Polycrystalline diamond power transmission surface

A technology of polycrystalline diamond and power transmission, which is applied in the direction of engine components, sliding contact bearings, bearings of rotating motion, etc., and can solve problems such as failure and component wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1. A power transmission system includes: a first component having at least one power transmission surface thereon, the at least one power transmission surface comprising polycrystalline diamonds; second components, the second The component has at least one relative power transmission surface, which includes a material comprising at least 2 weight percent diamond solvent-catalysts based on the total weight of the material; wherein the first components are The two components can be coupled to engage the polycrystalline diamonds with the diamond solvent-catalyst, and drive one of the first components and the second component to move the other of the second part.

Embodiment 2

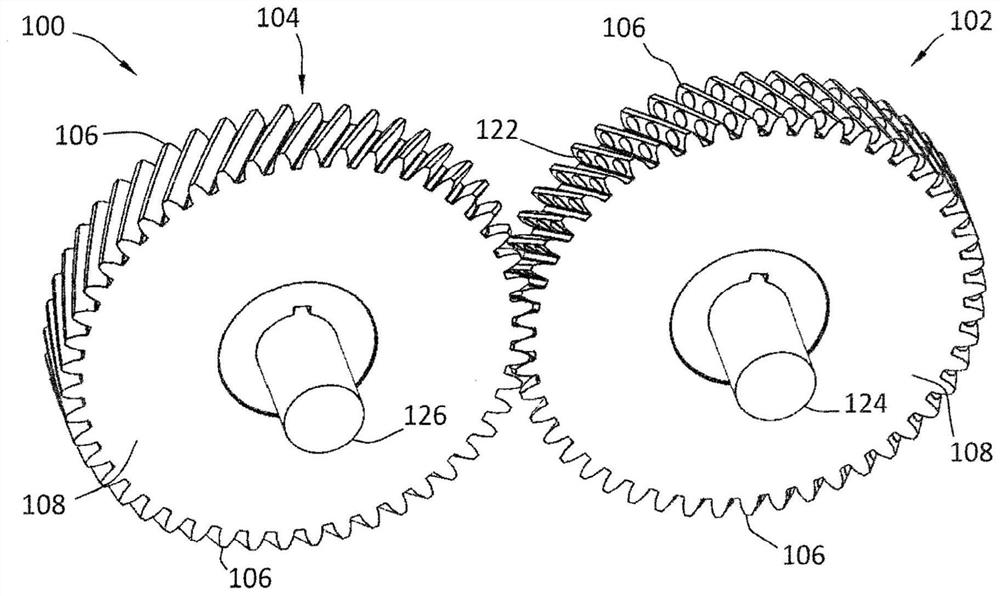

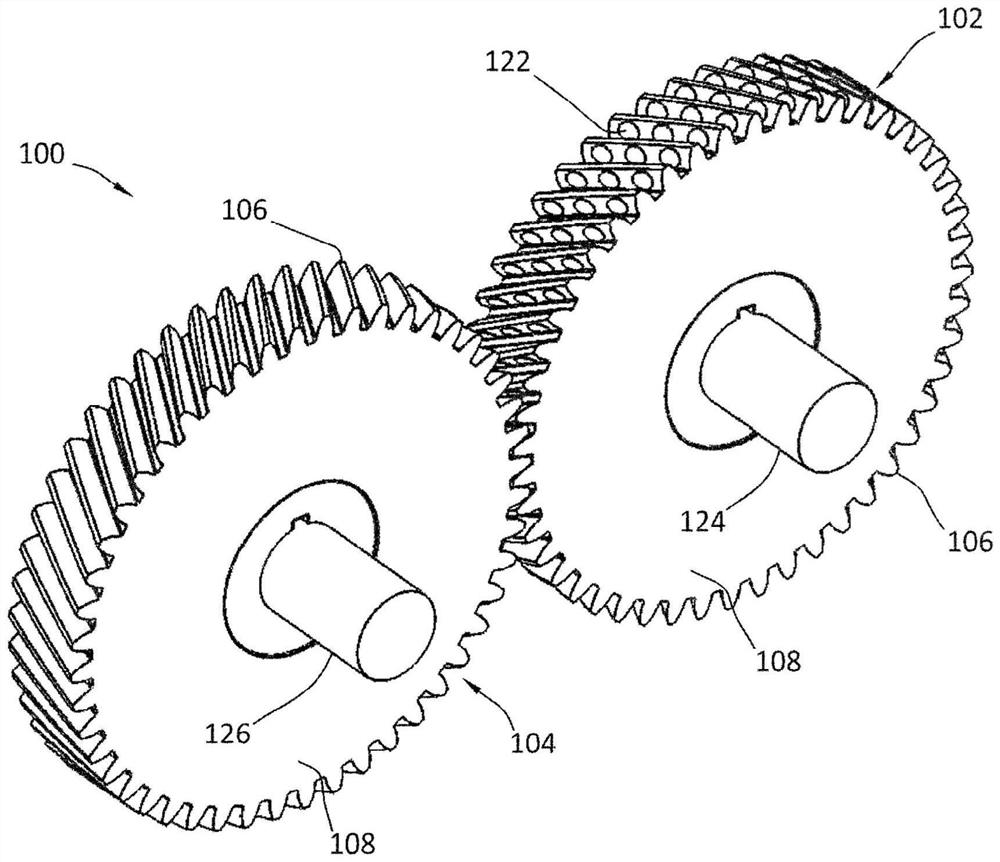

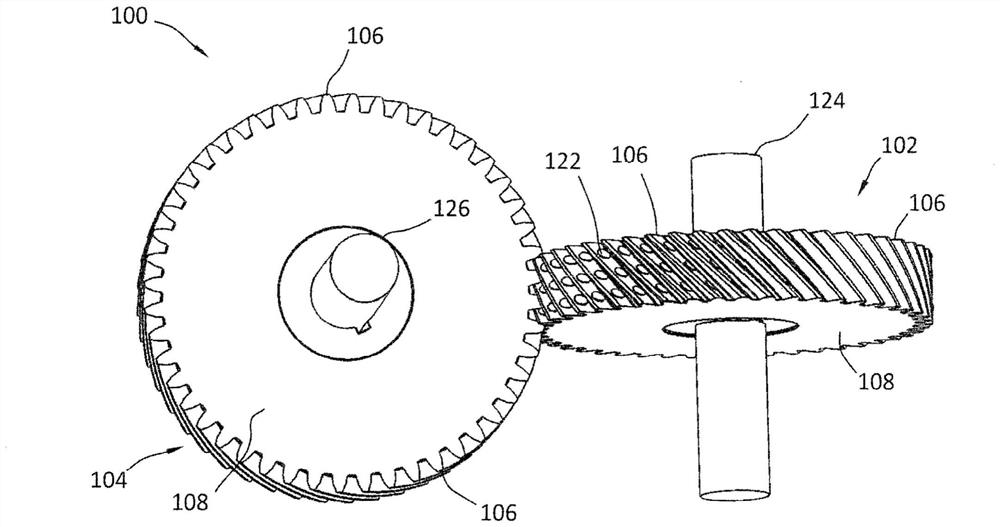

[0072] Example 2. The power transmission system according to Example 1, wherein the first component is a first gear, wherein the second member is a second gear, a first gear and a second gear meshing.

Embodiment 3

[0073] Example 3. The power transmission system according to Example 2, wherein the at least one power transmission surface is at least one gear teeth of the first gear, and at least one relative power transmission surface is at least one gear teeth of the second gear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com