A solar cell laminate comprising crystalline silicon photo-electricity device and process to make such a laminate

A technology of solar cells and optoelectronic devices, which is applied to solar collectors, solar thermal energy, solar collectors and other directions in specific environments, can solve the problems of crystalline silicon being easily damaged, and achieve easy transportation, good flexibility, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

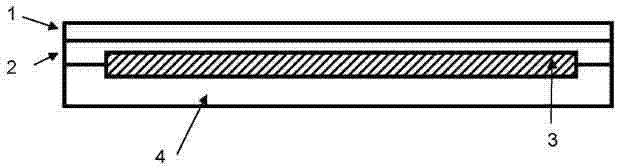

[0077] A 100 μm sheet of Halar (ethylene chlorotrifluoroethylene copolymer, ECTFE) from Solvay Solexis was placed on the glass surface. A 23 g / m 2 Glass fiber prepreg (Cycom® 759F 70% A1100 / 23gsm glass fiber). The glass transition temperature of the thermosetting polymer of the prepreg is >135°C. Another solar cell, SunPower A300 (crystalline silicon photovoltaic device), was placed with the light-sensitive side facing down. Then place another piece of 23g / m on top of it 2 glass fiber prepreg (Cycom® 759F 70% A1100 / 23gsm glass fiber).

[0078] After placing the release film, placing the pressure divider / vent valve and vacuum bag, applying a vacuum of 5 mbar, the laminate was degassed for 4 h. Subsequently, the temperature was raised to 100° C., and the laminate was cured for 4 hours. Subsequently, the laminate was allowed to cool to room temperature. The vacuum was released at room temperature to obtain a 14*14 cm solar cell laminate containing crystalline silicon ph...

Embodiment 2

[0081] A 100 μm sheet of Halar (ethylene chlorotrifluoroethylene copolymer, ECTFE) from Solvay Solexis was placed on the glass processing surface. Put a piece of 49g / m on top of the Halar tablet 2 Glass fiber prepreg (MTM59 / GF1200-50%RW). The glass transition temperature of the thermosetting polymer of the prepreg is >135°C. Another solar cell, SunPower A300 (crystalline silicon photovoltaic device), was placed with the light-sensitive side facing down. Place another piece of 49g / m on top of it 2 Glass fiber prepreg (MTM59 / GF1200-50%RW).

[0082] After the release film was placed, the pressure divider / vent valve and vacuum bag were placed, a vacuum of 5 mbar was applied and the laminate was degassed for 4 h. Subsequently, the temperature was raised to 100° C., and the laminate was cured for 4 hours. Subsequently, the laminate was allowed to cool to room temperature. The vacuum was released at room temperature to obtain a 14*14 cm solar cell laminate containing cr...

Embodiment 3

[0085] Place a release film on the glass processing surface. Place a piece of 49g / m on the release film 2 Glass fiber prepreg (MTM59 / GF1200-50%RW). The glass transition temperature of the thermosetting polymer of the prepreg is >135°C. Place the solar cell SunPower A300 (crystalline silicon photoelectric device) with its photosensitive side facing down. Place another piece of 49g / m on top of it 2 Glass fiber prepreg (MTM59 / GF1200-50%RW).

[0086] After placing the release film, place the pressure divider / vent valve and vacuum bag and apply a vacuum of 5 mbar. The laminate was degassed for 4 h. Subsequently, the temperature was raised to 100° C., and the laminate was cured for 4 hours. Subsequently, the laminate was allowed to cool to room temperature. The vacuum was released at room temperature to obtain a 14*14 cm solar cell laminate containing crystalline silicon photovoltaic devices with a size of 12*12 cm. The thickness of the laminates is between 200 and 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com