Production device for silicon oxide film and production method thereof

A silicon dioxide and production method technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of many factors affecting the control process, many factors affecting CVD, complex CVD equipment, etc. The process is easy to control, the effect of improving acid and alkali corrosion resistance, and reducing the deposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

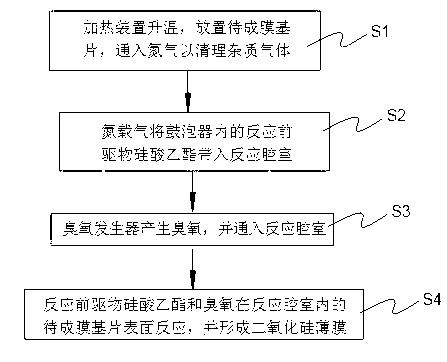

[0025] In order to explain in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with embodiments and accompanying drawings.

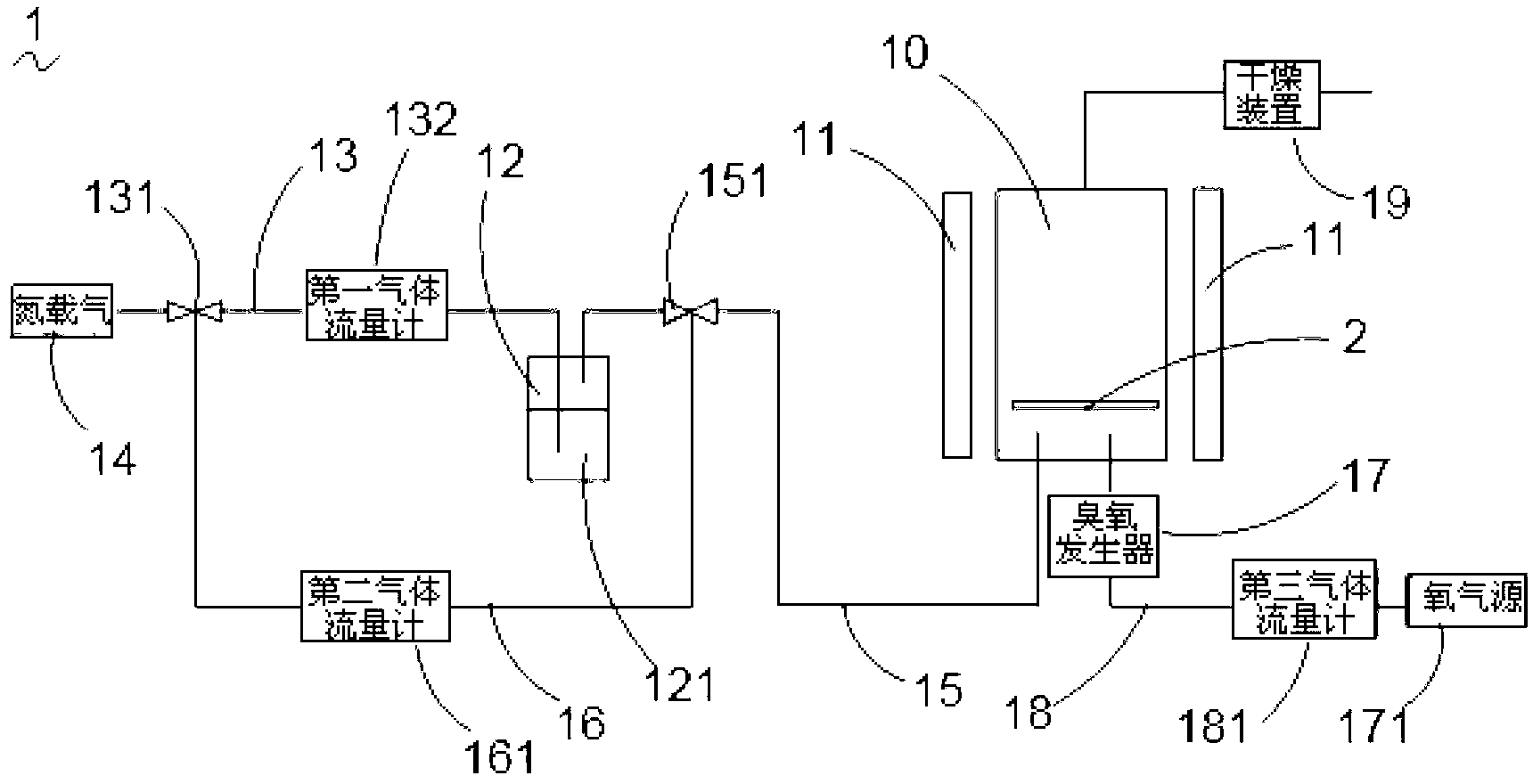

[0026] See figure 1 , figure 1 Shown is a schematic diagram of the frame structure of the silicon dioxide film production equipment of the present invention. The silicon dioxide film production equipment 1 includes a reaction chamber 10, and the reaction chamber 10 is used to set the substrate 2 to be filmed and deposit silicon dioxide on the substrate 2 to be filmed. Thin film (not shown); heating device 11, the heating device 11 is respectively arranged on both sides of the reaction chamber 10; bubbler 12, the reaction precursor ethyl silicate 121 is set in the bubbler 12 A first gas pipeline 13 with a first splitter 131, a first gas flow meter 132 is set on the first gas pipeline 13, and one end of the first gas pipeline 13 and the nitroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com