A kind of cold mix epoxy asphalt material and preparation method thereof

A technology of epoxy asphalt materials and cold-mixed epoxy asphalt, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of harmful asphalt smoke, physical and environmental impact, and difficult transportation, and achieve excellent anti-corrosion Effects of rutting performance, improved compatibility, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

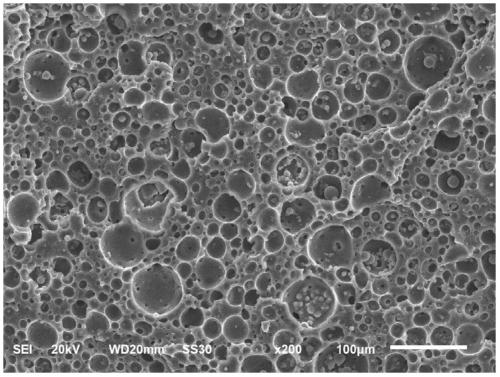

Image

Examples

preparation example Construction

[0046] The present invention provides a kind of preparation method of a kind of cold mix epoxy asphalt material described in above-mentioned technical scheme, comprises the following steps:

[0047] a) Add asphalt, asphalt diluent, epoxy asphalt compatibilizer, and epoxy asphalt curing agent into a common reaction kettle and mix to obtain part A of epoxy asphalt material;

[0048] b) Add epoxy resin and epoxy diluent together into an ordinary reaction kettle and stir and mix to obtain part B of epoxy asphalt material;

[0049] c) Mix part A of the epoxy asphalt material obtained in step a) with part B of the epoxy asphalt material obtained in step b) to obtain an epoxy asphalt material, the weight ratio of the part A to the part B For (0.5~5): 1;

[0050] The step a) and the step b) are in no sequence.

[0051] According to the present invention, the parts A and B are the same as those described above, and will not be repeated here.

[0052] In the present invention, some s...

Embodiment 1

[0064] Accurately weigh 30g of asphalt (Shell asphalt No. 70, the same below), 10g of epoxy asphalt thinner styrene (purchased from Tianjin Bodi Chemical Co., Ltd., the same below), 17g of epoxy asphalt compatibilizer epoxy hard Octyl acetate (purchased from Wuhan Jinnuo Chemical Co., Ltd., the same below), 10g of epoxy curing agent polyamide 650 (purchased from Shanghai Resin Factory Co., Ltd., the same below), were added to a common reaction kettle at 80°C and stirred for 60 minutes, Obtain part A of the epoxy asphalt material; weigh 8g of epoxy resin diluent 632 (purchased from Yantai Yusheng Chemical Co., Ltd.), 20g of epoxy resin (brand E-51, purchased from Sinopec Baling Petrochemical Co., Ltd. Company, the same below), added to the reaction kettle at 80°C and stirred for 45 minutes to obtain part B of the epoxy asphalt material; After 20 minutes, after mixing evenly, cool the obtained mixed material to room temperature to obtain the epoxy asphalt material.

[0065] The p...

Embodiment 2

[0068] Accurately weigh 30g of asphalt, 12g of asphalt diluent styrene, 15g of epoxy asphalt compatibilizer epoxy octyl stearate, 12g of epoxy curing agent polyamide 650, and add them to an ordinary reaction kettle at 80°C and stir for 60min to obtain ring Part A of the epoxy asphalt material; Weigh 8g of epoxy resin diluent 632 and 20g of epoxy resin, add it to a reaction kettle at 80°C and stir for 45min to obtain part B of the epoxy asphalt material; then mix the A part of the epoxy asphalt material Part B and part B of the epoxy asphalt material were added to a normal temperature reactor and stirred for 20 minutes, and after mixing evenly, the resulting mixture was cooled to room temperature to obtain the epoxy asphalt material.

[0069] The performance of the epoxy asphalt material obtained in Example 2 was tested, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com