Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1520 results about "Sodium Acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-swellable copolymers and articles and coatings made therefrom

Owner:TYCO HEALTHCARE GRP LP

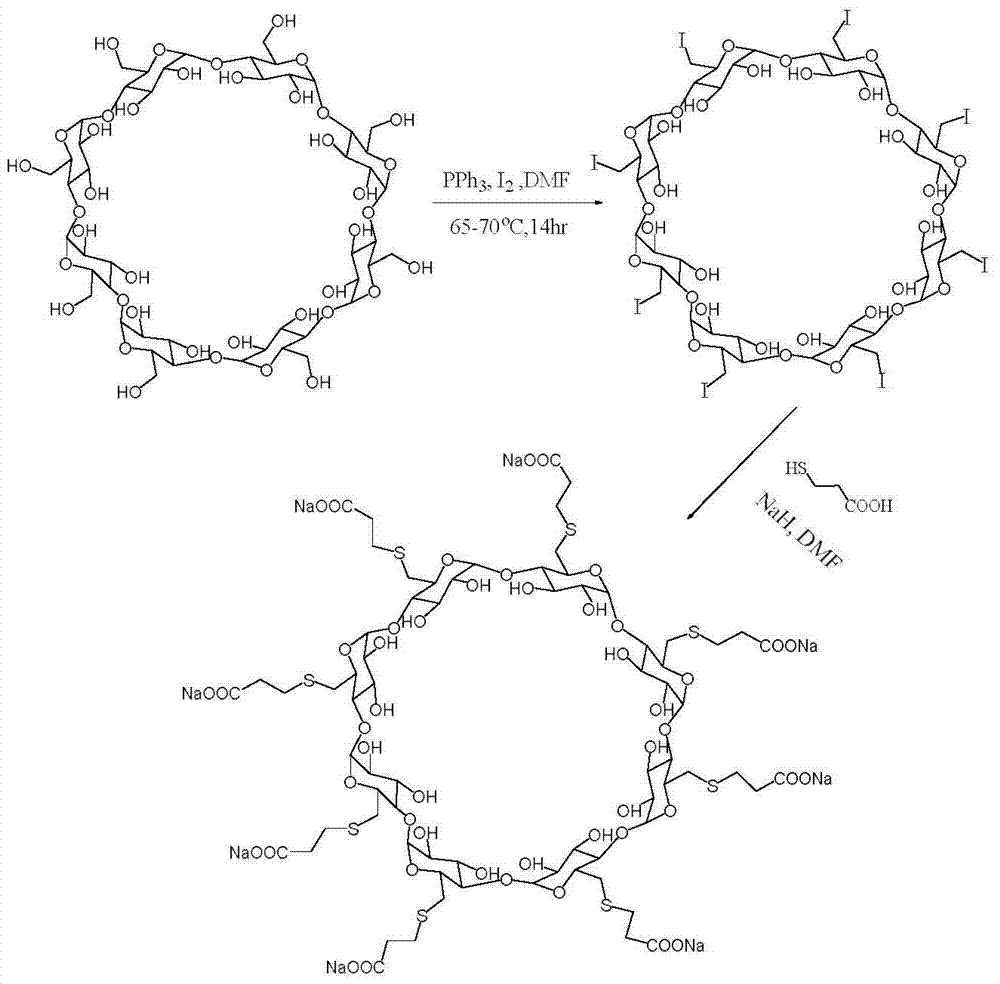

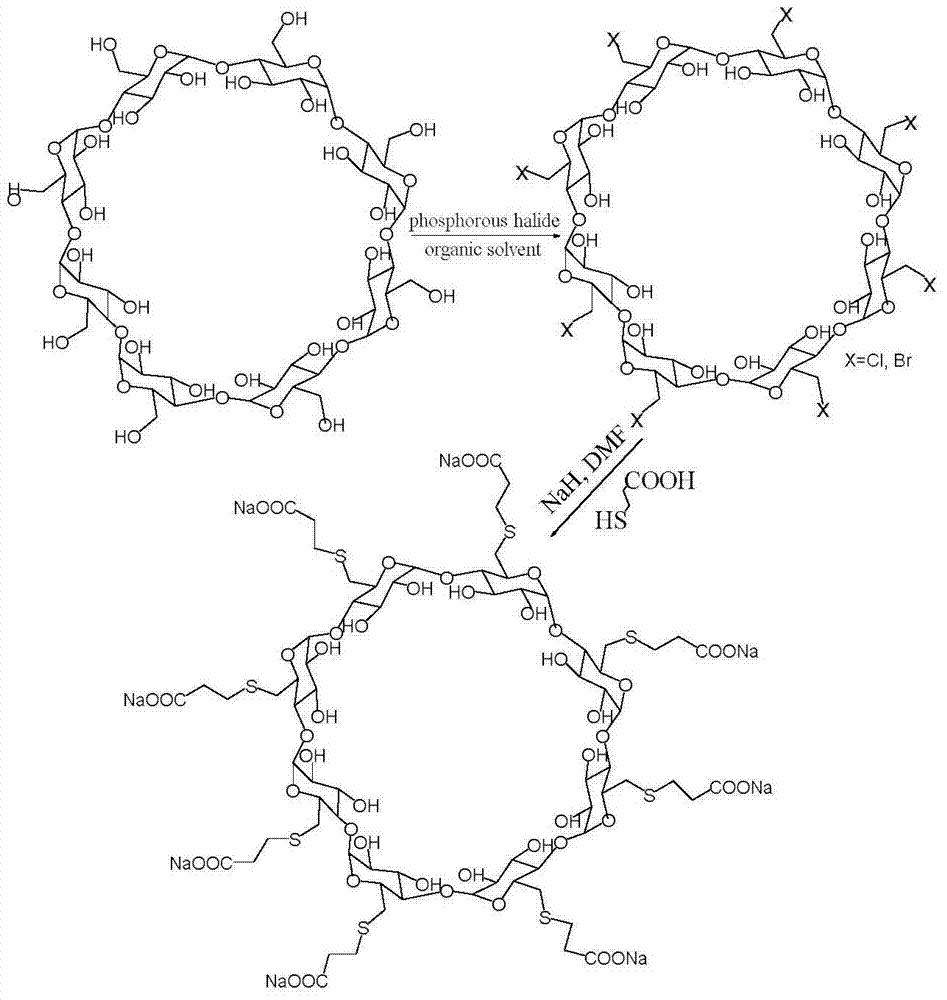

Preparation method for sugammadex sodium

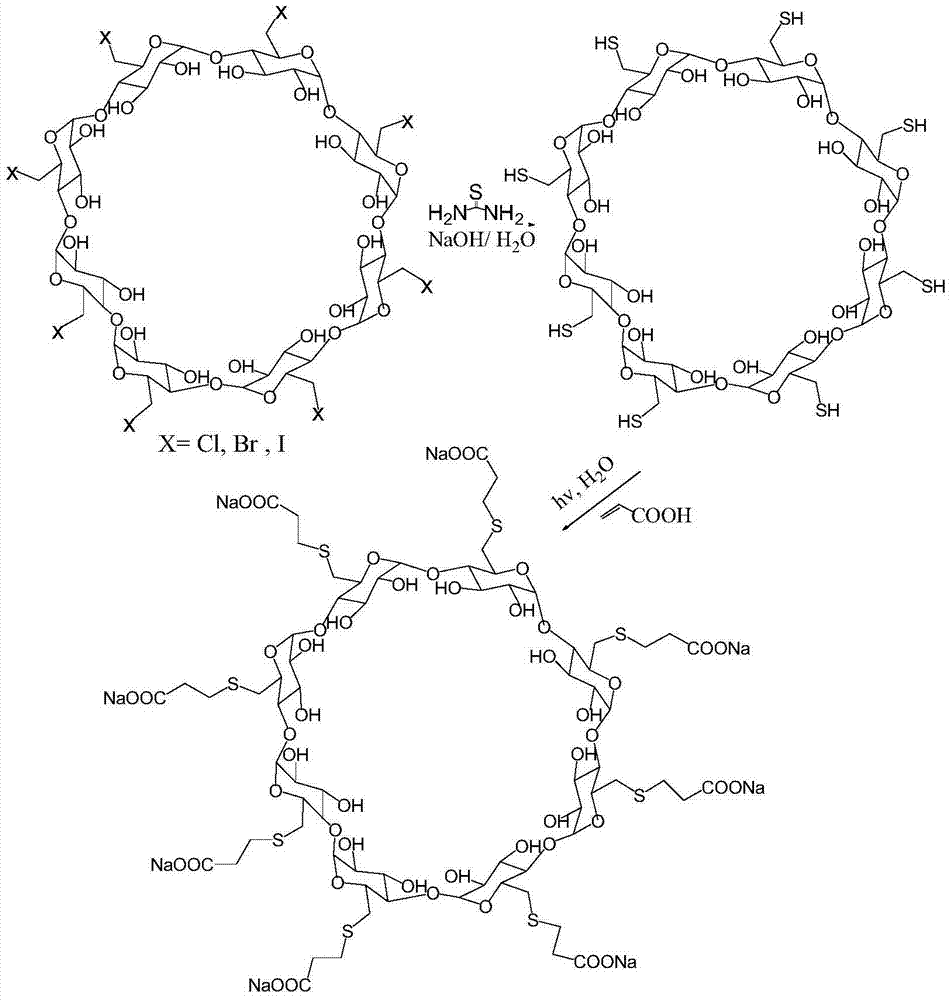

The invention relates to a preparation method for a muscle relaxing antagonistic agent sugammadex sodium. The preparation method comprises the following steps: preparing sulfydryl gamma-cyclodextrin by taking halogenated gamma-cyclodextrin and thiourea as reactants; then, initiating sulfydryl-alkene click reaction by illuminating or using an initiator on sulfydryl gamma-cyclodextrin with acrylic acid or acrylic esters or sodium acrylate so as to prepare high-purity sugammadex sodium in a water phase. According to the preparation method for the sugammadex sodium, the the operation environment is gentle, the yield is increased, and the purifying process for the final product sugammadex sodium is simpler.

Owner:SHANDONG BINZHOU ZHIYUAN BIO TECH CO LTD

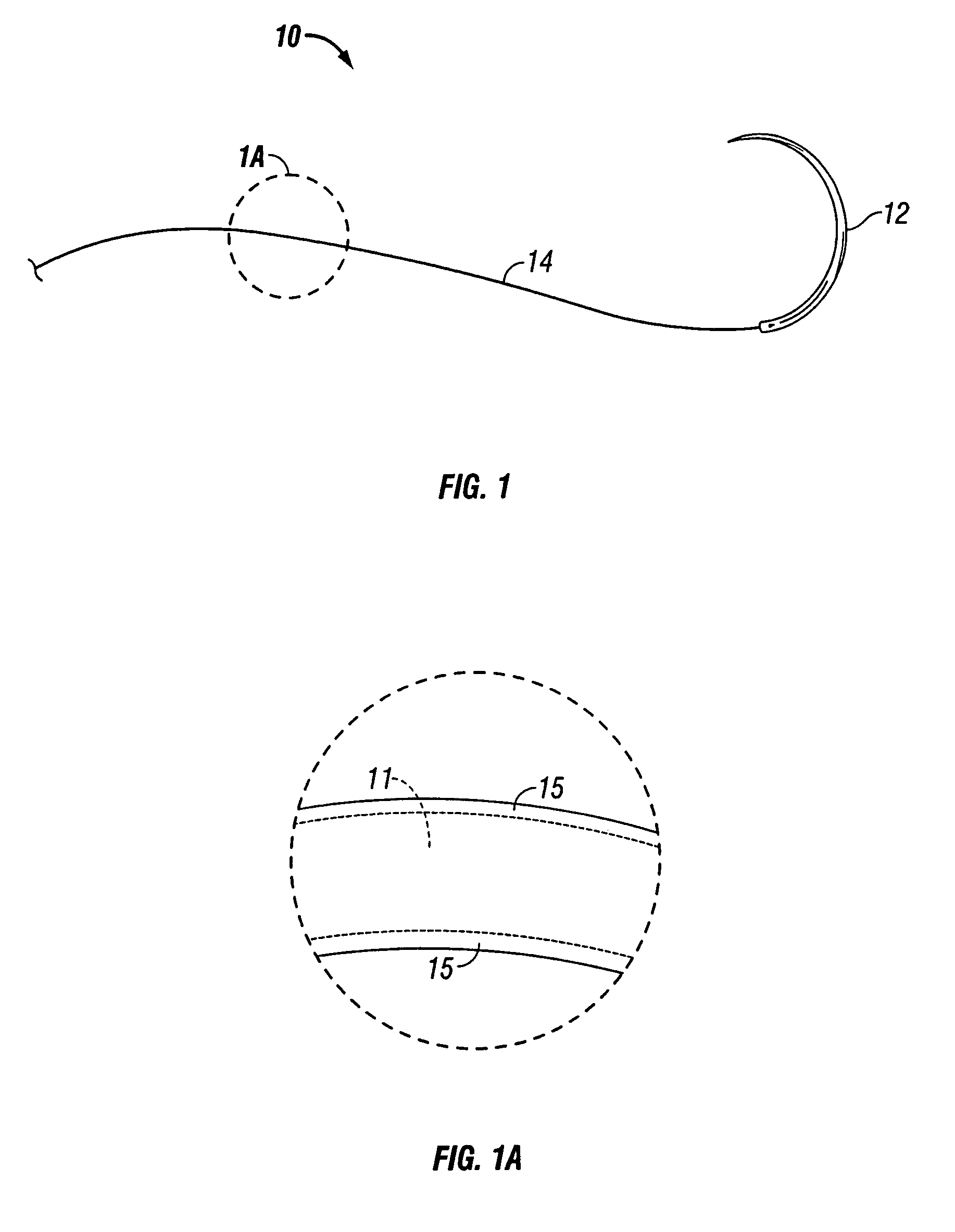

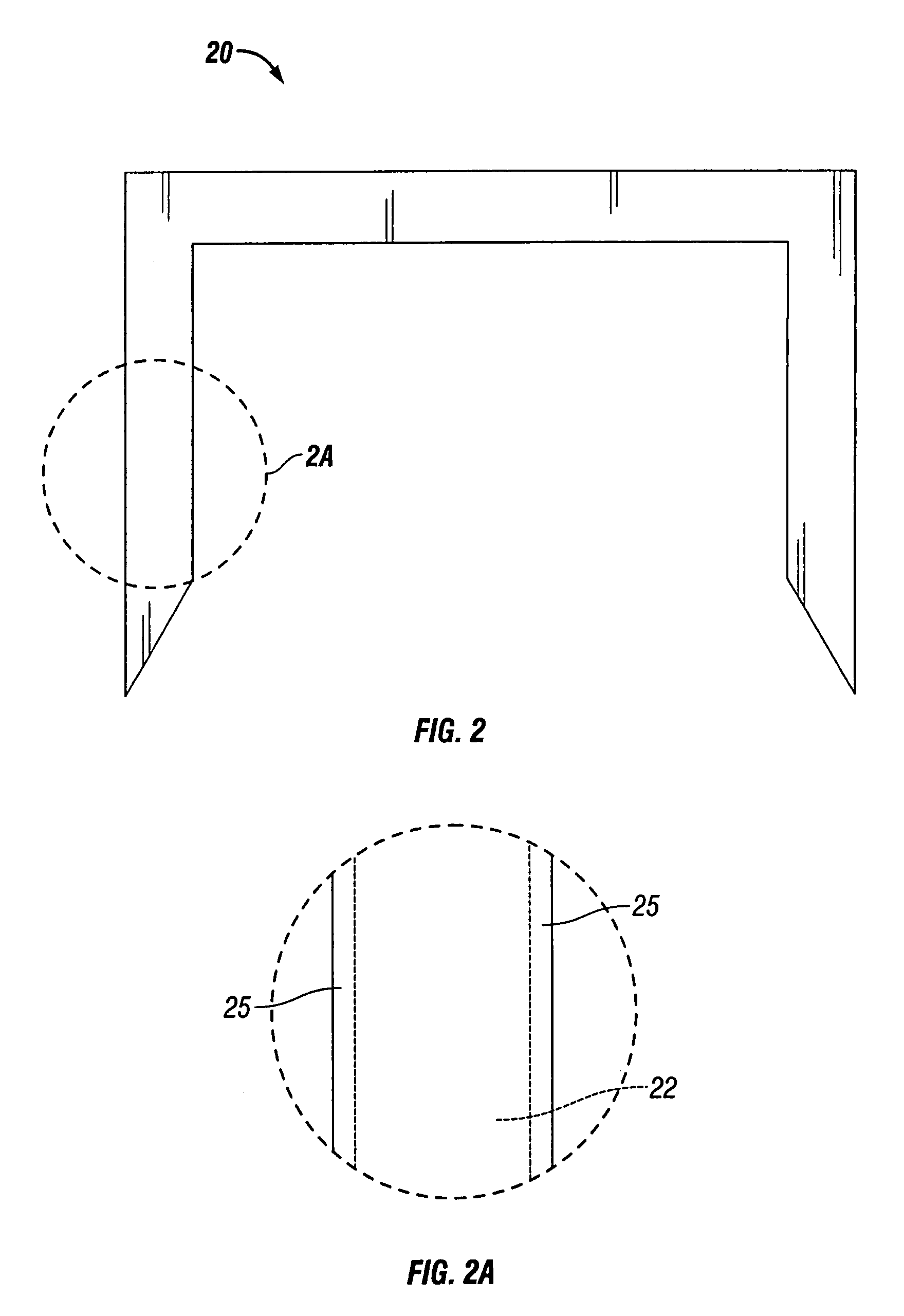

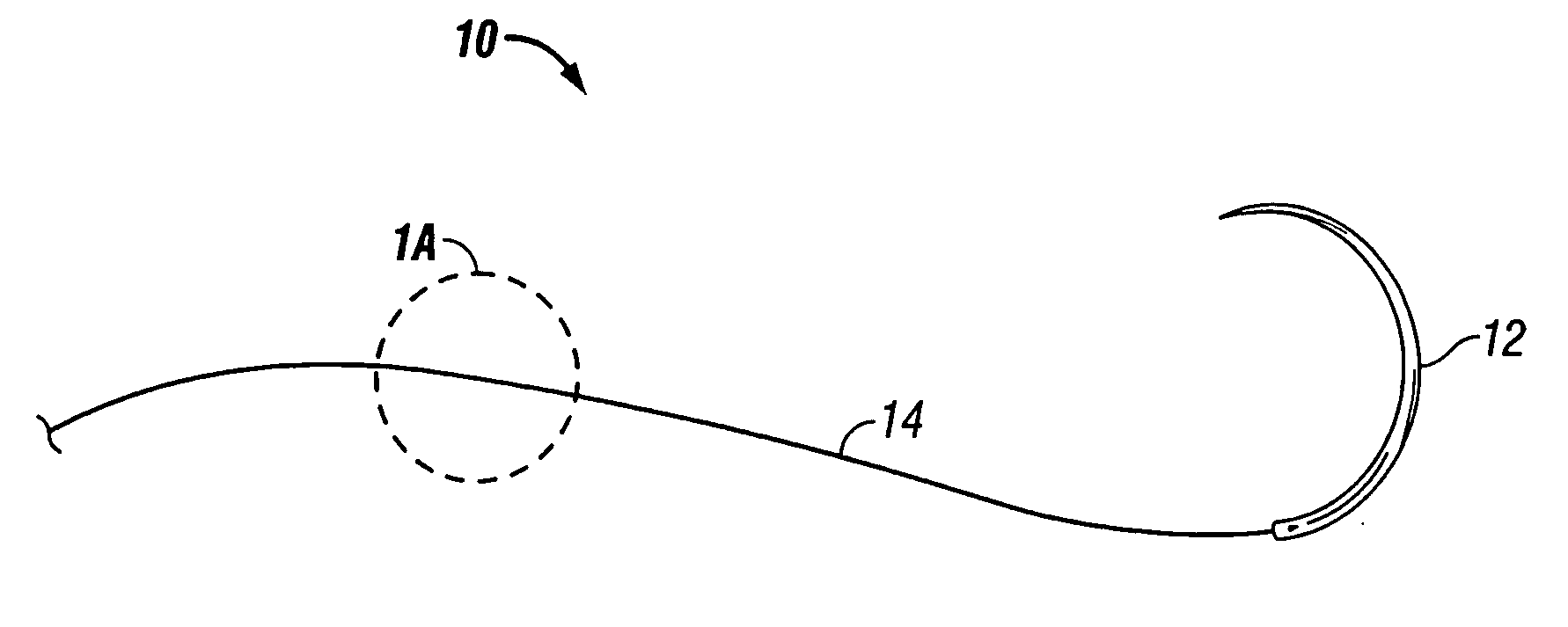

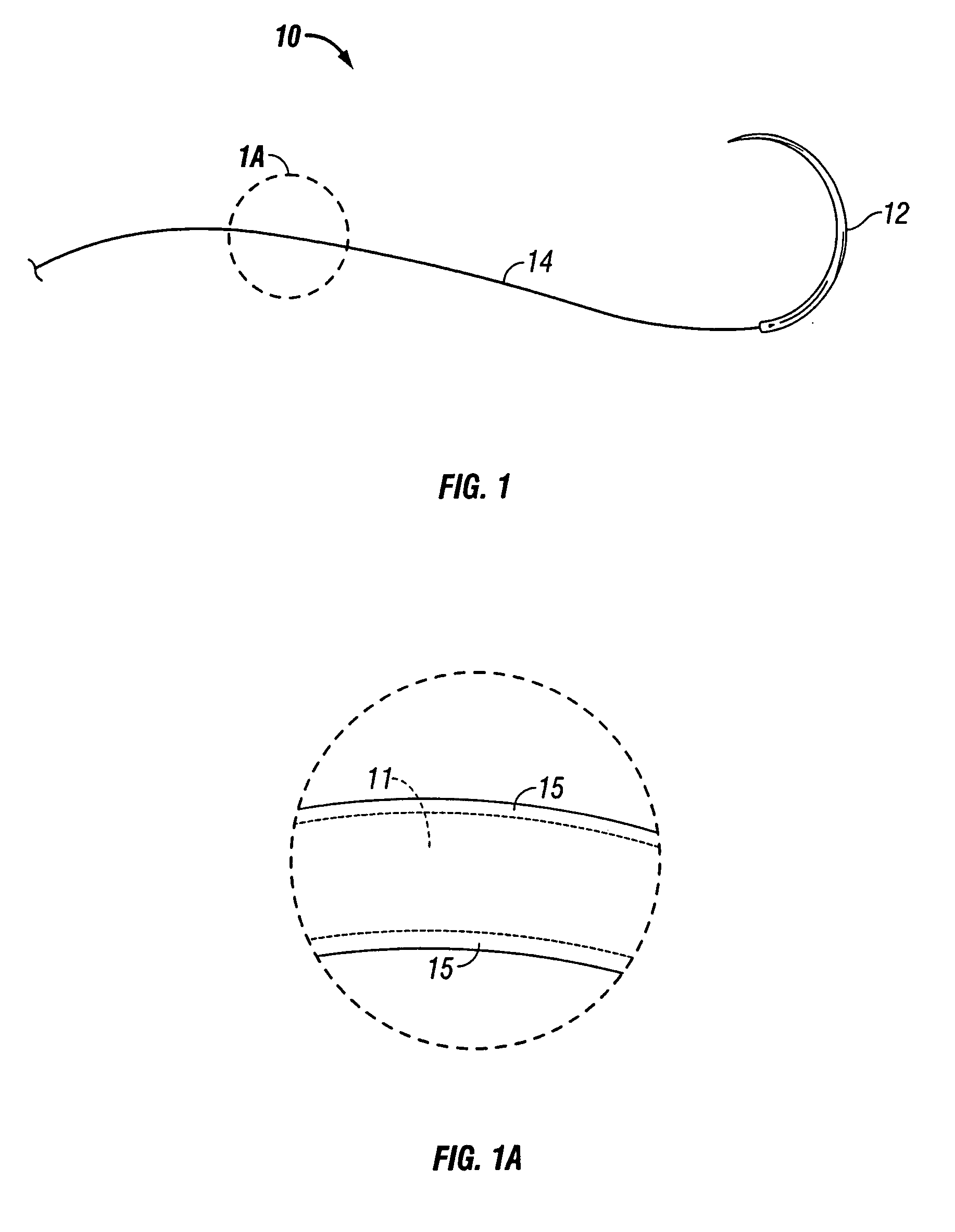

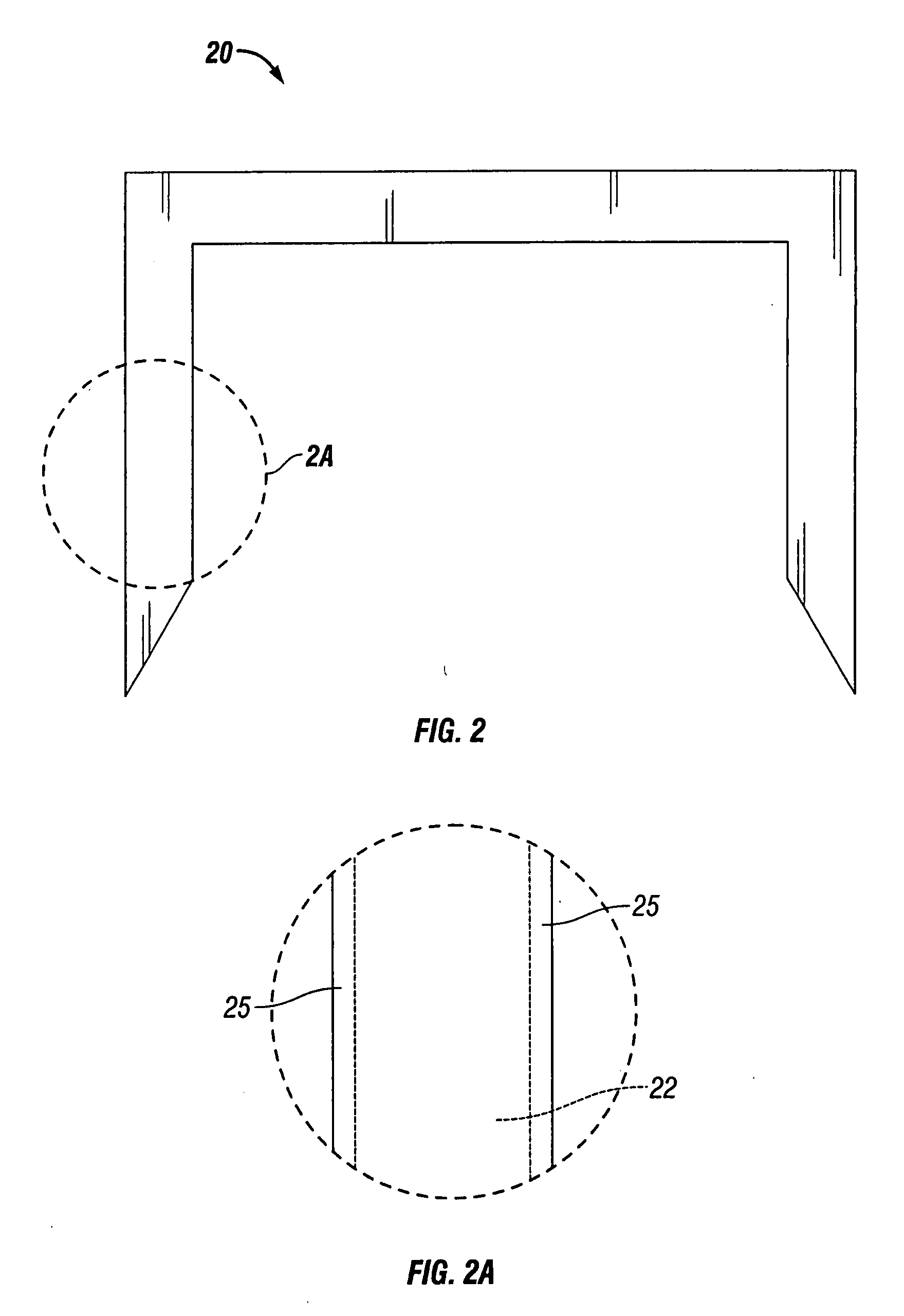

Water-Swellable Copolymers And Articles And Coatings Made Therefrom

The present disclosure relates to compositions comprising a copolymer that includes a first monomer and a second monomer that is different from the first monomer, wherein both the first and second monomer are selected from the group consisting of 3-sulfopropyl acrylate potassium salt, sodium acrylate, N-(tris(hydroxyl methyl)methyl)acrylamide, and 2-acrylamideo-2-methyl-1-propane sulfonic acid. The present disclosure further relates to methods for preparing the copolymer compositions and shaped articles comprising the copolymers.

Owner:TYCO HEALTHCARE GRP LP

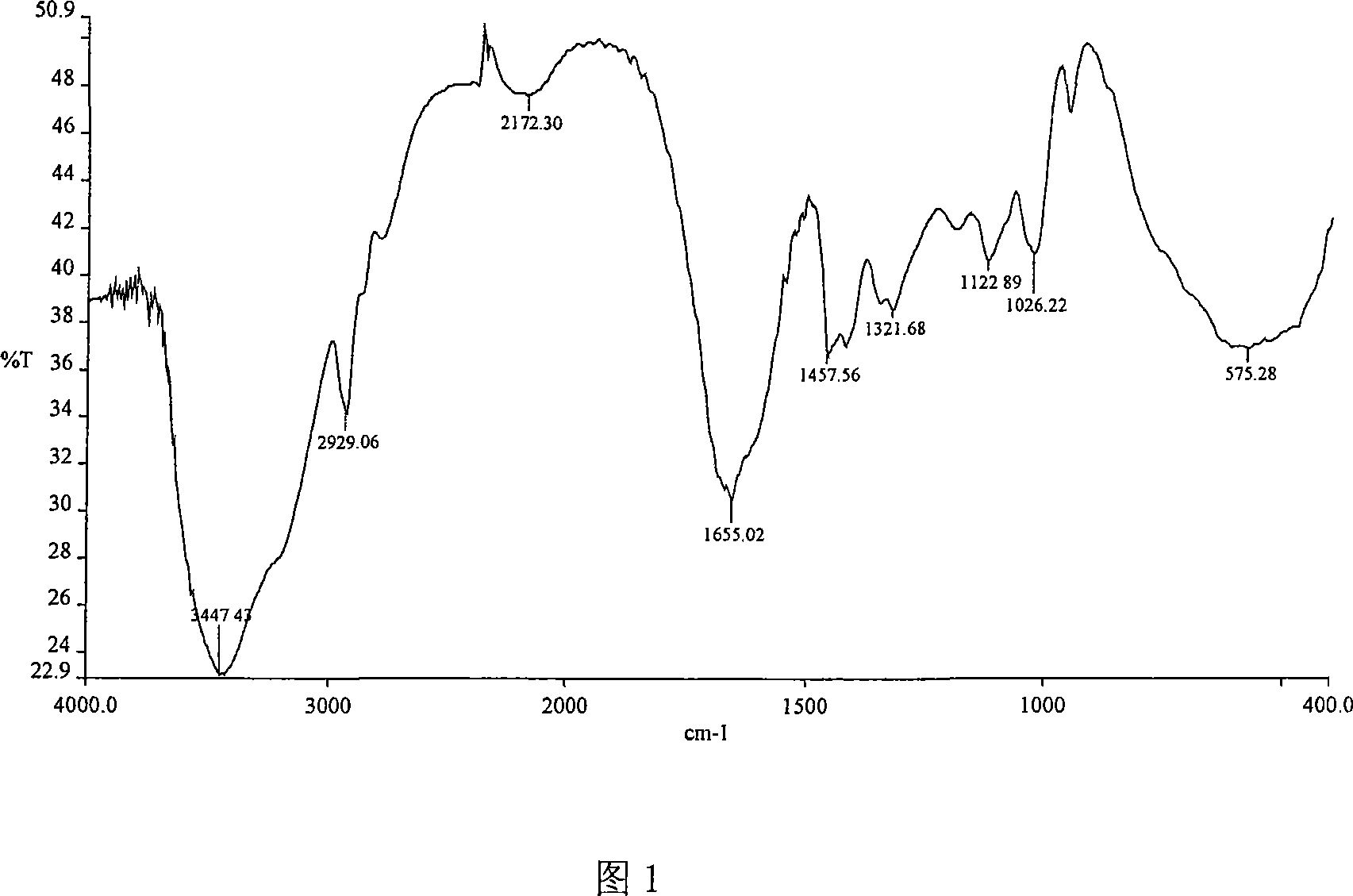

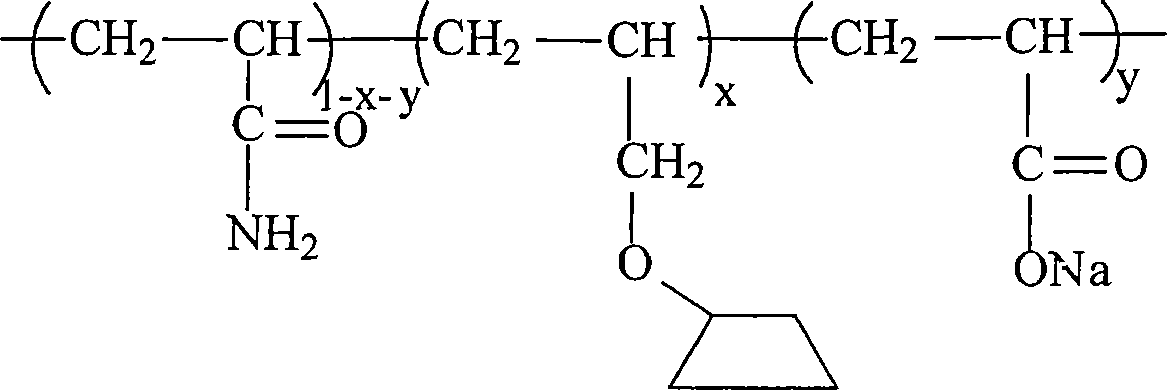

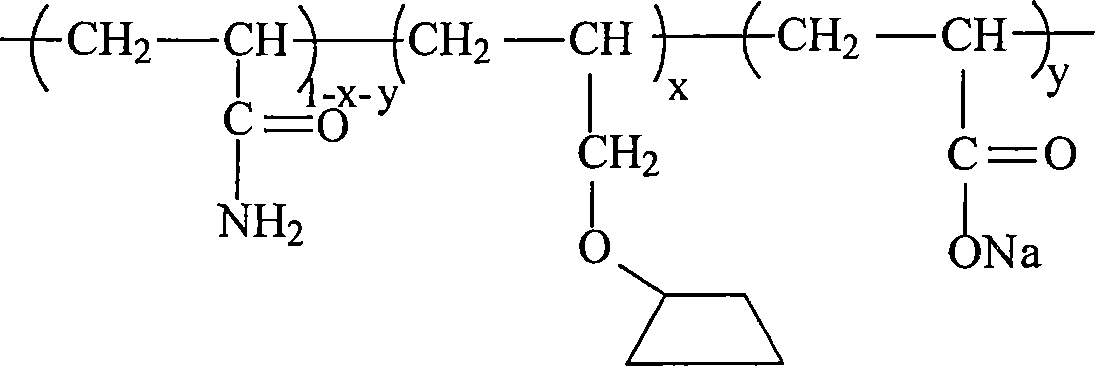

AM/NaAA/allylcyclodextrin polymer with inclusion function and synthetic method thereof

InactiveCN101104665AThe preparation method is simple and feasibleMild reaction conditionsWater/sewage treatmentDrilling compositionSynthesis methodsSolvent

The invention relates to an AM / NaAA / allyl cyclodextrin polymerization with a inclusion function and a synthesis method of the AM / NaAA / allyl cyclodextrin (CD) polymerization, which comprises three structure units of acrylamide, sodium acrylate and allyl cyclodextrin. The synthesis method is as follow: the allyl cyclodextrin is synthesized with DMSO and DMF as solvent, CD as raw material and under the temperature of 0 to 10 DEG C. Then AM is put into the allyl-beta-cyclodextrin water solution, then initiator is added to prepare AM / allyl-beta-cyclodextrin binary copolymer under the conditions that monomer concentration is 10 to 20 percent, initiation system concentration is 40 to 80 mg / l, the temperature is 30 to 50 DEG C, and the time is for 1 to 8 hours. NaOH solution is put into the binary copolymer to hydrolyze, then the AM / NaAA / allyl cyclodextrin polymerization is obtained. The synthesis method of the polymer is processed under the mild condition with simple operation, the product is easy to be purified and separated. The AM / NaAA / allyl cyclodextrin polymerization can be used in the fields such as petroleum exploitation, waste water treatment, chemistry and medicine.

Owner:SOUTHWEST PETROLEUM UNIV

Method of dewatering thin stillage processing streams

ActiveUS7497955B2Improve agglomerationAbility to withstandWater treatment parameter controlWater treatment compoundsSodium methacrylateSodium salt

A method dewatering thin stillage process streams generated in the processing of grain to ethanol comprising adding to the process streams an effective flocculating amount of an anionic copolymer comprising acrylic acid sodium salt, methacrylic acid sodium salt or 2-acrylamido-2-methyl-1-propanesulfonic acid sodium salt to form a mixture of water and flocculated solids; and separating the water from the flocculated solids using a dewatering device.

Owner:ECOLAB USA INC

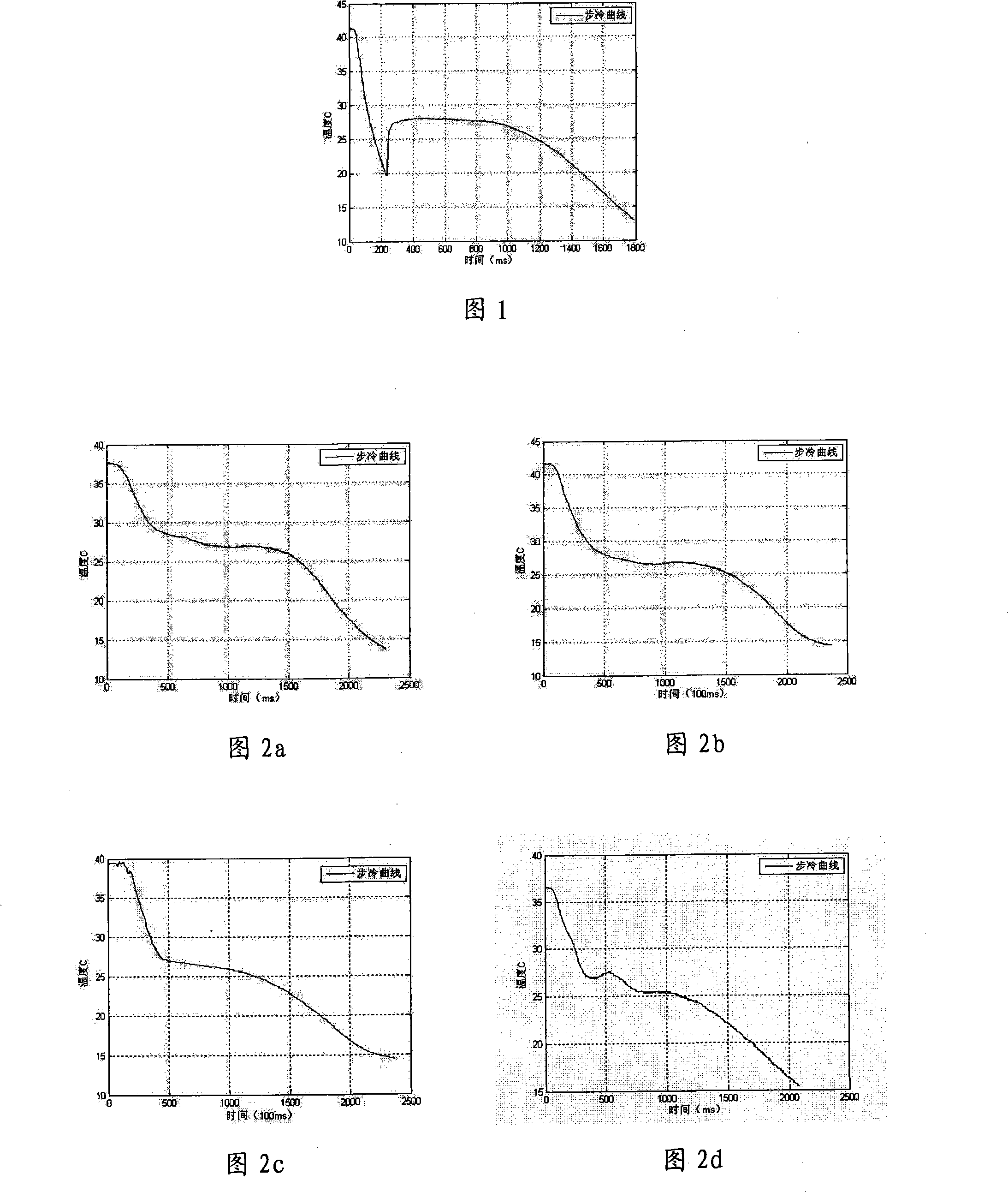

Method for preparing inorganic hydrous salt phase transition energy-storing material

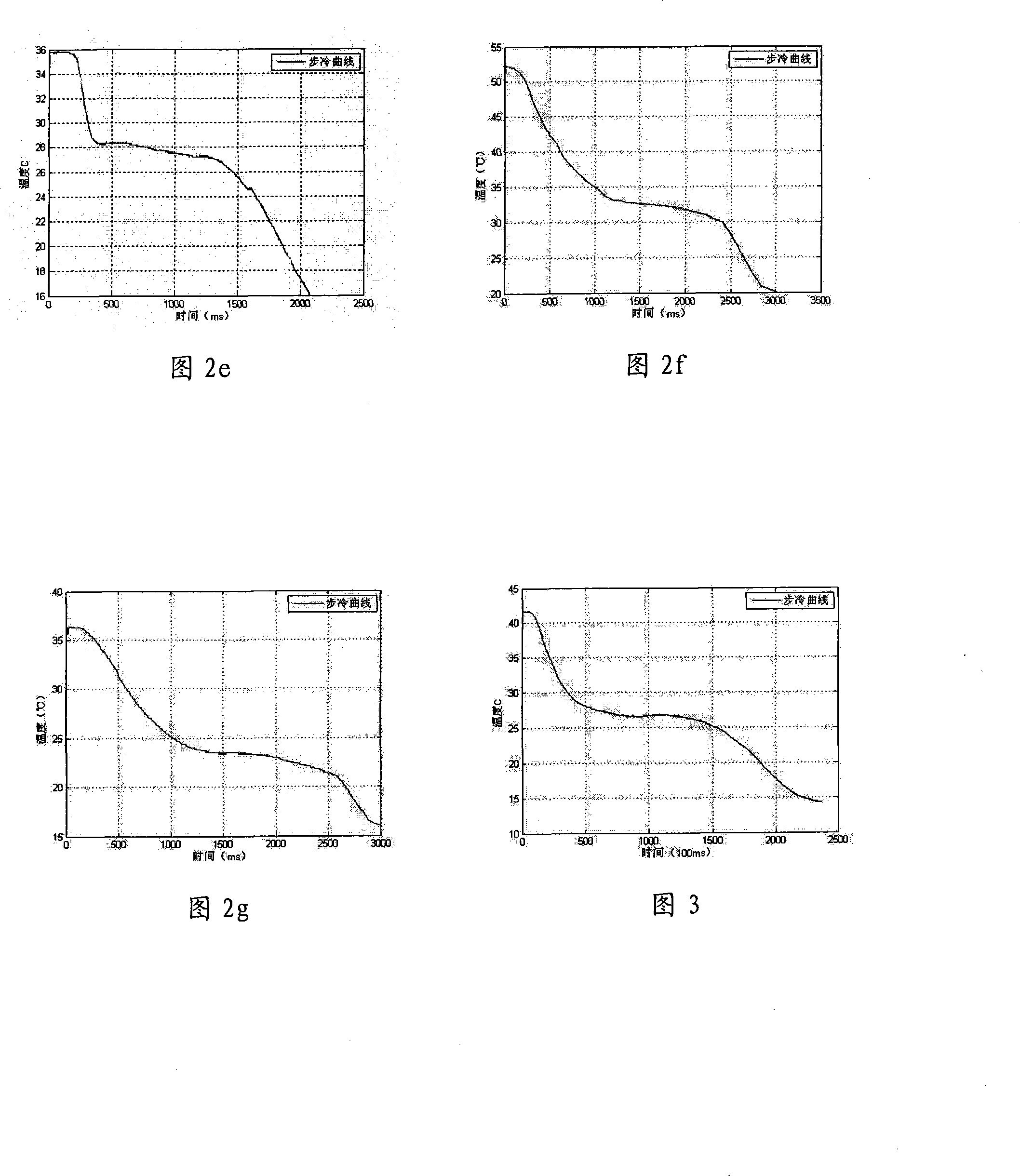

ActiveCN101235272APrevent overcoolingAvoid separabilityHeat-exchange elementsInorganic saltsPhase change

The invention discloses a preparation process of inorganic salt hydrate phase-change energy-storage material, comprises the following steps that adding 40-60g inorganic salt particles and 3-5g overcooling- resistance agent in 100g water, stirring and mixing to prepare hydrating inorganic salt solution, adding 5-10g poly-sodium acrylate in the hydrating inorganic salt solution, and stirring and mixing to prepare viscous hydrating inorganic salt mixed solution. The preparation process of hydrating inorganic salt phase-change material which is provided by the invention is added with overcooling- resistance agent and poly-sodium acrylate in the preparation process, which can effectively avoid the hydrating inorganic salt phase-change material from generating the phenomenon of over-cooling and phase separation in the phase change process, and ensures hydrating inorganic salt phase-change material to keep uniformity after repeated circulating.

Owner:SHENZHEN INST OF ADVANCED TECH

Preparation method of porous sodium acrylate super absorbent resin

ActiveCN102225981AImprove pass rateRealize continuous productionAbsorbent padsBandagesCross-linkNitrogen gas

The invention relates to a preparation method of a porous sodium acrylate super absorbent resin. The preparation method comprises the following steps: an aqueous solution containing 30 to 45 wt% of acrylic acid monomers with a neutralization rate of 60 to 90 mole%, a cross linking agent, a porogenic agent, and a polymerization initiator are polymerized together under nitrogen protection; and porous particles are prepared through preparing granulums with diameters of 2 to 10 mm from hydrogel prepared through polymerization, and adding the surface cross linking agent and an inorganic filler to carry out surface processing. The preparation method of the invention allows continuous production to be realized, productivity to be improved, manpower to be decreased, a problem of slow imbibition to be solved, drying period to be substantially decreased, product performances to be substantially improved, the qualified rate of products to be high, reaction to be mild, and three wastes to be less.

Owner:浙江卫星新材料科技有限公司

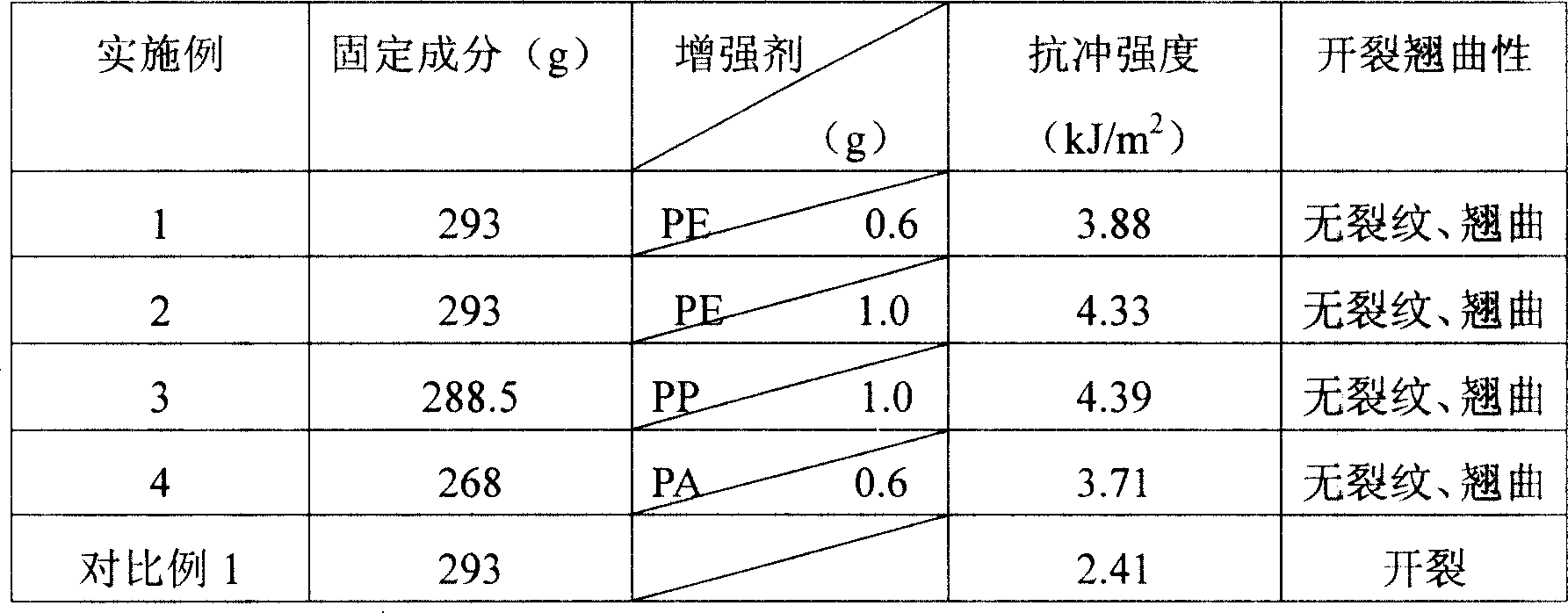

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

Dust-suppression agent and use method thereof

InactiveCN101824303ANot corrosiveEasy to degradeOther chemical processesCross-linkMaterials preparation

The invention relates to a dust-suppression agent, which is prepared by the following methods: A. material preparation: respectively weighing 3 to 5 parts of starch, 35 to 40 parts of water, 15 to 20 parts of crylic acid, 30 to 40 percent of 30 percent sodium hydroxide, 8 to 12 parts of initiating agent and 1 to 5 parts of cross-linking agent by weight parts for standby; and B. preparation: firstly, mixing the crylic acid and 30 percent sodium hydroxide to be prepared into sodium acrylate solution for standby, adding the starch and the water into a reaction kettle to be stirred and uniformly mixed at the room temperature, heating the materials to 75 to 80 DEG C, then, carrying out pasting for 1 hour at the constant temperature, stopping heating for reducing the temperature in the reaction kettle to 45 to 50 DEG C, then, maintaining the constant temperature, introducing nitrogen gas for replacing air in the reaction kettle, sequentially adding the prepared sodium acrylate solution, the initiating agent and the cross-linking agent into the reaction kettle, continuously introducing the nitrogen gas, carrying out reaction for 3 hours under slow stirring at the constant temperature, filtering out water, drying the materials in a baking oven between 70 and 80 DEG C, and obtaining a powdery dust-suppression agent after the pulverization. The dust-suppression agent is used for bulk coal pile surface layer dust prevention treatment, and can effectively suppress the flying of the bulk coal pile surface layer dust.

Owner:北京嘉孚科技有限公司

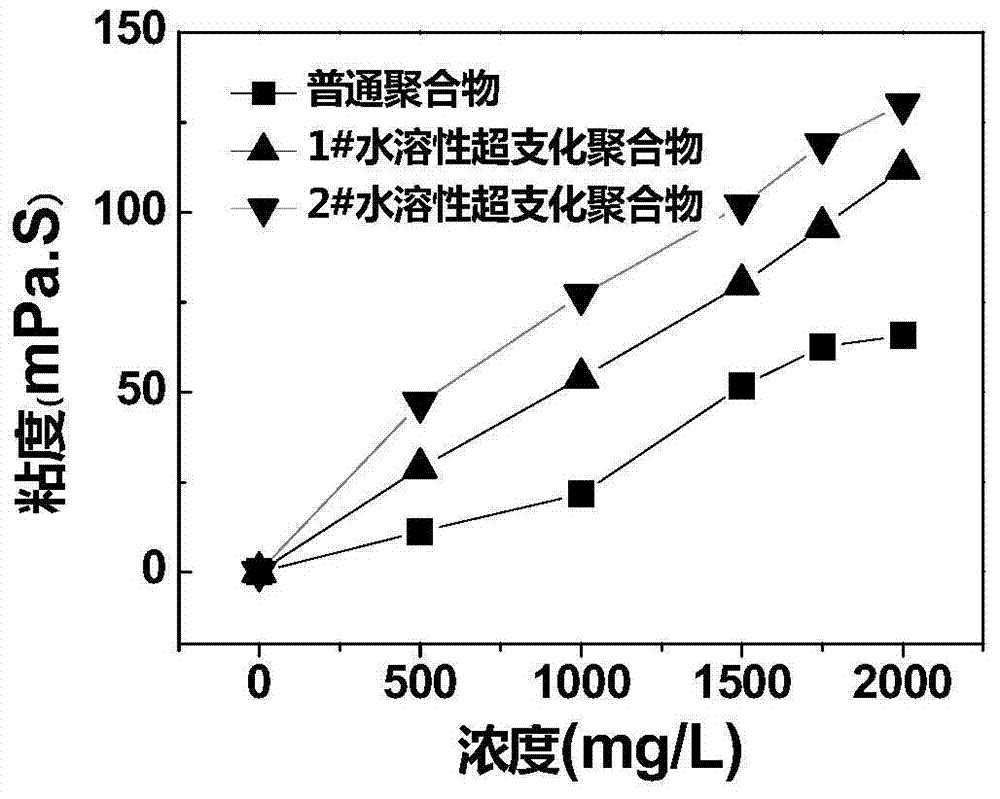

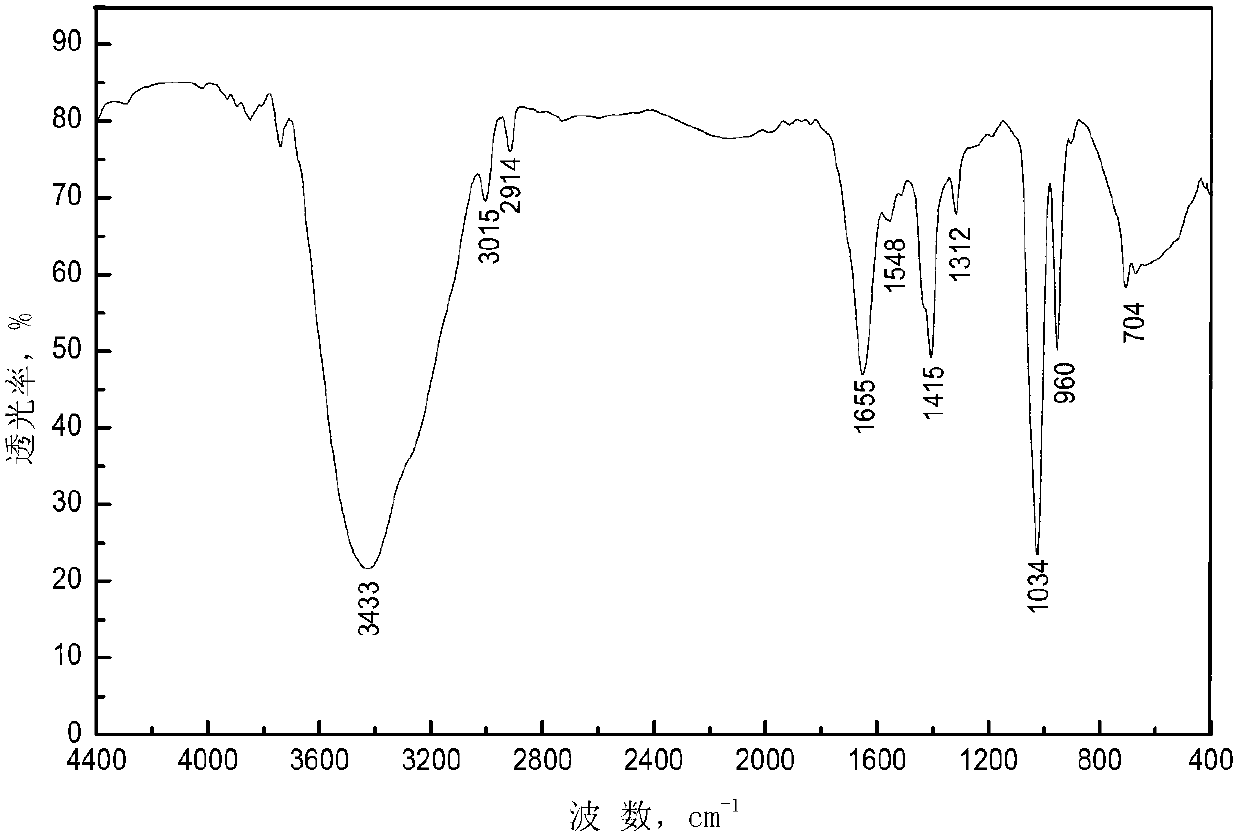

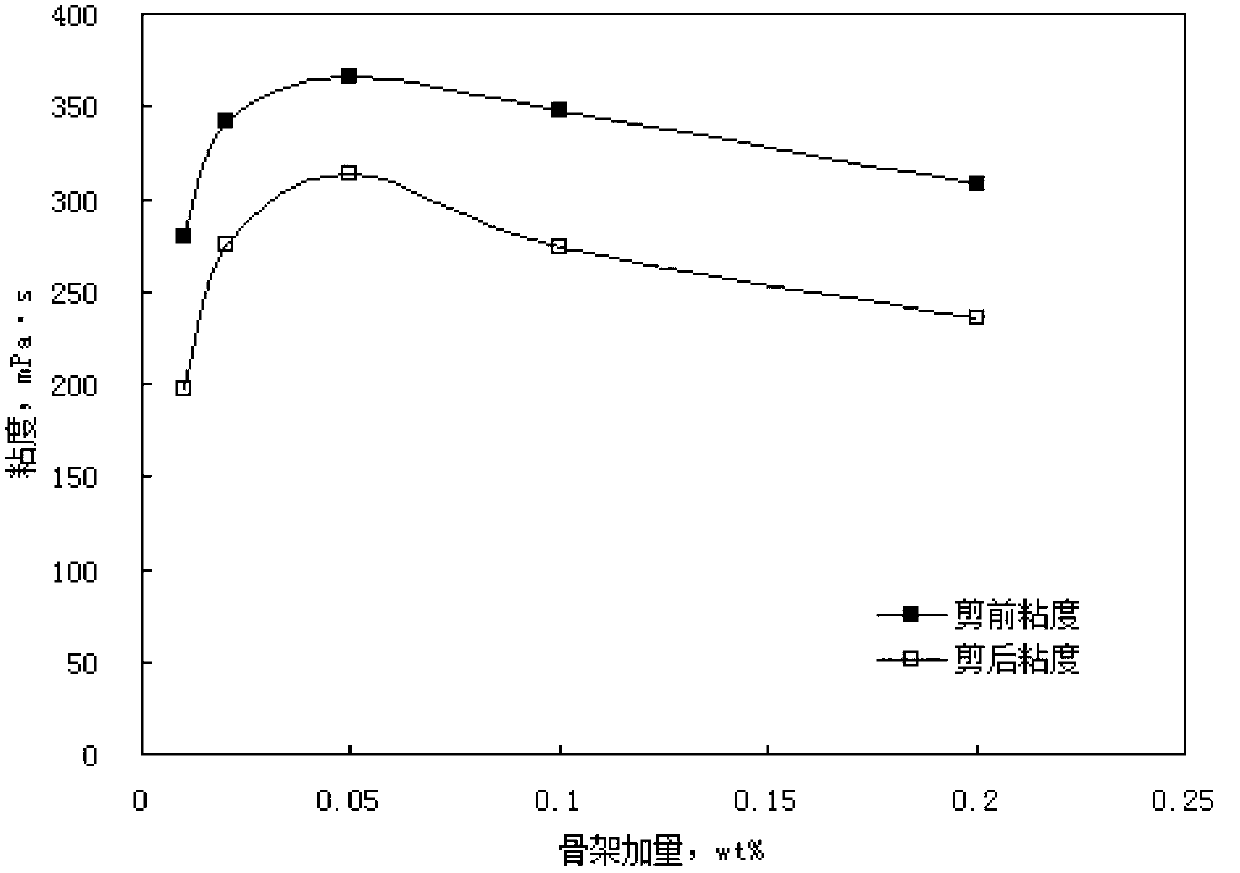

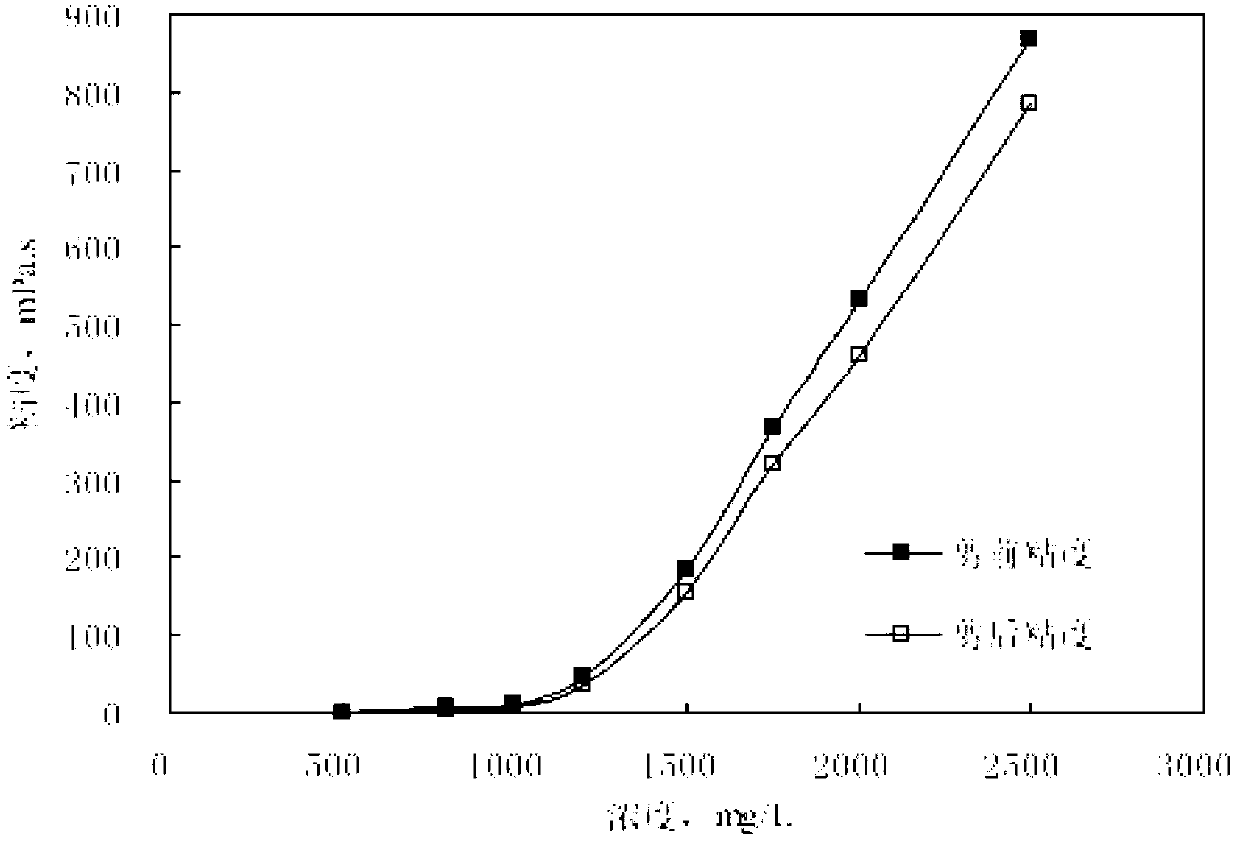

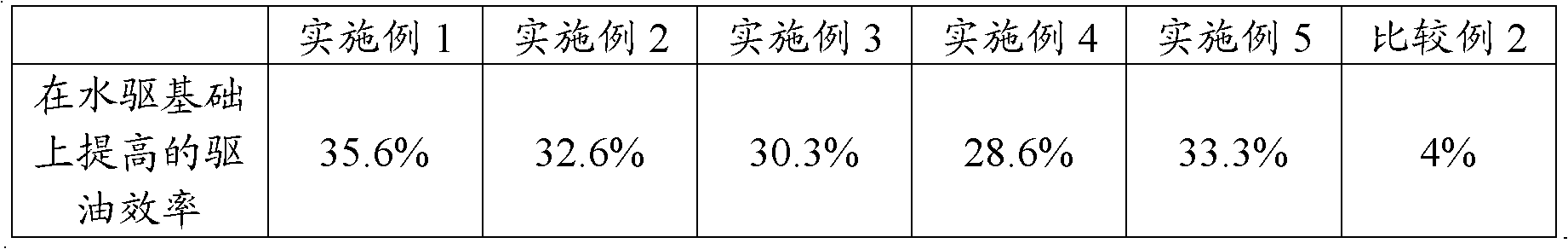

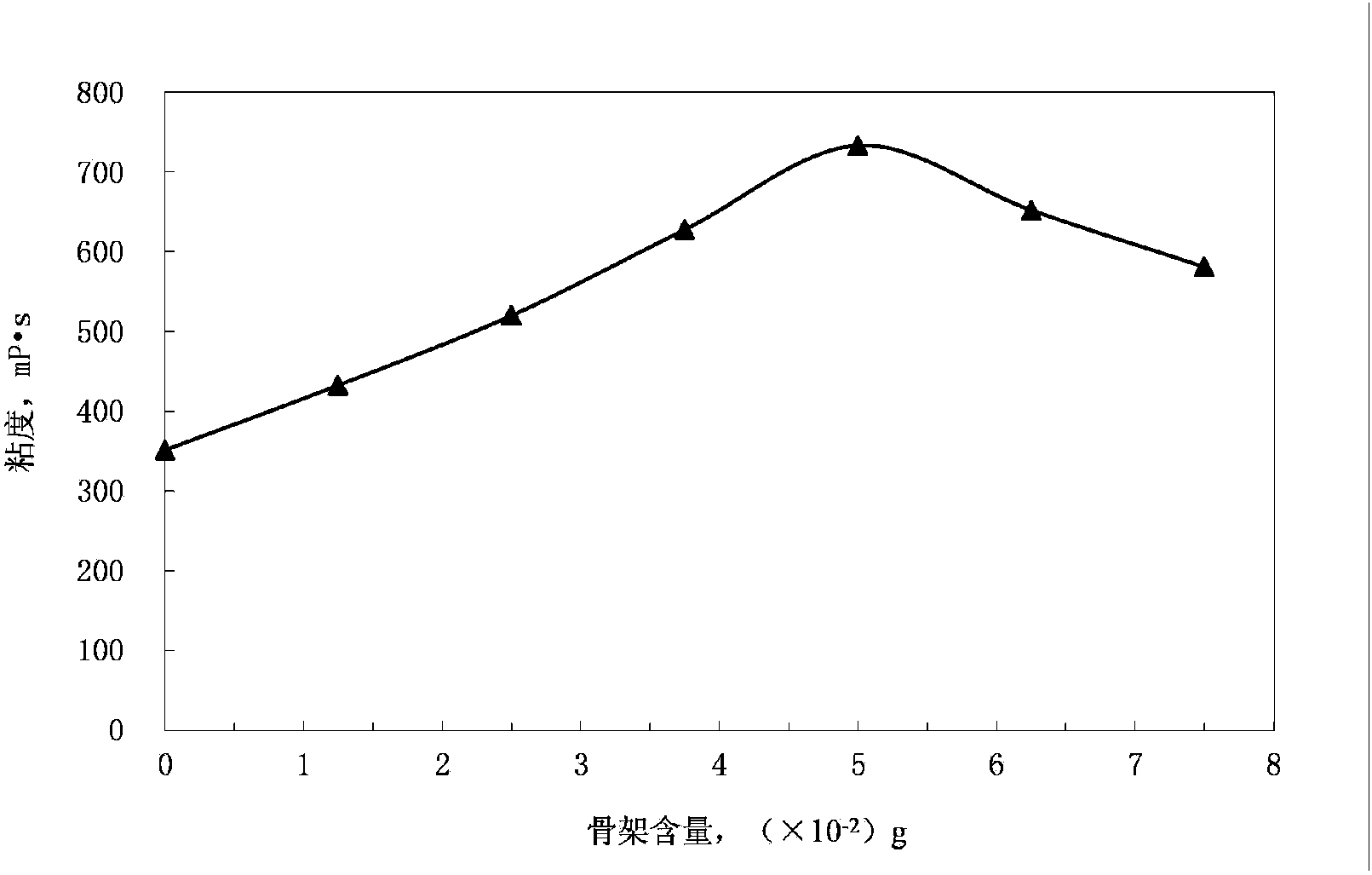

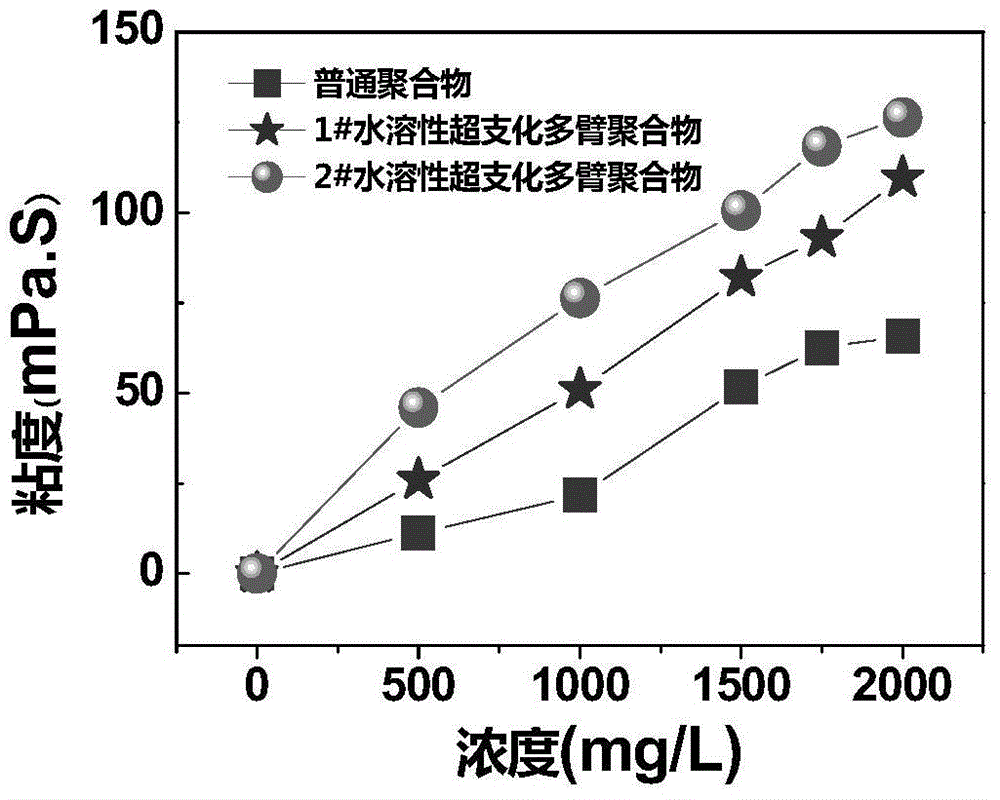

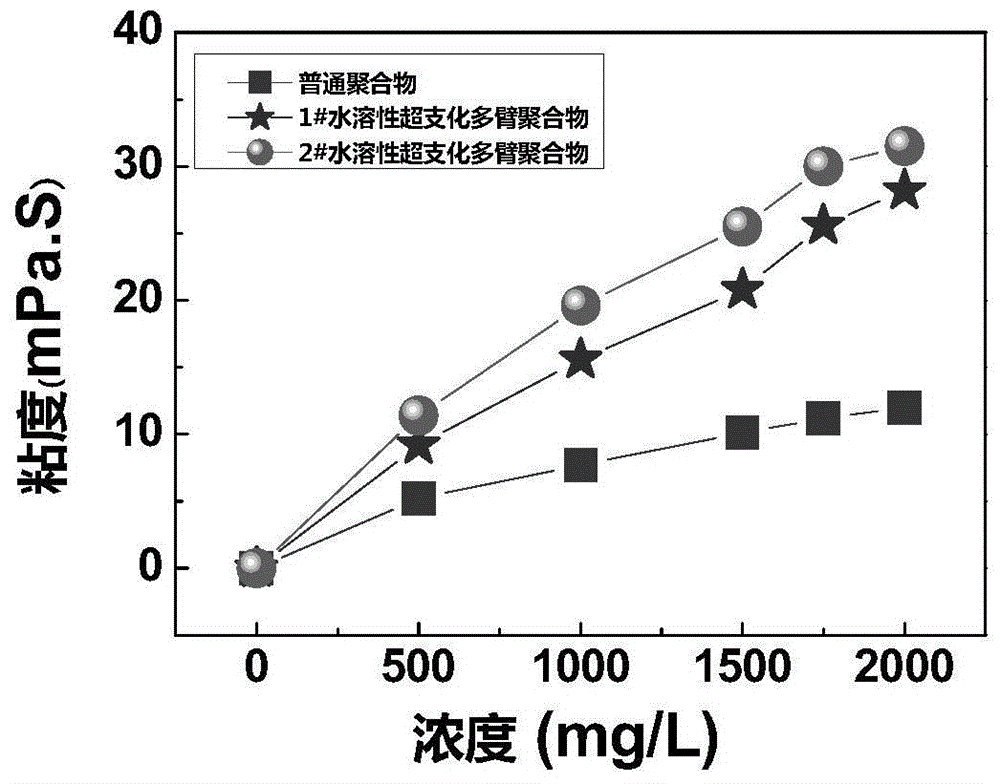

Water-soluble hyper-branched polymer oil displacement agent and preparation method thereof

The invention provides a water-soluble hyper-branched polymer oil displacement agent and a preparation method thereof. The water-soluble hyper-branched polymer oil displacement agent is composed of a spherical parent nucleus HCD, an acrylamide-sodium acrylate irregular copolymerization chain segment and a poly-amphoteric multi-claw type hydrophobic function chain segment, wherein the acrylamide-sodium acrylate irregular copolymerization chain segment and the poly-amphoteric multi-claw type hydrophobic function chain segment are connected in sequence; the poly-amphoteric multi-claw type hydrophobic function chain segment is formed by polymerizing an acrylic acid glycine betaine monomer or an acrylic acid bromo-quaternary ammonium salt monomer. The preparation process of the water-soluble hyper-branched polymer oil displacement agent is mild in condition, and simple and easy to operate; water-phase free radical polymerization is green and pollution-free, a human body cannot be harmed, products with a series of molecular weights and structures can be obtained, higher water solubility and good tackifying performance can be kept under the high salinity and the strong shearing action, and the water-soluble hyper-branched polymer oil displacement agent can be applied to enhanced oil recovery through the tertiary oil recovery of an oil field.

Owner:CHINA NAT OFFSHORE OIL CORP +1

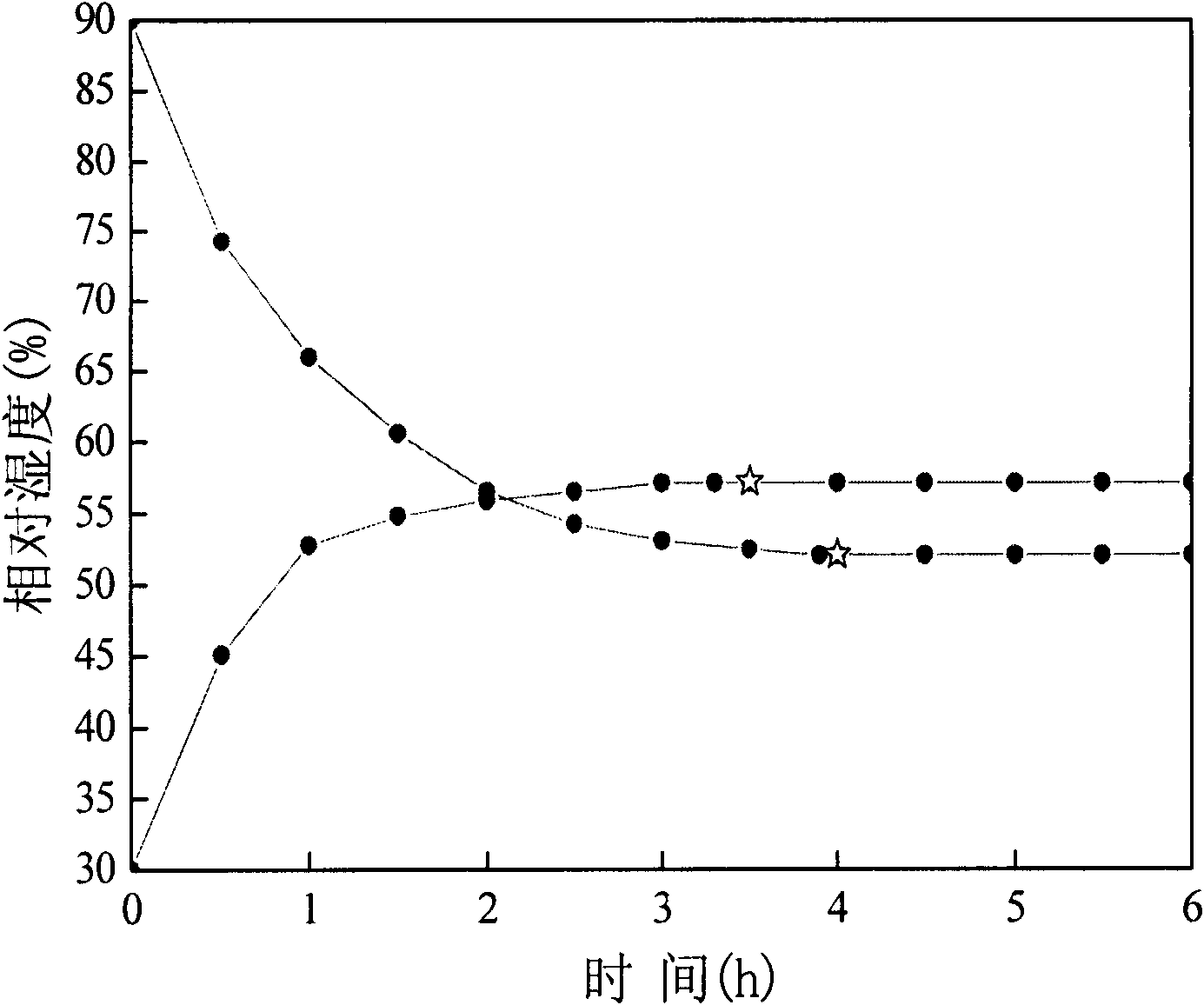

Method for preparing high-efficiency composite humidity controlling agent

InactiveCN101914257AQuickly adjust relative humidityLarge moisture absorption capacityHigh absorptionDesorption

The invention relates to a method for preparing a high-efficiency composite humidity controlling agent. In the method, raw materials, such as acrylamide, sodium polyacrylate, carboxymethylcellulose, sepiolite and the like, are synthesized into a humidity controlling material, so that the advantages of various humidity controlling materials are combined and the wet unit weight and the humidity controlling property of the synthetic material per se are improved; and a great number of hole structures with aperture between 2 and 50 nanometers are formed on the material through the synthesis process, so that the absorption and desorption properties of the product are further improved. Compared with the prior art, the method has the advantages of: 1) large absorption and desorption capacities, high absorption and desorption response speed and capacity of efficiently and quickly adjusting the relative humidity of a microenvironment; 2) very convenient regeneration and reutilization; 3) simple production process and equipment and easy industrialization; and 4) no harmful substance generated in the production process.

Owner:CHINA NAT SILK MUSEUM

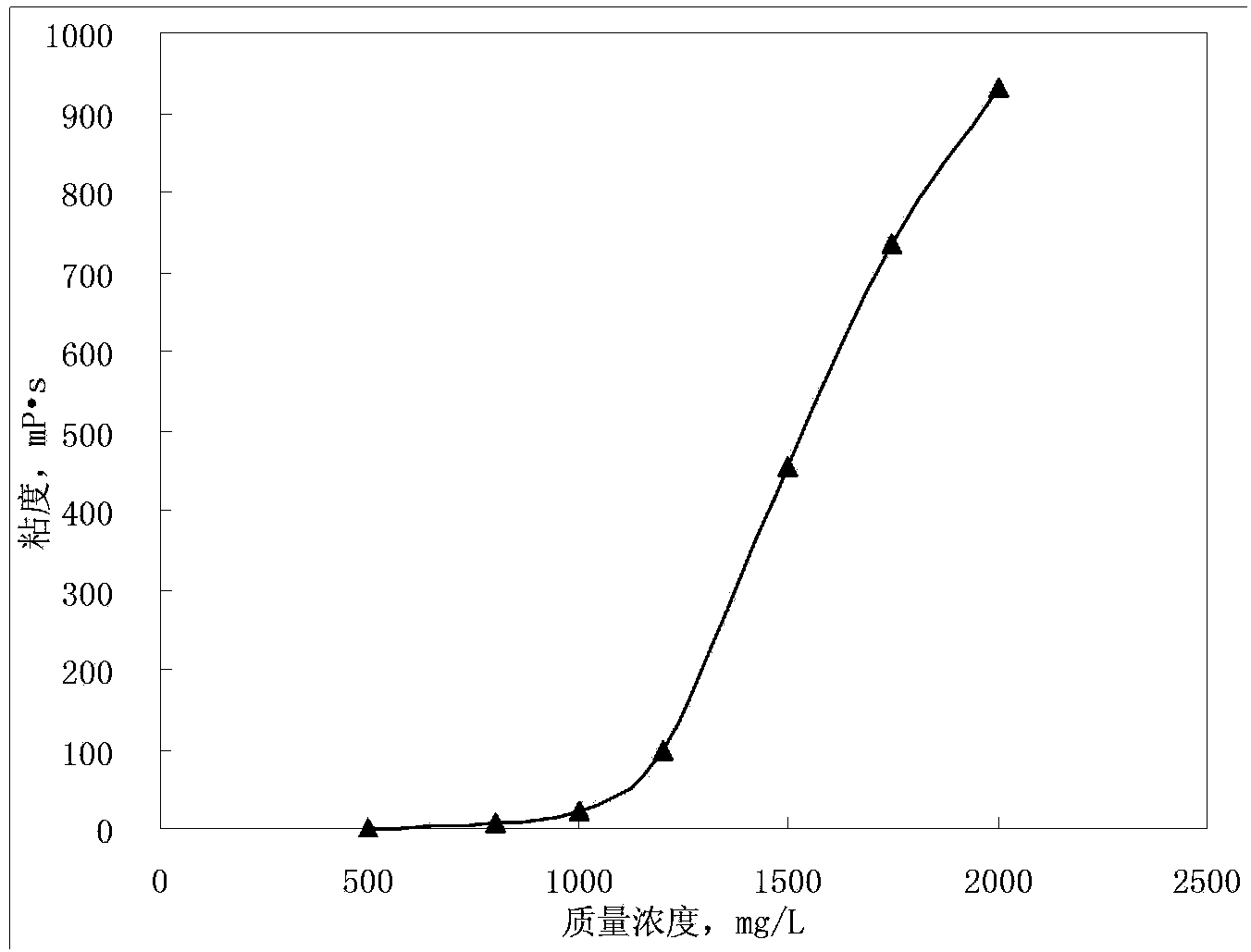

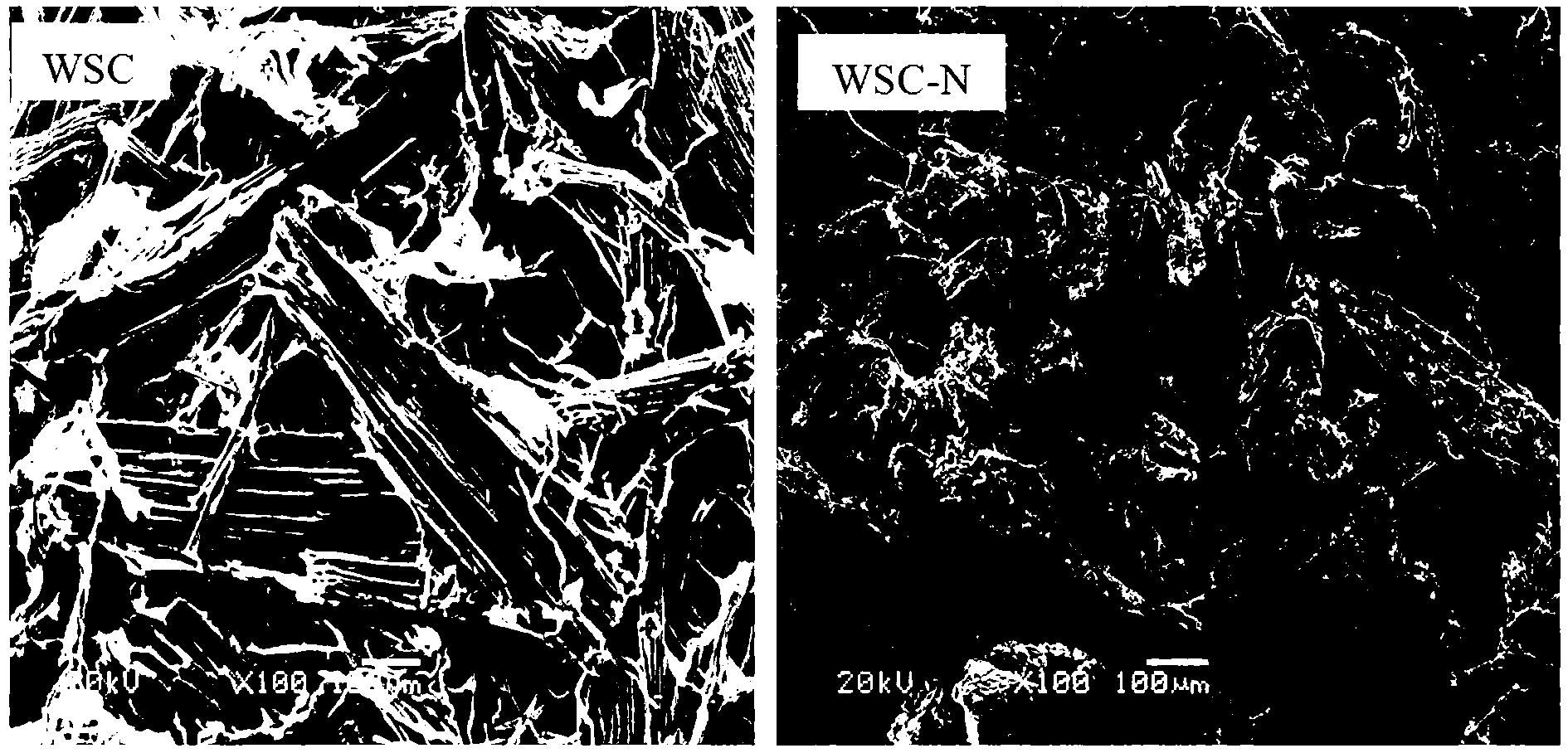

Hyperbranched hydrophobical-associating water-soluble polymer and its preparation method

InactiveCN103130967AGood viscosity increasing effectImprove solubilityDrilling compositionPolymer sciencePolyamide

The invention discloses a hyperbranched hydrophobical-associating water-soluble polymer and its preparation method. The polymer is obtained through copolymerizing acrylamide, acrylic acid, a hydrophobic monomer and functional hyperbranched macromolecules. The preparation method of the polymer comprises the following steps: 1, respectively dissolving a hyperbranched polyamide-amine macro-molecular skeleton treating diethylenetriamine as a core and maleic anhydride (or acryloyl chloride or acrylic anhydride) in dimethyl sulphoxide, slowly adding the skeleton monomer solution to the maleic anhydride solution in a dropwise manner, letting in nitrogen, placing the obtained system in an icy salt bath, stopping the dropwise addition of the skeleton monomer solution when the pH value of a reaction solution reaches 4-5, and precipitating with chloroform to obtain a functionalized skeleton monomer; and 2, carrying out free radical aqueous solution polymerization of sodium acrylate, acrylamide, the hydrophobic monomer dimethylallyl-N-alkylammonium chloride and the functional skeleton monomer. The preparation method has a reliable principle and is simple to operate, and the synthesized polymer still has a good thickening capability and a good seepage performance under a high mineralization degree and a strong shearing action.

Owner:SOUTHWEST PETROLEUM UNIV

Polyacrylamide microgel as well as preparation method and application thereof

ActiveCN102127189AImprove stabilityPrevent implosionDrilling compositionN,N-MethylenebisacrylamideMethylene bisacrylamide

The invention discloses a polyacrylamide microgel as well as a preparation method and application thereof. The particle size of the polyacrylamide microgel is 30-150 micrometers, acrylamide, sodium acrylate, N,N'-bisacrylamide, 2-acrylamide-2-methylpropanesulfonic acid sodium, styrenesulfonate and the like serve as polymerized monomers, white oil and the like serve as disperse phases, and the polymerized monomers and the disperse phases are subjected to thermal initiation suspension polymerization to obtain the polyacrylamide microgel. The polyacrylamide microgel synthetized by the method can be directly injected into an oil layer without being processed and has a good plugging effect.

Owner:北京石大万嘉新材料科技有限公司

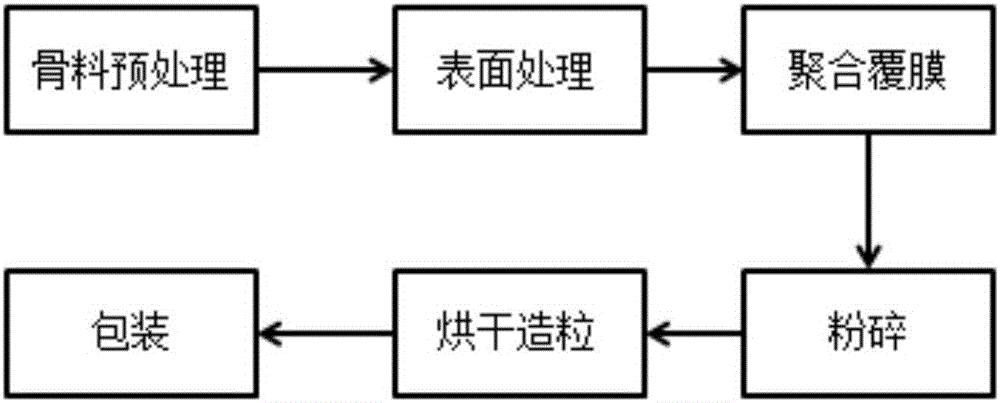

Preparation method for self-suspension propping agent in laboratory

InactiveCN106634939AReduced fracturing costsShear stableFluid removalDrilling compositionFunctional monomerExpanded clay aggregate

The invention belongs to the technical field of yield increasing and fracturing of petroleum engineering and provides a method for preparing a self-suspension propping agent in a laboratory. The method comprises the following steps: taking quartz sand / ceramsite / propping agent as aggregates; pre-treating with an organic solvent and treating the surface with a coupling reagent; polymerizing and coating; and crushing, drying, pelletizing and then packaging. A coating polymerizing product (as shown in the figure) is acquired through the polybasic polymerization of the reactant and acrylamide / sodium acrylate / functional monomer / cross-linking agent. The expansion times of the prepared self-suspension propping agent is 3-12 times; the self-suspension propping agent can be completely hydrated within 1min-2min; the hydrated layer is stably expanded at 2 DEG C to 193 DEG C; the self-suspension propping agent swells once encountering with water, the volume density is reduced from 2.4g / cm3 to 1.3g / cm3 and the excellent self-suspension characteristic after the clean water system swelling is presented. The self-suspension propping agent prepared in the laboratory can realize the onsite mixing for hydraulic fracturing construction, the water for fracturing is greatly reduced, the labor cost is lowered and the application prospect is wide.

Owner:王展旭

Leave-on facial mask with added pearl hydrolysate liposome

InactiveCN102058510AGood nourishing effectPrevent agingCosmetic preparationsToilet preparationsHydrolysateButanediol

The invention discloses a leave-on facial mask with added pearl hydrolysate liposome, prepared by mixing, heating and homogenizing deionized water, pearl hydrolysate liposome, glycerol, butanediol, trimethylglyine, cyclohexasiloxane, isononyl isononanoate, polydimethylsiloxane, acrylic acid (ester) / C10-30 alkyl acrylate crosslinked polymer, triethanolamine, sodium acrylate / dimethyl propylene amine taurine multipolymer, allantoin, methyl hydroxybenzoate, propyl hydroxybenzoate, phenoxyethanol, disodium EDTA (Ethylene Diamine Tetraacetie Acid), hyaluronic acid and essence. The leave-on facial mask with added pearl hydrolysate liposome improves the nourishing effect of the facial mask on the face by effectively utilizing effective components in the pearl hydrolysate liposome, has the functions of caring the skin, keeping moisture, nourishing, whitening the skin, and the like, takes the action of effectively caring and nourishing the skin, preventing skin aging and tendering the skin, and has optimal use performance.

Owner:HAINAN JINGRUN PEARL BIOTECH

Treatment method of methacrylate or acrylate industrial wastewater

ActiveCN101786742AEmission reductionMultistage water/sewage treatmentNature of treatment waterUltrafiltrationReducing agent

The invention discloses a treatment method of methacrylate or acrylate industrial wastewater. The method comprises the following steps: adjusting the pH value of methacrylate or acrylate industrial wastewater to 6-8, ensuring the wastewater to pass through an activated carbon layer for filtering and pretreatment, adding chain transfer agent in the pretreated wastewater, stirring to dissolve solids, heating to 40-90 DEG C; dropping an aqueous solution dissolved with initiator, keeping temperature for 1-10 hours to perform polymerization reaction; cooling the reacted wastewater to the room temperature, and passing through a nanofiltration membrane and / or ultrafiltration membrane separating component to remove partial water and small molecule salts and obtain a sodium polymethacrylate or sodium polyacrylate aqueous solution. By using the method of the invention, the wastewater discharge is reduced during the production process of methacrylate or acrylate; the sodium methacrylate or sodium acrylate in wastewater is recycled, and the byproduct low molecular weight sodium polymethacrylate or sodium polyacrylate aqueous solution can be used as the dispersant, antisludging agent and water reducing agent of cement.

Owner:GUANGDONG RITOP FINE CHEM

Branched hydrophobic associated polymer oil-displacing agent and preparation method thereof

ActiveCN103849367AGood viscosity increasing effectImprove solubilityDrilling compositionDendrimerPolymer science

The invention discloses a branched hydrophobic associated polymer oil-displacing agent and a preparation method thereof. The polymer for oil displacement is copolymerized by acrylamide, sodium acrylate, hydrophobic monomer and functionalized skeleton monomer, wherein the hydrophobic monomer is dimethyl allyl-alkyl benzyl ammonium chloride, the functionalized skeleton monomer is formed by 2 substituted polyamide-amine dendrimer skeleton monomer or maleic anhydride or acrylic anhydride through reaction in dimethylsulfoxide solution. By using the branchedness of the polyamide-amine dendrimer skeleton, interaction between molecular chains is enhanced, and flexibility of molecules is lowered; by virtue of the association of hydrophobic group on the molecular chain in water solution, the tackifying capacity of low molecular weight polymer solution is improved; the preparation method has a reliable principle and is simple and convenient to operate, the synthesized polymer still has good tackifying capacity at high temperature, hypersalinity and strong shear action, thus having broad market prospect.

Owner:SOUTHWEST PETROLEUM UNIV

Method for preparing profile control agent and blocking water agent by employing oilfield waste polymers

The invention relates to a method for utilizing waste polymers in the oilfield to prepare a profile control and water plugging agent. The acrylamide and the sodium acrylate monomers are added into the waste polymer gel produced in the oilfield development to carry out the copolymerization and crosslinking so as to synthesize a bulk expansive profile adjusting agent for oilfield which is used for adjusting the large pore reservoir deep profile in the oilfield development. The obtained profile control and water plugging agent for oilfield is applied in the high water bearing region and is a bulk expansive profile adjusting agent for oilfield.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing dust suppressing covering agent

InactiveCN102558579AWide variety of sourcesReliable sourceOther chemical processesPolymer scienceCross linker

The invention relates to a method for preparing a dust suppressing covering agent, comprising the following steps: preparing raw materials including 3-10 parts of natural starch, 35-50 parts of water, 10-20 parts of acrylic acid, 30-40 parts of 30% sodium hydroxide, 1-5 parts of cross-linking agent and 5-15 parts of initiator; mixing the acrylic acid and the 30% sodium hydroxide to prepare sodium acrylate solution, and filling the sodium acrylate solution into a sodium acrylate solution storage tank for later use; fully mixing the natural starch and the water, and filling starch slurry into a starch slurry storage tank; pumping the starch slurry into a stirring reactor by using a starch slurry pump, heating for 75-80 DEG C by using a clamp sleeve of the stirring reactor, and gelatinizing for 1 hour at constant temperature; stopping heating, decreasing the temperature in the stirring reactor to 45-50 DEG C, keeping the temperature constant, and introducing nitrogen into the stirring reactor to replace the air inside the stirring reactor; adding the prepared sodium acrylate solution, the initiator and the cross-linking agent into the stirring reactor in sequence, introducing nitrogen into the stirring reactor continuously, and the stirring slowly for reaction of 3 hours at constant temperature.

Owner:NANJING TECH UNIV

Preparation of cellulose grafted acrylate copolymer and application of copolymer as adsorbent

InactiveCN103159896AImprove adsorption capacityHigh decolorization rateOther chemical processesWater contaminantsCross-linkCellulose

The invention discloses a preparation method of cellulose graft acrylate copolymer. The method comprises the following steps of: by utilizing water as a solvent, N, N-methylene bis-acrylamide as a cross-linking agent, azobisisobutyronitrile as an initiator, cellulose as a base body and sodium acrylate and N-vinyl pyrrolidone as comonomers, and adopting a solvent polymerization method, polymerizing so as to obtain the copolymer. The strong chelation capability of a macromolecular chelating agent and the strong adsorption capabilities of carboxyl and amido bond are utilized, so that the copolymer has the characteristics of strong adsorption capability, large adsorption capacity and high decolorization rate on heavy metal ions and organic cationic dyes in the wastewater, and can be used for absorbing and removing organic cationic dyes such as metal ions and methylene blue in the wastewater. The removal rates of the cellulose graft acrylate copolymer on copper ions and methylene blue in the wastewater respectively reach 95.1% and 99.5%. In addition, the cellulose graft acrylate copolymer adopts raw materials which are low in cost and easily obtained, is simple in preparation technology, low in cost and beneficial to industrialization.

Owner:NORTHWEST NORMAL UNIVERSITY

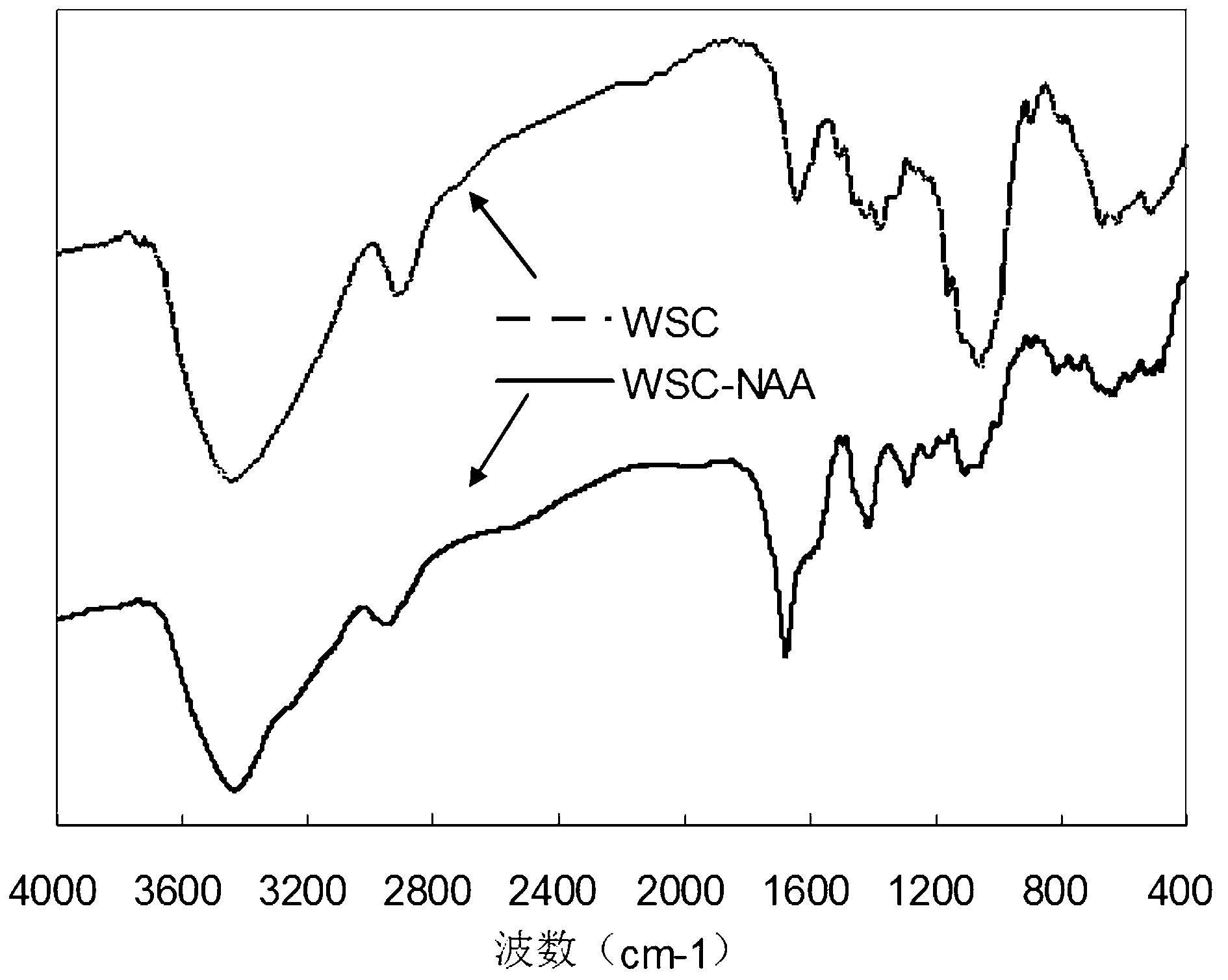

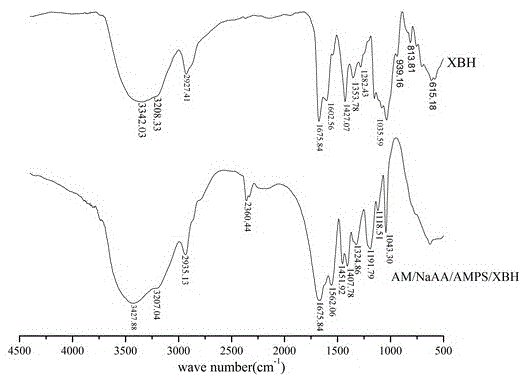

Polymer clay stabilizer containing Beta-cyclodextrin structure and synthesis method thereof

InactiveCN102618237AWith parcel landfill functionGood water solubilityDrilling compositionSolubilityPolymer science

The invention relates to a polymer clay stabilizer containing Beta-cyclodextrin structure and a synthesis method thereof, wherein the polymer clay stabilizer is used for restraining clay hydration swelling of an oil well. The technical scheme is as follows: the polymer clay stabilizer comprises the following materials and monomers in percentage by mass: 35-54.8% of acrylamide AM, 15-25% of sodium acrylate NaAA, 8-20% of 2-acryloyl-methyl-propyl sulfonate AMPS, and 0.2% of 2-O (propenyloxy-2-hydroxy-propyl)-Beta-cyclodextrin XBH; 0.02g of XBH and 2g of AMPS are added into a flask, and then 5.48g AM, 1.915g of AA and 0.585 g of NaOH are added into the flask, so a water solution with the monomer mass percentage concentration of 20% is prepared, and nitrogen is introduced into the water solution for 20 min; (NH4)2S2O8 solution and NaHSO3 solution are then added into the water solution while nitrogen is continuously introduced into the water solution for 10-20 min, and reaction is carried out at the temperature of 35 DEG C for 4-12 hours; and finally, the reacted solution is subjected to washing with absolute ethyl alcohol, smashing and drying to obtain AM / NaAA / AMPS / XBH quaternary polymer. The polymer clay stabilizer has good water solubility, viscosifying capacity, temperature resistance, salt resistance, anti-shearing capacity and clay-swelling restraining capacity, and reaches the swelling prevention rate of 84.37% towards sodium-montmorillonite.

Owner:SOUTHWEST PETROLEUM UNIV

Super absorbent degradable colorful crystal soil containing nano-clay and preparation method thereof

The invention relates to a super absorbent degradable colorful crystal soil containing nano-clay and a preparation method thereof. The polymerization of acrylamide monomer M1, sodium acrylate M2, N, N'-methylene-bisacrylamide M3, inorganic nano-clay M4, water soluble biomacromolecule M5 and water soluble pigment M6 are dissolved in water and are synthesized to prepare the crystal soil in redox initiator system. The crystal soil not only processes high water absorption and color absorption, but also has certain mechanical property and biodegradability. The preparation method is simple and has controllable condition without polluting the environment. The water-absorbing capacity and the biodegradation time of the prepared crystal soil can be adjusted by parameters of temperature, PH value, degree of cross linking, dosage and type of water soluble biomacromolecule and nano-clay and reactant proportion, and the appearance color can be adjusted by the pigment type. The crystal soil of the invention is used for environment decoration of household, flower market and gardening, etc, and engineering field of nursery stock breeding, garden greening, agricultural producing, environment improving, revegetating, etc.

Owner:天津市志润德科技有限公司

Preparation method of hydrophobically associating polymer inverse emulsion

The invention relates to a preparation method of hydrophobically associating polymer inverse emulsion and belongs to the technical field of water-soluble polymer synthesis. The preparation method comprises the following steps: changing the dissolution or interfacial property of a hydrophobic monomer by virtue of inclusion interaction cyclodextrin, and on this basis, copolymerizing the hydrophobic monomer with water-soluble monomers of acrylamide, sodium acrylate, 2-acrylamido-2-sodium methylallyl sulfonate and the like in inverse emulsion to obtain a hydrophobically associating polymer inverse emulsion product by taking potassium persulphate-tetramethylethylenediamine as a redox initiator system. The preparation method is cheap and easily-available in raw material and simple in process and after treatment; and meanwhile, the product is good in water-solubility, can be dissolved quickly, and has significant thickening property, shearing resistance and temperature and salt resistance, so that the product has an extensive application prospect in the fields of oil field, daily chemical, water treatment and the like.

Owner:陕西亘合石油科技有限公司

Water-soluble hyperbranched multi-arm polyacrylamide polymer and preparation method thereof

The invention provides a water-soluble hyperbranched multi-arm polyacrylamide polymer and a preparation method thereof. The polymer is composed of a spherical parent nucleus, an arm A and an arm B, wherein one end of the arm A is connected with the spherical parent nucleus, and the other end is connected with the arm B. The viscosity-average molecular weight of the polymer is 3.5-10 million, the mass ratio of the spherical parent nucleus to the arm A to the arm B is 1:(200-350):(7-18), and the degree of hydrolysis of the polymer is 20-40%. The spherical parent nucleus is polycyclodextrin with rich hydroxy groups at terminal groups. The arm A is an acrylamide-sodium acrylate random copolymer chain segment. The arm B is a poly-zwitterion choline functional chain segment. The preparation process of the water-soluble hyperbranched multi-arm polyacrylamide polymer is mild in conditions and simple and easy to implement, is green and pollution-free due to water-phase free-radical polymerization, and can not do harm to the human body. The water-soluble hyperbranched multi-arm polyacrylamide polymer has obviously higher tackifying property, salt resistance and shear resistance than the conventional linear polyacrylamide polymer, and has application prospects in oilfields.

Owner:CHINA NAT OFFSHORE OIL CORP +1

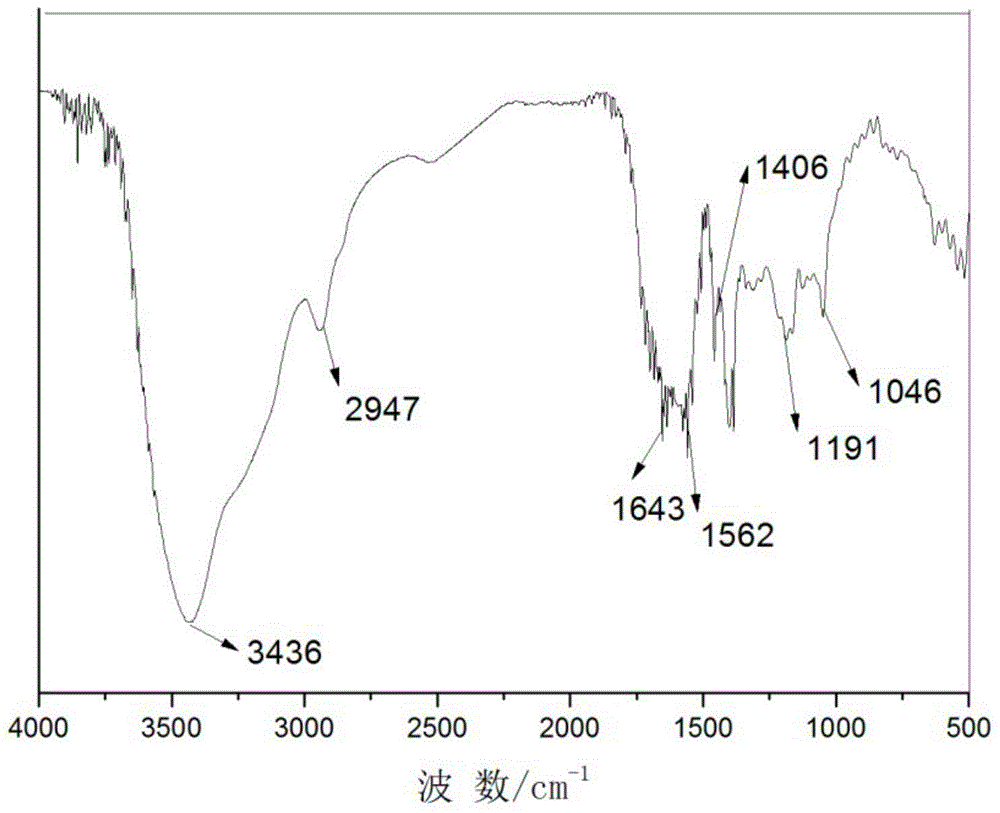

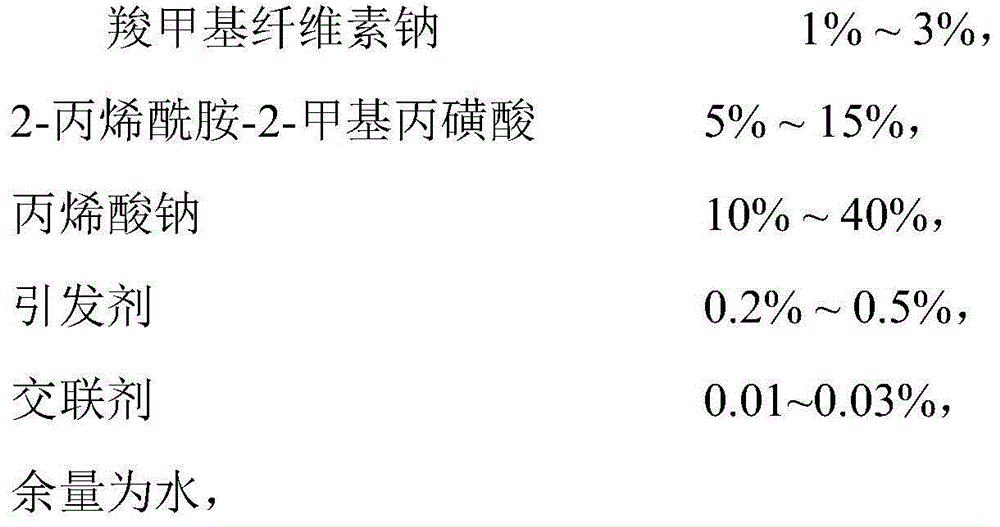

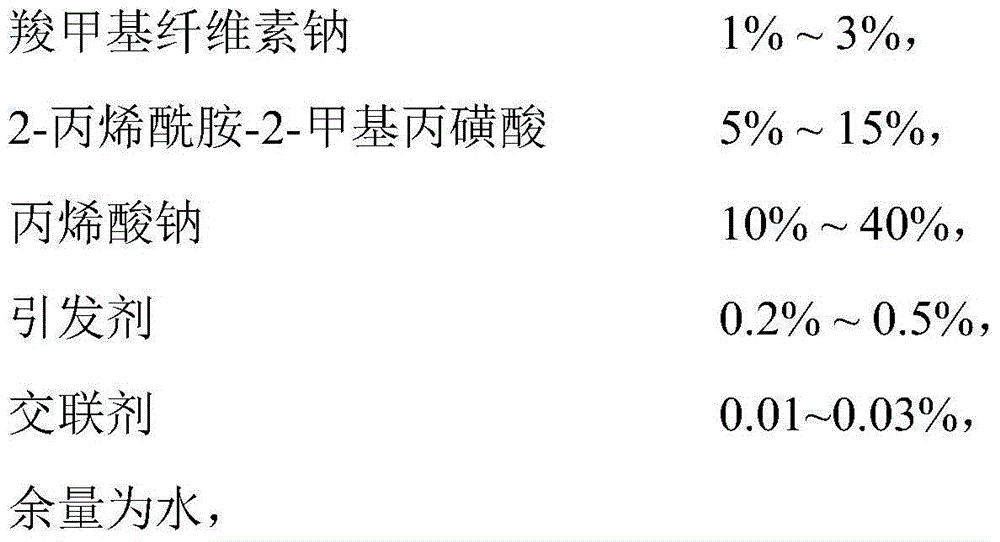

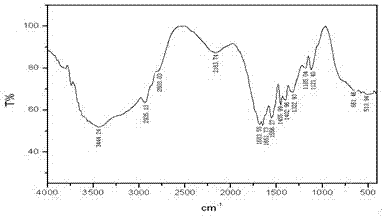

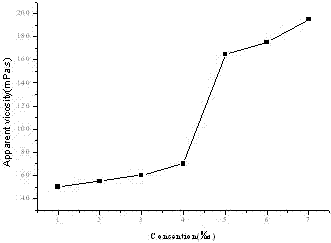

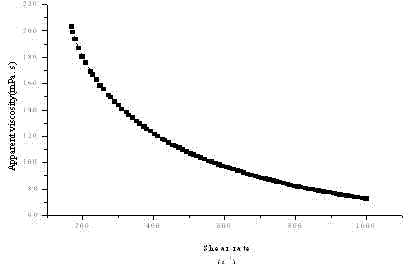

Heat resistance and salt tolerance polymer filtrate reducer and preparation method therefor

ActiveCN104927804AGood salt and temperature resistanceReduce dosageDrilling compositionCross-linkReaction temperature

The invention discloses a heat resistance and salt tolerance polymer filtrate reducer. The heat resistance and salt tolerance polymer filtrate reducer is prepared from 1% to 3% of sodium carboxymethylcellulose, 5% to 12% of 2-acrylamide-2-methyl propane sulfonic acid, 10% to 40% of sodium acrylate, 0.2% to 0.5% of initiator and 0.01% to 0.03% of cross-linking agent in percentages by weight in an aqueous solution, wherein the initiator is ammonium persulfate or potassium peroxodisulfate; and the cross-linking agent is N,N-methylene bisacrylamide. The heat resistance and salt tolerance polymer filtrate reducer is good in heat stability, low in cost and high in heat resistance and salt tolerance capacity. The invention also discloses a preparation method of the heat resistance and salt tolerance polymer filtrate reducer adopting a graft copolymerization method in the aqueous solution; and the method is simple, convenient and practicable, the preparation reaction temperature does not exceed 80 DEG C, and the condition is mild and controllable.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

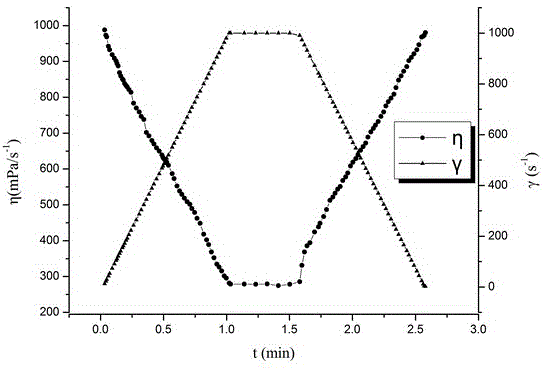

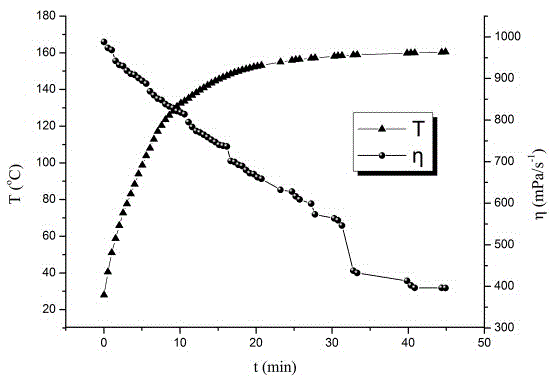

Hydrophobically associating water-soluble polymer (HAWSP) oil displacement agent and preparation method thereof

InactiveCN102391417ASoluble in waterGood temperature and salt resistanceDrilling compositionPolymer sciencePolymer flood

The invention relates to a hydrophobically associating water-soluble polymer (HAWSP) oil displacement agent and a preparation method thereof. The technical scheme is that: the HAWSP oil displacement agent comprises the following monomers and monomers in percentage by mass: 53.5 to 59.9 percent of acrylamide (AM), 40 to 45 percent of sodium acrylate (NaAA) and 0.1 to 1.5 percent of N-allyl oleylamine (NAO); and the preparation method comprises the following steps of: adding the NAO into a reactor; adding OP-10 and water; adding the AM, AA and NaOH after emulsification is performed completely to prepare a solution with the monomer total mass percentage concentration of 10 to 25 percent; adjusting the pH value to 7.5 to 11; introducing N2 for 20 minutes; adding an initiator; continuously introducing N2 for 20 minutes; reacting at the temperature of between 30 and 70 DEG C for 4 to 12 hours; washing by using absolute ethanol; and crushing and drying to prepare AM / NaAA / NAO terpolymer. The polymer has water solubility and high temperature tolerance, salt tolerance and shearing resistance, and can increase a crude oil recovery rate by over 10 percent simulatively.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation and use method of downhole intelligent plug

ActiveCN103160261AEnsure job safetyAffect production capacityDrilling compositionSealing/packingCross-linkOperation safety

The invention discloses a preparation and use method of a downhole intelligent plug. The preparation method is as below: using acrylamide and sodium acrylate as raw materials, adding an initiator sodium sulphite to synthesize a jelly, preparing a base fluid, and crosslinking with a cross-linking agent to form a stable plug capable of automatically breaking at a set time. The downhole intelligent plug provided by the invention is in a liquid shape before gelatinization, and is pumped to a preset position of the wellhole by a ground pump; after gelatinization, the rubber plug can seal the wellhole and prevent up transportation of stratum oil gas, so as to ensure wellhole operation safety; meanwhile the rubber plug can avoid entering of killing fluid into the stratum to cause reservoir damage affecting well productivity, and the rubber plug can automatically degrade after operation, thereby ensuring smoothness of the wellhole.

Owner:PETROCHINA CO LTD

Compositions for improved production of acrylic acid

InactiveUS20190002385A1Easy to storeEasy to transportPreparation from carboxylic acid esters/lactonesAcrylic monomersChemistry

The present invention is directed to compositions which may undergo thermolysis to produce a higher purity acrylic acid product. In preferred embodiments of the present invention, the compositions comprise polypropiolactone and one or more active salts. The one or more active salts may catalyze thermolysis of the polypropiolactone so that the polymer depolymerizes into acrylic acid monomers. Certain concentrations of the one or more active salts result in higher purity acrylic acid products of thermolysis. In certain preferred embodiments, the one or more active salts include an acrylate group which may decompose under thermolysis to provide acrylic acid and thus decrease the concentration of undesirable contaminants in the acrylic acid product. In certain preferred embodiment, the one or more active salts comprise sodium acrylate.

Owner:NOVOMER INC

Preparation method of graphene oxide composite gel applicable to heavy metal adsorption

InactiveCN105601850AGood mechanical propertiesHigh mechanical strengthOther chemical processesWater contaminantsPotassium persulfateFreeze-drying

The invention discloses a preparation method of a graphene oxide composite gel applicable to heavy metal adsorption. The preparation method comprises the following steps: by using sodium acrylate and acrylamide as monomers, a graphene oxide hydrogel as an additive, potassium persulfate as an initiator, N,N-methylene-bis-acrylamide as a crosslinking agent and deionized water as a reaction solvent, adding the potassium persulfate and N,N-methylene-bis-acrylamide into a graphene oxide-sodium acrylate-acrylamide mixed water liquid to react at 45-60 DEG C in an N2 atmosphere for 2-3 hours, thereby obtaining a massive composite hydrogel product; and carrying out freeze-drying and vacuum drying on the composite hydrogel product to obtain the macroporous network-polymer graphene oxide composite gel. The graphene oxide composite gel can be well used in treating wastewater containing Pb<2+> and Cd<2+>, and has the advantages of low cost and simpler preparation method.

Owner:JISHOU UNIVERSITY

Instant-dissolved cationic polyacrylamide capsulation agent and preparing method thereof

The invention belongs to the field of cationic polymer capsulation agents, and relates to an instant-dissolved low-molecular-weight polyacrylamide capsulation agent and a preparing method thereof. The capsulation agent is prepared from three monomers in a copolymerization mode, wherein the first monomer is one of acrylamide and sodium acrylate, the second monomer is one of cationic monomers including dimethyl diallyl ammonium chloride, diethyl diallyl ammonium chloride, acryloxyethyl ethyl dimethyl benzyl ammonium chloride, methacryloyl oxyethyl dimethyl-benzyl ammonium chloride and methacryloyloxyethyl trimethyl ammonium chloride, and the third monomer is one of hydroxyethyl methylacrylate and hydroxypropyl methacrylate. The molecular structures of the monomers contain hydroxyl, the hydroxyl can interact with drilling cuttings, and the capsulation inhibiting performance is improved. According to the capsulation agent, the inverse emulsion polymerization technology is adopted, the aftertreatment technology is simple, the granular product can be conveniently stored for a long time and transported, the dissolving time is short in use, convenience is brought to site utilization, the capsulation inhibiting effect is good, and the performance of a drilling fluid system can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com