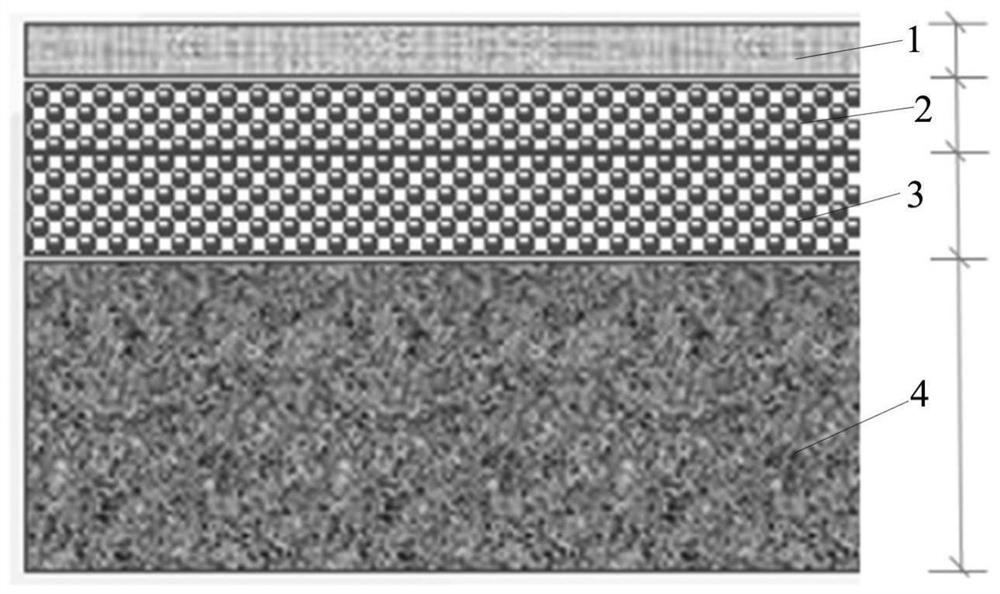

Nano-toughened rubber asphalt Kaipu pavement structure and construction method thereof

A technology of rubber asphalt and pavement structure, which is applied in the direction of roads, roads, on-site paved cohesive pavements, etc., which can solve the problems of inconvenient spreading and difficult processing of high-viscosity rubber asphalt, and achieve fast construction, excellent economic and environmental benefits , excellent waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment is implemented based on the reconstruction project of the Banqiao-Xiaoyuanzi secondary road in Qingyang City, Gansu Province in 2019. The three-layer Cape seal layer structure is used to replace the lower layer of the originally designed asphalt pavement. The implementation length is 100m and the road width is 8.5m.

[0062] Prepare the required raw materials before construction, including matrix asphalt, waste tire recycled rubber powder, nano-materials, modified emulsified asphalt, gravel, fine aggregate, cement, water, etc. One-step work; and prepare the mechanical equipment required for the construction of each structural layer, such as: asphalt spreader, aggregate spreader, rubber wheel roller, steel wheel roller, brush cleaning machine, slurry sealer.

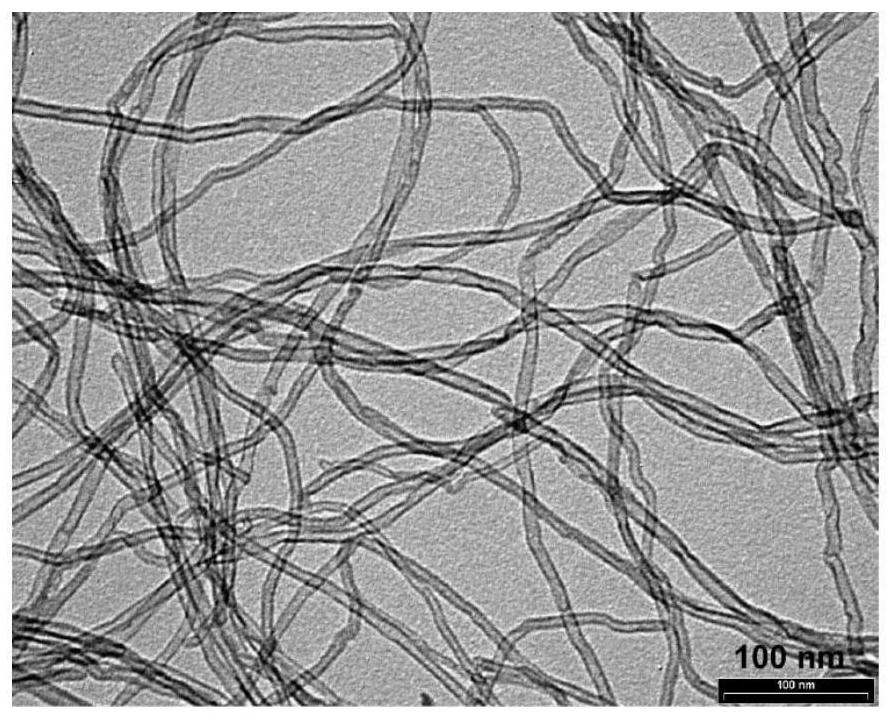

[0063] In this embodiment, the nanomaterials of toughened rubber asphalt adopt the functional masterbatch made by pre-dispersing carbon nanomaterials in resin. The matrix resin is high-density polypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com