Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

137results about How to "Prevent implosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyaramide resin modified by aromatic heterocycle and chloromonomer

InactiveCN101165078AGood molecular weightHigh molecular weightPolyamide coatingsMonocomponent polyamides artificial filamentTwo stepMonomer

The present invention discloses process of producing aromatic heterocycle and chlorated monomer modified polyaramide resin. Monomers including paraphthaloyl chloride and p-phenylene diamine in the calculated equivalents and 2-(4-aminophenyl)-5(6) aminophenyl benzimidazole in 20-80 % the calculated equivalent are synthesized inside NMP / CaCl2 solvent system into high molecular weight resin through one two-step process including the first reaction between partial paraphthaloyl chloride and all the p-phenylene diamine to form amido group terminated low molecular weight oligomer and the subsequent reaction between the rest paraphthaloyl chloride and the amido group terminated low molecular weight oligomer to form the high molecular weight resin. The aromatic heterocycle and chlorated monomer modified polyaramide resin has the advantages of high fireproof performance, high mechanical strength and low cost.

Owner:四川华通特种工程塑料研究中心有限公司

Preparation method of starch grafted acrylamide flocculating agent

InactiveCN101704928AHigh solid contentHigh molecular weightWater/sewage treatment by flocculation/precipitationParaffin waxEmulsion

The invention provides a preparation method of a starch grafted acrylamide flocculating agent, which comprises the following concrete step of polymerizing starch and acrylamide in a reversed emulsion formed by liquid paraffin, water and a compounded emulsifying agent to form a graft copolymer of the starch and the acrylamide, wherein potassium permanganate is used as an initiator, and the compounded emulsifying agent comprises span 80, Tween 80 and alkylphenol polyoxyethylene (4) in a mass ratio of 7-9:0.1-0.5:0.9-2.5. The method adopts the compounded emulsifying agent comprising the span 80, the Tween 80 and the alkylphenol polyoxyethylene (4) for preparing the reversed emulsion, thereby stabilizing the system of the reversed emulsion, providing a stable reaction environment for polyreaction, and being helpful for improving the stability of products. In addition, in the method, the potassium permanganate is also selected as the initiator, thereby effectively improving the efficiency of initiating the polyreaction.

Owner:GUANGZHOU UNIVERSITY

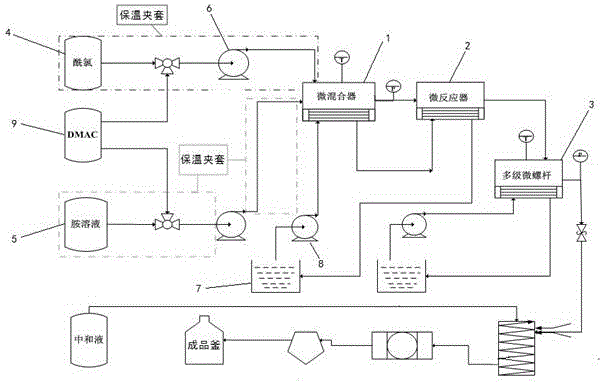

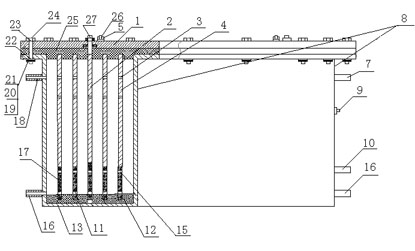

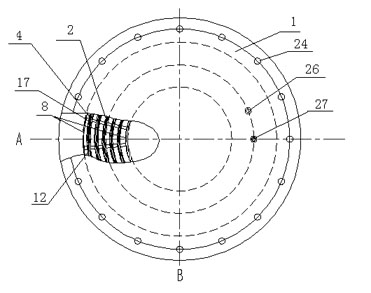

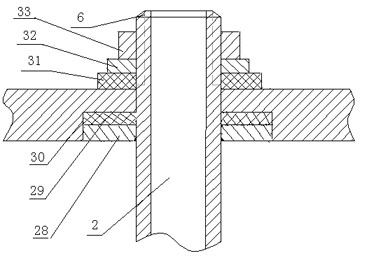

Continuous micro-reaction device and method for preparing meta-aramid resin and product

ActiveCN106478940AEasy transferReduce polydispersityChemical/physical/physico-chemical microreactorsMonocomponent polyamides artificial filamentAfter treatmentEngineering

A continuous micro-reaction device for preparing meta-aramid resin comprises a prepolymerization system, a polycondensation system, an after-treatment system and a heat exchange system, wherein the prepolymerization system, the polycondensation system and the after-treatment system are connected in sequence, and the heat exchange system is connected with the prepolymerization system and the polycondensation system to control temperatures of the prepolymerization system and the polycondensation system. The continuous micro-reaction device is characterized in that the prepolymerisation system comprises a raw material storage device, a micro-mixer and a micro-reactor which are connected in sequence; the polycondensation system comprises a multistage micro-screw device, and the micro-reactor is connected with multistage micro-screw device. The continuous micro-reaction device for preparing the meta-aramid resin improves the heat transfer effect at the polycondensation stage and the mass transfer effect at the polycondensation stage during preparation of the meta-aramid resin, and achieves the purpose of improving the performance of a meta-aramid resin product. The invention further provides a continuous micro-reaction method for preparing the meta-aramid resin and the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

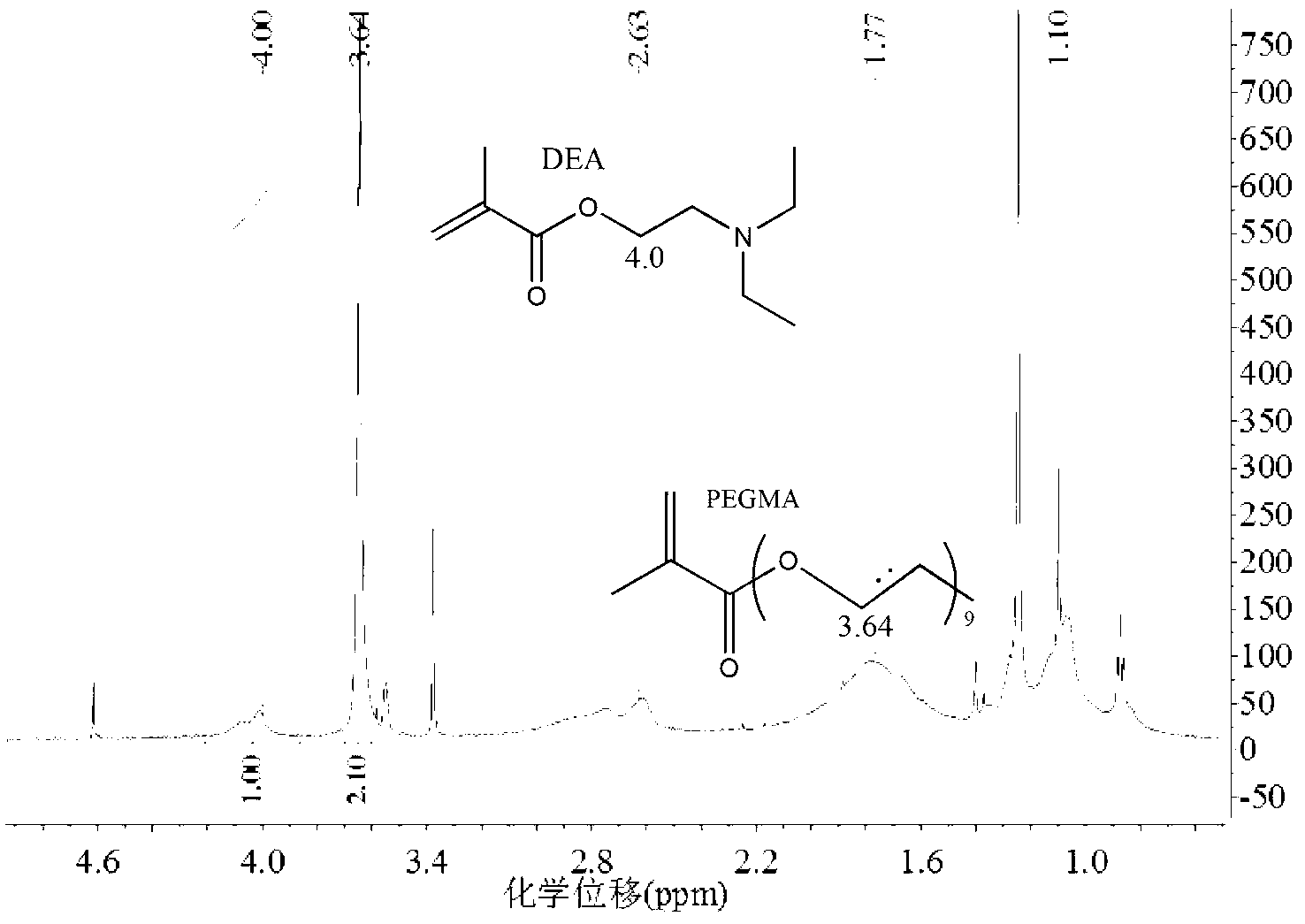

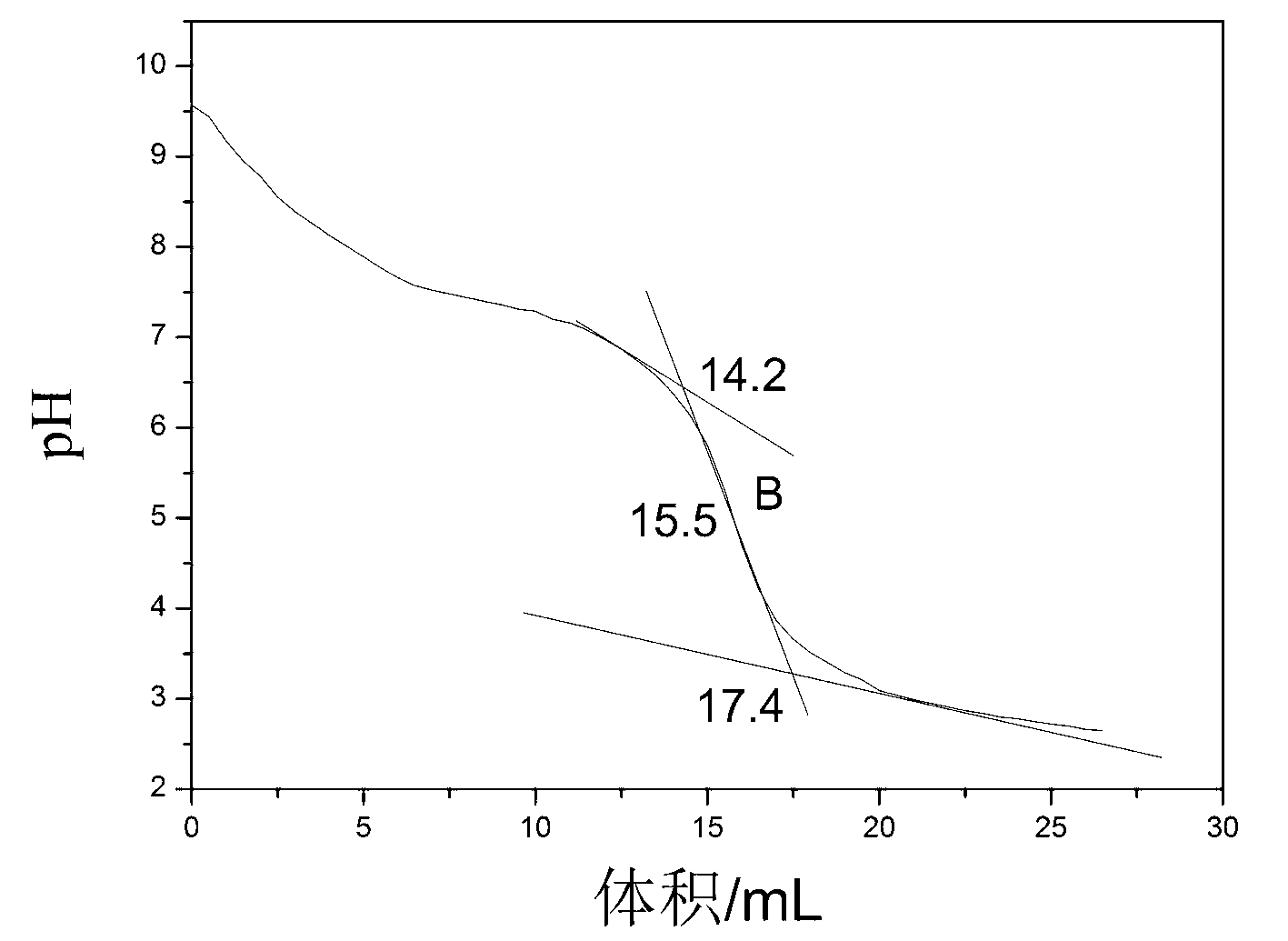

Preparation method of pH responsive cation nanogel

InactiveCN103275268AGood pH responsivenessImprove dispersion stabilityDispersion stabilityMethacrylate

The invention discloses a preparation method of pH responsive cation nanogel. The preparation method comprises the following steps: lauryl sodium sulfate and polyethylene glycol dimethyl acrylic ester are sufficiently dissolved in water to prepare a water-phase solution, ethylene glycol dimethacrylate and cationic monomer methylacrylic acid-(N, N-diethyl amine) ethyl ester or 2-(diisopropyl amino) ethyl methacrylate are uniformly mixed to obtain a mixture, and then the mixture is added into the water-phase solution to prepare microemulsion, and a water solution with an initiator is added in the microemulsion to react for 20-24 h to obtain the pH responsive cation nanogel dispersion liquid. The nanogel prepared has good pH responsiveness and dispersion stability, can be placed stably for more than 3 months, and the number-average grain size of the nanogel is smaller than 100 nm.

Owner:TAIYUAN UNIV OF TECH

Surface sizing agent and its production method

InactiveCN101457499ASubstantiveGood water solubilityWater-repelling agents additionFunctional monomerMechanical stability

The invention relates to a method for preparing a surface sizing agent for papers. The raw materials used for preparing the surface sizing agent for papers consist of main agents and assistant agents. The main agents are rigid monomers, soft monomers and functional monomers; and the assistant agents are compound emulsifying agents, protective colloids and evocating agents. The proportions of the main agents by weight are as follows: 100 portions of rigid monomers, 40 to 100 portions of soft monomers and 5-40 portions of functional monomers; and the proportions of the assistant agents by weight are as follows: 1 to 10 portions of compound emulsifying agents, 1 to 10 portions of protective colloids and 1 to 8 portions of evocating agents. Compared with the styrene-maleic anhydride surface sizing agent prepared by common emulsifying agents, the surface sizing agent for papers prepared by the method has good mechanical stability, the latex contains no residual emulsifying agents, the particle surface is clean, and no side influence resulted from the emulsifying agents is existed during the sizing and drying process; the surface sizing agent has good membrane forming performance on the paper surface so as to provide excellent water-proof performance and surface flatness for the paper; and the surface sizing agent can increase the stiffness and the smoothness of the paper surface greatly.

Owner:上海埃格环保科技有限公司

Ultrasonic atomization micro-mixer, micro-channel reactor, prepolymerization system and para-aramid resin continuous polymerization reaction system and method

PendingCN110605079ASolve removeEasy to removeProcess control/regulationSequential/parallel process reactionsInlet channelUltrasonic atomization

The invention provides an ultrasonic atomization micro-mixer, an ultrasonic oscillation micro-channel reactor, a prepolymerization system and a para-aramid resin continuous polymerization reaction system and method. The ultrasonic atomization micro-mixer comprises a mixing reactor body and an ultrasonic atomizer. The side lower part of the mixing reactor body is connected with a first raw materialinlet channel and a second raw material inlet channel in a penetrating manner, The ultrasonic atomizer acts in the first raw material inlet channel and the second raw material inlet channel and is used for atomizing a first raw material and a second raw material. A first outlet is formed in the upper end of the mixing reactor body, and a second outlet is formed in the lower end of the mixing reactor body. According to the technical scheme, the problem that in the para-aramid resin preparation process, reaction heat in the pre-polymerization stage is difficult to remove, and consequently temperature rise is large is solved, implosion and generation of low-molecular-weight byproducts caused by local overheating of a reaction system are prevented, and it is guaranteed that the intrinsic viscosity of product resin is stable and controllable.

Owner:惠生(中国)投资有限公司

Preparation method for polycarboxylate high-performance water reducer

Provided is a preparation method for a polycarboxylate high-performance water reducer. The water reducer is prepared by copolymerization reaction of macromolecule monomer methoxy polyethylene glycol mono(meth) acrylate ester, small molecule monomer (meth)acrylic acid and sodium styrene sulfonate in an aqueous solution under the protection of inert gas and the action of a redox initiation system and a chain transferring agent. According to the invention, a high-activity redox initiation system is employed, which enhances the polymerization rate, reduces polymerization temperature, shortens reaction time, ensures non-hydrolysis of macro-molecular polyester monomers in the process of polymerization and a high conversion rate of raw materials, and guarantees that polymers have long side chains arraying at uniform intervals and an ideal comb shaped molecular structure. The water reducer prepared in the invention has the characteristics of a high water-reducing rate, a small slump loss and the like, and enables concrete with the water reducer to have high strength; simultaneously, the copolymerization reaction is carried out in water in the method, and therefore the method has the characteristics of simple preparation technology, environmental protection, low cost, etc.

Owner:江苏天音化工有限公司 +1

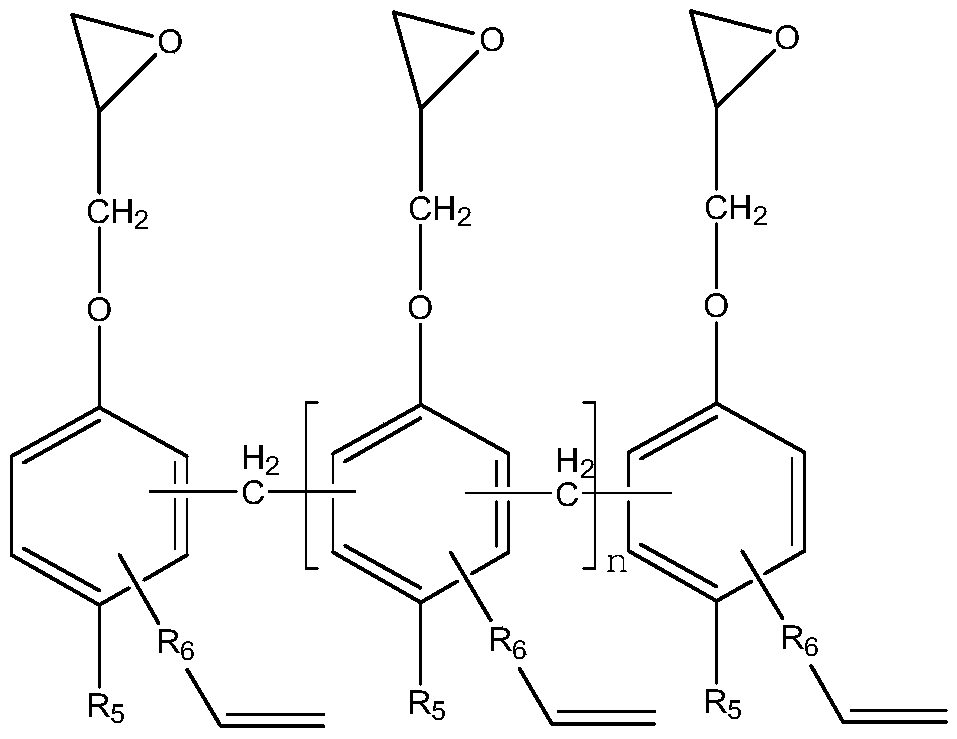

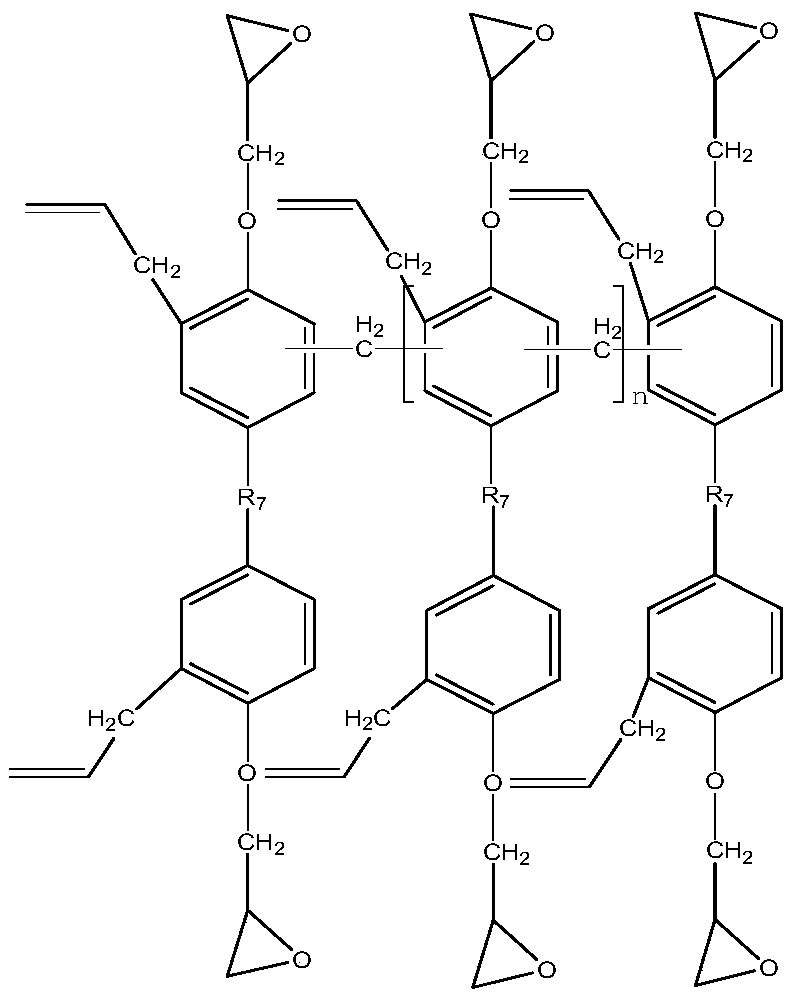

Modified hydrocarbon resin prepolymer, copper-clad plate and preparation method of copper-clad plate

ActiveCN111072979AImprove heat resistanceHigh peel strengthSynthetic resin layered productsLaminationEpoxyImide

The invention discloses a modified hydrocarbon resin prepolymer, a copper-clad plate and preparation methods of the modified hydrocarbon resin prepolymer and the copper-clad plate. The modified hydrocarbon resin prepolymer is prepared by mixing and reacting 50-450 parts by mass of hydrocarbon resin, 50 parts by mass of a mixture of epoxy resin / maleimide resin containing double bonds, 1-5 parts bymass of an initiator A and 180-280 parts by mass of a solvent A through a micro-channel reactor and removing the part of the solvent; the modified hydrocarbon resin copper-clad plate is prepared froma the composition of the modified hydrocarbon resin prepolymer, high-heat-resistance high-toughness low-dielectric fluorenyl benzoxazine resin, an inorganic filler, an initiator B, an accelerator A, areinforcing material with a mass ration being 90: (10-30): (40-100): (0.01-1): (0.01-1): (70-200); the prepared modified hydrocarbon resin copper-clad plate has the characteristics of low dielectricconstant, low dielectric loss, low water absorption, high glass-transition temperature and high peel strength.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Modified hydrocarbon resin prepolymer, modified hydrocarbon-DCPD epoxy composite material copper-clad plate and preparation method

The invention discloses a modified hydrocarbon resin prepolymer, a modified hydrocarbon-DCPD epoxy composite material copper-clad plate and a preparation method thereof. The modified hydrocarbon resinprepolymer is prepared by mixing and reacting 50-200 parts by mass of hydrocarbon resin, 50 parts by mass of a resin mixture containing double-bond benzoxazine resin / modified polyphenyl ether resin,1-5 parts by mass of an initiator A and 110-280 parts by mass of a solvent A through a micro-channel reactor and removing part of the solvent. The modified hydrocarbon-DCPD epoxy composite material copper-clad plate is prepared by thermally curing a composition and a copper foil, wherein the mass ratio of a modified hydrocarbon resin prepolymer to DCPD epoxy resin to an inorganic filler to an initiator B to an accelerant A to a reinforcing material is 90: (10-30): (40-100): (0.01-1): (0.01-1): (70-200); the ceramic has the characteristics of low dielectric constant, low dielectric loss, low water absorption, high glass-transition temperature and high peel strength.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Automatic control method of butadiene polymerization

ActiveCN101864017ARealize automatic controlHigh coincidenceSimultaneous control of multiple variablesLower limitAutomatic control

The invention relates to an automatic control method of butadiene polymerization, which comprises the steps that: the reaction temperature is divided into six stages, when the temperature in a reactor changes, the actual value of the temperature and the set valve of the temperature have difference, and the output valve of a PID regulation action temperature regulator is taken as the set valve of a liquid ammonia regulator; the temperature of the reactor is controlled within the normal range; when the pressure exceeds the high limit valve, the set valve of the temperature regulator at this moment is stored into a register, and the set valve of the temperature regulator is endowed with lower valve again; the pressure in the reactor is reduced; when the liquid level of ammonia reaches to the high limit valve, the output valve of the ammonia regulator is manually set into a full-closed state until the liquid level of ammonia is lower than low limit valve, and temperature-liquid level cascade stage adjustment is changed back; and the data stored into the register is taken as the set valve of the temperature regulator again for automatic control. The automatic control method improves the quality of butadiene, leads the conversion rate to reach 91-92%, avoids the phenomena of implosion and surfusion, reduces the energy consumption and material consumption, and ensures a device to have stable operation.

Owner:PETROCHINA CO LTD

Polymer microgel oil-displacing agent, preparing method thereof and applications thereof

The invention relates to the technical field of petroleum recovery efficiency increasing, profile control, flooding, water plugging, and other production increasing fields in oilfield development, and discloses a polymer microgel oil-displacing agent, a preparing method thereof and applications thereof. By adopting a water soluble hydroxy-containing monomer and / or a water soluble hydroxy-containing polymer as the main molecule and by adopting an acrylamide monomer as an auxiliary molecule, the polymer microgel oil-displacing agent is prepared by one-step in-situ crosslinking through an inverse emulsion polymerization method. The preparing process is simple. The prepared polymer microgel oil-displacing agent has characteristics of hydration swelling, elastic deformation, high-temperature resistance, and high-salt resistance, and can be used in an oilfield having a temperature of 20-160 DEG C.

Owner:中国石油勘探开发研究院采油工程研究所 +1

Synthesizing method of reticular cross-linked zinc polyacrylic acid and using method of synthesized product

ActiveCN106117412AImprove energy efficiencyContribution to energy saving and emission reductionNickel accumulatorsFertilizerPower performance

The invention relates to a synthesizing method of cross-linked zinc polyacrylic acid and a representative using method of the cross-linked zinc polyacrylic acid, in particular to a synthesizing method of reticular cross-linked zinc polyacrylic acid and a using method of the cross-linked zinc polyacrylic acid in batteries. According to the synthesizing method, acrylic acid serves as a monomer, zinc oxide serves as a neutralizing agent, and synthesizing of the reticular cross-linked zinc polyacrylic acid is achieved in an aqueous system under the action of a cross-linking agent and a one-component initiator. A synthesized product is used for replacing an anode active material of a nickel-zinc secondary battery, in this way, the representative using method of the cross-linked zinc polyacrylic acid is achieved, and the practicability of the cross-linked zinc polyacrylic acid in improving low-temperature power performance and self-discharge control of a nickel-zinc rechargeable battery and the like is achieved. A reference is provided for application of the cross-linked zinc polyacrylic acid in silver-zinc batteries, MnO2-zinc batteries, Edison batteries and the like. The polymerization method has the advantages of being short in process, easy to operate, high in safety, low in product cost and the like, and a basis is laid for application of the synthesized product in the fields such as non-toxic preservation of potatoes, efficient utilization of feminine sanitary towels, green mildew preventives for leather, micro-element fertilizers and accelerants.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Coating-containing core as well as core holder anti-corrosion method and core displacement experiment method

ActiveCN103257101AScratch resistantCorrosion resistantPreparing sample for investigationPermeability/surface area analysisRock coreTemperature resistance

The invention provides a coating-containing core as well as a core holder anti-corrosion method and a core displacement experiment method. The coating-containing core comprises a pretreated raw material core and a coating which is located on the surface of the pretreated raw material core. The core holder anti-corrosion method comprises the following steps of: coating paint on the contact surface between the pretreated raw material core and a core holder before a core displacement experiment, and drying to obtain the coating-containing core. The core displacement experiment method comprises the following steps of: coating paint on the contact surface between the pretreated raw material core and the core holder, drying to obtain the coating-containing core, and carrying out a core CO2 displacement experiment by using the coating-containing core. The coating has high temperature resistance, corrosion resistance, airtightness and core surface adhesiveness. According to the coating-containing core as well as the core holder anti-corrosion method and the core displacement experiment method, the core holder can be protected from CO2 corrosion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

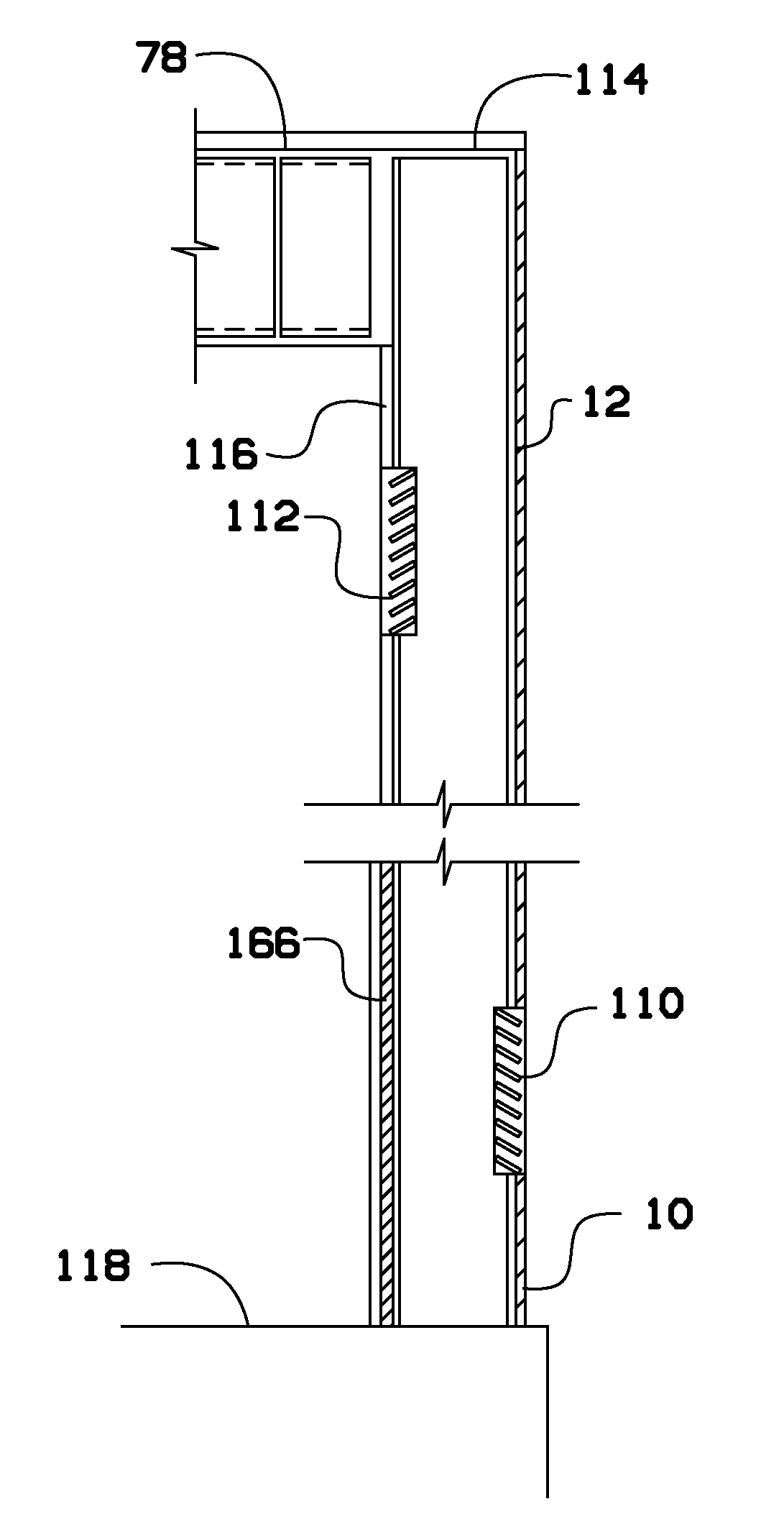

Shelter that is capable of withstanding strong winds

ActiveUS8505253B1Improve stabilityEasy to adjustHuman health protectionDucting arrangementsAnchor boltLoad bearing

A shelter is capable of withstanding extreme winds. The shelter comprises a concrete foundation mechanically coupled to a lower continuous track by an anchor bolt. The lower continuous track is mechanically coupled to load bearing studs and second load bearing studs. The load bearing studs and second load bearing studs are mechanically coupled to an upper continuous track. The arrangement of studs secured between two tracks provides additional stability against variable wind loads that normally damage buildings. The load bearing studs are arranged with second load bearing studs to create walls, where the walls are covered by a first exterior layer and a second exterior layer. The first exterior layer plates provide protection against live force loads and the second external layer provides protection against vibration. The upper continuous track is mechanically coupled to roofing.

Owner:MEDFORD HOLLAND

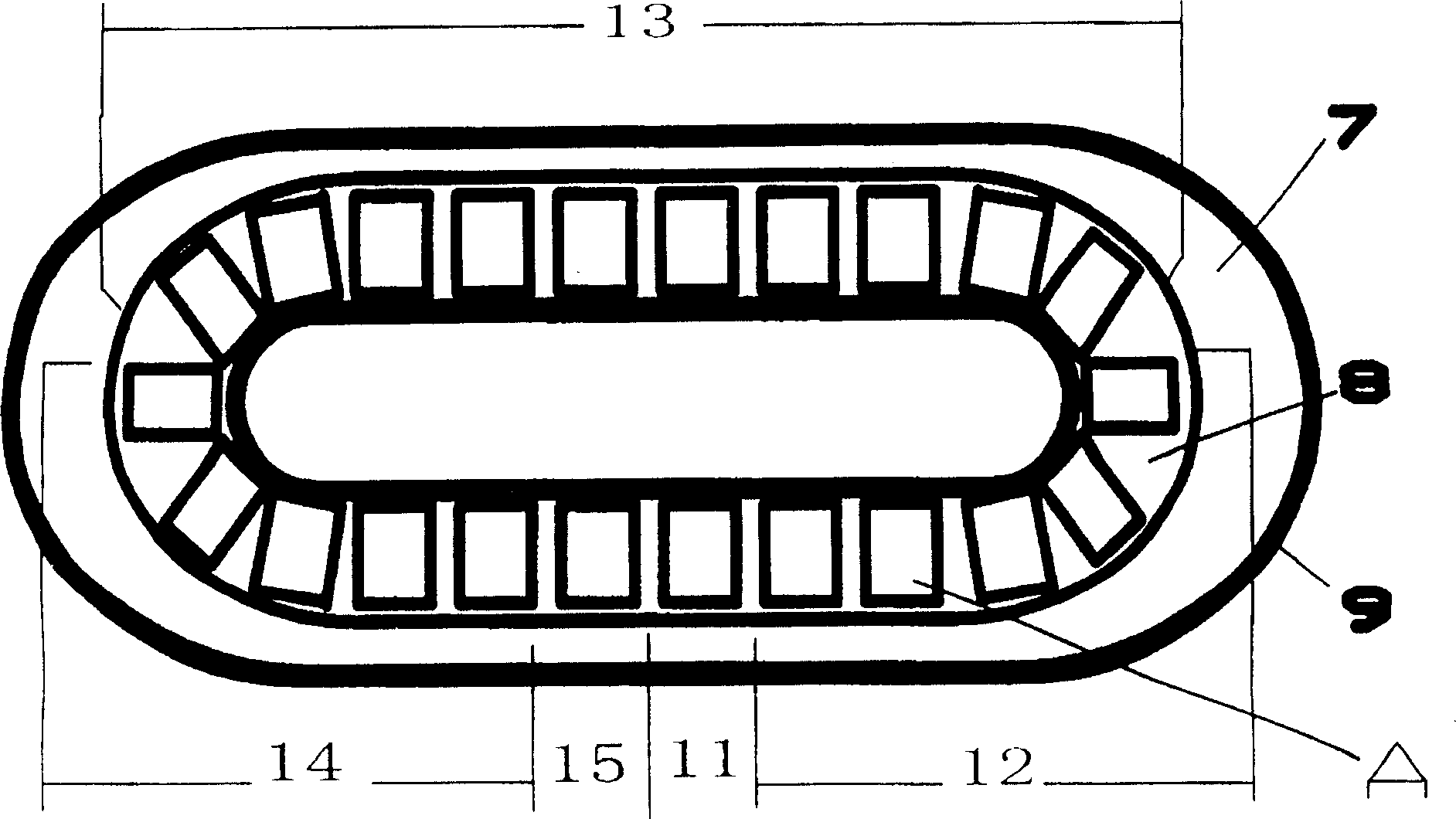

Design method of combined electrolytic tank

The invention relates to a design method of a water electrolysis hydrogen-oxygen generation device, in particular to a design method of a combined electrolytic tank. The electrolytic tank is characterized by being formed by sleeving and combining an anode, electrodes and a cathode in turn, particularly formed by sleeving two or eight tubular electrodes (4) with different tube diameters between a round anode (2) and a tubular cathode (8) at equal intervals in turn. The electrolytic tank has high anti-detonating property and sealing performance, a small sealing surface and a simple structure and is convenient to assemble and disassemble, electrolyte is difficult to leak, and the manufacturing cost is reduced.

Owner:SHAANXI HUAQIN NEW ENERGY TECH CO LTD

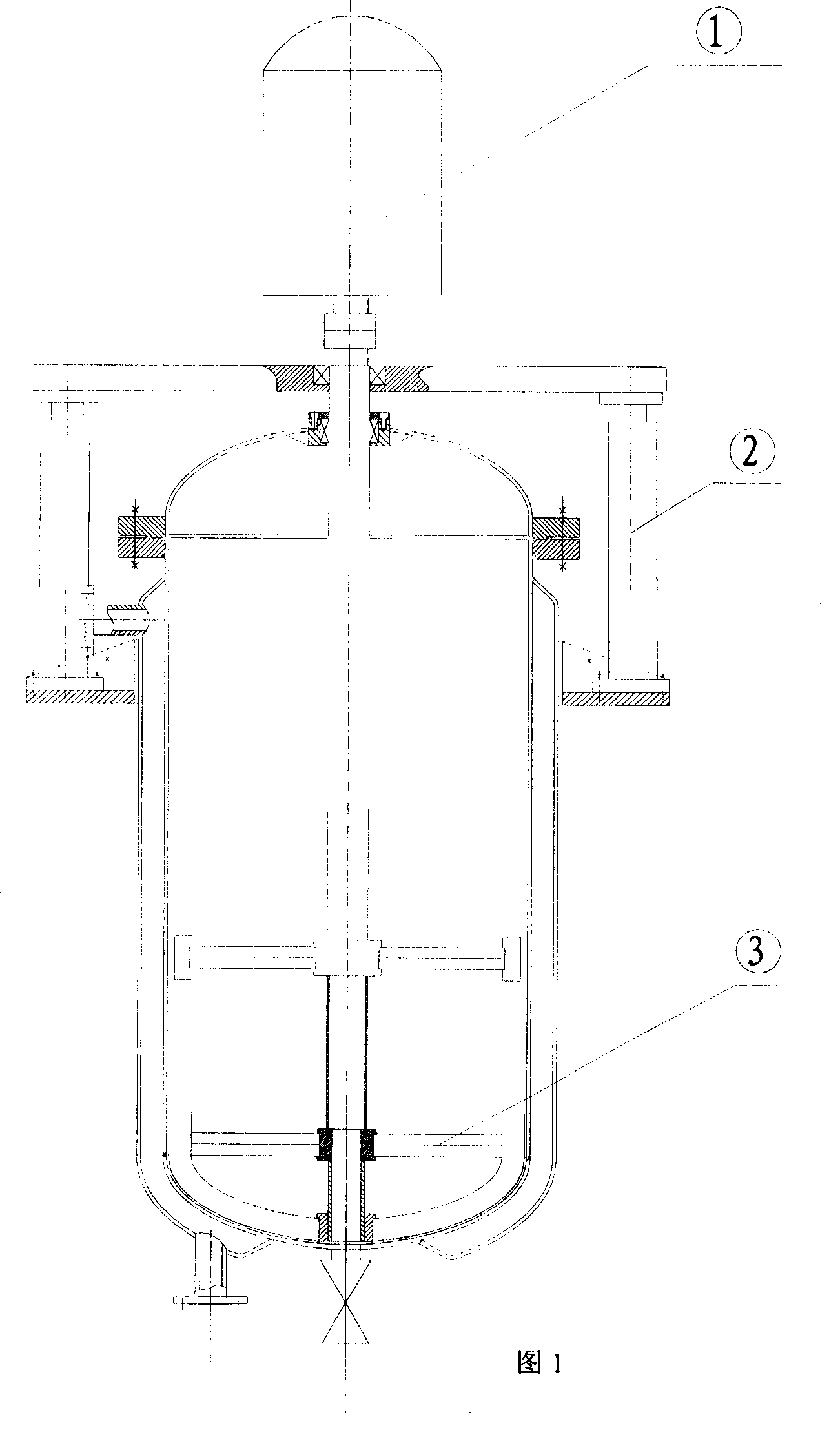

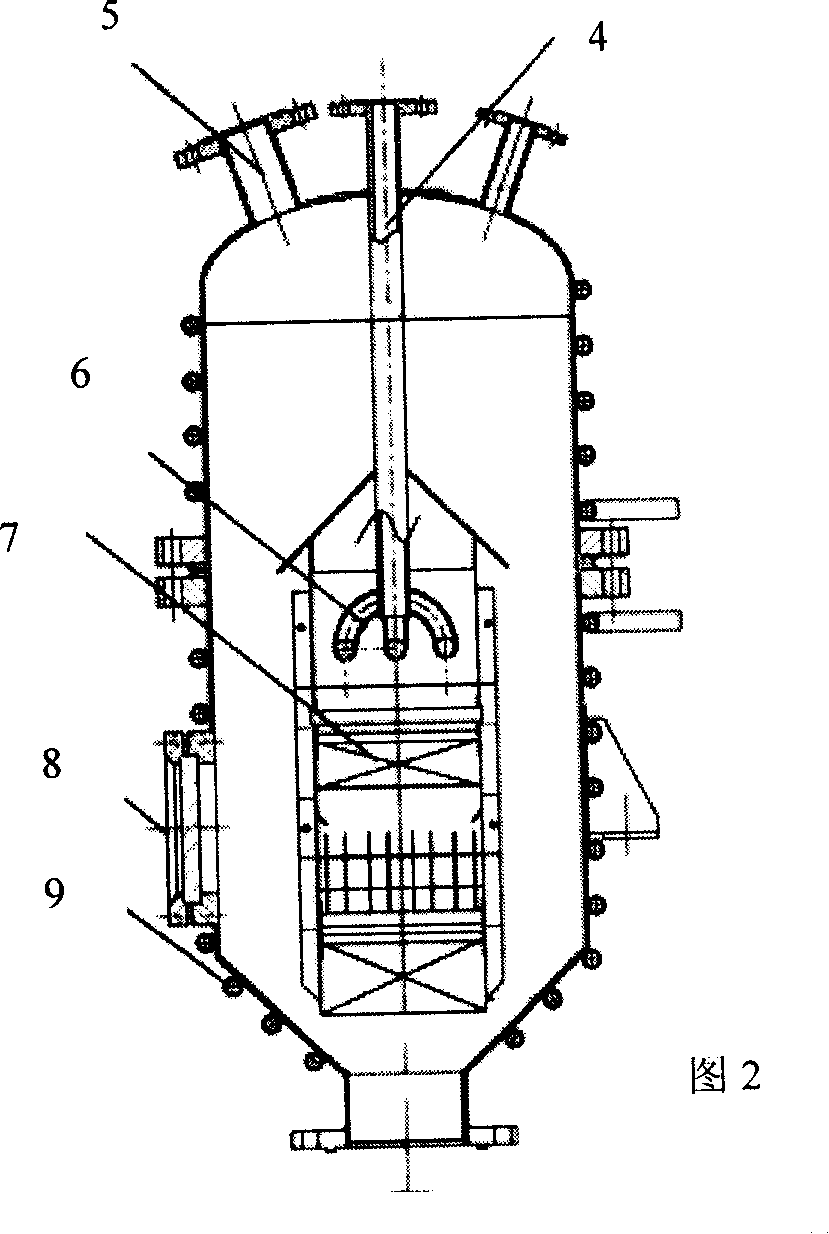

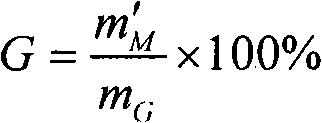

Method and device for preparing water-absorbent resin

The invention discloses a process for preparing absorbent resin comprising, charging water, sodium hydroxide, acrylic acid, N, N'-methylene di-propenamide and potassium peroxodisulfate into stirring still, homogenizing, going through preheating section, reaction section, heat preservation section in sequence, carrying out heat exchange and polymerization reaction.

Owner:WUHAN UNIV +1

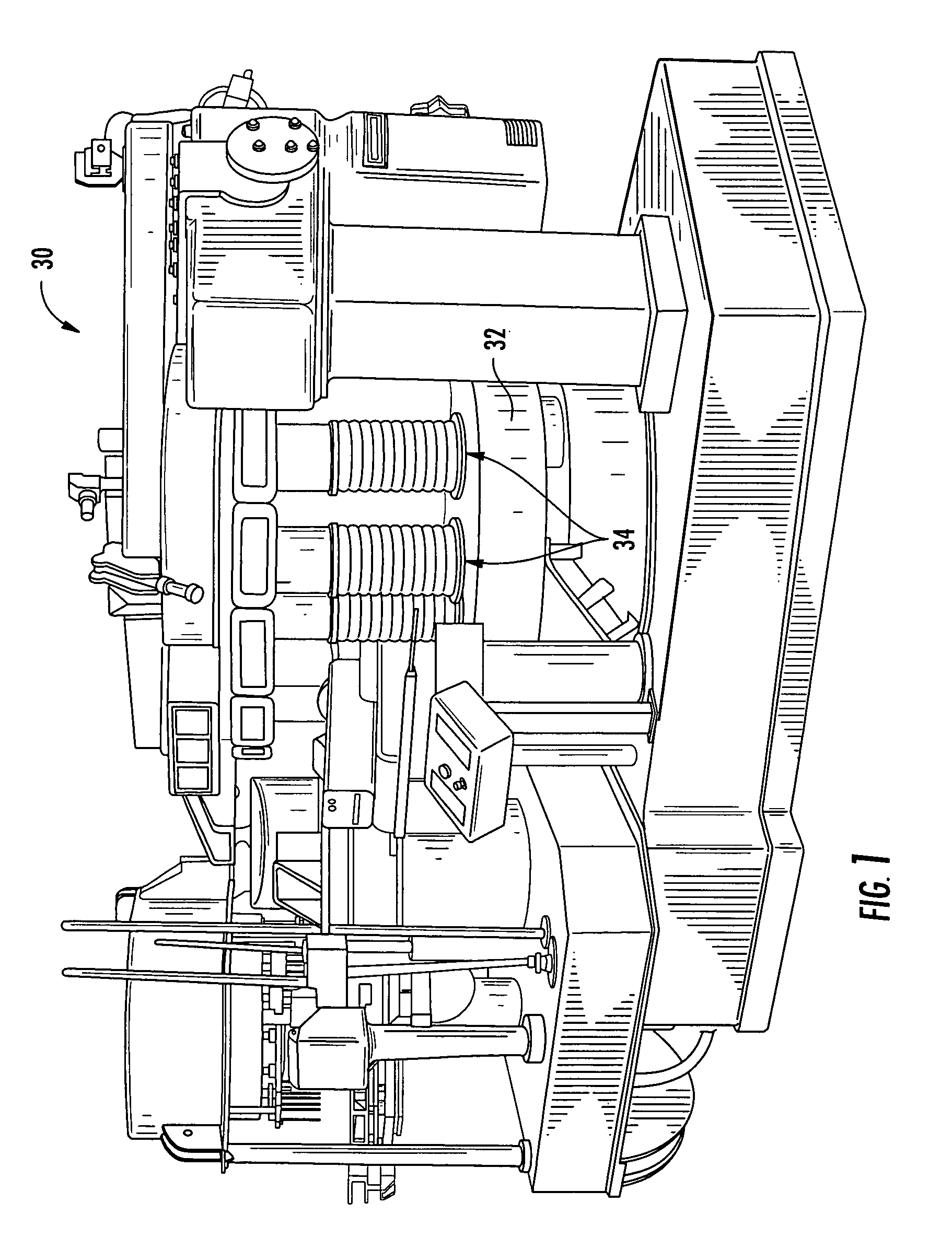

Apparatus and method for seaming a metal end onto a composite can

A seaming apparatus and method wherein a composite container with a metal end loosely placed thereon is supported on a lifting plate in a vacuum chamber, air is evacuated from the chamber, the lifting plate is raised to engage the metal end with a magnetic seaming chuck, the lifting plate is then lowered to lower the container (optionally aided by one or more magnets in the lifting plate) so as to produce a gap between the metal end and the container, an inert gas is introduced into the chamber, the lifting plate is then raised to engage the container with the metal end, and the metal end is seamed onto the container.

Owner:SONOCO DEV INC

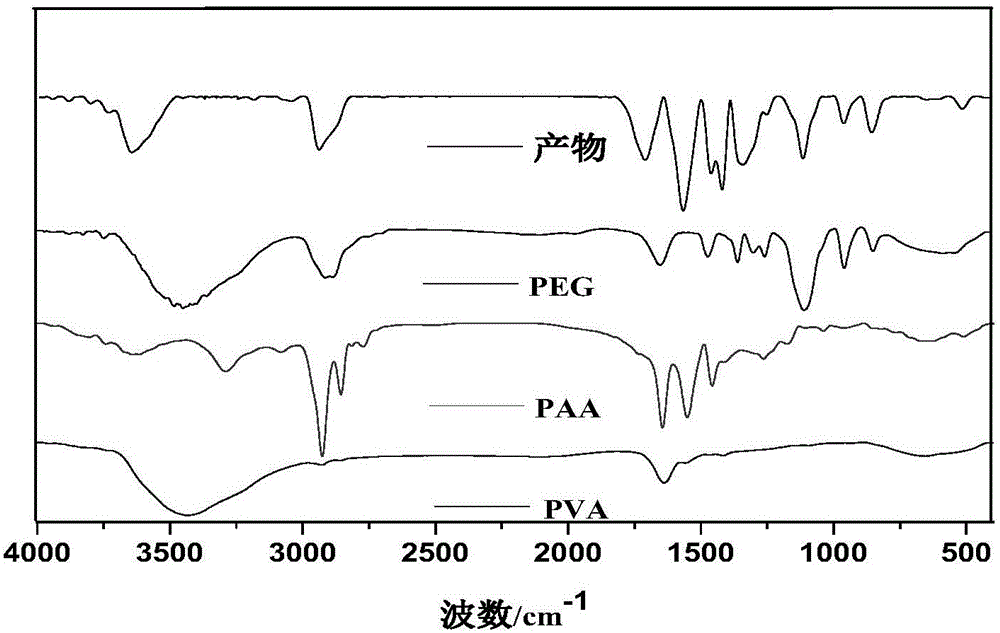

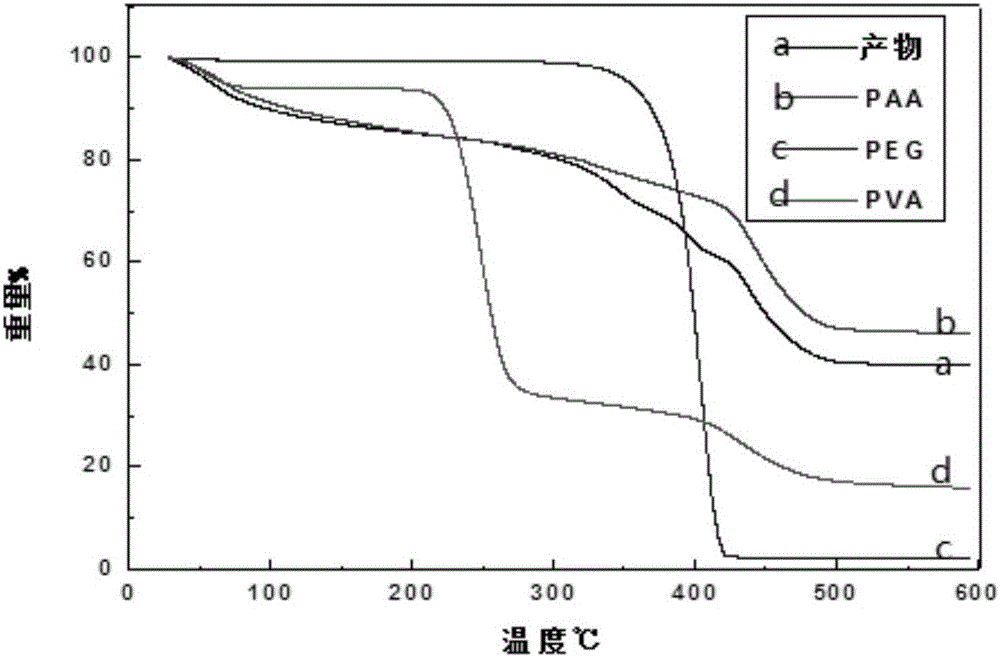

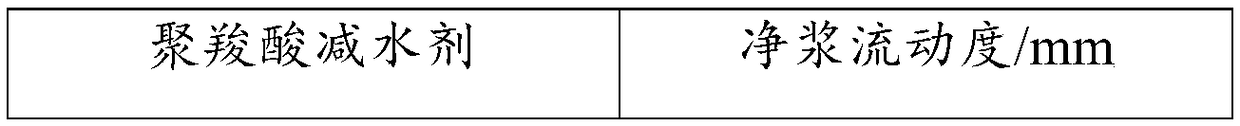

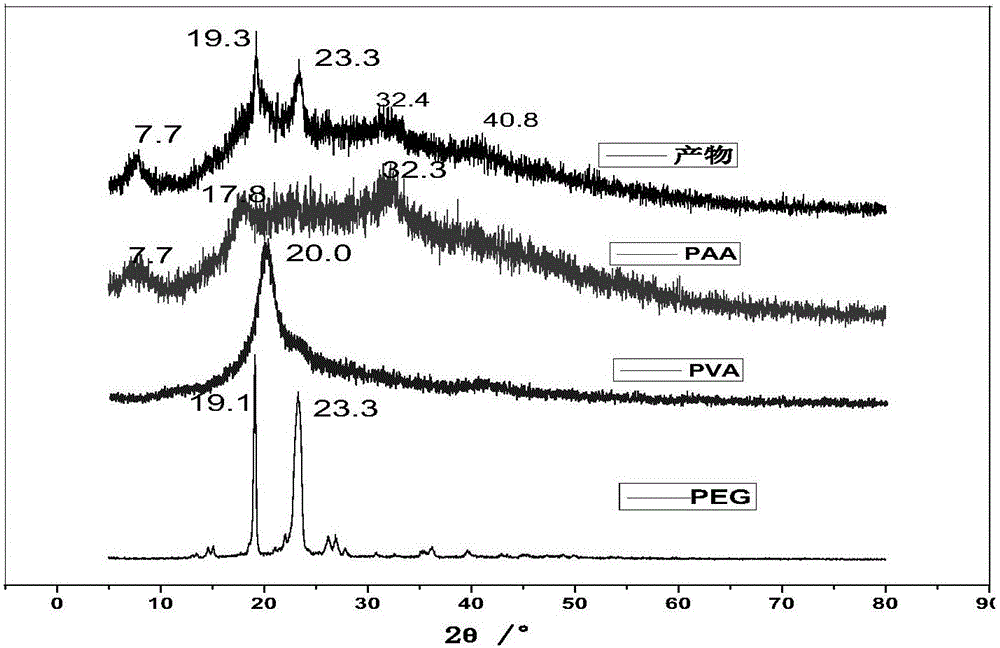

Water-retaining humic acid controlled-release fertilizer and preparation method thereof

ActiveCN105906414AEasy to degradeMeet environmental protection requirementsOrganic fertilisersLayered/coated fertilisersWater savingCross-link

The invention discloses a water-retaining humic acid controlled-release fertilizer and its preparation method. The preparation method comprises the following steps: firstly preparing a reaction solution of complex water-absorbent resin from PEG, PVA and AA under the action of an initiator and a cross-linking agent; putting humic acid particles into a coating machine before stopping stirring the reaction solution; and spraying the prepared reaction solution of water-absorbent resin while rotating, uniformly stirring, heating up, and drying until water content is not more than 5.0% so as to obtain PEG / PVA / PAA complex water-absorbent resin coated humic acid water-retaining controlled-release particles. The coating in the invention has water-saving, water-retaining and biodegradable properties. Thus, soil structure is improved but not affected; loss of nutrients is prevented; and the coating has a strong effect of absorbing nutritive elements such as K<+>, NH4<+> and NO3<+>, etc. In addition, the coating material is a composite material with a three-dimensional special network structure. The coating material has high jelly strength, is not easy to damage and can prolong controlled-release period.

Owner:SHAANXI UNIV OF SCI & TECH

Anti-static high-viscosity acrylate adhesive and preparation process thereof

ActiveCN106398602AReduced VOCEnvironmentally friendlyNon-macromolecular adhesive additivesMacromolecular adhesive additivesIsooctyl acrylateDispersity

The invention relates to the technical field of adhesives, in particular to an anti-static high-viscosity acrylate adhesive and a preparation process thereof. The anti-static high-viscosity acrylate adhesive comprises the following raw materials components in parts by weight: 800 parts of butyl acrylate, 80 parts of ethylhexyl acrylate, 70 parts of acrylic acid, 1,364 parts of ethyl acetate, 7 parts of acrylic acid-2- hydroxyethyl acrylate, 10 parts of AIBN, 230 parts of rosin resin and 1.3 parts of graphite powder. Downstream products of the product do not have volatilization of methylbenzene, and are environmentally friendly; and meanwhile, a method for adding materials in different steps is adopted in the preparation process of the product, implosion is prevented effectively, the product is high in dispersity, so that VOC amount of the downstream products is reduced obviously, more importantly, the viscosity is improved, and the product has anti-static performance.

Owner:YASUSA CHEM CO LTD

Solution polymerization preparation method of perfluorinated sulfonic acid resin

The invention discloses a solution polymerization preparation method of perfluorinated sulfonic acid resin. The method comprises the following steps: taking tetrafluoroethylene A, a monomer B containing a sulfonyl fluoride terminal group and a monomer C containing a sulfonyl fluoride terminal group as comonomers, pre-adding a fluorine-containing solvent and the comonomers into a reactor, performing heating to 20-120 DEG C at a pressure of 0.2-5 MPa, adding an initiator to initiate a polymerization reaction, and supplementing the comonomers in the reaction process so as to finally obtain the sulfonyl fluoride type perfluorinated sulfonic acid resin. The structural formula of the monomer B is CF2 = CFO[CF2CF(CF3)O]a[CF2CF2]bSO2F, wherein the a is an integer from 0 to 1, and the b is an integer from 1 to 2. The structural formula of the monomer C is as follows: the perfluorosulfonic acid resin disclosed by the invention further comprises a fluorine-containing cyclic monomer unit containing a perfluoroalkoxy group of an ether bond and a sulfonyl fluoride group, so that the processability in a general solvent is improved, and the perfluorosulfonic acid resin is high in conductivity and oxygen permeability. The perfluorinated sulfonic acid resin with low hydrogen permeability is provided for proton exchange membrane application in a fuel cell or high oxygen permeability is provided for electrode application. The solution polymerization method is low in dangerousness, and the molecular weight and molecular weight distribution of the product are easy to adjust.

Owner:JUHUA GROUP TECH CENT

Lignin modified thermoplastic phenolic resin and preparation method thereof

The invention relates to lignin modified thermoplastic phenolic resin which is characterized in that the thermoplastic phenolic resin is prepared by a component A and a component B through polycondensation. The component A is a product obtained through an activating reaction on lignin by using a phenolic compound and rare-earth oxide / an activated carbon catalyst, and the component B is an acid catalyst and an aldehydes compound. A carrier of the rare-earth oxide / the activated carbon catalyst is activated carbon, and active component loaded on the activated carbon is the rare-earth oxide. The invention further relates to a method for preparing the lignin modified thermoplastic phenolic resin. The method is that the rare-earth oxide / the activated carbon catalyst is added to increase absolute quantity of phenolic hydroxyl groups and alcoholic hydroxyl groups of the lignin, increase of phenolic hydroxyl group quantity can substantially improve reactivity of the lignin, and a substitution rate of the lignin on phenol is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

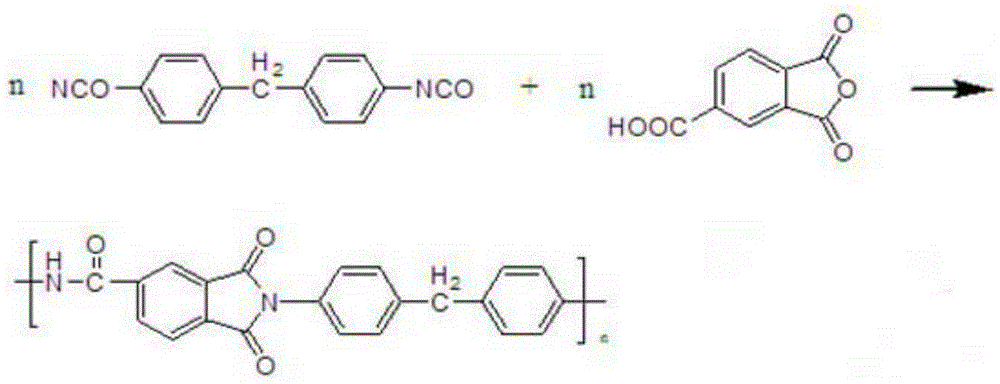

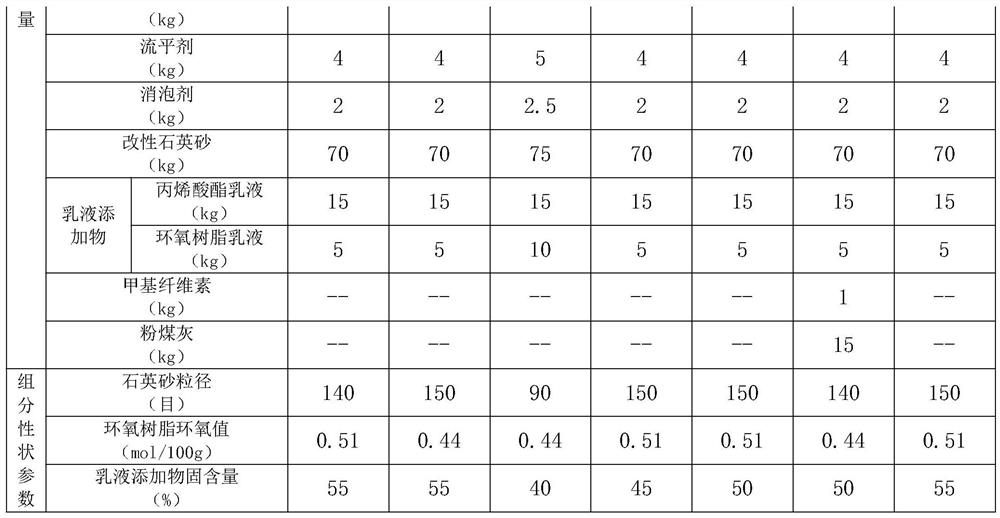

Polyimide polymer preparation method

ActiveCN105295047ASimplify feeding stepsThe synthesis steps are simplePolymer scienceReaction temperature

The invention relates to a polyimide polymer preparation method. The polyimide polymer preparation method comprises the following steps: dissolving trimellitic anhydride in 1-methyl-2-pyrrolidone; then, adding diphenyl-methane-diisocyanate and a catalyst; controlling proceeding of reaction by the staged heating method to prepare a polyimide polymer, wherein the feeding molar ratio of trimellitic anhydride to diphenyl-methane-diisocyanate is 1:(1-1.2). According to the polyimide polymer preparation method, a one-step synthesis process is adopted, trimellitic anhydride and diphenyl-methane-diisocyanate with a certain ratio are selected in a proper solvent, and under the action of the catalyst, heating reaction is realized by the staged heating method to prepare polyimide. The polyimide polymer preparation method is very simple, dispenses with harsh reaction conditions and excessive reagents and experimental steps, and can adjust the molecular mass of prepared polyimide by controlling the reaction temperature and time.

Owner:SUZHOU TAIHU ELECTRIC ADVANCED MATERIAL CO LTD

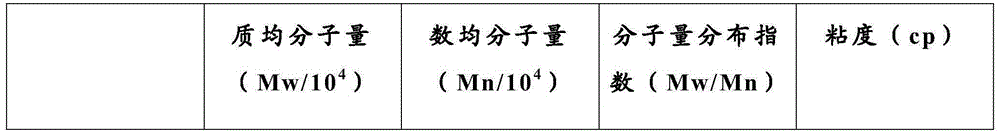

Self-leveling mortar and preparation process thereof

The invention relates to the field of mortar, and particularly discloses self-leveling mortar and a preparation process thereof, and the self-leveling mortar is mainly prepared from the following raw materials by mass: 90-100 parts of aluminate cement; 5-6 parts of a water reducing agent; 4-5 parts of leveling agent; 2-2.5 parts of a defoaming agent; 70-75 parts of modified quartz sand; 20-25 parts of an emulsion additive; and 20-25 parts of water; wherein the modified quartz sand is ethylenediamine modified quartz sand; and the emulsion additive is a mixed emulsion of an acrylate emulsion and an epoxy resin emulsion, and the dosage ratio of the acrylate emulsion to the epoxy resin emulsion is 3: (1-2). The self-leveling mortar prepared in the invention has higher wear resistance and a smoother surface, and can be directly used as a surface layer of a terrace.

Owner:杭州康勋建设有限公司

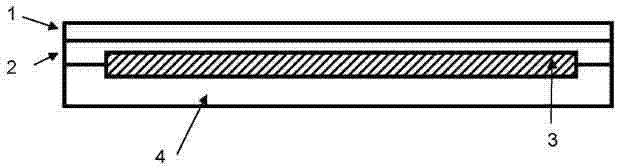

A solar cell laminate comprising crystalline silicon photo-electricity device and process to make such a laminate

InactiveCN103370797APrevent implosionStrong enoughSolar heating energyWaterborne vesselsFiberPolymer science

The invention is directed to a solar cell laminate comprising crystalline silicon photo-electricity device and comprising of the following layers: (i) a first layer comprising of a woven or knit glass mat and a thermoset polymer, (ii) a second layer comprising a crystalline silicon photo-electricity device, and (iii) a third layer comprising of a woven or knit fibre mat and a thermoset polymer.

Owner:FLEXSOL SOLUTIONS

Modified thermoplastic phenolic resin adhesive used in automobile brake pad and preparation method thereof

The invention provides a modified thermoplastic phenolic resin adhesive used in automobile brake pads and a preparation method thereof. The adhesive is prepared from following components, by weight: 100 parts of phenols, 73-80 parts of aldehydes, 0.05-0.08 parts of acids, 1-7 parts of nano organic modified montmorillonite, 2-4 parts of D-glucose and 1-7 parts of dialdehydes. The preparation method comprises following steps: (A) adding the nano organic modified montmorillonite and the acid into a reaction container according to ratio and stirring the mixture for 30 min at 50-60 DEG C; (B) increasing the temperature to 90-100 DEG C, adding 73-80 parts of aldehydes to the reaction liquid within 60-90 min, and continuously performing the reaction with temperature maintained for 30-60 min; (C) adding 2-4 parts of D-glucose to the reaction liquid, and performing a reaction for 10-20 min at 90-100 DEG C; (D) adding 1-7 parts of dialdehydes to the reaction liquid,, and performing a reaction at 90-100 DEG C for 25-40 min; and (E) starting a vacuum pump to control the pressure in the reaction container to be -0.08 MPa, and performing dehydration for 5 h to prepare the modified thermoplastic phenolic resin adhesive. The method increases the heat resistance and toughness of phenolic resin and reduces the contents of free phenols and volatiles in the resin.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

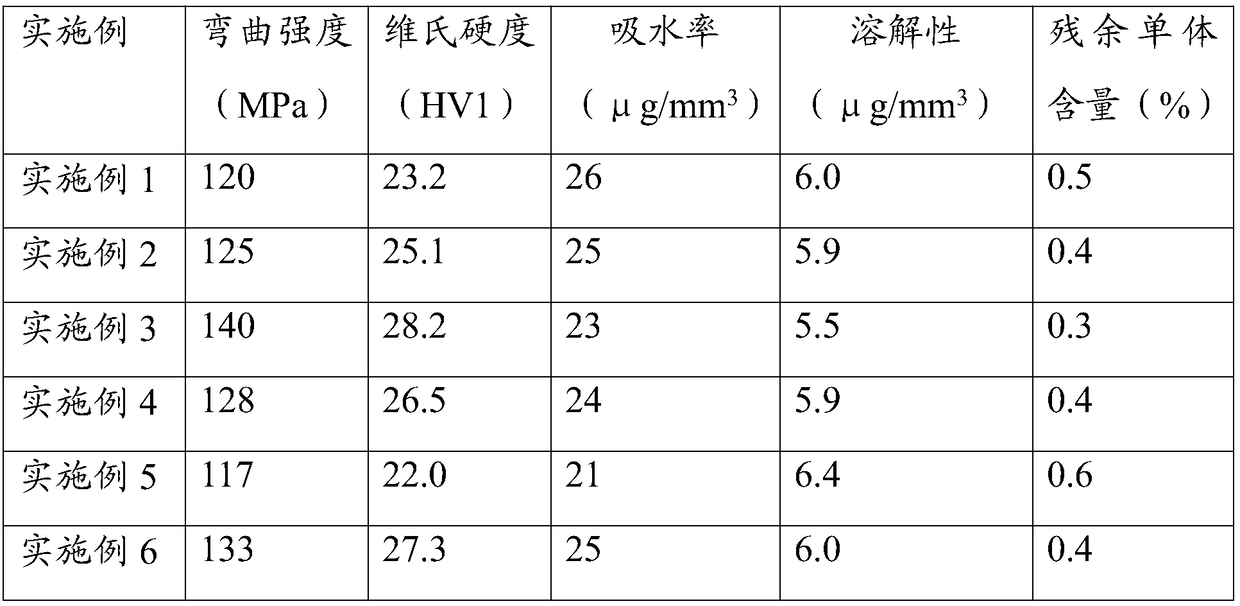

Dental CAD/CAM machinable PMMA and preparation method thereof

The invention discloses a dental CAD / CAM machinable PMMA and a preparation method thereof. Raw materials used are MMA monomers, initiators, cross-linking agents and colorants; the MMA monomers, the initiators and the cross-linking agents are added to a reactor, clockwise stirring of 20-30 turns is conducted, standing is conducted for 10-20 minutes, the MMA monomers, the initiators and the cross-linking agents are put into a water bath at 60-80 DEG C, and pre-polymerization is carried out; the raw materials are taken out after the pre-polymerization is completed, and the raw materials are placed in ice water to be cooled to 20-30 DEG C; the colorants are added to pre-polymerized slurry, then stirred for 30-60 minutes by using a stirrer, and packed into a mold by weight according to the product specifications, a polymerization reaction is carried out, after the completion of the polymerization, the mold is removed, and the PMMA is obtained. A bulk polymerization method has high production efficiency, no waste discharge, simple process, small floor space, low cost and convenient equipment cleaning.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

Preparation method of powdery carboxylic acid water reducing agent

The invention provides a preparation method of a powdery carboxylic acid water reducing agent. The preparation method includes the steps: (1) mixing a water reducing agent monomer and water, and heating and fusing mixture; (2) adding initiators, chain transfer agents and unsaturated carboxylic acid into a system fused in the step (1), performing mass polymerization reaction to generate a polycarboxylic acid water reducing agent precursor; (3) neutralizing and crushing the polycarboxylic acid water reducing agent precursor to prepare the powdery carboxylic acid water reducing agent. According the preparation method, water is added in the mass polymerization reaction, the water serves as a reactant to react with the water reducing agent monomer and the unsaturated carboxylic acid, the systemviscosity of the mass polymerization reaction is reduced, the powdery carboxylic acid water reducing agent with high performance is synthesized when effective generation of the mass polymerization reaction and generation of solid polycarboxylic acid water reducing agent are ensured, long-distance transportation of the water reducing agent is facilitated, transportation cost is reduced, and the application range of the polycarboxylic acid water reducing agent is widened, so that the water reducing agent is applicable to products such as dry-mixed mortar and high-performance concrete.

Owner:佳化化学(抚顺)新材料有限公司

Preparation method of high-performance low-viscosity glue for low-viscosity PET (polyethylene terephthalate) protective film

ActiveCN108864968AEasy to tear offImprove fitPolyureas/polyurethane adhesivesFilm/foil adhesive release linersOrganic solventPolyol

The invention provides a preparation method of high-performance low-viscosity glue for a low-viscosity PET protective film. The preparation method comprises the steps that macromolecular polyhydric alcohol is subjected to vacuum dehydration for 1-5 hours at the temperature of 100-120 DEG C, and then cooled to be 60-80 DEG C; isocyanate, an organic solvent and a catalyst are added, the mixture is subjected to thermostatic reaction for 2-6 hours under the condition of 500-1500 r / min; a chain extender is added to conduct chain extension reaction for 1-5 hours, and the product is cooled to be 30-50 DEG C; and a salt-forming agent and deionized water are added, high-speed shearing dispersing is conducted for 0.5-2 hours under the condition of 1000-3000 r / min, and the high-performance low-viscosity glue is obtained. The preparation technology is simple and easy to operate, and is suitable for industrialized production. The high-performance low-viscosity glue produced by adopting the method is applied to the PET protective film, so that the PET protective film has the characteristics of being low in viscosity, easy to tear, free of glue residue, good in adhesion, good in high temperatureresistance and excellent in mechanical performance.

Owner:NINGBO KELAIEN NEW MATERIAL TECH CO LTD

Method for preparing plates with three-dimensional images and texts and computer

The invention discloses a method for preparing plates with three-dimensional images and texts, which comprises the steps of: drawing a first prepolymer according to a first image on the surface of the first part of a mould to obtain an insert prepolymer; solidifying the insert prepolymer on the surface of a template to obtain an insert on the surface of the template after solidification; assembling the first part of the mould with the insert and the second part of the mould into the mould; injecting a second prepolymer into the mould, wherein the second prepolymer and the first prepolymer have the visual effect difference; and solidifying the second prepolymer in the mould to obtain the plates with the insert. Compared with the prior art, the invention has the advantages that the cost is beneficial to being reduced because the preparation working procedure of the mould with the insert is saved; the insert prepolymer is drawn on the surface of the template after being solidified; and the problems of difficult accurate positioning and fixing of mass separation components in the course of the casting of the insert or the injection molding of the insert.

Owner:LENOVO (BEIJING) CO LTD

Water-retaining chitosan bacteriostatic antibiotic fertilizer and preparation method thereof

ActiveCN105906413AEasy to degradeMeet environmental protection requirementsLayered/coated fertilisersFertilizer mixturesNutrientWater content

The invention discloses a water-retaining chitosan bacteriostatic antibiotic fertilizer and its preparation method. The preparation method comprises the following steps: firstly preparing a reaction solution of complex water-absorbent resin from PEG, PVA and AA under the action of an initiator and a cross-linking agent; putting chitosan particles into a coating machine before stopping stirring the reaction solution; and spraying the prepared reaction solution of water-absorbent resin while rotating, uniformly stirring, heating up, and drying until water content is not more than 5.0% so as to obtain PEG / PVA / PAA complex water-absorbent resin coated chitosan bacteriostatic antibiotic particles. The coating in the invention has water-saving, water-retaining and biodegradable properties. Thus, soil structure is improved but not affected; loss of nutrients is prevented; and the coating has a strong effect of absorbing nutritive elements such as K<+>, NH4<+> and NO3<+>, etc. In addition, the coating material is a composite material with a three-dimensional special network structure. The coating material has high jelly strength, is not easy to damage and can prolong controlled-release period.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com