Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about "Knife-edge bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

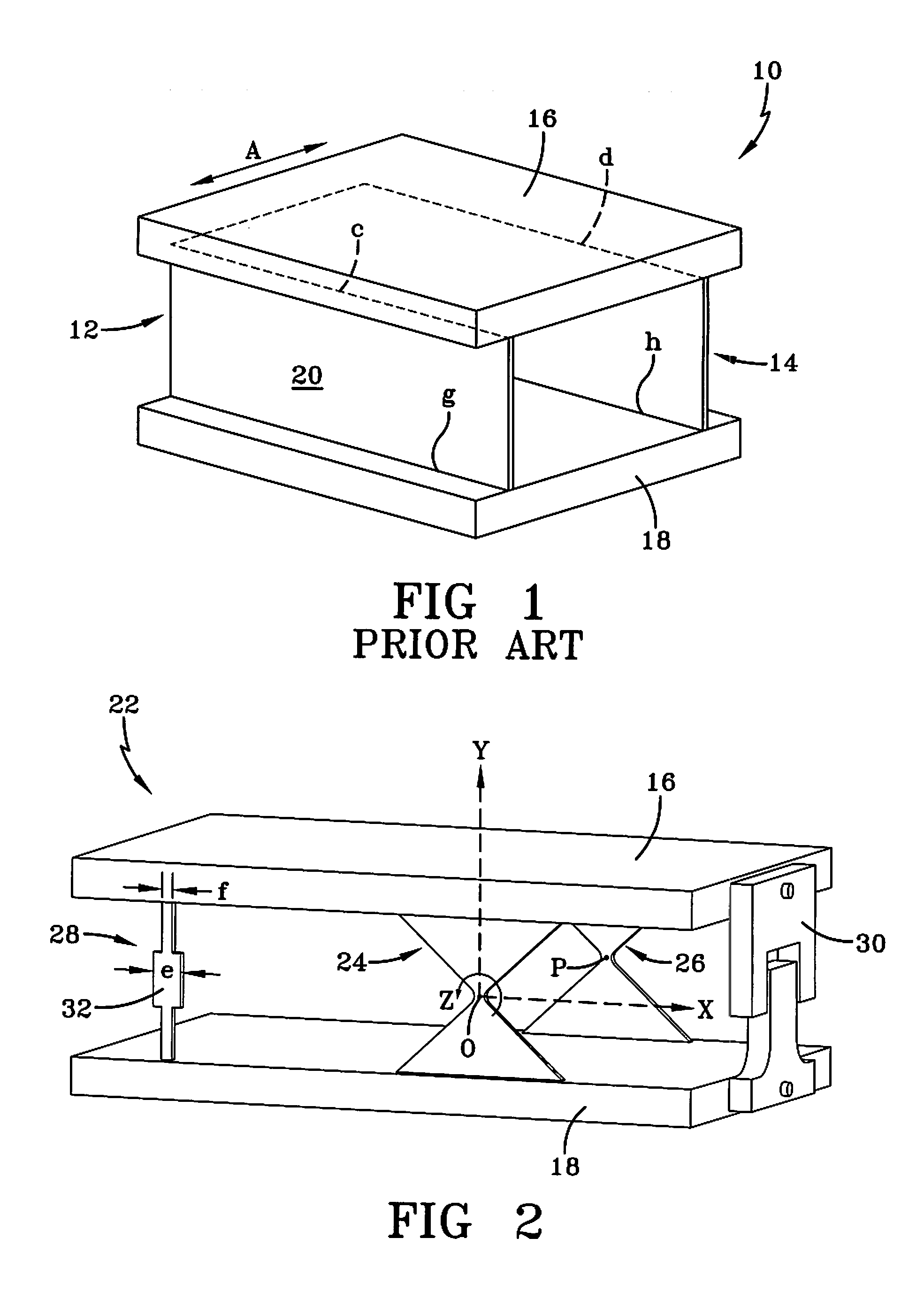

Positioning hinge having a cam block

InactiveUS6108868AMachine supportsElectrical apparatus contructional detailsDisplay deviceEngineering

Owner:LIN DAVYS

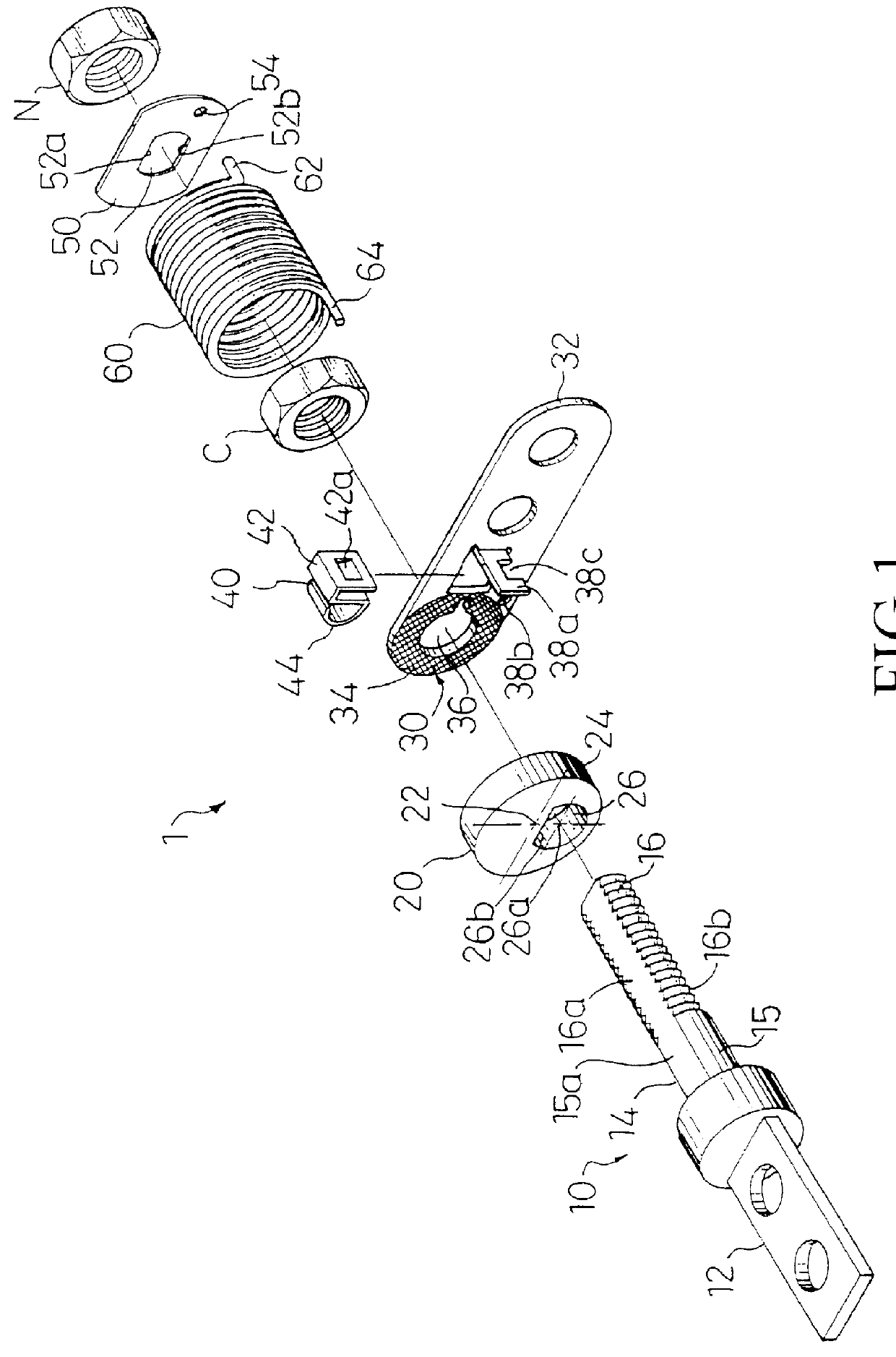

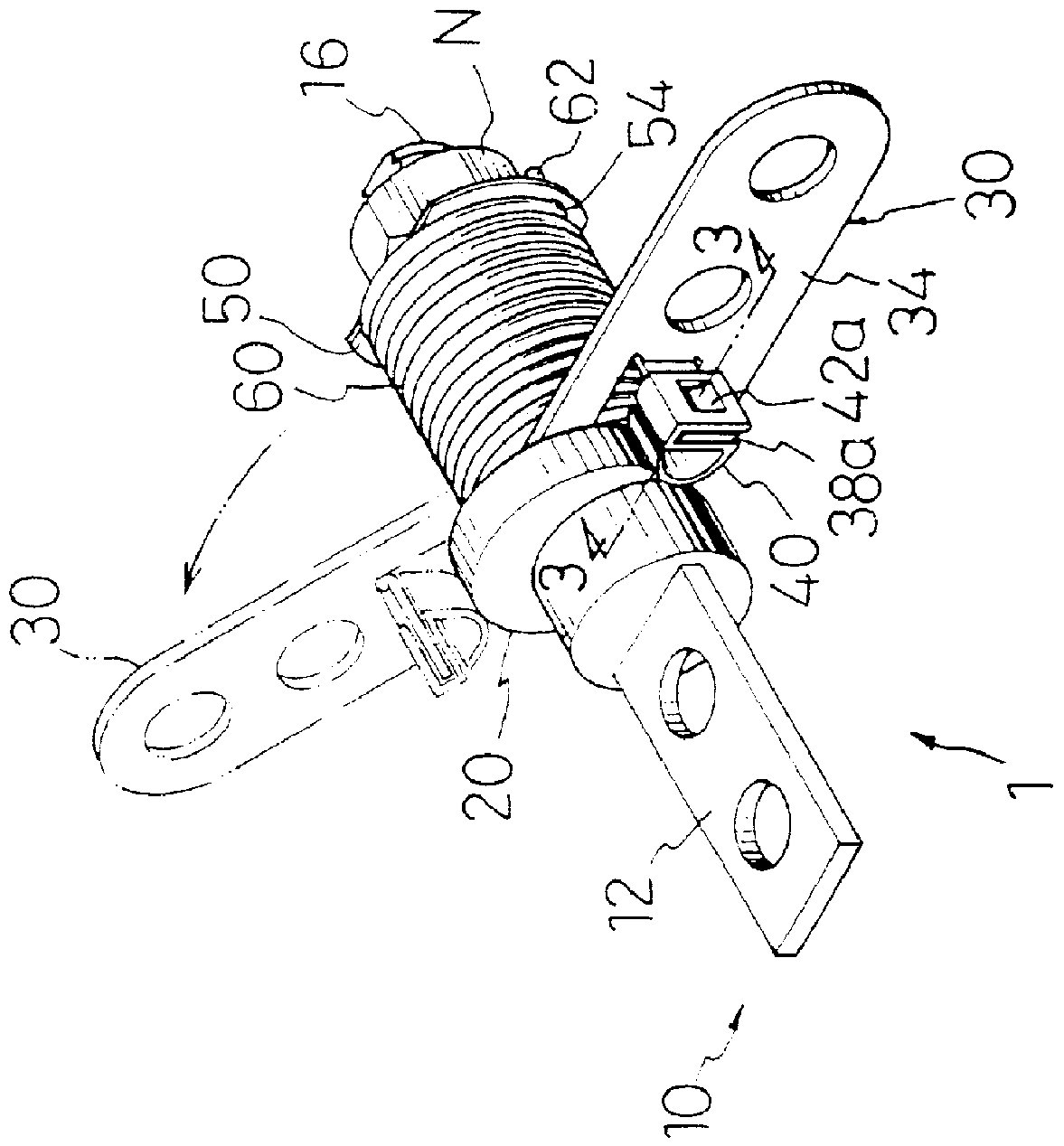

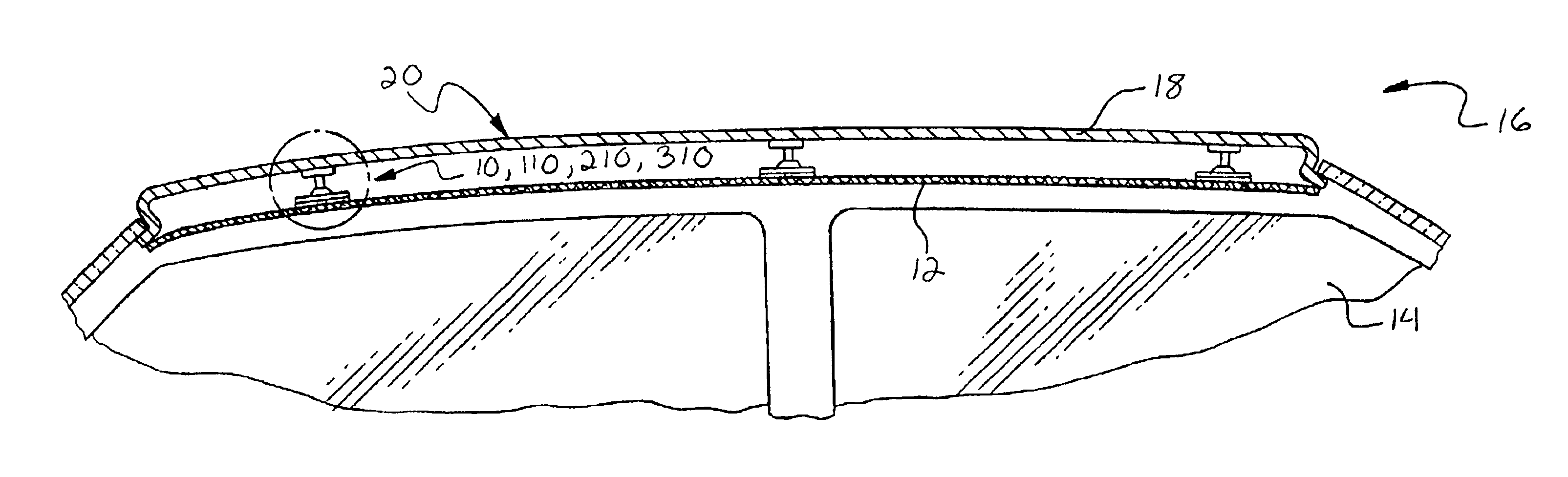

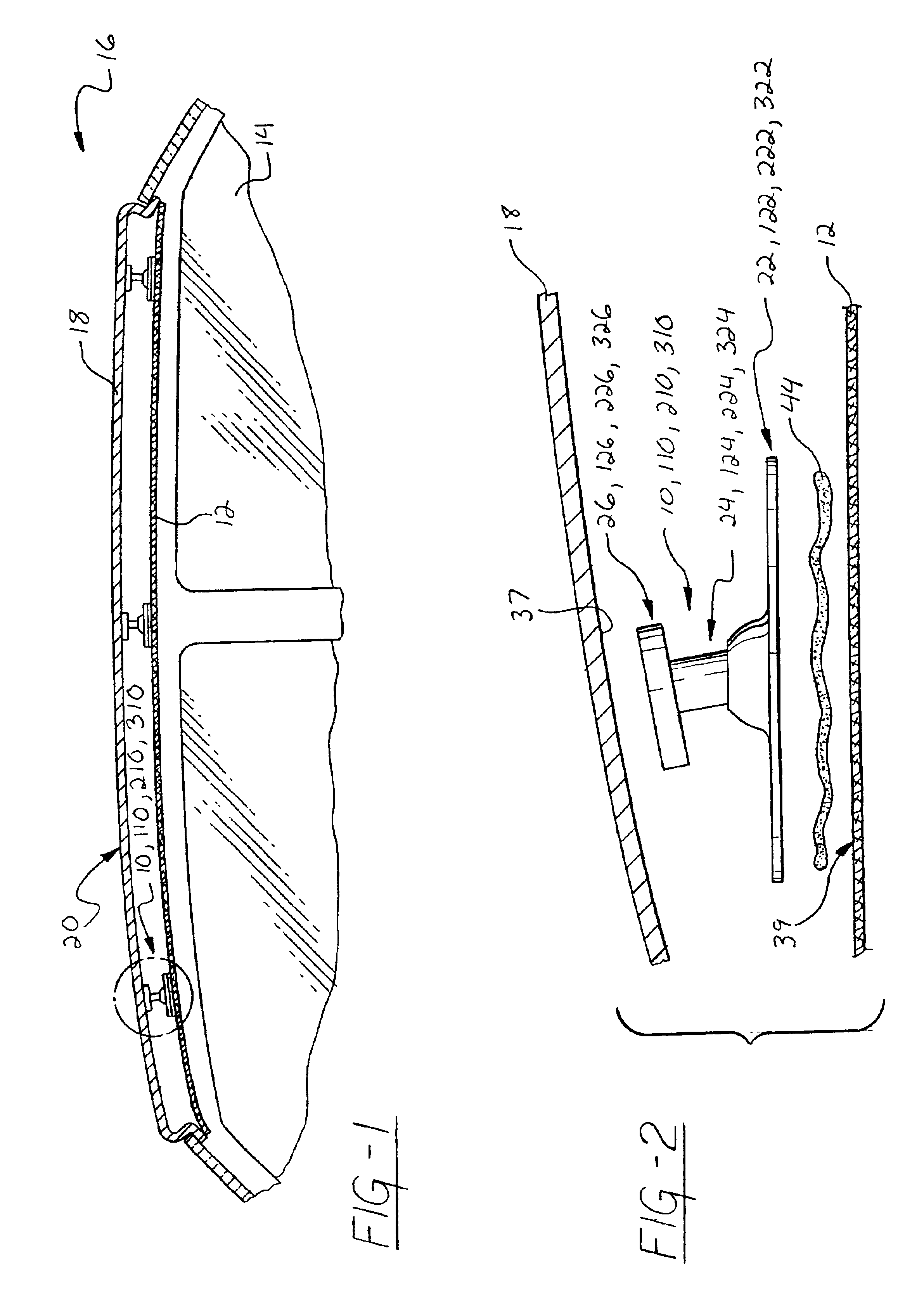

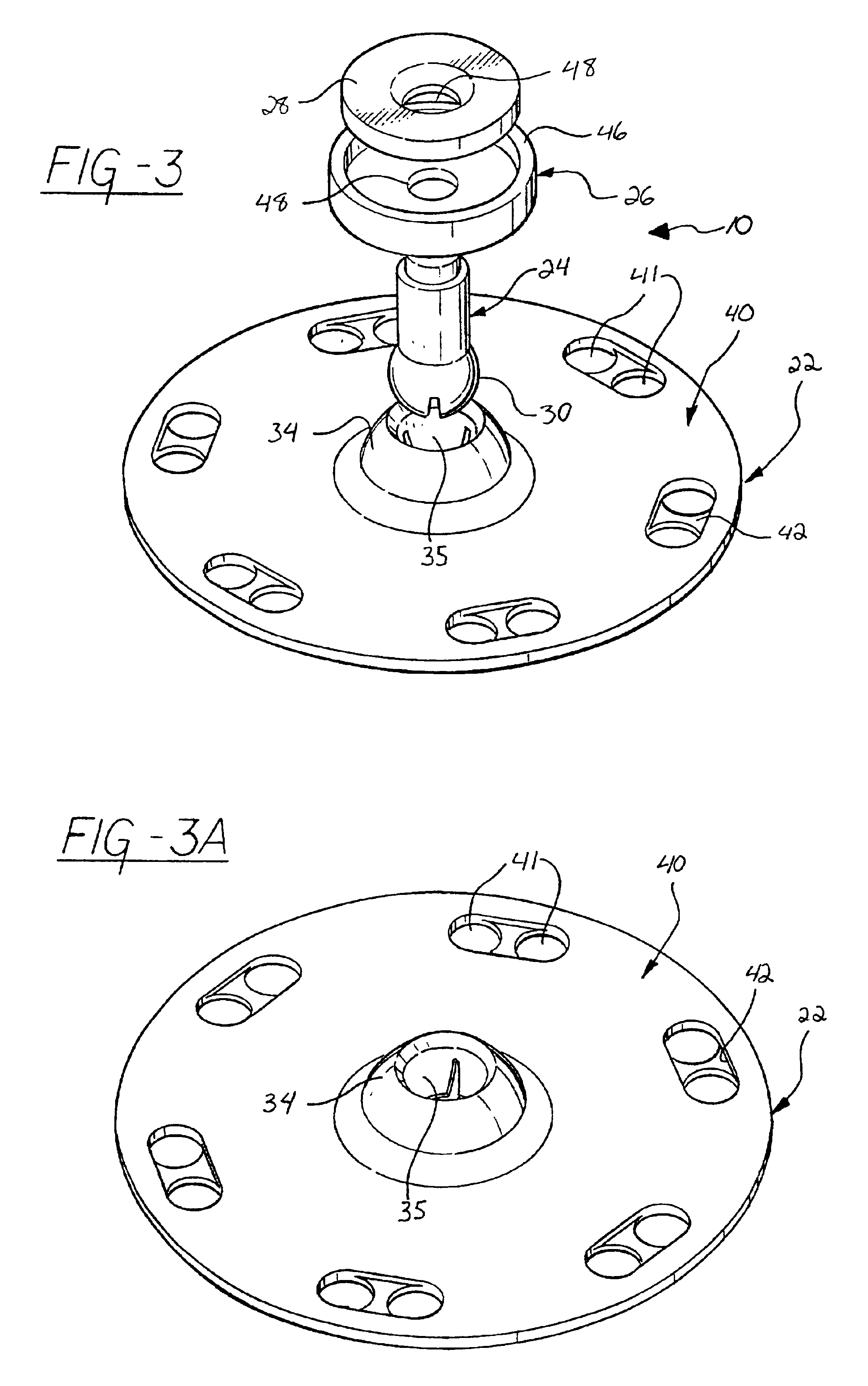

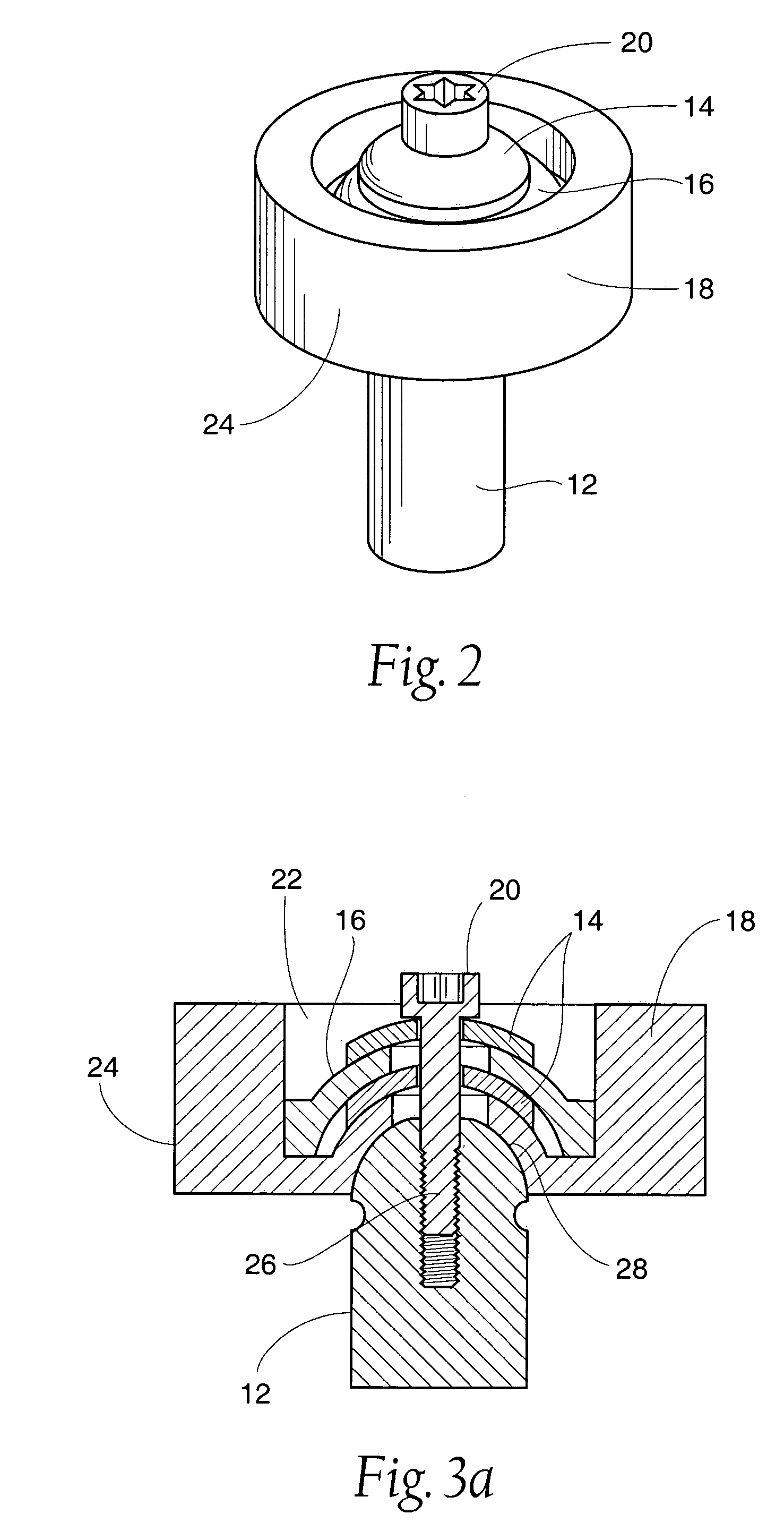

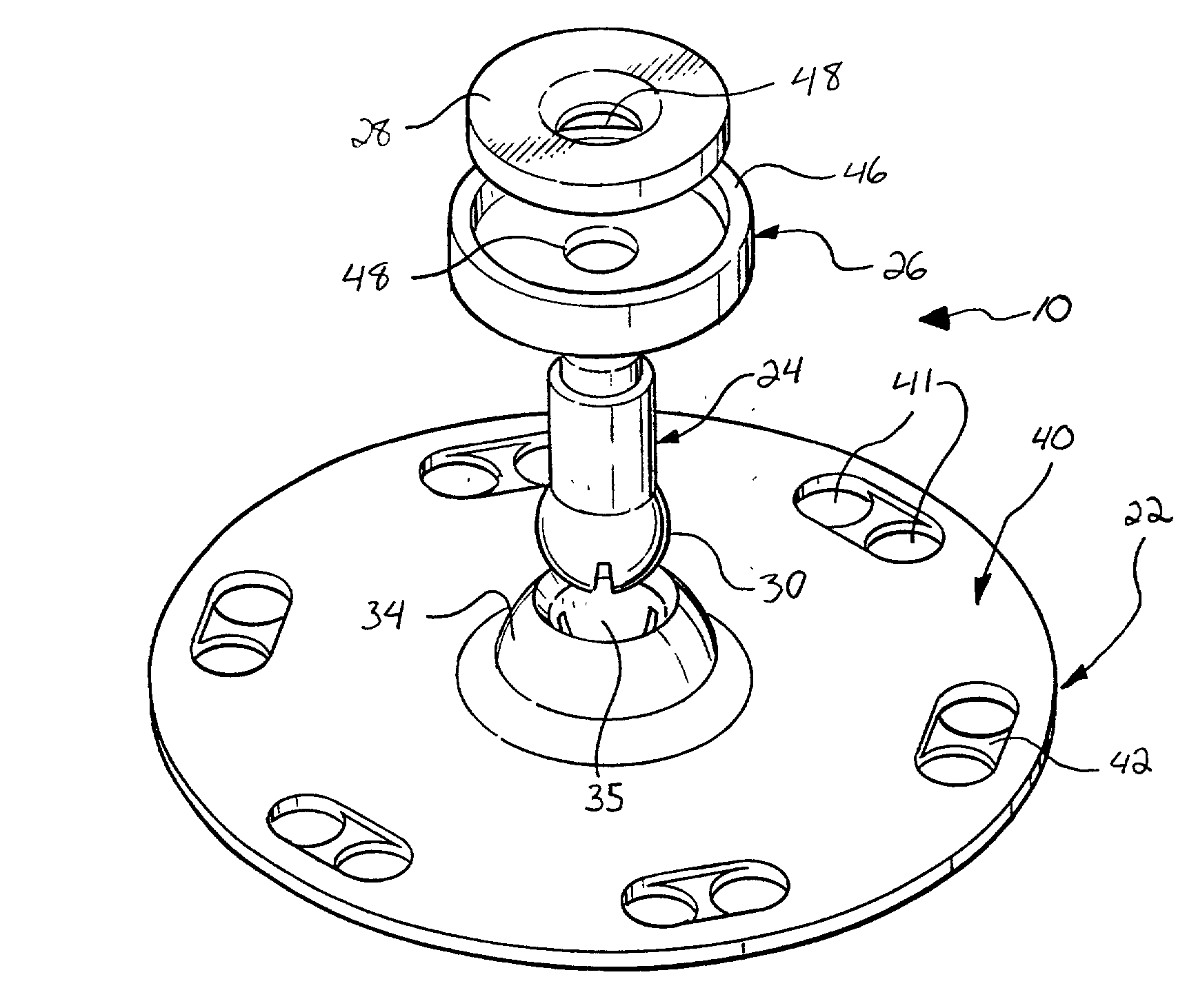

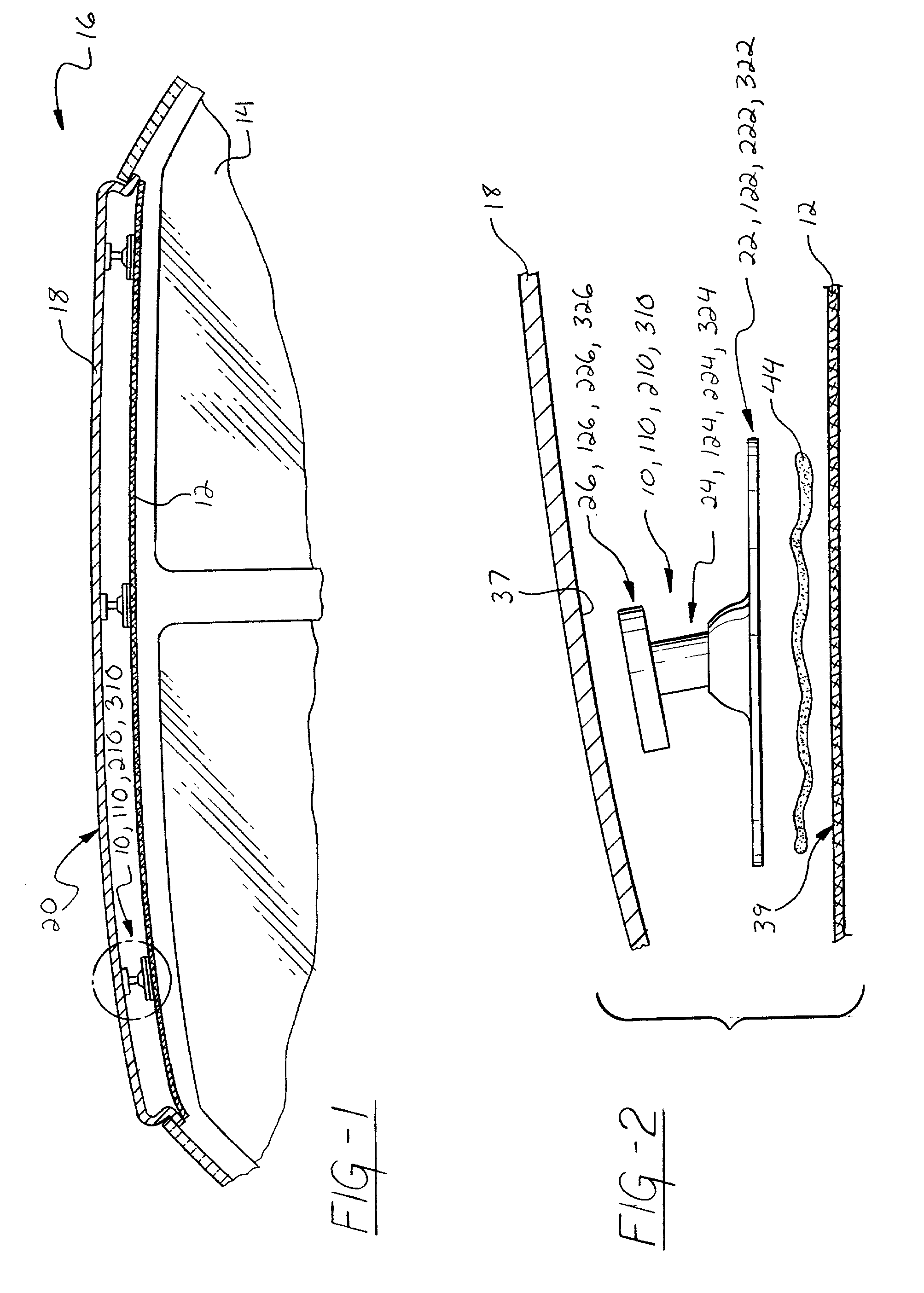

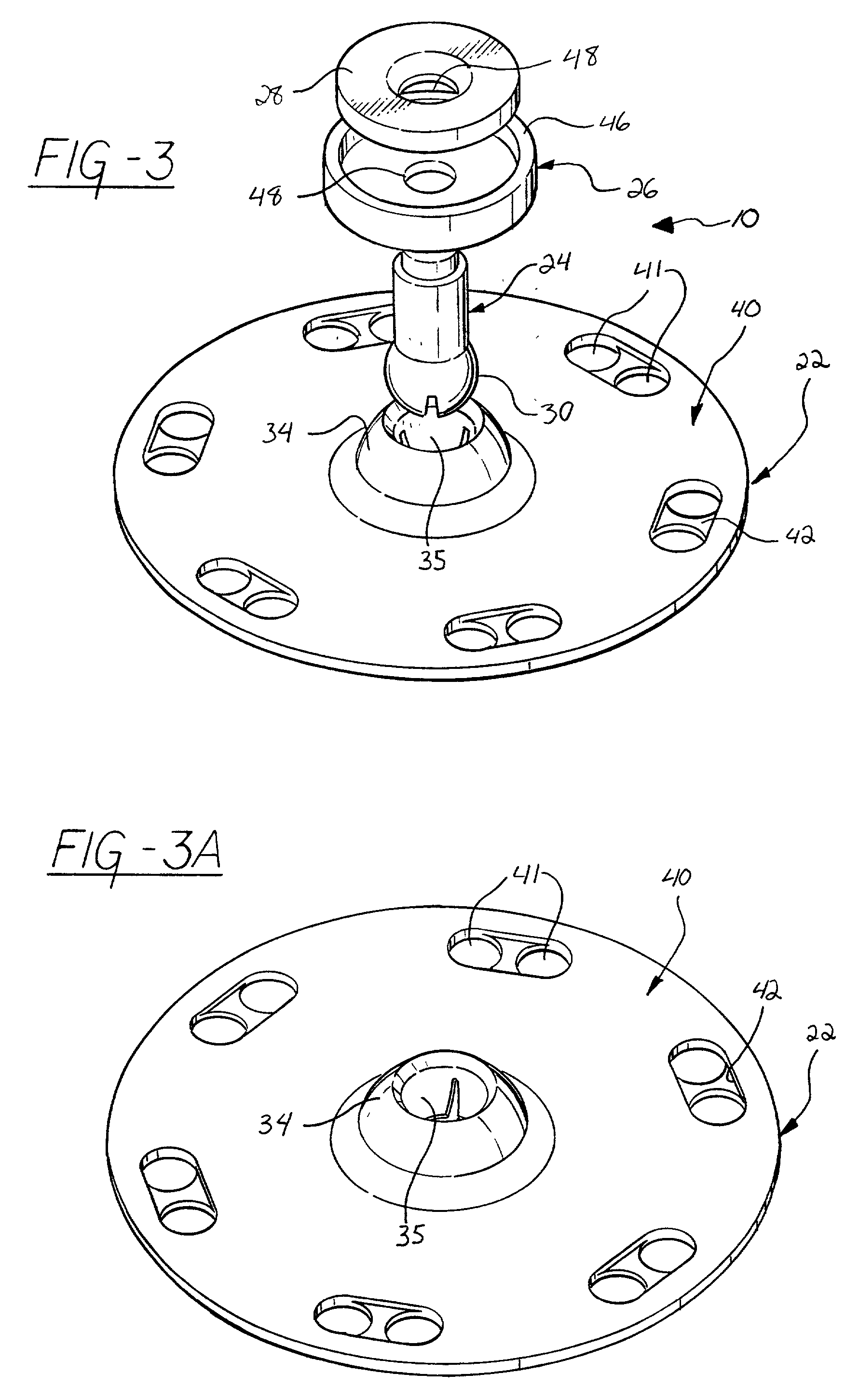

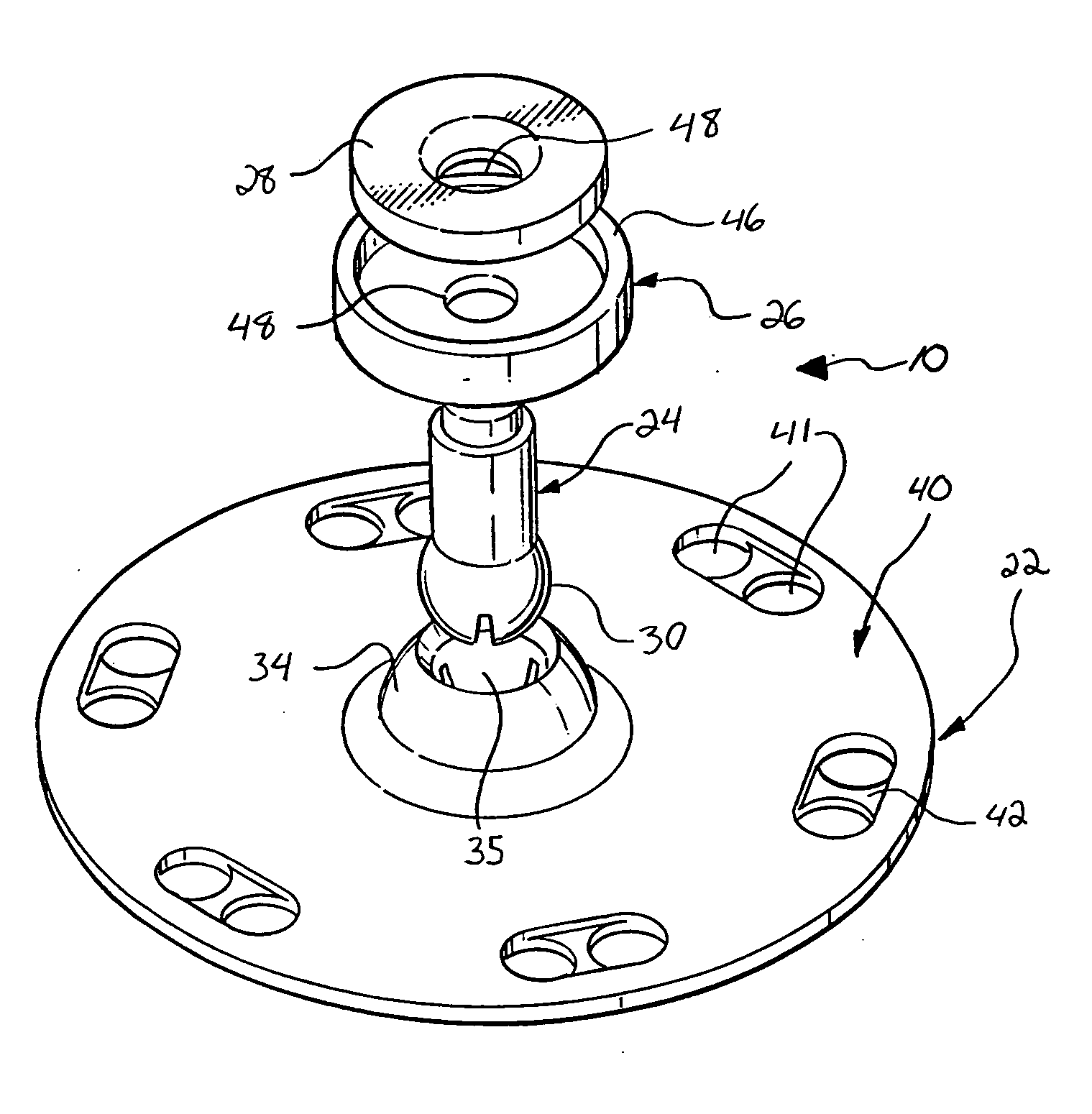

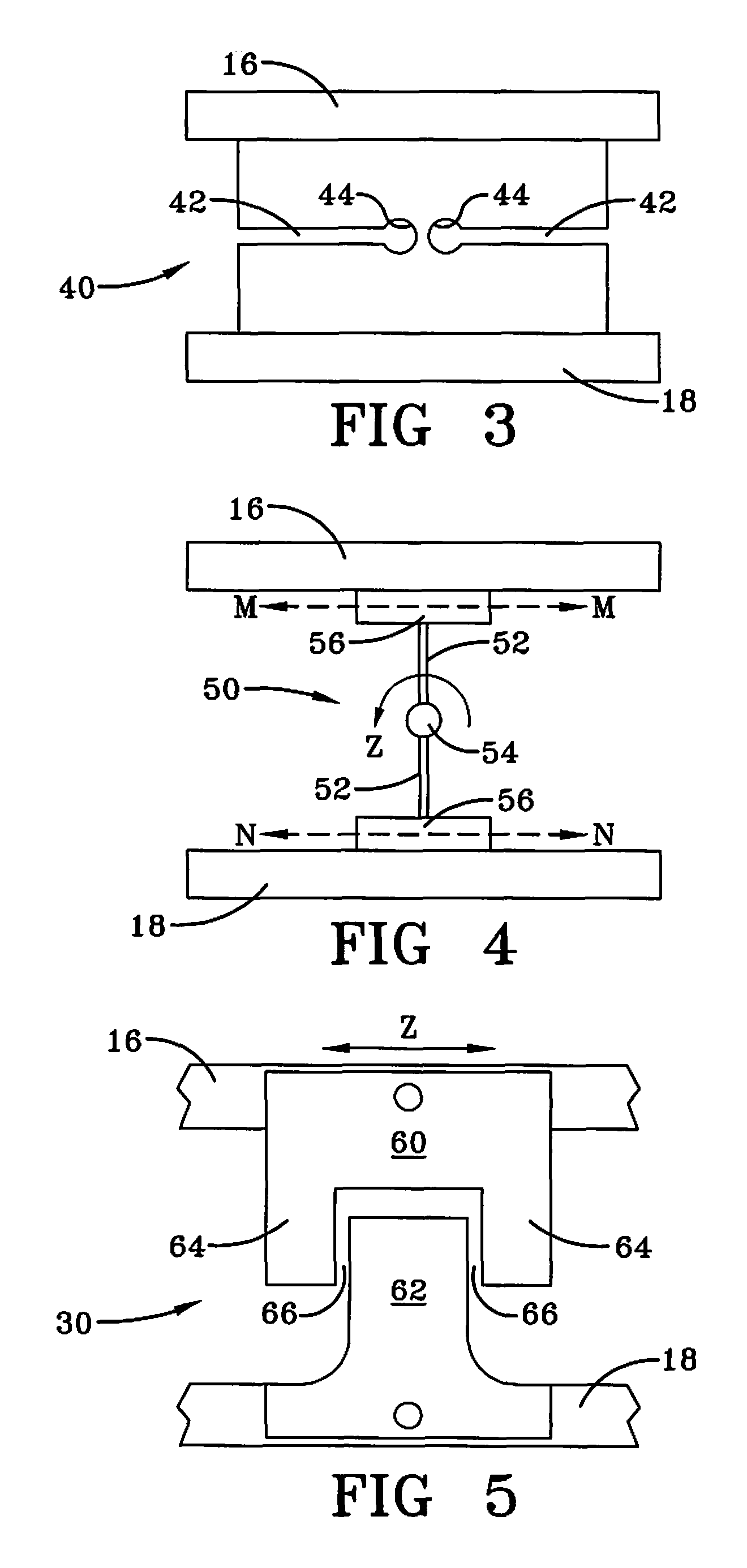

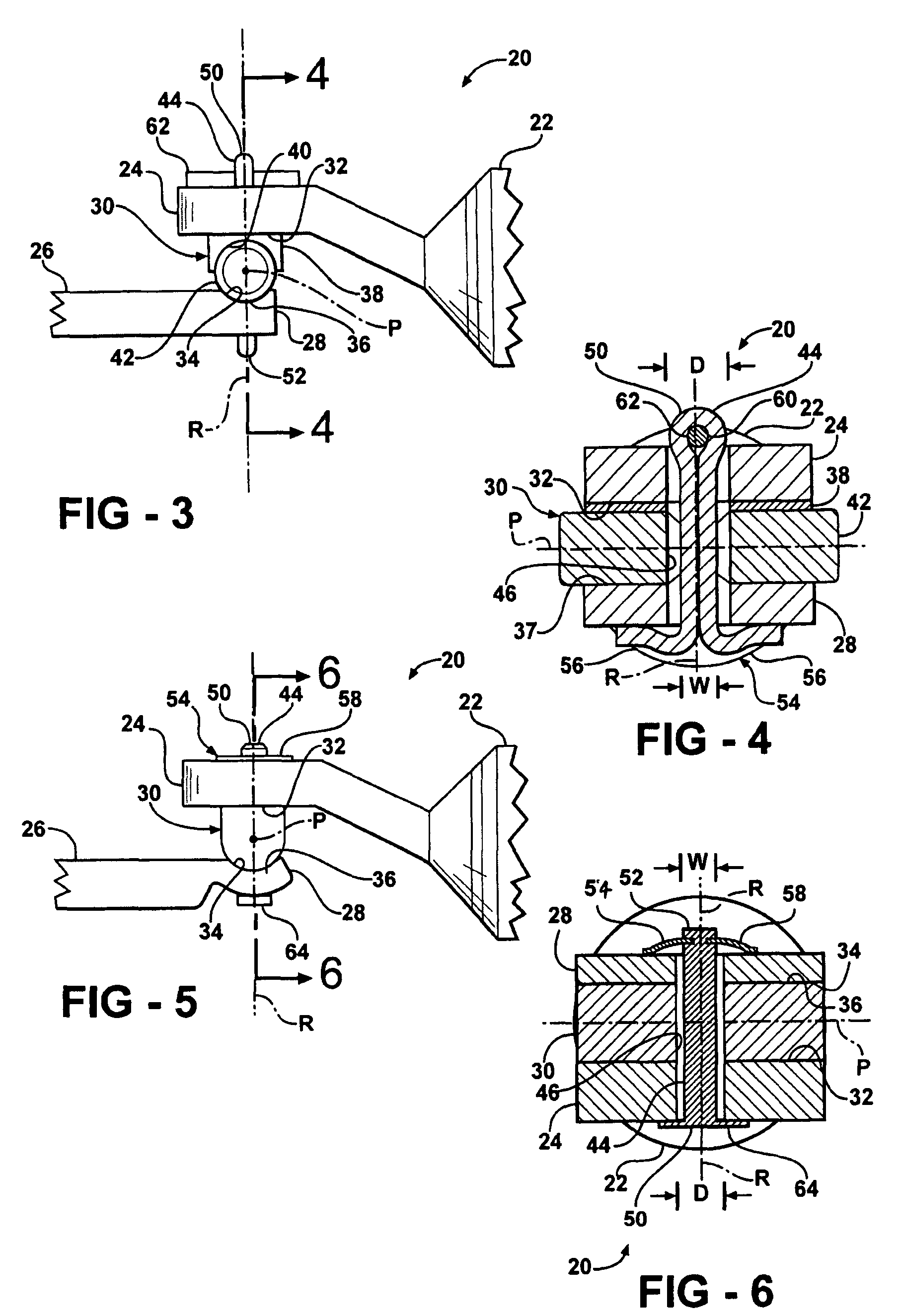

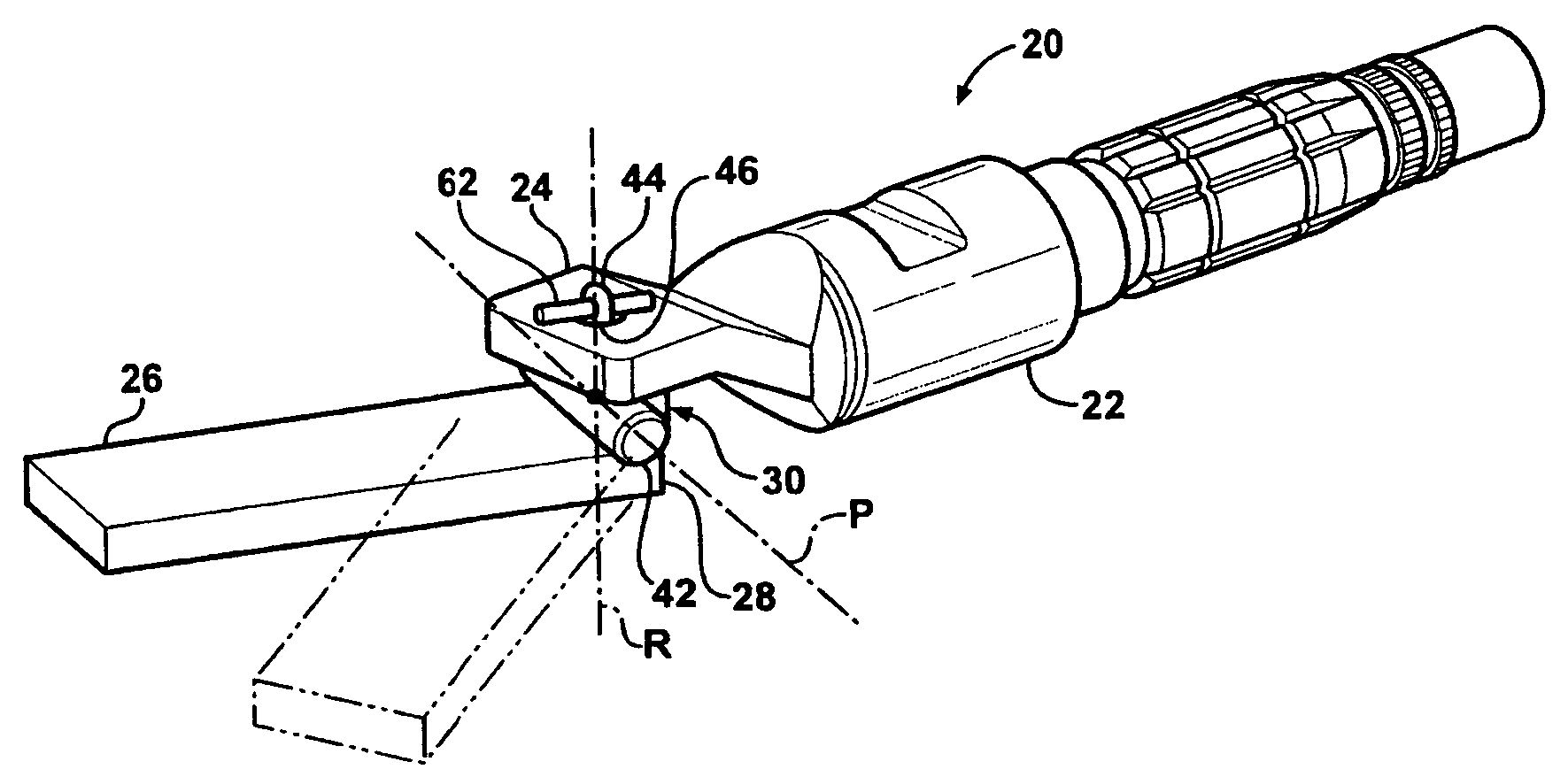

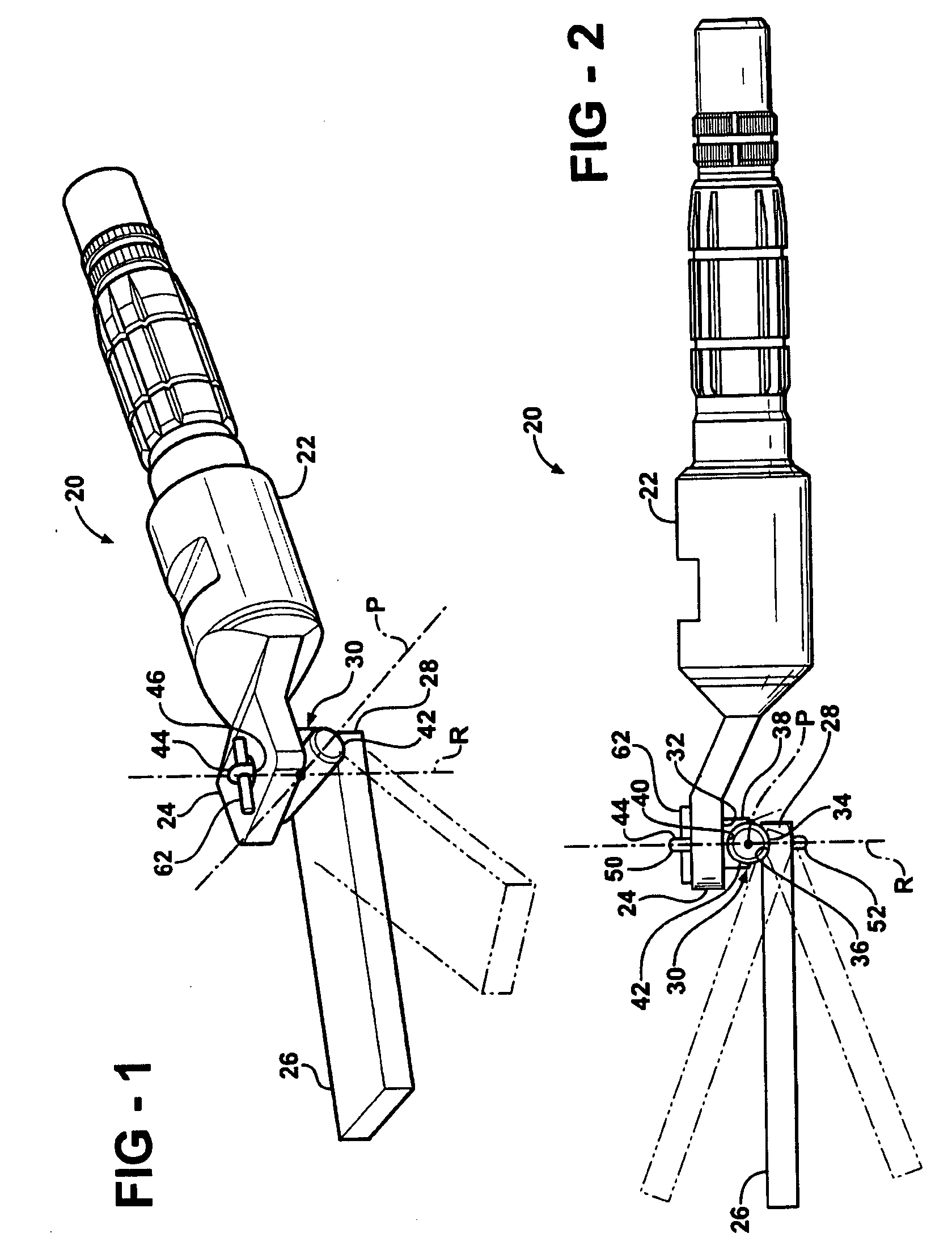

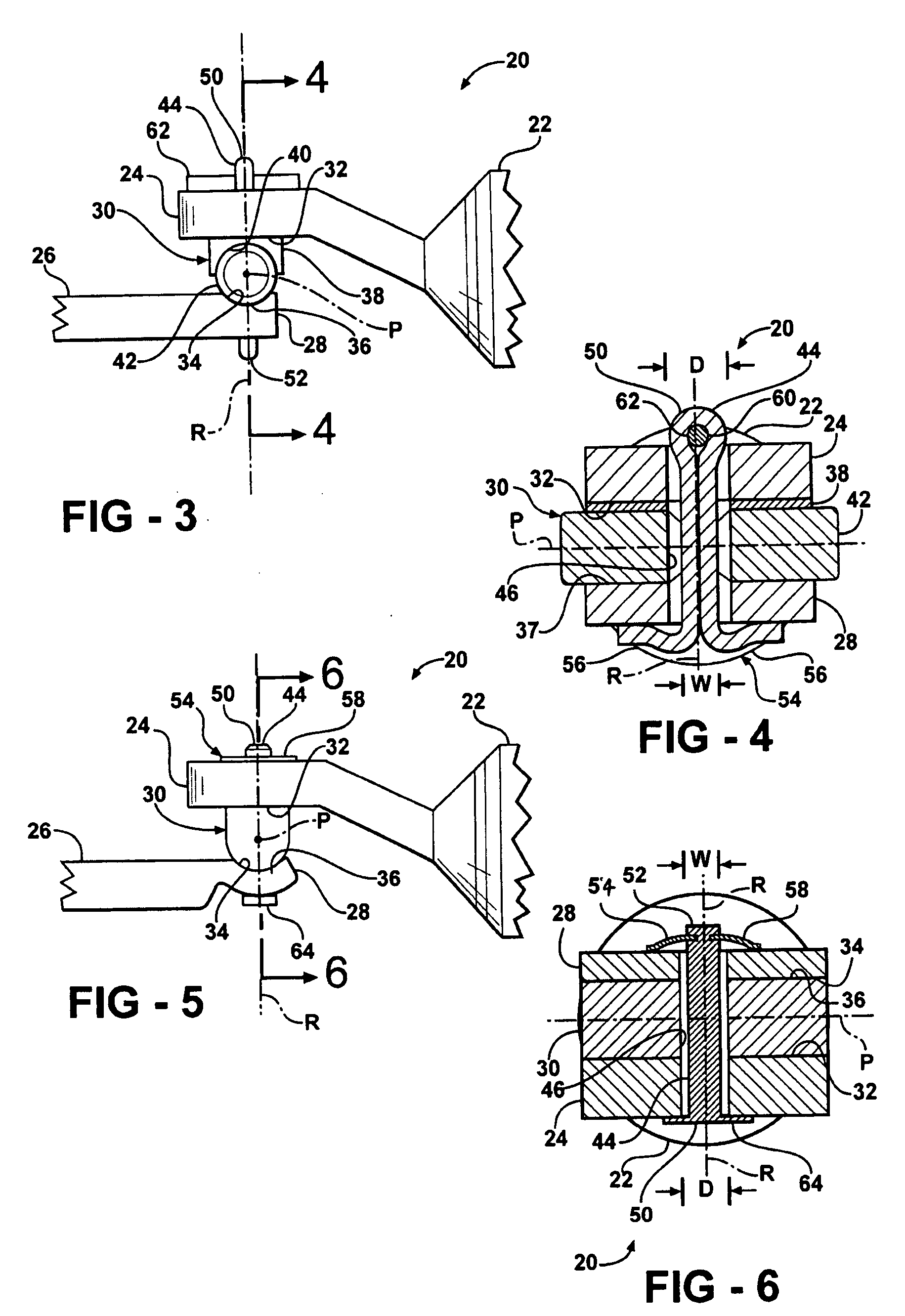

Articulating fastener assembly

InactiveUS6857809B2Facilitates an automotive headlinerSuperstructure subunitsPivotal connectionsEngineeringFastener

Owner:COMML IMPORTS & ASSEMBLY

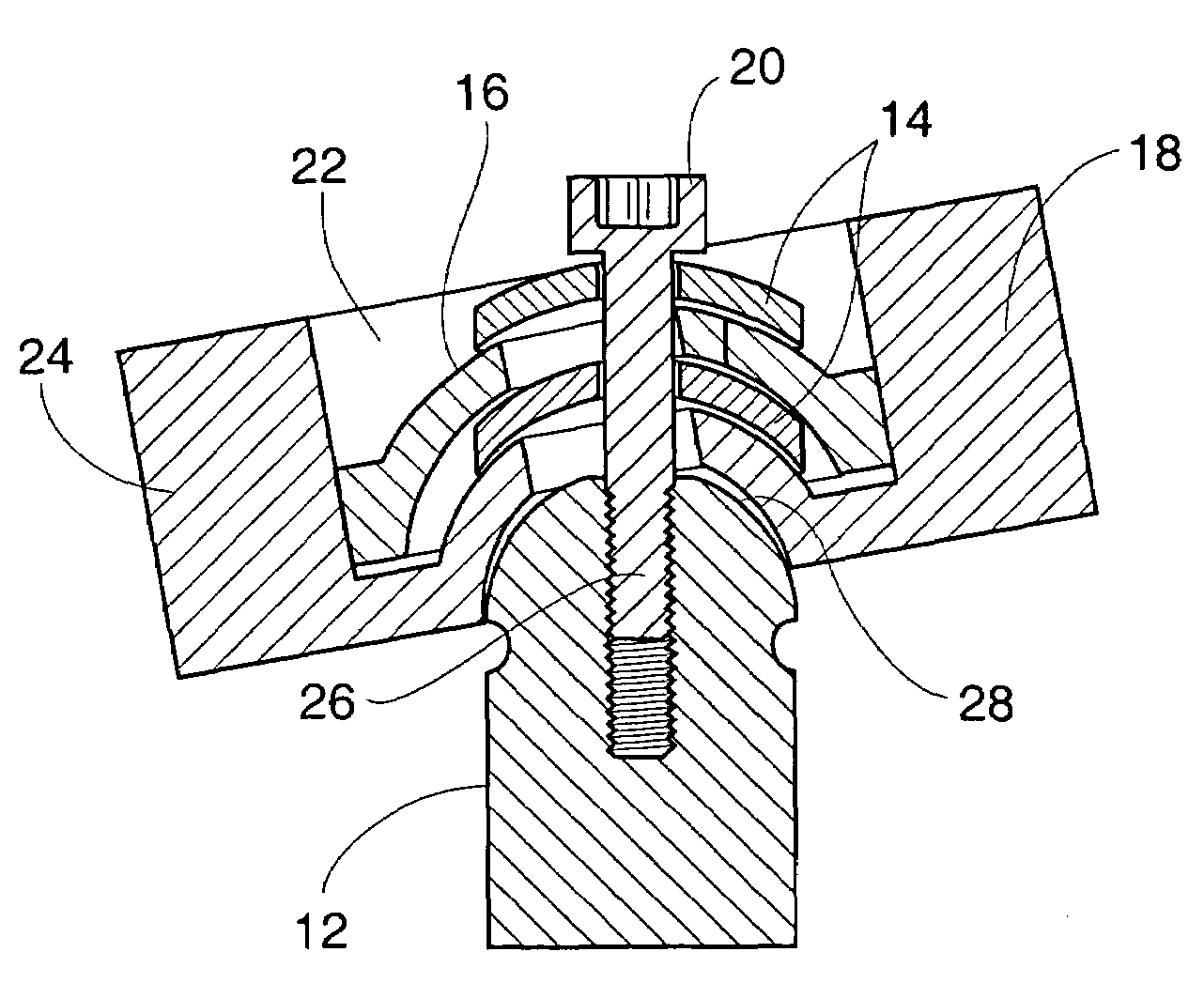

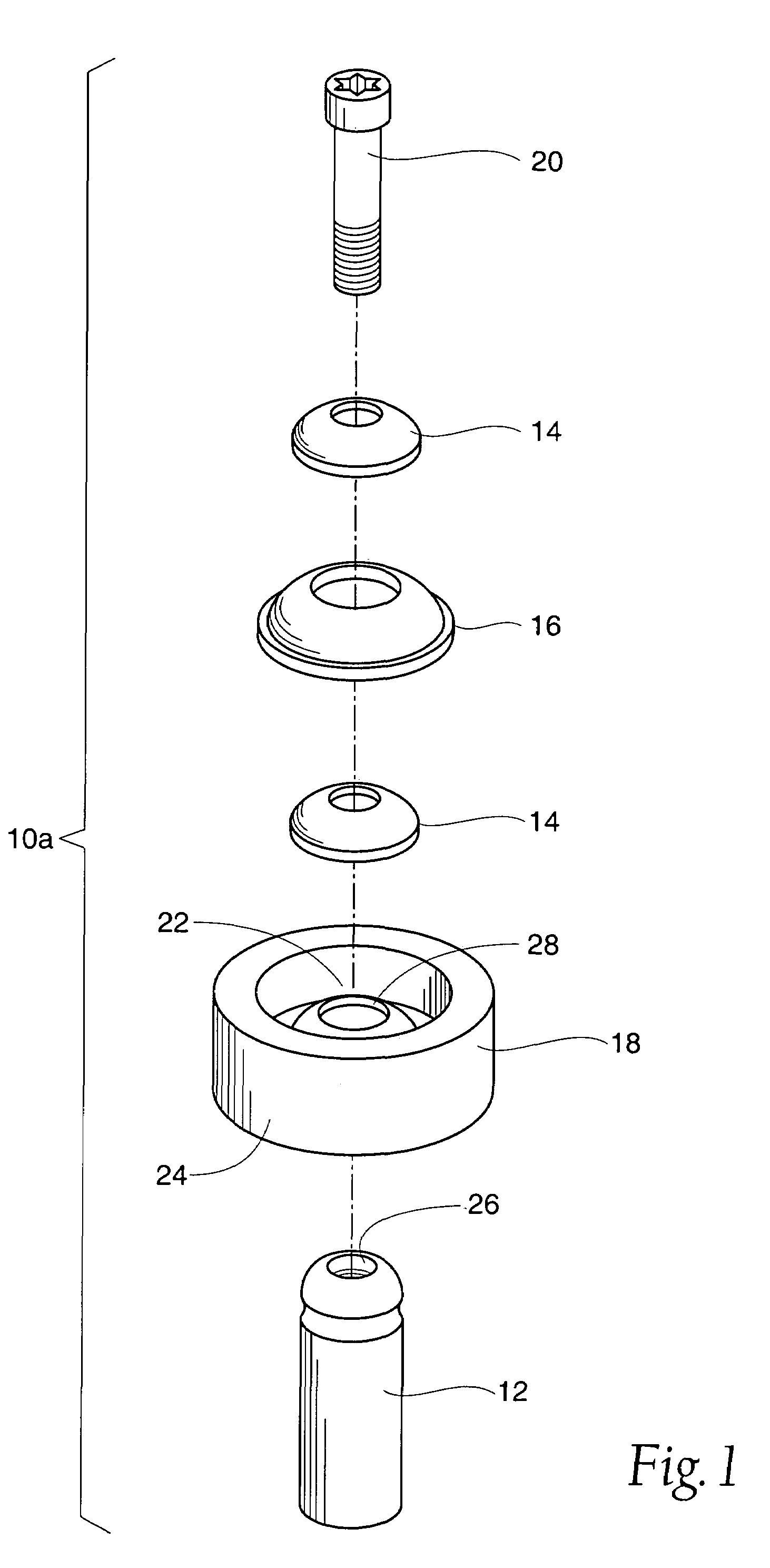

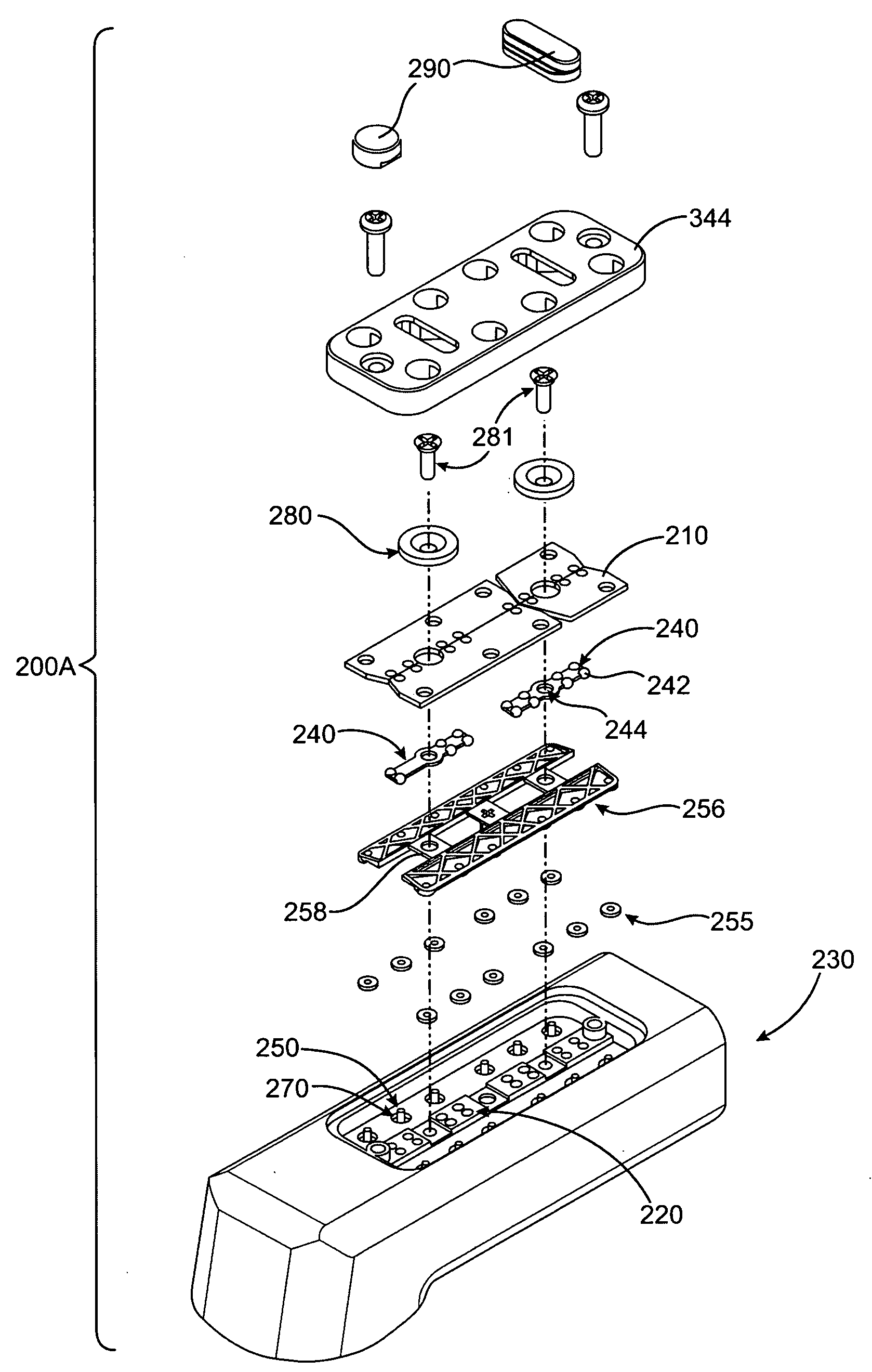

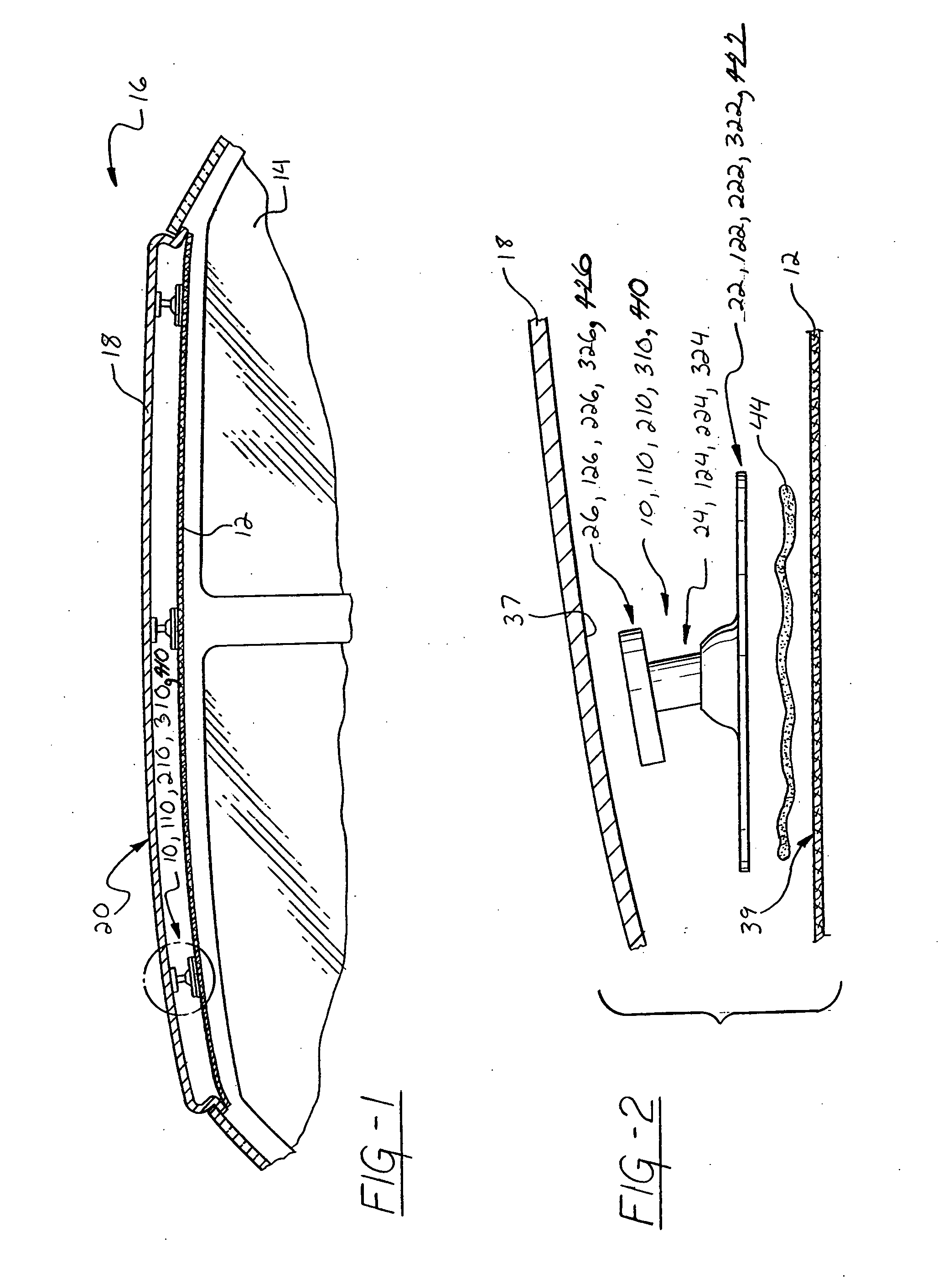

Adjustable bone prostheses and related methods

InactiveUS7166132B2Straightforward and yet robustYielding couplingBone implantBone prosthesisBiomedical engineering

Adjustable prostheses and related methods provide a wide range of adjustment along or about multiple axes. The prostheses and related methods make possible a straightforward, yet robust way of securing, e.g., a humeral head prosthesis in a desired position and maintaining the prosthesis in the desired position during use.

Owner:TORNIER INC

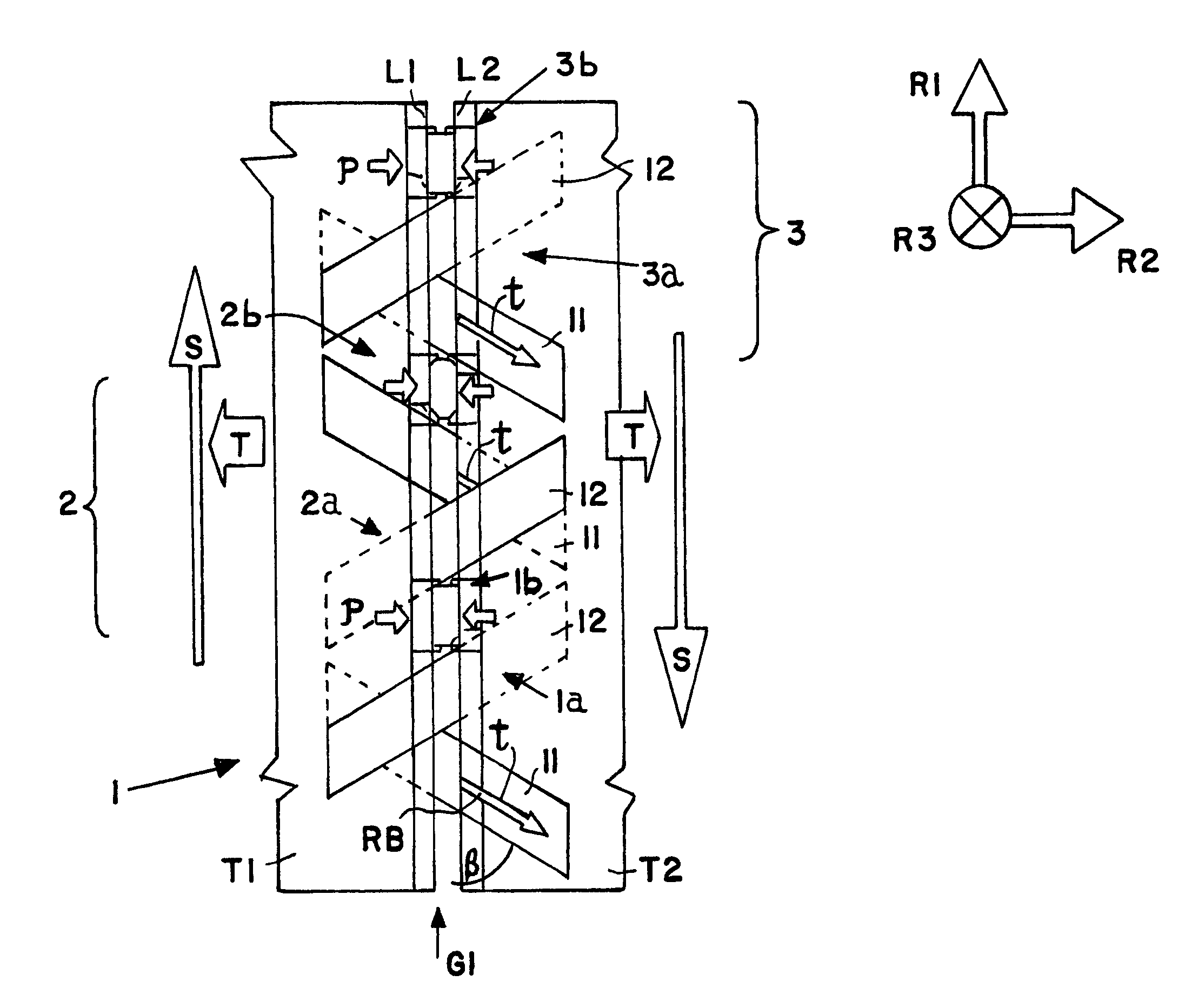

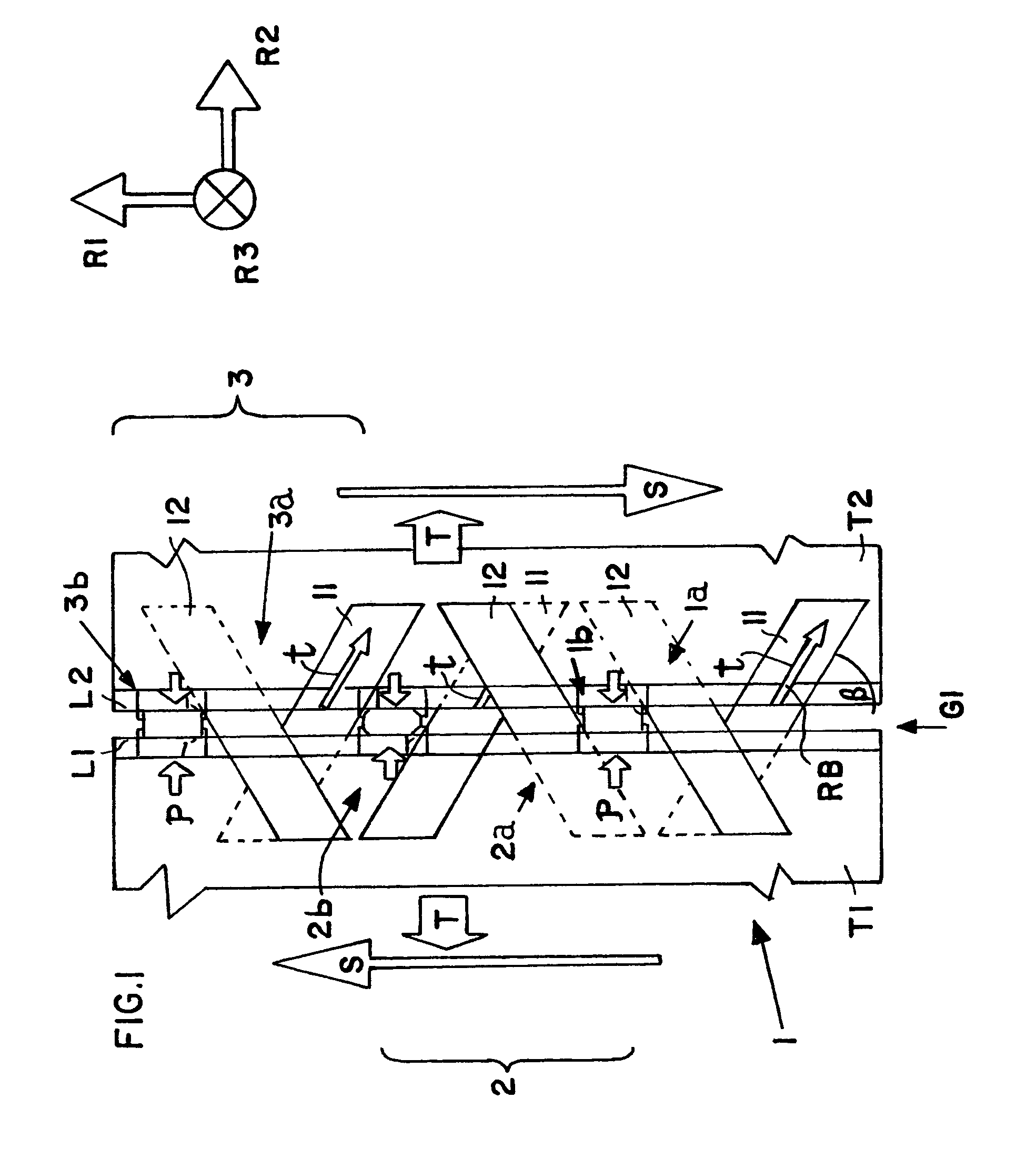

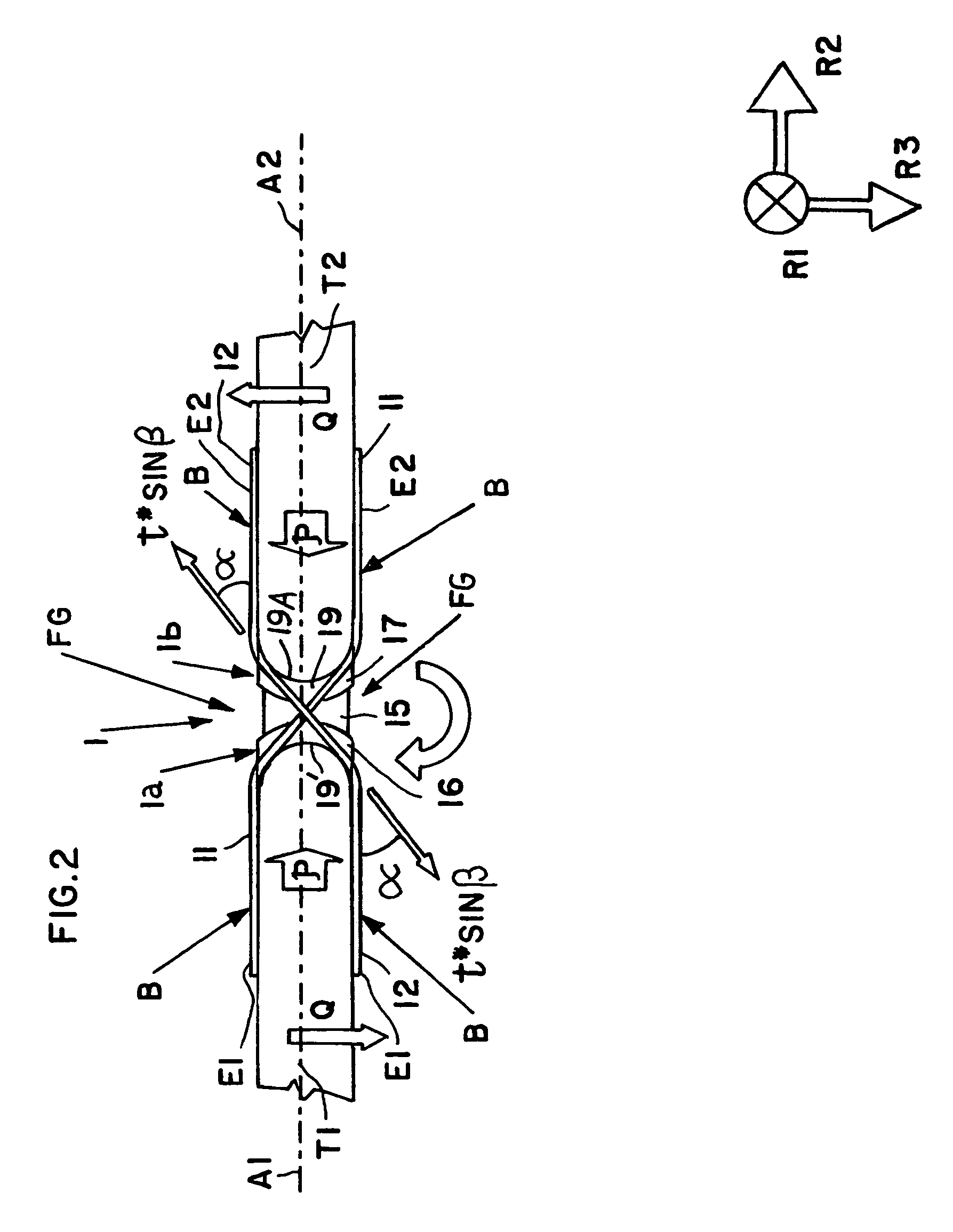

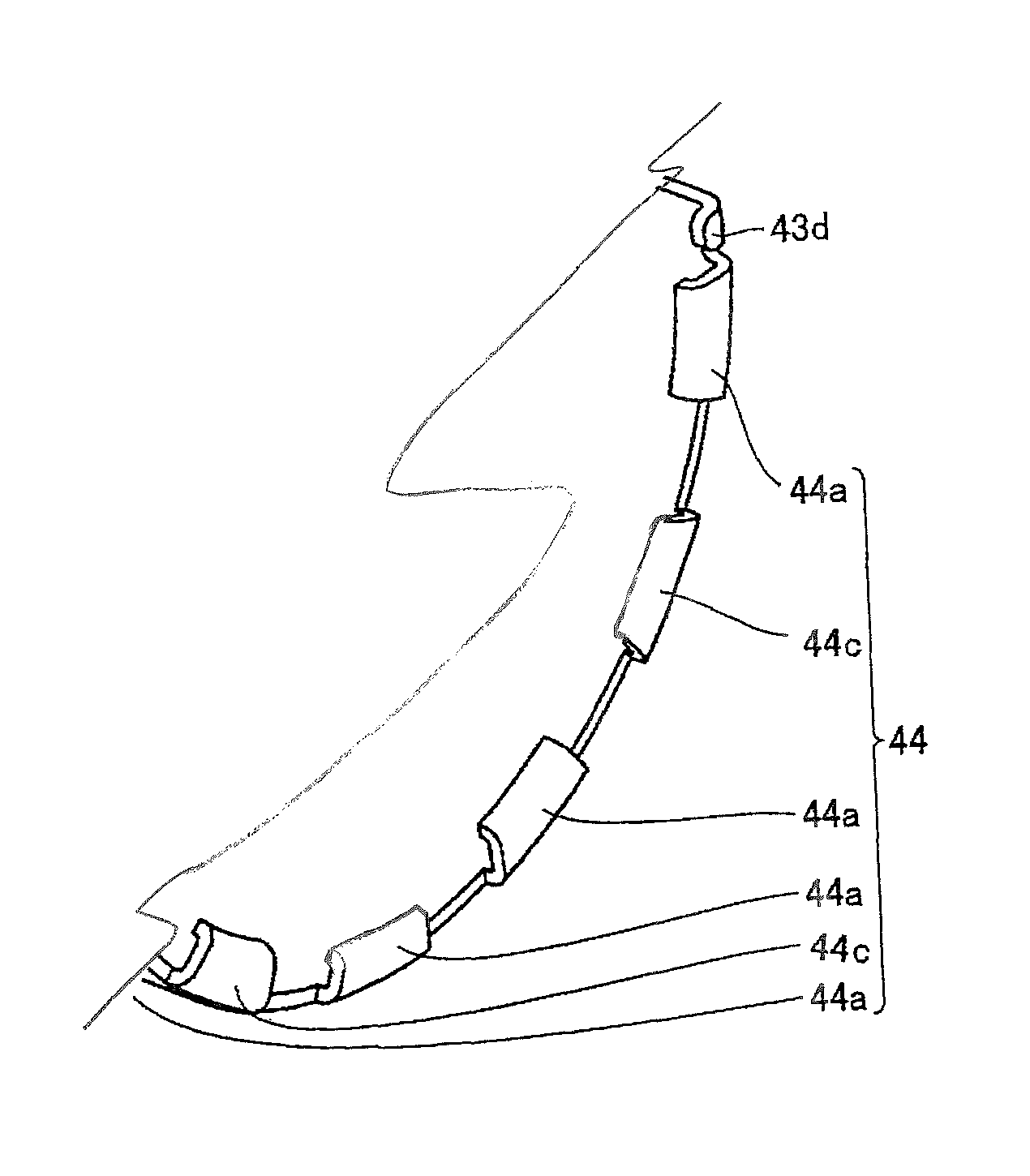

Joint for connecting components together on opposite longitudinal sides in addition to a flexible strip used for said joint

A joint for the connection of components (T1, T2) that are movable relative to one another, on respective longitudinal sides (L1, L2), includes at least two cooperating bands, which are secured with their first ends (E1) respectively on sides of the first component (T1) lying opposite one another and with their second ends (E2) respectively on sides of the second component (T2) lying opposite one another, so that the paths of the bands extend opposite one another in relation to the center axes (A1, A2) of the components.

Owner:AIRBUS OPERATIONS GMBH

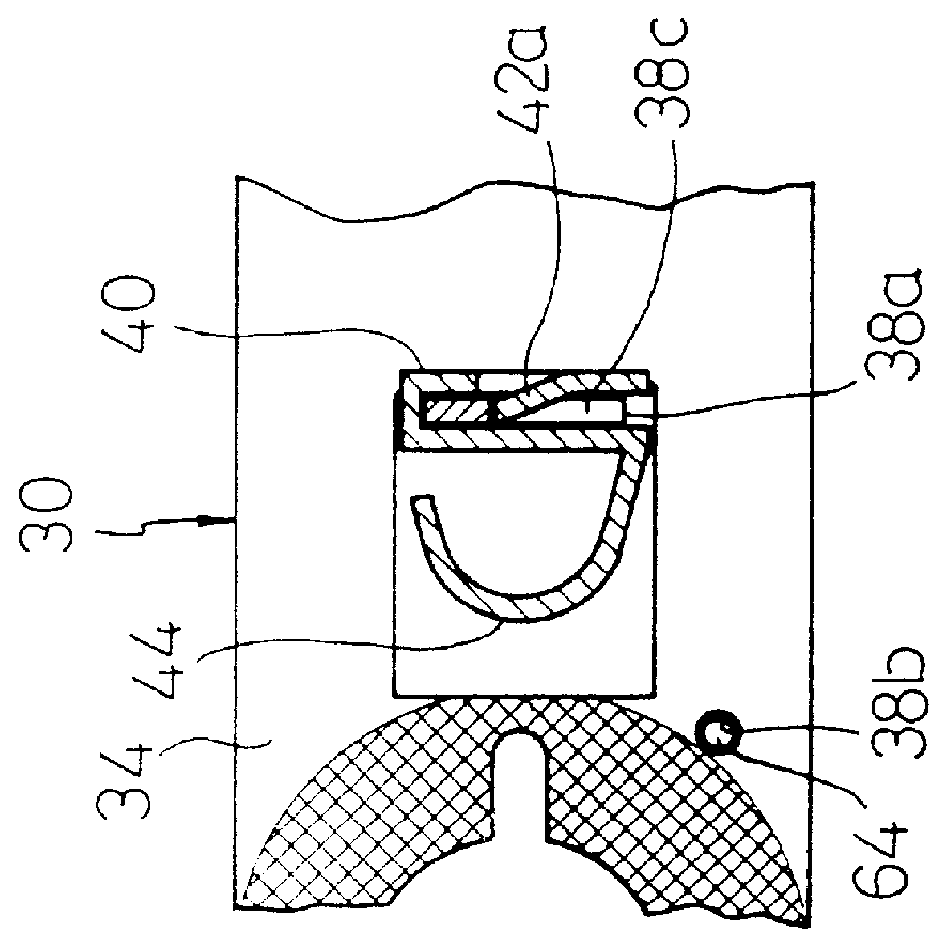

Articulating fastener assembly

A fastener assembly for securely fastening a decorative panel in spaced relation to a support backing includes a base member adapted to be operatively mounted to the decorative panel, a carrier member, and a linking member operatively extending between the base member and the carrier member such that the base member is disposed spaced from the carrier member. A fastening medium is supported by the carrier member and adapted to operatively interconnect the carrier member to the support backing. The linking member operatively interconnects the base member and the carrier member in articulating fashion such that the base member is transversely moveable relative to the carrier member.

Owner:COMML IMPORTS & ASSEMBLY

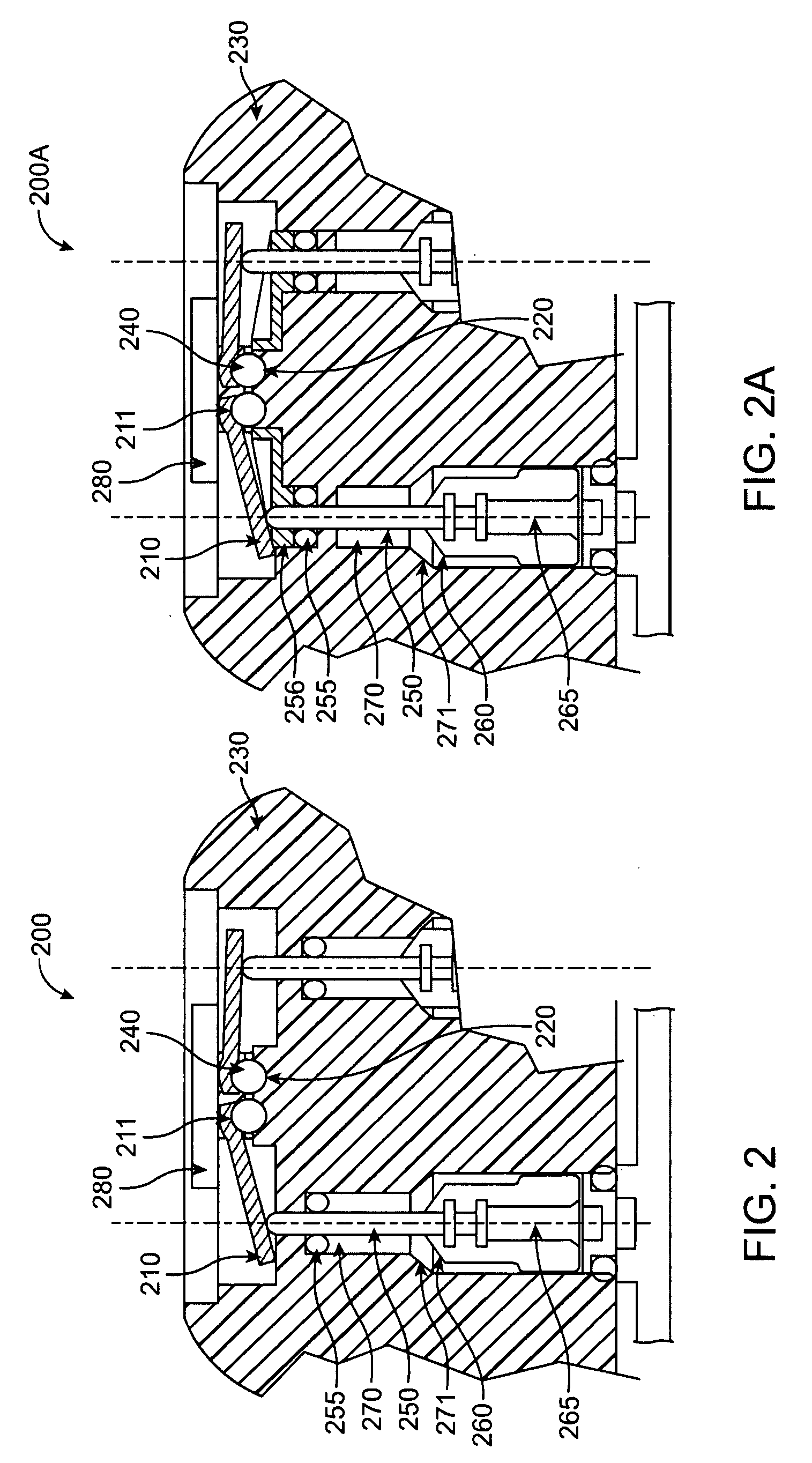

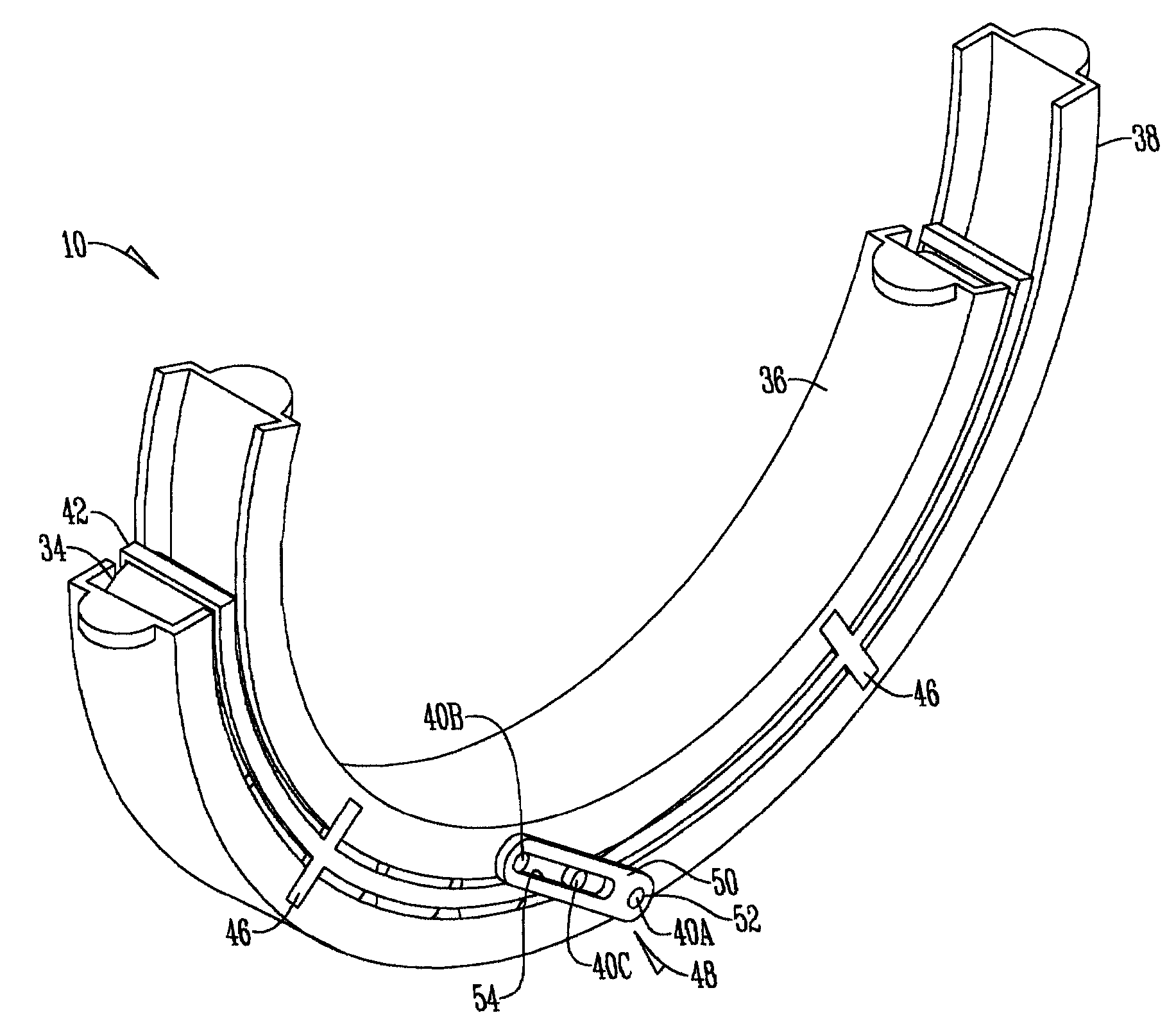

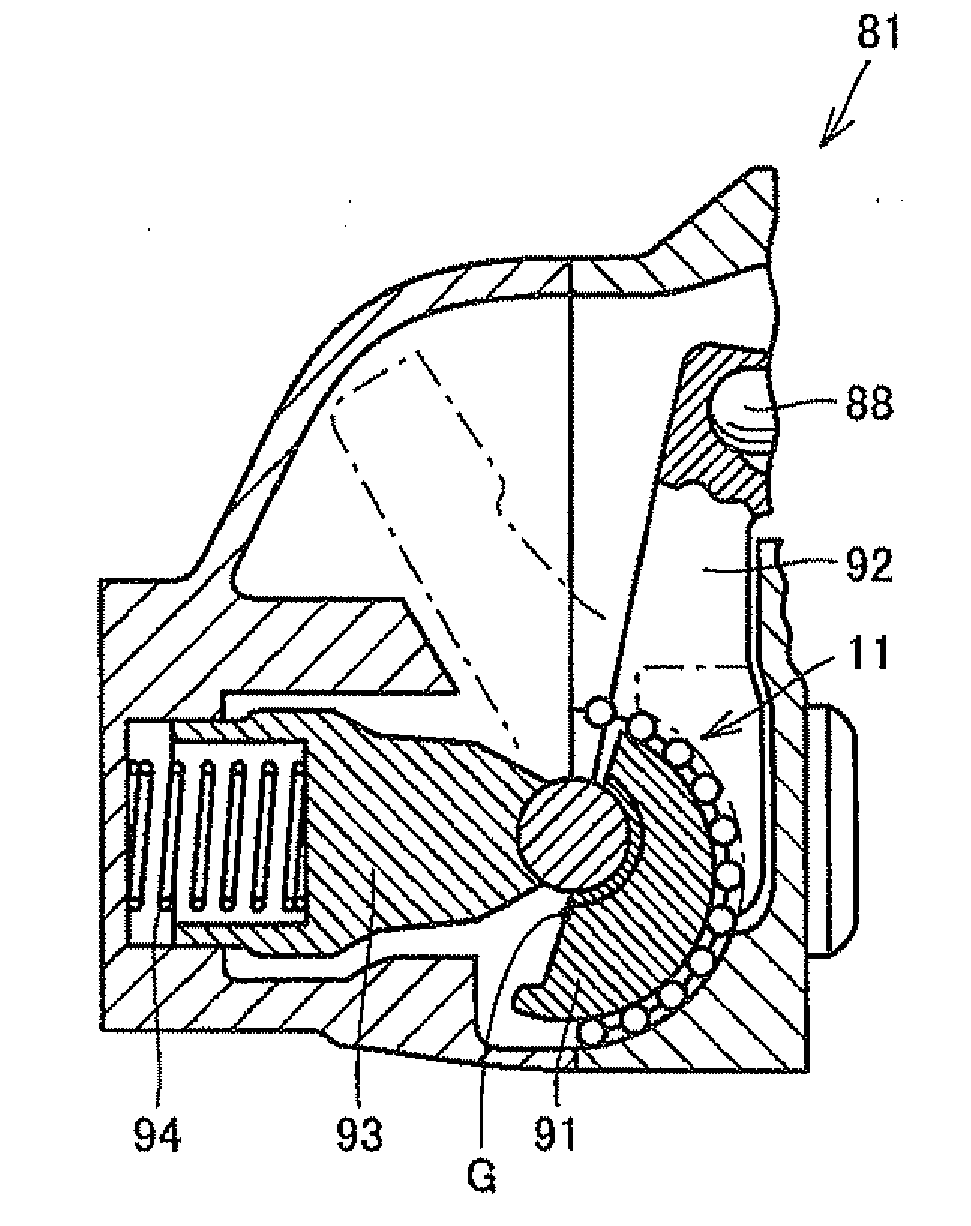

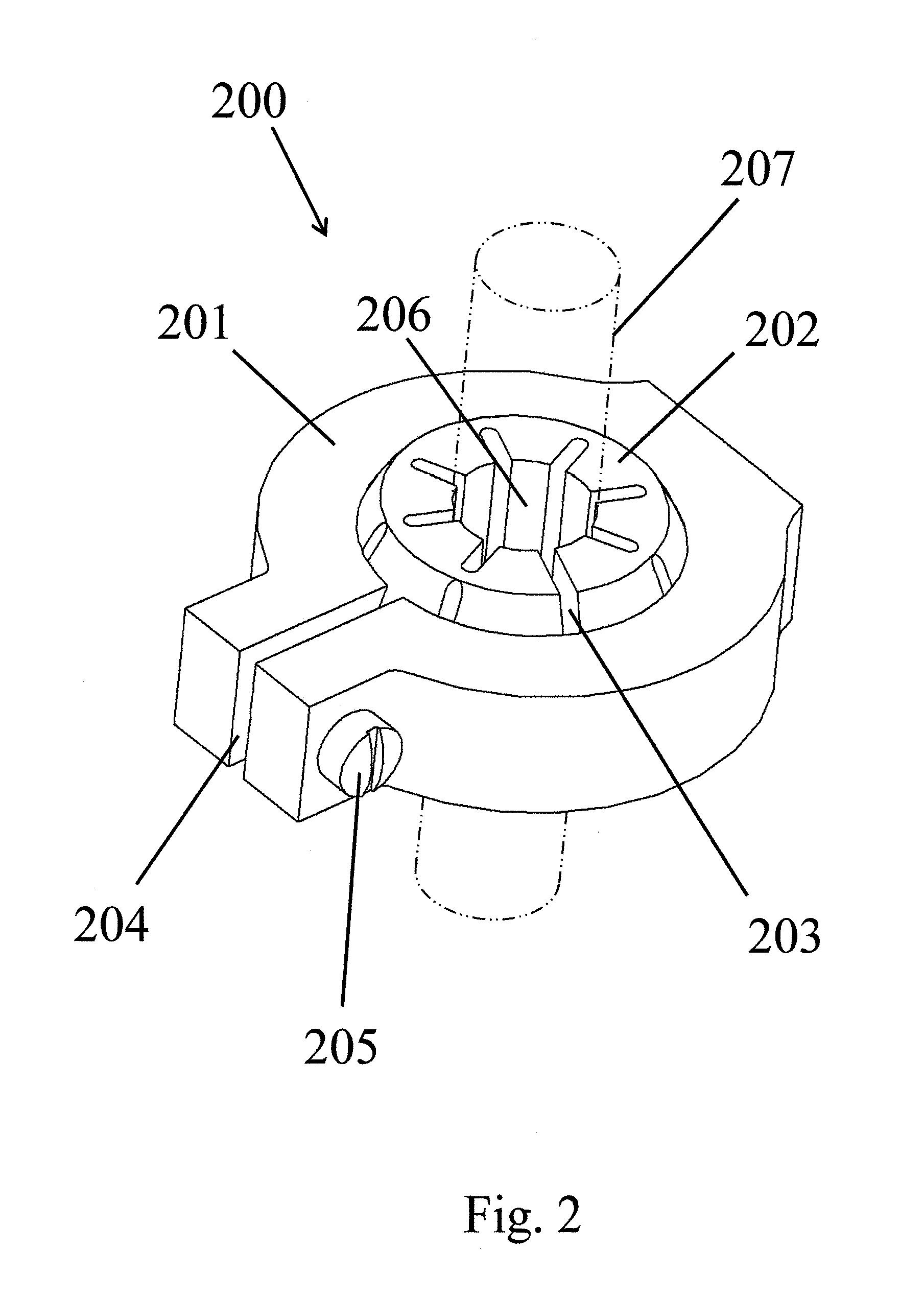

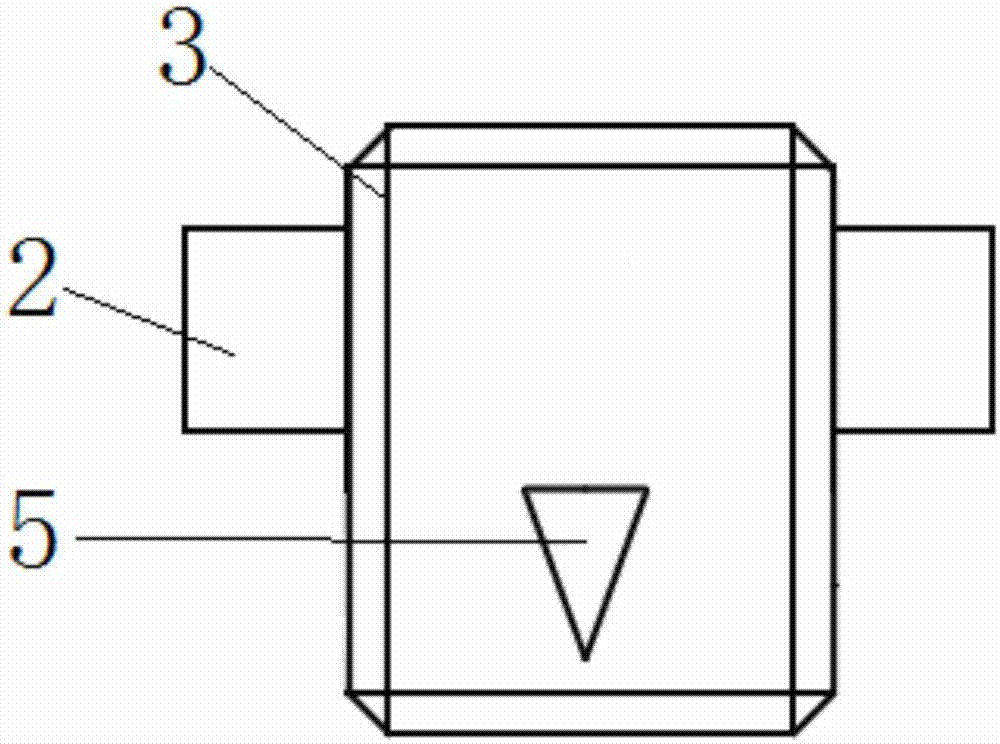

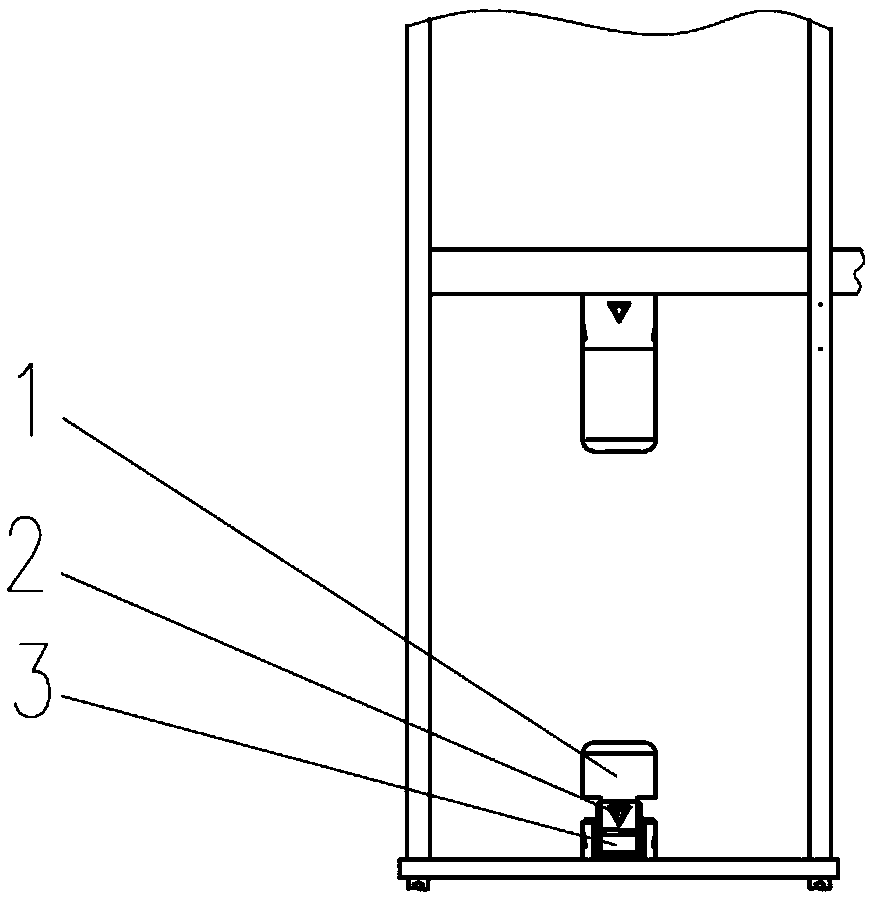

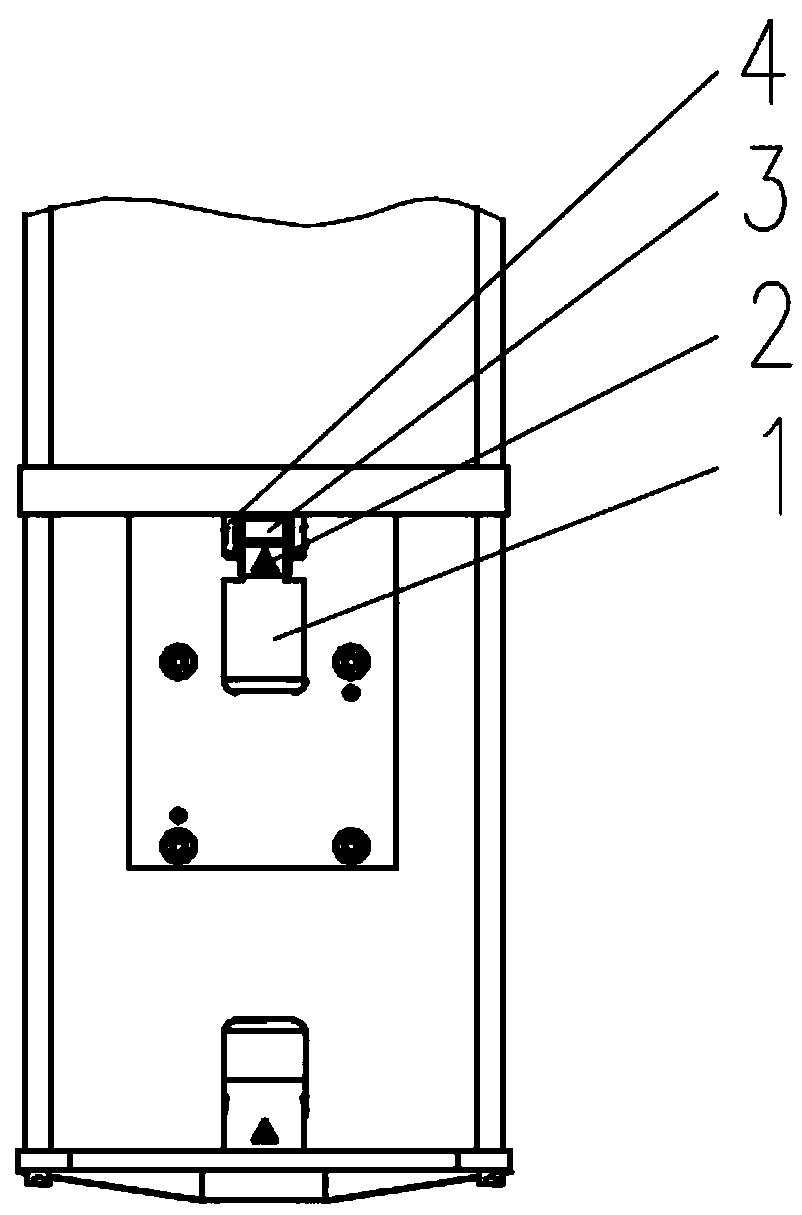

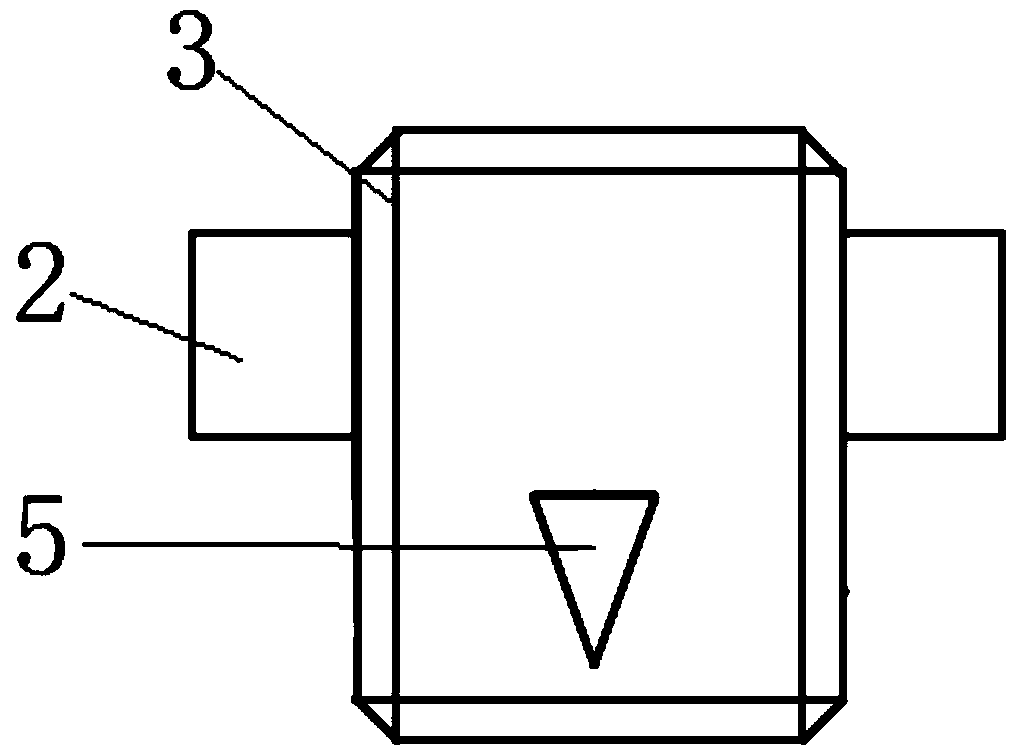

Beverage Dispensing Apparatus with Butterfly Plates and Molded Cluster Bearings

ActiveUS20090145927A1Eliminate weldsLeast expensiveOperating means/releasing devices for valvesBall bearingsBall bearingSteel ball

The present invention provides a butterfly plate assembly for a bar gun that includes a ball cluster bearing sized and dimensioned to operationally couple the butterfly plates with an interior surface of a handle upon which the ball cluster bearing rests. The welding of the steel balls to the butterfly plates and the need to purchase such precise and intricately small balls is eliminated by using the molded ball bearing clusters that are shaped and dimensioned to fit in the recesses in the sockets of the bar gun handle.

Owner:AUTOMATIC BAR CONTROLS

Beverage Dispensing Apparatus with Butterfly Plates and a Molded O-Ring Retainer

ActiveUS20090230148A1High retention rateEasy to replaceSpindle sealingsOperating means/releasing devices for valvesEnvironmental resistanceBall bearing

The present invention provides improved retention of O-rings and easier O-ring replacement by using an O-ring retainer in a bar gun. Furthermore, the assembly of the butterfly plates of the bar gun is improved by using molded ball bearing clusters that fit in recesses in the butterfly plates, thus eliminating the welding of the balls to the butterfly plates and the need to purchase such precise and intricately small balls. The O-ring retainer and molded ball bearing cluster are preferably made from bearing quality acetal plastic materials.

Owner:AUTOMATIC BAR CONTROLS

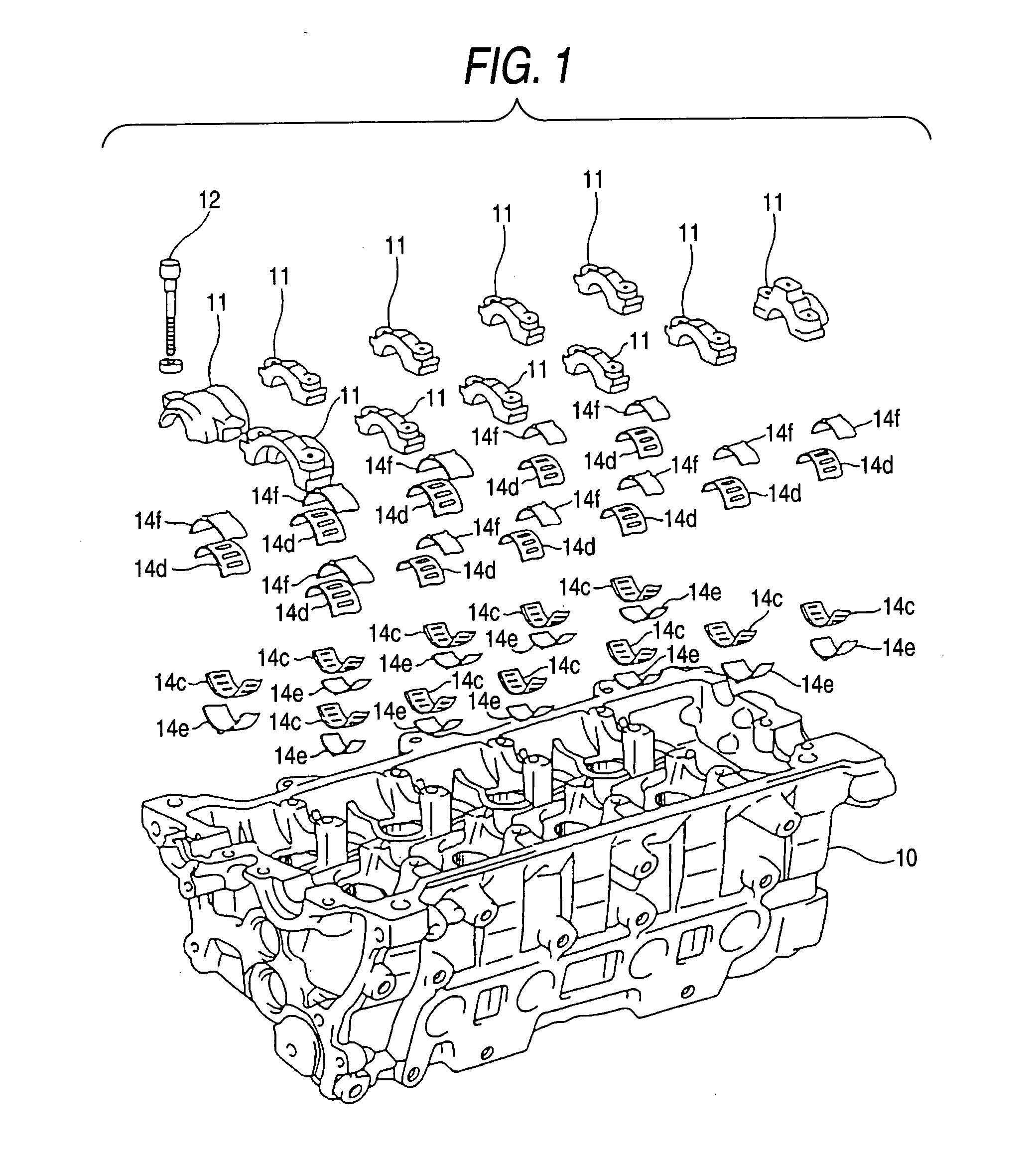

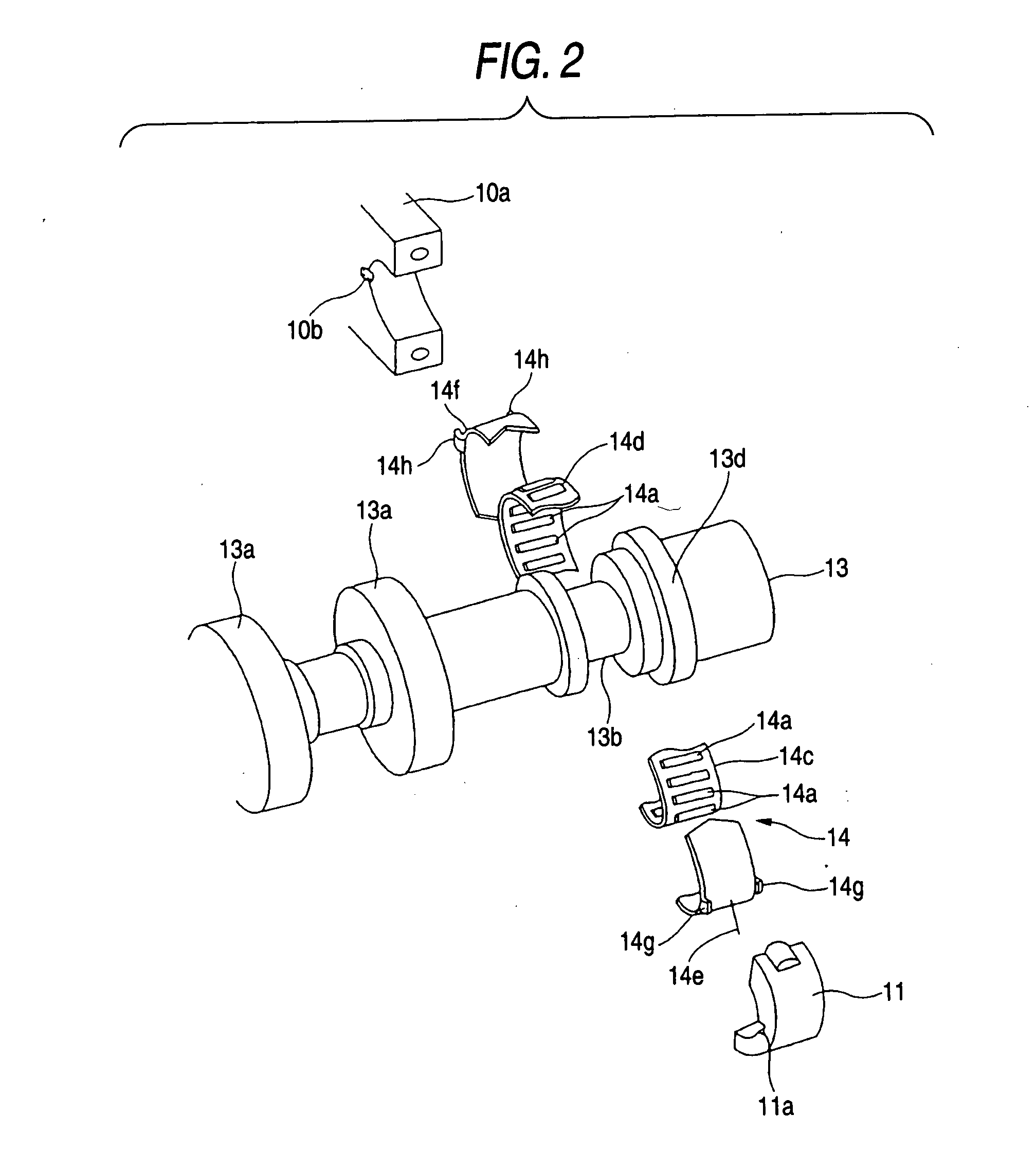

Roller bearing

A roller bearing for rotatably supporting a rotating shaft of an internal combustion engine between a main body and a cap of the internal combustion engine. The roller bearing including: a plurality of rollers; a retainer which is cirumferentially splittable and supports the plurality of rollers; and an outer race which is cirumferentially splittable and forms a raceway surface for the plurality of rollers. The retainer is split into a plurality of retaining members. The outer race is split into a plurality of race plates. At least one of the race plates is provided with one of a projection and a cavity to be engaged with one of the main body and the cap to restrict a relative movement between the one of the race plates and the one of the cylinder head and the cap.

Owner:NSK LTD

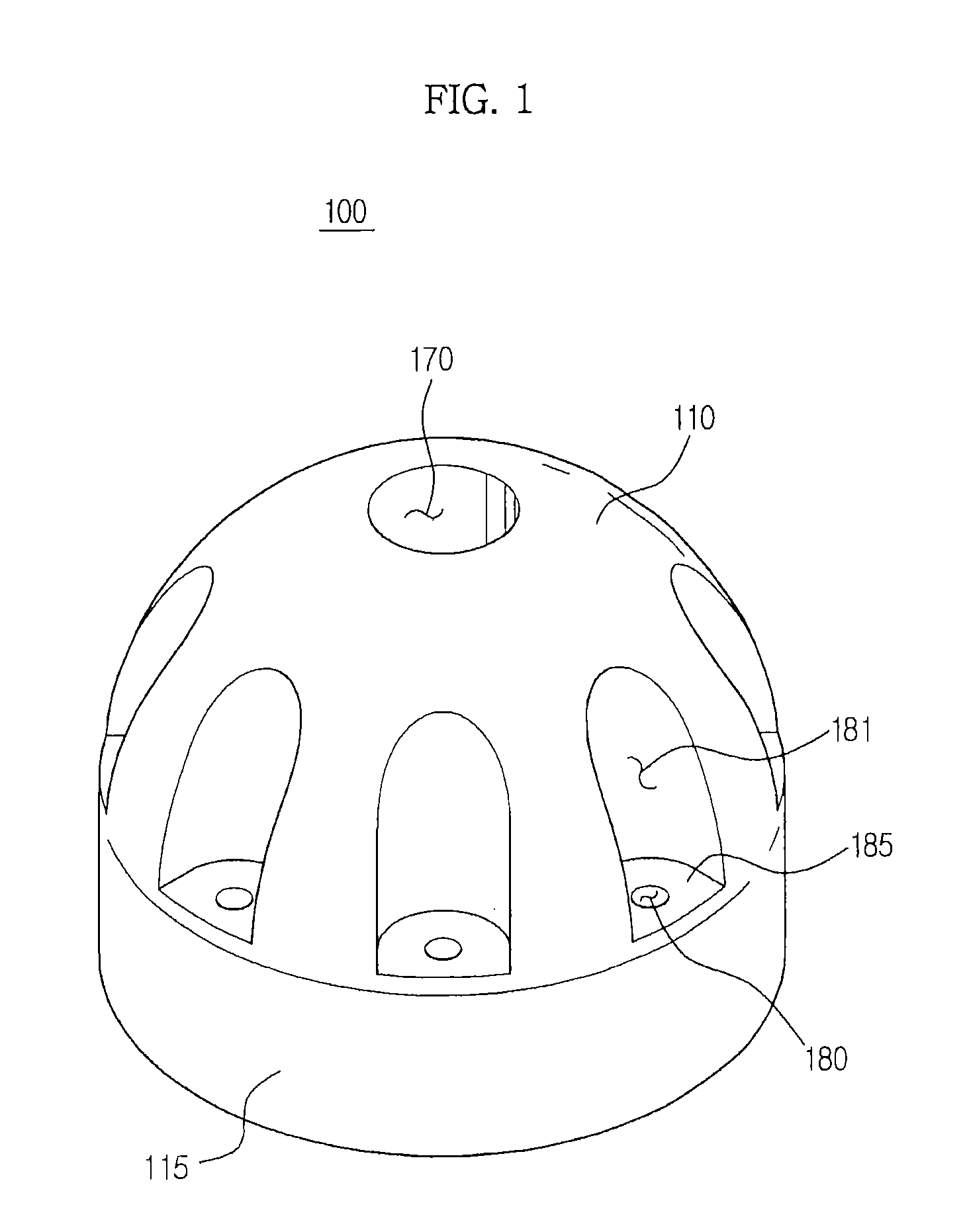

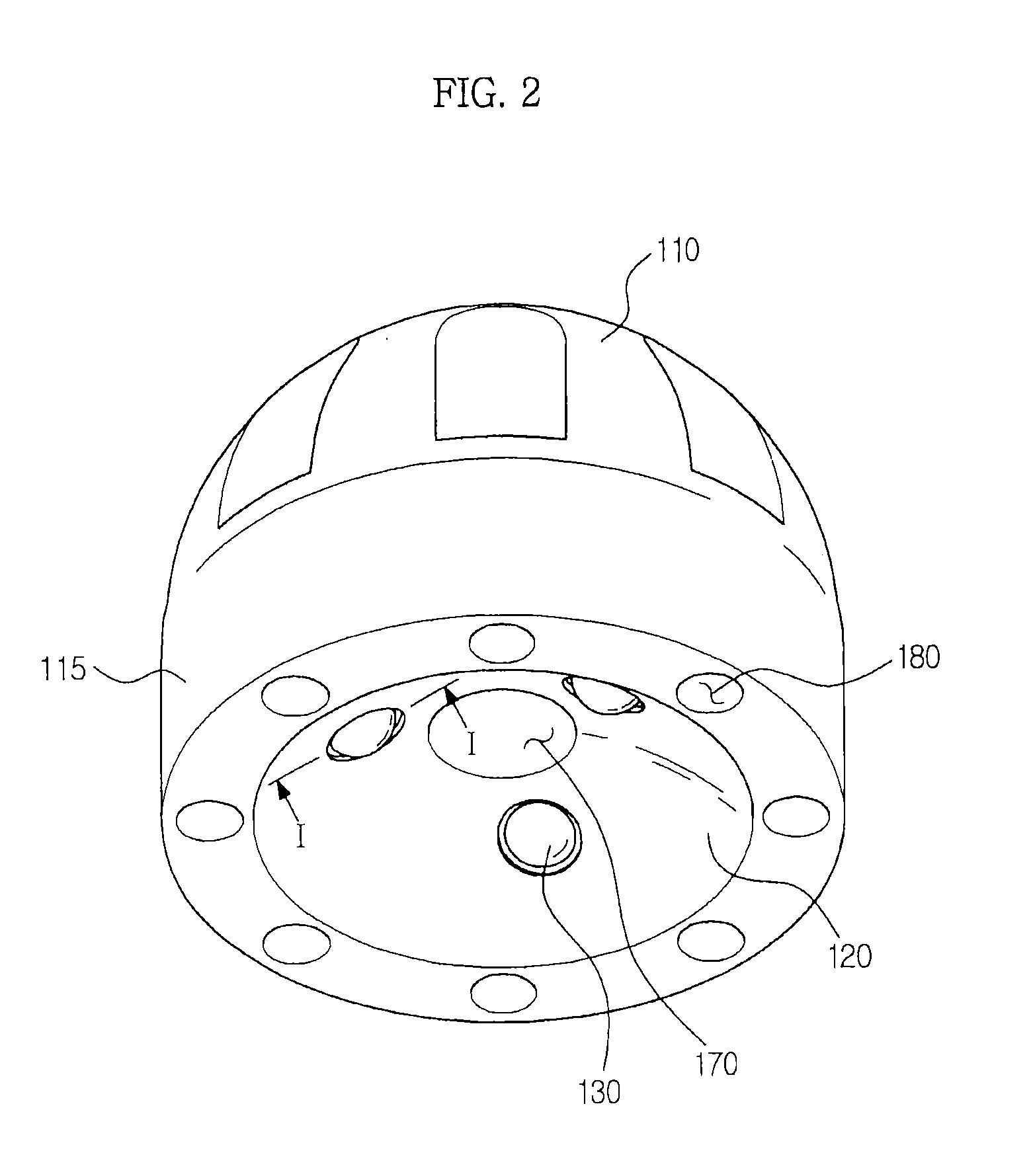

Link unit, arm module, and surgical apparatus including the same

ActiveUS20130199327A1Improve rigidityProgramme-controlled manipulatorJointsEngineeringDegrees of freedom

Owner:SAMSUNG ELECTRONICS CO LTD

Connector element for a glass post and beam construction

Owner:DORMA GMBH & CO KG

Pivot bearing

InactiveUS8376615B2Prevent slippingSpend lessRolling contact bearingsShaftsEngineeringBearing surface

A pivot bearing having a first bearing surface of hollow cylindrical design, at least in sections. Guided in the first bearing surface is a second bearing surface of hollow cylindrical design, at least in sections. Rolling bodies are arranged between the bearing surfaces. The pivot bearing also has a cage for guiding the rolling bodies, and a slide block to prevent the cage from slipping. A first grove is formed in the first bearing surface and a second grove is formed in the second bearing surface. The groves are inclined transversely with respect to the running direction of the rolling bodies. The opposite inclination of the groves has the result that, if the spacing between the bearing surfaces is neglected, the grooves intersect. The sliding block is guided between the grooves. The cage has a recess that holds the sliding block permitting cage control.

Owner:SCHAEFFLER TECH AG & CO KG

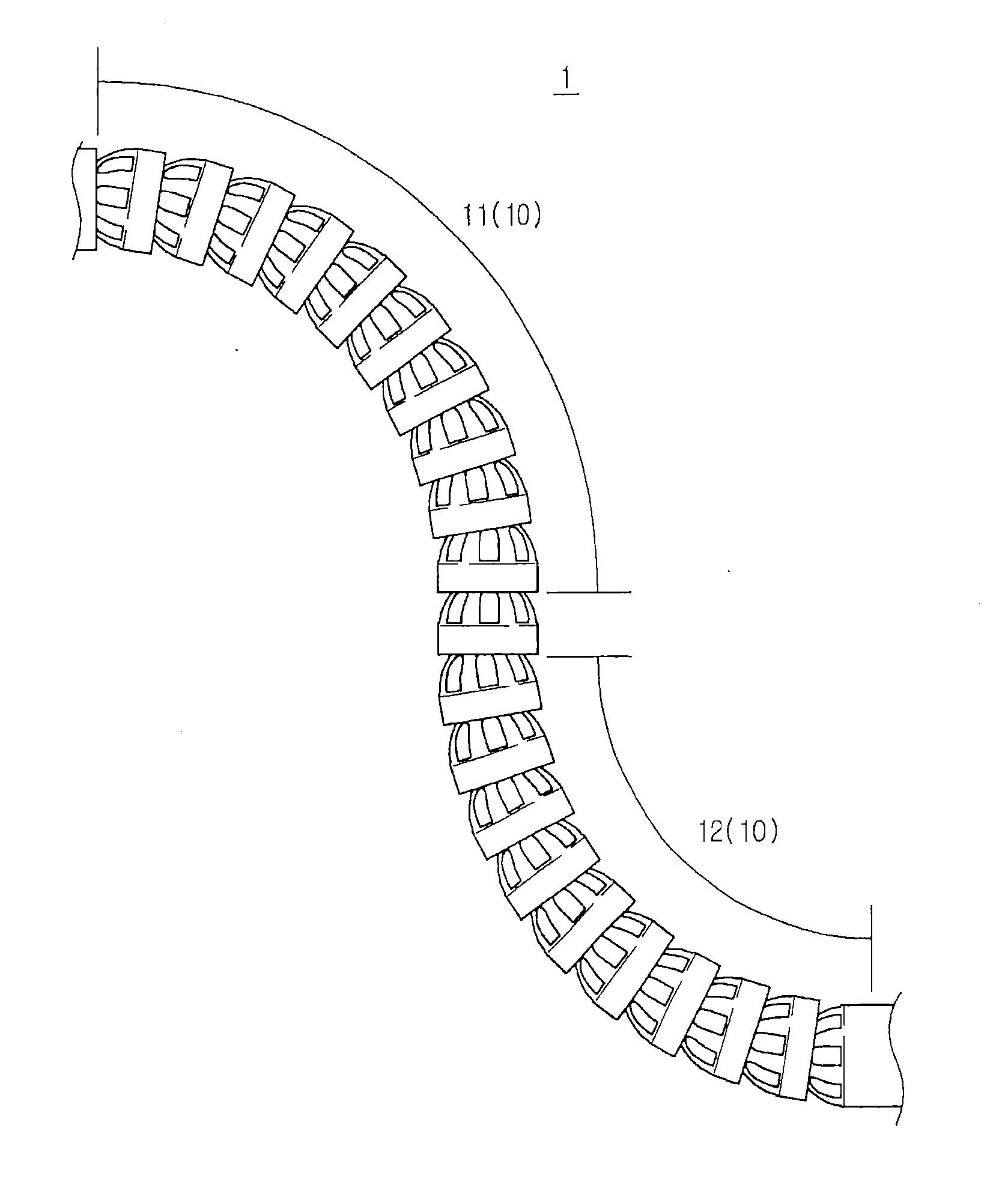

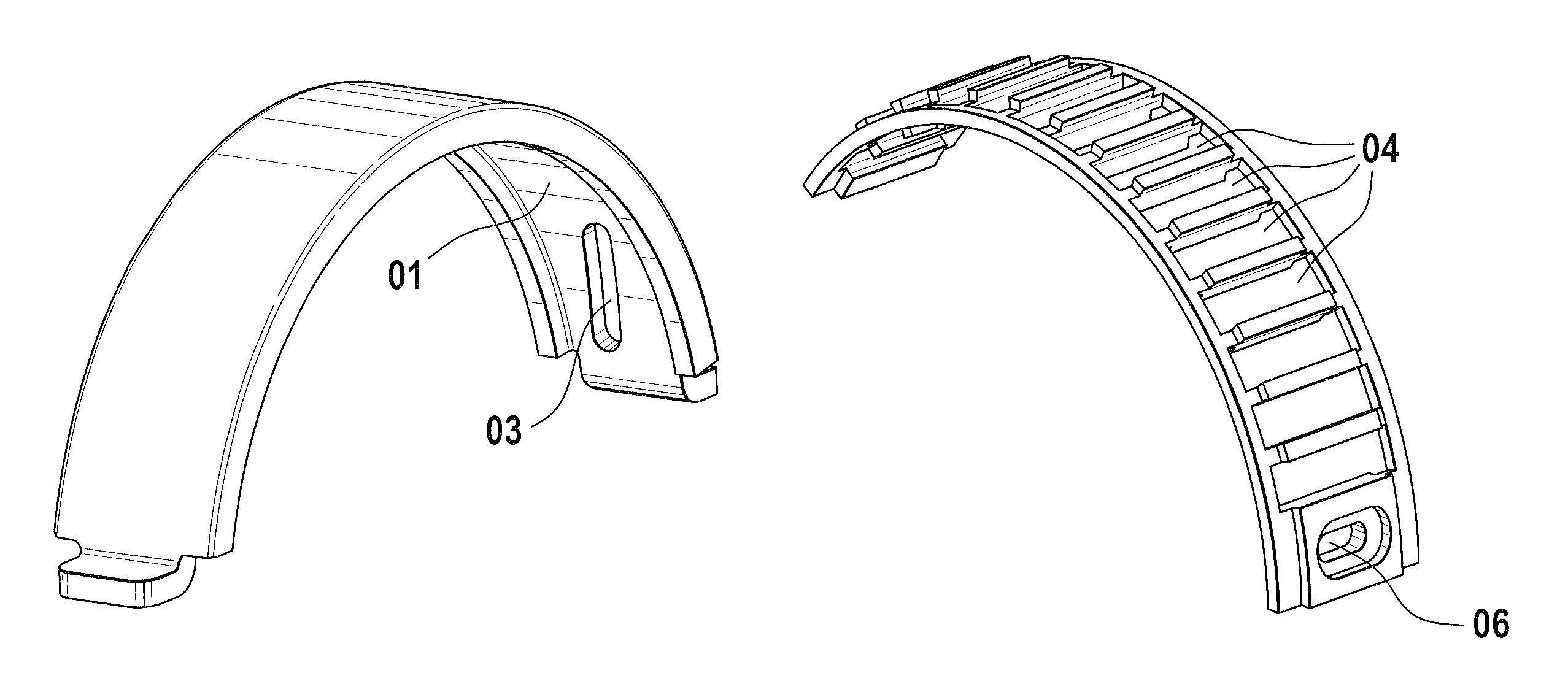

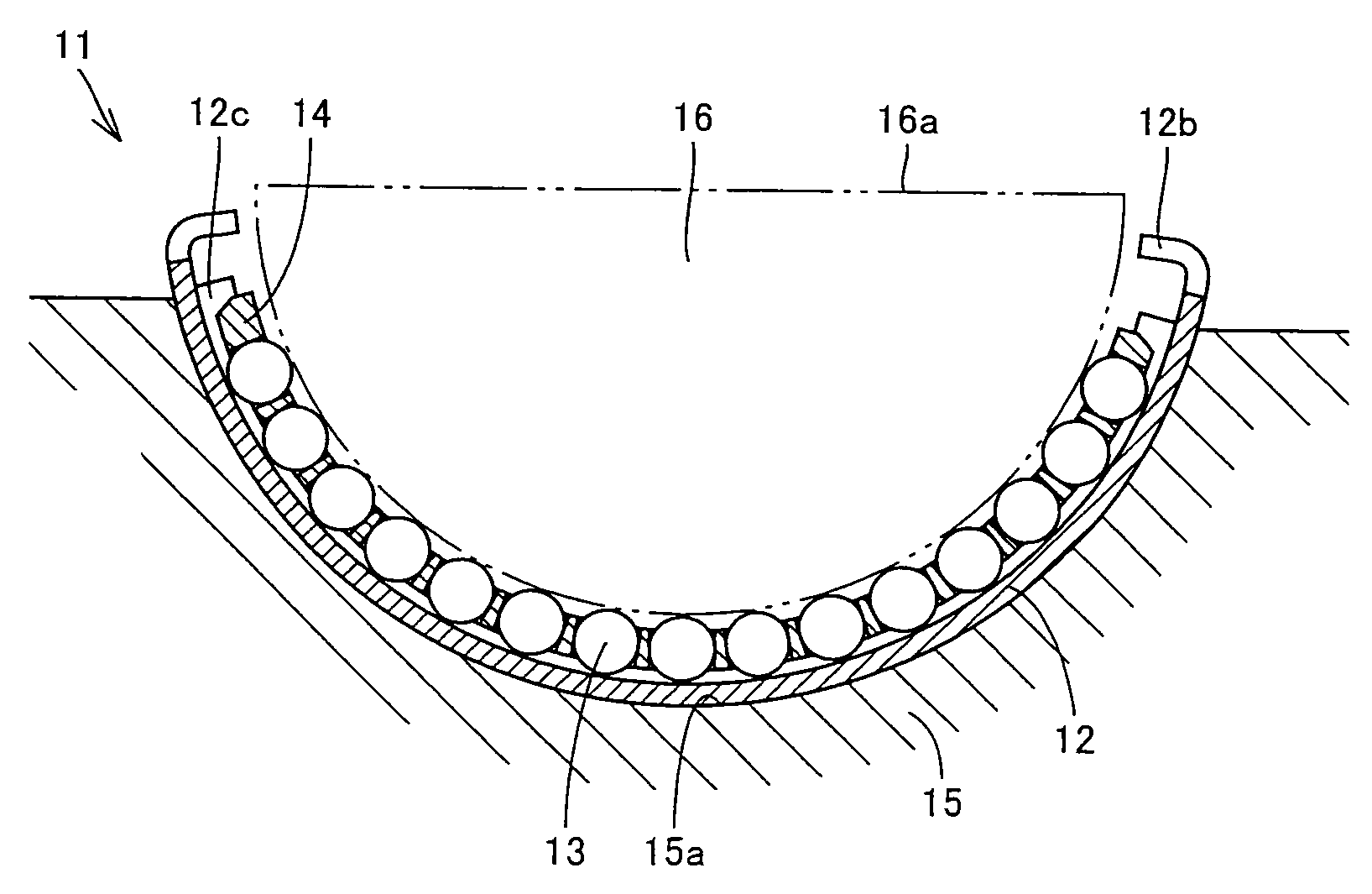

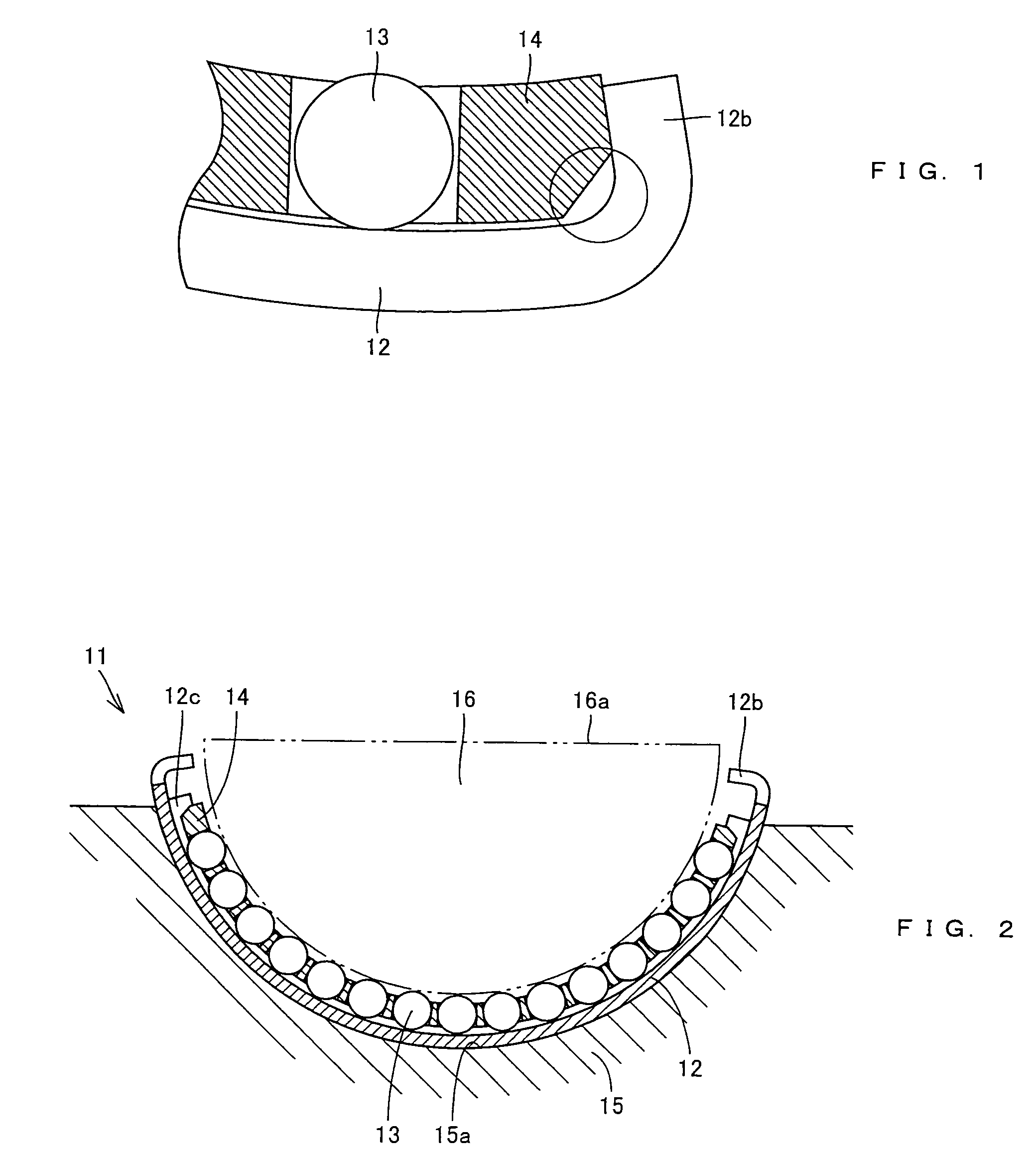

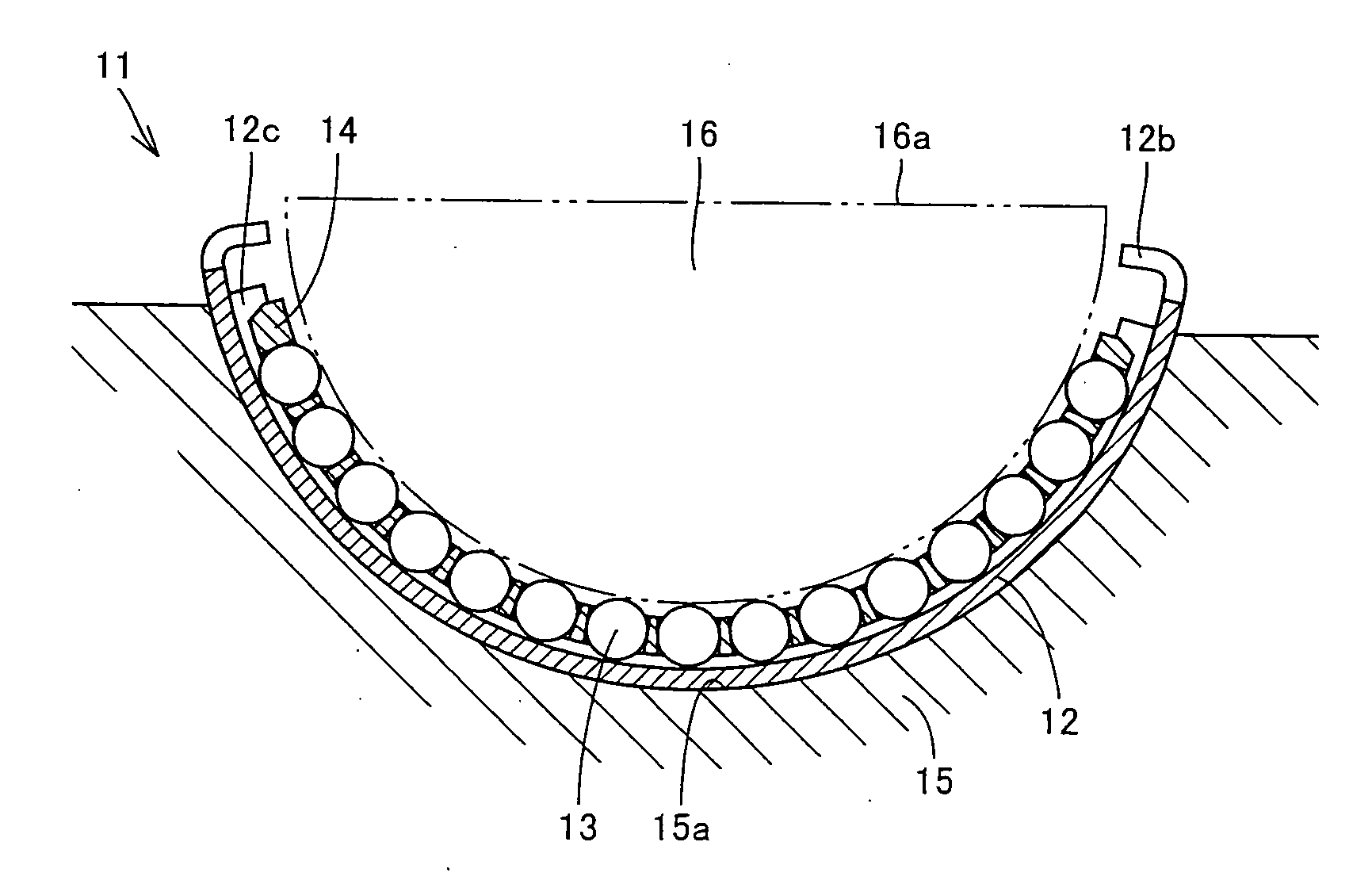

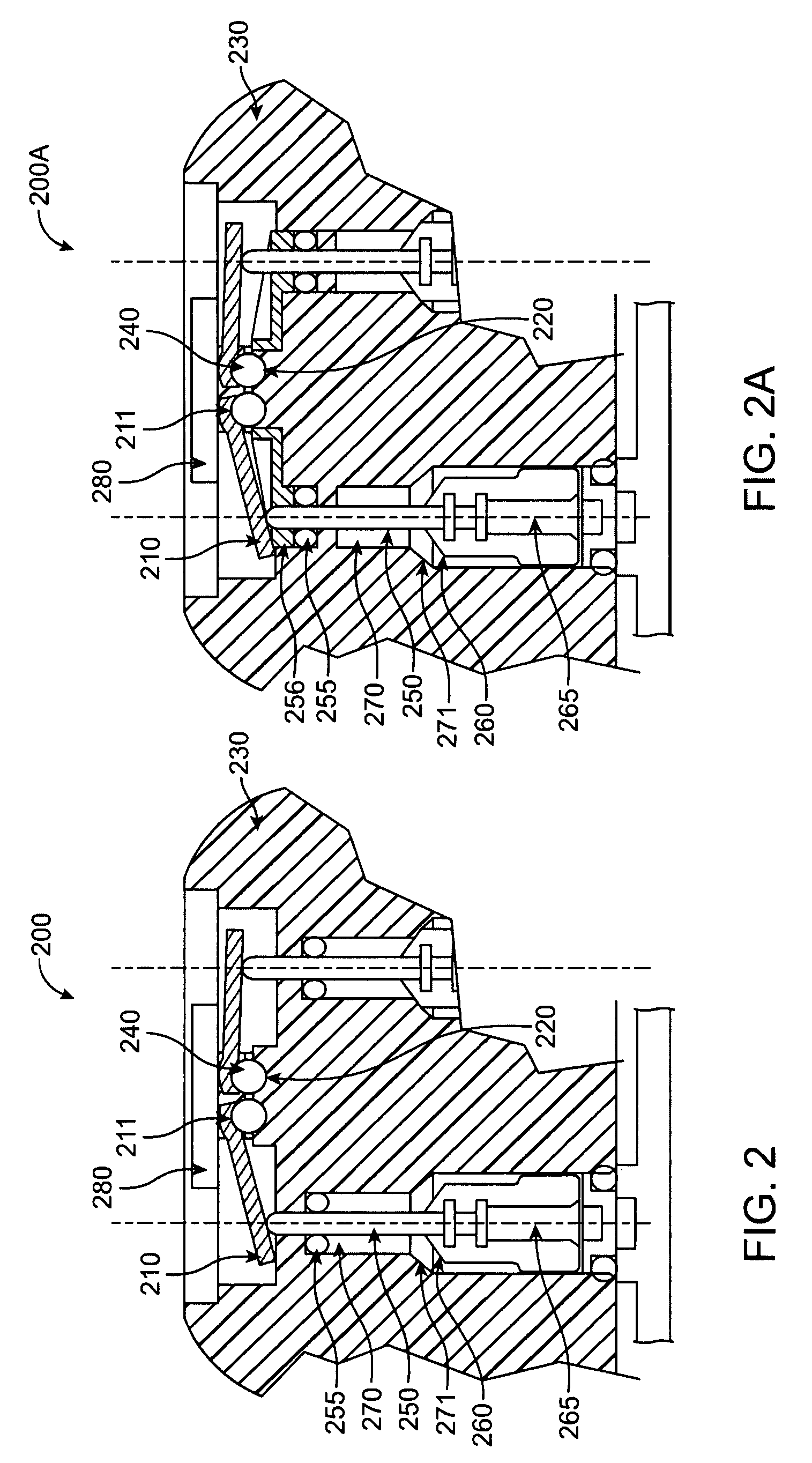

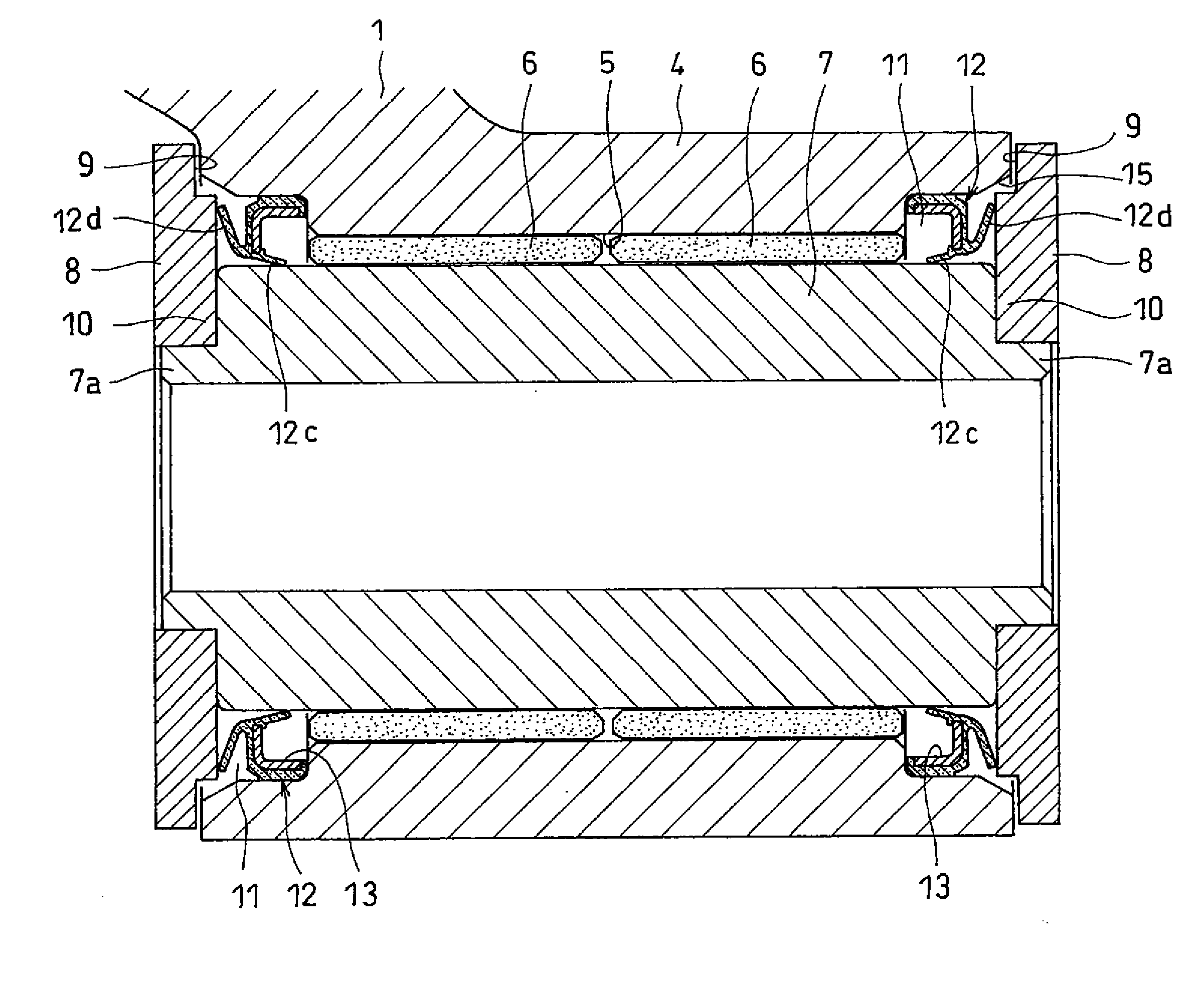

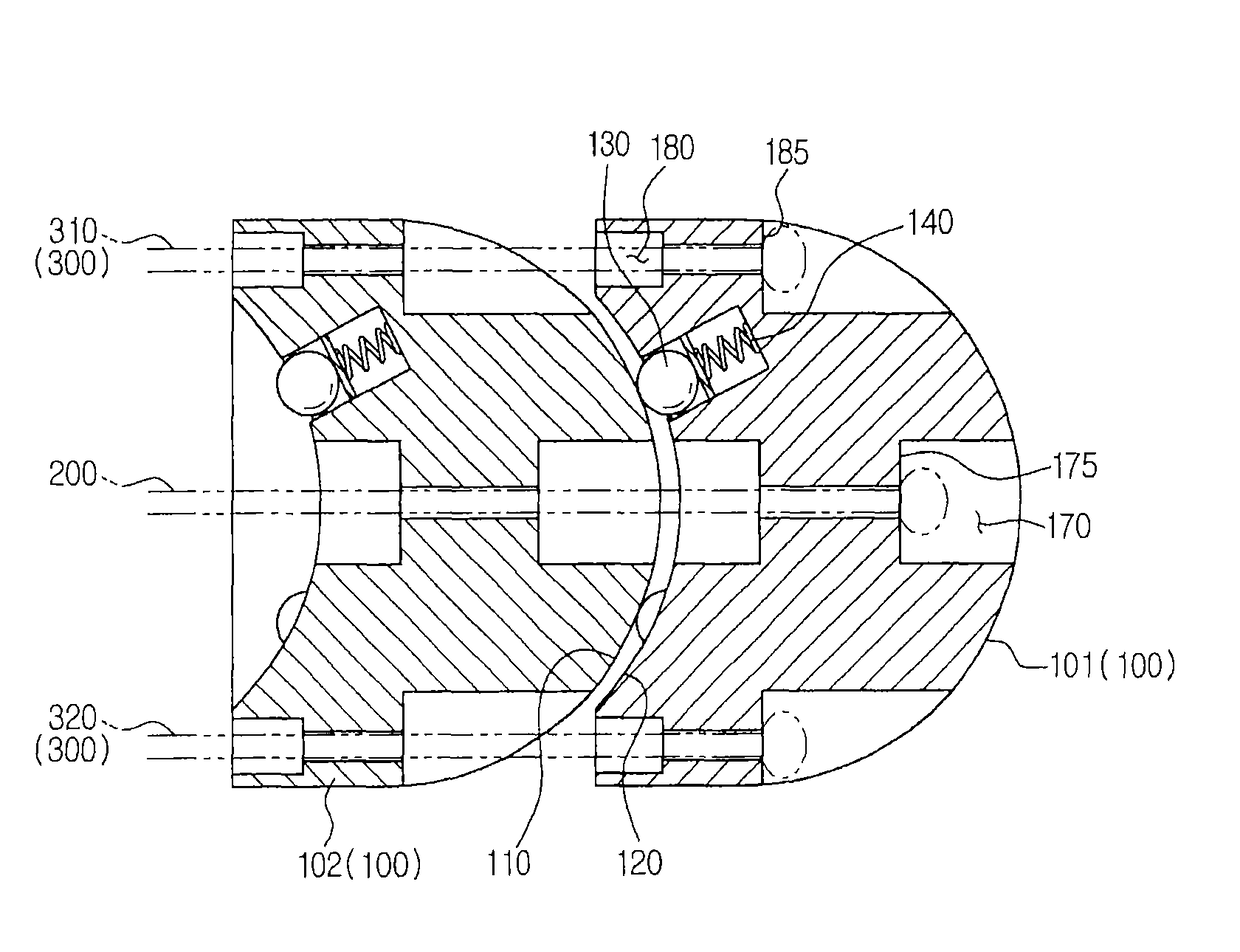

Cradle bearing

ActiveUS7517156B2Avoid damageReduce pressureRolling contact bearingsShaftsEngineeringMechanical engineering

A cradle bearing comprises a circular arcuate outer race arranged in a circular arcuate recessed part provided in a housing, a plurality of rollers arranged along the inner circumferential surface of the outer race and supporting a swash plate swingably, and a retainer for retaining the interval between the rollers. An engagement member and the end face of the retainer in the circumferential direction are in face-to-face contact with each other.

Owner:NTN CORP

Articulating fastener assembly

InactiveUS20080056810A1Facilitates a vehicle headlinerPicture framesDomestic mirrorsEngineeringFastener

A fastener assembly securely fastens a decorative panel in spaced relation to a support backing. The fastener assembly includes a base member adapted to be operatively mounted to the decorative panel, a carrier member, and a fastening medium supported by the carrier member and adapted to operatively interconnect the carrier member to the support backing. At least one biasing member is adapted to operatively support the carrier member and provide swiveling articulation of the carrier member relative to the base member. At least one leg extends from the base member and is adapted to operatively engage the carrier member so as to attach the carrier member to the base member in articulating fashion.

Owner:EYPEX CORP

Cradle bearing

ActiveUS20070053621A1Avoid damageReduce pressureRolling contact bearingsShaftsEngineeringMechanical engineering

A cradle bearing comprises a circular arcuate outer race arranged in a circular arcuate recessed part provided in a housing, a plurality of rollers arranged along the inner circumferential surface of the outer race and supporting a swash plate swingably, and a retainer for retaining the interval between the rollers. An engagement member and the end face of the retainer in the circumferential direction are in face-to-face contact with each other.

Owner:NTN CORP

Beverage dispensing apparatus with butterfly plates and a molded O-ring retainer

ActiveUS8272536B2High retention rateEasy to replaceSpindle sealingsOperating means/releasing devices for valvesEnvironmental resistanceBall bearing

The present invention provides improved retention of O-rings and easier O-ring replacement by using an O-ring retainer in a bar gun. Furthermore, the assembly of the butterfly plates of the bar gun is improved by using molded ball bearing clusters that fit in recesses in the butterfly plates, thus eliminating the welding of the balls to the butterfly plates and the need to purchase such precise and intricately small balls. The O-ring retainer and molded ball bearing cluster are preferably made from bearing quality acetal plastic materials.

Owner:AUTOMATIC BAR CONTROLS

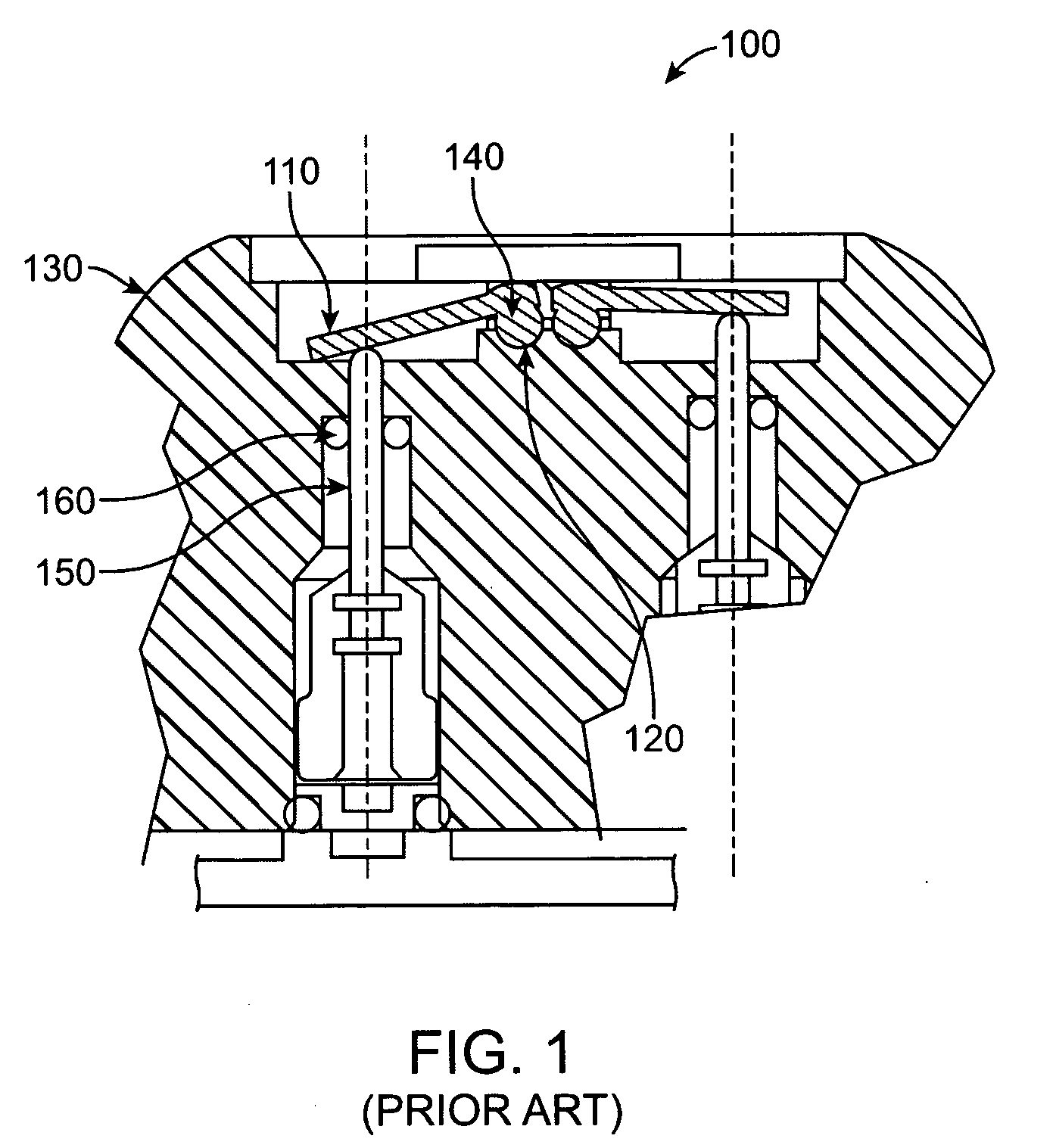

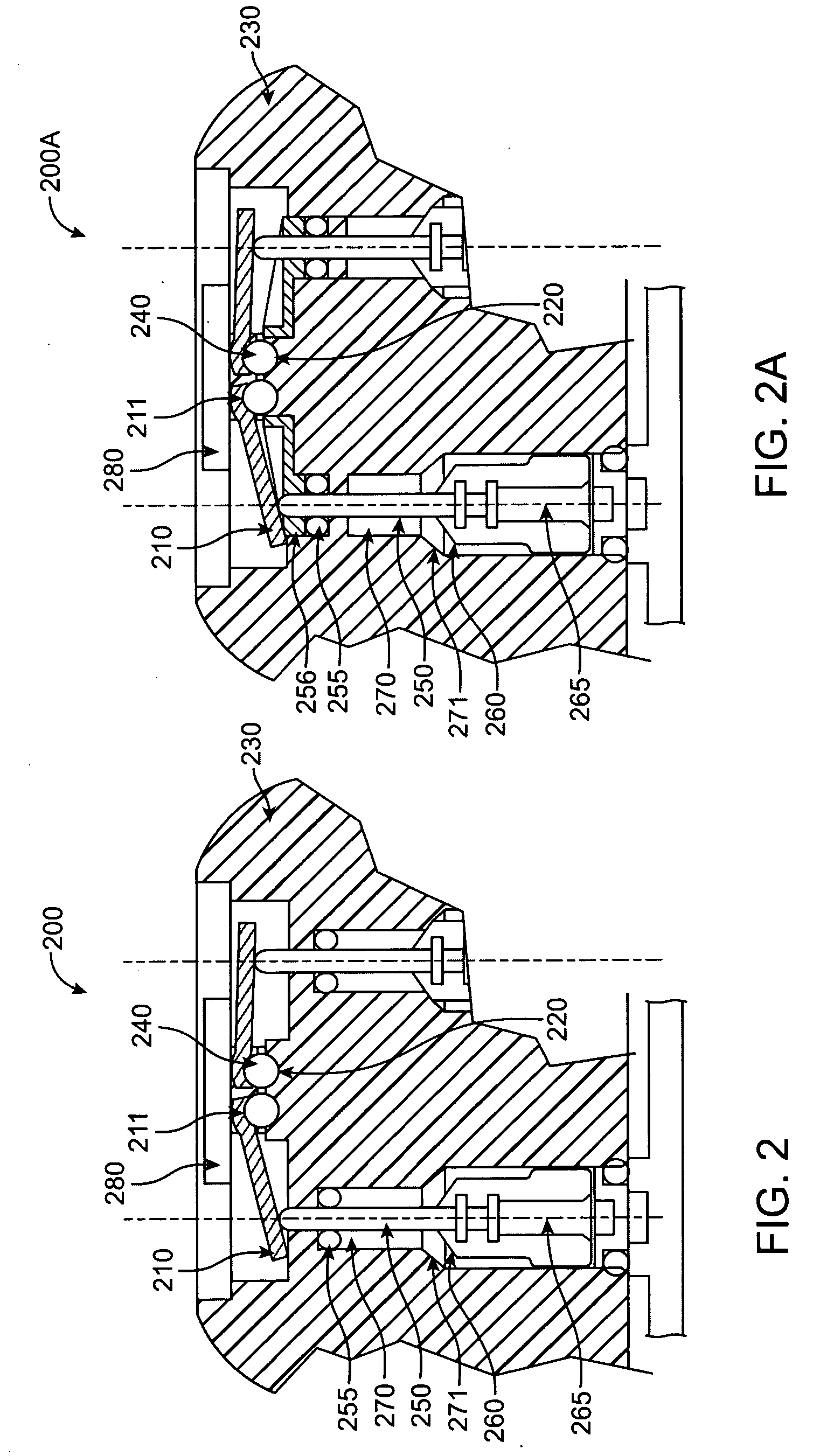

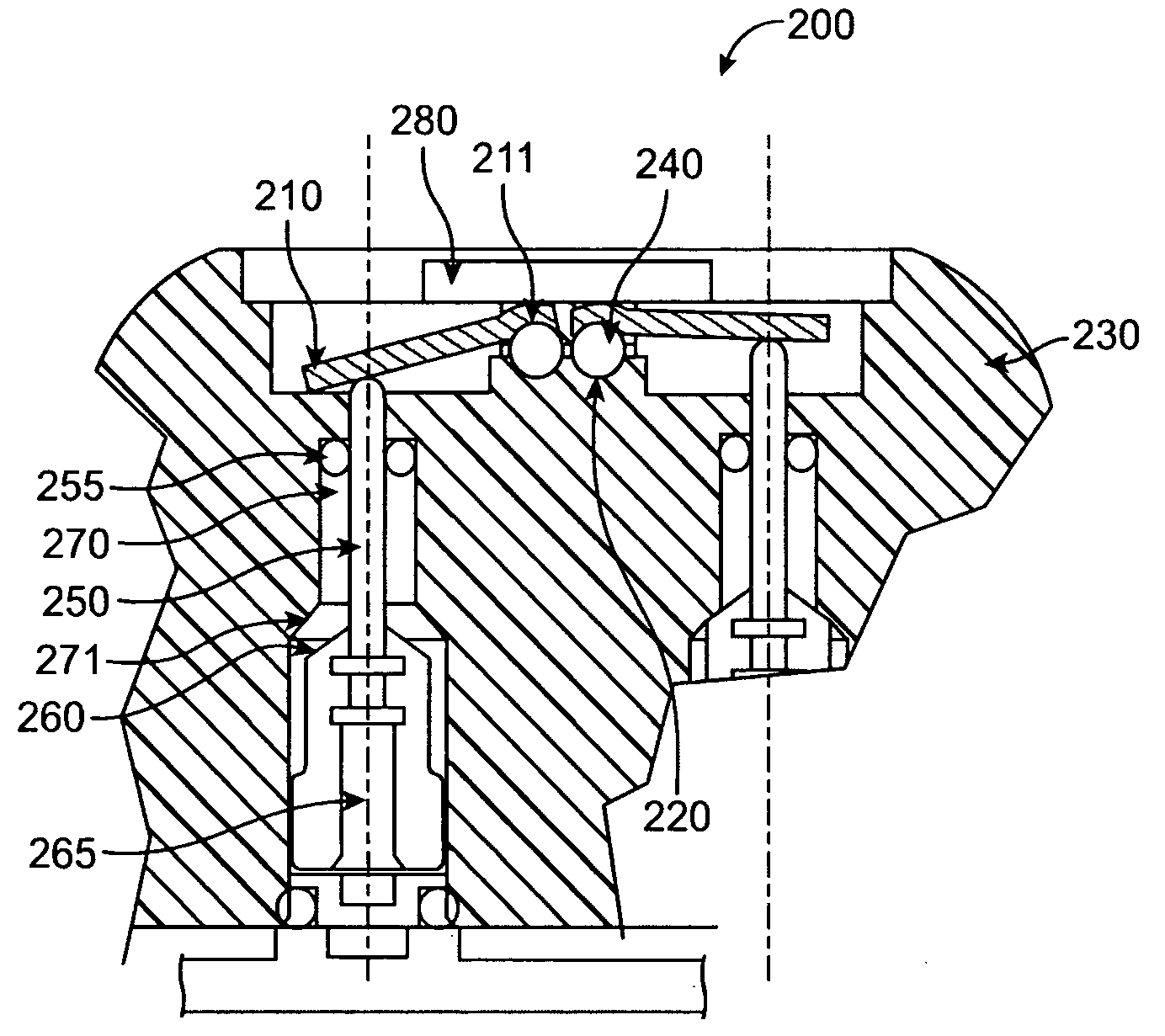

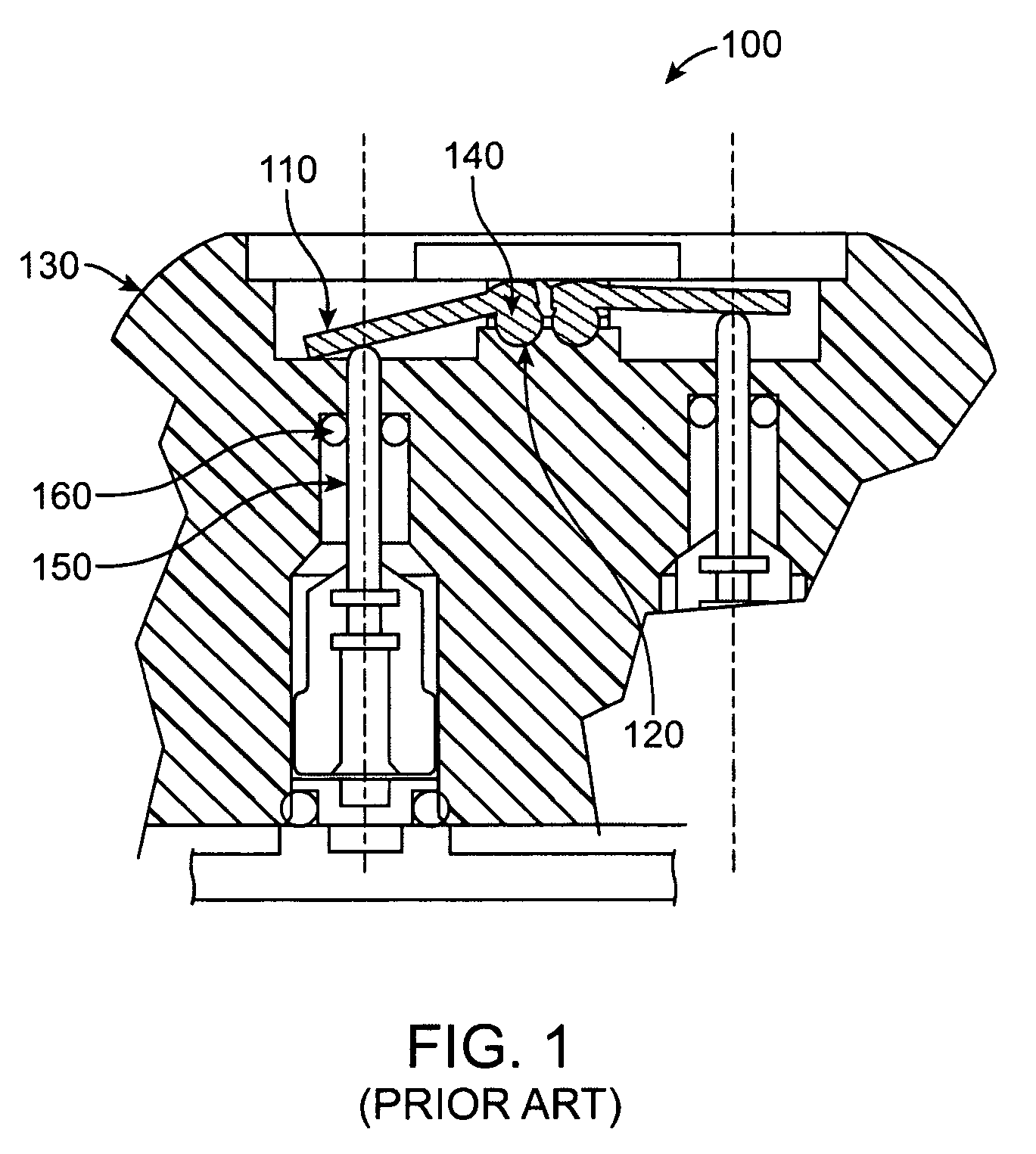

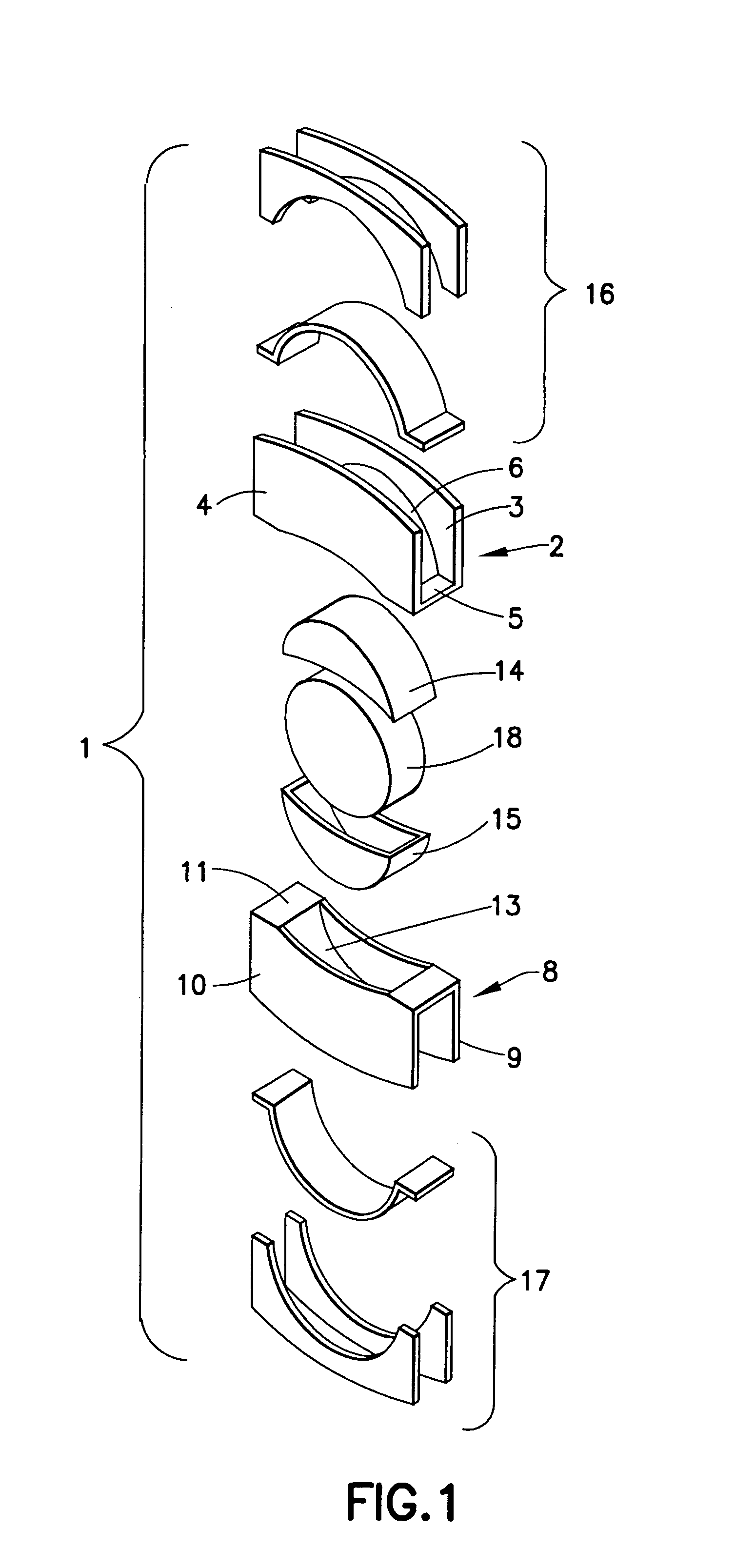

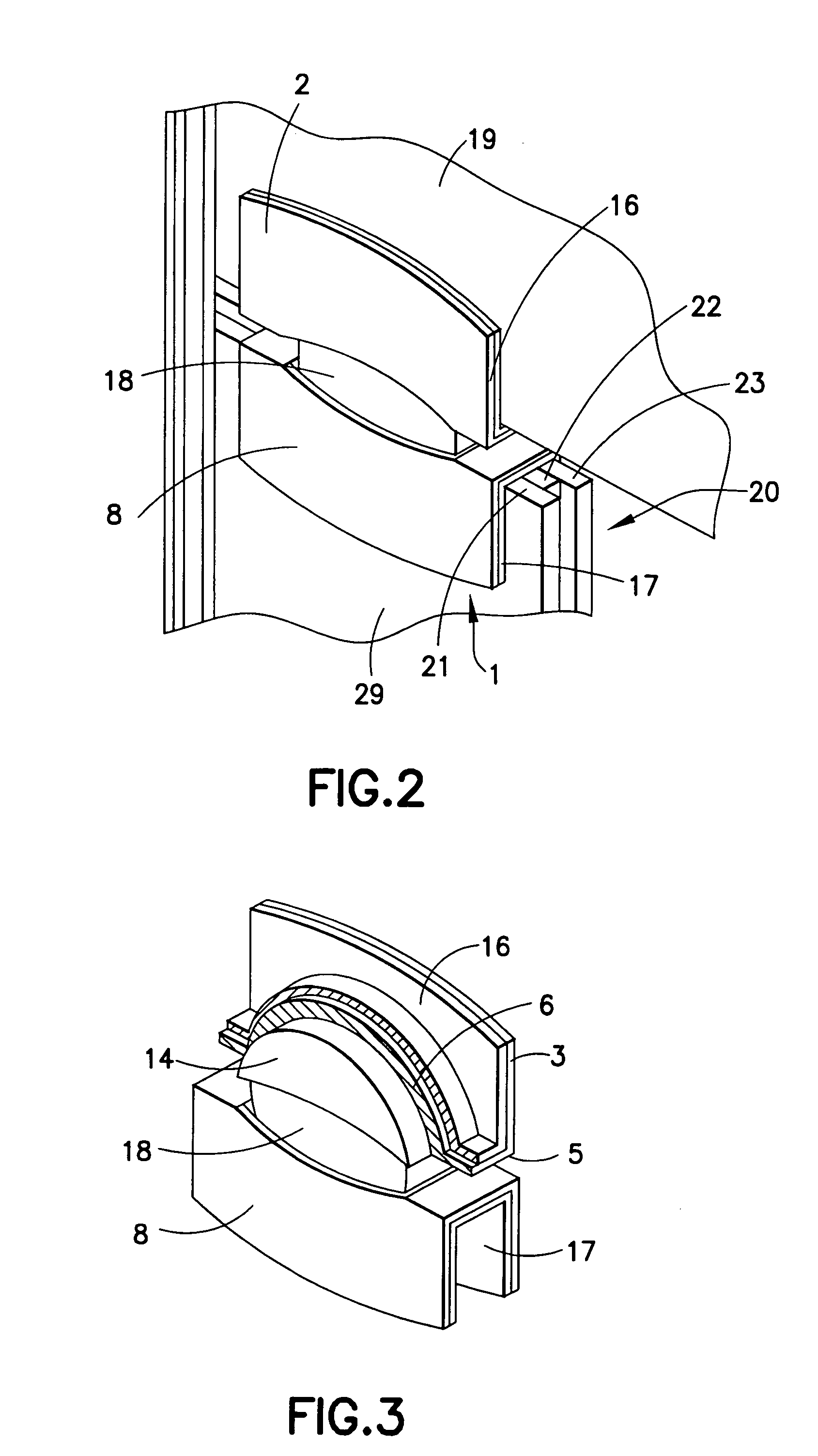

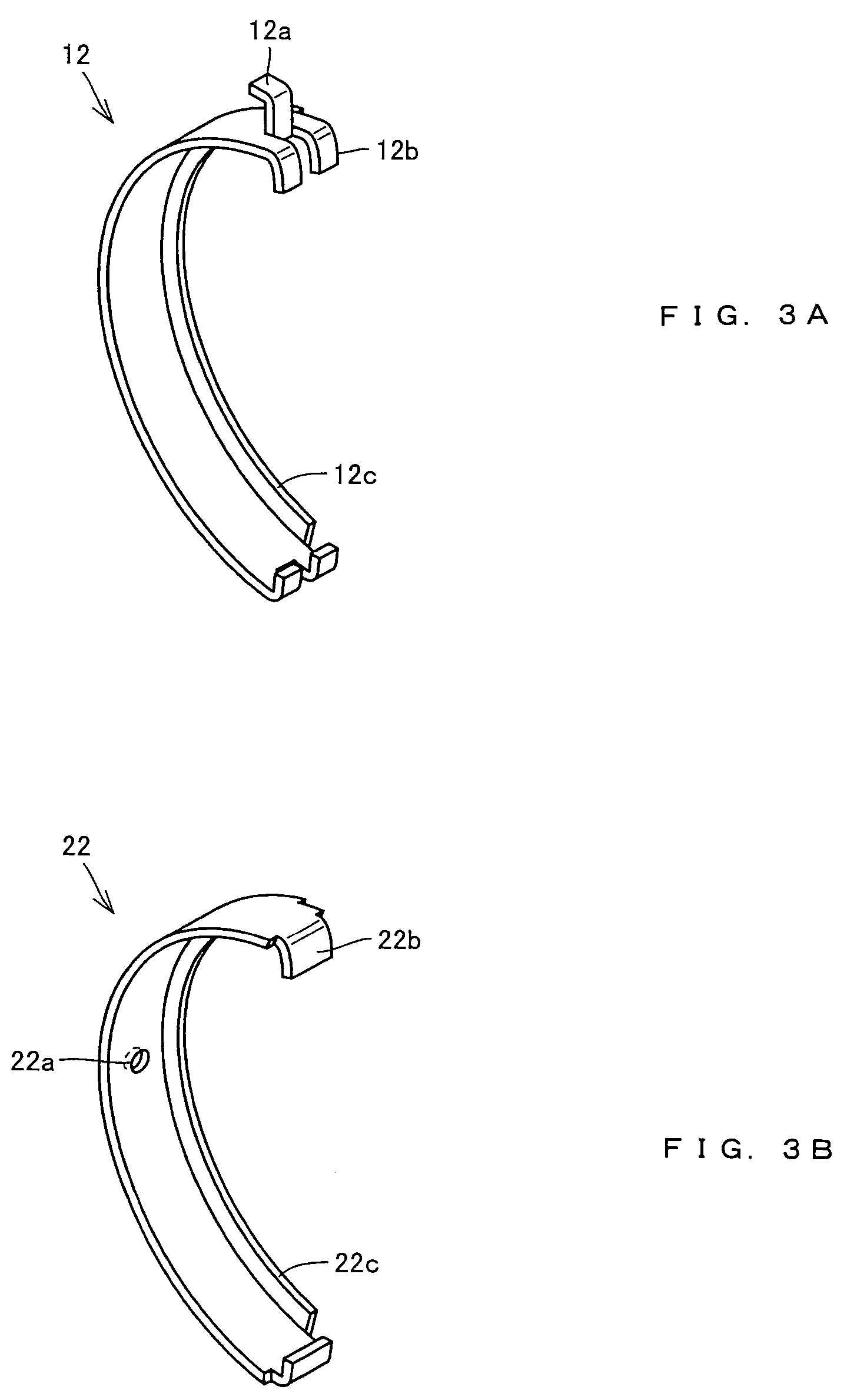

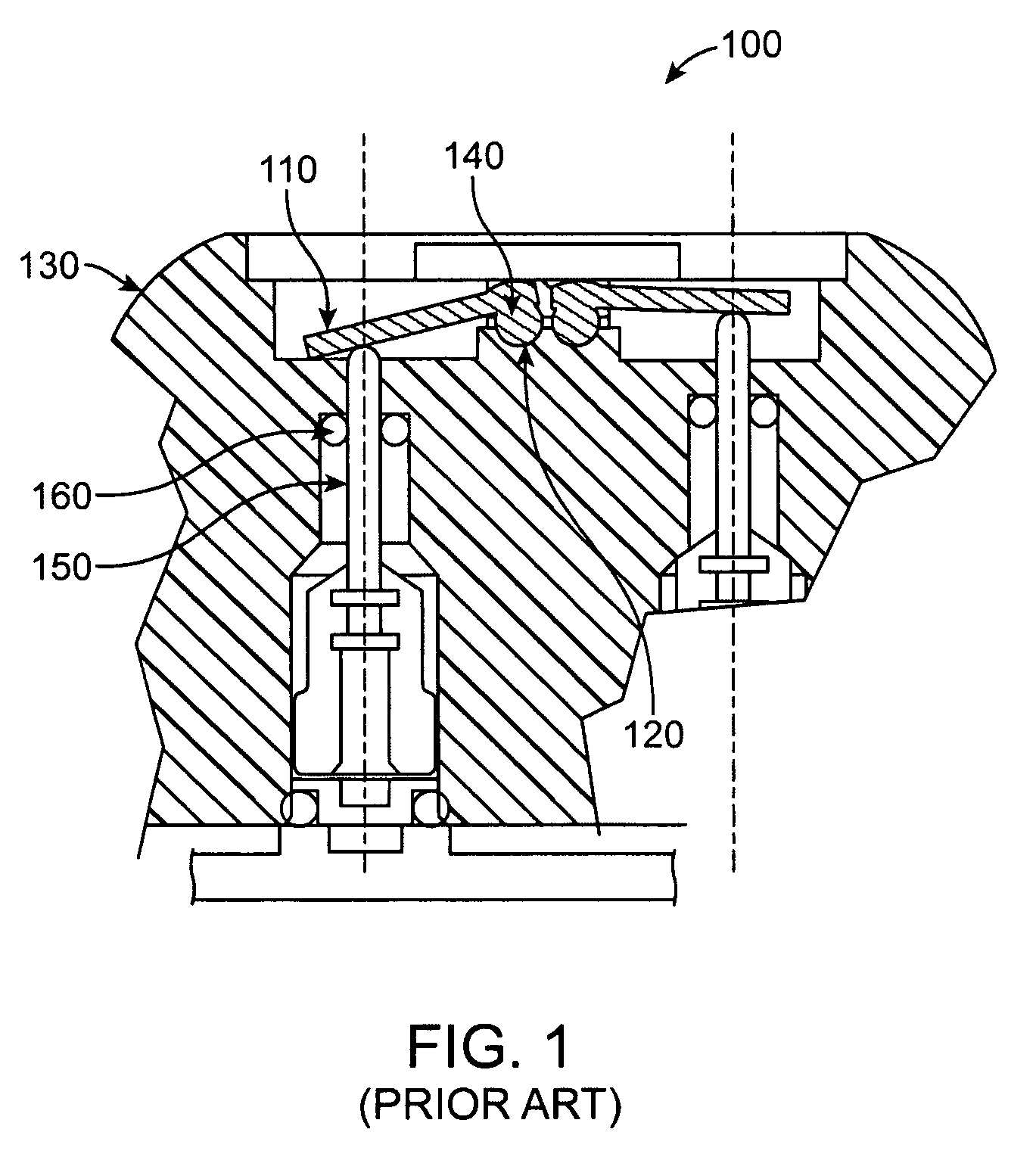

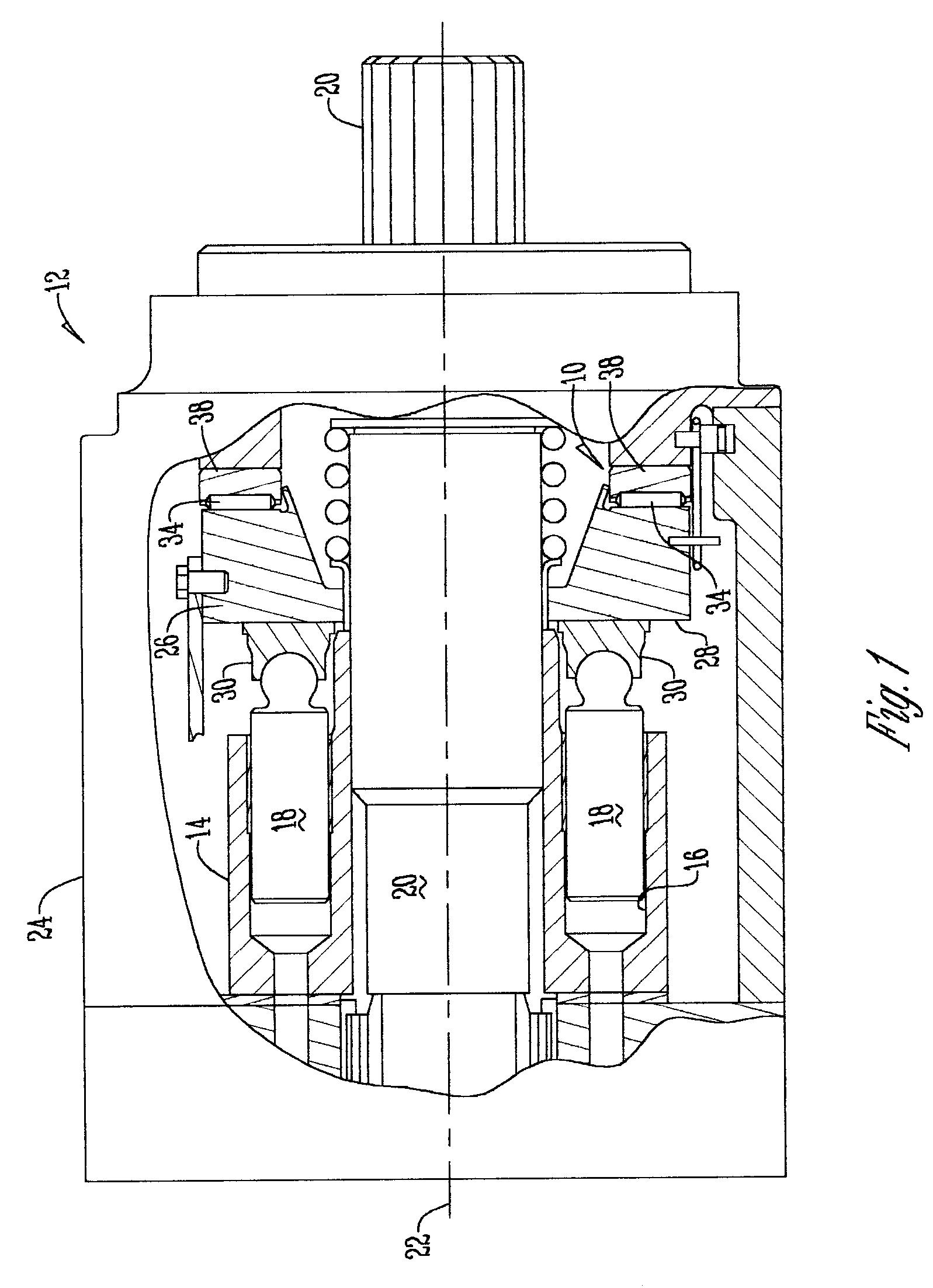

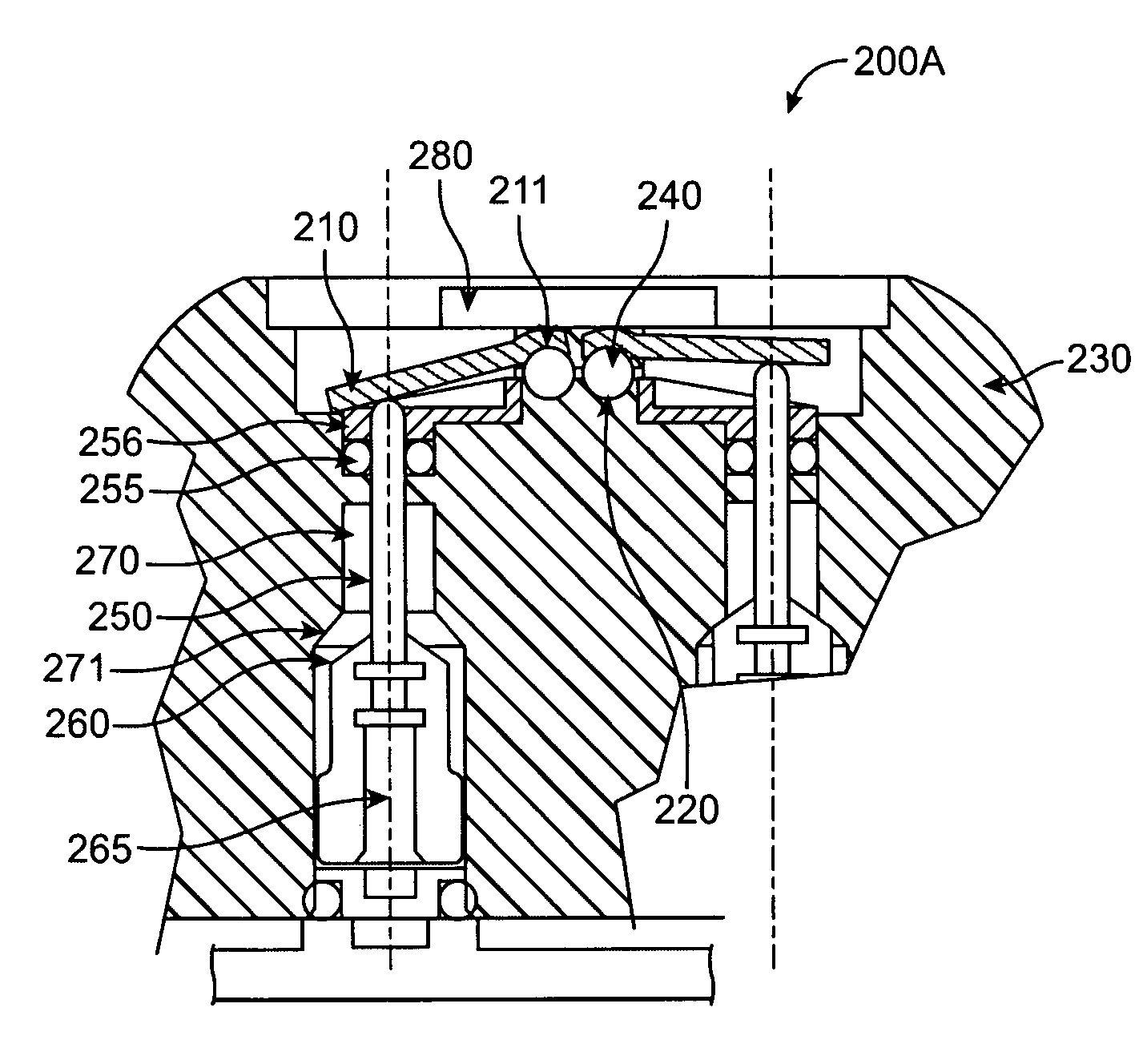

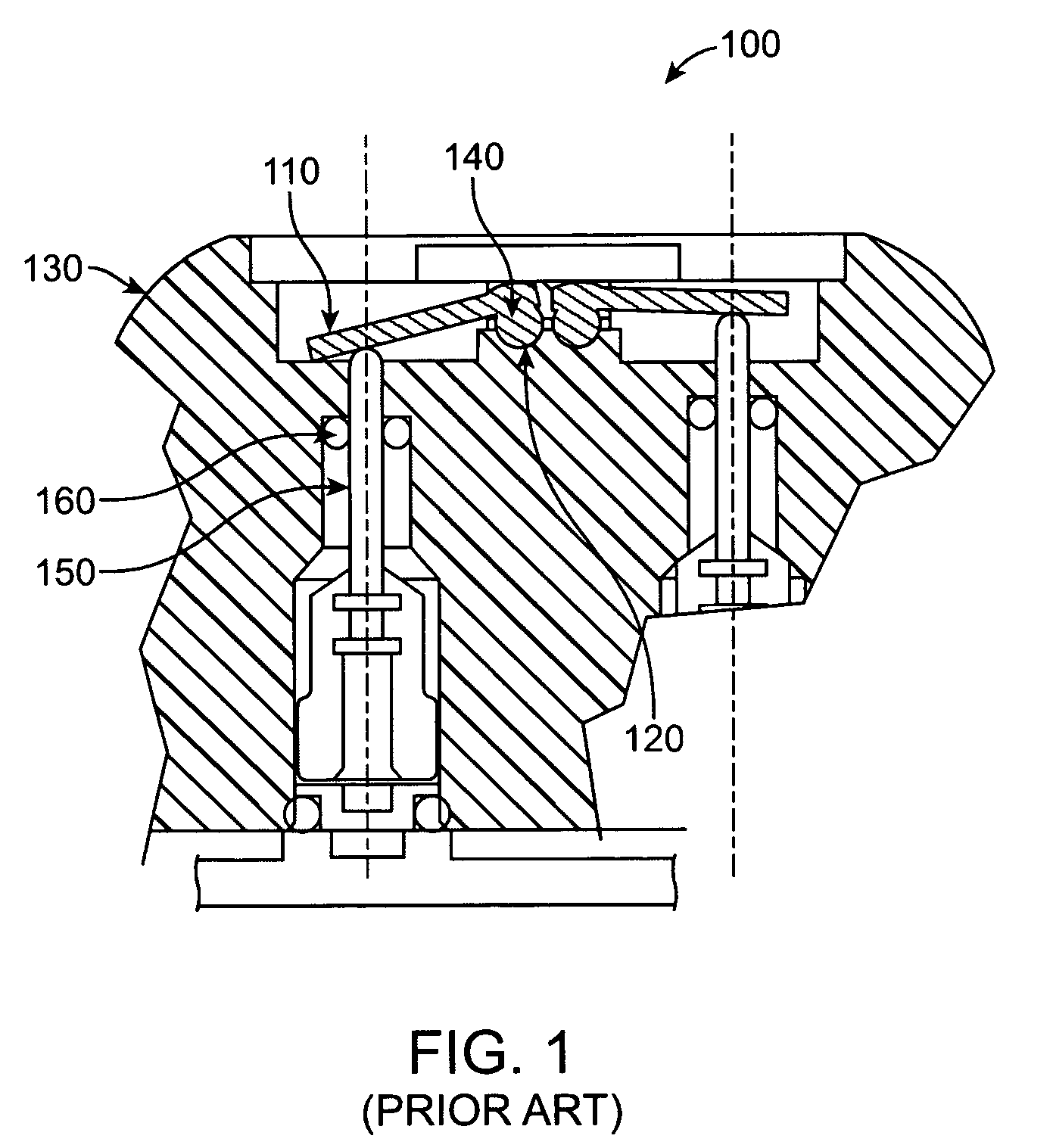

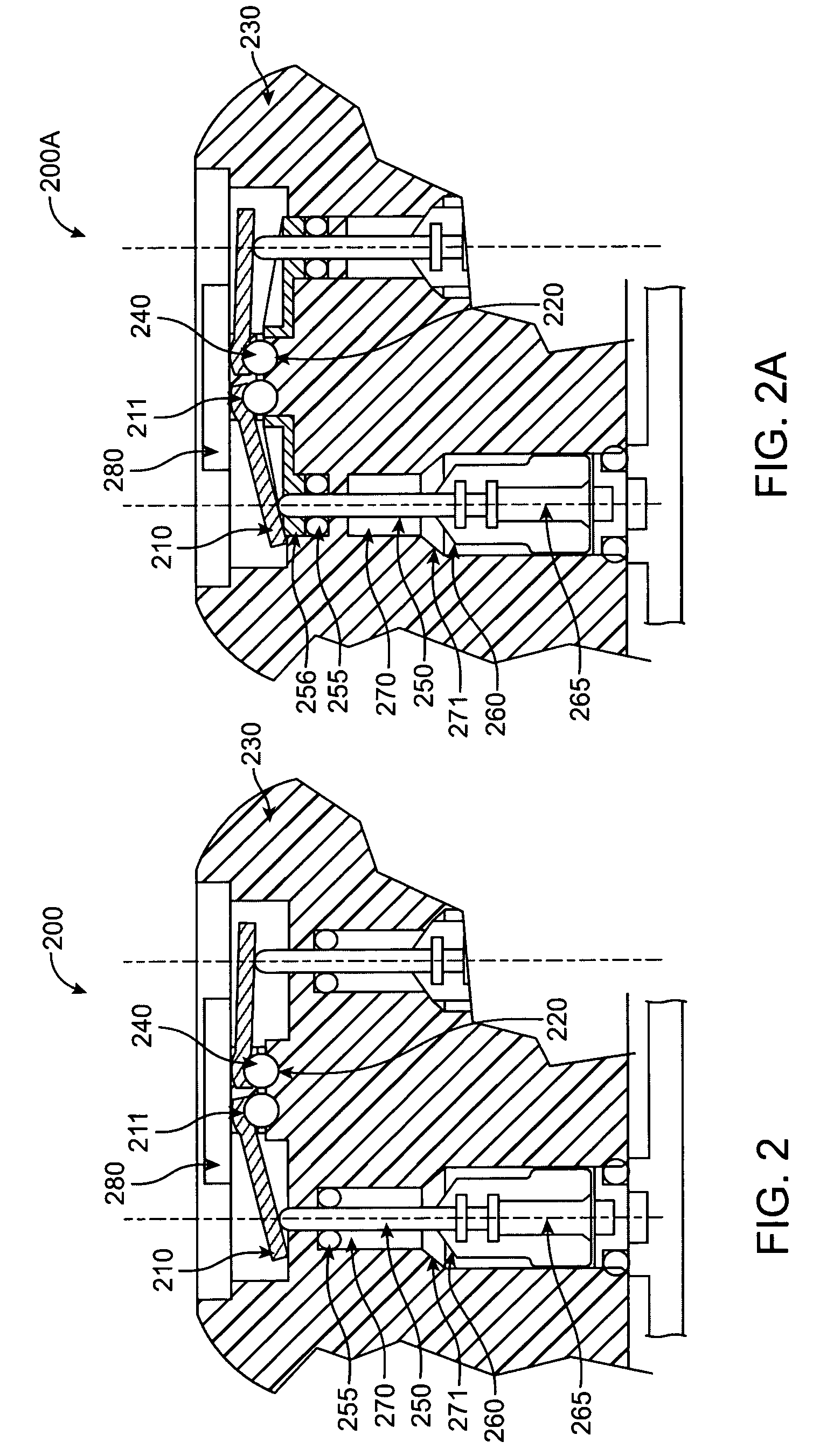

Compact unitized cradle swashplate bearing

InactiveUS20060110082A1Restrict movementRolling contact bearingsShaftsMechanical engineeringSwashplate

A roller bearing assembly for a variable displacement hydrostatic unit. The roller bearing has an inner race and an outer race with a cage therebetween that holds a plurality of rollable elements. A link is mounted to the inner and outer race such that the link is able to limit the arcuate movement of the cage element.

Owner:SAUER DANFOSS NORDBERG

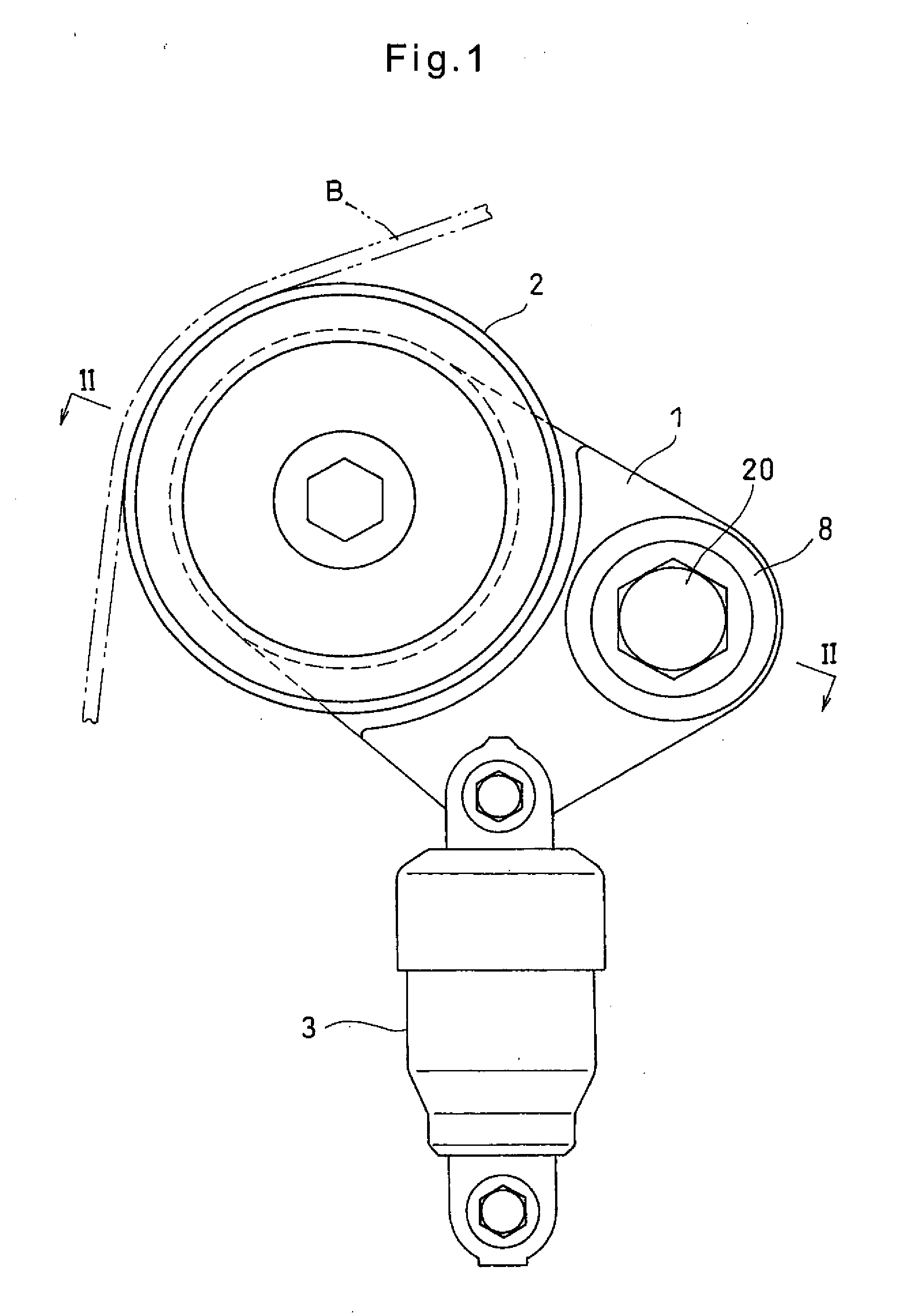

Fulcrum bearing device for pulley arm

ActiveUS20150275976A1Improve sealingStably prevent foreign objects from goingGearingBearing componentsEngineeringPulley

In a fulcrum bearing device for a pulley arm, a sleeve is inserted in a shaft hole formed in a boss portion of a pulley arm, washers are fitted on the outer peripheries of small diameter tube portions formed at the respective end portions of the sleeve, and the sleeve is fixed to an engine block by means of a bolt inserted through the sleeve and tightened, so that the pulley arm is pivotally supported. The shaft hole is formed at its respective end portions with seal receiving recesses having large diameters. Each seal member includes a cylindrical portion provided on its outer peripheral portion and press-fitted in the seal receiving recess, and a radial lip extending obliquely inwardly and provided on the inner periphery of the seal member. The distal end portions of the radial lips are kept in elastic contact with the outer diameter surface of the sleeve.

Owner:NTN CORP

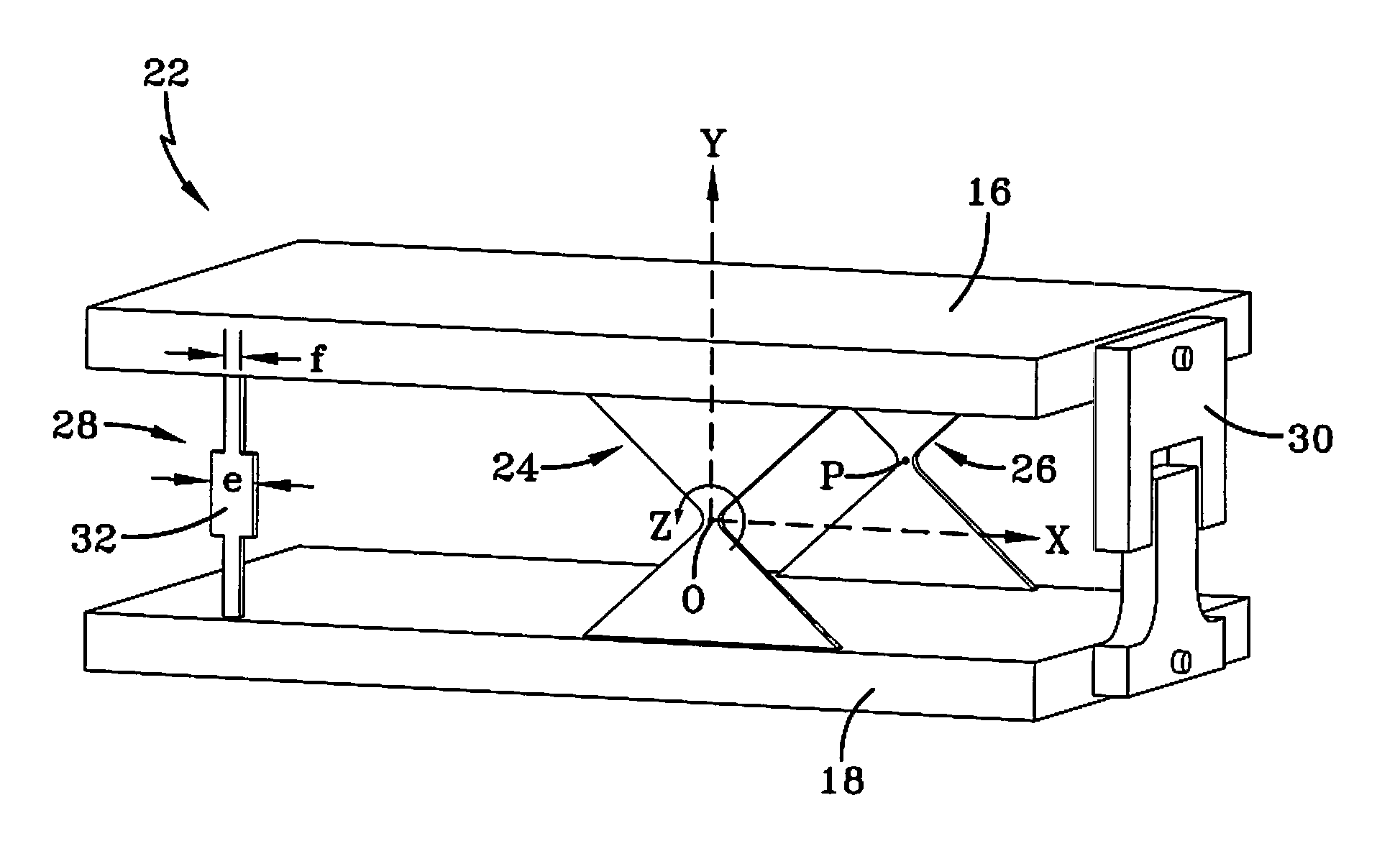

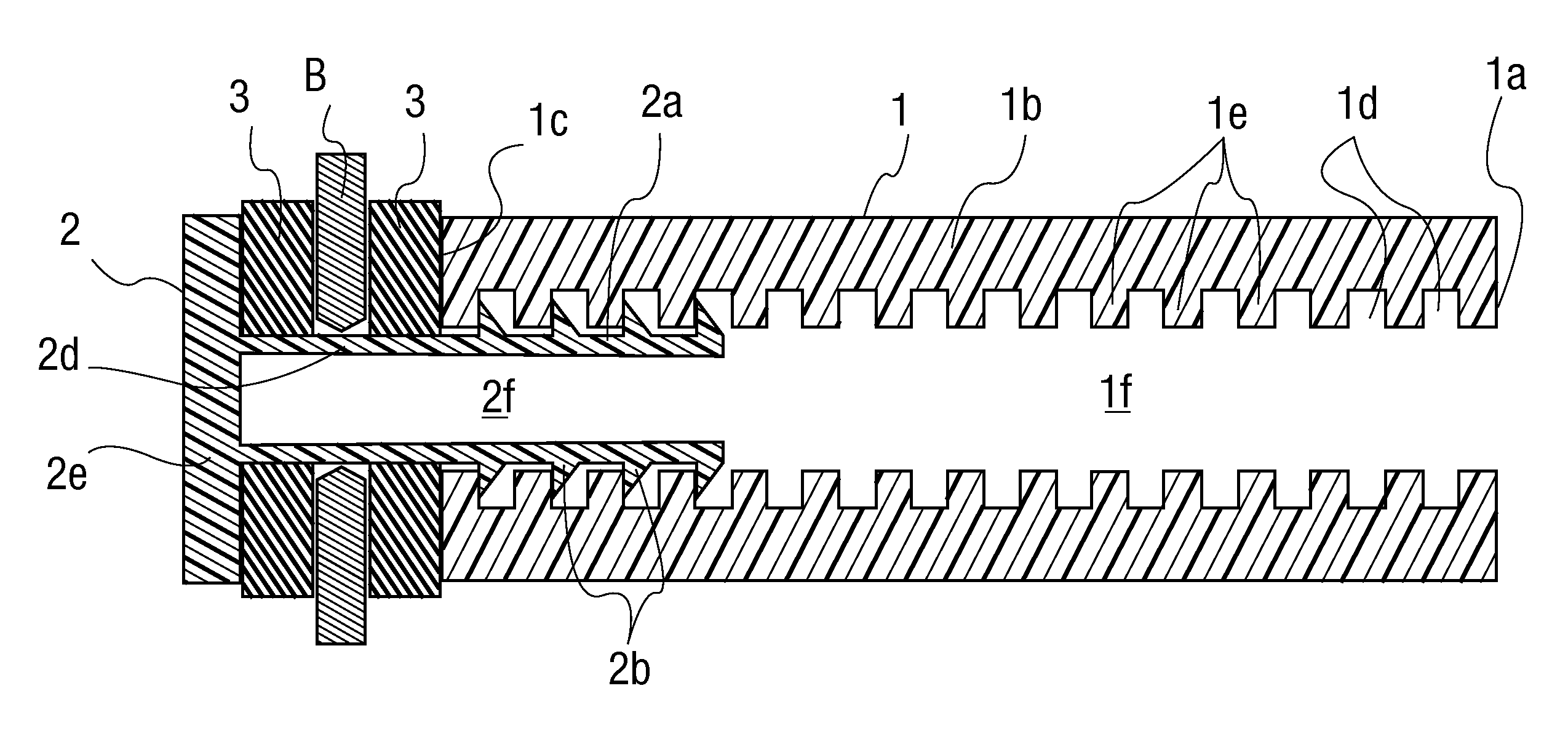

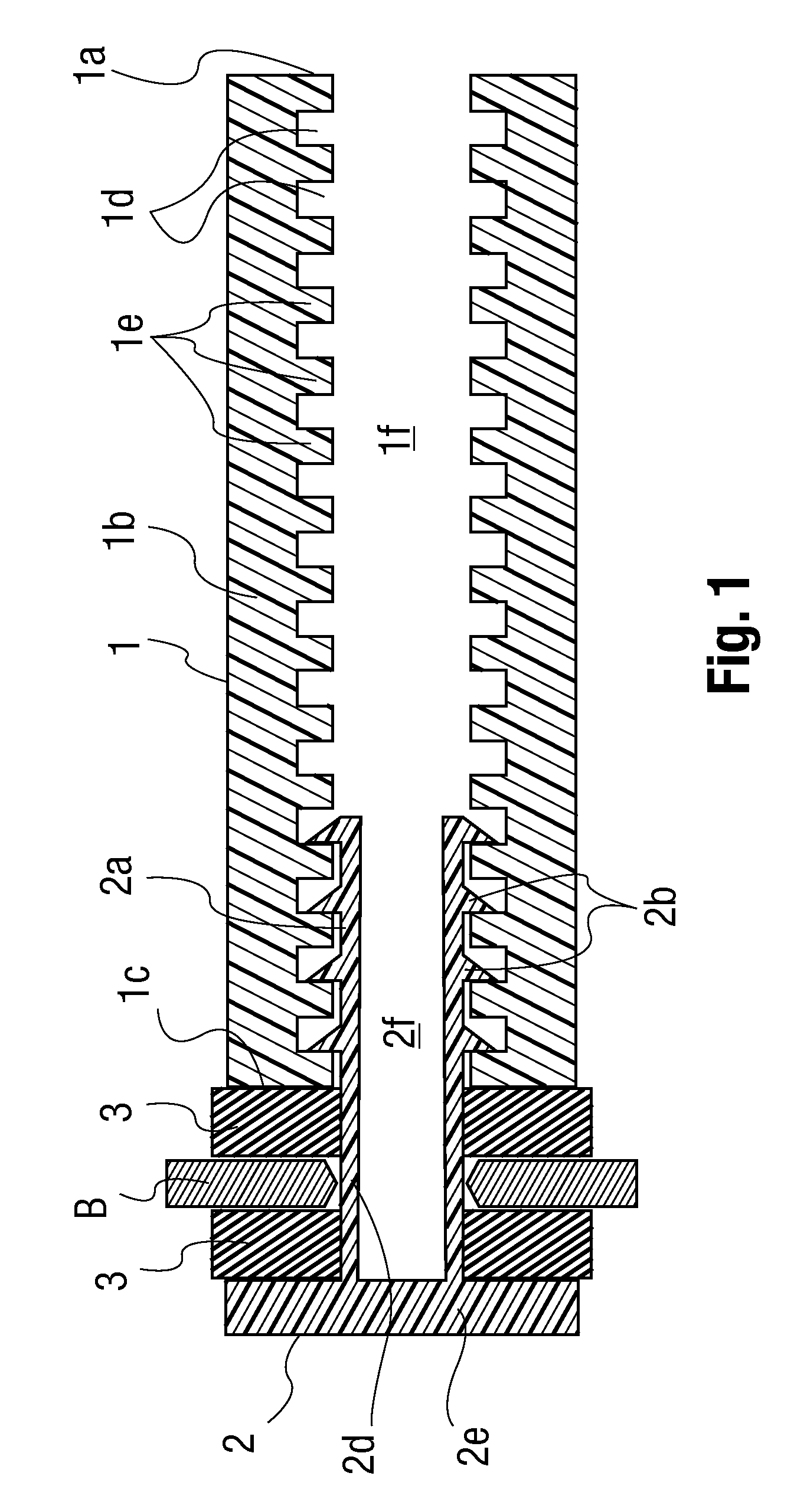

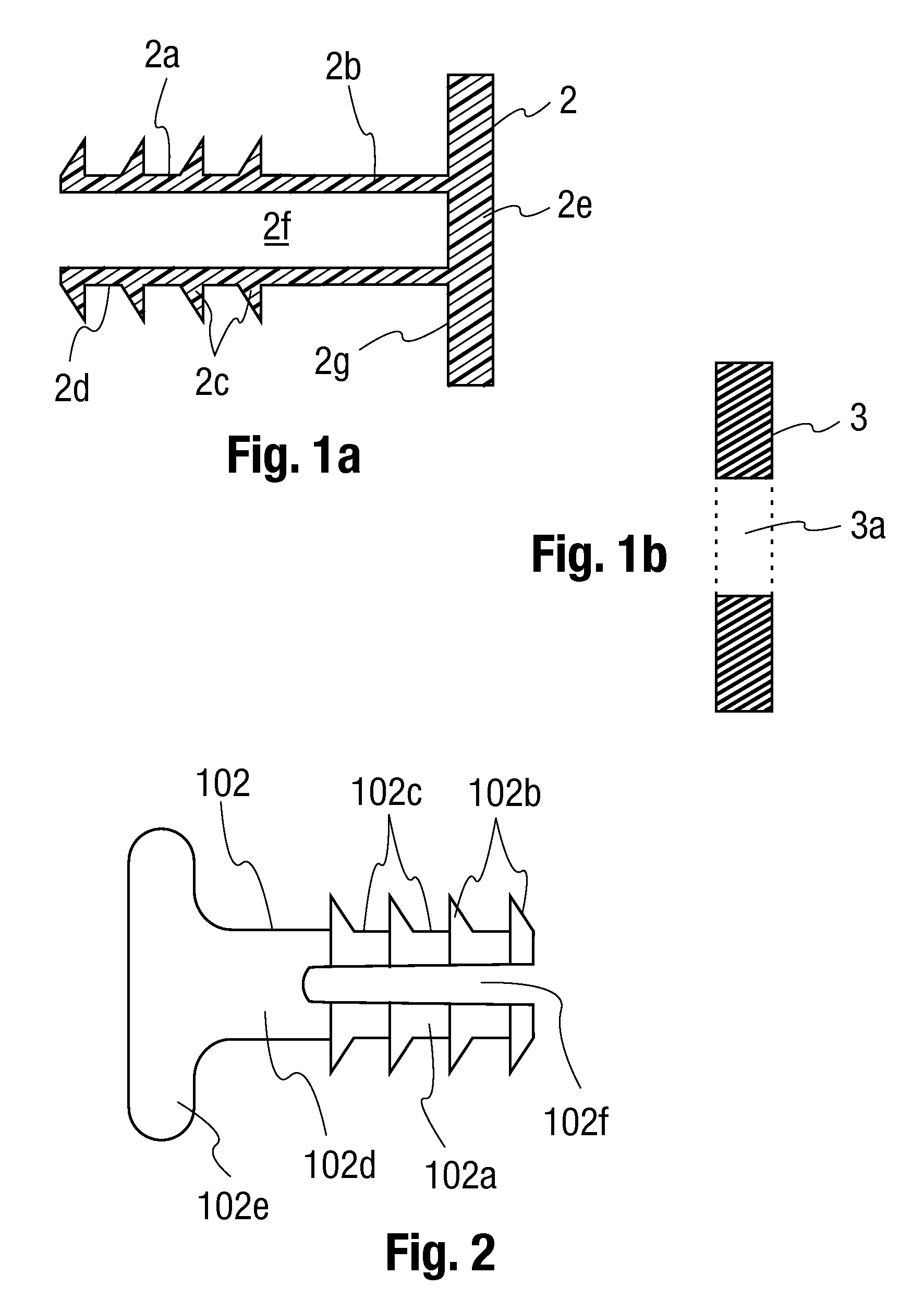

Flexure based linear and rotary bearings

ActiveUS9371855B2Minimal internal stressRolling contact bearingsKnife-edge bearingsDegrees of freedomRelative motion

A flexure based linear bearing includes top and bottom parallel rigid plates; first and second flexures connecting the top and bottom plates and constraining exactly four degrees of freedom of relative motion of the plates, the four degrees of freedom being X and Y axis translation and rotation about the X and Y axes; and a strut connecting the top and bottom plates and further constraining exactly one degree of freedom of the plates, the one degree of freedom being one of Z axis translation and rotation about the Z axis.

Owner:NASA

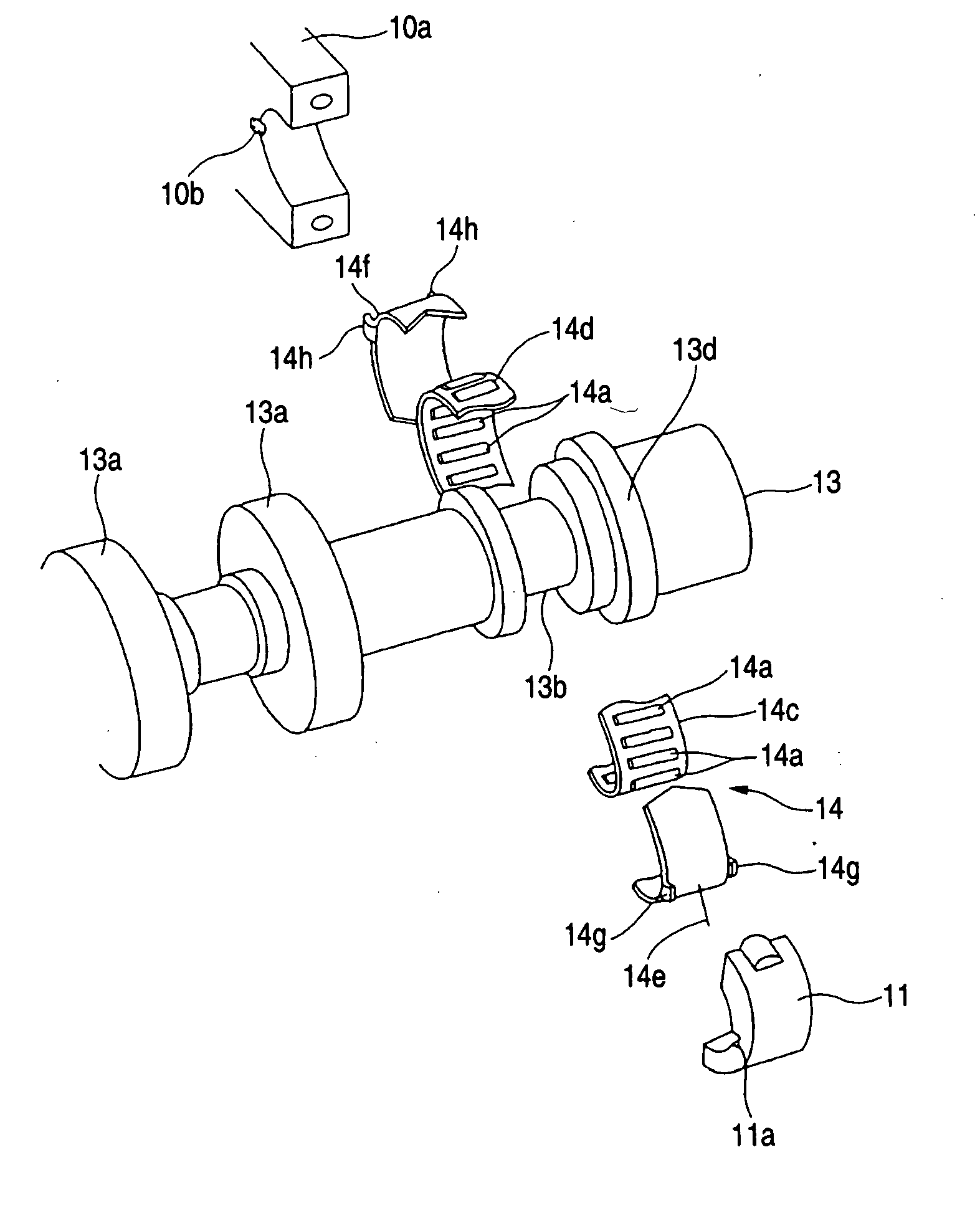

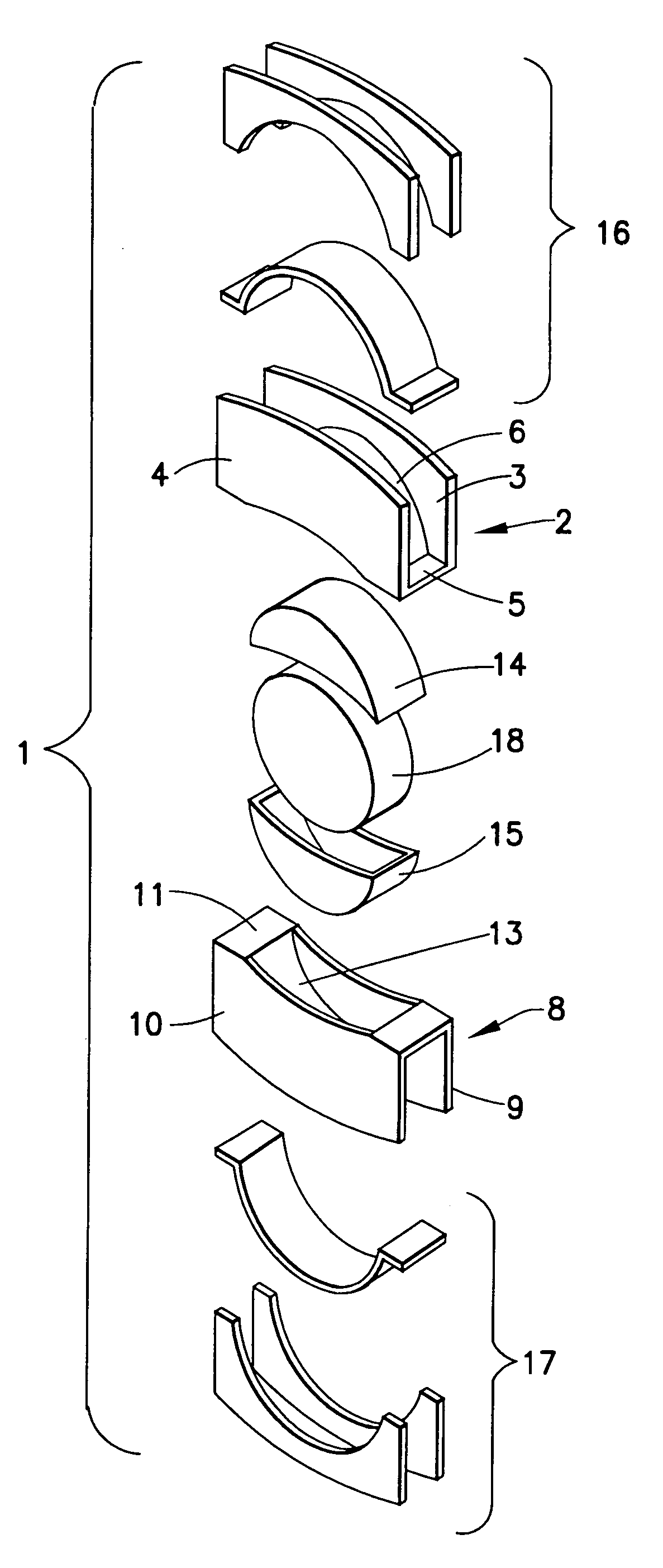

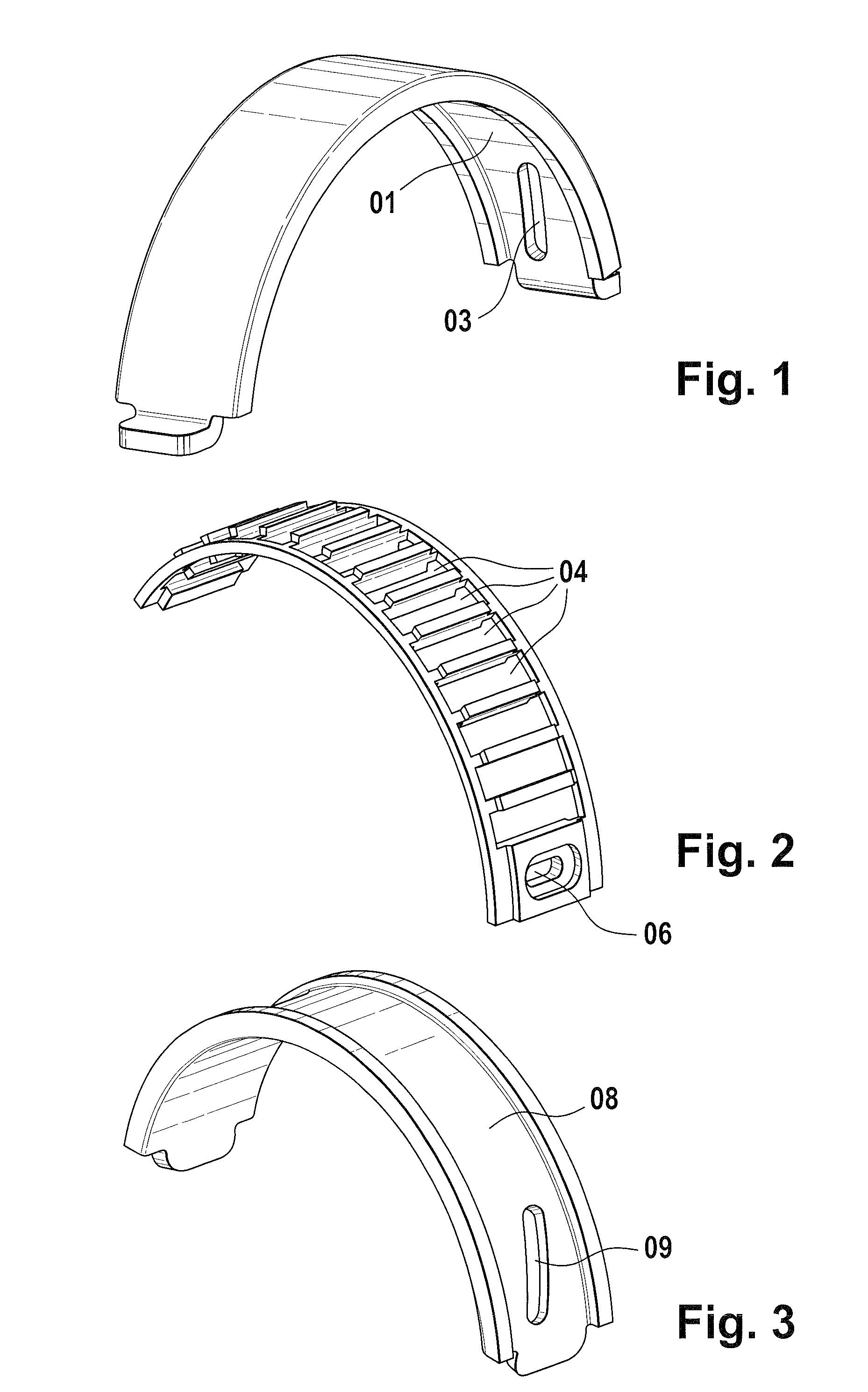

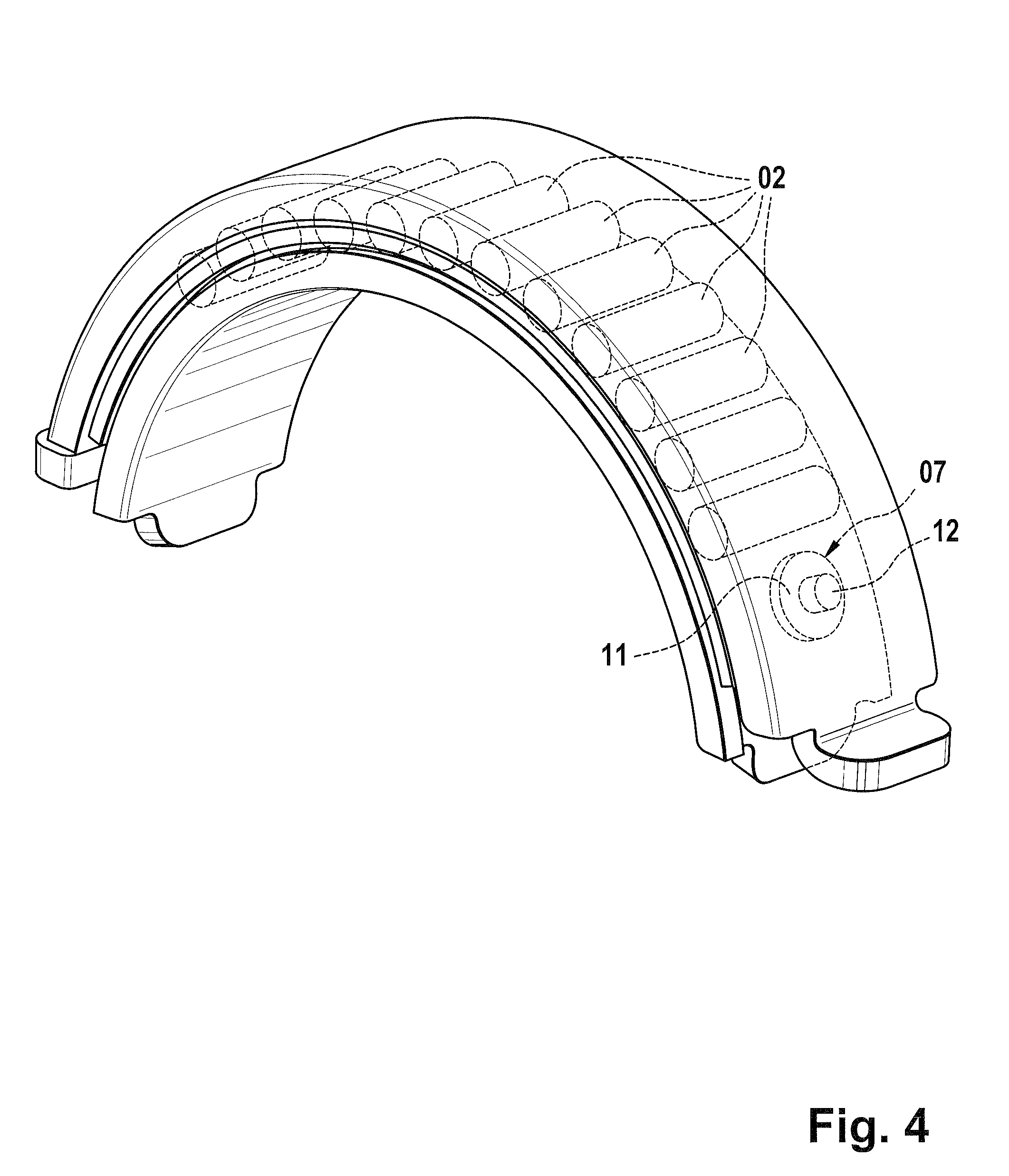

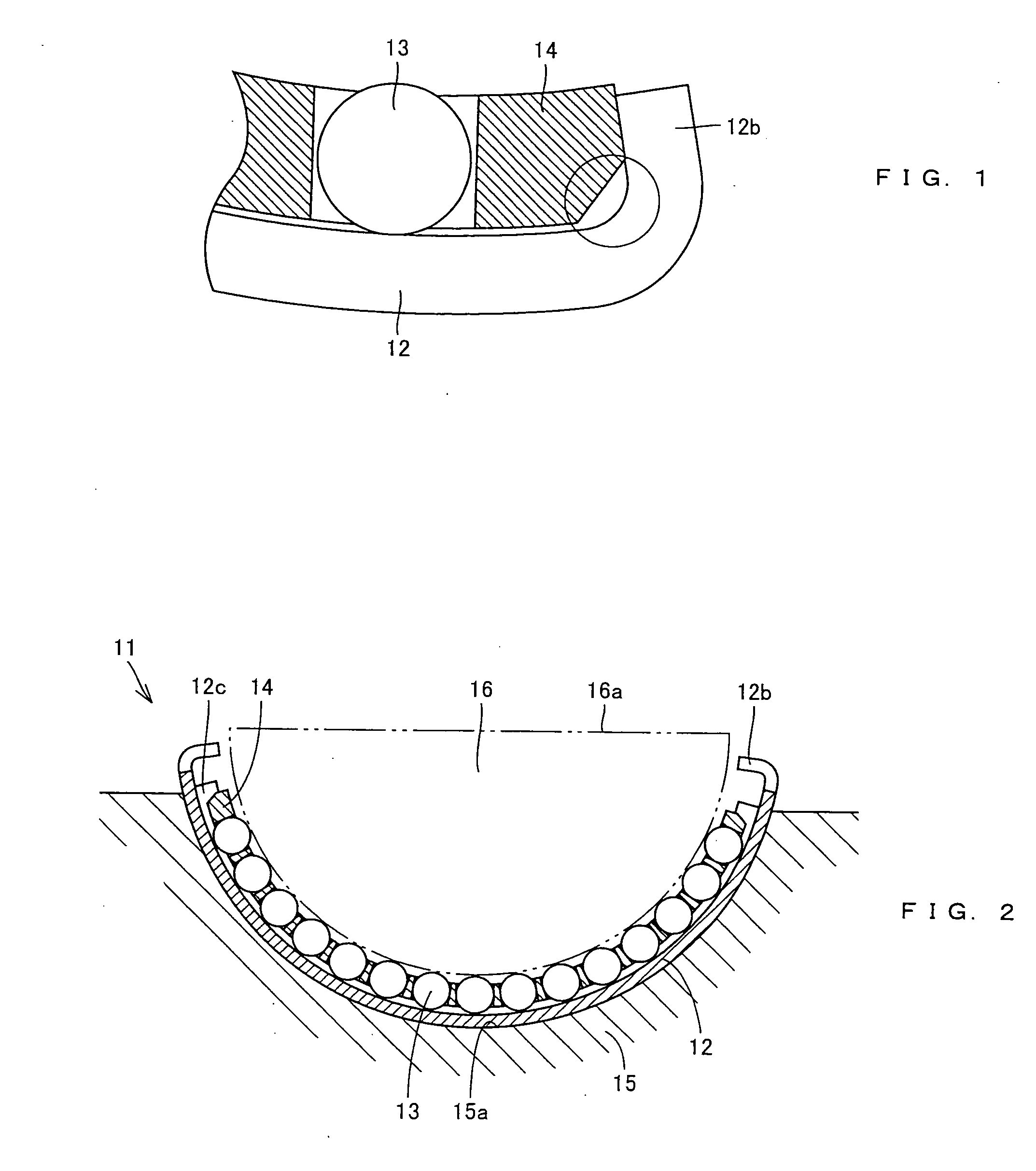

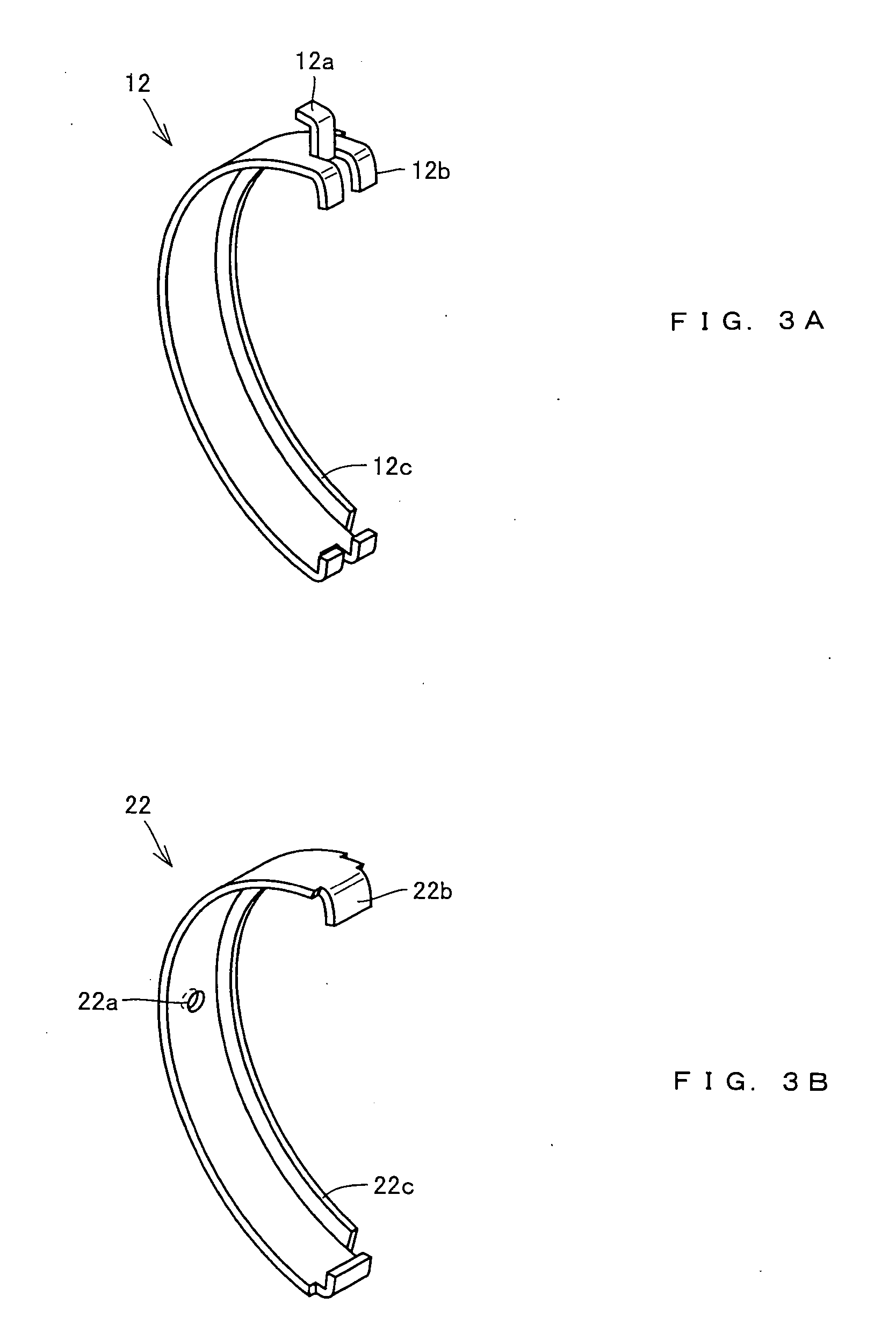

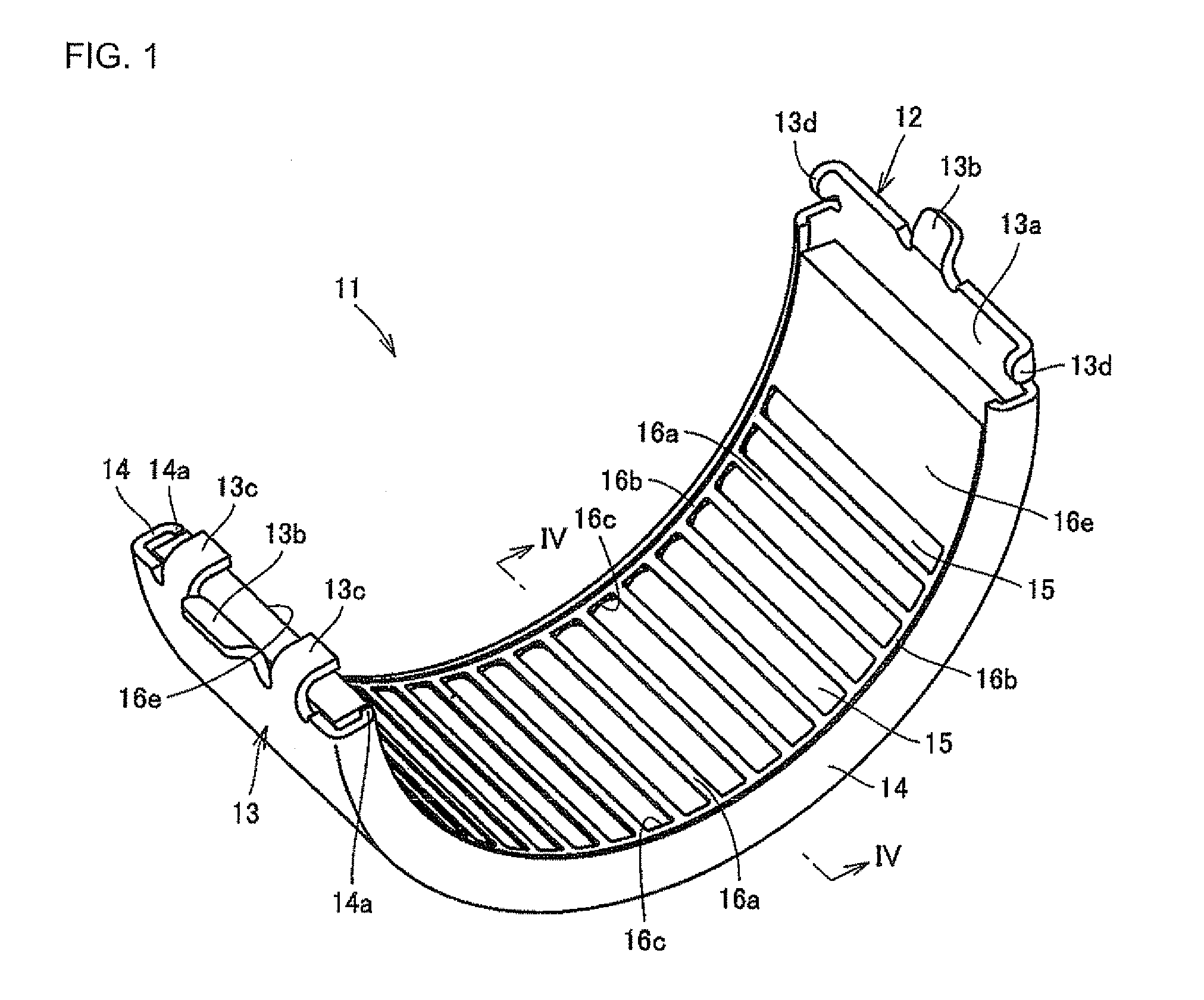

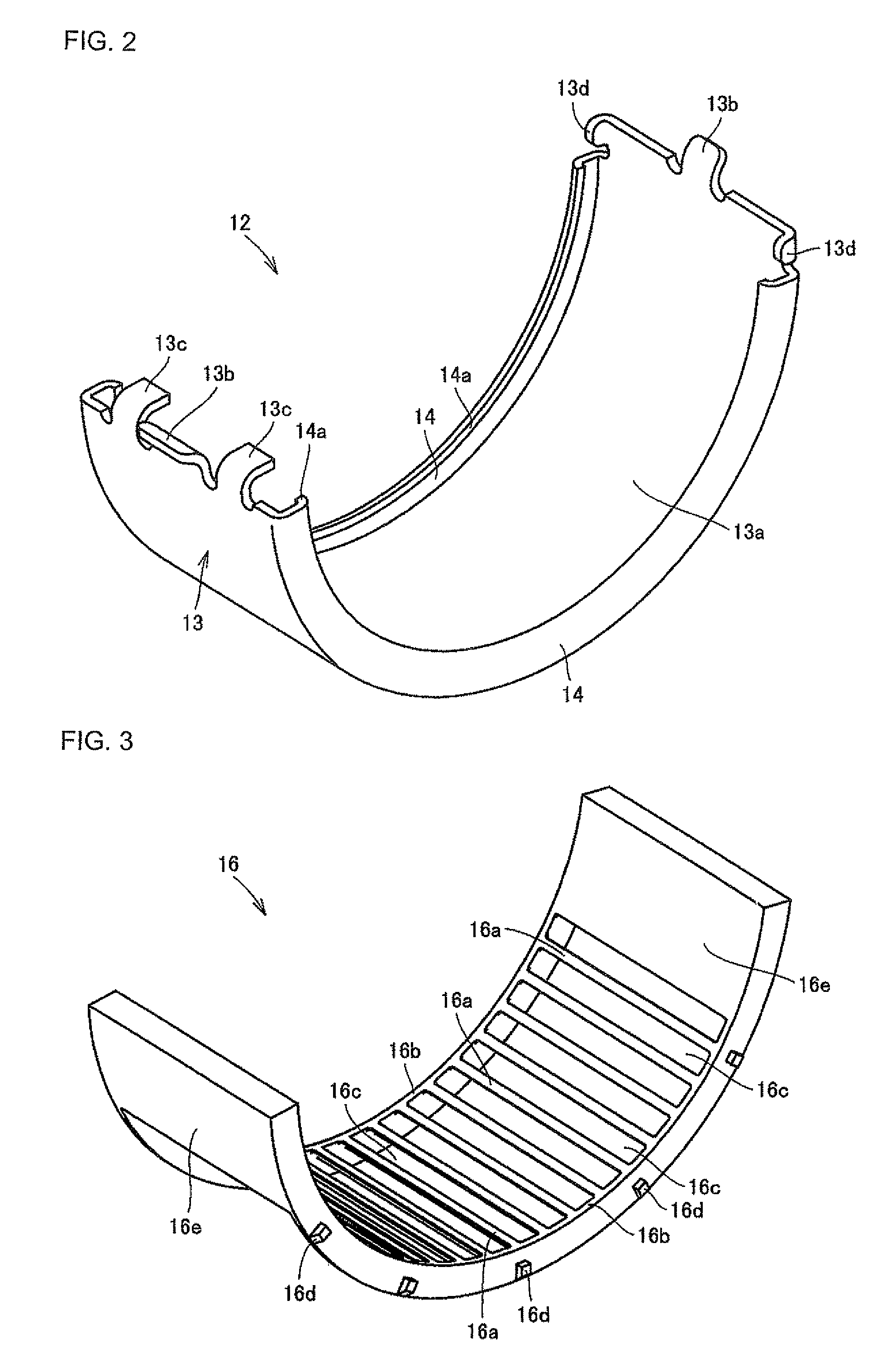

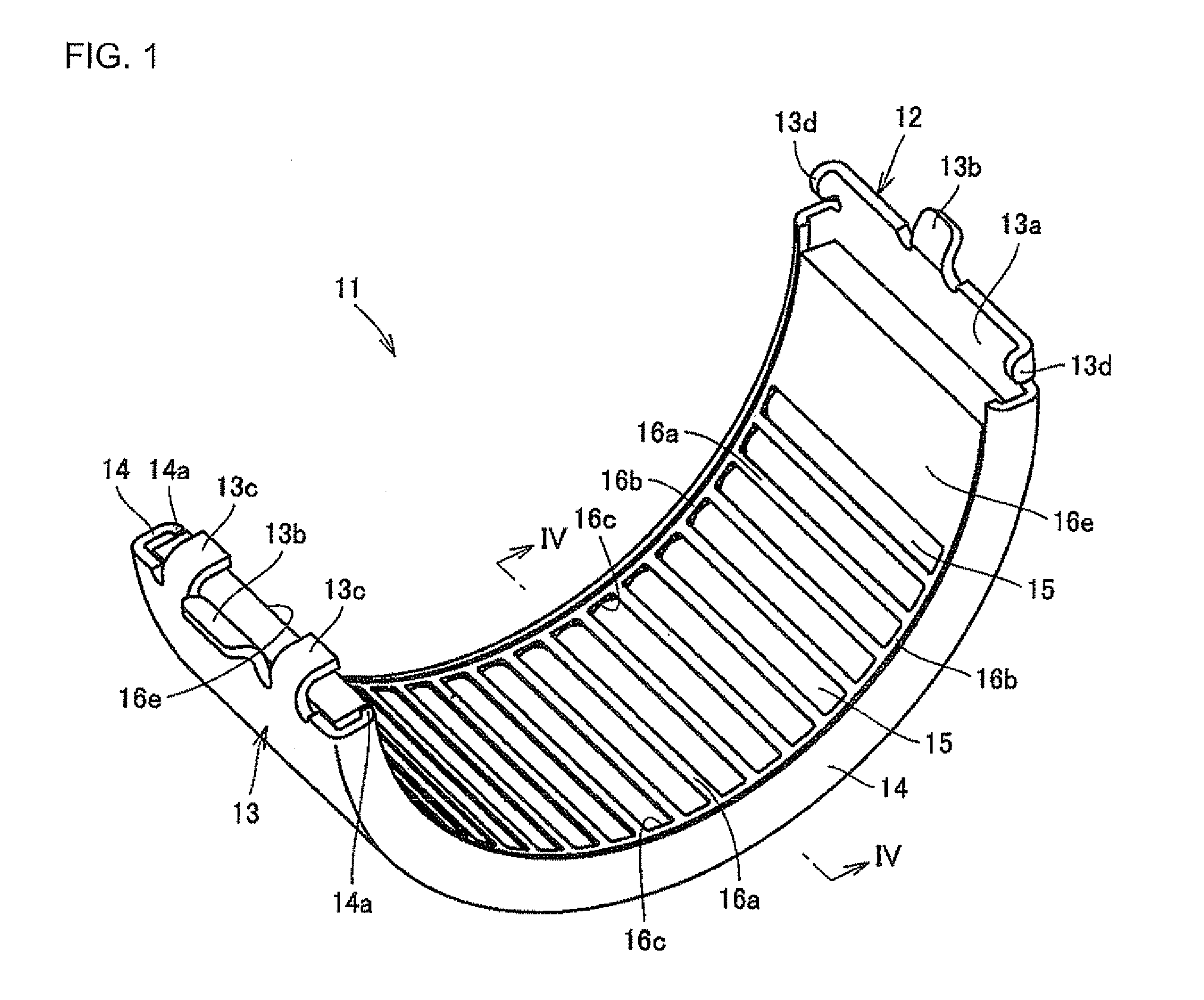

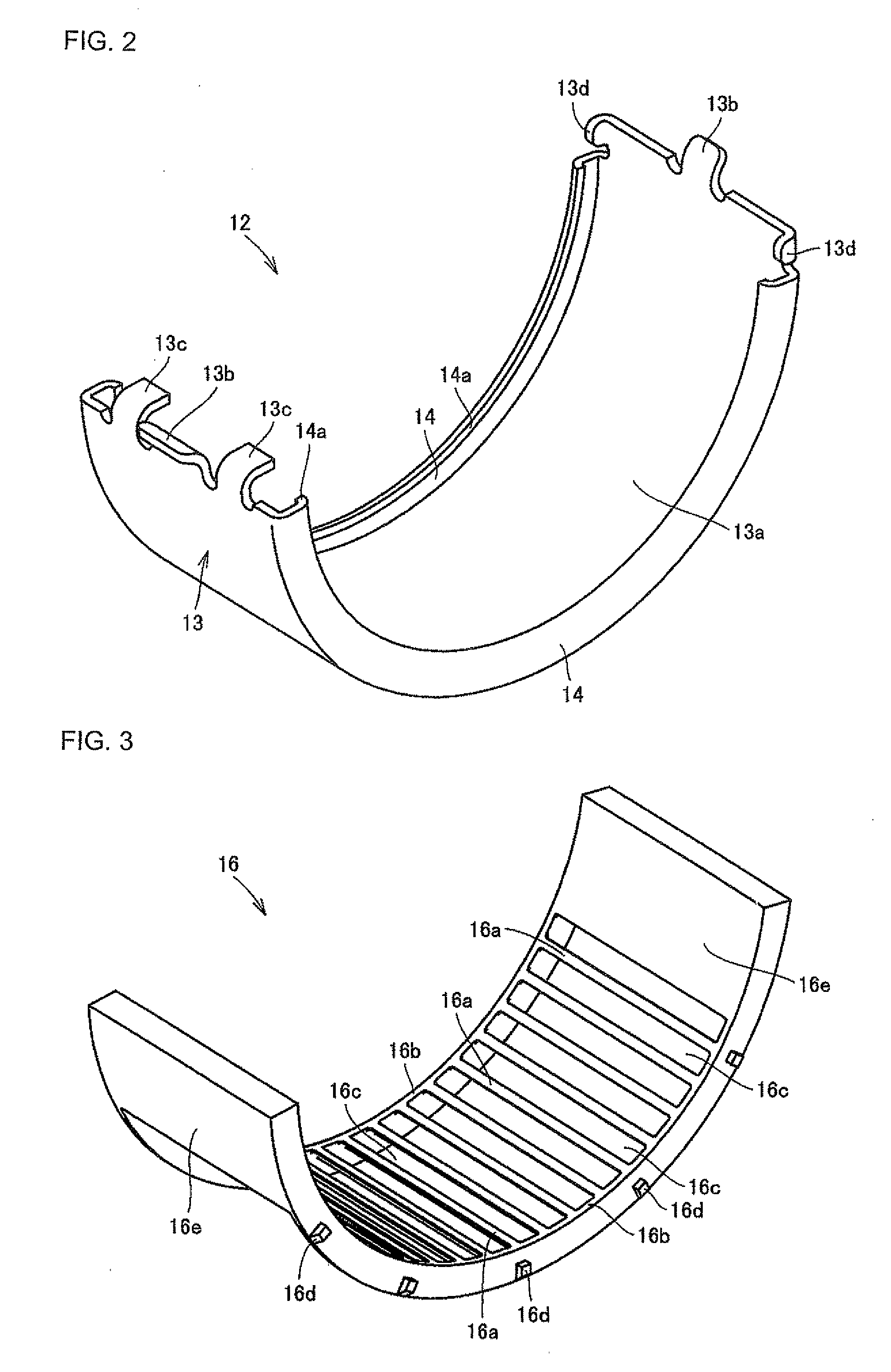

Rocking bearing outer ring, rocking bearing, air disc brake device, and fitting structure of rocking bearing outer ring

InactiveUS8632256B2Close contactAvoid separationRolling contact bearingsShaftsEngineeringMechanical engineering

A rocking bearing outer ring (12) includes an arcuate track member (13) having a track surface on its inner diameter surface, and a flange portion (14) projecting radially inward from each widthwise end portion of the track member (13). In addition, when it is assumed that L1 represents a circumferential length of the track member (13) and L2 represents a circumferential length of the flange portion (14), 0.2≦L2 / L1≦8 is satisfied.

Owner:NTN CORP

Link unit, arm module, and surgical apparatus including the same

ActiveUS9604370B2Improve rigidityProgramme-controlled manipulatorSurgical needlesEngineeringDegrees of freedom

Owner:SAMSUNG ELECTRONICS CO LTD

Rocking bearing outer ring, rocking bearing, air disc brake device, and fitting structure of rocking bearing outer ring

A rocking bearing outer ring (12) includes an arcuate track member (13) having a track surface on its inner diameter surface, and a flange portion (14) projecting radially inward from each widthwise end portion of the track member (13). In addition, when it is assumed that L1 represents a circumferential length of the track member (13) and L2 represents a circumferential length of the flange portion (14), 0.2≦L2 / L1≦8 is satisfied.

Owner:NTN CORP

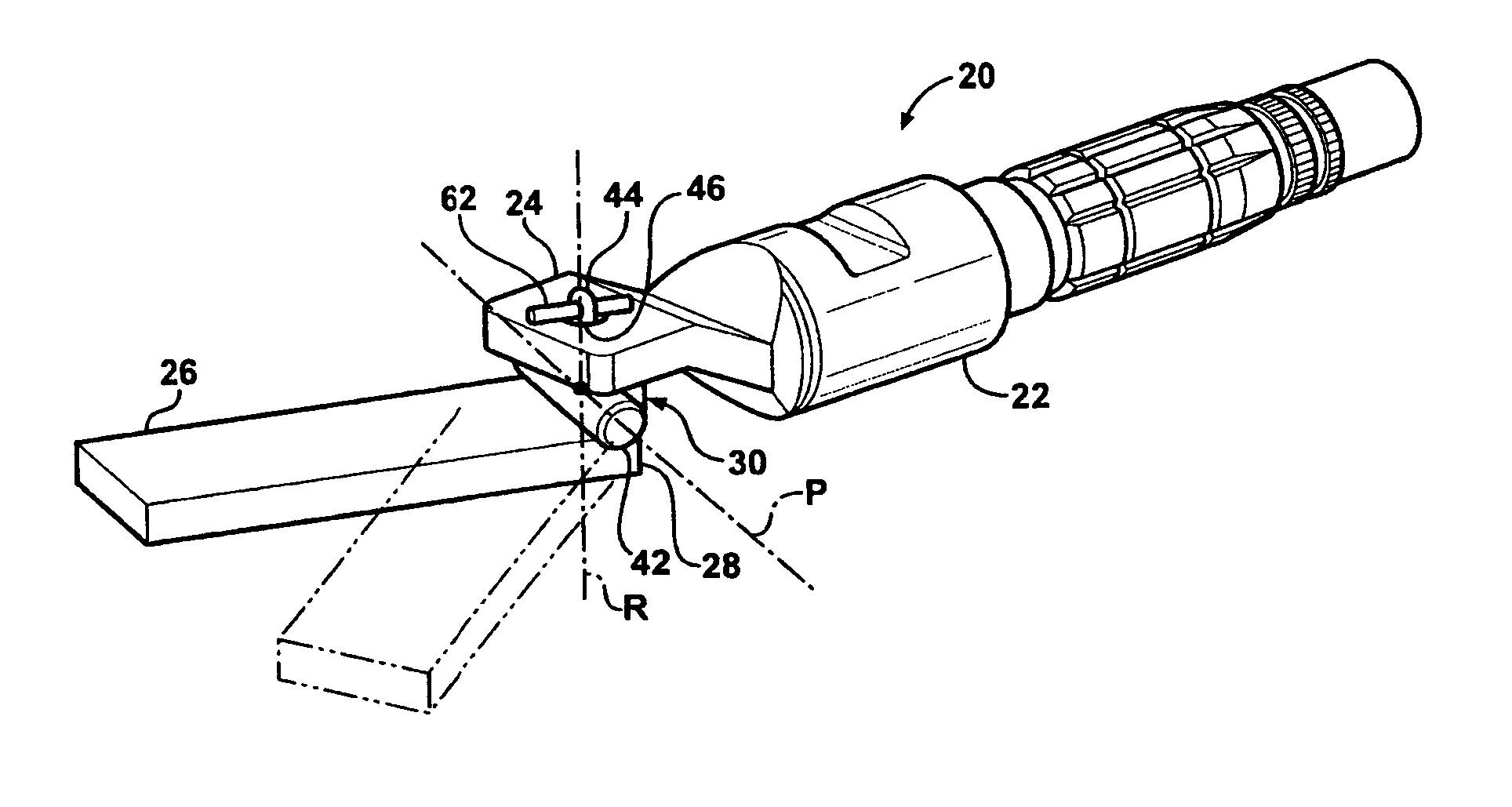

Shaft assembly with lash free bipot joint connection

Owner:STEERING SOLUTIONS IP HLDG +1

Shaft assembly with lash free bipot joint connection

A shaft assembly having a first shaft and a second shaft interconnected by a bipot joint is disclosed. The first shaft and the second shaft are disposed in overlapping spaced relationship. The bipot joint includes a pivot block sandwiched between the first shaft and the second shaft. The pivot defines a mounting surface abutting one of the first and second shafts, and a semi-annular surface opposing the mounting surface and abutting the other of the first shaft and the second shaft. A fastener extends through a bore defined by the first shaft, the pivot block and the second shaft to interconnect the first shaft, the pivot block and the second shaft. The fastener includes a spring to bias the first shaft, the pivot block and the second shaft together, thereby de-lashing the bipot joint.

Owner:STEERING SOLUTIONS IP HLDG +1

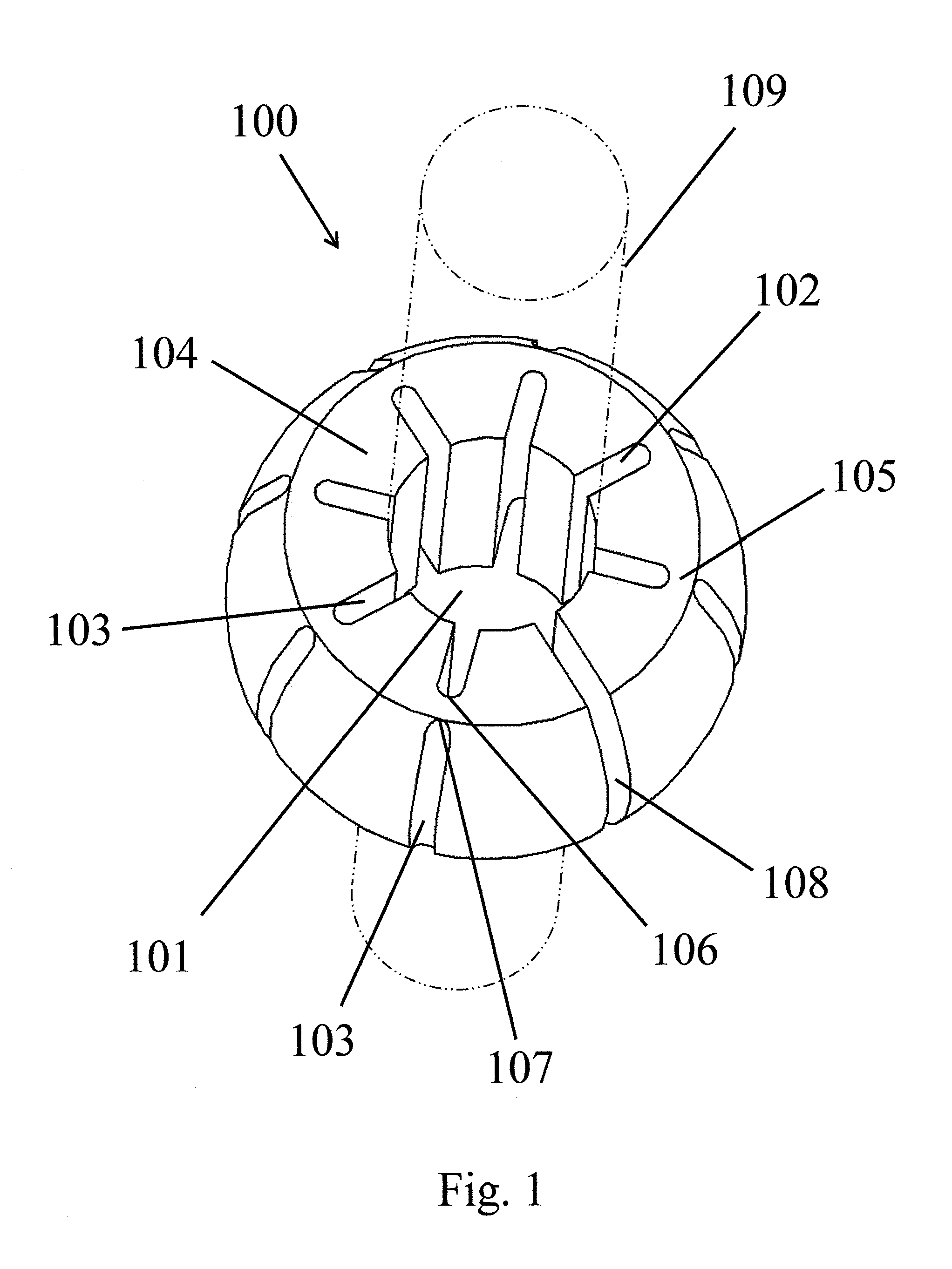

Beverage dispensing apparatus with butterfly plates and molded cluster bearings

ActiveUS8177100B2Eliminate weldsLess costlyOperating means/releasing devices for valvesBall bearingsBall bearingEngineering

An apparatus for dispensing a beverage, for use with pressurized sources of one or more fluids, includes a handle having one or more valve chambers; a fluid valve in each valve chamber; one or more butterfly plates, each configured to bias one or more of the valve stems of the valves towards a valve-open position when the butterfly plate is pressed, thus opening fluidic communication from each of the fluid sources to a corresponding discharge opening; and a ball bearing cluster which provides one or more pivot points for the butterfly plates. The ball bearing cluster includes a retainer and at least one ball-shaped projection projecting from the retainer. The ball-shaped projection remains in a substantially fixed position and orientation with respect to both the retainer and the handle when one or more of the butterfly plates is pressed. The ball bearing cluster and butterfly plate may be molded.

Owner:AUTOMATIC BAR CONTROLS

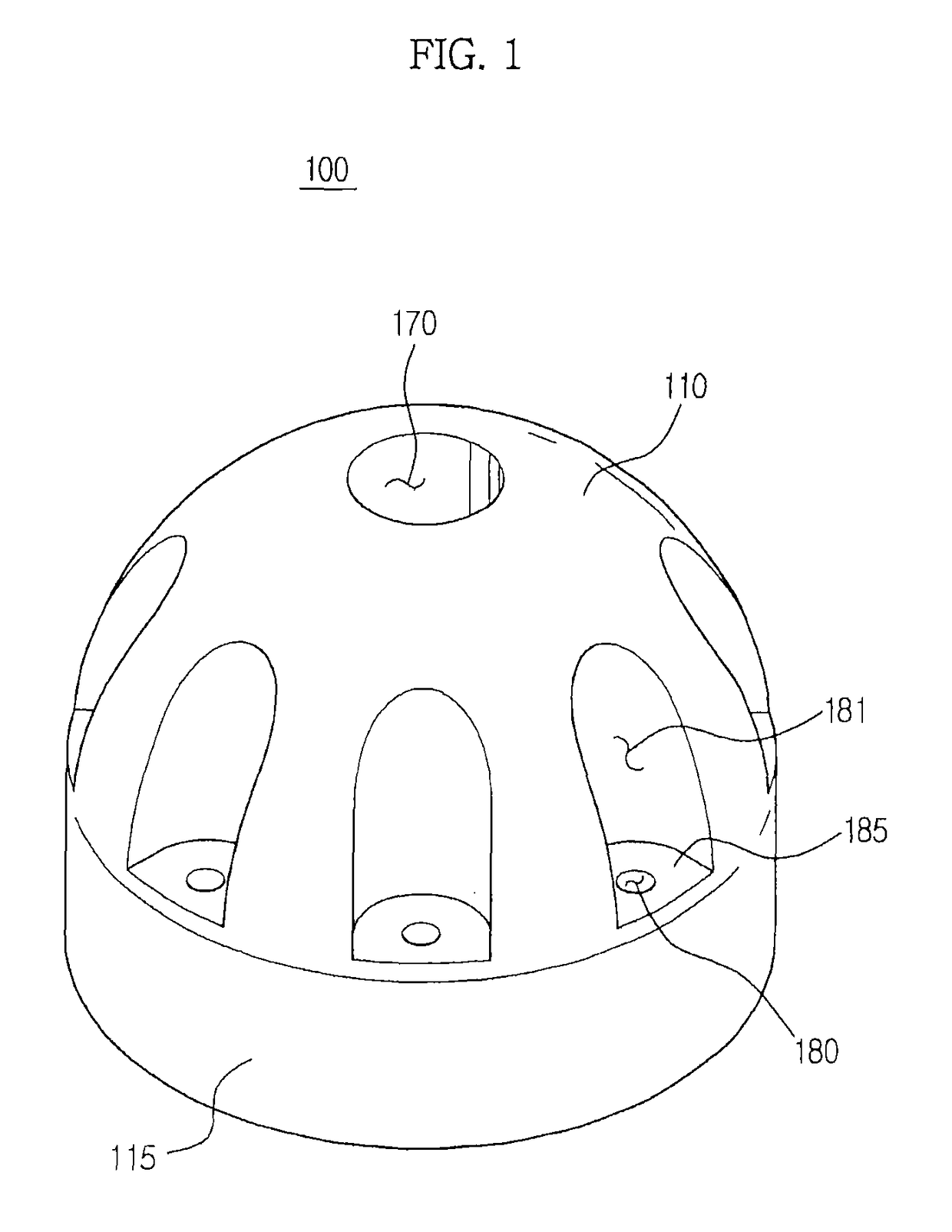

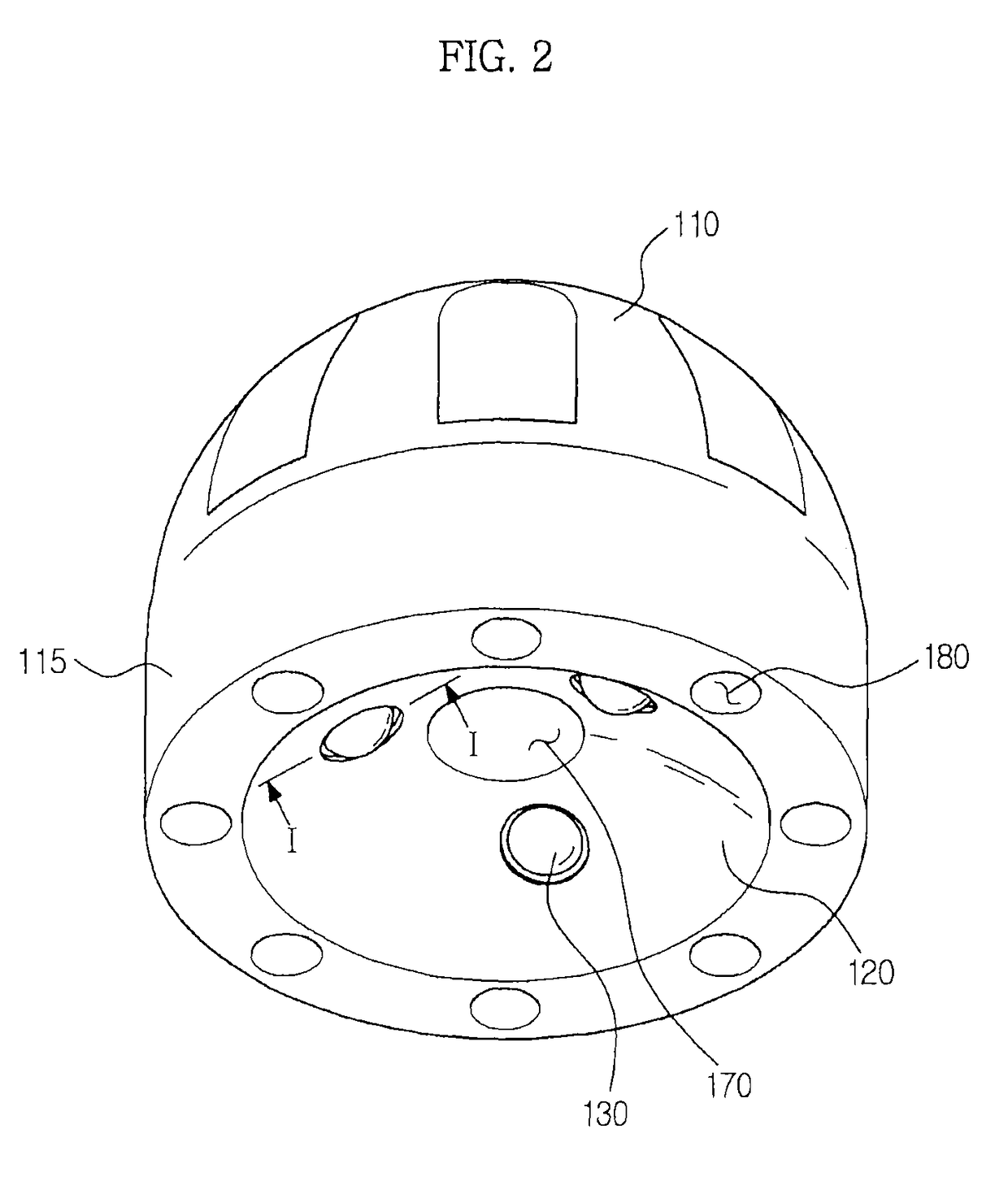

Method and apparatus for releasably immobilizing an attachment to an external object

InactiveUS20150345547A1Difficult to useUnreliable clampingMetal-working apparatusBearing componentsSpherical bearingEngineering

A spherical bearing for releasably immobilizing an attachment to a shaft or other external object is provided. The spherical bearing comprises a truncated flexible spherical core with an annular hole through the center of the spherical core for appending the core on the shaft or external object. Segments around the spherical core are created by relief cuts in the spherical core, and deflection flexure points displaced from the annular hole are formed by the relief cuts in the core. A housing provides compression against the core and immobilization of the shaft or other external object.

Owner:JUNGEBERG KENNETH ALVIN

Rocker pendulum made of an extruded section

A rocker pendulum for a motor vehicle has an oblong basic body via at least one fastening element, wherein the basic body is a hollow extruded section.

Owner:ZF LEMFOERDER METALLWAREN AG

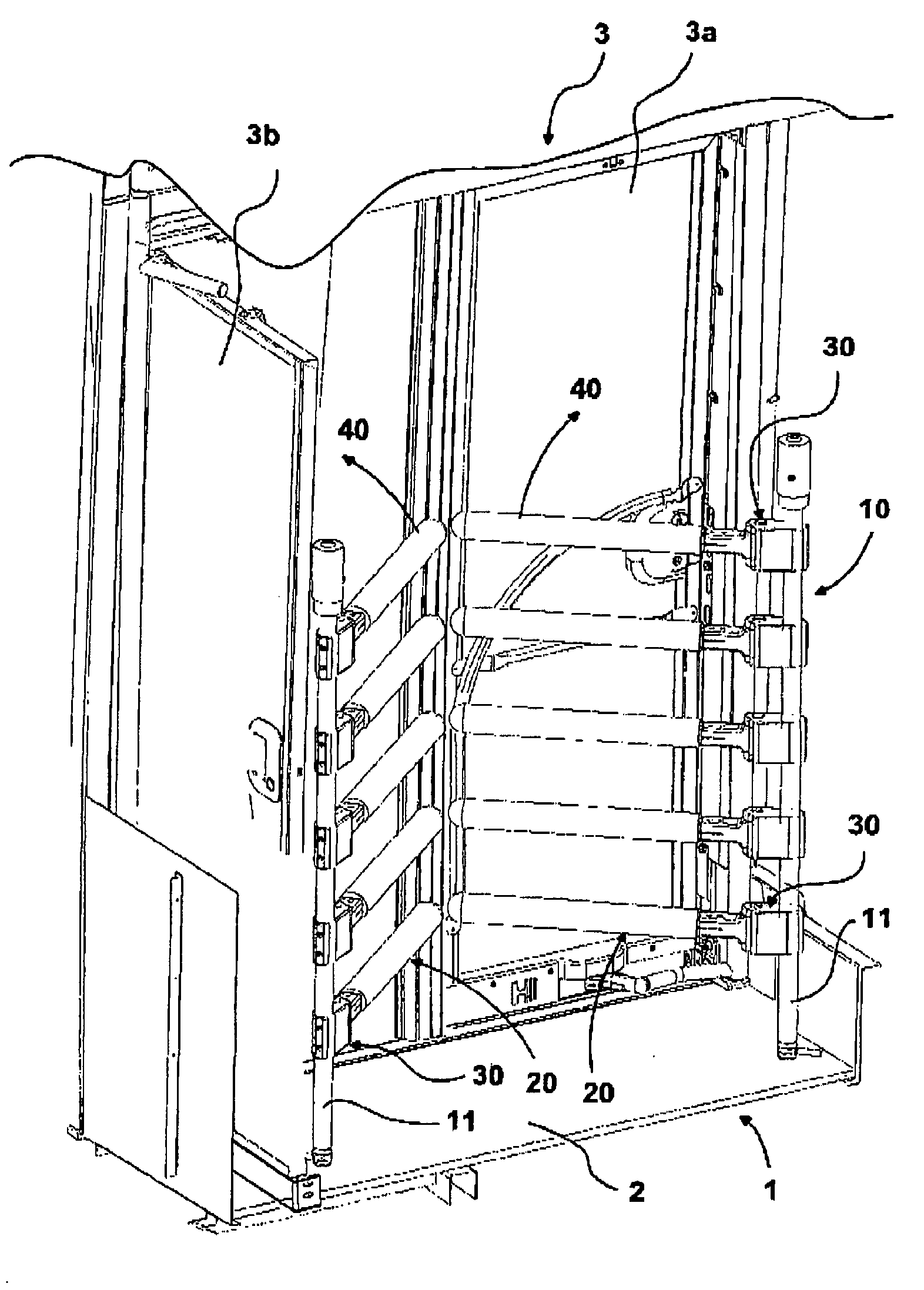

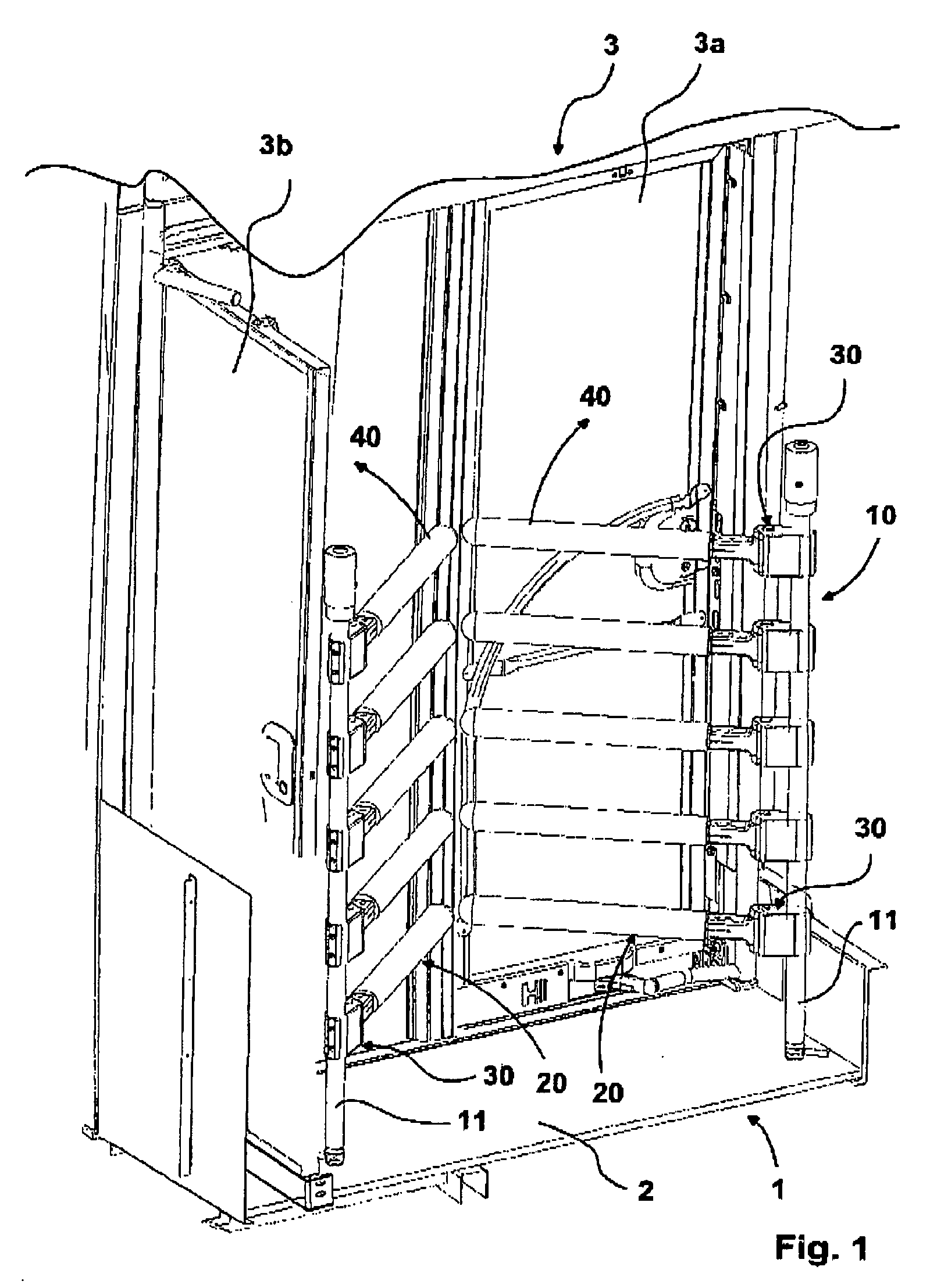

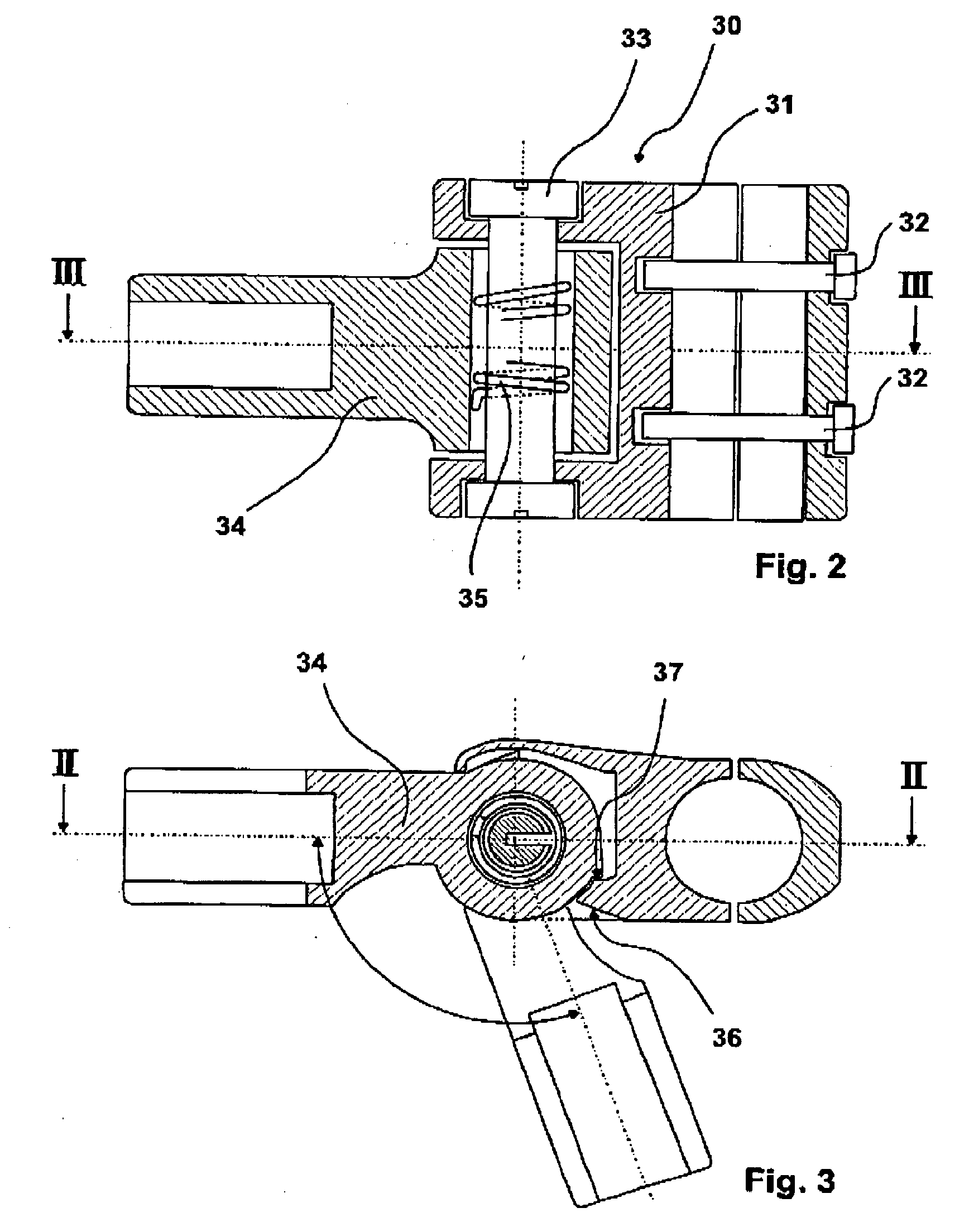

Device for preventing persons from boarding a vehicle, more specifically a bus, through a door opening

The subject matter of the invention is a device for preventing persons from boarding a vehicle, more specifically a bus, through the open door opening, said device including a stopper system (10) that is pivotal outward from the interior of the vehicle, said stopper system (10) including two rows of a plurality of arms that are arranged on top of one another said arms (20) are individually pivotable toward the outside, said arms (20), which are lying on one plane with respect to one another, being oriented so as to point angularly outward.

Owner:HUBNER GMBH

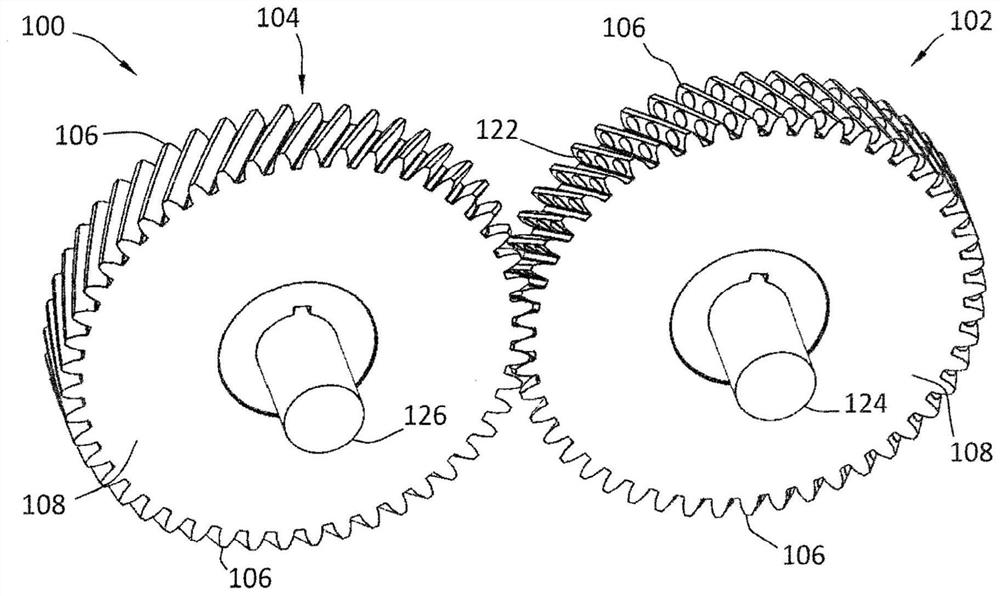

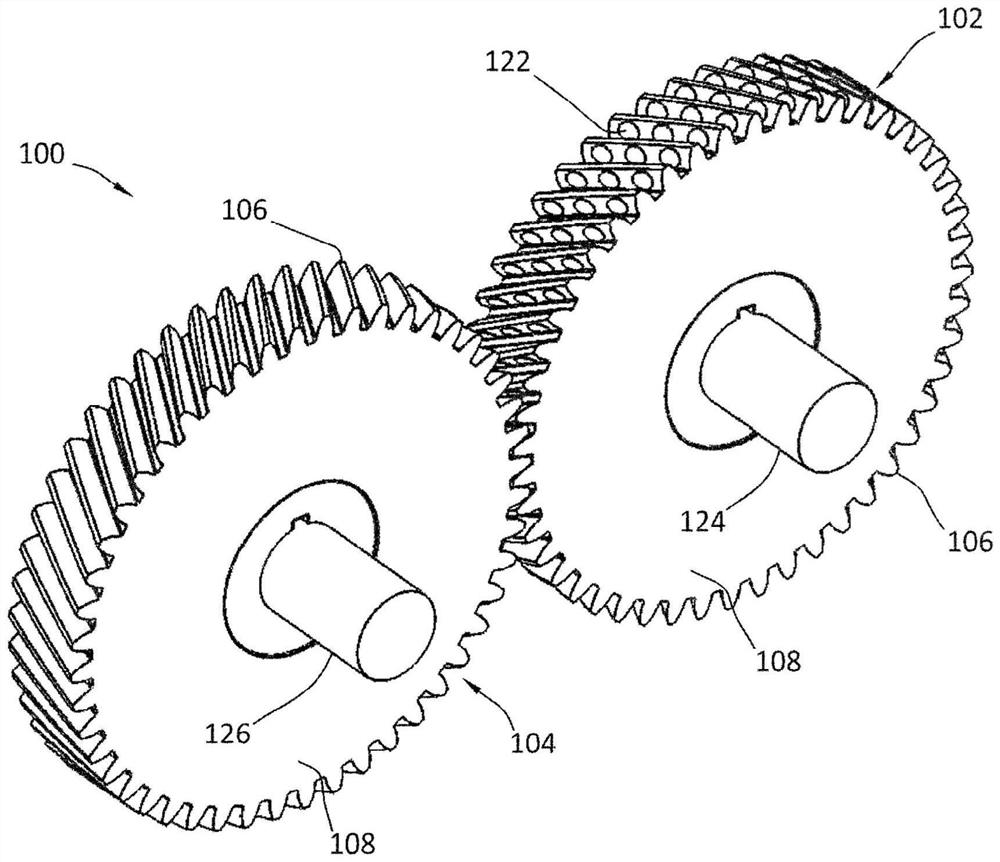

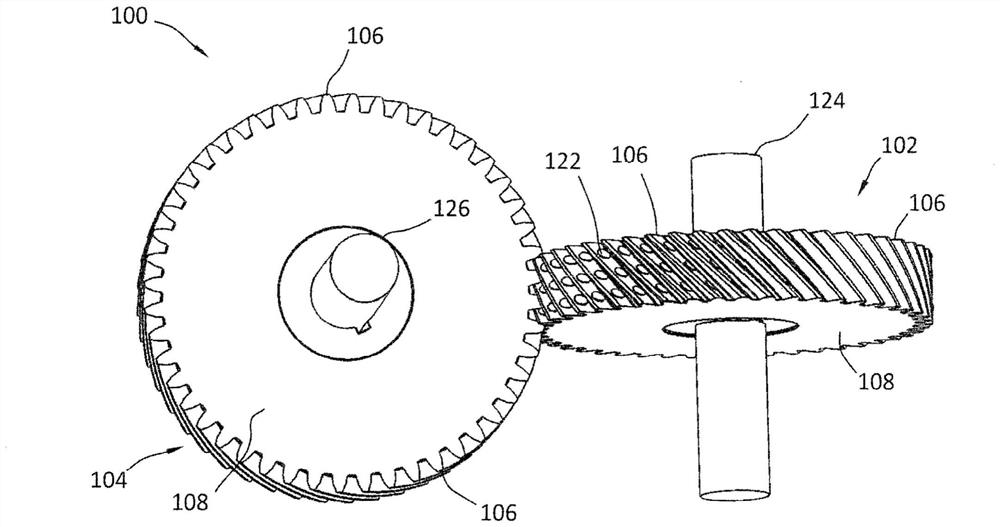

Polycrystalline diamond power transmission surface

A powertrain system is provided that includes a polycrystalline diamond powertrain surface that engages a diamond solvent-catalyst powertrain surface. The power transmission system can be a gear, a universal joint or other power transmission system or component or comprises a gear, a universal joint or other power transmission system or component.

Owner:XR DOWNHOLE LLC

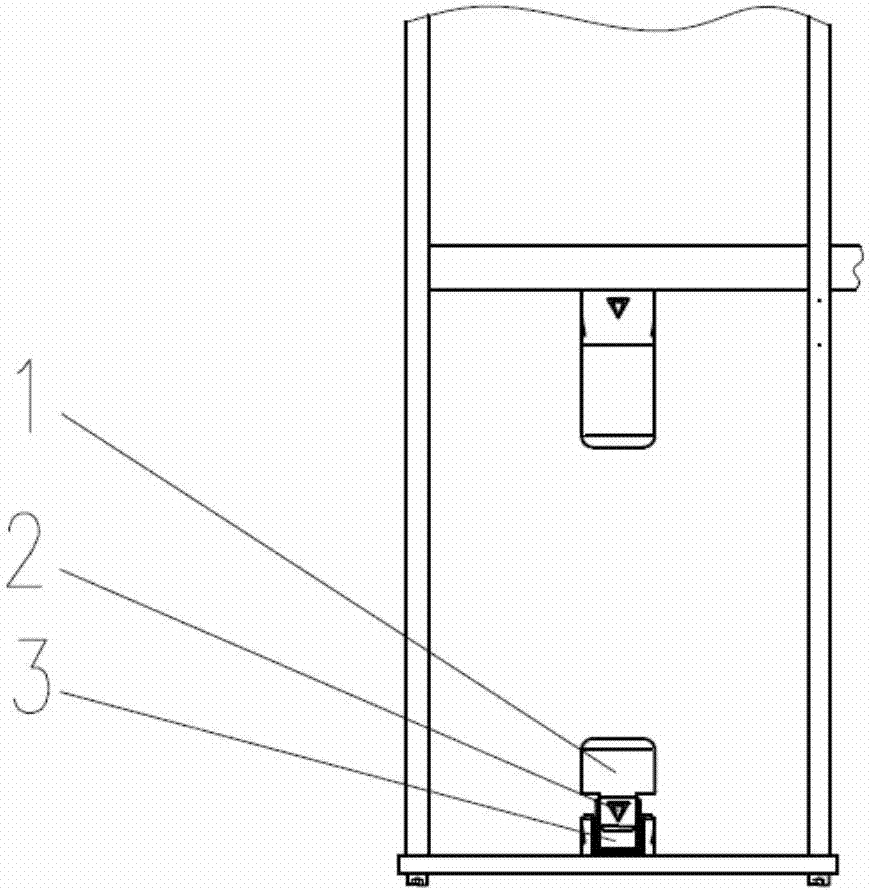

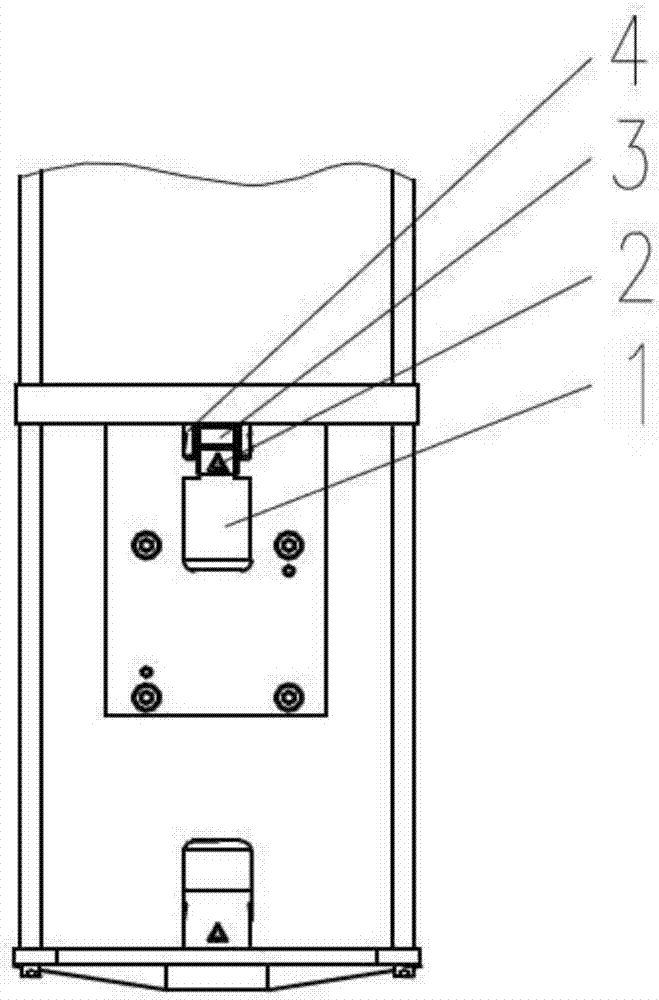

Knife edge universal joint used for dead load type micro-force value standard device

The invention discloses a knife edge universal joint used for a dead load type micro-force value standard device. The knife edge universal joint comprises a cross head, a first knife edge, a second knife edge, a universal joint base and a universal joint pull head; a first through groove is formed in the upper portion of the cross head, a second through groove is formed in the lower portion of the cross head, the first knife edge is arranged in the first through groove, the two ends of the first knife edge stretch out of the first through groove, the second knife edge is arranged in the second through groove, the two ends of the second knife edge stretch out of the second through groove, the universal joint base is connected with the two ends of the first knife edge, and is used for fixing the knife edge universal joint to the dead load type micro-force value standard device, the universal joint base can swing with the first knife edge as the axis, the universal joint pull head is connected with the two ends of the second knife edge, and the universal joint pull head can swing with the second knife edge as the axis. Meanwhile, in the swing process, knife edge liner contact is achieved, the friction force is small, and the knife edge universal joint is small in friction force, high in accuracy, small in space position and suitable for being used for the dead load type micro-force value standard device

Owner:SHANGHAI MARINE EQUIP RES INST

Knife-edge universal joints for deadweight small force standard devices

The invention discloses a knife edge universal joint used for a dead load type micro-force value standard device. The knife edge universal joint comprises a cross head, a first knife edge, a second knife edge, a universal joint base and a universal joint pull head; a first through groove is formed in the upper portion of the cross head, a second through groove is formed in the lower portion of the cross head, the first knife edge is arranged in the first through groove, the two ends of the first knife edge stretch out of the first through groove, the second knife edge is arranged in the second through groove, the two ends of the second knife edge stretch out of the second through groove, the universal joint base is connected with the two ends of the first knife edge, and is used for fixing the knife edge universal joint to the dead load type micro-force value standard device, the universal joint base can swing with the first knife edge as the axis, the universal joint pull head is connected with the two ends of the second knife edge, and the universal joint pull head can swing with the second knife edge as the axis. Meanwhile, in the swing process, knife edge liner contact is achieved, the friction force is small, and the knife edge universal joint is small in friction force, high in accuracy, small in space position and suitable for being used for the dead load type micro-force value standard device

Owner:SHANGHAI MARINE EQUIP RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com