Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

469results about How to "Improve oxidation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

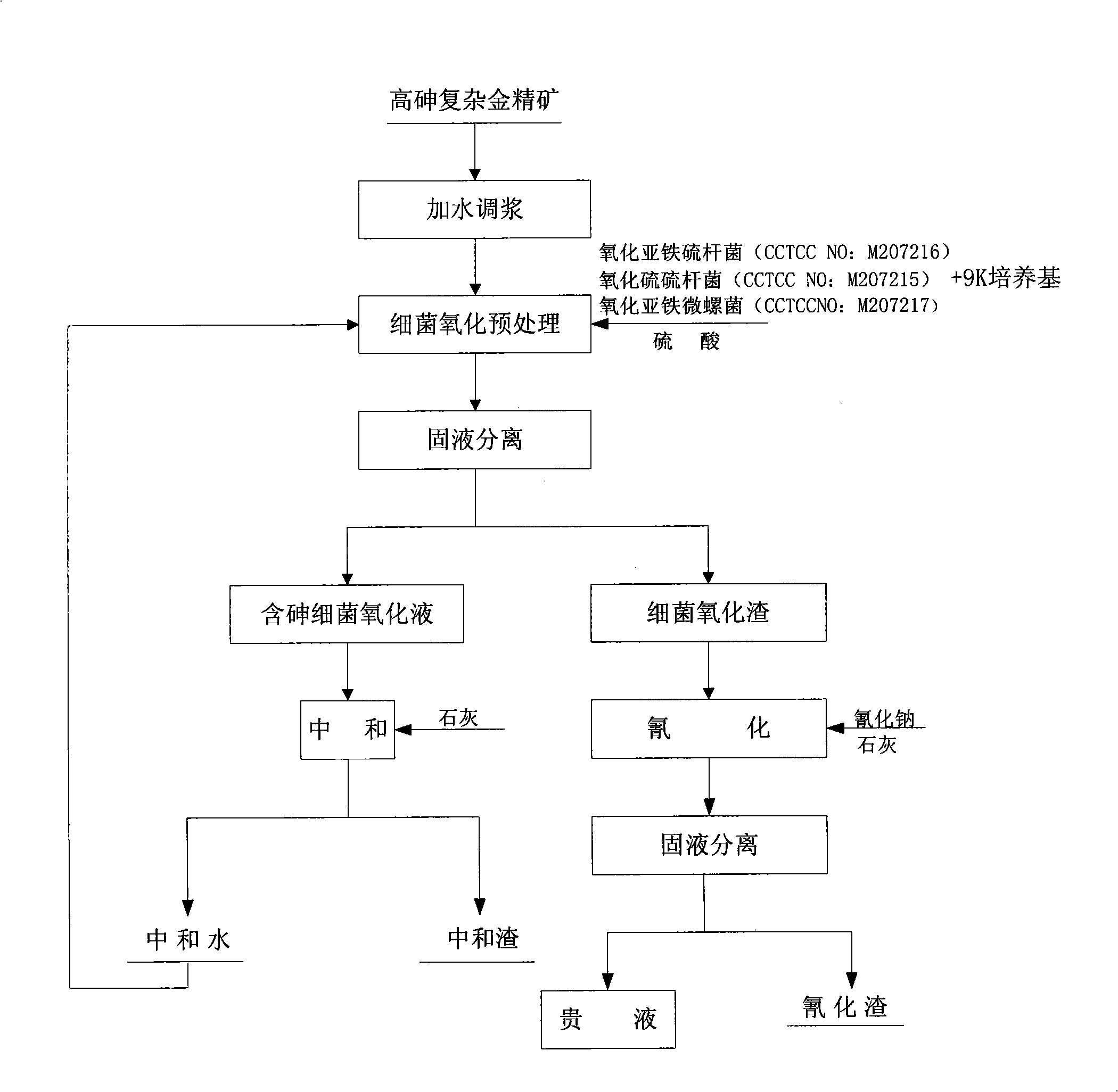

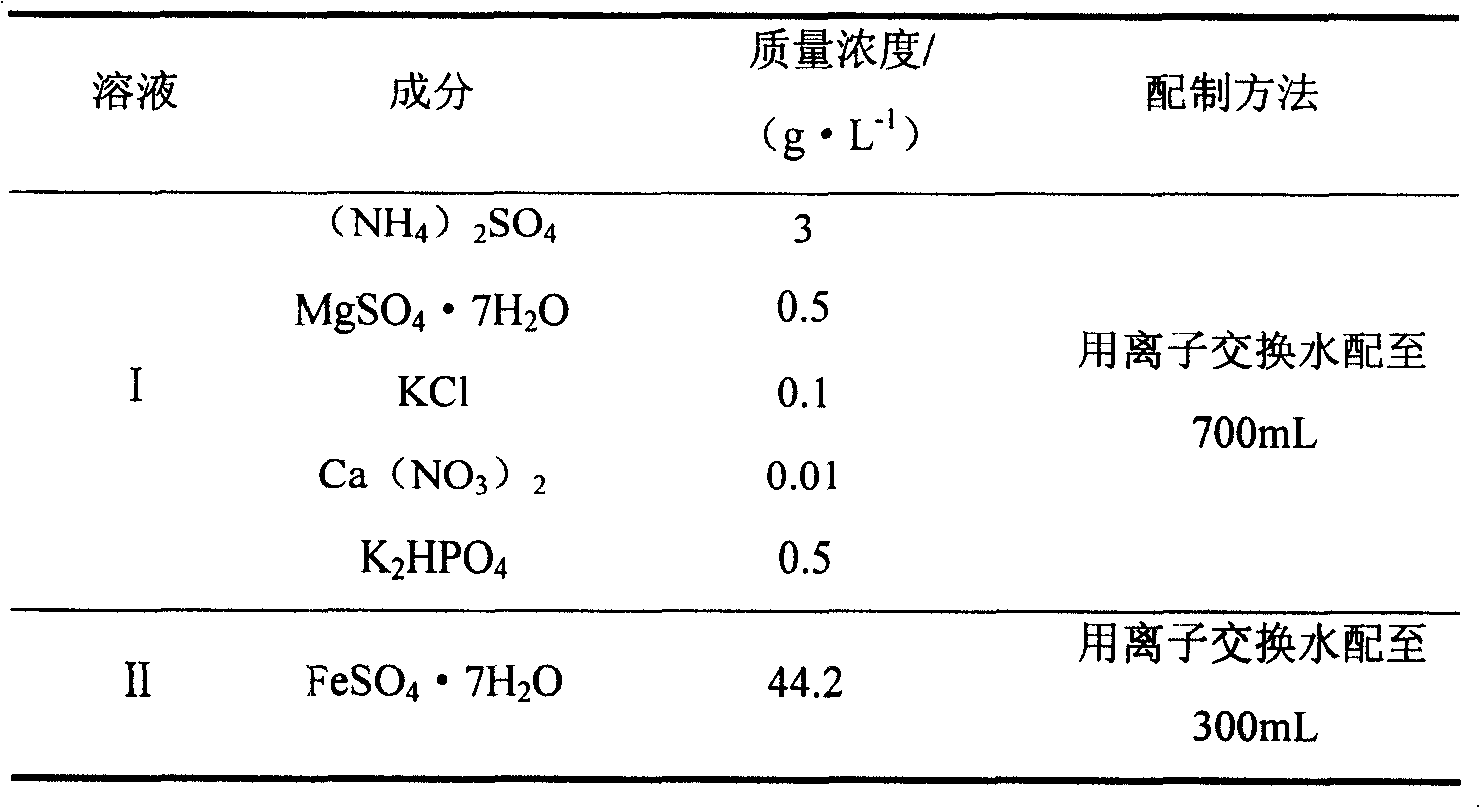

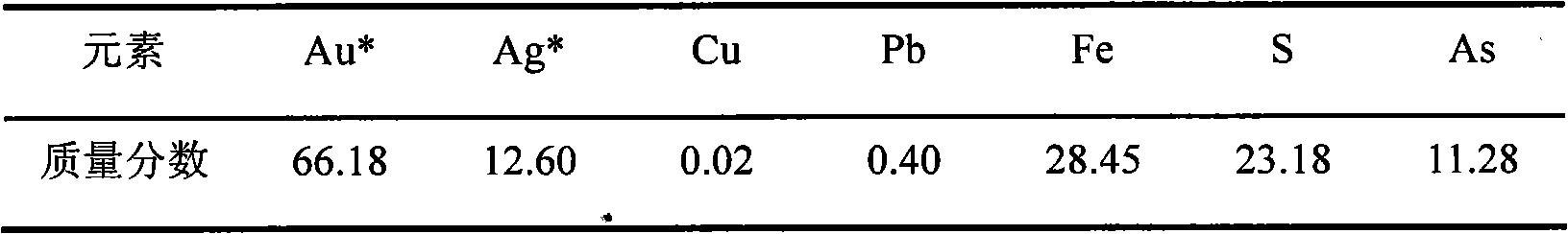

Cyanidation aurum-extracting method for preprocessing high-arsenic complex refractory gold ore by oxidation with arsenic resistant strains

InactiveCN101333599AIncrease growth temperatureStable temperatureProcess efficiency improvementThiobacillus ferrooxidansResistant strain

Disclosed is a cyaniding gold extraction method for pre-treating high-arsenic complex refractory gold ore by arsenic-resistant bacteria oxidation, comprising five steps of arsenic-resistant bacteria culture, flotation concentrate mixing, bacterial oxidation of flotation concentrates, solid-liquid separation and cyaniding gold extraction. The cyaniding gold extraction method adopts specific arsenic-resistant bacteria which are prepared by mixing Thiobacillus ferrooxidans, Thiobacillus thiooxidans and Leptospirillum ferrooxidans, and conducts oxidation pretreatment of high-arsenic complex refractory gold ore. The high-arsenic complex gold ore containing 8 to 20 percent of arsenic can be pretreated, and the arsenic removal rate is 85 to 98 percent. The leaching rate of gold is up to 90 to 95 percent after cyaniding leaching. The cyaniding gold extraction method adopts unique bacteria for leaching ores, greatly saves cooling cost, conducts direct oxidation of high-arsenic complex gold ore containing 8 to 20 percent of arsenic, and has advantages of being widely adaptable, simple in operation, environmentally friendly and remarkably beneficial.

Owner:NORTHEASTERN UNIV

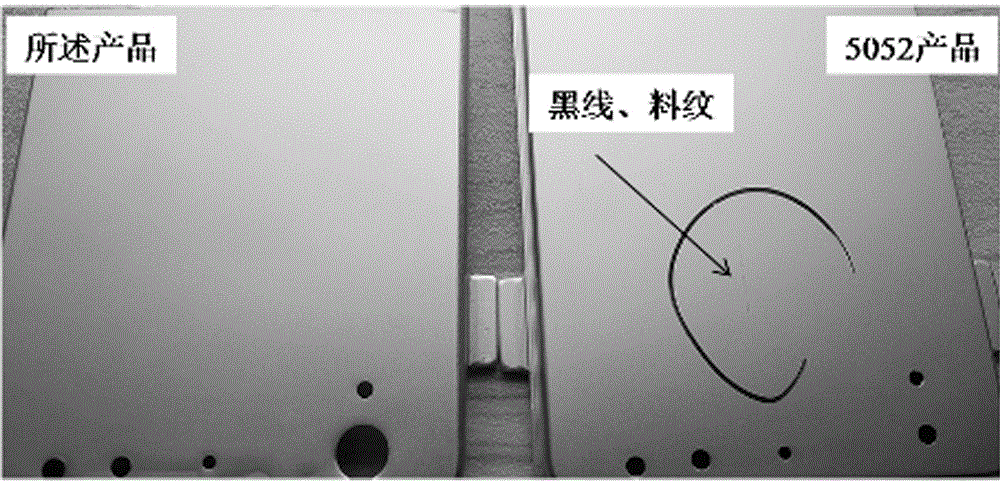

Preparing method of aluminum alloy base material for electronic product shell

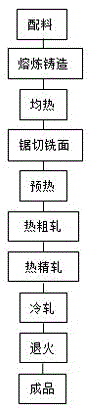

A preparing method of an aluminum alloy base material for an electronic product shell comprises the steps that burdening is carried out according to the weight ratio of various alloy components, pure aluminum, pure zinc, AlCu50 alloy and AlZr5 alloy are put into a smelting furnace to be smelted, and the smelting temperature is 720-770 DEG C; then pure magnesium is input, and the temperature is controlled between 750 DEG C and 770 DEG C during inputting; the mixture is transferred into a holding furnace at the temperature of 710-730 DEG C to be subjected to heat preservation, the holding furnace is inflated with chlorine and argon for refining for 1-2 h, standing is conducted for 1-2 h, the holding furnace is inflated with chlorine and argon again for refining for 1-2 h, and standing is conducted for 1-2 h; the mixture is transferred into an online degassing and deslagging device, during online degassing, the volume proportion of chlorine is 2-5%, and a grain refiner is added online; and finally, filtering and deslagging are conducted, a cast ingot with the uniform structure is cast, and after the cast ingot is subjected to homogenization, preheating and rolling and reaches the target thickness, a product is obtained through annealing via a continuous annealing device. According to the preparing method, the actual production situation is combined, aluminum alloy good in color and luster, low in black line reject ratio and free of bank marks after being subjected to anodic oxidation is developed, and sheet strips uniform in performance can be stably produced on a large scale.

Owner:广西南南铝加工有限公司

Magnesium alloy surface treatment method

InactiveCN104805345AReduce heat sensitivityImprove solderabilityMolten spray coatingMetallurgyMaterials science

The invention discloses a magnesium alloy surface treatment method which comprises three stages including a pretreatment stage, a spraying stage and an after-spraying treatment stage. By adoption of a compound spraying method, an anti-corrosion and anti-abrasion coating layer which is high in bonding strength, high in compactness and small in environment pollution is formed on the magnesium alloy surface; the surface treatment method is simple and feasible and is low in cost.

Owner:SUZHOU TONGMING MACHINERY

Restoration method for organic contaminated soil

InactiveCN102950149ARapid responseGood degradation effectContaminated soil reclamationContaminated soilsEnvironmental chemistry

The invention belongs to the technical field of associated contained soil restoration of environment protection and relates to a novel restoration method for organic contaminated soil. The method comprises the following steps of: using an oxidation reaction system consisting of amino carboxylic acid substances (ethylene diamine tetraacetic acid (EDTA), ethylenediaminedisuccinic acid (EDDS), sodium triglycollamate(NTA) and the like), zero-valent iron (ZVI) and air (AIR) to complex dissolved oxygen through a series of reactions between amino carboxylic acid complexing agent and Fe<2+>; and finally, enabling O-O bond to brake and activate for in-situ generating H2O2, reacting the generated H2O2 with Fenton formed by Fe<2+> to quickly degrade organic pollutant in the soil, and simultaneously degrading the amino carboxylic acid complexing agent. Compared with the traditional Fenton and ZVI / H2O2 type Fenton, the novel oxidation system also can react under neutral and alkaline conditions without additionally adding acid to adjust the acidity; the H2O2 can be generated in situ without being additionally added. The restoration method has the advantages of high degradation rate, environmental friendliness, simplicity in operation and low cost, and is an effective method for quickly and effectively restoring high-concentration organic contaminated site soil.

Owner:WUHAN HUAXINYUAN ENVIRONMENT TECH CO LTD

Air compressor oil composition and preparing method thereof

ActiveCN103820192AImprove lubricity and wear resistanceImprove solubilityLubricant compositionEmulsionAir compressor

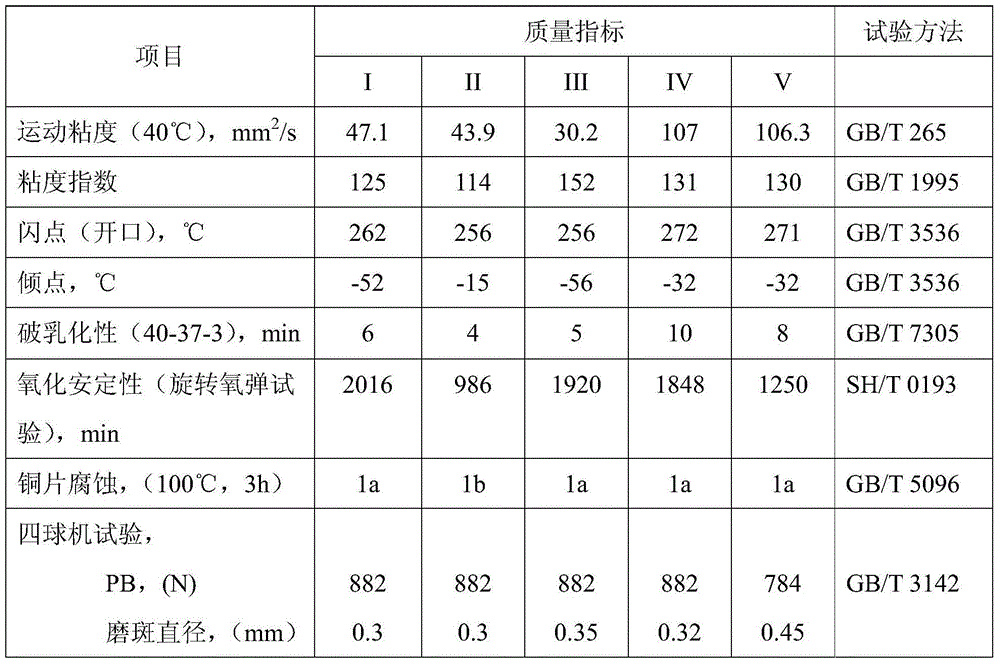

The invention relates to an air compressor oil composition and a preparing method thereof. The air compressor oil composition comprises the following ingredients: A, base oil consisting of ester oil and PAO (Polyalphaolefin) oil; B, antioxidant consisting of an amine antioxidant and dialkyl dithiocarbamate ester; C, at least one oiliness additive; D, at least one high-viscosity complex ester compound; E, at least one metal passivator; F, at least one emulsion breaker; G, at least one antifoamer. The air compressor oil composition has the advantages of environment-friendliness, capability of saving energy and reducing consumption and excellent oxidation resistance. The invention further relates to the preparing method of the air compressor oil composition.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

Process for producing direct methanol fuel cell electro-catalyst

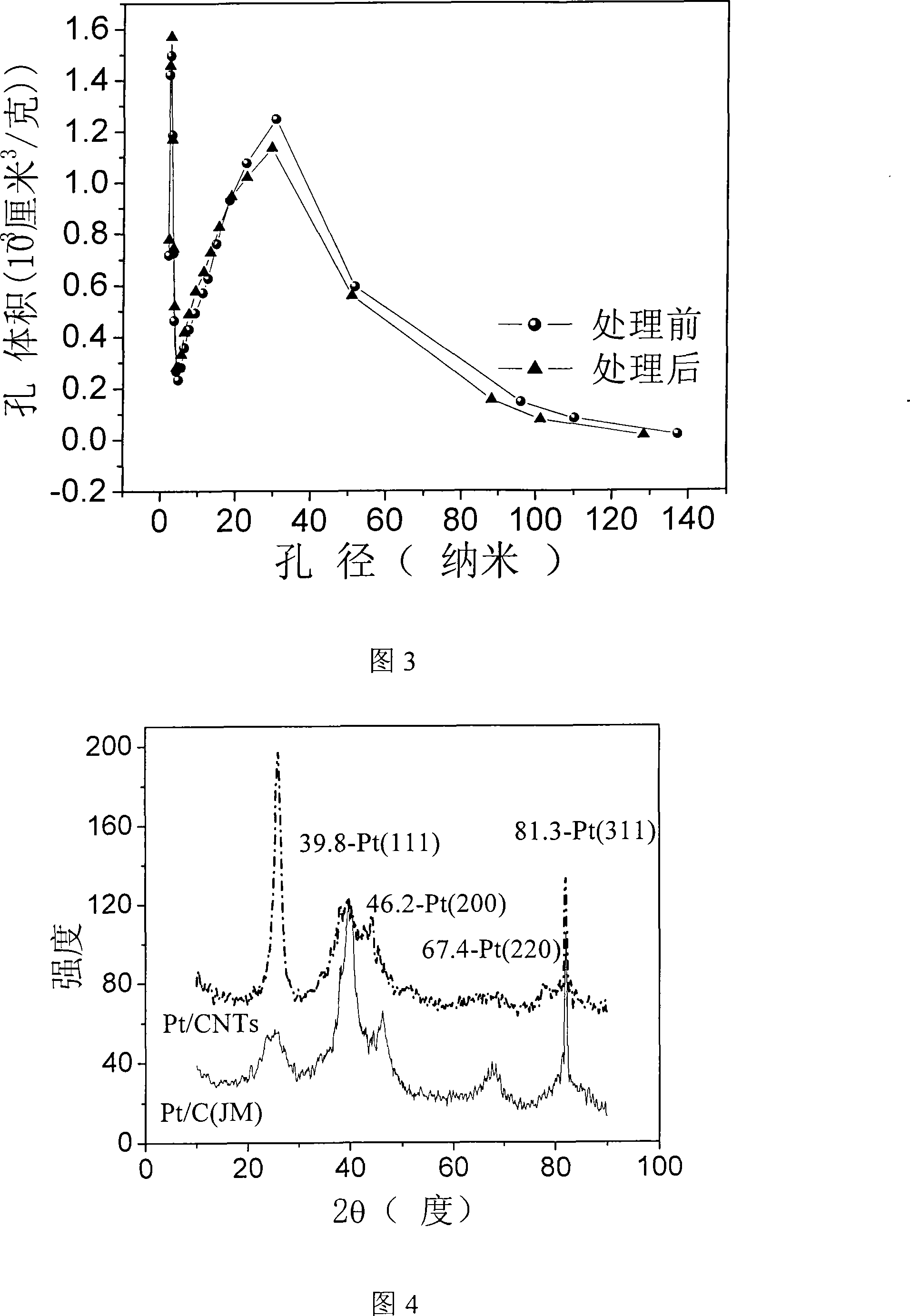

InactiveCN101219378AEasy to prepareWon't reuniteCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeMetal particle

The invention discloses a preparation method of an electrocatalyst of direct methanol fueled battery. A carbon nano tube carrier is purified and activated, and then a solution of platinum or platinum-ruthenium mixture nano particles is prepared; the carbon nano tube and platinum or platinum-ruthenium mixture are mixed in a mass ratio of 1: 0.02 to 1: 0.80: firstly, the carbon nano tube is dispersed with glycol, and added with the platinum or platinum- ruthenium mixture nano particle solution, then treated by 200 to 500W ultrasonic for 1 to 5 hours, thus the electrocatalyst of the direct methanol fueled battery is prepared. The preparation method of the electrocatalyst of the invention does not need surfactant, stabilizer or functional molecule, metal particles do not congregate at normal temperature and are loaded on high density small grain diameter of the carbon nano tubes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Coal-saving devulcanized coke cleaning clean synergistic agent and preparation technique thereof

InactiveCN101348743ALower ignition pointImprove oxidation effectSolid fuelsStrontium carbonateFerrosilicon

The invention relates to a process for preparing a clean synergist for saving coal, desulfurization and cleaning coke. Active calcium oxide and magnesium hydrate are mixed and added with sodium carbonate, ferrosilicon powders, manganese dioxide, strontium carbonate and barium hydroxide in turn and finally added with active carbon and evenly mixed to prepare the clean synergist which comprises the following compositions in percentage by weight: 20 to 30 percent of the active calcium oxide, 9 to 12 percent of the magnesium hydrate, 12 to 20 percent of the sodium carbonate, 8 to 10 percent of active carbon, 12 to 15 percent of the ferrosilicon powders, 8 to 12 percent of the manganese dioxide, 3 to 5 percent of the strontium carbonate and 5 to 7 percent of the barium hydroxide. on the premise of unchanging the prior coal burning process and equipment of various boilers and the prior smoke exhaust process and equipment, the clean synergist of the process is only needed to add according to the physicochemical index of coal used by customers, thereby achieving the functions of saving the coal, the desulfurization and cleaning the coke.

Owner:陈宏谋 +1

Die-casting rare earth aluminum alloy with characteristics of high fluidity and oxidability

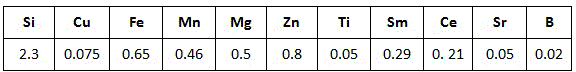

InactiveCN104789824AImprove die casting effectImprove oxidation effectUltimate tensile strengthMaterials science

The present invention discloses a die-casting rare earth aluminum alloy with characteristics of high fluidity and oxidability. The die-casting rare earth aluminum alloy contains, by weight, 1.8-4% of Si, 0.03-0.15% of Cu, 0.2-0.9% of Fe, 0-0.7% of Mn, 0-1.8% of Mg, 0.2-1.6% of Zn, 0-0.15% of Ti, 0.2-0.45% of Sm, 0.1-0.3% of Ce, 0.01-0.15% of Sr, 0-0.1% of B, and the balance of Al and unavoidable impurities. The die-casting rare earth aluminum alloy has characteristics of high strength, good die-casting performance, good oxidation effect, good corrosion resistance, and low price, and meets the high requirements of vehicle products, household products and 3C products on the material.

Owner:苏州聚数精密铸造有限公司

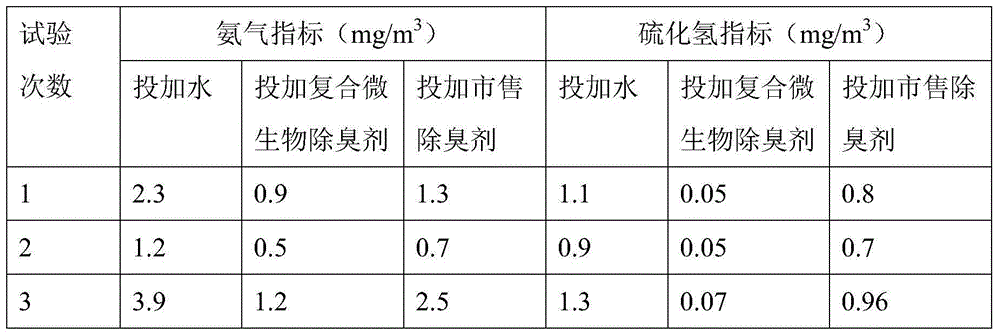

Composite microbial deodorant and preparation method thereof

InactiveCN104399098AGrowth inhibitionPromote rapid proliferationFungiBacteriaDeodorantBacterial colony

The invention discloses a composite microbial deodorant and a preparation method thereof. Each liter of the deodorant comprises the following bacteria: photosynthetic bacterium with a viable count of 1.3-7.5*108 CFU, bacillus with a viable count of 0.9-7.8*108 CFU, saccharomycete with a viable count of 1.02-1.92*108 CFU, nitro-bacterium with a viable count of 1-10*108 CFU, thiobacillus with a viable count of 1-6*108 CFU, melanomyces with a viable count of 4.8-13.5*108 CFU, and aspergillus flavus with a viable count of 4.8-11.7*108 CFU. The bacteria mentioned above are basically obtained from garbage, and domesticated by garbage leachate. The deodorant can act on the garbage and garbage leachate, and thus cut off the odor source. The beneficial bacterial colonies can decompose and degrade odorous pollutants in garbage, eliminate the garbage odors, and generate a great amount of beneficial metabolic products and enzymes.

Owner:LINYI QINGYU ENVIRONMENTAL RESOURCES ENG EQUIP

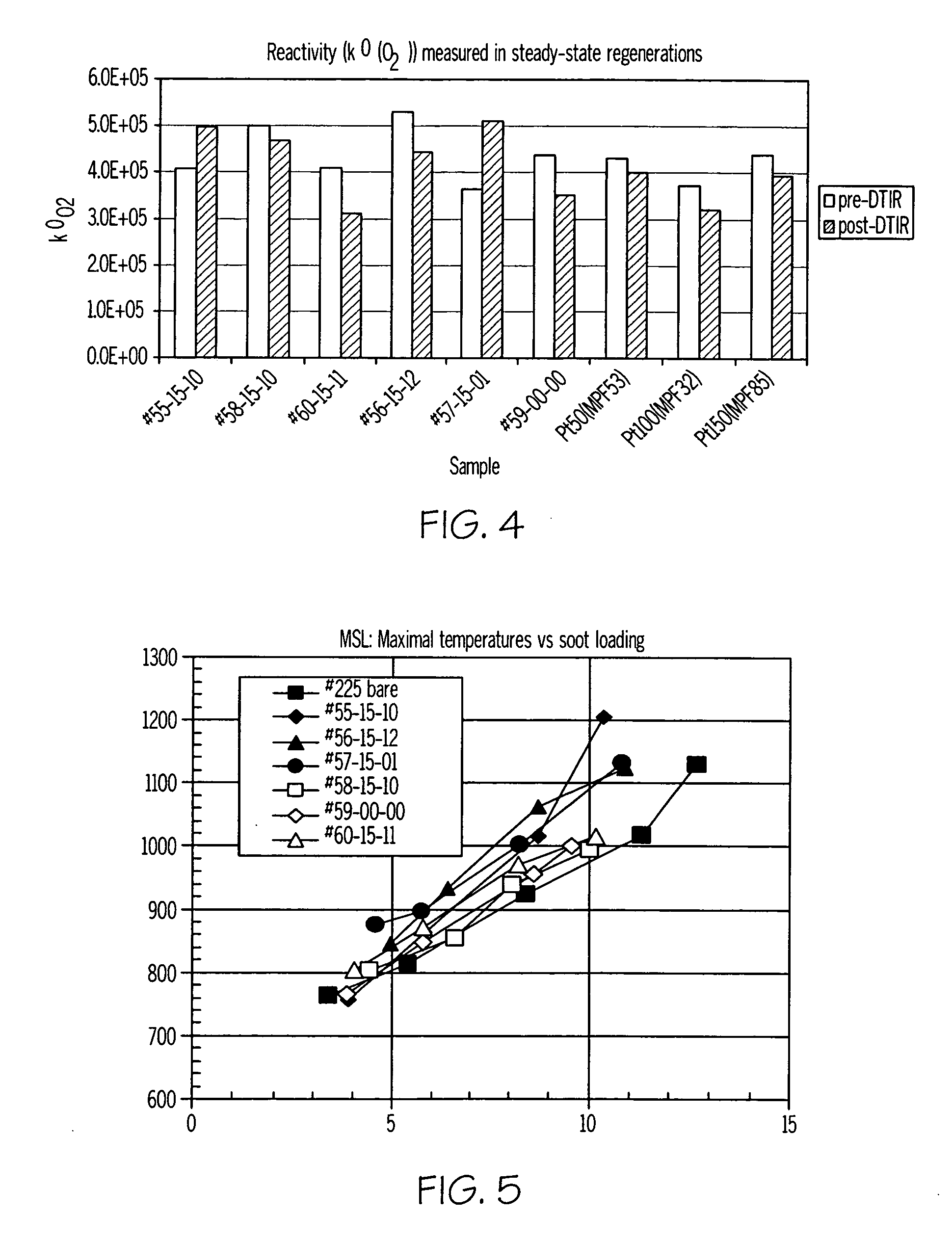

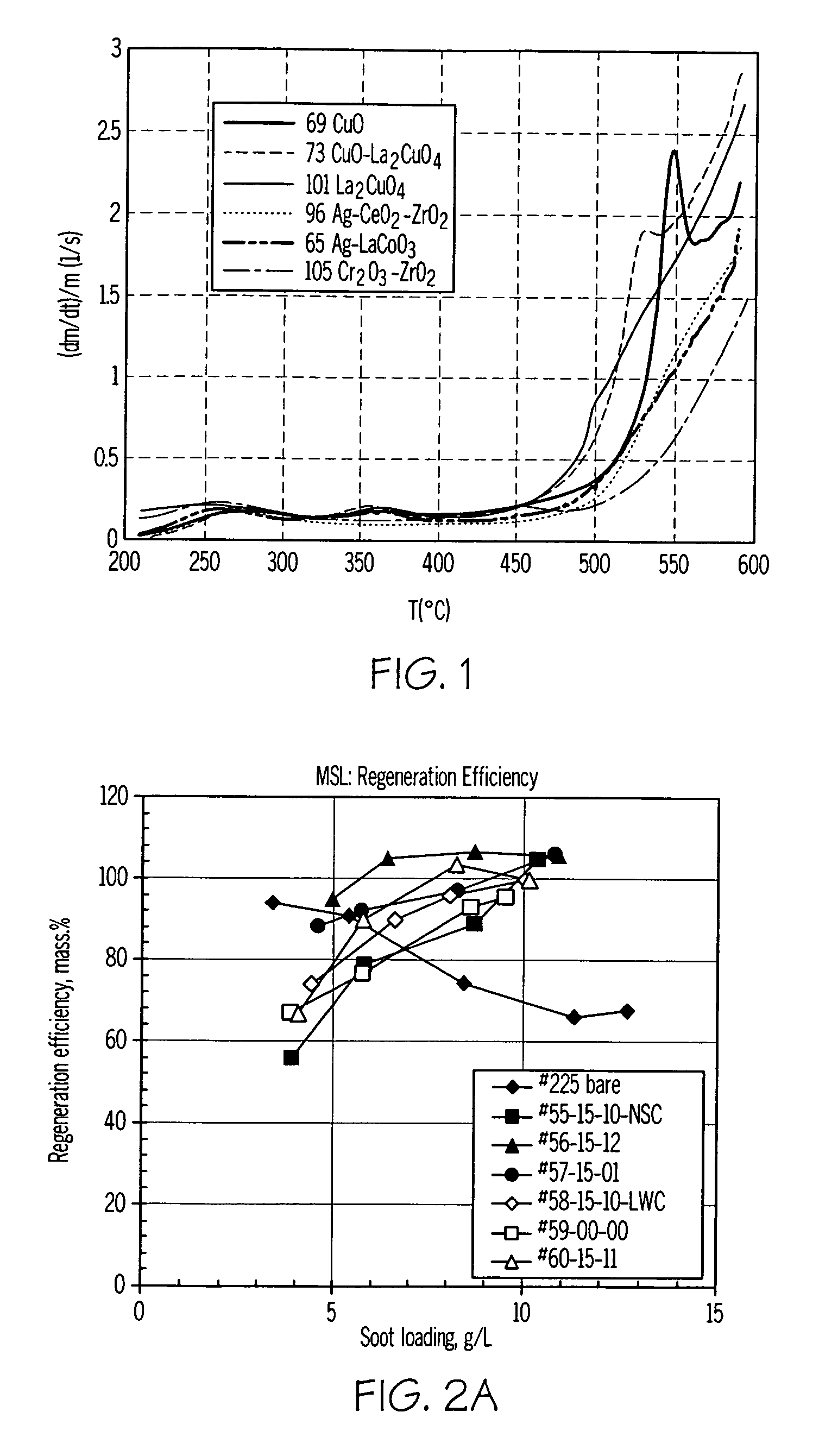

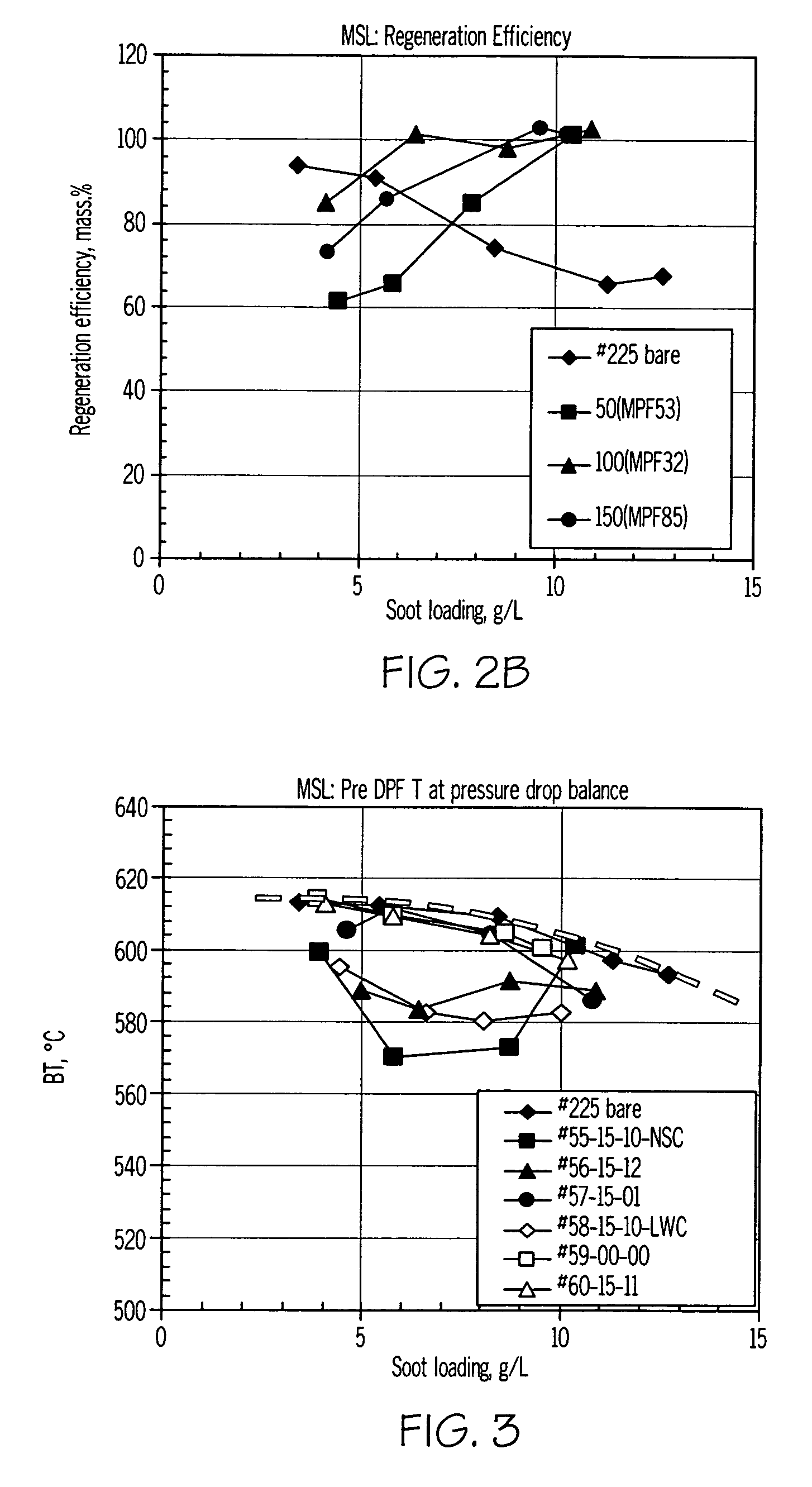

Soot oxidation catalyst and method of making

InactiveUS20070219088A1Efficiently oxidizedPrevent materialCombination devicesNitrogen compoundsDiesel particulate filterGlycerol

A catalyst composition for facilitating the oxidation of soot from diesel engine exhaust is provided. The catalyst composition includes a catalytic metal selected from Pt, Pd, Pt—Pd, Ag, or combinations thereof, an active metal oxide component containing Cu and La, and a support selected from alumina, silica, zirconia, or combinations thereof. The platinum group metal loading of the composition is less than about 20 g / ft3. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the active metal oxide precursor(s) and the catalytic metal precursor(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, and exhibits minimal backpressure.

Owner:FORD GLOBAL TECH LLC

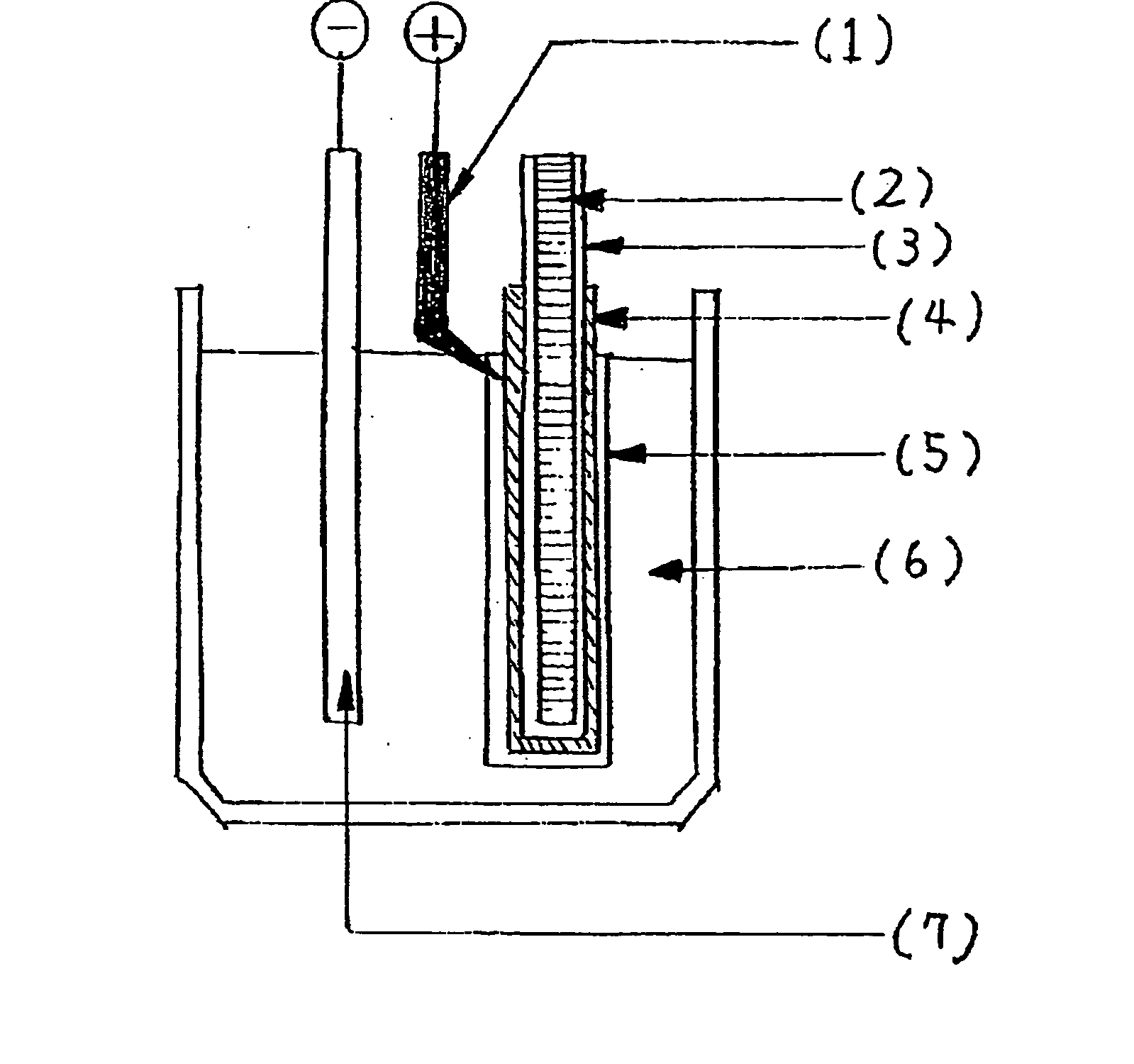

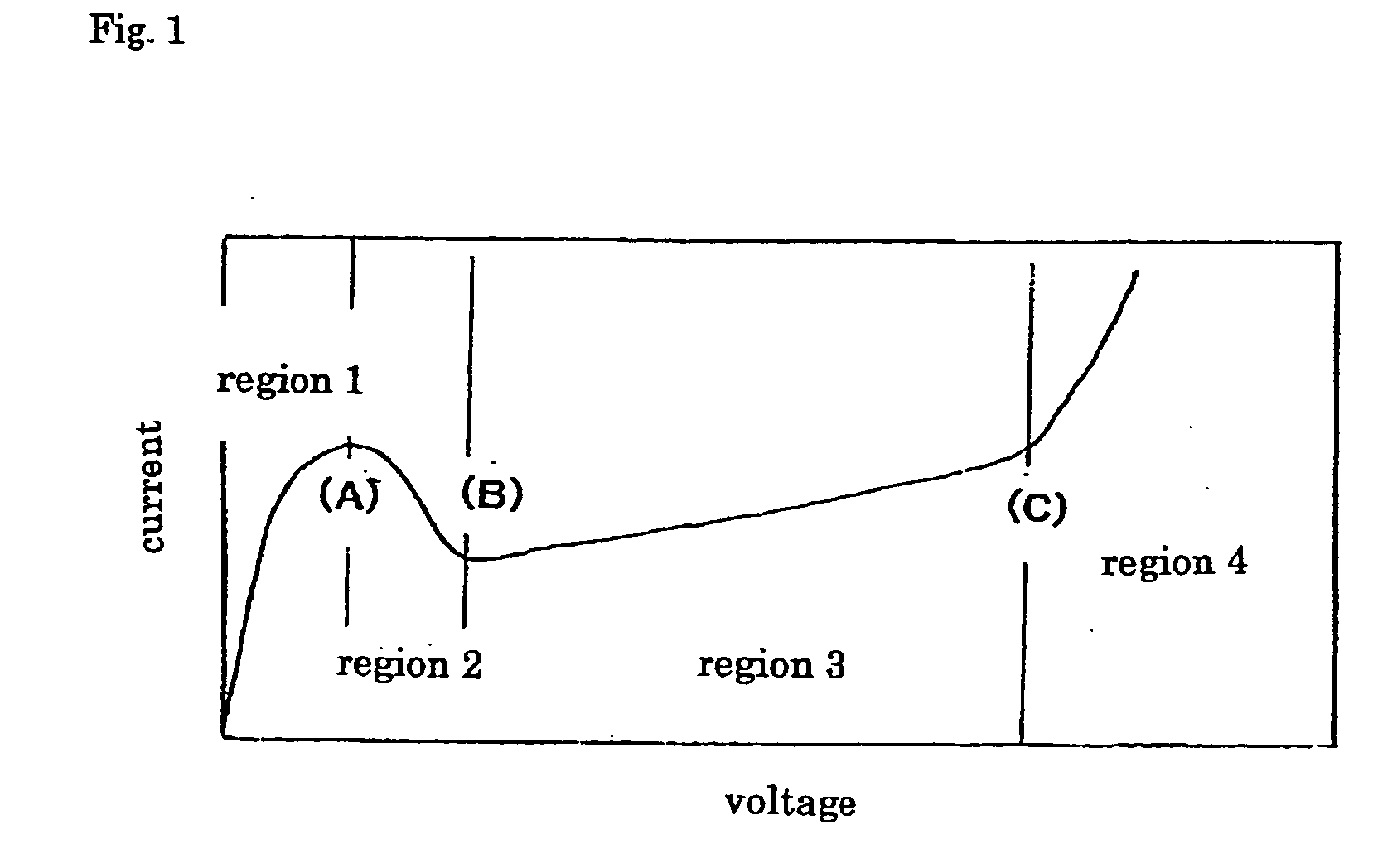

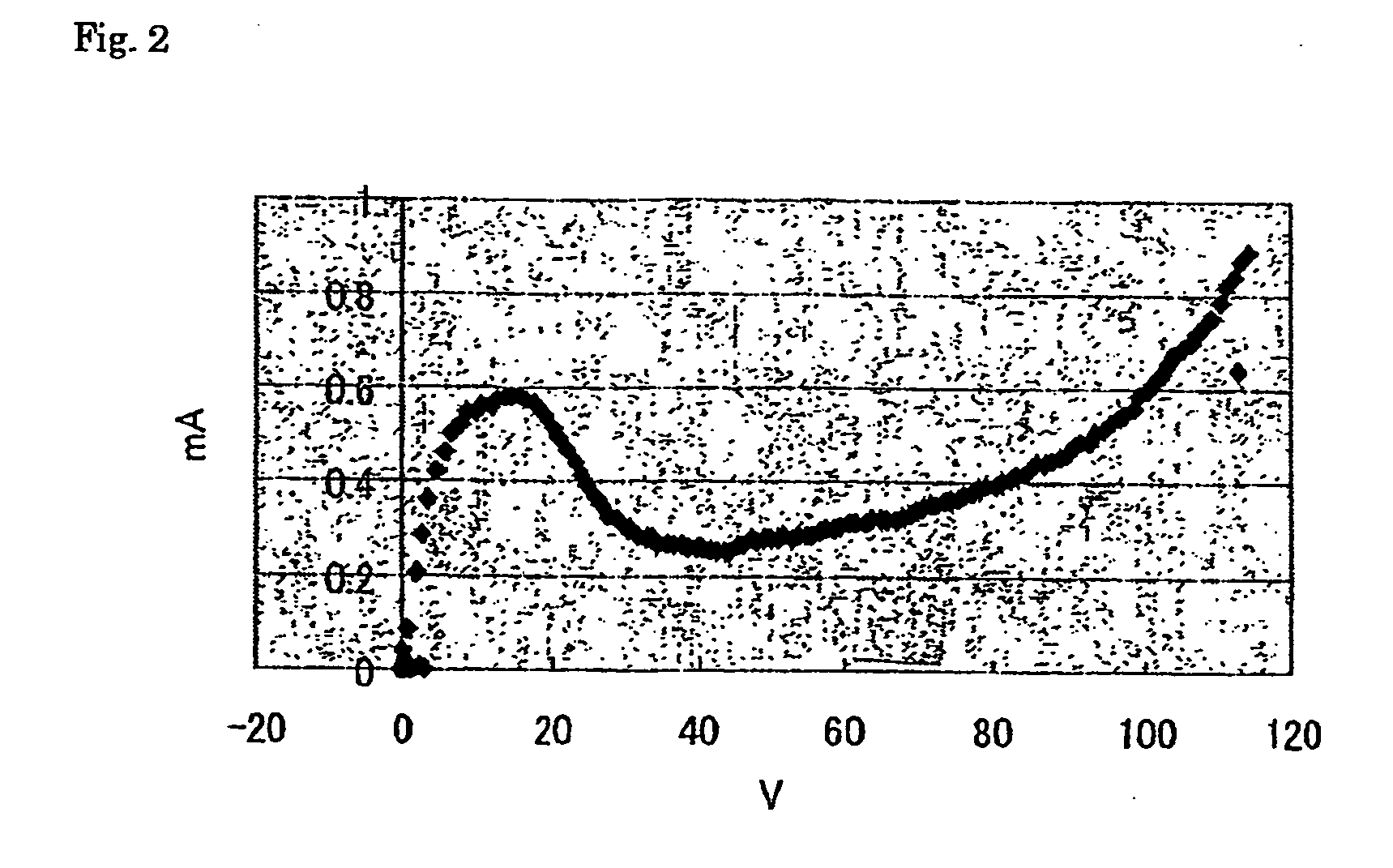

Method for forming oxide film on metal surface using ionic liquid, electrolytic capacitor and electrolyte thereof

ActiveUS20060181835A1Excellent metal oxidizing abilityImprove abilitiesAnodisationClosuresElectrolysisConductive polymer

The present invention provides means for forming an oxide film on a metal surface, means for repairing a defect of an oxide film, a high-performance electrolytic capacitor using the means, and an electrolyte of the capacitor. Namely, the prevent invention provides a method for easily forming an oxide film on the surface of a metal or an alloy thereof by anodization using a solution containing an ionic liquid. In an application of this method, an electrolytic capacitor having means for repairing a defect of an oxide film can be formed by a method using, as an electrolyte, an ionic liquid, a solution containing an ionic liquid and a salt, or a solution containing an ionic liquid and a conductive polymer or a TCNQ salt, and a valve metal or an alloy thereof as a metal.

Owner:KANEKA CORP

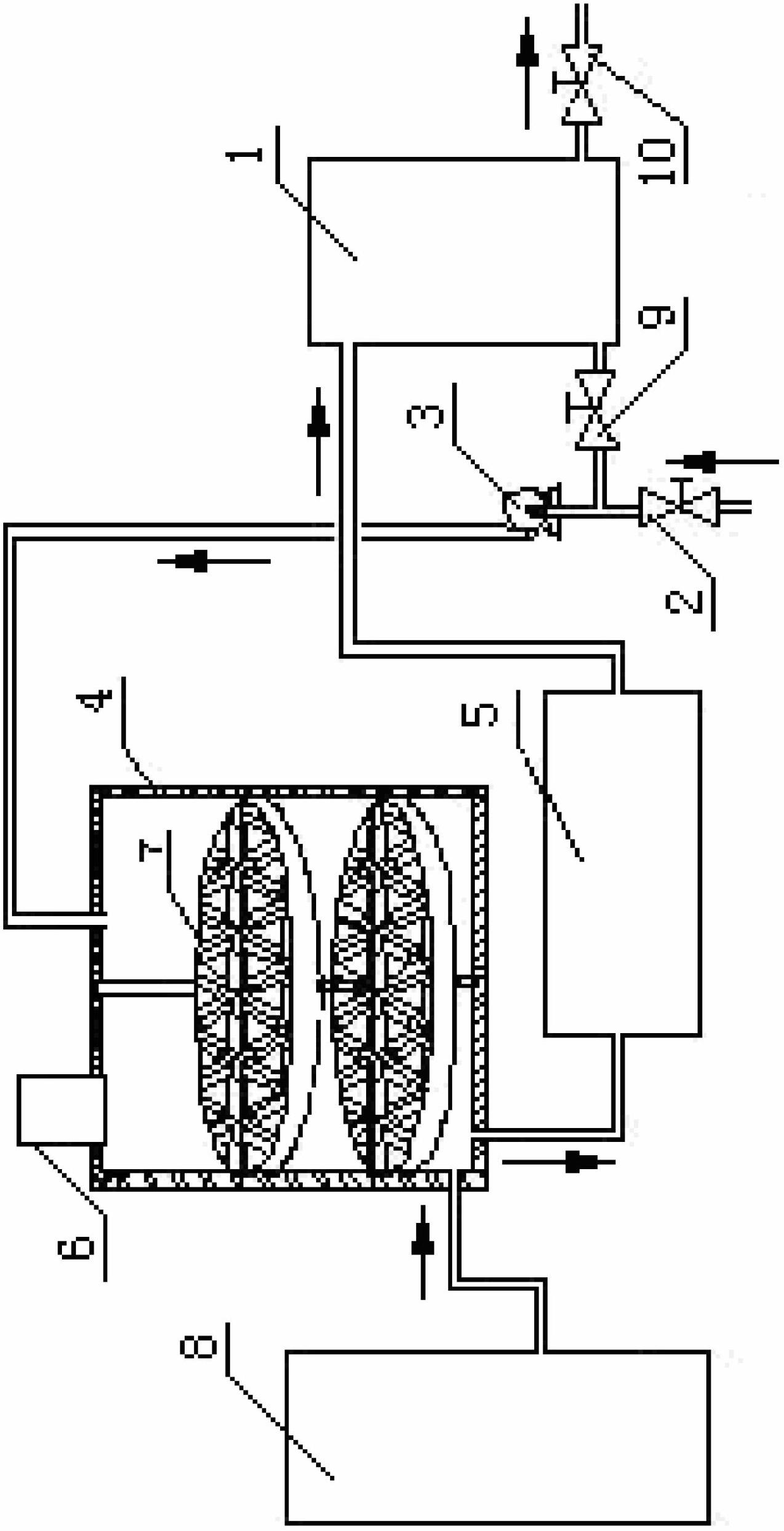

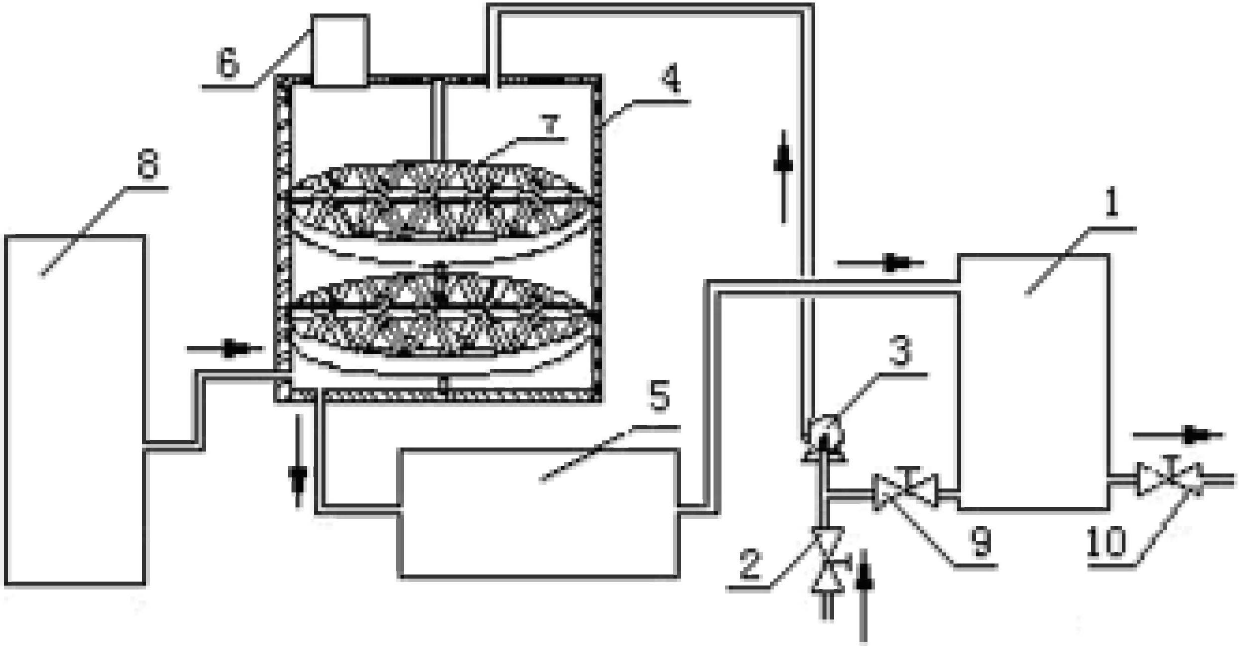

Method for treating low-concentration methanol wastewater under synergistic action of ultrasonic waves and ozone

ActiveCN102674528ALow costImprove efficiencyWater contaminantsWater/sewage treatment with mechanical oscillationsCavitationCatalytic oxidation

The invention discloses a method for treating methanol wastewater produced during production of natural gas under synergistic effect of ultrasonic waves and ozone. The method is applied to treatment of wastewater of an oil and gas field. The method is characterized by comprising the following steps of: feeding the methanol wastewater into a rotating packed bed, and introducing ozone in a refluent way; feeding outlet wastewater into an ultrasonic wave reaction device; generating .OH and other free radicals with high oxidation capacity under the synergistic action of ultrasonic waves and ozone, and oxidizing methanol in the wastewater; and feeding into a middle circulation water channel, and further performing catalytic oxidation. The method has the advantages that a good effect of degrading methanol is achieved, and the rotary packed bed improves the utilization rate of ozone; the free radicals with high oxidation capacity can be produced by ultrasonic waves under cavitation action, and the oxidation capacity of the ozone is enhanced further at high temperature and under high pressure locally by the ultrasonic waves; the oxidation of methanol in the ozone is accelerated under the action of active carbon loaded copper oxide and ferric oxide; and a small amount of dilute acid is added into the methanol wastewater, so that the effect of degrading methanol is improved.

Owner:PETROCHINA CO LTD

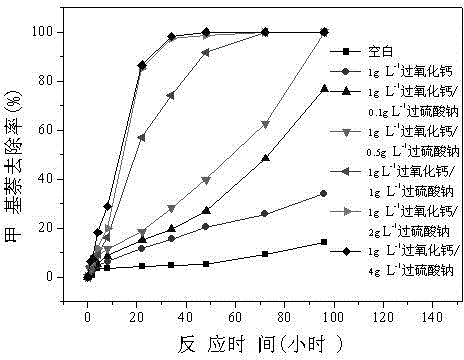

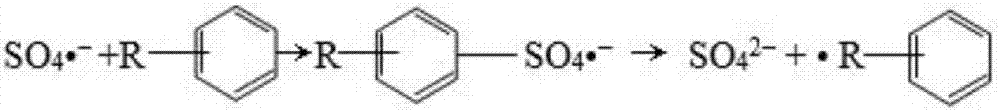

Method for removing polycyclic aromatic hydrocarbon methylnaphthalene substance by adopting double oxidants including persulfate and calcium peroxide

ActiveCN104445570ALow costEasy to transportWater treatment parameter controlWater treatment compoundsPolycyclic aromatic hydrocarbonSulfate radicals

The invention relates to a method for removing a polycyclic aromatic hydrocarbon methylnaphthalene substance by adopting double oxidants including persulfate and calcium peroxide. The method comprises the steps of adding persulfate and calcium peroxide into a water body containing methylnaphthalene, stirring uniformly, and reacting for 4-5 days under the condition that the pH of the system is neutral and weakly acidic, thus removing the pollutant by oxidization. The double oxidants are added into the water, and free hydroxy and sulfate radicals are generated to attack the pollutant, so that the pollutant is effectively degraded. The double oxidants including persulfate and calcium peroxide can simultaneously generate free hydroxy and sulfate radicals with extremely strong oxidation, so that the acting pollutant range is wider than that of a traditional method, and the pollutant sensitive to the free hydroxy and sulfate radicals can be simultaneously removed. The acting time is long, the applicable pH range is wide, a promotion effect on microbes in the environment is achieved, the bioremediation efficiency of microbes in environmental media can be improved, and then the repair efficiency of a polluted area is improved. The method is applicable in the field of polluted underground water repair.

Owner:TONGJI UNIV

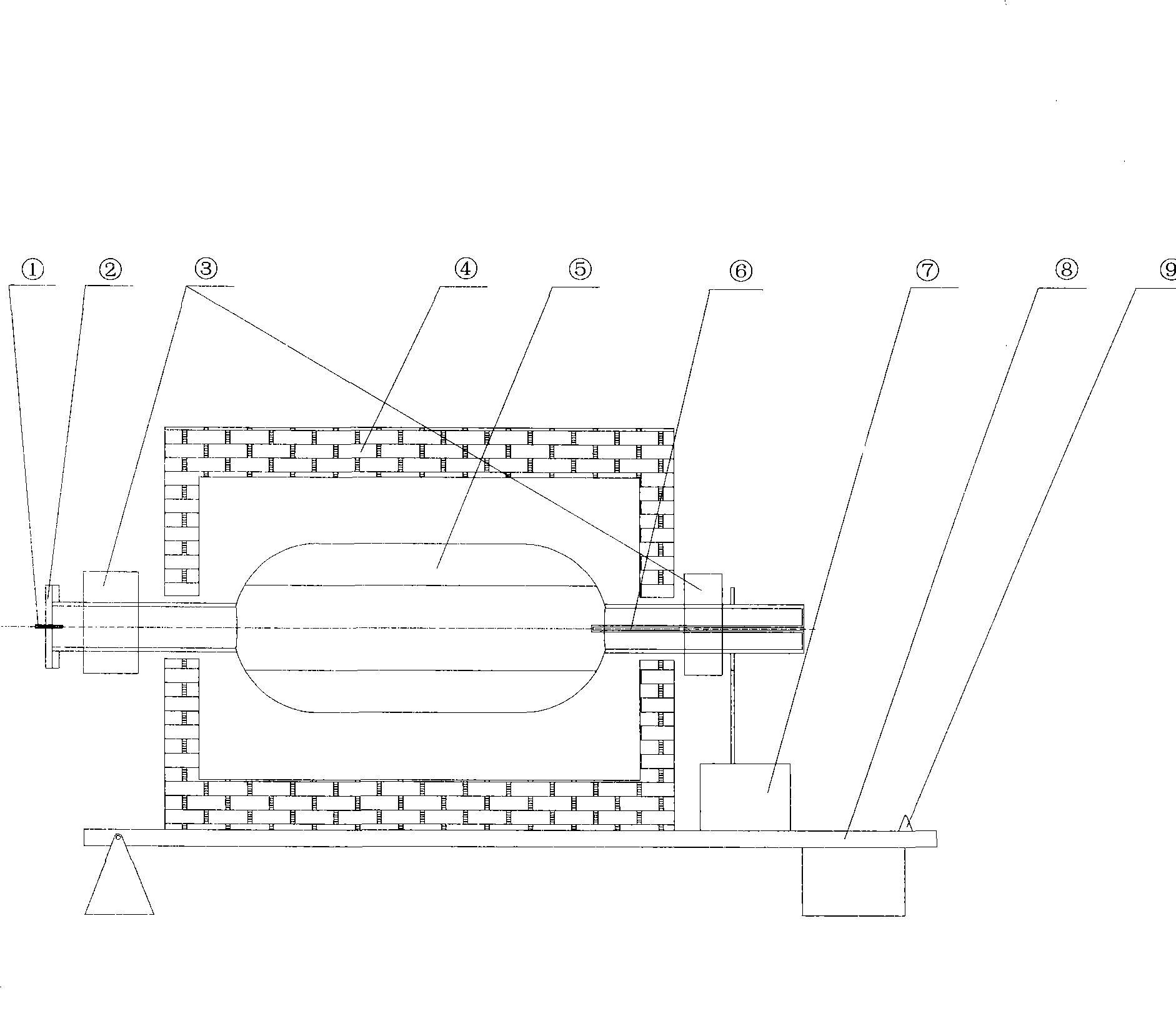

Design and structure for controllable atmosphere rotating furnace for oxidizing albronze alloy powder

ActiveCN101392987AFully contactedIncrease productivityRotary drum furnacesElectrical resistance and conductanceDifferential pressure

The invention provides a gas atmosphere controllable revolving furnace structure for the oxygen distribution in the oxidation of copper-aluminum alloy powder, which mainly consists of an air inlet(pumping) pipe, a roller cover, water cooling sleeves, a resistance furnace, rollers, an electrothermal couple pipe, a transmission mechanism, a furnace body bracket and a lifting hook, wherein the resistance furnace is fixed on the furnace body bracket, one end of the furnace body bracket is provided with the lifting hook and is supported by a lower end platform, the other end of the furnace body bracket is provided with a lower end triangular support which can rotate around the triangular support; the inside of the resistance furnace is provided with the roller rotating around the resistance furnace, two ends of the roller(5) arranged outside the resistance furnace are additionally provided with the water cooling sleeves, and the extension end of the roller, which is close to the triangular support end, is provided with the electrothermal couple pipe and is also provided with the transmission mechanism making the rollers rotate. The revolving furnace structure has the advantages that the production efficiency is high; and during the rotation of the rollers, power is fully contacted with the gas atmosphere, and the oxidation time is reduced by increasing the oxygen differential pressure in the rollers. The oxidation time is one-tenth of the oven baking time, so that the oxidation time is shortened.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Large-size ceramic plate with good forming performance and high strength and preparation method thereof

The invention relates to a large-size ceramic plate with good forming performance and high strength and a preparation method thereof. The raw material of the ceramic green body of the ceramic plate comprises 8-15wt% of needle-like kaolin. According to the invention, the raw material of the ceramic green body comprises the high-plasticity needle-like kaolin, the high-plasticity needle-like kaolin has high plasticity, so that the use amount of clay in the formula is reduced, good strength of the green body can still be maintained, and the use amount of clay is reduced, so that the oxidation performance of the body is good. Meanwhile, the needle-like kaolin crystals are arranged in a crossed manner, so that the reduction of molding layering of a press and the improvement of the strength of the green body after firing are facilitated, and the green body has relatively good molding performance, high strength and oxidation performance.

Owner:MONALISA GRP CO LTD

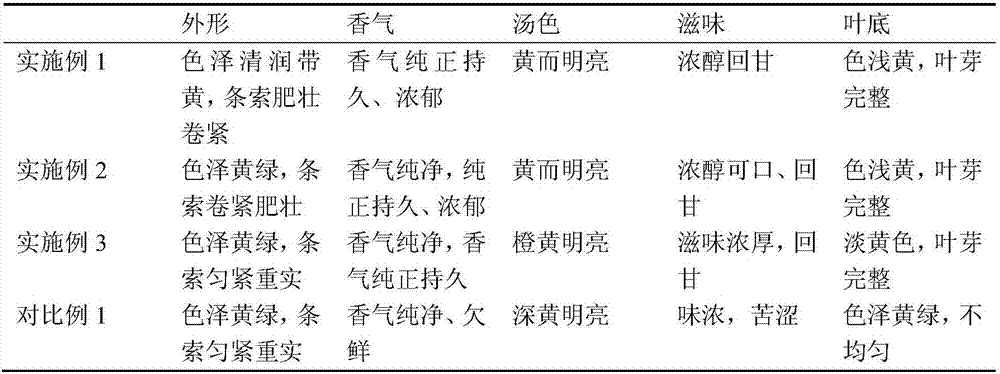

Guangdong big-leaf yellow tea processing technology

ActiveCN107410540AHigh activityMellow tastePre-extraction tea treatmentCooking & bakingYellow green color

The invention belongs to the field of tea processing and particularly relates to a Guangdong big-leaf yellow tea processing technology which comprises the technical processes of fresh leaf picking and withering, fixation, spreading for cooling, rolling, heaping for yellowing, preliminary baking, spreading for cooling and drying. Compared with the traditional Guangdong big-leaf yellow tea processing technology, the Guangdong big-leaf yellow tea processing technology provided by the invention has the advantages that the processes of fixation, heaping for yellowing, and the like for tea are improved; and during fixation for tea, a low temperature-high temperature-low temperature fixation mode is adopted, so that the activity of most of enzymes in the tea can be destroyed, the green grass smell in the tea can be eliminated, favorable tea aroma can be produced, and a small amount of enzymes can be kept in the tea to achieve a fermentation effect in the operation of heaping for yellowing. The tea processed by the technology provided by the invention has the advantages of strip-shaped compact shape, heavy weight, yellow-green color, pure endogenous aroma, deep-yellow and bright liquor color, mellow and sweet taste, light-yellow leaf bases and complete leaf buds. The processed tea has unique color, aroma, taste and shape, the added values of the tea are improved, and the historical tea reputation of the Guangdong big-leaf yellow tea is kept and inherited.

Owner:TEA RES INST GUANGDONG ACAD OF AGRI SCI

Soot oxidation catalyst and method of making

InactiveUS7771669B2Efficiently oxidizedPrevent materialCombination devicesNitrogen compoundsGlycerolCatalytic metal

A catalyst composition for facilitating the oxidation of soot from diesel engine exhaust is provided. The catalyst composition includes a catalytic metal selected from Pt, Pd, Pt—Pd, Ag, or combinations thereof, an active metal oxide component containing Cu and La, and a support selected from alumina, silica, zirconia, or combinations thereof. The platinum group metal loading of the composition is less than about 20 g / ft3. The catalyst composition may be provided on a diesel particulate filter by impregnating the filter with an alumina, silica or zirconia sol solution modified with glycerol and / or saccharose, impregnating the filter with a stabilizing solution, and impregnating the filter with a solution containing the active metal oxide precursor(s) and the catalytic metal precursor(s). The resulting catalyst coated diesel particulate filter provides effective soot oxidation, exhibits good thermal stability, has a high BET surface area, and exhibits minimal backpressure.

Owner:FORD GLOBAL TECH LLC

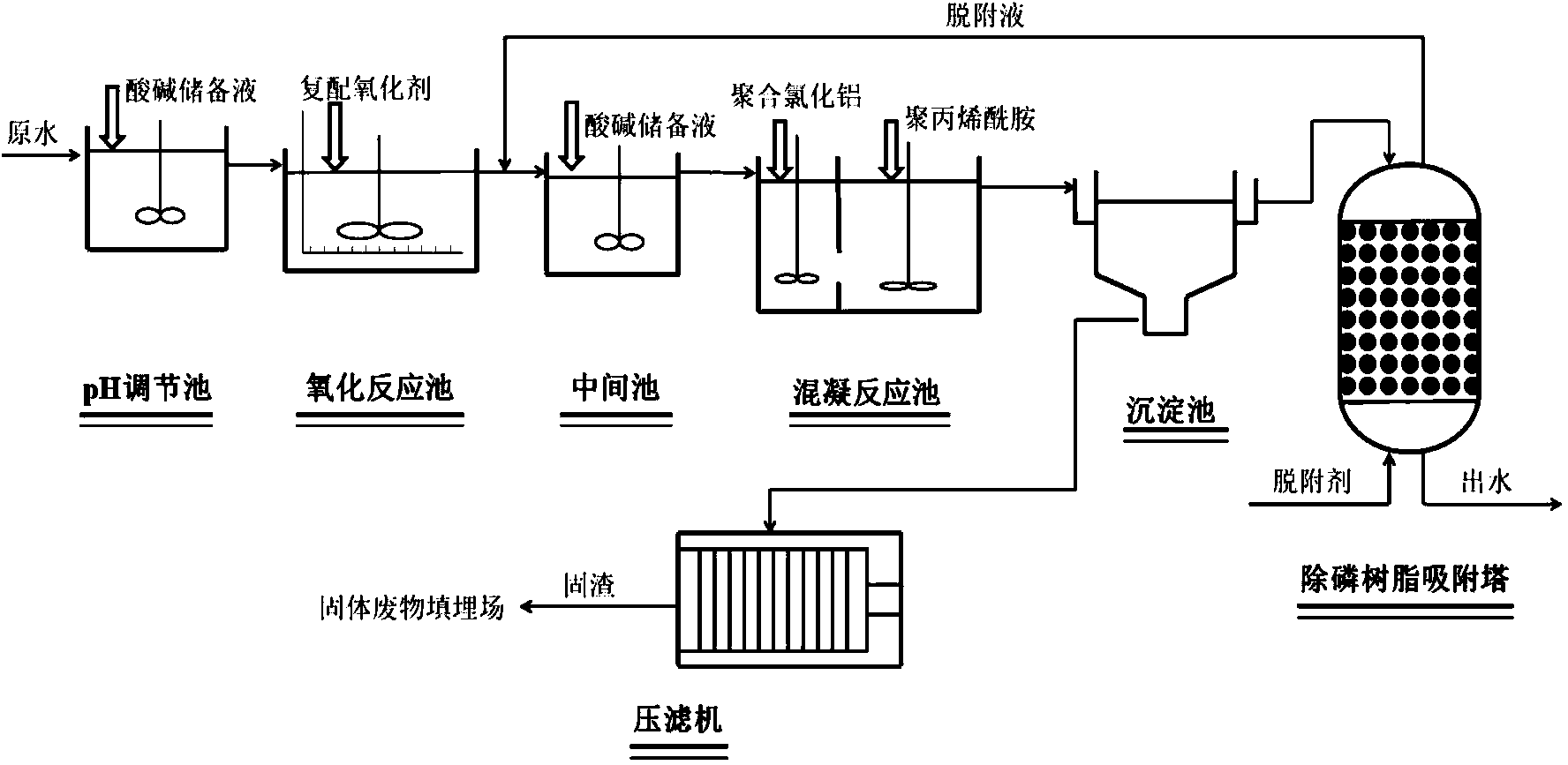

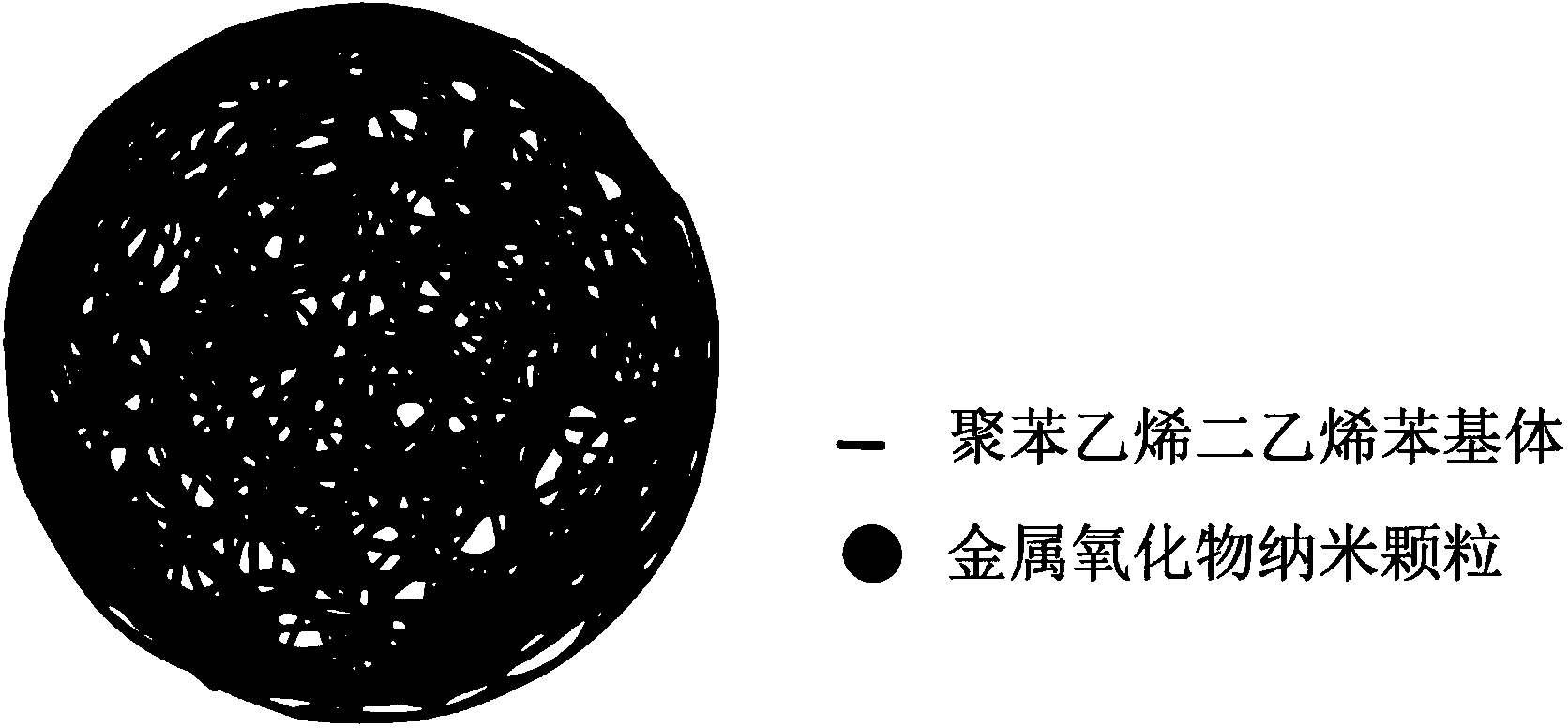

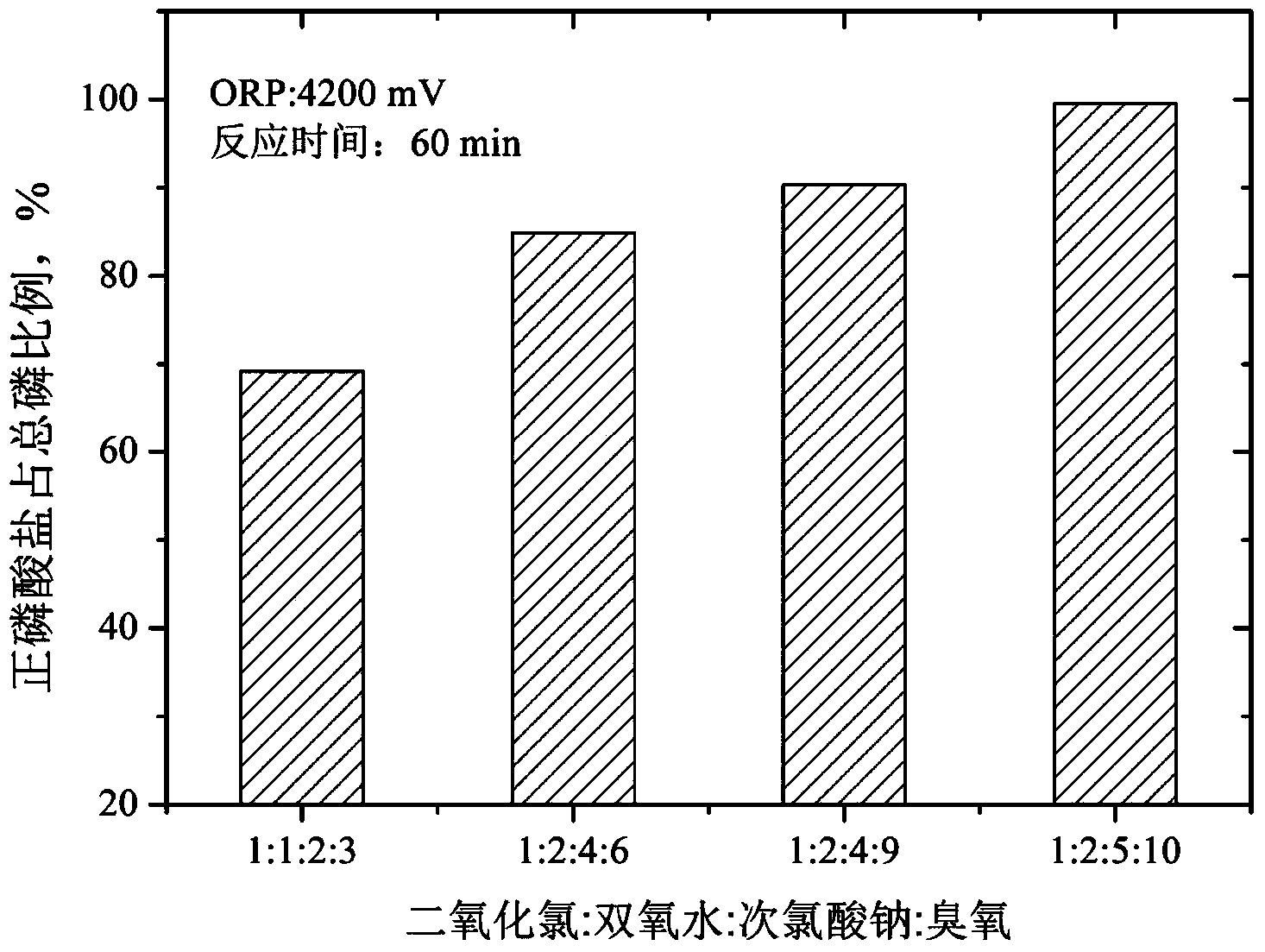

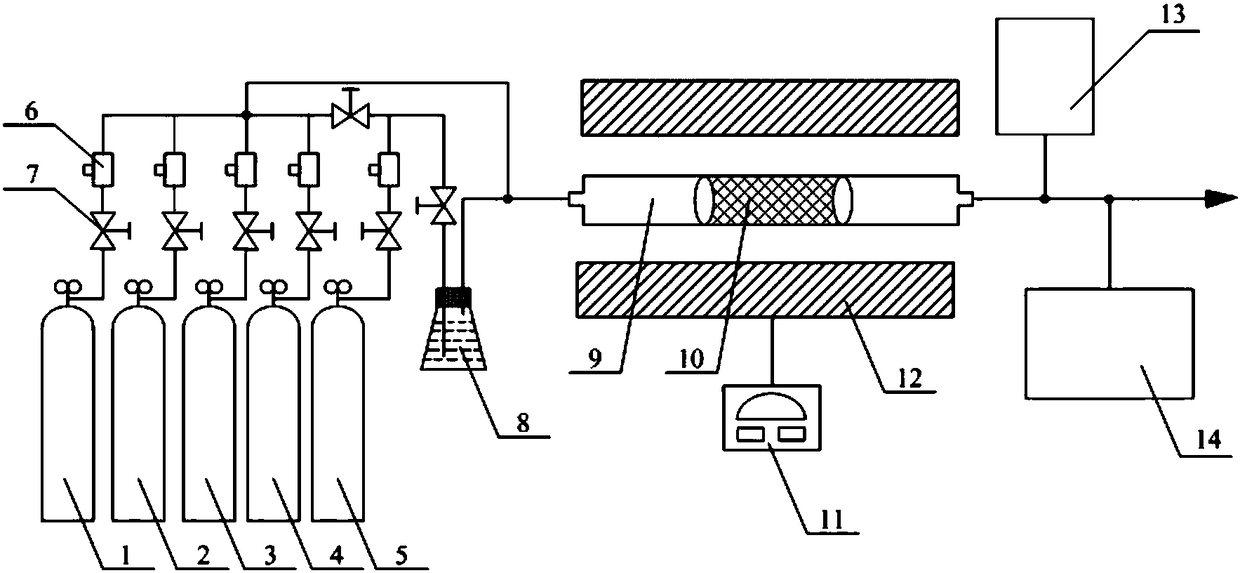

Compound oxidant for advanced treatment of electroplate phosphorate wastewater and wastewater treatment method

ActiveCN104071887AImprove oxidation efficiencyStrong oxidation abilityWaste water treatment from metallurgical processMultistage water/sewage treatmentChlorine dioxidePhosphate

The invention discloses a compound oxidant for advanced treatment of electroplate phosphorate wastewater and a wastewater treatment method, and belongs to the technical field of wastewater treatment. The wastewater treatment method adopts the compound oxidant, which is compounded by a chlorine dioxide solution oxidant, a hydrogen peroxide solution oxidant, a sodium hypochlorite solution oxidant and an ozone gas oxidant according to a certain proportion, and adopts a compound technology of oxidation-coagulating sedimentation-resin adsorption to treat the wastewater. The compound oxidant can be used for conducting advanced treatment on the electroplate phosphorate wastewater, the specific compound oxidant and a special dephosphorizing resin are adopted to conduct advanced treatment on the oxidized and precipitated phosphate, and compared with the conventional adsorption materials such as activated charcoal, the compound oxidant is more suitable for the engineering sewage treatment system, the oxidation ability of the method is strong, the oxidation effect is good, the oxidation efficiency is high, the wastewater treatment quantity is large, and the total phosphorus content in the treated water is steadily reduced below 0.2 mg / L.

Owner:NANJING UNIV

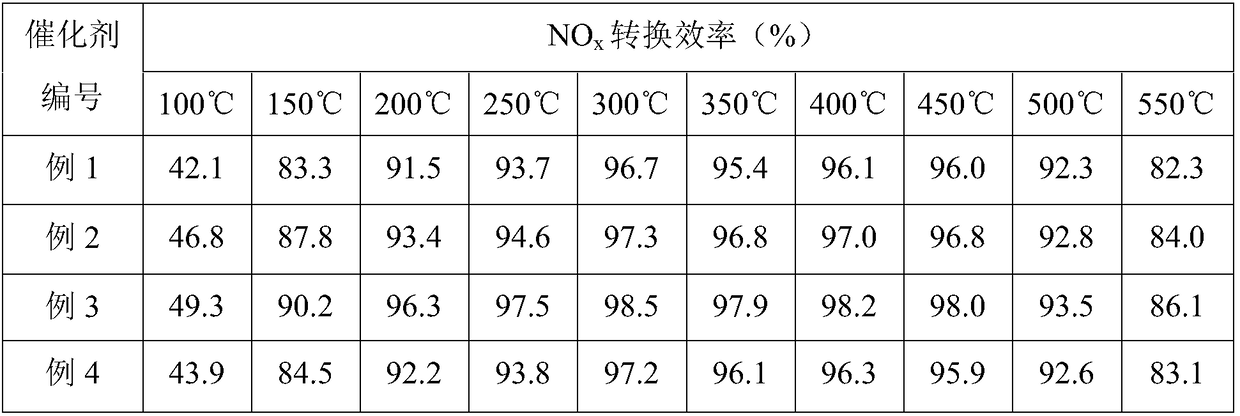

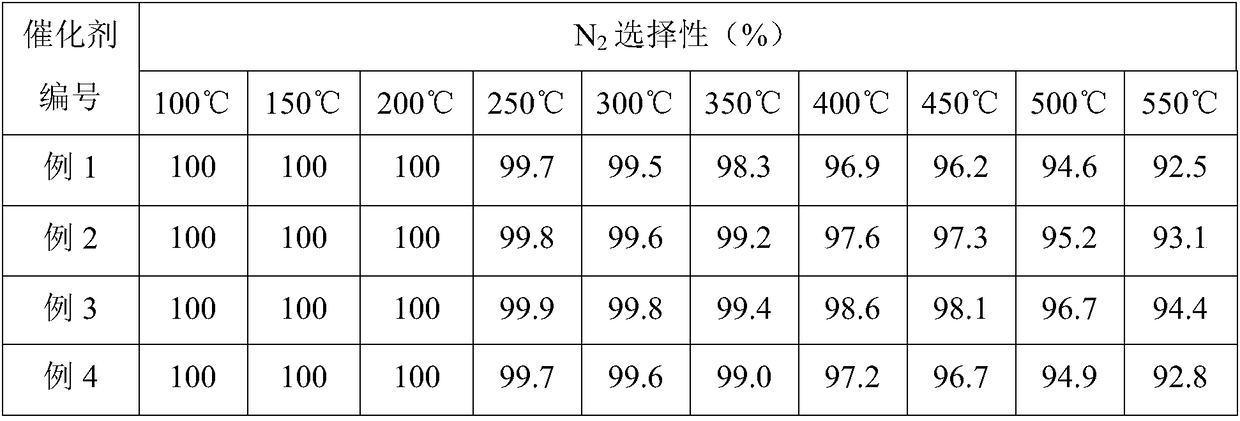

Copper-based molecular sieve catalyst used for diesel engine NOx removing using low-temperature NH3-SCR and preparation method of copper-based molecular sieve catalyst

InactiveCN108525701AWide active temperature windowImprove removal efficiencyInternal combustion piston enginesMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a copper-based molecular sieve catalyst used for diesel engine NOx removing using low-temperature NH3-SCR and a preparation method of the copper-based molecular sieve catalystand belongs to the technical field of diesel engine tail gas pollutant control. The catalyst uses silicon-aluminum-phosphorus-oxygen tetrahedron (SAPO-34) as the carrier, Cu as the main active component and Ce as the promoter component. Chemical element proportion used during the preparation is 1Al:1P:0.25Si:0.06Cu-TEPA:(0.01 / 0.04 / 0.06 / 0.08)Ce:1.6PA:40H2O. The preparation method specifically includes: synthesizing Cu-TEPA; loading the copper serving as the main active component, determining the loading capacity of the Ce serving as the promoter, loading the Ce serving as the promoter, and performing one-pot synthesizing of the CuCe-SAPO-34 integral structure. The copper-based molecular sieve catalyst and the preparation method thereof have the advantages that the copper and cerium molecular sieve catalyst is used to replace a traditional vanadium-based catalyst, the environmental harm of the catalyst is lowered, low-temperature activity and high-temperature and low-temperature selectivity are increased greatly, the catalyst can effectively reduce NOx in the wide temperature window of 150-550 DEG C, and the catalyst is high in sulfur resistance and hydrothermal aging resistance andapplicable to high-sulfur diesel oil and city road traffic conditions of China.

Owner:上海倍绿环保科技有限公司

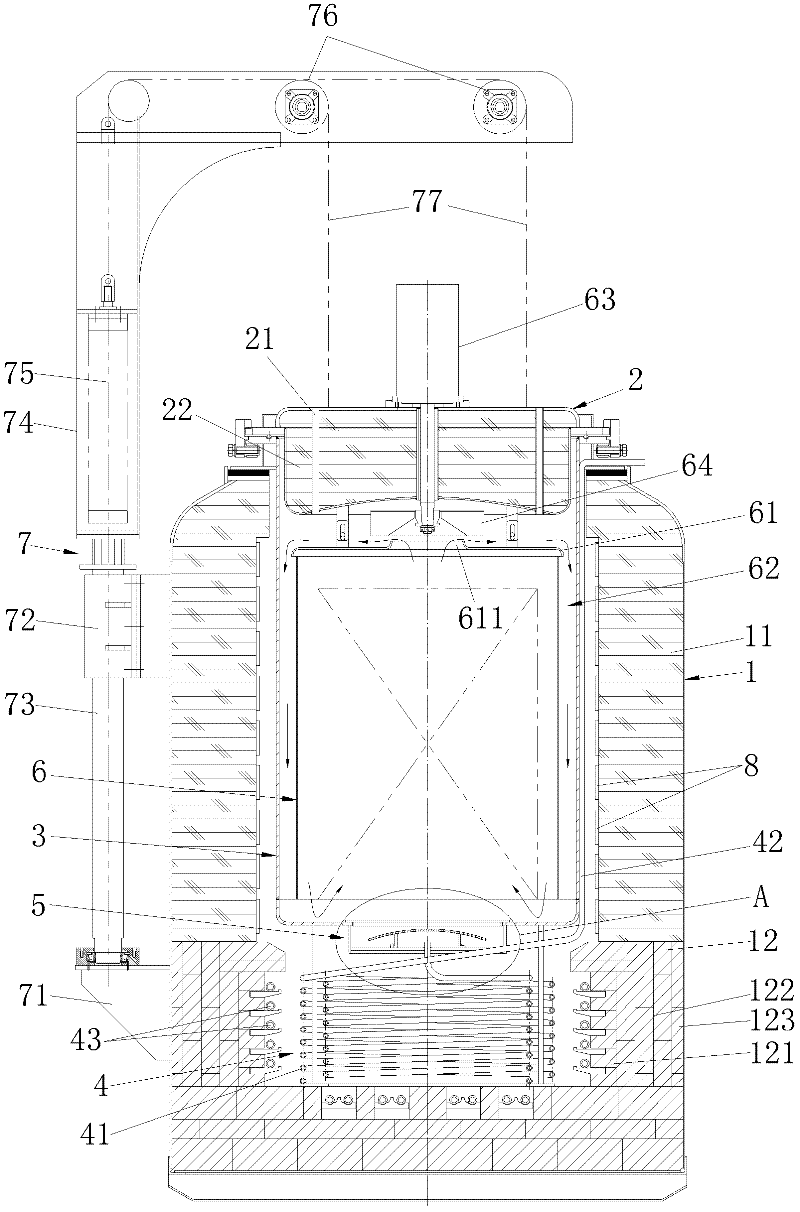

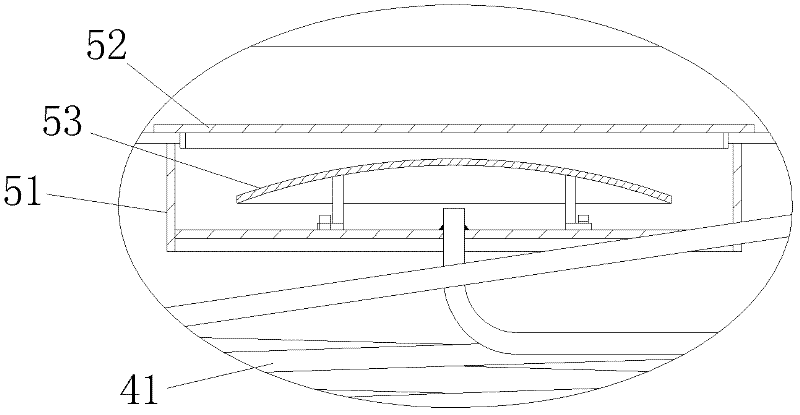

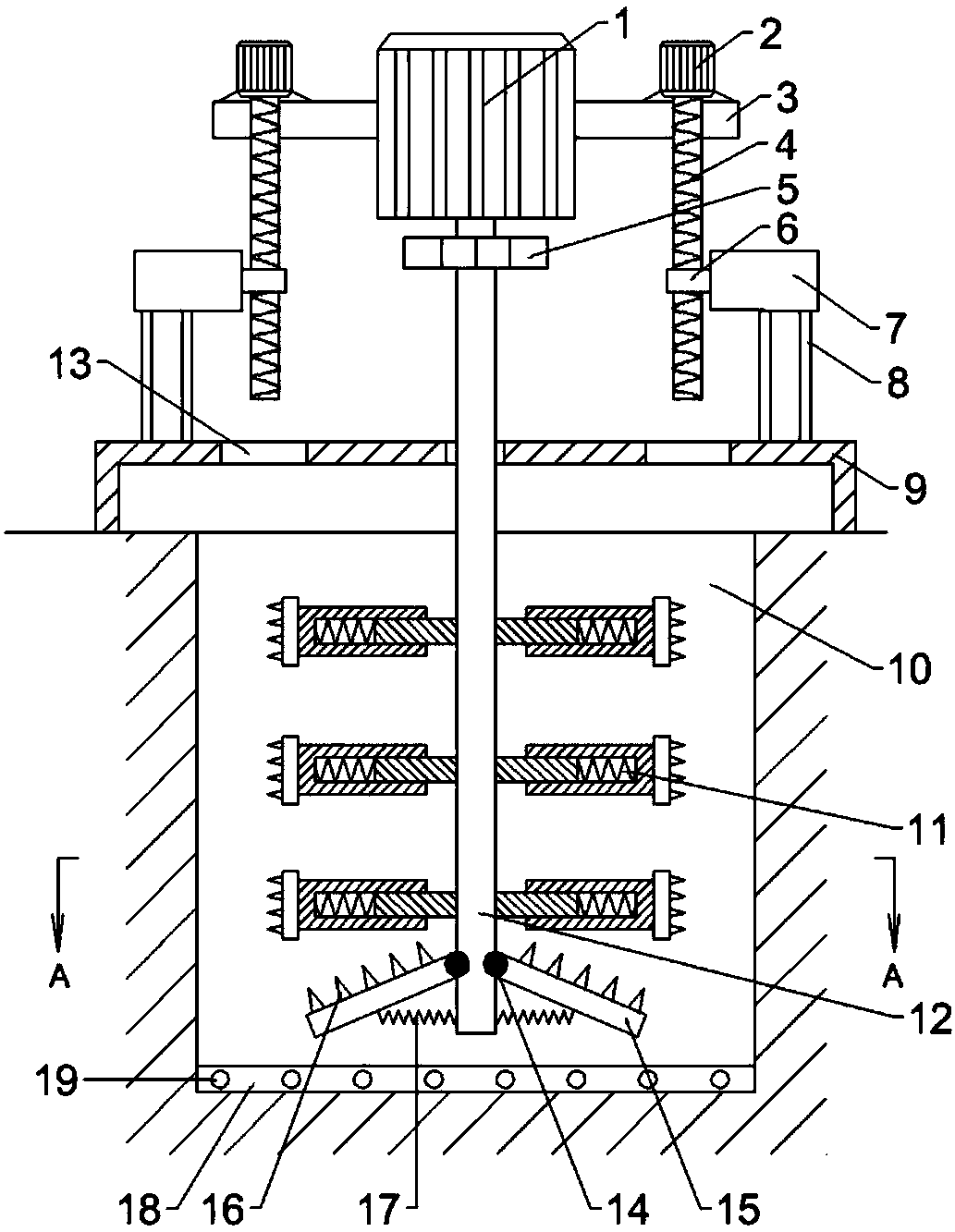

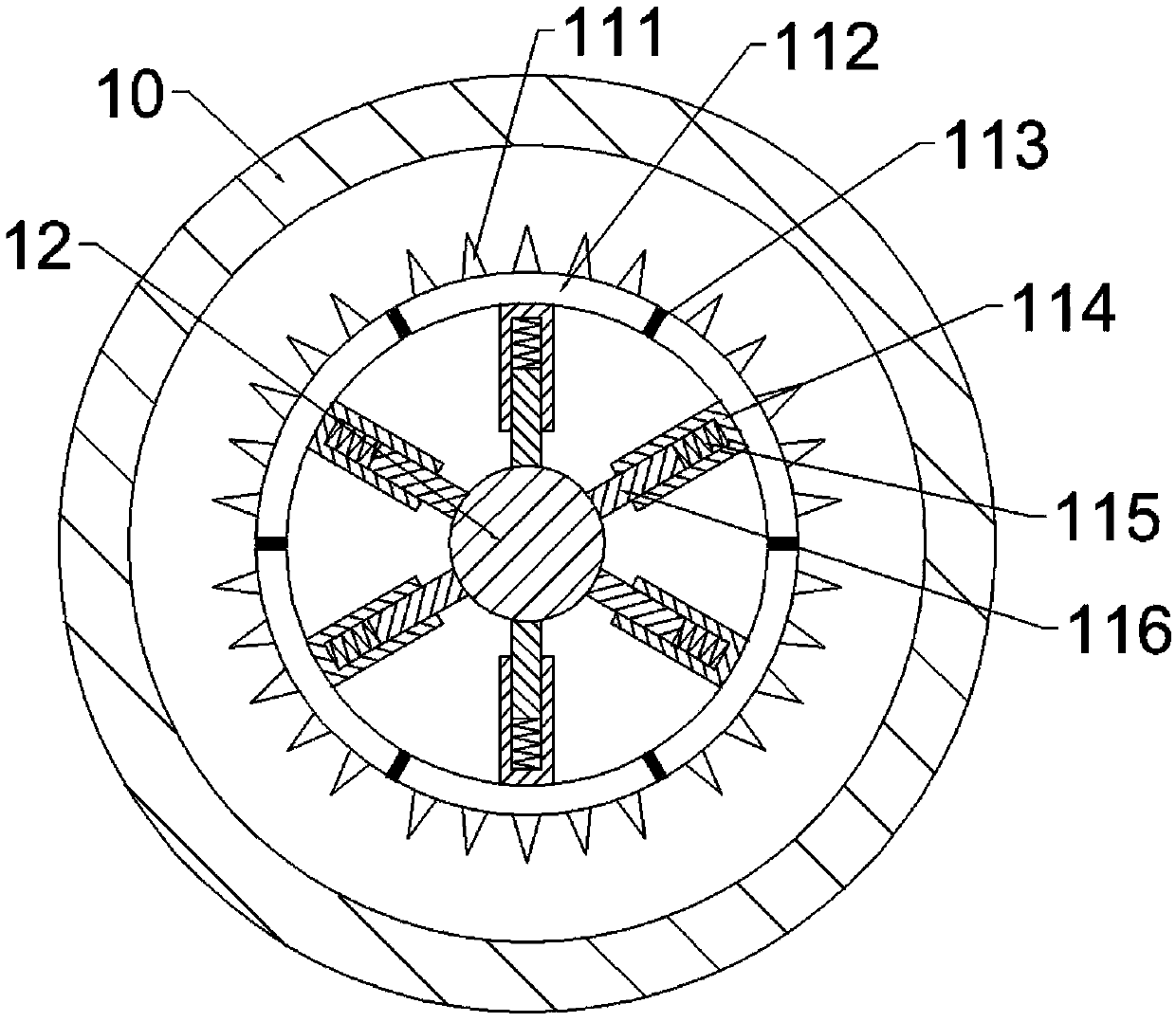

A Steam Oxidation Pit Furnace

ActiveCN102297583ASmall temperature fluctuationsReduce thermal expansion and contractionSolid state diffusion coatingVertical furnacesThermal expansionEngineering

The invention discloses a steam oxidation well furnace which comprises a furnace shell, a furnace cover, a furnace tank and a heating mechanism, wherein the furnace tank is arranged in the furnace shell; the heating mechanism is used for heating work pieces in the furnace tank; the bottom part of the furnace shell is provided with a steam preheating mechanism which is connected with an external steam source; and the steam preheating mechanism is communicated with the bottom part of the furnace tank through the steam diffusion structure. An individual steam preheating mechanism is added below the furnace tank, steam enters the furnace tank after the steam is heated by the steam preheating mechanism and is diffused uniformly by the steam diffusion structure, the temperature vibration in the furnace tank is reduced greatly, the expansion and contraction phenomenon in the furnace body is reduced, the welding point of the steam pipeline is difficult to drop off, and the steam pipeline is difficult to crack; and simultaneously the steam can be fused with metal work pieces more uniformly, the oxidation effect is improved obviously, the density of oxidizing materials on the surfaces of the metal work pieces is better, and the content of ferroferric oxide can reach more than 90%.

Owner:浙江省长兴精工电炉制造有限公司

Method for preparing material containing amorphous iron oxide hydroxide and methods for regenerating the same

ActiveCN101767830AHigh sulfur capacityGood desulfurization effectIron oxides/hydroxidesIron oxideHydroxide

The invention relates to a method for preparing a material containing amorphous iron oxide hydroxide and two methods for regenerating the same after being used as desulfurizer. The content of the amorphous iron oxide hydroxide in the material prepared by the invention is as high as 65% to 100%, so the sulfur capacity of the material is high; and the desulfurizer in the prior art is non-regenerative or costly for regeneration, so that the desulfurizer in a large amount cannot but be dumped as waste liquid in landfills, while the amorphous iron oxide hydroxide in the material of the invention can be repeatedly regenerated and reused after the material is used as the desulfurizer, thereby solving the problems of the waste of effective resources in the original desulfurizer and the severe environmental pollution.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

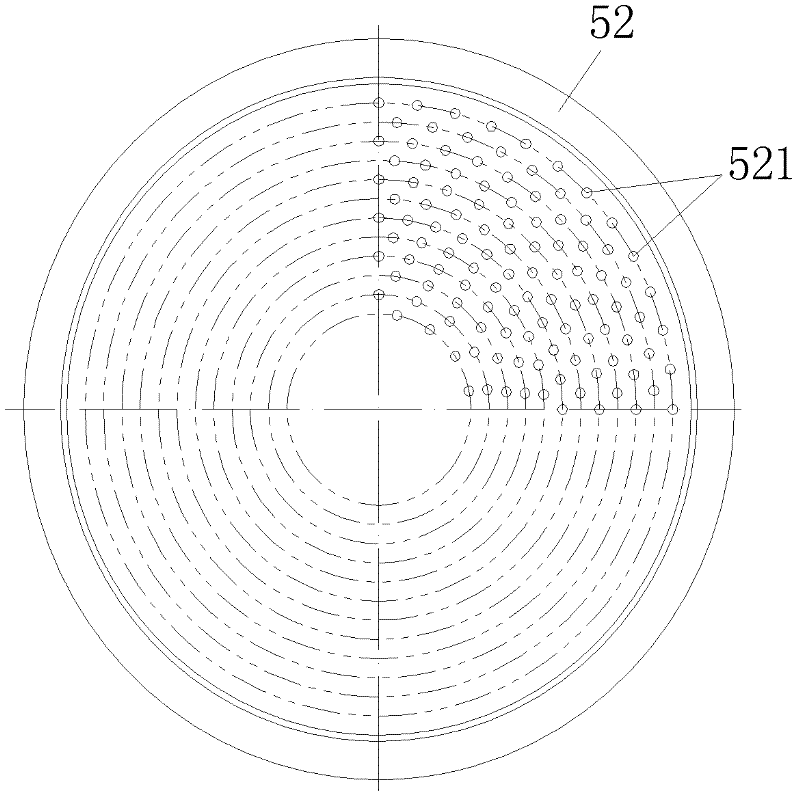

Photocatalysis oxidation water purification tank

InactiveCN101468845AHigh activityImprove the degree of purificationWater/sewage treatment by irradiationWater treatment compoundsVena contracta diameterFluidized bed

The invention relates to a photocatalytic oxidation and purification tank. The photocatalytic oxidation and purification tank is provided with an upper transverse clapboard and a lower transverse clapboard to divide a space of the tank into a middle part, an upper part and a lower part; the upper clapboard and the lower clapboard are orifice plates, wherein the upper clapboard is a small orifice plate; the lower clapboard is a large orifice plate; the middle part of the space in a tank body is a fluidized bed chamber; the lower part is a mixed chamber; the upper part is a steady flow chamber; the fluidized bed treatment chamber is provided with a plurality of ultraviolet lamps; the inside of each ultraviolet lamp is filled with photocatalyst particles; the surfaces of the photocatalyst particles are distributed with photocatalyst; a water inlet pipe of the purification tank is connected with the mixing chamber; the extending direction of the water inlet pipe is oblique or tangential; a water outlet pipe of the purification tank is connected with the steady flow chamber; the extending direction of the water outlet pipe is radial; and the tank body is also provided with an ozone inlet pipe which can be independently mounted or can adopt the same pipe with the water inlet pipe. The device has high purification degree, relatively large treatment amount and relatively lower treatment cost and is mainly suitable for occasion with higher requirement on purification degree of outlet water.

Owner:BEIJING JINAOHUARONG TECH

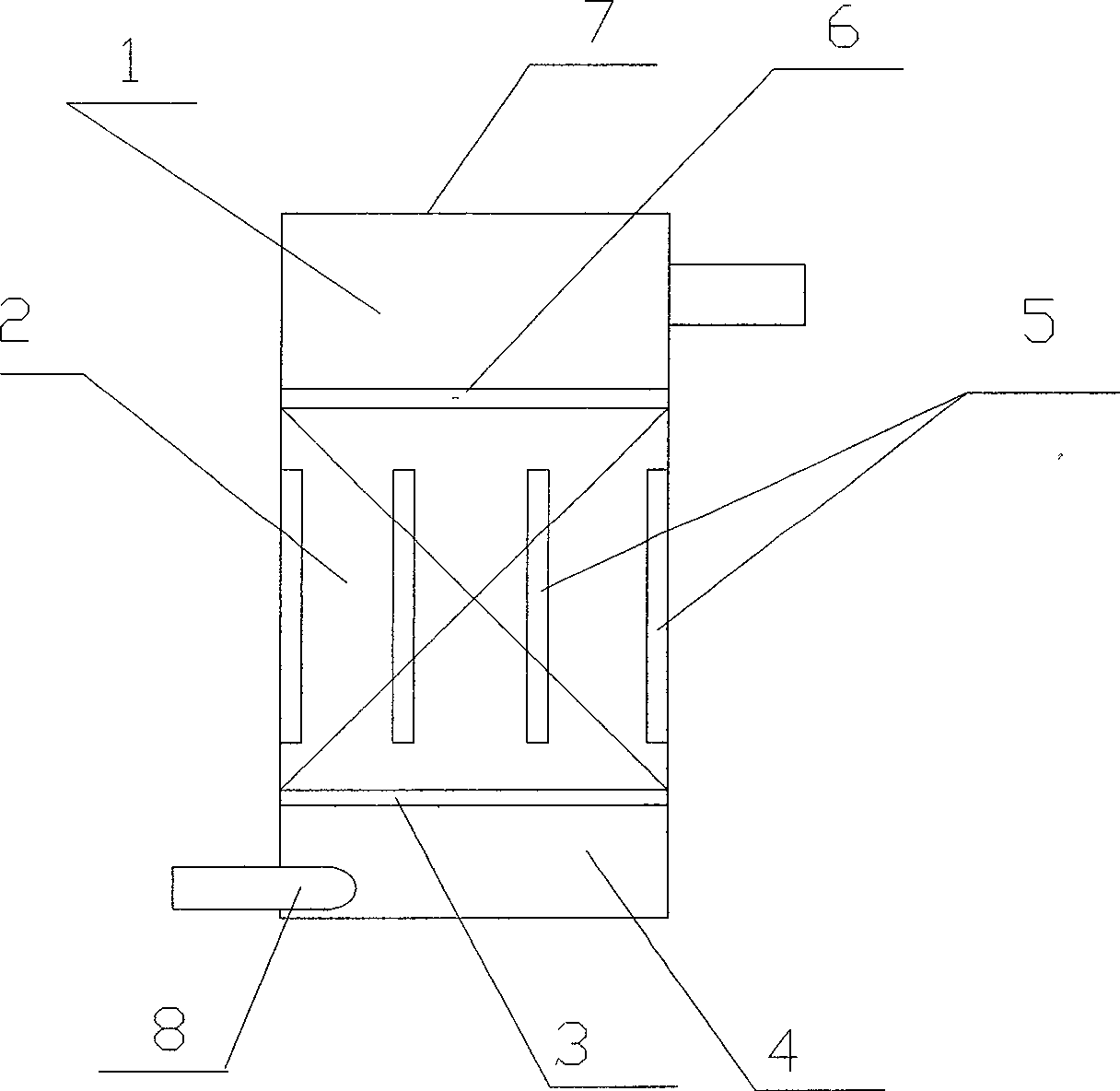

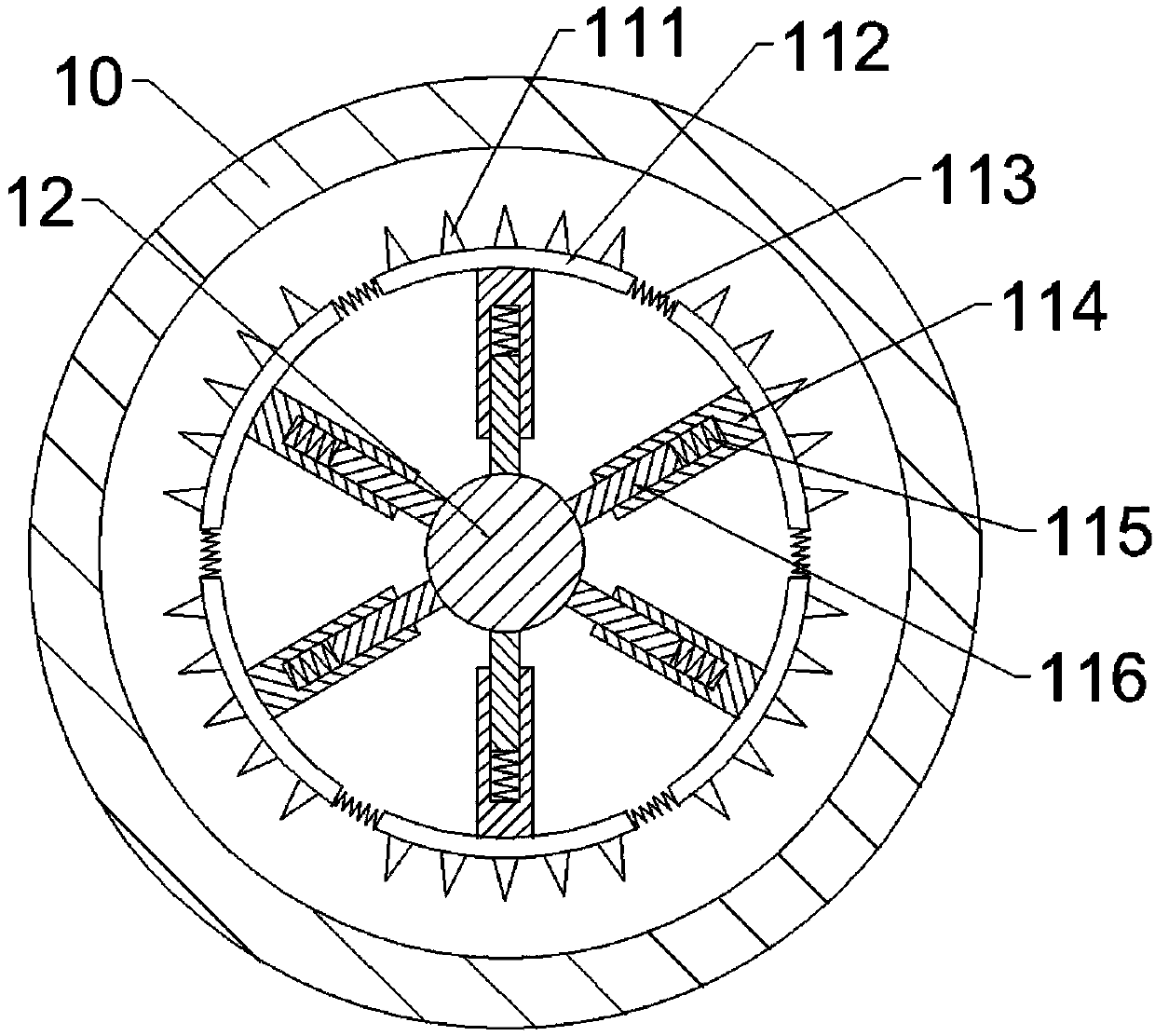

Environmentally friendly sewage treatment equipment with disturbance device

InactiveCN107619106AEffective stirring and mixingImprove oxidation effectRotary stirring mixersSustainable biological treatmentSludgeArchitectural engineering

The invention relates to environmentally friendly sewage treatment equipment with a disturbance device. The environmentally friendly sewage treatment equipment comprises a stirring shaft, a variable frequency motor and a support plate, the support plate is arranged on a sludge tank, the variable frequency motor is fixed at the middle position above the support plate, the stirring shaft is locatedin the sludge tank and is connected with the variable frequency motor through a speed reducer, two support frames are symmetrically arranged on the upper surface of the support plate, motors are fixedon the support frames and are further connected with nuts, connecting rods are arranged on the two sides of the variable frequency motor, a screw rod is arranged on the lower side of one end, deviating from the variable frequency motor, of each connecting rod, and the screw rods are matched with the nuts; and a stirring device is connected to the lower part of the stirring shaft. The environmentally friendly sewage treatment equipment has the beneficial effects that the stirring device moves up and down to regulate the position according to the actual conditions; compared with a relatively simple stirring blade, the stirring efficiency of the stirring device is higher; and a gas supply device is matched with the stirring device in use, so that the mixing effect of oxygen and the activatedsludge is improved.

Owner:苏州浔宇新材料科技有限公司

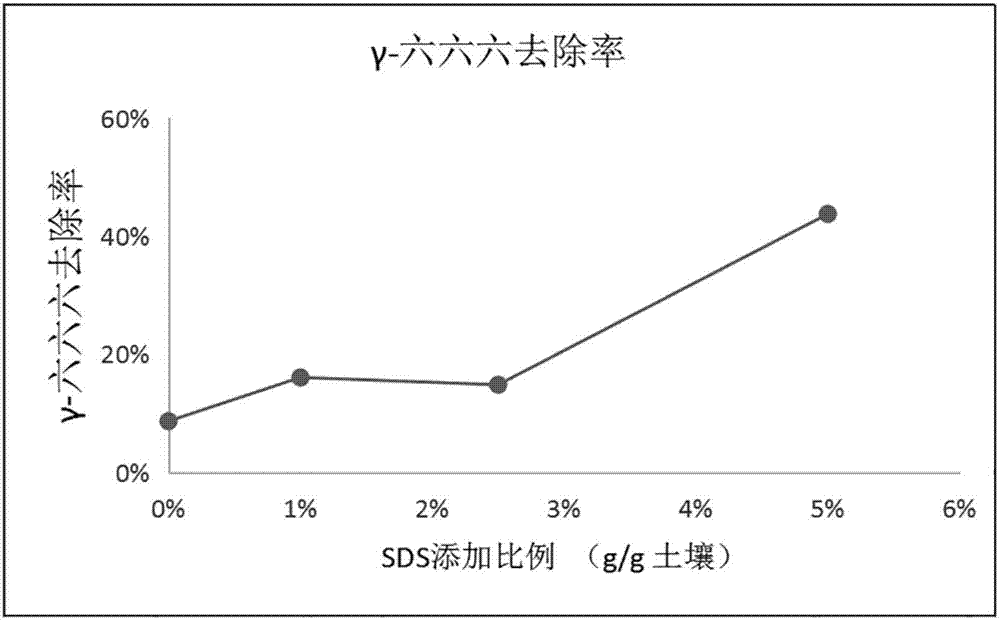

Using method of medicament used for chemically oxidizing and restoring pesticide contaminated soil

InactiveCN107159705AReliable qualityGood oxidation effectContaminated soil reclamationPesticidePre treatment

The invention discloses a using method of a medicament used for chemically oxidizing and restoring pesticide contaminated soil. The medicament comprises a component A and a component B. The component A comprises sodium sulfate, and the component B comprises sodium dodecyl sulfate and calcium hydroxide. The method comprises the steps that 1, the adding ratio of the component A is calculated; 2, the using amount and matching ratio of the component B are calculated, and the component B is prepared; 3, soil is pretreated; 4, the component B is added into the contaminated soil, and the mixture is stirred and mixed to be uniform; 5, the component A is added into the soil into which the component B is added, and the mixture is stirred and mixed to be uniform; 6, the moisture content of the soil into which the component A and the component B are added is adjusted, and maintenance is carried out for 3-7 days; and 7, the soil pH is detected and analyzed in the maintenance period to ensure that the soil pH reaches 10.0 after the mixture is mixed to be uniform. By means of the using method of the medicament used for chemically oxidizing and restoring pesticide contaminated soil, pesticide matter difficult to degrade in soil can be rapidly and efficiently oxidized, decomposed and removed.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

Oxidation treatment method for leachate biological treatment effluent

InactiveCN106976949AAvoid disadvantagesReduce use costMetal/metal-oxides/metal-hydroxide catalystsContaminated groundwater/leachate treatmentChemical oxygen demandSludge

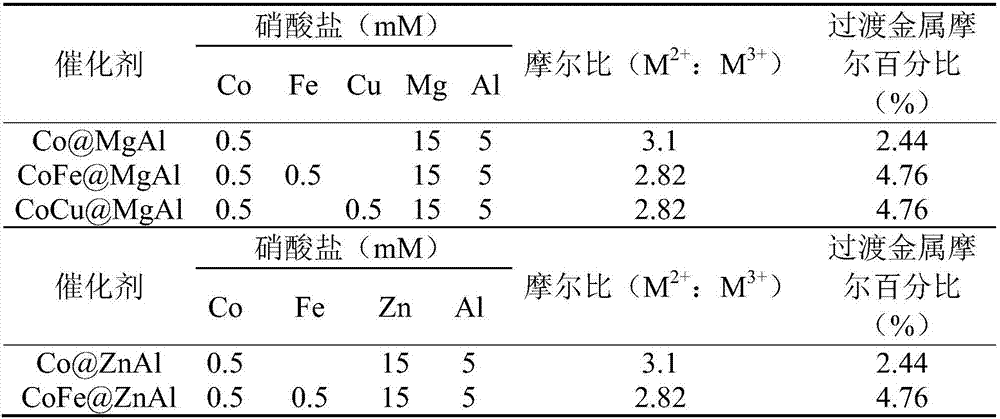

The invention discloses an advanced oxidation method for higher COD (Chemical Oxygen Demand) of leachate biological treatment effluent. The deep oxidation method comprises the following steps: feeding H2O2 and PMS as dual oxidants; feeding a CoFe@MgAl-LDH hydrotalcite catalyst for catalyzing the H2O2 and the PMS to generate .OH and SO4<->.; meanwhile, synergizing the PMS with the H2O2 to generate more .OH, prolonging action time, and further oxidizing to remove refractory organic compounds. According to the advanced oxidation method disclosed by the invention, by adopting multiphase catalytic dual oxidants, the problems that a large amount of concentrated solutions are generated in a membrane treatment method which is mainly adopted by an existing advanced treatment method for leachate, a large amount of chemical sludge is generated in an adopted Fenton oxidation process, secondary pollution metal ions are introduced and the like are solved; according to engineering requirements, coagulation also can be adopted for pretreatment before multiphase oxidation. The advanced oxidation method disclosed by the invention is a clean and high-efficiency advanced oxidation treatment method for the leachate; in addition, the treatment cost is controlled, and the treatment effect is guaranteed.

Owner:HUAZHONG UNIV OF SCI & TECH

Gas-phase double-dynamic tobacco alcoholization fermentation method

The gas-phase double-dynamic alcoholization fermentation method of tobacco is characterized by that it can make the tobacco raw material placed in fermentation tank implement fermentation under the following conditions; introducing compressed air into fermentation tank and making periodic pulsed pressurization and decompression process, the pressure pressurized into the fermentation tank every time is up to 0.10-0.25 MPa, and retained in 1-50 min., then the pressure is released, and decompressed to 0.0-0.5 Mpa, and retained in 1-60 min., and the periodic pulsed circulation time from pressurization to decompression is 1-120 min., its fermentation temp. is 26-46 deg.C, humidity is 80%-95%, and the fermentation time is 20-30 day so as to implement gas-phase double-dynamic fermentation of tobacco alcoholization, and can raise colour and taste of tabacco.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Triazinethiol-containing anticorrosive coating, anticorrosion treatment method, and anticorrosion treated metal materials

InactiveUS6096139AImprove oxidation effectAnticorrosion propertyPretreated surfacesAnti-corrosive paintsThiolPhosphoric acid

A solution and a process for non-chromium rust proof coating is disclose. The rust proof coating solution includes a composite of which the main components are an aqueous resin and water, with 0.2-20 g / l of triazine thiol compound and 0.1 / 5 g / l phosphoric acid contained therein. The rust proof process is a process for coating a zinc-coated steel or a non-coated steel with the rust proof coating solution as described above.

Owner:NIPPON PAINT CO LTD

Method for preparing polyacrylonitrile spinning stoste

InactiveCN1710159AStable concentrationSmall molecular weight distributionMonocomponent synthetic polymer artificial filamentYarnPolymer science

The poly-acrylonitrile spinning stost is prepared by mixing acrylonitrile, azobisisobutyronitrile and dimethyl sulfoxide according to a certain weight proportion, stirring uniformly, leading in nitrogen gas under the stirring speed of 230-290 turn / min., making them react under reaction temp. of 52-65 degree C, continuously feeding in acryamide solution to react for 8-13 hours in which the ratio of feed amount per min. to container volume is 2x10-5 -1x10-4 min-1 , then demonomorizing and defoaming. Advantages: obviously reduced poly-acrylonitrile molecular weight distribution, improved spinning property of polymer and the oxidisability of raw yarn and simple process etc..

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for catalyzing alkylated waste sulfuric acid through lignocellulose ester

ActiveCN105502309APromote oxidationImprove decolorization effectOrganic-compounds/hydrides/coordination-complexes catalystsClimate change adaptationFertilizerChemistry

Provided is a method for catalyzing alkylated waste sulfuric acid through lignocellulose ester. The method comprises the steps that the alkylated waste sulfuric acid is added to metallic oxide or hydroxide to react till the pH value is weak acidic, then catalyst lignocellulose ester and an oxidizing agent are added for a redox reaction, and organic matter in the alkylated waste sulfuric acid is converted into CO2, H2O, N2 and other harmless micromolecular matter. Obtained reaction liquid generated after oxydative degradation and decoloration is refined to be prepared into inorganic salt. Selected lignocellulose ester has a catalyzing function, and has the functions of activating the oxidizing agent and achieving adsorption decoloration. Other impurities are not introduced in the production process, secondary pollution cannot be caused, the organic matter in the waste acid is oxidized to be degraded, all mother liquor is cyclically utilized, and product quality cannot be influenced, and reaches the quality standard of the feed grade and the industrial grade. The production process is easy to operate, safe and reliable, operation is carried out at normal pressure, and investment is reduced. The lignocellulose ester catalyst can be biodegraded, and can serve as a raw material of biofertilizer, and no three wastes are discharged in the production process.

Owner:GUANGXI UNIV

Method for preparing aluminum sulfate by catalyzing alkylated waste sulfuric acid with lignocellulose ester

ActiveCN105480998APromote degradationEasy to passOrganic-compounds/hydrides/coordination-complexes catalystsAluminium sulfatesFiberAluminium hydroxide

The invention relates to a method for preparing aluminum sulfate by catalyzing alkylated waste sulfuric acid with lignocellulose ester. The method includes the steps that the alkylated waste sulfuric acid is added into aluminum oxide or aluminium hydroxide to react until the pH value is faintly acid to obtain a mixed solution, and the mixed solution is filtered to obtain leached residues and a reaction solution; the catalyst lignocellulose ester and an oxidizing agent are added into the reaction solution to conduct a redox reaction, organic substances in the alkylated waste sulfuric acid are completely converted into harmless micromolecule substances such as CO2, H2O and N2, cellulosic filter residues and a refined solution are obtained through solid-liquid separation, and finally the refined solution is crystallized to obtain the industrial-grade aluminum sulfate product. The selected lignocellulose ester has the catalysis function, the oxidizing agent activating function and the adsorption and decoloration functions. No other impurities are introduced in the production process, so that secondary pollution is avoided; the organic substances in the waste acid are oxidatively degraded, the mother solution is completely recycled, and product quality is not affected and reaches the industrial-grade quality standard; the production process is easy to operate, safe and reliable and adopts normal-pressure operation, and investment is saved. The lignocellulose ester catalyst is biodegradable and can serve as a raw material of biofertilizer, and no three-waste emission exists in the production process.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com