Method of exploiting deep layer oil shale to manufacture shale oil and oil shale gas

A technology of oil shale gas and oil shale, which is applied in the direction of exploitation fluid, earthwork drilling, wellbore/well parts, etc., which can solve the problems of air pollution, large land occupation, large area of waste ash, etc., and achieve The effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

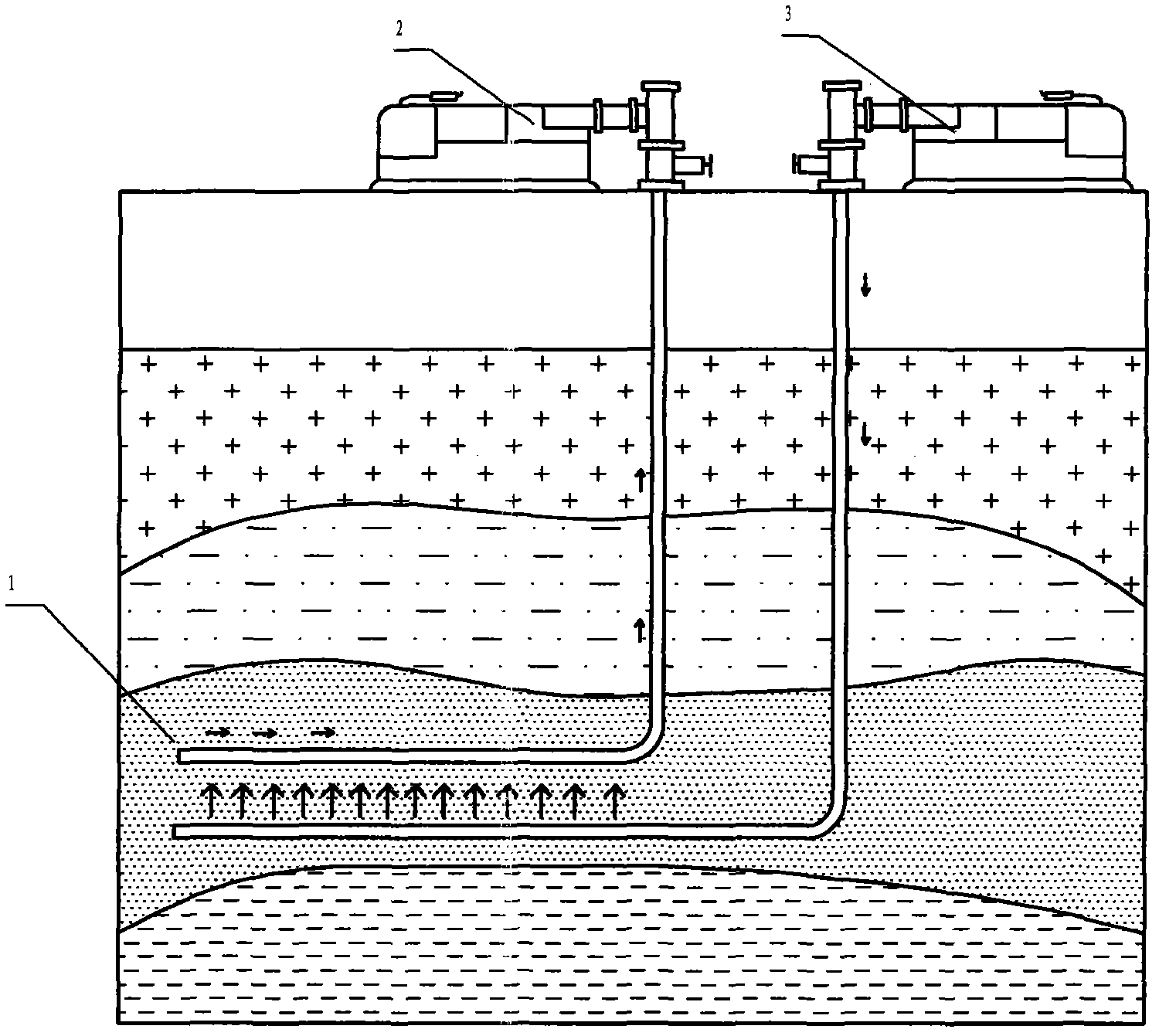

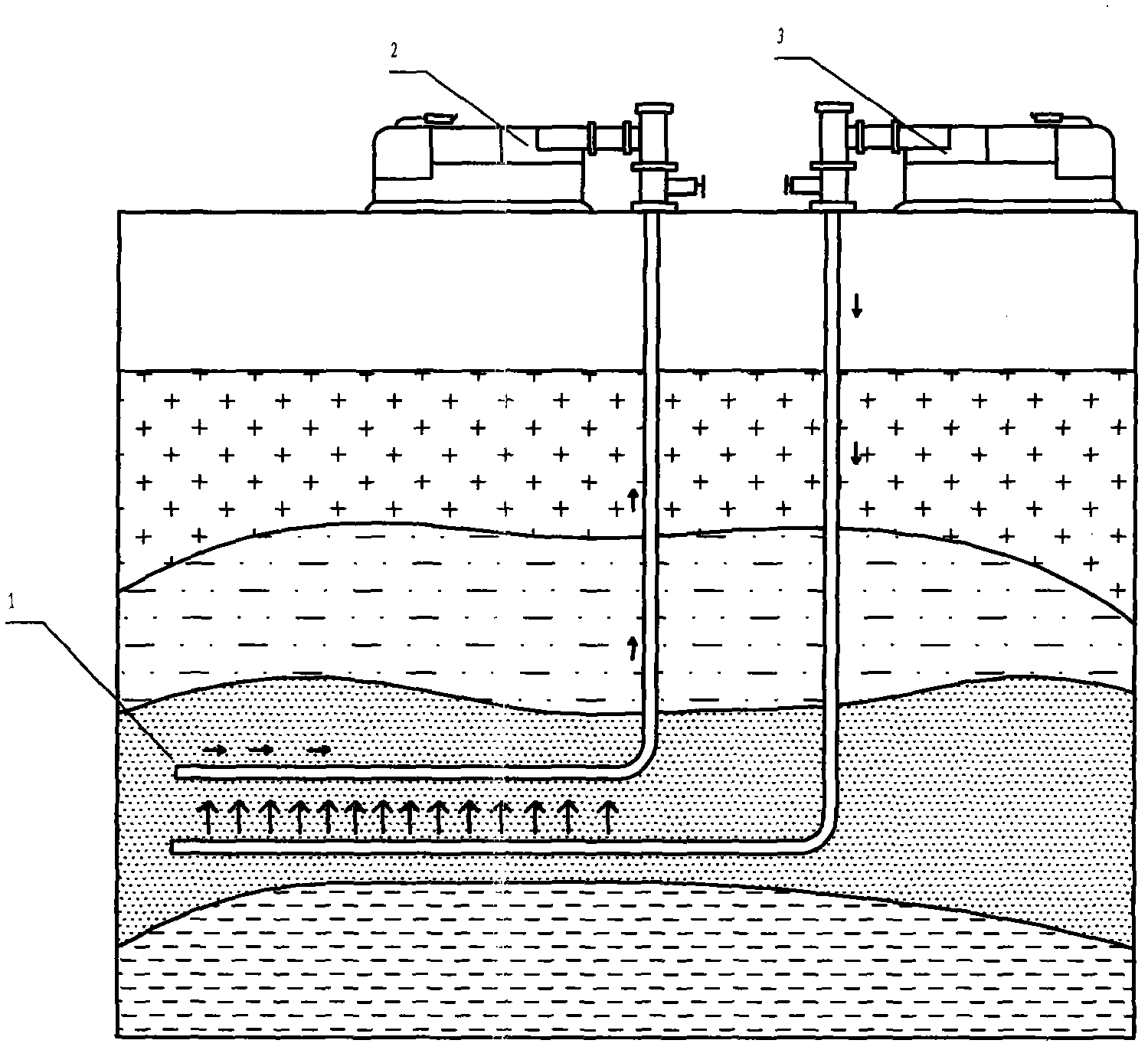

[0019] Example: see attached figure 1 A method for mining deep oil shale to produce shale oil and oil shale gas is characterized in that it comprises the following steps:

[0020] a. First, drill three horizontal wells in the oil shale formation far away from the water layer, fault zone, and at a depth of 100 meters to 3000 meters. Two gas production horizontal wells are located at the bottom of the oil shale formation, and a high-pressure gas injection well is located at the upper part with a dip angle of 40° , the well spacing is 30 meters; two gas production shafts adopt advanced completion technology;

[0021] b. Use horizontal wells for large-scale fracturing. Since the oil shale reservoirs generally have low porosity and low permeability properties, and the resistance to gas flow is large, all wells need to undergo reservoir fracturing to be exploited. Form irregular gaps in the formation, form well-to-well connections, and form gas channels for the next gas injection w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com