Polymer modified asphalt and preparation method thereof

A technology of modified asphalt and polymers, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of high water absorption rate of vitrified microbeads, easy softening of road surface, poor thermal conductivity, etc., and can solve the problem of easy cracking at low temperature , solve processing difficulties, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

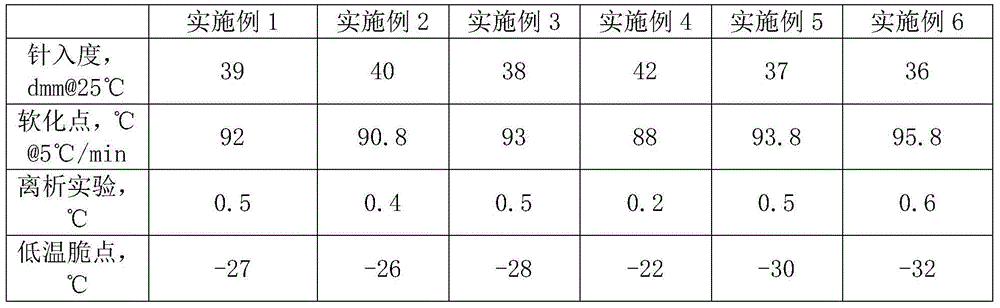

Examples

Embodiment 1

[0030] A polymer modified asphalt, in parts by weight, comprises the following components:

[0031] 55 parts of asphalt, 5 parts of polymer modifier,

[0032] 2 parts of rubber powder, 1 part of nano-titanium oxide,

[0033] 2 parts polyacrylate, 2 parts surfactant,

[0034] 1 part heat stabilizer, 2 parts antiaging agent.

[0035] Its preparation method comprises the following steps:

[0036] Heat 55 parts of asphalt to 170°C, add 5 parts of polymer modifier and stir to disperse and swell, then add 1 part of nano-titanium oxide, 2 parts of rubber powder, 2 parts of polyacrylate, 2 parts of surfactant, continue Stir and disperse, and finally add 1 part of heat stabilizer and 2 parts of anti-aging agent, input it into a high-speed shear homogenizing mill with oil-soluble heat preservation, and further disperse and mix at 170 ° C to obtain polymer-modified asphalt.

Embodiment 2

[0038] A polymer modified asphalt, in parts by weight, comprises the following components:

[0039] 100 parts of asphalt, 6 parts of polymer modifier,

[0040] 7 parts of rubber powder, 8 parts of nano-titanium oxide,

[0041] 10 parts of polyacrylate, 5 parts of surfactant,

[0042] 8 parts of heat stabilizer, 8 parts of anti-aging agent.

[0043] Its preparation method comprises the following steps:

[0044] Heat 100 parts of asphalt to 190°C, add 6 parts of polymer modifier and stir to disperse and swell, then add 8 parts of nano-titanium oxide, 7 parts of rubber powder, 10 parts of polyacrylate, 5 parts of surfactant, and continue Stir and disperse, and finally add 8 parts of heat stabilizer and 8 parts of anti-aging agent, input it into a high-speed shear homogenizing mill with oil-soluble heat preservation, and further disperse and mix at 190°C to obtain polymer-modified asphalt.

Embodiment 3

[0046] A polymer modified asphalt, in parts by weight, comprises the following components:

[0047] 66 parts of asphalt, 6 parts of polymer modifier,

[0048] 3 parts of rubber powder, 2 parts of nano-titanium oxide,

[0049] 3 parts of polyacrylate, 3 parts of surfactant,

[0050] 2 parts of heat stabilizer, 3 parts of anti-aging agent.

[0051] Its preparation method comprises the following steps:

[0052] Heat 66 parts of asphalt to 175°C, add 6 parts of polymer modifier and stir to disperse and swell, then add 2 parts of nano-titanium oxide, 3 parts of rubber powder, 3 parts of polyacrylate, 3 parts of surfactant, continue Stir and disperse, and finally add 2 parts of heat stabilizer and 3 parts of anti-aging agent, input it into a high-speed shear homogenizing mill with oil-soluble heat preservation, and further disperse and mix at 175°C to obtain polymer-modified asphalt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com