Lithium titanate composite electrode material with fluoride surface coating layer and preparation method thereof

A surface coating, composite electrode technology, applied in battery electrodes, circuits, electrical components and other directions, can solve the problems of flatulence, poor rate performance, not built in, and achieve the effect of simple process, good rate performance, and flatulence inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

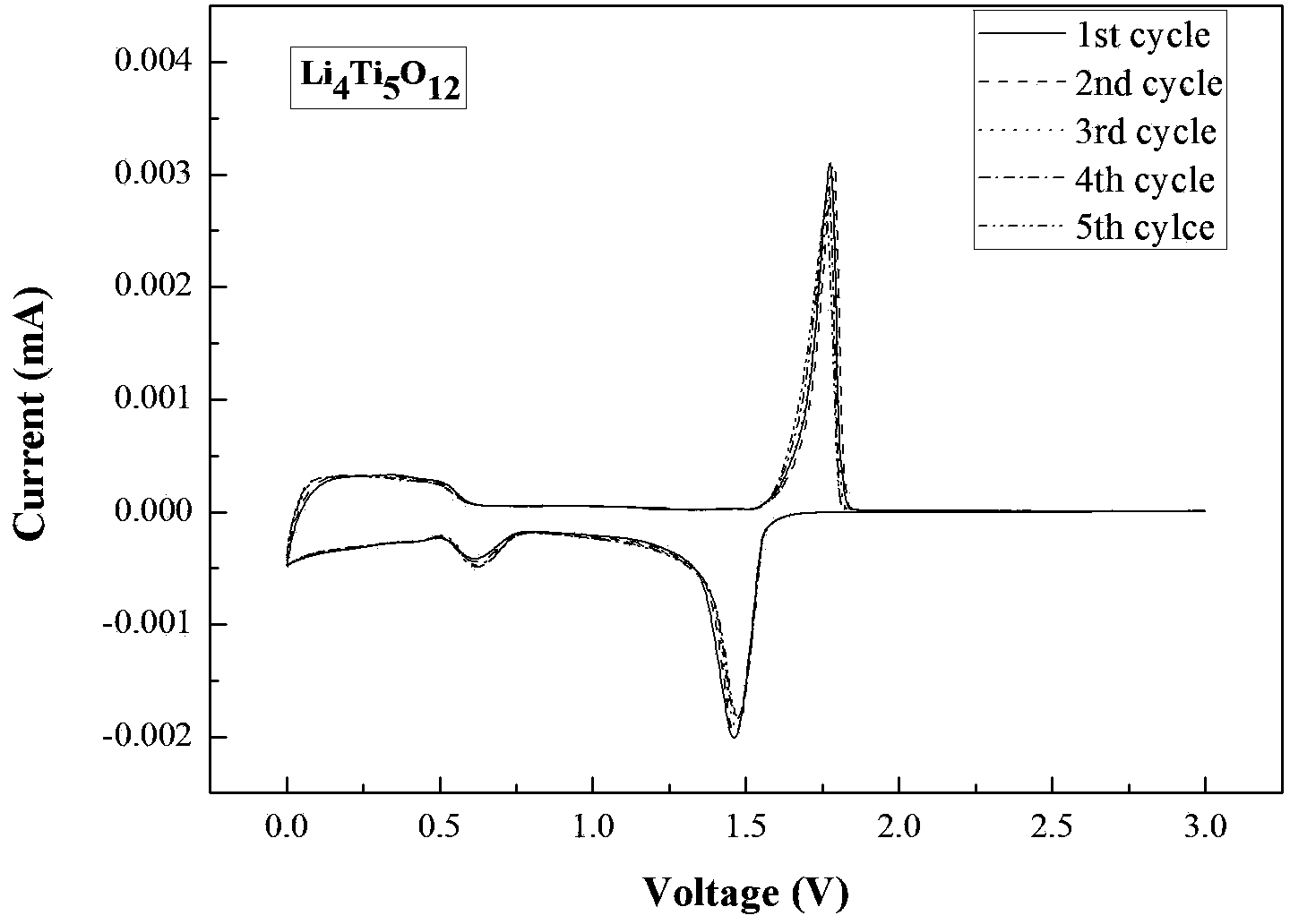

Image

Examples

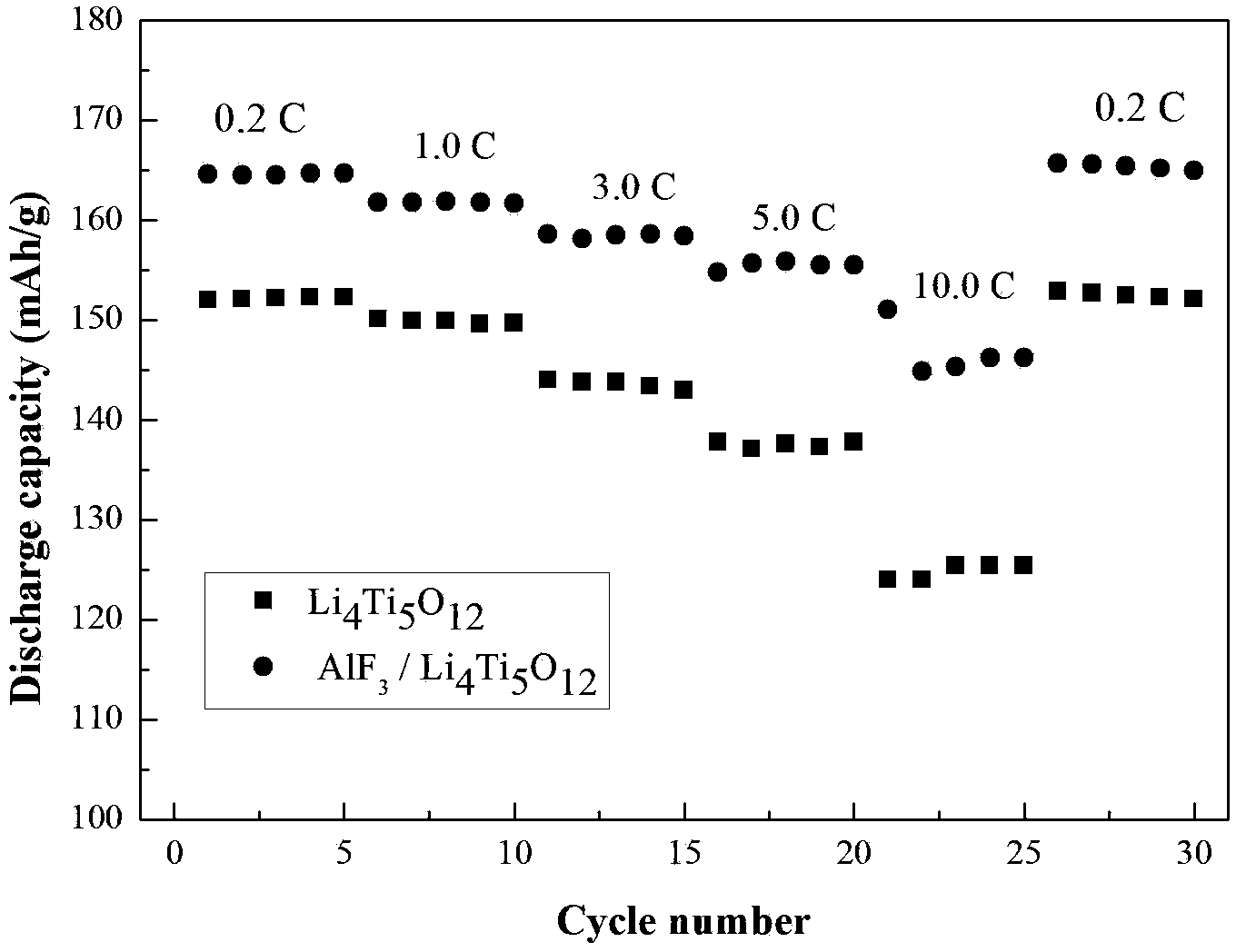

Embodiment 1

[0028]Weigh 0.4445 g of aluminum nitrate and dissolve it in 100 mL of secondary deionized water, stir well to form a concentration of 1.19×10 -2 mol / L stable solution. Then add 5.000 g of lithium titanate to the above solution, continue stirring to form a uniform suspension with a concentration of 50.00 g / L, and define this suspension as A. Weigh 0.1323 g of ammonium fluoride and dissolve it in 50 mL of secondary deionized water to form a concentration of 7.14×10 -2 moL / L stable solution, and define this solution as B. Add solution B dropwise into suspension A at a rate of 1 mL / min, heat at 80 °C for 5 h, let stand, settle, and remove water at 100 °C to obtain a dry aluminum fluoride-coated lithium titanate precursor. The precursor was placed in a nitrogen atmosphere and calcined at 400 °C for 5 h to prepare an aluminum fluoride-coated lithium titanate composite electrode material with an aluminum fluoride coating layer of about 2% by mass. The electrode material was asse...

Embodiment 2

[0030] Weigh 44.45 g of aluminum nitrate and dissolve it in 1000 mL of secondary deionized water, stir well to form a stable solution with a concentration of 0.119 mol / L. Then add 500 g of lithium titanate to the above solution, continue stirring to form a uniform suspension with a concentration of 500 g / L, and define this suspension as A. Weigh 13.23 g of ammonium fluoride and dissolve it in 500 mL of secondary deionized water to form a stable solution with a concentration of 0.714 moL / L, and define this solution as B. Add solution B dropwise into suspension A at a rate of 10 mL / min, heat at 80 °C for 10 h, let stand, settle, and remove water at 100 °C to obtain a dry aluminum fluoride-coated lithium titanate precursor. The precursor was placed in a nitrogen atmosphere and calcined at 400 °C for 10 h to prepare an aluminum fluoride-coated lithium titanate composite electrode material with an aluminum fluoride coating layer of about 2% by mass. The aluminum fluoride-coated li...

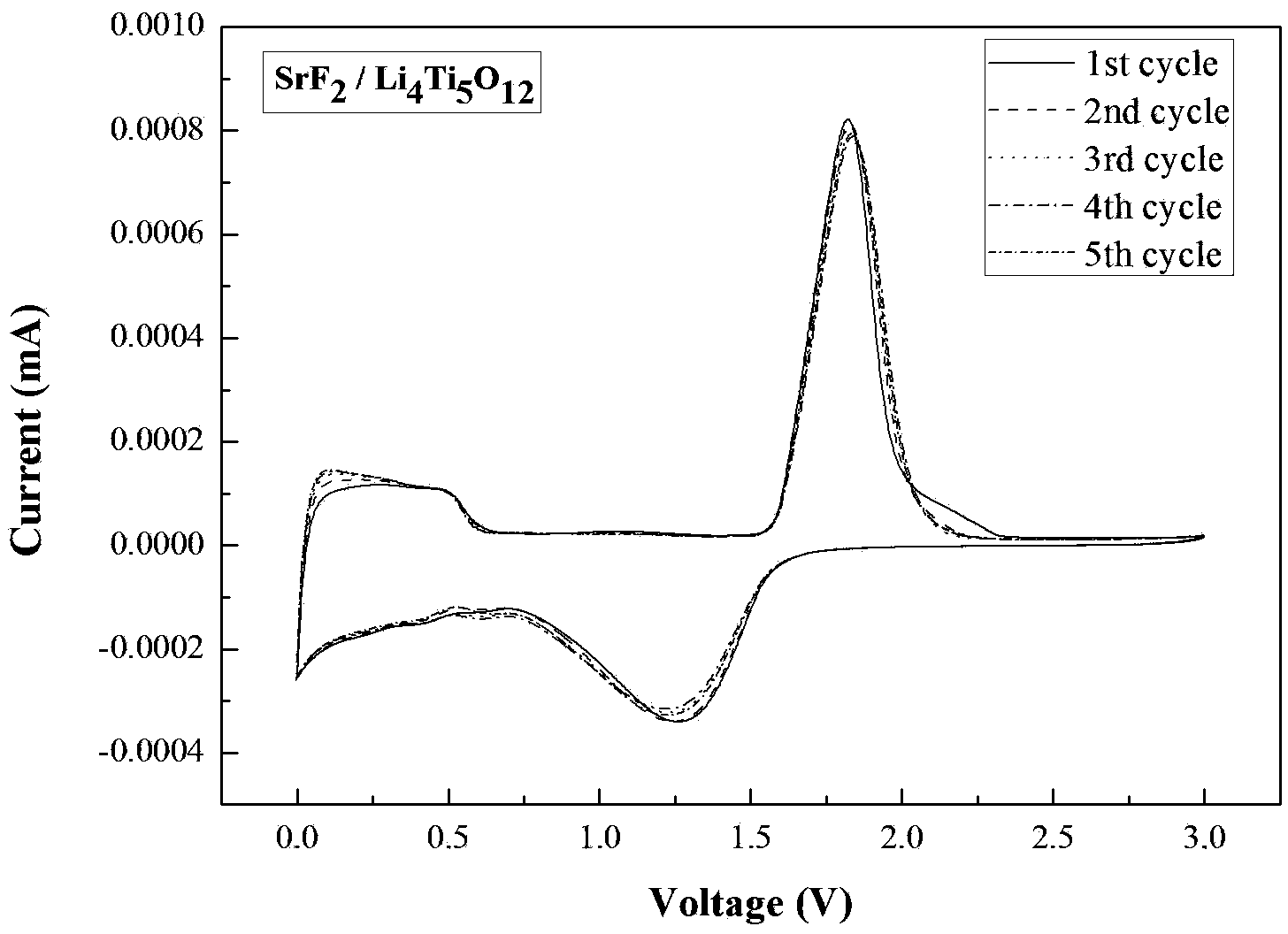

Embodiment 3

[0032] Weigh 0.1196 g of strontium nitrate and dissolve it in 100 mL of secondary deionized water to form a concentration of 5.65×10 -3 mol / L stable solution. Then add 2.2958 g of lithium titanate to the above solution, ultrasonically and mechanically stir to form a uniform suspension with a concentration of 22.958 g / L, and define this suspension as A. Next, weigh 0.0418 g of ammonium fluoride and dissolve it in 10 mL of secondary deionized water to form a concentration of 11.30×10 -2 moL / L stable solution, and define this solution as B. Solution B was added dropwise into suspension A at a rate of 1 mL / min, allowed to stand, settle, and remove water at 90°C to obtain a dry strontium fluoride-coated lithium titanate precursor. The precursor was placed in a nitrogen atmosphere and calcined at 400 °C for 2 h to prepare strontium fluoride-coated titanic acid with a coating thickness of about 5 nm and a mass percentage of strontium fluoride coating of about 3%. Lithium com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com