Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

302results about How to "Reduce the use temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

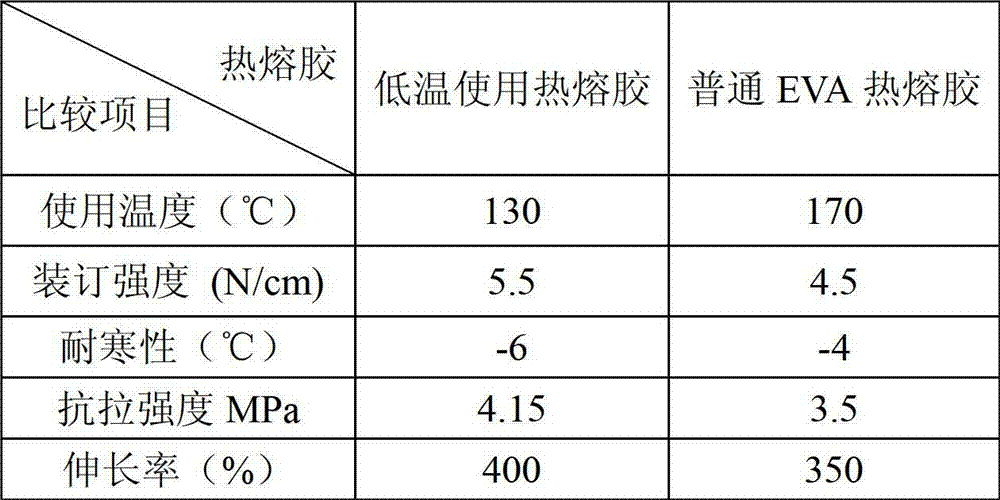

Book thermoplastic binding hot melt glue used at low temperature and preparation method thereof

InactiveCN102925080AImprove performanceNot easy to carbonizeMineral oil hydrocarbon copolymer adhesivesRosin adhesivesThermoplasticPolymer science

The invention relates to hot melt glue and a preparation method thereof, and belongs to the technical field of preparation of hot melt glue. The preparation method comprises the following steps of: starting stirring and opening a heat-conduction oil heating valve; sequentially filling ethylene-vinyl acetate (EVA) resin, a filler, a wax diluents and an antioxygen according to the proportion into a reaction kettle for heating; totally melting each component; adding tackified resin to heat until the tackified resin is totally melted; vacuumizing a reaction system until the reaction system has no bubbles; adding a filter screen and discharging at a discharging port of the reaction kettle; and cooling and forming the materials to obtain a product. The book thermoplastic binding hot melt glue can be used at about 130 DEG C, and is suitable for linkage line production; compared with the traditional book thermoplastic binding hot melt glue, the using temperature is reduced by 30 DEG C to 50 DEG C, so that the production energy consumption (electric energy, heat energy and the like) is reduced, the maintenance cost of equipment is reduced, and the production efficiency is improved; and the glue performance in a glue groove is stable, energy-saving production is facilitated, and the hot melt glue is environment-friendly.

Owner:WUXI WANLI ADHESION MATERIALS

Catalyst for catalytic pyrolysis

ActiveCN101428233AHigh hydrothermal stabilityIncrease acidityMolecular sieve catalystsBulk chemical productionCatalytic pyrolysisPetroleum naphtha

The invention relates to a catalyst for catalytic cracking and mainly solves the problems of high service temperature and low yield of ethylene-propylene copolymer in the prior catalyst for catalytic cracking in ethylene-propylene copolymer synthesis. In order to solve the problems, the technical scheme is as follows: the catalyst is obtained by loading at least one element of the group IB or the group IIB in the periodic table of elements on a ZSM-5 / mordenite molecular sieve, ZSM-5 / beta-zeolite molecular sieve or ZSM-5 / Y-zeolite molecular sieve. The catalyst is applied to the industrial production of ethylene-propylene copolymer via catalytic cracking of petroleum naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

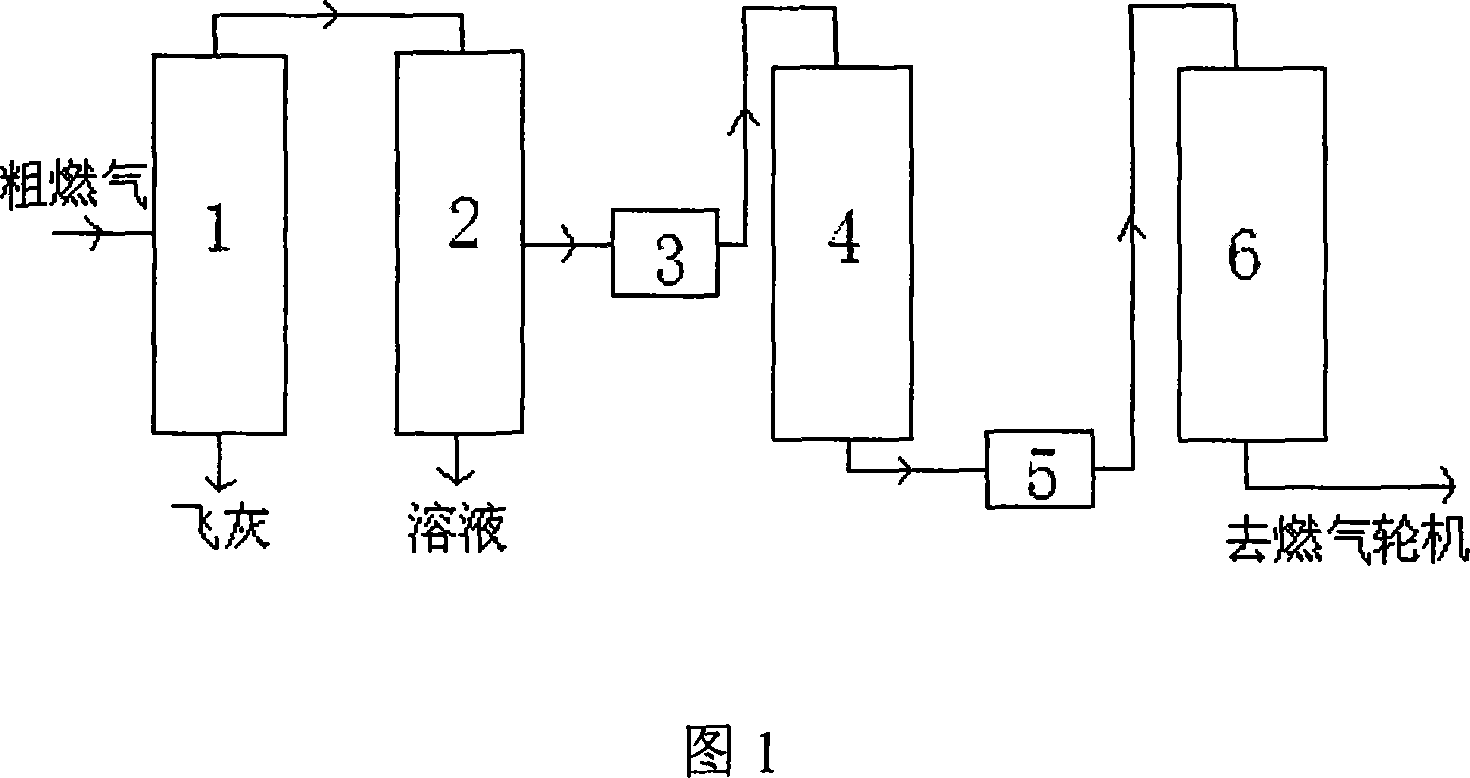

Method for purifying HCN and COS in fuel gas produced from coal

InactiveCN101050389AReduce the use temperatureGas purification by catalytic conversionSteelmakingAlkali metal oxide

This invention discloses a method for purifying HCN and COS in coal-prepared fuel gas. The method relates to hydrolytic conversion of HCN and COS of coal-prepared steelmaking fuel gas, electricity-generation fuel gas, or boiler fuel gas in the presence of the same catalyst. The catalyst is Co-Mo, Fe-Mo or Ni-Mo or Ni-Mo, and alkali metal oxide supported by active aluminum oxide carrier, and used at a temperature of 50-400 deg.C and a space velocity of 500-30000 / h. The method has can effectively remove HCN and COS with the conversion rates both higher than 90%. The method thus can realize environmentally friendly exhaust of gas turbine.

Owner:HAISO TECH +1

Cleaning agent for heavy oil dirt

InactiveCN103074174AEasy to cleanReduce the use temperatureNon-ionic surface-active compoundsDetergent compounding agentsNitritePhosphate

The invention discloses a cleaning agent for heavy oil dirt. The cleaning agent for the heavy oil dirt is characterized by comprising the following components in percentage by weight: 8 to 15 percent of surfactant, 2 to 8 percent of cosolvent, 4 to 10 percent of corrosion inhibitor, 3 to 12 percent of wash aid and the balance of deionized water. The cleaning agent for the heavy oil dirt has the advantages of excellent cleaning capability, low using temperature, wide application range, environmental friendliness and no pollution, does not contain ozone depleting substances (ODS), phosphate and nitrite, has excellent cleaning effect on oil dirt generated by machining of steel, aluminum and copper, and is a high-efficiency, environment-friendly and multi-purpose cleaning agent product for the heavy oil dirt.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

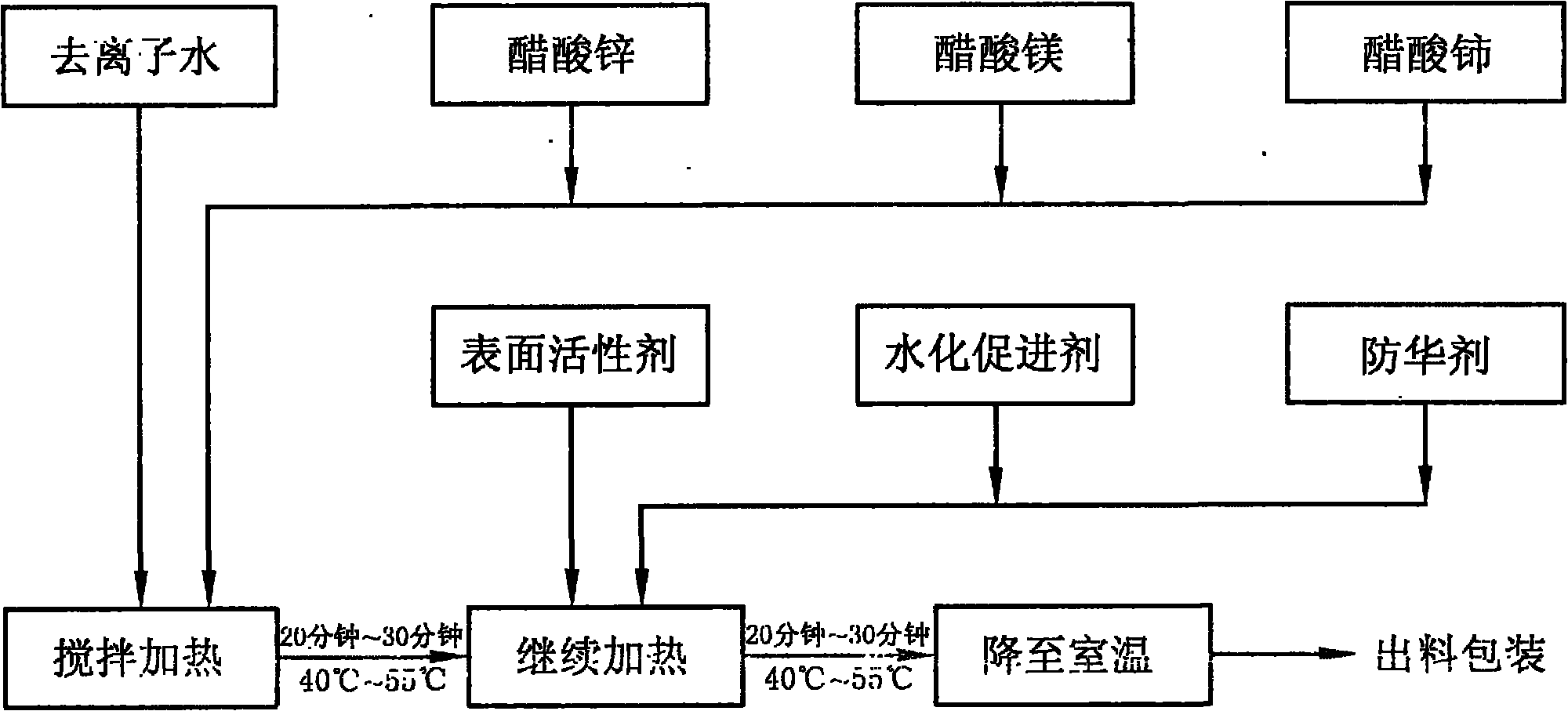

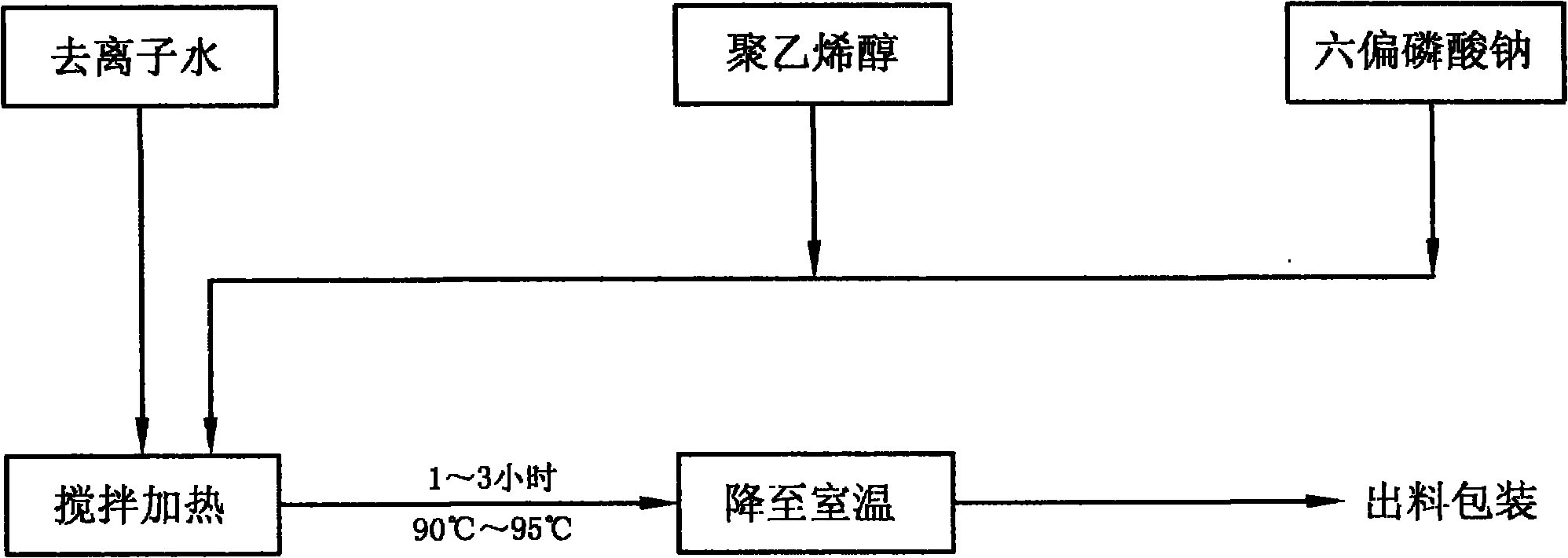

Method for preparing aluminum alloy anodic oxide film sealant

InactiveCN101812713AImprove pass rateImprove protectionSurface reaction electrolytic coatingSODIUM METAPHOSPHATEPolyvinyl alcohol

The invention discloses a method for preparing an aluminum alloy anodic oxide film sealant, which comprises the main processes of adding deionized water, zinc acetate, magnesium acetate, cerium acetate, surfactant, hydration promoter and sublimation preventing agent into a reaction kettle in turn, and mixing, stirring and heating the components to form the sealant. One of the important components of the sealant is sublimation preventing agent which is prepared by mixing the deionized water, polyvinyl alcohol and sodium hexametaphosphate together and then stirring and heating the mixture in the reaction kettle. The raw materials adopted by the preparation method do not contain nickel and fluorine elements, so the sealant is favorable for environmental protection; and the sealant reduces energy consumption during use, and improves the qualification rate of aluminum alloy products.

Owner:李继光

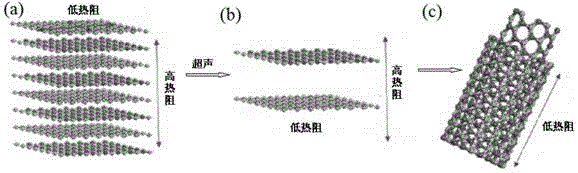

Polymer dielectric medium with low dielectric constant and low loss and preparation method of polymer dielectric medium

InactiveCN103980664AGood dispersionImprove thermal conductivitySynthetic resin layered productsEpoxyHeat conducting

The invention discloses a polymer dielectric medium with low dielectric constant and low loss and a preparation method of the polymer dielectric medium. The polymer dielectric medium comprises the following raw materials: 50-60% of epoxy resin system, and 40-50% of mixed boron nitride nanoparticles, wherein the mixed boron nitride nanoparticle is a mixture of a boron nitride nanotube and a boron nitride nanotube; the epoxy resin system is formed by 100phr of epoxy resin E-51, 85phr of methyl hexahydrophthalic anhydride and 1phr of benzyl dimethylamine in a mixing manner. The thermal breakdown voltage of the polymer dielectric medium is significantly improved by the polymer dielectric material with high heat conductivity and high electric breakdown, the service life is prolonged, the dielectric constant and loss and the heat expansion coefficient are reduced, the mechanical strength and the tenacity are improved, the highest heat conductivity can be up to 5.26W / mK, the volume resistivity is about 1014ohm.cm, the thermal breakdown voltage is about 2-3kV / mm higher than that of the similar heat-conducting polymer dielectric medium, and the dielectric constant and the loss are a little lower than those of pure resin.

Owner:XIAN UNIV OF SCI & TECH

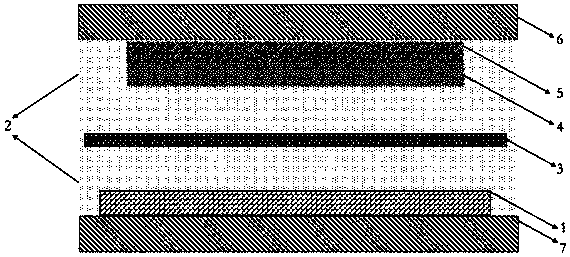

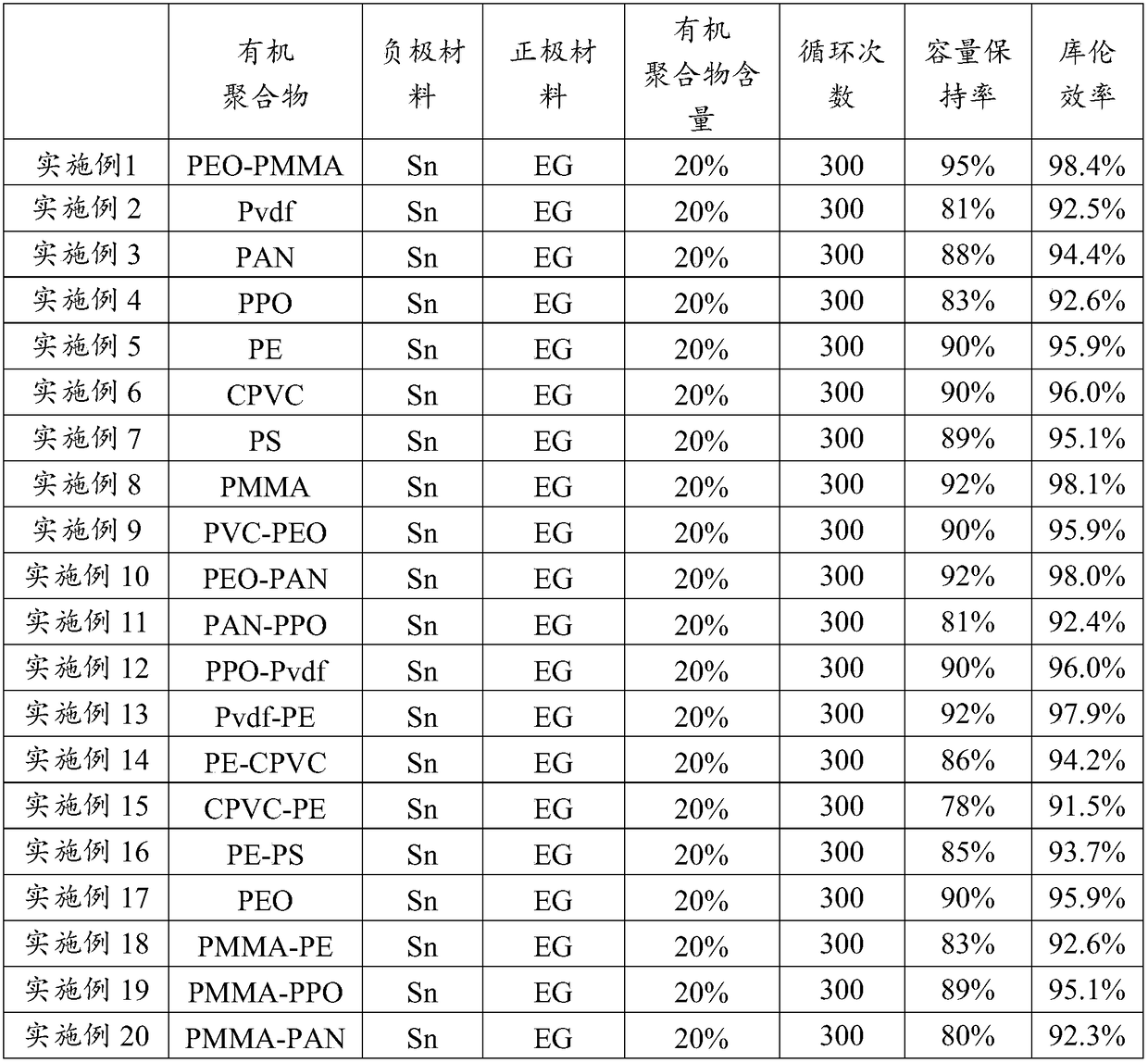

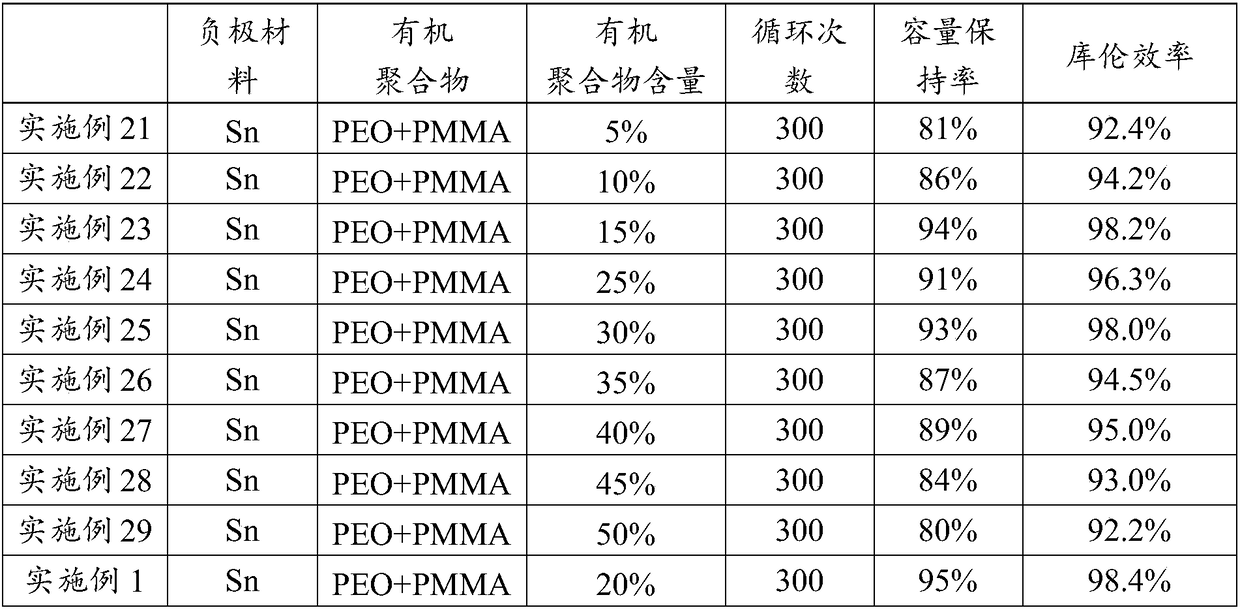

Organic gel electrolyte, application, sodium-based double-ion organic solid-state battery and preparation method thereof

InactiveCN108183257AImprove electronic conductivityHigh ion conductivitySecondary cellsOrganic electrolytesMetal alloySolvent

The invention discloses organic gel electrolyte, application, a sodium-based double-ion organic solid-state battery and a preparation method thereof and relates to the field of electrochemical energystorage devices. The organic gel electrolyte is prepared from electrolyte sodium salt, a non-aqueous solvent and an organic polymer. The sodium-based double-ion organic solid-state battery comprises anegative electrode, a positive electrode, a diaphragm and the organic gel electrolyte; the negative electrode can be sodium ion alloyed metal, a metal alloy or a metal compound; the positive electrode comprises a positive electrode current collector and a positive electrode material; an active substance of the positive electrode material is a laminar material which can be used for reversibly embedding and disembedding sodium salt anions. According to the organic gel electrolyte disclosed by the invention, the problems that organic electrolyte is easy to volatilize, combust and explode, a sodium ion solid-state battery cannot consider ion conducting performance and electrical conductivity at the same time, and the safety performance is not good at high temperature are alleviated. The organic gel electrolyte disclosed by the invention has very good ion conducting performance and electrical conductivity and an electrode piece powdering problem caused by the fact that volume expansion iscaused by alloying can be alleviated; the battery has good circulating stability and safety performance.

Owner:SHENZHEN INST OF ADVANCED TECH

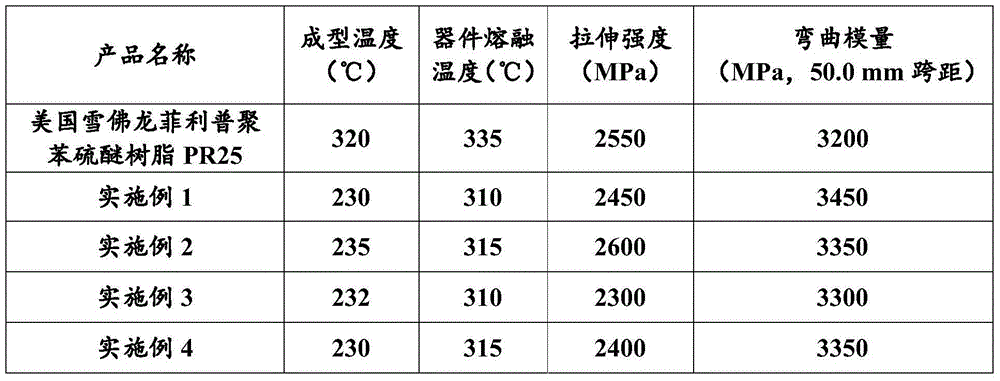

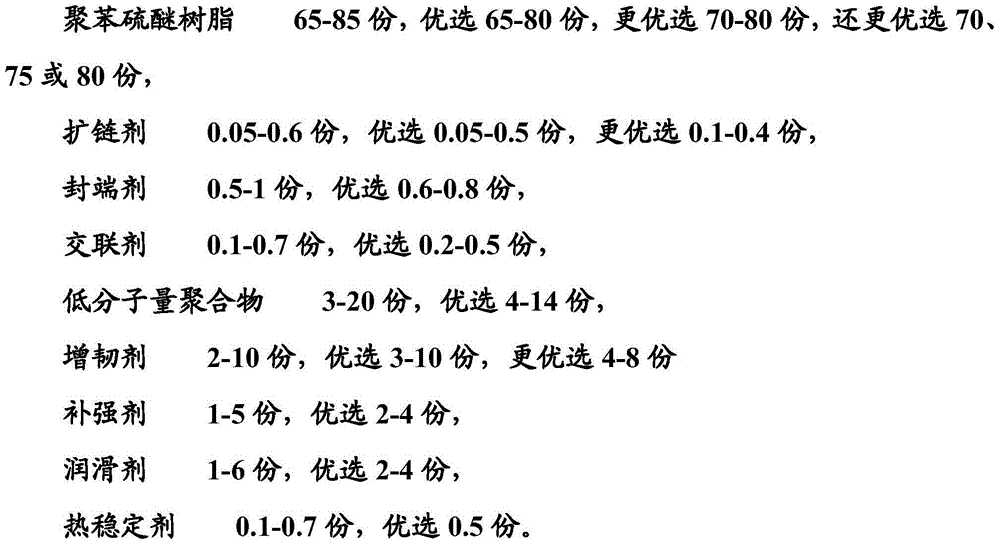

Modified polyphenylene sulfide resin suitable for 3D printing as well as preparation method and application of modified polyphenylene sulfide resin

ActiveCN104650587AIncrease profitImprove toughnessAdditive manufacturing apparatusDevice formToughness

The invention discloses modified polyphenylene sulfide resin suitable for 3D printing. The modified polyphenylene sulfide resin is a combination of the following components in parts by weight: 65-85 parts of polyphenylene sulfide resin, 0.05-0.6 part of a chain extender, 0.5-1 part of an end capping agent, 0.1-0.7 part of a crosslinking agent, 3-20 parts of low-molecular-weight polymer, 2-10 parts of a toughening agent, 1-5 parts of a reinforcing agent, 1-6 parts of a lubricating agent and 0.1-0.7 part of a heat stabilizer. The polyphenylene sulfide resin is modified by adopting the simple processes of mixing materials and extruding, and the processing temperature of the modified polyphenylene sulfide resin is reduced greatly. The melting temperature of the device formed by printing by adopting the modified polyphenylene sulfide resin is not reduced significantly, and the toughness is improved, and thus the polyphenylene sulfide resin can be widely applied to the field of 3D printing.

Owner:INST OF CHEM CHINESE ACAD OF SCI

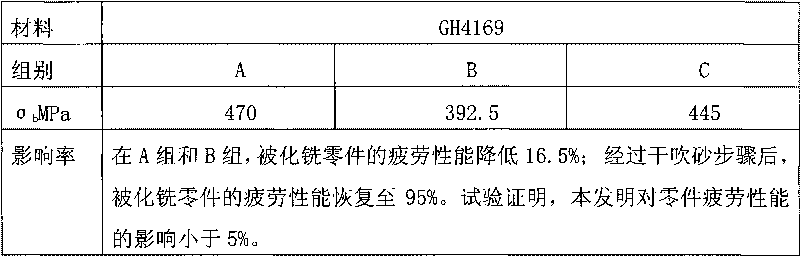

Precision-forging chemical-milling solution for high-temperature alloy blades and chemical milling method

The invention provides a precision-forging chemical-milling solution for high-temperature alloy blades and a chemical milling method. 55 to 75 g / L of hydrochloric acid, 100 to 135 g / L of nitric acid and 400 to 500 g / L of ferric chloride are adopted to be prepared with water into a chemical milling solution, and precision-forging parts of high-temperature alloy blades are chemically milled through size grouping, oil removal, hot washing, activation, hanging ash removal, repeated chemical milling and restoring performance. The solution can effectively remove metal, and the parts chemically milled are easy to clean. The method has the chemical-milling temperature lower than 50 DEG C, has the material-removing speed approximately between 0.02 and 0.05 mm / min, and can minimize the fatigue properties of materials. The method has the advantages of little influence on material properties and capability of effectively removing metal, and the solution is low in use temperature and little in environmental pollution and has the characteristics of simple operation, safety and reliability.

Owner:AECC AVIATION POWER CO LTD

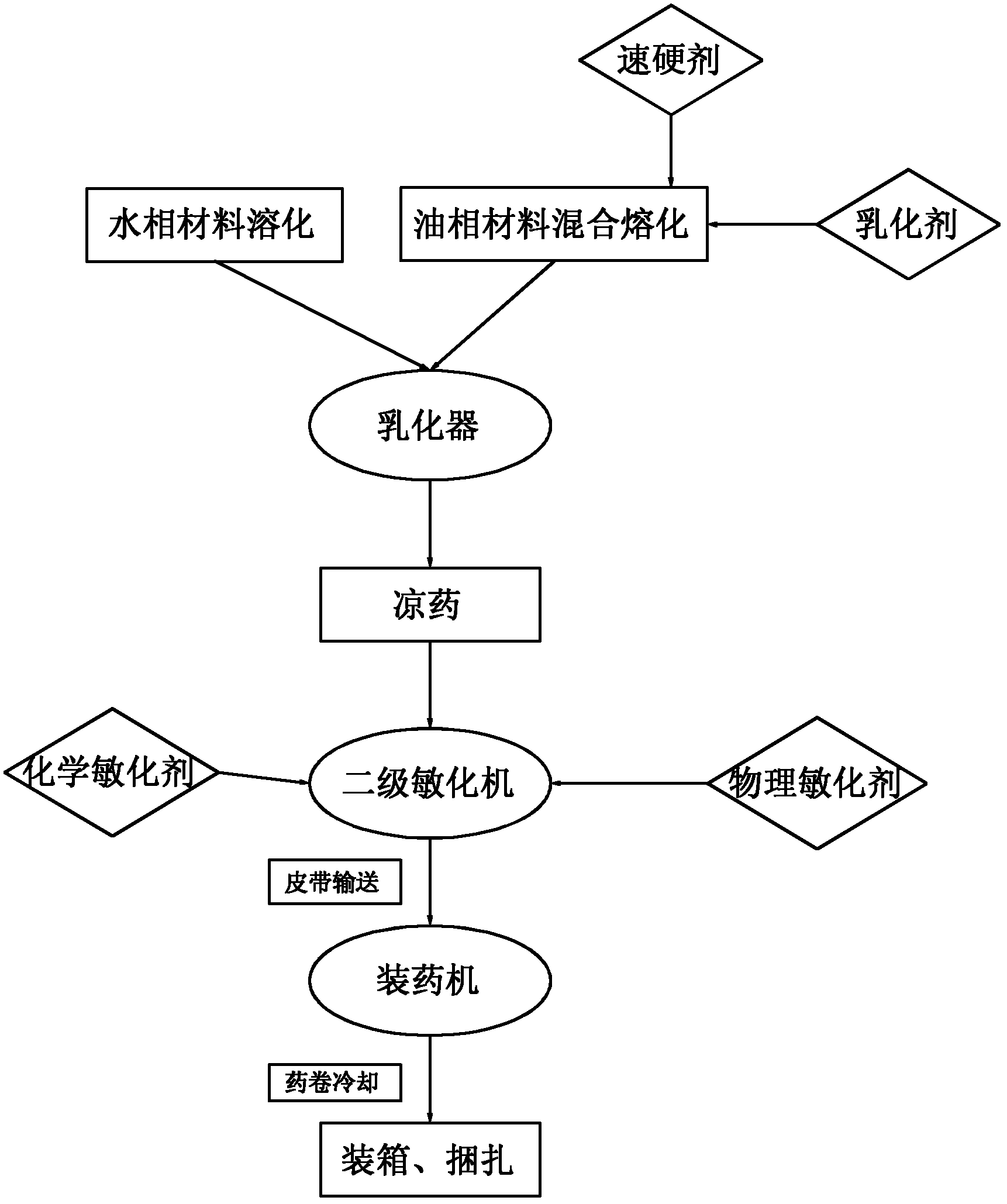

High-temperature acceleratingly-hardened emulsion explosive and preparation method for same

ActiveCN102633580AIncrease the hardness of the outer phaseMolecular chain lengthNon-explosive/non-thermic compositionsEmulsion explosiveHardness

The invention relates to a high-temperature acceleratingly-hardened emulsion explosive, which comprises water-phase materials, oil-phase materials, emulsifier, sensitizer and hardening accelerator, wherein the water-phase materials include wax and / or fatty acid; the sensitizer includes physical sensitizer and chemical sensitizer simultaneously; and the hardening accelerator is selected from silicate and / or alkaline matter. The temperature of the emulsion explosive is higher than 35 DEG C, and the emulsion explosive has a certain hardness and is non-sticky, thereby being applicable to open-air filling operation in hot summer, and being high in explosion performance.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

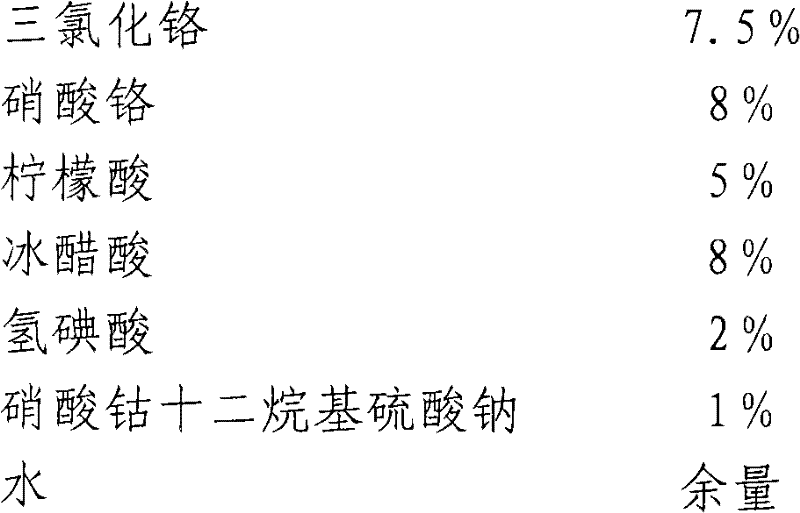

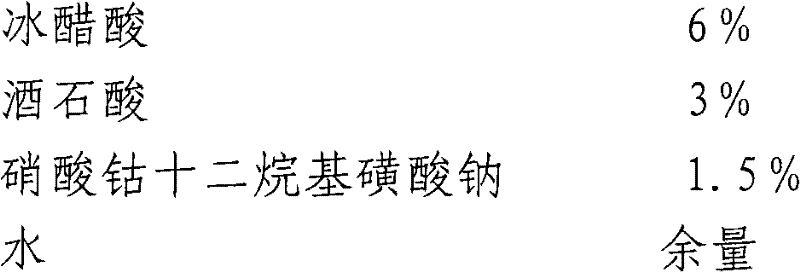

A kind of trivalent chromium multicolored passivator

InactiveCN102260867AGood salt spray performanceReduce the use temperatureMetallic material coating processesHexavalent chromiumHolding time

A trivalent chromium multicolored passivator belongs to the technical field of surface treatment. This passivating agent is used for trivalent chromium multicolored passivating agent after passivation treatment after various electroplating galvanizing processes, and hexavalent chromium will not appear during use. It can prevent the aging of the passivation film and last for a long time through the detection by boiling method. Time to keep the passivation film bright, excellent corrosion resistance. The passivating agent is composed of: 15-30% trivalent chromium composite main salt, 10-25% composite chelating agent, 3-8% reducing agent, 3-10% salt spray resistance additive, 1-3% surfactant, etc. , and the balance is composed of water.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

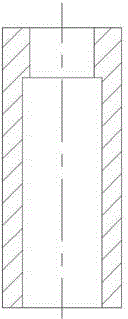

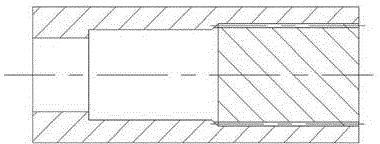

Process for cold extrusion forming of one-way device spline sleeve

InactiveCN104148888AEliminates drilling/boring stepsDrilling/boring steps meetEngineeringUltimate tensile strength

The invention provides a process for cold extrusion forming of a one-way device spline sleeve. The process comprises the steps of utilizing hollow pipes to serve as raw materials, performing blanking according to specified dimensions, sequentially performing annealing, head flattening, shot blasting, phosphatization and saponification treatment, cold extrusion shaping, cold extrusion spline forming, machining, quenching, tempering, shot blasting, cleaning and grinding machine processing, and obtaining finished product one-way device spline sleeves. The one-way device spline sleeves obtained through the process are high in precision, small in individual differences, good in strength performance and long in service lives.

Owner:宁波惠山汽配制造有限公司

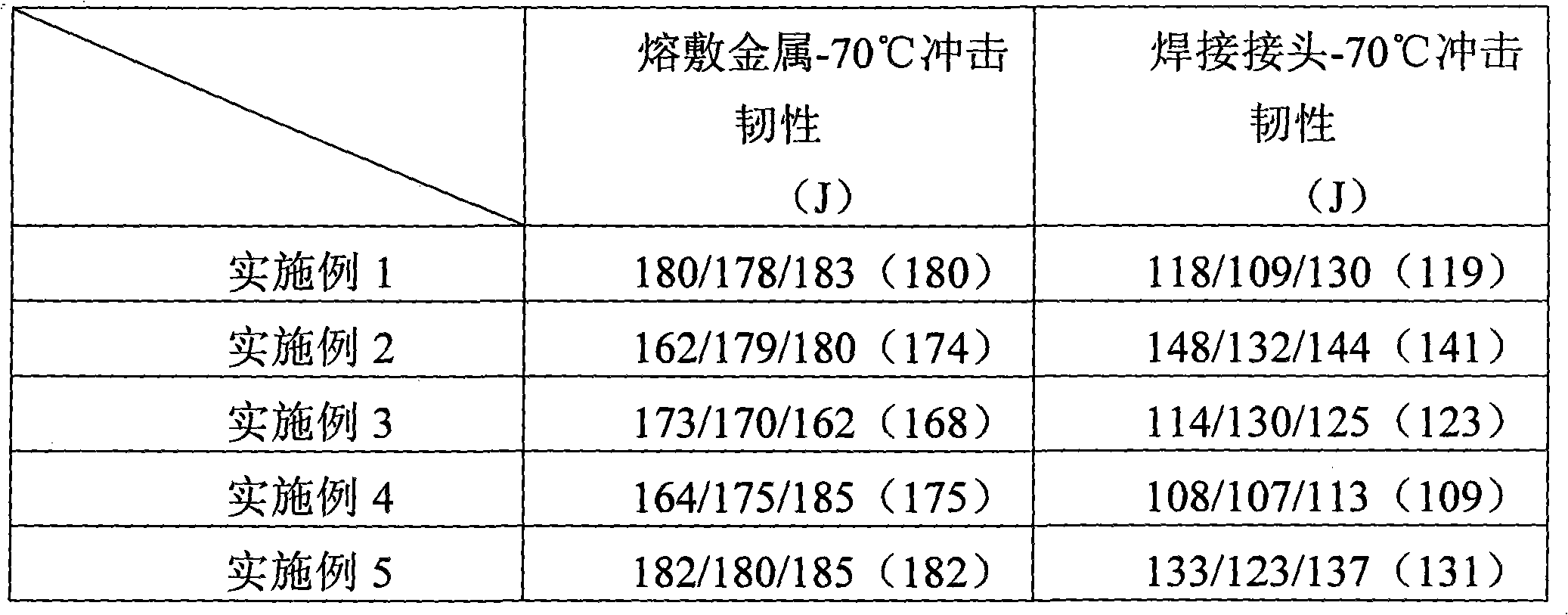

Special welding rod for -70 DEG C ferrite type low-temperature steel

ActiveCN101879672AExcellent all-position welding processabilityExcellent and stable arcWelding/cutting media/materialsSoldering mediaElectrolysisManganese

The invention discloses a special welding rod for -70 DEG C ferrite type low-temperature steel. The special welding rod is characterized in that the special welding rod is prepared by the following steps of: mixing the following powdery raw materials in part by weight: 35 to 38 parts of marble, 27 to 29 parts of fluorite, 1 to 3 parts of titanium white powder, 1 to 3 parts of quartz, 3 to 5 parts of mica, 4 to 6 parts of ferrosilicon, 7 to 9 parts of ferrotitanium, 3 to 5 parts of electrolytic manganese, 6 to 8 parts of nickel metal powder, 1 to 3 parts of sodium carbonate, 2 to 4 parts of feldspar and 3 to 5 parts of iron sand; adding potassium sodium water glass in an amount which is 25 percent of the total weight of the powdery raw materials; stirring the mixture uniformly; and press-coating the mixture on a carbon steel core wire to form a low-allow steel welding rod. A weld metal and a weld joint of the welding rod have excellent and stable -70 DEG C low-temperature impact property, the mean value of -70 DEG C V-shaped notch impact power of the weld metal is 160J, and the mean value of 70 DEG C V-shaped notch impact power of the weld joint is 110J, thus fully meeting the engineering requirement.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Foamless low temperature degreasing agent

The invention provides a non-foaming low-temperature degreasant which belongs to the chemical technique field. The non-foaming low-temperature degreasant is prepared from components by weight percentage as follows: water 77.4-96.35%, sodium hydroxide 3-20%, polyoxyethylene nonyl phenyl ether 0.1-0.5%, fatty alcohd-polyoxyethlene ether 0.1-0.5%, carmowax 0.05-0.1%, disodium EDTA 0.2-0.5%, silicone antifoam agent 0.1-0.5%, fatty alcohol polyethenoxy ether type osmotic agent 0.1-0.5%. The non-foaming low-temperature degreasant has advantages of better oil removing effect, low use temperature, and simple preparing method. The non-foaming low-temperature degreasant has better application prospect.

Owner:NORTHEASTERN UNIV

Single-component moisture-curing polyurethane adhesive for car roof and preparation method thereof

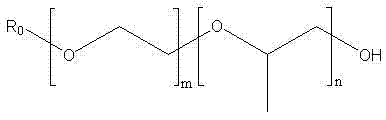

ActiveCN104017533AReduce the use temperatureFast curingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolyurethane adhesiveAdhesive cement

The invention relates to a single-component moisture-curing polyurethane adhesive for a car roof and a preparation method thereof. The obtained adhesive has the advantages of low application temperature, rapid curing speed and convenience in application. By introducing an ethylene oxide chain link in the adhesive molecular structure, the probability of reaction of the NCO groups with water in the later stage is increased, and then by combination with a composite catalyst, the latter curing speed is greatly improved; by adding No. 6 solvent oil, the anti-freezing performance of the adhesive is improved, and the storage is also more stable; and by adding a certain amount of a water removal agent, the effect of water in raw materials and the environment on the stability of the adhesive is eliminated.

Owner:重庆中科力泰高分子材料有限公司

Industrial cleaning agent and its production method

InactiveCN1730640ANo rust treatment requiredNo solubilityOrganic detergent compounding agentsSurface-active detergent compositionsSodium bicarbonateAlkylphenol

The invention discloses a cleaning agent for industrial use and its preparing process, wherein the product comprises sodium carbonate, sodium bicarbonate, sodium tripolyphosphate, sodium silicate, sodium metasillcate, sodium polyacrylate, sodium acrylate, alkylphenol polyether, triethanolamine, and sodium alkyl benzene sulphonate.

Owner:XIAN JIANNENG TECH

Waterborne polyurethane hot melt adhesive as well as preparation method and application thereof

InactiveCN104927747AReduce liquidityEasy to usePolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention belongs to the technical field of hot melt adhesives, and discloses a waterborne polyurethane hot melt adhesive as well as a preparation method and application thereof. The preparation method comprises the following steps: (1) adding polyether polyol in a reaction kettle, heating to 120-130 DEG C, and carrying out heat preservation, water removal and cooling; (2) under the condition of stirring, dropwise adding a catalyst into the reaction kettle and then adding polyisocyanate, heating to 80-88 DEG C, and carrying out a heat preservation reaction to obtain a mixture; (3) dropwise adding a carboxylic monomer solution into the mixture, adjusting the temperature, and carrying out heat preservation reaction to obtain a crude product; (4) adding acetone into the crude product, increasing the rotating speed of a stirrer, cooling to 35-40 DEG C, adding a neutralizing agent for neutralization, taking out the obtained material, adding distilled water, and conducting high-speed shearing emulsification and rotating evaporation to obtain the waterborne polyurethane hot melt adhesive. The waterborne polyurethane hot melt adhesive provided by the invention is low in melt temperature, and high in solid content and stripping force, and remains in a liquid state at normal temperature; meanwhile, the preparation method is mild in reaction condition and low in energy consumption; the waterborne polyurethane hot melt adhesive is applied to the field of adhesives.

Owner:SOUTH CHINA UNIV OF TECH

Environmentally-friendly weak alkaline low-temperature deburring softening solution, and preparation method and use method thereof

ActiveCN102808190ALower operating temperatureImprove softening effectNo productionCryogenic deflashing

The invention discloses a preparation method and a use method of environmentally-friendly weak alkaline low-temperature deburring softening solution. The environmentally-friendly weak alkaline low-temperature deburring softening solution comprises the components with weight percentages as follows: 10 to 35 percent of tetrahydrofuran, 10 to 35 percent of propylene glycol, 1 to 5 percent of alkyl phenol polyoxyethylene ether, 5 to 20 percent of ethanolamine, 1 to 10 percent of N-methyldiethanolamine and the balance of water. The environment-friendly weak alkaline low-temperature deburring softening solution provided by the invention has the advantages of low use temperature, good softening and flashing effect, no production of poisons and harmful gases, excellent deoiling effect, safety, environmental friendliness, adoption of formula substances completely satisfying of an environmentally-friendly requirement, product stability, simple process, energy conservation and high efficiency, and is convenient to use.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

Polyurethane heat reflection ship hull coating

InactiveCN101550314ASolve the problem of external corrosion protectionWith heat reflection functionAnti-corrosive paintsPolyurea/polyurethane coatingsAdhesion forceAcrylic resin

The invention discloses polyurethane heat reflection ship hull coating, and relates to double-component acrylic polyurethane weathering heat reflection ship hull coating which can reach the film thickness requirements by generally applying one to two topcoat in coating. The film forming matters of the polyurethane heat reflection ship hull coating includes aliphatic polyurethane resin and acrylic resin, which are simultaneously added with weathering pigments and fillers and heat reflection materials so that various mechanical physical performances and weathering performances of the coating are greatly improved. The coating is double-component acrylic polyurethane corrosion protective coating, including acrylic resin, polyurethane resin, plasticizers, heat reflection material, pigments and fillers, imported dispersants, anti-sedimentation agents, and the like; and the weight ratio of A component and B component is 8:1. The coating has very excellent aging resistant performance, hard coating film, high glossiness and strong adhesion force, can achieve good external corrosion prevention effect, and is widely used in steel structures, pipelines, storage tanks, tank cars and equipment in the industries such as the chemical engineering, the machinery, the ship, the metallurgy and the like as the surface corrosion prevention coating.

Owner:上海海悦涂料有限公司

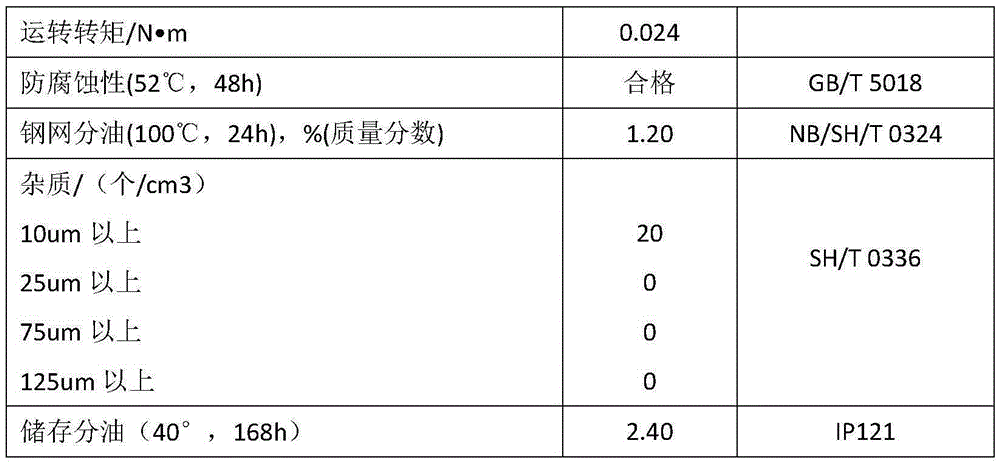

Composition of special ultralow-temperature grease for casters and preparation method of special ultralow-temperature grease

InactiveCN105316097AReduce the use temperatureExtended service lifeLubricant compositionWork performanceOil separation

The invention relates to a special ultralow-temperature grease for casters and a preparation method of the special ultralow-temperature grease. The special ultralow-temperature grease comprises the raw materials of 85-90 percent of base oil and 10-15 percent of a thickening agent by mass, and 1 percent of a grease structural improver, 0.5 percent of an anti-oxidant and 0.5 percent of a rust inhibitor are added into the raw materials. The grease prepared from naphthenic base oil has an ultralow application temperature and a relatively long service life, and tests on racks of caster manufacturing plants show that the grease has excellent low-temperature start performance, low-temperature working performance and oil separation resistance and favorable rustproof performance. The special ultralow-temperature grease for the casters has the ultralow application temperature (50 DEG C below zero), the relatively long service life and the relatively low production cost and can completely meet the application requirements of the casters in severe cold regions.

Owner:CHINA PETROLEUM & CHEM CORP

Method for manufacturing high-strength and energy-saving xonotlite heat-insulation product

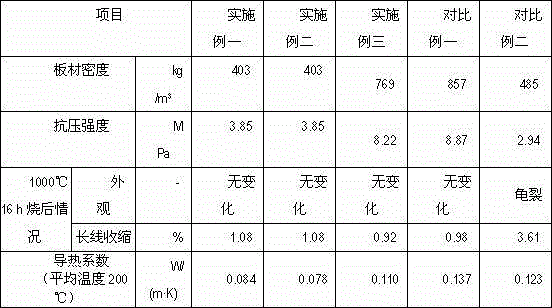

InactiveCN103951363AHigh strengthLow densityWater-setting substance layered productHigh densityVolumetric Mass Density

The invention discloses a method for manufacturing a high-strength and energy-saving xonotlite heat-insulation product. On the basis of a high-density plate production process based on a static method, xonotlite slurry synthesized by using a dynamic hydrothermal method is added to reduce the density of a plate so as to obtain the high-strength and energy-saving xonotlite heat-insulation product with moderate density and relatively high strength. Meanwhile, a layer of aluminum foil is coated to ensure that the product has water resistance, the heat insulation effect of materials is enhanced, and the condition of the product is optimized.

Owner:莱州明发隔热材料有限公司

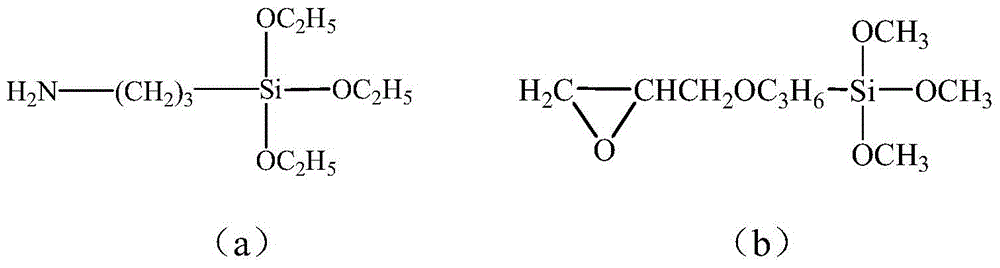

Organosilicone modified waterborne polyurethane emulsion, and preparation method and application thereof

InactiveCN106674472AImprove temperature resistanceReduce the use temperaturePolyureas/polyurethane adhesivesAdhesiveTemperature resistance

The invention belongs to the field of materials, and concretely relates to an organosilicone modified waterborne polyurethane emulsion, which is prepared from the following components in parts by mass: 25 to 30 parts of polyhydric alcohols, 6 to 12 parts of diisocyanate, 1 to 4 parts of alcohol chain extender, 0.01 to 0.05 part of organic tin catalyst, 1 to 2 parts of hydrophilic chain extender, 0.05 to 0.1 part of organosilicone, and 55 to 60 parts of deionized water. The organosilicone modified waterborne polyurethane emulsion provided by the invention well solves the contradiction problems of low activation temperature and high temperature resistance, has significance on realistic research and practical application, and can be applied in the fields requiring low operating temperature, high bonding strength and especially high temperature resistance, such as the industries of 3D (Three-dimensional) furniture paint-free blister adhesive and fabric composite.

Owner:重庆中科力泰高分子材料有限公司

Catalyst applied to hydrogen chloride oxidization to prepare chlorine as well as preparation method and application thereof

ActiveCN108097232AExtended service lifeHigh activityMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementFluidized bed

The invention provides a catalyst applied to hydrogen chloride oxidization to prepare chlorine as well as a preparation method and application thereof. The catalyst applied to hydrogen chloride oxidization to prepare chlorine disclosed by the invention is prepared from a catalyst precursor A, a catalyst precursor B and an inorganic membrane, wherein the catalyst precursor A is coated by the inorganic membrane, and the catalyst precursor B and the catalyst precursor A are separated by the inorganic membrane; the catalyst precursor A is prepared from a carrier, a copper element, an alkali metalelement and a rare earth element, and the copper element, the alkali metal element and the rare earth element are loaded to the carrier; the catalyst precursor B is prepared from a carrier, an alkalimetal element and a rare earth element, the alkali metal element and the rare earth element are loaded to the carrier, and the catalyst precursor B does not contain the copper element. The catalyst disclosed by the invention is especially suitable for being applied to catalyze hydrogen chloride to be oxidized to prepare chlorine in a fluidized bed reactor and has the characteristics of low copperloss, high activity, reactor corrosion resistance and the like.

Owner:WANHUA CHEM GRP CO LTD

Method for preparing phenol from benzene through one-step process

InactiveCN102463124AHigh activityHigh selectivityOrganic chemistryPhysical/chemical process catalystsWater bathsFiltration

The invention relates to a method for preparing phenol from benzene through a one-step process. According to the method, a catalyst treats coal-based active carbon as a carrier and a ferric salt as an active component, and the carrier of the catalyst is processed according to the following steps: 1, adding 100g of the coal-based active carbon washed by water to a flask, adding 250ml of a nitric acid solution with the concentration of 2-12mol / L, connecting a condenser tube to the flask, carrying out reflux processing for 10h in a 25-90DEG C water bath, absorbing a tail gas with an NaOH or Na2CO3 solution, fully washing the coal-based active carbon with tap water until the pH value is unchanged, leaching the coal-based active carbon with distilled water three times, carrying out pumping filtration, and drying the coal-based active carbon in a 110DEG C constant temperature drying box; and 2, dipping the coal-based active carbon in 20-50mL of an aqueous Fe2(SO4)3 solution with the concentration of 0.04-0.20mol / L, laying them aside for 0.5-24h at room temperature, carrying out pumping filtration, and drying the coal-based active carbon in the 110DEG C constant temperature drying box. The catalyst has the advantages of high activity, high selectivity, high stability, production cost reduction, and product quality improvement.

Owner:PETROCHINA CO LTD +1

Ammonia synthetic catalyst and method for making the same

InactiveCN1481933AKeep the use temperatureReduce the use temperatureMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionAlkaline earth metalElectronegativity

The present invention relates to catalyst, and is especially new ammonia synthesizing catalyst, which has noble metal Ru as active component, fluoride of alkali metal or alkali earth metal as assistant and magnesia as carrier and has high activity, and its preparation process. The catalyst has Ru / MgO ratio of 3-8 % and molar Ru / MFx of 0.5-8, the solvent adopted is water or organic solvent capable of dissolving RuCl3.nH2O or carbonyl ruthenium. The catalyst is prepared via soaking process or mechanically mixing, calcination and soaking process. It is used mainly in catalyzing the synthesis of ammonia with nitrogen and hydrogen. The greater electronegativity of F in fluoride may accelerate the hydrogenation of N to synthesize ammonia, and the catalyst has activity 1-3 times that of catalyst with oxide rather than fluoride and has the lower use temperature and pressure of ammonia synthesizing Ru catalyst maintained.

Owner:XIAMEN UNIV

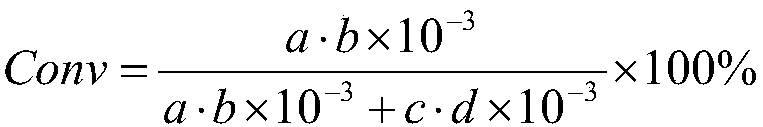

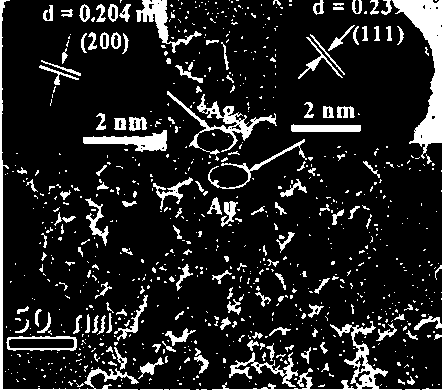

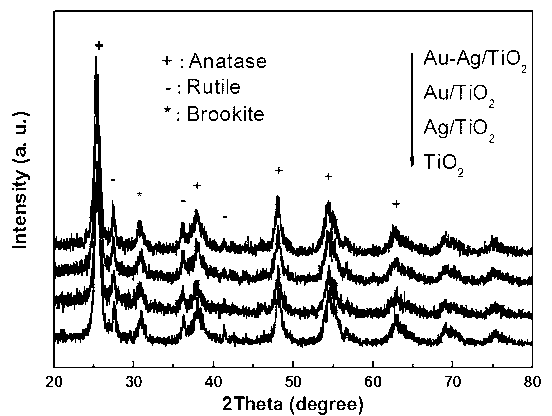

Supported bimetallic catalyst for CO catalytic oxidation through visible light at room temperature

ActiveCN102935364ATake advantage ofReduce the use temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSingle supportActive component

The invention discloses a supported bimetallic catalyst for CO catalytic oxidation through visible light at the room temperature and a preparation method and applications thereof. Au and Ag nanometer particles absorbing visible light are used as active components to be supported on TiO2 carriers to prepare the supported bimetallic catalyst. The supported bimetallic catalyst is prepared through two steps: preparing intermediates containing Ag, and preparing the supported bimetallic catalyst containing Au and Ag. Afterwards, visible light is led in a reaction system to improve photo-catalysis performances of the catalyst for CO catalytic oxidation. The catalyst can be used for removing CO at the room temperature. Compared with a single supported Au catalyst, the promotion effect of visible light on CO catalytic oxidation by the Au and Ag bimetallic catalyst is improved apparently (that is, the utilization efficiency of the visible light is improved), and the catalyst preparation method is simple and easy to implement, low in cost and is good for being popularized and used.

Owner:FUZHOU UNIV

Phosphatide based metal processing emulsion

The invention relates to a phosphatide based metal processing emulsion, which comprises the following components in percentage by volume: 10 to 50 percent of modified soybean phosphatide, 3 to 16 percent of tween-80, 0.3 to 5 percent of absolute ethyl alcohol, 0.5 to 6 percent of phosphating solution antirust agent, 0.5 to 8 percent of sym-triazine preservative bactericide, 0.5 to 7 percent of organic silicon antifoaming agent, 1.5 to 8 percent of 20- 45% (w / v) NaOH aqueous solution, and the balance of water. During preparation, the components are uniformly mixed, and then the mixture is homogenized to prepare the emulsion. The phosphatide based metal processing emulsion has a reasonable formula, and the product has excellent lubricating property, rust-preventing characteristic, cooling characteristic, cleaning characteristic, bactericidal characteristic and high stability, can meet the uses and various processing requirements of machine tools, grinding machines, turning machines and the like, also has the advantages of low volatility, non-toxicity, high biodegradability, reutilization and the like, and can be used as a universal metal processing cutting solution to replace mineral oil based metal processing fluid; besides, the performance of the phosphatide based metal processing emulsion is superior to that of common mineral oil based processing fluid.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

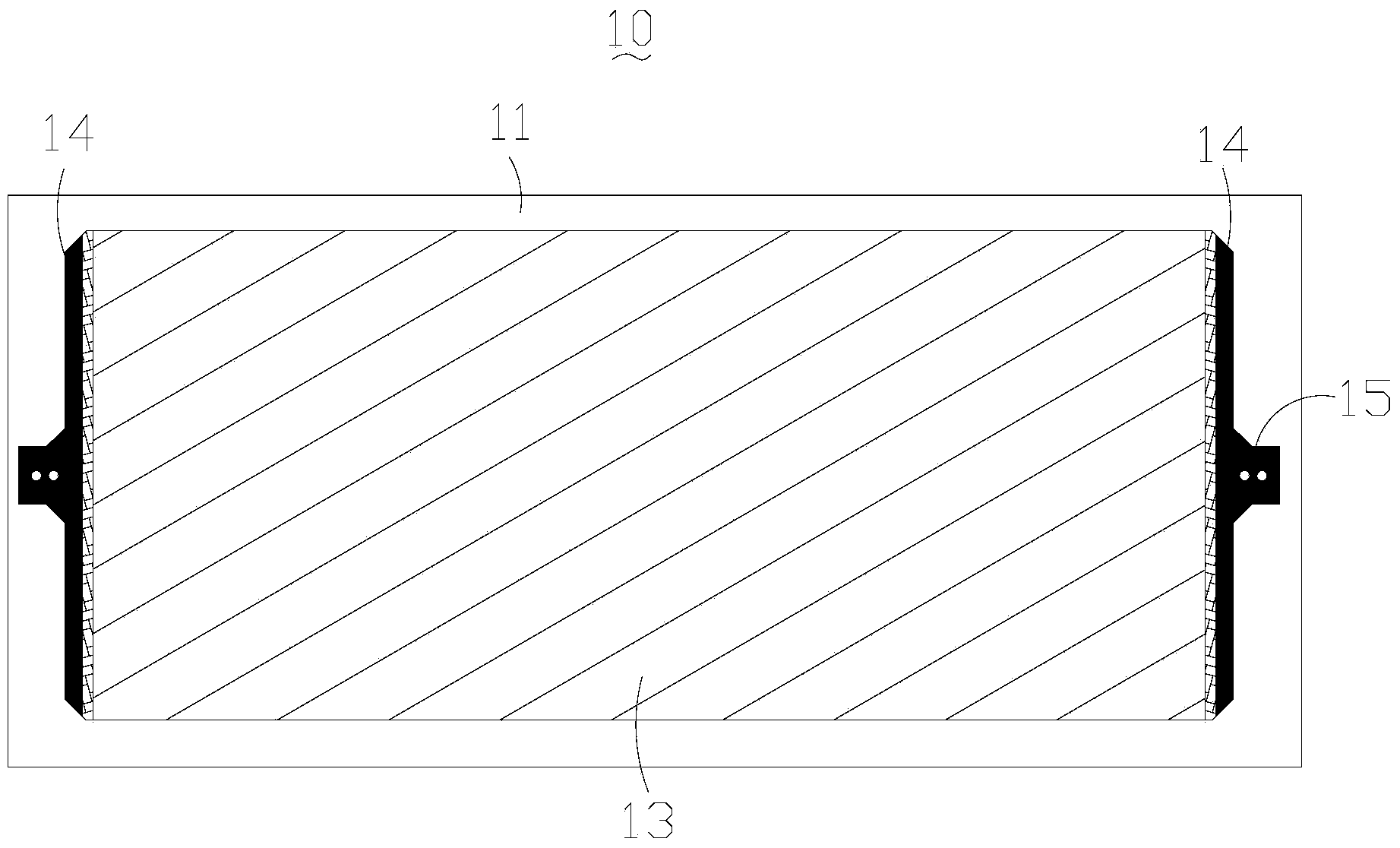

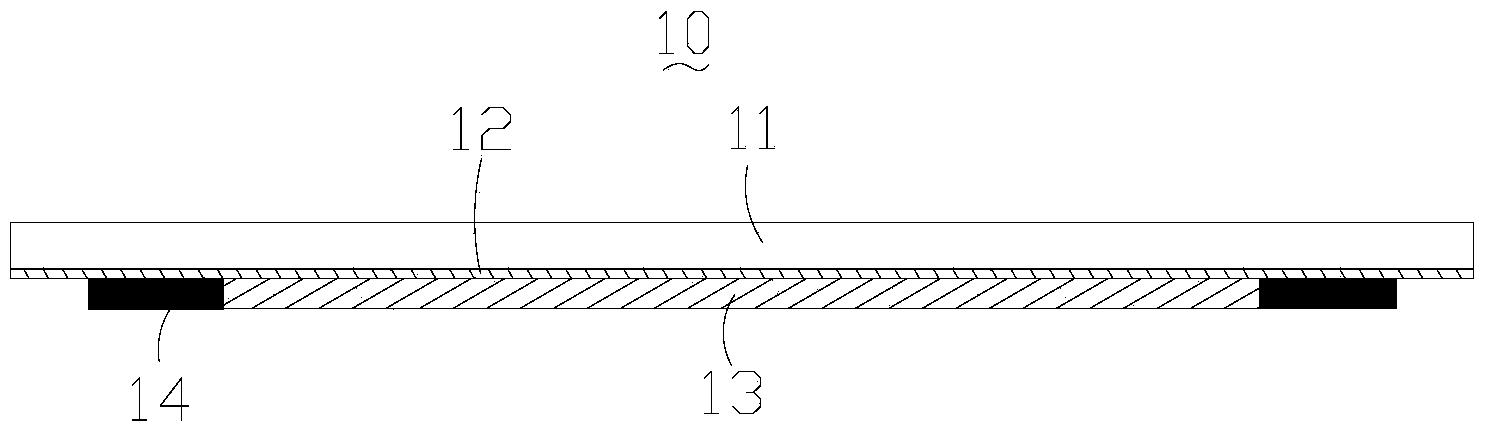

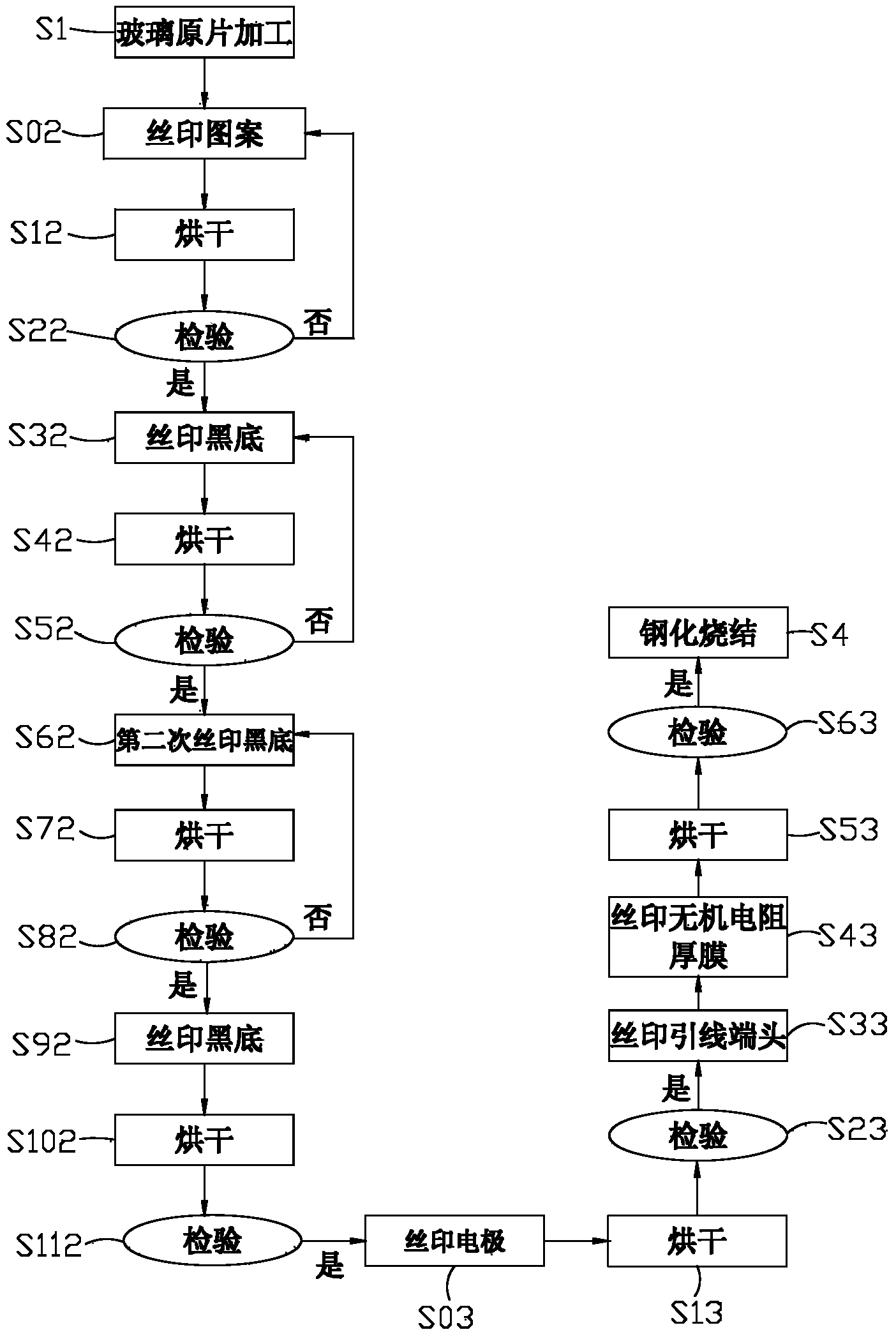

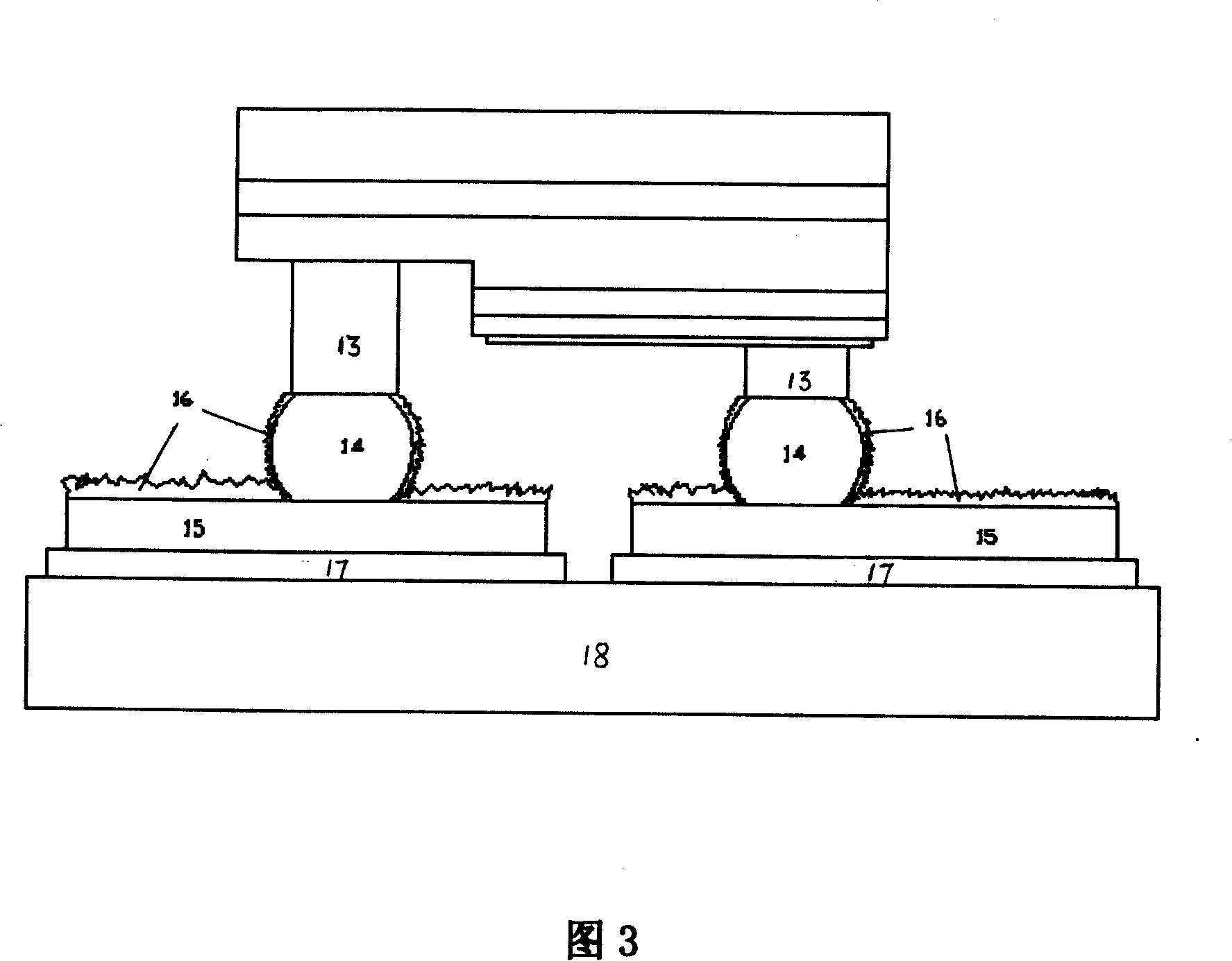

Hot wall glass coated with inorganic resistance thick film and manufacturing method thereof and heating module

ActiveCN103491660ASolve the problem of easy explosionLower unit power densityLighting and heating apparatusElectric heating systemElectrical resistance and conductanceStrontium carbonate

The invention provides hot wall glass coated with an inorganic resistance thick film. The hot wall glass comprises a glass substrate, an inorganic decorative enamel layer sintered on the glass substrate at high temperature, a face-shaped inorganic resistance thick film coating the inorganic decorative enamel layer, an electrode enabling the inorganic resistance thick film to be connected to a circuit and a lead end connected with a supply lead. The lead end is electrically connected with the electrode, the electrode is electrically connected with the inorganic resistance thick film, and the inorganic resistance thick film is sintered on the glass substrate at high temperature. The inorganic resistance thick film comprises graphite powder, bismuth oxide, boric oxide, silica, antimonous oxide, zinc oxide, strontium carbonate and the like. The problem that according to a glass heating product in the prior art, oxidation color fading, falling, peculiar smell and cracks caused by local overheating of the glass decorative enamel layer, aging separation of an adhesive layer between the glass and a heating body, and high product cost are solved. The invention further provides a method for manufacturing the hot wall glass and a heating module provided with the hot wall glass.

Owner:简伟雄 +1

Epoxy-modified sulfonic waterborne polyurethane emulsion and preparing method and application thereof

InactiveCN105131243AImprove hydrolysis resistanceImprove performancePolyurea/polyurethane coatingsEpoxyPolyurethane adhesive

The invention discloses an epoxy-modified sulfonic waterborne polyurethane emulsion and a preparing method and application thereof. The sulfonic waterborne polyurethane emulsion is prepared from, by weight, 70-80 parts of polyhydric alcohol, 10-15 parts of diisocyanate, 1-2 parts of small molecular alcohol chain extender, 0.01-0.05 part of organobismuth and / or organotin catalyst, 2.5-3.5 parts of hydrophilic chain extender and 5-15 parts of epoxy resin. The formula is simple, blending stability is high, the hydrolysis resistance of a waterborne polyurethane adhesive is improved, and the epoxy-modified sulfonic waterborne polyurethane emulsion can be used for preparing 3D furniture paint-free blister adhesives and has the advantages of low use temperature, high adhesion strength, high temperature resistance and the like.

Owner:重庆中科力泰高分子材料有限公司

Method for enhancing upside-down mounting welding core plate brightness

InactiveCN101140963AReduce absorptionReduce the use temperatureSolid-state devicesSemiconductor/solid-state device manufacturingGold ballSurface oxidation

The invention relates to a method for lighting up the backbonded chip, which is characterized in plating the metal of high reflectivity onto the original metal circuit and the light absorbed golden ball. The method is: first, oxidizing the silicon substrate with heat reacting furnace to generate a silicon dioxide layer, photoetching the pattern by photo exposure machine and etching the needless silicon dioxide with hydrofluoric acid buffer solution of 1% to 3%, vapor depositing a layer of high reflectivity metal onto the silicon dioxide layer by thermal coater and etching two adjacent positive and negative electrodes which covers 40% to 95% surface areas of the silicon substrate ferric nitrate mixed solution; second, balling the golden balls on the surface of both positive and negative electrodes by balling machine, plating a layer of high reflectivity metal respectively on two positive and negative electrodes and the golden balls by thermal coater, etching the high reflectivity metal layer with hydrofluoric acid buffer solution and the left metal layer is adhered to two positive and negative electrodes and the golden balls; finally, converting the chip by wire bonder to make its electrodes aligned with the golden balls, and compaginating the electrodes with golden balls by heating and ultra audible sound. The invention has the advantage of increasing the optical efficiency of 40% more than that of traditional backbonded chip.

Owner:上海蓝宝光电材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com