Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3999results about "Material gluing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

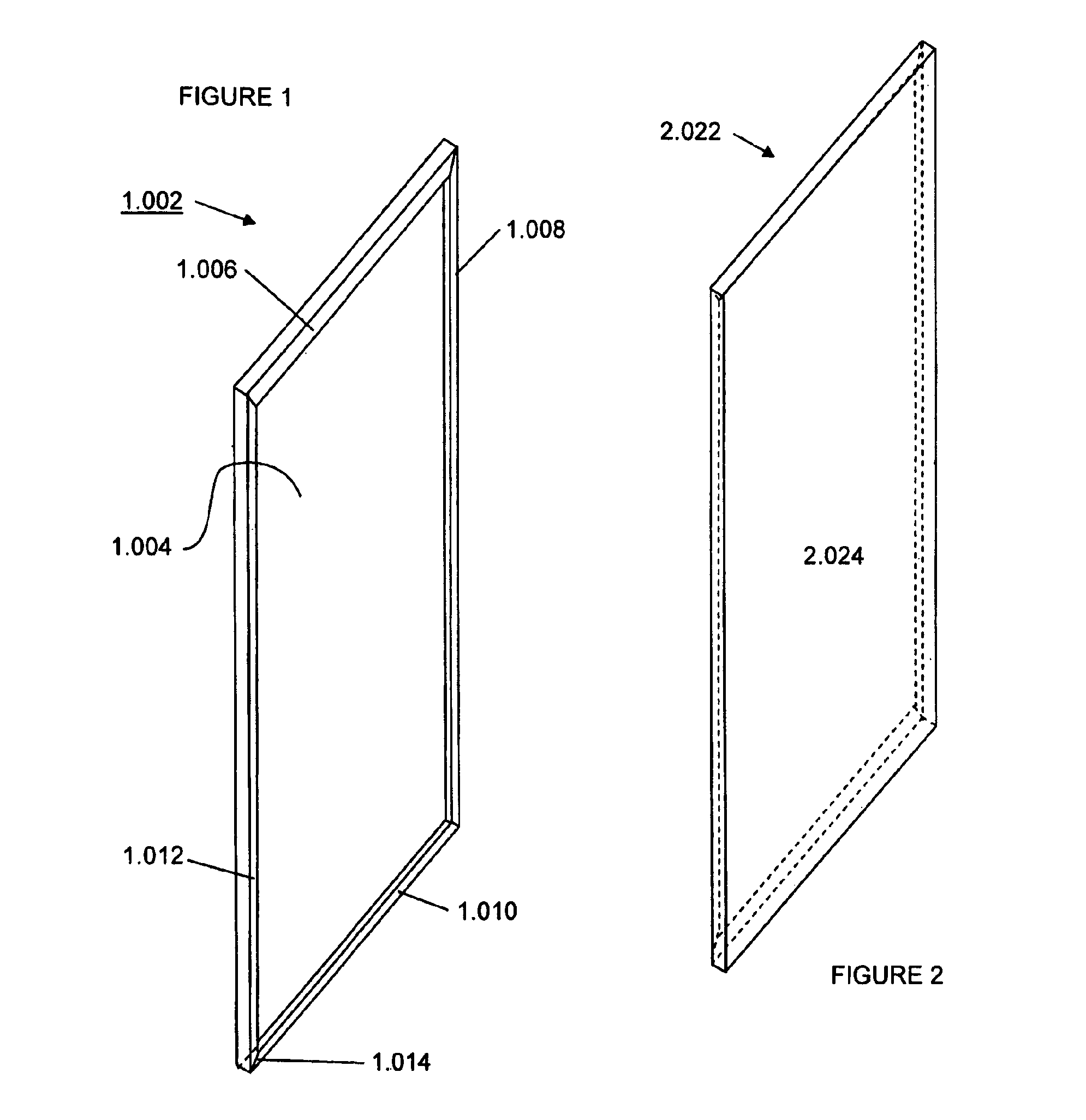

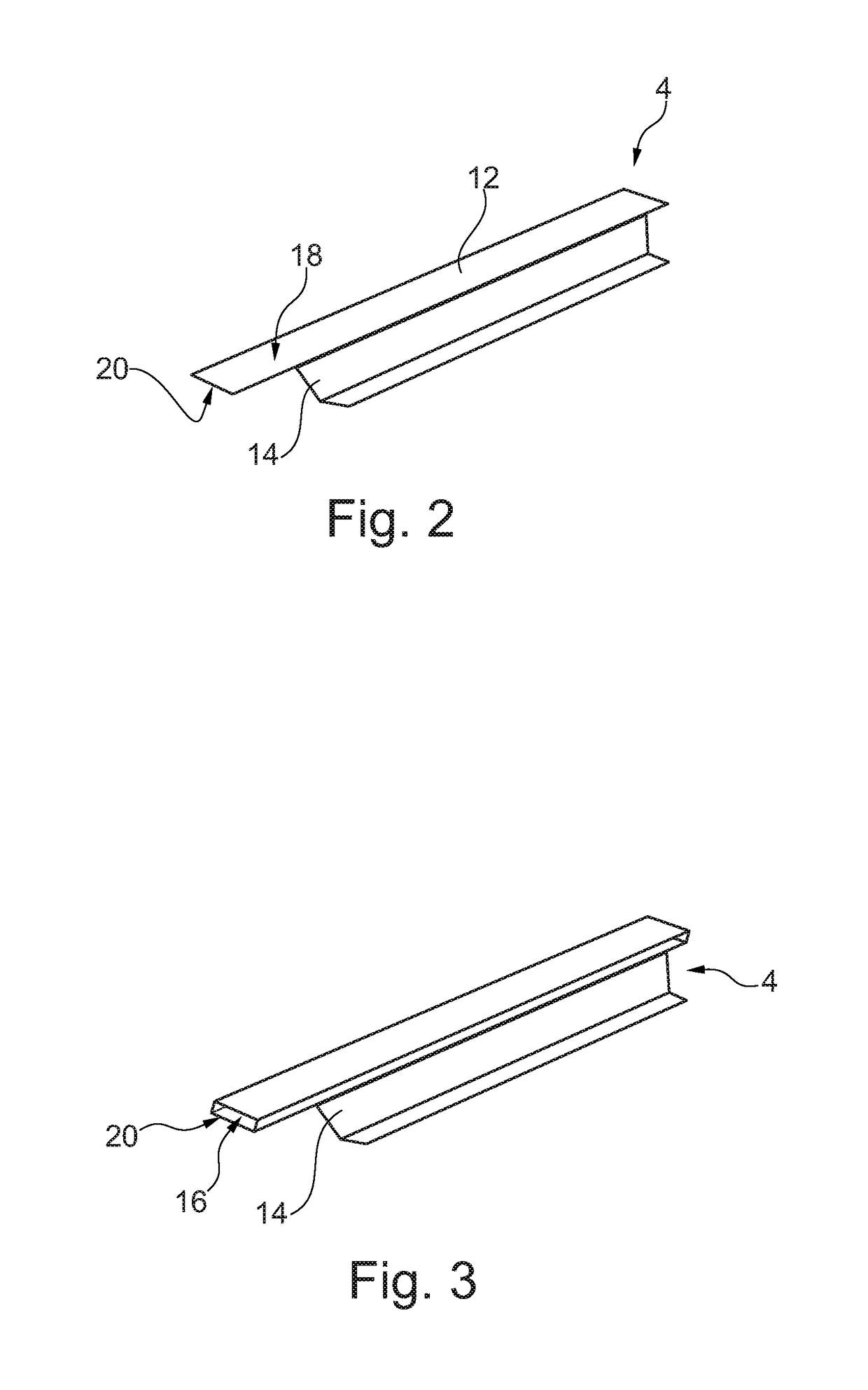

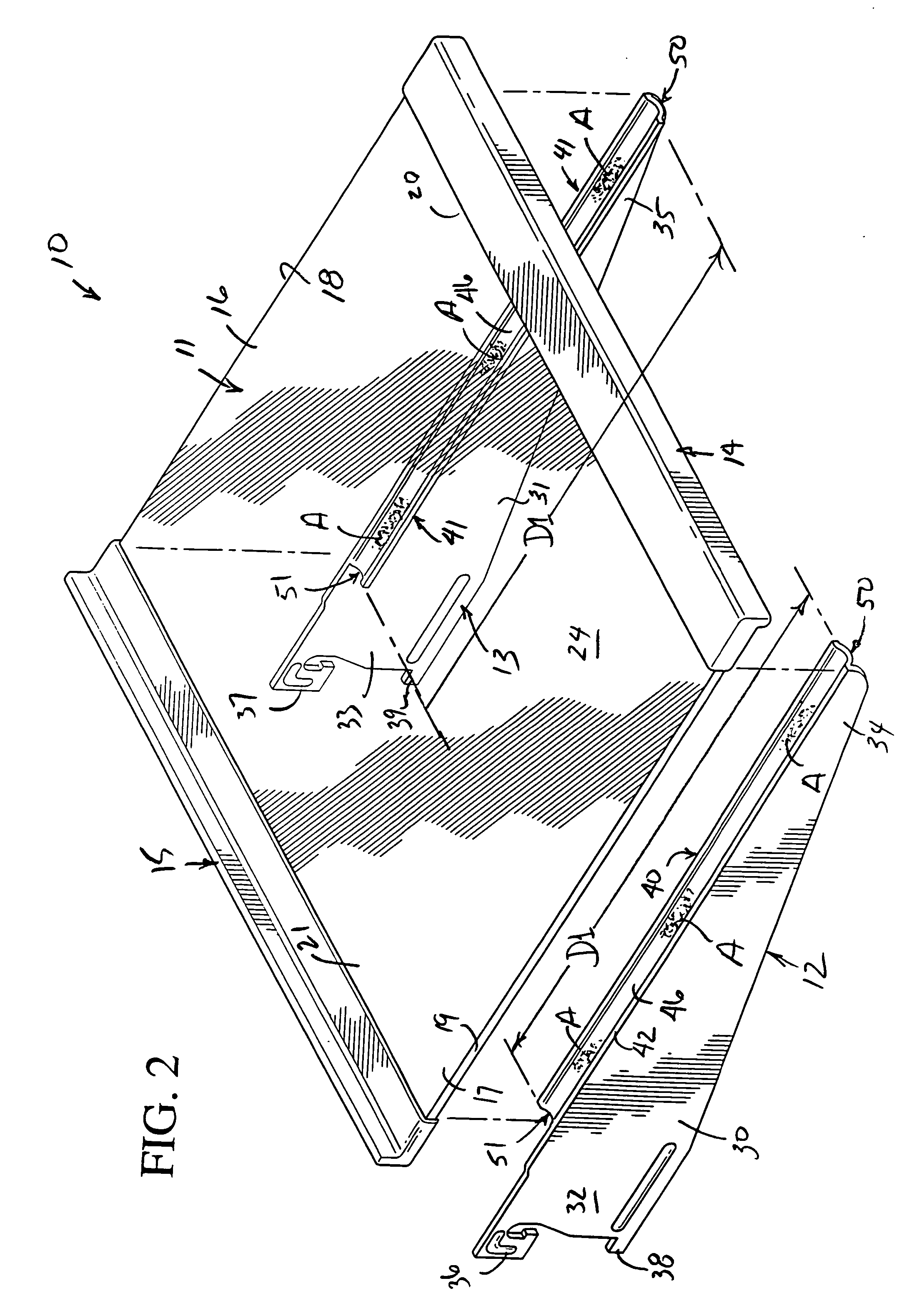

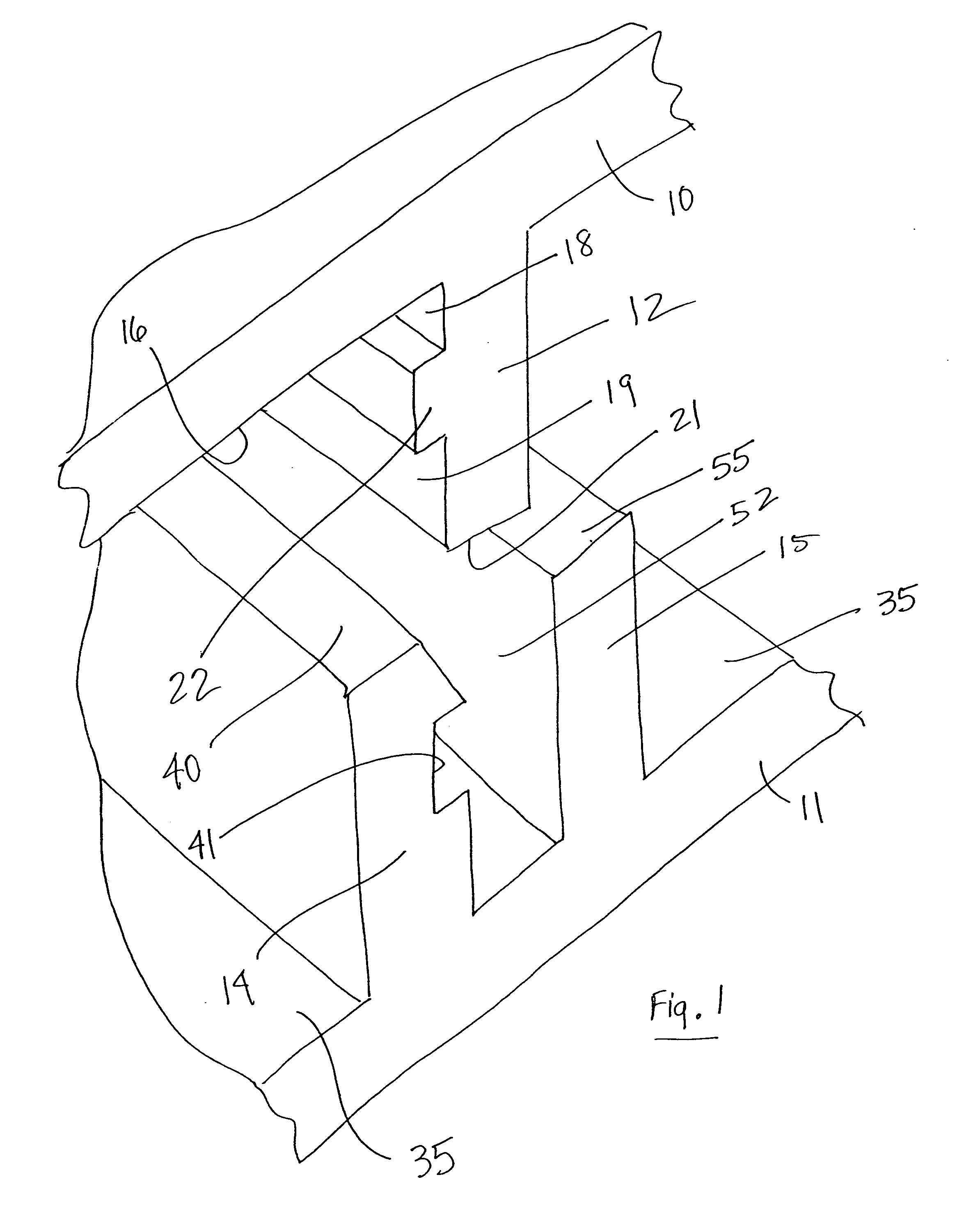

Flooring panel with first and second decorative surfaces

A flooring panel for a flooring system comprises a core interposed between a first decorative surface and a second decorative surface. The core has opposing first and second side surfaces extending substantially perpendicular to the first and second decorative surfaces. The first and second decorative surfaces have different visible designs, and at least the first side surface is provided with at least a portion of a locking member.

Owner:ARMSTRONG WORLD INDUSTRIES

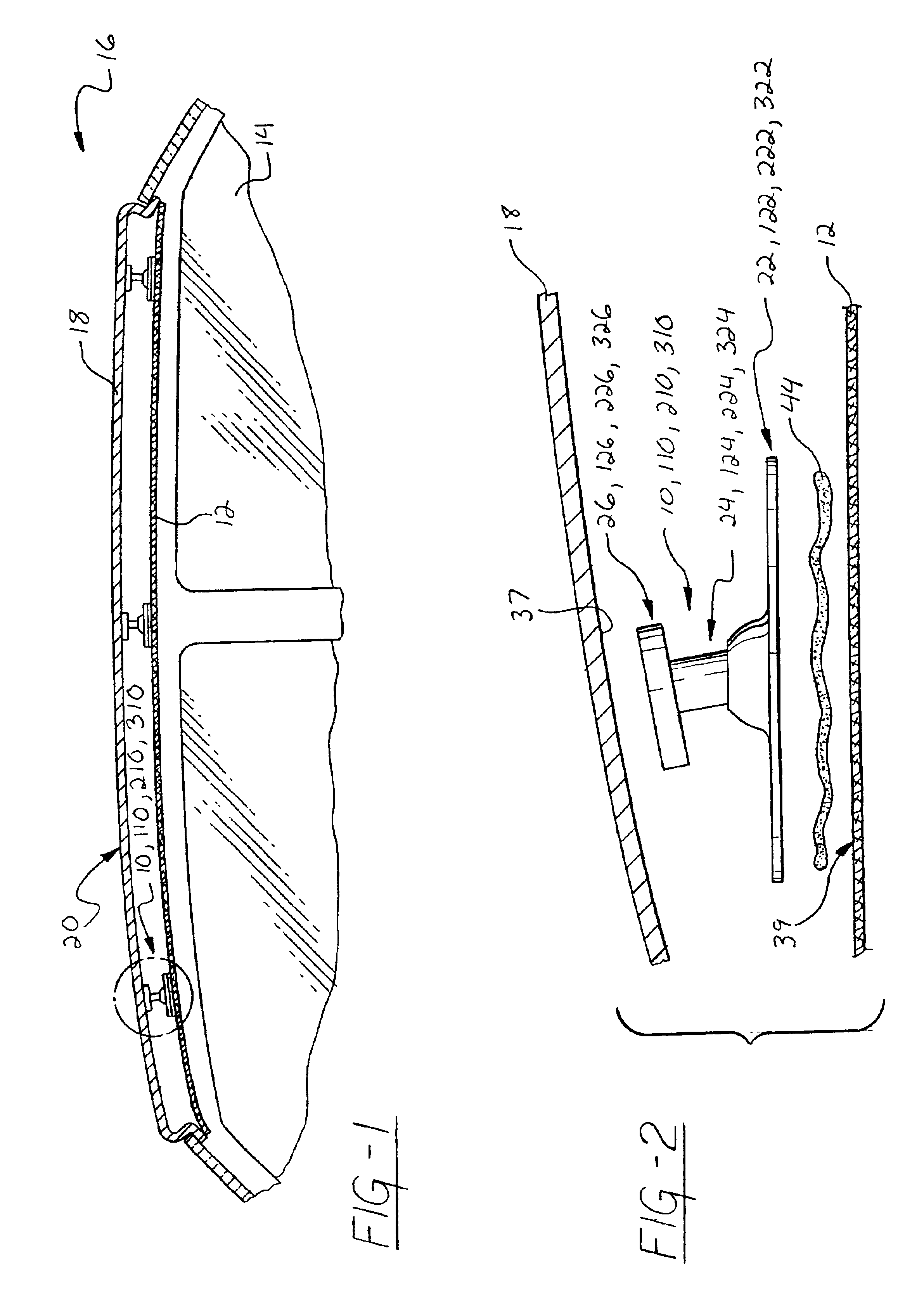

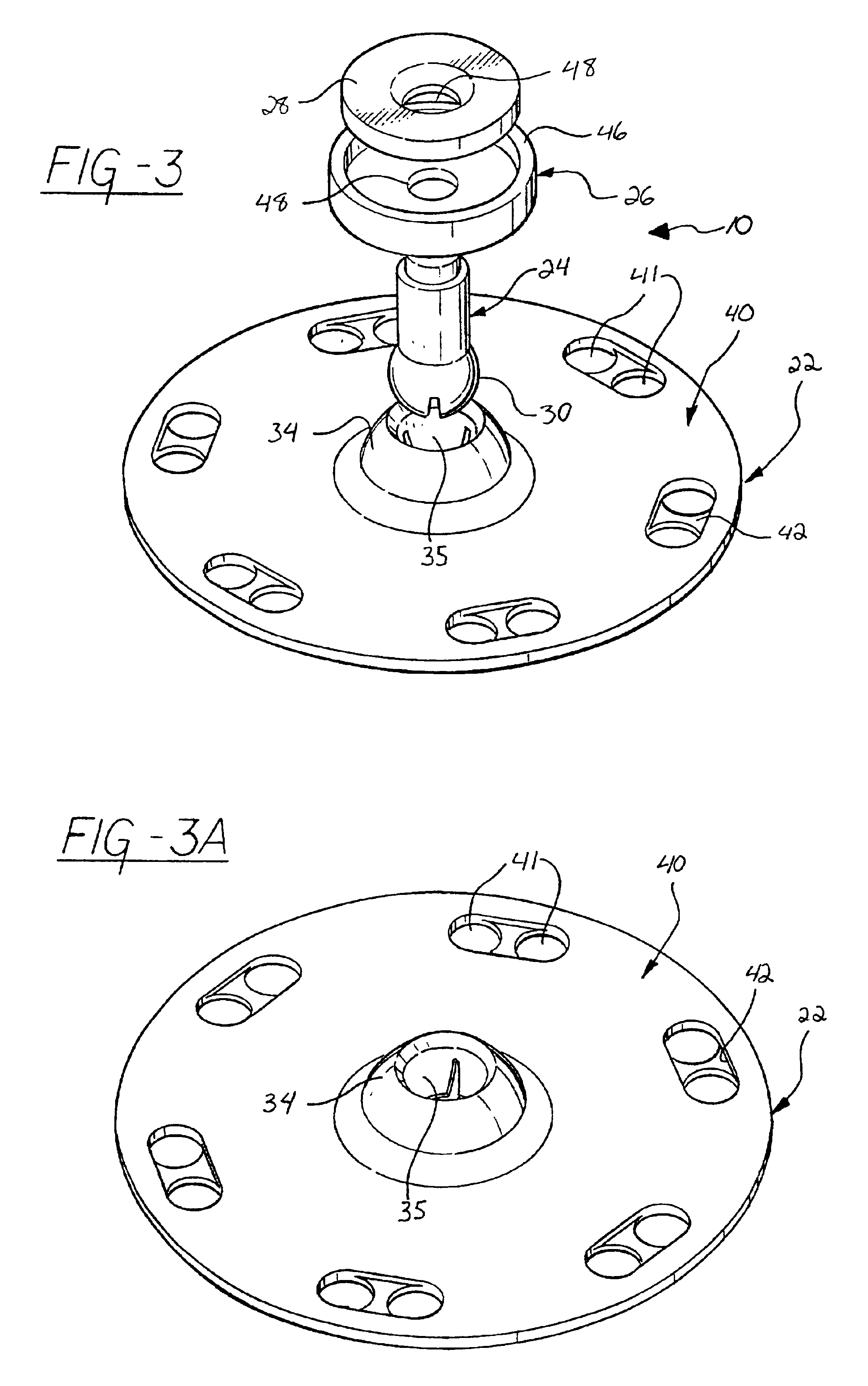

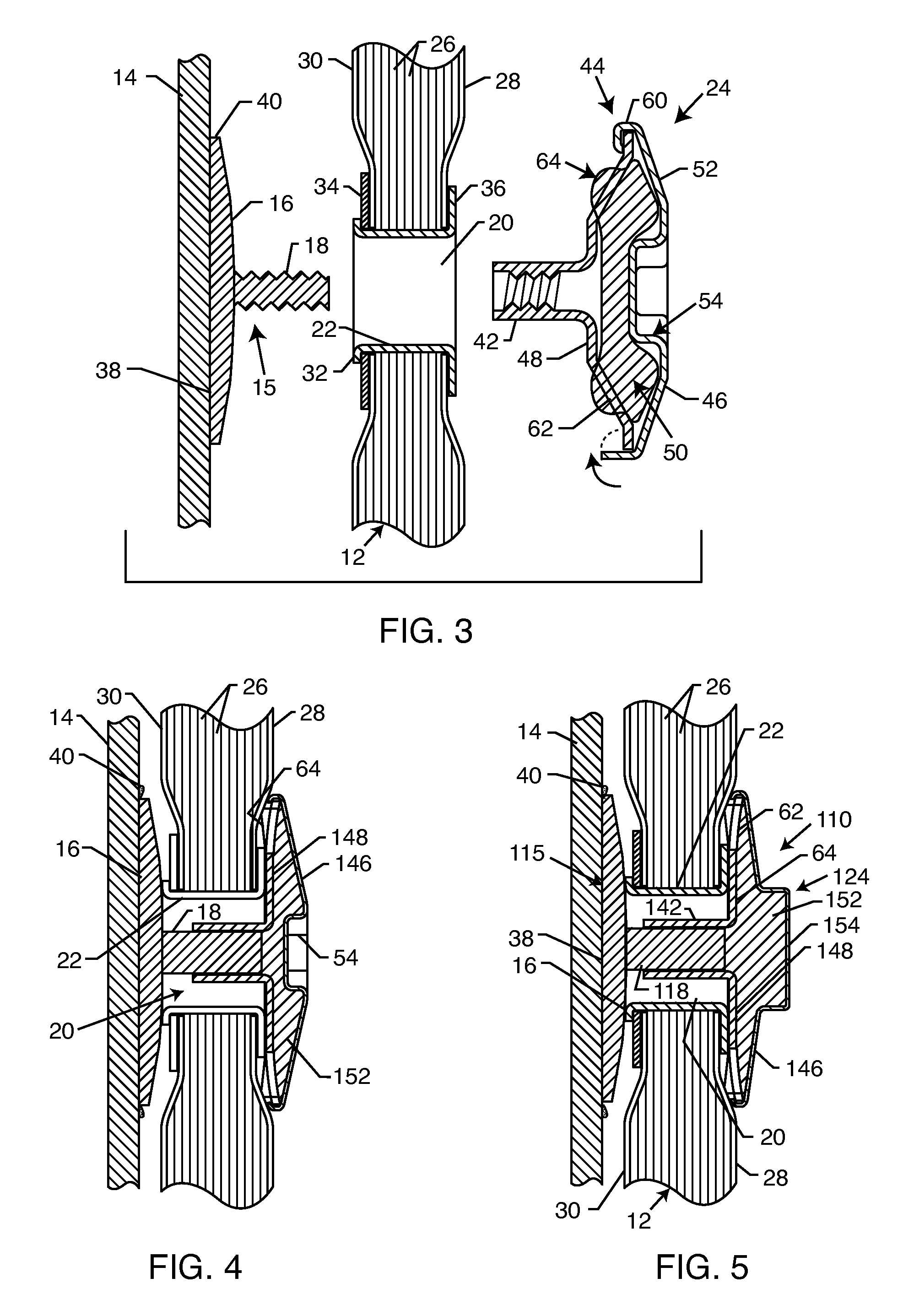

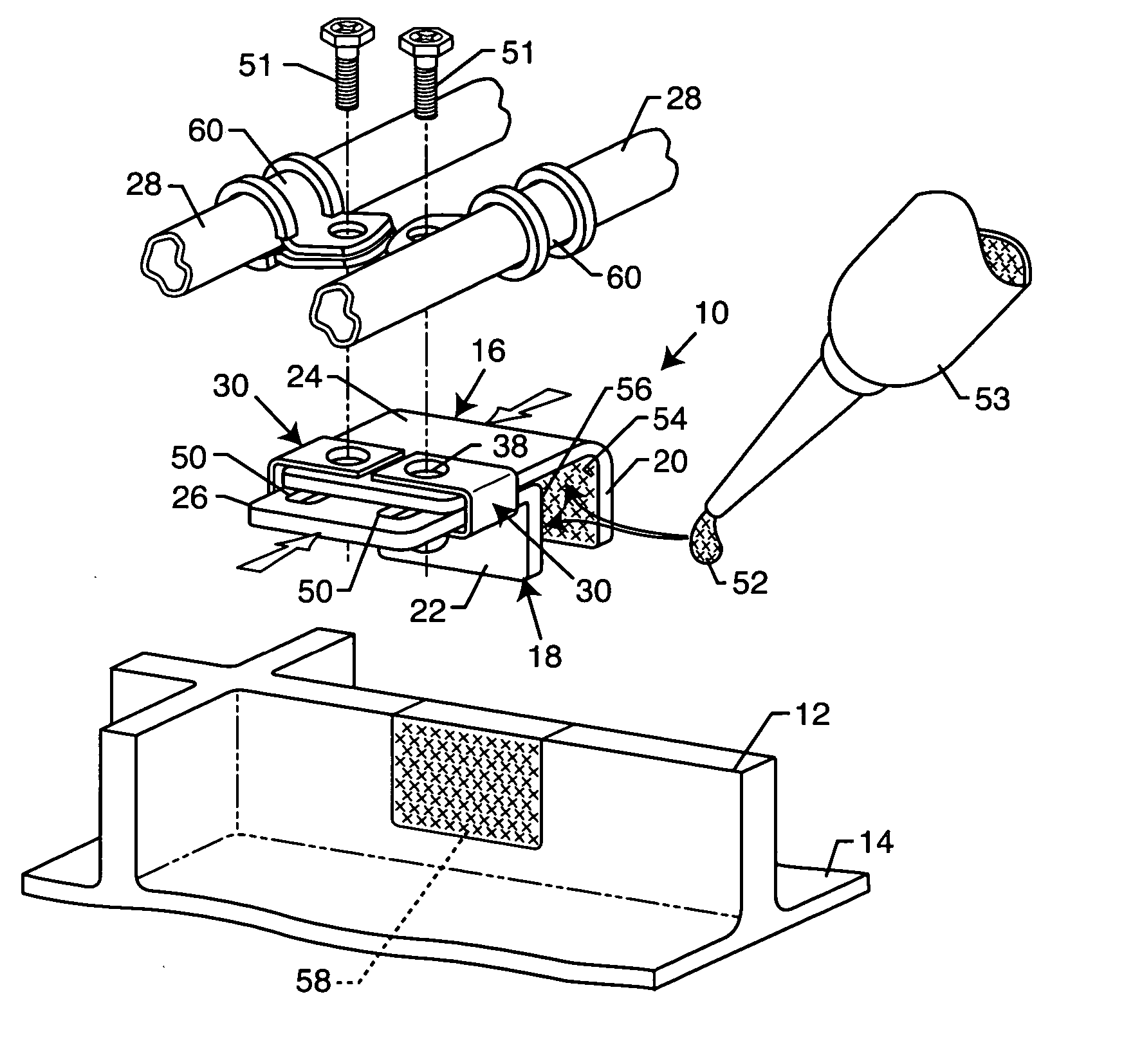

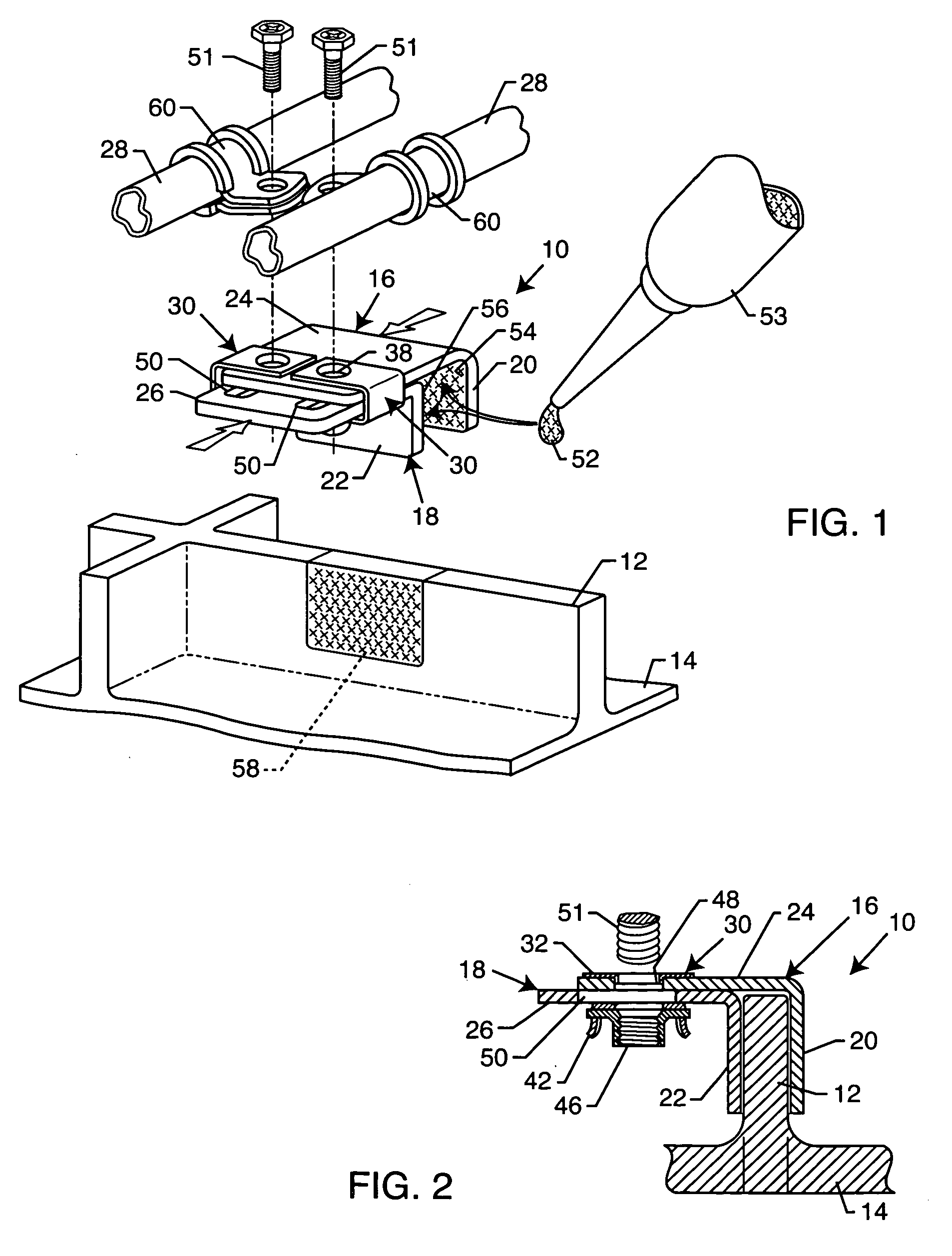

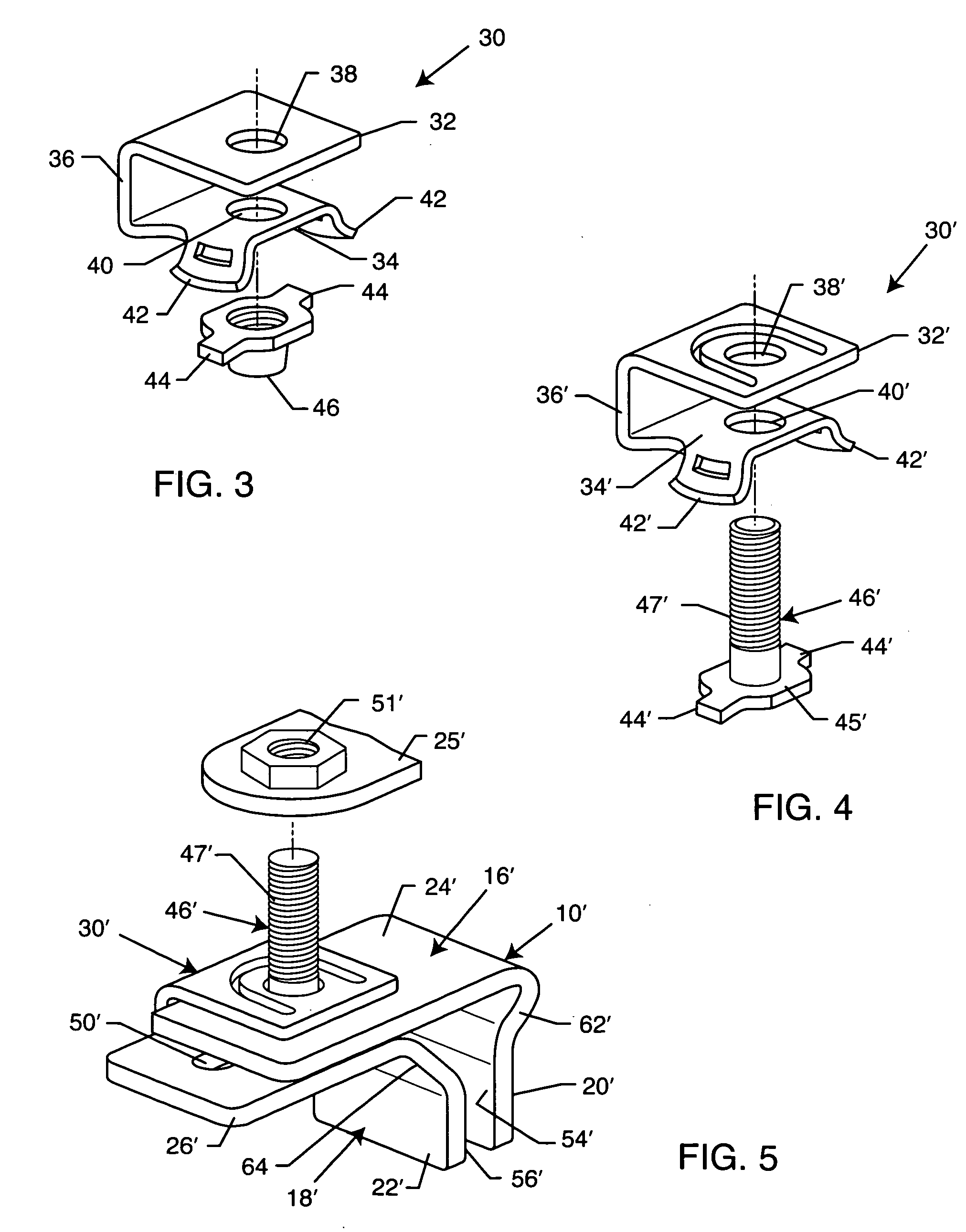

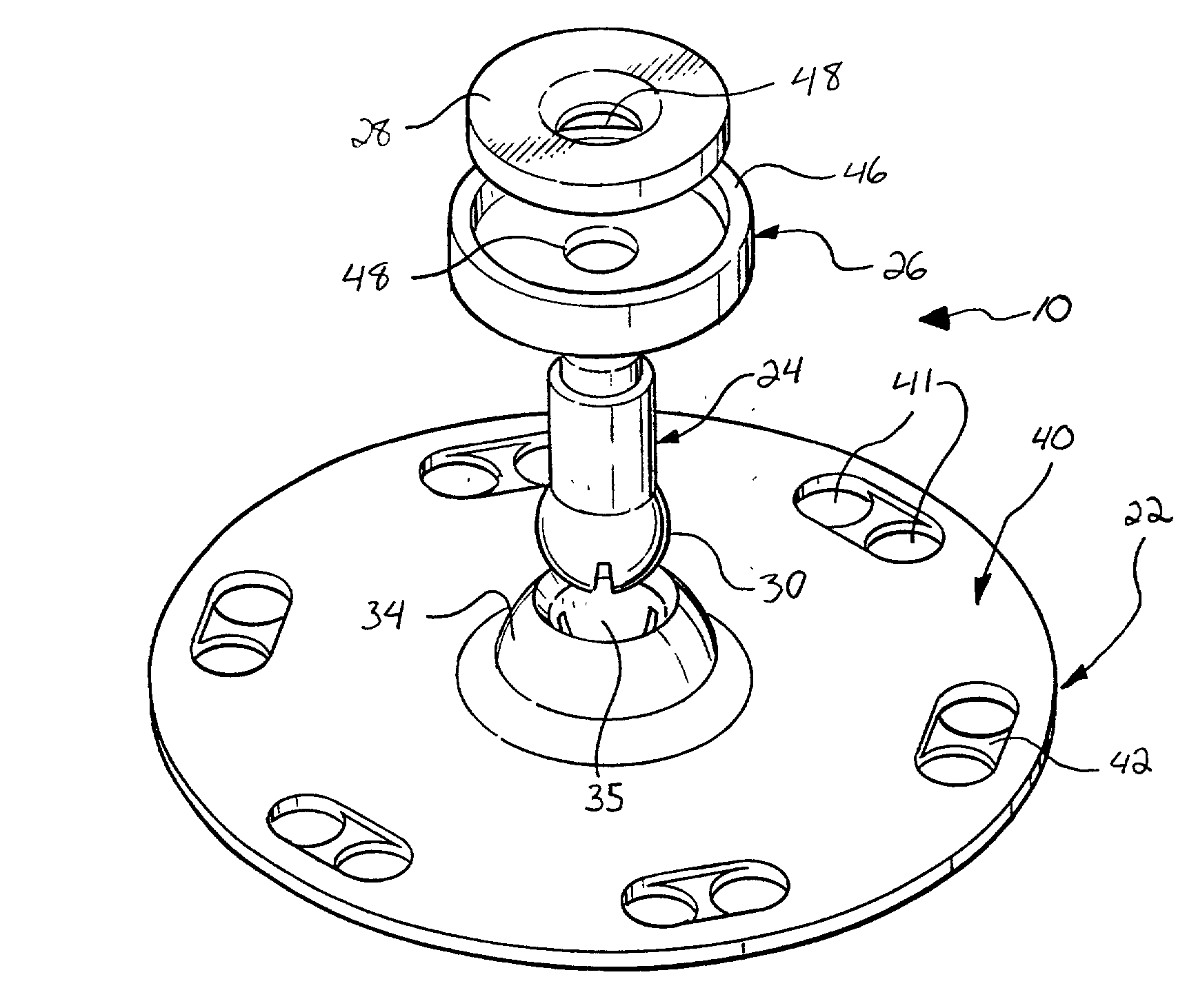

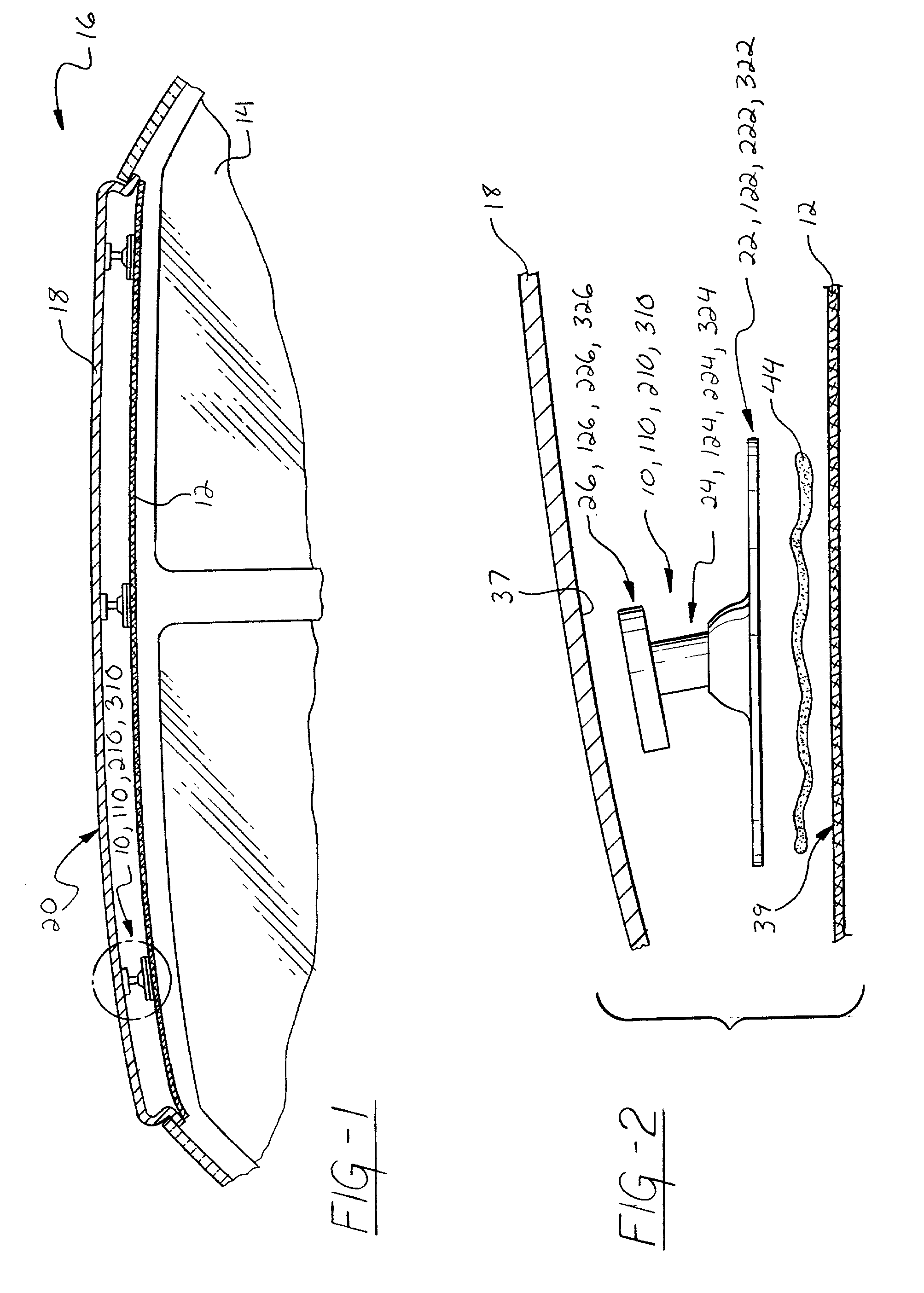

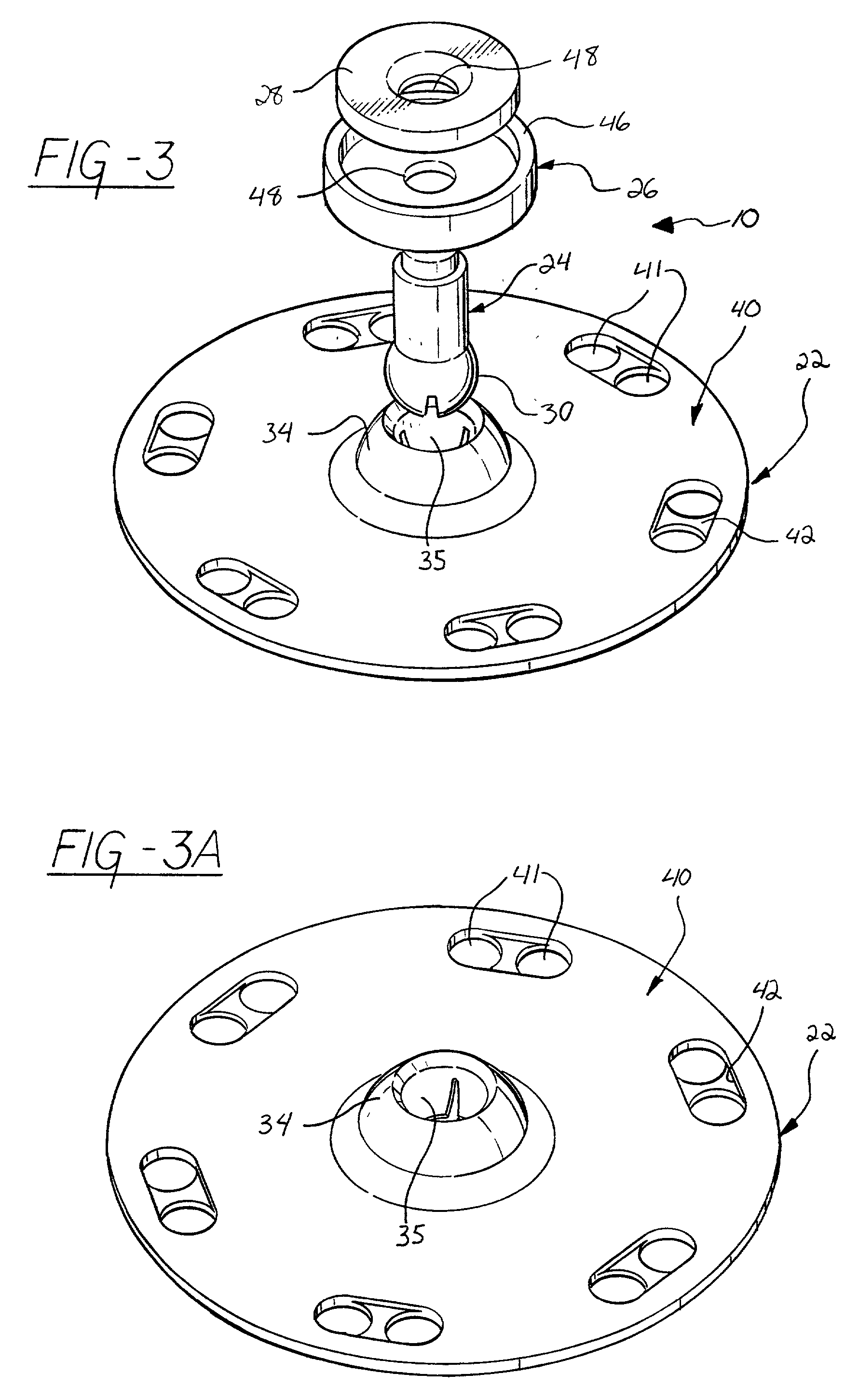

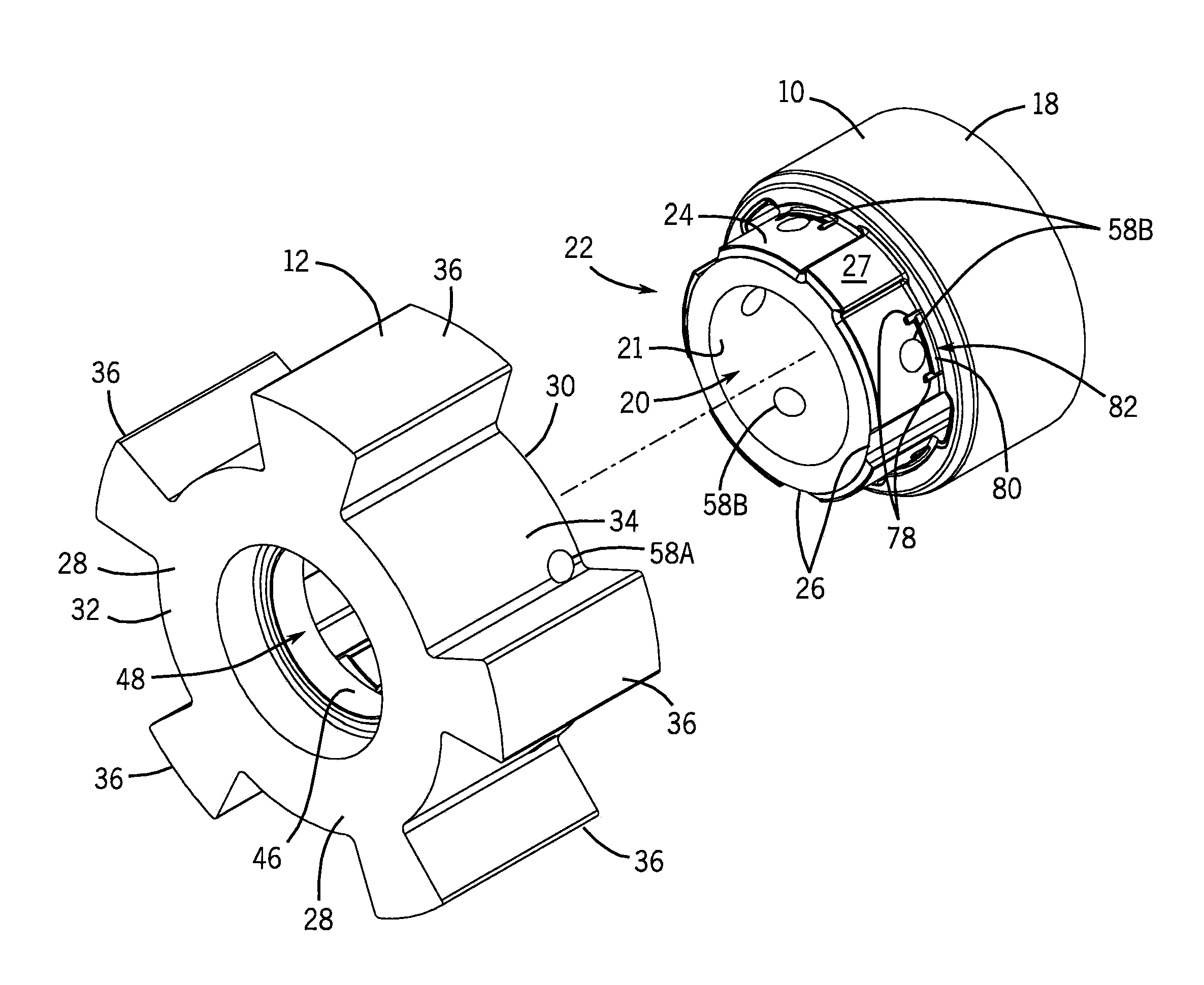

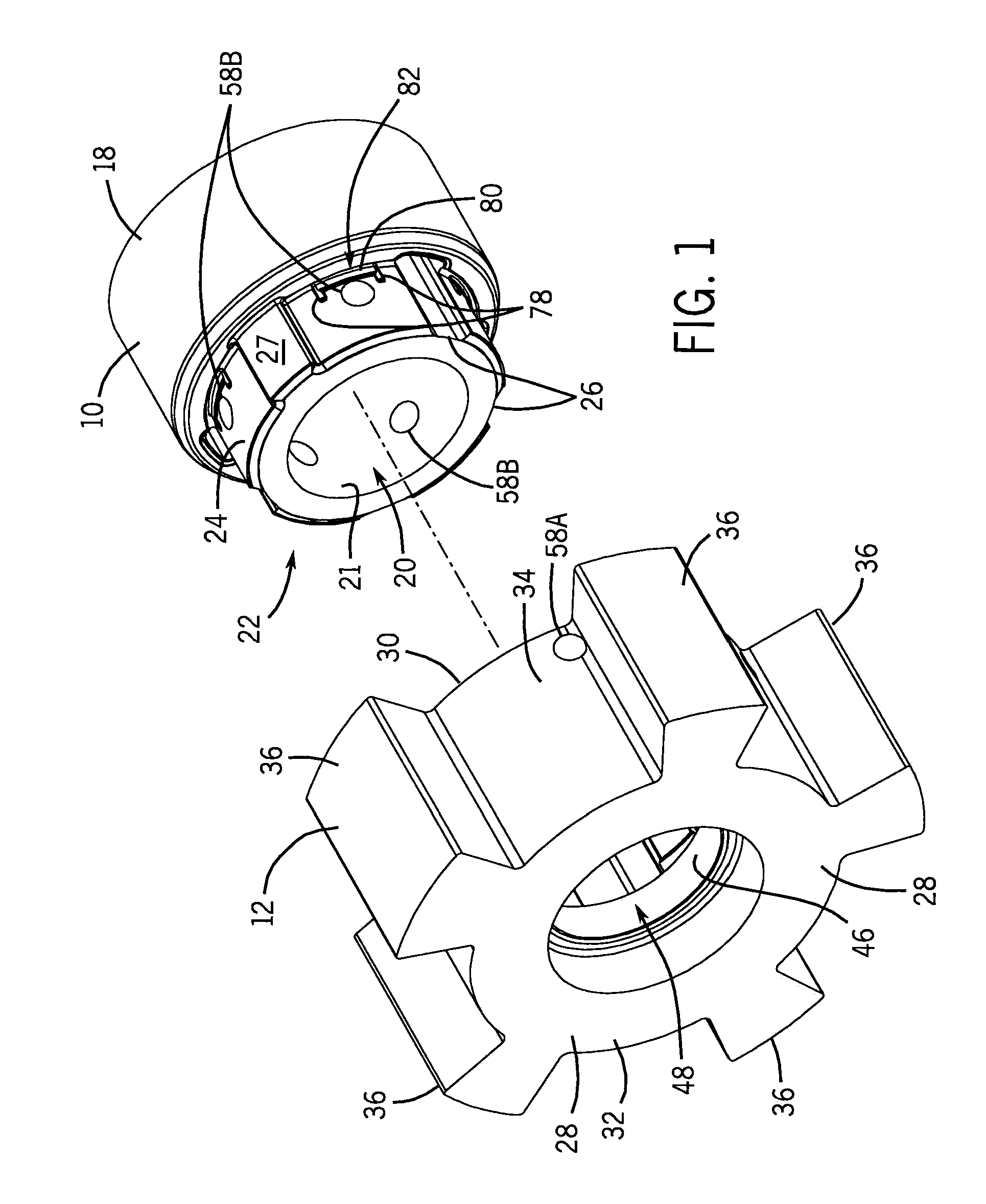

Articulating fastener assembly

InactiveUS6857809B2Facilitates an automotive headlinerSuperstructure subunitsPivotal connectionsEngineeringFastener

Owner:COMML IMPORTS & ASSEMBLY

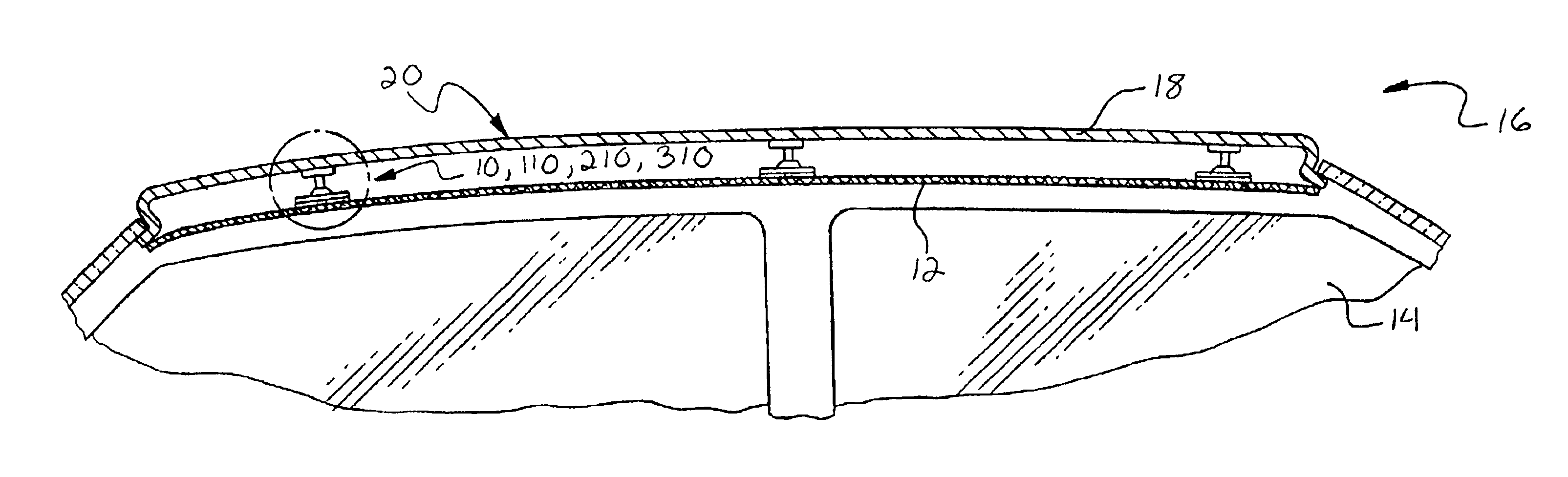

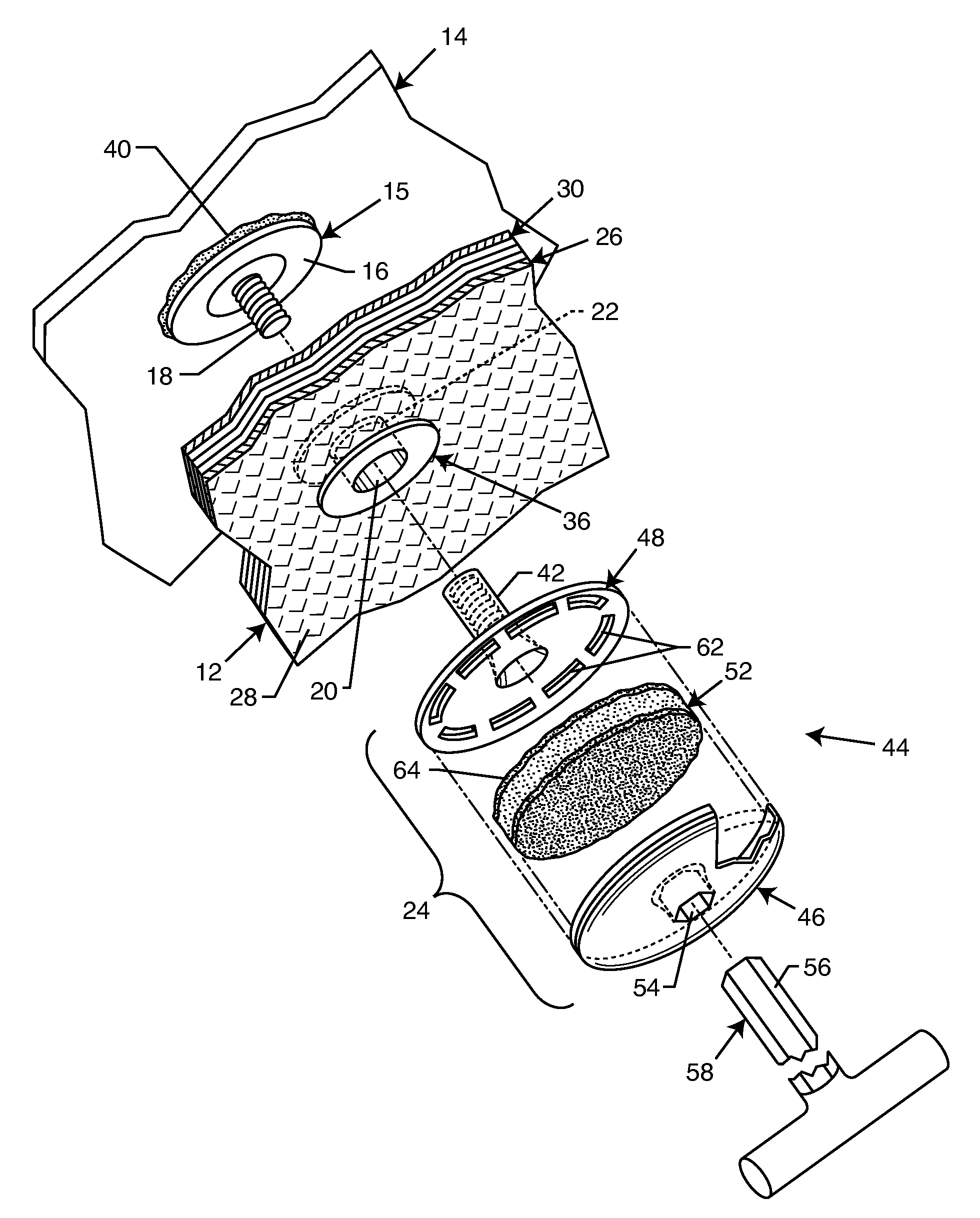

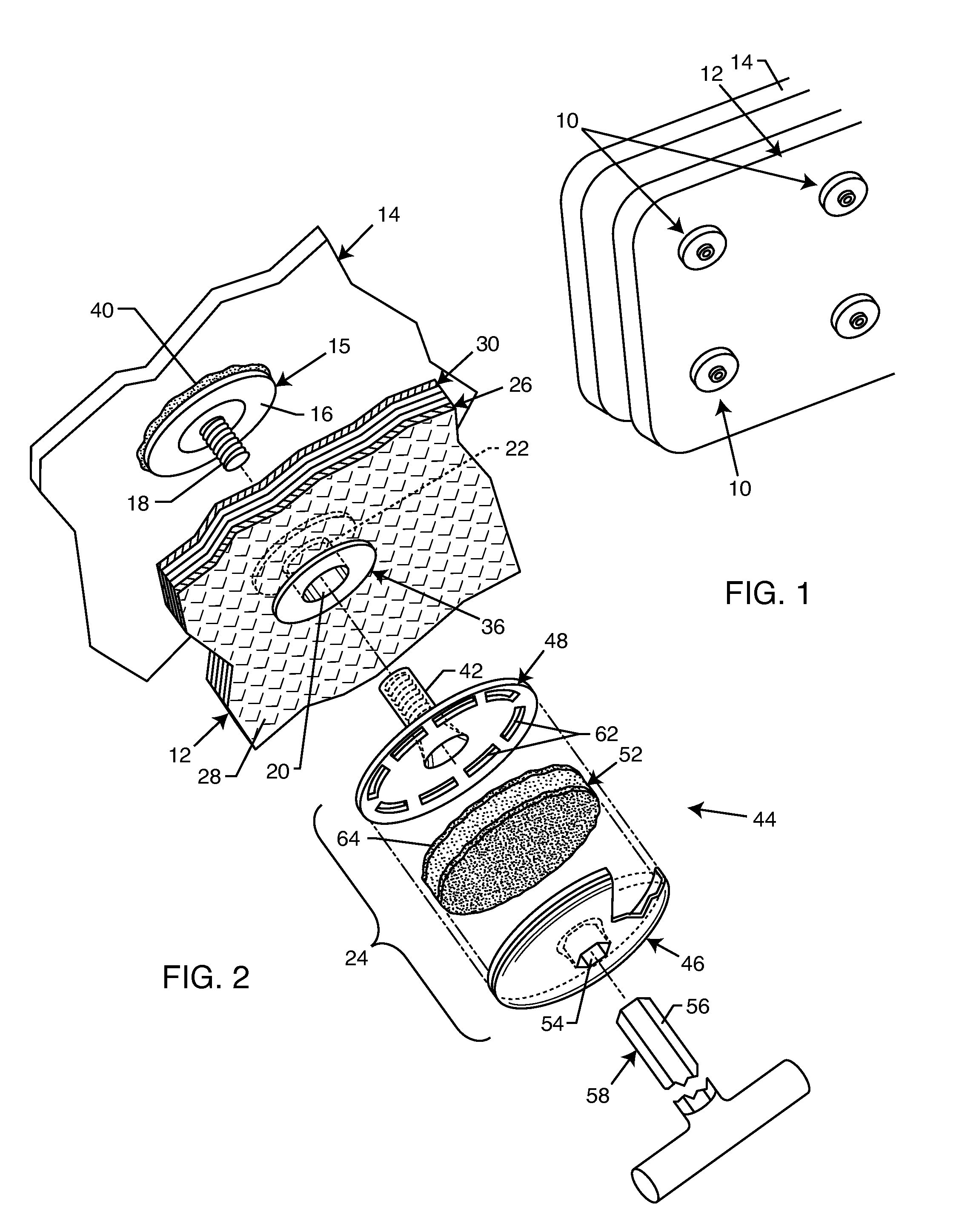

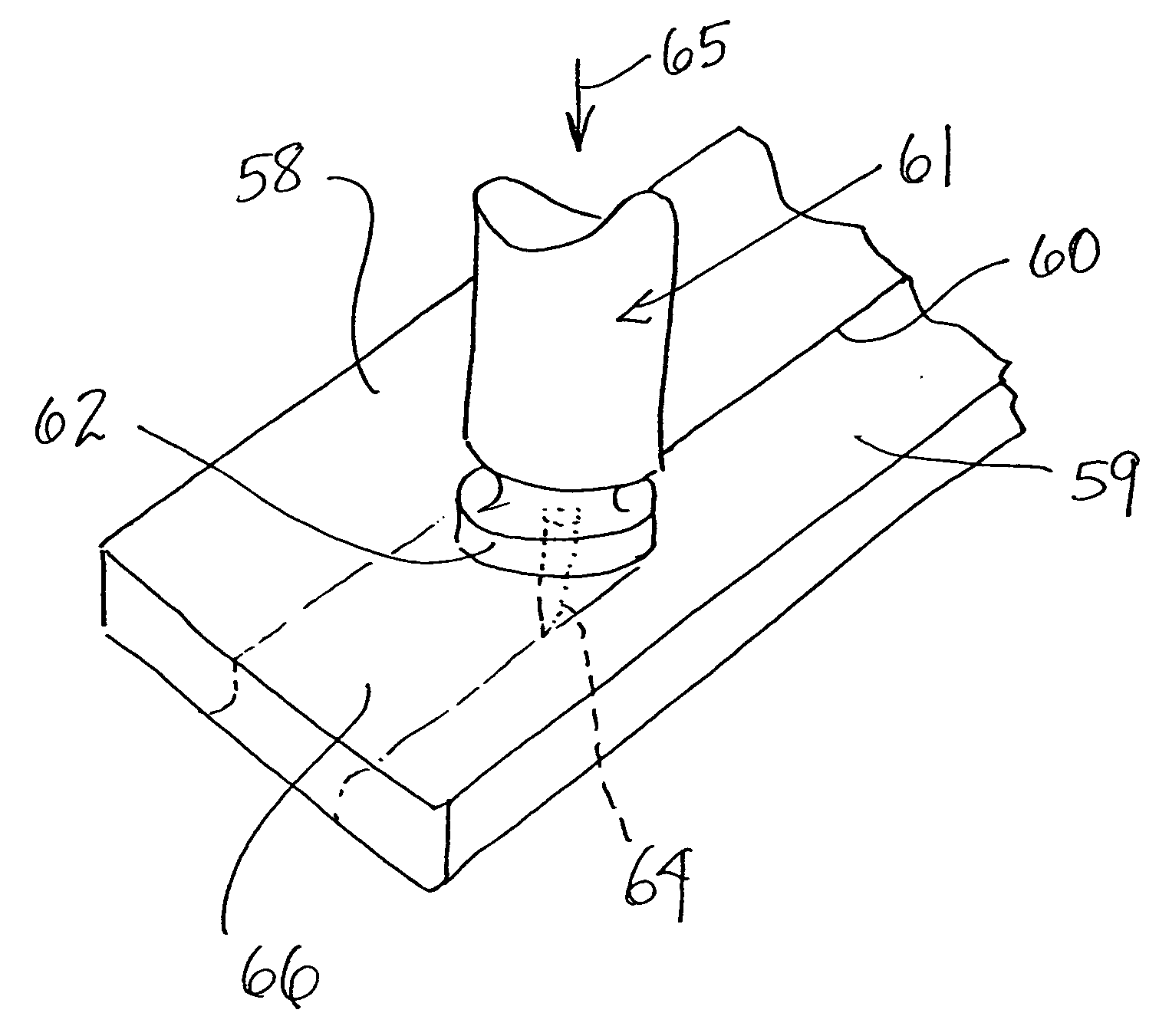

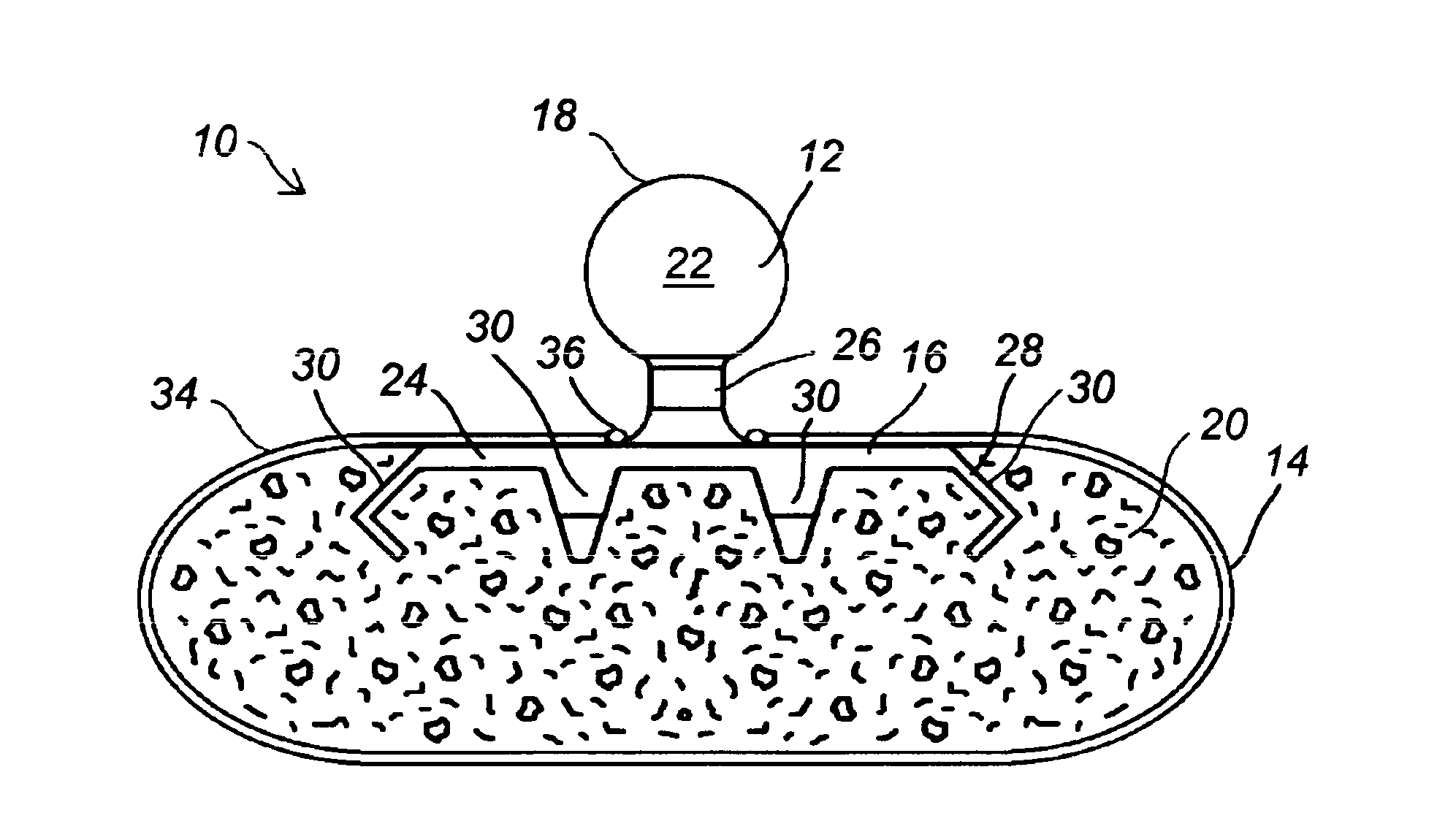

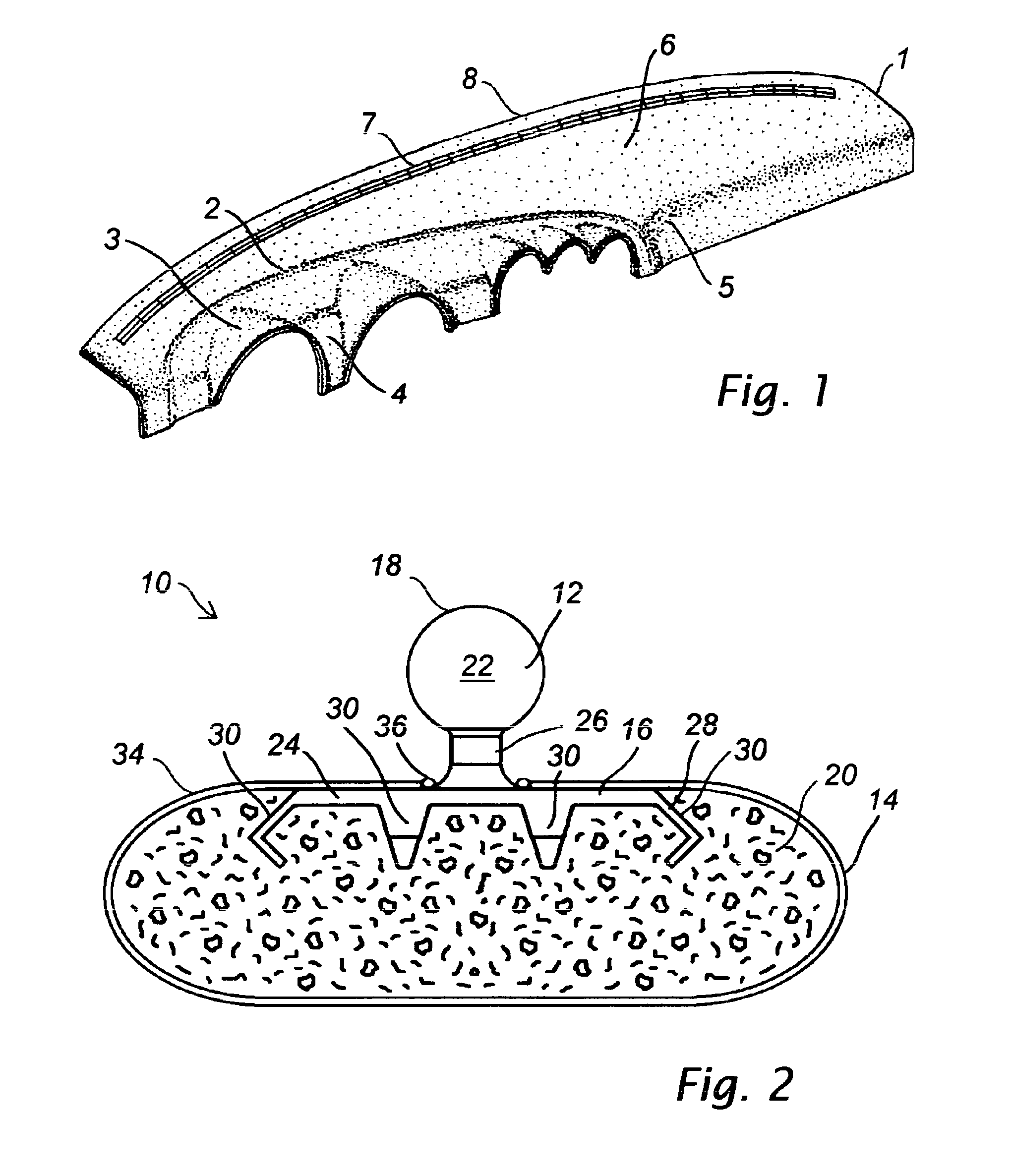

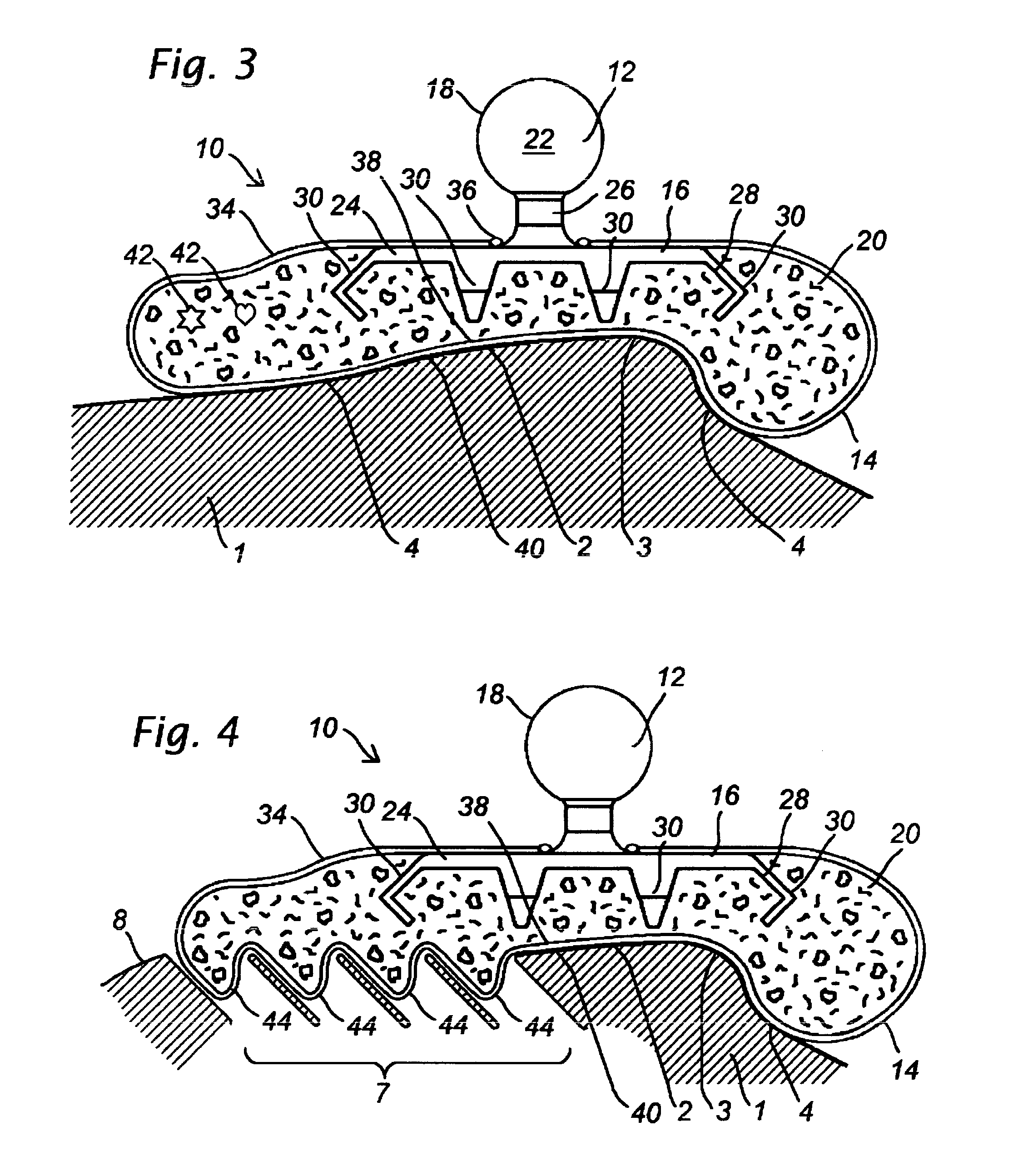

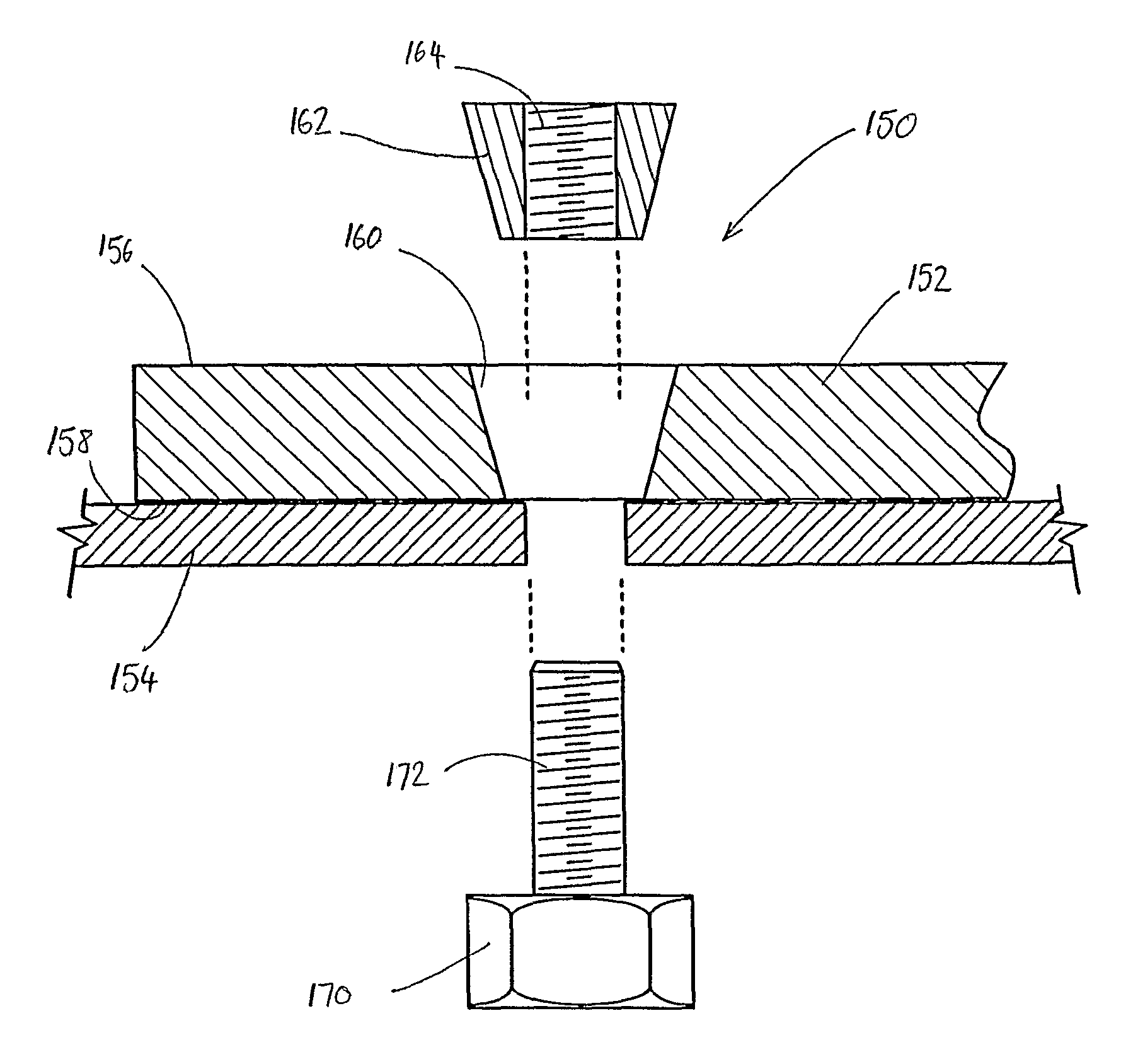

Adhesive bonded attachment assembly for an insulation blanket

An adhesive bonded attachment assembly is provided for supporting and retaining an insulation blanket on a substrate such as aircraft engine nacelle or the like. The attachment assembly includes a stud attachment having a base for adhesive bonded affixation to the nacelle substrate and a fastener element such as a threaded stud extending from the base at least partially into a grommet-lined mounting port formed in the insulation blanket. A radially enlarged, insulated cap fastener is secured to the fastener element to retain the insulation blanket on the nacelle substrate in a manner shielding surrounding structures and components from heat generated during engine operation. The insulated cap fastener projects radially beyond the associated grommet for improved heat-shielding of the adhesive bonded stud attachment, thereby safeguarding against debonding of the attachment base in response to high temperature exposure.

Owner:PHYSICAL SYST

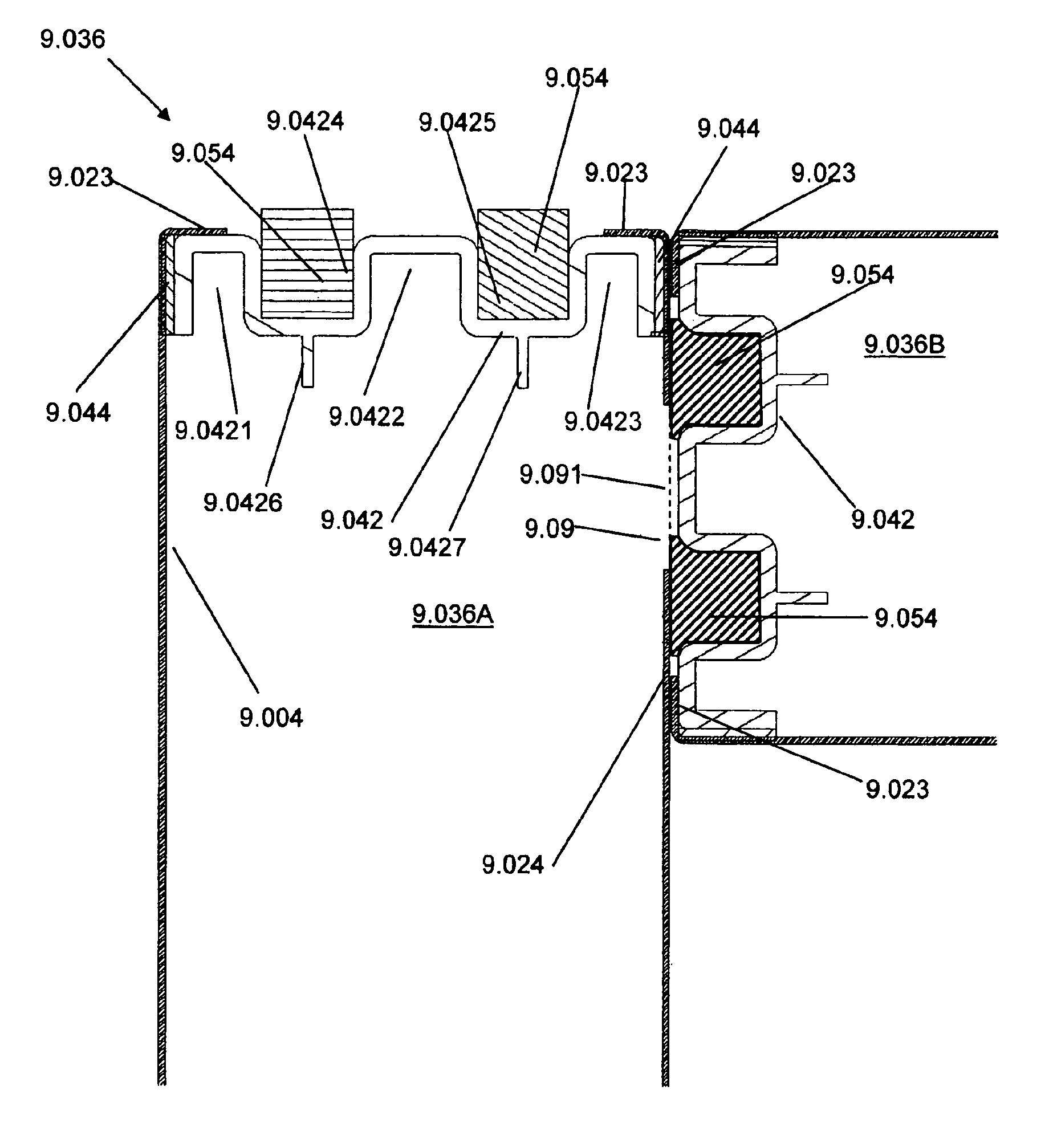

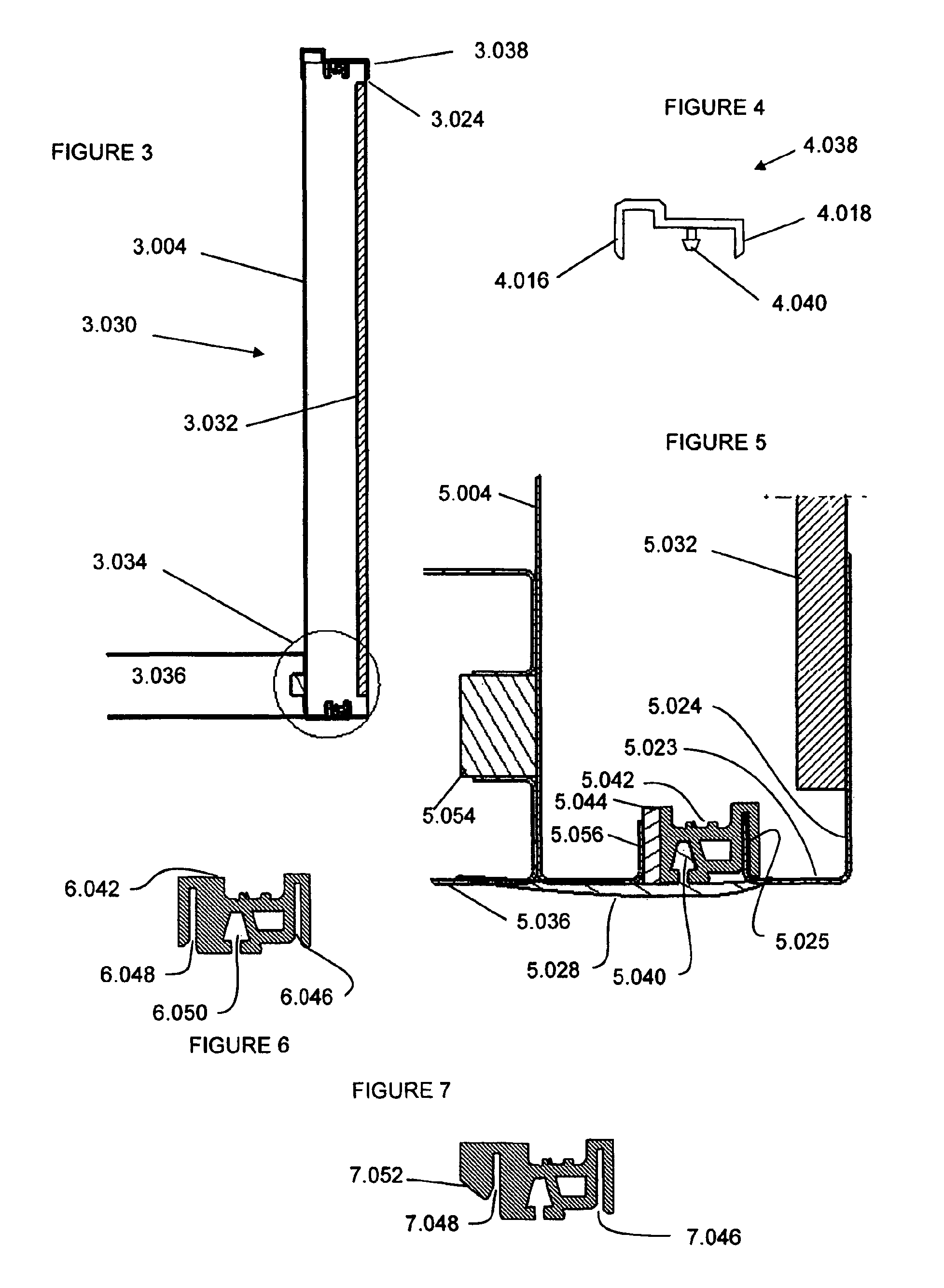

Insulated panel and method of assembly

An insulated panel including first and second walls (5.004, 5.024) spaced apart by a predetermined distance, each wall including an internal peripheral channel formed by first and second bends, the second bend forming an internal peripheral flange (5.025, 5.056), the panel including an intermediate joining member (5.042) adapted to connect to the internal peripheral flanges of the first and second walls. The connection to a first flange can be via a slot (6.046), and the connection to the second flange can be by adhesive (5.044).

Owner:ELECTROLUX HOME PROD PTY LTD

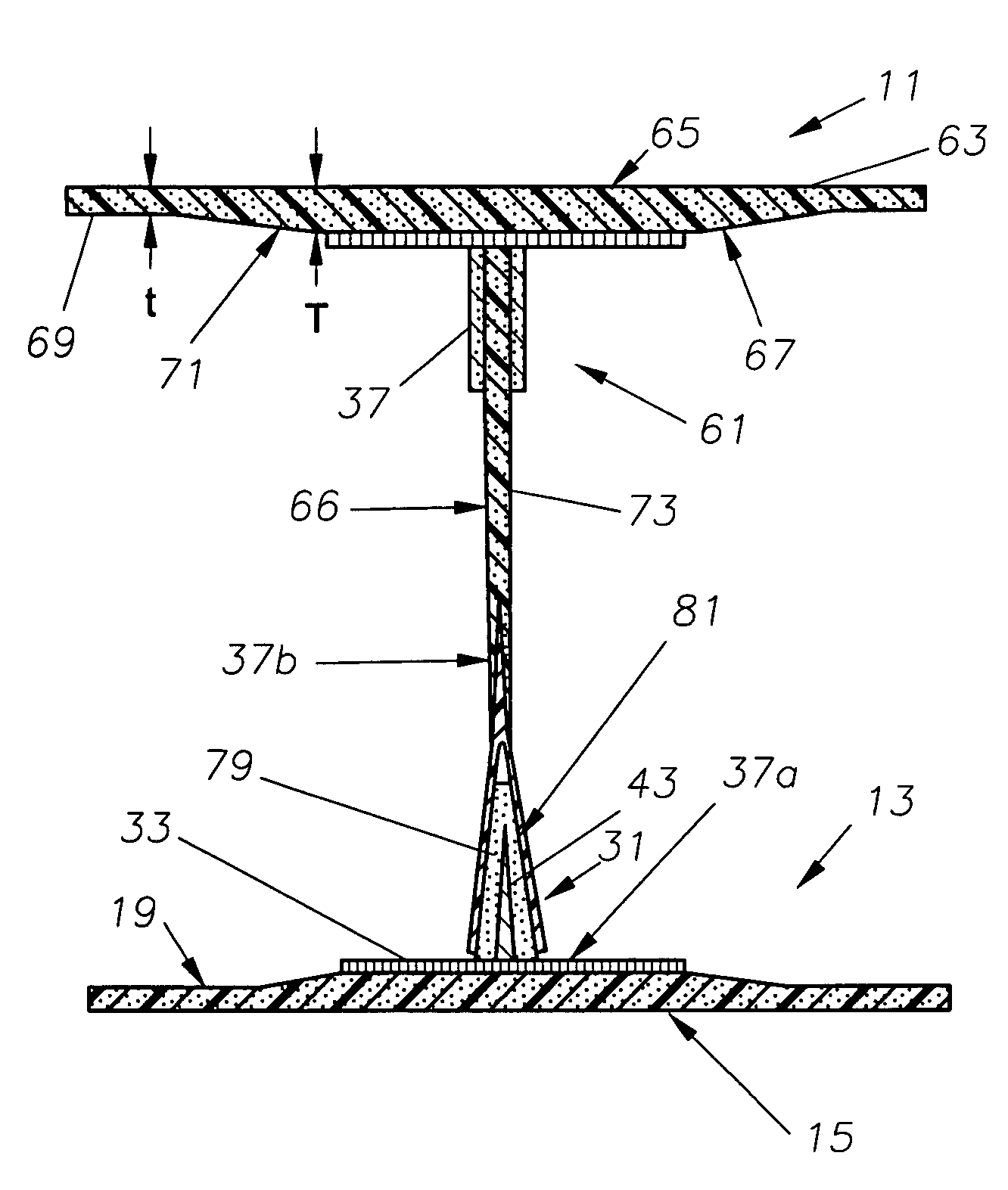

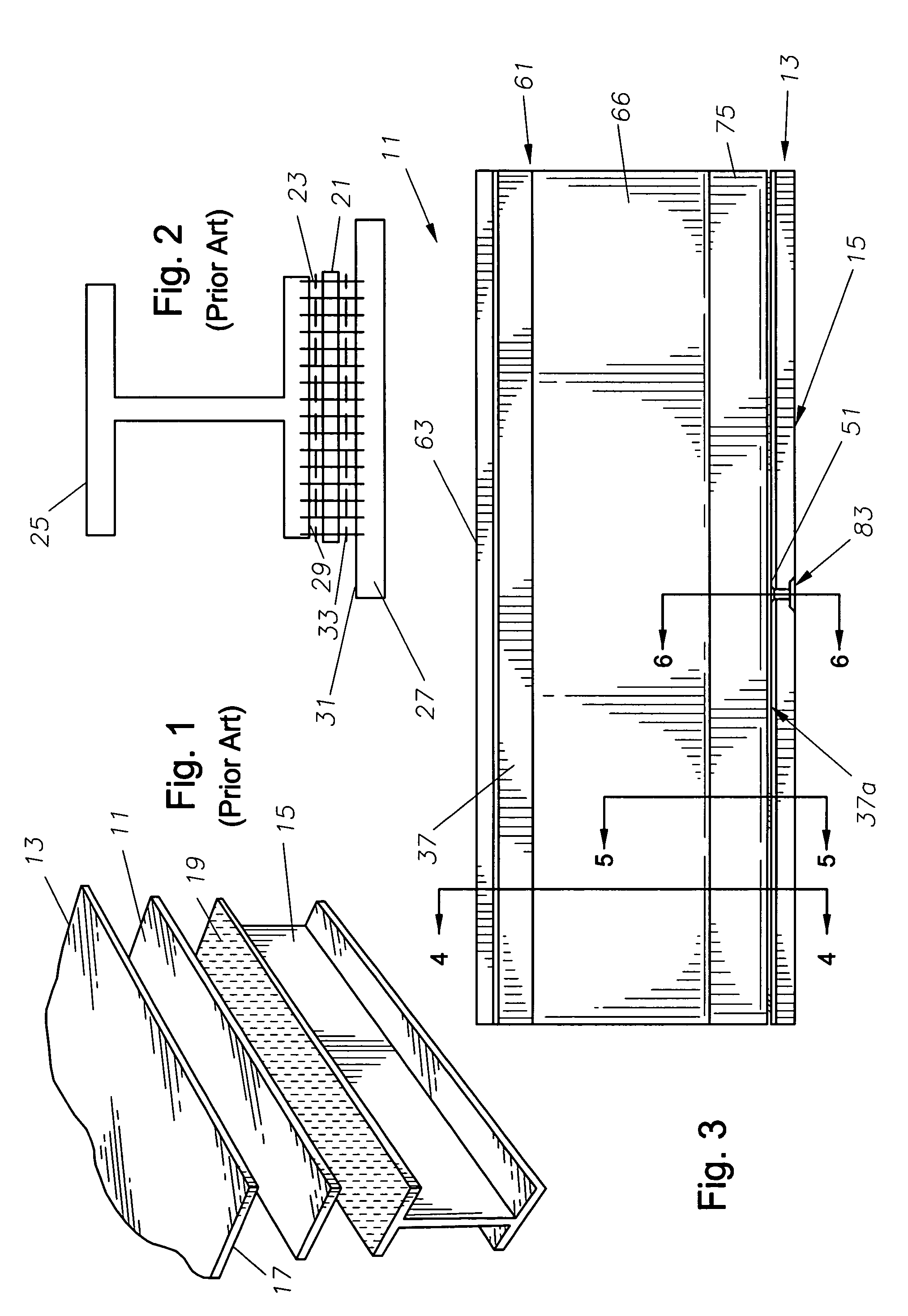

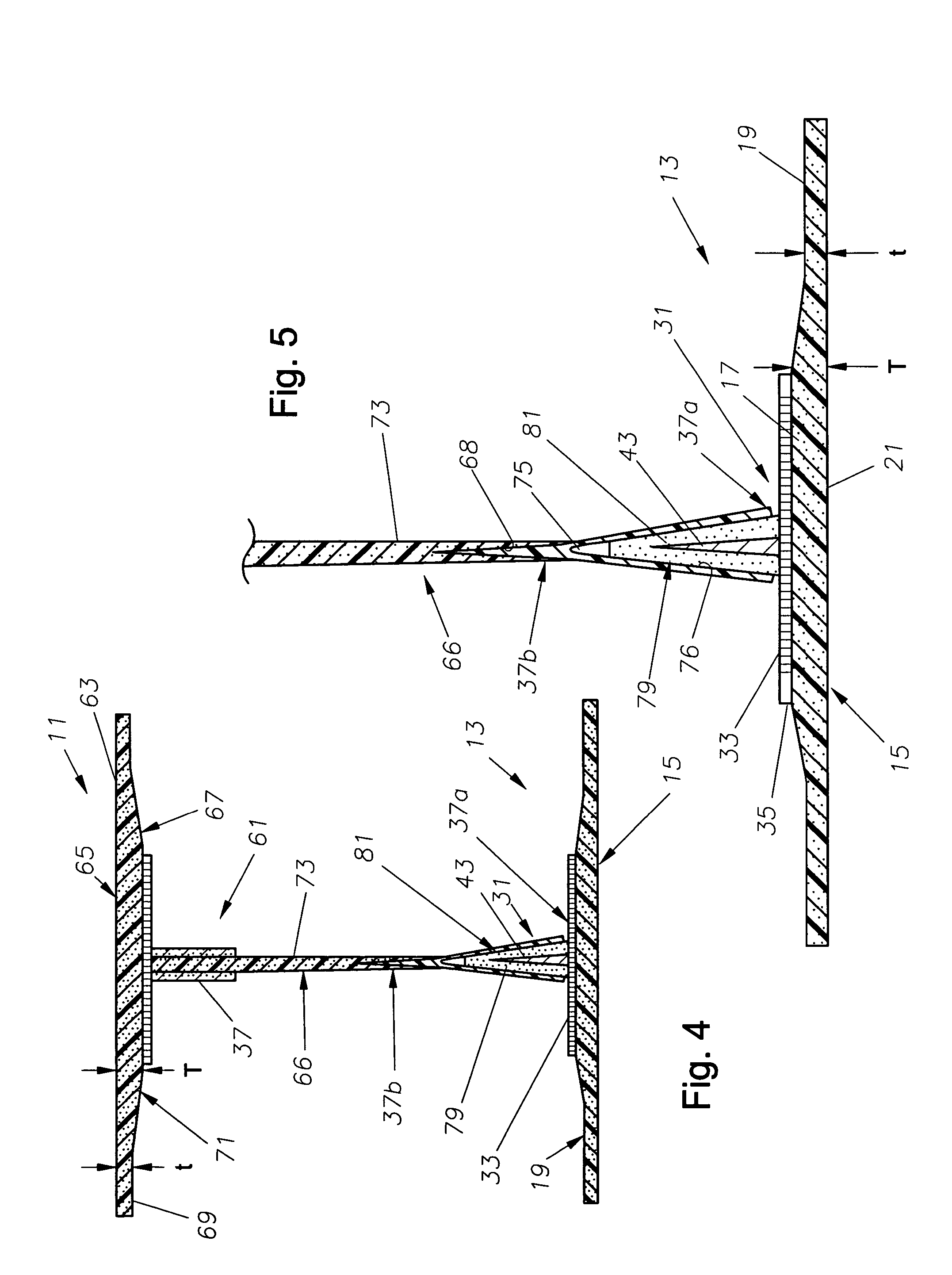

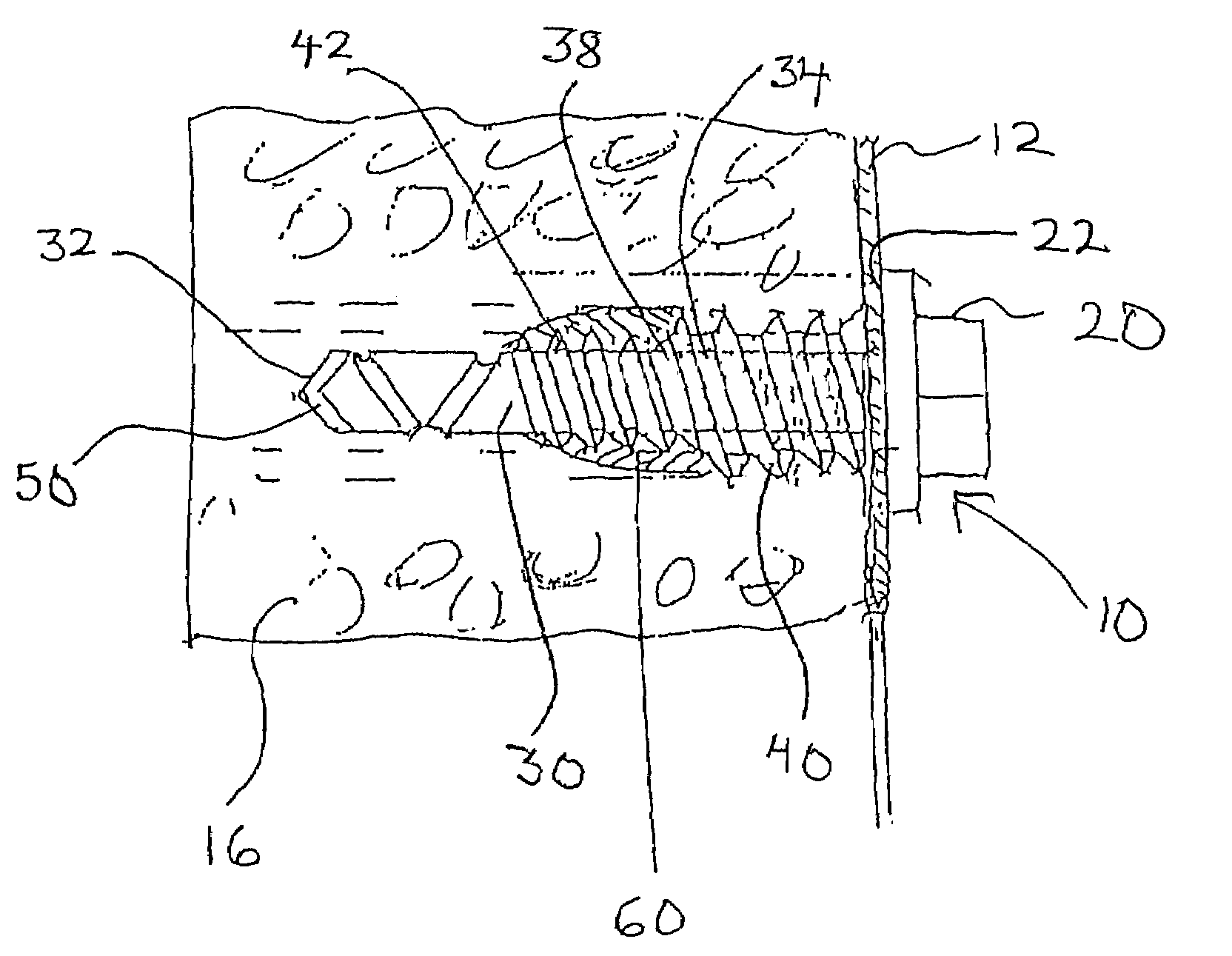

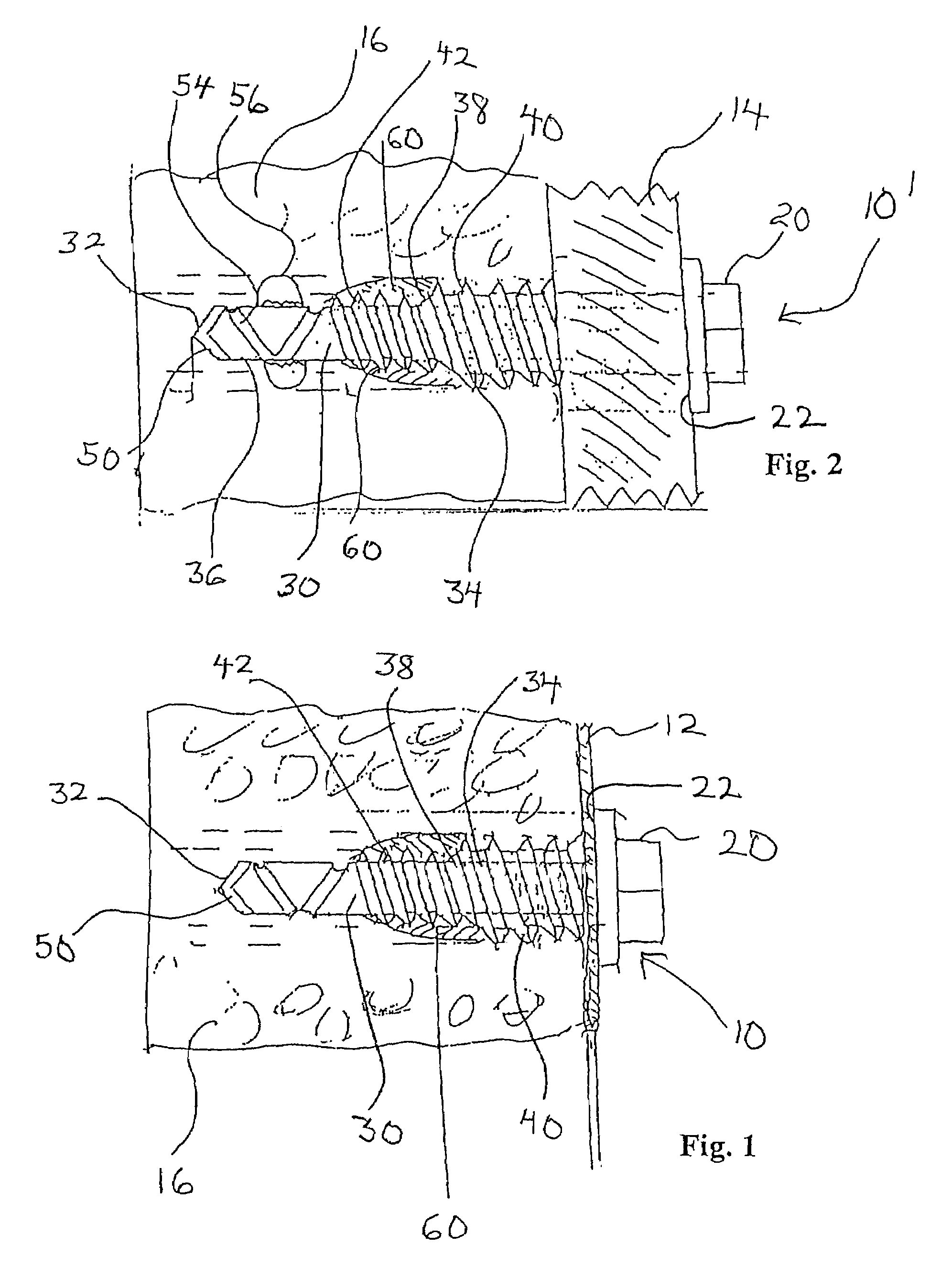

Apparatus, system, and method of joining structural components with a tapered tension bond joint

InactiveUS7244487B2Enhanced ballistics survivabilityStop crackingFuselage framesAircraft stabilisationEngineeringHigh intensity

A system of composite and adhesive materials provides for a high strength, producible closeout joint in the form of tapered tension bond joint for high performance structures. The system includes one skin that is co-bonded to flat panel spars, with the joint being positioned at the opposite side of the spars. The spar includes a female receptacle that receives a male blade from the closeout skin assembly. The blade and receptacle are wedge-shaped woven preforms. The flat panel spars have imbedded nut elements that serve as “internal tooling” to provide a positive stop for locating and clamping the structural members together.

Owner:LOCKHEED MARTIN CORP

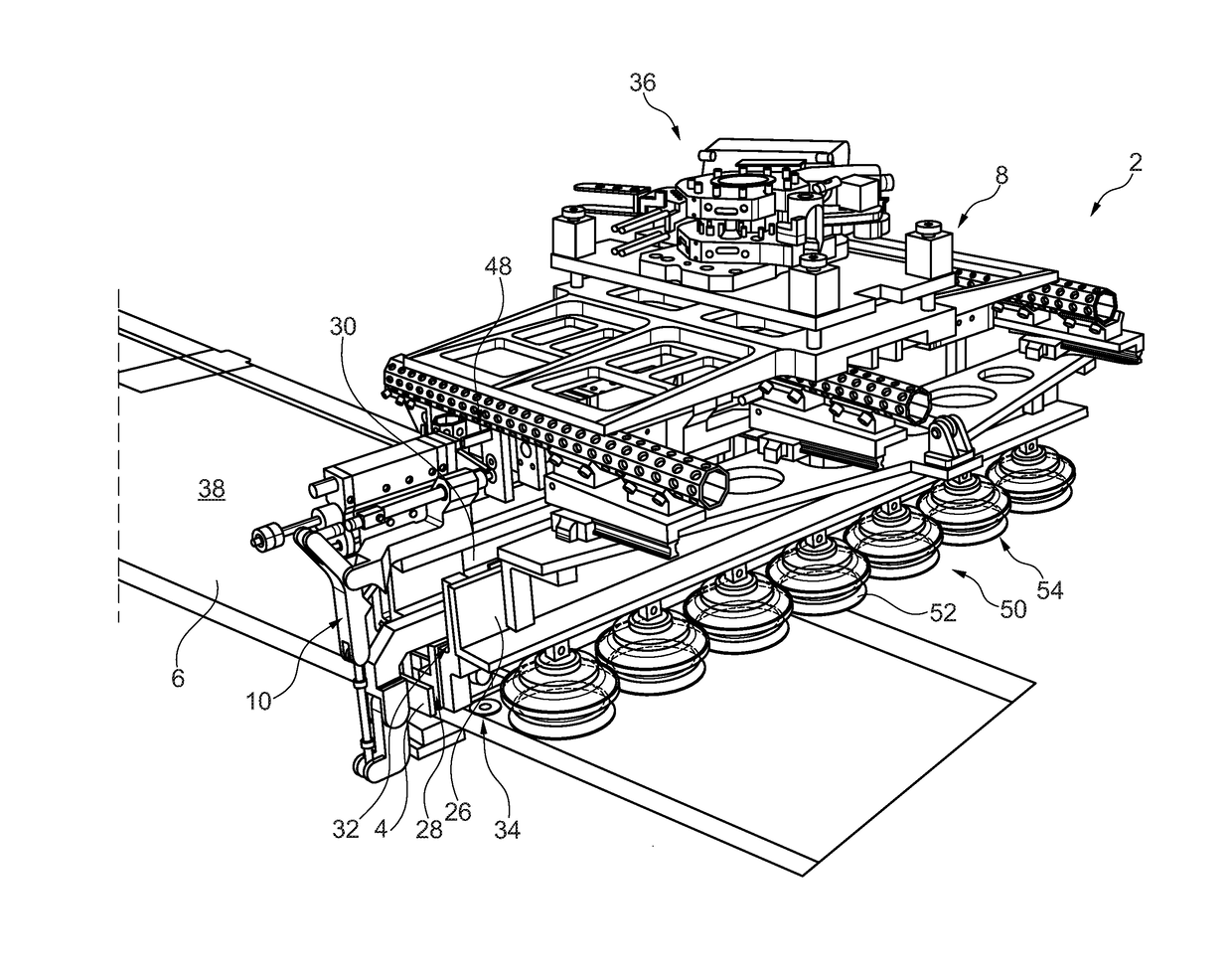

System and method for handling a component

A system for handling a first component includes: a main-device and a module-device, the module-device having a pressing section arranged to form an outer surface of the module-device, the module-device configured to releasably receive the first component, such that a connection section of the first component is attachable to the pressing section of the module-device. The module-device is releasably connected to a second component, wherein the main-device includes a grabbing unit adapted for releasably connecting the module-device, such that the pressing section is arranged to form a first outer surface section of the main-device, and wherein the main-device includes a connector for connecting to a handling-unit for arranging the main-device at the second component, such that the connection section of the first component, if attached to the pressing section of the module-device, is at least indirectly attachable to a front surface of the second component.

Owner:AIRBUS OPERATIONS GMBH

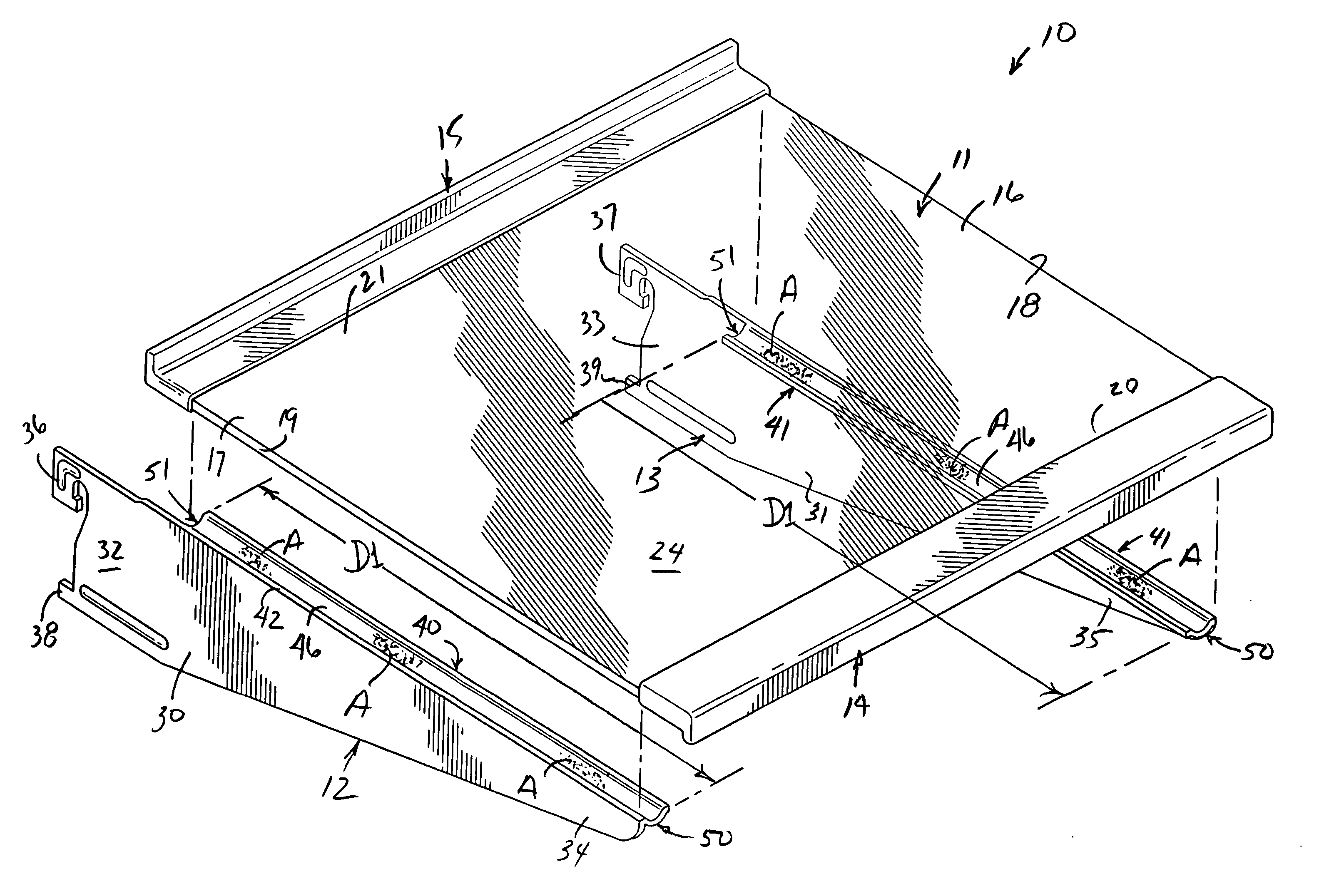

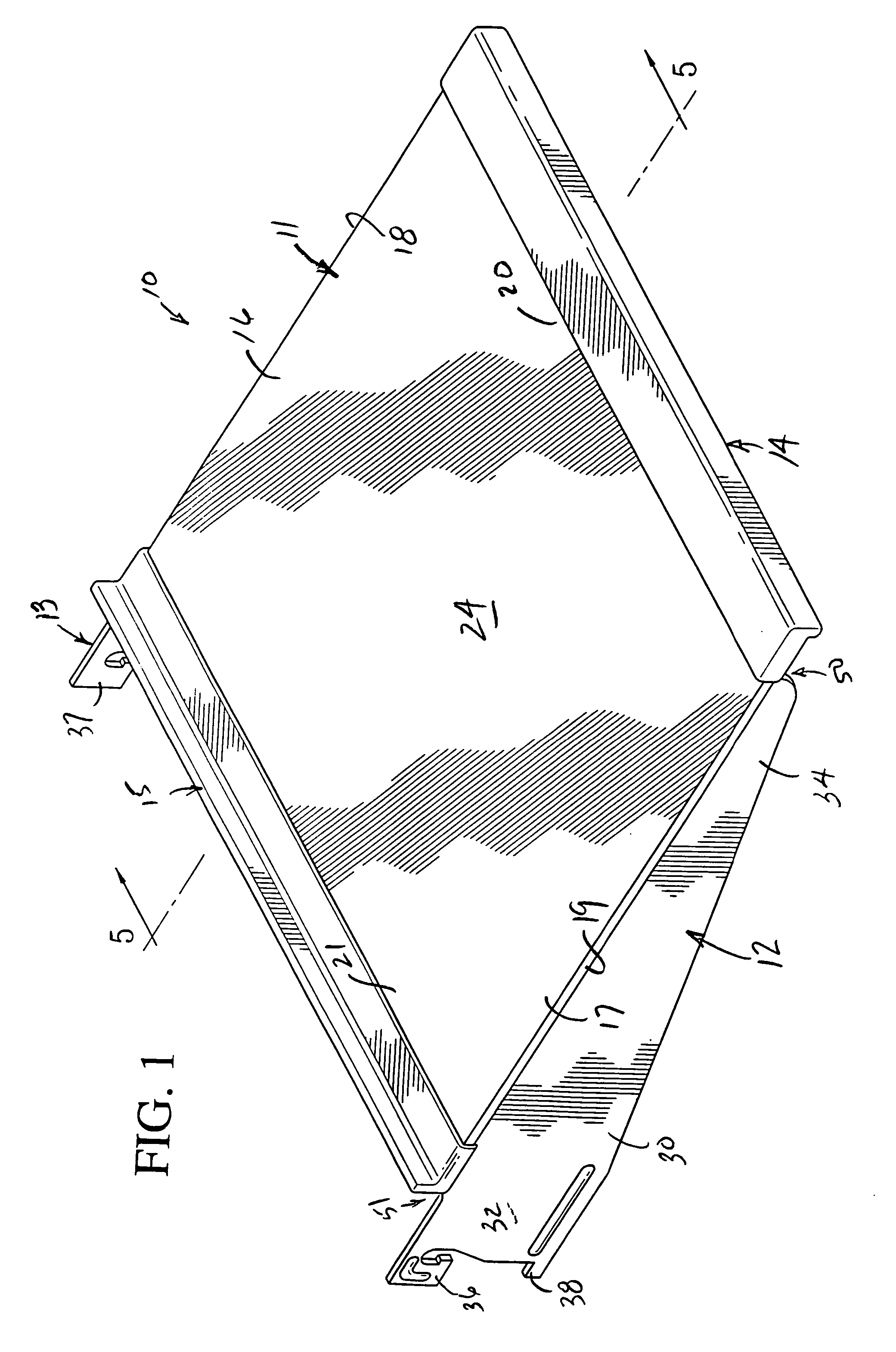

Refrigerator shelf

ActiveUS20060213849A1Enhances anti-torquing characteristicImprove rigidityLighting and heating apparatusMaterial gluingAdhesiveEngineering

A shelf is defined by a tempered glass panel bonded to opposing flanges of a pair of metal shelf brackets carrying hooks for connection to and adjustment along vertical trackways in refrigerator compartments. Adhesive constitutes the sole means for maintaining the shelf substantially rigidly united. Each shelf bracket includes at least one abutment surface for engaging an edge of the shelf panel or a handgrip member carried thereby to assure perfect alignment between the components during curing of the adhesive. Each shelf bracket is defined by a shelf arm and a flange with the flanges having pockets housing the adhesive. The shelf arms may additionally include uppermost projections for engaging side edges of the shelf panel and / or at least one additional flange, such that side edge portions of the shelf panel can be housed between the pair of vertically spaced longitudinally offset flanges of each shelf bracket.

Owner:GEMTRON

Connection mechanism and method

InactiveUS20050247756A1High strengthIncrease connection forceCooking-vessel materialsMaterial gluingEngineeringSelf locking

Owner:REMMELE ENG

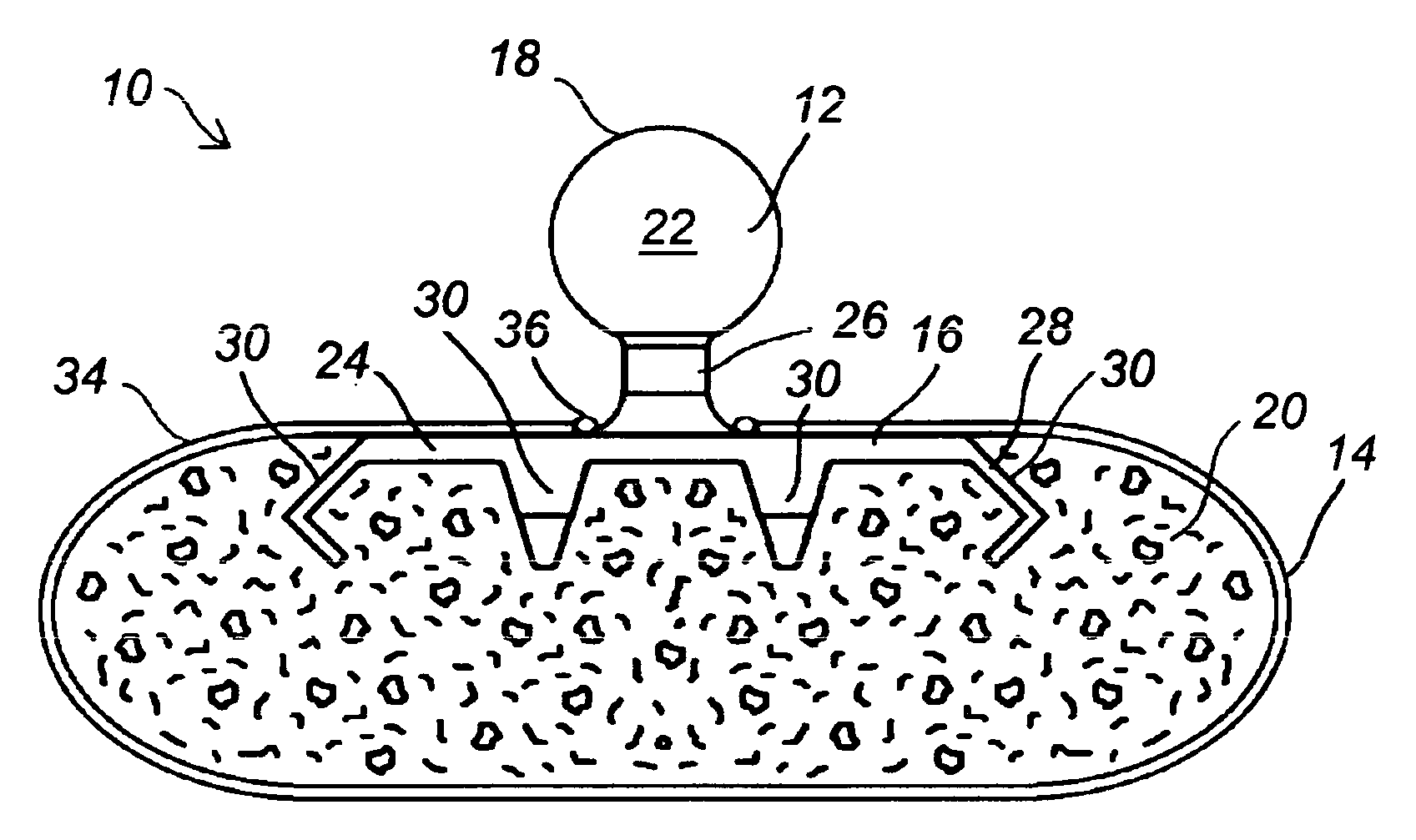

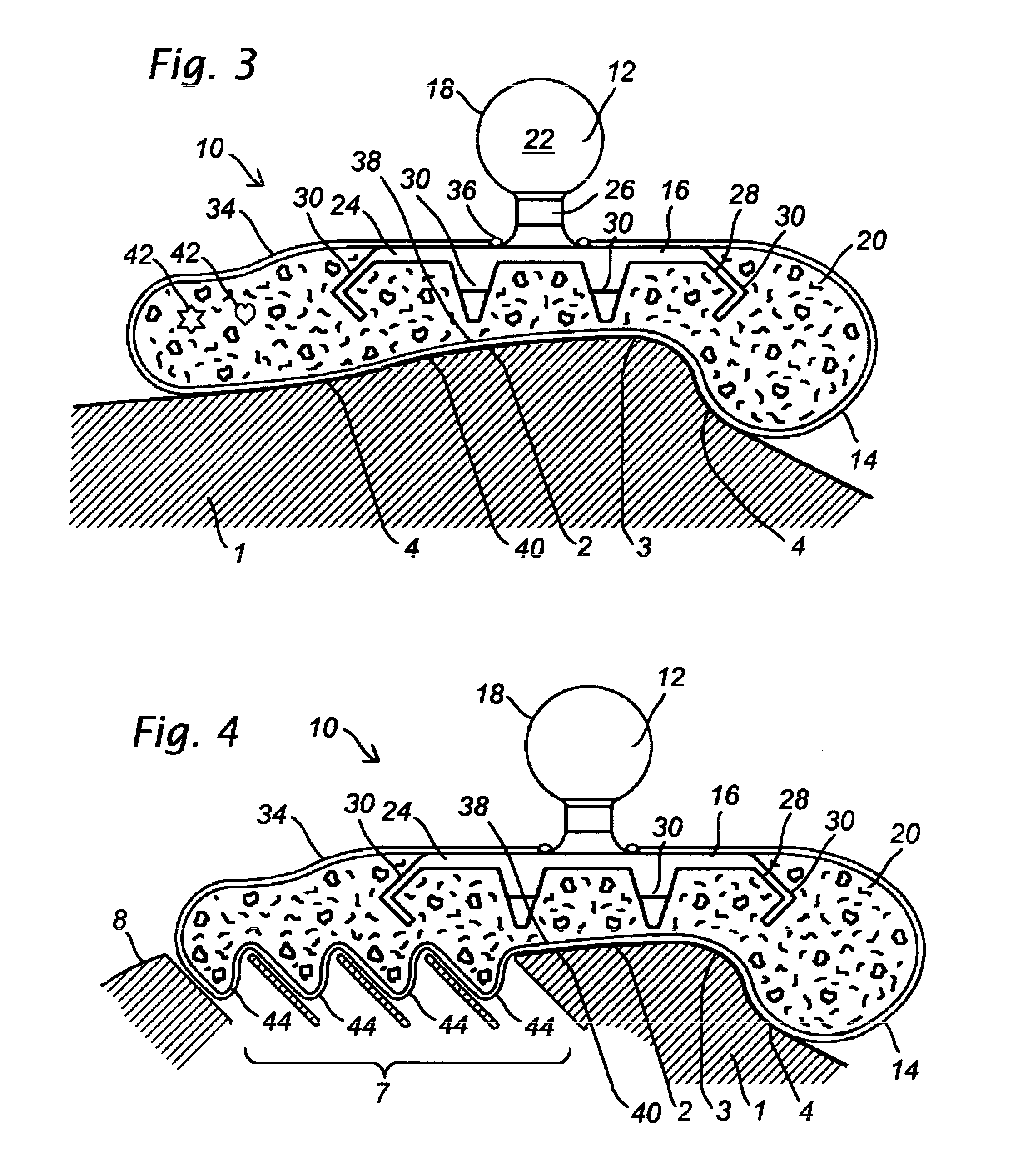

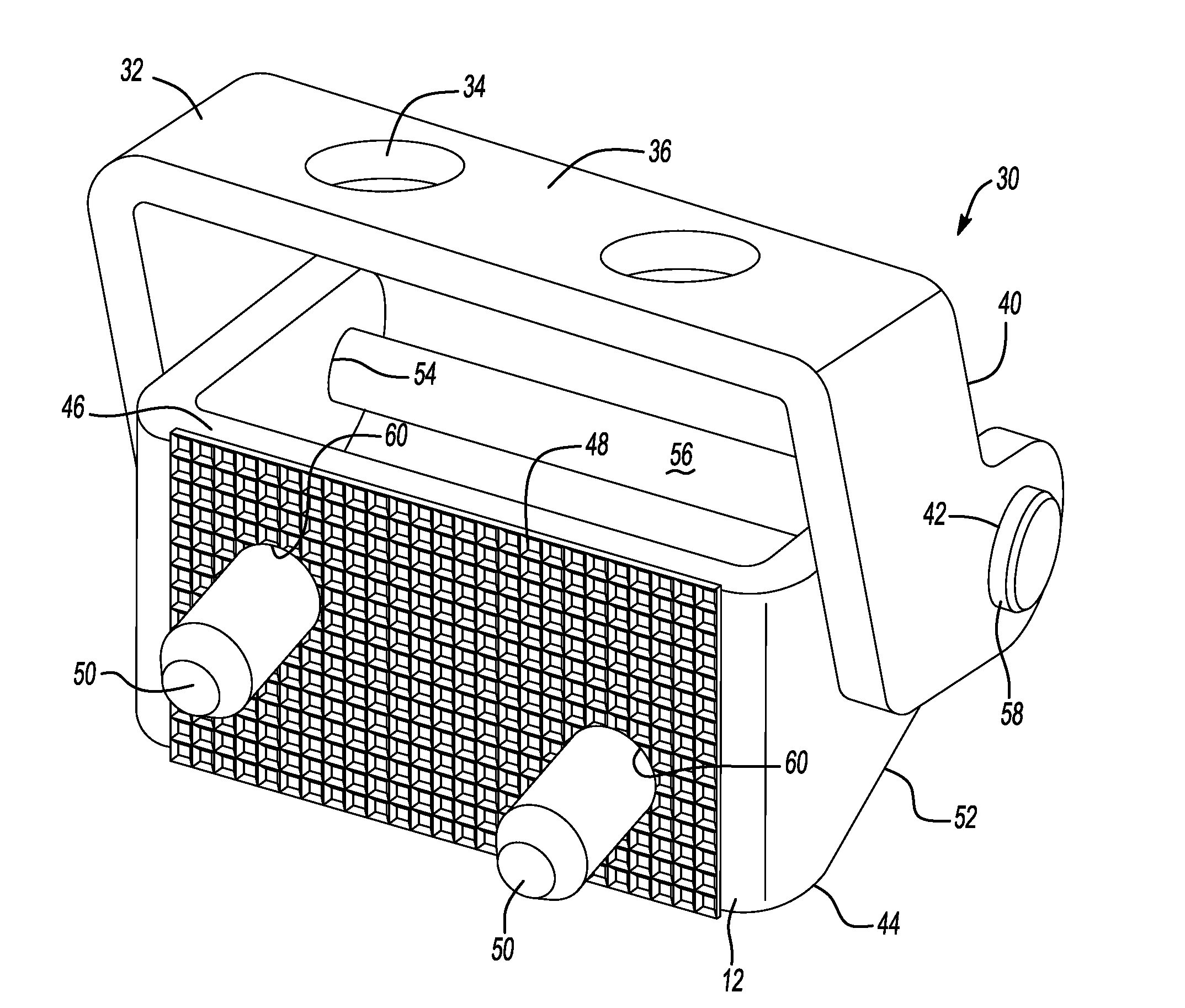

Adaptive mounting structure

InactiveUS7988106B2Effectively mounts and secures objectsOvercome limitationsStands/trestlesKitchen equipmentEngineeringSelf adaptive

A novel adaptive mounting device that effectively mounts and secures objects to nonplanar surfaces, and in particular effectively mounts and secures objects in a quick and efficient manner to complex contours of different automotive vehicle dashboard and other interior vehicle surfaces having differing coverings of differing textures. By example and without limitation, this novel adaptive mounting device includes a substantially flexible container containing a substantially plastically formable composition; a frame at least partially embedded in the plastically formable composition; and a presentation structure substantially supported on the frame external of the container. A method for manufacturing the novel adaptive mounting device is also provided.

Owner:CARNEVALI JEFFREY D

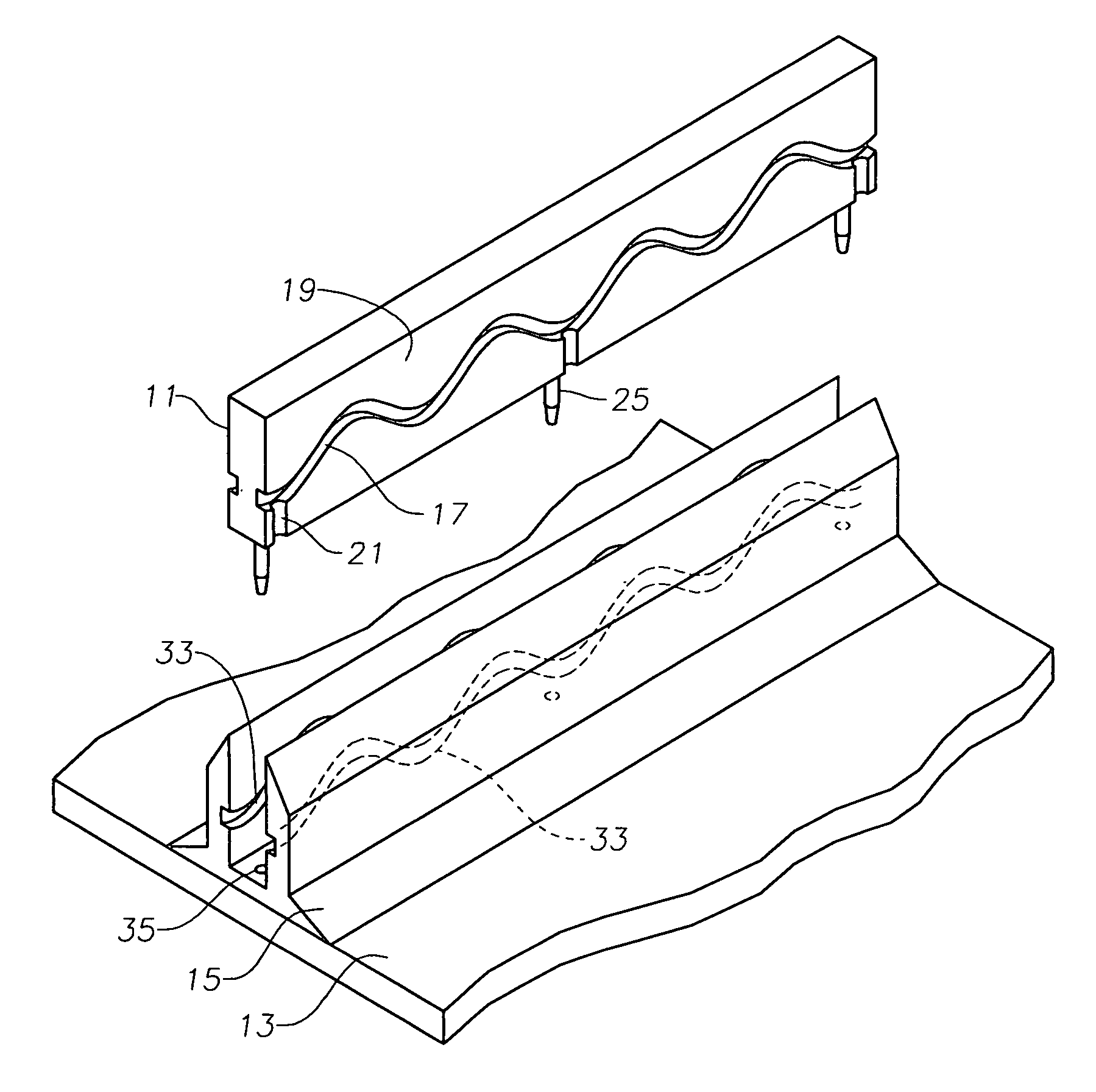

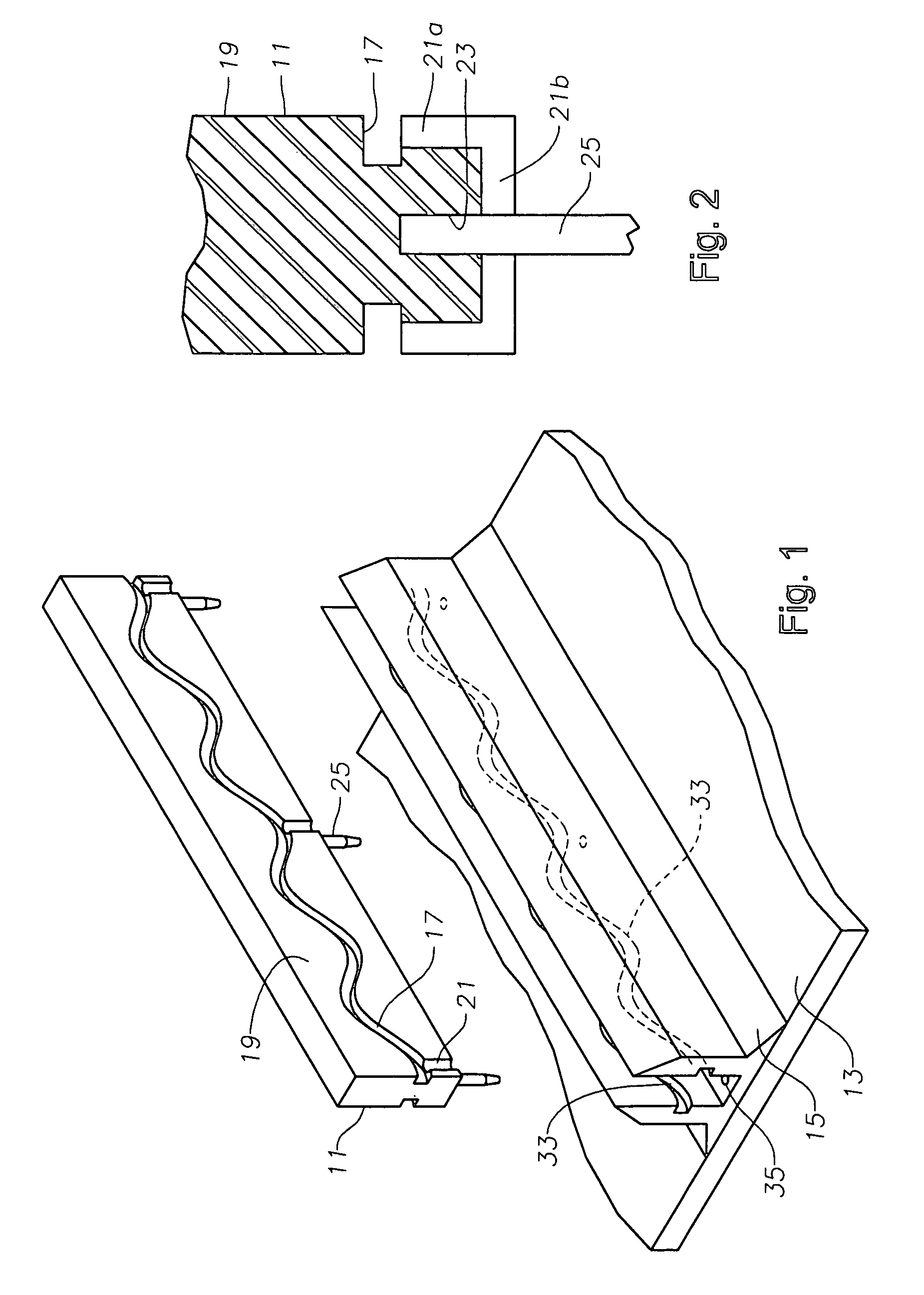

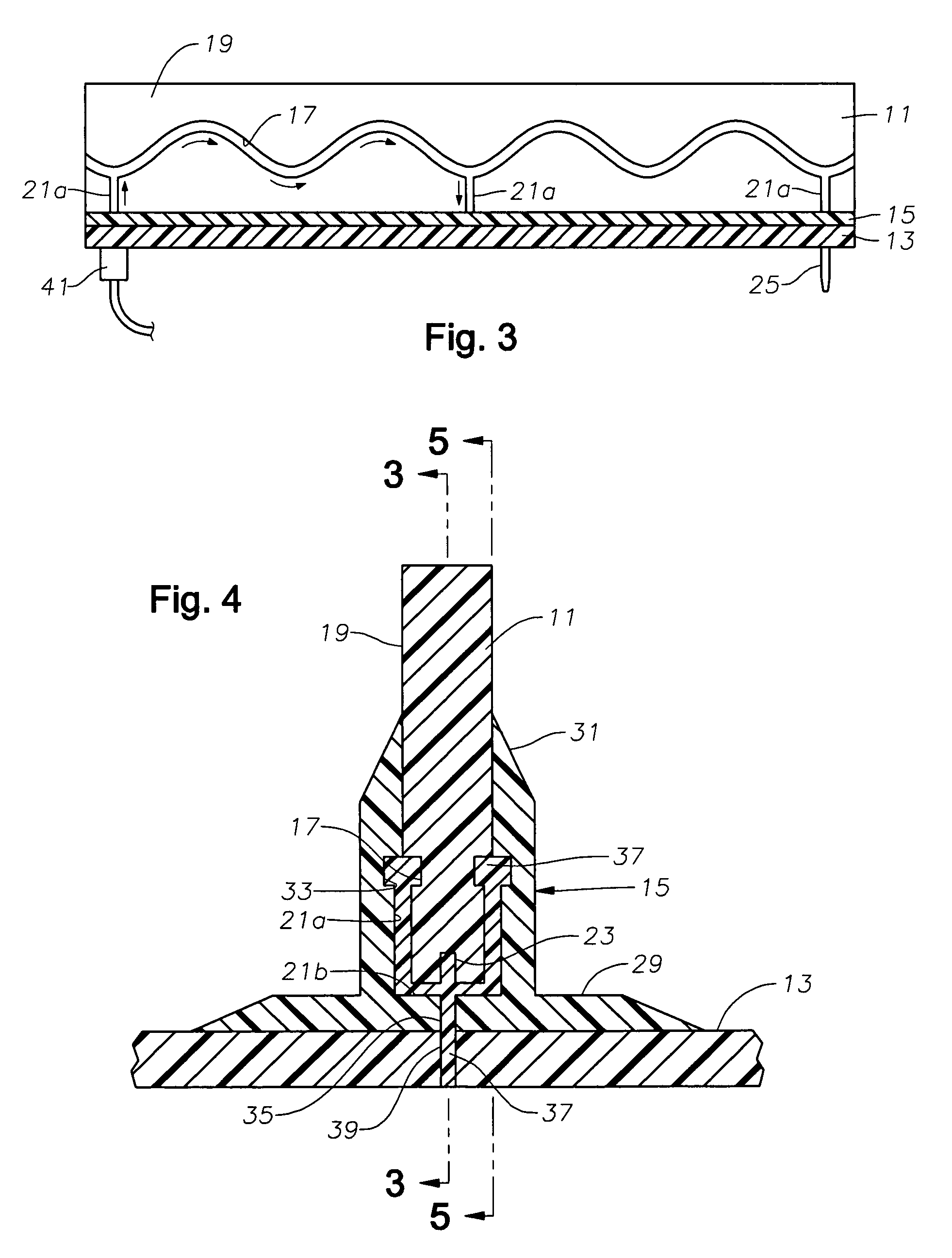

Failsafe injected adhesive joint

ActiveUS20070261787A1Convenient verificationCross sectional areaMaterial gluingCylinder headsAdhesion forceInjection port

A composite member is joined to another composite or noncomposite member, using liquid or paste adhesive resin that cures in the joint. The joint is configured in such a way that the adhesive forms an interlocking key within recesses in the joined members that prevents joint disassembly once the adhesive has cured and hardened. Both of the members are provided with recesses extending along their lengths in the joint. The recesses register with each other to define a cavity and may undulate. The recessed are designed in such a way as to take the full load capability if the joint, even if there is no adhesion to the joined members. Adhesive is injected into the cavity through injection ports spaced periodically along the length of the joint.

Owner:LOCKHEED MARTIN CORP

Methods of joining structures and joints formed thereby

A method of joining a first structure to a second structure using a joint element. The joint element has a base and at least two legs extending from the base and the legs define a slot having opposing sides and a bottom. The method comprises attaching the joint element to the first structure and inserting the second structure into the slot. The method further includes injecting an adhesive into the slot. The method also includes ensuring a cavity is formed between the bottom of the slot and the second structure and the cavity is substantially free of adhesive.

Owner:THE BOEING CO

Adaptive mounting structure

InactiveUS20080203263A1Effective installationRapid and efficient mannerMetal rolling stand detailsMaterial gluingDashboardEngineering

A novel adaptive mounting device that effectively mounts and secures objects to nonplanar surfaces, and in particular effectively mounts and secures objects in a quick and efficient manner to complex contours of different automotive vehicle dashboard and other interior vehicle surfaces having differing coverings of differing textures. By example and without limitation, this novel adaptive mounting device includes a substantially flexible container containing a substantially plastically formable composition; a frame at least partially embedded in the plastically formable composition; and a presentation structure substantially supported on the frame external of the container. A method for manufacturing the novel adaptive mounting device is also provided.

Owner:CARNEVALI JEFFREY D

Adjustable mounting bracket

ActiveUS20050284995A1The process is convenient and fastQuick and easy subsequent mountingCandle holdersLighting support devicesEngineeringMechanical engineering

An adjustable mounting bracket for secure mounting as by adhesive attachment onto an exposed edge of a substrate, wherein the mounting bracket is adapted for quick and easy subsequent mounting of a selected structure such as tubing, wire bundles, etc., relative to the substrate. The adjustable mounting bracket includes a pair of slidably interfitting, generally L-shaped bracket members which cooperatively define a slidably overlying pair of mounting plates and an associated pair of slidably separable clamp jaw plates. The slidably interfitting mounting plates accommodate adjustable spaced-apart separation of the clamp jaw plates to seat firmly against opposed surfaces of the substrate edge, such as mounting onto a rib protruding from the substrate or mounting onto an inner diameter edge of an opening formed in the substrate.

Owner:PHYSICAL SYST

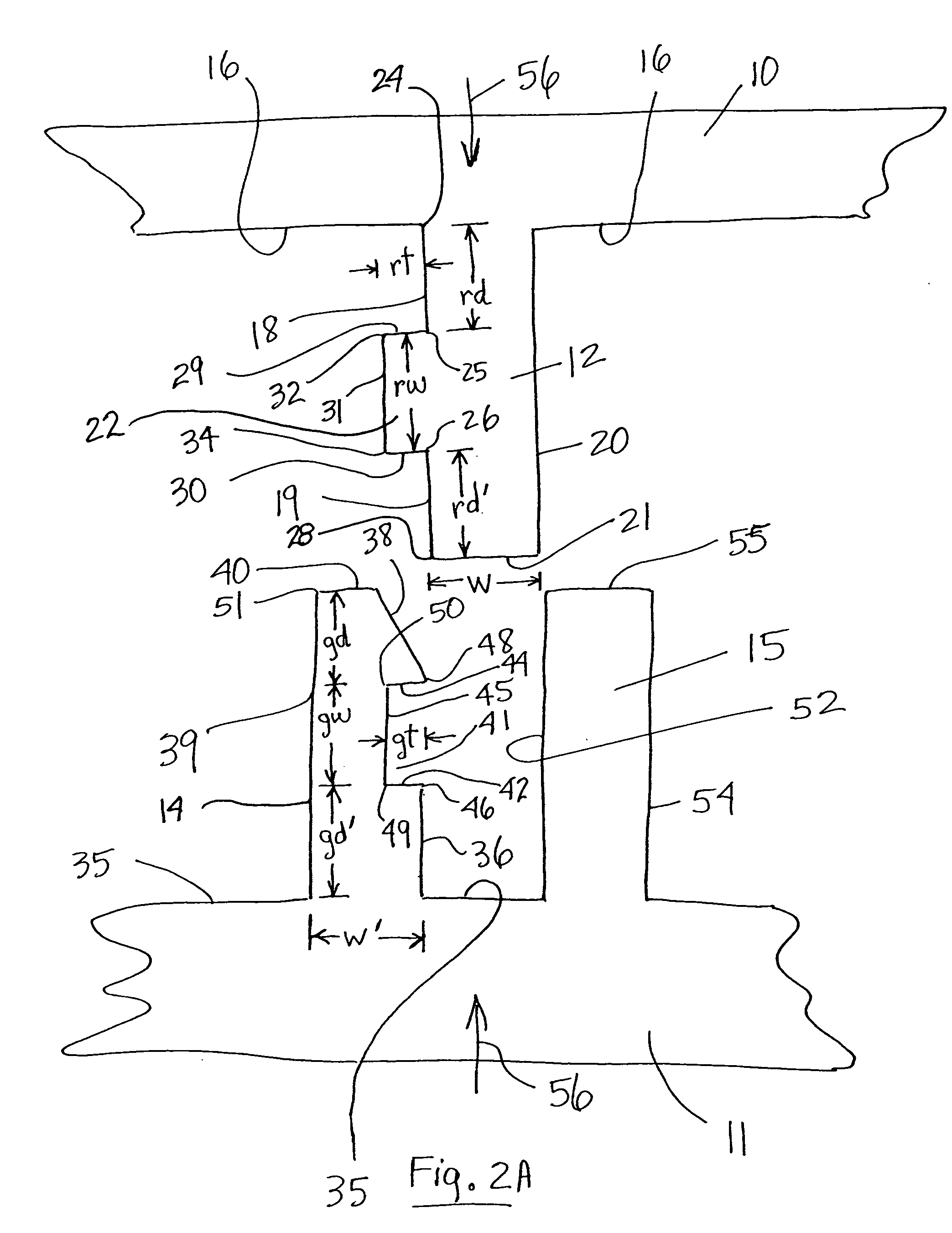

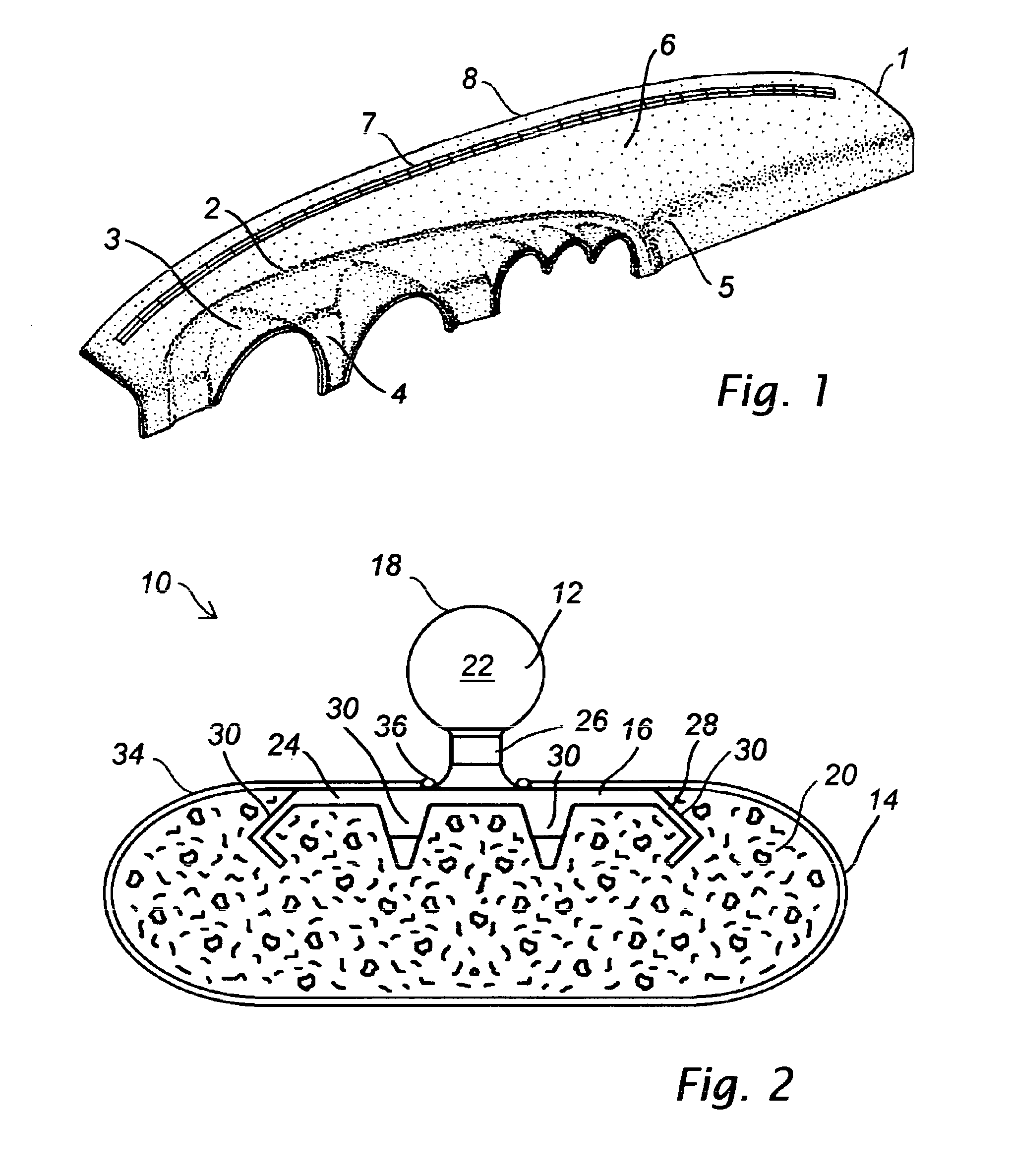

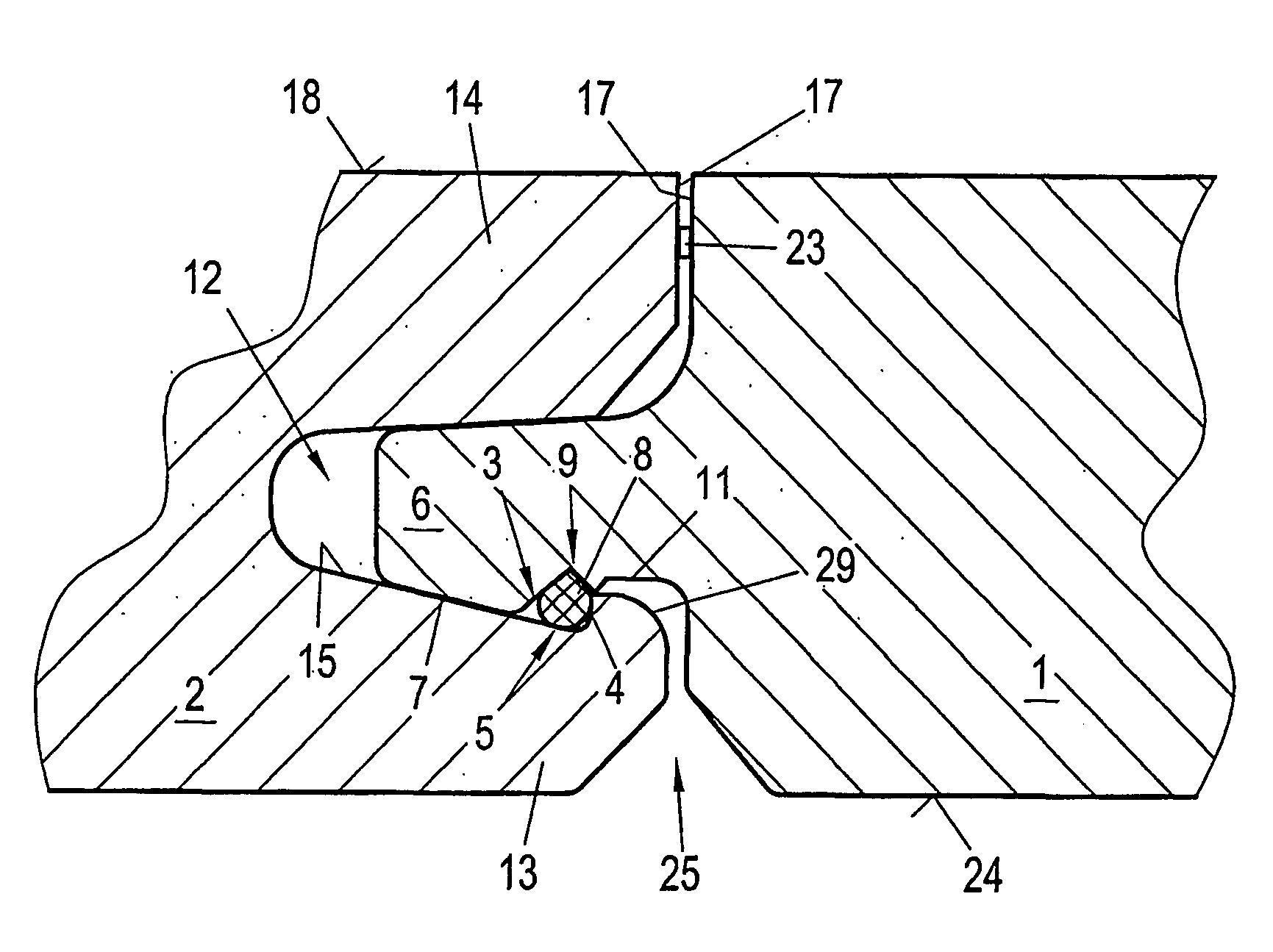

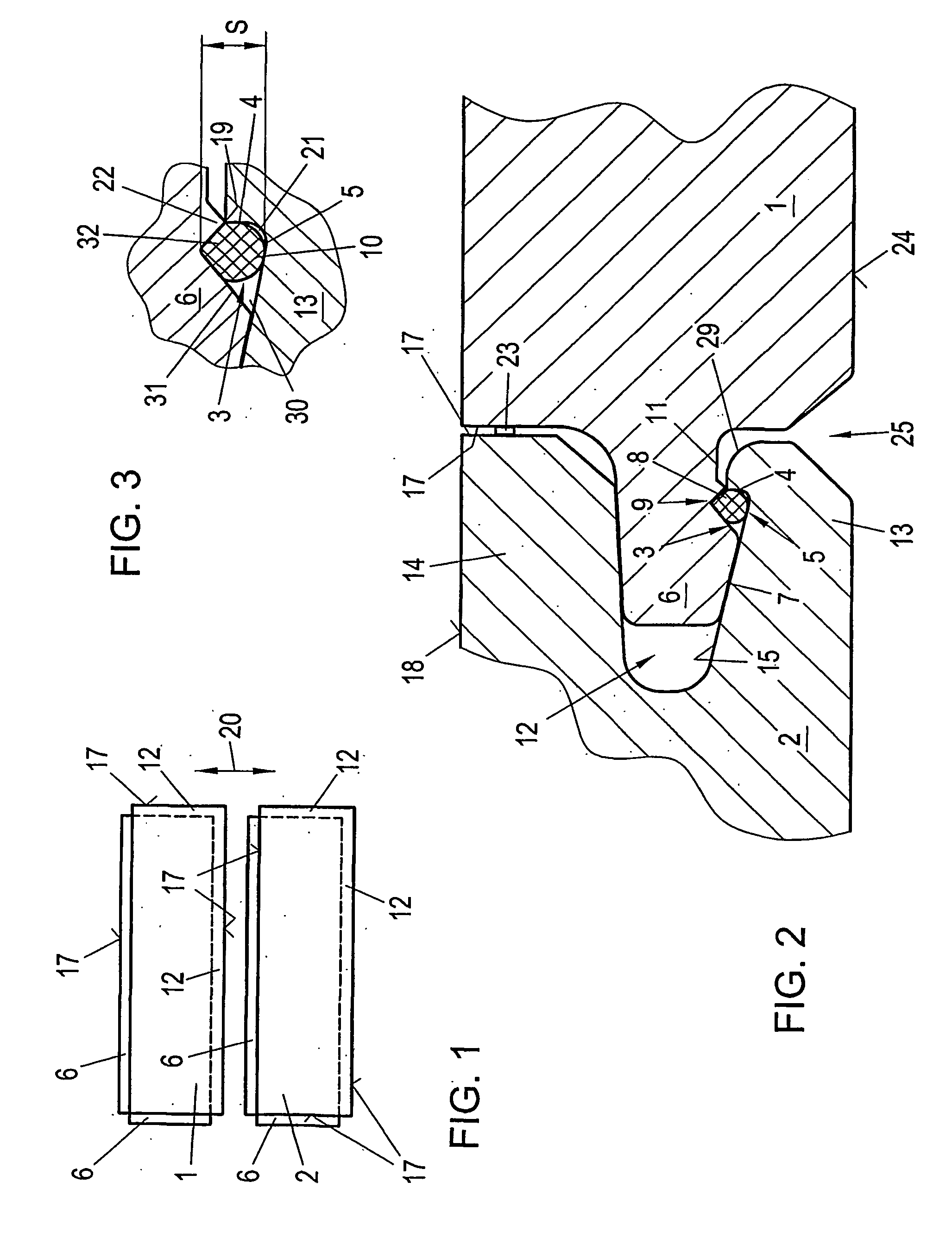

Joining Panel

InactiveUS20080295438A1Manufacture panelEconomical and simpleCeilingsFlanged jointsTongue surfaceMechanical engineering

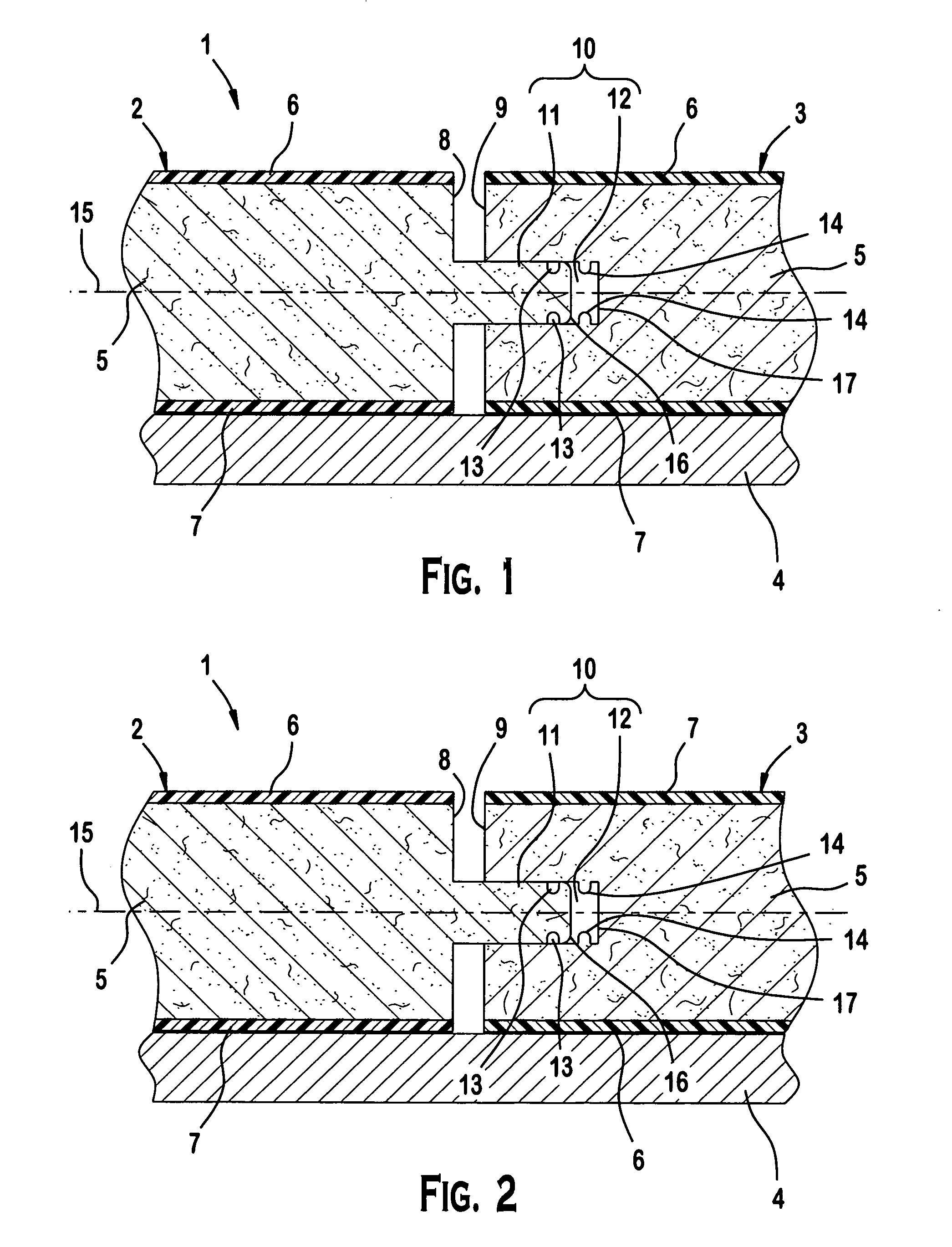

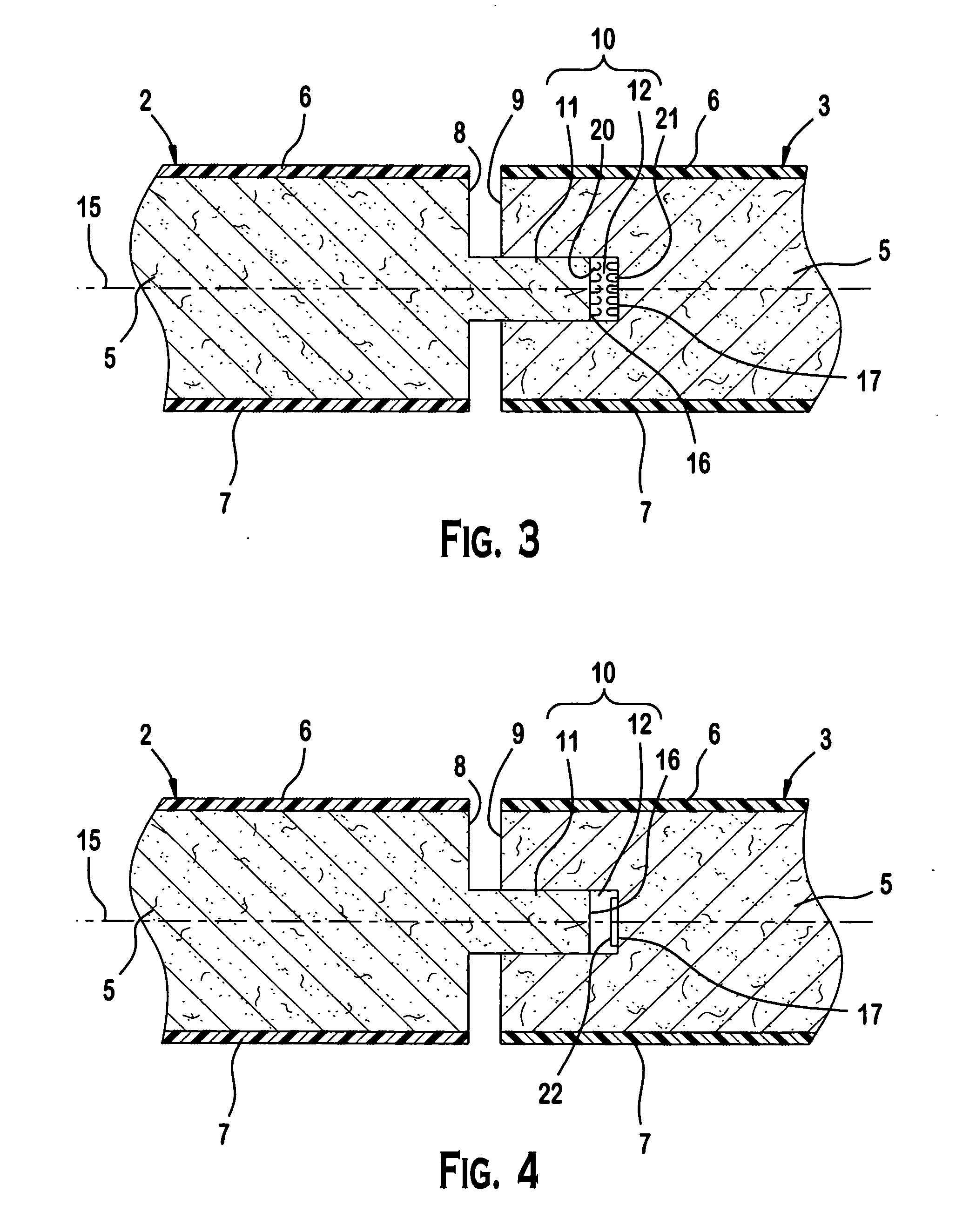

Covering panel(s) for floors have a groove (12) along at least one edge and have a tongue (6) along another edge (17). Panels (1, 2) to be joined to one another can be joined by inserting the tongue (6) into the groove (12). A bead (8) made of an adhesive and / or plastic is placed on or affixed to at least one tongue surface (7). According to the invention, a recess (3) is formed in the tongue surface (7) and serves to accommodate the bead (8), and a detent recess (5), which is delimited by a detent surface (4), is formed in the inside wall surface (15) of the groove, this surface facing the tongue surface (7). When the tongue (6) is inserted into the groove (12), the bead (8) projects into the detent recess (5) whereby enabling the bead (8) and the detent surface (4) to latch.

Owner:KAINDL FLOORING GMBH

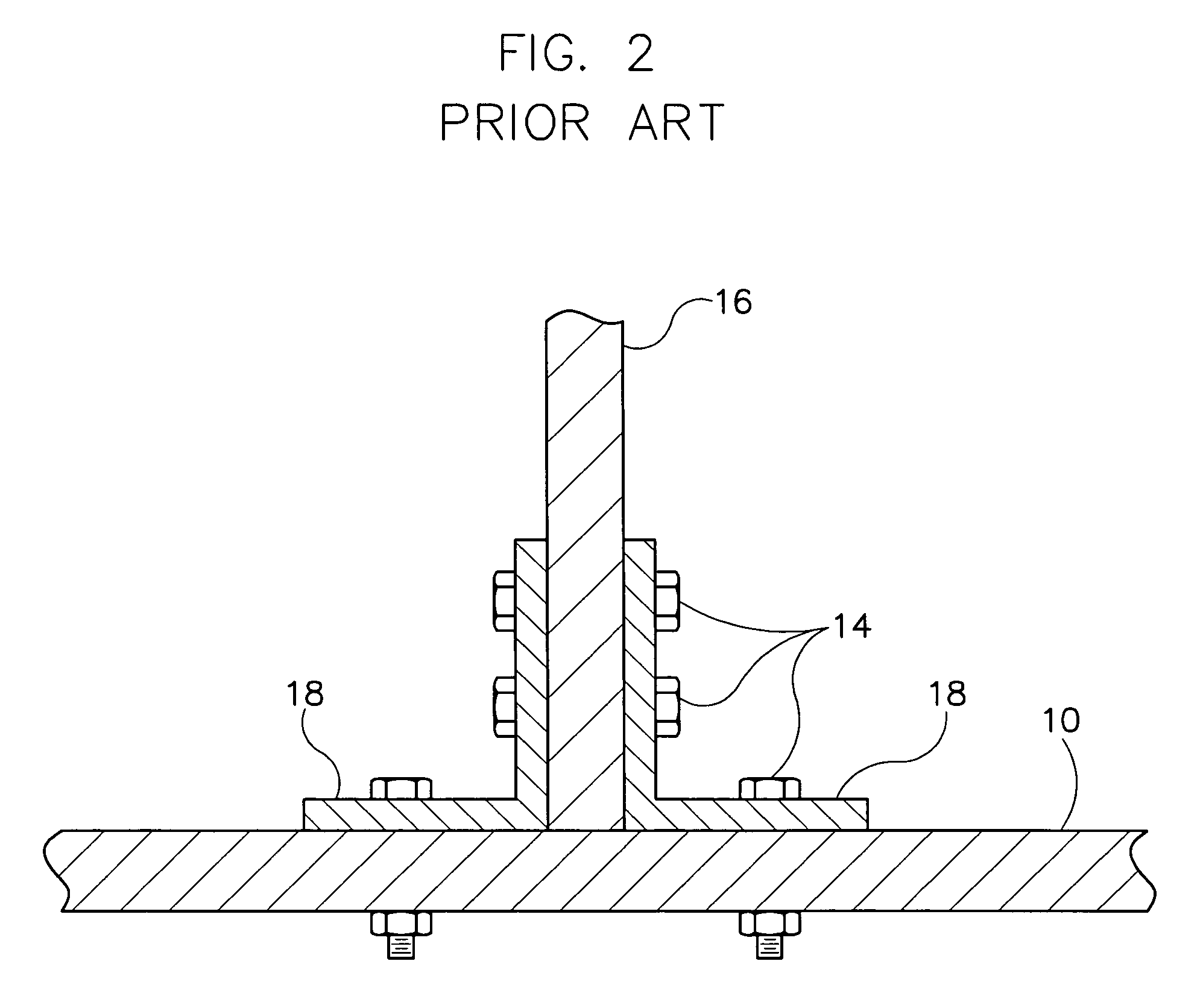

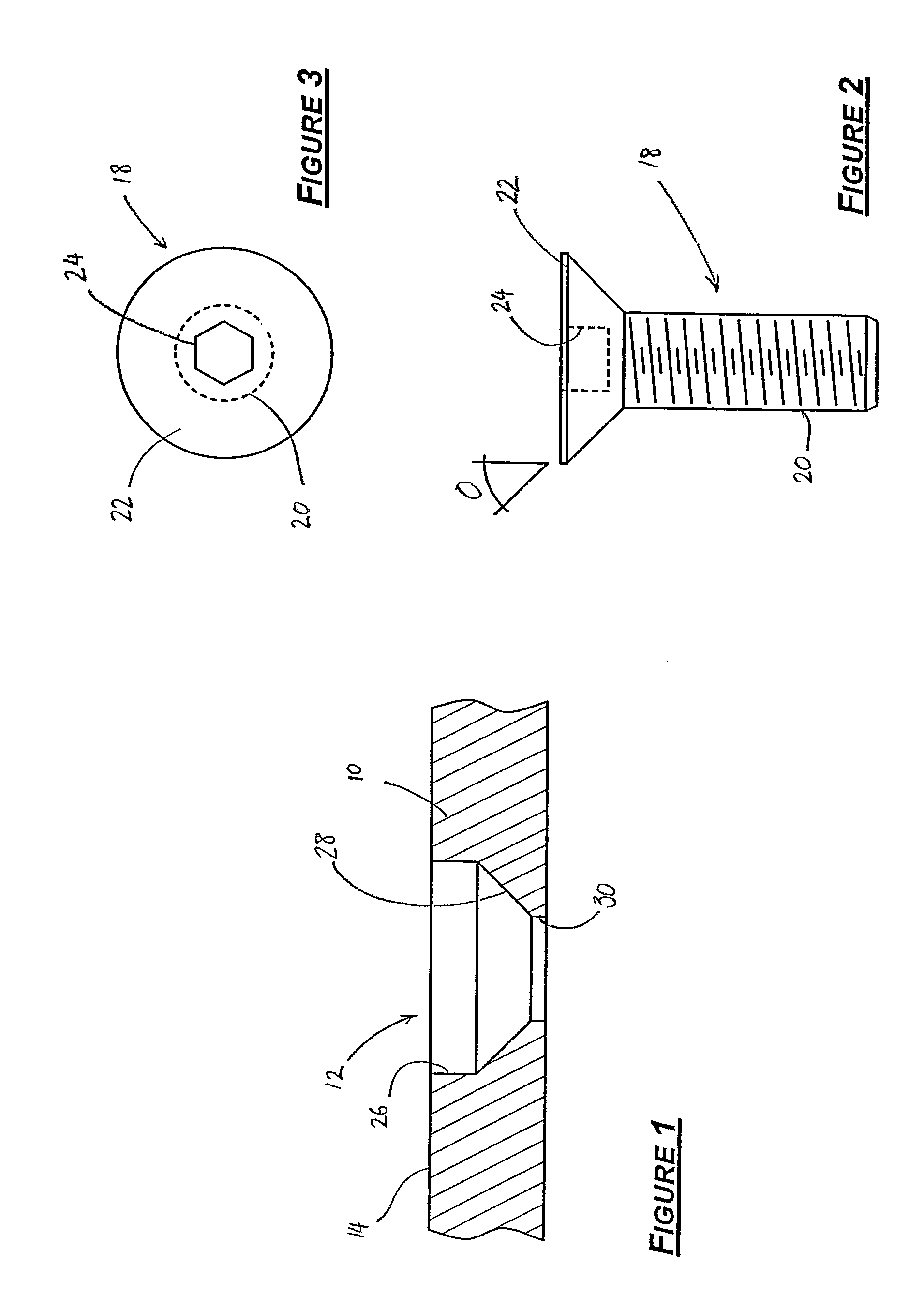

Fastener system for fixing hardened plates

A fastener system for fixing hardened plates includes a fastener element having a frusto-conical head and a threaded shaft portion, wherein a smallest outer diameter of the frusto-conical head is adjacent the threaded shaft, and a largest outer width of the shaft is smaller than a smallest diameter of the head.

Owner:METSO OUTOTEC (FINLAND) OY

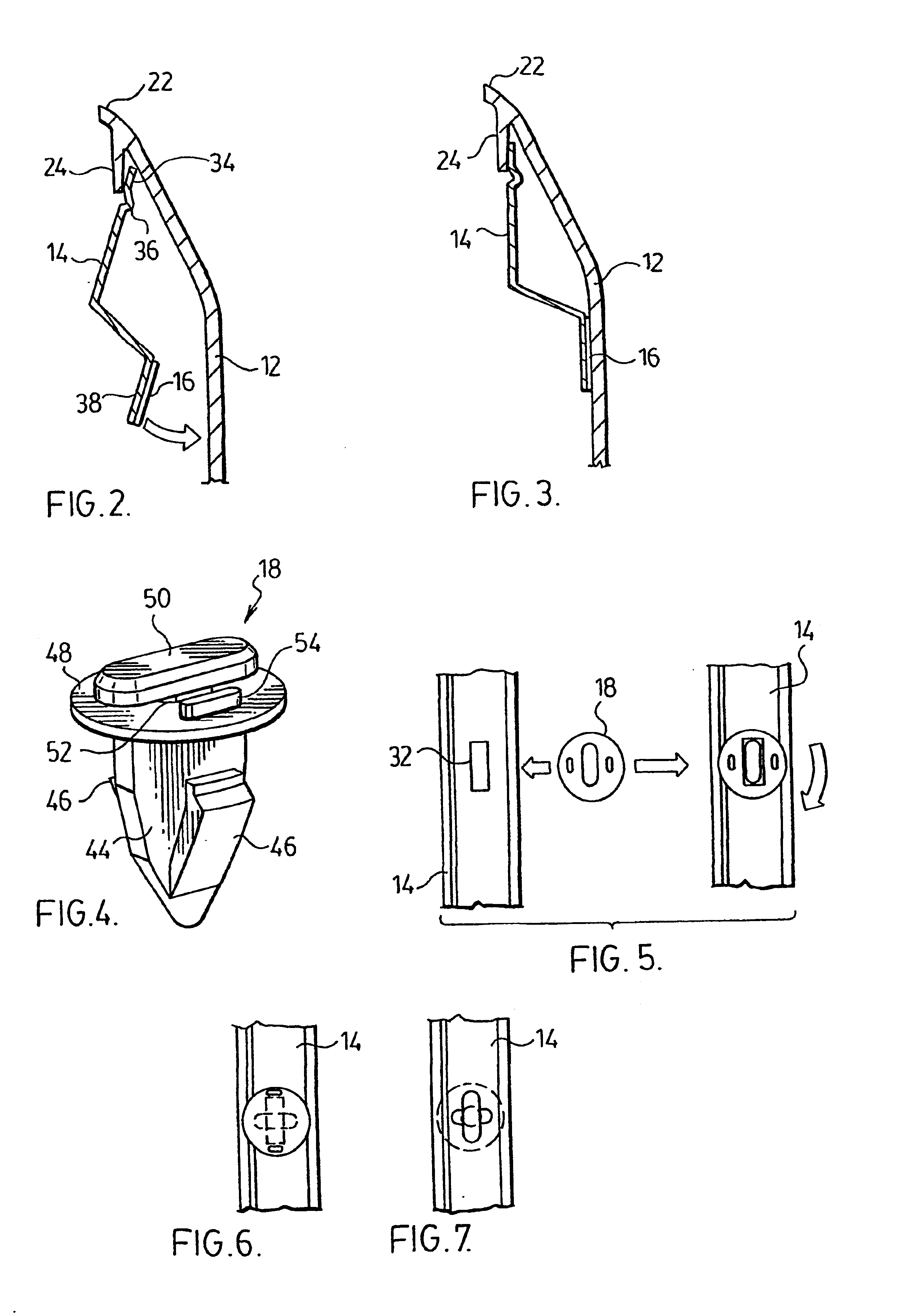

Method of attaching a cladding to a vehicle

A mounting method for mounting a plastic panel (12) to a vehicle substrate provides a support flange (24) on an inner surface of the panel. A reference nodule (28) is positioned on the inner surface of the panel. An elongate bracket (14) has an upper edge (34) thereof engaging the support flange (24). The bracket (14) has a reference notch (40) engaging the reference nodule (28) positioning the bracket (14) relative to the panel (12). A plurality of retainers (18) are mounted on the bracket (14). A double-sided adhesive tape (16) has a first adhesive on a first side thereof compatible for adhesion to the bracket (14) and a second adhesive on a second side thereof compatible for adhesion to the panel (12). The first side of the adhesive tape (16) is applied to the bracket (14) and the second side is applied to the panel (12). The tape (16) allows expansion and contraction movement of the panel (12) while securely retaining the panel (12) to the vehicle substrate.

Owner:DECOMA EXTERIOR TRIM

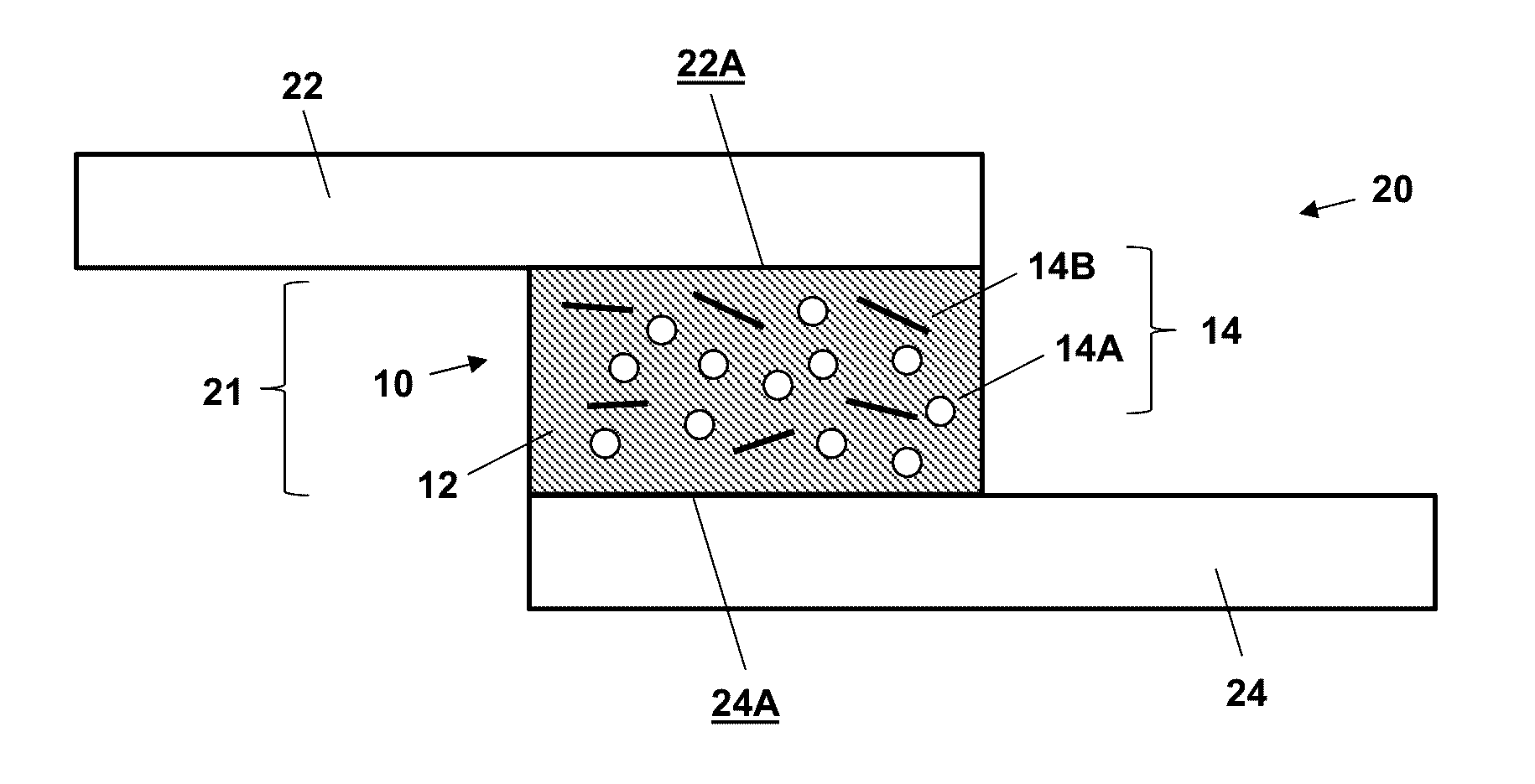

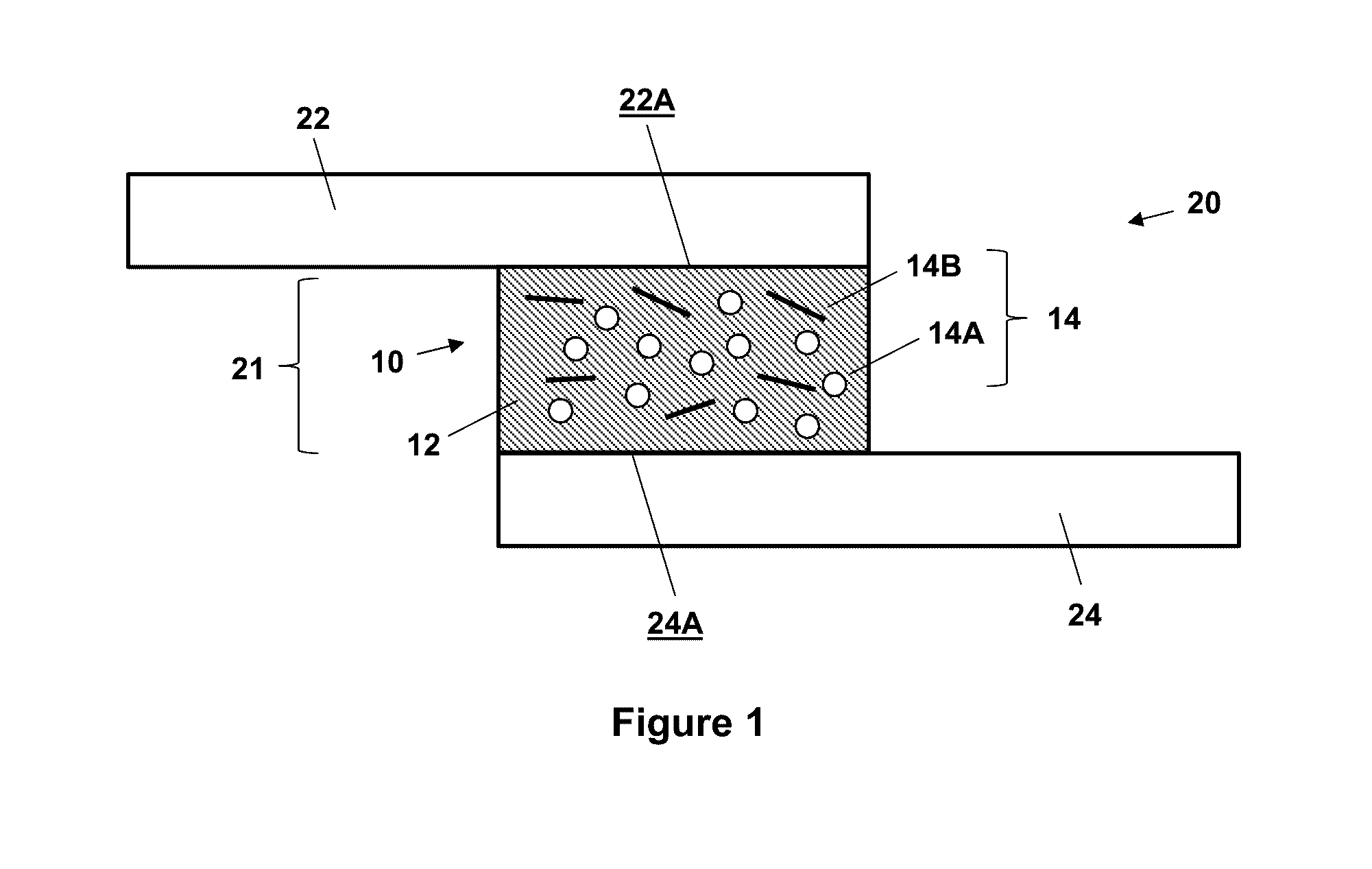

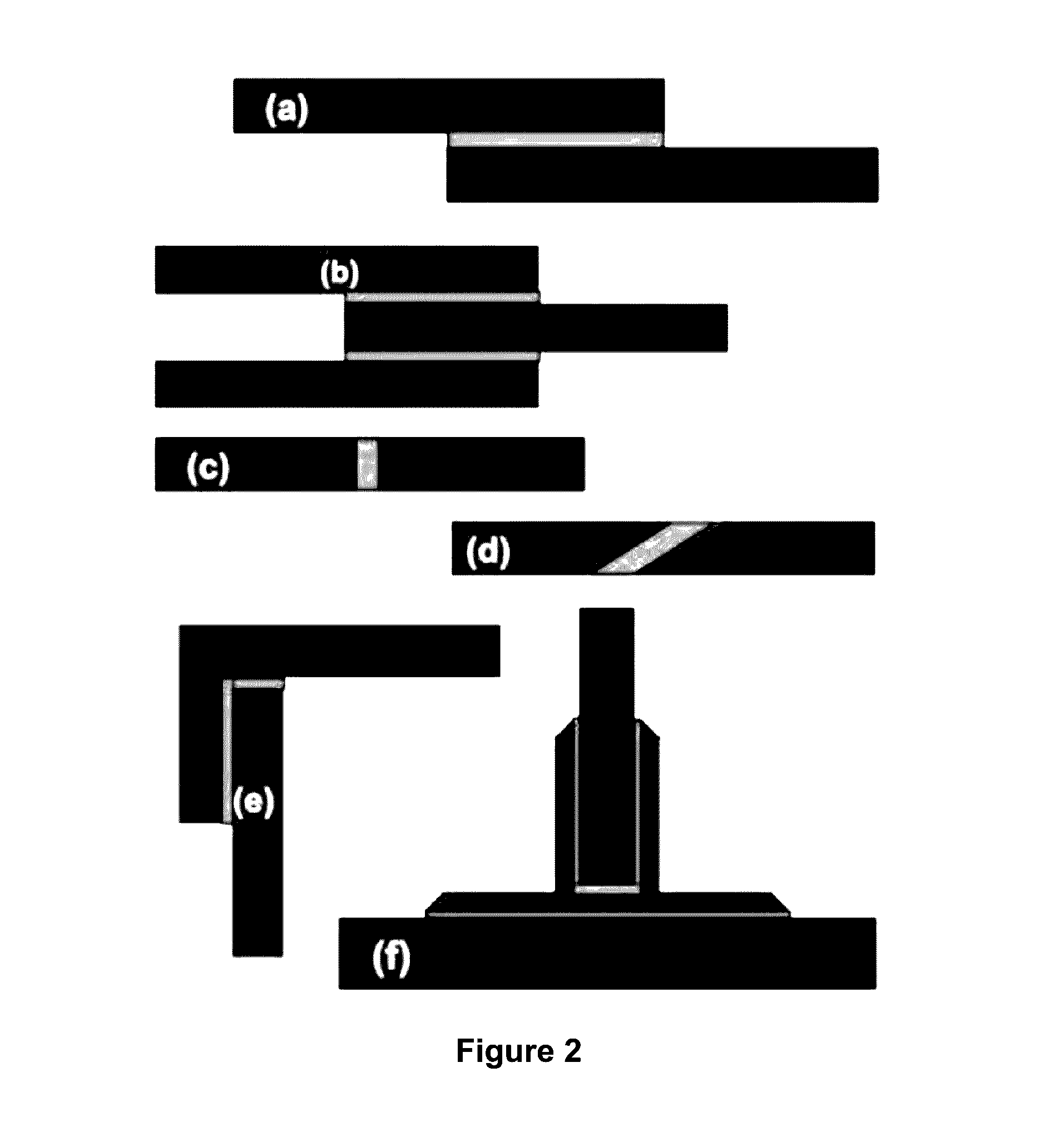

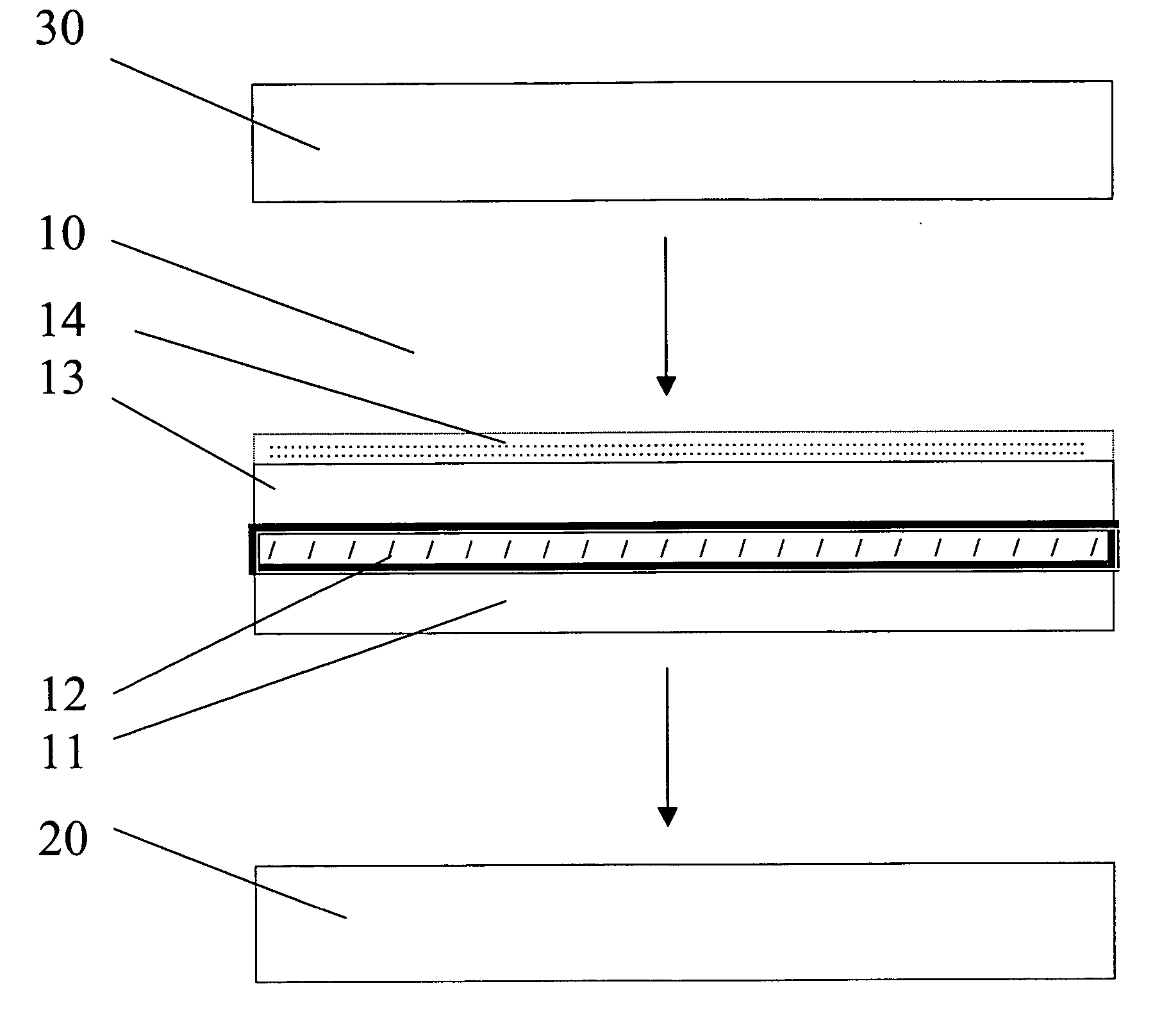

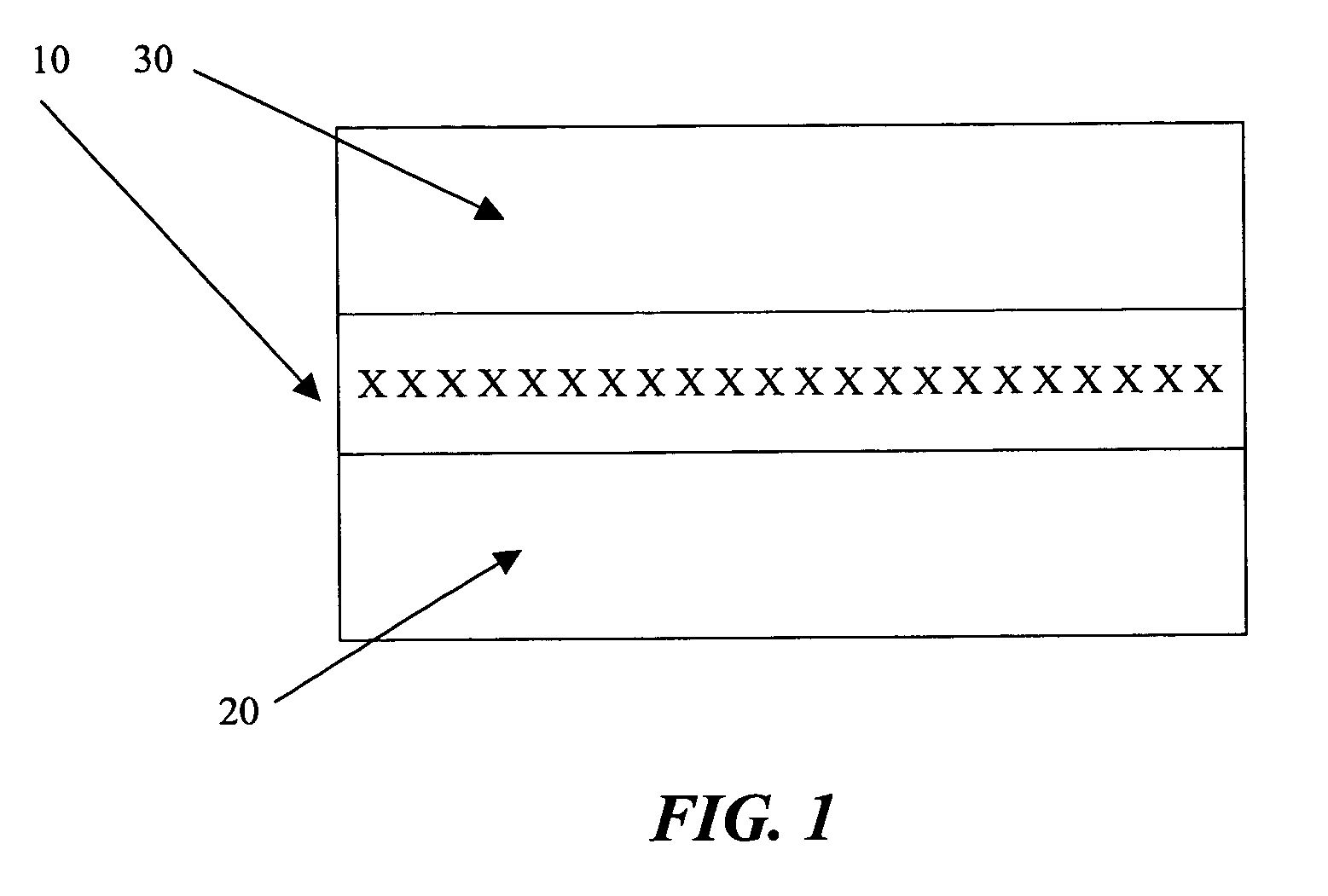

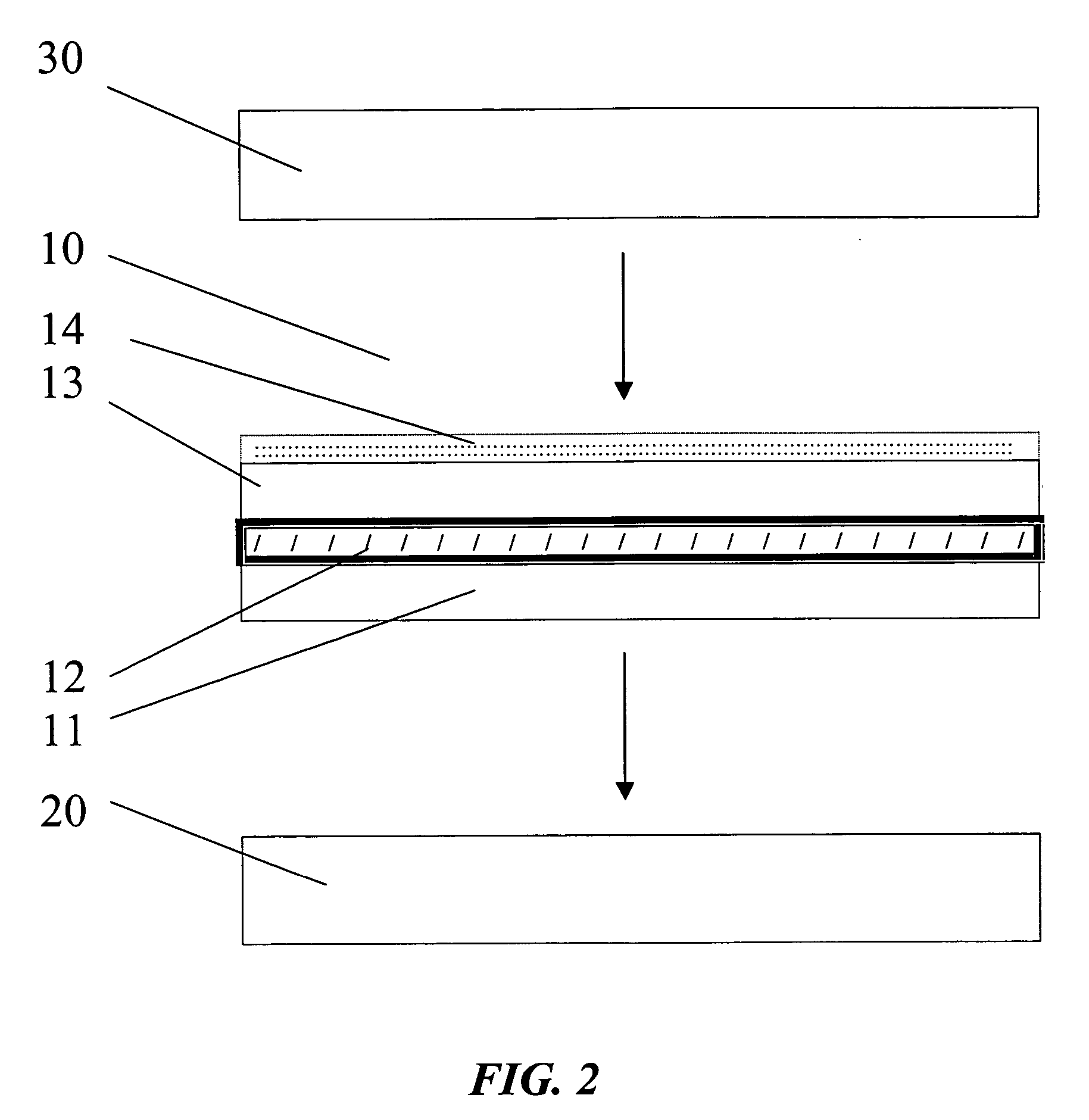

Reversible Adhesive Compositions and Related Methods

ActiveUS20160284449A1Negligible changeMaterial gluingSynthetic resin layered productsHybrid materialMixed materials

The disclosure relates to reversible bonded structural joints using active adhesive compositions that can allow for dis-assembly, repair, and re-assembly. The disclosure is particularly directed to the adhesive composition material, irrespective of the type of the substrate(s) being joined. The adhesive composition can include any thermoplastic adhesive material that can be remotely activated for targeted heating of just the adhesive composition (e.g., and not the surrounding substrates being joined) via the inclusion of electromagnetically excitable particles in the adhesive composition. The substrates can be any metal material, any composite material, any hybrid material, or otherwise. The disclosed adhesive compositions allow for recyclability of parts at the end of their lifetime and repair / replacement of parts during their lifetime.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

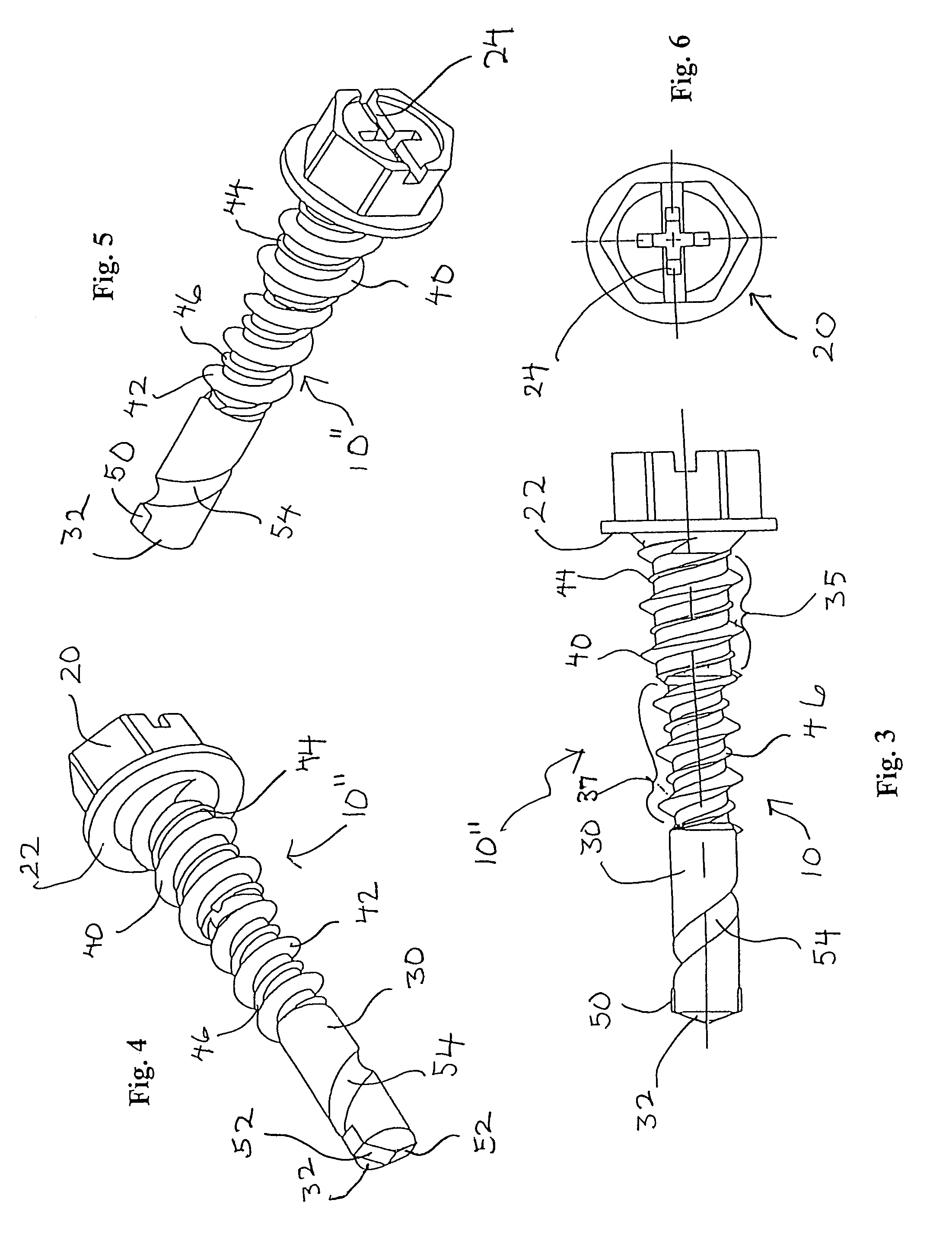

Self-drilling, self-anchoring fastener for concrete

A fastener adapted for anchoring into a masonry structure, such as a concrete block, employs an epoxy resin system so that the fastener is both mechanically engaged and bonded to the structure. In one preferred configuration, the bead is composed of a hardener, a resin and a nylon powder and has a cardioid-shaped configuration which subtends substantially 360° around the shank at an intermediate position of a threaded portion of the fastener. Various configurations are disclosed, including a fastener wherein adhesive in microencapsulated form is also applied to a lower intermediate portion. In addition, wings may extend from the shank.

Owner:SIMPSON STRONG TIE

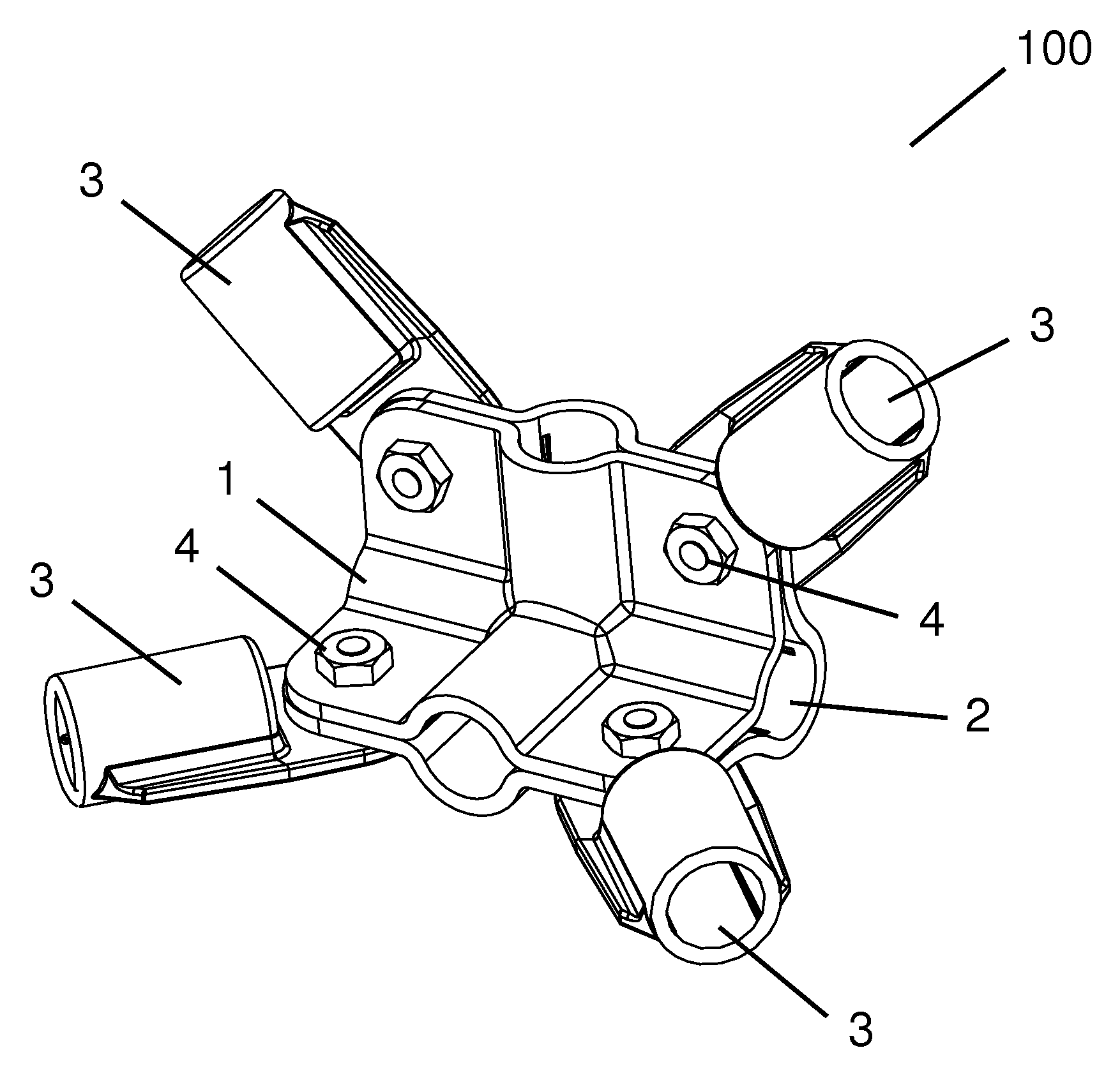

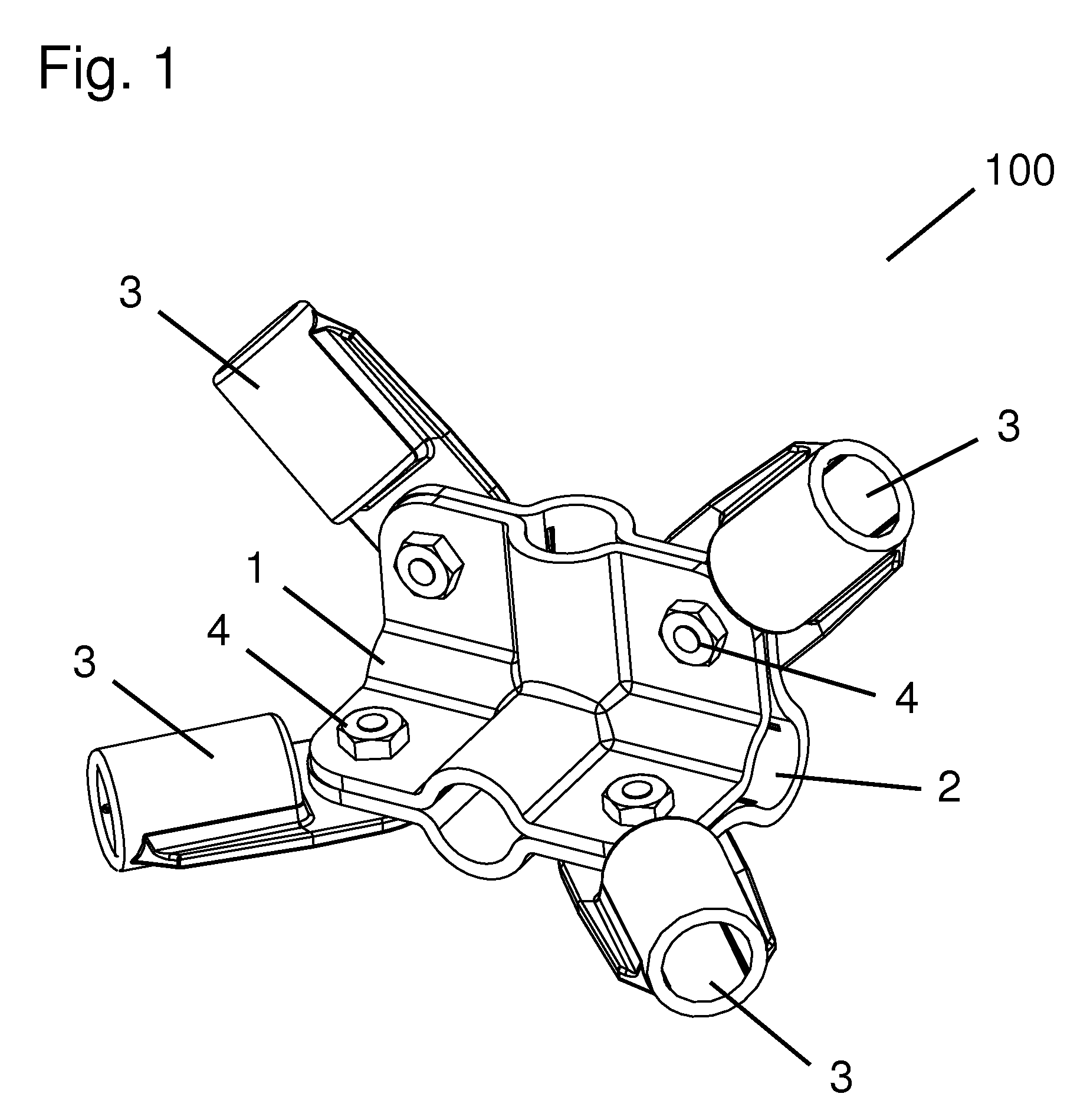

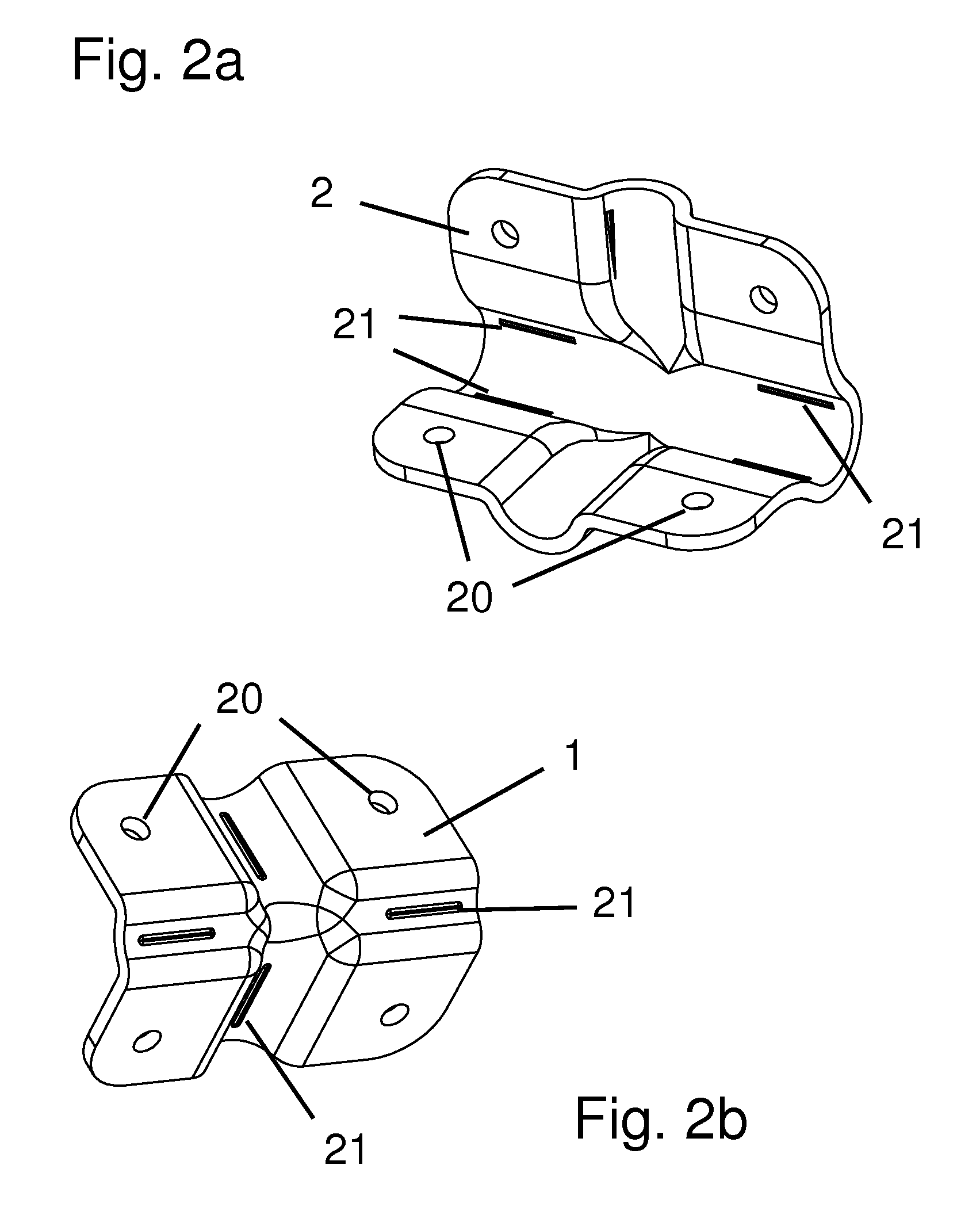

3-dimensional universal tube connector system

ActiveUS20100192506A1Simple and easy and inexpensive fabricationSecuring devicesGirdersFiberAdhesive

The present invention includes a system for connecting tubes or rods, which are preferably uni-directional pultruded, filament wound, or roll-wrapped carbon-fiber tubes or rods, together to form trusses and other structures using a series of connector pieces preferably bonded together with adhesive.

Owner:ALLRED & ASSOC INC

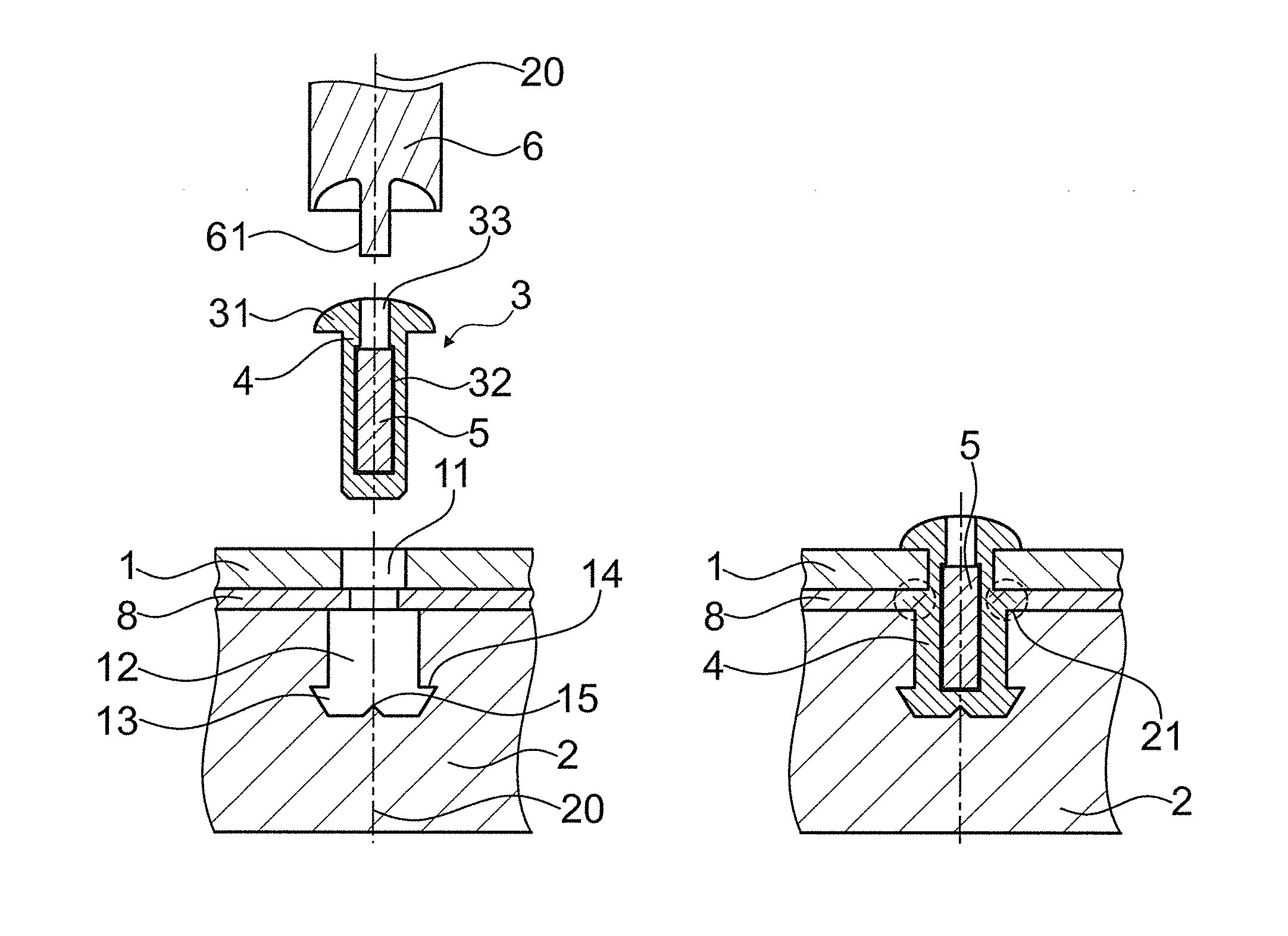

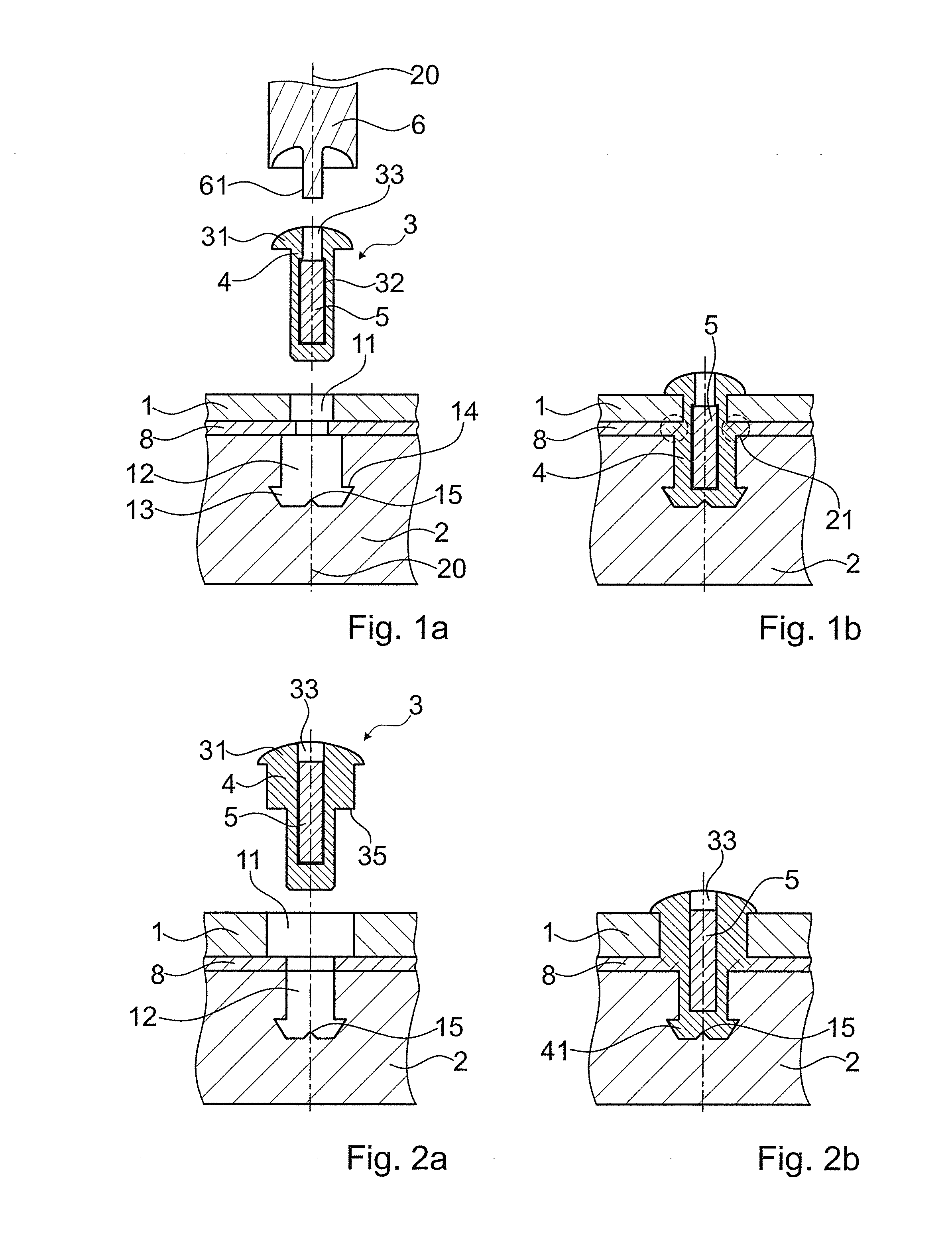

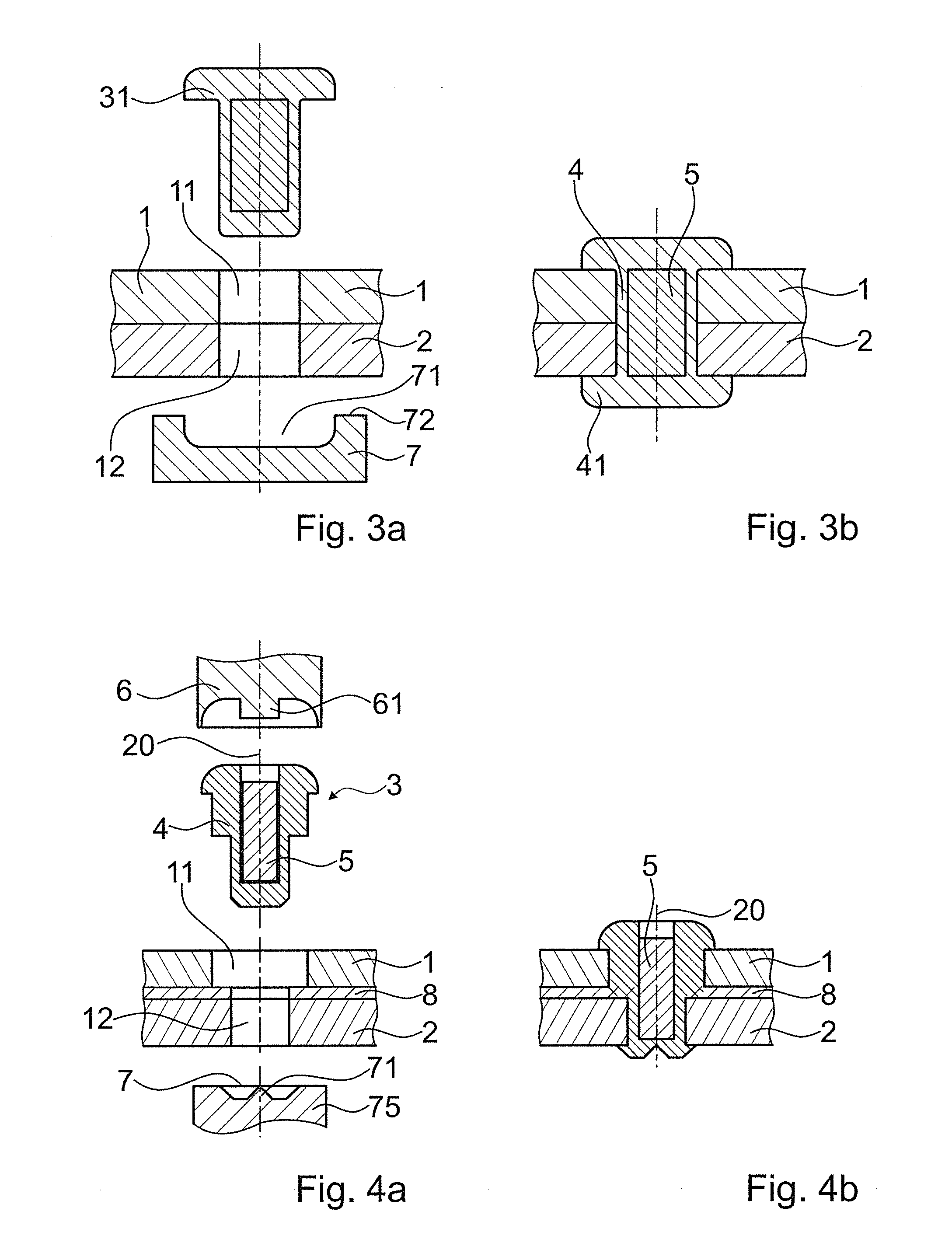

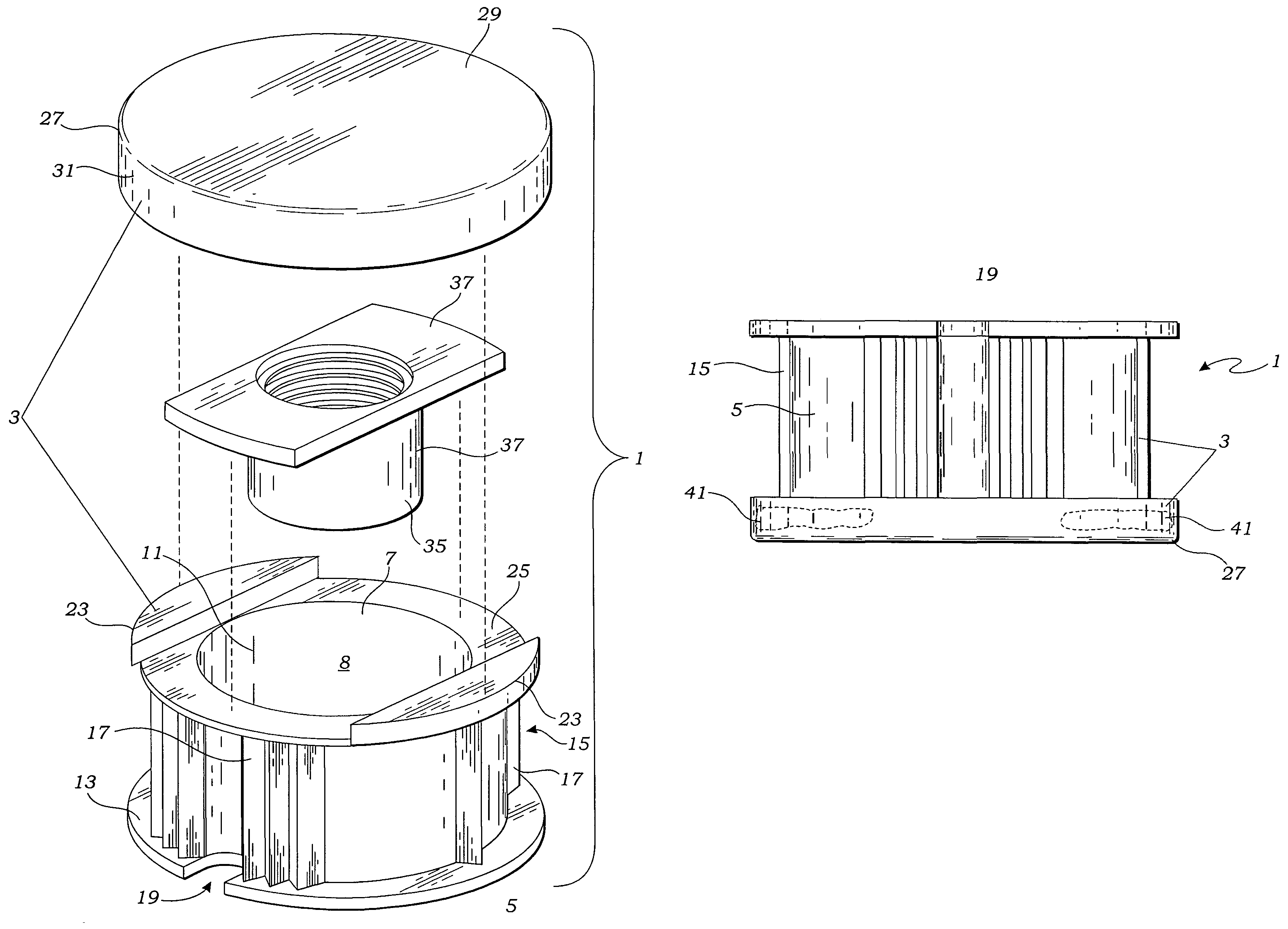

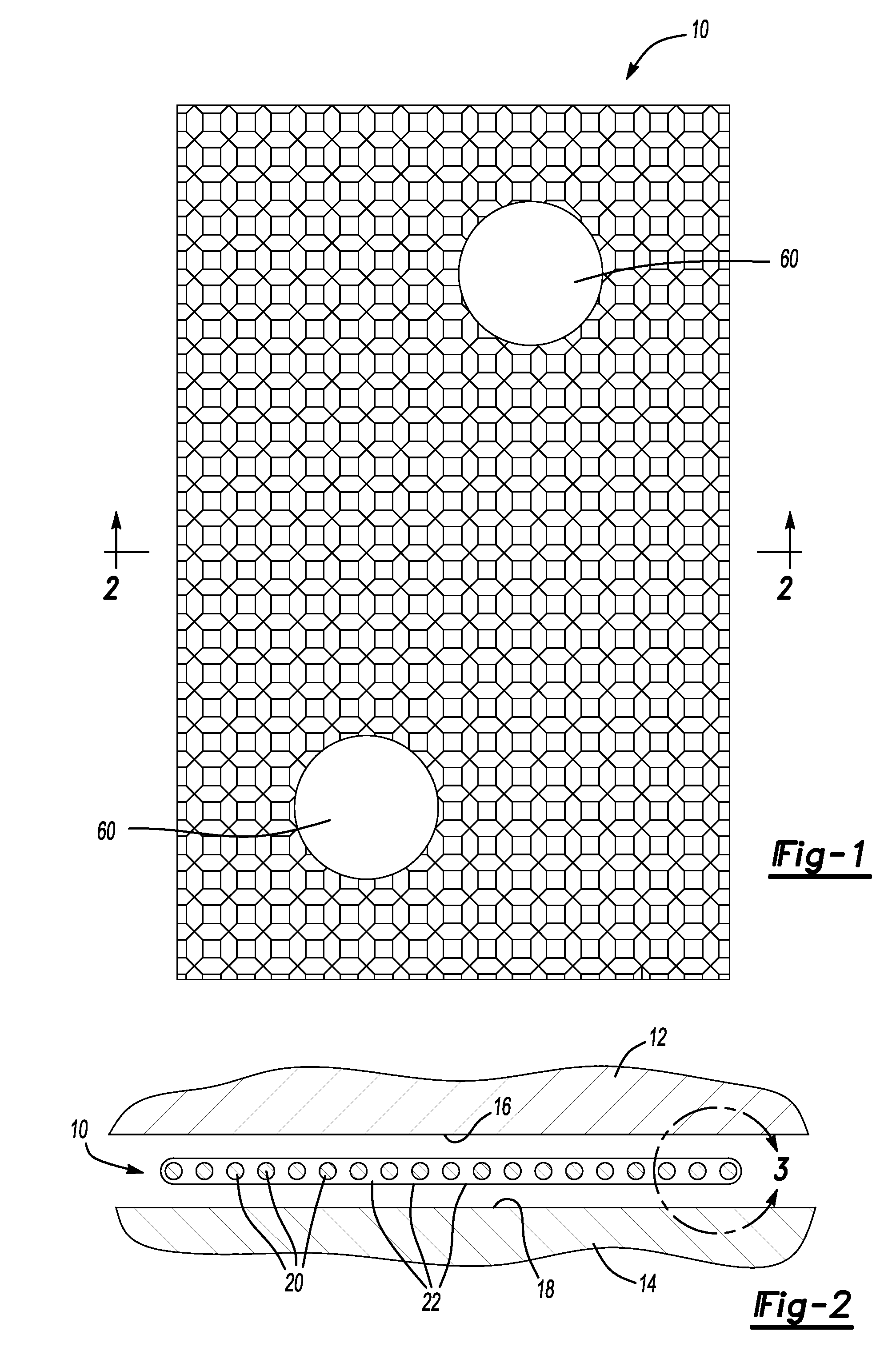

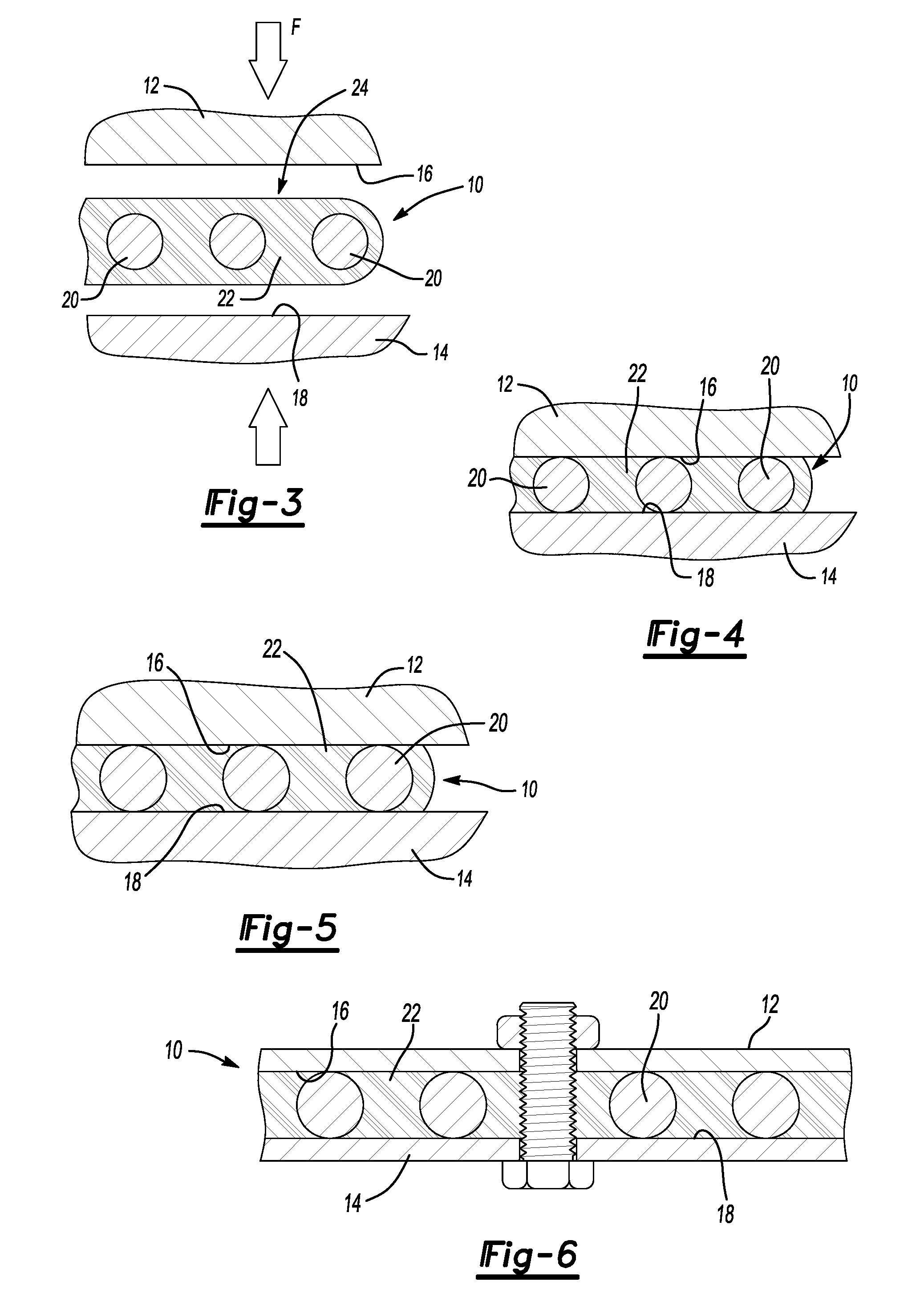

Bonding objects together

ActiveUS20160341234A1Improve shear resistanceImprove ductilityMaterial gluingSheet joiningEngineeringMechanical pressure

A method of bonding a connector to a first object includes providing the connector, the connector being separate from the first object and including a thermoplastic material; arranging the first object and the connector relative to one another so that the connector reaches from a proximal side of the object through a first opening in the object; generating and applying vibrations and mechanical pressure to the connector until a flow portion of the thermoplastic material is liquefied and caused to flow sideways radially into an open space; and removing the source of the vibrations and causing the liquefied thermoplastic material to re-solidify, resulting in the connector with a foot portion, a head portion, and a shaft portion between the foot portion and the head portion. The shaft portion extends along an axis through the first opening, and secures the connector to the first object.

Owner:WOODWELDING

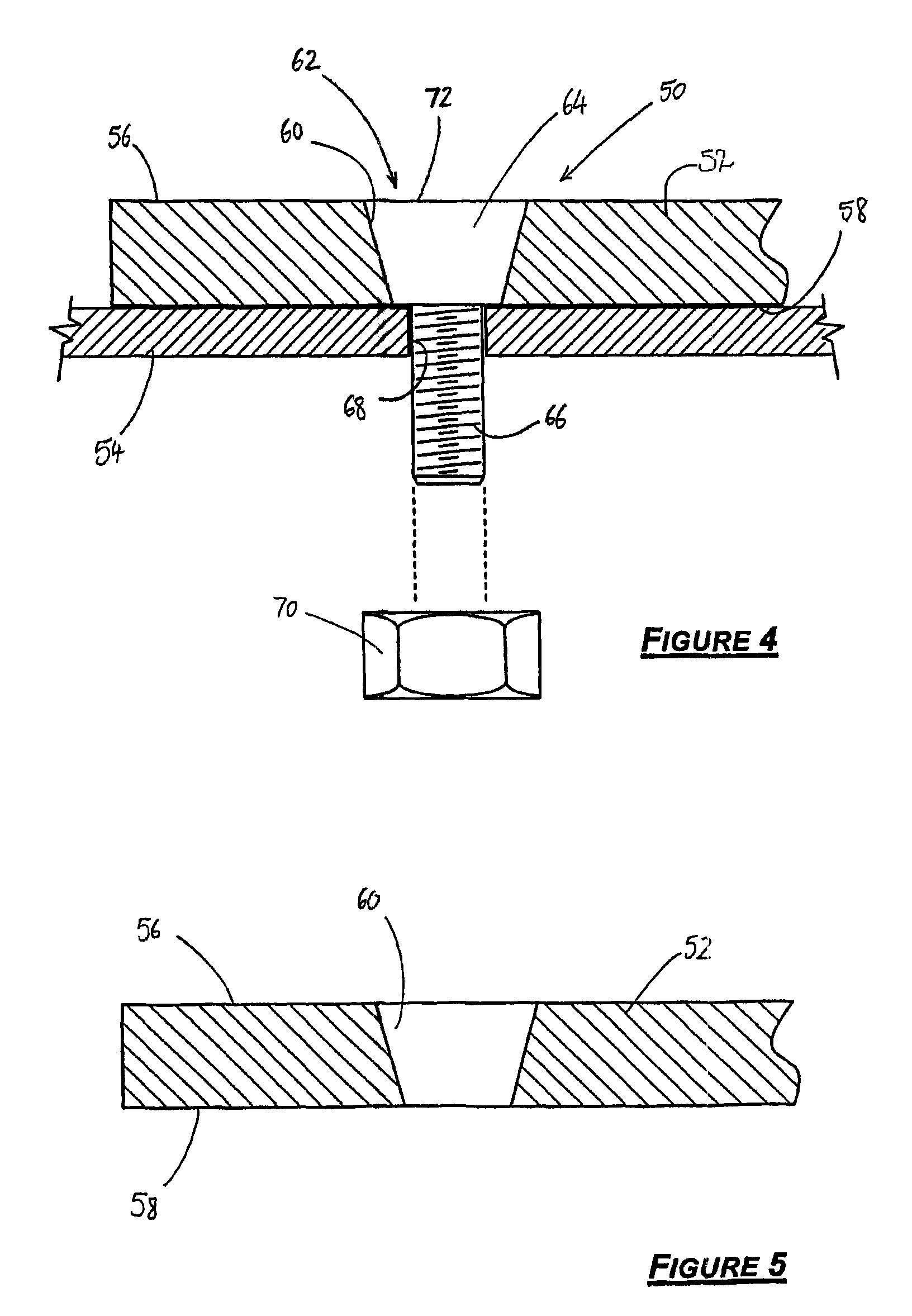

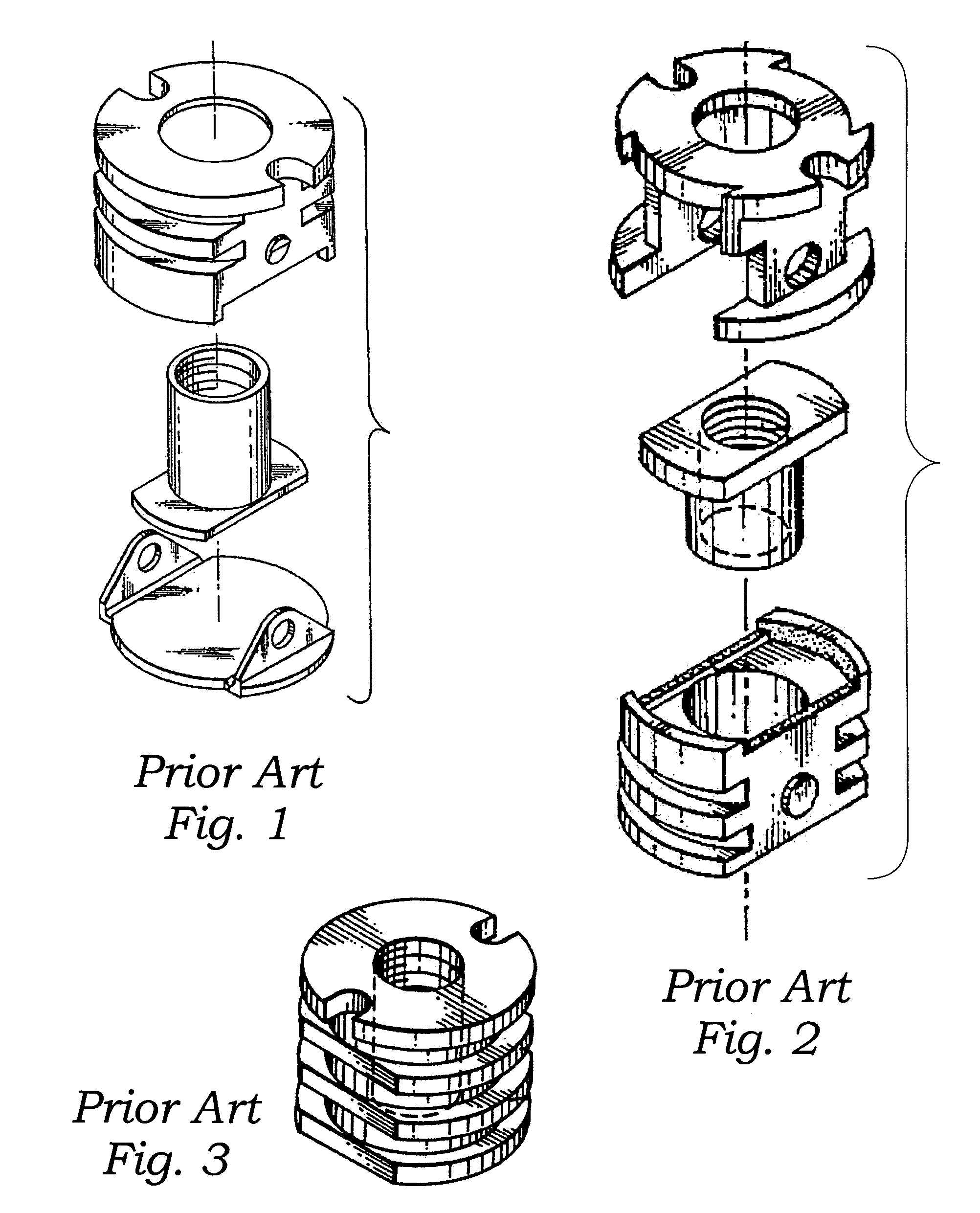

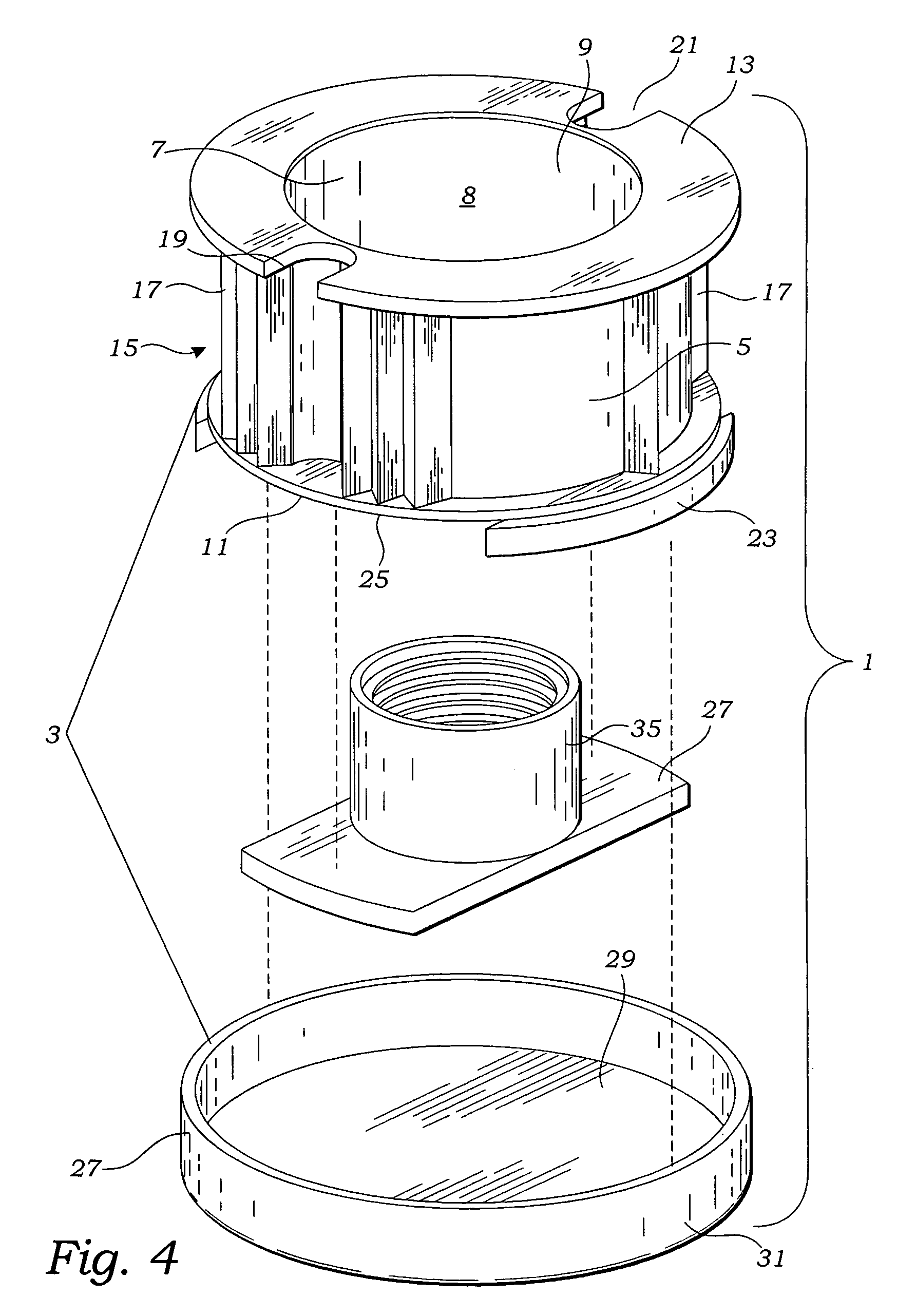

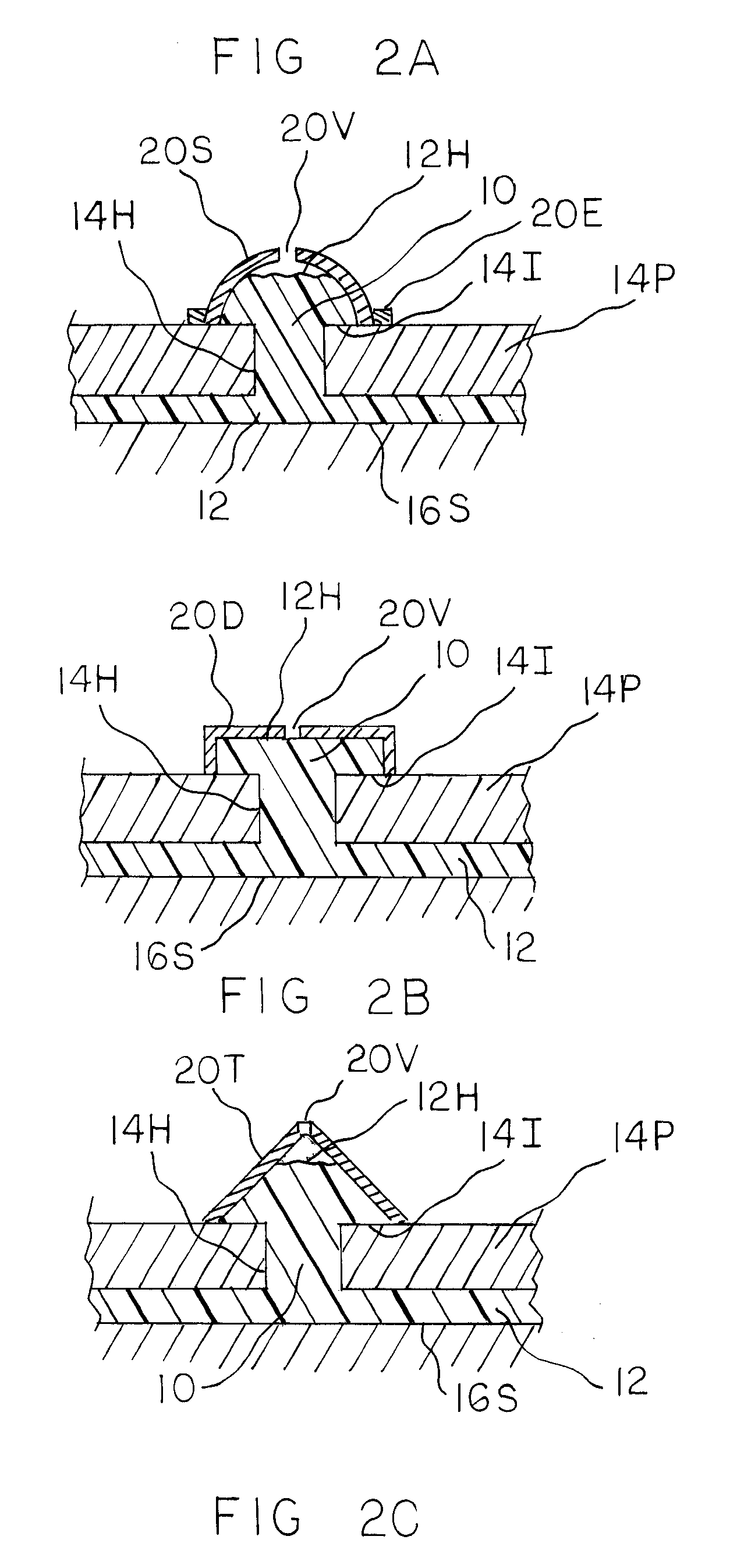

Inset panel fastener

ActiveUS7195436B1Simple engagementPoint of failureRemovable ornamentalMaterial gluingHoneycombAcoustic wave

An inset panel fastener anchors into honeycomb substrates employed in the aircraft industry. The inset panel fastener provides significantly increased load carrying capabilities with a simple inexpensive construction. The inset panel fastener includes a plastic casing and a central floating fastener element. The casing includes a body, disk and cap. The body is generally barrel shaped including a central chamber for holding the fastener element which is preferably a female fastener. The disk radially projects from the top of the body and includes a fill hole and vent hole. Meanwhile, the cap engages and covers the bottom of the barrel shaped body. The cap is affixed in place using a weld, such as a sonic weld.

Owner:NMC GROUP +1

Integral Rivets Formed Of An Adhesive For Fastening Rodenticide Bait Stations To A Substrate And Ballasted Bait Station

A rivet formed of an adhesive to form a mechanical attachment to a bait station which is then adhered by the adhesive to a substrate at the intended location of use. In another embodiment, adhesive rivet is also mechanically attached to the substrate. The invention also comprises a ballasted bait station of a sufficient weight to immobilize the bait station. The ballasted bait station may then simply be placed in the intended location.

Owner:RHINO HIDE

Method for fastening building materials together

InactiveUS20060059825A1The process is convenient and fastProvide structural integrityAdhesive processesCeilingsRoof tileAdhesive

Methods and structures involving the use of a double-sided adhesive membrane assembly having one adhesive surface with low initial tackiness to permit a substrate to be re-positionable even if pressed into contact against the adhesive. The method allows wood deck components, flooring planks, roofing tiles, and other building material components to be fastened together conveniently while securing a waterproofing and / or sound-deadening effect.

Owner:WIERCINSKI ROBERT A +2

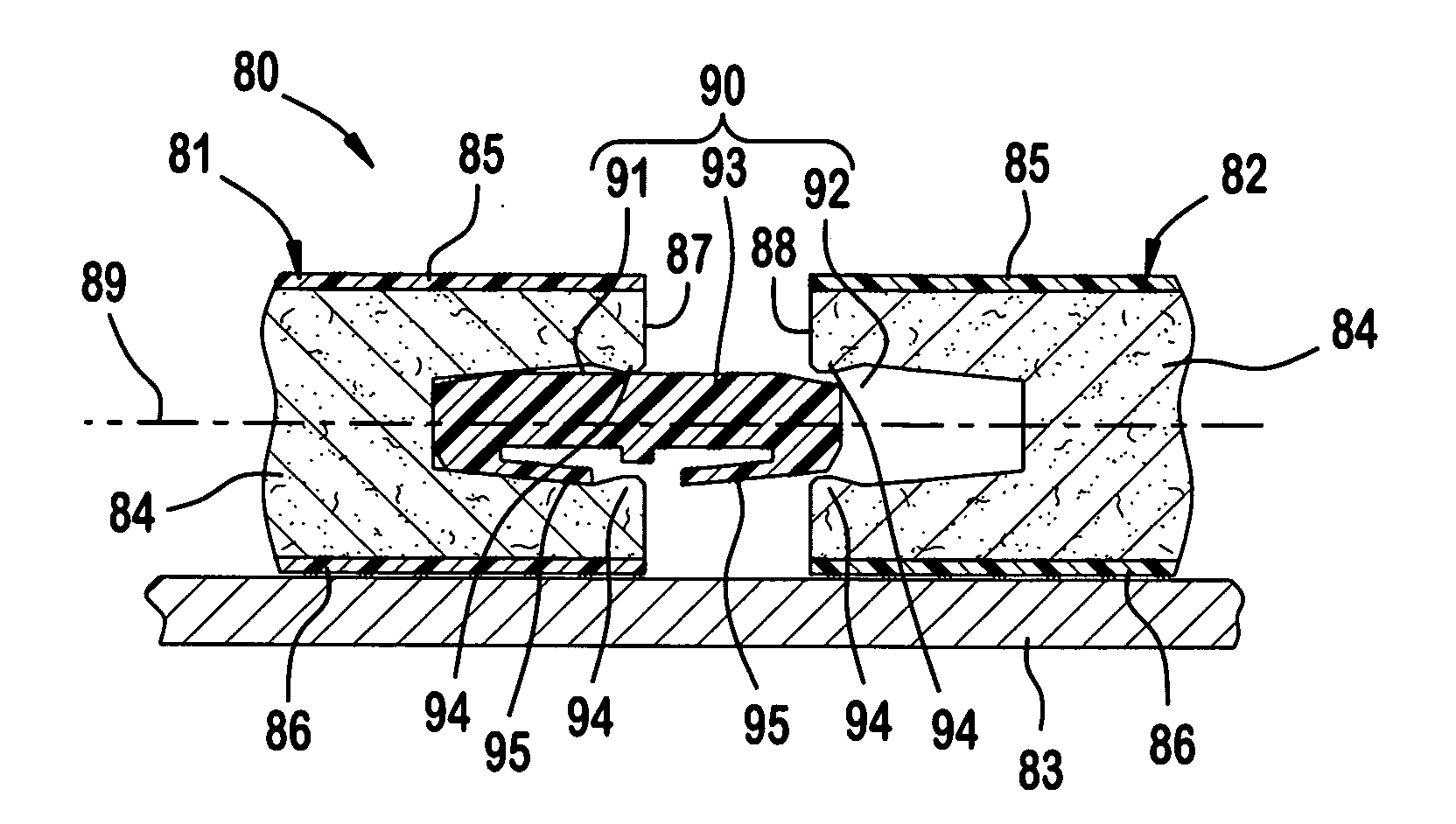

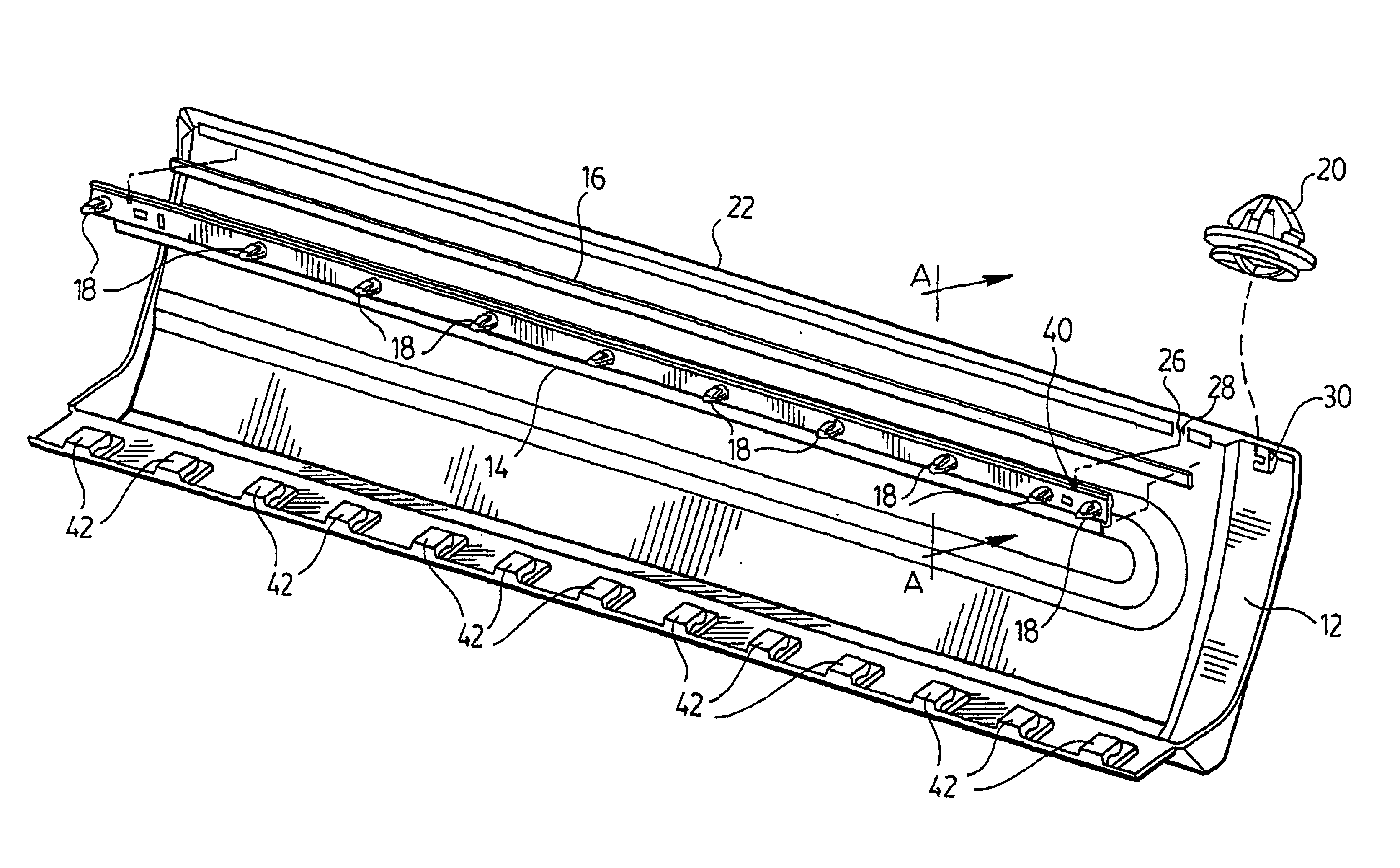

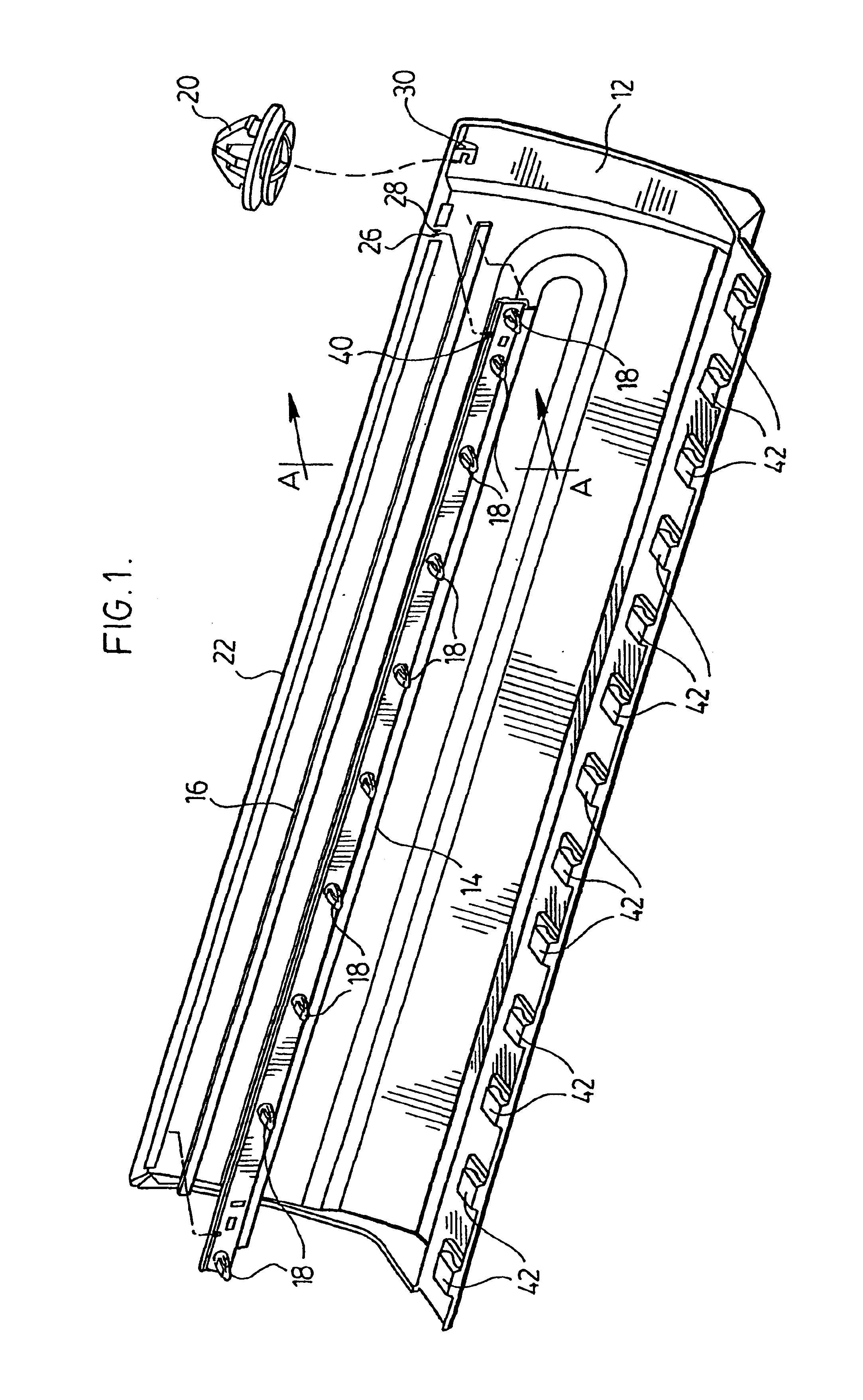

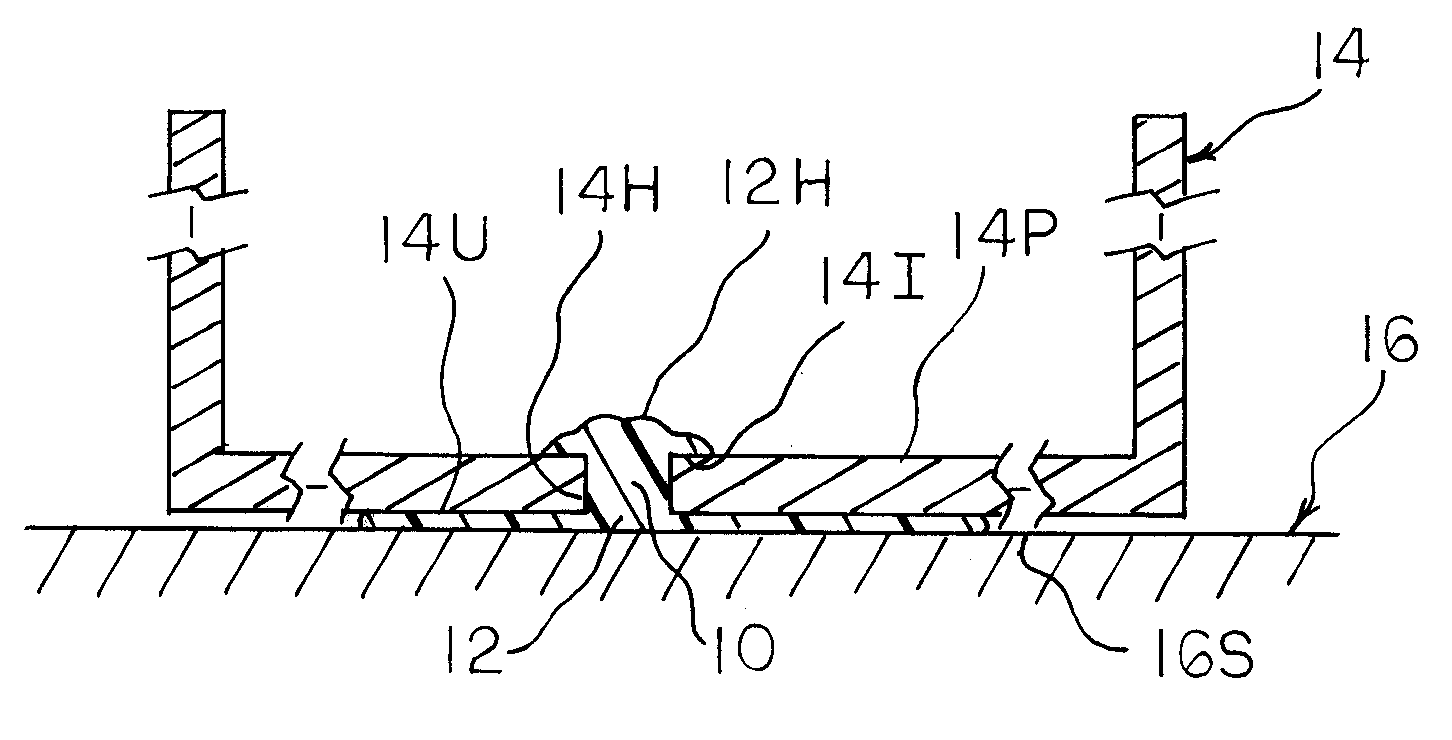

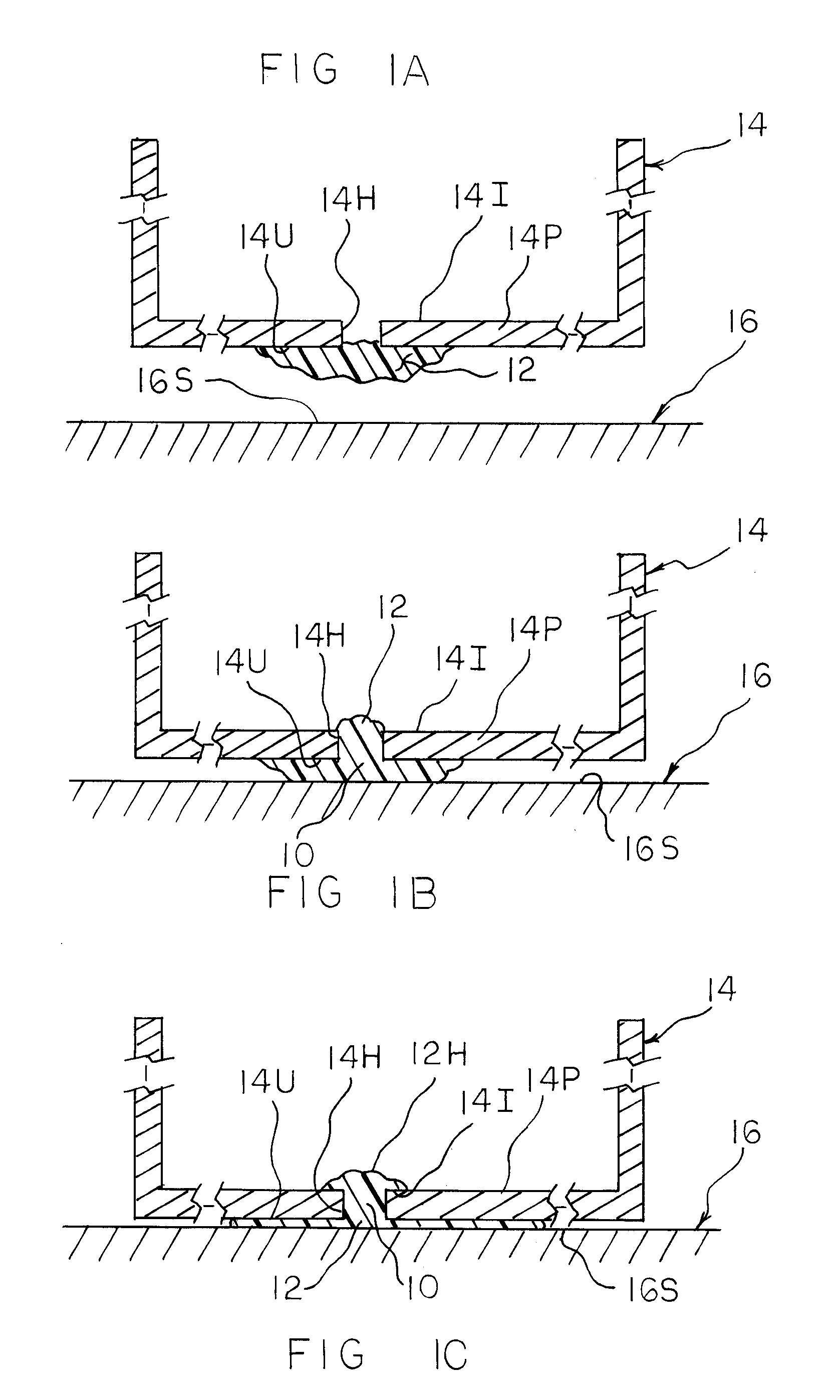

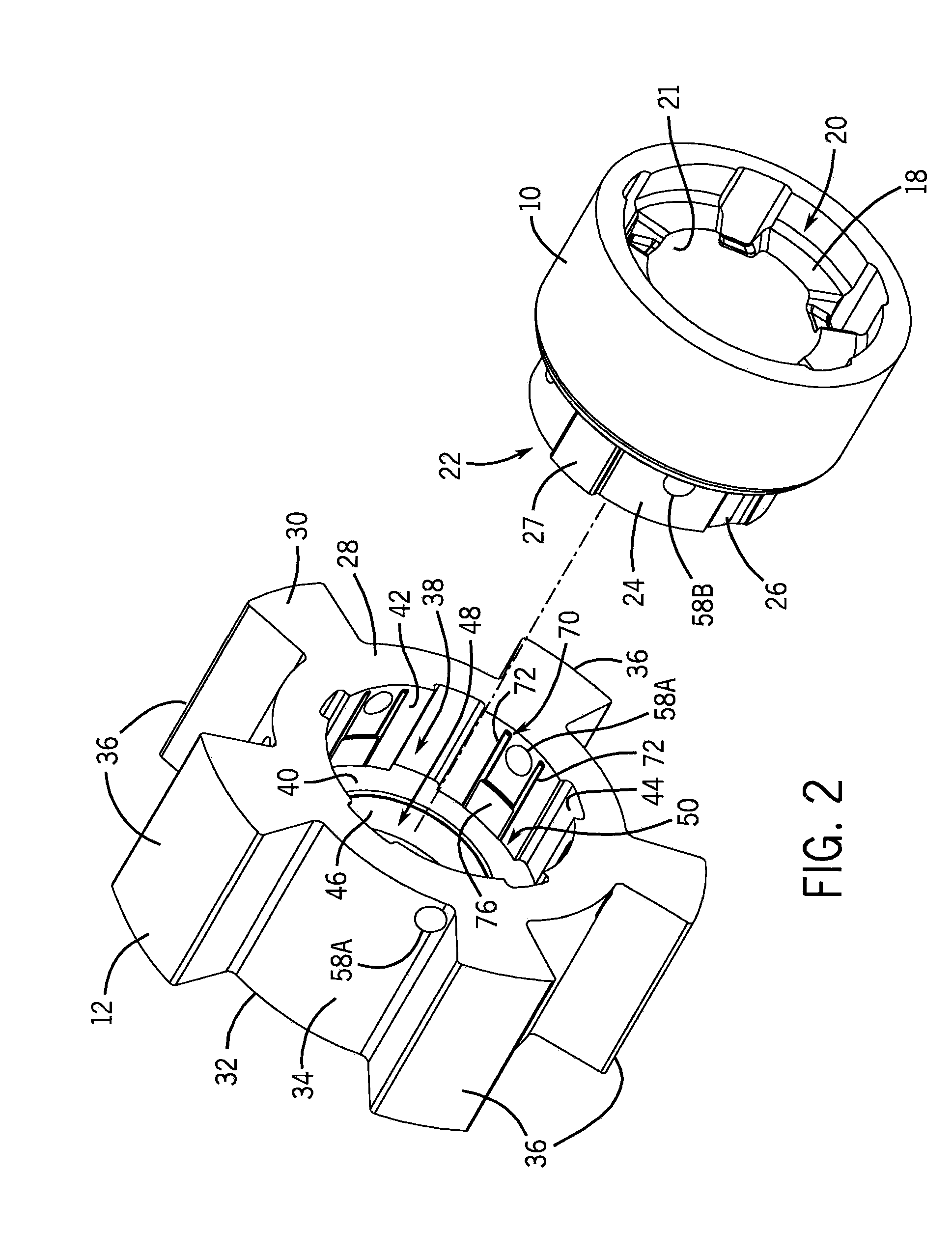

Articulating fastener assembly

A fastener assembly for securely fastening a decorative panel in spaced relation to a support backing includes a base member adapted to be operatively mounted to the decorative panel, a carrier member, and a linking member operatively extending between the base member and the carrier member such that the base member is disposed spaced from the carrier member. A fastening medium is supported by the carrier member and adapted to operatively interconnect the carrier member to the support backing. The linking member operatively interconnects the base member and the carrier member in articulating fashion such that the base member is transversely moveable relative to the carrier member.

Owner:COMML IMPORTS & ASSEMBLY

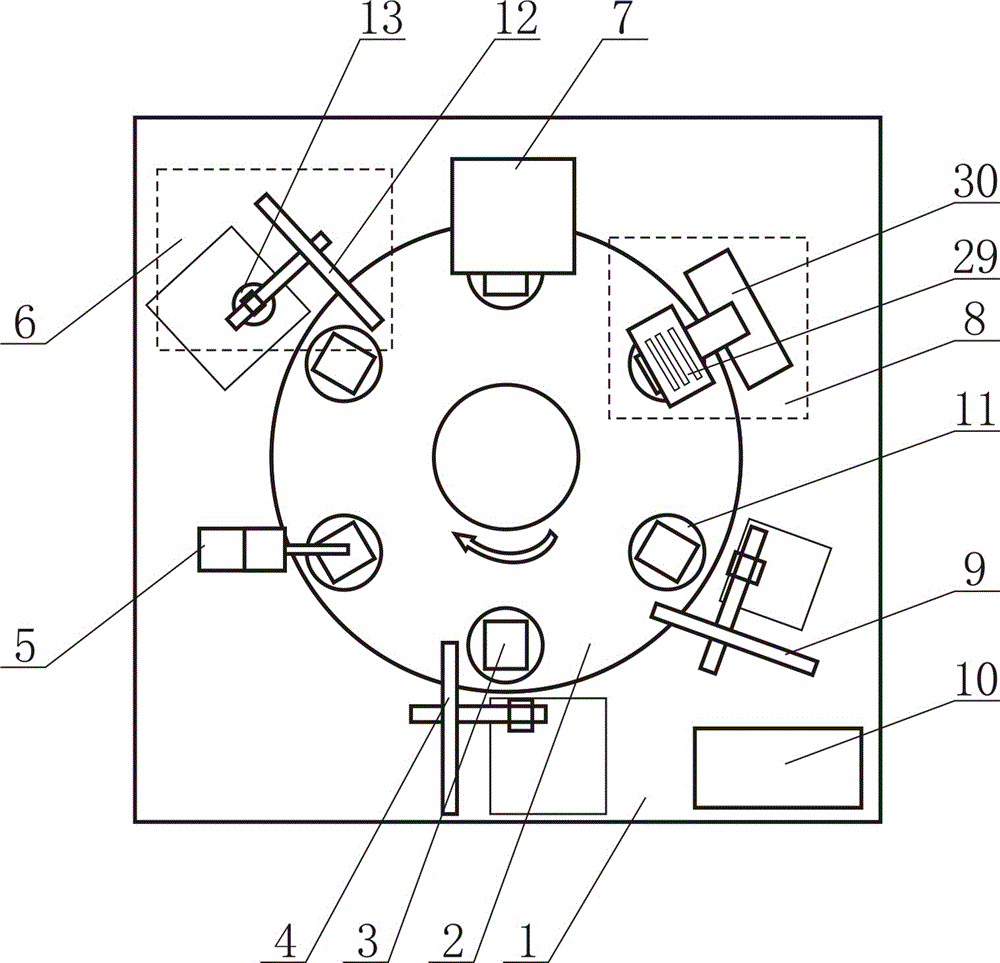

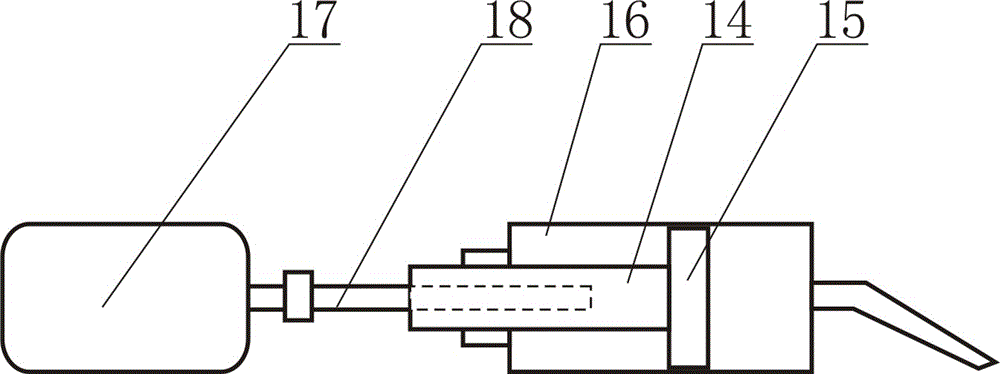

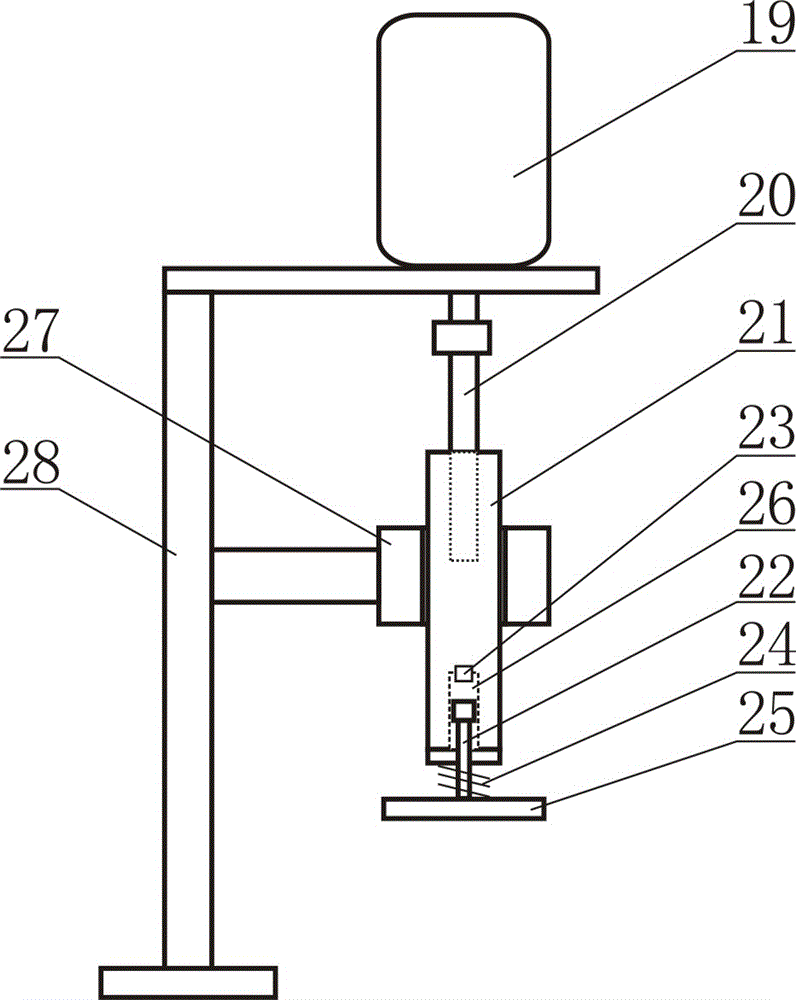

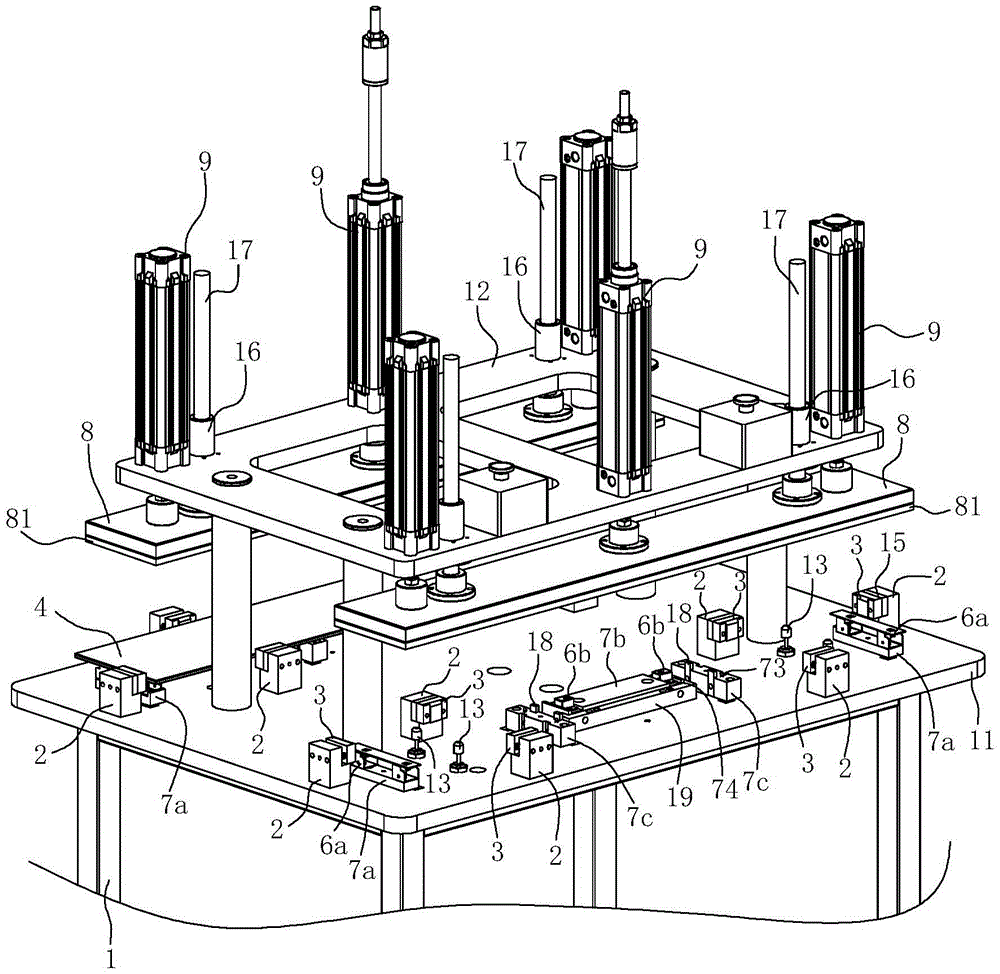

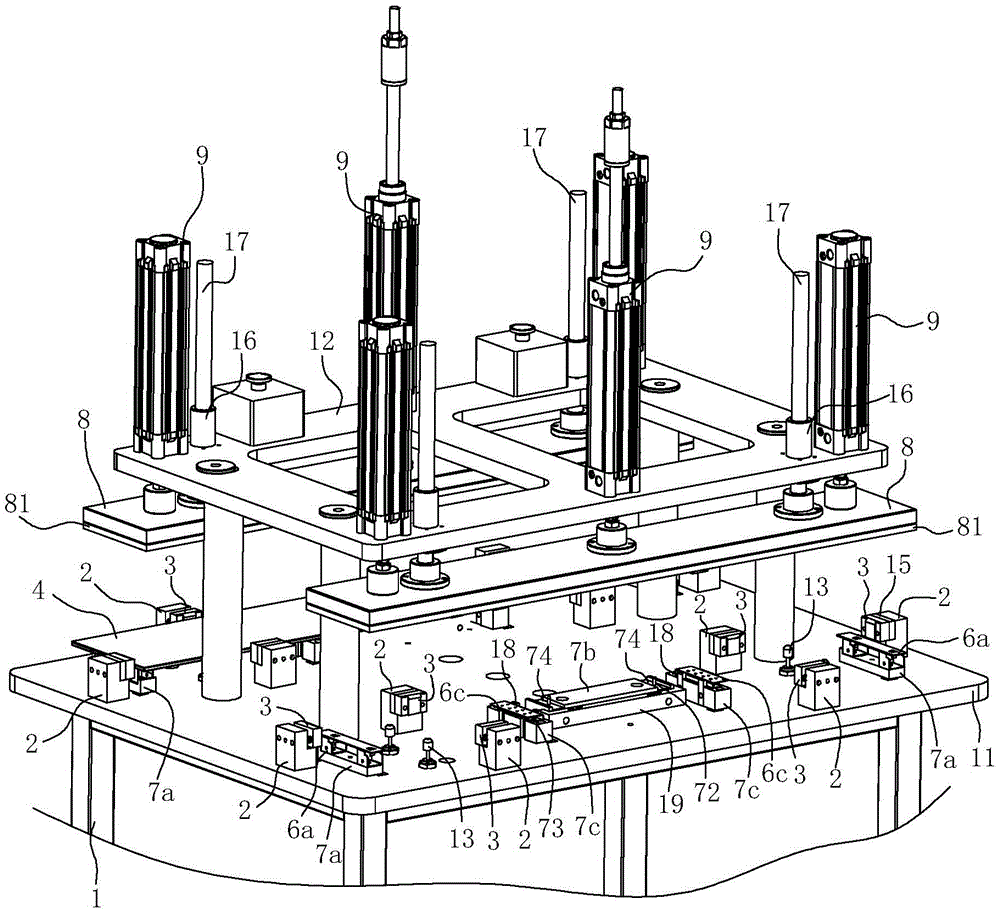

Optical module automatic chip mounting and assembling machine

InactiveCN106239902AHigh precisionIncrease productivityMaterial gluingOptical articlesUV curingOptical Module

The invention discloses an optical module automatic chip mounting and assembling machine. The optical module automatic chip mounting and assembling machine comprises a worktable and an intermittent rotary plate arranged on the worktable. Six tool clamps are evenly distributed along the periphery of the intermittent rotary plate at intervals. A glass prism feeding manipulator, a glue dispensing device, an optical filter feeding device, a chip mounting press-fitting device, a UV curing device, a finished product taking manipulator and a controller which correspond to the tool clamps are sequentially arranged on the worktable and around the intermittent rotary plate. Linkage of all the processes is realized through the intermittent rotary plate with six stations, glass prism feeding, glue dispensing, optical filter feeding, chip mounting press-fitting, UV curing and finished product taking are carried out in sequence, and automatic operation of all the procedures is realized. Automatic batch production is realized through various sensors and electric element control machines and mechanisms, and the production efficiency, and reliability and consistency of novel products are improved. As the glue outlet amount can be controlled accurately, the accuracy of chip mounting and assembling is greatly improved, and product quality is improved.

Owner:OPTIMAL COATECH GUANGZHOU CO LTD

Adhesive joining for powder metal components

A method of joining multiple powder metal components to form a powder metal component assembly using an adhesive is disclosed. By machining at least one of the powder metal components prior to the adhesive joining, otherwise difficult to machine features can be more easily machined for less cost and at higher production rates. Unlike high temperature joining techniques, the adhesive joins the powder metal components at room temperature. This room temperature adhesive joining eliminates the thermal distortions in pre-joined machined features common to high temperature joining techniques such as brazing or welding that bring these features out of specification during joining.

Owner:SKN SINTER METALS LLC (US) +1

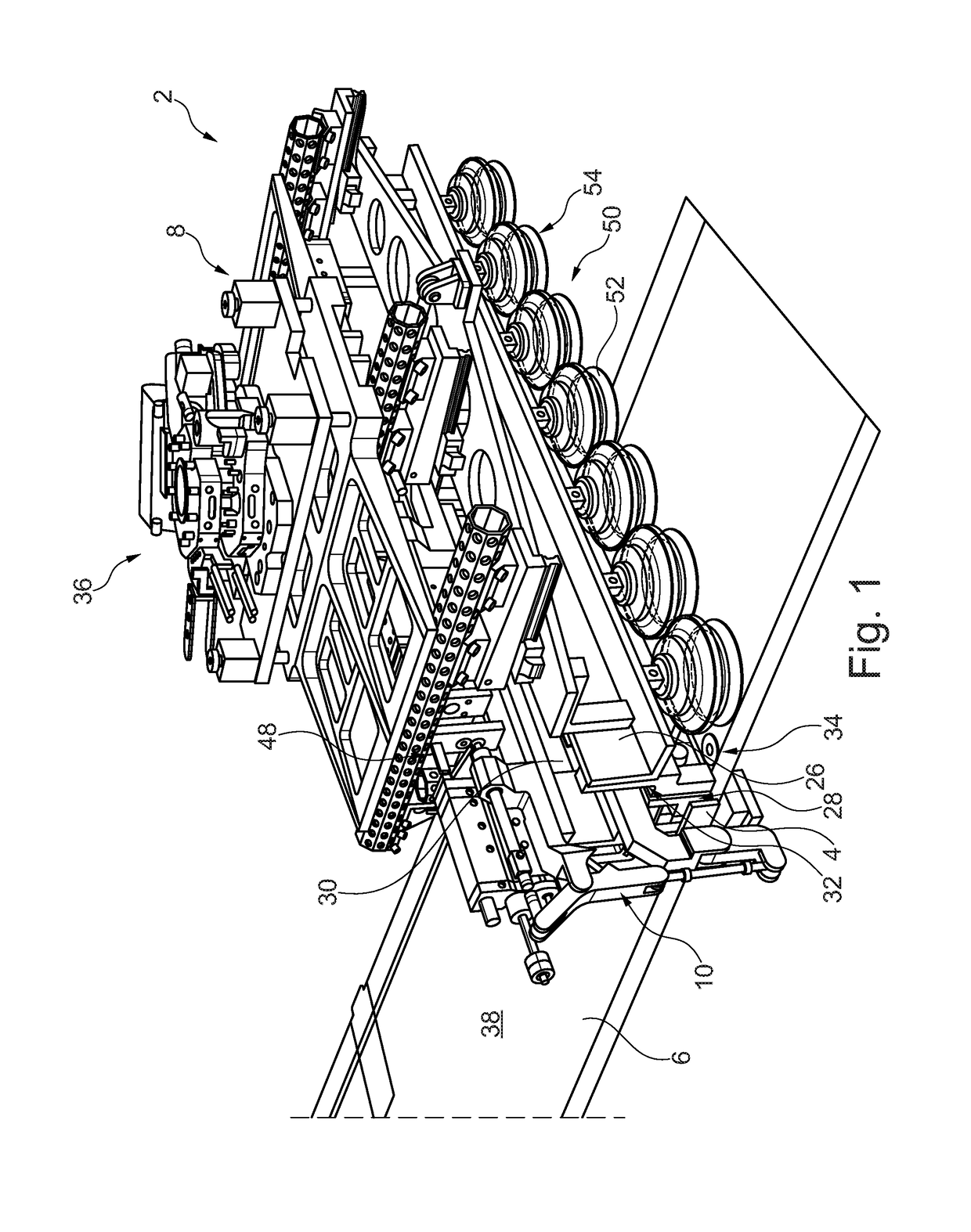

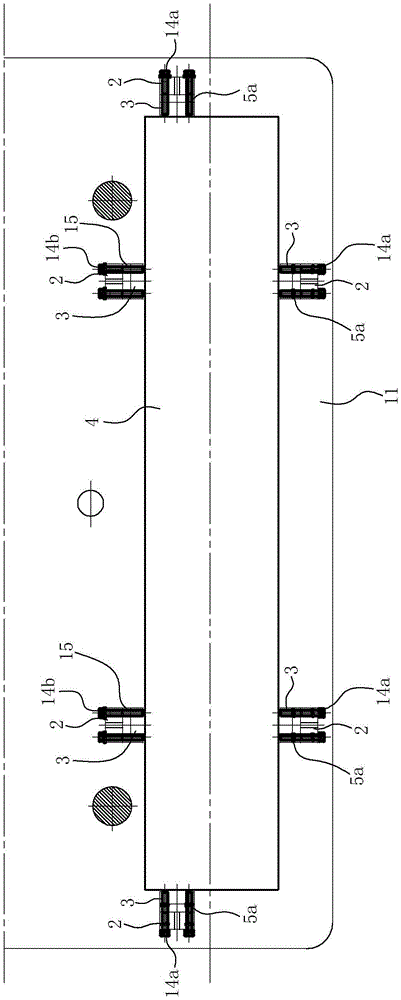

Bonding tool capable of simultaneously bonding various parts onto glass panel

ActiveCN105422567AImprove bonding efficiencyHigh bonding precisionMaterial gluingElectrical junctionEngineering

The invention relates to a bonding tool capable of simultaneously bonding various parts onto a glass panel. The bonding tool comprises a frame body which is provided with a table board and an upper mounting plate, and at least one set of a bonding structure. The bonding tool is characterized in that the bonding structure comprises a peripheral limiting structure for peripherally restraining the glass panel, a first lay-up block which is fixed on the table board for restraining a glass panel bracket, a second lay-up block which is fixed on the table board for restraining a first switch bracket, a third lay-up block which is fixed on the table board for restraining a second switch bracket, and a pressure maintaining block which is arranged above the table board, is driven by a pressure maintaining air cylinder mounted on the upper mounting plate to move up and down vertically, wherein the pressure maintaining block is pressed for pressing the glass panel to the bonding surface of each bracket to carry out pressure maintaining. The tool works once, so that not only can the glass bracket and the switch bracket be bonded onto the glass panel, but also bonding mounting of switch brackets of different models on the glass panel can be adapted, and therefore, the tool has the advantages of high bonding efficiency and high bonding precision, less processes, and convenient operation.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

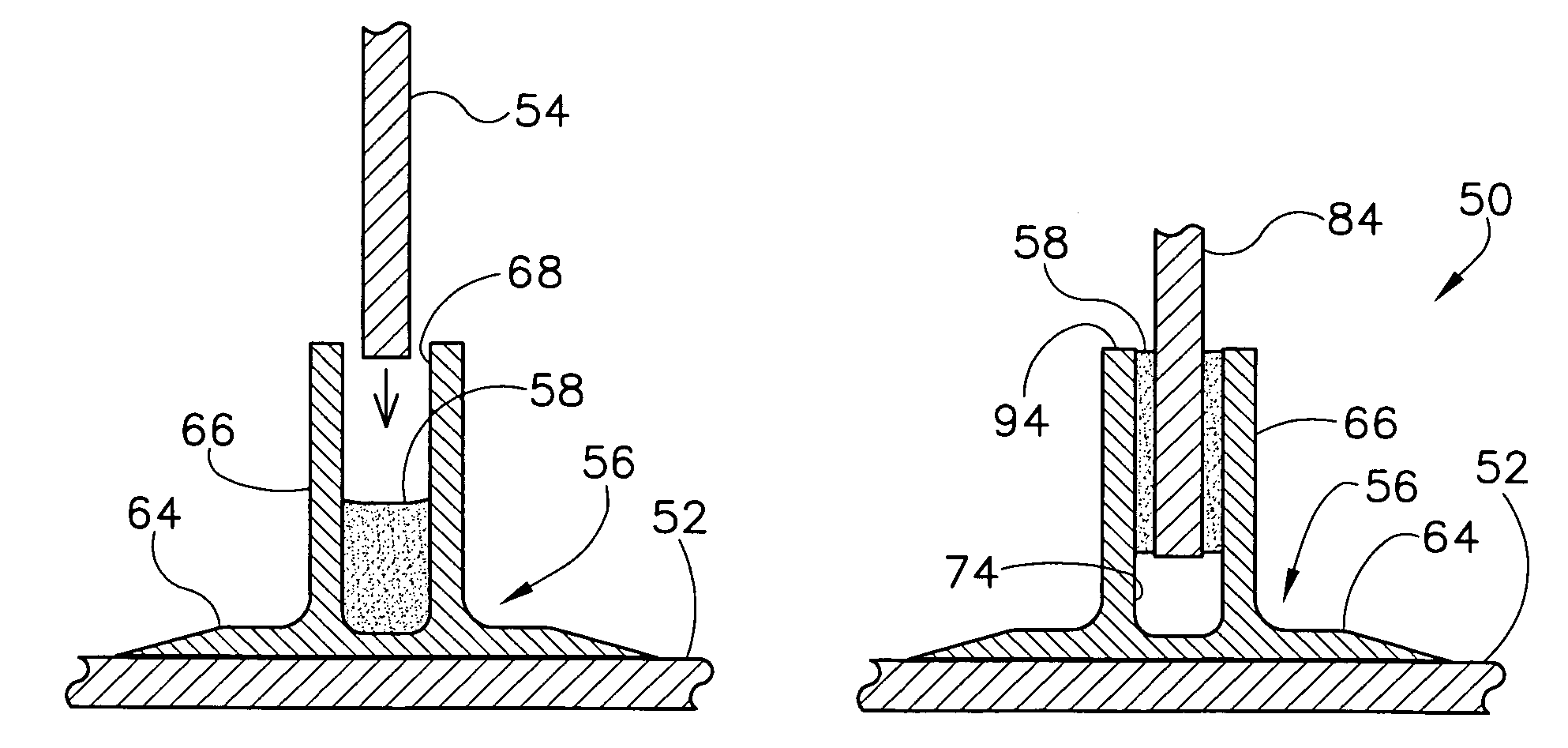

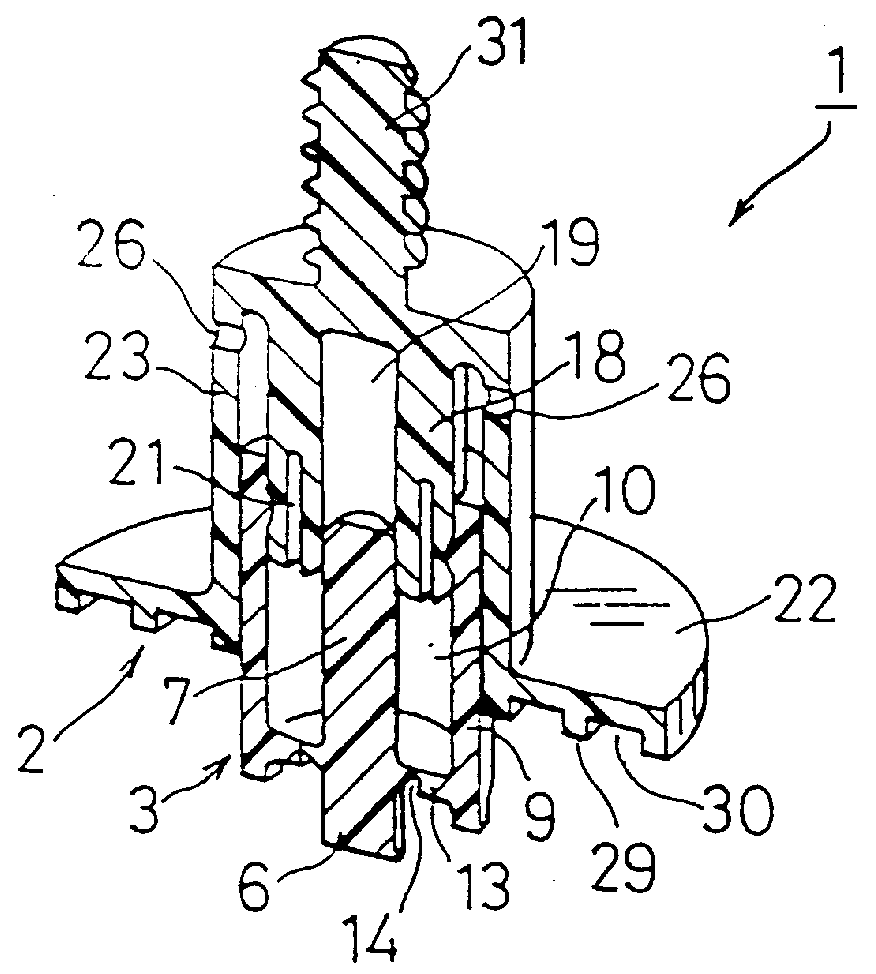

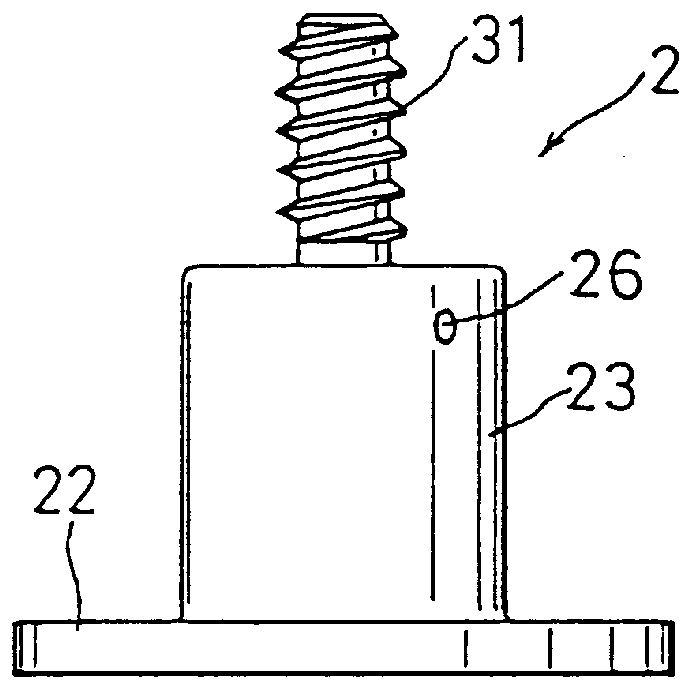

Structural mounting insert

InactiveUS20080179913A1Limit and prevents torque fall off and looseningAdhesive processesVehicle seatsEngineeringMechanical engineering

Owner:ZEPHYROS INC

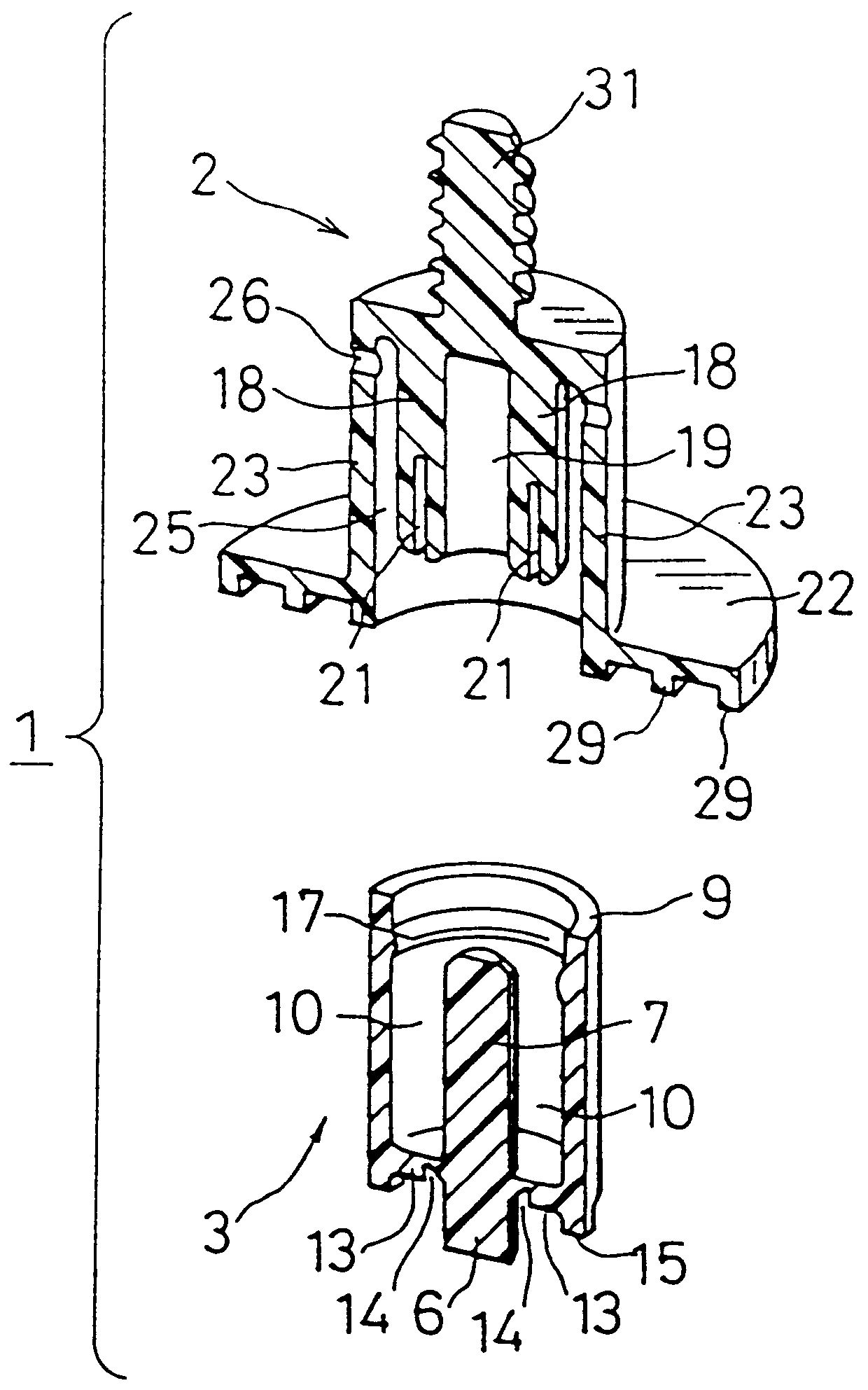

Adhesive-dispensing fastener

To provide an adhesive fastener which has no need of a vacuum cup or a tab, an adhesive fastener 1 comprises a body member 2 and a tank member 3. The tank member 3 forms an adhesive container 10 in which adhesive material is contained. One end of the tank member is open but the other end is closed by a rigid end wall 13 and a frangible thin portion 14. The body member 2 has a plunger 18 which is slidably inserted from the opening side into the adhesive container 10 and forces out the adhesive from the frangible end, and an adhesive surface 22 which is formed outside the tank member so as to move together with the plunger and comes into contact with the surface of an attachment member to be bonded to the attachment member by means of the adhesive material. On the frangible end of the tank member, a protrusion 6 protruding axially outwardly is provided in the center or axis. In the initial state that the adhesive material contained in the adhesive container 10 is sealed by the plunger 18, the adhesive surface 22 is positioned farther from the frangible end than the surface of the attachment member is. When the protrusion 6 is brought into contact with the attachment member and the body member 2 is pressed, the plunger 18 presses the adhesive material in the tank member and breaks the frangible thin portion 14 to cause the adhesive to material flow out onto the surface of the attachment member. When the body member is pressed further, the adhesive surface comes into contact with the surface of the attachment member and is fixed to the attachment member by means of the adhesive which has flowed out.

Owner:NEWFREY

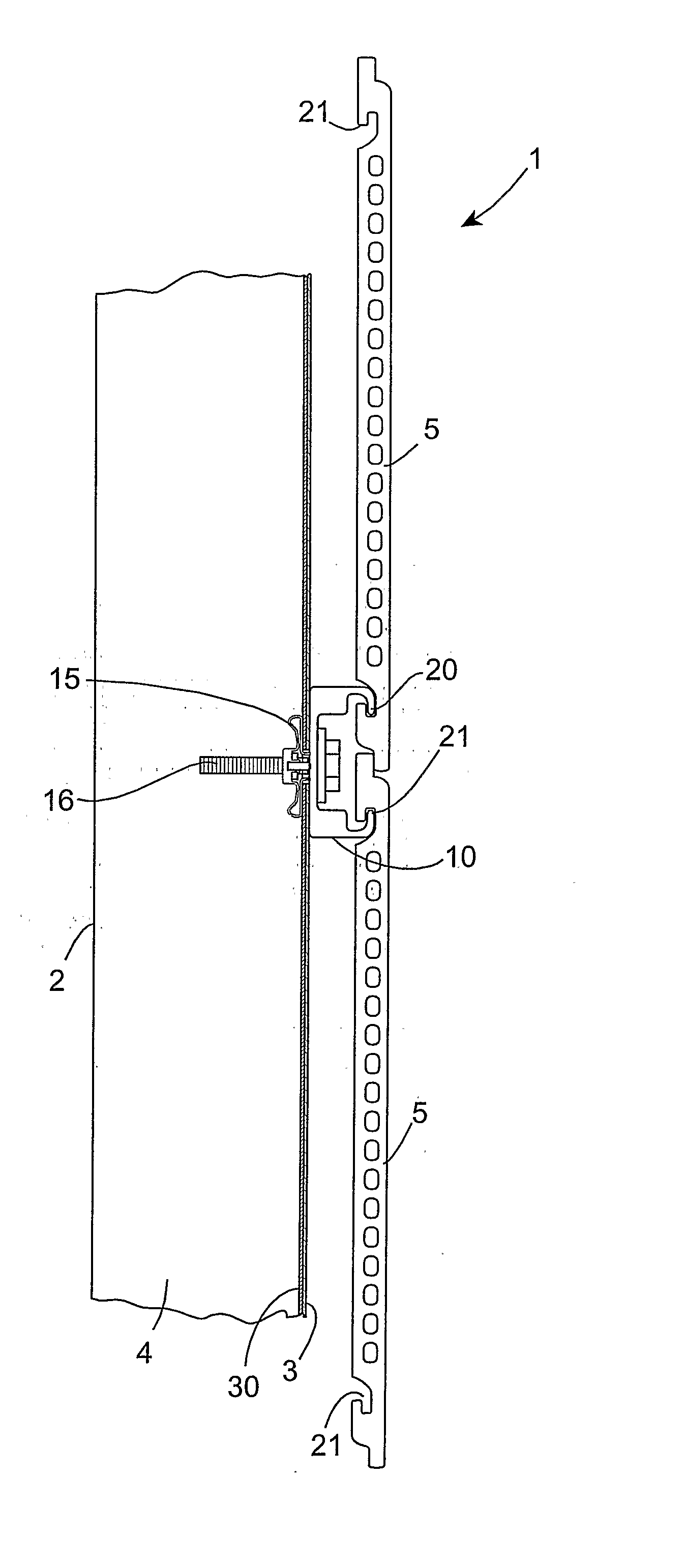

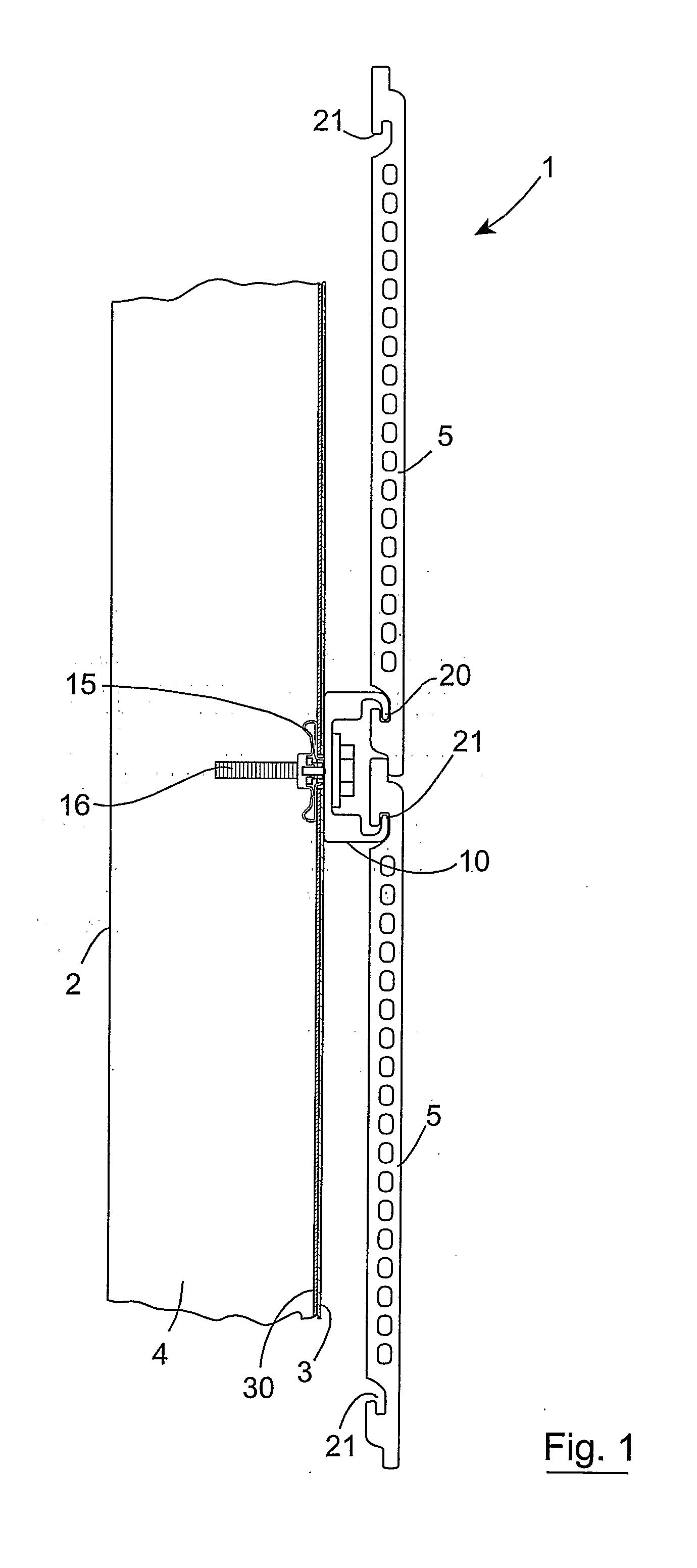

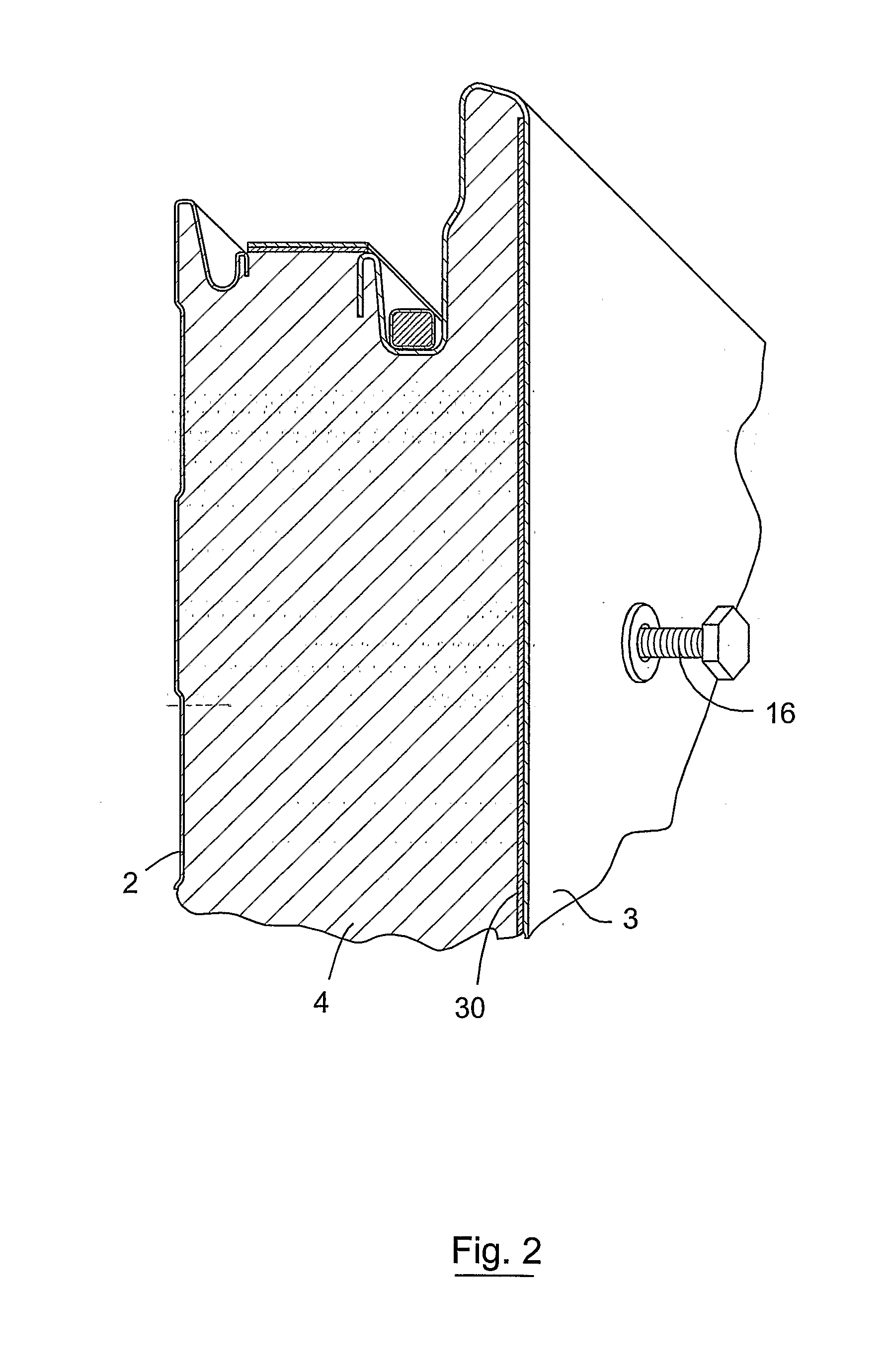

Composite Cladding

InactiveUS20080127586A1Erected quickly and more cheaplyConstruction materialCovering/liningsAdhesiveEngineering

The panel 1 comprises a steel skin or backing tray (2) and an external steel skin (3) with a layer of foam insulation material (4) such as a phenolic or polyurethane based foam material therebetween. One of the skins, in this case the external skin 3 has a plurality of mountings for fixing cladding elements such as tiles (5) to the panel to form a cladding. The mountings comprise rails (10) and fasteners (12) for fastening the rails (10) to the external skin (3). Each fastener (12) comprises an internal clamping sleeve (15) and a bolt (16). A hole is first drilled through the skin (3) and the sleeve (15) is inserted. On tightening of the bolt (16), the sleeve (15) splays and is clamped against the inside surface of the external skin (3), and the rails (10) are fixed to the panels. To enhance the peel strength of the composite panel a layer (30) of an adhesive is applied to the internal face of the external skin (3). The adhesive layer (30) is a pre-lay-down adhesive which is compatible with the material of the insulting core (4). The use of such an adhesive greatly enhances the peel strength of the panel and enables the panel to carry the additional load of the cladding tiles.

Owner:KINGSPAN HLDG (IRL) LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com