Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3426results about How to "Low technical requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

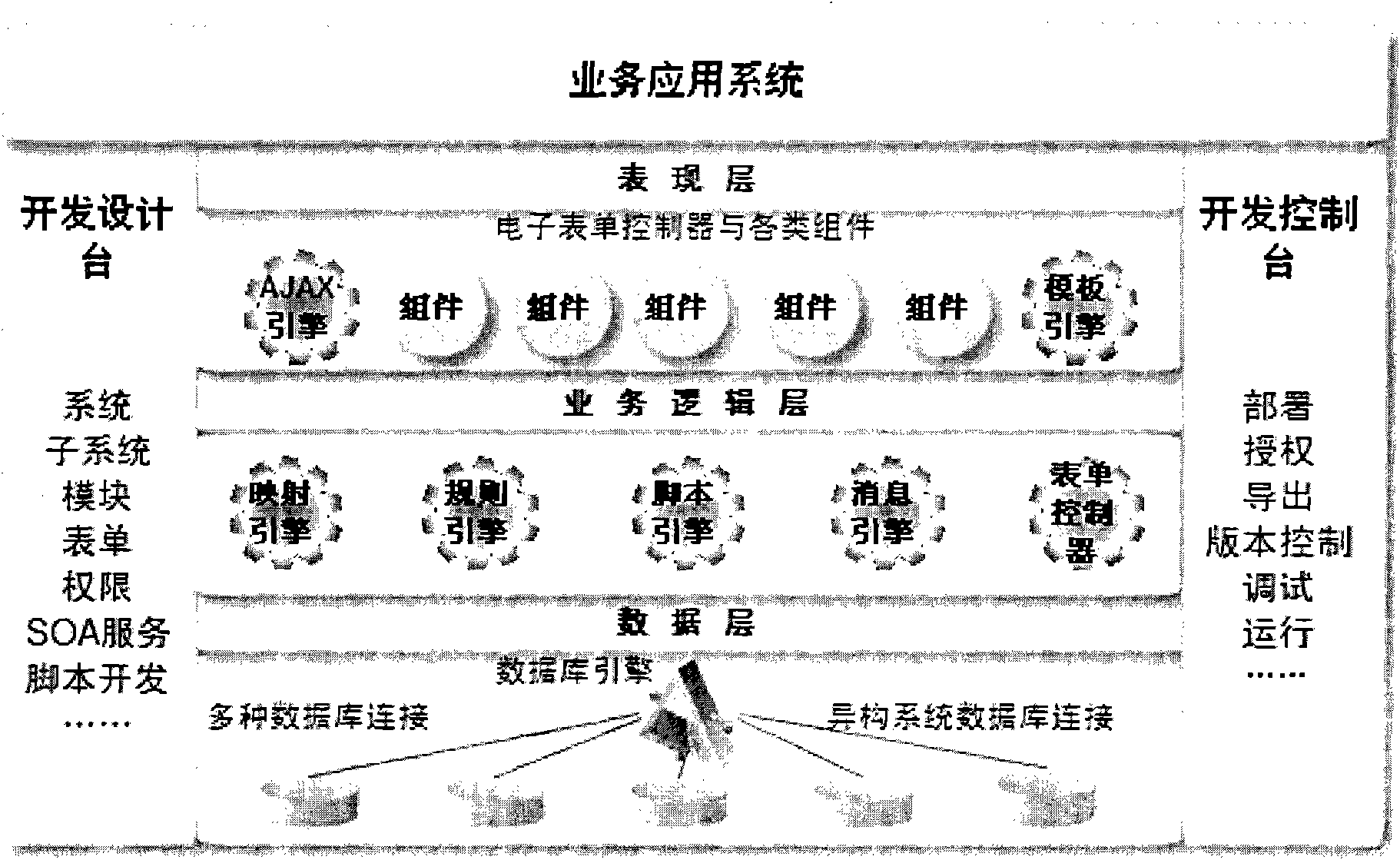

Technical implementation method for application development through electronic form

InactiveCN102063306ARapid Visual DevelopmentReduce the amount of developmentSpecific program execution arrangementsOperational systemElectronic form

The invention discloses a technical implementation method for application development through an electronic form. The electronic form technique integrates data acquisition and presentation functions into a whole; an electronic form system is divided into an interface representation layer, a service logic layer and a data exchange layer; and the electronic form technique reduces the development programming codes by over 90 percent in comparison with the traditional development mode, the development efficiency is improved by one order of magnitude in comparison with the traditional mode, the configured design concept and the development mode are improved, the agility of a service system is greatly promoted, data sharing and application integration are realized by adopting service-oriented architecture (SOA) loose coupling application integration technology, different bottom-layer operating systems and databases can be spanned, and the application system has good compatibility and mobility.

Owner:夏春秋

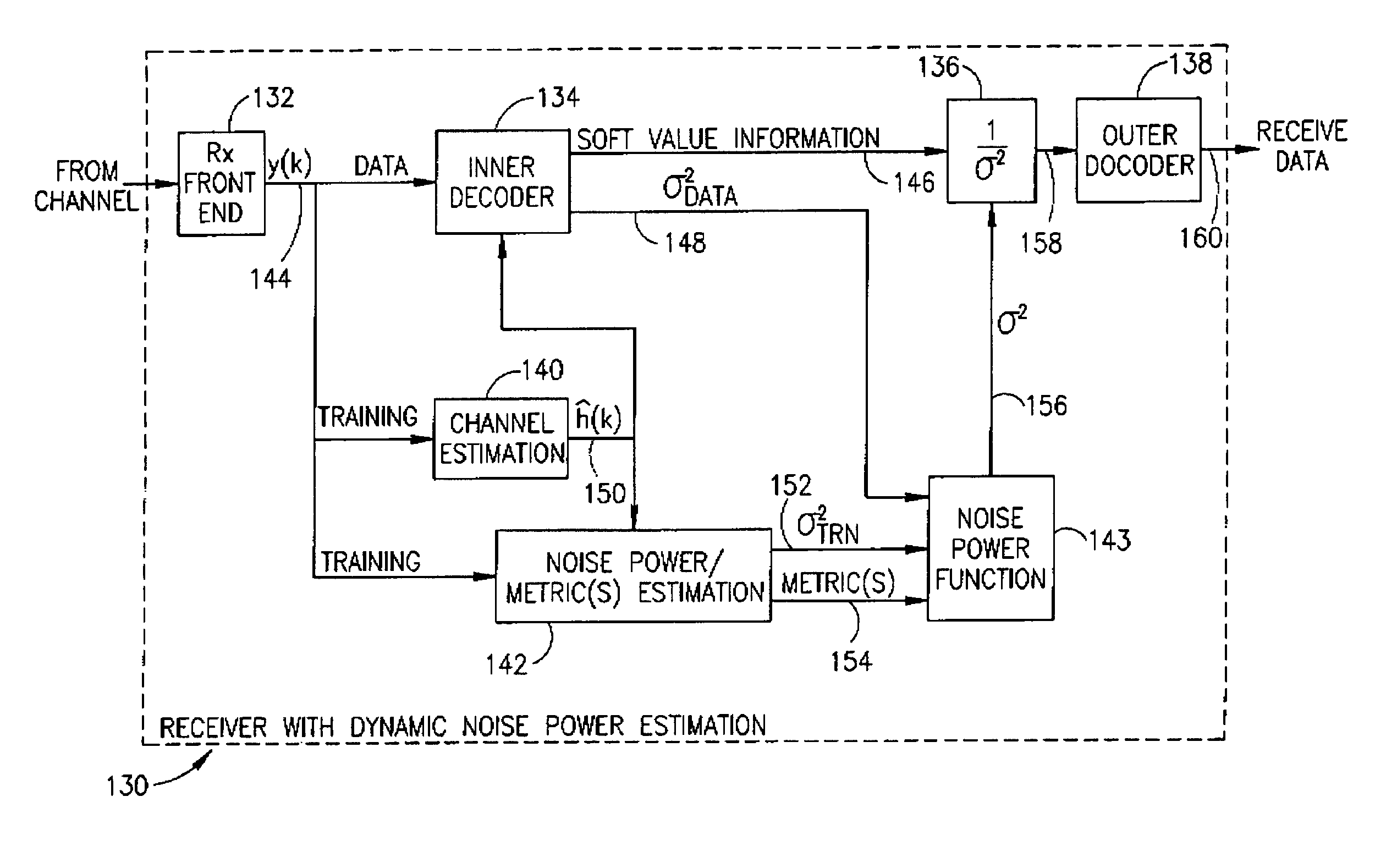

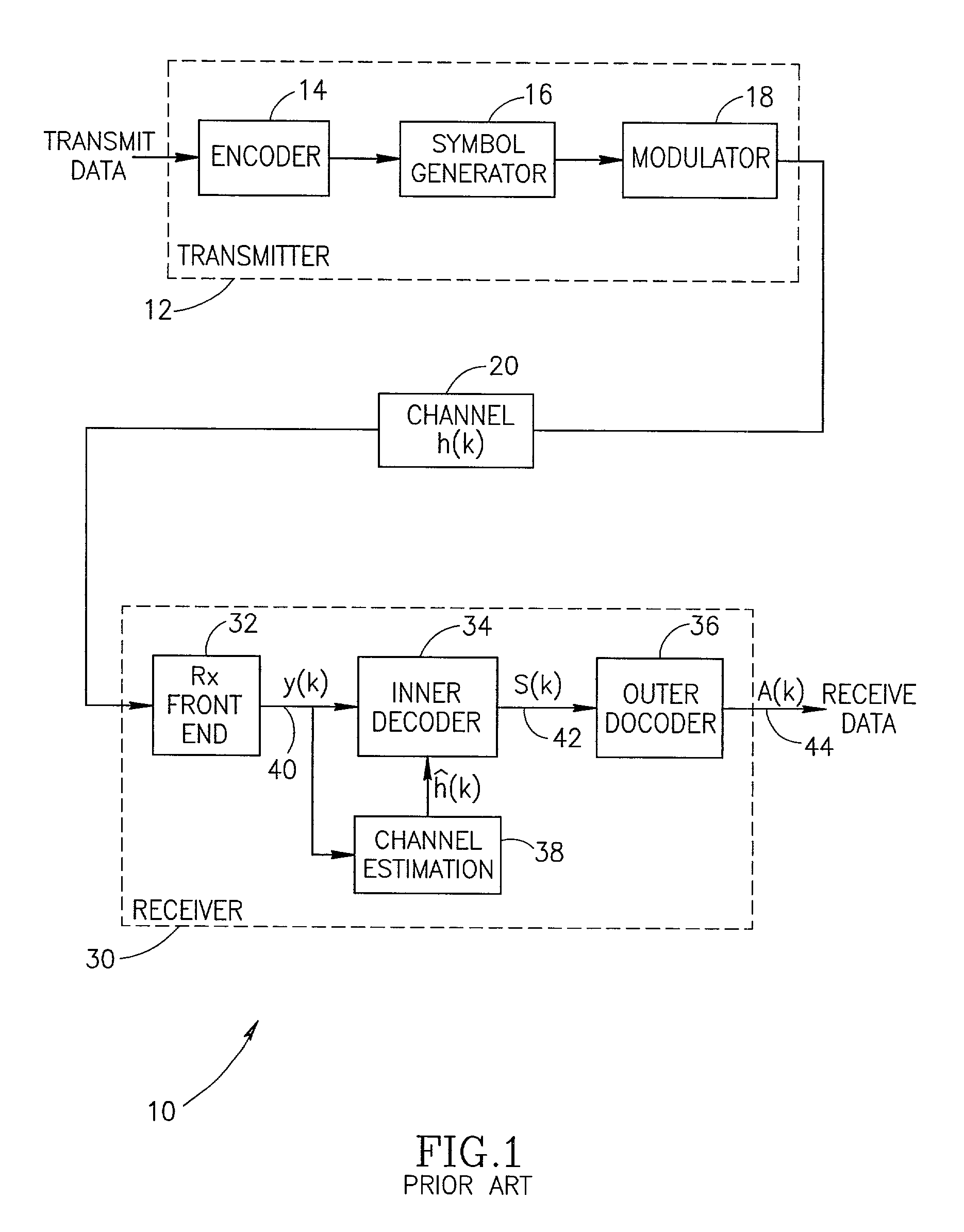

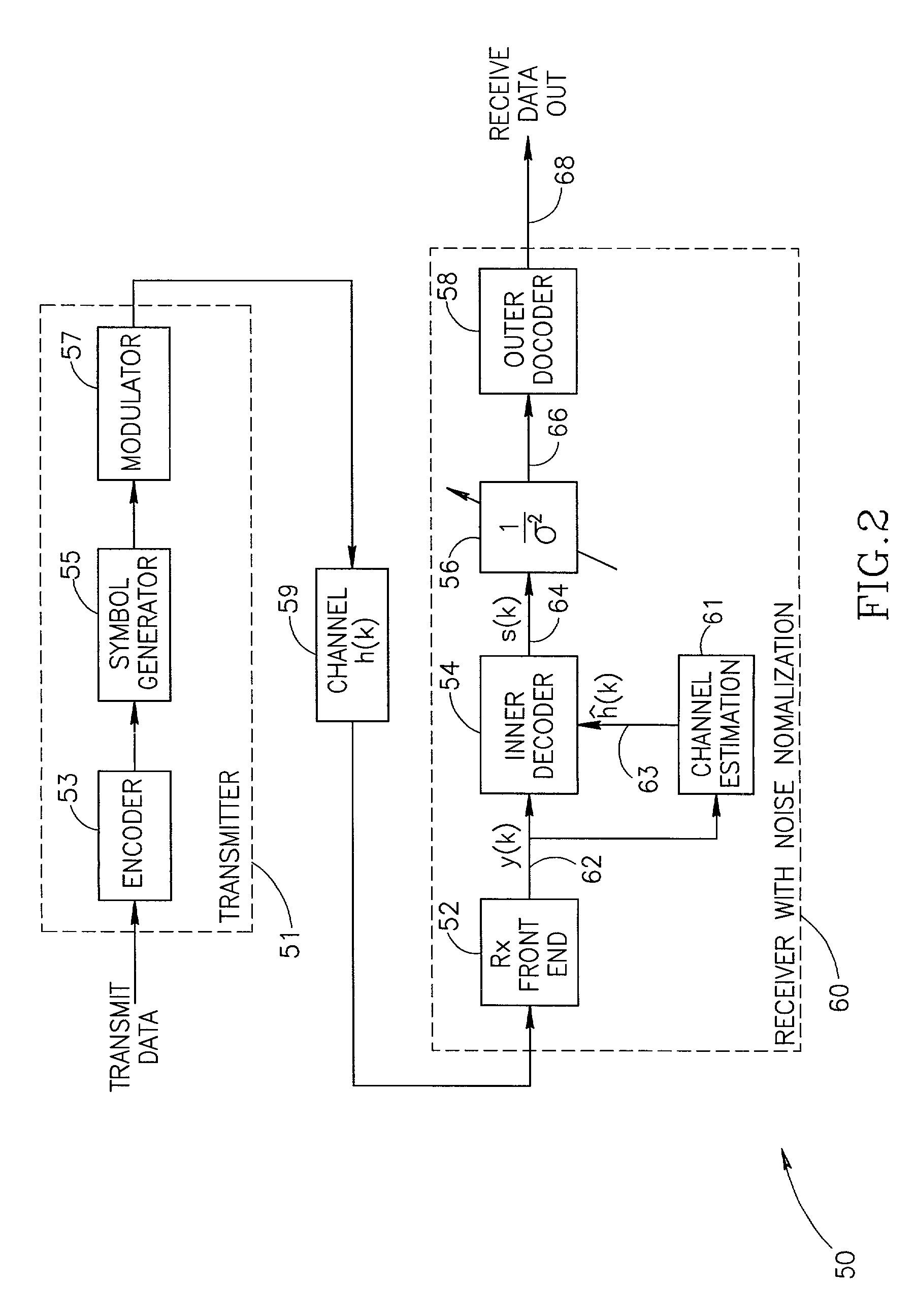

Normalization of equalizer soft output for channels with varying noise power

InactiveUS6980602B1Overcome disadvantagesSuitable for useData representation error detection/correctionError preventionSignal-to-noise ratio (imaging)Computer science

An apparatus for and method of generating normalized soft decision information output from an inner decoder (i.e. equalizer) in a communications receiver. The invention is operative to normalize the soft decision information before it enters a soft outer decoder. The normalization is performed using a noise power estimate that is dynamically calculated in response to changing noise statistics on the channel. The normalized soft decision output is then applied to the soft outer decoder thus realizing maximum performance therefrom. The noise power estimate is derived from the training sequence and / or the data portion of the received signal. Both types of estimates are calculated. A binary or smoothly weighted average is calculated using both types of estimates. The weighting factor is determined based on one or more performance metrics, such as the Signal to Noise Ratio (SNR).

Owner:COMSYS COMM & SIGNAL PROC

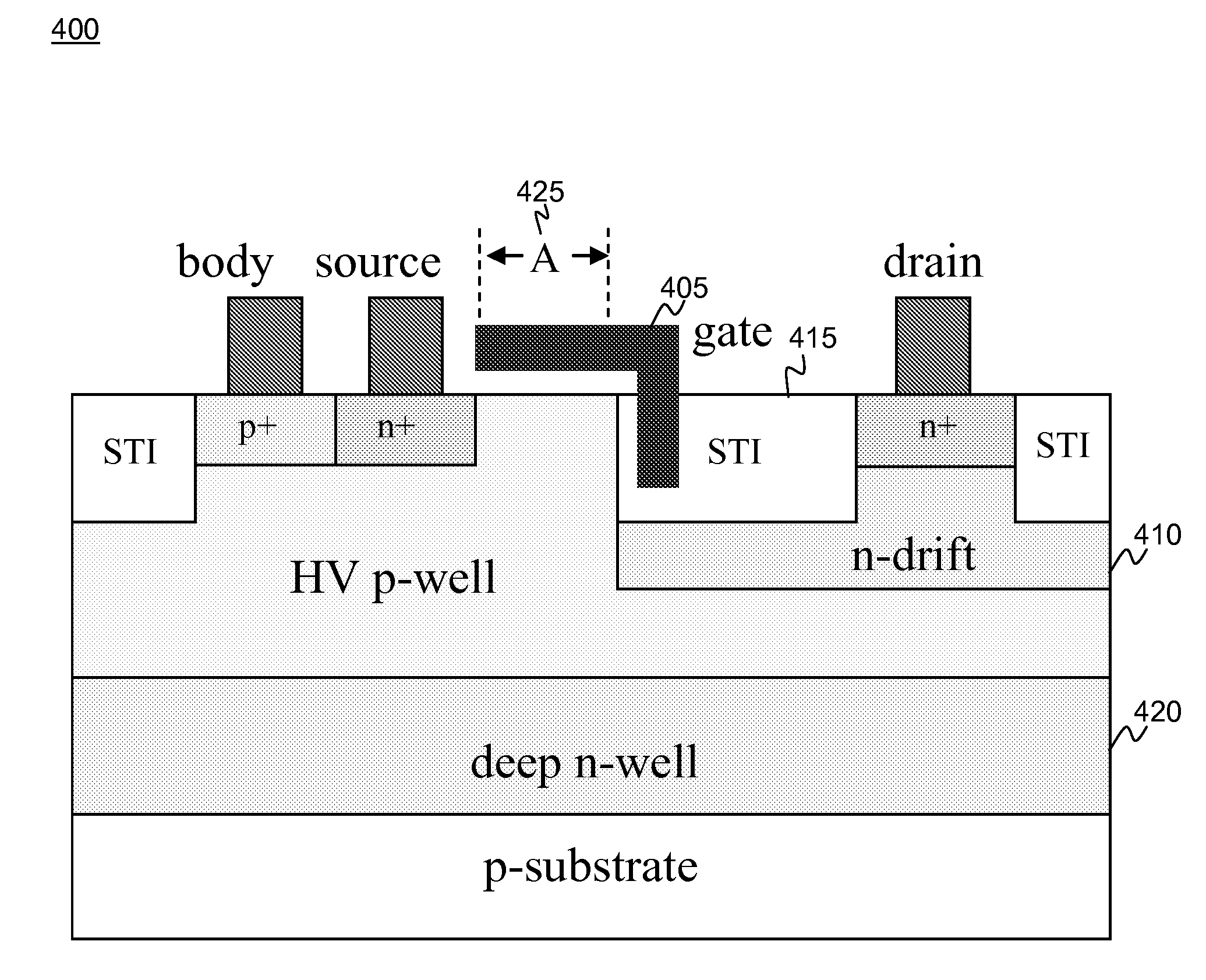

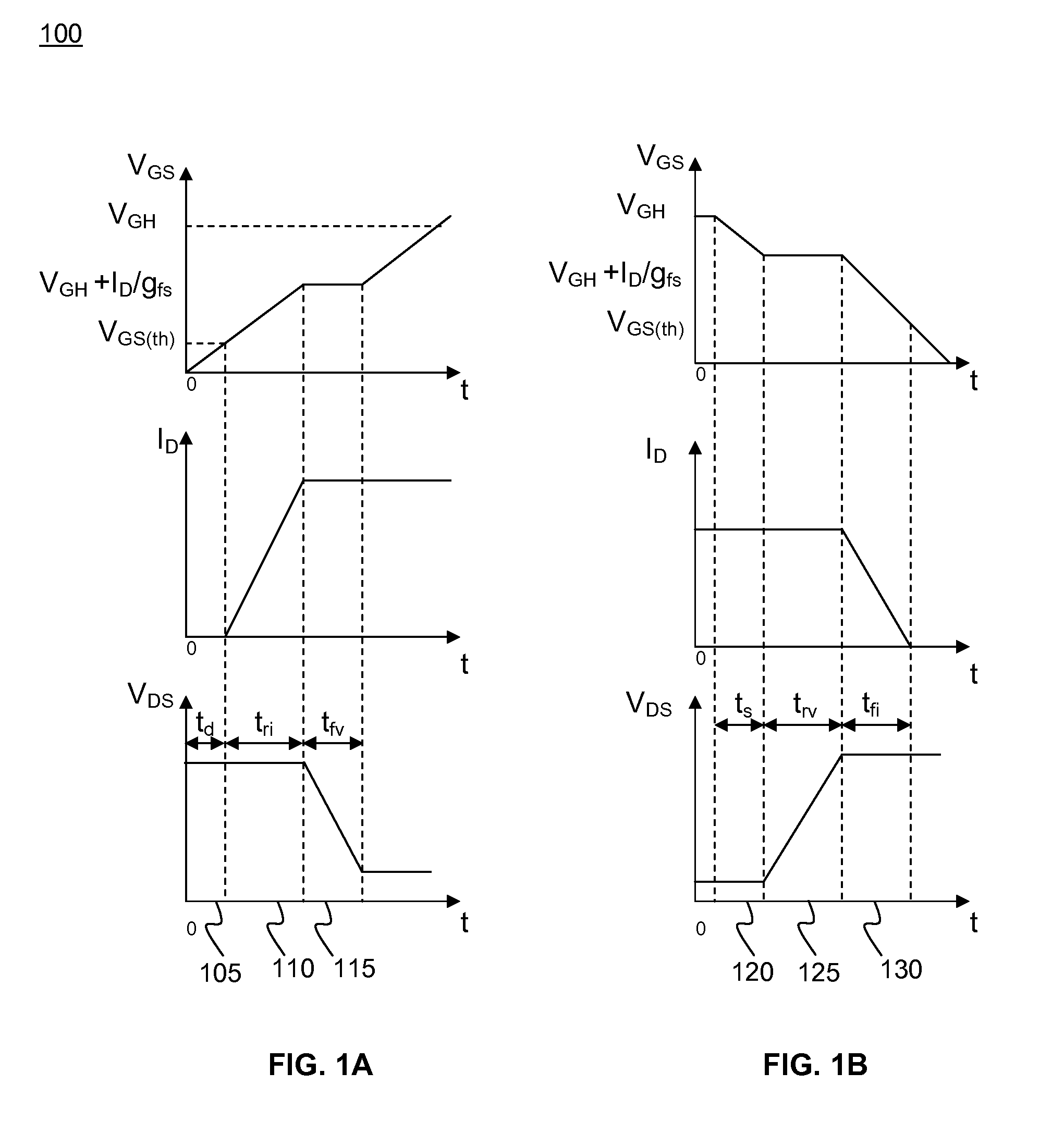

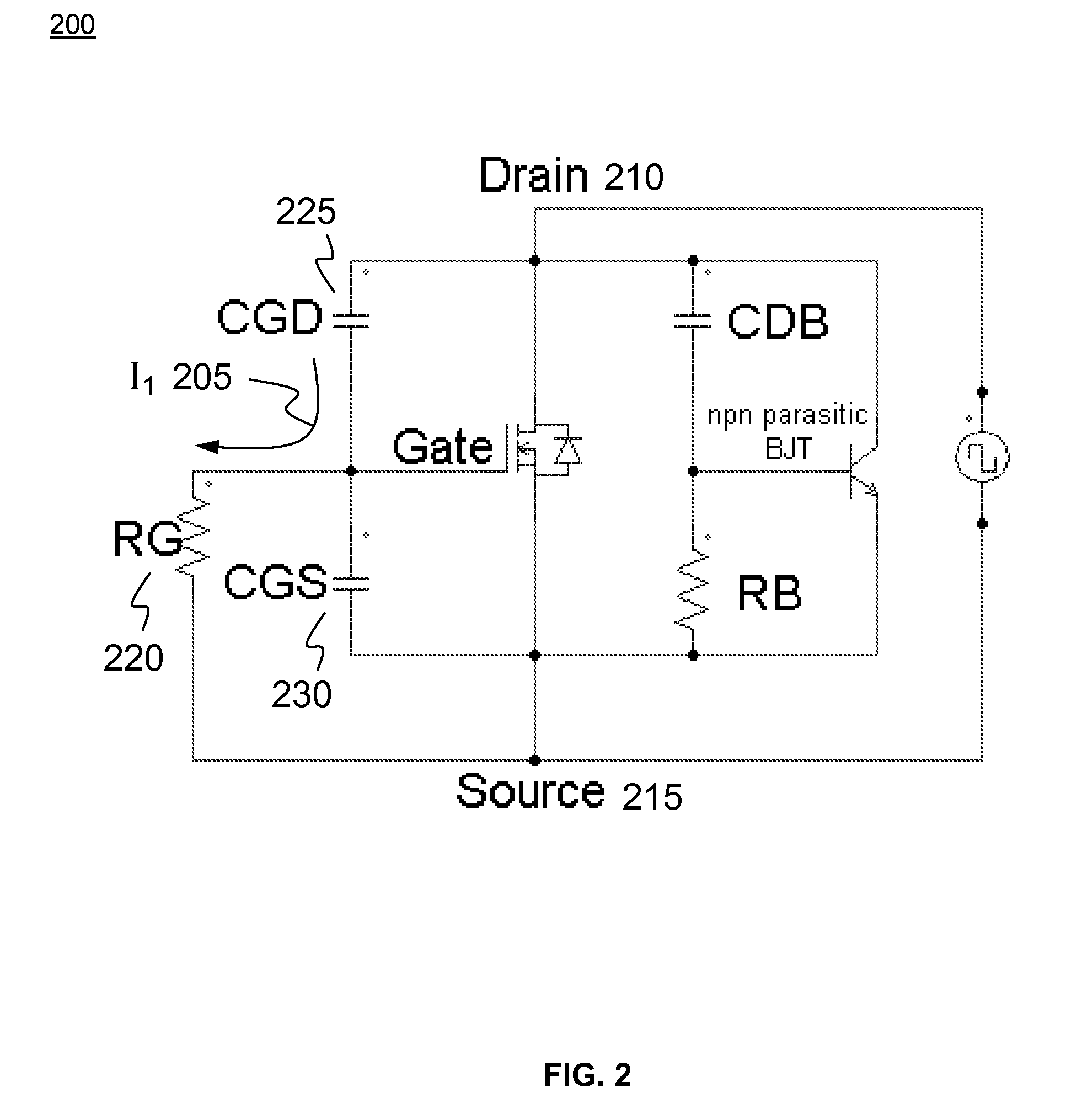

High speed orthogonal gate edmos device and fabrication

InactiveUS20090283825A1Reduce gate-to-drain capacitanceMinimizesSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETCapacitance

An orthogonal gate extended drain MOSFET (EDMOS) structure provides a low gate-to-drain capacitance (CGD) and exhibits increased reliability. It has a gate electrode that is folded into the shallow trench isolation (STI) oxide region. Horizontal and vertical gate electrode segments provide gate control. It accommodates both high voltage devices and standard CMOS components on the same substrate. Reduced surface field (RESURF) technology is employed to optimize tradeoffs between high breakdown voltage and specific on-resistance. Device fabrication steps are compatible with standard CMOS flow and process modules can be added or removed from baseline CMOS technology.

Owner:ASAHI KASEI ELECTRONICS CO LTD

Storage system and method for reorganizing data to improve prefetch effectiveness and reduce seek distance

InactiveUS20060026344A1Improve spatial localityImprove system performanceInput/output to record carriersMemory adressing/allocation/relocationParallel computingComputer science

Owner:INT BUSINESS MASCH CORP

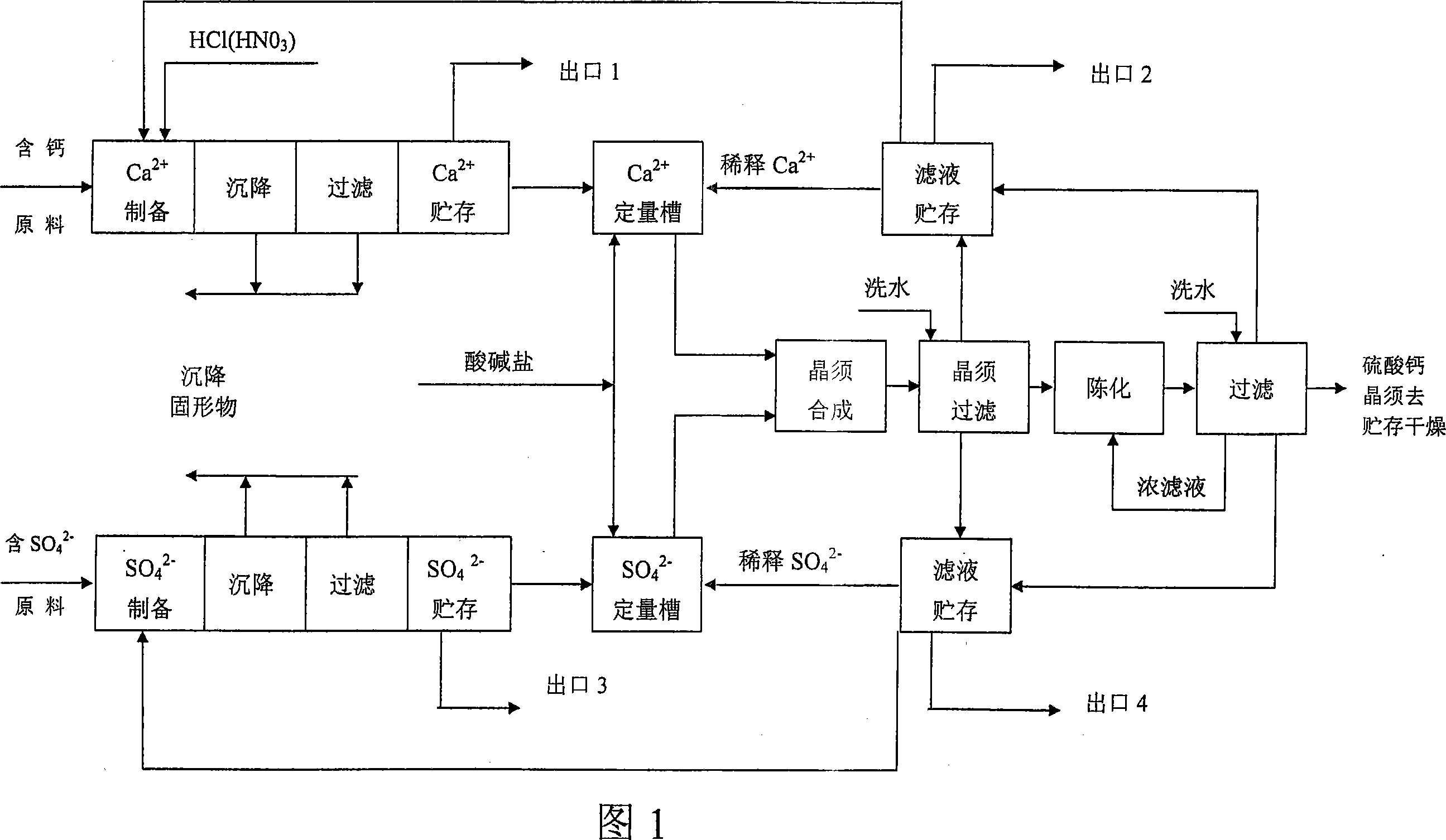

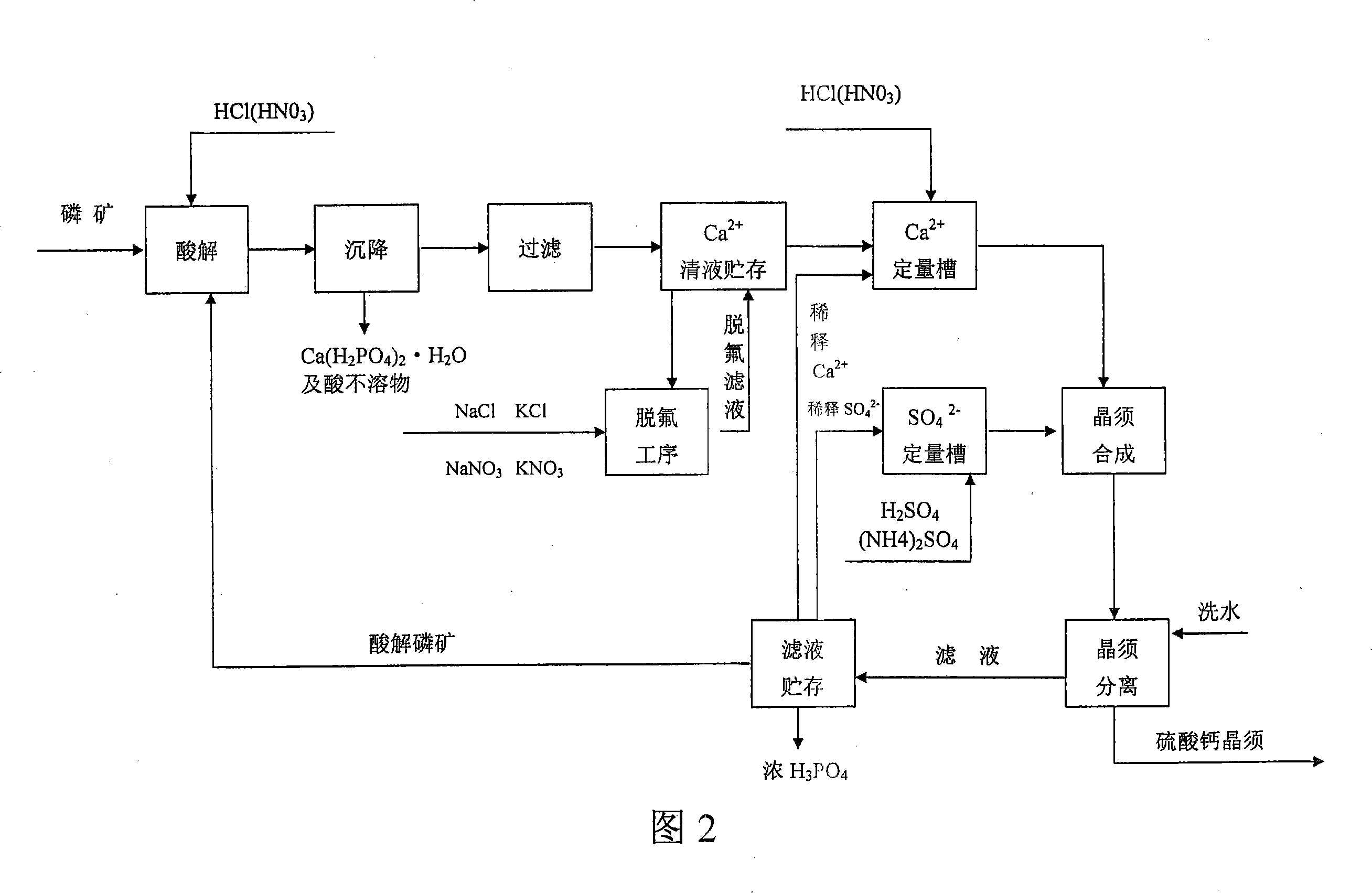

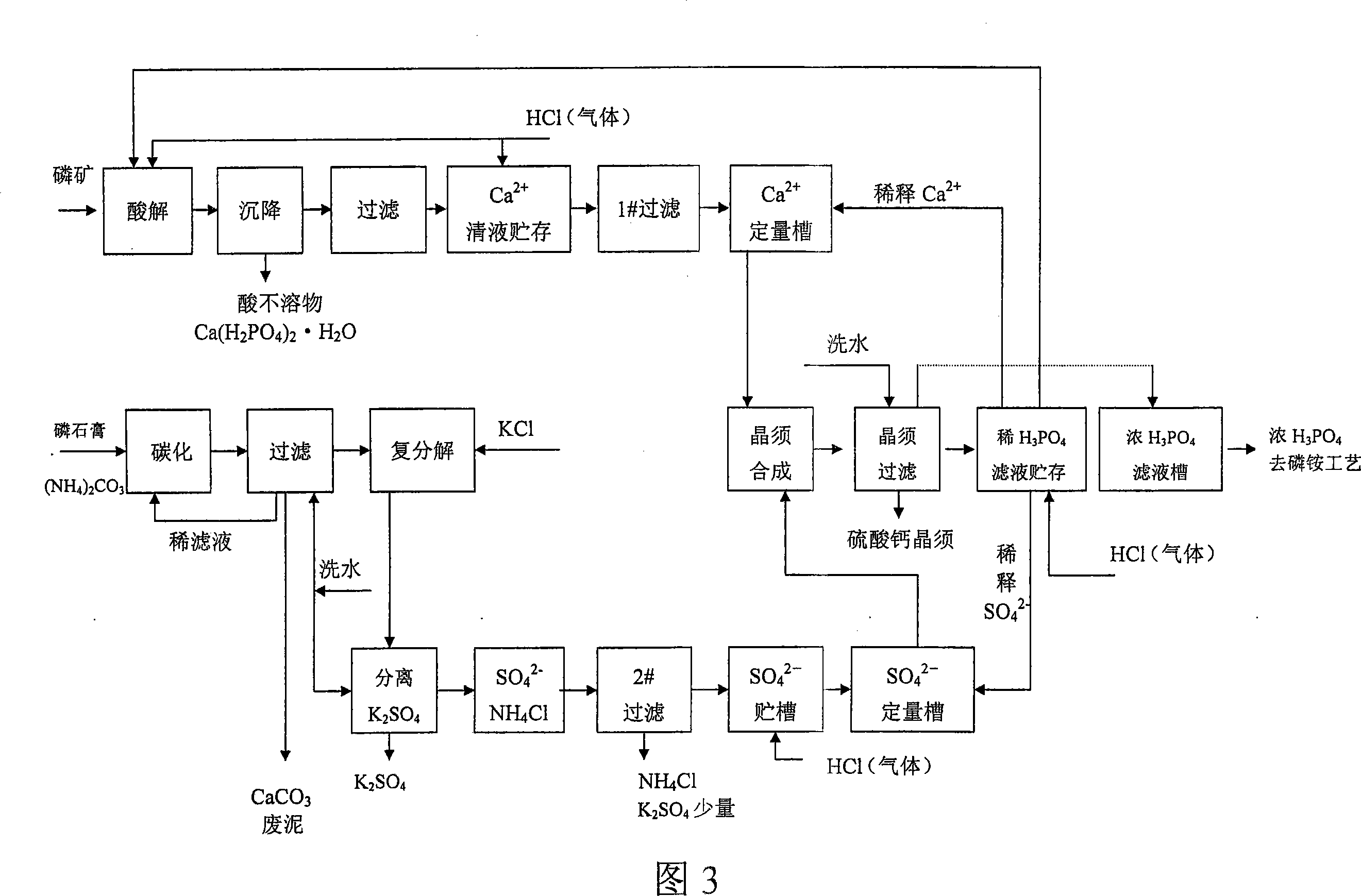

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

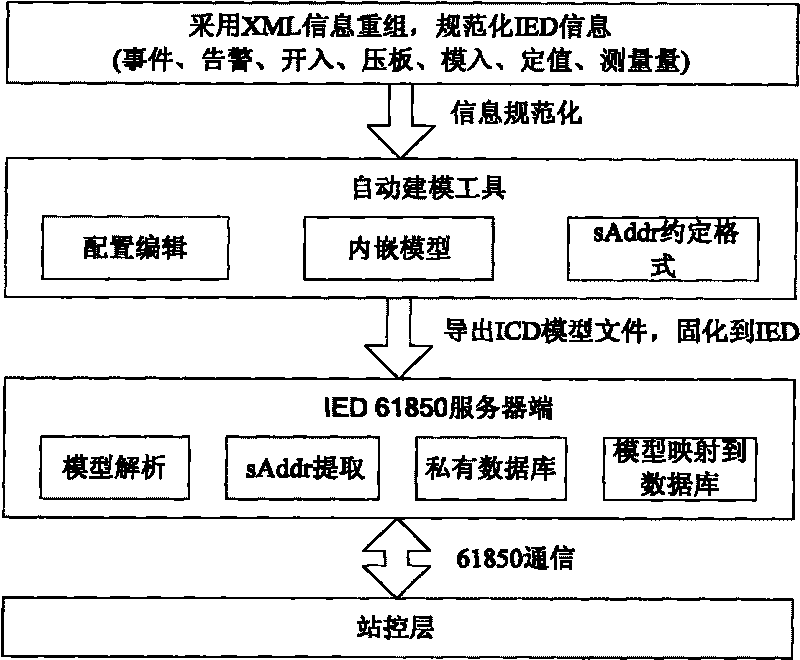

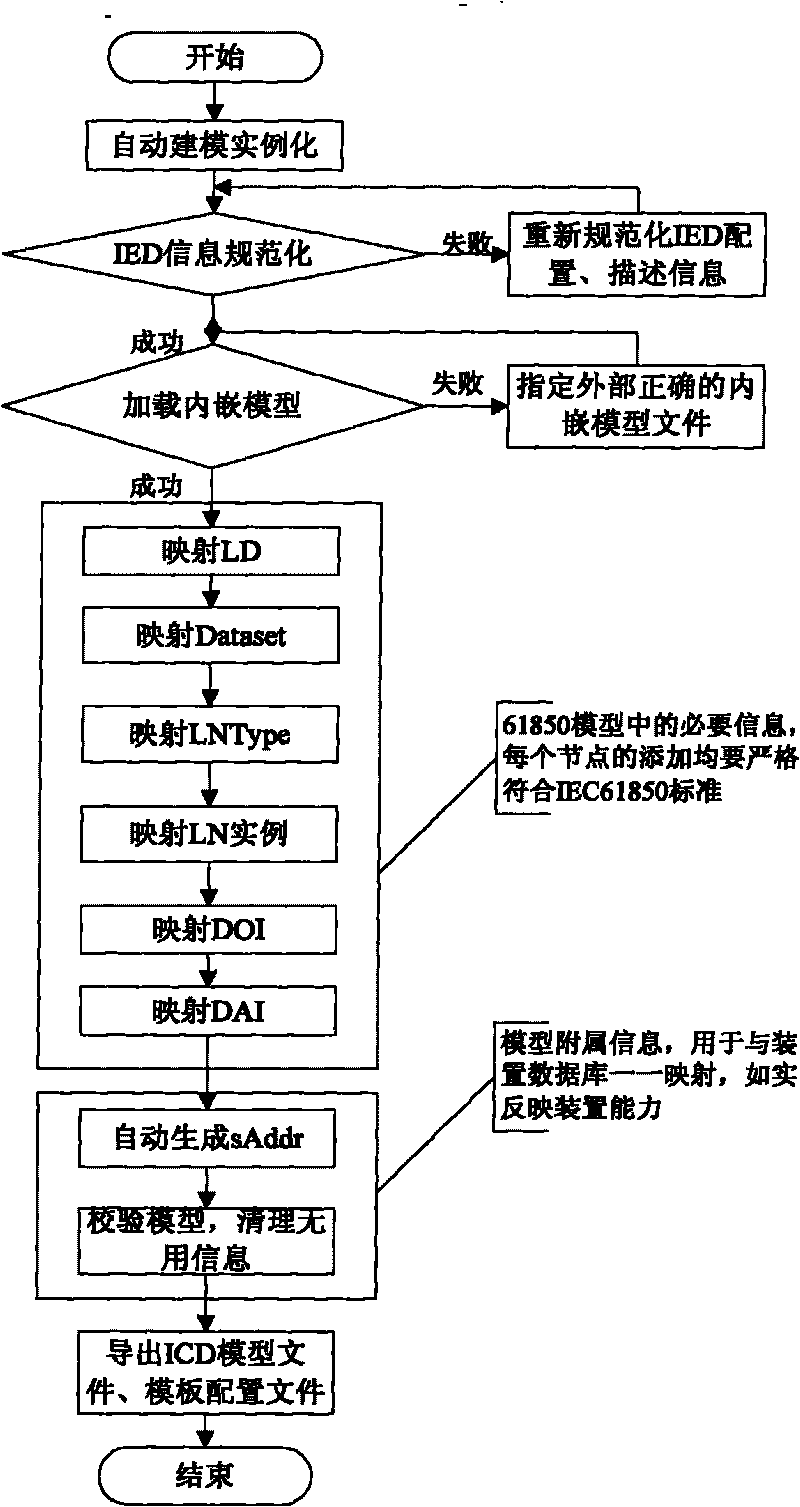

Method for realizing fast and automatic modeling of transformer substation IEC 61850 by adopting XML information recombination

ActiveCN101706773AEasy system maintenanceStrong maneuverabilityCircuit arrangementsSpecial data processing applicationsCollocationDigitization

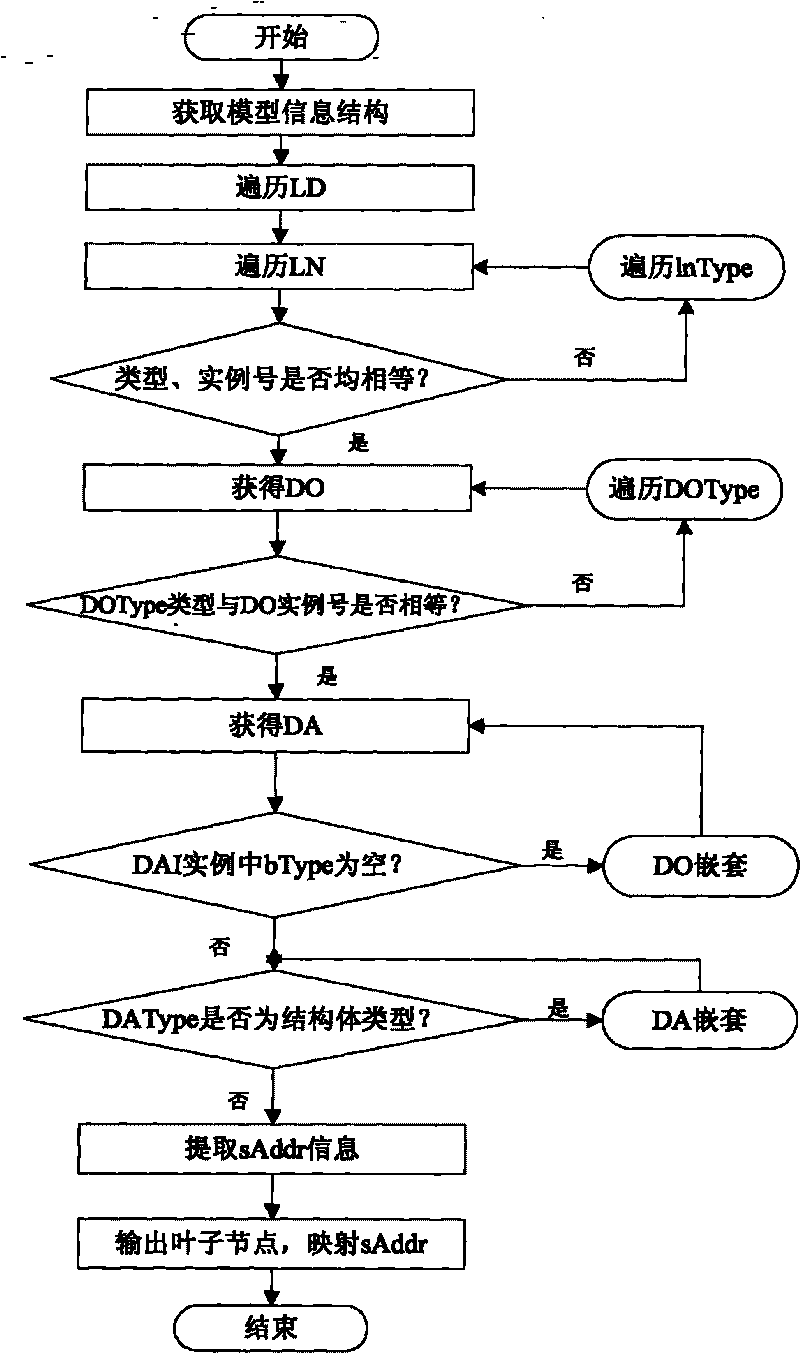

The invention provides a method for realizing fast and automatic modeling of a transformer substation IEC 61850 by adopting XML information recombination, which is applied to IED modeling of space layers in a digital transformer substation and a traditional transformer substation by adopting IEC 61850 communication. The method comprises the following steps of: recombining the IED information by adopting XML, and providing an IED information standardization interface; editing and setting the standardized XML files; loading an embedded minimum model which accords to the IEC61850 standard; appointing an sAddr information format in advance, automatically adding sAddr information and leading out an ICD model file; analyzing the led-out ICD model file by the IED, and automatically extracting the sAddr information, and automatically mapping model leafage nodes to a real-time database according to the sAddr information; and enabling the information of the real-time database to normally communicate with station control layer equipment by the IED through adopting an IEC61850 protocol. The model collocation can be set by engineering personnel according to actual engineering. Therefore, the invention greatly shortens the time for generating the IEC61850 model, improves the efficiency of production and regulation and is convenient for 61850 engineered actualization and generalization.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

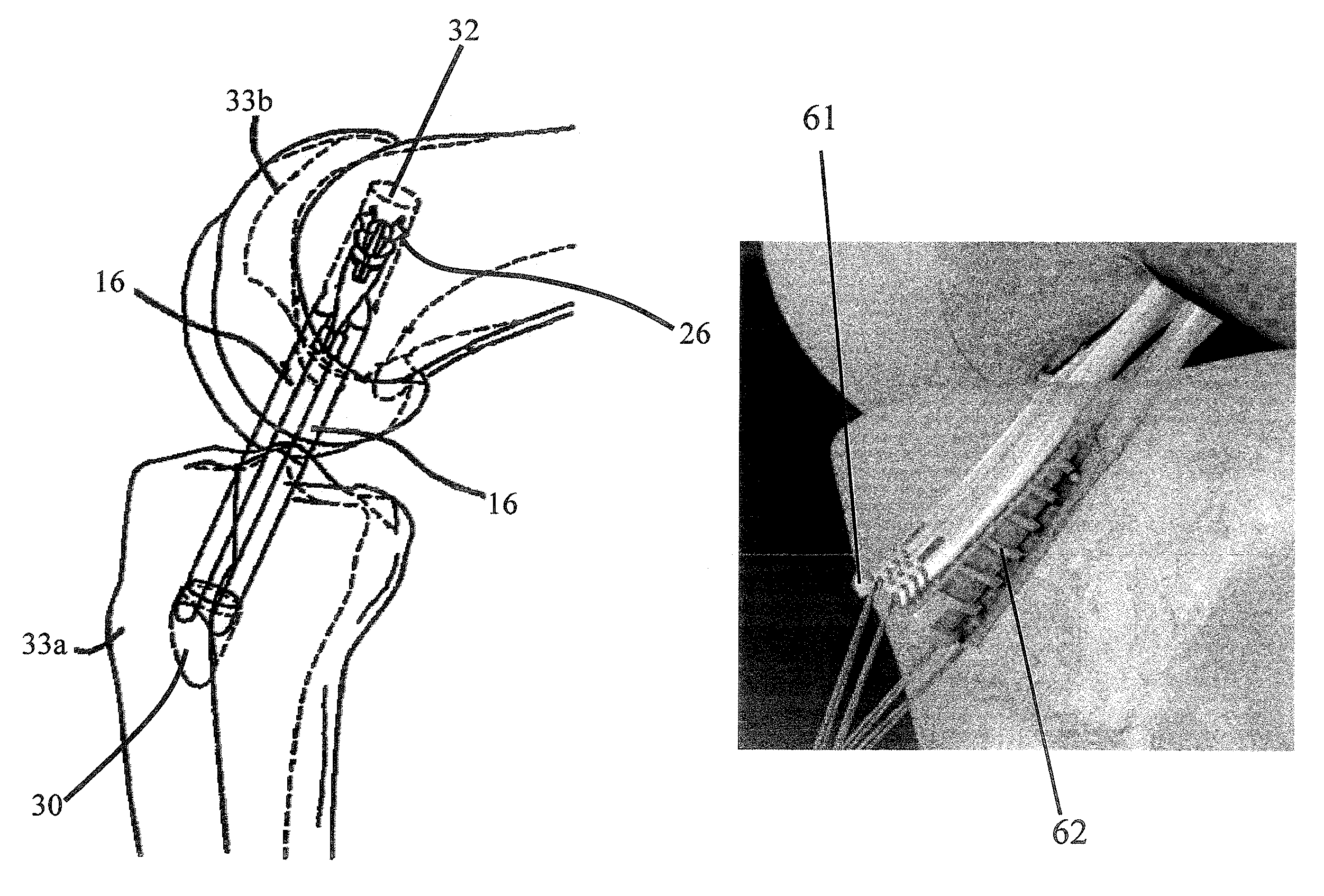

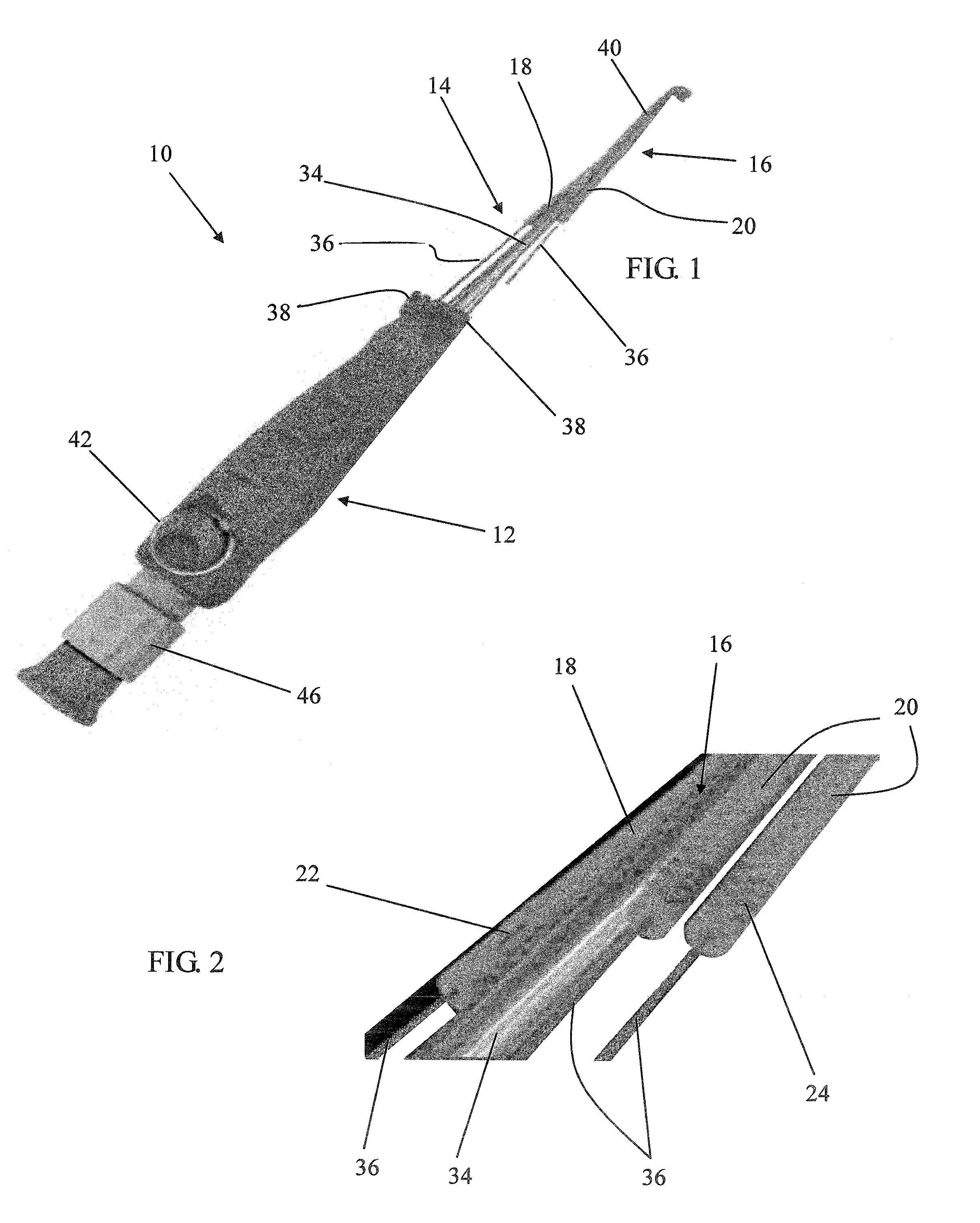

Method for surgically repairing a damaged ligament

An anterior cruciate ligament (ACL) surgical repair technique involves the use of a single femoral and tibial tunnel and an implant that separates and positions two distinct bundles. This allows for the surgeon to create a more anatomic reconstruction with a procedure that is less technically demanding, can be performed using a transtibial or anteromedial approach, minimizes tunnel widening, and decreases operative time. The result is a strong fixation option for soft tissue grafts, with circumferential graft compression at the aperture, high pull-out strength, and ease of use. The graft bundles are positioned in a more anatomic orientation through the above noted single femoral and tibial tunnel.

Owner:CAYENNE MEDICAL INC

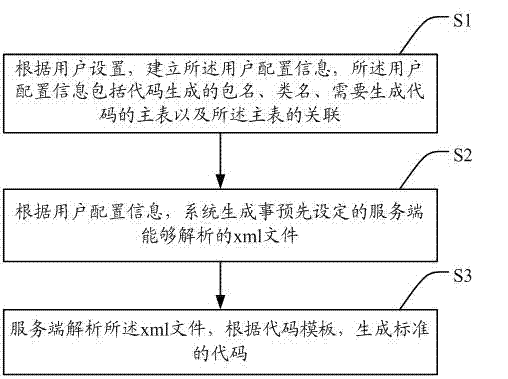

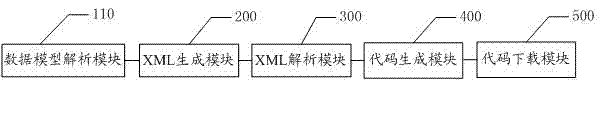

Method and system for automatically generating code based on data model drive

ActiveCN102968306AImprove efficiencyImprove readabilitySpecific program execution arrangementsMaintainabilityXML

The invention discloses a method and a system for automatically generating a code based on a data model drive. The method comprises the steps as follows: firstly, establishing user configuration information according to user settings, wherein the user configuration information comprises a package name generated by the code, a class name, a primary table required to generate the code and an association of the primary table; secondly, generating an xml (extensive markup language) file capable of being parsed by a preset server side by the system according to the user configuration information; and lastly, parsing the xml file by the server side, and generating the standard code according to a code template. Compared with the prior art, the method has the advantages of high efficiency, standard and uniform code, high readability, strong maintainability and the like; and meanwhile, the operation is visualized, convenient and quick, errors are not easily caused, and the technical requirements are lowered.

Owner:QTONE EDUCATION GROUP (GUANGDONG) CO LTD

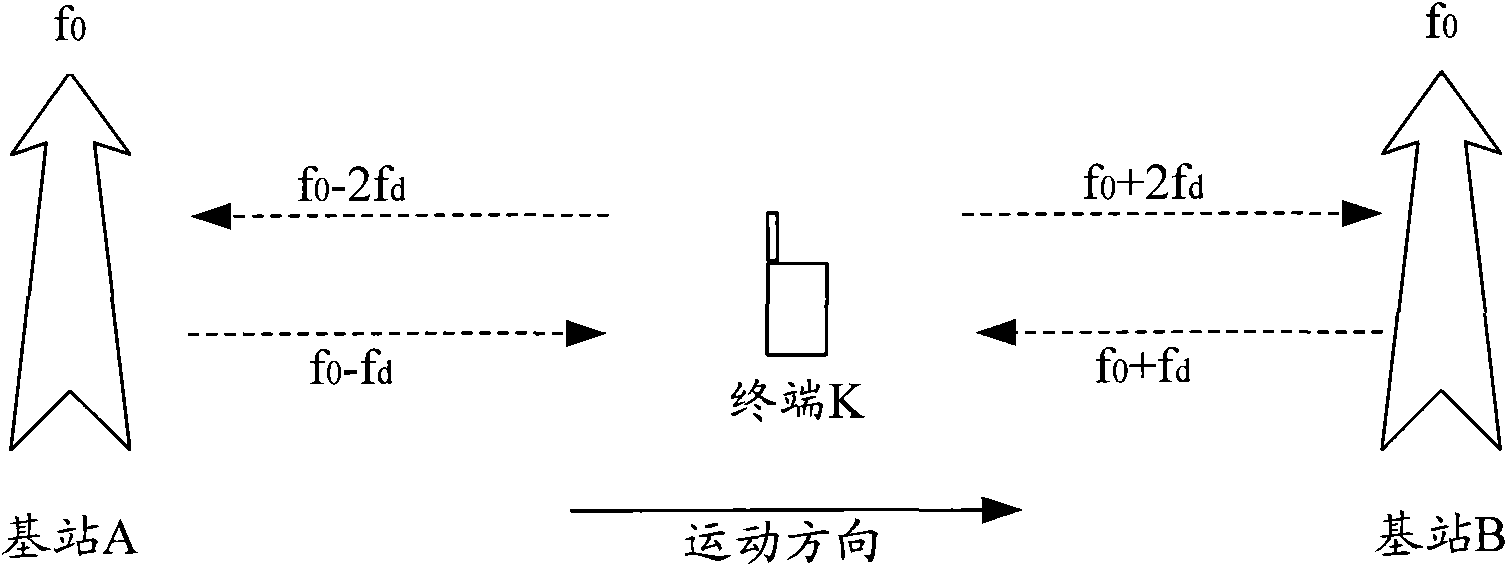

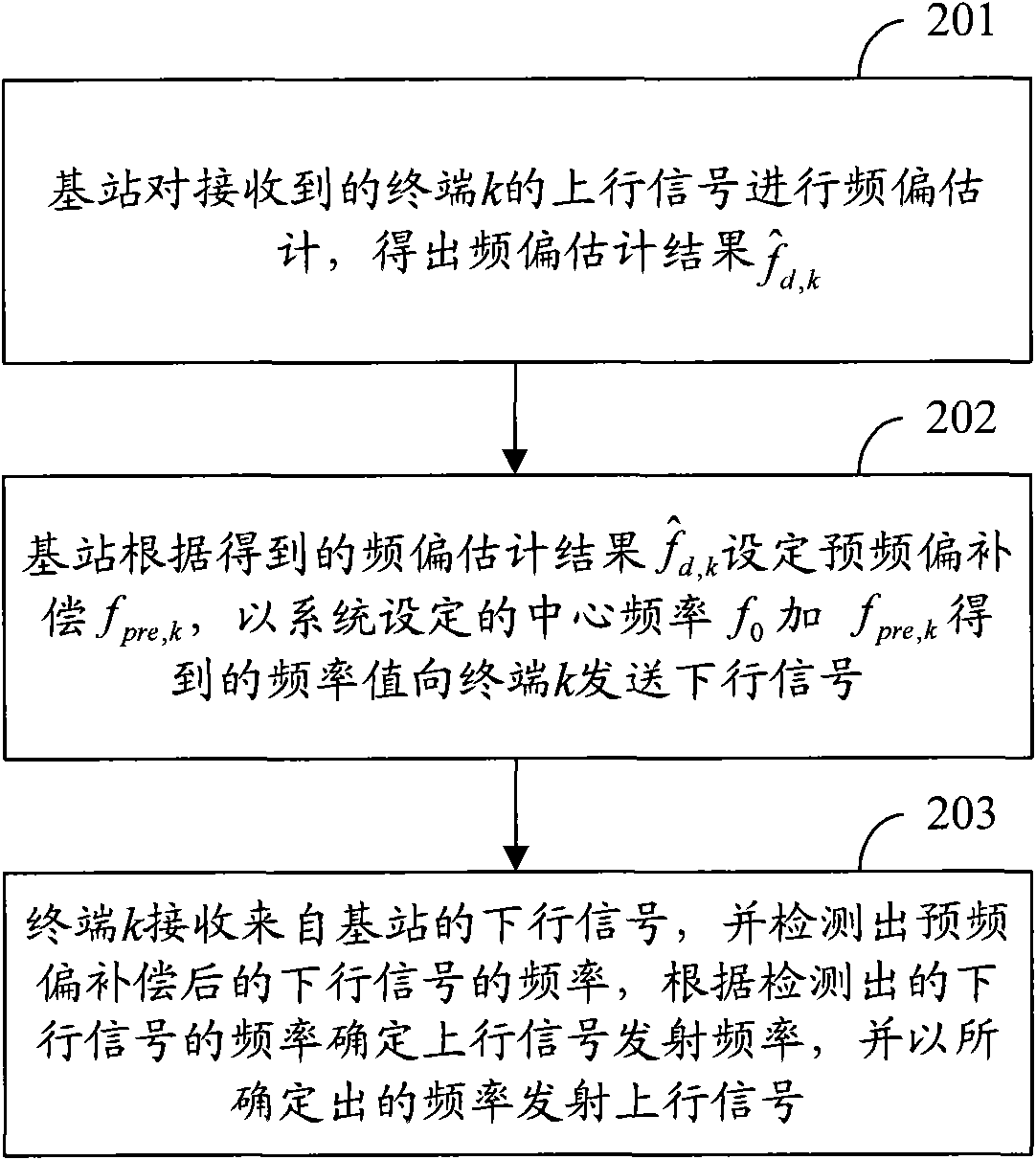

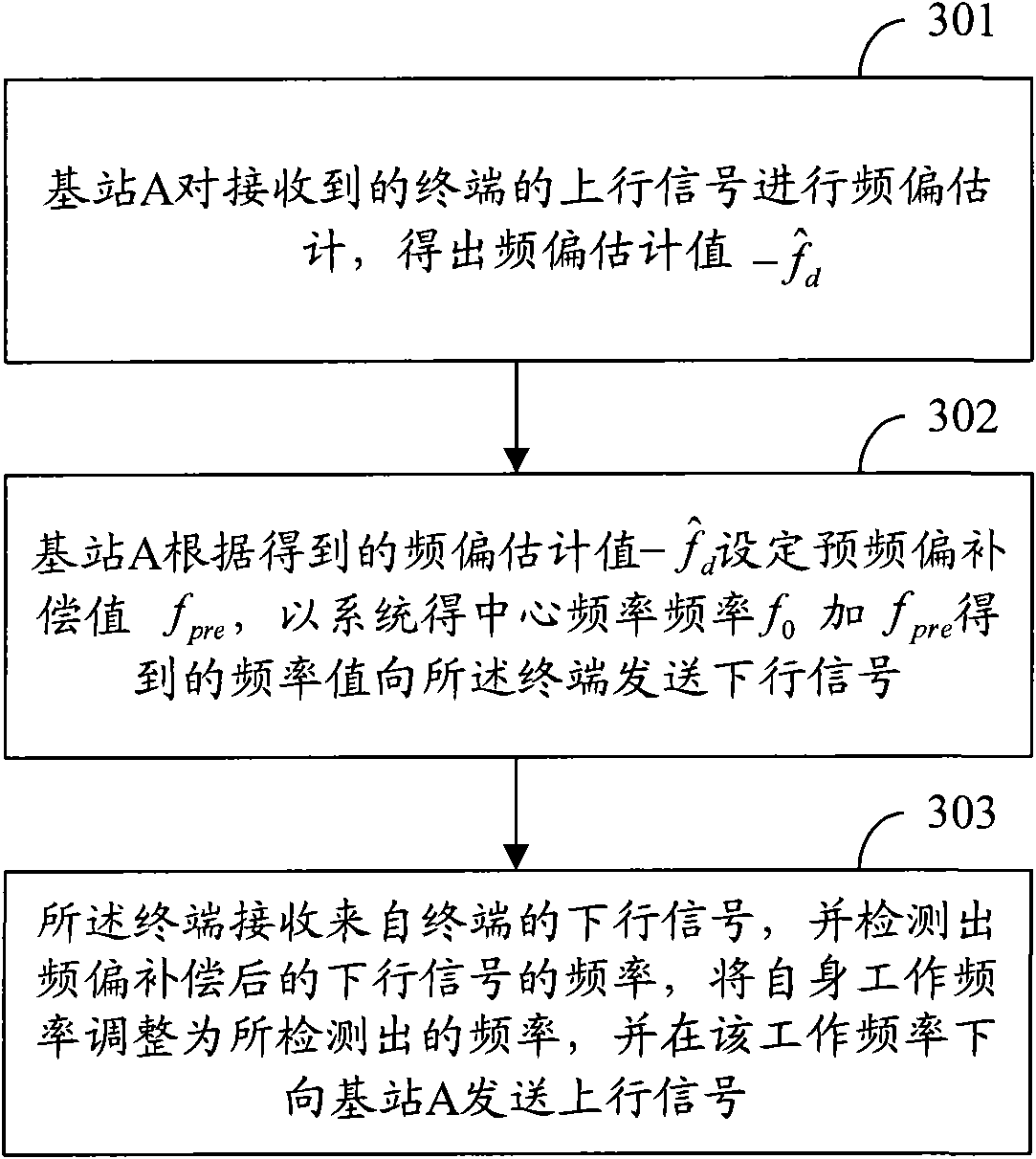

Frequency offset compensation method and device

ActiveCN101567708ATake the Stress Out of Frequency CorrectionCommunication service quality is reliableTransmitter/receiver shaping networksSignal frequencyEngineering

The invention discloses a frequency offset compensation method, which comprises the following steps that: a base station performs frequency offset estimation on received uplink signals to obtain a frequency offset estimation result, and pre frequency offset compensation is performed on downlink signals according to the frequency offset estimation result; a terminal detects the frequency of the received downlink signals after the frequency offset compensation, the emission frequency of the uplink signals is determined according to the detected frequency of the downlink signals, and the uplink signals are emitted in the determined frequency; and a terminal side performs the pre frequency offset compensation by the same method. The invention also discloses a frequency offset compensation device, which comprises a frequency offset estimation module, a pre frequency offset compensation module and a frequency detection and frequency modulation module. The method and the device can effectively reduce the frequency offset of uplinks and downlinks, perform the frequency offset compensation of the uplinks and the downlinks, and not only reduce the relative frequency offset between the base station and the terminal, but also reduce frequency jump variable when the terminal switches between the base stations, so that both the base station and the terminal can correctly correct the receivedsignals to ensure communication quality.

Owner:ZTE CORP

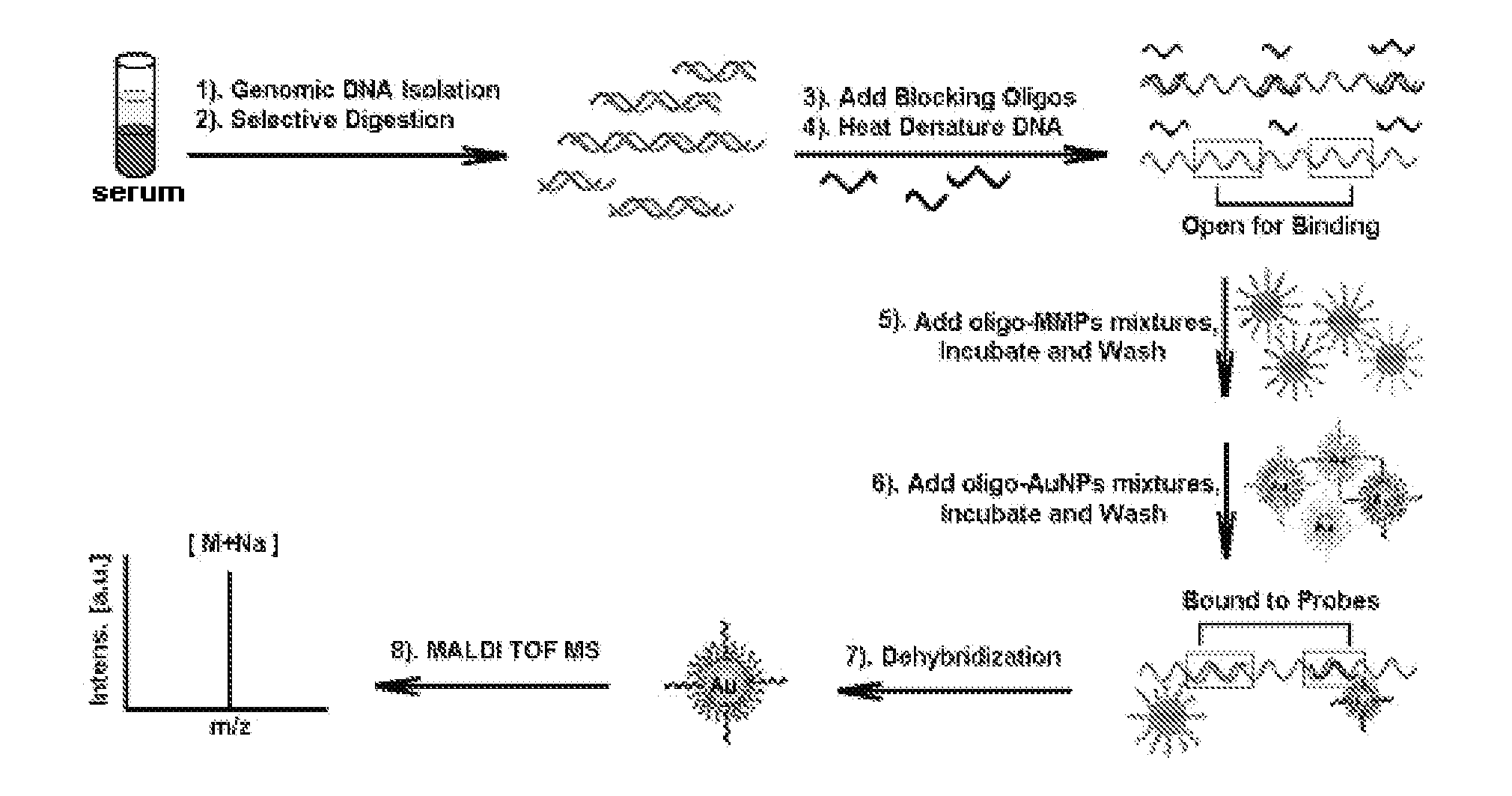

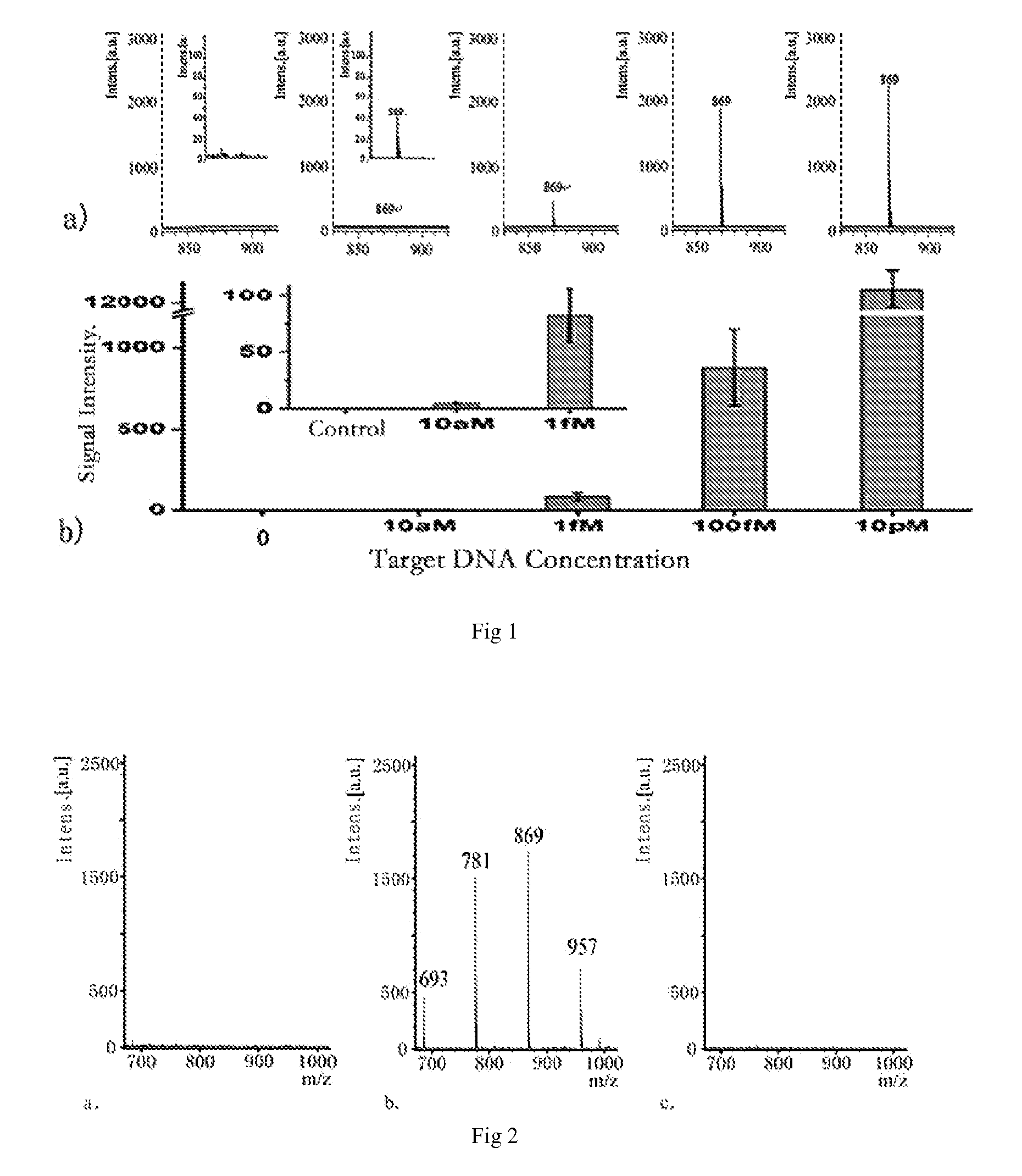

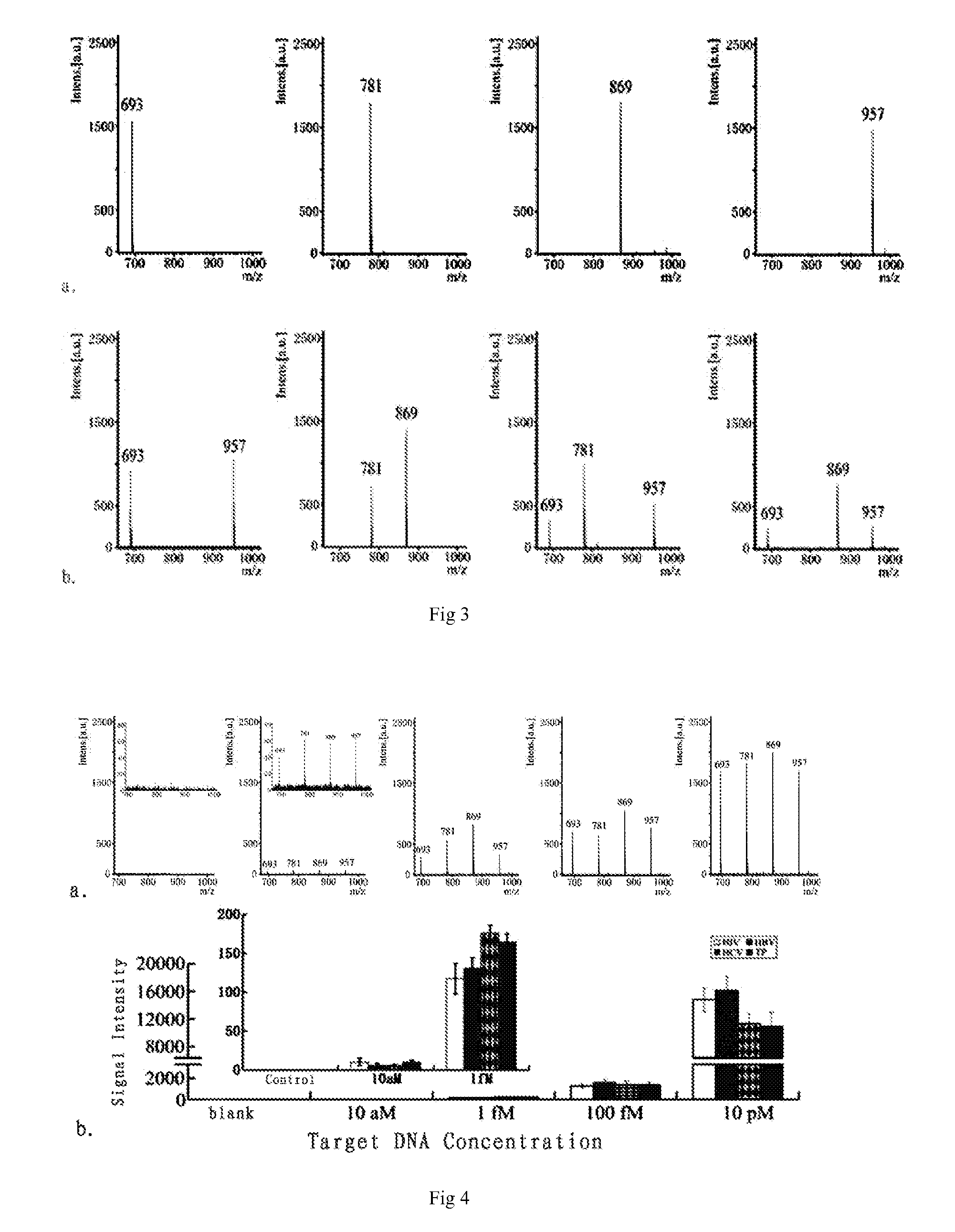

Gene detecting methods without using PCR

ActiveUS8704165B2Enhanced signalHigh sensitivityMicrobiological testing/measurementParticle spectrometer methodsMicroparticleBiology

Gene detecting methods without using PCR are disclosed. The methods comprise forming sandwich complexes by target genes with nano-probes and capture probes, wherein nano-probes are modified with recognition molecules and magnetic microparticles modified with capture molecules; then separating the sandwich complexes; releasing the nano-probes; and detecting molecular ion peaks of encoding molecules on the surface of nano-probes by mass spectrometric detection directly, characterized in that the proportions of recognition molecules and encoding molecules on the nano-probes are 300-2000:1.

Owner:JIANGSU SINOBIOPHARMA

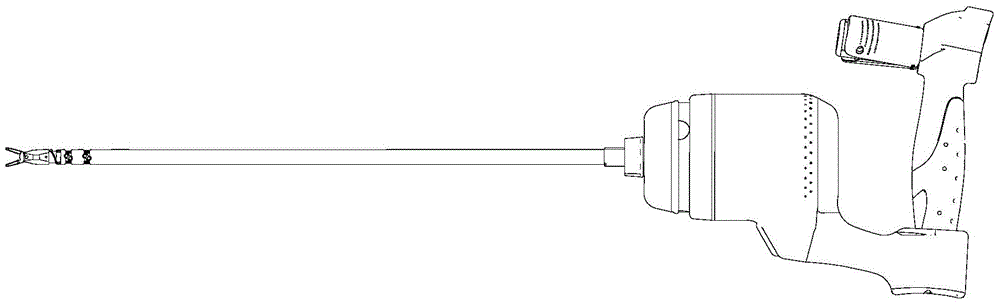

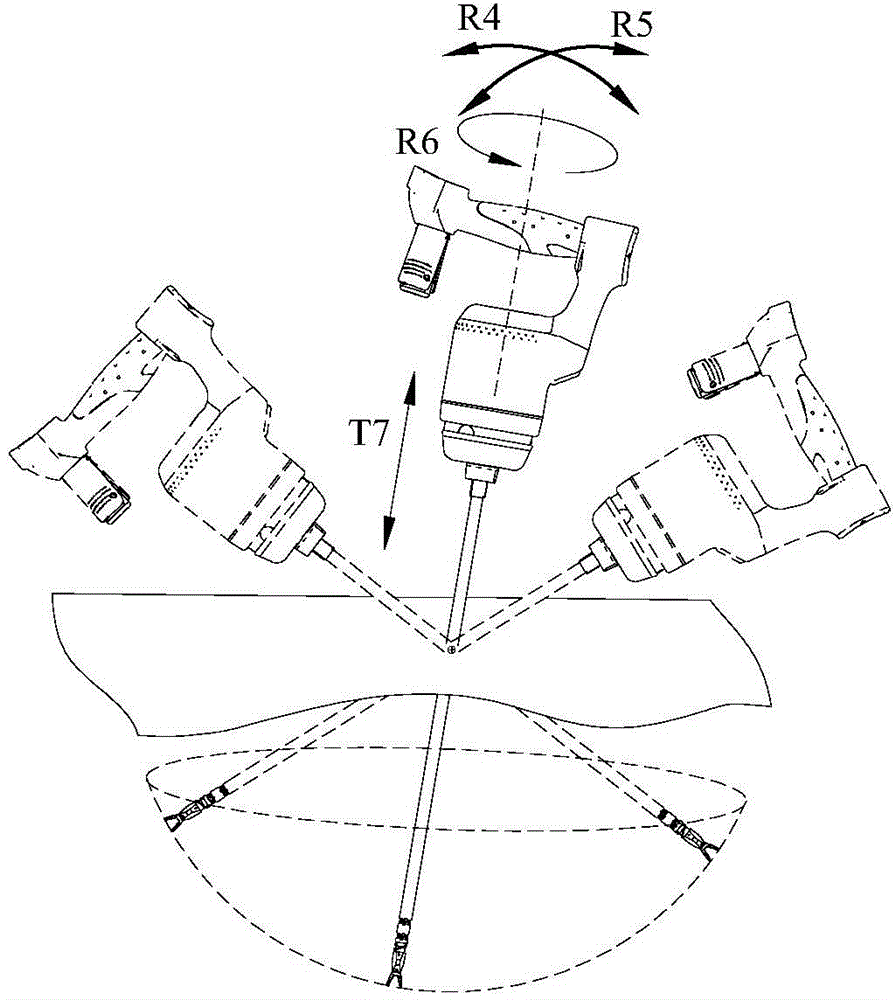

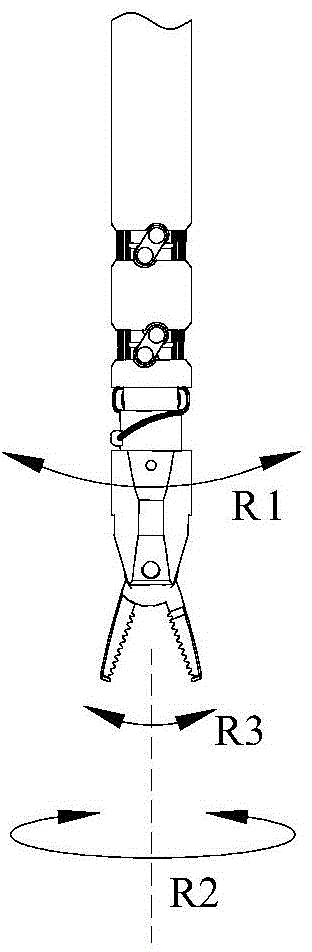

Surgery operational method by adopting intelligentized minimally invasive surgery instrument

InactiveCN104783846AFlexibleLow technical requirementsDiagnosticsSurgeryLess invasive surgeryControl signal

The invention discloses a surgery operational method by adopting an intelligentized minimally invasive surgery instrument. The method comprises the following steps that 1, the intelligentized minimally invasive surgery instrument is held in hand, and a tail-end motion joint of the instrument is made to enter into a human body for conducting the surgery operation, wherein the hand-holding operation process comprises the steps of operating a handle driving device of the instrument by hand, and then outputting a detected space multi-freedom-degree motion control signal of the hand-operated handle driving device to a driving motor; 2, according to the space multi-freedom-degree motion control signal, the driving motor drives a transmission device to move to transmit the hand operation motion to the tail-end motion joint, and the tail-end motion joint outputs space multi-freedom-degree motion. By the adoption of the intuition operation in the method, the equipment cost is low, the maintenance cost and use cost are high, the operation technical requirements for a doctor are low, and the method conforms to operational habits of the doctor.

Owner:TIANJIN SHOUZHI MEDICAL TECH CO LTD

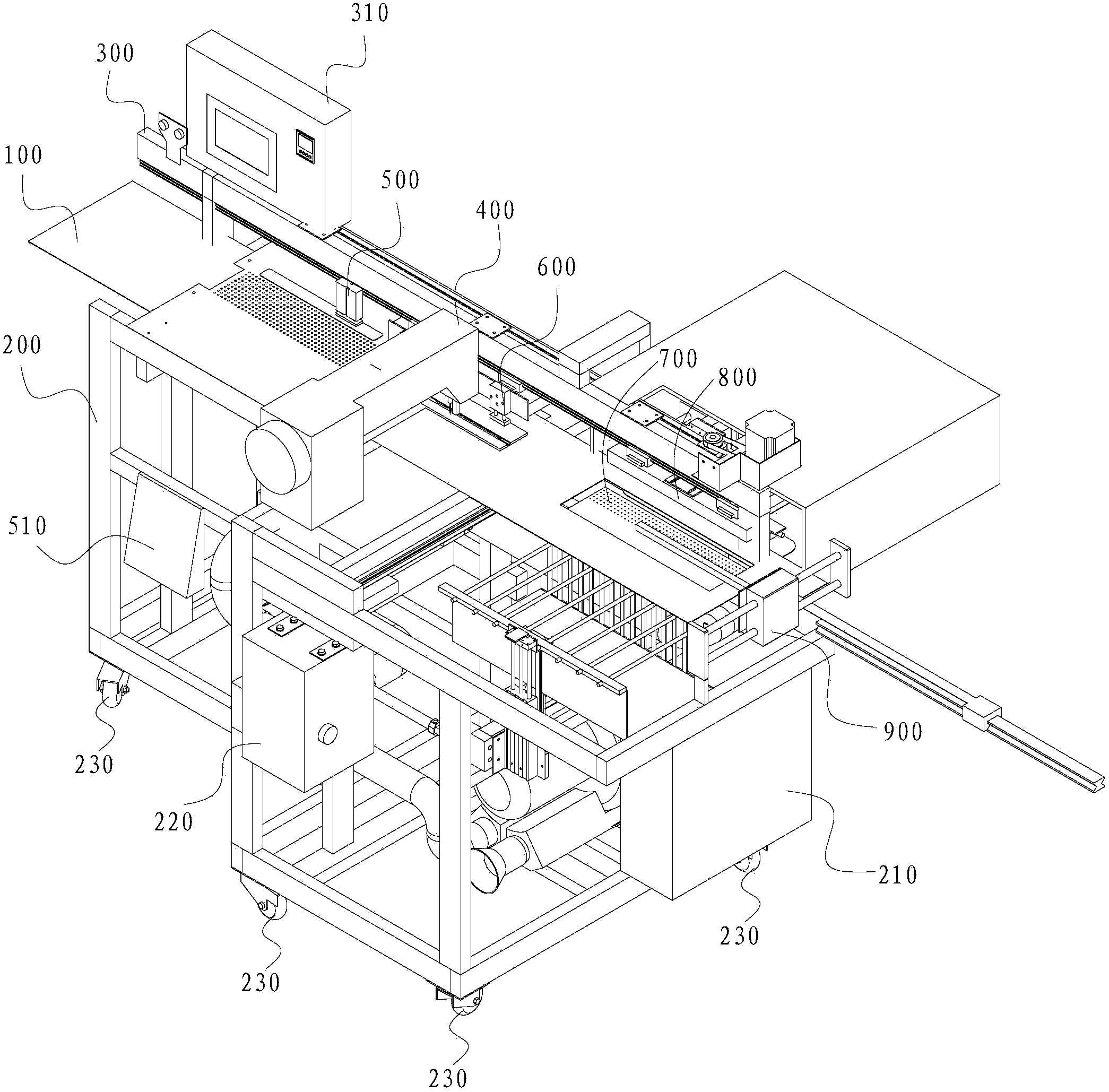

Automatic sewing device and method

ActiveCN104233637AReduce manual processHigh degree of automationProgramme-controlled sewing machinesSewing machineEngineering

The invention discloses an automatic sewing device and method. The automatic sewing device comprises a machine frame, a workbench arranged on the machine frame, a sewing machine head and a main bracket, wherein the sewing machine unit and the main bracket are arranged on the workbench and are perpendicular to each other; an adsorbing positioning mechanism is arranged on one side of the sewing machine head, an automatic bending mechanism is arranged on the other side of the sewing machine head; a feeding mechanism is arranged between the adsorbing positioning mechanism and the automatic bending mechanism; an ironing mechanism is arranged on the automatic bending mechanism. With the technical scheme provided by the invention, the whole process of sewing a cuff lining is automated, and the production efficiency is improved; the manual operation process is reduced, the technical requirement for workers is low, the operation difficulty is low, and the product quality is guaranteed.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

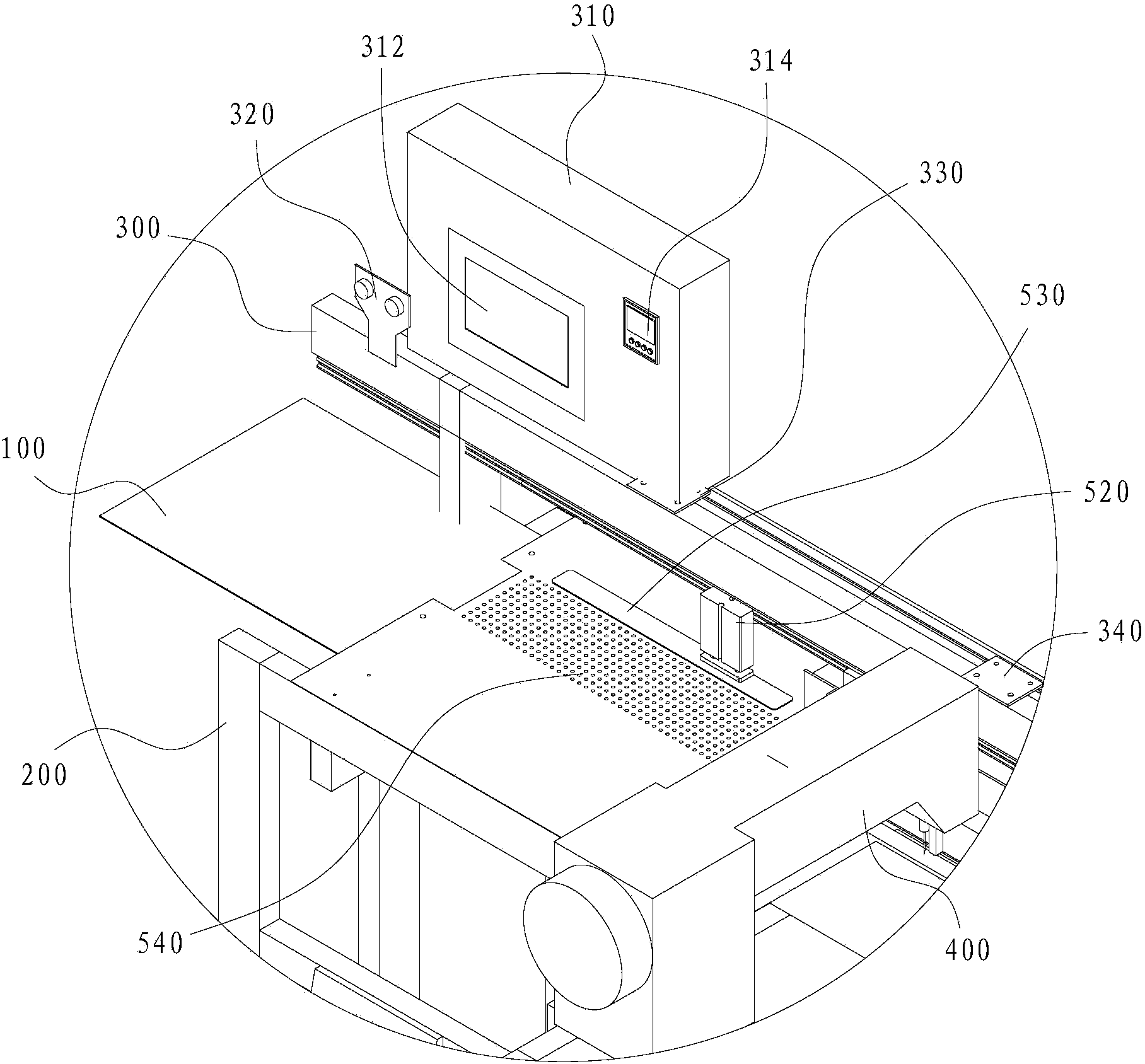

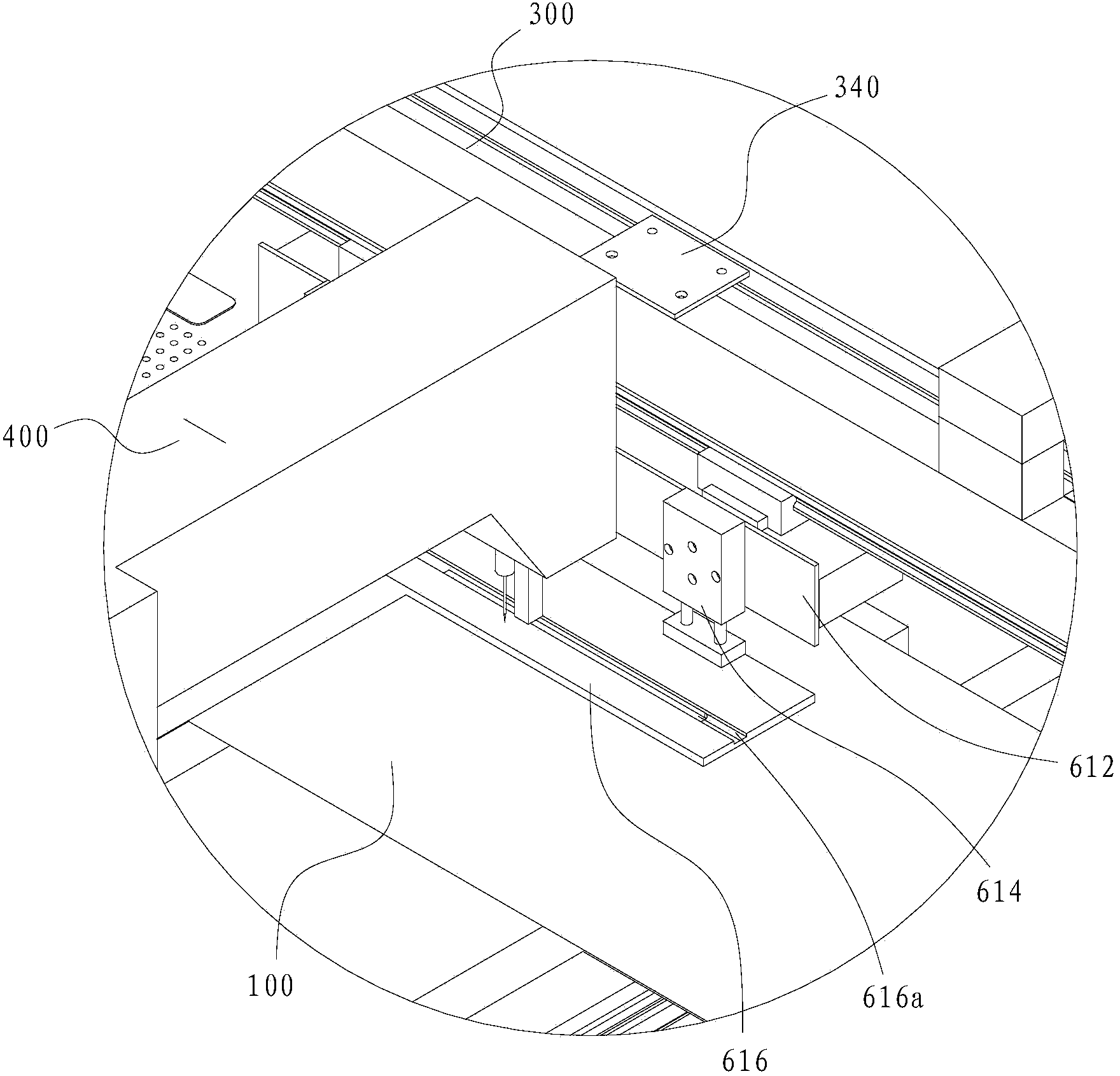

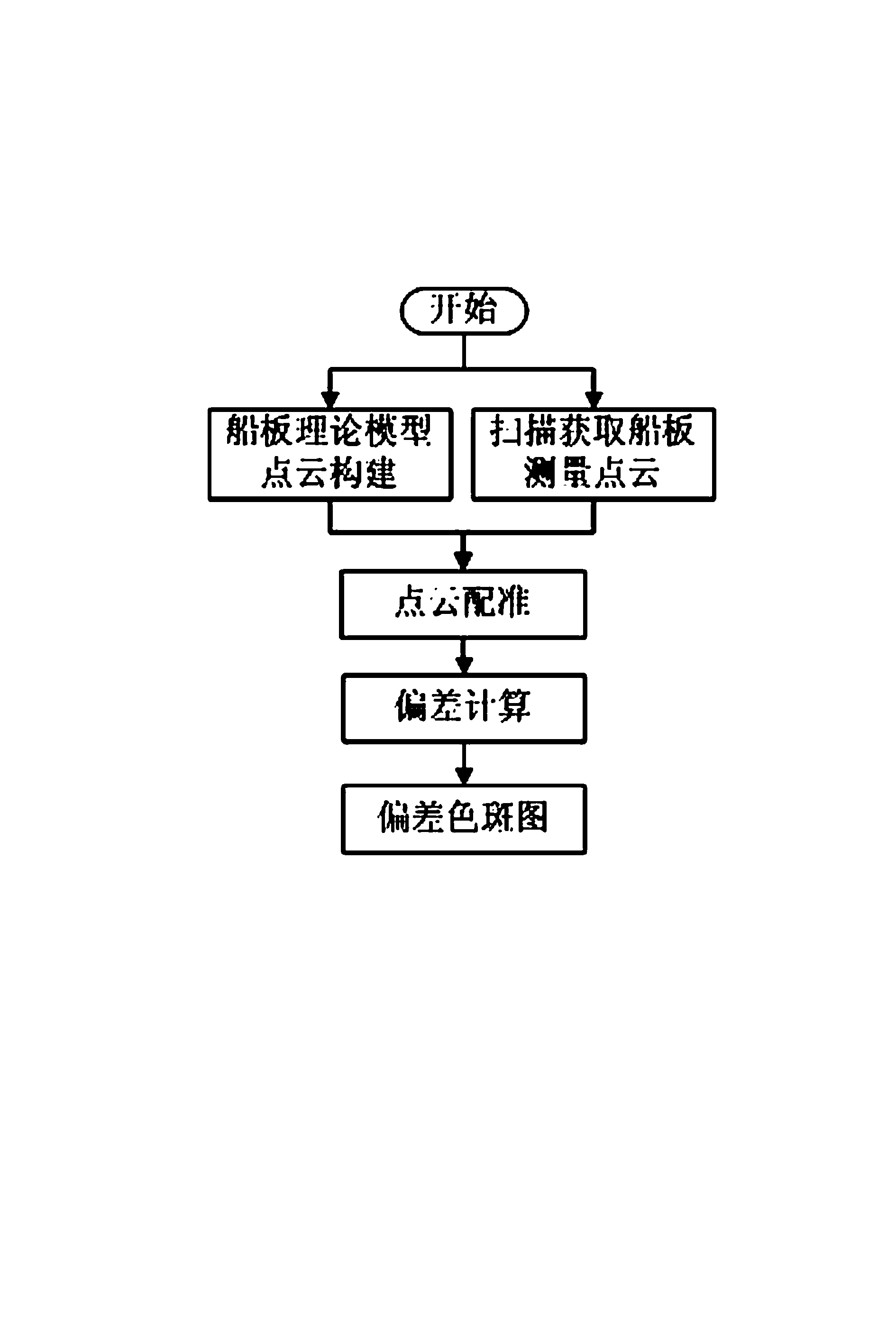

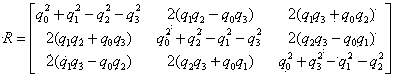

On-line detection method for line heating forming

The invention discloses an on-line detection method for line heat forming of a ship outer plate, and belongs to the field of shipbuilding technologies and optical measurement. The method comprises the following steps: A, establishing a ship theoretical model point cloud; B, scanning and obtaining a ship measurement point cloud; C, performing coordinate system registration for ship theoretical model point cloud and the ship measurement point cloud; D, calculating the distance between every point in the ship measurement point cloud and a theoretical curve surface so as to present the deviation between the measurement point cloud and the theoretical model point cloud; E, expressing the deviation value by a color map. Compared with a traditional sample case / sample plate detection method, the method is high in detection efficiency and precision, and the detection result can be quantized and is good in readability.

Owner:SHANGHAI SHIPBUILDING TECH RES INST +1

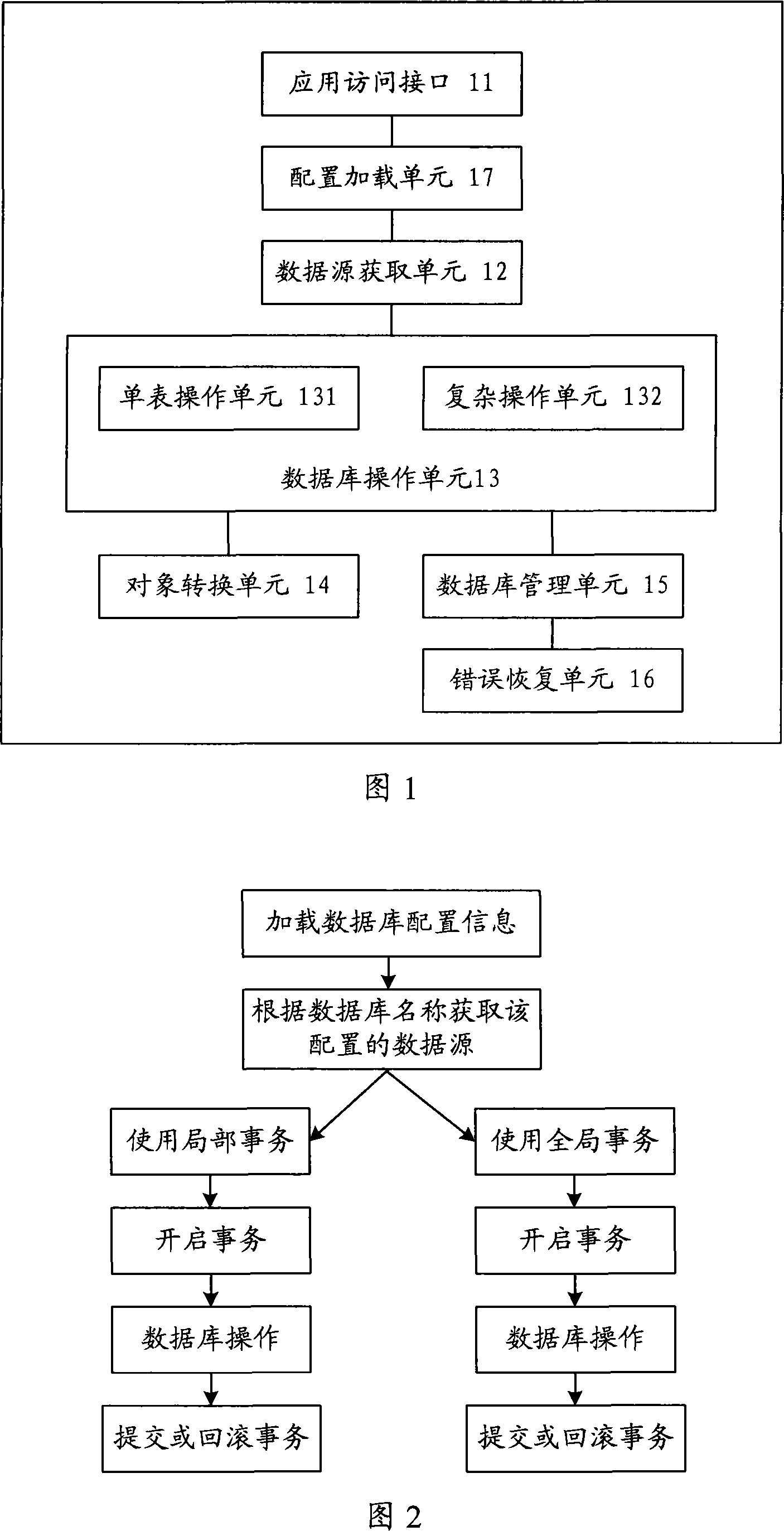

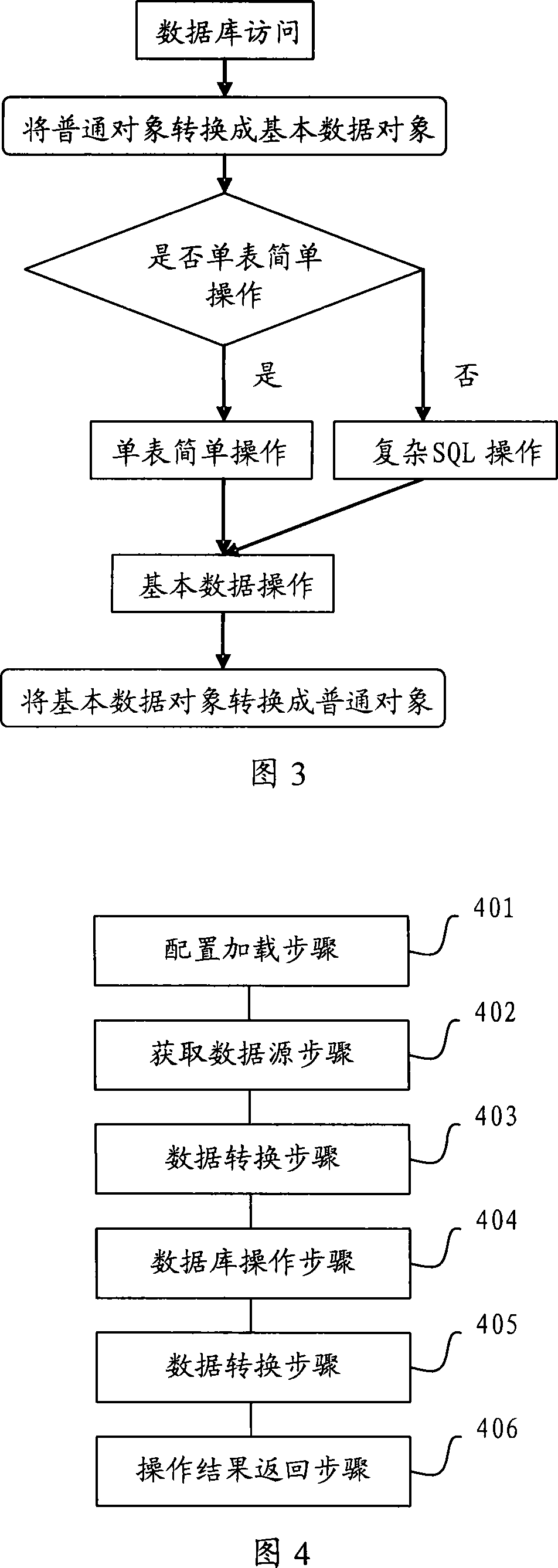

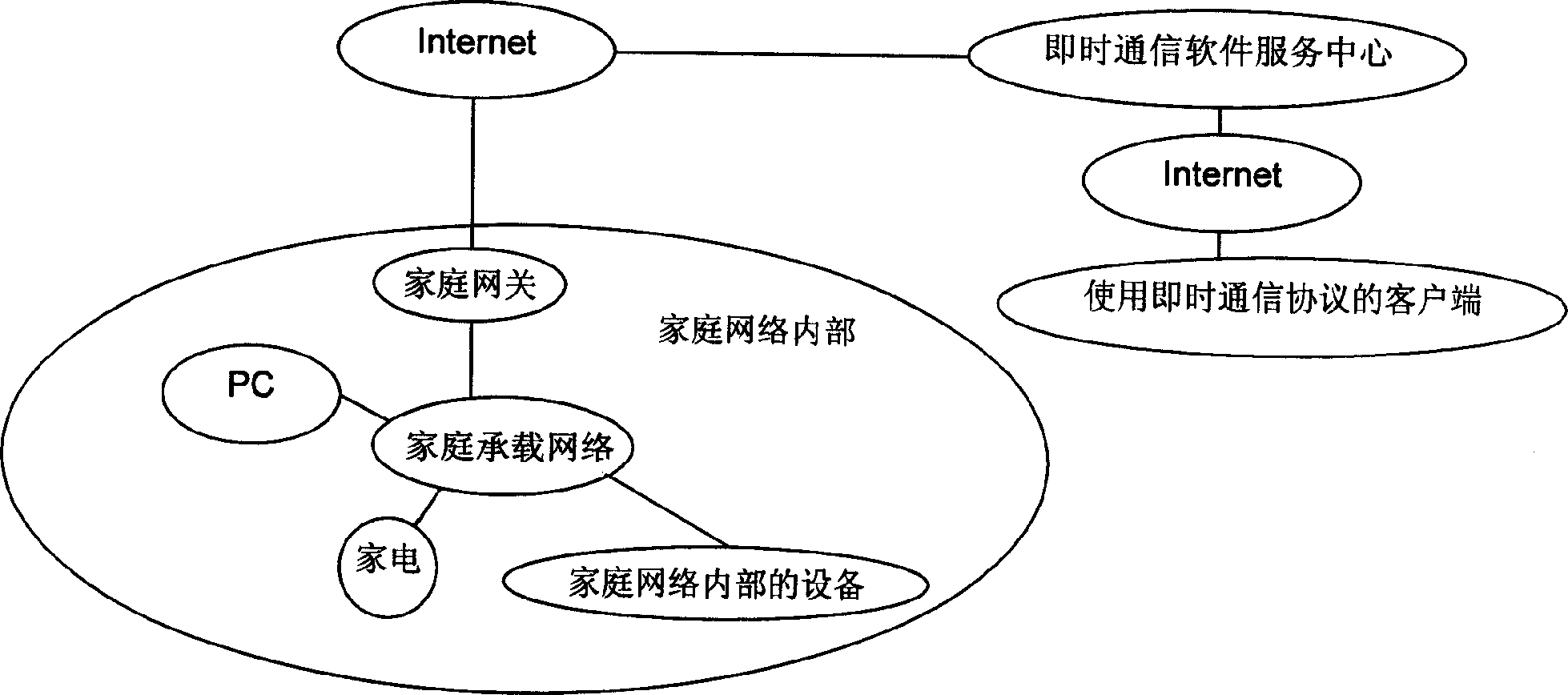

Database access platform and access method thereof

InactiveCN101196926ALow technical requirementsEnsure safetySpecial data processing applicationsSQLDatabase access

The invention discloses a database access platform and access method, which solves problems of high requirements on technician, impalpable code and safety of traditional database operation mode. The platform mainly comprises an application access interface for supplying setting of database configuration information and feeding back database operation result; a data source acquisition unit for connecting corresponding database according to the database names in the configuration information; a database single table operation unit for calling corresponding table structure information according to the access parameters in the configuration information and executing corresponding SQL operation in combination with generation of SQL sentence; a database complex operation unit for calling corresponding SQL template according to the access parameter in the configuration information and executing corresponding SQL operation in combination with generation of SQL sentence. Because of shielding direct SQL operation, the platform facilitates developers unnecessary to concern detailed SQL sentence spelling and database operation and greatly reduces the technical requirements on developers.

Owner:CHINA CONSTRUCTION BANK

Environment-friendly diatom ooze wall material powder and wall material and preparation method thereof

InactiveCN101700965AImprove adsorption capacityAdequate adsorptionMoisture absorptionAir purification

The invention discloses environment-friendly diatom ooze wall material powder and a wall material as well as a preparation method and application thereof. The diatom ooze wall material with macromolecule sieve structure is prepared by taking a plurality of natural environment-friendly non-metal material having strong adsorbability and good plasticity as main materials through a simple process. The environment-friendly diatom ooze wall material powder has the advantages of low cost, air purification, moisture absorption, deodorization, inflaming retarding, heat insulation, easy popularization,and the like.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

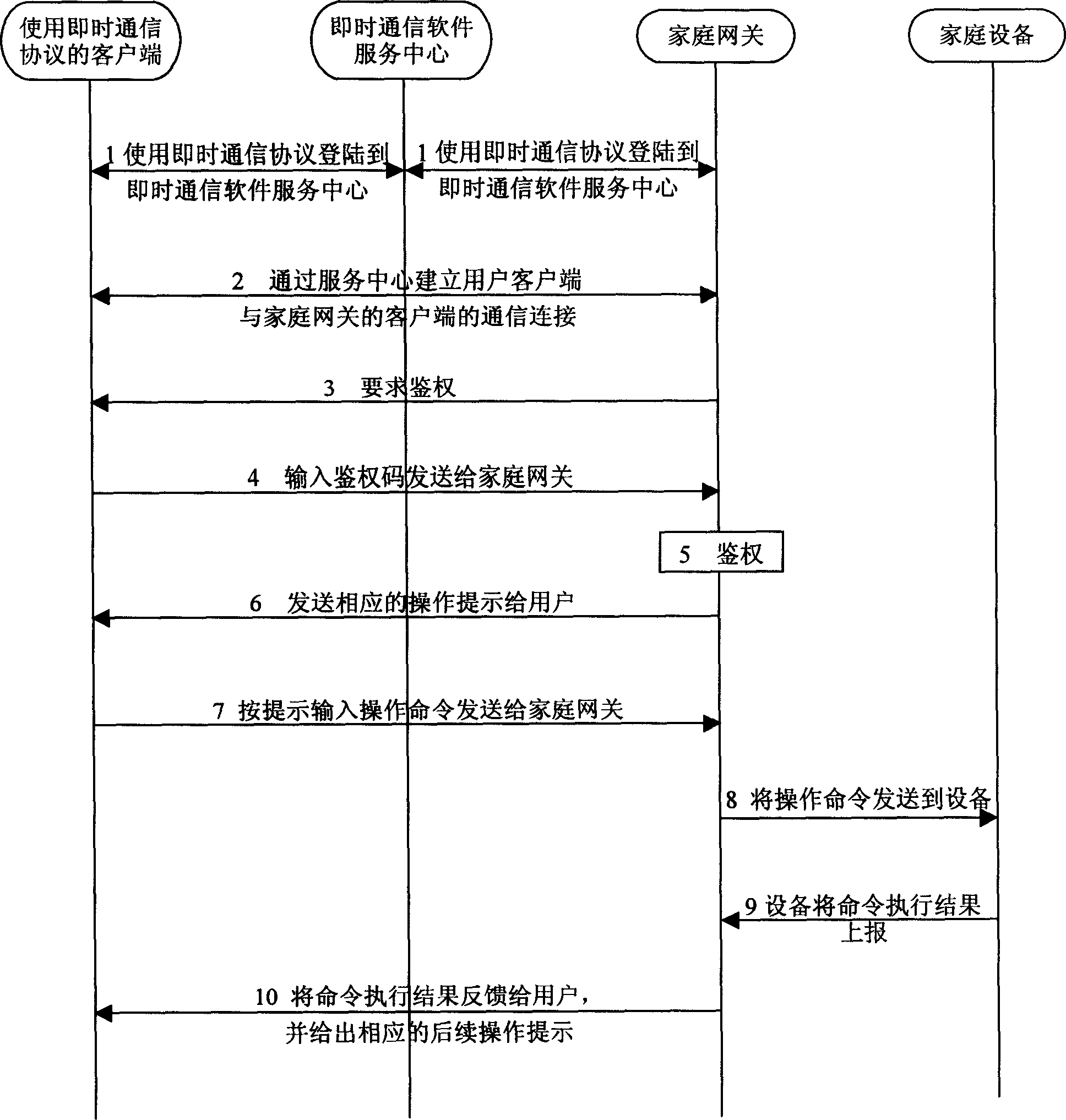

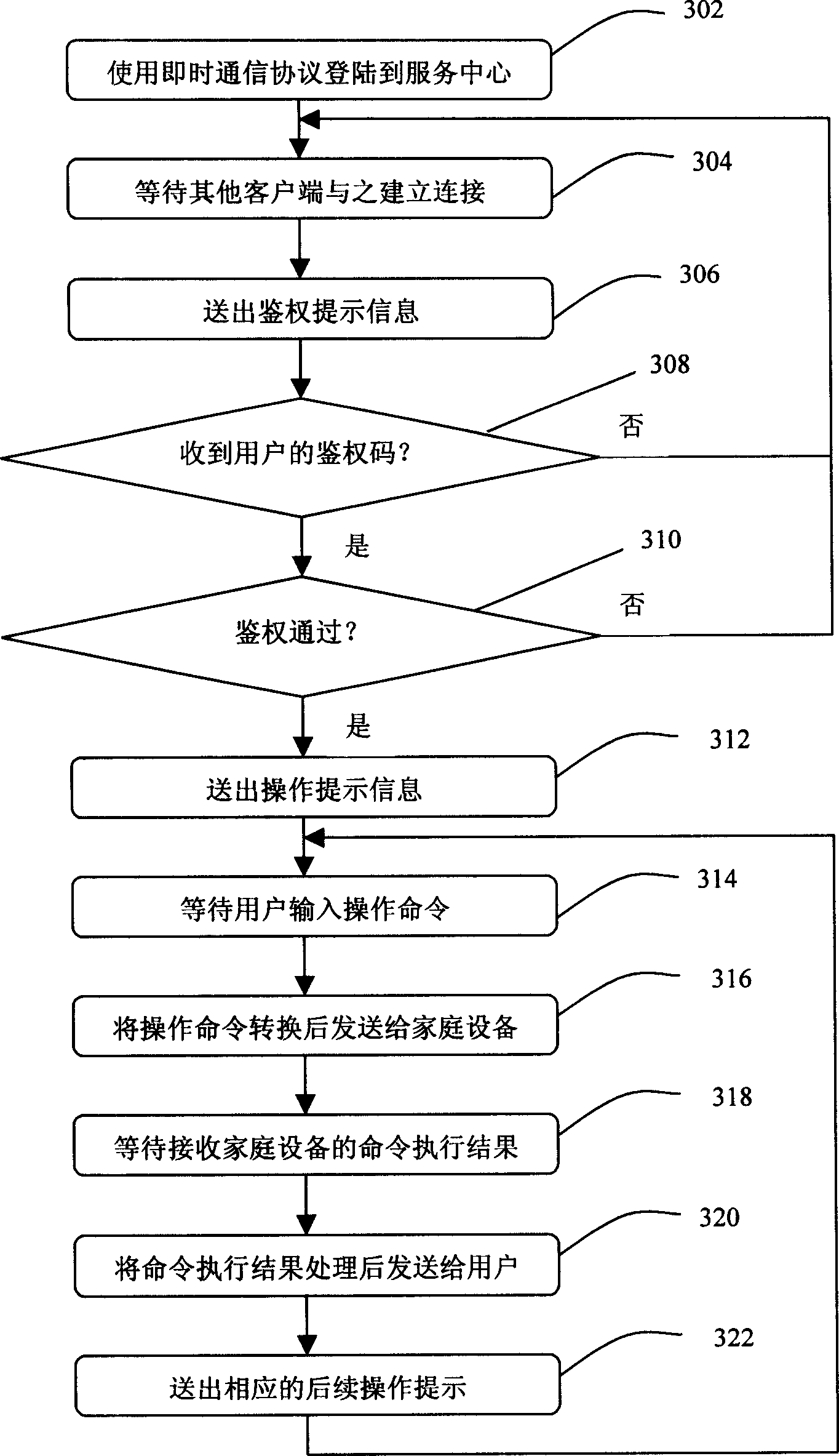

Method for remote control of domestic network apparatus

ActiveCN1852195ASimple and efficient operationLow technical requirementsData switching by path configurationLoad carryingComputer network

The method configures arrangement as following: through household load-carrying network, the household network equipment is connected to household gateway; through Internet, and software service center of instant communication, remote control end builds instant communication connection to household gateway; remote control end sends operation command to household gateway; the household gateway sends operation command to relevant device; the device executes the operation command, and sends back executed result to the remote control end. Advantages are: simple operation, low technical requirement; user can monitor states of household devices expediently in real time, and devices inside household network can define own hint; high expansibility and good compatibility.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

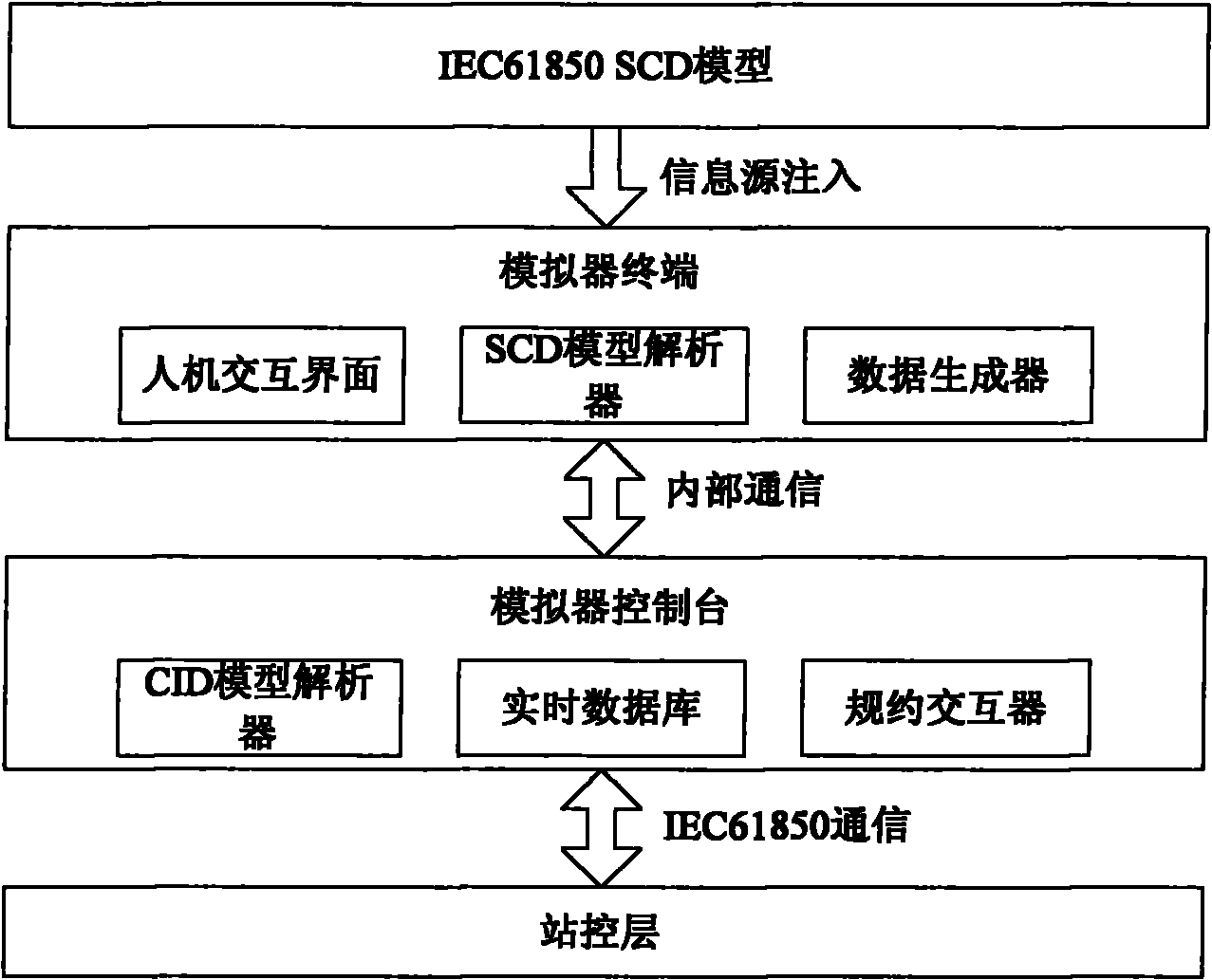

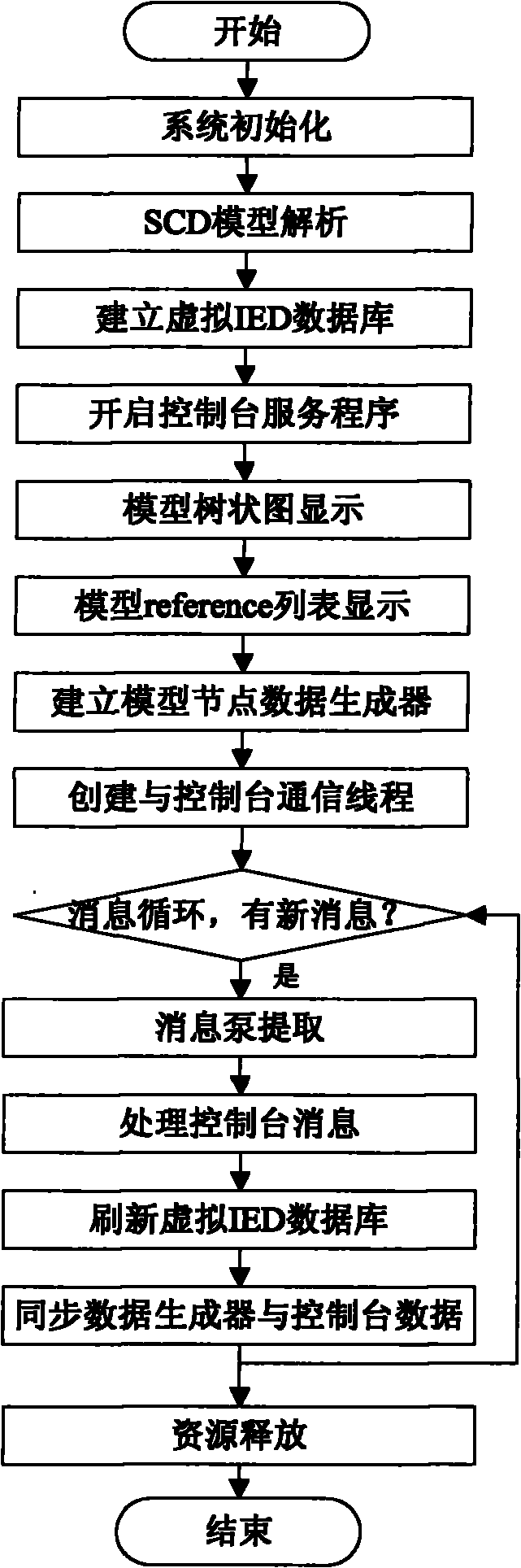

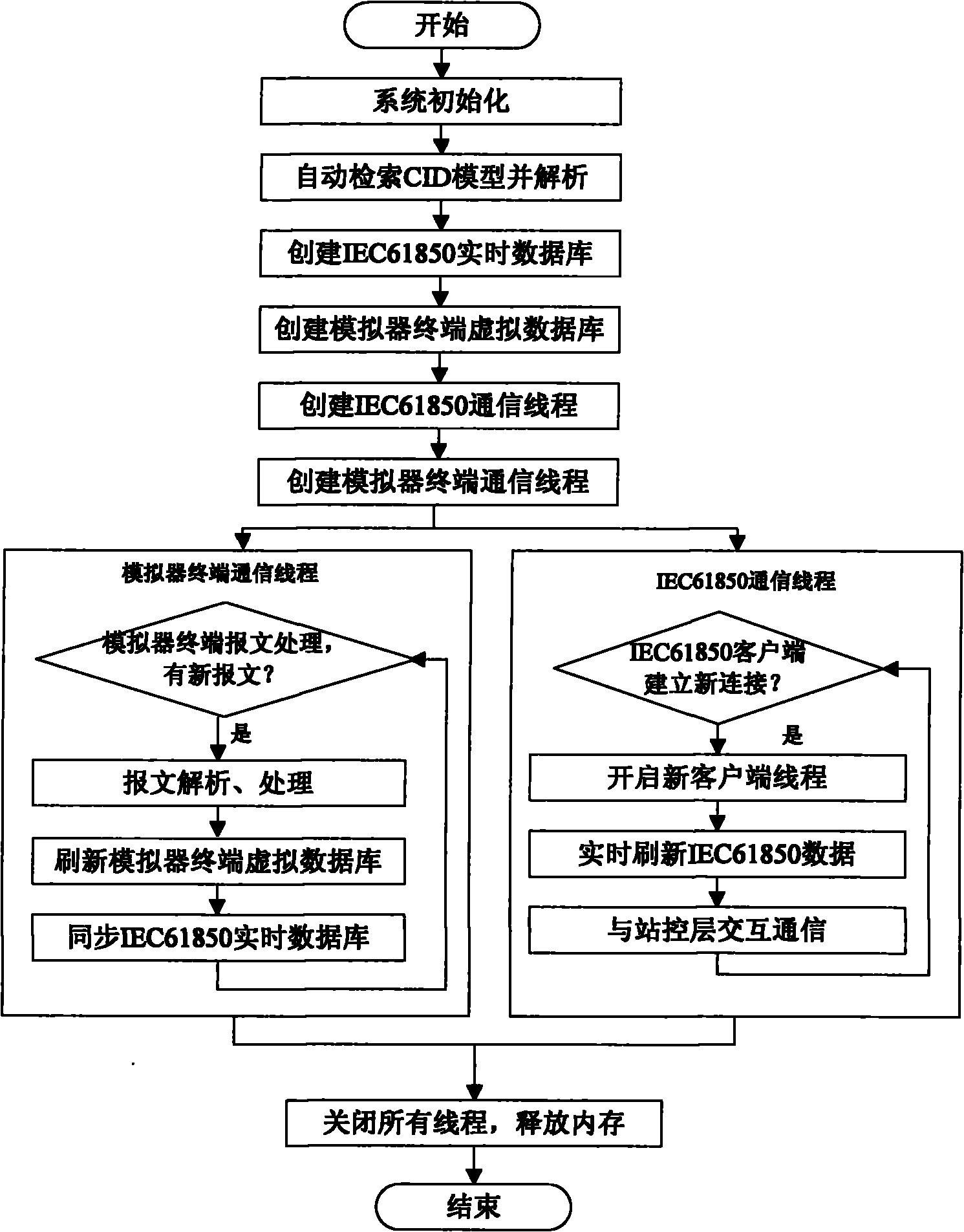

Server-side simulating system based on IEC61850 and method thereof

ActiveCN101771581AReduced commissioning timeLow technical requirementsData switching networksControl layerSimulation

The invention provides a server-side simulating system based on an IEC61850 and a method thereof, which are applied to digital substations adopting the IEC61850 for communication and traditional substations. The system consists of a simulator terminal and a simulator console. The method comprises the following steps: loading an SCD model at the simulator terminal for analyzing; breaking out a CID model file needed by an IED; carrying out man-machine interaction in a tree diagram and tabular form to allocate one data generator for each module data; generating state sequence through the data generator; downloading the state sequence to the simulator control table; loading the CID model broken out by the simulator terminal on the simulator console for analyzing; establishing an IEC61850 database, organizing the trackback path information of the IEC61850 model orderly; addressing the IEC61850 database according to the model trackback path corresponding the data generator; refreshing the IEC61850 database state in real time; and interactively communicating with a station monitor and control layer through the IEC61850, thereby finishing the simulation of the IED server terminal. The invention can carry out simulating preview on the whole substation IED, greatly saves project debugging time and has the characteristics of strong operability, high efficiency, flexible configuration and the like.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

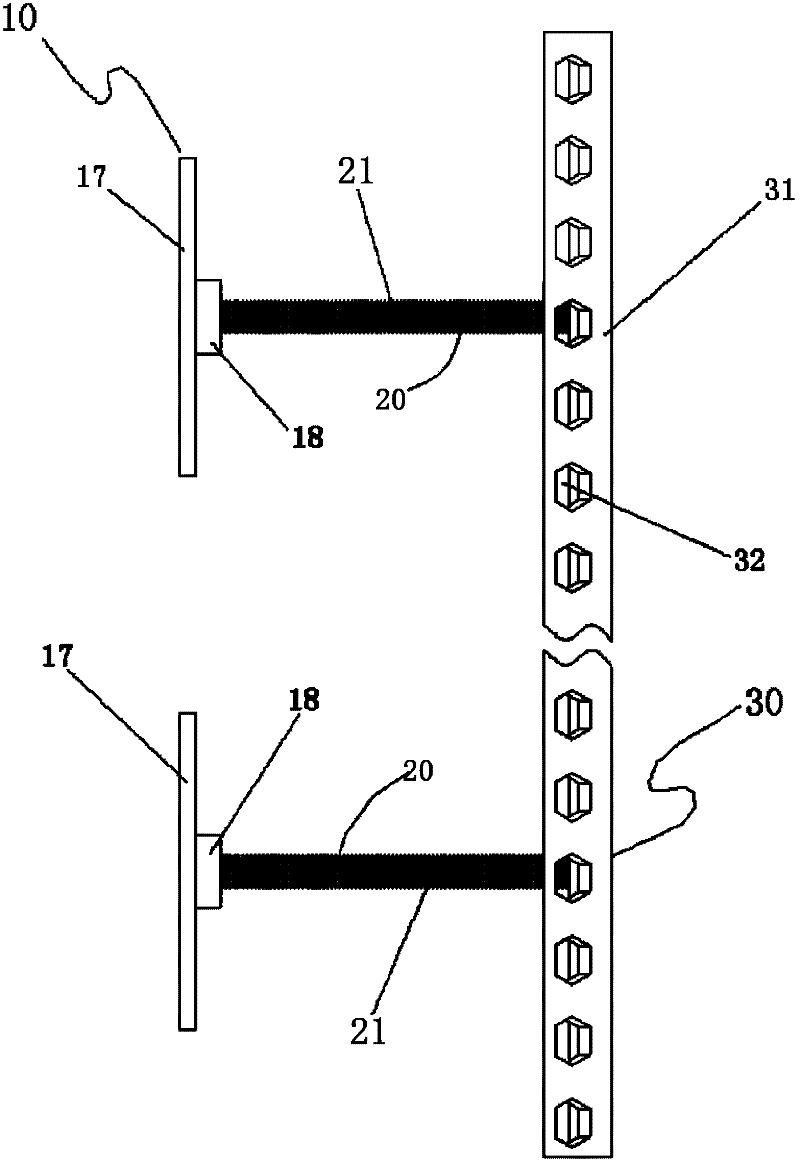

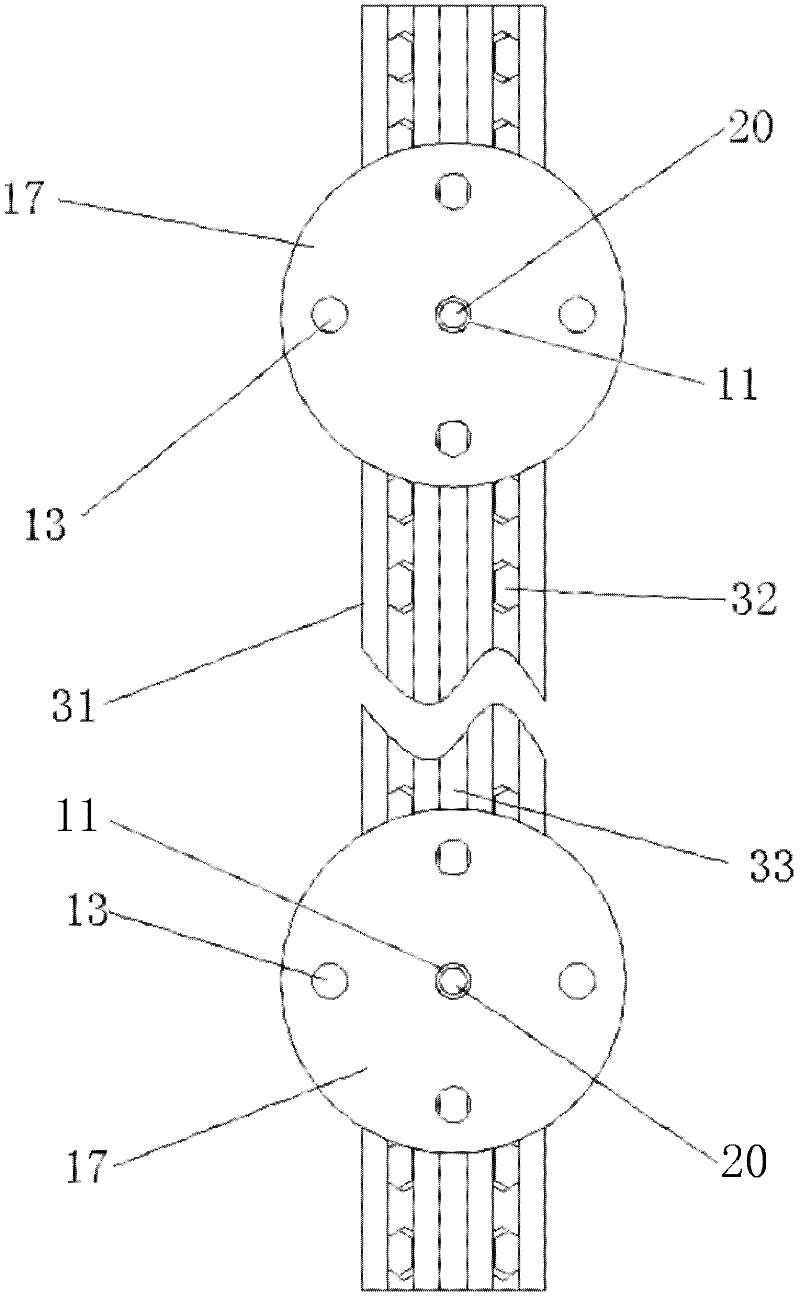

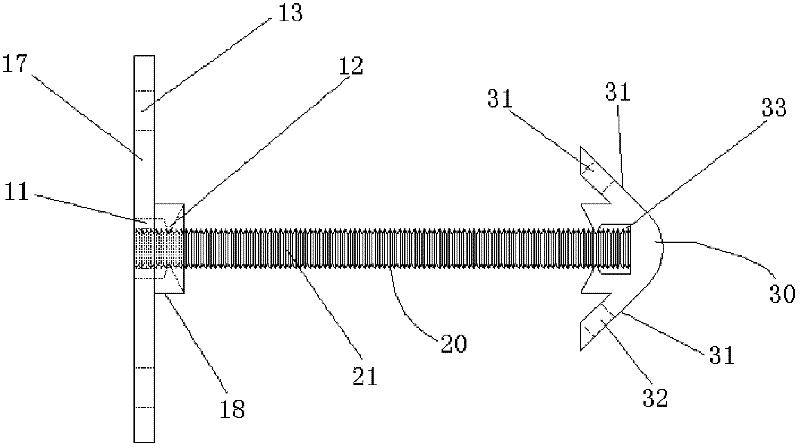

Module splicing structure

ActiveCN105569194AReduce sizeEasy to factory processCovering/liningsCoastlines protectionBuilding construction

The invention relates to a module splicing structure. The module splicing structure comprises splicing modules, connecting parts, reinforcement accessories and functional accessories. Connecting structures of the splicing modules are provided with holes or grooves, the connecting parts are inserted into the holes or the grooves of the adjacent splicing modules, and the shapes of the cross sections of the wholes or the portions, inserted into the splicing modules, of the connecting parts are the same as the shapes of the cross sections of the holes or the grooves of the splicing modules. Due to connection of the connecting parts, the multiple splicing modules are spliced to form a structural whole or a structure. Under the effect of loads and external force acting on the spliced structure, the adjacent splicing modules and the connecting parts can generate torque to resist deformation and collapse of the spliced structure, and the spliced structure is kept stable. The module splicing structure is applied to the field of engineering construction, and is rapid and convenient to assemble, disassemble and maintain, the parts can be produced in an industrialized mode, universality is high, the requirements for the skills of assembling-disassembling operators are low, quality can be easily guaranteed, and the module splicing structure is convenient to transport and capable of being reused.

Owner:金胜昔

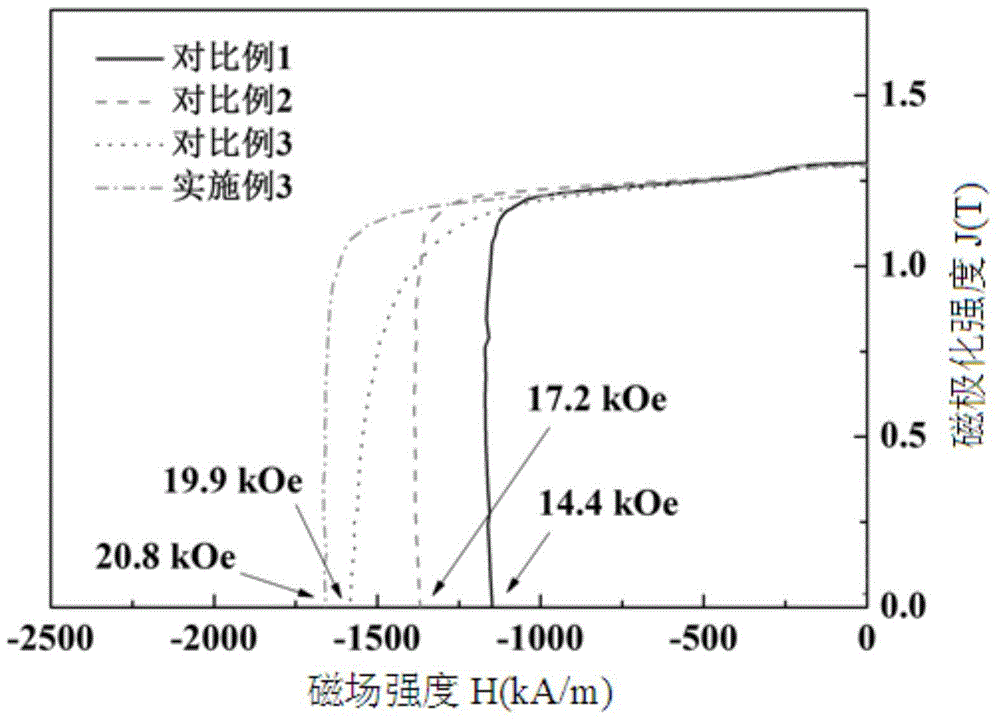

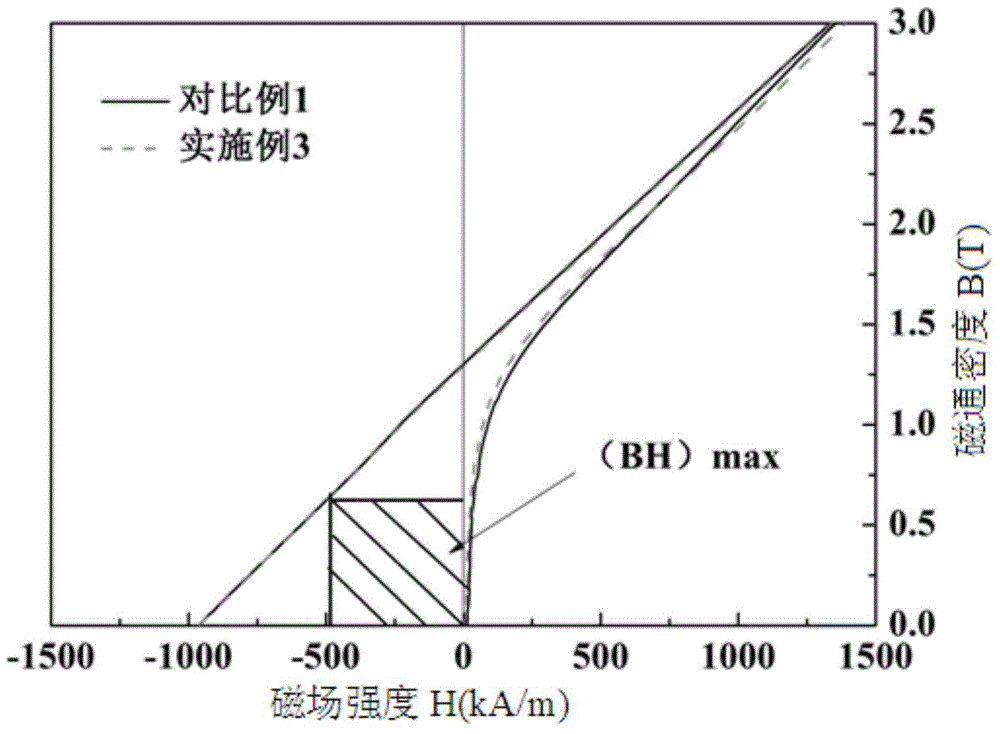

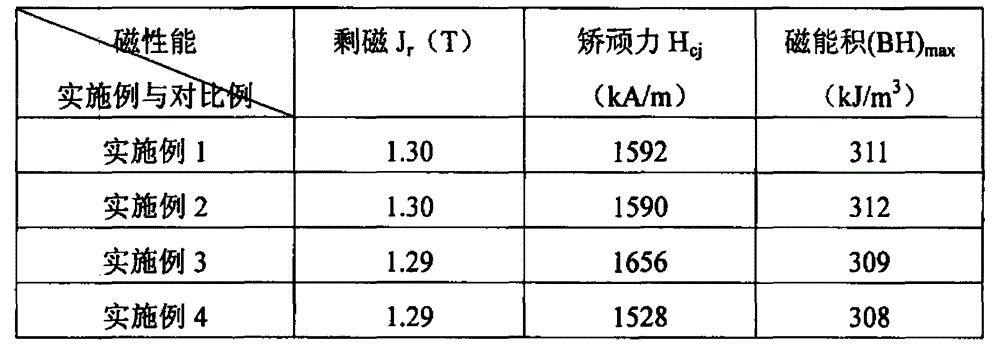

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

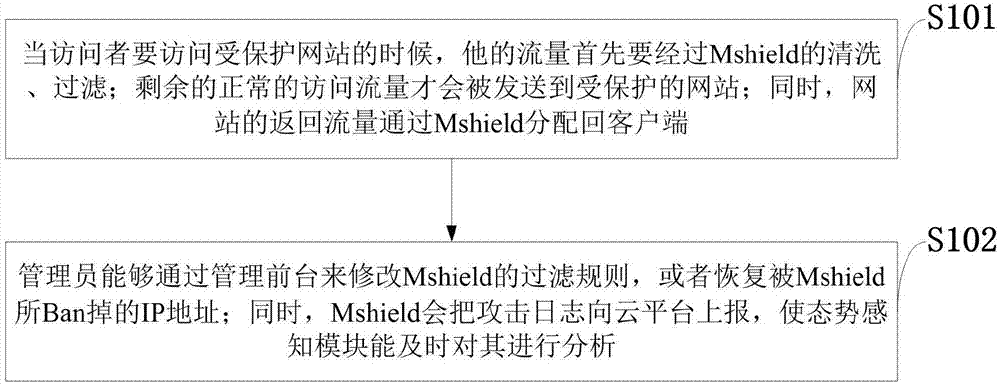

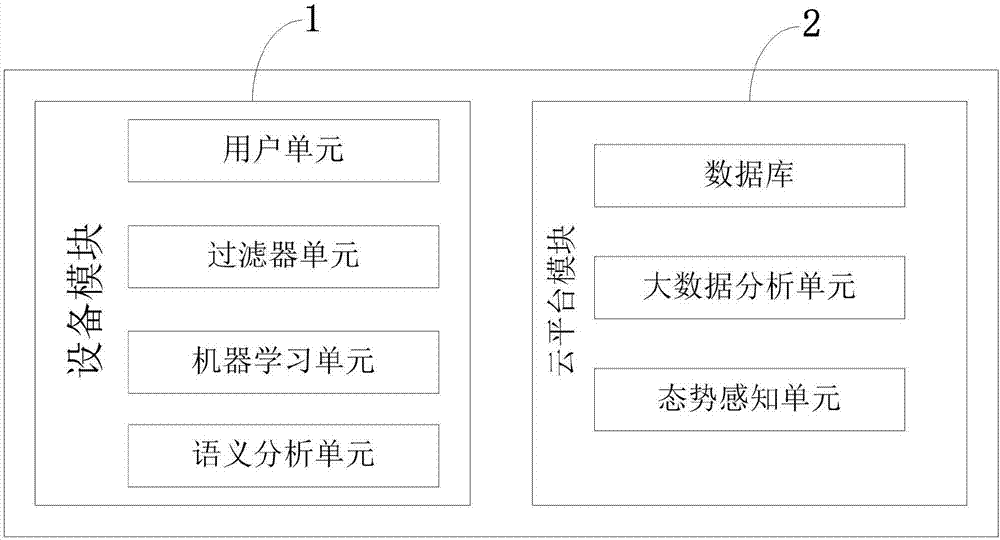

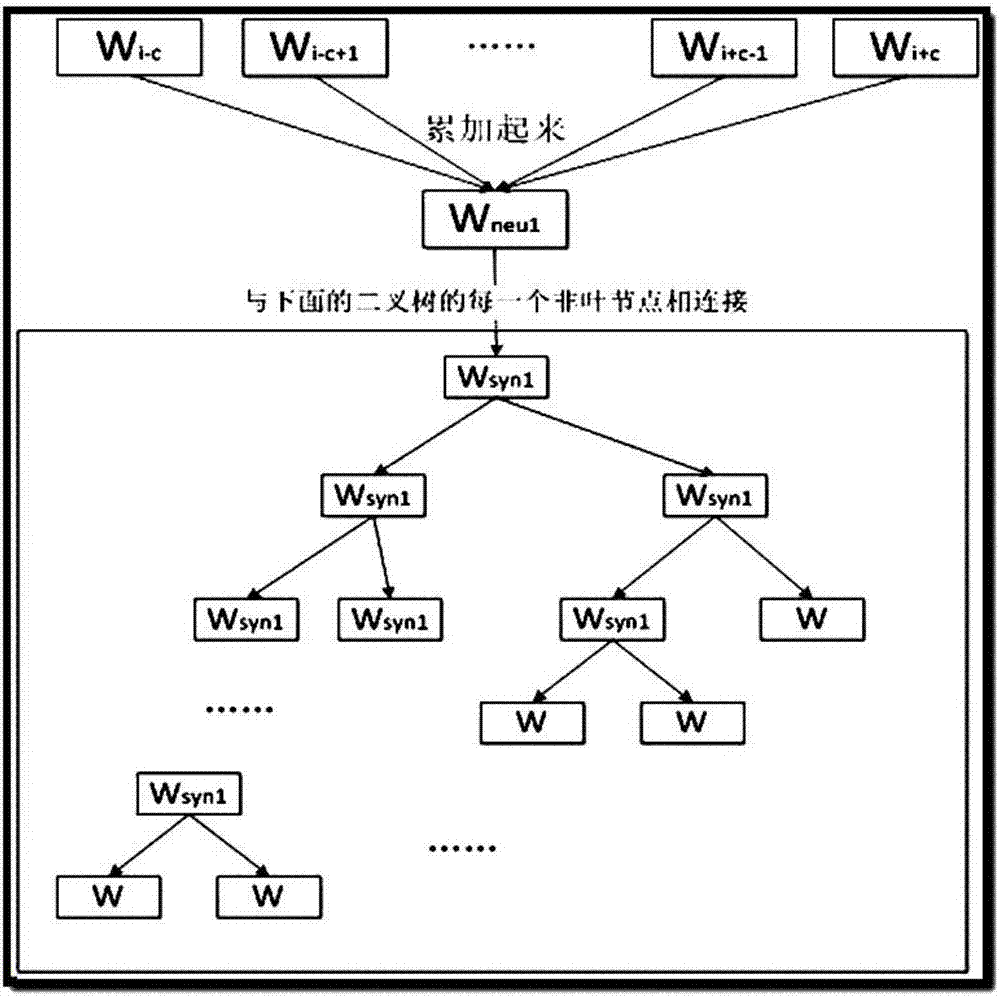

Multi-mode Web application protection method based on Mshield machine learning

InactiveCN107404473ALow technical requirementsEfficient and more secure protection capabilitiesCharacter and pattern recognitionTransmissionData warehouseData set

The invention belongs to the technical field of the Web application protection, and discloses a multi-mode Web application protection method based on Mshield machine learning. The method comprises the following steps: extracting features through a semantic analysis unit, transmitting to a machine learning unit to recognize, and applying a random forest algorithm and a logic regression algorithm; effectively distinguishing hostile attack from a normal access request, and immediately intercepting the attack, wherein the Mshield cloud platform screens logs reported by the device everyday and them summarizes to place in a database as the iteration and a data set for improving the algorithm effect; performing deduction according to the past security posture, predicting the possible attack event and an application easy to be attacked in future. By acquiring the features of mega attack load data, through the training and the generalization of a machine learning model, the Mshield is more efficient and safer protection capacity in the face of the current even the unknown Web attack in future in comparison with the traditional WAF.

Owner:XIDIAN UNIV

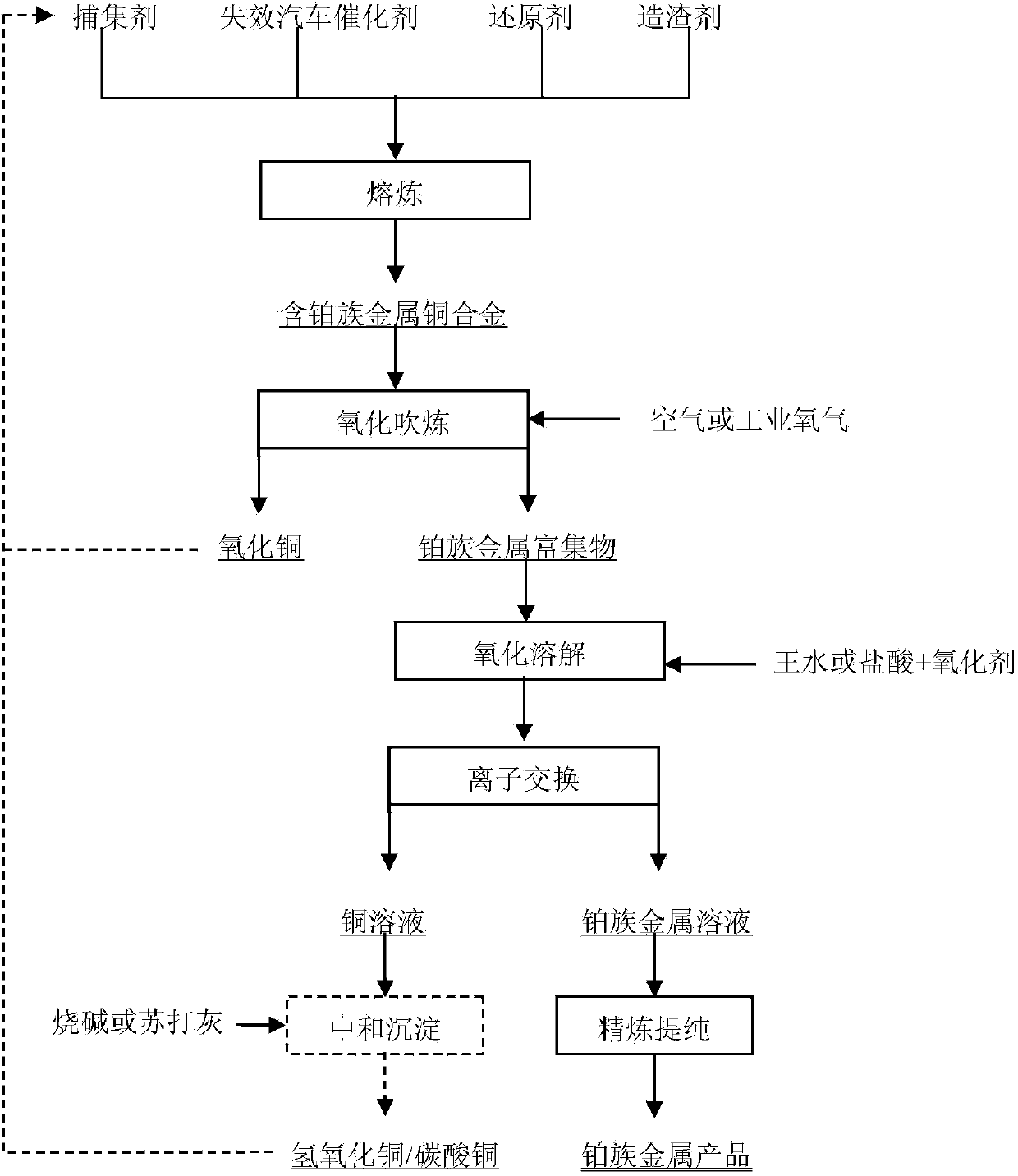

Method for efficiently and cleanly recovering platinum group metals from spent automobile catalyst

InactiveCN104178634ALower melting temperatureHigh recovery rateProcess efficiency improvementIon exchangePalladium

The invention discloses a method for efficiently and cleanly recovering platinum group metals from a spent automobile catalyst, which comprises the following steps: (1) smelting and collection: mixing the spent automobile exhaust catalyst with a collector, a reducer and a slag former, and carrying out high-temperature smelting to obtain a collected metal-platinum group metal alloy; (2) alloy phase oxidation and converting: blowing oxidizing gas into the collected metal-platinum group metal alloy to perform converting; (3) high-grade platinum group metal enrichment dissolution and separation: carrying out oxidizing solvent dissolution and ion-exchange separation to obtain a platinum group metal solution, adding alkali into the exchange raffinate to neutralize and precipitate, and returning the precipitate as the collector for the smelting step; and (4) platinum group metal refinement: refining and purifying the platinum group metal solution to obtain the platinum group metal product. The method efficiently recovers the platinum group metals; the recovery rate of the platinum group metals is greater than 99%, and the platinum+palladium+rhodium content in the smelting slag is less than 10g / t; and the collector can be recycled, so that the method is clean and pollution-free and can easily implement industrialization.

Owner:KUNMING INST OF PRECIOUS METALS

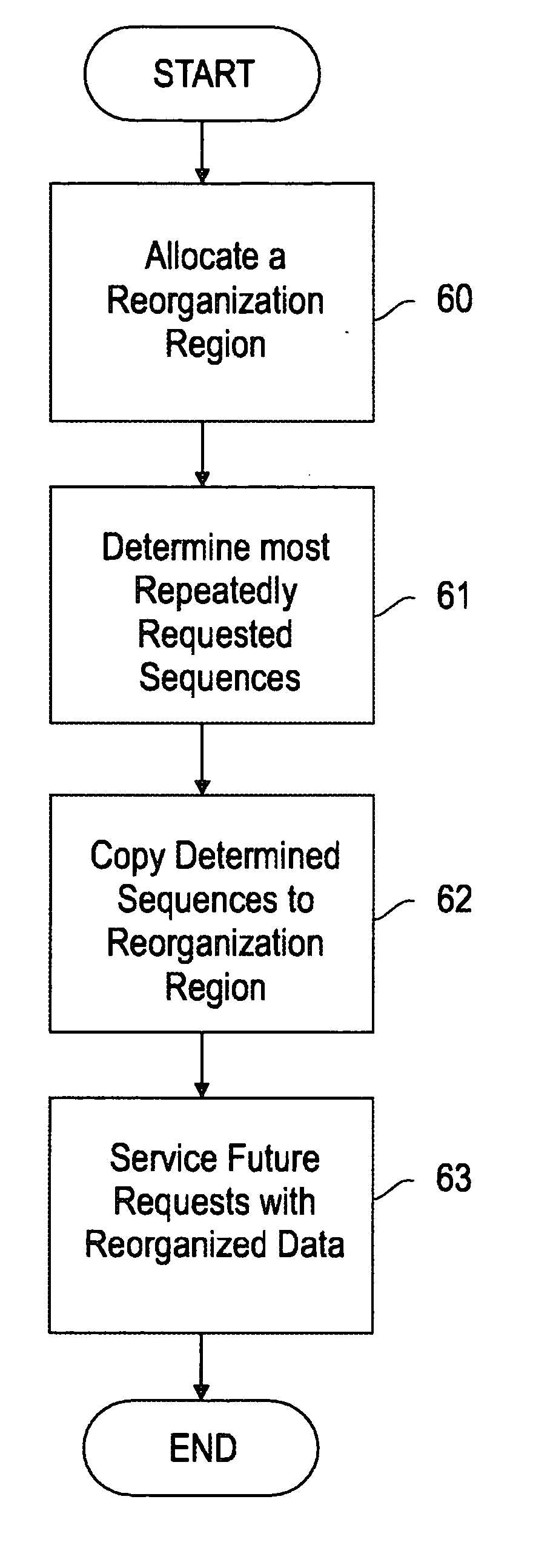

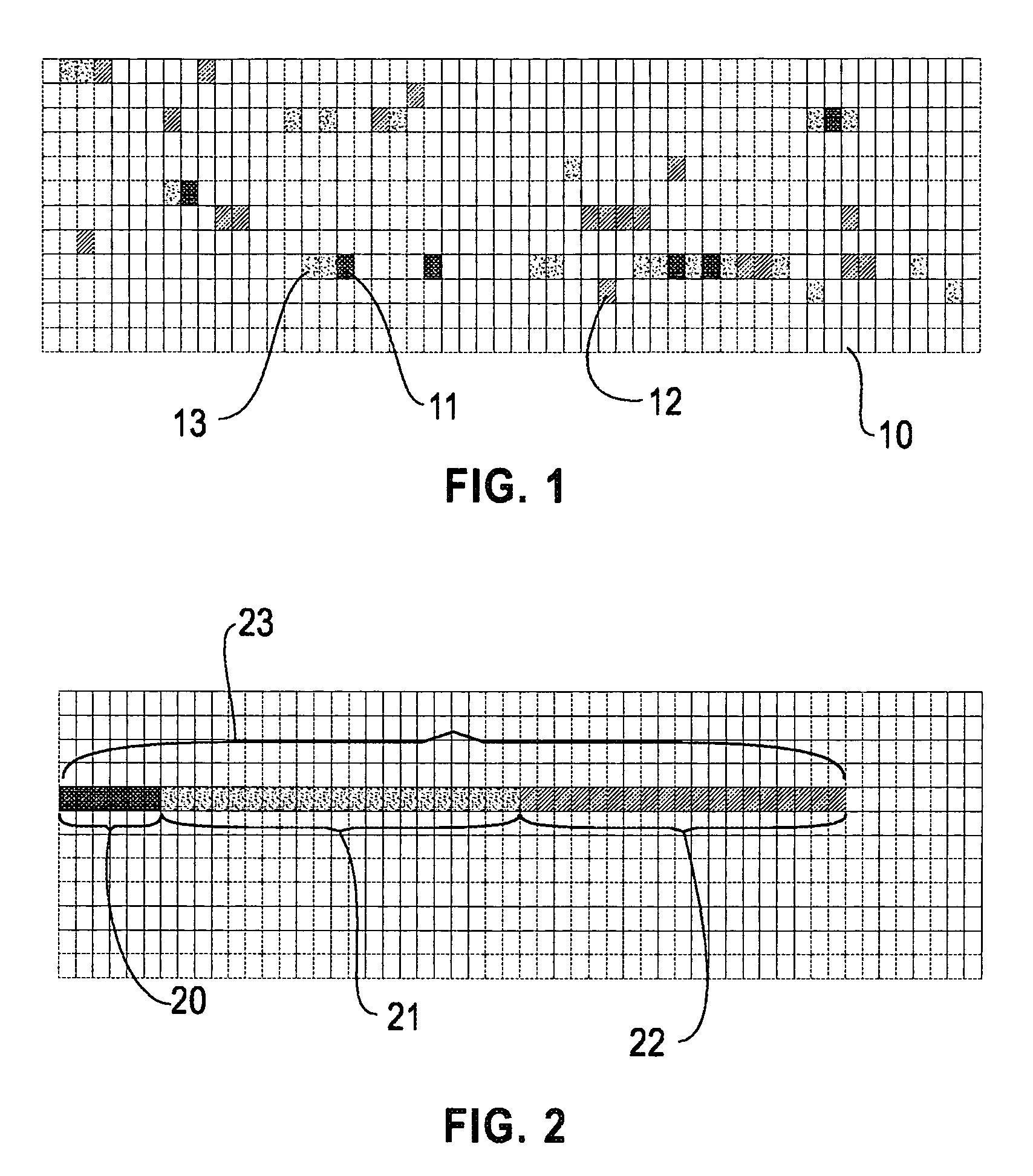

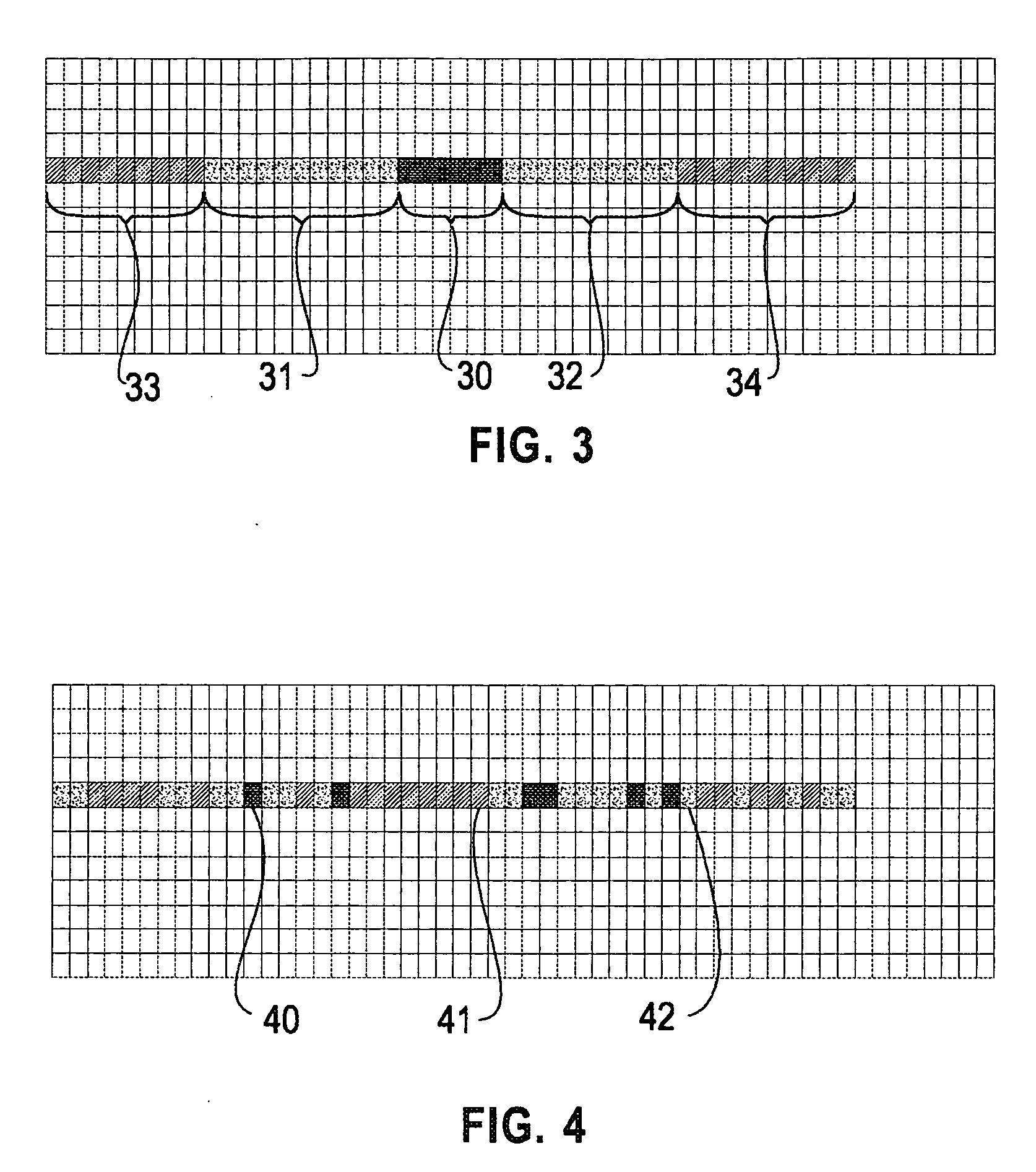

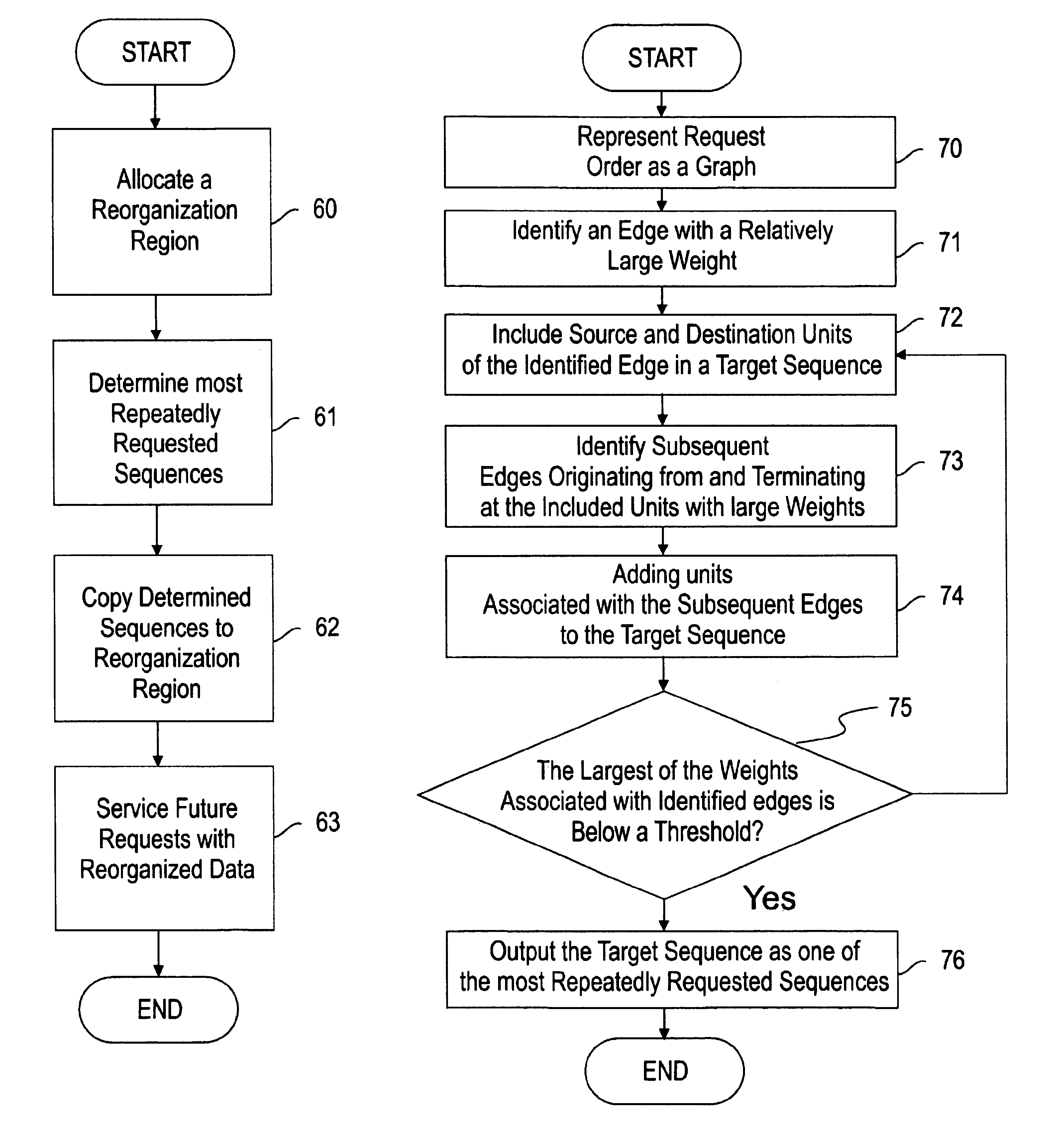

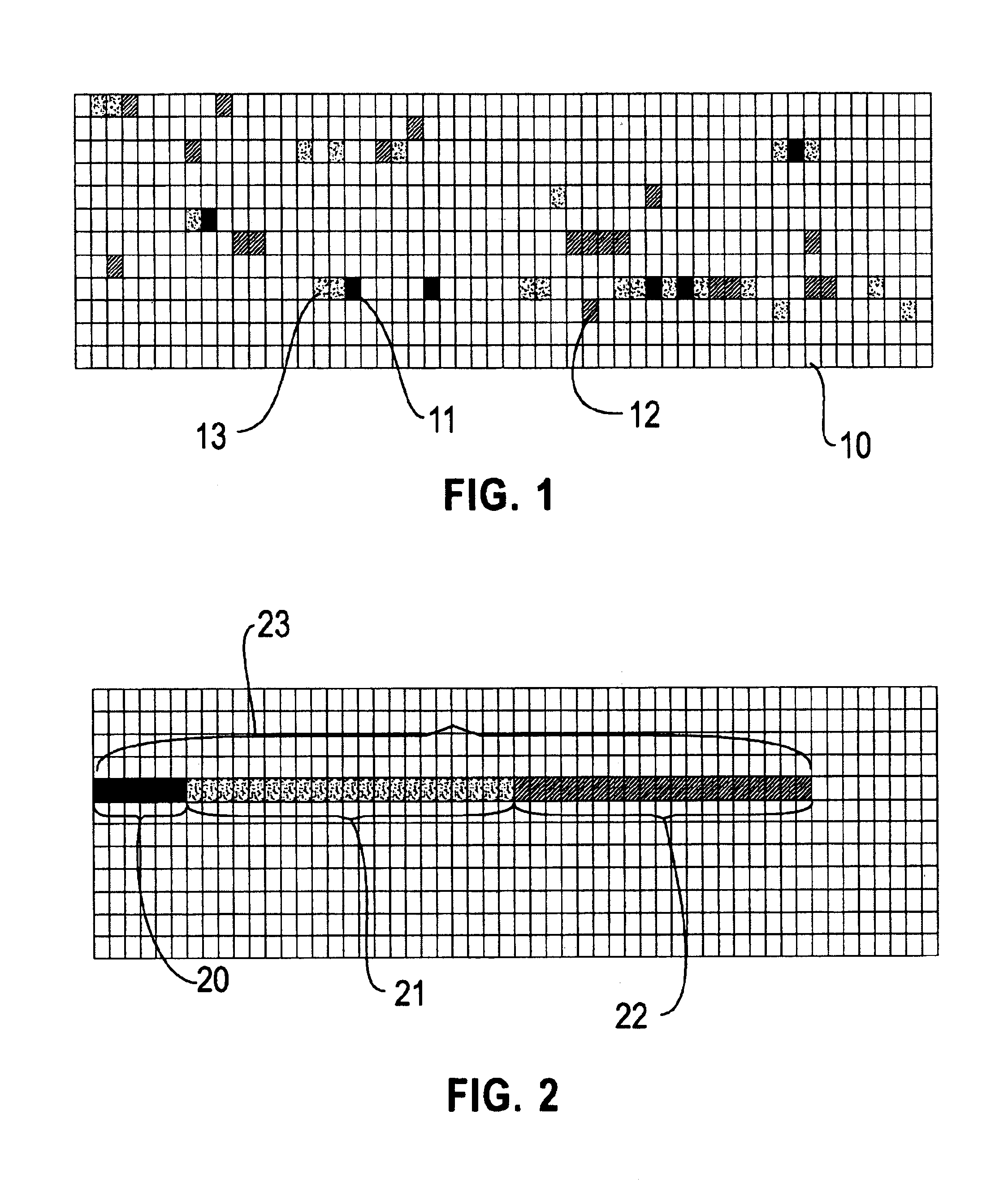

Storage system and method for reorganizing data to improve prefetch effectiveness and reduce seek distance

InactiveUS6963959B2Improve spatial localityImprove system performanceInput/output to record carriersMemory adressing/allocation/relocationData reorganizationDatabase

A data storage system and method for reorganizing data to improve the effectiveness of data prefetching and reduce the data seek distance. A data reorganization region is allocated in which data is reorganized to service future requests for data. Sequences of data units that have been repeatedly requested are determined from a request stream, preferably using a graph where each vertex of the graph represents a requested data unit and each edge represents that a destination unit is requested shortly after a source unit the frequency of this occurrence. The most frequently requested data units are also determined from the request stream. The determined data is copied into the reorganization region and reorganized according to the determined sequences and most frequently requested units. The reorganized data might then be used to service future requests for data.

Owner:IBM CORP

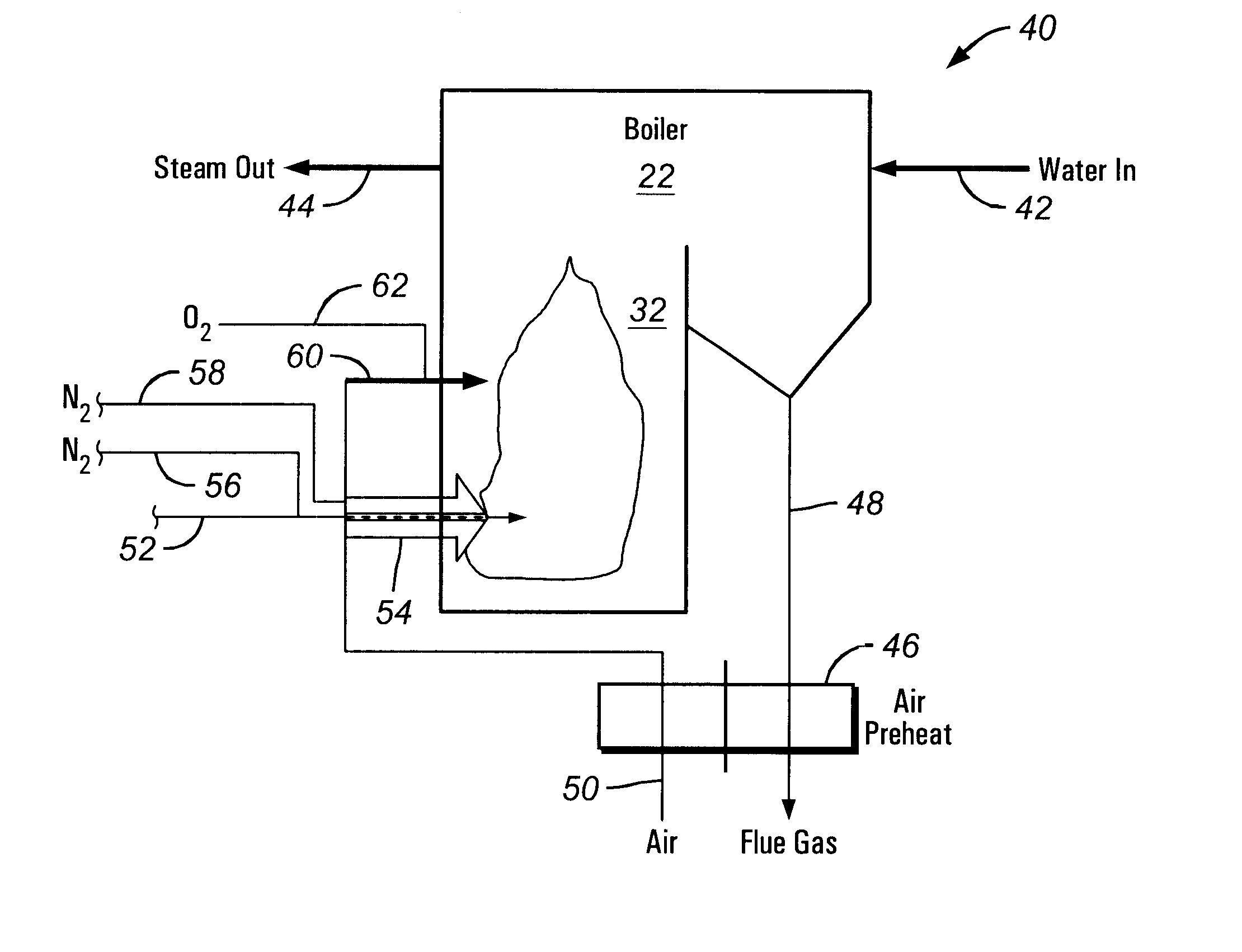

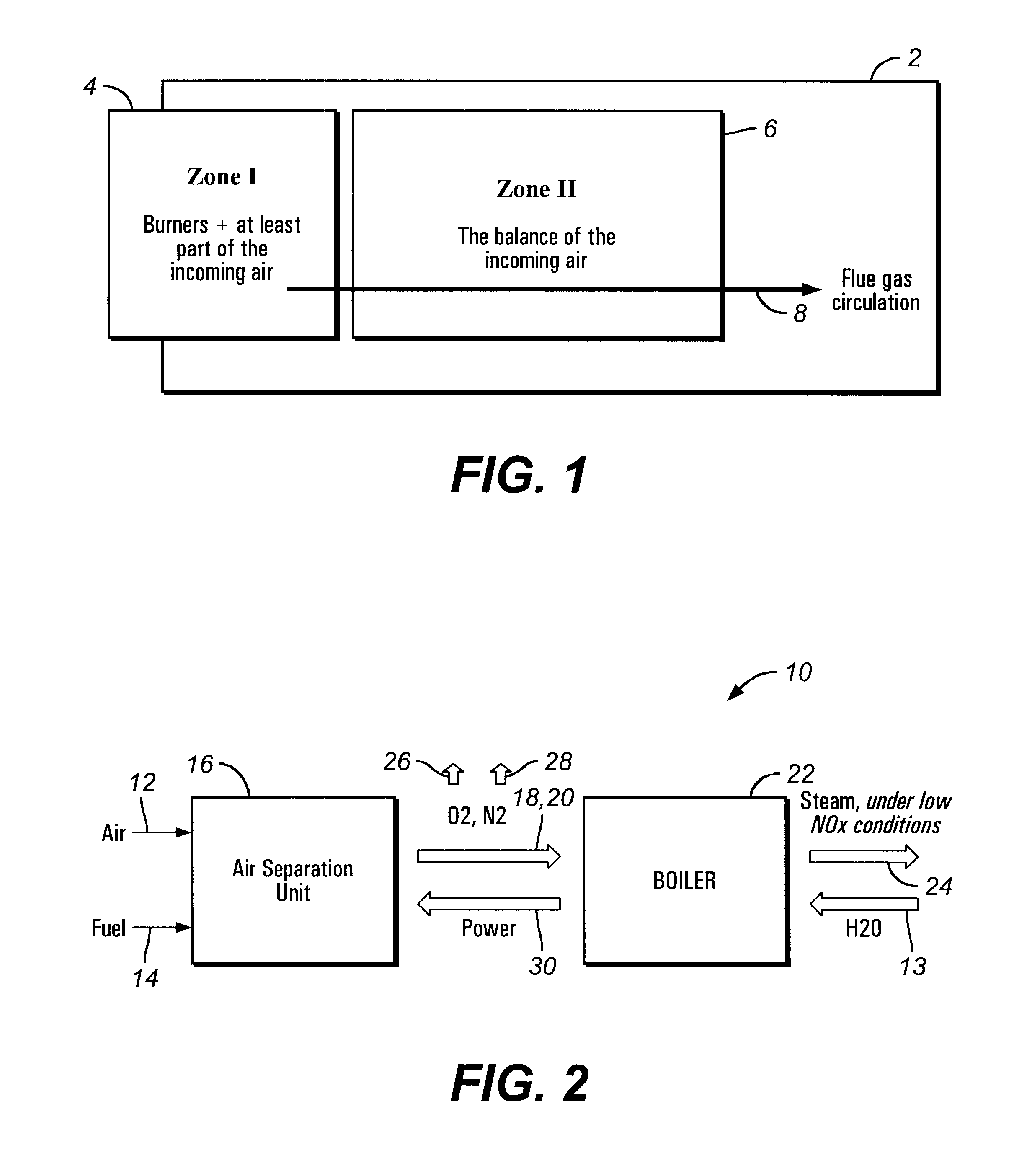

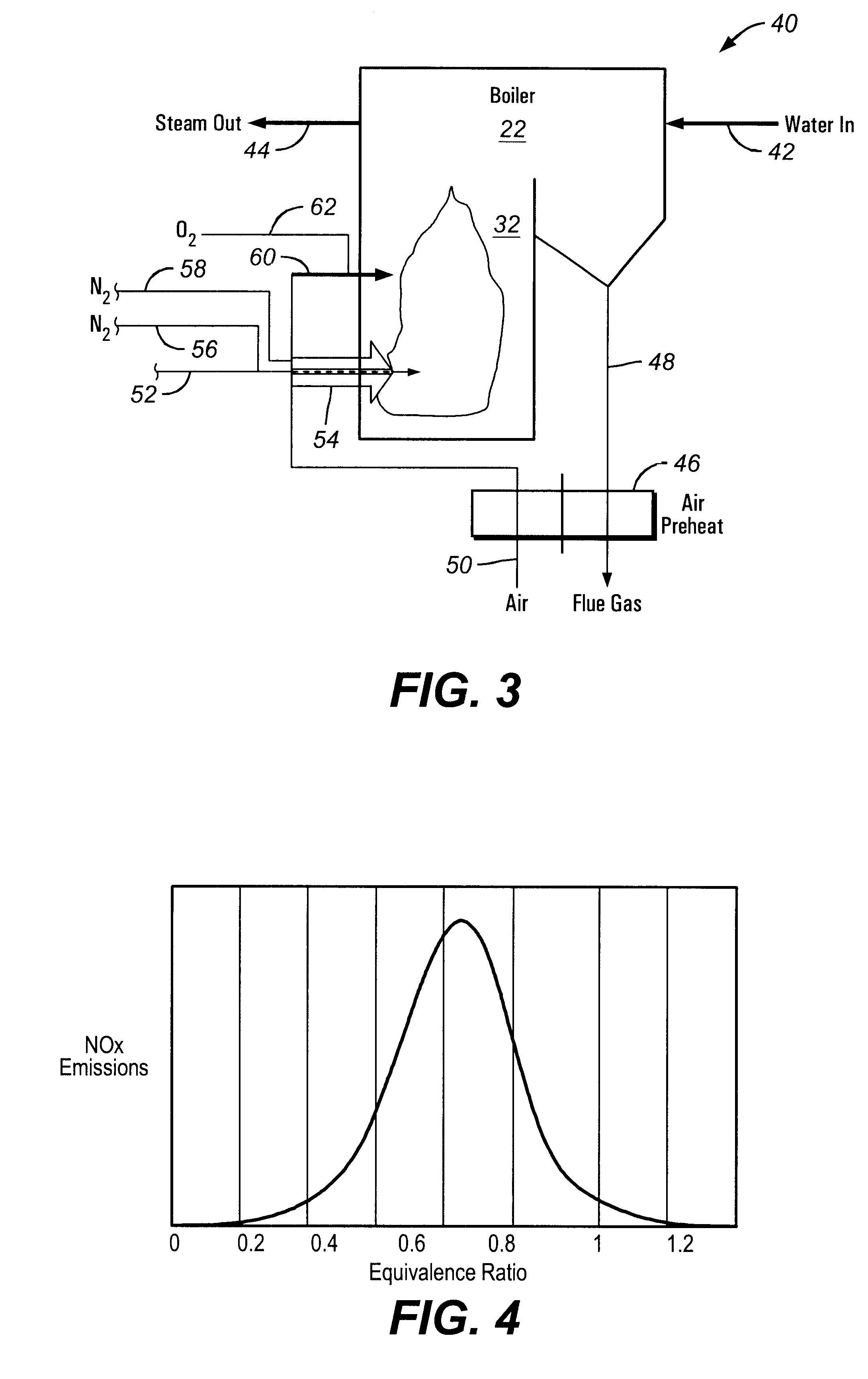

Combination air separation and steam-generation processes and plants therefore

InactiveUS6568185B1Low quality scoreIncreases adiabatic temperature of flameSolidificationLiquefactionNitrogenAir separation

This invention proposes innovative techniques of NOx reduction in boiler operation through an adaptation of staged combustion in combustion boilers. In preferred processes, air is fed into an air separation unit, and a nitrogen-enriched stream is combined with air to produce a nitrogen-enriched first stage air stream, and at least a portion of an oxygen-enriched stream is mixed with air to produce an oxygen-enriched second stage air stream. A reduction in NOx and increase in efficiency is promoted by the inventive processes and systems.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

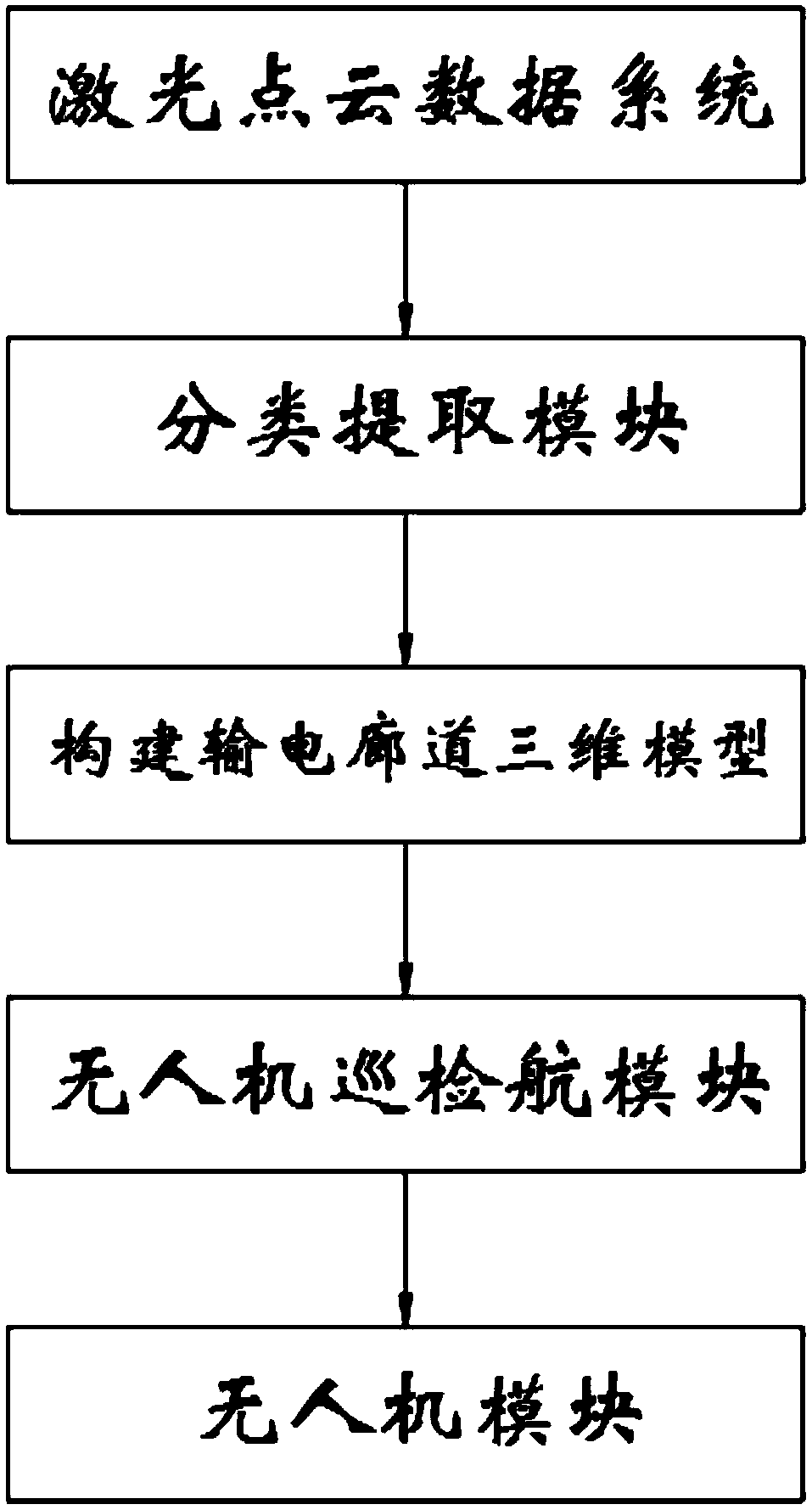

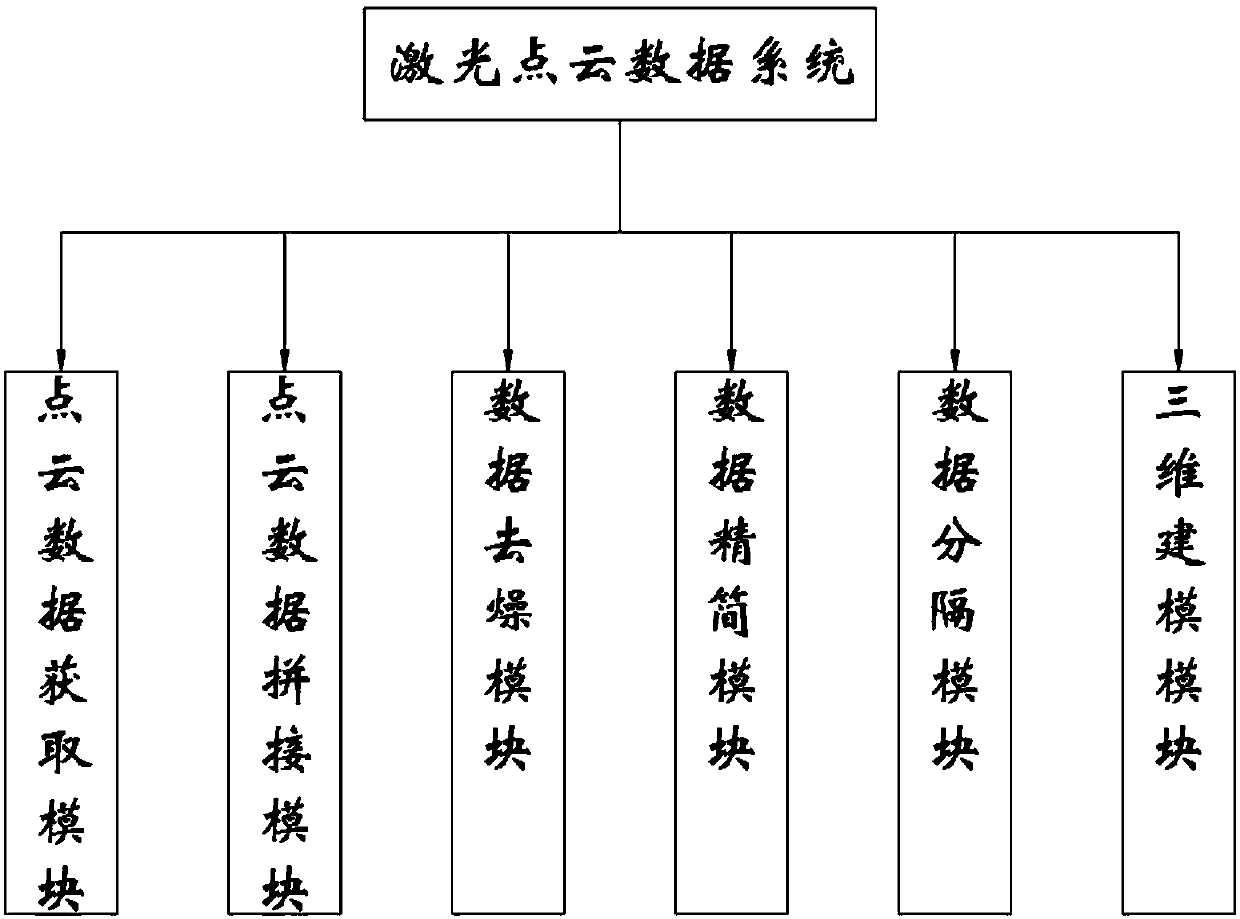

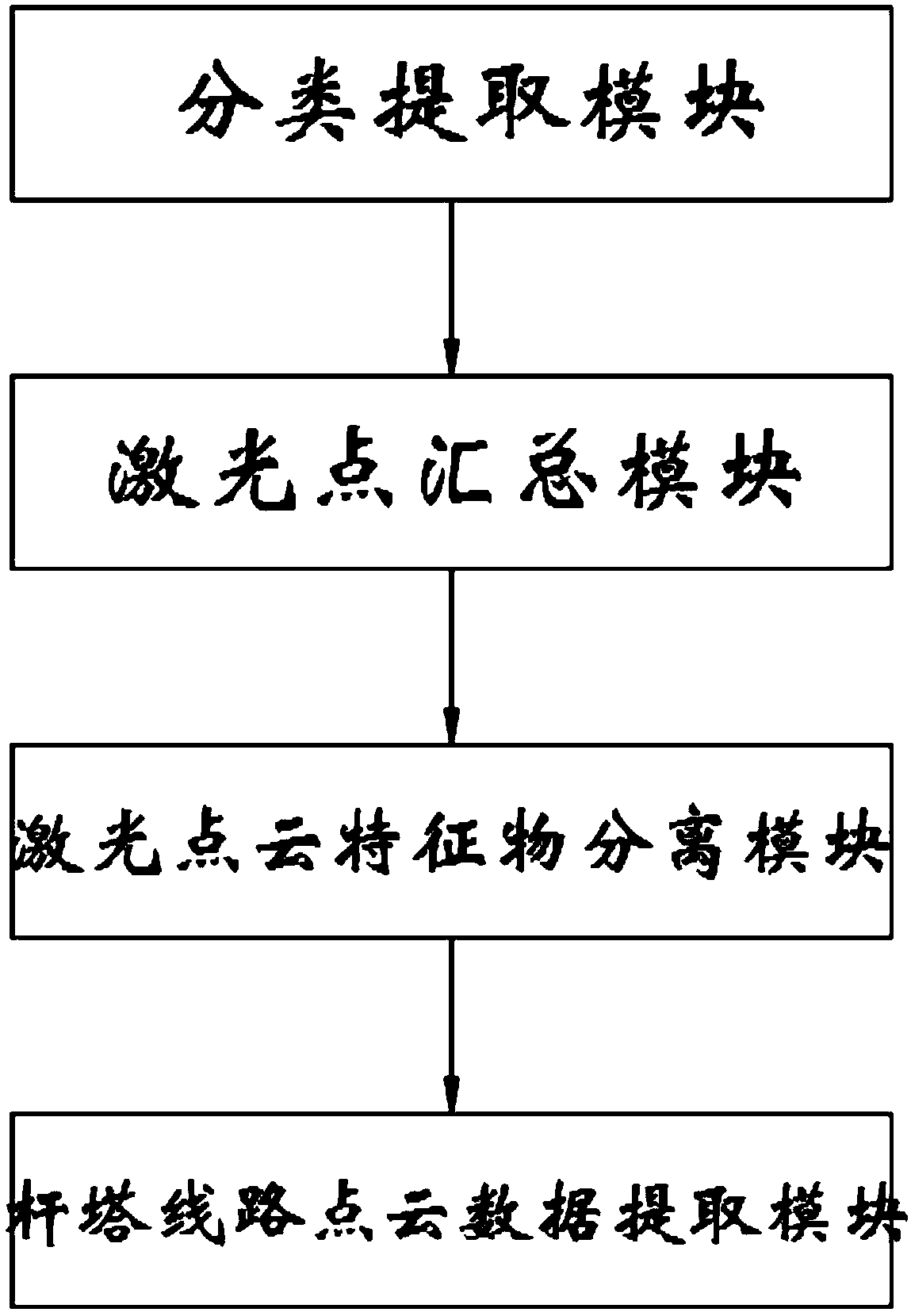

Transmission inspection three-dimensional flight path automatic planning method based on laser point cloud data

PendingCN109633674ALow technical requirementsAccurate trackingOptical rangefindersUsing optical meansPoint cloudUncrewed vehicle

The invention relates to the technical field of power grid inspection, in particular to a transmission inspection three-dimensional flight path automatic planning method based on laser point cloud data. The transmission inspection three-dimensional flight path automatic planning method comprises a laser point cloud data system, an analysis module and an unmanned aerial vehicle module. According tothe transmission patrol three-dimensional flight path automatic planning method based on the laser point cloud data, the laser point cloud data system is used as the basis, a ground point and a non-ground point are separated by combining a classification and extraction module, and a flight path of an unmanned aerial vehicle patrol power transmission channel and a tower is planned the basis, so that not only are the technical requirements of unmanned aerial vehicle control personnel reduced, but also accurate tracking and fine polling can be carried out on the line targets, and it is guaranteed that the whole inspection work is carried out smoothly; and the unmanned aerial vehicle inspection flight path module is adopted, so that the unmanned aerial vehicle inspection flight path capable of achieving automatic planning is achieved, potential safety hazards and missed detection in the manual control unmanned plane inspection of the unmanned aerial vehicle can be effectively avoided, andthe safety and the efficiency of electric power patrol are improved.

Owner:云南电网有限责任公司输电分公司

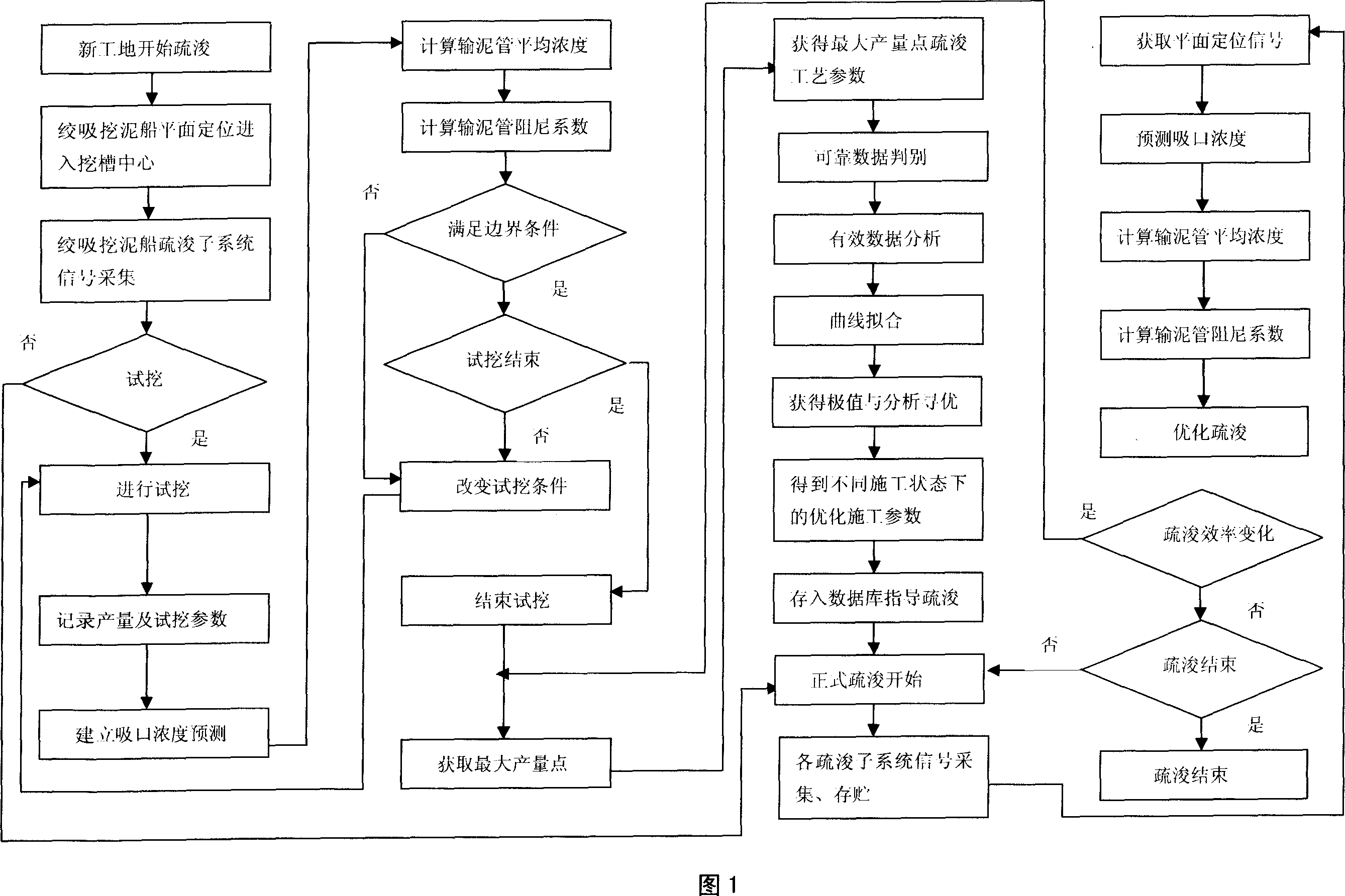

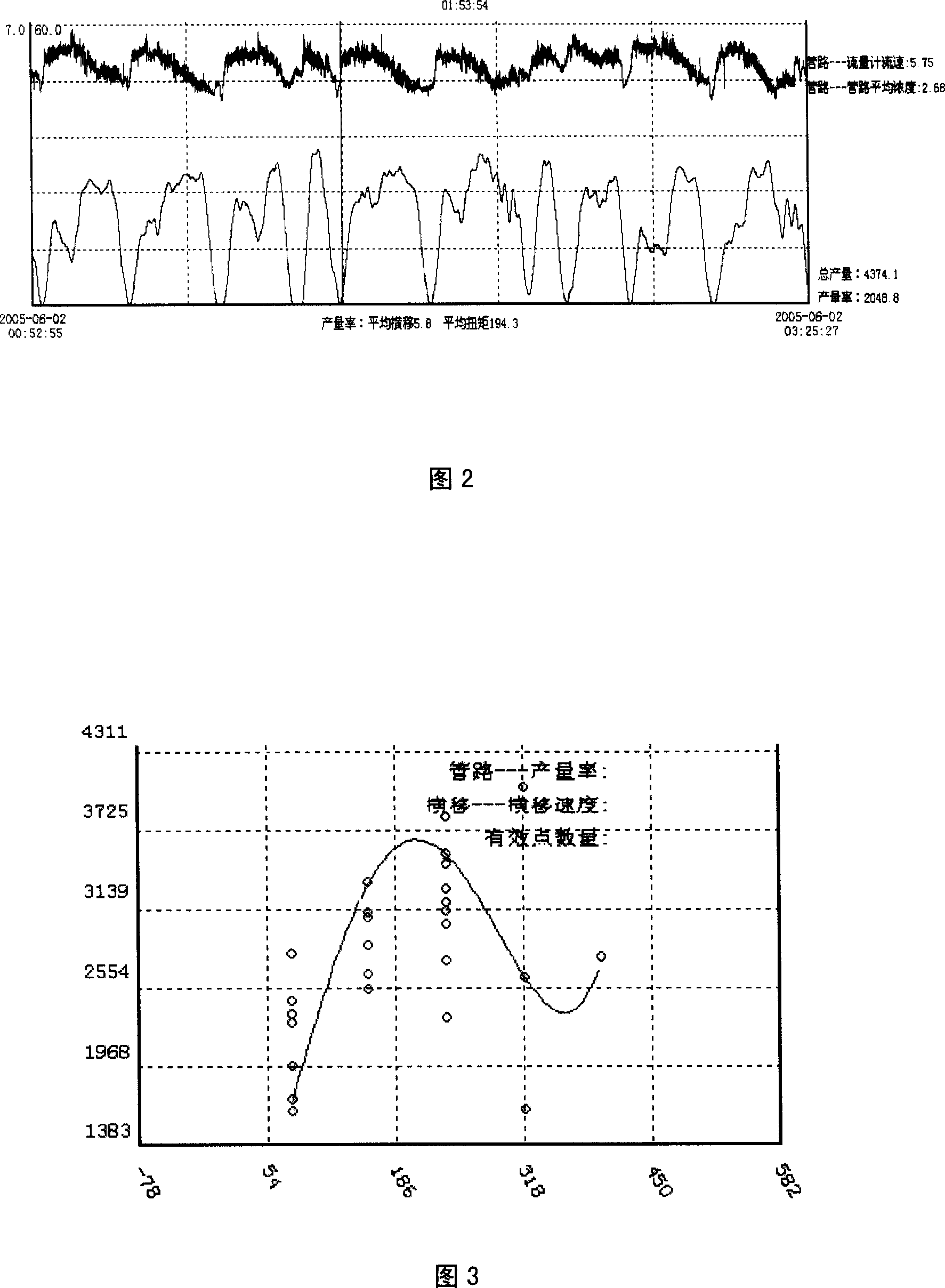

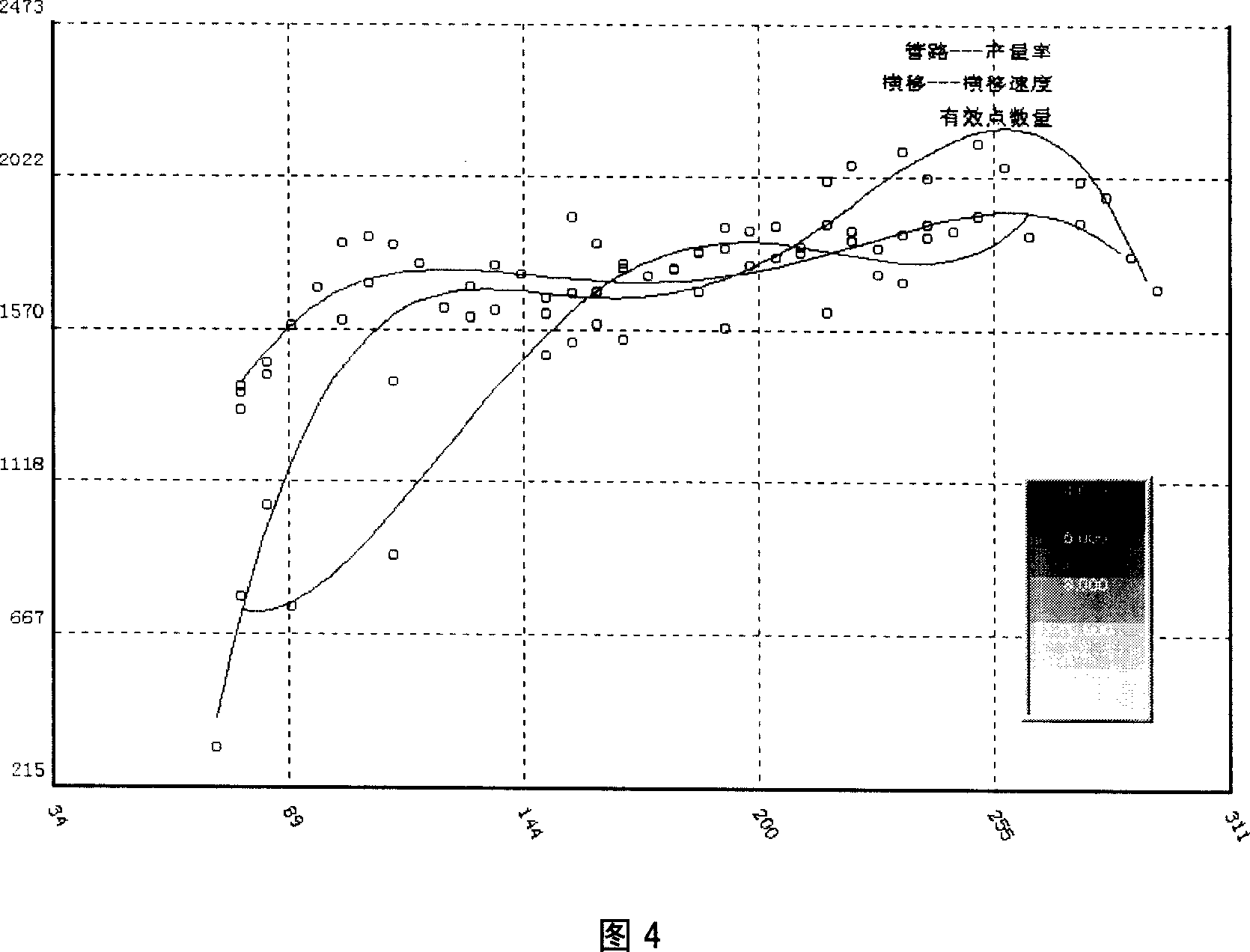

Automatic computerized selecting optimized dredging method for cutter suction dredger

InactiveCN101021878ALow technical requirementsOptimum Construction ParametersMechanical machines/dredgersSpecial data processing applicationsComputer-aidedCurve fitting

This invention relates to an automatic optimizing method for assistant dredging up with a computer of a cutter suction dredger including: collecting the dredge up subsystem signals of a cutter suction dredger, registering the output and related trial digging parameter, setting up a forecast model of suction density, computing the mean density, and dampon coefficient for mud transporting tubes and judging if the trial digging parameter and result meet the set border condition, reliable data judgment, effective data analysis, curve fit to get the optimum construction parameter to carry out optimized dredge up.

Owner:中国交通建设集团有限公司

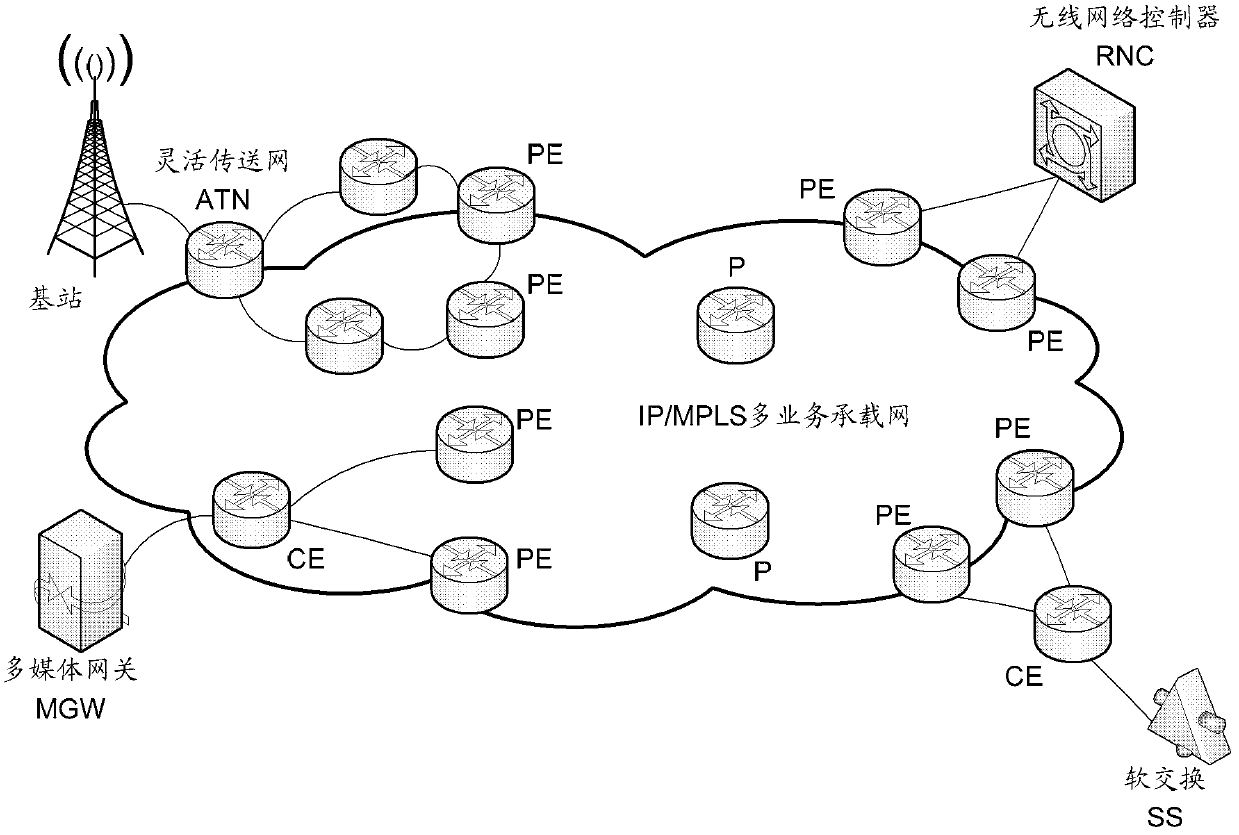

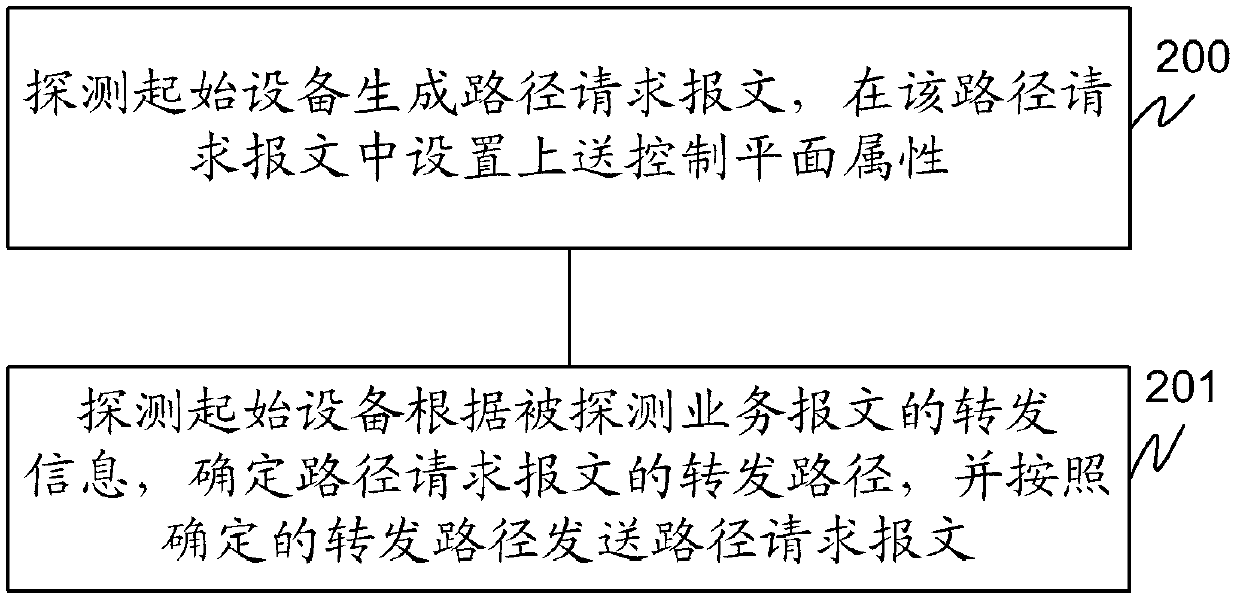

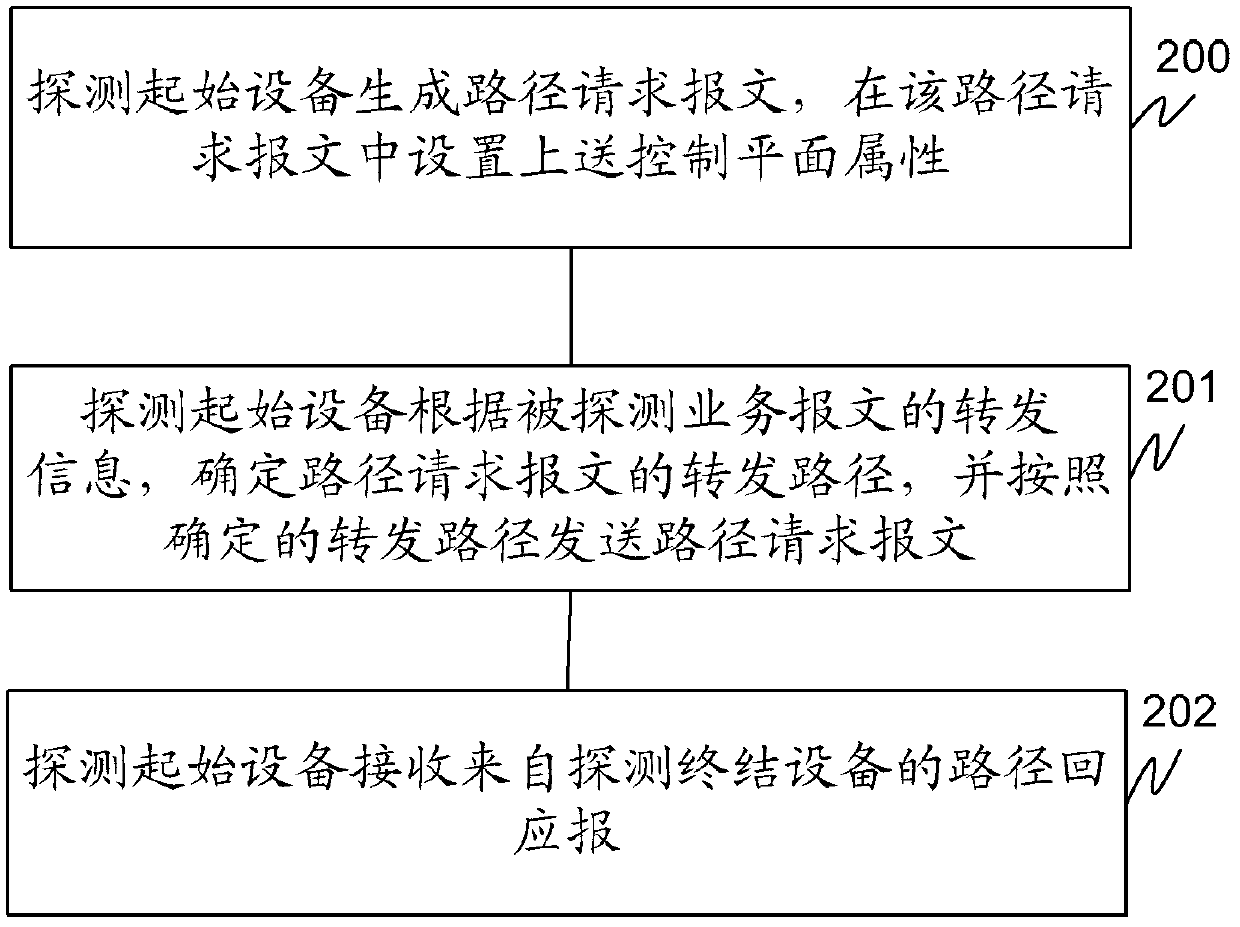

Detection method and device of service path

ActiveCN102437931AImprove fault location efficiencyLow technical requirementsData switching networksMultiprotocol Label SwitchingInternet Protocol

The invention discloses a detection method and device of a service path. The method comprises the following steps of: generating a path request message by a detection starting device; configuring an upper control panel attribute in the path request message, wherein forwarded information of a detected service message is carried by the path request message; according to the forwarded information of the detected service message, determining a forwarding path of the path request message by the detection starting device and sending the path request message according to the determined forwarding path. By realizing the technical scheme provided by the invention, the path of the path request message is the same as an actual path of the detected service message, so that the technical problem in the existing scheme that the actual service path cannot be obtained in a multi-service loading network is solved, the fault location efficiency of an IP / MPLS (Internet Protocol / Multiprotocol Label Switch) loading network is improved and the technical requirements on operation and maintenance personnel are reduced.

Owner:HUAWEI TECH CO LTD

Method for architectural decoration plastering construction

The invention provides a method for architectural decoration plastering construction. The method comprises the following steps: firstly, base treatment, secondly, screeding, thirdly, plastering, and fourthly, wall surface grinding; screeding in the second step means that construction positioning paying-off is performed according to required plastering height, screeding templates are longitudinally installed along a wall surface subjected to base treatment in the first step according to the paying-off height, and the lateral distance between adjacent screeding templates is 1.3 to 1.8 meters. Wall surface grinding in the fourth step means that the wall surface subjected to plastering in the third step is subjected to standing for 12 to 24 hours till plastering mortar on the wall surface is at a half-dried compact hardened state, and teeth of a saw blade are used for grinding the mortar along the two adjacent screeding templates through a rule till the mortar is even. Due to the method, the plastering construction efficiency can be improved, the construction quality is guaranteed, the large-area construction efficiency is further improved with the matching of mechanized construction, and the defects of low efficiency of traditional manual construction and high technical requirements on constructors are overcome.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

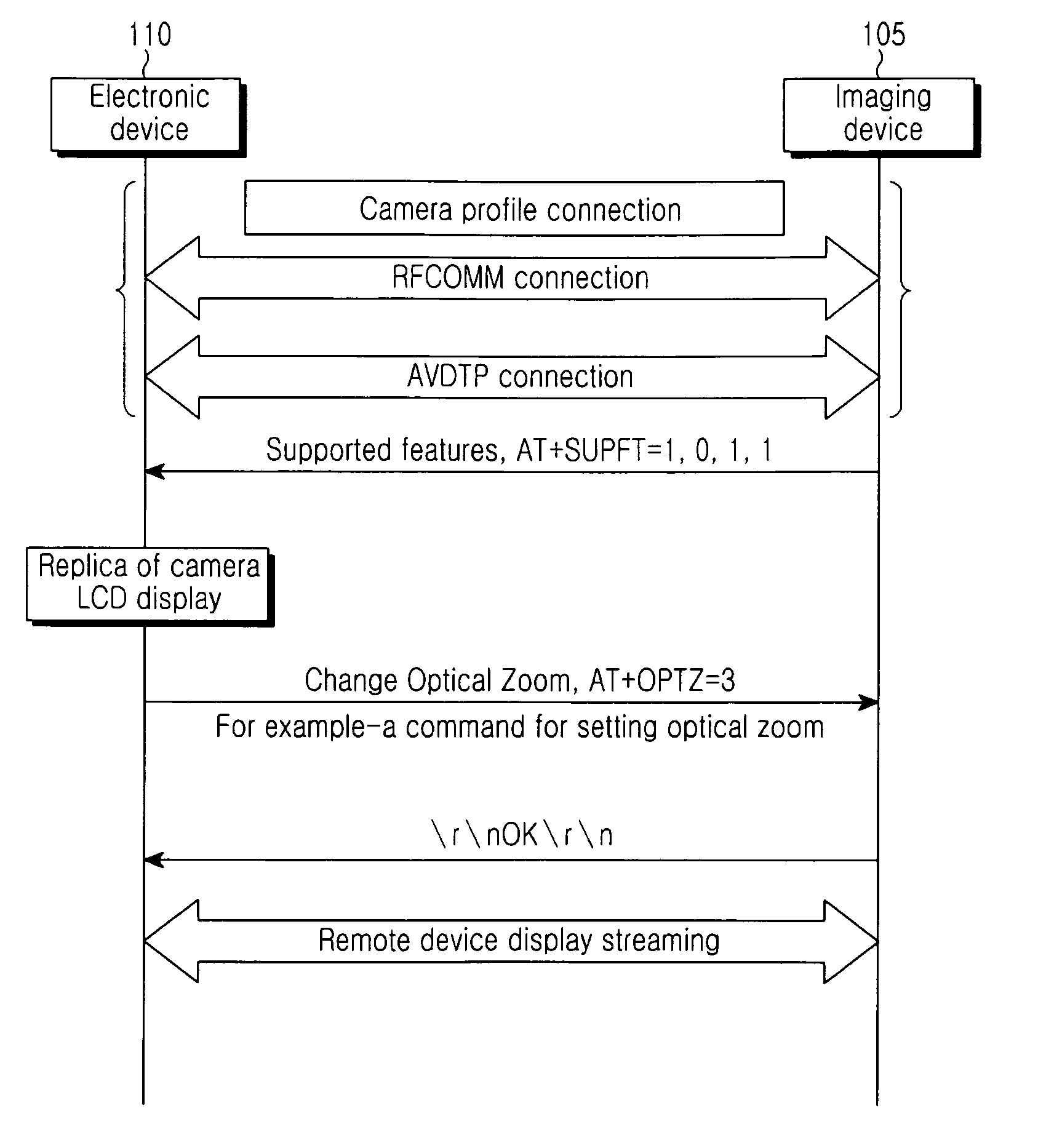

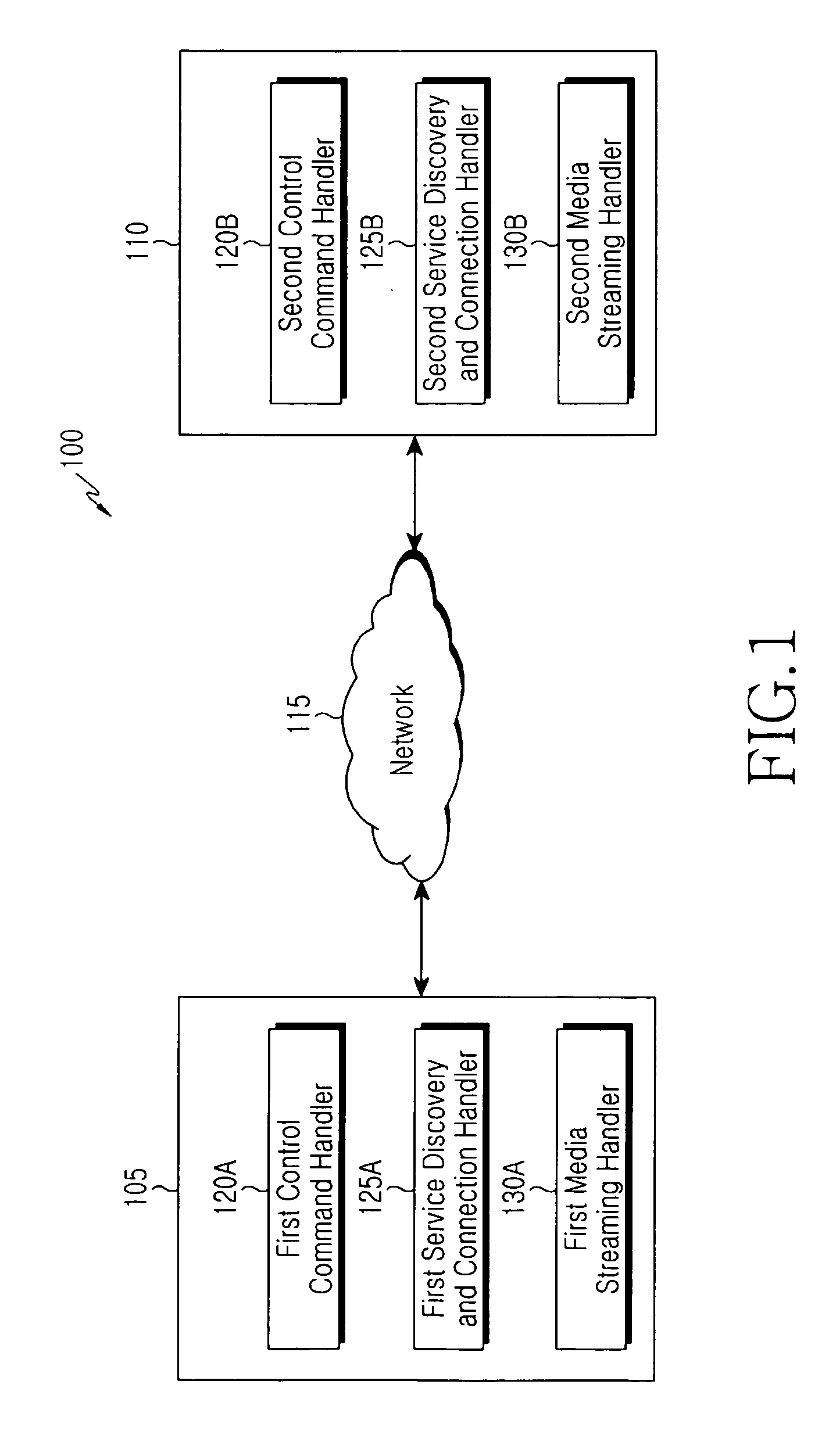

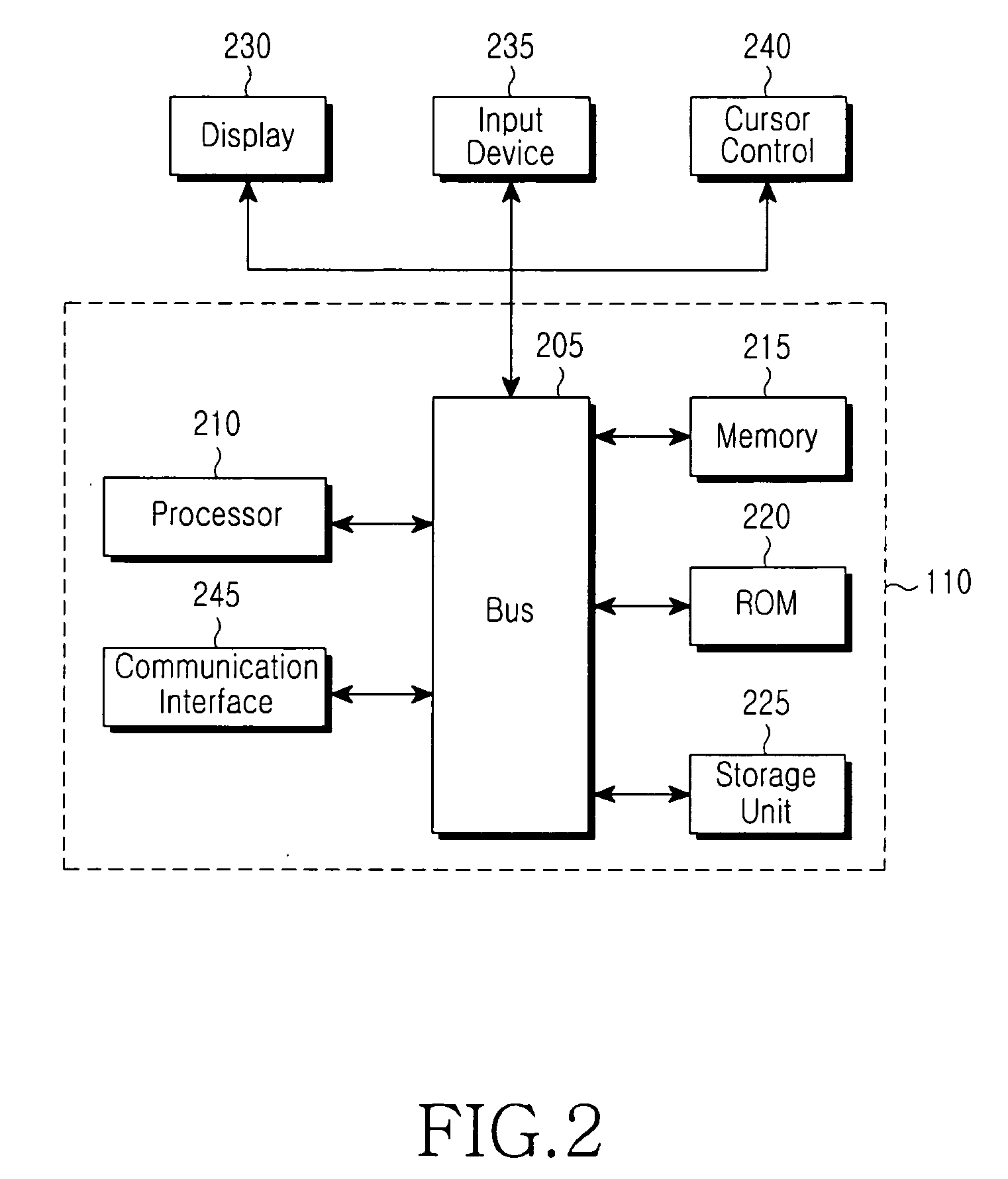

Method and system for managing an imaging device by an electronic device located remotely to the imaging device

ActiveUS20100079607A1Simple technologyLow technical requirementsTelevision system detailsTransmission systemsRemote controlData rate

A method and system enables the control of an imaging device by an electronic device located remotely to the imaging device. The method includes displaying a media captured by the imaging device at the electronic device using at least one of Bluetooth basic rate technique and Bluetooth enhanced data rate technique. The method also includes controlling, by the electronic device, properties of the imaging device that are associated with capturing of the media using at least one of Bluetooth low energy technique, the Bluetooth basic rate technique and the Bluetooth enhanced data rate technique, thereby controlling capturing of the media by the imaging device and corresponding display of the media at the electronic device. Further, the method includes controlling of display features of imaging device using at least one of audio video remote control profile and audio video control transport protocol.

Owner:SAMSUNG ELECTRONICS CO LTD

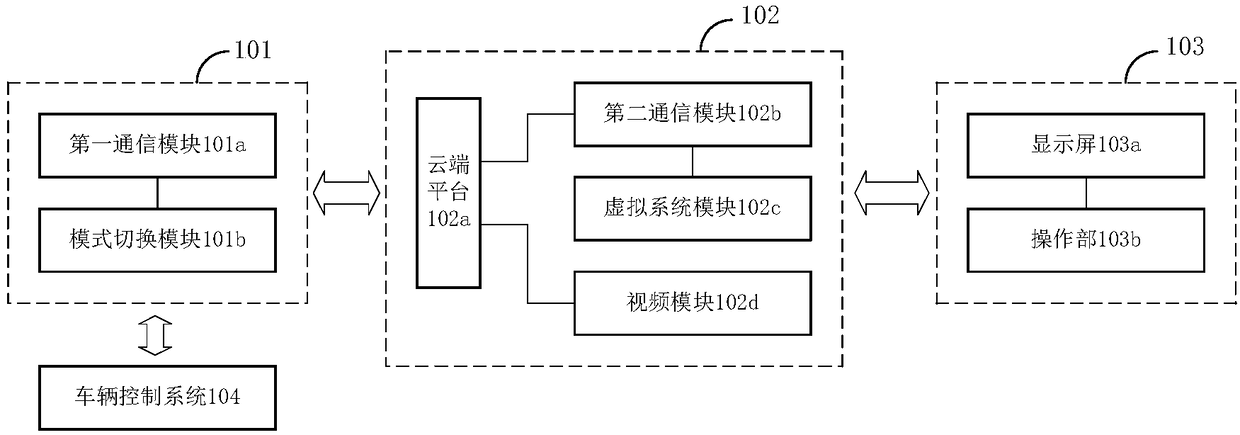

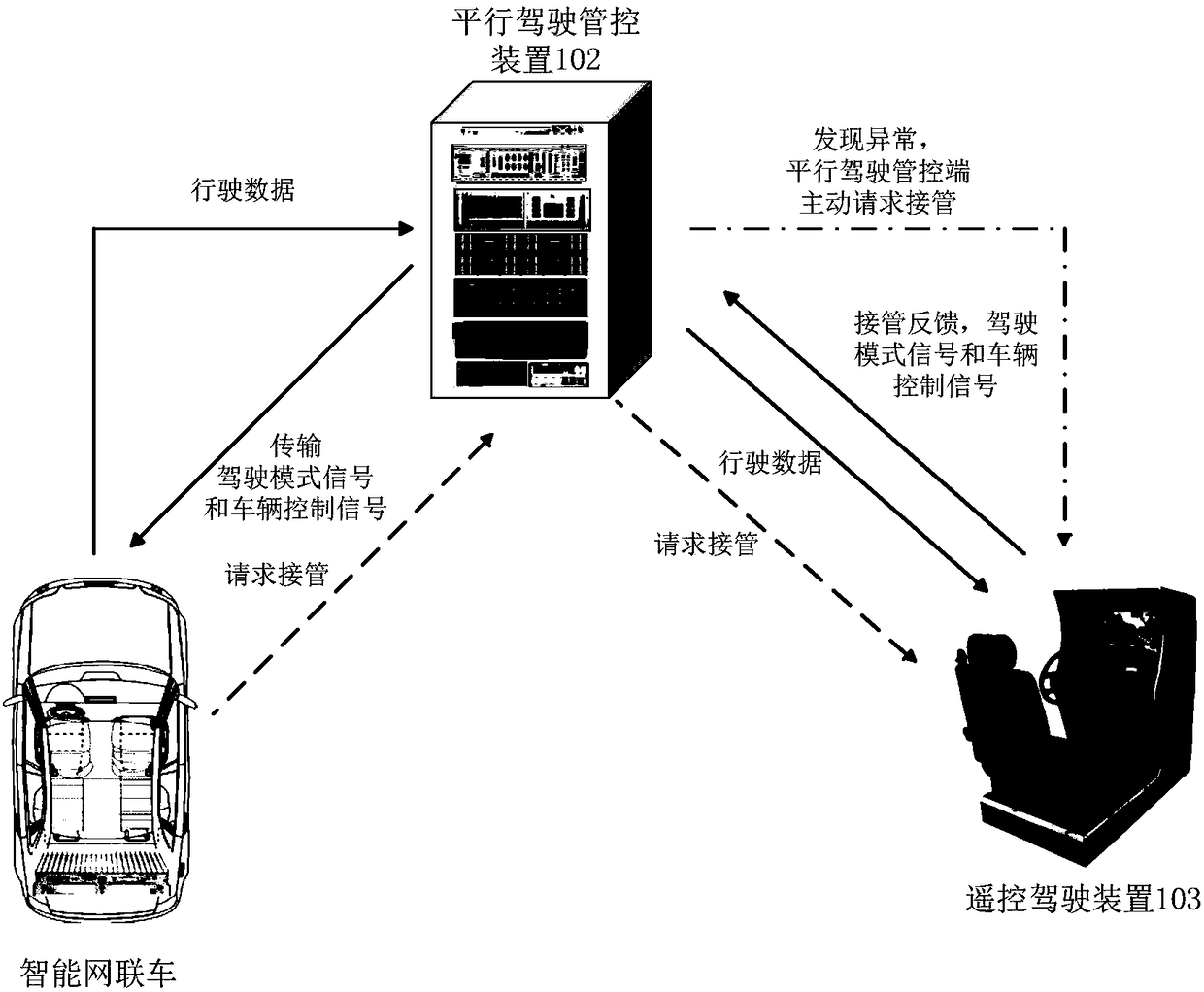

Parallel remote control driving system for intelligent network connection vehicle

ActiveCN108428357AReduce labor costsLow technical requirementsRoad vehicles traffic controlVehicle position/course/altitude controlIntelligent NetworkControl signal

The invention discloses a parallel remote control driving system for an intelligent network connection vehicle. The system comprises an intelligent network connection vehicle control device, a parallel driving control device and a remote control driving device. The remote control driving device can generate remote control driving indication signals according to remote control driving request signal signals transmitted by the parallel driving control device, generate driving mode signals and vehicle control signals according to user operations and transmit the signals to the intelligent networkconnection vehicle control device through the parallel driving control device so as to achieve remote control over the intelligent network connection vehicle. According to the parallel remote controldriving system, no human driver must be configured when the intelligent network connection vehicle is on the way, the driver training cost and other labor costs can be remarkably lowered, the technical requirement and the security cost can be remarkably lowered, and the intelligent network connection vehicle is convenient to popularize.

Owner:QINGDAO VEHICLE INTELLIGENCE PIONEERS INC

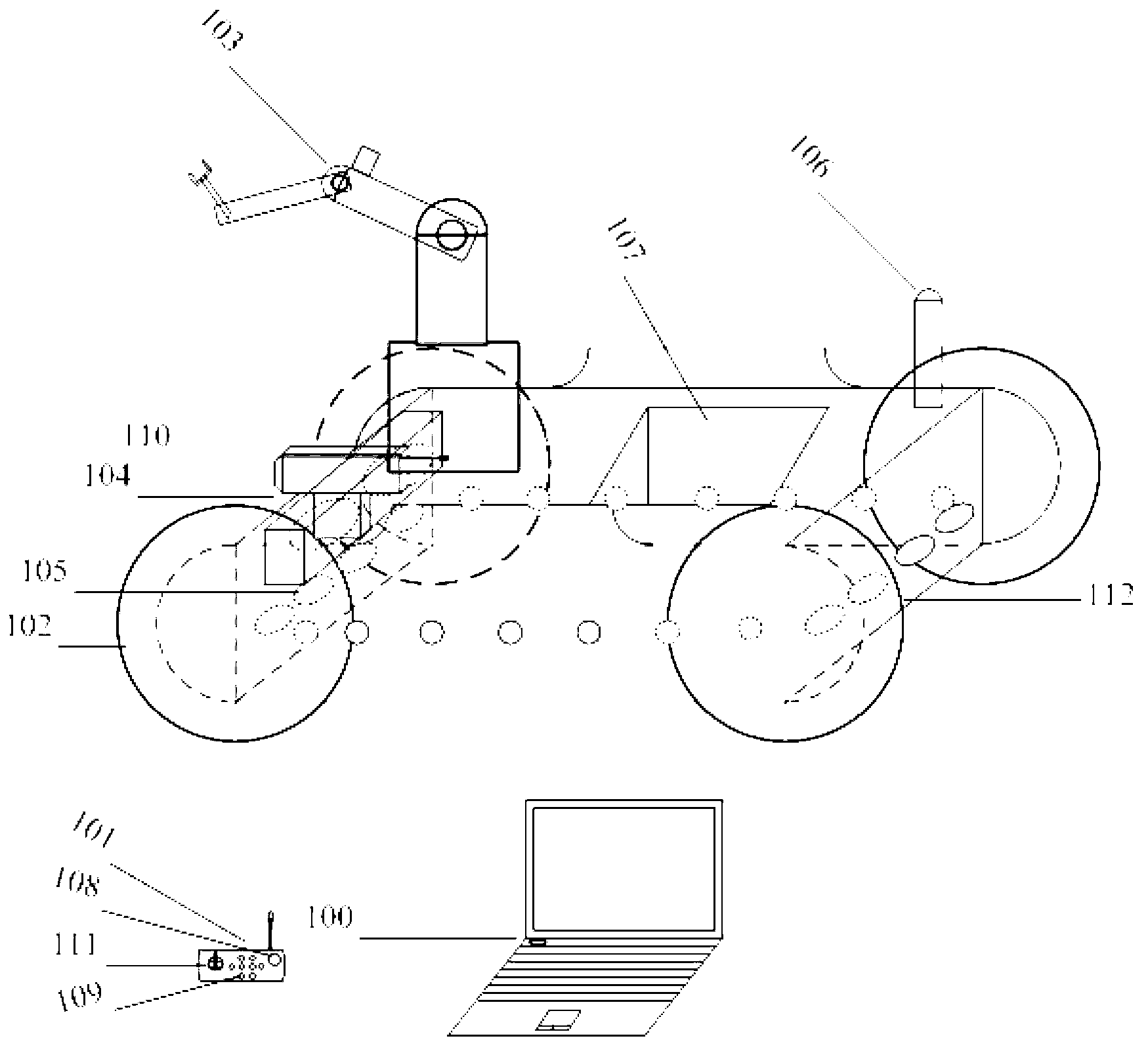

Voice-control multi-functional intelligent service robot

InactiveCN103324197AReduce the burden onPracticalTransmission systemsSpeech recognitionWireless dataComputer module

The invention discloses a voice-control multi-functional intelligent service robot. The voice-control multi-functional intelligent service robot at least comprises a vehicle-mounted operating platform, a voice control device and an image receiving and processing terminal, the vehicle-mounted operating platform is driven by four wheels and is provided with a containing box, the image receiving and processing terminal is connected with an image collecting device on the vehicle-mounted operating platform, and an infrared sensor set, an ultrasonic ranging locating sensor, a wireless camera, a mechanical arm with six degrees of freedom and a wireless data receiving and sending module are respectively arranged on the vehicle-mounted operating platform. The wireless data receiving and sending module receives voice commands sent by an operator to the voice control device, and transmits the voice commands to the vehicle-mounted operating platform to execute corresponding operations. The wireless camera collects and transmits image information to the image receiving and processing terminal through the wireless data receiving and sending module, and therefore voice control over the vehicle-mounted operating platform, intelligent and automatic navigation and obstacle avoidance and real-time image monitor are achieved. The robot can intelligently distinguish operated articles and can carry out automatic navigation and obstacle avoidance, and the real-time monitor load of the operator is reduced.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com