Method for processing integrated stainless steel micro-fluid reactors

A technology of microfluidic reactors and processing methods, applied in chemical instruments and methods, metal processing equipment, manufacturing tools, etc., can solve problems such as high cost and difficult processing, and achieve good air tightness, low raw material cost, and small investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

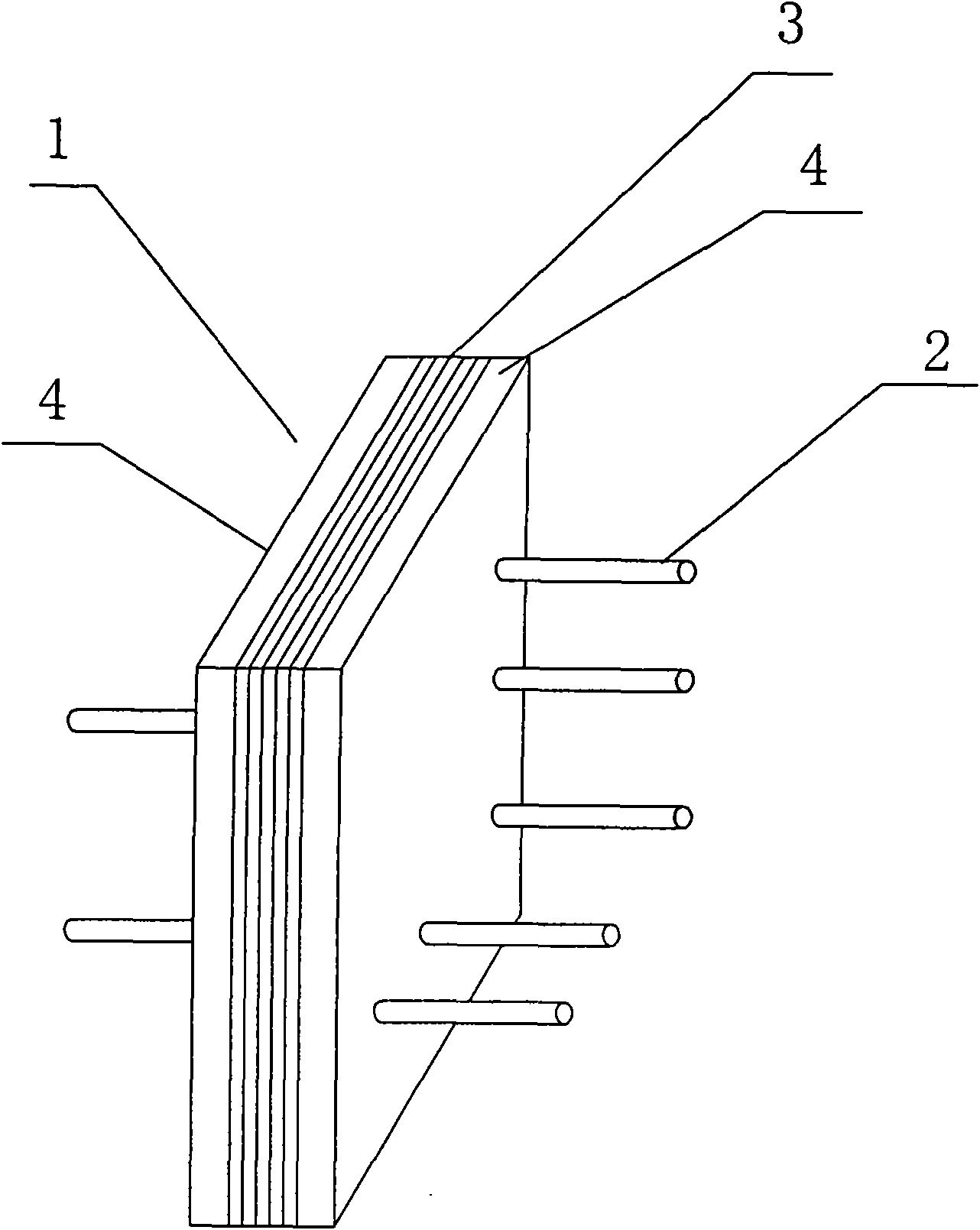

[0019] like figure 1 shown.

[0020] A processing method for an integrated stainless steel microfluidic reactor mainly includes the following process steps: electric discharge machining of microfluidic channels and holes, cleaning and grinding, vacuum diffusion welding packaging, and connection of inlet and outlet interfaces.

[0021] The details are as follows:

[0022] 1. First select the stainless steel plate 3 whose plate thickness matches the depth of the micro-channel or the hole as the base material, and use the EDM method and the ordinary machine tool processing method to process the required reaction micro-channel and / or Holes, to complete the EDM of stainless steel micro-flow channels and holes; the specific steps are: first draw the DWG AUTOCAD file drawings according to the design requirements, and convert them into DXF files that can be r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com