Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Reactive deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

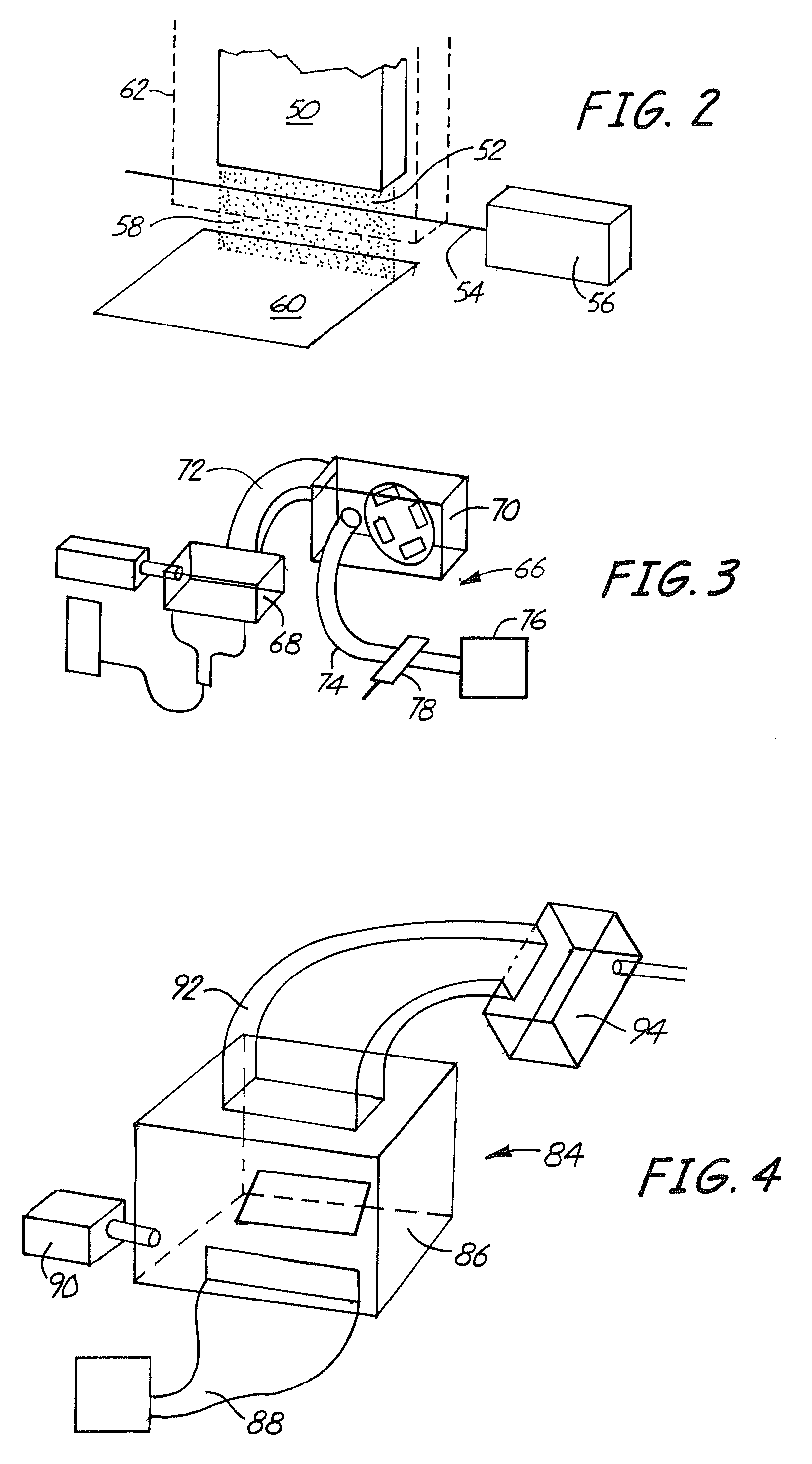

Reactive deposition for electrochemical cell production

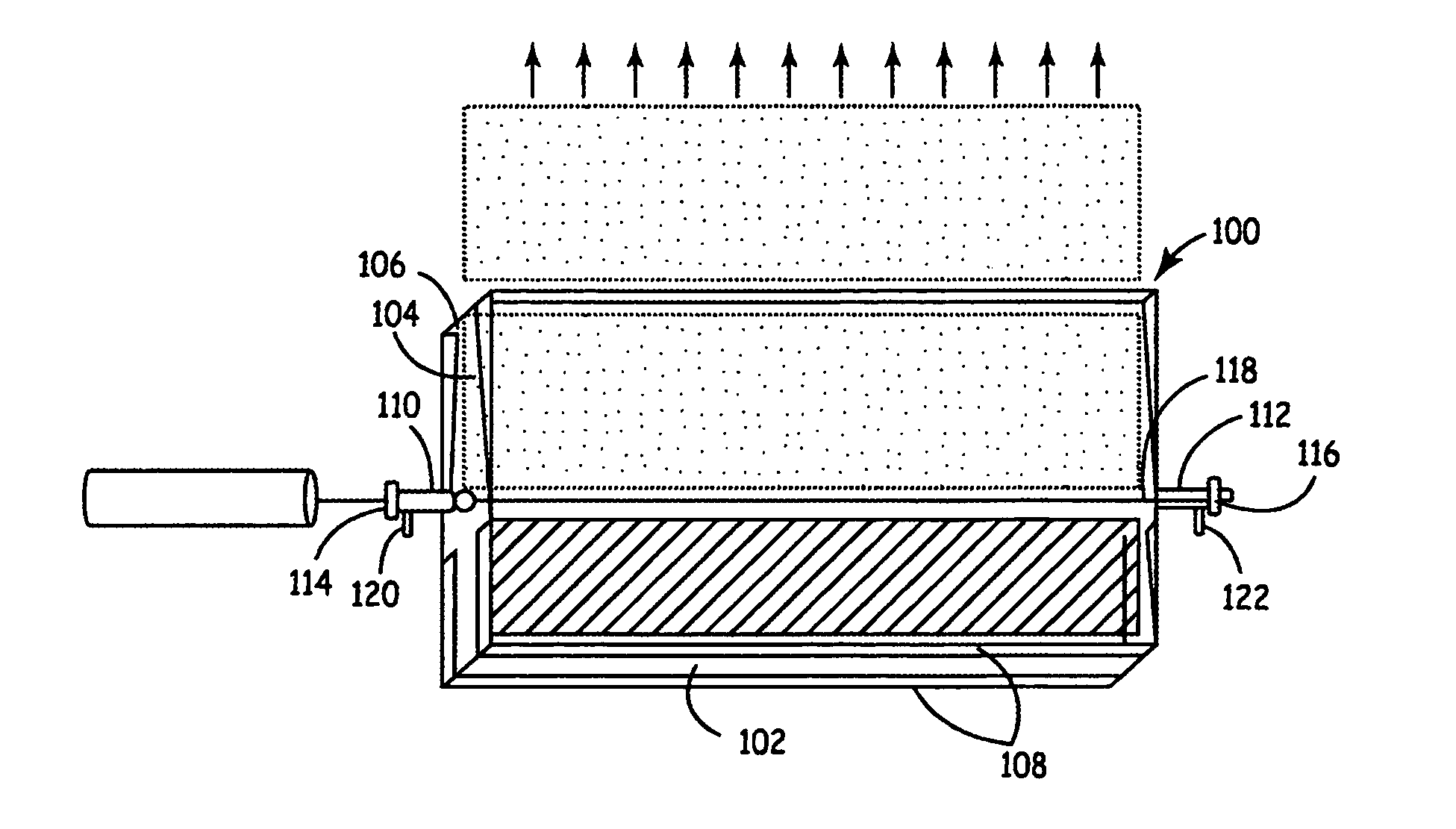

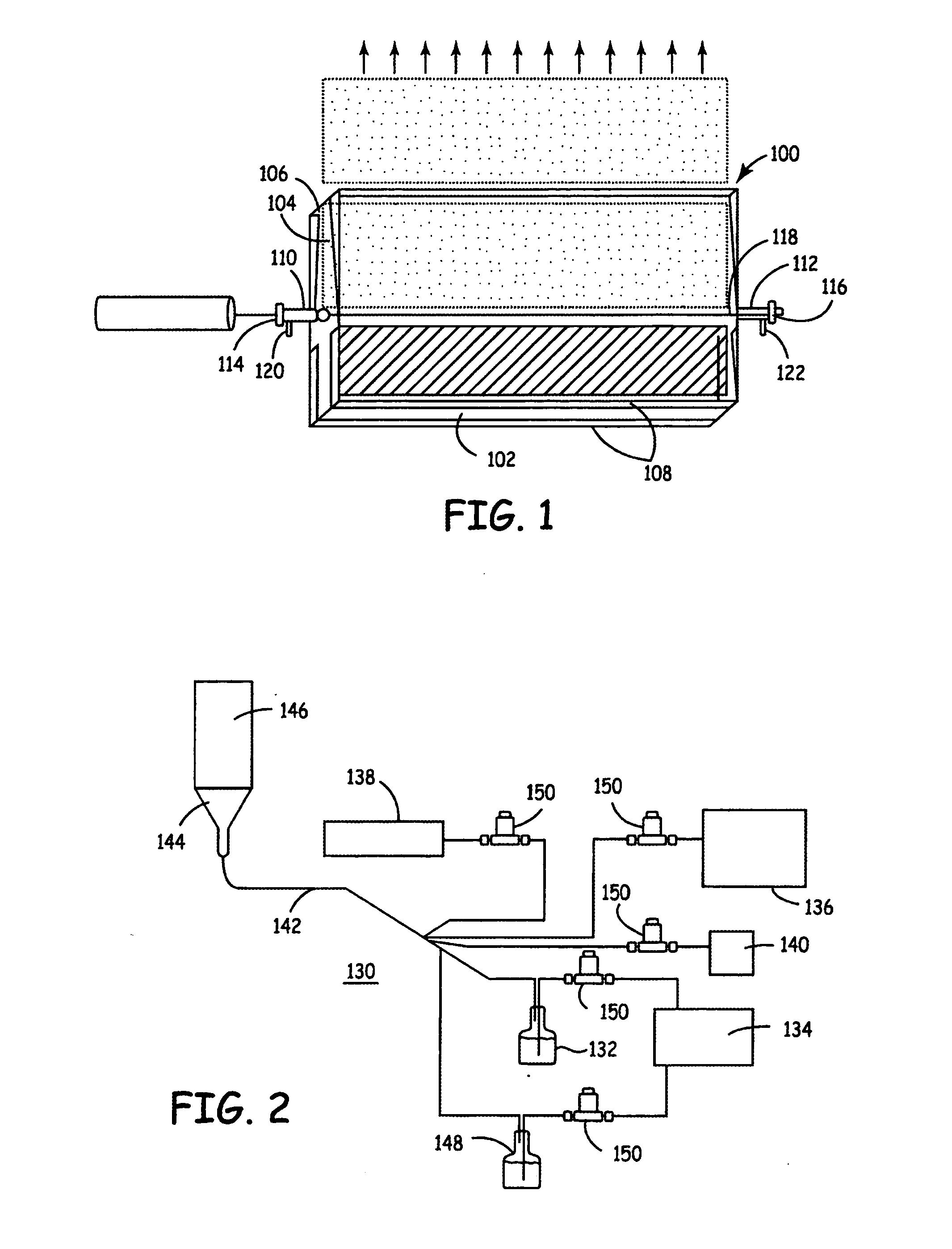

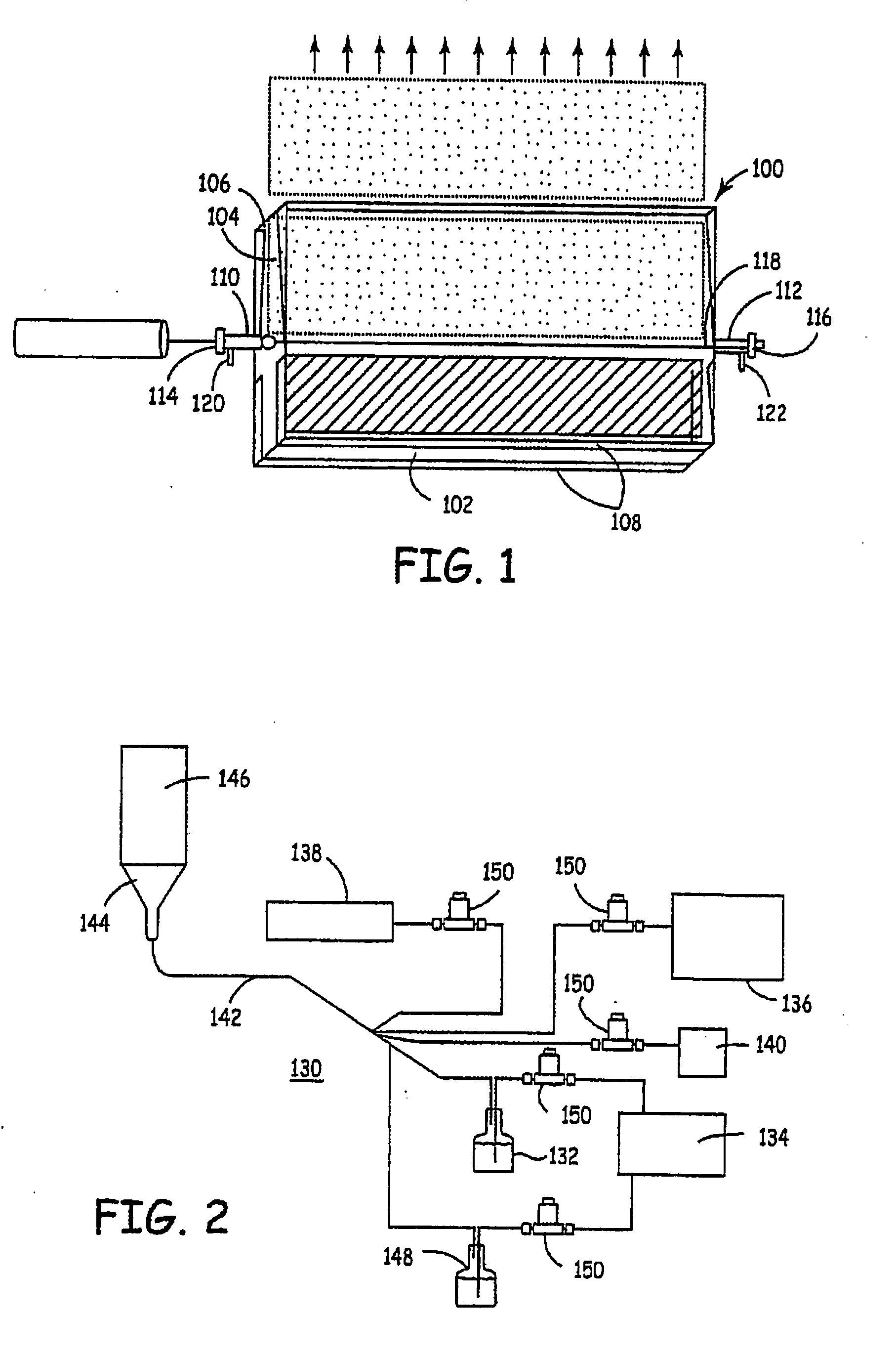

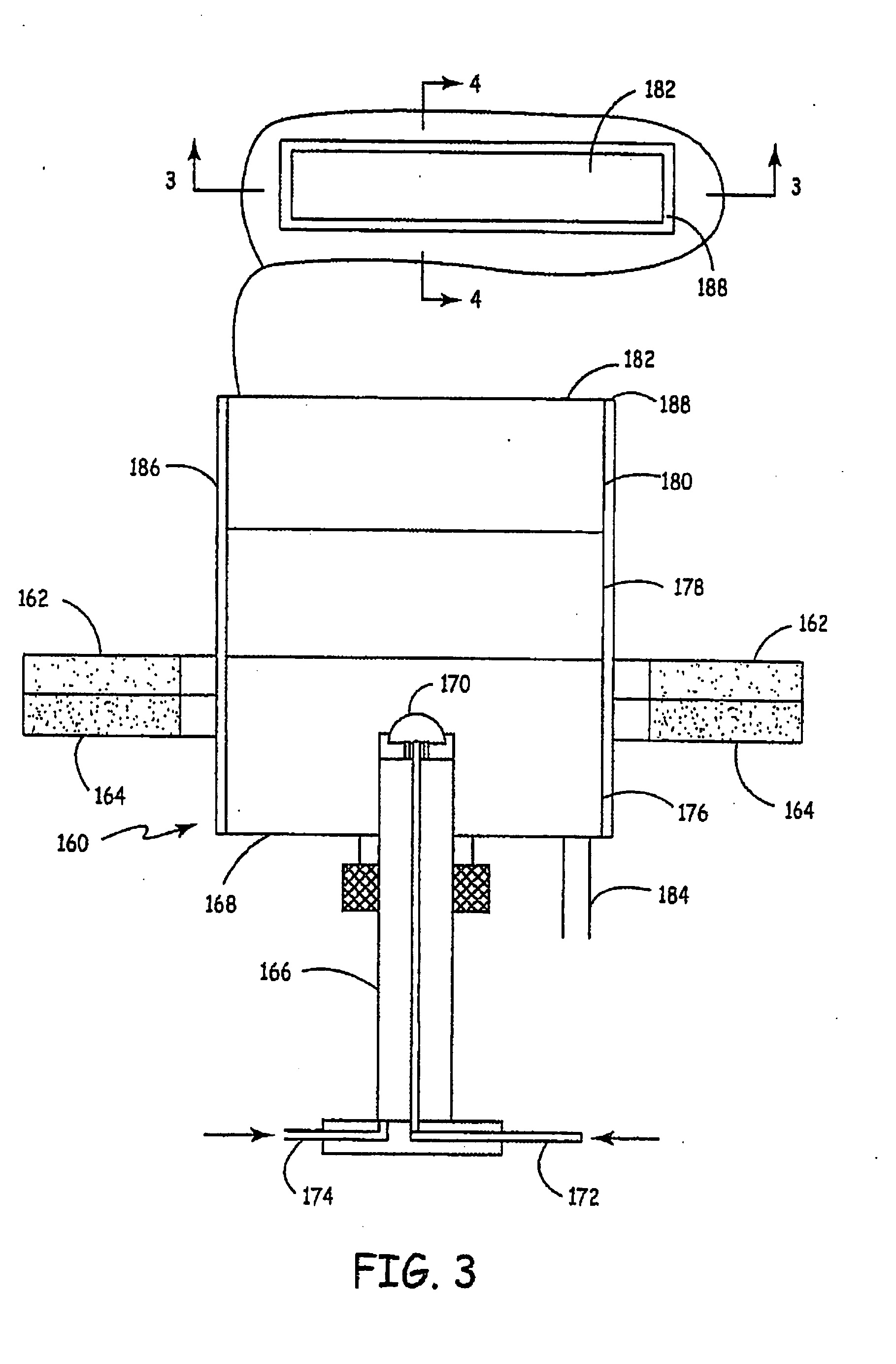

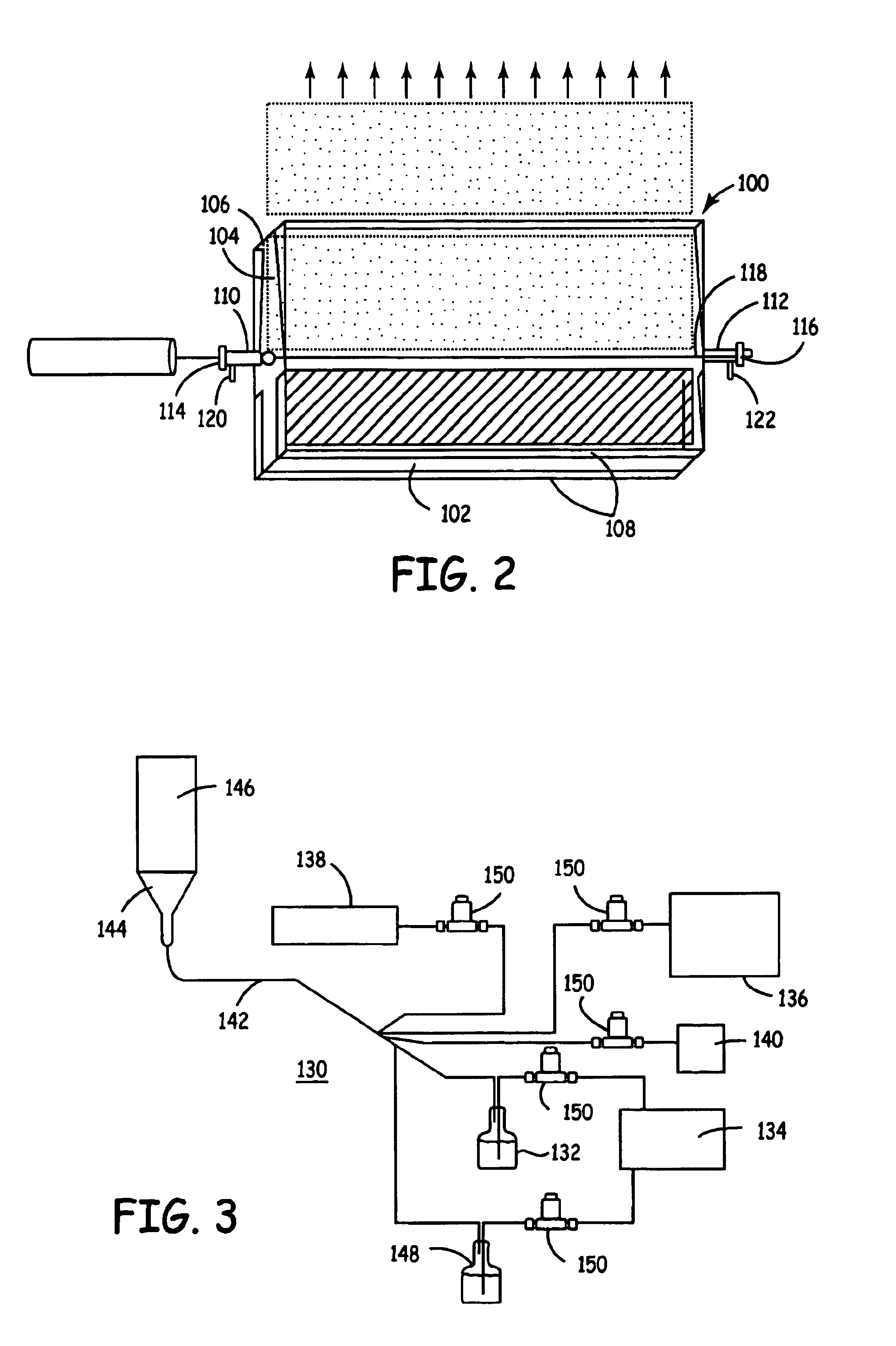

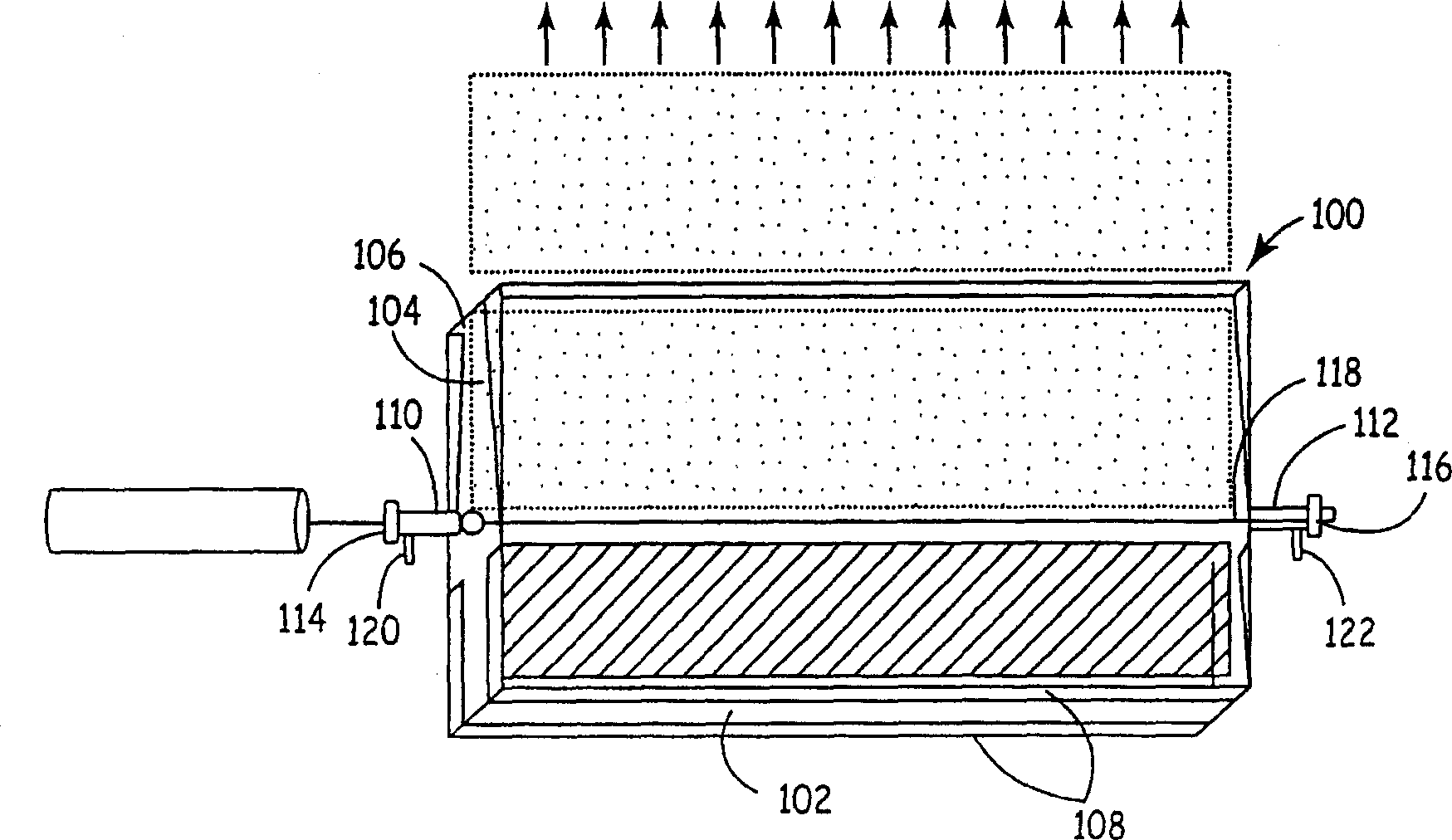

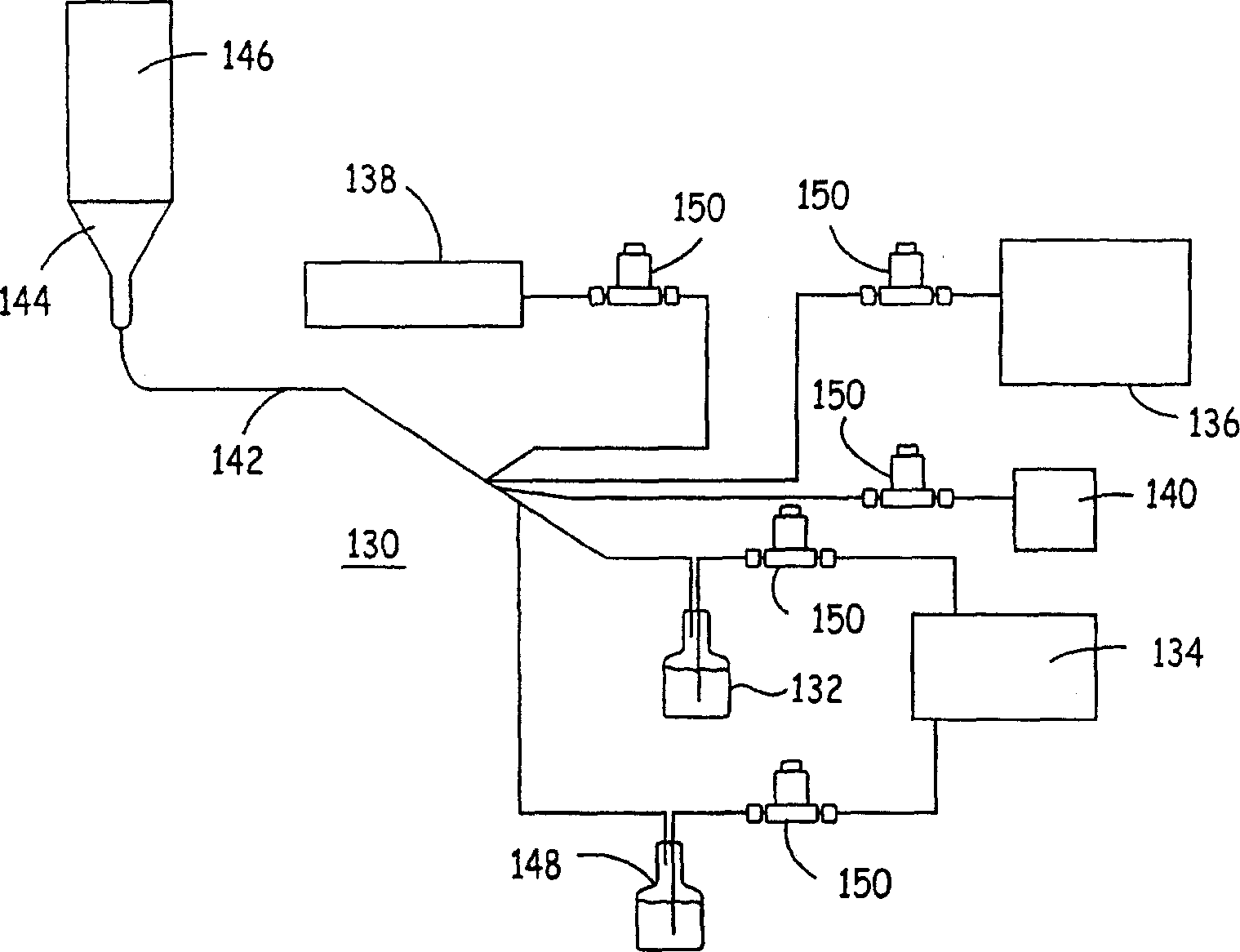

Light reactive deposition can be adapted effectively for the deposition of one or more electrochemical cell components. In particular, electrodes, electrolytes, electrical interconnects can be deposited form a reactive flow. In some embodiments, the reactive flow comprises a reactant stream that intersects a light beam to drive a reaction within a light reactive zone to produce product that is deposited on a substrate. The approach is extremely versatile for the production of a range of compositions that are useful in electrochemical cells and fuel cell, in particular. The properties of the materials, including the density and porosity can be adjusted based on the deposition properties and any subsequent processing including, for example, heat treatments.

Owner:NANOGRAM

Thin silicon or germanium sheets and photovoltaics formed from thin sheets

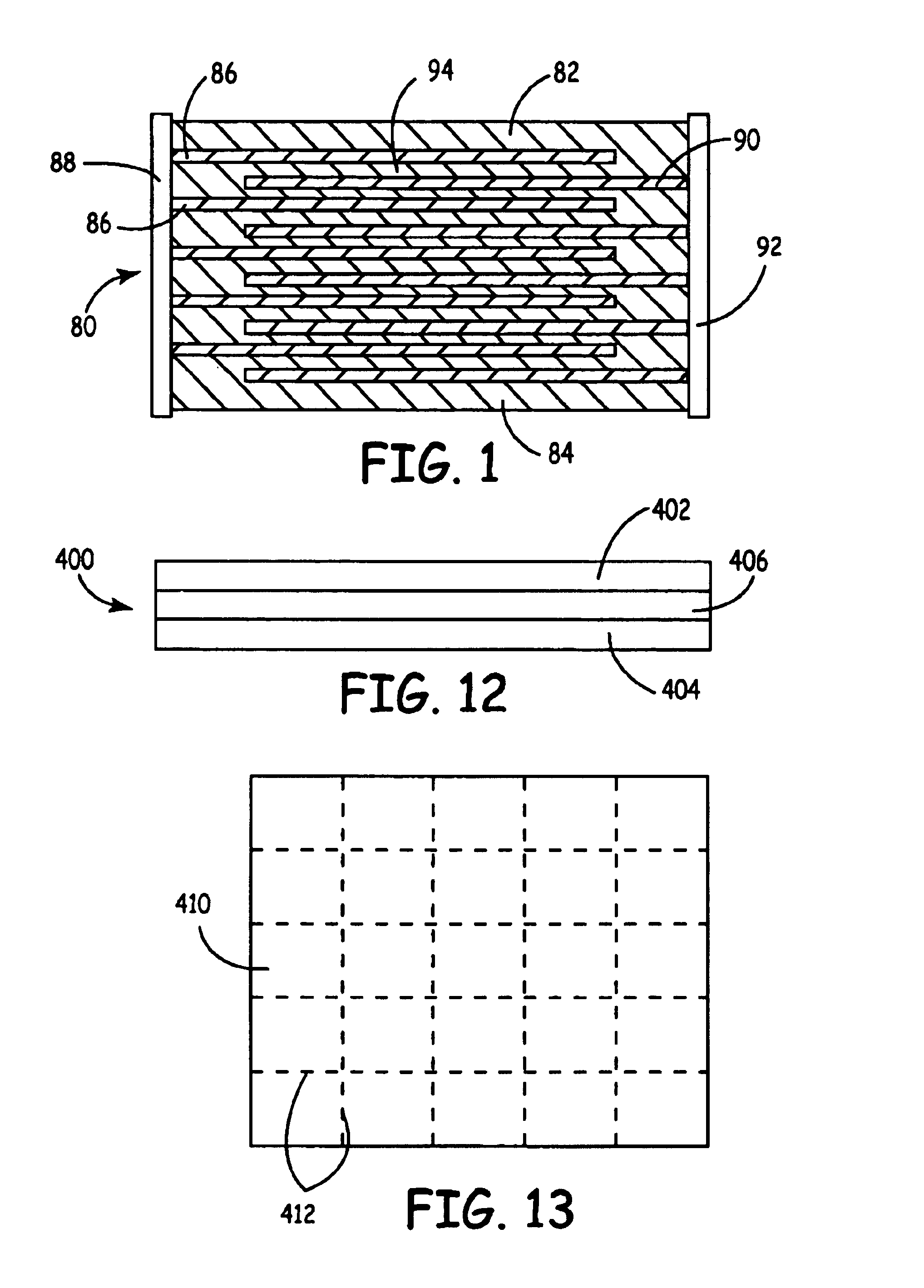

Thin semiconductor foils can be formed using light reactive deposition. These foils can have an average thickness of less than 100 microns. In some embodiments, the semiconductor foils can have a large surface area, such as greater than about 900 square centimeters. The foil can be free standing or releasably held on one surface. The semiconductor foil can comprise elemental silicon, elemental germanium, silicon carbide, doped forms thereof, alloys thereof or mixtures thereof. The foils can be formed using a release layer that can release the foil after its deposition. The foils can be patterned, cut and processed in other ways for the formation of devices. Suitable devices that can be formed form the foils include, for example, photovoltaic modules and display control circuits.

Owner:NANOGRAM

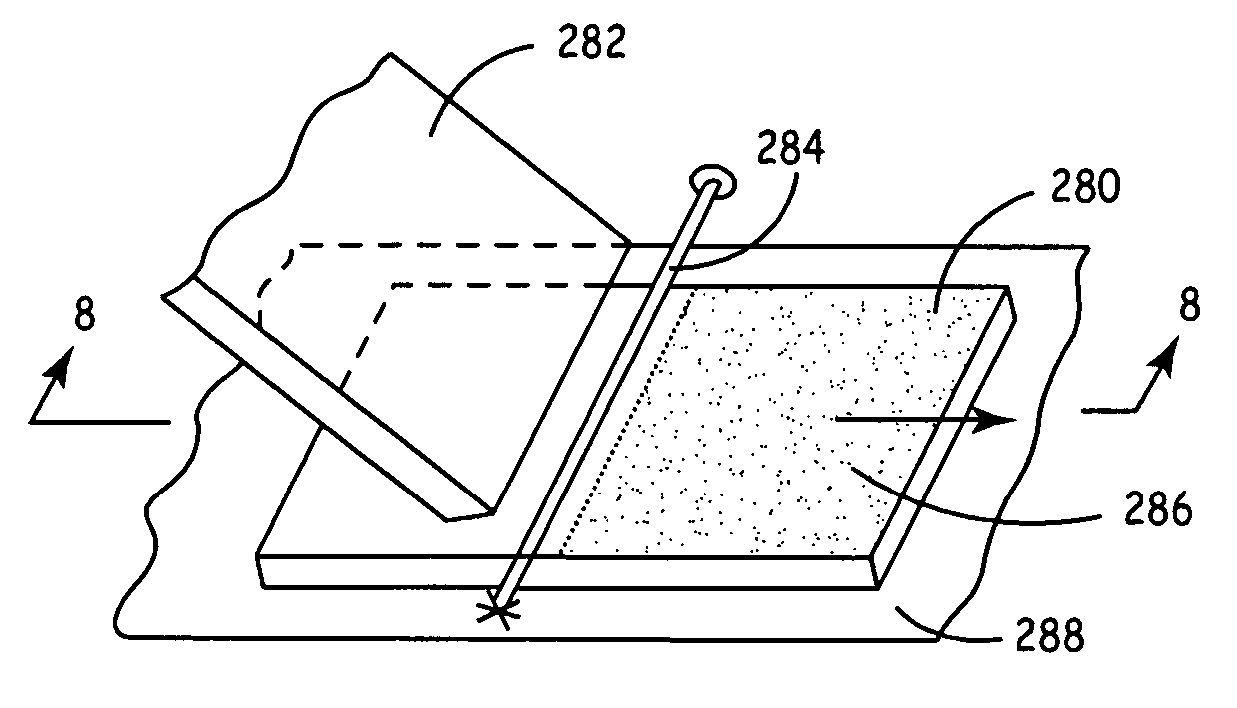

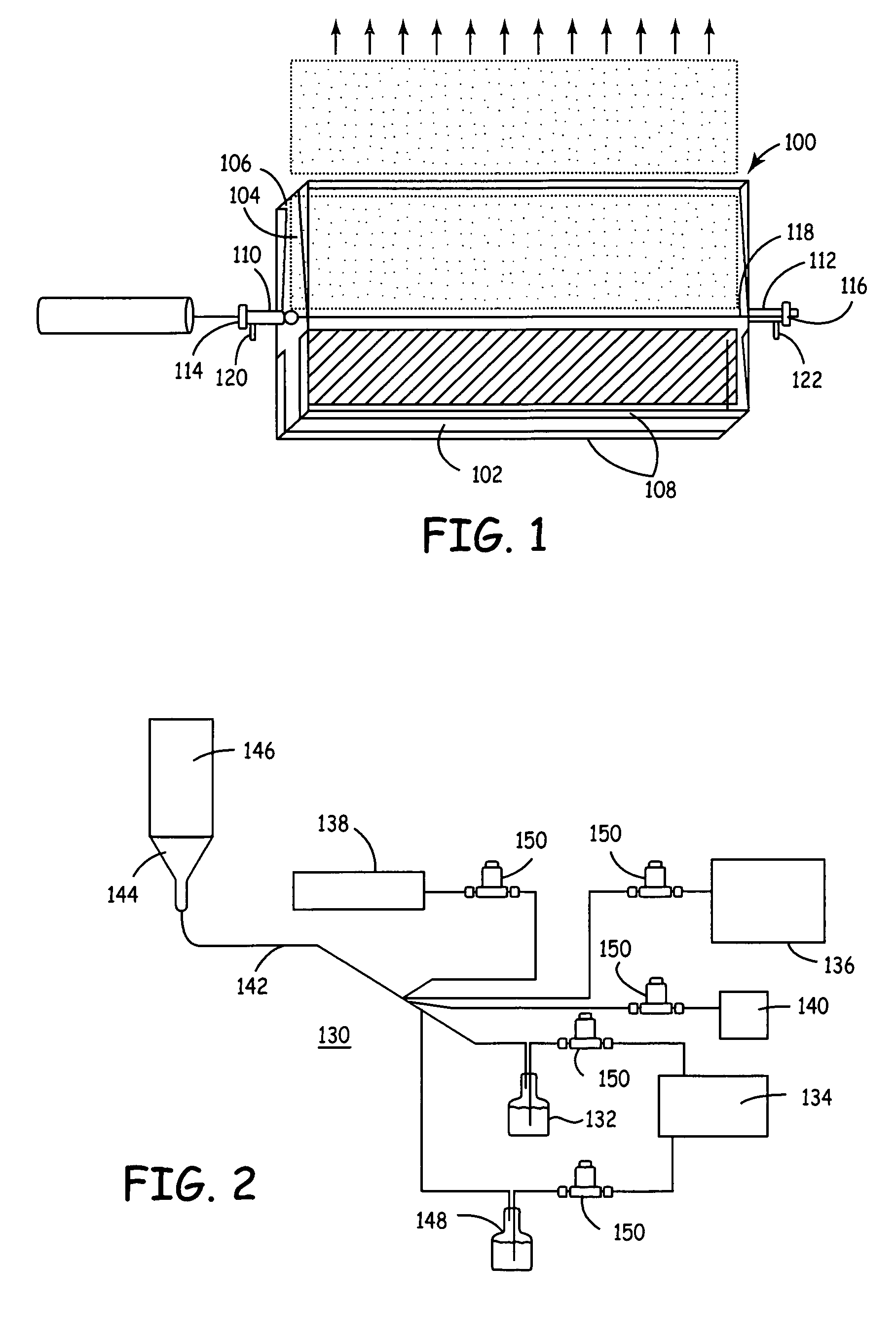

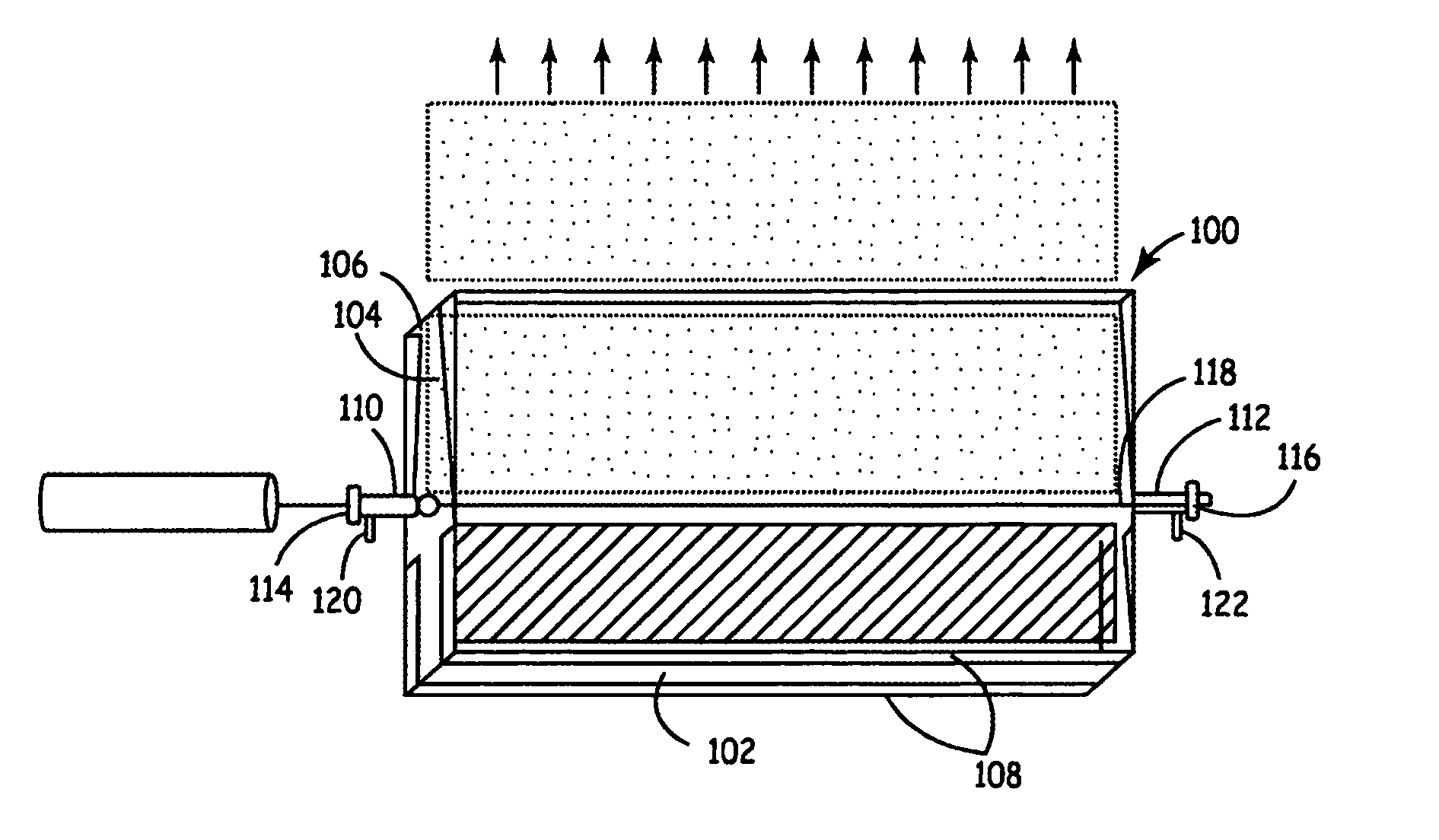

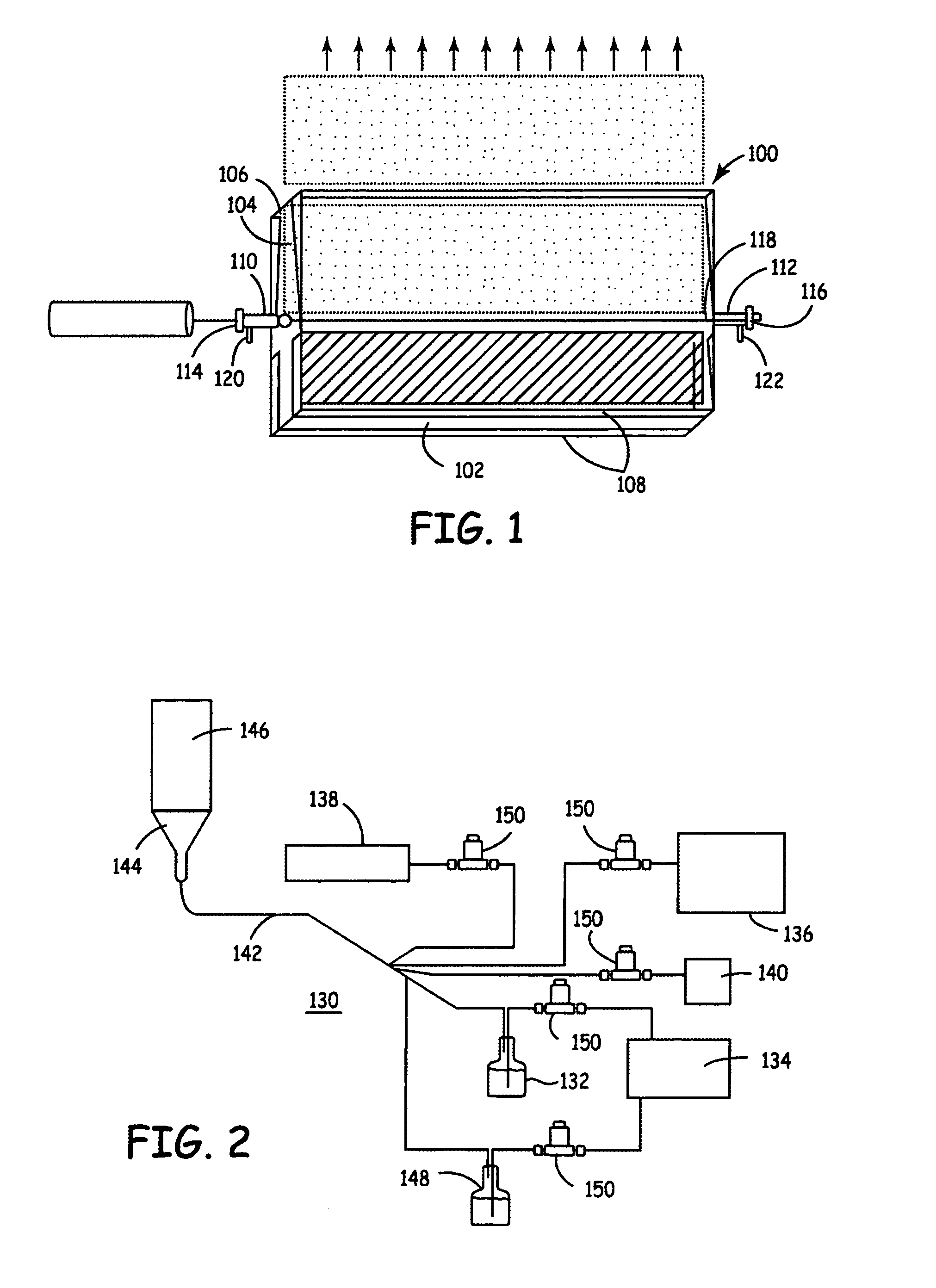

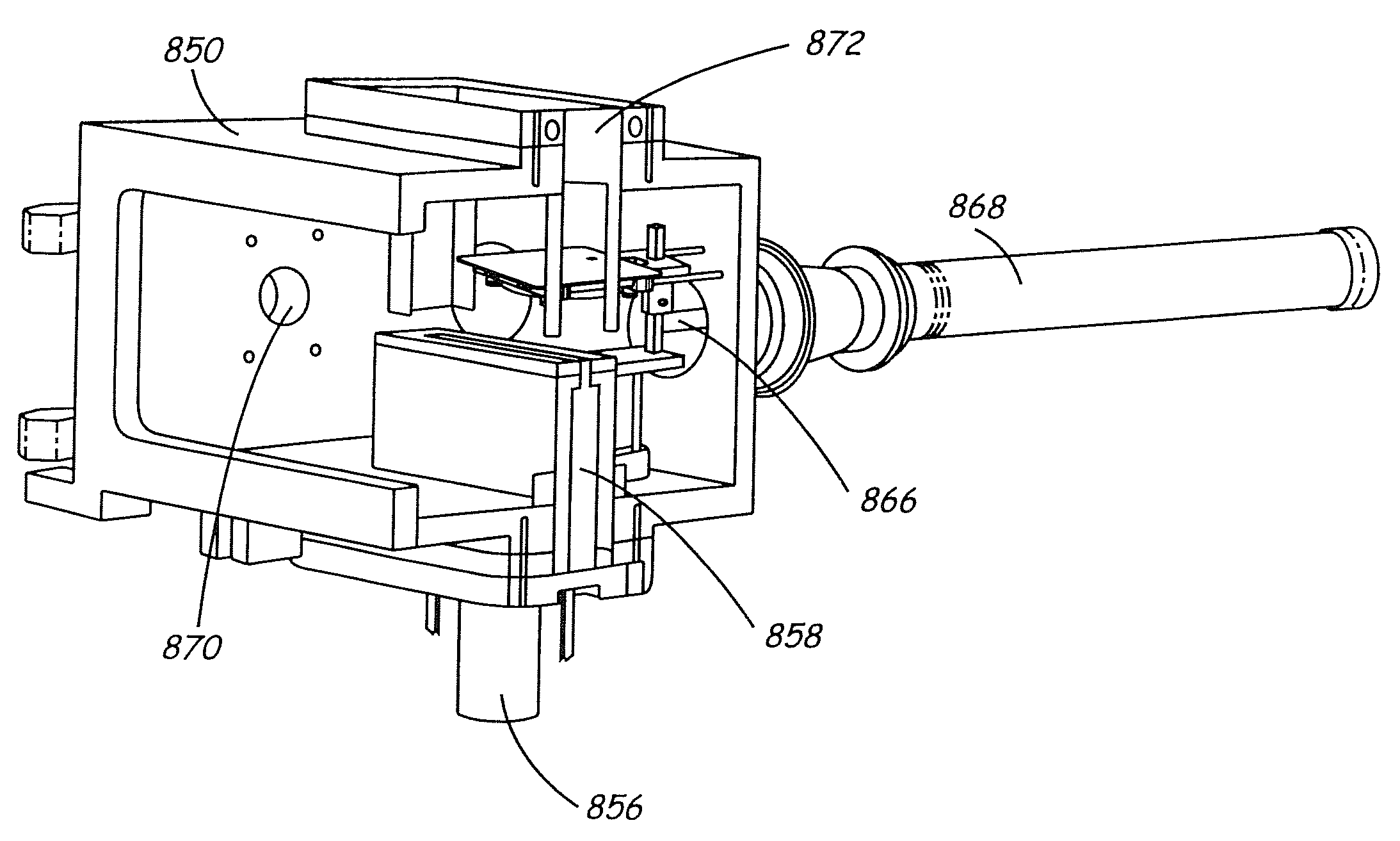

Coating formation by reactive deposition

InactiveUS7575784B1Pretreated surfacesChemical vapor deposition coatingChemical reactionReactive deposition

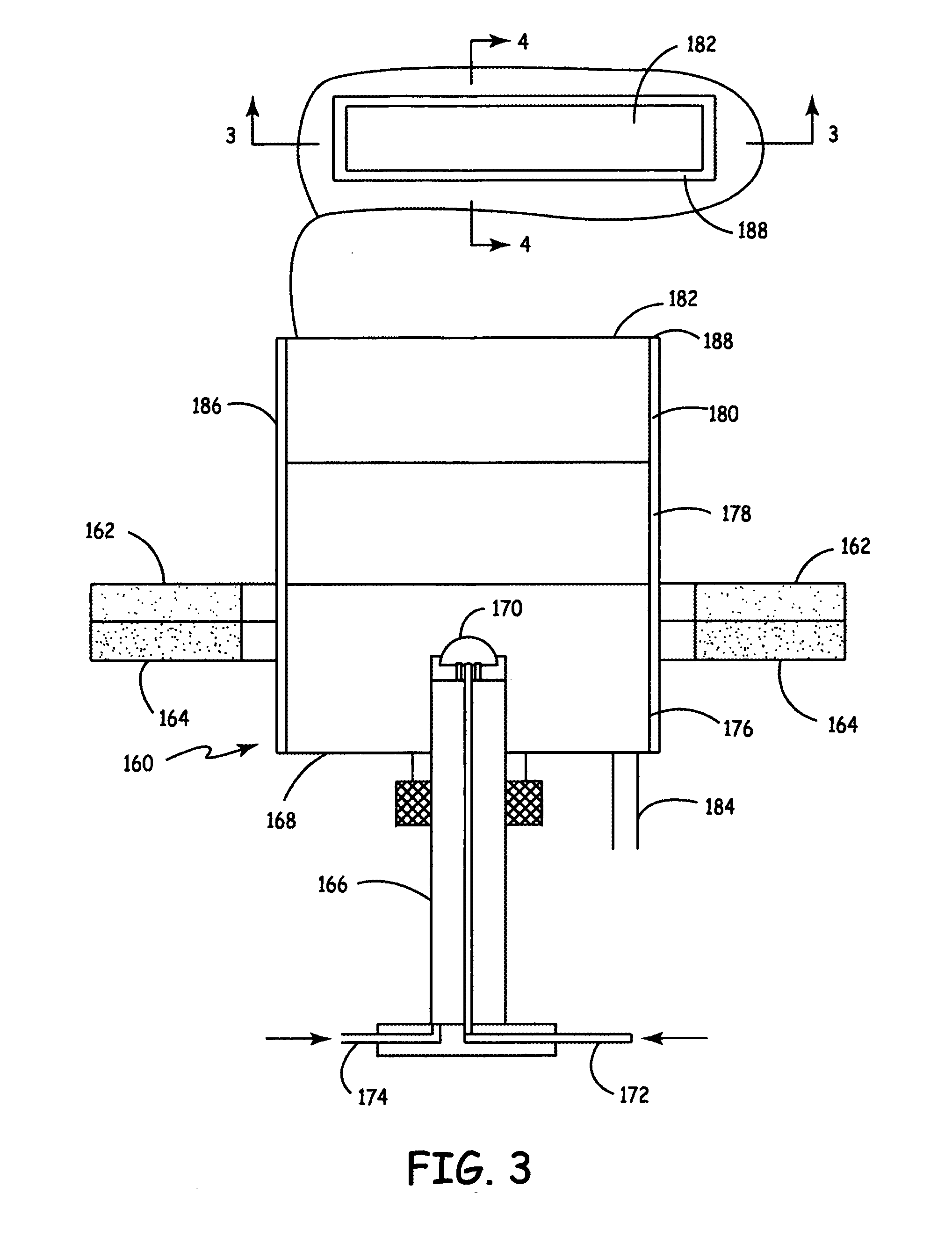

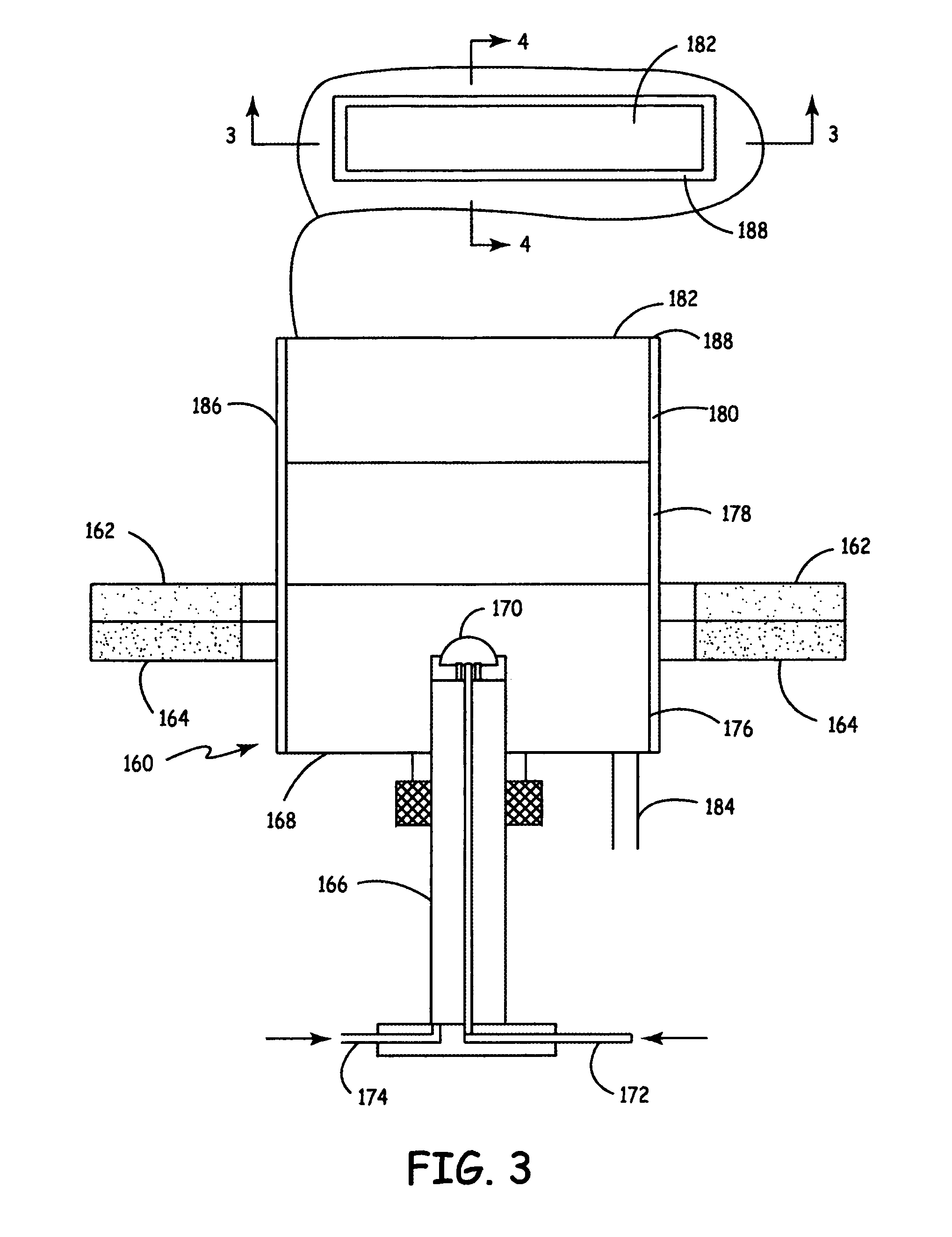

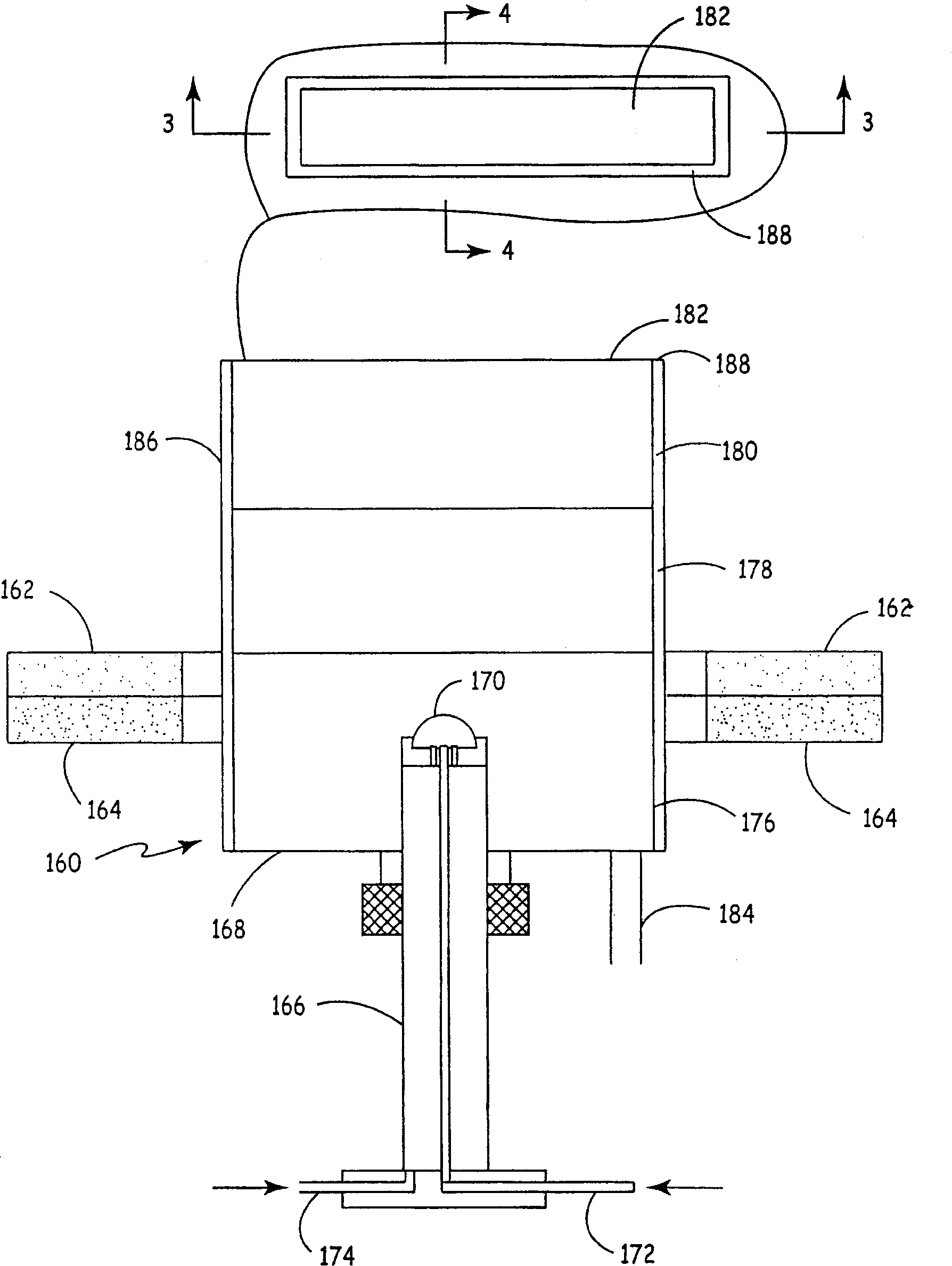

Light reactive deposition uses an intense light beam to form particles that are directly coated onto a substrate surface. In preferred embodiments, a coating apparatus comprising a noncircular reactant inlet, optical elements forming a light path, a first substrate, and a motor connected to the apparatus. The reactant inlet defines a reactant stream path. The light path intersects the reactant stream path at a reaction zone with a product stream path continuing from the reaction zone. The substrate intersects the product stream path. Also, operation of the motor moves the first substrate relative to the product stream. Various broad methods are described for using light driven chemical reactions to produce efficiently highly uniform coatings.

Owner:NANOGRAM

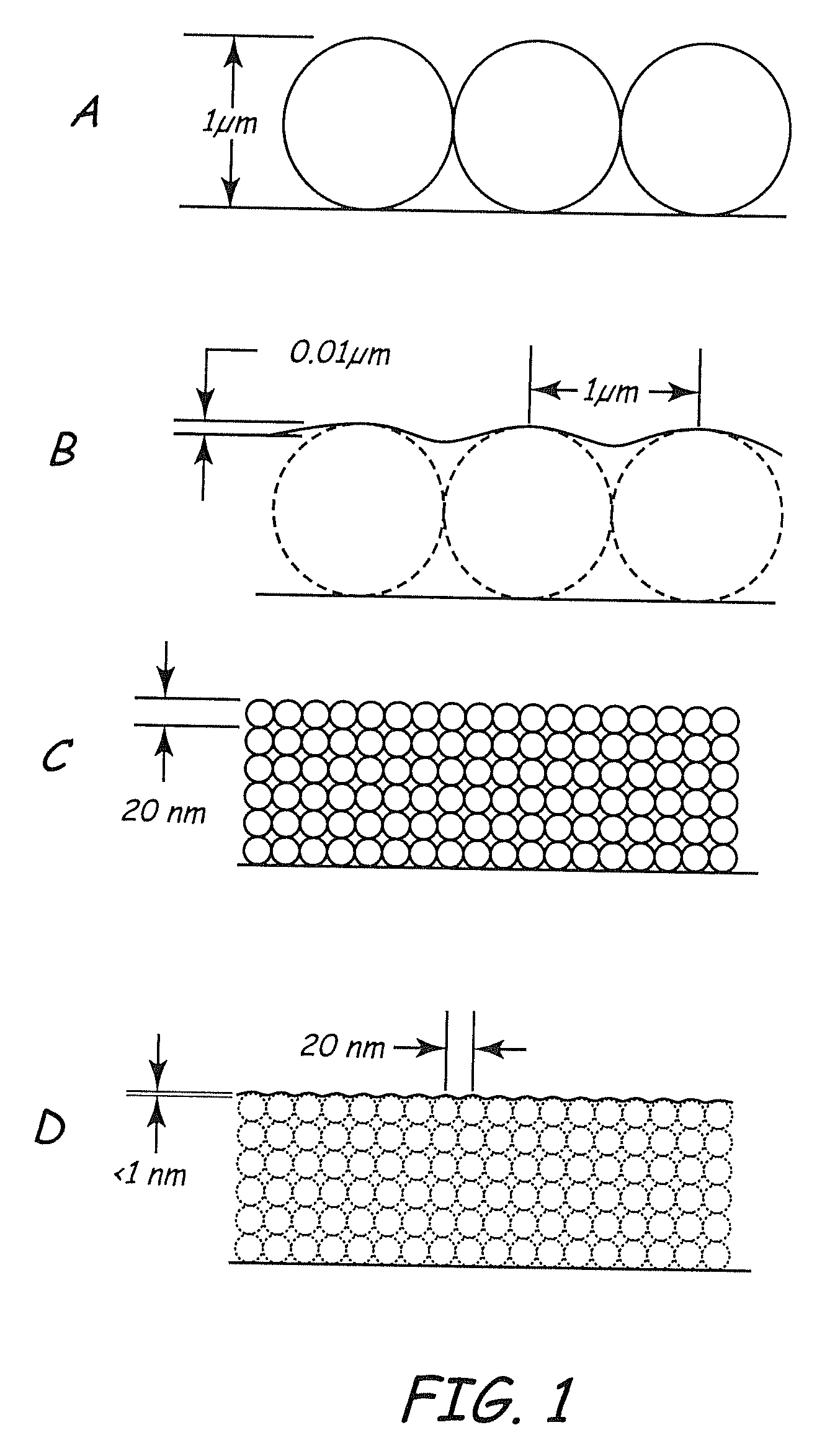

Dense coating formation by reactive deposition

InactiveUS7491431B2Vacuum evaporation coatingSputtering coatingReactive depositionVolumetric Mass Density

Owner:NANOGRAM

Interface control for film deposition by gas-cluster ion-beam processing

InactiveUS6498107B1Improve practicalitySimple interfaceTransistorElectric discharge tubesIon beam depositionReactive deposition

Methods are disclosed for gas-cluster ion-beam deposition of thin films on silicon wafers rendered free of native oxides by termination of the surface bonds and subsequent reactive deposition. Hydrogen termination of the surface of silicon renders it inert to reoxidation from oxygen-containing environmental gasses, even those found as residue in vacuum systems, such as those used to deposit films. Nitrogen termination improves the interface with overlying metal-oxide thin films. The film is formed in intimate contact with the silicon crystal surface forming a nearly ideal interface.

Owner:JDSU OPTICAL

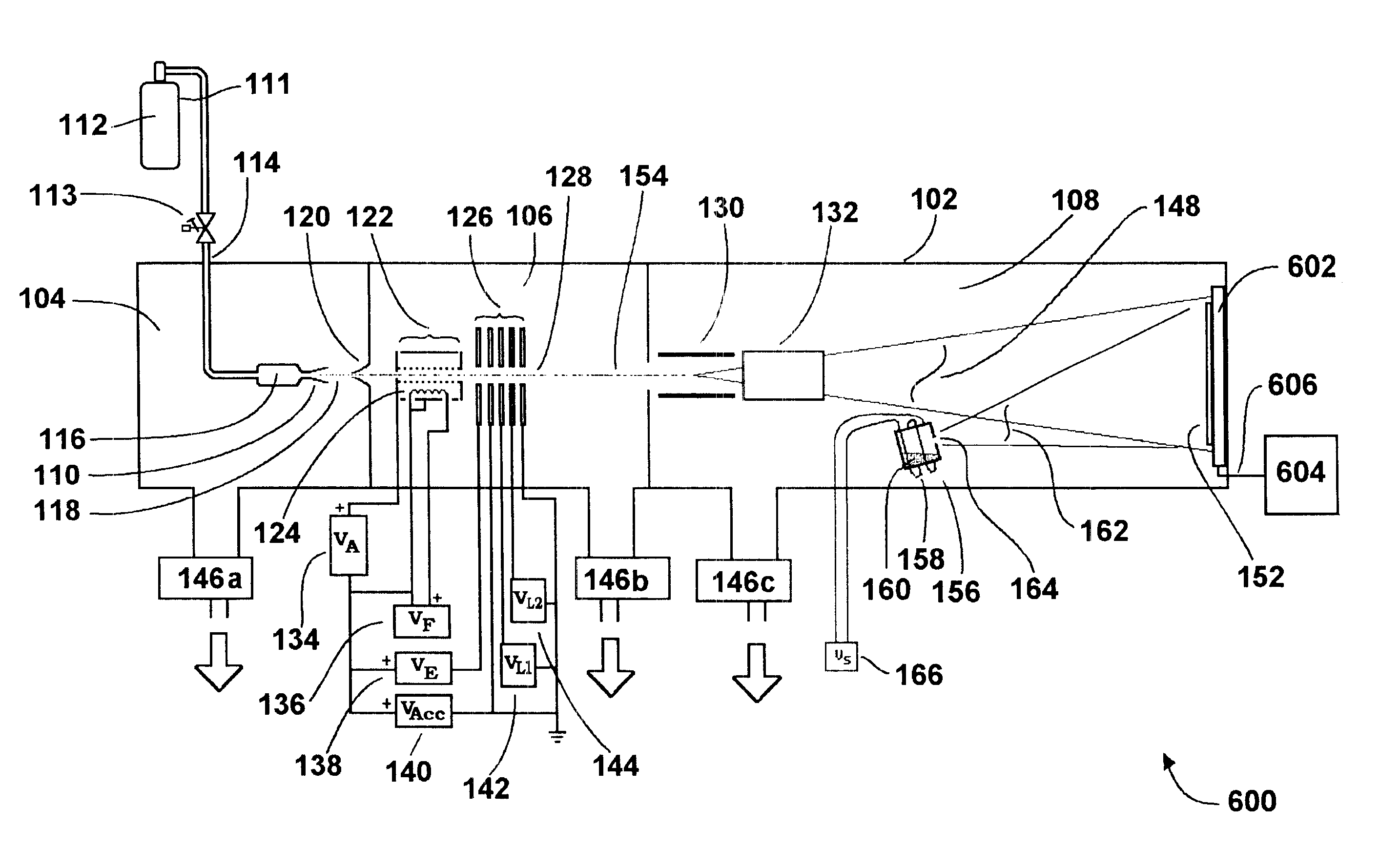

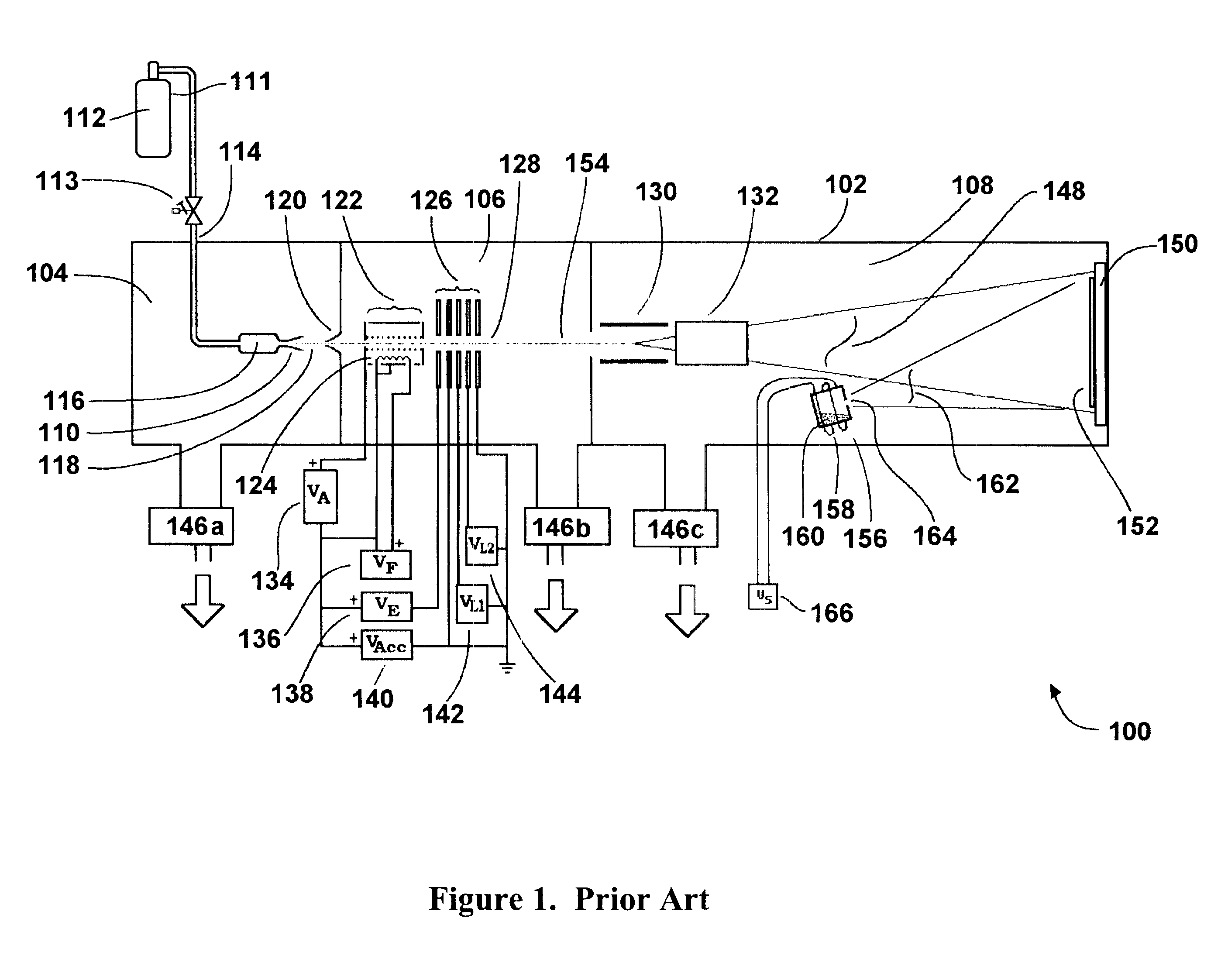

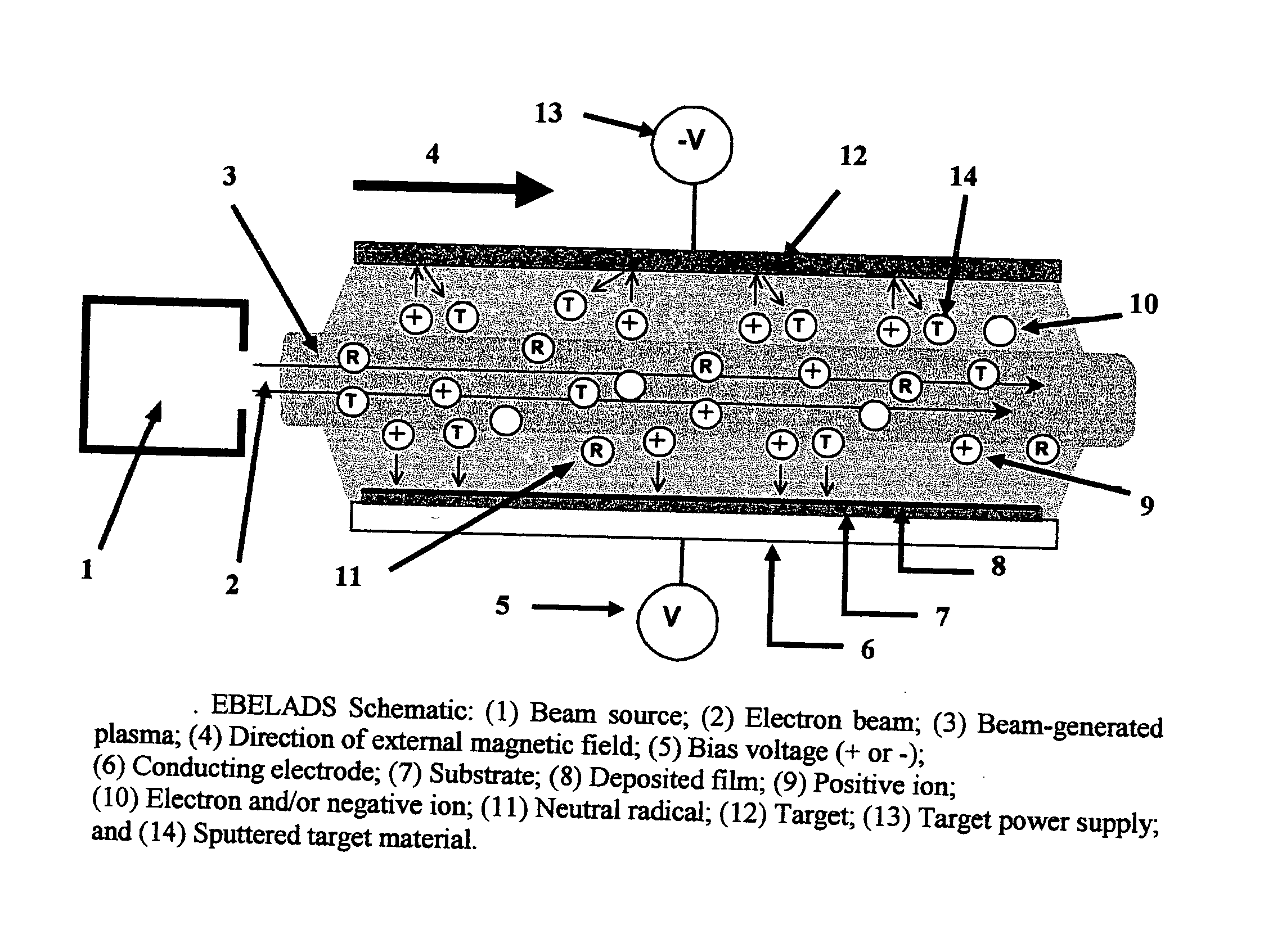

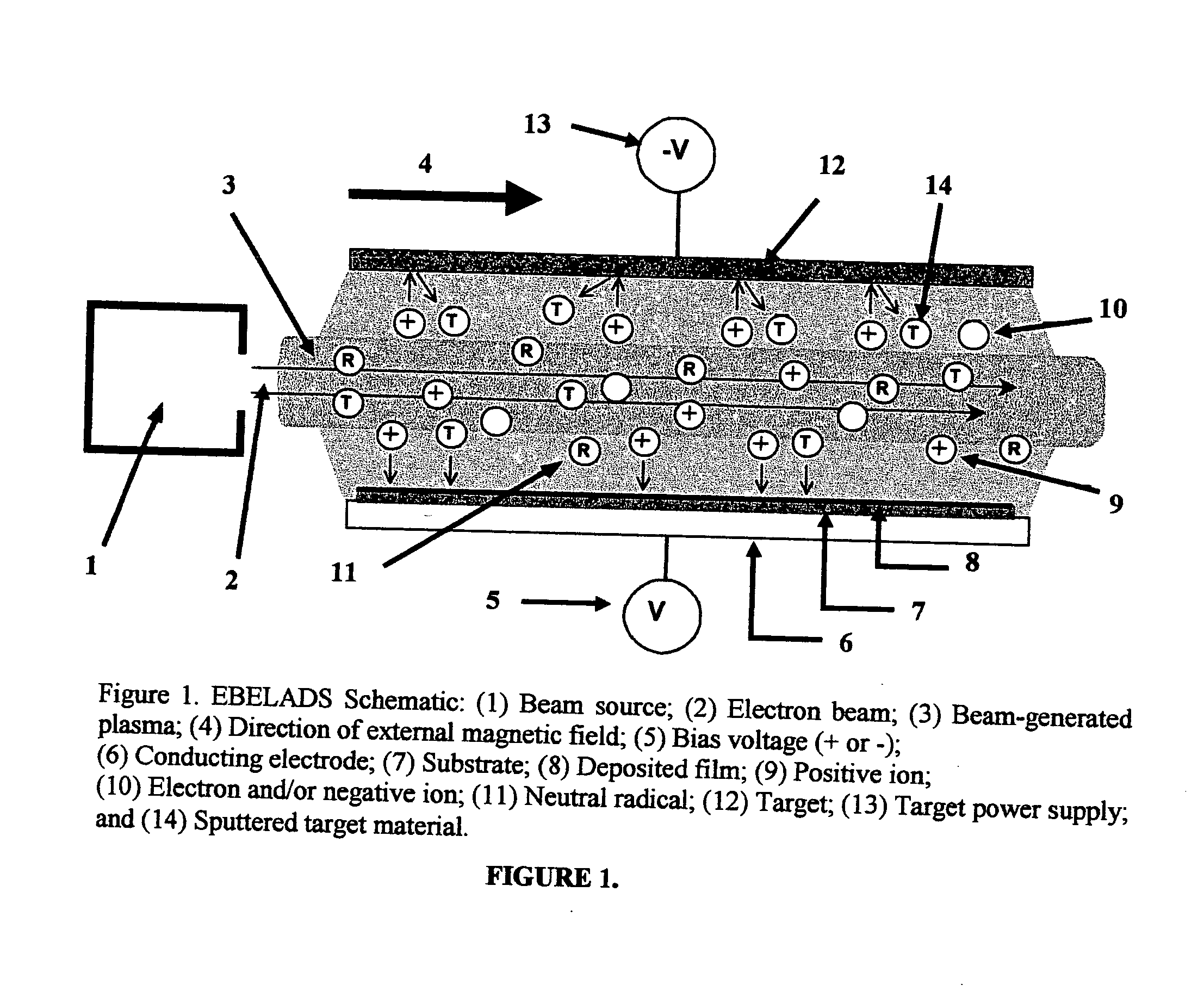

Electron beam enhanced large area deposition system

This invention provides a means to deposit thin films and coatings on a substrate using an electron beam generated plasma. The plasma can be used as an ion source in sputter applications, where the ions are used to liberate material from a target surface which can then condense on a substrate to form the film or coating. Alternatively, the plasma may be combined with existing deposition sources including those based on sputter or evaporation techniques. In either configuration, the plasma serves as a source of ion and radical species at the growing film surface in reactive deposition processes. The electron beam large area deposition system (EBELADS) is a new approach to the production of thin films or coatings up to and including several square meters.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Coating formation by reactive deposition

InactiveUS20090288601A1Increase chanceMolten spray coatingTransportation and packagingChemical reactionReactive deposition

Light reactive deposition uses an intense light beam to form particles that are directly coated onto a substrate surface. In some embodiments, a coating apparatus comprising a noncircular reactant inlet, optical elements forming a light path, a first substrate, and a motor connected to the apparatus. The reactant inlet defines a reactant stream path. The light path intersects the reactant stream path at a reaction zone with a product stream path continuing from the reaction zone. The substrate intersects the product stream path. Also, operation of the motor moves the first substrate relative to the product stream. Various broad methods are described for using light driven chemical reactions to produce efficiently highly uniform coatings.

Owner:NANOGRAM

Reactive deposition for electrochemical cell production

Light reactive deposition can be adapted effectively for the deposition of one or more electrochemical cell components. In particular, electrodes, electrolytes, electrical interconnects can be deposited form a reactive flow. In some embodiments, the reactive flow comprises a reactant stream that intersects a light beam to drive a reaction within a light reactive zone to produce product that is deposited on a substrate. The approach is extremely versatile for the production of a range of compositions that are useful in electrochemical cells and fuel cell, in particular. The properties of the materials, including the density and porosity can be adjusted based on the deposition properties and any subsequent processing including, for example, heat treatments.

Owner:NANOGRAM

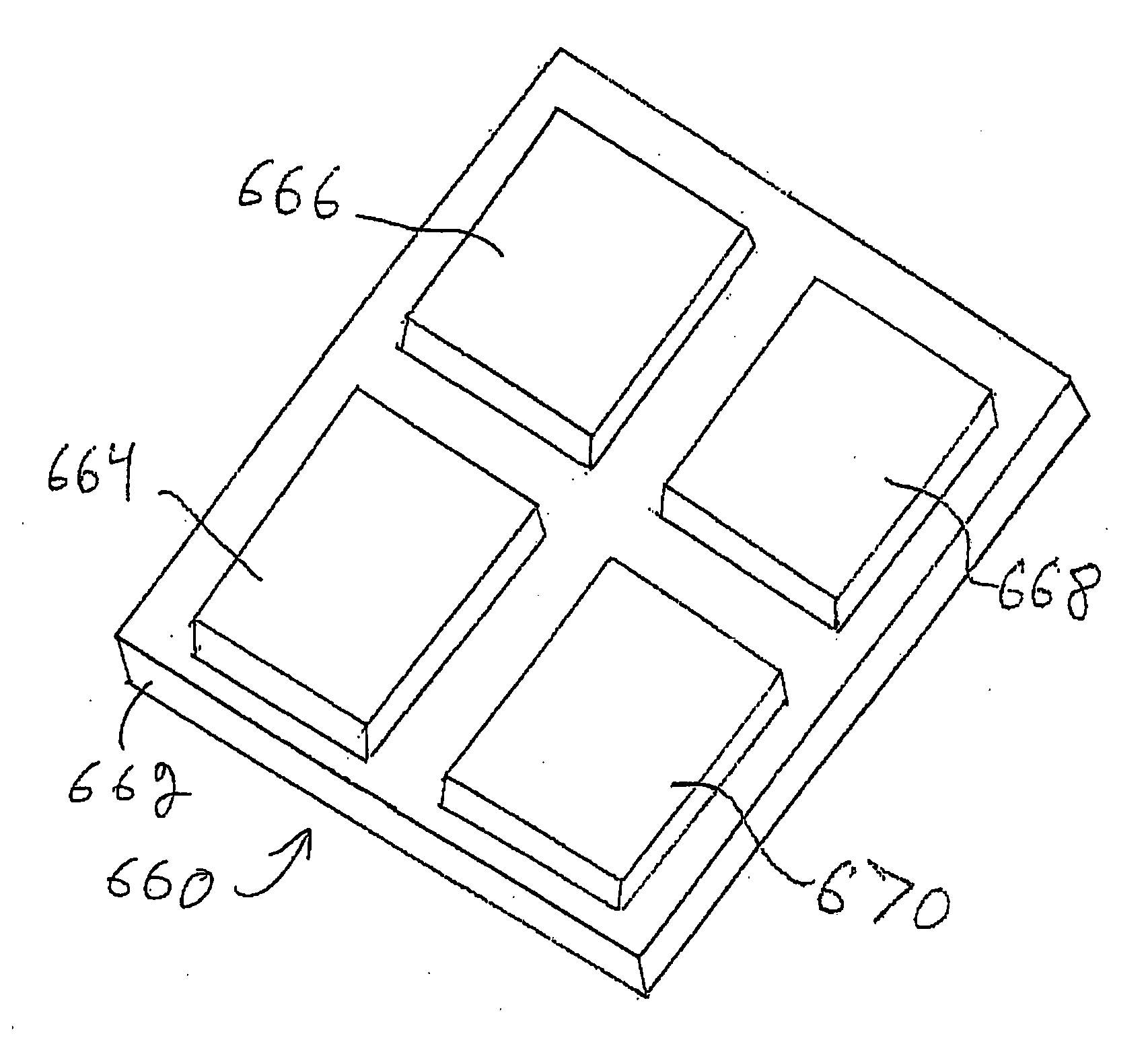

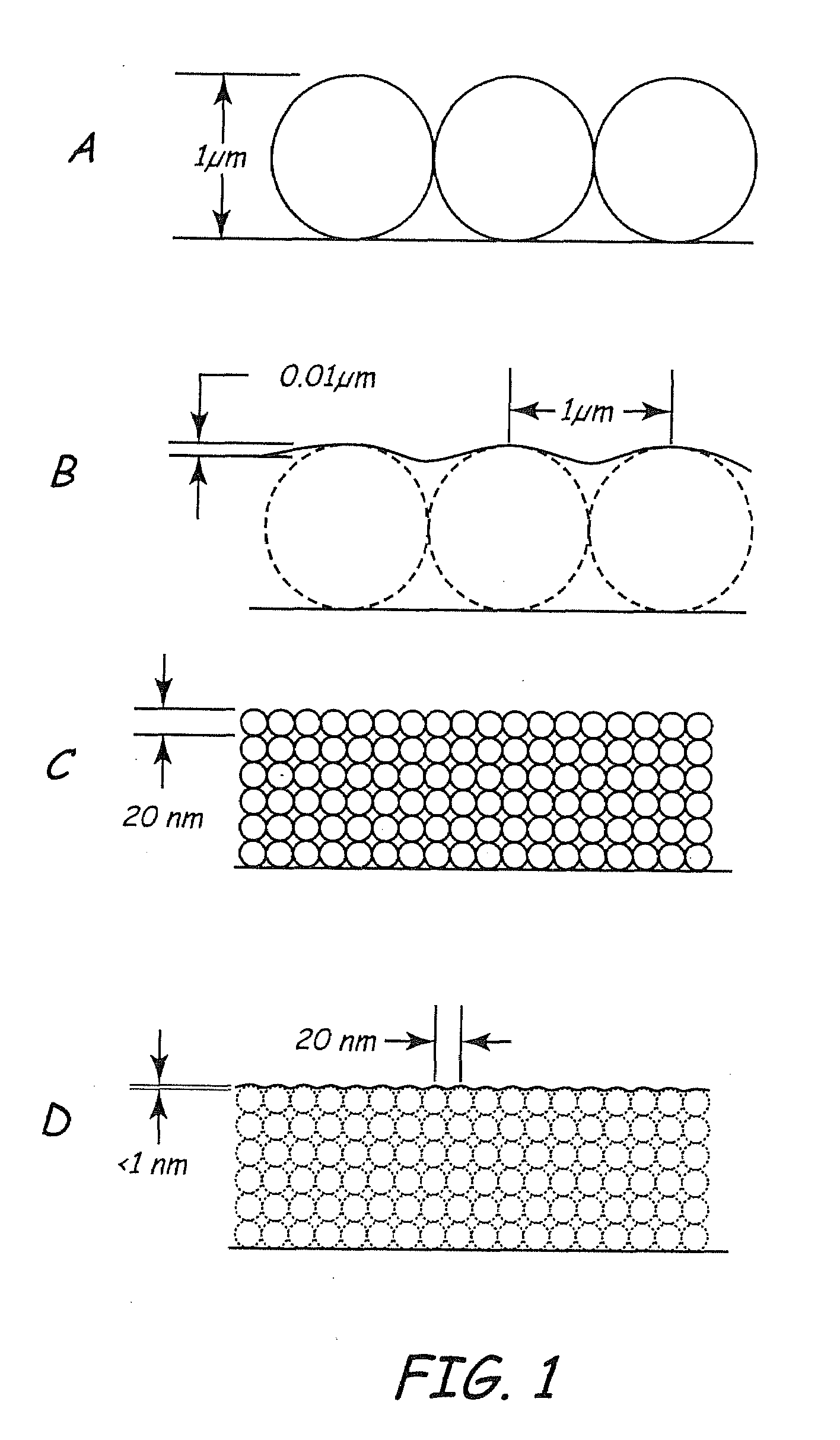

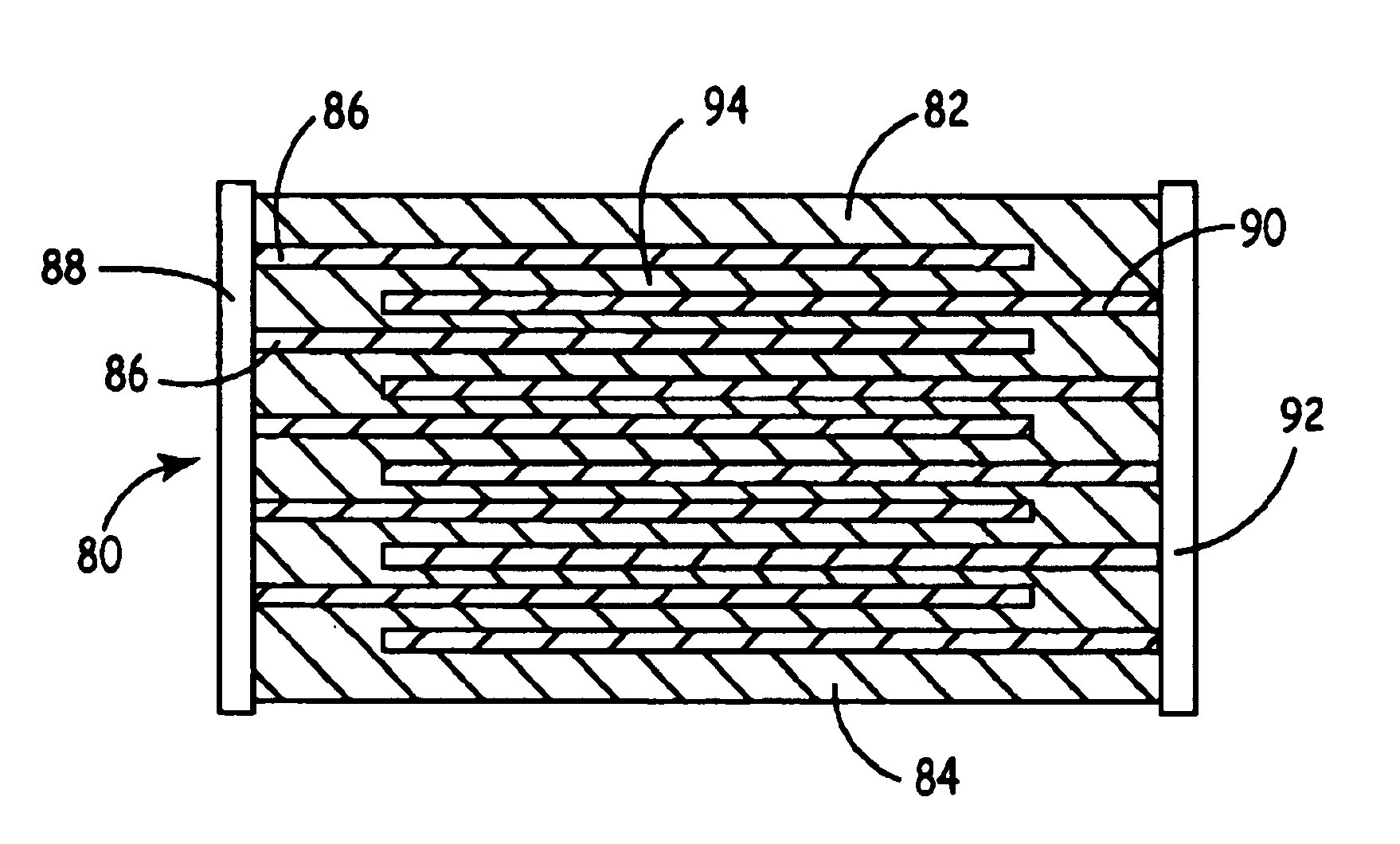

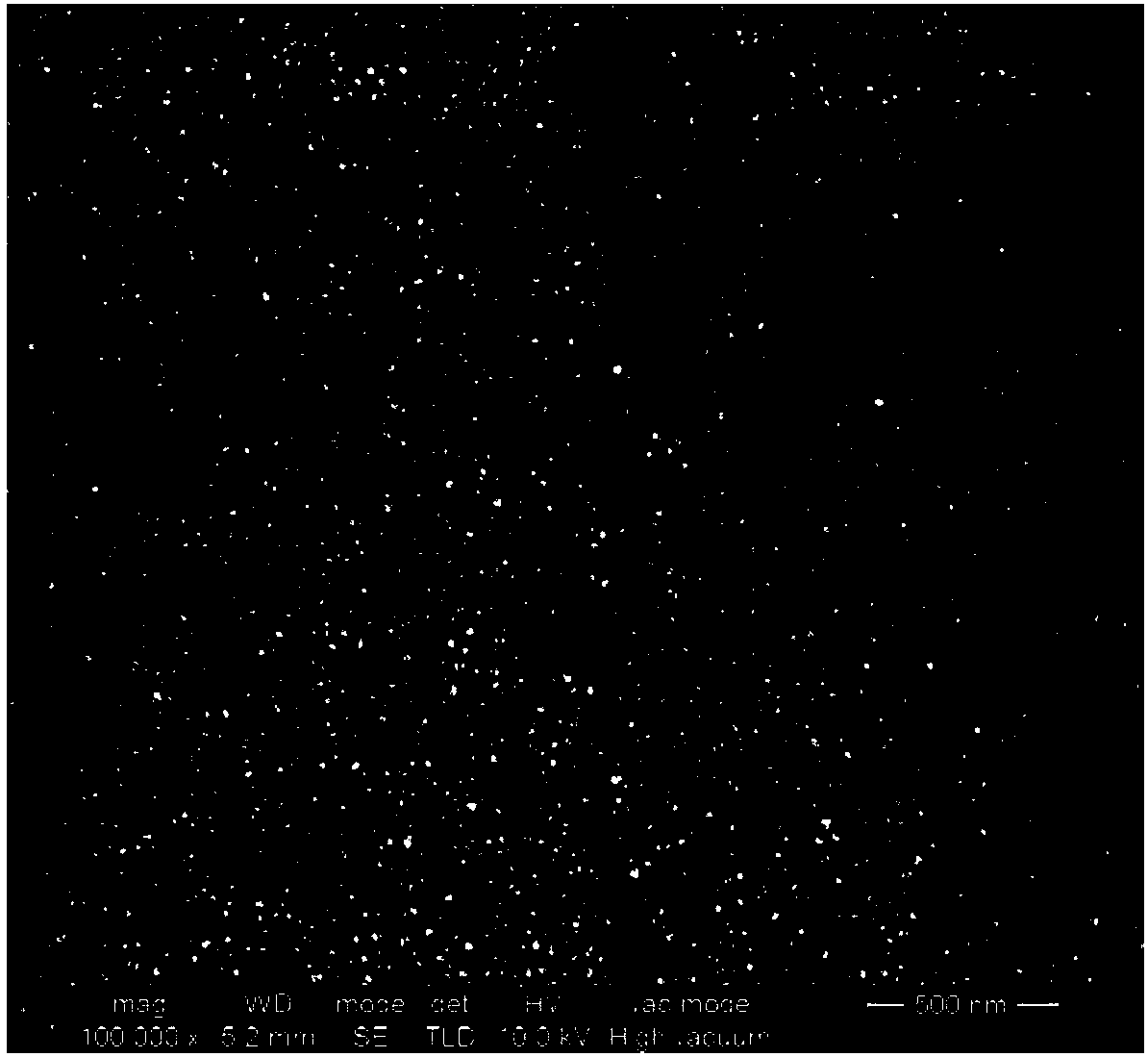

Reactive deposition for the formation of chip capacitors

InactiveUS6917511B1Fixed capacitor dielectricCapacitor manufactureReactive depositionAverage diameter

Methods for the production of ceramic chip capacitors include the deposition of at least two layers of electrical conductor and at least one layer of a dielectric between electrical conducting layers. The compositions in the dielectric layer are deposited from a flow in which flowing reactants react to form particles in a reaction driven by light at a light reaction zone. In some embodiments, a plurality of dielectric layers is deposited. Suitable dielectric materials include barium titanate. A collection of barium titanate particles can be formed in the coating process having an average diameter less than about 90 nanometers. Thus, ceramic chip capacitors can be formed with barium titanate particles having an average diameter less than about 90 nanometers.

Owner:NANOGRAM

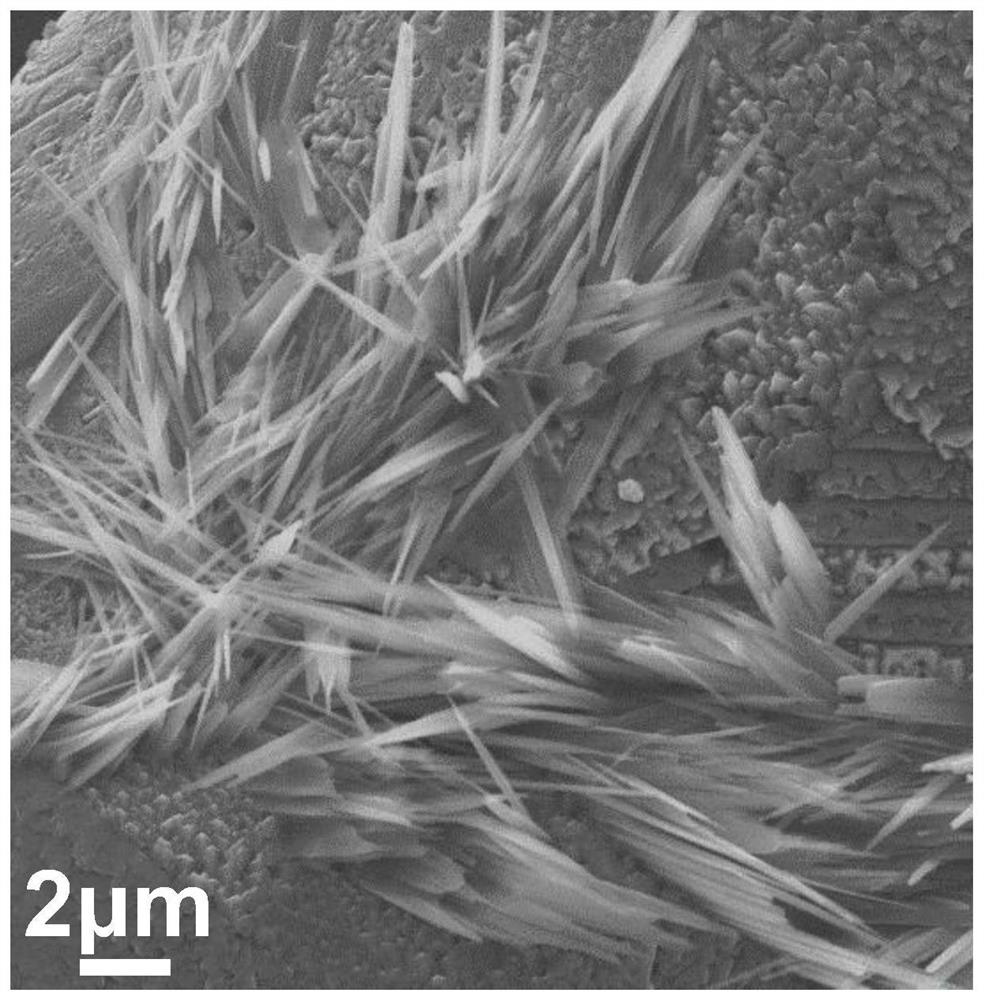

Preparation method of flaky zinc powder

ActiveCN103122468AThe process is reasonable and convenientSimple processElectrolysis componentsElectrochemical responseElectrolytic agent

The invention relates to a preparation method of flaky zinc powder. The preparation method comprises the following steps in sequence: machining metallic zinc into a flake and using the flake as a soluble anode; in an anode chamber of an electrochemical reactor, taking zinc sulfate and sulfuric acid water solution as an electrolyte, oxidizing the soluble anode into zinc ions and enabling the zinc ions to enter anolyte; and after solid-liquid separation and anolyte impurity removal, adding an alkyl glycoside surfactant to the anolyte and adjusting the pH value to 5.0-6.5, then injecting the electrolyte into a cathode chamber of the electrochemical reactor, carrying out electrochemical reduction reaction on the cathode and separating out metallic zinc through deposition, simultaneously starting an ultrasonic generating device to strip metallic zinc on the cathode and deposit metallic zinc in the electrolyte below the cathode and then obtaining the qualified flaky zinc powder through solid-liquid separation, washing, vacuum drying, screening and packaging. The preparation method has the advantages of reasonable and convenient process, safe and reliable preparation course and good prepared product quality.

Owner:YANGZHOU SHUANGSHENG ZINC IND

Reactive deposition for electrochemical cell production

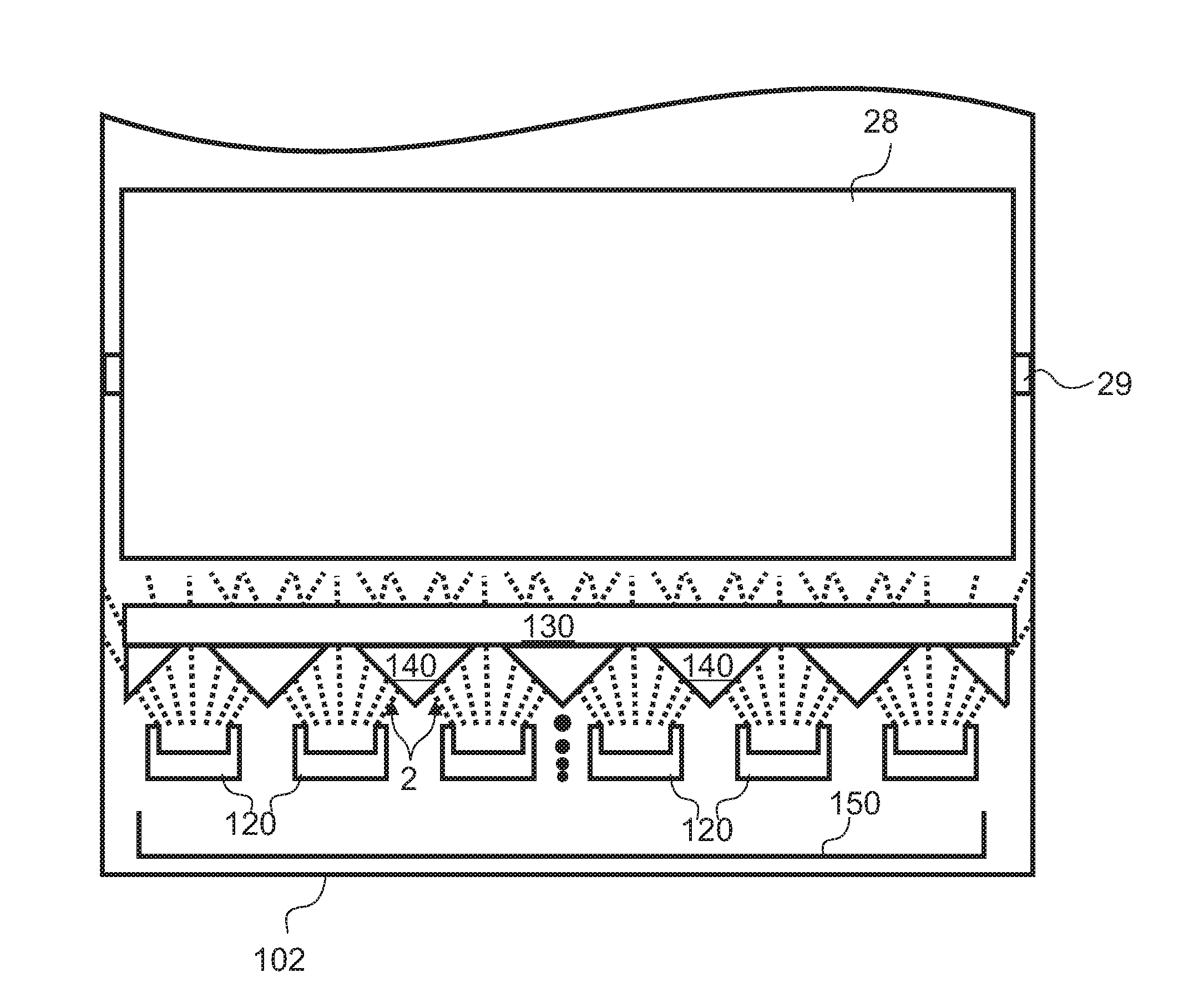

InactiveCN1820090ALiquid/solution decomposition chemical coatingChemical vapor deposition coatingPorosityElectricity

Photoreactive deposition can be effectively used to deposit one or more components of an electrochemical unit cell. Specifically, electrodes, electrolytes and electrical interconnects can be deposited from the reactive flow. In certain embodiments, the reaction stream includes a reactant stream that intersects the light beam to drive a reaction in the photoreaction zone to produce a product deposited on the substrate (422). This method is extremely versatile for the manufacture of a variety of compositions useful particularly in electrochemical cells and fuel cells. The properties of the material including density and porosity can be adjusted based on the deposition properties and any subsequent processing including, for example, thermal treatment.

Owner:NANOGRAM

Lithium secondary battery and positive electrode for lithium secondary battery

InactiveUS6979516B2Improve discharge capacityExcellent in charge-discharge cycle characteristicElectrode manufacturing processesElectrode carriers/collectorsLithium metalGas phase

Owner:SANYO ELECTRIC CO LTD

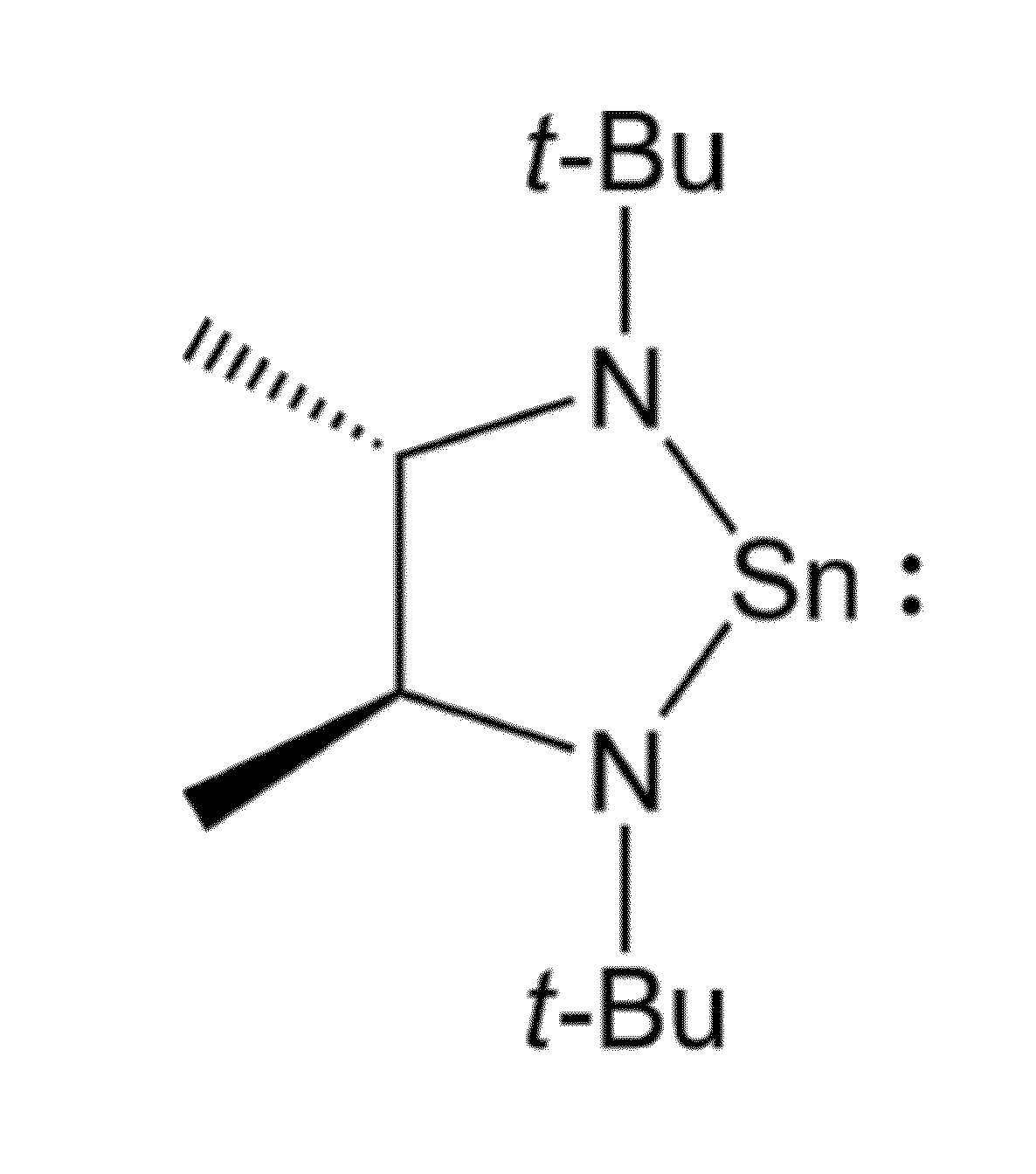

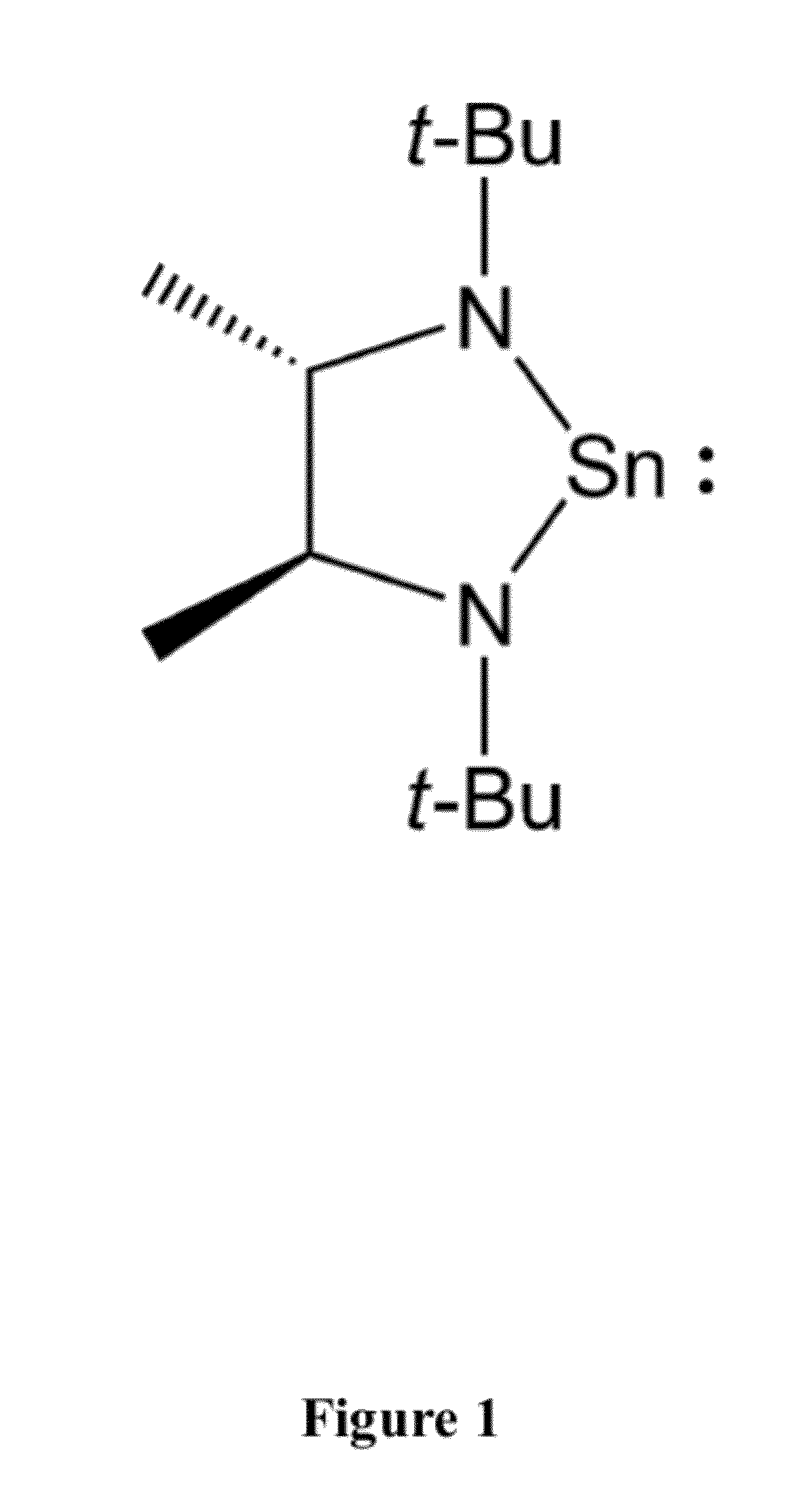

Cyclic metal amides and vapor deposition using them

ActiveUS8796483B2Flat surfaceImprove conductivityTin organic compoundsGroup 4/14 organic compounds without C-metal linkagesBorideGas phase

Novel cyclic amides containing tin or lead are disclosed. These cyclic amides can be used for atomic layer deposition or chemical vapor deposition of tin or lead as well as their oxides, sulfides, selenides, nitrides, phosphides, carbides, silicides or borides or other compounds. Tin(IV) oxide, SnO2, films were deposited by reaction of a cyclic tin amide vapor and H2O2 or NO2 as oxygen sources. The films have high purity, smoothness, transparency, electrical conductivity, density, and uniform thickness even inside very narrow holes or trenches. Deposition temperatures are low enough for thermally sensitive substrates such as plastics. Suitable applications of these films include displays, light-emitting diodes, solar cells and gas sensors. Doping SnO2 with aluminum was used to reduce its conductivity, making material suitable as the active semiconductor layer in electron multipliers or transparent transistors. Deposition using the same tin precursor and H2S deposited tin monosulfide, SnS, a material suitable for solar cells.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Lithium titanate composite electrode material with fluoride surface coating layer and preparation method thereof

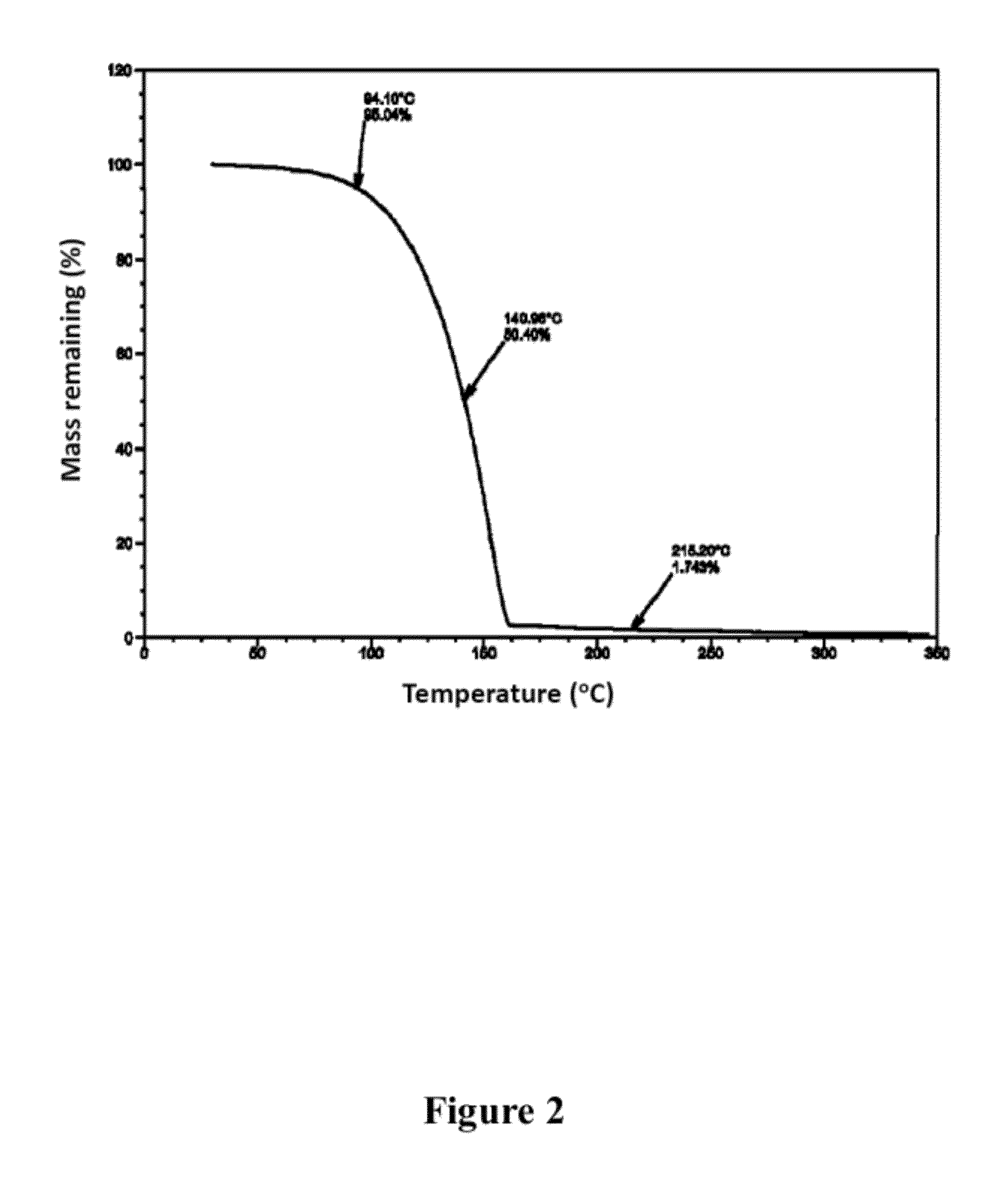

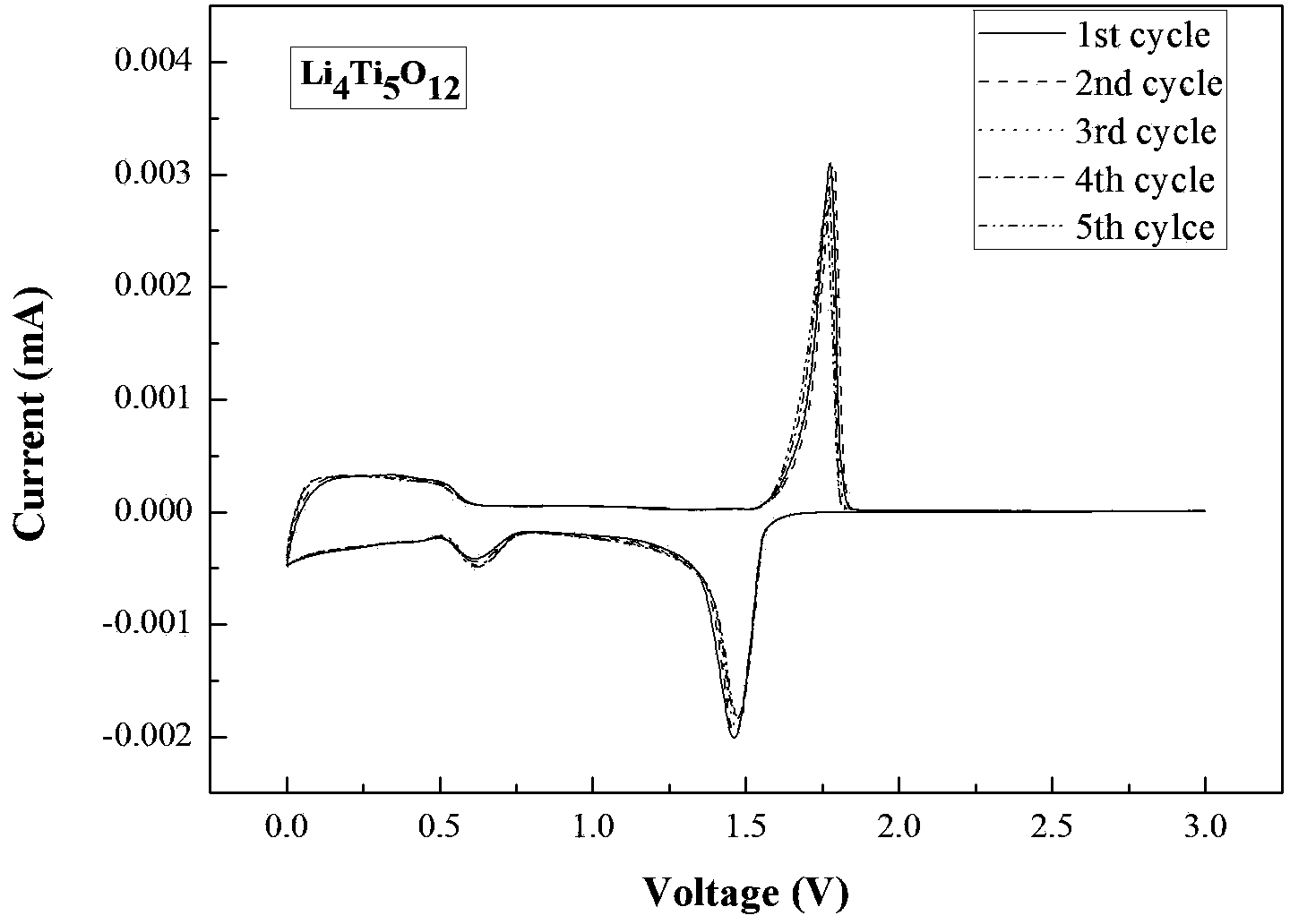

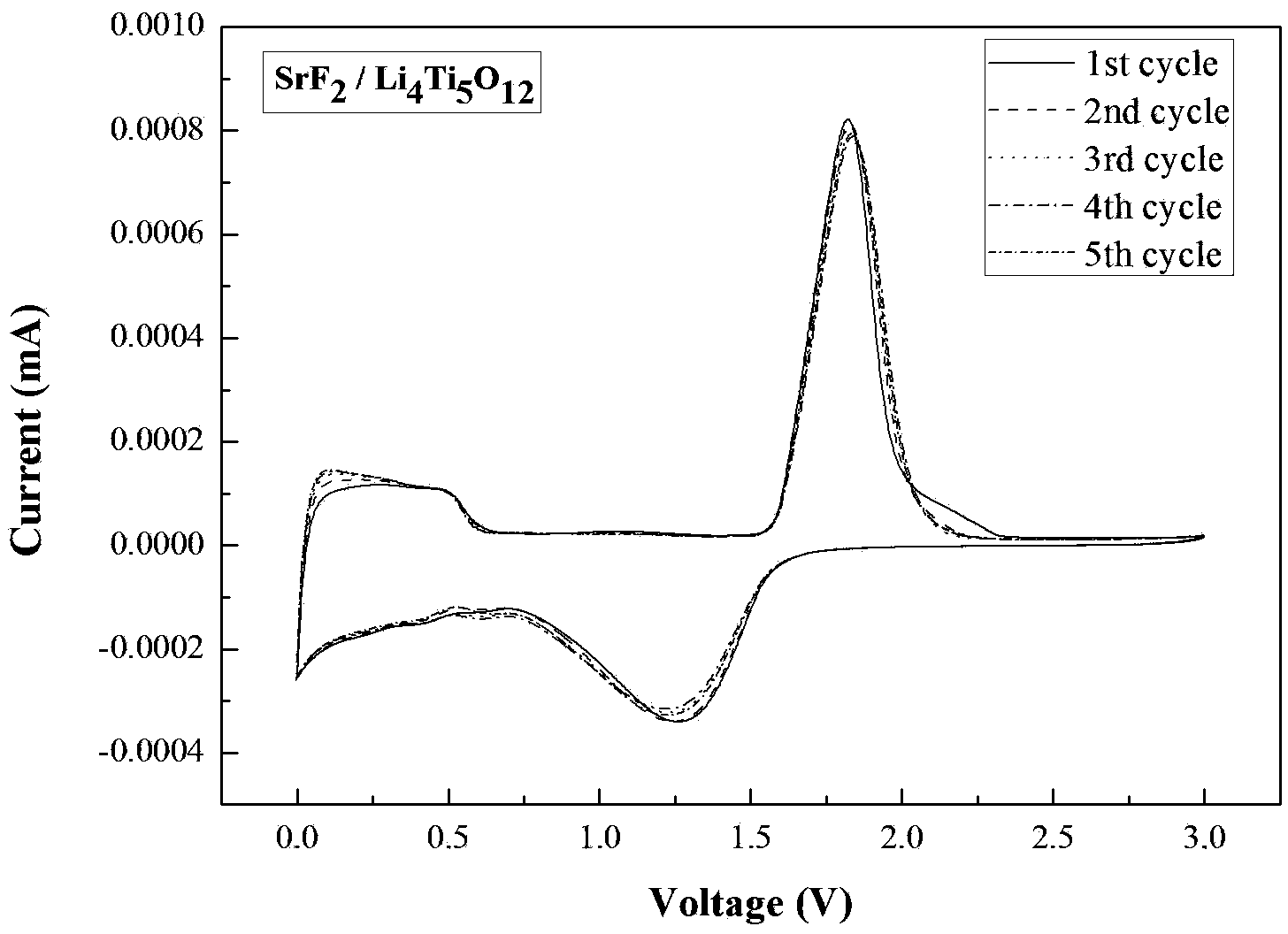

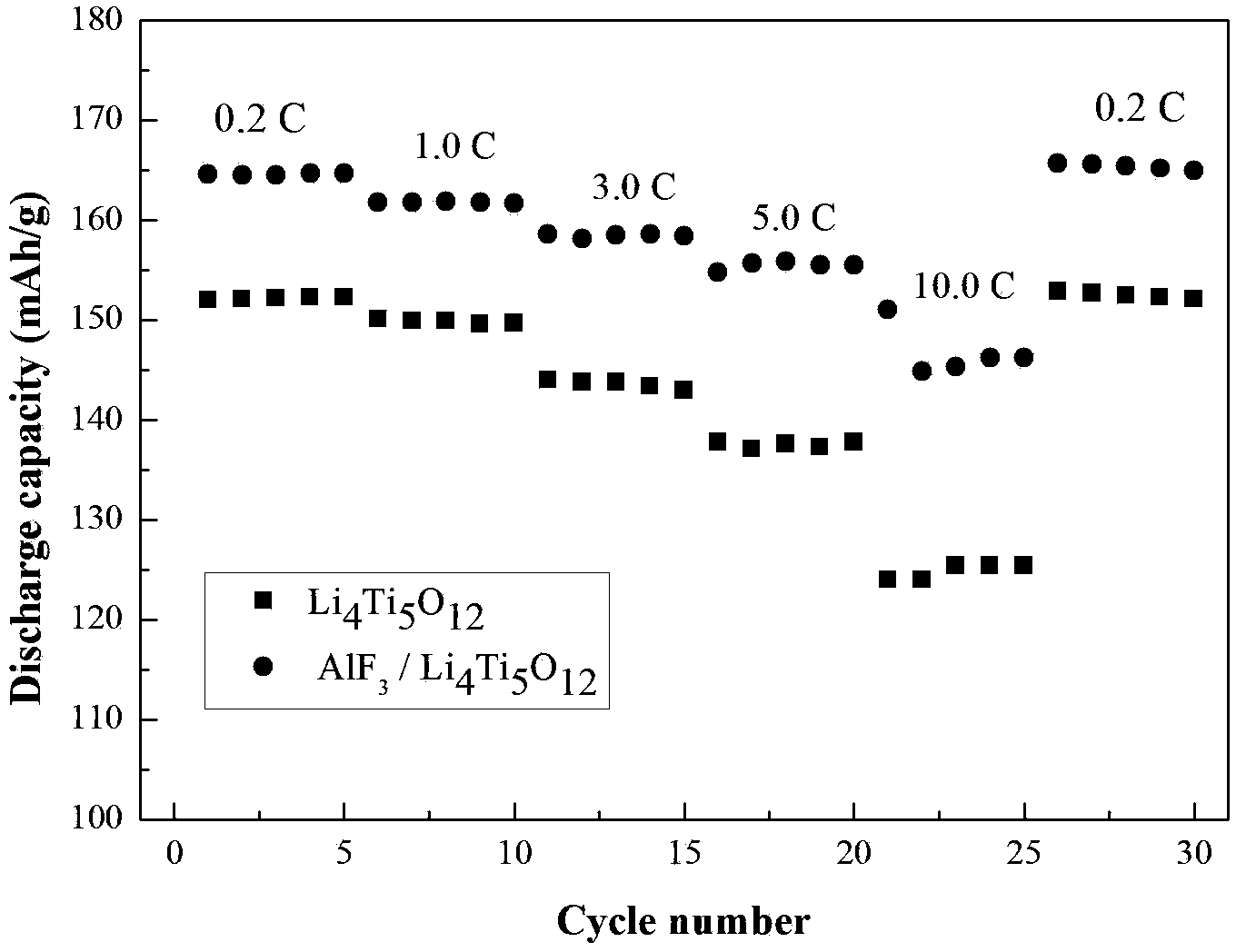

InactiveCN103474644AHigh capacity retentionExcellent rate performanceCell electrodesSecondary cells servicing/maintenanceMaterials scienceHeat treated

The invention discloses a lithium titanate composite electrode material with a fluoride surface coating layer and a preparation method thereof. The coating layer of the composite electrode material is fluoride (MxFy) of one or more types of metals, wherein M is lithium, magnesium, strontium, barium, aluminum or lead, the thickness of the coating layer is 0.1-100nm, the coating layer accounts for 0.01-20% of the mass ratio of the composite electrode material, and lithium titanate is a crystal material with a spinel structure. According to the preparation method, a water-soluble salt of M and ammonium fluoride are used as raw materials, and n the surface of lithium titanate is in situ coated with fluoride through in situ chemical reaction deposition in combination with inert atmosphere heat treatment. The coating layer of the composite electrode material can shield active spots on the surface of the lithium titanate electrode material so that the lithium titanate electrode material can not bloat and has the advantages of good rate performance, high capacity retention ratio and excellent cycle performance; and the lithium titanate composite electrode material is simple and convenient in process, low in cost and suitable for large-scale production and has a wide market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Gas system for reactive deposition process

A gas lance unit configured for a reactive deposition process with a plurality of spaced apart crucibles, wherein spaces are provided between the crucibles, is described. The gas lance unit includes a gas guiding tube having one or more outlets for providing a gas for the reactive deposition process, and a condensate guiding element for guiding a condensate, particularly an aluminum condensate, to one or more positions above the spaces.

Owner:APPLIED MATERIALS INC

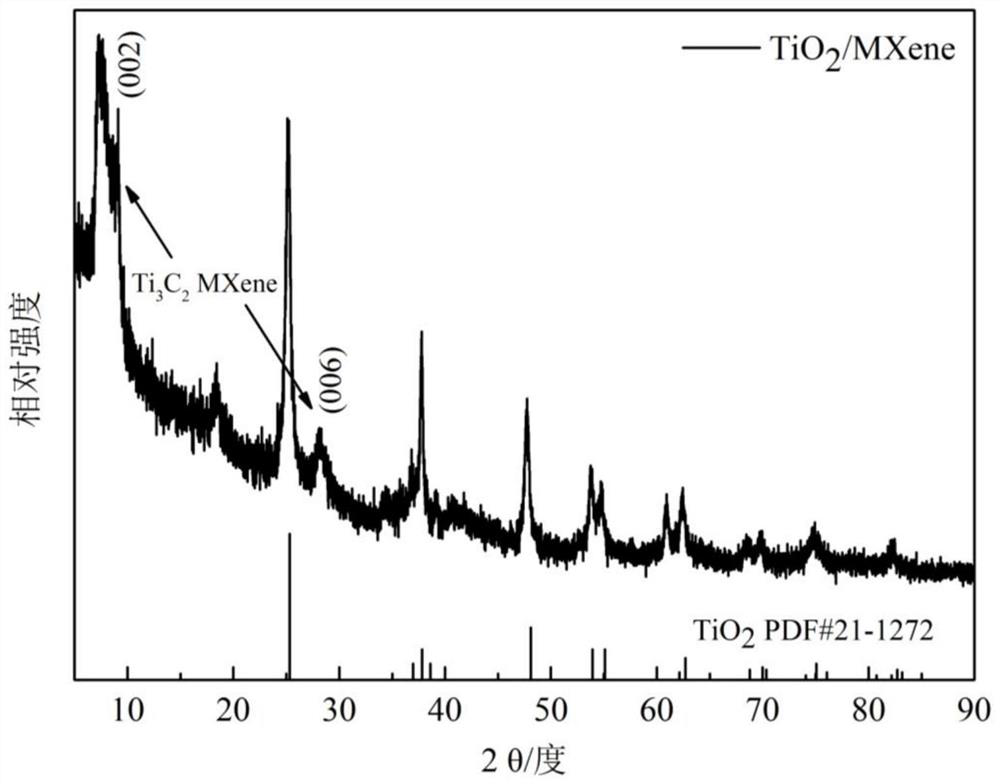

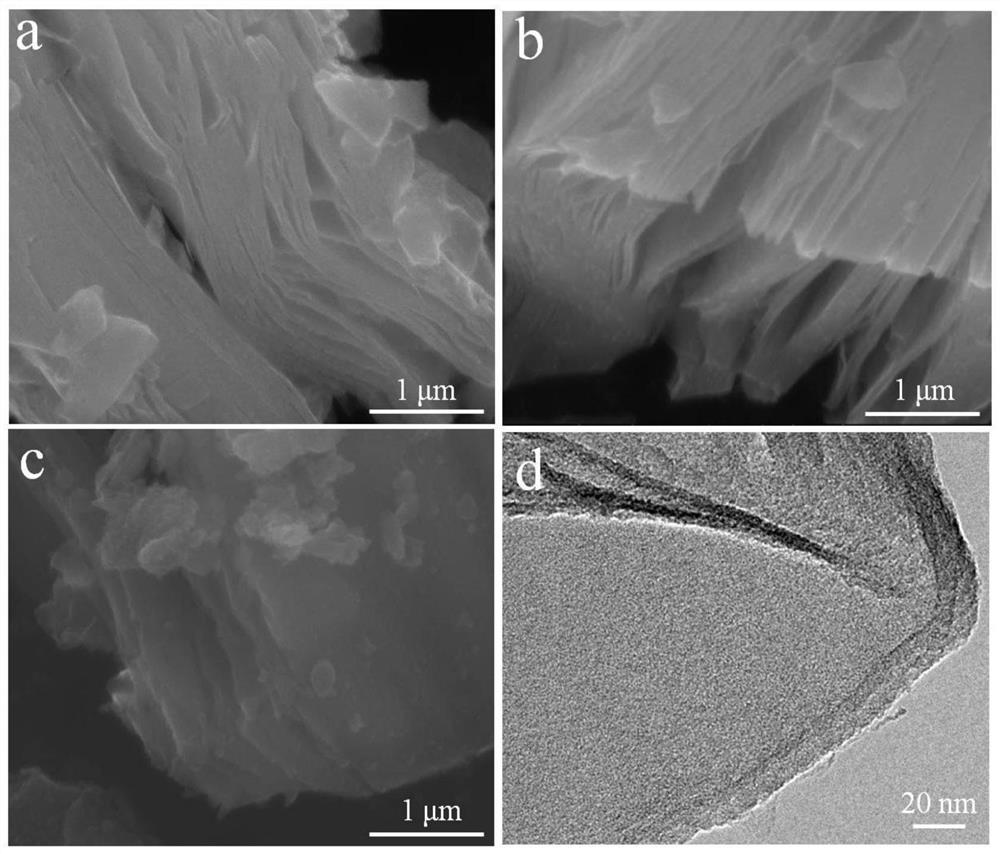

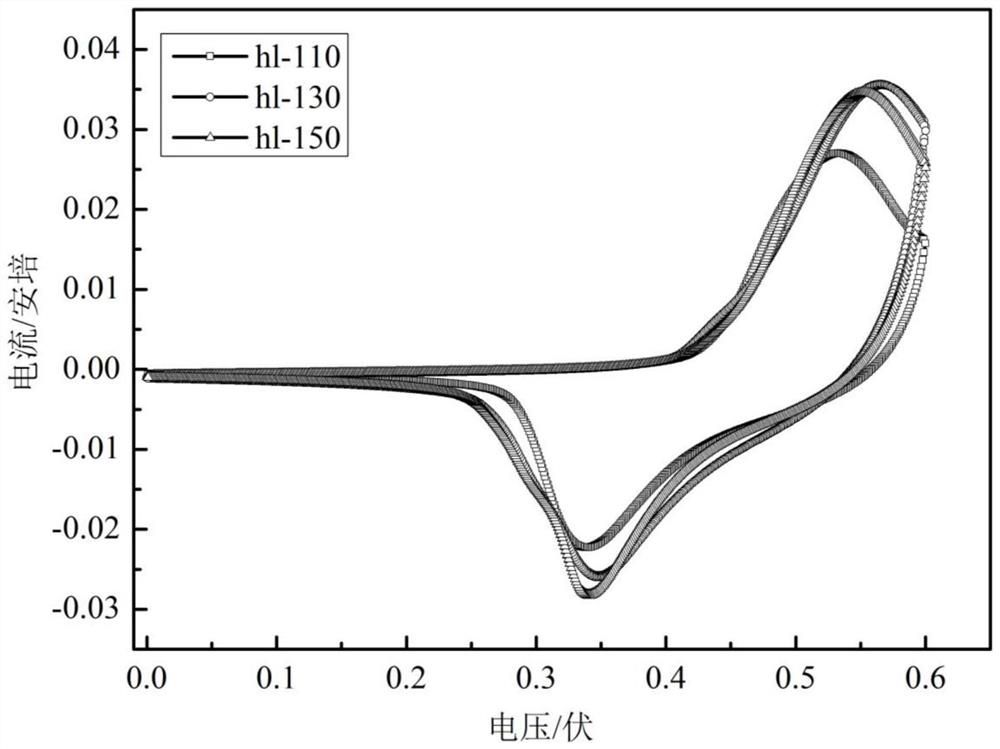

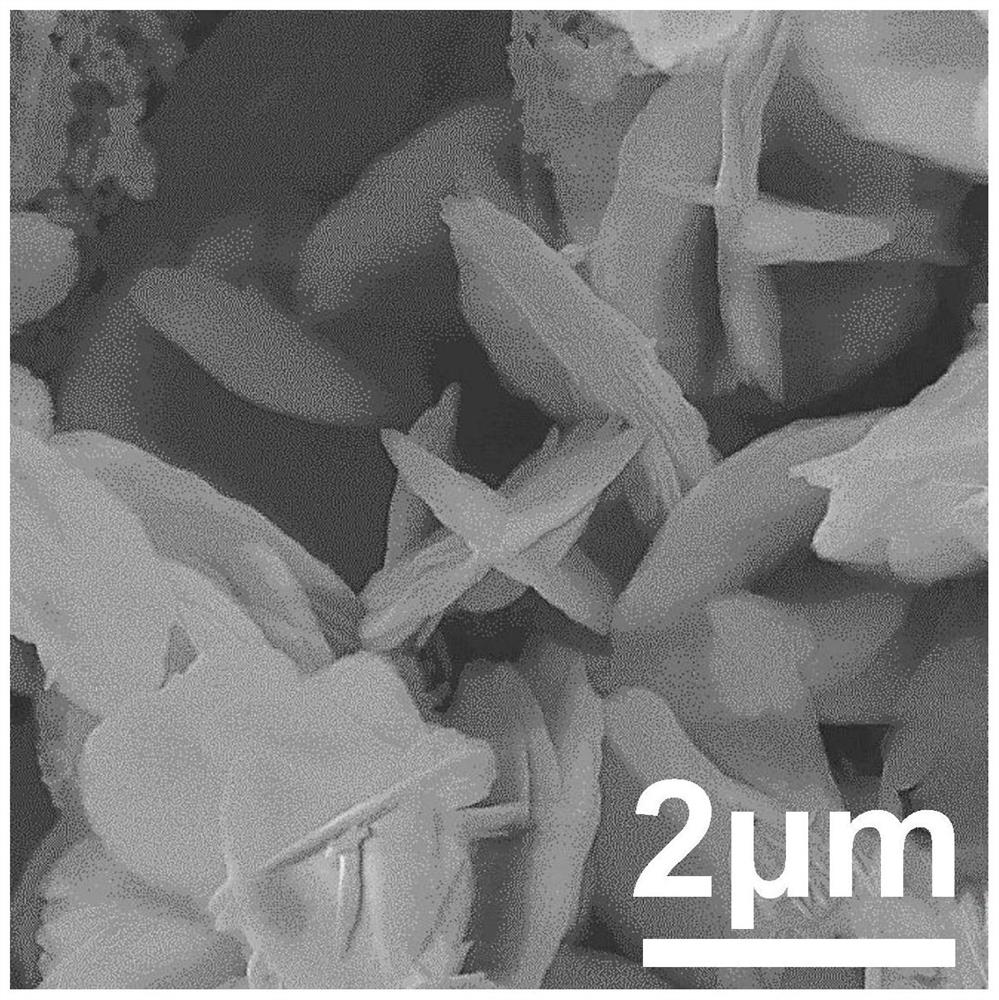

MXene two-dimensional material as well as preparation method and application thereof

ActiveCN111755685AIncrease layer spacingLarge specific surface areaCell electrodesTitanium carbideHydrogen fluorideReactive deposition

The invention discloses an MXene two-dimensional material and a preparation method thereof, and belongs to the field of materials. The MXene two-dimensional material comprises an MXene precursor and areaction deposition solution, wherein the reaction deposition solution is a mixed solution of villiaumite and boric acid; the villiaumite comprises one or more of ammonium fluoride, ammonium hydrogenfluoride and metal fluoride salt; the molar ratio of villiaumite to boric acid in the mixed solution is (0.01-0.3):(0.02-1.5), and the MXene precursor comprises any one or a combination of more thantwo of Ti3AlC2, Ti2AlC, V2AlC, Mo2AlC and Nb2AlC. According to the MXene two-dimensional material, villiaumite and boric acid are adopted as reaction deposition solution, the reaction is mild and easyto control, and the prepared MXene two-dimensional material has large interlayer spacing and large specific surface area. The invention further discloses a preparation method of the MXene two-dimensional material and application of the MXene two-dimensional material to electrode preparation.

Owner:NANCHANG INST OF TECH

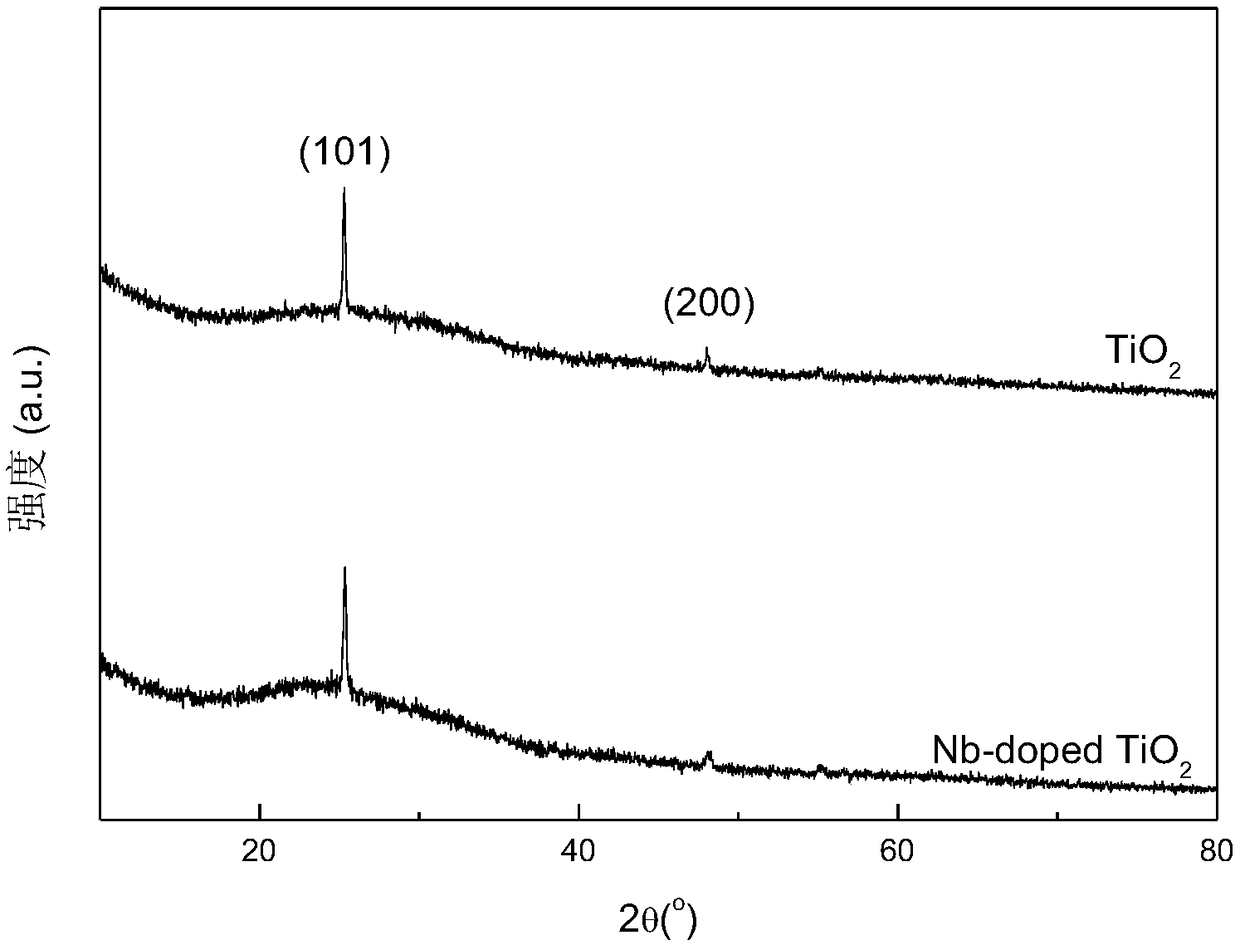

Niobium-doped titanium dioxide coated glass and preparation method thereof

The invention discloses a preparation method of a niobium-doped titanium dioxide coated glass. The preparation method adopts a chemical vapor deposition method, and comprises the following steps of (1) mixing a titanium source and a niobium source, so as to obtain a source material mixture; or, mixing the titanium source, the niobium source and a solvent, so as to obtain the source material mixture; (2) converting the source material mixture into vapor-phase reaction gas by an air bubbling or evaporating and gasifying method; (3) carrying the vapor-phase reaction gas to the pretreated high-temperature glass substrate by carrying gas, reacting, and depositing, so as to obtain the niobium-doped titanium dioxide coated glass. The prepared niobium-doped titanium dioxide coated glass has the advantages that the bonding force of a film layer is excellent, and the physical stability and chemical stability are good; the thin film is made of anatase-phase titanium dioxide, and the mass concentration of the niobium-doped material is 0.5 to 15%; the photo-induced super-hydrophilicity is realized; the niobium-doped titanium dioxide coated glass is prepared at high temperature, and is suitablefor the low-cost preparation of large-area coated film; the cleaning is easy, and the stain-resistant property is realized.

Owner:ZHEJIANG UNIV

Chromium carbide modified iron-based metal bipolar plate and preparation method thereof

ActiveCN102637880AGuaranteed StrengthDoes not affect strengthCell electrodesSolid state diffusion coatingContact resistanceSurface modification

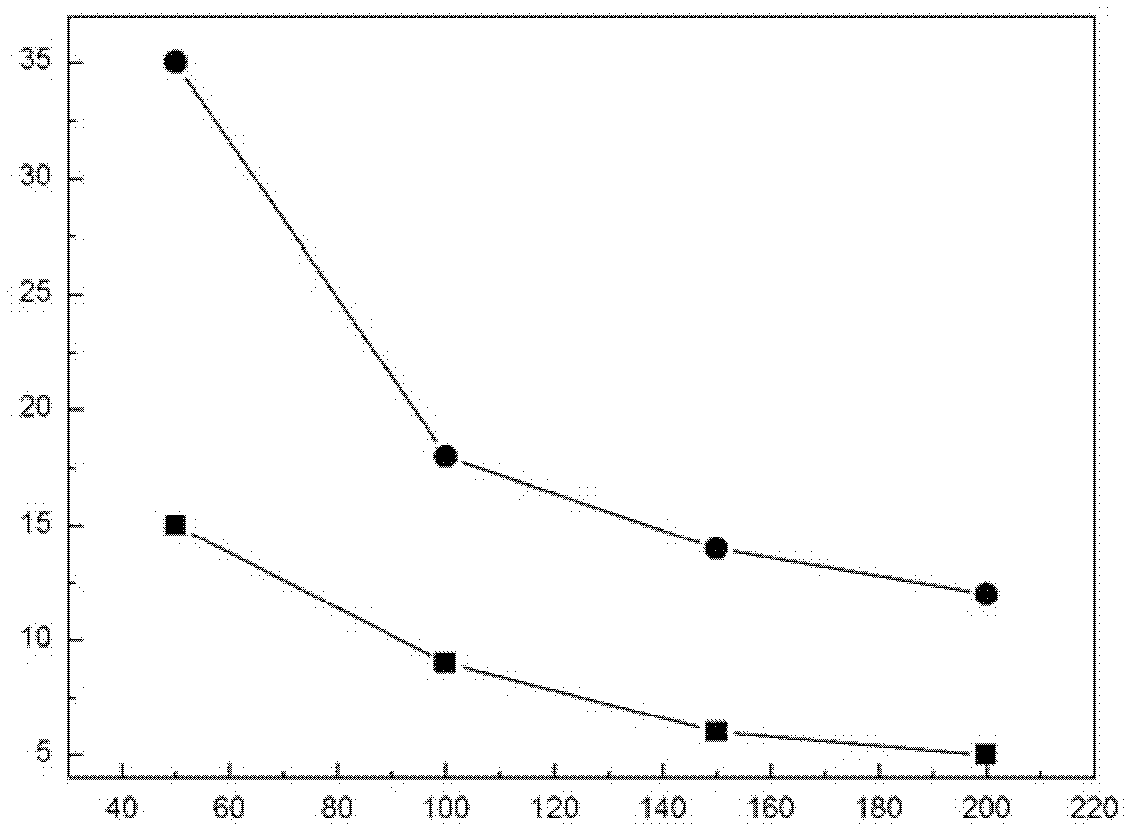

The invention provides a chromium carbide modified iron-based metal bipolar plate for a fuel battery and a preparation method thereof. An iron-based alloy metal plate is subjected to surface modification by using plasma carburization and a combined thermal reactive deposition and diffusion surface modification process. The modified surface of the metal plate is a chromium carbide diffusion layer with high conductivity and corrosion resistance, the thickness is 1-30 microns, and the corrosion speed is lower than 10 microamperes / square centimeter. When the pressure is 150-200 N / square centimeter, the contact resistance is 10-20 micro-ohms*square centimeter, and a chromium carbide diffusion layer is made of Cr3C2 and / or Cr7C3 and / or Cr23C6. According to the method provided by the invention, the corrosion resistance of the metal bipolar plate can be obviously improved in a condition of ensuring the intensity of the bipolar plate and not influencing battery properties of the bipolar plate. The chromium carbide diffusion layer with the modified surface and a base body are in metallurgical combination. Furthermore, components of the chromium carbide diffusion layer can be controlled by adjusting isothermal diffusion temperature and time.

Owner:DALIAN JIAOTONG UNIVERSITY

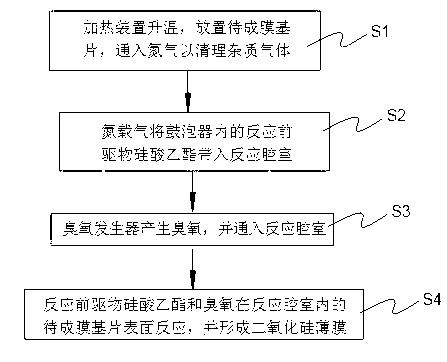

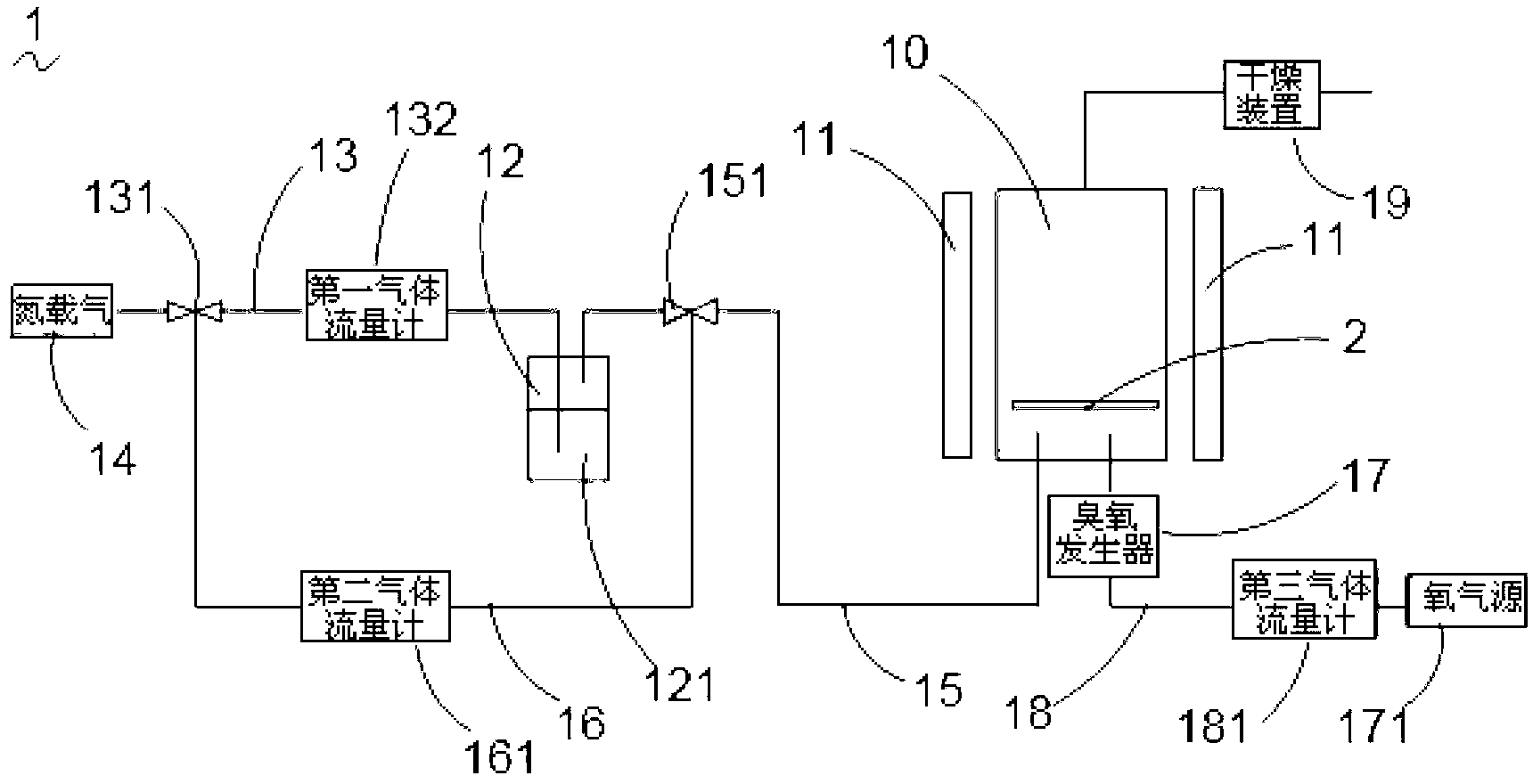

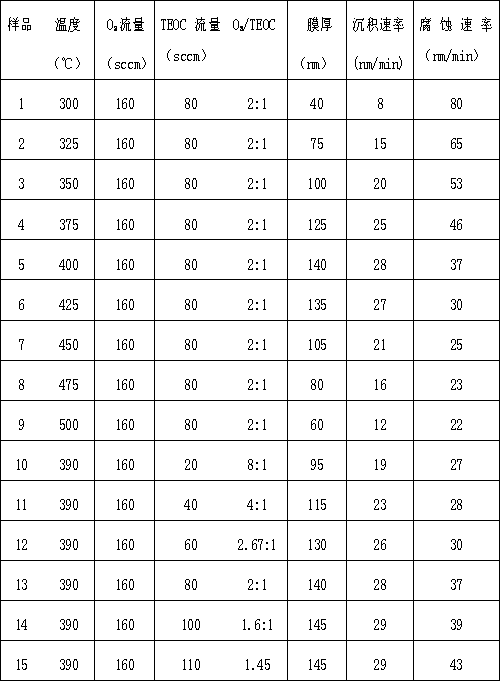

Production device for silicon oxide film and production method thereof

InactiveCN103305808ASimple production equipmentThe process is easy to controlChemical vapor deposition coatingSilicon oxideOxygen

The invention provides a production method of silicon oxide, and the production method comprises the following steps of: warming a heating device, setting a to-be-filmed substrate, and introducing nitrogen to remove the impurity gas in the reaction chamber; bringing the reaction precursor ethyl silicate into the reaction chamber by the nitrogen carrier gas; conveying the oxygen in an oxygen source to an ozone generator, conveying the generated ozone into the reaction chamber; performing reactive deposition on the surface of the to-be-filmed substrate by the precursor ethyl silicate and the ozone in the reaction chamber, so as to prepare the silicon oxide film. In the production method of the silicon oxide film provided by the invention, a thermal reaction mode is used, plasma damage of the to-be-filmed substrate is avoided, and the production device of the silicon oxide film is simple, the technological process is easy to control, and the deposition temperature of the silicon oxide film is lowered effectively. Moreover, the silicon oxide film is deposited on the top layer of the Low-E glass, the properties, such as acid and alkali corrosion resistance, oxidation resistance, heat and humidity resistance and high temperature resistance, of the functional glass are improved greatly.

Owner:林嘉佑

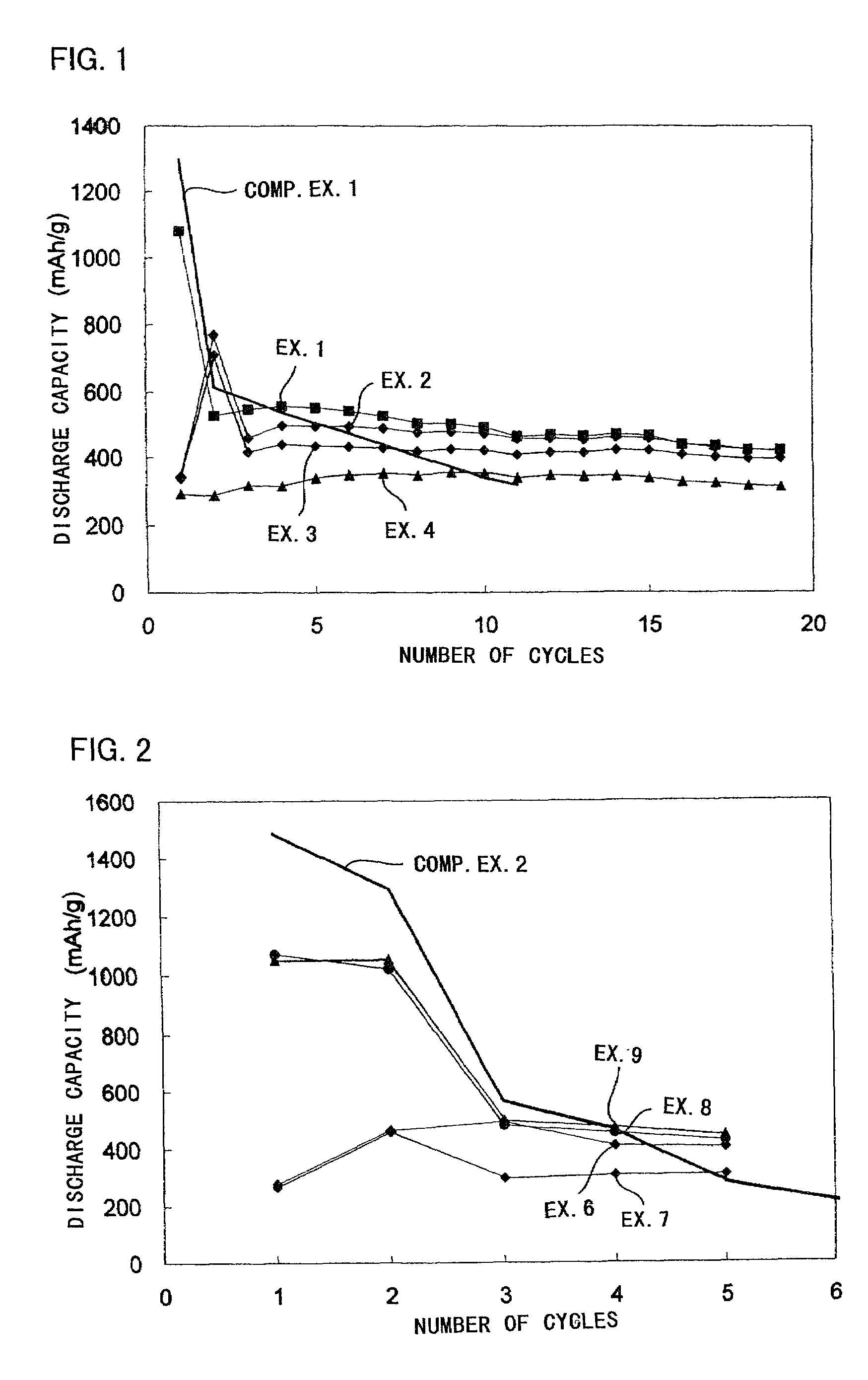

Nitride thin film of transition metal capable of being as anode material of batteries its preparation method

InactiveCN1447463AHigh specific capacityGood reversible cycleElectrode manufacturing processesChemical vapor deposition coatingLithium-ion batteryMaterials science

The invention discloses the new typed nitride Co3N, Fe3N and Ni3N thin films to be used as anode materials of lithium ion batteries. Under nitrogen atmosphere, the thin films can be obtained through the reactive deposition of pulse lasers. The particle sizes are 20-500 nm presenting the polycrystal cube structure. The discharge platforms are appeared at about 0.64V, 0.70V and 0.92V when the battery consists of the said thin films as the electrode and metal lithium. Excellent reversibility of charging and discharging cycles is maintained at 3.50-0.01 V and current density 7 micron A / cm2. The specific capacities are at about 420, 440 and 420 mAh / g. after 80 times of cycle, the loss of reversible capacity is less than about 5%.

Owner:FUDAN UNIV

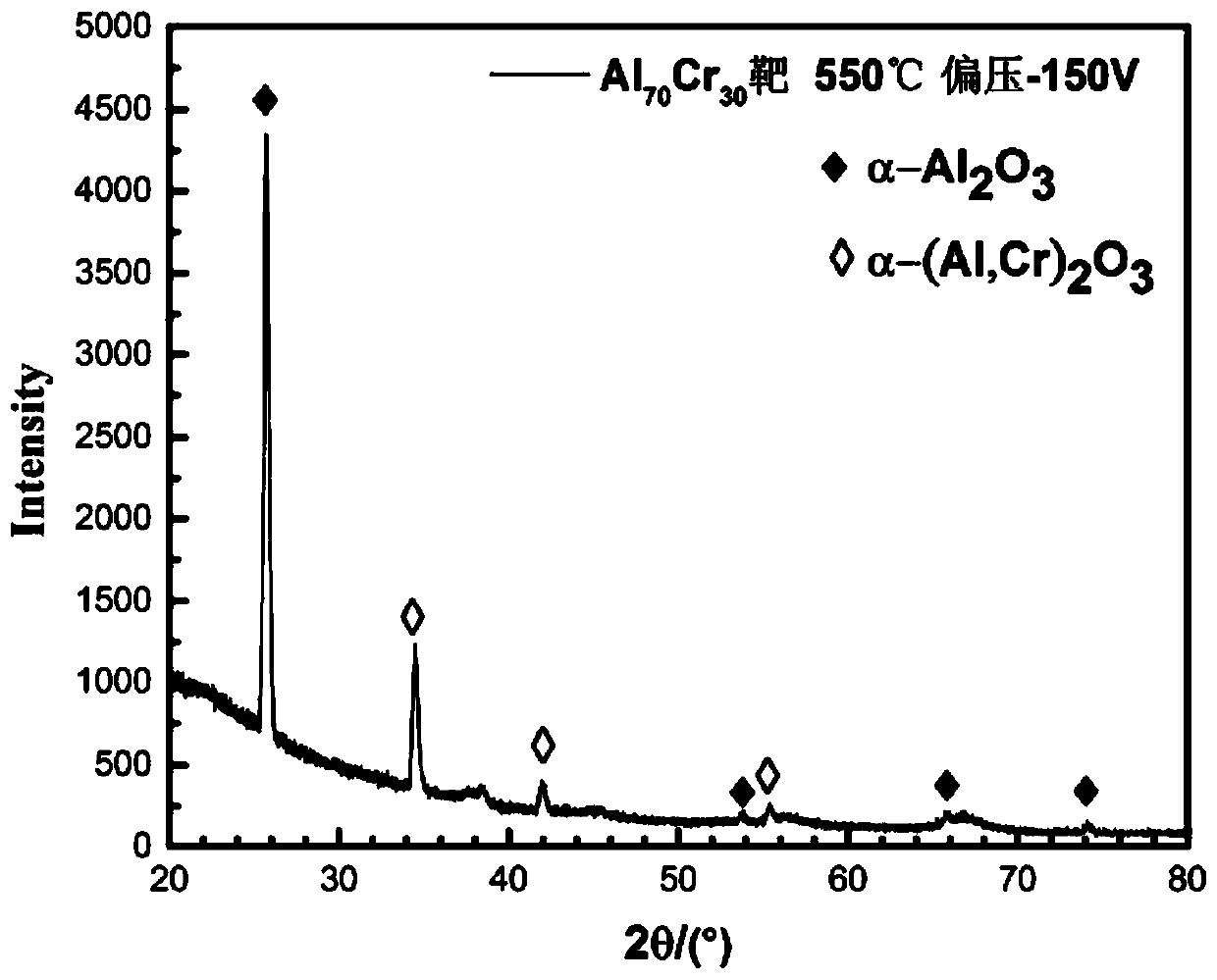

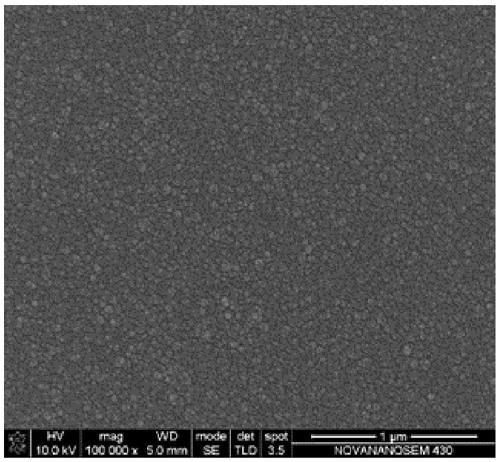

Al-rich corundum structure Al-Cr-O thin film and preparation method thereof

ActiveCN111455333AImprove thermal stabilityReduce coefficient of frictionVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringAlloy

The invention belongs to the technical field of metal and oxide coatings thereof, and discloses an Al-rich corundum structure Al-Cr-O thin film and a preparation method thereof. Firstly, a DC magnetron sputtering pure Cr target is used for preparing a pure Cr transition layer under the Ar gas condition and the matrix temperature ranging from 540 DEG C to 560 DEG , then the pulse DC negative bias voltage within the range from -150 V to -100 V is applied to a matrix, Ar+O2 mixed gas with the O2 partial pressure being 10%-12.5% is input, the matrix temperature is adjusted to range from 540 DEG Cto 560 DEG C, a radio frequency magnetron sputtering Al70Cr30 alloy target is used for reaction deposition, and the Al-rich corundum structure Al-Cr-O thin film is obtained. The thin film is composedof alpha-Al2O3 and alpha-(Al,Cr)2O3, and the maximum Al content can reach 39.9wt%.

Owner:SOUTH CHINA UNIV OF TECH

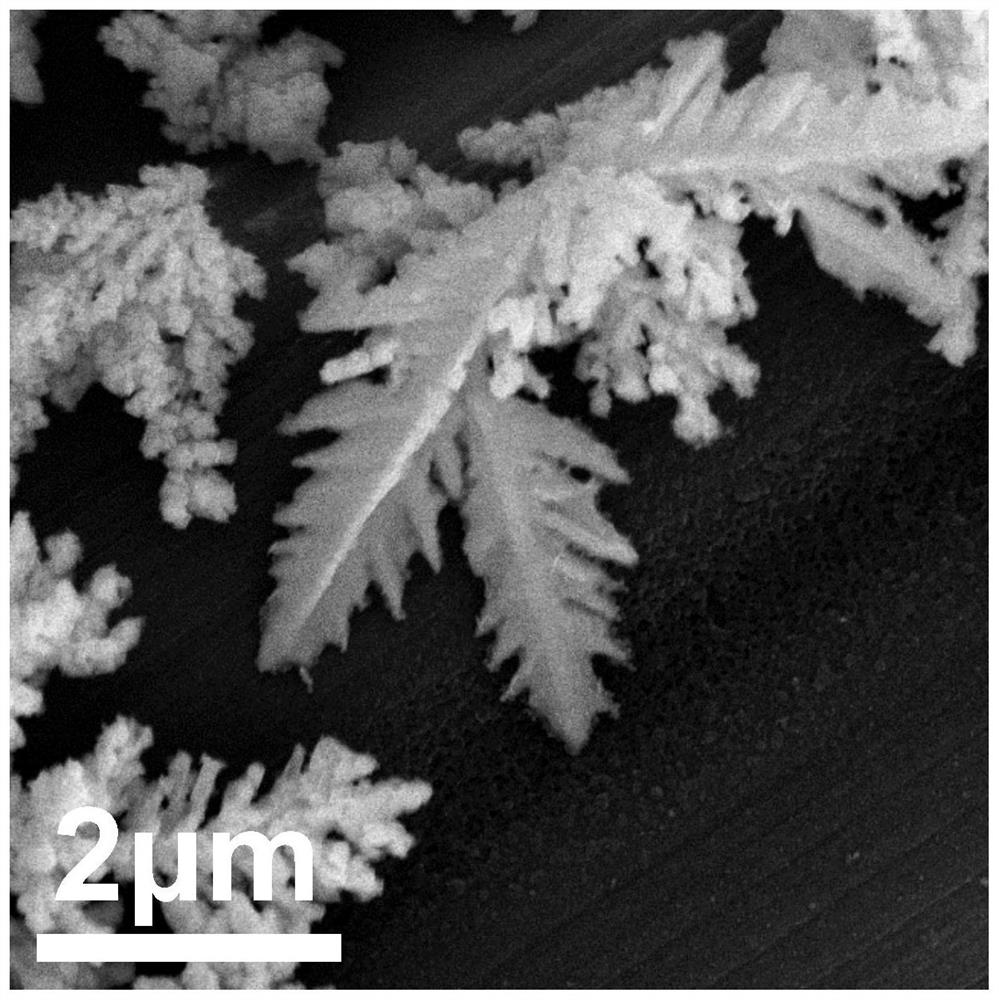

Preparation method of Bi/Cu catalyst for artificial photosynthesis

ActiveCN112342568AHigh reduction selectivityElectrolytic organic productionElectrodesPtru catalystReactive deposition

The invention relates to a preparation method of a Bi / Cu catalyst for artificial photosynthesis, which comprises the following steps of preparing an electrodeposition solution: adding bismuth chlorideBiCl3 and sodium citrate C6H9Na3O9 into a hydrochloric acid solution with the concentration of 1 mol / L or above, and sufficiently stirring the solution until the BiCl3 is completely dissolved and thesolution is transparent, thereby obtaining the electrodeposition solution, and electro-deposition reaction: forming a pair of electrodes by taking foamy copper as a cathode and a carbon rod as an anode, then immersing the electrodes into the prepared electrodeposition solution, carrying out constant-potential deposition reaction, and depositing 3-6 C charge quantity to obtain the Bi / Cu catalyst.Due to the fact that replacement reaction occurs under the acidic condition, Cu on the surface of the copper substrate is replaced into a solution and then deposited on the substrate again, and the coralline Bi / Cu catalyst with copper as a framework is formed. The Bi / Cu catalyst prepared through artificial photosynthesis has very high CO2 reduction selectivity.

Owner:NANJING UNIV +1

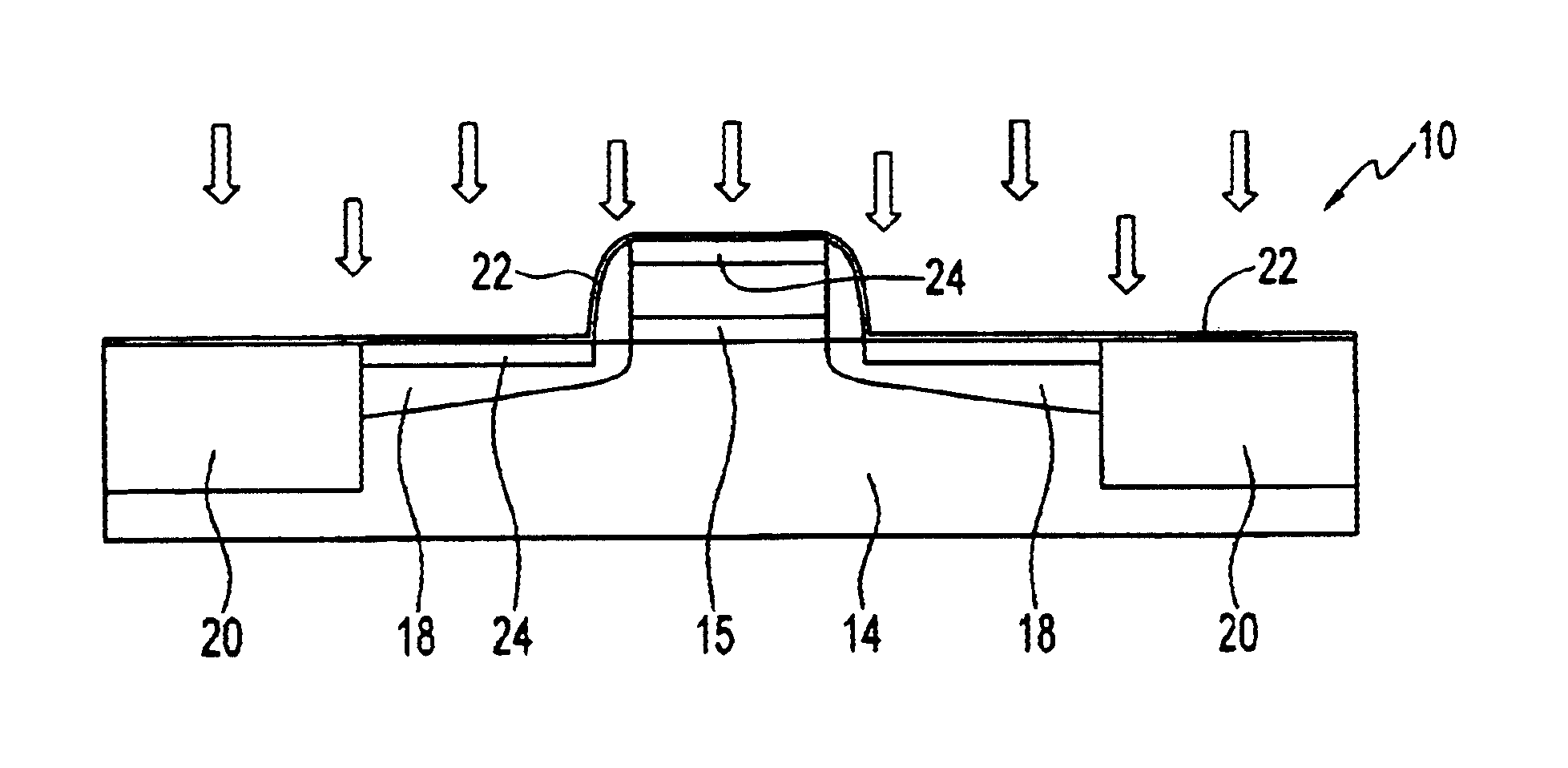

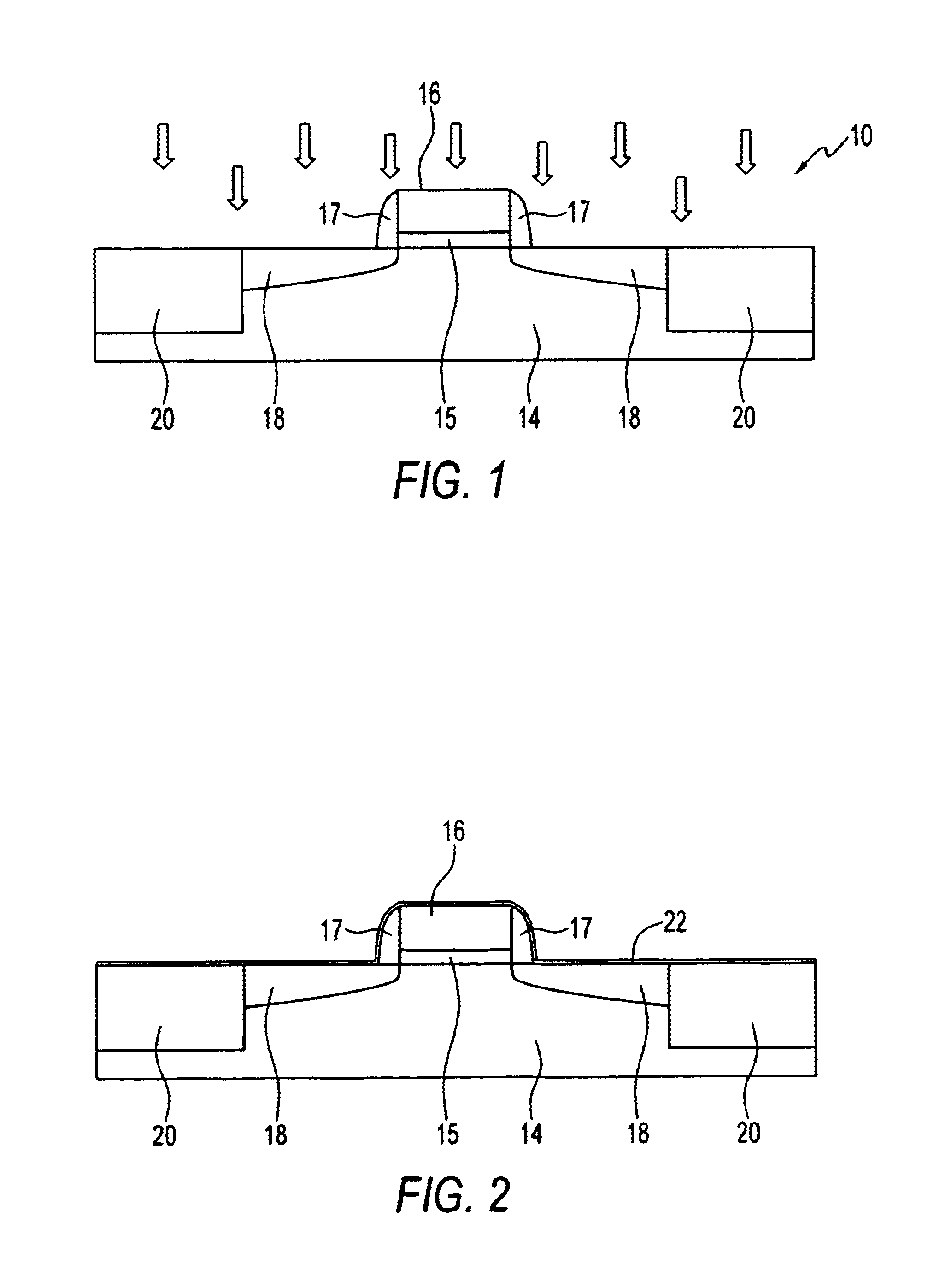

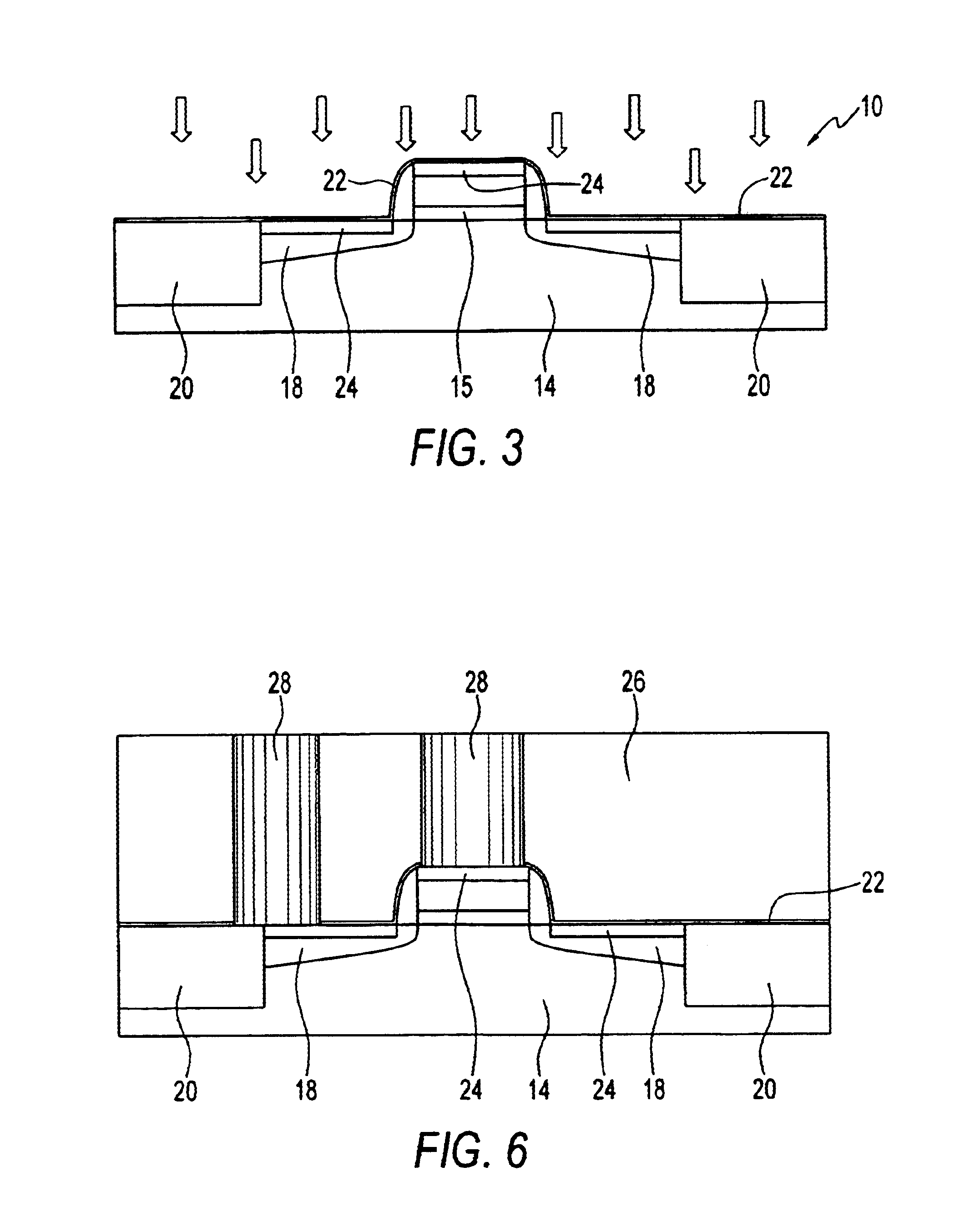

Epitaxial CoSi2 on MOS devices

An SixNy or SiOxNy liner is formed on a MOS device. Cobalt is then deposited and reacts to form an epitaxial CoSi2 layer underneath the liner. The CoSi2 layer may be formed through a solid phase epitaxy or reactive deposition epitaxy salicide process. In addition to high quality epitaxial CoSi2 layers, the liner formed during the invention can protect device portions during etching processes used to form device contacts. The liner can act as an etch stop layer to prevent excessive removal of the shallow trench isolation, and protect against excessive loss of the CoSi2 layer.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

AlCrSiN/VSiN multi-layer nano-coating and preparation method thereof

ActiveCN107740053AImprove wear resistanceInhibition of Diffusion ReactionVacuum evaporation coatingSputtering coatingEvaporationOxidation resistant

The invention provides a preparation method of an AlCrSiN / VSiN multi-layer nano-coating. The preparation method of the AlCrSiN / VSiN multi-layer nano-coating comprises the following steps that (a) cathode electric arcs are used for achieving evaporative deposition of an Al50Cr50N transition layer on the surface of a matrix; and (b) a VSi target is sputtered through a high-power pulse magnetic control power supply, a direct-current arc power supply is used for achieving cathode evaporation of an AlCrSi target, and reactive deposition of the AlCrSiN / VSiN multi-layer nano-coating is achieved in the mixed atmosphere of Ar gas and N2 gas. According to the preparation method of the AlCrSiN / VSiN multi-layer nano-coating, the electric arc ion plating technique and the high-power pulse magnetron sputtering technique are used in a quasi coupling mode, so that the element V is prevented from being diffused outwards rapidly through a multi-layer nanostructure and a composite nanostructure, the high-temperature mechanical performance, the high temperature resistance and the oxidization resistance of the coating are improved, and the diffusion reaction between titanium and the coating at a high temperature is restrained; and under the synergistic effect of the multi-layer nanostructure, the composite nanostructure and the doped element V, the surface of the AlCrSiN / VSiN multi-layer coating has high temperature oxidization resistance, self-lubrication performance and high abrasion resistance, and the AlCrSiN / VSiN multi-layer nano-coating which is of the multi-layer nanostructure and has high bonding force, excellent temperature resistance and self-lubrication performance is finally obtained.

Owner:GUANGDONG UNIV OF TECH

Method for preparing surface SiC-C coating of carbon material in graphite-heating-element furnace

The invention relates to a method for preparing a surface laminated SiC-C coating of a carbon material in a graphite-heating-element heating furnace. The method is characterized by comprising the steps: vacuumizing the graphite-heating-element heating furnace subjected to high-temperature treatment, and heating the graphite-heating-element heating furnace to 1,100 DEG C to 1,250 DEG C; then, introducing argon gas into the heating furnace, starting to introduce hydrogen gas into the heating furnace 15 to 30 minutes later, and starting to introduce trichloromethylsilane (MTS) into the heating furnace 15 to 30 minutes later when the internal environment of the furnace is stable; carrying out a chemical vapor deposition reaction in the furnace for 5 to 10 hours, then, stopping to introduce trichloromethylsilane, starting to introduce propylene gas into the heating furnace 15 to 30 minutes later, carrying out a gas-phase reaction to pyrolyze a carbon interface layer, and continuing to introduce the hydrogen gas and the argon gas according to original gas flow; stabilizing the furnace inside temperature to 900 DEG C to 1,100 DEG C, stopping to introduce the propylene gas 1 to 5 hours later, introducing trichloromethylsilane into the heating furnace again 15 to 30 minutes later, and continuing to carry out a reaction, so as to deposit an SiC coating; and carrying out repeated deposition on the SiC coating and the C interface layer for 5 to 10 times in this way, thereby obtaining the surface laminated SiC-C coating of the carbon material in the graphite-heating-element heating furnace. The chemical vapor deposited silicon carbide coating and the pyrolytic carbon layer are uniform and dense, and the protection and service life of the carbon material caused by the coating is prolonged due to the laminated structure.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Closed loop control

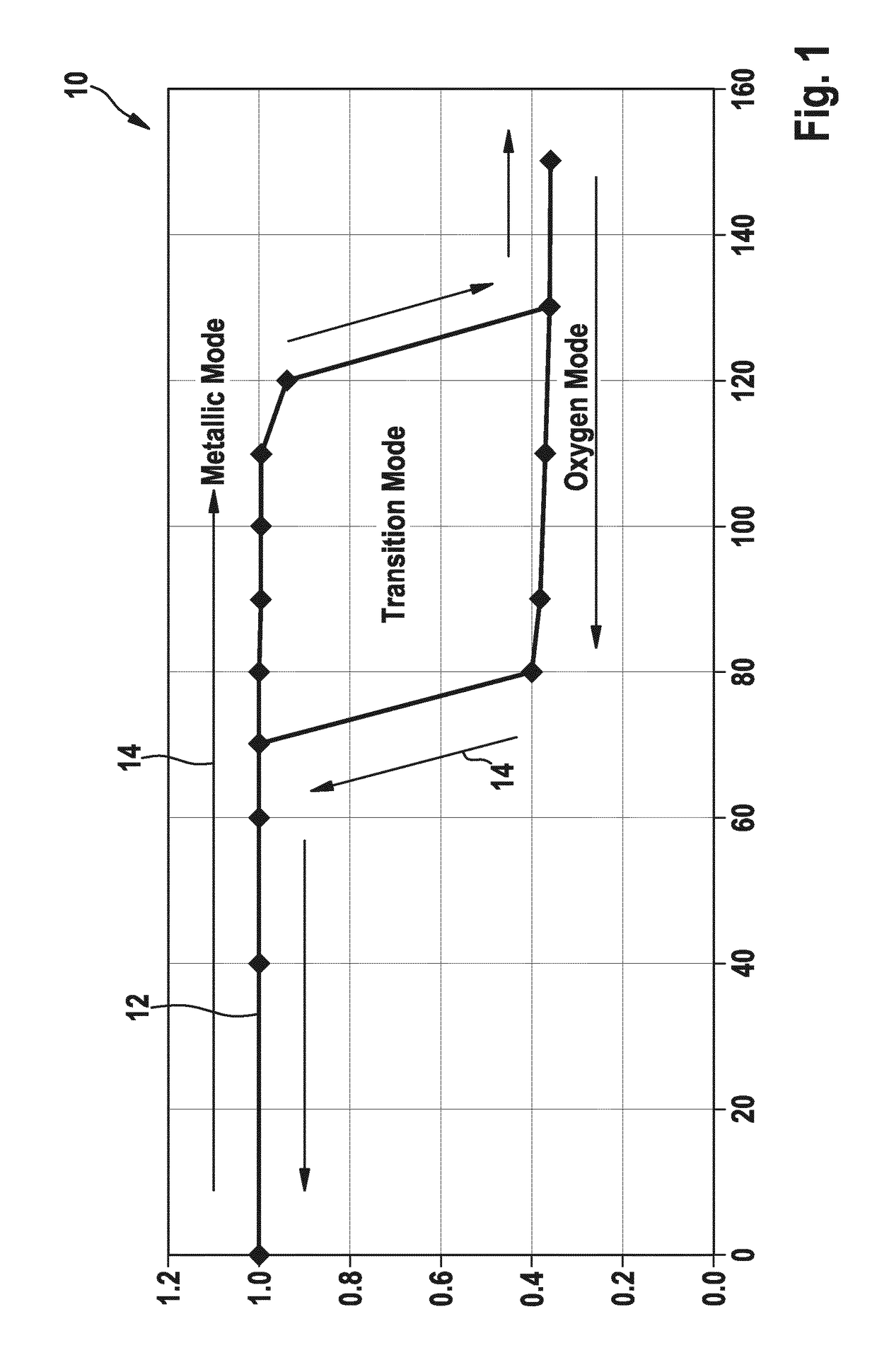

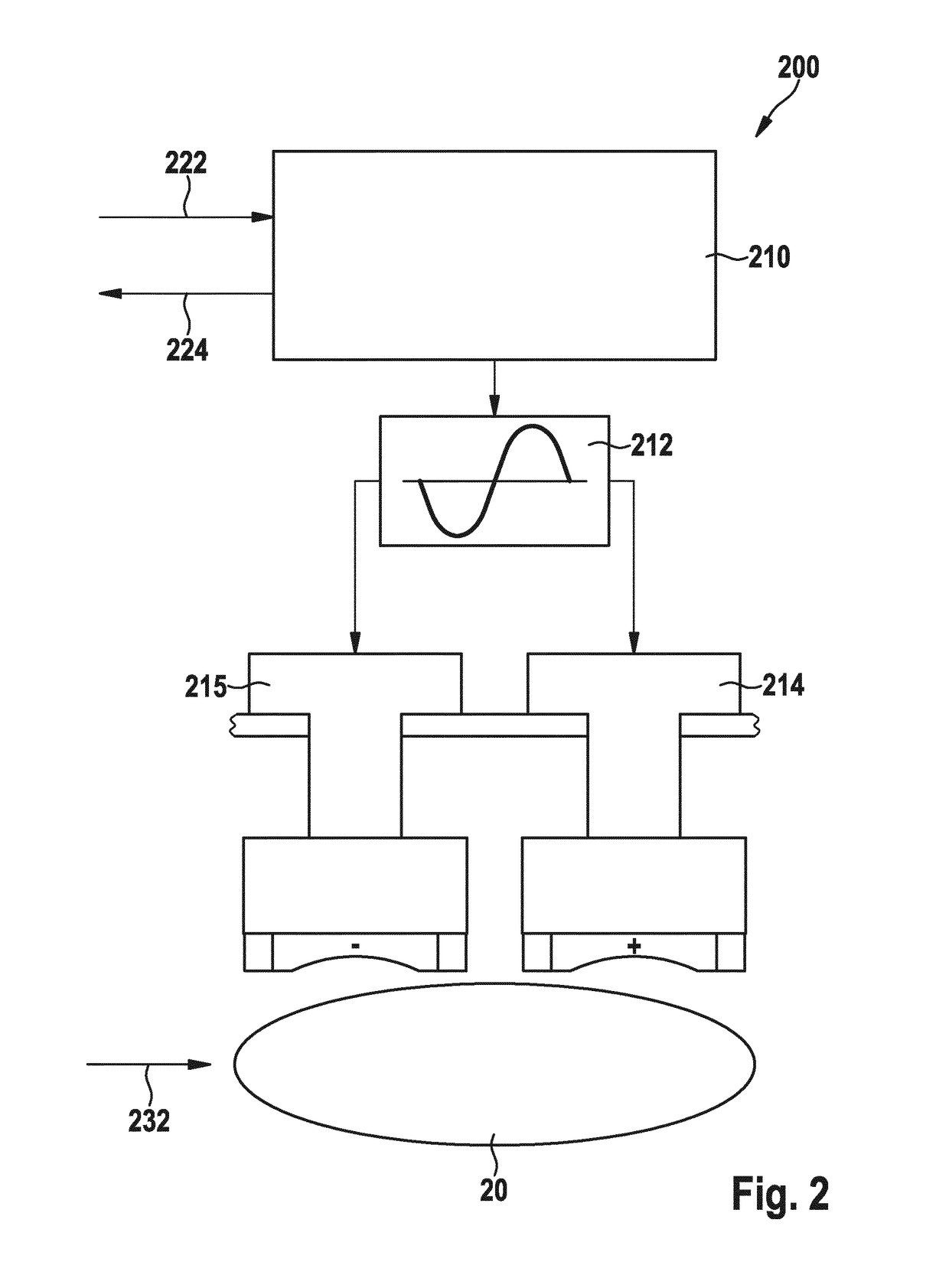

InactiveUS9758855B2Electric discharge tubesVacuum evaporation coatingLoop controlReactive deposition

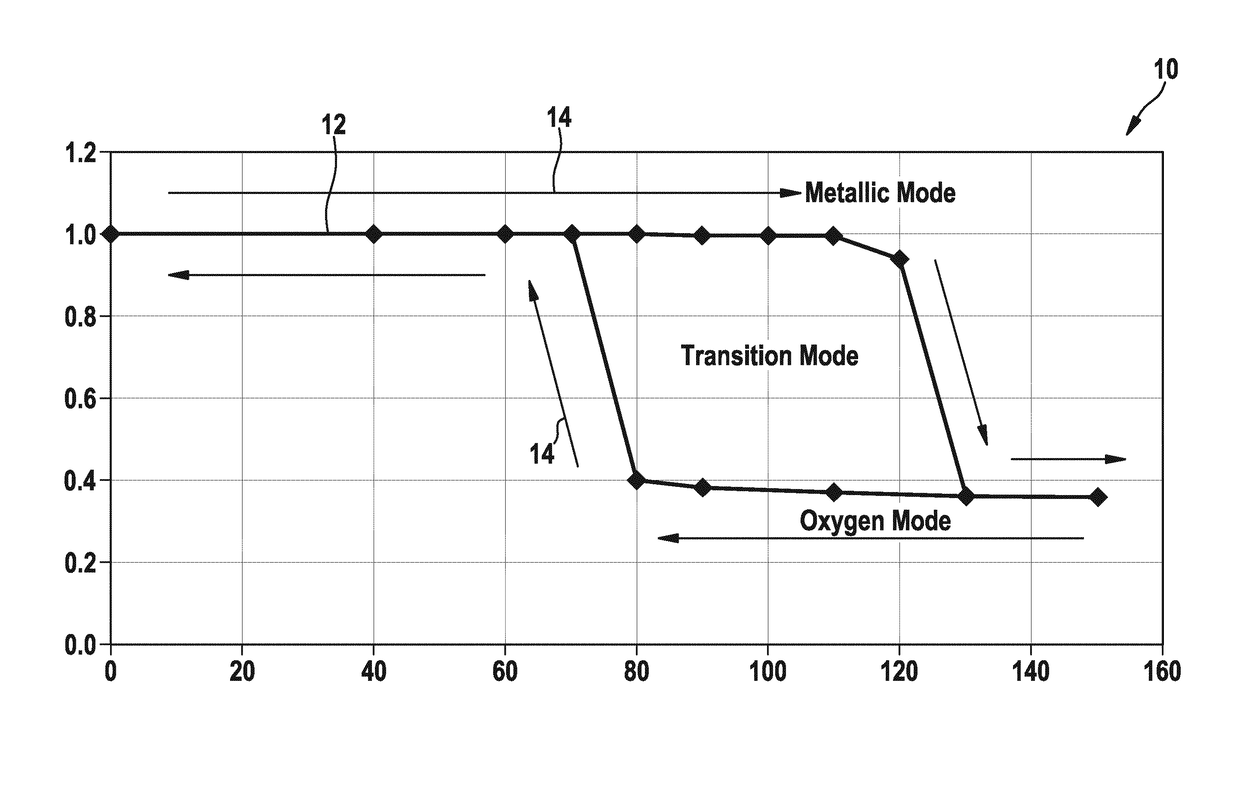

A method of controlling a reactive deposition process and a corresponding assembly and / or apparatus are described. The method includes providing power to a cathode with a power supply, providing a voltage set point to the power supply, receiving a power value correlating the power provided to the cathode, and controlling a flow of a process gas in dependence of the power value to provide a closed loop control for the power value.

Owner:APPLIED MATERIALS INC

Lithium secondary battery and positive electrode for lithium secondary battery

InactiveUS20020168571A1Not easily brokenDecrease of capacity can be suppressedElectrode manufacturing processesElectrode carriers/collectorsLithium metalGas phase

A lithium secondary battery comprises a negative electrode containing lithium metal or a material previously storing lithium as an active material, a positive electrode containing a positive active material, and an electrolyte containing a non-aqueous electrolyte solution. The positive active material is a thin film formed by depositing on a substrate from vapor phase or liquid phase and including an oxide containing at least iron as a main constituent by a sputtering method, a reactive deposition method, a vacuum deposition method, a chemical vapor deposition method, a spraying method, a plating method, or a method in combination of these methods.

Owner:SANYO ELECTRIC CO LTD

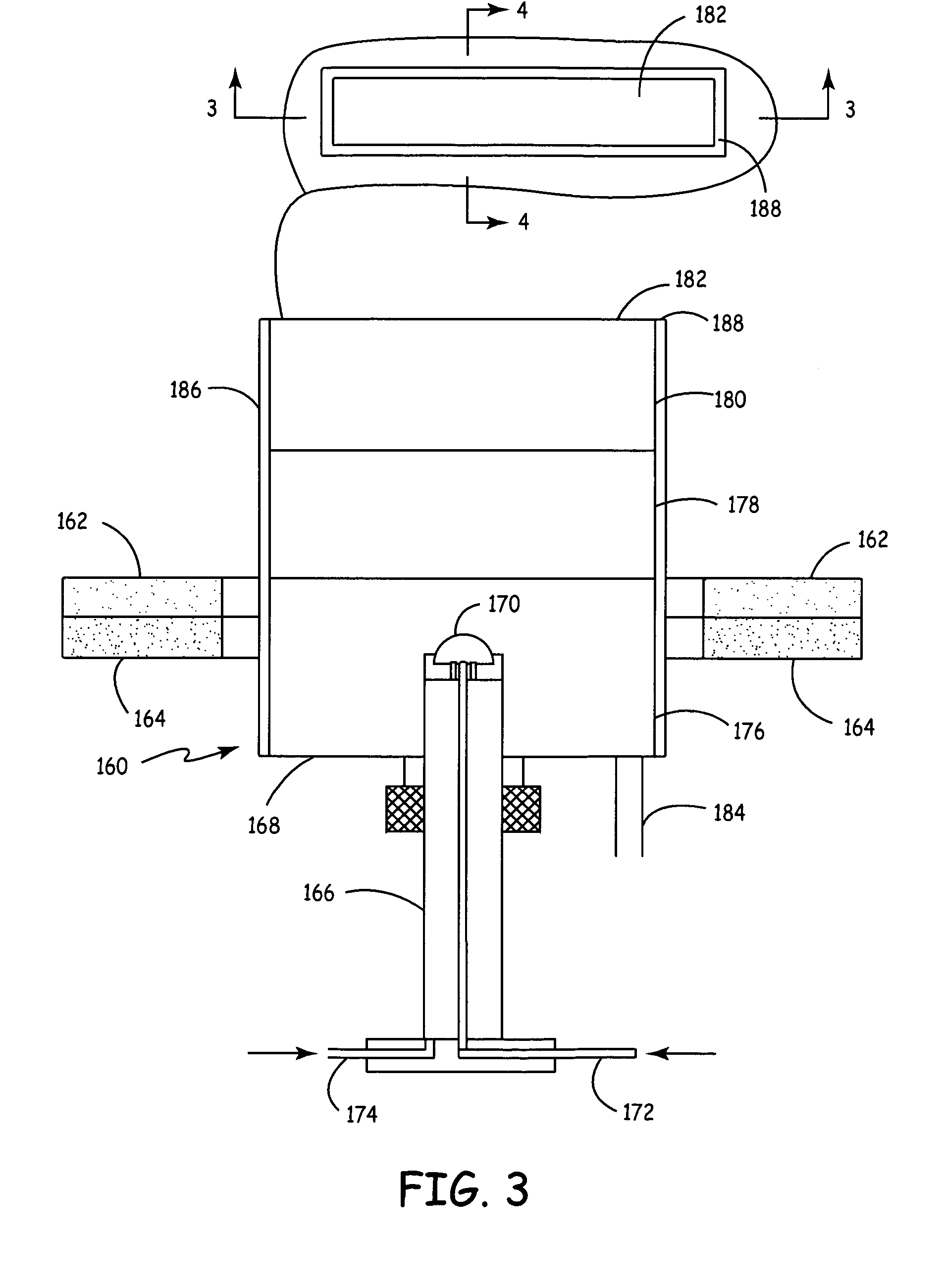

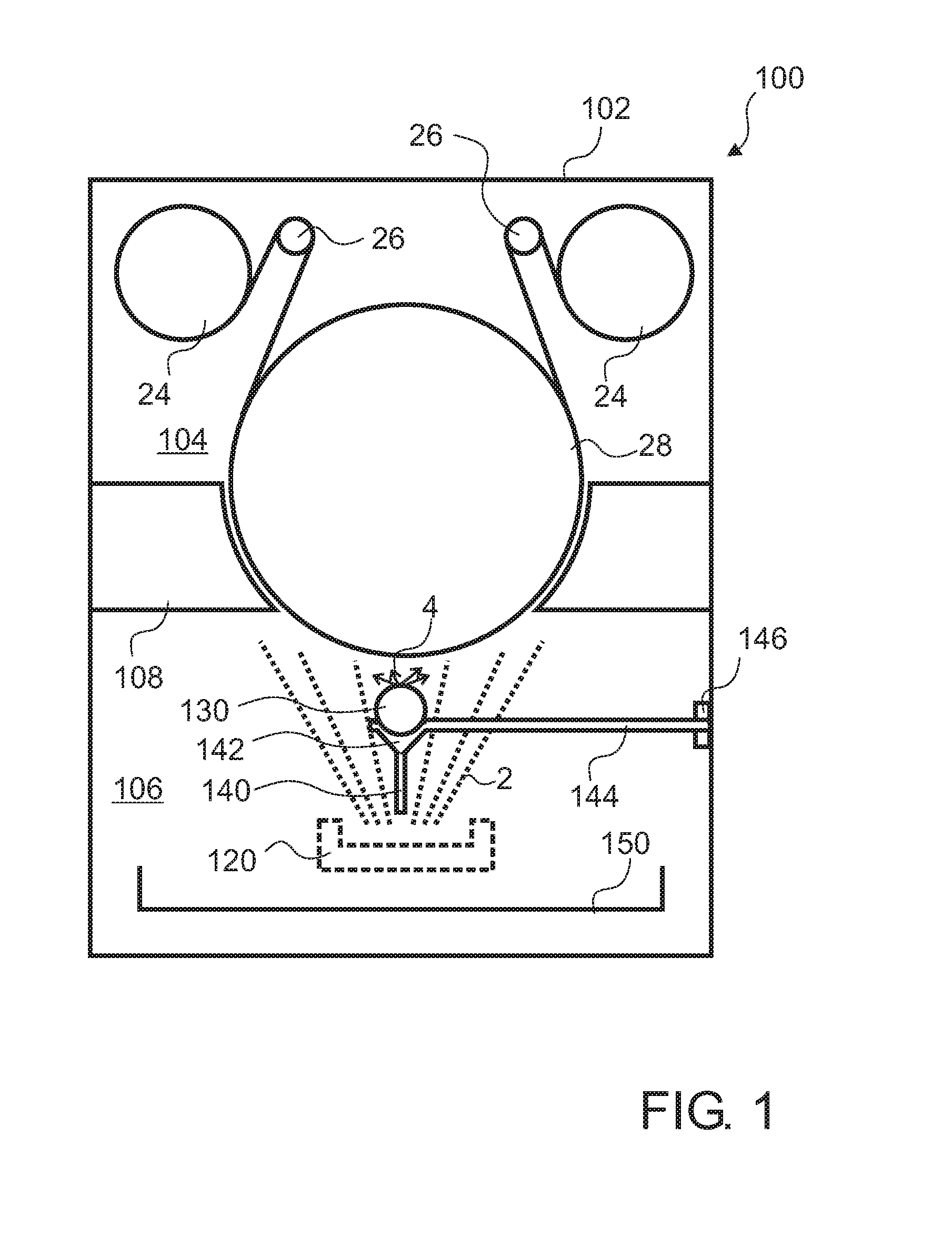

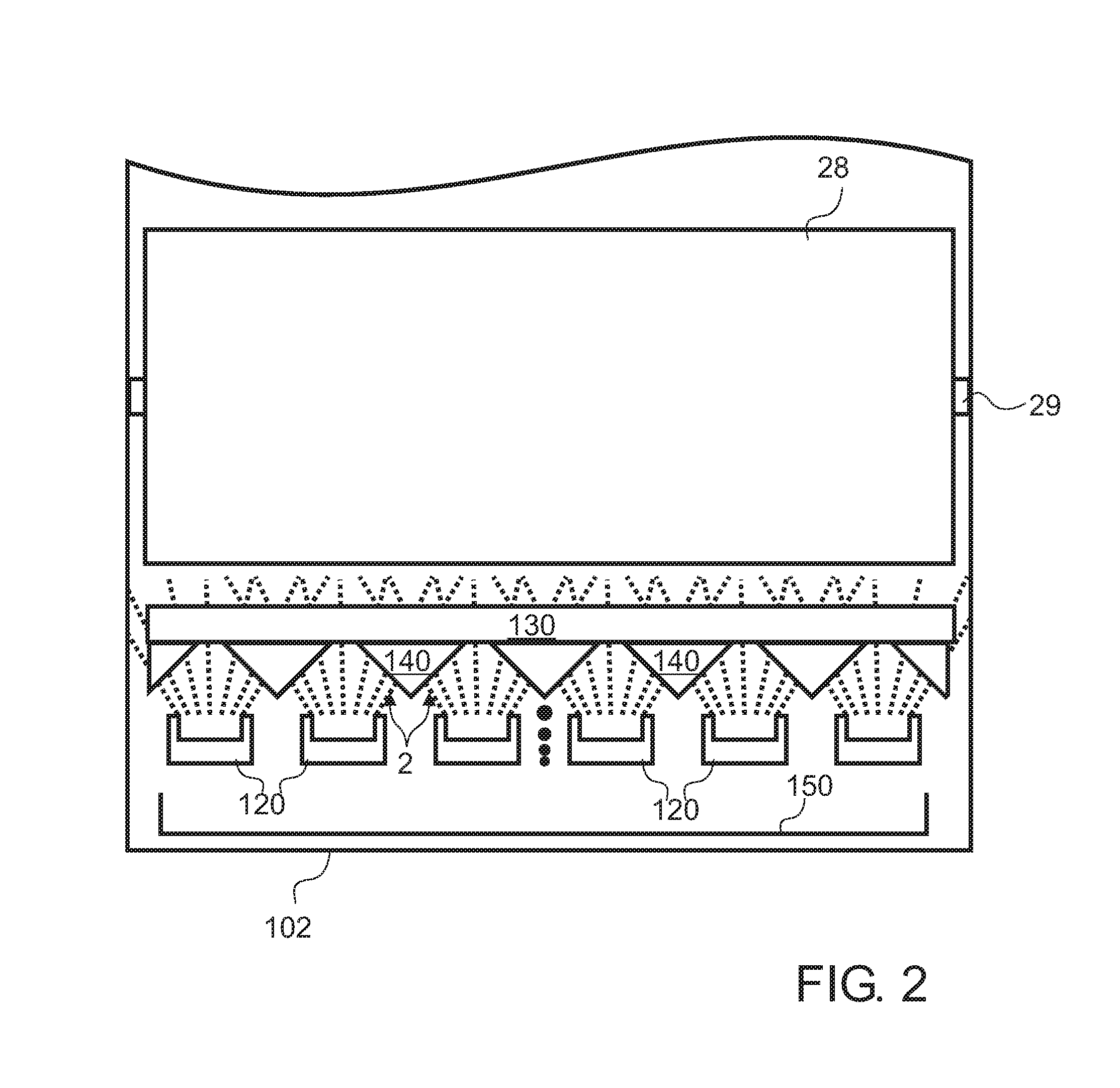

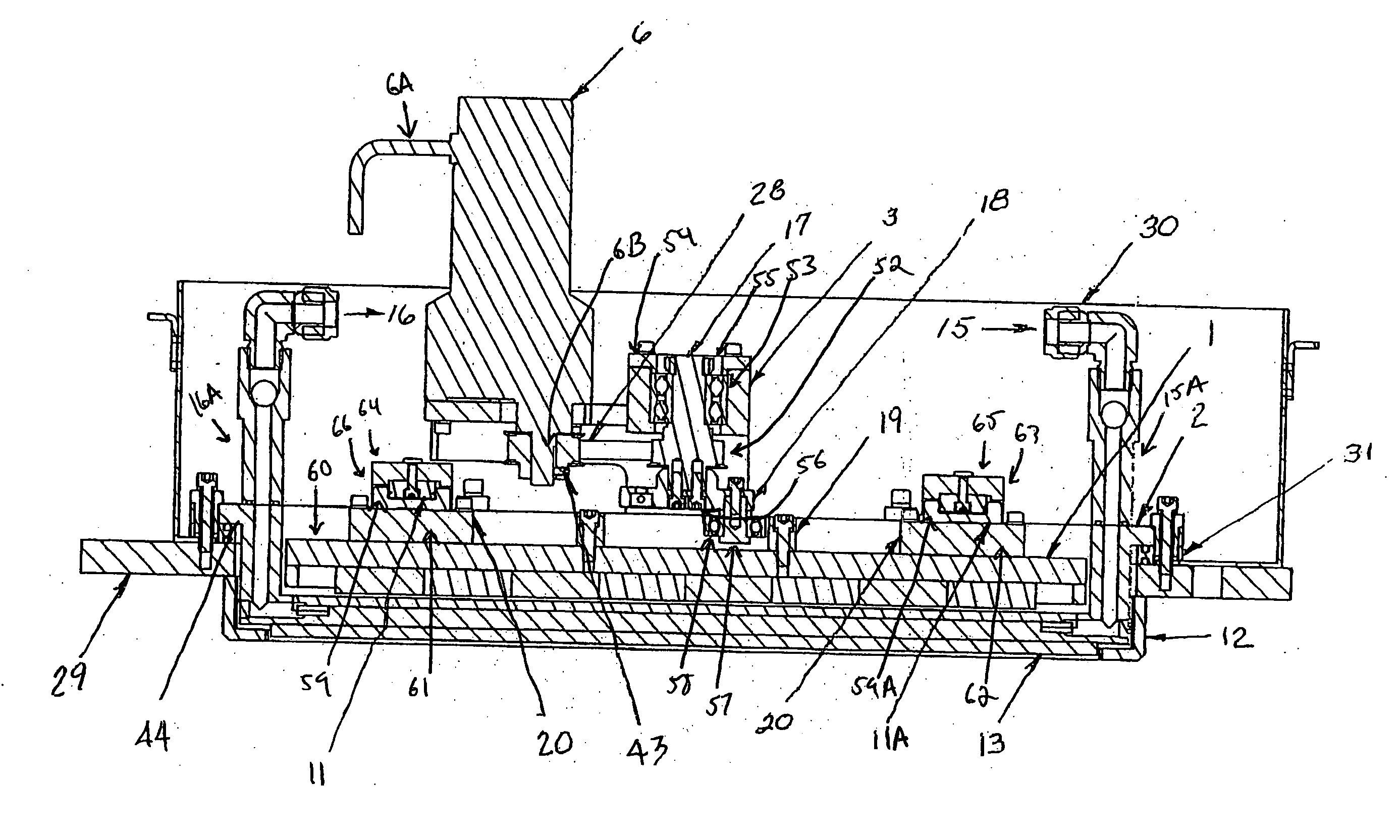

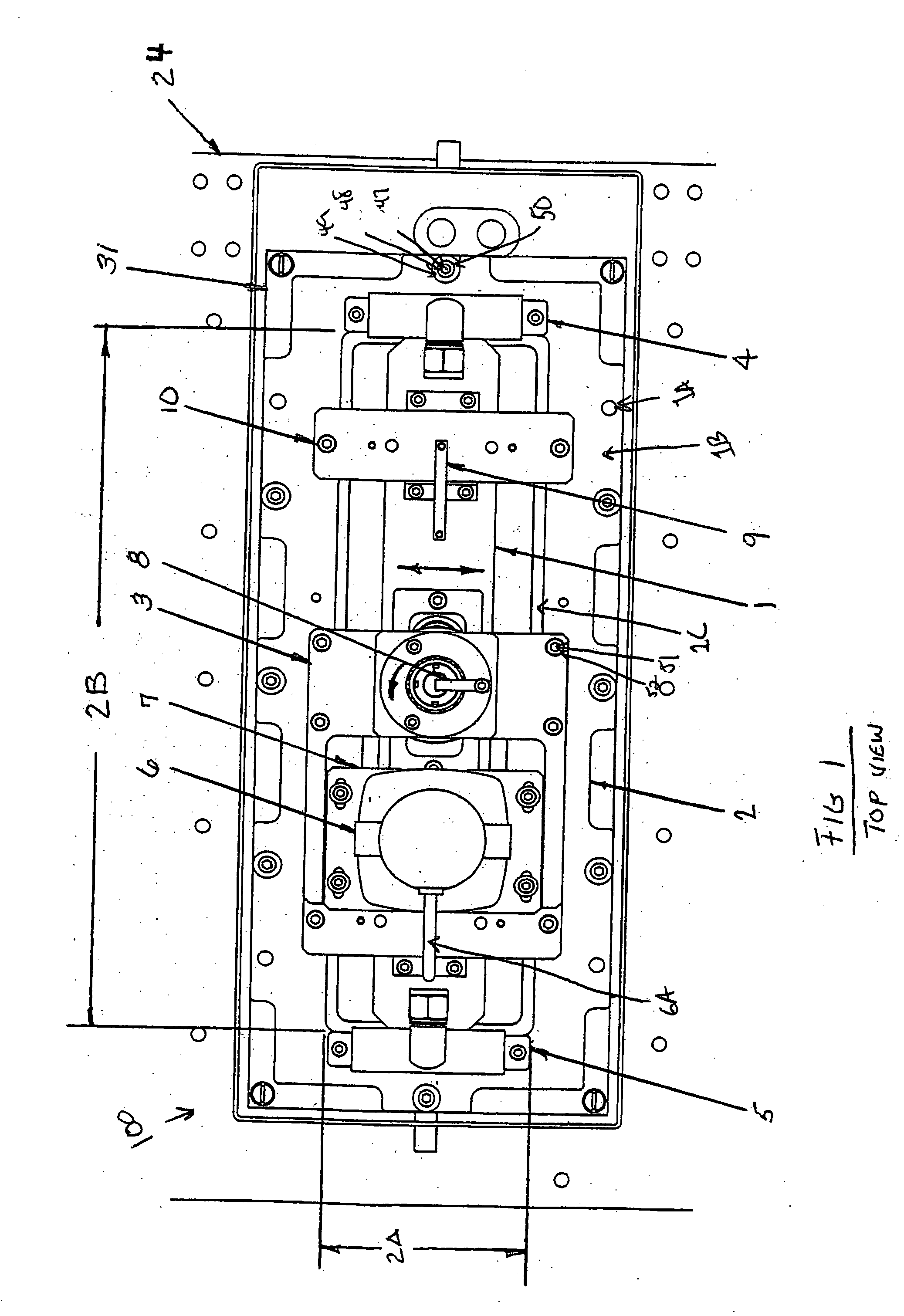

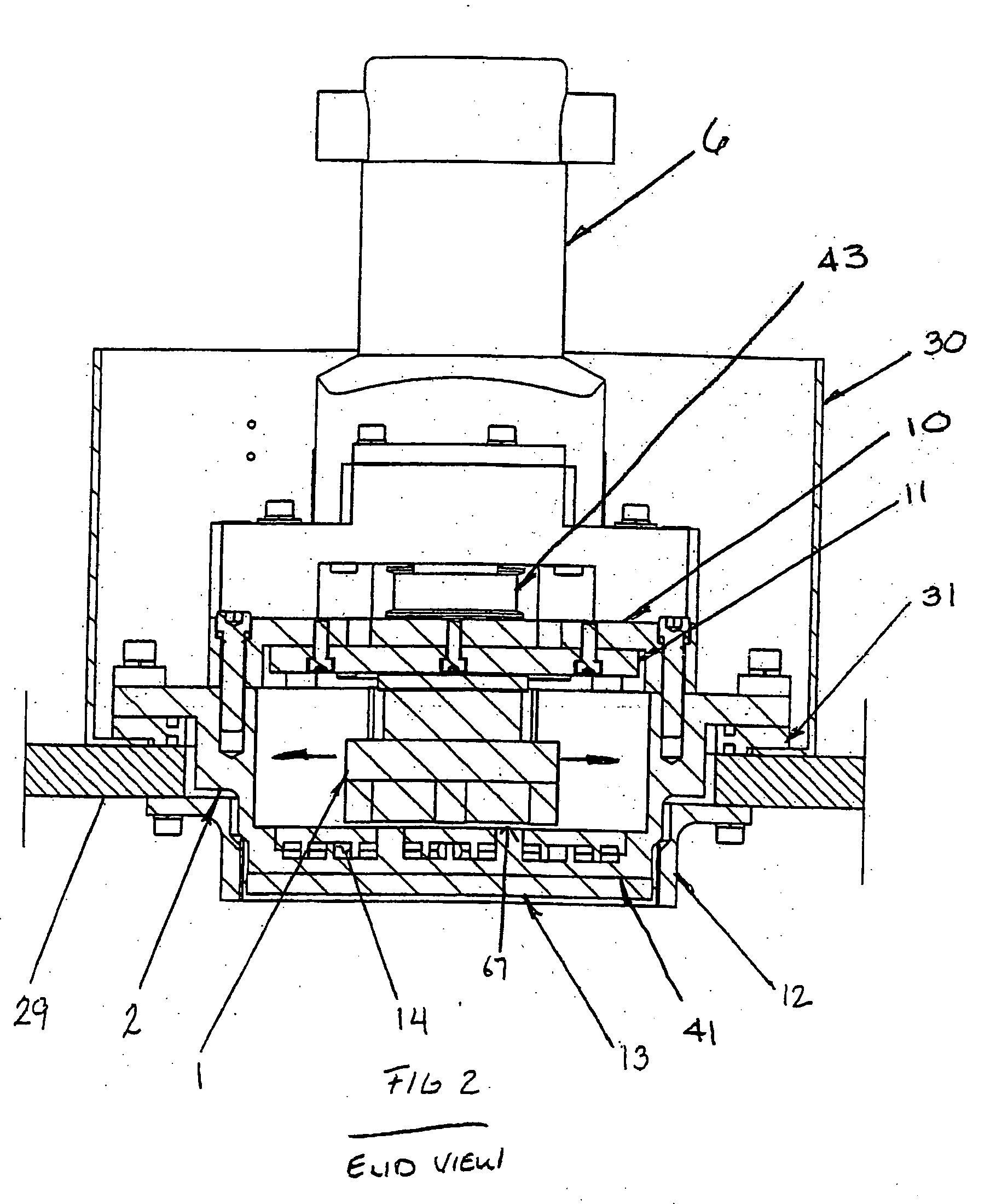

Apparatus for coating formation by light reactive deposition

InactiveUS9163308B2Molten spray coatingTransportation and packagingChemical reactionReactive deposition

Light reactive deposition uses an intense light beam to form particles that are directly coated onto a substrate surface. In some embodiments, a coating apparatus comprising a noncircular reactant inlet, optical elements forming a light path, a first substrate, and a motor connected to the apparatus. The reactant inlet defines a reactant stream path. The light path intersects the reactant stream path at a reaction zone with a product stream path continuing from the reaction zone. The substrate intersects the product stream path. Also, operation of the motor moves the first substrate relative to the product stream. Various broad methods are described for using light driven chemical reactions to produce efficiently highly uniform coatings.

Owner:NANOGRAM

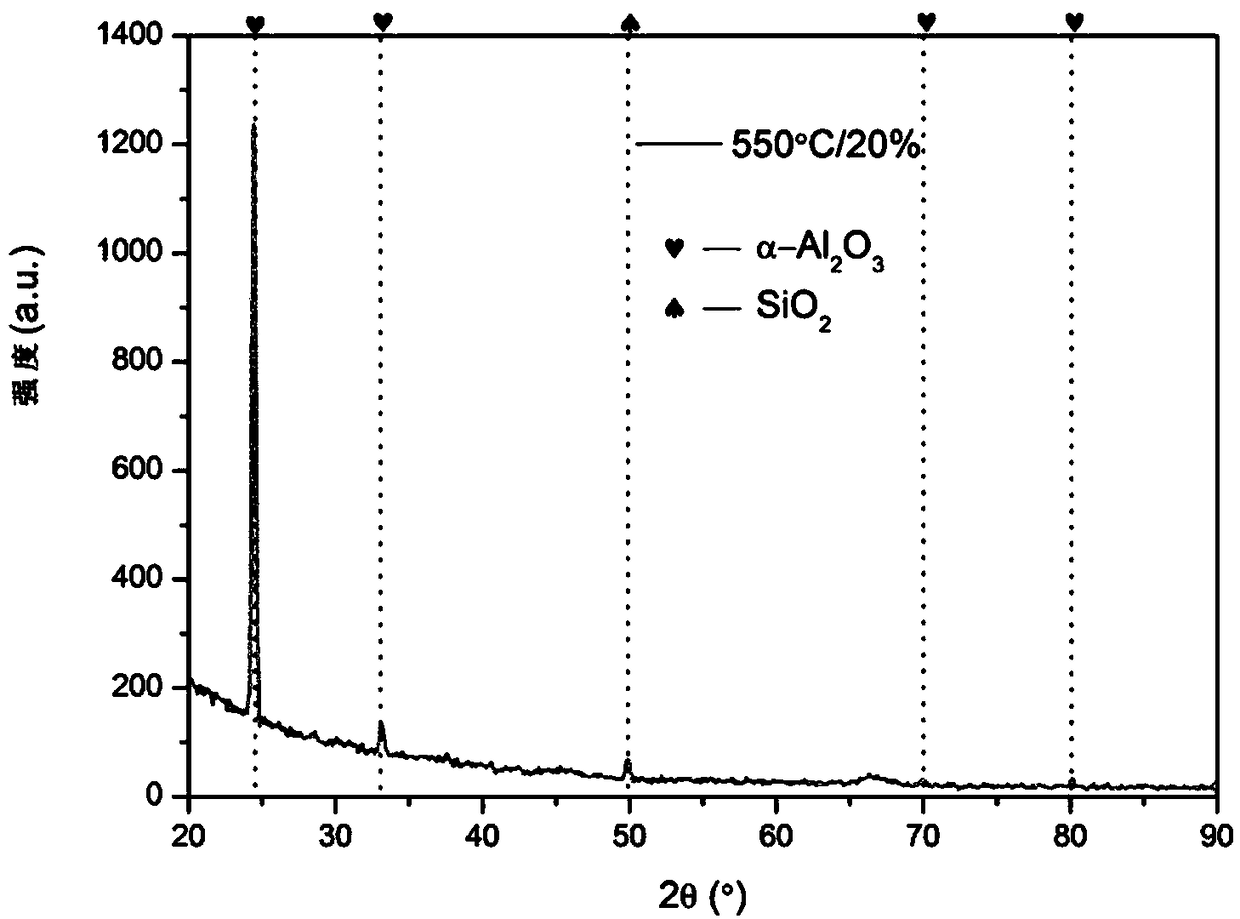

Method for low-temperature reactive sputtering deposition of nanometer alpha-Al2O3 coating

InactiveCN108411262AStable α-phase structurePrevent Adhesive WearVacuum evaporation coatingSputtering coatingAl powderRadio frequency magnetron sputtering

The invention belongs to the technical field of metal oxide coatings and discloses a method for low-temperature reactive sputtering deposition of a nanometer alpha-Al2O3 coating. The method comprisesthe following steps: manufacturing Al powder and alpha-Al2O3 powder into a composite material through a powder metallurgy method; after cutting the composite material to reach the size required for equipment, mounting the composite material of the required size on a target station for radio frequency magnetron sputtering as a deposition target material, and mounting a workpiece substrate on a sample table in a deposition cavity; after removing residual steam in the deposition cavity, vacuumizing to achieve base pressure, and then injecting a gas mixture of Ar and O2 for pre-oxidation treatment; and adjusting the partial pressure of O2 in the gas mixture of Ar and O2 to reach the range of 15% to 25%, adjusting the temperature of the workpiece substrate to reach the range of 550 DEG C to 750DEG C, starting a radio frequency magnetron sputtering film coating system, and starting reactive deposition so as to obtain the nanometer alpha-Al2O3 coating. The nanometer alpha-Al2O3 coating obtained through the method disclosed by the invention is of a nanocrystalline structure, is high in toughness, can be firmly combined with the workpiece substrate, and has a stable alpha-phase structure at relatively low temperature.

Owner:SOUTH CHINA UNIV OF TECH +1

Linear sweeping magnetron sputtering cathode and scanning in-line system for arc-free reactive deposition and high target utilization

A sweeping linear magnetron is described. The magnetron has a cathode backing plate, a drive housing attached to the cathode backing plate and a motor held in the drive housing. The motor drives a yoke positioned within a cut-out in the backing plate. The yoke has a magnet pack attached thereto said yoke such that the magnet pack is adapted to being moved over a target material and wherein the target material is being sputtered within a vacuum chamber onto a substrate.

Owner:GUPTA SUBHADRA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com