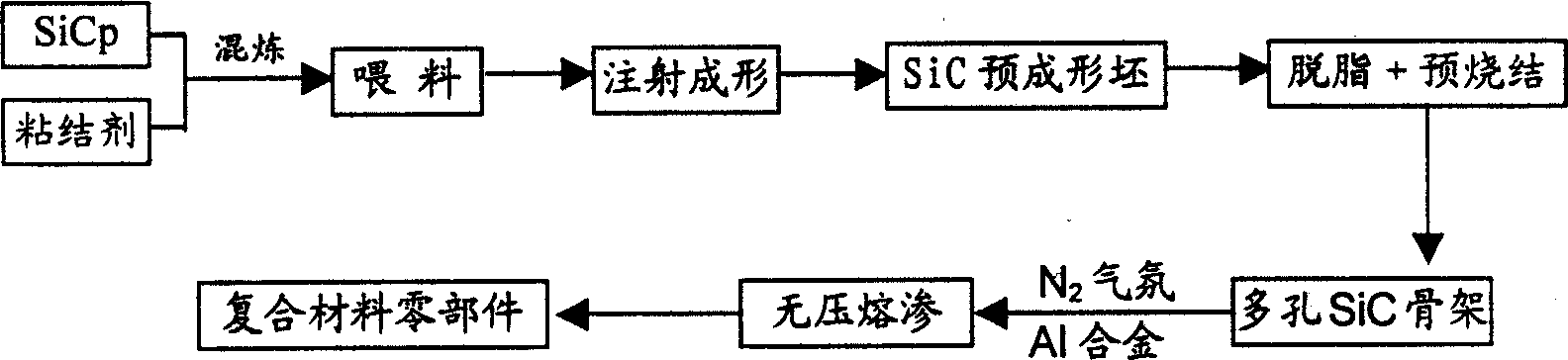

Method for producing high-volume fractional silicon-carbide particle reinforced aluminium-base composite material member

A technology with high volume fraction and silicon carbide particles, which is applied in the forming field of metal matrix composite parts, can solve the problems of difficult machining of SiCp/Al composite materials, difficulty in achieving complete penetration, uneven density of formed blanks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1: Preparation of a SiCp / Al composite material part with a SiC volume fraction of 62%

[0012] The average particle size of SiC is 10 μm, and the binder adopts a multi-polymer component paraffin-based binder, and the weight percentage of each component is PW:HDPE:EVA:SA=79:10:6:5. The binder was mixed on a mixer at 130°C for 1.5 hours, and then mixed with SiC powder on a mixer at 110°C for 2 hours. The powder loading was 62% by volume. For injection molding, the injection temperature is 150°C and the injection pressure is 105MPa. The obtained SiC preform is first dissolved and degreased in trichlorethylene, the solution temperature is 40°C, then the SiC preform is heated to 200°C in a vacuum degreasing furnace and kept for 1 hour, and then heated to 500°C for 2 hours to completely degrease. Remove binder. The degreased SiC preform is heated up to 1000° C. and kept for 2 hours for pre-sintering to obtain a porous SiC skeleton. Finally, the Al alloy (Al alloy c...

Embodiment 2

[0013] Example 2: Preparation of a SiCp / Al composite material part with a SiC volume fraction of 64%

[0014] The average particle size of SiC is 10 μm, and the binder adopts a multi-polymer component paraffin-based binder, and the weight percentage of each component is PW:HDPE:EVA:=75:15:10. The binder was mixed on a mixer at 130°C for 1.5 hours and then mixed with SiC powder on a mixer at 110°C for 2 hours. The powder loading was 64% by volume. For injection molding, the injection temperature is 150°C and the injection pressure is 110MPa. The obtained SiC preform is first dissolved and degreased in trichlorethylene, the solution temperature is 40°C, then the SiC preform is heated to 200°C in a vacuum degreasing furnace and kept for 1 hour, and then heated to 500°C for 2 hours to completely degrease. Remove binder. Continue to heat up the degreased SiC preform to 1150° C. and keep it warm for 2 hours for pre-sintering to obtain a porous SiC skeleton. Finally, the Al alloy ...

Embodiment 3

[0015] Example 3: Preparation of a SiCp / Al composite material part with a SiC volume fraction of 69%

[0016] The average particle size of SiC is 18 μm, and the binder adopts a multi-polymer component paraffin-based binder, and the weight percentage of each component is PW:HDPE:EVA:SA=72:15:10:3. The binder was mixed on a mixer at 130°C for 1.5 hours, and then mixed with SiC powder on a mixer at 130°C for 1.5 hours. The powder loading was 69% by volume. For injection molding, the injection temperature is 160°C and the injection pressure is 120MPa. The obtained SiC preform is first dissolved and degreased in trichlorethylene, the solution temperature is 40°C, then the SiC preform is heated to 200°C in a vacuum degreasing furnace and kept for 1 hour, and then heated to 500°C for 2 hours to completely degrease. Remove binder. Continue to heat up the degreased SiC preform to 1150° C. and keep it warm for 2 hours for pre-sintering to obtain a porous SiC skeleton. Finally, the Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com