Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

299results about How to "Solve processing difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

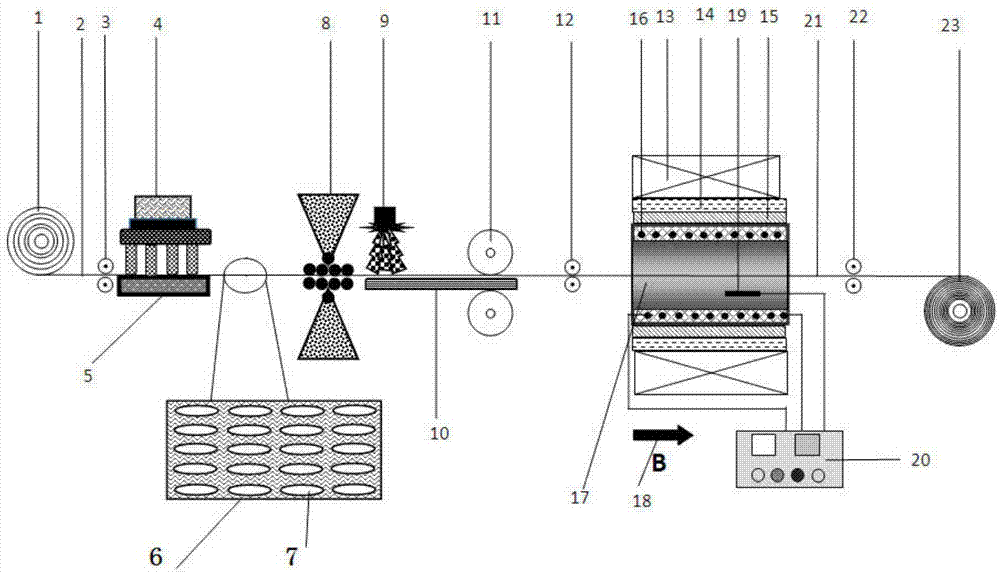

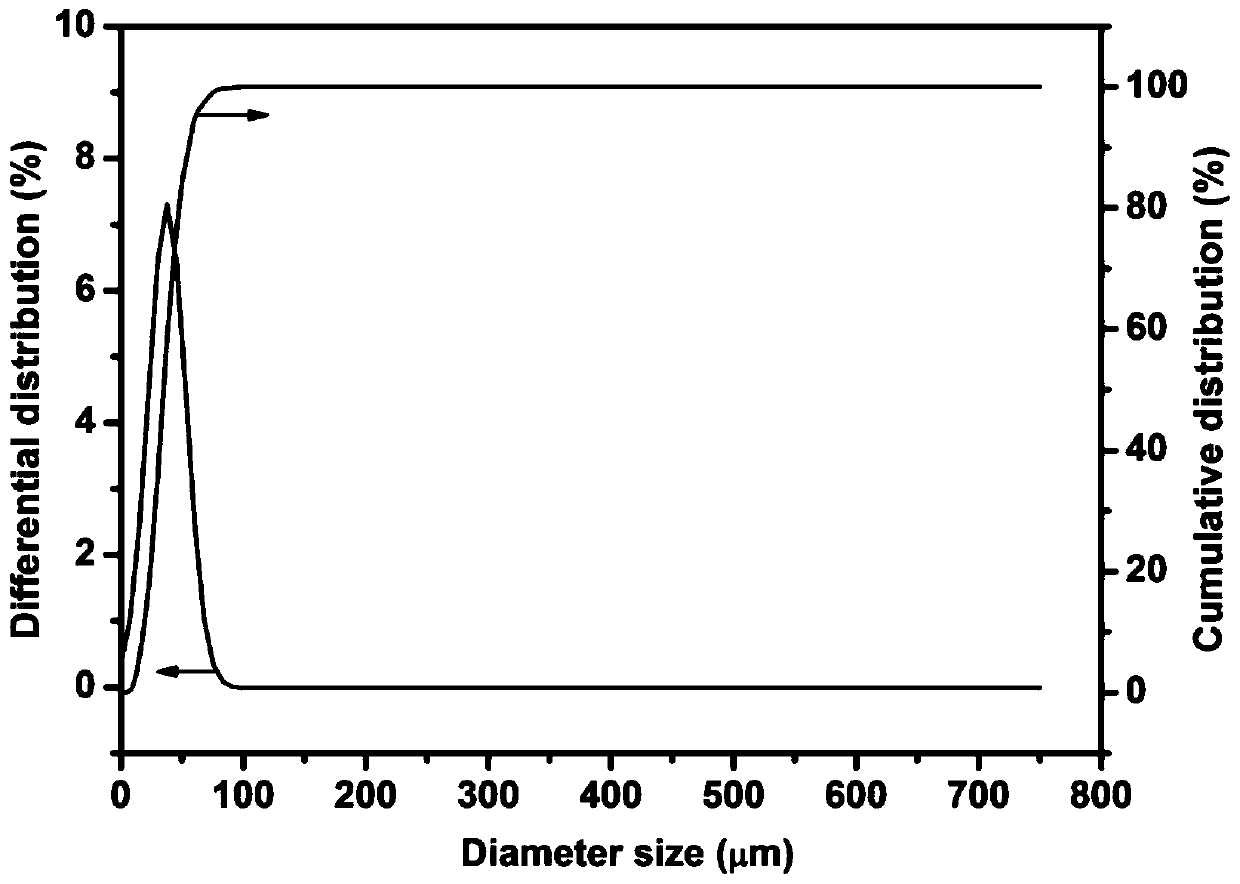

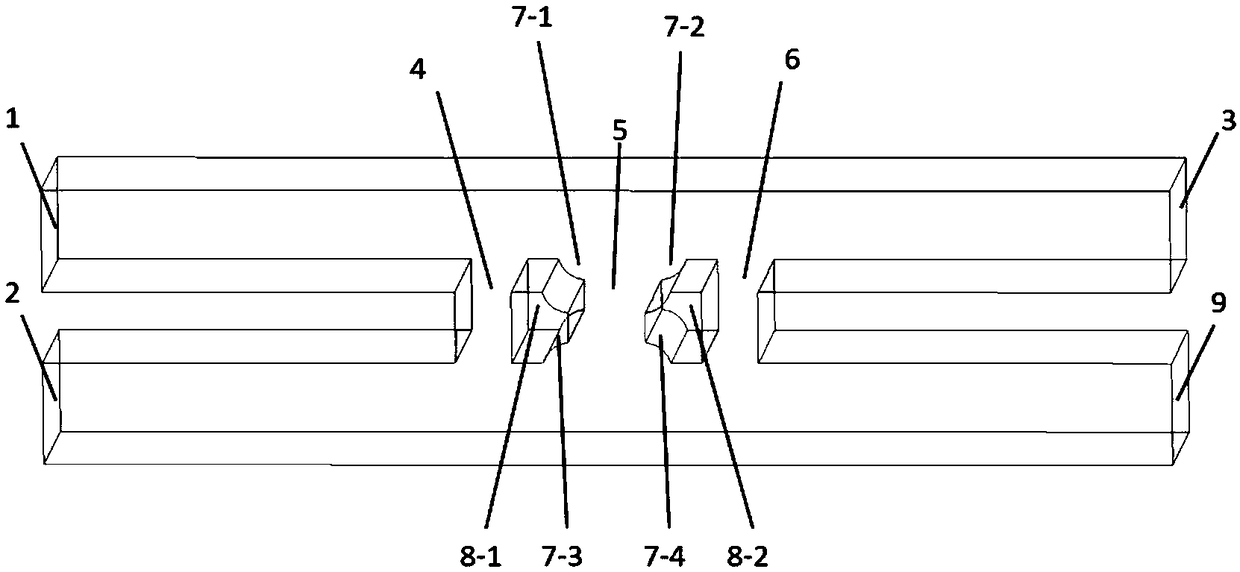

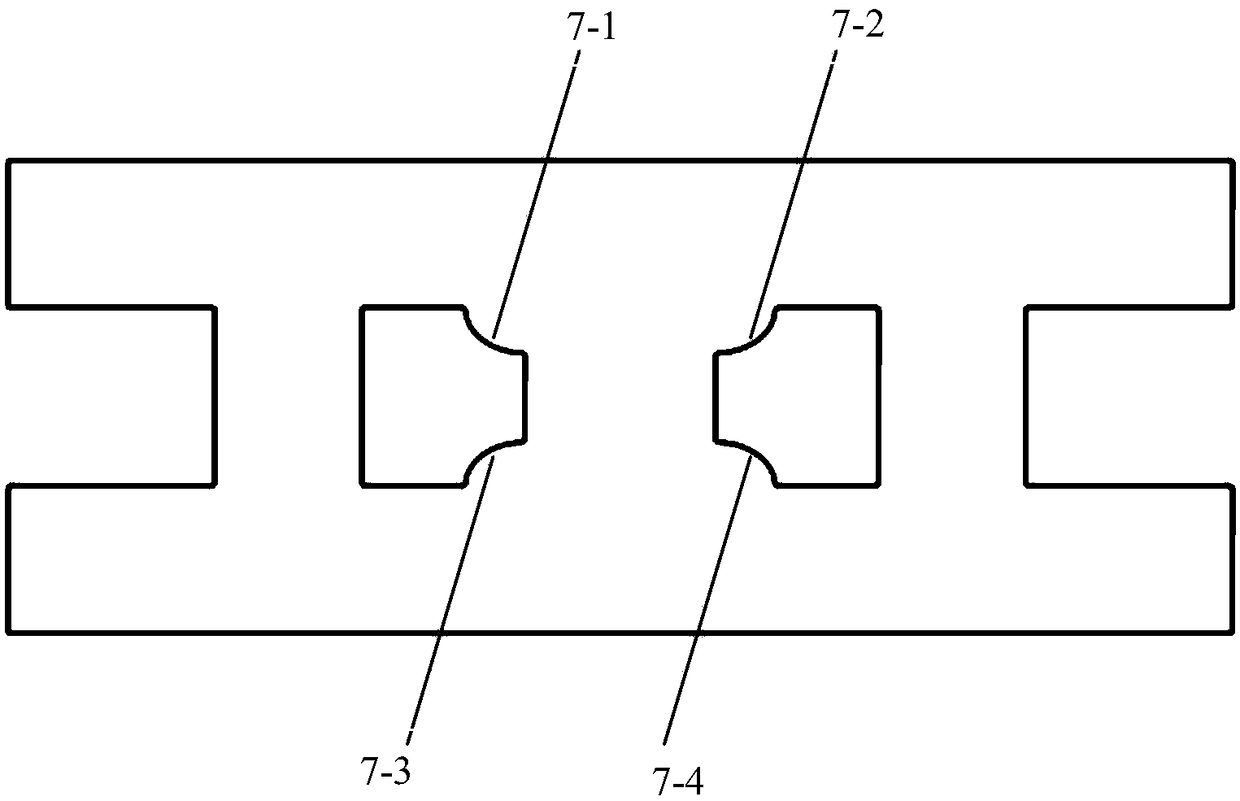

Method and device for preparing high-silicon silicon steel thin strip under magnetic field through powder diffusion method

PendingCN107282928AAvoid processing difficultiesEnhanced diffusionContinuous operationNear net shape

The invention discloses a method and a device for preparing a high-silicon silicon steel thin strip under a magnetic field through a powder diffusion method. According to the method, holes are formed in a low-silicon steel strip to be machined, then surface reinforcing treatment is carried out on the low-silicon steel strip to be machined, the holes are filled with an iron-silicon alloy powder and rolling forming is carried out on the powder, and then heat treatment is carried out on the powder in a magnetic field environment to obtain the high-silicon silicon steel thin strip with certain orientation, a silicon content of 6.5wt%Si and excellent magnetic performance. According to the method and the device, long-size and continuous operation can be realized; and moreover, a near-net-shape thin strip can be prepared, and therefore, a preparation cost can be remarkably lowered.

Owner:GUIZHOU INST OF TECH

Method for preparing Fe-6.5Wt%Si magnetically soft steel sheet

InactiveCN101122022ALittle impact on the original structureAvoid mass formationSolid state diffusion coatingSuperimposed coating processElectricityDiffusion

A method of preparing an Fe-6.5 weight percent Si soft magnetic steel sheet belongs to the technical field of metallurgy materials, and is used to solve the problem of technical difficulty of current methods in preparing Fe-6.5 weight percent Si soft magnetic steel sheets. The method consists of procedures of a silicon steel sheet with less than 3.5percent Si as the matrix, siliconizing by molten salt preparation and electric deposition on the silicon steel sheet, even diffusion and annealing, etc. The method of the invention is essentially characterized in that: (1) the whole preparation process does not include pressure processing or other plastic deformation processes, which can thoroughly prevent any processing difficulty produced by low plasticity of the Fe-6.5percent Si. (2)the deposition speed and diffusion speed of the Si can be basically equal by regulating the current density and temperature parameters of deposition, so as to prevent a large amount of silicide on the surface. (3) the influence on the original structure of the matrix is small. (4) the medical preparation used in the method is low in cost, easily available and little consumable.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

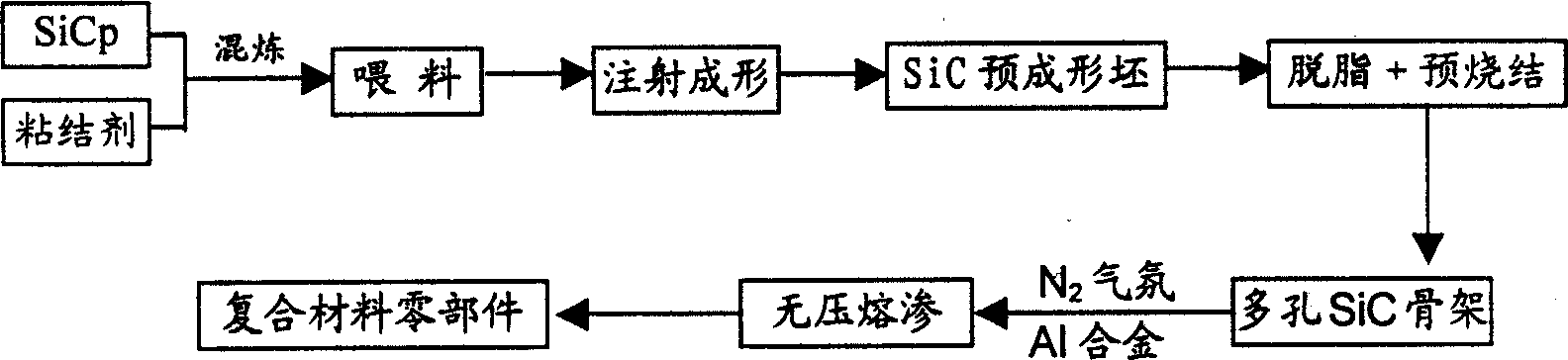

Method for producing high-volume fractional silicon-carbide particle reinforced aluminium-base composite material member

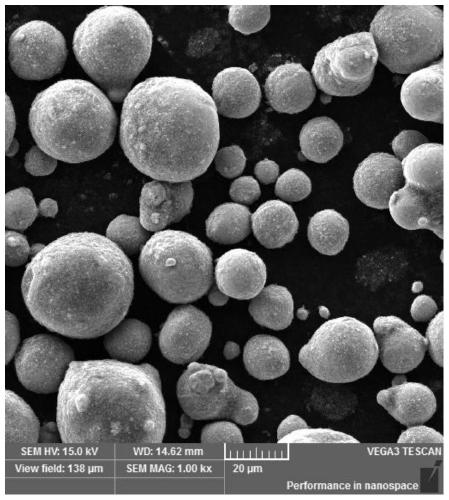

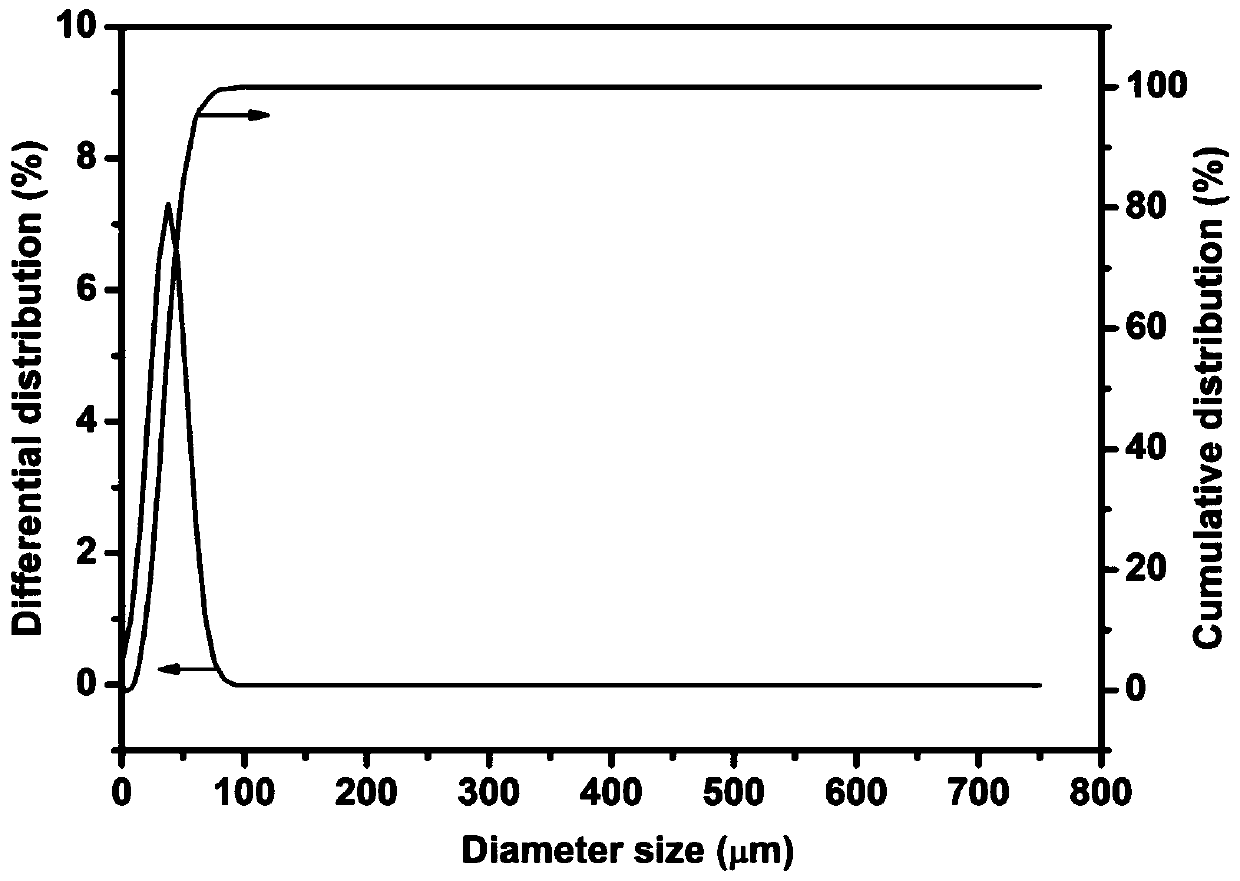

A technology for preparing the silicon carbide particles reinforced Al-based workpiece (SiCp / Al) with high volume fraction includes such steps as proportionally mixing SiC particles with paraffin wax based multi-polymer adhesive, stirring, granulating, injection moulding, thermal defatting in solvent, presintering at 1000-1150 deg.C, and osmosizing the molten Al alloy into SiC skeleton at 1100-1200 deg.C in N2 atmosphere.

Owner:UNIV OF SCI & TECH BEIJING

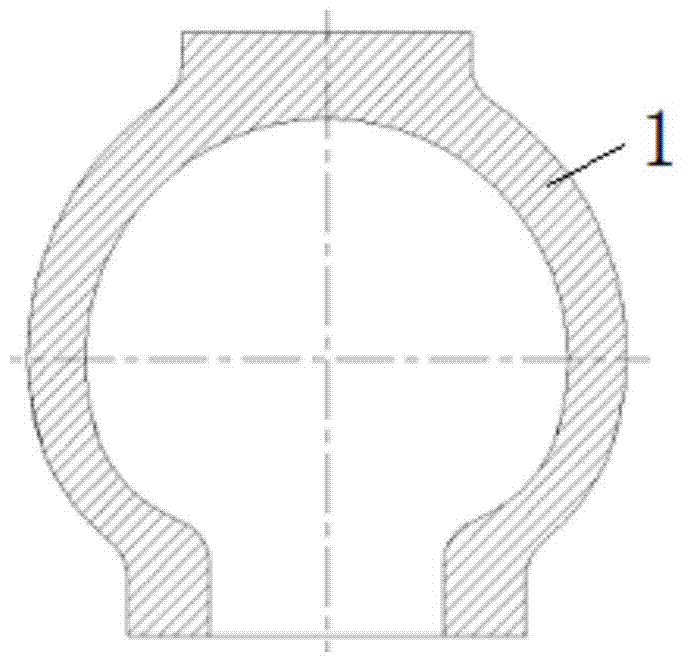

Method for machining all-metal screw pump stator

InactiveCN102501016ASolve processing difficultiesReduce processing difficultyElectrochemical machining apparatusHydroformingScrew pump

The invention discloses a method for machining an all-metal screw pump stator. The method comprises the following steps of: 1) machining a stator blank, so that a central hole for forming a stator inner cavity is formed in the stator blank; 2) forming the stator inner cavity by an electrolytic process; 3) polishing the stator inner cavity; and 4) performing surface-hardening treatment on the stator inner cavity. According to the method, the problem of difficulty in machining of the all-metal screw pump stator is solved by combining polishing treatment and surface-hardening treatment by adopting the electrolytic process. The method has obvious advantages on the machining of materials which are difficult to machine and parts with complex shapes or thin-wall parts, and has the characteristics of wide range of the machined materials, high production efficiency, high forming accuracy, capability of recycling electrode assemblies and the like. By the method, the technical blockade of hydraulically-formed all-metal screw pump stators which are used abroad is broken through, and a new method for manufacturing the all-metal screw pump stator is opened up, so that the machining difficulty of the all-metal screw pump stator is reduced effectively, and the machining efficiency is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

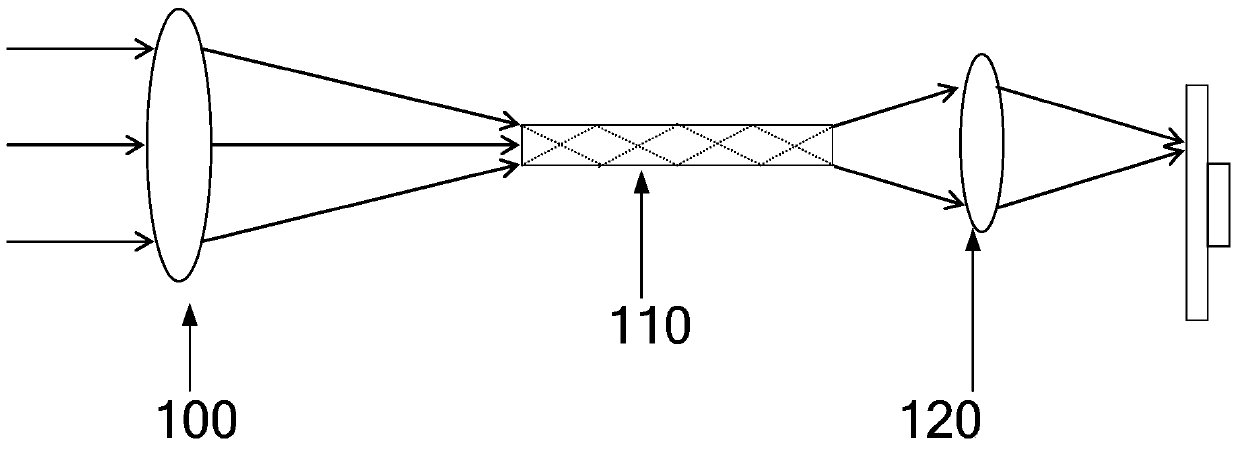

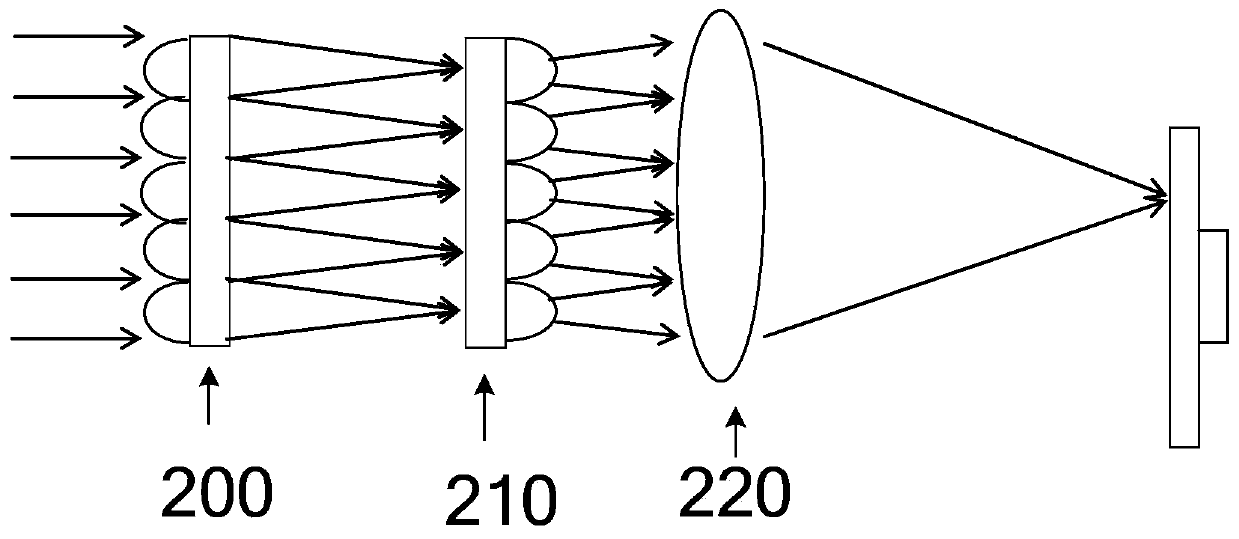

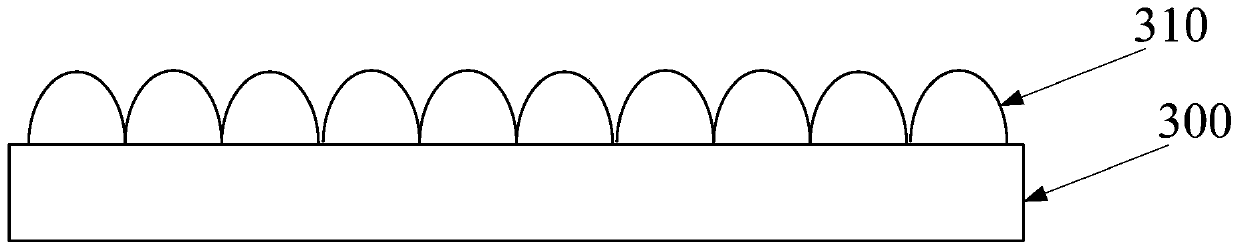

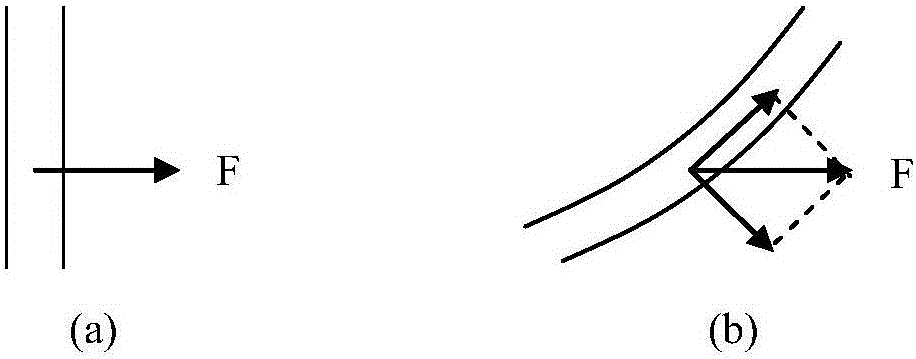

Light homogenizing structure, manufacturing method thereof and light homogenizing system

The invention discloses a light homogenizing structure, a manufacturing method thereof and a light homogenizing system. The light homogenizing structure comprises a base plate and a pattern structure arranged on the surface of the base plate. The pattern structure is formed via the transfer technology and comprises multiple micro-structures used for homogenizing incident beams irradiating the surfaces thereof. According to the invention, by refracting the incident beams irradiating the surfaces via the micro-structures, direction of propagation of the incident beams is changed; and the micro-structures will divide the incident beams into several fine sub-beams, so when the sub-beams are re-overlaid, small in-homogeneity of each sub-beam will be smoothened during the overlaying process, thereby allowing the sub-beams to be mixed more uniformly. Thus, homogeneity of the incident beams of the light homogenizing structure is improved; light homogenizing is achieved; and processing difficulties in the current laser light homogenizing device during satisfaction of requirements on quite small extension quantity of the beams can be solved.

Owner:APPOTRONICS CORP LTD

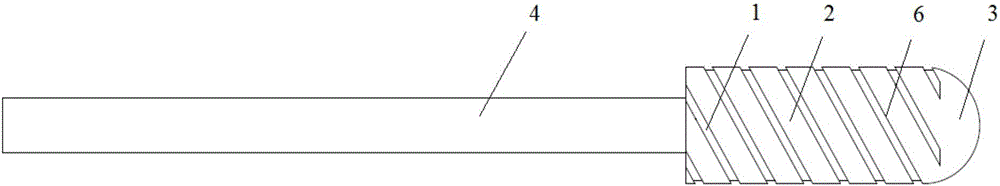

Method for machining narrow groove system impeller, grinding head and preparation method of grinding head

The invention provides a method for machining a narrow groove system impeller, a grinding head and a preparation method of the grinding head. The grinding head is a cylinder. The top end of the grinding head is in the shape of a spherical surface, and a spiral groove is formed in the side wall of the grinding head. The preparation method includes the steps that materials for use are calculated; ingredients are weighed; wetting and material mixing are performed; pressing of grinding head sand blocks is performed; drying is performed; the firing link is performed; and the grinding head sand blocks which are qualified through checking are selected and enter an adhesion processing procedure of a cutter handle, the cutter handle is bonded, after adhesives are cured and stabilized, laser dressing is performed, grooving is performed, and acceptance check of the grinding head is performed, and therefore preparation of the grinding head is completed. The method for machining the narrow groove system impeller through the grinding head includes the steps that fluttering stability analysis is performed, and a stable lobe graph of a grinding system is established; the technological parameter selecting range of stable grinding is determined; and technological parameters of stable grinding are selected, and the grinding head is installed for grinding machining. By means of the grinding head, the grinding temperature is effectively lowered, the adhesion and abrasion effects of cuttings on the grinding head are reduced, the machining surface burning problem is reduced, and better machining surface quality is acquired.

Owner:NORTHEASTERN UNIV

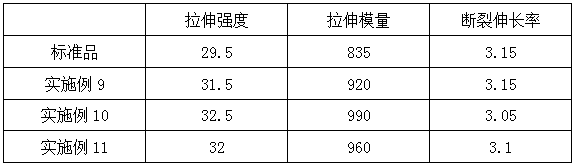

Multistage stretching technology for manufacture aramid fiber III

ActiveCN102797061AImprove mechanical propertiesImprove product qualityArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceAramid

The invention relates to a multistage stretching technology for manufacture aramid fiber III, which belongs to the technical field of chemical fiber. The multistage stretching technology comprises a negative stretching technology, plasticizing stretching treatment, water washing and plasticizing stretching treatment again to obtain final products. The multistage stretching technology can obviously improve the mechanical property of aramid fiber III, the multifilament stretching strength is increased to 32cN / dtex from 30cN / dtex, and the stretching modulus is increased to 950cN / dtex from 850cN / dtex. High-strength and high-modulus fiber obtained can be applied to applicable fields with higher market requirements.

Owner:中蓝晨光化工有限公司

Casting method of mud pump air dome shell for bearing pressure

ActiveCN104722718ADense tissueSolve processing difficultiesFoundry mouldsFoundry coresEngineeringSolid pattern

The invention discloses a casting method of a mud pump air dome shell for bearing pressure. The method comprises the following steps: step one. setting process, namely selecting the air dome shell with a downward big opening; optimizing working allowance layer on an outer sphere of the air dome shell; manufacturing a sphere sand core and a core head and a corresponding fixing rod; arranging a thermal-preservation open riser on the top end of the air dome shell; arranging two chilling blocks at the opening end of the air dome shell; installing a pouring runner; and drawing an art work sheet; step two, casting, namely manufacturing a wood core box for a solid pattern and the ball-shaped spherical sand core and the core head; modeling, taking out the solid pattern to form a cavity; manufacturing the spherical sand core, the core head, and a sand core skeleton, and placing an exhaust rope; spraying the paint; carrying out mold assembling, baking a sand mold, pouring, opening the mold; primarily blasting sand; grinding and repairing; normalizing, secondarily blasting sand to obtain the product. Through the adoption of the method disclosed by the invention, the manufactured air dome shell is high in cast precision, and the production cost is obviously reduced.

Owner:BAOJI PETROLEUM MASCH CO LTD

Manufacturing method of precision casting of titanium alloy impeller

InactiveCN103111588AEliminate low precision performance substandardSolve processing difficultiesFoundry mouldsFoundry coresImpellerTitanium alloy

The invention provides a manufacturing method of a precision casting of a titanium alloy impeller, which is used for manufacturing a casting by using an impeller splitting and mould assembly method. The manufacturing method comprises the following steps of mould design, machining of a curve outline of an impeller mould, finishing, swabbing, mould detection, single-impeller splitting and mould assembly, degassing, assembly, pouring, core removal, and casting detection, wherein positioning spigots are respectively arranged on an upper mould and a lower mould of the impeller mould, so as to prevent the mould from shifting; a mould core is arranged between the upper mould and the lower mould of the impeller mould; a single impeller parting line and a wire passing fixing groove are arranged on the mould core; a mould of the mould core is designed to be an opened single impeller mould, and a process step hole is designed and cut in the middle of the mould core; and a positioning pin is assembled on the process step hole of the mould core when the mould core is detected, and the two impeller moulds with sequential numbers are combined together by using a positioning step pin as an axis center. With the adoption of the manufacturing method provided by the invention, the technical difficulties in the normal manufacturing method that the mould core is difficult to machine and the size and an inner cavity of the mould cannot be detected can be overcome, so that the precision requirement of the CT (Casting Tolerance) 7 level of the mould can be ensured, and the problem that the casting precision is low can be solved.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Method for processing integrated stainless steel micro-fluid reactors

InactiveCN101554577ASimple methodSolve processing difficultiesChemical/physical/physico-chemical processesNon-electric welding apparatusEngineeringTemperature resistance

The invention provides a method for processing integrated stainless steel micro-fluid reactors, which is characterized in that the drawing is designed in advance and output as a DXF format in AUTOCAD according to the requirements, and the correction of drawing lines, the enlargement and the reduction are performed after the drawing in the DXF format is accepted by an electro discharge machining device. The method comprises the following steps: selecting the thickness of different plates as the characteristic scales of the micro-fluid reactors according to the requirements; processing all the micro-fluid channels and further cutting the plates to the overall size of the micro-fluid reactors; then, processing all the holes; grinding all the surfaces to be welded into mirror surfaces; cleaning, stacking in sequence, vacuum-diffusion welding and packaging; and finally welding entrance and exit nozzles to finish all the assembly. The invention has the advantages of high air tightness, high-temperature and low-temperature resistance, common material selection, easy assembly and feasible mass production, and reduces the production cost.

Owner:NANJING UNIV OF TECH

Titanium alloy composite material, preparation method thereof and laser additive manufacturing forming method

InactiveCN109735743AHigh hardnessHigh strengthAdditive manufacturing apparatusAlloy compositeHardness

The technical proposal discloses a titanium alloy composite material. The titanium alloy composite material is prepared from titanium alloy powder and reinforcing phase powder, wherein the reinforcingphase powder is prepared from titanium carbide, titanium boride and titanium silicide, and the weight fraction of reinforcing phase powder accounts for the titanium alloy composite material is 0.5%-20%. According to the technical scheme, a ball milling method is adopted to insert titanium carbide, titanium boride and boron carbide powder into the titanium alloy powder to form a composite powder material of titanium alloy and titanium carbide, titanium boride and boron carbide, so that the hardness and strength of the titanium alloy material is greatly improved. And meanwhile, the prepared composite powder is subjected to laser additive manufacturing forming, by regulating laser manufacturing parameters, metallurgical defects such as cracks and pores of the titanium alloy composite material during laser manufacturing are reduced or eliminated, and the comprehensive mechanical properties such as density, hardness and strength of parts are significantly improved, and the problem of difficult to manufacture the titanium alloy material is solved.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

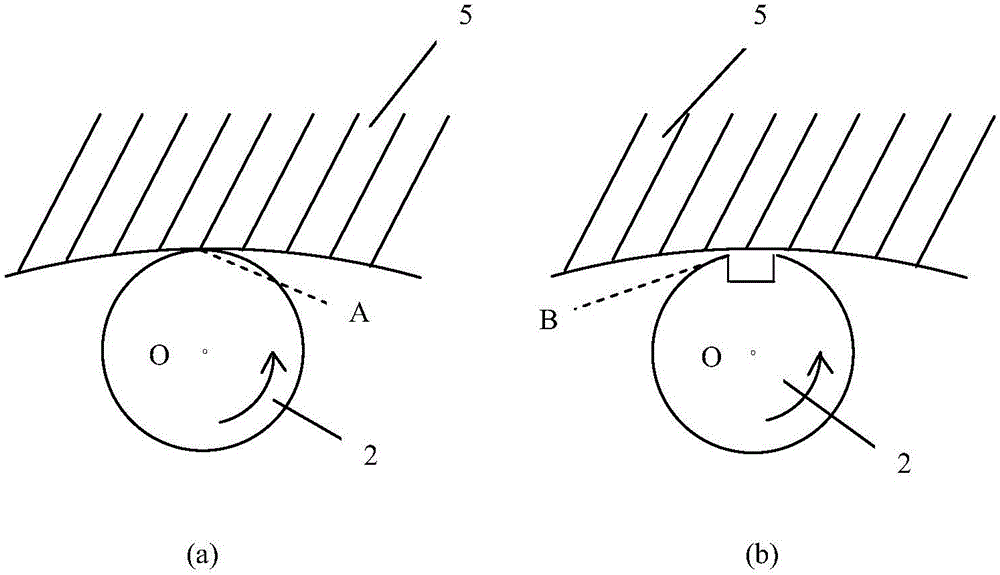

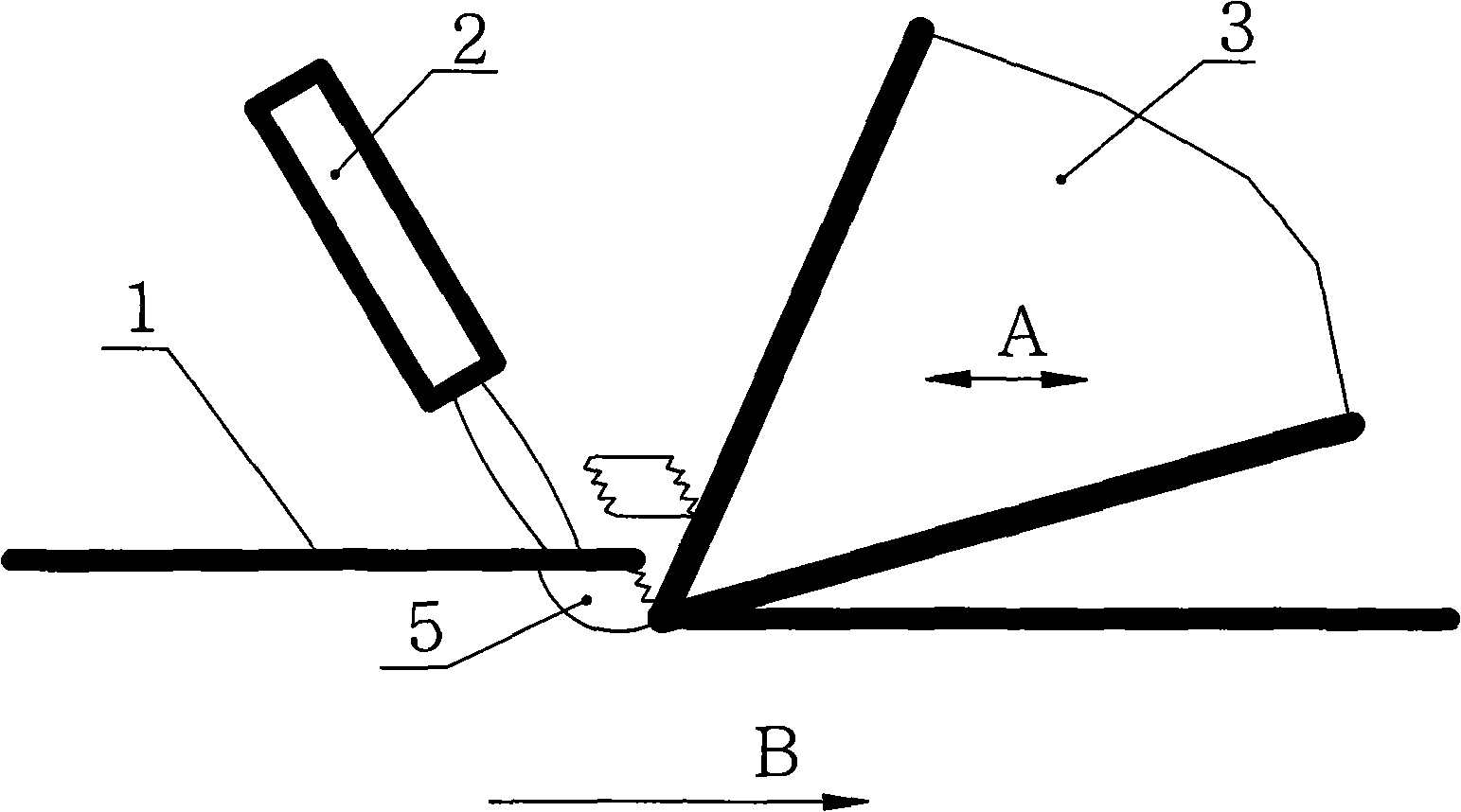

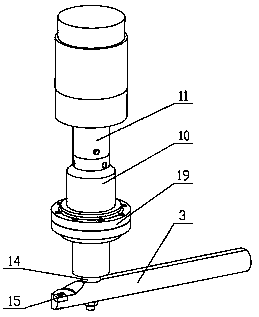

Method for auxiliary heating with pulse laser and machining with supersonic vibration

InactiveCN101559529AEfficient removalWon't hurtMetal working apparatusNon-electric welding apparatusImpulse frequencyTransducer

The invention discloses a method for auxiliary heating with pulse laser and machining with supersonic vibration, specifically comprising the following steps: (1) installing a work piece 1 which is to be machined and selecting a proper tool 3, and installing the tool 3; (2) according to different technological parameters, adjusting laser impulse frequency to be integral multiple of supersonic vibration frequency; (3) adjusting the irradiating position of a pulsing laser 2, starting up a machine tool and presetting the tool; (4) sending 1-n beams of laser pulse by the pulsing laser 2 so that the laser pulse irradiates a part which is to be machined by the step 3, and heating up materials; (5) sending vibration by an ultrasonic frequency generator, driving the work piece (or the tool) to be vibrated at one time by an energy transducer to remove the materials of the heated part; (6) repeating the step 4 and the step 5 till that all the needed materials are removed; and (7) switching off the laser, retracting the tool, shutting down the machine tool, and replacing the old component to machine the next component. The invention solves the problem that fire-resistant and corrosion-resistant hard-brittle materials are difficult to machine.

Owner:SHENYANG INST OF AERONAUTICAL ENG

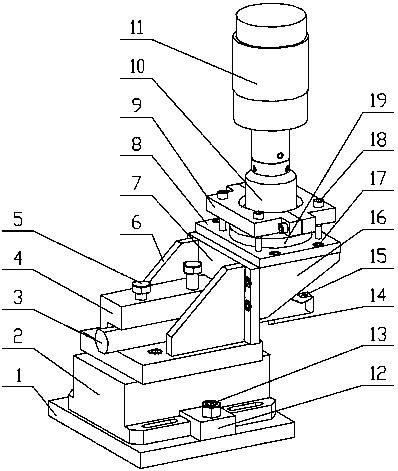

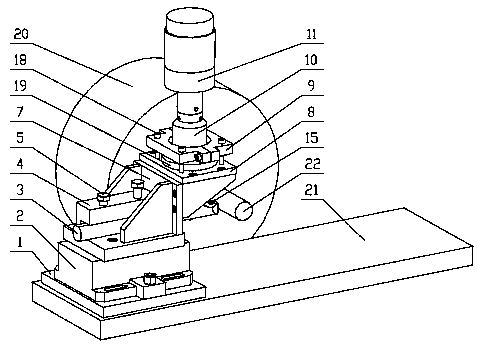

Cutting force measuring system for ultrasonic vibration turning

PendingCN109129015AReal-time measurement of cutting forceConvenient and flexible useMeasurement/indication equipmentsData acquisitionEngineering

The invention discloses a cutting force measuring system for ultrasonic vibration turning. The cutting force measuring system for ultrasonic vibration turning comprises an ultrasonic vibration mechanism, a special fixture, a force measuring mechanism and an engine lathe; the special fixture comprises a base part and a fixture part; the force measuring mechanism comprises a force measurement unit,a charge amplifier, a data collection system, a data analysis system and a computer which are connected with each other in sequence through signal wires; the force measurement unit is connected with the engine lathe through the base part; and the force measurement unit is connected with the ultrasonic vibration mechanism through the fixture part. The cutting force measuring system for ultrasonic vibration turning has the characteristics of convenient structure mounting, simple and easy detaching, low economic cost and the like. When the cutting force measuring system for ultrasonic vibration turning is used for ultrasonic vibration turning, shortcomings in the traditional turning technology can be overcome, the machining quality can be effectively improved, and the machining efficiency canbe enhanced.

Owner:EAST CHINA UNIV OF TECH

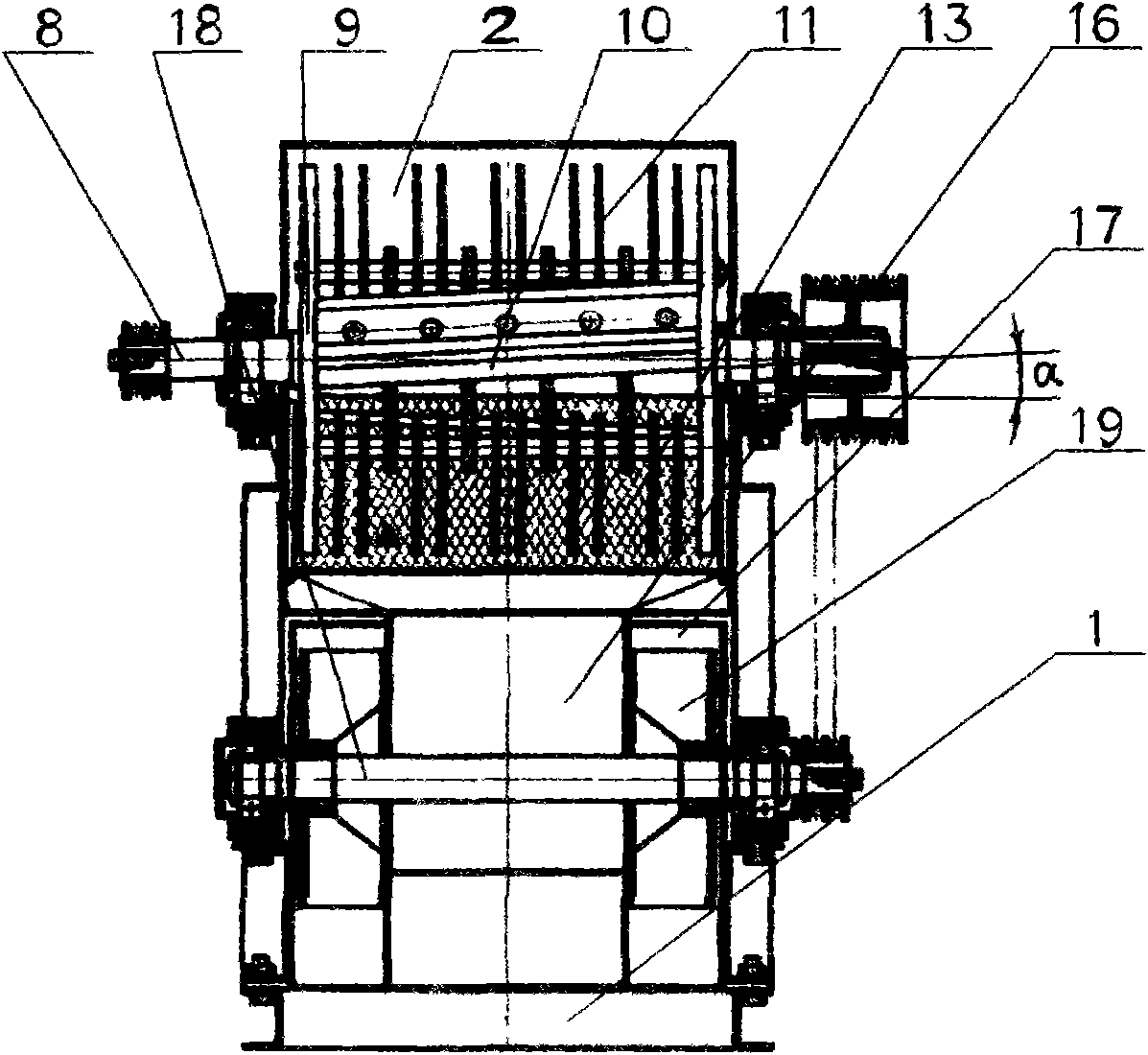

Double-use plant material cutting grinder

InactiveCN101786034AReduce energy consumptionStable suctionCuttersGrain treatmentsImpellerEngineering

The invention relates to processing machinery for producing edible fungi culture materials, in particular to a double-use plant material cutting grinder. The grinder comprises a frame, a cutting-grinding chamber arranged on the frame, a feeding hopper, a material outlet, a power device and a variable-speed transmission mechanism, wherein a public blanking hopper is directly arranged below the cutting-grinding chamber, namely at the bottom of a filter screen; a centrifugal material-sucking fan device is arranged in the public blanking hopper; the centrifugal material-sucking fan device consists of a pair of air impellers arranged on two sides of the same centrifugal fan main shaft ; and an air outlet of the centrifugal material-sucking fan device is communicated with the material outlet. The grinder can cut and grind straw of various plant materials, weeds, branches, woodwork shavings and other soft / hard raw materials, and helps to directly and smoothly suck out raw material particles even with high water content, thereby achieving the effects of reducing energy consumption, simplifying process and improving production efficiency.

Owner:翁赐和

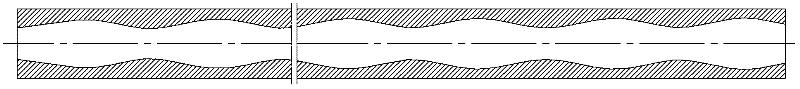

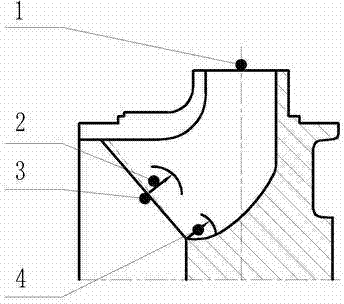

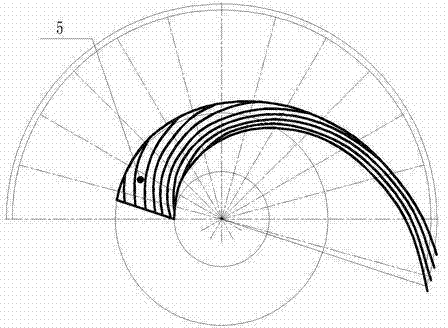

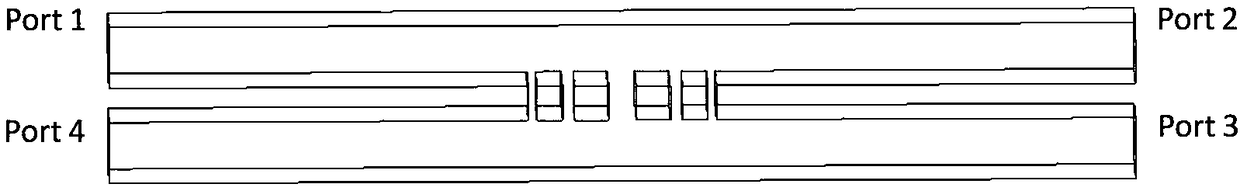

Improved terahertz branch waveguide coupler

An improved terahertz branch waveguide coupler relates to the field of directional branch waveguide couplers. In the terahertz branch waveguide coupler, a second electromagnetic field channel is located between a first metal barrier and a second metal barrier, a first coupling fillet is formed at the end, close to a main channel and the second electromagnetic field channel, of the first metal barrier, a third coupling fillet is formed at the end, close to a coupling channel and the second electromagnetic field channel, of the first metal barrier, a second coupling fillet is formed at the end,close to the main channel and the second electromagnetic field channel, of the second metal barrier, and a fourth coupling fillet is formed at the end, close to the coupling channel and the second electromagnetic field channel, of the second metal barrier. According to the invention, four fillets are formed on the metal barriers on both sides of the second electromagnetic field channel, which increases the coupling coefficient of the second electromagnetic field channel, on the basis of ensuring the same or even better performance as the ordinary 5-branch line structure coupler, the width of the narrowest coupling channel of the branch waveguide structure is increased to 0.3 mm level, and thus the processing difficulty and cost are greatly reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Titanium alloy gear and preparation method thereof

ActiveCN107893228AImprove power densityReduce power densityAdditive manufacturing apparatusPortable liftingHardnessTitanium alloy

The invention provides a preparation method for a titanium alloy gear. The preparation method includes the steps that a titanium alloy gear substrate is prepared through a 3D printing method; the titanium alloy gear substrate is subjected to hot isostatic pressing treatment, and a titanium alloy gear blank is obtained; a hardened layer is formed on the surface of the titanium alloy gear blank through a fusion covering method, and the titanium alloy gear is obtained; and the thickness of the hardened layer is 1-2 mm. According to the preparation method for the titanium alloy gear, the mechanical properties of the gear substrate are improved through hot isostatic pressing treatment, and the thick hardened layer can be formed on the surface of the gear substrate through the fusion covering method. The titanium alloy gear prepared through the process is high in surface hardness, low in friction coefficient, resistant to abrasion, high in impact resistance and fatigue performance, and suitable for gear transmission equipment in the aerospace industry, automobile industry and the like.

Owner:SEED TECH CORP LTD

Method for preparing diamond/copper composite material parts with high volume fraction

ActiveCN106583735AVolume fraction adjustmentHigh densityLiquid/solution decomposition chemical coatingUltra high pressureChemical plating

The invention provides a method for preparing diamond / copper composite material parts with high volume fraction. The method comprises the following steps: plating the surface of diamond with a uniform Mo2C layer by using a salt-bath plating technology to improve wettability of the diamond and copper; and then continuing copperizing the surface of the Mo2C layer by using a chemical plating method, and controlling the thickness of a copperizing layer by controlling the content of Cu2+ in a plating solution so as to prepare copper-containing double-plating-layer Cu-Mo2C-Diamond powder with the volume fraction of 30-50 vol.%. The Cu-Mo2C-Diamond powder is formed by an ultra-high-pressure cold pressing method, and Diamond / Cu composite material parts are prepared by a vacuum pressureless sintering method. The method has the advantages that the Diamond / Cu composite material parts with complicated shapes and high volume fractions of (50-70 vol. %) can be directly prepared, meanwhile, composite materials are uniform in structure and high in compactness, the Diamond / Cu composite material parts can be produced in batches, and the production cost is low.

Owner:UNIV OF SCI & TECH BEIJING

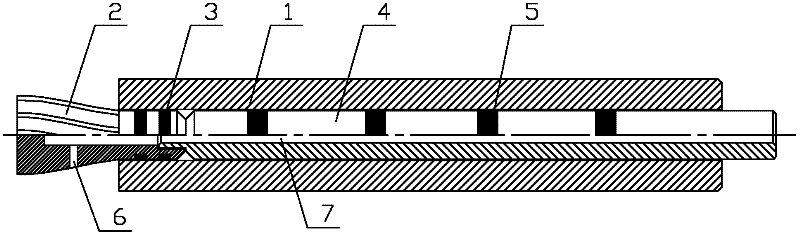

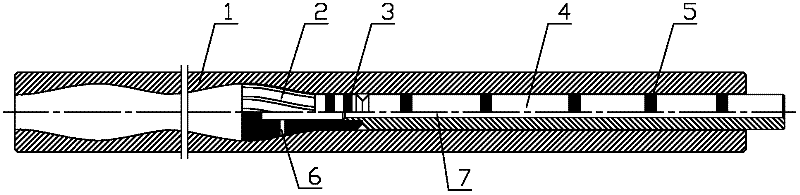

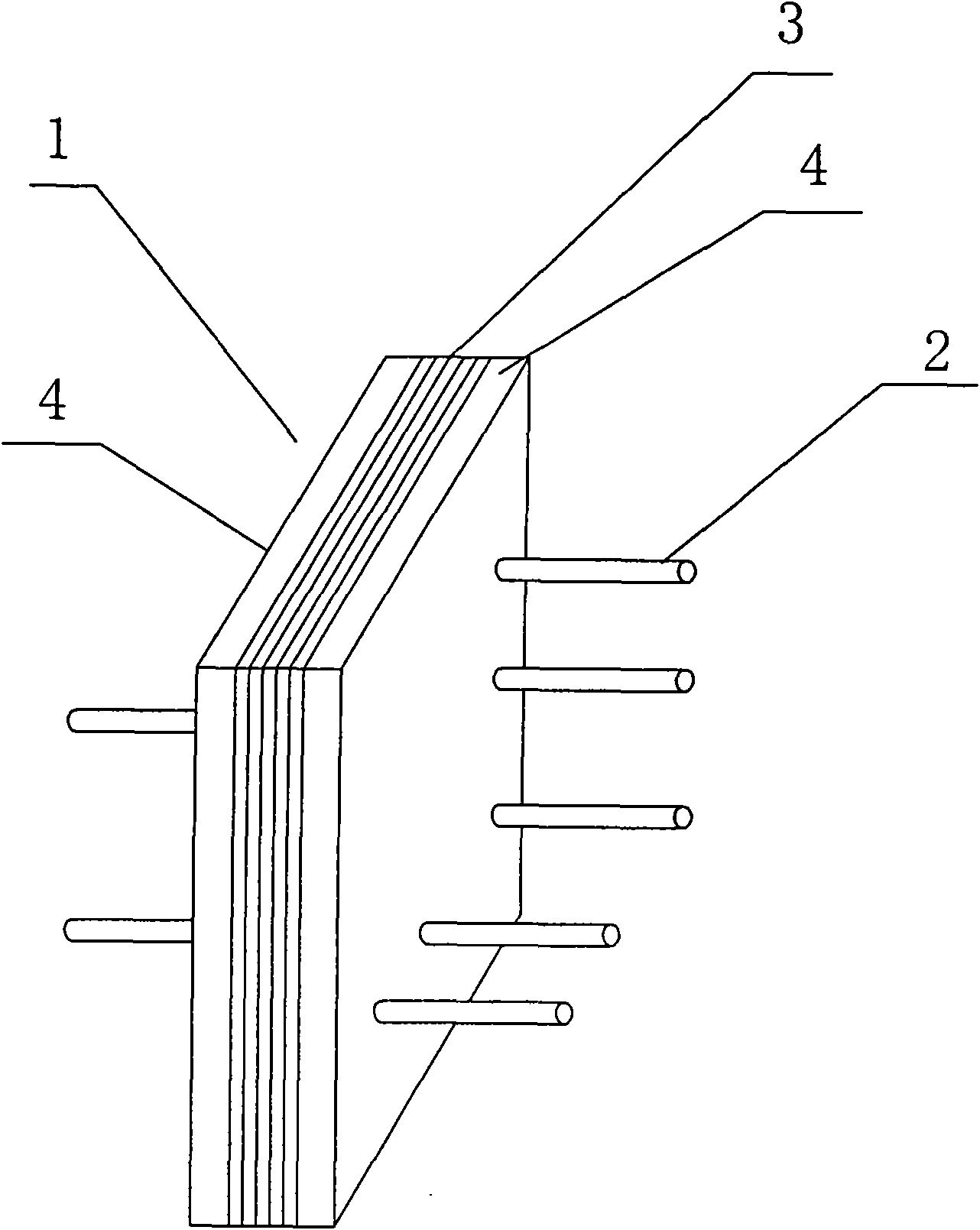

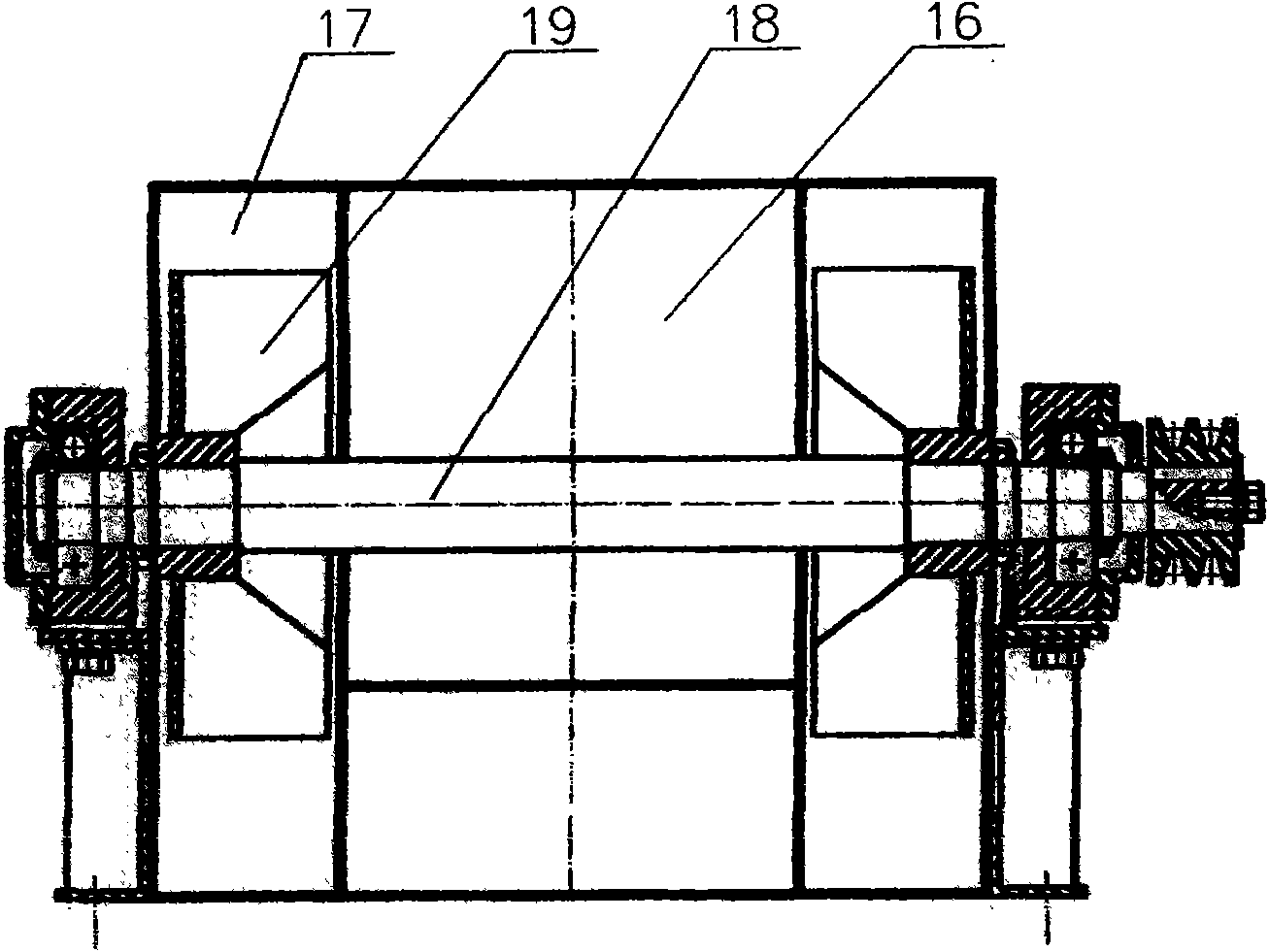

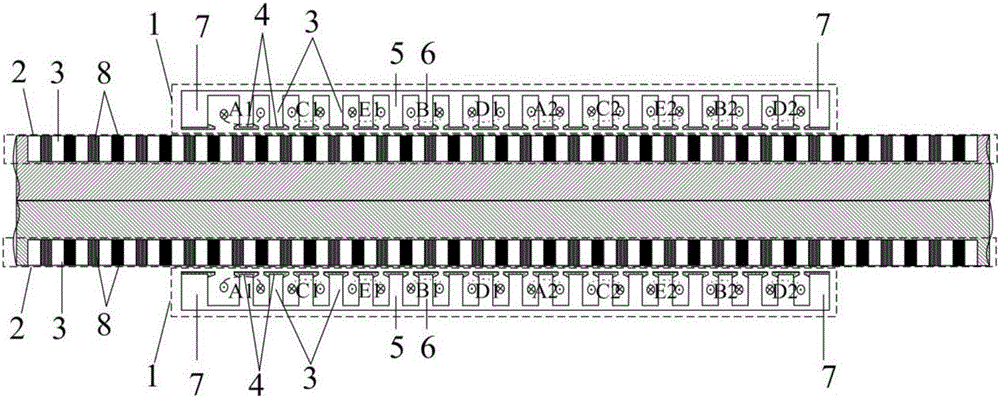

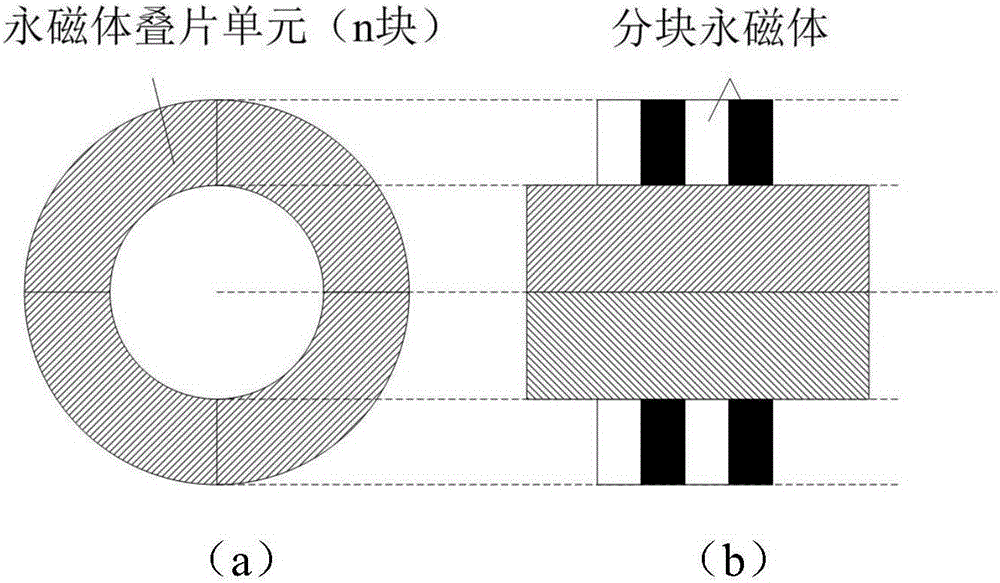

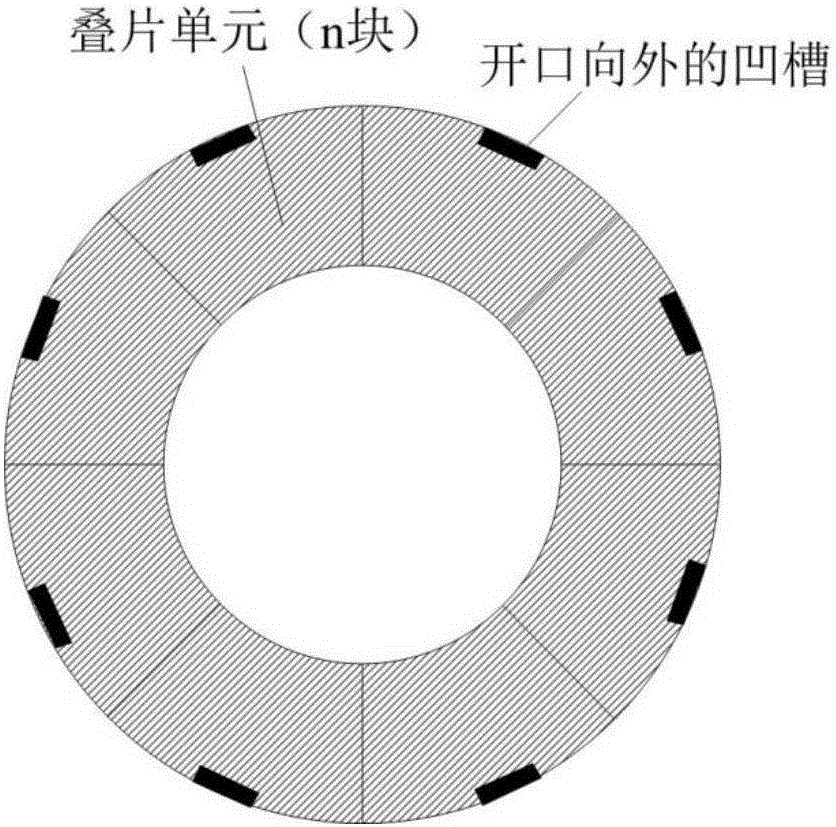

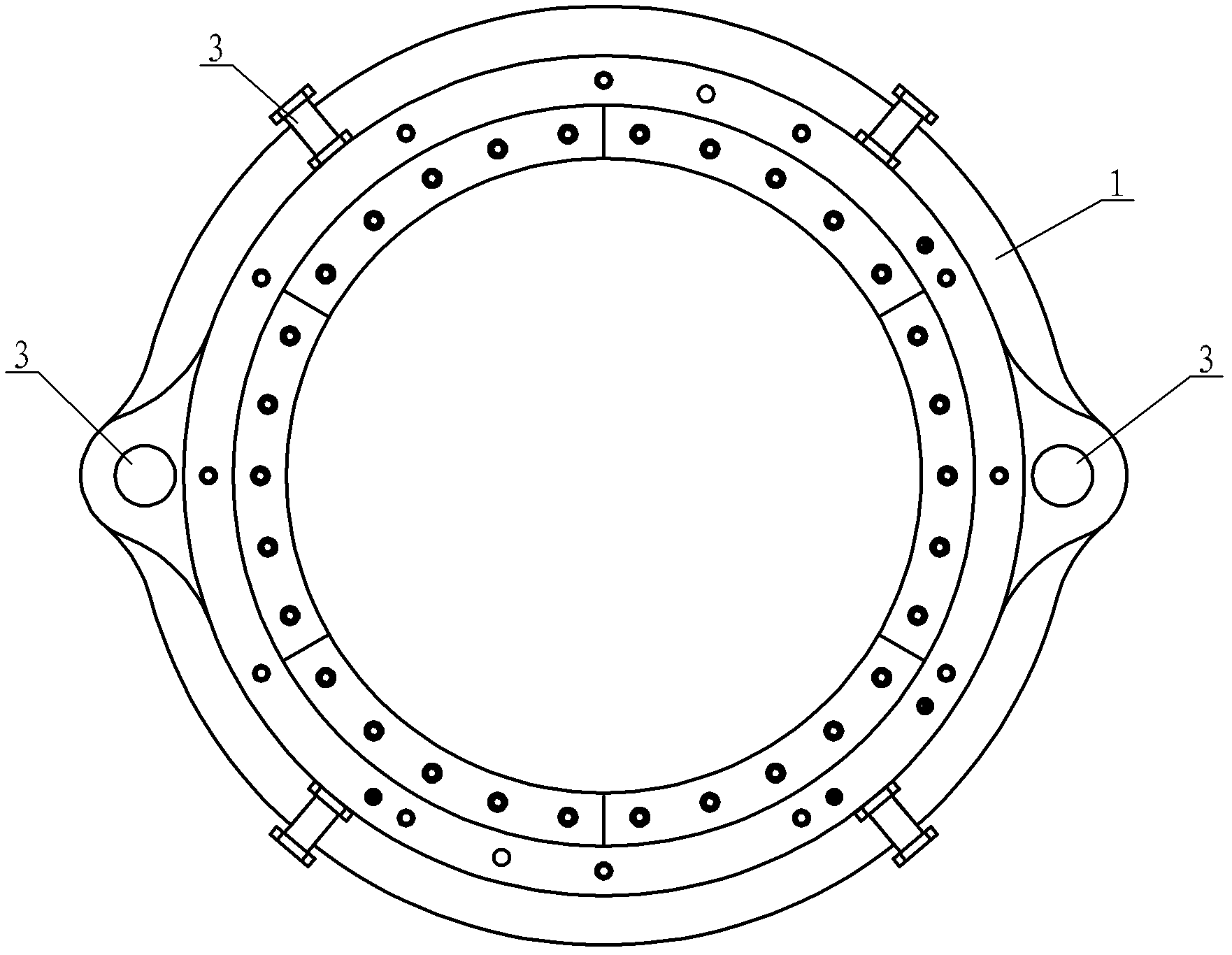

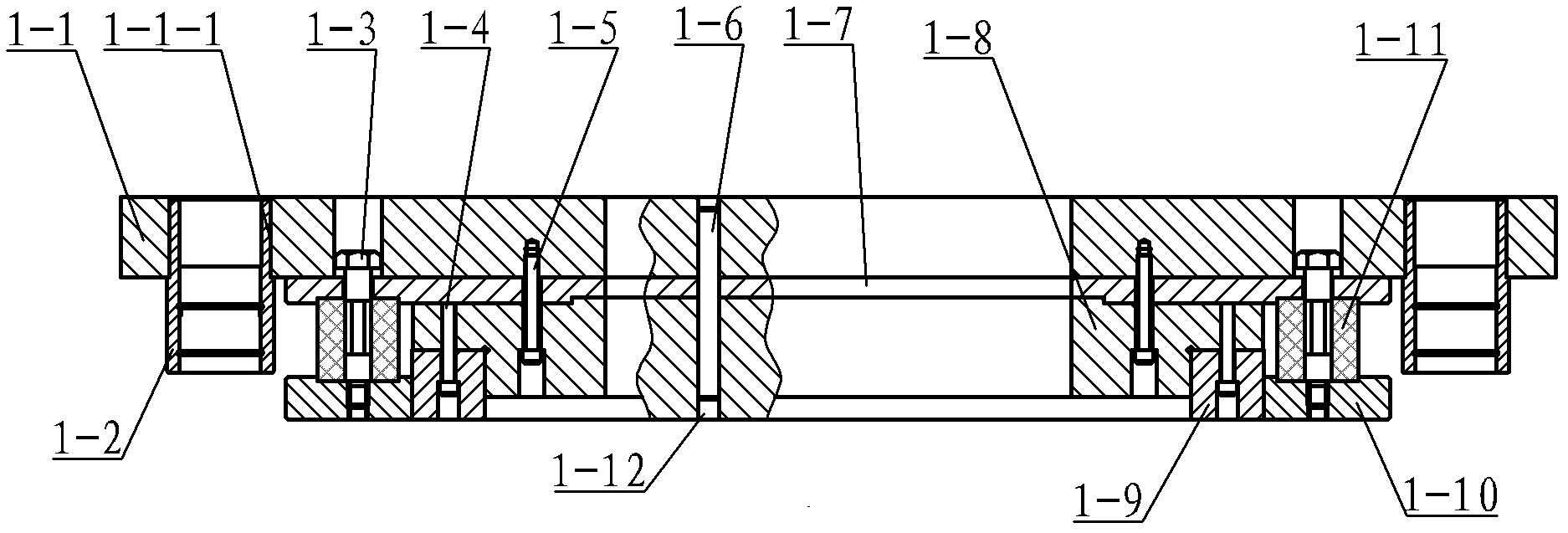

Low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor and machining method thereof

InactiveCN106067720ASolve processing difficultiesImprove efficiencyMagnetic circuit stationary partsPropulsion systemsElectric machineSecondary stage

The invention discloses a low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor and a machining method thereof. The system comprises a primary stage and a secondary stage. The length of the primary stage is smaller than the length of the secondary stage. An air gap is formed between the primary stage and the secondary stage. The primary stage is composed of a yoke part and teeth, wherein the teeth are composed of armature teeth and fault-tolerant teeth. The end portions of the teeth are provided with pole shoes. A coil winding is arranged in a tooth space. The armature teeth and the fault-tolerant teeth are the same in number and are arranged in a staggered manner. The primary stage is composed of a primary stator iron core and the primary stator iron core is composed of silicon steel sheets and an electrical pure iron. The secondary stage is composed of a permanent magnet and a secondary iron core. The permanent magnet is embedded in the secondary iron core. The secondary iron core is composed of axially laminated silicon steel sheets. Each silicon steel laminated sheet is divided into a plurality of fan-shaped laminated pieces. The inner diameter of each secondary silicon steel sheet is smaller than the inner diameter of the secondary permanent magnet. According to the invention, the low-loss half-closed trough type fault-tolerant permanent magnet cylinder linear motor is convenient to machine and manufacture, and the designing and machining cost of the motor is reduced. Meanwhile, the efficiency of the motor is improved on the basis that the performance of an original permanent magnet embedded cylindrical linear motor is ensured.

Owner:JIANGSU UNIV

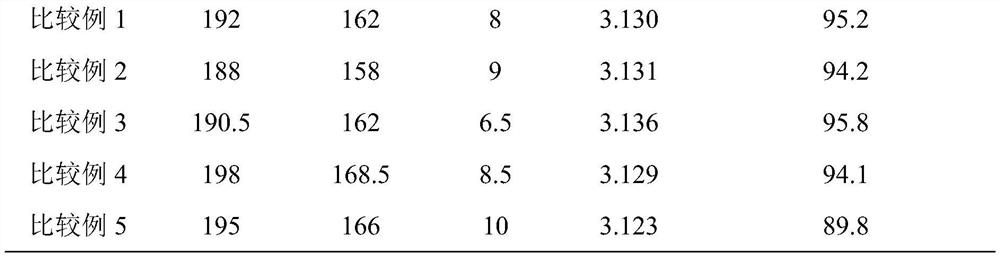

High-energy-density lithium iron phosphate battery

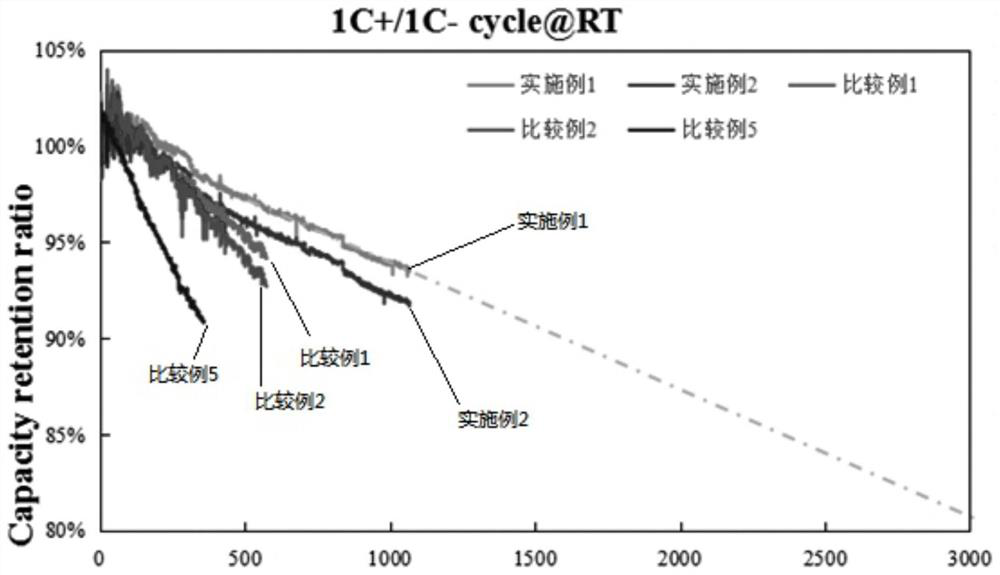

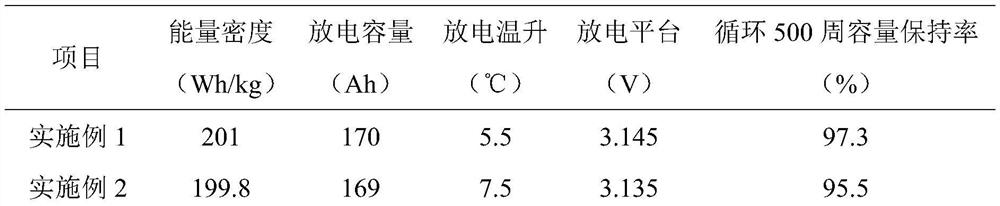

ActiveCN113078305ASignificant progressIncrease capacityMaterial nanotechnologyFinal product manufactureElectrolytic agentMagnesium doping

The invention belongs to the technical field of electrochemistry, and particularly relates to a high-energy-density lithium iron phosphate battery. A positive electrode active material is selected from titanium / magnesium-doped lithium iron phosphate, the surface density of a positive plate is 190-210 g / m<2>, the compaction density is greater than or equal to 2.60 g / cc, a negative electrode active material is carbon-coated single particle and secondary particle needle coke blend artificial graphite, and the compaction density of a negative plate is greater than or equal to 1.70 g / cc. The density of the electrolyte is equal to 1.15 g / cc, the wall thickness of the aluminum shell body is 0.40-0.50 mm, a positive electrode current collector is an aluminum foil with the diameter of 12-13 [mu]m, a negative electrode current collector is a copper foil with the diameter of 4.5 [mu]m, a diaphragm is a 7 + 2C + 2P ceramic gluing diaphragm, a conductive binder is used for replacing a positive electrode, the addition amount is 1.0-2.0%, and the weight ratio of a positive electrode active material to a positive electrode dressing is greater than or equal to 98%. According to the invention, the energy density of the battery is greatly improved and reaches 200Wh / kg.

Owner:江西安驰新能源科技有限公司

Rhombus plug gauge processing method

ActiveCN103128512ASolve processing difficultiesReduce processing difficultyFeeler gaugeGrinding wheel

The invention provides a rhombus plug gauge processing method includes the following steps of preparing materials, selecting forge piece blanking which is intact in materials, and free from flaws and sand holes, carrying out lathe operator process, miller process, heat treatment process, sand blowing process, surface treatment process, and cutter grinding process, firstly grinding a D surface and a surface parallel to the D surface until required sizes are reached, then enabling a rhombus plug gauge to be clamped on a sine platform, enabling the grinded D surface and the surface parallel to the D surface to face the left side face and the right side face of the sine platform, wherein two non-grinded surfaces face the upper surface and the lower surface of the sine platform, calculating thickness of a feeler gauge according to angle of the rhombus, enabling the feeler gauge to be cushioned under the sine platform, enabling a grinding wheel to begin to carry out cutting feed along the track of the grinding wheel, firstly grinding an E surface, then turning the rhombus plug gauge to begin to grind a surface parallel to the E surface after the E surface is well grinded, carrying out fitter process, and carving marks. The rhombus plug gauge processing method reduces processing difficulty of the rhombus plug gauge, and ensures accuracy requirements of the rhombus plug gauge.

Owner:SHENYANG AIRCRAFT CORP

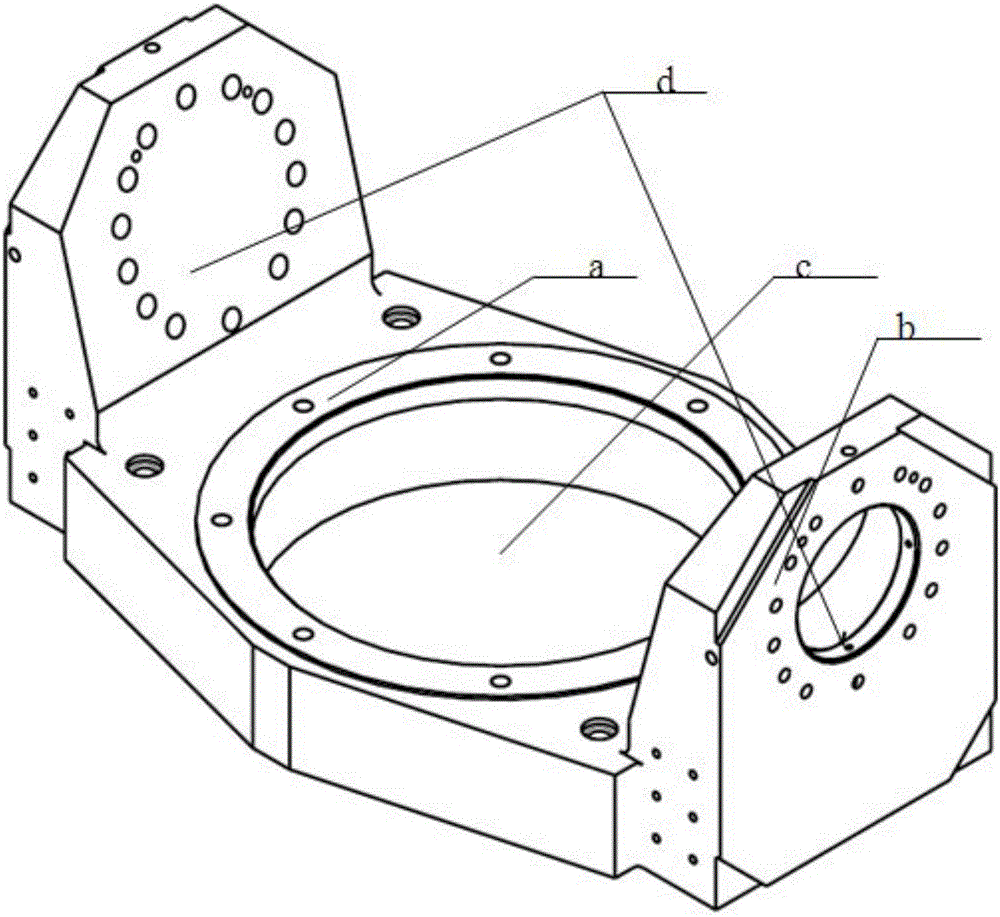

Integral cast aluminum cradle type five-axis swinging frame and manufacturing method thereof

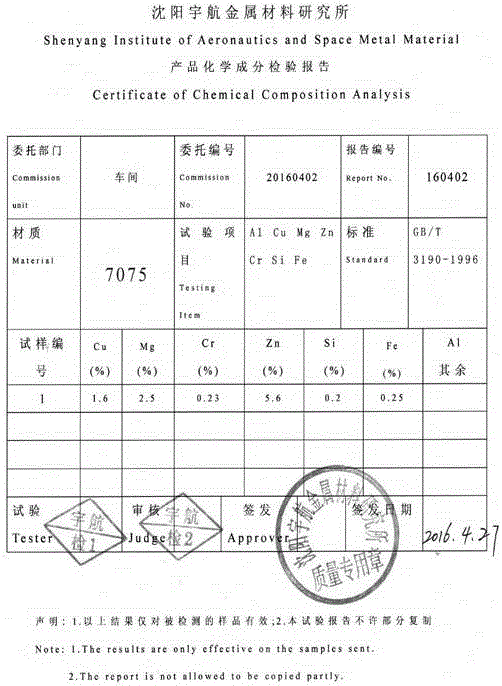

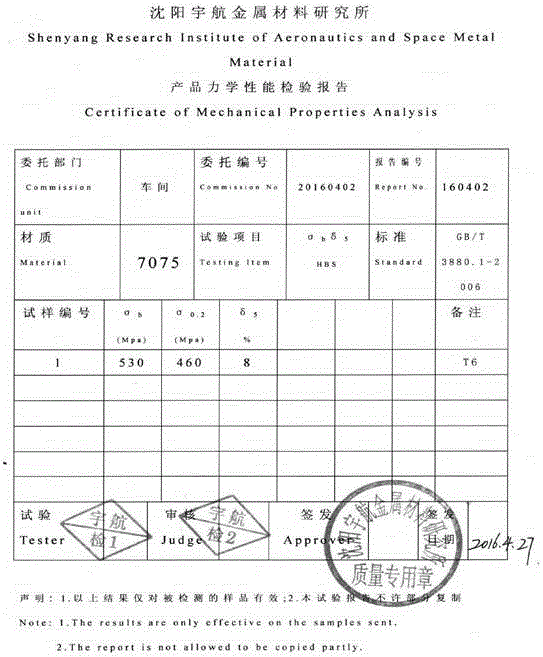

Provided is an integral cast aluminum cradle type five-axis swinging frame. The integral cast aluminum cradle type five-axis swinging frame is characterized in that the swinging frame is made of cast aluminum alloy 7075; as for the mechanical properties, sigma b is 530 Mpa, sigma 0.2 is 460 Mpa, and sigma 5 is 8%; axial holes d of two shafts A are coaxial with the planeness being within 0.01 mm; and the planeness of the mounting plane a of a C-axis motor and the planeness of the mounting plane b of an A-axis motor are 0.005 mm. The integral cast aluminum cradle type five-axis swinging frame is formed through integral casting and machining. A manufacturing method comprises the steps that the alloy is smelted and poured, and the swinging frame is subjected to casting, thermal treatment and integral machining. As for applied clamps, the integral cast aluminum cradle type five-axis swinging frame is characterized in that lengthening jack catches are manufactured and combined to claws of a four-claw square chuck through flat keys and screws, so that the lengthening jack catches are lengthened to be equal to the internal diameter of a horizontal axle hole of the swinging frame, and the jacking end faces of the lengthening jack catches are trimmed according to the diameter of a machined axial hole. A cast iron swinging frame is 205 Kg heavy while the cast aluminum swinging frame is only 75 Kg heavy, that is, the overall weight is reduced by 130 Kg. The A-axis acceleration of a cast iron swinging table is 7 rad / s<2> while the acceleration of the cast aluminum swinging frame applied to an intelligent multi-axis vertical machining center is 18 rad / s<2>. The speed gain of the cast aluminum swinging frame can also be doubled. The acceleration and response speed of a machine tool are remarkably improved.

Owner:沈阳优尼斯智能装备有限公司

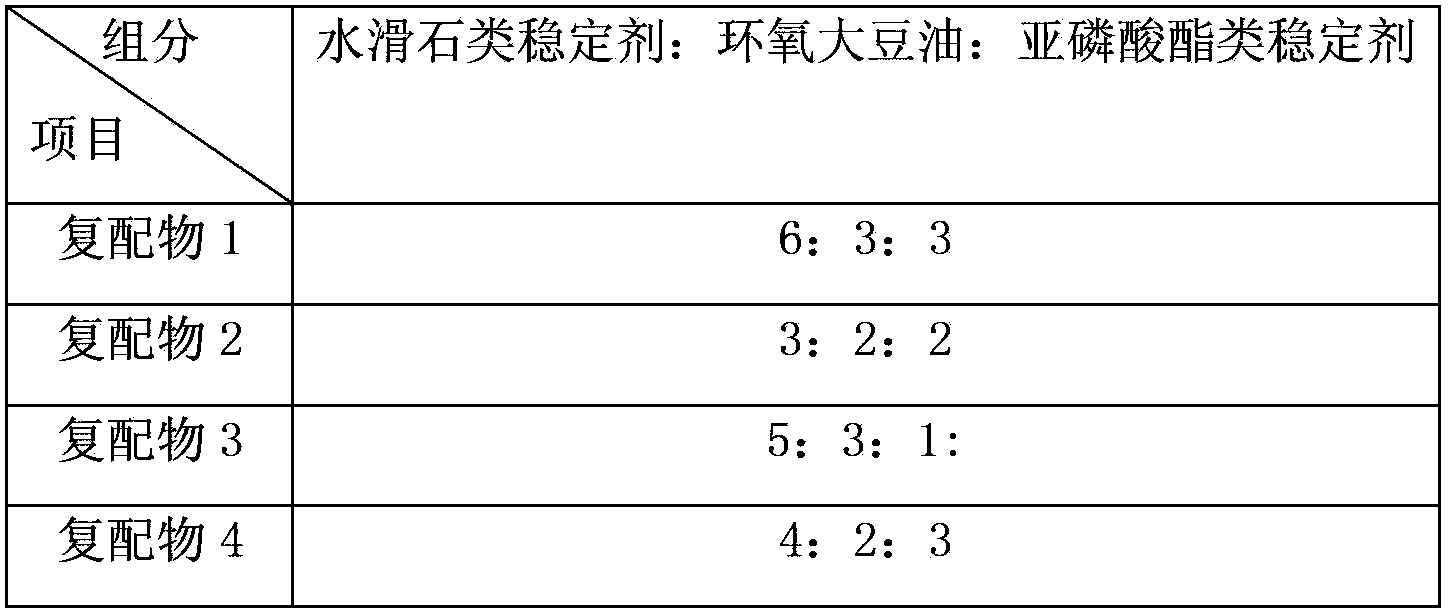

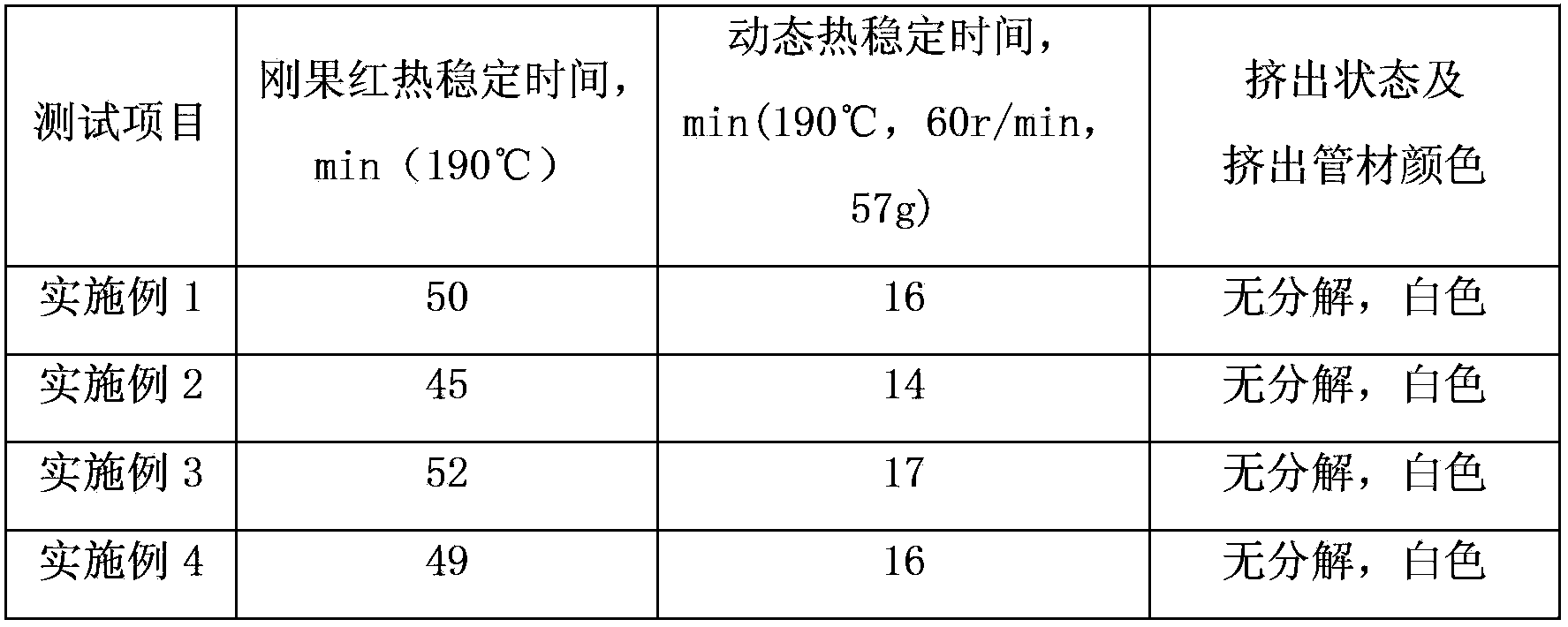

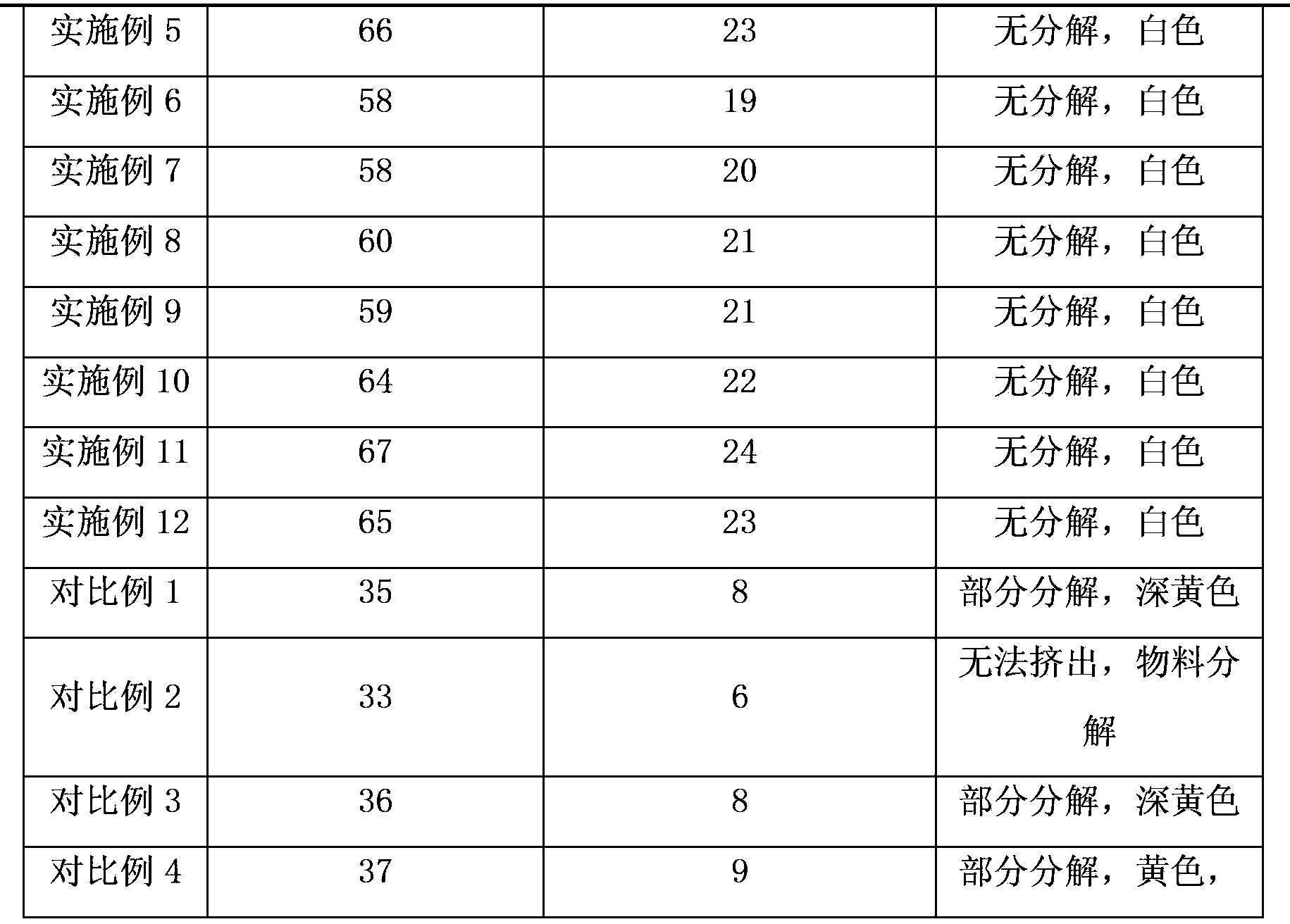

CPVC (Chlorinated Polyvinyl Chloride) composition with good heat stability and preparation method thereof

The invention relates to a CPVC (Chlorinated Polyvinyl Chloride) composition with good heat stability and a preparation method thereof, belongs to the field of high-molecular processing materials, and mainly relates to the CPVC composition with good heat stability and the preparation method thereof. The CPVC composition is prepared from the following components in parts by weight: 100 parts of CPVC resin, 3-6 parts of composite stabilizer, 0.5-1.5 parts of internal lubricating agent, 0.5-1.5 parts of external lubricating agent, 6-12 parts of impact modifier and 3-20 parts of filling agent. The CPVC composition with good heat stability, which is disclosed by the invention, can enhance the heat stability of the CPVC composition in a processing process, thereby solving the problem of difficult processing of the CPVC composition.

Owner:CHINA PETROLEUM & CHEM CORP

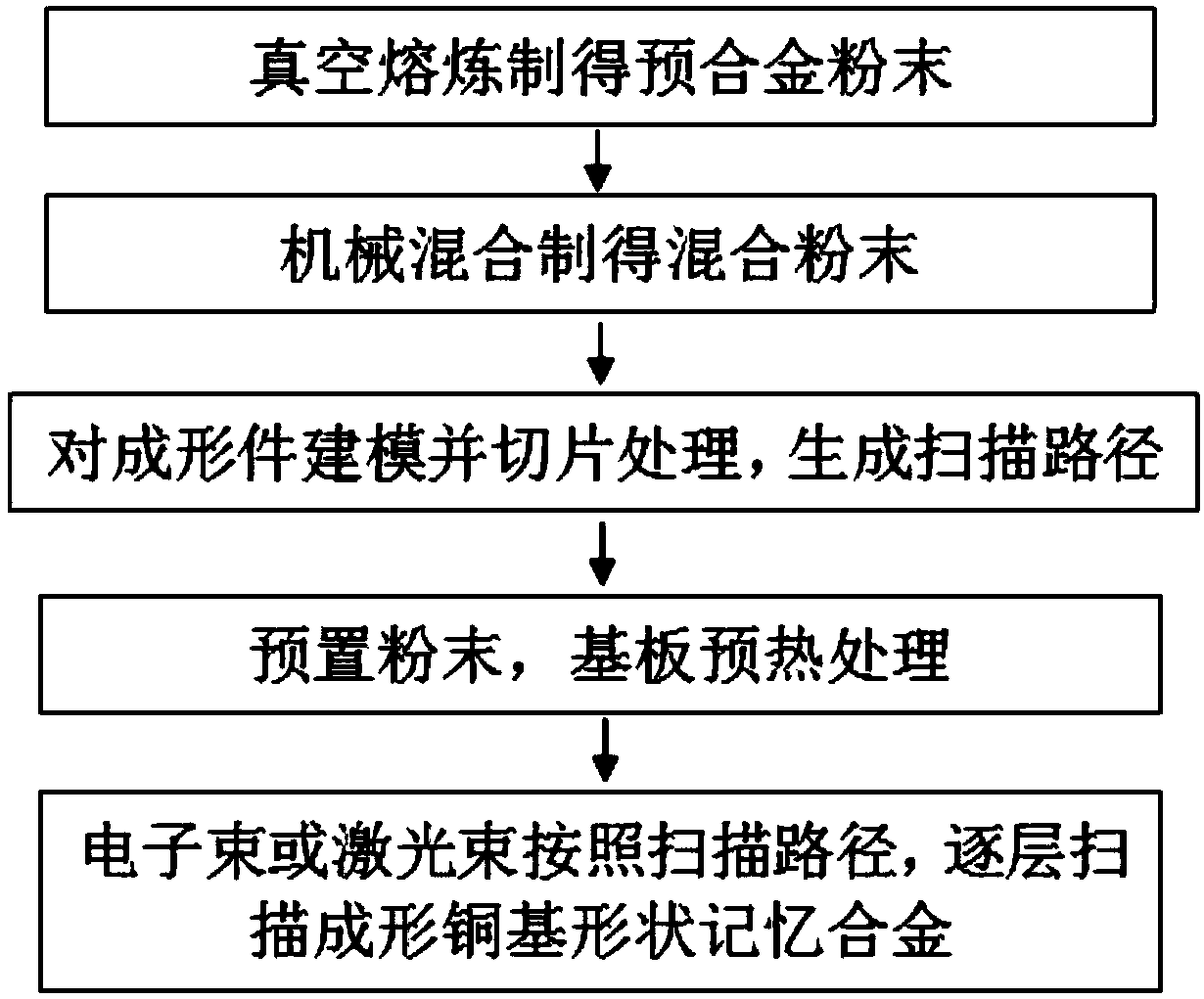

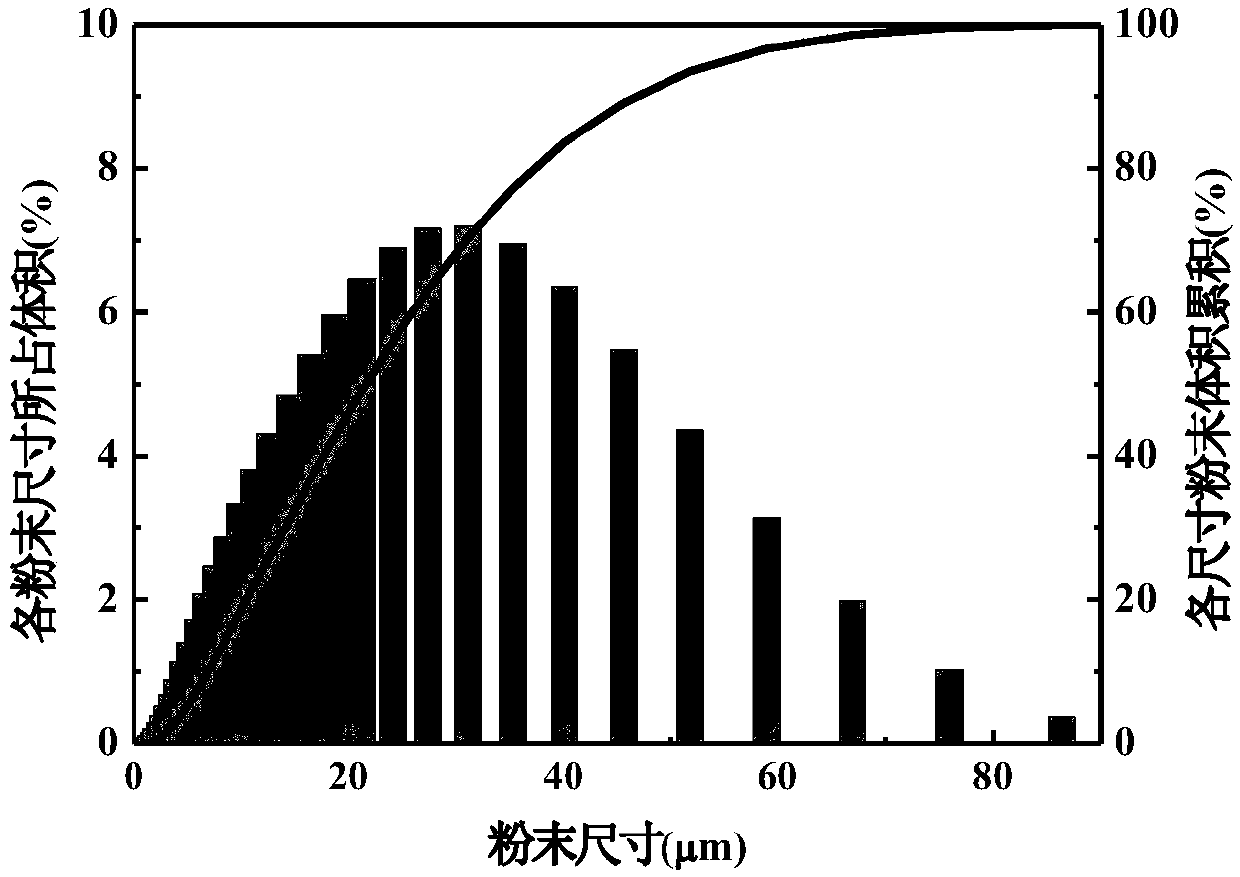

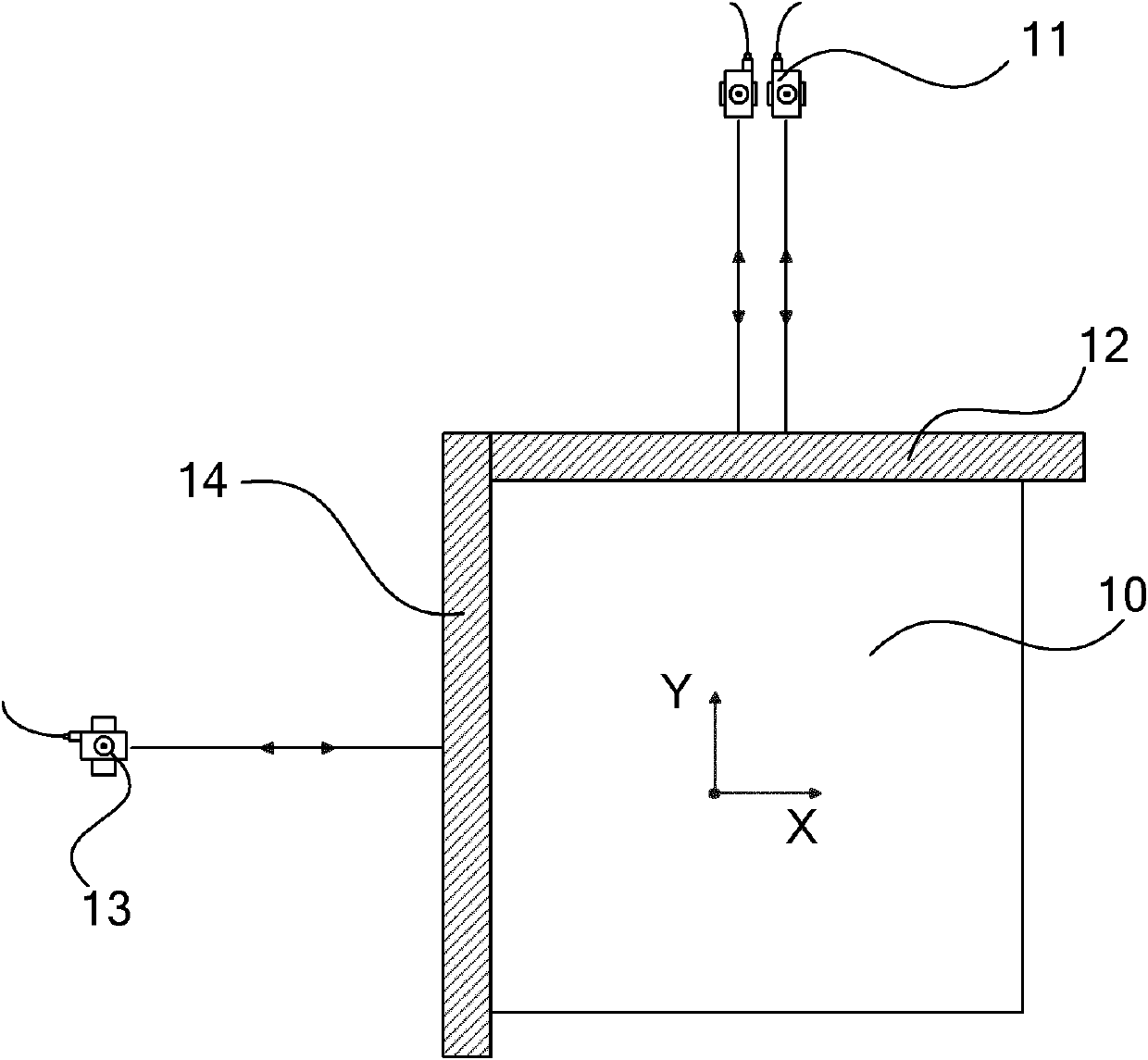

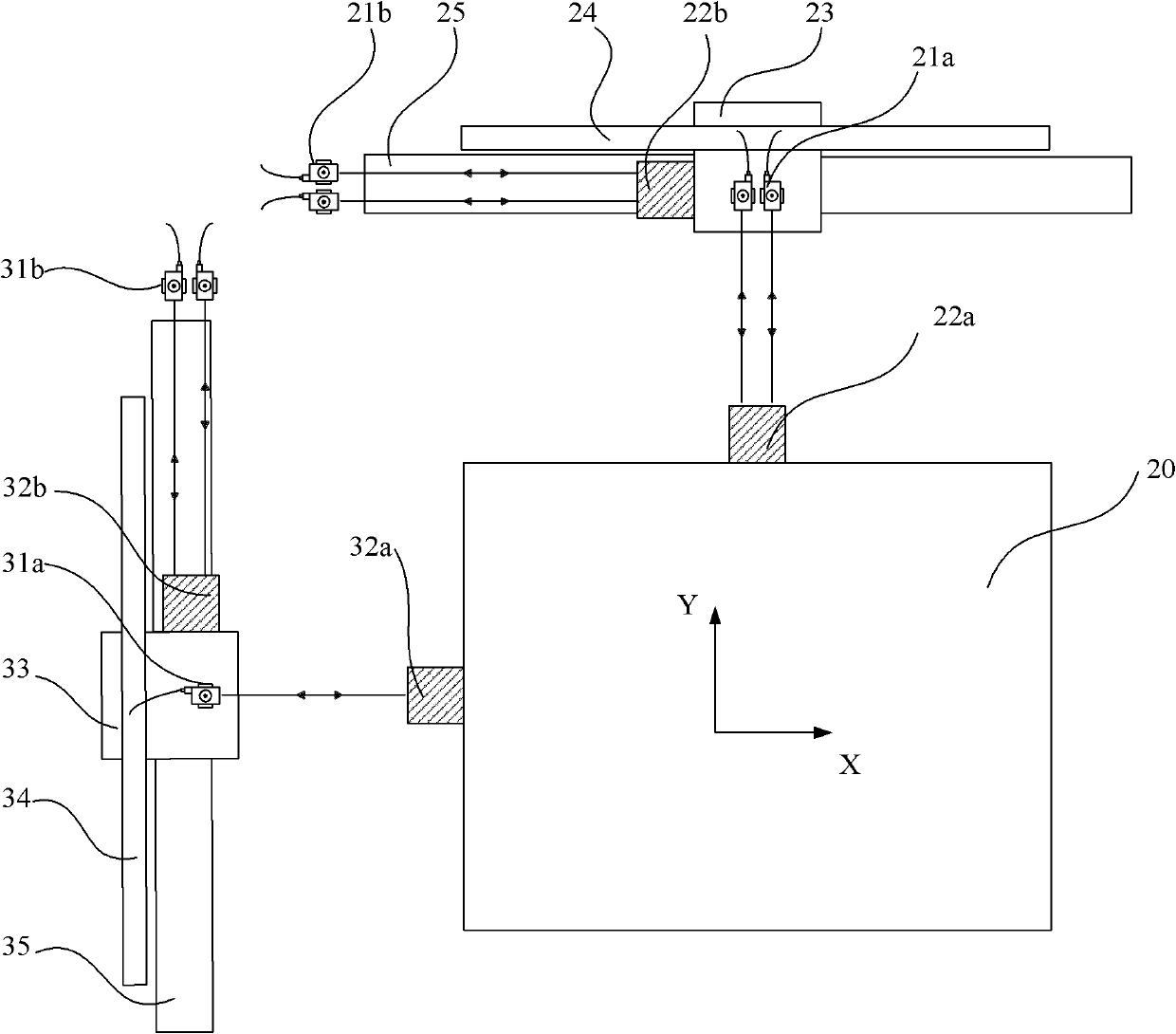

Method for in-situ preparation of copper-based shape memory alloy through additive manufacturing

InactiveCN109648091AGuaranteed uniformityRaise the remelting zoneAdditive manufacturing apparatusIncreasing energy efficiencyIn situ reactionHigh density

The invention belongs to the field of preparation of copper-based shape memory alloys, and discloses a method for the in-situ preparation of any copper-based shape memory alloy through additive manufacturing. The method includes the following steps that (a) mixed powder needed by the element in a part is prepared and used as a raw material, and (b) the copper alloy is used as a forming substrate,electron beams or laser beams are used for conducting the selection melting technology to prepare the required copper-based memory alloy part, in the process, all the components in the mixed powder are instantly heated above melting points of the components and melted into a liquid phase without difference, the in-situ reaction diffusion is conducted under the liquid phase, the atomic reaction isfast, the diffusion time is short, and the composition segregation is avoided; and in addition, the parent phase formed by the main elements is not dissolved to form brittle gamma 2 phase but to formthe martensite phase, and the memory performance and hyperelasticity of the desired product are improved. By means of the method for the in-situ preparation of the copper-based shape memory alloy through the additive manufacturing, the product with any shape, high density, memory performance, super elasticity and high toughness are quickly prepared.

Owner:HUAZHONG UNIV OF SCI & TECH

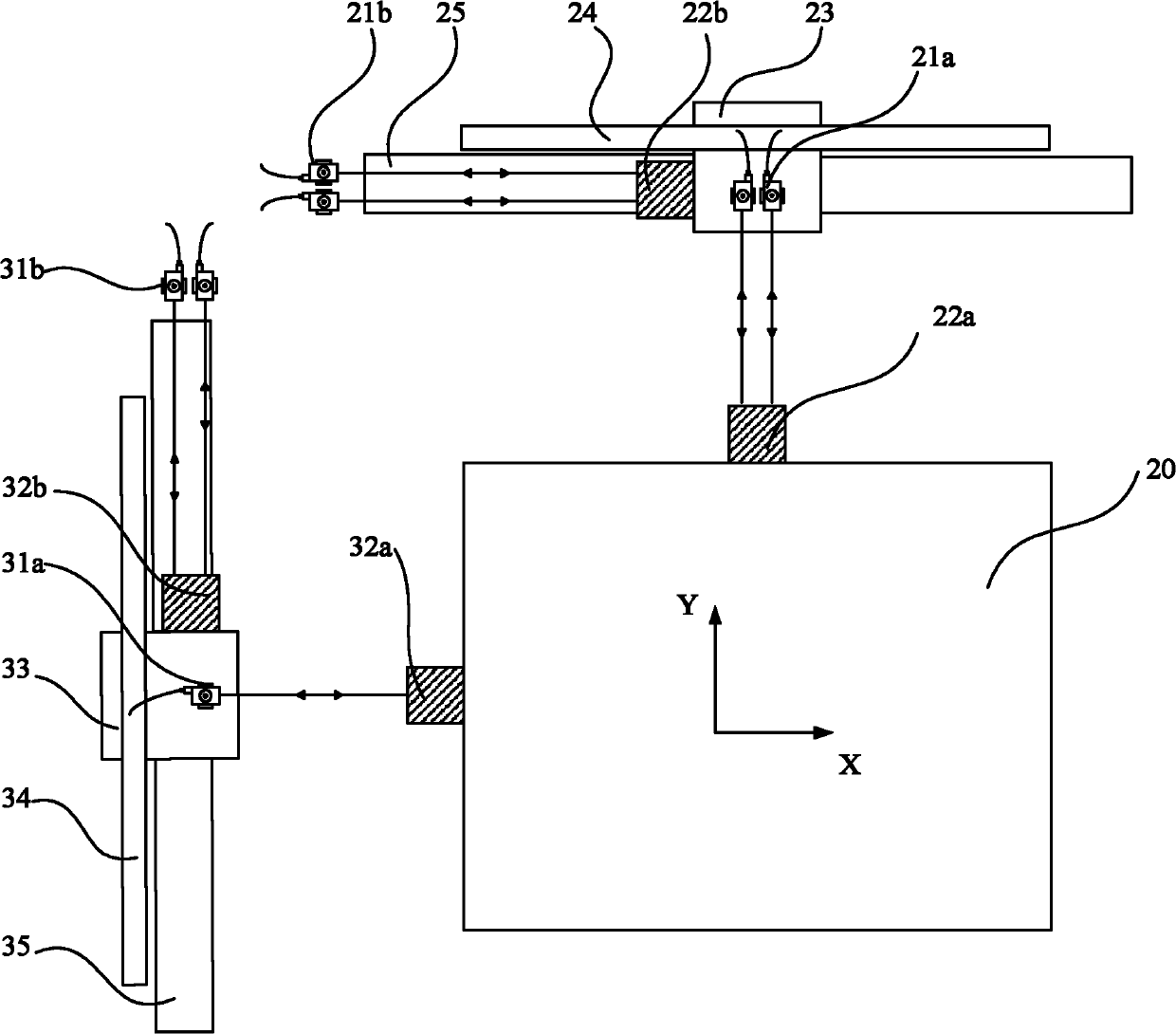

Measuring apparatus and measuring method

ActiveCN102564303ARealize high-precision measurementSolve processing difficultiesUsing optical meansPhotomechanical exposure apparatusMeasurement deviceLarge size

The invention provides a long-travel workpiece table measuring apparatus and a measuring method. The measuring apparatus comprises two sets of measuring systems which are perpendicular to each other and are applied on a first direction and a second direction, movable interferometers and workpiece table reflectors in the measuring systems respectively monitor and measure the moving positions of a workpiece table along the first direction or the second direction, and fixed interferometers and interferometer reflectors in the measuring systems are utilized to compensate the error of the moving position of the workpiece table measured by the movable interferometers and the workpiece table reflectors. The difficulty of processing and manufacturing large-size strip-shaped reflectors is avoided, and the high-precision measurement of the long-travel position of the workpiece table is realized.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

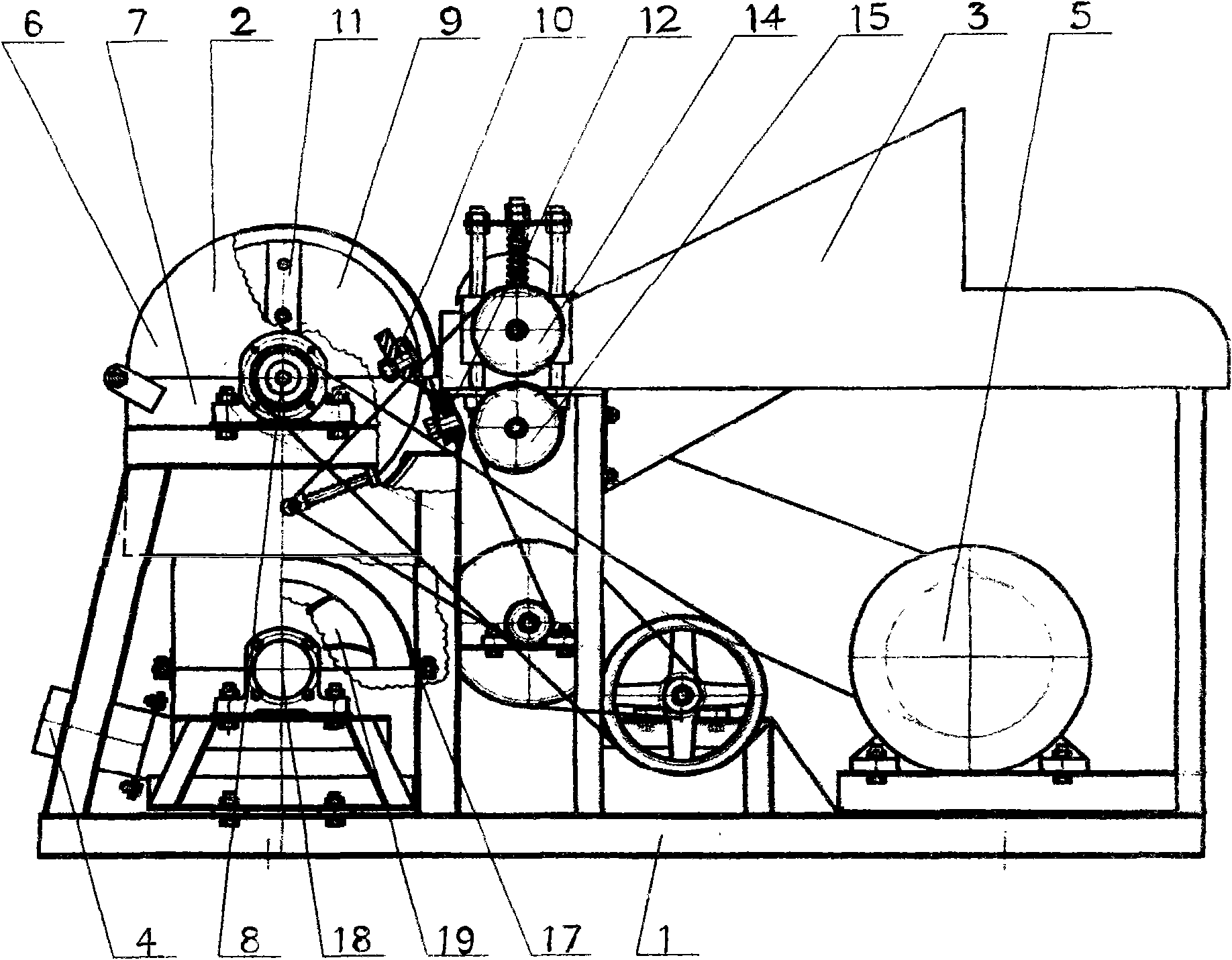

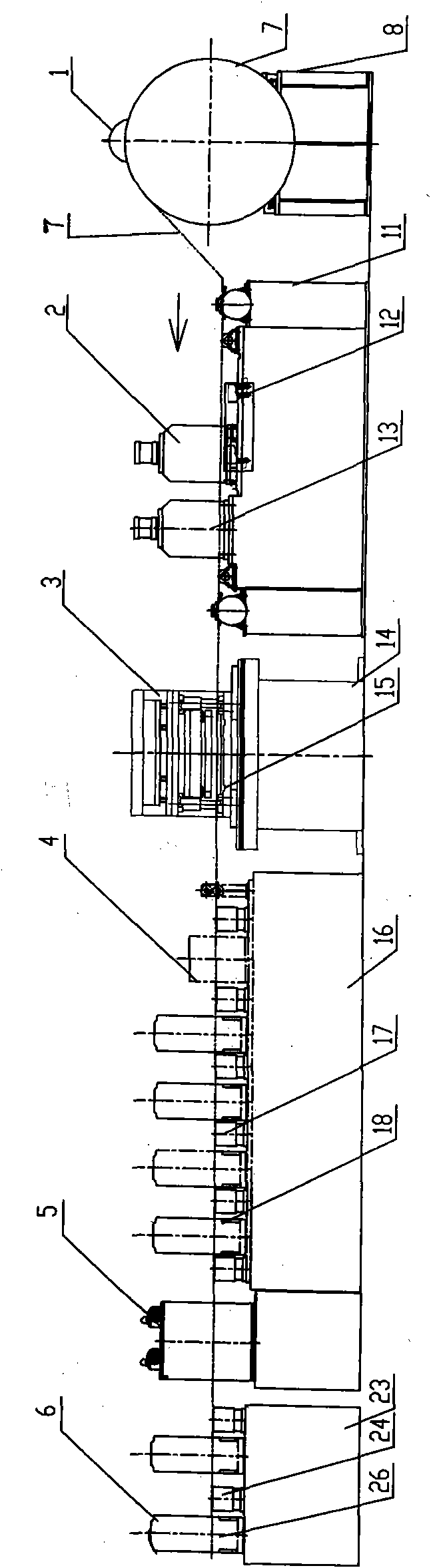

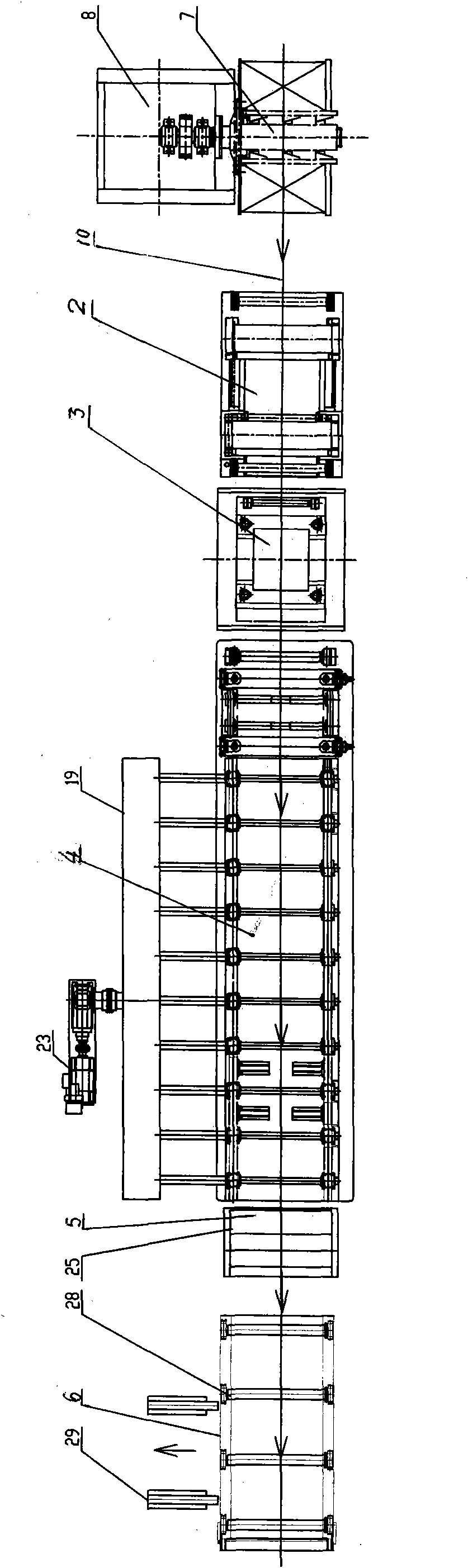

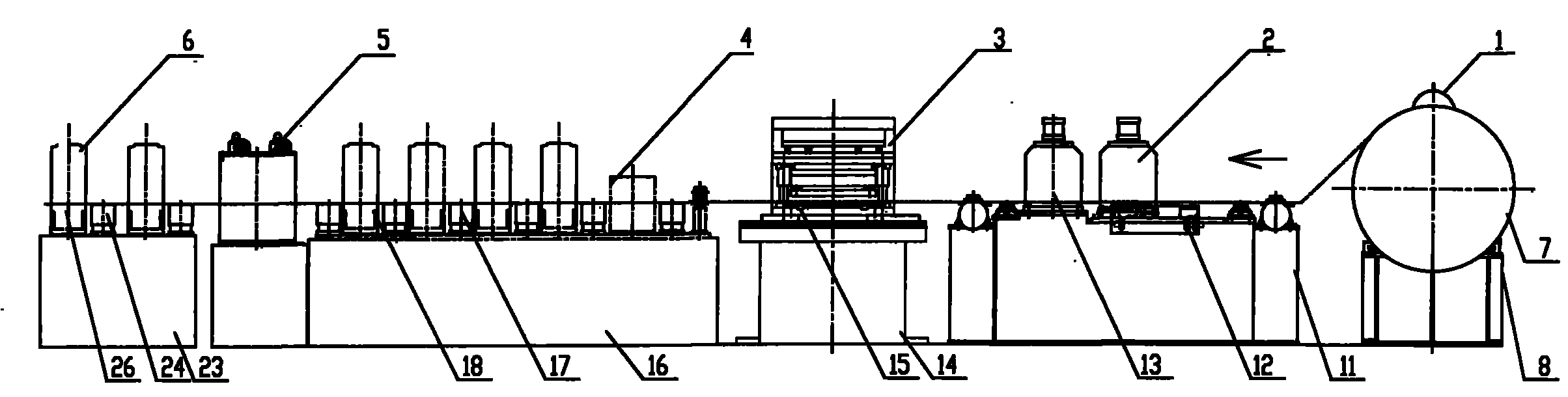

Punched high-frequency welded pipe unit

InactiveCN102029524ASolve processing difficultiesSave production equipment costOther manufacturing equipments/toolsPunchingMolding machine

The invention belongs to equipment for manufacturing perforated steel pipes and particularly relates to a punched high-frequency welded pipe unit, which comprises a punching machine and is characterized in that: a punched high-frequency welded pipe production unit which consists of a decoiling machine, a stepping feeding device, a punching device, a molding machine, a high-frequency welding device and a sizing device is arranged according to a continuous punched high-frequency welded pipe production process; a band plate to be processed which is supported on the decoiling machine is fed into the punching device through the stepping feeding device for punching; the punched band plate is driven into a pipe blank molding machine which consists of a base, a plurality of vertical roll frames and a plurality of horizontal roll frames; the high-frequency welding device which consists of a water cooling box, an electric control box and a high-frequency coil is arranged behind the pipe blank molding machine; and a welded pipe which is welded at a high frequency enters the sizing device. The punched high-frequency welded pipe unit has the advantages of reasonable design, compact structure, realization of mechanization, high production efficiency, good product quality, low labor intensity, safety of operation, convenience of use and the like.

Owner:DALIAN SAGE GROUP

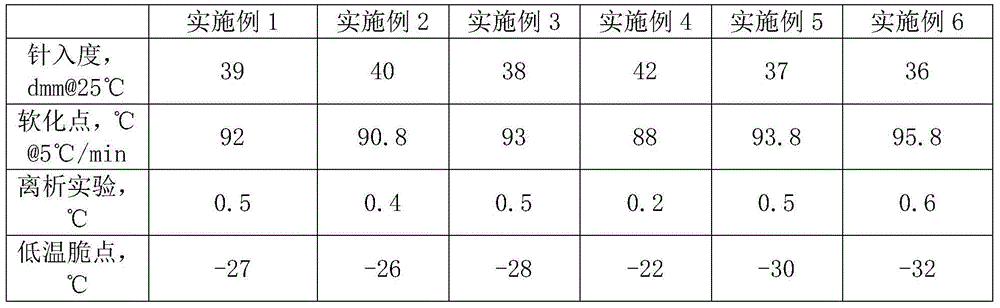

Polymer modified asphalt and preparation method thereof

InactiveCN104962091AGood flexibilitySolve the problem of easy cracking at low temperatureBuilding insulationsPolymer modifiedPolymer science

The invention discloses polymer modified asphalt. The polymer modified asphalt comprises the following components in parts by weight: 50 to 100 parts of asphalt, 10 to 20 parts of polymer modifier, 2 to 7 parts of rubber powder, 1 to 8 parts of nano titanium oxide, 2 to 10 parts of polyacrylate, 2 to 5 parts of surfactant, 1 to 8 parts of heat stabilizer and 2 to 8 parts of anti-aging agent. The invention also discloses a preparation method of the polymer modified asphalt. The polymer modified asphalt is good in low temperature resistance, high temperature resistance, rigidness, flexibility and stability, simple in preparation method and low in cost; no toxic substance is released in the preparation process, and the environmental protection can be facilitated.

Owner:浙江兰亭道路工程技术有限公司

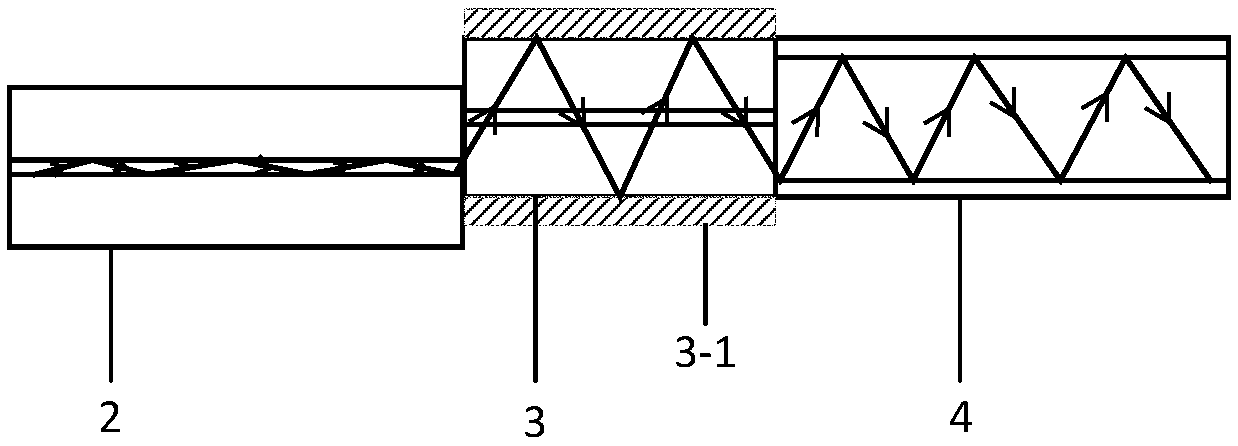

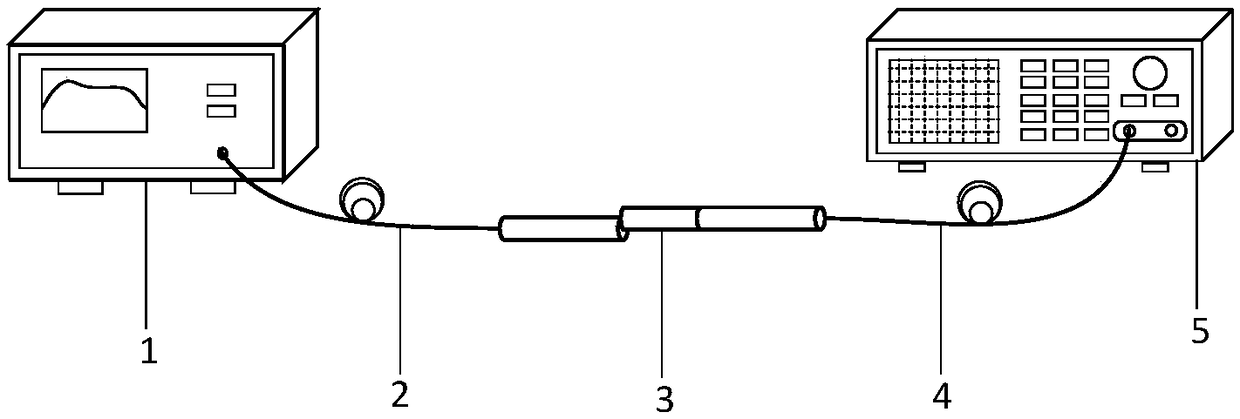

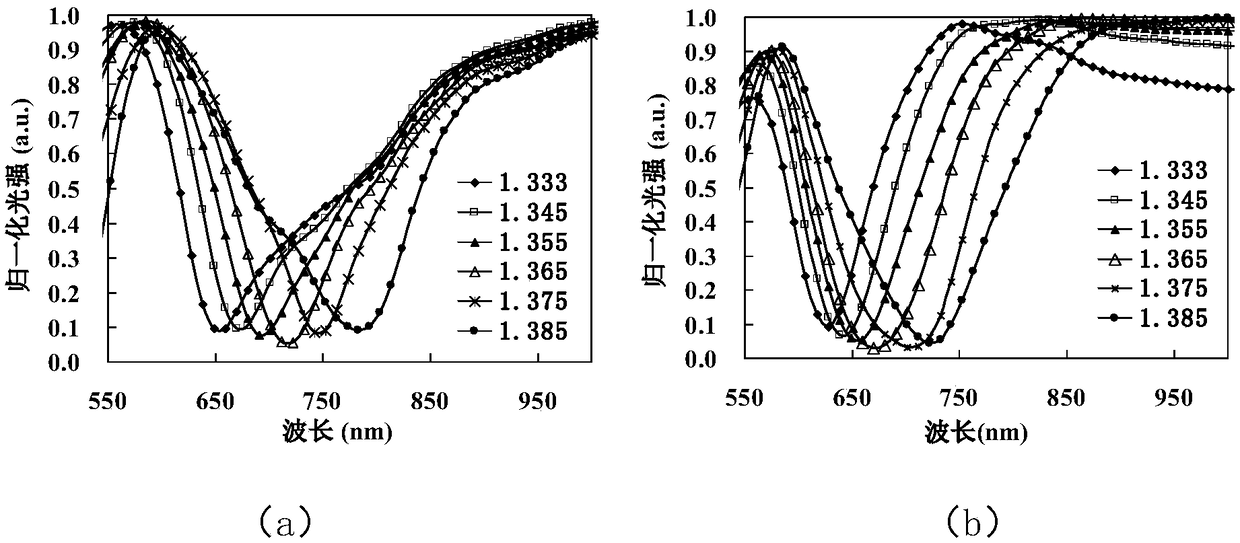

Optical fiber cladding SPR sensor, and use method and manufacture method thereof

PendingCN109238963ASolve processing difficultiesDifficult to makeMaterial analysis by optical meansFood safetyOptical fiber cable

The invention belongs to the technical field of optical fiber sensing, and mainly relates to an optical fiber cladding SPR sensor, and a use method and a manufacture method thereof. The invention aimsat providing an optical fiber cladding SPR sensor, and solves a problem that the conventional optical fiber SPR sensor is difficult to process and manufacture, evanescent waves are hard to obtain andcost is high. According to the invention, a normal optical fiber is subjected to core shift welding on an optical fiber welding machine, light in a fiber core is leaked in the cladding, when the light arrives at an interface of the cladding and the air, the evanescent waves can be leaked from the cladding, a nanoscale gold film is formed at the interface of the cladding and the air through plating, thus, an SPR effect happens at the outside of the cladding, and complex processing technologies are avoided; compared with the conventional optical fiber SPR sensor, the optical fiber cladding SPRsensor provided by the invention has the advantages of being small in volume, novel in structure and less difficult to manufacture, and so on, and is widely researched and applied in the fields of bio-pharmaceuticals, food safety inspection and chemical detection.

Owner:CHONGQING THREE GORGES UNIV

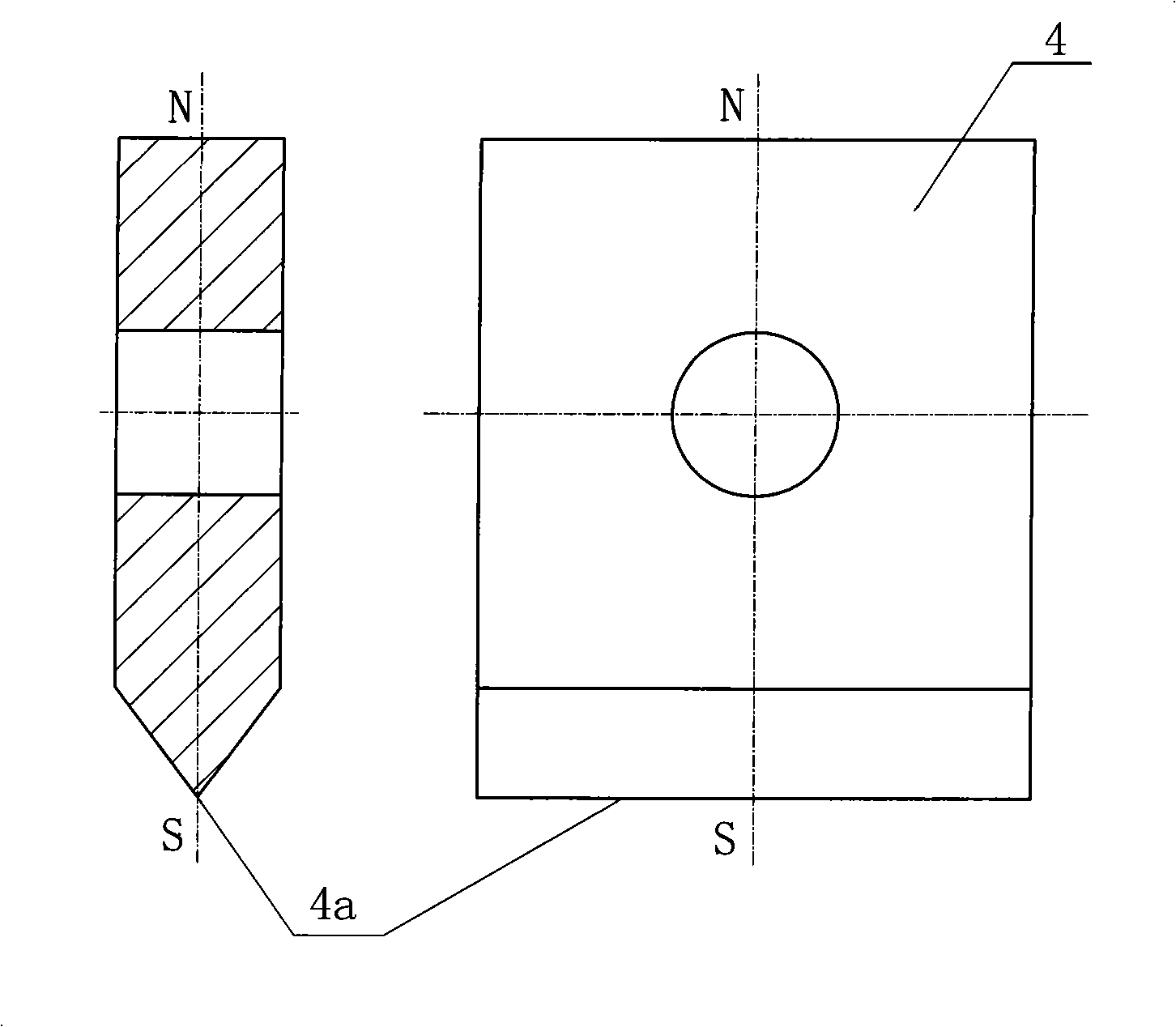

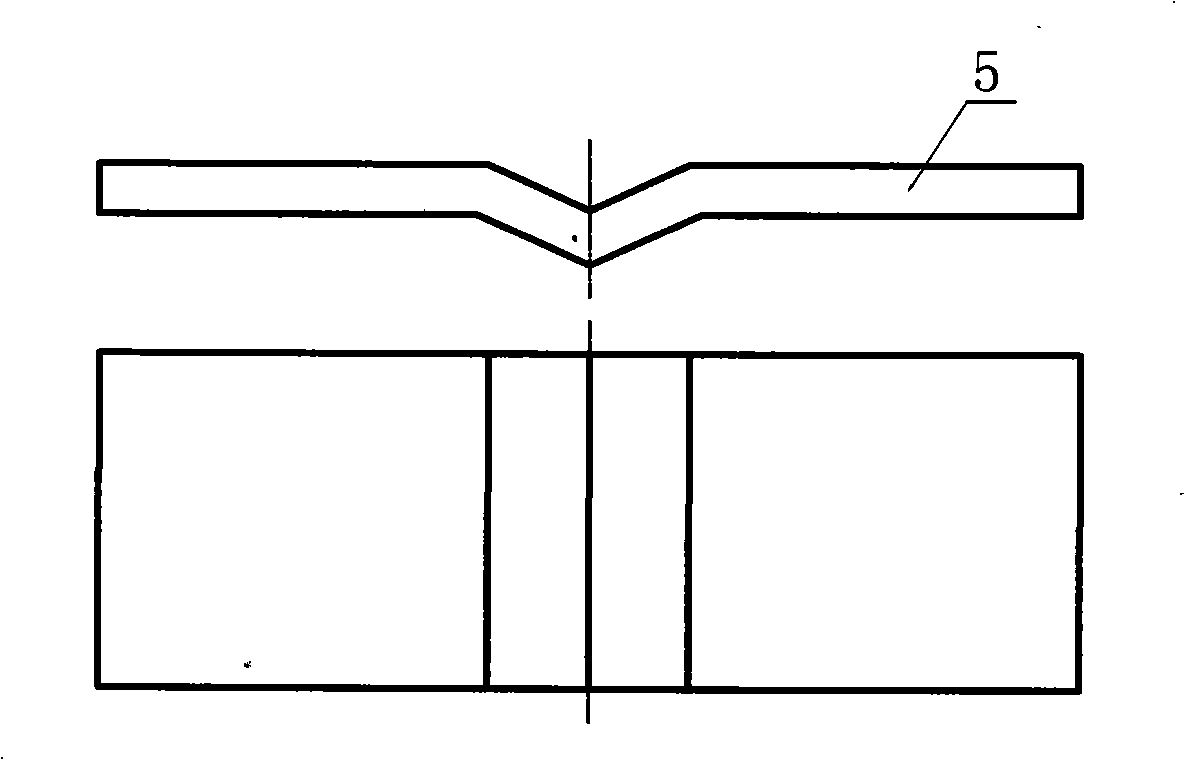

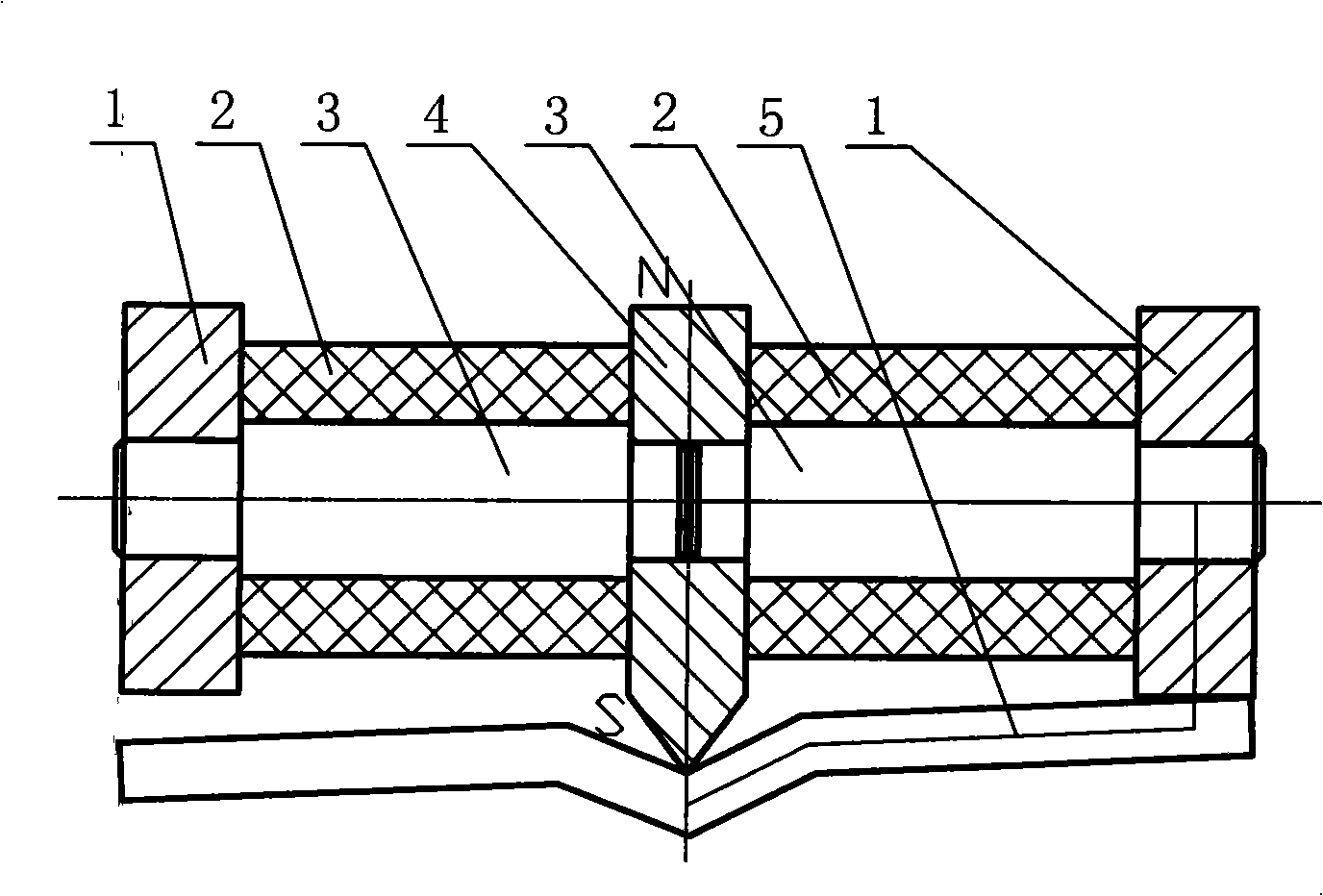

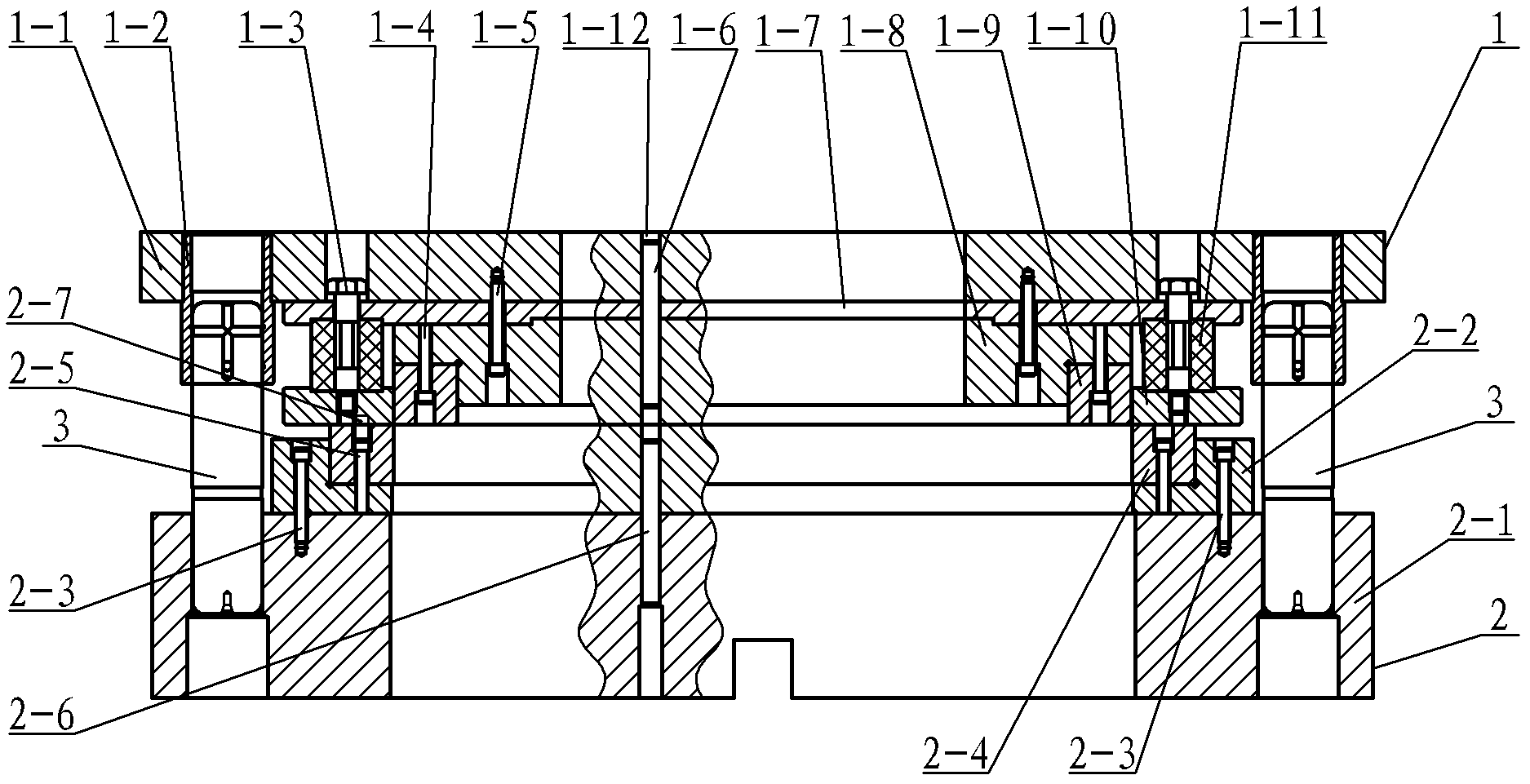

Unipolar permenant-magnet excitation bi-stable electromagnetic system of relay

InactiveCN101527225ASolve processing difficultiesSolve the problem of high assembly precision requirementsNon-polarised relaysPhysicsMagnet

The invention relates to a unipolar permenant-magnet excitation bi-stable electromagnetic system of a relay, which consists of yoke irons, exciting coils, magnet cores, a permanent magnet steel and an armature iron; two exciting coils adopt a horizontal coaxial structure; the permanent magnet steel adopts a knife edge type unipolar structure; the two coils adopt a separate magnet core and yoke iron segmental structure; the two exciting coils are provided with separate magnet cores and yoke irons respectively, and separately work to form separate magnetic loops; the armature iron has a symmetrical structure, the middle of the armature iron is supported on the knife edge of the magnet steel, and two ends of the armature iron are in working contact with two yoke irons respectively; and the magnet steel, the two coils, and the two yoke irons are connected on the same horizontal shaft through two magnet cores. The unipolar permenant-magnet excitation bi-stable electromagnetic system overcomes the inherent defects of differential type, balance type and bridge type electromagnetic systems.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Large-scale embedded blanking mould

ActiveCN102962335ASolve the overall processing difficultiesSolve processing difficultiesShaping toolsEngineeringSharpening

The invention discloses a large-scale embedded blanking mould, and relates to a blanking mould, aiming to solve the problems of materials waste, difficult manufacture, short service life of a mould, difficulty in sharpening, maintenance, assembly and disassembly during integrally manufacturing a large-scale blanking mould and a punch die. The mould comprises an upper die component, a lower die component and at least two guide columns, wherein the upper die component comprises an upper die seat, a terrace die pad, a terrace die fixing board, an unloading ring, at least two guide sleeves, two terrace die positioning pins, at least four embedded terrace dies, eight unloading rubbers, a plurality of unloading screws, a plurality of terrace die fixing screws, and a plurality of fixing screws, the lower die component comprises a lower die seat, an embedded female die fixing seat, a plurality of fixing seat fixing screws, at least four embedded female dies, a plurality of female die fixing screws, two female die positioning pins and at least two material guiding and blocking pins, one end of each guide column is arranged in the guide sleeve corresponding to the upper die component, and the other end of each guide column is arranged in the guide column hole corresponding to the lower die component. The mould is applied in the blanking of a large batch of thick board materials.

Owner:HARBIN JIANCHENG GRP

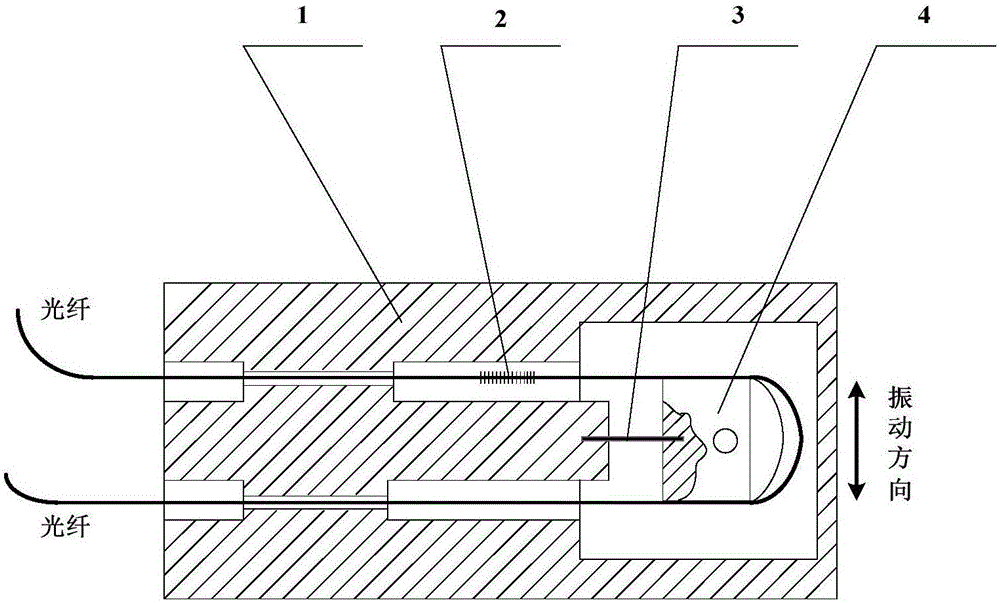

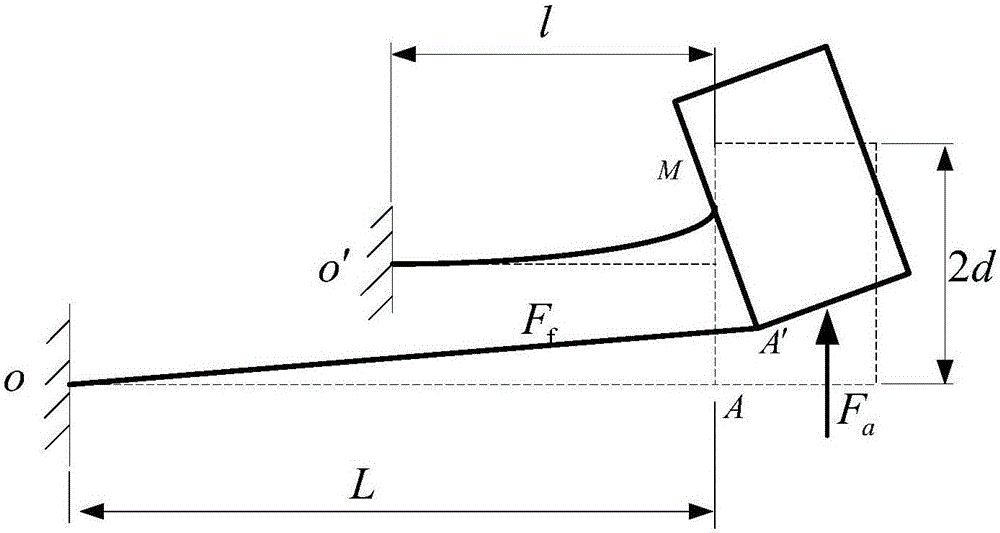

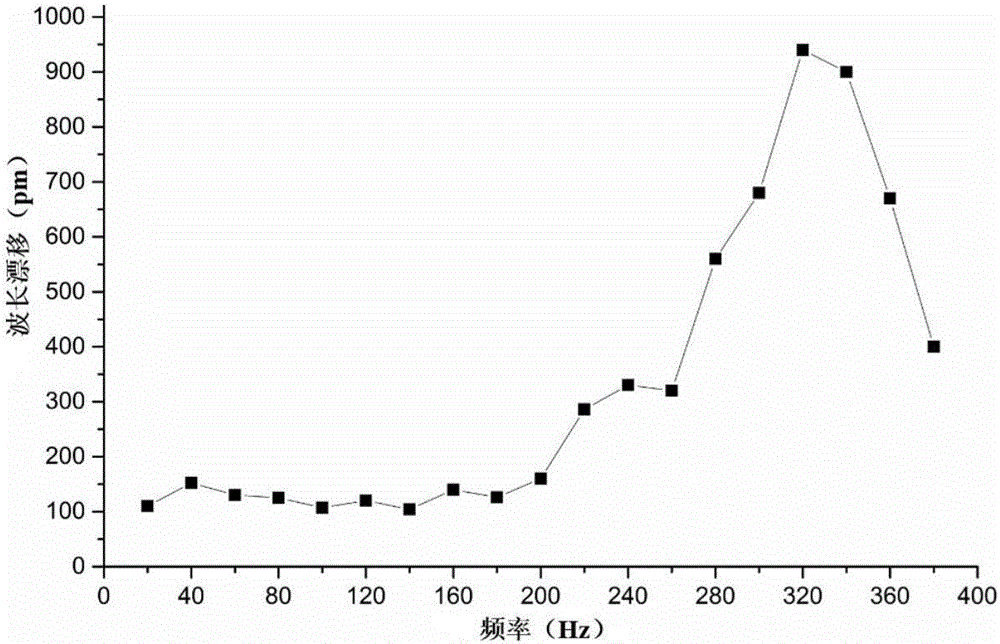

Manufacturing method of cantilever beam fiber grating accelerometer

The present invention provides a manufacturing method of a cantilever beam fiber grating accelerometer. The sensor comprises a substrate, a spring leaf, a quality block, a side cover and a fiber grating. The substrate, the spring leaf and the quality block are assembled through mechanical coordination and laser welding to form a cantilever structure. The fiber grating performs etching on the G.657 fiber, the fiber tension performance is improved through adoption of macromolecule ultrathin coating, and the epoxy resin dispensing is employed to fix the positions between the fiber grating and substrate and the quality block to assemble a fiber grating acceleration sensor. A balance weight hole is processed on the quality block in advance, the assembled sensor is calibrated, and the dispensing or machining is performed on the balance weight hole to flexibly regulate the sensitivity and the resonant frequency point of the sensor to optimize the performance index of the acceleration sensor. The manufacturing method of the cantilever beam fiber grating accelerometer simplifies the design and processing requirement of the acceleration sensor, simple in operation method and high in practicality, and the made sensor is high in sensitivity, small in insertion loss and excellent in performace.

Owner:湖北三峡物联网知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com