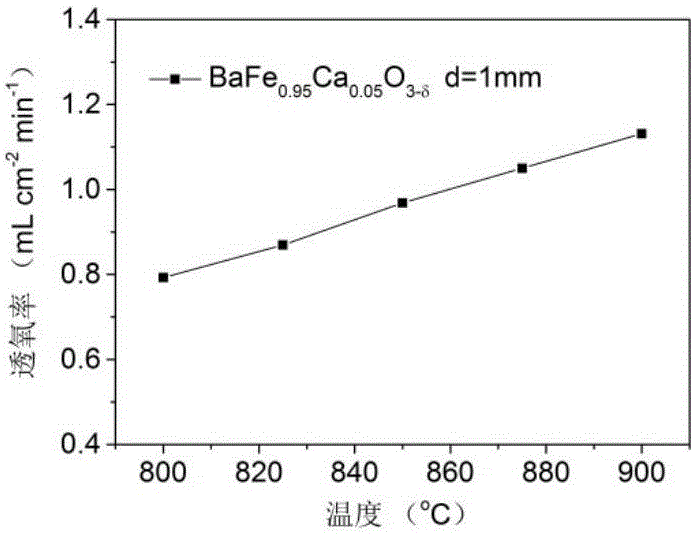

bafeo doped with ca element at b site 3-δ Ceramic based oxygen permeable membrane material

ActiveCN104258740BStable phase structureHigh oxygen permeabilitySemi-permeable membranesRare-earth elementPartial oxidation

The invention discloses a kind of BaFeO doped with Ca element at the B site 3‑δ The invention relates to a ceramic-based oxygen-permeable membrane material and relates to an inorganic oxygen-permeable membrane material. Its invention is characterized in that: for perovskite BaFeO 3‑δ Materials, for the first time doped Ca with a large radius and low valence state at the B site 2+ ions to improve the structural stability of the material. The "lattice stress effect" is used to increase the oxygen vacancy concentration of the material and improve the oxygen permeability of the material. At the same time, the Ca-containing raw material is cheaper than other rare earth metal element dopants, which can effectively control the production cost of the oxygen-permeable material. Molecular formula is BaFe 1‑ x Ca x o 3‑δ , where x=0.02‑0.5. The present invention prepares B-site doped Ca 2+ Element's low-cost oxygen-permeable membrane material has a compact structure, high oxygen permeability and good structural stability. It is an oxygen-permeable membrane material with excellent performance and can be applied to continuous oxygen supply for partial oxidation of methane and other oxygen-containing gases. Industrial process for oxygen separation and purification in China.

Owner:UNIV OF SCI & TECH BEIJING

Preparation process of high temperature oxidation resistant zrnx/(zralfe)n/(zralfem)n composite gradient coating

ActiveCN109207953BReduce internal stressImprove the interface binding forceVacuum evaporation coatingSputtering coatingOxidation resistantZr alloy

The invention discloses a preparation process of a zirconium alloy surface high-temperature oxidization resistant ZrNx / (ZrAlFe)N / (ZrAlFeM)N composite gradient coating, wherein M is any two kinds of elements in Ti, V and Nb. The concrete process comprises the steps of substrate pretreatment, target material cleaning, ZrNx / (ZrAlFe)N / (ZrAlFeM)N composite coating deposition and the like. The compositecoating preparation is performed in two steps; in the first step, a ZrNx / (ZrAlFe)N gradient transition layer is prepared; firstly, a Zr coating is deposited for 3min on the substrate; then, N2 is gradually introduced at the flow from 0sccm to 6sccm for depositing ZrNx, wherein the flow rate of N2 is 2sccm / min; then, continuous transition is performed to (ZrAlFe)N; in the second step, a (ZrAlFeM)Nmulti-component nitride layer is prepared. In the decomposed (ZrAlFe)N transition layer, the Zr element atom content is in gradient change from 100 at percent to 30 at percent in the thickness direction; the Al and Fe element atom contents are in gradient change from 0 at percent to 35 at percent in the thickness direction; the Zr, Al, Fe and M element atom contents in the decomposed (ZrAlFeM)N multi-component nitride layer are between 10 at percent and 35 at percent; the N element atom content is between 5 at percent and 20 at percent. The process has the characteristics that through the design of a structure with the coating in the gradient change state, the residue stress in the coating can be relieved; the high-temperature oxidization resistance performance is realized; the mechanicalproperty is excellent, and the like.

Owner:田海军

A kind of preparation method of high-strength toughness high-entropy alloy

ActiveCN113122763BHigh strengthIncrease stacking fault energyHigh entropy alloysUltimate tensile strength

The invention discloses a method for preparing a high-strength toughness high-entropy alloy, which relates to the technical field of alloy material production; the specific steps are: configuring Mn with an atomic percentage of 27-30%, Co with 8-12%, Cr with 8-12% and 0.4 ~1.3% C, the rest is high-entropy alloy powder of Fe; the high-entropy alloy powder is ball-milled, and then pre-pressed, the pressure is 300-500MPa, and the pressure is maintained for 200-300s to obtain a pre-pressed block of the high-entropy alloy; The pre-pressed block is vacuum annealed, vacuum hot-pressed and sintered, and then cold-rolled and deformed; the cold-rolled and deformed high-entropy alloy sheet is subjected to a restricted carbon distribution treatment at 400-550 ° C to diffuse free carbon elements; the present invention prepares a compound containing The non-isoatomic FeMnCoCrC high-entropy alloy of C has excellent strength and plastic bonding, and at the same time improves the problem of uneven composition and unstable structure of the high-entropy alloy prepared by the traditional process.

Owner:ZHONGBEI UNIV

Preparation method of rare earth surface modified aluminum nitride powder

The invention discloses rare earth surface modified aluminum nitride powder and preparation method thereof, and relates to a modifying method of aluminum nitride powder. The rare earth surface modified aluminum nitride powder disclosed by the invention aims at solving the technical problems that the performance of a composite material using AlN as a reinforcement phase is influenced since impurity elements are introduced into the existing modified AlN powder and the modified AlN power and the metal are non-wetting. The rare earth surface modified aluminum nitride powder is aluminum nitride powder coated by rare earth oxide. The preparation method comprises the following steps: step one, preparing a rare earth nitrate solution; step two, adding the AlN powder in the rare earth nitrate solution, dropwise adding strong ammonia water while stirring, so as to obtain a mixed slurry; step three, filtering, washing and drying the mixed slurry; step four, sintering in a muffle furnace to obtain the rare earth surface modified aluminum nitride powder. The powder cannot be hydrolyzed after being soaked in water at 60 DEG.C for 30 hours, and the wetting angle of the powder and the copper at 1200 DEG.C is 85-89 DEG according to a sessile drop method, and the powder can be applied to a metal-based composite material as reinforcement.

Owner:HEILONGJIANG HEIKE TECH CO LTD +1

A kind of microwave dielectric ceramic temperature-frequency characteristic regulator and its ltcc material

ActiveCN106927804BStable phase structureExcellent microwave dielectric propertiesAlkaline-earth metal silicatesPrinted circuitsReducing atmosphereFrequency characteristic

The invention discloses a microwave dielectric ceramic, a microwave dielectric ceramic temperature-frequency characteristic regulator and an LTCC material thereof. The microwave dielectric ceramic includes a main crystal phase, and the chemical formula of the main crystal phase is BaSi x O 2x+1 (1.56≤x≤1.85). The ceramic has a low dielectric constant (ε r =7.1~7.9), high quality factor (Q×f=10973~20350GHz), wide sintering temperature (750℃~1250℃), and the main crystal phase in reducing atmosphere N 2 ‑1vol%H 2 After sintering, it still has excellent microwave dielectric properties. It is a microwave dielectric ceramic material with good reduction resistance. The microwave dielectric ceramic can be used as a temperature-frequency characteristic regulator of microwave dielectric ceramics. It can It maintains a stable phase structure and good microwave dielectric properties (reduction resistance), which has obvious advantages over traditional regulators. It is a new temperature-frequency characteristic regulator that can be applied to BME‑MLCC.

Owner:HUAZHONG UNIV OF SCI & TECH

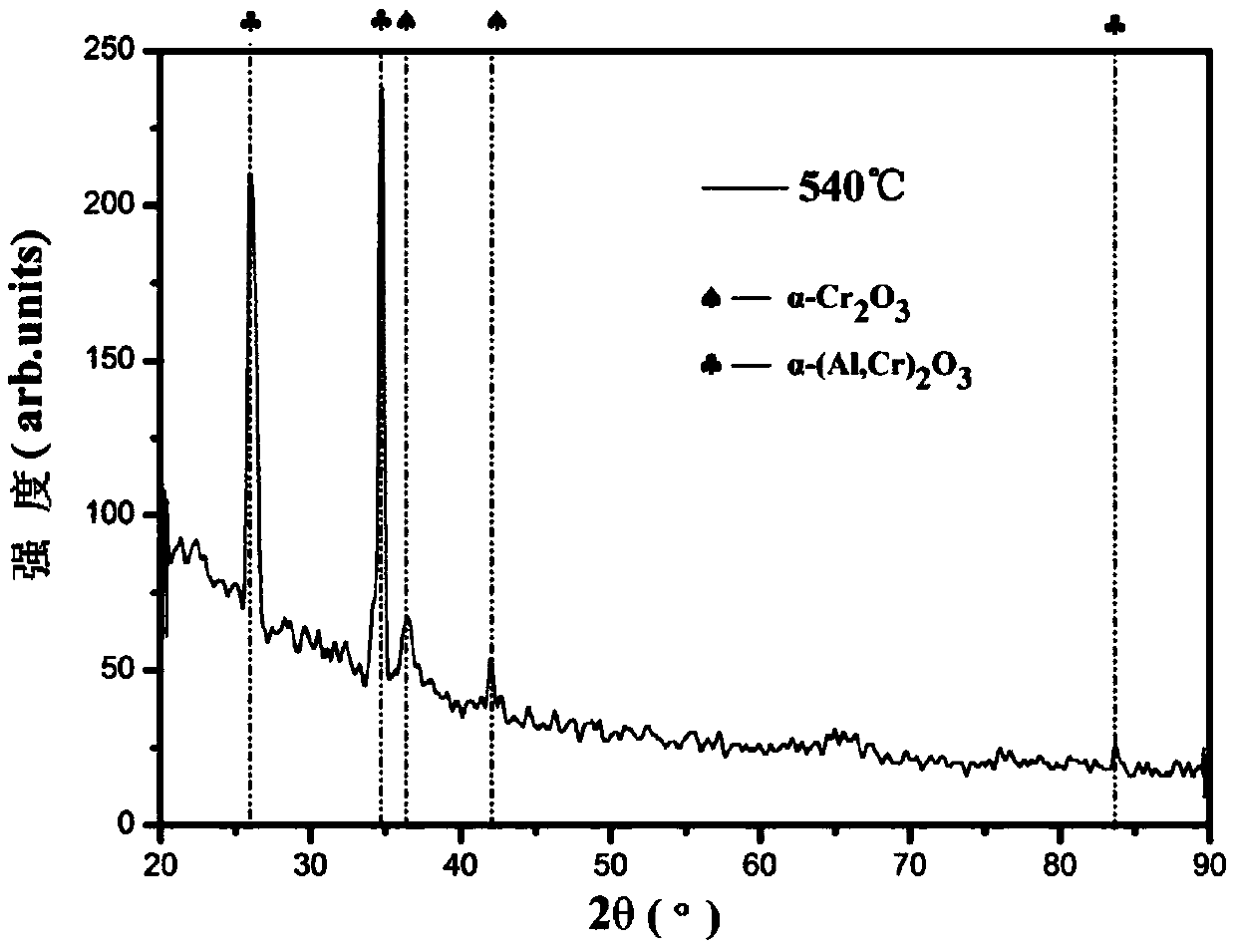

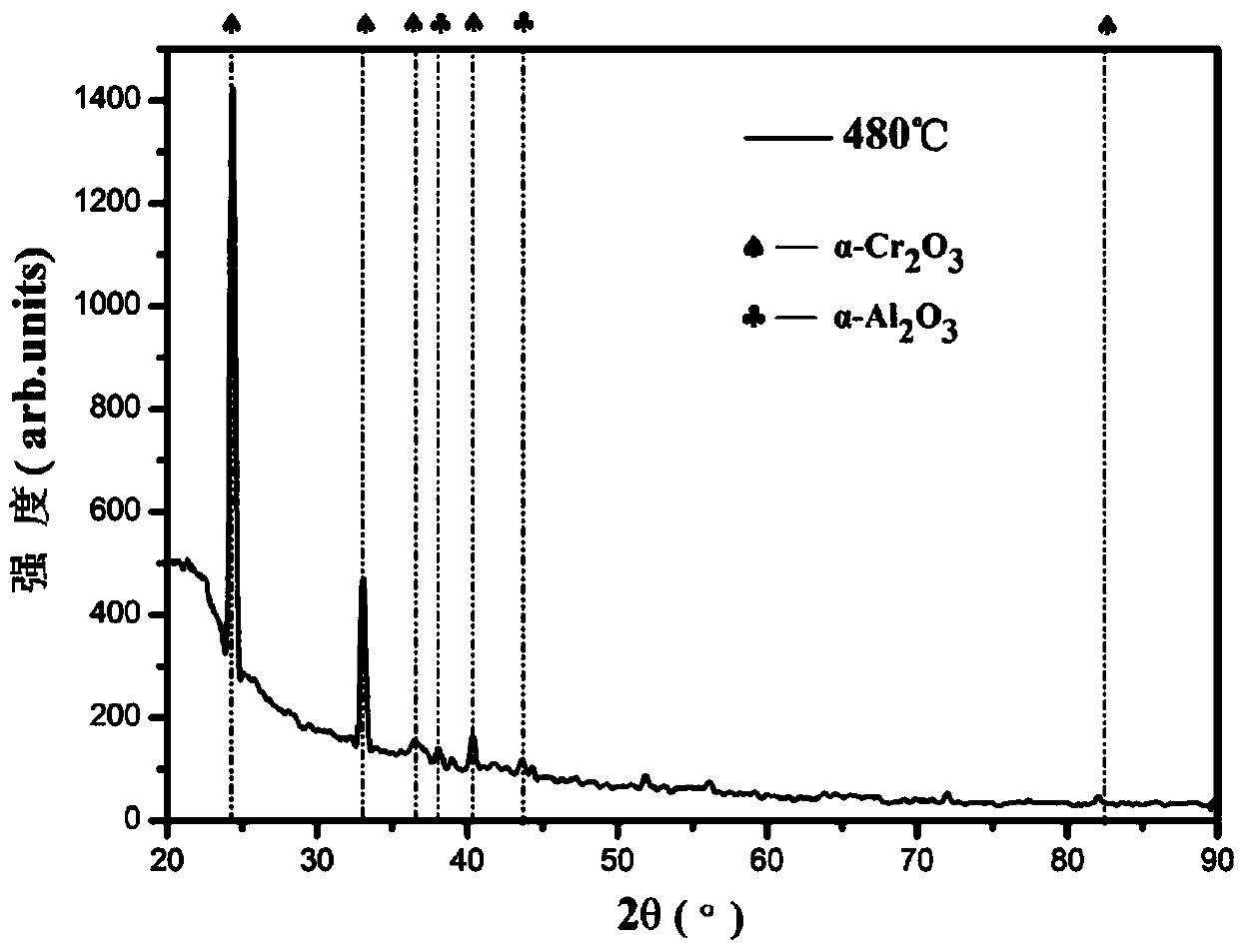

A kind of nano-α-alumina/chromia composite coating and preparation method thereof

ActiveCN106939404BStable α-phase structurePrevent Adhesive WearVacuum evaporation coatingSputtering coatingWater vaporAlloy

The invention belongs to the technical field of metal coatings and discloses a nano alpha-aluminum oxide / chromium oxide composite coating and a preparation method thereof. The preparation method comprises the steps that AlCr alloy serves as a deposition target material, and the deposition target material and a workpiece base body are installed on a high power pulsed magnetron sputtering target station and a deposition chamber sample platform correspondingly; after residual water vapor in a vacuum chamber is removed, the vacuum chamber is pumped to a base vacuum; the workpiece base body is heated to the required temperature, then mixed gas of Ar and O2 is injected, and pre-oxidation treatment is conducted; and the partial pressure of the O2 in the mixed gas of the Ar and the O2 is adjusted to be 6%-15%, the temperature of the workpiece base body is adjusted to be 480-700 DEG C, a high power pulsed magnetron sputtering film coating system is started, reaction and deposition are started, and the nano alpha-aluminum oxide / chromium oxide composite coating is obtained. The nano alpha-aluminum oxide / chromium oxide composite coating obtained through the preparation method is a nanocrystalline structure coating, good in toughness and firmly combined with the base body and has a stable alpha phase structure.

Owner:SOUTH CHINA UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com