Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1033 results about "Thermosetting polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermosetting polymer, resin, or plastic, often called a thermoset, is a polymer that is irreversibly hardened by curing from a soft solid or viscous liquid prepolymer or resin. Curing is induced by heat or suitable radiation and may be promoted by high pressure, or mixing with a catalyst. It results in chemical reactions that create extensive cross-linking between polymer chains to produce an infusible and insoluble polymer network.

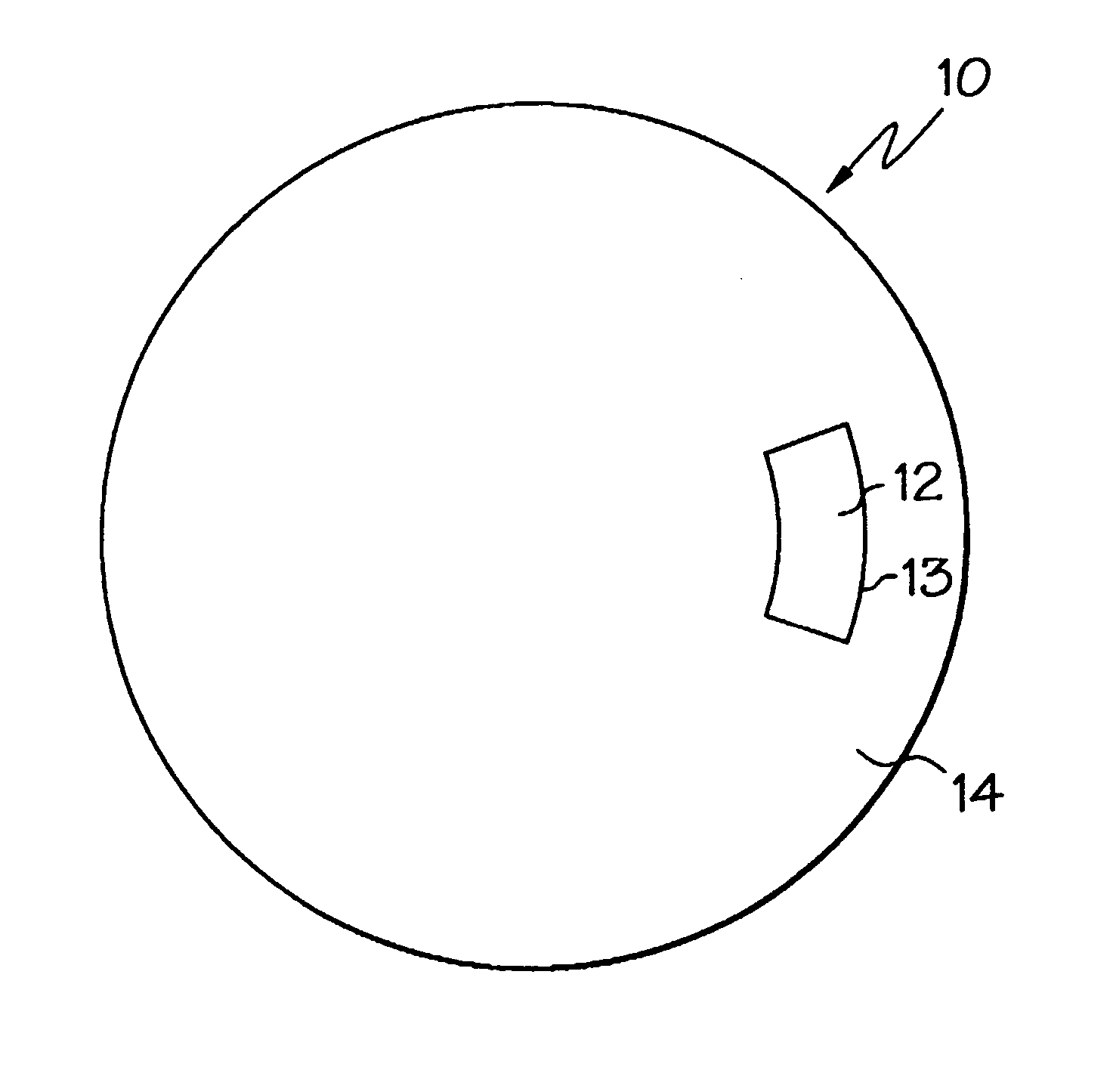

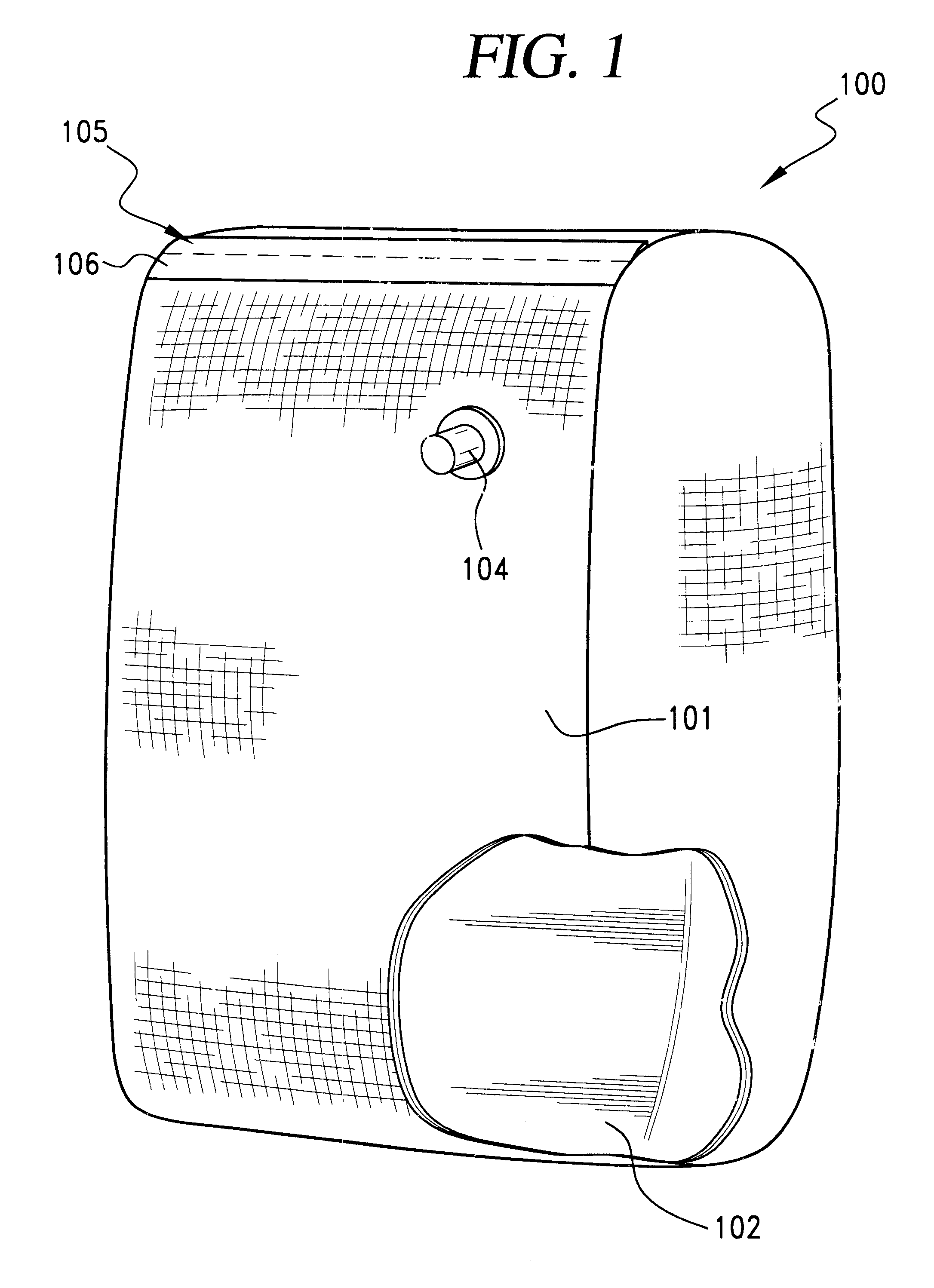

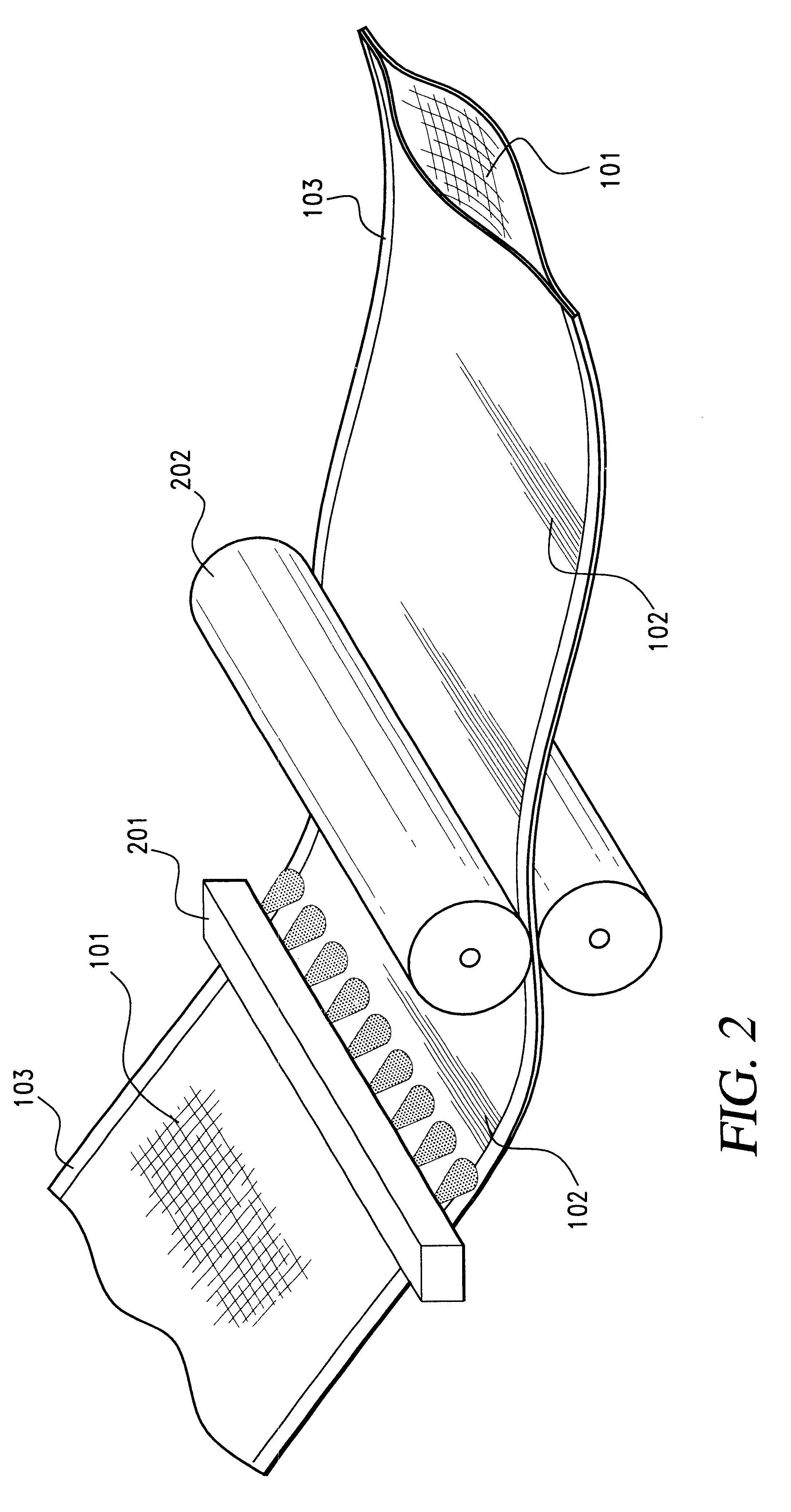

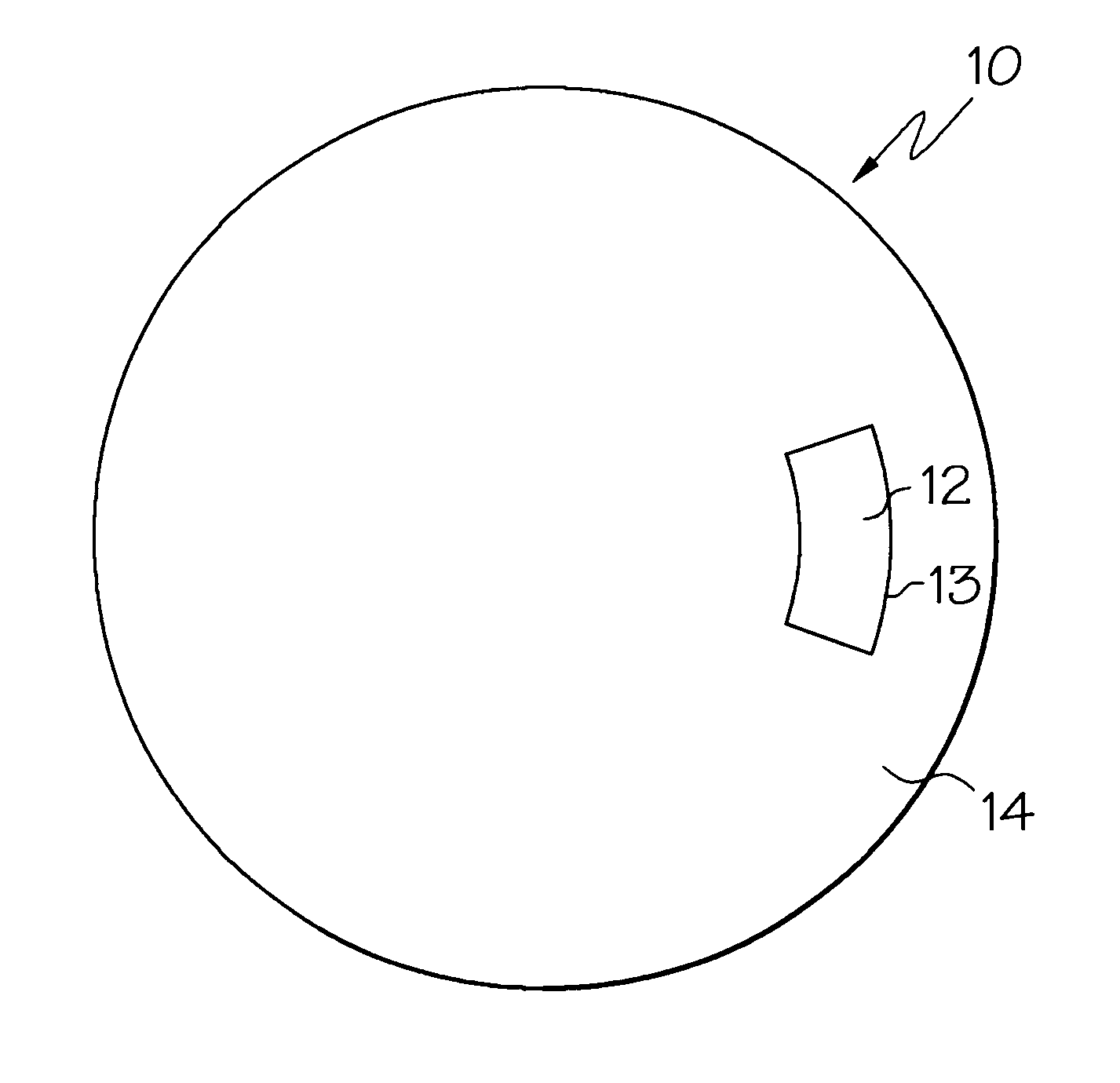

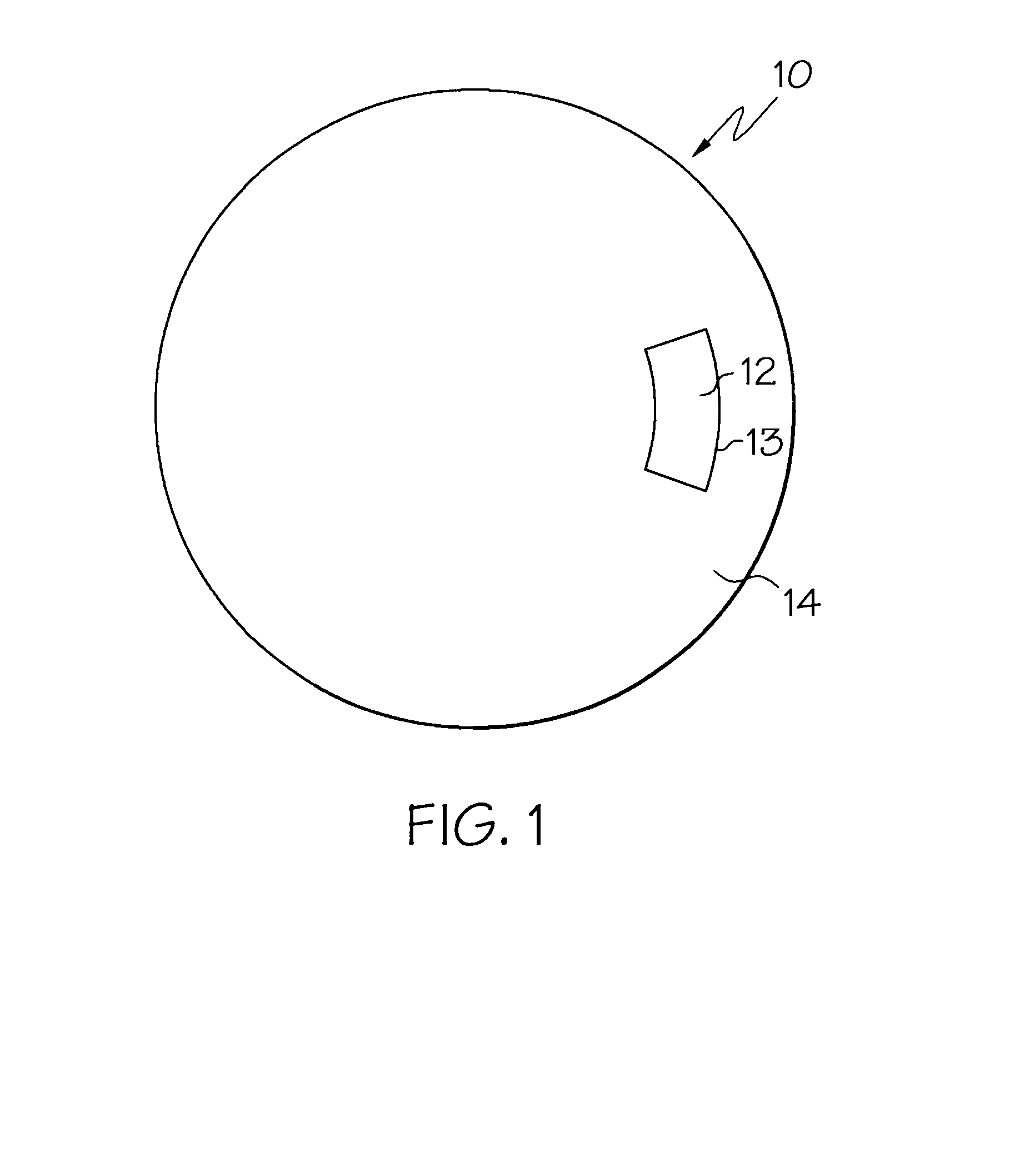

Molded polishing pad having integral window

A polishing pad is formed as a one-piece article having a region which is transparent and an adjacent region which is opaque. The article is formed by solidifying a flowable polymeric material which at least initially has a uniform composition. The flowable polymeric material is processed during a molding operation to provide the transparent region and the adjacent opaque region. Types of polymeric material suitable for making the polishing pad include a single thermoplastic material, a blend of thermoplastic materials, and a reactive thermosetting polymer.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Thermally conductive thermoplastic

InactiveUS6162849AImprove thermal conductivityImprove mechanical propertiesPlastic/resin/waxes insulatorsMixingThermoplasticPolymer science

This invention relates to a thermally conductive moldable polymer blend comprising a thermoplastic polymer having a tensile at yield of at least 10,000 psi; at least 60% by weight of a mixture of boron nitride powders having an average particle size of at least 50 microns; and a coupling agent. The composition displays a thermal conductivity of at least about 15 W / m DEG K and it is capable of being molded using high speed molding techniques such as injection molding.

Owner:FERRO CORP

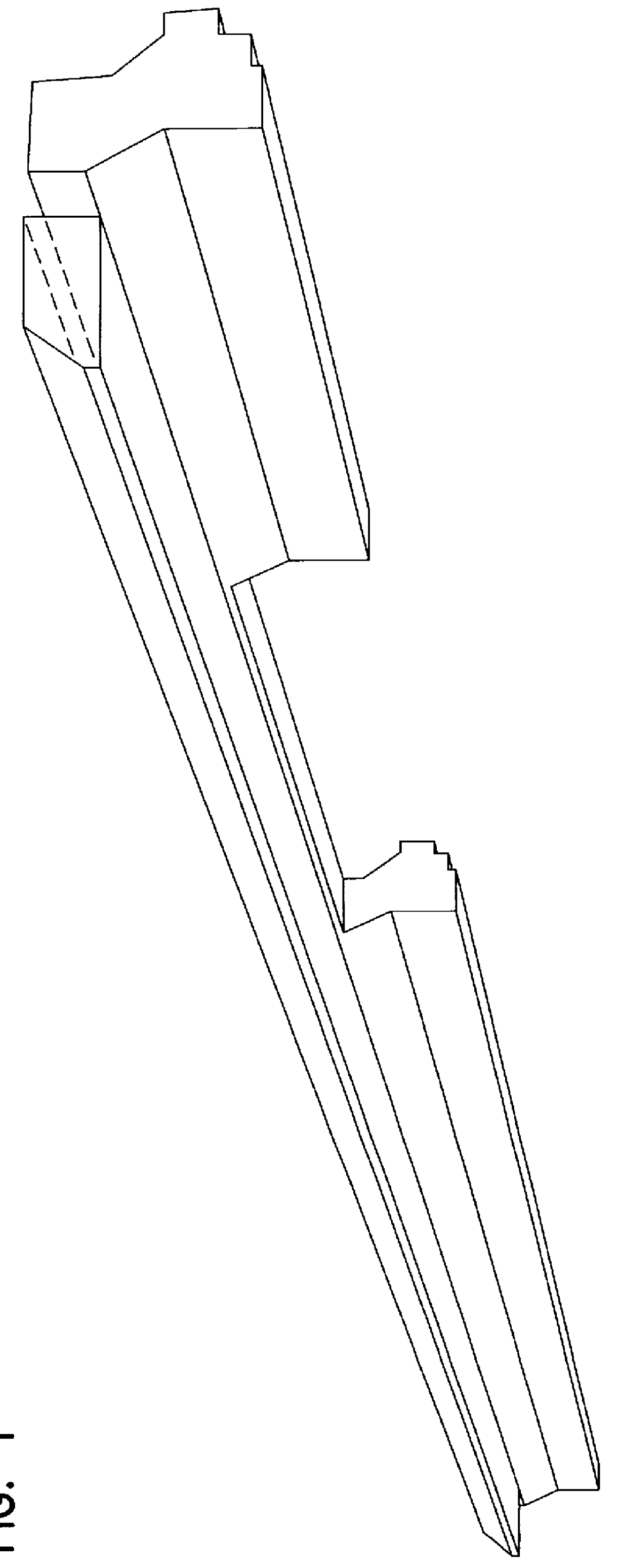

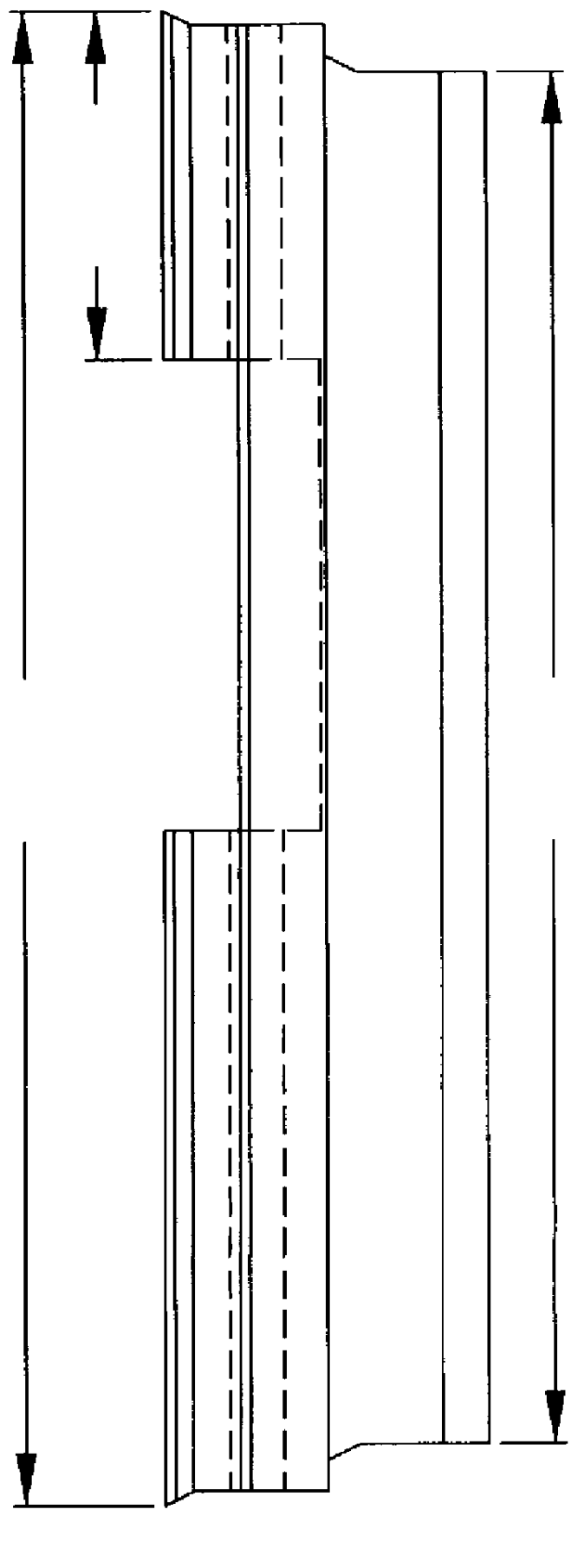

Foamed thermoplastic polymer and wood fiber profile and member

InactiveUS6054207AHigh compressive strengthImproved fastener retentionConstruction materialLoad-supporting elementsComposite constructionThermoplastic

Advanced structural components comprising a foamed thermoplastic that can be used in virtually any application where wooden components have a use. Such structural components can comprise sized lumber, shaped trim, posts, beams or shaped structural members. An advanced profile composite structural component comprising an exterior capping layer with an interior comprising a foamed thermoplastic can be used in the assembly of fenestration units adapted to residential and commercial structures. Preferably the profile structural component can be used in a window or door assembly. The profile member is adapted for ease of construction of the fenestration units, can be easily installed in a rough opening to framing members, and can be trimmed and adjusted on site. The profile is structurally strong, thermally stable, shrink resistant and will accept and retain the insertion of fasteners such as staples, nails and screws permanently with substantial retention and little or no damage to the units. The profile structural components possess strength that permits the manufacture of a structurally sound fenestration unit from two or more foamed profile members or other conventional members.

Owner:ANDERSEN CORPORATION

Poly (vinyl alcohol) - based formaldehyde-free curable aqueous composition

A formaldehyde-free curable aqueous composition containing polyvinyl alcohol, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition may be used as a binder for non-woven products such as fiberglass insulation. The non-woven products are formed by contacting the formaldehyde-free curable aqueous composition with fibrous components and the mixture is cured to form a rigid thermoset polymer providing excellent strength and water resistance of the cured nonwoven product.

Owner:ARCLIN USA

Expandable microspheres for foam insulation and methods

InactiveUS20050079352A1Use in some applicationHigh of encapsulationLiquid surface applicatorsGlass/slag layered productsPolymer scienceFoaming agent

Hollow thermoexpandable particles or microspheres are provided that contain hydrocarbon blowing agents and have a shell polymer that can be softened at the onset of the expansion temperature and solidified at a higher temperature (thermoset) in an expanded state. Preferably, the microspheres have a shell of thermally expandable and thermally crosslinkable polymer and a hollow interior that contains a hydrocarbon liquid that boils at a temperature below the heat activated crosslinking temperature of the polymer shell. The crosslinking of the shell polymer during or after expansion, which is heat activated at an elevated temperature, can solidify the shell polymer and, then, maintain the expanded volume of the microspheres. The thermoexpandable thermoset polymer particles are useful in insulation, packaging, for making foam materials such as polyurethane or polyisocyanurate rigid foams. The invented thermoset microspheres can substantially improve the close cell percentage and compressive strength of the foam materials and make the foam manufacturing less hazardous.

Owner:IP RIGHTS +1

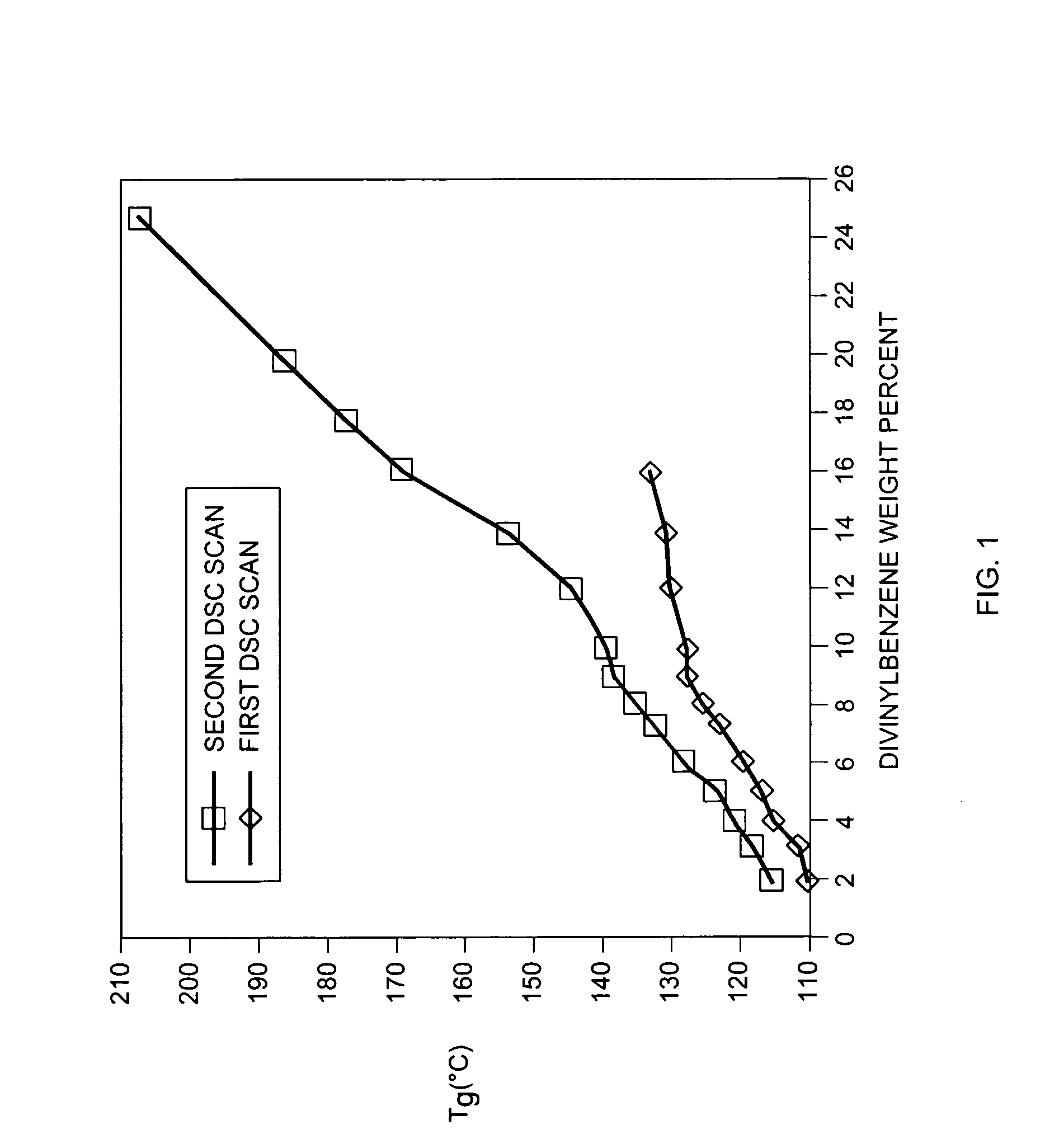

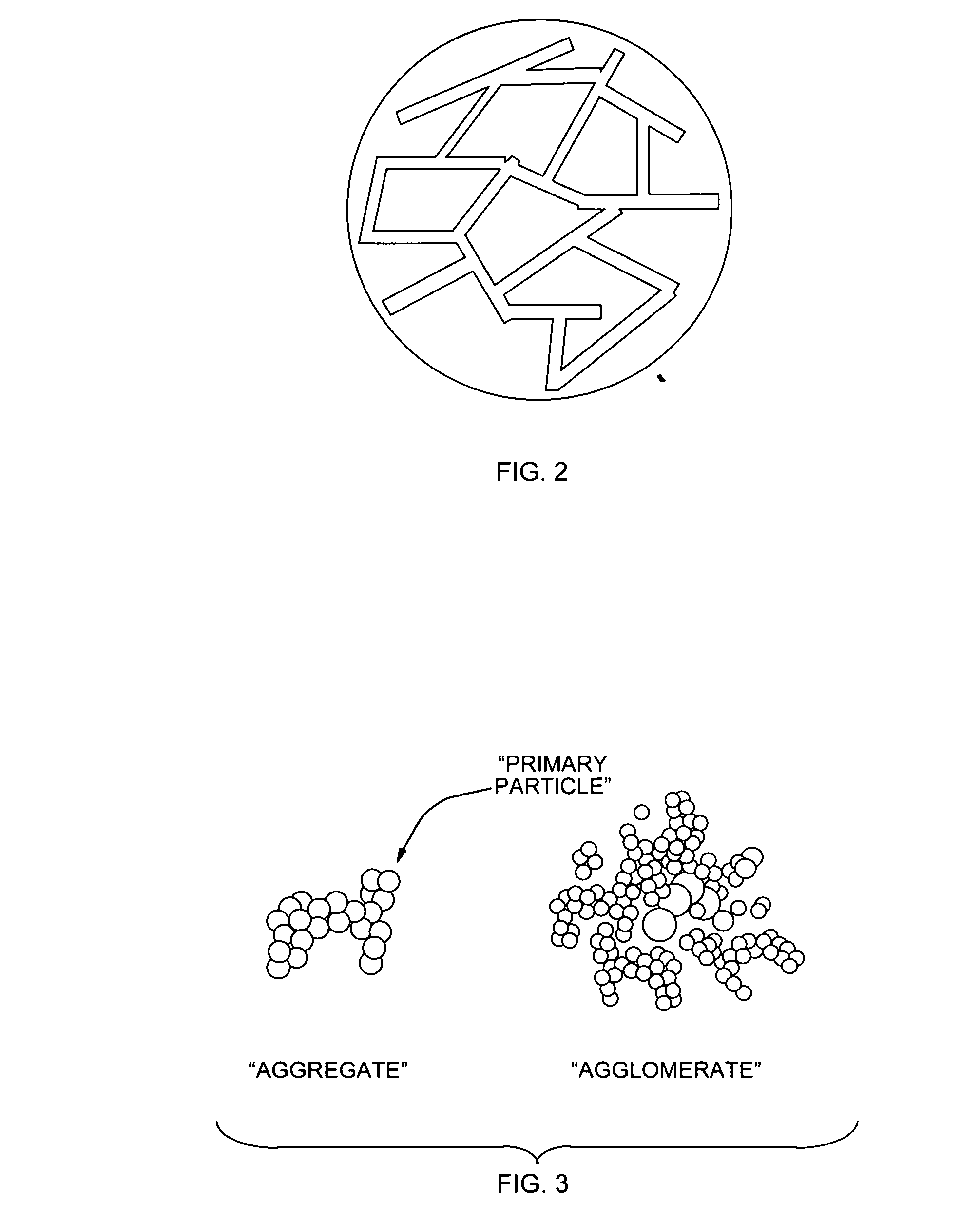

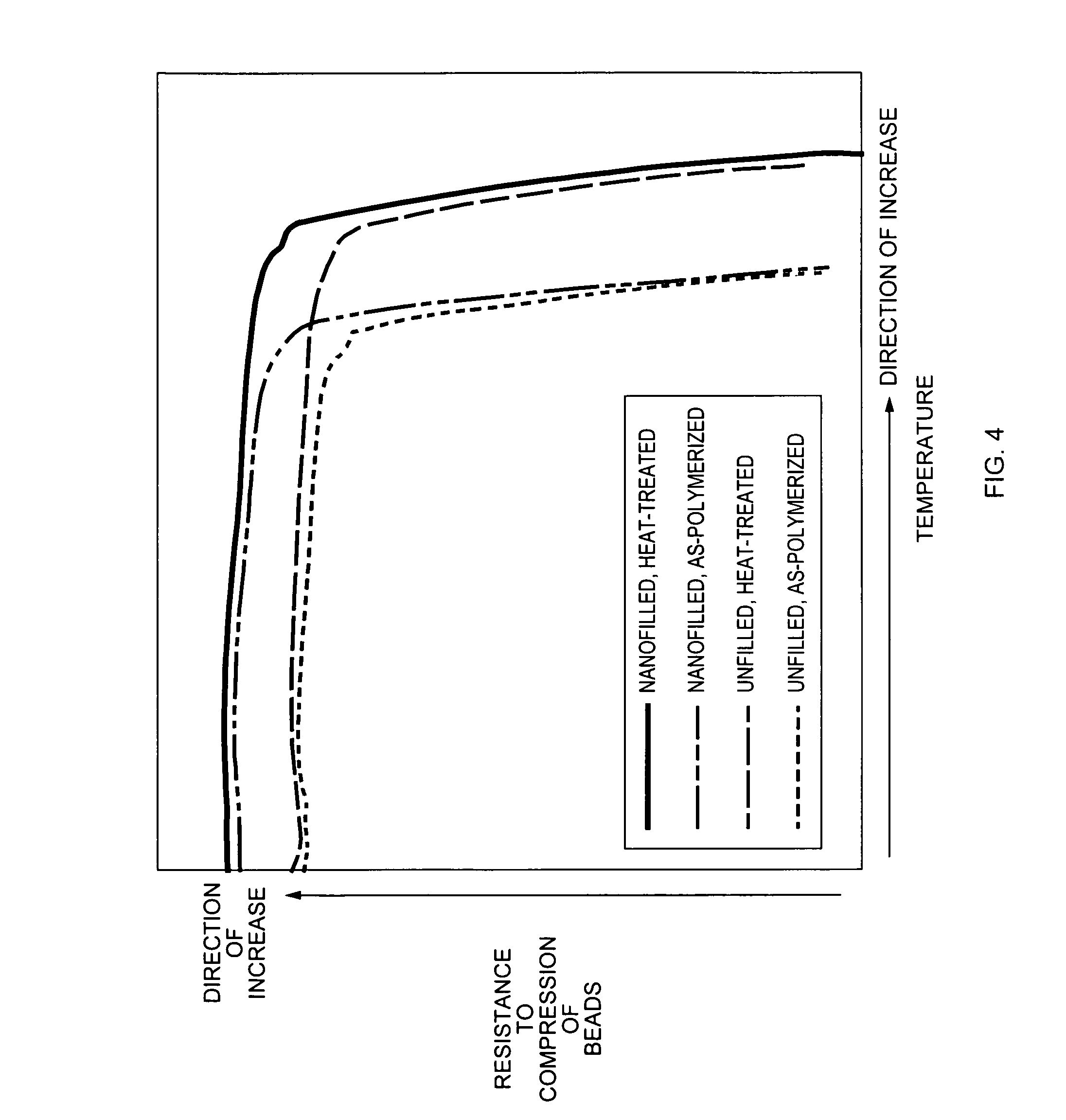

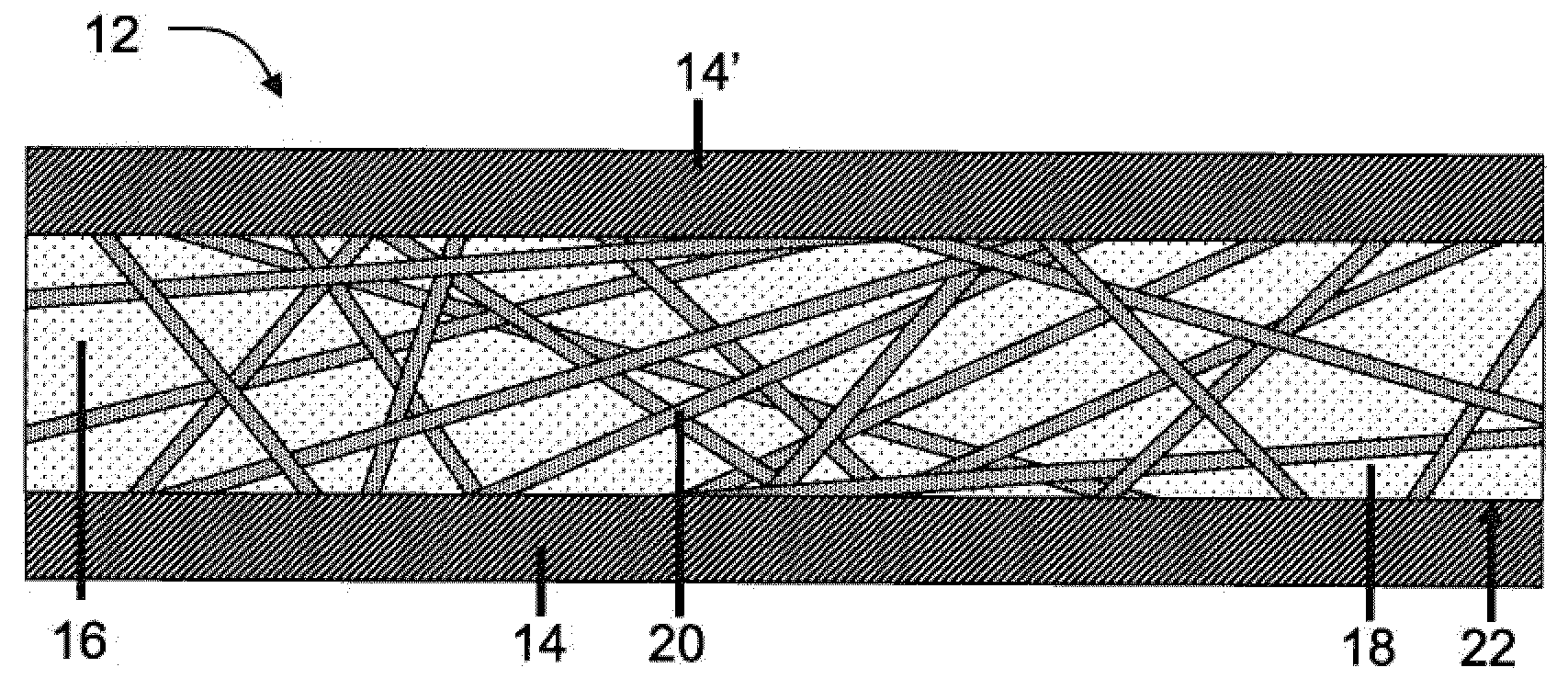

Thermoset nanocomposite particles, processing for their production, and their use in oil and natural gas drilling applications

ActiveUS20070066491A1Improve curingImprove heat transfer performanceMaterial nanotechnologySynthetic resin layered productsEnvironmental resistanceBall bearing

Thermoset polymer particles are used in many applications requiring lightweight particles possessing high stiffness, strength, temperature resistance, and / or resistance to aggressive environments. The present invention relates to the use of two different methods, either each by itself or in combination, to enhance the stiffness, strength, maximum possible use temperature, and environmental resistance of such particles. One method is the application of post-polymerization process steps (and especially heat treatment) to advance the curing reaction and to thus obtain a more densely crosslinked polymer network. In general, its main benefits are the enhancement of the maximum possible use temperature and the environmental resistance. The other method is the incorporation of nanofillers, resulting in a heterogeneous “nanocomposite” morphology. In general, its main benefits are increased stiffness and strength. Nanofiller incorporation and post-polymerization heat treatment can also be combined to obtain the benefits of both methods simultaneously. The present invention relates to the development of thermoset nanocomposite particles. It also relates to the optional further improvement of the heat resistance and environmental resistance of said particles via post-polymerization heat treatment. Furthermore, it also relates to processes for the manufacture of said particles. Finally, it also relates to the use of said particles in the construction, drilling, completion and / or fracture stimulation of oil and natural gas wells; for example, as a proppant partial monolayer, a proppant pack, an integral component of a gravel pack completion, a ball bearing, a solid lubricant, a drilling mud constituent, and / or a cement additive.

Owner:SUN DRILLING PRODS

Formable light weight composites

ActiveUS20100040902A1Synthetic resin layered productsLaminationElectrical resistance and conductanceMetal fibers

The present invention relates to light weight composite materials which comprise a metallic layer and a polymeric layer, the polymeric layer containing a filled thermoplastic polymer which includes a thermoplastic polymer and a metallic fiber. The composite materials of the present invention may be formed using conventional stamping equipment at ambient temperatures. Composite materials of the present invention may also be capable of being welded to other metal materials using a resistance welding process such as resistance spot welding.

Owner:PRODIVE RES

Thermosettable adhesive

Owner:3M INNOVATIVE PROPERTIES CO

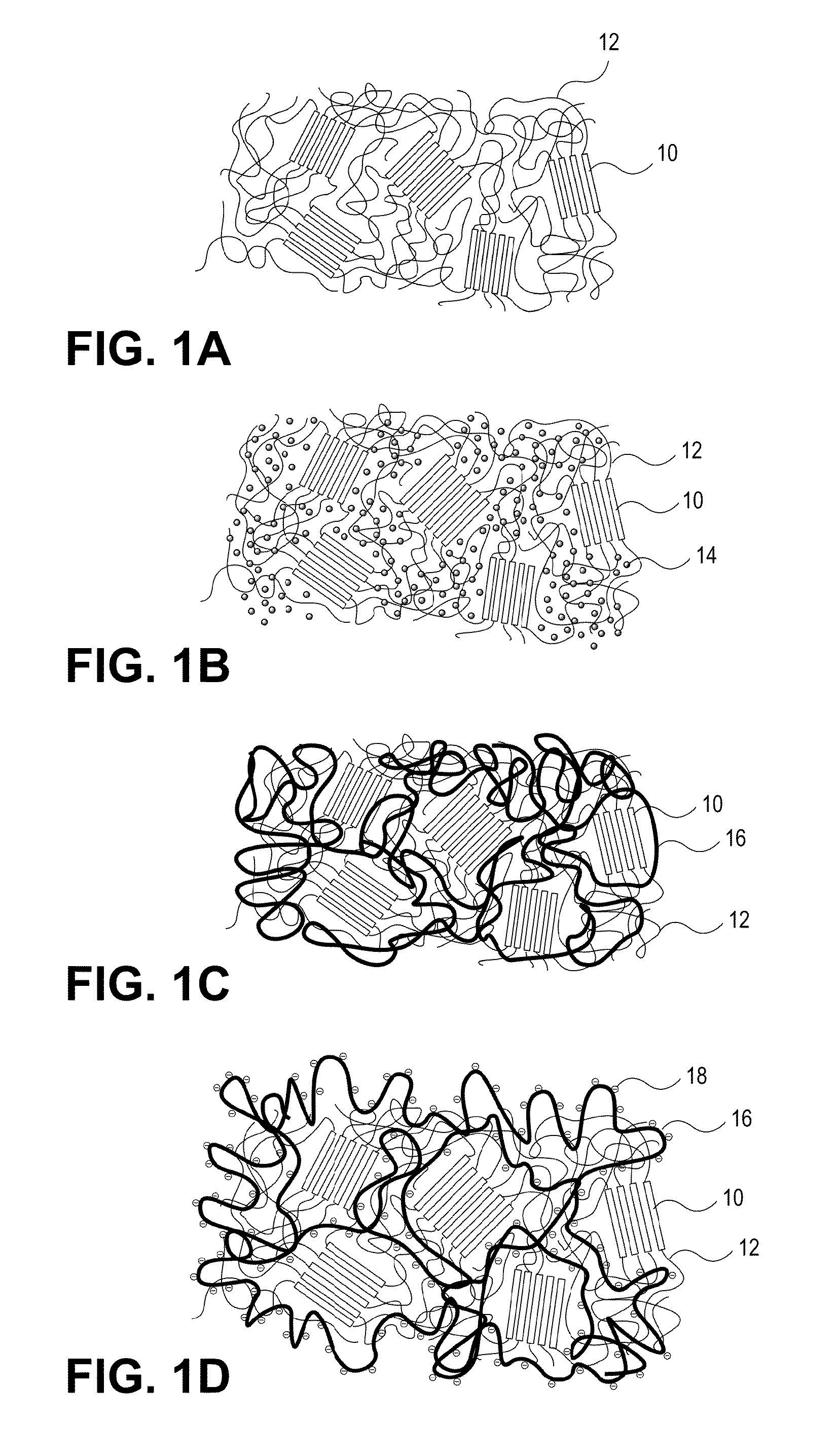

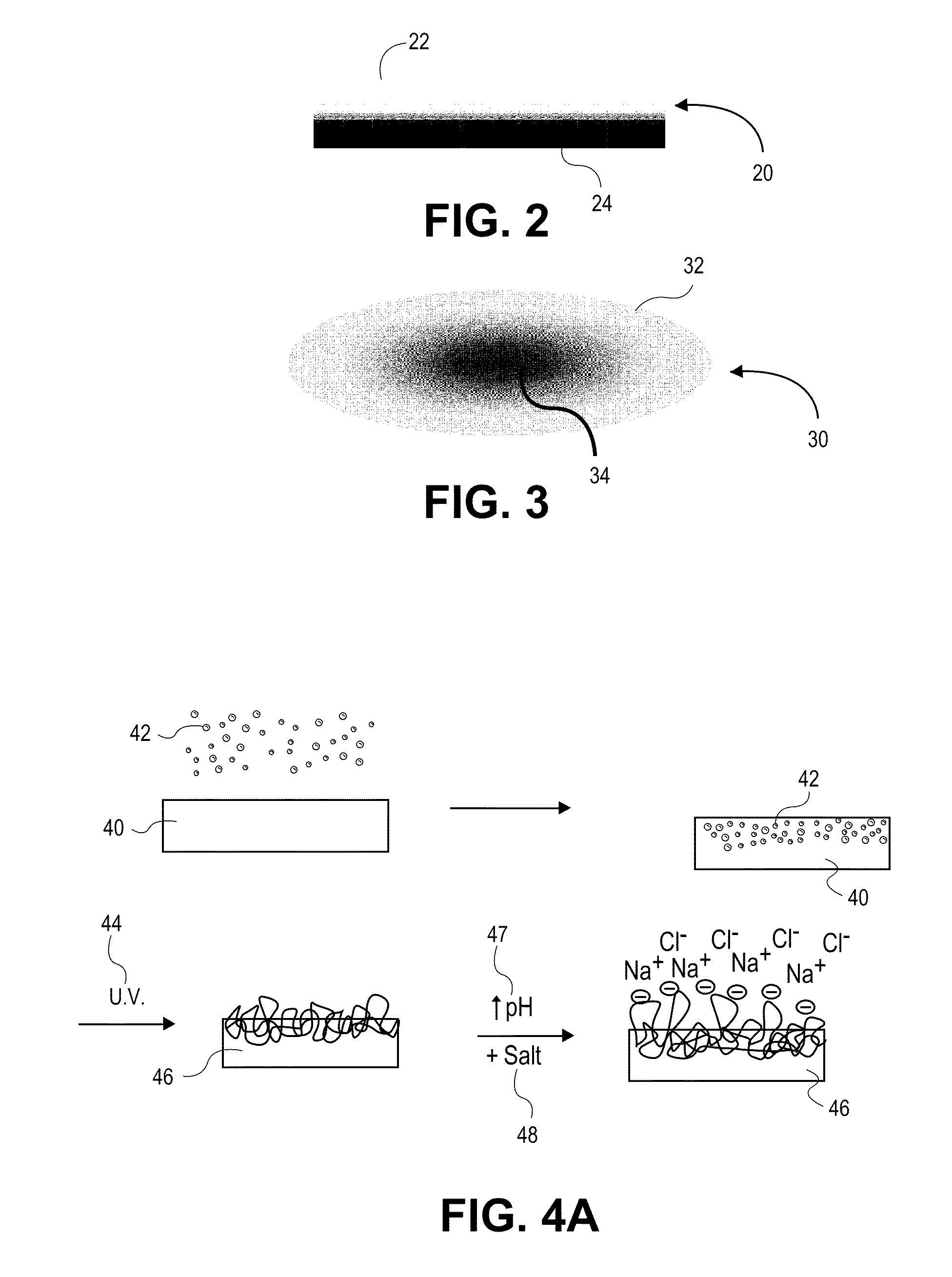

Hydrophilic Interpenetrating Polymer Networks Derived From Hydrophobic Polymers

InactiveUS20100010114A1High mechanical strengthReduce coefficient of frictionCosmetic preparationsImpression capsHydrophobic polymerThermoplastic elastomer

A composition of matter comprising a water-swellable IPN or semi-IPN including a hydrophobic thermoset or thermoplastic polymer and an ionic polymer, articles made from such composition and methods of using such articles. The invention also includes a process for producing a water-swellable IPN or semi-IPN from a hydrophobic thermoset or thermoplastic polymer including the steps of placing an ionizable monomer solution in contact with a solid form of the hydrophobic thermoset or thermoplastic polymer; diffusing the ionizable monomer solution into the hydrophobic thermoset or thermoplastic polymer; and polymerizing the ionizable monomers to form a ionic polymer inside the hydrophobic thermoset or thermoplastic polymer, thereby forming the IPN or semi-IPN.

Owner:BIOMIMEDICA

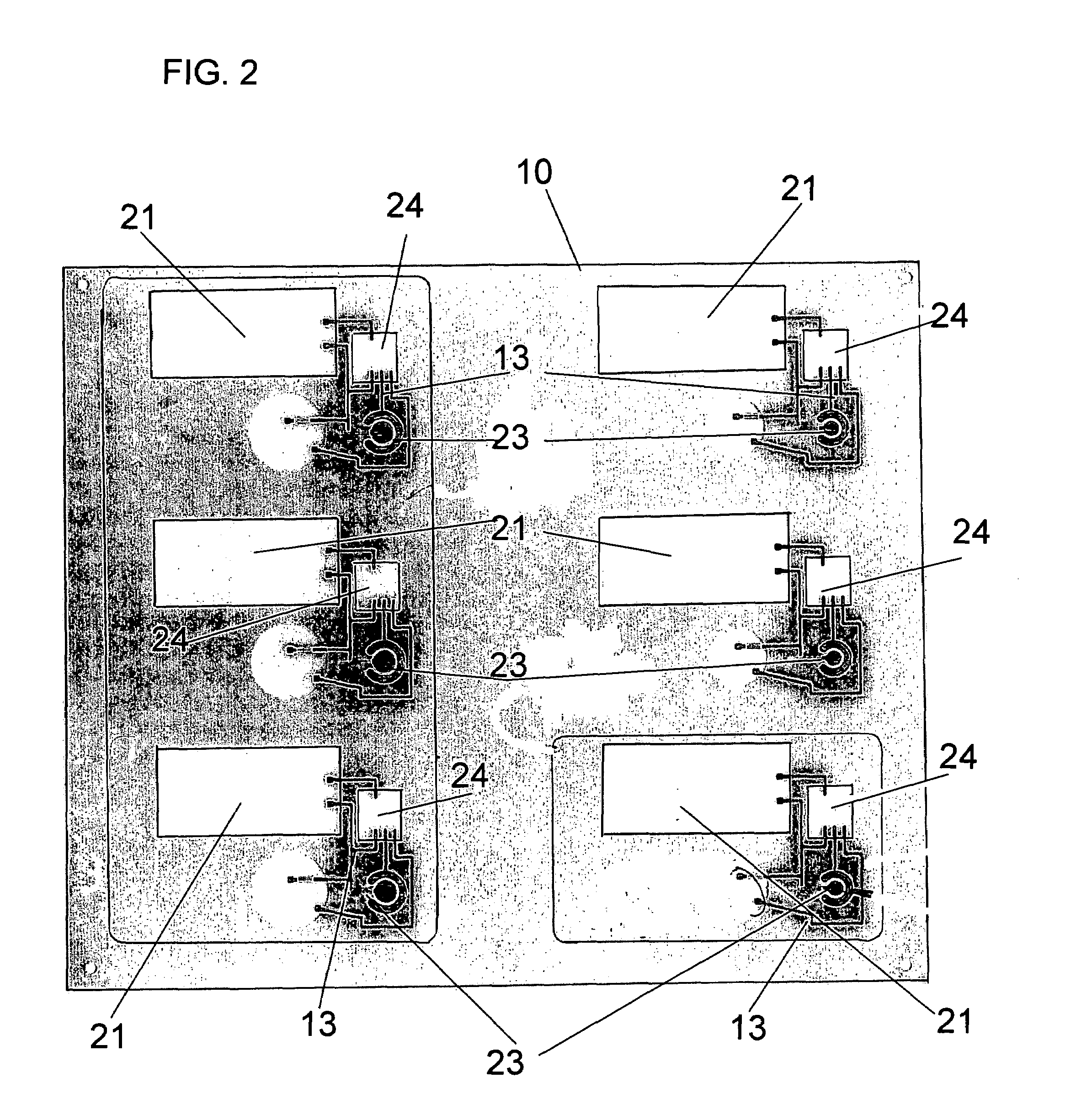

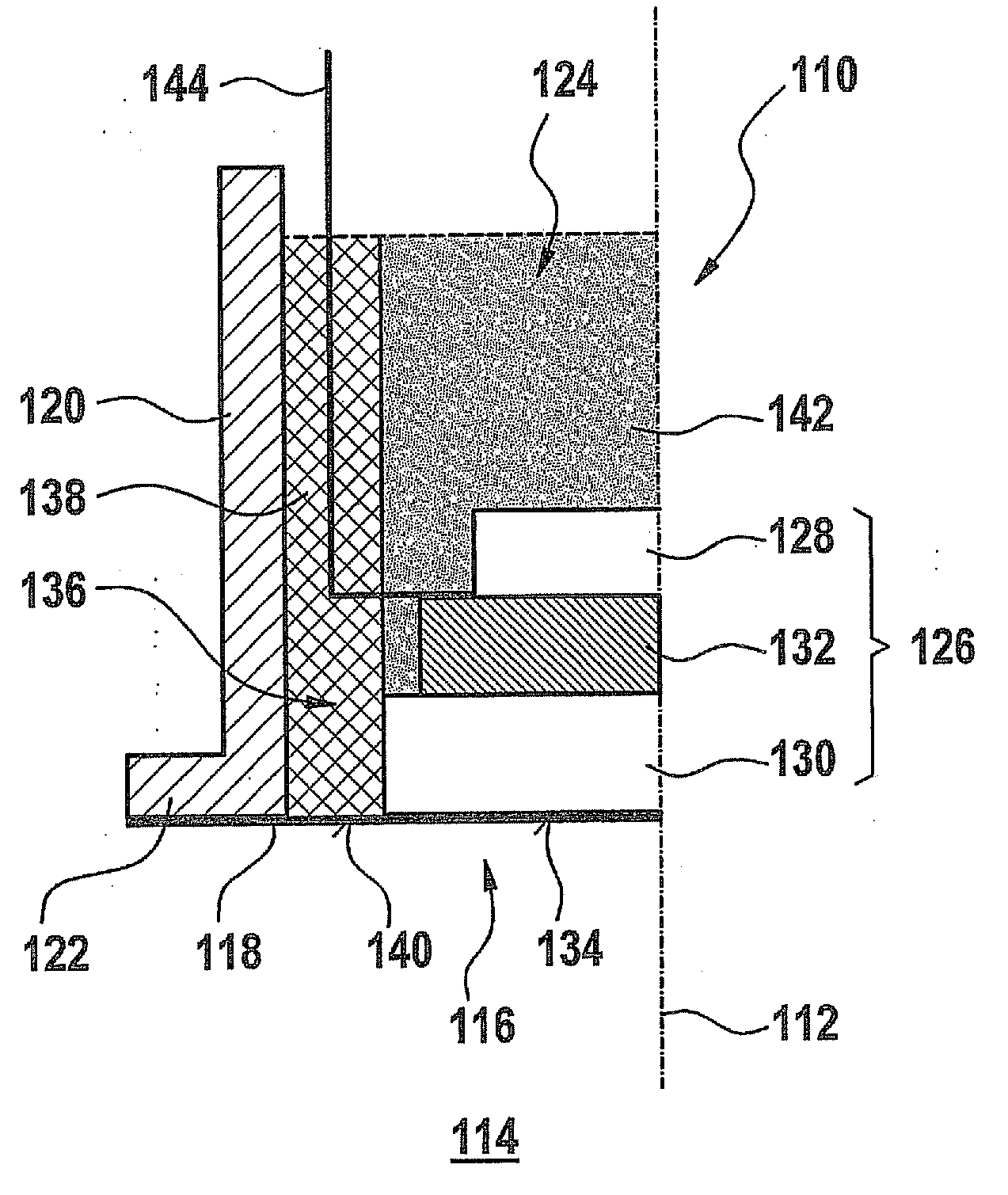

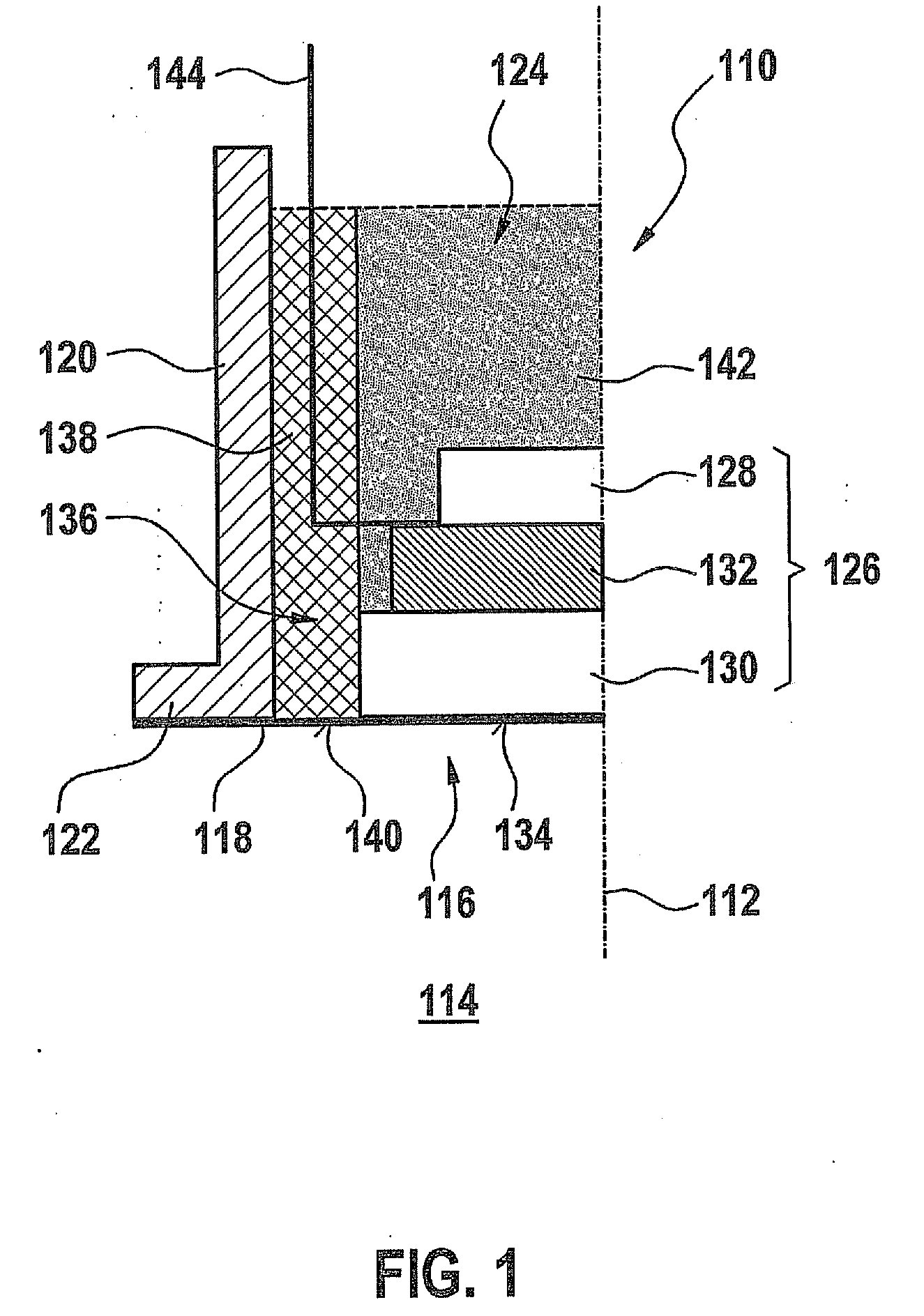

Smart card and method for manufacturing a smart card

InactiveUS7237724B2Improve protectionEasy to adaptPrinted circuit assemblingLine/current collector detailsSmart cardThermosetting polymer

A smart card and a method for manufacturing the same wherein the smart card is composed of a printed circuit board, having a top surface and a bottom surface, a plurality of circuit components attached to the top surface of the printed circuit board, a filler board, attached to the top surface of the printed circuit board, a bottom overlay attached to the bottom surface of the printed circuit board, a top overlay positioned above the top surface of the printed circuit board and a thermosetting polymeric layer positioned between the top surface of the printed circuit board and the top overlay.

Owner:CARDXX

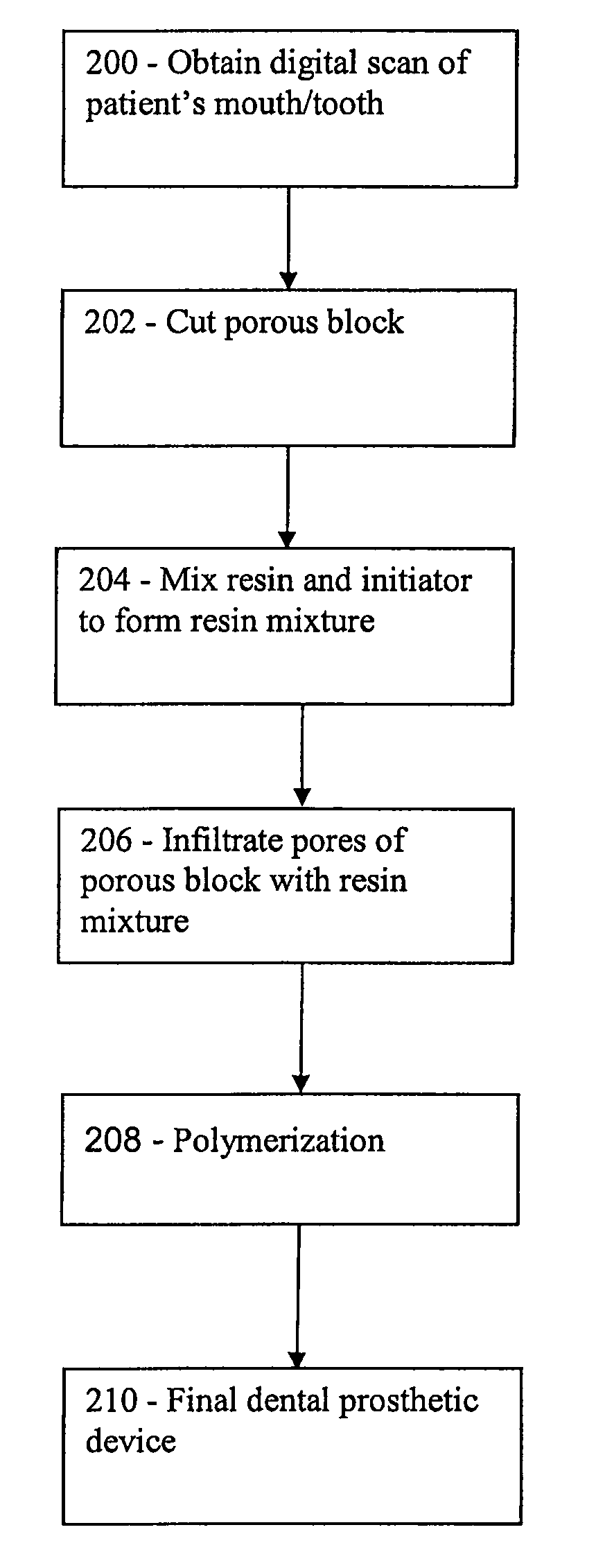

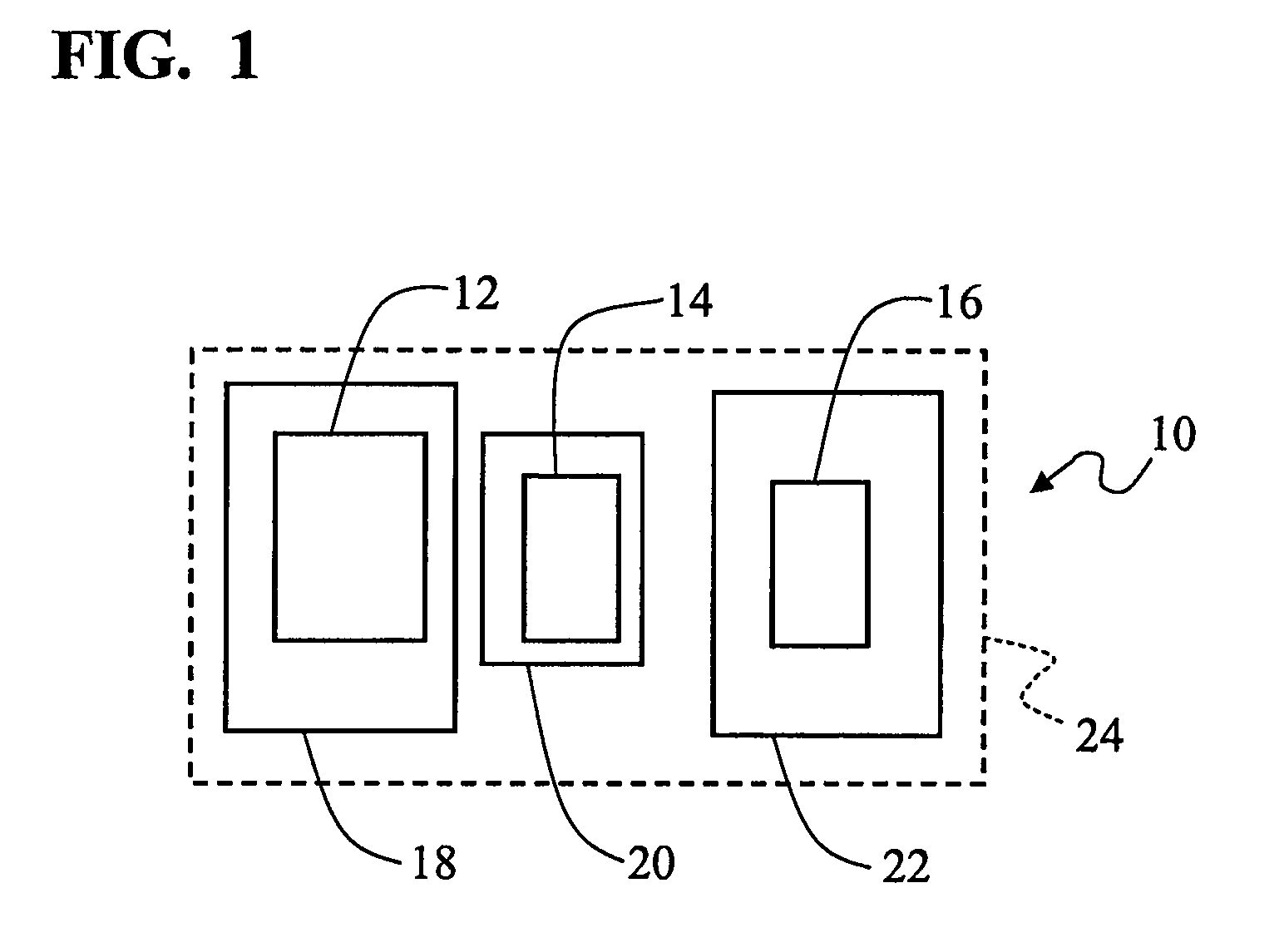

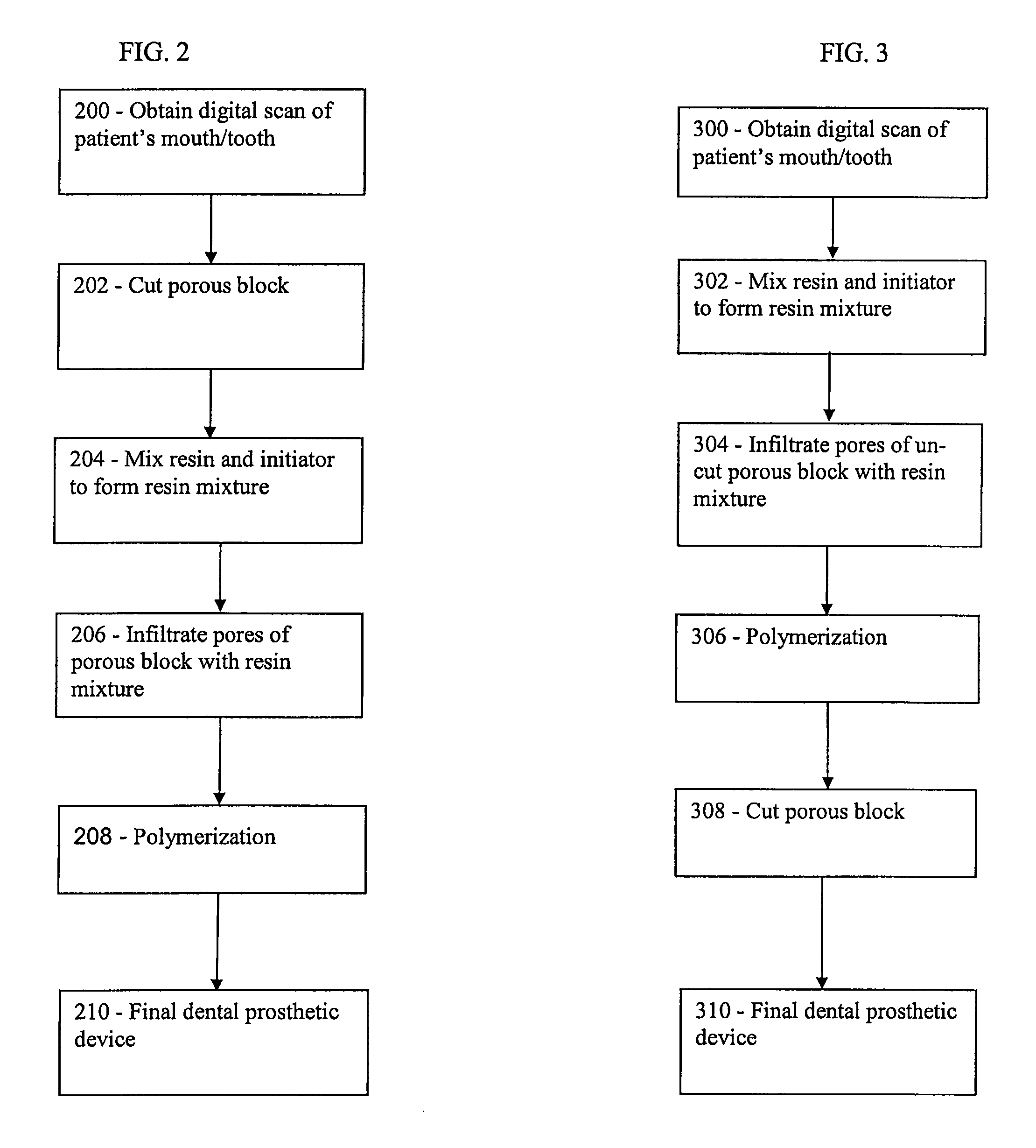

Method of making a dental implant and prosthetic device

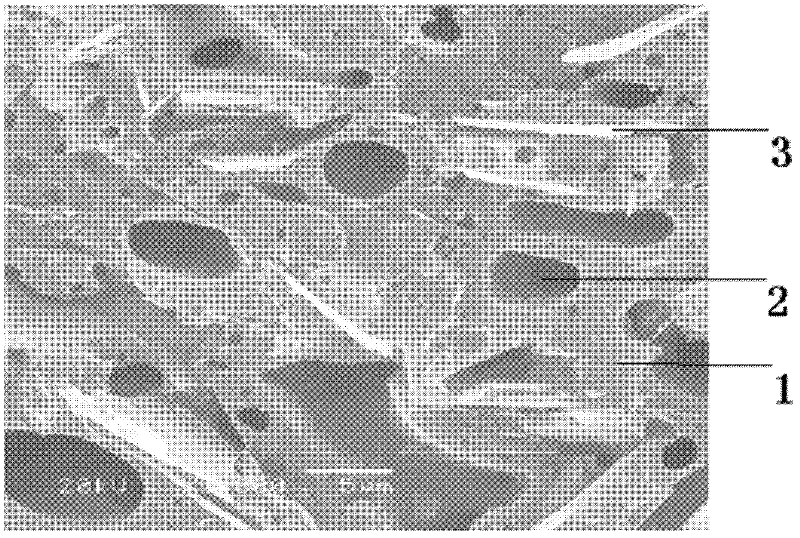

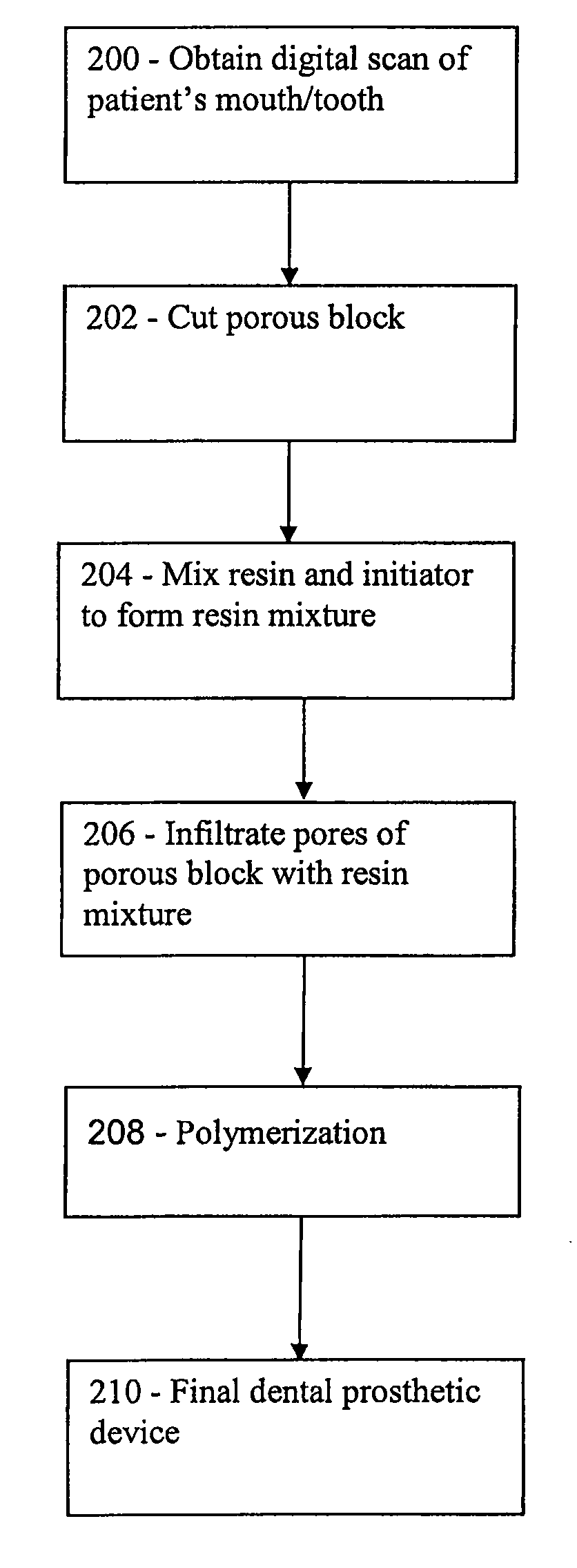

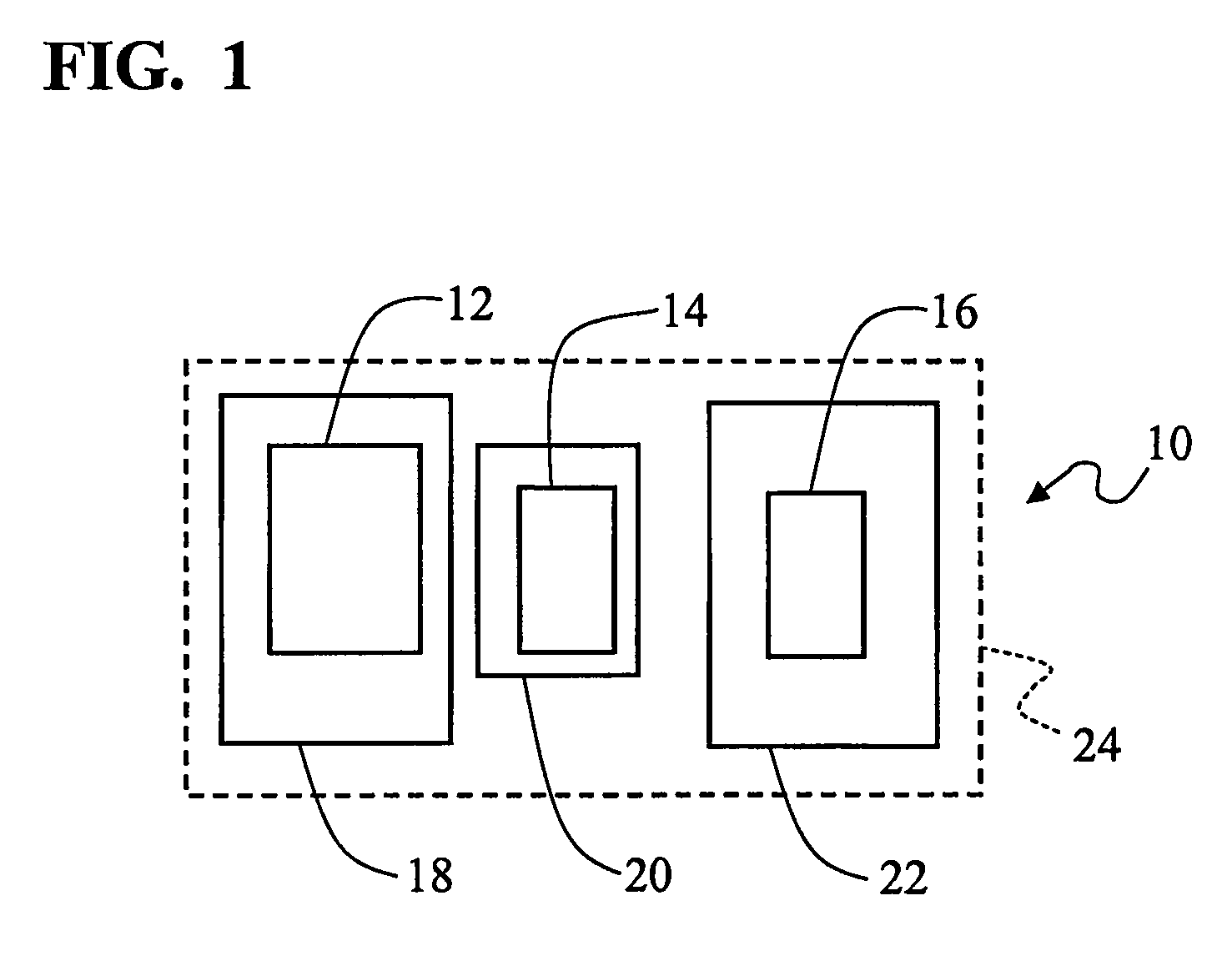

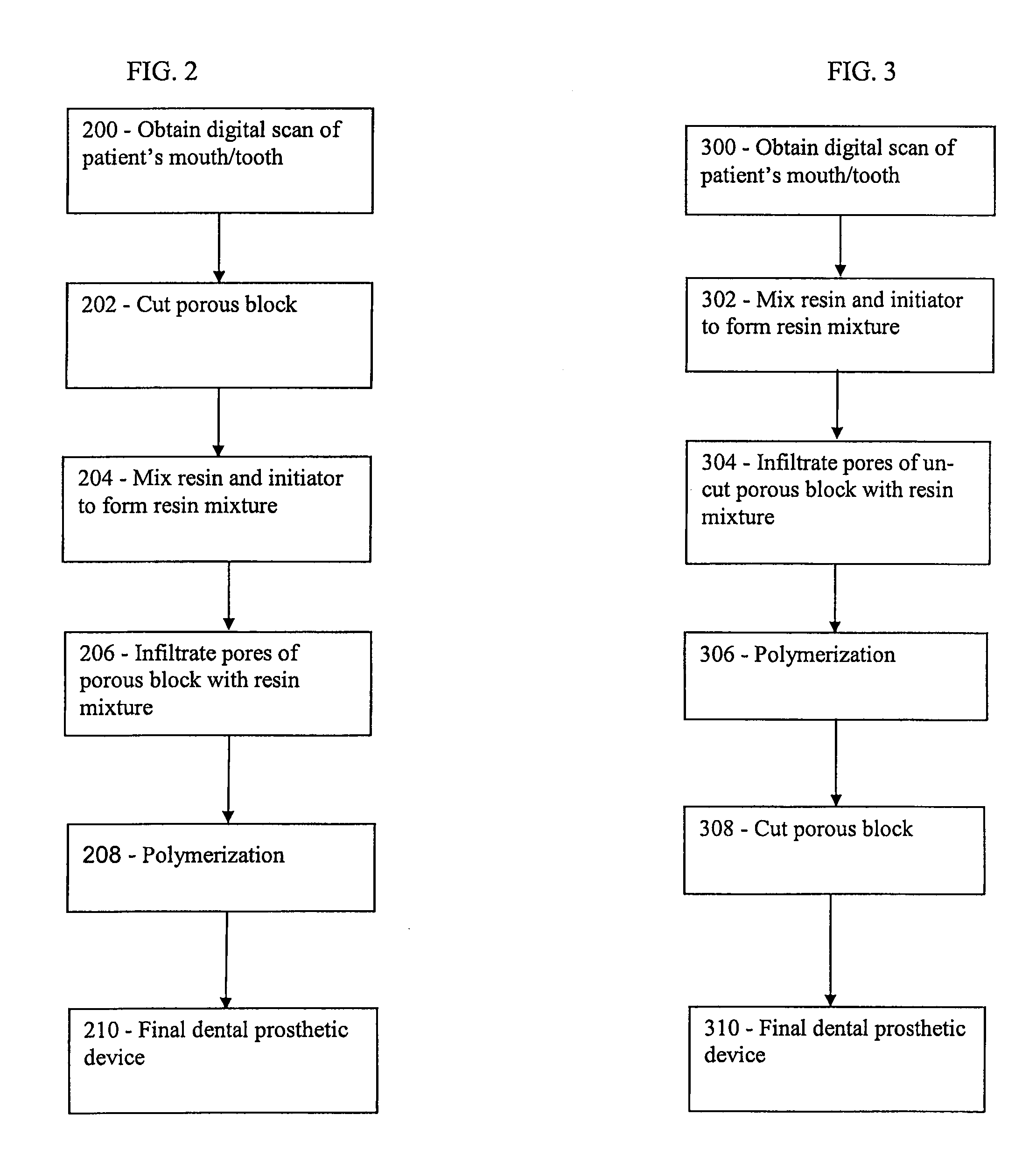

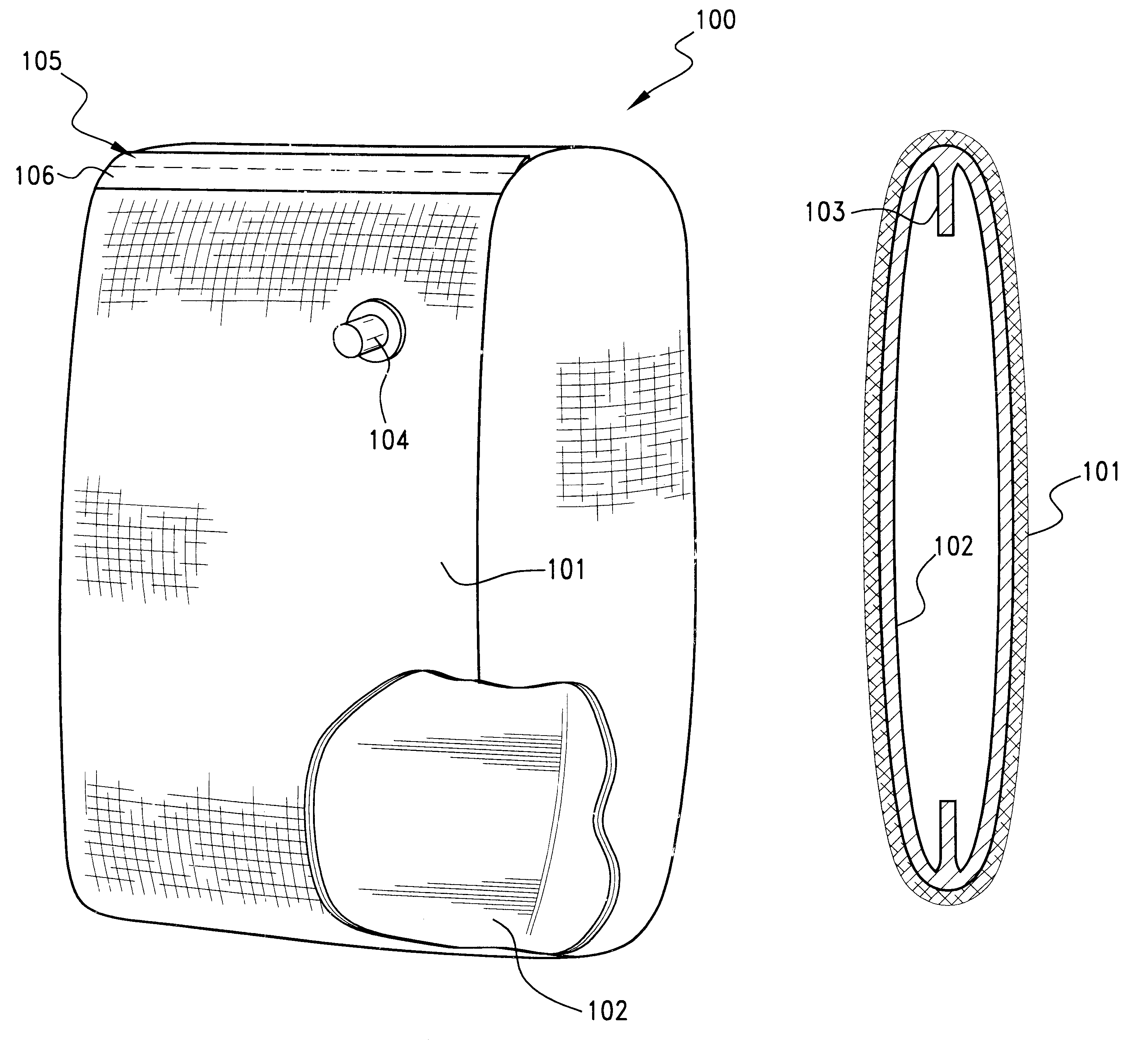

A method of preparing a dental implant and prosthetic device in-house at the site of a dental procedure from a preparation kit, without requiring an external third-party lab to prepare the final prosthetic device. The kit contains a porous block, a thermoset polymeric resin, and an initiator, where the resin and initiator are both packaged in substantially airtight and substantially opaque packaging. The resin and initiator are combined together to form a resin mixture which is then infiltrated into the pores of the porous block to form an esthetic material. A digital scan of at least a portion of a patient's jaw is used to provide the desired shape of the dental device to a cutting mechanism, which then cuts the filled or un-filled porous block based on the shape provided to it from the digital scan.

Owner:ZIMMER DENTAL INC

A thermoplastic polymer-based thermally conductive composite material and its preparation method

InactiveCN102286207AImprove thermal conductivityHeat-exchange elementsPolymer scienceVolumetric Mass Density

The invention discloses a thermoplastic polymer-based heat-conducting composite material, which belongs to the technical field of polymer materials. The thermoplastic polymer-based thermally conductive composite material provided by the present invention has a higher thermal conductivity when adding less thermally conductive filler; the thermally conductive composite material includes a thermoplastic polymer matrix and a thermally conductive filler, and also includes compatible polymers. The present invention introduces a polymer that is incompatible with the polymer matrix into the composite system, so that the thermally conductive filler is selectively distributed in one of the phases, thereby significantly increasing the packing density of the thermally conductive filler in the polymer component of this phase, thereby improving the The overall thermal conductivity of the material; when the ratio of the two is 50 / 50, the thermal conductivity of the material can reach the thermal conductivity when the amount of thermal conductive filler is doubled.

Owner:SICHUAN UNIV

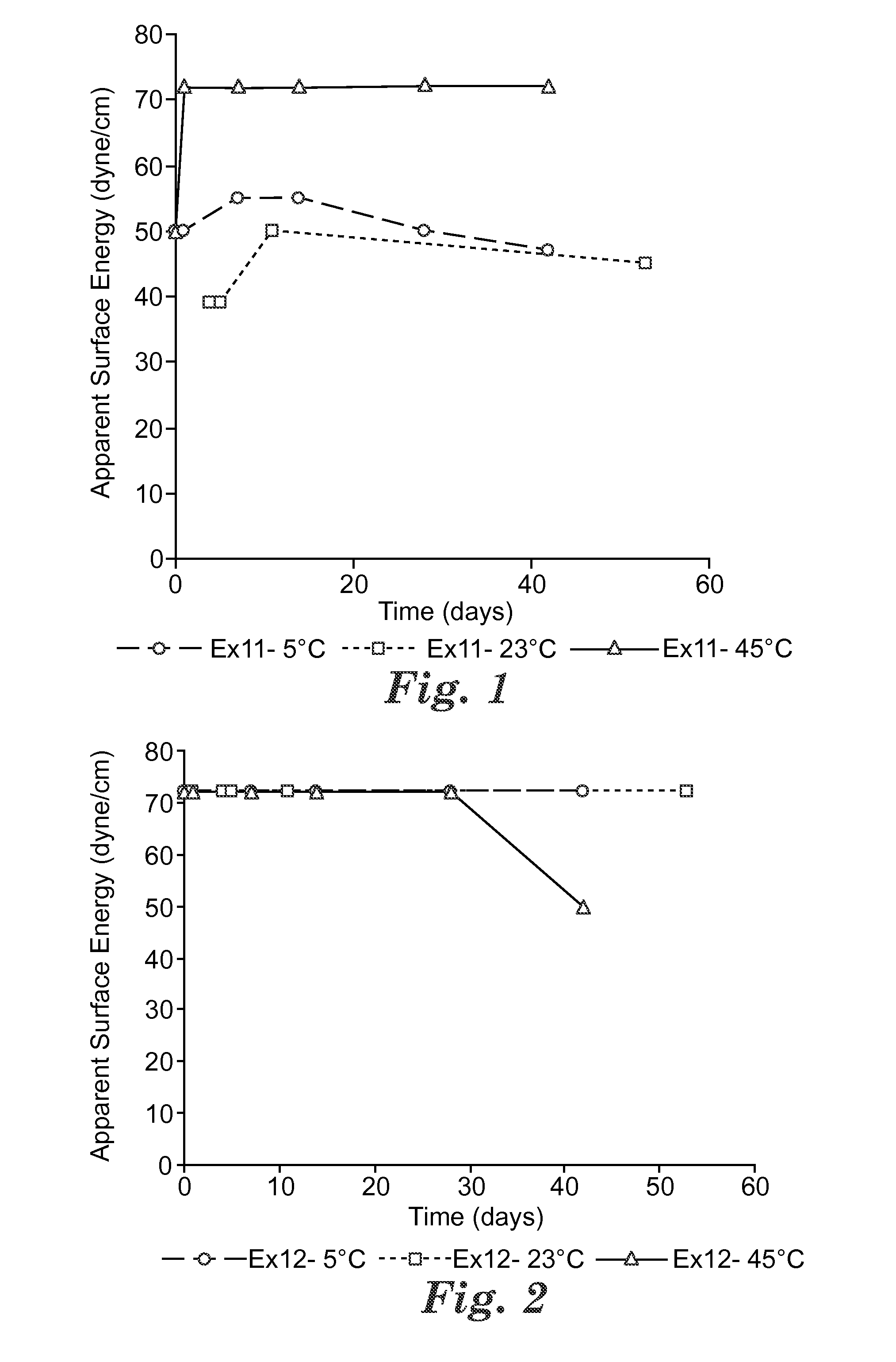

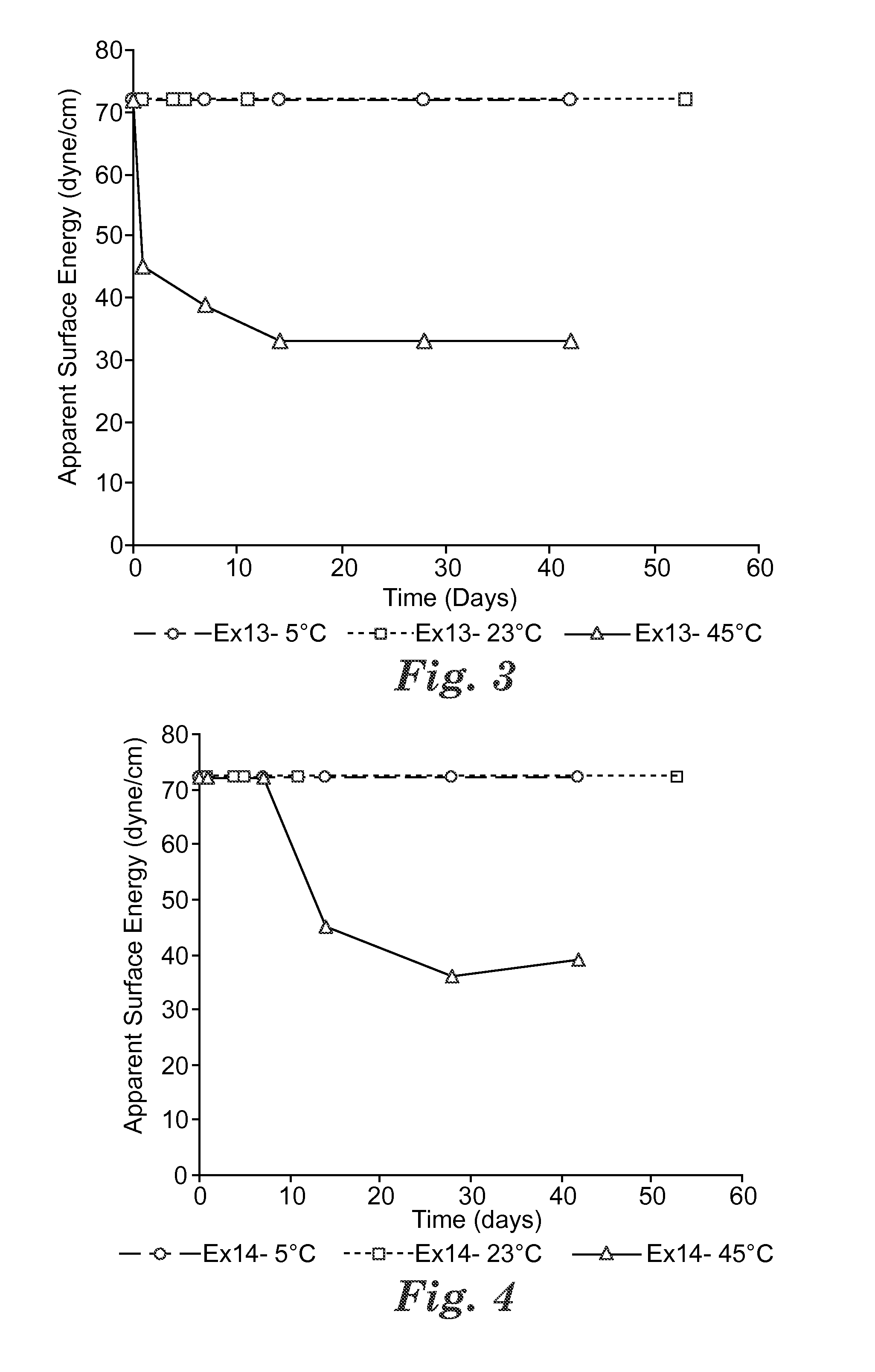

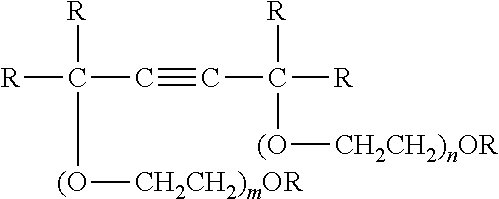

Hydrophilic polyproylene melt additives

InactiveUS20120077886A1Stable and durable hydrophilicityLow costBiocideCosmetic preparationsPolymer scienceThermosetting polymer

Melt additive ionic and non-ionic surfactants to impart stable durable hydrophilicity to thermoplastic polymers or blends thereof.

Owner:3M INNOVATIVE PROPERTIES CO

Dental implant and prosthetic device preparation kit

A preparation kit for preparing dental prosthetic devices in-house at the site of a dental procedure, without requiring an external third-party lab to prepare the final prosthetic device. The kit contains a porous block, a thermoset polymeric resin, and an initiator, where the resin and initiator are both packaged in substantially airtight and substantially opaque packaging. The resin and initiator are combined together to form a resin mixture which is then infiltrated into the pores of the porous block to form an esthetic material. A digital scan of at least a portion of a patient's jaw is used to provide the desired shape of the dental device to a cutting mechanism, which then cuts the filled or un-filled porous block based on the shape provided to it from the digital scan.

Owner:ZIMMER DENTAL INC

Method of making dunnage bags

InactiveUS6435787B1Abrasion resistanceReduce manufacturing costLoad securingCargo supporting/securing componentsDunnageAdhesive

A method of manufacturing an inflatable dunnage bag having a wall construction of two integrally fused layers of thermoplastic polymer, the outer layer of which is a sleeve of strips of woven polymer, the inner of layer of which is a continuous layer of gas impervious polymer. The ends of the sleeve are sealed against the escape of gas. The wall of the bag has a valve for the admittance of gas to the interior of the bag. The bag is formed by deposition of a continuous molten layer of gas impervious polymer to a sleeve of strips of woven polymer, installing a valve for admittance of gas into the wall of the sleeve and forming a gas tight seal at the ends of the sleeve. Deposition of the continuous layer of gas impervious polymer may be a two-step process wherein a molten layer of gas impervious polymer is deposited to one exterior side of the flattened sleeve, then to the other exterior side of the flattened sleeve and the sleeve turned "inside-out". The ends of the bag are sealed, may be folded, the folds secured to the exterior of the bag by adhesive and a binding strip. The dunnage so manufactured is strong, lightweight, scuff resistant, moisture resistant, reusable or easily recyclable.

Owner:JOHN DAVID M

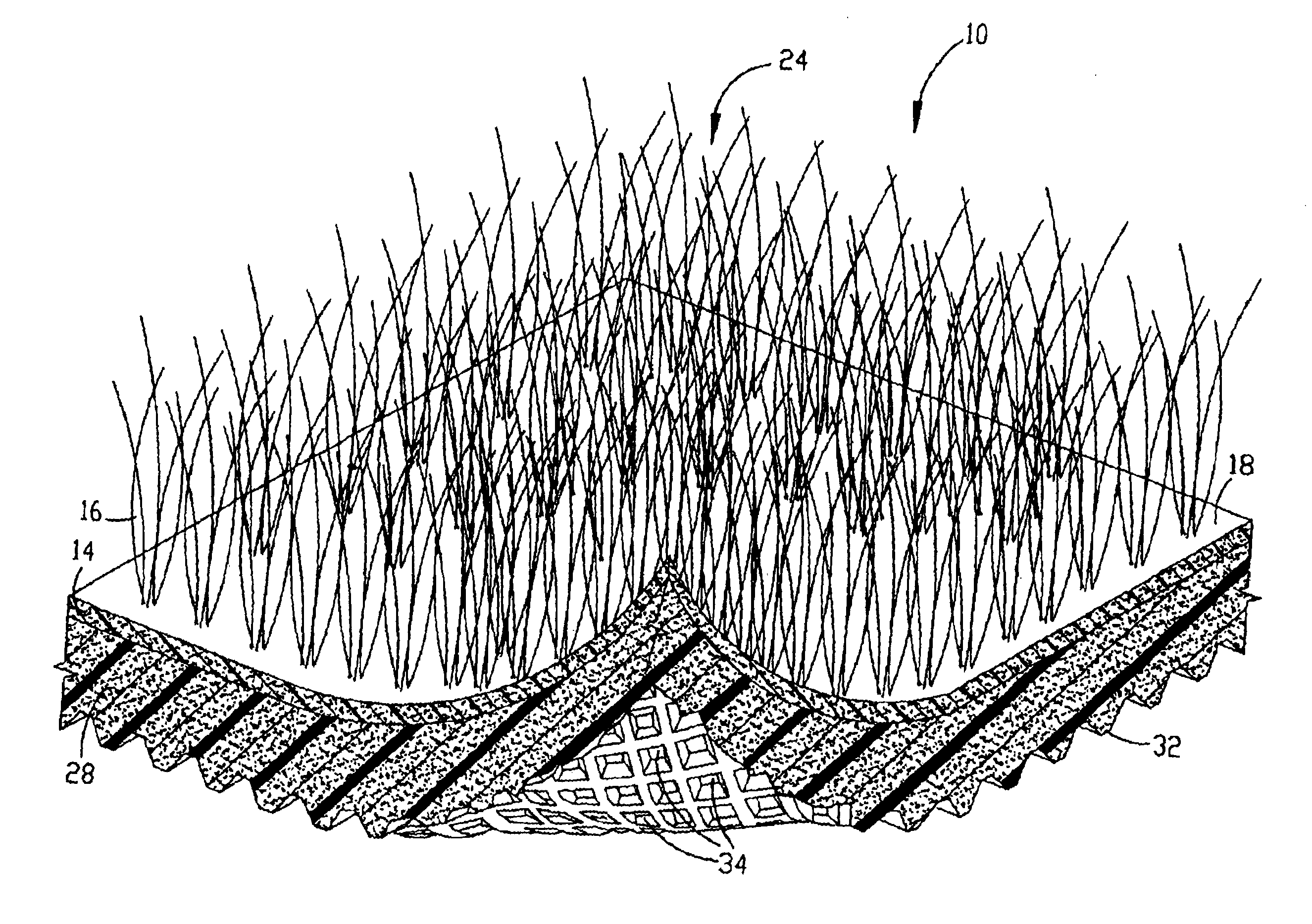

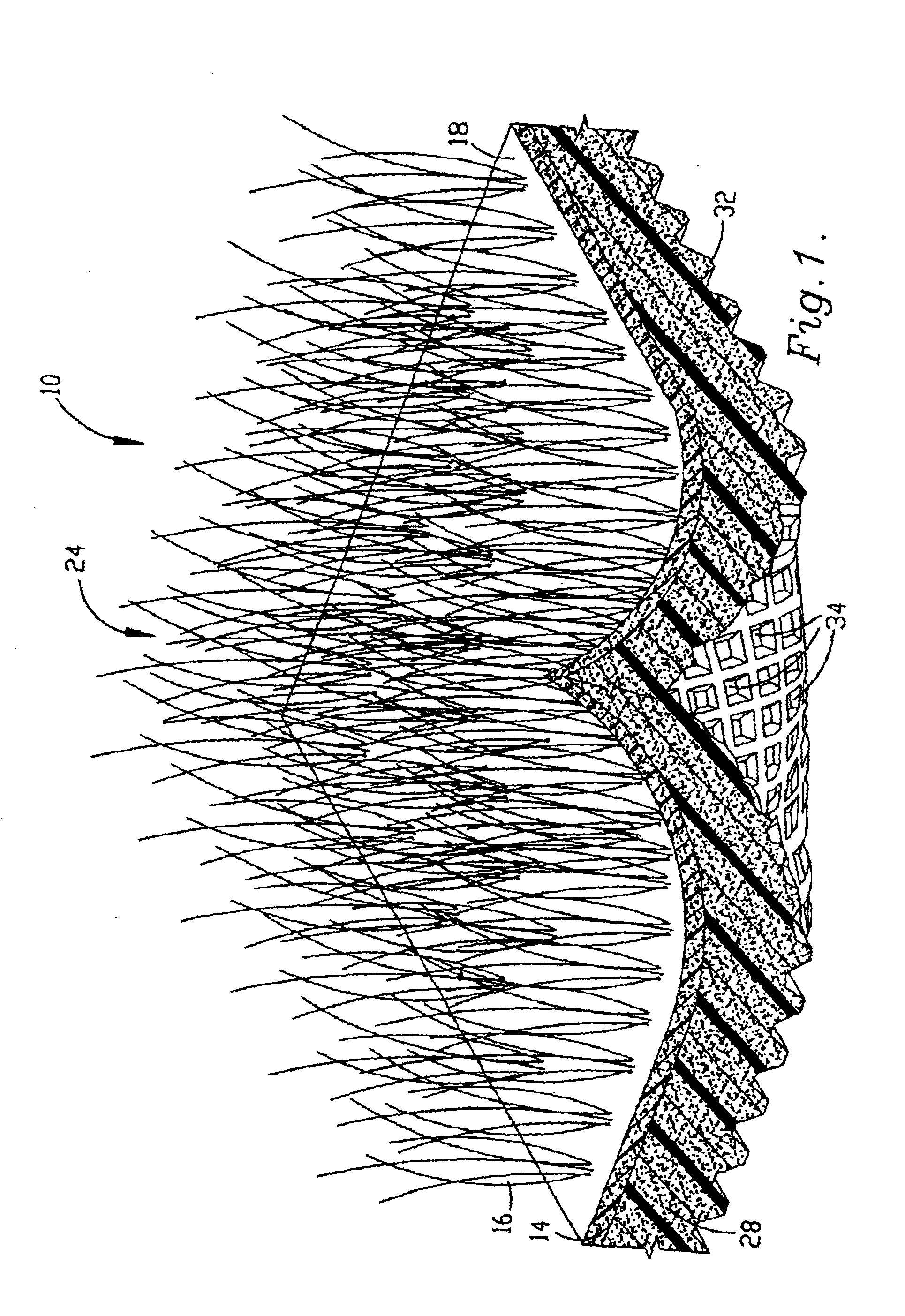

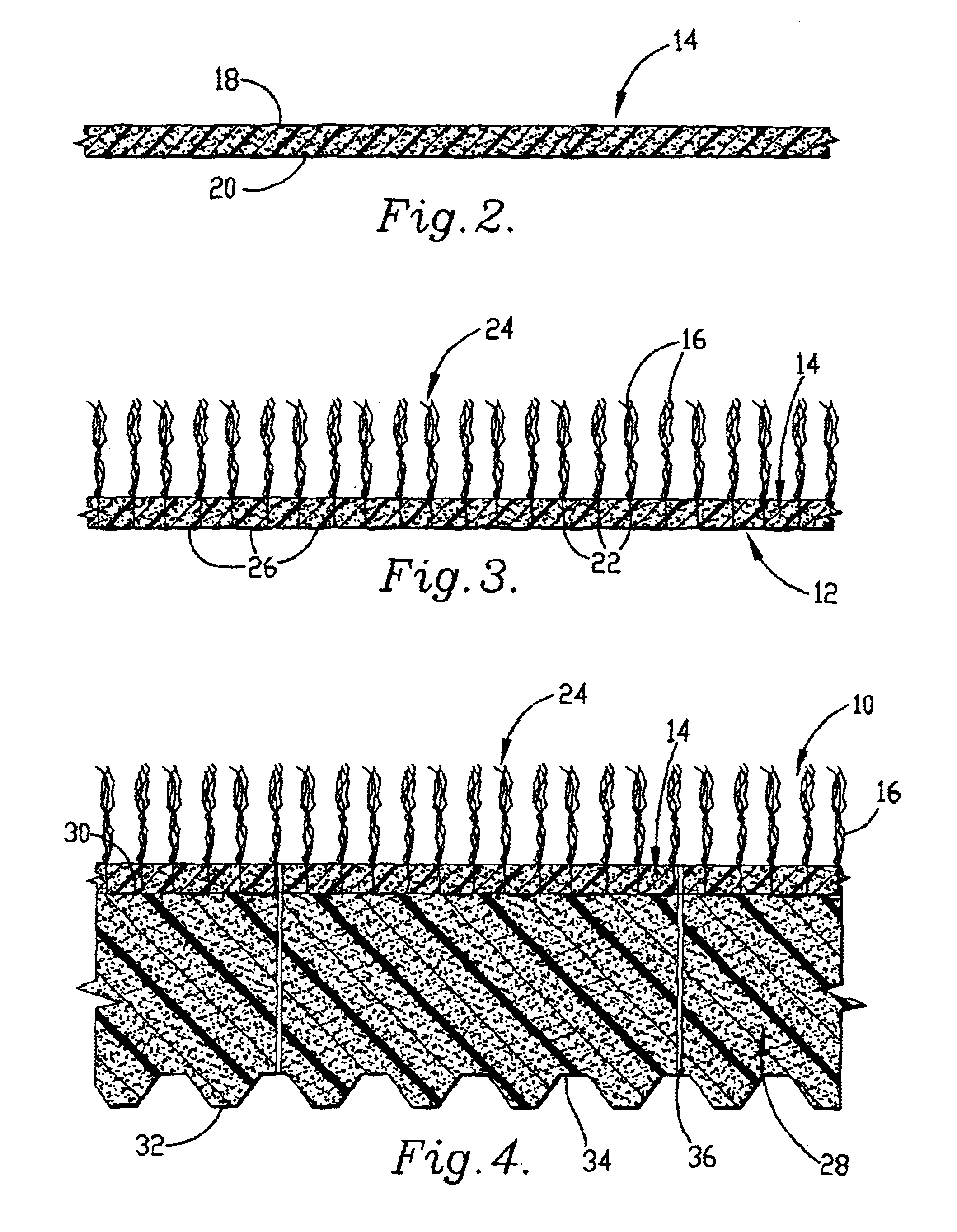

Tufted surface covering and method

The tufted surface covering includes a base formed from particles of a thermosetting polymer compound mixed with a particle binding agent causing a portion of the particles to bind together to form a self supporting web. The base is tufted with a tufting material. Thermosetting vulcanized natural and / or synthetic rubber compounds are employed. The polymer layer is tufted with a tufting material and heated to a temperature of from about 110° C. to about 220° C. at an elevated pressure of up to two tons per square inch, to cause the particles to bind together at elevated temperature and pressure to anchor and seal the tufts in place. Cross-linking agents and polar polymer containing compounds may be employed as particle binding agents. In another aspect of the invention, a second layer of particles of a thermosetting polymer mixed with a particle binding agent may be joined together with the particles of the first layer at elevated temperature and pressure. A series of spaced apertures extends through the first and second layers to enable free draining of the surface covering. The lower surface of the covering includes spaced indentations to reduce the weight of the covering.

Owner:WALTERS IAN D

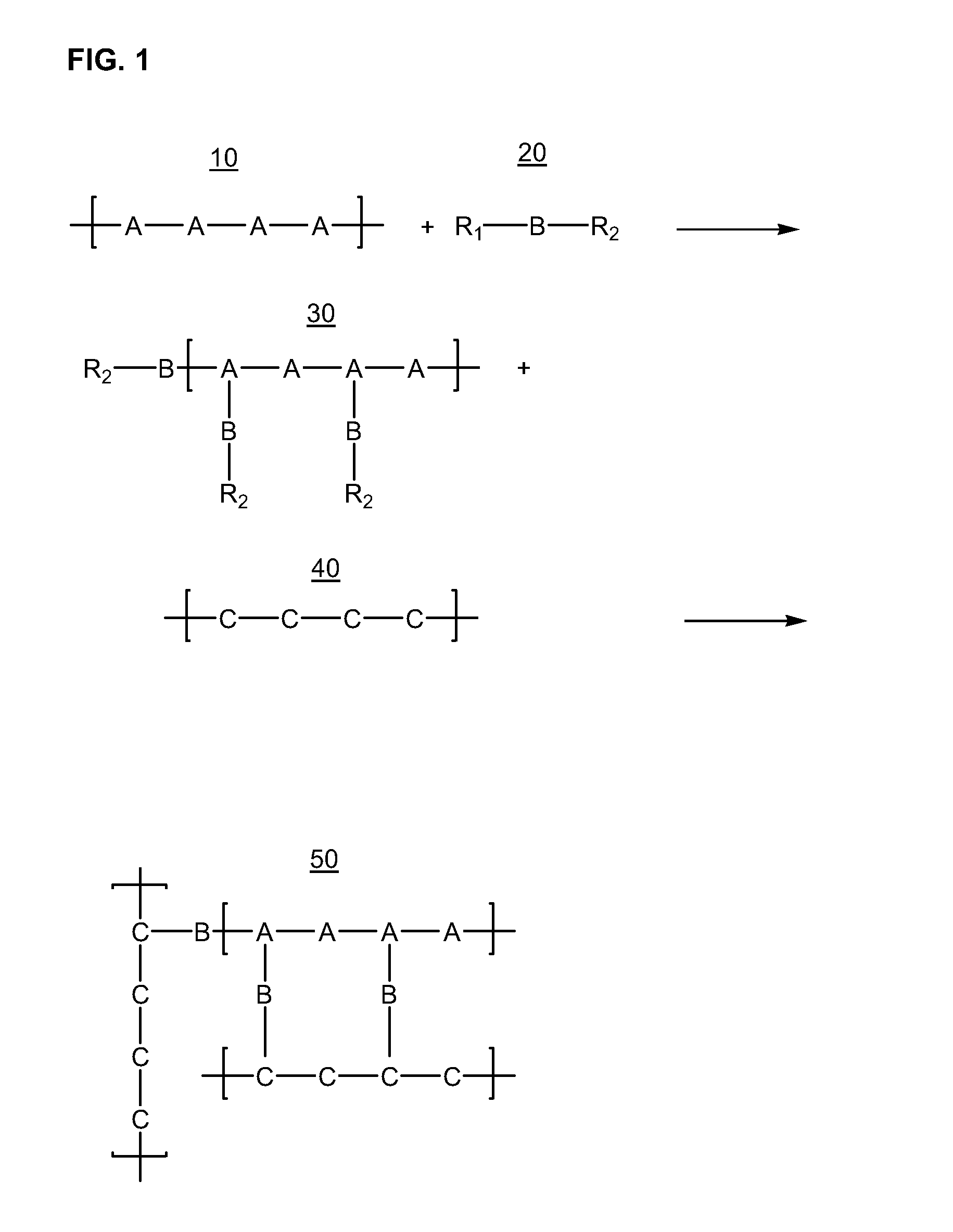

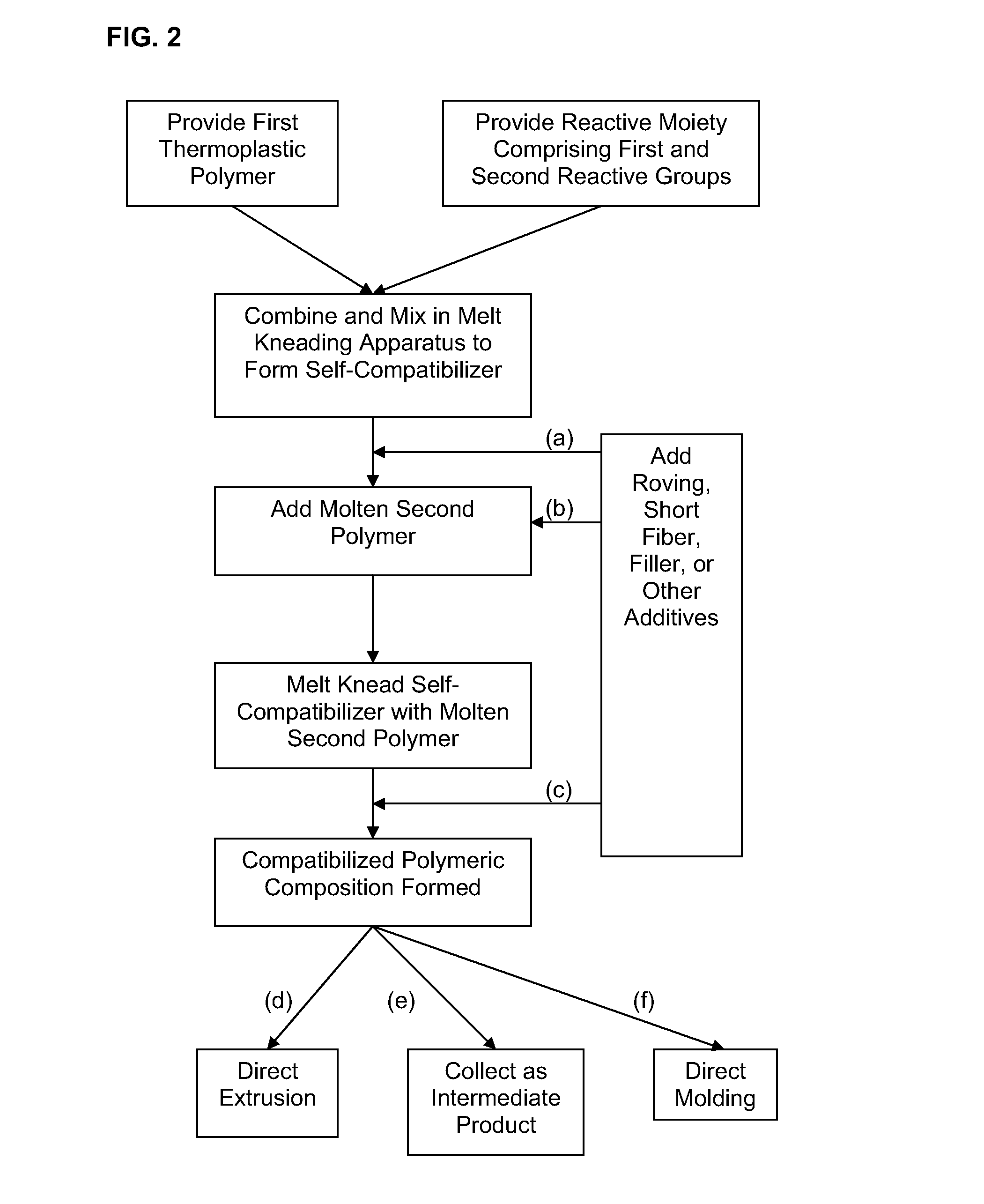

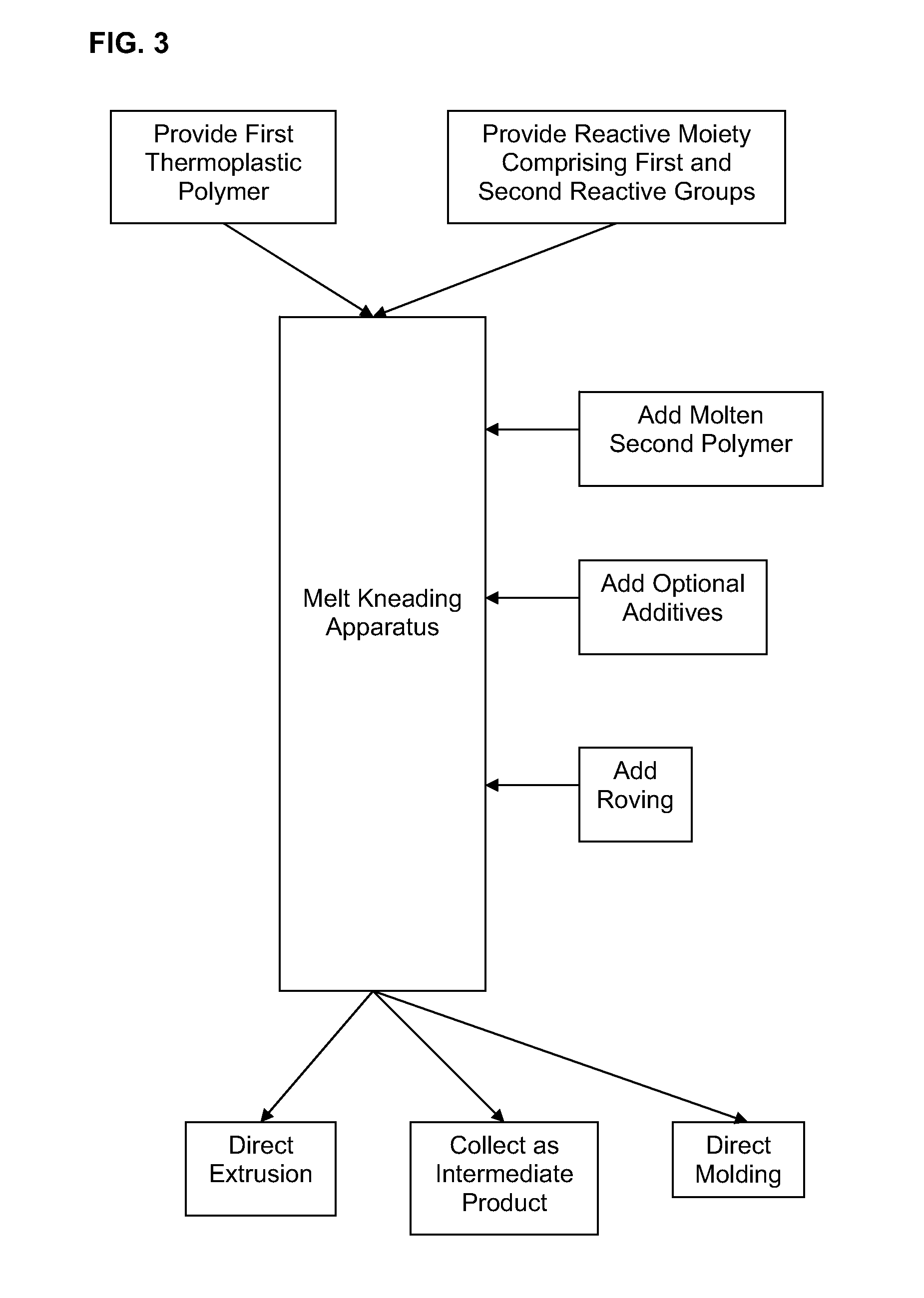

Process for producing compatibilized polymer blends

ActiveUS20080214699A1Save energyLow costConductive materialOrganic dyesPolymer scienceThermosetting polymer

A process is provided for producing a compatibilized polymeric blend. A first thermoplastic polymer and a reactive moiety are provided to a progressive melt kneading apparatus. The reactive moiety comprises a first reactive group capable of reacting with the first thermoplastic polymer but not a second polymer and a second reactive group capable of reacting with the second polymer but not the first polymer. The first thermoplastic polymer and the reactive moiety are then melt kneaded so that the first reactive group reacts with the first thermoplastic polymer and the second reactive group is grafted to the first thermoplastic polymer, forming a molten self-compatibilizer. A molten second polymer is then provided. The molten self-compatibilizer is melt kneaded with the molten second polymer so that the second reactive group reacts with the second polymer to form a compatibilized polymeric blend. Also provided are articles formed from the compatibilized polymer blend.

Owner:GEOTECH TECHNOLOGIES LTD

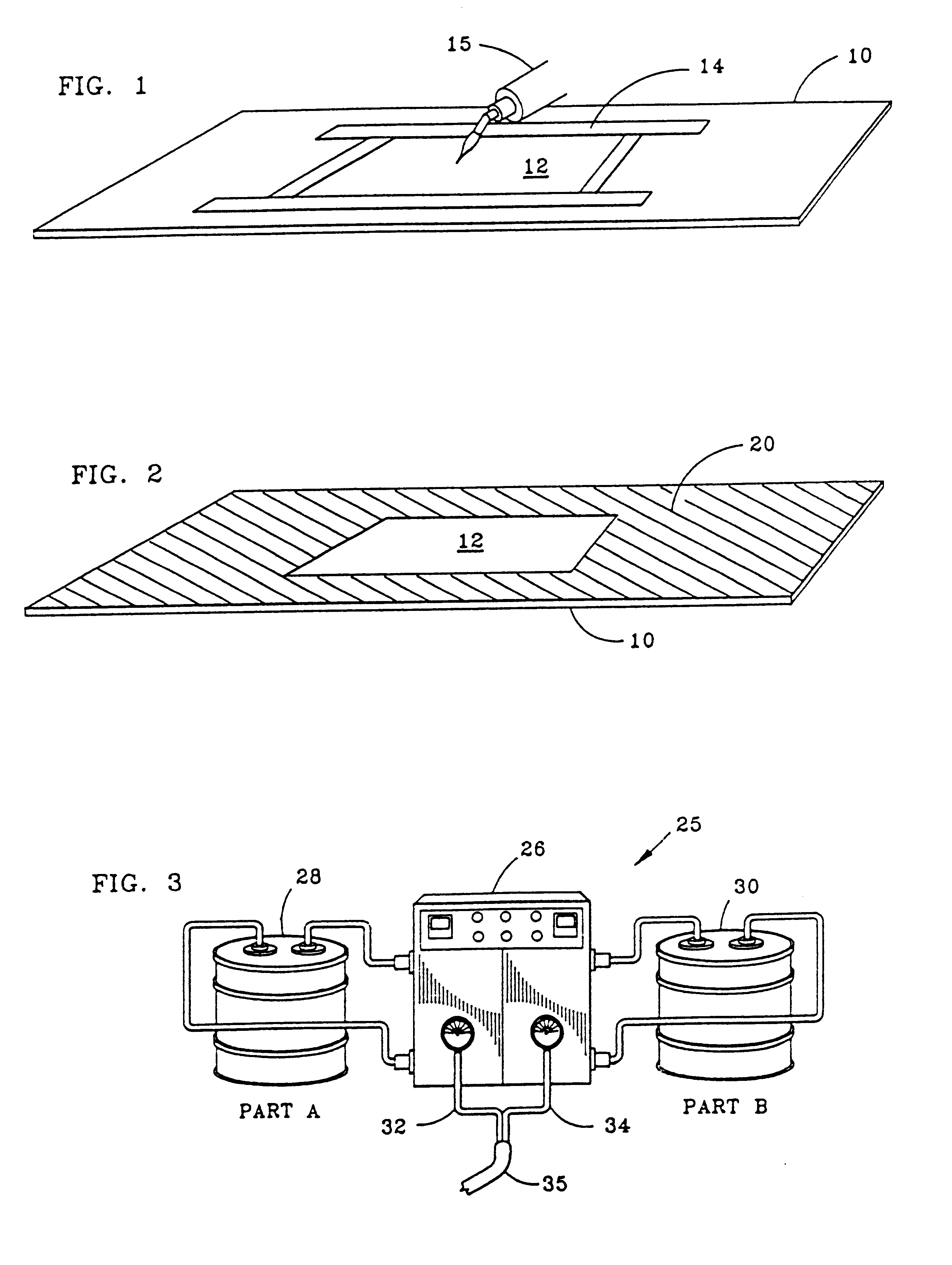

Molding a polishing pad having integral window

A polishing pad is formed by solidifying a flowable polymeric material at different rates of cooling to provide a polishing pad with a transparent region and an adjacent opaque region. Types of polymeric material suitable for making the polishing pad include a single thermoplastic material, a blend of thermoplastic materials, and a reactive thermosetting polymer.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

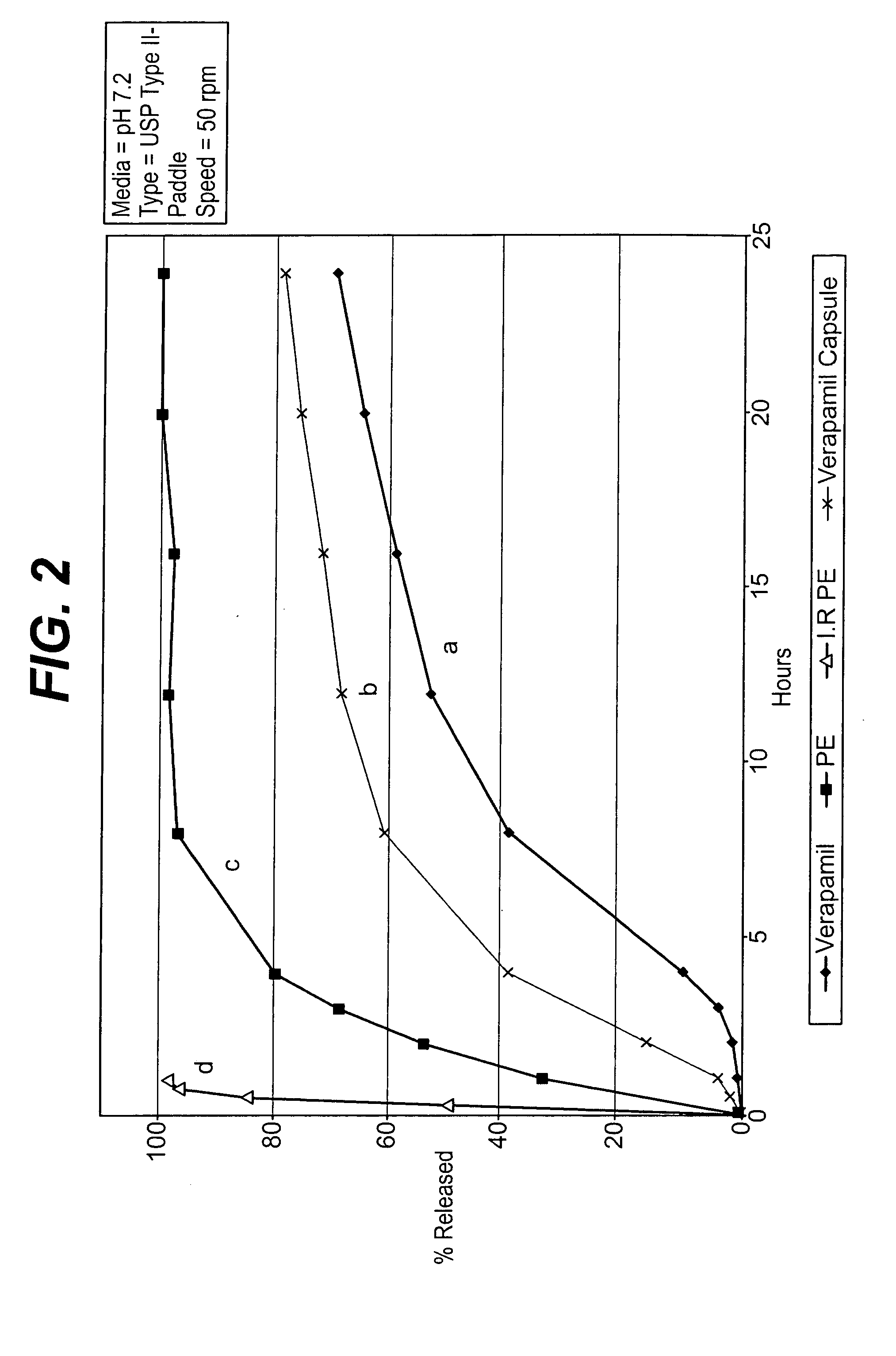

Modified release dosage forms

In one embodiment a dosage form comprises at least one active ingredient and a molded matrix which comprises 10-100% of a material having a melting point of less than about 100 degrees C. selected from the stamp consisting of thermoplastic polyalkylene oxides, low melting hydrophobic materials, thermoplastic polymers, thermoplastic starches and combinations thereof, and the matrix is capable of providing modified release of the active ingredient upon contacting of the dosage form with a liquid medium. The dosage form may additionally comprise uncoated particles which may contain at least one active ingredient. In another embodiment, a dosage form comprises at least one active ingredient, a plurality of particles and a molded matrix, wherein at least a portion of the particles are coated. The coated particles, the matrix or both may comprise at least one active ingredient, and the coated particles or the matrix or a combination thereof is capable of providing modified release of the active ingredient upon contacting of the dosage form with a liquid medium.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

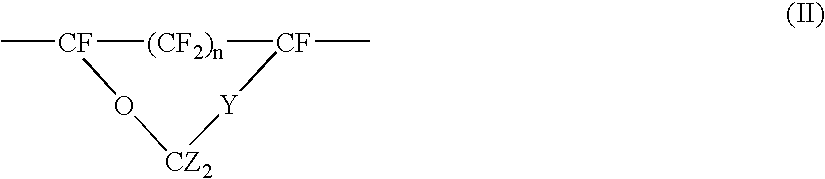

Fluoropolymer blends and multilayer articles

InactiveUS6849314B2Improve thermal stabilityLower surface energySynthetic resin layered productsFlexible pipesPolymer scienceThermosetting polymer

Owner:3M INNOVATIVE PROPERTIES CO

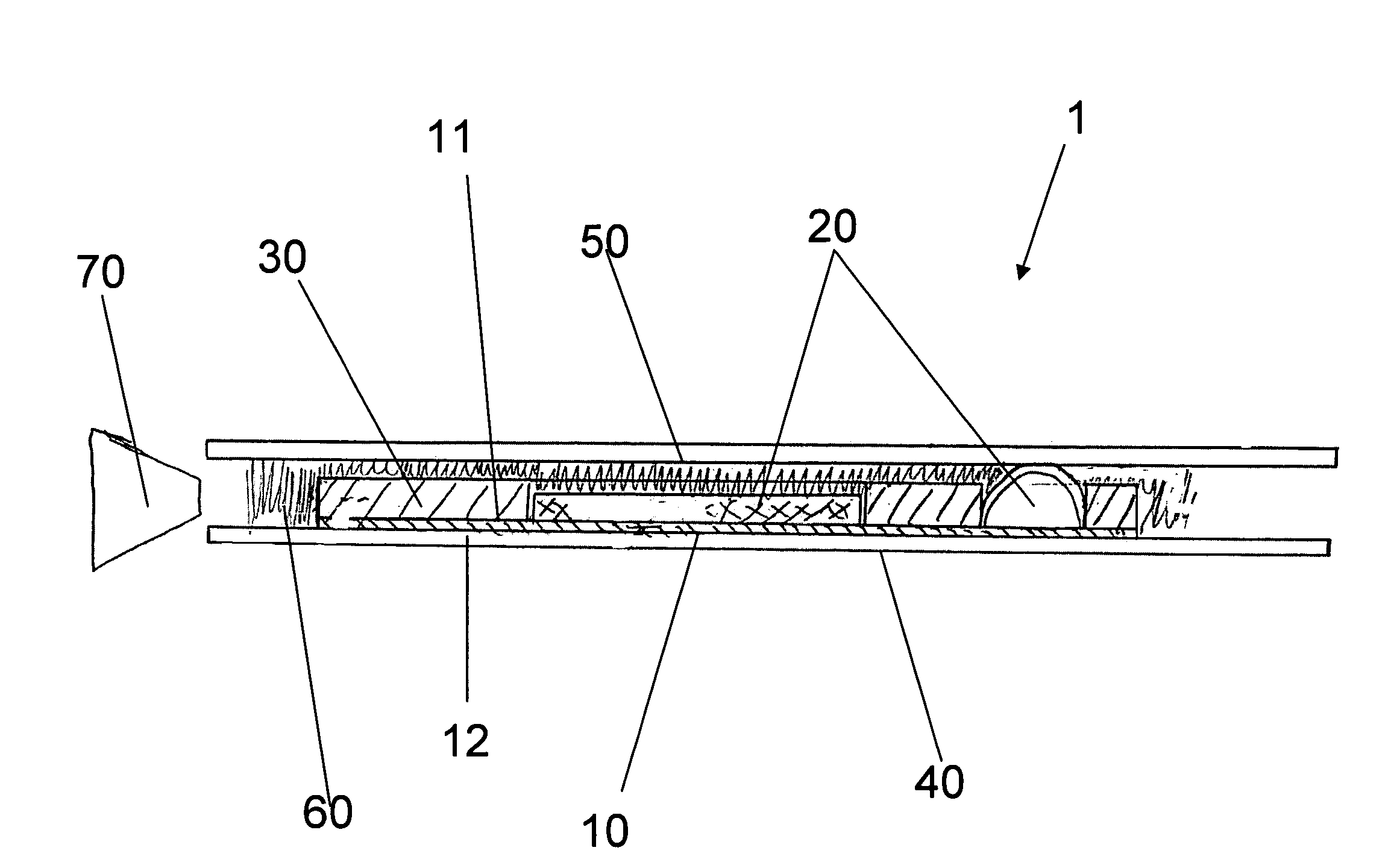

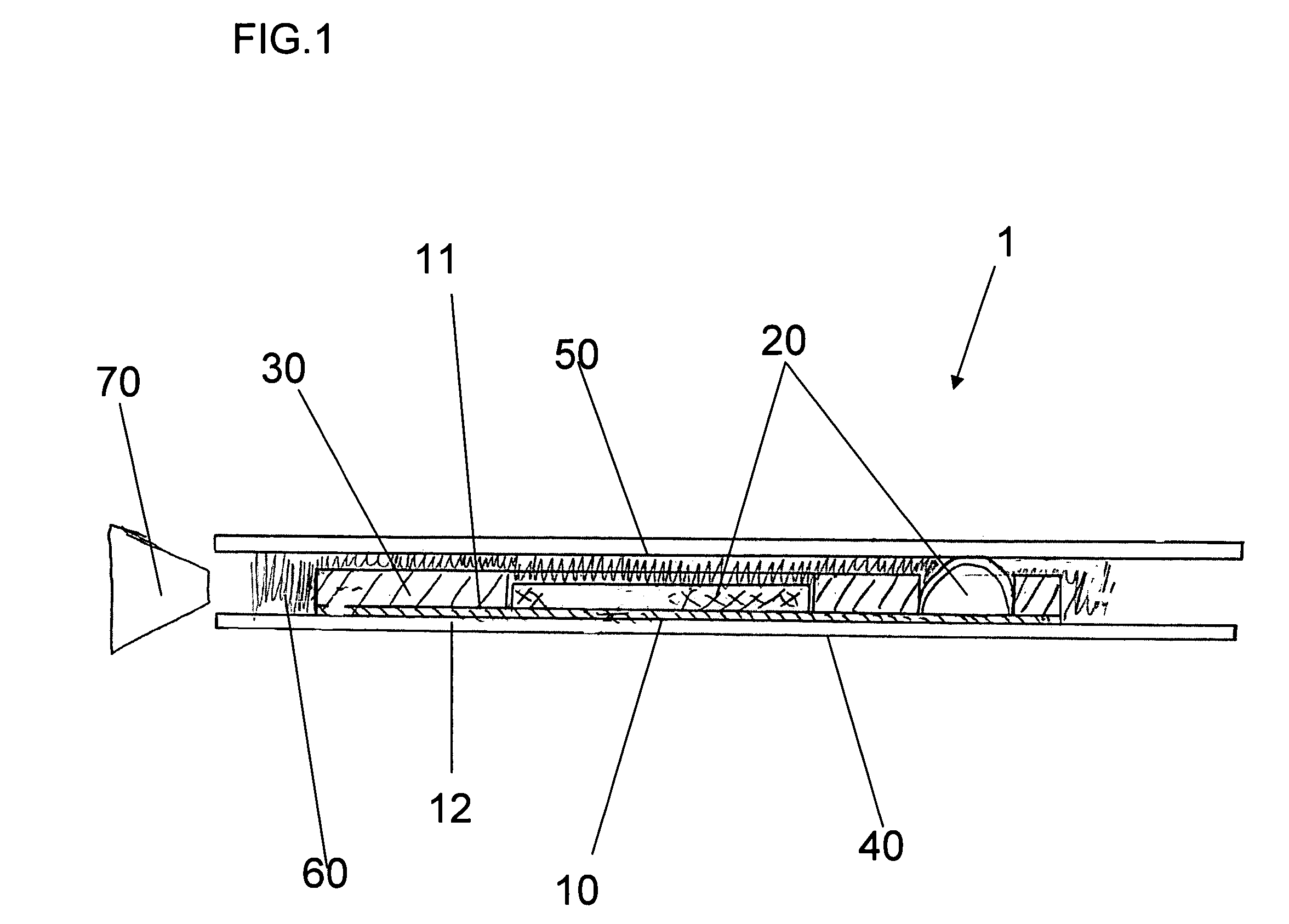

Ultrasonic transducer for use in a fluid medium

InactiveUS20110125024A1Reduce noise couplingHigh materialUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesThermoplasticPlastic materials

An ultrasonic transducer for use in a fluid medium includes at least one transducer core having at least one acoustic / electric transducer element. The ultrasonic transducer furthermore includes at least one decoupling element which is configured to reduce a structure-borne noise coupling between the transducer core and a housing. The decoupling element includes at least one porous plastic material, in particular a foamed plastic material. The porous plastic material includes at least one thermosetting polymer and / or at least one thermoplastic.

Owner:ROBERT BOSCH GMBH

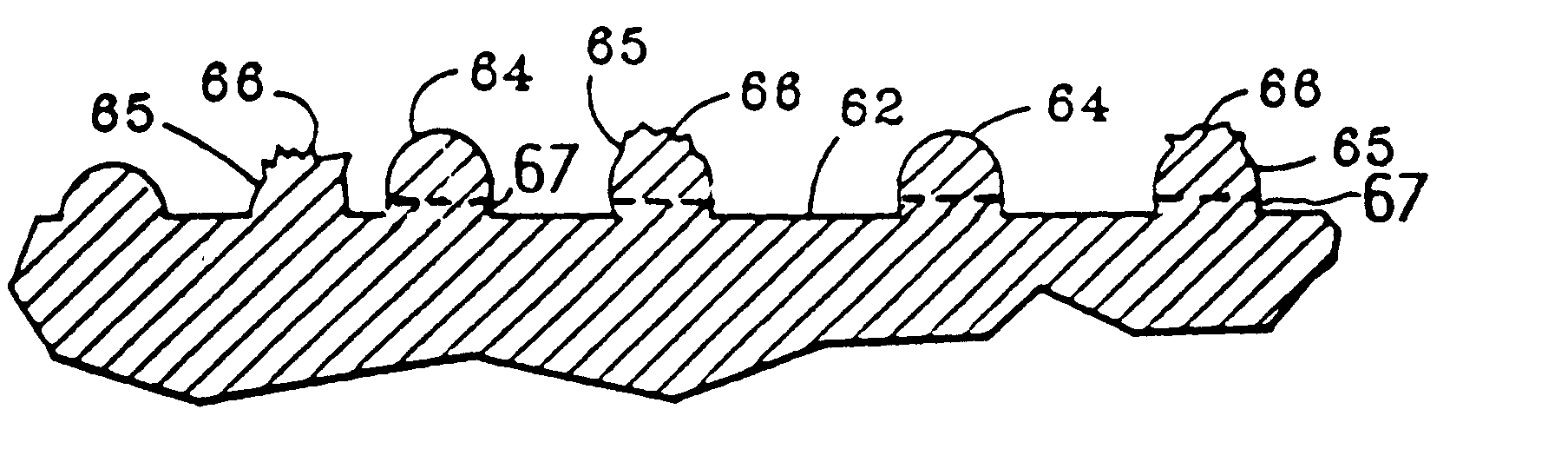

Thermoplastic products having antislip surfaces

InactiveUS6509084B2Effective antislip surface propertyGood adhesion and durability and wearabilityKitchenware cleanersCleaning machinesEngineeringVolcano

Thermoplastic products such as vehicle cargo area liners, floor mats, recreational and playground equipment, cargo pallets, and wet area walking surfaces are provided with an antislip surface treatment. The antislip surface is made up of individual non-interconnected asperities of an antislip polymer material, which do not form a continuous film over the surface of the thermoplastic product. The thermoplastic product is especially made of high density polyethylene. The antislip polymer is preferably a thermoset polymer, and most particularly is a polyurea / isocyanate polymer. The antislip polymer is preferably applied by spraying, and then the product is heat treated at a temperature in the range from 100 to 200° F., or is thermoformed at a temperature in the range from 250 to 550° F. The antislip asperities are durably bonded onto the thermoplastic base material, and provide a significantly increased coefficient of friction. The asperity size, height, and hardness can be controlled by adjusting the processing conditions. The asperities may have an increased surface relief due to a so-called "moth effect" and an increased surface roughness due to cratering as a result of a so-called "volcano effect" in the process using thermoforming.

Owner:CUSTOM PLASTICS MOLDING

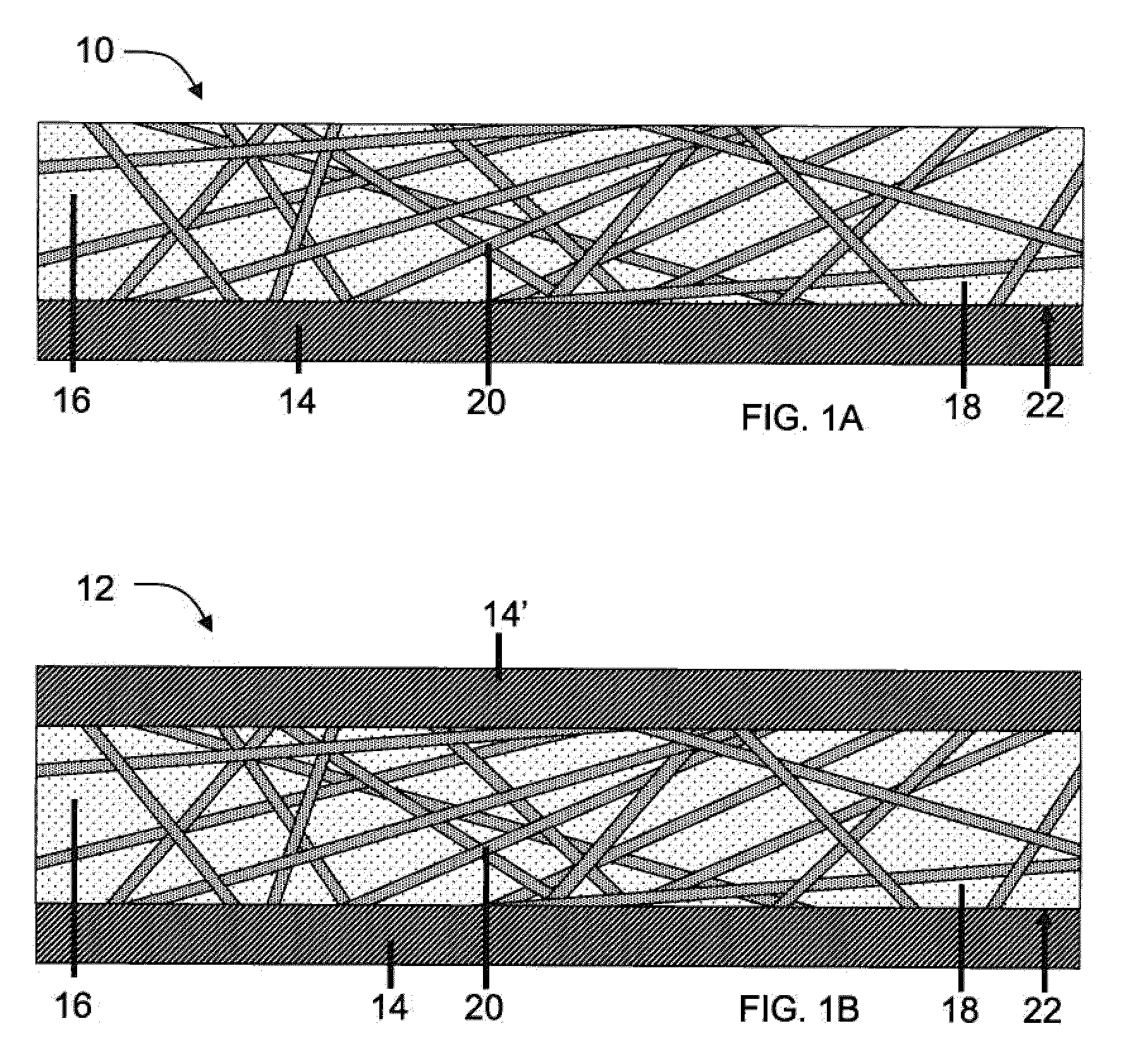

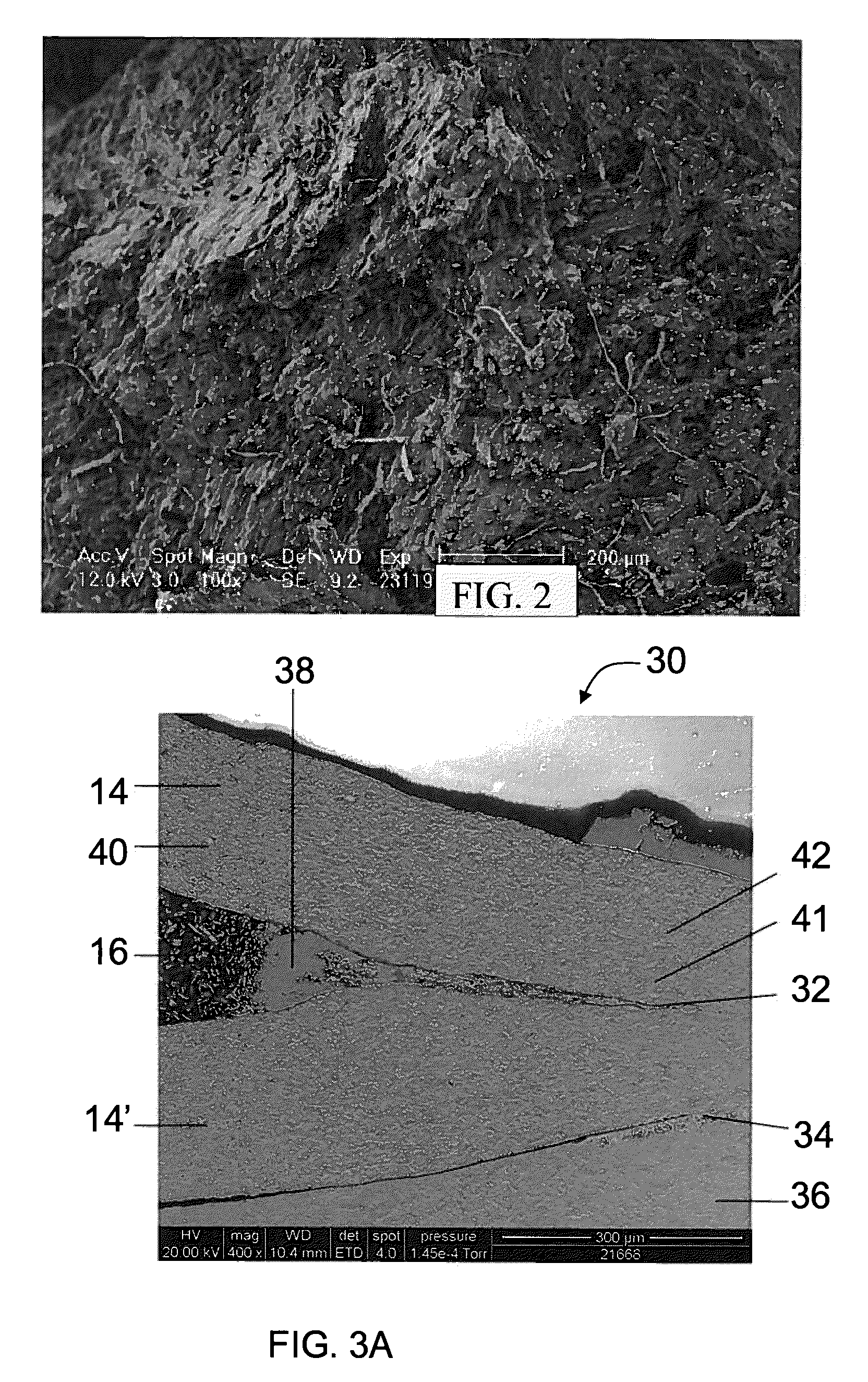

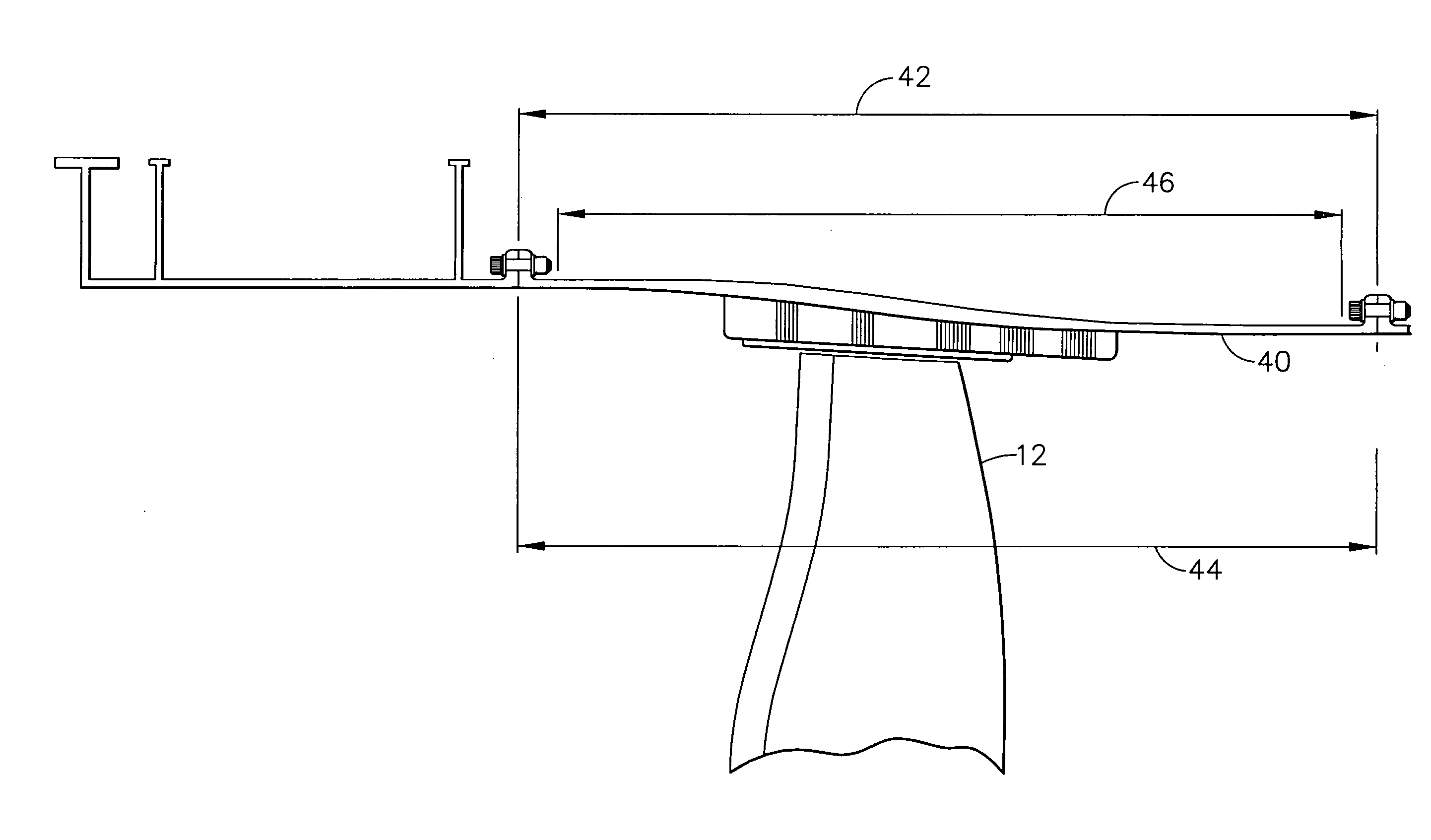

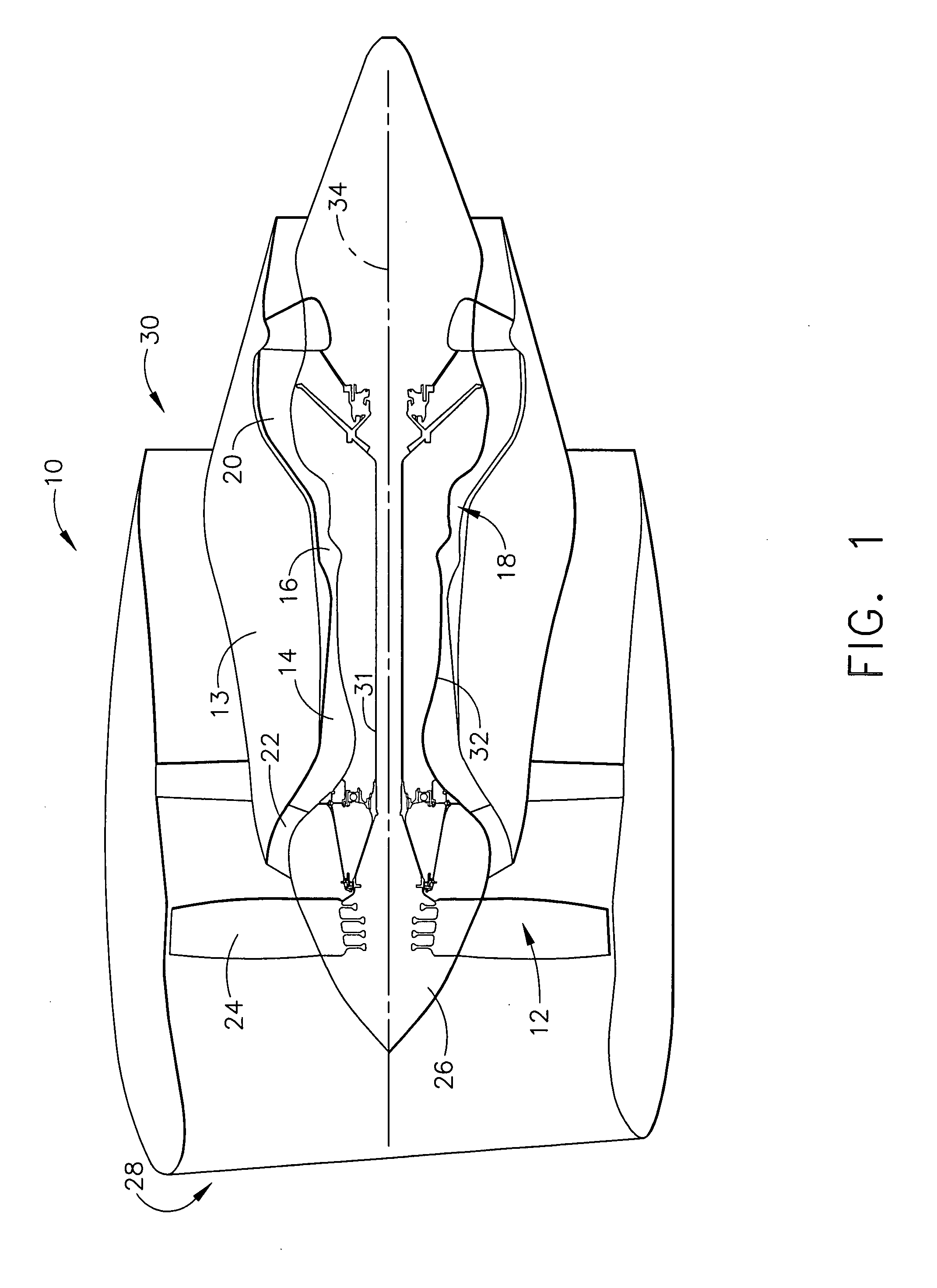

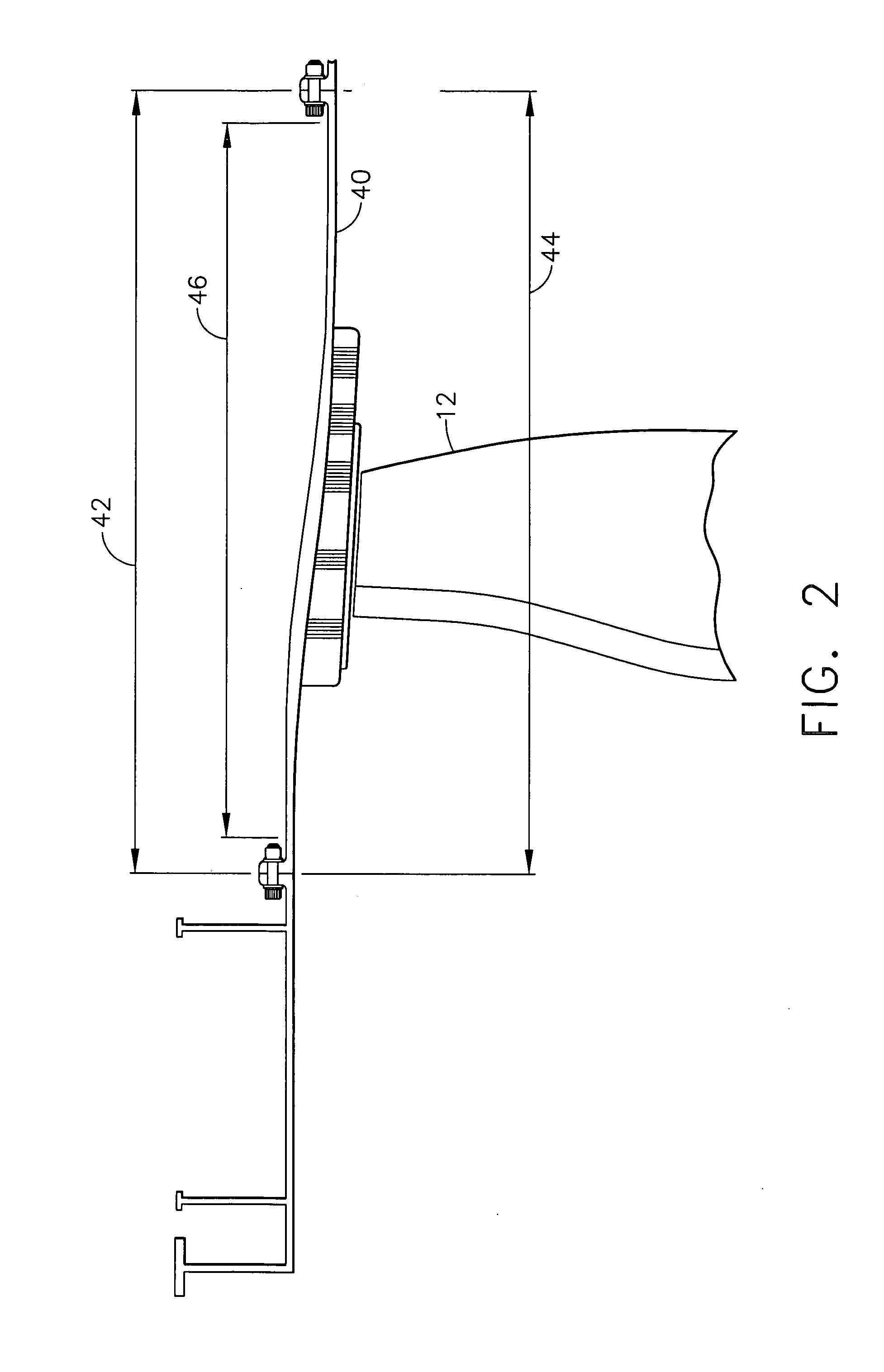

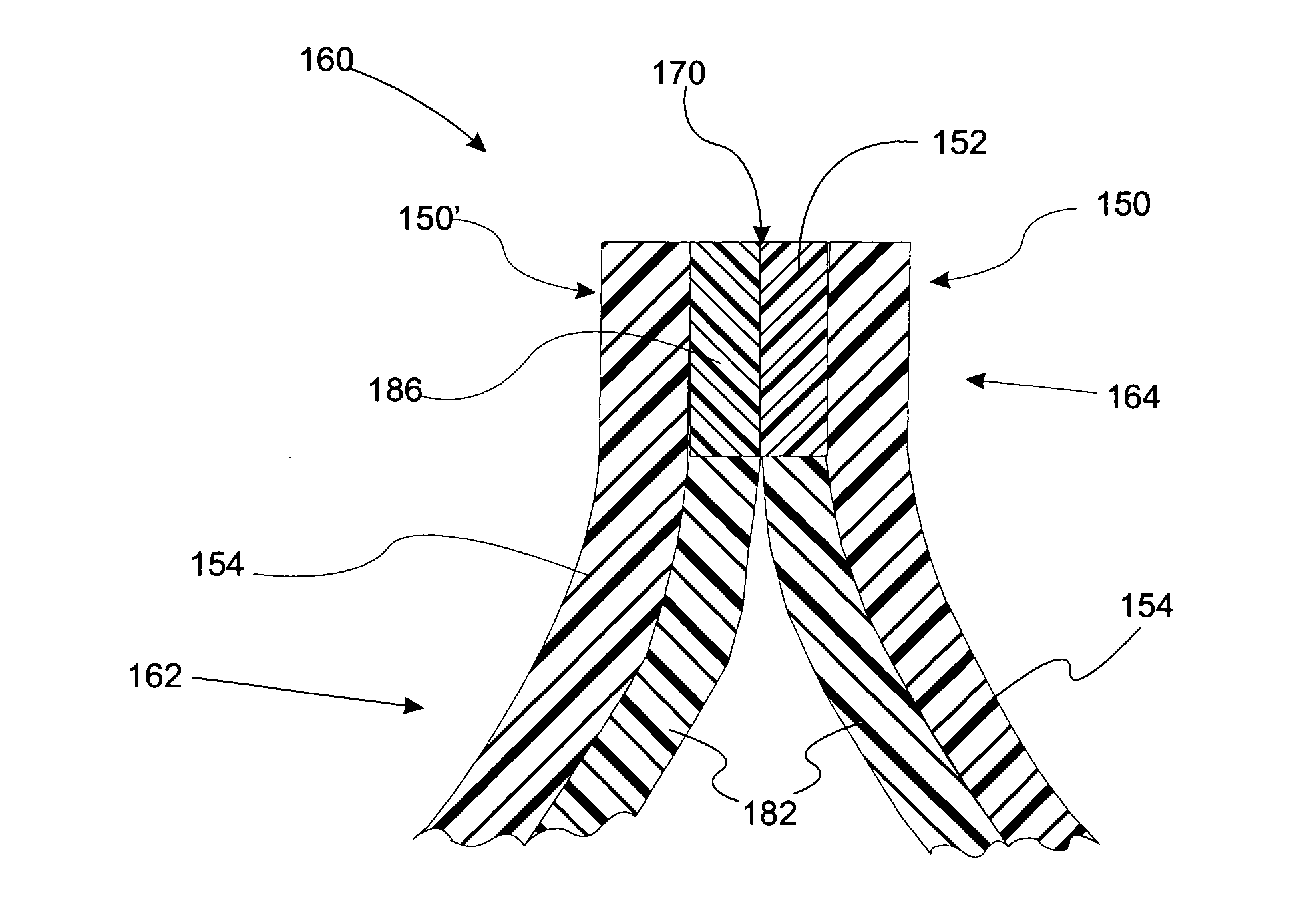

Composite containment case for turbine engines

A composite fan casing for a gas turbine engine includes, in an exemplary embodiment, a core having a plurality of core layers of reinforcing fiber bonded together with a thermosetting polymeric resin. Each core layer includes a plurality of braided reinforcing fiber tows. The braids of reinforcing fiber tows are aligned in a circumferential direction with each fiber tow including a plurality of reinforcing fibers. The core also includes at least one additional fiber tow braided into at least one predetermined axial location to form at least one concentrated stiffening ring.

Owner:GENERAL ELECTRIC CO

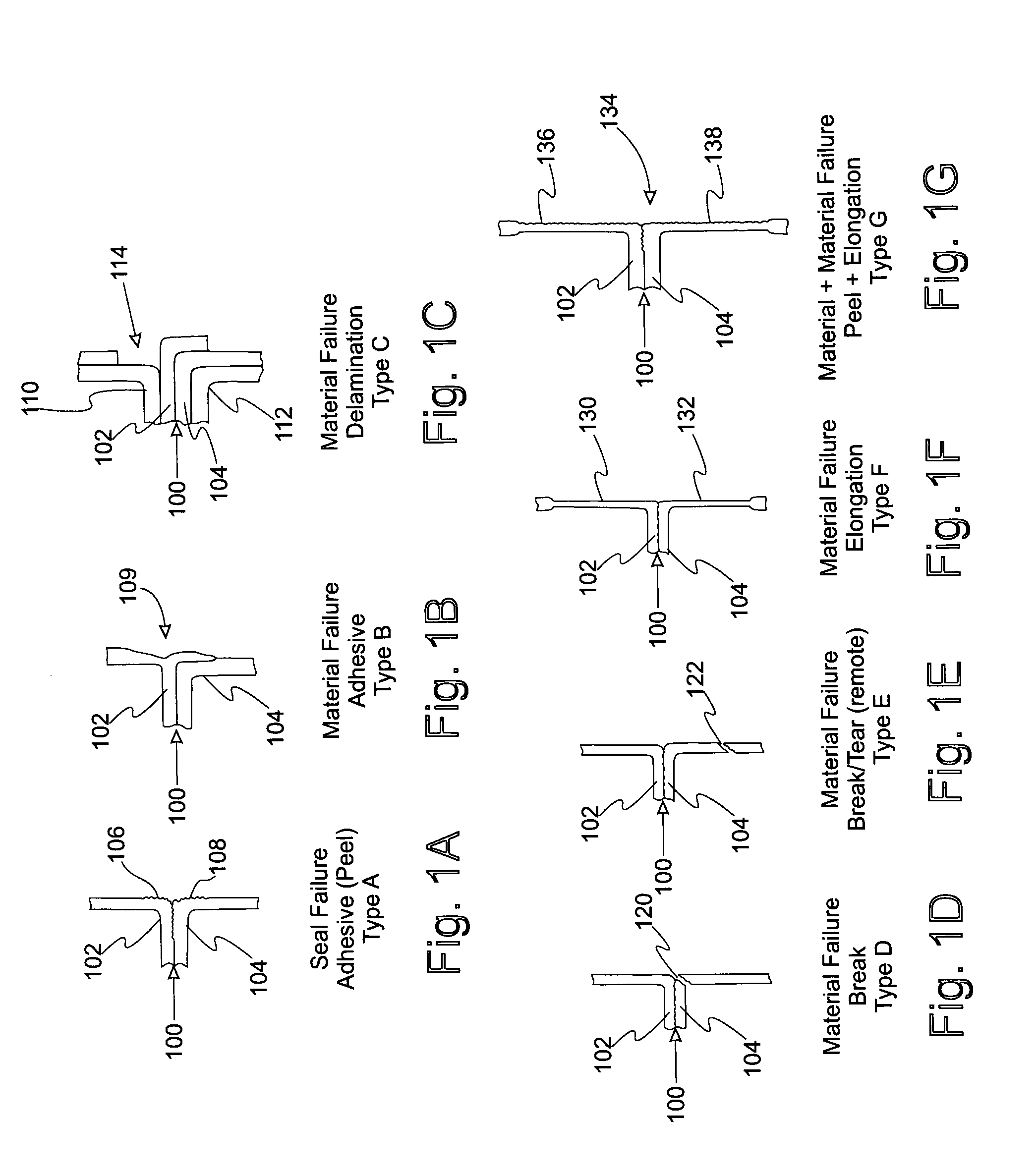

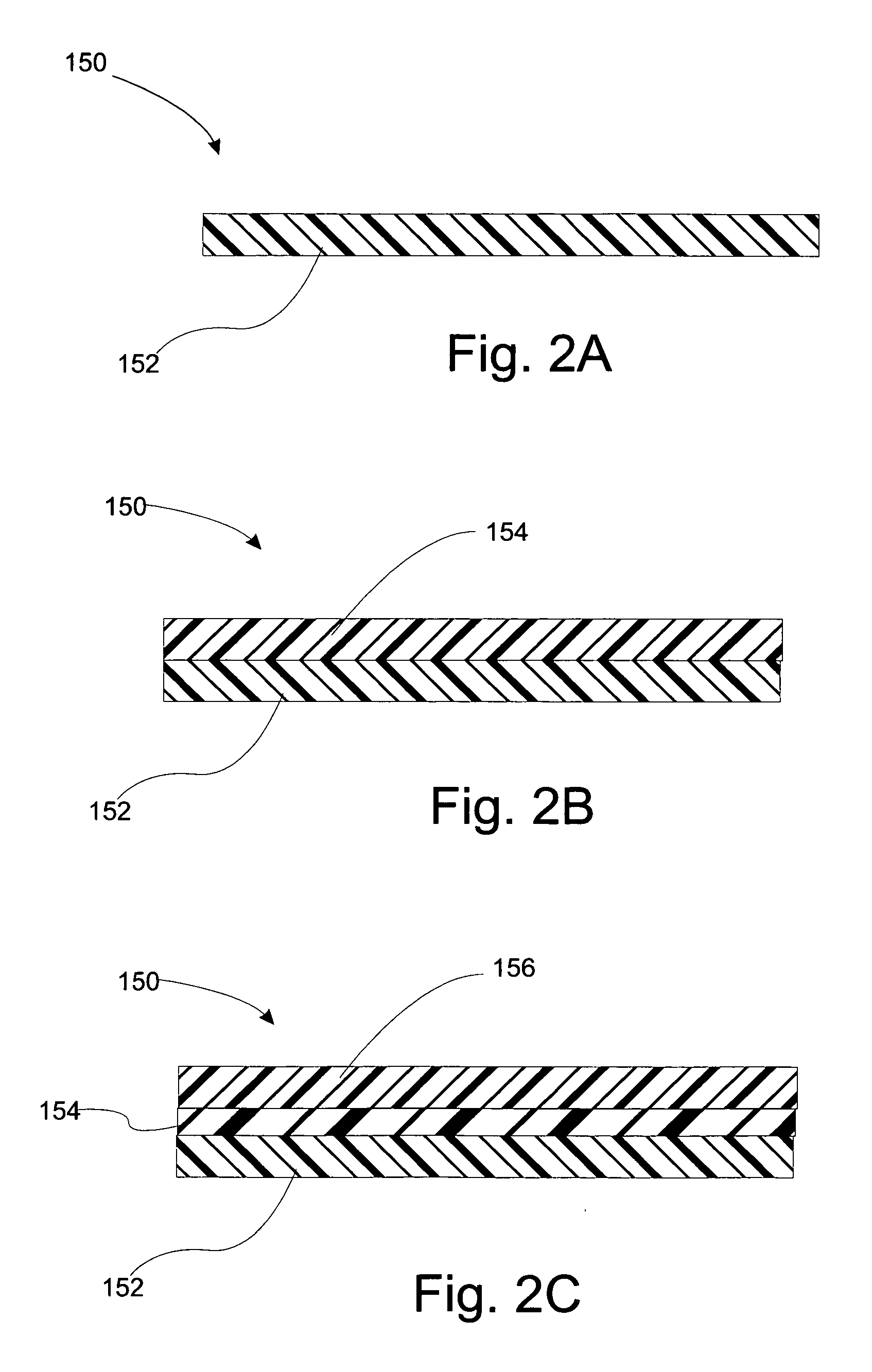

Peelable composite thermoplastic sealants in packaging films

A peelable sealing structure includes a sealing layer and one or more optional additional layers. The peelable sealing structure includes a sealing surface that is formable into a peelable seal upon contact with a sealing substrate at all temperatures in a peelable seal temperature range. Moreover, the peelable sealing structure comprises a thermoplastic polymer and an additive dispersed within at least a portion of the thermoplastic polymer with the peelable sealing structure defining the sealing surface.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

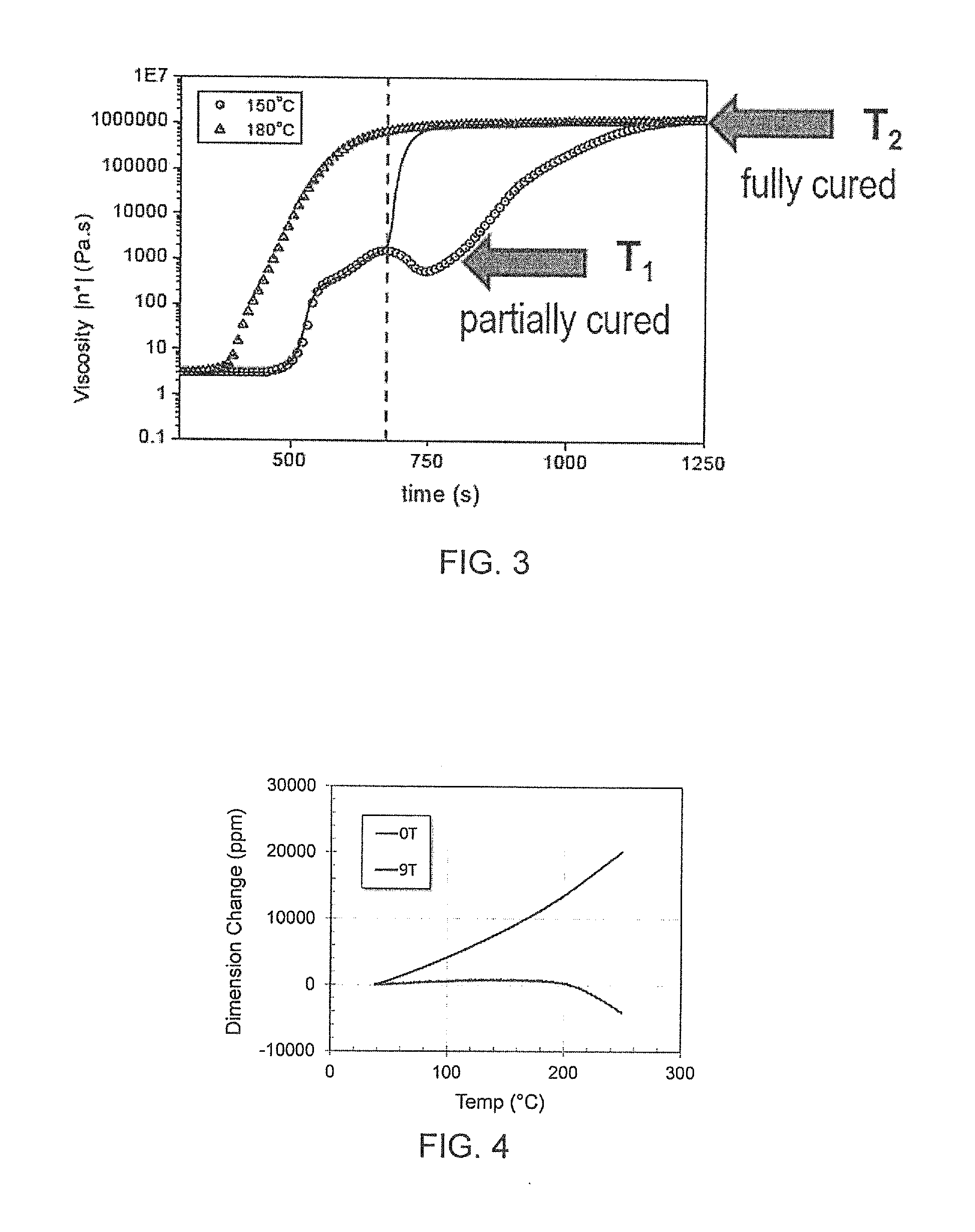

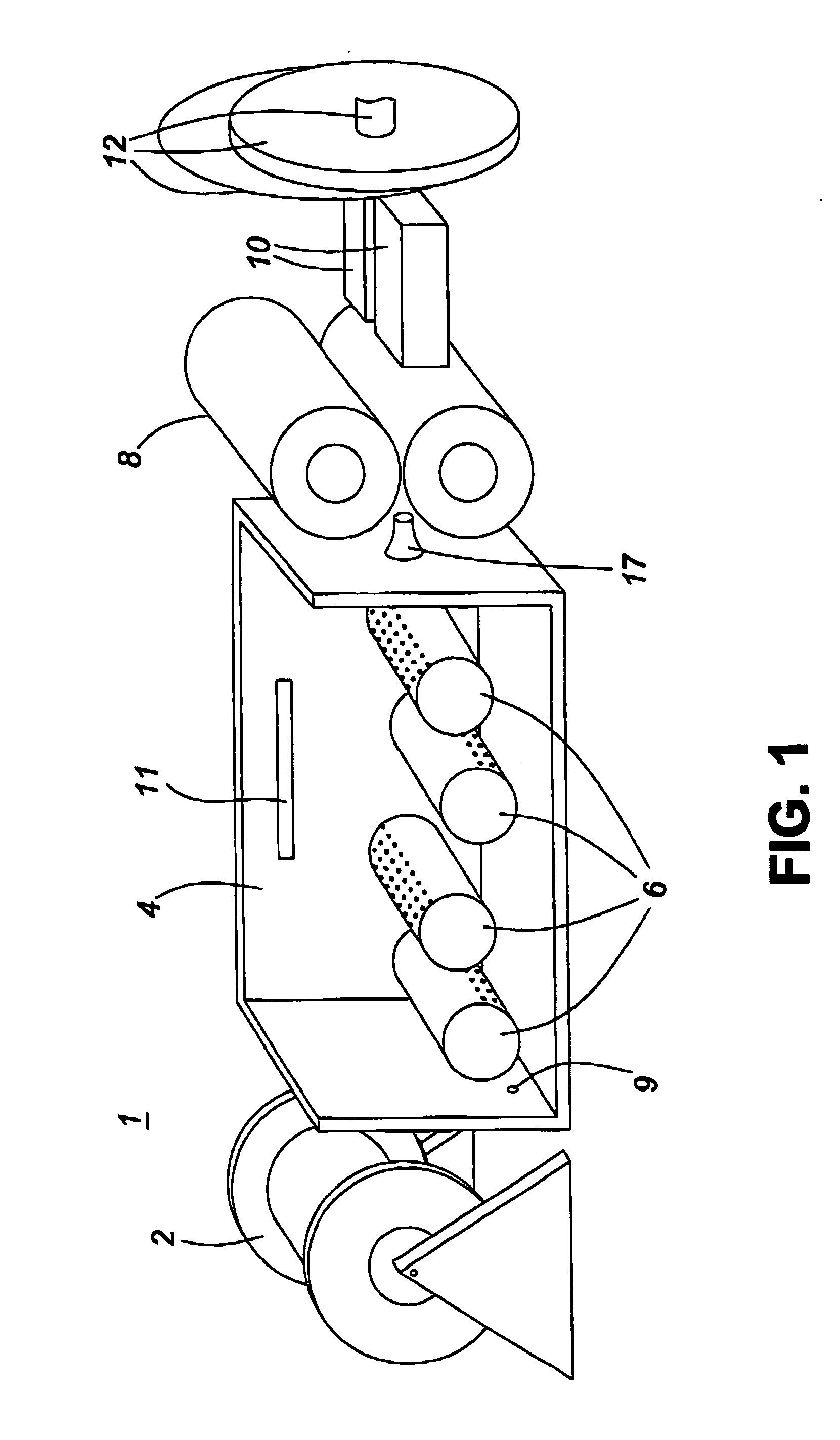

Reactive polymer fused deposition manufacturing

ActiveUS20150291833A1Improve bindingHigh mechanical strengthAdditive manufacturing apparatusElectric discharge heatingEpoxyCross-link

Methods and compositions for additive manufacturing that include reactive or thermosetting polymers, such as urethanes and epoxies. The polymers are melted, partially cross-linked prior to the depositing, deposited to form a component object, solidified, and fully cross-linked. These polymers form networks of chemical bonds that span the deposited layers. Application of a directional electromagnetic field can be applied to aromatic polymers after deposition to align the polymers for improved bonding between the deposited layers.

Owner:UT BATTELLE LLC

Thermoplastic cellulosic fiber blends as lost circulation materials

ActiveUS9453156B2Reduce circulation lossHigh densitySolid waste managementFlushingThermoplasticThermosetting polymer

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

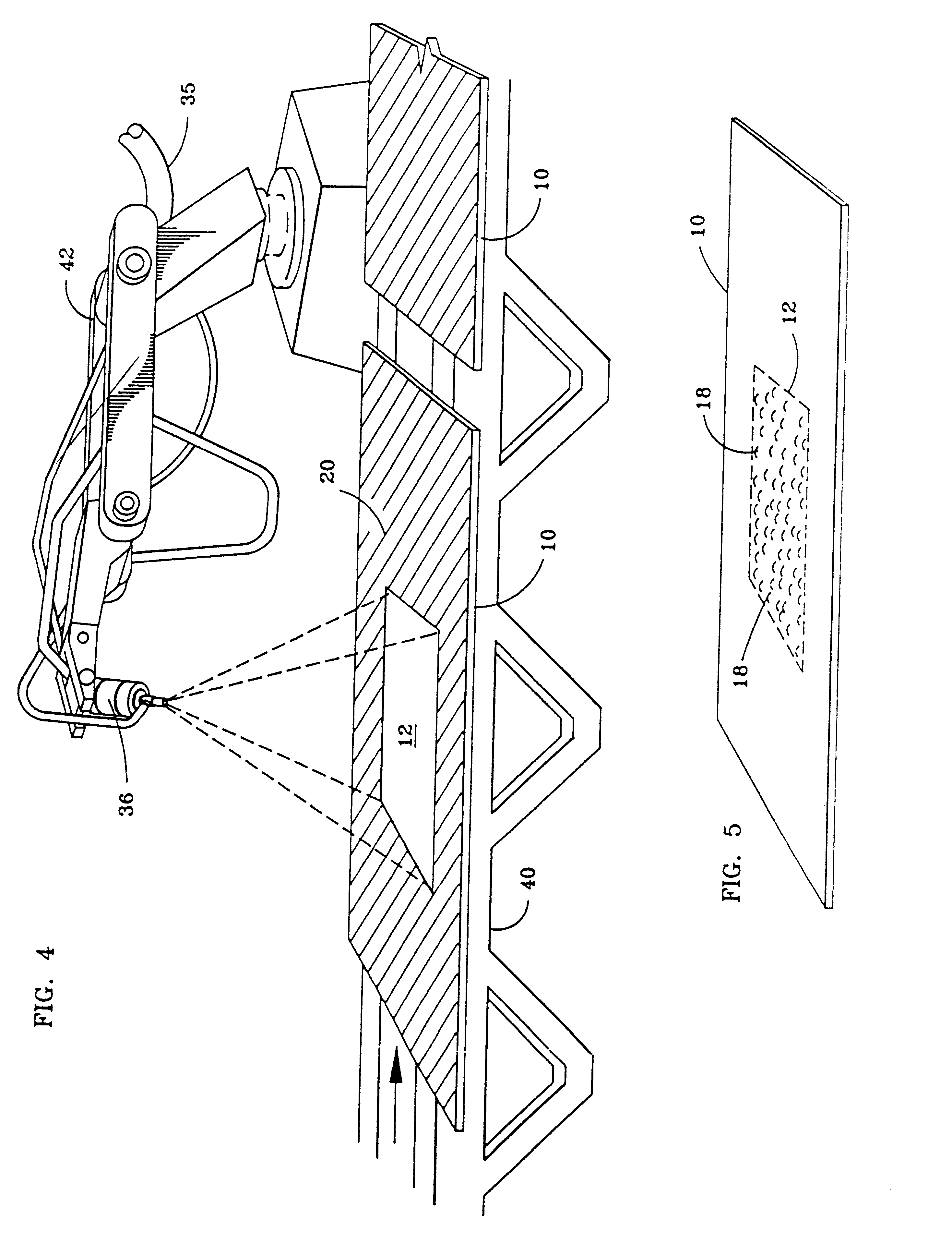

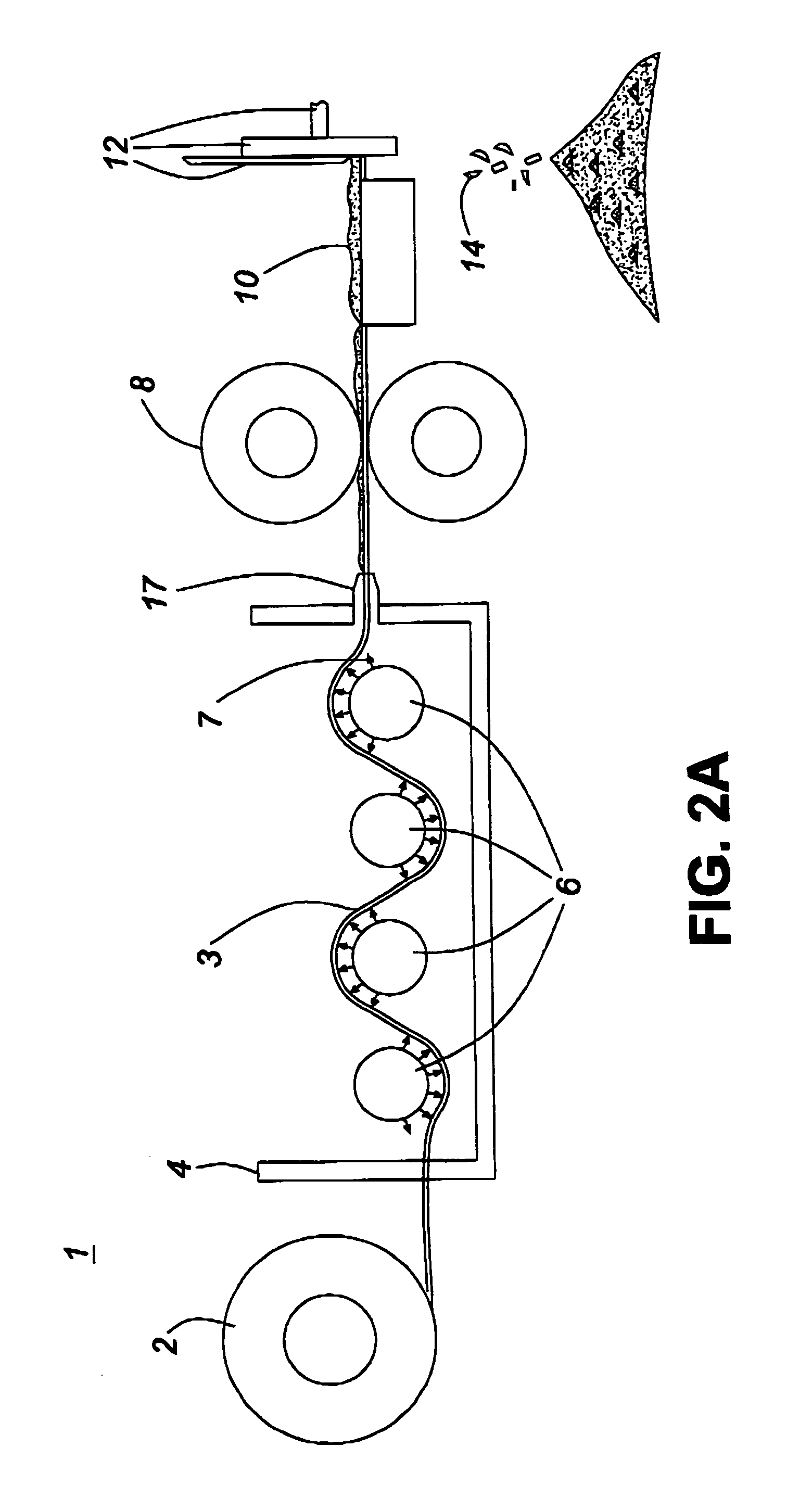

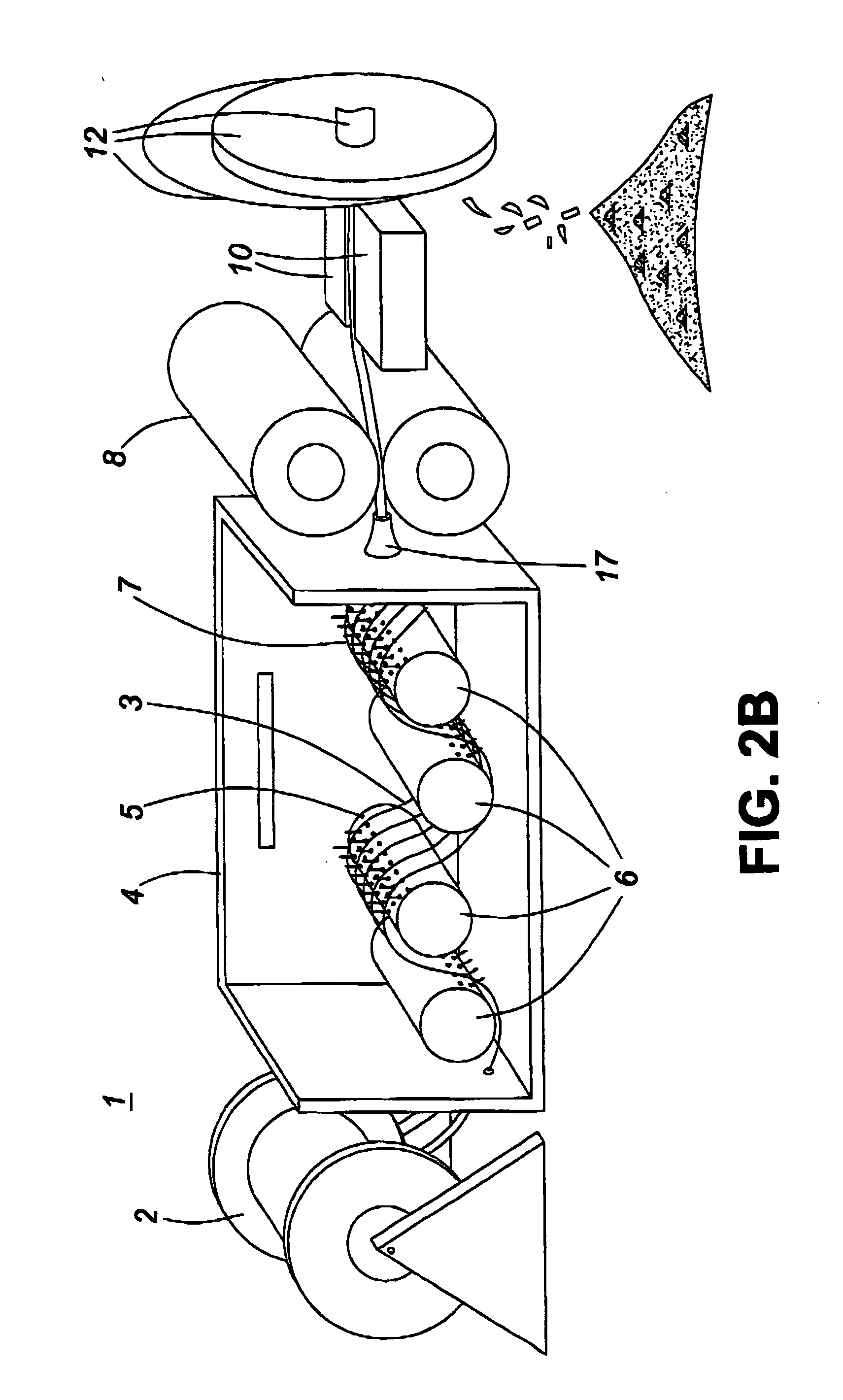

Method and apparatus for fabrication of polymer-coated fibers

InactiveUS20050221085A1Uniform coverageAvoid damageLiquid surface applicatorsFibre chemical featuresThermoplasticPolymer science

The present invention discloses the fabrication of polymer-coated, coated fiber composites, hybrid composites and a method and apparatus for fabricating the same. The invention provides for the maximum spraying and coating of a roving of coated fibers with molten polymer streams without making physical contact with a solid media, thus simultaneously preventing the fiber surface from getting damaged and stripping off the coating. When metal-coated fiber is used the invention improves the electromagnetic shielding properties of any subsequent product made from the inventive composite. The method and apparatus of the present invention uses sets of nozzle-type sprayers having multiple orifices to enable the thermoplastic or thermoset polymer to penetrate more efficiently into the fiber bundle, thereby providing a more uniform coverage of all fibers. The hybrid composites can consist of two or more types of reinforcements and one or more type of matrix polymer.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Adhesive composition comprising a particulate thermoplastic component

InactiveUS6548579B2Improve interface adhesionInhibition formationMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedParticulates

The invention is directed to an adhesive composition comprising a water based component including a film-forming polymer and a particulate thermoplastic component selected from the group consisting of thermoplastic polymers, thermoplastic resins, hot melt adhesive compositions, and mixtures thereof. The thermoplastic component has a mean particle size of from about 10 microns to about 1,500 microns. The adhesive composition is useful as a one-shot bookbinding adhesive, a primer composition as well as a second-shot adhesive for two-shot bookbinding method. The invention is also directed to the bookbinding methods using the adhesive composition.

Owner:HB FULLER CO

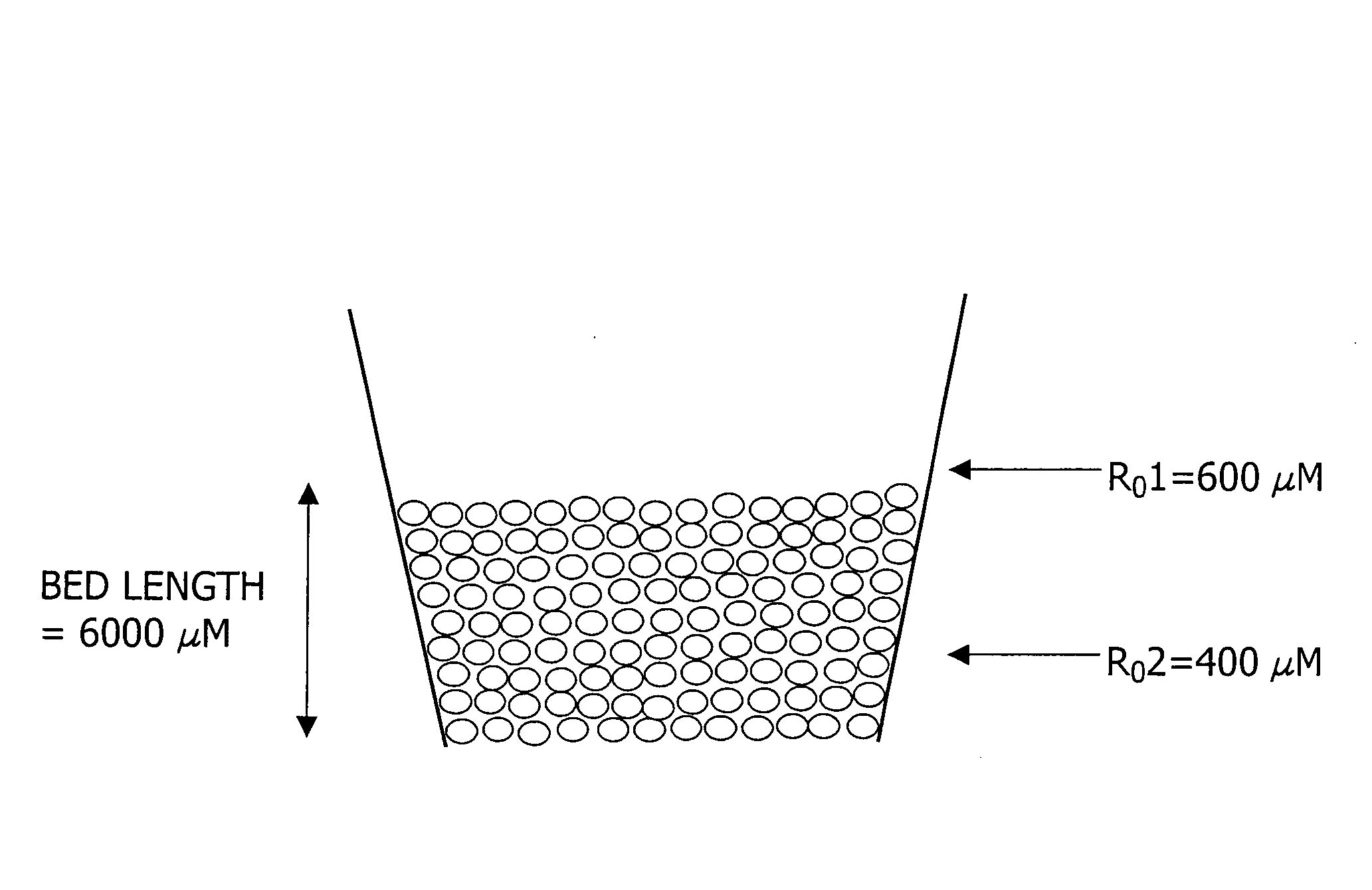

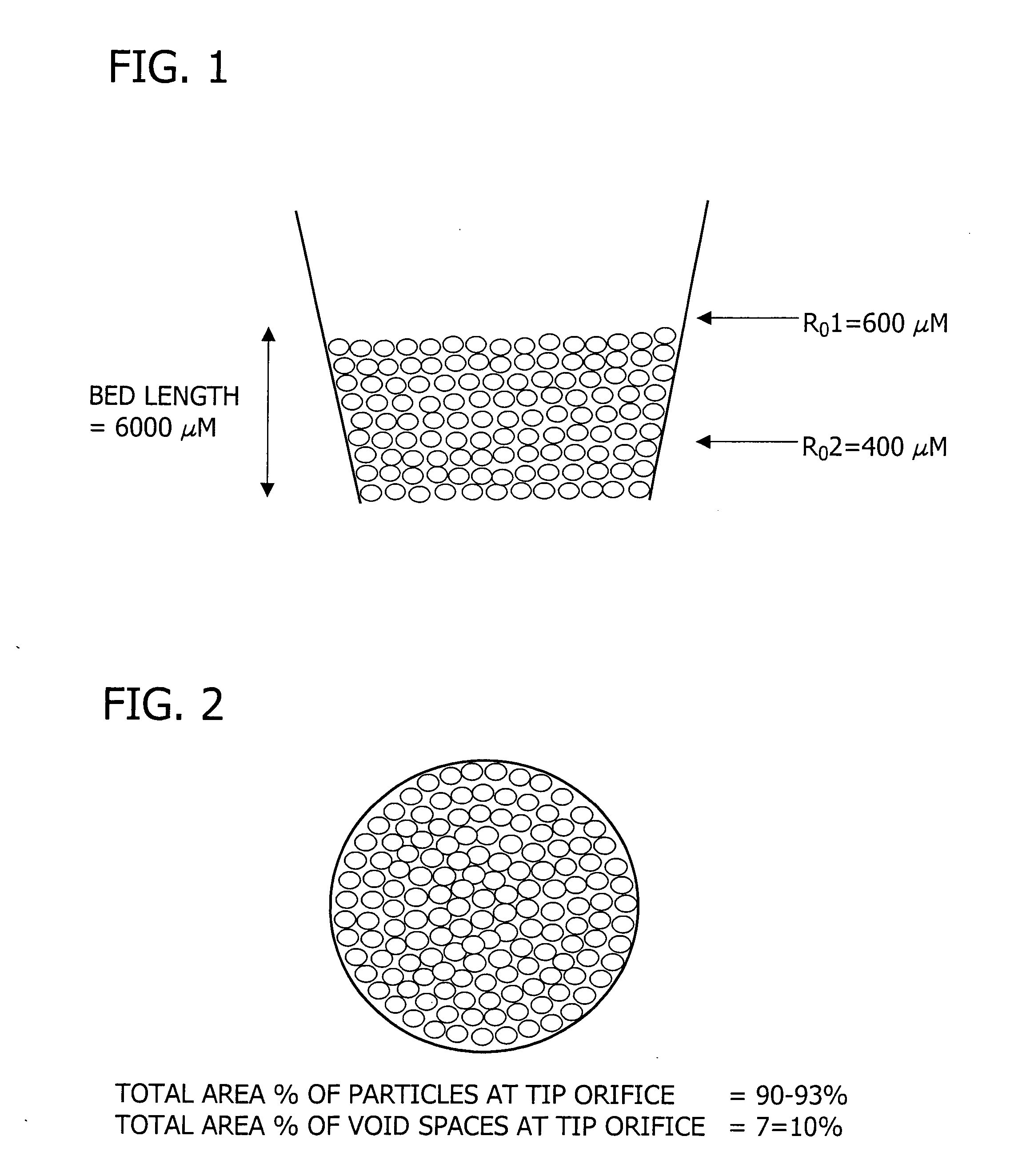

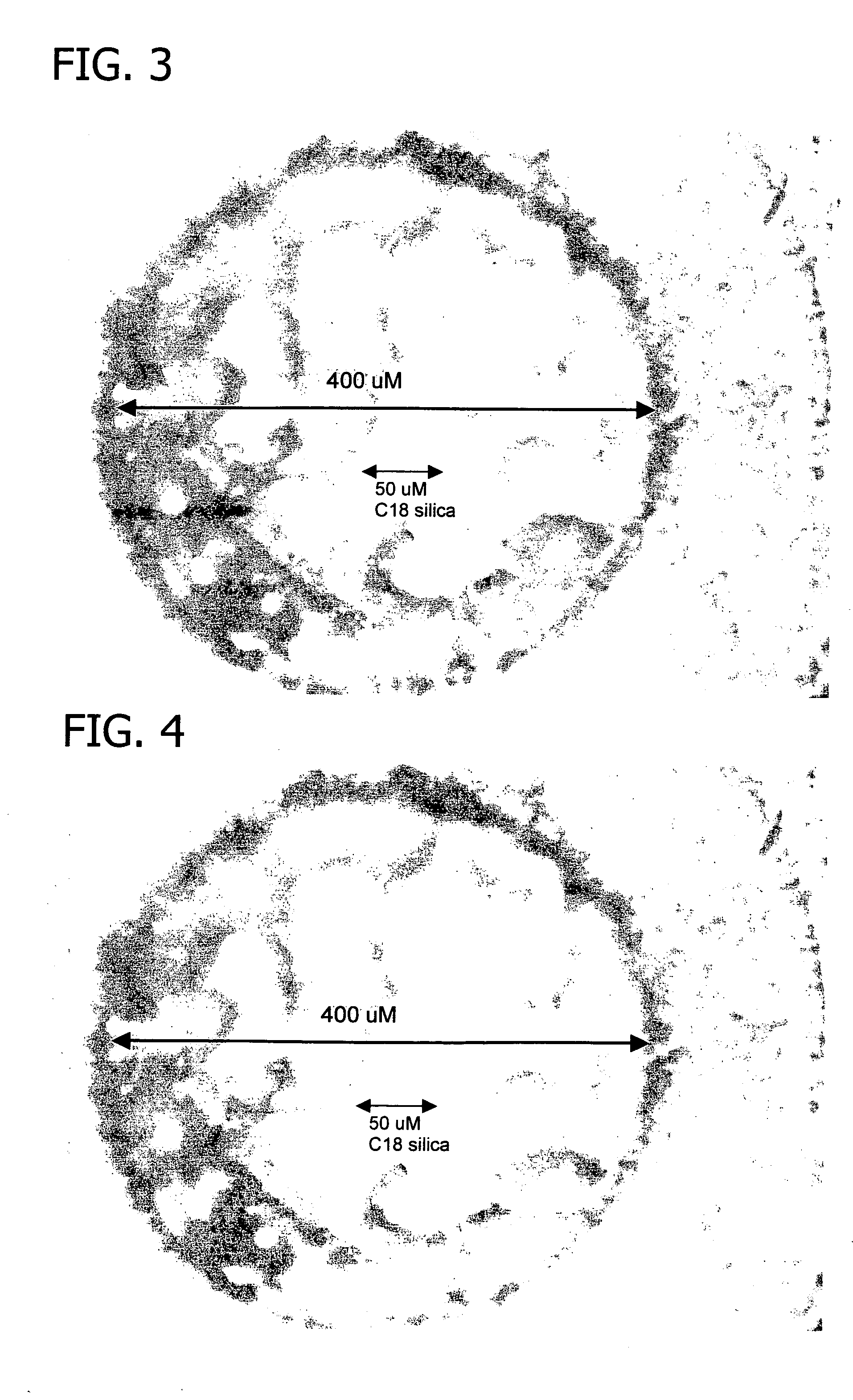

Polysilazane thermosetting polymers for use in chromatographic systems and applications

Owner:SIGMA ALDRICH CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com