Asphalt base composite material for pavement crack repair

A technology for composite materials and pavement cracks, which is applied in the field of pavement repair materials to achieve the effects of not easy secondary cracking, simple construction and long validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

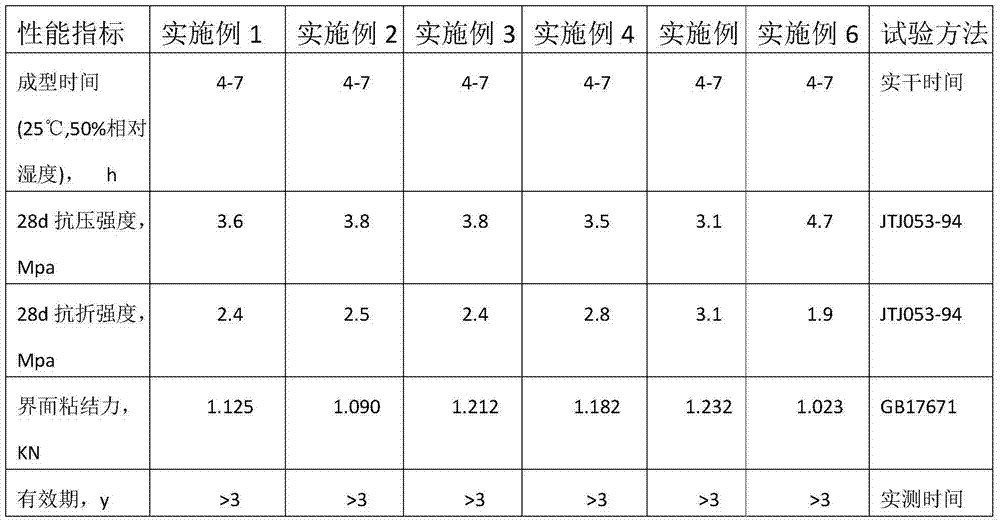

Examples

Embodiment 1

[0033] Component A: Select 5.2g of anionic emulsifier (carboxylate type), 46g of water and 9.8g of heavy traffic road asphalt AH-7079.8g to prepare emulsified asphalt in a colloid mill; select 133g of anionic emulsified asphalt (carboxylate type), 1g of Mix water agent (polycarboxylic acid type), 1g defoamer (silicon type), and 3g water-based acrylic resin in a mortar mixer for 10 minutes to obtain component A. The control speed is 1200rpm.

[0034] Component B: Mix 100g of PO42.5 cement, 90g of quartz sand and 1g of aluminum powder in a mortar mixer for 15 minutes to obtain component B. The control speed is 60rpm.

[0035] When in use, mix A and B components evenly on site, and then the joint filling construction can be carried out.

Embodiment 2

[0037] Component A: Select 6g of anionic emulsifier (carboxylate type), 54g of water and heavy traffic road asphalt AH-9090g to prepare emulsified asphalt in a colloid mill; prepare 150g of anionic emulsified asphalt (carboxylate type), 3g of water reducer (aliphatic type), 1g defoamer (organic silicon type), 5g SBR latex, 10g water and stir in a mortar mixer for 10min to obtain component A. The control speed is 1200rpm.

[0038] Component B: Mix 100g of PO42.5R cement, 110g of quartz sand and 1g of calcium oxide in a mortar mixer for 15 minutes to obtain Component B. The control speed is 60rpm.

[0039] When in use, mix A and B components evenly on site, and then the joint filling construction can be carried out.

Embodiment 3

[0041] Component A: Select 4.8g of anionic emulsifier (sulfonate type), 43.2g of water and heavy traffic road asphalt AH-11072g to prepare emulsified asphalt in a colloid mill; prepare 120g of anionic emulsified asphalt (sulfonate type), 1g of Aqueous agent (naphthalene type), 1g defoamer (polyether type), 4g water-based epoxy resin, 10g water are stirred in a mortar mixer for 10min to obtain component A. The control speed is 1200rpm.

[0042] Component B: Mix 100g of PO42.5R cement, 70g of quartz sand and 1g of calcium oxide in a mortar mixer for 15 minutes to obtain Component B. The control speed is 60rpm.

[0043] When in use, mix A and B components evenly on site, and then the joint filling construction can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com