Fracturing flowback fluid treatment method

A fracturing flowback fluid and treatment method technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, oxidized water/sewage treatment, etc. problem, to achieve the effect of good economy, reducing the amount of liquid dispensing, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

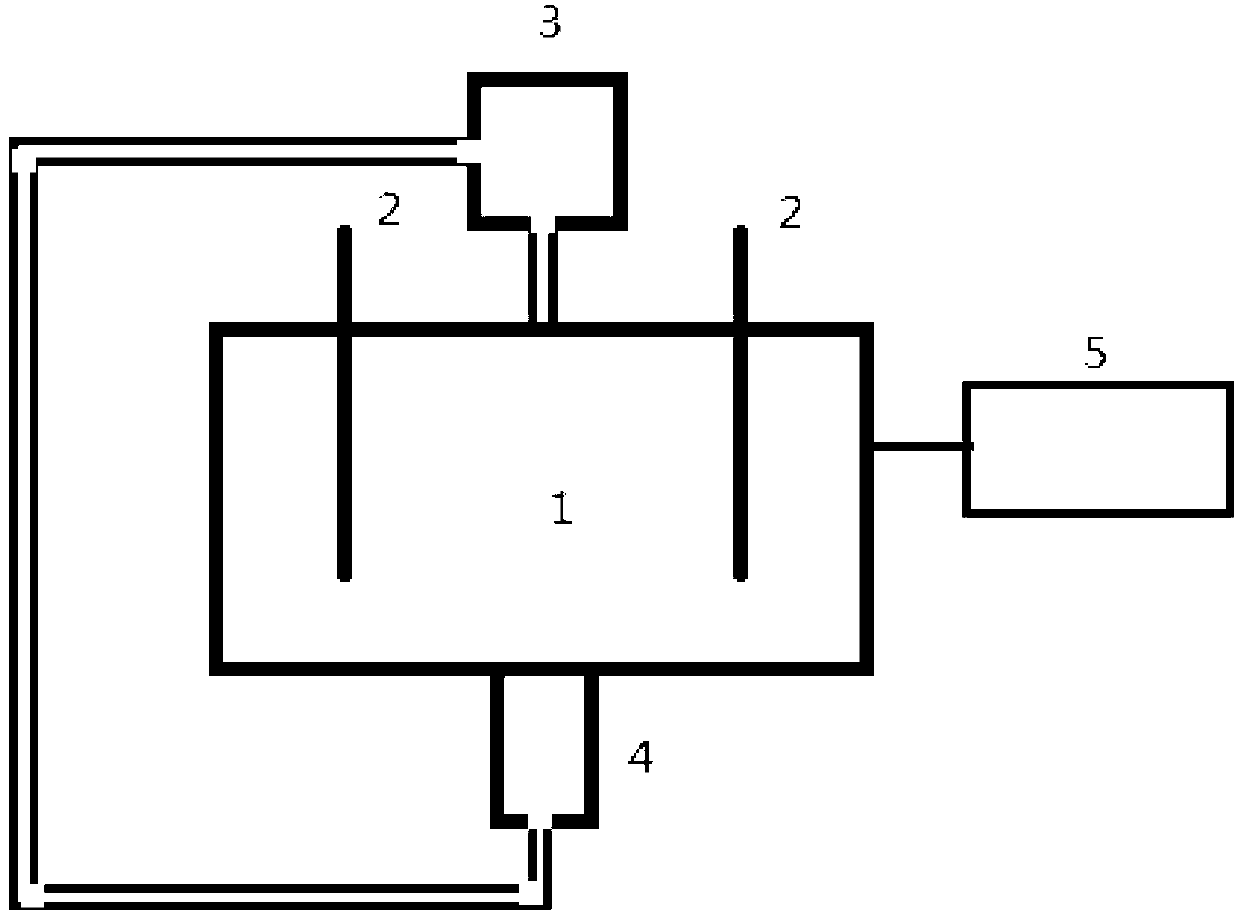

Image

Examples

Embodiment 1

[0048] Composition A of the fracturing flowback fluid sample: Petroleum = 678mg / L, COD = 3195mg / L, Ca = 5620mg / L, SS = 1220mg / L. The treatment method for the flowback liquid is to first add 1.7% sodium carbonate, 0.5% calcium hydroxide, 4mg / l PAM, 0.3% PAC and other composite flocculation precipitation to remove scaling elements, stir for 30 minutes, and then carry out liquid-solid separation .

[0049] The solution after filtration and precipitation enters the auto-oxidation generating device, and in the electric field of V=8.4~8.5V, I=8A, the chlorine ions in the wastewater are converted into hypochlorite and chlorine gas through the excitation effect of the electric field. After 30 minutes, the concentration of hypochlorite oxidizing agent in the solution reaches 5~8mg / L, then carry out stirring oxidation aeration reaction for 2 hours, and finally carry out filtration treatment. At this time, the solution COD=498mg / L, petroleum=26mg / L, Ca=382mg / L.

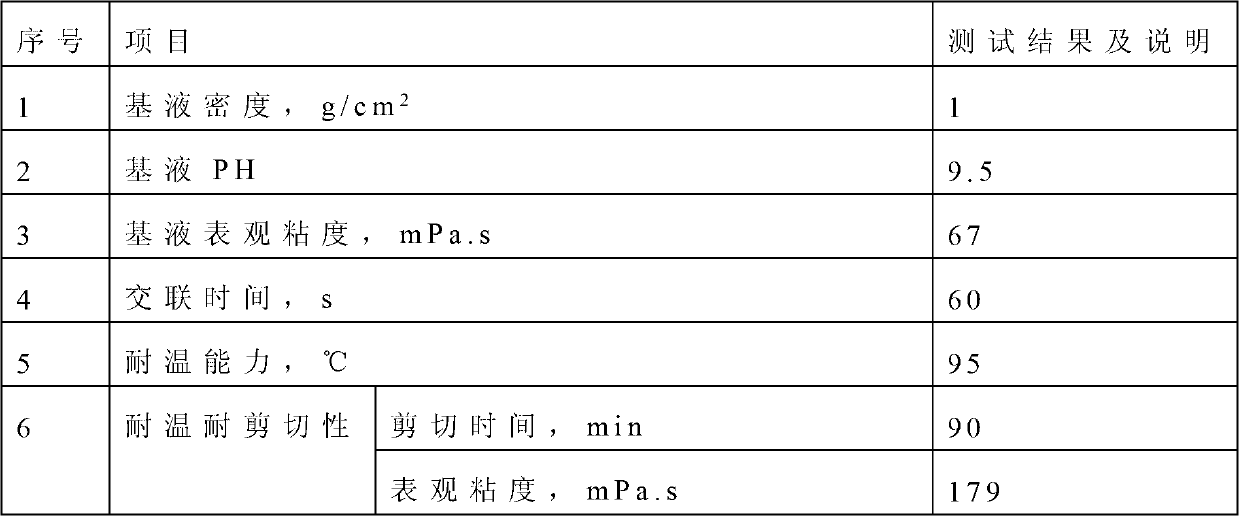

[0050] The solution wa...

Embodiment 2

[0052] The process of this embodiment is to add ultrasonic assisted catalysis in the autoxidation stage in embodiment 1. In an electric field of V=8.4~8.5V, I=1A, ultrasonic waves with a frequency range of 17.5-22.5Hz are used to convert chlorine ions in wastewater into hypochlorite and chlorine gas. After 20 minutes, the concentration of hypochlorite oxidizing agent in the solution reaches 5~8mg / L, then carry out stirring oxidation aeration reaction for 2 hours, and finally carry out filtration treatment. At this time, the solution COD=460mg / L, petroleum=20mg / L, Ca=382mg / L

[0053] The solution was prepared according to the requirements of "Water-based Fracturing Fluid Performance Evaluation Method" SY / T5107-1995. The result was that the six-speed rotary viscometer was used at room temperature for 170s -1 Shear, base fluid viscosity 54mPa.s; at 65°C, 170s -1 Continuous shearing at a shear rate of 90 minutes, viscosity = 90mPa.s, meets the requirements of liquid preparation,...

Embodiment 3

[0055] The process of this embodiment is to add ultraviolet light to assist catalysis in the autoxidation stage in embodiment 1. In the electric field of V=8.4~8.5V, I=1A, and under the assisted excitation of ultraviolet light (UVC for short) with a wavelength of 100-275nm, the chlorine ions in the wastewater are converted into hypochlorite and chlorine gas. After 20 minutes, the concentration of hypochlorite oxidizing agent in the solution reaches 5~8mg / L, then carry out stirring oxidation aeration reaction for 2 hours, and finally carry out filtration treatment. At this time, COD of the solution=442mg / L, petroleum=23mg / L, Ca=382mg / L

[0056] The solution was prepared according to the requirements of "Water-based Fracturing Fluid Performance Evaluation Method" SY / T5107-1995. The result was that the six-speed rotary viscometer was used at room temperature for 170s -1 Shear, base fluid viscosity 54mPa.s; at 65°C, 170s -1 Continuous shearing at a shear rate of 90 minutes, visc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com