Integral cast aluminum cradle type five-axis swinging frame and manufacturing method thereof

An integral casting and integral casting technology, which is applied to the manufacture of cast aluminum and metal material processing, can solve the problems of large contour size, high magnesium content, and difficult feeding of castings, and achieve acceleration and response improvement, corrosion resistance Good, the effect of speed gain increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

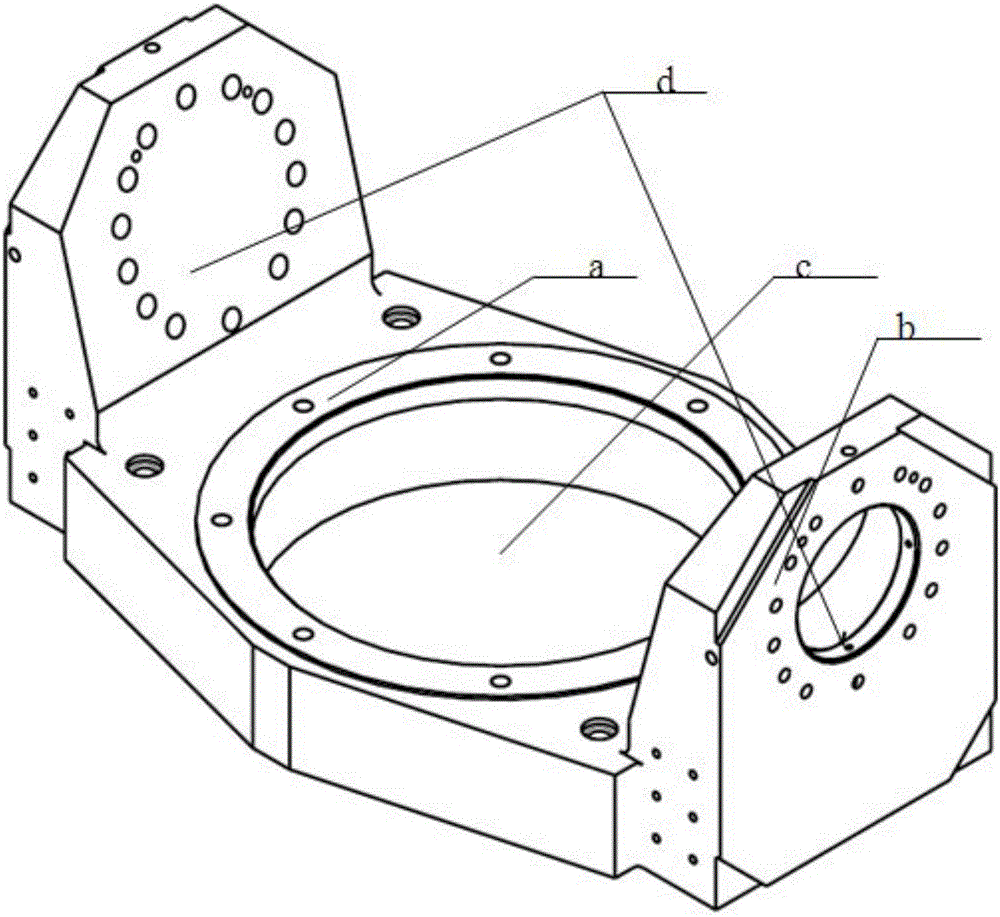

[0034] The structure of the cradle-type five-axis pendulum frame of integral cast aluminum of the present invention is shown in figure 1 , the pendulum frame for A-axis single drive, in the figure d is the two coaxial holes of the A-axis motor mounting hole, there is a through hole at the support end marked b, which is the through hole of the support end, and there is a blind hole on the opposite side , is the A-axis motor installation hole; if the A-axis is a dual-drive, there are blind holes on the outside of both support ends, and there are no through holes. The radial hole c of the C-axis motor is perpendicular to the installation hole d of the A-axis motor.

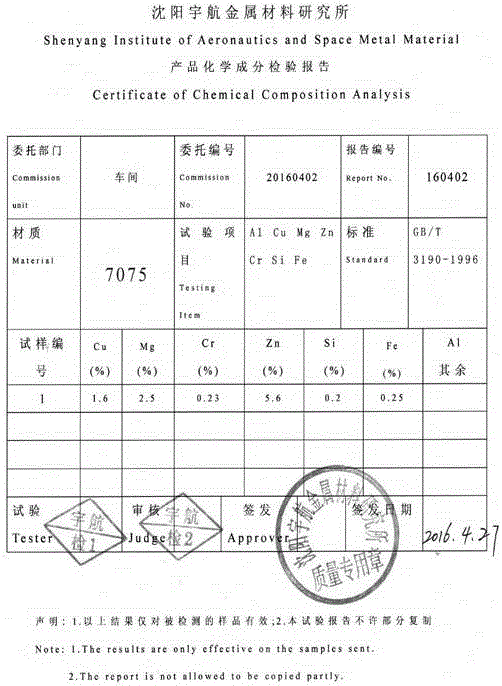

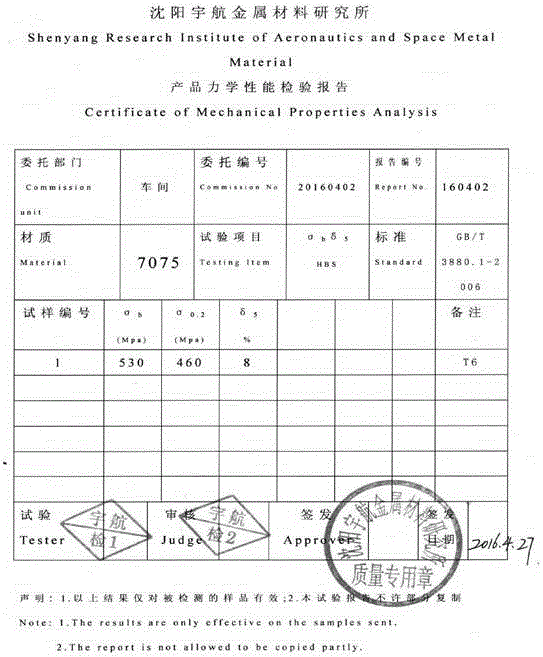

[0035] The composition of the integral cast aluminum cradle five-axis pendulum is shown in image 3 :

[0036] The main component of the rack blank is aluminum 7075, and the non-aluminum components also include copper Cu1.6%, magnesium Mg2.5%, chromium Cr0.23%, zinc Zn5.6%, silicon Si0.2%, by weight percentage, Ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com