Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

597 results about "Oil shale gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil shale gas (also: retort gas or retorting gas) is a synthetic non-condensable gas mixture (syngas) produced by oil shale thermal processing (pyrolysis). Although often referred to as shale gas, it differs from the natural gas produced from shale, which is also known as shale gas.

Recovery of products from oil shale

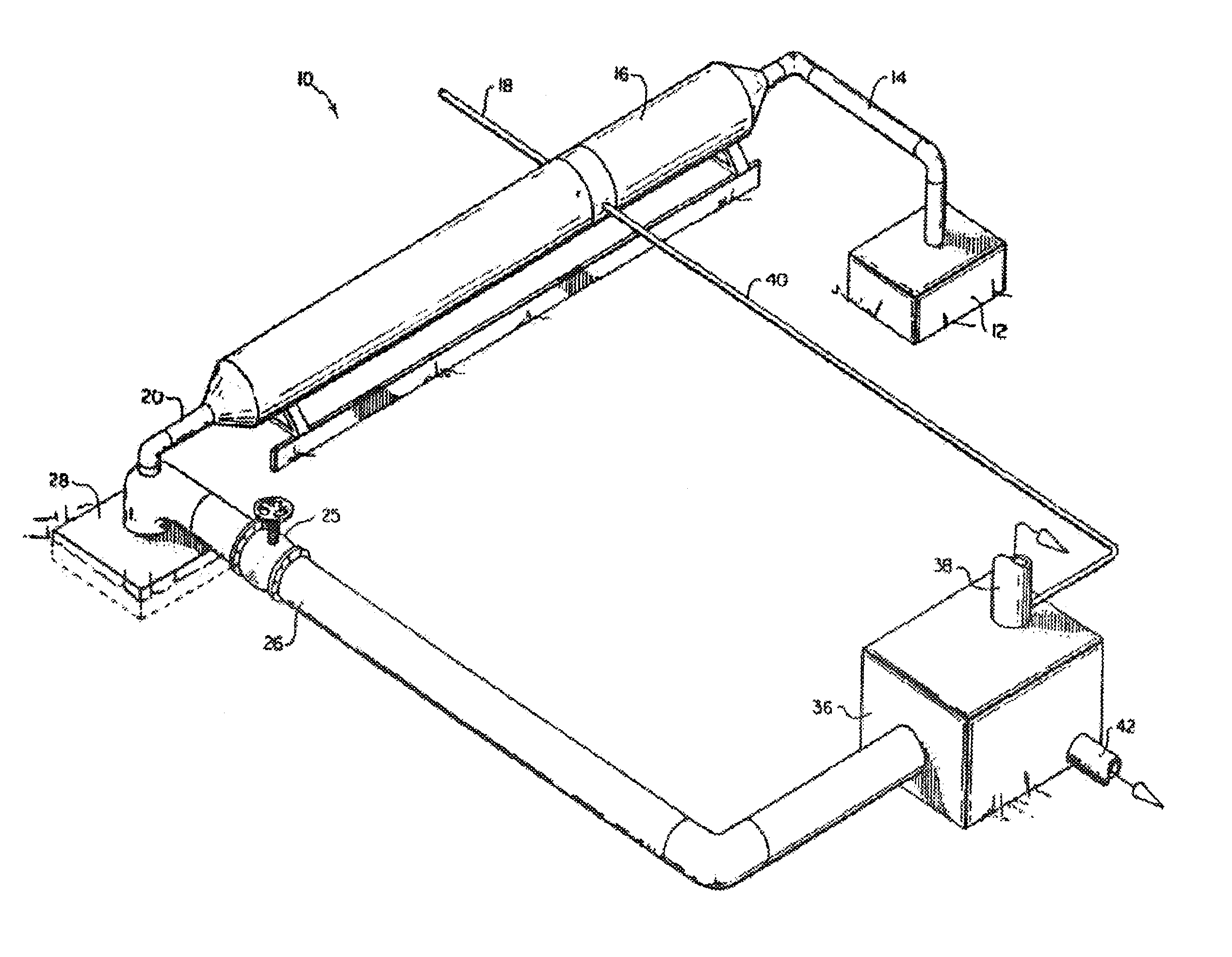

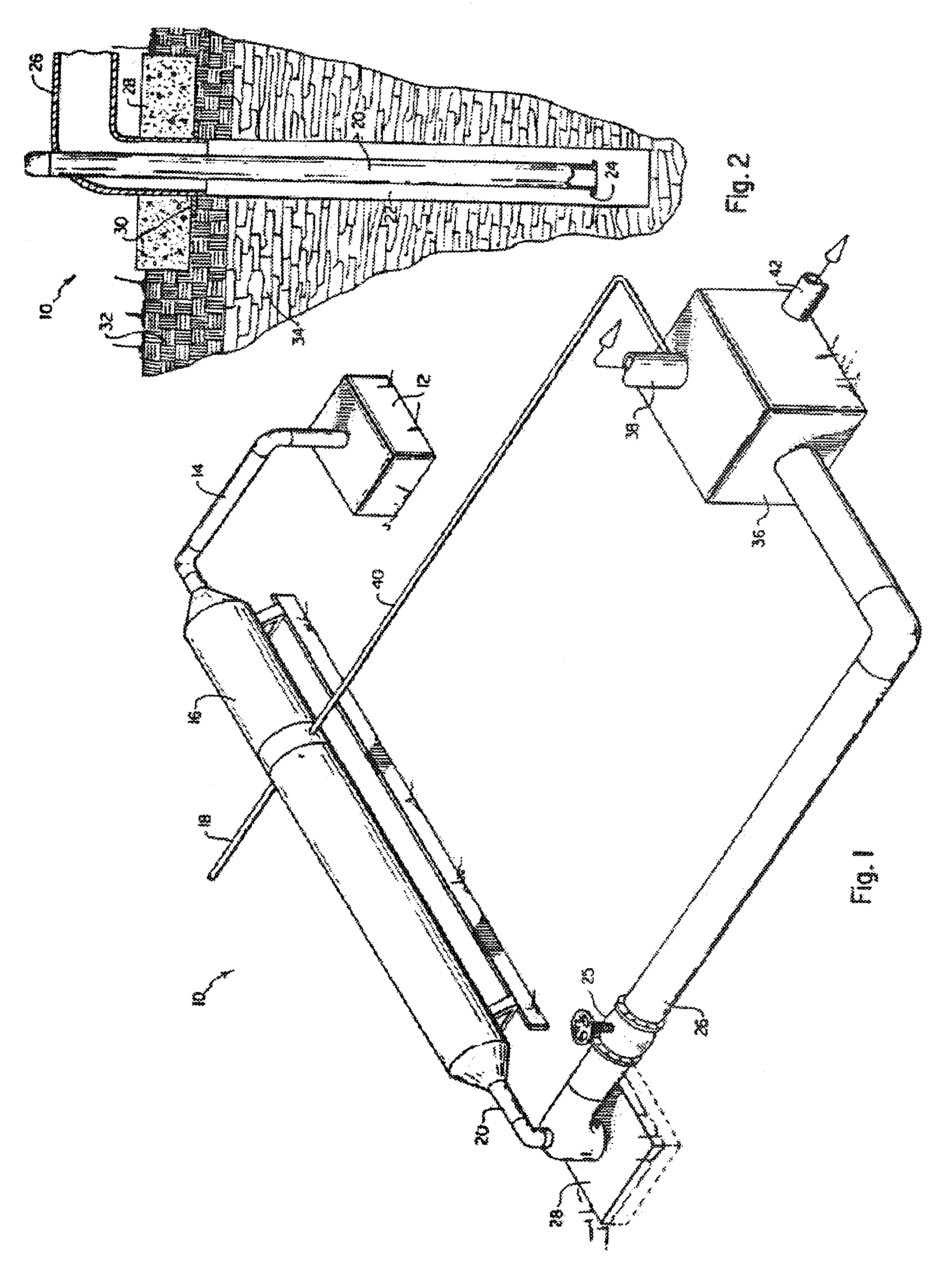

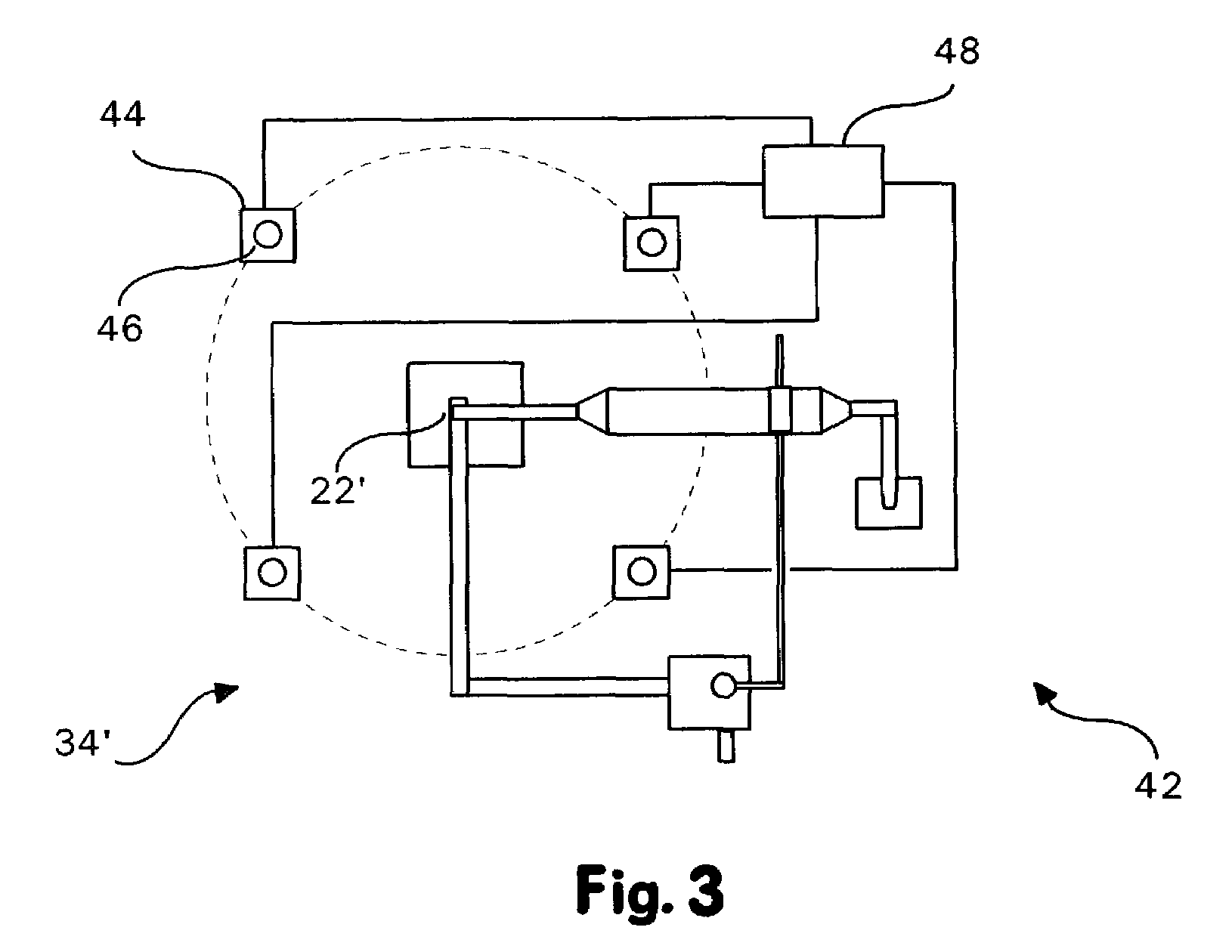

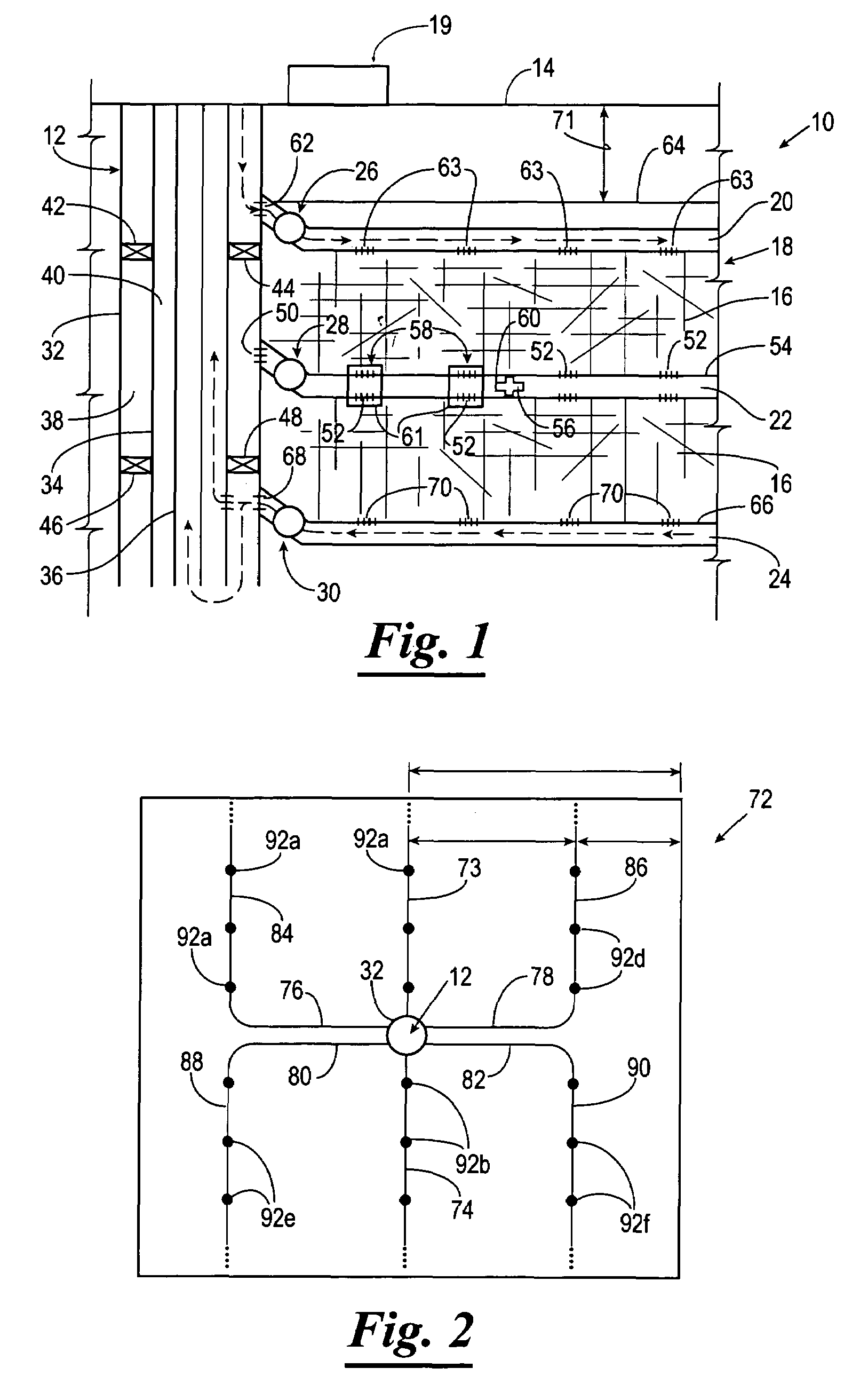

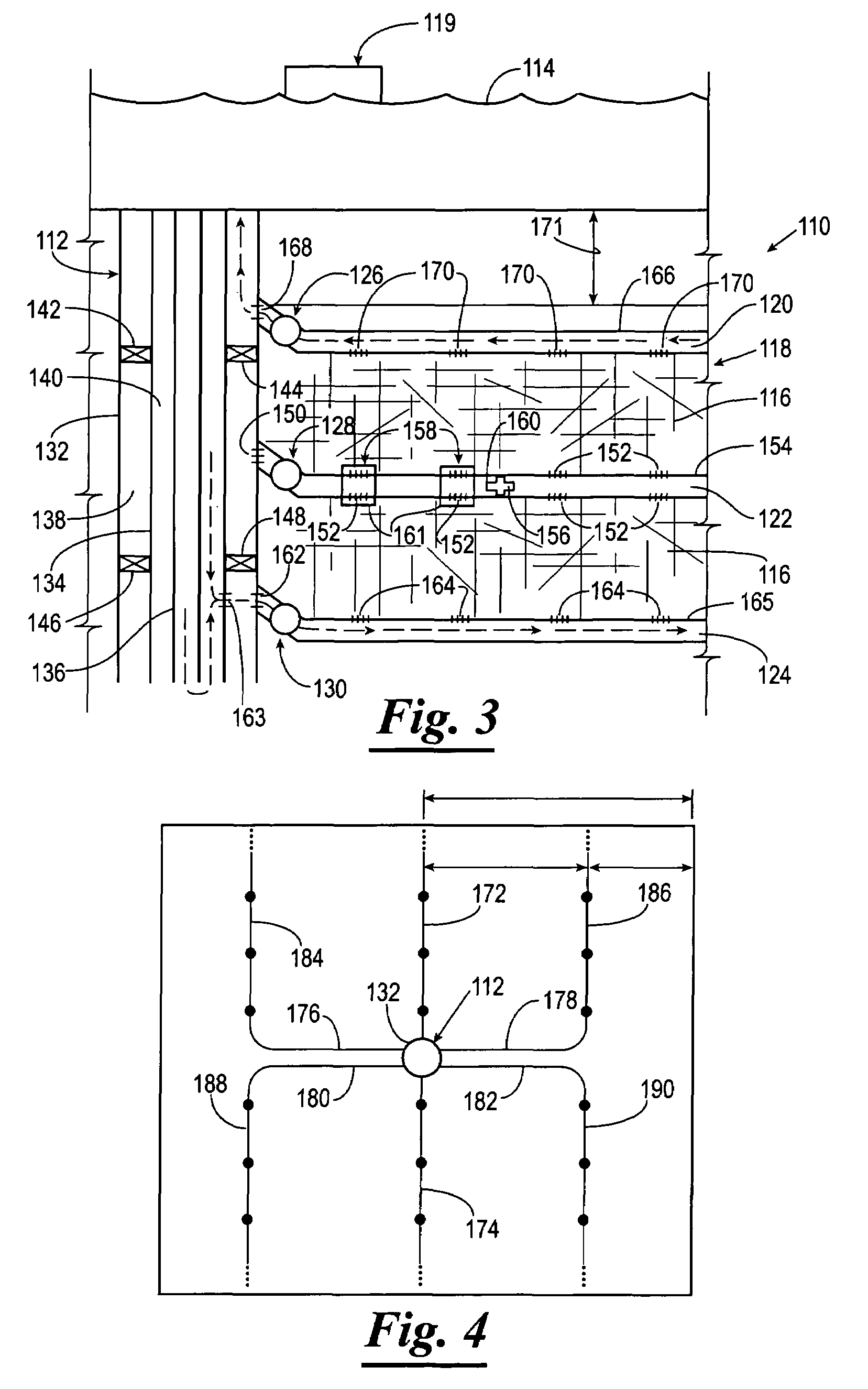

InactiveUS7048051B2Maximize recoveryProcedure is time-consume and expensiveFluid removalKerogenThermal energy

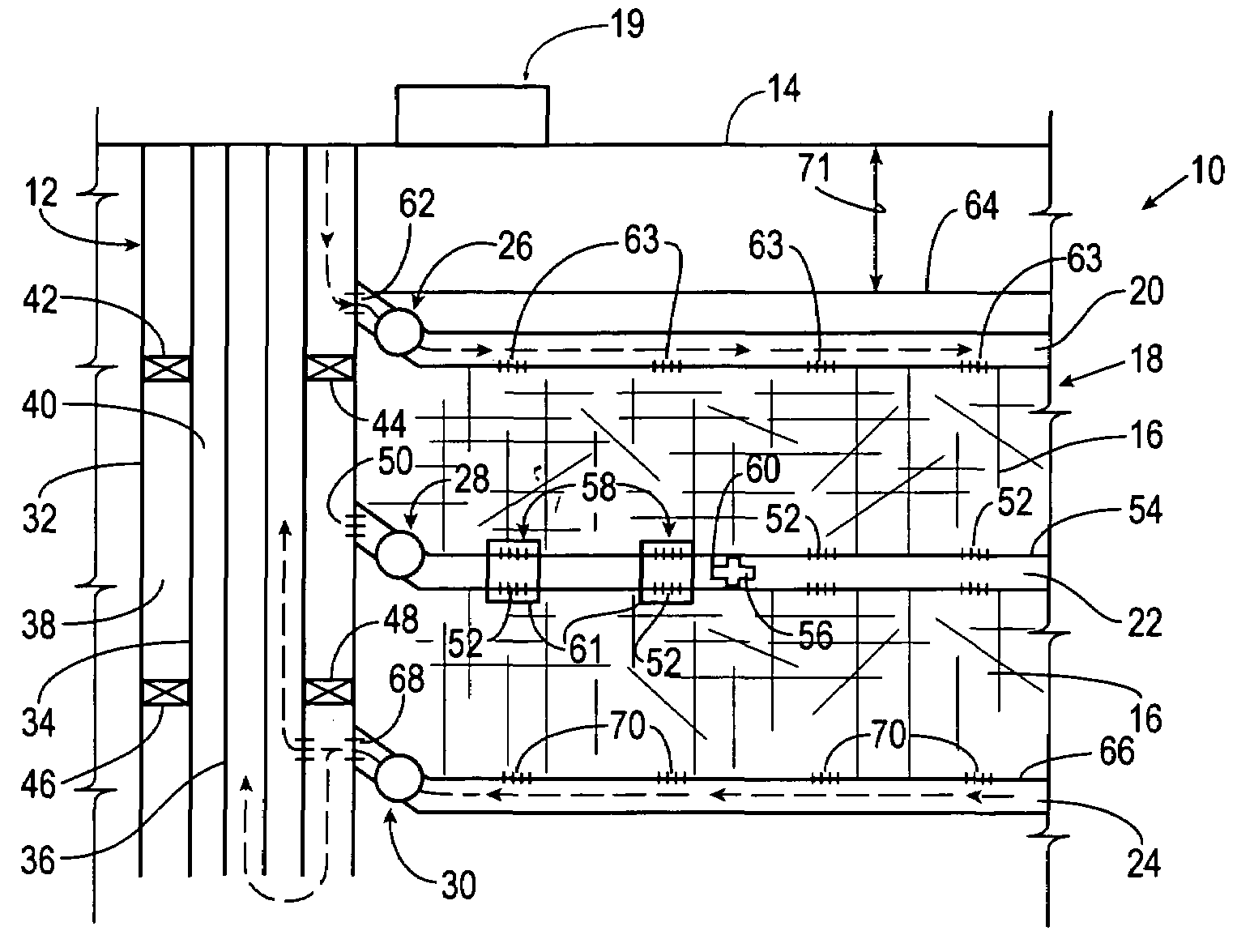

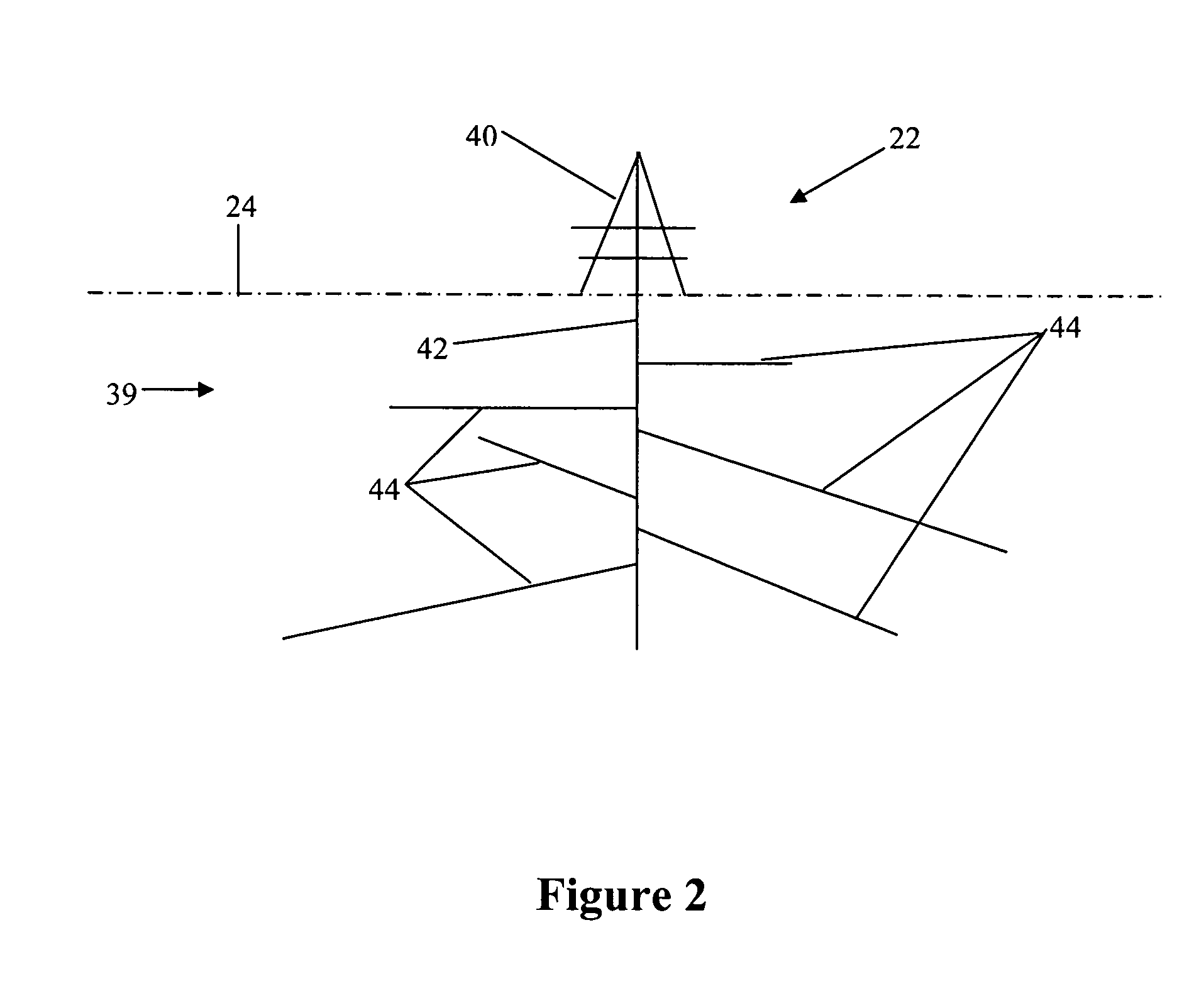

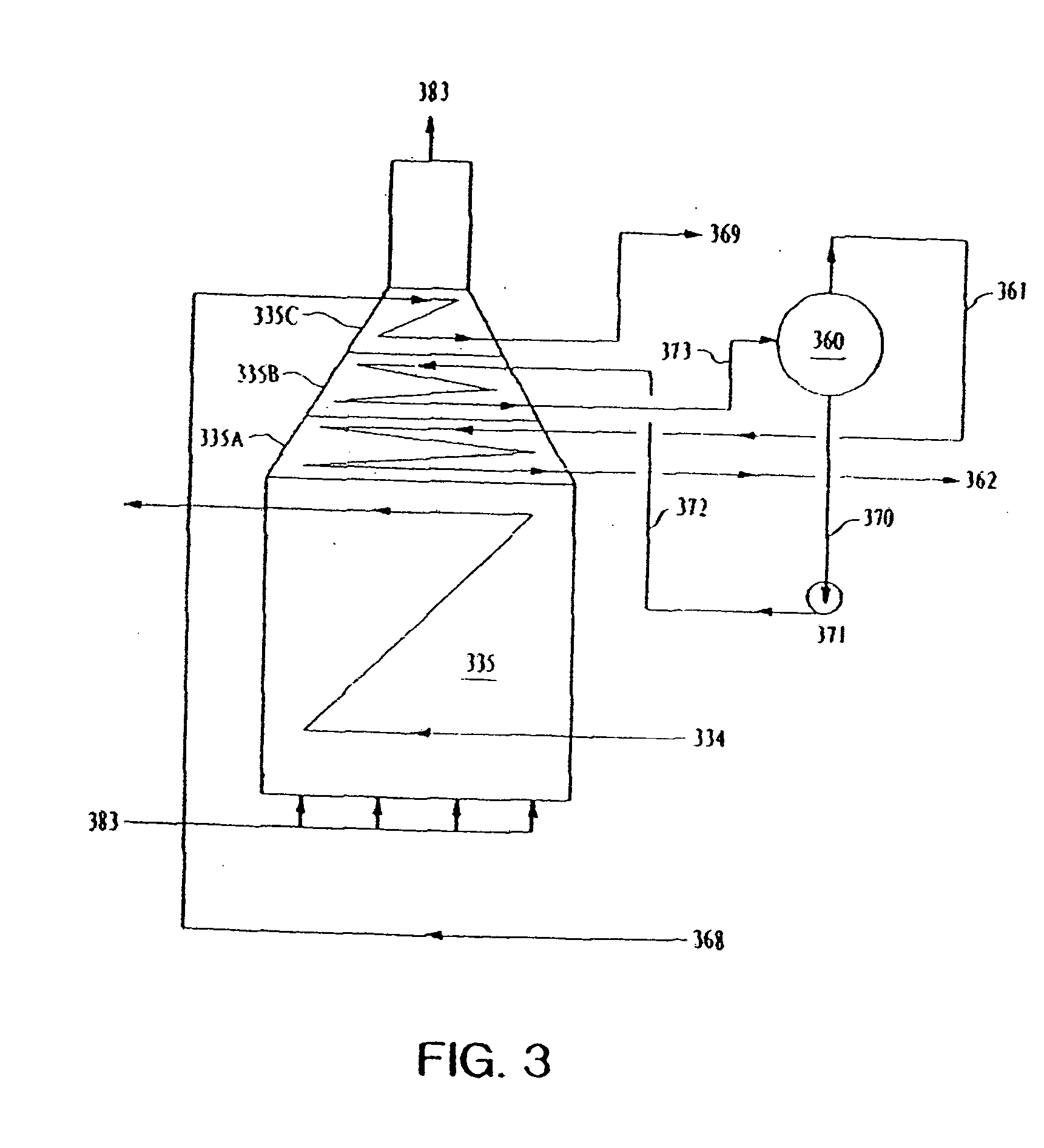

A process and system for recovering hydrocarbonaceous products from in situ oil shale formations. A hole is drilled in the oil shale formation and a processing gas inlet conduit is positioned within the hole. A processing gas is pressurized, heated, and introduced through the processing gas inlet conduit and into the hole. The processing gas creates a nonburning thermal energy front within the oil shale formation so as to convert kerogen in the oil shale to hydrocarbonaceous products. The products are withdrawn with the processing gas through an effluent gas conduit positioned around the opening of the hole, and are then transferred to a condenser wherein a liquid fraction of the products is formed and separated from a gaseous fraction.

Owner:GENERAL SYNFUELS INT

Method and system for extraction of hydrocarbons from oil shale

Owner:ULTRA SAFE NUCLEAR CORP

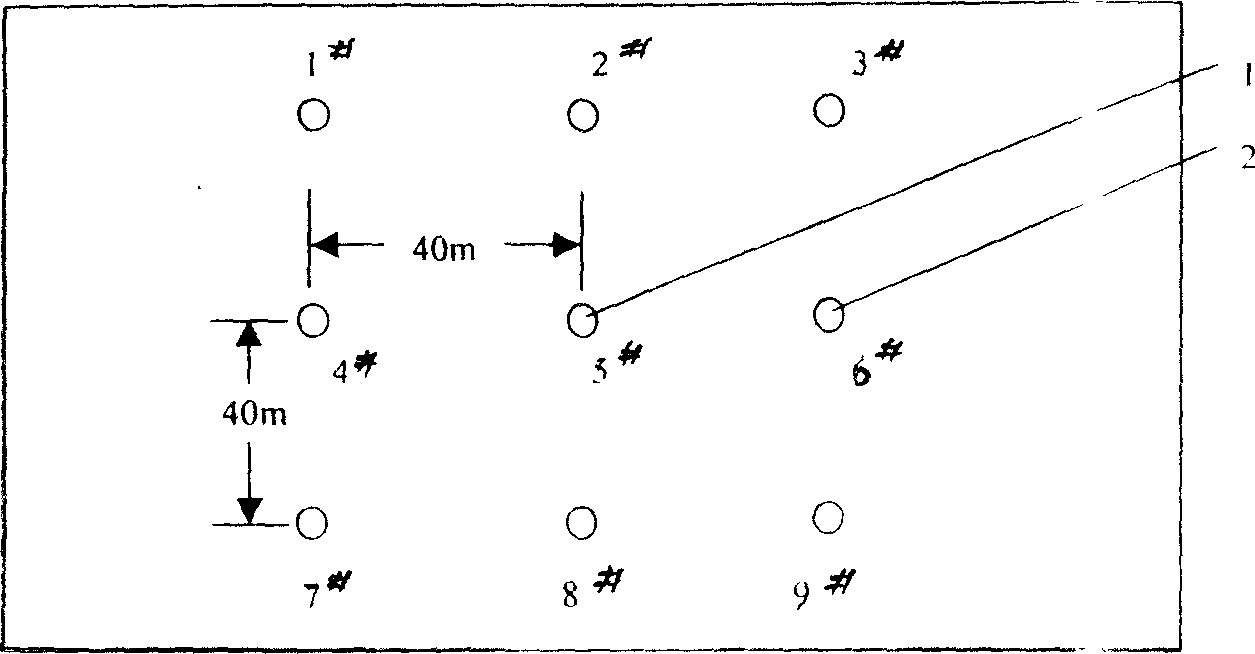

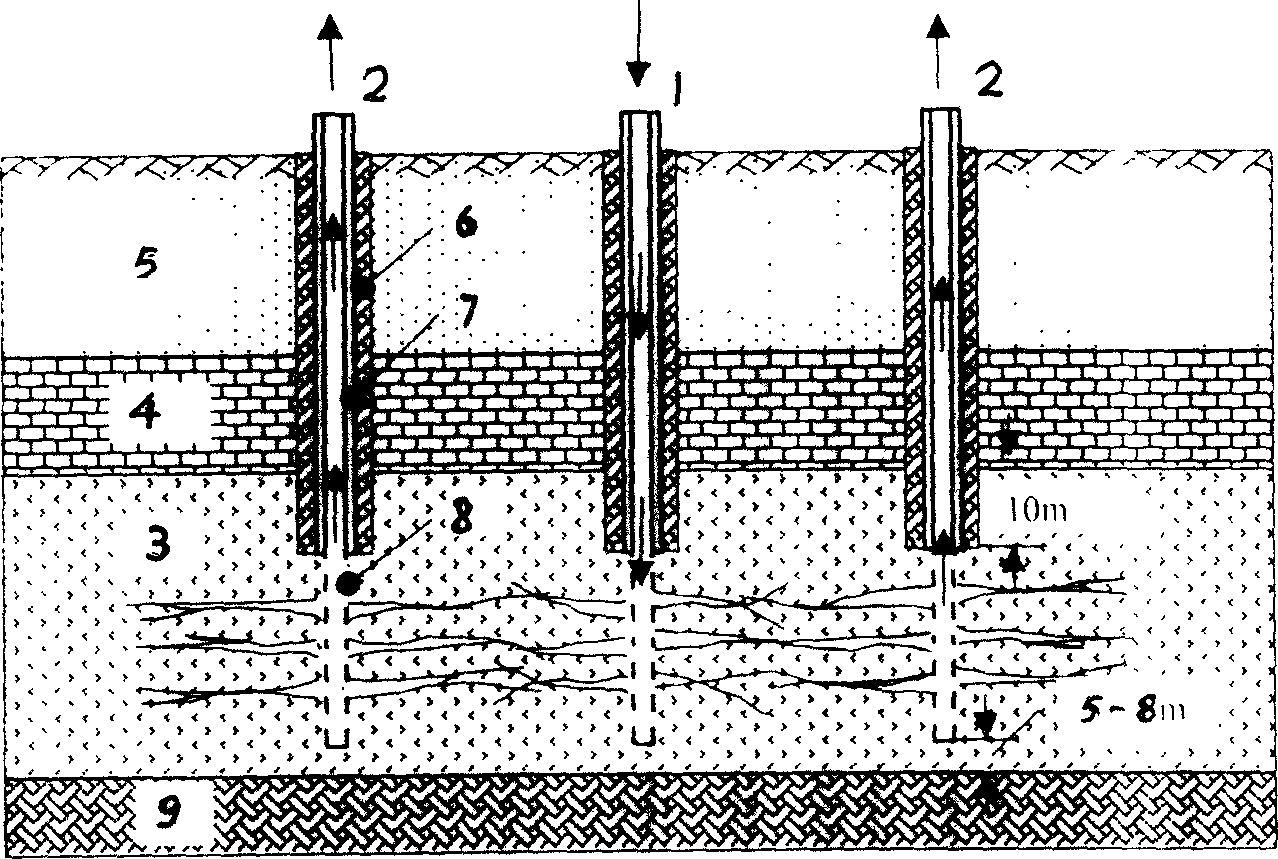

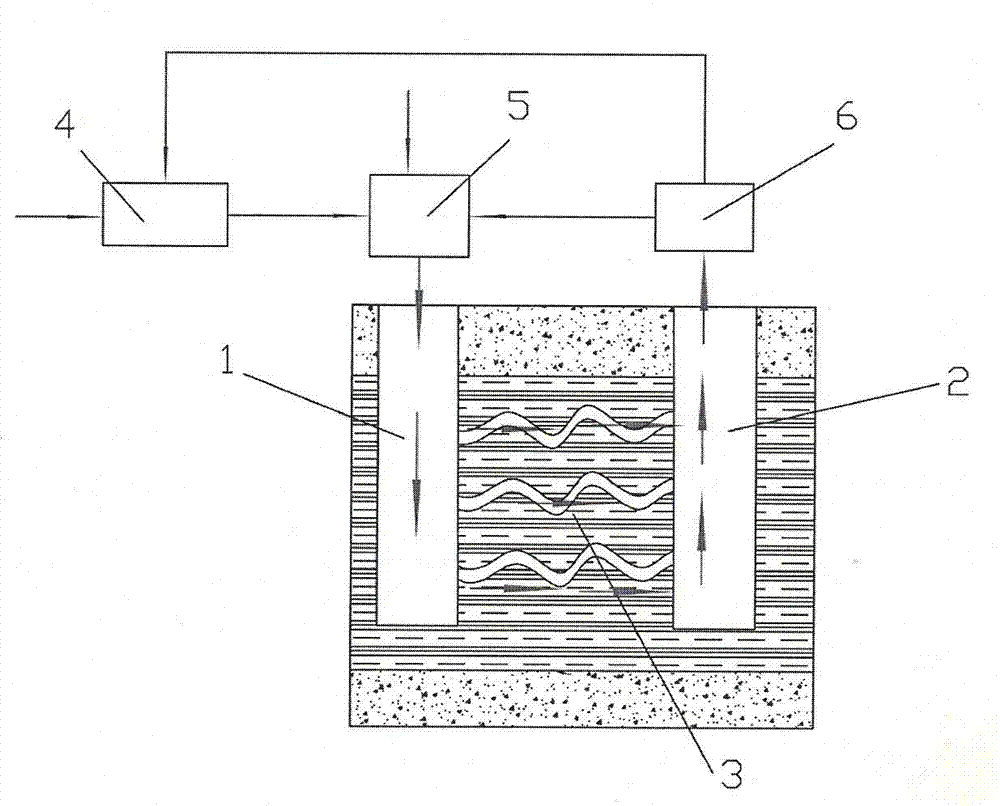

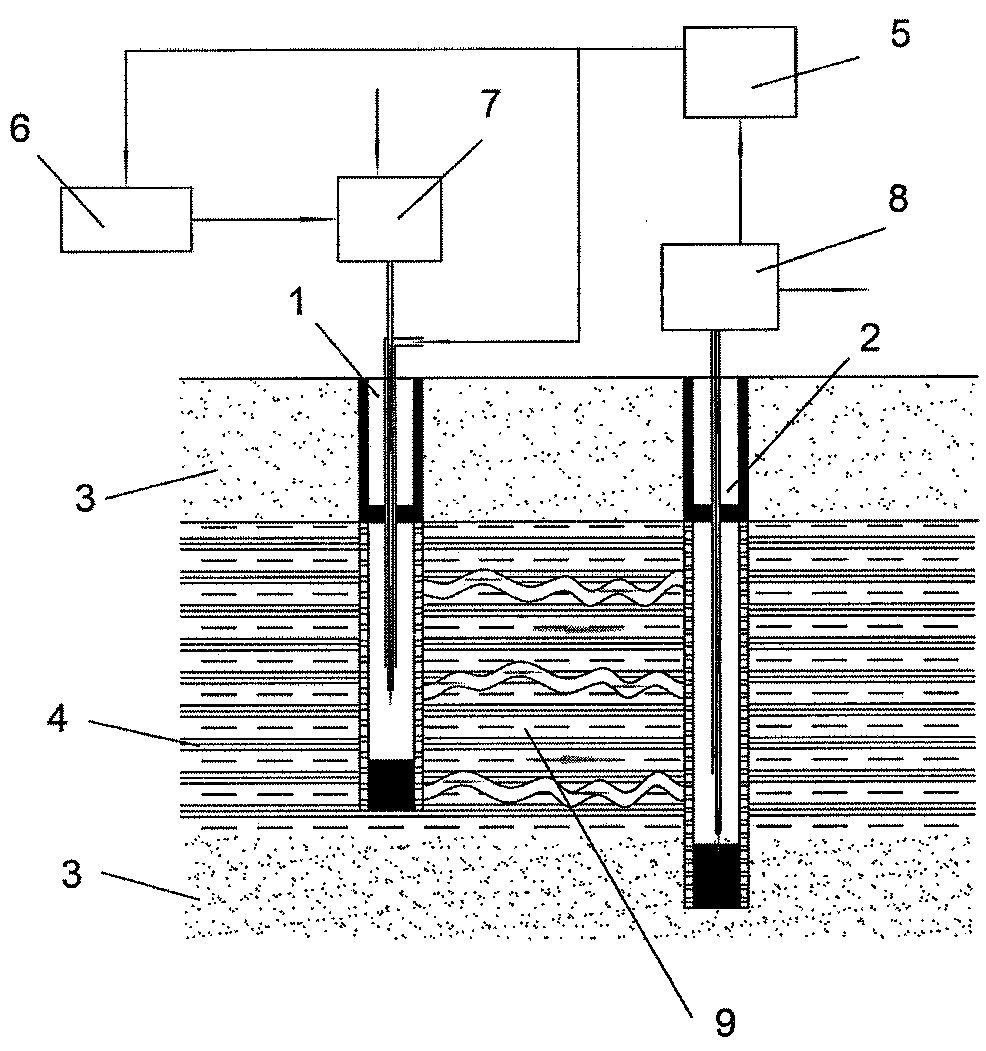

Method for extracting oil and gas by convection heating of oil shale

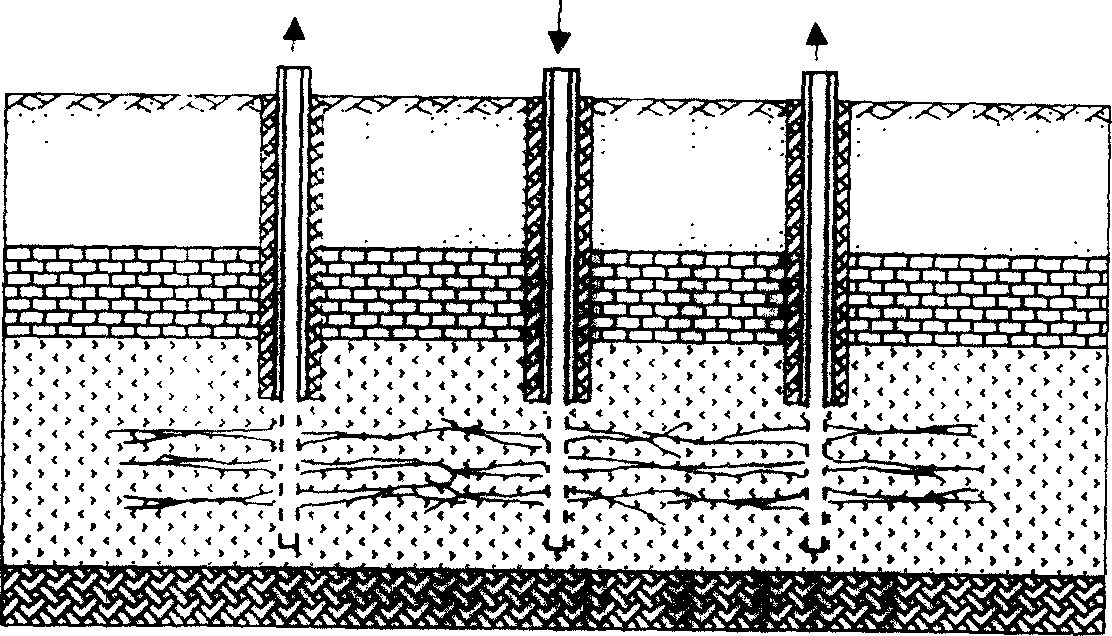

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

Hydrocarbon recovery from impermeable oil shales

Owner:EXXONMOBIL UPSTREAM RES CO

In-situ method of producing oil shale and gas (methane) hydrates, on-shore and off-shore

A method is provided for in-situ production of oil shale and gas (methane) hydrates wherein a network of fractures is formed by injecting liquified gases into at least one substantially horizontally disposed fracturing borehole. Heat is thereafter applied to liquify the kerogen or to dissociate the gas (methane) hydrates so that oil shale oil and / or gases can be recovered from the fractured formations.

Owner:MAGUIRE JAMES Q

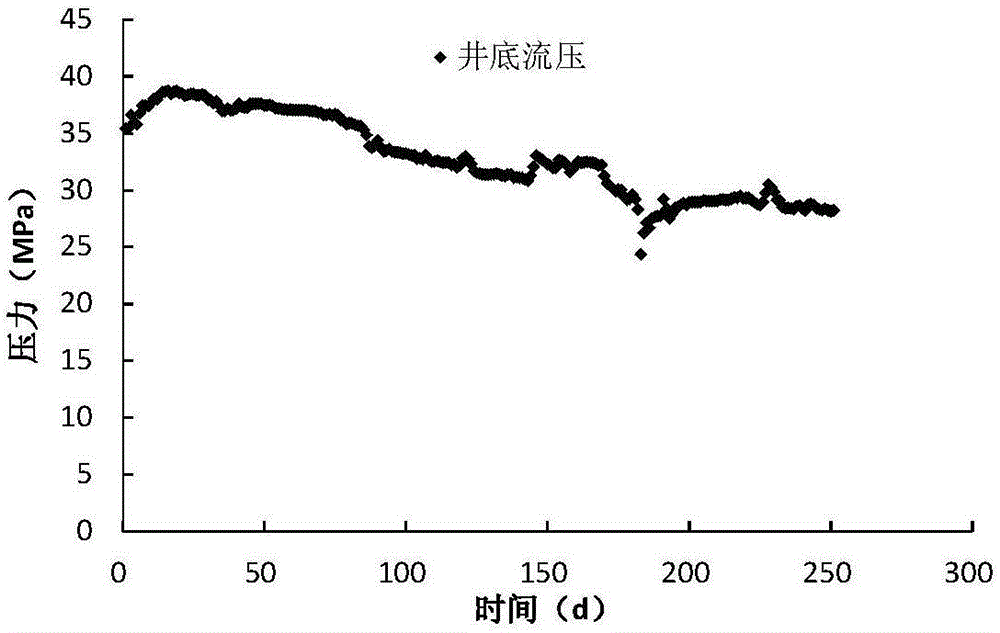

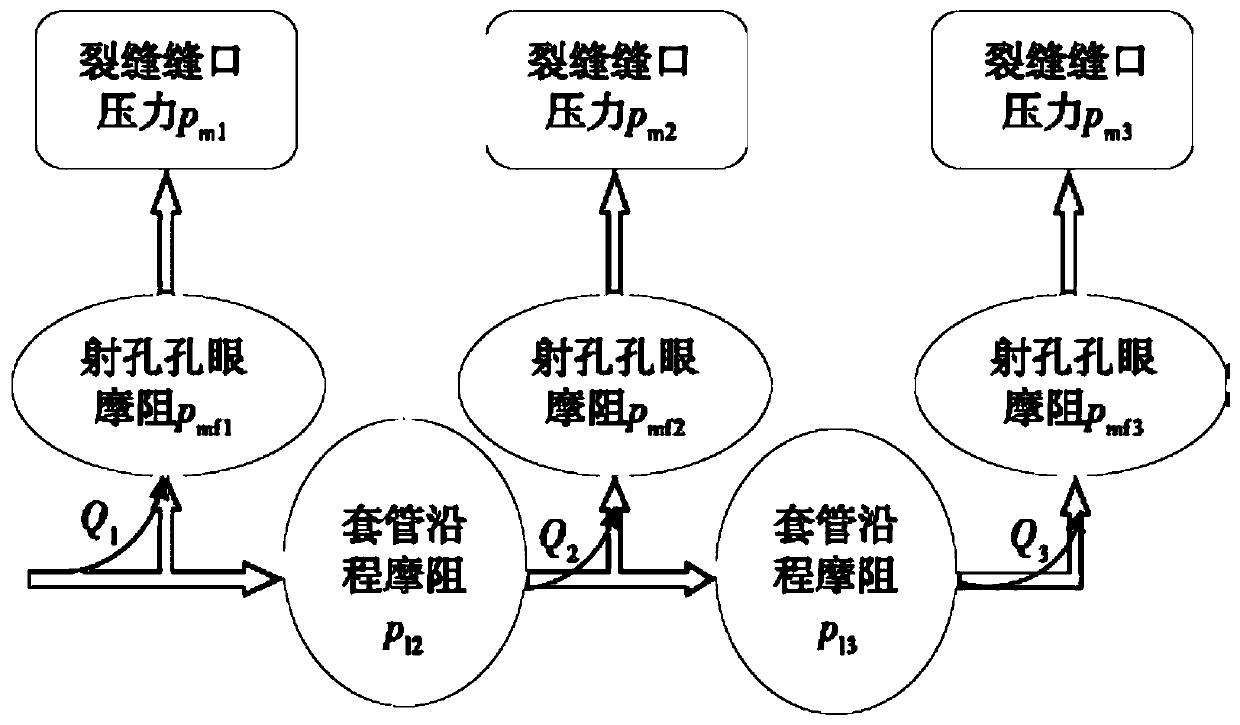

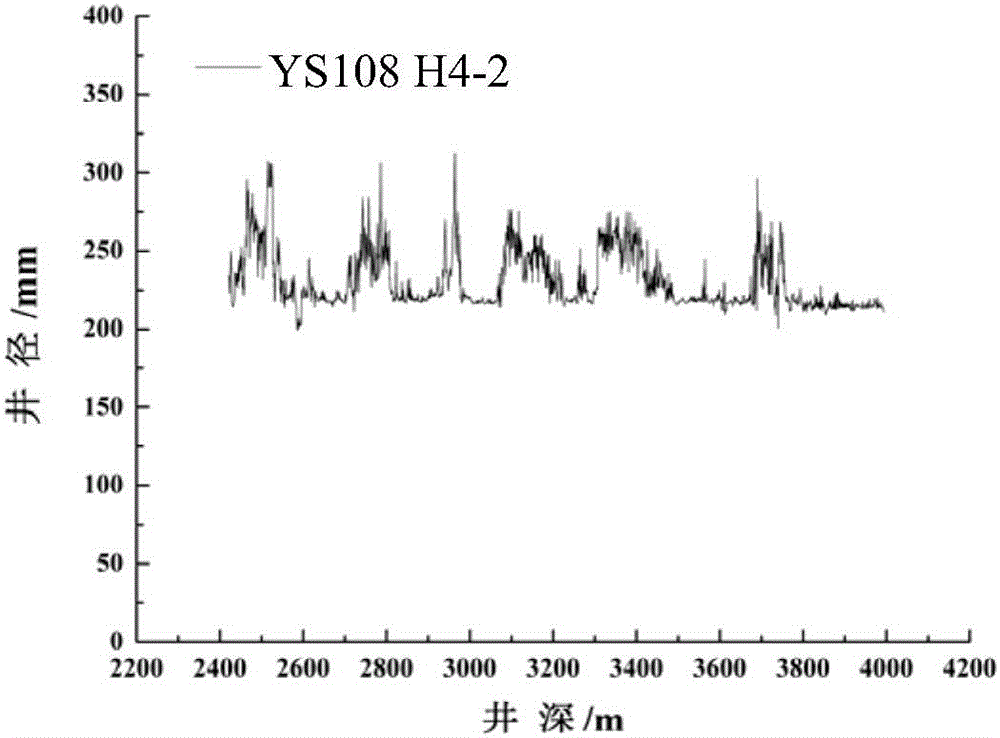

Shale gas well productivity evaluation and prediction method

ActiveCN104389594AAccurate Capacity ForecastImprove economic efficiencyInformaticsSpecial data processing applicationsMatrix differential equationDesorption

The invention discloses a shale gas well productivity evaluation and prediction method. The method comprises the following steps: an expression of a differential equation of a single-phase seepage mathematical model is obtained; the differential equation is solved and represented by a pressure form to obtain a seepage velocity and output formula; a deliverability equation is determined through fitting production data; the derived output formula is arranged to obtain a shale gas horizontal well staged fracturing output formula; boundary pressure (pe) required to be known can be known from the shale gas output formula; and as shale gas has the influences of absorption and desorption, a deviation factor is required to be corrected to obtain formation pressure of a shale gas reservoir. The prediction method deduces the deliverability equation for a shale vertical well and a horizontal well according to the desorption and dispersion characteristics of the shale gas, so that a shale gas output evaluation method is built, the precise output prediction is obtained, and the economic efficiency is improved.

Owner:CHENGDU CHUANGYUAN OIL & GAS TECH DEV

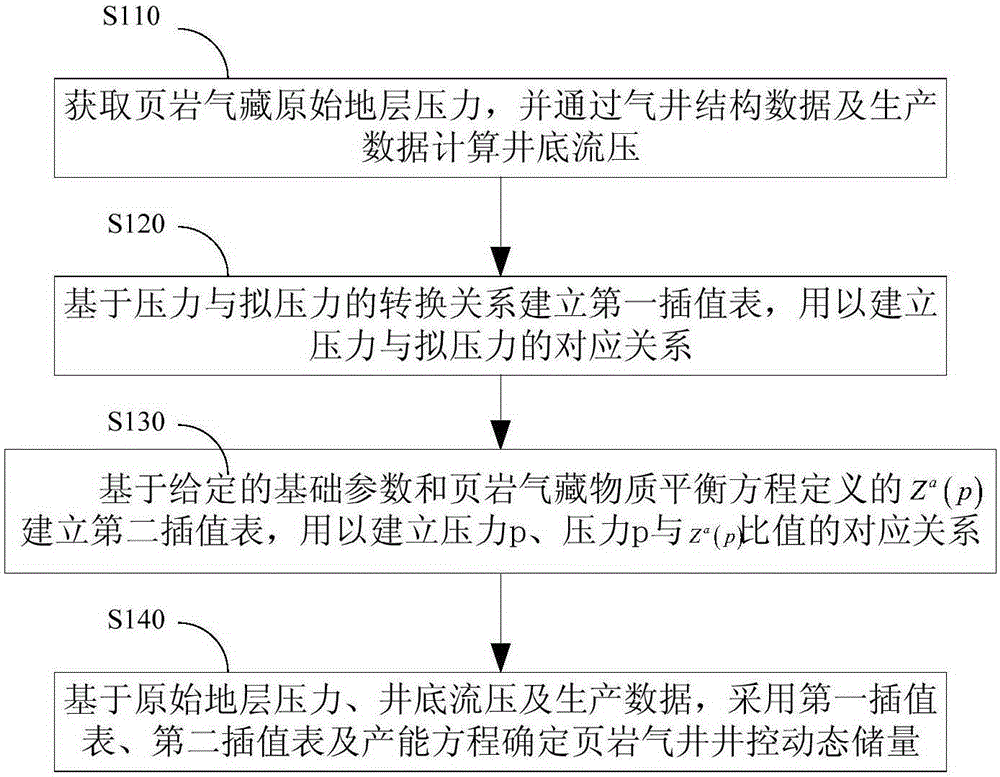

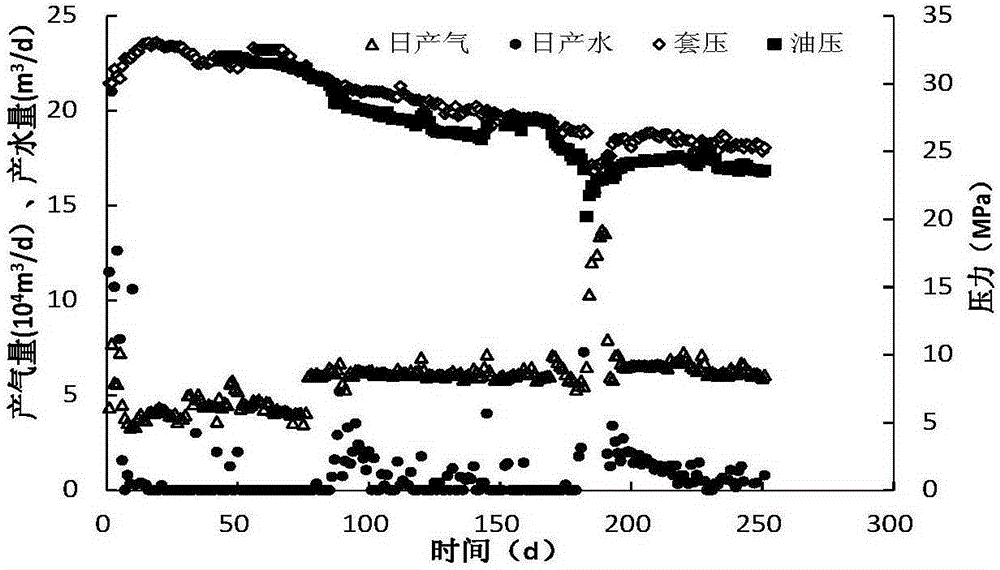

Method and system used for determining well control dynamic reserves of shale gas well

The invention discloses a method and a system used for determining well control dynamic reserves of a shale gas well. The method comprises the steps of obtaining an initial formation pressure of a shale gas reservoir, and calculating a well bottom flow pressure through structure data and production data of the gas well; establishing a first interpolation table based on a conversion relationship between a pressure and a pseudo-pressure to establish a corresponding relationship between the pressure p and the pseudo-pressure m(p); establishing a second interpolation table based on given basic parameters and Za(p) defined by a matter balance equation of the shale gas reservoir to establish a corresponding relationship between the pressure p and a ratio of the pressure p to Za(p); and based on the initial formation pressure, the well bottom flow pressure and the production data, determining the well control dynamic reserves of the shale gas well by adopting the first interpolation table, the second interpolation table and a productivity equation. According to the method and the system, a shut-in pressure is not needed to recover an evaluated average formation pressure in calculation; and a calculation result is suitable for various applications such as reasonable shale gas well production allocation, reasonable development technology policy making, development scheme optimization and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

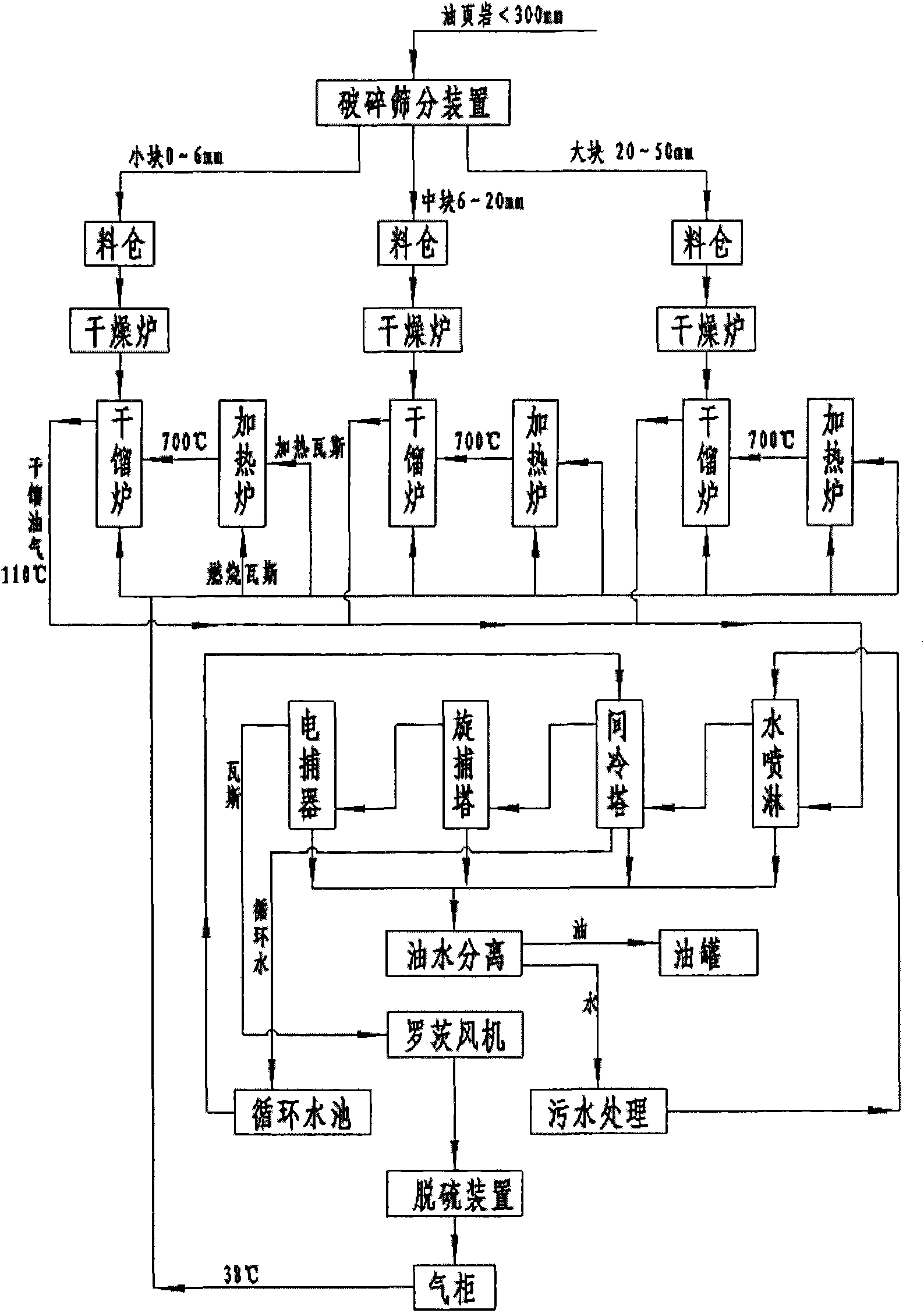

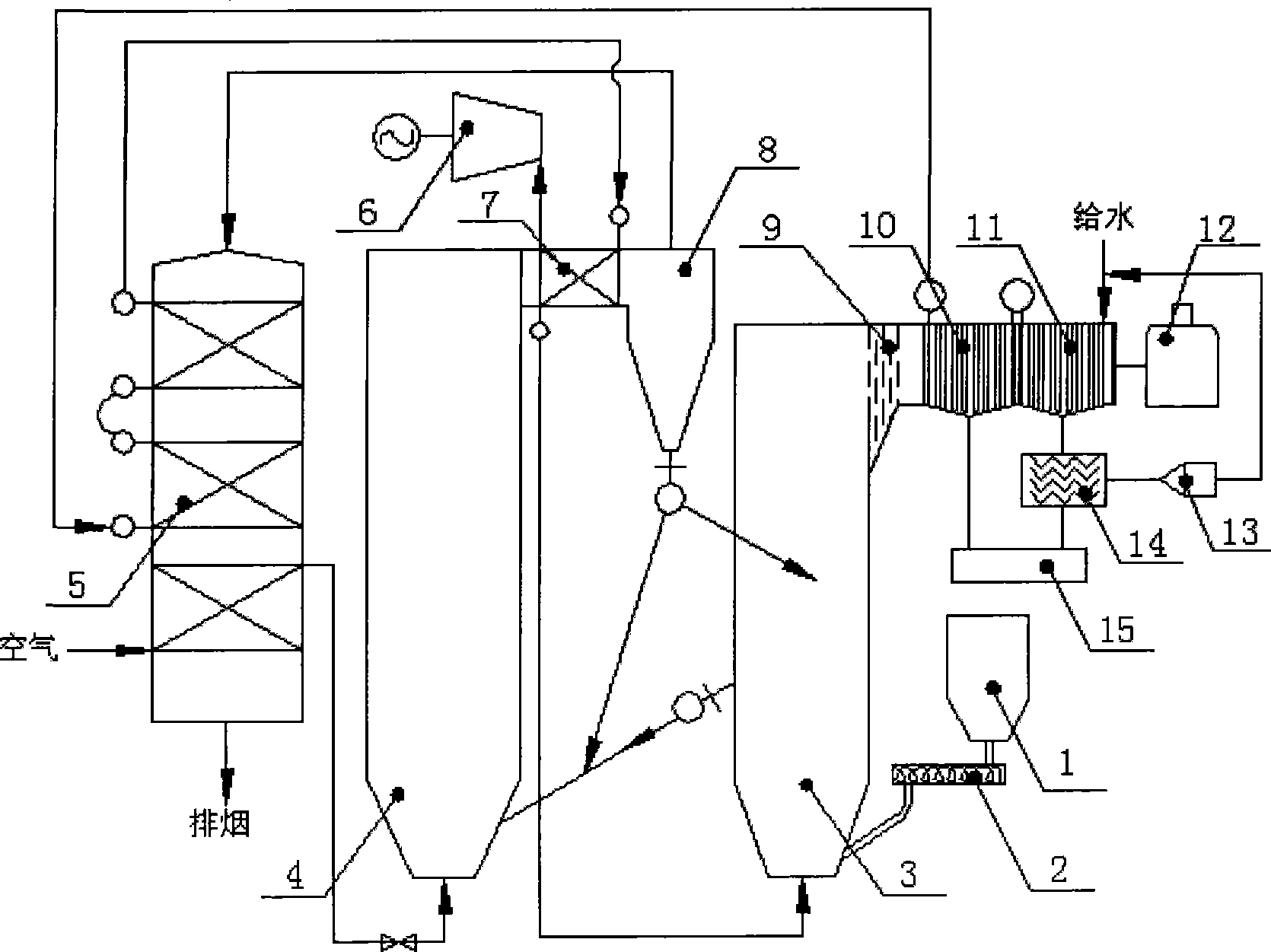

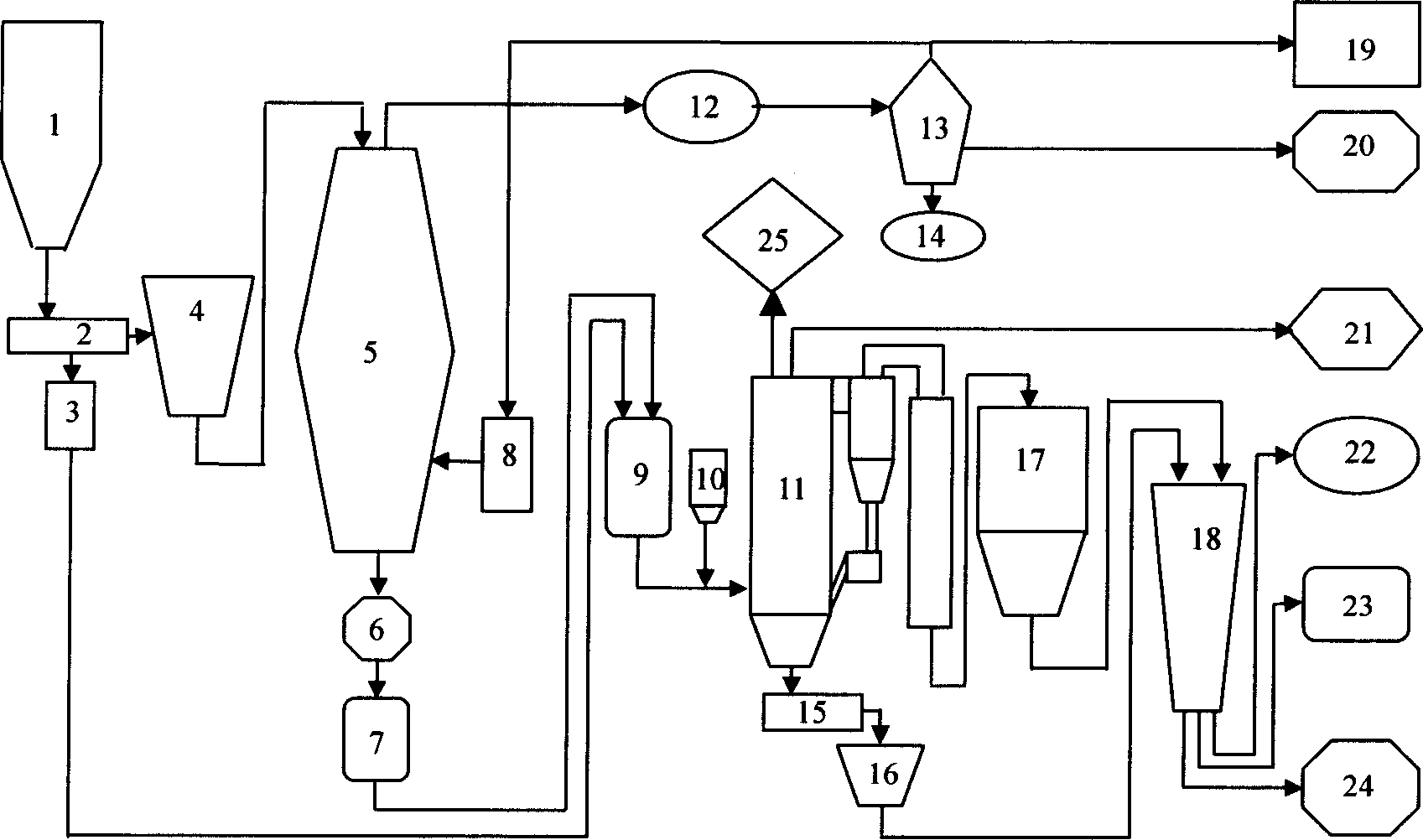

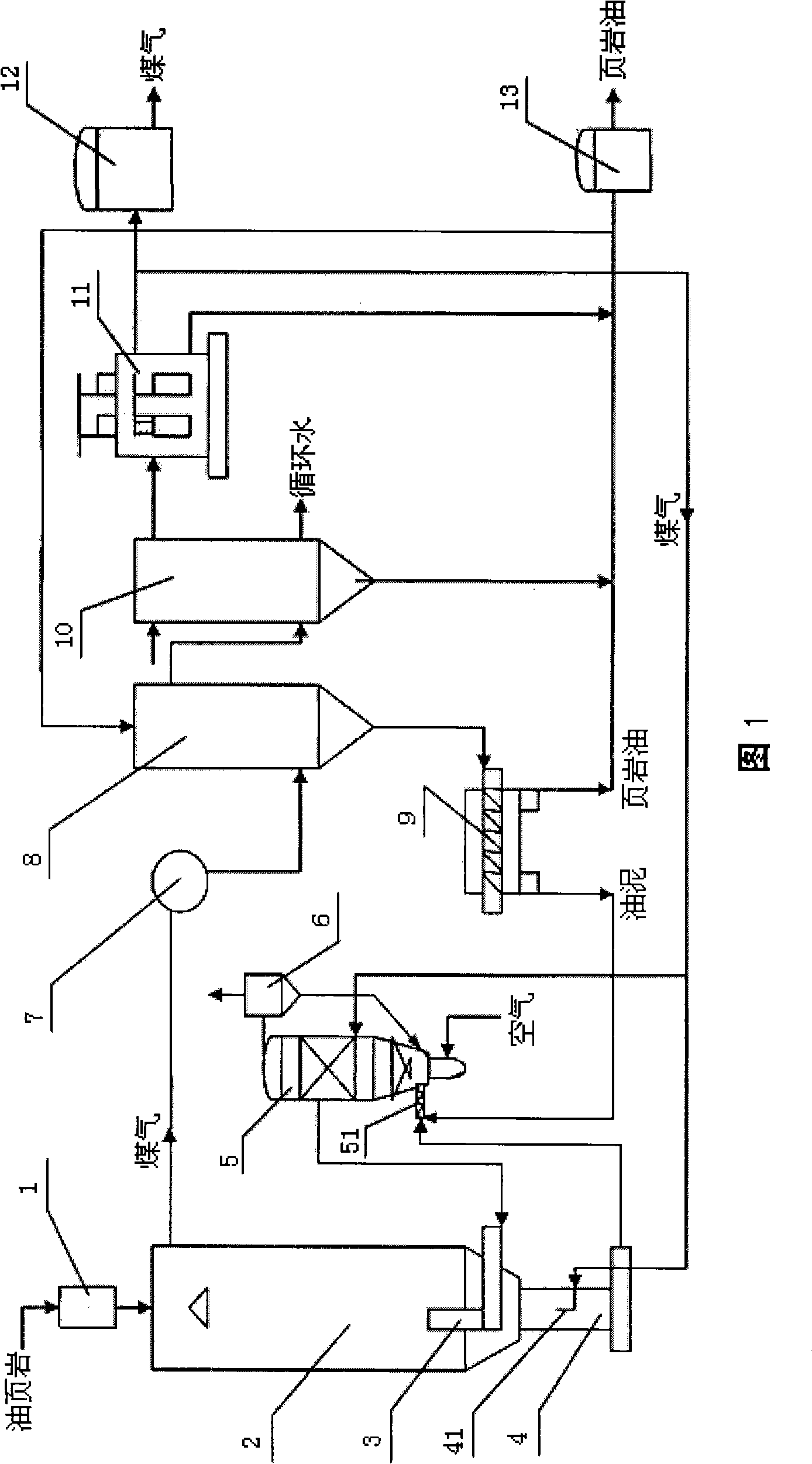

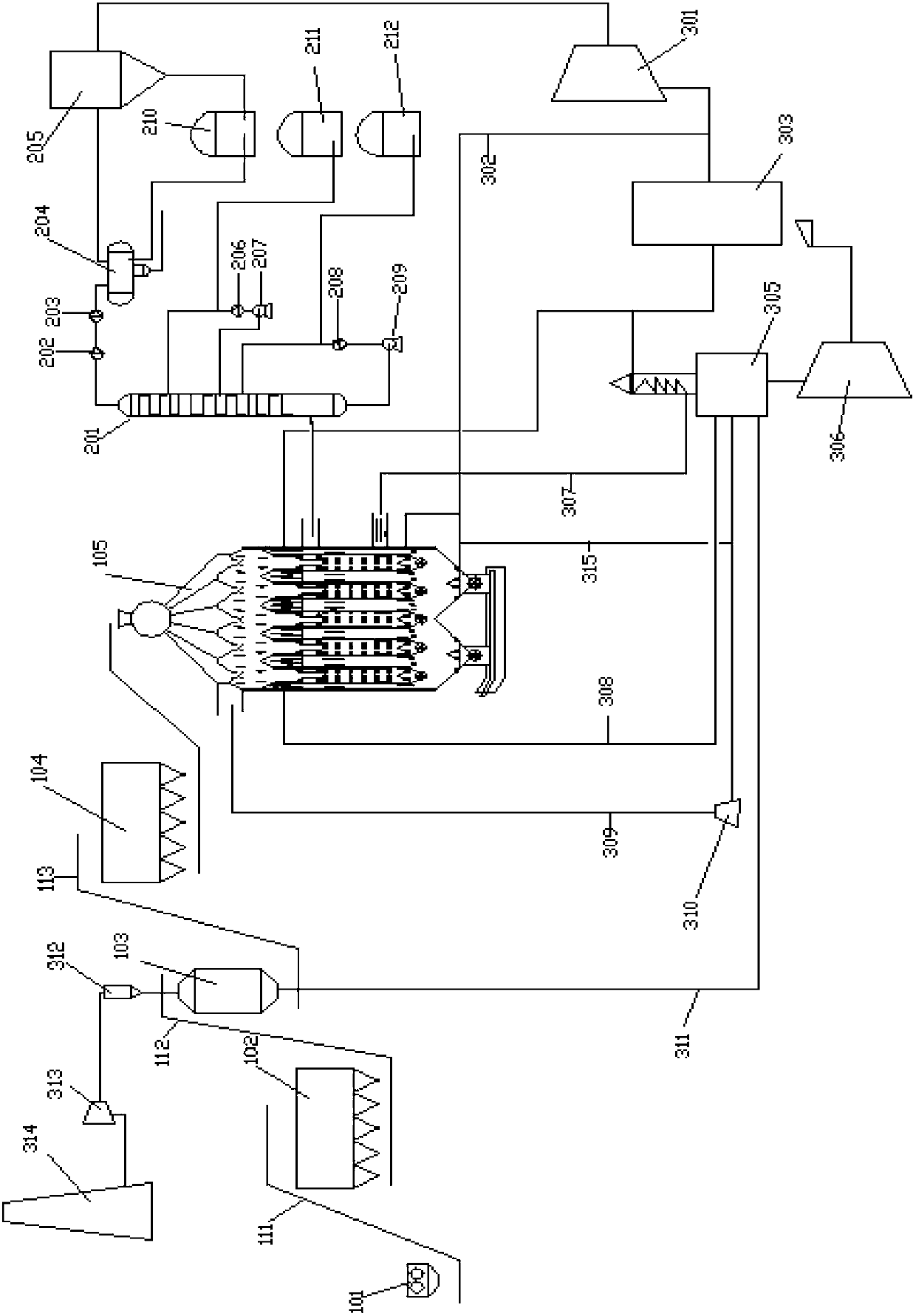

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

Method for extracting shale oil and gas from oil shale in situ

The invention discloses a method for extracting shale oil and gas from oil shale in situ. The method comprises the steps that hot nitrogen is injected into an oil shale layer to crack kerogen in situ; after being extracted and separated, combustible gas which is generated initially is injected into a well together with the nitrogen by a certain proportion to have chemical reaction with the oil shale, so as to further crack organic substances in the oil shale, and extract shale oil and combustible gas; the hot nitrogen is an inert gas which is not only a carrier for transferring heat but also a carrier which carries shale oil and gas to above the ground; meanwhile, due to the pressure action of fluid, an oil and gas channel is favorably formed in the oil shale layer. The circulating combustible gas can have chemical reaction with the kerogen in the oil shale, so as to accelerate the reaction. According to the method for extracting shale oil and gas from the oil shale in situ, mining cost and risks are greatly reduced, the operability is greatly improved, problems caused by a surface dry distillation technology and an existing in-situ technology are fundamentally solved, the construction difficulty and cost are effectively reduced, and the method does not pollute underground water, is environment-friendly and is non-toxic.

Owner:JILIN UNIV +1

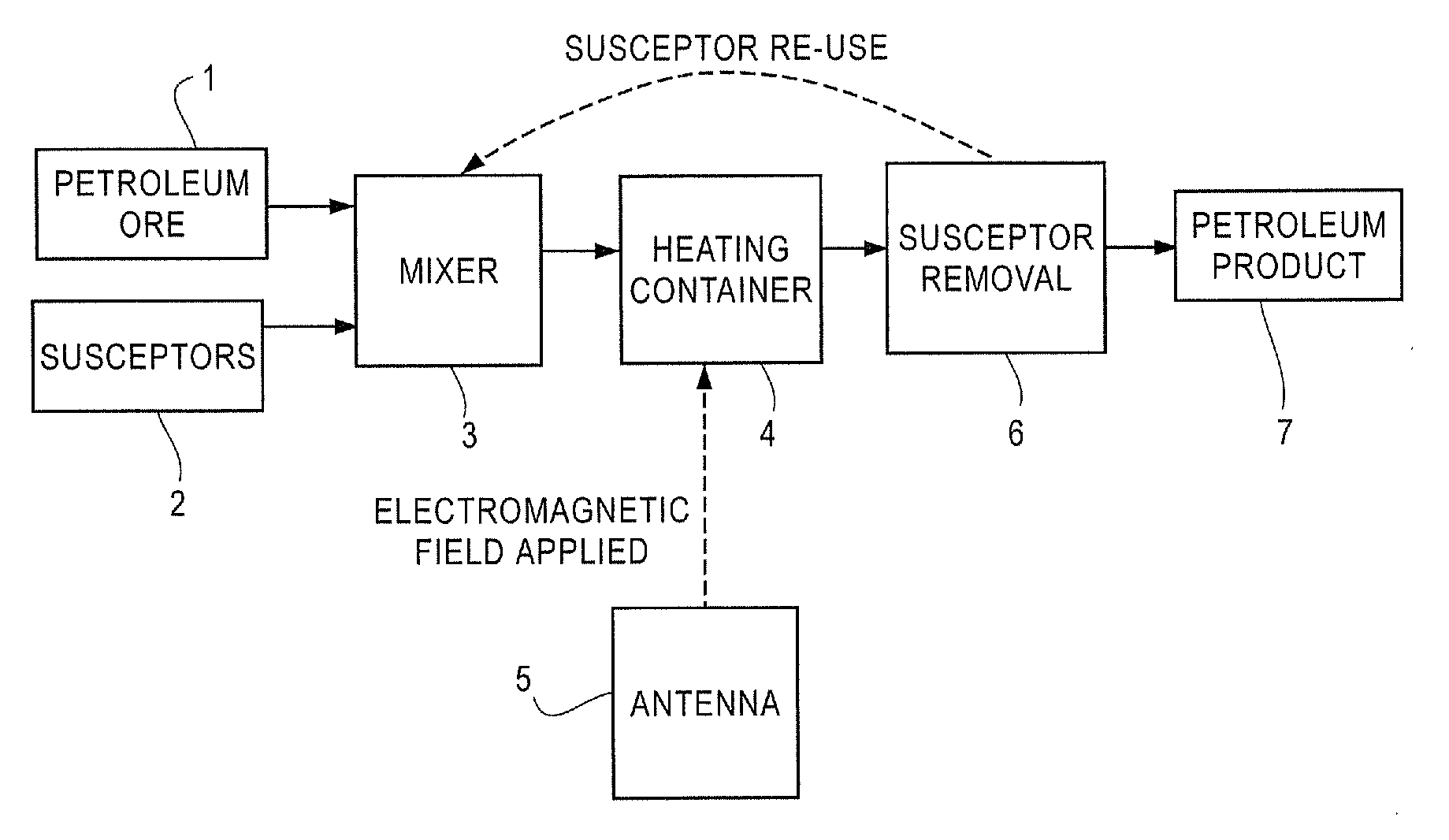

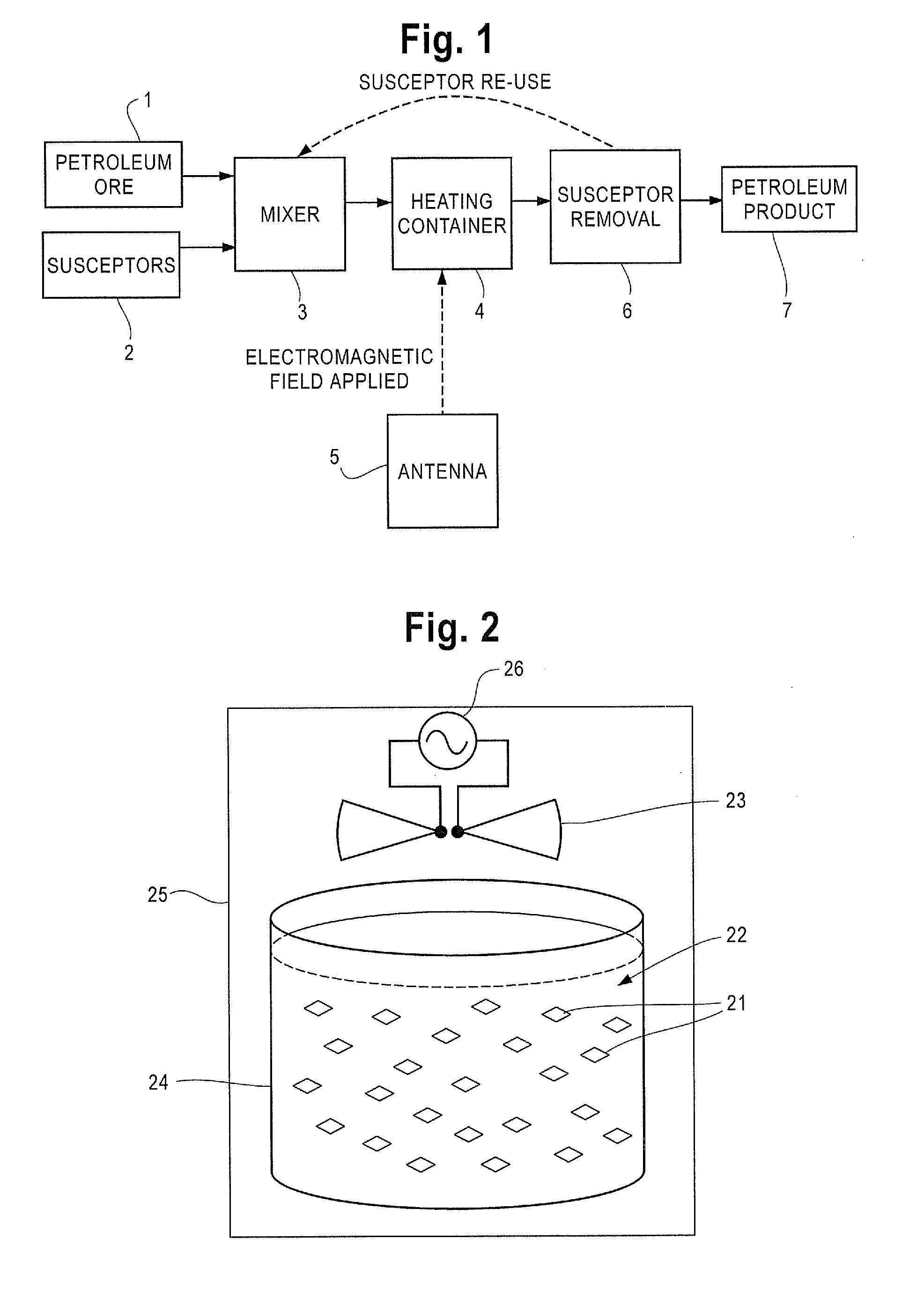

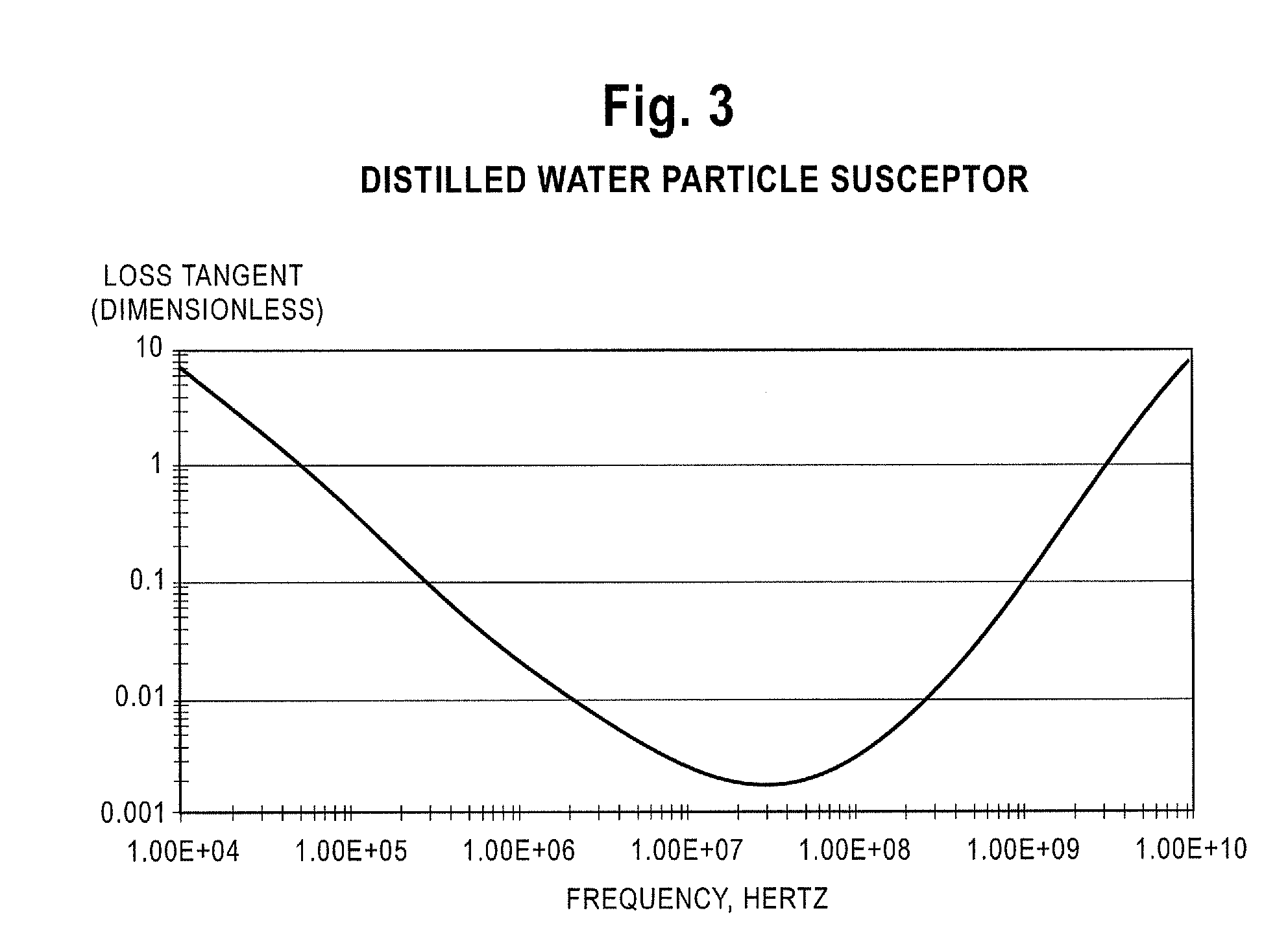

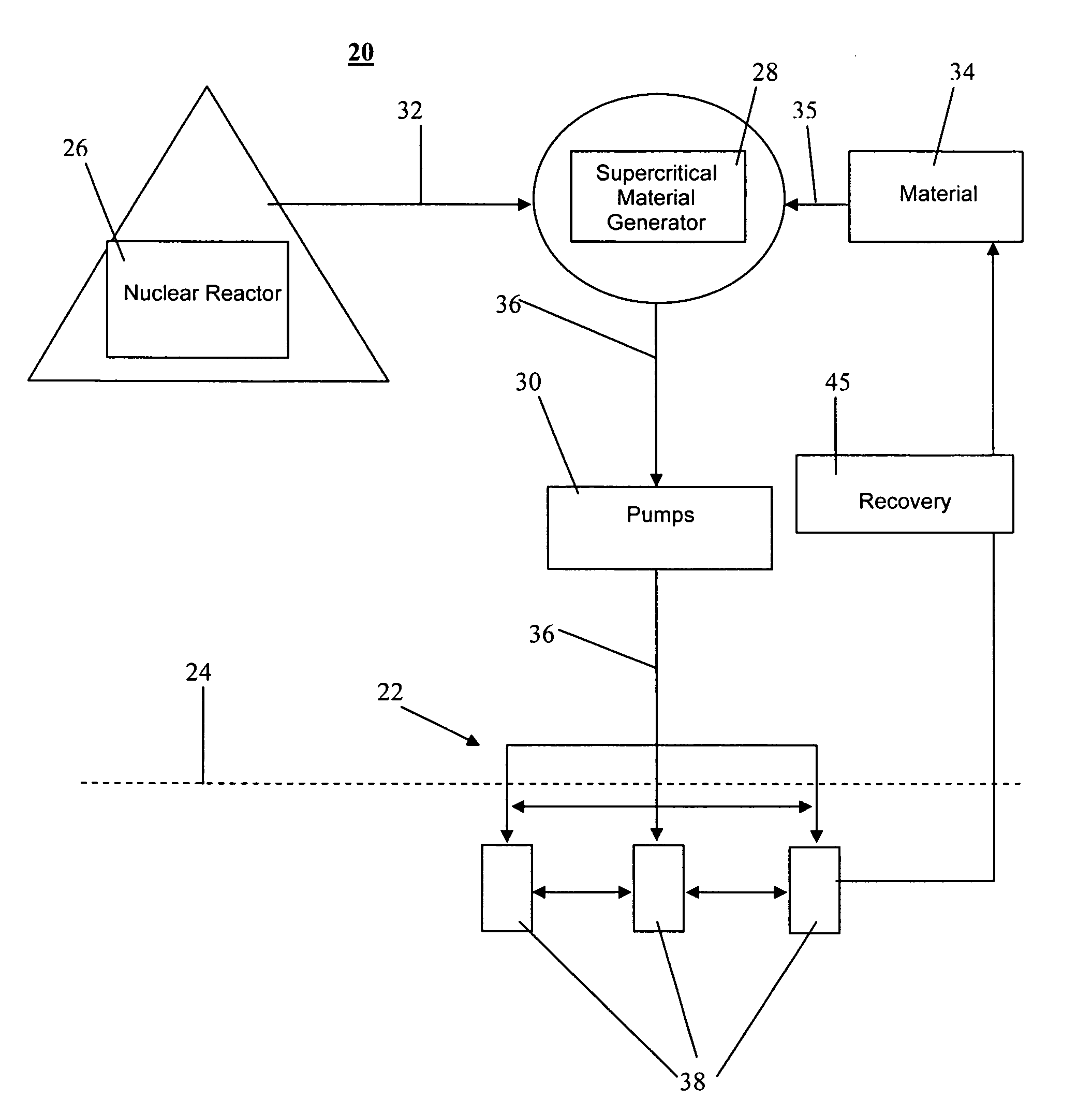

Radio frequency heating of petroleum ore by particle susceptors

ActiveUS20100219107A1Increase temperatureThermal non-catalytic crackingMagnetic paintsSusceptorDistillation

A method for heating materials by application of radio frequency (“RF”) energy is disclosed. For example, the disclosure concerns a method for RF heating of petroleum ore, such as bitumen, oil sands, oil shale, tar sands, or heavy oil. Petroleum ore is mixed with a substance comprising susceptor particles that absorb RF energy. A source is provided which applies RF energy to the mixture of a power and frequency sufficient to heat the susceptor particles. The RF energy is applied for a sufficient time to allow the susceptor particles to heat the mixture to an average temperature greater than about 212° F. (100° C.). Optionally, the susceptor particles can be removed from the mixture after the desired average temperature has been achieved. The susceptor particles may provide for anhydrous processing, and temperatures sufficient for cracking, distillation, or pyrolysis.

Owner:HARRIS CORP

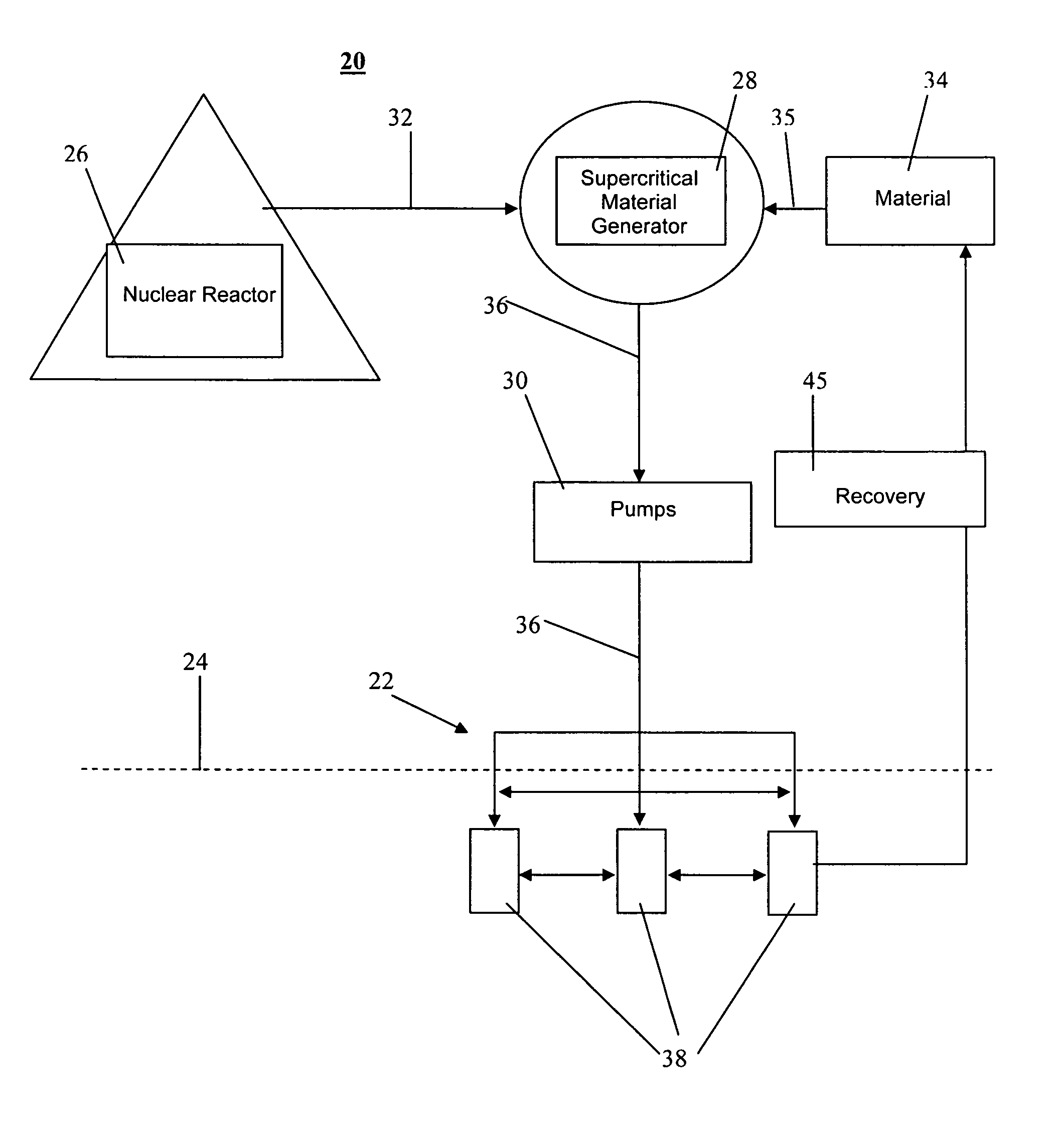

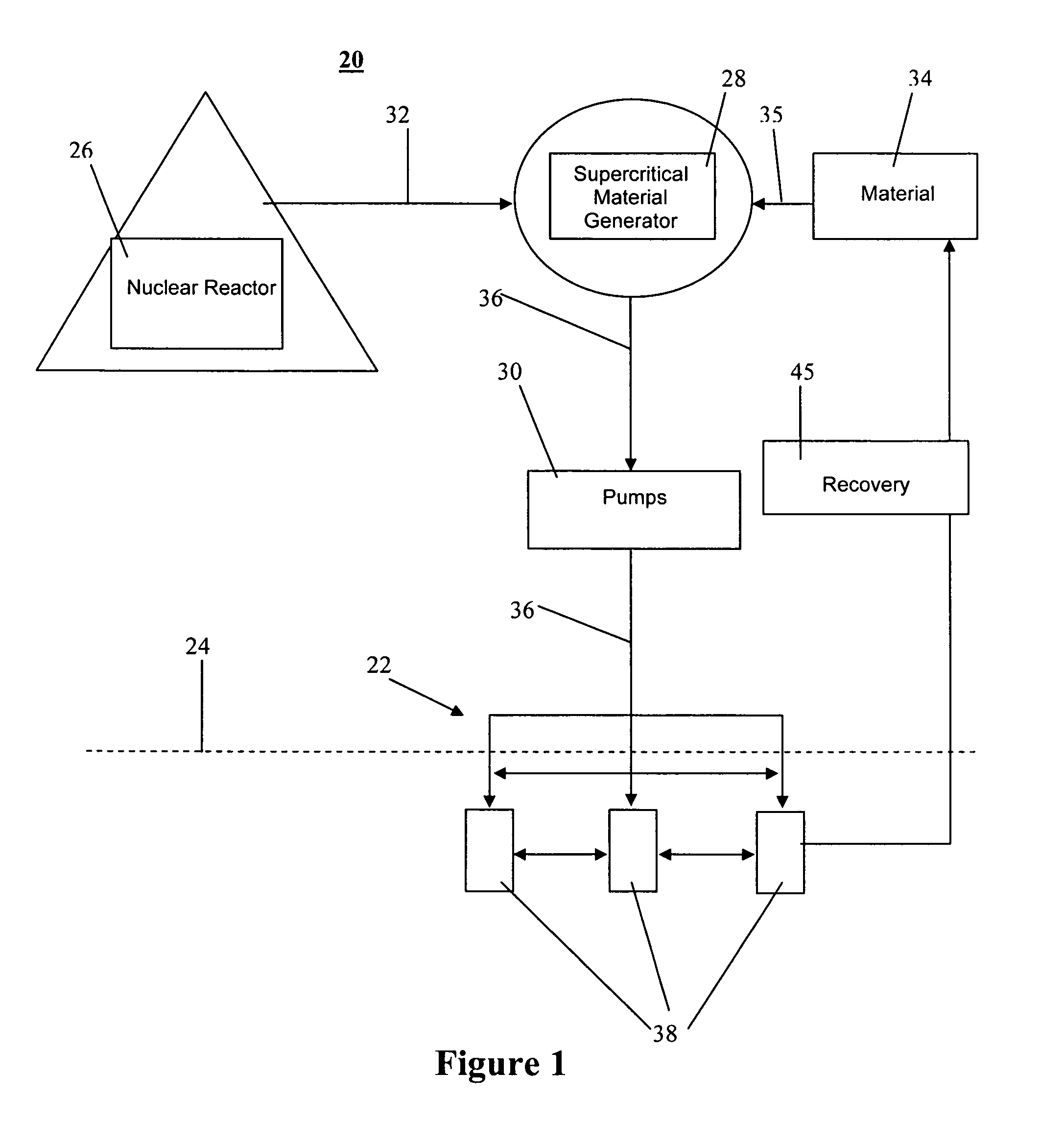

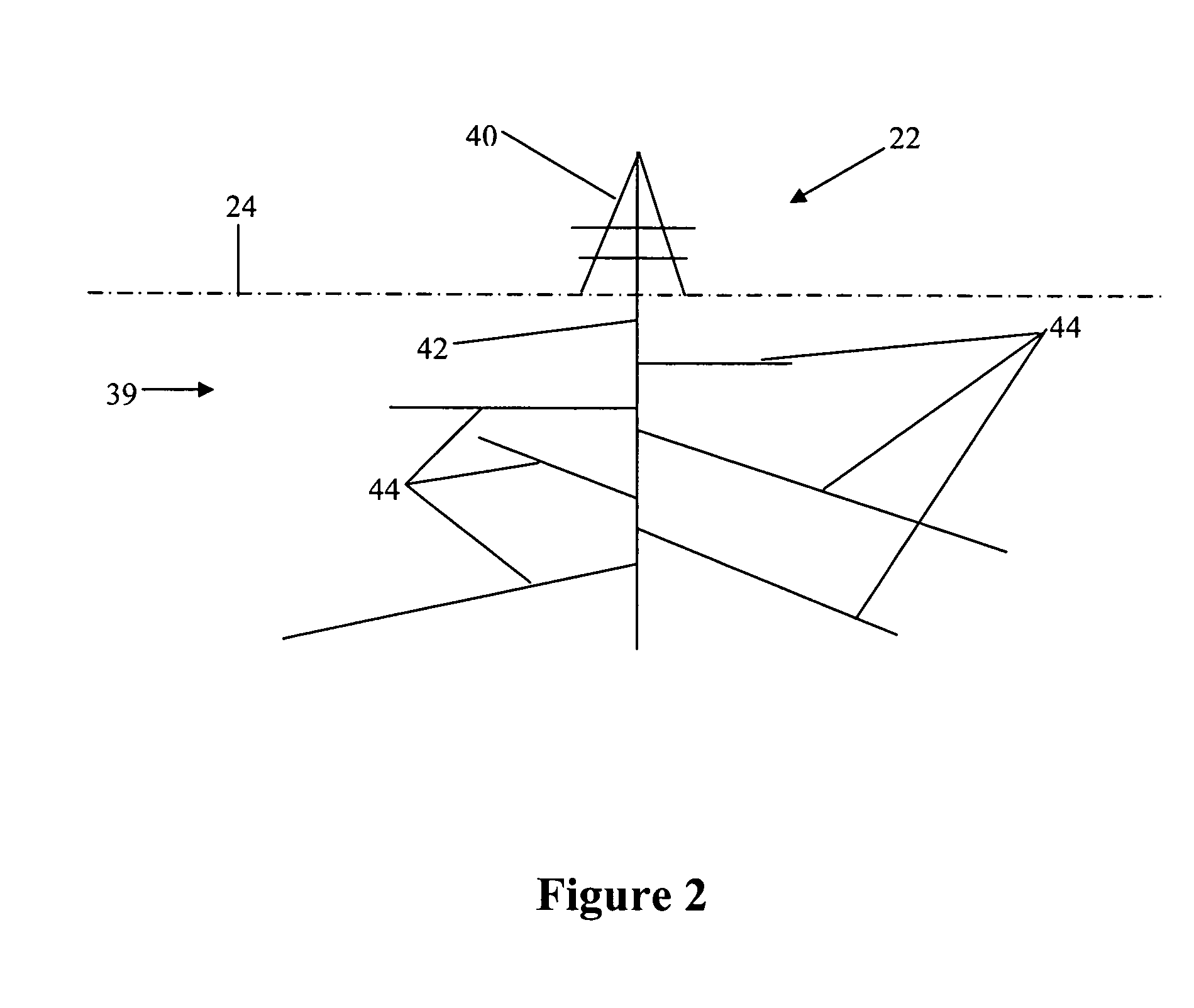

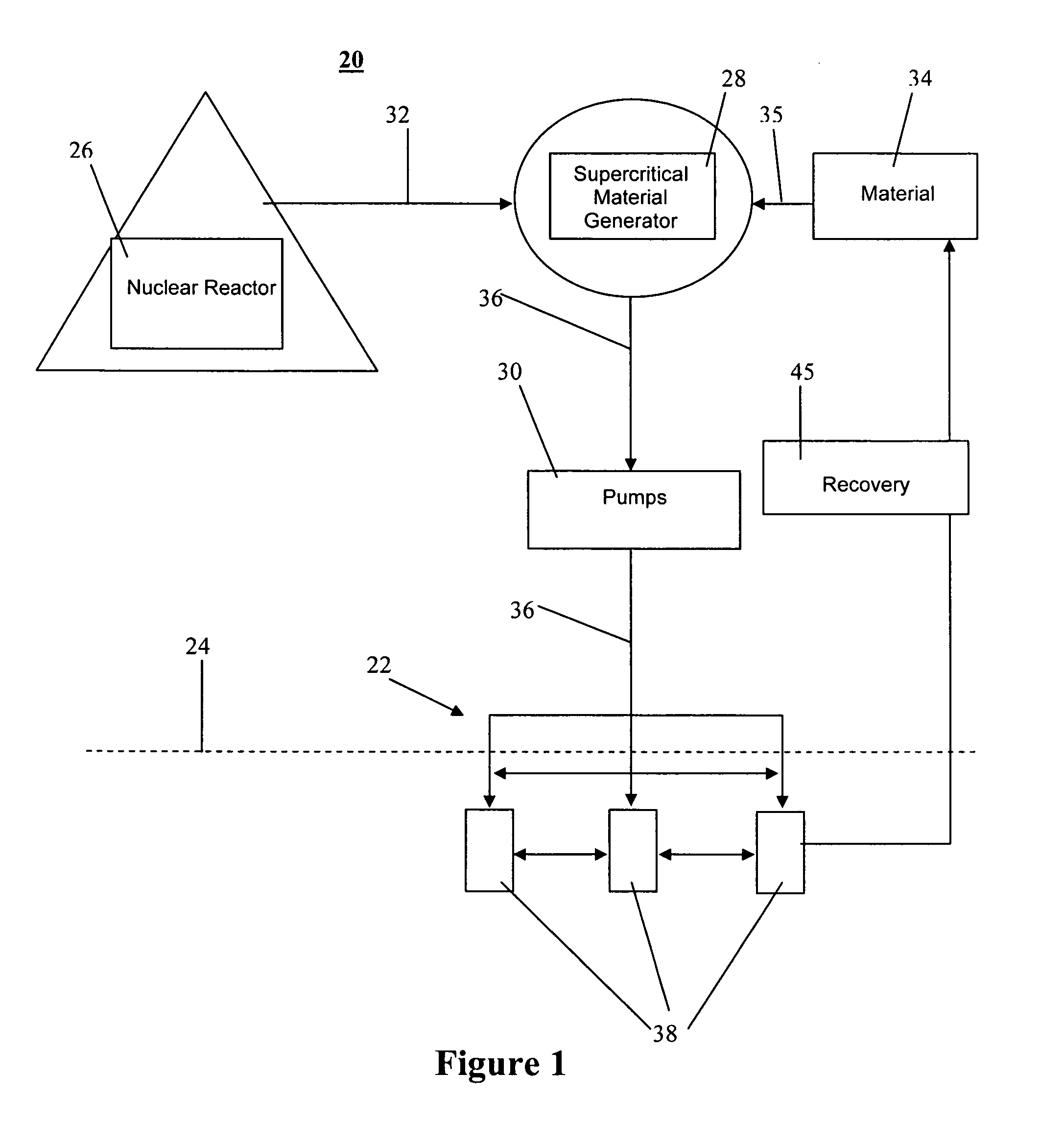

Method and system for extraction of hydrocarbons from oil shale

InactiveUS20070181301A1Improve permeabilityHigh porosityInsulationFluid removalOil shale gasEnergy source

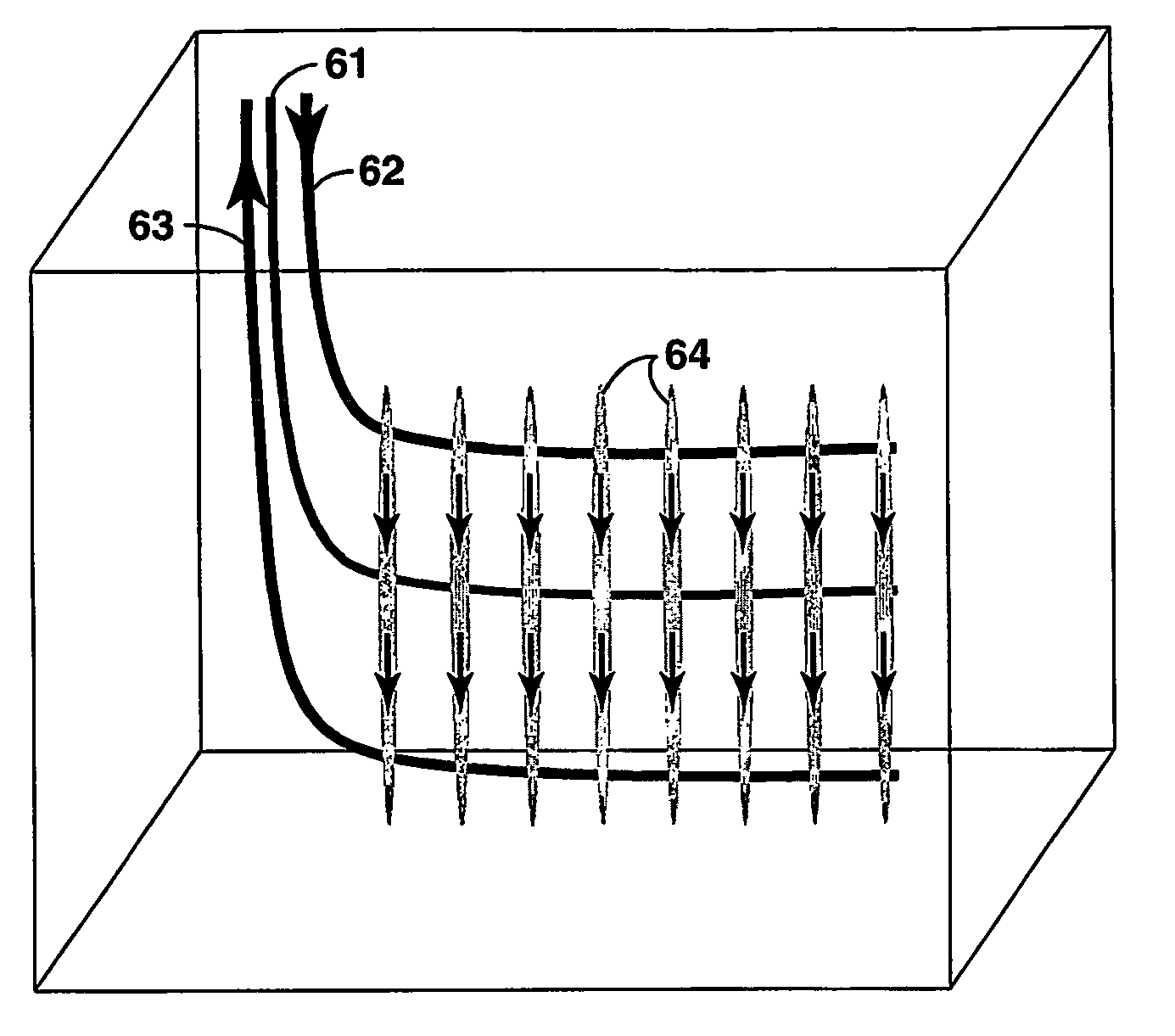

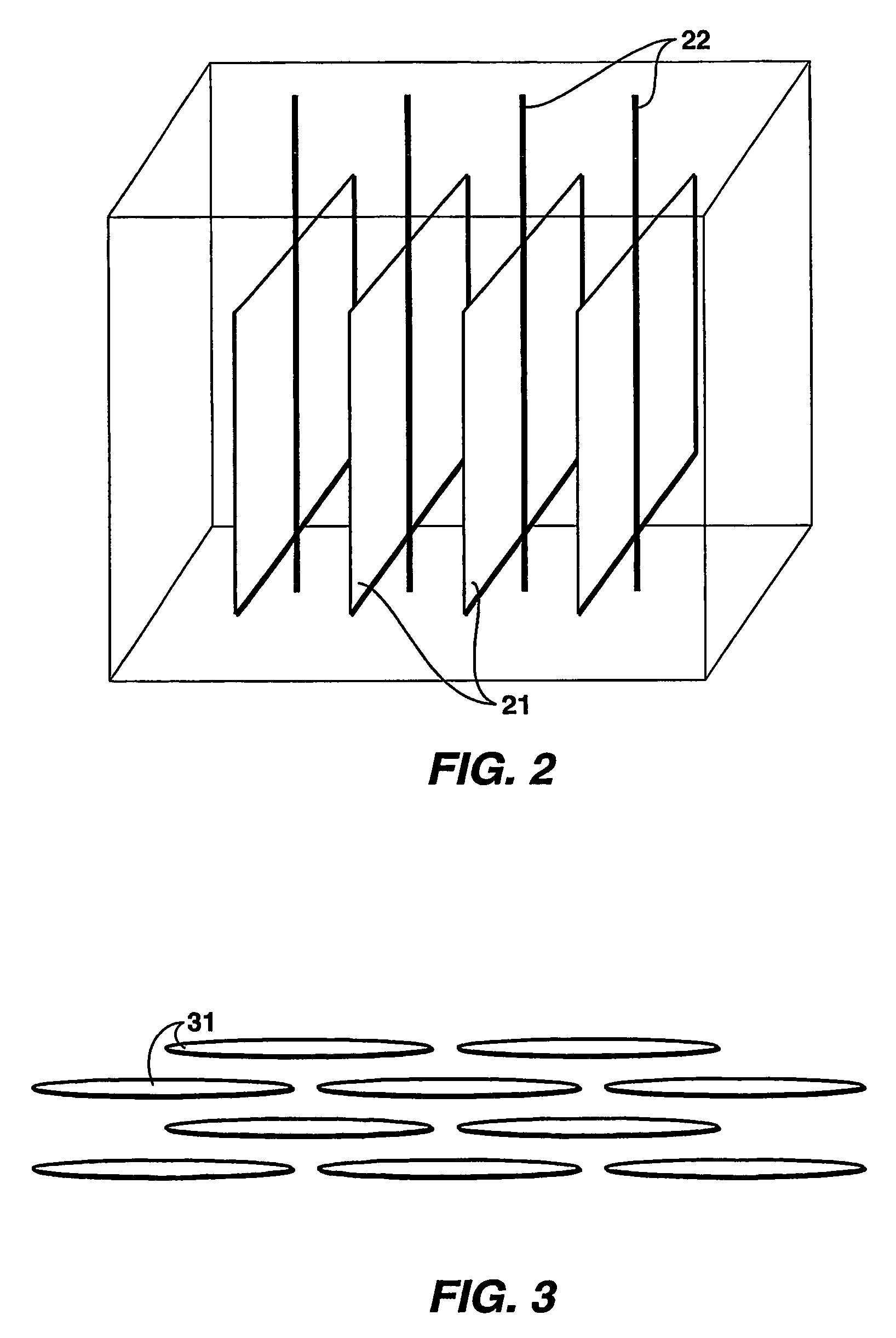

A system and method for extracting hydrocarbon products from oil shale using nuclear energy sources for energy to fracture the oil shale formations and provide sufficient heat and pressure to produce liquid and gaseous hydrocarbon products. Embodiments of the present invention also disclose steps for extracting the hydrocarbon products from the oil shale formations.

Owner:ULTRA SAFE NUCLEAR CORP

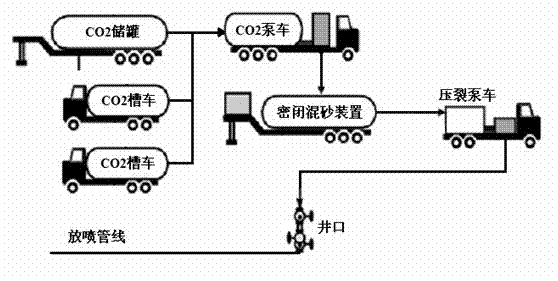

Liquid CO2 fracturing technology for shale gas well

ActiveCN102852508AMaximum fracturing effectMaximize the effect of fracturing stimulationFluid removalCo2 storageOil shale gas

The invention relates to the technical field of shale gas exploitation, in particular to a liquid CO2 fracturing technology for a shale gas well. When the liquid CO2 fracturing technology is constructed, a fracturing pump truck, a sealed fracturing blender truck, a CO2 boosting pump truck, a measuring truck, a fracturing pipeline truck, a CO2 tank vehicle and a CO2 storage tank need to be arranged; the fracturing pipeline truck is provided with a pressure manifold and a high pressure manifold; and the measuring truck is provided with a monitoring instrument. The liquid CO2 fracturing technology is characterized in that the liquid CO2 fracturing technology is executed according to six steps of placing fracturing equipment and construction vehicles, testing the pressure, processing pre-acid, constructing liquid CO2 fracturing, closing the well after carrying out fracturing and opening the well for gushing and carrying out flowback after carrying out fracturing. The liquid CO2 fracturing technology for the shale gas well implements high flowback speed and short operation period and basically has harmlessness to a shale gas reservoir stratum.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

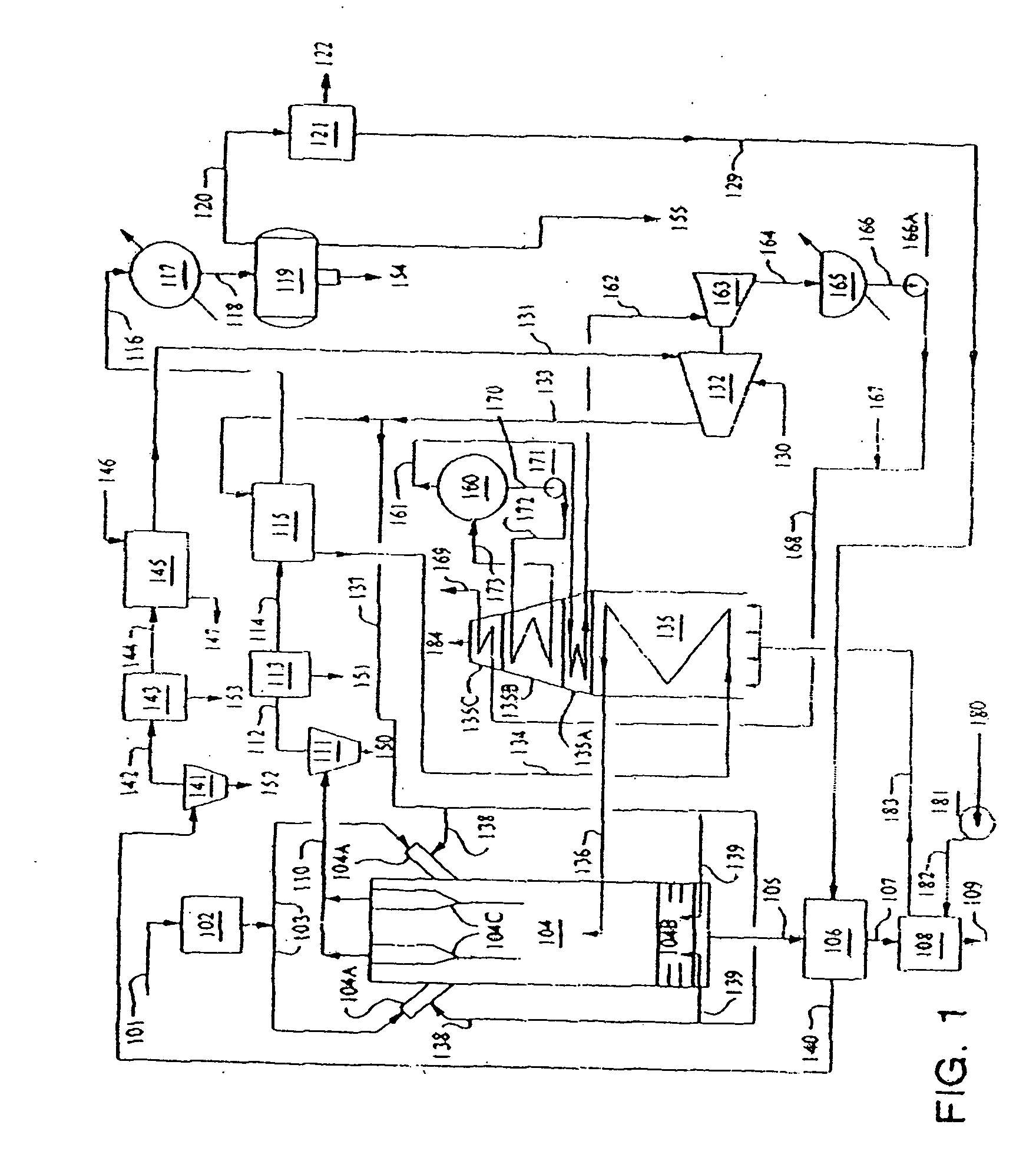

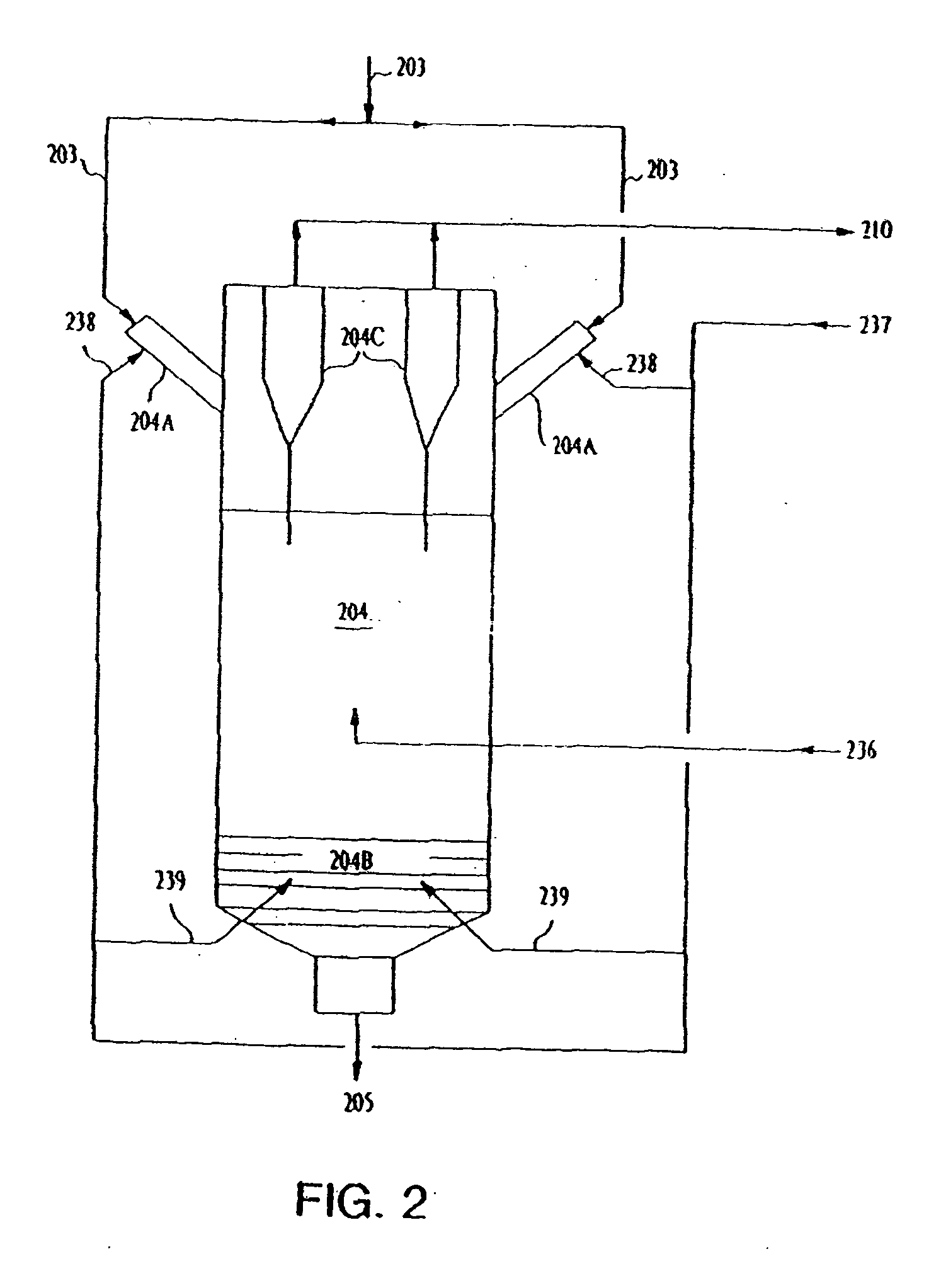

Process and apparatus for converting oil shale or oil sand (tar sand) to oil

InactiveUS20050252833A1Flexibility in processingLiquid hydrocarbon mixture productionHydrocarbon oil crackingOil shale gasPetroleum

Three new embodiments to the Chattanooga Process that convert or upgrade oil bitumen, a combination of oil sands and bitumen, a combination of sand and bitumen, and oil shale to high grade low sulfur (about 0.1 to 0.5 wt. % sulfur, or less) crude oil. The invention relates to a continuous process for producing synthetic crude oil (SCO) from oil sand bitumen which has been extracted from under ground via in situ processes, or strip mined and extracted via hot water extraction processes before upgrading. It can also apply to kerogen extracted in situ from shale underground. The process involves treating the hot bitumen with sand from an extraction process or the hot oil from kerogen with ground shale containing kerogen in a fluid bed reactor where the reactant and fluidizing medium is only hydrogen. The invention also relates to a continuous process for producing synthetic crude oil (SCO) from oil shale kerogen. The invention relates to a continuous process for producing synthetic crude oil from oil bearing material, e.g., oil shale or oil sand (tar sand), through continuous process for producing synthetic crude oil from bituminous oil sand (tar sand) or shale. The process includes treating the oil sand (tar sand) or shale to produce a fluidizable feed, feeding the fluidizable feed to a fluidized bed reactor, and fluidizing and reacting the fluidizable feed in the fluidized bed reactor with a feed of hydrogen provided by a feed stream having a stream containing hydrogen in a concentration greater than 90 vol % (90 vol %-100 vol % H2). In one embodiment, the invention relates to a continuous process which can recover methane and ethane from a recycle hydrogen stream. In one embodiment, the process can recover PSA tail gas as feed to a hydrogen plant. In one embodiment, the process can be operated to reduce or eliminate the requirement for externally provided methane feed to the hydrogen plant.

Owner:DOYLE JAMES A +1

Shale gas horizontal well refracturing productivity calculation method

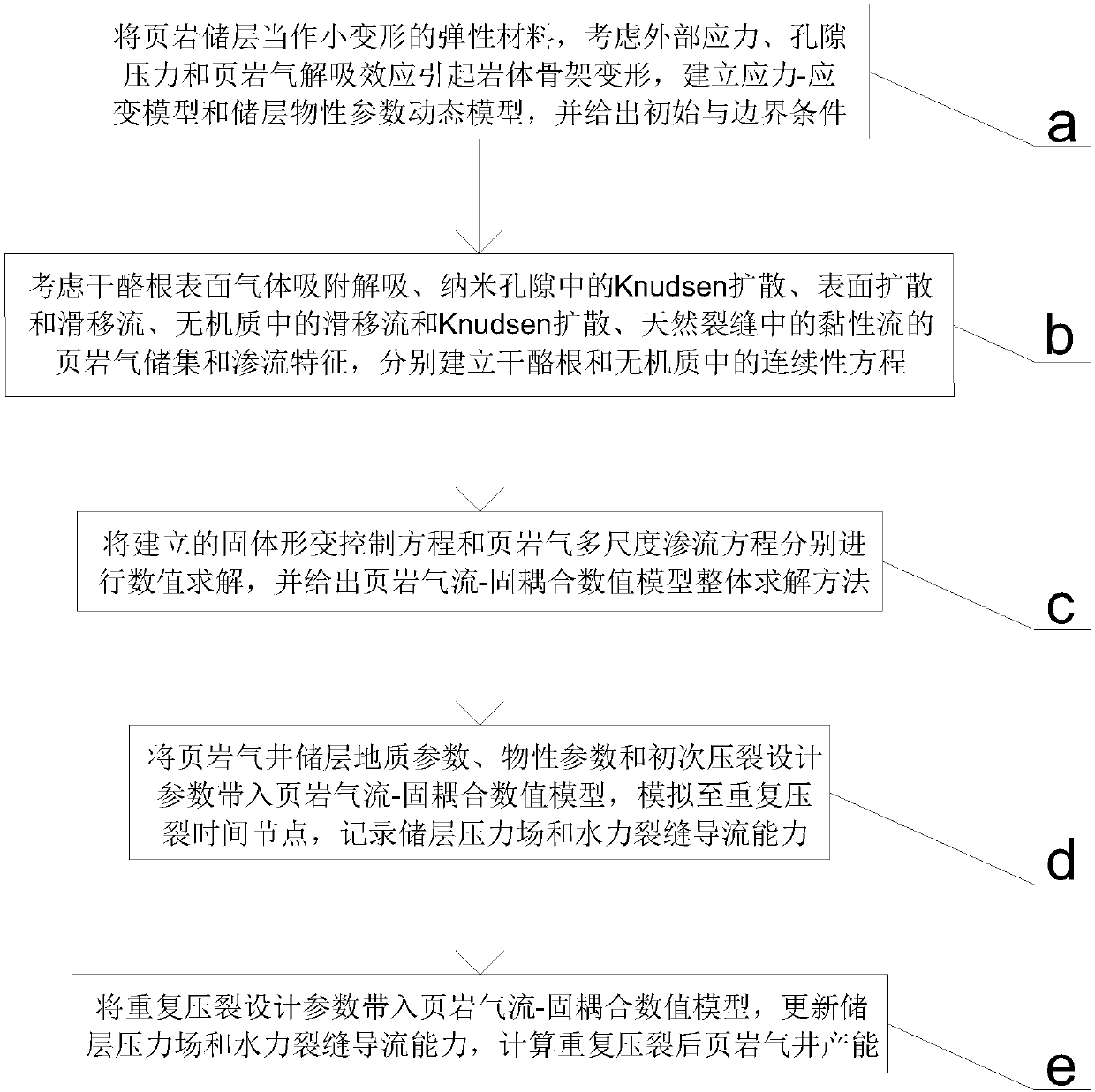

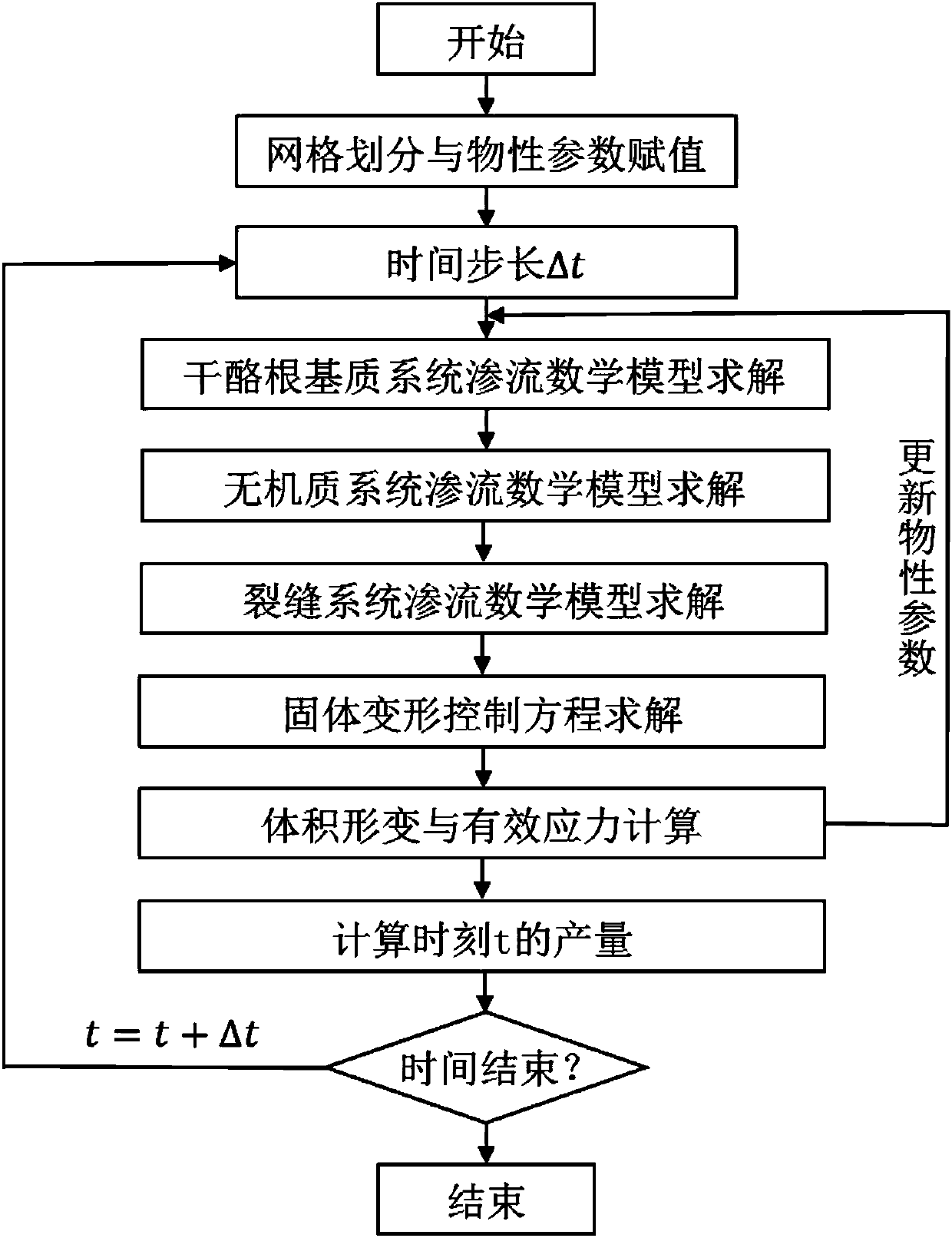

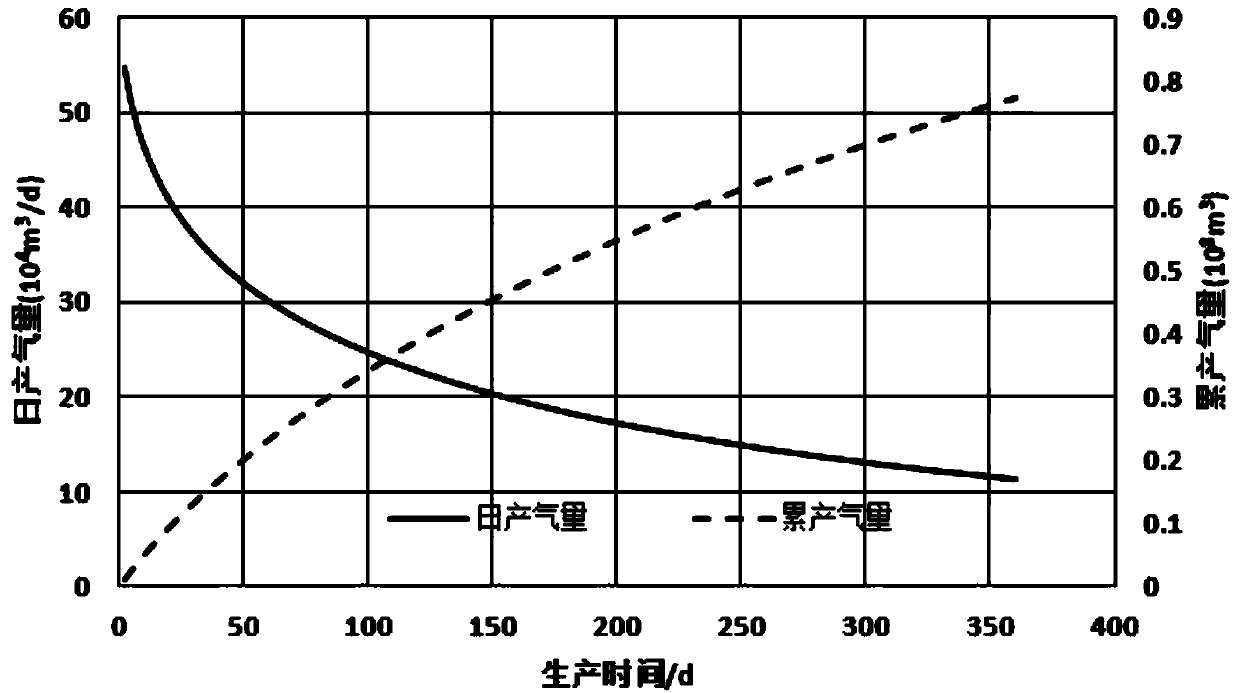

ActiveCN107622165ASolve the problem of inapplicable refracturing production capacity calculationFluid removalSpecial data processing applicationsKerogenDynamic models

The invention belongs to the technical field of unconventional oil gas production increasing transformation and particularly, relates to a shale gas horizontal well refracturing productivity calculation method. The method comprises the following steps of: by using a shale reservoir as an elastic material which is small in deformation, establishing a stress-strain model and a reservoir physical property parameter dynamic model; establishing a continuity equation in kerogen and an inorganic substance; respectively carrying out numerical solution on an established solid deformation control equation and shale gas multiscale seepage equation; bringing geological parameters, physical property parameters and primary fracturing design parameters of a shale gas well reservoir into a shale gas fluid-solid coupling numerical model, and recording a pressure field and hydraulic fracture flow conductivity of the reservoir; and bringing refracturing design parameters into the shale gas fluid-solid coupling numerical model, and calculating productivity of a shale gas well after refracturing. According to the method disclosed by the invention, seepage characteristics and stress-pressure field dynamic variations of the shale reservoir are considered, productivity and a recovery ratio of the shale reservoir after refracturing are predicted, and shale gas horizontal well refracturing optimizationdesign is guided.

Owner:SOUTHWEST PETROLEUM UNIV

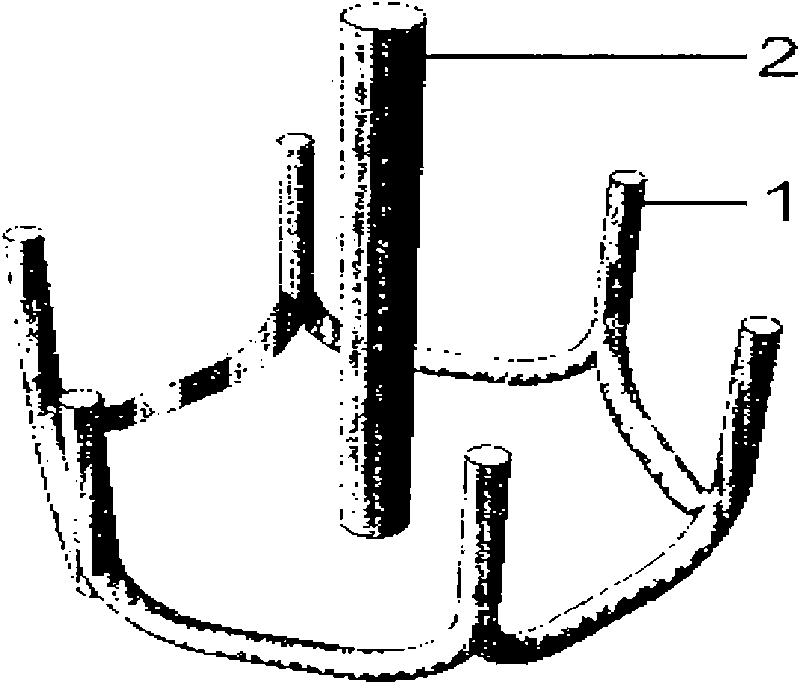

Method and apparatus of improving recovery efficiency of shale gas through a blast mode

ActiveCN102168543BIncrease the total specific surface areaImprove resolution rateFluid removalOil shale gasShale gas

The invention discloses a method and an apparatus of improving recovery efficiency of shale gas through a blast mode, The method is: setting an open hole well in shale gas acquisition area, Then setting a blast cracking area and a gas acquisition area in an assigned position of the open hole well; The two areas adjacent, But separated with each other, Detonating the explosive in the cracking area, Sidewall of the open hole well is cracked; The shale gas entering the gas acquisition area from the blast cracking area through rock crevice in sidewall of the open hole well, Then conveying to ground. The invention provided apparatus is arranged in the open hole well of the shale gas, Including an explosive loading and detonating apparatus and a gas conveying apparatus, Wherein the explosive loading and detonating apparatus is used to crack the shale around, The gas conveying apparatus is used to conveying the shale gas to ground.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

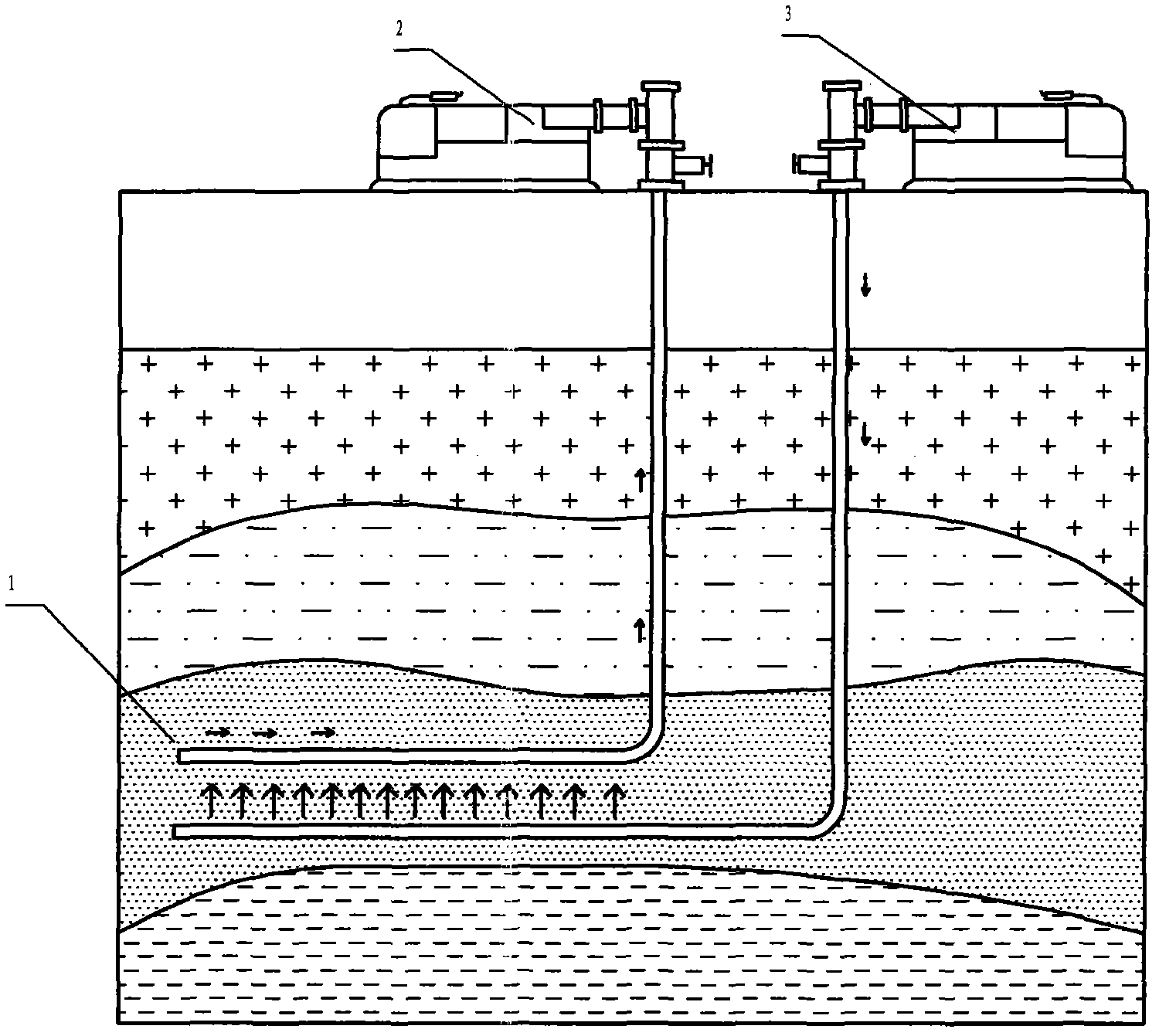

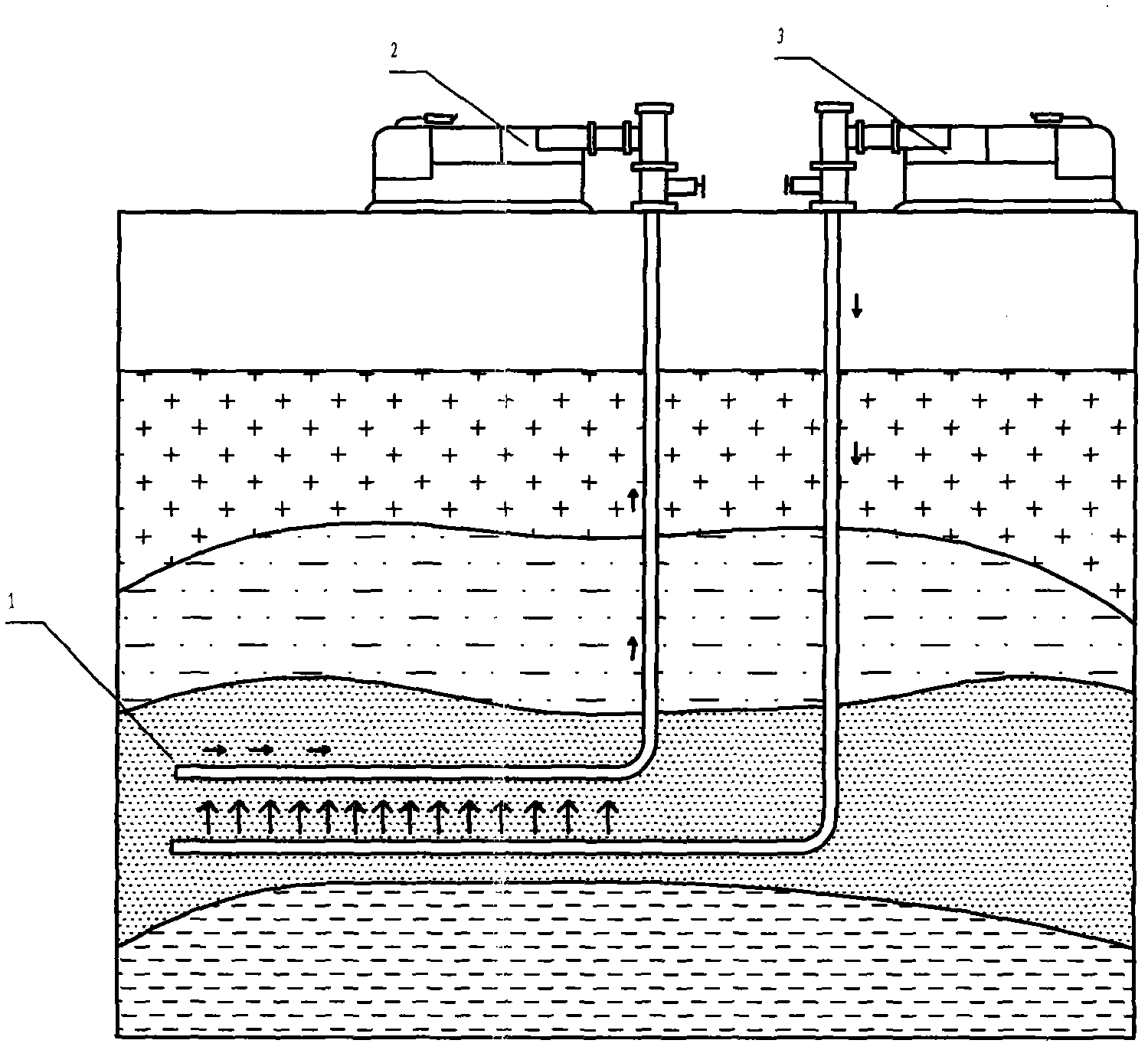

Method for underground in-situ extraction of hydrocarbon compound in oil shale

The invention relates to a method for the underground in-situ extraction of a hydrocarbon compound in an oil shale, which comprises the following steps: arranging at least one working well and one production well in an enclosed working region where the hydrocarbon compound in the oil shale is extracted, communicating the bottoms among the working wells by directional drilling after a drilling well enters an oil shale ore layer, injecting water and inert gas water vapor into the working well to form a near-critical water microenvironment, cracking the oil shale into organic compounds with different chain lengths to form an oil-water mixture, lifting the oil-water mixture to the ground through the production well, and obtaining the hydrocarbon compound through an oil-water separating system. The heat utilization ratio is improved through a multi-well integrated heat circulating system, the extraction ratio of hydrocarbon substances is greatly improved through repeated oil-water separating and circulating processes, and the technical process is shortened. A water micro-pool is formed after an oil shale layer is overflowed by water, the cracking of the oil shale can be realized within3 to 5 hours after a near-critical state is reached, and more energy sources and time are saved than an underground dry distillation method.

Owner:JILIN UNIV

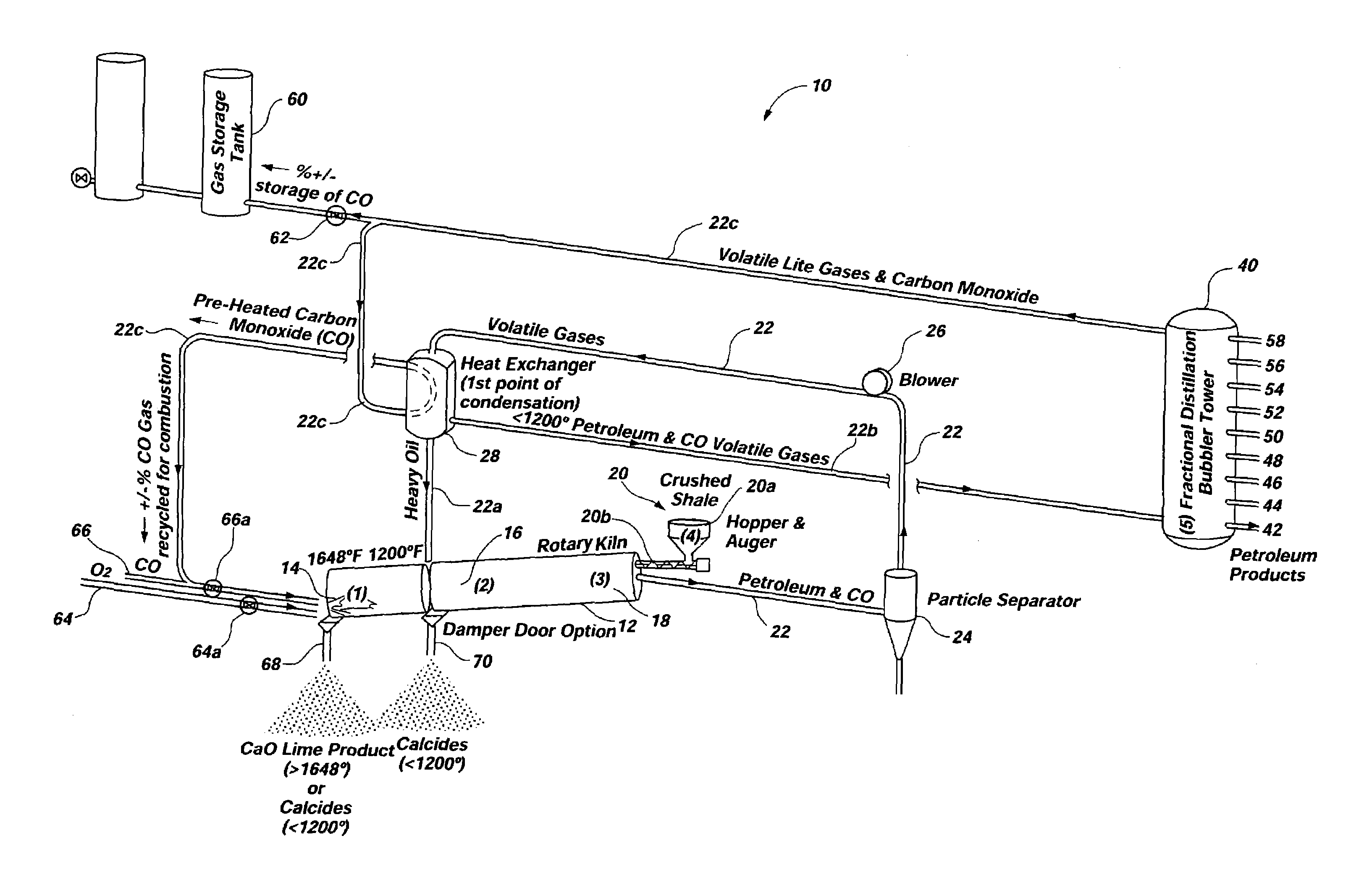

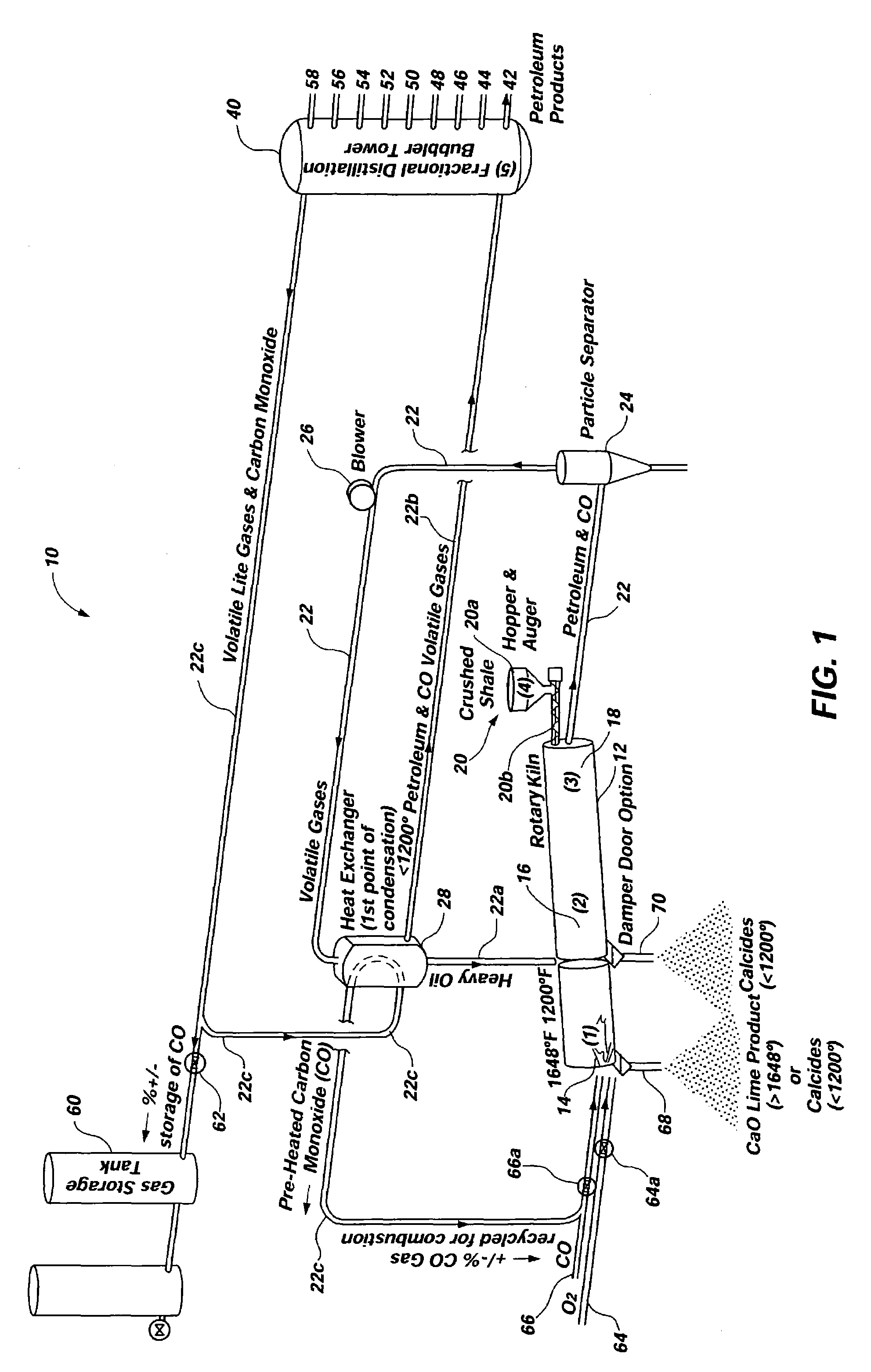

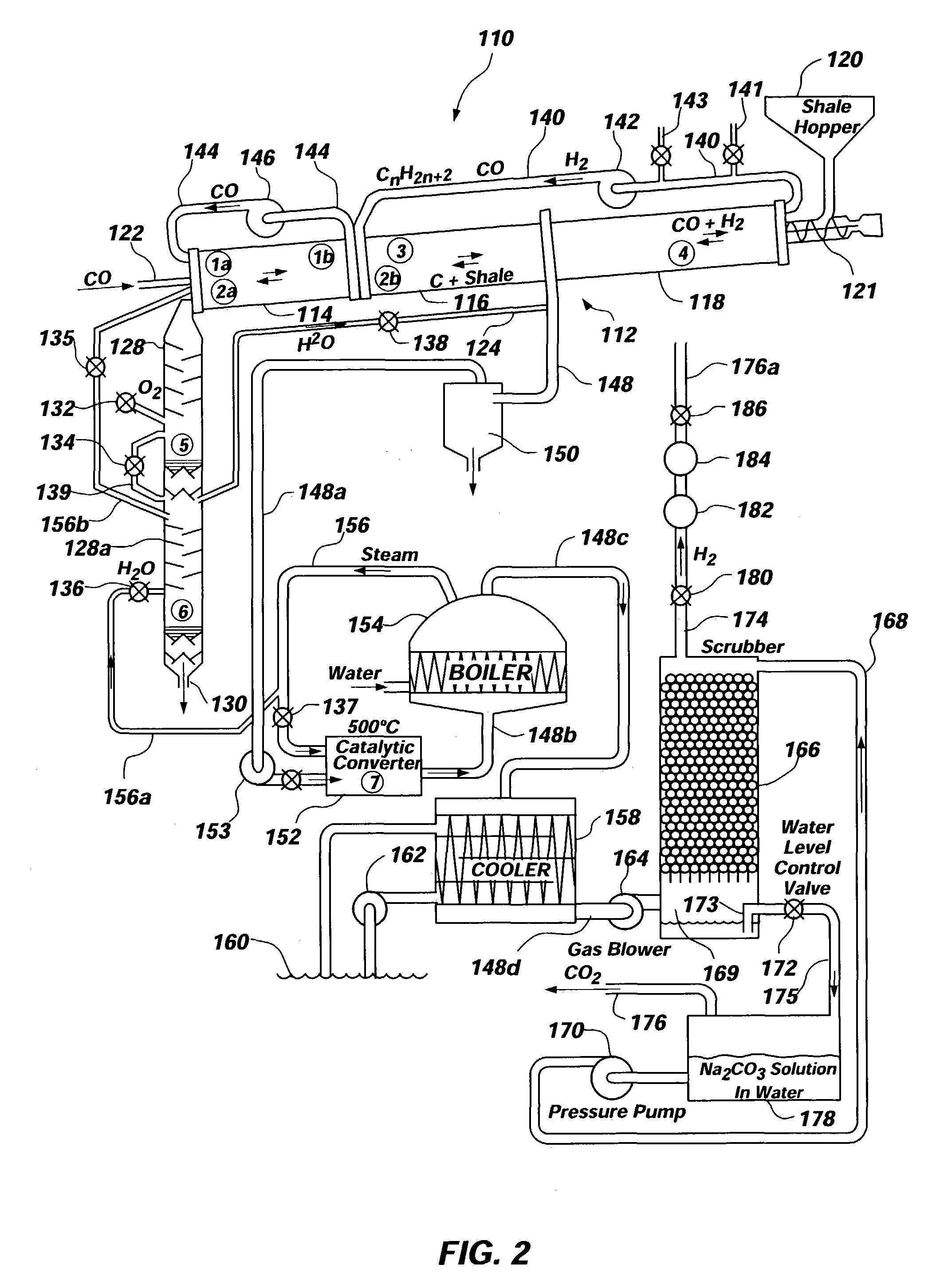

Process and apparatus for generating hydrogen from oil shale

A process and apparatus for generating hydrogen from oil shale. Crushed oil shale may be placed in a chamber and combusted with carbon monoxide, oxygen and steam to form a gas stream of hydrogen and carbon monoxide. The hydrogen and carbon monoxide stream may be passed through a mechanism to produce hydrogen. In one embodiment, the hydrogen and carbon monoxide stream may be passed through a catalytic converter to produce hydrogen and carbon dioxide. The hydrogen and carbon dioxide may be cooled further and passed through a scrubber to remove the carbon dioxide such that hydrogen is produced. In another embodiment, the hydrogen and carbon monoxide may be passed through fluidized beds of magnetite to produce metallic iron, carbon dioxide and water. The metallic iron may then be conveyed to another chamber, where it may be treated with steam, producing magnetite and hydrogen.

Owner:PETERSON OREN V

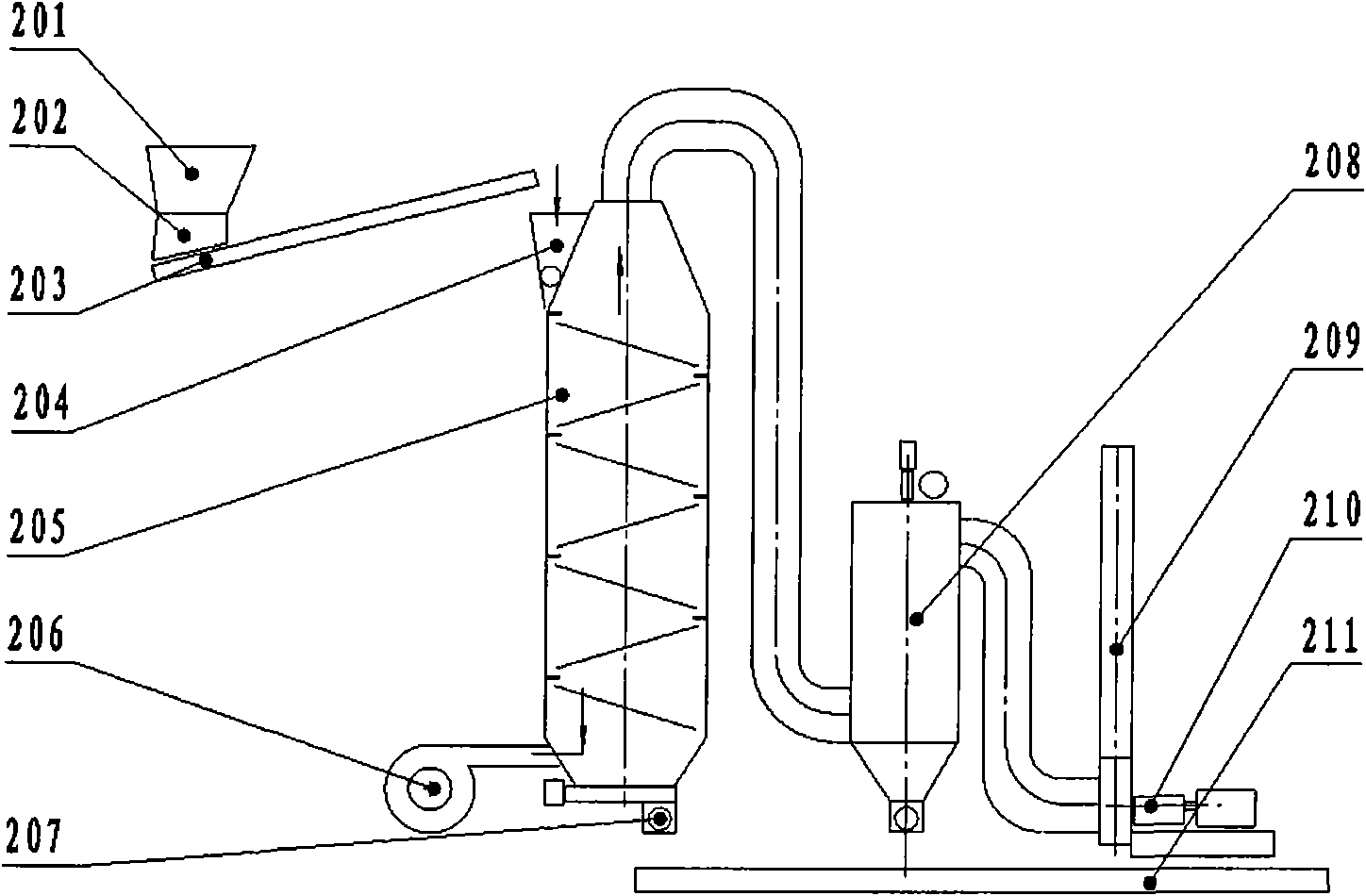

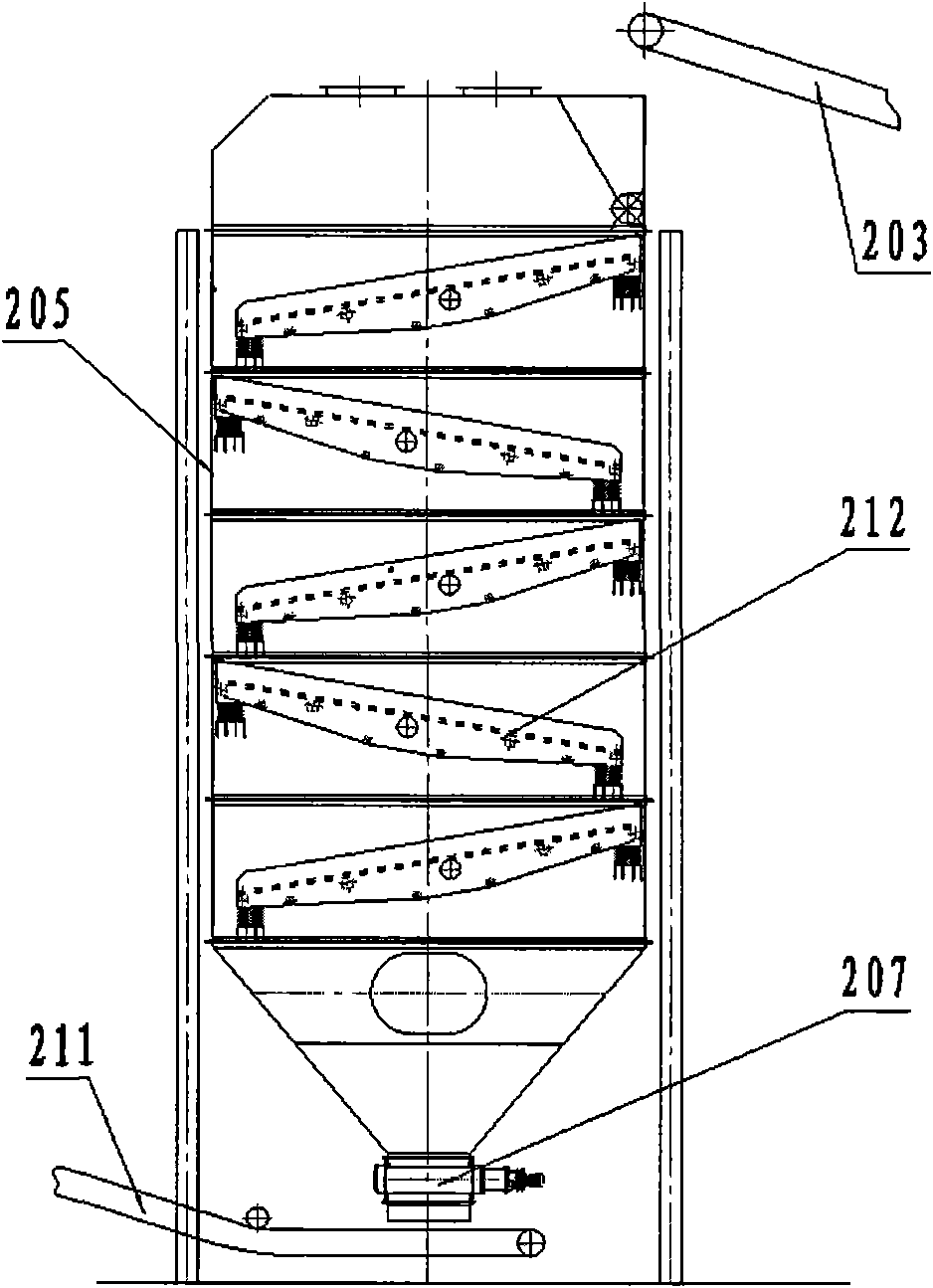

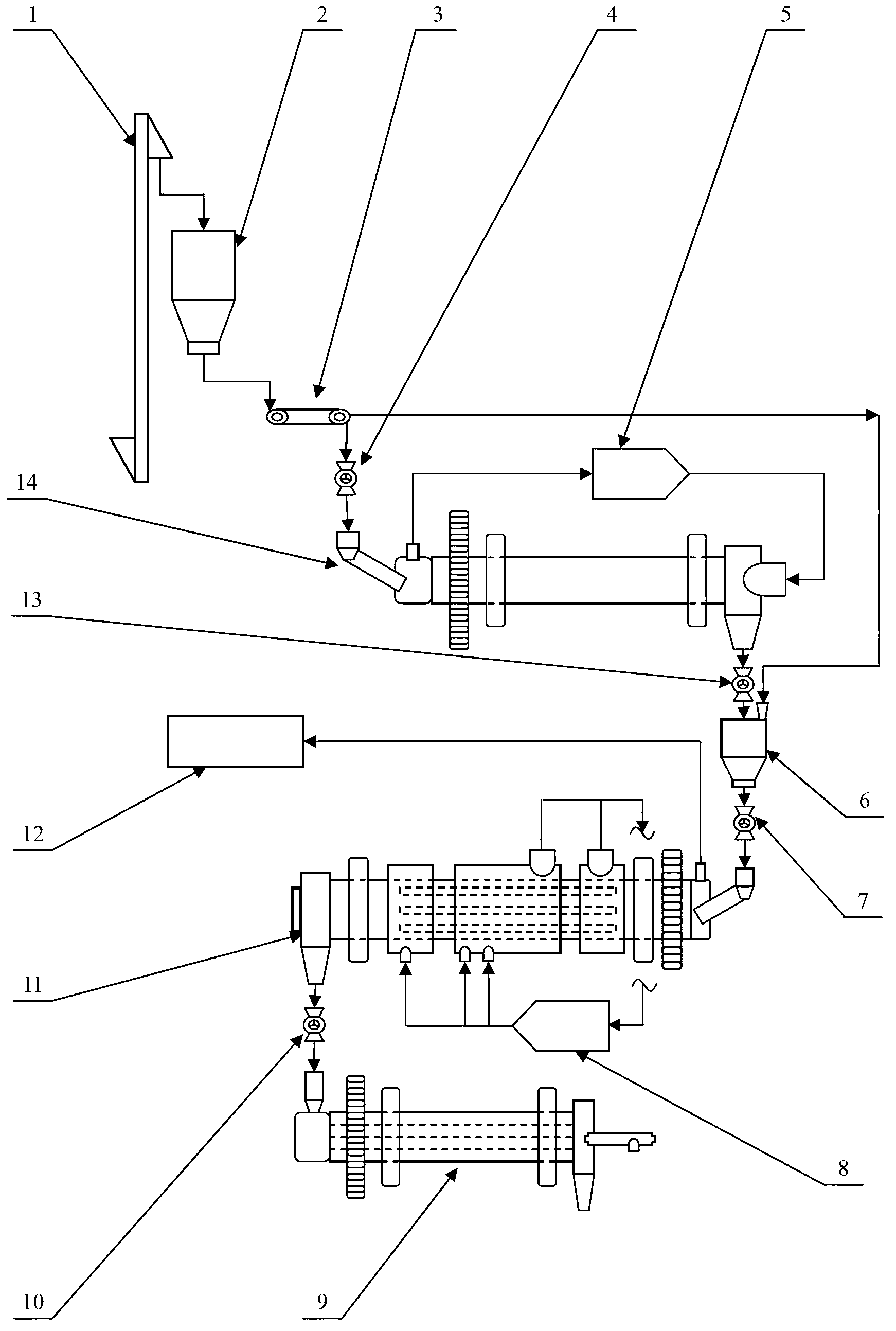

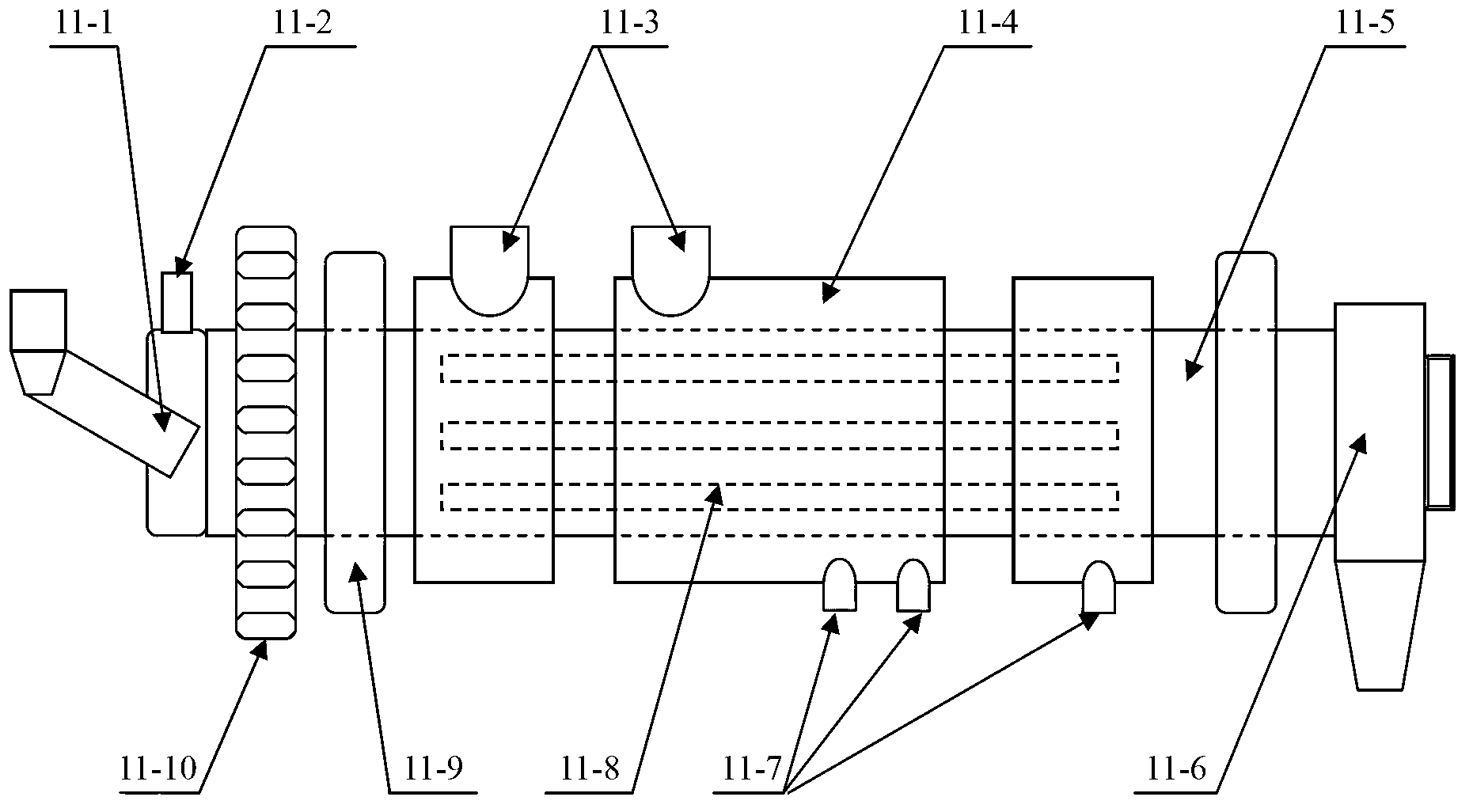

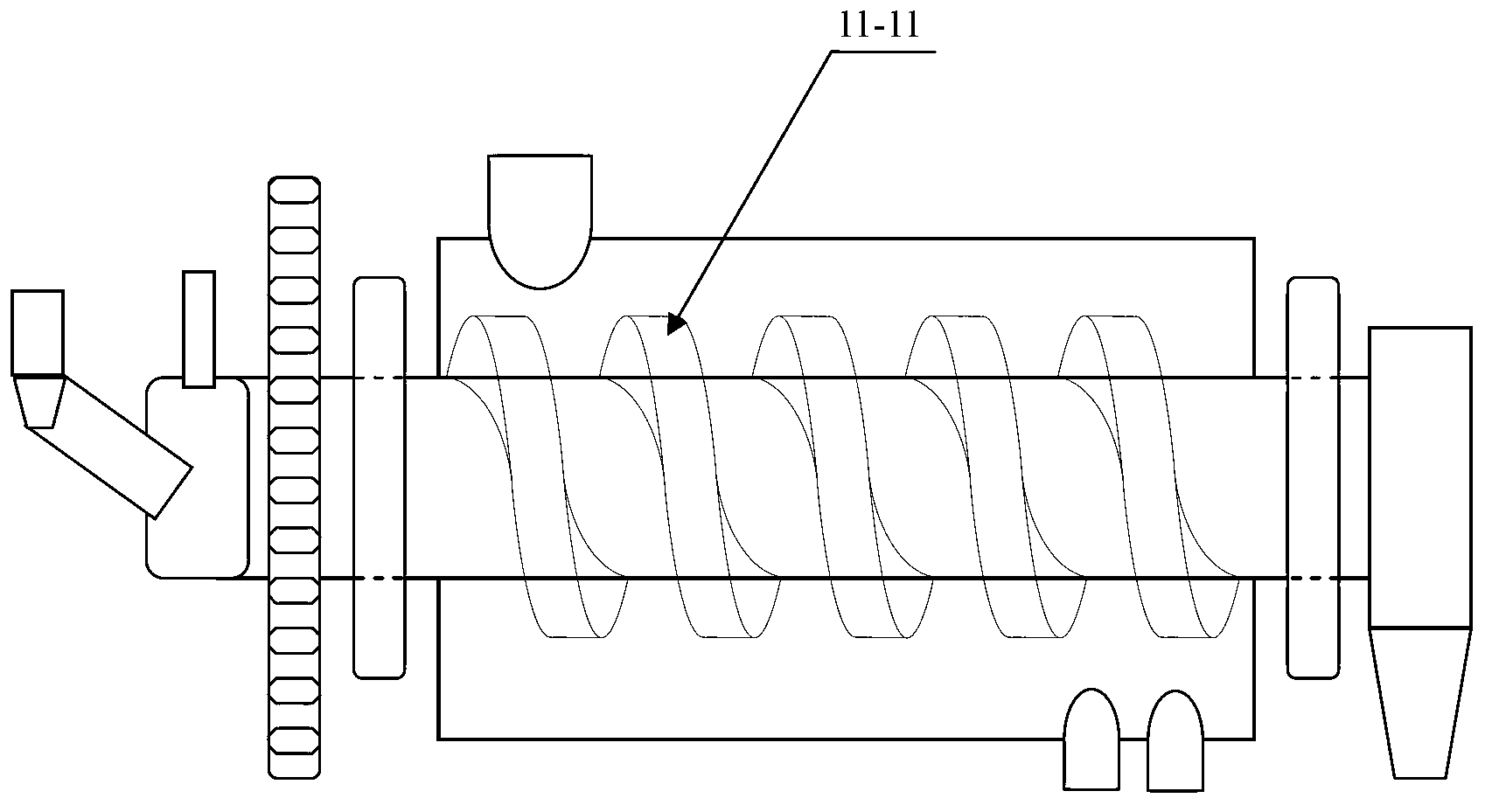

Low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass

ActiveCN103160301AIncrease profitReduce energy consumptionDirect heating destructive distillationBiofuelsCarbonizationOil shale gas

The invention discloses a low-temperature carbonization apparatus and method for oil sand, oil sludge, oil shale and biomass. The apparatus comprises a delivery apparatus, a storage bin, a metering apparatus, a drying furnace and a surge bin. The method comprises the following steps: drying, preheating, carbonizing, and cooling. The core of the invention is an external heating type rotary carbonization furnace which realizes the pyrolysis of oil sand, oil shale, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery) and biomass, and the product is high in purity and low in loss. The invention effectively solves the problems of solid materials such as adhesion, wall accretion and the like in the pyrolysis process by material returning. The technology provided by the invention is simple in process and reliable and stable in operation, and has obvious advantages in the treatment of small particle materials such as oil shale, oil sand, oil sludge (oil sludge on the ground, oil sludge at the bottom of a tank and oil-containing sludge from oil refinery), biomass and the like.

Owner:何建祥

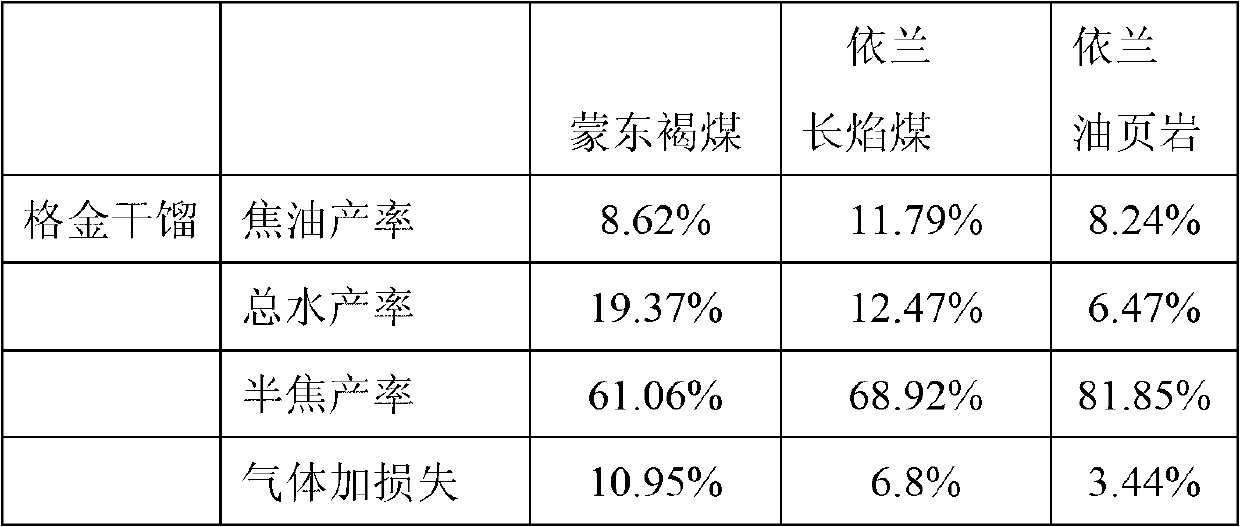

Oil shale fluidized bed dry distillation system

InactiveCN101440293ARealize scientific utilizationImprove heat transfer efficiencySpecial form destructive distillationWater vaporOil shale gas

The invention relates to a carbonization system of an oil shale fluidized bed. Oil shale with high oil content and low pyrolysis temperature is used as a carbonization material; high-temperature steam-gas and circulating hot ash are utilized to fluidize and heat the oil shale in a carbonization chamber of the fluidized bed; after ash removal, mixed airflow of generated shale oil and noncondensable gas and vapour in the carbonization chamber of the fluidized bed enters a cooler; the condensed oil-water mixture is divided into shale oil and water through the oil-water separator; the shale oil is transported to a shale oil storage tank; the water is purified and is conducted to the cooler; and noncondensable gas which is not condensed through the cooler is transported to a fuel gas storage tank. Oil shale carbocoal produced through the carbonization chamber of the fluidized bed is directly transported to a boiler of an oil shale carbocoal circulating fluidized bed, is burned and discharges heat; one part of the produced steam-gas is used as fluidized wind of the carbonization chamber of the fluidized bed; the residual steam-gas is conducted to a steam turbine-dynamo system, applies work and generates electricity; and part of circulating ash in the boiler is used as a heat source of the carbonization chamber of the fluidized bed. The carbonization system can realize high-efficient, clean and economic comprehensive utilization of the oil shale.

Owner:SHANGHAI JIAO TONG UNIV

New fracturing process suitable for encrypted development of shale gas well

ActiveCN109977612AIncrease the complexity of the transformationImprove the efficiency of transformationData processing applicationsFluid removalMulti clusterTransformation efficiency

The invention relates to the technical field of horizontal well fracturing, and discloses a new fracturing process suitable for the encrypted development of a shale gas well, which comprises the following steps of (1) collecting the data; (2) analyzing the stress and compressibility; (3) designing the interval of the segment clusters; (4) designing the number of clusters; (5) carrying out the temporary plugging design in the midway; (6) designing the construction displacement; (7) designing a fracturing scale; and (8) designing a sand adding mode. According to the essence of the method, the small-section multi-cluster segmented design of reducing the section cluster spacing is carried out on the target horizontal well by analyzing the single well ground stress characteristics and the compressibility of the shale gas well of encrypted development; meanwhile, the pumping design of the variable-density perforation, midway ball throwing temporary plugging and continuous sand adding is combined, and finally, the effect of improving the single well transformation complexity and the reservoir transformation efficiency is achieved, the volume transformation of the whole horizontal well isachieved, the crack complexity is improved, the transformation strength is improved to a larger extent through improvement of a sand adding mode and a pumping program, and meanwhile the single well construction cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

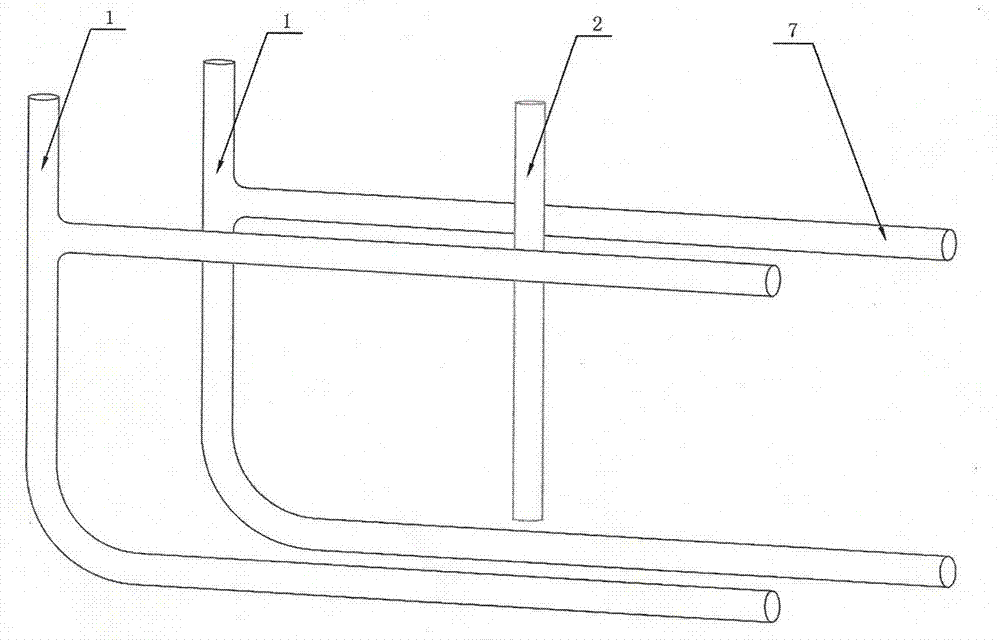

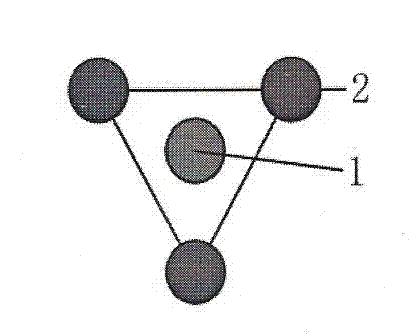

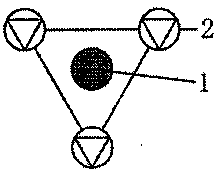

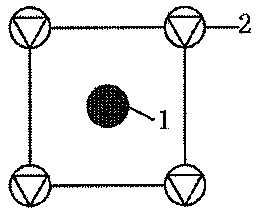

Method of exploiting deep layer oil shale to manufacture shale oil and oil shale gas

The invention relates to a method of exploiting deep layer oil shale to manufacture shale oil and oil shale gas. Firstly, three horizontal wells are drilled on oil shale layer away from water layers and broken layers and at the depth of 100 to 3000 meters, two gas production horizontal wells are respectively arranged at the bottom of the oil shale layer, one high pressure gas injection well is arranged at the upper portion with the inclined angle of 40 degrees, the well distance is 30 meters, and the two gas production wells adopt advanced well completion technique. Secondly, the horizontal wells are used to perform large scale crushing, and a storage layer of the oil shale layer is characterized by being low in holes and permeability. According to the method, oil shale underground is heated and crushed to generate gas motion channels in the oil shale and underground, oil shale is burned by injecting gas and oxygen, electrically heating and controllably burning to enable catalysis splitting and combustion splitting to happen in the oil shale, hydrocarbon can be exploited with gas, and shale oil and oil shale gas can be obtained.

Owner:GUODING DALIAN INVESTMENT

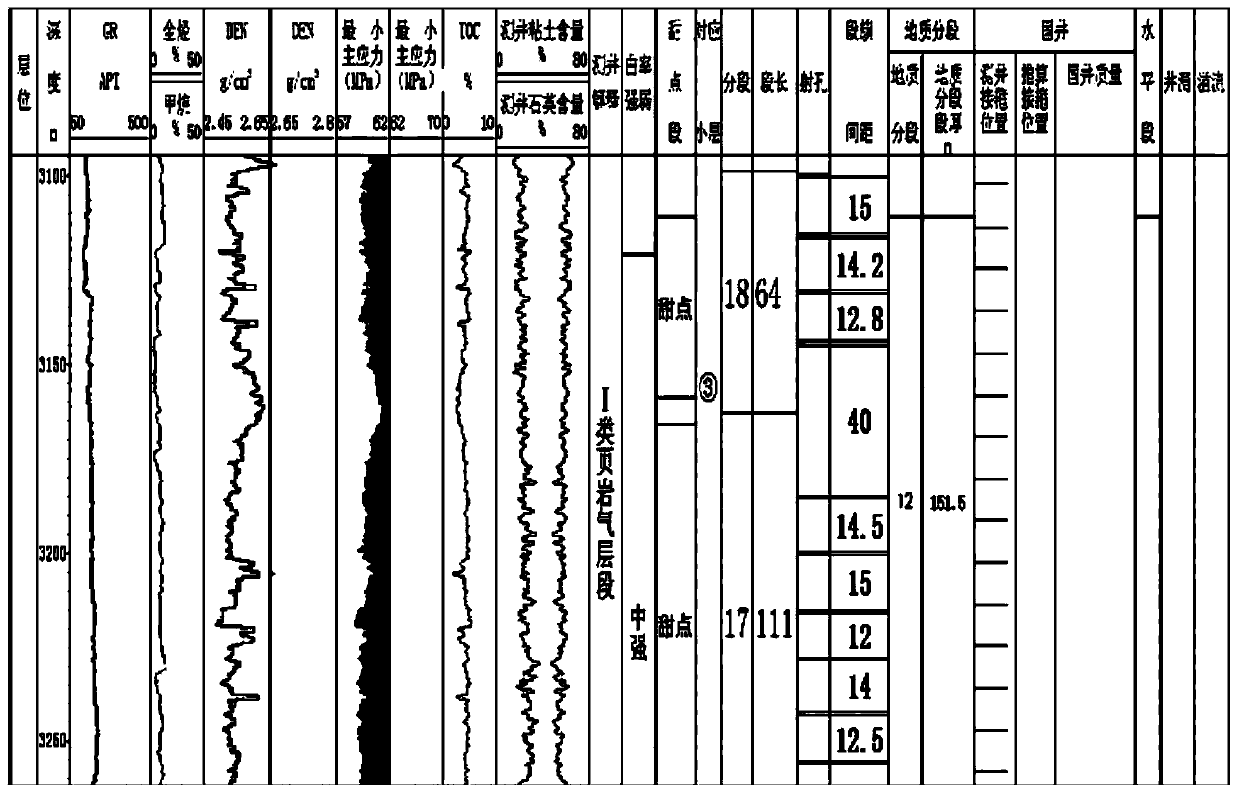

Shale gas physical geography quick evaluation method

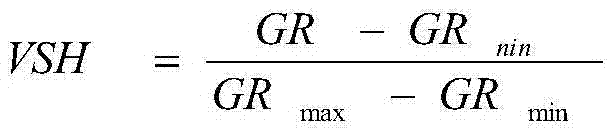

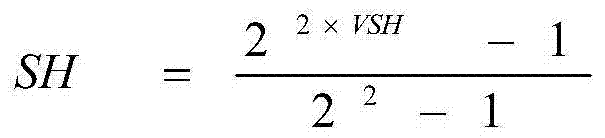

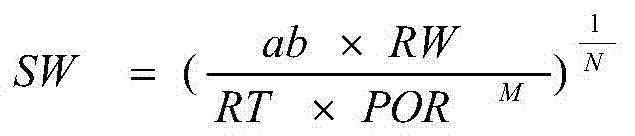

InactiveCN104500049AEasy to mineSolve the very inconvenient problem of miningInformaticsInstrumentsKerogenWell logging

The invention discloses a shale gas physical geography quick evaluation method. The geologic factors of production of shale gas are as follow: clay, kerogen, porosity, water saturation and permeability, and according to the above geologic factors, evaluation calculation with different models is performed: in the conventional well logging interpretation, the content of clay is calculated by a uranium-free gamma ray curve; the formation of kerogen is mostly in the reduction environment with relatively high content of the radioactive element U, so that a peak appears in the natural gamma ray curve, and as the density of kerogen is relatively low, TOC is integrally calculated with several methods; the value of porosity is calculated by a neutron-density crossplot, and the amount of minerals in rock can also be calculated through correction of the crossplot; the water saturation is calculated by the Archie's formula; and the permeability is calculated according to regression of porosity, and only the shale segment reservoir bed is subjected to regression. The shale gas physical geography production factors can be quickly and accurately calculated, and the results are accurate.

Owner:CHENGDU CHUANGYUAN OIL & GAS TECH DEV

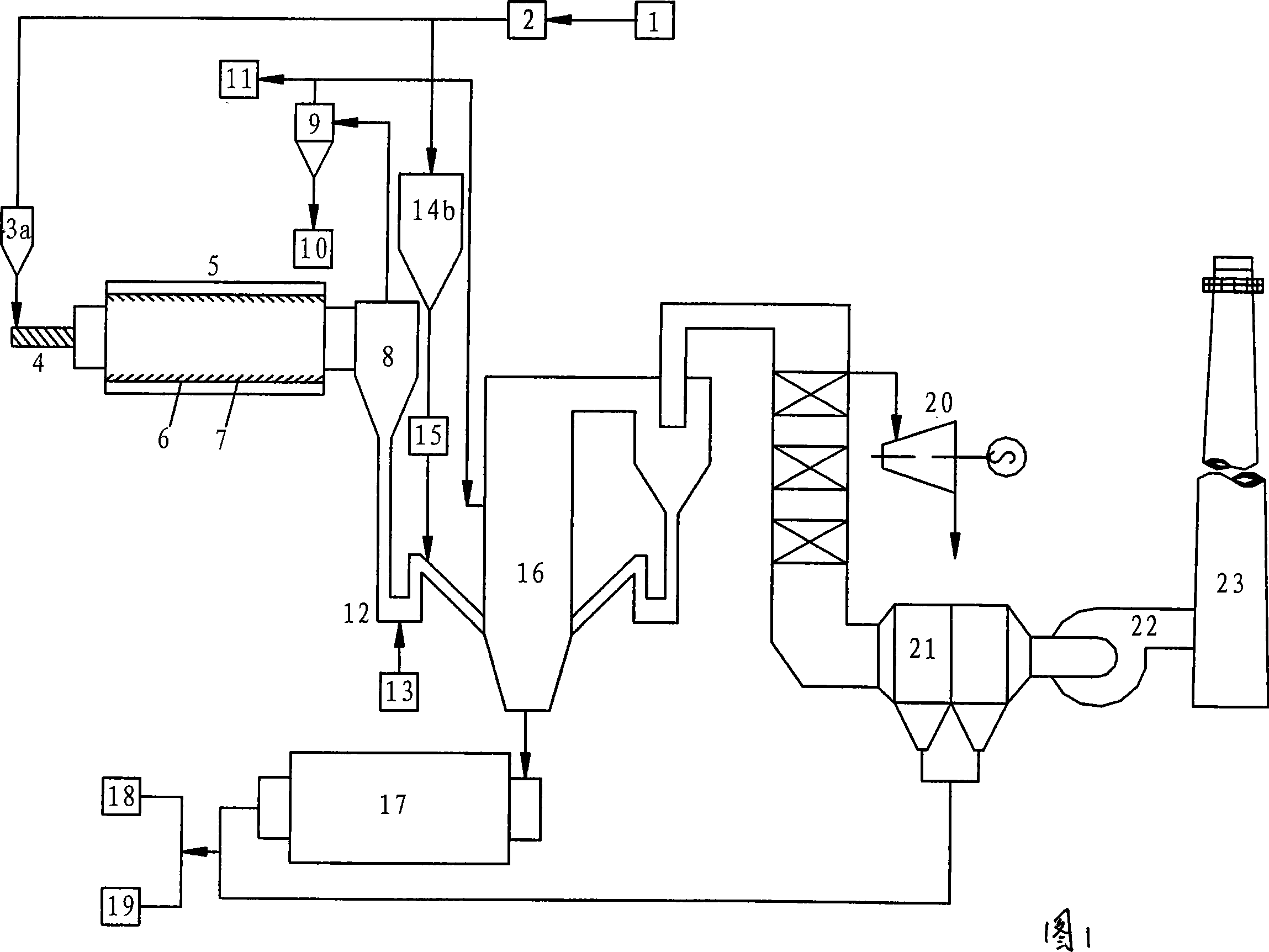

Method for complex optimum using oil shale

InactiveCN1683472AAchieve optimal utilizationIncrease profitLiquid hydrocarbon mixture productionSpecial form destructive distillationFluidized bedOil shale gas

The comprehensive optimized oil shale utilizing method includes crushing and sieving oil shale ore, dry distilling the 8-80 mm size component in retort furnace to produce shale oil and fuel gas, crushing the semicoke waste into 8 mm below size, mixing the crushed semicoke waste and 8 mm below size waste grain from oil refining to form mixed fuel for the circulating fluidized bed boiler, using the produced steam partially for externally supplying and partially to drive turbine generator, and using the cinder in producing cement, haydite and building block. The present invention provides one new way for comprehensive utilization of giant oil shale resource.

Owner:SHANGHAI JIAO TONG UNIV

Method for extracting shale oil gas by oil shale in-situ topochemical method

The invention discloses a method for extracting shale oil gas by an oil shale in-situ topochemical method. The method includes: a partial chemical reaction area is formed in an underground oil shale stratum via hot mixed gas; in the whole process, a series of 'chain reactions' are induced by means of controlling concentrations of injected hot mixed gas and recovered hot mixed gas, and along with gradual temperature rising and range widening of the reaction area, porosity and permeability of the oil shale stratum increase continuously, heat strengthening reaction processing is realized finally, and self catalytic cracking of the oil shale stratum from inner to outer is achieved to generate shale oil and fuel gas. After the chain reactions are over, fixed carbon in the oil shale stratum is continuously enabled to react to generate low-heating-value gas via the hot mixed gas, high-temperature waste heat in the area finished in cracking reaction is recycled, and self-supporting and maximal utilization of energy for the oil shale stratum cracking are realized. By the aid of the method, exploring method, environmental harms and commercial risks can be reduced.

Owner:JILIN UNIV +1

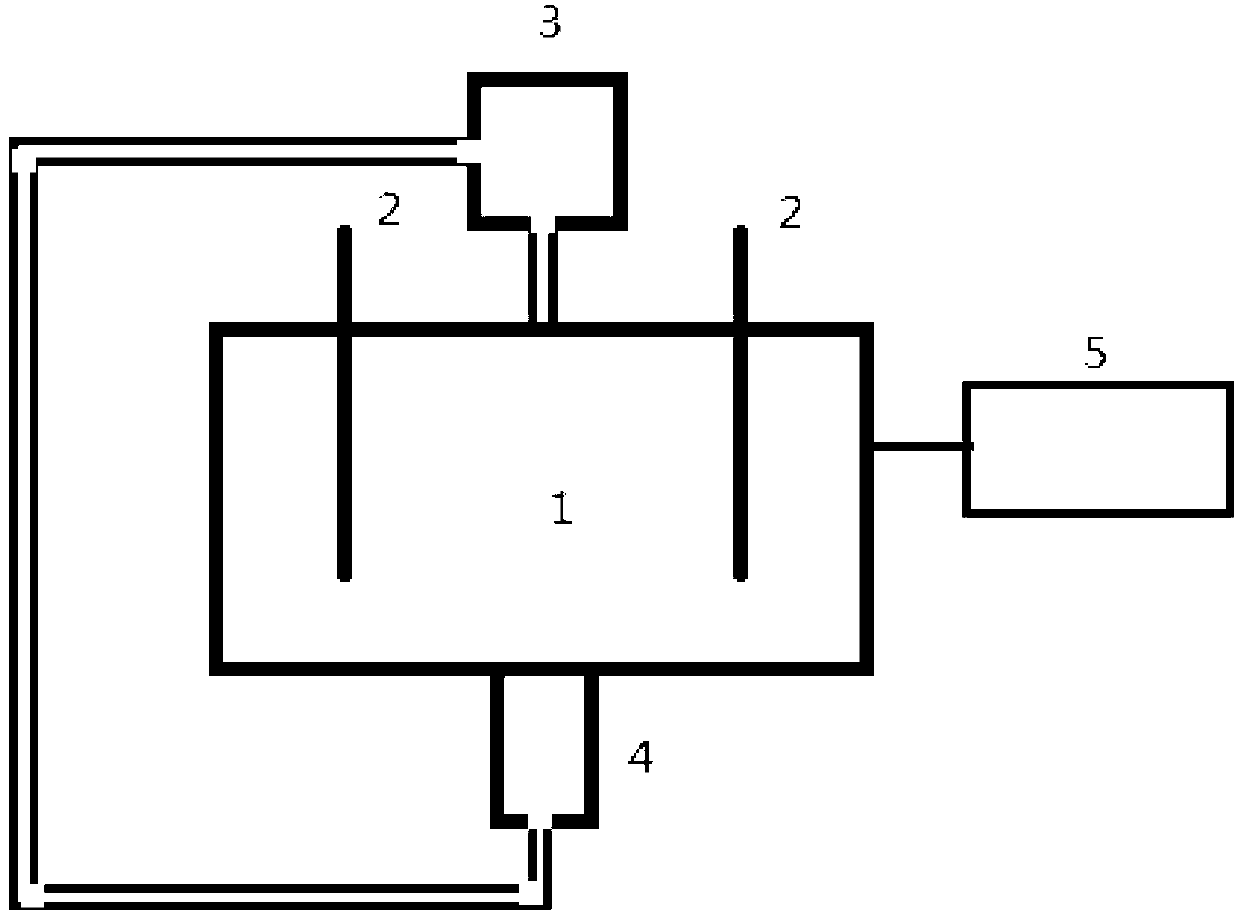

Full cycle dry distillation process and system for producing shale oil from oil shale (coal)

InactiveCN101280201AHigh calorific valueAchieve separationSpecial form destructive distillationDistillationOil sludge

The invention provides a full cycle dry distillation process and a system which use oil shale (coal) to produce shale oil; the technological process includes that the distillation of the oil shale is processed in an oil shale distillation system which is composed of an oil shale input storage tank, a non-oxygen coal-gas heating retort and a semi-coke discharge device to generate pyrogenous coal gas and the semi-coke; the pyrogenous coal gas is separated and purified by a pyrogenous coal gas multi-stage purifying system composed of a coal gas collecting pipe, an oil-washing tower, an intercooling tower and an electrical oil trap; the obtained coal gas is preheated by a coal gas preheating system composed of a fluidized bed combustion furnace, a spiral feeder and a duster collector and then is fed into the non-oxygen coal-gas heating retort for the dry distillation of the oil shale; the oil product separated from the oil-washing tower, the intercooling tower and the electrical oil trap is purified and collected through an oil product purifying and collecting system so that the shale oil product is obtained; the semi-coke and the sludge generated during the dry distillation and purification process are used as the materials for the preheating of the coal gas. The dry distillation process in the invention can effectively realize the functions of dry distillation, dust separation and combusting the semi-coke and sludge generated during the process of dry distillation for the preheating of the coal gas; thereby, the sources is utilized sufficiently and the environmental protection requirement is fulfilled.

Owner:ZHUHAI TOP ENERGY TECH

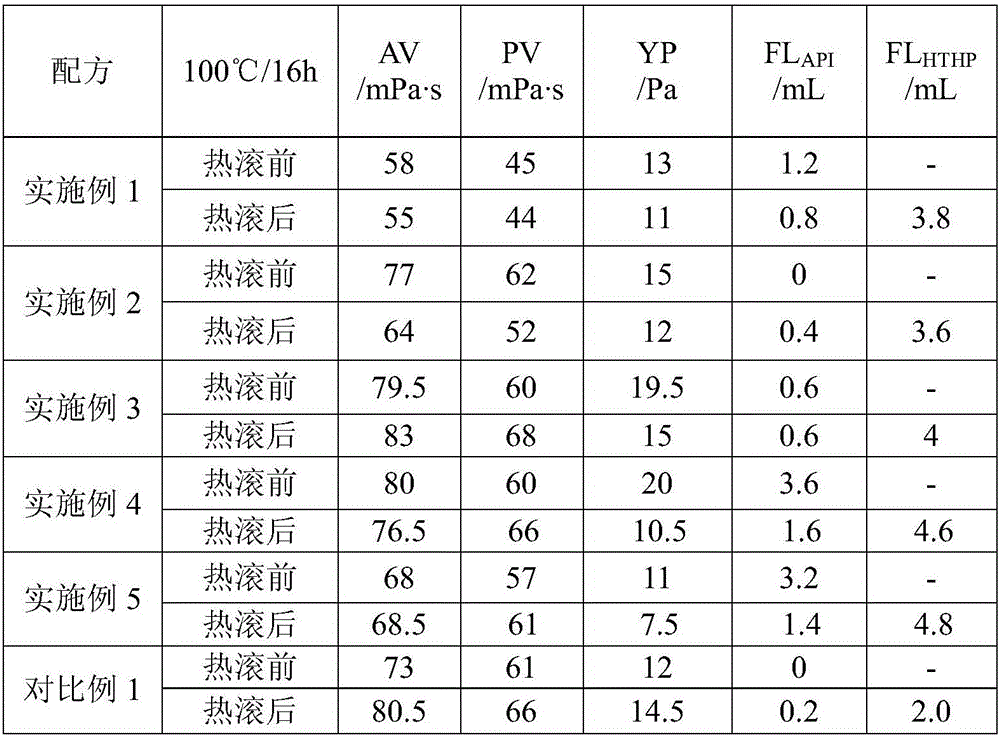

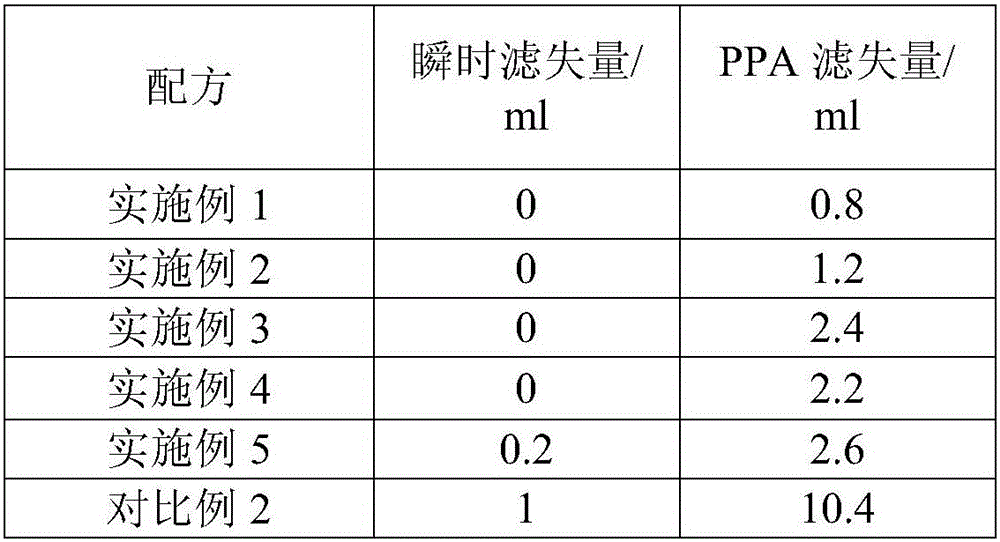

Water-based drilling fluid suitable for long-section horizontal well of shale gas and application of water-based drilling fluid

ActiveCN106833564AImprove rheologySlow or block pressure transmissionDrilling compositionWater basedMicro nano

The invention relates to a water-based drilling fluid suitable for a long-section horizontal well of a shale gas and an application of the water-based drilling fluid. The water-based drilling fluid is prepared from the following components in parts by weight: 100 parts of water, 0.5-5 parts of bentonite, 0.1-0.4 part of sodium carbonate, 0-8 parts of an inorganic salt, 1-5 parts of a filtrate reducer, 0.1-1 part of a viscosity enhancer and carrying agent, 0-1.5 parts of a wetting agent, 0.5-5 parts of a shale inhibitor, 1-5 parts of a lubricant, 1-6 parts of a micro-nano blocking agent, 0-3 parts of a viscosity reducer, 0-1 part of a pH modifier and 0-280 parts of a weighting material. According to the drilling fluid, the density can reach 2.3g / cm<3>, the high-temperature and high-pressure filter loss is smaller than 5ml and the rheological property, the filtration reducing property, the lubricity and the inhibitive ability are equivalent to those of an oil-based drilling fluid; the surface performance of the shale can be improved, the hydrophobicity can be strengthened and the compressive strength of the shale is retarded; the water-based drilling fluid has good antifouling property and high sealing capacity; shale micro cracks can be sealed; pressure transmission is retarded or blocked; and the well-bore stability of the shale is facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

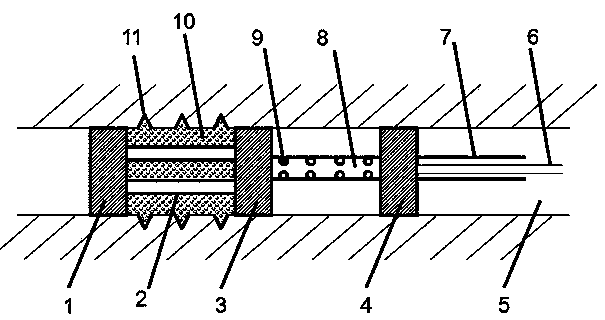

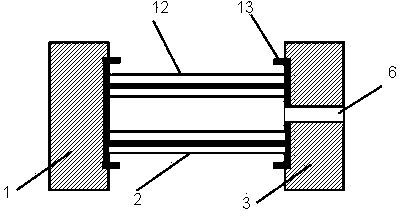

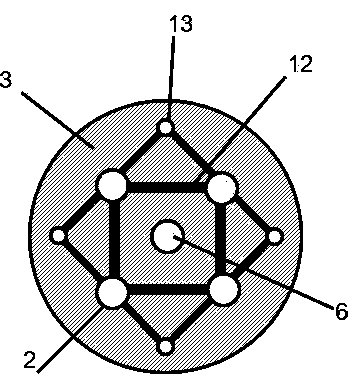

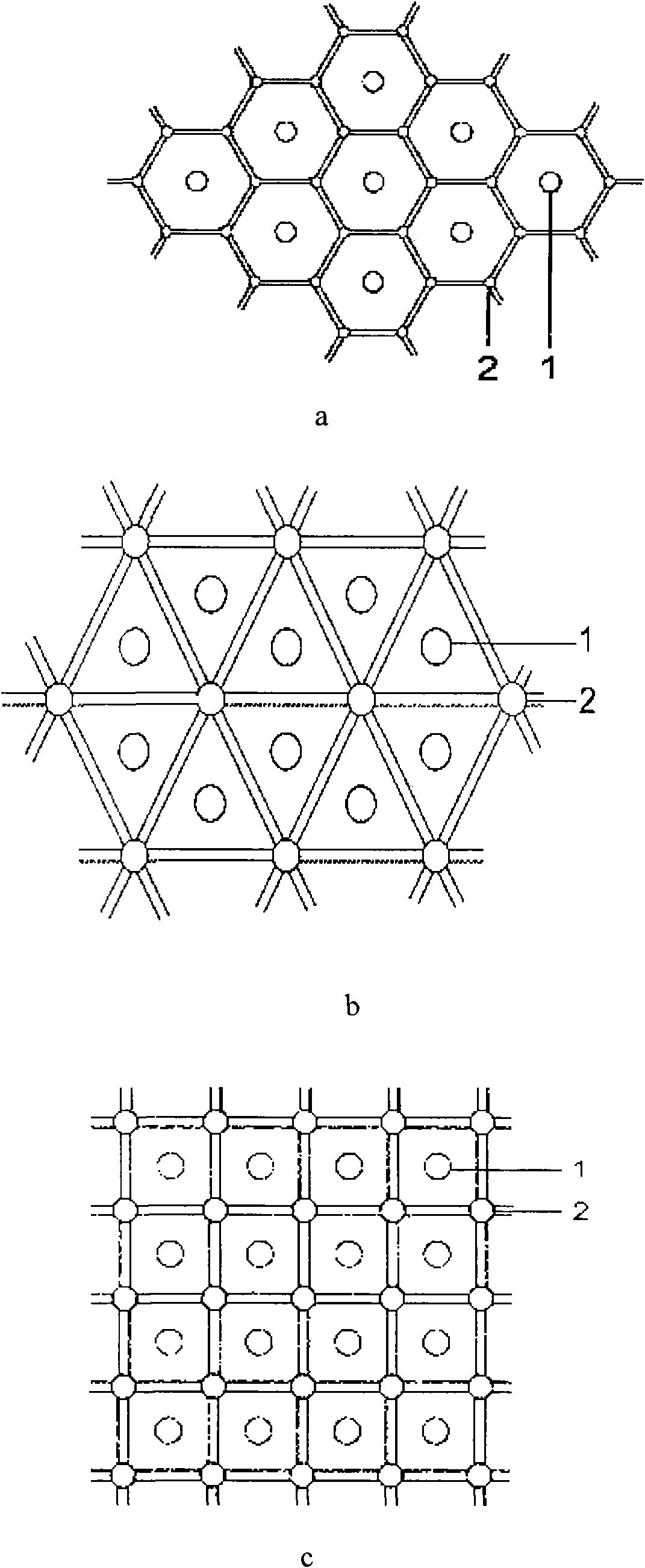

Tunnel pipe thin-layer retort for coal and oil shale and retort process thereof

InactiveCN103013544AImprove heat transfer performanceIncrease profitChemical industrySpecial form destructive distillationThin layerOil shale gas

The invention discloses a tunnel pipe thin-layer retort for coal and oil shale and a retort process thereof, relates to a retort and a process for producing coal tar and shale oil, and solves the problems that the conventional retorts and processes have large heat loss at semicoke cooling sections, the retort time is difficultly controlled accurately, the oil yield is low and the treatment capacity of the single furnace is small. The retort comprises a drying section, a retort section, a high temperature cooling section and a low temperature cooling section, wherein the semicoke cooling section is divided into two sections by a roller feeding machine, heat exchange of cooling wind is carried out at the high temperature semicoke section, the low temperature cooling section is communicated with a tunnel pipe, and drying gas enters the drying section via the tunnel pipe. According to the process, retort oil gas led out from a retort oil gas outlet of a retort furnace is purified and then used as circulation retort gas, and gas led out from a drying gas outlet of the retort furnace is used as the circulation drying gas to carry out retort. With the retort and the retort process, an addition of 20 percent of semicoke residual heat is recovered from per ton raw material, the retort time is accurately controlled, the oil yield is high, and the treatment amount of the single furnace is large; and the retort and the retort process are mainly applied to the field of coal chemical industry.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

Kerosene shale comprehensive utilization process

InactiveCN101113344ALarge amount of processingHigh utilization rate of dry distillationInternal combustion piston enginesGaseous engine fuelsWorking fluidSlag

The invention relates to a comprehensive utilization process of oil shale. Oil shale raw ore is crushed by a crushing and screening device until the particle size is less than 15mm; one part of crushed oil shale particles are transported to a screw feeder and then to a microwave drum dry distillation device, the oil shale particles absorb microwave and generate high temperature methane gas, distilled char and methane gas are entered into a closed solid and gas separating device, separated high temperature methane gas is entered into a condensing and recycling device and cooled to separate the oil shale; low temperature methane gas after oil extraction is entered into an internal combustion engine to be combusted for power generation and / or entered into a circulating fluidized bed boiler to be combusted, heat quantity released from the combustion is transmitted to water by the heating surface of a boiler, the superheated steam is supplied as working fluid or sent into a steam turbine to generate electricity; carbon-content of the slag and ashes is less than 2 percent and the finished product can be directly as building raw materials without roasting. The invention has the advantages of short process, comparatively small occupying space, high comprehensive utilization, low cost, being scientific and rational, etc.

Owner:NORTHEAST DIANLI UNIVERSITY +1

Fracturing flowback fluid treatment method

ActiveCN102992524AGood removal effectHigh activityMultistage water/sewage treatmentWater/sewage treatment by oxidationLiquid wasteChemical oxygen demand

The invention discloses a treatment method for flowback fluid in horizontal well fracturing exploitation of oil fields and unconventional oil and gas fields, such as natural gas and shale gas. The method comprises the steps of: removing scale-forming elements from fracturing flowback fluid by flocculation and sedimentation; and converting chloride ions in waste water into hypochlorite and chlorine gas by using an acousto-optic electrical excitation effect, and carrying out deep oxidation without adding extra oxidants in the whole process. According to the method, components influencing the preparation of the fracturing fluid are removed, and other useful components are reserved completely or partially, thereby reducing the waste liquid treatment cost, and reducing the addition cost of additives during the preparing of the fracturing fluid. According to the method provided by the invention, the process flow is short, the cost is low and the efficiency is high, and is particularly suitable for treating flowback fluid with high oil content, high COD (chemical oxygen demand) and high turbidity produced by horizontal well fracturing construction as well as waste waters produced by various kinds of oil fields.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for preparing white carbon black by using oil shale ash

A method of manufacturing carbon white using bituminous shale ash comprises the steps of: 1)crushing the bituminous shale ash; 2) mixing the crushed bituminous shale ash with NaOH solution to react for 0.5~24 hours at 20~200 DEG C with an agitating speed of 100~800 r / min; 3)dividing the reaction solution into two parts, an alkali solubility part and an alkali insolubility part, by means of vacuum filtration; 4) adding dispersant into the filtrate, adjusting the pH value to 3.0~10.0 using sulfuric acid or chlorine hydride, and agitating for 0.5~4 hours using a magnetic stirrer; 5) standing and aging for 0.5~24 hours, wherein white floc is generated; 6) filtering; 7)vacuum drying of the filter cake at a temperature of 40~80 DEG C. The present invention produces qualified carbon white with a simple technology and realizes the ecology utilization of bituminous shale ash.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com