Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Peel strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

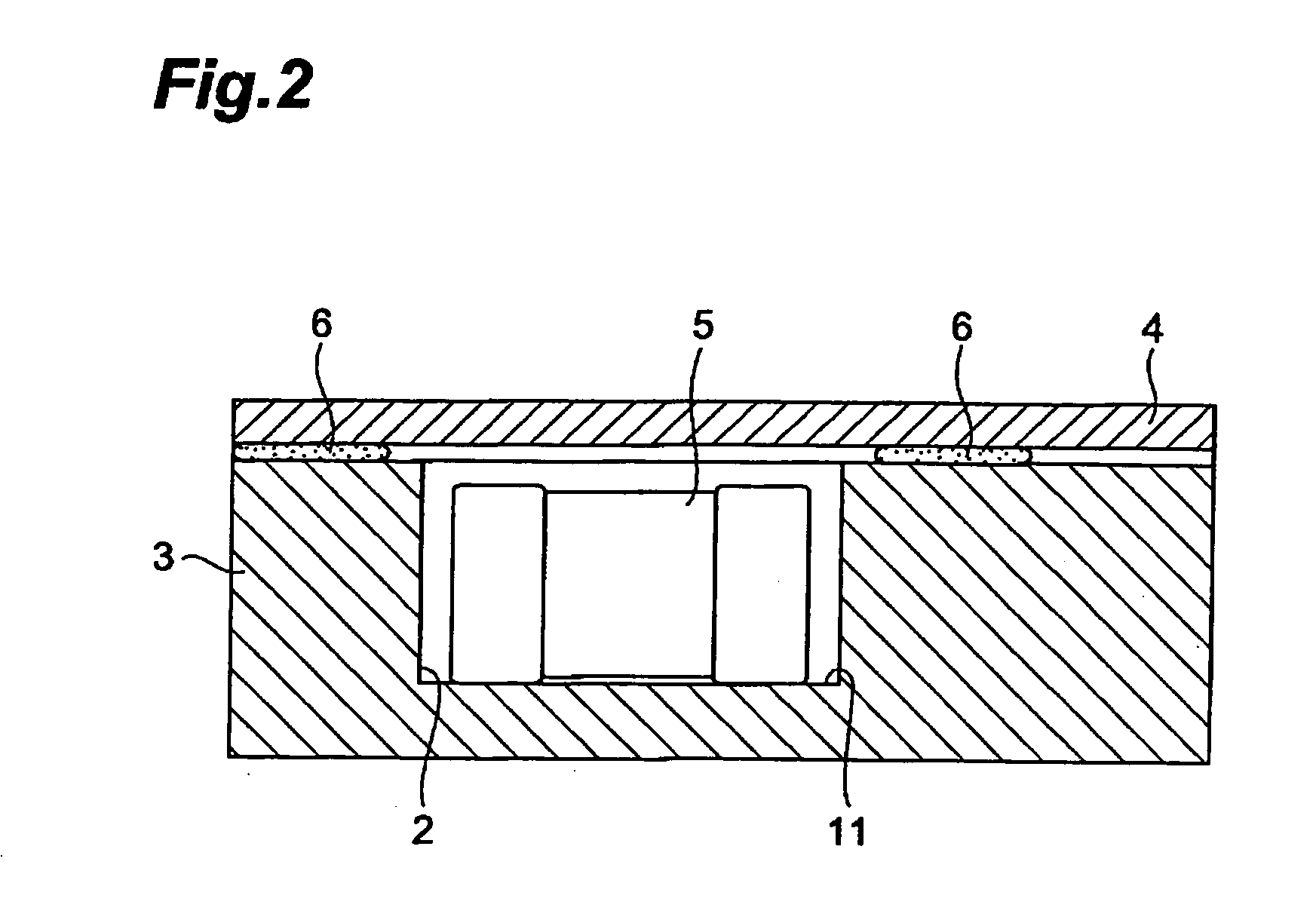

Printed wiring board and method for manufacturing the same

InactiveUS20070128855A1High peel strengthPeel strengthAdditive manufacturing apparatusPrinted circuit aspectsTwo stepThermal treatment

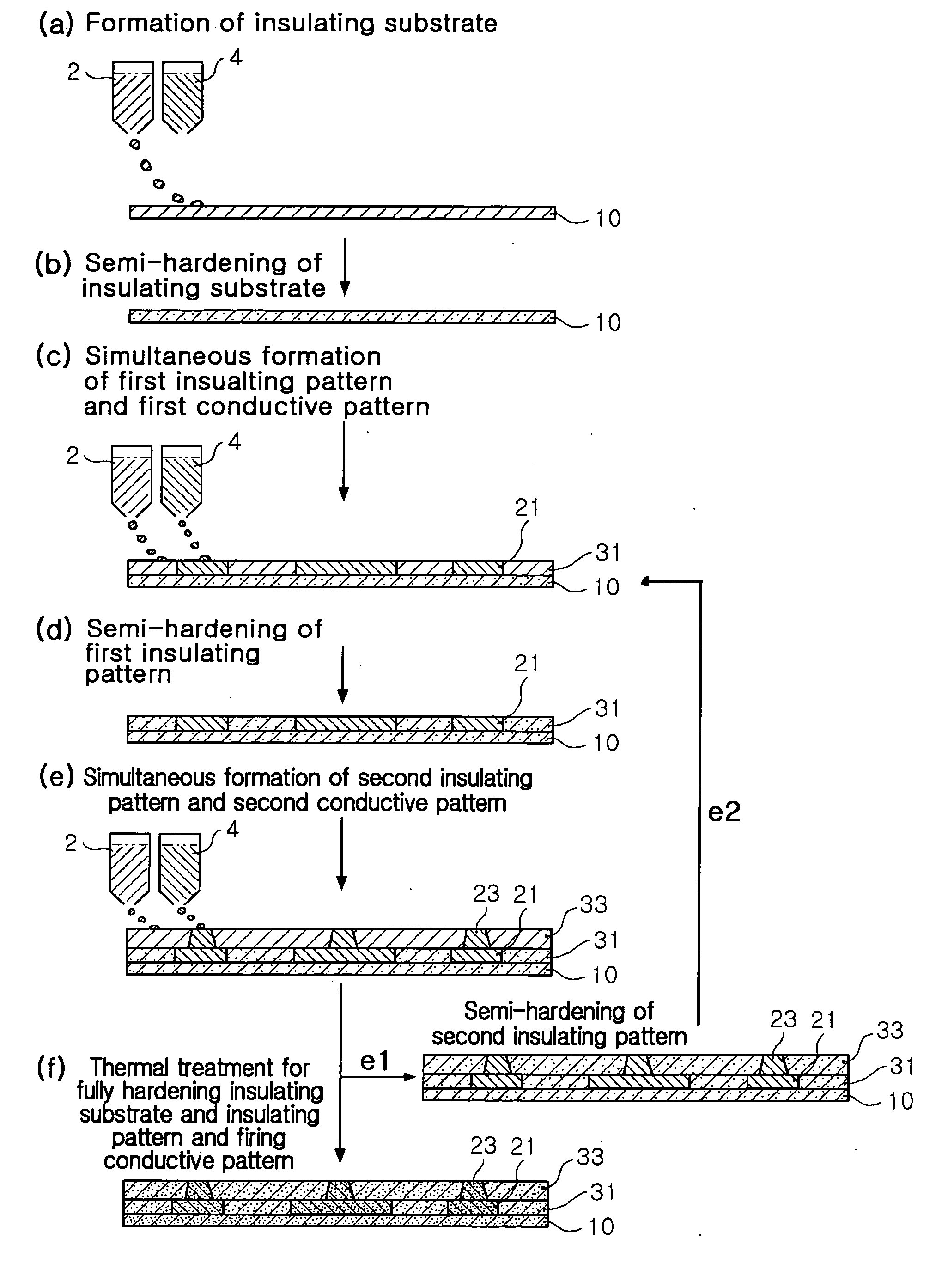

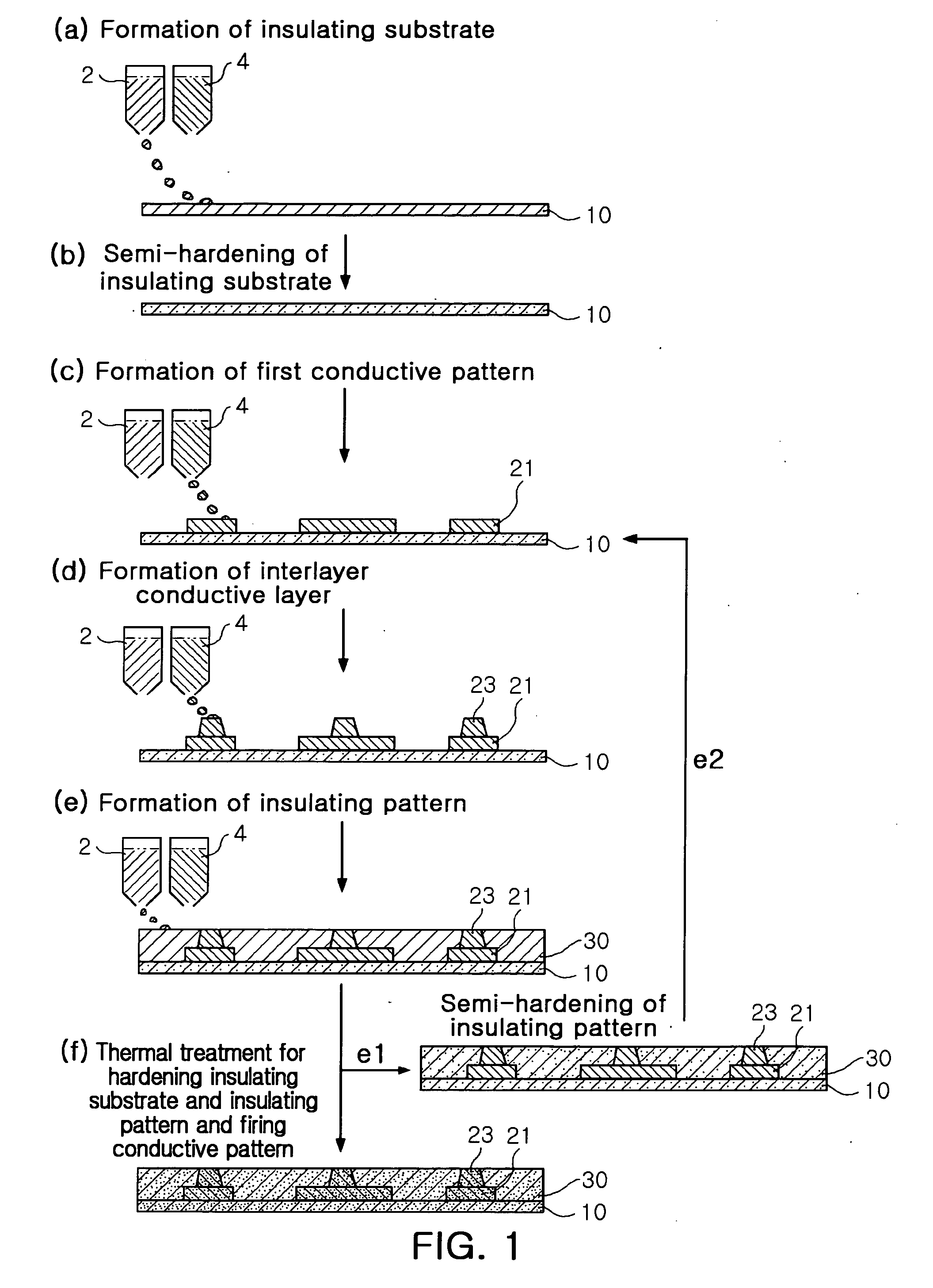

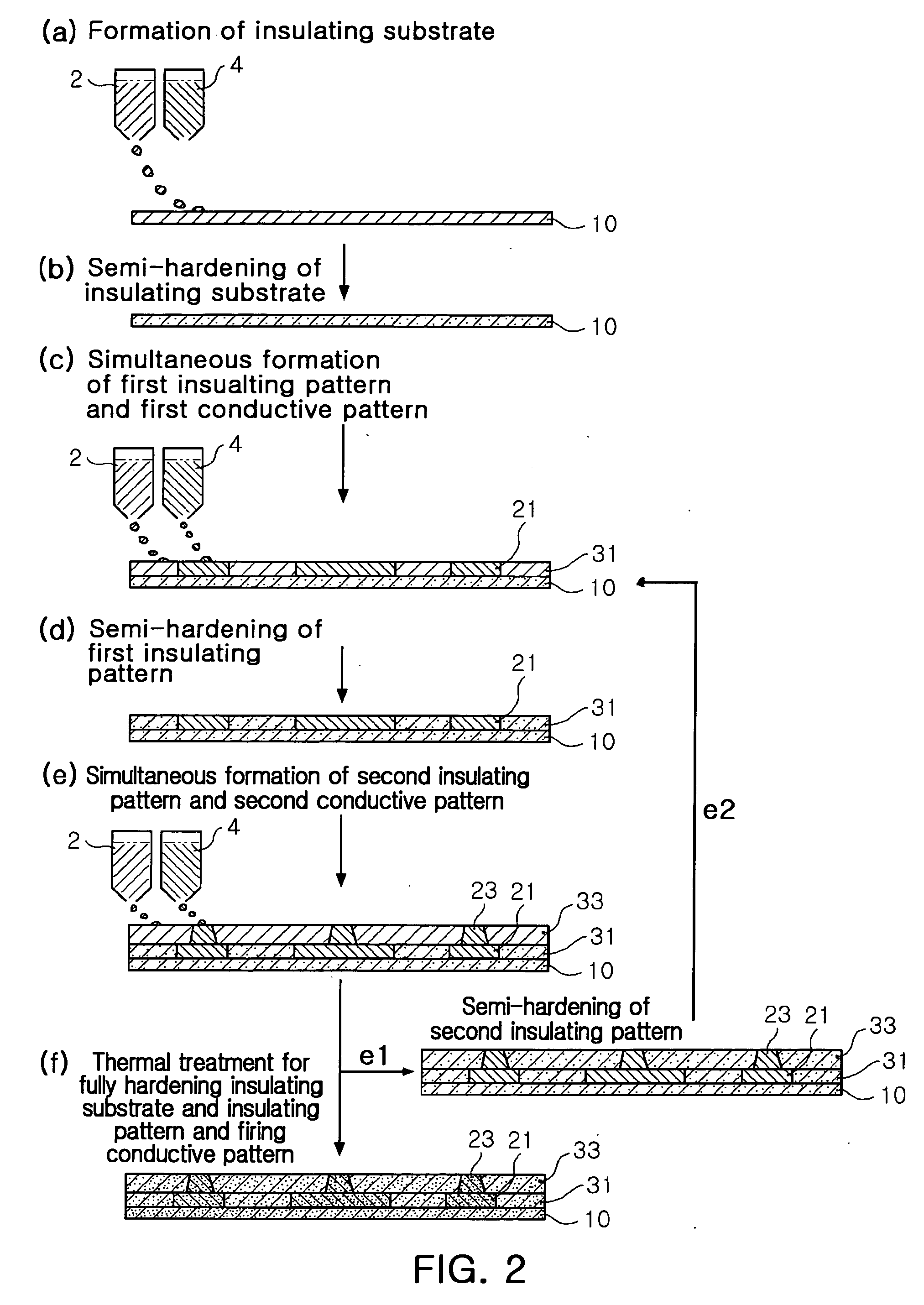

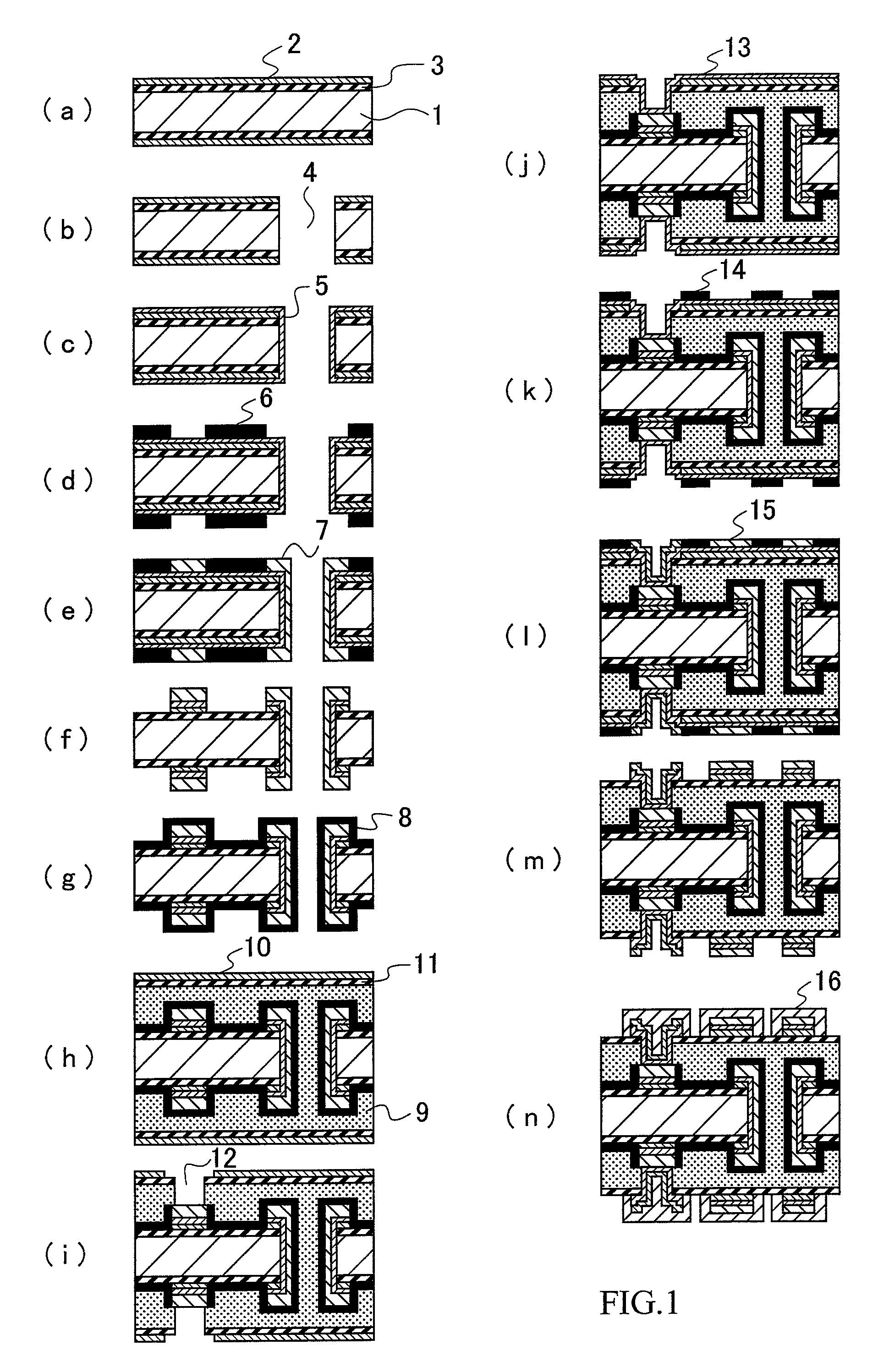

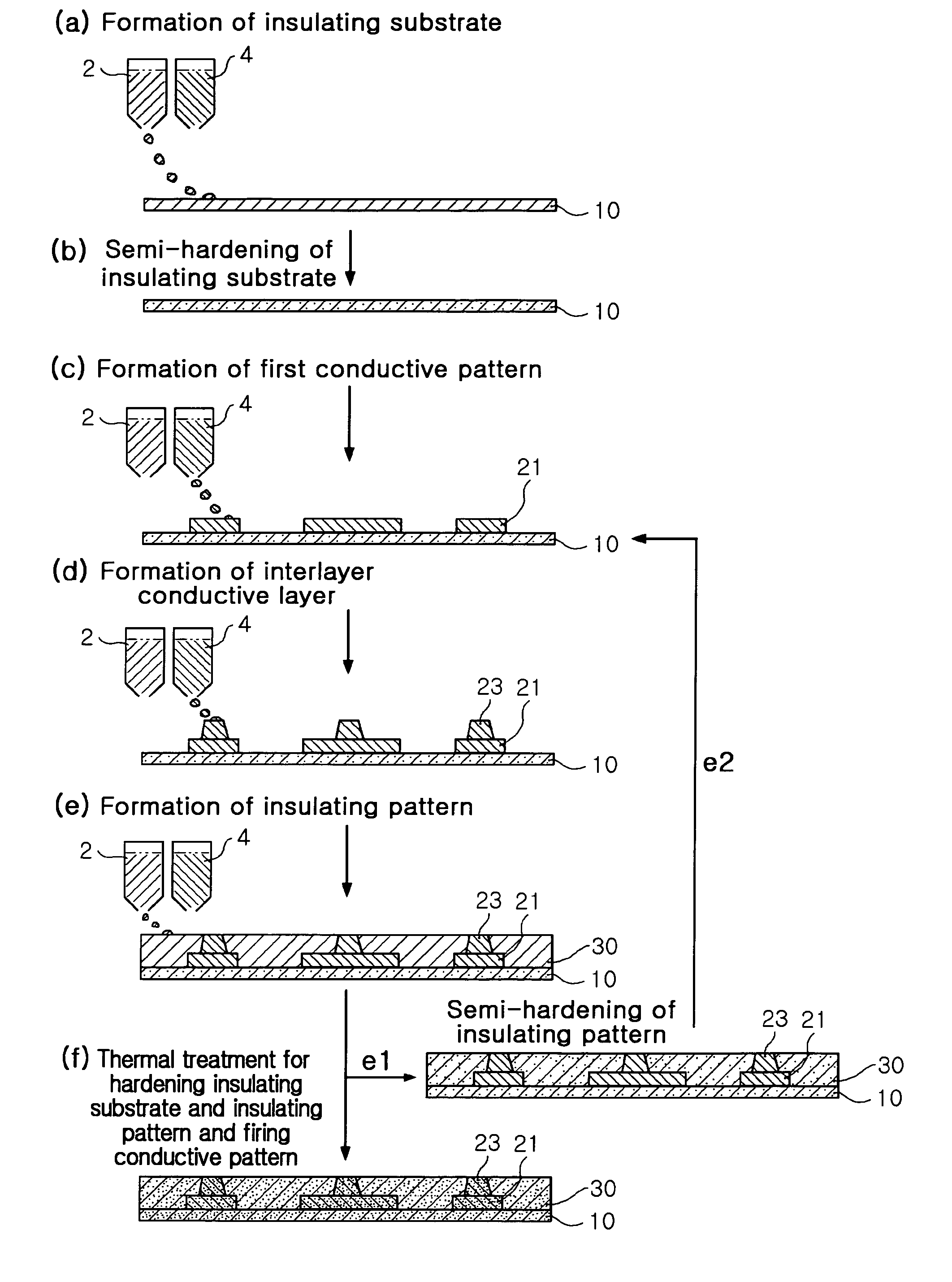

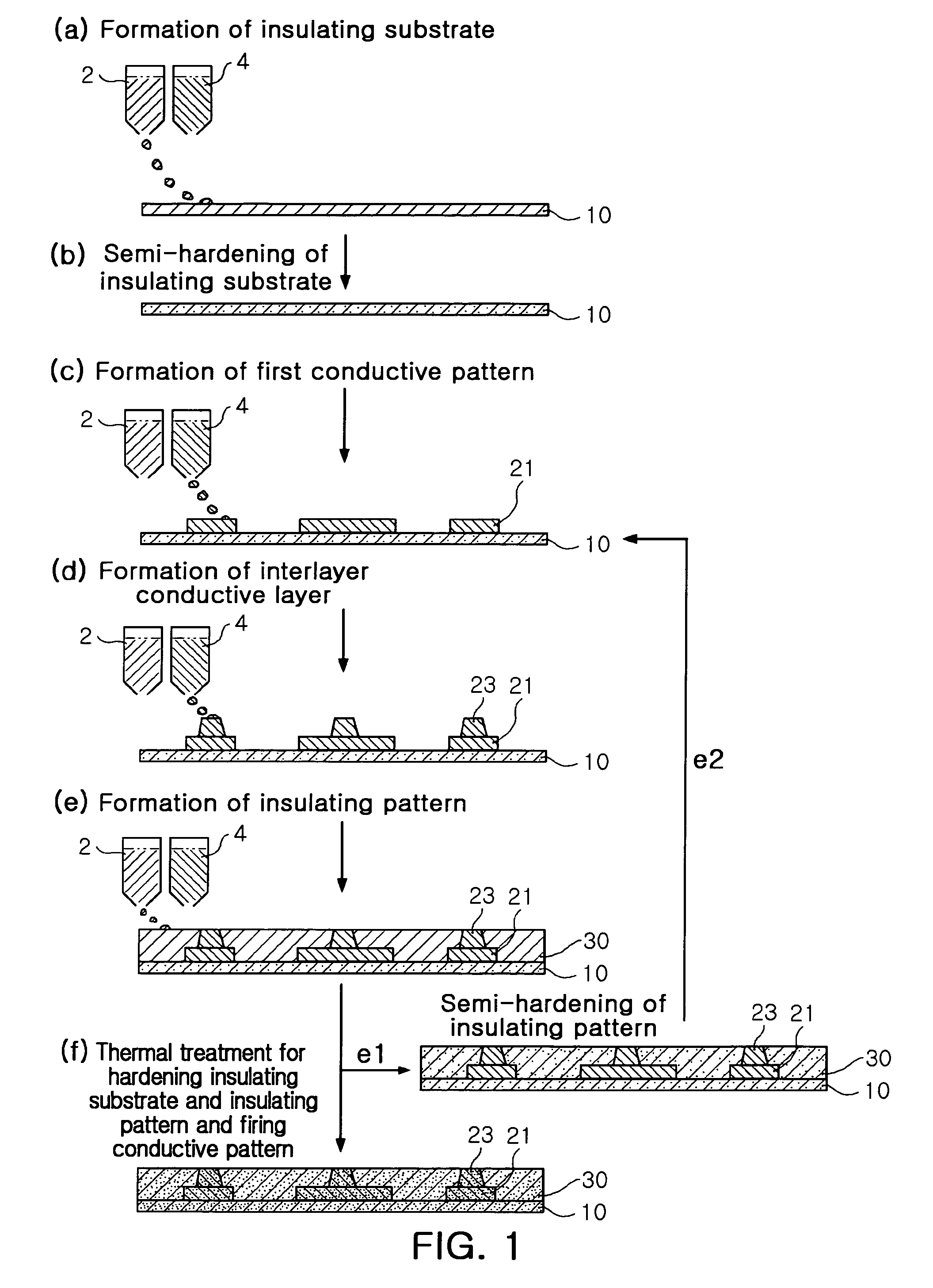

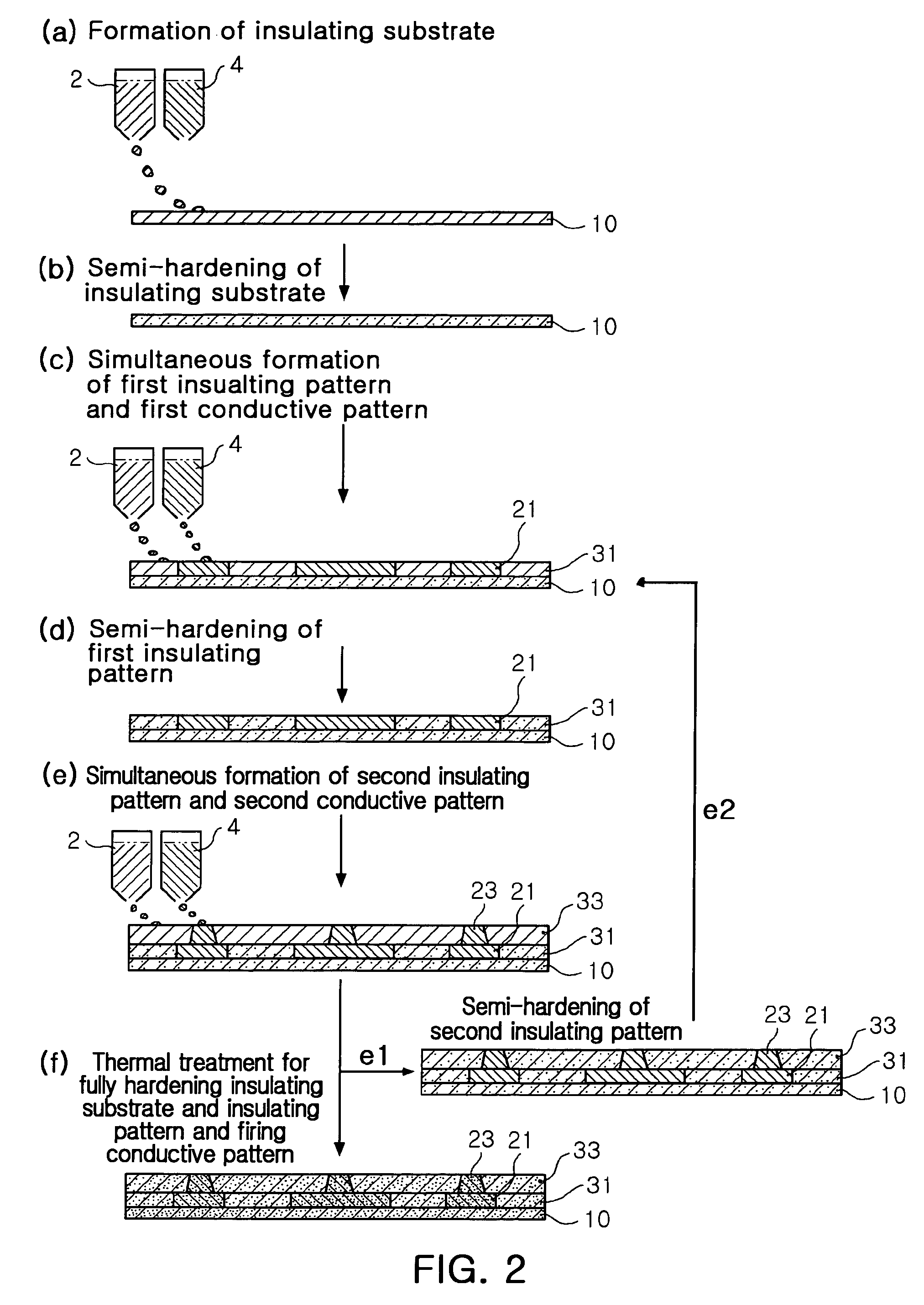

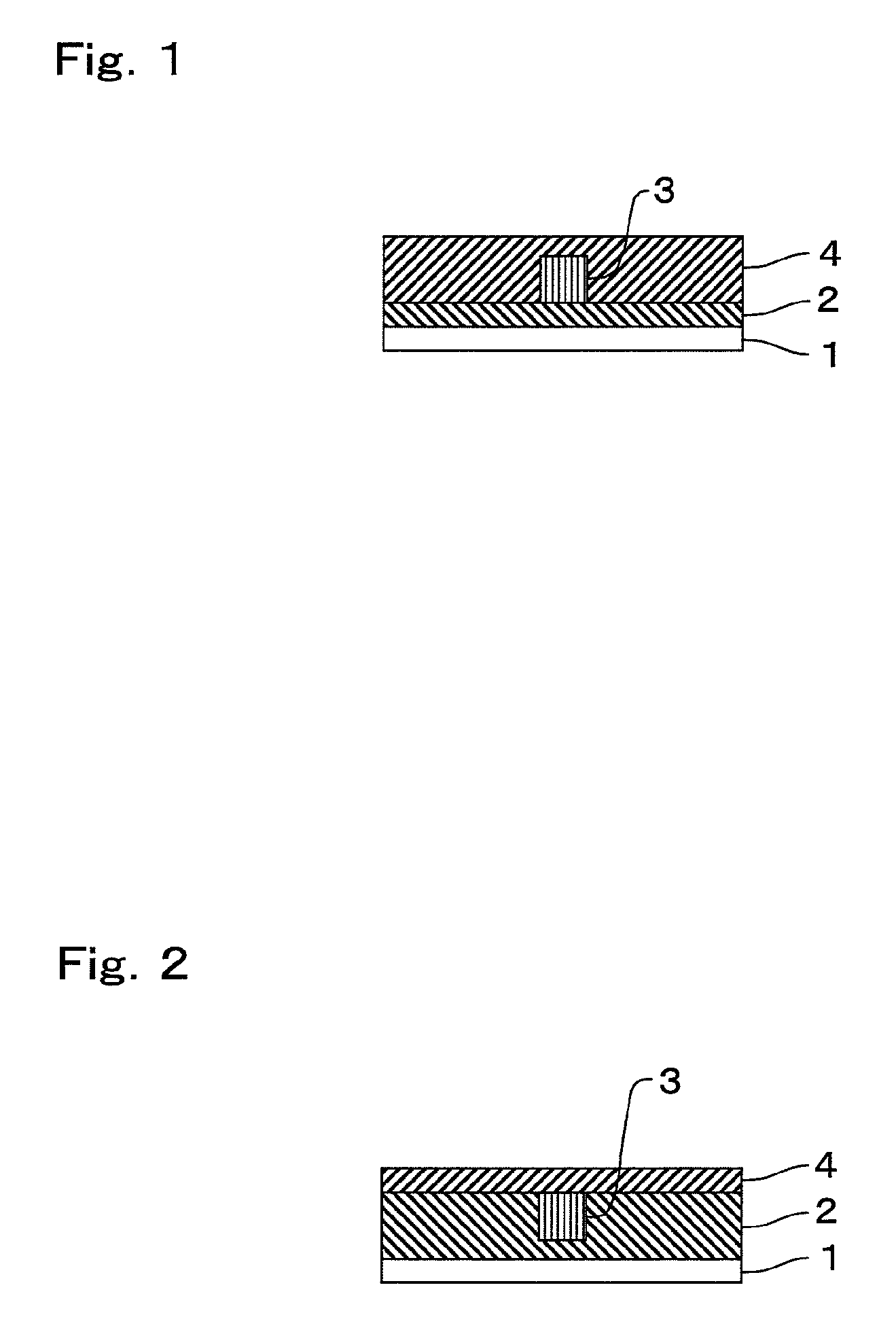

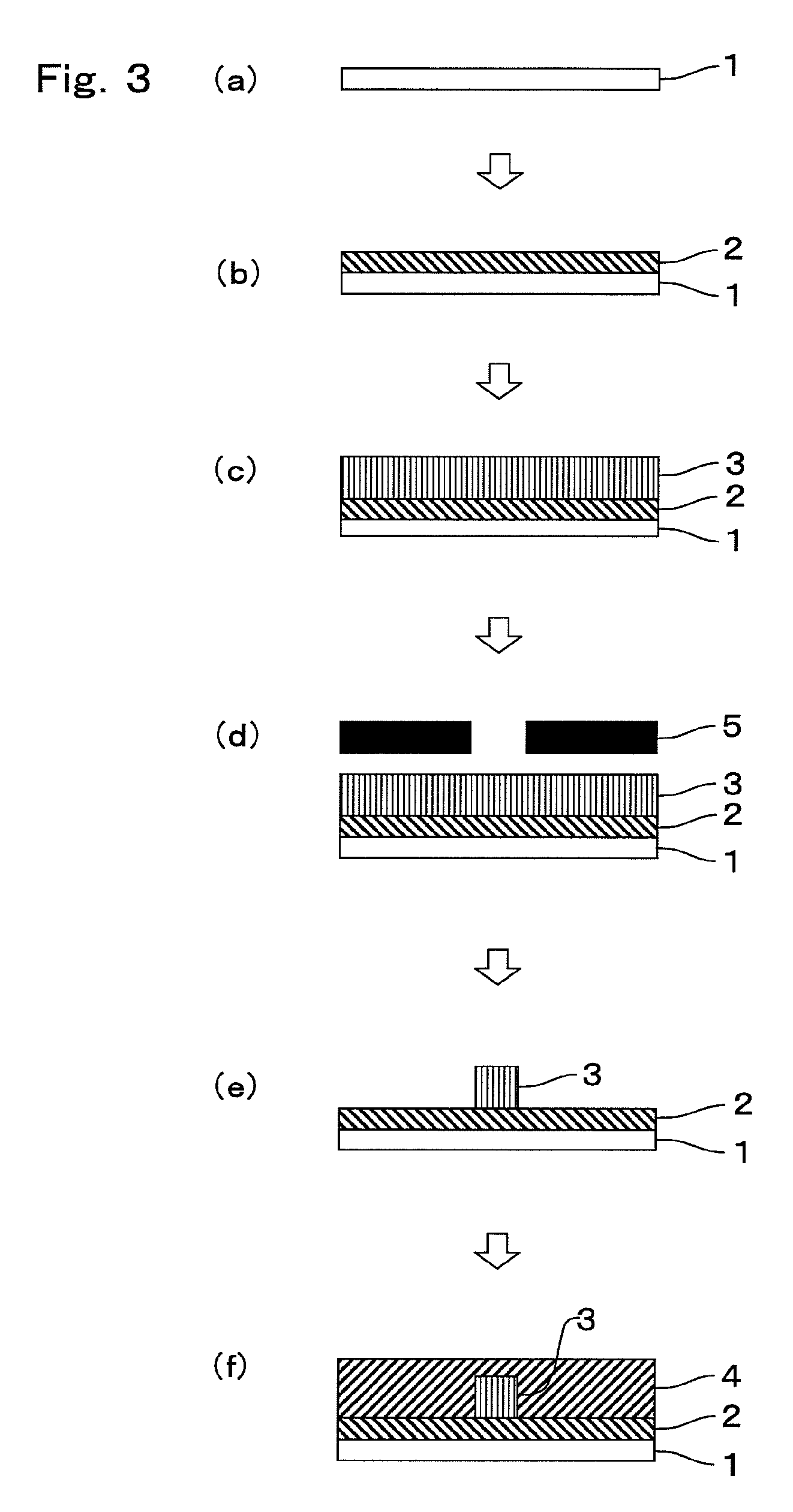

Provided is a method for manufacturing a printed wiring board, which can enhance the peel strength between an insulating layer and a conductive pattern by a two-step process, that is, a semi-hardening and full-hardening of the insulating layer. In the method for manufacturing the printed wiring board having one or more layers of a conductive pattern and an insulating pattern, an insulating pattern is formed on an insulating substrate, and at least one of the insulating substrate and the insulating pattern is semi-hardened. A conductive pattern is formed on the insulating substrate and / or the insulating pattern, thereby providing a stack structure. Then, a thermal treatment is performed on the stack structure to fully harden the semi-hardened insulating substrate and / or insulating pattern, and the conductive pattern is fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

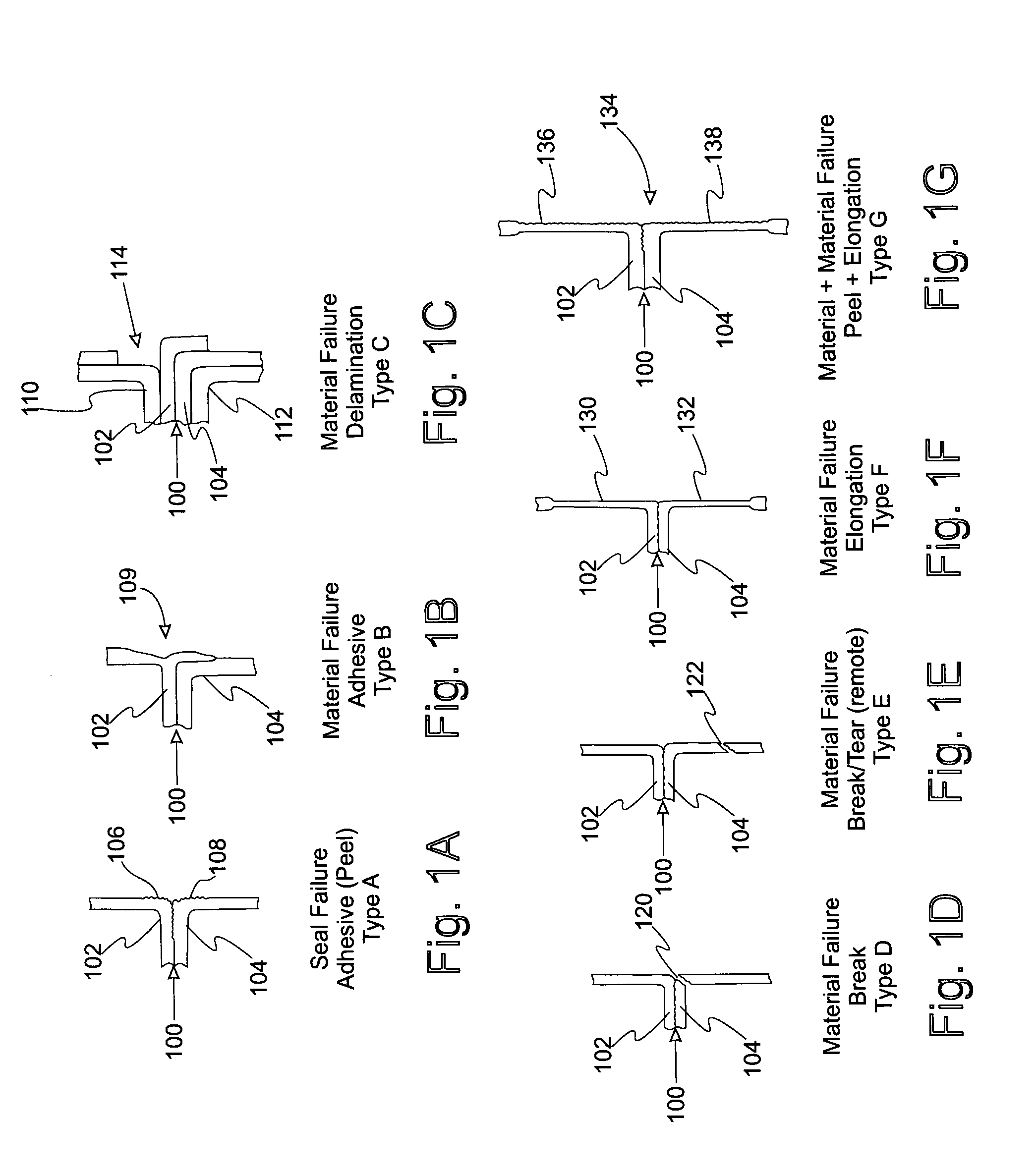

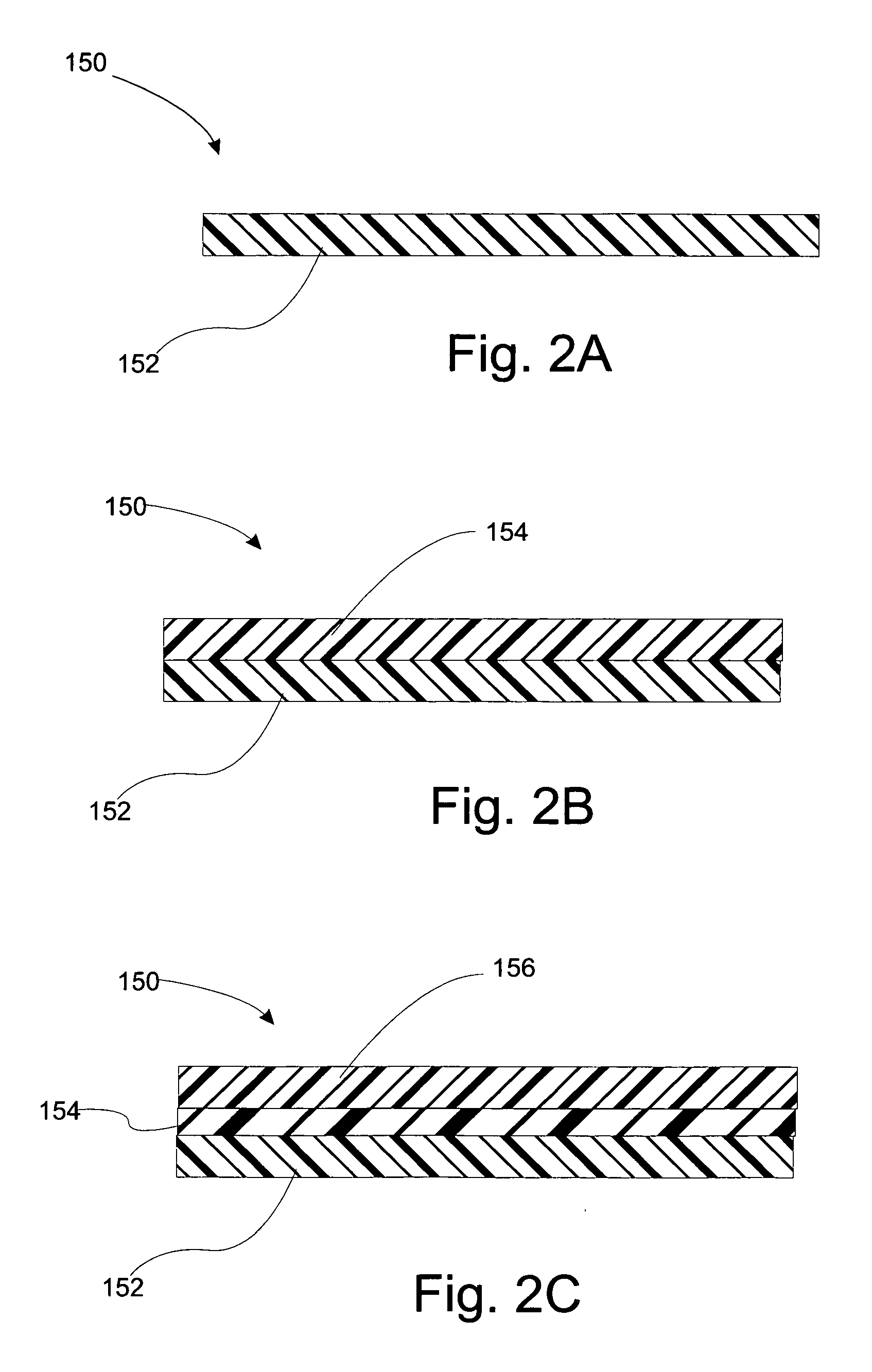

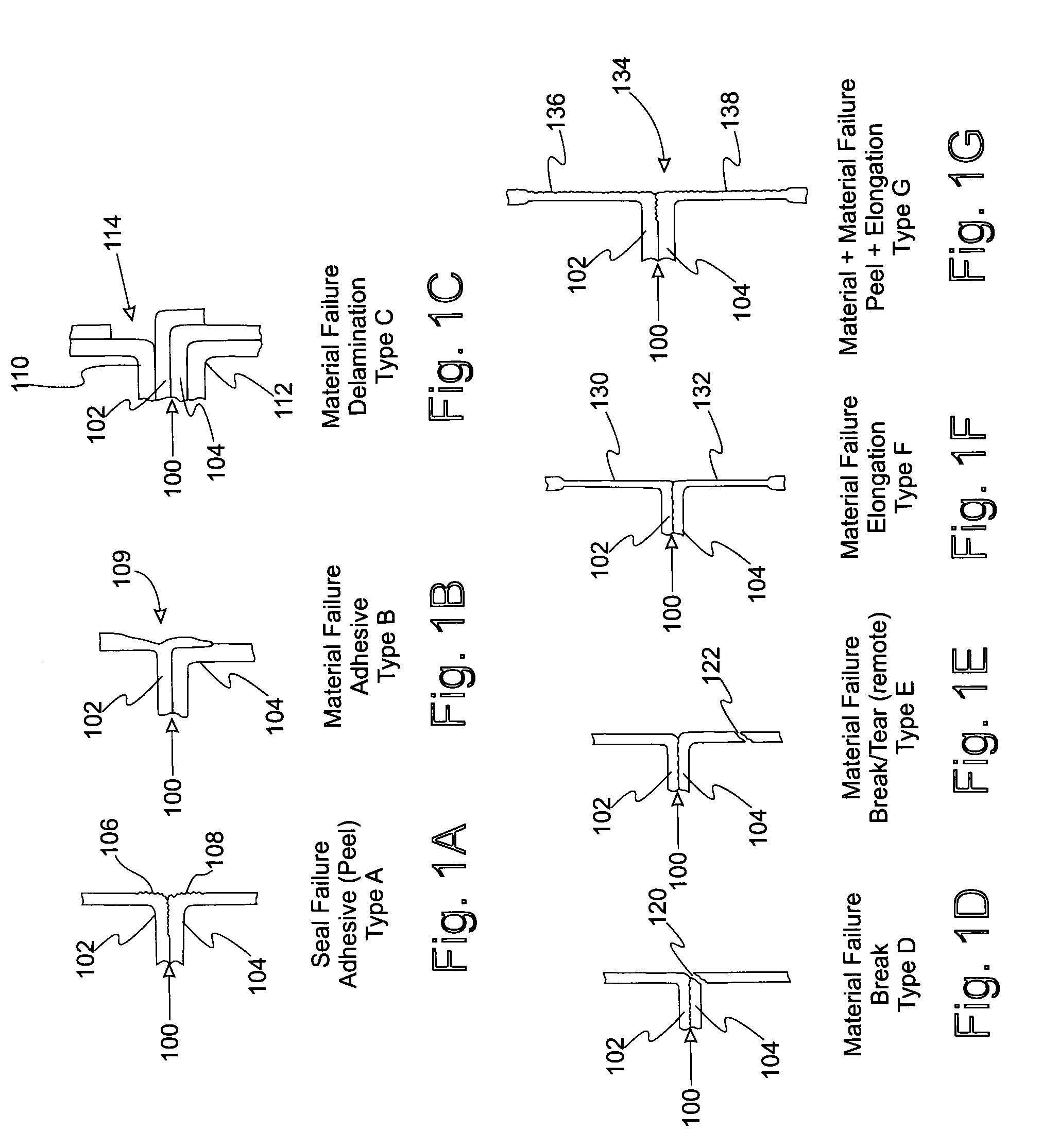

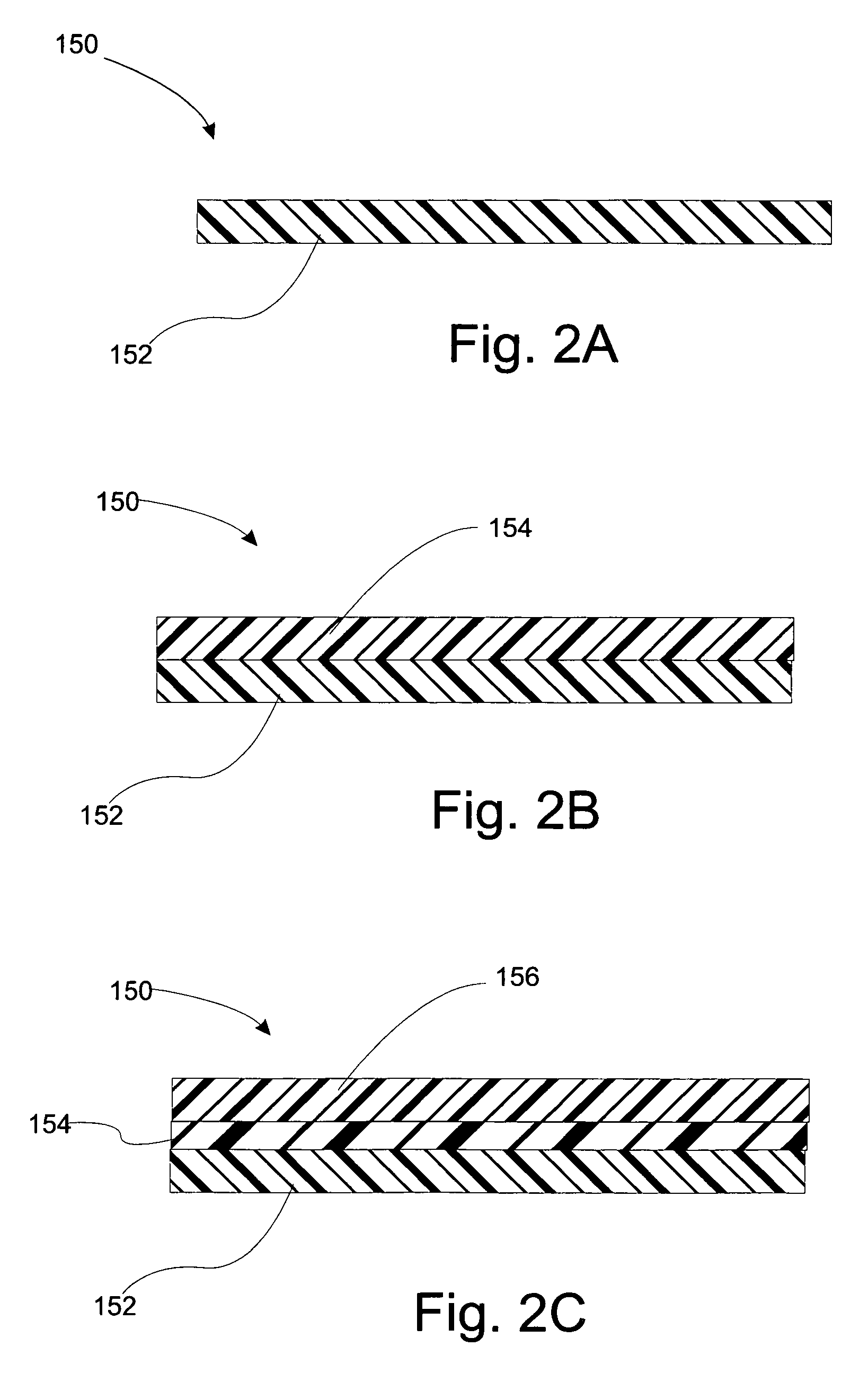

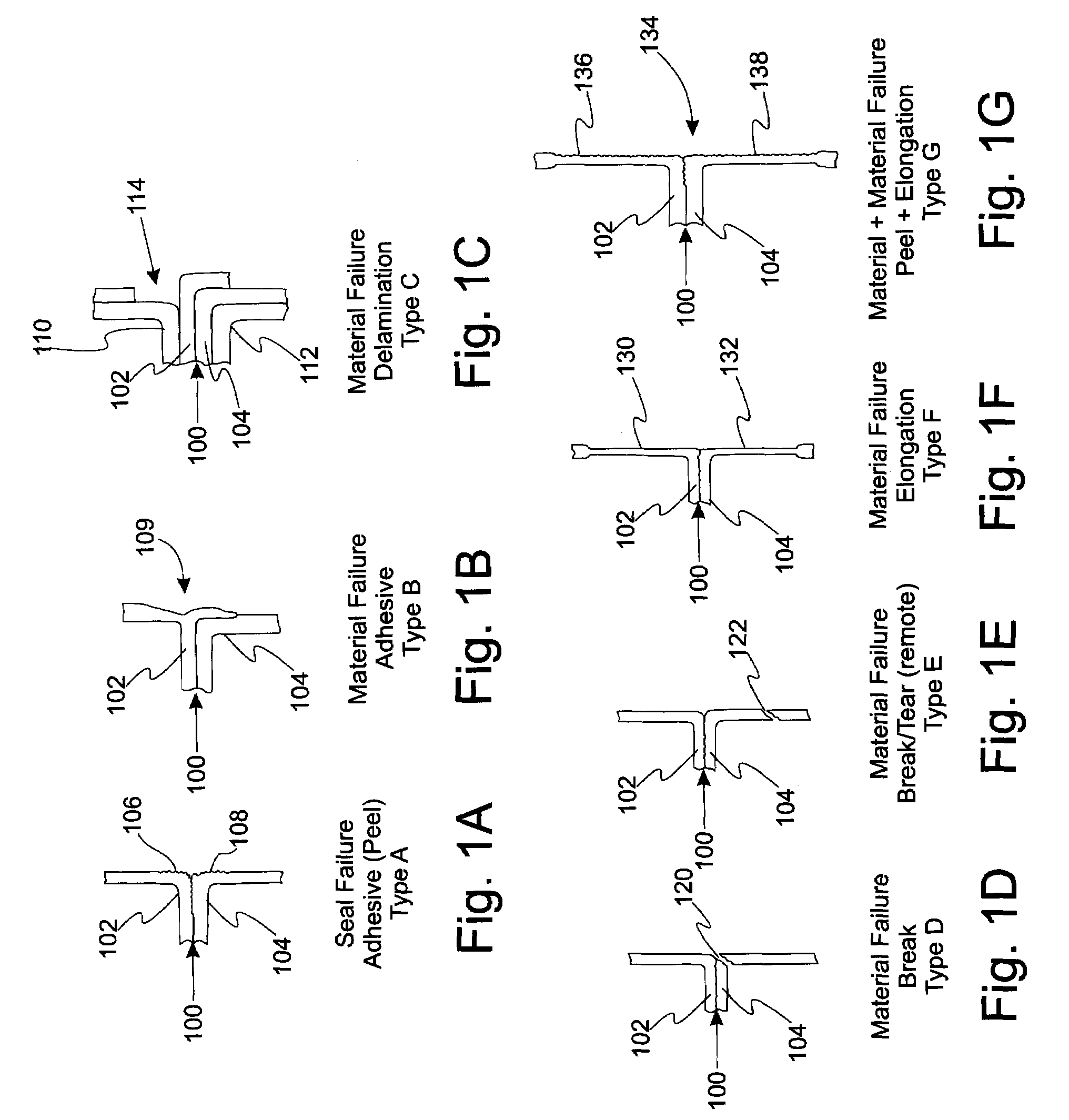

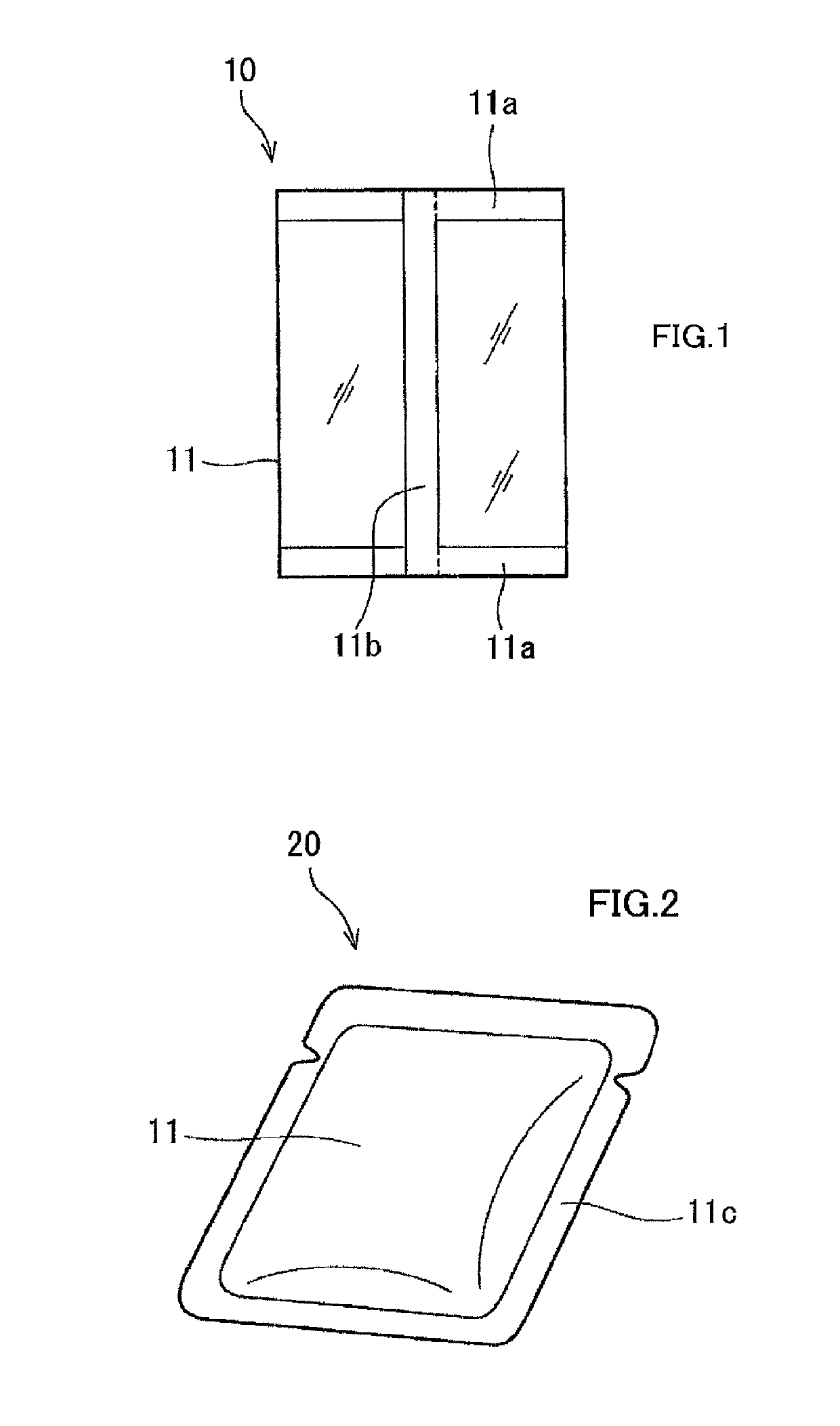

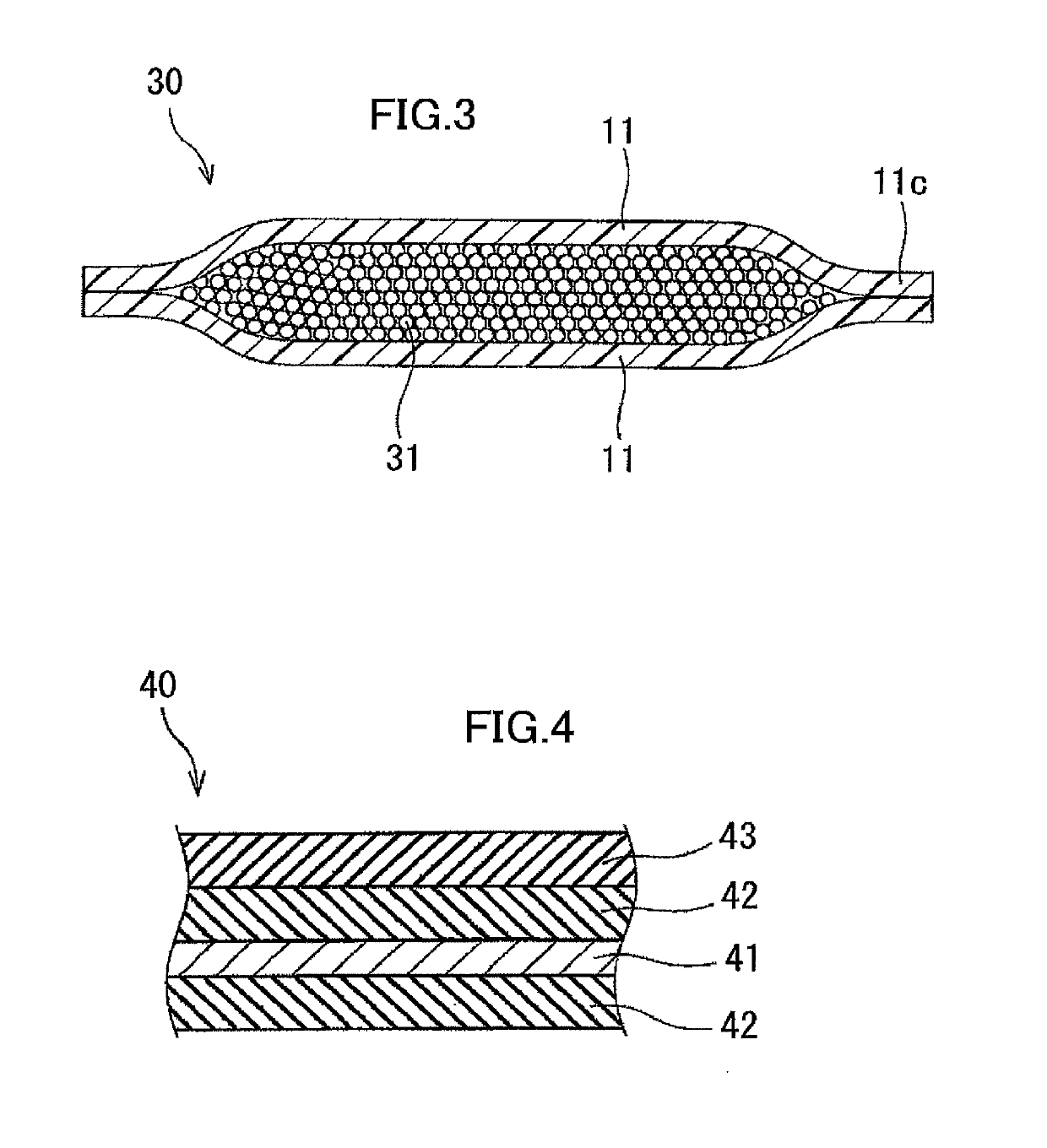

Peelable composite thermoplastic sealants in packaging films

A peelable sealing structure includes a sealing layer and one or more optional additional layers. The peelable sealing structure includes a sealing surface that is formable into a peelable seal upon contact with a sealing substrate at all temperatures in a peelable seal temperature range. Moreover, the peelable sealing structure comprises a thermoplastic polymer and an additive dispersed within at least a portion of the thermoplastic polymer with the peelable sealing structure defining the sealing surface.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

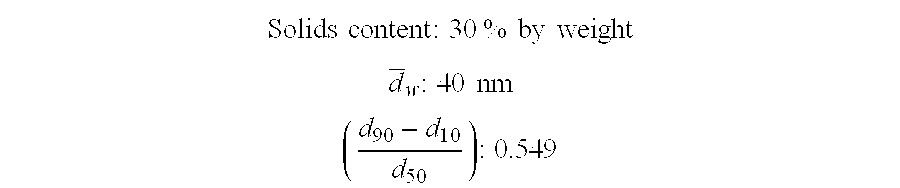

Transparent, electrically conductive and heat-sealable material and lidded container for carrier tape using the same

InactiveUS20030017328A1Peel strengthHigh heat sealing strengthSynthetic resin layered productsConjugated diene hydrocarbon coatingsVisual recognitionSynthetic resin

The present invention has a main object to provide a transparent conductive heat sealing material of which antistatic property does not deteriorates even at a low humidity, and has a transparency to an extent of permitting visual recognition of the contents and a carrier tape lid using the same. To achieve this object, the transparent conductive heat sealing material of the invention is characterized by a heat-sealable synthetic resin, and conductive fine particle having a 50% particle size of up to 1.0 mum.

Owner:DAI NIPPON PRINTING CO LTD

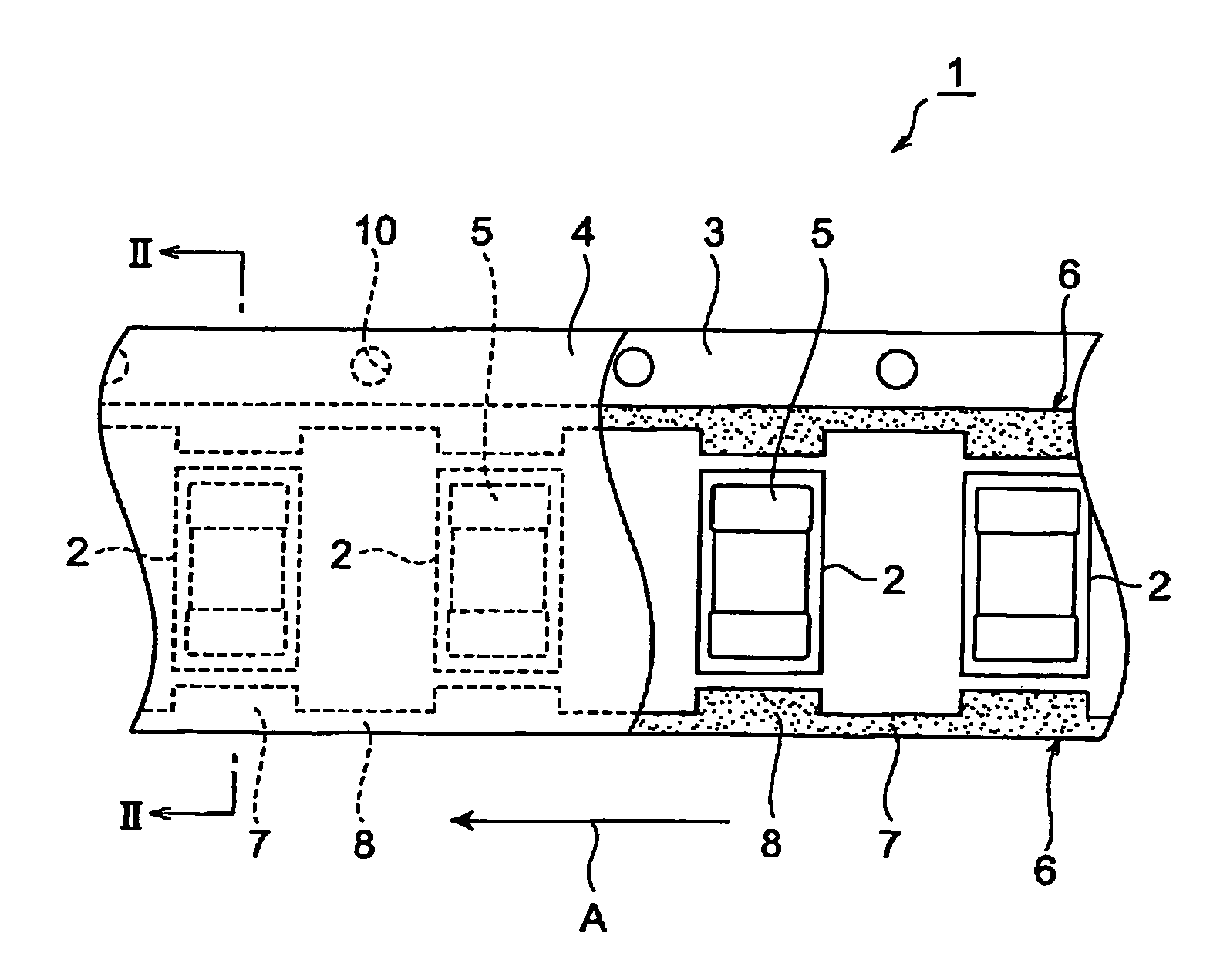

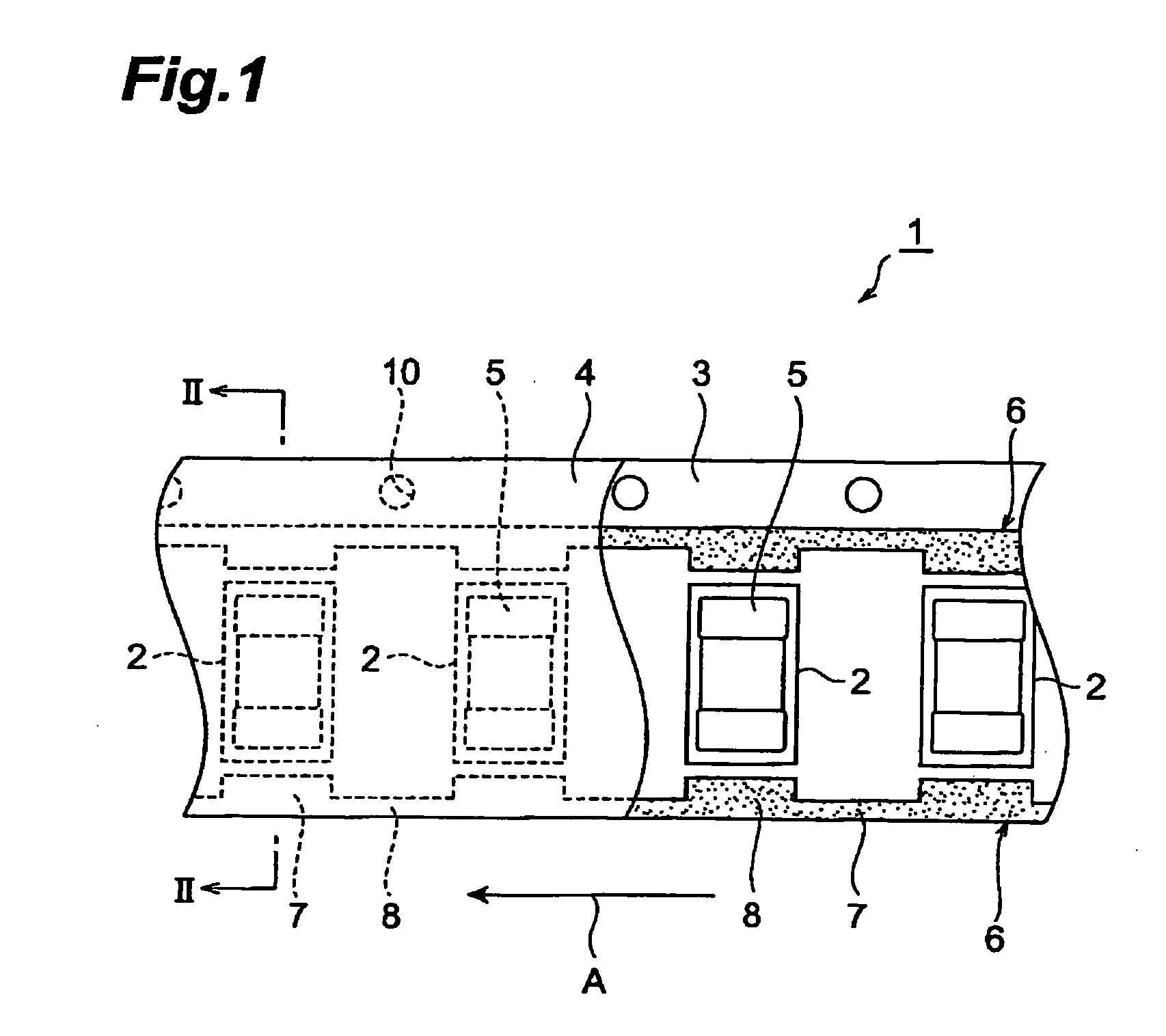

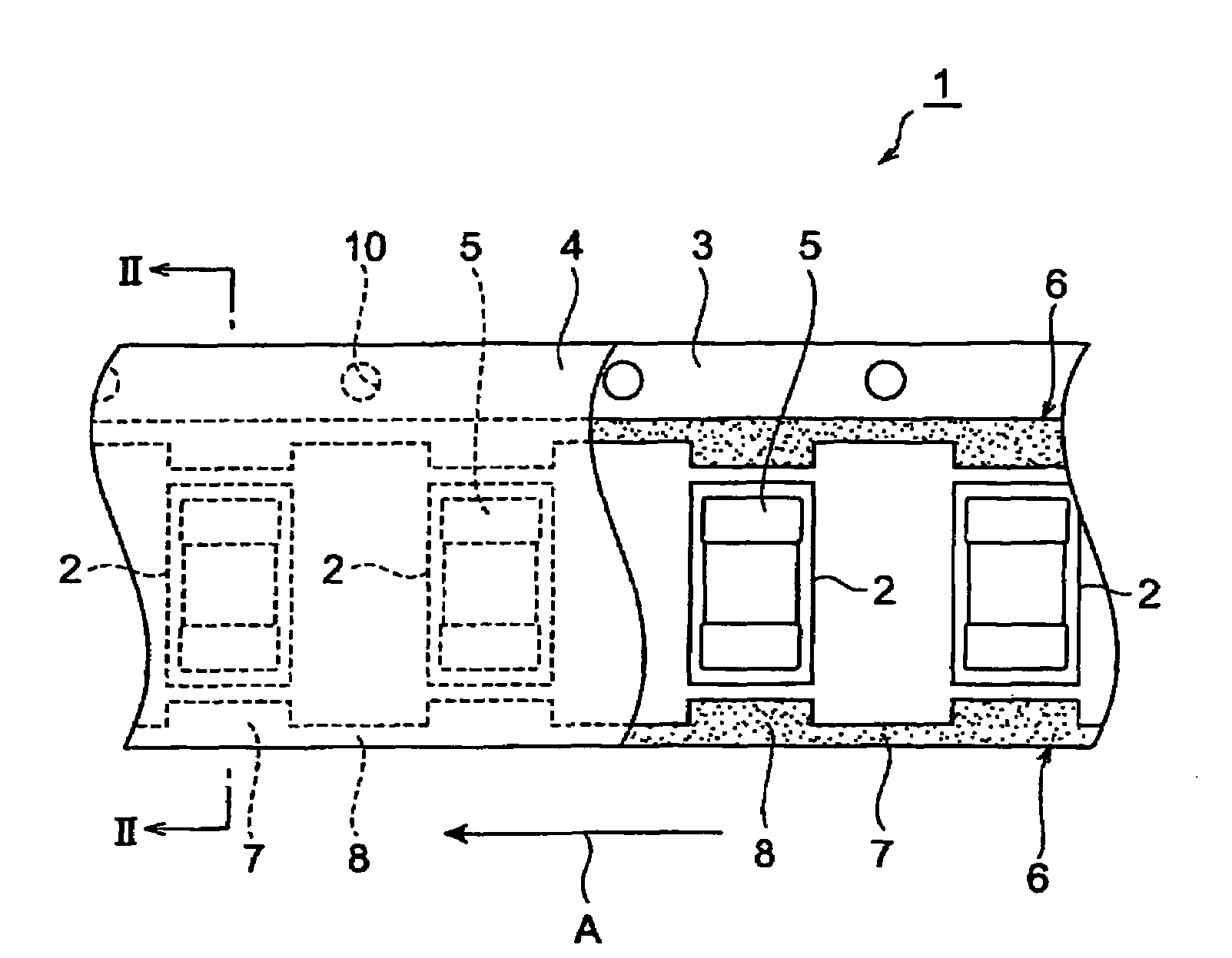

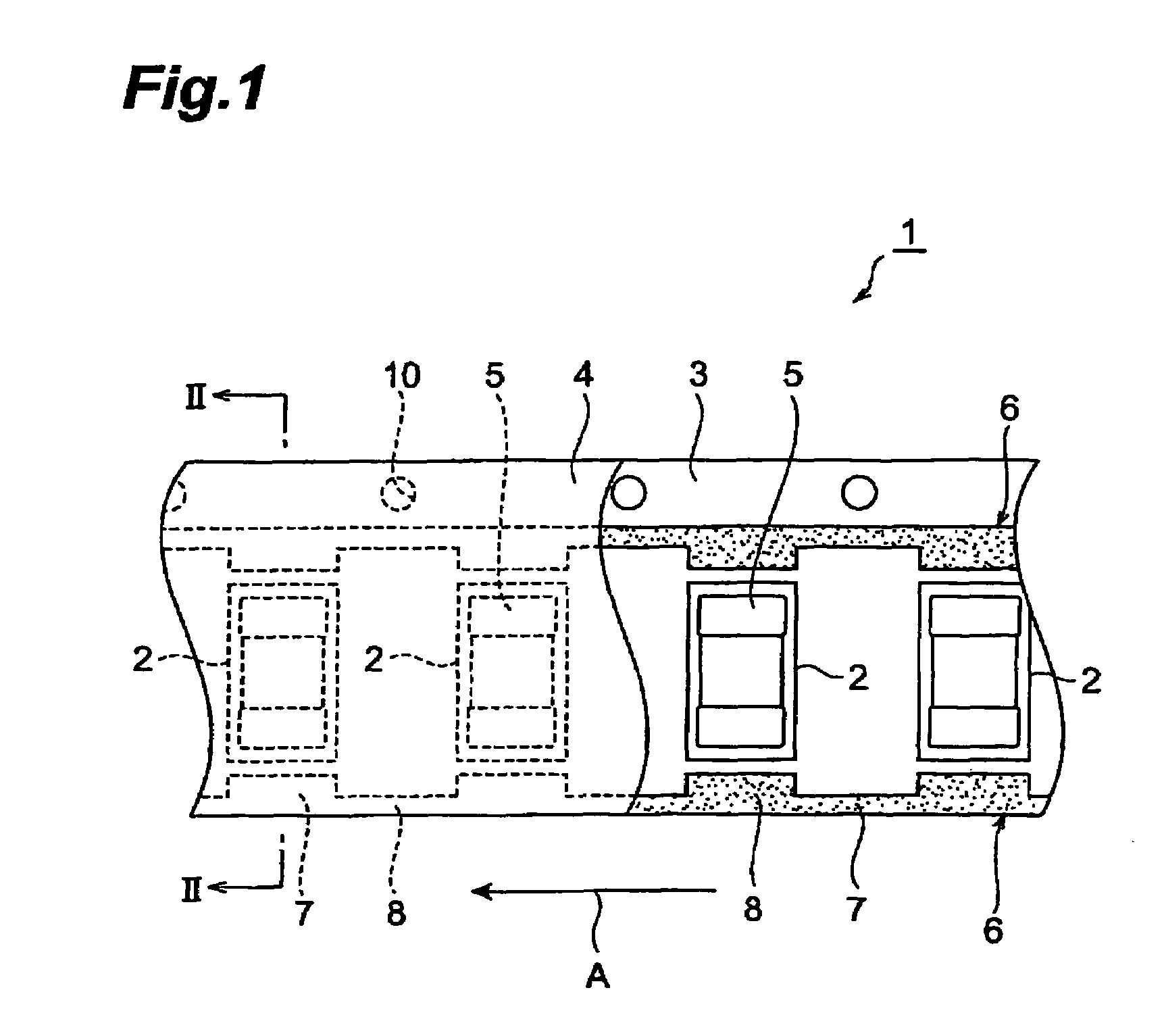

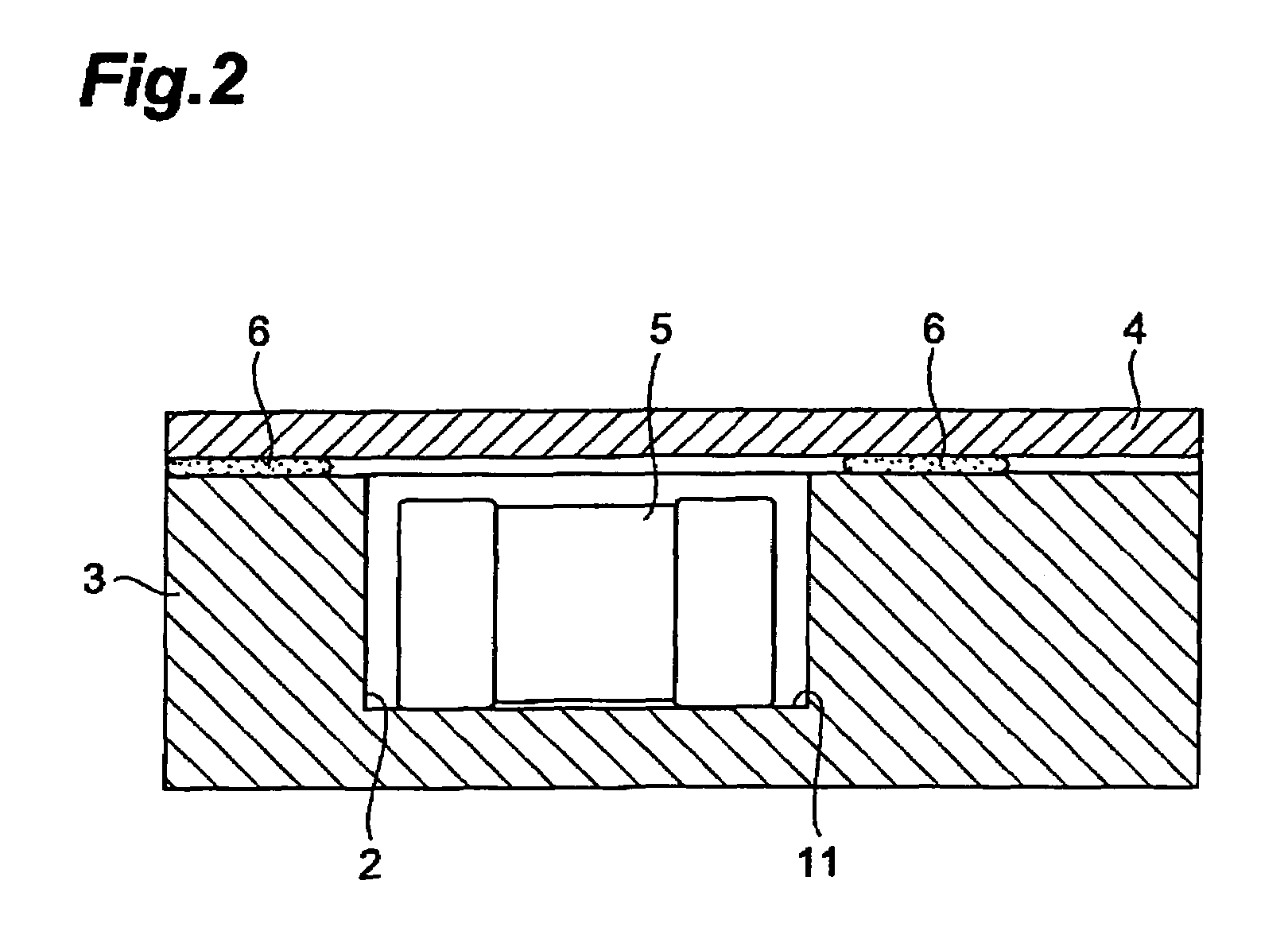

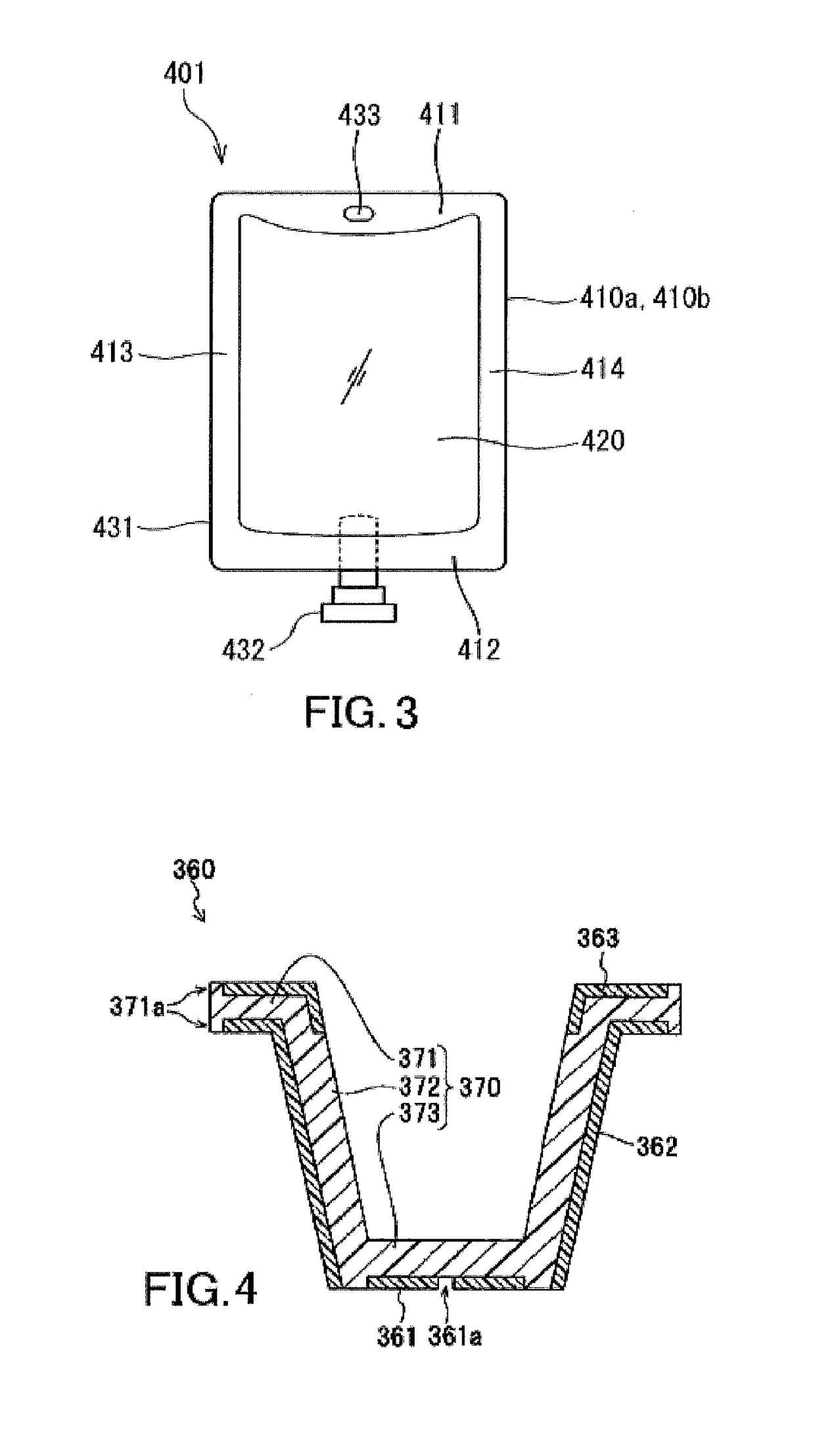

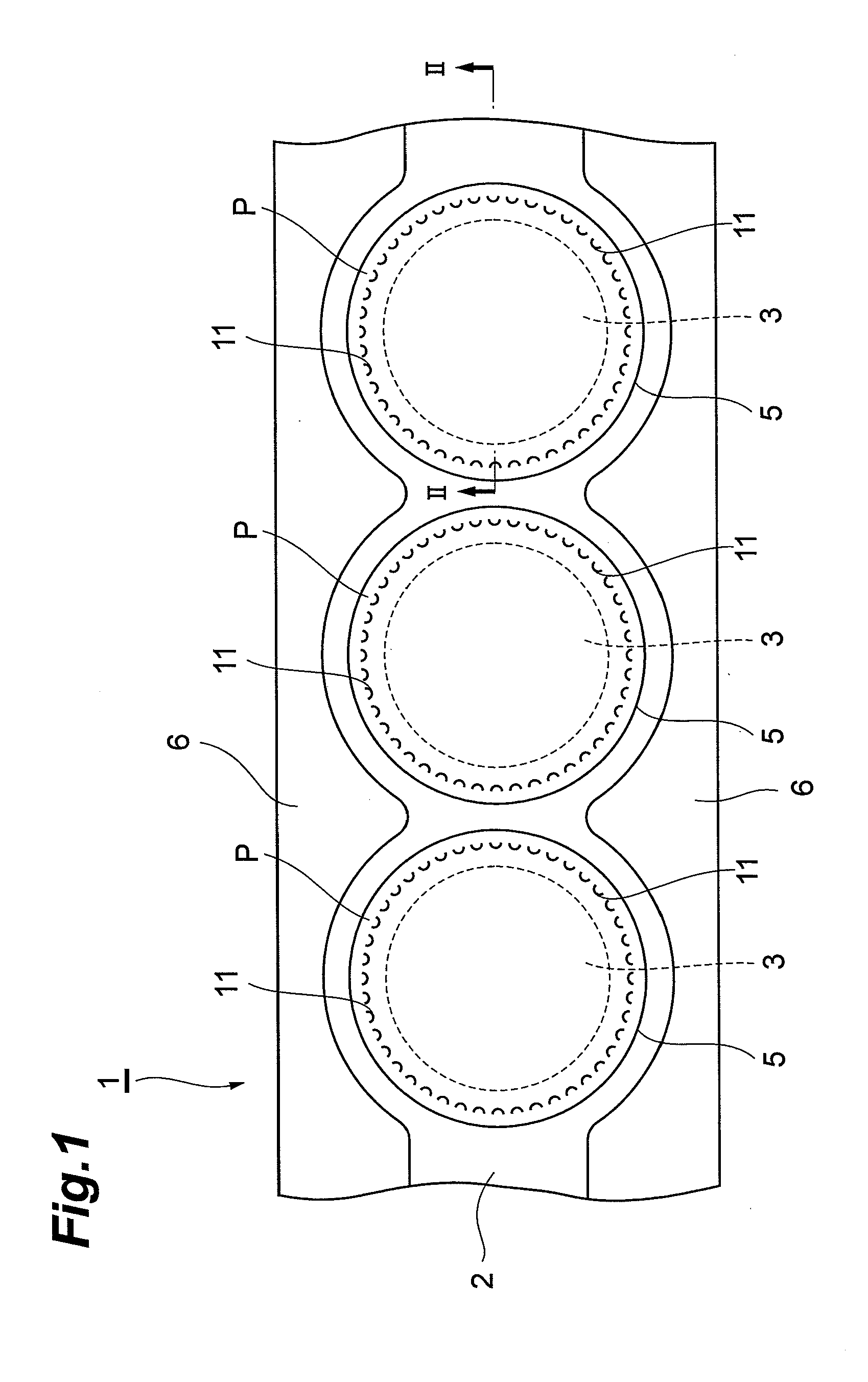

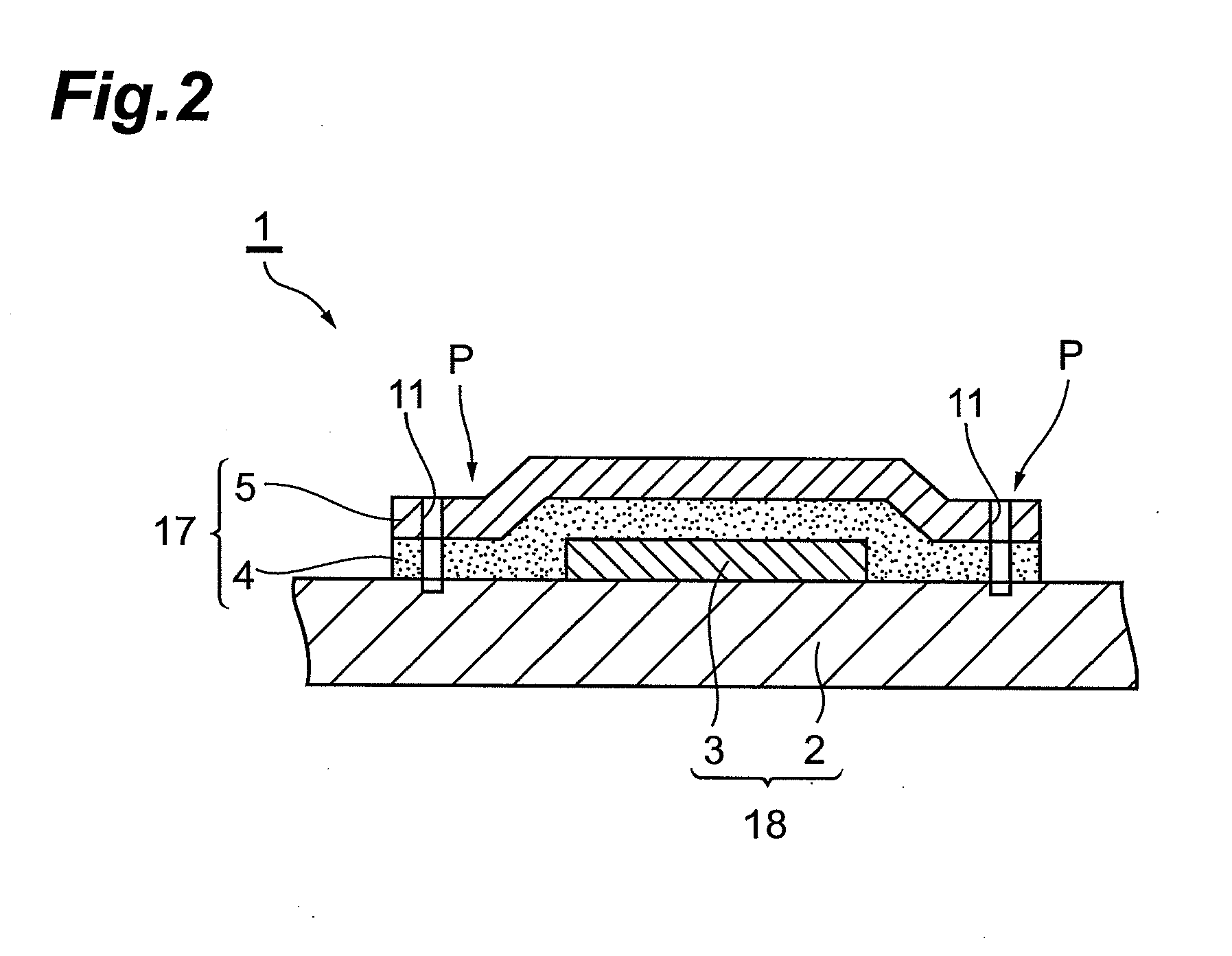

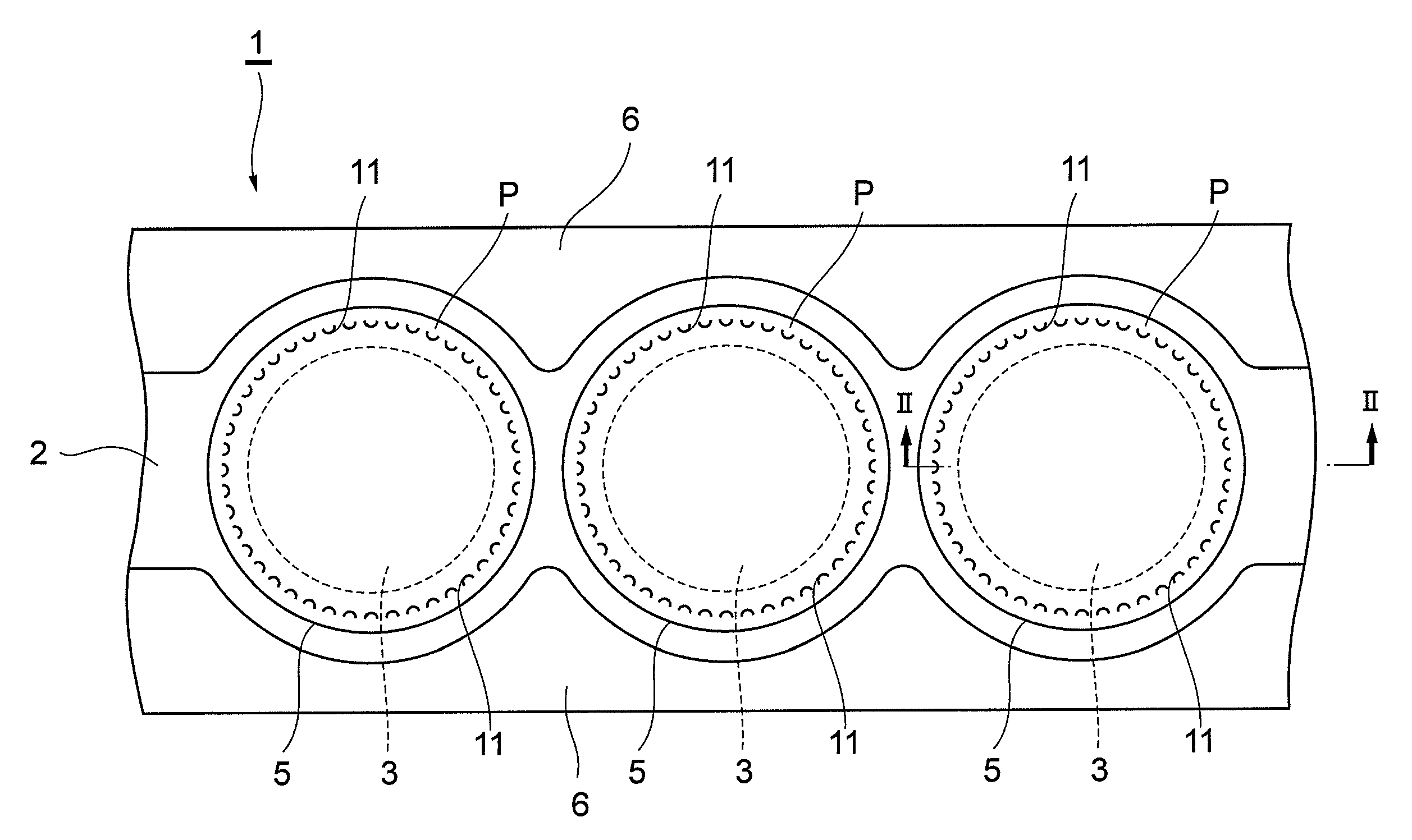

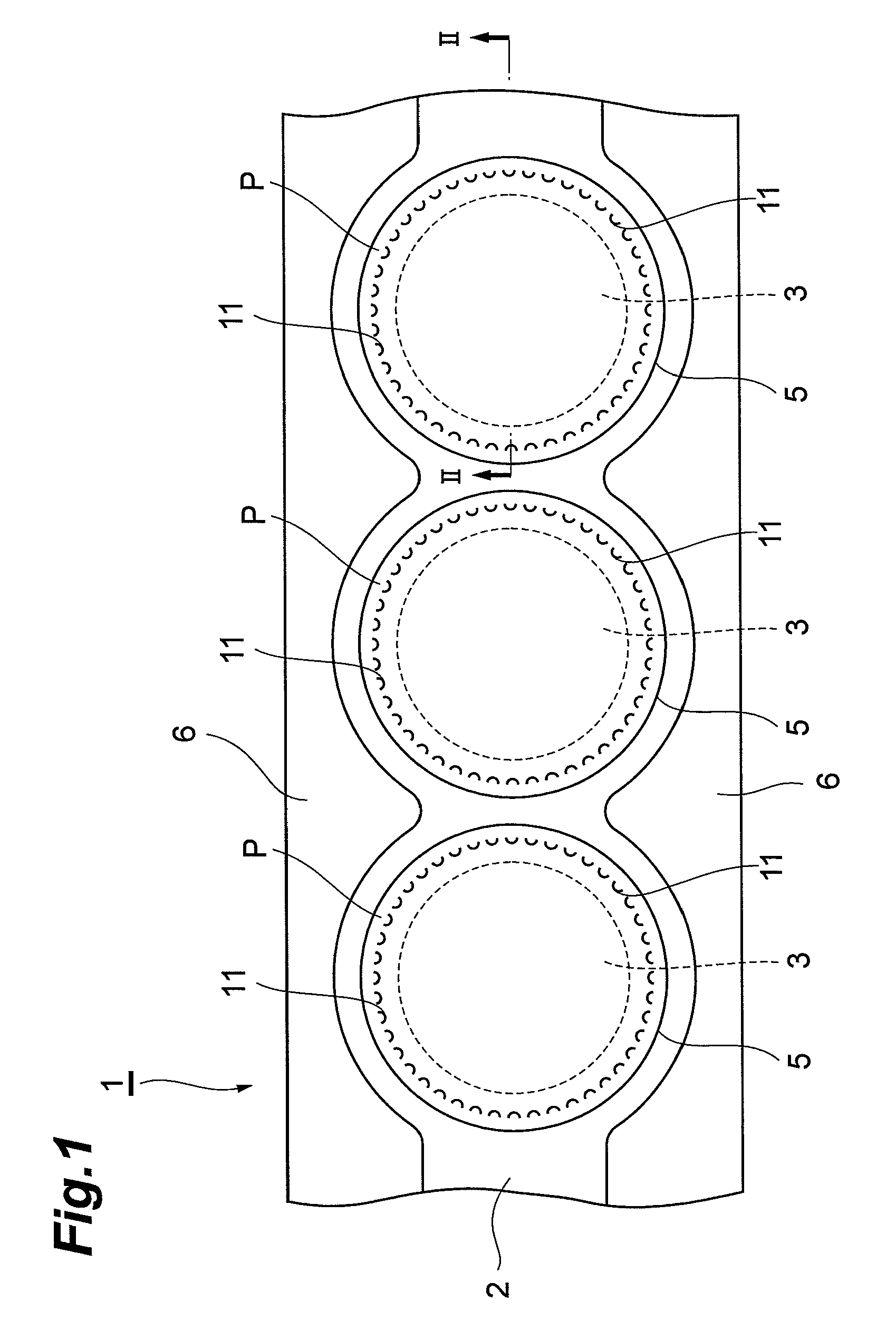

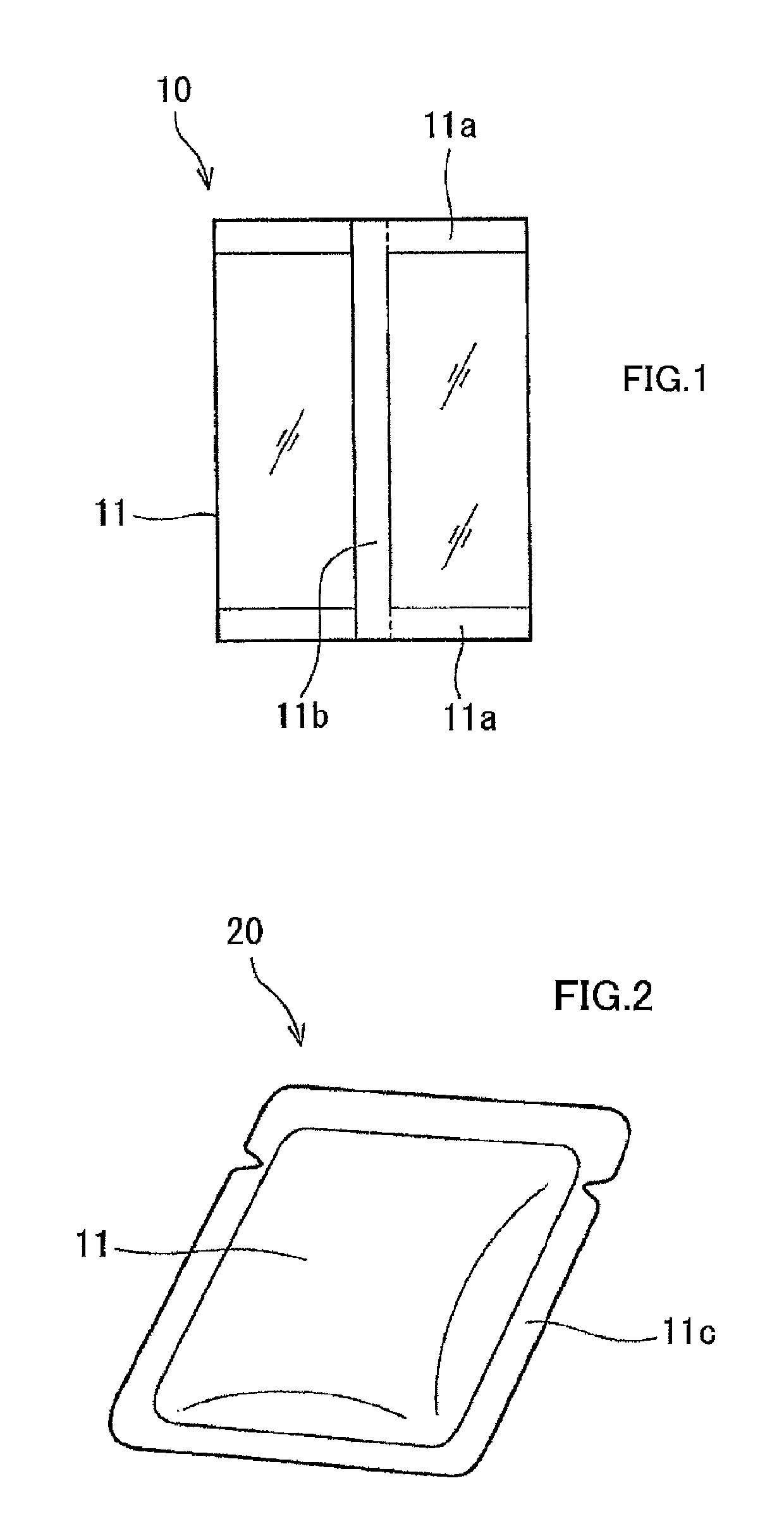

Electronic component series

ActiveUS20060138019A1Suppress vibration of the electronic componentsEasy to peelOther accessoriesContainer/bottle contructionEngineeringElectronic component

The present invention is an electronic component series, comprising a carrier tape which has a plurality of storage recesses cyclically arranged along the longitudinal direction, electronic components to be stored in the plurality of storage recesses, a cover tape established to cover the plurality of storage recesses of the carrier tape, and a pair of adhesive regions which adhere to the carrier tape and to the cover tape, and extend along the longitudinal direction of the carrier tape so as to enclose the plurality of storage recesses from both sides, wherein the adhesive width of the pair of adhesive regions is cyclically increased in size corresponding to the storage recesses respectively. With this electronic component series, the difference in the peel strength of the cover tape between the first adhesive regions and the second adhesive regions can be sufficiently reduced.

Owner:TDK CORPARATION

Adhesion Assisting Agent Fitted Metal Foil, and Printed Wiring Board Using Thereof

ActiveUS20080145689A1Good moisture absorptionExcellent in heat resisting propertyPrinted circuit secondary treatmentSurface layering apparatusEpoxyMetal foil

Provided is an adhesion assisting agent fitted metal foil, comprising an adhesion assisting agent layer having a thickness of 0.1 to 10 μm on a metal whose surface has a ten-point average roughness Rz of 2.0 μm or less, wherein the adhesion assisting agent layer is formed from an adhesion assisting agent composition comprising: (A) an epoxy resin selected from the group consisting of a novolak epoxy resin and an aralkyl epoxy resin; and (C) an epoxy resin curing agent.

Owner:RESONAC CORP

Copper foil for printed wiring board, method for producing said copper foil, resin substrate for printed wiring board and printed wiring board

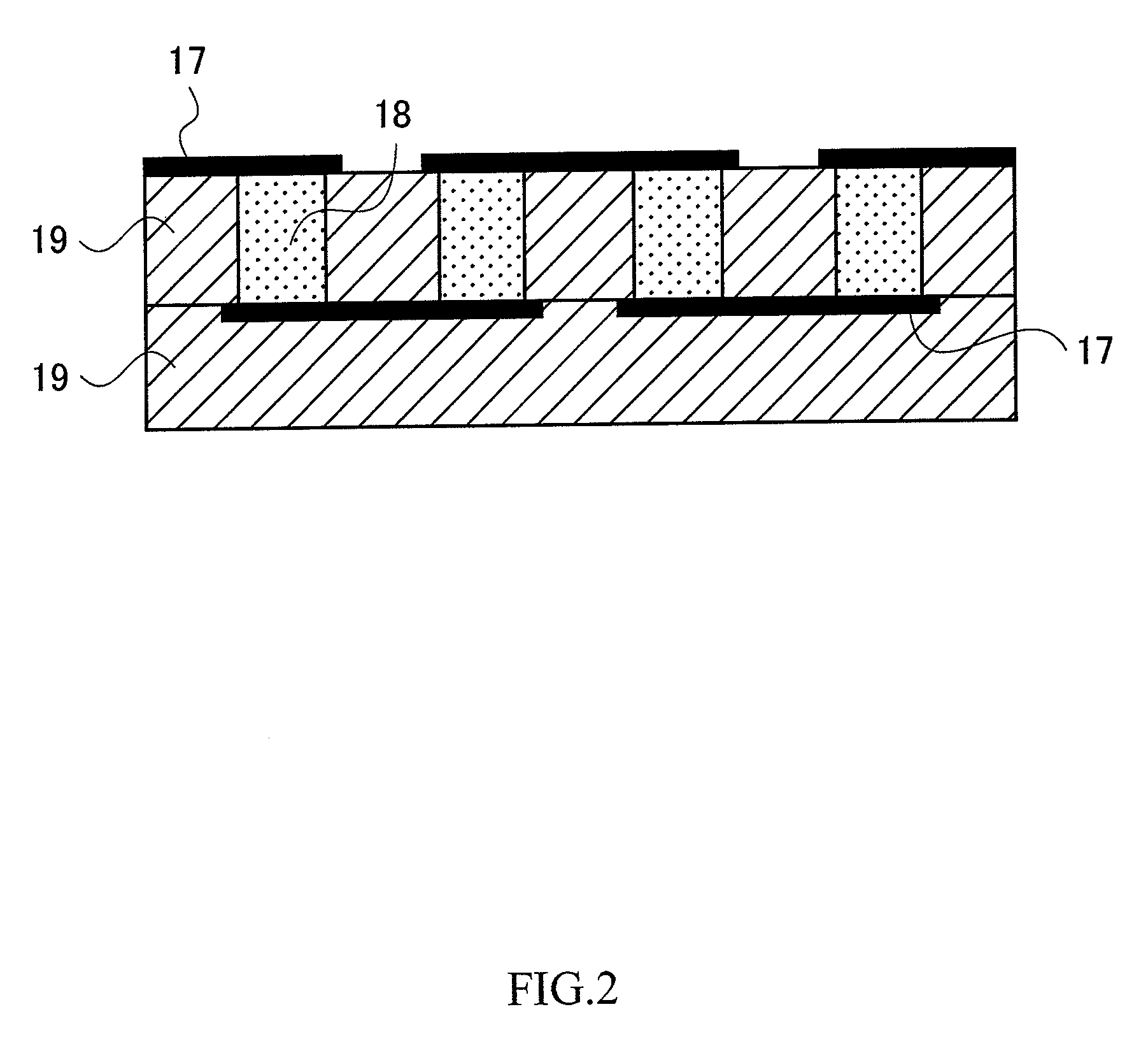

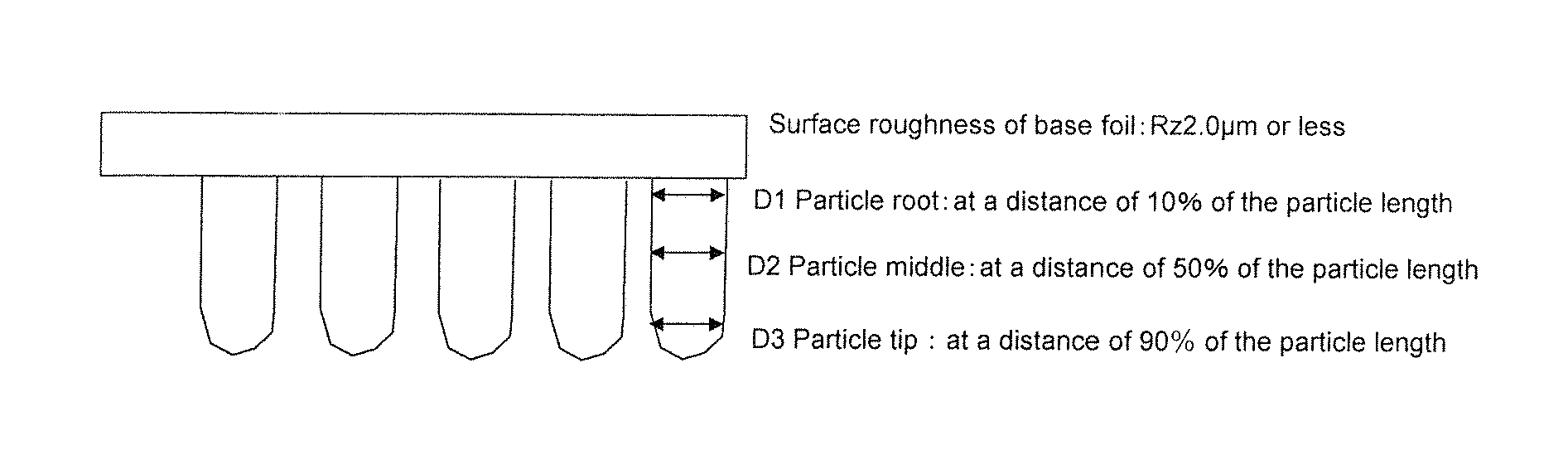

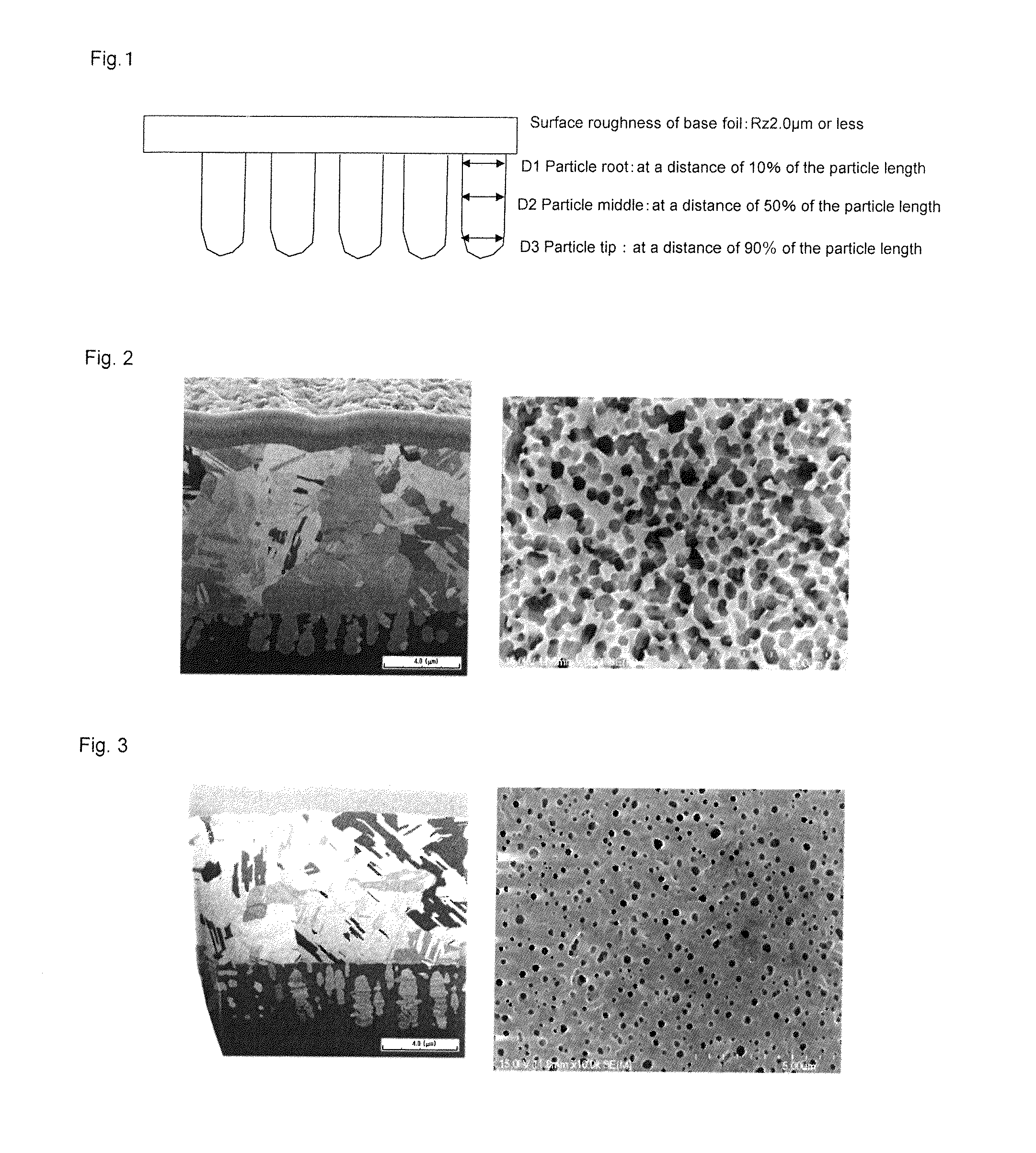

ActiveUS20130220685A1High frequencyHigh bonding strengthElectrolysis componentsChromatisationSemiconductor packageCopper foil

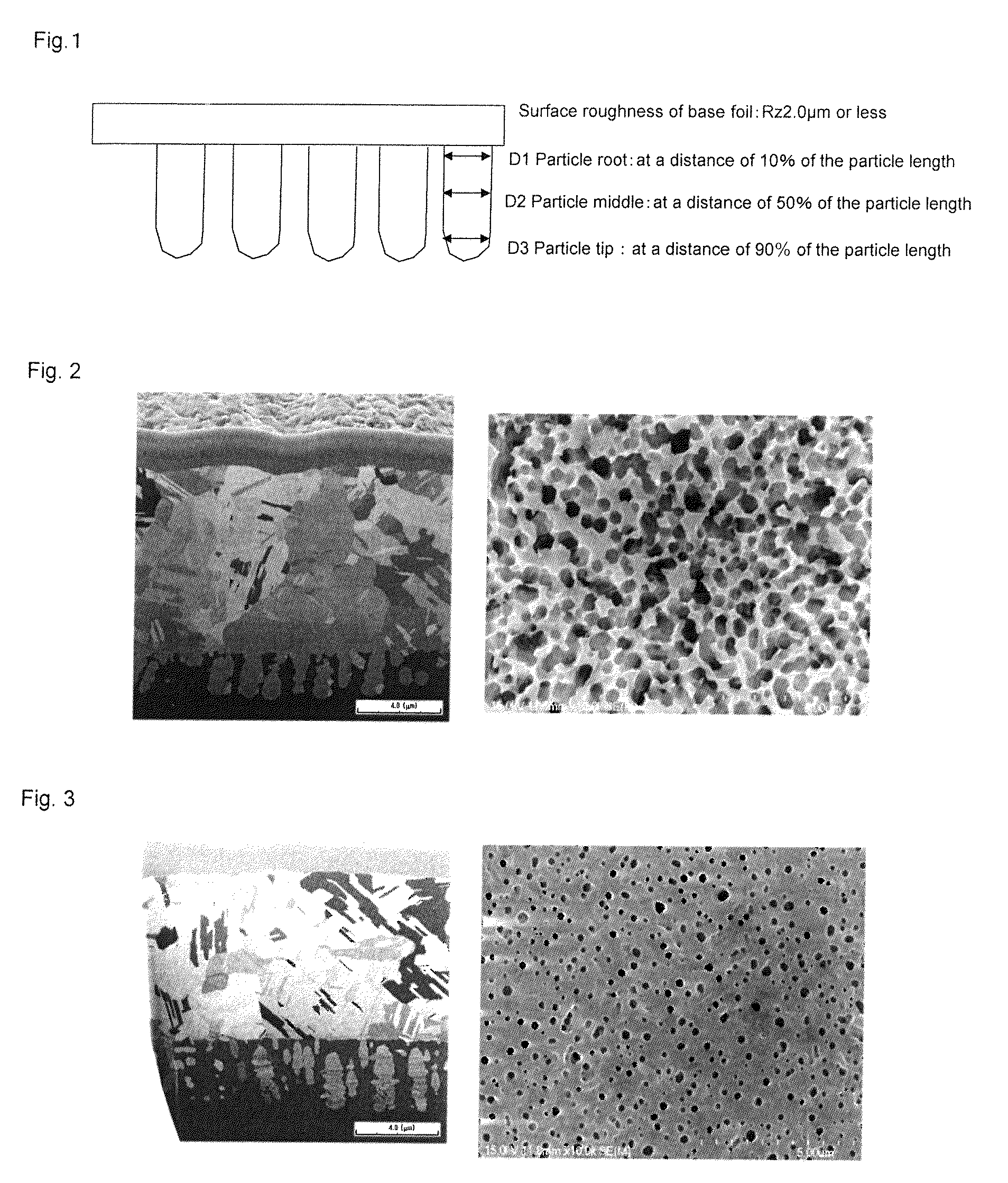

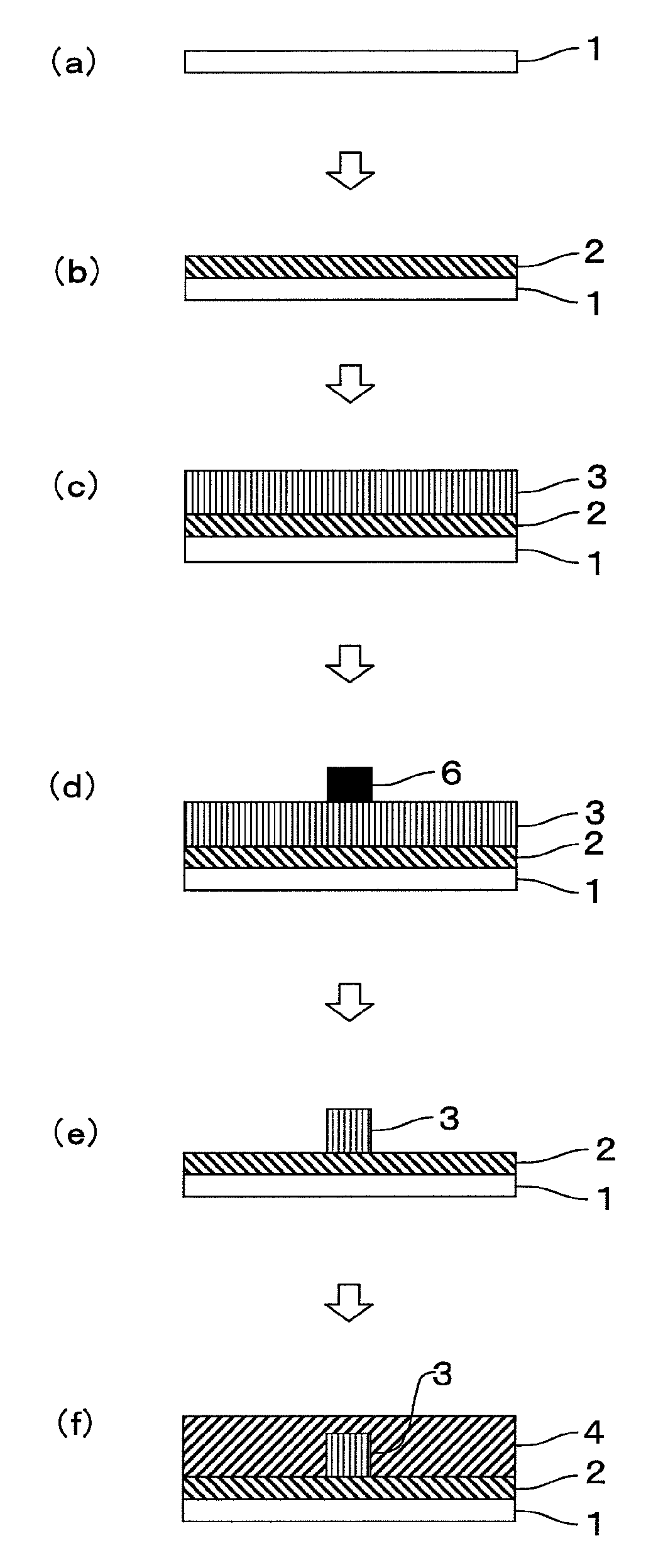

A copper foil for a printed wiring board, the copper foil being characterized by having, on at least one surface thereof, a roughed layer of the copper foil in which an average diameter at a particle root (D1) corresponding to a distance of 10% of a particle length from the root, is 0.2 μm to 1.0 μm, and a ratio of the particle length (L1) to the average diameter at the particle root (D1) is 15 or less when L1 / D1. A copper foil for a printed wiring board, wherein a sum of area covered by holes on an uneven and roughened surface of a resin is 20% or more at a surface of the resin formed by laminating the resin and a copper foil for a printed wiring having a roughened layer and then removing the copper layer by etching. An object of the present invention is to develop a copper foil for a semiconductor package board in which the aforementioned phenomenon of circuit erosion is avoided without deteriorating other properties of the copper foil. In particular, an object of the present invention is to provide a copper foil for a printed wiring board and a producing method thereof, wherein a roughened layer of the copper foil can be improved to enhance the adhesiveness between the copper foil and a resin.

Owner:JX NIPPON MINING& METALS CORP

Peelable composite thermoplastic sealants in packaging films

A peelable sealing structure includes a sealing layer and one or more optional additional layers. The peelable sealing structure includes a sealing surface that is formable into a peelable seal upon contact with a sealing substrate at all temperatures in a peelable seal temperature range. Moreover, the peelable sealing structure comprises a thermoplastic polymer and an additive dispersed within at least a portion of the thermoplastic polymer with the peelable sealing structure defining the sealing surface.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Electronic component series

ActiveUS7584853B2Suppress vibration of the electronic componentsEasy to peelOther accessoriesContainer/bottle contructionEngineeringElectronic component

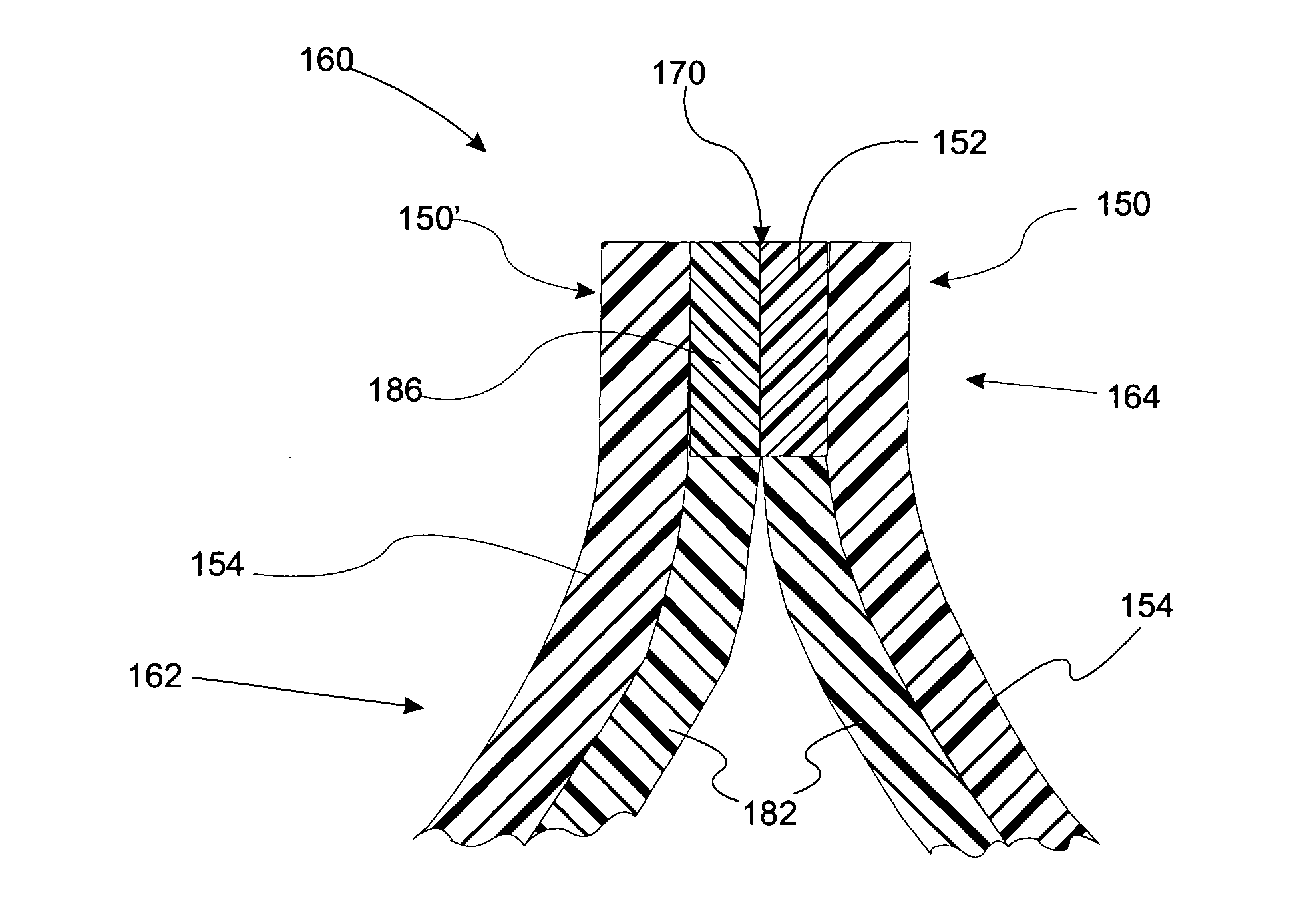

The present invention is an electronic component series, comprising a carrier tape which has a plurality of storage recesses cyclically arranged along the longitudinal direction, electronic components to be stored in the plurality of storage recesses, a cover tape established to cover the plurality of storage recesses of the carrier tape, and a pair of adhesive regions which adhere to the carrier tape and to the cover tape, and extend along the longitudinal direction of the carrier tape so as to enclose the plurality of storage recesses from both sides, wherein the adhesive width of the pair of adhesive regions is cyclically increased in size corresponding to the storage recesses respectively. With this electronic component series, the difference in the peel strength of the cover tape between the first adhesive regions and the second adhesive regions can be sufficiently reduced.

Owner:TDK CORPARATION

Peelable composite thermoplastic sealants in packaging films

A peelable sealing structure includes a sealing layer and one or more optional additional layers. The peelable sealing structure includes a sealing surface that is formable into a peelable seal upon contact with a sealing substrate at all temperatures in a peelable seal temperature range. Moreover, the peelable sealing structure comprises a thermoplastic polymer and an additive dispersed within at least a portion of the thermoplastic polymer with the peelable sealing structure defining the sealing surface.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Method for adhering a floor covering to a floor with a floor adhesive

InactiveUS6409860B1Good level of performance characteristicPeel strengthMonocarboxylic acid ester polymer adhesivesCovering/liningsOrganic solventPlasticizer

An aqueous composition is essentially free of organic solvents, plasticizers and additional tackifiers and contains water and 20-99% by weight of a polymer and 1-80% by weight of a filler, the percentages by weight being based on the sum of the components of the aqueous composition, with the exception of water.

Owner:BASF AG

Multilayer structure, packaging material and product including same, and protective sheet for electronic device

ActiveUS20180022073A1Maintain good propertiesImprove interlayer adhesionFlexible coversWrappersEtherOrganic phosphorus

The present invention relates to a multilayer structure including a base (X) and a layer (Y) stacked on the base (X). The layer (Y) contains an aluminum-containing compound (A), an organic phosphorus compound (BO), and a polymer (F) having an ether bond and having no glycosidic bond.

Owner:KURARAY CO LTD

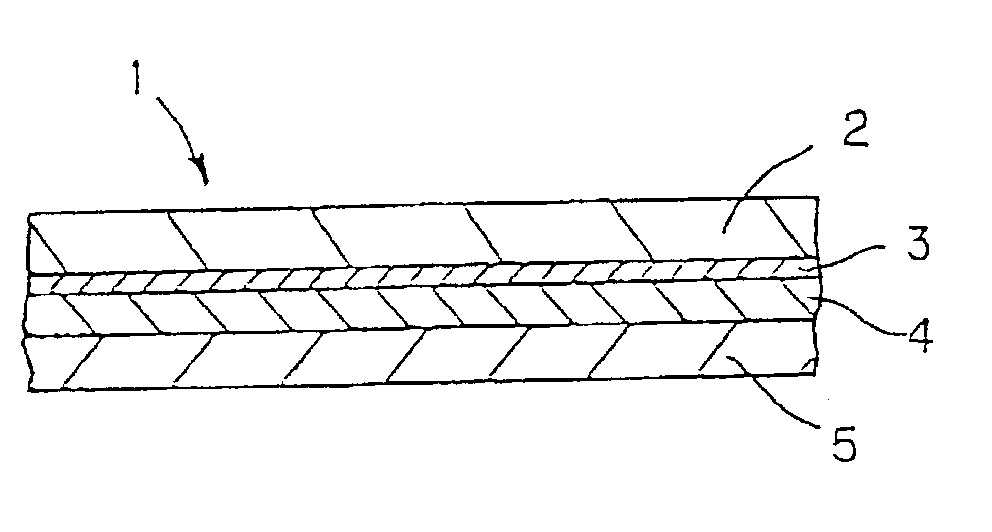

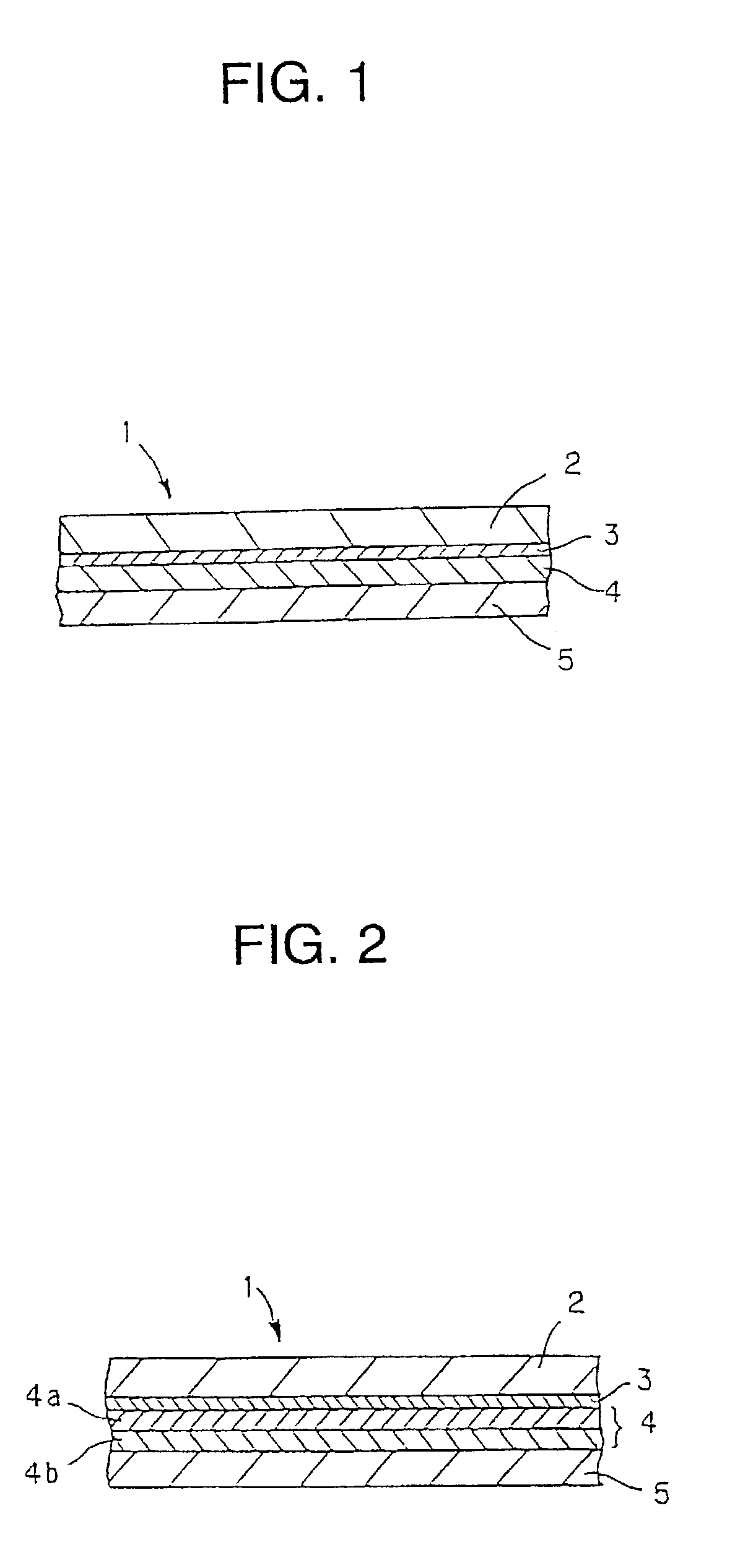

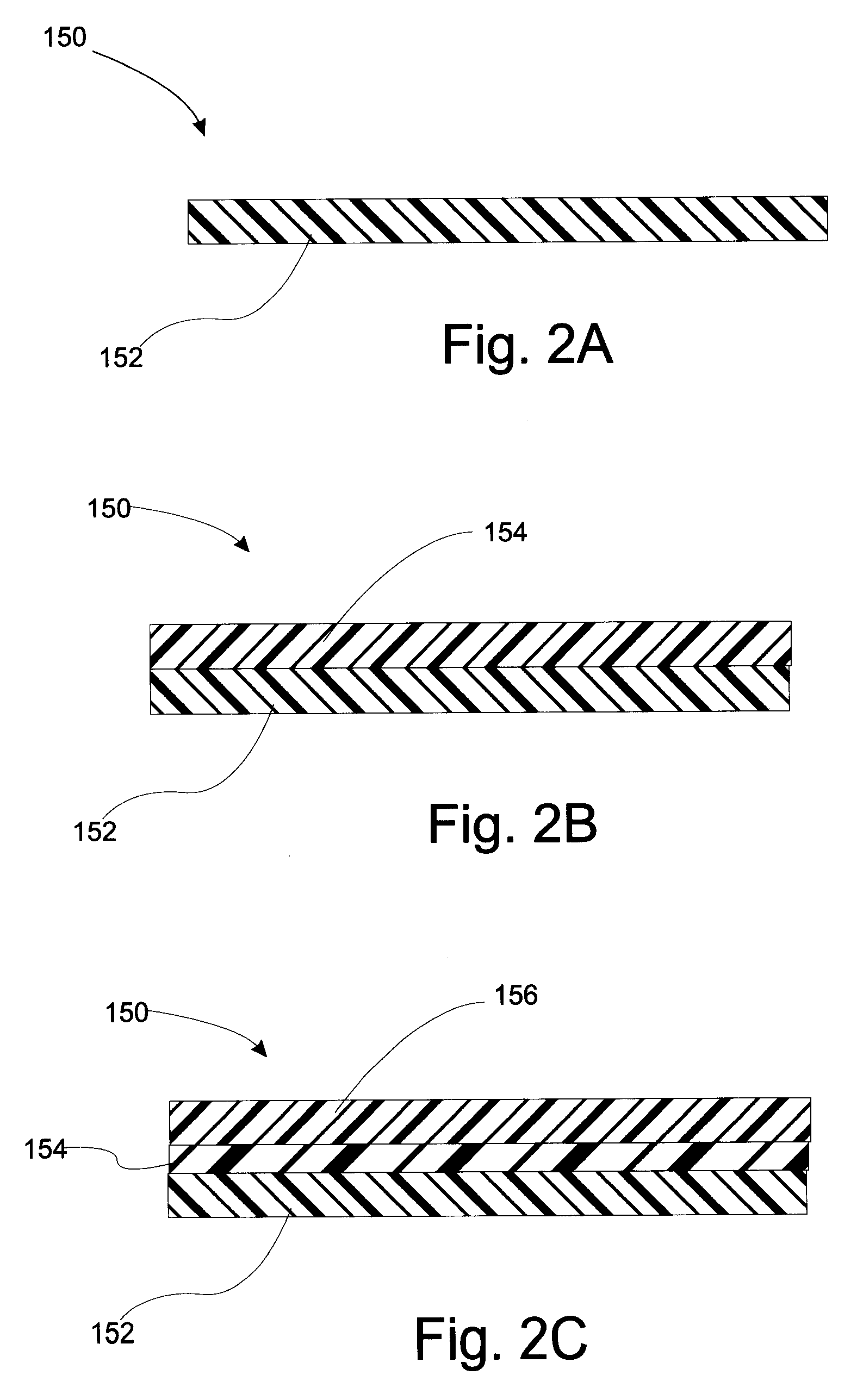

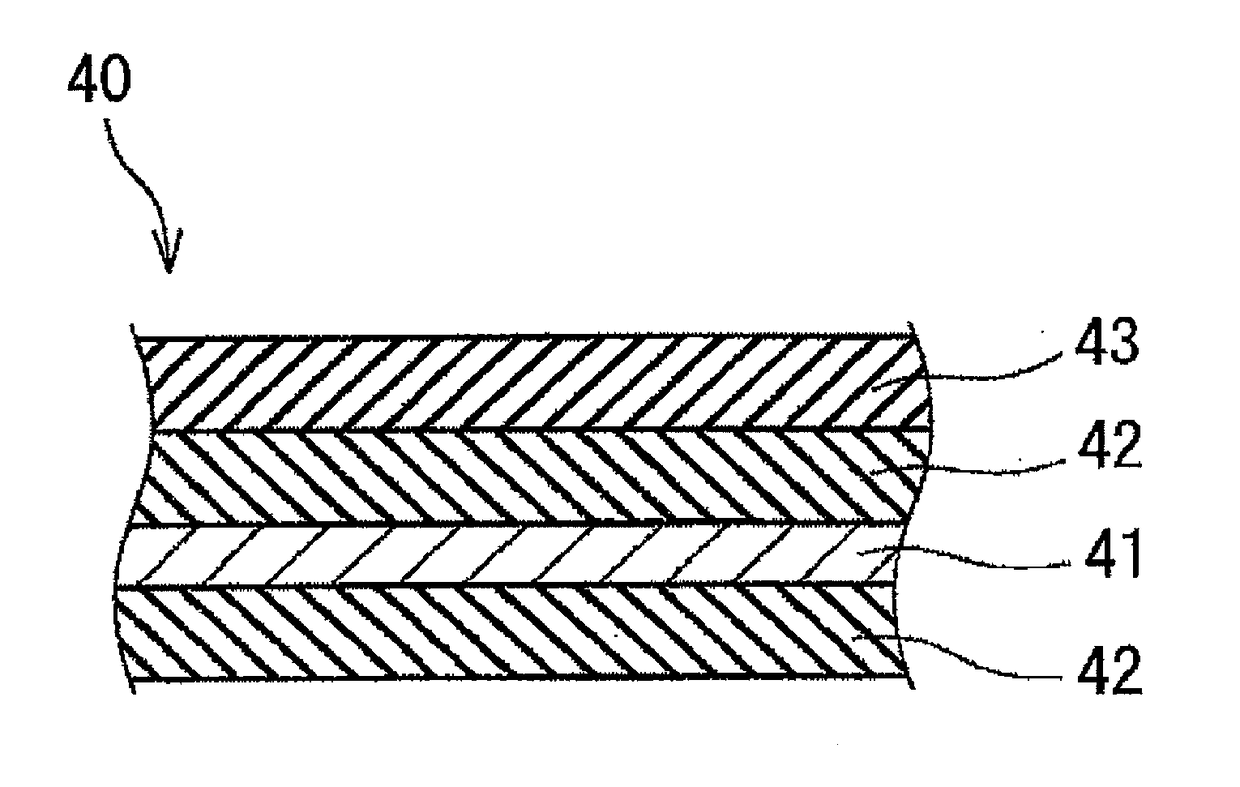

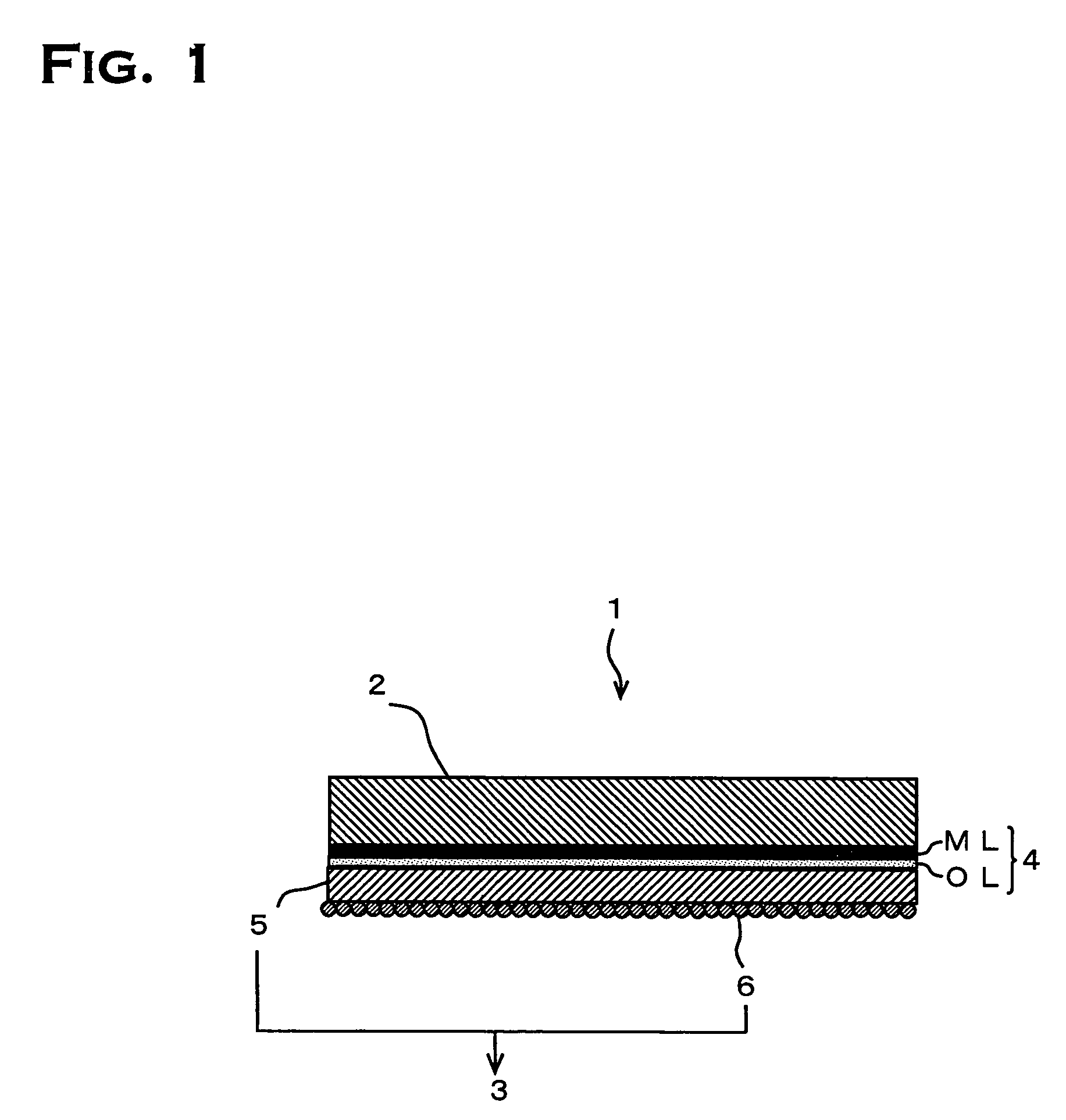

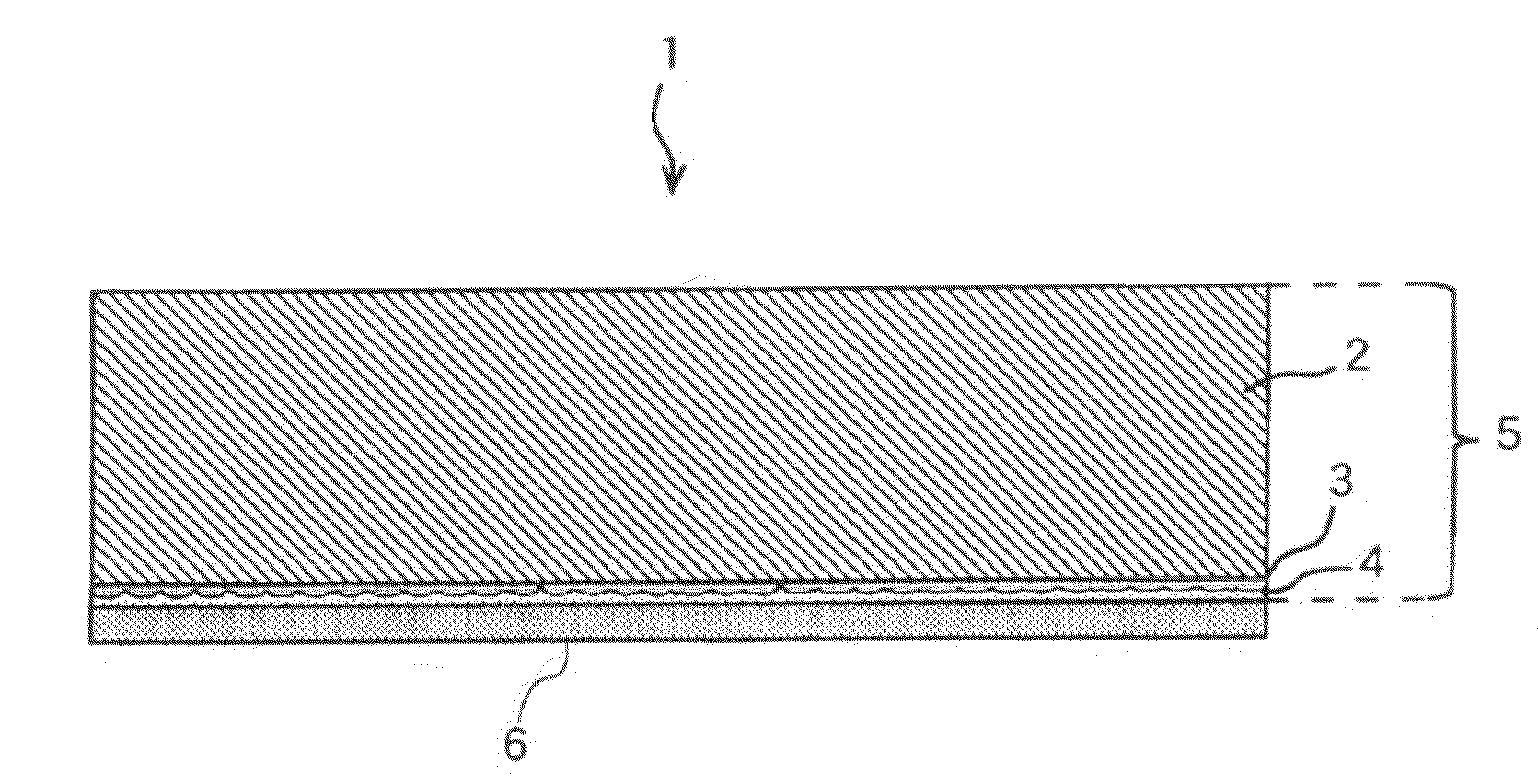

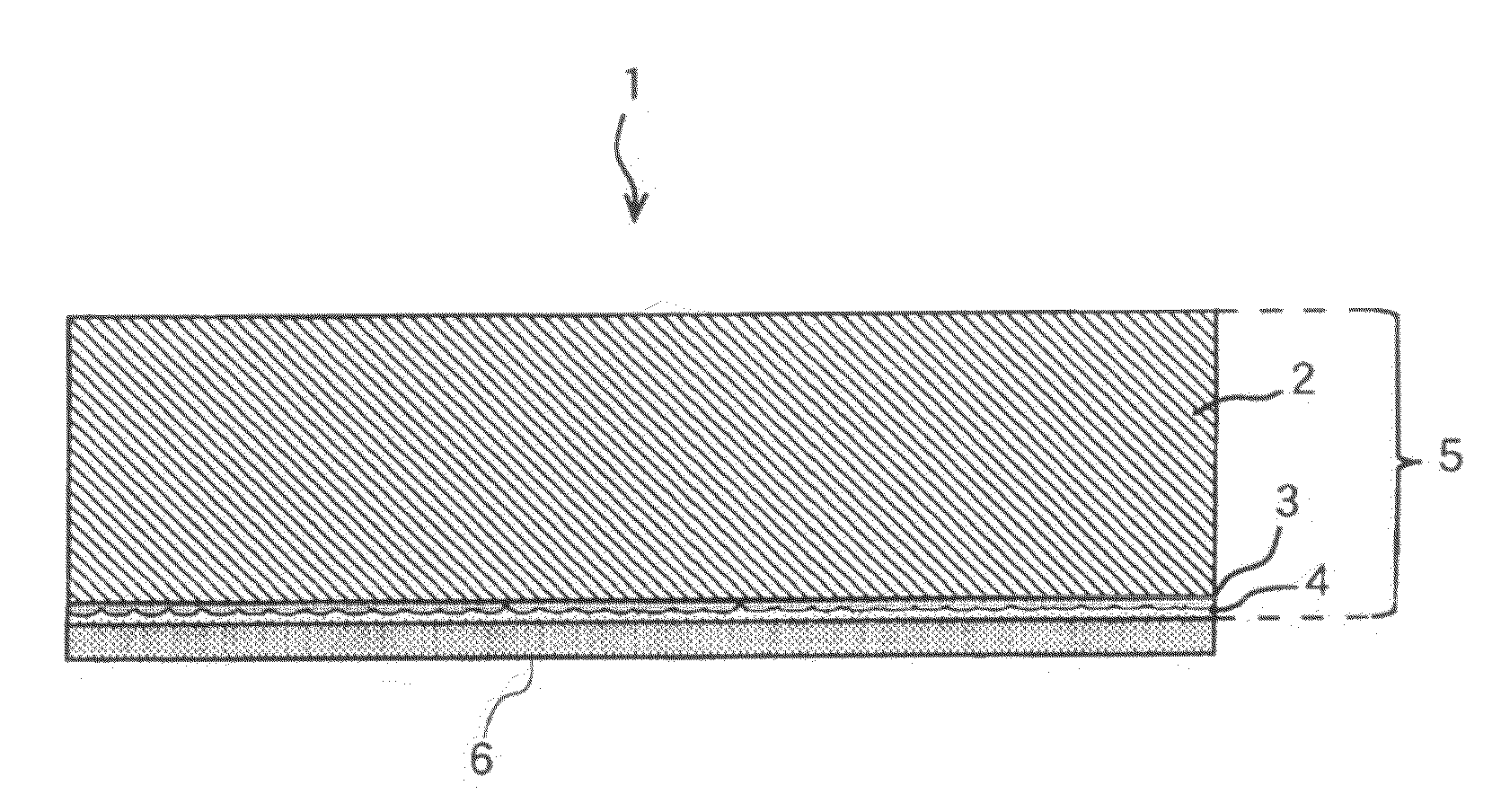

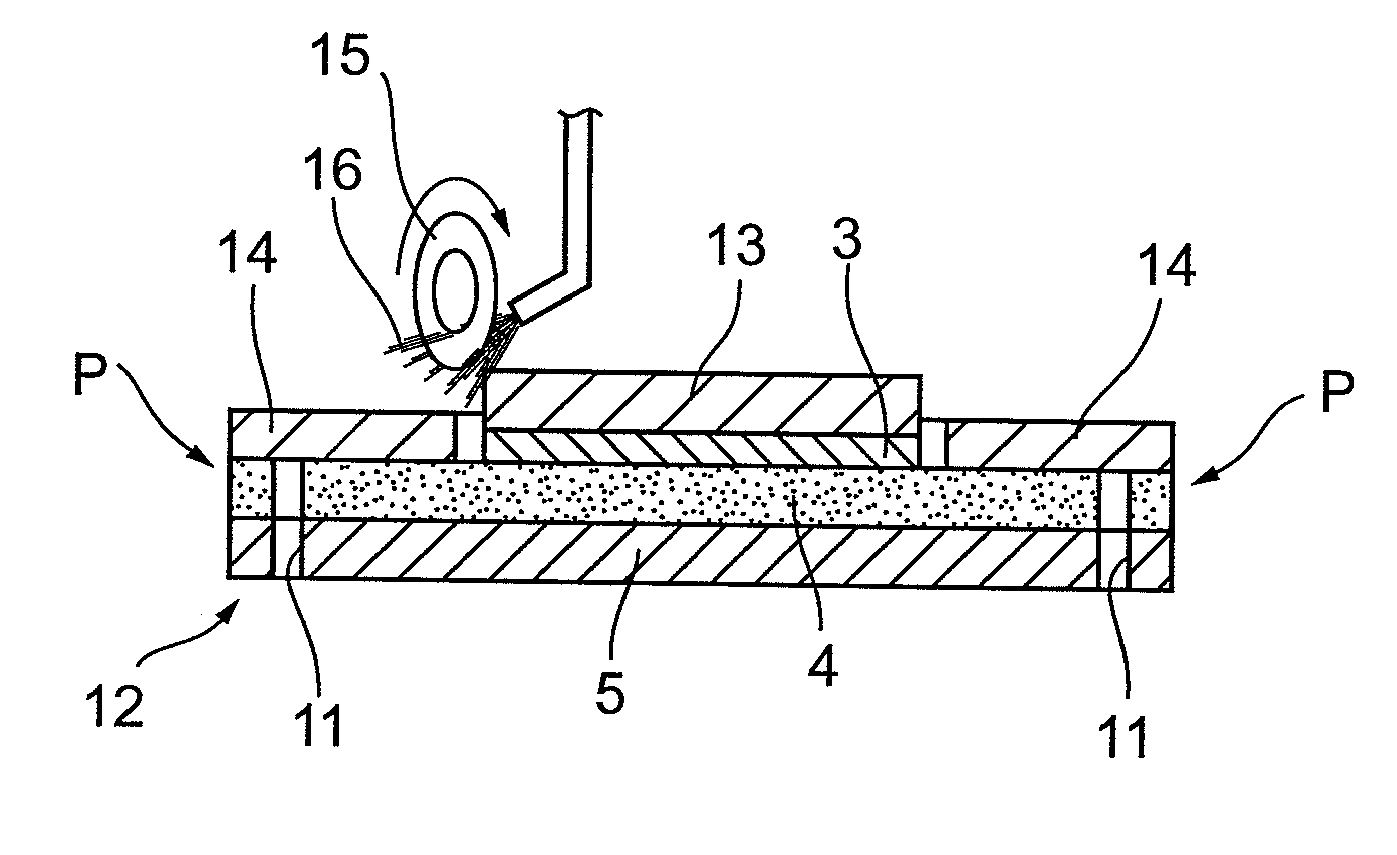

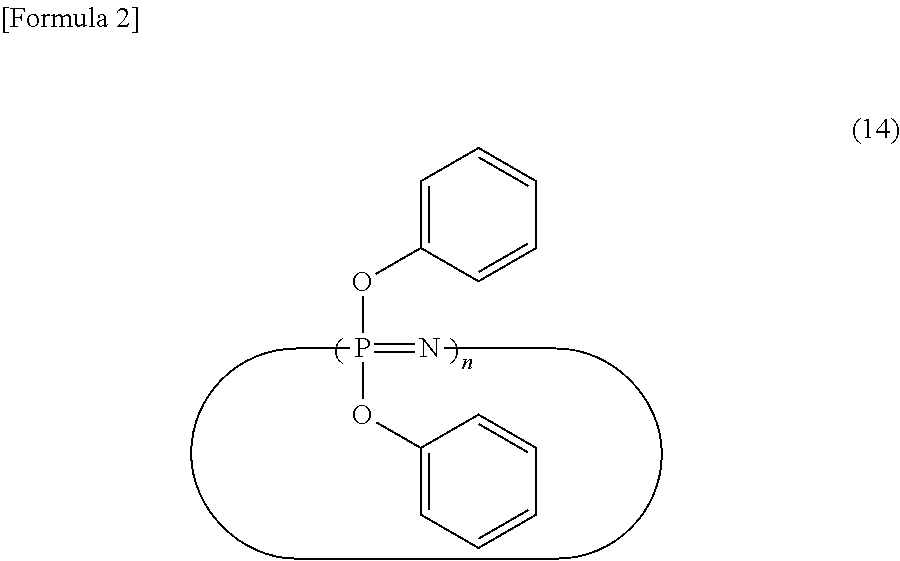

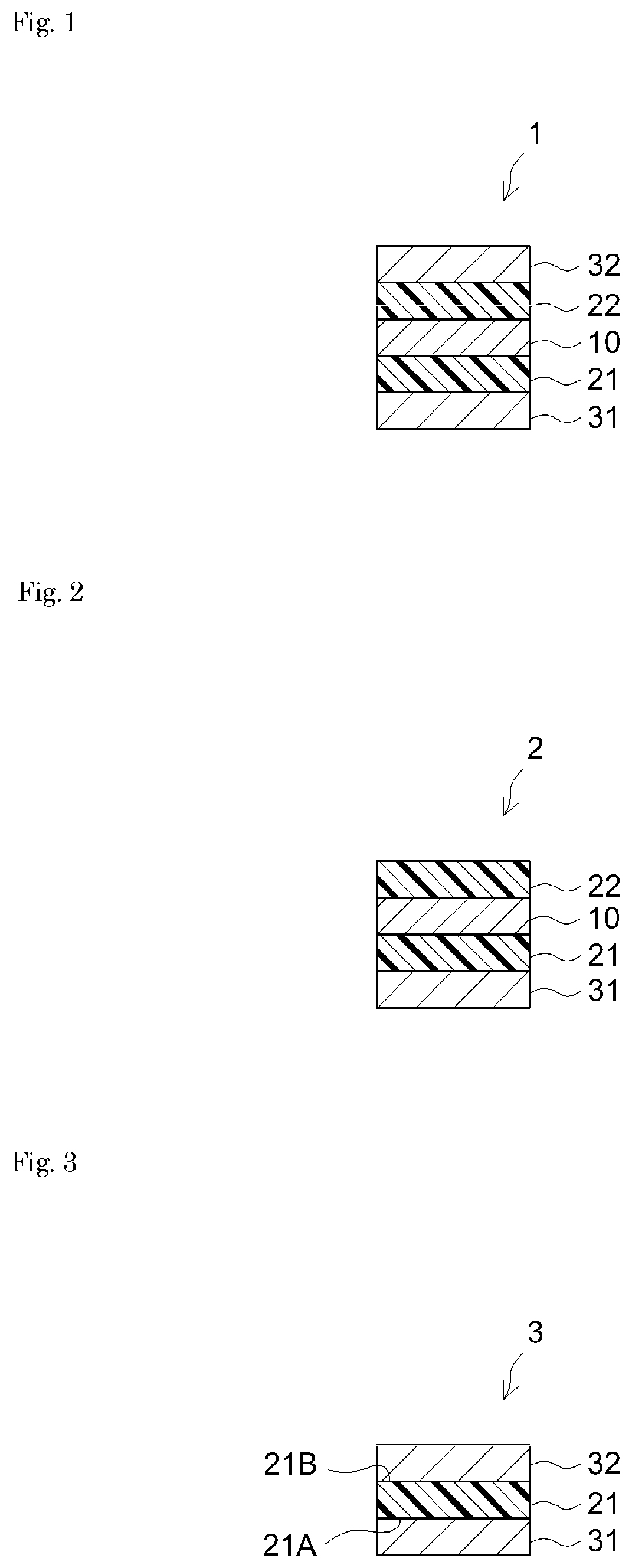

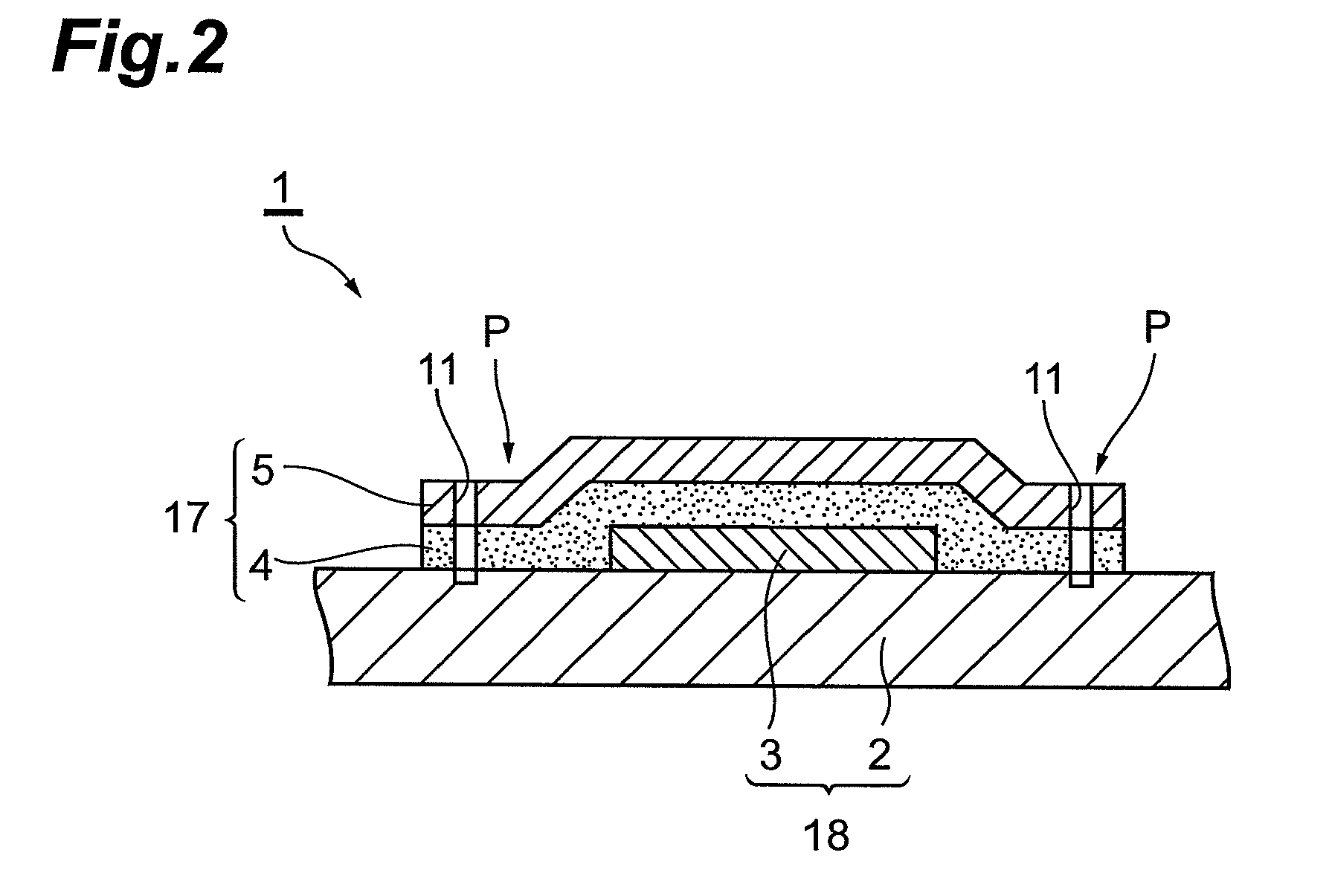

Electrolyte copper foil having carrier foil, manufacturing method thereof, and layered plate using the electrolyte copper foil having carrier foil

InactiveUS6984453B2Easy to peelPeel strengthRecord information storageMagnetic recordingInterface layerCopper foil

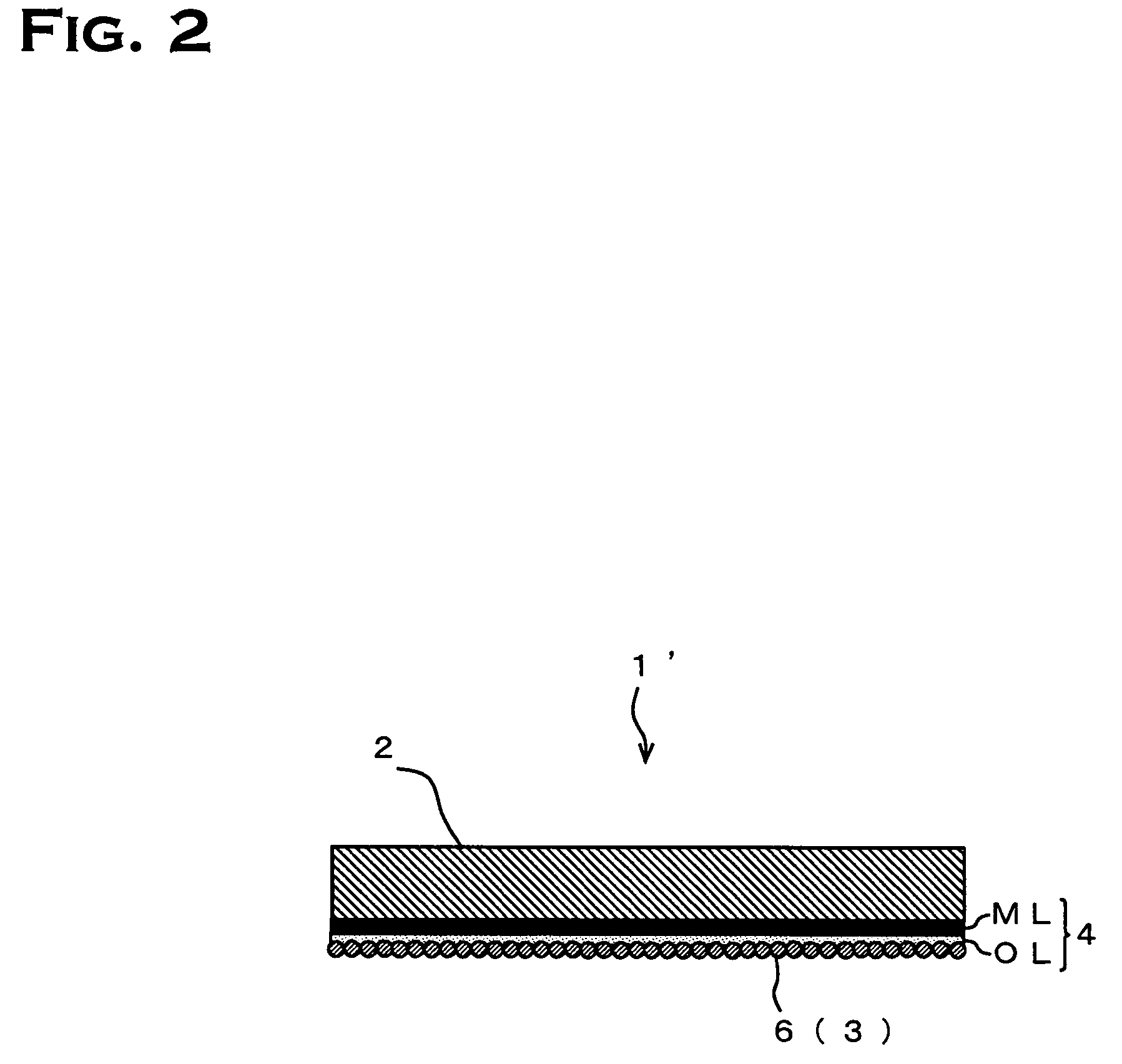

An object is the provision of a peelable electrodeposited copper foil with carrier foil that stabilizes the peel strength between the carrier foil and the electrodeposited copper foil layer even when used in manufacture of the printed wiring boards that requires pressing at the temperatures of 200° C. or higher. For the purpose of achieving the object, the electrodeposited copper foil with carrier foil 1, which includes an adhesive interface layer 4 arranged on one face of the carrier foil 2 and an electrodeposited copper foil layer 3 arranged on the adhesive interface layer 4, characterized in that the adhesive interface layer 4 is composed of a metal oxide layer ML and an organic material layer OL, and the like are used.

Owner:MITSUI MINING & SMELTING CO LTD

Printed wiring board and method for manufacturing the same

InactiveUS7713862B2High peel strengthPeel strengthAdditive manufacturing apparatusPrinted circuit aspectsEngineeringTwo step

Provided is a method for manufacturing a printed wiring board, which can enhance the peel strength between an insulating layer and a conductive pattern by a two-step process, that is, a semi-hardening and full-hardening of the insulating layer. In the method for manufacturing the printed wiring board having one or more layers of a conductive pattern and an insulating pattern, an insulating pattern is formed on an insulating substrate, and at least one of the insulating substrate and the insulating pattern is semi-hardened. A conductive pattern is formed on the insulating substrate and / or the insulating pattern, thereby providing a stack structure. Then, a thermal treatment is performed on the stack structure to fully harden the semi-hardened insulating substrate and / or insulating pattern, and the conductive pattern is fired.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

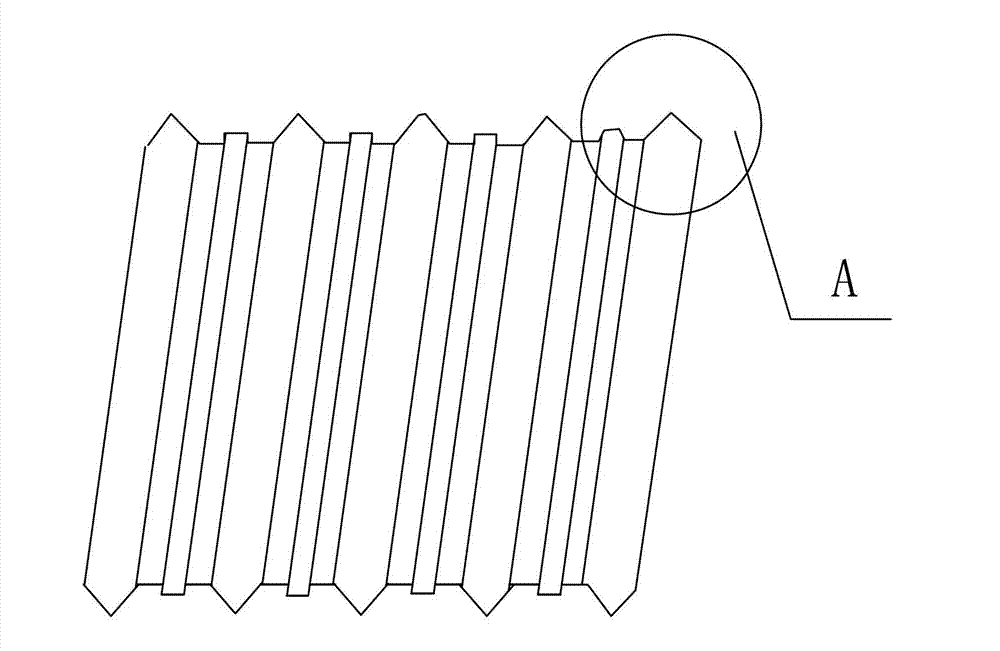

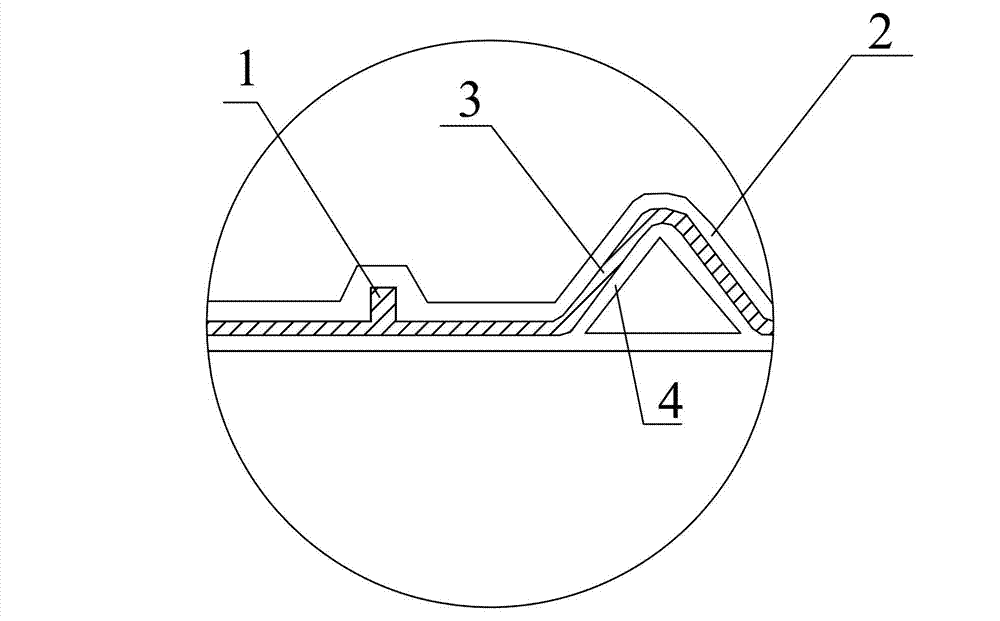

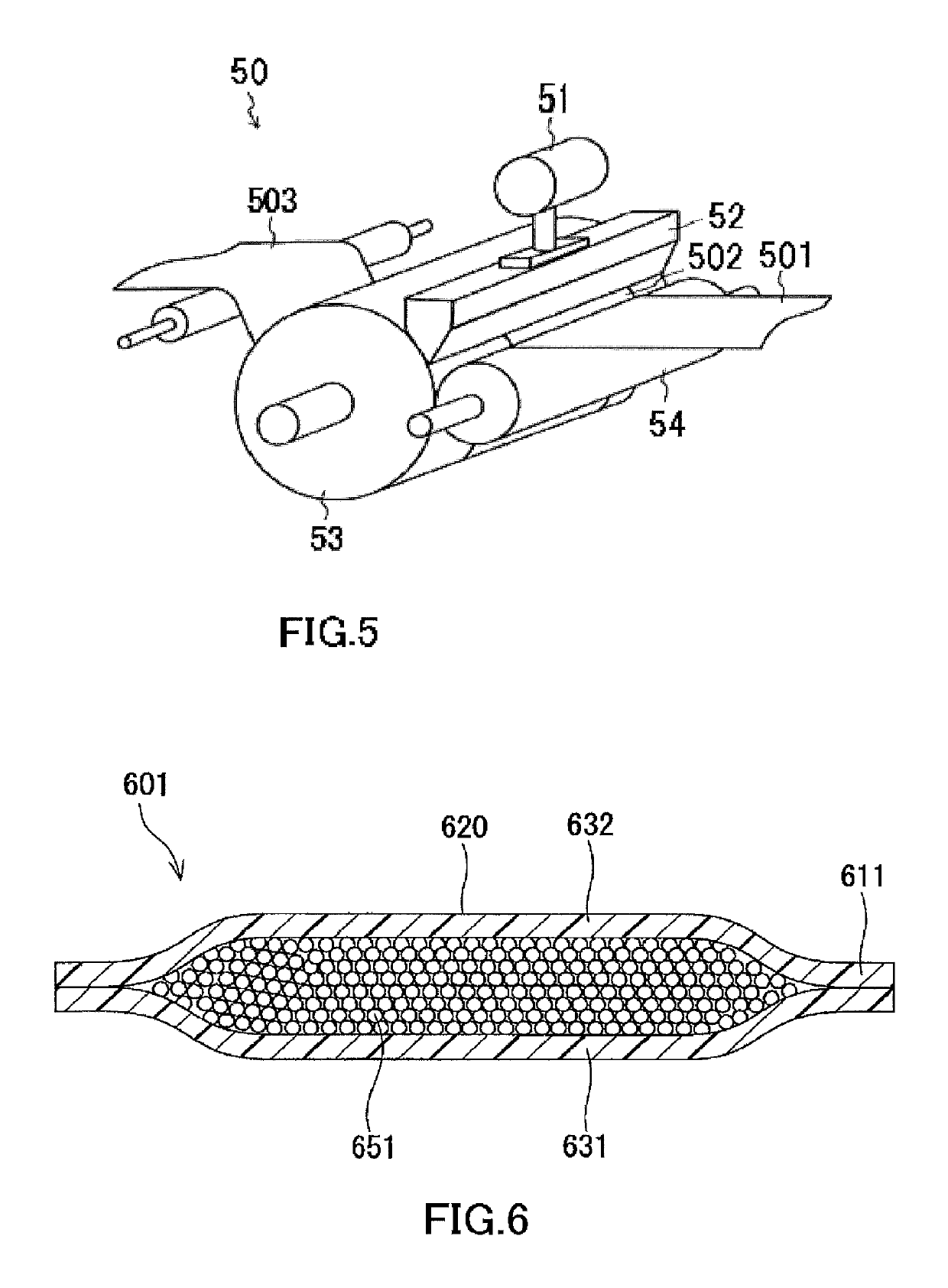

Production method of steel-plastic composite pipe

ActiveCN102774012AEliminates low longitudinal tensile capacityHigh peel strengthTubular articlesSteel beltPlane layer

The invention relates to a production method of a steel-plastic composite pipe, belonging to the field of steel-plastic composite pipes. The production method of the steel-plastic composite pipe is characterized by comprising the following steps of: under the traction of a traction apparatus, carrying out rust removal on a steel belt through a steel belt rust removal device and drying, and then placing the steel belt into a coating mould of an inner plastic coating layer extruder; under the traction of the traction apparatus, pressing the cooled and formed steel belt on a strip to obtain the waveform of a designed structural wall pipe; under the action of a tractor, placing the waveform-pressed steel belt into an extruder mould and forming a plane layer plastic which covers trough of the steel belt at the inner layer of the steel belt; placing the steel belt into a bending device and lapping and welding the steel belt with the edge of the coating strip; coating the weld joints by using inner and outer weld joint coating extruders; and cutting to obtain the finished pipe. In the traditional steel belt strengthened polyethylene helically corrugated pipe, steel belts are mot continuously strengthened in the longitudinal direction; and through continuous welding, the helically corrugated pipe can be strengthened by the steel belts in the longitudinal direction, so that the problem of low longitudinal tension resistance of the original products is eliminated.

Owner:山东金诚联创管业股份有限公司

Surface-treated copper foil, manufacturing method of the surface-treated copper foil, and surface-treated copper foil coated with very thin primer resin layer

InactiveUS8187723B2Good solder blisterImprove adhesionPretreated surfacesRecord information storageChromium freeChemical treatment

Owner:MITSUI MINING & SMELTING CO LTD

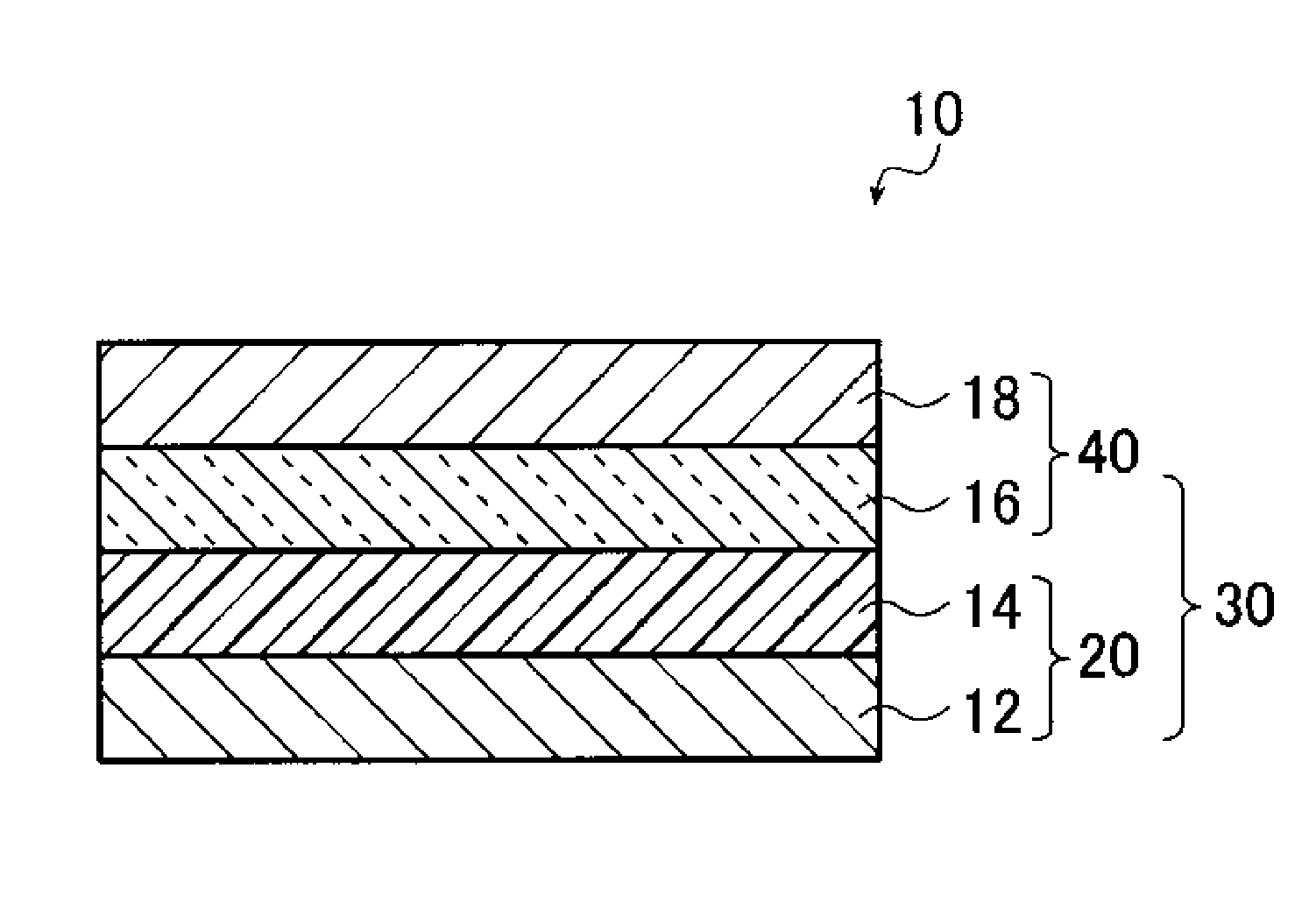

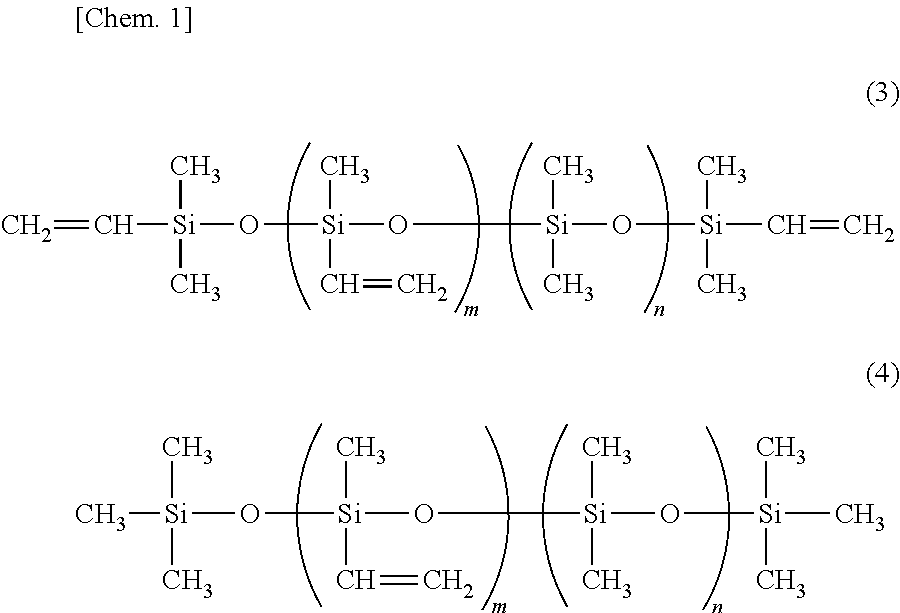

Support, glass substrate laminate, support-equipped display device panel, and method for manufacturing display device panel

ActiveUS8377552B2Improve heat resistanceHigh peel strengthPretreated surfacesRecord information storagePolymer scienceDisplay device

The present invention relates to a support including a supporting substrate and a cured silicone resin layer having a peelable surface and being disposed on one surface of the supporting substrate, for laminating a glass substrate on a surface of the cured silicone resin layer, in which a cured silicone resin of the cured silicone resin layer is a cured material of a curable silicone resin composition containing the specific linear organopolysiloxane (a) and the specific linear organopolysiloxane (b), and the cured silicone resin layer is a cured silicone resin layer formed by curing the curable silicone resin composition on a surface of the supporting substrate.

Owner:AGC INC

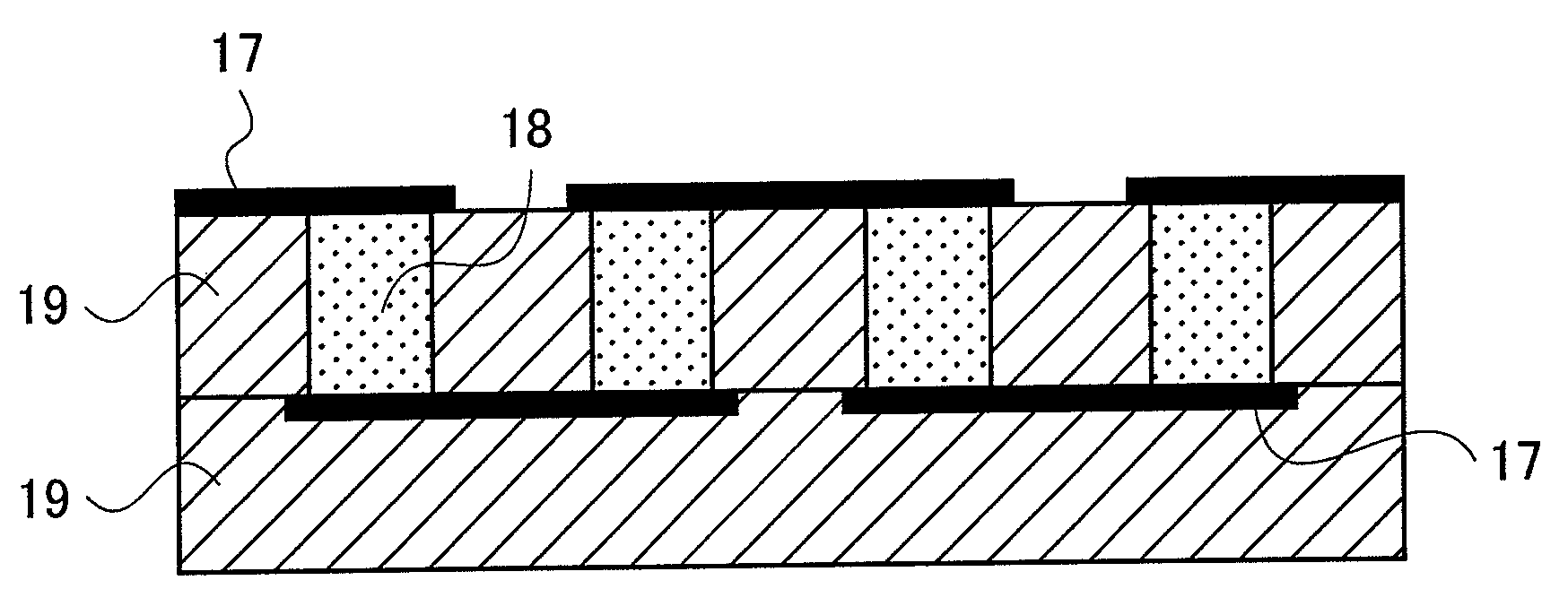

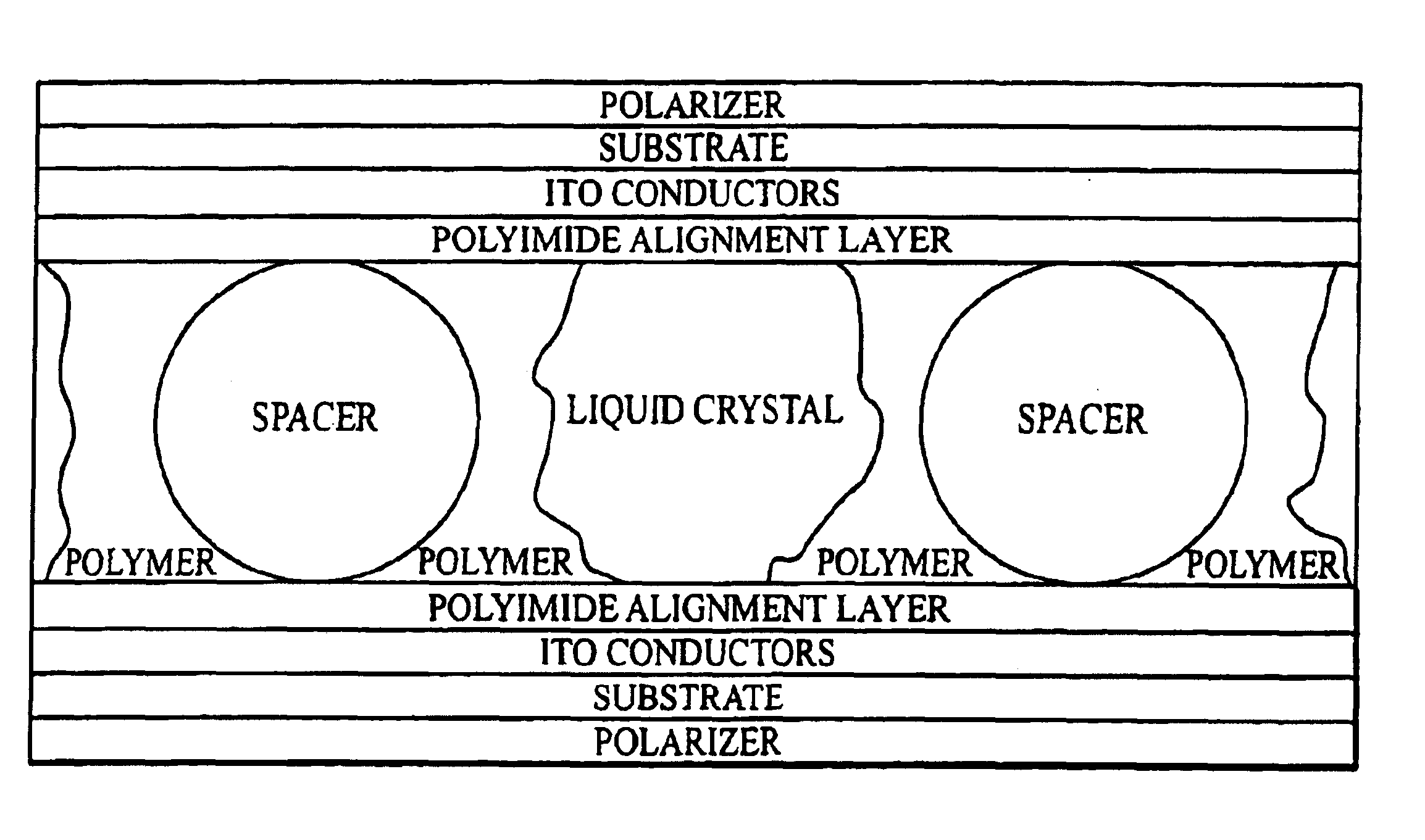

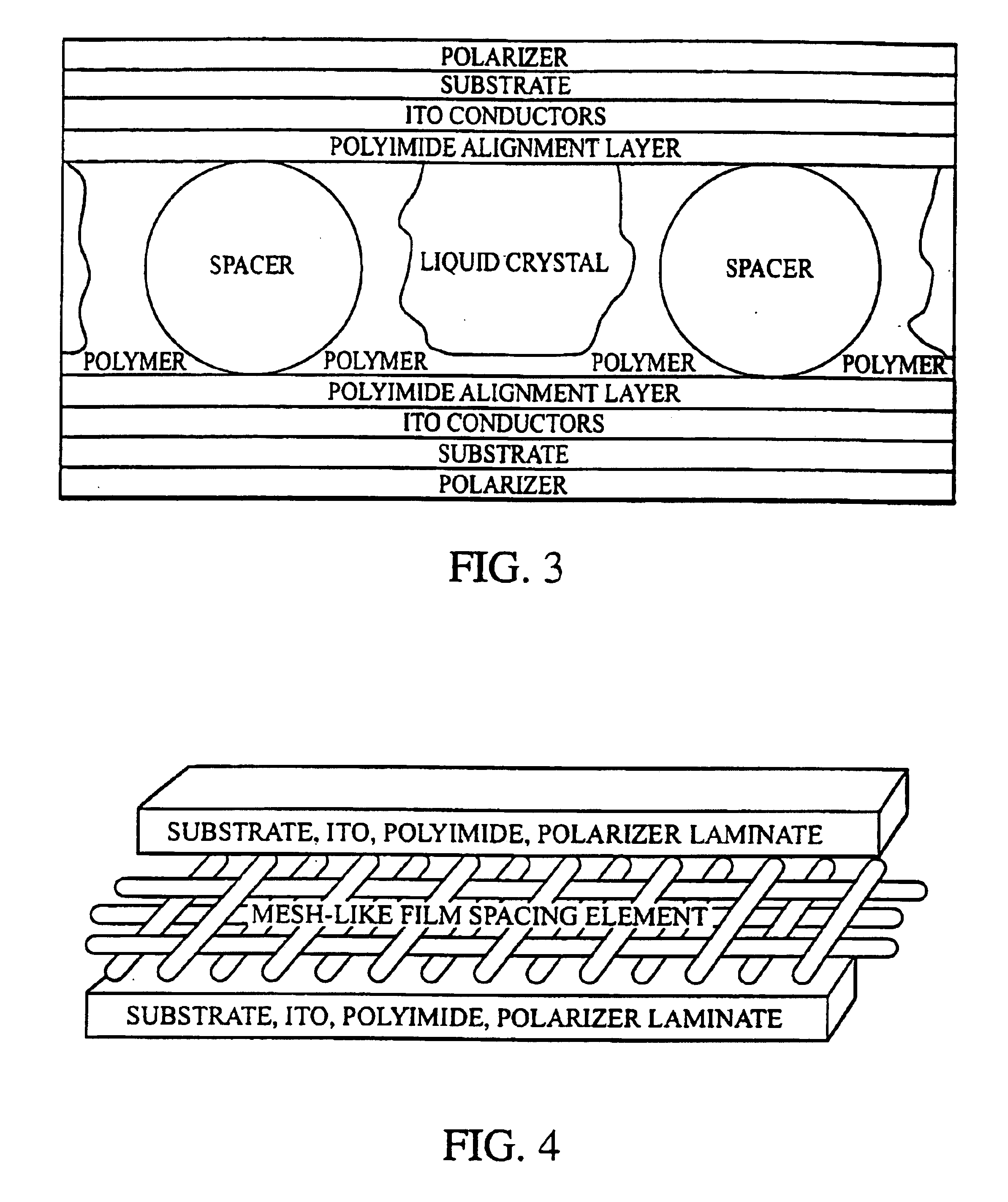

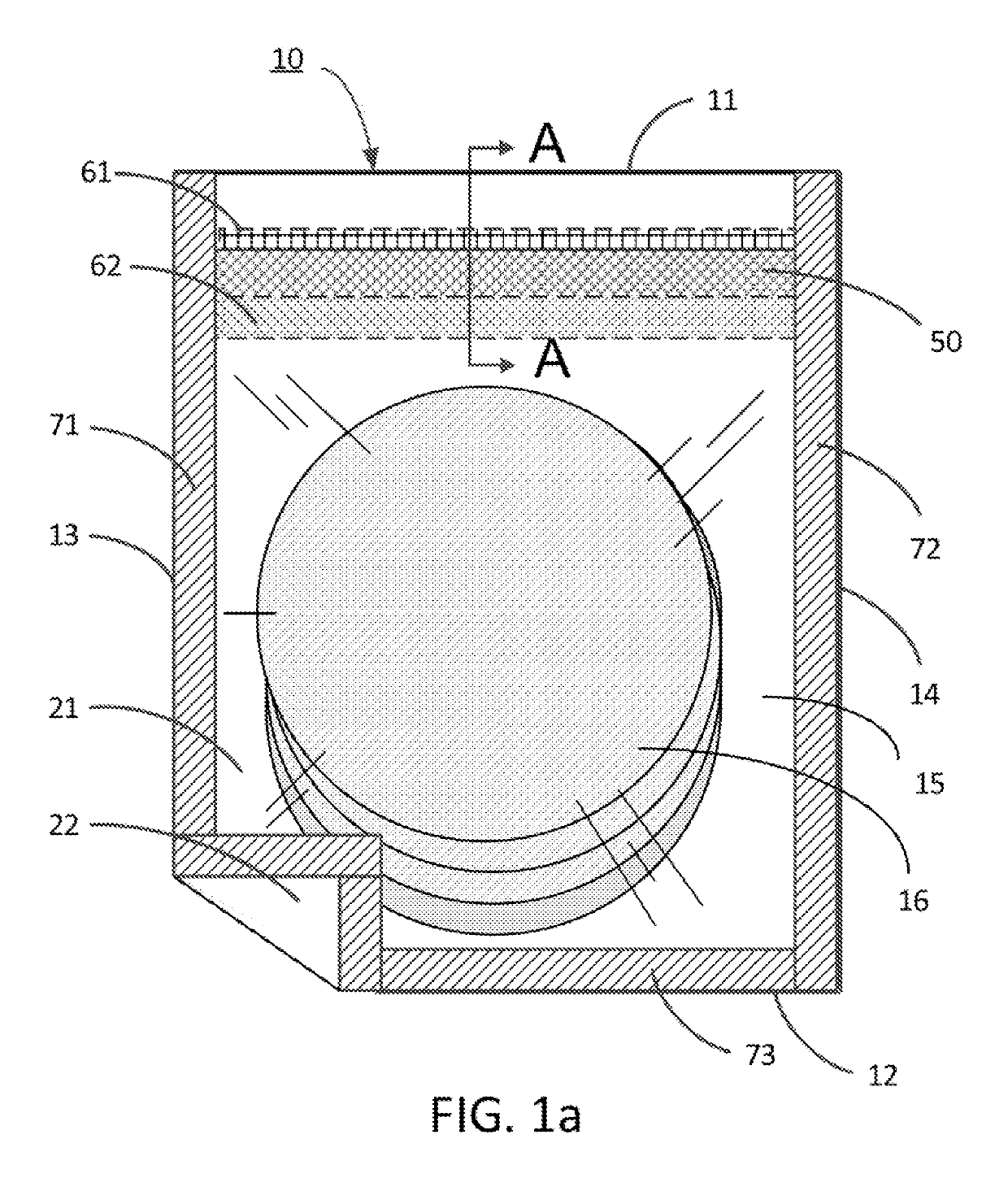

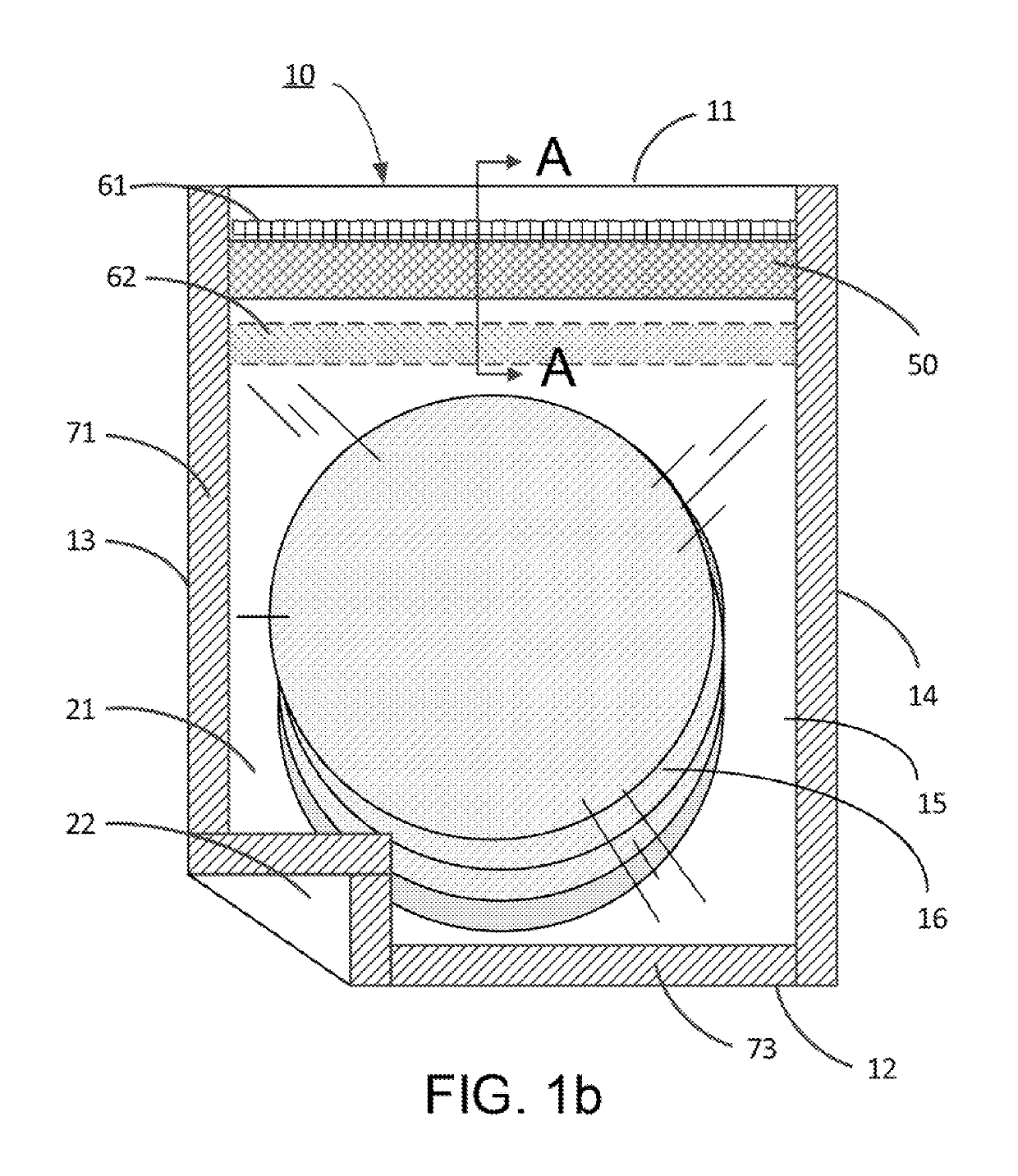

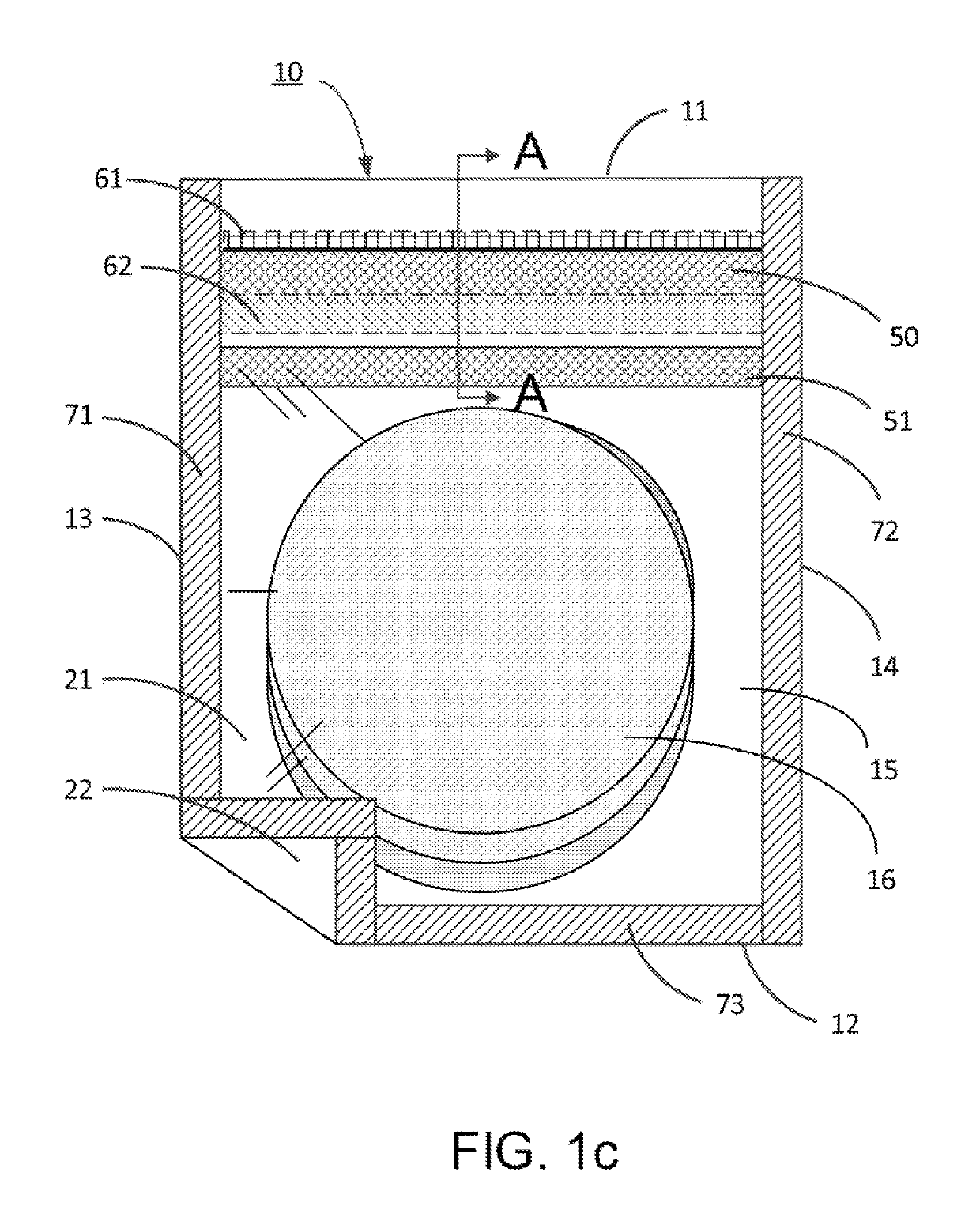

Electrooptical displays with polymer localized in vicinities of substrate spacers

InactiveUS6859249B2Simple structureImprove performanceStatic indicating devicesNon-linear opticsLiquid-crystal displayDisplay device

There is a liquid crystal display device with two substrates facing and spaced from each other, at least one of the substrates being transparent. Electrodes are positioned to establish an electric field in the space between the two substrates. One or more space elements are located between the substrates. One or more polymer supports are located primarily in the vicinities of the spacer elements. The polymer supports extend between the two substrates and have been polymerized in situ in response to polymerization initiating or enhancing (PIE) material carried on or within the spacer elements. Electrooptic-material (e.g., liquid crystal) fills at least a portion of the space between the two substrates.

Owner:SAMSUNG DISPLAY CO LTD

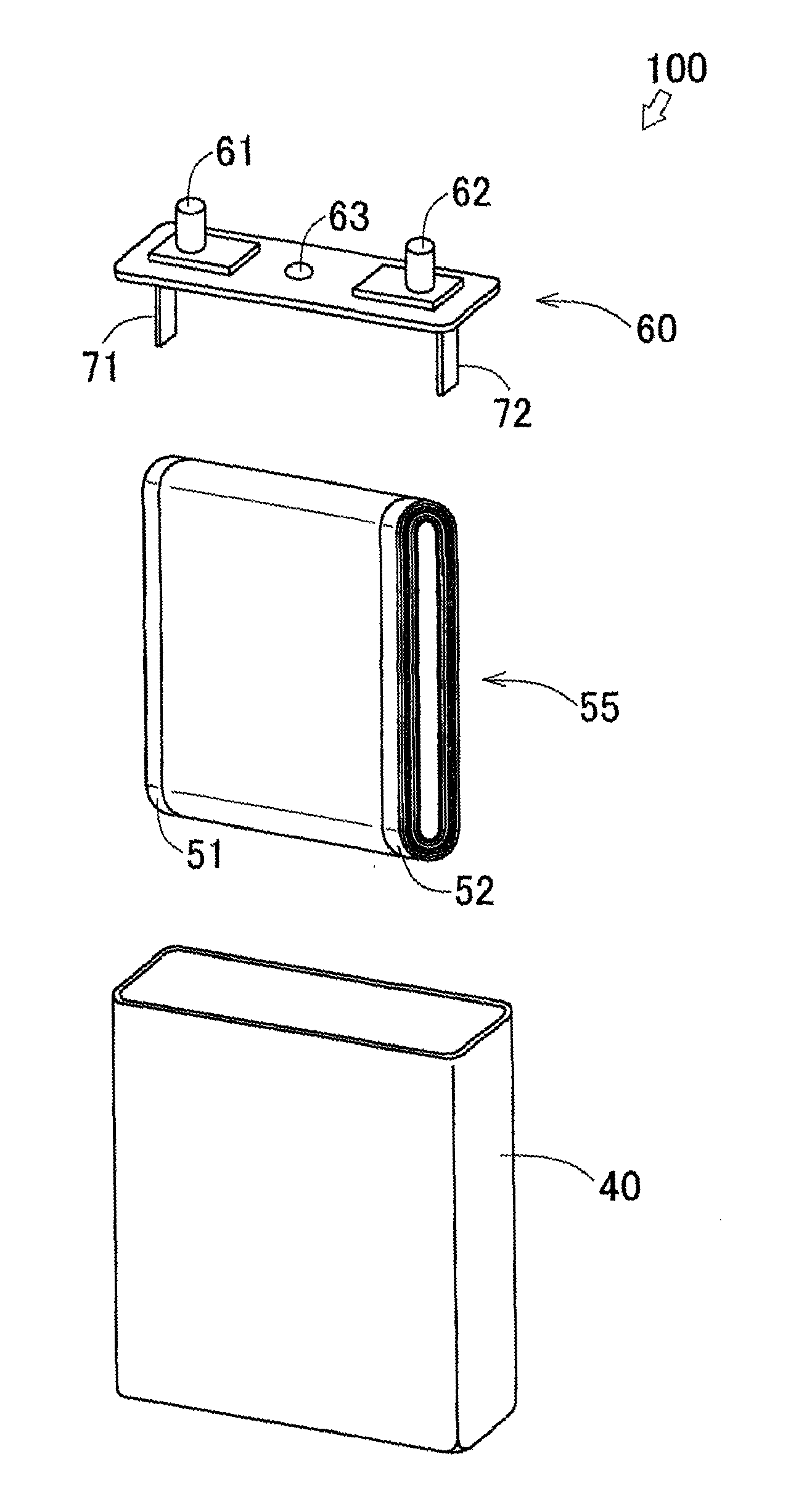

Wafer processing tape, method of manufacturing wafer processing tape, and method of manufacturing semiconductor device

ActiveUS20120094471A1Peel strengthImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

In a wafer processing tape, circular or tongue-shaped notched parts facing the center of an adhesive layer, as seen in a plan view, are formed so as to correspond to a pasting region to a wafer ring to a depth that reaches a release base material from the side of a base material film. Due to the formation of the notched parts, when a peeling force acts on the wafer processing tape, portions of a tacky material layer and the base material film which are more outward than the notched parts are peeled off first, and a portion that is more inward than the notched parts remains on the wafer ring in a protruding state. Accordingly, a peeling strength between the wafer processing tape and the wafer ring can be increased. Methods of manufacturing the tape and a semiconductor device are also provided.

Owner:RESONAC CORP

Copper foil for printed wiring board, method for producing said copper foil, resin substrate for printed wiring board and printed wiring board

ActiveUS9028972B2High bonding strengthGood effectElectrolysis componentsRecord information storageRough surfaceSemiconductor package

A copper foil for a printed wiring board, the copper foil being characterized by having, on at least one surface thereof, a roughed layer of the copper foil in which an average diameter at a particle root (D1) corresponding to a distance of 10% of a particle length from the root, is 0.2 μm to 1.0 μm, and a ratio of the particle length (L1) to the average diameter at the particle root (D1) is 15 or less when L1 / D1. A copper foil for a printed wiring board, wherein a sum of area covered by holes on an uneven and roughened surface of a resin is 20% or more at a surface of the resin formed by laminating the resin and a copper foil for a printed wiring having a roughened layer and then removing the copper layer by etching. An object of the present invention is to develop a copper foil for a semiconductor package board in which the aforementioned phenomenon of circuit erosion is avoided without deteriorating other properties of the copper foil. In particular, an object of the present invention is to provide a copper foil for a printed wiring board and a producing method thereof, wherein a roughened layer of the copper foil can be improved to enhance the adhesiveness between the copper foil and a resin.

Owner:JX NIPPON MINING & METALS CORP

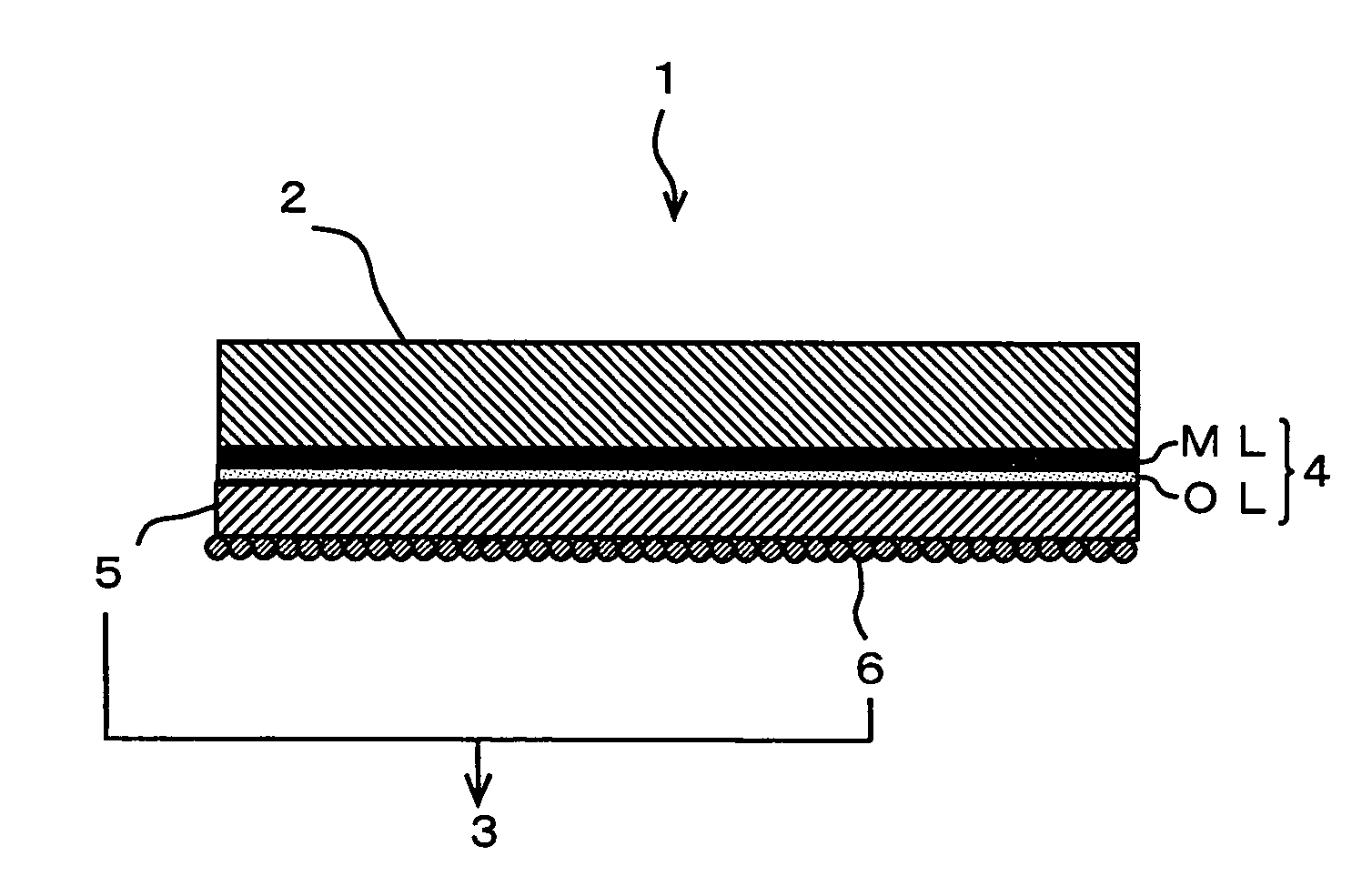

Flexible optical waveguide and process for its production

InactiveUS8155493B2Easy to produceSimple and easy mannerLamination ancillary operationsPretreated surfacesChemical treatmentAdhesive

The invention provides a flexible optical waveguide in which an optical waveguide film is directly formed on a substrate without using an adhesive and which is excellent in flexibility of the optical waveguide film, including the substrate, and excellent in adhesiveness between the substrate and the optical waveguide film, as well as a process for producing the flexible optical waveguide in a simple and easy manner. The flexible optical waveguide includes a lower cladding layer, a core layer, and an upper cladding layer successively formed on a substrate and a surface of the substrate, on which surface the lower cladding layer is to be formed, has an arithmetic average roughness (Ra) of 0.03 μm or higher. The flexible optical waveguide can be produced by subjecting a surface of the substrate, on which surface the lower cladding layer is to be formed, to physical treatment with a whetstone or chemical treatment with a corona discharge and then successively forming the lower cladding layer, the core layer, and the upper cladding layer on the surface of the substrate.

Owner:HITACHI CABLE +1

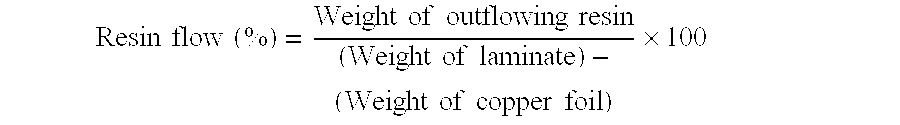

Resin composition, prepreg, resin sheet, and metal foil-clad laminate

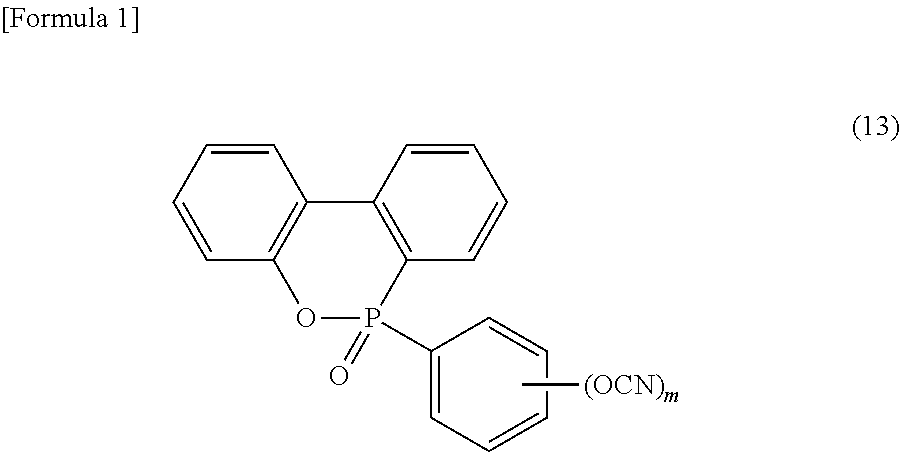

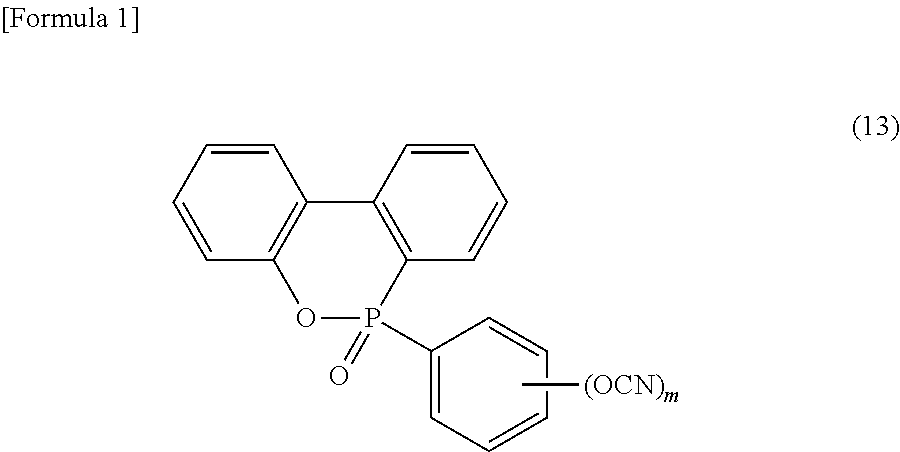

InactiveUS9394439B2Improve flame retardant performanceImprove heat resistancePrinted circuit aspectsSynthetic resin layered productsThermal dilatationPolymer science

A resin composition has high flame retardancy and excellent heat resistance, peel strength with copper foil, thermal expansion coefficient, heat resistance property upon moisture absorption, and electrical properties, a prepreg and single-layer or laminated sheet, a metal foil-clad laminate using the prepreg, and the like. The resin composition has polyphenylene ether (A) having a number average molecular weight of 500 to 5000, a phosphorus-containing cyanate ester compound (B) represented by formula (13), a cyclophosphazene compound (C), a halogen-free epoxy resin (D), a cyanate ester compound (E) other than the phosphorus-containing cyanate ester compound (B), an oligomer (F) of styrene and / or substituted styrene, and a filler (G), wherein a content of the phosphorus-containing cyanate ester compound (B) is 1 to 10 parts by mass based on 100 parts by mass of a total of the (A) to (F) components.wherein m represents an integer of 1 to 3.

Owner:MITSUBISHI GAS CHEM CO INC

Method for manufacturing polyester fabric for airbag

ActiveUS10246800B2Improve adhesion strengthSeparation of the sizing agent during the weaving process can be prevented or minimizedPedestrian/occupant safety arrangementFibre typesYarnPolyester

Disclosed is a method for manufacturing a polyester fabric for an airbag that can not only prevent or minimize the separation of a sizing agent, which is provided to a yarn through a sizing process, during a weaving process, but can also maximize a peel strength between a textile substrate and a coating layer to be subsequently formed thereon and lower the stiffness of an airbag fabric by effectively removing the sizing agent from the textile substrate after the weaving process is completed. The method of the present invention comprises: applying a polyester-based sizing agent to a polyester yarn; manufacturing a textile substrate with the sizing agent-applied polyester yarn; removing the sizing agent from the textile substrate under an alkaline condition of pH 8 to 10; and forming a coating layer on the sizing agent-removed textile substrate in order to enhance air-tightness.

Owner:KOLON IND INC

Portable electronic device and pressure-sensitive adhesive sheet

PendingUS20200148919A1Improve the immunityStrong adhesionSynthetic resin layered productsMacromolecular adhesive additivesPolyesterPolymer science

Provided is a PSA sheet capable of providing reliable adhesion even upon exposure to cosmetics, chemicals and the like containing polar compounds. The PSA sheet provided by this invention has a PSA layer comprising a polyester-based polymer. The PSA sheet has a 180° peel strength of 1 N / 5 mm or greater after ethanol immersion.

Owner:NITTO DENKO CORP

Peelable/resealable package with absorbent strip

ActiveUS10464728B2Easily brokenReadily manually peeled apartSynthetic resin layered productsContainers preventing decayAdhesiveEngineering

The present invention is directed to flexible peelable / reseatable packages uniquely well suited for packaging convenience foods such as processed meats, cheeses and the like. The packages include a peelable / resealable interface formed from a pressure sensitive adhesive (PSA) which permit the packages to be re-sealed after their initial opening. There is also an absorbent non-woven strip which is inserted between the first and second wall panels near the PSA interface. During the opening of the package when the wall panels are forced apart in opposite directions, the absorbent non-woven strip cohesively ruptures and at least a portion of the strip remains bonded to each wall panel after the package has been opened. The absorbent non-woven strip absorbs water and / or fats, grease and oils from the food products before these materials can contaminate the PSA interface.

Owner:BEMIS COMPANY INC

Wafer processing tape, method of manufacturing wafer processing tape, and method of manufacturing semiconductor device

ActiveUS9076832B2Improve peel forcePeel strengthSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

In a wafer processing tape, circular or tongue-shaped notched parts facing the center of an adhesive layer, as seen in a plan view, are formed so as to correspond to a pasting region to a wafer ring to a depth that reaches a release base material from the side of a base material film. Due to the formation of the notched parts, when a peeling force acts on the wafer processing tape, portions of a tacky material layer and the base material film which are more outward than the notched parts are peeled off first, and a portion that is more inward than the notched parts remains on the wafer ring in a protruding state. Accordingly, a peeling strength between the wafer processing tape and the wafer ring can be increased. Methods of manufacturing the tape and a semiconductor device are also provided.

Owner:RESONAC CORPORATION

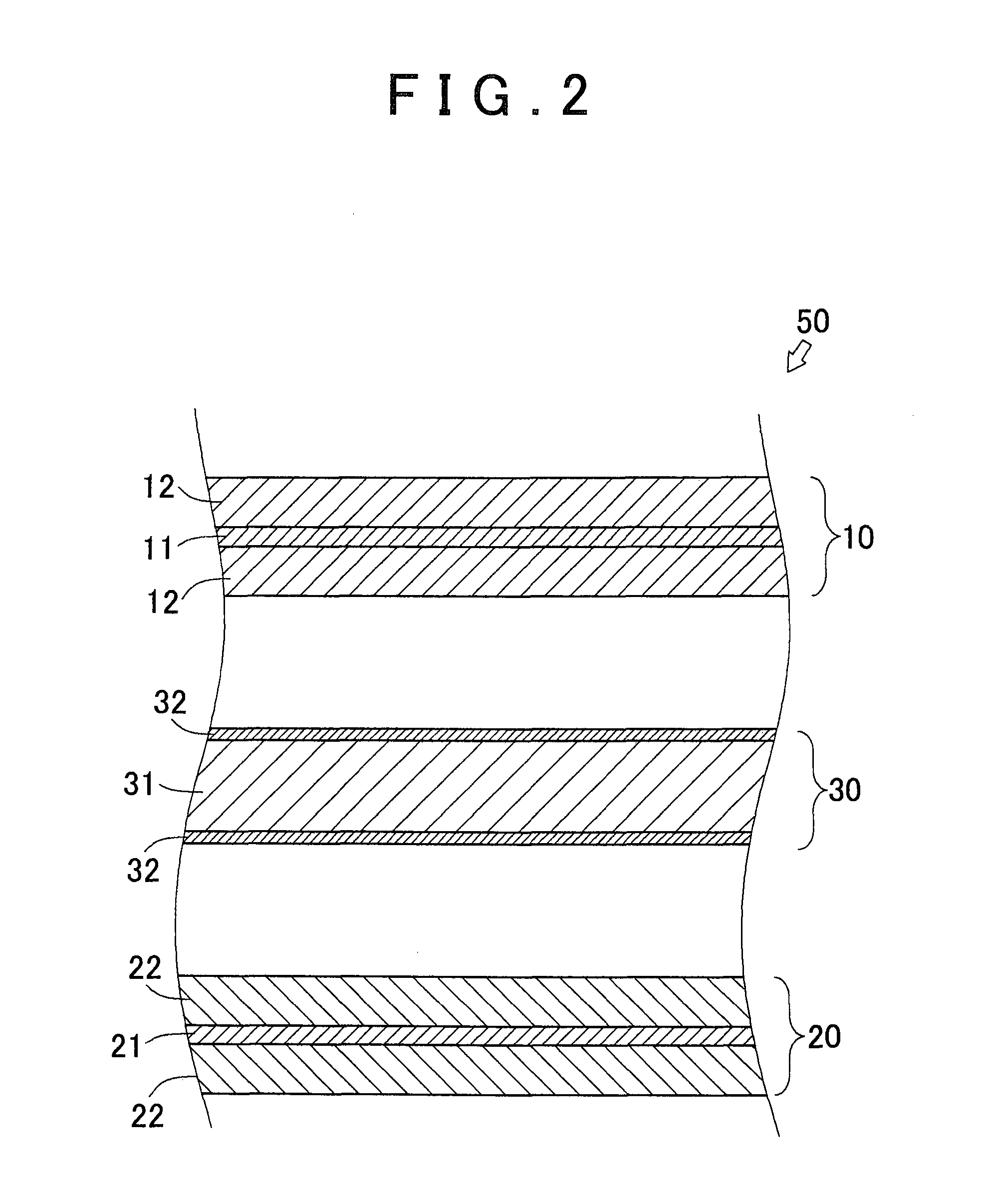

Nonaqueous electrolyte secondary battery and method of manufacturing nonaqueous electrolyte secondary battery

InactiveUS20150162640A1High porosityDeterioration of characteristicElectrode manufacturing processesFinal product manufactureAqueous solutionViscosity

A nonaqueous electrolyte secondary battery includes a positive electrode, a negative electrode having, on a surface thereof, a negative electrode mixture layer containing a negative electrode active material, a thickening agent and a binder, and a separator. The positive electrode and the negative electrode are coiled together with the separator therebetween. The negative electrode active material has an average particle size of at least 5 μm and not more than 20 μm and has a fines content, defined as the cumulative frequency of the negative electrode active material having a particle size of 3 μm or less, of at least 10% and not more than 50%. The thickening agent has a 1.0% aqueous solution viscosity of at least 4,980 mPa·s. The negative electrode mixture layer is in an unpressed state.

Owner:TOYOTA JIDOSHA KK

Multilayer structure and packaging material including same

ActiveUS10406787B2Maintain good propertiesImprove interlayer adhesionFlexible coversWrappersWater vaporOrganic phosphorus

The present invention provides a novel multilayer structure having good gas barrier properties and good water vapor barrier properties and further having high retort resistance and a packaging material including the multilayer structure. The present invention relates to a multilayer structure including a base (X) and a layer (Y) stacked on the base (X). The layer (Y) contains an aluminum-containing compound (A) and an organic phosphorus compound (BO), and the organic phosphorus compound (BO) contains a phosphorus atom-containing functional group and at least one metal ion (Z) selected from ions of metals of Groups 1 to 12 of the periodic table, the content of the metal ion (Z) being 0.4 to 8.0 mol % relative to the content of the phosphorus atom-containing functional group.

Owner:KURARAY CO LTD

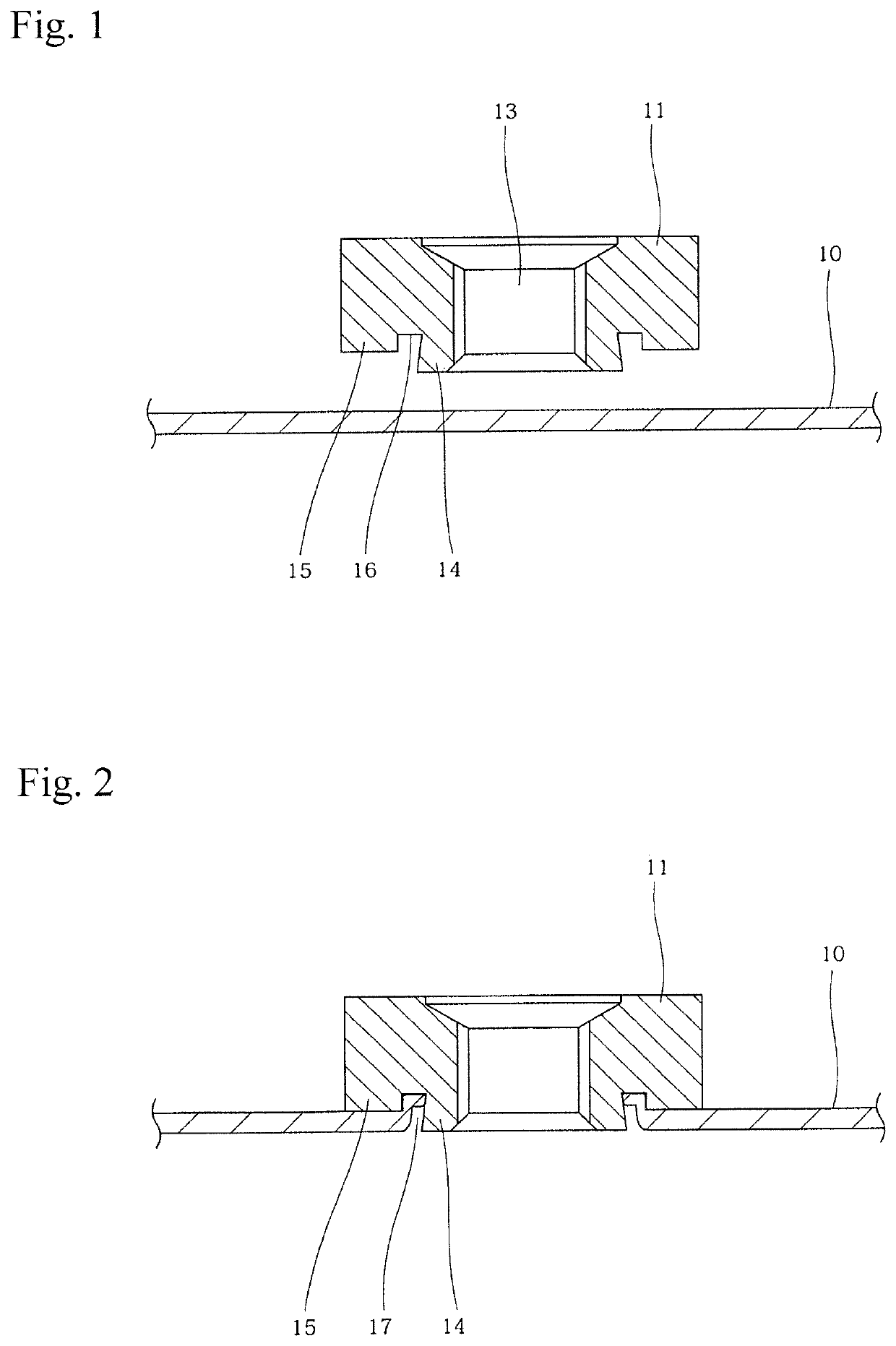

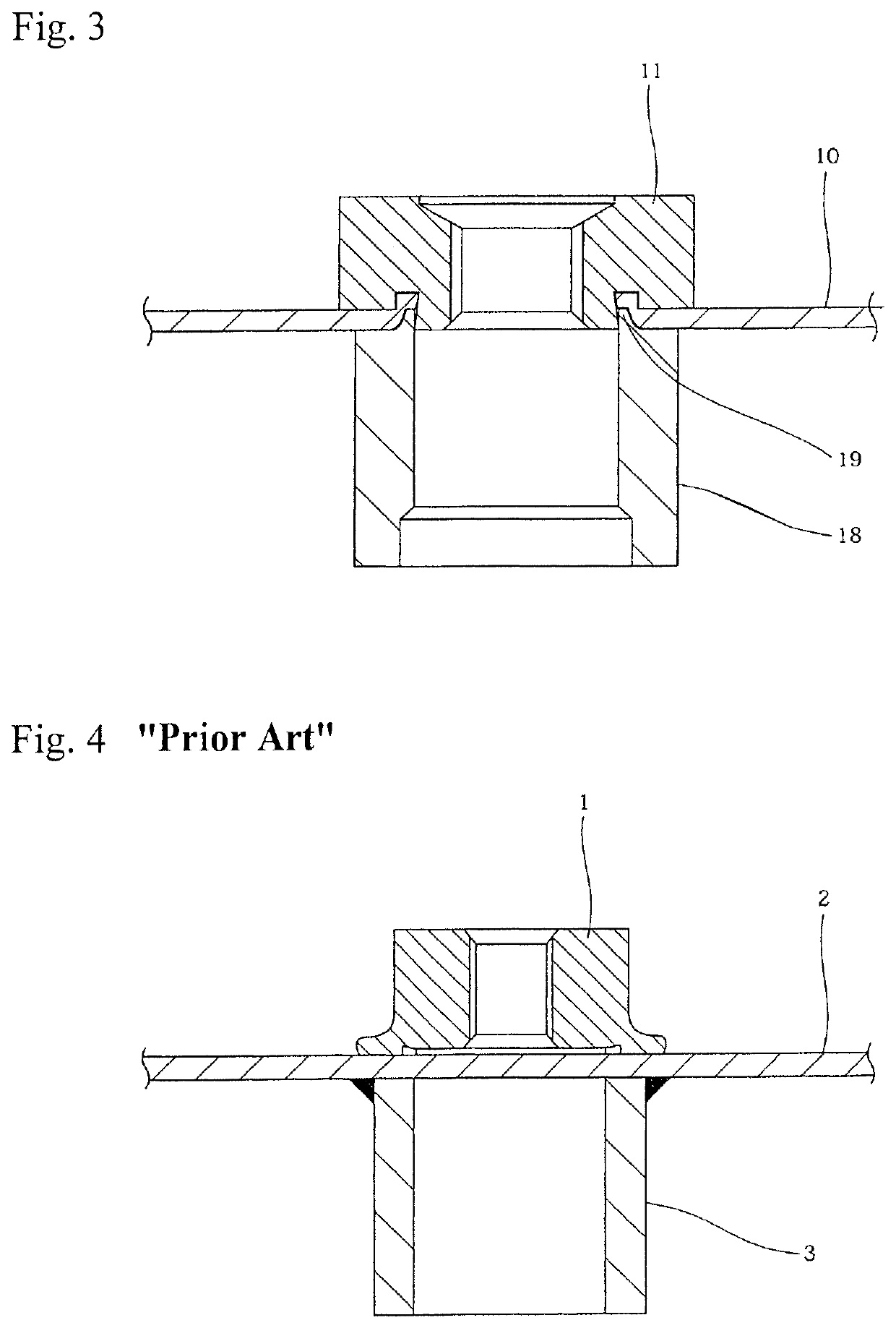

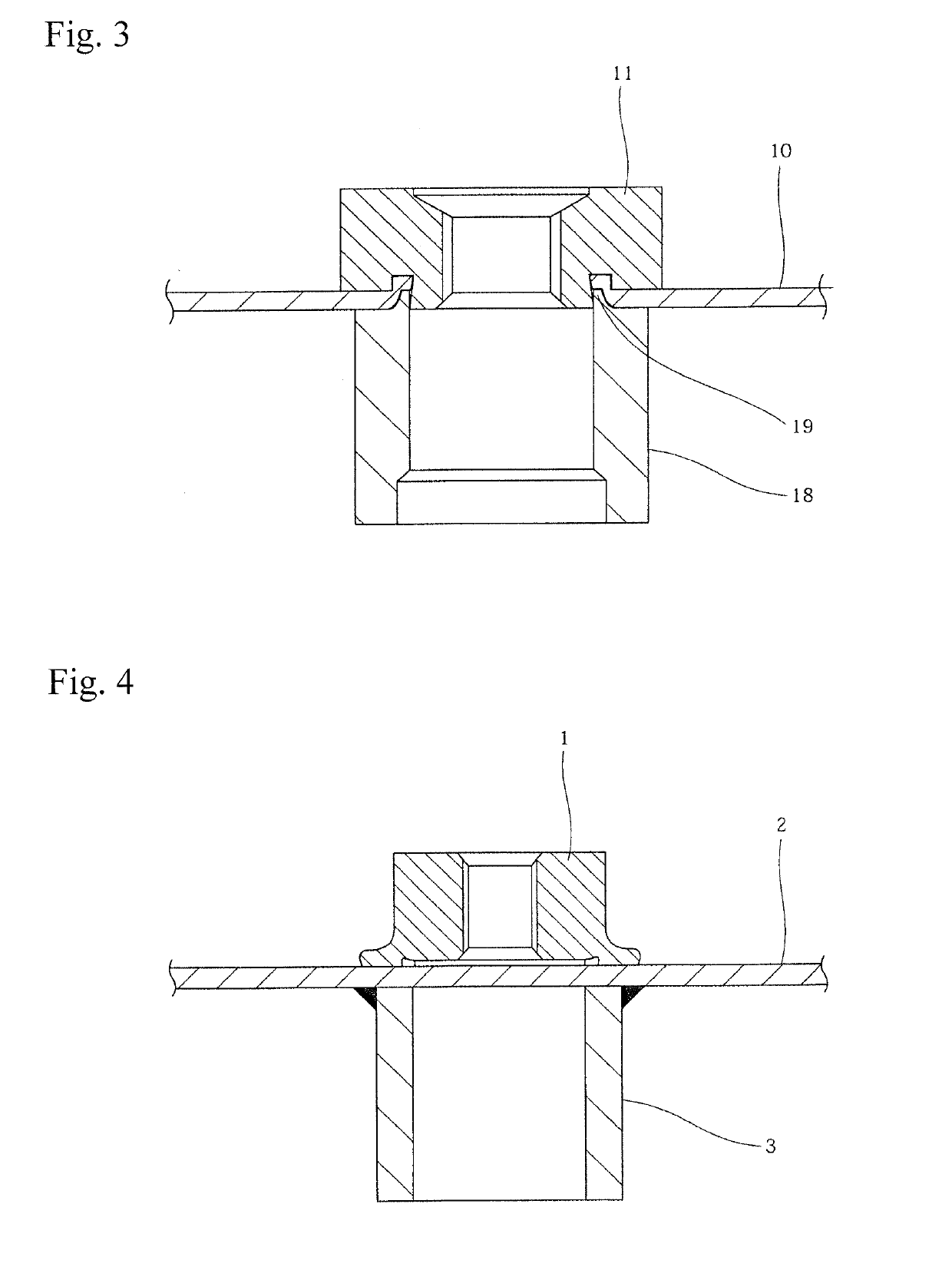

Method for attaching nut and collar to plate material and attachment structure of nut and collar to plate material

ActiveUS11015630B2Peel strengthImprove adhesion strengthMaterial gluingNutsMechanical engineeringThermal strain

A nut is caulked and fixed to a plate material and a protrusion at an end of a collar is press-fitted into a recessed groove generated on the opposite surface of the plate material at the time of the caulking fixation, thereby fixing the nut and the collar to both surfaces of the plate material, respectively. The plate material is, for example, a metal panel, and the nut is, for example, a pierce nut. Since the collar is caulked and fixed, thermal strain is not generated.

Owner:AOYAMA SEISAKUSHO CO LTD +1

Multilayer structure, packaging material and product including same, and protective sheet for electronic device

ActiveUS10479055B2Maintain good propertiesImprove interlayer adhesionFlexible coversWrappersEtherOrganic phosphorus

Owner:KURARAY CO LTD

Method for attaching nut and collar to plate material and attachment structure of nut and collar to plate material

ActiveUS20190226514A1Peel strengthImprove adhesion strengthMaterial gluingNutsEngineeringShaft collar

A nut is caulked and fixed to a plate material and a protrusion at an end of a collar is press-fitted into a recessed groove generated on the opposite surface of the plate material at the time of the caulking fixation, thereby fixing the nut and the collar to both surfaces of the plate material, respectively. The plate material is, for example, a metal panel, and the nut is, for example, a pierce nut. Since the collar is caulked and fixed, thermal strain is not generated.

Owner:AOYAMA SEISAKUSHO CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com