Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1076 results about "Bitumen emulsion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

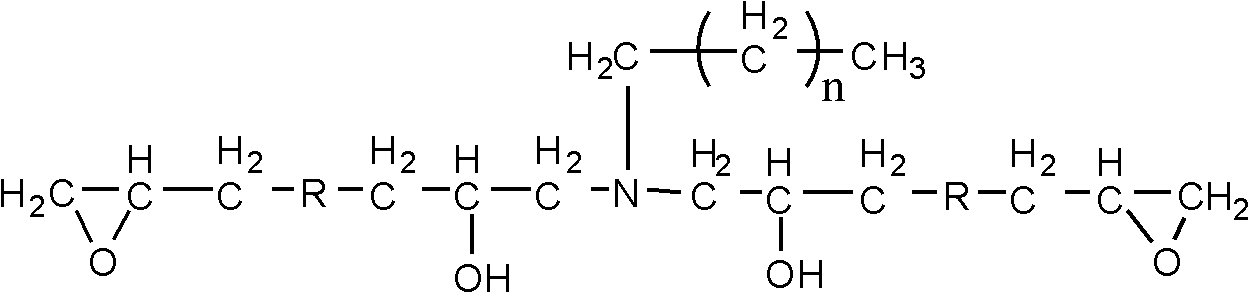

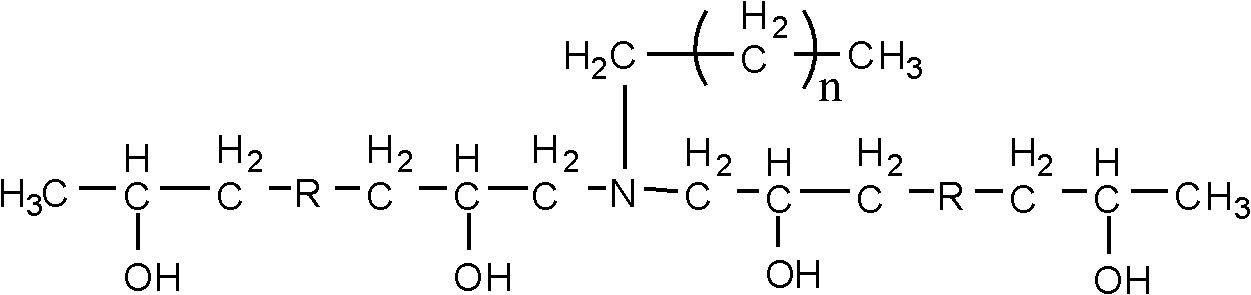

Method for producing bitumen compositions

ActiveUS20080060551A1Low viscosityHighly preventive effectBuilding insulationsBitumen emulsionRoad surface

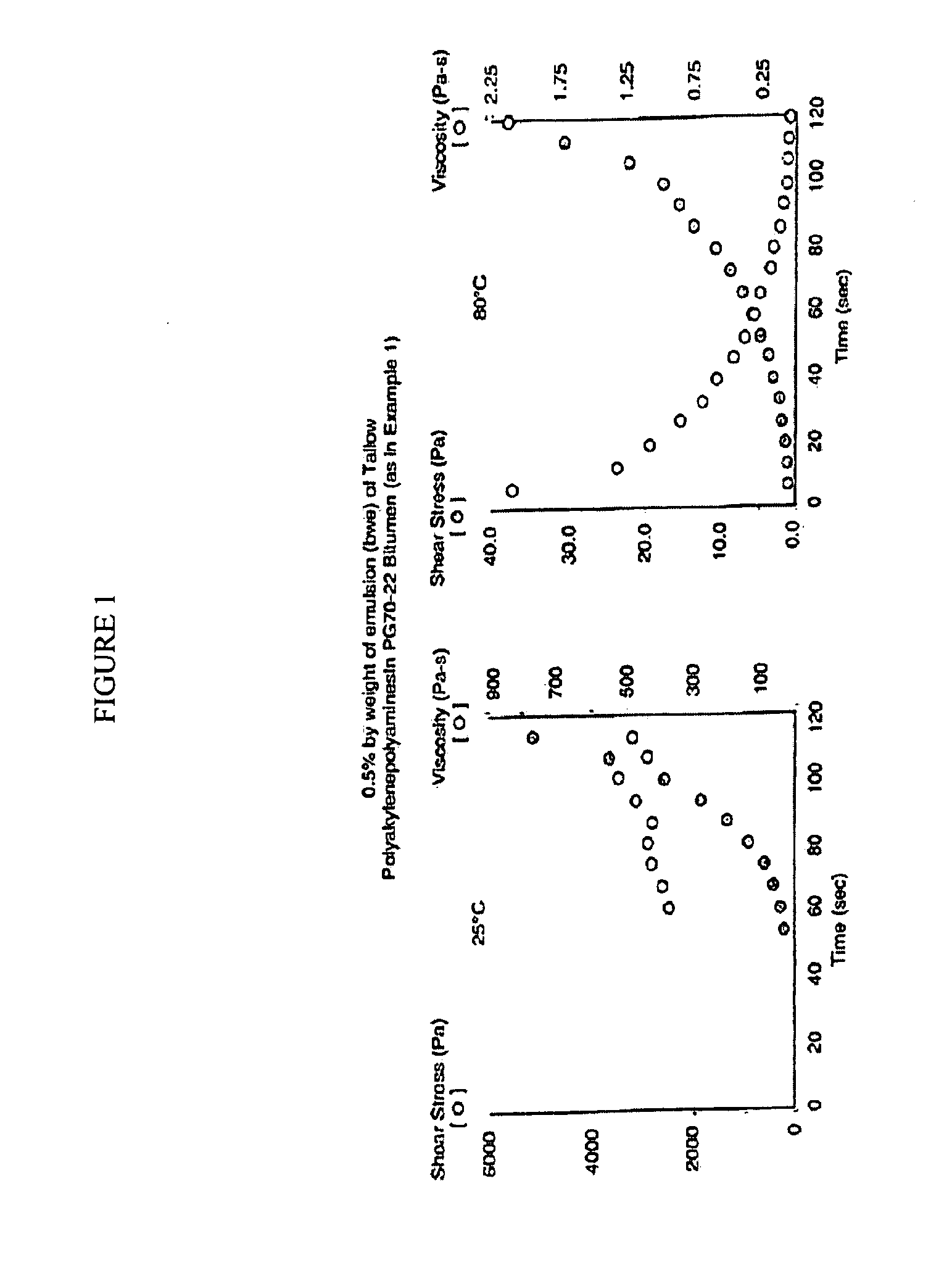

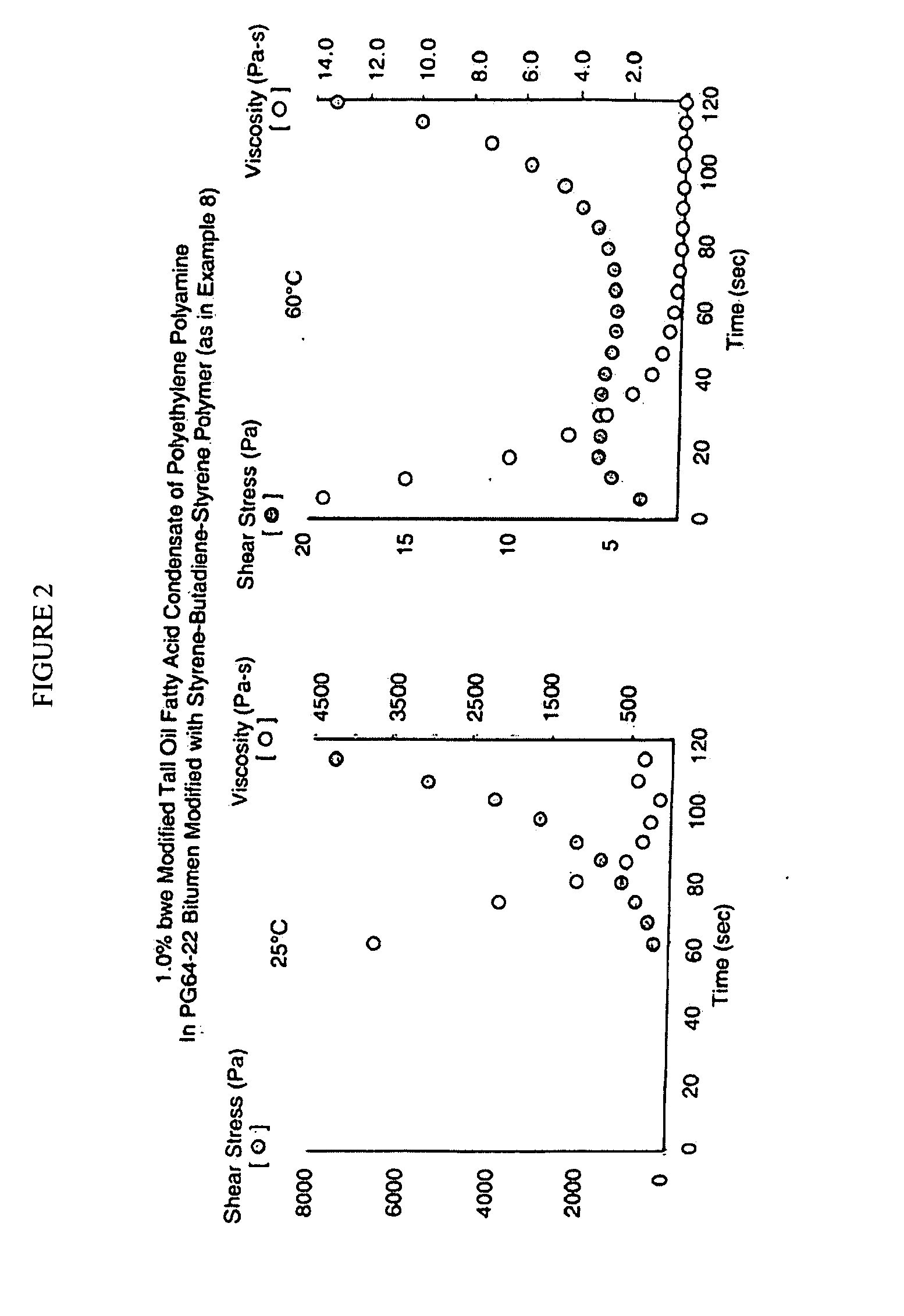

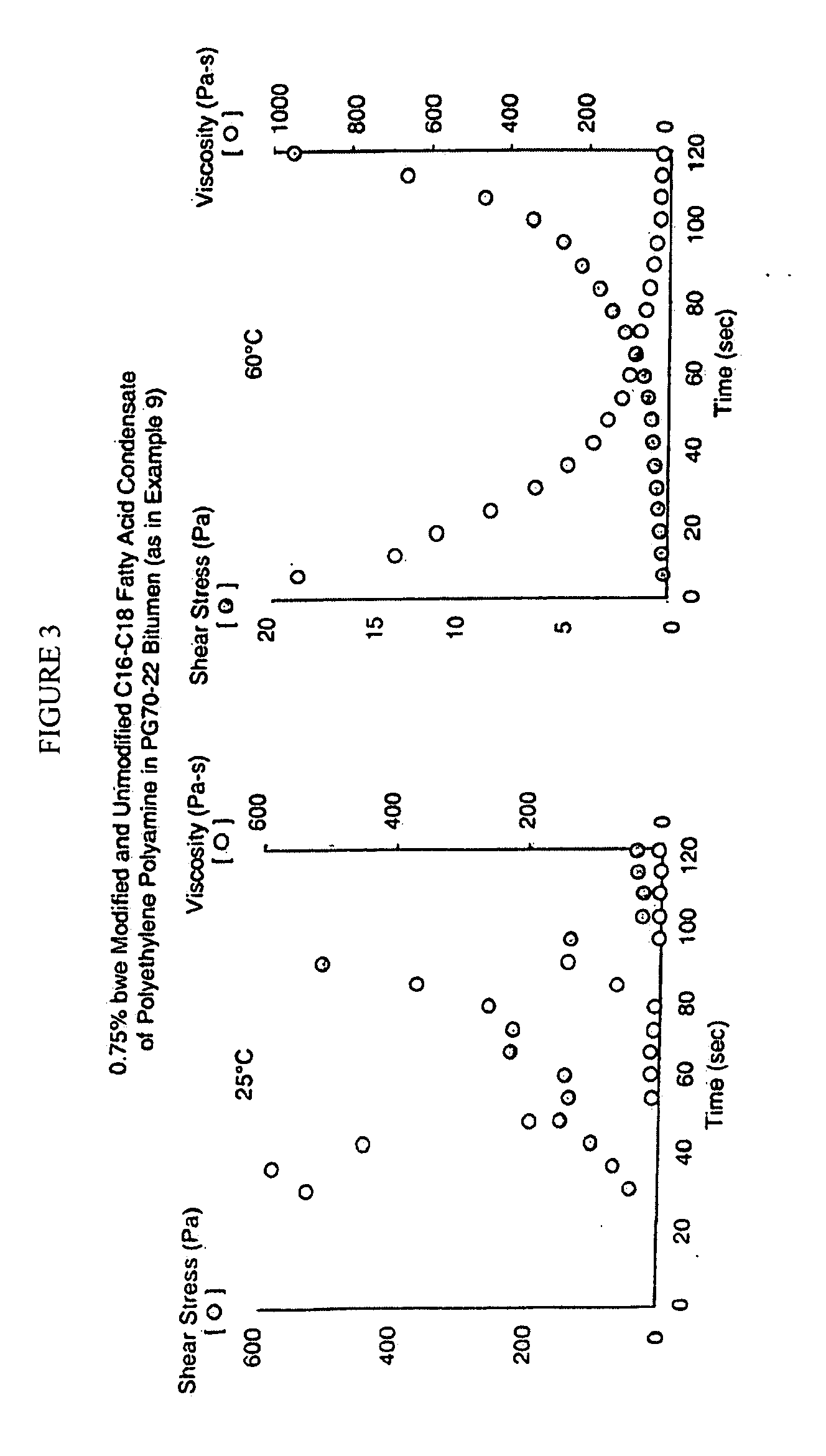

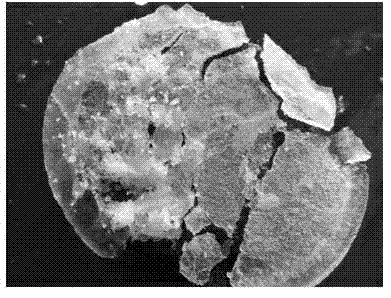

The present invention relates to bituminous compositions suitable for use in paving applications containing bitumen emulsion of performance-grade bitumen that is substantially free of volatile solvents and made by controlling temperature-dependent interfacial rheology through the use of selected emulsifiers. The invention bituminous paving compositions are suitable for the construction of load-bearing pavements with improved compaction to densities similar or superior to those achieved in the conventional hot mix bituminous paving compositions. Cure rate of the invention bituminous compositions is higher than those of cold mix bitumen emulsion-based paving compositions, and at least equal to those of hot mix bituminous paving compositions. Additionally, the invention bituminous compositions develop adhesive strength and load-bearing strength properties at rates comparable to those of hot mix bituminous paving compositions, and at rates faster than those of cold mix bituminous paving compositions.

Owner:INGEVITY SOUTH CAROLINA

Environment-friendly road surface ice and snow melt coating material, preparation method thereof and using method thereof

ActiveCN102199398AEnsure Snowmelt RequirementsPrevent loose grainsIn situ pavingsOther chemical processesSnow removalSnowpack

The invention relates to an environment-friendly road surface ice and snow melt coating material, a preparation method thereof and a using method thereof. Serious consequences such as traffic jam and the like can be caused by snow accumulation in winter; and at present, a snow removal method comprises passive snow removal and active snow removal, wherein in the passive snow removal, the operating efficiency of manual snow removal is low, mechanical snow removal is incomplete relatively in clearing, and for the spreading of a snow melt agent, substances with the snow melt effect are mixed simply only, so the spreading is non-uniform, and the snow melt agent dispersed to peripheral air has the major influence on environment; and the active snow removal is high in cost, and has a certain damage to structures of road surfaces, so the service life of roads is shortened. In the environment-friendly road surface ice and snow melt coating material, after being loaded on a carrier material, the snow melt substances are mixed with emulsified asphalt, water-soluble epoxy resin and a curing agent and sprayed on the road surfaces to form an ice and snow melt coating, so that the roads have the function of melting snow actively. By the environment-friendly road surface ice and snow melt coating material, an ice point of water is reduced to between -5 and -20 DEG C so as to clear the ice and snow of the roads, and the coating material has the sustained-release function, is high in coating adhesivity and wear-resisting effect, low in cost and convenient to maintain, and can prolong the life of the road surfaces effectively.

Owner:CCCC CIVIL ENG SCI & TECH

Half-flexible water drainage skid-free noise-reducing road surface pavement structure

The invention relates to a road paving structure, which is a semi-flexible, draining, antiskid and noise-reducing paving structure and comprises a semi-rigid foundation layer. The invention is characterized in that the semi-rigid foundation layer is paved with a modified emulsified asphalt slurry sealing layer, the sealing layer is filled with a semi-flexible road surface material structure layer on the surface, the semi-flexible road surface material structure layer is distributed with a high-viscosity modified asphalt adhesive layer, and the adhesive layer is paved with a draining, antiskid and noise-reducing abrasion layer. The road paving structure has stable property under high temperature, is provided with draining, noise-reducing and antiskid functions, and can effectively prevent water damages and has long service life.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Rubber powder-asphalt emulsion for concrete asphalt mortar and method for producing the same

ActiveCN101173106AImprove stabilityLow market priceBuilding insulationsPolymer scienceBitumen emulsion

The invention relates to a rubber powder-asphalt emulsion for cement asphalt mortar and a preparation method thereof. The rubber powder-asphalt emulsion is prepared from the following components in parts by mass: emulsifier: 0.1-3%, asphalt: 20-60%, rubber powder: 5-40%, stabilizer: 0.1-0.5%, thickener: 0.1-0.3%, auxiliary agent for adjusting pH value: 0-0.2%, and the balance is water. The preparation method includes first modifying asphalt with rubber powder, and then emulsifying; first emulsifying asphalt, then emulsifying rubber powder; first emulsifying rubber powder, and then emulsifying asphalt. The invention makes full use of solid waste—rubber powder, has the characteristics of environmental protection and energy saving, not only significantly improves the stability of CA mortar, but also reduces the cost of preparing CA mortar.

Owner:JIANGSU SOBUTE NEW MATERIALS

Mortar and concrete modified by emulsified asphalt

The invention relates to a mortar and concrete modified by emulsified asphalt and is mainly applied in the fields of building insulation and waterproofing. The invention is characterized in that the mortar and the concrete are mainly produced by mixing inorganic cementing material, emulsified asphalt, aggregate, water and other additives. The invention uses emulsified asphalt instead of polymer emulsion or rubber powder for producing the modified cement mortar and concrete, which improves the various properties of the mortar and the concrete and has an obvious effect in the fields of building exterior wall insulation and waterproofing. Compared with the concrete without adding asphalt emulsion and film-forming polymers, the water absorption of the produced waterproof concrete is reduced by more than 20%, and the anti-chloride permeability is improved by more than 30%, and the anti-carbonation performance is improved by more than 15%. In the construction energy-saving field of external wall insulation, the polyphenyl granule insulation mortar produced with emulsified asphalt, bonding mortar and surface mortar of polystyrene board insulation system can significantly save the material cost under the premise of guaranteeing the performances.

Owner:TSINGHUA UNIV +1

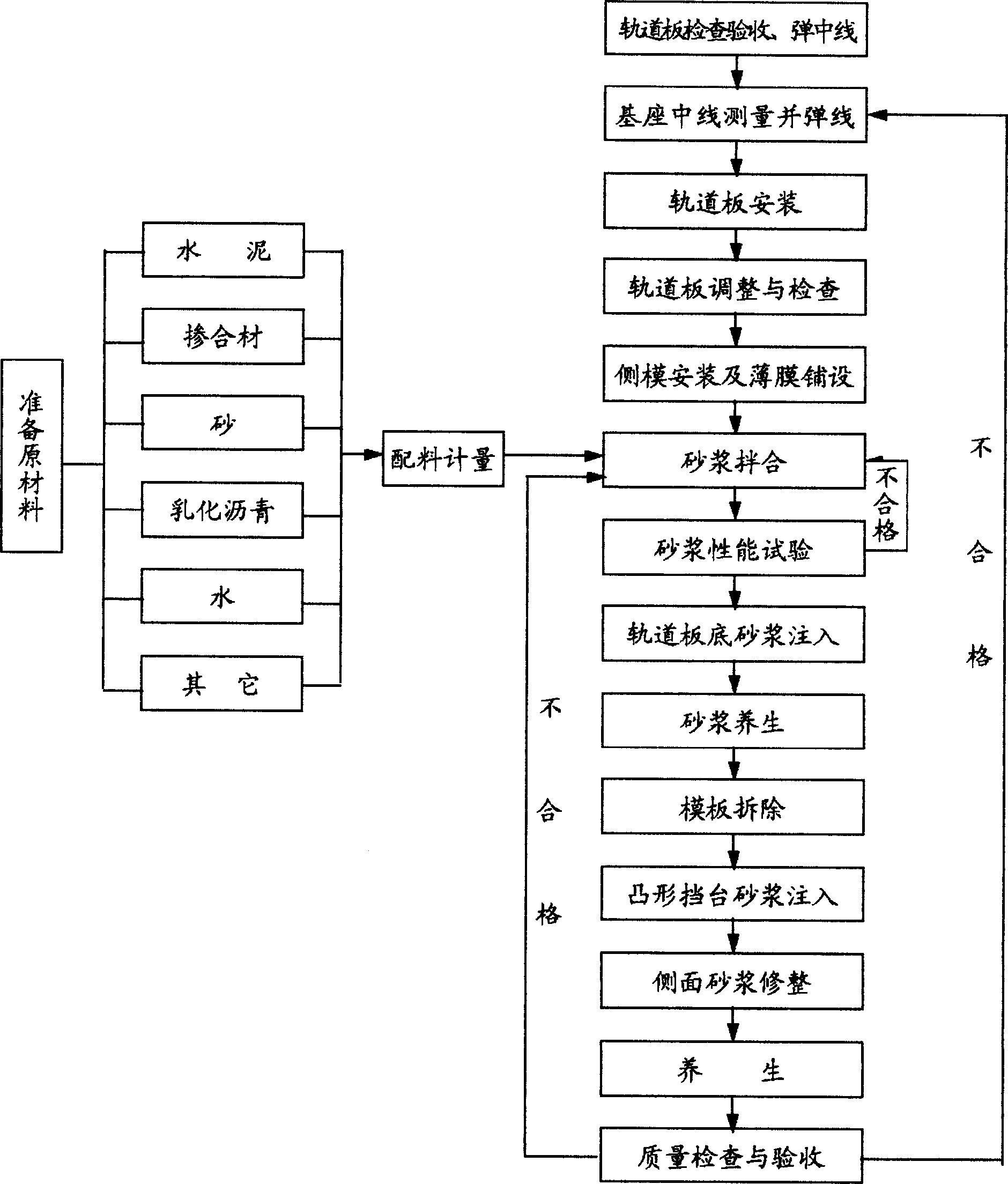

Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

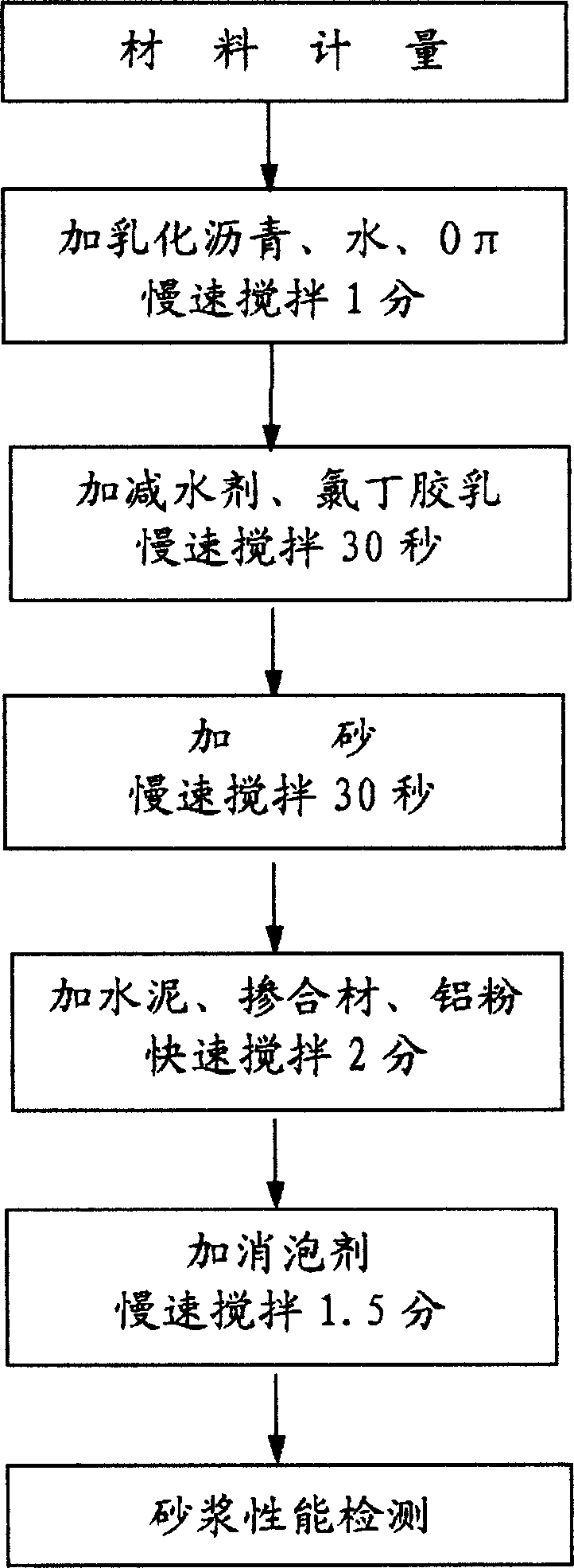

A cement-emulsified asphalt mortar used for railway and overhead railway in urban area contains cement and its additive, emulsified asphalt, sand, water, water-reducing agent, aluminium powder, surfactant, defoaming agent, polyacrylic fibres and chlorobutadiene latex. Its preparing process is also disclosed. Its advantages are high flowability, high strength and freeze-thawing resistance, and no environmental pollution.

Owner:CHINA RAILWAY 11TH BUREAU GRP

Spraying quick-setting rubber asphalt waterproof coating material

ActiveCN103627258AWith anti-adhesive effectImprove adhesionConjugated diene hydrocarbon coatingsNatural rubber coatingsComposite constructionWater based

The invention relates to a spraying quick-setting rubber asphalt waterproof coating material. A special technology is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material. The spraying quick-setting rubber asphalt waterproof coating material is a water-based spraying paint prepared according to a ratio, and a preparation method of the spraying quick-setting rubber asphalt waterproof coating material comprises following steps: a liquid rubber asphalt latex emulsion is prepared by mixing superfine, suspended and micro-emulsion modified emulsified asphalt with high-molecular polymer rubber latex; and the liquid rubber asphalt latex emulsion is mixed with a coagulant. Cold spraying construction is adopted for preparation of the spraying quick-setting rubber asphalt waterproof coating material; elastic coating film elongation is more than 1000%; restoration ratio is more than 95%. The spraying quick-setting rubber asphalt waterproof coating material possesses ultraviolet resistance, high construction efficiency, high bonding strength, excellent high-temperature resistance, excellent low temperature flexibility, and better quick setting effect; and is capable of forming films in 3 seconds. The spraying quick-setting rubber asphalt waterproof coating material is water based; is friendly to the environment; possesses no toxicity, and excellent endurance; is quick and convenient for construction; and is a novel environmental friendly waterproof paint with a wide application range. The spraying quick-setting rubber asphalt waterproof coating material is mainly used for various waterproof and anticorrosion projects. The spraying quick-setting rubber asphalt waterproof coating material is used for individual construction of waterproof projects, for composite construction of waterproof projects together with waterproof roll, and for individual construction of anticorrosion projects.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

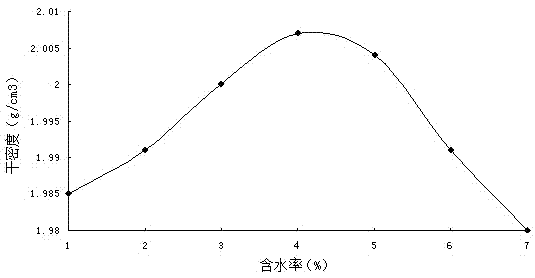

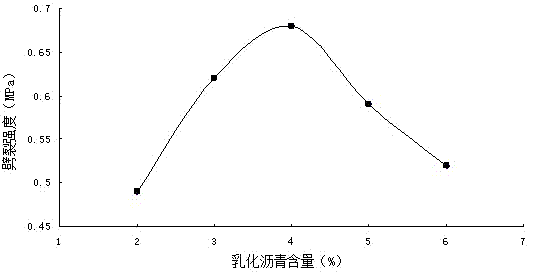

Preparation method of emulsified asphalt cold recycling asphalt mixture

InactiveCN102765902AGood dosageBest moisture contentSolid waste managementRoad engineeringBitumen emulsion

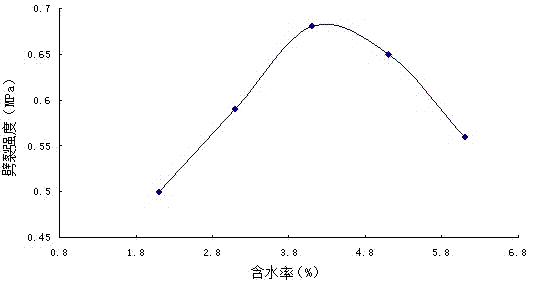

The invention provides a preparation method of an emulsified asphalt cold recycling asphalt mixture. The preparation method relates to the field of road engineering and includes the following steps: obtaining milling samples of old asphalt pavement, determining grading of filler, determining weight percentage of rough milling materials, fine milling materials, cement and mineral powder in raw materials, determining optimum moisture content a, determining optimum dosage of emulsified asphalt, determining optimum moisture content b, conducting checking and stirring the emulsified asphalt cold recycling asphalt mixture. The preparation method is rigor. Determination of optimum usage and optimum moisture content of emulsified asphalt gives consideration to the lubrication effect of water and asphalt in the molding process. The optimum moisture content and the optimum dosage of the emulsified asphalt are determined through checking. The preparation method adopts the processes of rotating, compacting, once molding and nourishment, accords with reality, and is reasonable and capable of meeting requirements for actual engineering.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD +2

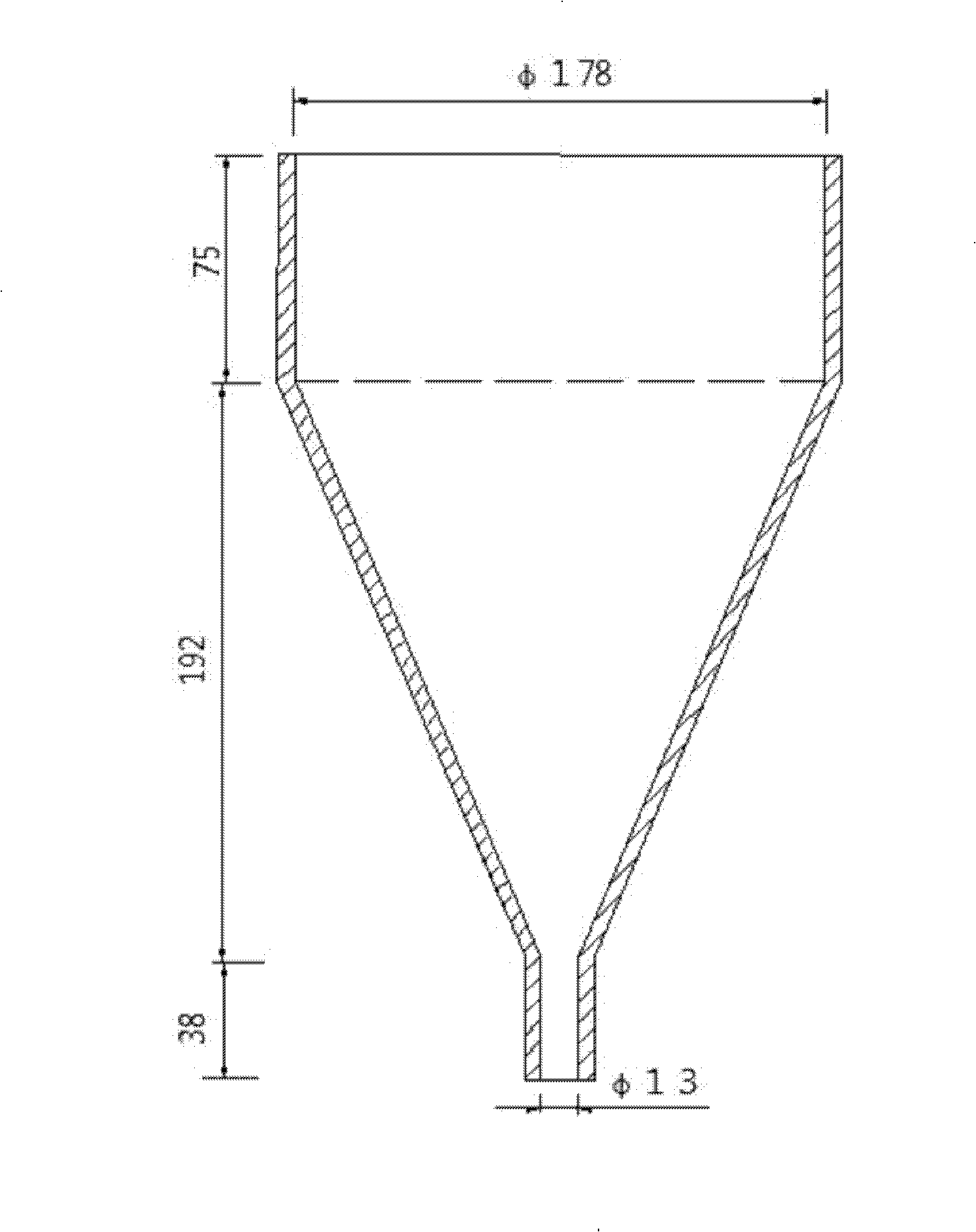

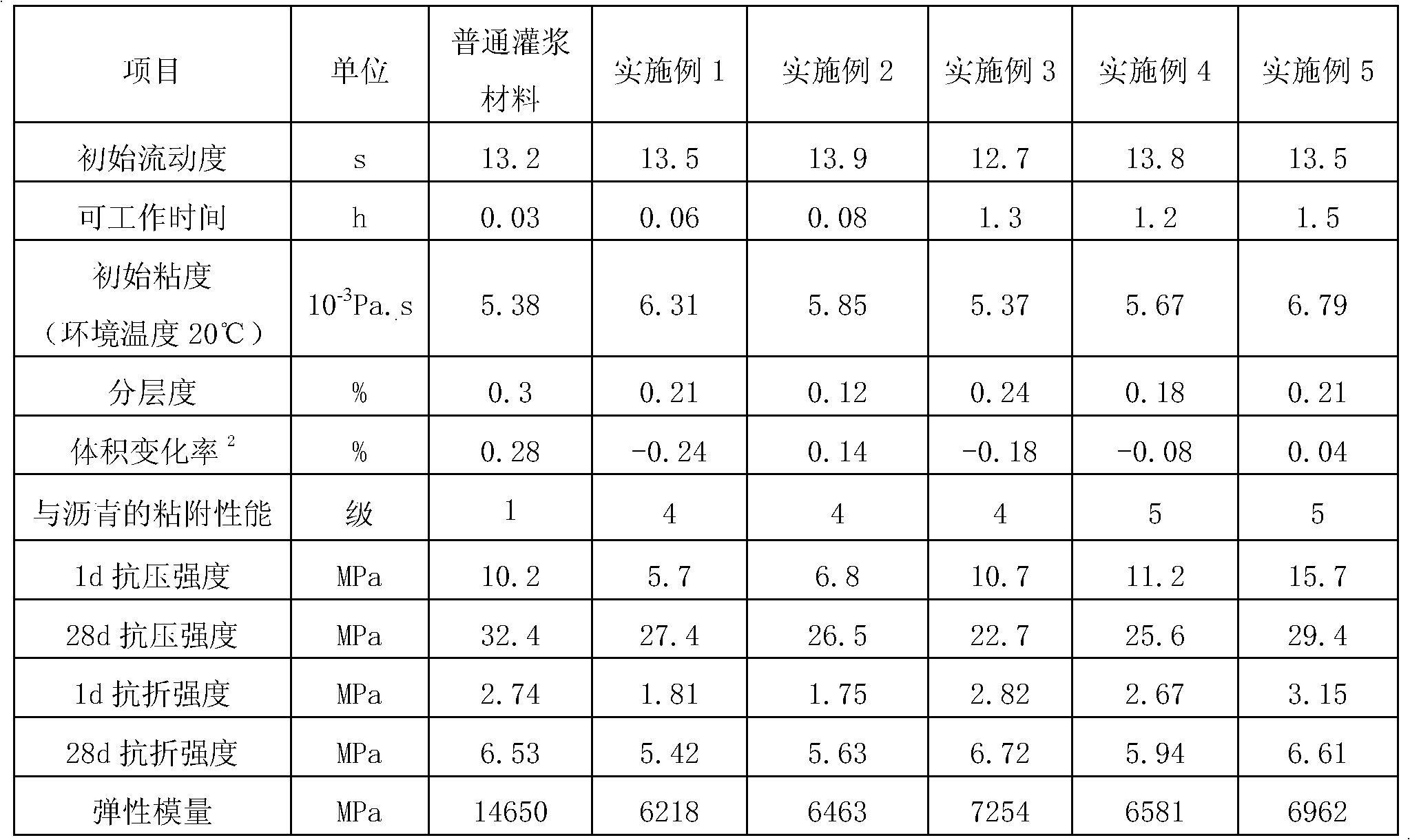

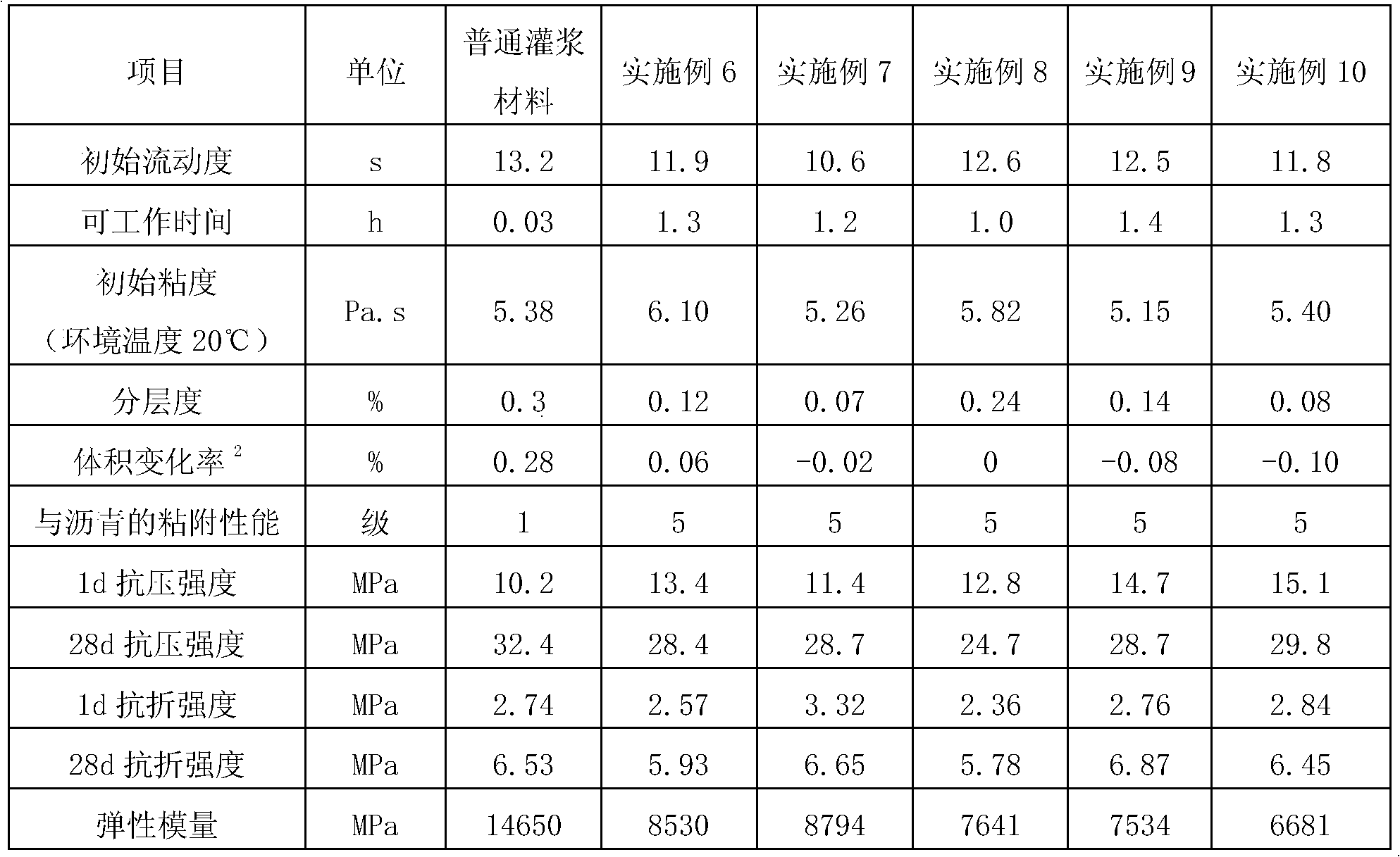

A cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement

The invention discloses a cement-emulsified asphalt self-permeable grouting material applied to semi-flexible pavement, which comprises 100 parts of cement, 50-150 parts of mineral admixture, 15-40 parts of expansion agent, 0-80 parts of river sand, 0.5-20 parts of water agent, 60-140 parts of water, and 50-150 parts of emulsified asphalt, all of which are parts by weight. The grouting material of the present invention is low in cost, good in fluidity, long in working time, and satisfies the grouting characteristics of self-permeation of slurry; has good interfacial bonding performance with asphalt, and has a certain early strength function; the volume change rate is small, and the degree of delamination is less than 0.3%, with good volume stability; both cationic emulsified asphalt and anionic emulsified asphalt can be used, with a wide range of applications; applying this grouting material to semi-flexible pavement can greatly improve the fatigue life of flexible pavement The shear performance is effectively improved.

Owner:JIANGSU SUBOTE MATERIAL +4

Long-acting environment-friendly ice-snow melting pavement coating and preparation method and using method of thereof

InactiveCN104629580AGood sustained release effectExtended snowmelt timeIn situ pavingsPaving detailsSnow meltingFirming agent

The invention relates to a long-acting environment-friendly ice-snow melting pavement coating and a preparation method and a using method of thereof. A snow-melting coating formed by spraying modified emulsified asphalt mixed with a porous carrier material absorbing a snow-melting substance onto a road surface can be taken away by rainwater so as to lose a snow-melting effect. The preparation method comprises the following steps: wrapping a snow-melting substance uniformly with a coating material so as to form a layer of continuous coating material thin film on the surface of the snow-melting substance, adding epoxy resin, an active diluent, a non-active diluent, a silane coupling agent, black paste, an accelerant and quartz sand, performing stirring uniformly, and then adding an epoxy resin curing agent to obtain a long-acting environment-friendly ice-snow melting pavement coating material. According to the preparation method, the snow-melting substance is wrapped with a high-molecular thin-film material so that the snow-melting substance has a better slow-release effect, the snow-melting life of the ice-snow melting coating is prolonged, the ice-snow melting function of a road can last for more than one year, and the coating is suitable for southern rainy regions.

Owner:西安中交万里新材料有限公司

Composite polymer modified asphalt and preparing method of composite polymer modified asphalt

InactiveCN104059369AMeet the use requirementsImprove anti-agingBuilding insulationsFiberPolymer science

The invention discloses composite polymer modified asphalt and a preparing method of the composite polymer modified asphalt. The composite polymer modified asphalt comprises, by weight, SBS, SBR, EVA, LDPE, rubber oil, matrix asphalt, crack resistant fibers, padding and nanometer age resisters. The preparing method of the composite polymer modified asphalt includes the steps of weighing the raw materials according to the weight proportion, adding the SBS, the SBR, the EVA, the LDPE and the rubber oil into a modification mixing tank, carrying out stirring at the rotation speed ranging from 800 r / min to 1000 r / min, then adding the matrix asphalt, sequentially adding the crack resistant fibers, the padding and the nanometer age resisters while stirring is carried out, carrying out stirring, heating the mixture to be at 195 DEG C to 235 DEG C, and carrying out high-speed shearing for 60 min to 90 min at the rotating speed ranging from 3000 r / min to 4000 r / min. The composite polymer modified asphalt is good in age resistance, the high-temperature resistance and the high-temperature storage stability are improved, and the asphalt road surface use requirement can be met.

Owner:无锡市鑫路道路材料有限公司

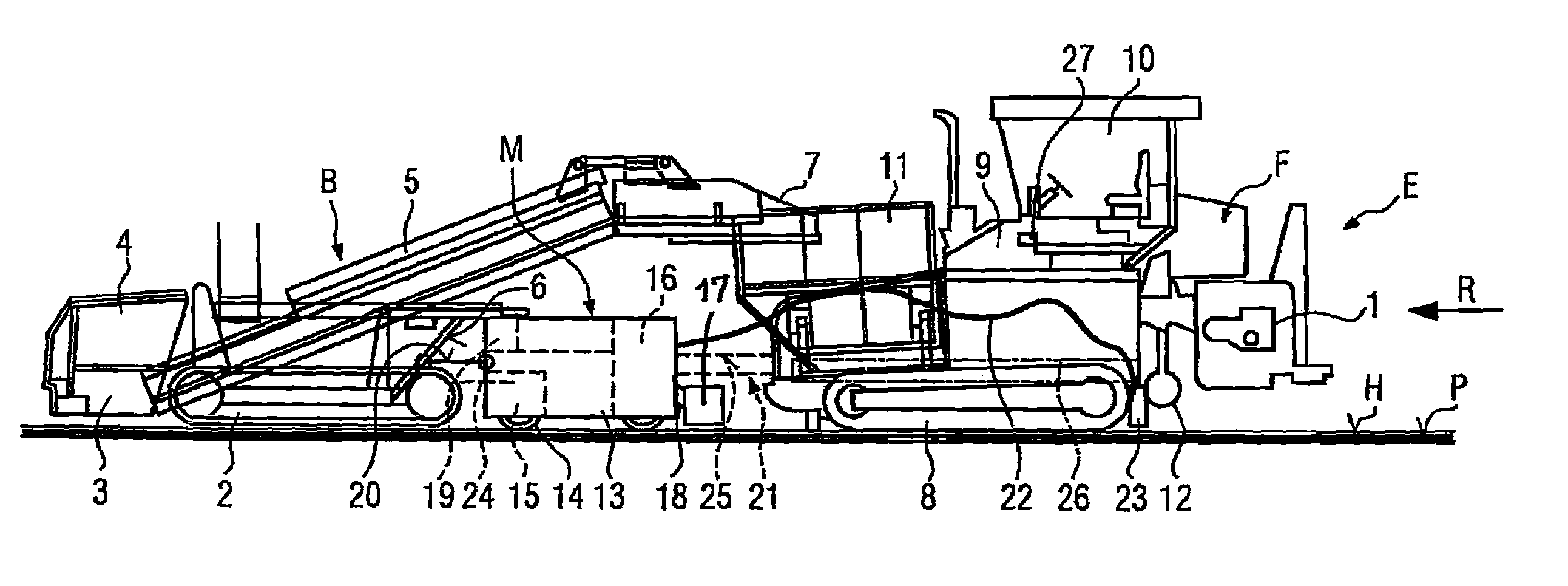

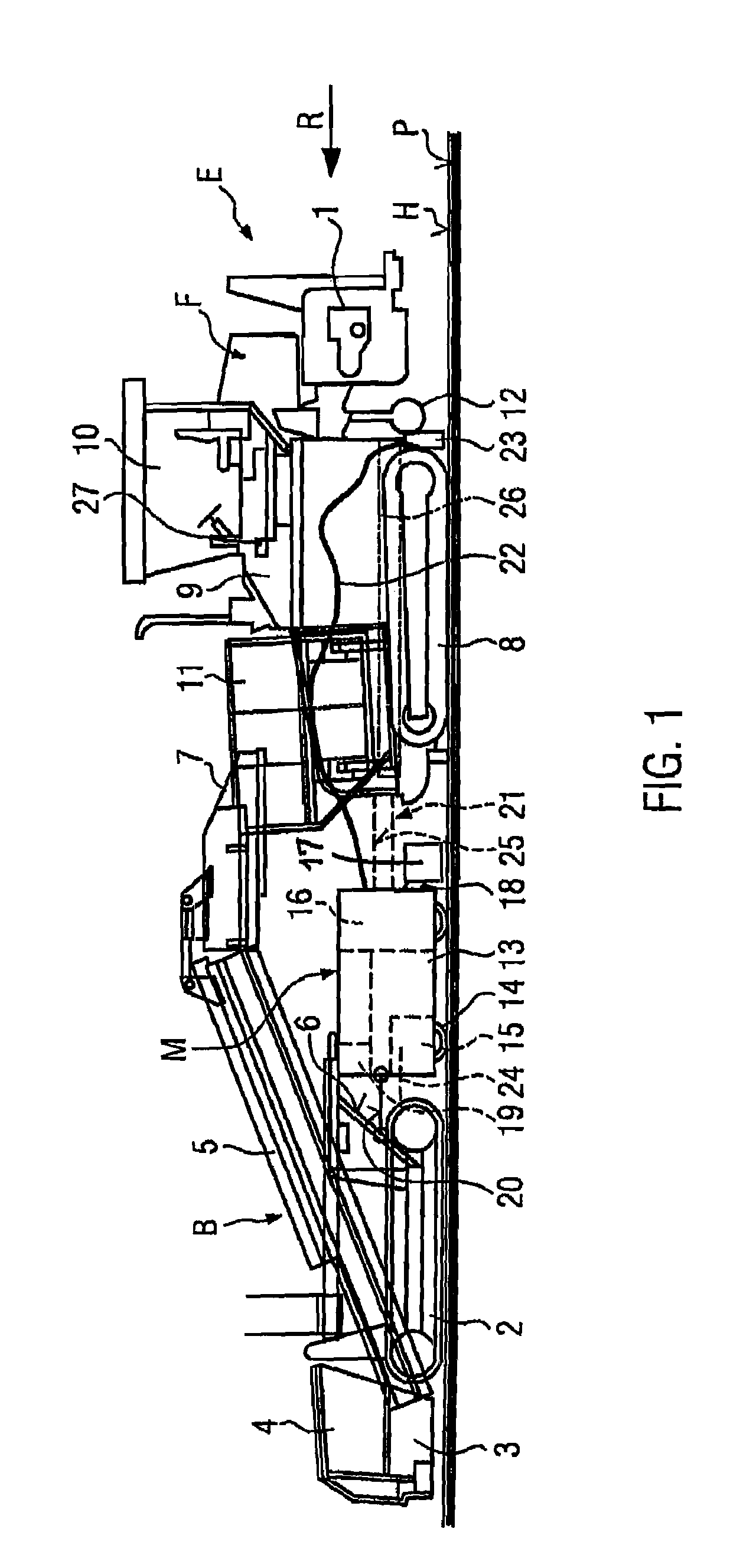

Paving convoy

ActiveUS7572081B2Lower base costFair costTemporary pavingsRoads maintainenceBitumen emulsionRoad surface

A paving convoy for producing a bituminous cover layer including a self-propelled road paver and a paving material feeding assembly which is self-propelled and travels in front of the road paver. A paving material conveying device extends from the feeding assembly to the road paver. A spraying module including its own undercarriage and components for storing and deploying bitumen emulsion is provided between the feeding assembly and the road paver. The spraying module has a spraying bar facing the front end of the road paver. The spraying module is either coupled to the feeder assembly by a detachable towing connection or to the road paver by detachable pulling connection.

Owner:JOSEPH VOEGELE AG

Emulsification asphalt cement mortar for plate-type slag-free orbit and its preparing method and application

ActiveCN101033122AGood temperature adaptability and constructionExcellent durability and anti-vibration fatigue performanceSlagDefoaming Agents

This invention relates to a panel dreg-free emulsified asphalt-cement mortar used in orbits, its manufacturing method and an application including cement, mixed materials, emulsified asphalt, sand, water, polymer latex, defoaming agent, Al powder, an air entrainer and a regulator, which solves the problem of short working time, poor adaptability to temperature, easy separation, hard expansion after 24 hours of injection of the present emulsified asphalt-cement mortar and provides a panel dreg-free emulsified asphalt-cement mortar working long, well suitable to temperature, hard separated, easily expanding, low cost and raw materials are got easily.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045AGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyRoad surface

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

Asphalt mastic utilizing petroleum refinery waste solids

InactiveUS20050241529A1Wide rangeEasy to useDewatering/demulsification with mechanical meansCoatingsBitumen emulsionAsphalt mastic

An asphalt mastic is prepared by combining comminuted waste solids from a petroleum refinery with liquid asphalt that is either a hot asphalt or an asphalt emulsion. The resulting composition is similar in performance to Trinidad Lake Asphalt and is useful either on its own or as a binder for asphalt-aggregate compositions, in both cases optionally in combination with polymeric additives that are common in the asphalt industry.

Owner:SIERRA PROCESS SYST A CORP OF THE STATE OF CALIFORNIA

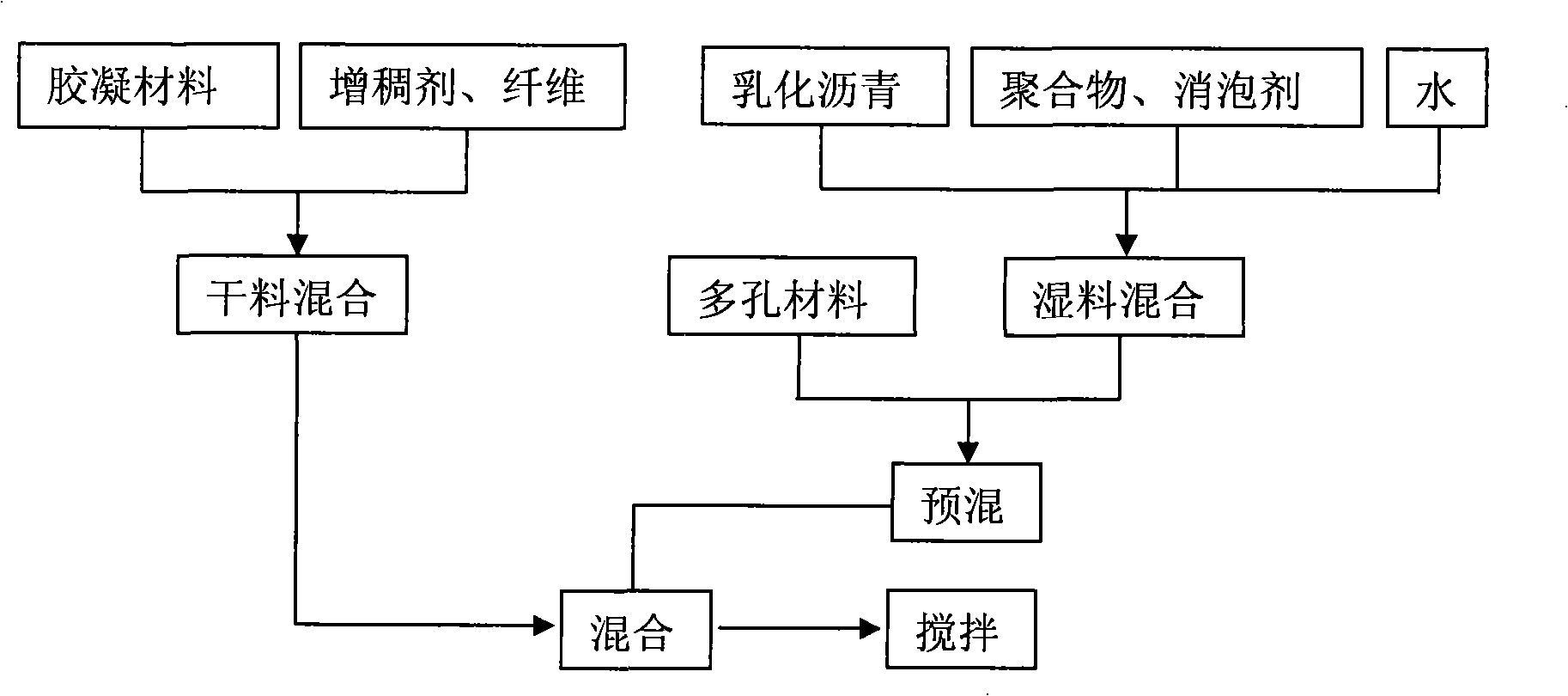

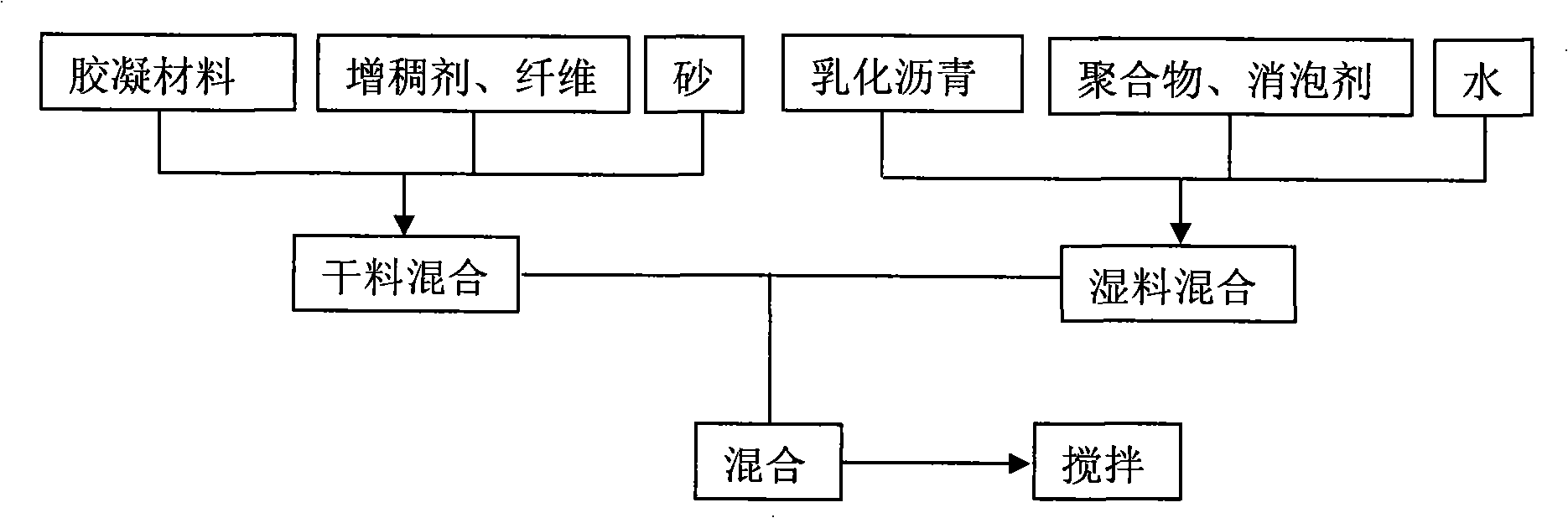

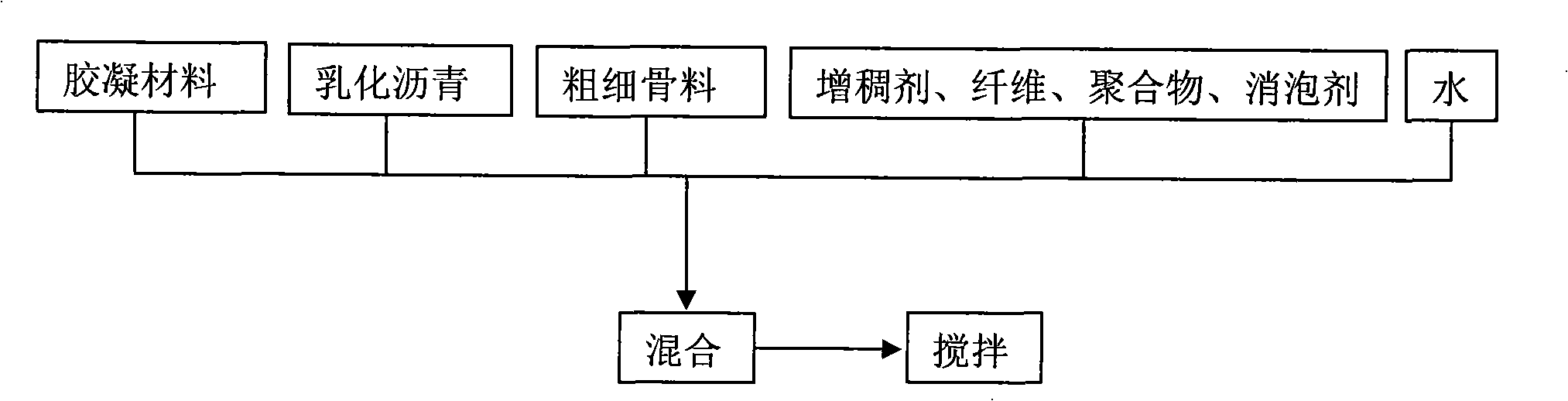

Waterborn polymer-modified emulsified asphalt mixture and process for producing the same

This present invention discloses a waterborne polymer modified emulsified asphalt mixture and the preparation method thereof, and particularly relates to a waterborne polyurethane emulsified asphalt concrete, a waterborne acrylic resin emulsified asphalt concrete, and a waterborne epoxy resin emulsified asphalt micro-surfacing mixture, and preparation methods thereof. A mixture containing a waterborne polymer modified emulsified asphalt forms a high-performance composite system having a spatial network structure, and has good performance and simple preparation process.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE +2

High-temperature resistant spray fast-setting rubber asphalt waterproof coating

ActiveCN102965016ANo pollutionExtended service lifeConjugated diene hydrocarbon coatingsNatural rubber coatingsPolymer scienceSpray coating

The invention relates to a high-temperature resistant spray fast-setting rubber asphalt waterproof coating which is a high-temperature resistant water-based spray coating prepared proportionally by adding a vulcanizing agent and a composite reinforcing agent into liquid rubber asphalt mastic emulsion prepared from modified emulsified asphalt and high-molecular polymer rubber latex and then mixing with a coagulating agent. The high-temperature resistant spray fast-setting rubber asphalt waterproof coating provided by the invention is a novel spray fast-setting rubber asphalt environment-friendly waterproof material which is nontoxic, tasteless and pollution-free and can be subjected to cold construction at normal temperature; and meanwhile, the high-temperature resistant spray fast-setting rubber asphalt waterproof coating has good heat resistance (160 DEG C), high elongation at break (greater than 1,000%), high elasticity recovery rate (greater than 90%), high bonding strength (greater than 0.5MPa), excellent low temperature resistance (without breakage at -30 DEG C) and excellent ageing resistance, acid / alkali resistance, cohesiveness and shear resistance, and can prevent structural damage caused by water penetration so as to prolong the service life of highway bridges.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

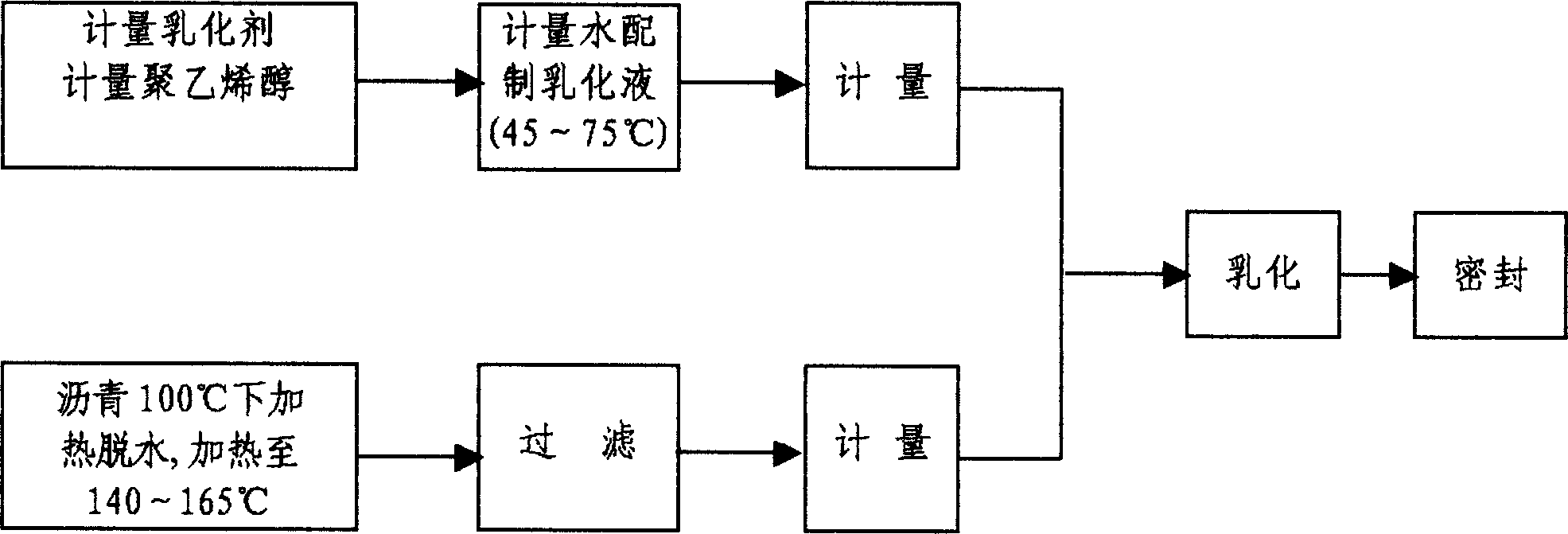

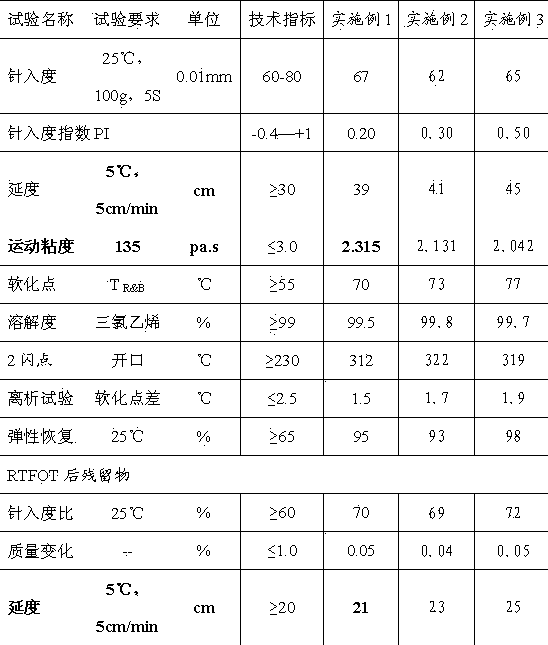

SBS (styrene butadiene styrene)/SBR (styrene butadiene rubber) composite modified emulsified asphalt and preparation method thereof

InactiveCN103951994AHigh softening pointImprove ductilityBuilding insulationsPolymer scienceBitumen emulsion

The invention relates to SBS (styrene butadiene styrene) / SBR (styrene butadiene rubber) composite modified emulsified asphalt. The SBS / SBR composite modified emulsified asphalt consists of matrix asphalt, linear SBS which accounts for 3.5%-5.5% of the weight of the matrix asphalt, compatilizer which accounts for 1%-4% of the weight of the matrix asphalt, stabilizer which accounts for 0.1%-0.4% of the weight of the matrix asphalt, viscosity reducer which accounts for 2.0%-10.0% of the weight of the matrix asphalt, emulsifier which accounts for 0.5%-1.5% of the weight of the matrix asphalt and SBS rubber latex which accounts for 1%-5% of the weight of the matrix asphalt. The SBS / SBR composite modified emulsified asphalt obtained in the invention has characteristics of being high in softening point, high in ductility, high in solid content and low in viscosity, achieves and is further higher than JTGF40-2004 product specification requirements of Ministry of Communications, and can be suitable for special high-grade bituminous pavements such as an ultrathin wearing layer, and the like as well as an associated construction process thereof.

Owner:中海沥青(泰州)有限责任公司

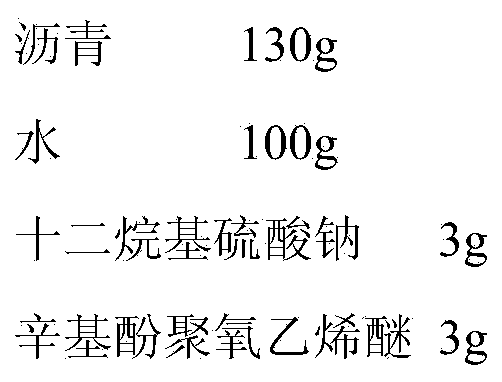

Emulsified asphalt profile control agent

Disclosed is an emulsified asphalt profile control agent. The emulsified asphalt profile control agent is applied to adjustment of injection profiles of water injection wells in the water injection development process of oil fields. The water drive wave and efficiency are improved. The emulsified asphalt profile control agent comprises, by weight, 45-65% of asphalt, 0.3-1.2% of dodecyl diphenyl ether sodium disulfonate, 0.3-1.2% of sodium alcohol ether sulphate, 0.05-0.1% of polyoxyethylene fatty acid, 0.02-0.8% of phenethyl phenyl polyoxypropylated polyoxyethylene ether, 0.3-1.5% of sodium pyrophosphate, 0.02-0.1% of ultra-fine calcium powder, 0.02-0.08% of carboxymethyl cellulose, 0.02-0.08% of anionic polyacrylamide, 0.000004-0.04% of sodium hydroxide and the balance fresh water of which the salinity is less than 1,000mg / L. The emulsified asphalt profile control agent has the advantages that the emulsified asphalt profile control agent can enter deep portions of oil reservoirs effectively, the water plugging rate is more than 90% under the condition that the injection capacity accounts for 1-15% of the reservoir preprocessing radius hole volume, the validity period of the water plugging is more than 2 years and oil flow channels are not damaged.

Owner:PETROCHINA CO LTD

Color polymer modified emulsion asphalt-base waterproof paint and preparation method thereof

ActiveCN103666260ACongeal fastEasy constructionChloropene polymer coatingsBituminous coatingsEpoxyHigh concentration

The invention belongs to the color polymer modified emulsion asphalt-base waterproof paint and a preparation method thereof. The color polymer modified emulsion asphalt-base waterproof paint is prepared by adopting multiple synthesis macromolecular polymers such as high-concentration ultrafine suspension micro-emulsion anion modified color emulsified asphalt, SBS (Styrene Butadiene Styrene) rubber, neoprene, macromolecular resin, epoxy resin and the like and multiple functional assistants such as the plasticizer as raw materials and by utilizing a special production process. After the color polymer modified emulsion asphalt-base waterproof paint forms a film, the color is bright, no brittle rupture exists at the low temperature of minus 30DEG C, no flowing exists at the high temperature of 120DEG C, the resilient return rate reaches 90 percent, the color polymer modified emulsion asphalt-base waterproof paint can be stably stored for more than 2 years, and the service life can reach 50 years.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

Rubber modified asphalt waterproof coating as well as preparation method and use method thereof

ActiveCN107118695ARapid demulsificationSimple construction processLiquid surface applicatorsConjugated diene hydrocarbon coatingsInorganic saltsEmulsion

The invention provides a rubber modified asphalt waterproof coating which comprises a component A and a component B, wherein the component A comprises modified emulsified asphalt and a rubber emulsion; the component B comprises inorganic salt and deionized water; the component A comprises the following components in parts by mass: 60-90 parts of the modified emulsified asphalt, and 10-40 parts of the rubber emulsion; and the component B comprises the following components in parts by mass: 9-14 parts of the inorganic salt and 86-91 parts of the deionized water. Through the development of the component A and the component B and application of a double-component spraying machine, the problem that cation emulsified asphalt is long in demulsification time is solved, full-pavement without seams and normal temperature cold construction of waterproof coatings are achieved, and in addition, the waterproof effect is greatly improved.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

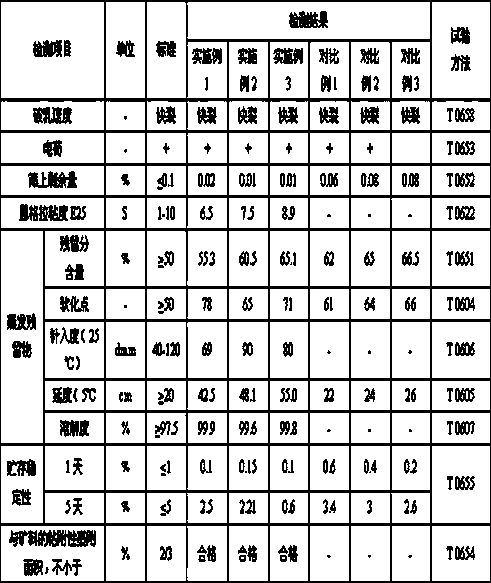

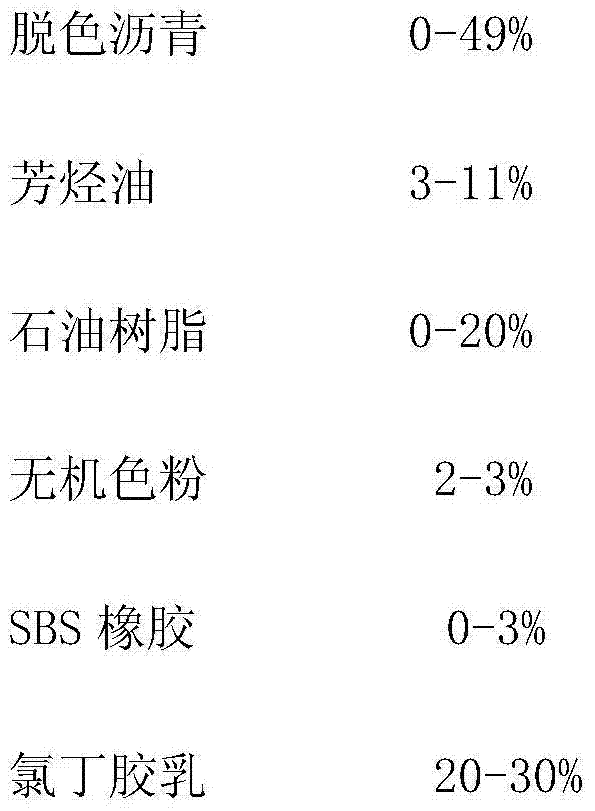

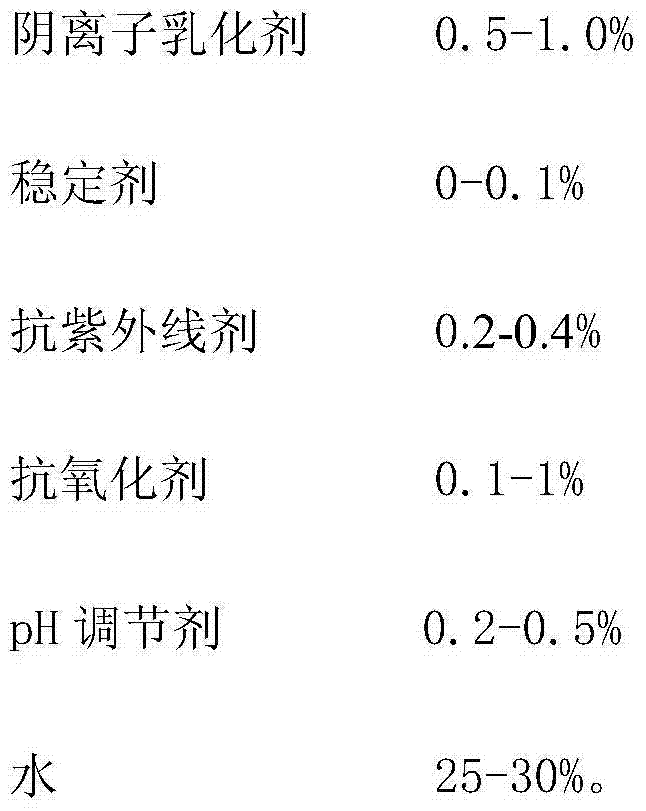

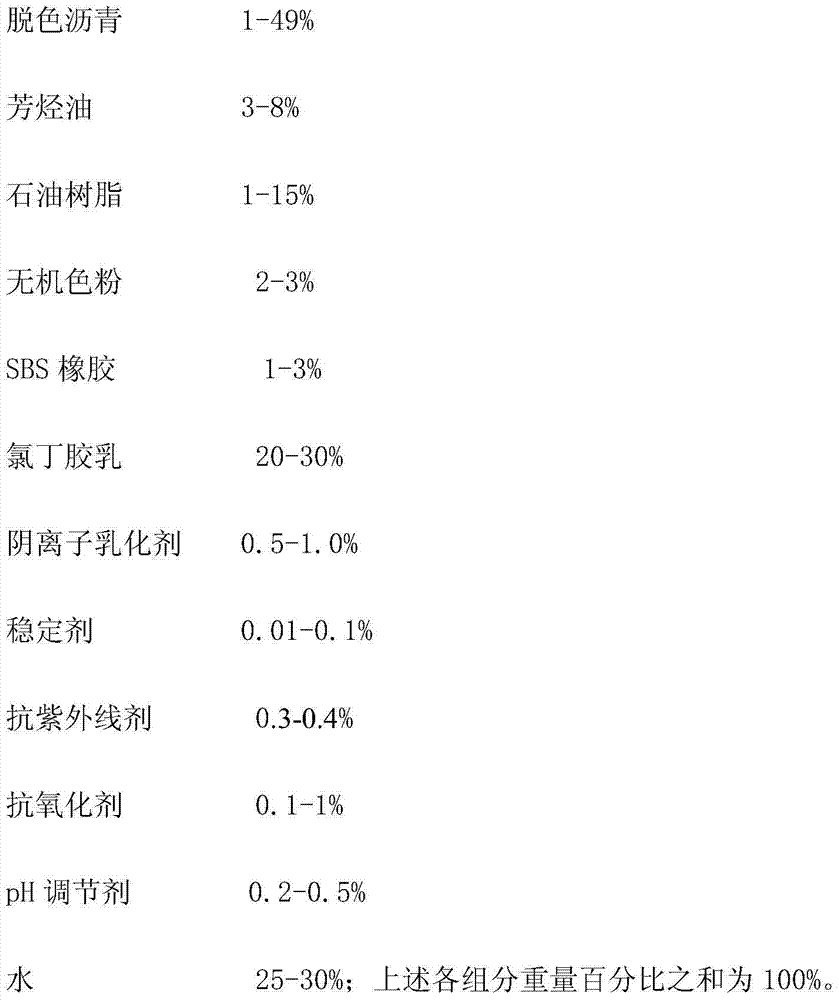

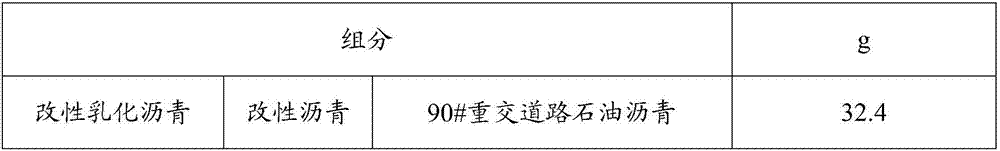

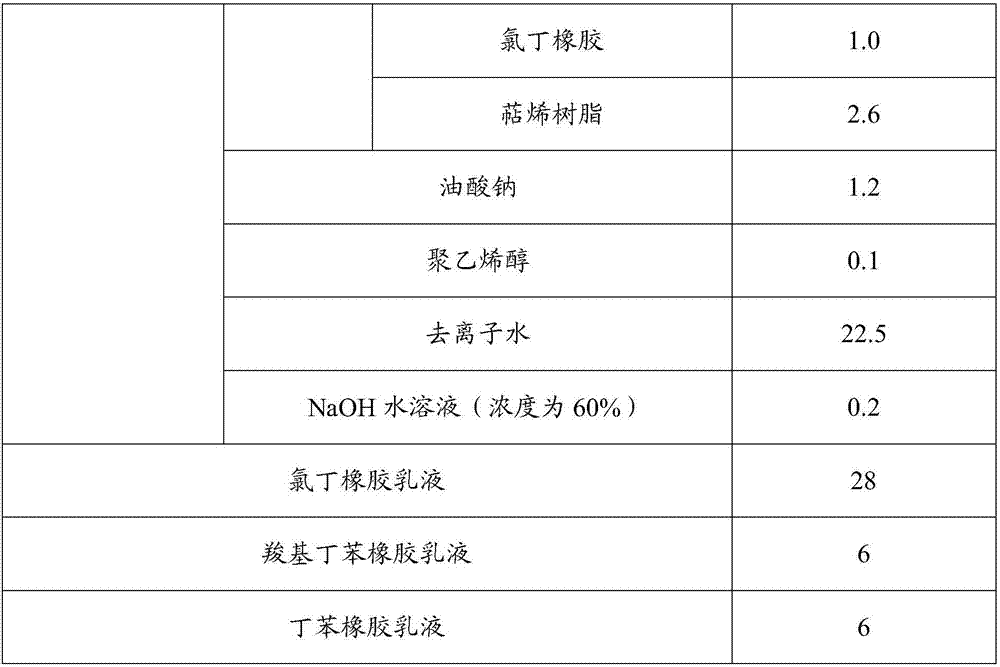

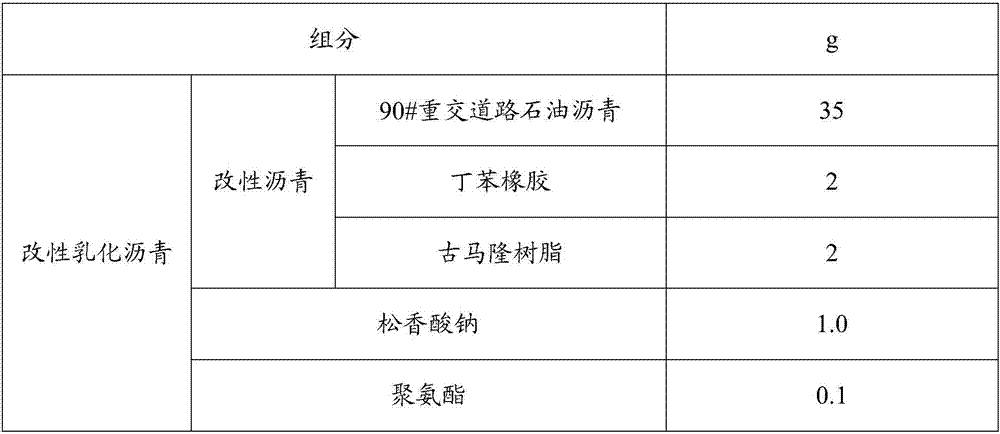

Polymer modified emulsified asphalt composition and preparation method thereof

ActiveCN102675889ARaw materials are cheap and easy to getImprove adhesionConjugated diene hydrocarbon coatingsChloropene polymer coatingsPolymer sciencePolymer modified

Owner:SHANXI MINGKESI TECH

Waterborne polyurethane emulsified asphalt concrete as well as preparation method and application thereof

The invention discloses a waterborne polyurethane emulsified asphalt concrete which is prepared from the following raw materials: mineral aggregates, emulsified asphalt and waterborne polyurethane emulsion, wherein the weight ratio of the mineral aggregates, the emulsified asphalt and the waterborne polyurethane emulsion is 100:(1-20):(7-20). The invention also discloses a preparation method of the waterborne polyurethane emulsified asphalt concrete, and the preparation method comprises the following steps: mixing the waterborne polyurethane emulsion with the emulsified asphalt, and uniformly stirring, so that waterborne polyurethane modified emulsified asphalt is obtained; adding the waterborne polyurethane modified emulsified asphalt into the mineral aggregates, uniformly stirring, and carrying out maintenance on the obtained product; or uniformly stirring the mineral aggregates, the emulsified asphalt, and the waterborne polyurethane emulsion, and carrying out maintenance on the obtained product. The prepared waterborne polyurethane emulsified asphalt concrete not only has the advantages of cold-mixed asphaltic concrete, but also has excellent mechanical properties and stability; the waterborne polyurethane emulsified asphalt concrete is excellent in pavement performance, and can be used for greatly prolonging the service life of pavements; and the maintenance time is short, and the traffic can be implemented in 1-3 days, therefore, the waterborne polyurethane emulsified asphalt concrete can be applied to the preparation of asphalt concrete paving materials, asphalt pavement repair materials, slurry seals for maintenance and asphalt mortar for micro-surfacing and high-speed railways.

Owner:山东大山绿道工程科技有限公司

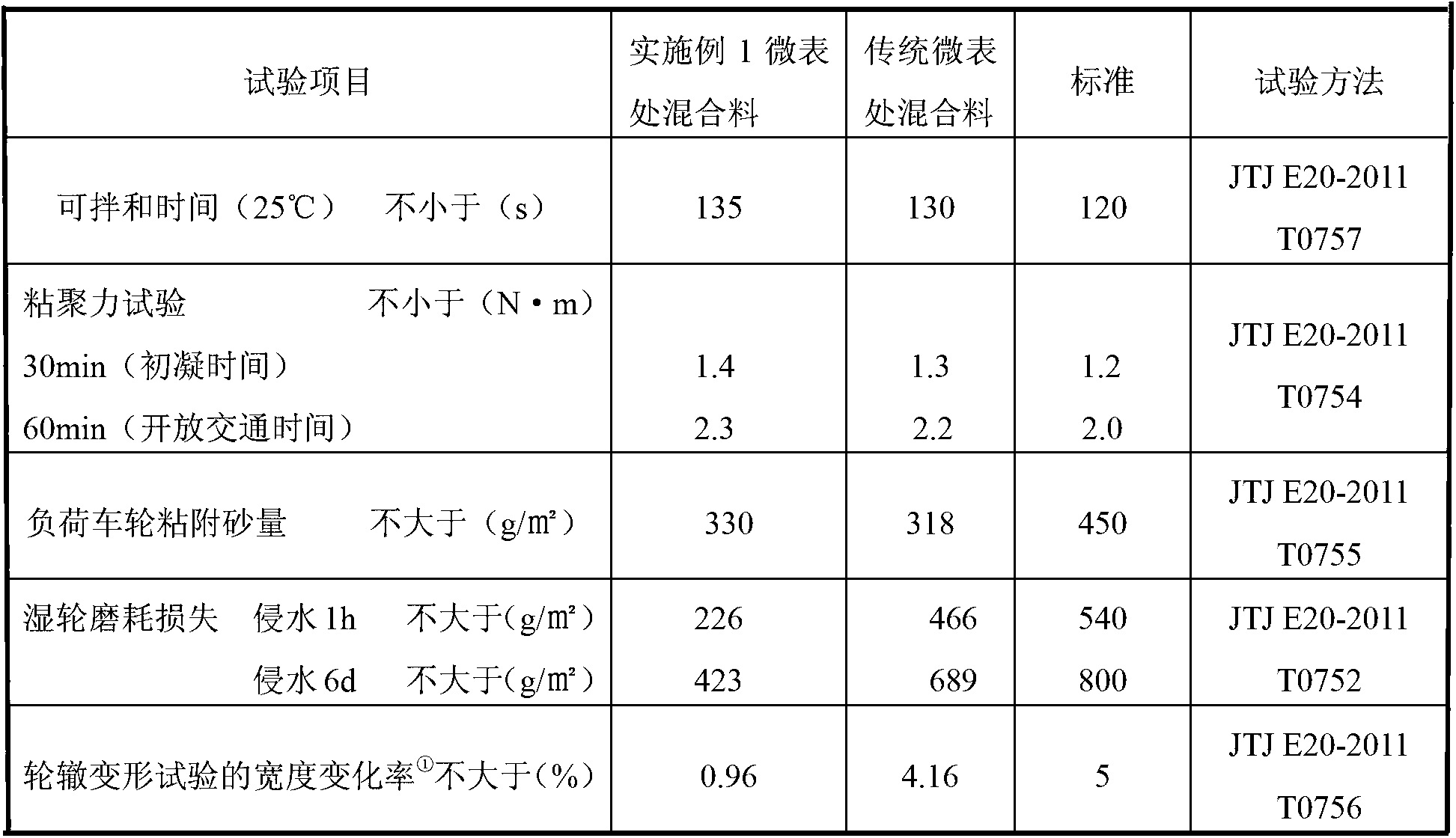

Micro-surfacing mixture

InactiveCN103073232AOvercome high temperature stabilityOvercoming poor low temperature crack resistancePolymer scienceBitumen emulsion

Owner:重庆市智翔铺道技术工程有限公司

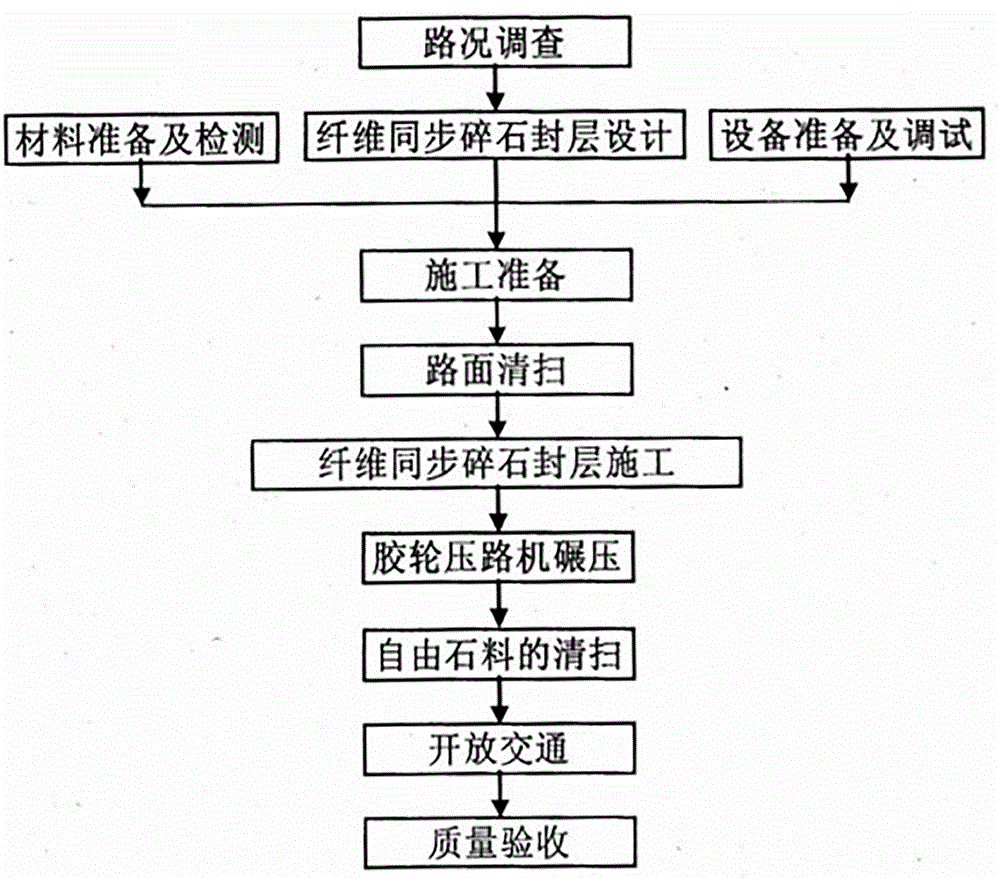

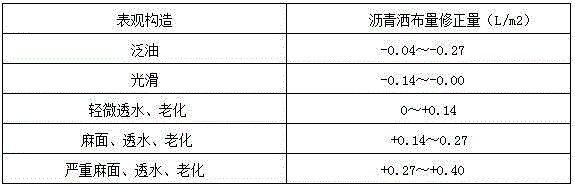

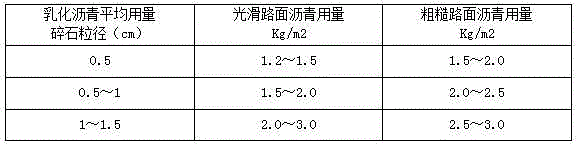

Modified emulsified asphalt fiber synchronous pavement surface dressing construction method

InactiveCN104652217AImprove skid resistanceRestore flatnessIn situ pavingsPaving detailsBitumen emulsionStructural engineering

Owner:成军

Preparation method and application of wheel sticking prevention emulsified asphalt for sticky layers

The invention discloses a preparation method and an application of wheel sticking prevention emulsified asphalt for sticky layers. The preparation method comprises the following steps: 1, adding 0-9 parts of a polymeric elastomer material, 0-5 parts of polyethylene wax or ethylene-vinyl acetate wax, 0-5 parts of a viscosity reducer and 0-5 parts of modified asphalt stabilizer to 450-600 parts of asphalt to prepare modified asphalt; 2, adding 1-10 parts of an emulsifier and 0.1-3 parts of an emulsified asphalt stabilizer to 300-500 parts of water, and mixing above materials to prepare a soap solution; and 3, grinding and emulsifying the soap solution and the modified asphalt according to a mass ratio of 1:1 through a modified asphalt colloid mill to prepare the target product, wherein the temperature of the soap solution is 40-60 DEG C, and the emulsification temperature of the modified asphalt is 160-180 DEG C. A high proportion of the polybutadiene elastomer is adopted as the modifier for adjusting the low temperature performances of asphalt, so the softening point of evaporation residues of the prepared wheel sticking prevention emulsified asphalt reaches up to 90 DEG C or above, the penetration degree is greater than 30 cm, and the 15 DEG C ductility is greater than 100 cm.

Owner:JIANGSU SINOROAD TRANSPORTATION SCI & TECH CO LTD

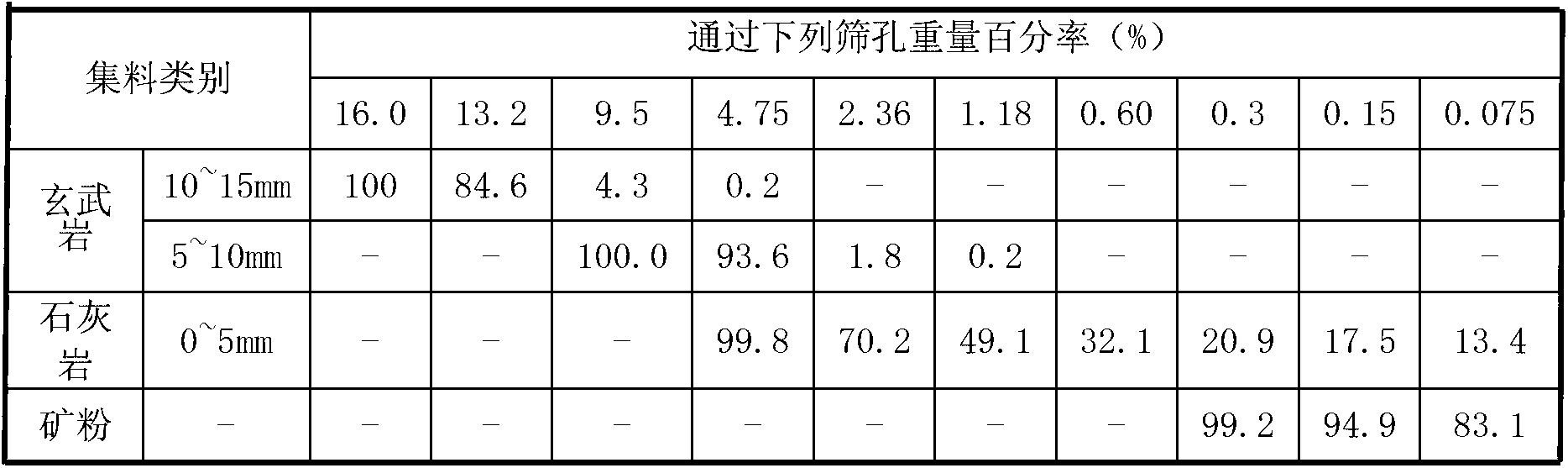

Emulsified asphalt concrete material cured by microwave heating and its preparation method

InactiveCN102295445AOvercome wasteOvercoming the problem of low early strengthRoads maintainencePavement maintenancePortland cement

The invention discloses a microwave heated and cured emulsified asphalt concrete material and a preparation method thereof. The emulsified asphalt concrete comprises the following components by mass: 79%-88% of basalt or limestone aggregate, 3%-6% of limestone mineral powder, 1%-4% of ordinary portland cement, 8%-11% of microwave heated and demulsified emulsified asphalt. The preparation method consists of the steps of: mixing the aggregate, mineral powder and cement at normal temperature for 1min, adding the microwave heated and demulsified special emulsified asphalt, and mixing the mixture for 2min, spreading out and pre-pressing the mixture to compactness of 50%, conducting microwave heating to a temperature above 50DEG C and implementing demulsification for draining, continuing heating the mixture to a temperature above 100DEG C, and carrying out final pressing, thus obtaining the concrete material. The method of the invention employs demulsification for draining after microwave heating as well as final pressing for curing, so that the demulsification time of the emulsified asphalt is controllable, and the pavement performance of the emulsified asphalt concrete is greatly improved. Being green and environmentally friendly as well as construction convenient, the method provided in the invention is suitable for application of the emulsified asphalt concrete to high-grade pavement layers, rapid pavement maintenance, asphalt concrete factory prefabrication, and other fields.

Owner:CHANGAN UNIV

High-performance styrene-butadiene-styrene block copolymer (SBS) modified emulsified asphalt and preparation method thereof

ActiveCN102719107AImprove adhesionReduce emulsification processing temperatureBuilding insulationsPolymer scienceBitumen emulsion

The invention relates to high-performance styrene-butadiene-styrene block copolymer (SBS) modified emulsified asphalt and a preparation method thereof. The high-performance SBS modified emulsified asphalt is prepared from the following components by weight percent: 56.0-67.0% of matrix asphalt, 1.2-2.5% of SBS, 0.5-1.5% of ethylene vinyl acetate (EVA) wax, 0.2-2.5% of cationic emulsifier, 0-0.2% of thickening agents and 30.0-42.0% of water. The high-performance SBS modified emulsified asphalt can generate a thick asphalt membrane after demulsification. The asphalt membrane has a high softening point, is high in performance (PG) grade and dynamic viscosity and good in low-temperature performance, and strengthens bond performance, waterproof performance and deformation-resisting capability. The SBS modified emulsified asphalt is remarkably superior to ordinary modified emulsified asphalt in high-temperature performance, low-temperature performance and bond performance, and ensures characteristics required by road construction, such as a bond layer for ultrathin overlay of pavement, and new construction or maintenance of hot or heavy-duty roads.

Owner:厦门华特公路沥青技术有限公司

High modulus cold-mixed asphalt as well as preparation method and mixture thereof

The invention relates to high modulus cold-mixed asphalt as well as a preparation method and a mixture thereof. The asphalt composition comprises the following components in parts by weight: 58-60 parts of petroleum asphalt, 1.5-3.0 parts of a polymer, 1.5-2.5 parts of a compatilizer, 1.0-2.5 parts of an emulgator and 0.3-1.2 parts of an interface repairing agent. The emulgator is in a twin structure with a polar group and a nonpolar group. According to the technology provided by the invention, the modulus of the emulsified asphalt cold-mixed mixture and the cold-recycling mixture is improved, and the mixture can be used as a material of a base layer, a lower surface layer and a middle surface layer of a newly constructed road and a reorganized and expanded road or used for structural repair of high-grade highways, thereby finding a convenient, energy-saving and environment-friendly solution capable adopting 100% reclaimed materials for structural repair of high-grade highways. With the adoption of the scheme of quick setting, the construction time is shortened and the cost is saved.

Owner:BEIJING TONGHUA ROAD MAINTENANCE

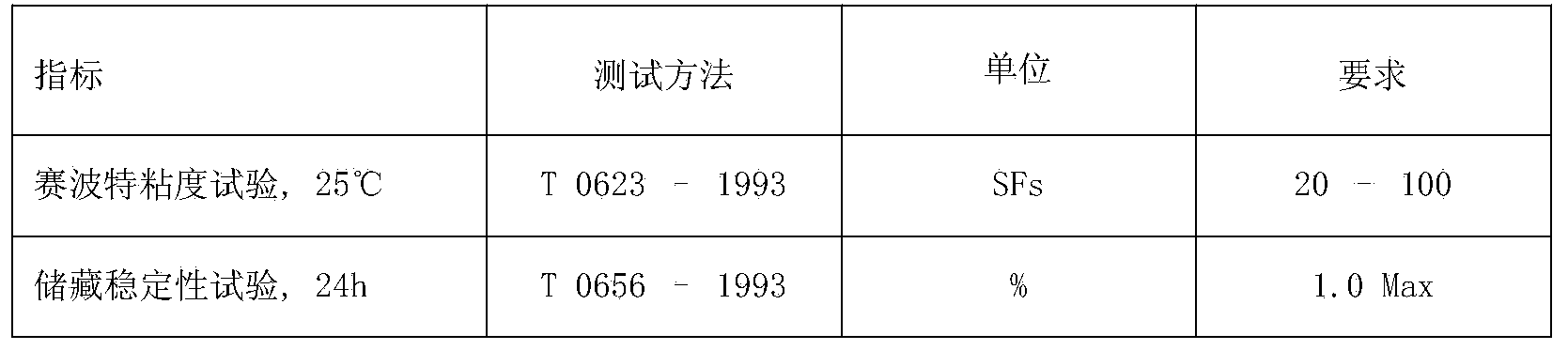

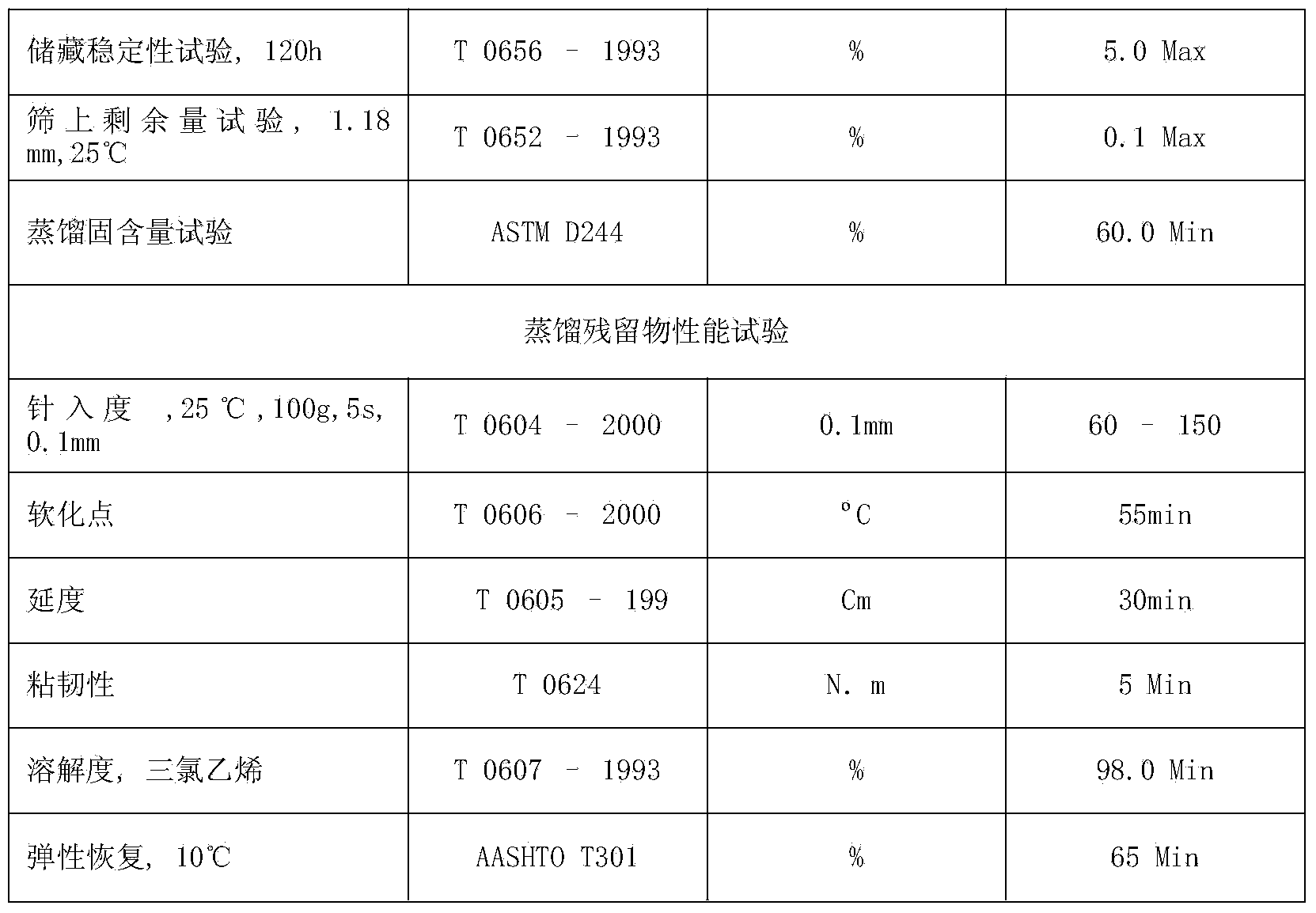

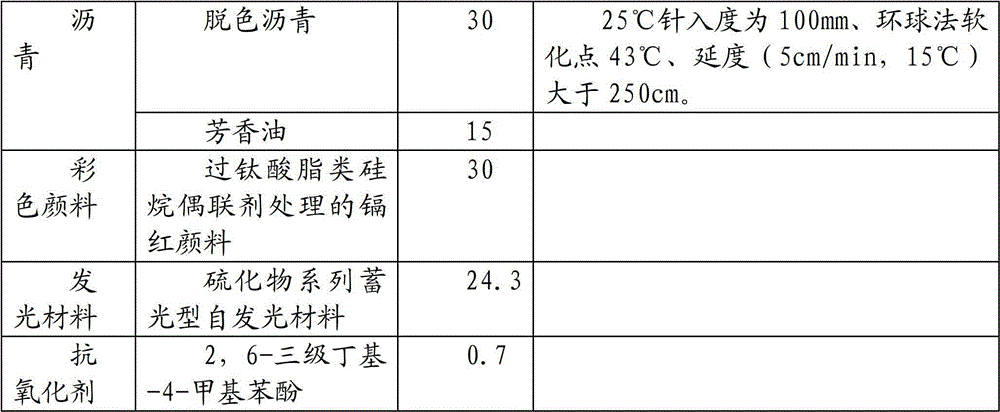

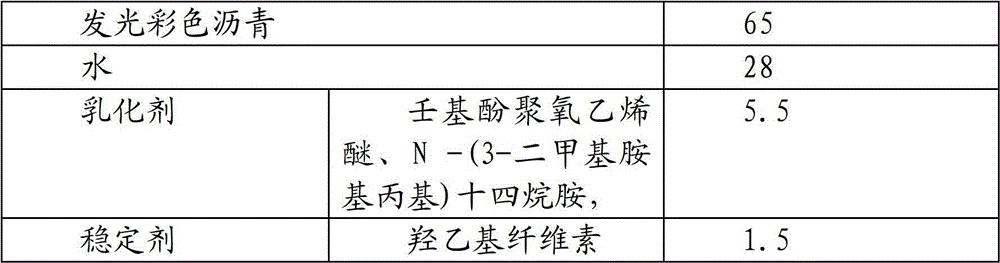

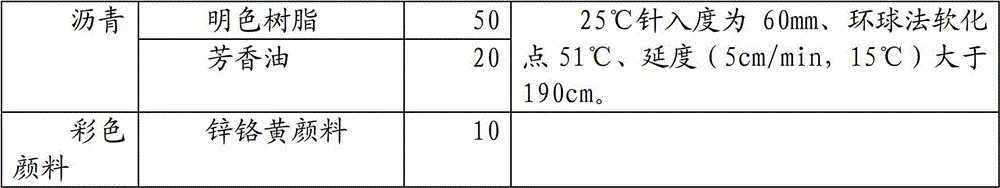

Luminescent colored bitumen emulsion and preparation method thereof

The invention discloses a luminescent colored bitumen emulsion and a preparation method of the bitumen emulsion. The method comprises the steps of: uniformly mixing 10-30 parts by mass of colored pigment, 10-30 parts by mass of luminescent material and 0.5-1.0 part by mass of antioxidant in high-speed stirring equipment, then adding 45-70 parts by mass of 130-160 DEG C bitumen, and stirring uniformly to prepare colored luminescent bitumen; adding 1.5-6.5 parts by mass of emulsifying agent and 1.0-5.0 parts by mass of stabilizer to 28-45 parts of 45-65 DEG C water, and stirring uniformly to prepare soap solution; and injecting the prepared soap solution and luminescent colored bitumen to a colloid mill, and grinding until the emulsion mode has particle size smaller than 5 mum and average grain size smaller than 7 mum. The emulsion contains 50-65 parts of the luminescent colored bitumen, 28-45 parts of water, 1.5-6.5 parts of the emulsifying agent and 1.0-5.0 parts of the stabilizer. The luminescent colored bitumen emulsion is advanced in process and simple in application; and the luminescent colored bitumen emulsion with excellent quality, luminescent effect and gorgeous color can be produced by adopting traditional equipment.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com