Double-use plant material cutting grinder

A plant material and pulverizer technology, applied in the application, cutting equipment, grain processing and other directions, can solve the problems of reducing output, clogging, effect of suction effect, etc., and achieve the effect of saving power and energy consumption, convenient use and maintenance, and great promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

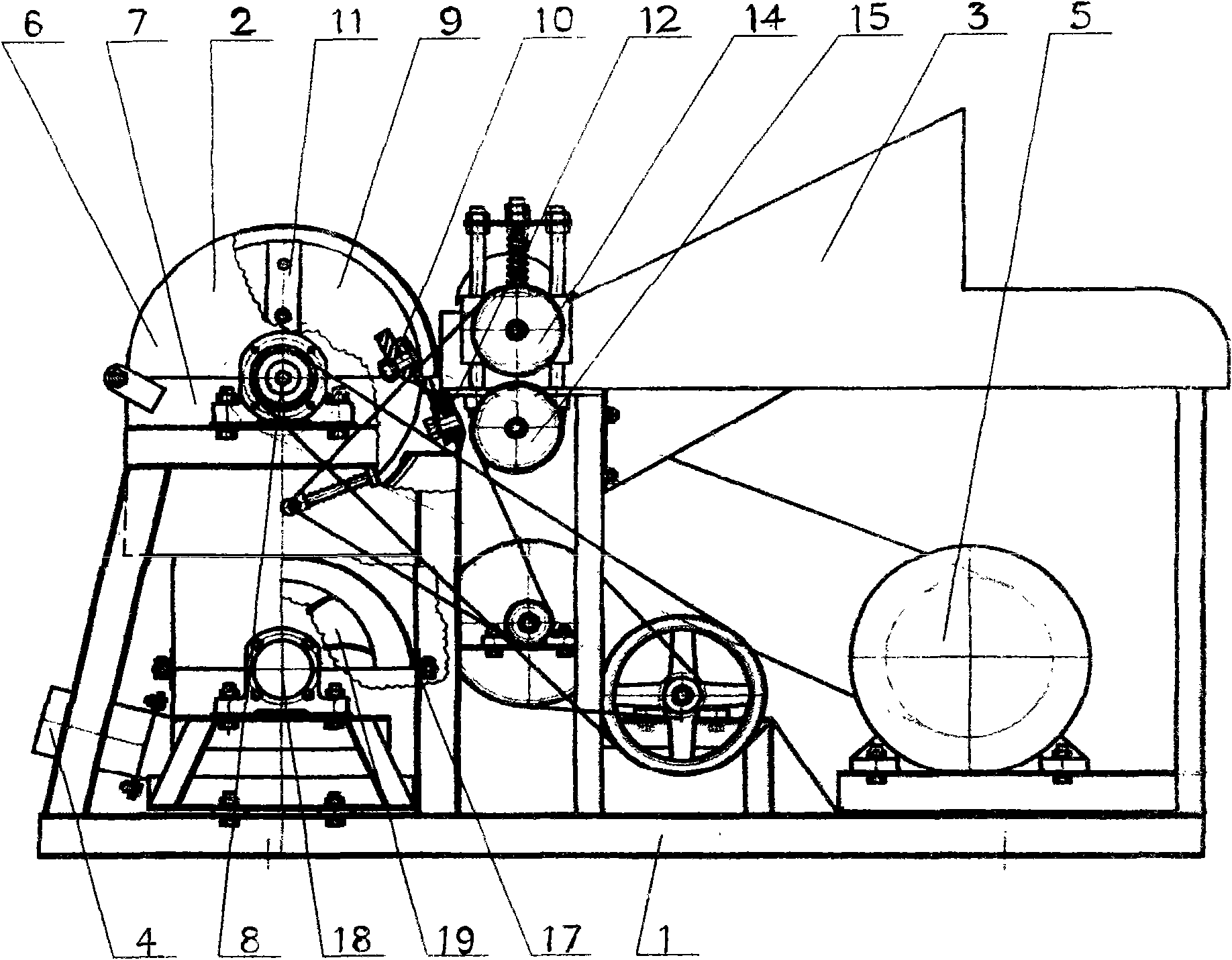

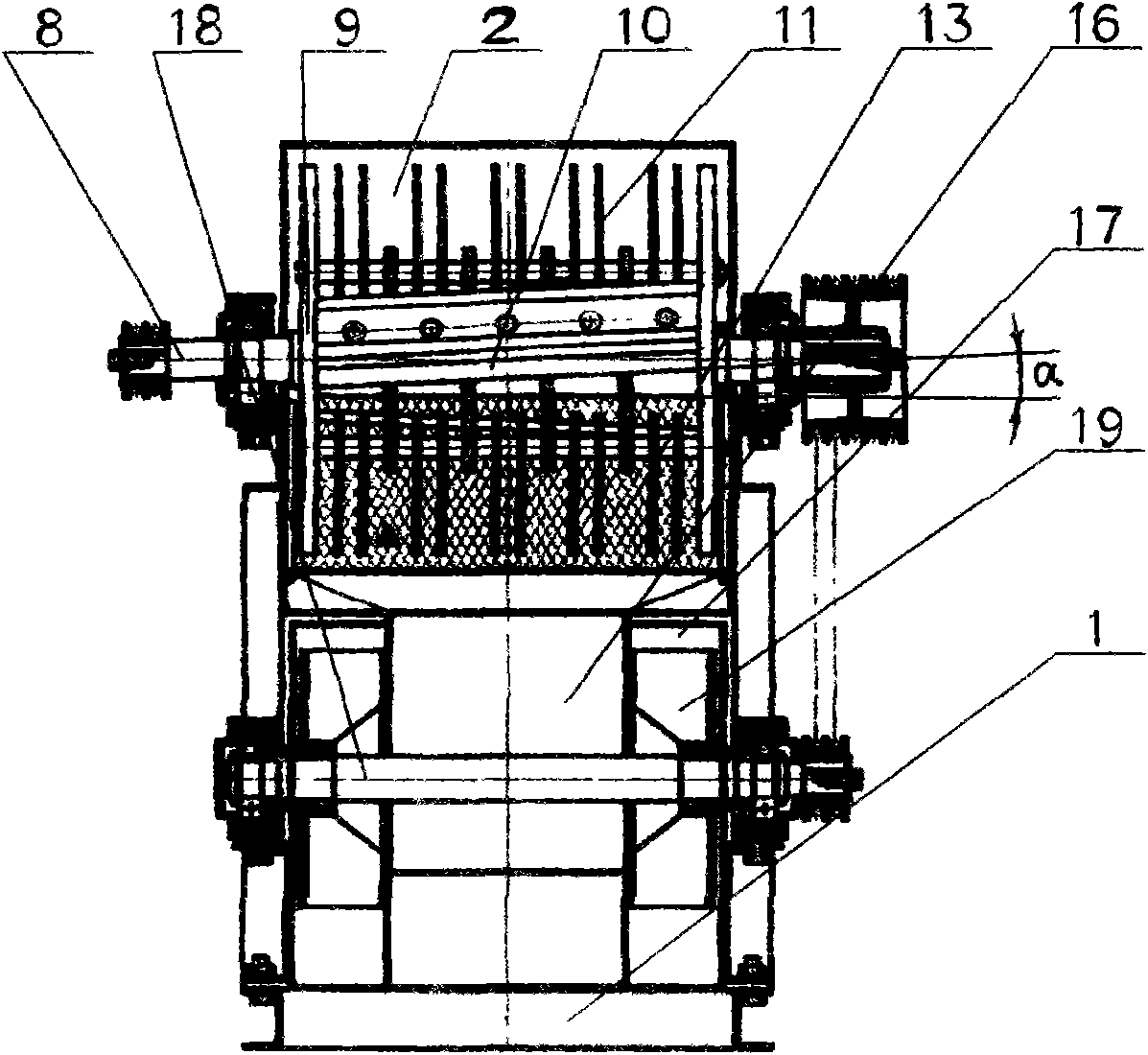

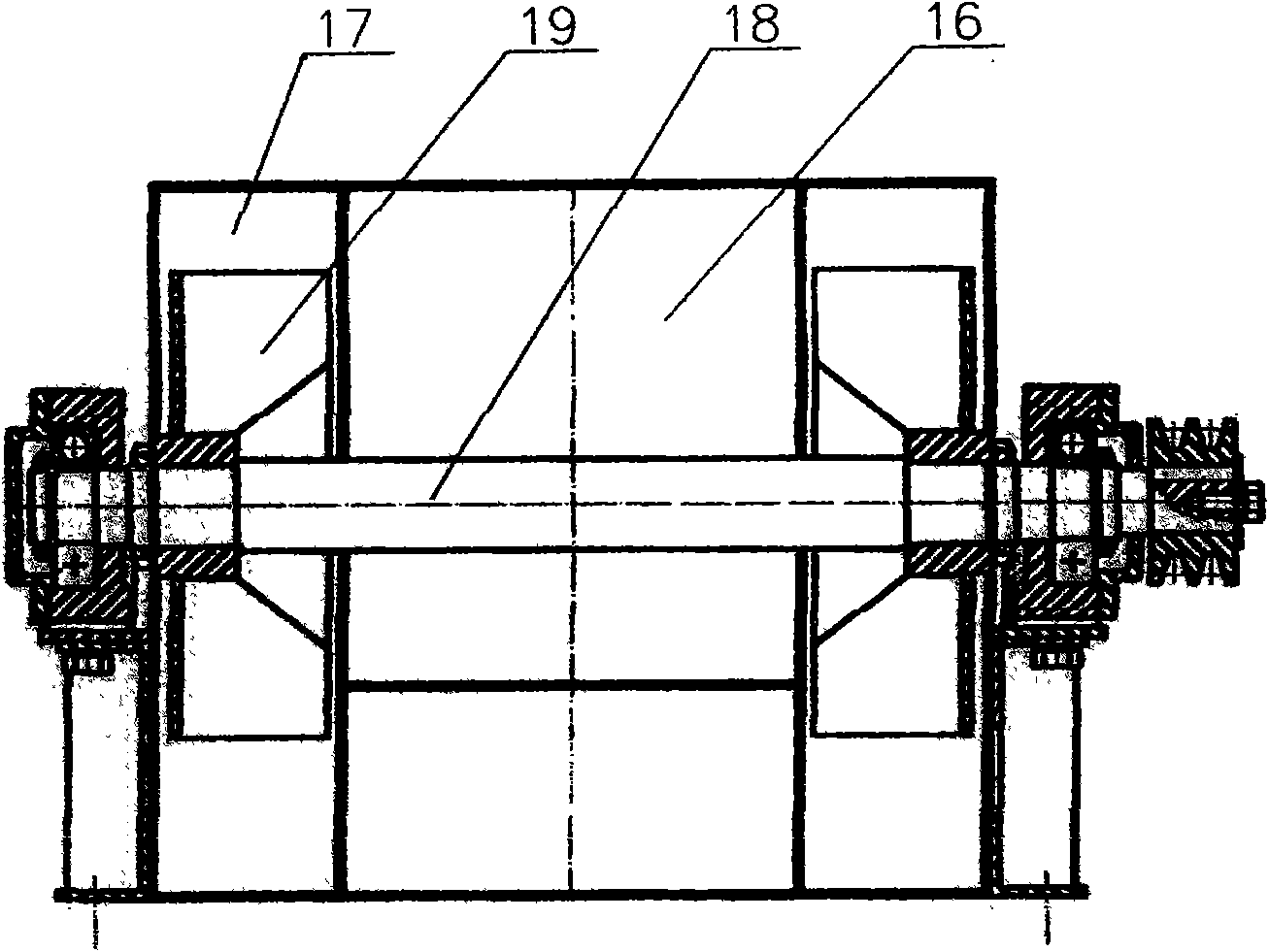

[0016] With reference to accompanying drawing, the embodiment of the present invention comprises machine base 1, be located at the guillotine cutting and pulverizing chamber 2 on the machine base 1, feeding hopper 3 (also claims feeding port), discharge port 4, motor 5 and speed change transmission mechanism, wherein The guillotine cutting and crushing chamber 2 is composed of the connection of the upper casing 6 and the lower casing 7. In the guillotine cutting and crushing chamber 2, there is a rotary cutterhead 9 installed on the main shaft 8. On the rotary cutterhead 9, there is also a guillotine cutter. The knife 10 and the rotary hammer set 11 used for crushing and hammering are equipped with a fixed knife 12 corresponding to the guillotine cutting flying knife at the lower casing 7 near the feeding hopper 3. The guillotine cutting flying knife 10 and the fixed knife 12 are They are installed at a certain inclination angle (small angle), and a filter screen 13 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com