Aluminum cell cathode carbon block with cylindrical grooves on upper surface and manufacturing method of aluminum cell cathode carbon block

A cathode carbon block and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolysis, can solve the problems of time-consuming, difficult processing, and consumption of electrode materials, and achieve the effect of avoiding processing difficulties and saving electrode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

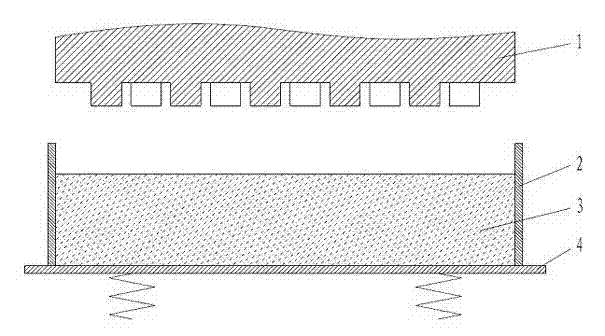

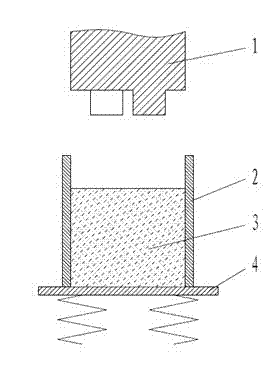

[0018] First, put the kneaded paste for making cathode carbon block of aluminum electrolytic cell into such as figure 1 and figure 2 Vibration molding box mold as shown, then flatten the paste in the box mold, then press the weight with cylindrical protrusions on the lower surface to the upper surface of the paste in the box mold, turn on the vibration molding machine, pre-prepared Vibrate, and then start to vibrate, so that the paste of the cathode carbon block in the box mold is vibrated into a bulk density of 1.60g / cm 3 Vibration forming block;

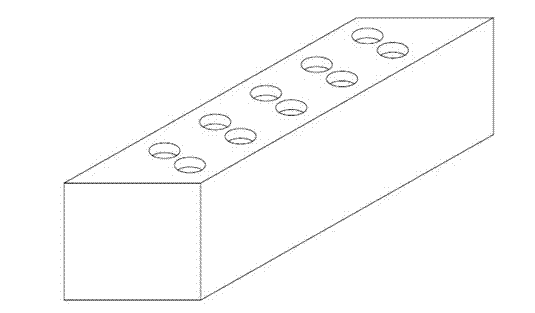

[0019] After the vibration molding is completed, lift the weight and the box mold, and push out the vibration forming block. At this time, a cathode carbon block green body with a cylindrical groove on the upper surface is formed, and the cylindrical groove on the upper surface of the cathode carbon block green body Arranged in two rows in the length direction of the upper surface, the number of cylindrical grooves in each row i...

Embodiment 2

[0023] First, put the kneaded paste for making cathode carbon block of aluminum electrolytic cell into such as figure 1 and figure 2 Vibration molding box mold as shown, then flatten the paste in the box mold, then press the weight with cylindrical protrusions on the lower surface to the upper surface of the paste in the box mold, turn on the vibration molding machine, pre-prepared Vibrate, and then start to vibrate, so that the paste of the cathode carbon block in the box mold is vibrated into a bulk density of 1.65g / cm 3 Vibration forming block;

[0024] After the vibration molding is completed, lift the weight and the box mold, and push out the vibration forming block. At this time, a cathode carbon block green body with a cylindrical groove on the upper surface is formed, and the cylindrical groove on the upper surface of the cathode carbon block green body Arranged in two rows in the length direction of the upper surface, the number of cylindrical grooves in each row i...

Embodiment 3

[0028] First, put the kneaded paste for making cathode carbon block of aluminum electrolytic cell into such as figure 1 and figure 2 Vibration molding box mold as shown, then flatten the paste in the box mold, then press the weight with cylindrical protrusions on the lower surface to the upper surface of the paste in the box mold, turn on the vibration molding machine, pre-prepared Vibrate, and then start to vibrate, so that the paste of the cathode carbon block in the box mold is vibrated to form a bulk density of 1.70g / cm 3 Vibration forming block;

[0029] After the vibration molding is completed, lift the weight and the box mold, and push out the vibration forming block. At this time, a cathode carbon block green body with a cylindrical groove on the upper surface is formed, and the cylindrical groove on the upper surface of the cathode carbon block green body Arranged in two rows in the length direction of the upper surface, the number of cylindrical grooves in each ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com