Composite Cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

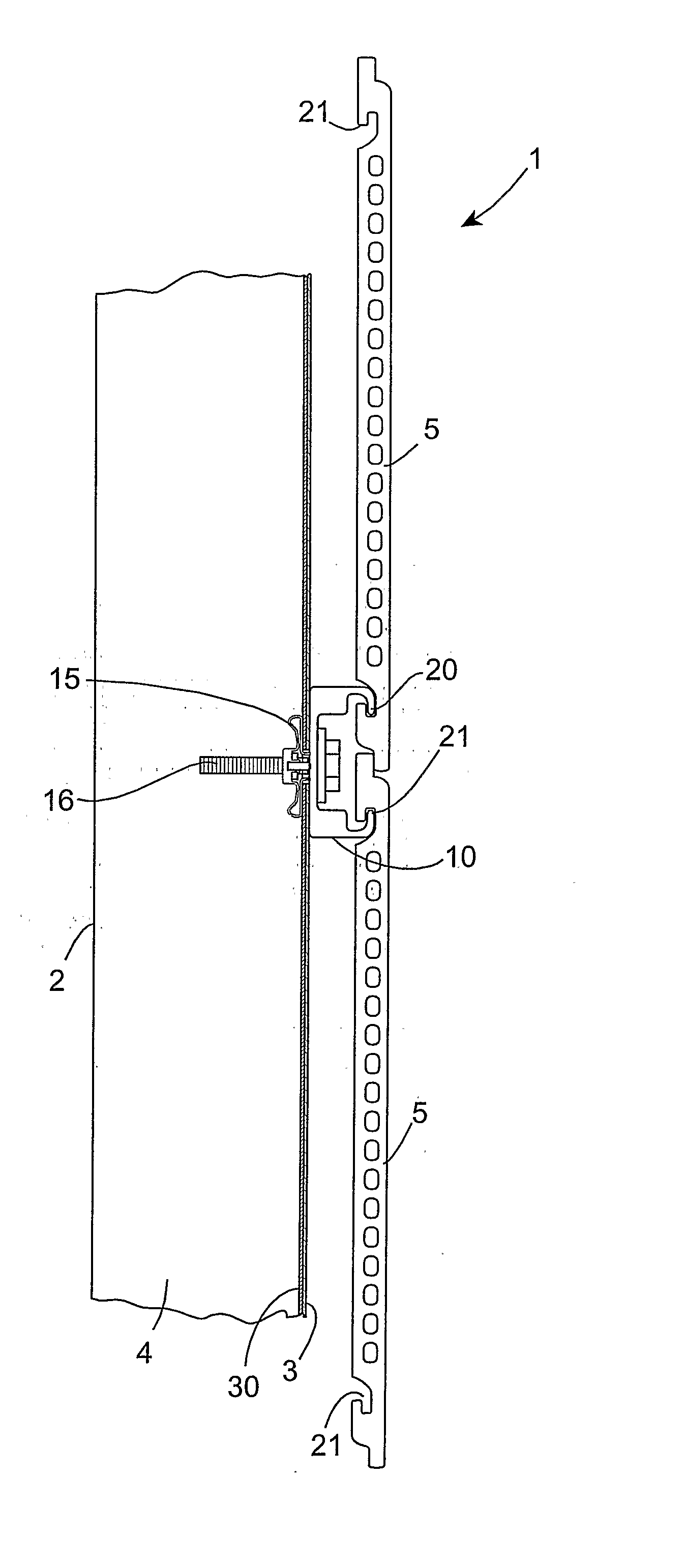

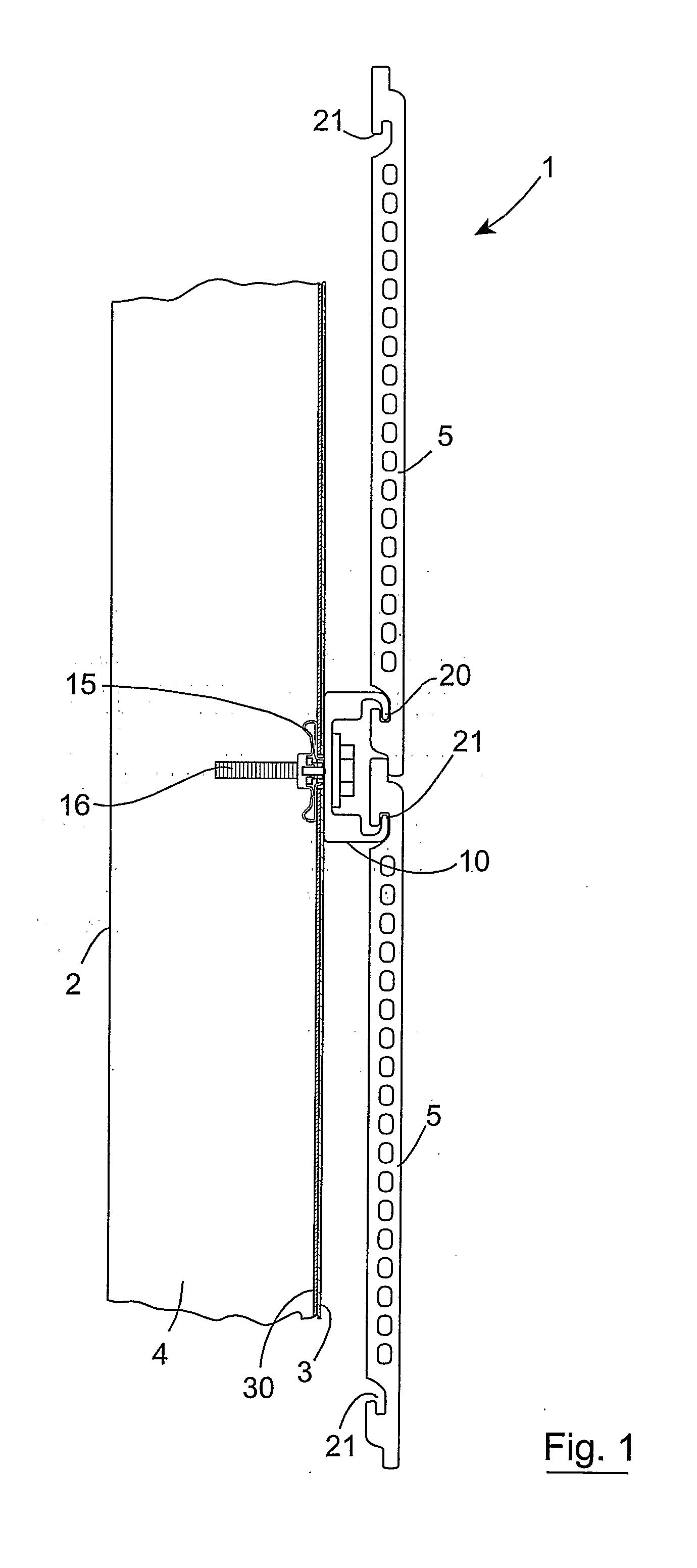

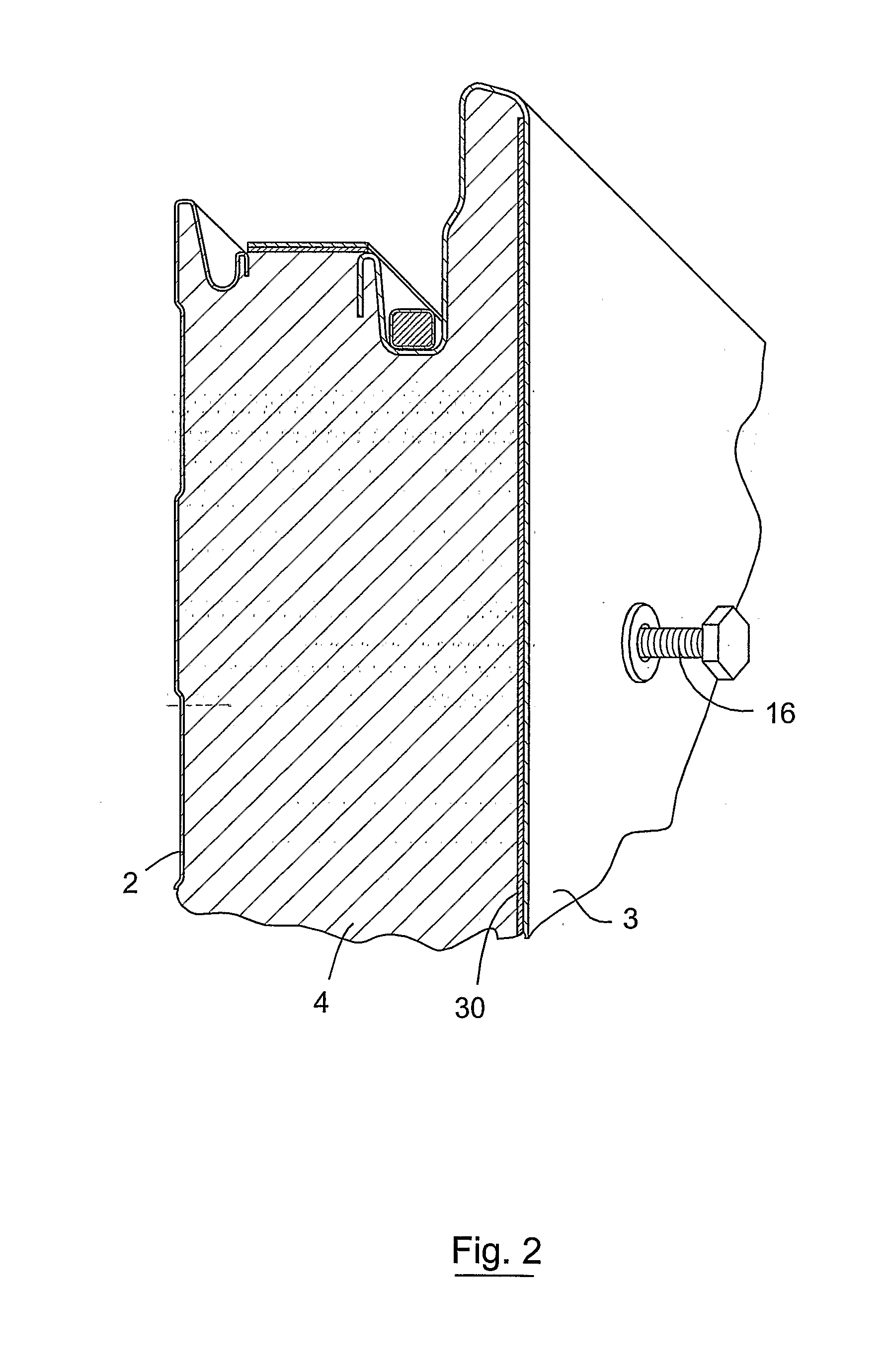

[0024]Referring to the drawings there is illustrated a composite cladding panel 1 according to the invention. The panel 1 comprises a steel skin or backing tray 2 and an external steel skin 3 with a layer of foam insulation material 4 such as a phenolic or polyurethane based foam material therebetween. The panel may be of any suitable type such as that described in our UK2325678A, the entire contents of which are hereby incorporated by reference.

[0025]One of the skins, in this case the external skin 3 has a plurality of mountings for fixing façade or cladding elements such as tiles 5 to the panel. The tiles may be brick, ceramic or the like to form a cladding for the panel. The mountings comprise rails 10 and fasteners 12 for fastening the rails 10 to the external skin 3.

[0026]Each fastener 12 comprises an internal clamping sleeve 15 and a bolt 16. One such fastening systems is that referred to in a Fablok (Trade Mark). A hole is first drilled through the skin 3 and the sleeve 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com