Preparation method of Bi/Cu catalyst for artificial photosynthesis

A catalyst, artificial light technology, applied in electrodes, electrolytic organic production, electrolysis process, etc., to achieve the effect of high CO2 reduction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

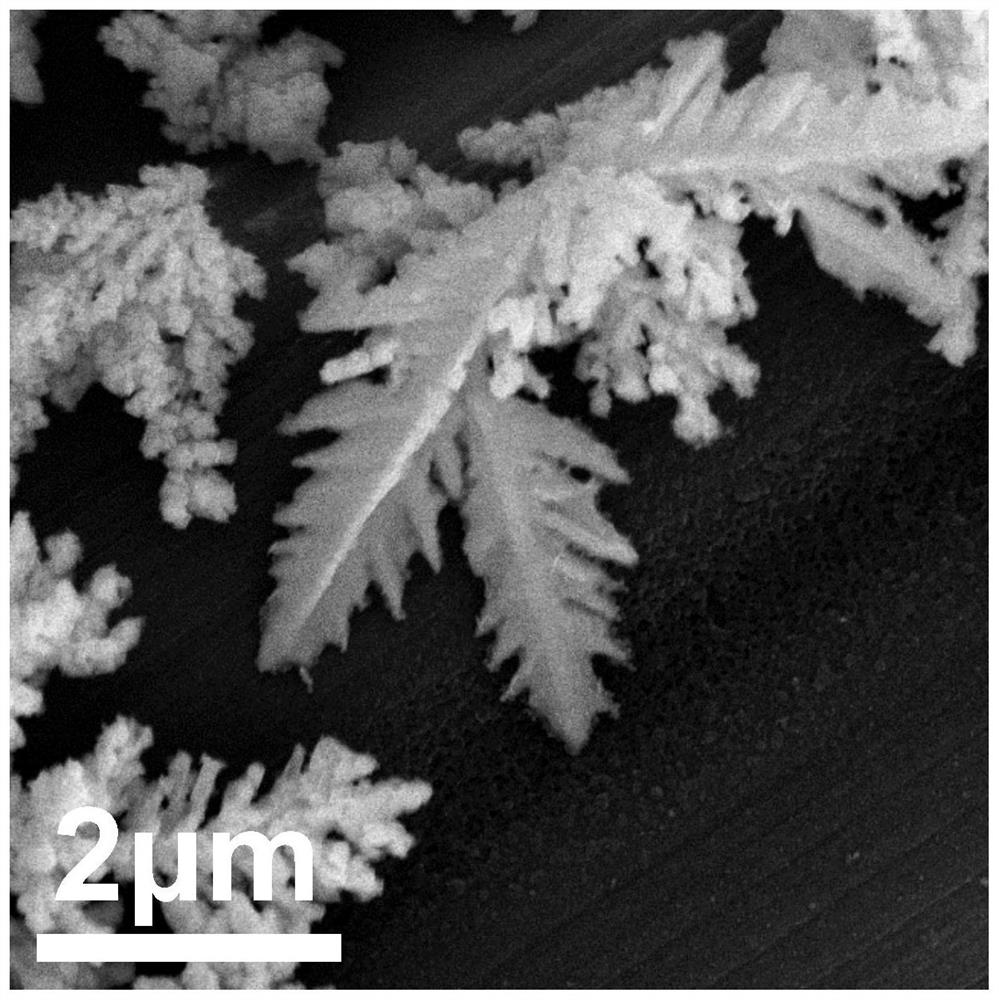

Embodiment 1

[0026] 1) Preparation of electrodeposition solution: 0.3153g bismuth chloride (BiCl 3 ), 1.47g sodium citrate (C 6 h 9 Na 3 o 9 ) was added into 50ml of 1.2mol / L HCl solution, and the solution was fully stirred until it was completely dissolved, and the solution was transparent to obtain an electrodeposition solution.

[0027] 2) Electrodeposition reaction: use copper foam as the cathode and a carbon rod as the anode to form a pair of electrodes, and then immerse the electrodes in the electrodeposition solution prepared in step 1) to perform a constant potential deposition reaction, and deposit a charge of about 3C to obtain Bi / Cu catalyst.

[0028] C must be added as described in step 1) 6 h 9 Na 3 o 9 And the amount of its substance should be guaranteed to be much larger than that of BiCl 3 amount of substance.

[0029] The concentration of the HCl solution described in step 1) should be more than 1mol / L and be stirred rapidly, preferably the HCl solution of 1.2mo...

Embodiment 2

[0035] What this embodiment provides is Bi / Cu catalyst pretreatment method, and described preparation method comprises the following steps:

[0036] 1) Pretreatment: immerse the Bi / Cu catalyst prepared above into 25mL of 0.5mol / L KHCO 3 The solution is used as the working electrode, Ag / AgCl is used as the reference electrode, platinum wire is used as the counter electrode, and saturated CO is passed into the H-type electrolytic cell. 2 The gas was subjected to 50 cycles of scanning cyclic voltammetry to obtain the prepared catalyst.

[0037] The voltage range of the scanning cyclic voltammetry step in step 1) is 0-1.2V vs. RHE, and the bismuth-copper stoichiometric ratio of the catalyst ranges from 9:1 to 1:1.

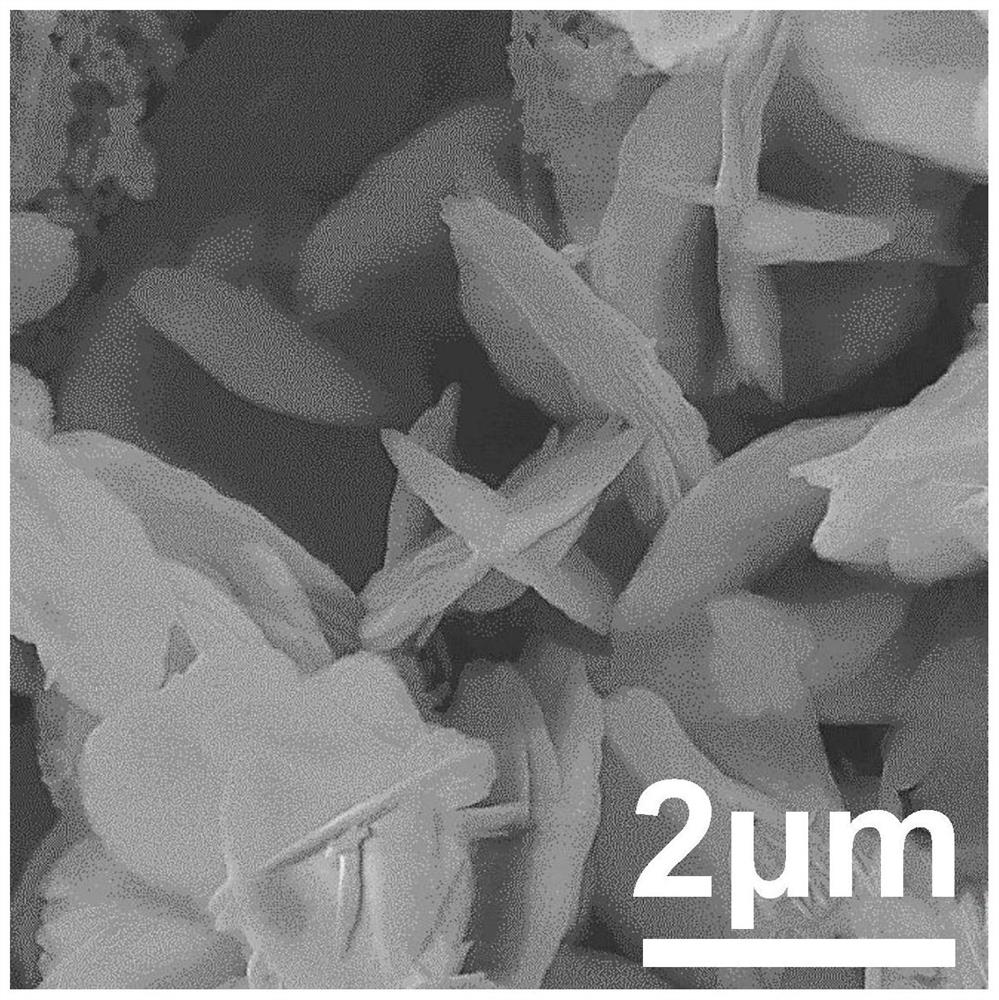

[0038] Such as figure 2 Shown is the SEM image of the pretreated Bi / Cu catalyst prepared in this example. It can be seen that the pretreated coral-like structure transforms into a flake-like structure with an average nanosheet size of 0.9 μm. XRD and XPS patterns sh...

Embodiment 3

[0041] What this embodiment provides is the CO of Bi / Cu catalyst artificial photosynthesis 2 Reduction performance testing method, described preparation method comprises the following steps:

[0042] 1) Artificial photosynthesis performance test: the pretreated Bi / Cu electrode was used as the working electrode, the Ag / AgCl was used as the reference electrode, and the platinum wire was used as the counter electrode. 2 Gas 25mL 0.5mol / L KHCO 3 CO in solution for artificial photosynthesis 2 Revert performance test. Including product faradaic efficiency test, current density test and stability test.

[0043] The artificially photosynthesized CO described in step 1) 2 The reduction performance test voltage range is -0.7~-1.2V vs. RHE.

[0044] Such as Figure 4 Shown is the CO of the Bi / Cu catalyst prepared in this example 2 Faradaic efficiency of reduced products and partial current density images of formic acid. It can be seen from the figure that the Bi / Cu catalyst catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com