A method for efficiently recovering platinum group precious metals from platinum-containing organic alcohol waste liquid

A technology of organic alcohols and precious metals, applied in the field of efficient recovery of platinum group precious metals, can solve the problems of poor product purity, low platinum recovery rate, unfriendly environment, etc., and achieve the effects of less environmental pollution, improved purity, and high reduction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

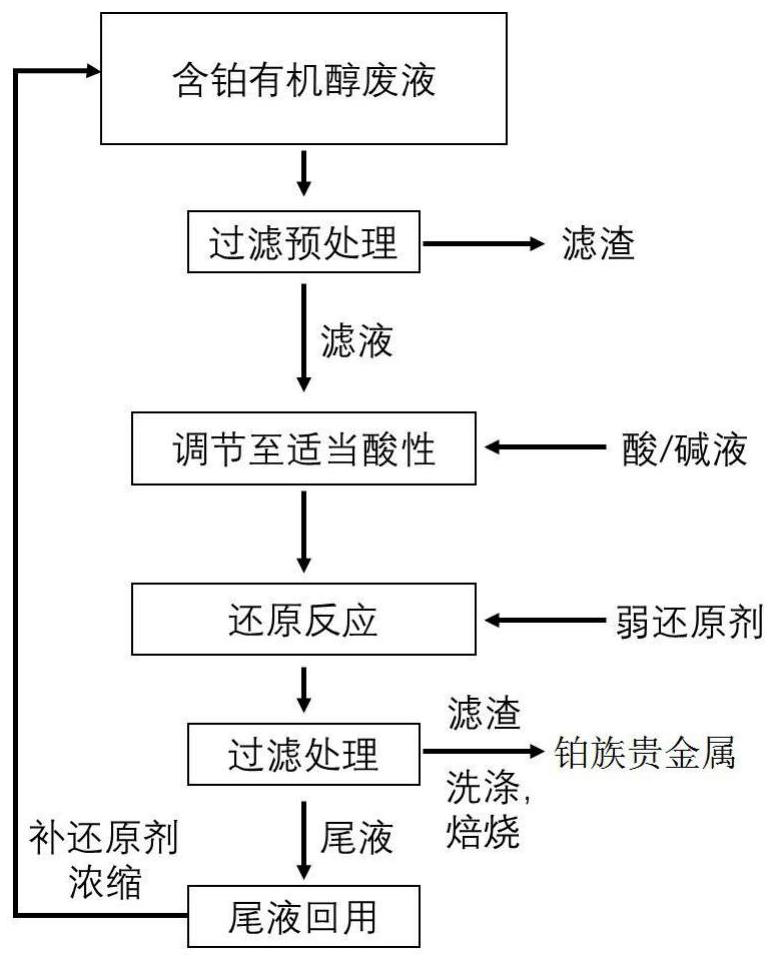

Method used

Image

Examples

Embodiment 1

[0022] This embodiment adopts a method for efficiently recovering platinum group noble metals from platinum-containing organic alcohol waste liquid in the above-mentioned present invention; platinum-containing organic alcohol waste liquid sample 1 contains metal ions Pt, Ni, Fe, Mg, and is detected by ICP. The platinum ion concentration is 107ppm, the organic alcohol liquid is a complex of ethylene glycol and water, and the pH is 10.4. After the initial waste liquid is suction filtered to remove the waste residue, take 5L of the filtrate, and under continuous and thorough stirring, add 10wt% sulfuric acid to adjust the pH to 1.5, then add 7g of sodium citrate and 4g of ascorbic acid, and stir the reaction at 80°C 12h. After the reaction was completed, it was filtered, and the black precipitate was washed and roasted to obtain 0.459 g of simple platinum. The calculated recovery rate was 93.6%.

[0023] In terms of the purity of the noble metal obtained, the detected impurity c...

Embodiment 2

[0028] This embodiment adopts a method for efficiently recovering platinum group noble metals from platinum-containing organic alcohol waste liquid in the above-mentioned present invention; platinum-containing organic alcohol waste liquid sample 2 contains metal ions Pt, Pd, Zn, Fe, Ca, Mg, According to ICP detection, the platinum ion concentration is 40ppm, the palladium ion concentration is 53ppm, the organic alcohol liquid is a complex of methanol and ethanol, and the pH is 3.1. After the initial waste liquid is suction filtered to remove the waste residue, take 5L of the filtrate, and under continuous and thorough stirring, add 10wt% hydrochloric acid to adjust the pH to 1.0, then add 35g of ascorbic acid and 11g of citric acid, and stir for 80 hours at 30°C . After the reaction was completed, it was filtered, and the black precipitate was washed and roasted to obtain 0.371 g of mixed noble metal elemental substance of platinum and palladium. The recovery rate was calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com