Rubber powder compound modified hyperviscous asphalt for noise-reducing and water draining pavement

A compound modification and asphalt-sticking technology, which is applied in building components, building insulation materials, construction, etc., can solve the problems of less than 50% of waste tires being harmlessly utilized, poor impact and scattering performance of the road surface, and viscous toughness of asphalt binders. Insufficient and other problems, achieve significant engineering application value, improve water damage resistance, elongation at break and high splitting tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

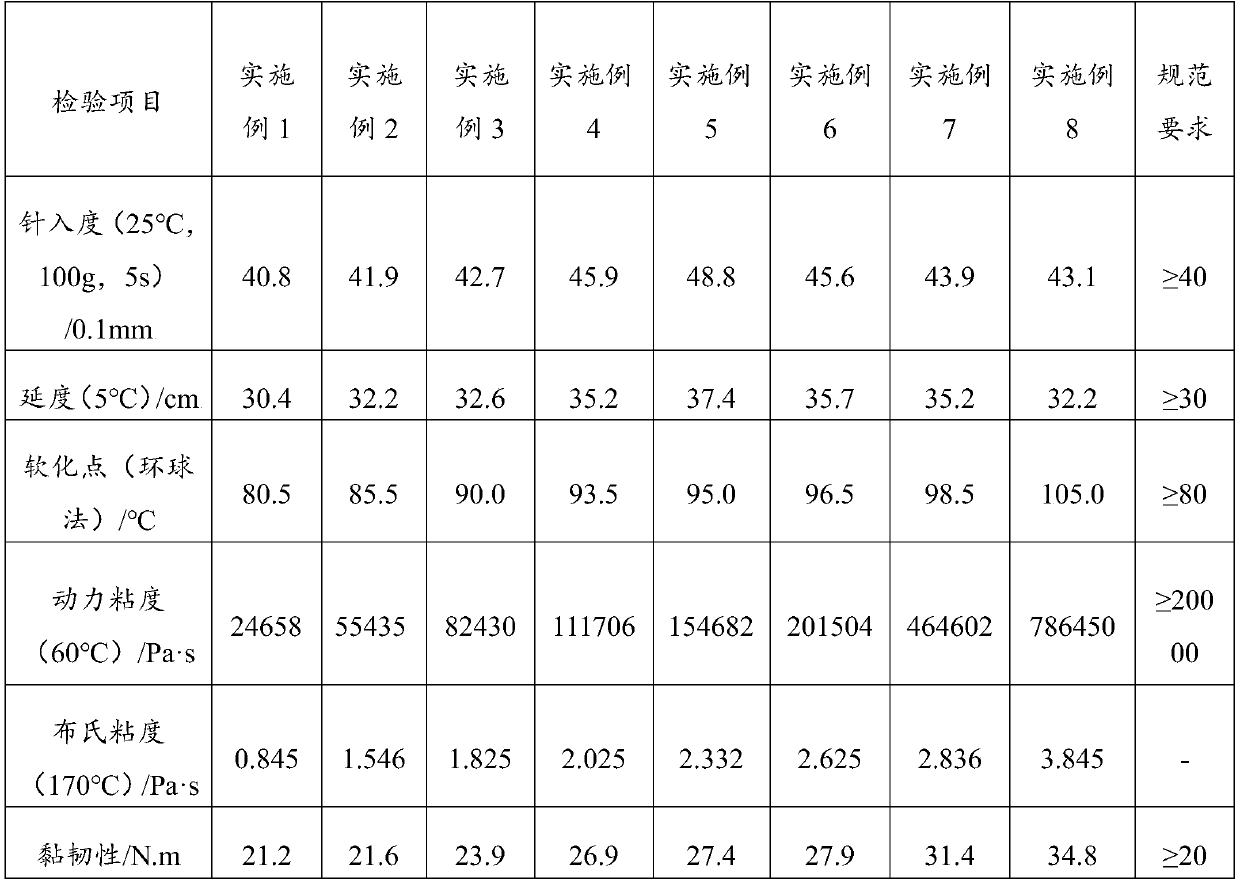

Embodiment 1

[0030] The rubber powder composite modified high-viscosity asphalt for noise reduction and drainage pavement of the present invention is composed of the following raw materials: 100 kg of road petroleum asphalt, 5 kg of activated rubber powder, 2 kg of SBS, 0.1 kg of sulfur, and 0.5 kg of trans polyoctene rubber;

[0031] Preheat the petroleum road asphalt to 170°C and maintain this temperature, add trans polyoctene rubber, stir and shear at a speed of 4000rpm for 60min, then add SBS and activated rubber powder with a particle size of 80 mesh, continue stirring and shearing for 30min, Then add sulfur and stir and shear at a speed of 500rpm for 30 minutes, and then develop the material at 170°C for 150 minutes to obtain rubber powder composite modified high-viscosity asphalt for noise reduction and drainage pavement.

Embodiment 2

[0033] The rubber powder composite modified high-viscosity asphalt for noise reduction and drainage pavement of the present invention is composed of the following raw materials: 100 kg of road petroleum asphalt, 9 kg of activated rubber powder, 4 kg of SEBS, 0.2 kg of sulfur, and 0.7 kg of trans polyoctene rubber;

[0034] Preheat the petroleum road asphalt to 176°C and maintain this temperature, add trans-polyoctene rubber, stir and shear at a speed of 4200rpm for 52min, then add SEBS and activated rubber powder with a particle size of 100 mesh, continue to stir and shear for 26min, Add sulfur and stir and shear at a speed of 600rpm for 24 minutes, and then develop the material at 180°C for 132 minutes to obtain rubber powder composite modified high-viscosity asphalt for noise reduction and drainage pavement.

Embodiment 3

[0036] The rubber powder composite modified high-viscosity asphalt for noise reduction and drainage pavement of the present invention is composed of the following raw materials: 100 kg of road petroleum asphalt, 10 kg of activated rubber powder, 5 kg of SEPS, 0.25 kg of sulfur, and 0.8 kg of trans polyoctene rubber;

[0037]Preheat the petroleum road asphalt to 178°C and maintain this temperature, add trans polyoctene rubber, stir and shear at a speed of 4300rpm for 48min, then add SEPS and activated rubber powder with a particle size of 110 mesh, continue to stir and shear for 24min, Add sulfur and stir and shear at a speed of 650rpm for 21 minutes, and then develop the material at 180°C for 125 minutes to obtain rubber powder composite modified high-viscosity asphalt for noise reduction and drainage pavement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com