Design method of combined electrolytic tank

A design method and electrolytic cell technology, applied in the direction of electrolytic components, electrolytic process, cells, etc., can solve the problems of large number of fastening bolts, complex combined structure, inconvenient loading and unloading maintenance, etc., so as to achieve resistance to deformation, displacement, and explosion resistance Good, easy loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

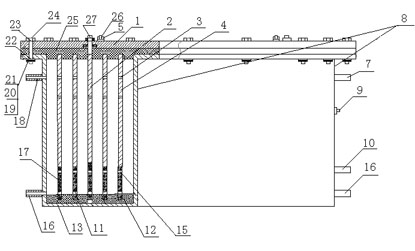

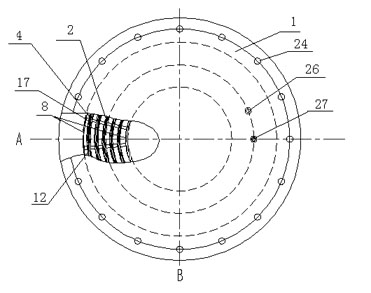

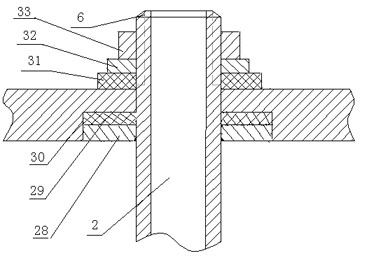

[0029] Embodiment 1 The design method of this combined electrolytic cell is composed of 2-8 tubular electrodes 4 with different pipe diameters and arranged in equal intervals between a circular anode 2 and a tubular cathode 8, which are sequentially nested. Here, there are two tubular electrodes 4 .

Embodiment 2

[0031] The design method of this combined electrolytic cell is that five tubular electrodes 4 with different pipe diameters and arranged at equal intervals are sequentially nested between a circular anode 2 and a tubular cathode 8 . The circular anode 2 is tubular or cylindrical; the tubular cathode 8 is a single-tube tank whose diameter is larger than that of the other tubular electrodes 4 and the circular anode 2 . The circular anode 2 is made of low-carbon steel column or steel pipe, and its surface is plated with a nickel layer; the tubular cathode 8 and the tubular electrode 4 are both made of low-carbon steel pipe, and their steel pipe surfaces are treated by sand blasting.

Embodiment 3

[0033] The design method of this combined electrolyzer is characterized in that it is composed of a circular anode 2 and a tubular cathode 8 with 8 tubular electrodes 4 with different tube diameters and equally spaced sleeves arranged in sequence. The circular anode 2 is tubular, made of steel pipe, and its surface is plated with a nickel layer; the tubular cathode 8 is formed by two concentric tubes with different diameters and equal heights, and the bottom is connected as a whole. The formed cross-section is formed by an annular cylinder; the tubular cathode 8 and the tubular electrode 4 are both made of low carbon steel pipes, and the surfaces of the steel pipes are treated by sand blowing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com