Method and device for preparing high-silicon silicon steel thin strip under magnetic field through powder diffusion method

A diffusion method and powder technology, which is applied in the field of preparing high-silicon silicon steel thin strips by powder diffusion method under a magnetic field, can solve the problems of reduced elongation and increased brittleness of silicon steel, and achieve low cost, low consumption, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

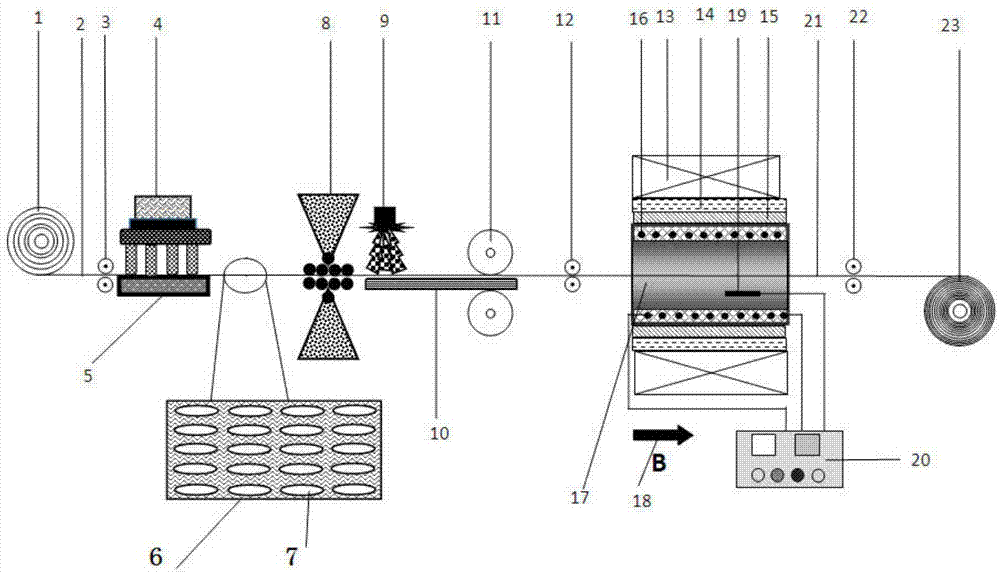

[0029] Embodiment 1 of the present invention: a method for preparing high-silicon silicon steel thin strip by powder diffusion method under a magnetic field, characterized in that: the method adopts the method of arranging holes on the low-silicon steel strip to be processed, and then performing surface strengthening on the low-silicon steel strip to be processed processing, filling the holes with iron-silicon alloy powder and rolling the powder, and then heat-treating it in a magnetic field environment to obtain a high-silicon silicon steel strip with a certain orientation and a silicon content of 6.5wt% Si with excellent magnetic properties.

[0030] Wherein the surface strengthening treatment process is one of rolling, laser pulse or shot peening or a mixture of the above processes, the iron-silicon alloy powder includes powder one and powder two, calculated in parts by mass, the composition of the powder one is: pure iron powder is 5 -20 parts, 0.01-5 parts for pure silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com