Composite panel

a technology of composite panels and panels, applied in the field of composite panels, can solve the problem that panels can be uninteresting aesthetically, and achieve the effect of reducing the number of panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

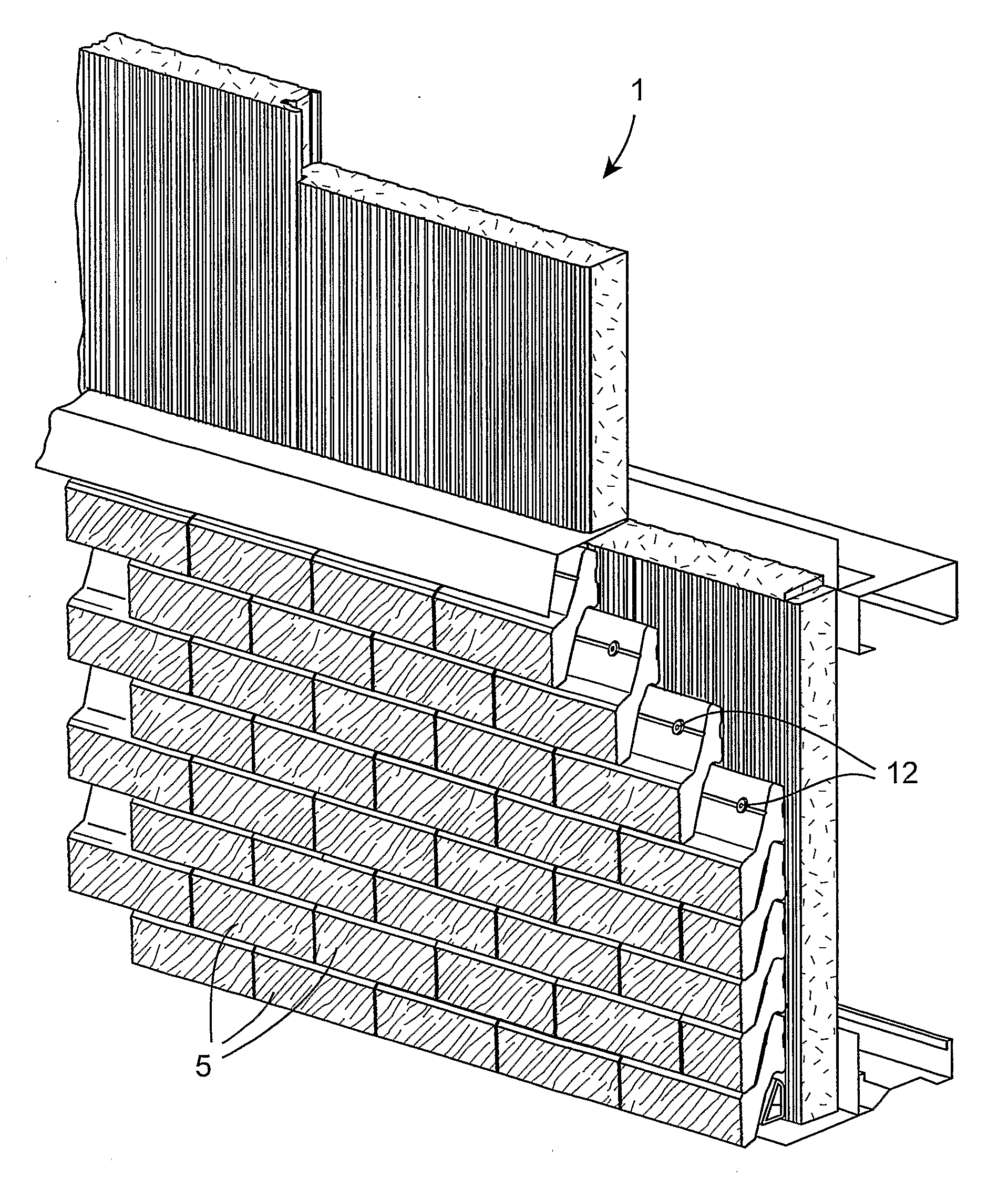

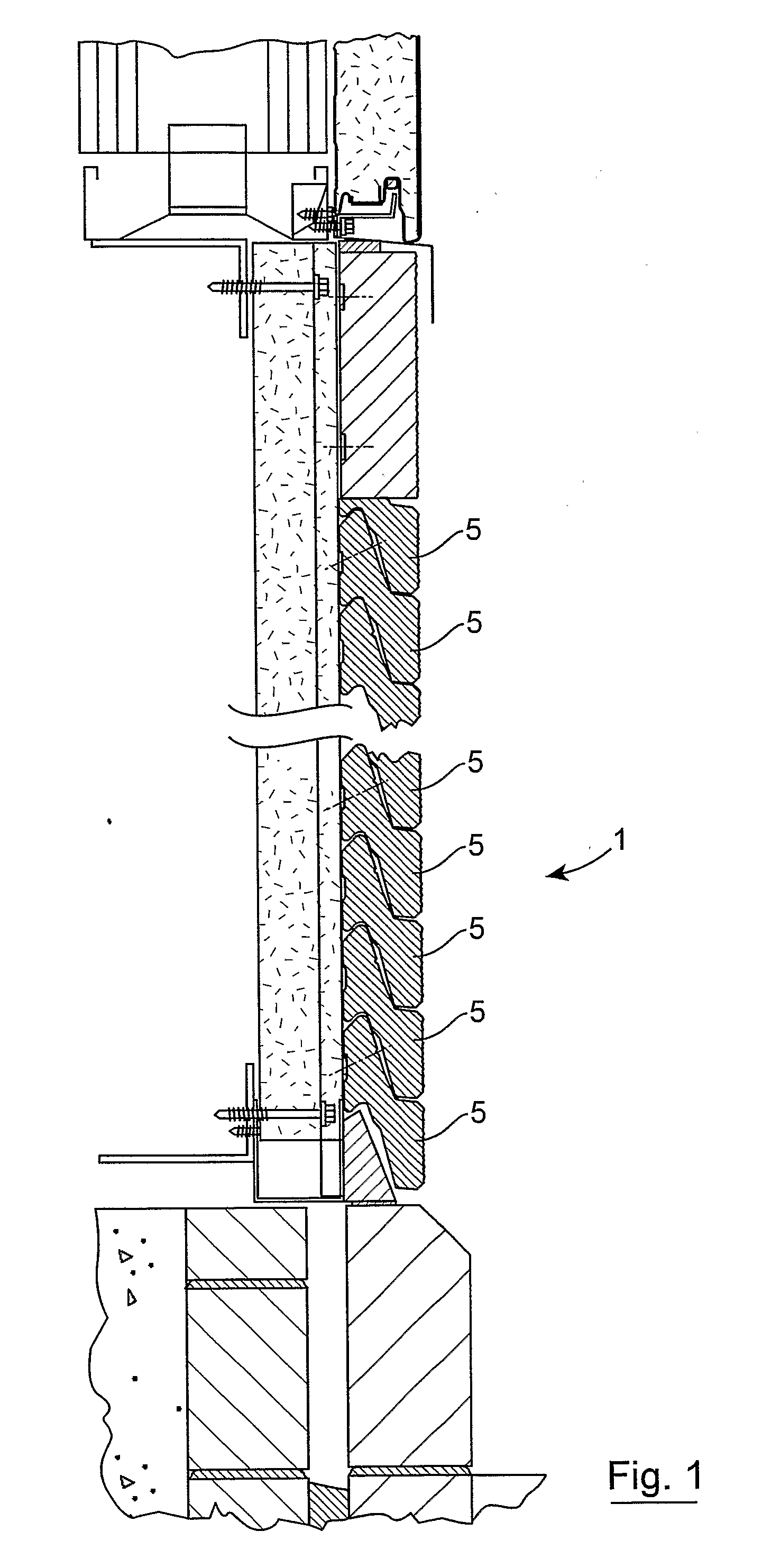

[0031]Referring to the drawings there is illustrated a composite cladding panel 1 according to the invention. The panel 1 comprises a steel skin or backing tray 2 and an external steel skin 3 with a layer of foam insulation material 4 such as a phenolic or polyurethane based foam material therebetween. The panel may be of any suitable type such as that described in our UK2325678A, the entire contents of which are hereby incorporated by reference.

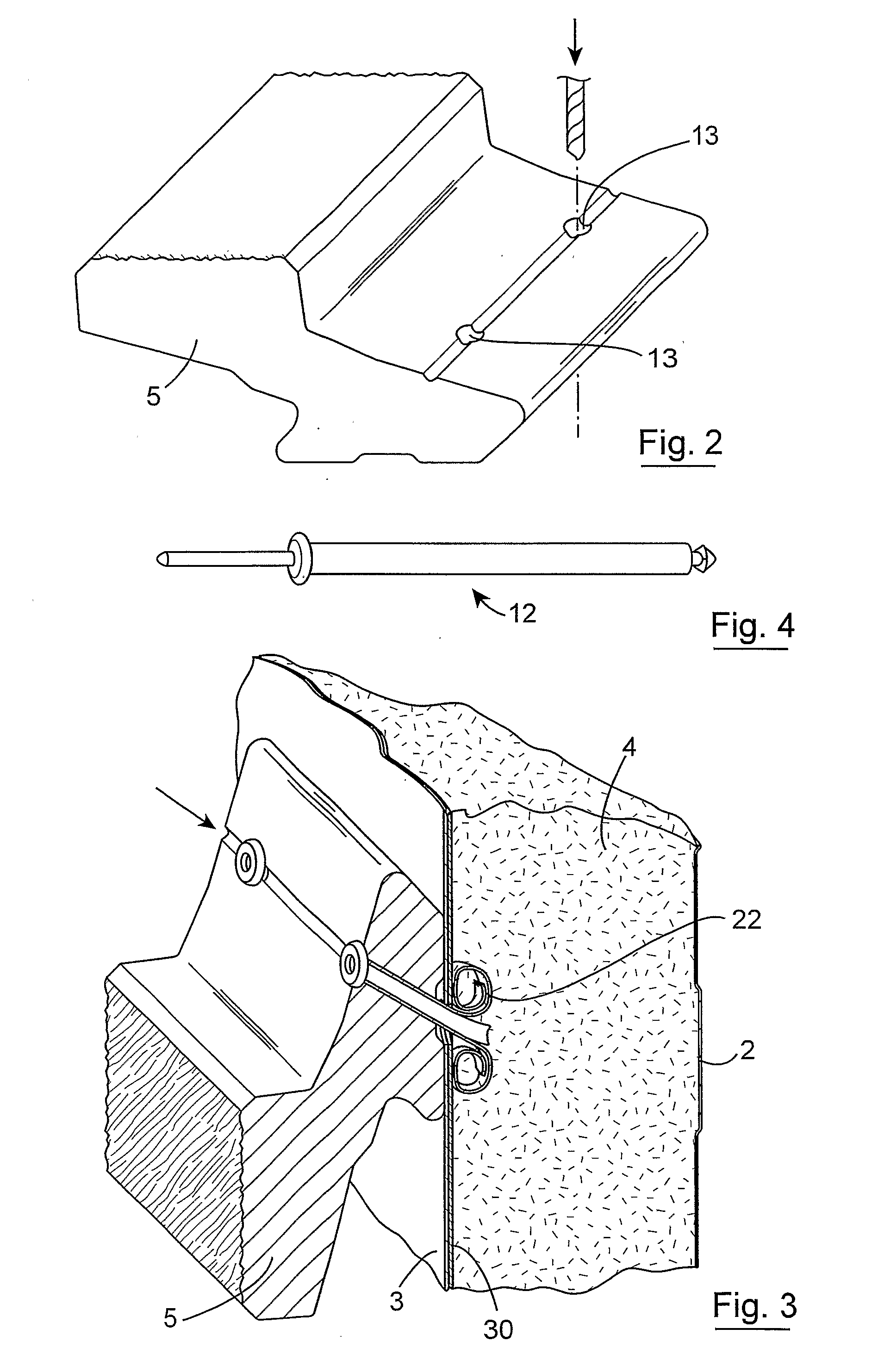

[0032]One of the skins, in this case the external skin 3 has a plurality of tongue and mortise blocks 5 such as those available from Novabrick fastened to the panel 1 by fasteners 12. Each fastener 12 in this case is a clamping fastener and comprises a peel rivet having a mandrel, a stress plate, and a main body. We have found that such a clamping fastener is particularly efficient in fastening such blocks to the panel.

[0033]Pilot holes 13 are first drilled through the blocks 5 and the rivet 12 is inserted. On operation of a rivet gun the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com