Dental CAD/CAM machinable PMMA and preparation method thereof

A CAD and dental technology, applied in the field of producing dental CAD/CAM machinable PMMA, can solve the problems of small molecular weight, poor heat resistance and poor mechanical properties of PMMA, and achieve high molecular weight, good heat resistance and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

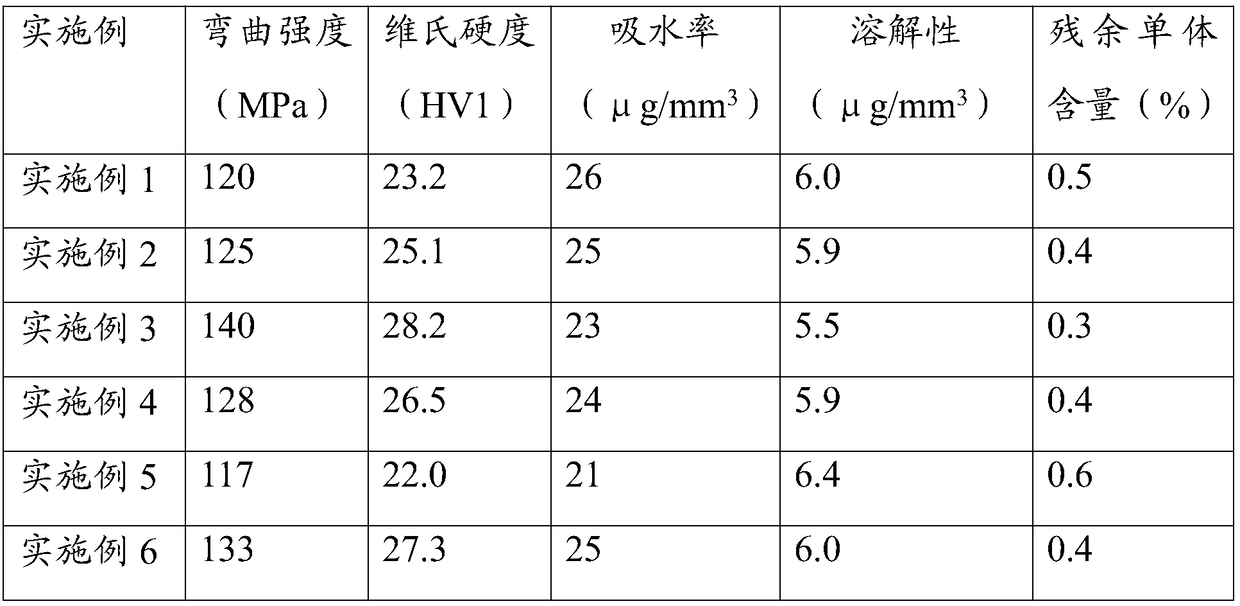

Examples

Embodiment 1

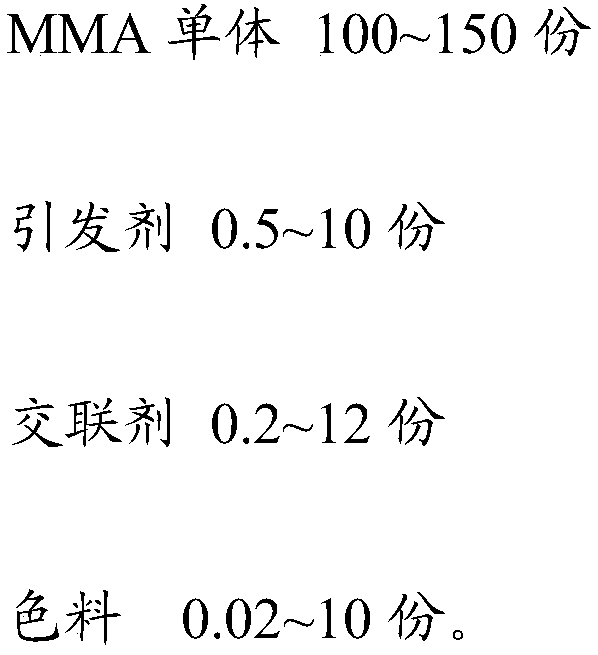

[0052] Weigh 100 parts of MMA monomer, 2 parts of initiator (AIBN: BPO=1:1) and 3 parts of crosslinking agent (TAC: DOP=2:1) into the reactor, stir clockwise for 20 laps, and then Let it stand for 10 minutes, put it into a water bath at 65°C for pre-polymerization;

[0053] Take out the pre-polymerized raw materials, put them in ice water and cool to 30°C; then weigh 1 part of the colorant and add it to the pre-polymerized slurry, then use a stirrer to stir for 30 minutes, and put it into the mold according to the product specification by weight , and then carry out the polymerization reaction of four stages in the later stage, the first low-temperature polymerization stage at 20°C, 800min; the second low-temperature polymerization stage at 40°C, 1000min; the first high-temperature polymerization stage at 60°C, 500min; After the polymerization is completed, demolding is carried out to obtain PMMA products.

Embodiment 2

[0055] Weigh 110 parts of MMA monomer, 3 parts of initiator (AIBN: BPO=1:1) and 4 parts of crosslinking agent (TAC: DOP=2:1) into the reactor, stir clockwise for 20 laps, and then Let it stand for 15 minutes, put it into a water bath at 70°C for pre-polymerization;

[0056] Take out the pre-polymerized raw materials, put them in ice water and cool to 30°C; then weigh 2 parts of the colorant and add it to the pre-polymerized slurry, then use a stirrer to stir for 35 minutes, and put it into the mold according to the product specification by weight , and then carry out the polymerization reaction of four stages in the later stage, the first low-temperature polymerization stage at 20°C, 800min; the second low-temperature polymerization stage at 40°C, 1000min; the first high-temperature polymerization stage at 60°C, 500min; After the polymerization, demoulding is carried out to obtain PMMA products.

Embodiment 3

[0058] Weigh 120 parts of MMA monomer, 2 parts of initiator (AIBN: BPO=1:1) and 4 parts of crosslinking agent (TAC: DOP=2:1) into the reactor, stir clockwise for 30 laps, and then Let it stand for 20 minutes, put it into a water bath at 75°C for pre-polymerization;

[0059] Take out the pre-polymerized raw materials, put them in ice water and cool to 30°C; then weigh 3 parts of the colorant and add them to the pre-polymerized slurry, then use a stirrer to stir for 30 minutes, and put them into the mold according to the product specifications by weight , and then carry out the polymerization reaction of four stages in the later stage, the first low-temperature polymerization stage at 30°C, 800min; the second low-temperature polymerization stage at 40°C, 1000min; the first high-temperature polymerization stage at 55°C, 500min; After the polymerization, demoulding is carried out to obtain PMMA products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com