Knife-edge universal joints for deadweight small force standard devices

A standard device and universal joint technology, applied in the field of knife-edge universal joints, can solve the problems of large friction, large space, complex structure, etc., and achieve the effect of small friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

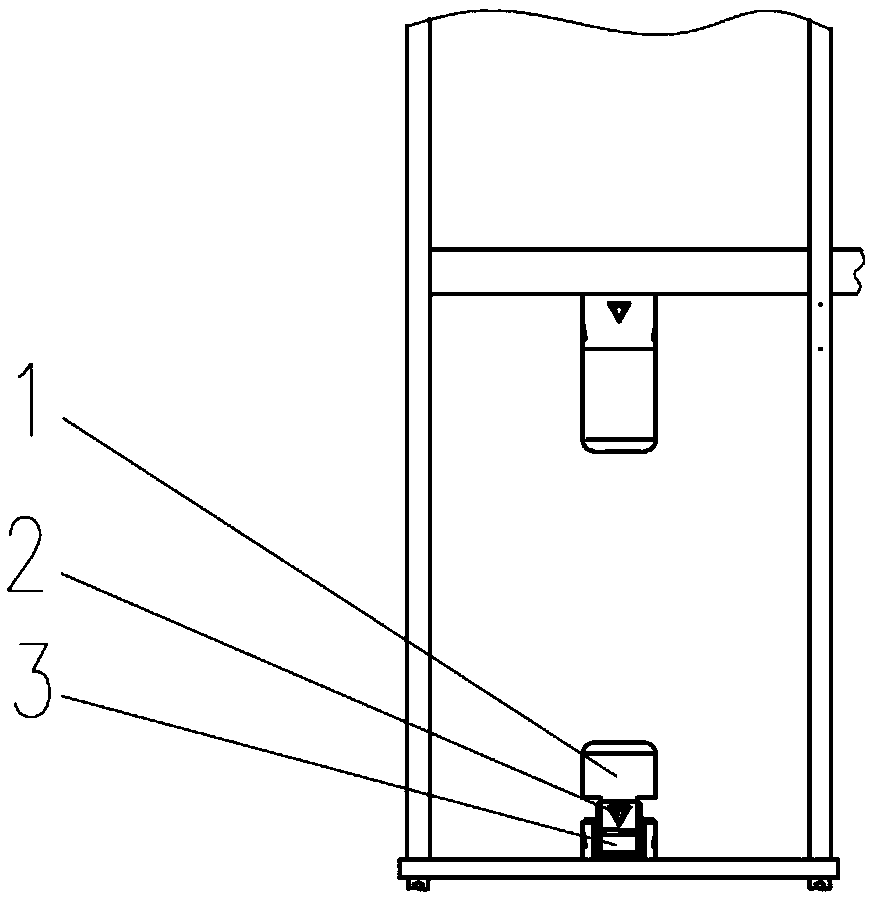

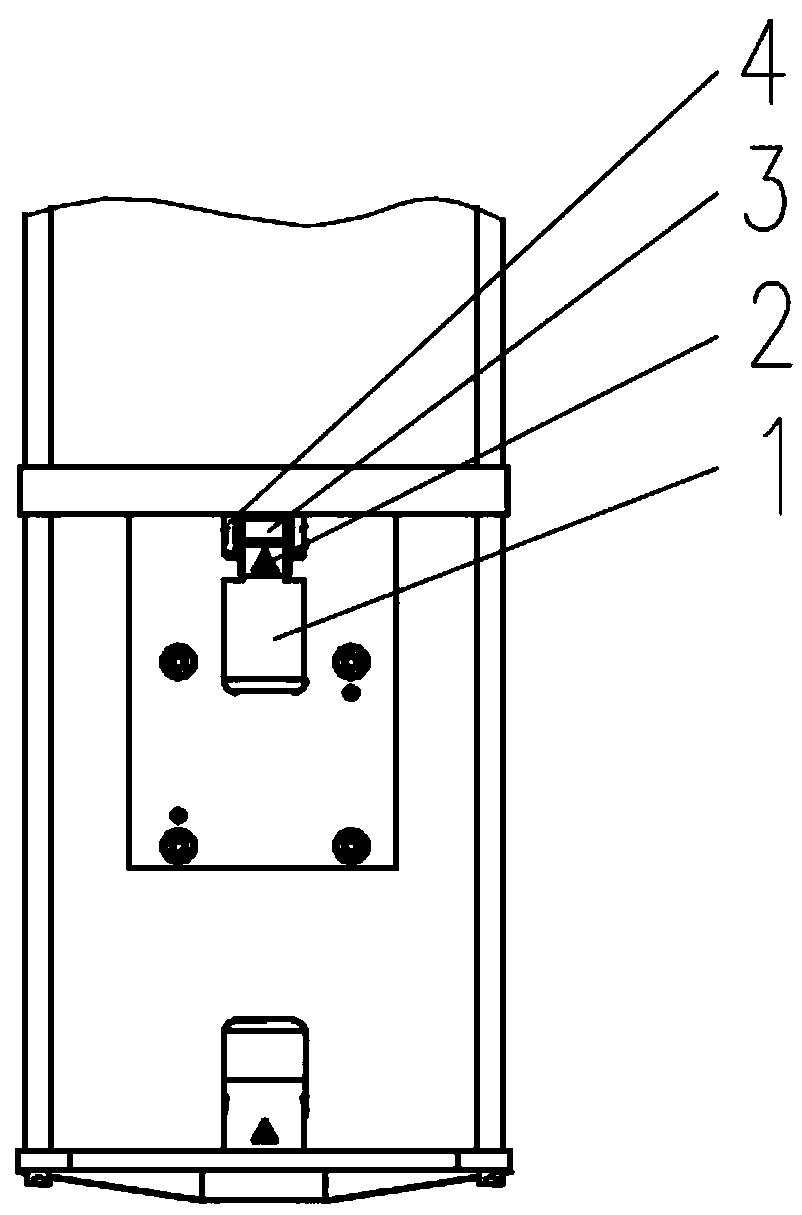

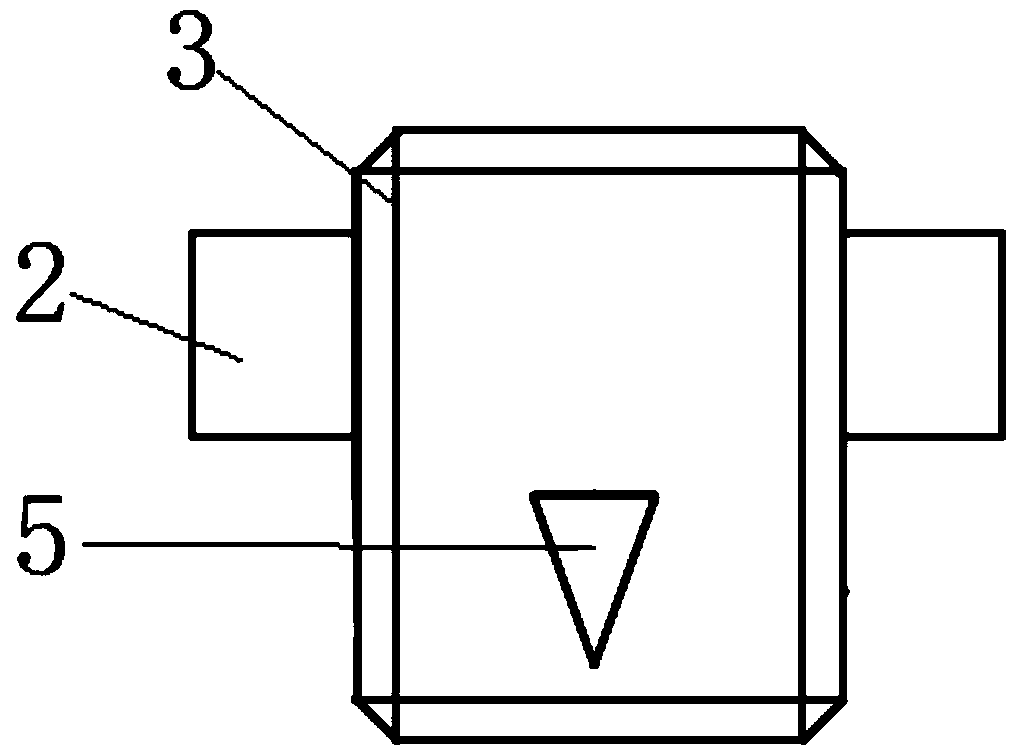

[0057] figure 1 It shows the front view of the use state of the knife-edge universal joint of the deadweight micro-force value standard device according to an embodiment of the present invention. figure 2 It shows the left view of the knife-edge universal joint in use according to an embodiment of the present invention. image 3 A connection diagram of the first knife edge and the second knife edge of the knife-edge universal joint of the deadweight micro-force value standard device according to an embodiment of the present invention is shown. Figure 4a-4b The distribution shows the left view and the front view of the first edge of the static weight micro force value standard device according to an embodiment of the present invention.

[0058] Such as figure 1 , 2 , 3, 4a and 4b, the knife-edge universal joint used for the static weight type small force value standard device includes: universal joint slider 1, first knife edge 2, crosshead 3, universal joint seat 4, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com