Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

242results about How to "Improve pourability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

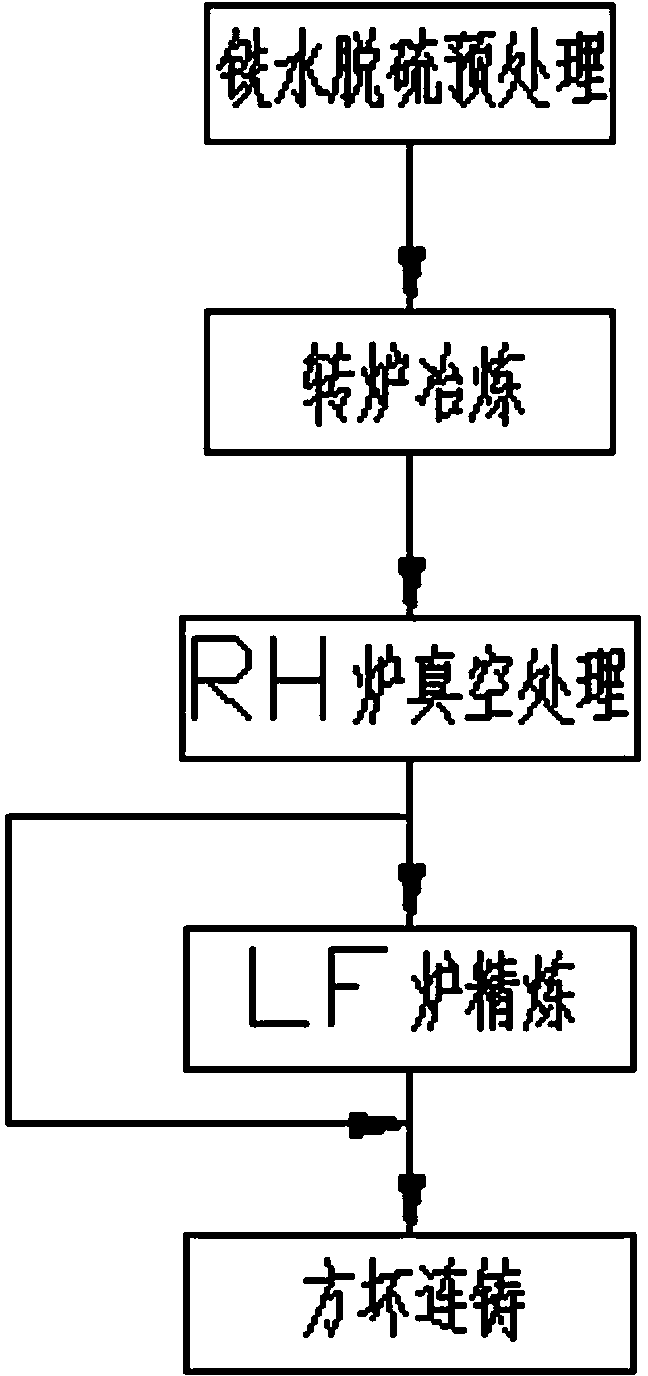

Production method of ultra low carbon steel

InactiveCN102719600AReduce the rate of oxygen blowing heating upReduce temperature dropManufacturing convertersSlagNitrogen

The invention provides a production method of an ultra low carbon steel. The method comprises the steps of: employing a blowing process for desulfurization and slag removal of molten iron, with control of oxygen blowing time and smelting cycle of a converter, argon bottom-blowing in the whole course, and control of S content in slag lime, [C] content at converter end point, and temperature and oxygen activity at the endpoint, adding lime in a tapping process, and modifying ladle top slag after tapping; employing natural decarburization to control carbon content in an RH, wherein Als in molten steel is less than 0.03% after deoxidation, carrying out vacuum-breaking, adding aluminum powder and top slag modifier into the top slag, blowing argon with stirring, vacuumizing again, and carrying out clean circulation for 2-10 min; and carrying out continuous casting with protective casting in the whole course, wherein a nitrogen increase amount in the molten steel is controlled at less than 2 ppm. The invention can effectively reduce temperature drop in a transmission process, reduce oxygen blowing heating rate in a subsequent RH refining treatment, save energy and shorten the time of refining. Besides, the method can effectively guarantee modification effect of the top slag, prevent nozzle clogging and realize sequence casting. Therefore, the method is particularly applicable to the production of high purity ultra low carbon steel.

Owner:ANGANG STEEL CO LTD

Method for manufacturing low-carbon and low-silicon steel

ActiveCN103627853AEasy to implementReduce oxidationManufacturing convertersDeoxidizationDecarburization

The invention relates to a method for manufacturing low-carbon and low-silicon steel. The requirement of the low-carbon and low-silicon steel on low contents of carbon and silicon is surely satisfied via decarbonizing and deoxidizing with an RH vacuum treatment device, as a result, the content of the end carbon of a steel-smelting furnace is increased, the after-blow is reduced, the oxidizability of molten steel is lowered, the cost of deoxidization and alloying is reduced, and the purity of the steel is improved; according to the quality requirement of the steel, the secondary refining of the molten steel can adopt two methods, i.e. RH vacuum treatment or combination of the RH vacuum treatment and LF (Ladle Furnace) refining. By utilizing vacuum natural decarbonization and deoxygenation, brittle Al2O3 impurities generated by aluminum deoxidation are reduced, the cleanliness of the steel is improved, silicon added to the molten steel can be effectively controlled from the steel-smelting furnace tapping to the RH vacuum treatment, C and Si in the steel are easy to control and stable; the Al2O3 impurities generated by deoxygenation are greatly reduced and reasonable Ca deformation treatment is performed, so that the castability of the molten steel is good, and the problem of nozzle clogging caused during continuously casting the type of steel is avoided.

Owner:SGIS SONGSHAN CO LTD

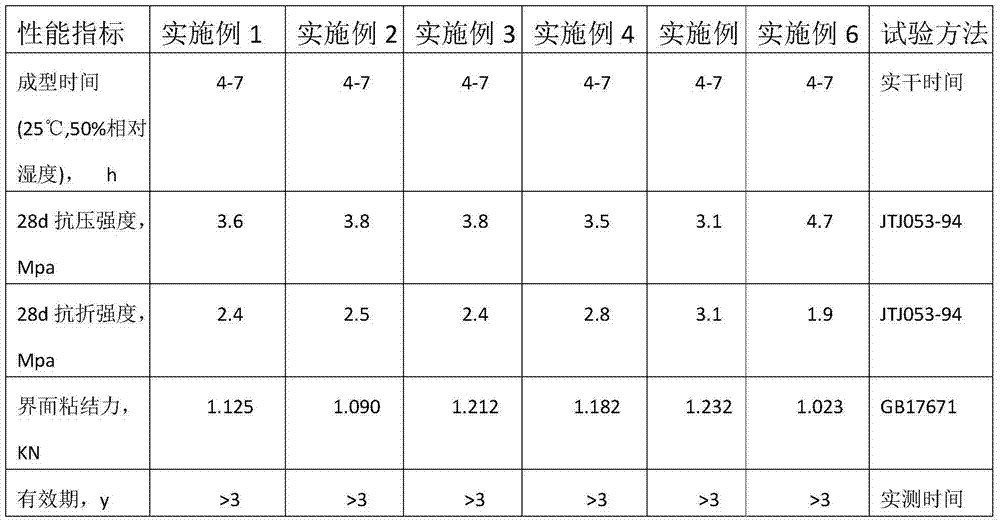

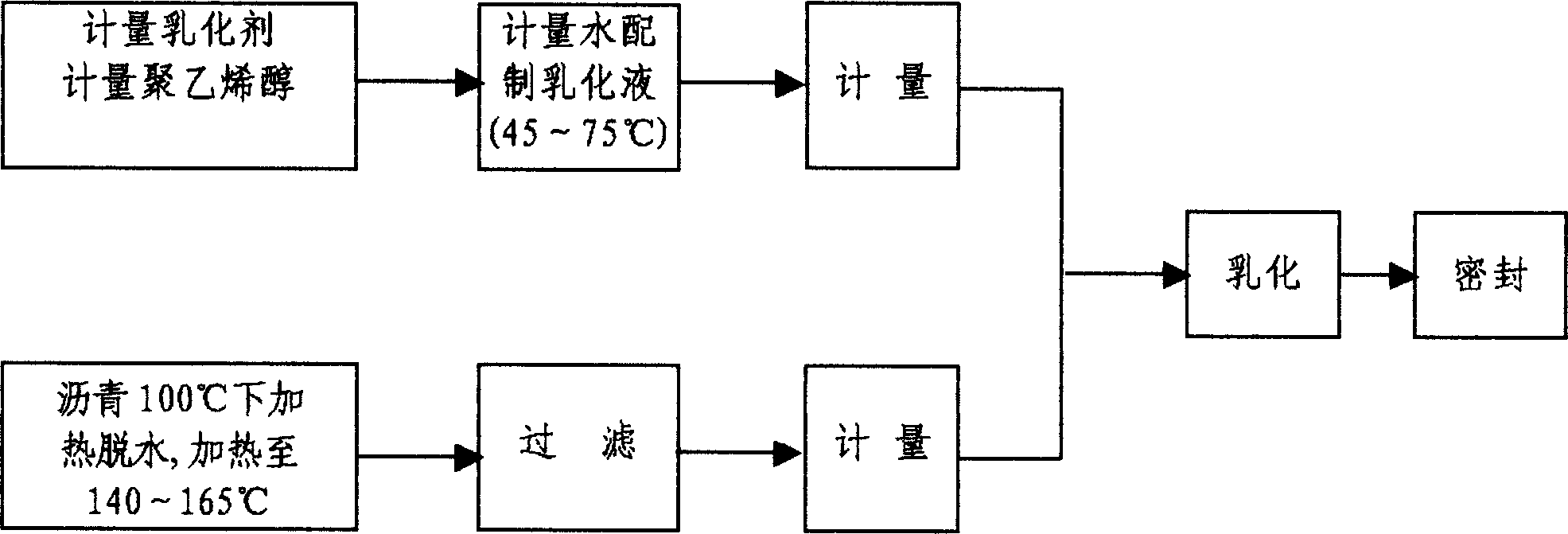

Asphalt base composite material for pavement crack repair

The invention discloses an asphalt base composite material for pavement crack repair. The asphalt base composite material for pavement crack repair is prepared from a component A and a component B, wherein the component A comprises the following raw materials in parts by weight: 120-150 parts of anionic emulsified asphalt, 1-3 parts of water reducing agent, 1-3 parts of defoaming agent, 3-8 parts of binder and 0-10 parts of water, and the component B comprises the following raw materials in parts by weight: 100 parts of cement, 70-110 parts of sand and 0.01-0.06 part of expanding agent. The asphalt base composite material for pavement crack repair has the flexibility of asphalt, the rigidity of cement and certain strength, is used for crack pouring and can bear and transfer loading force; the binder is added to the material so as to play a role of reinforcing the binding force between the material and crack walls, so that the service life of a pavement is prolonged, and the re-cracking phenomenon is difficult to occur. The asphalt base composite material for pavement crack repair has the advantages of low cost price, simple construction, low requirements on constructors, low energy consumption, low cost, strong binding power and long useful life and can be widely applied to the pavement crack repair.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

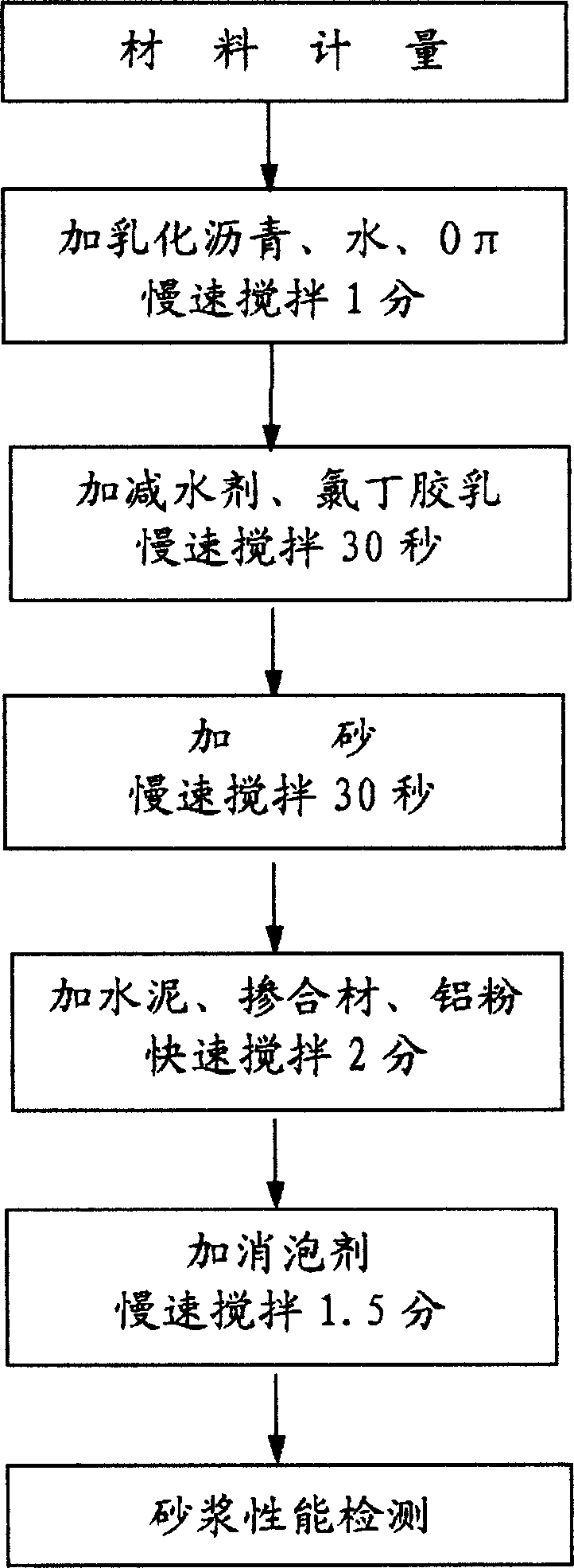

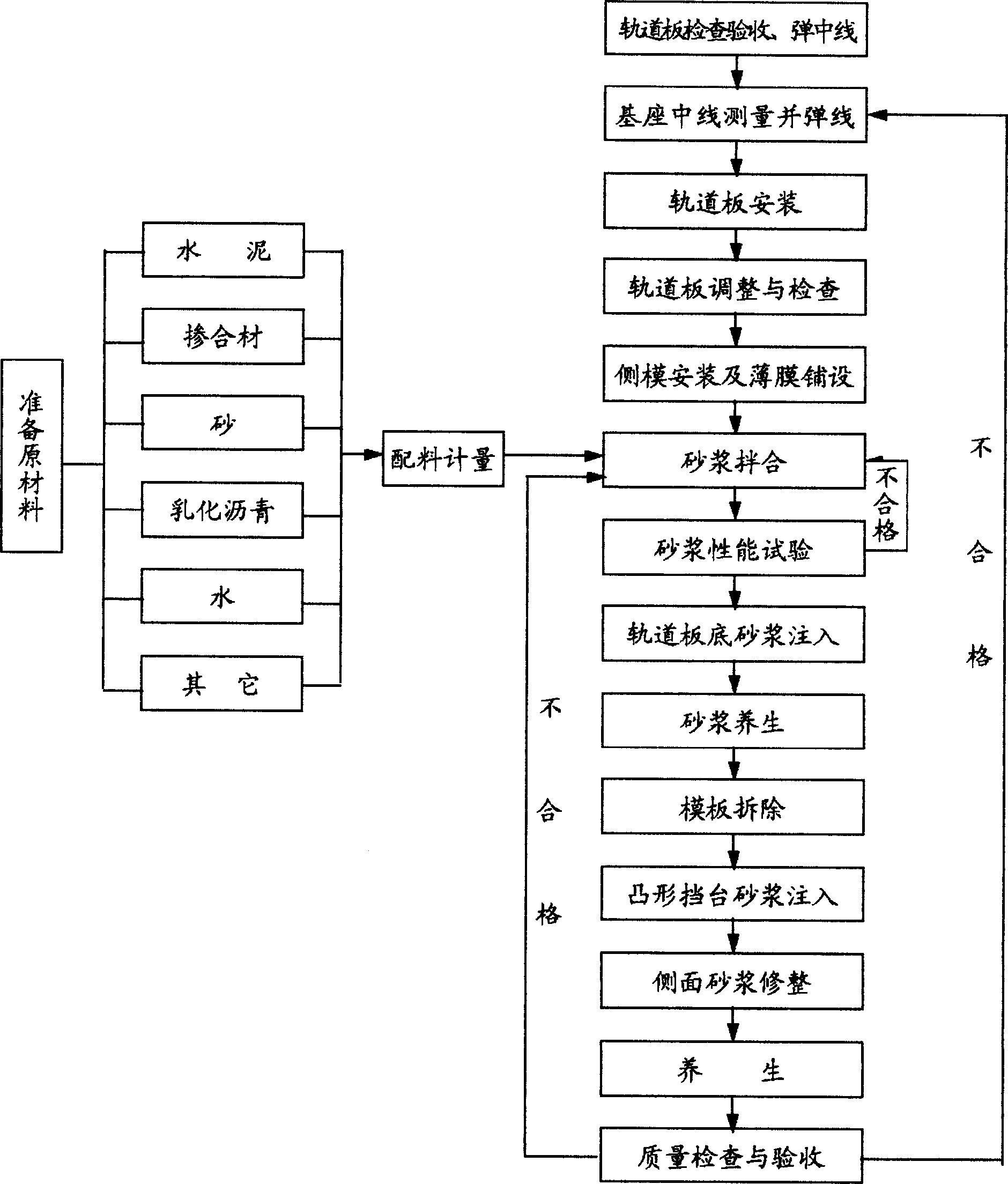

Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

A cement-emulsified asphalt mortar used for railway and overhead railway in urban area contains cement and its additive, emulsified asphalt, sand, water, water-reducing agent, aluminium powder, surfactant, defoaming agent, polyacrylic fibres and chlorobutadiene latex. Its preparing process is also disclosed. Its advantages are high flowability, high strength and freeze-thawing resistance, and no environmental pollution.

Owner:CHINA RAILWAY 11TH BUREAU GRP

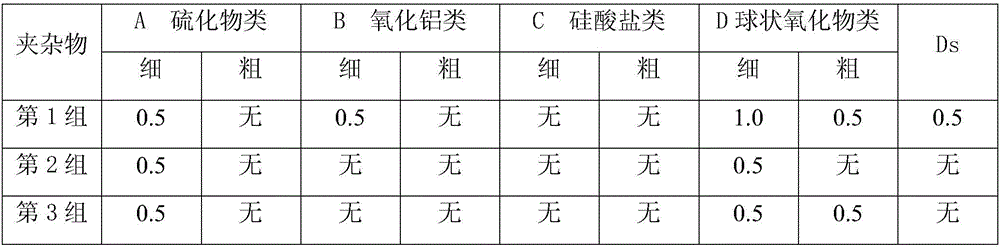

Production method of Mn-Cr high-performance gear steel

The invention belongs to the technical field of alloy steel, and in particular, relates to a manufacturing method of Mn-Cr gear steel. The gear steel comprises the following components: 0.17-0.22% of C, 0.15-0.25% of Si, 1.10-1.40% of Mn, 1.00-1.30% of Cr, Mo not more than 0.08%, B not more than 0.0005%, Cu not more than 0.02%, Ni not more than 0.02%, 0.025-0.055% of Al, P not more than 0.015%, 0.020-0.035% of S, N not more than 130 ppm, and the balance of iron. The method improves the cleanness of molten steel through optimizing the refining process and the slag system control, performs the nitrogen adding treatment through a wire feeding procedure to effectively refine grains of the aluminum deoxidation gear steel, realizes precise control of hardenability alloy elements, solves the deoxidation and sulfur maintaining contradiction, and guarantees excellent pouring performance of the molten steel and excellent cutting performance of the gear steel.

Owner:ZENITH STEEL GROUP CORP +1

Method for preparing concrete pavement brick by using recycled aggregate of construction waste

InactiveCN106673592ARealize resourcesQuality improvementSolid waste managementEcological environmentBrick

The invention relates to a method for preparing a concrete pavement brick by using recycled aggregate of construction waste. The method is characterized in that a concrete pavement is prepared from the following raw materials in parts by weight: 60-80 parts of recycled aggregate of the construction waste, 25-35 parts of superfine 52.5 Portland cement, 10-15 parts of a gelatinizing agent, 0.5-2 parts of a superplasticizer, 0.5-2 parts of a reinforcing agent, 0.1-0.5 part of a dispersing agent and 0.1-1 part of a retarder. The quality of the concrete pavement brick is ensured by adopting the construction waste as the aggregate and adjusting the ingredients and quality of the cement and an additive; the prepared concrete pavement brick has the characteristics of high strength, good abrasive resistance, stable quality, long service life, low cost and the like; and the concrete pavement brick is prepared by adopting the construction waste as the aggregate, so that the construction waste is comprehensively utilized to turn the waste into treasure, reclamation of the construction waste is achieved, the ecological environment is improved, and the aims of protecting the environment, saving resources and achieving low-carbon economy are achieved.

Owner:盛丹

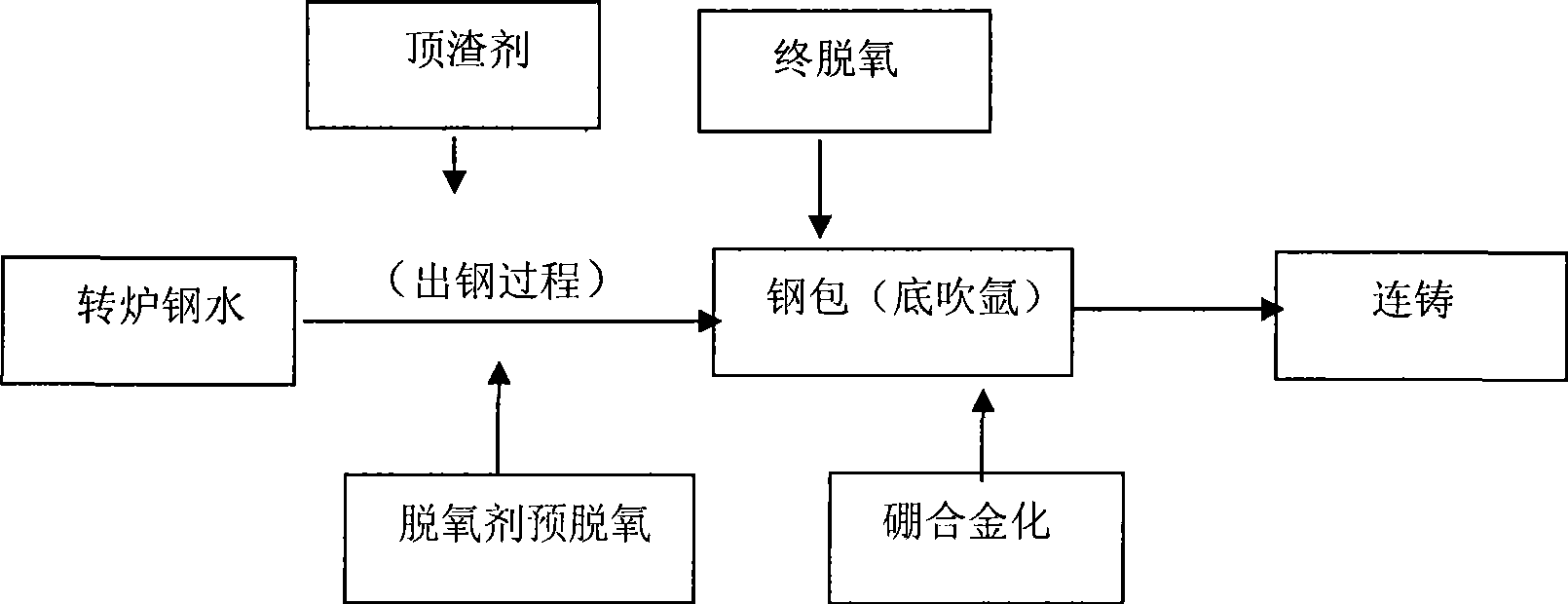

Method for producing boron steel by converter

InactiveCN101503746AAvoid stickinessAvoid water-prone mouthsManufacturing convertersAlloyMolten steel

The invention provides a method for producing boron steel in a converter, which is characterized in that argon subaeration is performed on a ladle in the whole process; a deoxidizer and alloys required by steel grades are begun to be added into the ladle for preliminary deoxidation and alloying under the condition of 1 / 4 tapping, and simultaneously a desulfurizer is added for desulfurization treatment; aluminum is added into the ladle in an argon blowing station for final deoxidation, and ferroboron is added into the ladle when the [O] is controlled to be between 0.0020 and 0.0040 percent; and the ferroboron is coated by an aluminum sheet and added into molten steel. The method has the advantages that: firstly, the method saves the refining procedure of an LF furnace and a vacuum furnace and has low production cost, short production procedure and high production efficiency; secondly, the pourability of the molten steel is good; thirdly, no requirement is put forward as for acid-soluble aluminum in the steel, so that the method solves the problems of pastiness of the molten steel, easy bonding of water gaps, reduction of the steel quality and the like caused by the increase of Al2O3 inclusion due to high acid-soluble aluminum; and fourthly, the recovery rate of boron can reach 60 to 75 percent and the wave range of the yield is small. Moreover, the method has good application prospect.

Owner:新余钢铁股份有限公司

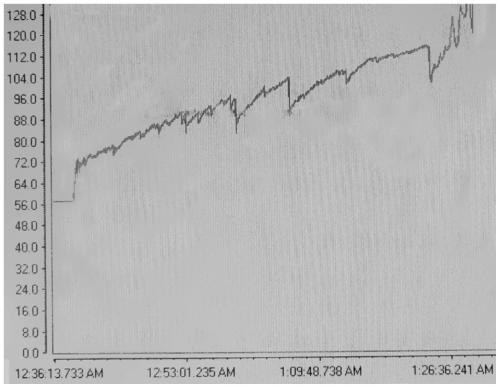

Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

The invention discloses a method for controlling cleanliness of molten steel, and a smelting control method capable of preventing a molten steel gap from nodulation during sulphur and aluminum contained steel pouring, and belongs to the field of smelting. The method for controlling cleanliness of the molten steel comprises the following steps that blast furnace molten iron without desulfuration issubjected to converter smelting, and during converter tapping, deoxygenation, alloying and tapping wash heat are carried out in sequence for carrying out inclusion removal treatment. Through an LF furnace, converter tapping is subjected to refining under the condition that acid soluble aluminum is not adjusted, that is, during tapping, a slagging constituent is added for controlling refining slagcomposition, and after the slag is dissolved, deoxygenation is carried out through a deoxidizing agent. Through the process, the content of sulphur in the molten steel is monitored, ferrous sulfide is used for adjusting the content of sulphur in the molten steel to the first target value, an RH furnace is used for refining LF furnace tapping, in the process, according to the content of the acid soluble aluminum of LF furnace tapping, selective aluminum feeding is carried out to adjust the content of the aluminum to the second target value, and after RH furnace refining is finished, calcium treatment is carried out. According to the process, the cleanliness of the molten steel can be improved, the nodulation problem during molten steel pouring can be avoided, and the stopper bar curve rising can be controlled.

Owner:SGIS SONGSHAN CO LTD

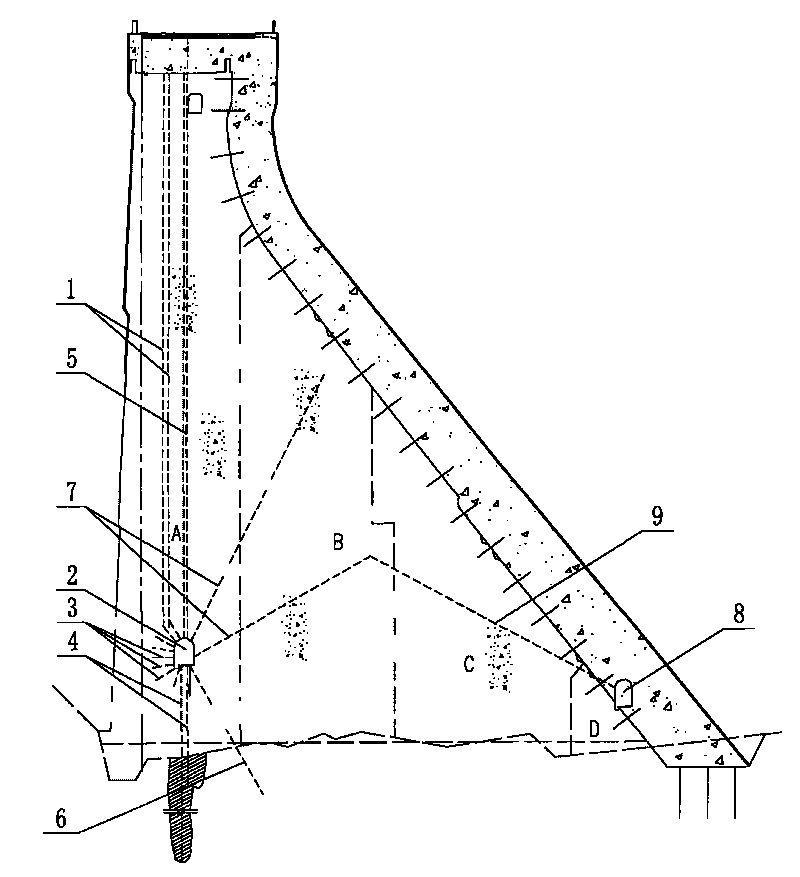

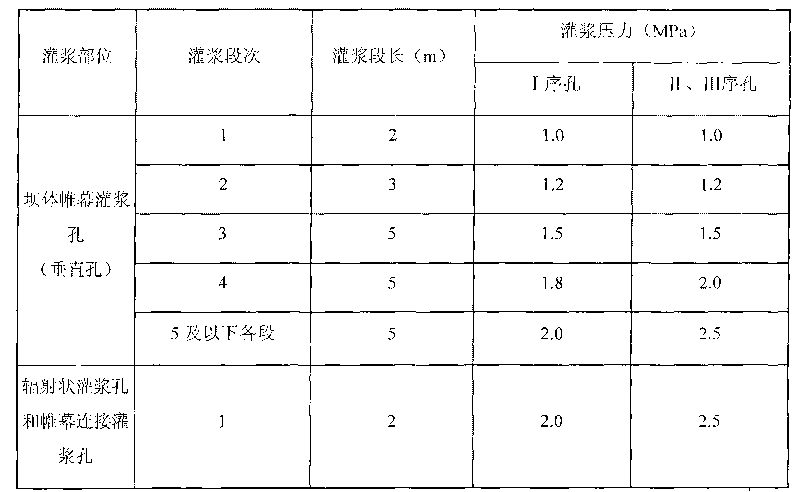

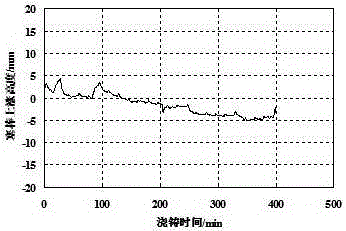

Construction method for dam body seepage preventing curtain grouting

ActiveCN101736719AIncreasing the thicknessIncreased durabilityMarine site engineeringWater dischargeSlurry

The invention relates to a construction method for dam body seepage preventing curtain grouting and provides a construction method for the dam body seepage preventing curtain grouting. The grouting is carried out by a technology of dense holes, high pressure, fine cement wet grinding and concentrated slurry, and the seepage preventing ability, the corrosion resistance and the durability of a dam body curtain are improved; the seepage is prevented in a way of front blockage and rear discharge, the downstream seepage escapement point elevation of a dam body and the uplifting pressure in a dam are reduced, and the problems of frozen thawing and frozen expansion of concrete are solved. The construction method for the dam body seepage preventing curtain grouting comprises the following steps of: a. downwards drilling a group of curtain grouting holes at the top of the dam; b. drilling radial grouting holes on the upstream surface in a basic gallery; c. downwards drilling curtain connection grouting holes extending into a dam foundation in the basic gallery; d. carrying out grouting by high pressure, fine cement wet grinding and concentrated slurry; and e. drilling a water discharge structure which is communicated with the basic gallery in the dam body. The invention is mainly used for the seepage prevention and discharge reinforcement processing of the concrete dam.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Crack repair material for asphalt concrete pavement

InactiveCN102827567AImprove liquidityImprove pourabilityMacromolecular adhesive additivesPaving detailsCross-linkRepair material

The invention discloses a crack repair material for an asphalt concrete pavement, and is characterized in that epoxy acrylate is taken as a substrate material, and a toughening agent, a diluent, an initiator, a promoter, a cross-linking agent and a pigment are doped to modify and adjust, by utilizing the invention, a big crack on the asphalt concrete pavement is repaired at high efficiency, and a tiny crack is effectively repaired, so that the capacity of resisting a vehicle load and influence of an environment factor of the asphalt concrete pavement can be greatly improved, and the service life of the asphalt concrete pavement is prolonged.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

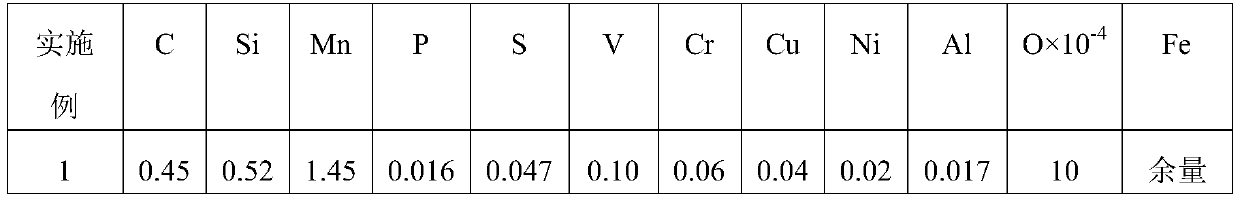

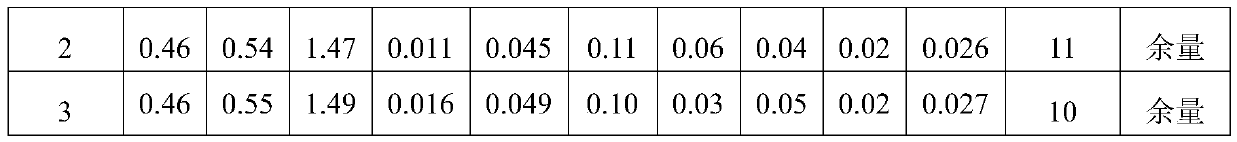

Magnesium and calcium-containing 45MnVS free machining quenched and tempered steel and manufacturing method thereof

ActiveCN105803308AImprove cutting performanceImprove purityProcess efficiency improvementMachinabilitySmelting

The invention provides magnesium and calcium-containing 45MnVS free machining quenched and tempered steel and a manufacturing method thereof. The steel comprises the main components of 0.42% to 0.51% of C, 0.15% to 0.6% of Si, 0.90% to 1.50% of Mn, 0.010% to 0.035% of P, 0.040% to 0.080% of S, 0.06% to 0.13% of V, 0.0005% to 0.008% of Mg, 0.01% to 0.04% of Al, 0.0008% to 0.005% of Ca, and the balance being Fe and unavoidable impurities. According to the magnesium and calcium-containing 45MnVS free machining quenched and tempered steel and the manufacturing method thereof, though adopting converter control smelting, LF+VD magnesium calcium compounded inclusion form treatment modification, M-EMS+F-EMS composite continuous casting and controlled rolling and controlled cooling, and adding a trace amount of magnesium and calcium on the basis of traditional 45MnVS steel, the sulfur-containing inclusion is modified, the material strength index is equivalent to the quenching and tempering condition of No.45 steel, and the calcium-containing 45MnVS free machining quenched and tempered steel has machinability and fatigue resistance better than the 45MnVS steel, and is applicable to parts and structural parts such as automobile connecting rods, crank shafts, knuckle spindles, drive shafts and front axles.

Owner:SHANGHAI UNIV

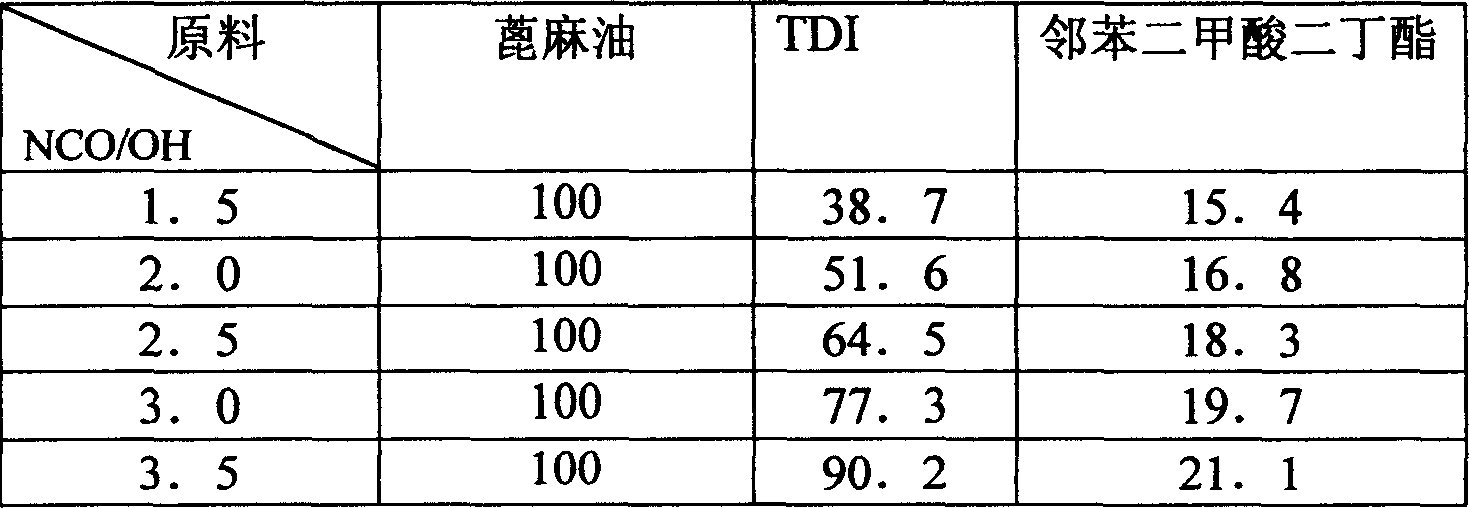

Mesh subaqueous patching material of interpenetrating polymer of epoxy/polyurethane, preparing process and application

InactiveCN1687190AImprove pourabilityImprove mechanical propertiesOther chemical processesEpoxyPolymer network

The present invention relates to an epoxy / polyurethane interpenetrating polymer network underwtaer repairing material. Its composition includes (by weight portions) acrylic epoxy resin 90-110 portions, polyurethane prepolymer 15-30 portions, diluting agent 30-60 prtions, initiator 0.5-1.0 portions of accelerator 0.1-0.2 portions. Besides, said invention also provides its excellent properties and extensive application range.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

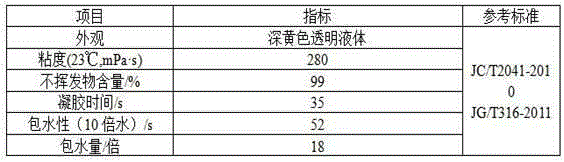

Hydrophilic double-component grouting plugging material

The invention relates to a hydrophilic double-component grouting plugging material. The hydrophilic double-component grouting plugging material comprises a component A and a component B with a grouting volume ratio of 1: 1-5, wherein the component A comprises the following substances in parts by weight: 100 parts of polyether polyol, 10-50 parts of a plasticizer, 20-60 parts of isocyanate, 0.05-0.3 part of a catalyst, 20-60 parts of a solvent and 0.01-0.05 part of a retarder; the component B comprises the following substances in parts by weight: 100 parts of sodium silicate, 2-5 parts of a cross-linking agent and 0.5-2 parts of a catalyst. The plugging material related to the invention also has the characteristics of environment protection, no pollution, low cost and high dynamic strength besides the properties of great grouting capability, high gelatinizing speed, large water containing quantity and rapid and efficient seepage-proof plugging. The grouting plugging material is suitable for the grouting plugging of various buildings, such as ponds, water towers and basements, and the grouting plugging engineering of various ports, docks, bridge piers, dams and hydropower station curtains.

Owner:JIANGSU SOBUTE NEW MATERIALS

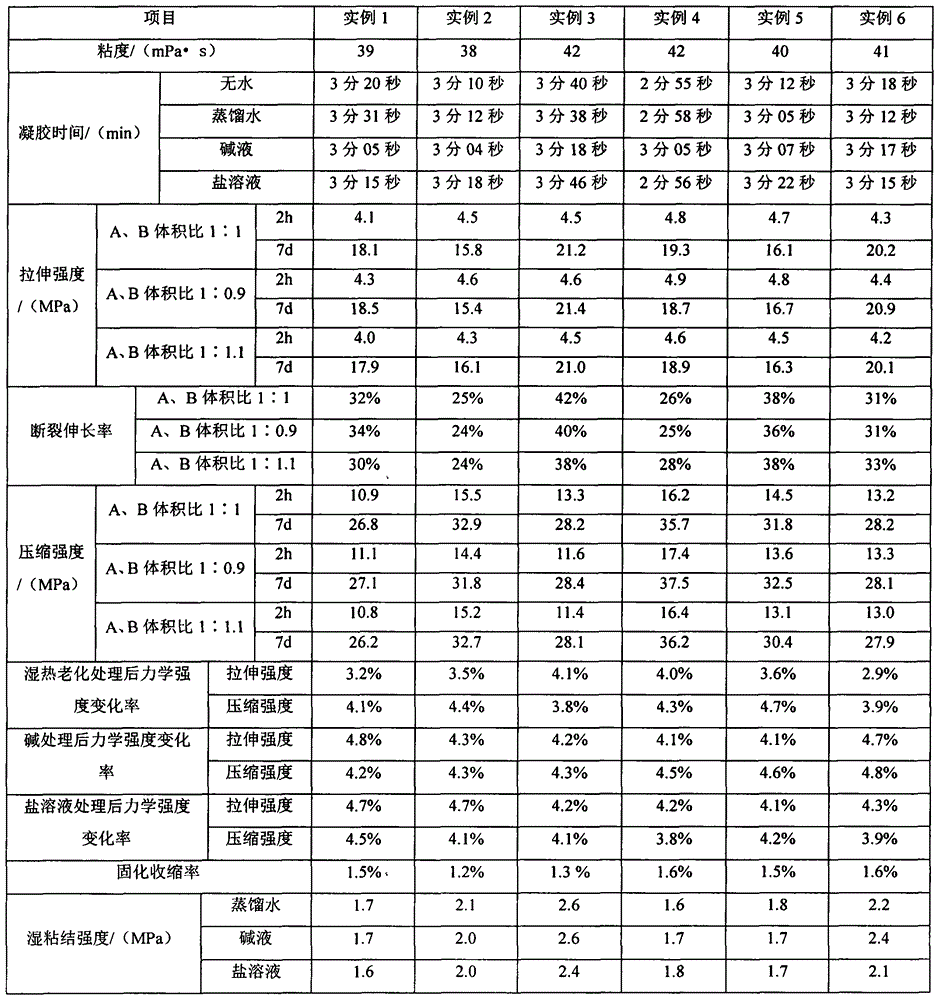

Foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material

The invention provides a foaming-free fast-curing high-strength leak-stopping waterproof polyurethane grouting material. The material is composed of a component A and a component B, wherein the component A comprises isocyanate monomer, isocyanate prepolymer and highly-hydrophobic environment-friendly plasticizer, the component B comprises high-activity polyether polyol, chain-extending cross-linking agent, highly-hydrophobic environment-friendly plasticizer and antioxidant, and a volume ratio of the component A to the component B is 1: 1. The leak-stopping waterproof polyurethane grouting material has low viscosity, is convenient to grout, has the characteristics of no foaming and fast curing and the advantages of good leak-stopping effect, high mechanical strength and wet bonding strength and excellent aging resistance, and is applicable to rapid leak stopping, water prevention and reinforcement of distress in concrete of an underground construction.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

Smelting method of sulfur bearing steel

ActiveCN104789734AReduce lossesSulfur content stability controlProcess efficiency improvementElectric furnaceLoss rateSlag

The invention relates to the technical field of ferrous metallurgy, in particular to a smelting method of sulfur bearing steel. The smelting method of the sulfur bearing steel comprises steps as follows: a, lime, a slag modifier and a compound deoxidizer are added to steel tapping slag of an electric furnace, so that the content of CaO is 30wt%-45wt% and the content of Al2O3 is 35wt%-45wt% in the slag; b, molten steel is sent into an LF (ladle furnace), the LF is powered on for slagging, the slag modifier is added to control the flowability of furnace slag, the furnace slag is turned into white slag through diffusion and deoxygenation, sulfur is fed into the LF for sulfur alloying, and calcification treatment is performed during LF steel tapping; c, slagging-off operation is performed after smelting by the LF is completed; d, the molten steel is transferred to a VD (vacuum degassing) furnace for smelting, and vacuum treatment is performed; a covering agent is added to a molten steel surface after degassing, and argon gas is adjusted for flexible argon blowing for 15-40 min. The content of S before and after VD treatment changes more slightly, the loss of sulfur in the steel after VD treatment is lower, the loss rate is smaller than or equal to 0.005%, the content of sulfur in molten steel after VD treatment is stably controlled, and stable product quality is obtained.

Owner:SHANDONG IRON & STEEL CO LTD

Non-quenched steel for camshafts and preparation method of non-quenched steel

InactiveCN110205547AMeet production needsImprove mechanical propertiesCalcium handlingContinuous casting

The invention belongs to the technical field of automobile steel and particularly relates to non-quenched steel for camshafts and a preparation method of the non-quenched steel. The steel is preparedfrom the chemical components in percentage by mass: 0.42%-0.49% of C, 0.30%-0.60% of Si, 1.00%-1.50% of Mn, 0.06-0.13% of V, 0.035%-0.075% of S, less than or equal to 0.035% of P, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Cu, 0.010%-0.040% of Alt, less than or equal to 15 ppm of [O], and the balance Fe and inevitable impurities, specifically, C+Si / 6+Mn / 4.5+1.8*V is equal to 1-1.1. Electric furnace smelting and LF refining are adopted, desulfuration, then sulfuration and proper calcium treatment process are adopted in the refining process, and Mn / S is controlled. The vacuum treatment time of the steel is longer than or equal to 12 minutes, and the soft blowing time is longer than or equal to 20 minutes. A casting blank is cast through continuous casting, the pulling speed and the superheat degree are controlled, and the continuous casting of twelve furnaces or more is achieved. The heating and soaking temperature, the heating time, the initial rolling temperature, the final rolling temperature, the cooling speed and the like are controlled in the rolling process, and finally, peeling and flaw detection are carried out, so that high-quality round steel is obtained; and the round steel can meet the requirement for direct cutting processing.

Owner:SHANDONG IRON & STEEL CO LTD

Inclusion control method for rod and wire alloy steel

The invention relates to the technical field of metallurgy, in particular to an inclusion control method for rod and wire alloy steel, which solves the problem of inclusion standard exceeding of the rod and wire material alloy steel, improves the molten steel cleanness and improving the molten steel casting performance. The method has the technical scheme that a production process of converter smelting, laser fusion (LF) refining, relative humidity (RH) refining and square blank continuous casting is adopted, the molten steel is subject to the calcium treatment after the LF refining completion during the production, and the RH treatment is then carried out after the soft blowing. The concrete steps are as follows: (1) the molten steel smelted by the converter is deoxidized by aluminum; (2) calcium wires are fed into the molten steel after the LF refining completion; (3) argon soft flowing is carried out on the molten steel after the wire feeding completion; (4) the molten steel is subject to RH vacuum treatment; (5) argon soft flowing is carried out on the molten steel after the RH vacuum treatment completion; and (6) tundish covering agents are added, and the continuous cast steel long nozzle argon blowing protection casting is adopted. The inclusion control method has the advantages that the production cost is greatly saved, and in addition, the inclusion grade is obviously reduced through being compared with that of the original process.

Owner:NORTHEASTERN UNIV +1

Novel grouting material and preparation method thereof

The invention discloses a novel grouting material. The novel grouting material is prepared from the following raw materials in parts by weight: 20 to 30 parts of waste concrete, 10 to 20 parts of cement, 8 to 15 parts of mineral powder, 15 to 25 parts of iron tailing slag, 10 to 30 parts of pulverized fuel ash, 7 to 22 parts of aggregate, 5 to 10 parts of waste stone, 6 to 12 parts of waste gypsum, 3 to 6 parts of polypropylene fiber, 2 to 3 parts of hydroxypropyl cellulose, 1 to 2 parts of nanometer calcium silicate hydrate, 3 to 8 parts of expanding agent, 2 to 3 parts of antifoaming agent, 0.5 to 1 part of water-reducing agent, 2 to 6 parts of early strength agent, 0.3 to 0.7 part of anti-settling agent, 0.1 to 0.3 part of air entraining agent and 0.2 to 0.4 part of retarder. The novel grouting material has very good compressive strength and flexural strength, and meets engineering requirements on basic materials; a preparation method of the novel grouting material is easy to operate, and is suitable for popularization.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Calcium treatment process of rod wire alloy steel

The invention belongs to the technical field of metallurgy of iron and steel, and particularly relates to a calcium treatment process of rod wire alloy steel. The invention adopts a converter smelting-LF (ladle furnace) refining-RH refining-square billet continuous casting production technique. The calcium treatment process is implemented in a way that: after the LF refining finishes, feeding an iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.08-0.16%; after the soft blow, carrying out RH treatment; after the RH treatment finishes, carrying out calcium carbonate treatment, and feeding the iron calcium wire, silico-calcium wire or solid calcium wire into molten steel at the linear speed of 50-250m / min to control the mass percent of calcium aluminum in the molten steel at 0.04-0.08%; and carrying out soft blow, and casting. When the treatment process is used for producing high-quality steel, the inclusion level can not deteriorate, the castability of the molten steel is good, the number of continuous casting furnaces is increased, the calcium content of the molten steel is low but does not influence the casting performance, and the treatment process plastifies the inclusions and improves the mechanical properties of steel.

Owner:NORTHEASTERN UNIV +1

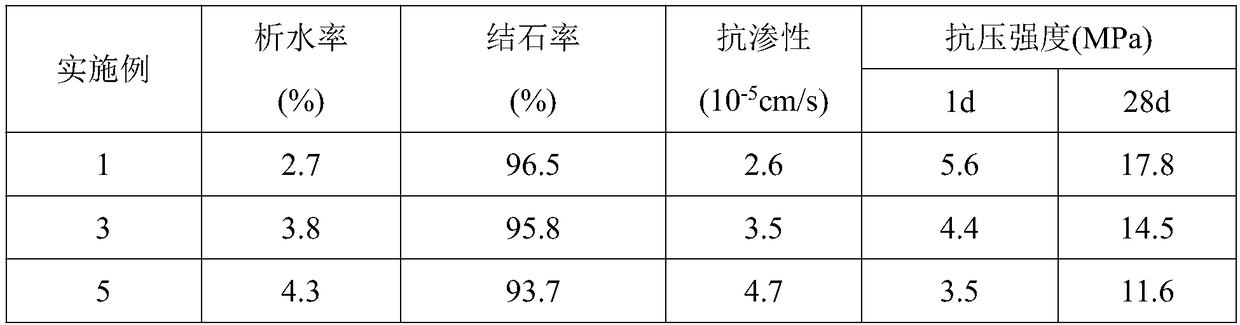

Controllable clay and cement seepage-proof reinforcement paste

The invention discloses controllable clay and cement seepage-proof reinforcement paste. The controllable clay and cement seepage-proof reinforcement paste is mainly prepared from clay raw stock, cement and water, wherein the clay raw stock is mainly obtained by stirring clay and water. A modifier is added in the controllable clay and cement seepage-proof reinforcement paste; the doping amount of the modifier is 1 to 3 percent; the modifier mainly comprises mineral additives, sulfate and bentonite in a mass ratio of a:b:c; and a:b:c is 5:(5-0):(0-5). The product has the advantages of high stability and water flow dilution resistance, controllable setting time, adjustable strength, high antiseepage performance, low cost, environment friendliness and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Ultra-low carbon aluminum killed steel molten steel treatment method

The invention discloses an ultra-low carbon aluminum killed steel molten steel treatment method and belongs to the technical field of iron and steel smelting. The ultra-low carbon aluminum killed steel molten steel treatment method aims at solving the problems that when ultra-low carbon aluminum killed steel molten steel is treated in the prior art, oxygen deficiency or high oxygen is generated easily during decarburization, molten steel inclusions are difficult to control, and the pourability is poor. The ultra-low carbon aluminum killed steel molten steel treatment method comprises the following steps that A, lime is added in a molten steel tapping process, and a slag regulating agent is added after tapping; B, high-alkalinity refining slag is added to a molten steel LF station, and theoxygen activity before the process of leaving the LF station is controlled to be within 800 ppm; and C, a molten steel RH station controls the oxygen activity of the molten steel to be within the range of 500 ppm-800 ppm, and the slag regulating agent is added during the process of leaving the RH station. By the adoption of the ultra-low carbon aluminum killed steel molten steel treatment method,the oxygen activity and slagging process of molten steel are properly controlled, the problems of insufficient oxygen and high oxygen during decarburization are solved, the state of molten steel inclusions is controlled stably, the refining processing capacity of the RH molten steel is improved, the pourability of the molten steel is improved, and the quality of continuous casting products is ensured.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Manufacturing method of low-oxygen low-inclusion bearing steel

The invention discloses a manufacturing method of low-oxygen low-inclusion bearing steel. The manufacturing method comprises the steps of preparing of raw materials, converter smelting and alloying, LF+VD refining, continuous casting, rolling and slow cooling, wherein the mass percent of chemical components of the bearing steel in content is controlled to reach the standards of 1.06-1.1% of C, 0.7-0.75% of Si, 1.30-1.35% of Mn, 0.02-0.05% of Mo, 0.06-0.08% of Ni, 1.85-1.9% of Cr, 0.02-0.04% of Co, 0.02-0.03% of V, 0.01-0.03% of Als, 0.02-0.03% of Hf, 0.01-0.02% of Ta, 0.005-0.008% of Te, 0.05-0.1% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025 of P, less than or equal to 10*10<-6> of O, less than or equal to 2*10<-6> of H and the balance Fe and inevitable impurities.According to the manufacturing method of the low-oxygen low-inclusion bearing steel smelting, the raw materials, the refining process, refining slag, crystallizer casting powder and the continuous casting process are controlled, so that the content of the obtained non-metal impurities of the bearing steel is low, and the content of the Ti is low; the phenomenon of nozzle nodulation is avoided inthe continuous casting process of square billets, blank throwing is smooth, the solidification speed of a blank shell is high, and safety of continuous casting is ensured, so that a final product is uniform in component, stable in performance and good in strength; and after heat treatment, the yield strength reaches 700 MPa, the tensile strength reaches 910 MPa, and the elongation at the cross section reaches 35%.

Owner:温州市赢创新材料技术有限公司

Micro-expansion grouting material and preparation method thereof

The invention discloses a micro-expansion grouting material. The micro-expansion grouting material is characterized by being prepared from the following materials in parts by mass: 30-50 parts of high-calcium flyash, 15-30 parts of calcined shale, 5-20 parts of phosphorus gypsum, 10-20 parts of ordinary silicate cement and 5-15 parts of rapidly-hardened sulphate aluminum cement. Further, additivematerials and water are added according to the times of the total parts by mass of the above materials on the basis that the total parts by mass of the materials are prepared to 100 parts. The additive materials comprise 0.5-1 part of a polycarboxylic acid water reducer, 0.1-1 part of redispersible latex powder, 0.05-0.15 part of hydroxypropyl methyl cellulose ether, 0.2-0.4 part of calcium lignosulphonate and 0.1-0.5 part of a cationic organic polymer; the water accounts for 8-10 parts. The micro-expansion grouting material has the characteristics of excellent mechanical property, micro expansion, low preparation cost, high solid waste utilization rate, green and environmental protection and high compatibility with soil.

Owner:重庆建工第七建筑工程有限责任公司 +1

Method for preparing geopolymer grouting material and method for applying geopolymer grouting material to static pressure grouting

ActiveCN106587782AReduce labor intensityLow viscosityCement productionRoads maintainenceSilica fumeSodium silicate

The invention provides a method for preparing a geopolymer grouting material and a method for applying the geopolymer grouting material to static pressure grouting. Raw materials for preparing the geopolymer grouting material include steel slag, mineral slag, sodium silicate, silica fume, calcium bentonite, softened water and a composite alkali activator. The method for preparing the geopolymer grouting material comprises the steps that 1, a component A is prepared; 2, a component B is prepared; 3, a component C is prepared; and 4, the geopolymer grouting material is prepared. The method for static pressure grouting comprises the steps of 1, survey; 2, assessment; 3, pit sounding; 4, hollowing general survey; 5, deflection value check; 6, comprehensive evaluation; 7, measurement and hole arrangement; 8, drilling; 9, grouting; 10, check; 11, grouting hole sealing; and 12, recheck to complete static pressure grouting. The methods have the advantages of environmental friendliness, low viscosity, high elasticity modulus, high cohesiveness, low cost, high efficiency and high durability.

Owner:中能化江苏矿山生态研究院有限公司

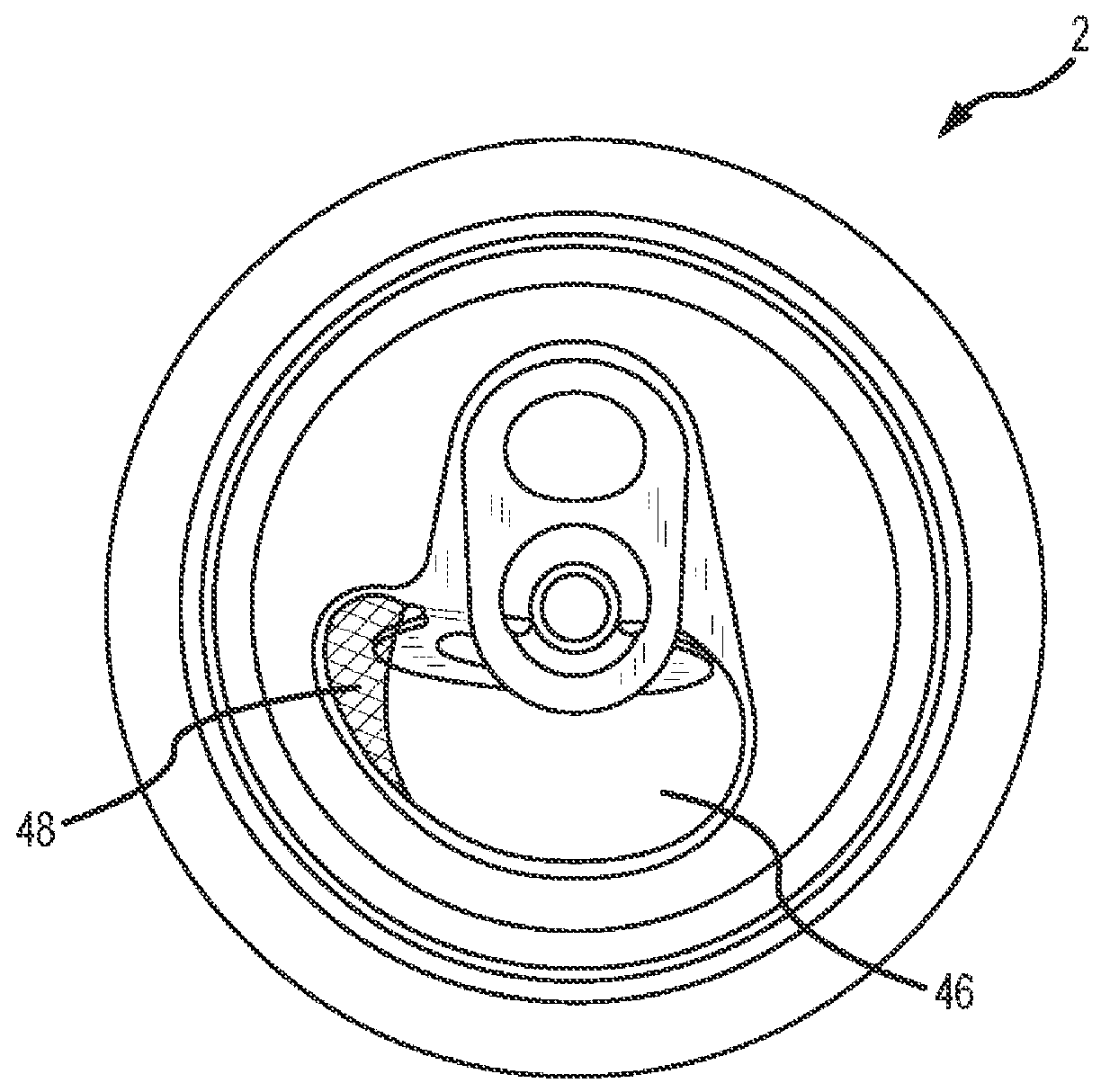

Metal end closure with an extended score which is opened with a secondary tool

ActiveUS20160052667A1Improve liquidityIncreased leverageOpening closed containersBottle/container closureEngineeringMechanical engineering

A metallic container end closure is provided that generally comprises a primary pour opening and an extended or secondary score which is opened with a secondary tool to form a secondary pour opening. The fact that a secondary tool is required allows the secondary score to be shallower, and thus more secure than deeper scores that are openable by finger pressure alone. Once the secondary tool is used to fracture the secondary score, a secondary pour opening is produced adjacent to the primary pour opening to form a larger opening. A user may insert materials such as ice or oranges through the enlarged pour opening.

Owner:BALL CORP

Low-viscosity high-early-strength polyurethane repair material for high speed railway slab ballastless track filling layer open joint repair

ActiveCN104479099AImprove performanceThe ratio is scientific and reasonableDefoaming AgentsRapid construction

The invention discloses a low-viscosity high-early-strength polyurethane repair material for high speed railway slab ballastless track filling layer open joint repair. The repair material consists of two parts, namely a part A and a part B, wherein the part A consists of the following raw materials in parts by mass: 100 parts of isocyanate and prepolymers thereof; the part B consists of the following raw materials in parts by mass: 60-80 parts of reactive hydrogen oligomer, 40-70 parts of a plasticizer, 0.5-2 parts of a defoaming agent and 0.1-1 part of an anti-aging agent; and the volume ratio of the part A to the part B is 1:1. The polyurethane open joint repair material has the advantages of low viscosity, high curing speed, high mechanical strength, high adhesive strength, high toughness and excellent durability, can meet the requirements on rapid construction in skylight time and instant traffic service after repair and can be used for rapid maintenance of the operating high speed railway slab ballastless track structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Production process for high-purity bearing steel

InactiveCN106591536ALow residual elementsReduce gas contentProcess efficiency improvementLow nitrogenSlag

The invention belongs to the technical field of steel preparation, and particularly relates to a production process for high-purity bearing steel. The production process comprises the following steps: firstly, adding blast-furnace molten iron and steel scrap in an electric converter and smelting; secondly, alloying a steel ladle by virtue of an alloy, an aluminium cake and a low-nitrogen carburant; thirdly, discharging molten steel into the steel ladle subjected to the alloying treatment after the smelting is completed, slagging and enabling the slagging result to meet the requirements of while slag in the earlier stage of refining, obtaining the while slag and then carrying out aluminium line feeding operation; fourthly, hoisting molten steel qualified after the refining into a vacuum tank and carrying out vacuum treatment; and finally carrying out continuous casting. Cancel of molten steel modification treatment is realized; and moreover, the molten steel is high in castability and meets the production requirements of high-standard bearing steel.

Owner:ZENITH STEEL GROUP CORP

Efficient alloying method for smelting 38CrMoAl steel

The invention discloses an efficient alloying method for smelting 38CrMoAl steel and relates to the field of ferrous metallurgy. The method includes the technological processes of electric arc furnace smelting, LF refining, VD vacuum refining and big round billet continuous casting in sequence. In the electric furnace steel tapping process, aluminum ingots, silicon iron, ferromanganese, ferrochromium, ferromolybdenum, pre-molten refining slag and lime are sequentially added to alloy and slag materials for pre-refining. In the LF refining process, molten steel components except aluminum are adjusted in place. In the VD vacuum refining process, vacuum treatment is conducted twice, 8.5-9.5 kg / t of the aluminum ingots are added at a time after first vacuum treatment is completed, and then second vacuum treatment is conducted to homogenize the molten steel components and denaturalize inclusions. In the big round billet continuous casting process, whole-course protective continuous casting is adopted. The aluminum yield and the molten steel cleanliness can be effectively increased, the service life of a steel ladle can be effectively prolonged, the molten steel is high in controllability of the chemical components and good in castability, and the stability of product performance can be improved.

Owner:DALIPAL PIPE

High performance no-contraction cement base grouting material and its preparing method

The high-performance no-contraction cement-base grouting material consists of portland cement, sulphoaluminate clinker, bentonite, sodium methyl naphthalenesulfonate condensate, defoaming agent, quartzite, etc. in certain proportion. The grouting material has controllable solidification time, excellent flowability, excellent grouting performance, relatively high volume stability and no contraction. The present invention may be used widely in the repair and construction of various concrete engineering.

Owner:TONGJI UNIV

Steelmaking method of sulfur and aluminum-containing steel

The invention relates to the technical field of steelmaking, in particular to a steelmaking method of sulfur and aluminum-containing steel. The steelmaking method of the sulfur and aluminum-containingsteel comprises the following steps: (1) converter smelting: prohibiting the molten iron pre-desulfurization process before the converter smelting process, controlling the sulfur content of molten iron entering a converter not to be less than 0.035 percent and then performing the converter smelting process; (2) steel tapping: adding an aluminum block or aluminum iron for deoxidization and addingferrosilicon and ferromanganese for alloying; (3) LF furnace refining: adding active lime, fluorite and aluminum pellets to make refining slag, feeding a silicon-calcium wire of 0.8-1.2 m / ton into molten steel at the LF refining later stage and prohibiting the addition of aluminum at the LF refining later stage; (4) RH vacuum: (5) sulfur addition: adding FeS in the molten steel, so that the content of S in the steel is that the required standard sulfur percentage content deducts 0.002 percent; (6) soft blowing. The steelmaking method provided by the invention has the benefits that not only canthe content of the sulfur in the sulfur and aluminum-containing steel be controlled stably, but also the nozzle nodulation phenomenon is avoided, and further the pourability of the molten steel is enhanced.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com