Light homogenizing structure, manufacturing method thereof and light homogenizing system

A manufacturing method and microstructure technology, which can be used in optics, optical components, instruments, etc., can solve the problems of difficult processing and small beam etendue, and achieve the effects of low cost, improved uniformity, and uniform mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

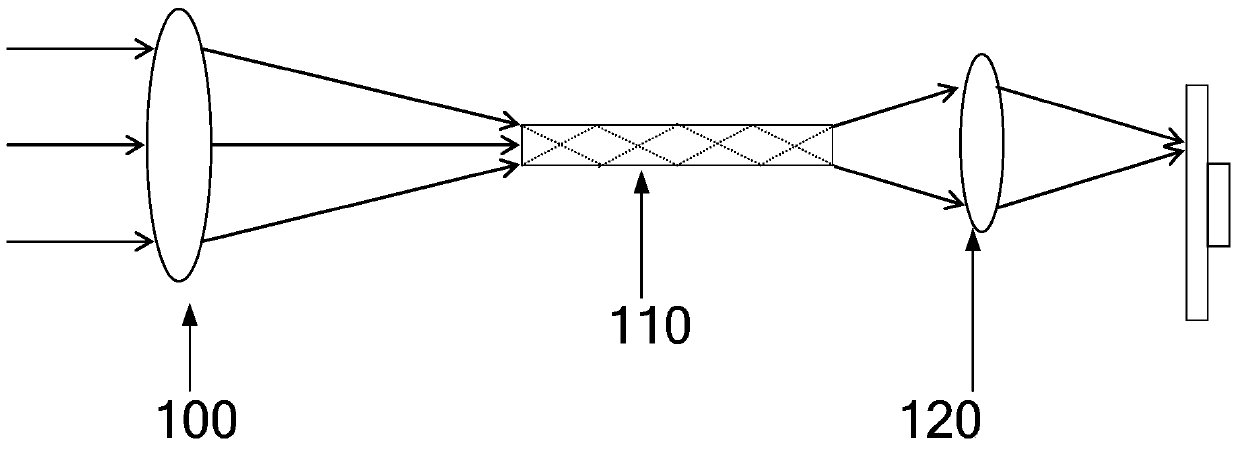

[0064] As mentioned in the background technology section, the laser homogenization device in the prior art has the problem of difficult processing when realizing a small etendue

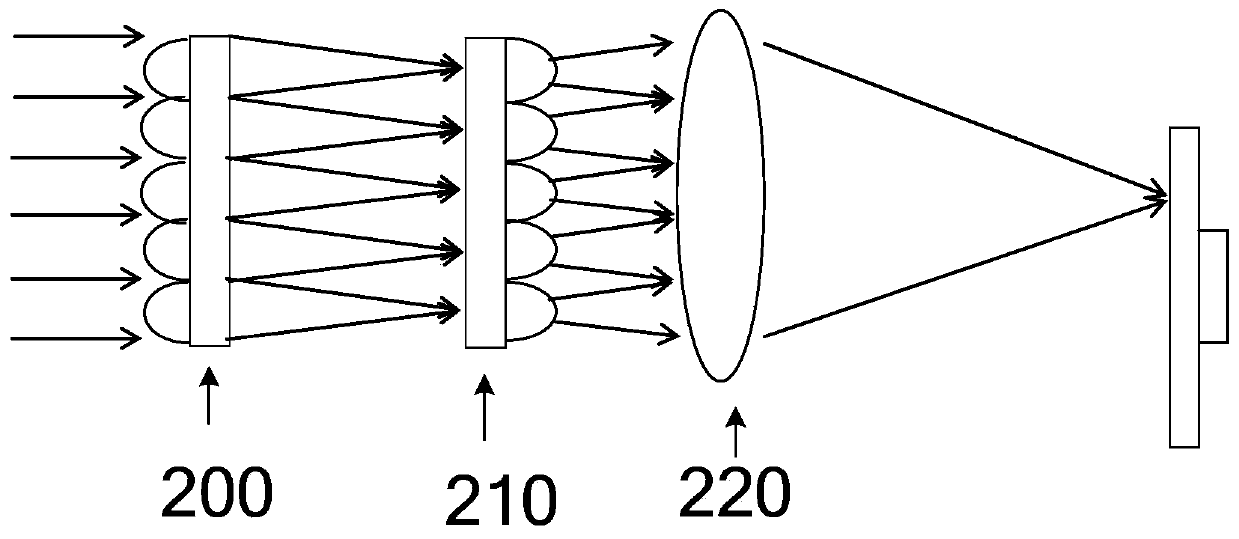

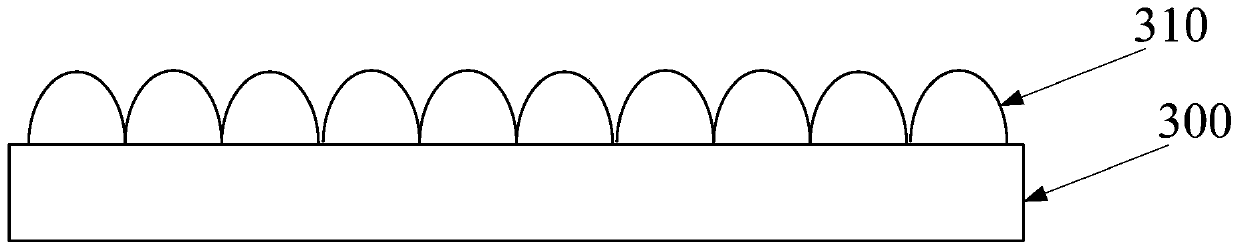

[0065] In view of this, an embodiment of the present invention provides a uniform light structure, including: a substrate and a pattern structure on the surface of the substrate; wherein, the formation process of the pattern structure is a transfer process, and the pattern structure includes multiple A microstructure is used to homogenize the incident light beam irradiated on its surface to form a uniform light beam.

[0066] Correspondingly, the embodiment of the present invention also provides a dodging system, including:

[0067] a laser for emitting a laser beam to form an incident beam;

[0068] The above uniform light structure is used to receive the incident light beam, and perform uniform light on the incident light beam irradiated on its surface to form a uniform light beam;

[0069] A flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com