Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

832results about How to "Improve environmental benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

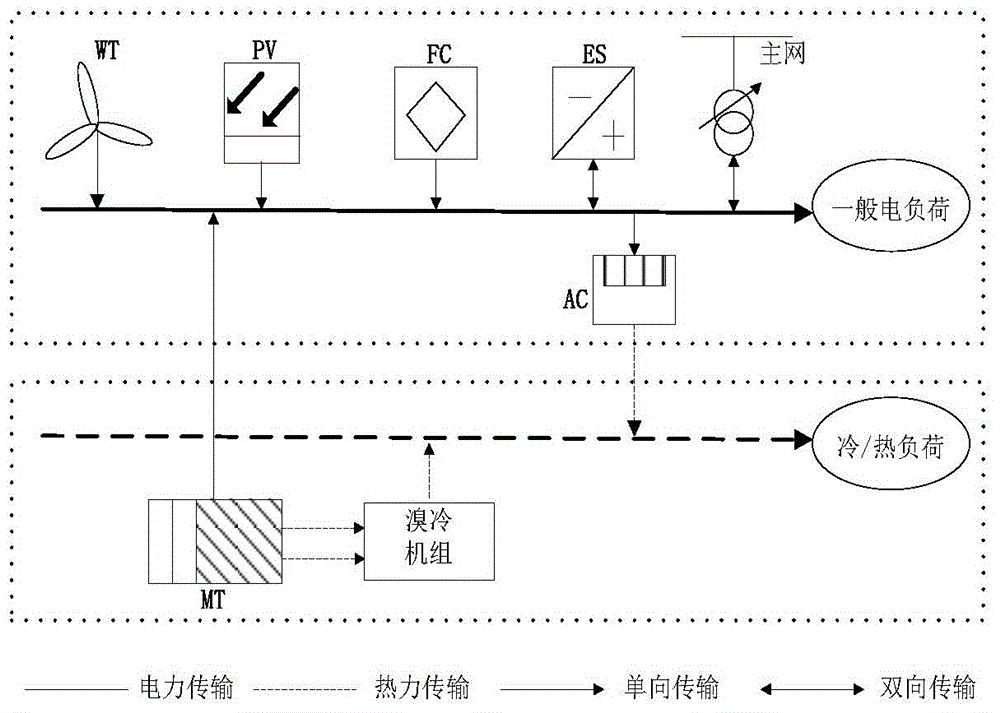

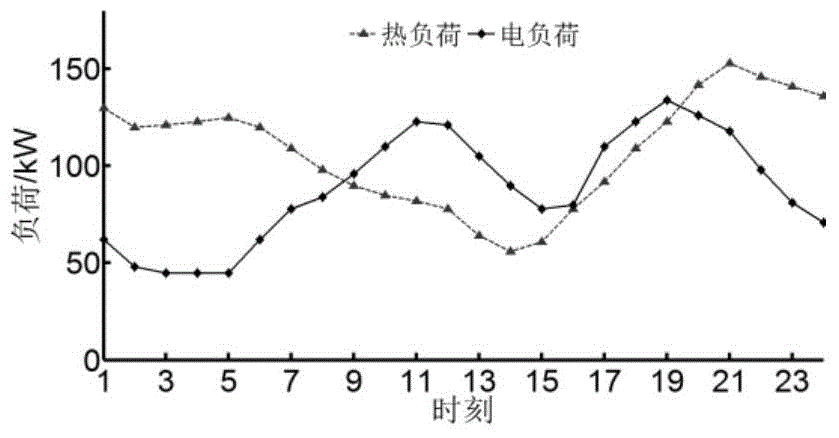

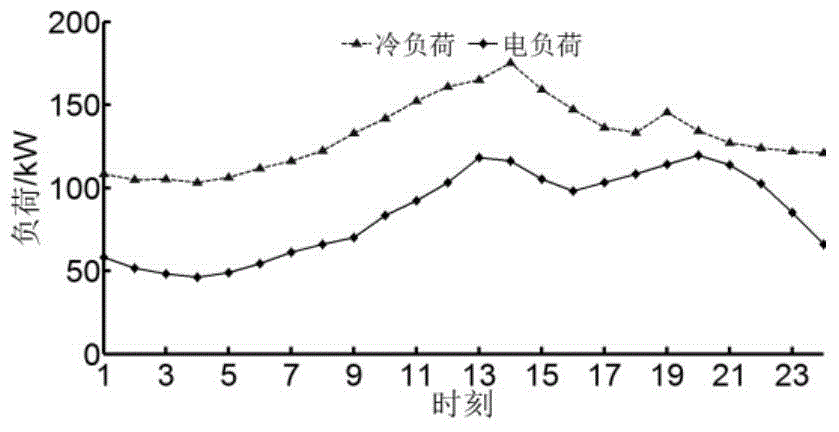

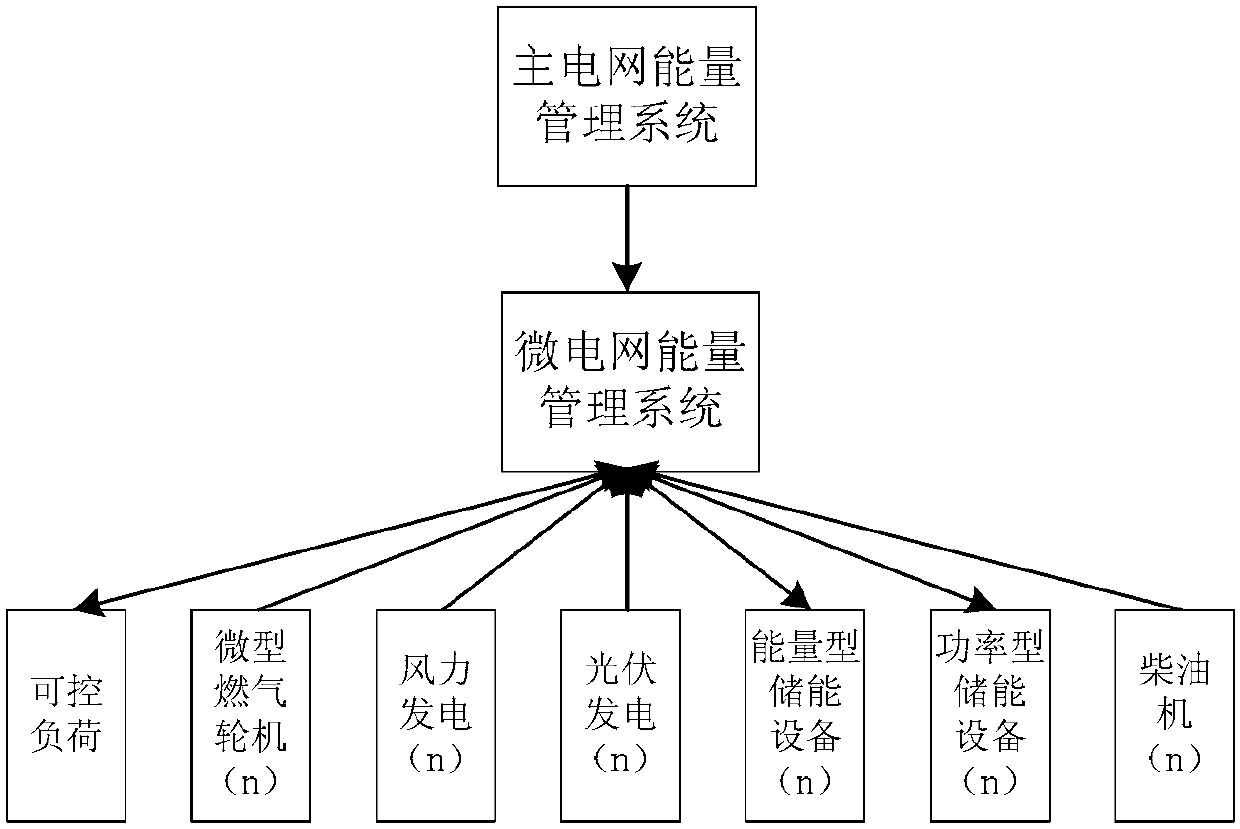

Microgrid operation optimizing method by considering combined supply of cooling, heating and power with stored energy operation strategy

InactiveCN104392286AIncrease revenue from electricity salesLow running costForecastingEnergy gradientMicrogrid

The invention discloses a microgrid operation optimizing method by considering combined supply of cooling, heating and power with a stored energy operation strategy.The microgrid operation optimizing method comprises the following steps of: establishing a CCHP (combined cooling heating and power) microgrid optimizing model; constructing a target optimizing function with a target of lowest generating cost under a microgrid grid-connected operation state; according to the established target optimizing function, comprehensively considering load level of front and time periods with an output trend of each micro power supply, and determining the operation principle of an energy storage unit and a fuel battery to determine the best operation mode of the whole CCHP system in a scheduling period. The microgrid operation optimizing method disclosed by the invention has the beneficial effects that the microgrid electricity selling profits can be effectively increased for energy storage optimization, obvious advantages are provided in lowering the operation cost of the microgrid; the energy resource utilization rate of the stem can be improved and the energy gradient utilization can be realized in comparison with the conventional heat-engine plant and thermal power plant, so that reference is provided for energy saving of the power system; moreover, the energy is saved and the emission is reduced, pollution of air pollutants is greatly reduced, and significance is achieved in improving environmental benefits.

Owner:SHANDONG UNIV

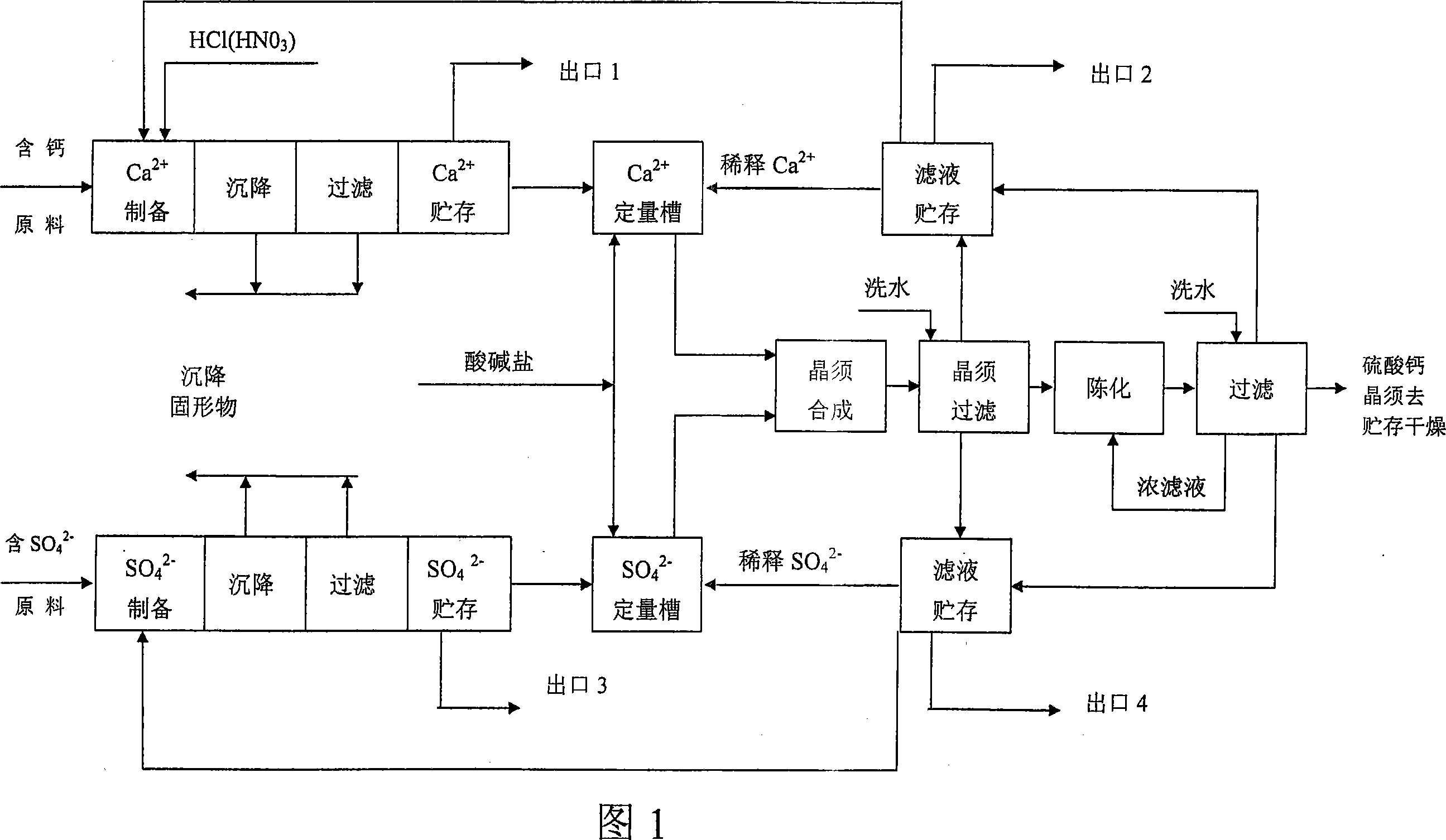

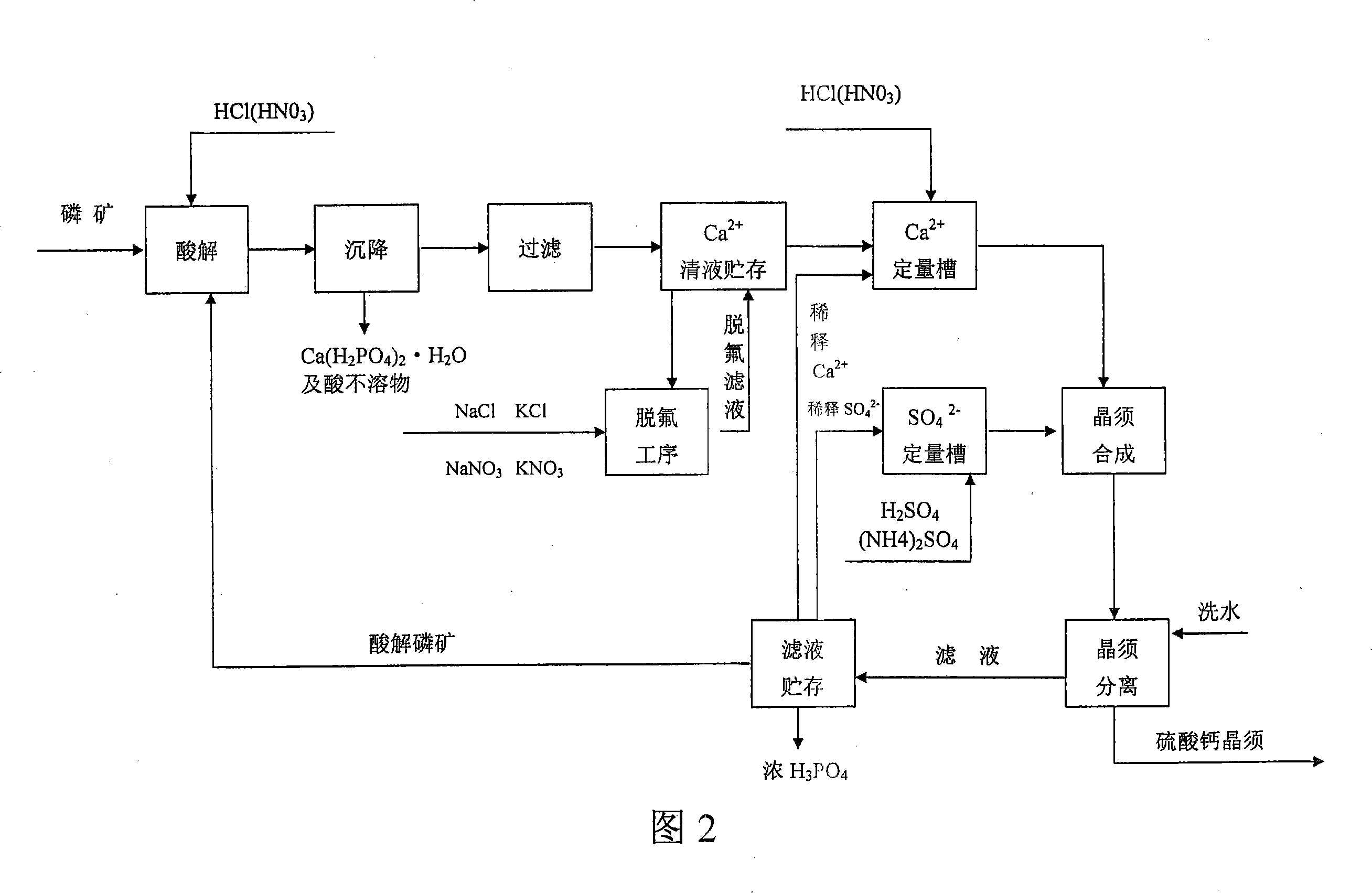

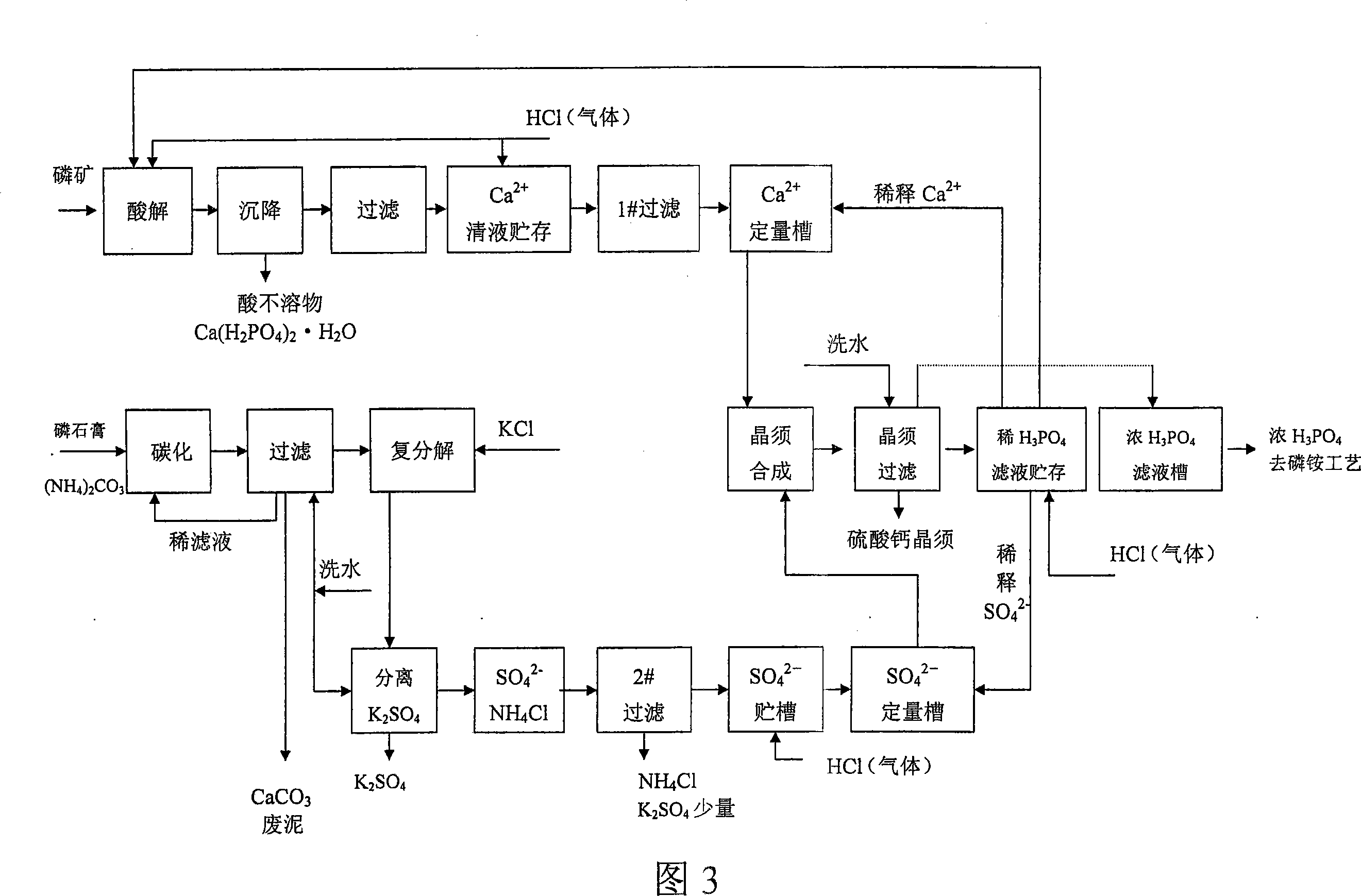

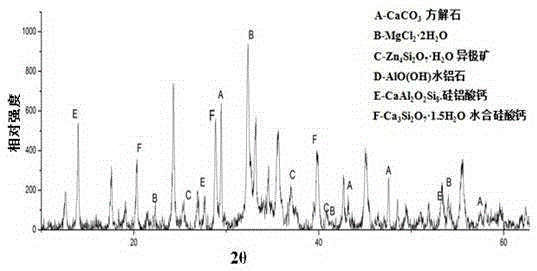

Mass production method for calcium sulfate whisker

ActiveCN101168852ALarge amount of preparationImprove environmental benefitsPolycrystalline material growthFrom normal temperature solutionsSulfateSludge

The invention discloses a new method for large-scale production of calcium sulfate whiskers, which is characterized in that a large number of cheap water-soluble Ca2+ and water-soluble SO42- ions are used at a certain pH, salt-containing impurities and whisker control agents and a certain synthesis Calcium sulfate whiskers were synthesized under conditions such as , aging, and temperature. The invention has the advantages of simple process, low investment, low cost and excellent products. It can be co-produced with various existing processes containing Ca2+ and SO42-, can eliminate the waste water and waste residue pollution of these processes, and can greatly improve these co-production processes. economic benefits.

Owner:武善东 +1

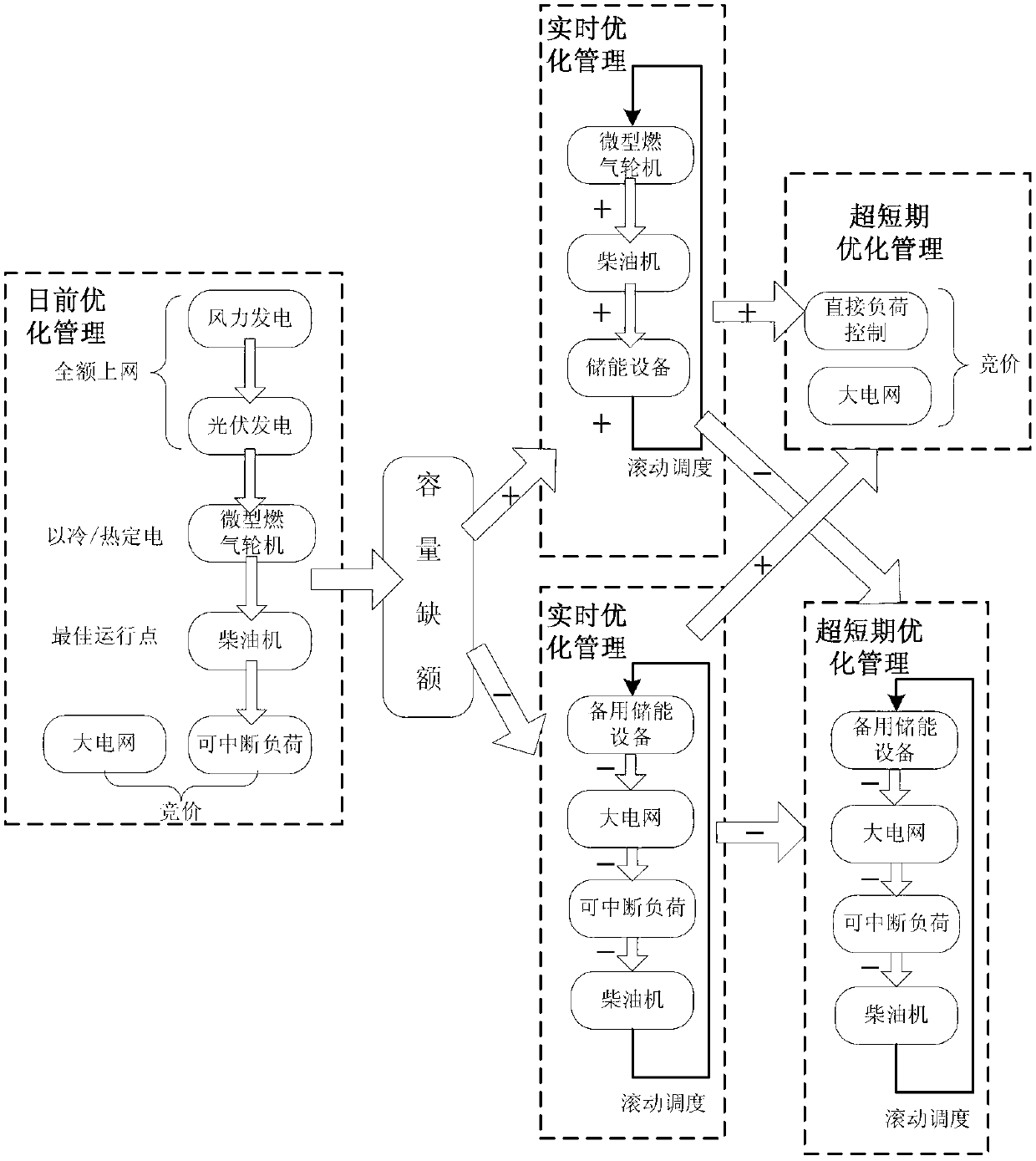

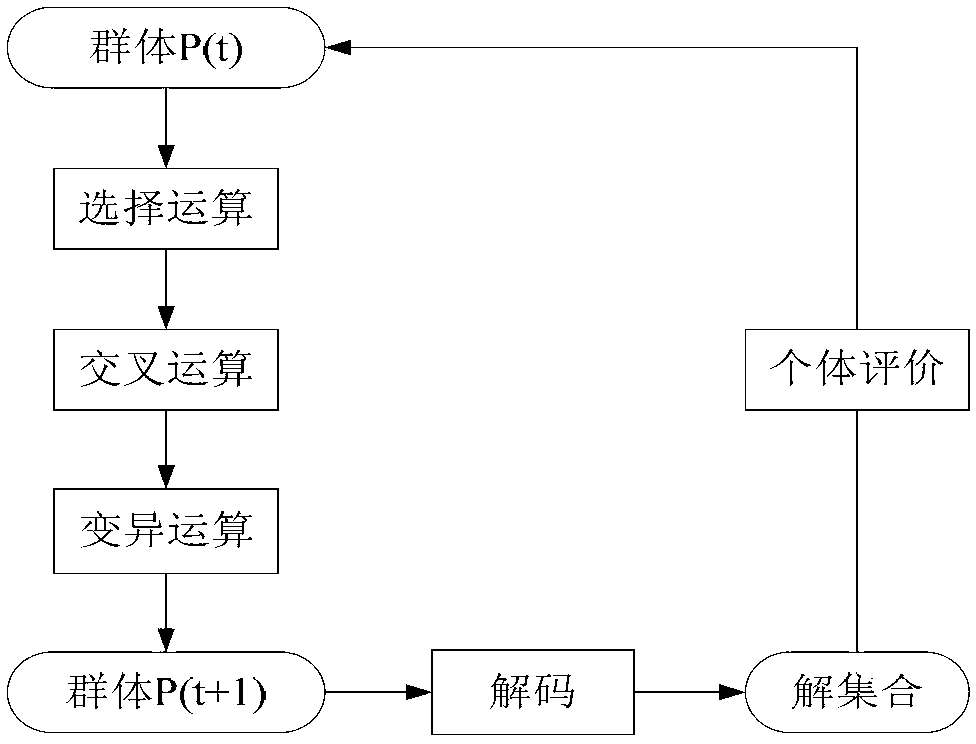

Multi-time scale microgrid energy control method considering demand response

ActiveCN103346562AImprove schedulabilityReduce spare capacitySpecial data processing applicationsAc network circuit arrangementsMicrogridEnergy control

The invention discloses a multi-time scale microgrid energy control method considering demand response. According to the multi-time scale microgrid energy control method considering the demand response, in order to achieve the purpose of lowest operation cost of a microgrid, the electricity generating characteristic of a micro power source and demand response load power utilization property difference are combined to provide a user side load interruptible capacity limiting value, an electricity generating unit power output limiting value, a climbing constraint condition, an energy storage unit storage capacity constraint condition and an interaction maximum capacity constraint condition, an economic combination which can guarantee the optimum environmental benefit is searched under the multi-time scale condition by means of the genetic optimization algorithm, frequency modulation and spare capacity of a main grid are indirectly reduced, and the economical performance of complete-period operation of the grid is improved.

Owner:CEEC JIANGSU ELECTRIC POWER DESIGN INST

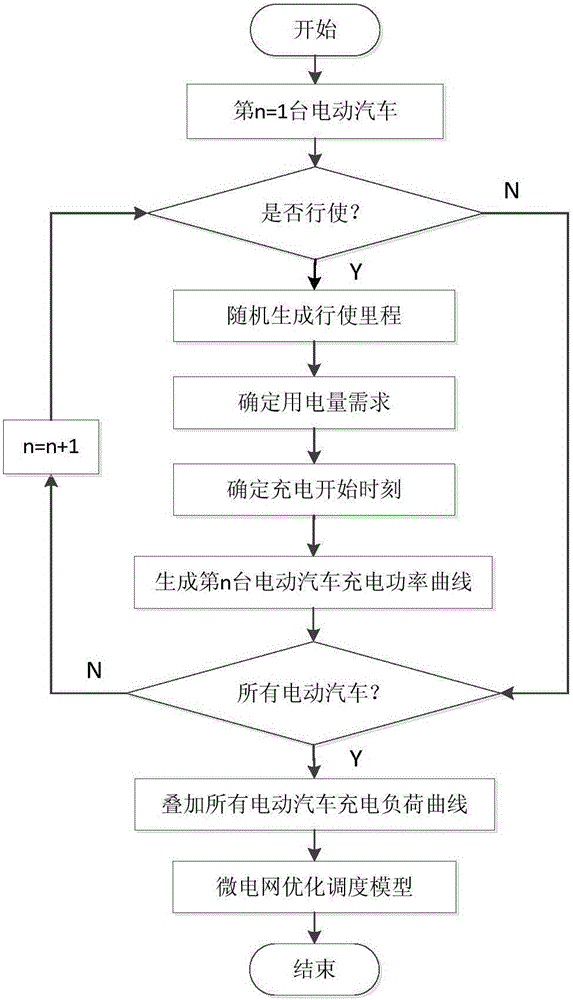

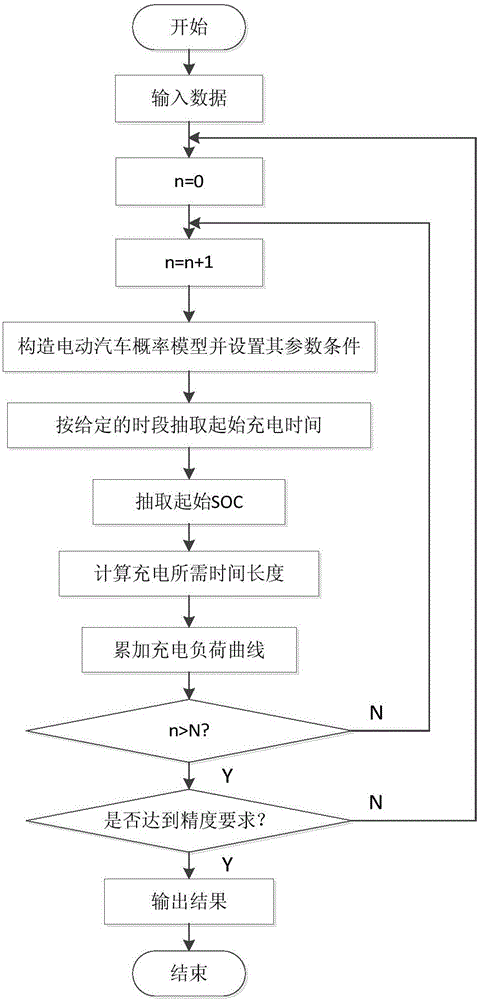

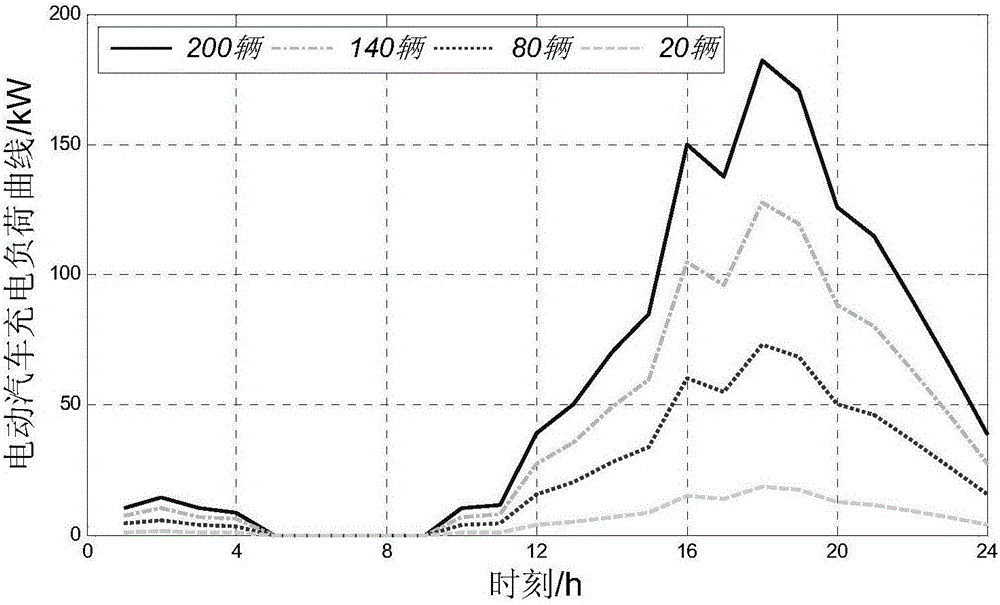

Electric-automobile-contained micro electric network multi-target optimization scheduling method

ActiveCN105160451ALow operating and maintenance costsImprove environmental benefitsResourcesState of artMicrogrid

Owner:上海顺翼能源科技有限公司

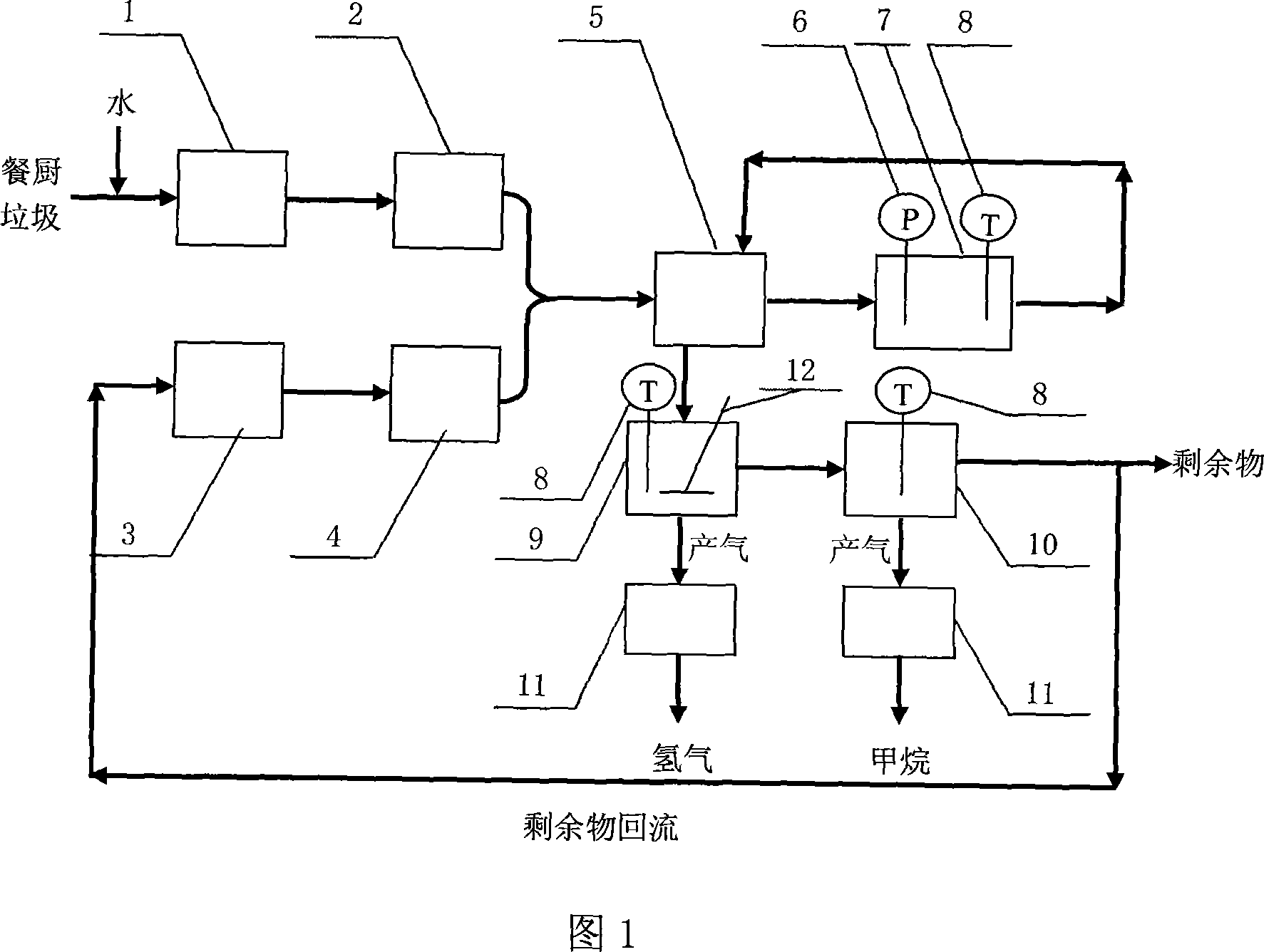

Method for producing hydrogen and methane by kitchen waste diphasic anaerobic fermentation

InactiveCN101134684APH controlLow running costBio-organic fraction processingClimate change adaptationHydrogenSludge

The biphase anaerobic fermentation process of kitchen refuse to produce hydrogen and methane includes the following steps: 1. sorting kitchen refuse and mixing with water in certain amount; 2. mixing with sludge from sewage treating yard and heat treatment; 3. heat exchange between heat treated mixture and mixture without through heat treatment; 4. anaerobic fermentation of the heat treated mixture in the first phase to produce hydrogen; 5. anaerobic fermentation of the residue from the first phase fermentation in the second phase to produce methane; and 6. using the residue from the second phase fermentation as fertilizer or returning to replace sludge serving as hydrogen producing bacteria source. The process is simple, can recover the biomass energy from kitchen refuse effectively, and has no secondary pollution.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

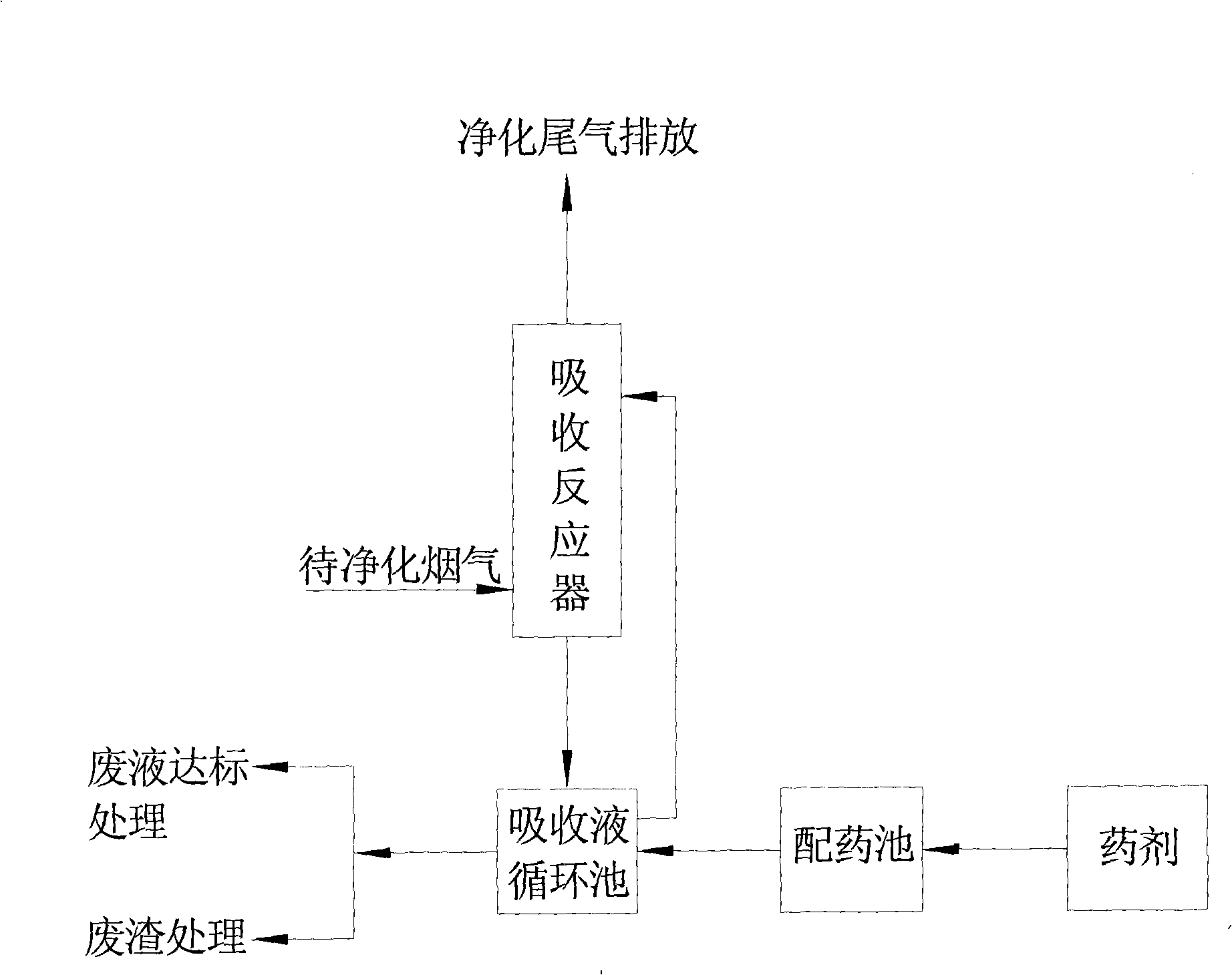

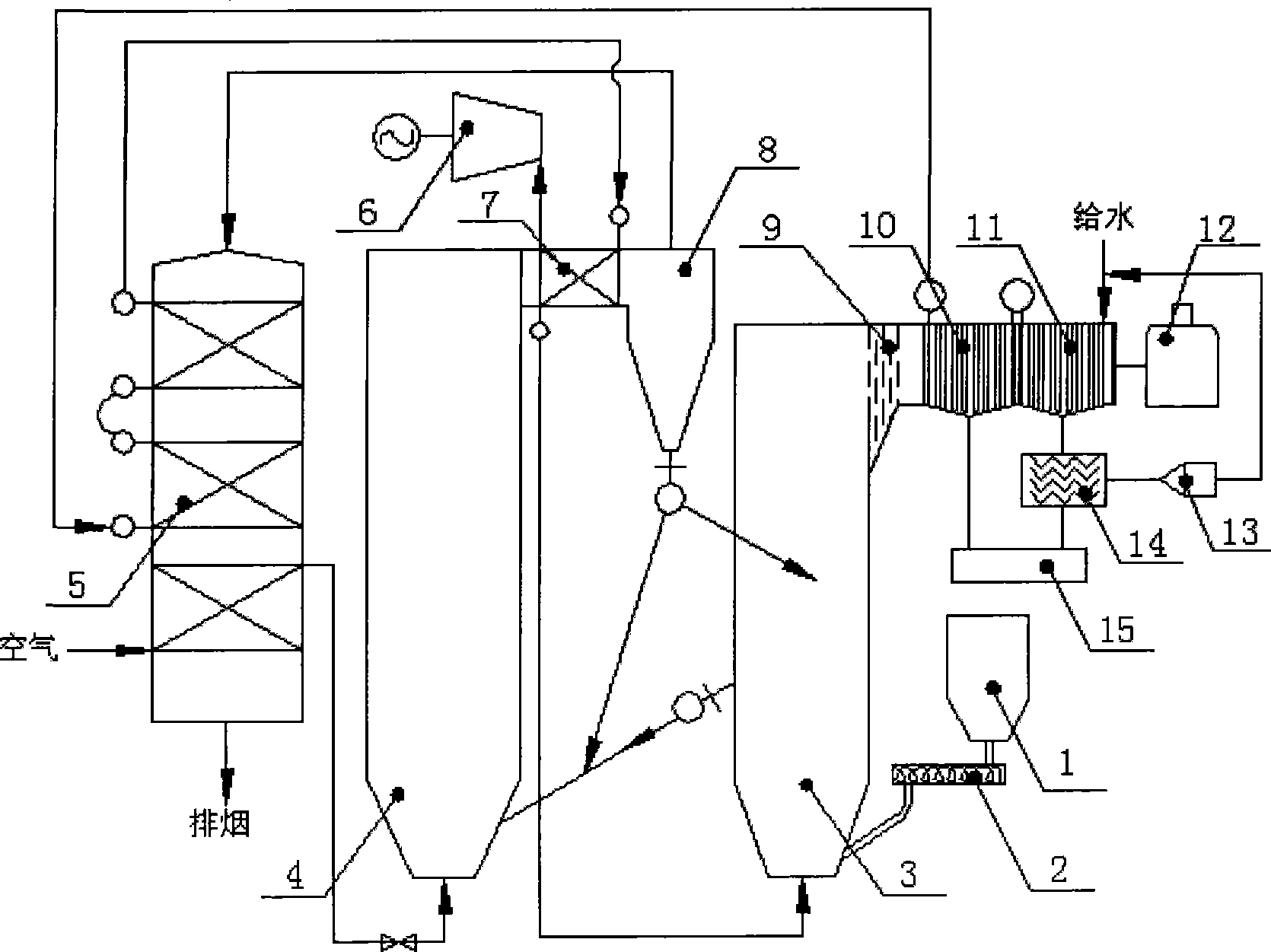

Simultaneous desulfuration and denitration technique by wet flue gas method

ActiveCN101352647AReduce usageWide variety of sourcesDispersed particle separationAir quality improvementFlue gasWastewater

The invention provides a process which carries out desulfurization and denitration at the same time by a smoke wet-method; the smoke to be purified enters an absorbing reactor and is sufficiently contacted with absorbent containing alkali desulfurizer (such as one out of lime, limestone, Na alkali or alkali wastewater), urea and strong oxidant, and the SO2 and NOx in the smoke can be purified at the same time. When the process of the invention is adopted to purify the smoke, more than 90% of desulfurization and 50-95% of denitration efficiency can be achieved. The process of the invention realizes the desulfurization and denitration at the same time on the basis of alkali desulfurizer wet-method desulfurization process widely adopted at present; furthermore, the absorbent has wide source and low cost; the dosage of the strong oxidant is small, and the desulfurization and denitration efficiency is high so as to generate larger environmental benefits with less investment.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

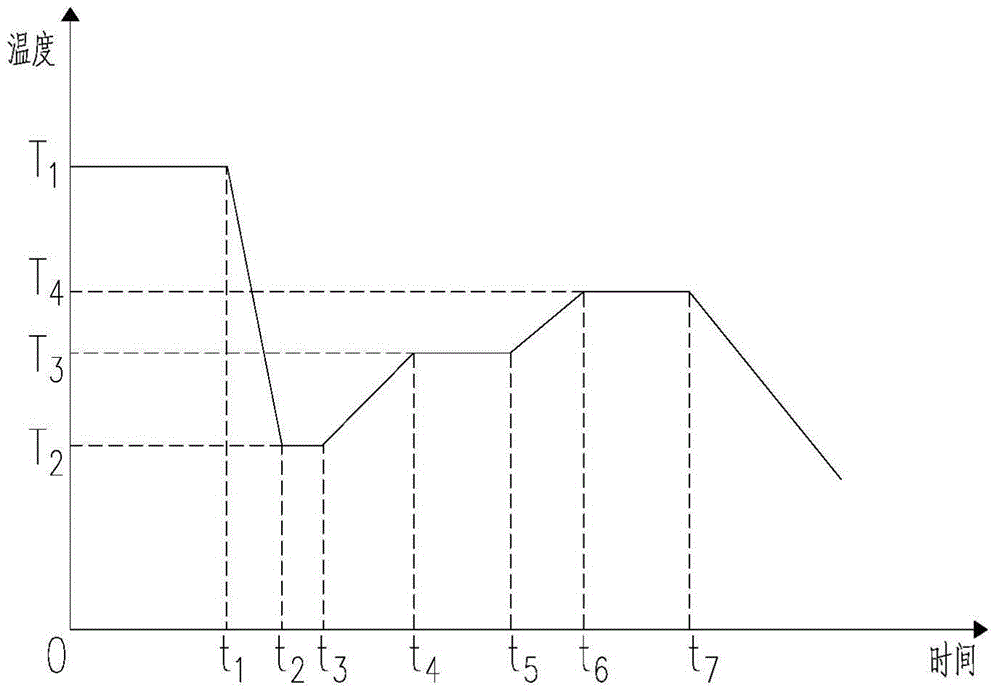

High-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as heat-carrying medium

InactiveCN101812310AReduce in quantityEfficient use ofCoke quenchingChemical industryEconomic benefitsTar

The invention relates to a low-temperature dry distillation process for coal, in particular to a high-efficiency lignite low-temperature dry distillation quality-enhancing process by using dry distillation coal gas as a heat-carrying medium. The process comprises a coal-preparing flow, a drying flow, a dry distillation flow, a heat source flow, a coal gas and tar processing flow and a semicoke cooling transfer flow; in the process, vapor self-generated by a drying tower is used as a drying medium, the coal gas of a generator is taken as a heat source to heat the self-generated dry distillation coal gas, and serves as a dry distillation medium, and the coal gas of the generator is used as fuel of a hot air furnace; the dry distillation semicoke is cooled in a cooling mode of drying fume exhaust plus semi water spraying; and condensation water is used for coke-quenching water, a gasifier of the coal gas of the generator and a tar cooling agent. The process has the advantages of producing high-index dry coal and dry semicoke, high-heating value coal gas and high-quality tar, having a flawless and high-efficiency energy recycling system, not using outside nature water, hardly discharging water to the outside, saving huge cost for sewage treatment, creating the maximum economic benefits for customers and having quite strong competitive power on economy, technology and market.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

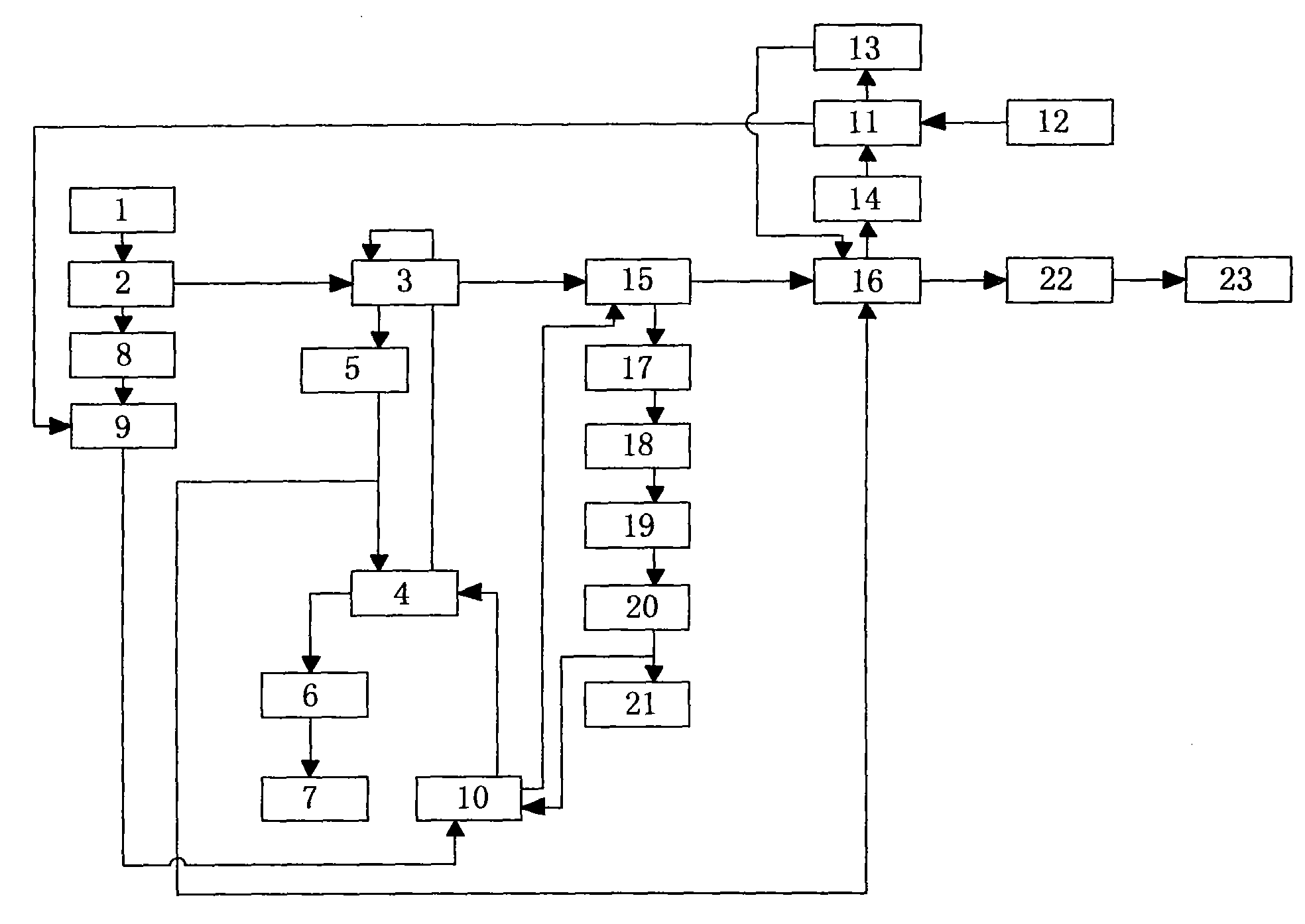

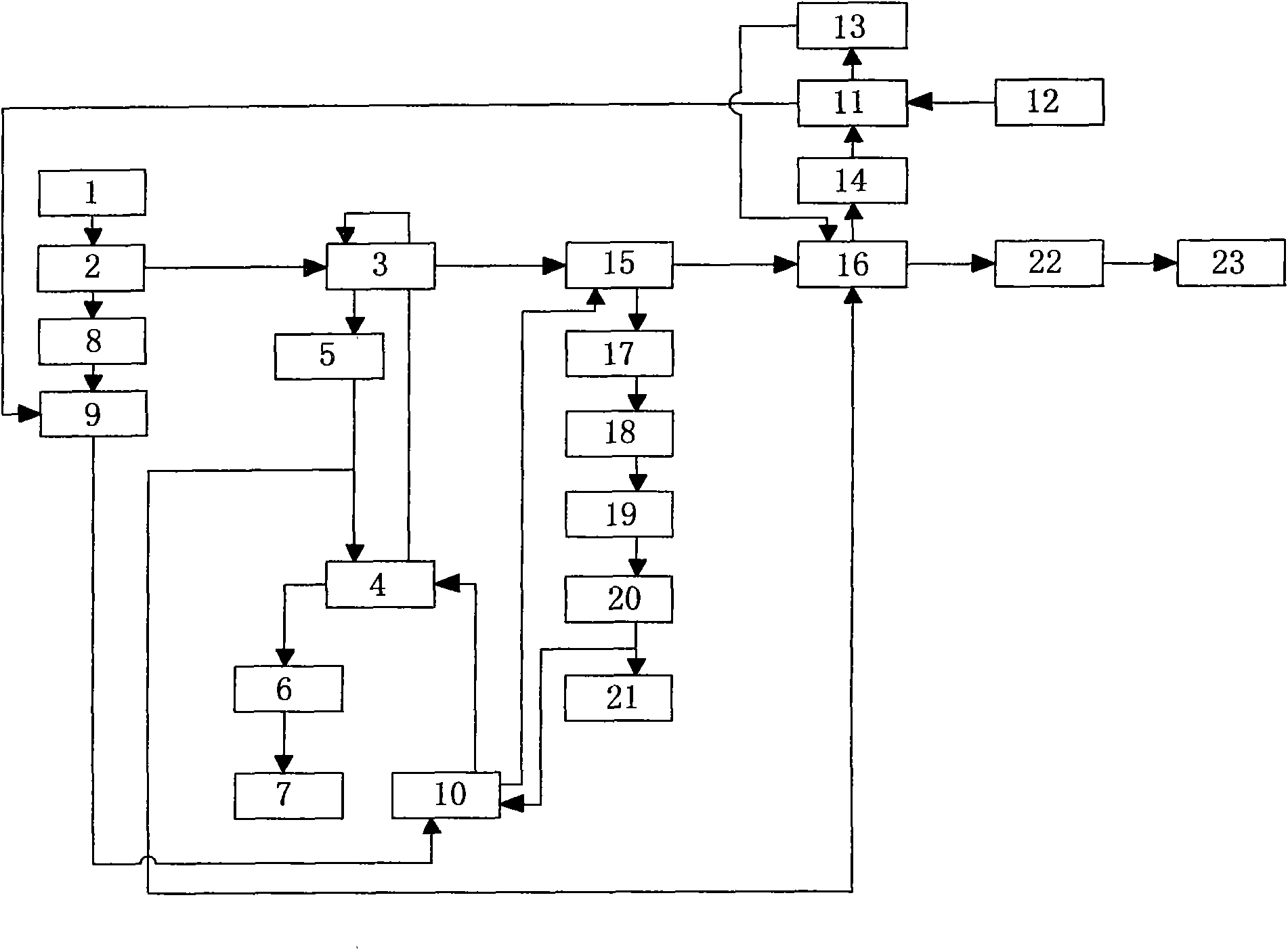

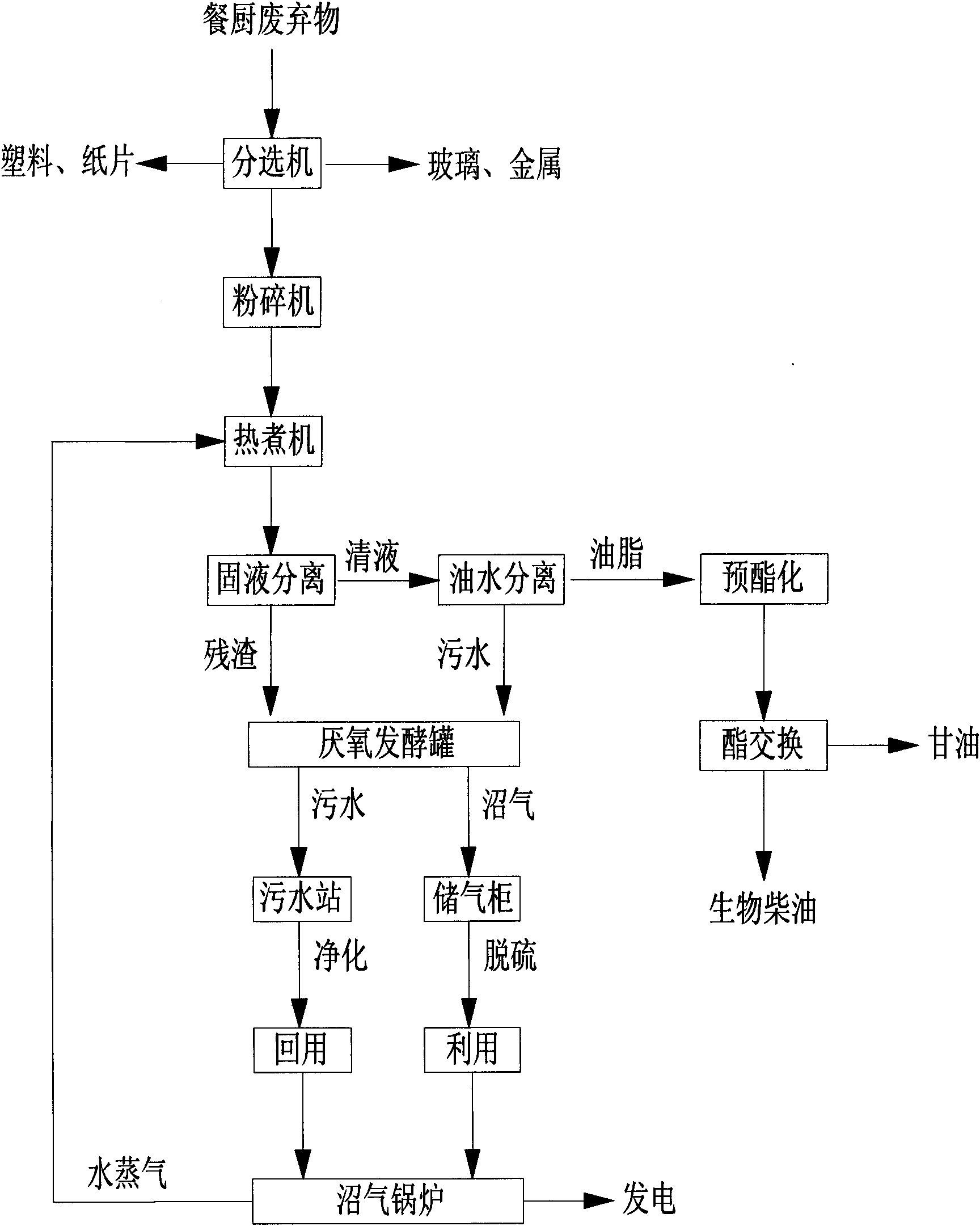

Urban kitchen waste recycling utilization and harmless treatment technology

ActiveCN102688881AReasonable process designSimple processBiological substance pretreatmentsFatty acid esterificationBiodieselWater vapor

The invention relates to an urban kitchen waste recycling utilization and harmless treatment technology. The urban kitchen waste recycling utilization and harmless treatment technology is characterized by grinding and sorting kitchen waste by a crushing sorting machine, separating out inorganic substances, carrying out high-temperature steam pyrolysis of organic matter slurry, and carrying out solid-liquid and oil-water separation, wherein separated residues and sewage are fed into a biogas fermentation tank and are subjected to anaerobic fermentation to produce biogas for power generation or civil heating; and separated waste oil undergoes an acid-base reaction to produce glycerin and biodiesel. The urban kitchen waste recycling utilization and harmless treatment technology realizes maximum recycle of active resources of kitchen waste, reduces the pollution and the damage on the environment, and has environmental, economic and social benefits.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

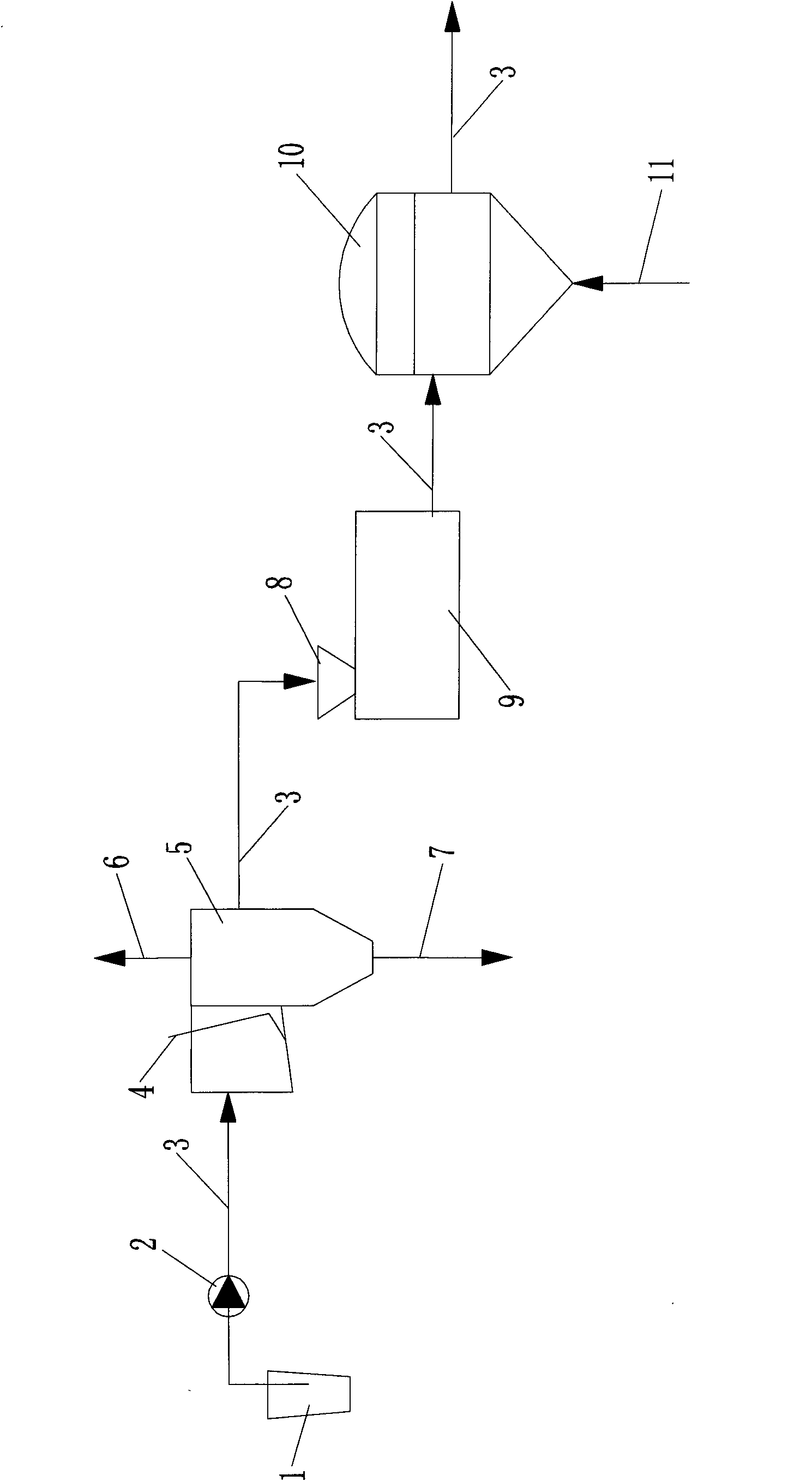

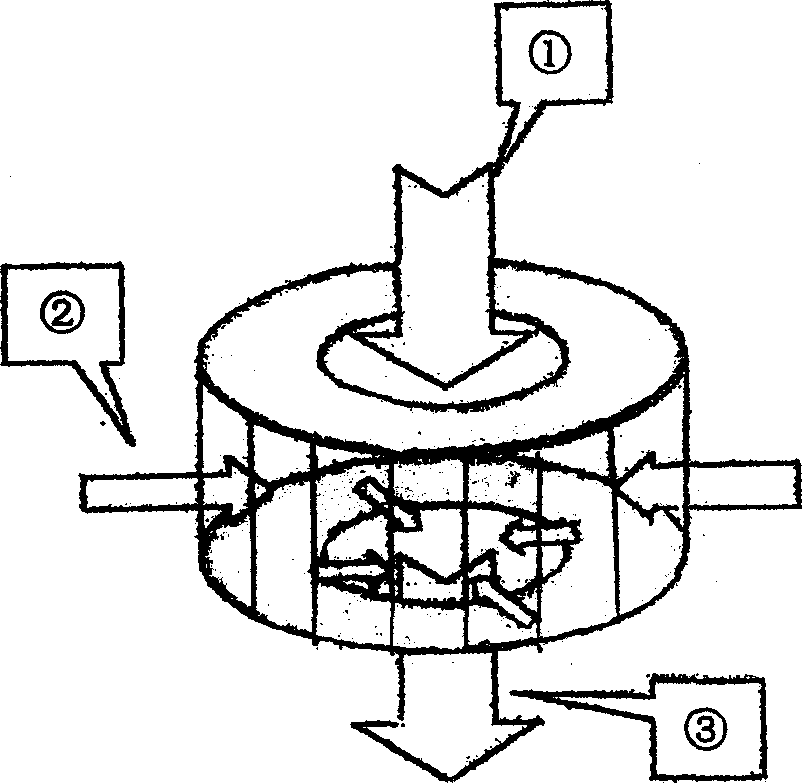

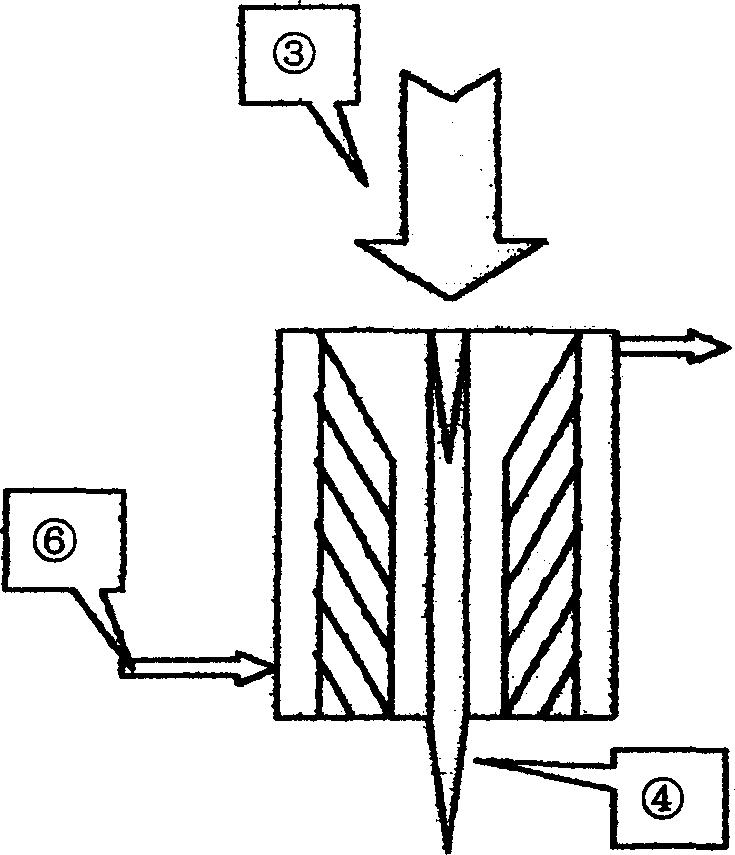

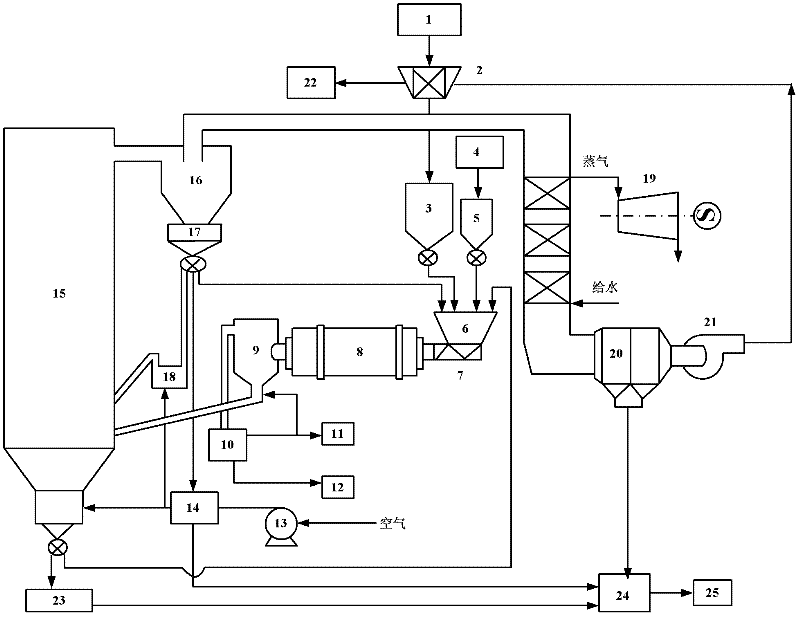

Oil shale fluidized bed dry distillation system

InactiveCN101440293ARealize scientific utilizationImprove heat transfer efficiencySpecial form destructive distillationWater vaporOil shale gas

The invention relates to a carbonization system of an oil shale fluidized bed. Oil shale with high oil content and low pyrolysis temperature is used as a carbonization material; high-temperature steam-gas and circulating hot ash are utilized to fluidize and heat the oil shale in a carbonization chamber of the fluidized bed; after ash removal, mixed airflow of generated shale oil and noncondensable gas and vapour in the carbonization chamber of the fluidized bed enters a cooler; the condensed oil-water mixture is divided into shale oil and water through the oil-water separator; the shale oil is transported to a shale oil storage tank; the water is purified and is conducted to the cooler; and noncondensable gas which is not condensed through the cooler is transported to a fuel gas storage tank. Oil shale carbocoal produced through the carbonization chamber of the fluidized bed is directly transported to a boiler of an oil shale carbocoal circulating fluidized bed, is burned and discharges heat; one part of the produced steam-gas is used as fluidized wind of the carbonization chamber of the fluidized bed; the residual steam-gas is conducted to a steam turbine-dynamo system, applies work and generates electricity; and part of circulating ash in the boiler is used as a heat source of the carbonization chamber of the fluidized bed. The carbonization system can realize high-efficient, clean and economic comprehensive utilization of the oil shale.

Owner:SHANGHAI JIAO TONG UNIV

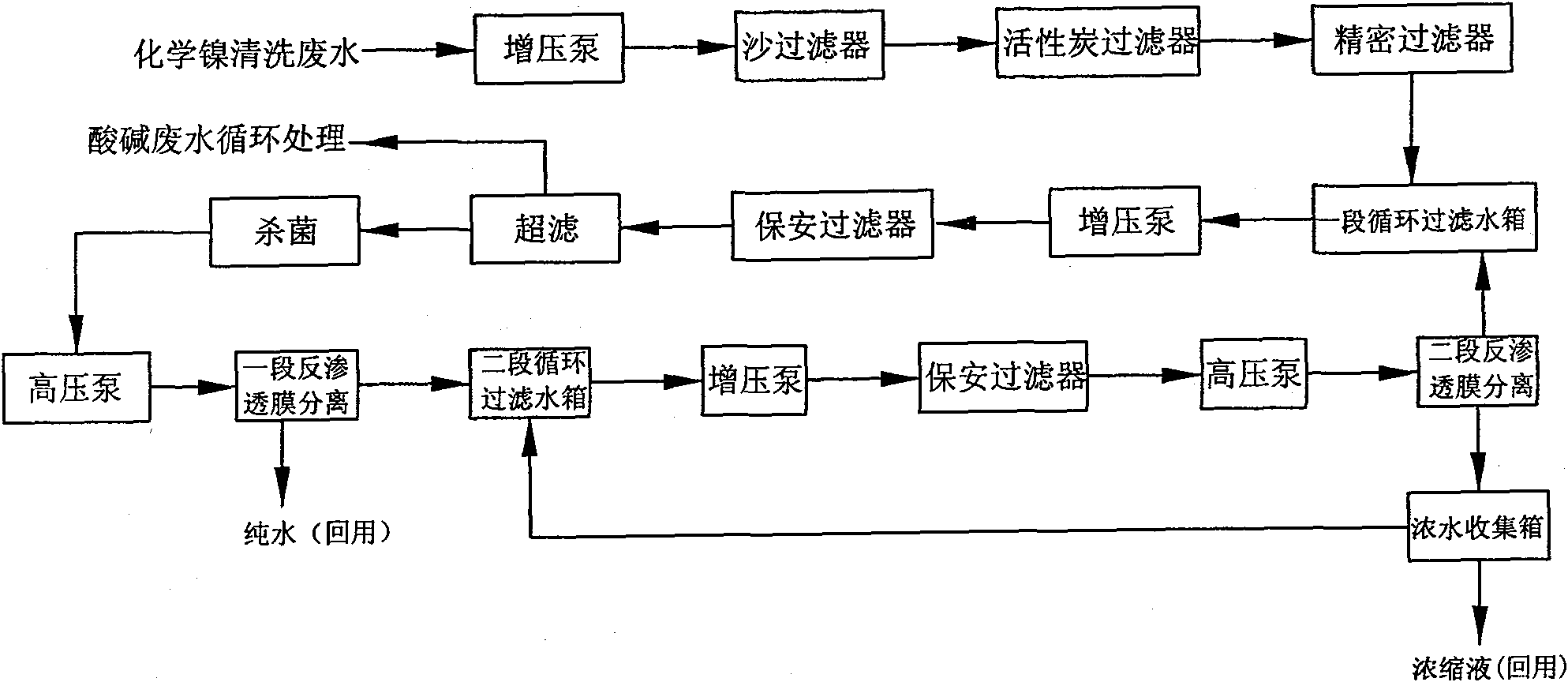

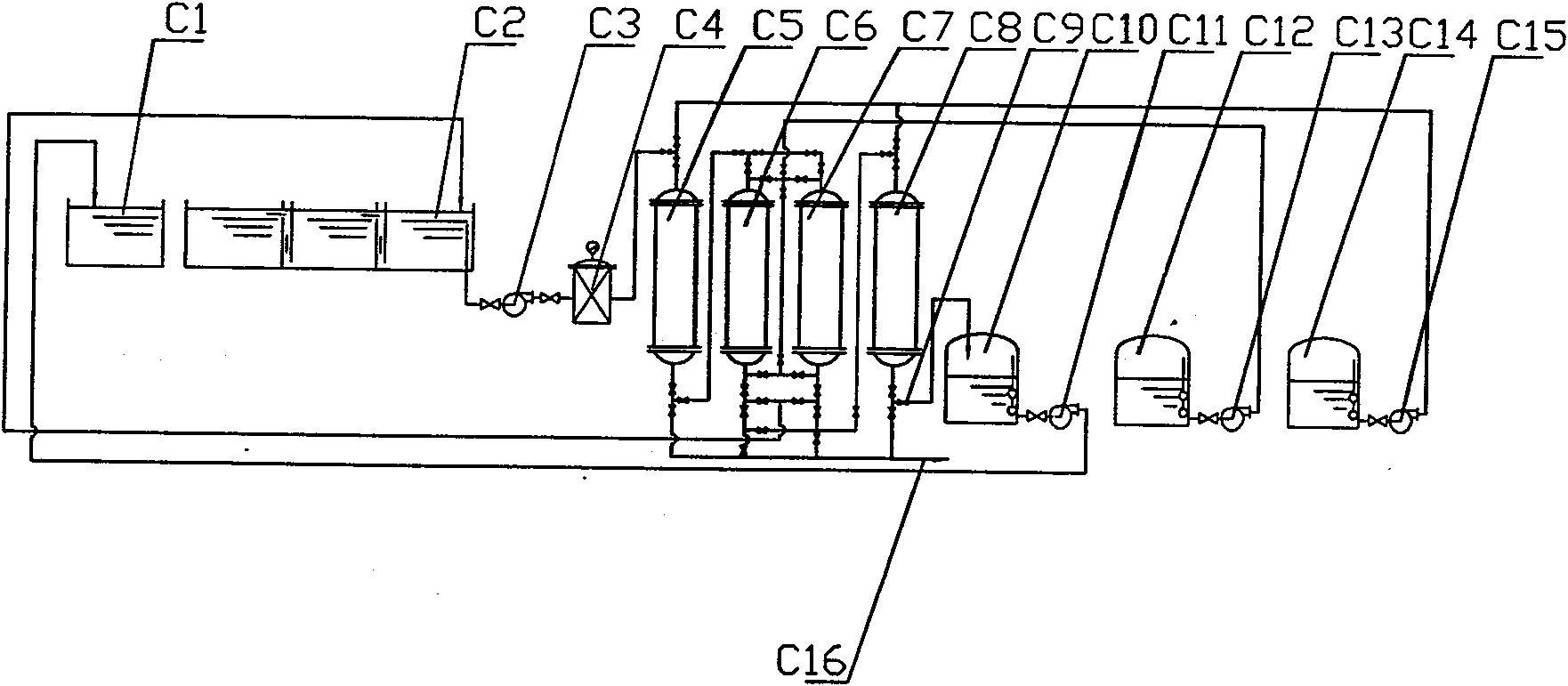

Method for classifying, treating and recycling plating washing water on line

ActiveCN101891323AAvoid cross contaminationStrong targetingWater contaminantsWater/sewage treatment by ion-exchangeCopper platingWater cycling

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Owner:NANJING YUANQUAN TECH CO LTD

Biodegradable coated compound fertilizer and preparation method thereof

The invention relates to a coated compound fertilizer, in particular to a totally biodegradable coated compound fertilizer and a preparation method thereof. The coated compound fertilizer consists of a coated layer and a compound fertilizer core. The main body of the coated layer is polylactic acid and / or polybutylene succinate. The coating process adopts fluidized bed spraying-coated technology, and comprises the following steps: dissolving polylactic acid and / or polybutylene succinate in trichloromethane, adding carboxymethylcellulose, urease and / or nitrification inhibitor, organic and / or inorganic conditioner in the solution, spraying and coating the surfaces of the fluidized compound fertilizer granules after uniformly mixing the mixture under the stirring of a stirrer to form the uniform and complete organic polymeric membrane layer. The process has the advantages of easy implementation, and capacity of effectively slowing down the release of the fertilizer nutrient to the outside and the conversion rate of nitrogen in soils, effectively controlling the release and conversion of the fertilizer nutrient in soils, and reducing the pressure on environment caused by the rapid release of nutrient. The coated material can be totally biodegradable, and the degradation products have no secondary pollution to the environment.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Method for preparing acetylene by hot plasma cracking methane containing gas

InactiveCN1552680AAvoid adverse consequencesIndustrial method improvementHydrocarbon by hydrocarbon crackingPlasma jetPlasma generator

A process for preparing acetylene by using hot plasma to crack the gas containing methane includes such steps as using plasma generator to ionize the argon or N2 or H2 to form a plasma jet, spraying raw gas via a gas inlet ring in reactor, mixing the plasma jet with the raw gas in the reactor, cracking reacting, and quickly cooling the cracked gas in an expansion cavity of cooler to obtain acetylene, carbon black and H2.

Owner:德阳市旌能天然气有限公司 +1

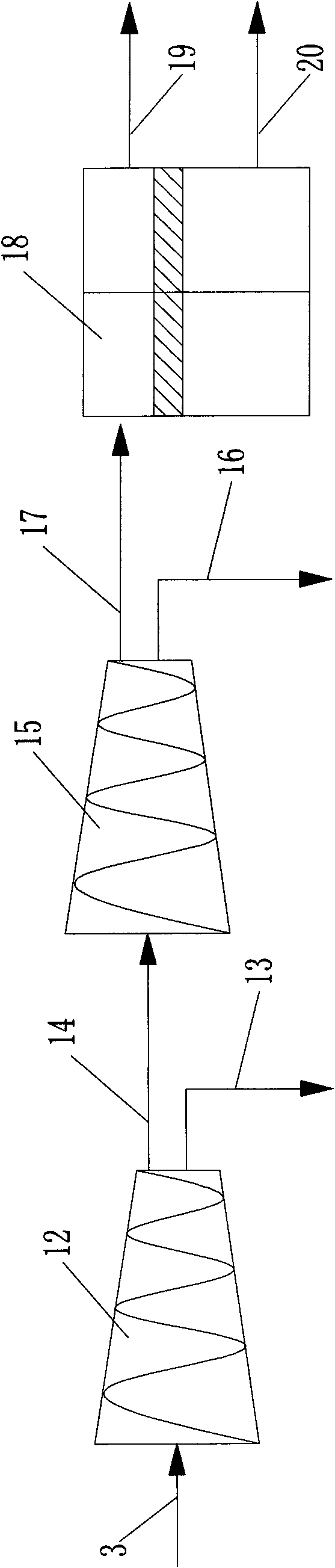

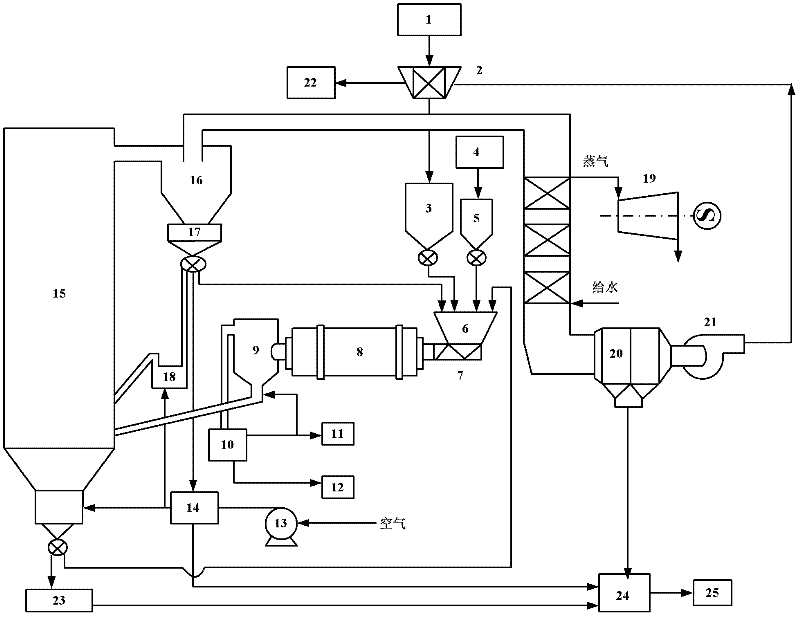

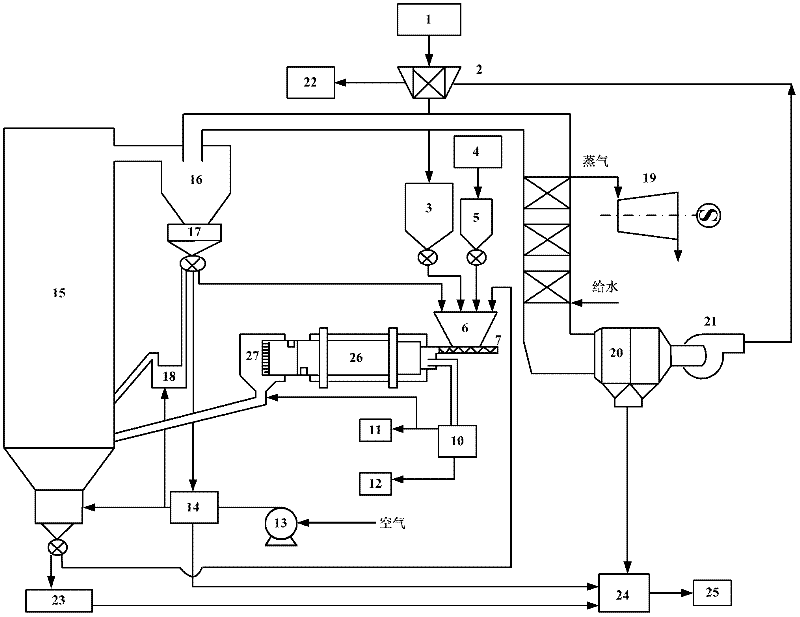

Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

InactiveCN102533296AImprove combustion efficiencyControl generationDirect heating destructive distillationBiofuelsBottom ashInternal combustion engine

An oil shale rotary kiln dry distillation and circulating fluidized bed combustion process makes organic combination of a rotary kiln dry distillation with a circulating fluidized bed; oil shale particles are mixed with thermal-cycle ash from a circulating fluidized bed boiler and part of circulating fluidized bed boiler bottom ash, and then are sent into a rotary kiln for dry distillation to prepare shale oil and dry distillation coal gas; the dry distillation coal gas has a high calorific value; a part of the coal gas is used as recycle wind of a semicoke material recycle device, and enters the circulating fluidized bed boiler with oil shale semicoke particles for combustion, and the residual part is delivered into an internal combustion engine for combustion generation. The invention can increase shale oil and coal gas quality, reduce energy loss and environment pollution, and improve the comprehensive utilization degree.

Owner:SHANGHAI JIAO TONG UNIV

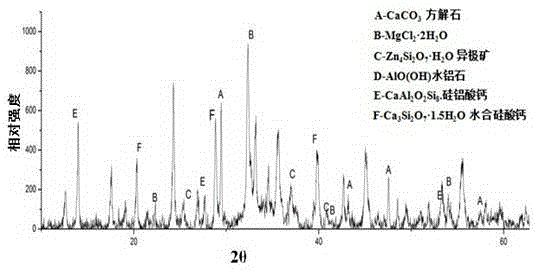

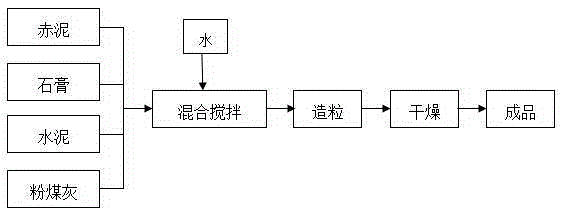

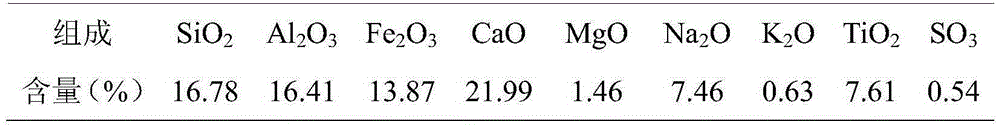

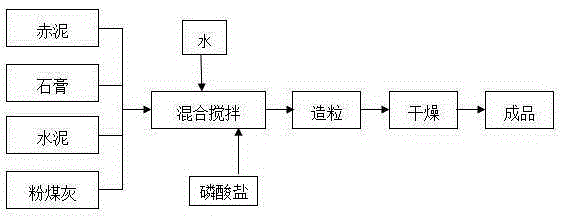

Red mud particle soil repairing adhesives and preparation method thereof

The invention discloses red mud particle soil repairing adhesives and a preparation method and application thereof. The red mud particle soil repairing adhesives are prepared through a series of steps of water adding, mixing, ball forming, room-temperature drying and solidifying by using red mud as the raw material, mixing gypsum into the red mud and using binding material Portland cement and powdered coal in a compound mode to achieve the synergistic interaction result and remarkably improve the red mud gelling property. Red mud powder is granulated and prepared at a room temperature, the obtained red mud particle soil repairing adhesives have certain mechanical strength and quite good heavy metal stabile solidifying performance, soil or mud polluted by heavy metal can be effectively treated, and meanwhile OH radical ions can be slowly released; the pH of soil is kept between 6.7 and 8.1 after soil is repaired through the repairing adhesives, the problems that when soil is repaired through red mud powder, the pH of soil rises too fast and plant growth is not facilitated can be effectively solved, and high application value and environment benefits are achieved.

Owner:国家电投集团山西铝业有限公司 +1

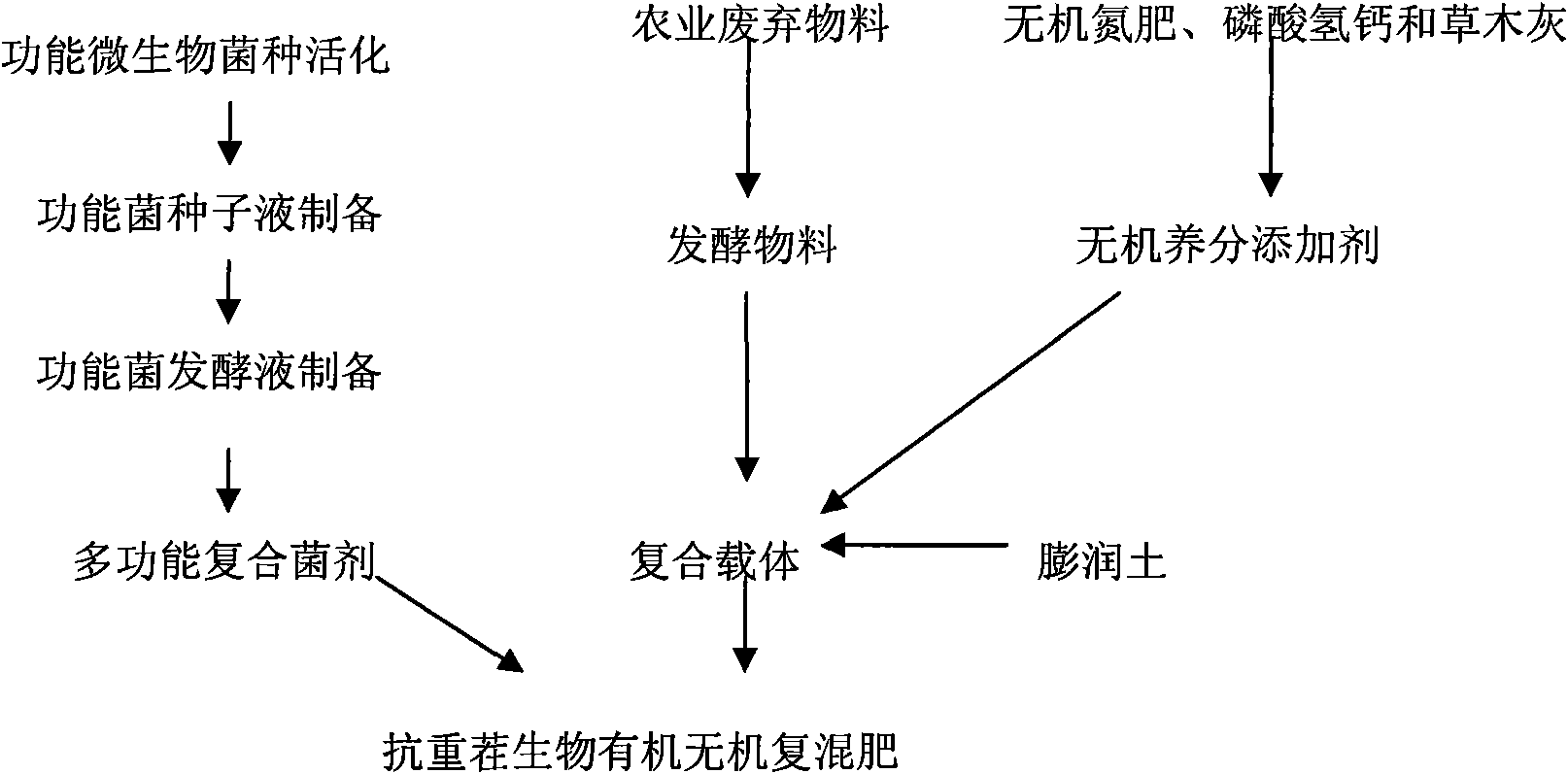

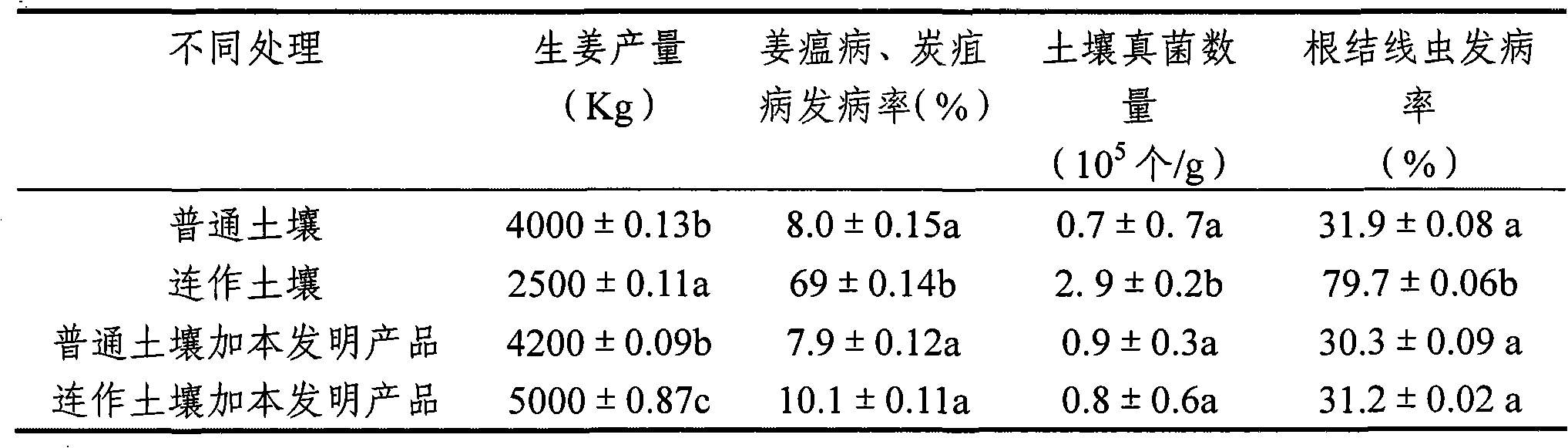

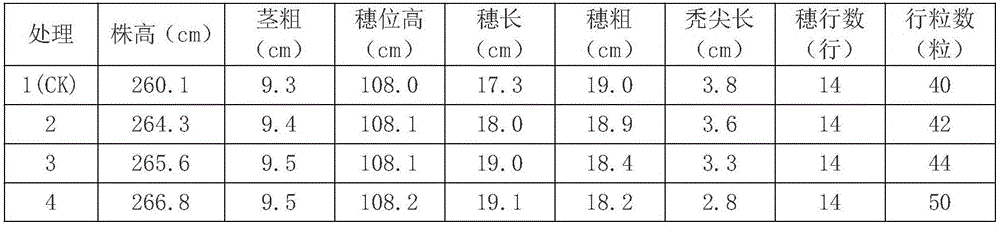

Continuous cropping resisting biological organic and inorganic compound fertilizer and production method thereof

ActiveCN101870608AInhibition of growth and reproductionImprove qualityFertilizer mixturesContinuous croppingEcological environment

The invention provides a continuous cropping resisting biological organic and inorganic compound fertilizer, which mainly contains a multifunctional compound bactericide, an agricultural organic waste fermenting material and an inorganic nutrient additive. The invention also provides a preparation method of the compound fertilizer, comprising the following steps of: respectively preparing the multifunctional compound bactericide, the agricultural organic waste fermenting material and the inorganic nutrient additive; mixing the agricultural organic waste fermenting material, the inorganic nutrient additive and a fertilizer filler according to a certain proportion, crushing to prepare a compound carrier, spraying the multifunctional compound bactericide on the surface of the compound carrier, uniformly mixing and pelleting. The continuous cropping resisting biological organic and inorganic compound fertilizer has chemical nutrients, long-acting of organic fertilizer and biological fertilizer and the function of improving soil, prevents the continuous cropping obstacles through adjusting the micro-ecological environment of soil and has the advantages of low cost, good fertilizer efficiency, high increase production, no pollution and good economic benefit.

Owner:SHANDONG BAOYUAN BIOTECH CO LTD

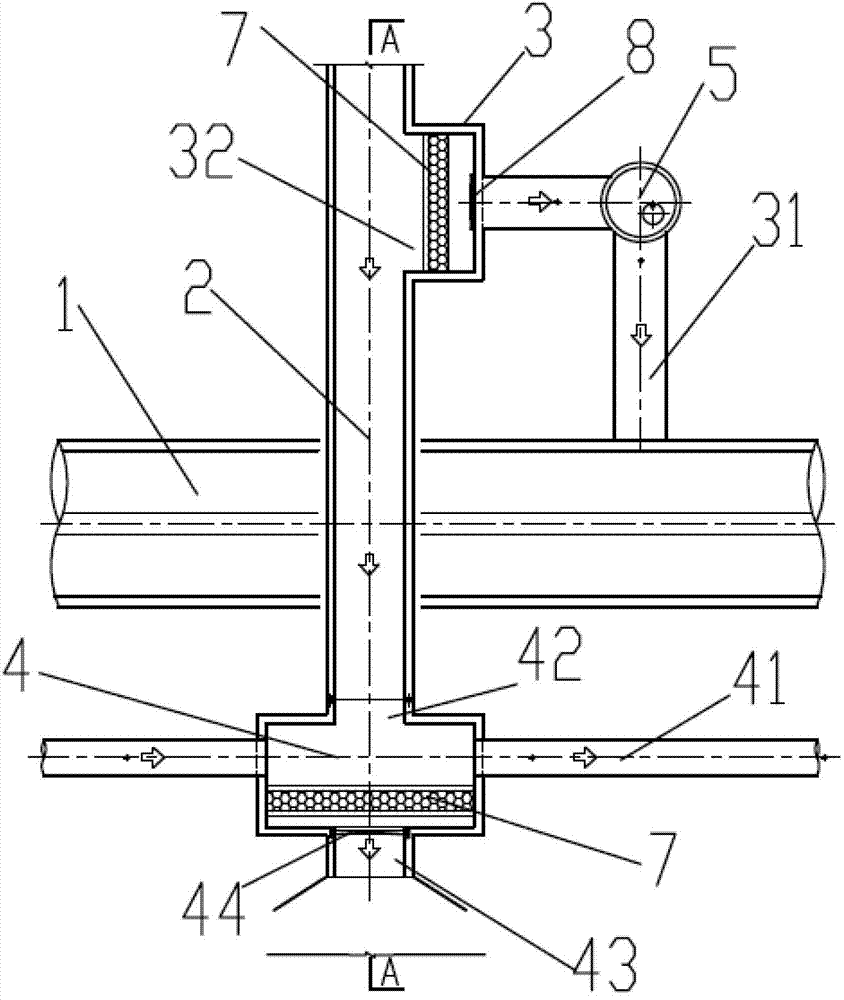

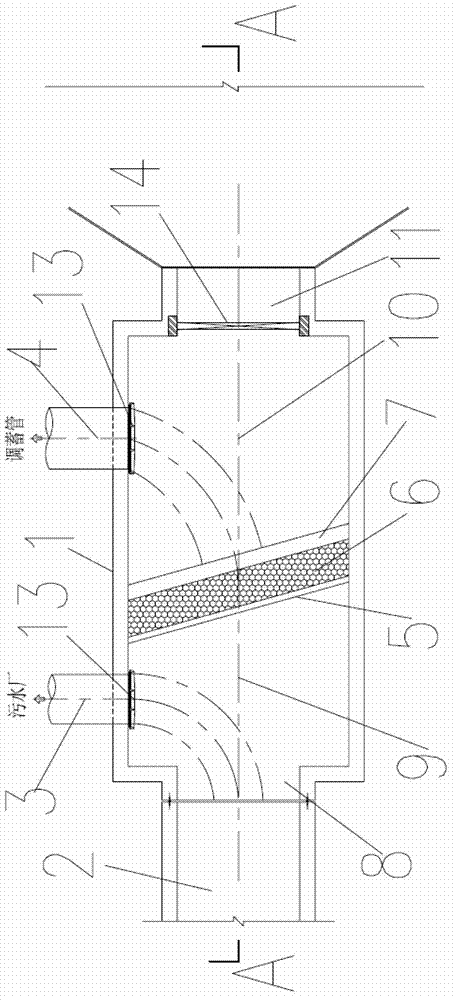

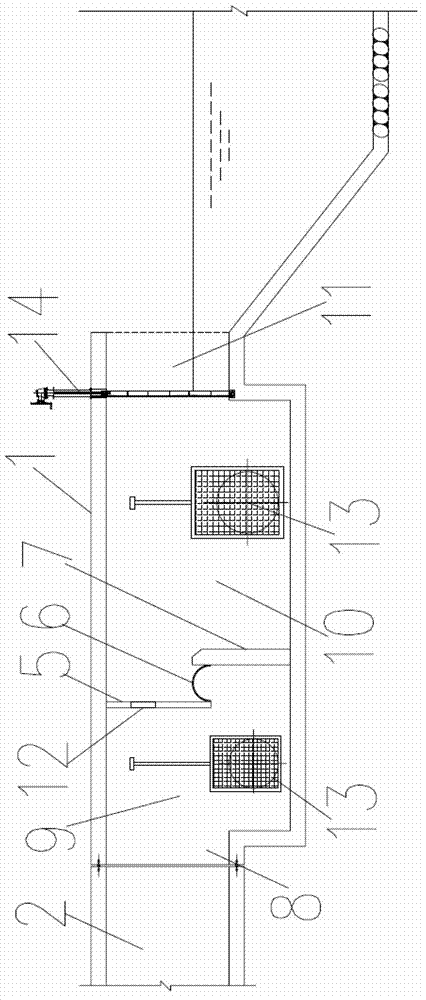

Separately-built type rainwater storage system

InactiveCN102776949ARealization of regulation and storage functionConducive to drainage regulation and storageFatty/oily/floating substances removal devicesSewerage structuresEngineeringSewage

The invention discloses a separately-built type rainwater regulation system, which is arranged on a plurality of different confluence tubes. The regulation system comprises a first interception well, a second interception well, a regulation tube, and filter layers which are arranged in the first interception well and the second interception well respectively; the first interception well is provided with a sewage interception tube which extends to a sewage plant, a drainage port connected with a river channel, and an end water inlet connected with the end parts of the confluence tubes; and the second interception well is provided with an initial rain interception tube which extends to the regulation tube, and a side water inlet connected with the side parts of the confluence tubes. The separately-built type rainwater regulation system disclosed by the invention is suitable for the current situation as well as still convenient and realizable in case of an insufficient site; simultaneously, the interception effect can be greatly improved, and the intercepted drought flow sewage is intercepted in the sewage treatment plant and rainwater is intercepted in the regulation tube, so as to reduce pollution on the river channel, and improve the regulation capacity of urban drainage.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Dry weather flow and initial rainwater multifunctional catch basin for combined network

The invention discloses a dry weather flow and initial rainwater multifunctional catch basin for a combined network. The dry weather flow and initial rainwater multifunctional catch basin for the combined network comprises a basin body. The basin body is provided with an interceptor sewer extending to a sewage plant, an initial rainwater interceptor extending to a regulation and storage pipe, a water outlet communicated with a river channel, and a water inlet communicated with a combining pipe. The catch basin further comprises a filter layer disposed in the basin body. The filter layer is disposed between the water inlet and the water outlet so that a water inlet area close to one side of the water inlet and a water outlet area close to one side of the water outlet form in the basin body. The filter layer comprises a stop board disposed on the upper portion of the basin body, an overflow weir disposed on the lower portion of the basin body and a filter net disposed between the stop board and the overflow weir. The stop board is provided with through holes. The dry weather flow and initial rainwater multifunctional catch basin for the combined network has the advantages that the multifunctional catch basin is convenient to implement, the filter layer can be cleaned automatically, intercepting effect is improved, service life of the catch basin is prolonged, and river channel pollution is reduced.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Nourishing liquid fertilizer for plant and method for preparing the same

InactiveCN1482110AAvoid pollutionSolve the rejuvenation periodFertilizer mixturesSodium metasilicateSucrose

The liquid fertilizer is compounded with potassium dihydrogen phosphate, potassium nitrate, boric acid, urea, calcium nitrate, magnesium sulfate, zinc sulfate, copper sulfate, manganese sulfate, nickel sulfate, ammonium molybdate, iron trichloride or ferrous sulfate, sodium silicate or sodium metasilicate, cane sugar or glucose, nitric acid, phosphoric acid, alcohol, rosin and sulfuric acid. Applying the liquid fertilizer can avoid pollution to soil, environment and river, and its application is saving in labor. The liquid fertilizer is non-toxic, harmless and pollution-free.

Owner:昆明虹之华园艺有限公司

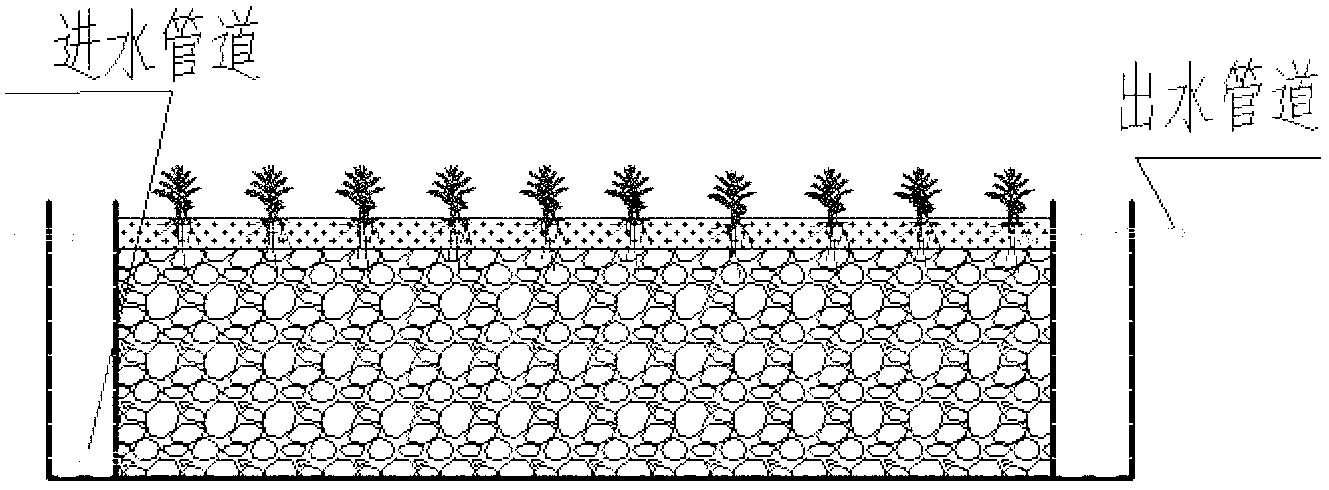

Compound constructed wetland tail water treatment system

InactiveCN103253822AReduce processing sizeIncrease investmentEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandEcological environment

The invention discloses a compound constructed wetland tail water treatment system, which belongs to the field of sewage treatment technology. The system mainly includes a pretreatment and a constructed wetland system. The pretreatment portion comprises an aeration oxidation pool and an ecological gravel bed; The constructed wetland system fuses a design of stabilization lagoon, which combines a vertical current constructed wetland and a surface flow constructed wetland, and a stabilization lagoon is arranged in step in series; the tail water to be treated passes the aeration oxidation pool, the ecological gravel bed, the vertical current constructed wetland, the stabilization lagoon in order, and finally passes the surface flow constructed wetland and flows out. The system combines physical, chemical and biological means organically, thereby effectively improving the tail water quality, and the water quality of water outlet basically reaches the surface water environment standard III grade, and the water outlet can directly returns to river ecological environment for supplementing water and can be used as city miscellaneous water; the invention has the advantages of low investment, simple operation, low energy consumption, high environment benefit and ecological benefit, etc.

Owner:HOHAI UNIV

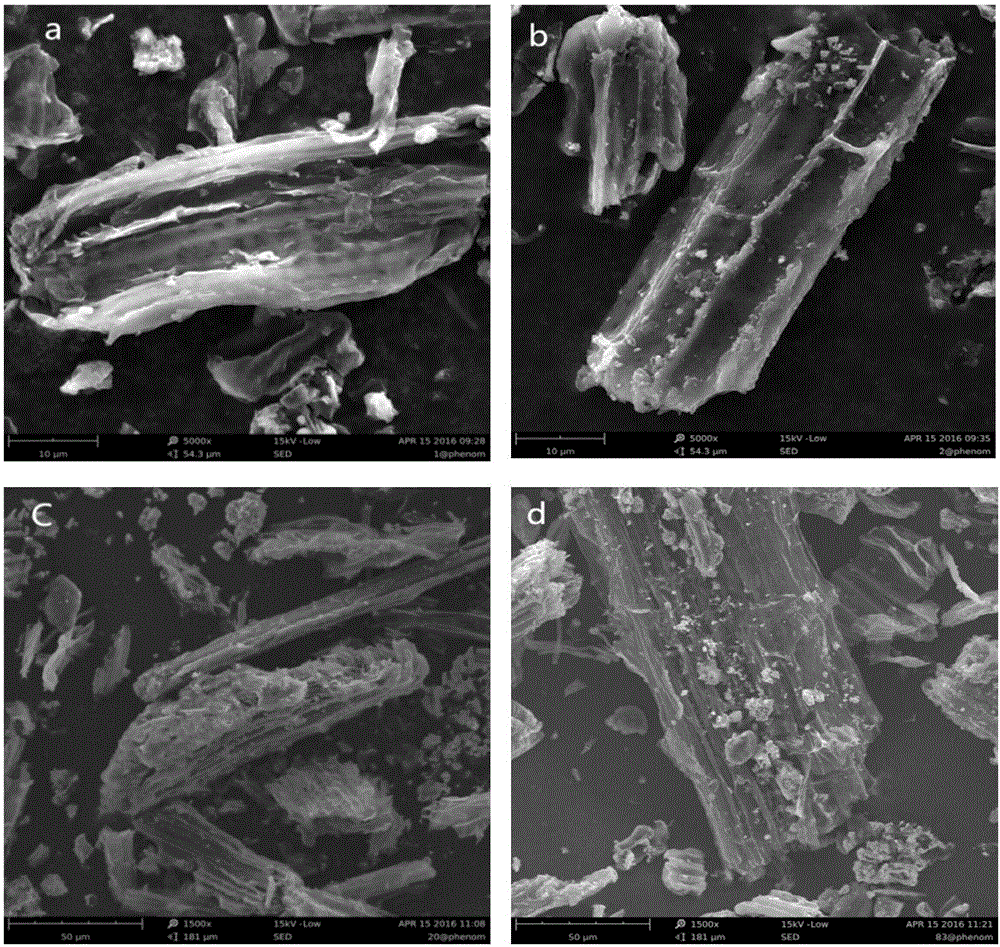

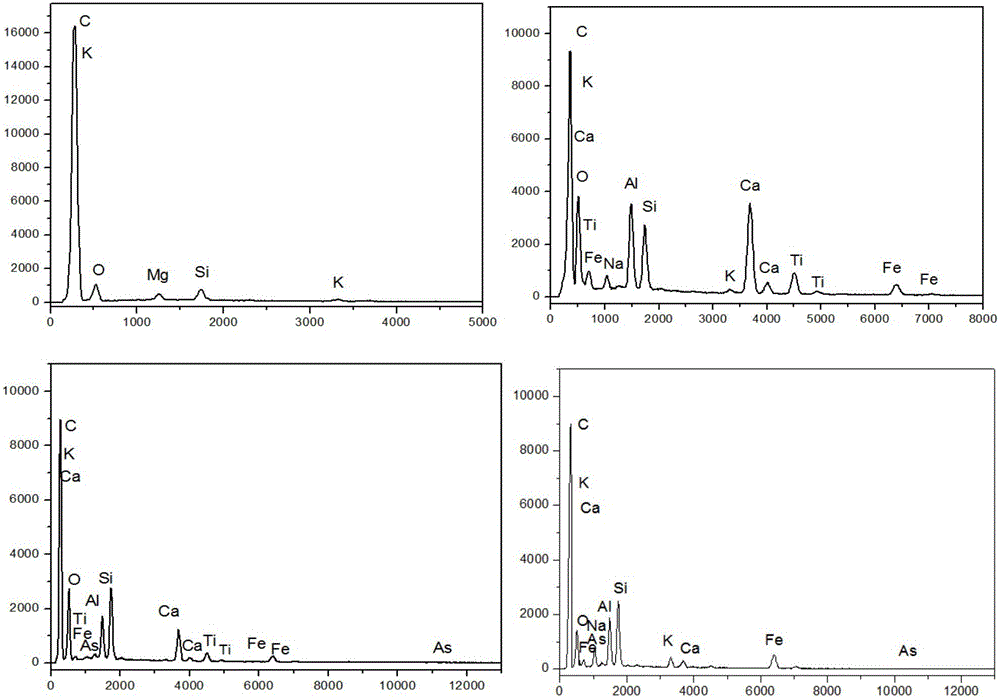

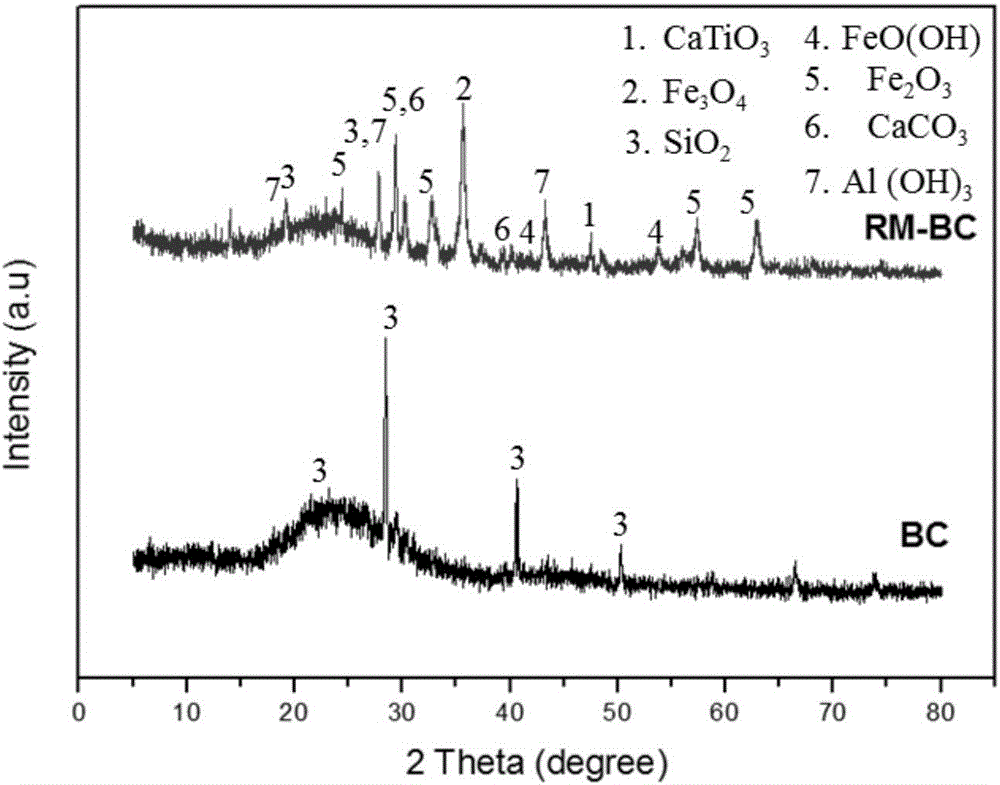

Modified biochar material for removing arsenic, and preparation and application thereof

InactiveCN106362685AImprove adsorption capacityWide variety of sourcesOther chemical processesWater contaminantsRed mudWastewater

The invention relates to a modified biochar material for removing arsenic, and preparation and application thereof. The preparation method comprises the following steps: adding biomass raw material powder into an ultrasonically-dispersed suspension of red mud and water, stirring the suspension to mix uniformly, and performing solid-liquid separation; roasting a obtained mixture of biomass and the red mud in a non-oxidizing atmosphere at the roasting temperature of 550 to 650 DEG C to obtain a carbonized product, namely, the modified biochar material. The modified biochar material is wide in raw material source, is convenient to prepare, has relatively high adsorption performance for arsenic-containing wastewater, is easy for large-scale production, and has a good application prospect.

Owner:CENT SOUTH UNIV

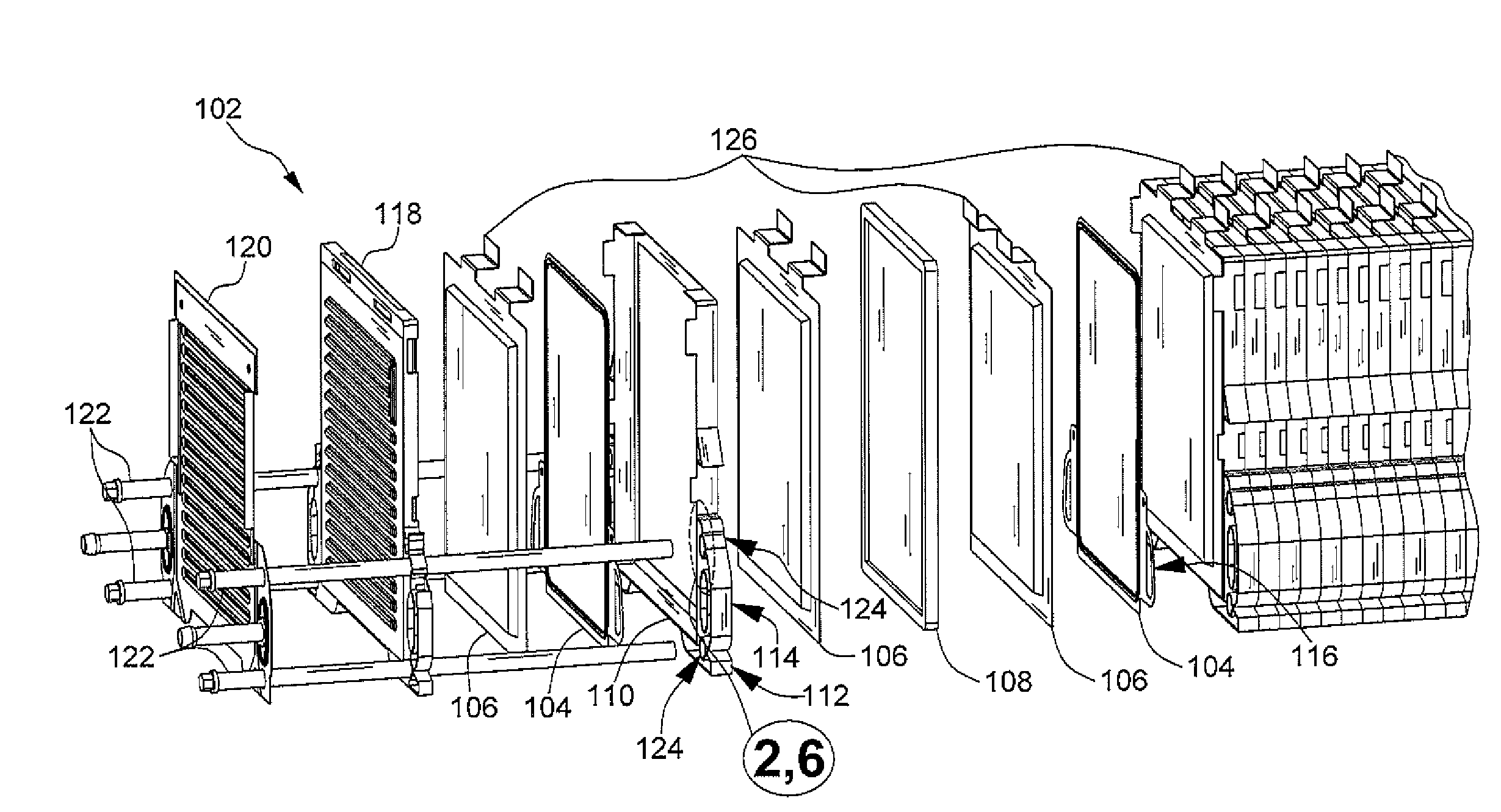

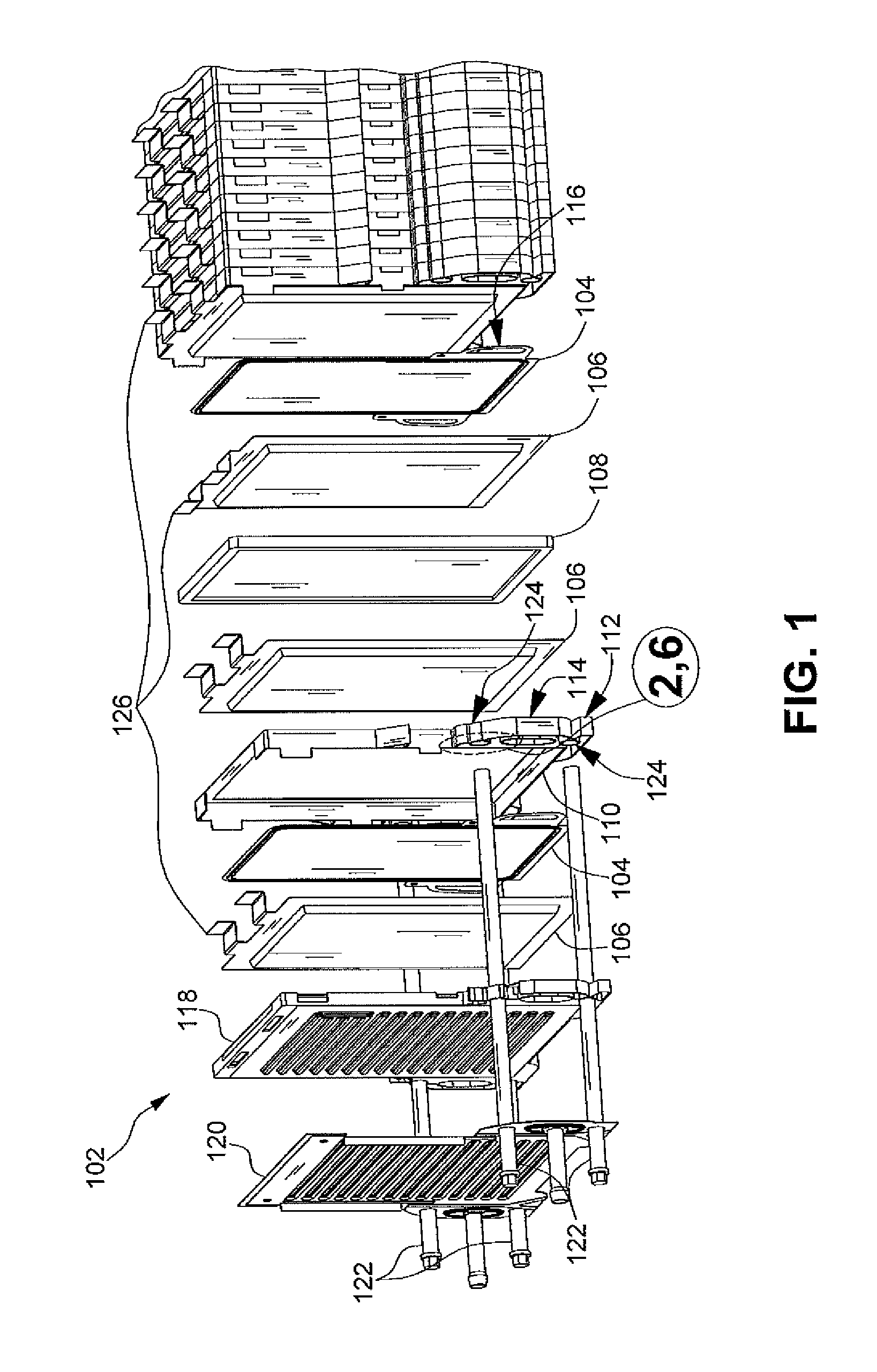

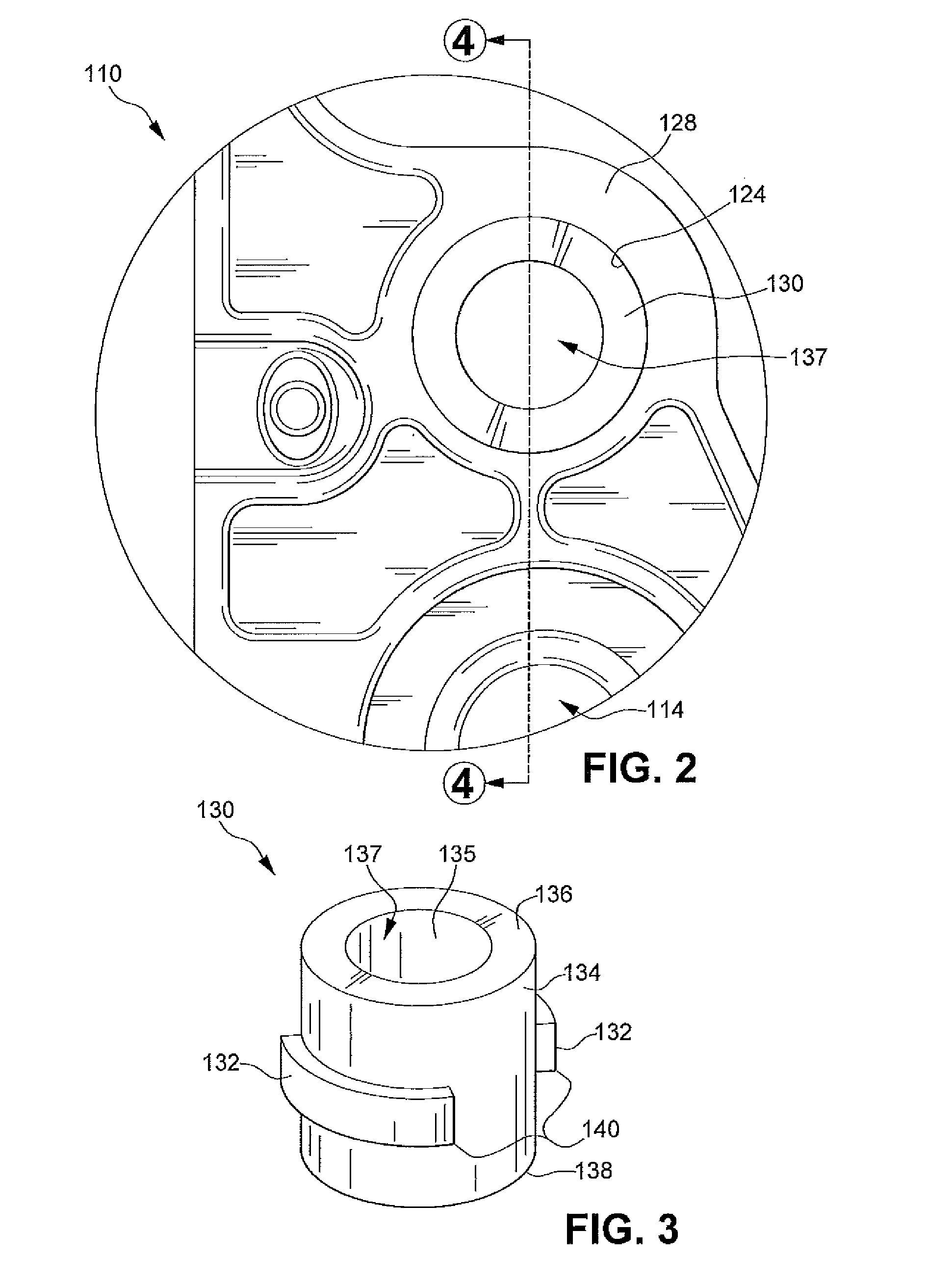

One piece compression resistant prismatic cell

ActiveUS20120107659A1Eliminate requirementsSpeed up the processLarge-sized flat cells/batteriesFinal product manufactureEngineeringBattery pack

A prismatic repeating frame assembly for a battery pack includes a main body and a hollow compression limiter. The main body is formed from a first polymer. The main body has an aperture formed therein. The hollow compression limiter is formed from a second polymer. The compression limiter is disposed in the aperture of the main body and permits a compression rod to be disposed therethrough. The second polymer is configured to withstand forces during an assembly of the battery pack and frequency inputs during an operation of the battery pack.

Owner:GM GLOBAL TECH OPERATIONS LLC

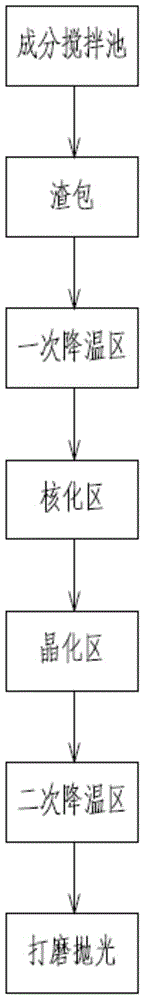

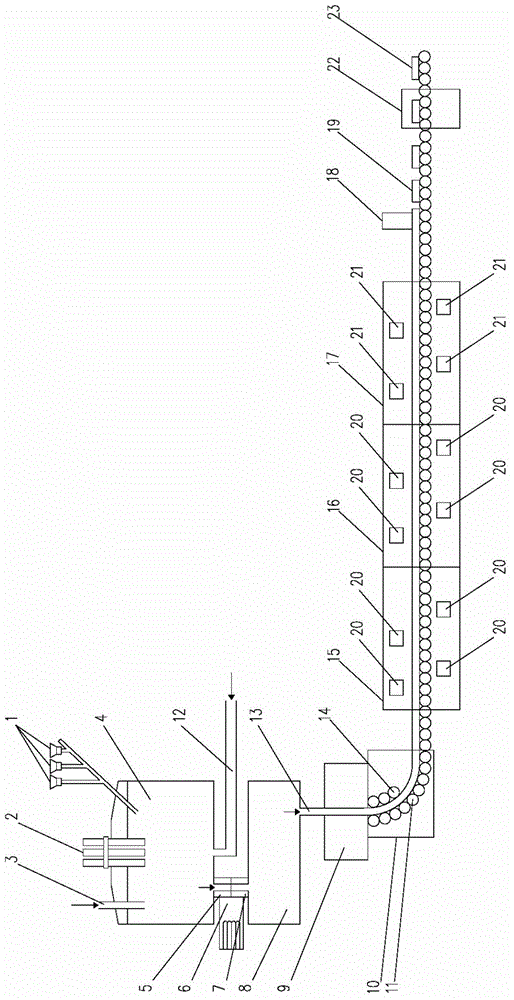

Continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace slag

The invention belongs to the fields of metallurgy and inorganic nonmetal materials, and provides a continuous casting and rolling method and device for producing glass ceramics by utilizing blast-furnace molten slag. The method comprises the following steps of (1) transferring a temperature interval when the blast-furnace molten slag is maintained in a blast-furnace tapping hole to a component tempering mixing pool, adding and uniformly stirring corresponding modifiers, coloring agents and nucleating agents, and ensuring that the molten slag stays in a high-temperature interval; (2) driving the molten slag to enter a rolling forming area through a slag port and then enter a primary cooling area, and ensuring that the molten slag enters a nucleating area before the temperature of the surface of a shell is not lower than 500DEG C; (3) continuously heating to a crystallization area; (4) entering a cooling area, and cooling the molten slag to obtain a formed product; (5) cutting the formed product in a fixed size and polishing the surface of the formed product to obtain finished product glass ceramics. By adopting the continuous casting and rolling method and the device, the blast-furnace slag and solid waste resource are utilized, the produced glass ceramics have the advantages of high strength and acid and alkali corrosion resistance, and the economic benefit and the environment-friendly benefit are obvious.

Owner:UNIV OF SCI & TECH BEIJING

Cleaning cocoon cooking method

InactiveCN103225112ANo emissionsThe total amount is controllableSilk filament obtainingChemical preparationDissolution

The invention discloses a cleaning cocoon cooking method. The method comprises the processes of: external vacuum infiltration, cooking by an automatic cooker, cocoon steaming, and adjustment, wherein a reelability agent originally used for cocoon cooking replaces a penetrating agent for penetrating to be used in the external vacuum infiltration cocoon cooking process; in the condition with 30-50 DEG C water temperature, the reelability agent can only have infiltration function with water to be adsorbed between cocoon layers and on the surface of a cocoon filament; and in the cocoon cooking process and in the condition with 60-80 DEG C water temperature, the reelability agent can promote the cocoon filament sericin dissolution to reduce adhesion between cocoon filaments for the smooth dissociation of the cocoon filaments, so that the reelability agent has the reelability function in the cocoon cooking process. One chemical preparation achieves two functions, the chemical preparation is less and easily controlled in dose, process is simple, operation is convenient, and production cost is low.

Owner:安徽绩溪县花神丝绸有限公司

Biodegradable polyols having higher biobased content

InactiveUS20180155490A1Promote degradationHigh biobased contentOrganic chemistryPolymer scienceTriol

The present invention is directed to biodegradable polyester polyol polymers having high bio-based content and methods for producing biodegradable polyester polyol polymers having high bio-based content. In preferred embodiments, β-lactone monomers may be produced from epoxide and carbon monoxide having high bio-based content. In certain preferred embodiment, the β-lactone is β-propiolactone produced from ethylene oxide and carbon monoxide. In certain embodiments, β-lactones may be polymerized with diols, triols, and polyols to form the biodegradable polyester polyol polymers having high bio-based content. In some embodiments, the biodegradable polyester polyol polymers having high bio-based content may be terpolymers formed from a first β-lactone, a diol, triol, or polyol, and a second β-lactone. In some other embodiments, the biodegradable polyester polyol polymers having high bio-based content may be copolymers formed from a polylactone oligomer and a diol, triol, or polyol.

Owner:NOVOMER INC

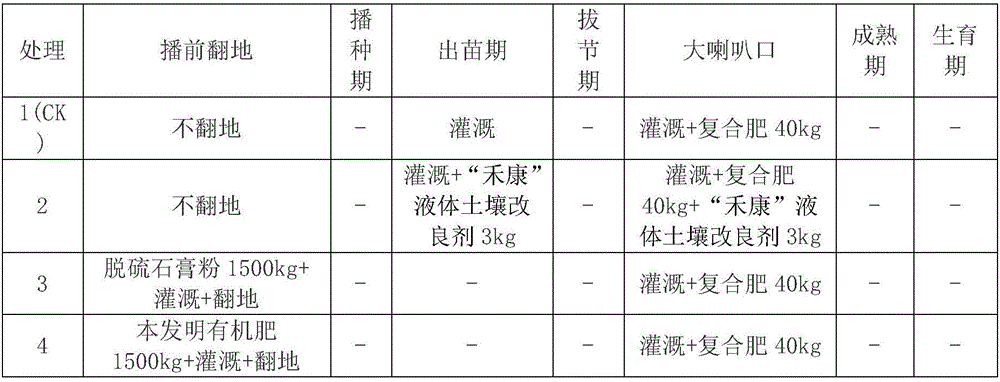

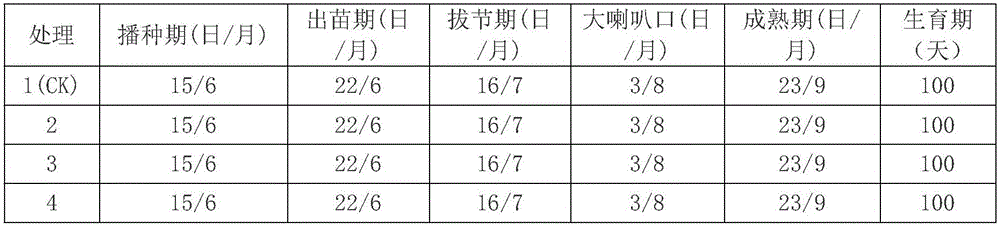

Special organic fertilizer for saline-alkaline soil improvement and preparation method and application of special organic fertilizer for saline-alkaline soil improvement

InactiveCN106278705AEffectively neutralizes alkalinityMeet the needs of useCalcareous fertilisersAmmonium salt fertilisersAlkali soilAmmonium sulfate

The invention discloses a special organic fertilizer for saline-alkaline soil improvement and a preparation method and application of the special organic fertilizer for saline-alkaline soil improvement. The special organic fertilizer for saline-alkaline soil improvement comprises, by weight, more than 90% of spent bleaching clay bleached by edible fat and oil, and particularly comprises, by weight, 90%-92% of spent bleaching clay bleached by edible fat and oil, 1%-6% of medium trace elements and 2%-9% of saline-alkaline soil improvement materials, wherein the medium trace elements comprise, by weight, 35-65% of potassium sulfate, 30-60% of ammonium sulfate, 1-4% of zinc sulfate and 0.5-2% of sodium borate, and the saline-alkaline soil improvement materials comprise, by weight, 70-100% of desulfurated gypsum powder and 0-30% of sulfur powder. The special organic fertilizer for saline-alkaline soil improvement has the advantages of reasonable organic fertilizer ratio, simplicity in use and capabilities of applying once, regulating a soil pH value and salinity-alkalinity and providing required nutritional ingredients and trace elements for crop growth.

Owner:北京盖希尔科技股份有限公司

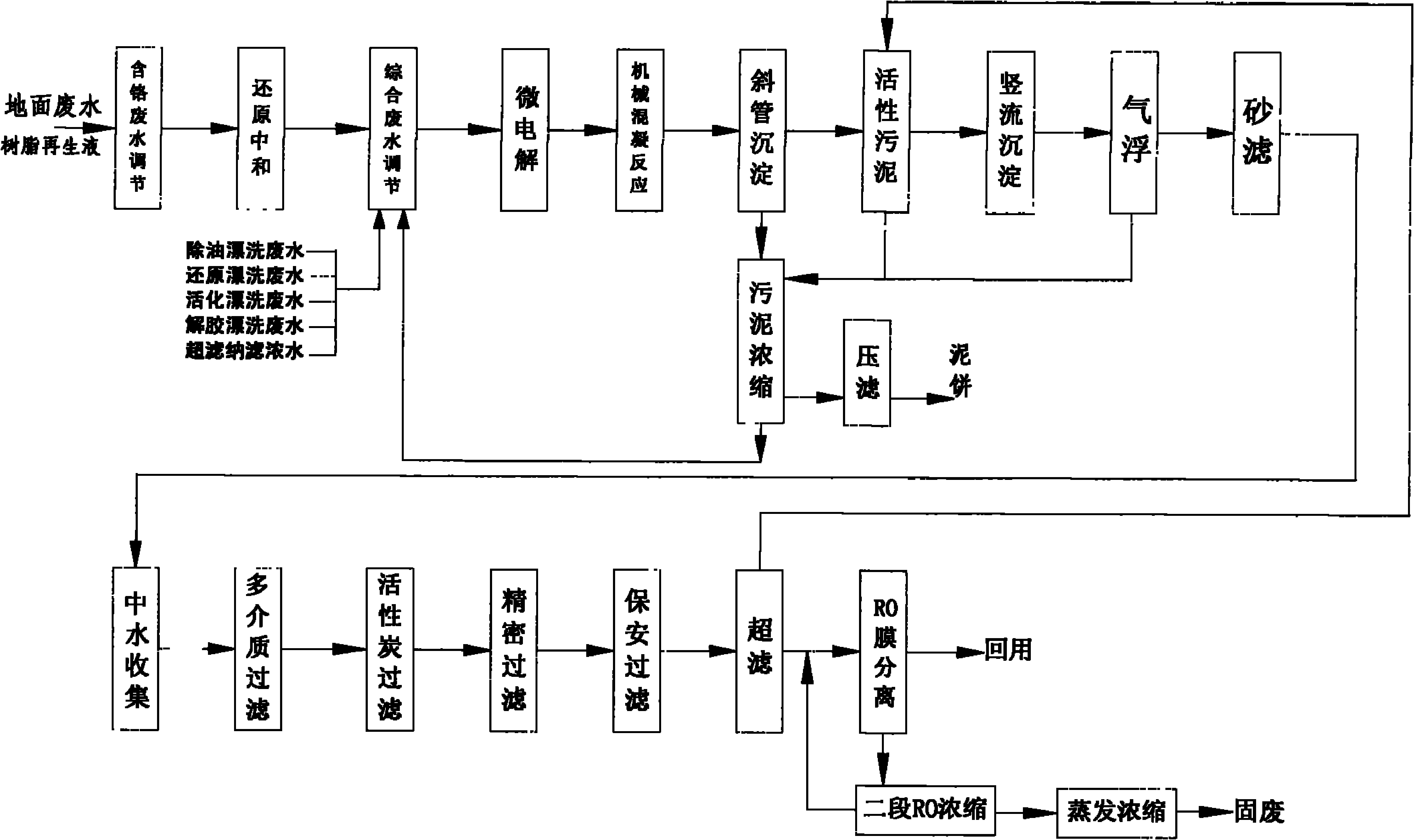

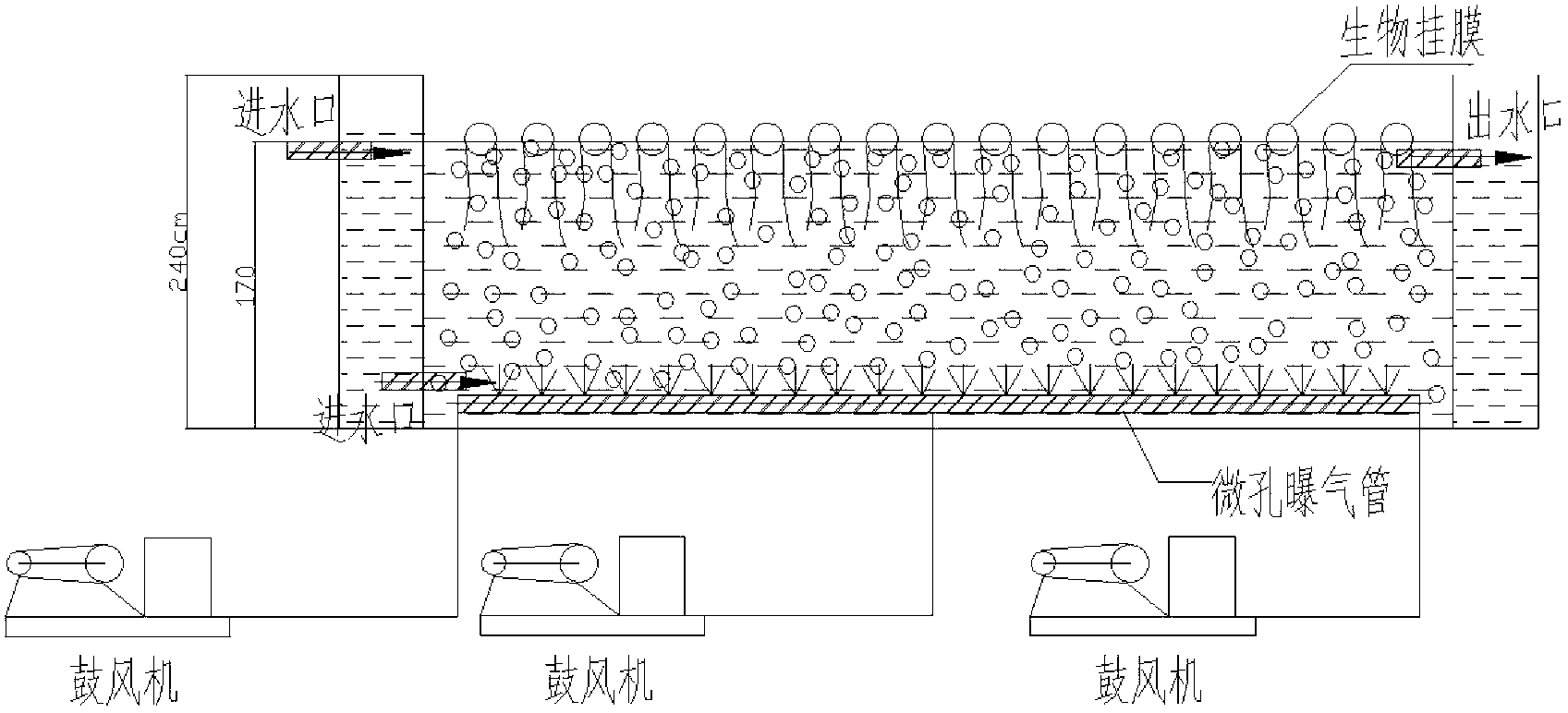

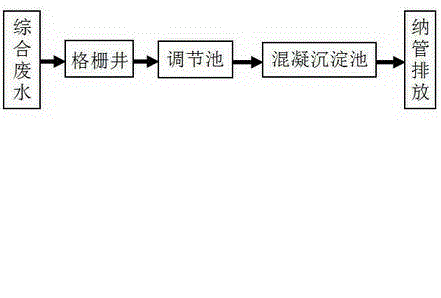

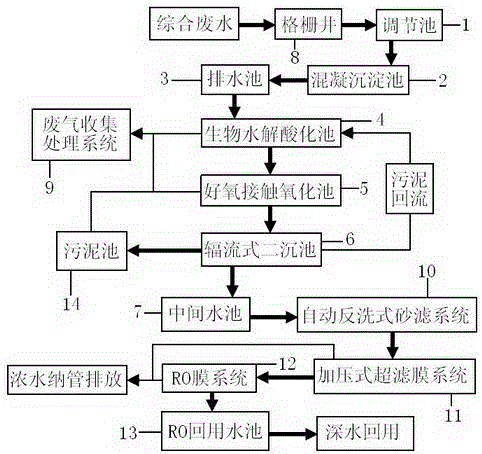

Printing and dyeing wastewater processing system

InactiveCN102616978ASolve the problem of exceeding the standardIncrease water reuseSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentWater dischargeSludge

The invention discloses a printing and dyeing wastewater processing system. The printing and dyeing wastewater processing system comprises a comprehensive wastewater preprocessing system, a depth reuse processing system and a sludge processing system, wherein the sludge processing system comprises a sludge pool; the comprehensive wastewater preprocessing system comprises an adjustment pool, a coagulative precipitation pool, a water discharging pool, a biological hydrolysis-acidification pool, an aerobic contact oxidation pool, a radial flow type secondary sedimentation pool and an intermediate water pool which are sequentially connected; the depth reuse processing system comprises an automatic backwashing sand filtration system, a pressure type ultrafilter membrane system, an RO membrane system and an RO reuse water pool which are sequentially connected; the sludge outlet of the radial flow type secondary sedimentation pool is communicated with the sludge pool; and the water outlet of the intermediate water pool is communicated with the automatic backwashing sand filtration system. According to the invention, the quality of the depth reuse water reaches outlet water quality standards; and the deepwater reuse can saves the water resource, and COD discharge is reduced year by year, so the content of discharged ammonia nitrogen can reach standards.

Owner:SHANGHAI ZHANGHUA FILM PURIFICATION

Method for repairing heavy metal-polluted soil by using red mud granular material

The invention discloses a red mud granular material and an application thereof. A red mud particle soil repairing agent takes red mud powder, gypsum, cement and fly ash as main materials, phosphate is doped as an activation material, thereby, gelling capability of red the mud powder and capability for fixing heavy metal ions in a stable mode can be increased, a series of processes of mixing by adding water, balling, and drying solidification at normal temperature can be carried out, so that the spherical particle soil repairing agent can be obtained by composite moulding of the red mud raw ore powder material. The method realizes preparation of the red mud powder with granulation at normal temperature, the obtained red mud particle soil repairing agent has certain mechanical strength and good heavy metal stable solidification performance, the heavy metal-polluted soil or sludge can be effectively processed, OH radical ions can be slowly released simultaneously, a pH value of the soil after restoration by the repairing agent is basically stabilized below 7.5, problems of fast increase of the pH value of the soil and poor growth condition for plants during a soil restoration process by the red mud powder can be effectively overcome, and the method has high application value and environment benefit.

Owner:SUN YAT SEN UNIV

Preparation method of tert-butyl peroxide

InactiveCN104557652AStrong acidPore structure highOrganic compound preparationPeroxy compound preparationPtru catalystDi-tert-butyl peroxide

The invention provides a method for preparing tert-butyl peroxide by using a heterogeneous catalyst. The method comprises the following steps: by using tert-butyl alcohol and oxydol as raw materials and an acidic ion exchange resin as a catalyst, reacting under reflux, cooling, standing, and separating to obtain an oil phase and a water phase; and washing the oil phase with alkali and water to obtain a di-tert-butyl peroxide solution (DTBP), wherein the oil phase water washing solution and water phase are the tert-butyl hydroperoxide water solution (TBHP). Since the ion exchange resin has the advantages of large pore structure, high acidity and high catalysis efficiency and the large pore structure can not be destroyed in reaction, the catalyst can be easily separated from the reaction product and can be recycled repeatedly, thereby having higher economic value. Besides, no sulfuric acid or any other strong acid is used in the production process, so the method has the advantages of low corrosion to equipment and no environment pollution, and has higher environmental benefit.

Owner:NORTHWEST NORMAL UNIVERSITY

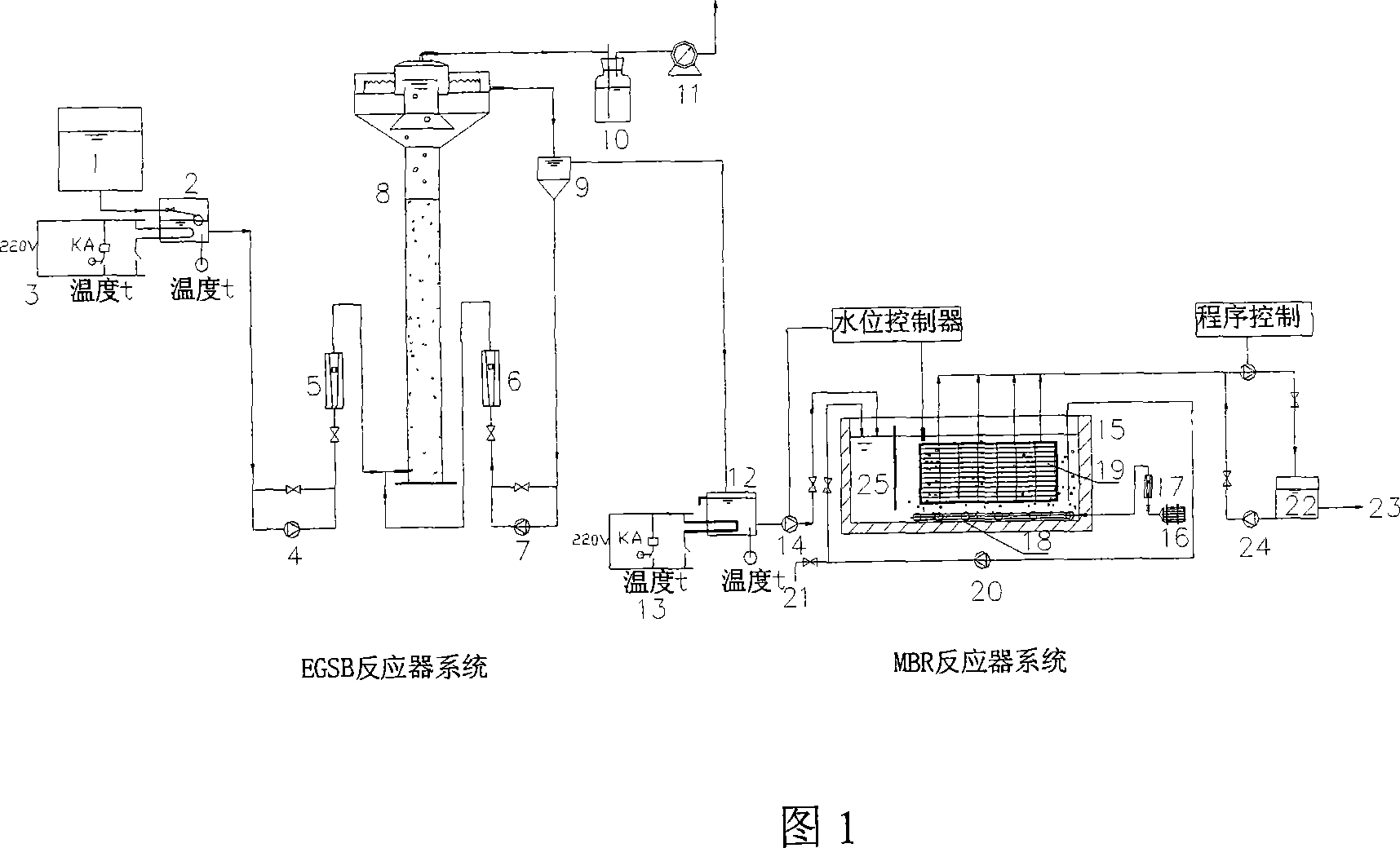

Method of treating hard-degrading high concentrated organic wastewater

InactiveCN101113047ALow costImprove biodegradabilityTreatment with aerobic and anaerobic processesWater/sewage treatment by oxidationHigh concentrationEmission standard

A treatment method for persistent high concentration organic wastewater pertains to environmental protection technology area. The invention utilizes the combined system of Fenton Oxidation Process (abbr. FOP), Expanded Granular Sludge Bed (abbr. EGSB) and Membrane Bioreactor (abbr. MBR) to treat persistent high concentration organic wastewater. The Fenton Higher Oxidation treatment can do part degradation of COD, and transform some persistent organic compound with toxic properties into chemical degradation-labile intermediate product, thereby improving the degradation performance of wastewater. The anaerobic treatment can get rid of most COD in the wastewater to guarantee high load and low cost in the complete treatment process. The aerobic treatment can ensure the effluent steadily achieves the discharge standard and realize the environment and social benefit of the whole techniques. By adopting the invention, the COD and TN in effluent with persistent high concentration organic wastewater can be reduced by 80 percent to 95 percent, and fully meet the grade one standard of national integrated wastewater discharge standard.

Owner:JIANGNAN UNIV

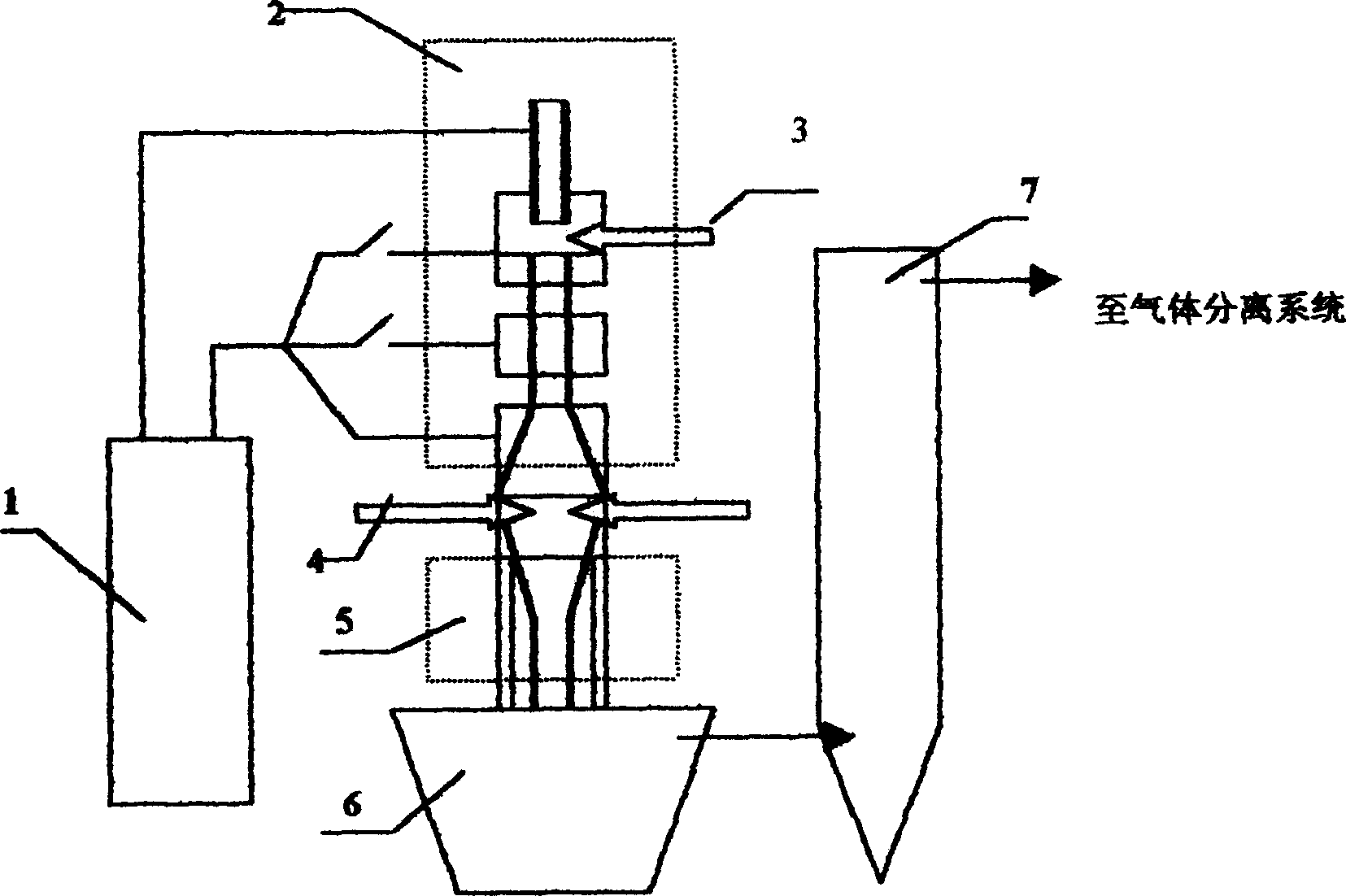

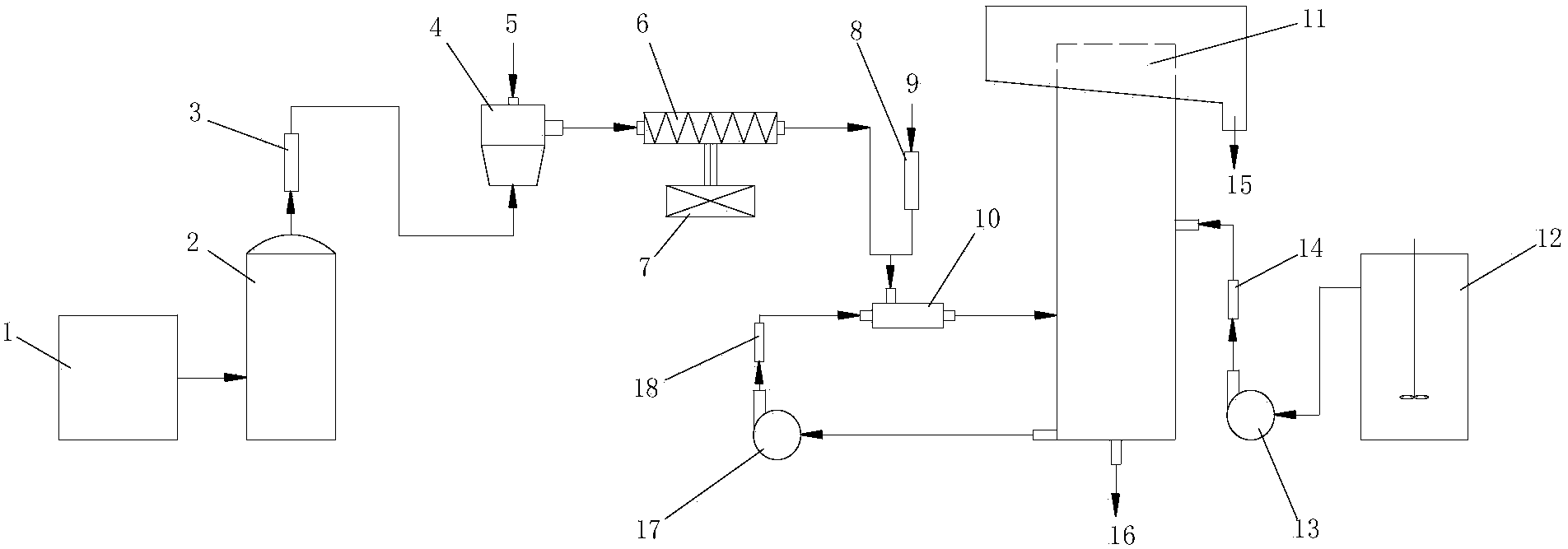

Method and device for reinforcing oil bubble column floatation process of low-order coal

The invention discloses a method and a device for reinforcing an oil bubble column floatation process of low-order coal, and belongs to floatation methods and floatation devices for the low-order coal. The method comprises the following steps: (1) adding a surfactant into a hydrocarbon oil collecting agent proportionally; (2) atomizing hydrocarbon oil mixed with the surfactant into oily mist beads in an atomizer by using air flow provided by an air compressor; (3) heating the air flow of the oily mist beads in a tubular temperature control evaporator until the temperature reaches hydrocarbon oil evaporation temperature to form oil evaporation gas; (4) mixing the heated oil evaporation gas with air, feeding the mixture into a bubble generator, and forming modified oil bubbles by wrapping bubbles with thin surfactant-modified hydrocarbon oil layers under the jet action of the bubble generator; (5) pre-wetting and uniformly mixing the low-order coal in a stirring barrel, and pumping the low-order coal into a floatation column; (6) in the floatation column, mineralizing the modified oil bubbles and low-order coal particles, carrying clean coal to float up by using the modified oil bubbles as carriers, and keeping tailings and high-ash fine silt which are not mineralized in the column to obtain the clean coal and the tailings. The method and the device have the advantages that the consumption of the hydrocarbon oil collecting agent is reduced; the floatation selectivity and the recovery rate of the low-order coal are improved.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com