Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Good anti-rutting performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane high-temperature-resistant anti-rutting modifier for road asphalt

ActiveCN103102706AGood anti-rutting performanceExcellent high temperature resistance and anti-rutting performanceBuilding insulationsPolymer sciencePolyol

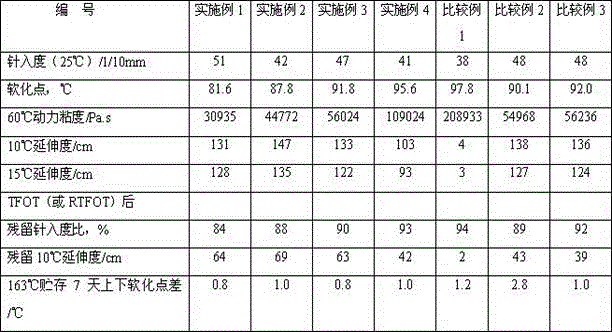

The invention discloses a polyurethane high-temperature-resistant anti-rutting modifier for road asphalt. The modifier comprises the following components in parts by the total weight of the modifier: 25-65 parts of one or two or more of diisocyanate, polyaryl polymethylene isocyanate and diisocyanate derivatives, 15-60 parts of one or two or more of polymer polyol and polymer polyamine, 2-15 parts of one or two or more of micromolecular polyol chain extender, micromolecular polyamine chain extender and micromolecular polyatomic acid chain extender, 0.01-3 parts of organic polyurethane catalyst, and 0-45 parts of poly-alkadiene polymer compound with a number-average molecular weight of 500-50000. The modifier can greatly improve the high-temperature resistance and anti-rutting properties of matrix asphalt and modified asphalt; and prepared modified asphalt is balanced in high and low-temperature performances, good in compatibility with matrix asphalt, and stored stably.

Owner:WANHUA CHEM GRP CO LTD +1

High-viscosity modified asphalt material and preparation method thereof

InactiveCN110041720AReduce manufacturing costOptimizing the distribution of ingredientsBuilding insulationsBituminous materialsWaste rubber

The invention discloses a high-viscosity modified asphalt material. The asphalt material is prepared from the following raw materials in parts by mass: 100 parts of matrix asphalt, 4-7 parts of a thermoplastic elastomer, 4-10 parts of waste rubber powder or an ethylene-vinyl acetate copolymer, 1-3 parts of a plasticizer, 2-4 parts of thermoplastic resin, 3-5 parts of a solubilizer, 0.2-2 parts ofa stabilizer, 0.5-1.5 parts of a chemical modifier and 0.2-0.7 part of polypropylene glycol. Through the high-viscosity modified asphalt material, the storage stability of high-viscosity modified asphalt is improved; meanwhile, high-temperature viscosity of the high-viscosity modified asphalt is reduced; when the high-viscosity modified asphalt material is applied to mixing of asphalt mixture, themixing temperature is low; the high-viscosity modified asphalt material is easy to construct, low in cost and simple in preparation method.

Owner:无锡市城市道桥科技有限公司

Asphalt modifier and preparation method thereof

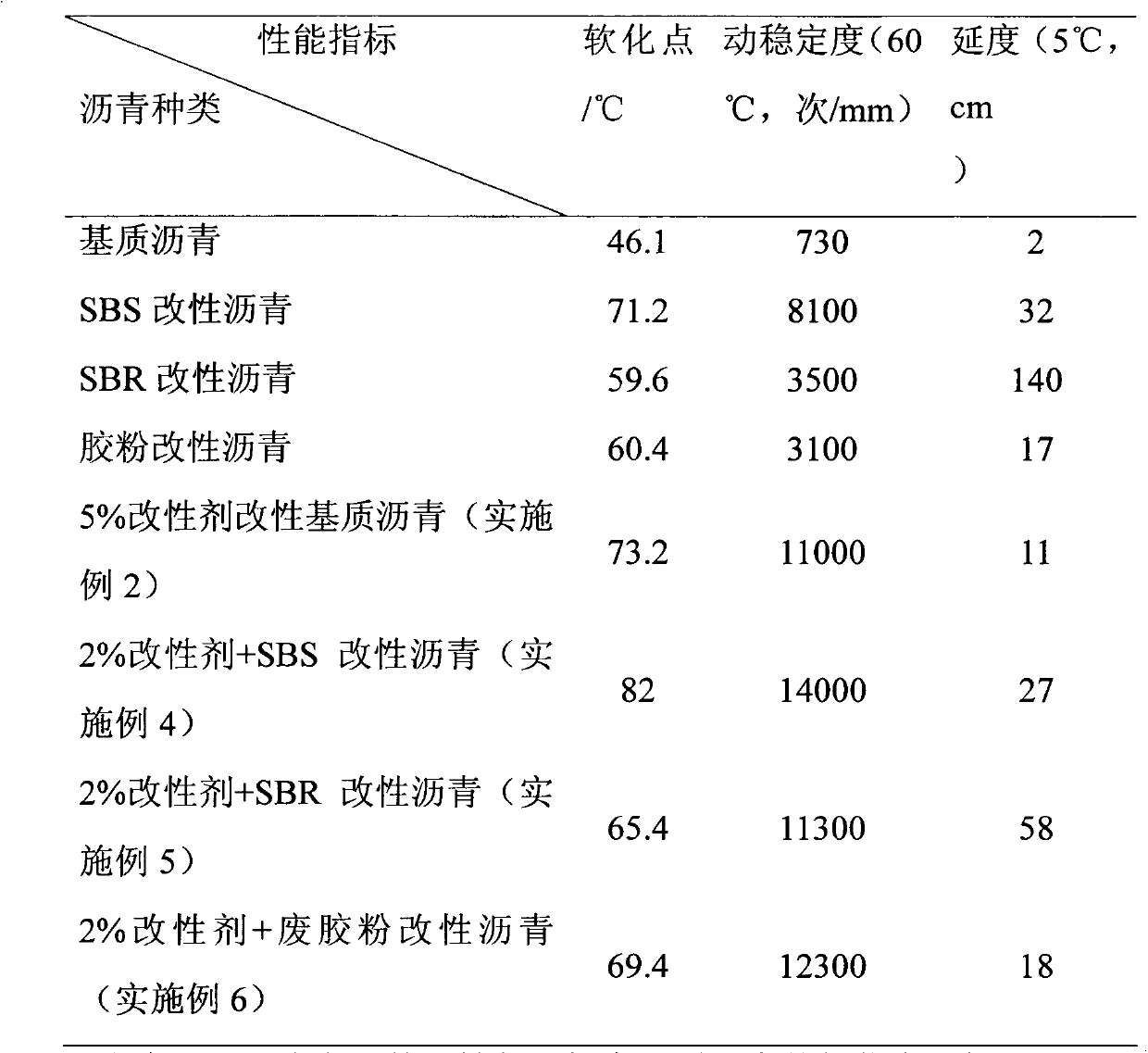

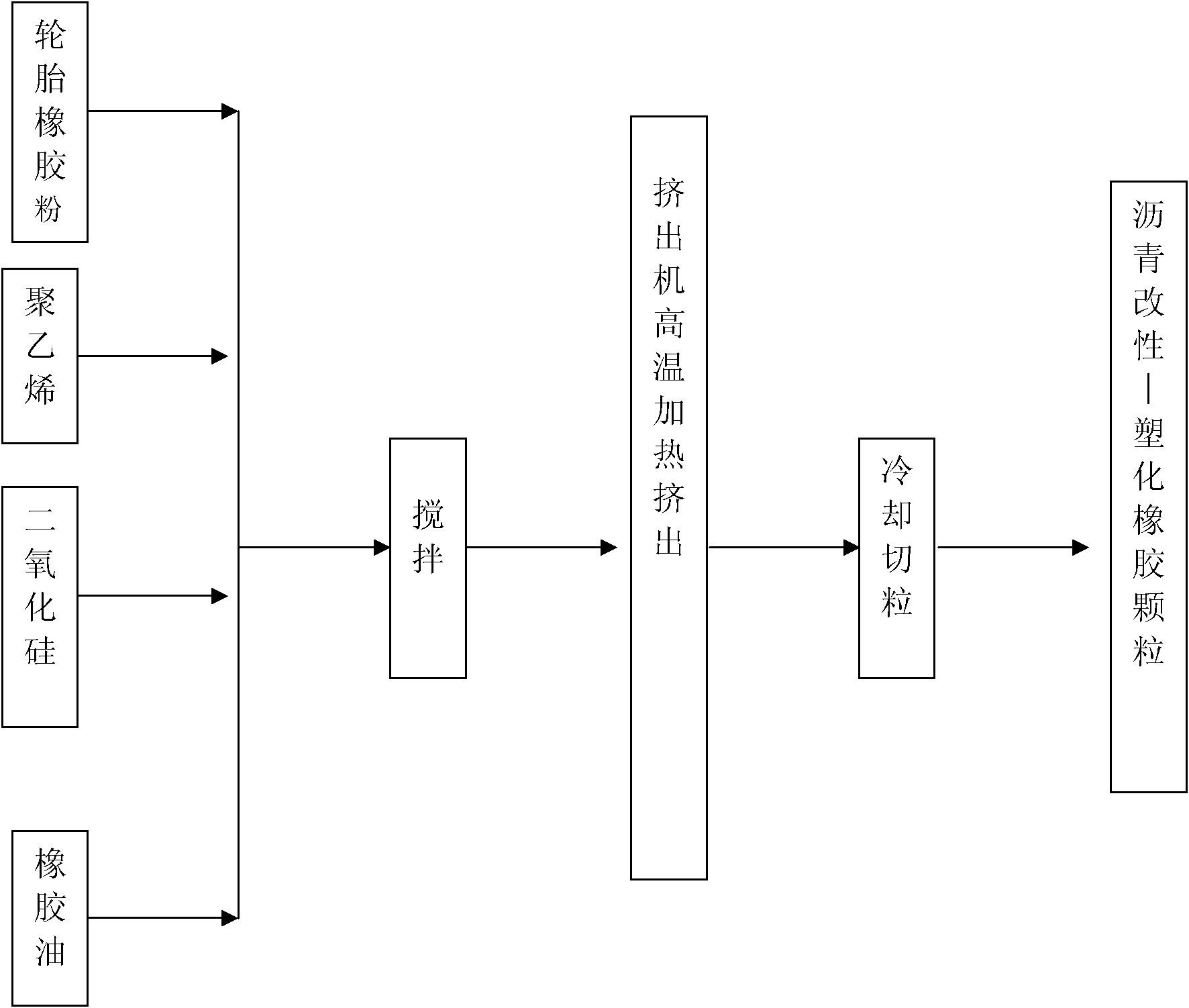

InactiveCN101979440AGood compatibilityGood dispersionIn situ pavingsBuilding insulationsPolymer scienceSilicon dioxide

The invention aims to provide an asphalt modifier and a preparation method thereof, which overcome the disadvantages of nonuniform modification, serious pollution and hidden danger caused by adding rubber powder into asphalt and solve the technical problem of the modification and prefabrication of the rubber powder. The invention provides the asphalt modifier. The asphalt modifier is characterized by comprising the following components of: tire rubber powder, polyethylene, silicon dioxide and rubber oil, wherein the components are stirred, heated, extruded, cooled and cut to obtain plasticized rubber sticky particles, namely the asphalt modifier. The plasticized rubber sticky particle product of the invention greatly reduce high-temperature processing and pollution of rubber asphalt; the produced rubber asphalt sticky particles are a directly thrown type novel internal modification material and can be directly thrown into the asphalt and stones for mixing; and the asphalt modifier is odorless, can reduce secondary pollution, and has better meltability than that of rubber powder modified asphalt. The rubber asphalt particles are black sticky particles and are easy to package and transport.

Owner:无锡市同义路面新材料有限公司 +1

Cold mixing epoxy asphalt repairing material and preparation method thereof

InactiveCN104031394AGood construction fluidityImprove performanceIn situ pavingsBuilding insulationsEpoxyDiluent

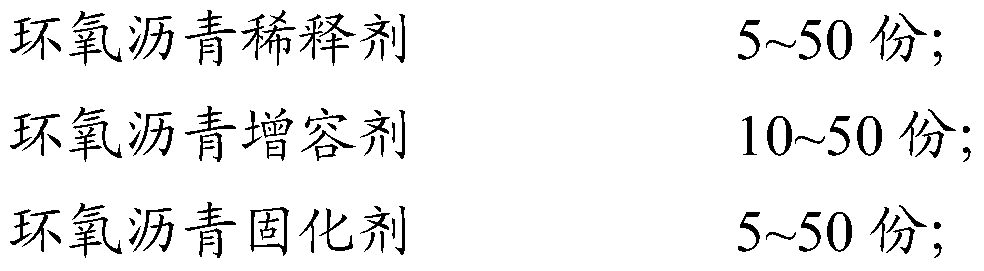

The invention provides a cold mixing epoxy asphalt repairing material and a preparation method. The cold mixing epoxy asphalt repairing material comprises a part A and a part B; the part A comprises the following components by weight: 100 parts of asphalt, 5-50 parts of epoxy asphalt diluents, 10-50 parts of epoxy asphalt compatibilizer and 5-50 parts of epoxy asphalt curing agent; the part B comprises the following components by weight: 40-100 parts of epoxy resin and 5-50 parts of epoxy resin diluents, wherein the weight ratio of the part A to part B is 0.5-5: 1. In the invention, epoxy asphalt repairing material has better construction fluidity under room temperature, and easily penetrate into the pavement cracks for repairing; and can be stirred under normal temperature for usage without heating and insulation transportation.

Owner:HUBEI UNIV

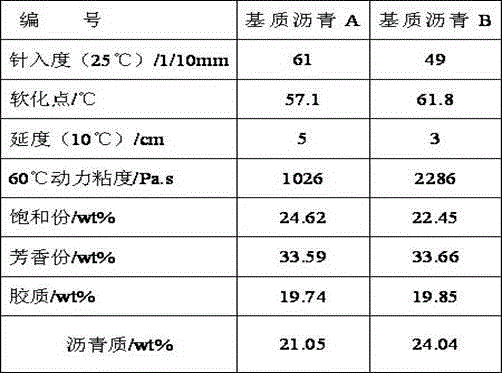

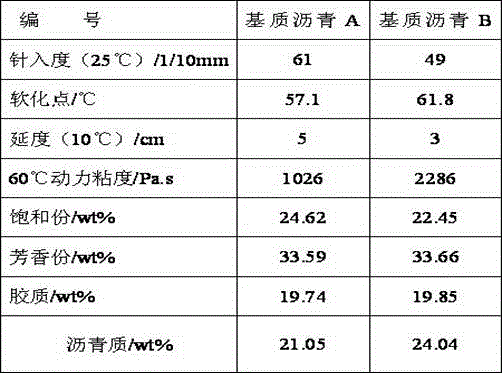

Novel high viscosity asphalt and preparation method thereof

ActiveCN104559235AHigh softening pointRaise the reaction temperatureBuilding insulationsPhosphoric acidRoad surface

The invention discloses novel high viscosity asphalt and a preparation method thereof. The novel high viscosity asphalt comprises the following raw materials in parts by weight: 100 parts of base asphalt with high asphaltene content, 0.1-1.2 part of polyphosphoric acid, 2-12 parts of a ductility improver mother liquid, 1-8 parts of a dispersant, and 0.2-0.5 part of a coupling agent. The preparation method comprises the following steps: adding the polyphosphoric acid in the molten base asphalt to perform a chemical modification reaction, then adding the ductility improver mother liquid, continuing to react, and finally adding the dispersant and the coupling agent to continue to react for a period of time to prepare high viscosity asphalt, wherein the whole process is performed under a highs-speed stirring condition. The high viscosity asphalt is high in 60-degree dynamic viscosity, high in softening point, high in low-temperature ductility, stable to store, and good in adhesion to aggregates, has excellent high temperature stability, excellent low temperature anti-cracking performance, excellent anti-fatigue performance and excellent water resistance, is especially suitable for high-temperature humid areas, areas with relatively high diurnal temperature difference, and paving of heavy-duty roads and drainable pavements, effectively prevents common pavement damages such as pavement rutting, pavement upheaval, pavement fatigue cracking, pavement cold cracking and water encroachment on pavements, and prolongs the service life of the pavement.

Owner:CHINA PETROLEUM & CHEM CORP +1

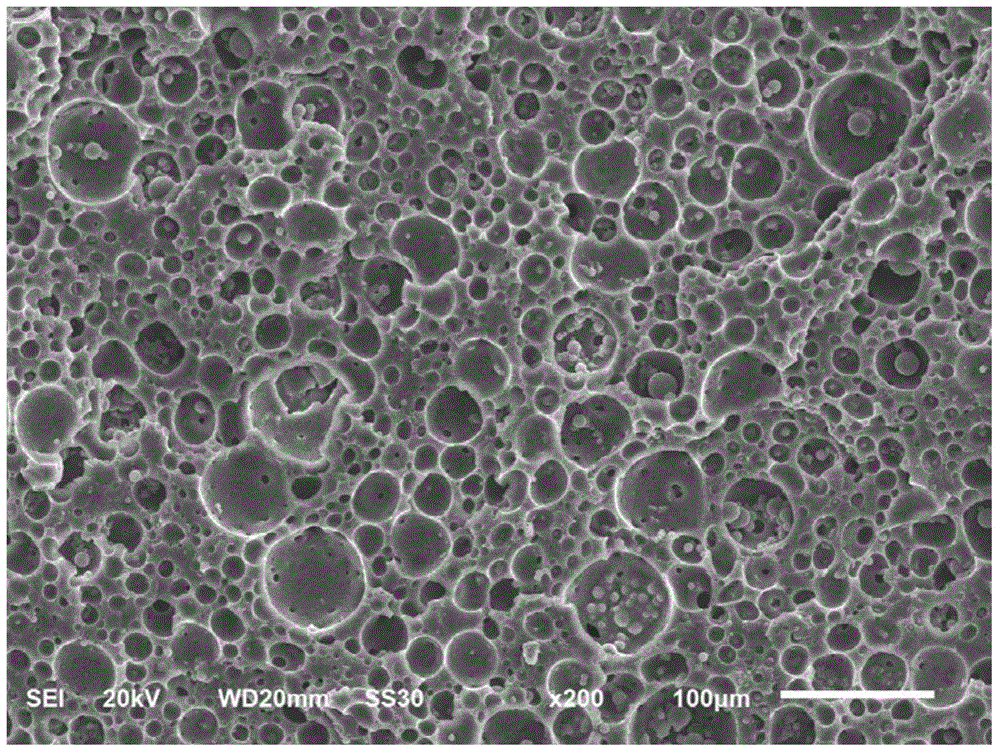

Foamed asphalt cold-regenerating structural layer mixture and construction method thereof

InactiveCN107386038AGood water stabilityGood anti-rutting performanceIn situ pavingsPulverised fuel ashAsphalt

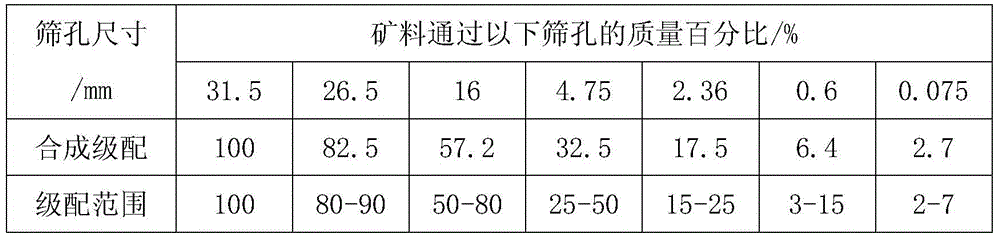

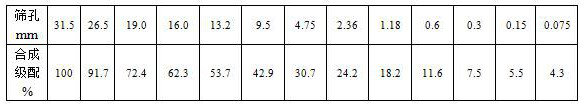

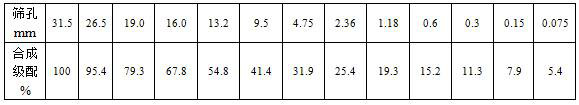

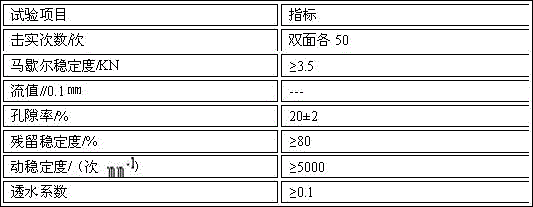

The invention discloses a foamed asphalt cold-regenerating structural layer mixture. The foamed asphalt cold-regenerating structural layer mixture is prepared from the following materials of a mineral aggregate, cement, an anti-stripping agent, mixing water, foamed asphalt and fiber. The mineral aggregate is composed of the following materials of, by mass, 30-40 parts of a milling-planing old material with the grain diameter being 10-30 mm, 35-45 parts of a milling-planing old material with the grain diameter being smaller than 10 mm, 2-8 parts of new aggregated rock with the grain diameter being 10-30 mm, 10-20 parts of new aggregated rock with the grain diameter being smaller than 10 mm and 4-6 parts of pulverized fuel ash. The dosage of the cement is 1.5-2.5% of the total dosage of the mineral aggregate, the mixing amount of the anti-stripping agent is 0.4-0.6% of the total dosage of the mineral aggregate, and the dosage of the mixing water is 4-5% of the total dosage of the mineral aggregate, the dosage of the foamed asphalt is 2.5-3.5% of the total dosage of the mineral aggregate, and the total mixing amount of the fiber is 0.35-0.45% of the total dosage of the mineral aggregate. The invention further discloses a construction method of the mixture. After construction of the foamed asphalt cold-regenerating structural layer mixture is conducted, a road can has good water stability and anti-rutting performance; and the road maintenance or transformation cost is reduced, the construction period is shortened, and the time of traffic stop is reduced.

Owner:SOUTHEAST UNIV

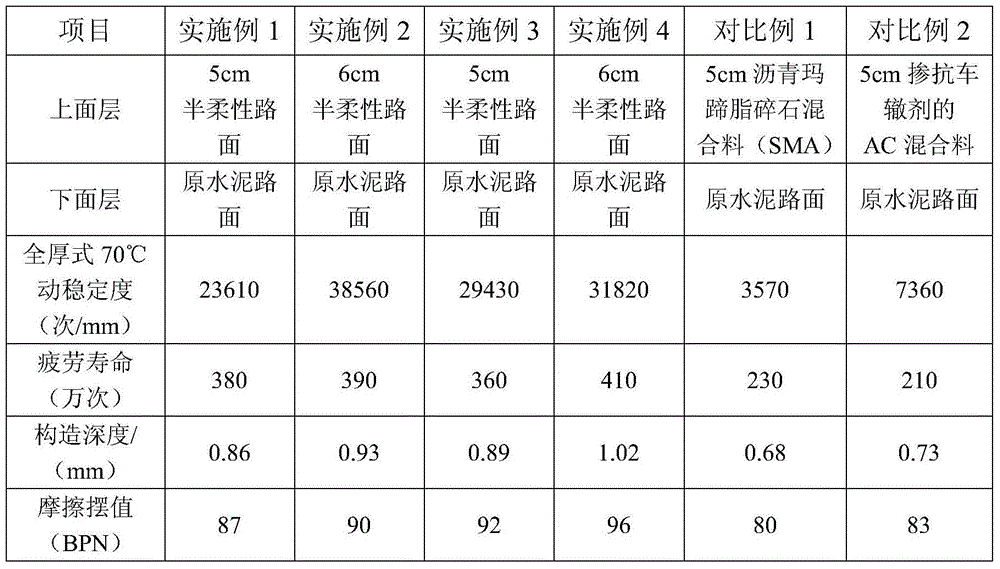

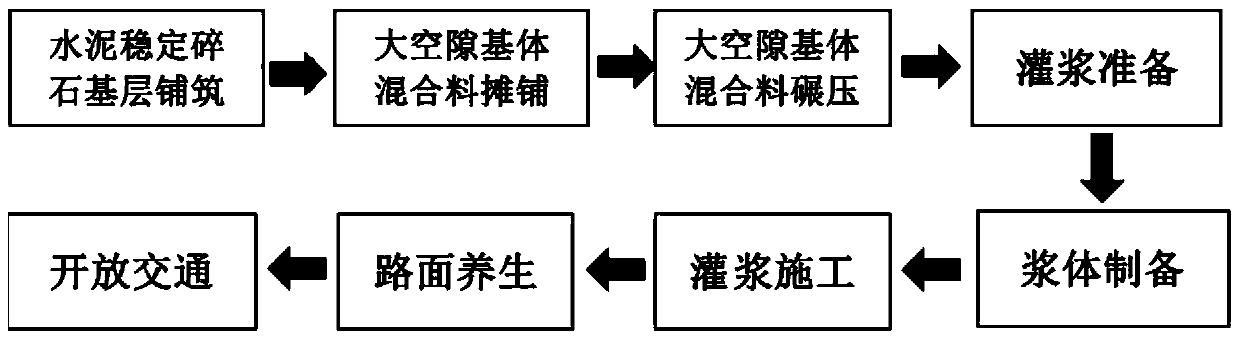

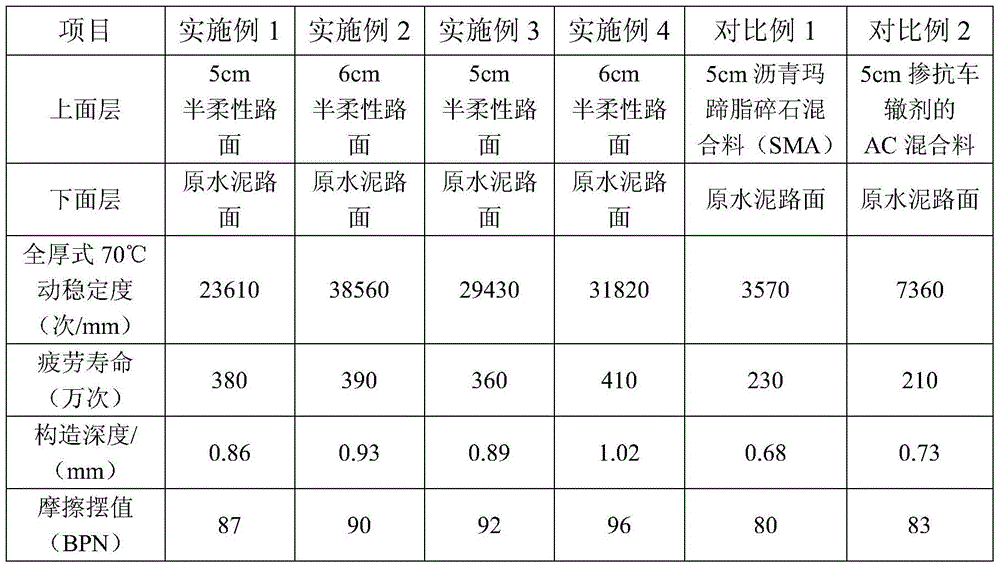

Improved construction method of old cement concrete pavement

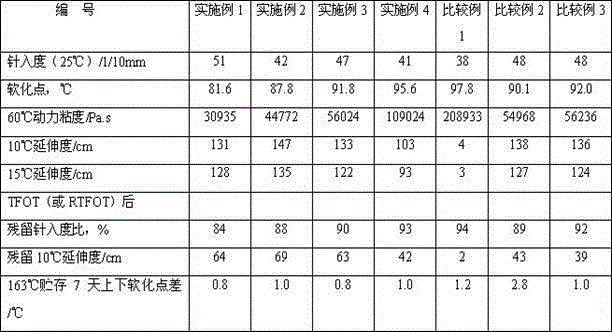

ActiveCN104652212ADoes not affect roadabilityImproves rutting resistanceIn situ pavingsRoad surfaceCement mortar

The invention provides an improved construction method of an old cement concrete pavement. The improved construction method comprises the following steps: disposing an old cement pavement disease and performing chiseling on the pavement surface; uniformly paving and spreading a layer of rubber modified emulsified asphalt mixture, and grinding on the old cement concrete pavement to form a crack inhibition function layer; paving a large-void asphalt mixture on the crack inhibition function layer; pouring cement mortar into the large-void asphalt mixture after the temperature of the large-void asphalt mixture is reduced to be under 50 DEG C, scraping the surface laitance with a brush to expose an aggregate structure after the large-void asphalt mixture is fully poured, and maintaining to open the traffic. The pavement constructed by the method can fully inherit the bearing capacity of the original cement concrete and has excellent anti-rutting performance and anti-fatigue performance, no lapped seam is formed on the pavement, the anti-sliding performance of the pavement is enhanced, the running safety is improved greatly and the improved construction method has wide application prospect.

Owner:XIDI (SUZHOU) SURVEY & DESIGN CONSULTING CO LTD

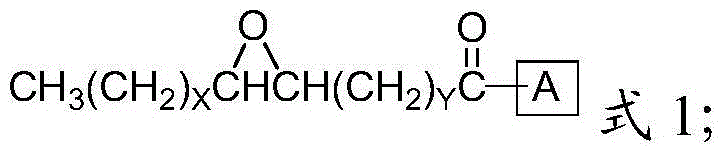

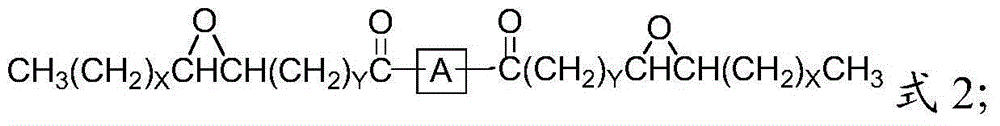

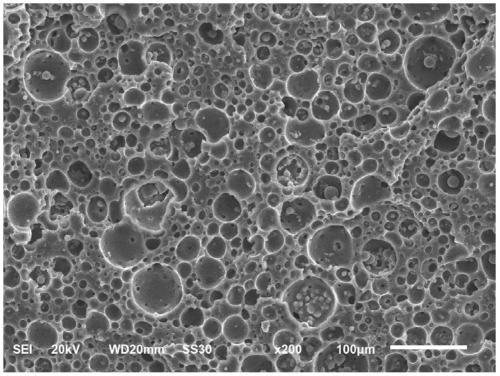

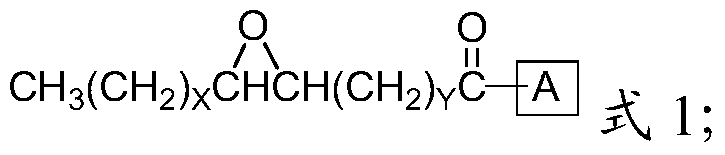

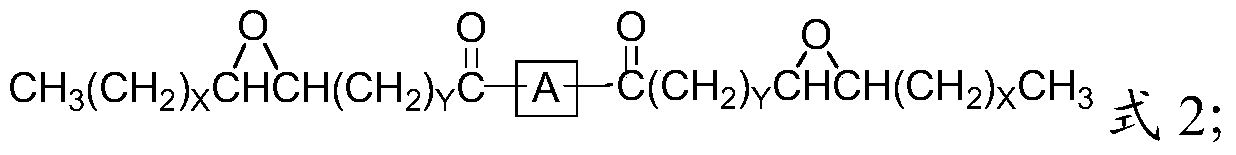

Epoxy asphalt compatibilizer, preparation method and application method thereof

ActiveCN104031395AHigh strengthImprove toughnessOrganic chemistryBuilding insulationsEpoxyCarbon chain

The invention provides an epoxy asphalt compatibilizer preparation method and a usage method. The preparation method comprises the following steps: unsaturated aliphatic carboxylic acid and polyatomic alcohol are subjected to an esterification reaction, and then the product is subjected to hydrogen peroxide epoxidation to obtain the epoxy asphalt compatibilizer. An epoxy asphalt material comprises a part A and a part B, the part A comprises the following components by weight: 100 parts of asphalt, 5-50 parts of asphalt diluents, 10-50 parts of epoxy asphalt compatibilizer and 5-50 parts of epoxy asphalt curing agent; the part B comprises the following components by weight: 40-100 parts of epoxy resin and 5-50 parts of epoxy diluents; wherein the weight ratio of part A to part B is 0.5-5: 1. According to the invention, a nonpolar carbon chain in an epoxy asphalt compatibilizer molecular chain is effectively compatible with asphalt, an epoxide group is effectively compatible with epoxy resin, and is subjected to a crosslinking reaction with an epoxy asphalt curing agent, so that mechanical strength and stability of the epoxy asphalt material can be increased.

Owner:HUBEI UNIV +1

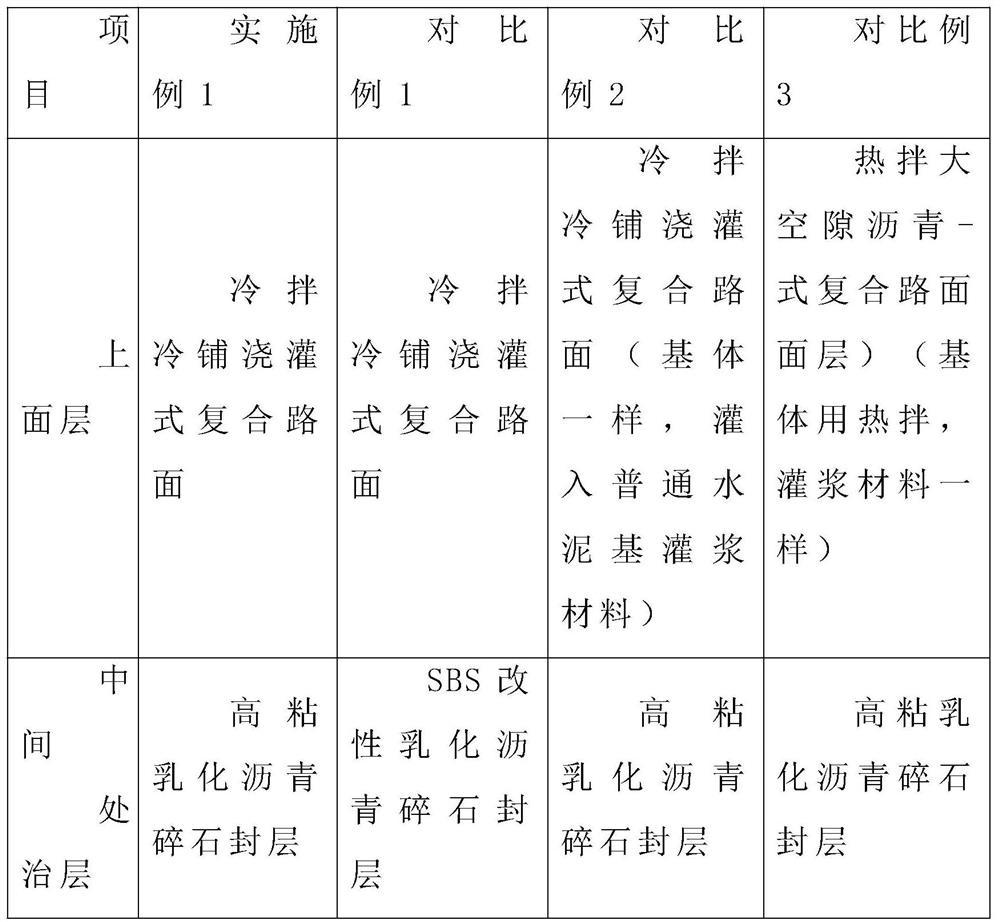

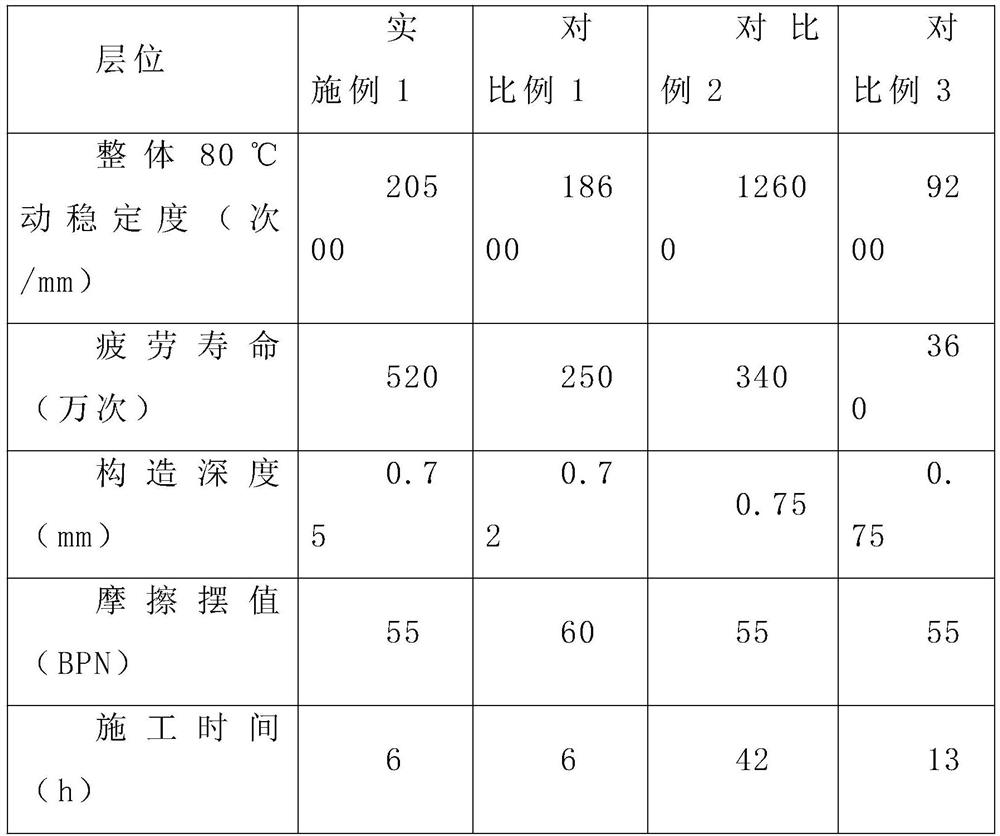

Anti-rut pavement paving method capable of continuously paving base layer and surface layer

PendingCN111549608ASolve temperature problemsSolving Difficult to Compact ProblemsIn situ pavingsRoad engineeringStructural engineering

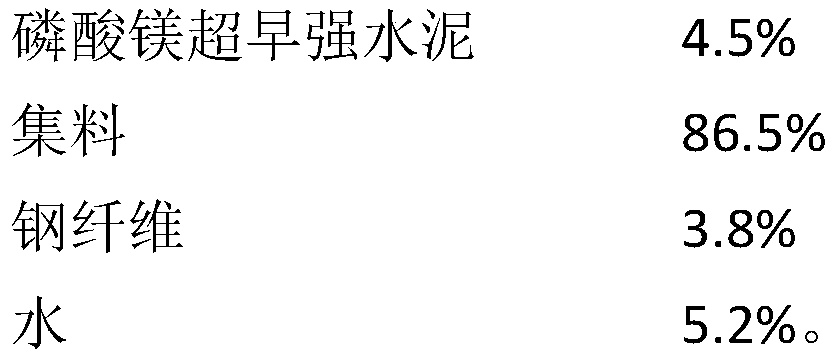

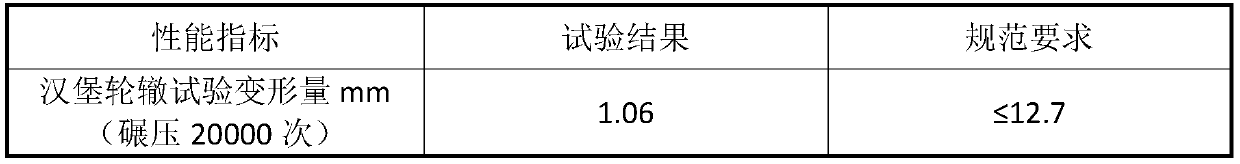

The invention discloses an anti-rut pavement paving method capable of continuously paving a base layer and a surface layer, and belongs to the field of road engineering. The method is characterized inthat a super-early-strength anti-cracking cement stabilized macadam base layer is paved firstly, and after the base layer is rolled, a cold-mixed cold-paved rigid-flexible composite surface layer ispaved under the condition that the surface is still in a wet state. Compared with the prior art, according to the anti-rut pavement paving method capable of continuously paving the base layer and thesurface layer, continuous paving of the cement stabilized macadam base layer and the surface layer can be realized; maintenance time for 7 days of the cement stabilized macadam base layer can be omitted, meanwhile, the continuity of the base layer and the surface layer is improved, the overall cooperative stress of the pavement structure is guaranteed, a permeable layer and a macadam sealing layerdo not need to be sprayed on the surface of the cement stabilized macadam base layer, and the construction cost is reduced. Meanwhile, the cold-mixed and cold-paved rigid-flexible composite surface layer does not need centralized hot mixing, so that construction is convenient, resources are saved, and the environment is protected. The anti-rutt pavement structure with the base layer and the surface layer capable of being continuously paved has high high-temperature anti-rutting performance, anti-cracking performance, water stability and durability, and has high popularization and applicationvalues.

Owner:SHANDONG TRANSPORTATION INST +2

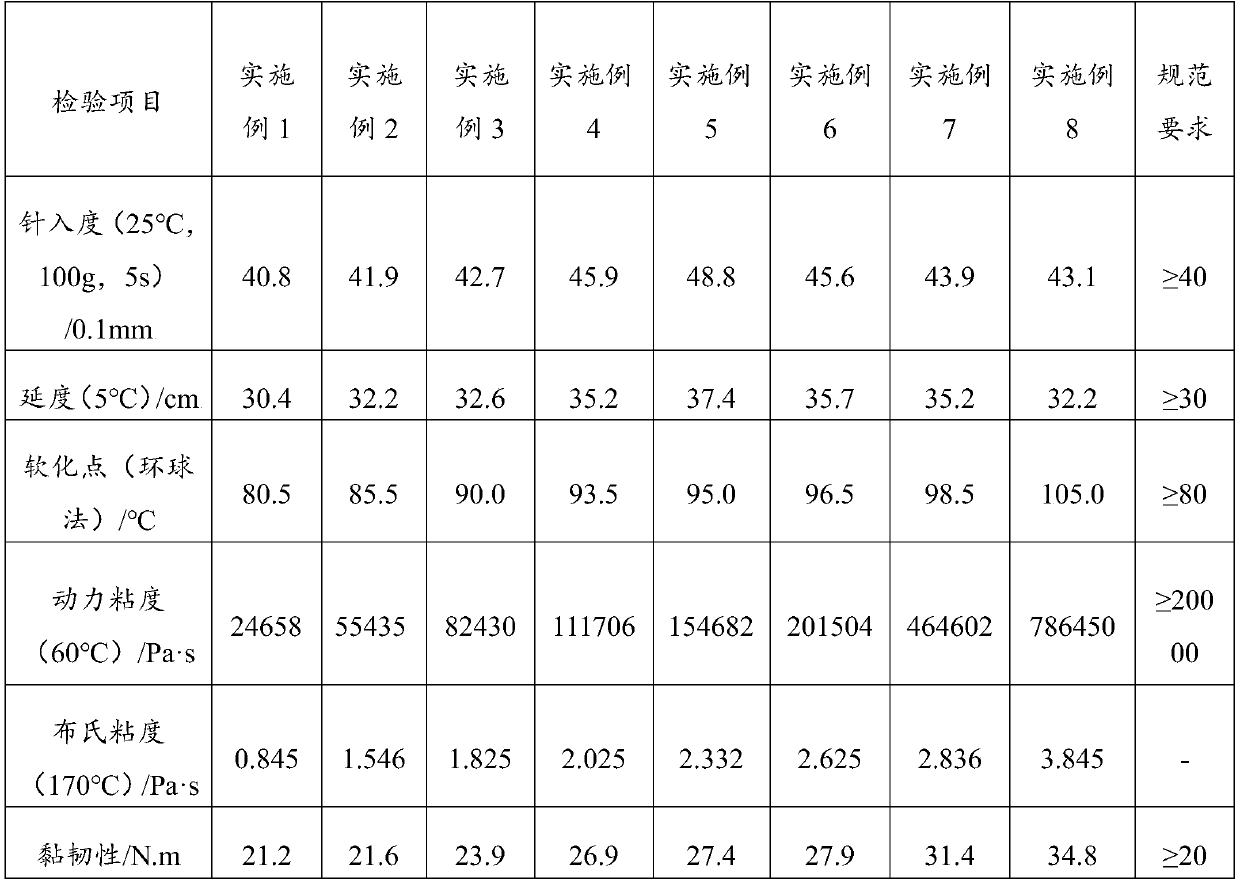

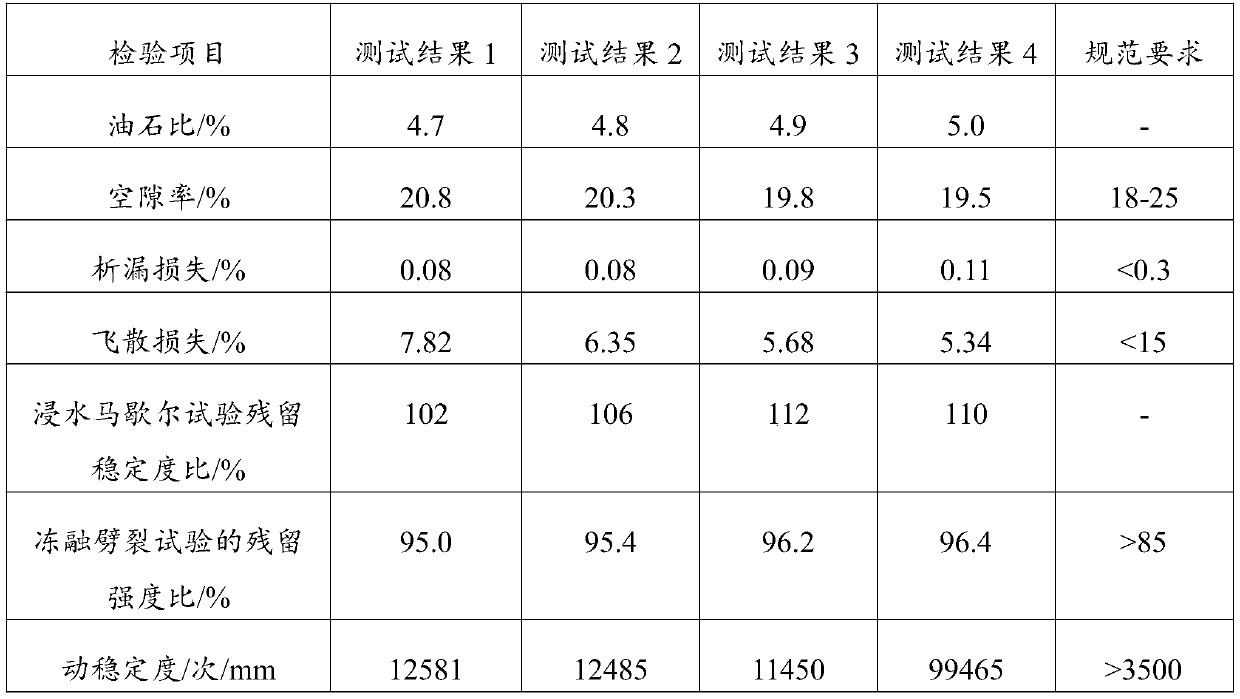

Rubber powder compound modified hyperviscous asphalt for noise-reducing and water draining pavement

PendingCN109943085AHigh softening pointImprove high temperature stabilityBuilding insulationsPolymer scienceRoad surface

The invention discloses rubber powder compound modified hyperviscous asphalt for a noise-reducing and water draining pavement. The asphalt is prepared from pavement petroleum asphalt, activated rubberpowder, a styrene thermoplastic elastomer, a stabilizer and a tackifier. The preparation method comprises the following steps: adding the tackifier into the preheated pavement petroleum asphalt to besheared for 30-60 min; then adding the activated rubber powder and the styrene thermoplastic elastomer to be further sheared; then adding the stabilizer to be sheared for 10-30 min; and developing the material for 60-150 min to obtain the rubber powder compound modified hyperviscous asphalt for the noise-reducing and water draining pavement. The modified hyperviscous asphalt provided by the invention is high in dynamic viscosity, high in softening point, relatively good in sticky toughness and relatively small in flyoff loss and leakage loss, detection results such as needle penetration, ductility and dynamic viscosity can reach a code requirement, and the water damage preventing performance and high temperature anti-rut performance can be improved obviously. The rubber powder compound modified hyperviscous asphalt also has the advantages of being high in low temperature anti-crack ability, long in service life, low in cost and the like, is high in cost performance, and has remarkableengineering application value.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

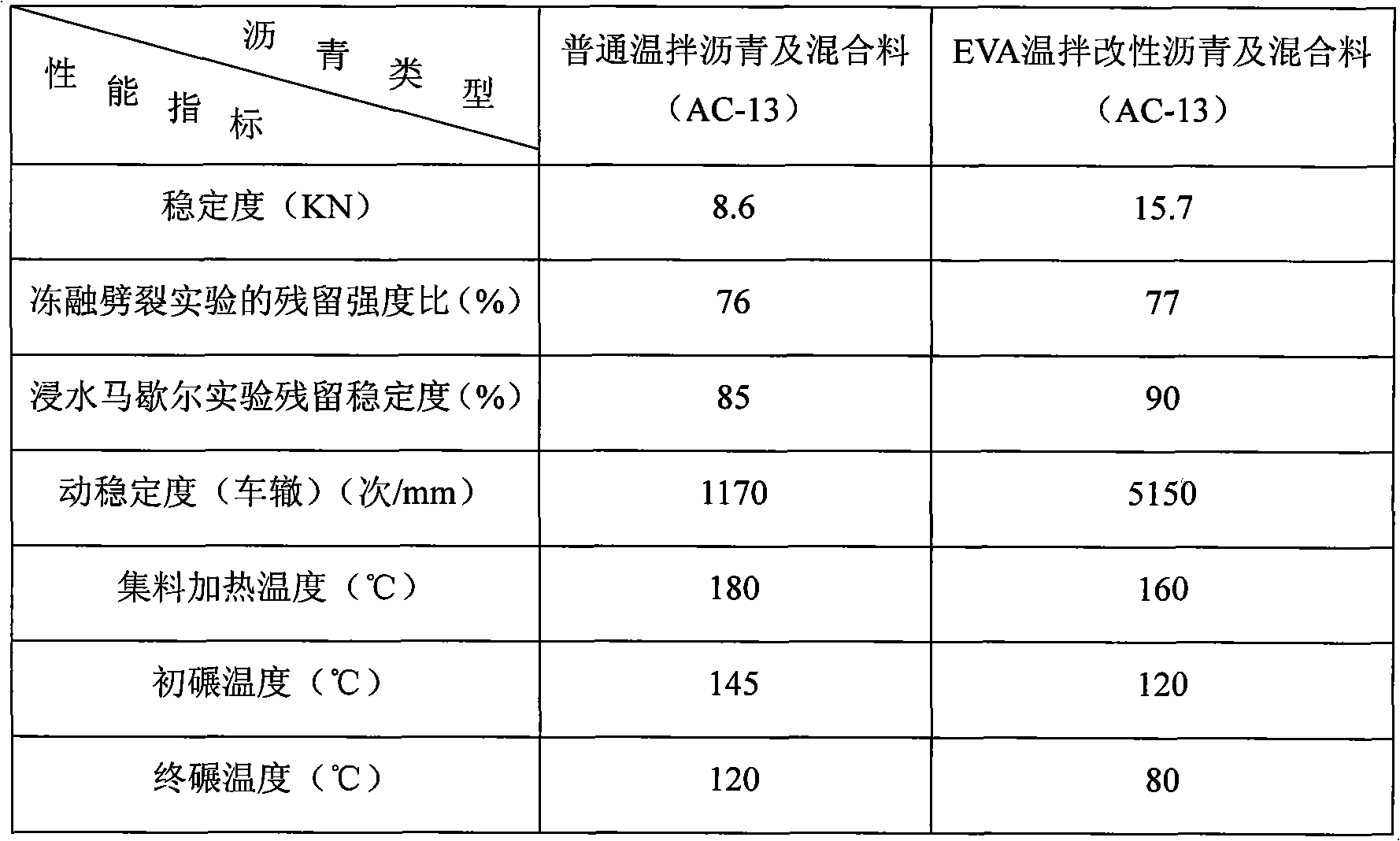

Method for preparing plastic warm-stirred modified asphalt mixture

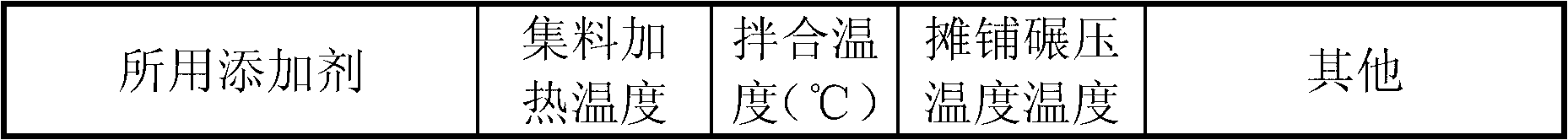

InactiveCN102050599AImprove high temperature anti-rutting abilityRelaxation of construction conditionsClimate change adaptationColloidal particlePitch blende

The invention discloses a method for preparing a plastic warm-stirred modified asphalt mixture, which comprises the steps of: taking asphalt, aggregate, warm-stirred modifier and ethylene-vinylacetate copolymer colloidal particles as raw materials, putting the aggregate preheated to 160 DEG C into a blender, adding the ethylene-vinylacetate copolymer colloidal particles and dry blending, and then adding 145-DEG C hot melted asphalt and warm-stirred modified asphalt for stirring to acquire the plastic warm-stirred modified asphalt mixture. The raw materials are in the following parts by mass: 100 parts of aggregate and 4.5-5.5 parts of asphalt, wherein the mass part of the warm-stirred modified asphalt is 0.09-0.12 time that of the asphalt and the mass part of the ethylene-vinylacetate copolymer colloidal particles is 0.06 to 0.10 time that of the asphalt. The plastic warm-stirred modified asphalt mixture can be used for bituminous pavements with extra heavy traffic volumes, has all better technical indexes compared with the common bituminous pavement, is economic and environment-friendly, and has better water damage resistance property and track resistance property.

Owner:GUANGDONG UNIV OF TECH

Interface enhancer for watering-type pavement material preparation and application thereof

ActiveCN103601418AIncreased surface-interface adhesionSolve the lack of crack resistanceAcrylic acidMaterials preparation

The invention provides an interface enhancer for watering-type pavement material preparation, and the interface enhancer is prepared from the following components in parts by weight: 10-25 parts of acrylic monomer, 5-12 parts of organosilane, 0.2-3 parts of a surfactant and 0.04-0.04 part of an accelerant. The invention also provides a method for preparation of a watering-type pavement material by used of the interface enhancer. The interface enhancer can increase the surface interface bonding power between a cement-based grouting agent and an asphalt mixture, the problems of insufficient crack resistance and poor durability caused by the poor surface interface bonding property of asphalt and cement mortar are solved, and the interface enhancer has obvious economic benefits and application values.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

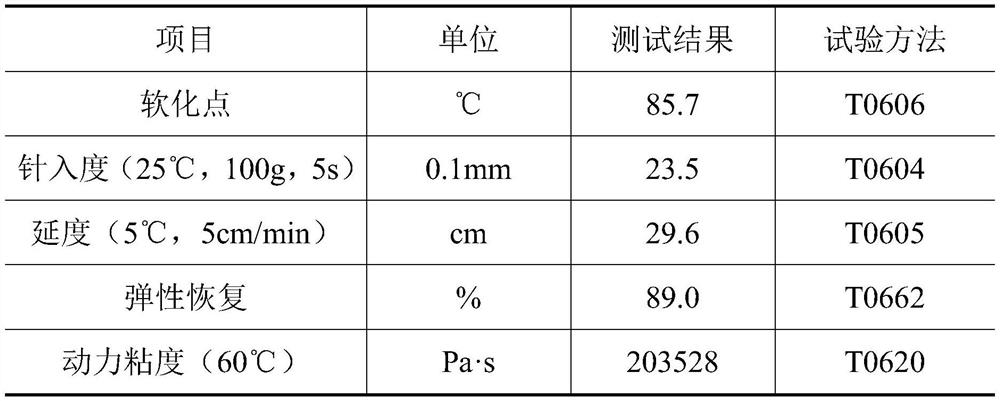

High-viscosity anti-rut modified asphalt for ultrathin overlay and preparation method thereof

InactiveCN111777865ALarge particle sizeRich shape typesBuilding insulationsWaste tiresAsphalt pavement

The invention discloses a high-viscosity anti-rut modified asphalt for an ultrathin overlay and a preparation method thereof, and belongs to the technical field of road maintenance. The modified asphalt is prepared from 100 to 110 parts of matrix asphalt, 25 to 30 parts of waste tire rubber powder pretreated by a silane coupling agent, 5 to 8 parts of SBS and 1 to 3 parts of DOMIX. The softening point (DEG C) of the prepared high-viscosity anti-rut modified asphalt is 85.7, the needle penetration (25 DEG C, 0.1 mm) is 23.5, the ductility (5 DEG C, 5cm / min) is 29.6, the elastic recovery (%) is89.0, and the dynamic viscosity (60 DEG C, Pa.s) is 203528. The asphalt has excellent high-temperature stability, low-temperature crack resistance, viscosity, self-healing property and economical efficiency; and the preparation method is simple, green and efficient, can be used for large-scale batch production in construction sites and factories, can adapt to various engineering application requirements, and has important significance for promoting application and popularization of preventive maintenance technologies such as ultrathin overlay and the like in new construction and maintenance ofasphalt pavements in China.

Owner:CHINA MCC17 GRP

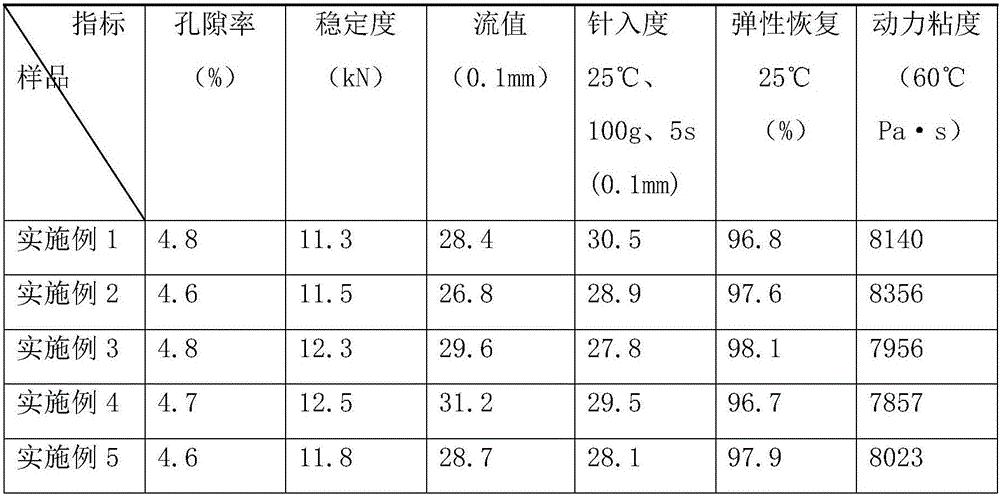

Anti-rut agent for cool mixing and cool spreading of asphalt road

The invention discloses an anti-rut agent for cool mixing and cool spreading of an asphalt road. The anti-rut agent mainly comprises a high-rigidity normal-temperature asphalt blend and a concentrated curing agent, wherein the curing agent and the normal-temperature asphalt blend are cured to form reinforced fibers, and a polymer and the curing agent have chemical bonding, thus the interfacial binding is also strengthened, and the interfacial fracture energy can be improved, therefore, the overall toughened, high-strength and consistent gel structure can be formed by modifying the normal-temperature asphalt. In addition, the different amounts of the curing agents have certain impact on demulsification of the asphalt blend. The usage amounts of the curing agent and the emulsifier can be selected according to the construction requirements, and the demulsification time can be controlled so as to guarantee the successful running of the construction.

Owner:南通福伦利新材料有限公司

A kind of high-viscosity asphalt and its preparation method

ActiveCN104559235BHigh softening pointRaise the reaction temperatureBuilding insulationsPolymer sciencePhosphoric acid

The invention discloses novel high viscosity asphalt and a preparation method thereof. The novel high viscosity asphalt comprises the following raw materials in parts by weight: 100 parts of base asphalt with high asphaltene content, 0.1-1.2 part of polyphosphoric acid, 2-12 parts of a ductility improver mother liquid, 1-8 parts of a dispersant, and 0.2-0.5 part of a coupling agent. The preparation method comprises the following steps: adding the polyphosphoric acid in the molten base asphalt to perform a chemical modification reaction, then adding the ductility improver mother liquid, continuing to react, and finally adding the dispersant and the coupling agent to continue to react for a period of time to prepare high viscosity asphalt, wherein the whole process is performed under a highs-speed stirring condition. The high viscosity asphalt is high in 60-degree dynamic viscosity, high in softening point, high in low-temperature ductility, stable to store, and good in adhesion to aggregates, has excellent high temperature stability, excellent low temperature anti-cracking performance, excellent anti-fatigue performance and excellent water resistance, is especially suitable for high-temperature humid areas, areas with relatively high diurnal temperature difference, and paving of heavy-duty roads and drainable pavements, effectively prevents common pavement damages such as pavement rutting, pavement upheaval, pavement fatigue cracking, pavement cold cracking and water encroachment on pavements, and prolongs the service life of the pavement.

Owner:CHINA PETROLEUM & CHEM CORP +1

Warm-mix anti-furrow agent for enhancing high-temperature stability of asphalt pavement and production method thereof

The invention discloses a warm-mix anti-furrow agent for enhancing high-temperature stability of an asphalt pavement. The warm-mix anti-furrow agent comprises the following materials in parts by weight: 10-50 parts of organic compound, 10-60 parts of modified low-density polyethylene, 5-35 parts of high-density polyethylene and 0-5 parts of assistant. The invention also discloses a production method of the warm-mix anti-furrow agent for enhancing the high-temperature stability of the asphalt pavement. The method comprises the following steps: modifying the low-density polyethylene; mixing the organic compound, the modified low-density polyethylene, the high-density polyethylene and the assistant; extruding out a cylindrical semi-finished product by a screw extruder; and grinding to obtain a finished product. The warm-mix anti-furrow agent as an asphalt additive has good anti-furrow property under the conditions that the heating temperature of aggregate and blending temperature of an asphalt mixture and that the paving and grinding temperatures are less than 20 DEG C, so that organic combination of warm mix and anti-furrow properties is realized.

Owner:四川阳罡能源科技有限公司

Low-carbon rapid maintenance and pavement method for asphalt pavement ruts

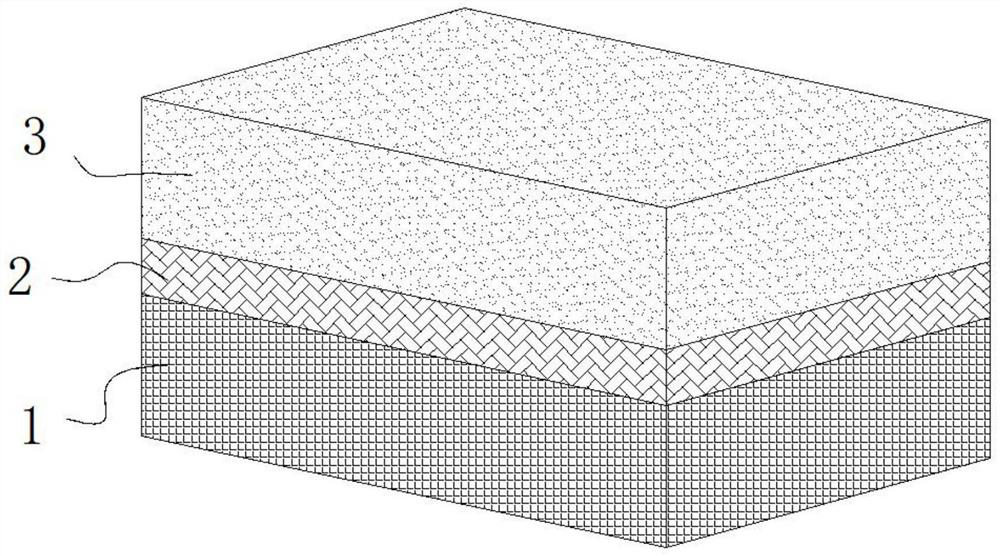

ActiveCN113622247AResistance to reflective cracking issuesImproves rutting resistanceIn situ pavingsRoads maintainenceBitumen emulsionStructural engineering

The invention discloses a low-carbon rapid maintenance and pavement method for asphalt pavement ruts. The method comprises the following steps: (1), milling an asphalt surface layer; (2), paving a super-viscous emulsified asphalt macadam sealing layer; and (3), paving the surface layer of the cold-mixing and cold-paving pouring type composite pavement. The combined pavement layer obtained by the method has the characteristics of excellent rut resistance, simple maintenance process and environmental protection, and the whole structure has the characteristics of high rut resistance, skid resistance, wear resistance, long service life and low carbon.

Owner:浙江固路交通科技有限公司

Asphalt mixture for heavy traffic roads and preparation method thereof

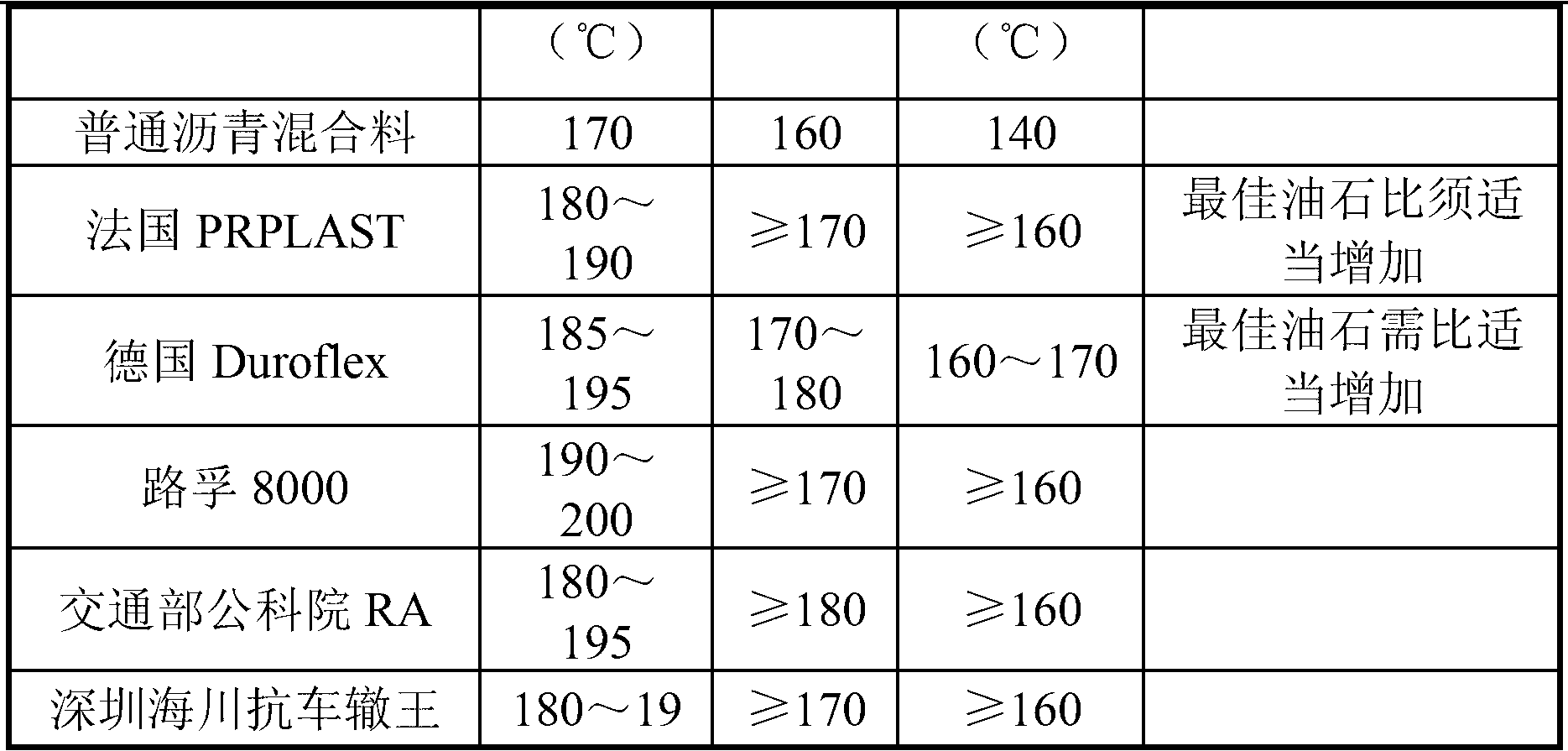

ActiveCN105801006BImprove road performanceGood anti-rutting performanceBuilding insulationsFiberPolymer science

The invention discloses an asphalt mixture for a heavy traffic road. The asphalt mixture is prepared from the following raw materials in parts by weight: 50-100 parts of asphalt, 200-350 parts of mineral powder, 50-100 parts of aggregate, 5-10 parts of inorganic fiber, 10-20 parts of ultrahigh molecular weight polyethylene, 20-40 parts of rubber powder and 10-20 parts of kieselguhr. The asphalt mixture disclosed by the invention has high stability and obviously low needle penetration and is a harder asphalt mixture while the dynamic viscosity is lower than that of common asphalt. Therefore, the asphalt mixture disclosed by the invention has better constructability and higher viscosity and toughness and shows stronger mechanical strength; and moreover, the asphalt mixture has good elastic recovery property and shows perfect high-temperature stability.

Owner:郑卫忠 +5

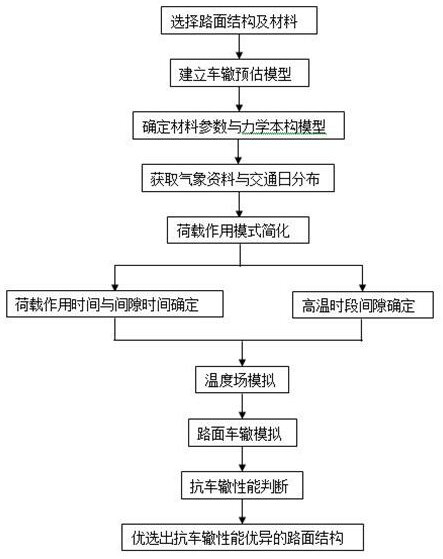

A Simulation Method for Anti-rutting Performance of Asphalt Pavement Considering Load and High Temperature Gap

ActiveCN107908847BGood anti-rutting performanceSolve the problem of large error in simulation resultsGeometric CADDesign optimisation/simulationStructural engineeringRoad surface

The invention provides a method for simulating anti-rutting performance of asphalt pavement considering load and high temperature gap, using finite element software, comprising the following steps: selecting pavement structure and materials; establishing a rutting prediction model; selecting material parameters and a mechanical constitutive model Obtain meteorological data and daily traffic distribution; simplify the load action mode; determine the load action time and gap time; determine the gap during high temperature periods; simulate the temperature field; predict road rutting; The invention takes into account the characteristics of asphalt pavement self-recovering part of the deformation in the gap between loads and high-temperature periods, so that the rutting simulation is closer to the real situation, and solves the problem of large errors in the simulation results of the existing method; at the same time, it can judge the specific pavement structure Excellent anti-rutting performance, that is, to select a pavement structure with better anti-rutting performance through virtual tests, without the need to build test roads for comparative experiments, which saves a lot of cost.

Owner:SOUTHEAST UNIV

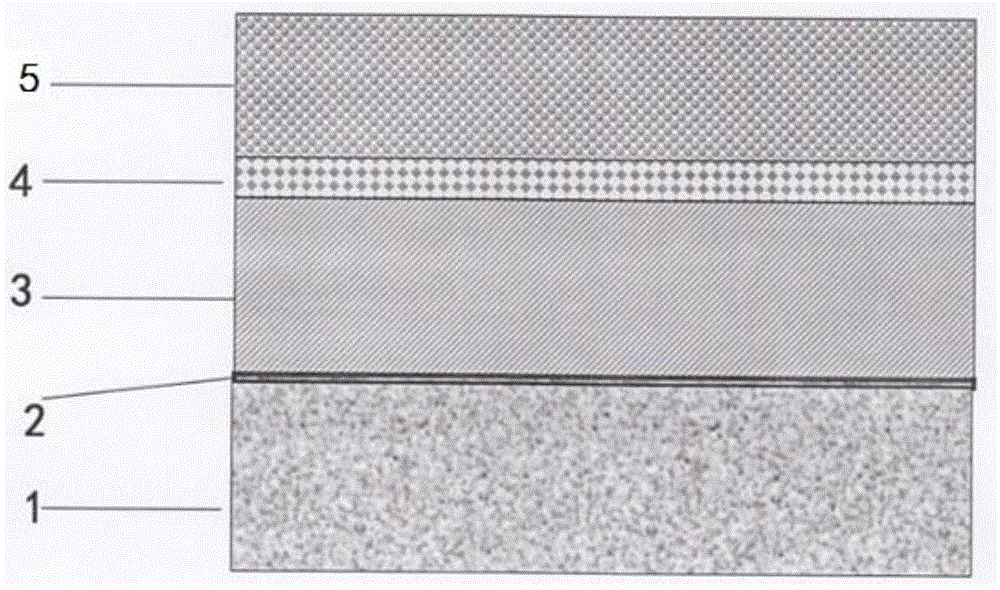

A method for upgrading and reforming old cement concrete pavement

ActiveCN104652212BDoes not affect roadabilityImproves rutting resistanceIn situ pavingsDiseaseRoad surface

The invention provides an improved construction method of an old cement concrete pavement. The improved construction method comprises the following steps: disposing an old cement pavement disease and performing chiseling on the pavement surface; uniformly paving and spreading a layer of rubber modified emulsified asphalt mixture, and grinding on the old cement concrete pavement to form a crack inhibition function layer; paving a large-void asphalt mixture on the crack inhibition function layer; pouring cement mortar into the large-void asphalt mixture after the temperature of the large-void asphalt mixture is reduced to be under 50 DEG C, scraping the surface laitance with a brush to expose an aggregate structure after the large-void asphalt mixture is fully poured, and maintaining to open the traffic. The pavement constructed by the method can fully inherit the bearing capacity of the original cement concrete and has excellent anti-rutting performance and anti-fatigue performance, no lapped seam is formed on the pavement, the anti-sliding performance of the pavement is enhanced, the running safety is improved greatly and the improved construction method has wide application prospect.

Owner:XIDI (SUZHOU) SURVEY & DESIGN CONSULTING CO LTD

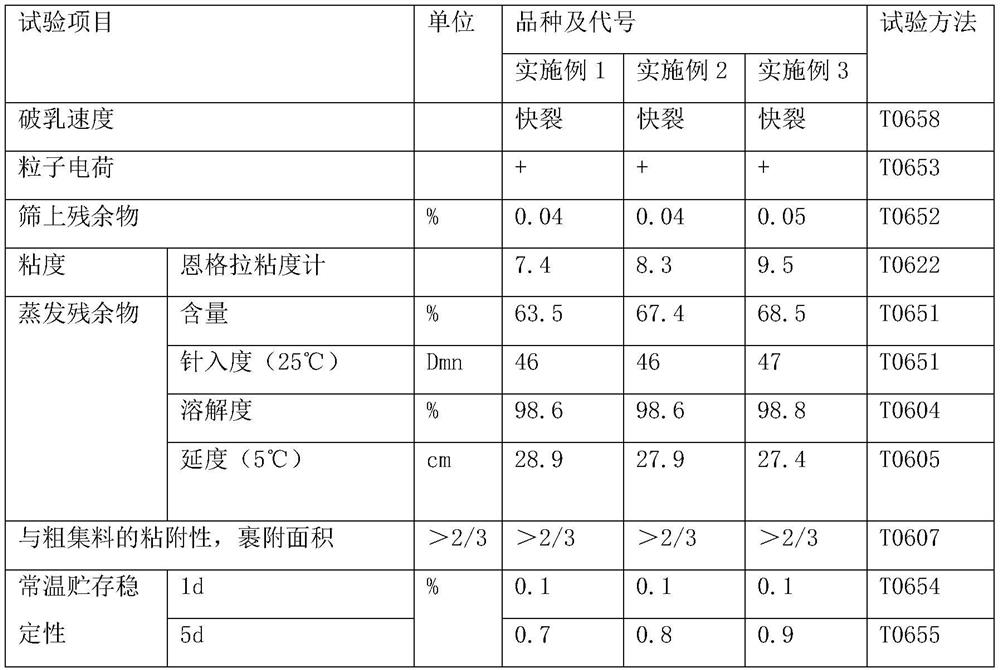

A kind of SBS high-viscosity modified emulsified asphalt material and its preparation process

ActiveCN111286209BEasy constructionHigh softening pointBuilding insulationsPolymer scienceBitumen emulsion

The invention discloses a method for emulsifying SBS high-viscosity modified asphalt; the preparation process is suitable for industrial production, and has high viscosity under the premise of simple process, and the SBS high-viscosity modified emulsification obtained in the invention Asphalt is suitable for ultra-thin asphalt wear layer on high-grade roads and special adhesive layer for new roads. It has the characteristics of easy construction, high softening point, good adhesion, easy storage, and the prepared asphalt wear layer has strong anti-loosening ability.

Owner:SOUTHEAST UNIV

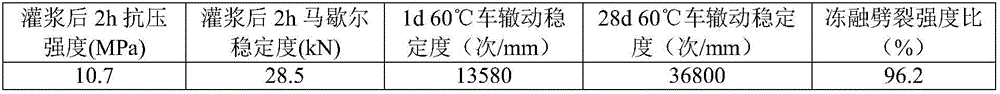

A semi-flexible pavement material for rapid opening of traffic and its method for paving

The invention discloses a half-flexible pavement material for rapid traffic opening and a method of the half-flexible pavement material for paving a pavement. The half-flexible pavement material comprises a porous mixed material and a cement-based grouting material filled into pores of the porous mixed material, wherein the porosity of the porous mixed material is 16-23%; the porous mixed material consists of the following components in percentage by mass: 3.5-7% of aqueous epoxy resin, 0.5-2.5% of flexible latex, 87-92% of aggregate and 3.5-5% of mineral powder; the cement-based grouting material consists of the following components in percentage by mass: 35-50% of rapidly hardened sulfate aluminum cement, 25-45% of grinded slag powder, 0.15-0.35% of a water reducing agent, 1-2.5% of a shrinkage reducing agent and 18-25% of water. By adopting the half-flexible pavement material for rapid traffic opening, normal temperature construction can be achieved in the whole process, only 2-4 hours are taken when the aqueous epoxy resin porous mixed material is mixed until the traffic of a half-flexible pavement is opened, and the half-flexible pavement material is excellent in track resistance, relatively long in service life, low in repairing expense, very wide in application prospect and high in use value.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

A municipal road rut maintenance pavement method

The invention provides a method for rut maintaining and paving of a municipal road. The method comprises the following steps: (1) milling an asphalt surface layer; (2) spreading a modified emulsified asphalt bonding layer; (3) paving an emulsified asphalt cold-recycling mixture lower surface layer; (4) paving a high-elasticity rubber asphalt stress absorption layer; and (5) paving a cement-asphalt pouring type composite pavement surface layer. The combined paving layer obtained through the method has an excellent anti-rutting property and can sufficiently utilize a milled waste asphalt mixture; the integral structure has the characteristics of high rutting resistance, skid resistance, abrasion resistance, long life and low carbon.

Owner:XIDI (SUZHOU) SURVEY & DESIGN CONSULTING CO LTD +1

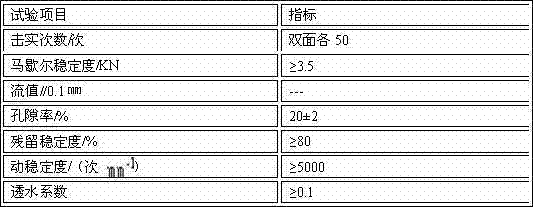

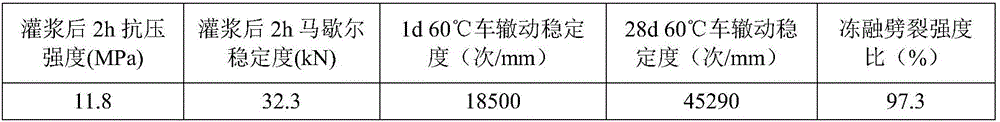

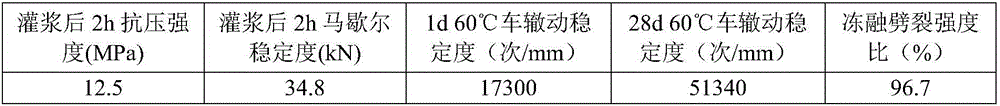

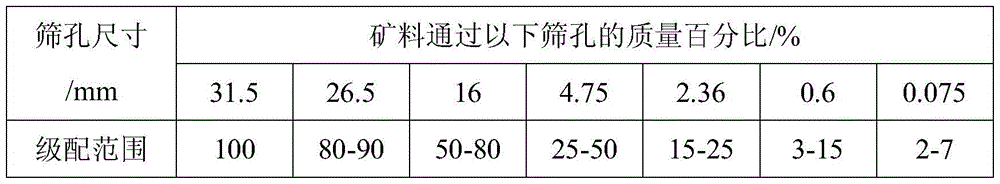

A kind of reinforcing material for pavement base course and preparation method thereof

ActiveCN109437677BGuaranteed performanceGood anti-rutting performanceRoad surfaceUltimate tensile strength

The invention relates to a reinforcing material used for pavement bases and a preparation method thereof. The corresponding mixture of the reinforcing material includes 3.5-4.5 parts by mass of low-grade asphalt, 1.0-2.0 parts by mass of cement, and 95.0-98.0 parts by mass of ore material, 1.0-3.0 parts of quality mineral powder; among them: the penetration of low-grade asphalt is 20-60mm, the softening point is 49-100°C, the dynamic viscosity at 60°C is 200-400pas, and the ductility at 15°C is 100-200cm. There are corresponding requirements for grading, and there are relevant requirements for the dynamic stability, residual stability, and freeze-thaw splitting strength ratio of the reinforcing material specimen; the preparation method has specific heating and heat preservation requirements for the component materials and intermediate materials. temperature setting. Therefore, through the setting of material-related performance indicators, combined with the synthetic gradation of mineral materials and the control of temperature during the preparation process, the reinforcing material not only has good anti-rutting performance, but also has a relatively low price. At the same time, through relevant performance tests on the test pieces, it is ensured that the products meet the performance requirements of the design.

Owner:贵州省都匀公路管理局 +1

An anti-rutting agent for cold mixing and paving of asphalt roads

ActiveCN104496258BIncrease the interface fracture energyGuaranteed smoothnessFiberInterfacial binding

Owner:南通福伦利新材料有限公司

A kind of steel bridge epoxy asphalt mixture and its preparation and use method

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +2

Anti-freezing asphalt pavement material and preparation method thereof

ActiveCN112521762ASimple manufacturing methodEasy to operate and controlIn situ pavingsPaving detailsEpoxyFiber

The invention discloses an anti-freezing asphalt pavement material which is characterized by being prepared from the following raw materials in parts by weight: 60-80 parts of asphalt, 10-20 parts ofvinyl-terminated fluorosilicone oil, 3-6 parts of 2-naphthylamine-3, 6, 8-trisulfonic acid, 2-3 parts of epoxy modified bis (2-hydroxyethyl) amino (trimethylol) methane, 5-10 parts of carboxylated butyl rubber, 4-8 parts of amino-terminated hyperbranched polybenzimidazole, 3-5 parts of pig hair fibers, 0.5-1.5 parts of graphene nanosheets and 2-4 parts of phosphorus pentoxide. The invention also provides a preparation method of the anti-freezing asphalt pavement material. The anti-freezing asphalt pavement material provided by the invention is better in comprehensive performance and performance stability, better in anti-freezing effect, excellent in anti-rutting performance, not easy to deform, long in service life and capable of effectively improving the transportation efficiency and traffic safety of roads.

Owner:安徽力聚投资集团有限公司

A kind of epoxy asphalt compatibilizer and its preparation method and use method

ActiveCN104031395BImprove performanceImprove low temperature resistanceOrganic chemistryBuilding insulationsEpoxyAlcohol

The invention provides an epoxy asphalt compatibilizer preparation method and a usage method. The preparation method comprises the following steps: unsaturated aliphatic carboxylic acid and polyatomic alcohol are subjected to an esterification reaction, and then the product is subjected to hydrogen peroxide epoxidation to obtain the epoxy asphalt compatibilizer. An epoxy asphalt material comprises a part A and a part B, the part A comprises the following components by weight: 100 parts of asphalt, 5-50 parts of asphalt diluents, 10-50 parts of epoxy asphalt compatibilizer and 5-50 parts of epoxy asphalt curing agent; the part B comprises the following components by weight: 40-100 parts of epoxy resin and 5-50 parts of epoxy diluents; wherein the weight ratio of part A to part B is 0.5-5: 1. According to the invention, a nonpolar carbon chain in an epoxy asphalt compatibilizer molecular chain is effectively compatible with asphalt, an epoxide group is effectively compatible with epoxy resin, and is subjected to a crosslinking reaction with an epoxy asphalt curing agent, so that mechanical strength and stability of the epoxy asphalt material can be increased.

Owner:HUBEI UNIV +1

A kind of cold mix type epoxy asphalt repair material and preparation method thereof

InactiveCN104031394BGood construction fluidityImprove performanceIn situ pavingsBuilding insulationsEpoxyRepair material

Owner:HUBEI UNIV

A kind of cold mix epoxy asphalt material and preparation method thereof

ActiveCN104031396BImprove performanceImprove low temperature resistanceBuilding insulationsPolymer scienceFirming agent

The invention provides a cold mixing epoxy asphalt material and a preparation method. The cold mixing epoxy asphalt material comprises a part A and a part B; the part A comprises the following components by weight: 100 parts of asphalt, 5-50 parts of epoxy asphalt diluents, 10-50 parts of epoxy asphalt compatibilizer and 5-50 parts of epoxy asphalt curing agent; the part B comprises the following components by weight: 40-100 parts of epoxy resin and 5-50 parts of epoxy resin diluents, wherein the weight ratio of the part A to part B is 0.5-5: 1. In the invention, the asphalt diluent and the epoxy diluent provide better construction fluidity to the epoxy asphalt material under room temperature, and easily penetrate into the pavement cracks for repairing; and can be stirred under normal temperature for usage without heating and insulation transportation.

Owner:HUBEI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com