Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Increased pull-out strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

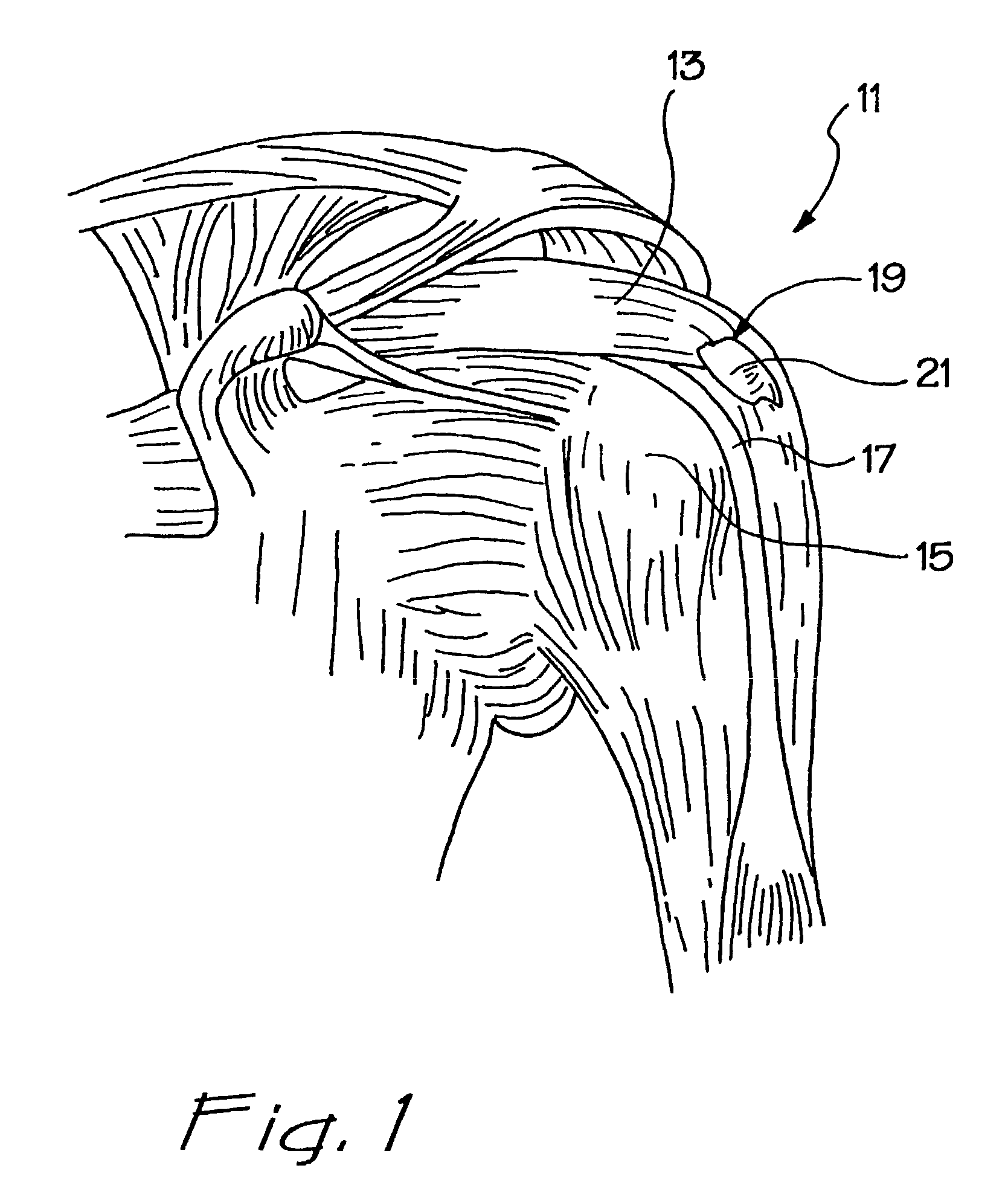

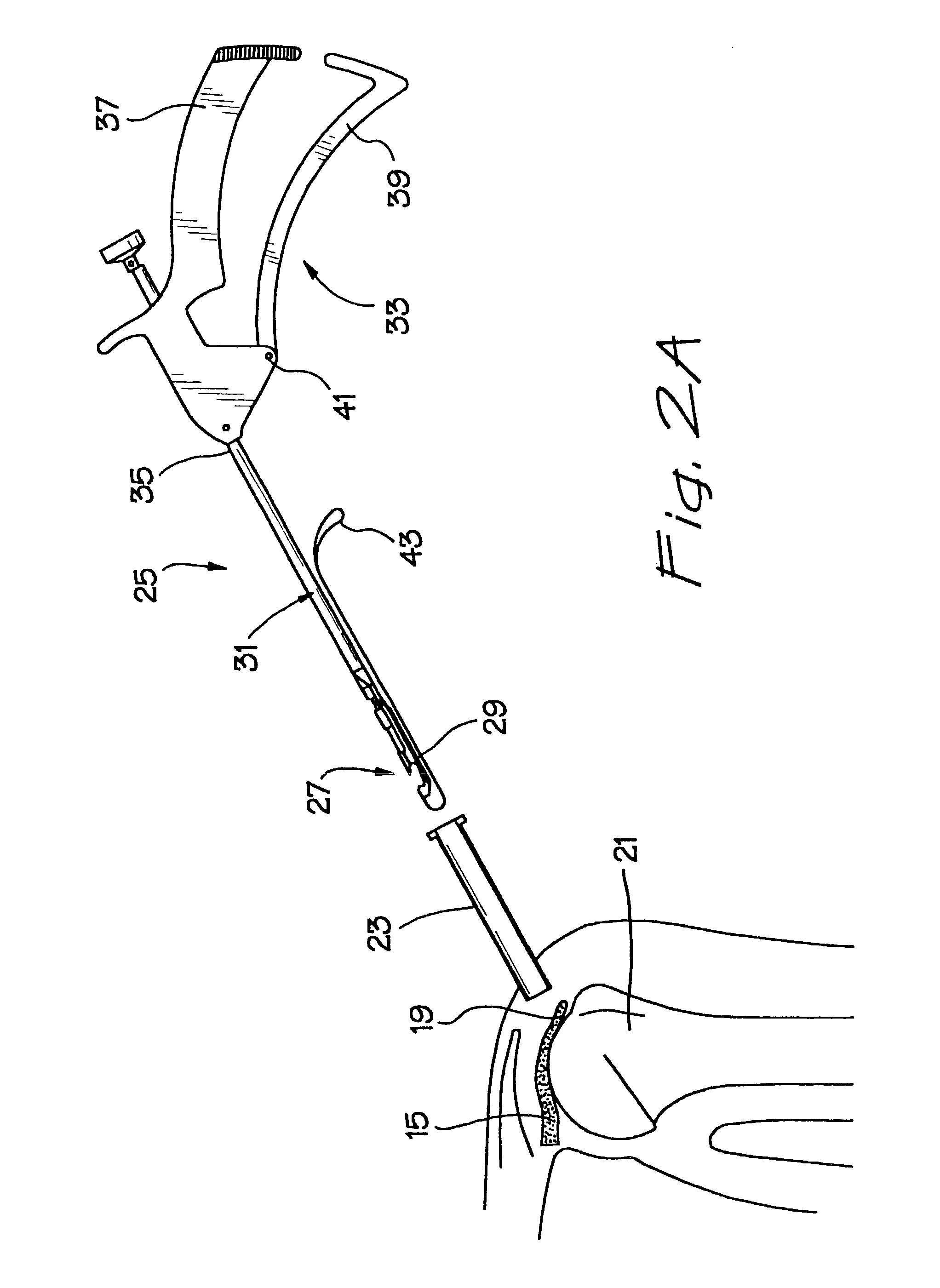

Interference fit knotless suture anchor fixation

Owner:ARTHREX

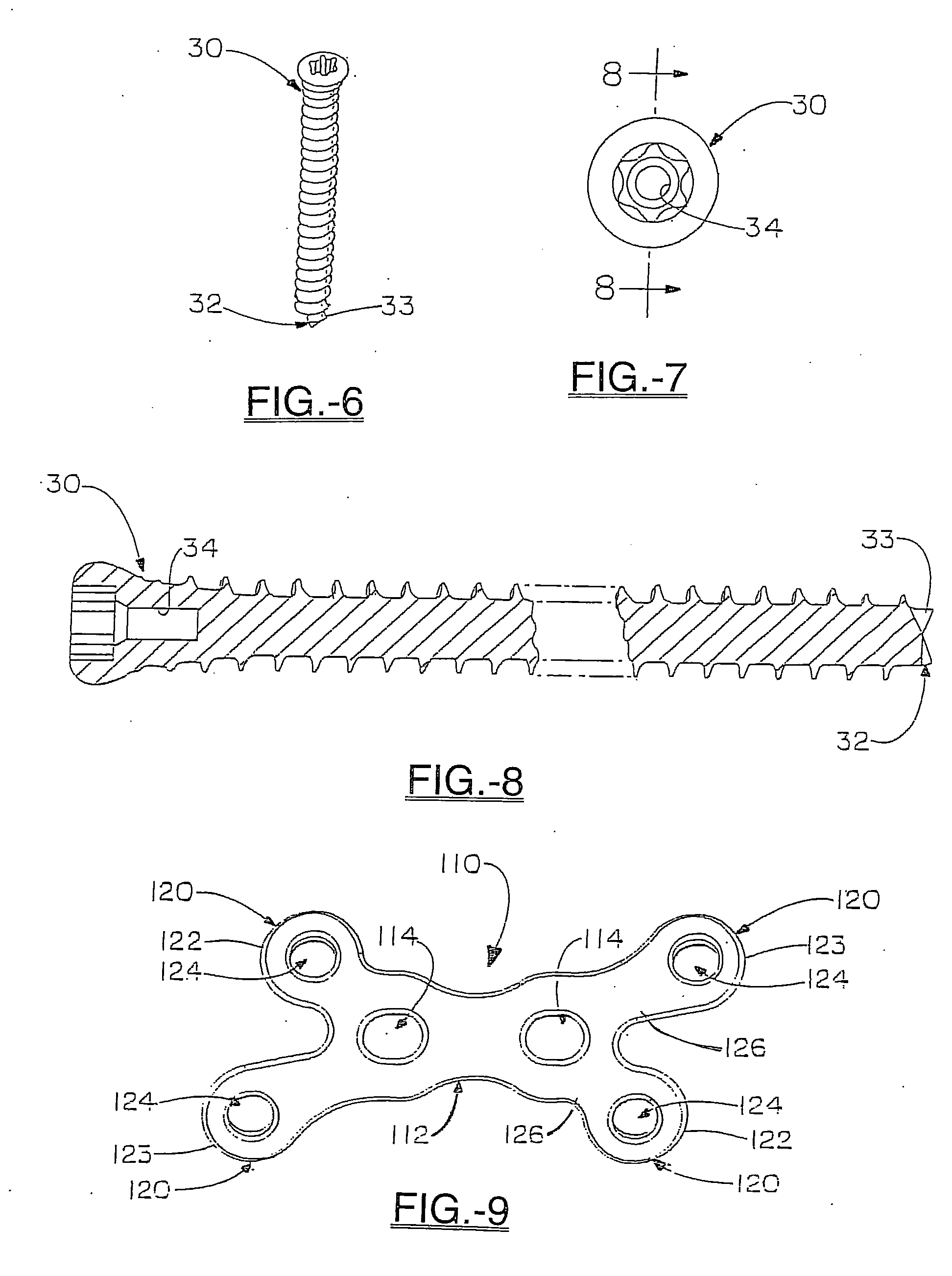

Fully-threaded bioabsorbable suture anchor

ActiveUS20070060922A1Minimal frictionIncreased pull-out strengthSuture equipmentsLigamentsPullout strengthUltimate tensile strength

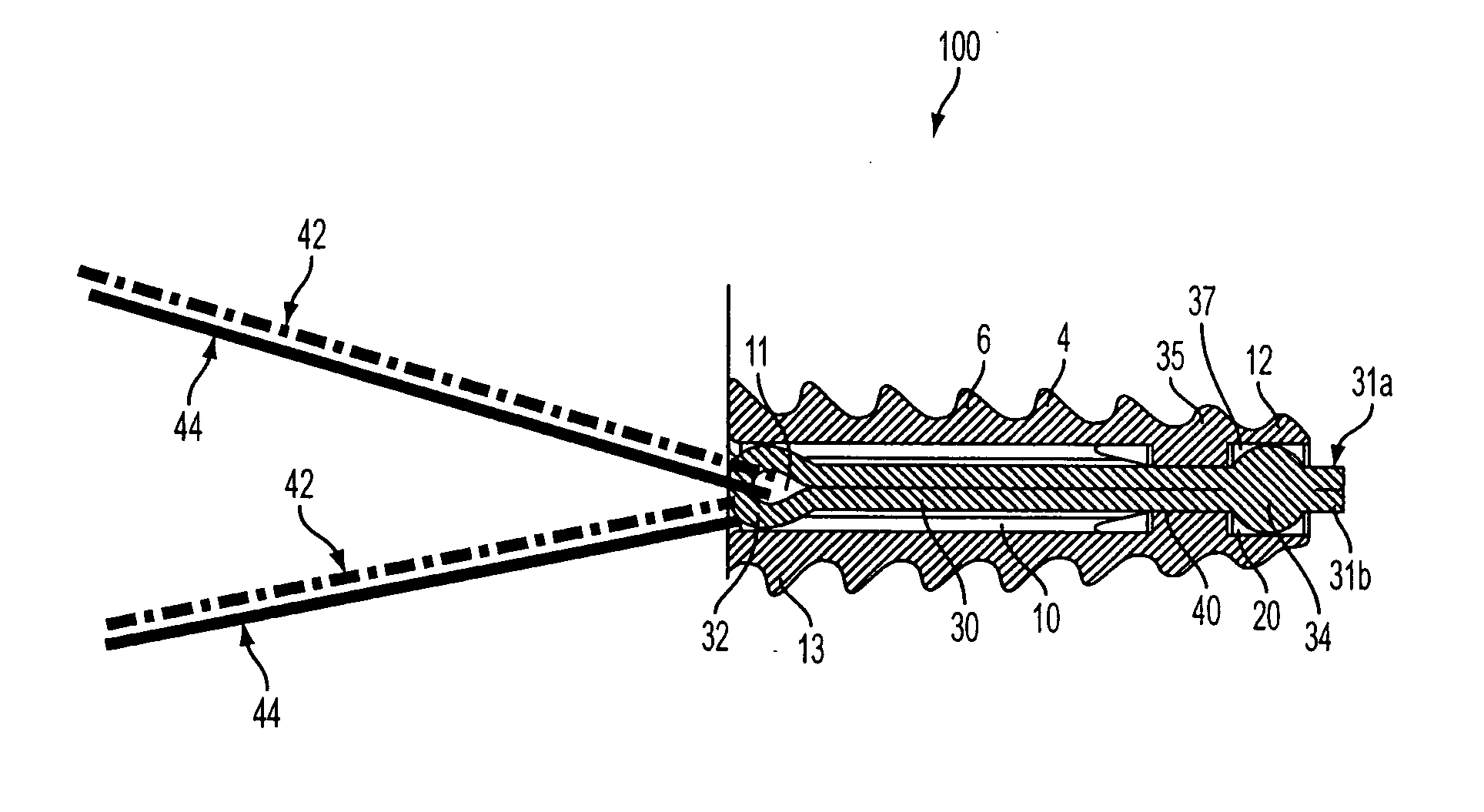

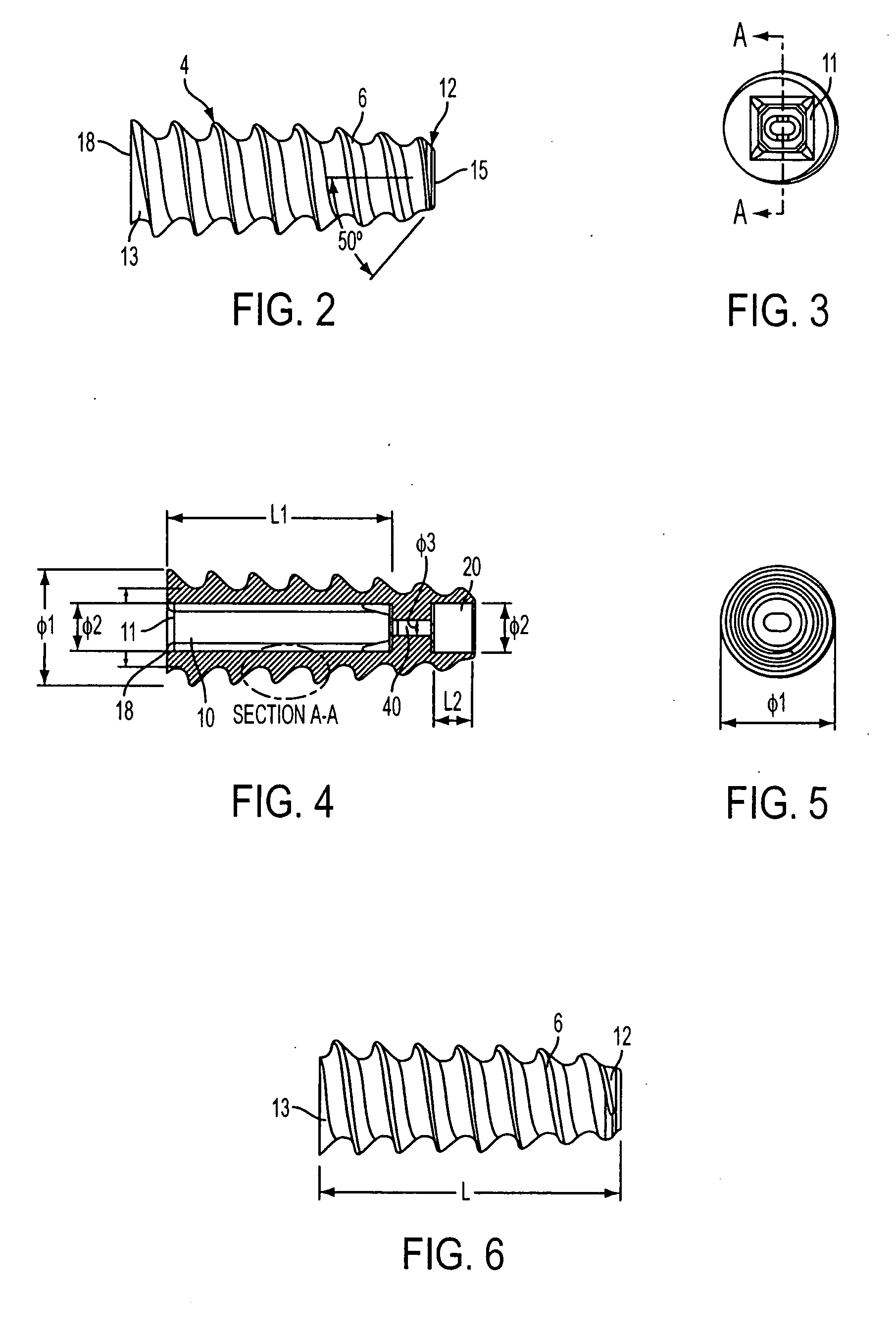

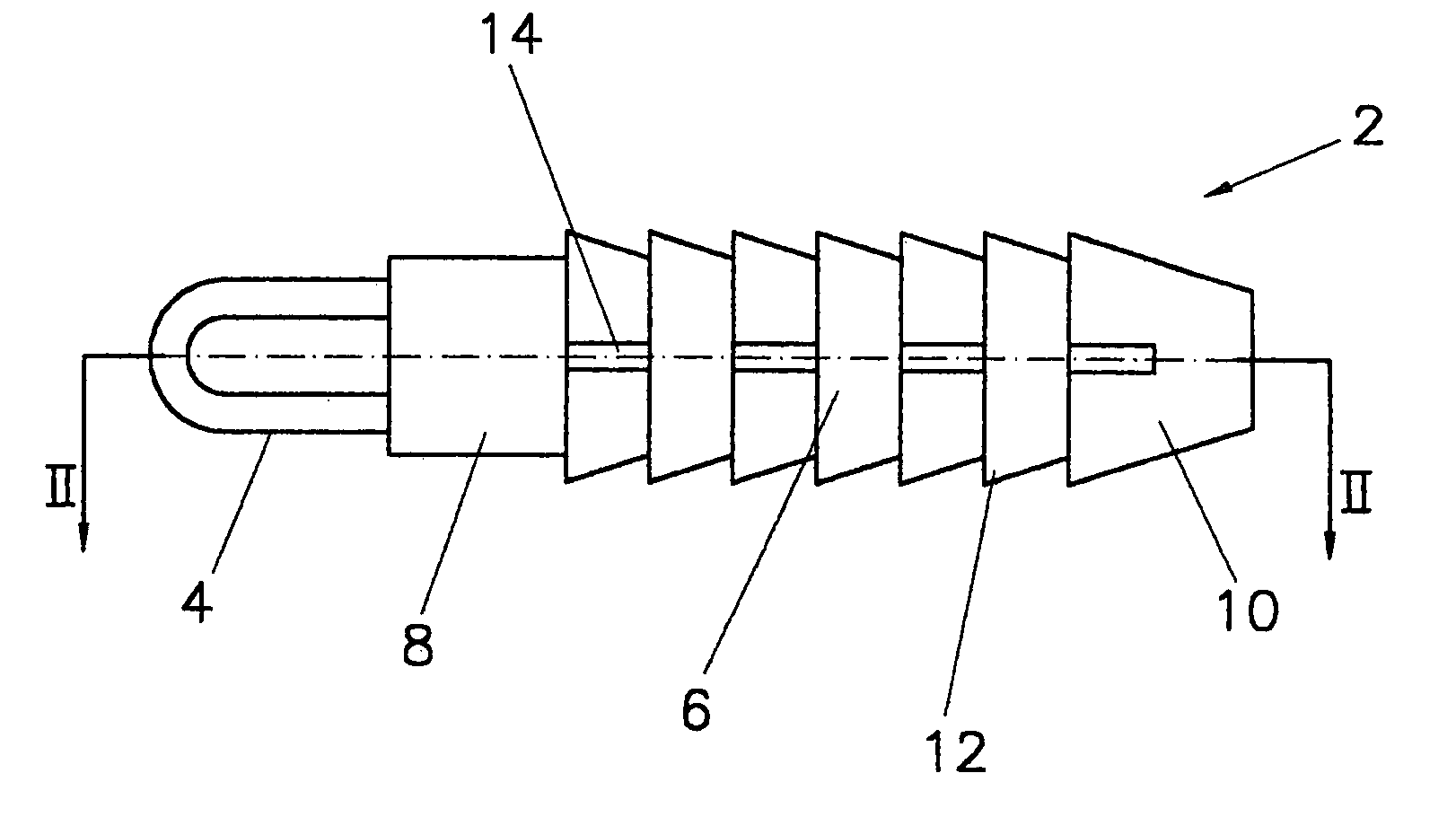

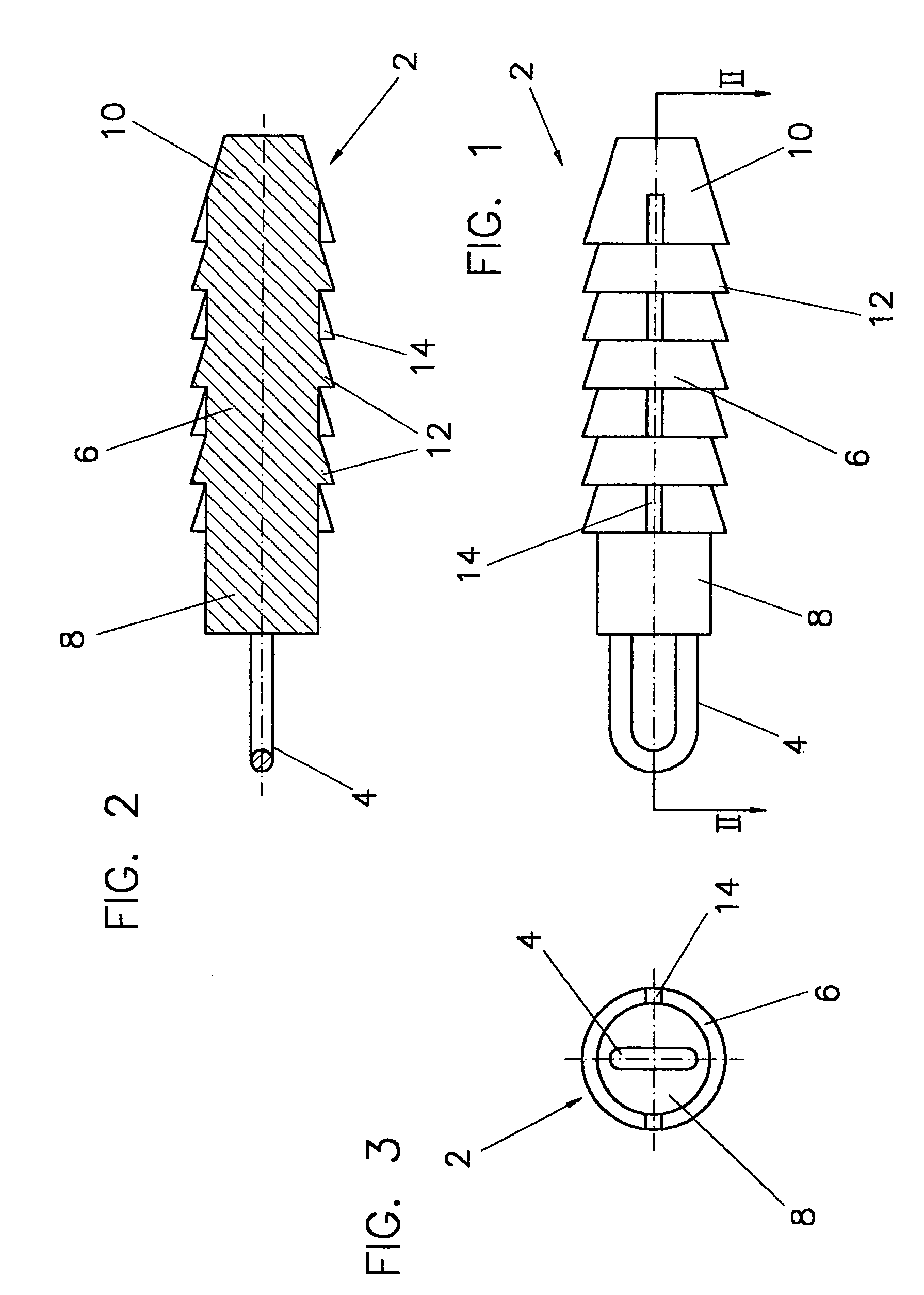

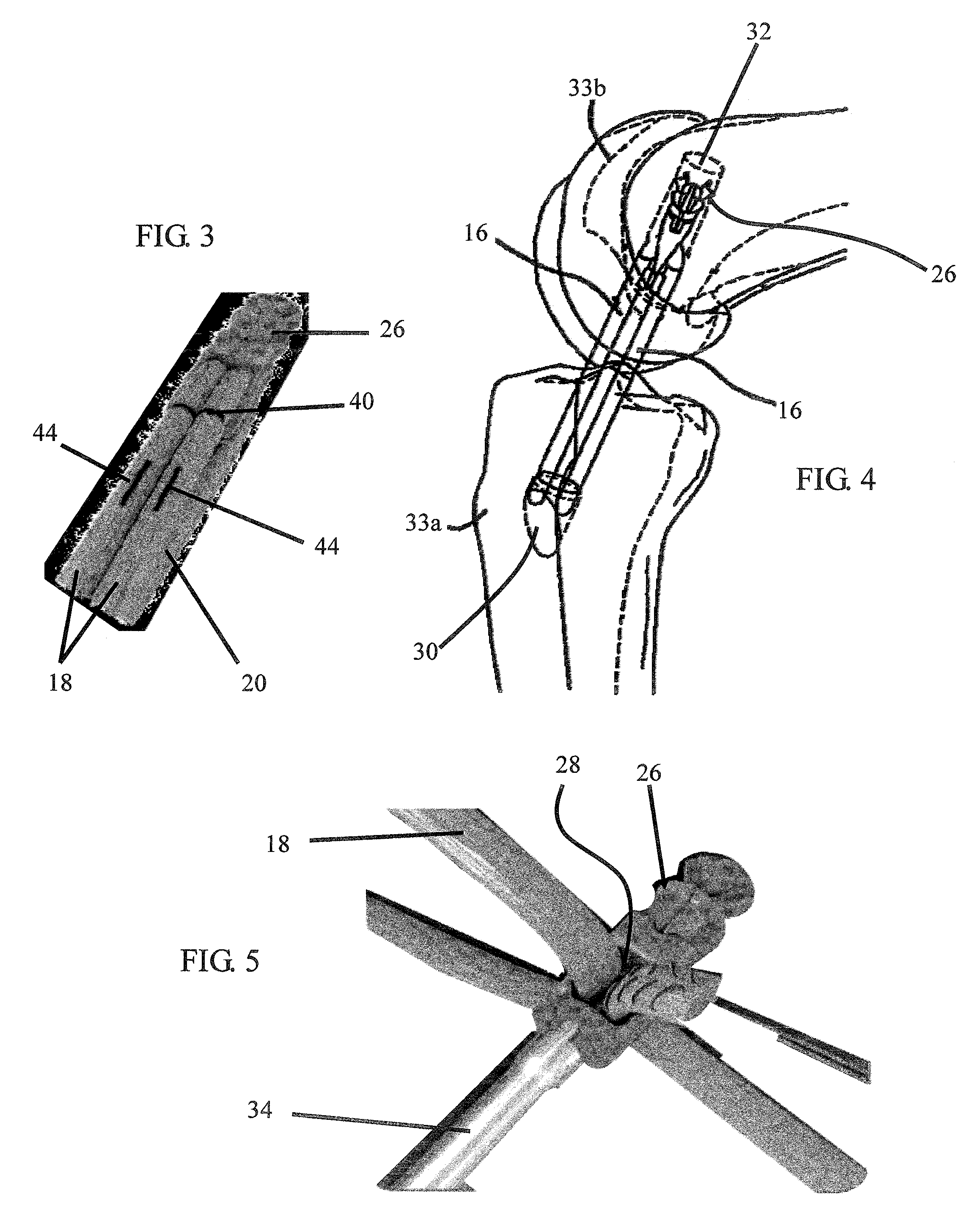

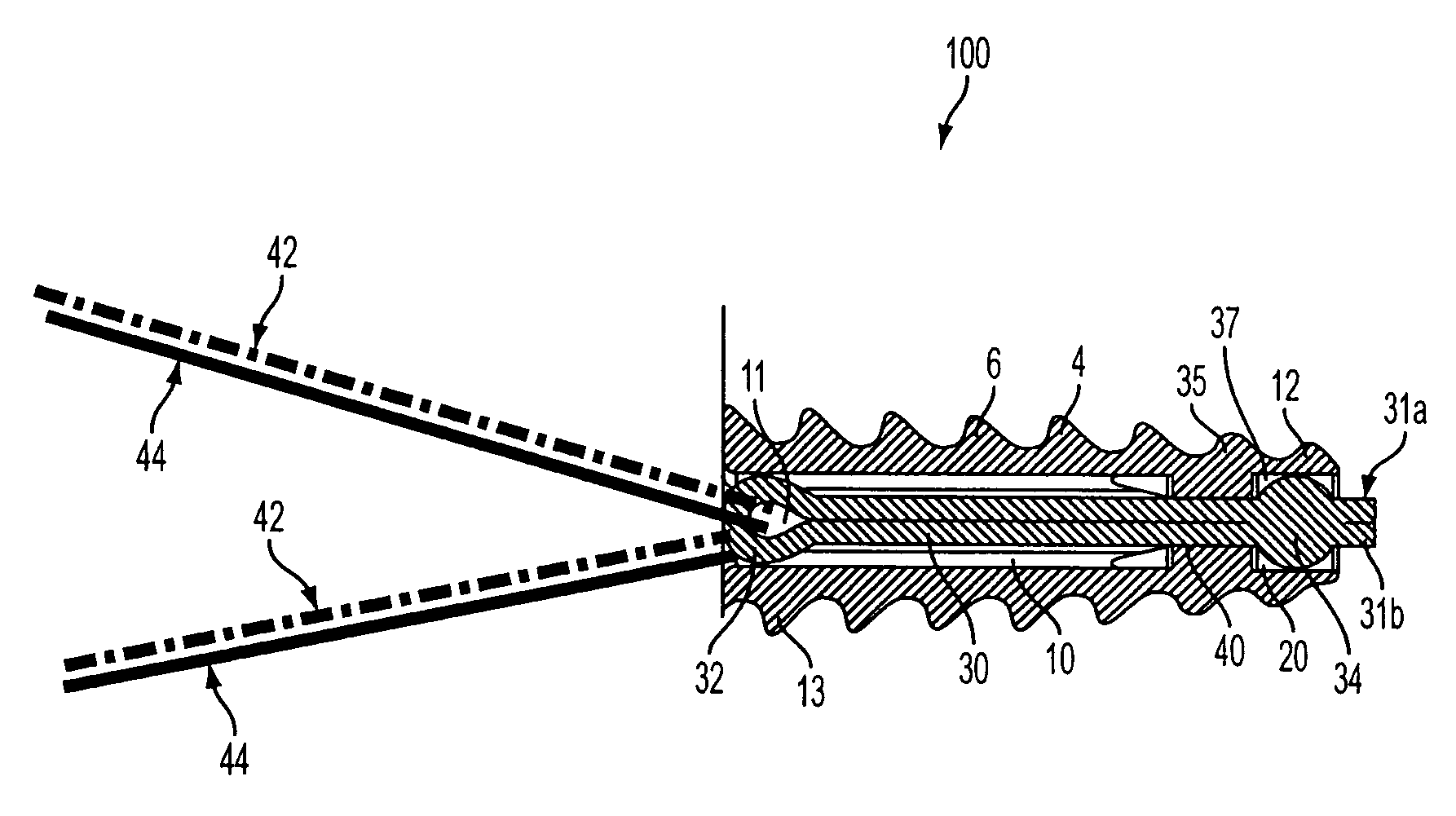

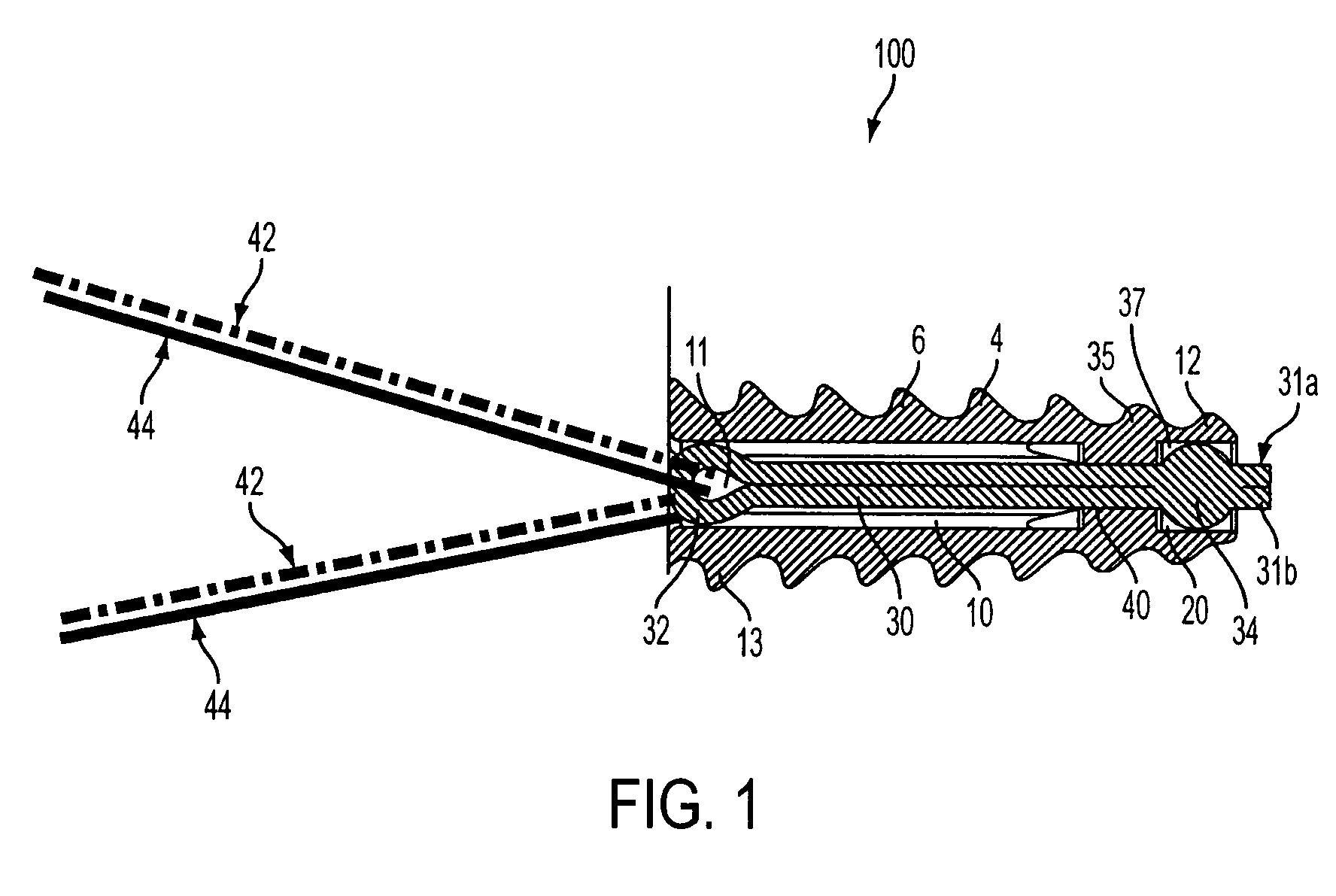

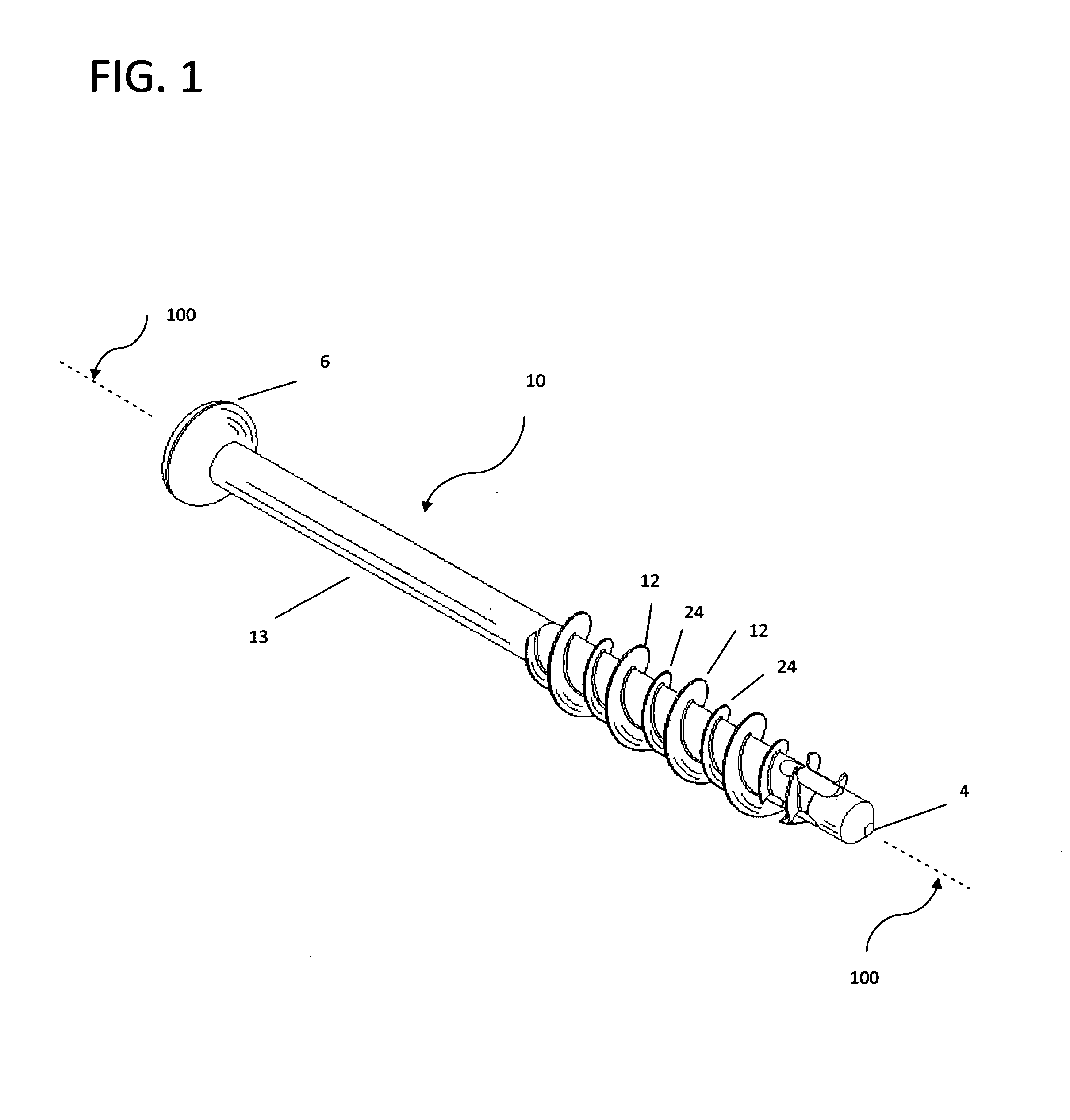

A suture anchor includes a threaded anchor body having a first central bore in communication with a second central bore. The suture anchor includes an internal eyelet formed of a loop disposed at least partially inside the first central bore. The ends extending from the loop are tied together to form at least one knot which is housed in the second central bore provided at the distal end of the anchor body. The knot increases the pullout strength of the suture even in soft bone, provides increased suture fixation, and eliminates the anchor “pull back.”

Owner:ARTHREX

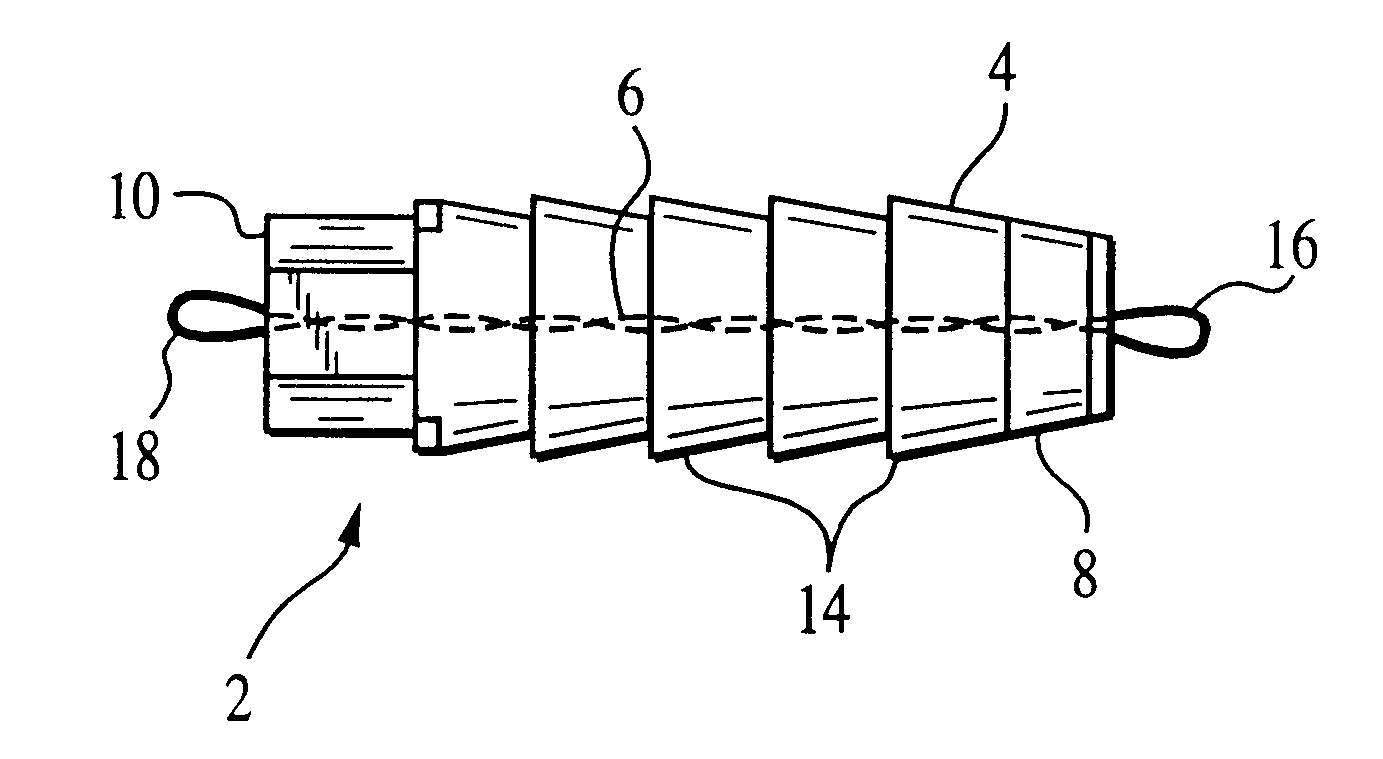

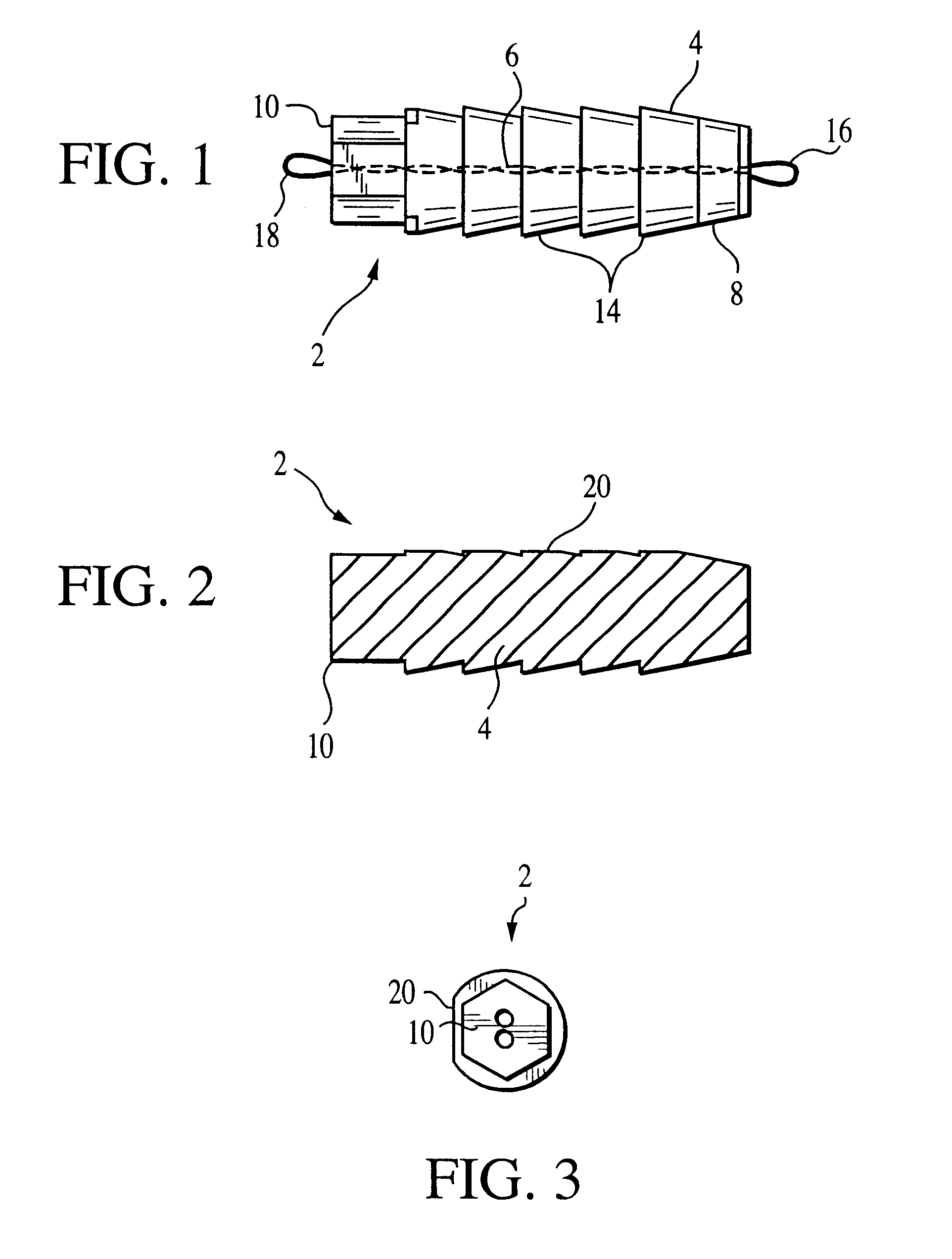

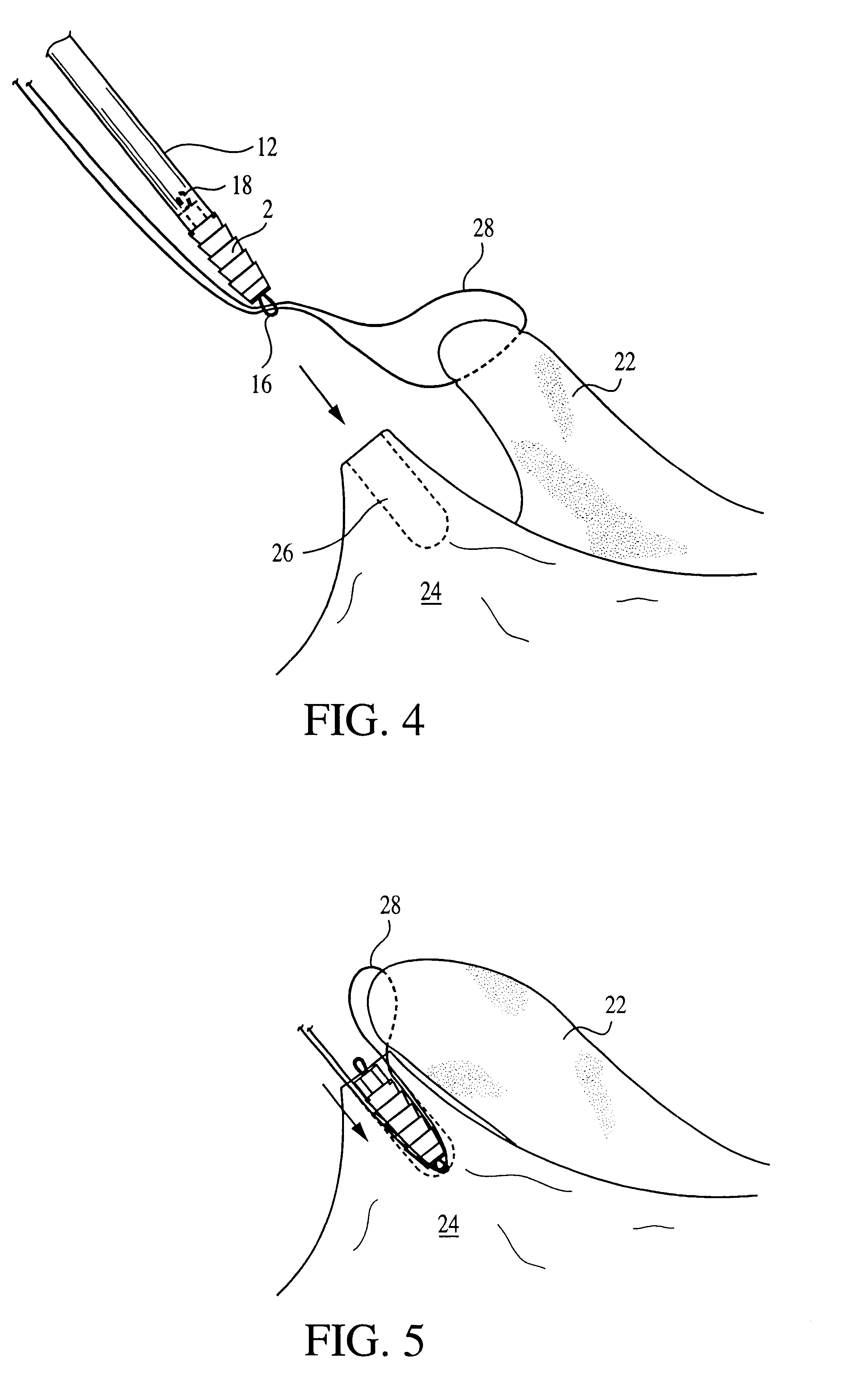

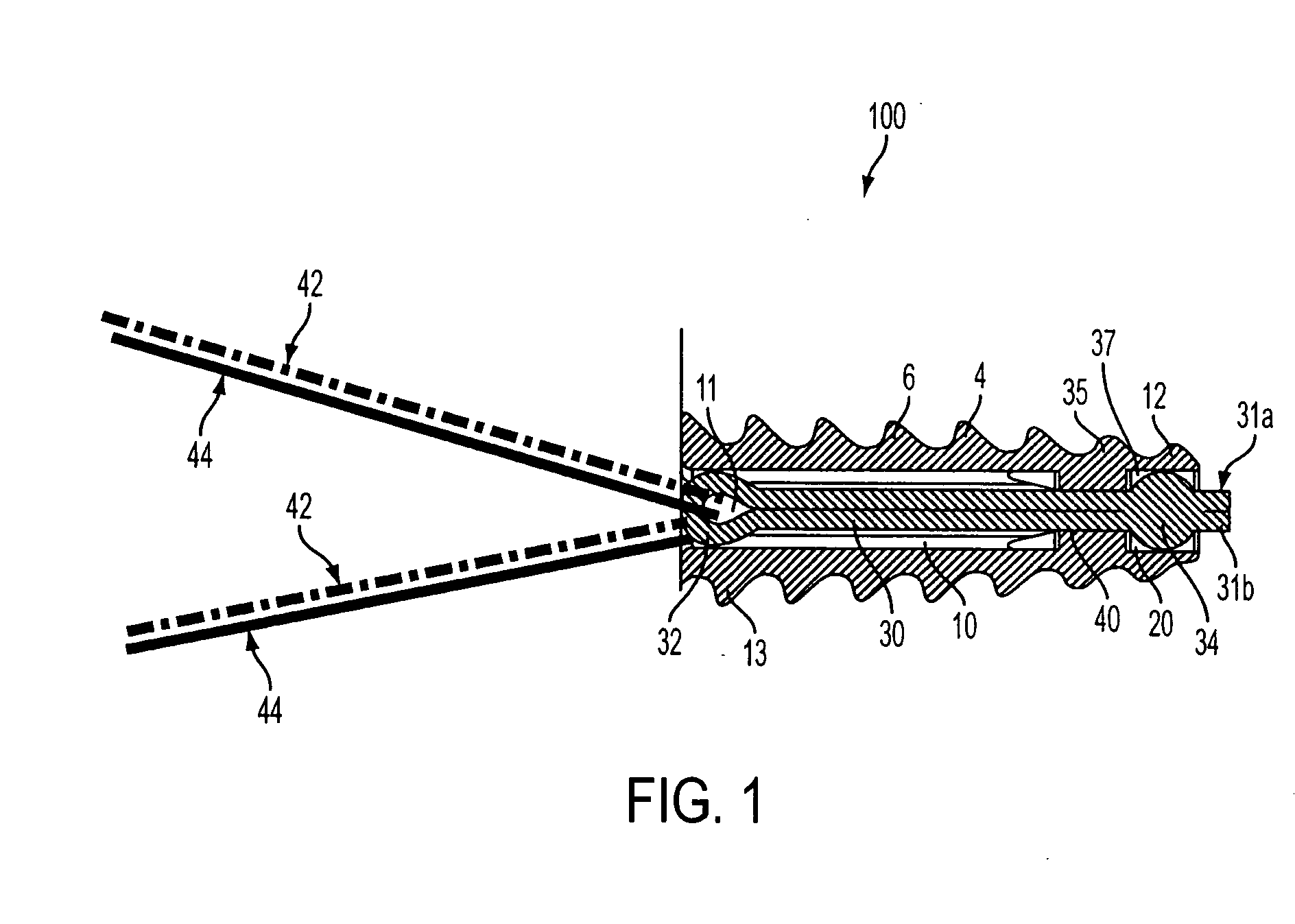

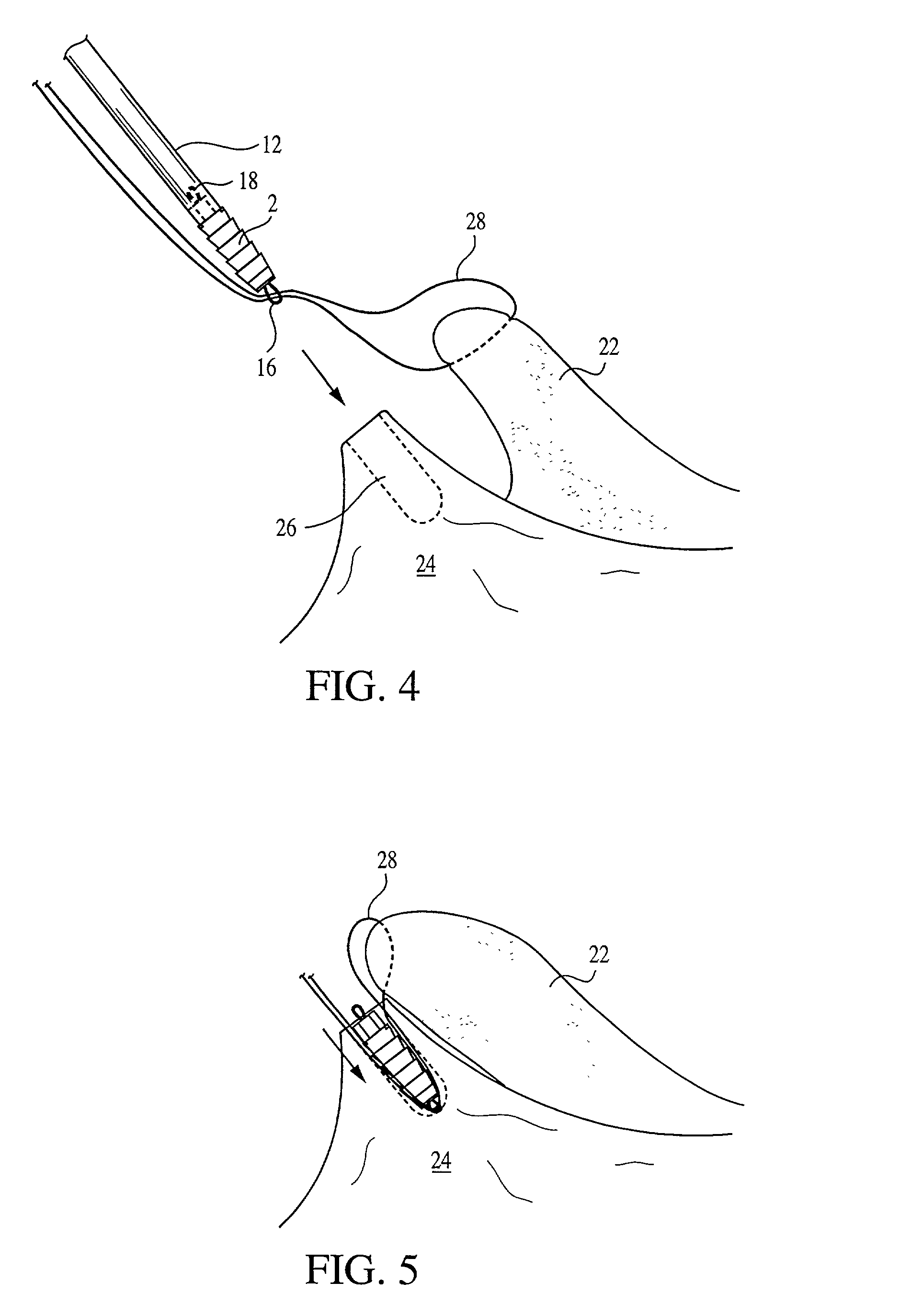

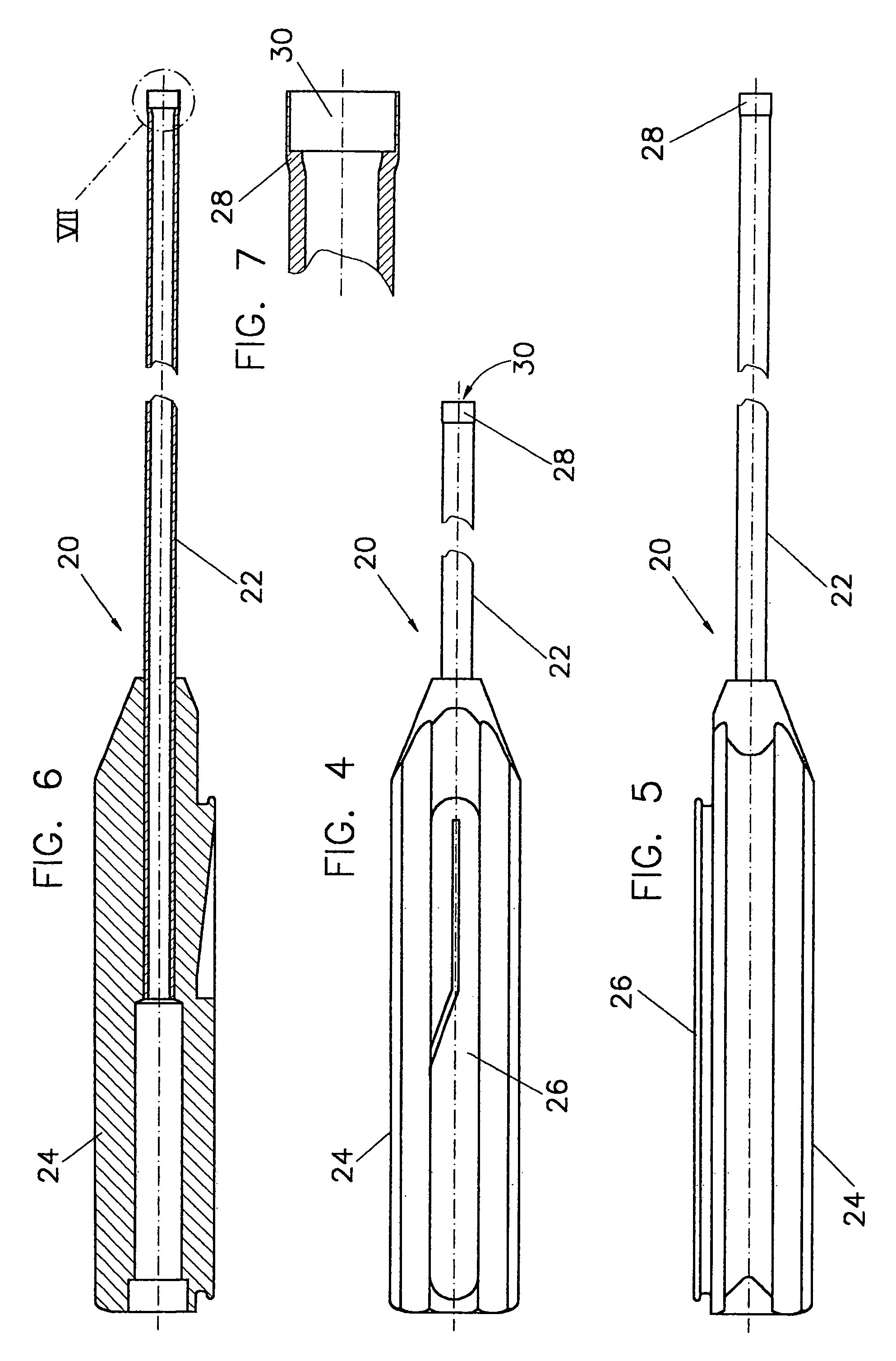

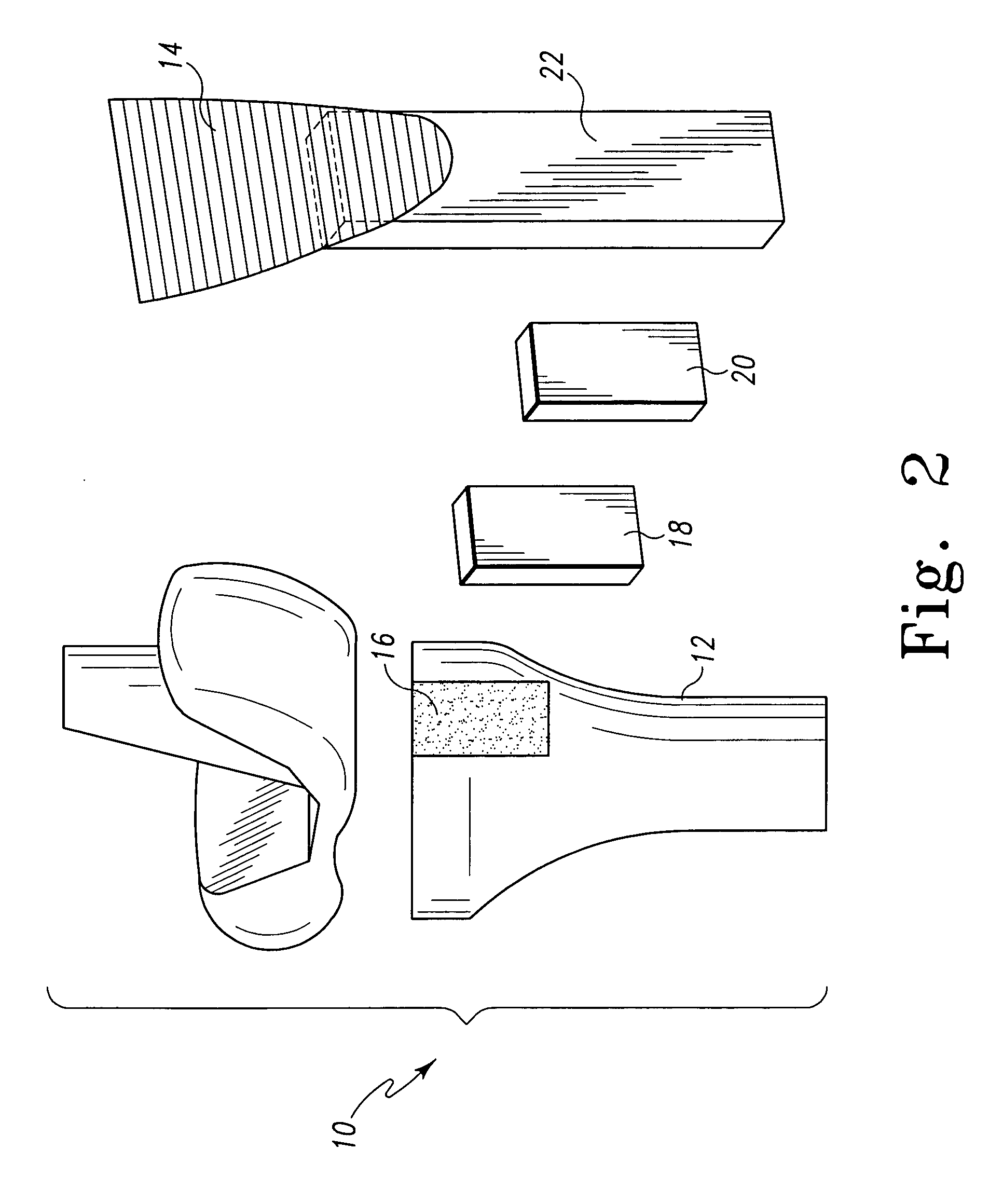

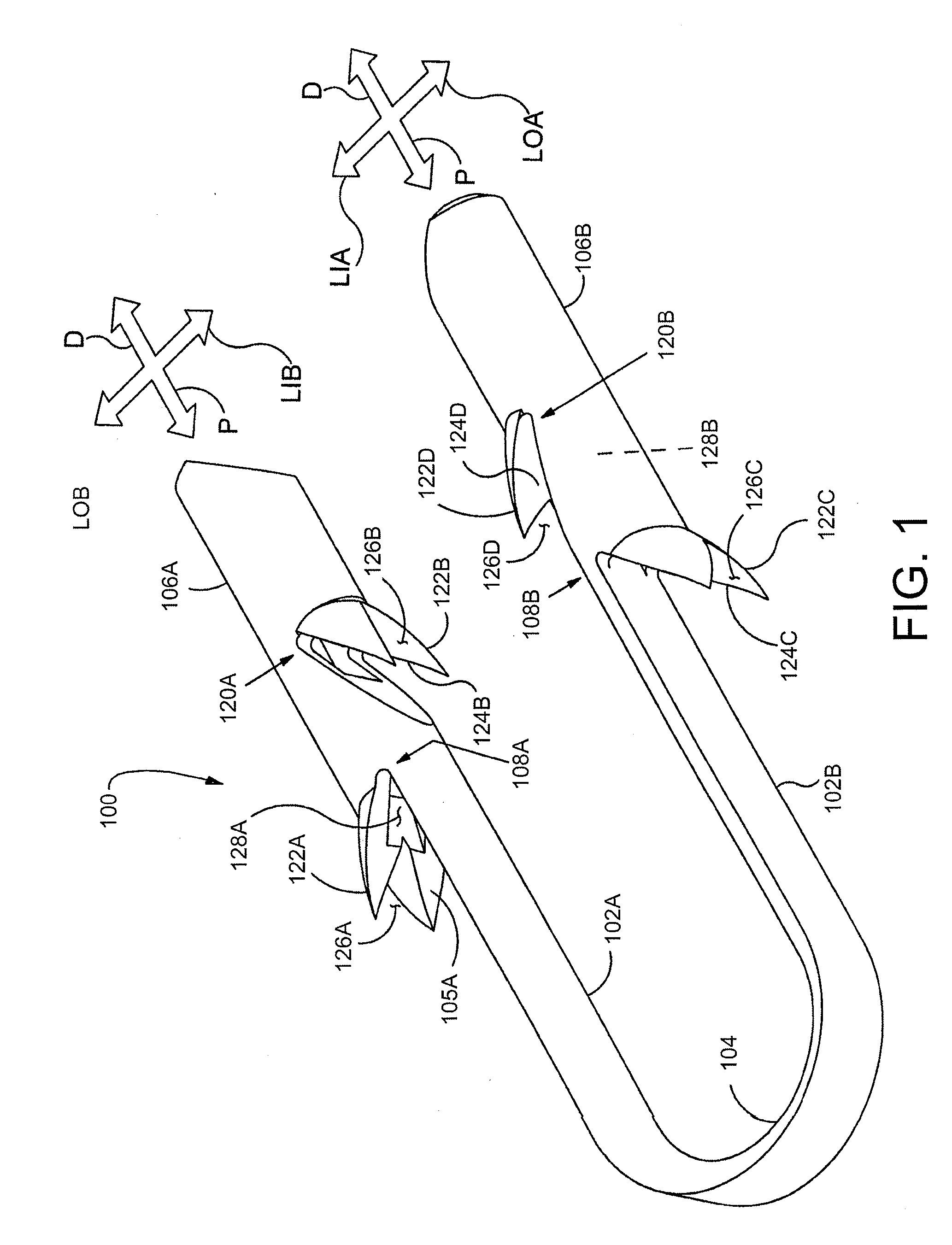

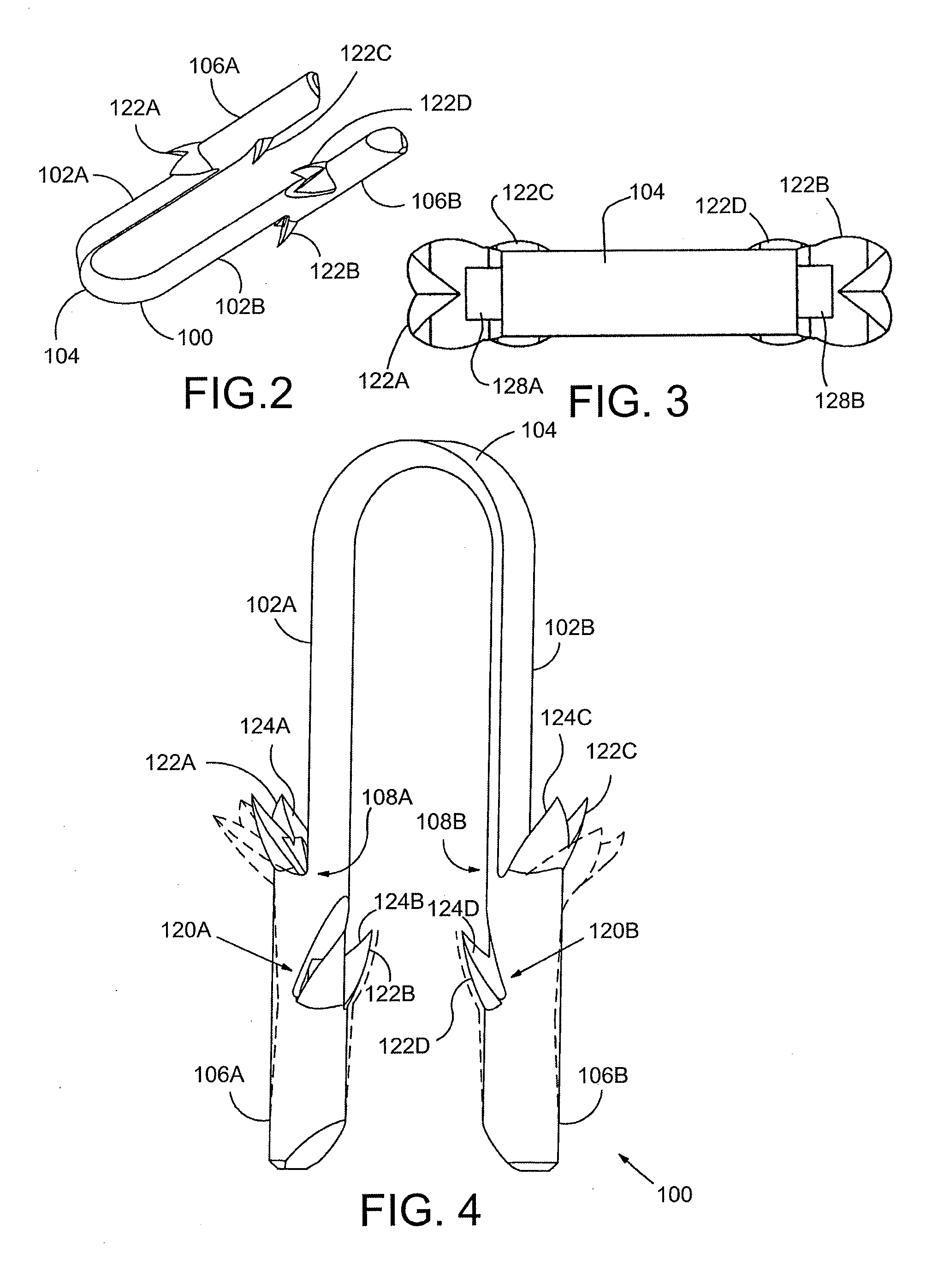

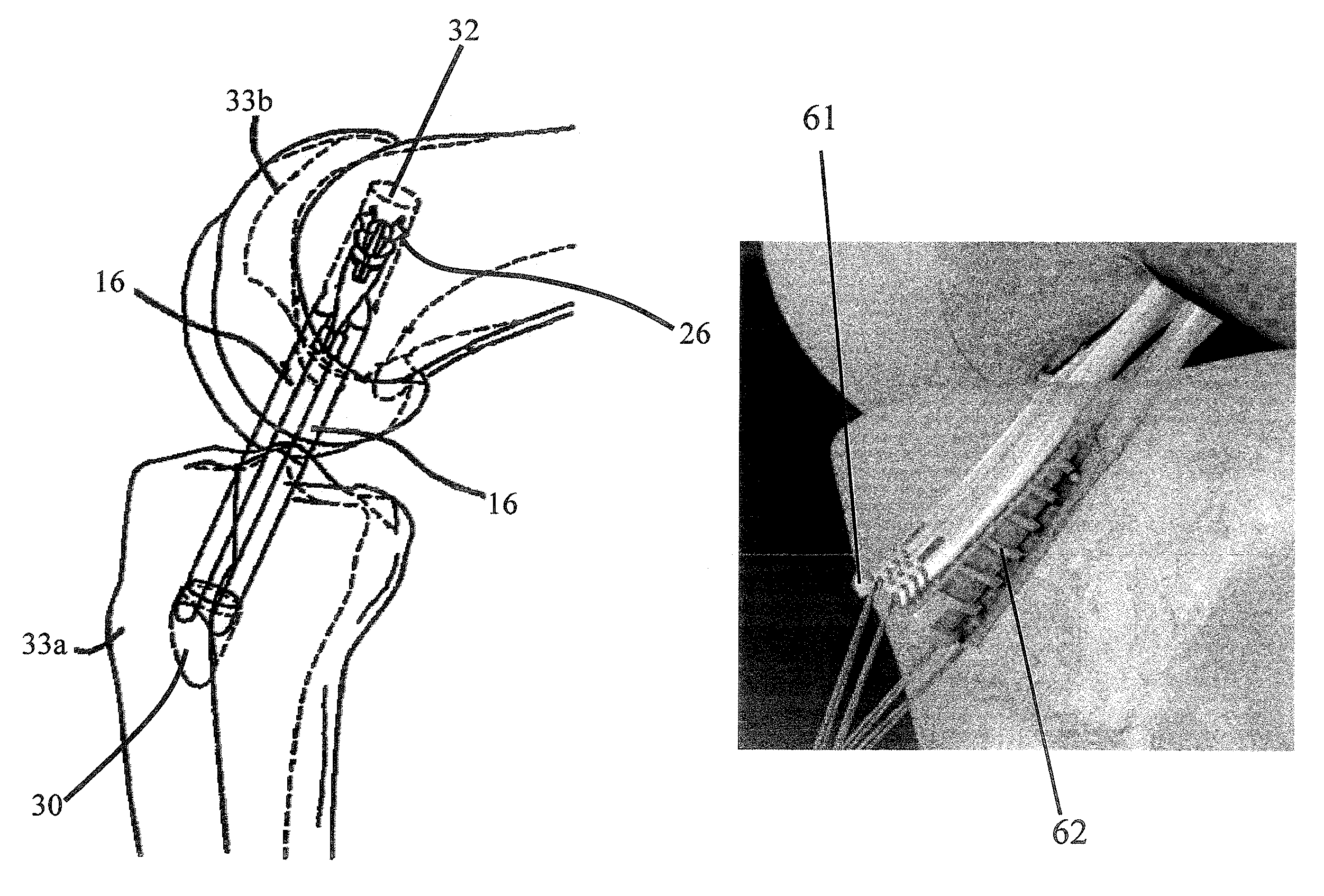

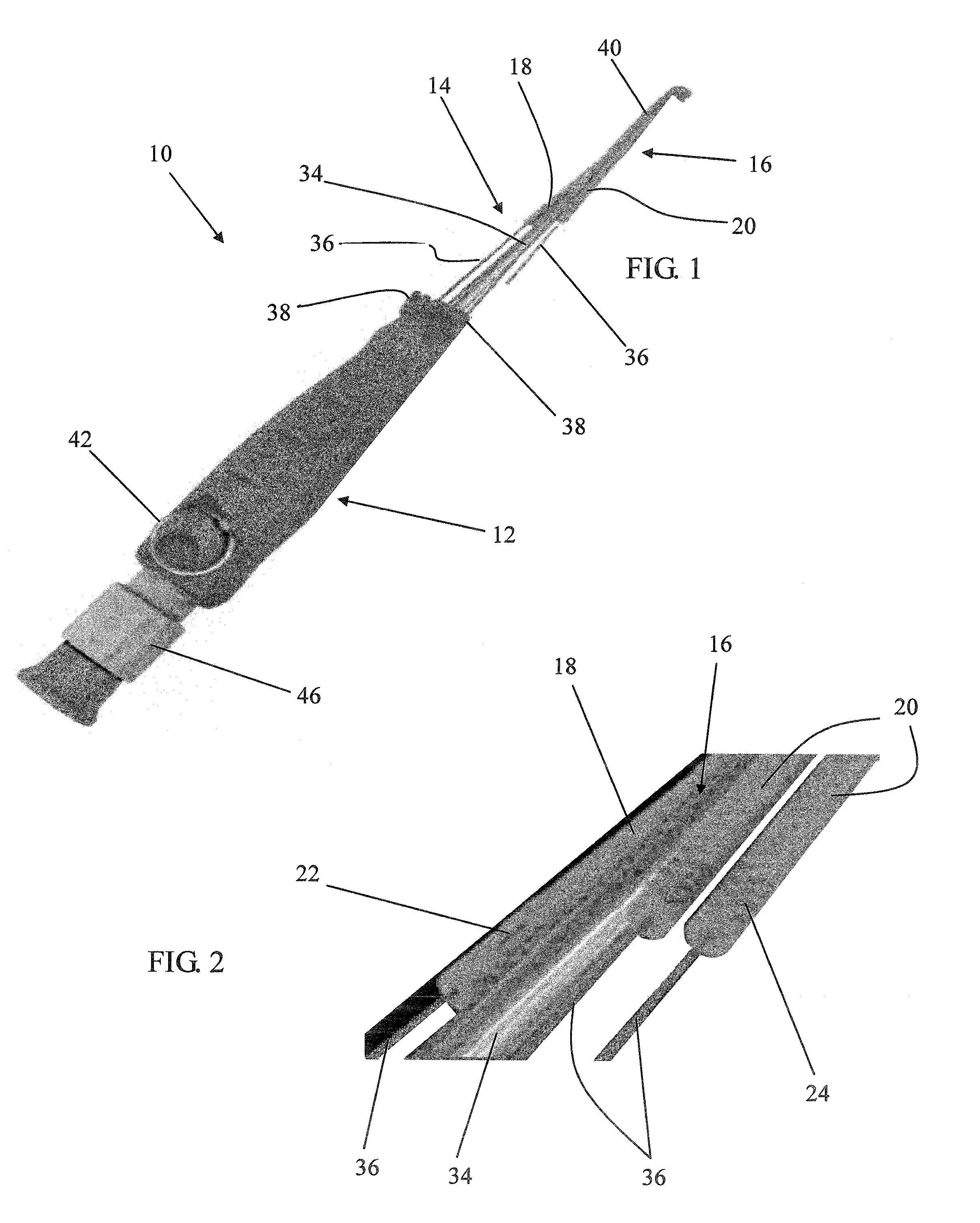

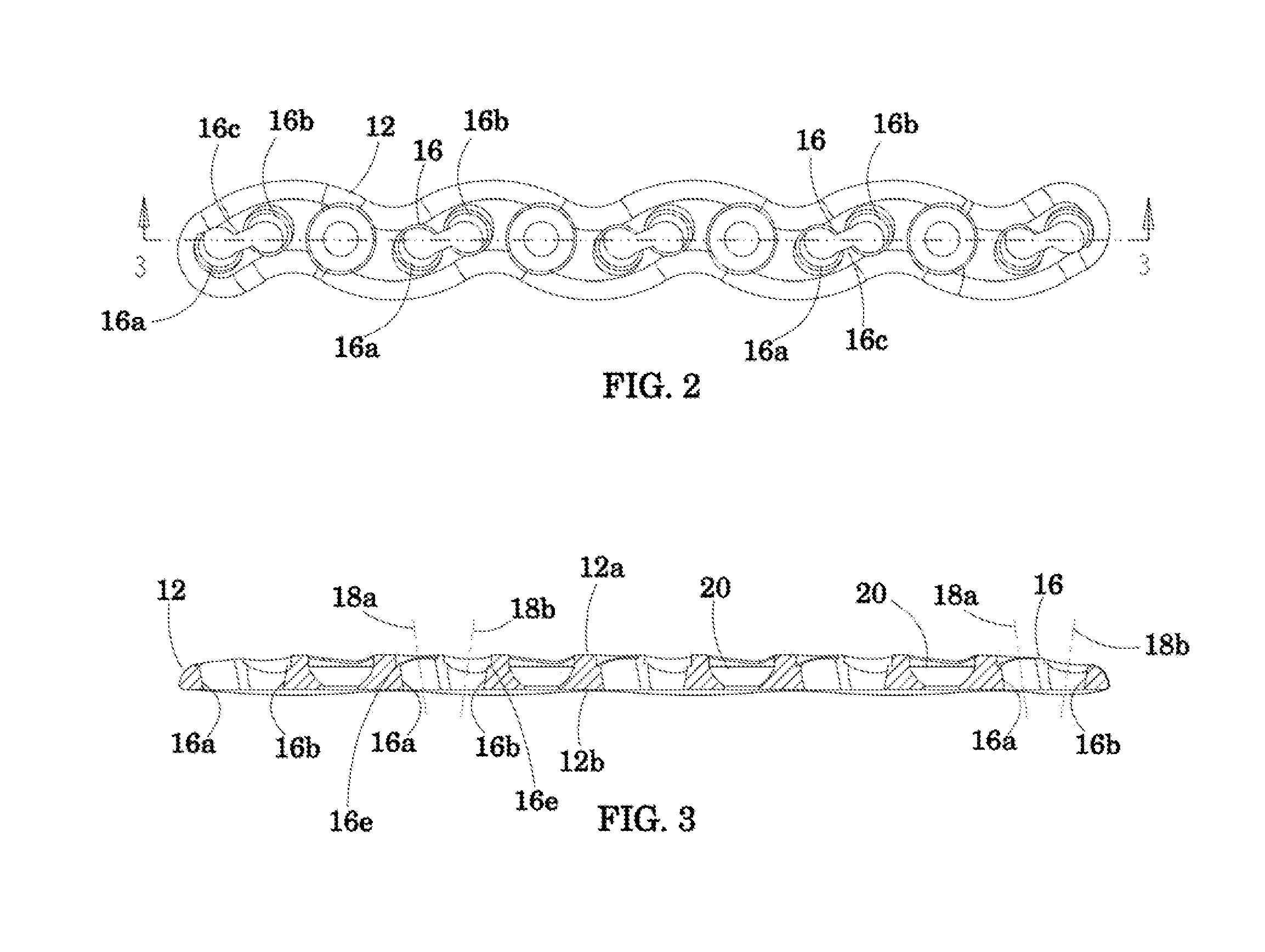

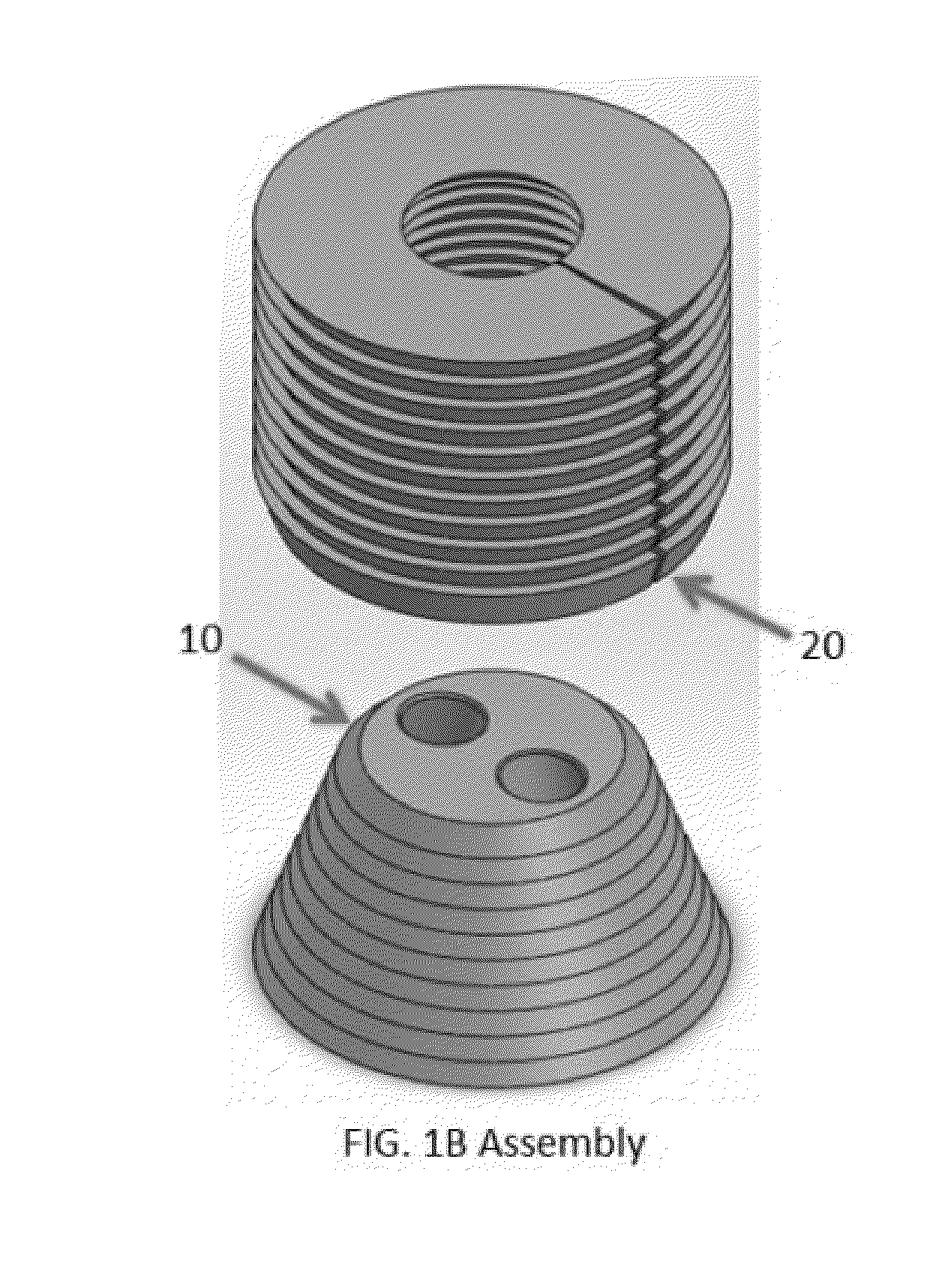

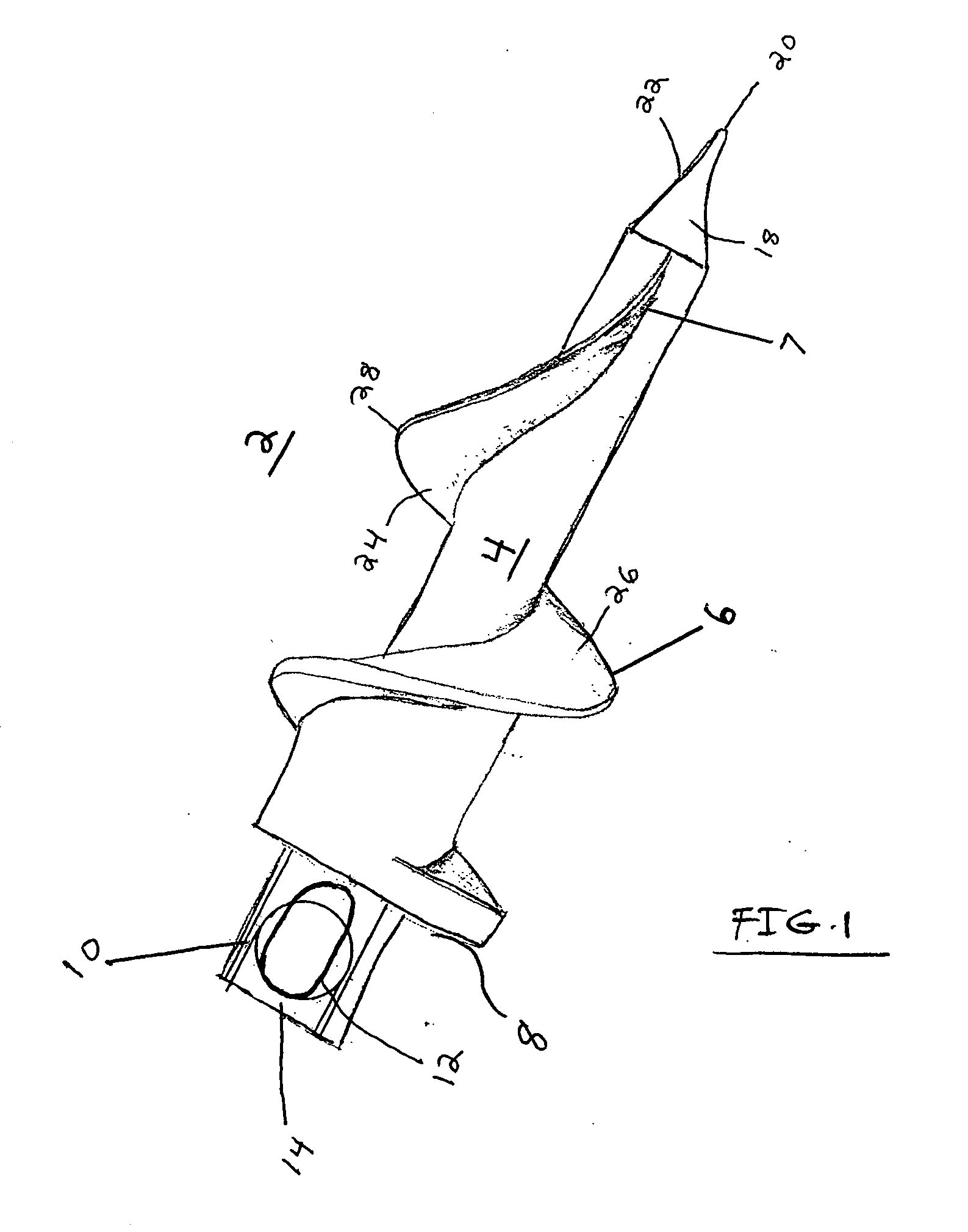

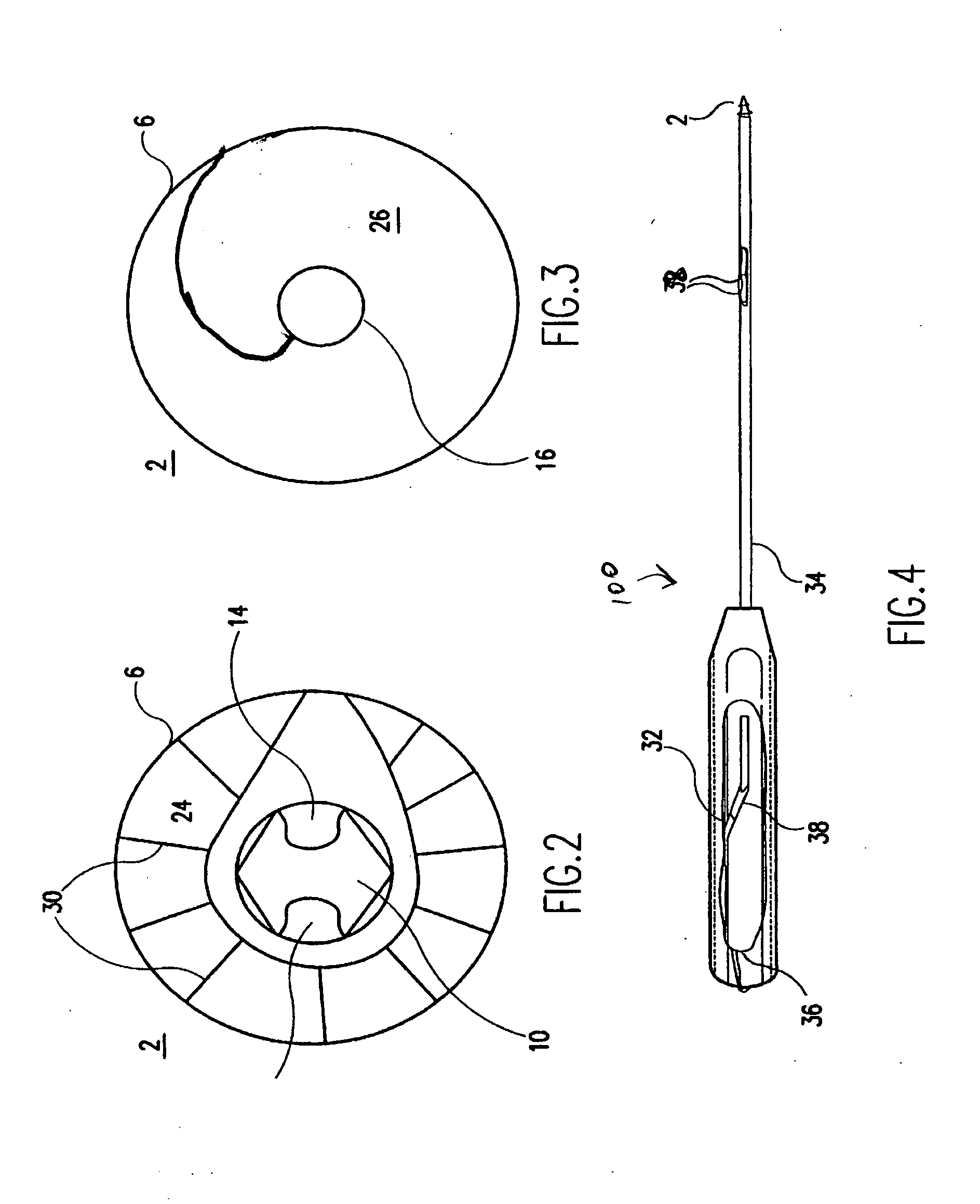

Interference fit knotless suture anchor fixation

A suture anchor includes a body having a distal end and a proximal end. Projections in the form of ribs or threads are formed on the body for retaining the anchor in a hole formed in bone. An eyelet formed on the distal end of the body accepts suture. The eyelet preferably is formed by a loop of suture. Where the body of the anchor is formed of a polymer, the suture loop can be formed by insert-molding the suture into the body. Tissue is reattached to bone using the suture anchor by securing a length of suture to the tissue, and threading the length of suture through the eyelet on the distal end of the anchor, leaving lengths of suture extending from either side of the eyelet. Installing the suture anchor into the bone wedges the lengths of suture between the suture anchor and the bone, thereby securing the tissue without the need for tying knots. Pullout strength can be enhanced by twisting the lengths of suture prior to installation of the anchor into the bone.

Owner:ARTHREX

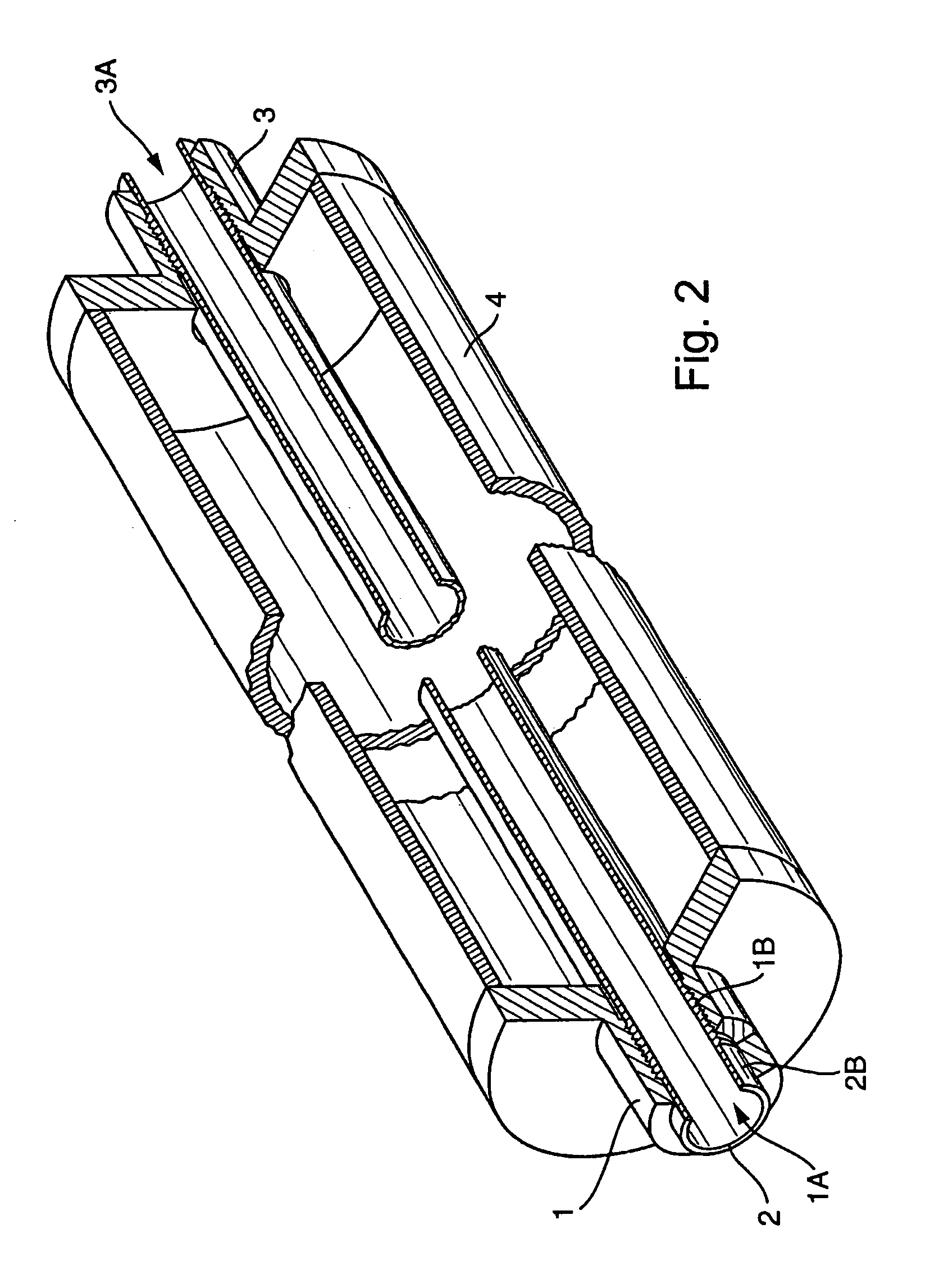

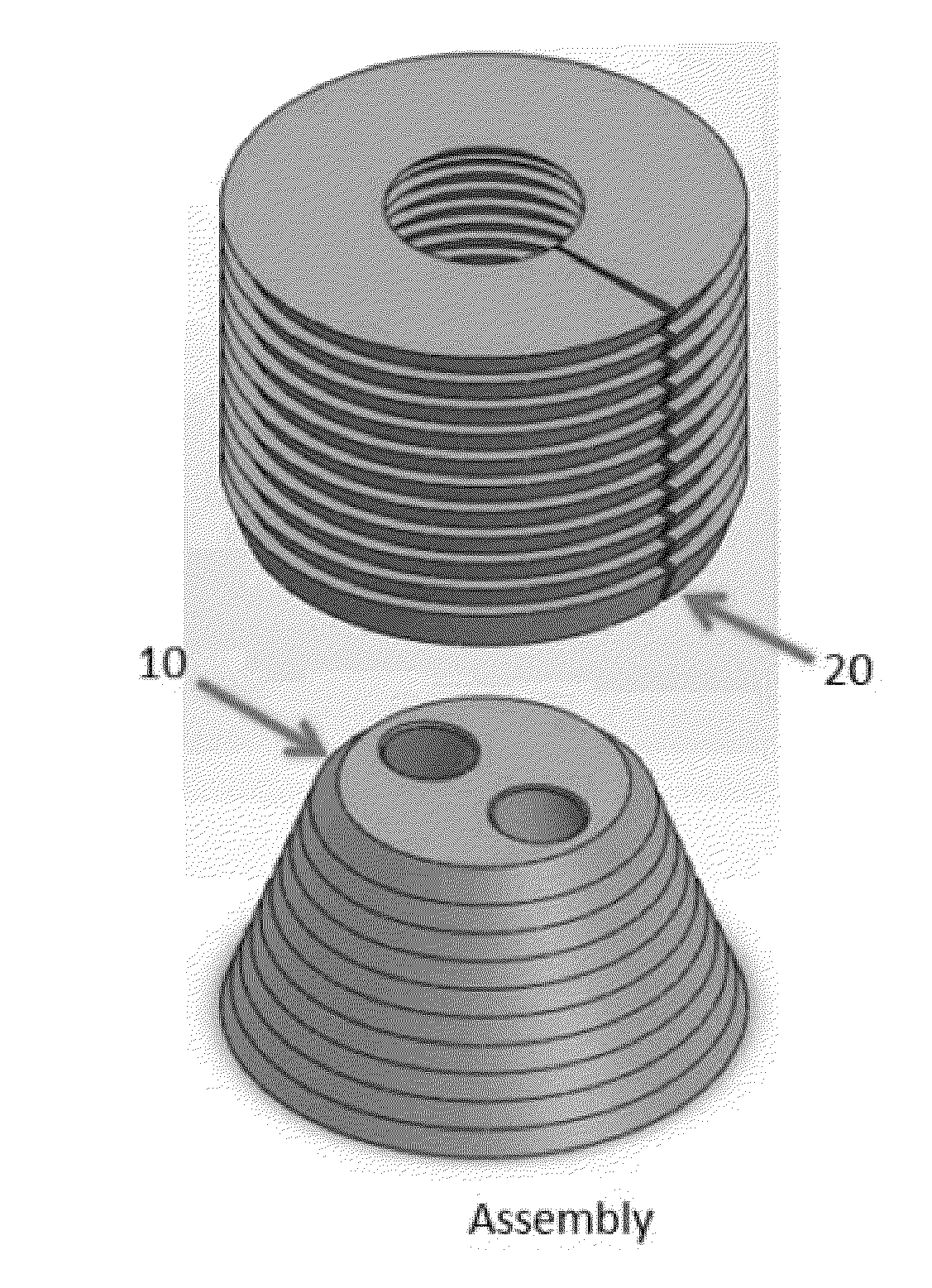

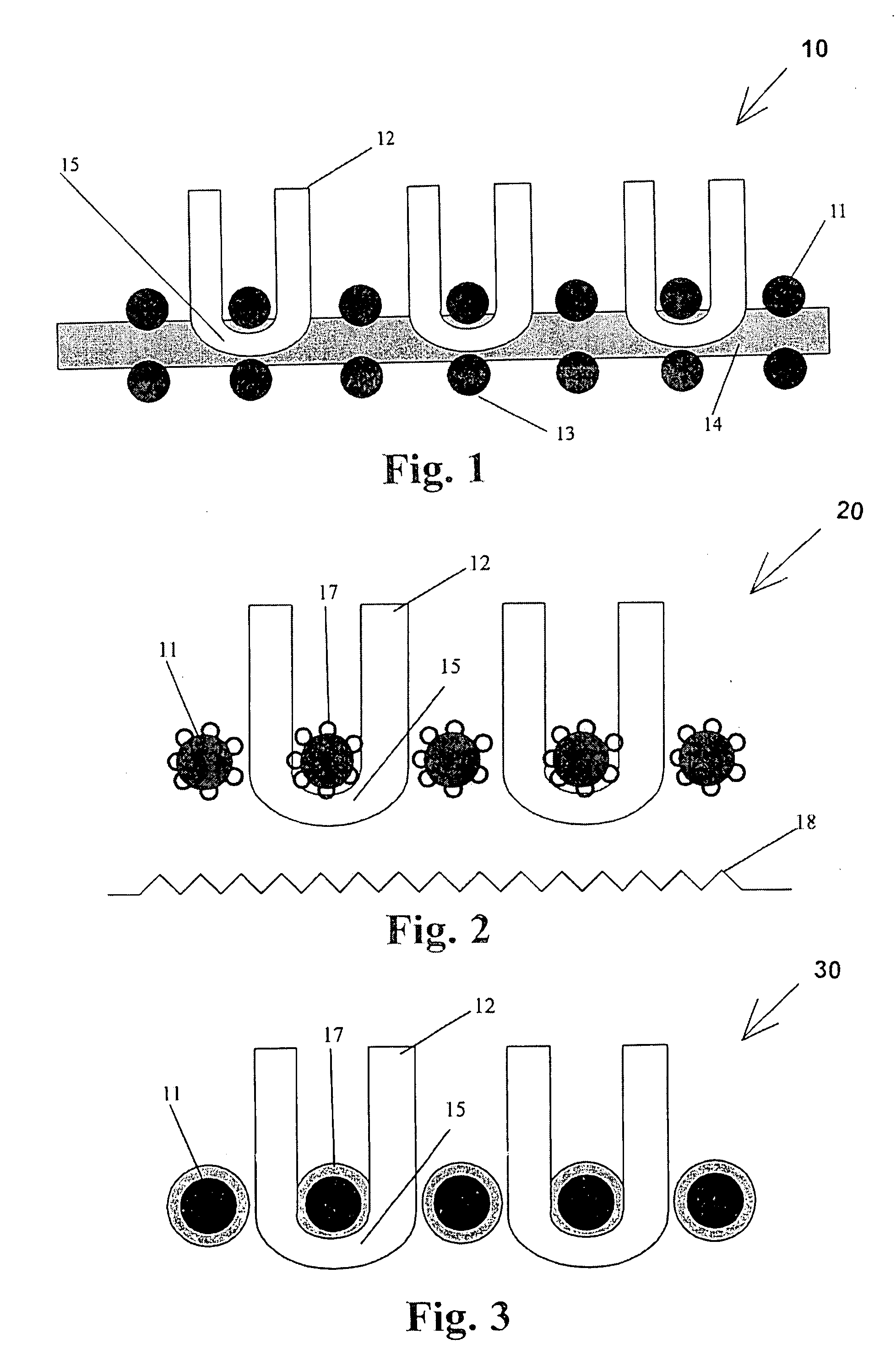

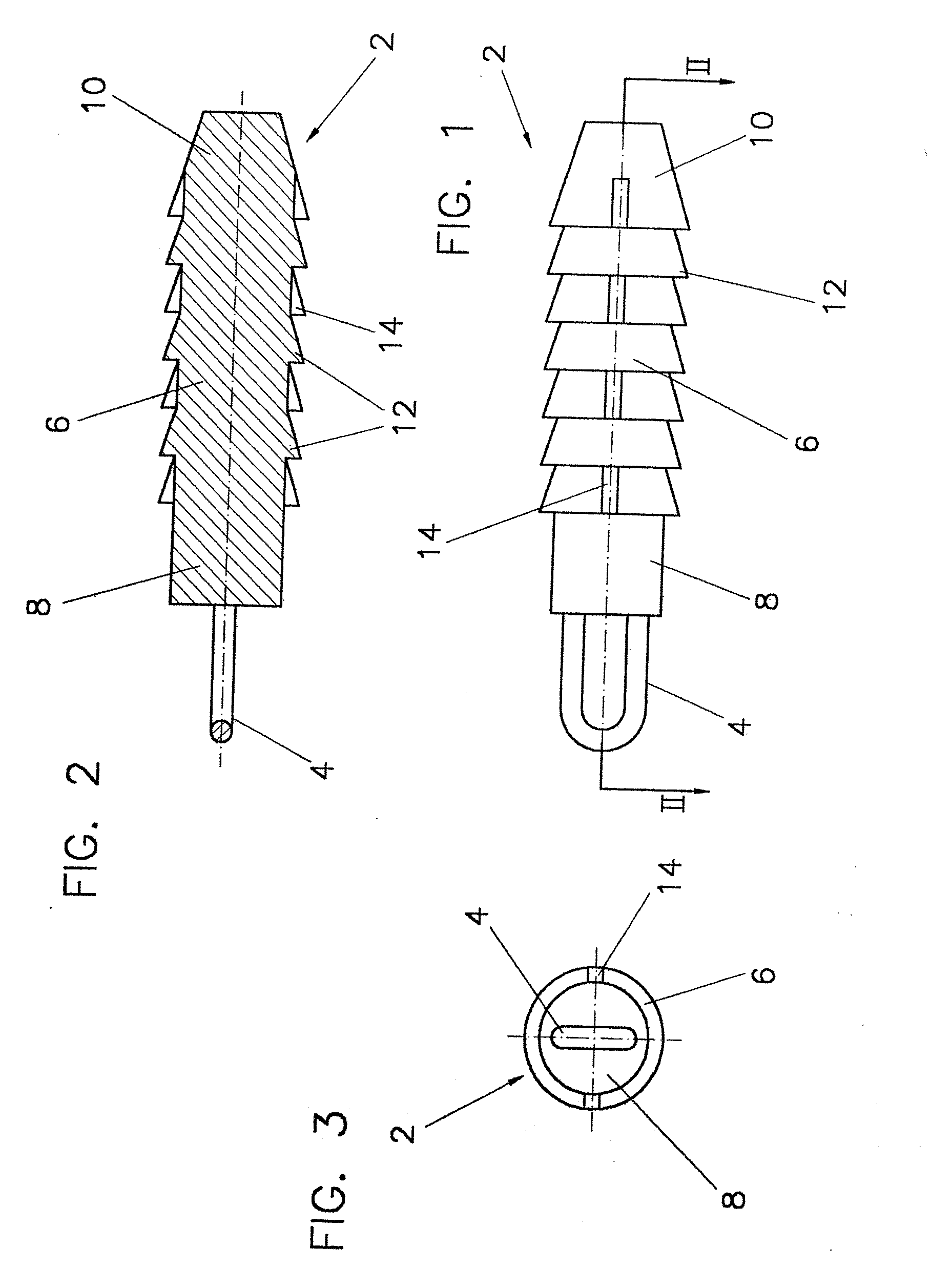

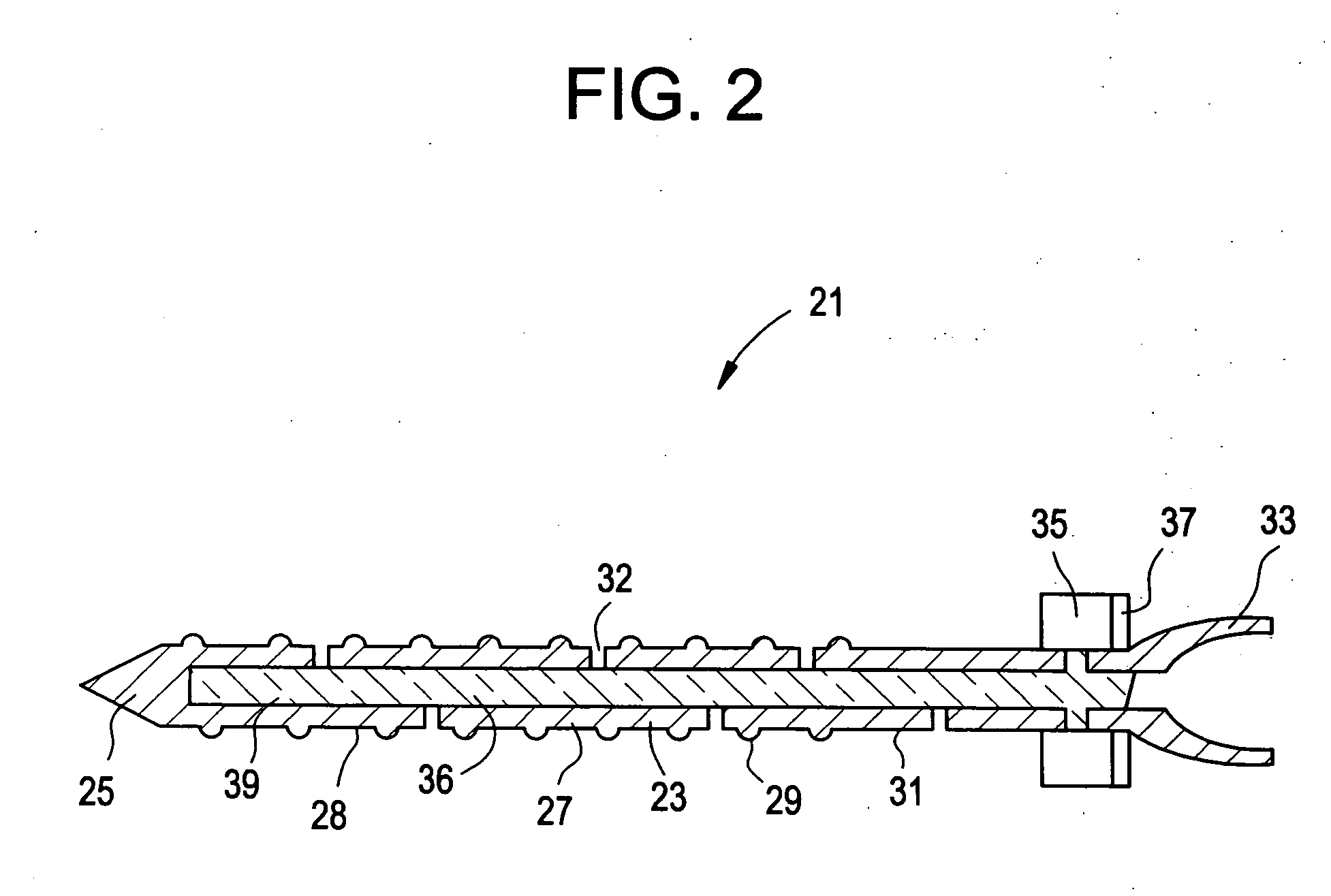

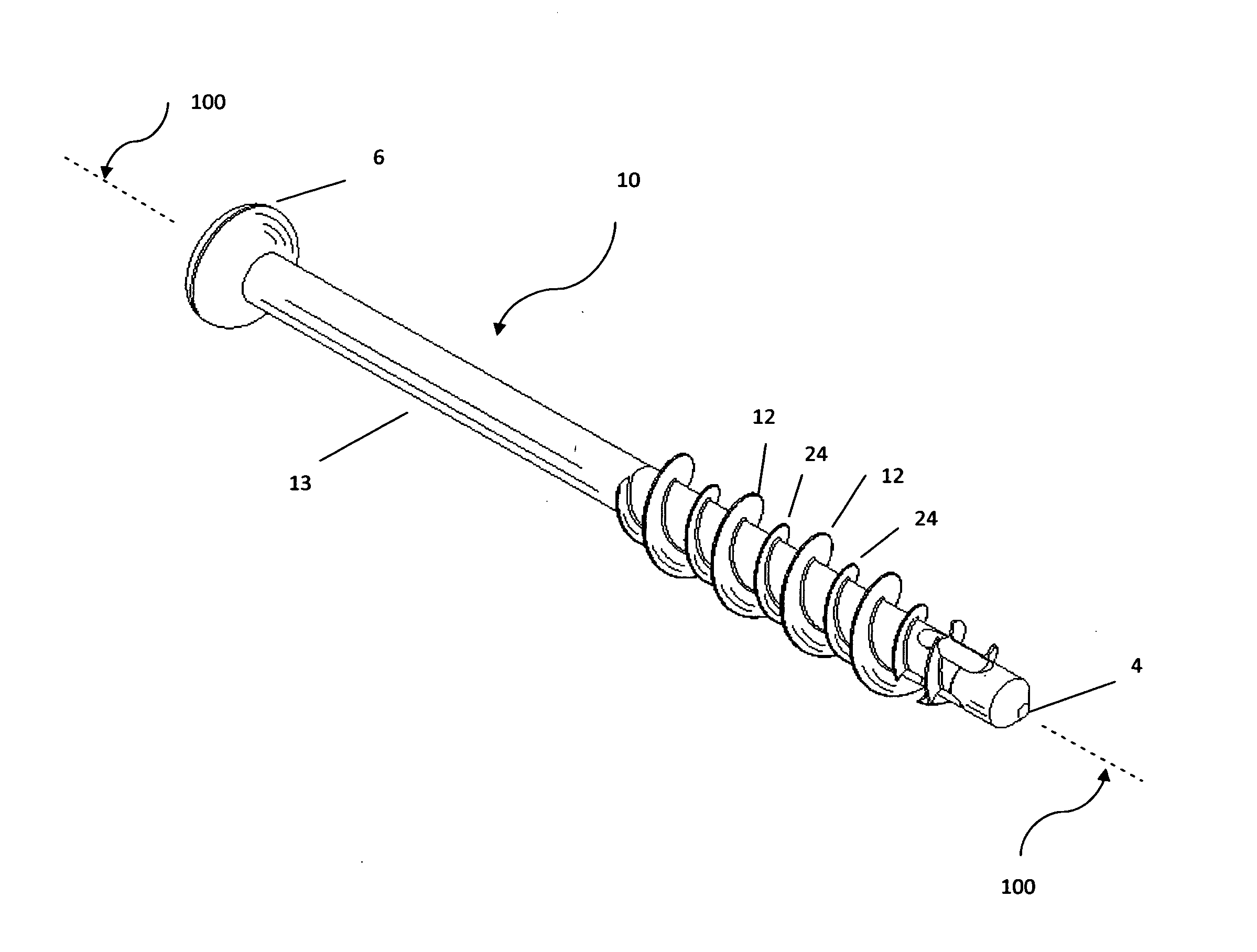

Insert molded suture anchor

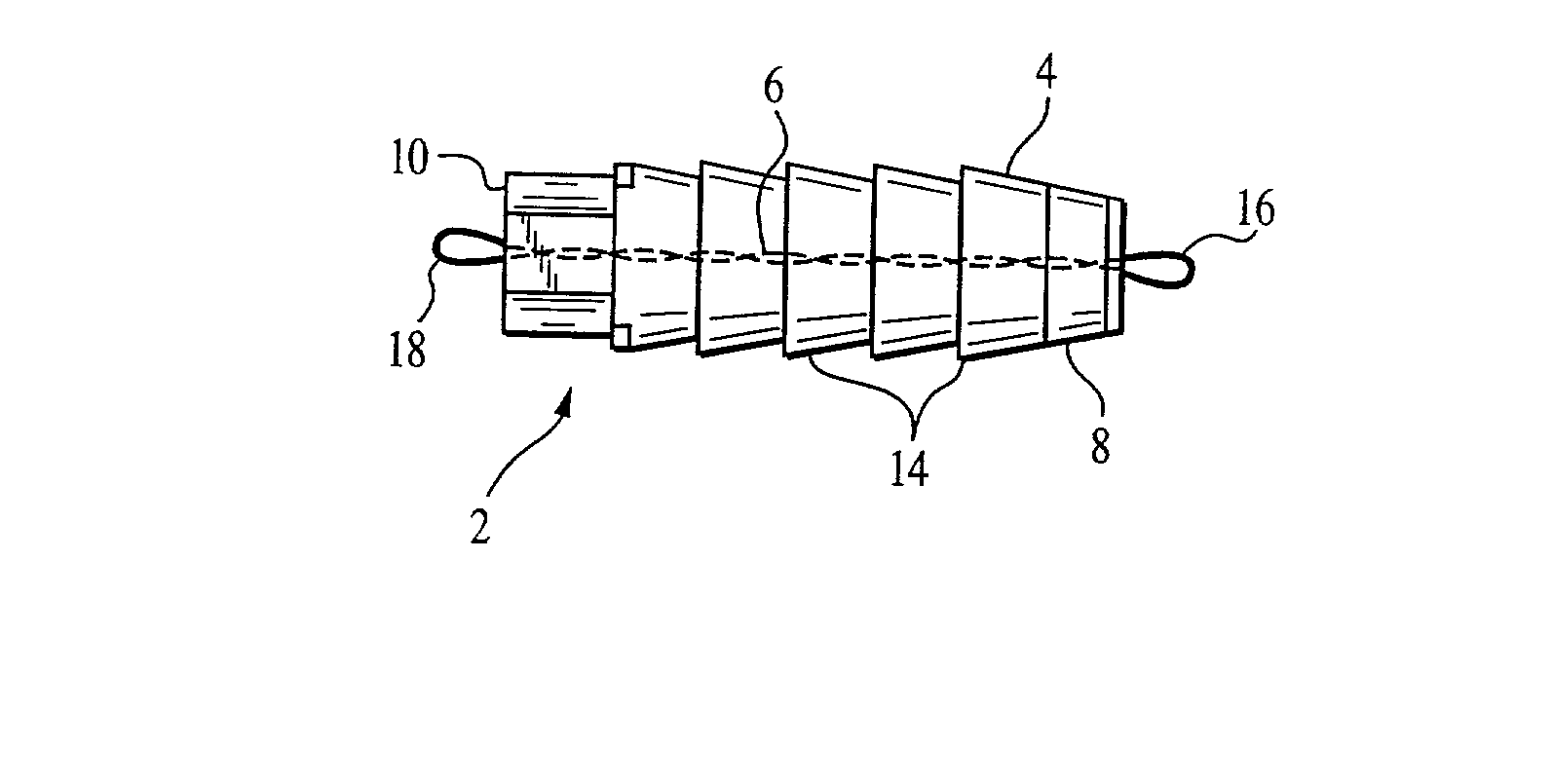

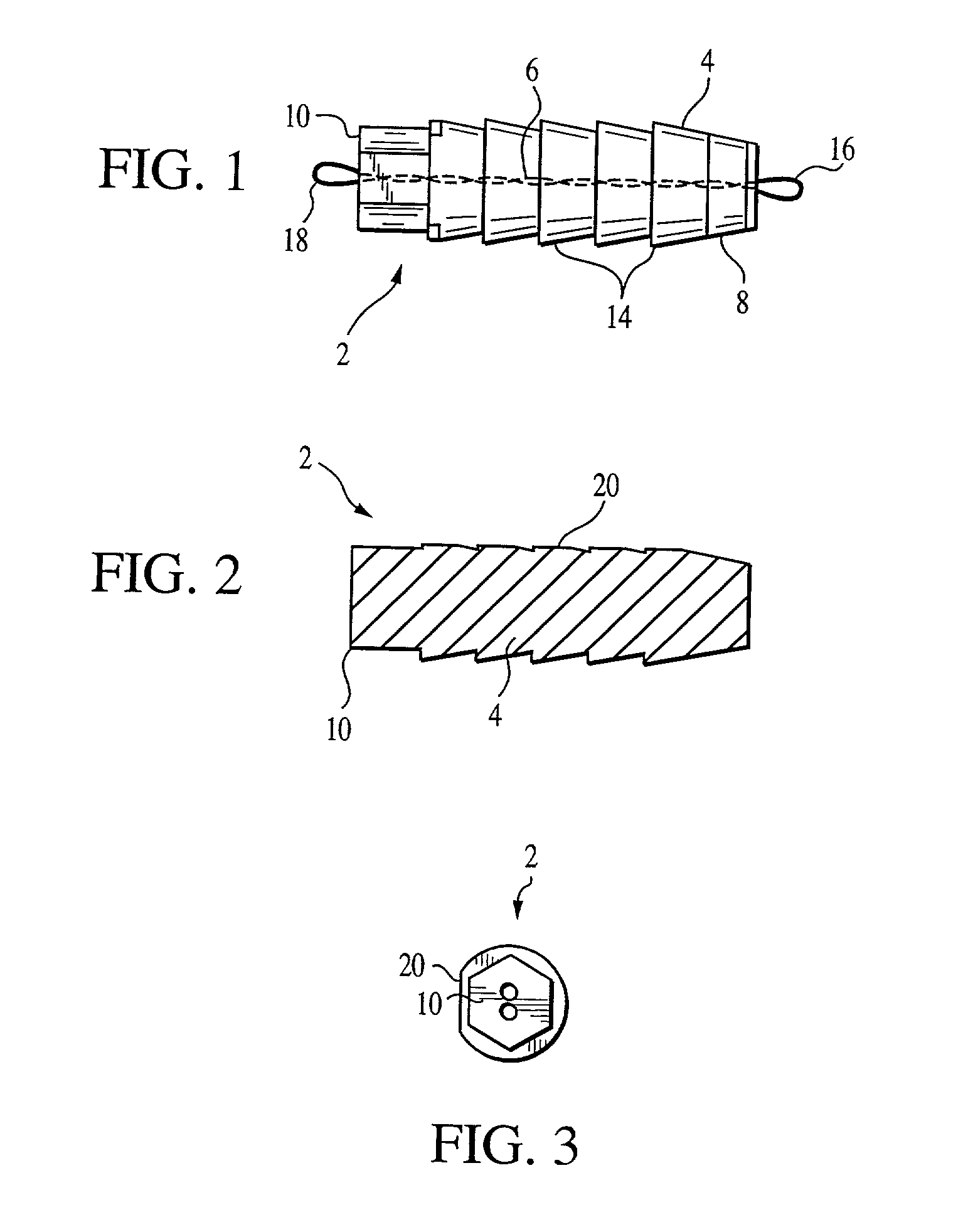

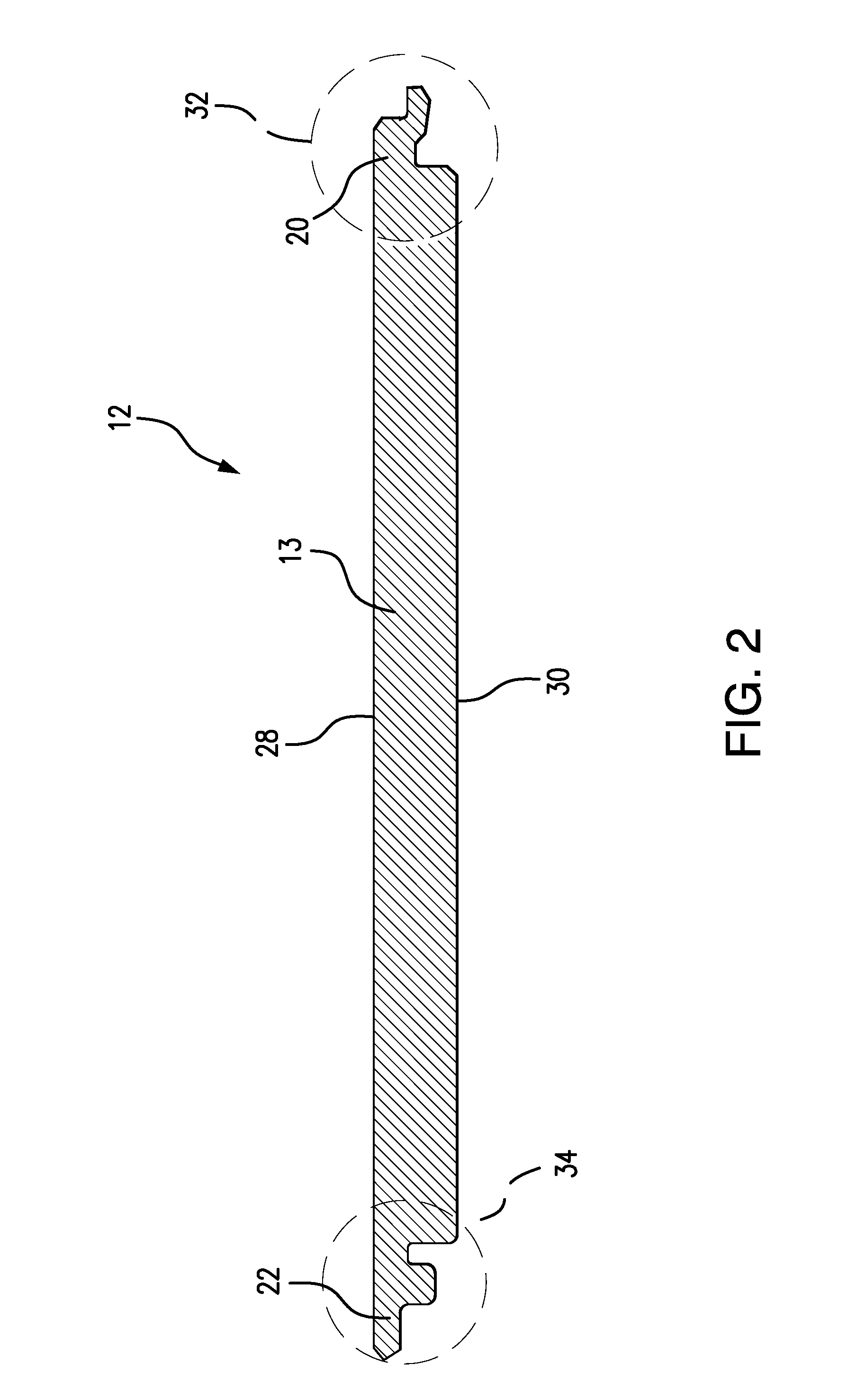

InactiveUS7226469B2Prevents suture abrasionIncreased pull-out strengthSuture equipmentsStaplesSuture anchorsSurgery

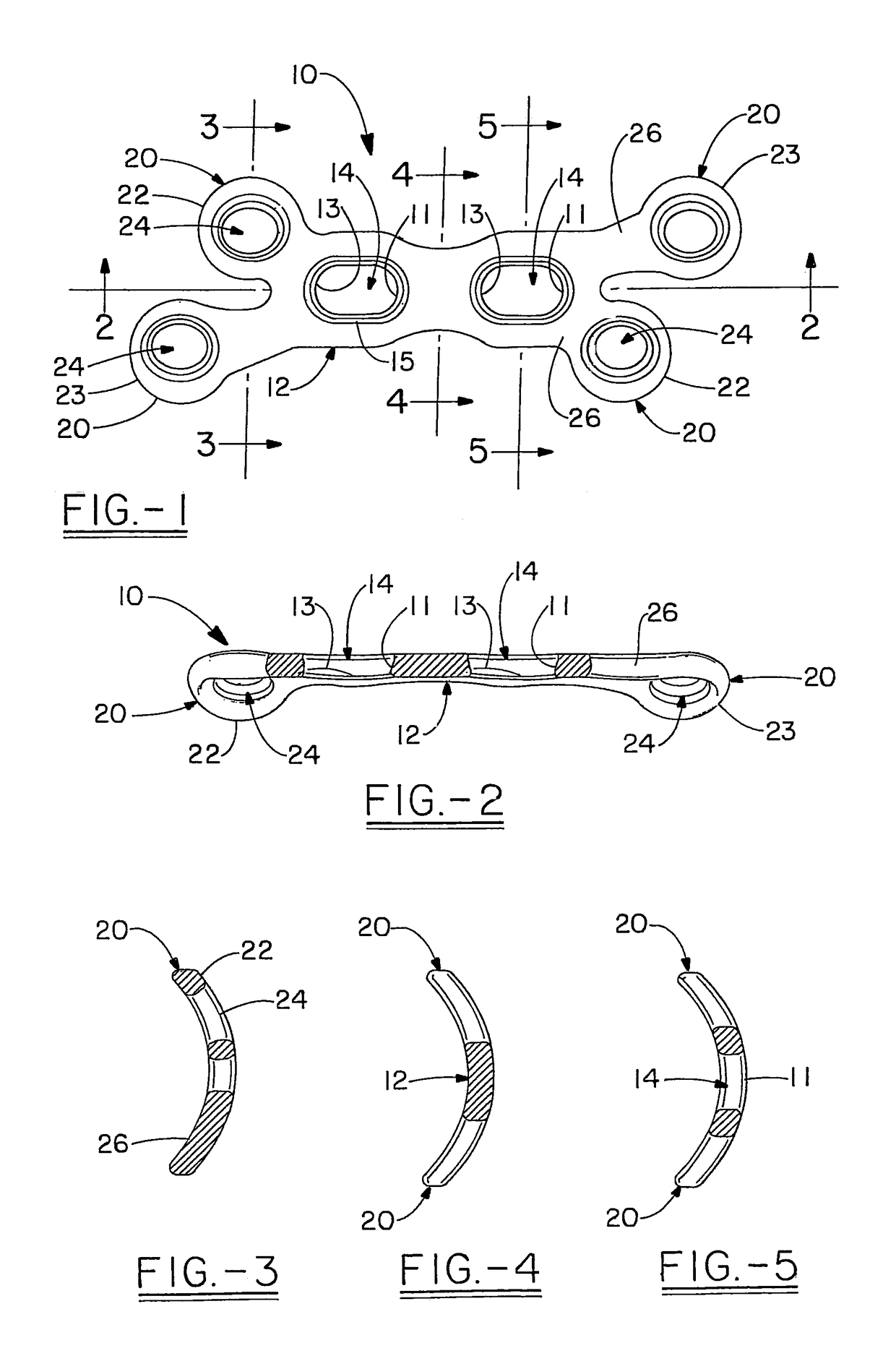

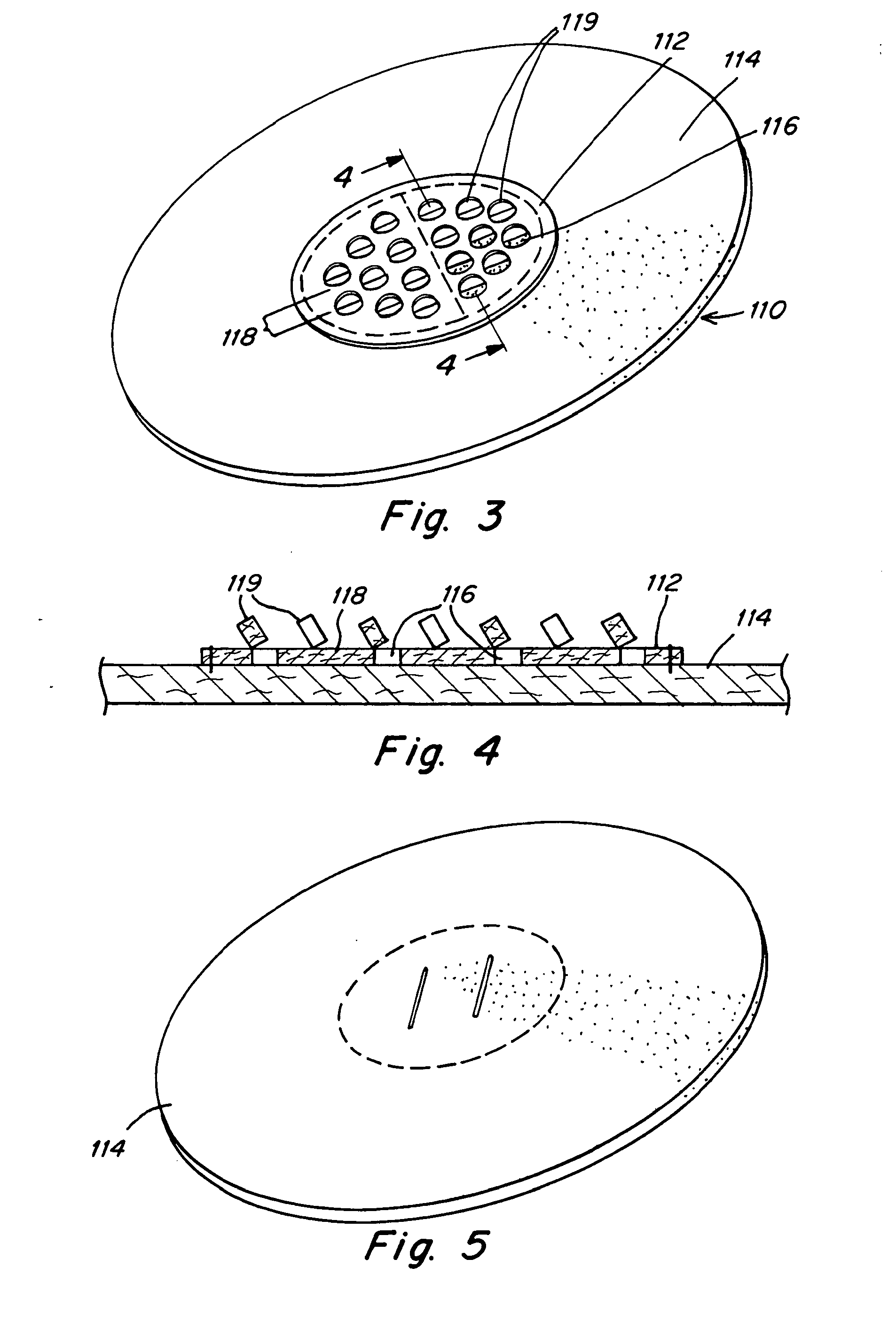

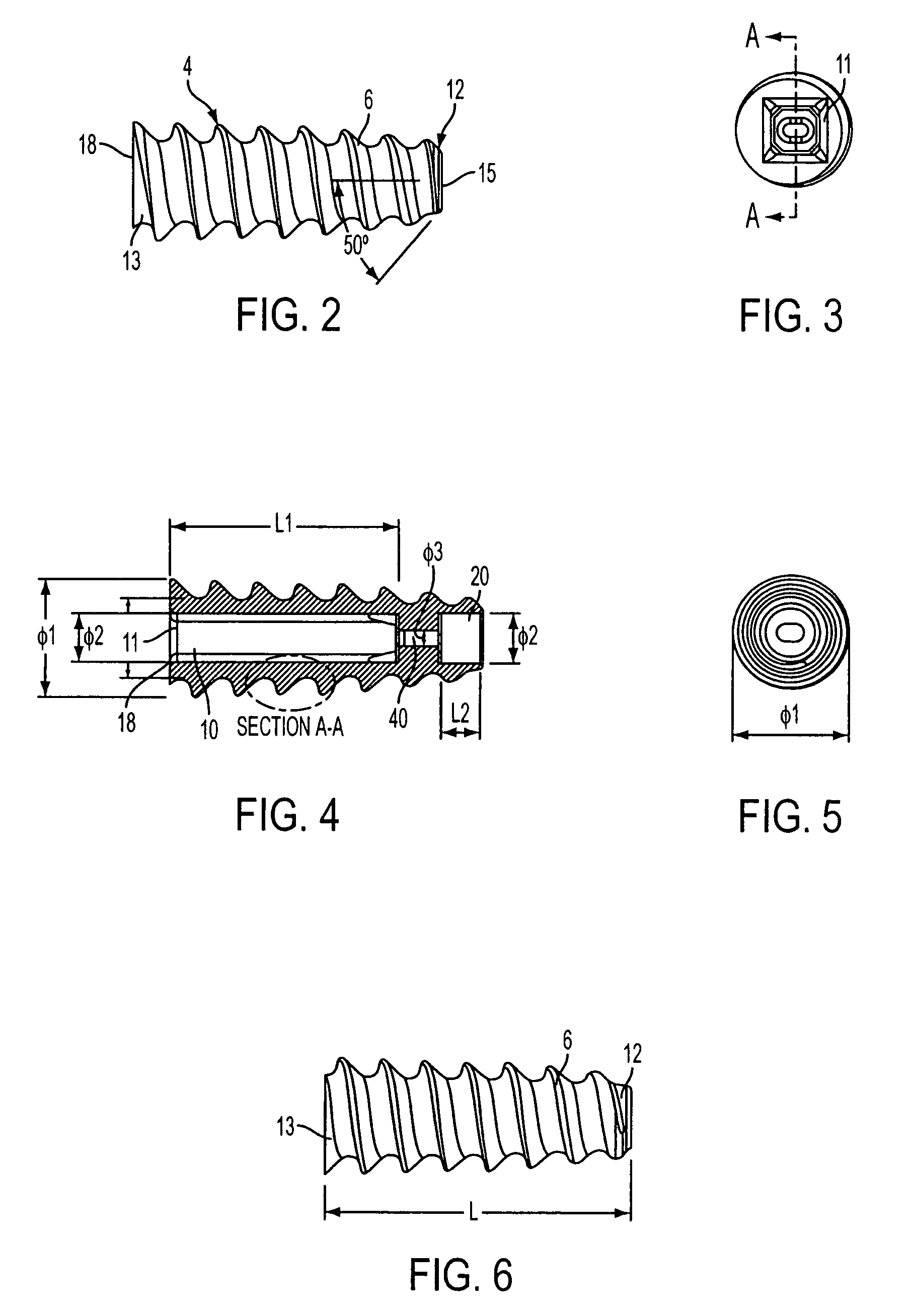

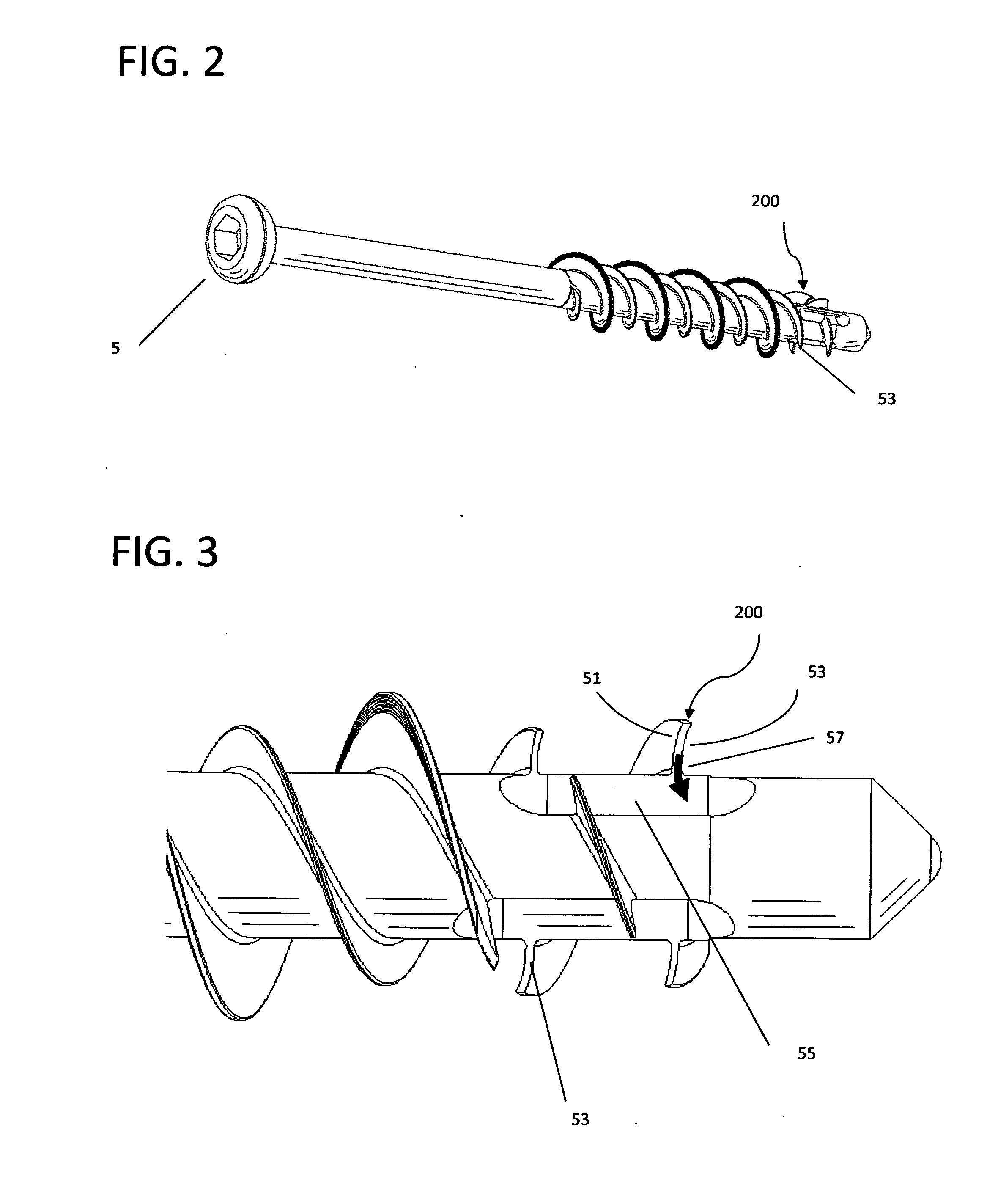

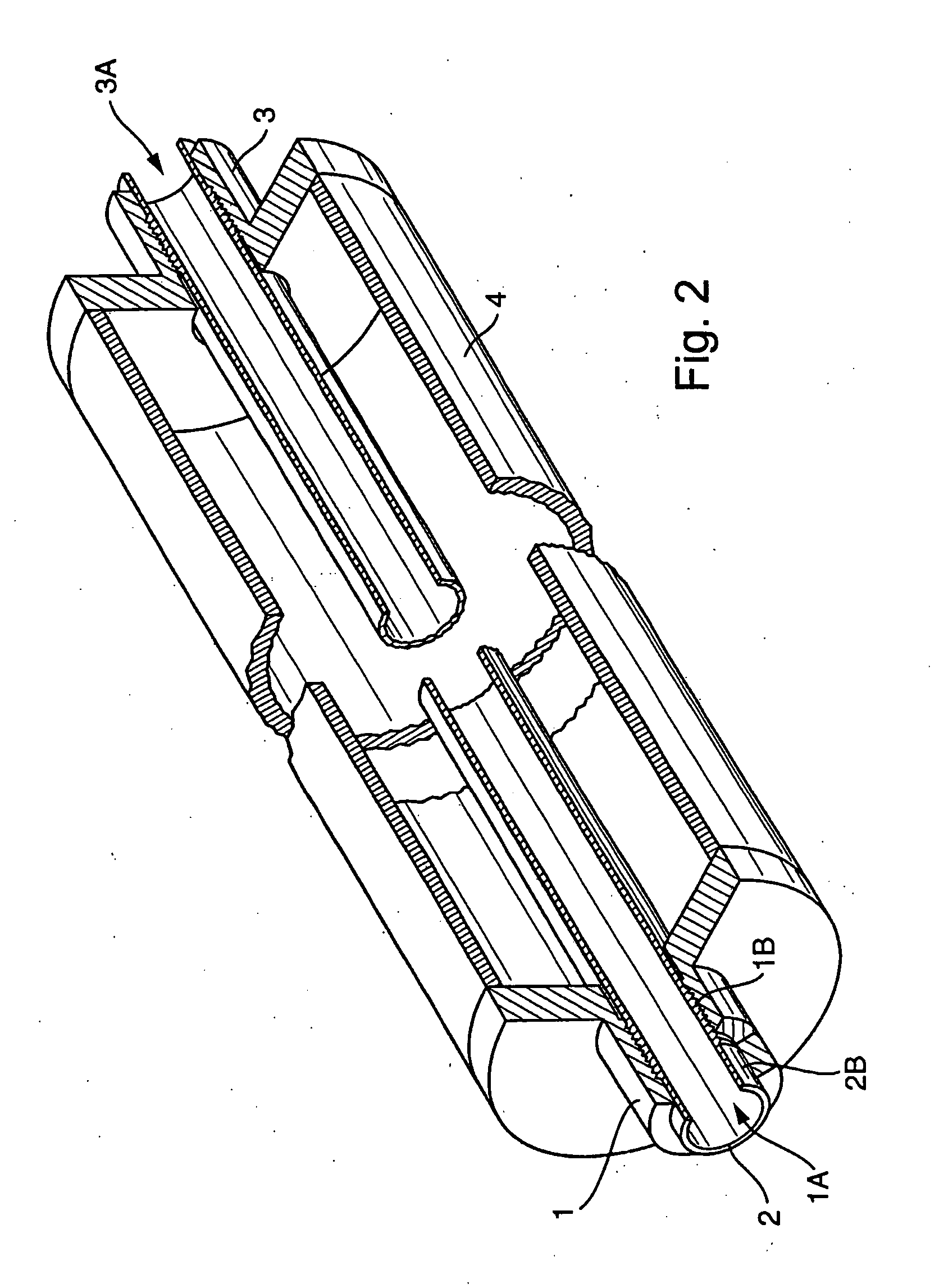

An insert-molded suture anchor has a biodegradable polymer body molded around a loop of suture. A tapered end disposed on the proximal end of the body is received into a recess in the distal end of a hand driver. Anchoring ribs are formed along the remaining length of the anchor. The suture is held securely within the anchor body during the insert molding process. The anchor is produced by placing the braided suture within an injection mold, and injecting biodegradable polymer into the mold. Using a preferred plication driver, the suture anchor can be utilized for capsular plication procedures.

Owner:ARTHREX

System and method for attaching soft tissue to an implant

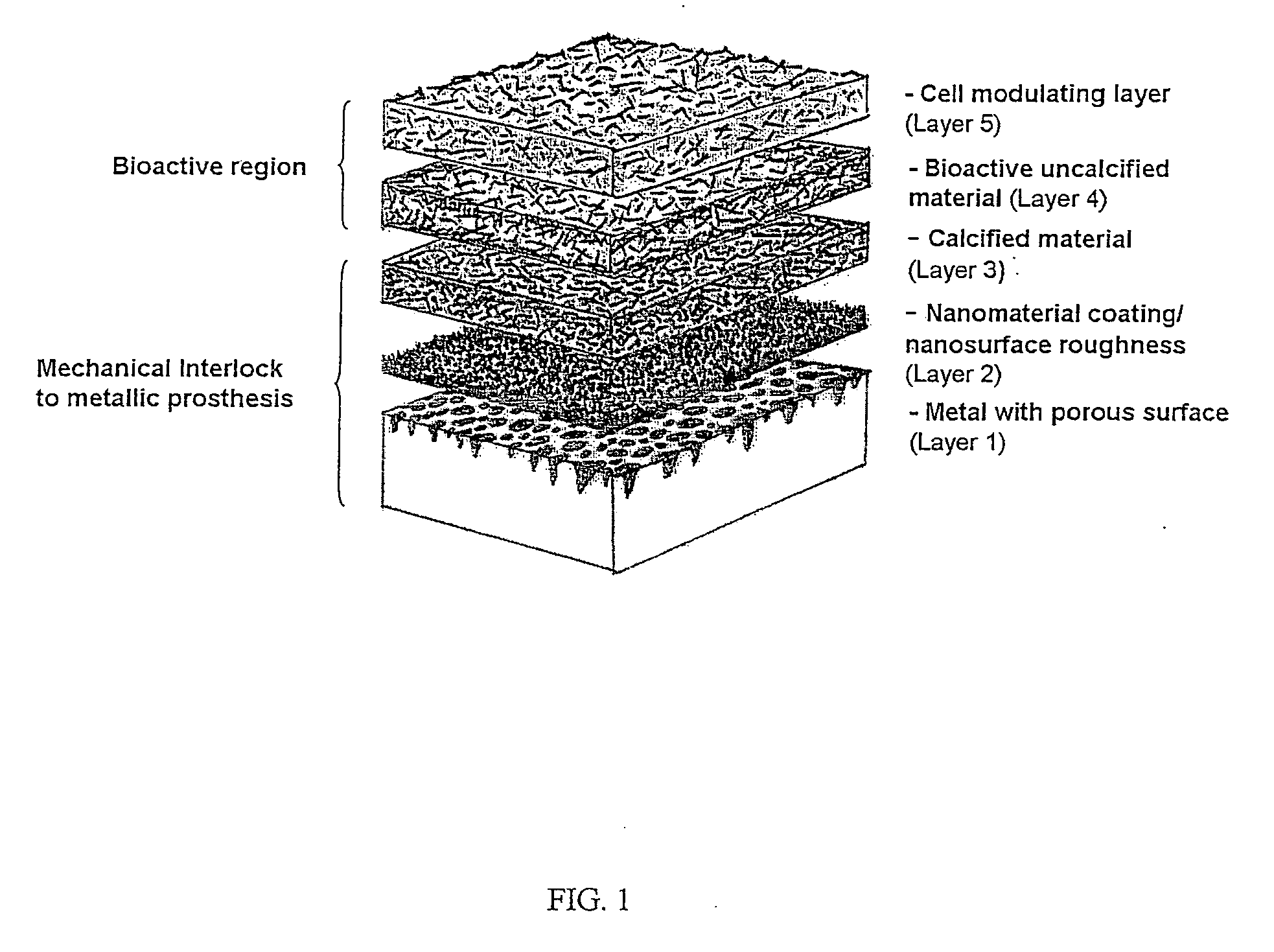

ActiveUS20060105015A1Firmly connectedIncreased pull-out strengthAnodisationBiocideCell-Extracellular MatrixProsthesis

One embodiment of the present invention is directed to compositions and methods for enhancing attachment of soft tissues to a metal prosthetic device. In one embodiment a construct is provided comprising a metal implant having a porous metal region, wherein said porous region exhibits a nano-textured surface, and a biocompatible polymer matrix coating the nano-textured surface. The polymer matrix coating comprises a naturally occurring extracellular matrix with biocompatible inorganic materials distributed within the matrix, or a biocompatible polymer and an osteo-inductive agent.

Owner:DEPUY SYNTHES PROD INC +1

Device and method for locking two building boards

InactiveUS8336272B2Easy to transportIncreased pull-out strengthWallsBuilding repairsArchitectural engineering

Owner:FLOORING TECH

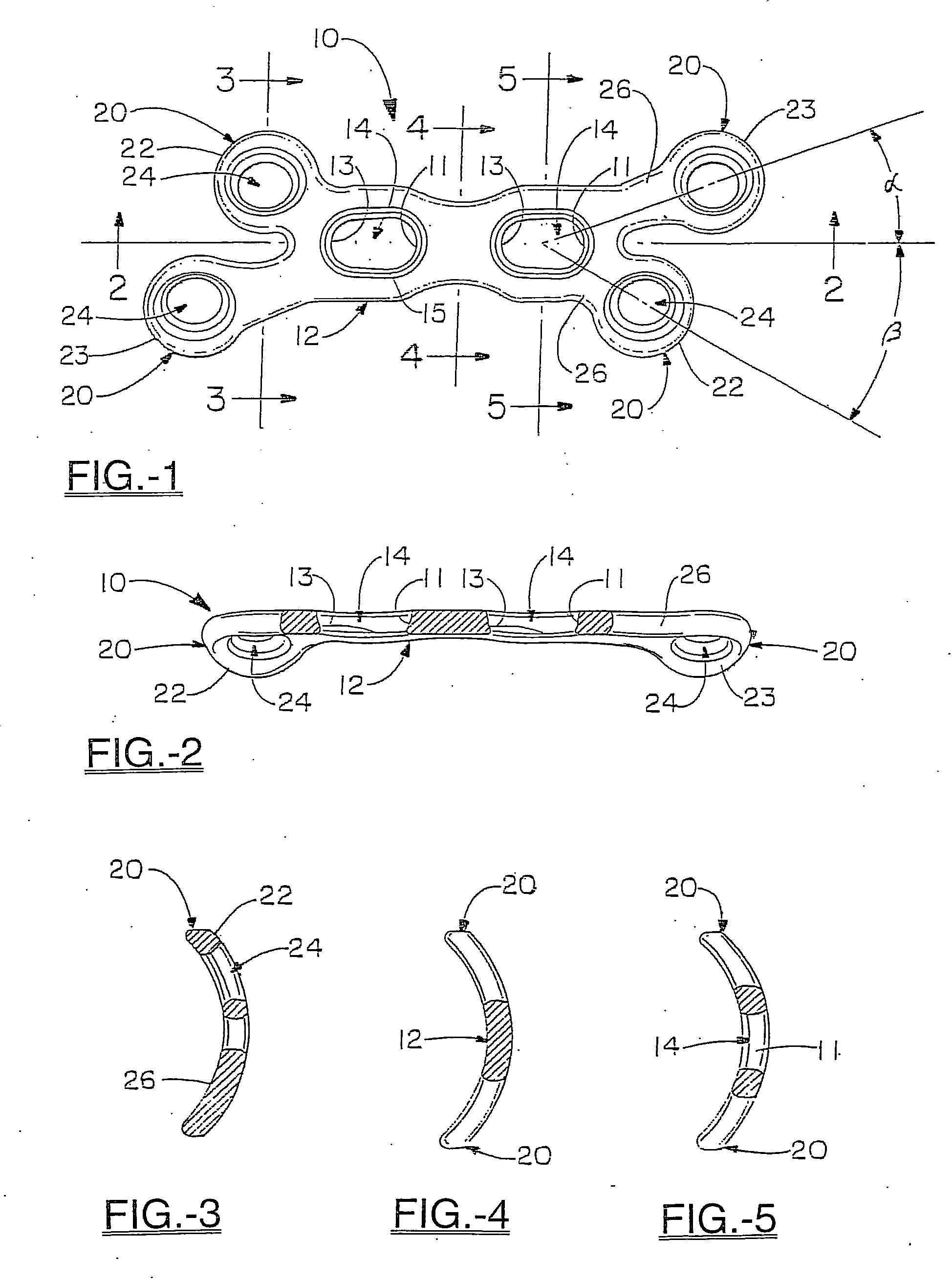

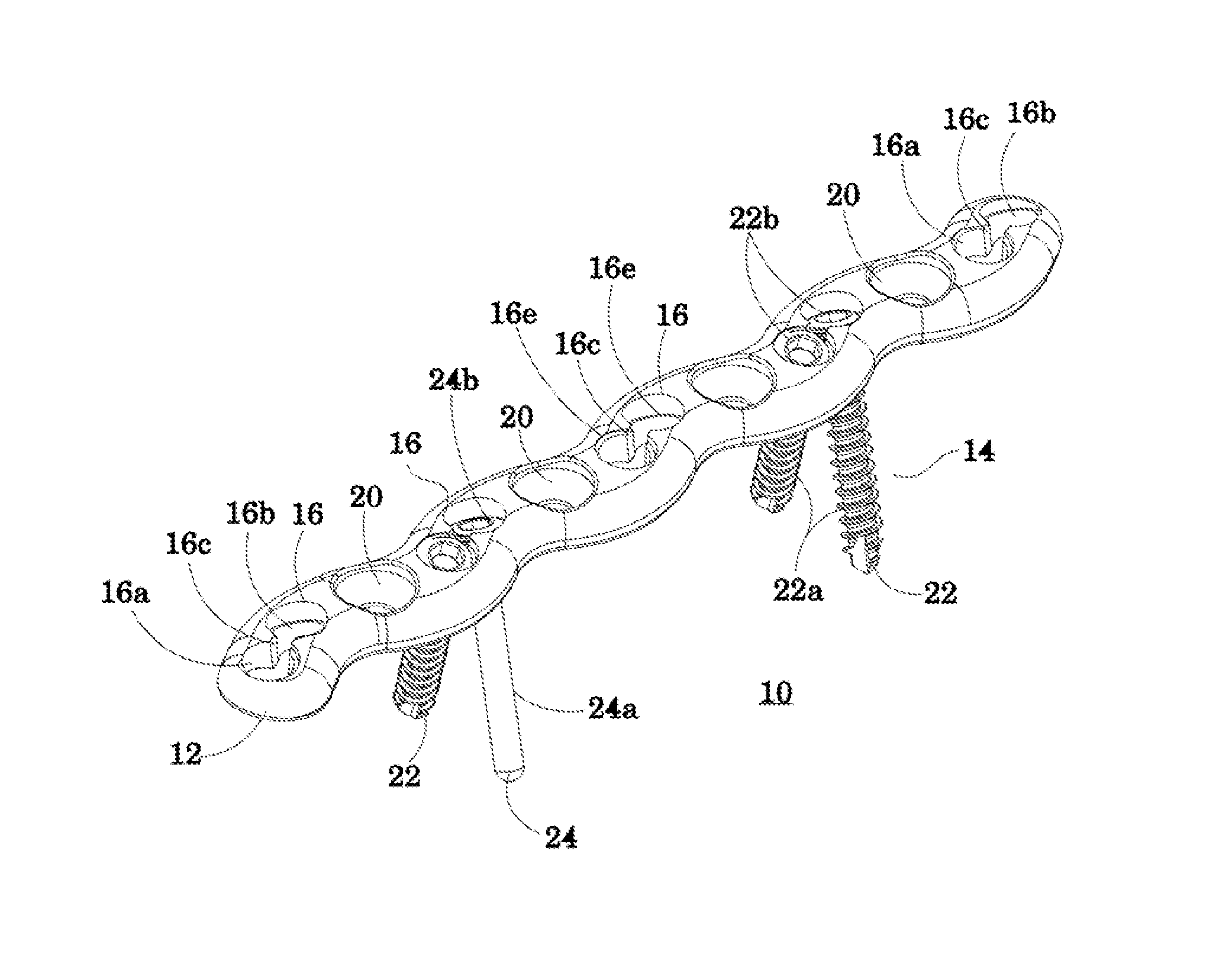

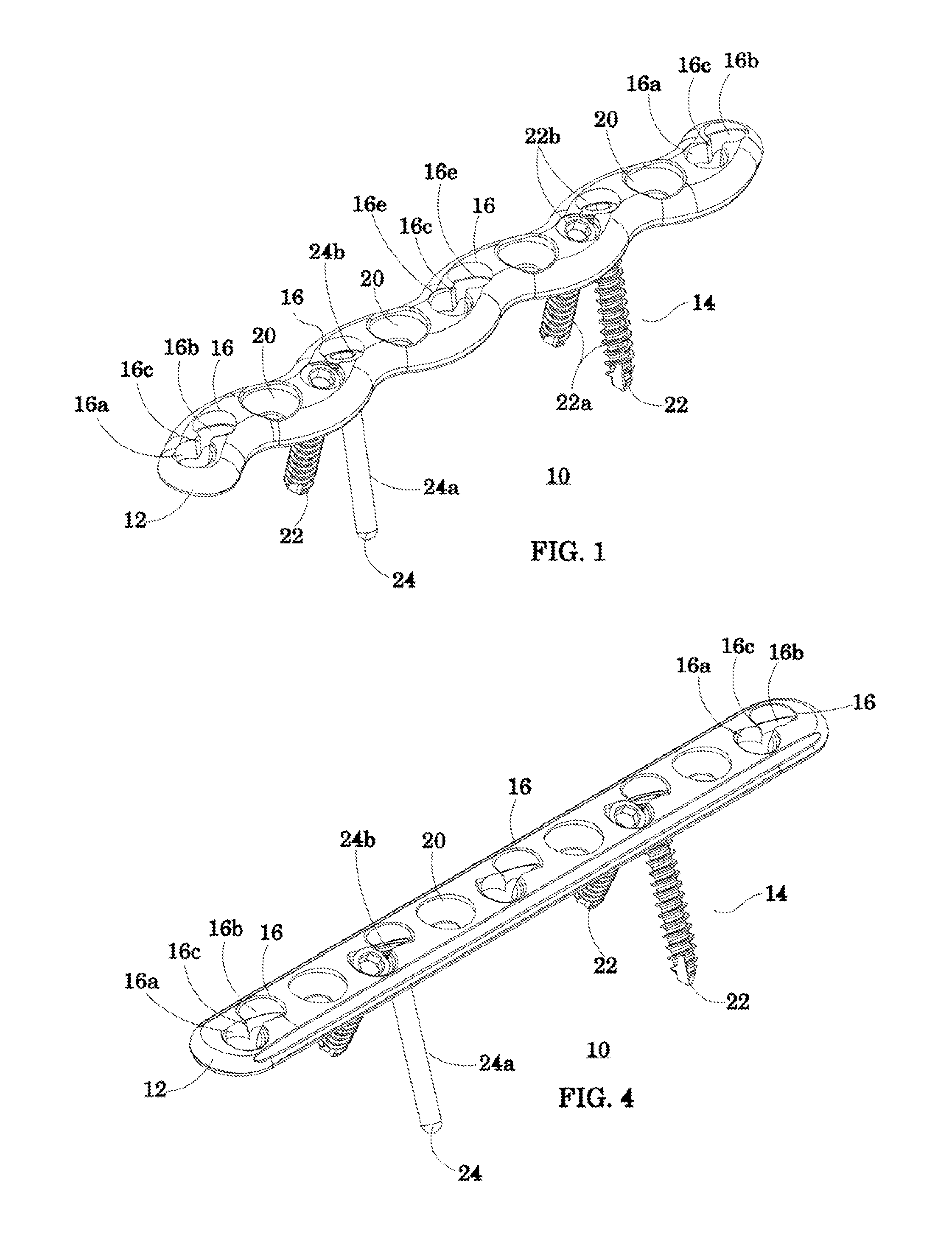

Orthopedic plate

ActiveUS20060200145A1Increased pull-out strengthAvoid confictJoint implantsBone platesSmall patellaeBone tissue

The present invention relates to an orthopedic plate and screw system and instruments for surgical fixation of a small bone or bones including specifically the small bones of the spine. The plate facilitates three dimensional contouring to provide for a variety of applications and to accommodate individual variation in bone shape. The plate has a modified x shape including a central trunk portion including one or more screw holes along a longitudinal axis and a set of divergent upper and an oppositely extending set of divergent lower arms, each arm including screw holes which are placed at a radially equal distance but which diverging asymmetrically from the longitudinal axis relative to its paired upper or lower mate. The screws of the system are self-starting, self-tapping screws including the option of partial or full cannulation. In a further embodiment, the plate is intended for use through the length of the spine.

Owner:ORTHOHELIX SURGICAL DESIGNS

Fasteners and fastener delivery devices for affixing sheet-like materials to bone or tissue

Owner:ROTATION MEDICAL

Low-profile upholstery clip for attaching a bead to a foam substrate

ActiveUS8099837B2Improve performanceIncreased durabilitySnap fastenersVehicle seatsHigh resistanceMechanical engineering

Owner:HOPE GLOBAL DIV OF NFA

Method for surgically repairing a damaged ligament

An anterior cruciate ligament (ACL) surgical repair technique involves the use of a single femoral and tibial tunnel and an implant that separates and positions two distinct bundles. This allows for the surgeon to create a more anatomic reconstruction with a procedure that is less technically demanding, can be performed using a transtibial or anteromedial approach, minimizes tunnel widening, and decreases operative time. The result is a strong fixation option for soft tissue grafts, with circumferential graft compression at the aperture, high pull-out strength, and ease of use. The graft bundles are positioned in a more anatomic orientation through the above noted single femoral and tibial tunnel.

Owner:CAYENNE MEDICAL INC

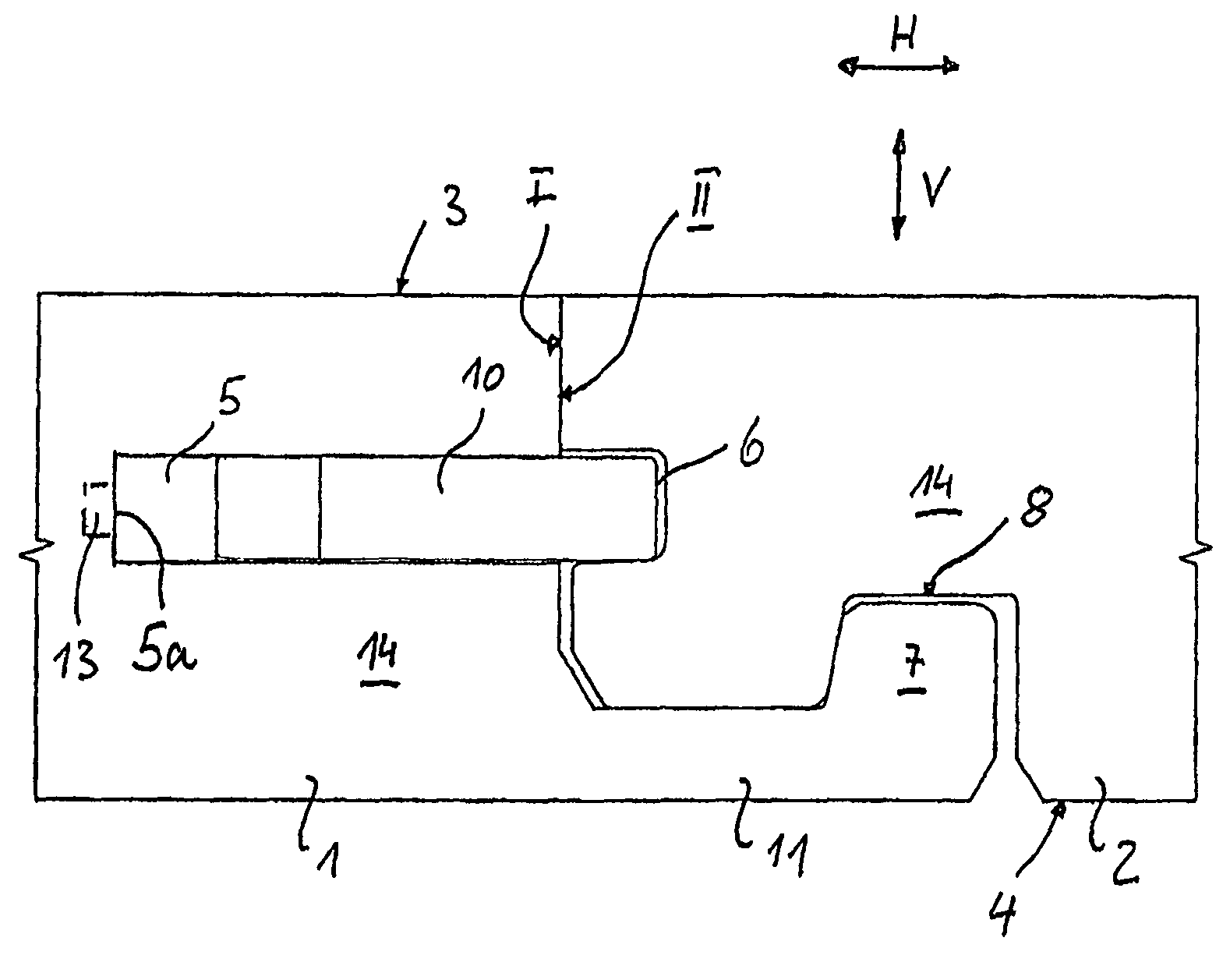

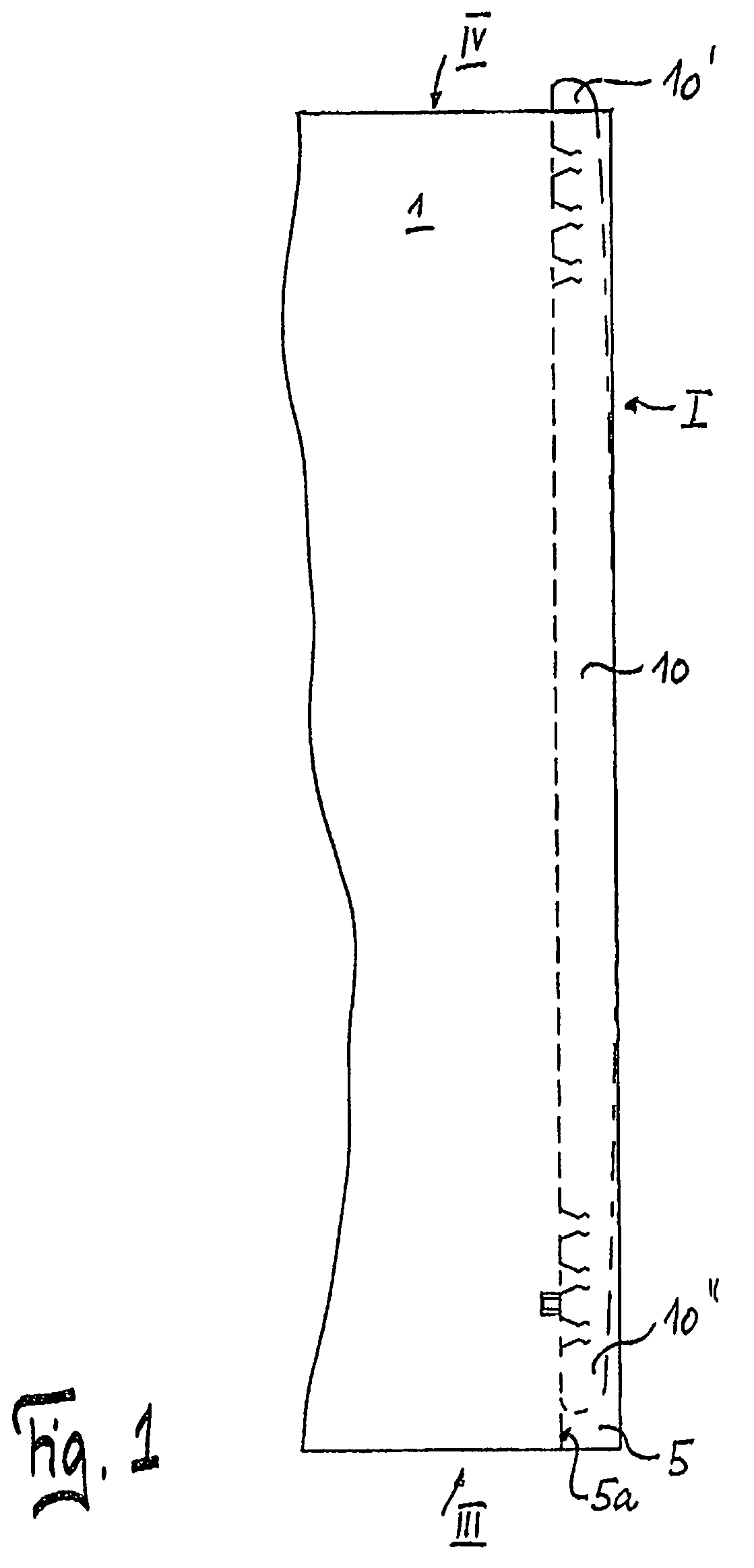

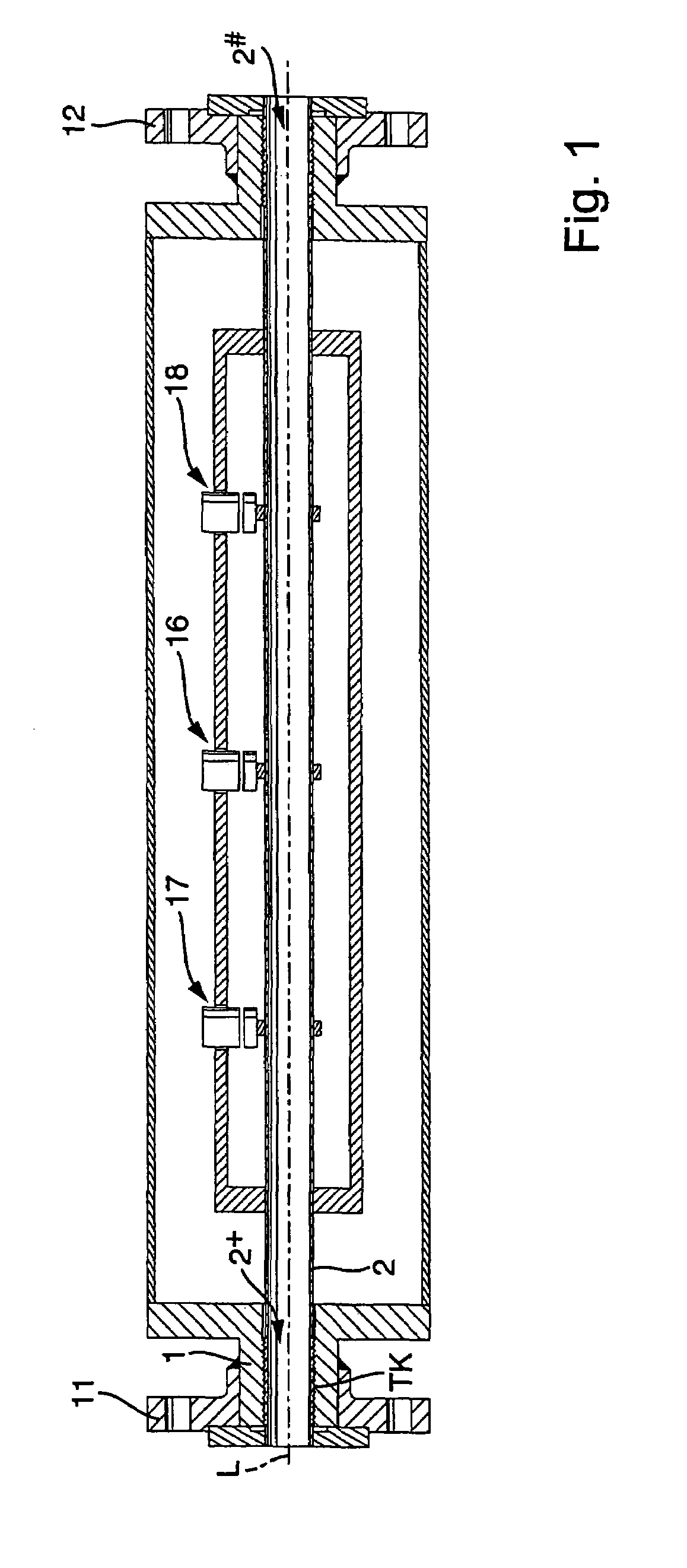

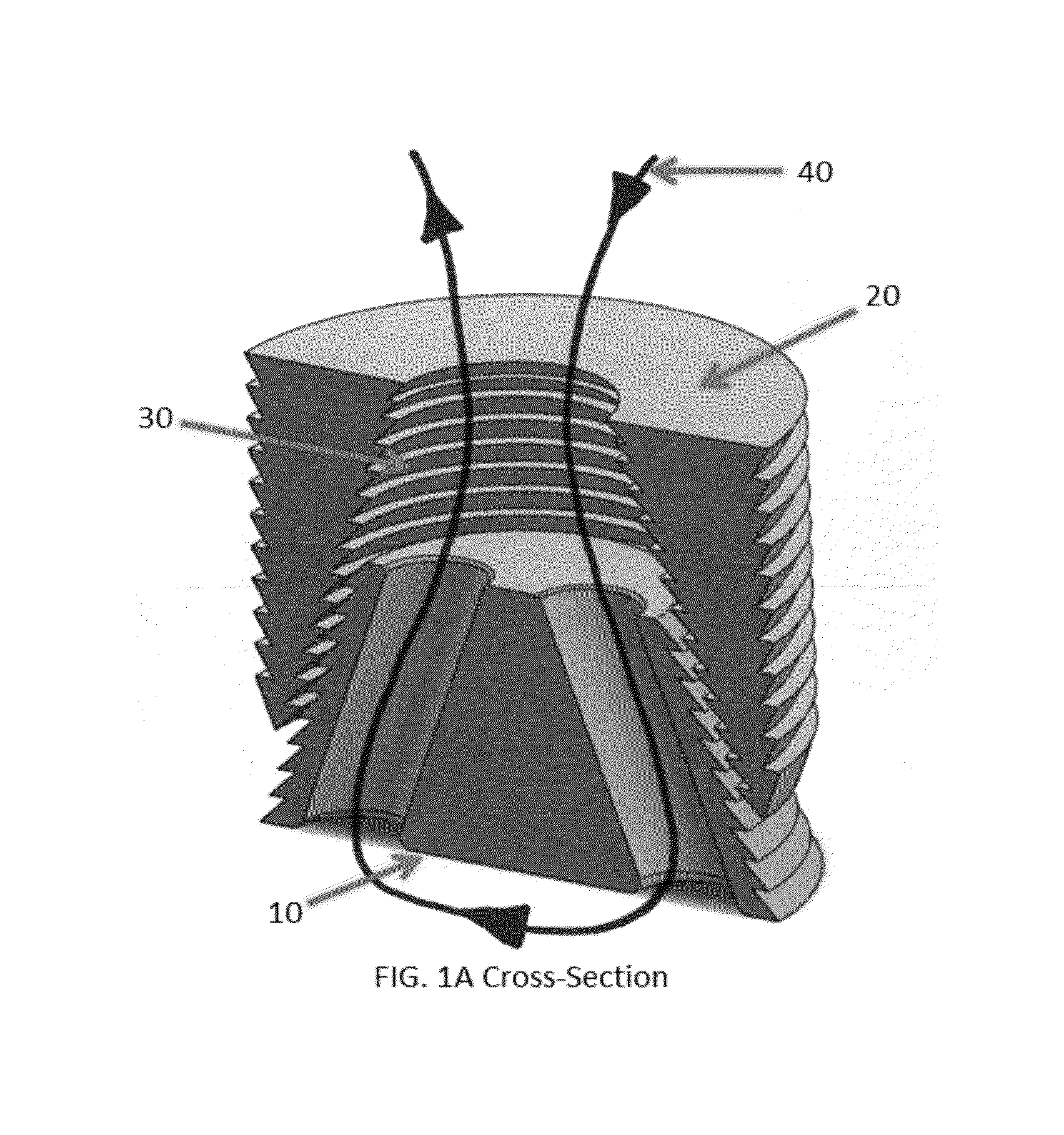

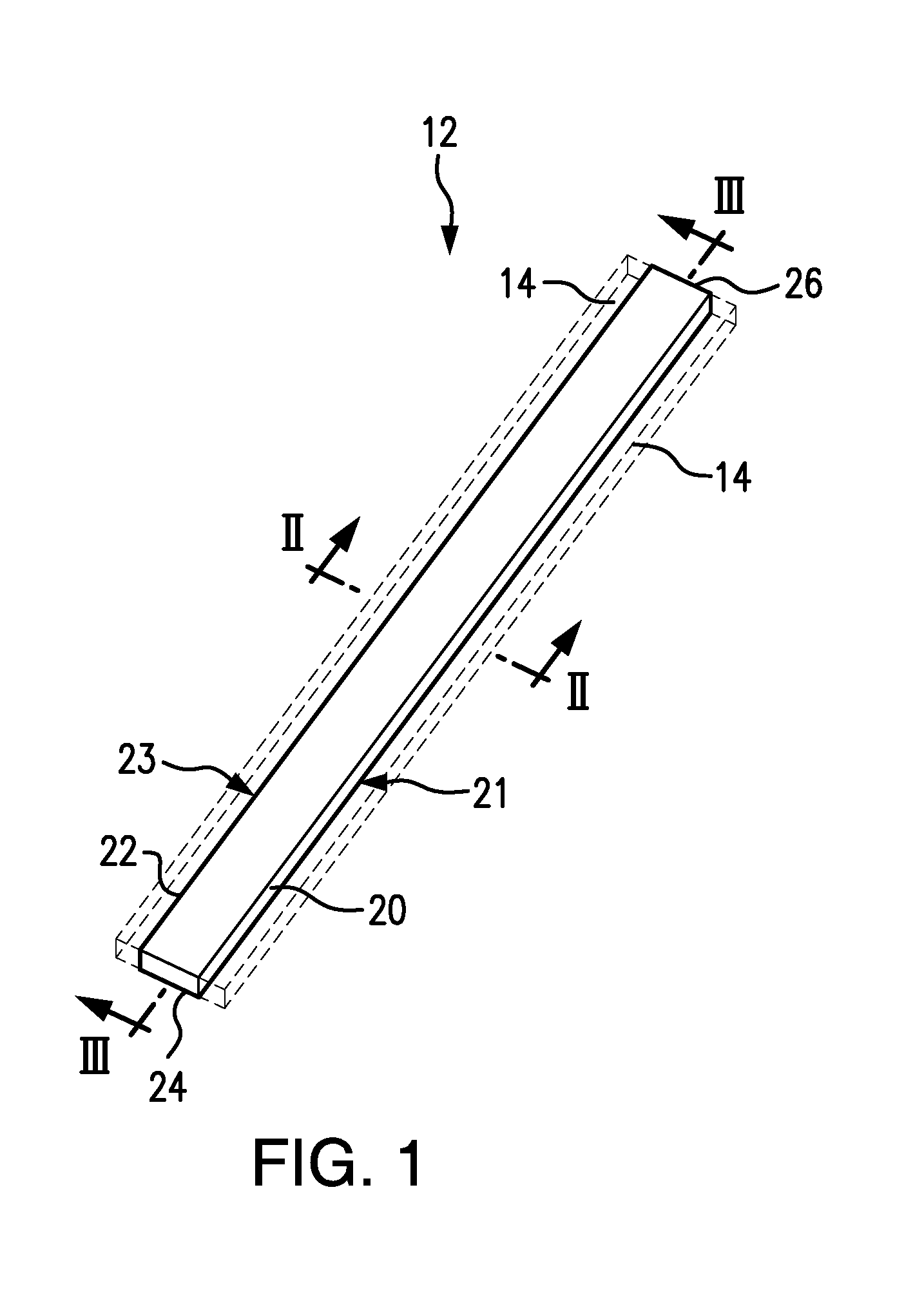

Composite system, method for its manufacture, and measurement pickup using such a composite system

ActiveUS7299699B2Stable, high-strength and lasting,Increased pull-out strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesPig casting plantsEngineeringCompound system

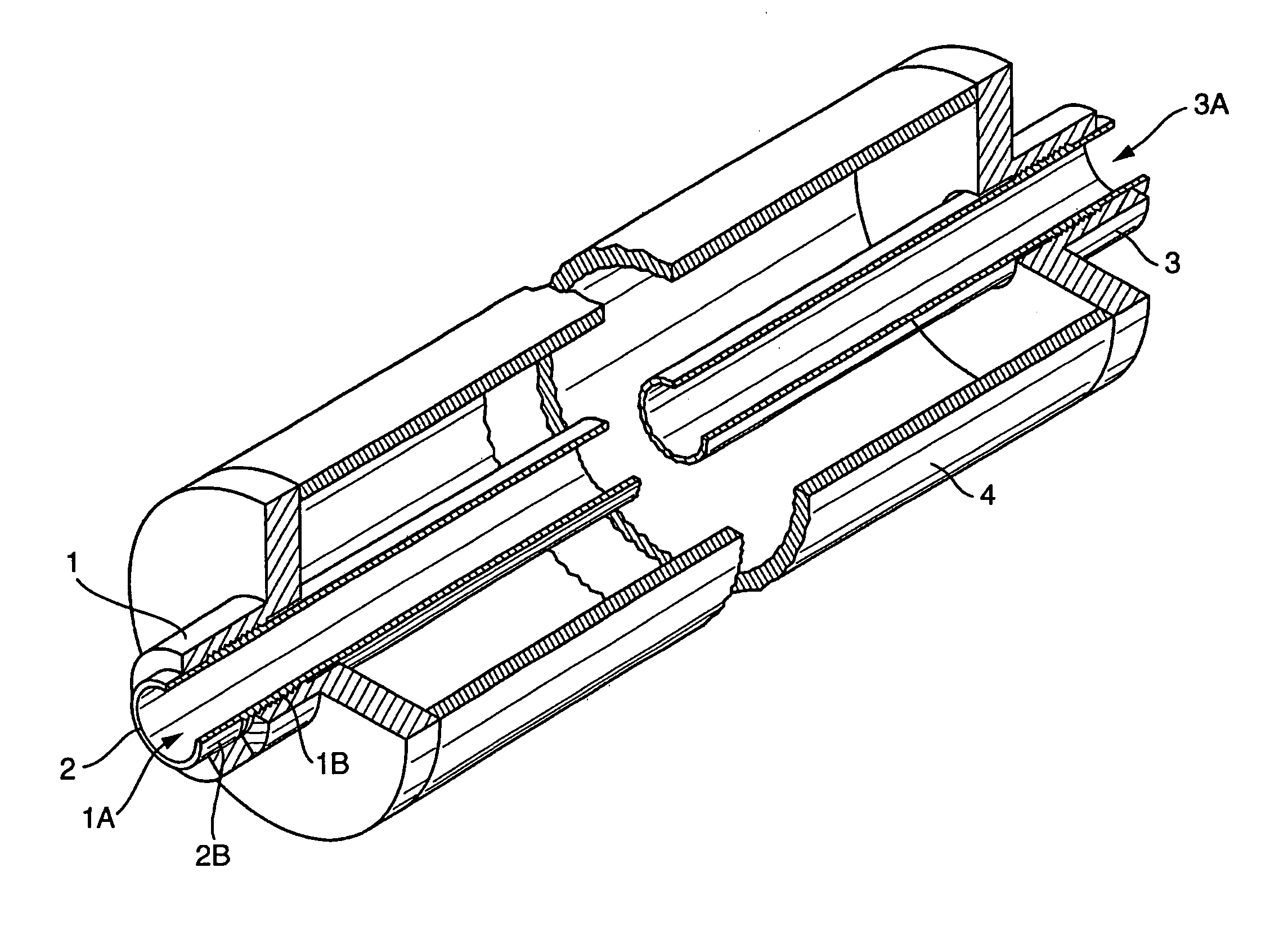

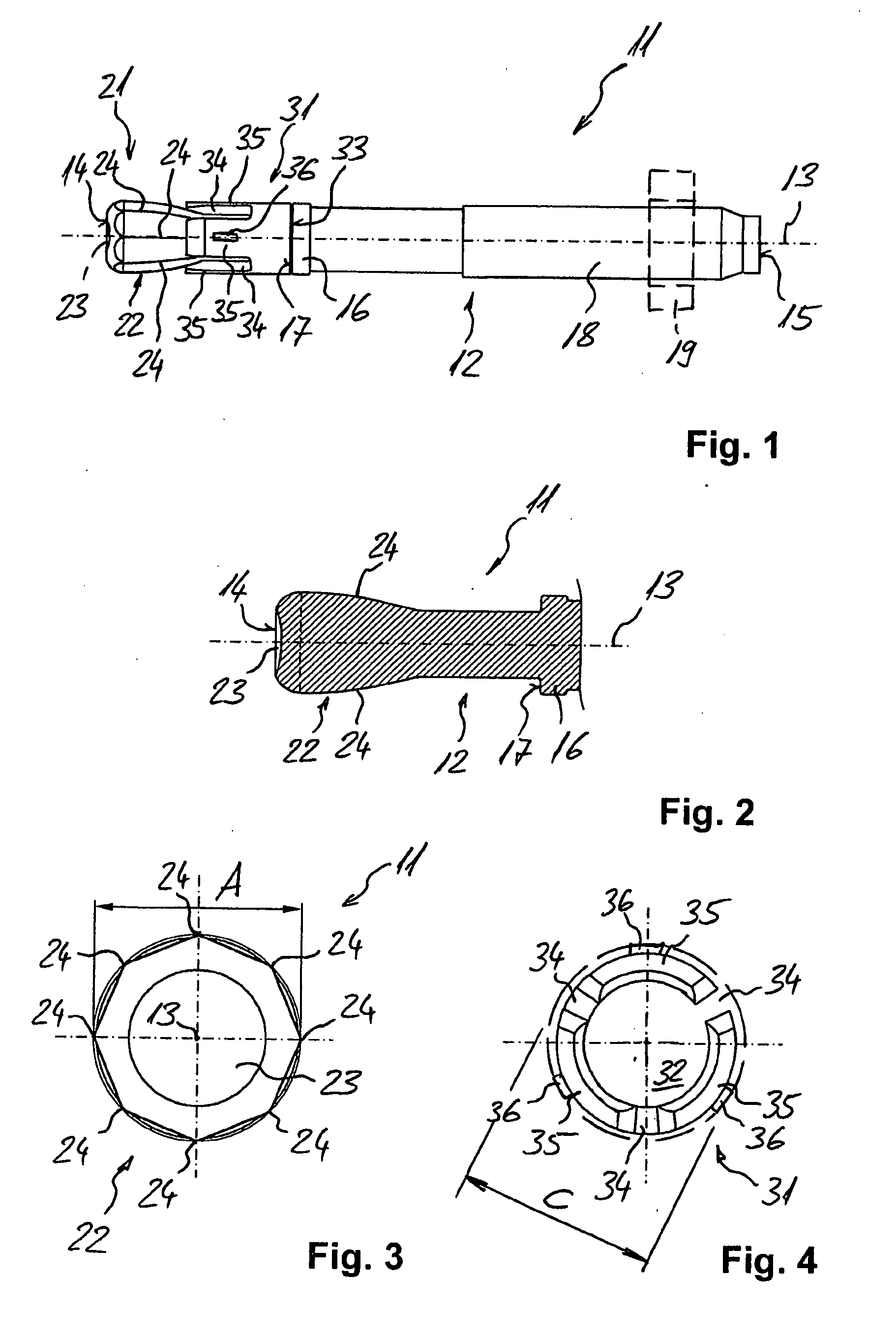

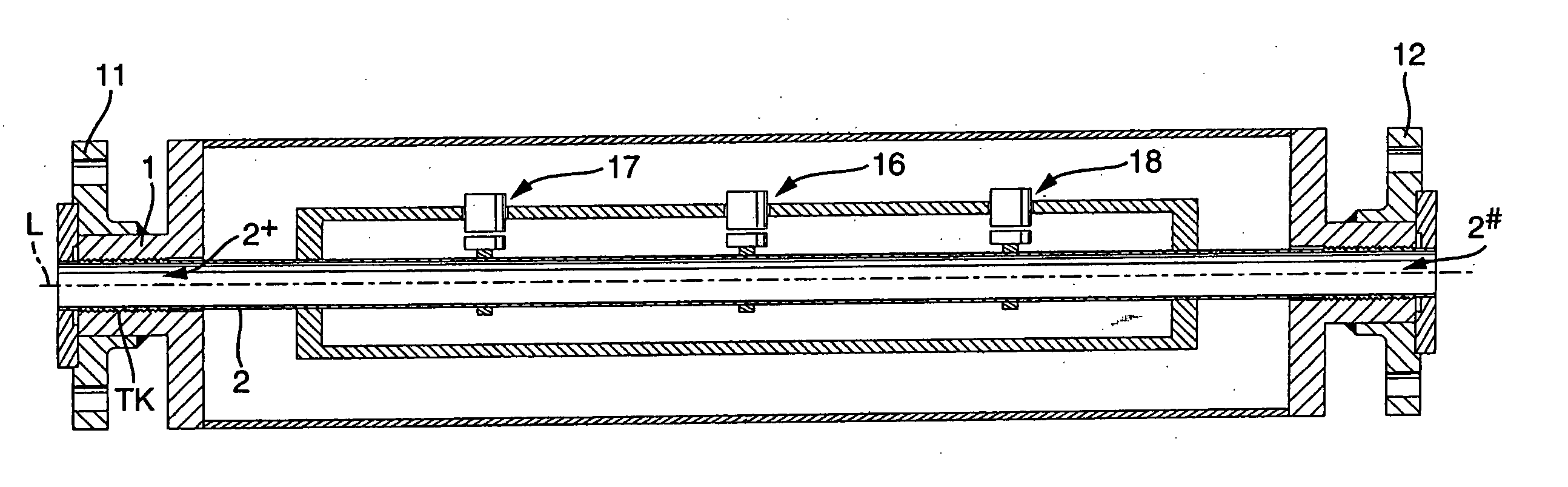

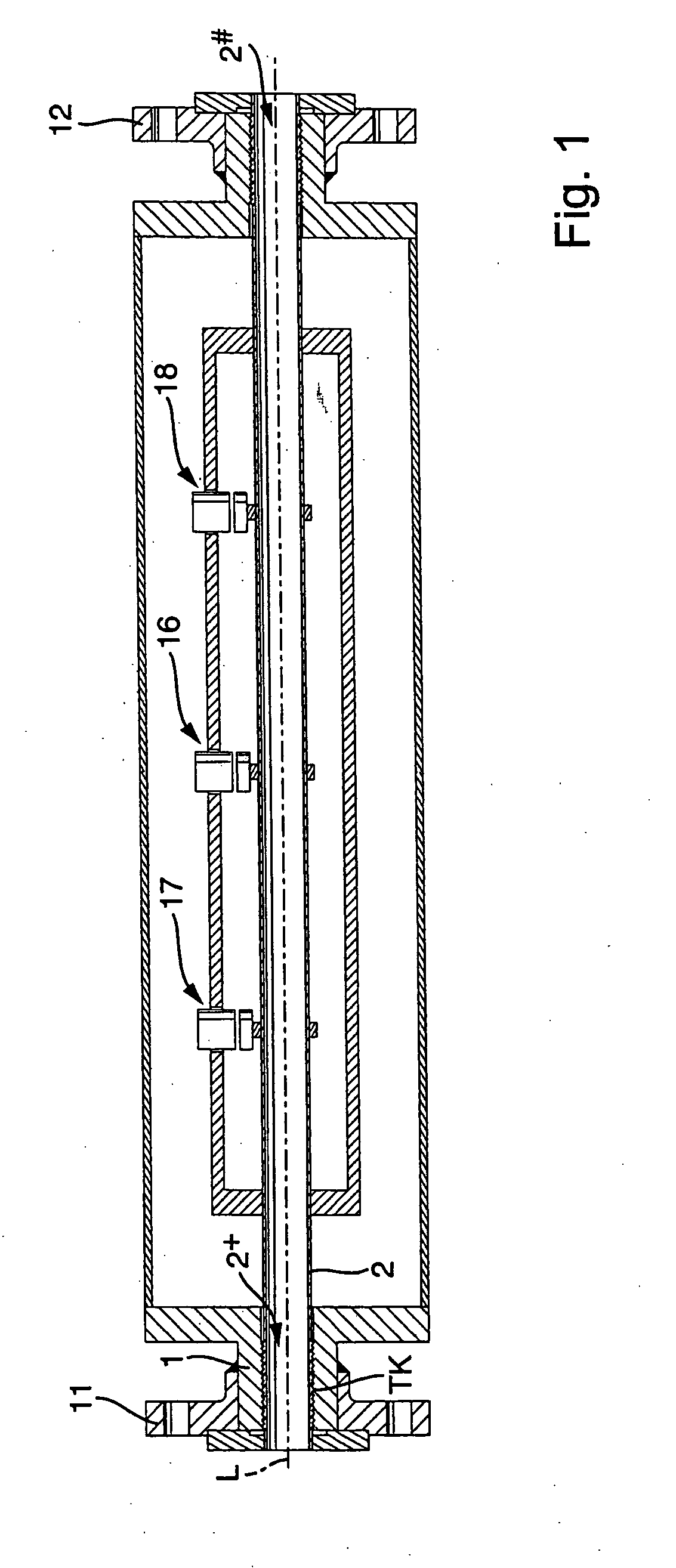

A composite system includes a first component, for instance of metal, and a second component extending at least partly through the first component along an imaginary longitudinal axis of the composite system. The second component contacts, with an at least partially curved, especially cylindrical, outer surface, an inner surface of the first component flushly such that the first component at least sectionally, at least partly, grips around the second component. Joining surfaces of the composite system, which are formed by the mutually contacting surfaces of the two components, are formed in such a manner that the two components exhibit contour portions in the area of these joining surfaces embodied as self-closing, peripheral surfaces. The contour portions fit at least partly into one another, to form a mechanical interference locking effective, at least in part, likewise in the direction of the longitudinal axis. Additionally, the second component, with its outer surface, contacts the inner surface of the first component flushly, such that the two components are mechanically tightly connected together also by means of a frictional locking effective at least partly in the direction of the longitudinal axis. Alternatively, or in supplementation thereof, at least one of the components is subjected at least partly to lastingly elastic, especially mixed plastic-elastic, deformations. The composite system is distinguished by a high pull-out strength, even in the presence of repeatedly arising vibrations in one of the components and is, therefore, especially suited also for use in a vibration-type measurement pickup.

Owner:ENDRESS HAUSER FLOWTEC AG

Bone fixation system and method

ActiveUS8728126B2Optimizes alignment and stabilizationMinimize the numberJoint implantsFastenersHead bonesBone fixation

A bone fixation system includes a bone plate having bi-directional combination holes extending therethrough, each hole being composed of a pair of domains and an interconnect which prevents the holes from overlapping. Each of the holes is configured and dimensioned to receive a set of full head bone screws adapted to be anchored into a bone or fragments thereof. The system also includes a pair of bone screws received in at least one of the combination holes, each bone screw having a shaft and a full head and being oriented in non-parallel directions. Various bone plate and screw embodiments are disclosed as is a method for fixating a bone fracture using the fixation system.

Owner:STEFFEN DENNIS L

Orthopedic plate for use in fibula repair

ActiveUS8118848B2Increased pull-out strengthRoom for improvementJoint implantsBone platesEngineeringIliac screw

The present invention relates to an orthopedic plate for use in repair of a fibula. The plate has a Y-shaped profile which has the contour of a spoon where the bowl includes a terminal pair of arms that form differing angles and lengths relative to the trunk portion of the plate. The arms include locking screw holes where the screws converge toward each other, but do not impinge so as to provide-multiplanar fixation.

Owner:WRIGHT MEDICAL TECH

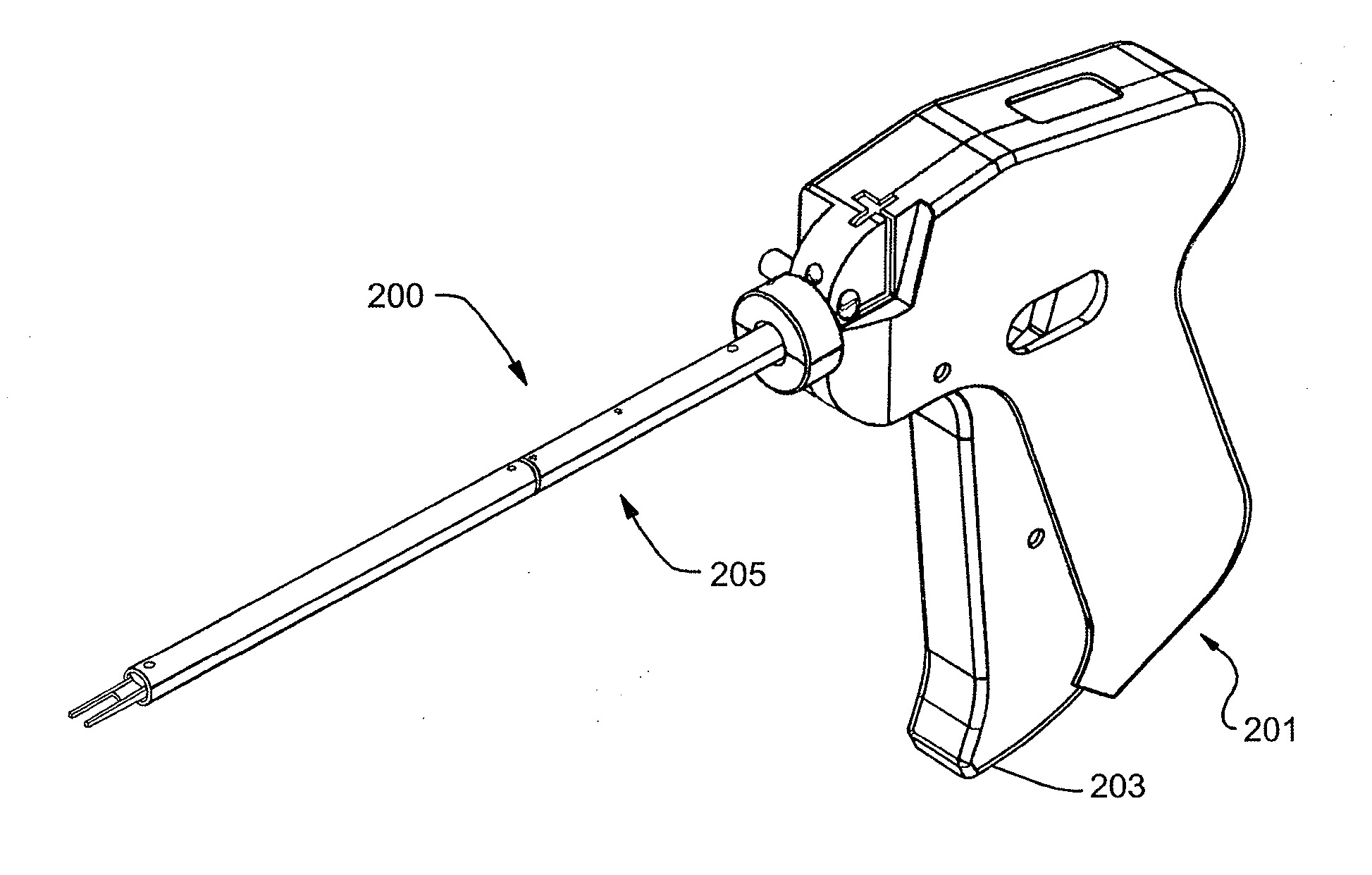

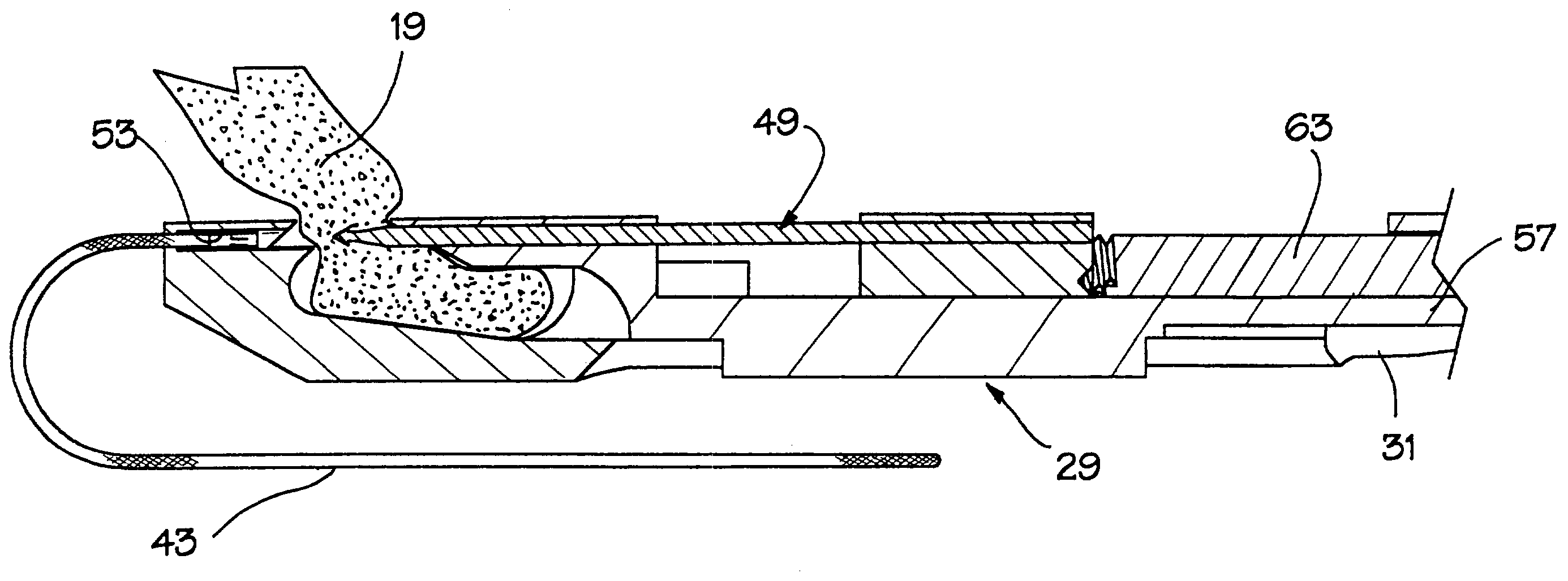

Linear suturing apparatus and methods

InactiveUS7544199B2Simple and economical mannerIncreased pull-out strengthSuture equipmentsSurgical needlesSuturing instrumentSingle strand

A suturing instrument and methods for placing mattress stitches in soft tissues comprises an elongate shaft with a stationary jaw and a movable jaw disposed at a distal end thereof. The movable jaw is coupled to a handle grip at the proximal end of the shaft and is configured to manipulate the movable jaw into open and closed positions respective to the stationary jaw. The jaws are configured to permit atraumatic grasping of soft tissues to be sutured. The stationary jaw is comprised of a serrated face, incorporating apertures through which needles may be driven distally into and through the grasped tissue and into needle capture cans attached to opposing ends of a single strand of suture material. The serrated upper jaw is configured with capture means adapted to accept and capture the needles and suture. The handle is released to open the movable jaw, after which the instrument may be withdrawn, trailing the suture, and leaving a mattress stitch in the grasped tissue.

Owner:ARTHROCARE

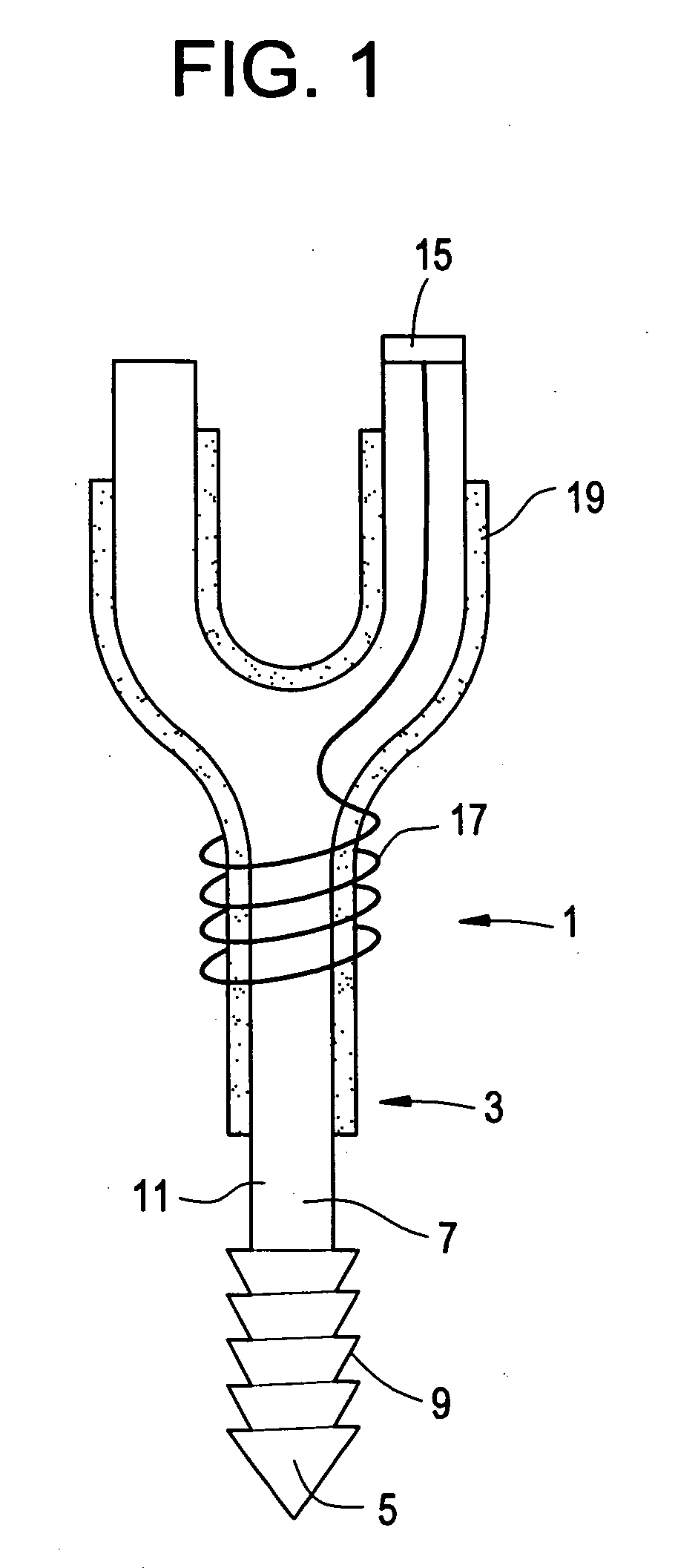

Soft suture anchor

ActiveUS20150018878A1Promote osseointegrationIncreased pull-out strengthSuture equipmentsTextiles and paperOsseointegrationSuture anchors

Compositions and materials for making soft suture anchors comprising materials that improve osteointegration have been developed. These compositions and materials comprise bioceramics, resorbable materials, and combinations thereof. A preferred embodiment comprises a soft suture anchor comprising a resorbable ceramic and a resorbable suture.

Owner:TEPHA INC

Carpet primary backing having enhanced tufting and tuft securing characteristics

InactiveUS20070270064A1Reduce in quantityFacilitates enhanced bondingLiquid surface applicatorsElectric shock equipmentsFiberYarn

A primary carpet backing is provided for use in the formation of a tufted carpet which eliminates or reduces the need for a latex adhesive layer or the use of a secondary backing. The external surfaces of a woven or non-woven fibrous mat are coated with thermoplastic polymer particles having a lower melting temperature than the fibers of the mat. The mat possesses sufficient openings between fibers to be capable of undergoing tufting. Following tufting the tufted mat is heat treated so as to melt the thermoplastic polymer particles and to create a bond between the tufted carpet yarn fibers and the primary backing mat.

Owner:JOHNS MANVILLE CORP

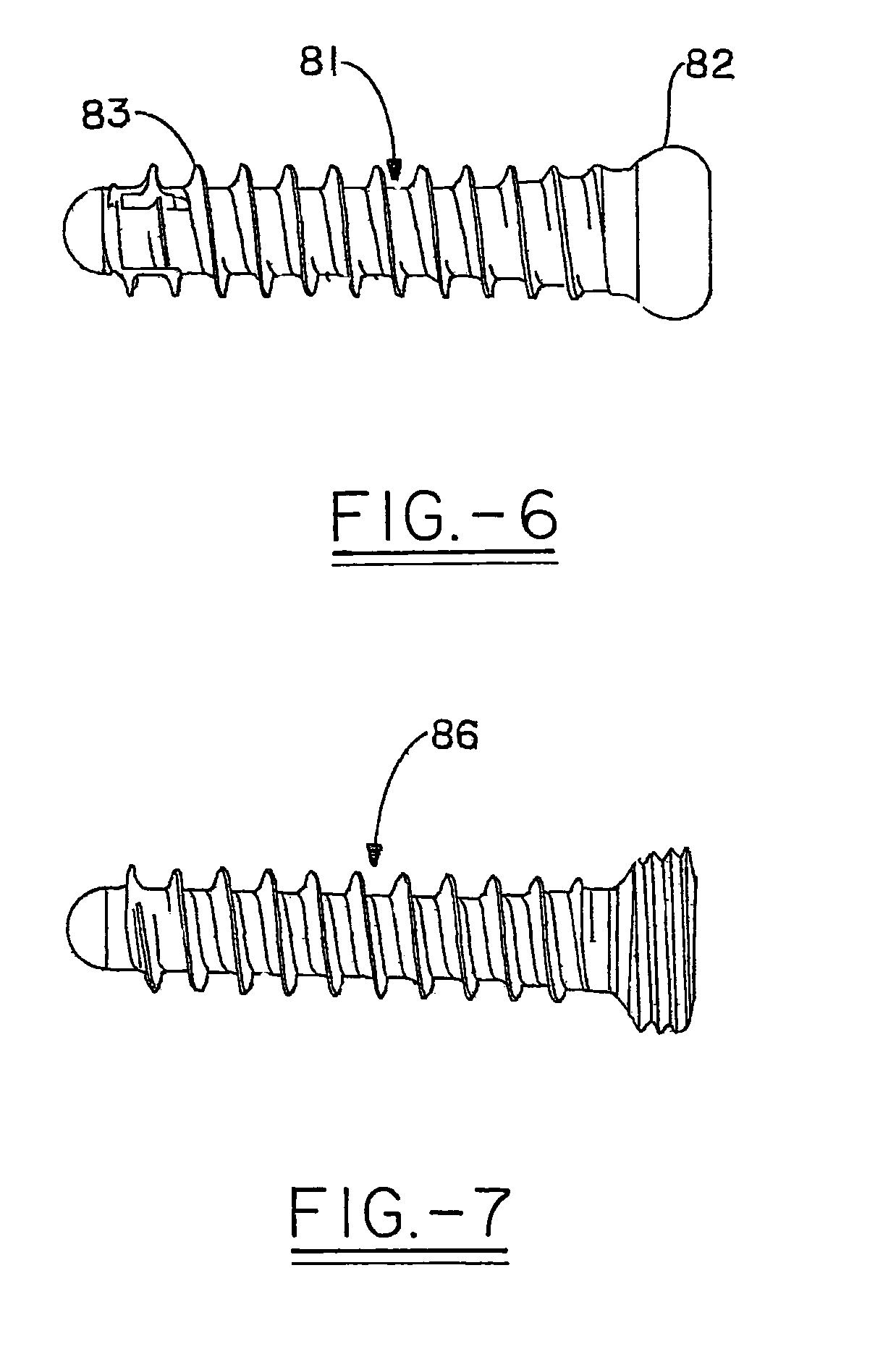

Threaded suture anchor with starting pitch

InactiveUS20070142837A1Easy to insertIncrease surface areaSuture equipmentsFastenersMedicineSuture anchors

A suture anchor has a continuous thread spiralling around a tapering central core. At the distal end of the thread, the suture anchor has a starting pitch to facilitate insertion of the anchor into bone. The proximal end of the suture anchor receives at least one strand of suture. At the proximal end, the suture anchor has a large thread surface per turn of thread.

Owner:ARTHREX

Implantable prosthesis

A prosthetic device including biologically compatible and preferably fully resorbable materials includes a tissue infiltratable portion and a second portion. The two portion may have different rates of resorption. The ingrowth portion may include a plurality of openings to encourage tissue ingrowth and vascularization. The second portion may be stronger than the ingrowth portion and provide a location for fixation of the device. The portion may be attached using resorbable adhesives, sutures or other constructs to render a fully resorbable prosthesis.

Owner:CR BARD INC

Fully-threaded bioabsorbable suture anchor

ActiveUS9521999B2Increased pull-out strengthMinimal frictionSuture equipmentsLigamentsPullout strengthUltimate tensile strength

A suture anchor includes a threaded anchor body having a first central bore in communication with a second central bore. The suture anchor includes an internal eyelet formed of a loop disposed at least partially inside the first central bore. The ends extending from the loop are tied together to form at least one knot which is housed in the second central bore provided at the distal end of the anchor body. The knot increases the pullout strength of the suture even in soft bone, provides increased suture fixation, and eliminates the anchor “pull back.”

Owner:ARTHREX

Spinal implant with expandable fixation

ActiveUS8932355B2Easy to installMinimizing chanceBone implantJoint implantsIntervertebral spacesSpinal implant

A spinal implant which is configured to be deployed between adjacent vertebral bodies. The implant has at least one fixation element with a retracted configuration to facilitate deployment of the implant and an extended configuration so as to engage a surface of an adjacent vertebral body and secure the implant between two vertebral bodies. Preferably, the implant is expandable and has a minimal dimension in its unexpanded state that is smaller than the dimensions of the neuroforamen through which it must pass to be deployed within the intervertebral space. Once within the space between vertebral bodies, the implant can be expanded so as to engage the endplates of the adjacent vertebrae to effectively distract the anterior disc space, stabilize the motion segments and eliminate pathologic spine motion. Angular deformities can be corrected, and natural curvatures restored and maintained.

Owner:HOWMEDICA OSTEONICS CORP

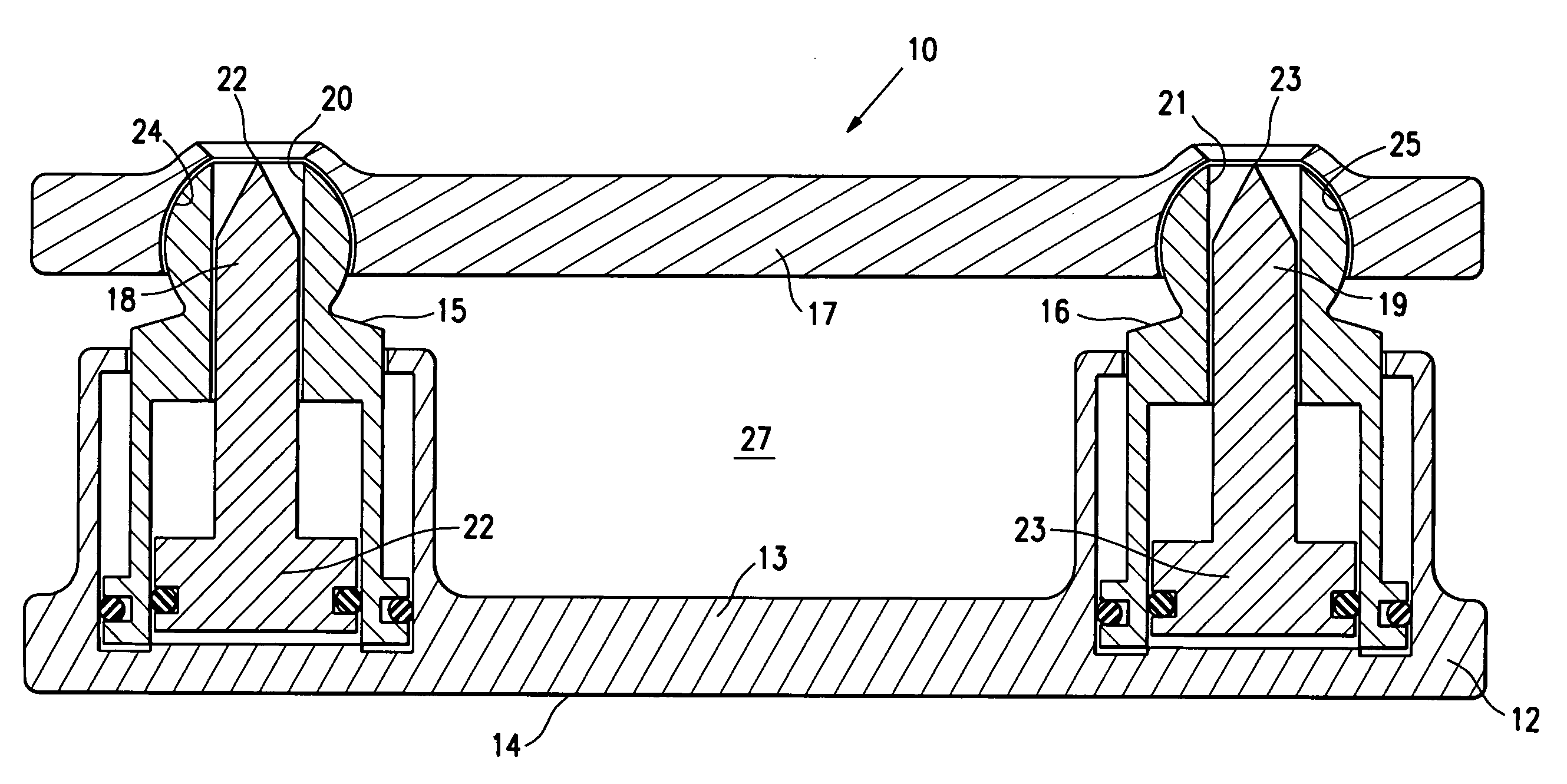

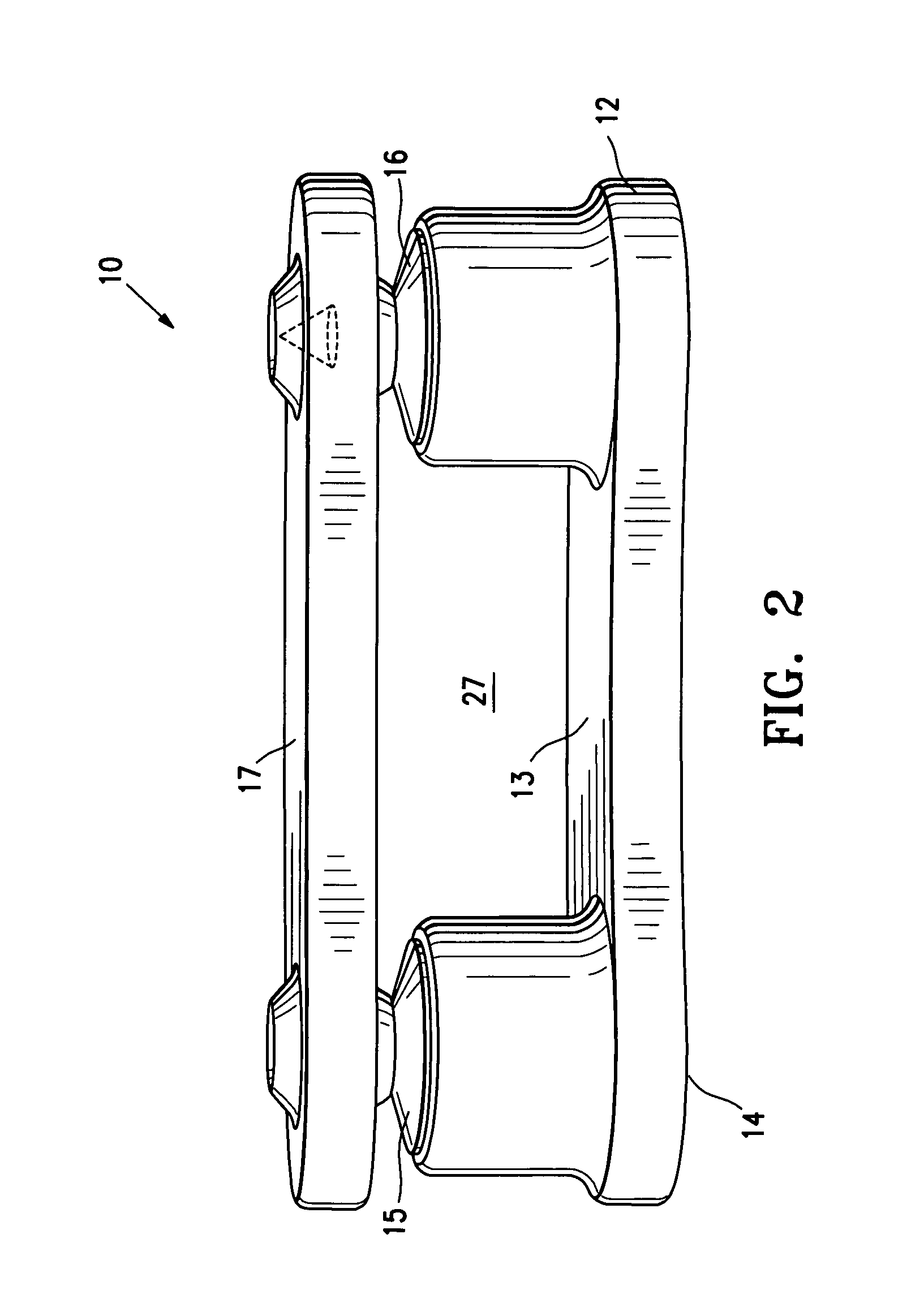

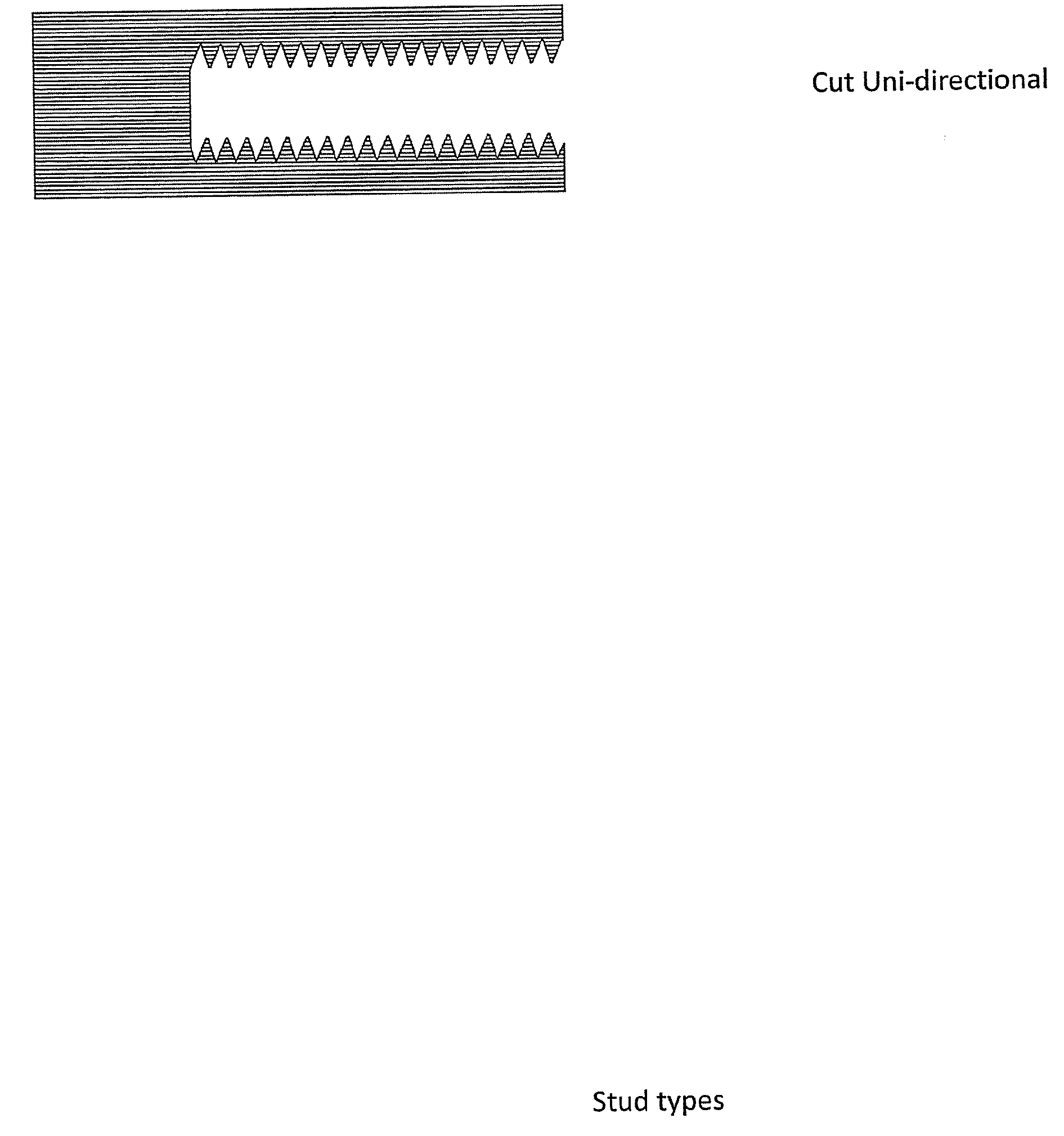

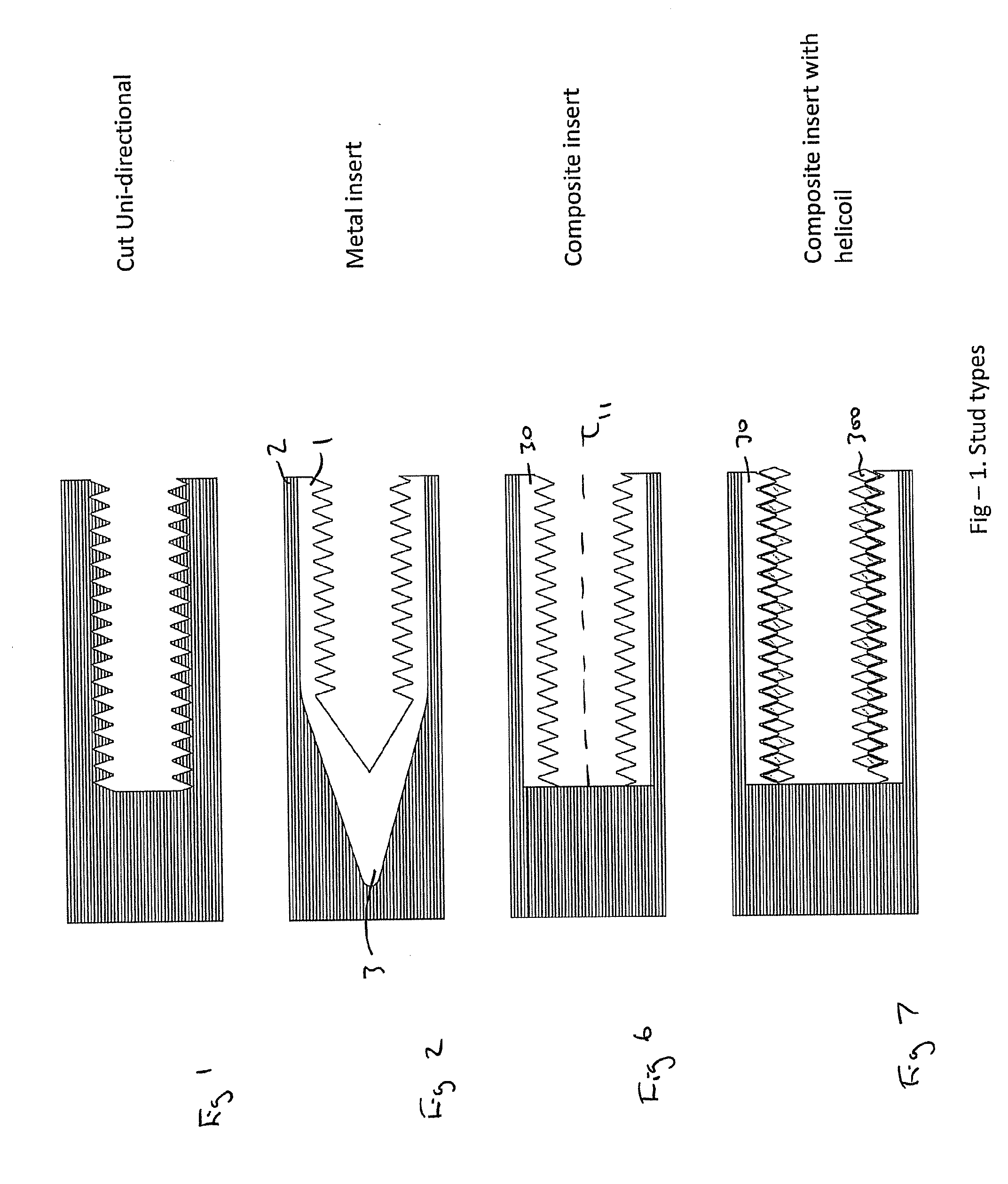

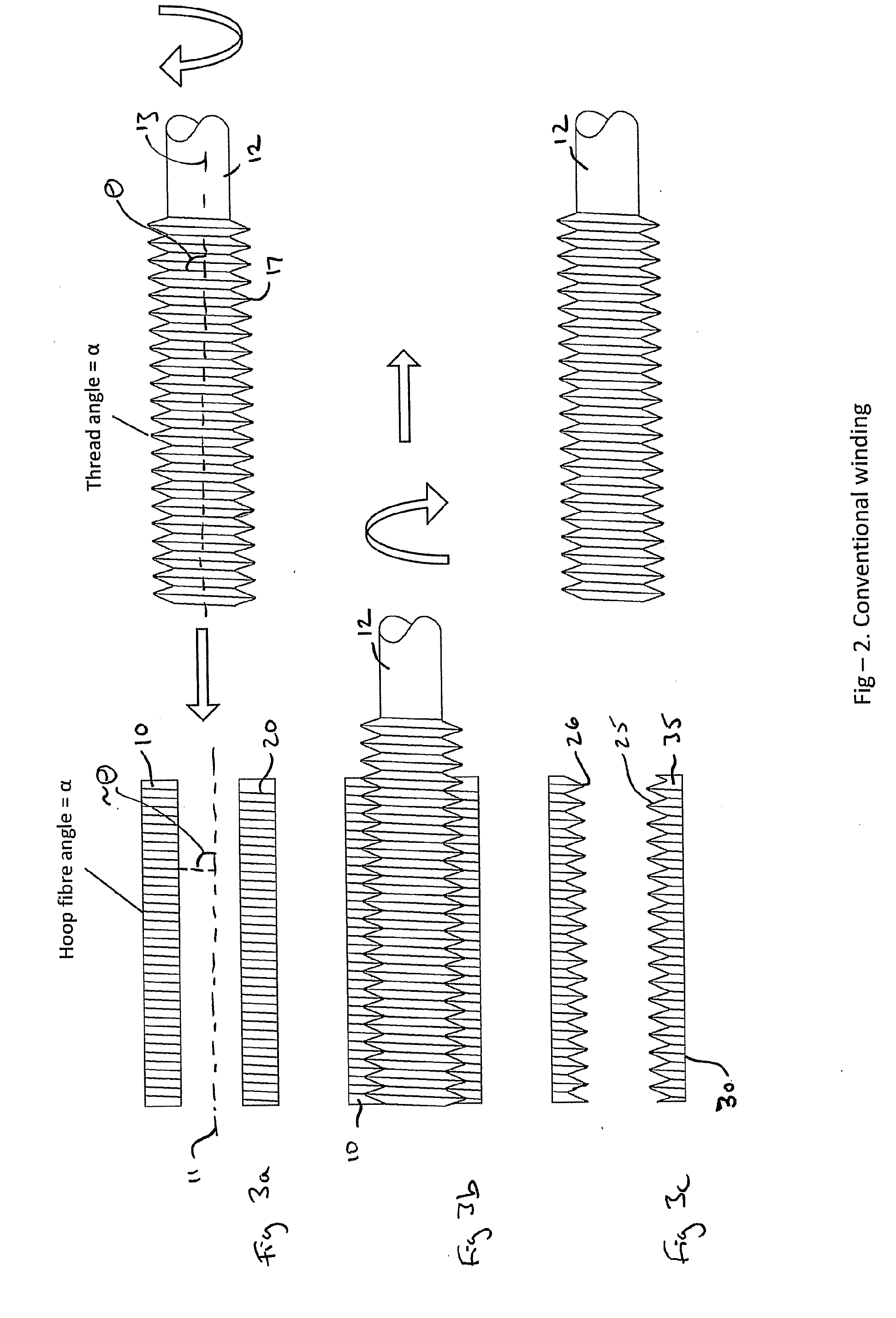

Insert for forming an end connection in a uni-axial composite material

ActiveUS20100084079A1Improve reusabilityReduce mismatchFinal product manufactureSecuring devicesFiberEngineering

An insert for forming an end connection in a uni-axial composite material, and an end connection comprising at least one insert, is disclosed. The insert comprises a sleeve which comprises a plurality of fibres having a multi-axial arrangement. At least a portion of the interior surface of the sleeve comprises a thread formation. A method of forming an end connection in a uni-axial composite material is also disclosed. The method comprises providing a sleeve comprising a plurality of fibres having a multi-axial arrangement and providing a thread formation on at least a portion of the interior surface of the sleeve. The sleeve is positioned and secured within the uni-axial composite material.

Owner:BLADE DYNAMICS LTD

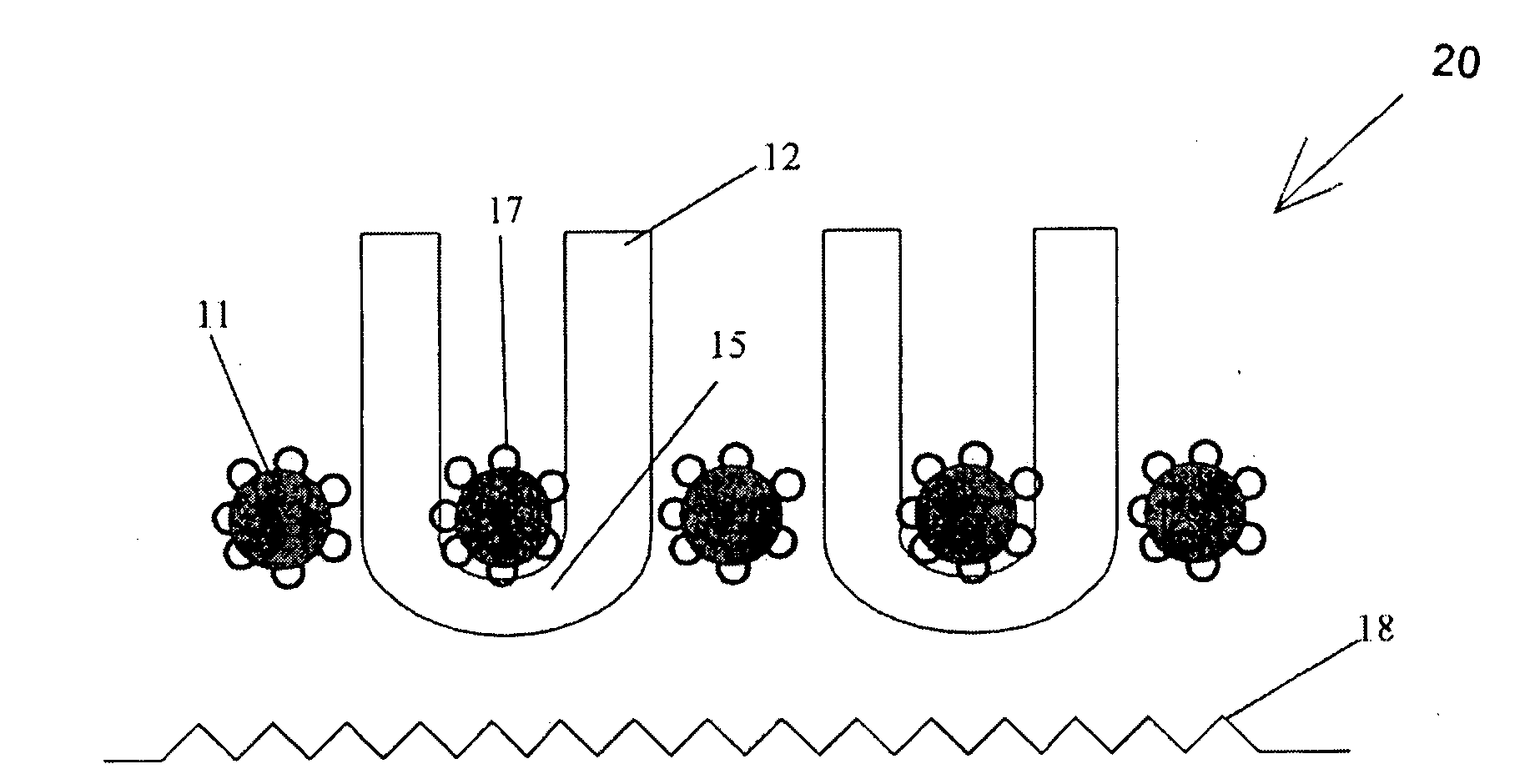

Insert molded suture anchor

InactiveUS20070225764A1Increased pull-out strengthAvoid abrasionsSuture equipmentsStaplesSuture anchorsSurgery

An insert-molded suture anchor has a biodegradable polymer body molded around a loop of suture. A tapered end disposed on the proximal end of the body is received into a recess in the distal end of a hand driver. Anchoring ribs are formed along the remaining length of the anchor. The suture is held securely within the anchor body during the insert molding process. The anchor is produced by placing the suture within an injection mold, and injecting biodegradable polymer into the mold. Using a preferred plication driver, the suture anchor can be utilized for capsular plication procedures.

Owner:BENAVITZ WILLIAM C +2

Expansion anchor

Owner:HILTI AG

Red light implant for treating osteoporosis

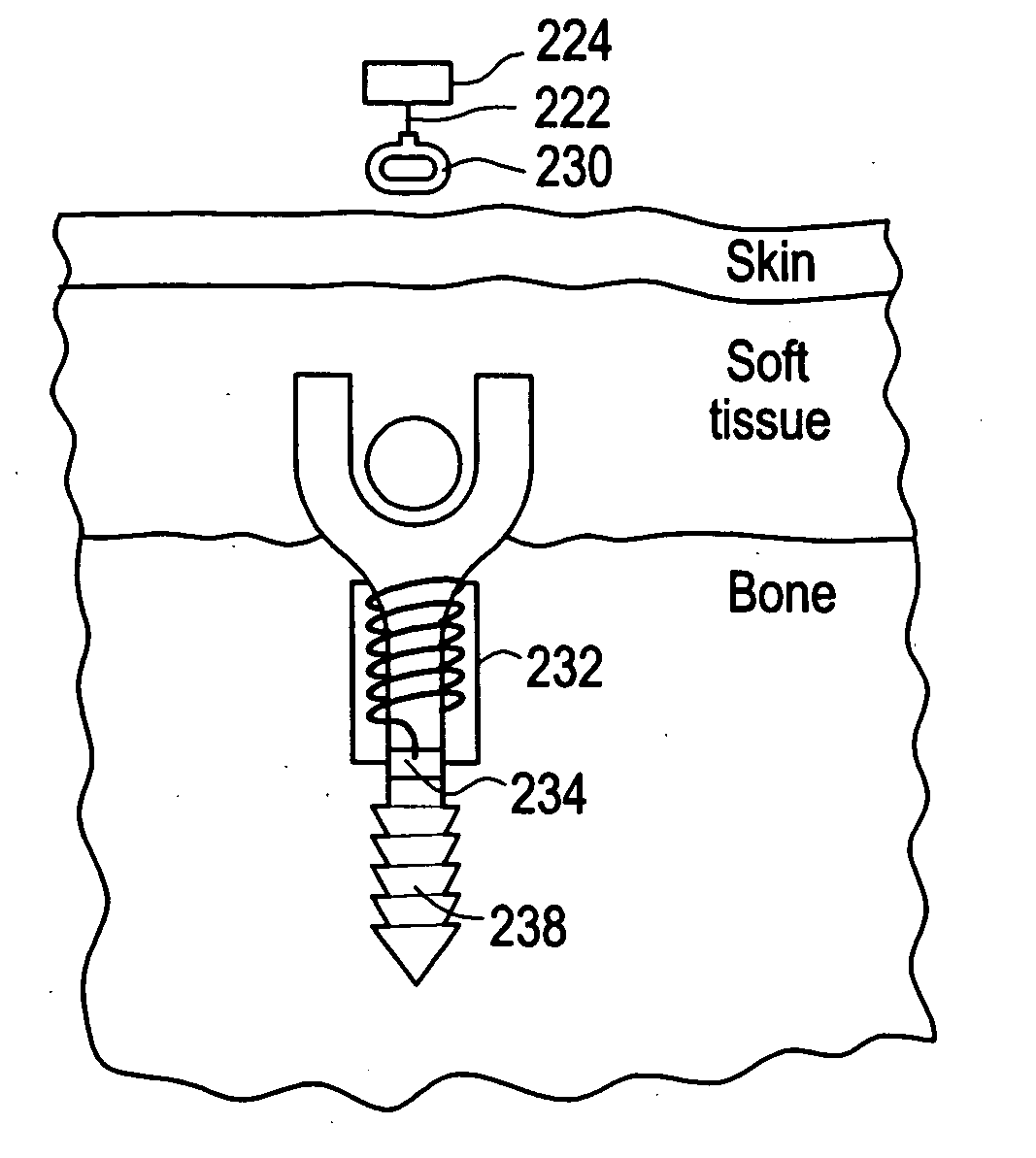

ActiveUS20070073300A1Highly integratedIncreased pull-out strengthSuture equipmentsInternal osteosythesisOsseointegrationOsteoporosis

Owner:DEPUY SYNTHES PROD INC

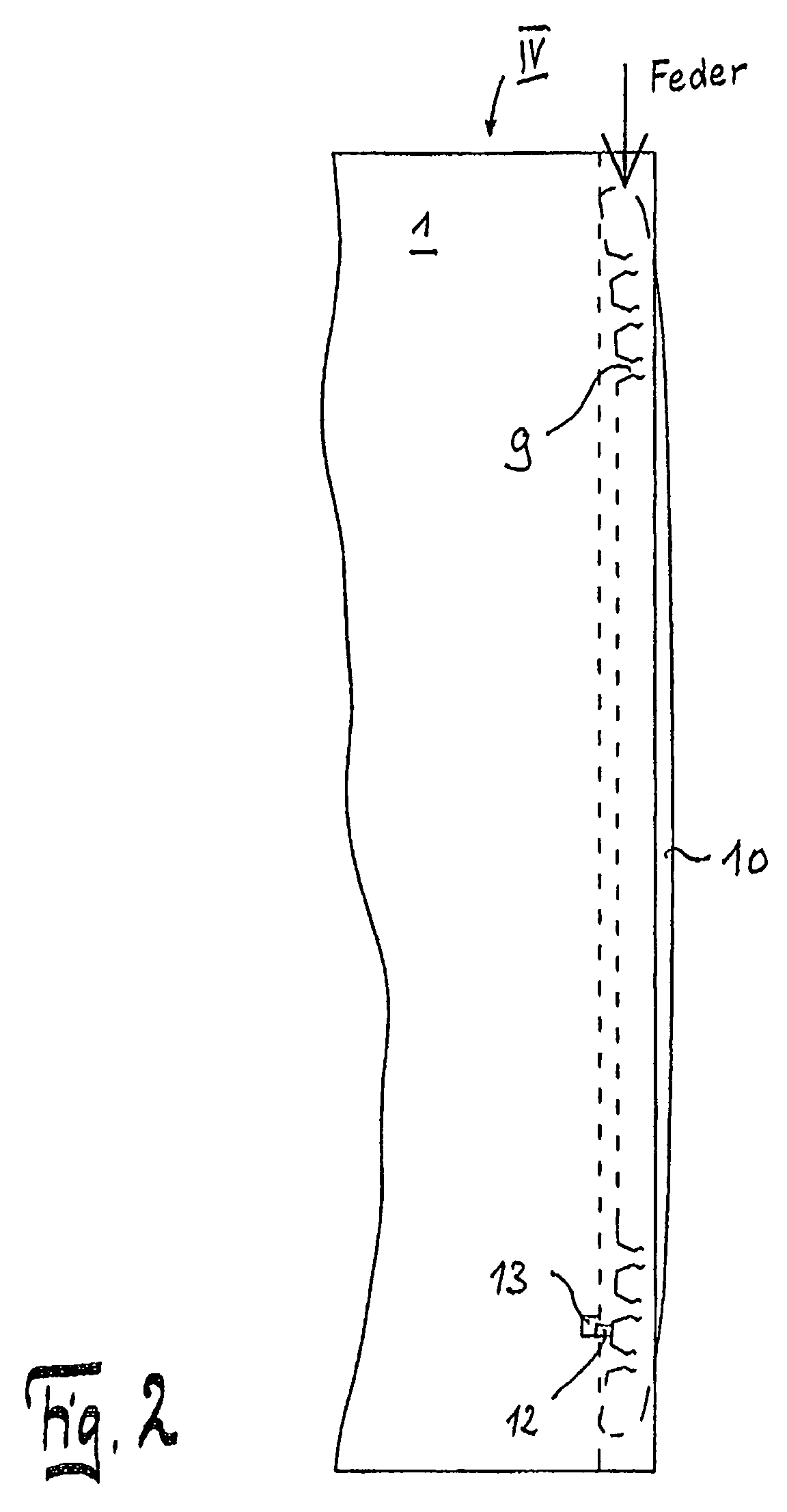

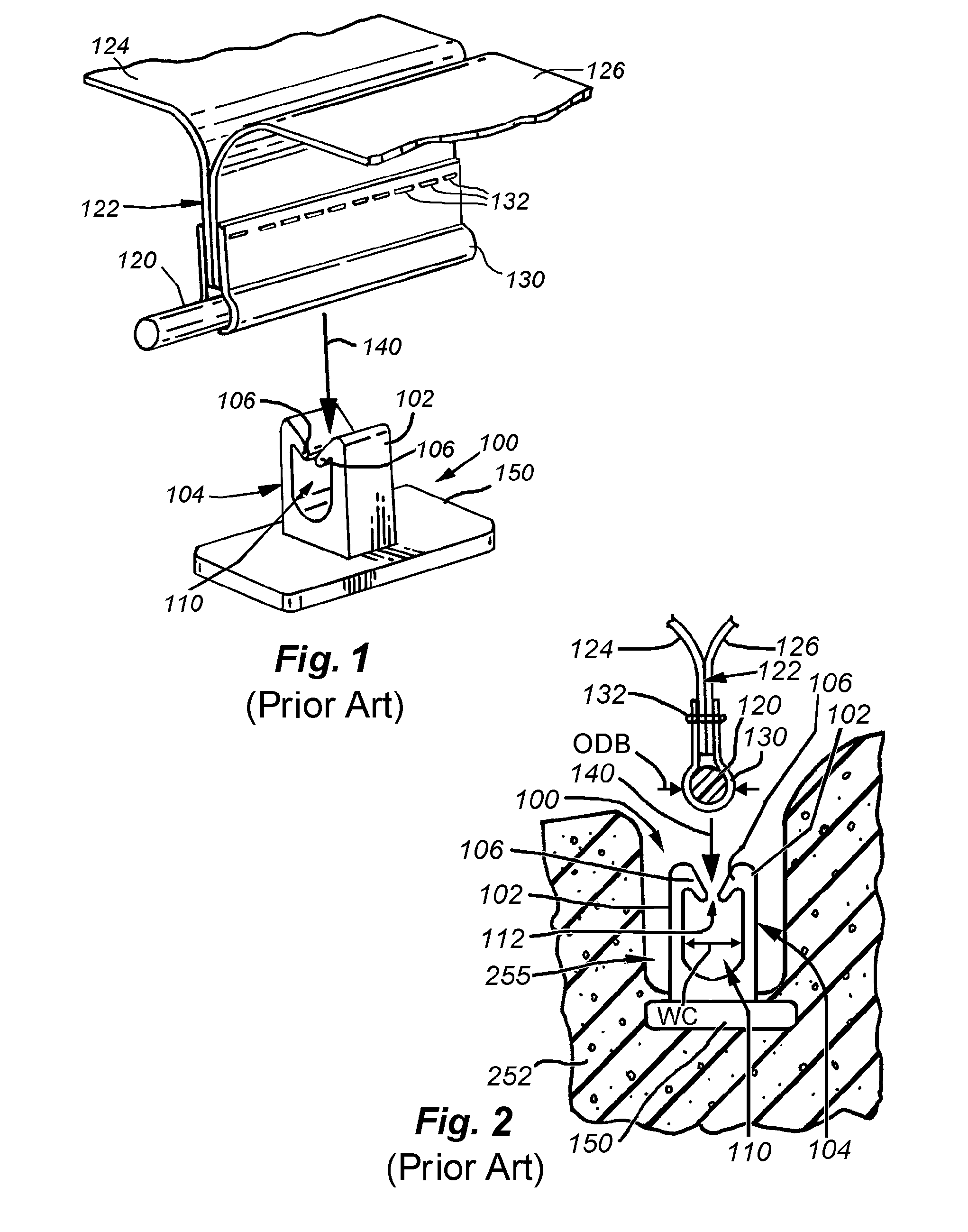

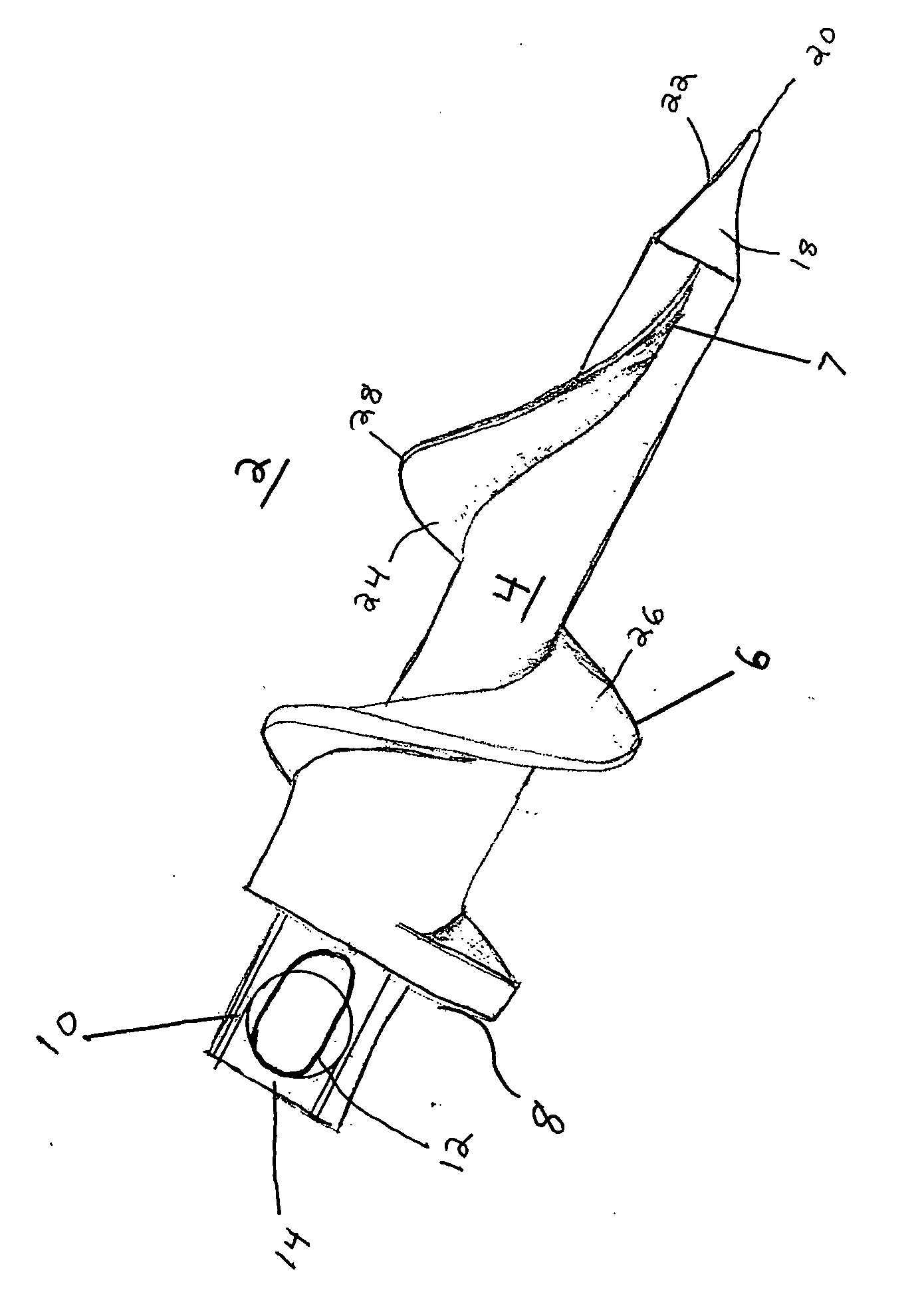

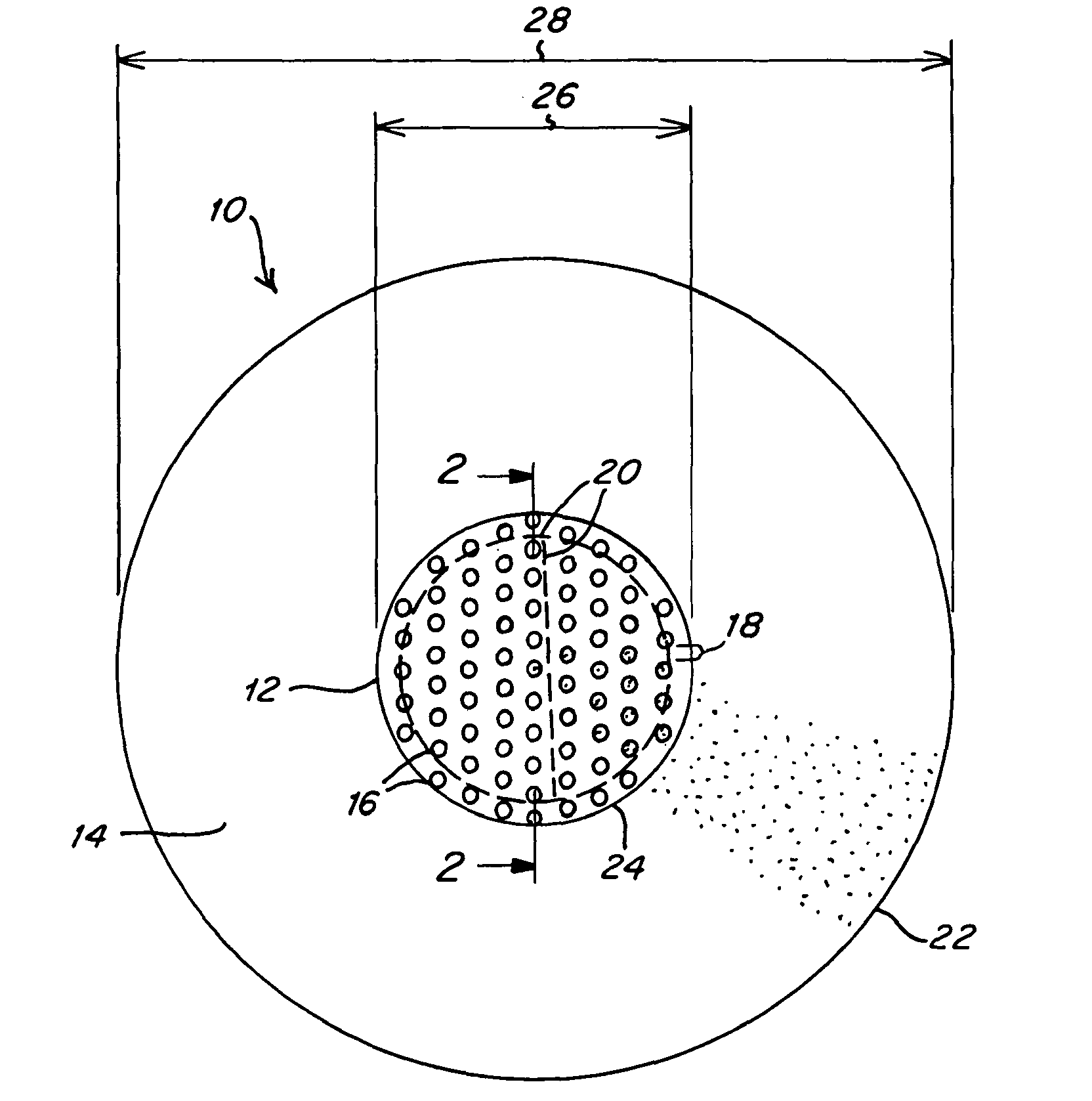

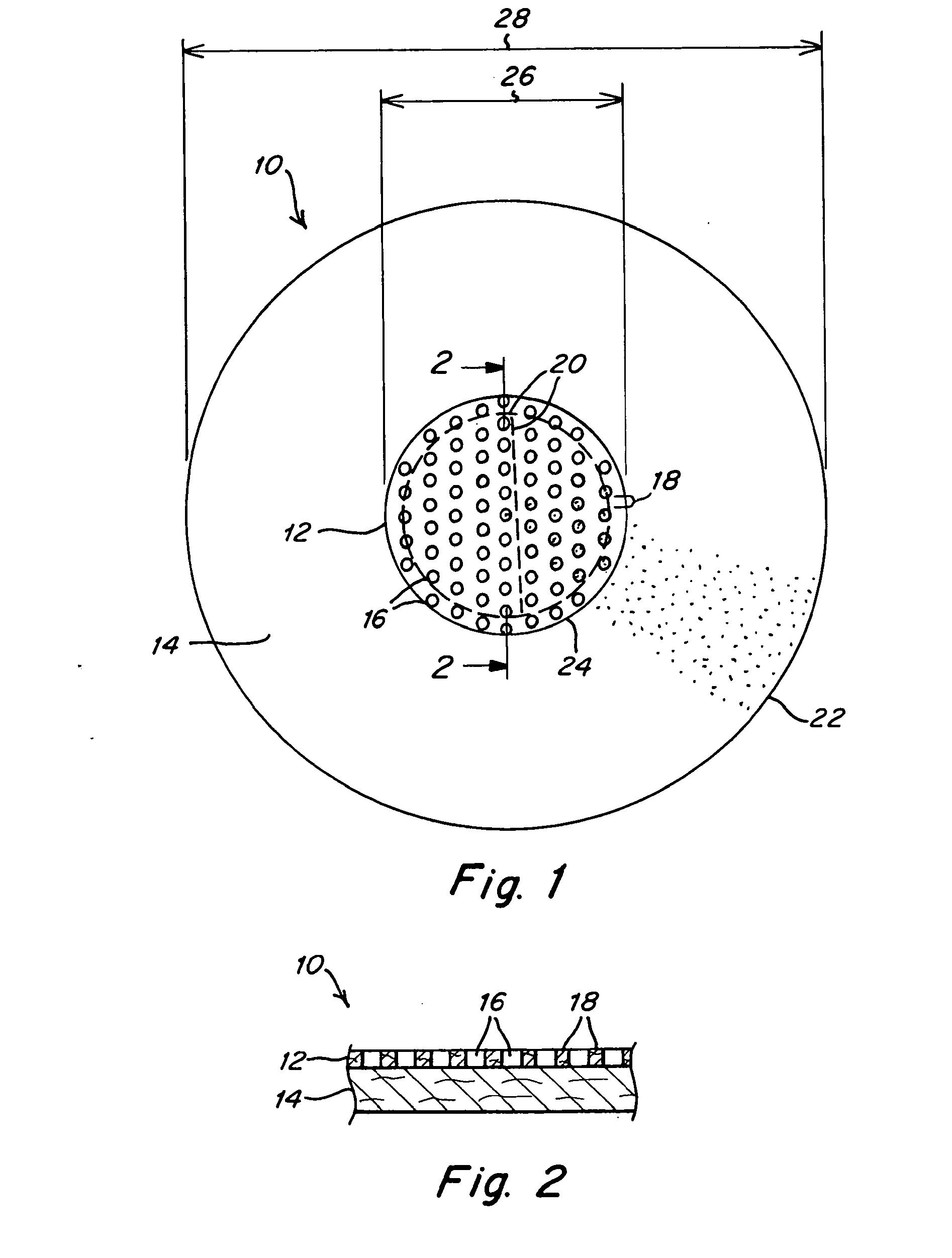

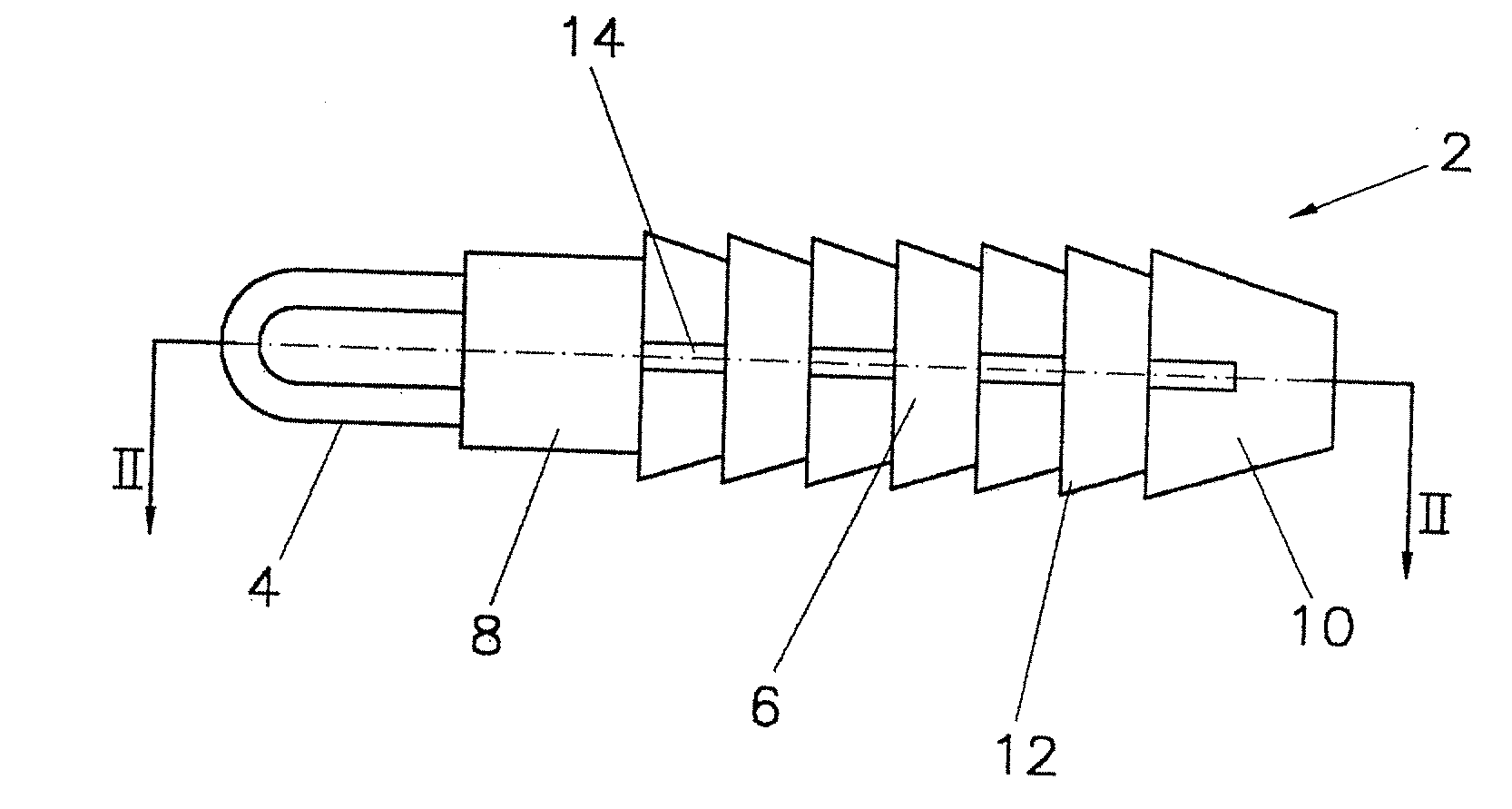

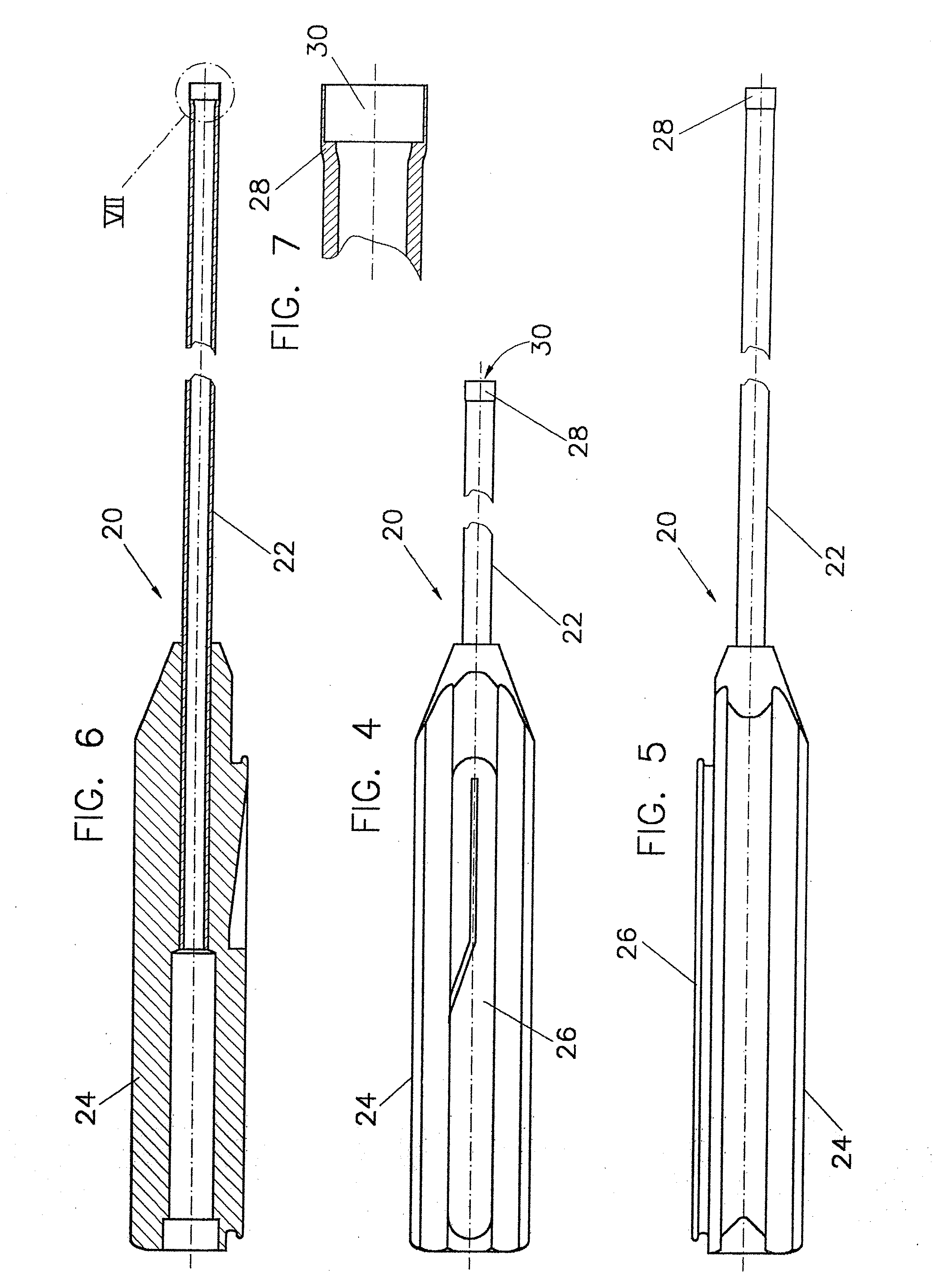

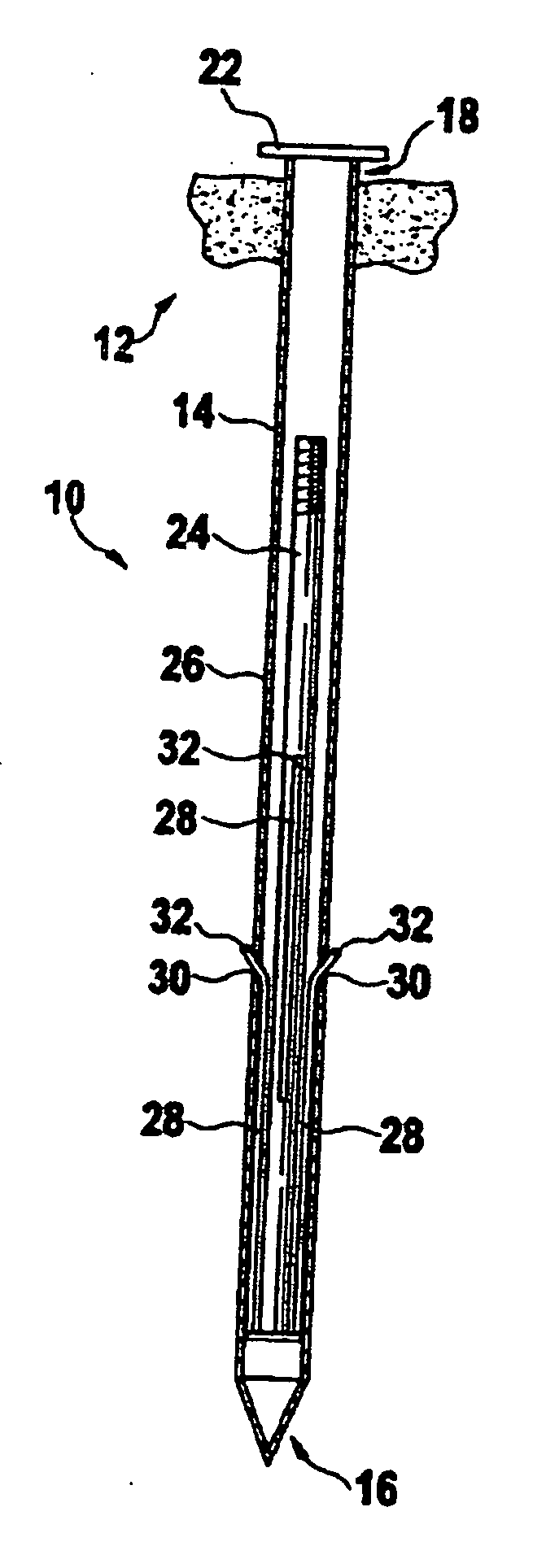

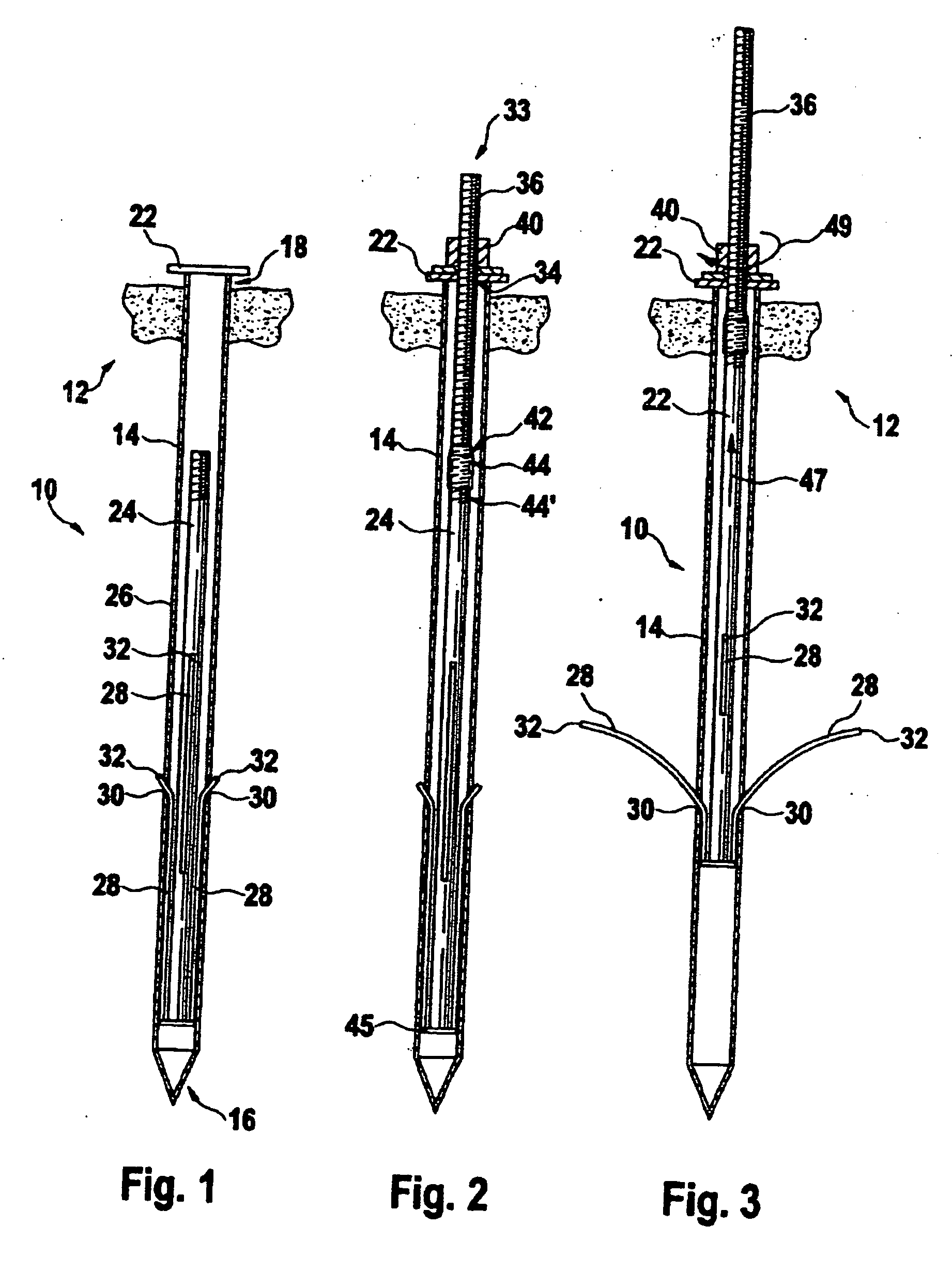

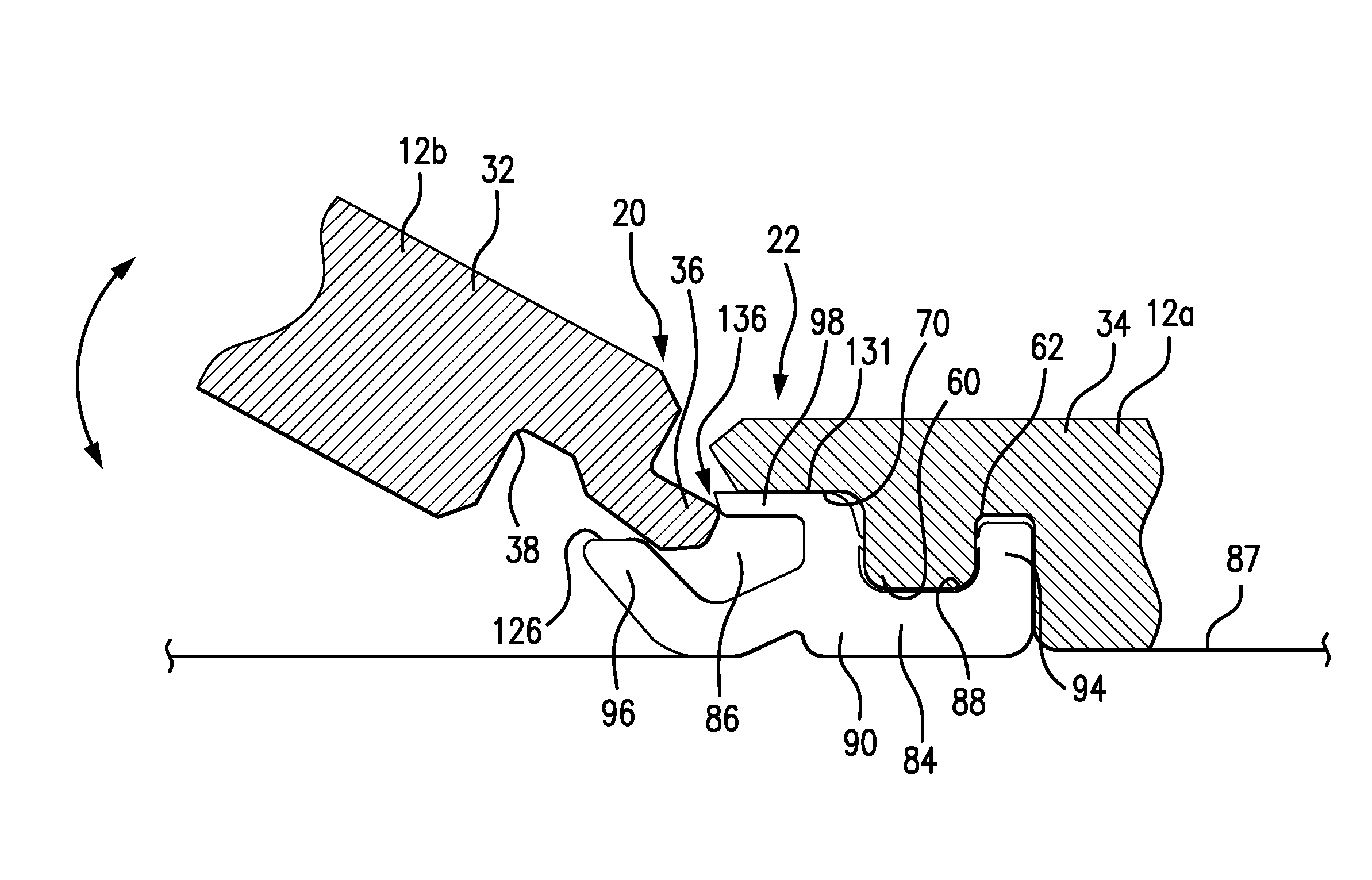

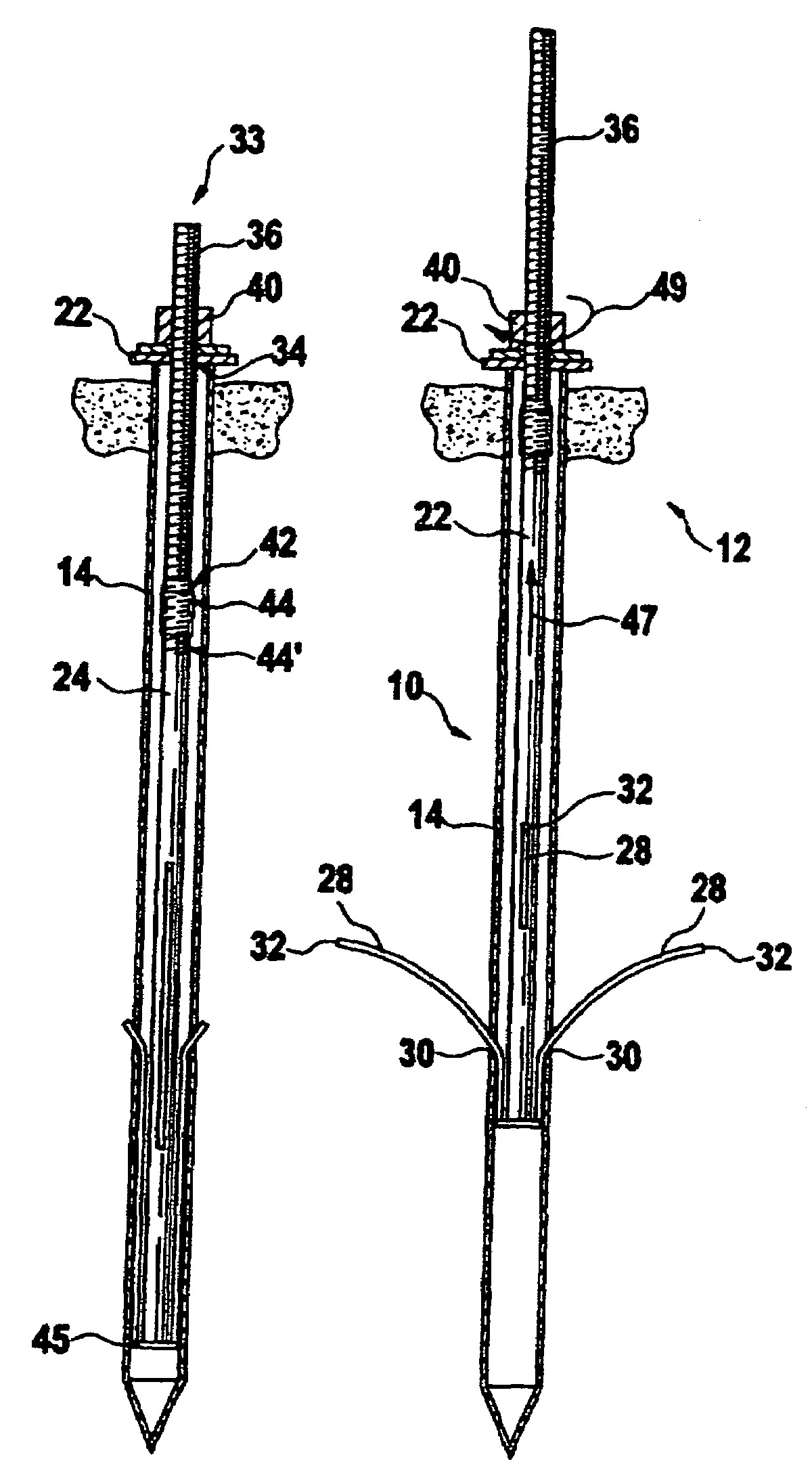

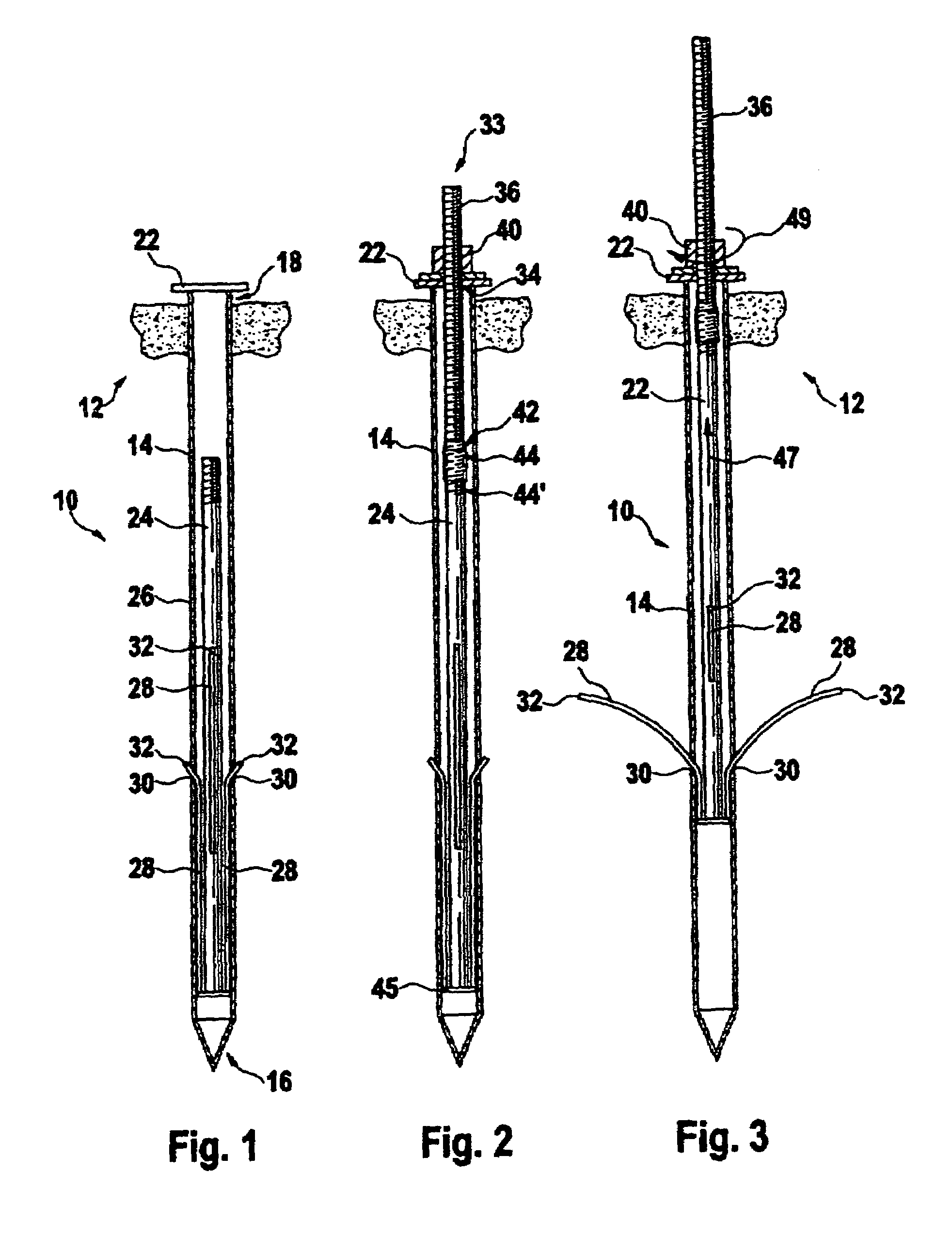

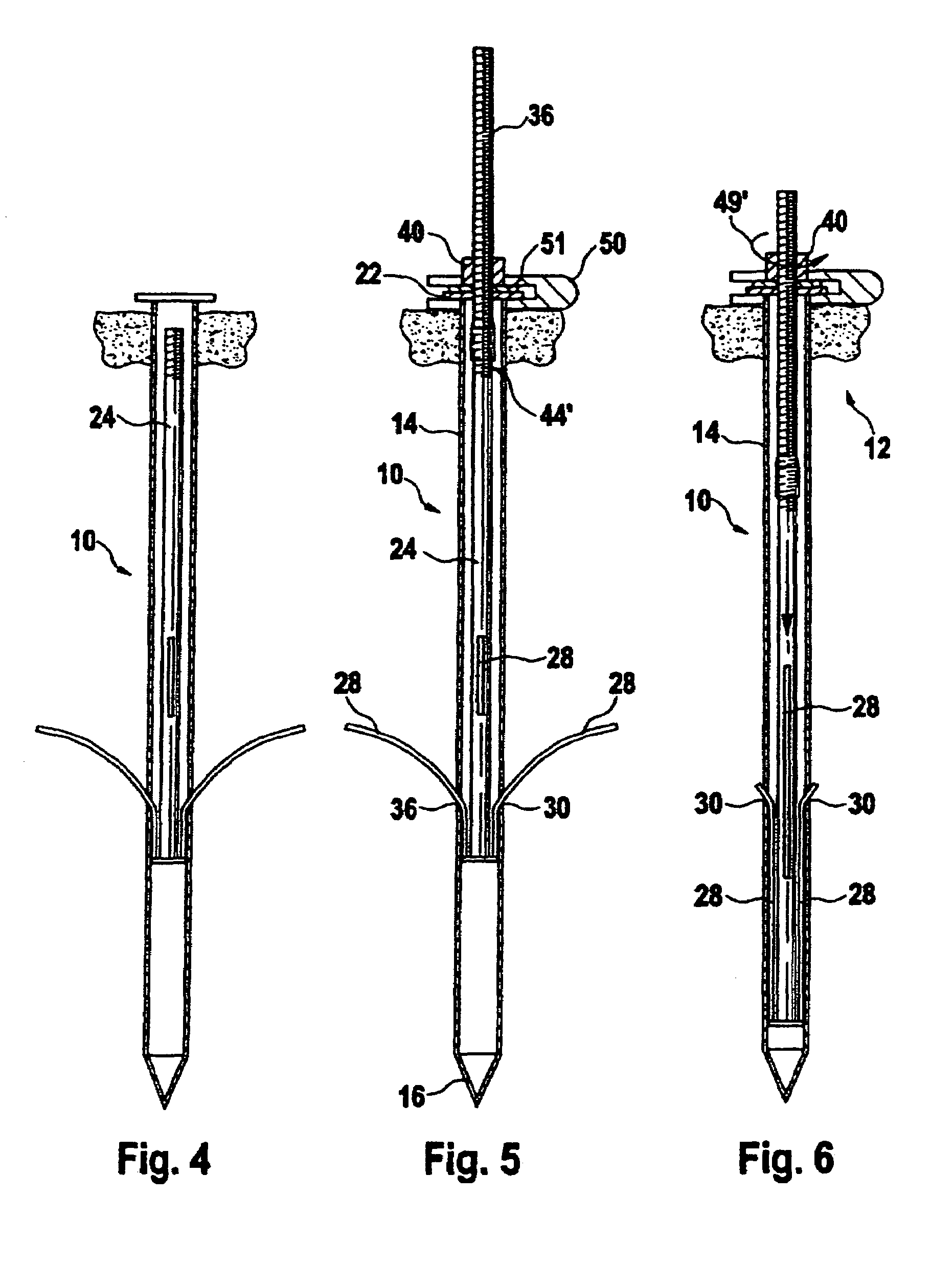

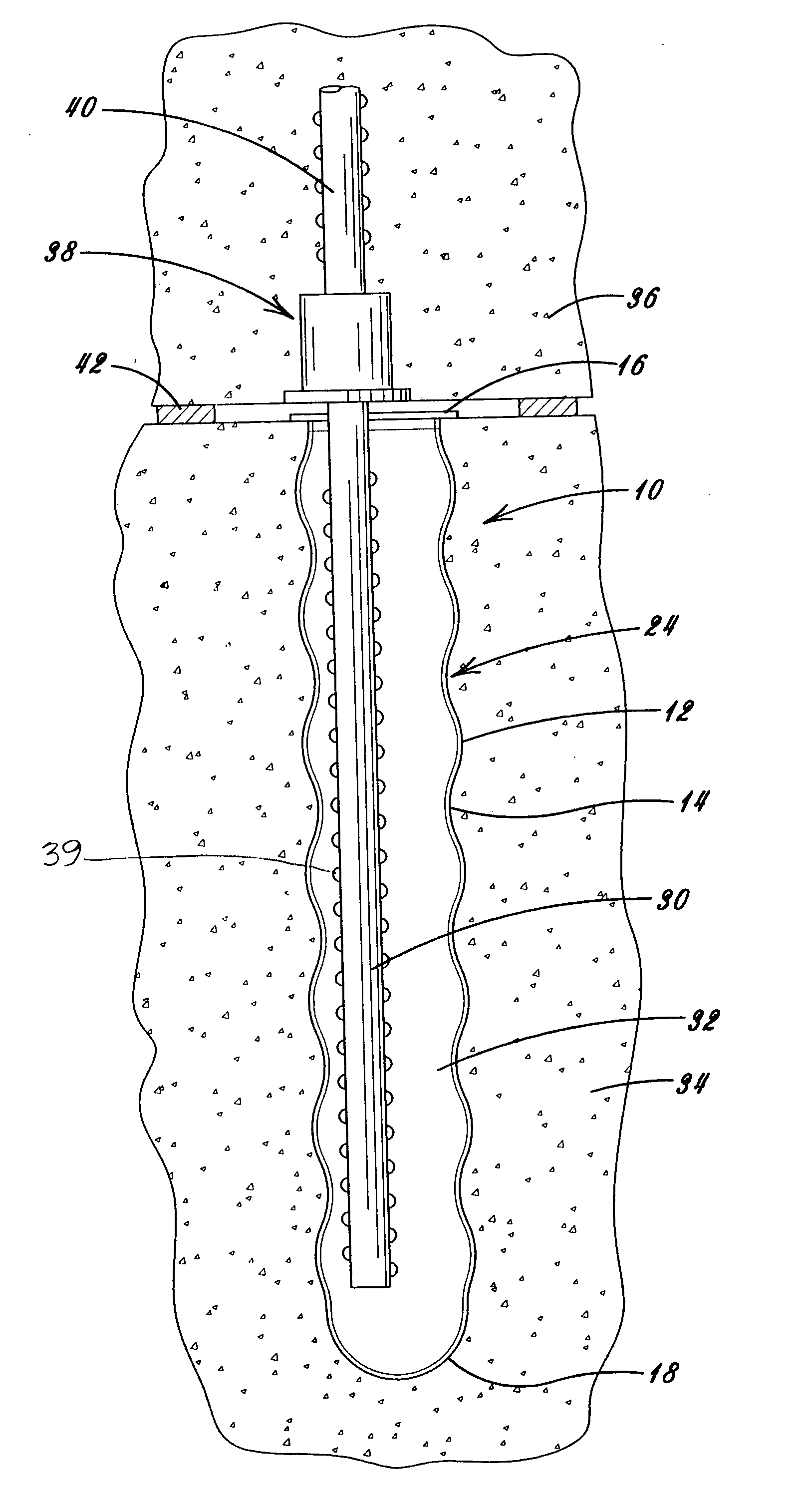

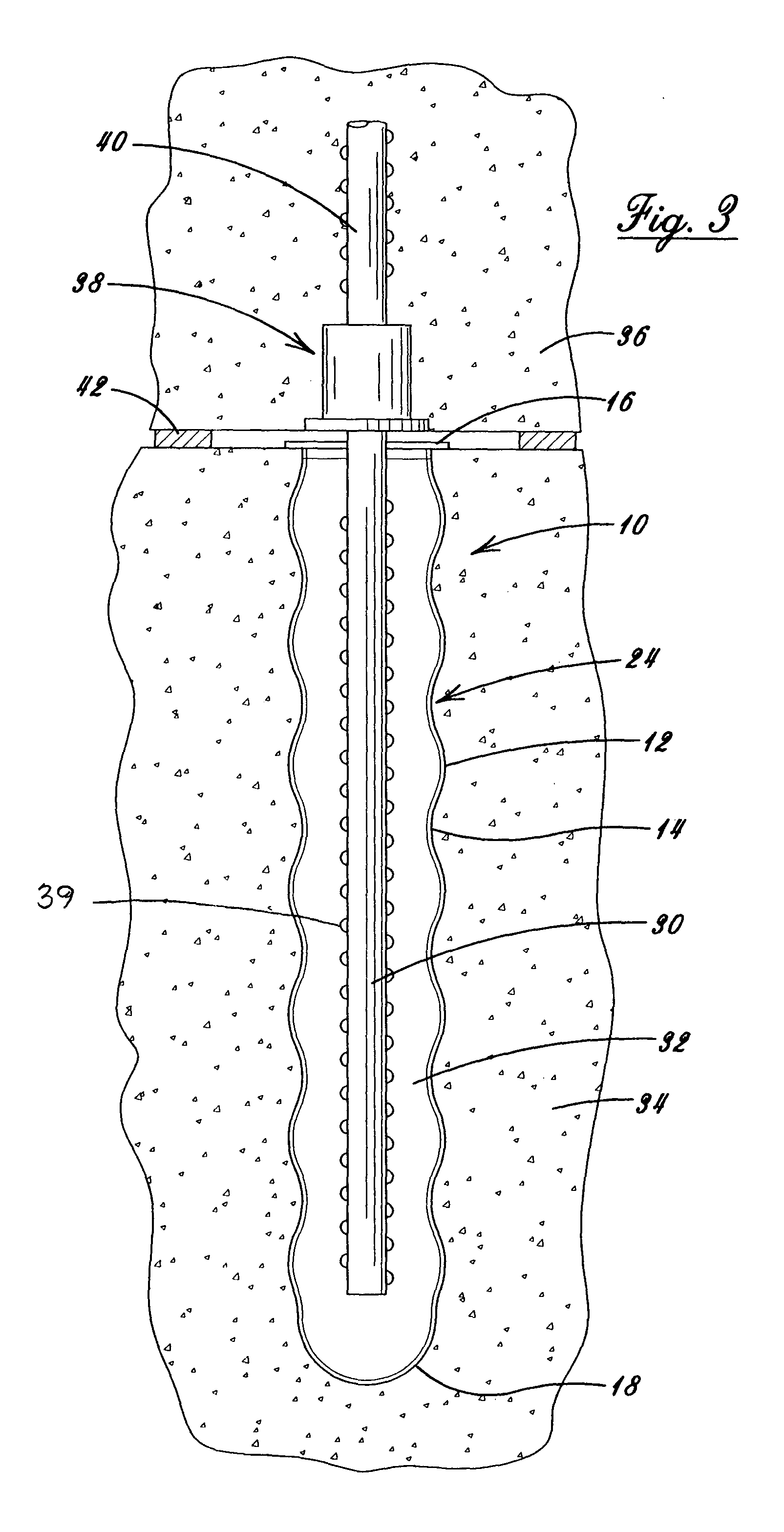

System for fixing an object in the ground by means of a peg

InactiveUS20070017166A1Increased pull-out strengthHigh strengthMachine supportsBuilding repairsEngineeringHead parts

The invention relates to a system for fixing an object in the ground, comprising at least one fixing peg (10) and means for carrying out the above. The peg (10) comprises a tube (14) and at least two lugs (28) on the lower end of a central support rod (24). An axial tension acting on the rod (24) which runs axially in the tube (14) and is fixed in rotation therein, causes the lugs (28) to deploy through openings (30) in the tube (14), such as to cause the extension thereof in the direction of tension at an angle to the length of the tube (14). An operating mechanism (33) comprises a threaded pin (36) with a screw (40) pressing on the head of the tube. The lower end of said threaded pin (36) is coupled to the upper end of the central support (24) in order to transmit an axial tension thereto on turning the screw (40) in a first direction.

Owner:NICOLET

Connecting system for surface coverings

ActiveUS8429870B2Firmly connectedIncreased pull-out strengthWallsBuilding repairsEngineeringSurface cover

A plank, and system and method for joining surface-covering planks, which includes a disengageable connector(s) for detachably connecting multiple planks simultaneously are described. A plank can include a tongue-profiled edge and an opposite rib-profiled edge, and a disengageable connector can have a groove that can be mated with the tongue on one side edge of the plank, and also has a rib-receiving portion that alternatively can be mated with a downward extending rib on the opposite side edge of the plank. The plank can have a variety of designs on the other edges of the plank.

Owner:MANNINGTON MILLS

System for fixing an object in the ground by means of a peg

InactiveUS7497053B2Easy to placeIncreased pull-out strengthMachine supportsBuilding repairsEngineeringScrew thread

The invention relates to a system for fixing an object in the ground, comprising at least one fixing peg (10) and means for carrying out the above. The peg (10) comprises a tube (14) and at least two lugs (28) on the lower end of a central support rod (24). An axial tension acting on the rod (24) which runs axially in the tube (14) and is fixed in rotation therein, causes the lugs (28) to deploy through openings (30) in the tube (14), such as to cause the extension thereof in the direction of tension at an angle to the length of the tube (14). An operating mechanism (33) comprises a threaded pin (36) with a screw (40) pressing on the head of the tube. The lower end of said threaded pin (36) is coupled to the upper end of the central support (24) in order to transmit an axial tension thereto on turning the screw (40) in a first direction.

Owner:NICOLET

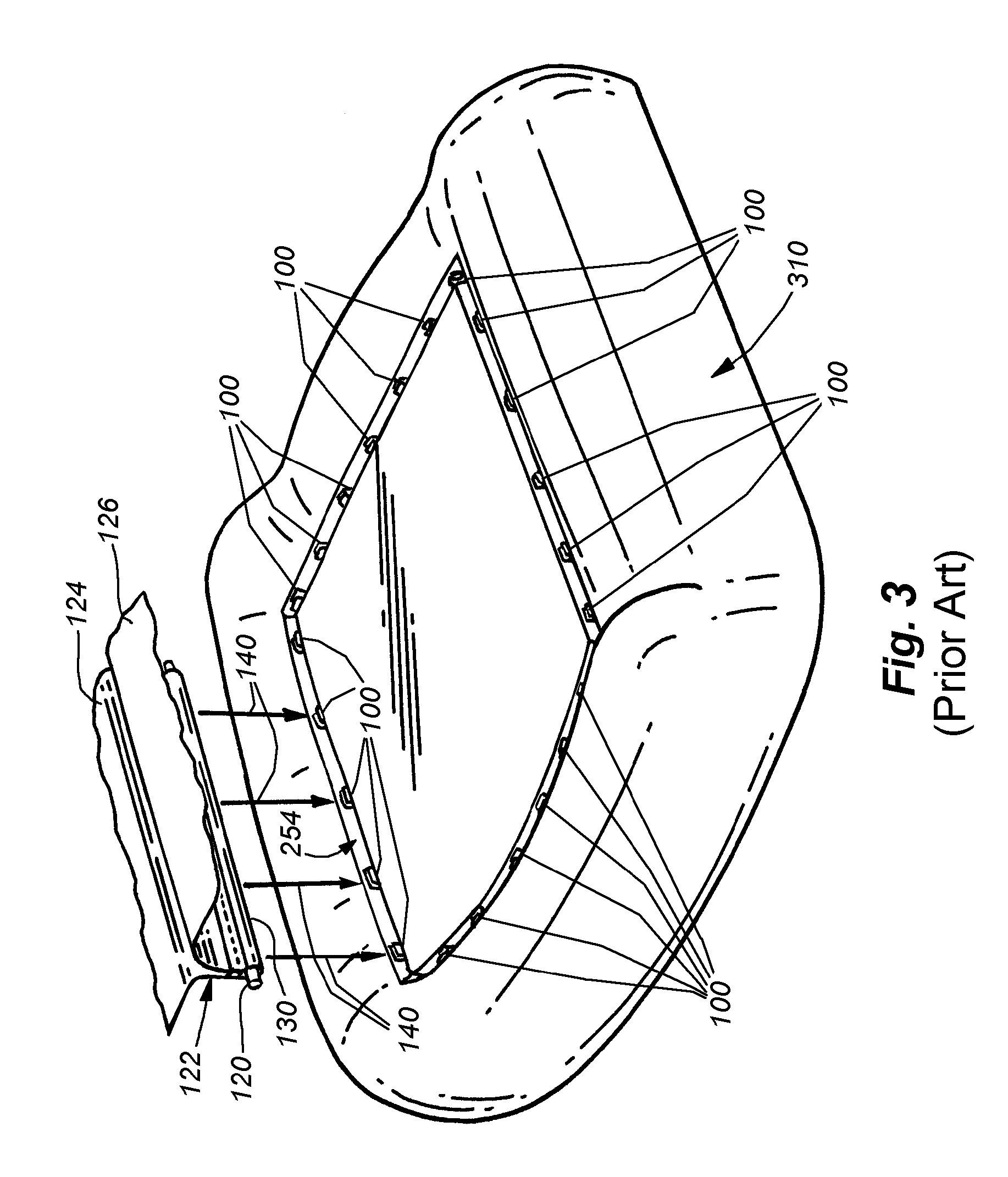

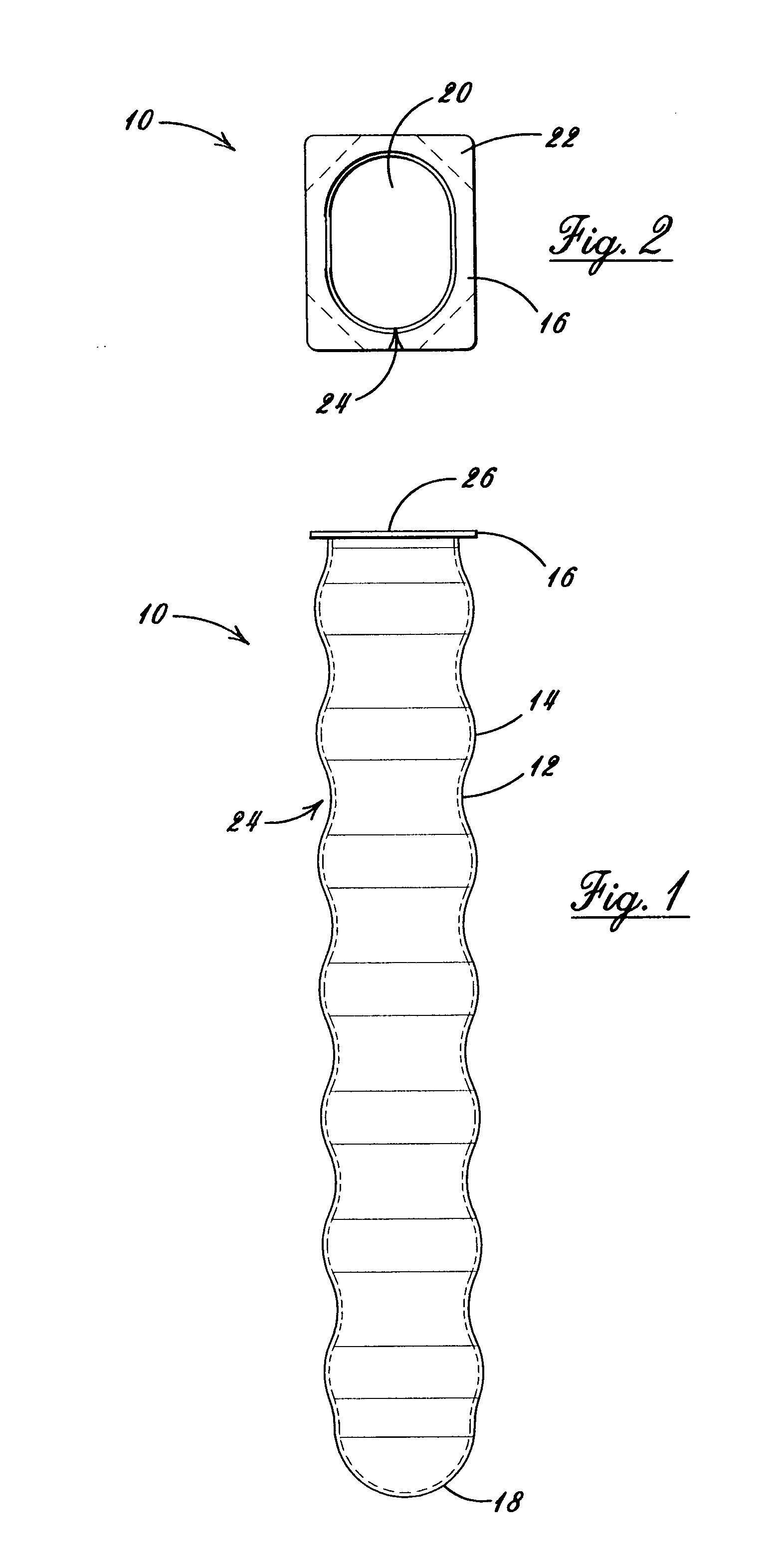

Ovalized concrete block-out tube with tear away nailing flange

ActiveUS20050044809A1High pullout strengthStrong connectionOperating means/releasing devices for valvesLoad-supporting elementsGroutPrecast concrete

A block-out tube for use in joining together pre-cast concrete members, the block-out tube having an ovalized cross-section, an integral elongate imperforate hollow tubular body with smoothly curved corrugated walls, a rounded tip closing the bottom end thereof, a mounting flange with tear-away nail tabs at the top open end thereof, and a removable transparent member for sealing the top end for preventing water and debris from entering the interior of the tube. The block-out tube, secured by attaching the tear-away tabs to a concrete pouring form, is cast into the top of the lower concrete member, the ovalized corrugated body being embedded therein and the top sealed end being exposed at the top surface thereof, after the removal of the form. When the concrete members are erected and joined, the transparent sealing means at the top end is removed, the block-out tube is filled with grout, and a structural rod extending outwardly from one member is fitted into the grout-filled tube as the one member is joined to the other member, the grout engaging the structural rod and the corrugated tube wall, forming a strong joint between the two concrete members.

Owner:THOMPSON HARRY A

Medical fastener

ActiveUS20140094859A1Easy to removeEasy to installSuture equipmentsLigamentsScrew threadBiomedical engineering

A dual-start fastener is disclosed having two threads helically wound about its shaft. The thread tooth profile (in section) constitutes substantially parallel upper and lower facets on each thread flank. A first thread has a crest diameter greater than a second thread. A distal end of the fastener includes self-tapping cutters formed on the threads which force shards of bone to advance into shallow troughs adjacent the cutters for subsequent resorption by adjacent osseous tissue.

Owner:RTG SCI LLC

Composite system, method for its manufacture, and measurement pickup using such a composite system

ActiveUS20060083941A1Stable and high-strength and lasting and mechanical connectionIncreased pull-out strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesPig casting plantsEngineeringCompound system

A composite system includes a first component, for instance of metal, and a second component extending at least partly through the first component along an imaginary longitudinal axis of the composite system. The second component contacts, with an at least partially curved, especially cylindrical, outer surface, an inner surface of the first component flushly such that the first component at least sectionally, at least partly, grips around the second component. Joining surfaces of the composite system, which are formed by the mutually contacting surfaces of the two components, are formed in such a manner that the two components exhibit contour portions in the area of these joining surfaces embodied as self-closing, peripheral surfaces. The contour portions fit at least partly into one another, to form a mechanical interference locking effective, at least in part, likewise in the direction of the longitudinal axis. Additionally, the second component, with its outer surface, contacts the inner surface of the first component flushly, such that the two components are mechanically tightly connected together also by means of a frictional locking effective at least partly in the direction of the longitudinal axis. Alternatively, or in supplementation thereof, at least one of the components is subjected at least partly to lastingly elastic, especially mixed plastic-elastic, deformations. The composite system is distinguished by a high pull-out strength, even in the presence of repeatedly arising vibrations in one of the components and is, therefore, especially suited also for use in a vibration-type measurement pickup.

Owner:ENDRESS HAUSER FLOWTEC AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com