Copper-based molecular sieve catalyst used for diesel engine NOx removing using low-temperature NH3-SCR and preparation method of copper-based molecular sieve catalyst

A technology of NH3-SCR and diesel engine, which is applied to molecular sieve catalysts, separation methods, chemical instruments and methods, etc. It can solve the problems of poor selectivity, low catalyst activity, and narrow activation temperature window, so as to prevent large-scale generation, improve removal efficiency, Taking into account the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

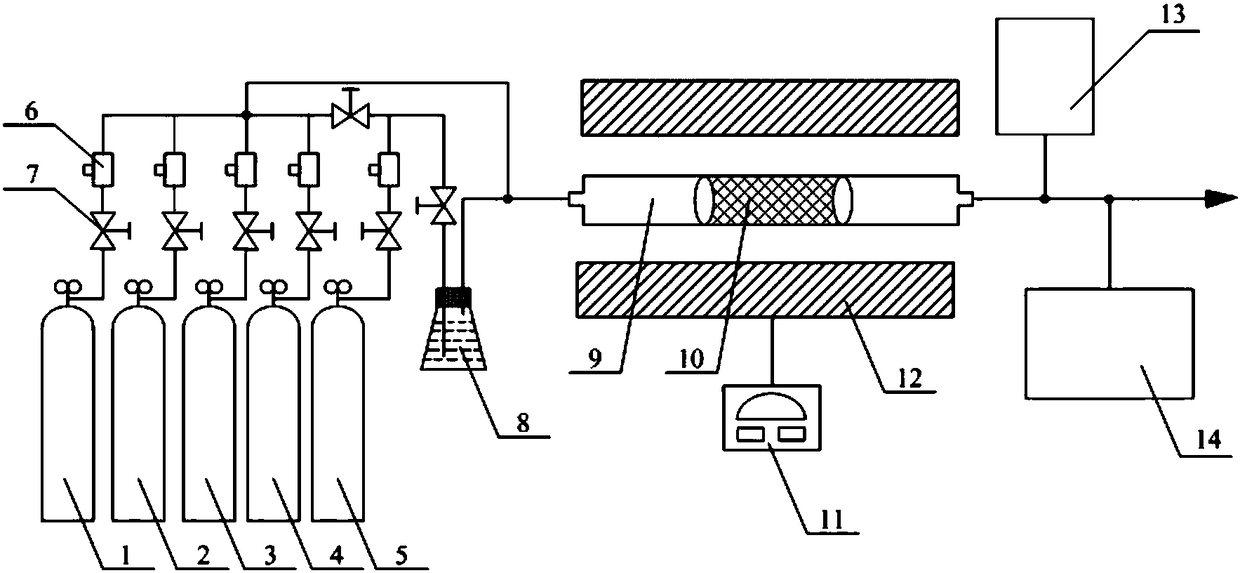

Image

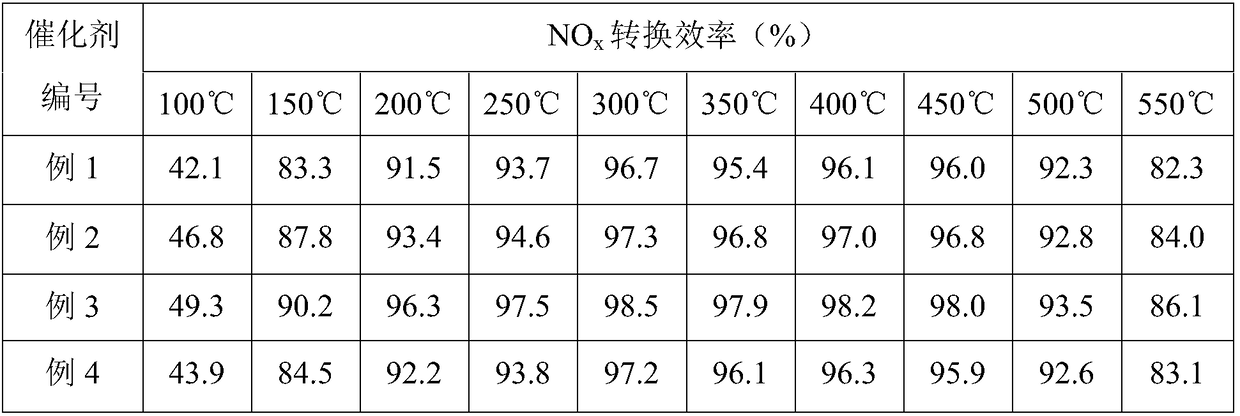

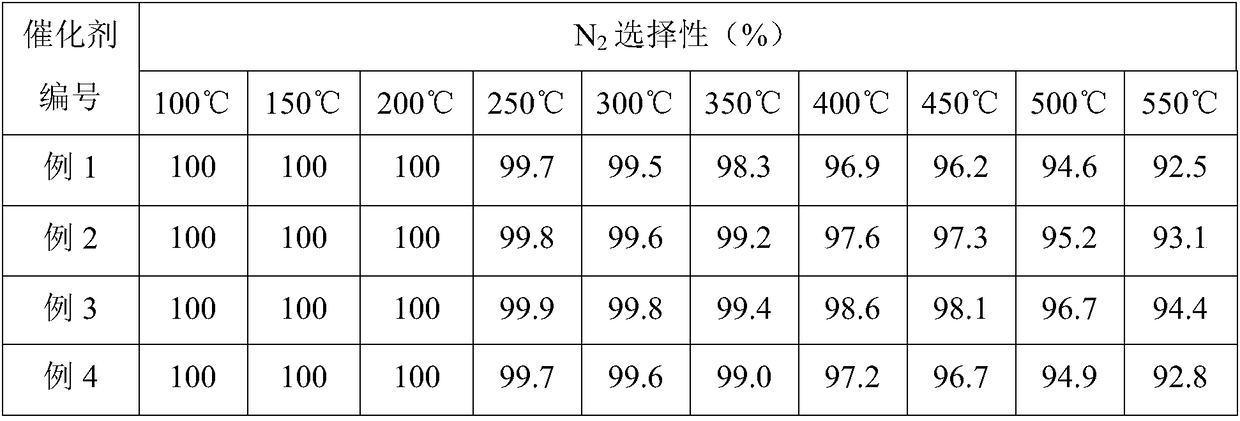

Examples

Embodiment 1

[0041] Synthesis ratio 1Al:1P:0.25Si:0.06Cu-TEPA:0.01Ce:1.6PA:40H2O

[0042] First, the synthesis of Cu-TEPA complex:

[0043] Weigh 48g of 20wt% CuSO4 solution and 12.62g of tetraethylenepentamine TEPA solution, mix the two, place on a magnetic stirrer and stir for 2 hours until completely dissolved;

[0044] Second, the synthesis of CuCe-TEPA complex:

[0045] Add the weighed Ce(NO3)3·6H2O with a mass of 4.34g to the solution, place it on a magnetic stirrer, and mix and stir for 2 hours until the two are fully mixed to form a CuCe-TEPA complex with a ratio of 0.01 Ce. Compound.

[0046] Third, the determination of the precursor quality of the silicon aluminum phosphorus oxide tetrahedron (SAPO-34) carrier element:

[0047] According to the ratio of synthetic elements: 1Al:1P:0.25Si:0.06Cu-TEPA:0.01Ce:1.6PA:40H2O. Each 72.85g pseudo-boehmite produces 51g Al2O3, every 115.3g phosphoric acid solution produces 98g H3PO4, every 15g white carbon black produces 15g SiO2, every 15g copper su...

Embodiment 2

[0052] Synthesis ratio: 1Al:1P:0.25Si:0.06Cu-TEPA:0.04Ce:1.6PA:40H2O

[0053] First, the synthesis of Cu-TEPA complex:

[0054] Weigh 48g of 20wt% CuSO4 solution and 12.62g of tetraethylenepentamine TEPA solution, mix the two, place them on a magnetic stirrer and stir for 2 hours until completely dissolved;

[0055] Second, the synthesis of CuCe-TEPA complex:

[0056] Add the weighed Ce(NO3)3·6H2O with a mass of 17.37g to the solution, place it on a magnetic stirrer, and mix and stir for 2 hours until the two are fully mixed to form a CuCe-TEPA complex with a ratio of 0.01 Ce. Compound.

[0057] Third, the determination of the precursor material quality of the silicon aluminum phosphorus oxide tetrahedron (SAPO-34) carrier element:

[0058] According to the ratio of synthetic elements: 1Al:1P:0.25Si:0.06Cu-TEPA:0.01Ce:1.6PA:40H2O. Each 72.85g pseudo-boehmite produces 51g Al2O3, every 115.3g phosphoric acid solution produces 98g H3PO4, every 15g white carbon black produces 15g SiO2, eve...

Embodiment 3

[0063] Synthesis ratio: 1Al:1P:0.25Si:0.06Cu-TEPA:0.06Ce:1.6PA:40H2O

[0064] First, the synthesis of Cu-TEPA complex:

[0065] Weigh 48g of 20wt% CuSO4 solution and 12.62g of tetraethylenepentamine TEPA solution, mix the two, place them on a magnetic stirrer and stir for 2 hours until completely dissolved;

[0066] Second, the synthesis of CuCe-TEPA complex:

[0067] Add the weighed Ce(NO3)3·6H2O with a mass of 26.05g to the solution, place it on a magnetic stirrer, and mix and stir for 2 hours until the two are fully mixed to form a CuCe-TEPA complex with a ratio of 0.01 Ce Compound.

[0068] Third, the determination of the precursor material quality of the silicon aluminum phosphorus oxide tetrahedron (SAPO-34) carrier element:

[0069] According to claim 3, the ratio of synthetic elements is: 1Al:1P:0.25Si:0.06Cu-TEPA:0.01Ce:1.6PA:40H2O. Each 72.85g pseudo-boehmite produces 51g Al2O3, every 115.3g phosphoric acid solution produces 98g H3PO4, every 15g white carbon black produces 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com