Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Elastic fibres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

See Article History. Elastic fibre, any of the yellowish branching fibres composed primarily of the protein elastin, frequently arranged in plates or perforated membranes, as in the walls of the large arteries.

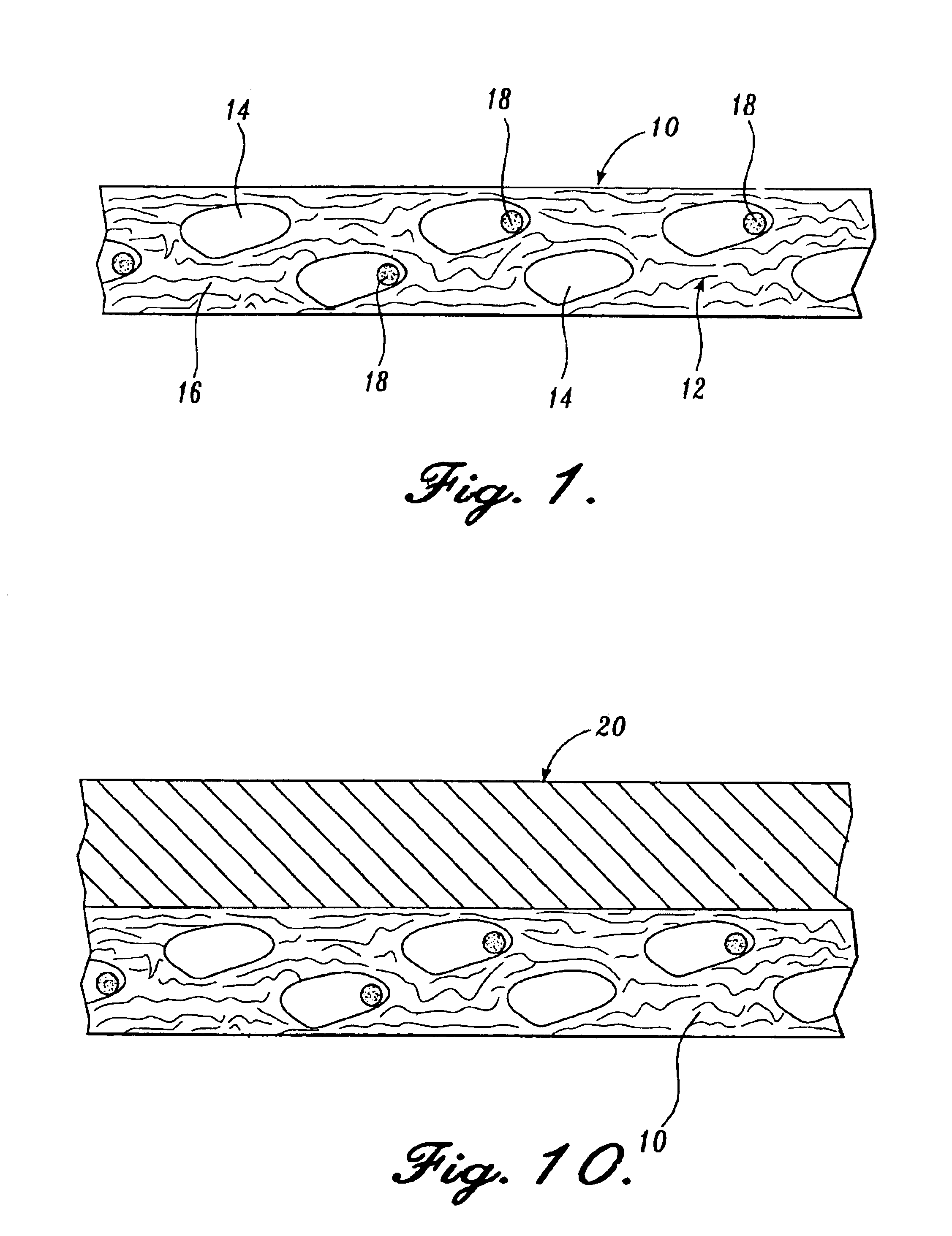

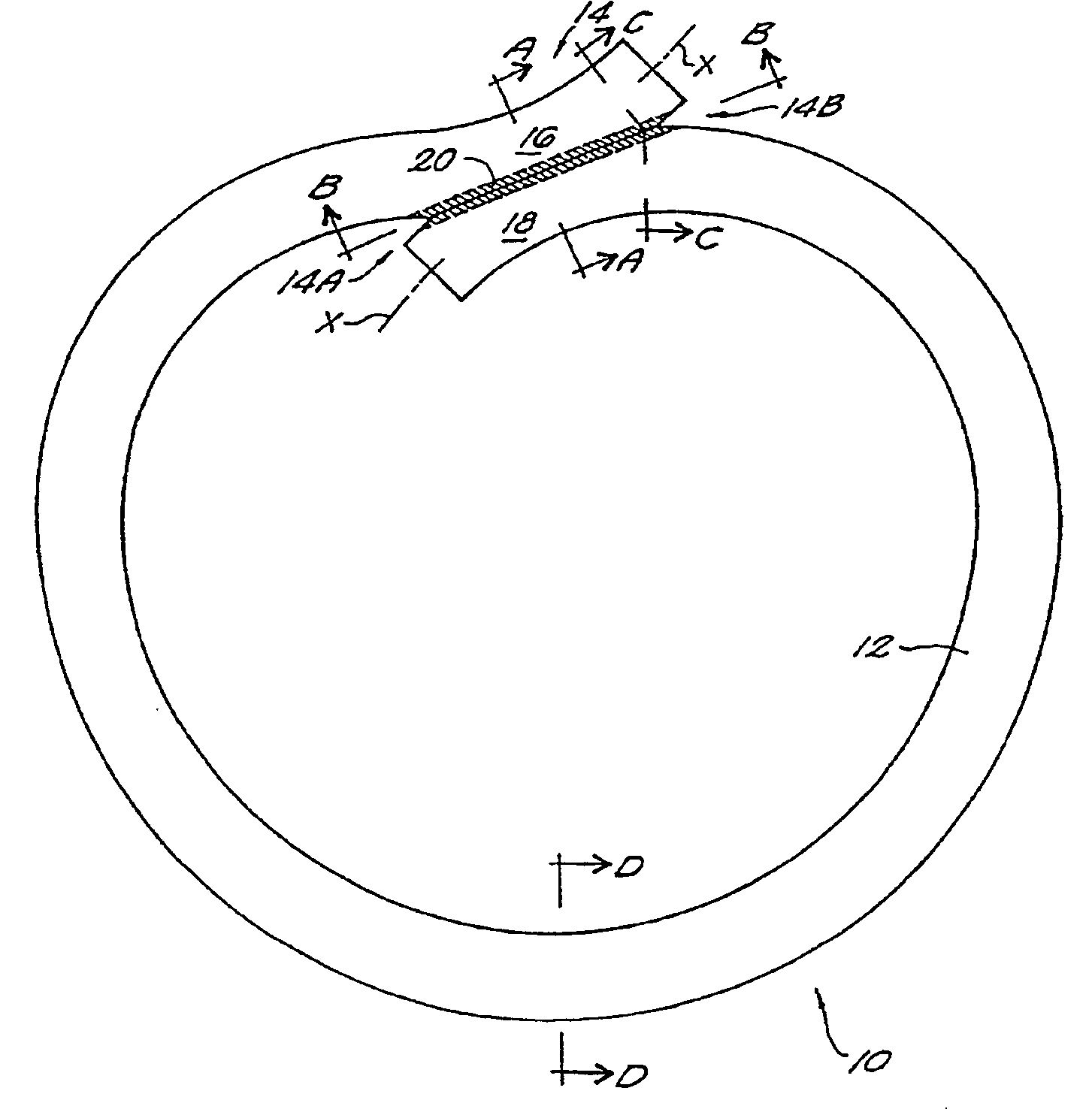

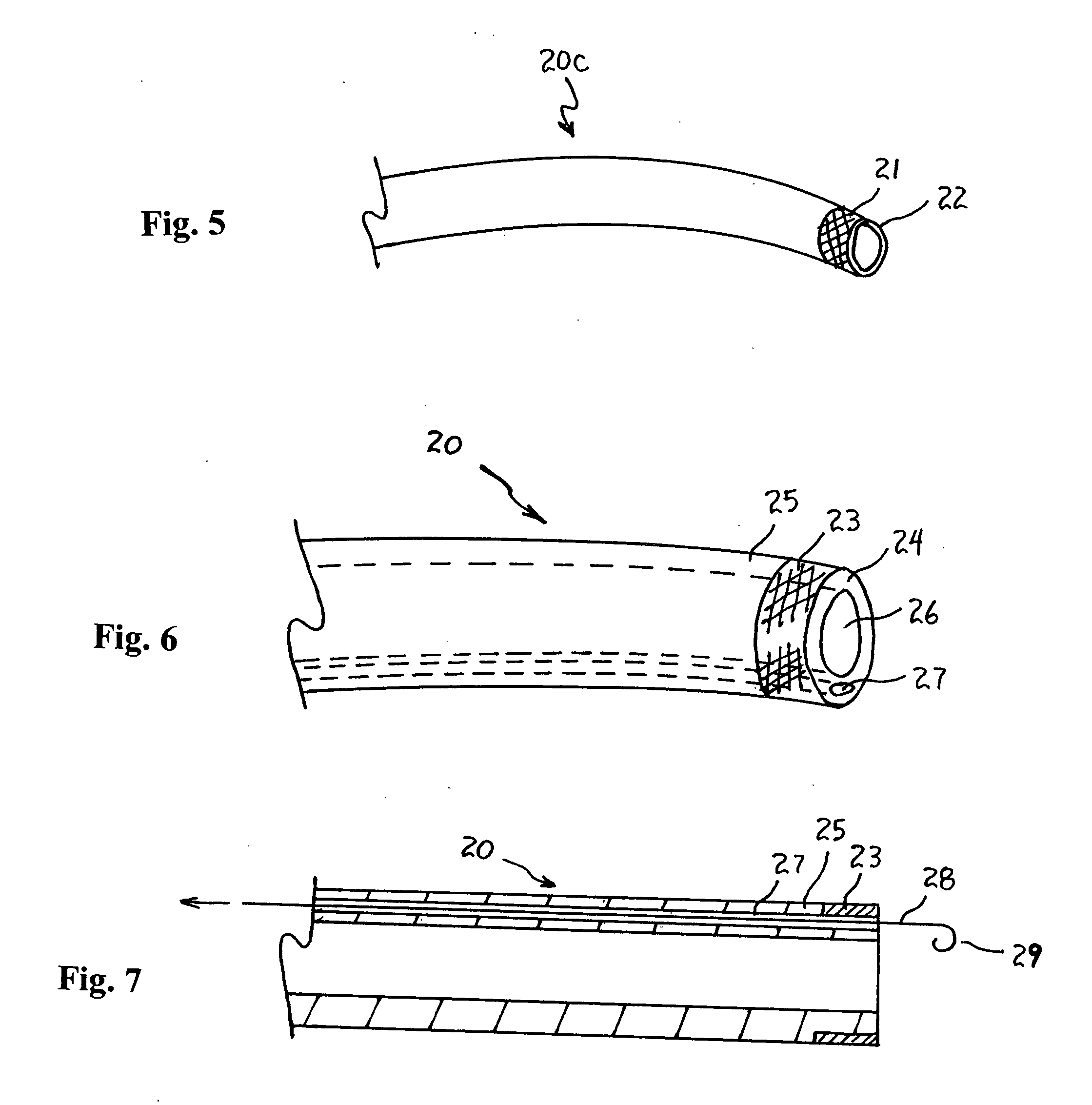

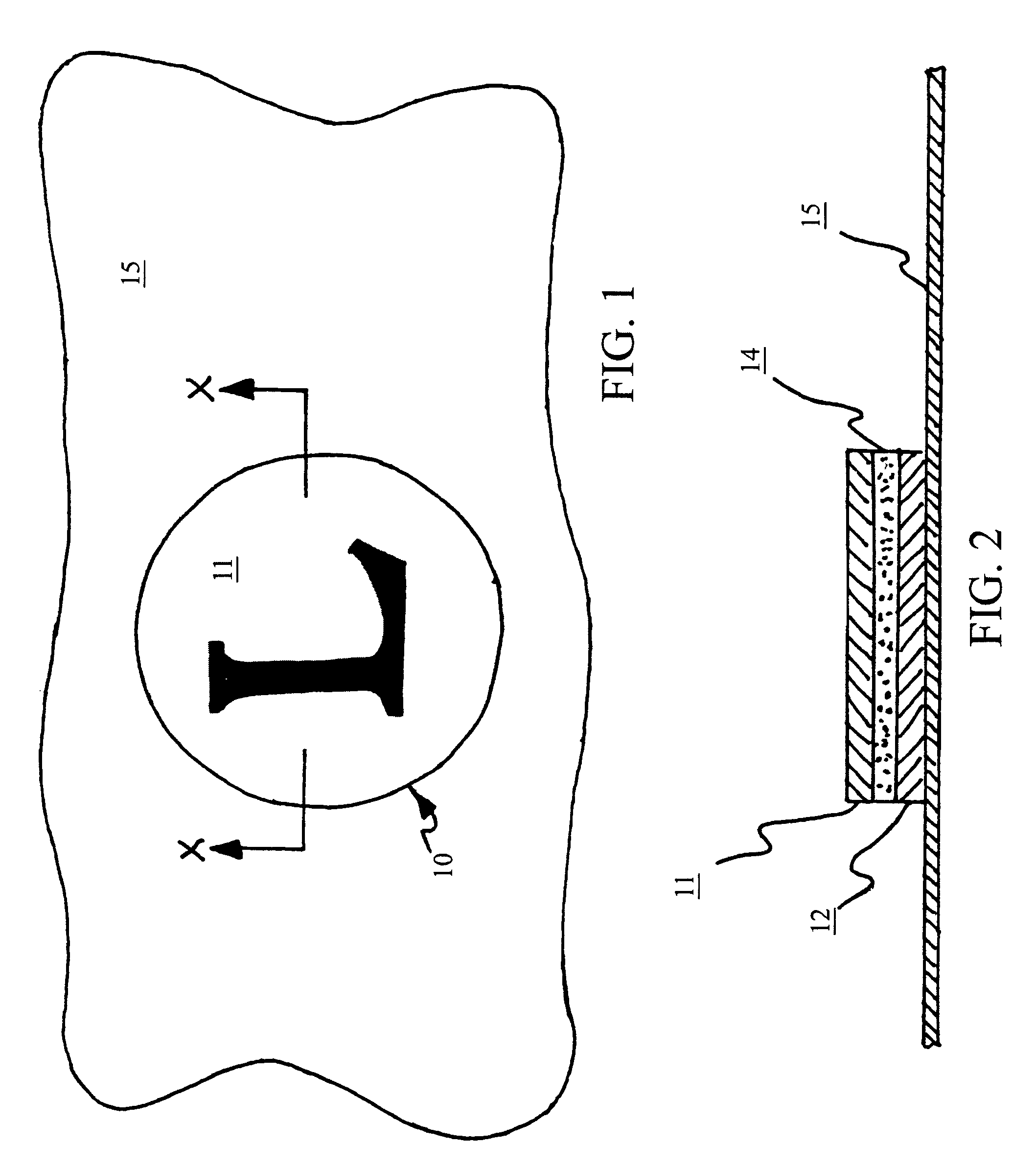

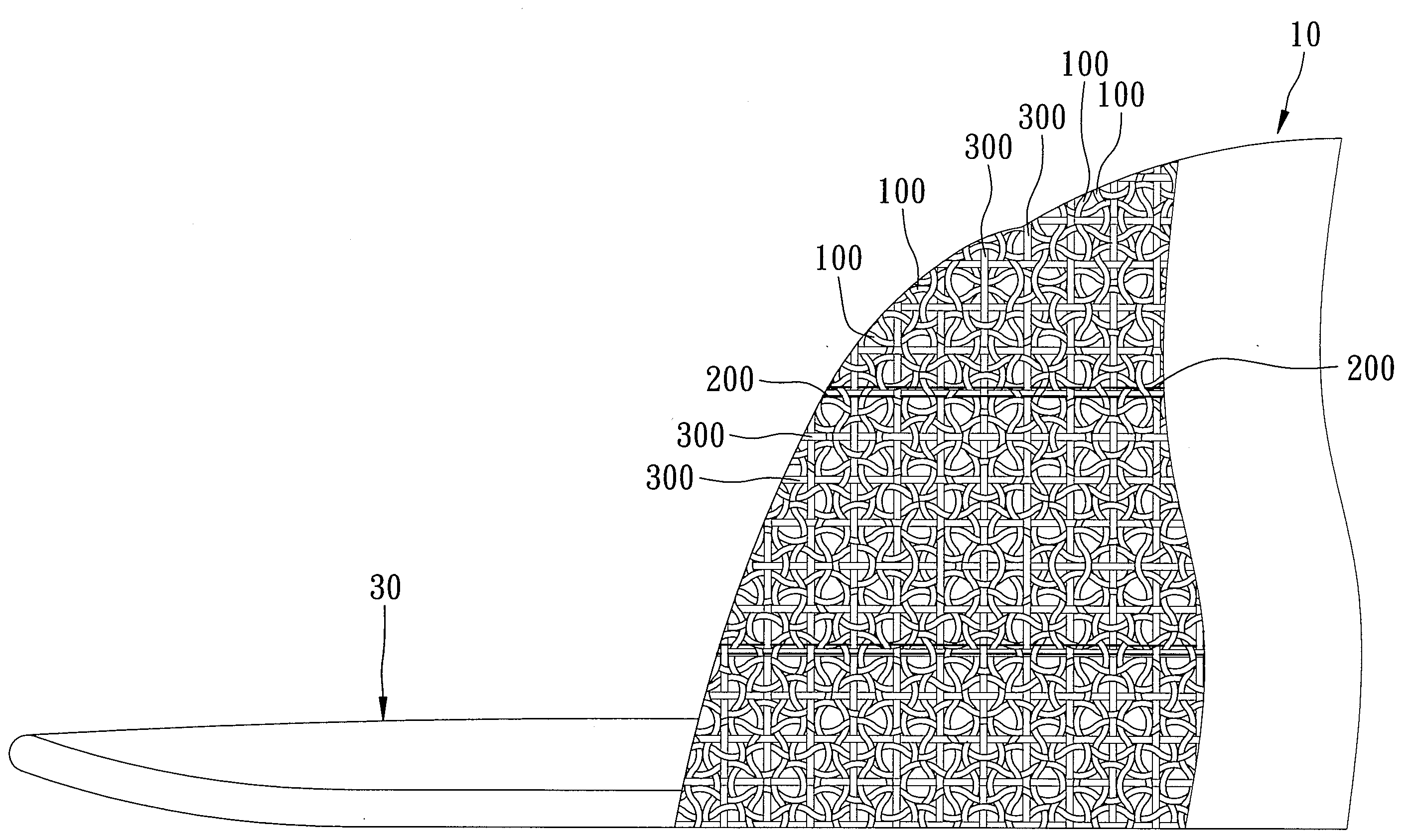

Reticulated absorbent composite

InactiveUS6969781B2Promote absorptionImprove acquisitionLayered productsBaby linensElastic fibresFiber

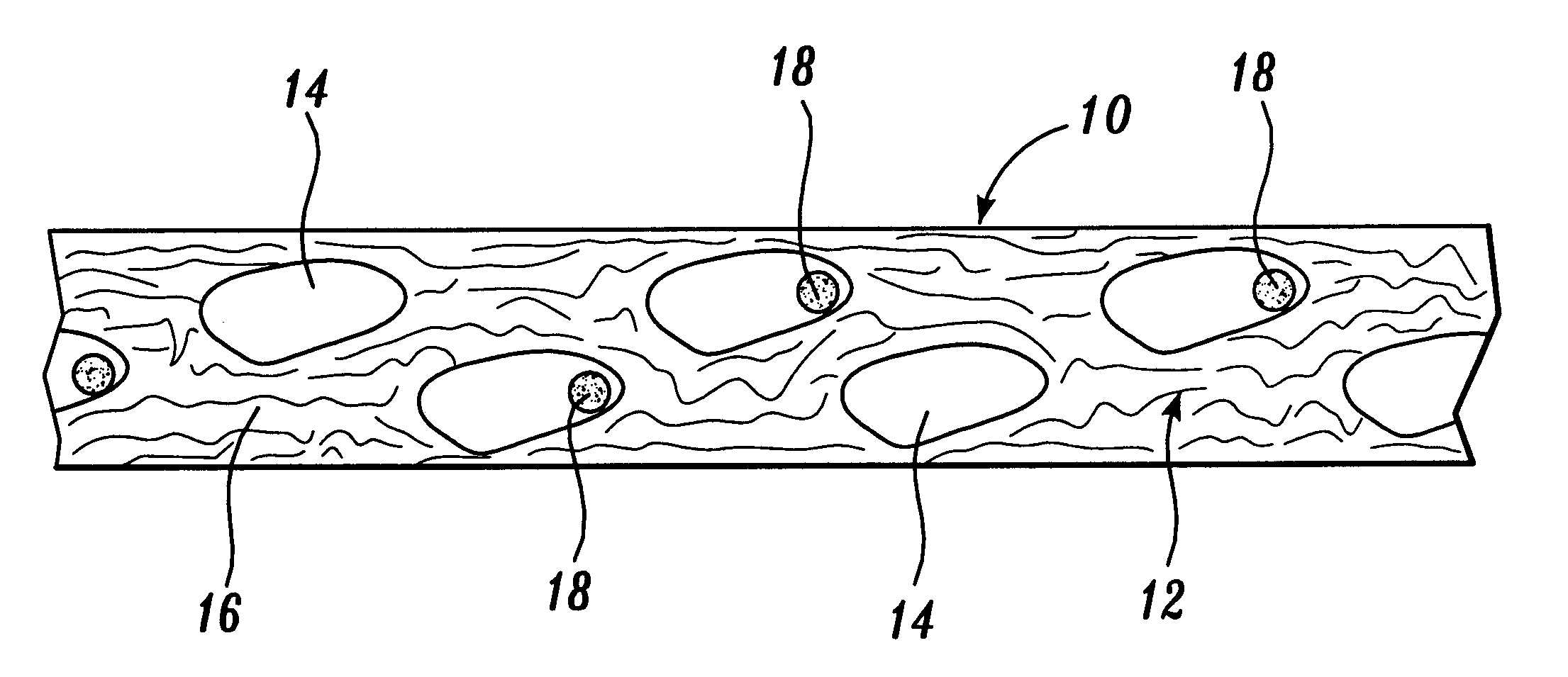

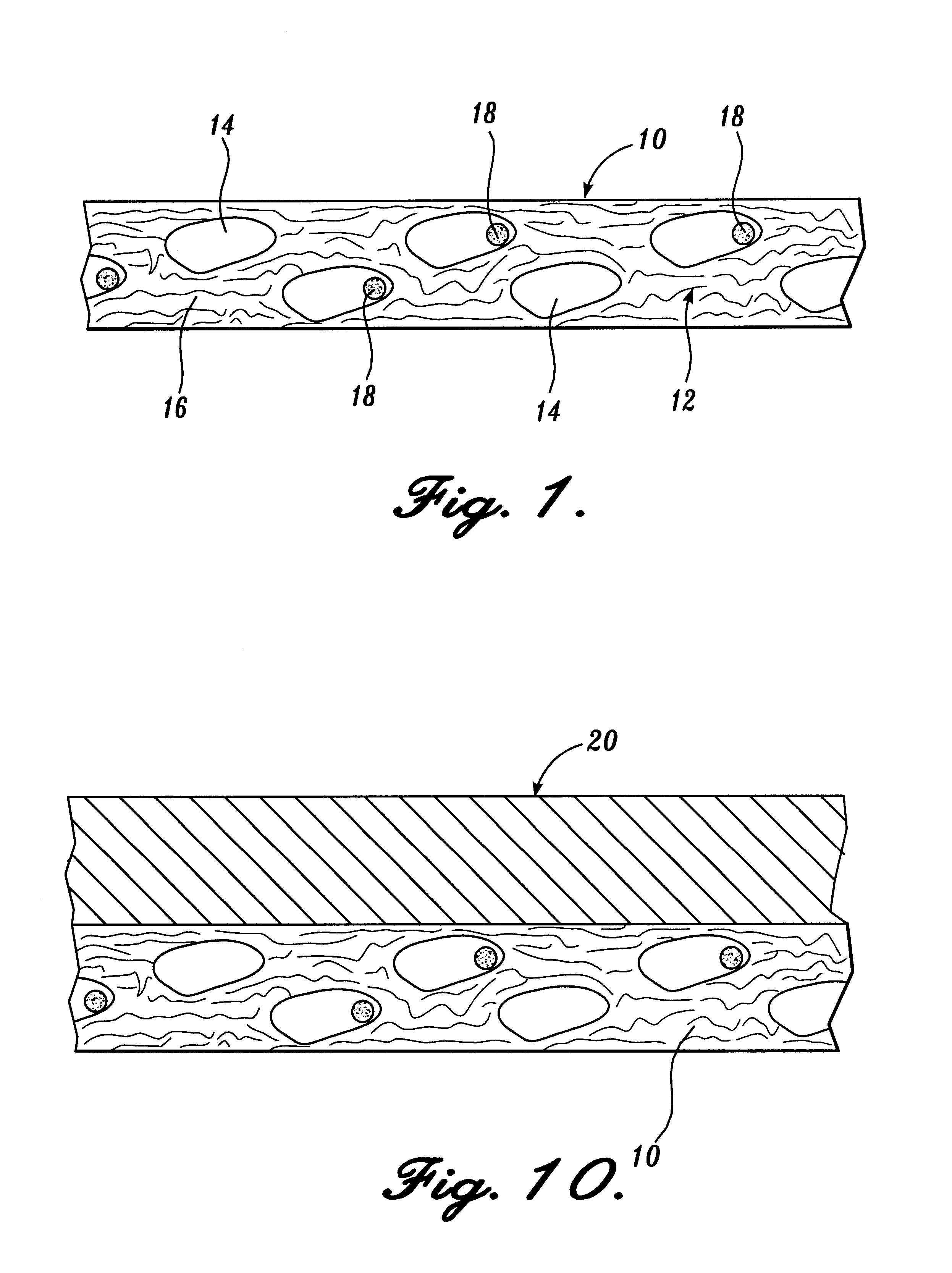

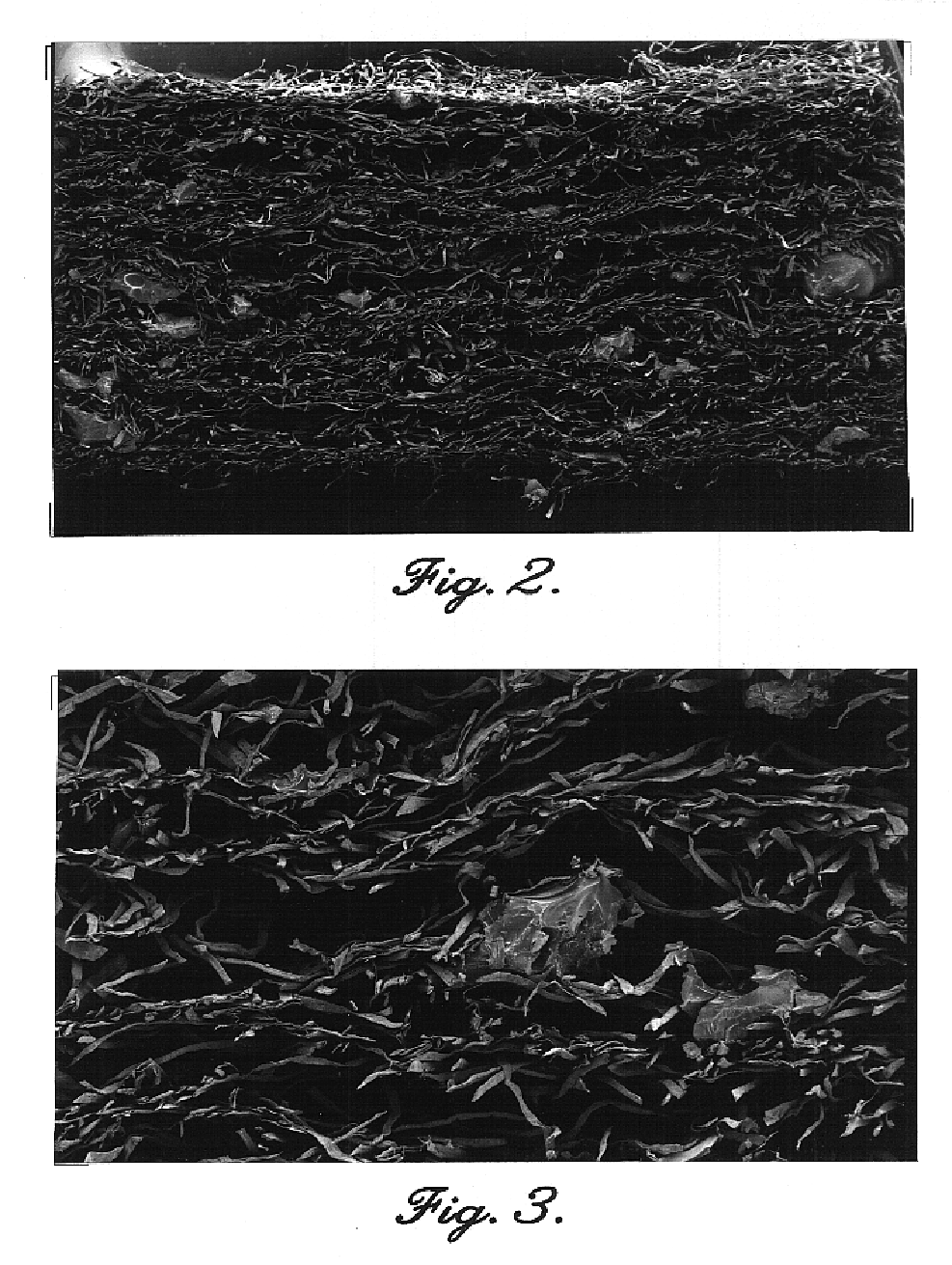

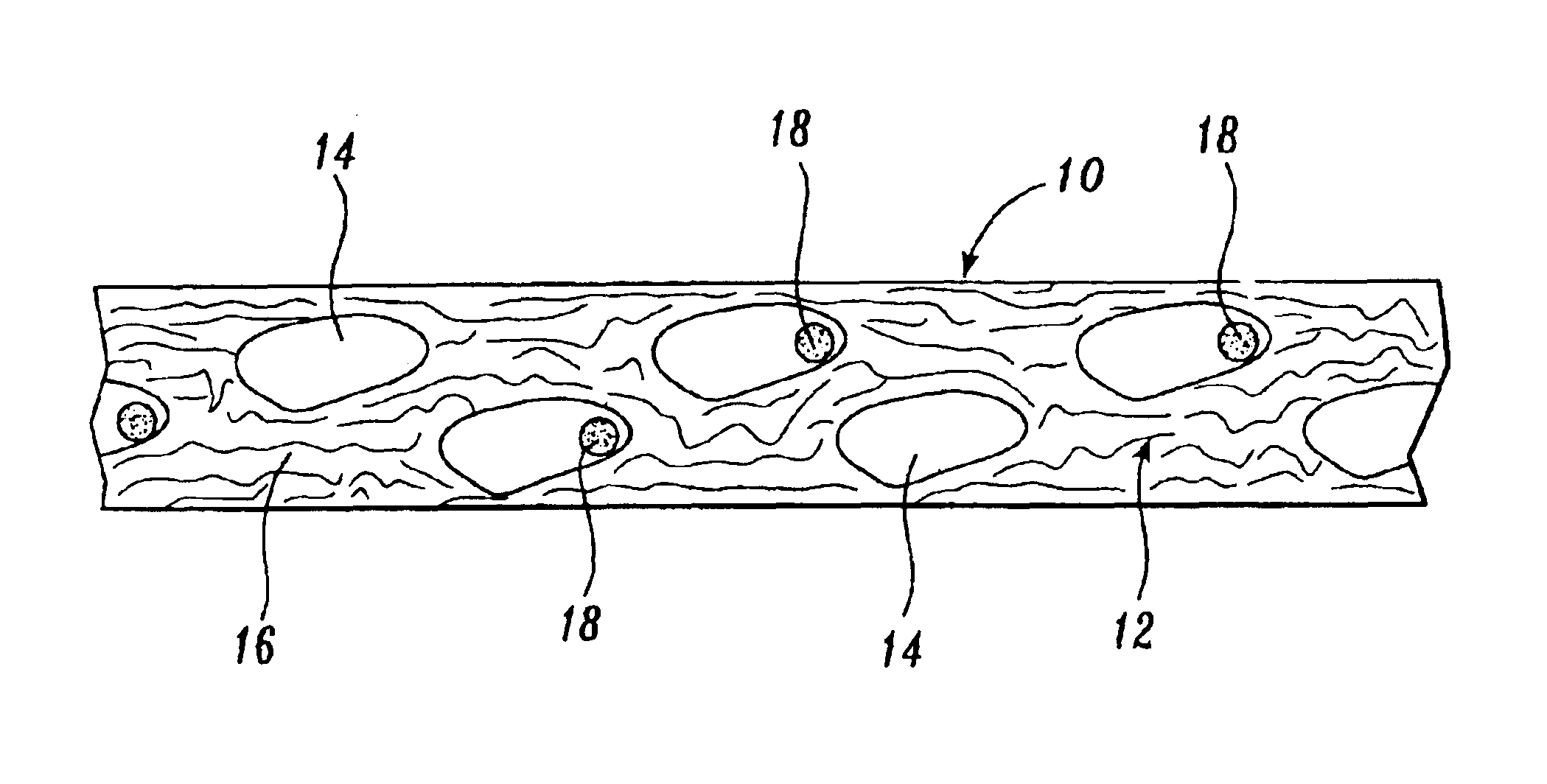

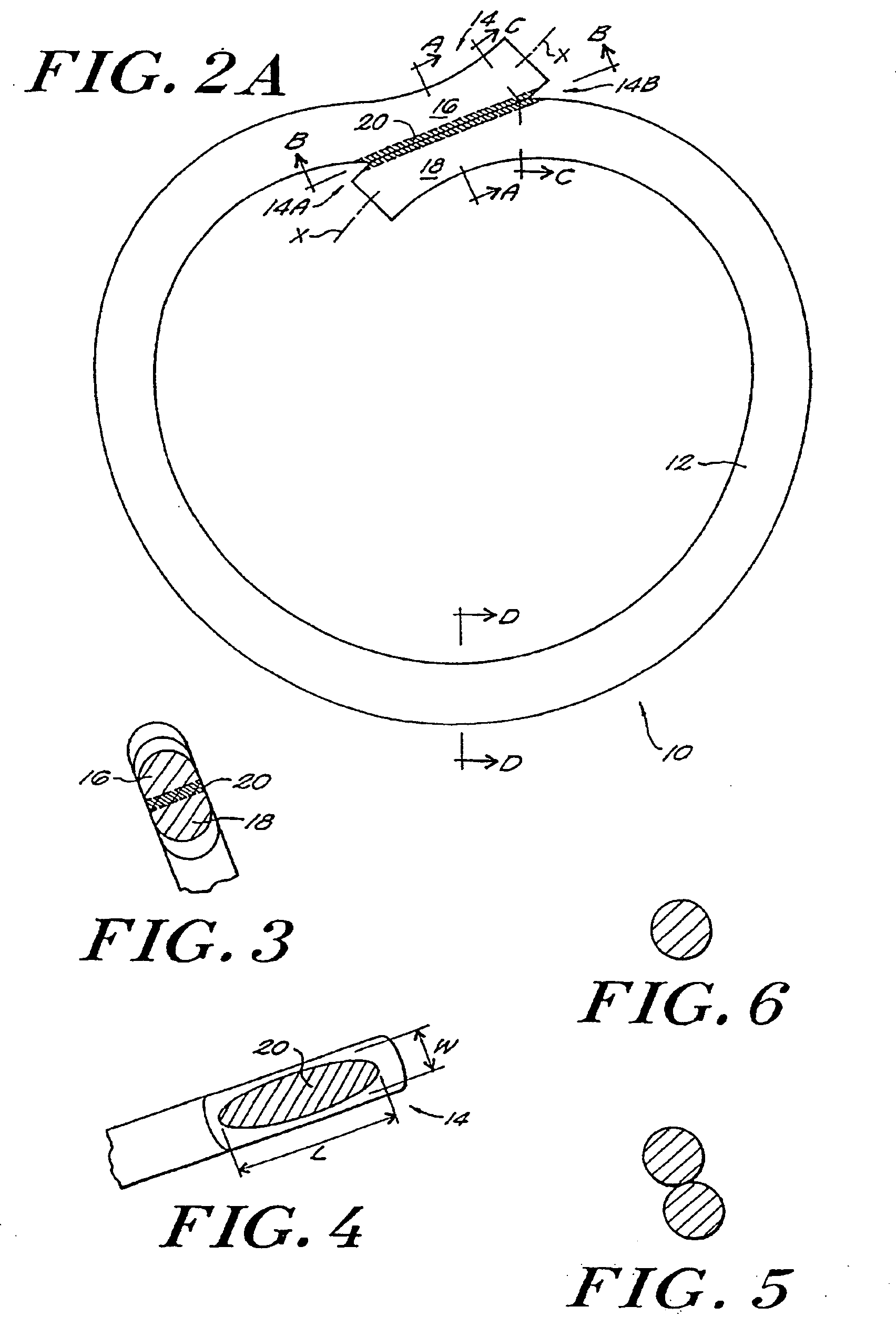

An absorbent composite (10) having a fibrous matrix that includes absorbent material is disclosed. The fibrous matrix defines voids (14) and passages between the voids, which are distributed throughout the composite. Absorbent material (18) is located within some of the voids (14). Absorbent material located in these voids is expandable into the void. In a preferred embodiment, the composite's fibrous matrix includes resilient and matrix fibers (16). The composite optionally includes a wet strength agent.

Owner:NAT INST FOR STRATEGIC TECH ACQUISITIONS & COMMLIZATION

Reticulated absorbent composite

InactiveUS6962645B2Promote absorptionImprove acquisitionCellulosic pulp after-treatmentNon-fibrous pulp additionElastic fibresFiber

An absorbent composite (10) having a fibrous matrix that includes absorbent material is disclosed. The fibrous matrix defines voids (14) and passages between the voids, which are distributed throughout the composite. Absorbent material (18) is located within some of the voids (14). Absorbent material located in these voids is expandable into the void. In a preferred embodiment, the composite's fibrous matrix includes resilient and matrix fibers (16). The composite optionally includes a wet strength agent.

Owner:NAT INST FOR STRATEGIC TECH ACQUISITIONS & COMMLIZATION

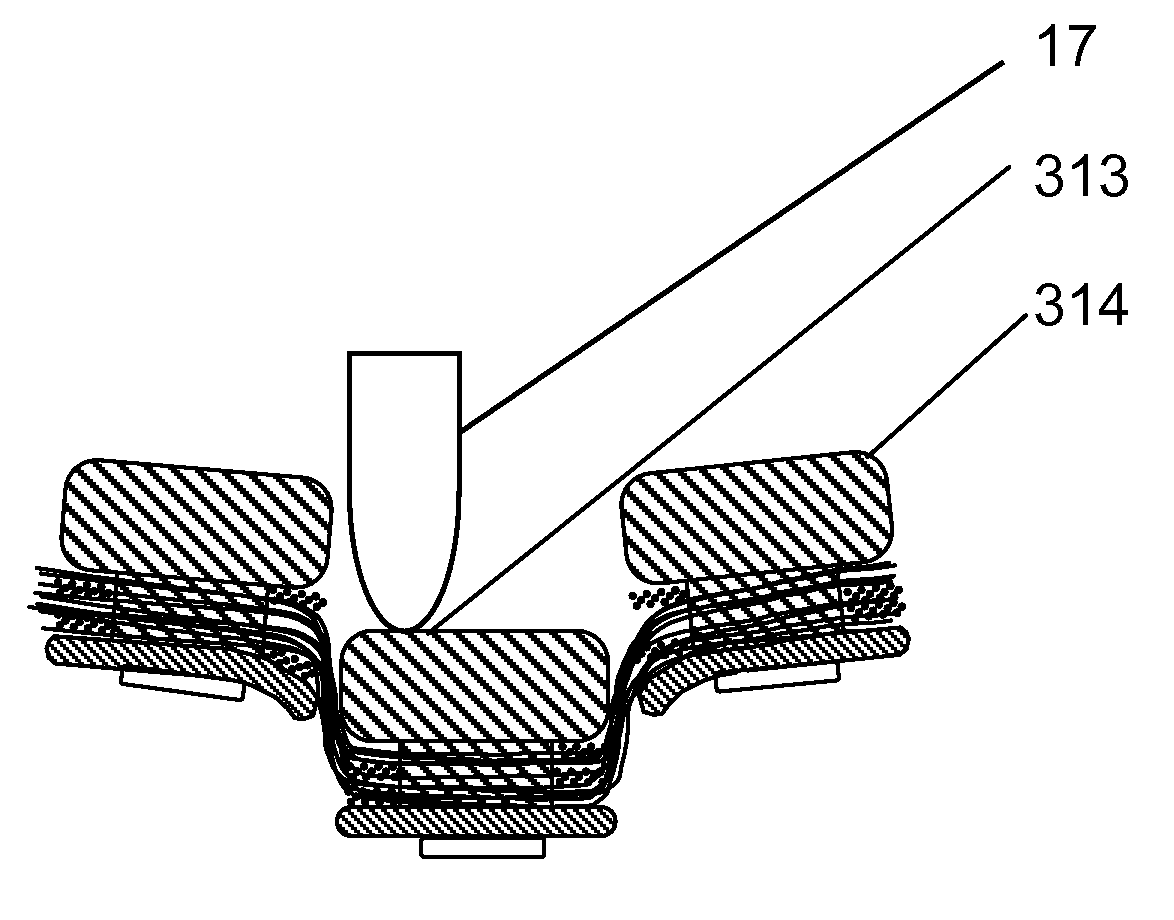

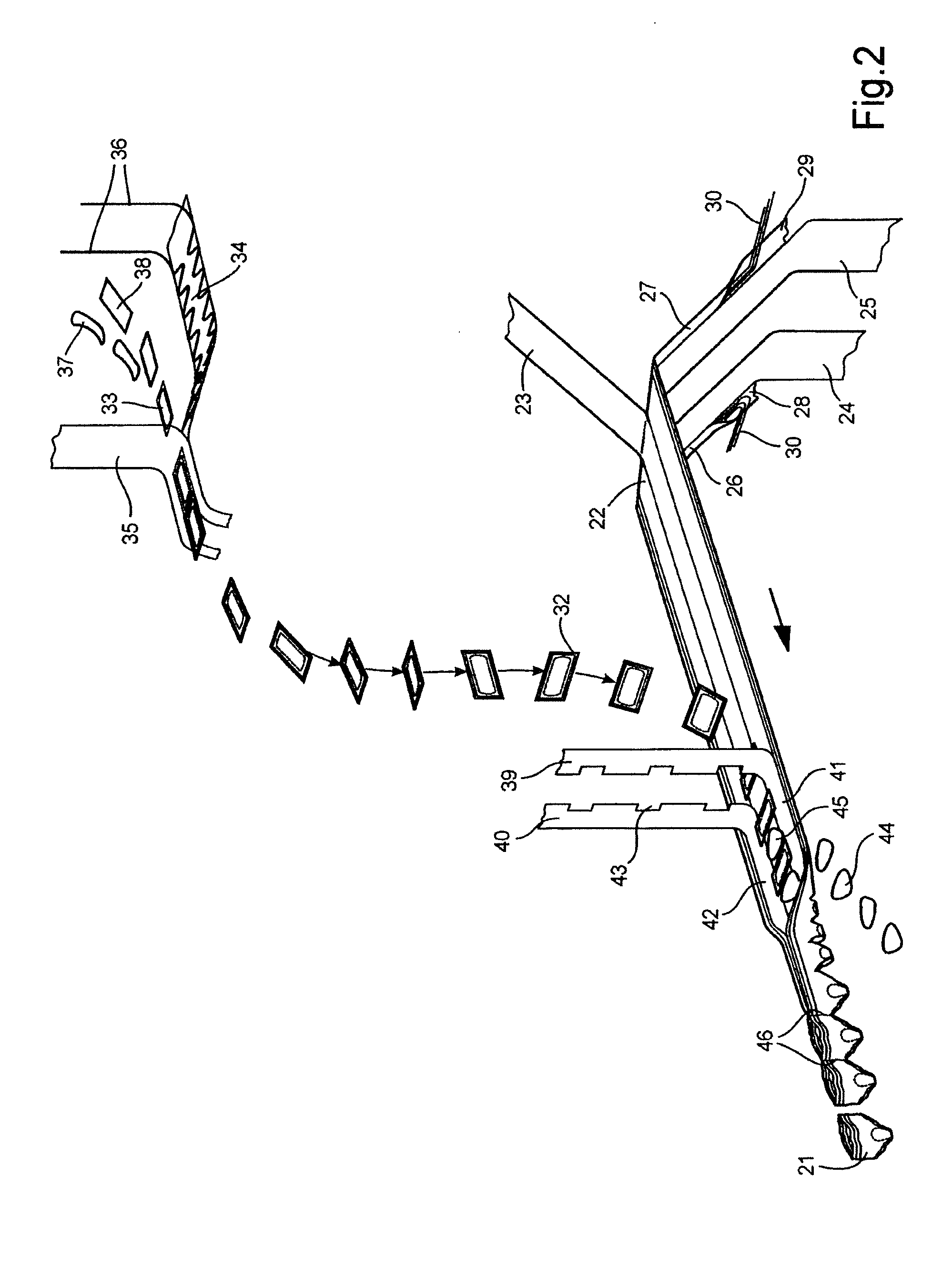

Method And Apparatus For Protecting Against Ballistic Projectiles

InactiveUS20080307553A1Slow downAvoid relative motionPersonal protection gearArmour platesFiberElastic fibres

A composite material comprising a multitude of masses and fibers supported on a flexible substrate arranged in a manner to absorb energy from a ballistic projectile and thereby protect persons or property from ballistic injury or damage. An array of small, tough disc-like masses are suspended in a three dimensional cradle of high-tensile elastomeric fibers such that energy from an incoming ballistic projectile is first imparted to one or more masses and the motion of the masses are restrained by tensile strain of elastomeric fibers substantially in the direction of travel of the incoming projectile. The projectile is eventually decelerated to harmless velocity through a combination of transfer of momentum to the masses and the elastic and plastic tensile deformation of the fibers. One or more layers of the composite material can be assembled to form body protective armor (“bullet-proof vest”) or property protective armor, the number and characteristics of the layers being adjusted according to the specific ballistic threat anticipated.

Owner:ENERGY SCI

Hemostatic microfibrous constructs

Elastomeric fibrous constructs are formed from multicomponent, non-woven nano- / microfibers having a core and sheath configuration made primarily of an absorbable polymer and preferably a water-soluble one, respectively. Most preferably, the nano- / microfibers are produced by electrostatic spinning. Depending on clinical use of these constructs, suitable bioactive agents can be incorporated into the construct.

Owner:POLY MED

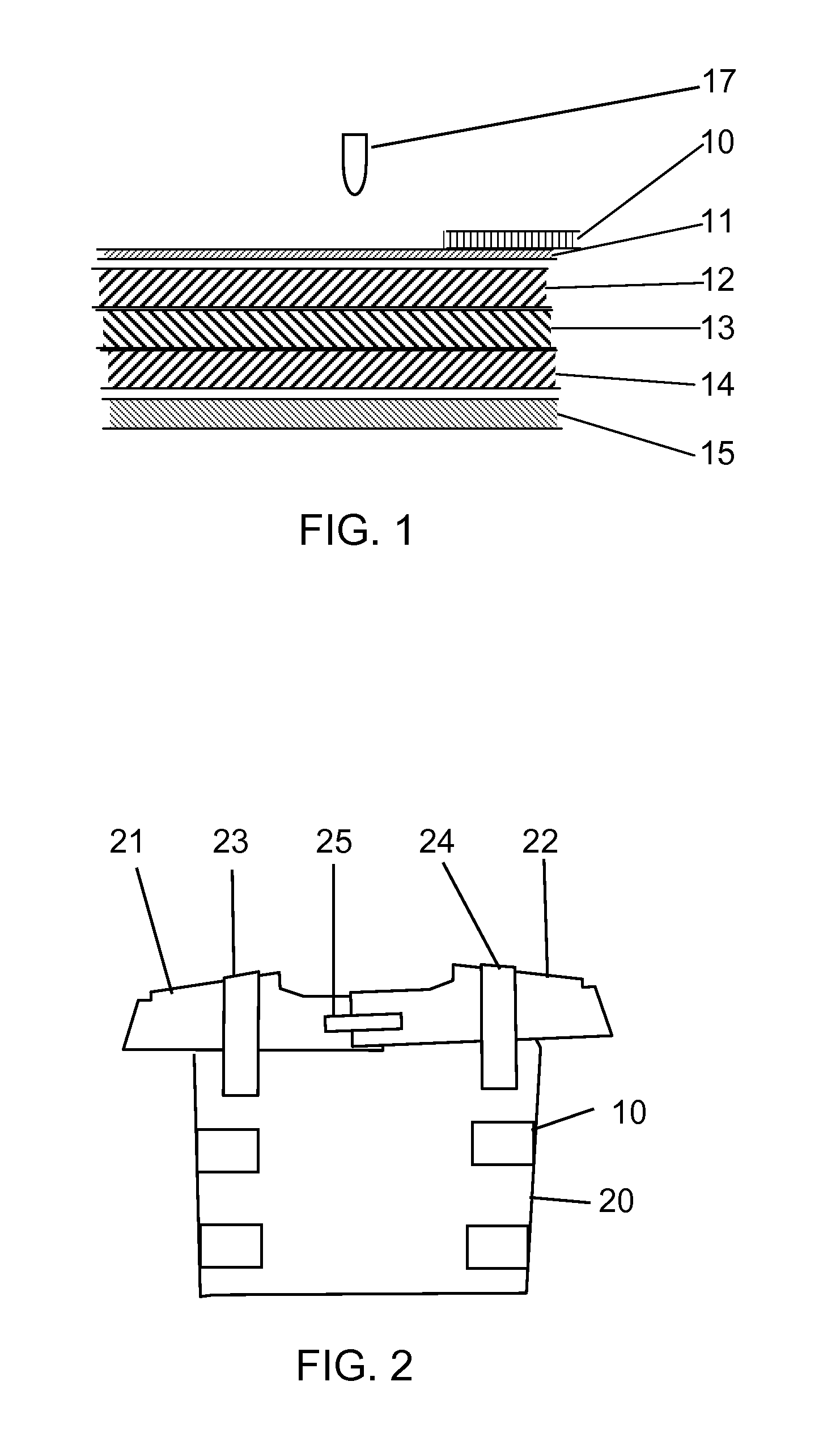

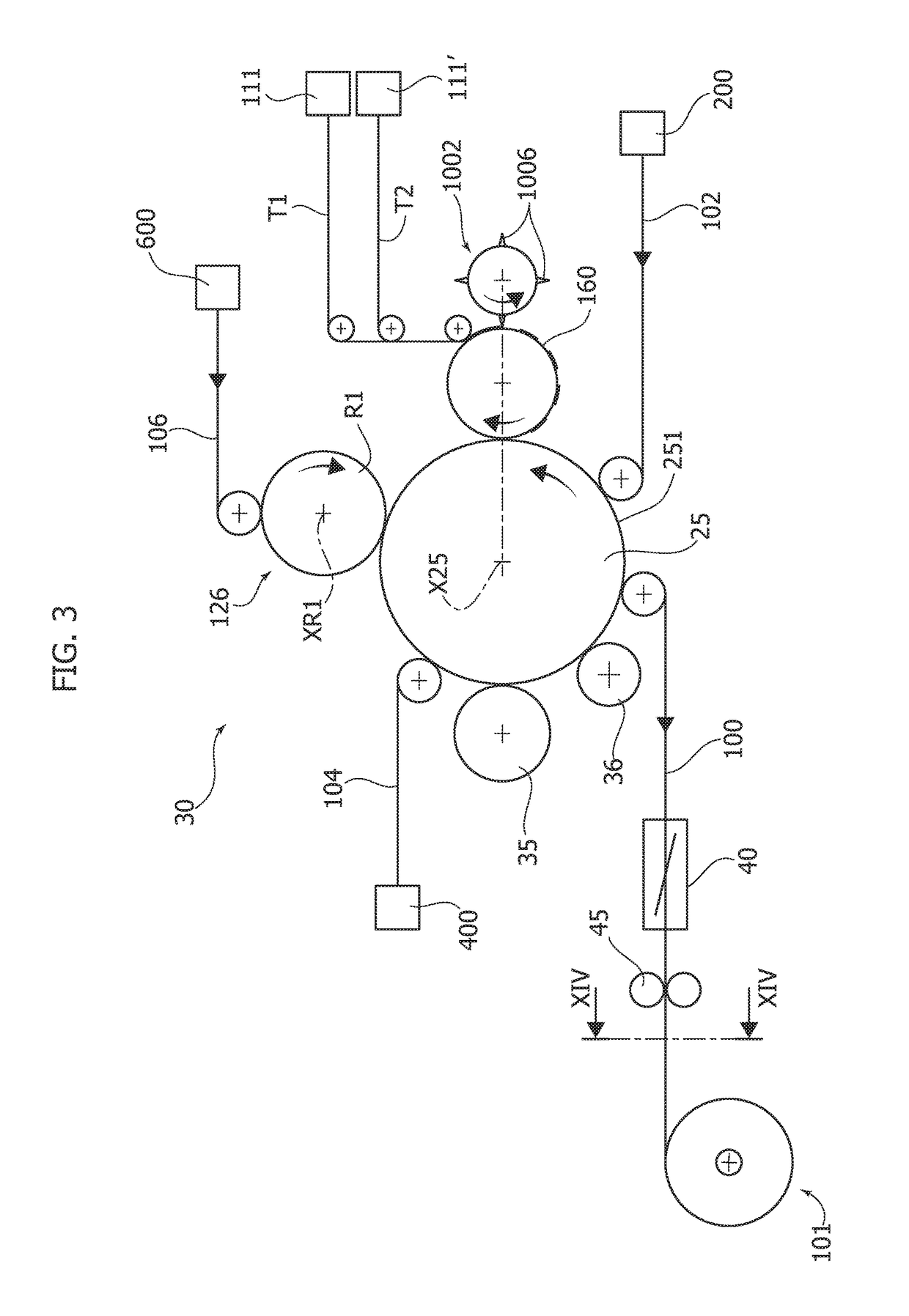

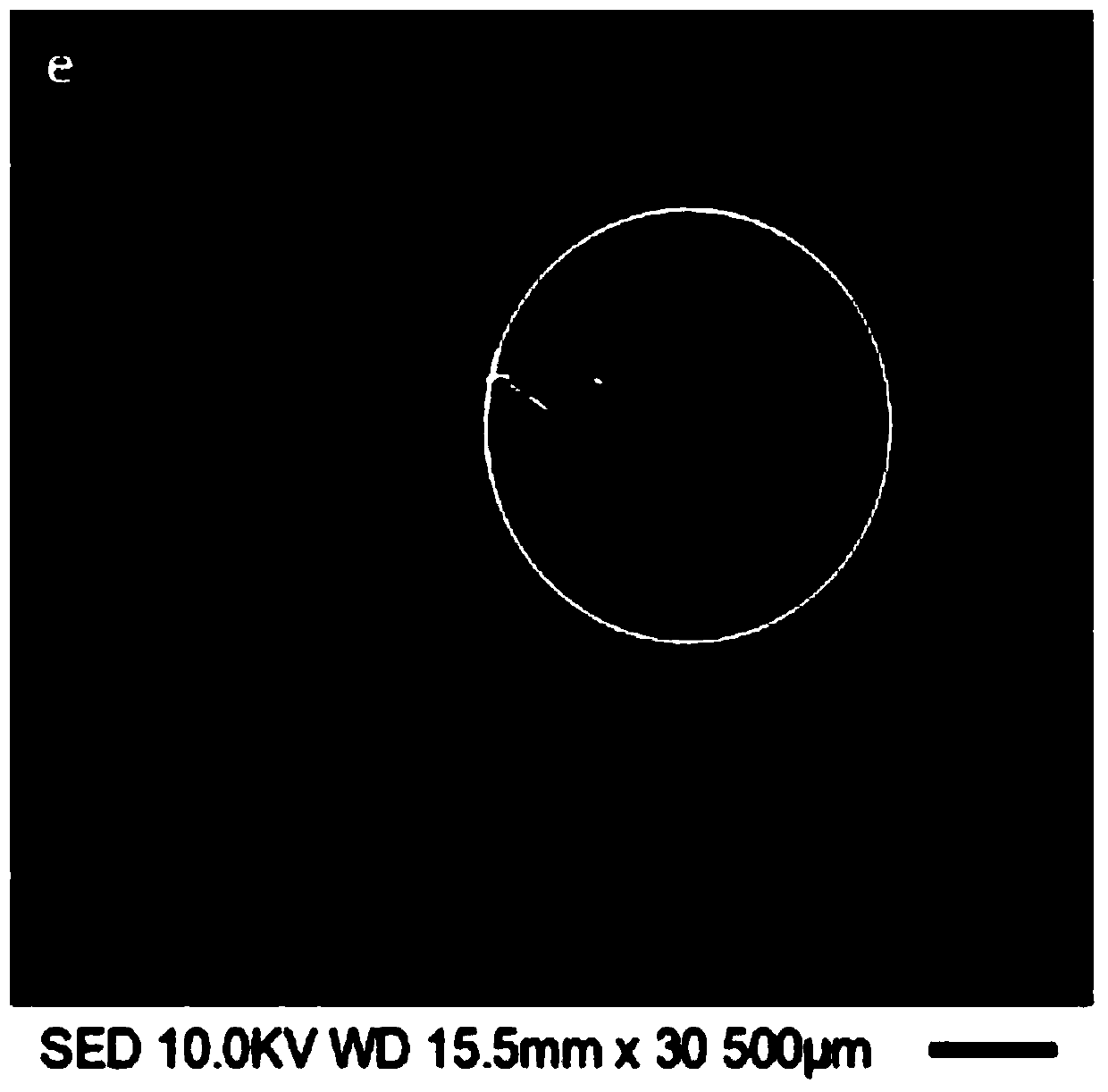

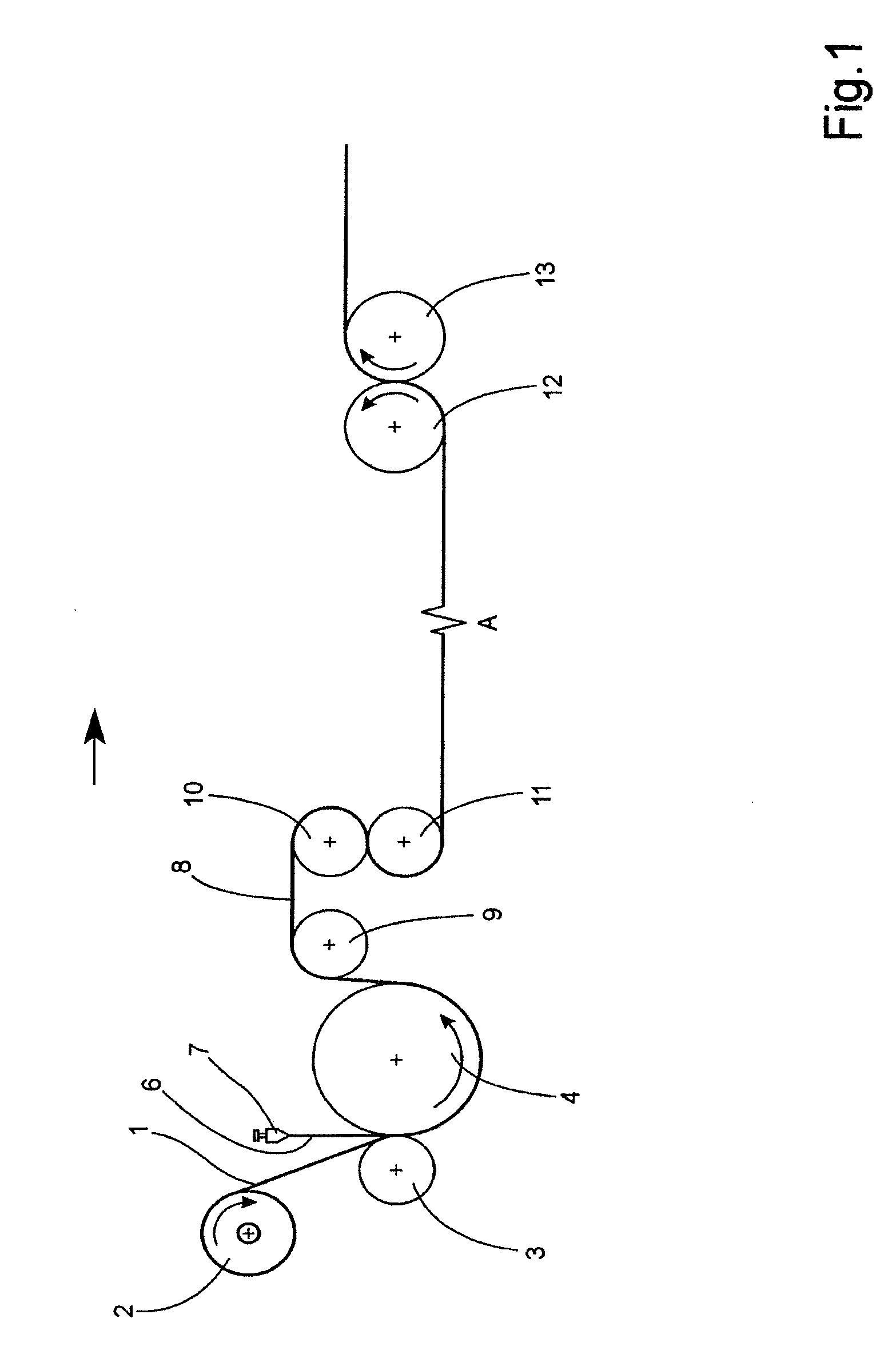

Pant-type absorbent article and a method for producing pant-type absorbent articles

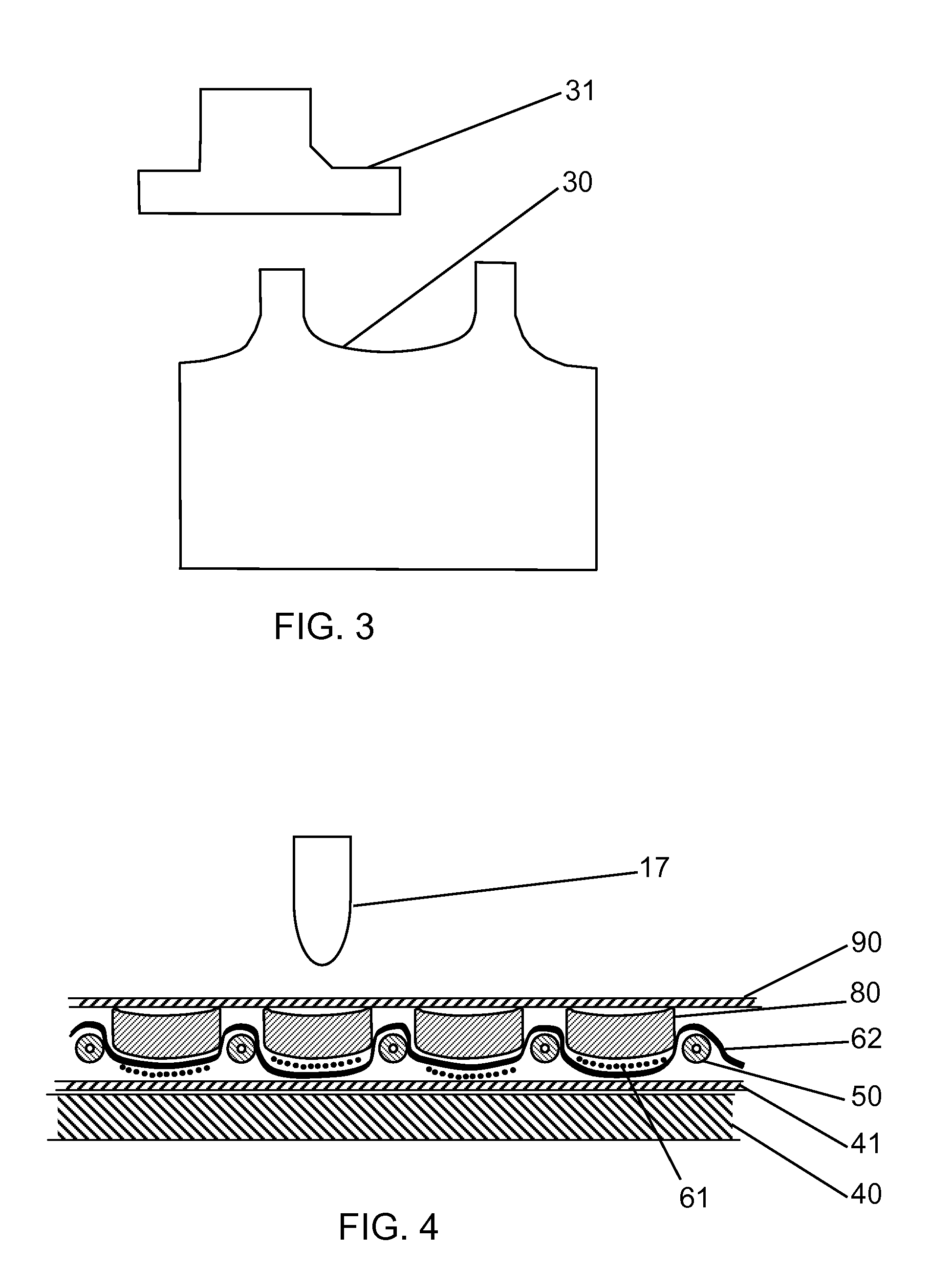

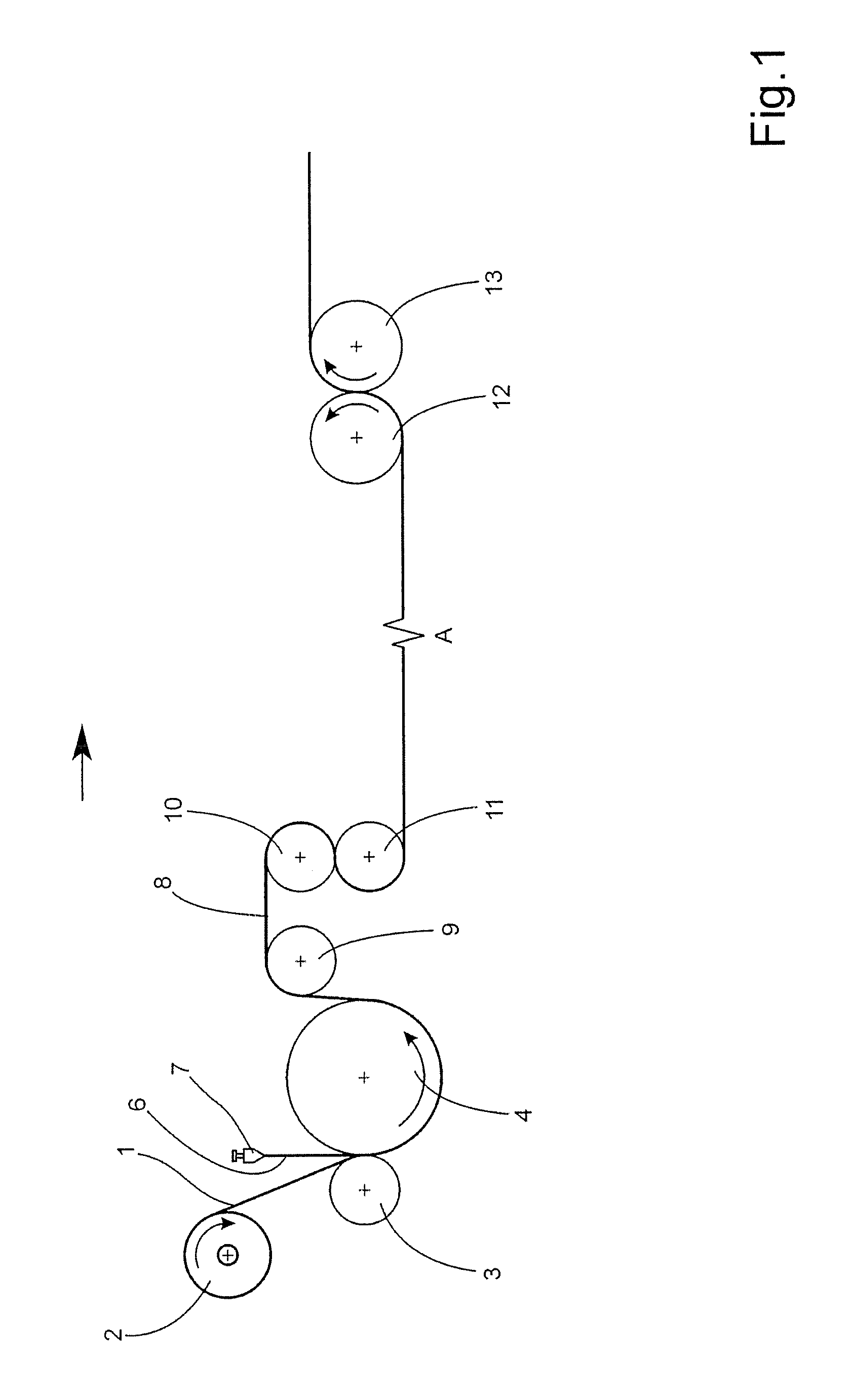

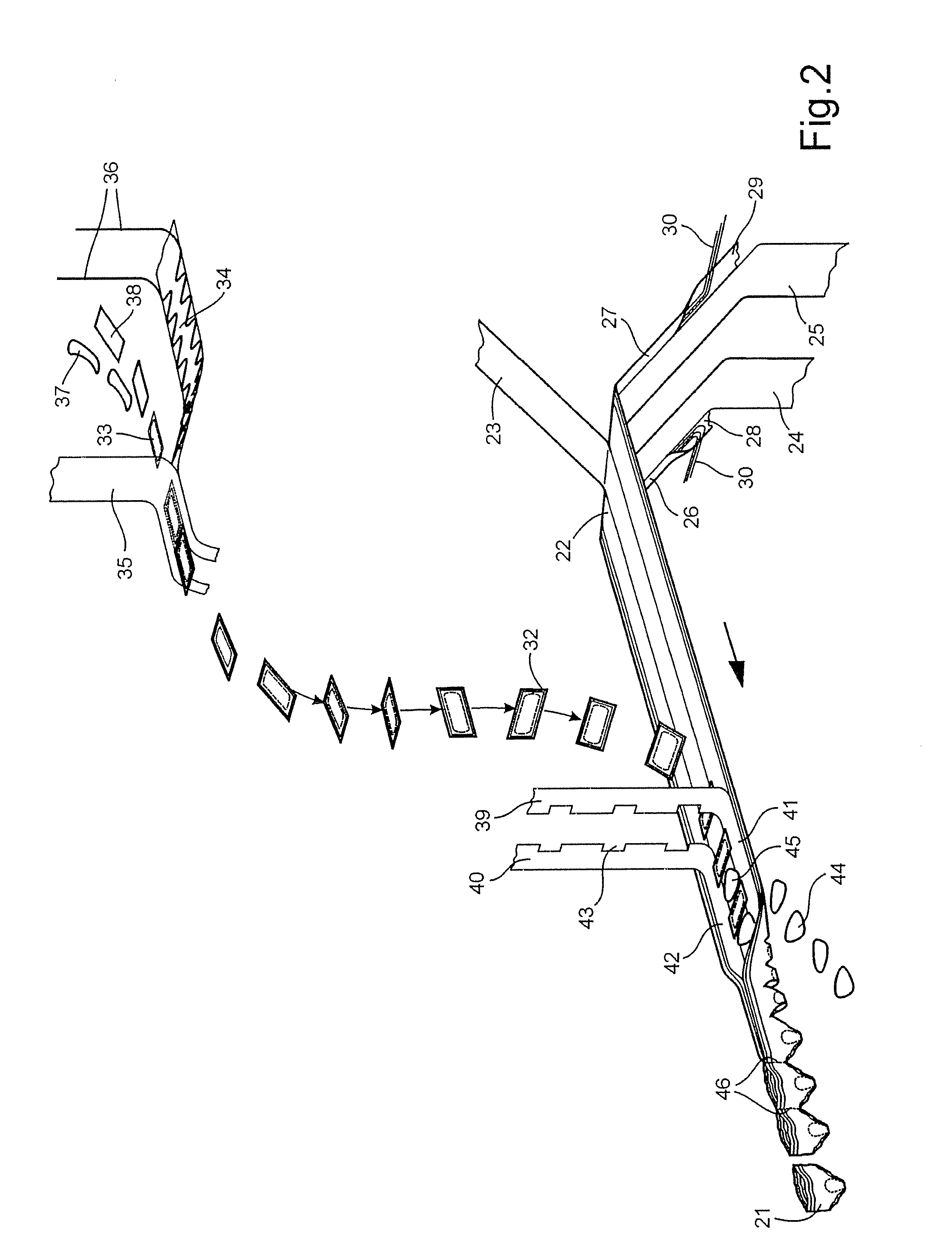

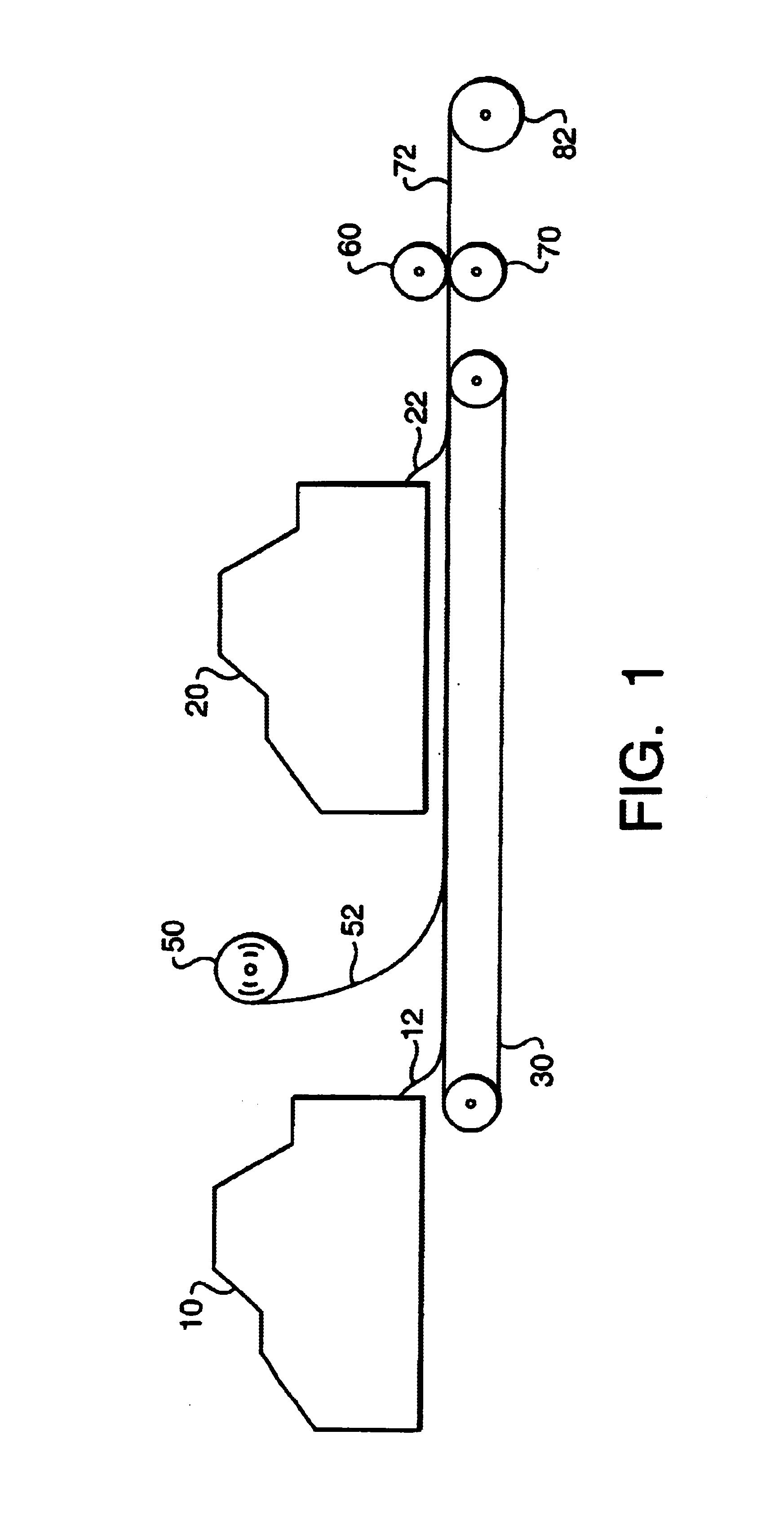

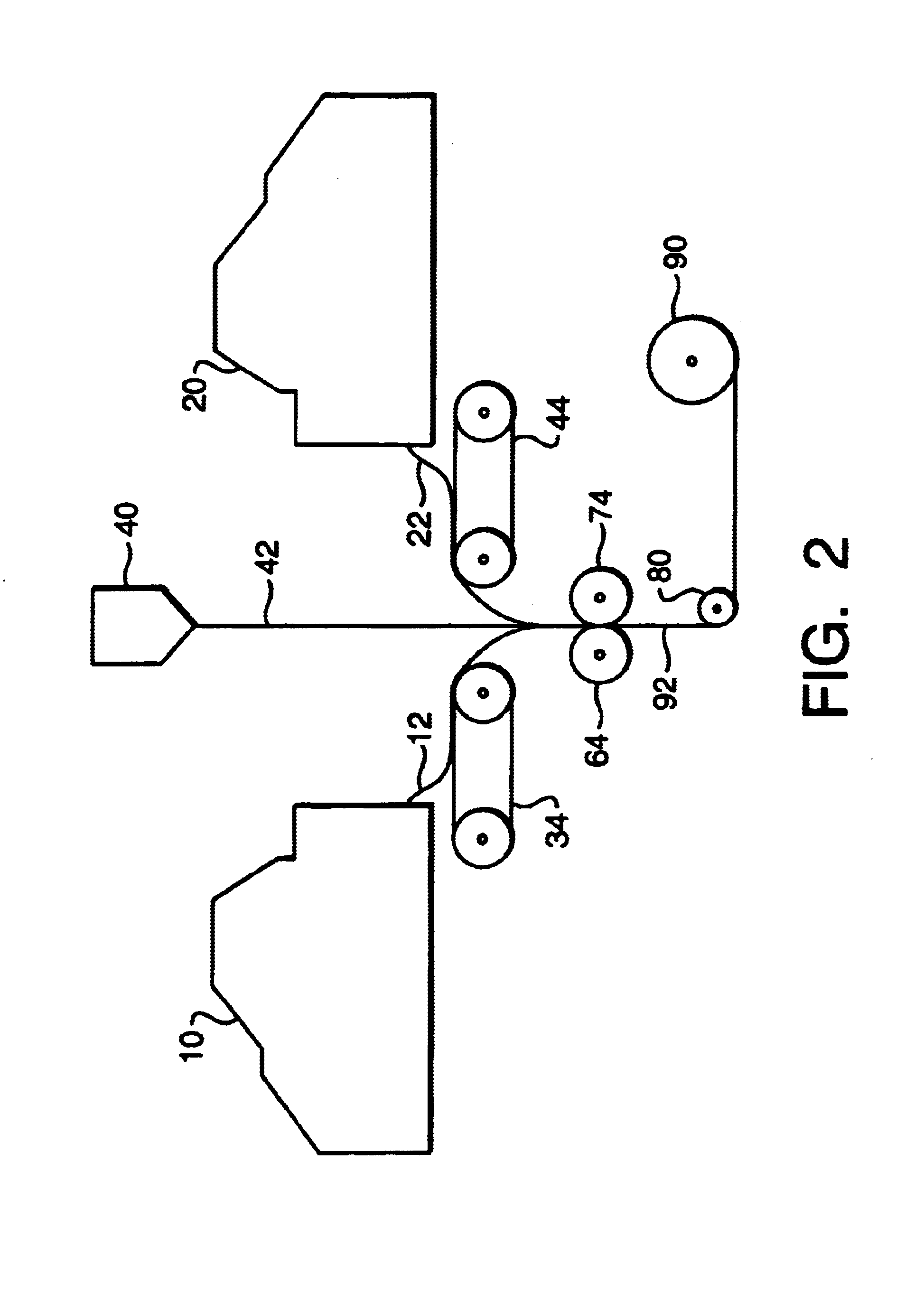

InactiveUS20090326503A1Improved tensile strength in the elastic parts of the pant chassisIncrease resistanceMechanical working/deformationLamination ancillary operationsElastic fibresCore component

A method for producing pant-type absorbent articles, each article including a chassis structure having at least one elastic panel and an integrated absorbent core component, the method including a continuous pant-forming process including forming the chassis structure and incorporating the absorbent core component into the chassis structure. The at least one elastic panel is formed by a) separately producing a two-layer laminate having a first non-elastic fibrous nonwoven web and an elastic film, b) activating the two-layer laminate by incremental stretching in at least one activation direction to render the two-layer laminate (elastically stretchable, c) stretching the activated two-layer laminate by 35-200% in the activation direction, d) introducing the two-layer laminate in the pant-forming process, and e) laminating the elastic film of the stretched two-layer laminate to an elastic or nonwoven chassis component. An absorbent pant-type article produced in accordance with the method.

Owner:ESSITY HYGIENE & HEALTH AB

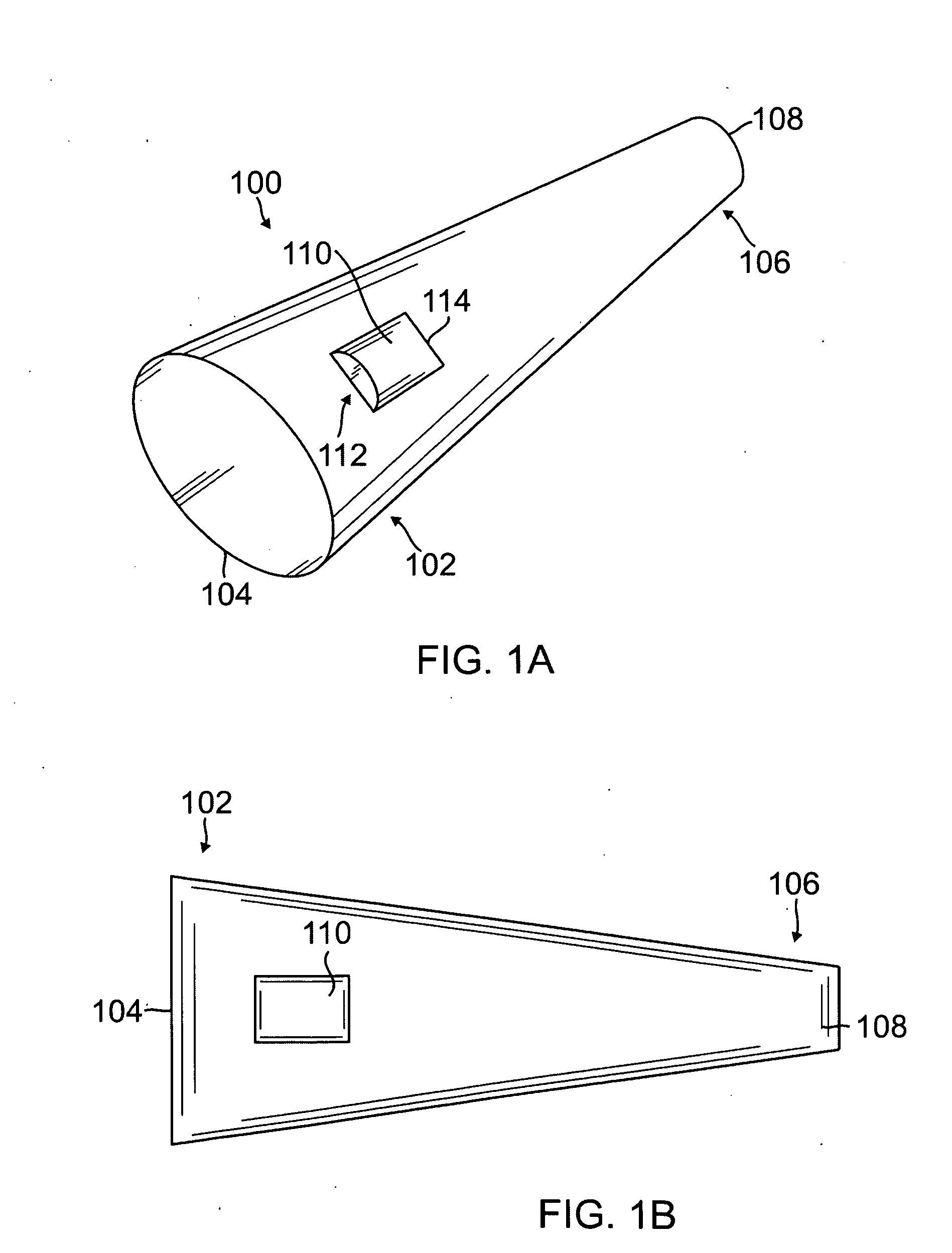

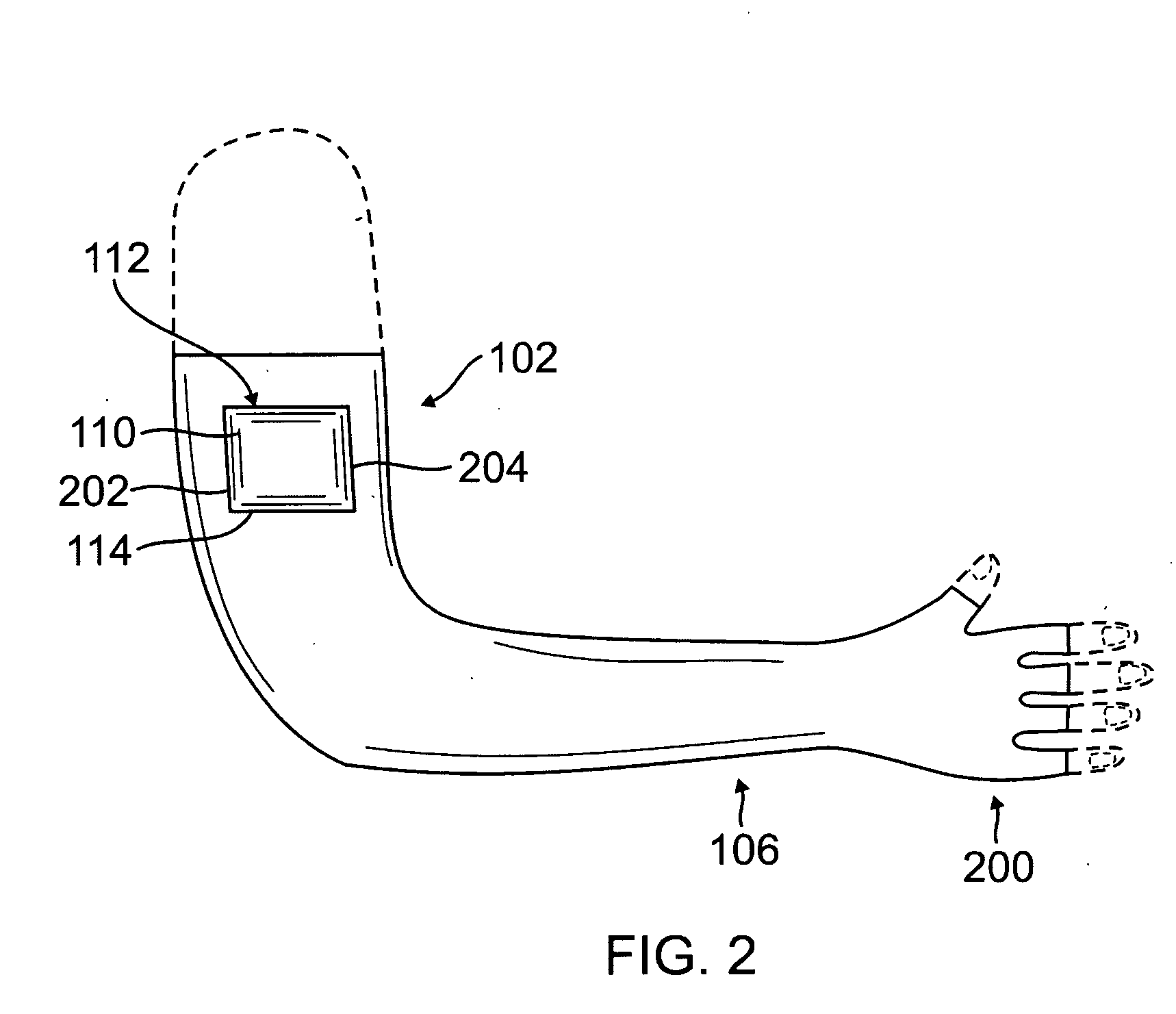

UV protected arm sleeves

An arm sleeve comprising an upper arm portion, a lower arm portion, and a pocket, wherein the arm sleeve provides protection against harmful ultraviolet rays. The arm sleeve may be made out of spandex or a combination of spandex and any one or more of bamboo, polyester, nylon, hemp, maize, lyocell, or other wood pulp based fabric, or other synthetic or natural knitted or woven fabric. The arm sleeve may also have a fastener to attach two or more arm sleeves together.

Owner:CHANGING WEIGHS

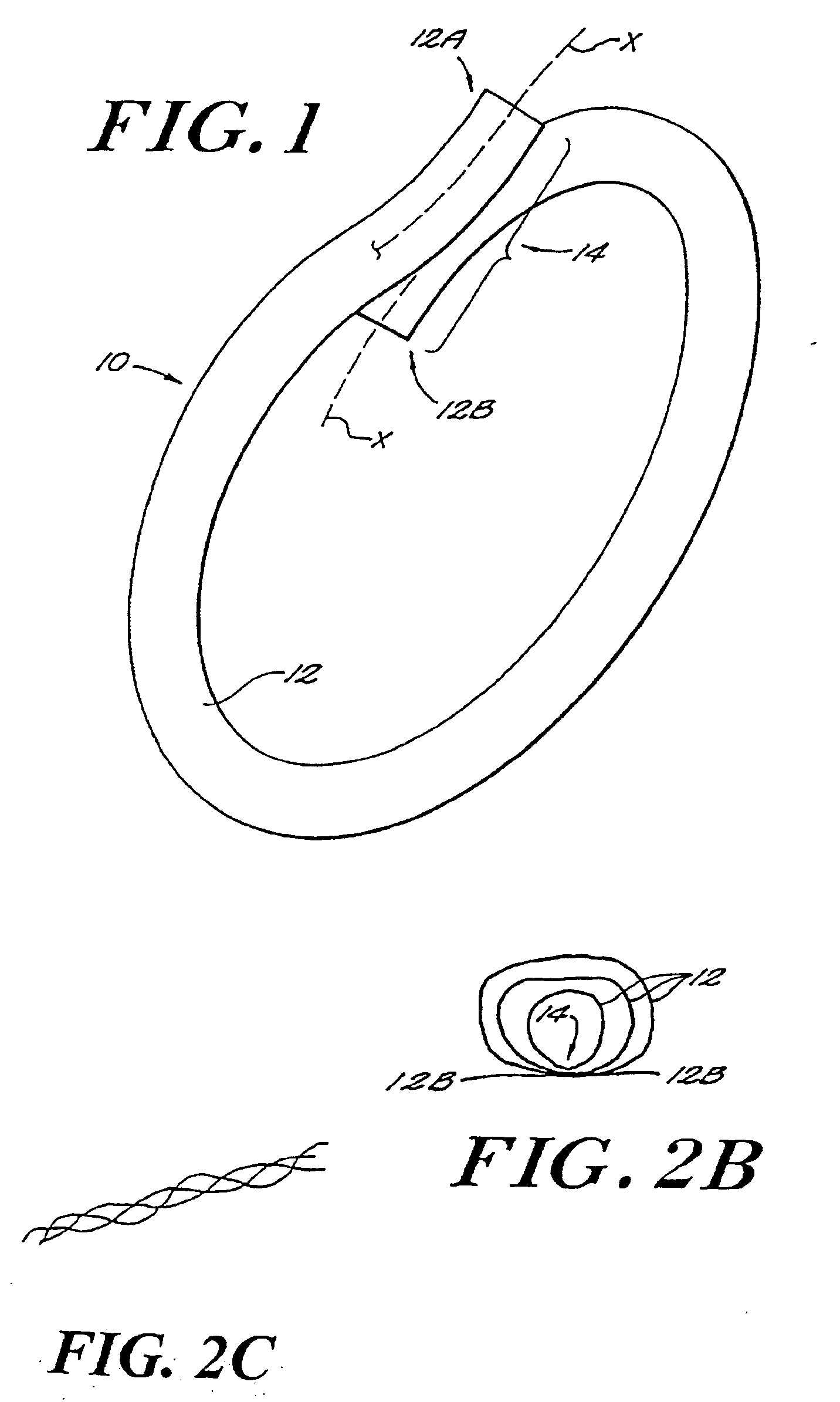

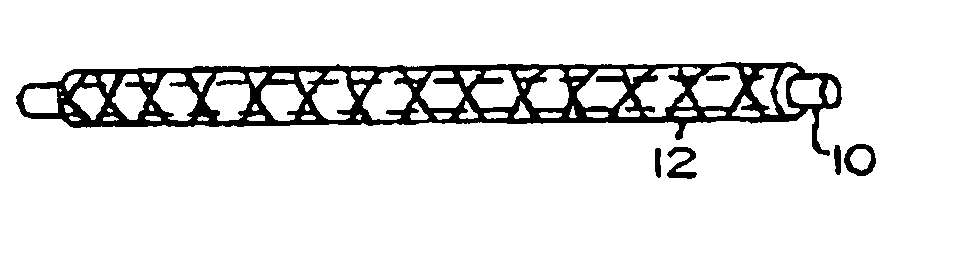

Fused loop of filamentous material and apparatus for making same

InactiveUS20050216058A1Maximize joint strengthSuture equipmentsSurgical needlesElastic fibresPolymer science

A method of forming an elastic cloth structure comprising fibers of synthetic, organic, relatively elastomeric polymer and fibers of a synthetic, organic, elongatable, but relatively nonelastic polymer. The relatively elastomeric fibers and the elongatable but relatively nonelastic fibers are forwarded for well dispersed random lay down of an unbonded web with random fiber crossings on a porous forming surface. Some of the fiber crossings are then bonded to provide a coherent bonded cloth web and the web is stretched to elongate some of the fibers in at least one direction. The web is then released so that retraction by the relatively elastomeric fibers provides looping and bunching of the elongated relatively nonelastic fibers to thereby provide a low modulus of elasticity in the direction in which the web was worked.

Owner:HOWMEDICA OSTEONICS CORP

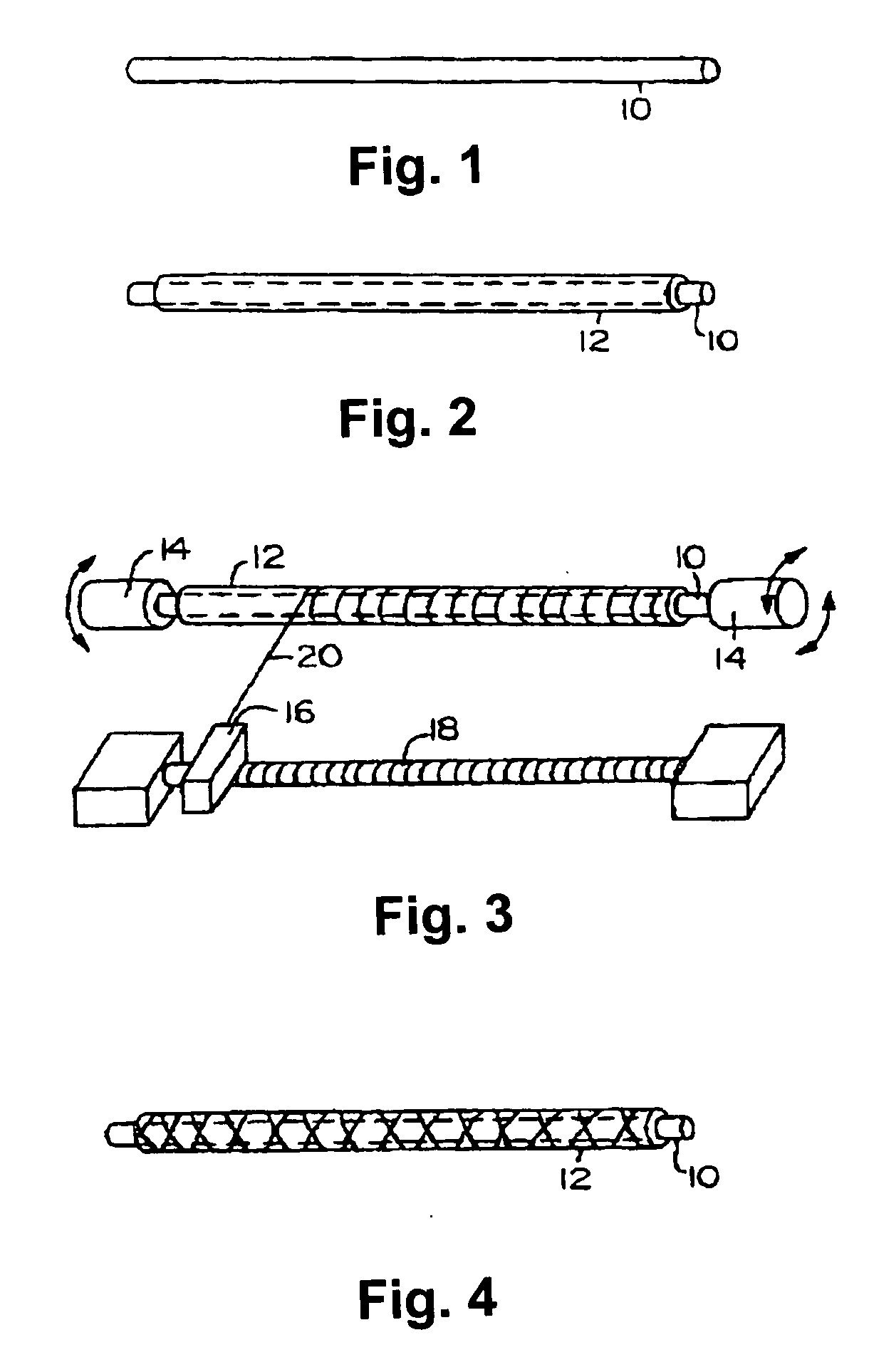

Low-cost elastic laminate material

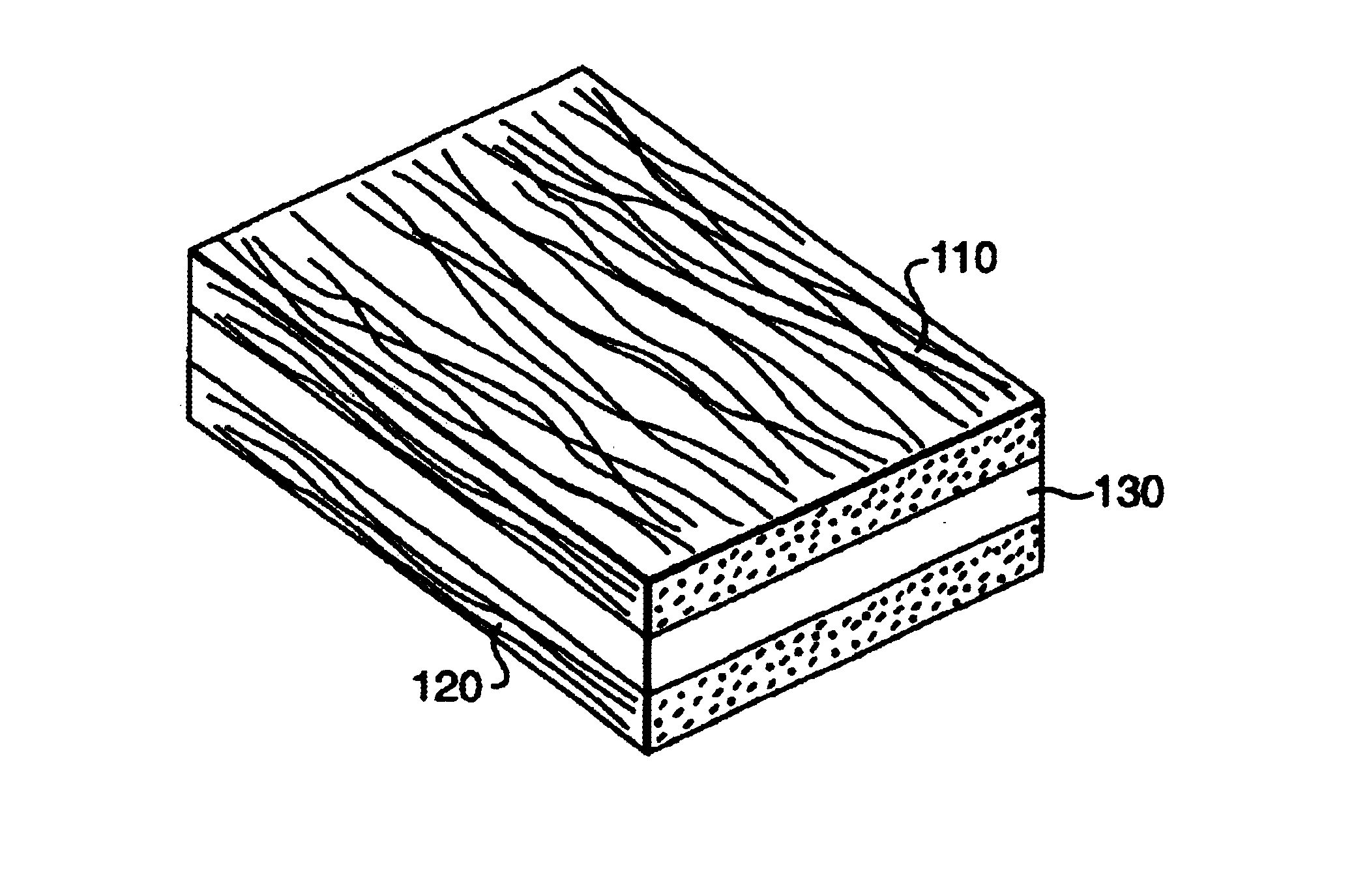

InactiveUS7078089B2Improve bindingMechanical working/deformationPaper/cardboard wound articlesElastic fibresEngineering

Disclosed herein are elastic laminate materials. The elastic laminate materials are laminates of extensible nonwoven fibrous webs and thermoplastic elastic materials. The laminate may be a two-layer composite material having a single nonwoven fibrous web bonded to one side of the thermoplastic elastic material, or it may be a three-layer composite having a nonwoven fibrous web bonded to each side of the thermoplastic elastic material. The extensible nonwoven fibrous webs may be staple fiber webs. The thermoplastic elastic material may be single-layer or multi-layer elastic films, or elastic fibrous layers. Where single- or multi-layer elastic films are used, the films may be breathable films. The elastic material, or some of the staple fibers, or both, may be selected such that the staple fiber webs are thermally compatible with the thermoplastic elastic material to facilitate laminate bonding. Processes for forming the elastic laminate material are also disclosed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Extensible laminar material, in particular for sanitary articles, and relative manufacturing method

A transversely extensible elastic laminar web material comprising a first and a second web material each of which defines a first and a second distal region adjacent to corresponding longitudinal side edges and a central region between the aforesaid distal regions, at least one web of elastomeric material applied to these central regions of the first and second web materials and a plurality of connection formations applied to at least one distal region of said first and second web materials and projecting from a respective longitudinal edge. In the transversely extensible elastic laminar web material, the elastomeric web material and the connection formations are interposed between said first and second web materials and are joined thereto by mechanical welds.

Owner:FAMECCANICA DATA SPA

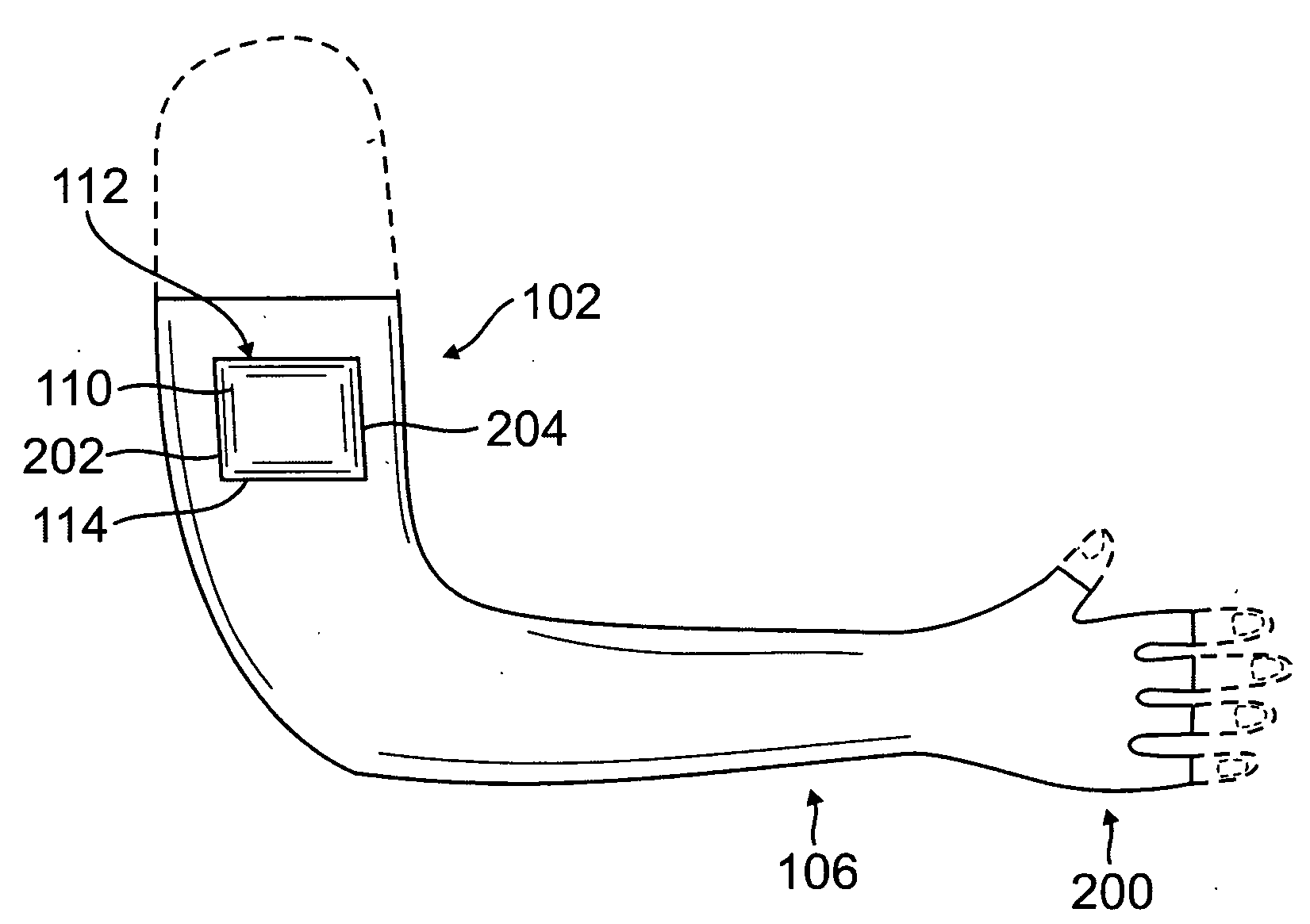

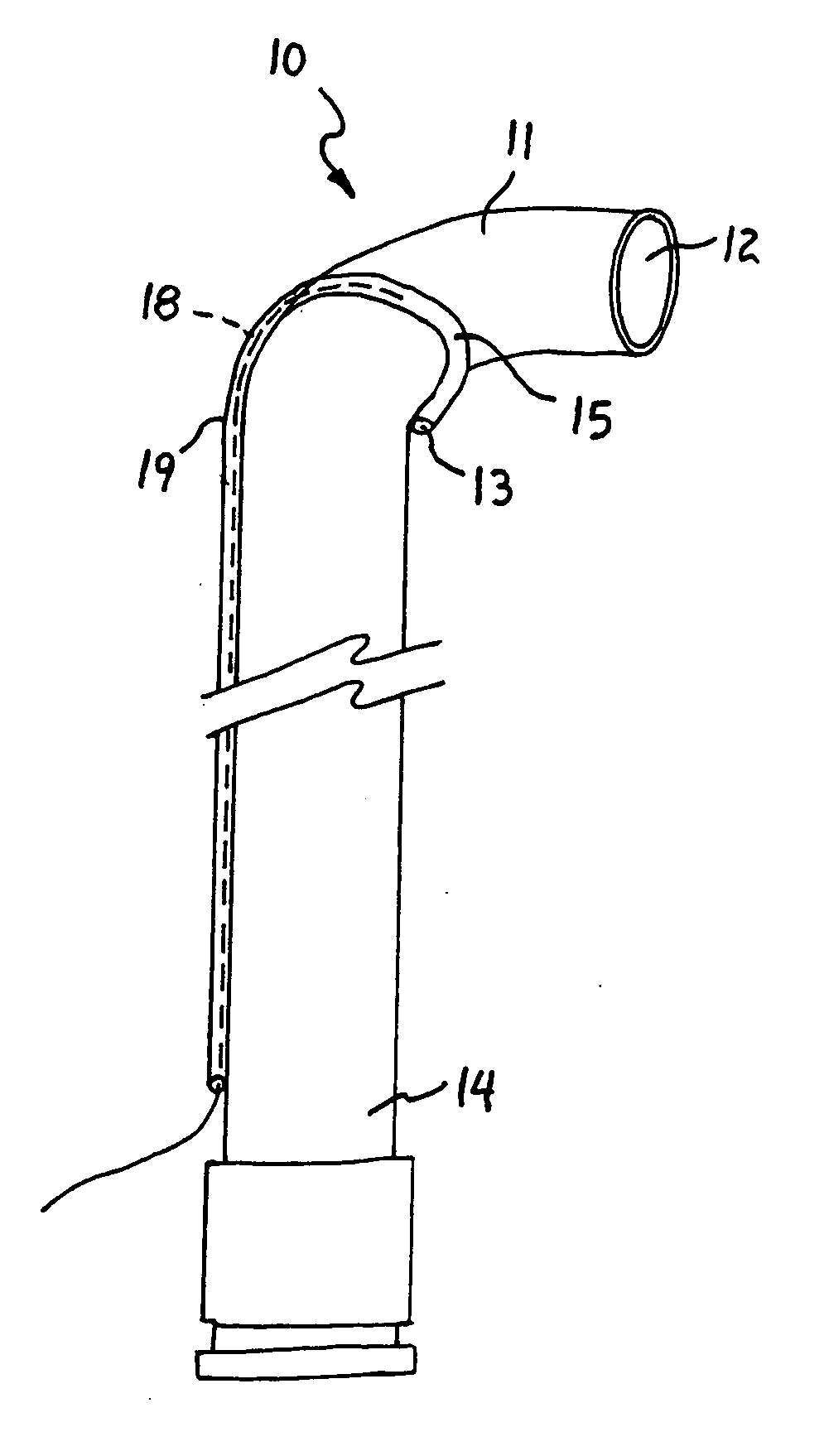

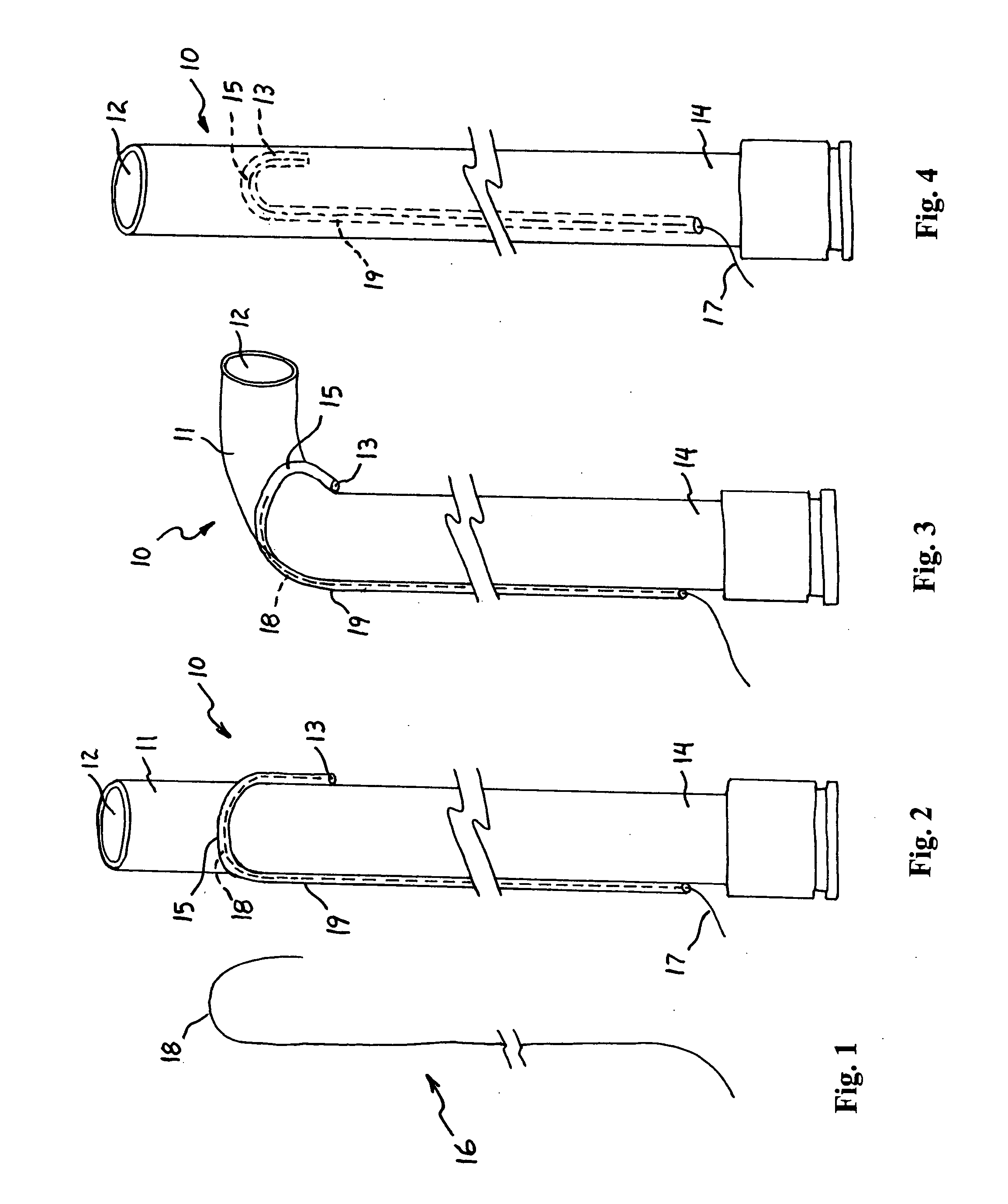

Method and apparatus for curving a catheter

InactiveUS20050004555A1Simple methodPrecise positioningCatheterRadiation diagnosticsFiberElastic fibres

An apparatus and method for curving a catheter after deployment include a catheter having a primary lumen, a secondary lumen, and a resilient fiber contained within the secondary lumen. The resilient fiber and the secondary lumen have corresponding, preformed curve shapes when the catheter is in a straight, unstressed condition. The resilient fiber is slidable within the secondary lumen to create a desired curve shape in the catheter as the curved portion of the resilient fiber slides into an originally straight portion of the secondary lumen. In another embodiment, the preformed curve shape of the resilient fiber is held in a straight condition within a stiff, marker ring segment of the catheter until after the catheter is deployed. Once deployed, the resilient fiber is slid out of the marker ring segment, and the preformed curve shape of the resilient fiber creates a corresponding curve shape in the catheter.

Owner:VOLCANO CORP

Bombax cotton thermal shell fabric and its manufacturing method

The invention discloses a kapok warm face material. The fiber ingredients and the ratio are: natural kapok fiber 10-100%, cotton or other fiber 0-90%, urethane elastic fiber and other elastic fiber 0-50%. The invention also discloses the manufacture method including the following steps: selecting the fiber ingredients; spinning after mixing the raw material; weaving on the knitting great circle machine; dyeing and after processing. The advantage of the invention is good warm effect, soft tactility and comfort.

Owner:DONGHUA UNIV

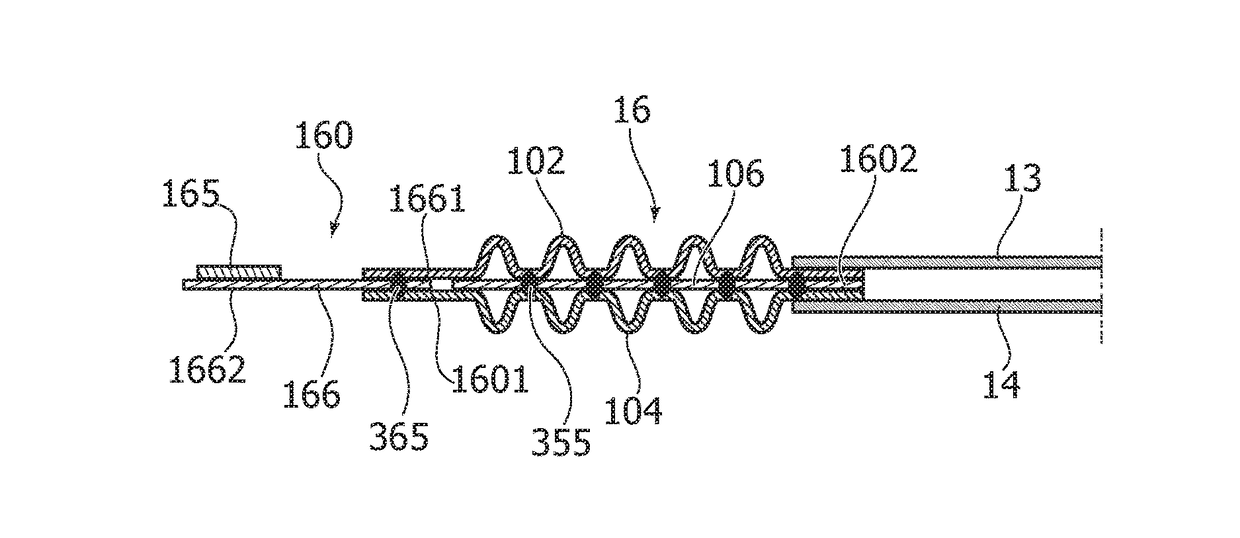

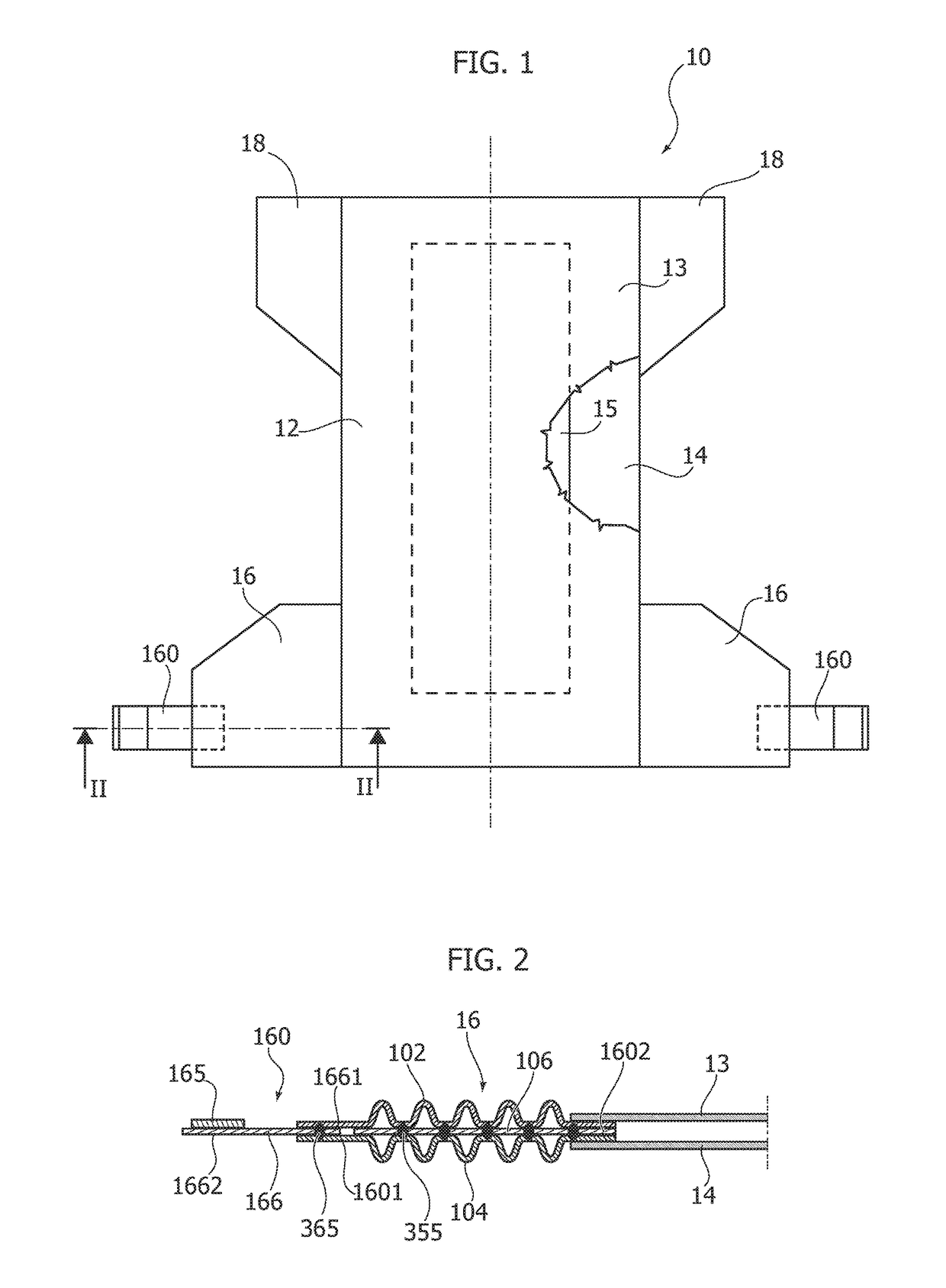

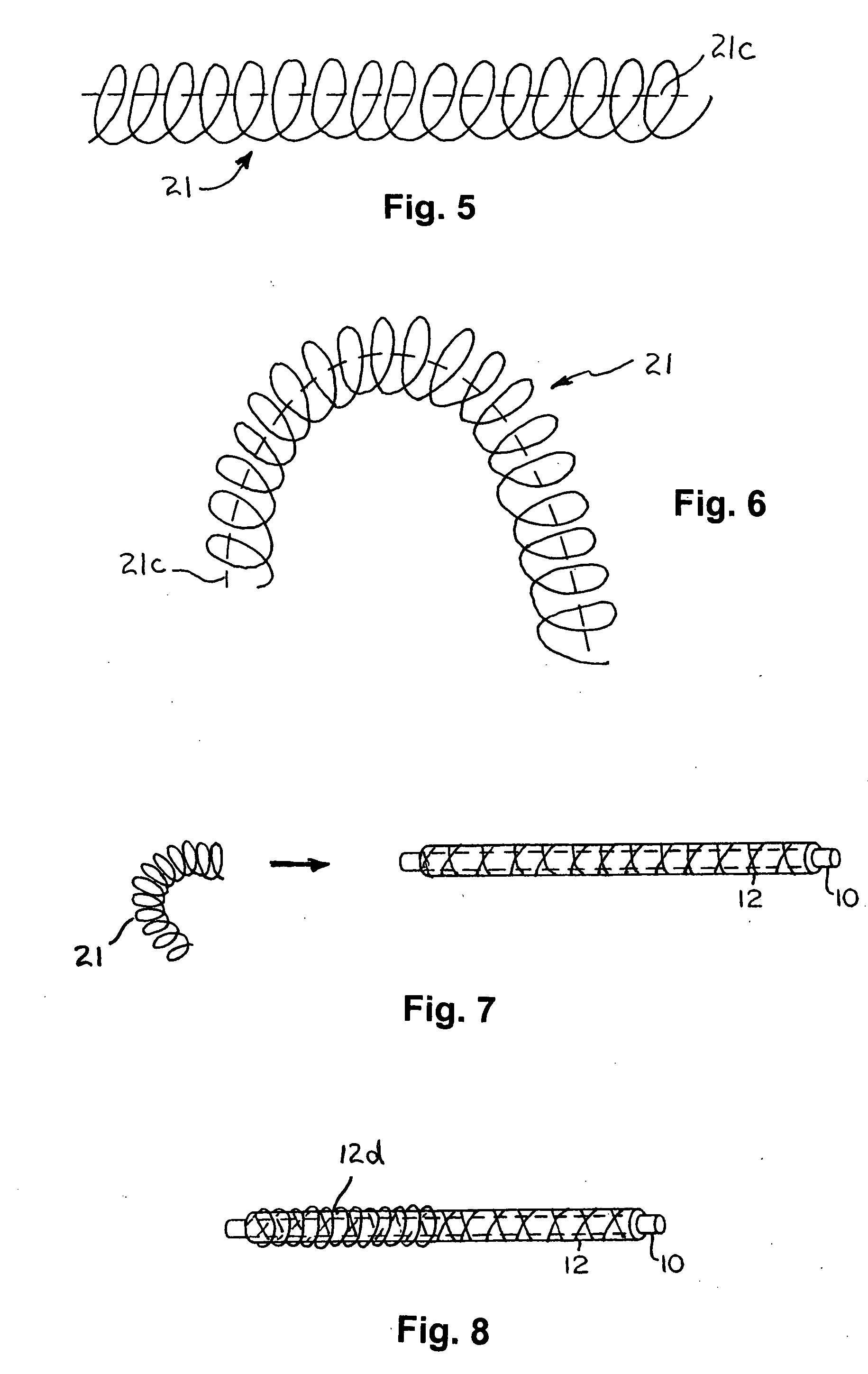

Catheter with curved distal end and method of making the same

A catheter having a curved distal end is disclosed in which a resilient fiber embedded in a polymer material of the sidewall imparts a bend in the catheter. The resilient fiber has a helical coil shape with a series of helical coils disposed about a center line. During manufacturing, the resilient fiber is bent into a curved condition in which the center line is curved, and then the resilient fiber is heated while in its curved condition to create a memory set in the helical coil shape. The resilient fiber is then placed over a mandrel along with a fibrous reinforcement material, and a polymer material is applied over the mandrel to form a catheter with the resilient fiber embedded in the sidewall. Upon removing the mandrel from the lumen of the catheter, the catheter will bend into a curved shape corresponding to the memory set in the resilient fiber.

Owner:IMPACT MEDICAL TECH

Underclothing fabric and processing technique thereof

InactiveCN102031624AGood warmth retentionGood skin affinityWeft knittingDyeing processYarnAcrylic fibre

The invention relates to an underclothing fabric which comprises the following raw materials in percentage by weight: 4-18% of heating fiber, 30-52% of anti-pilling acrylic fiber, 35-40% of Lenzing Modal fiber, 4-6% of nylon fiber and 3-5% of Lycra elastic fiber. The processing technique comprises the following steps: spinning the heating fiber, the anti-pilling acrylic fiber and the Lenzing Modal fiber into sirospun yarns, coating the Lycra elastic fiber with the sirospun yarns and the nylon fiber, weaving with a circular weft knitting machine, carrying out dyeing pretreatment, dyeing, cleaning, neutralizing, fixing, soaping, softening, drying, scutching, sanding, shaping and the like. The underclothing fabric has favorable warm-keeping effect, has the advantages of good skin friendliness, low pilling possibility, easeful elasticity and high air permeability and is comfortable to wear.

Owner:格来德服饰贸易(上海)有限公司 +1

Newdal fibre inner wear face fabric and processing technique thereof

The present invention relates to Newdal fiber underwear fabric, and is characterized in that the present invention is composed of raw materials having the following weight percentages: 45 percent to 52 percent of Newdal fiber, 45 percent to 52 percent of cotton fiber, and 3 percent to 8 percent of Lycra elastic fiber. The processing craft is that the Newdal fiber and the cotton fiber are firstly blended for spinning, and then are interwoven with the Lycra elastic fiber, so as to make the underwear fabric. The present invention has the advantages of better gloss, skin-friendly property, smooth hand feeling and comfortable flexibility.

Owner:SHANGHAI PLANDOO TEXTILE TECH DEV

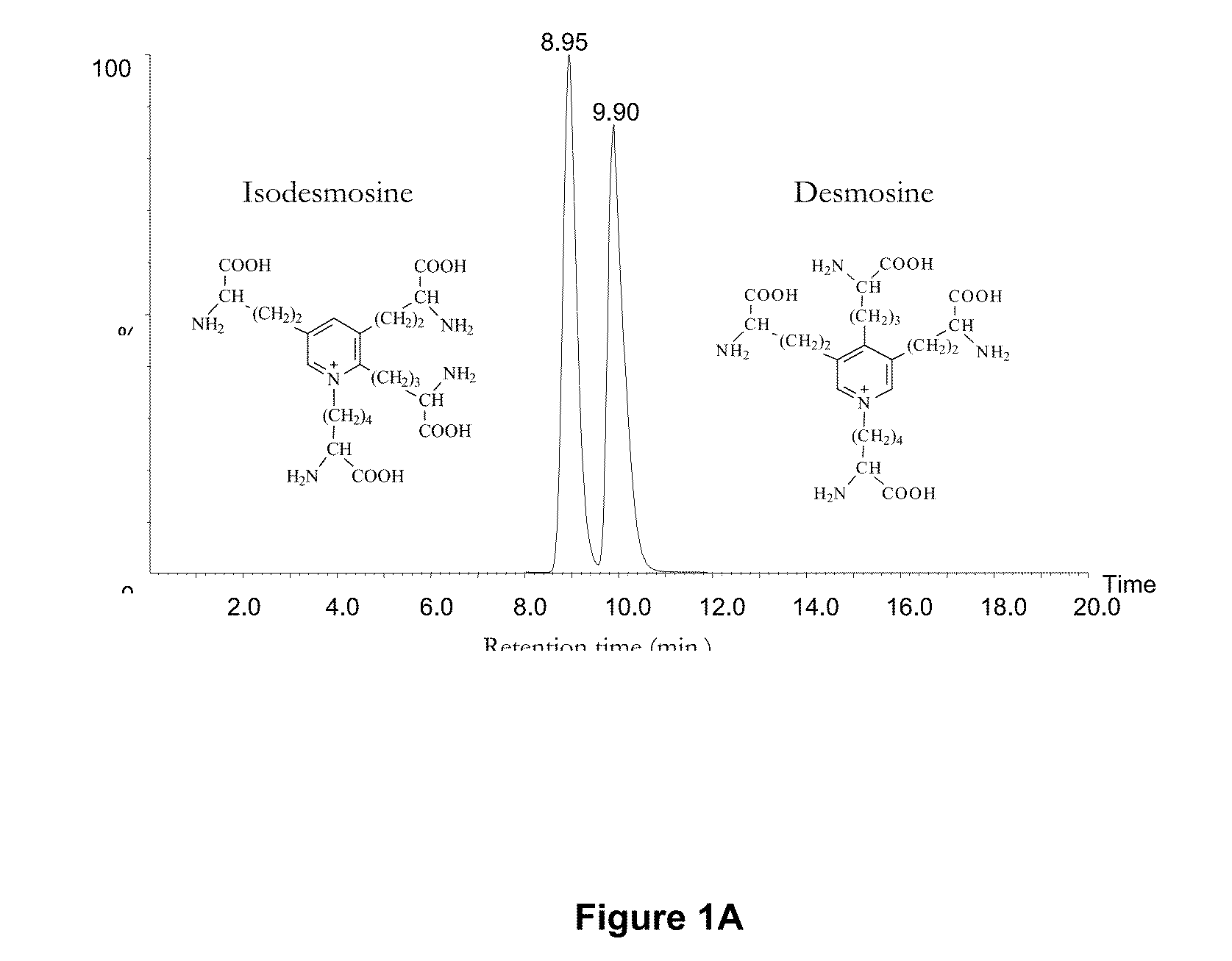

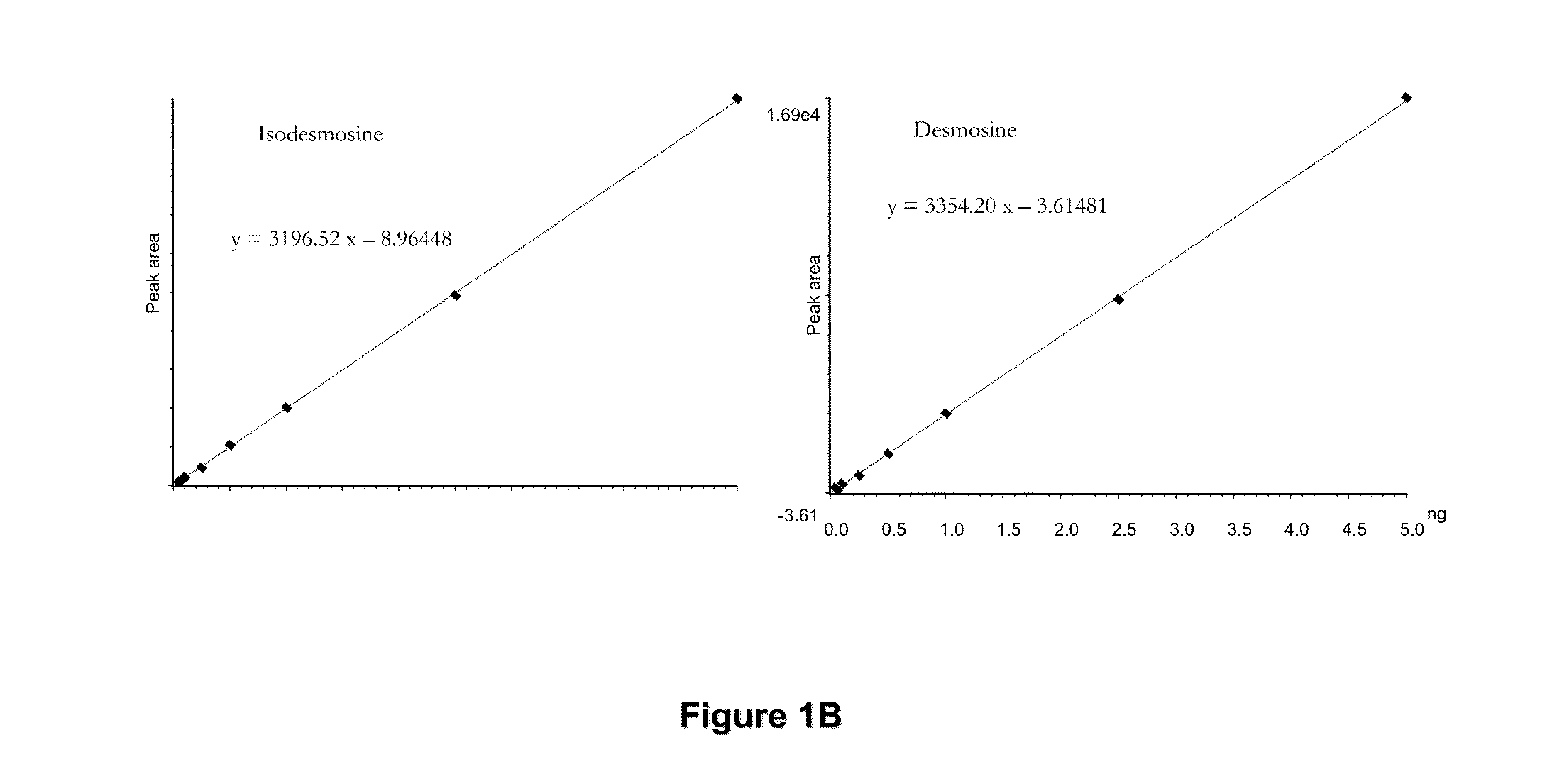

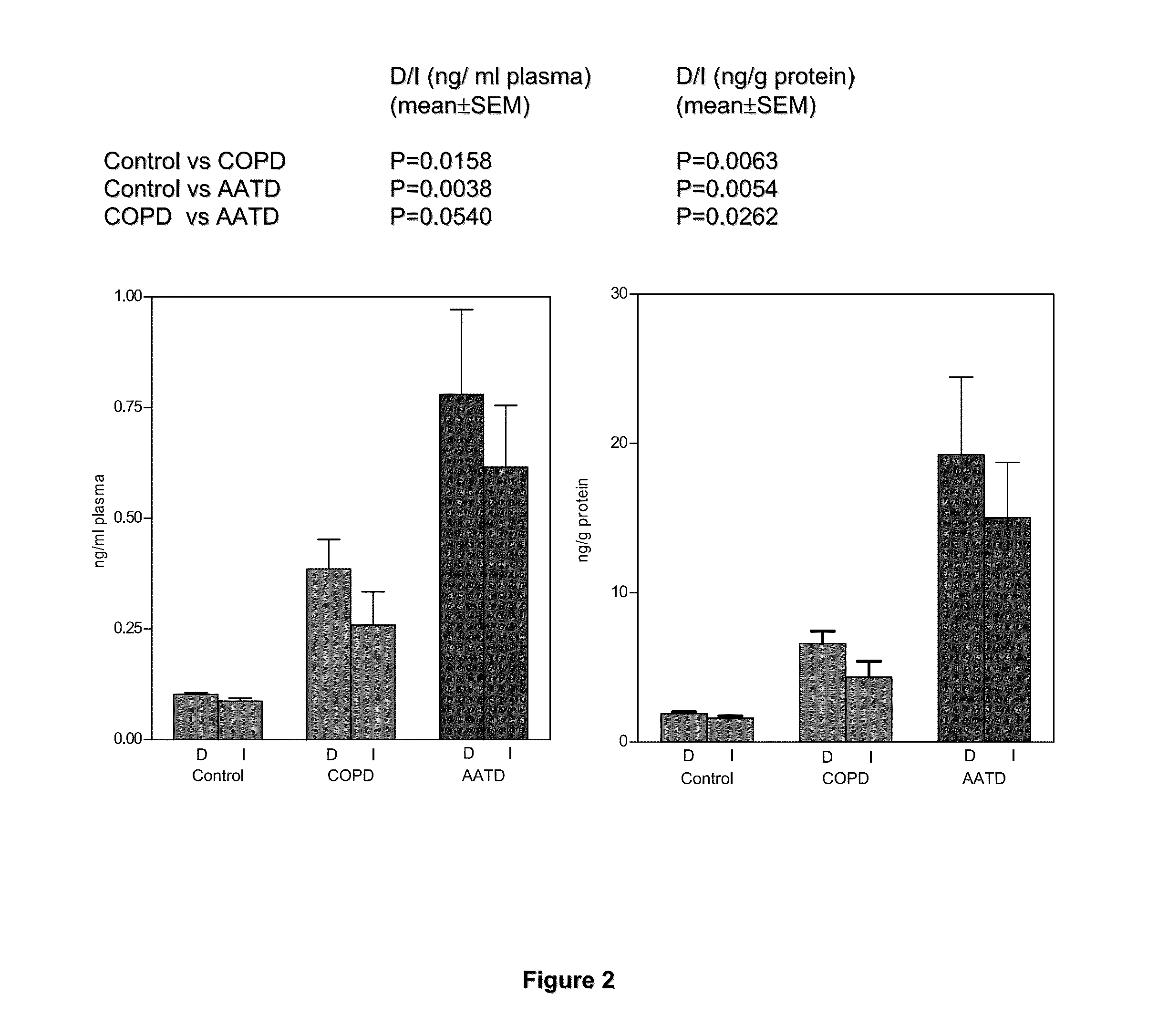

Methods of validating candidate compounds for use in treating COPD and other diseases

ActiveUS20130273586A1Improve the level ofLower Level RequirementsCompound screeningApoptosis detectionInternal standardMass Spectrometry-Mass Spectrometry

The present invention relates to methods of diagnosing, monitoring, and treating elastin fiber injuries. In additional preferred embodiments, the present invention relates to methods of validating candidate compounds for use in treating chronic obstructive pulmonary disease (COPD), chronic bronchitis, emphysema, refractory asthma, and other related diseases. Examples of such methods include determining if the candidate compound decreases the degradation of elastic fiber in a patient administered the candidate compound by measuring, using mass spectrometry employing an internal standard, a marker of elastic fiber degradation in a sample of a body fluid or a tissue of the patient. The invention provides that a decrease in the presence of the marker compared to a control validates that the candidate compound is effective to treat, prevent, or ameliorate the disease.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

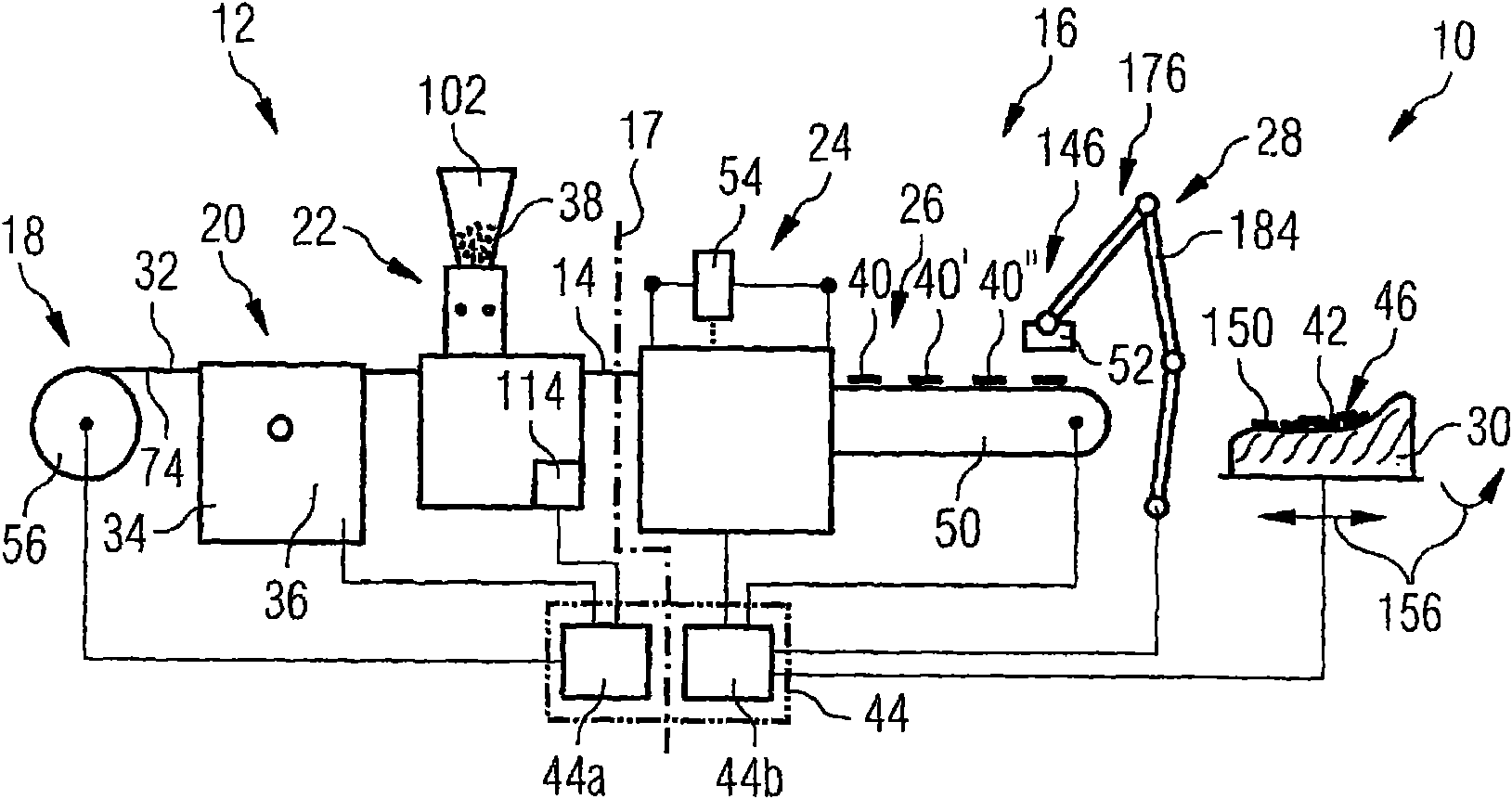

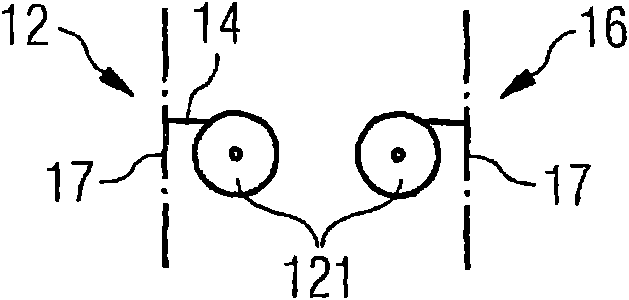

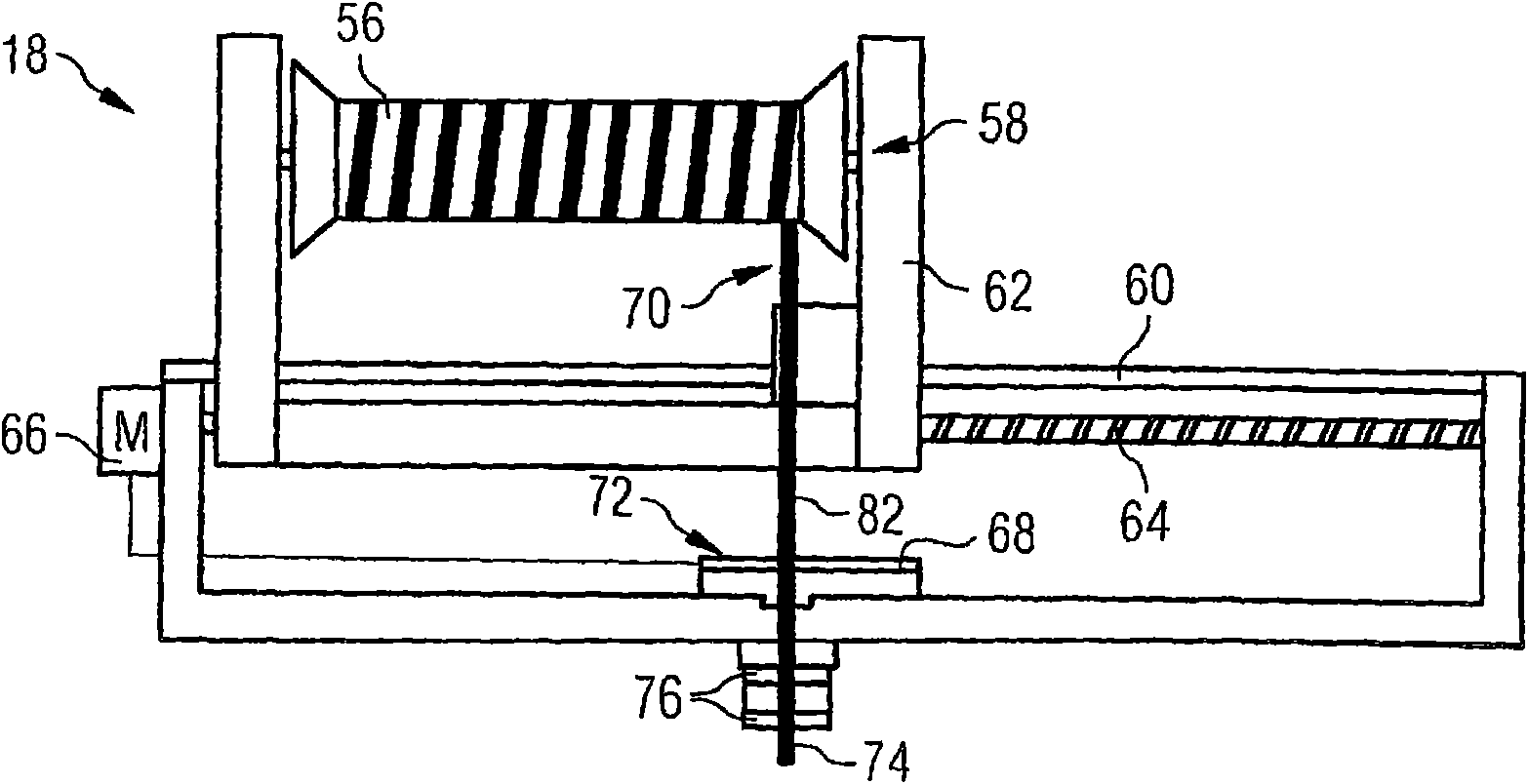

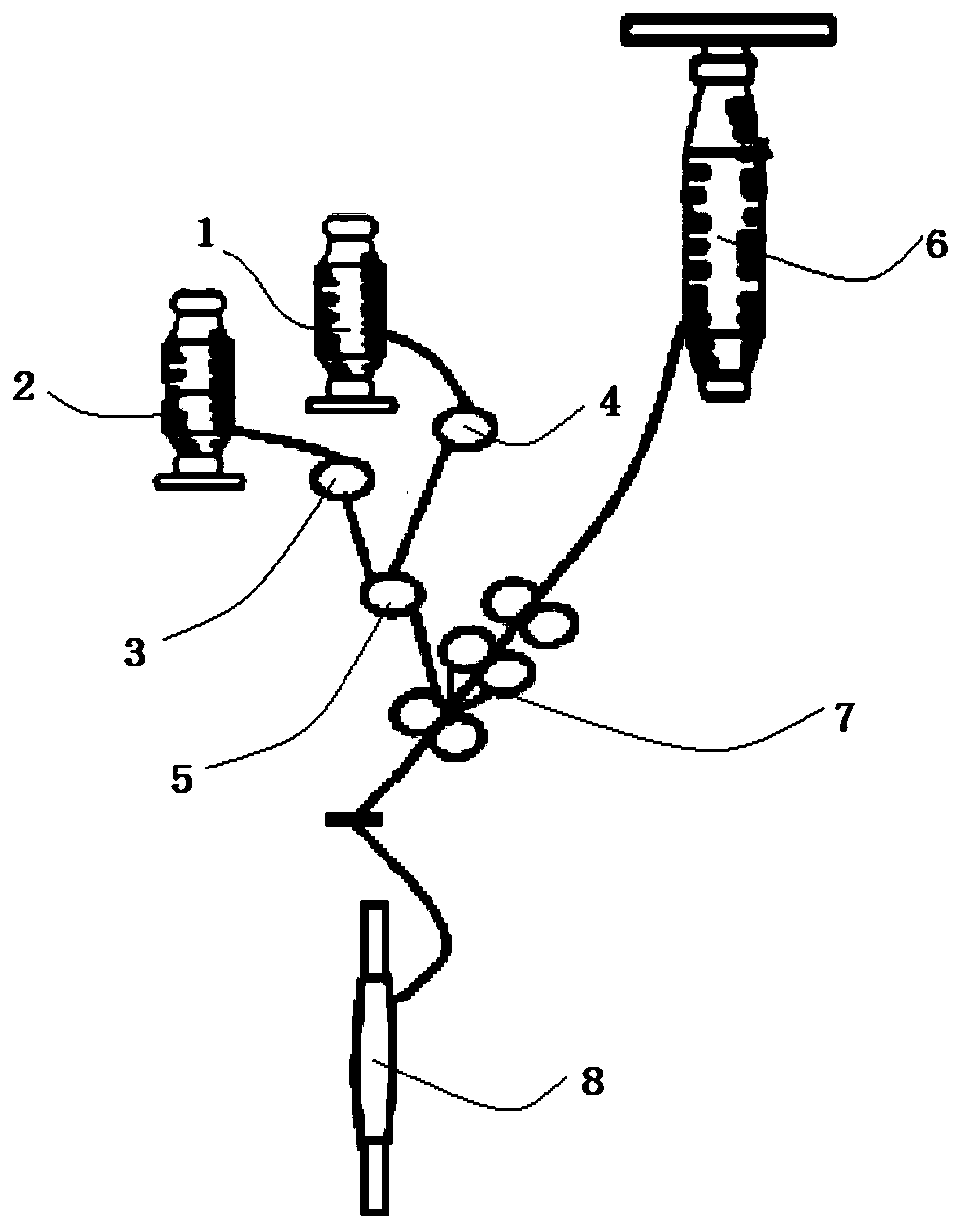

Elastic fibre laying die, laying device comprising such a die, and use of said device

Owner:EADS DEUT GMBH

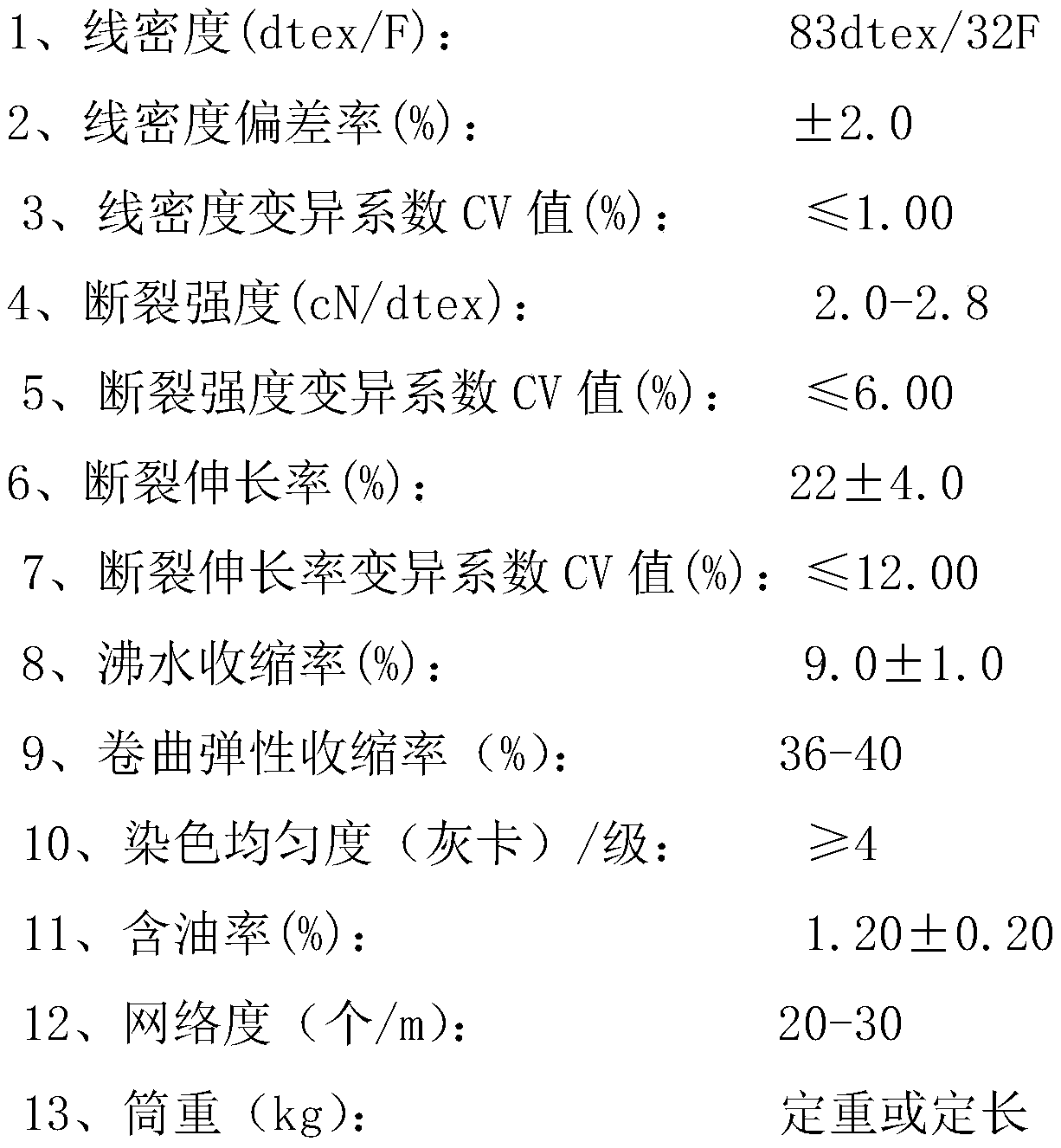

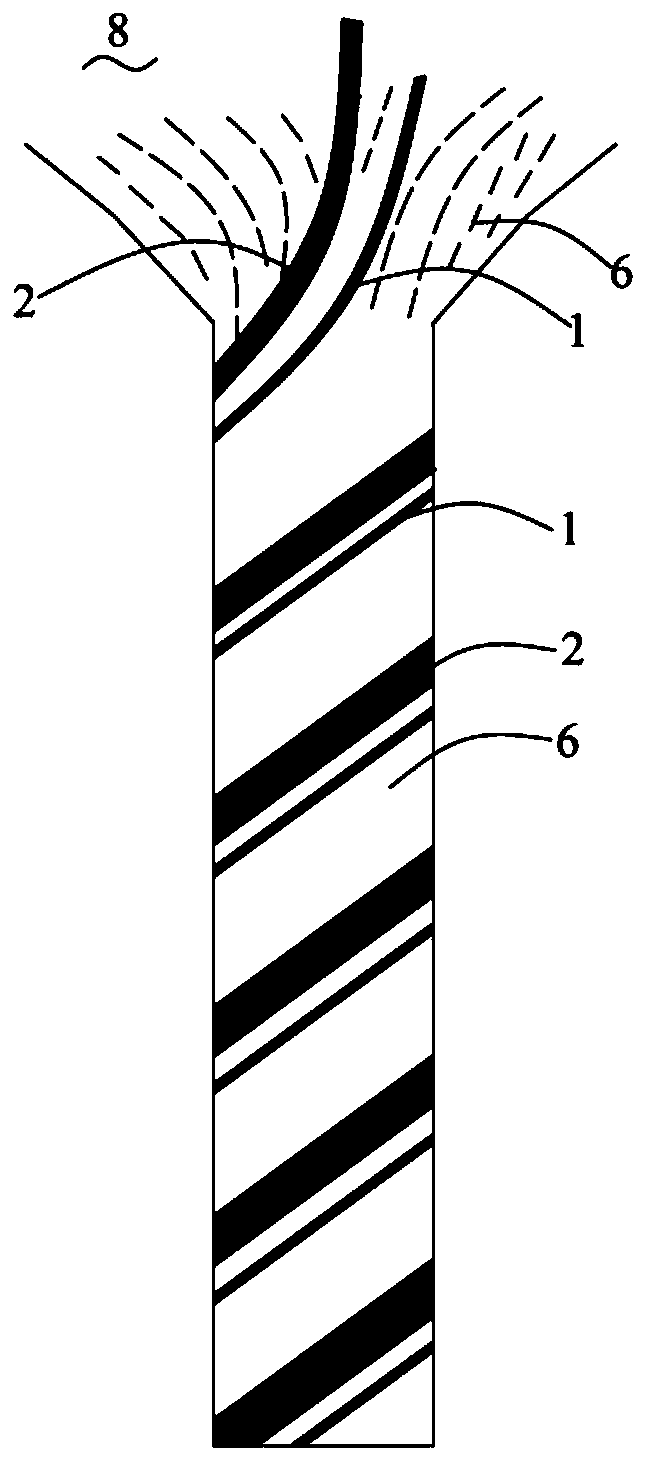

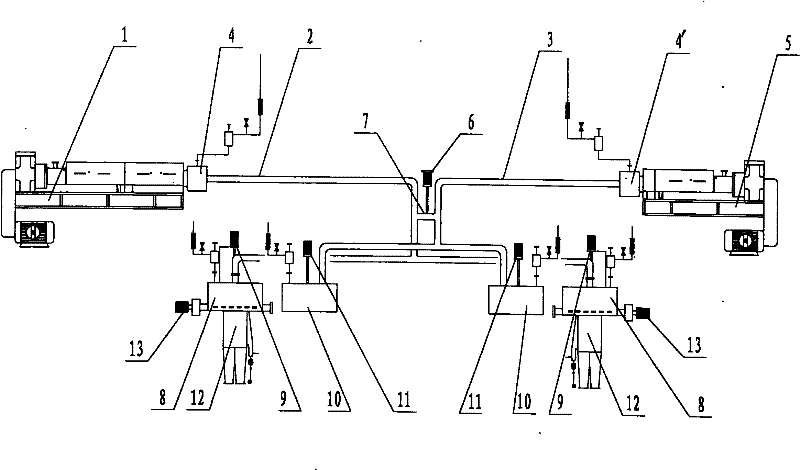

Production method of high-elasticity fiber

InactiveCN110158194AImprove dye uptakeReduce dyeing costsMelt spinning methodsConjugated synthetic polymer artificial filamentsFiberPerspiration

The invention discloses a production method of high-elasticity fiber. The production method includes: selecting PET and PBT to be conveyed to a spinning component through a double-screw conveyor for mixing, and performing lateral air blowing, oiling, pre-networking, drafting and setting, main-networking, winding for forming, inspecting and graded packaging to complete production, wherein PET enters the spinning component through conveying, pre-crystallizing, drying, melted extrusion, filtering and a box metering pump, PBT enters the spinning component through conveying, drying, melted extrusion, filtering and the box metering pump, viscosity of PET is 0.45-0.55dl / g, viscosity of PBT is 1.25-1.4dl / g, and a proportion of PET and PBT is 1:1-1:1.1. The fiber produced by the method has characteristics of both PBT and PET; due to a side-by-side compositing mode, the fabric has lasting and stable high elasticity and functions of moisture absorption and perspiration.

Owner:TONGKUN GRP

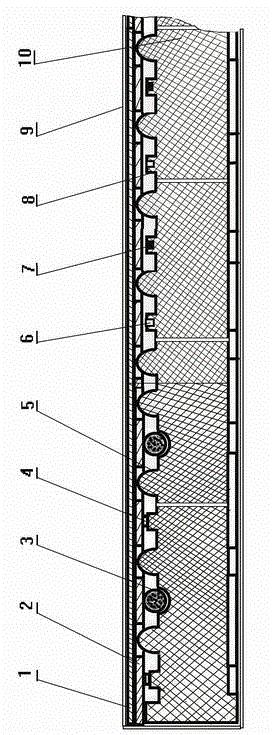

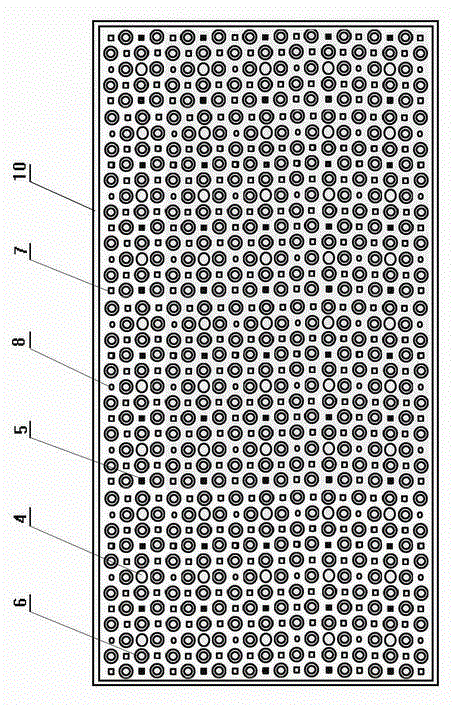

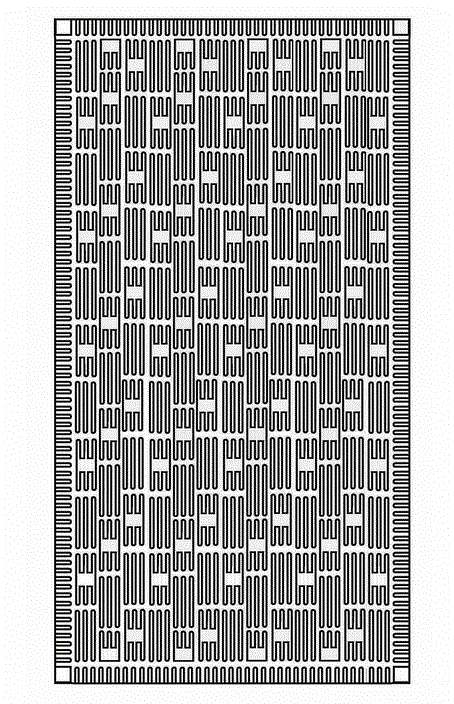

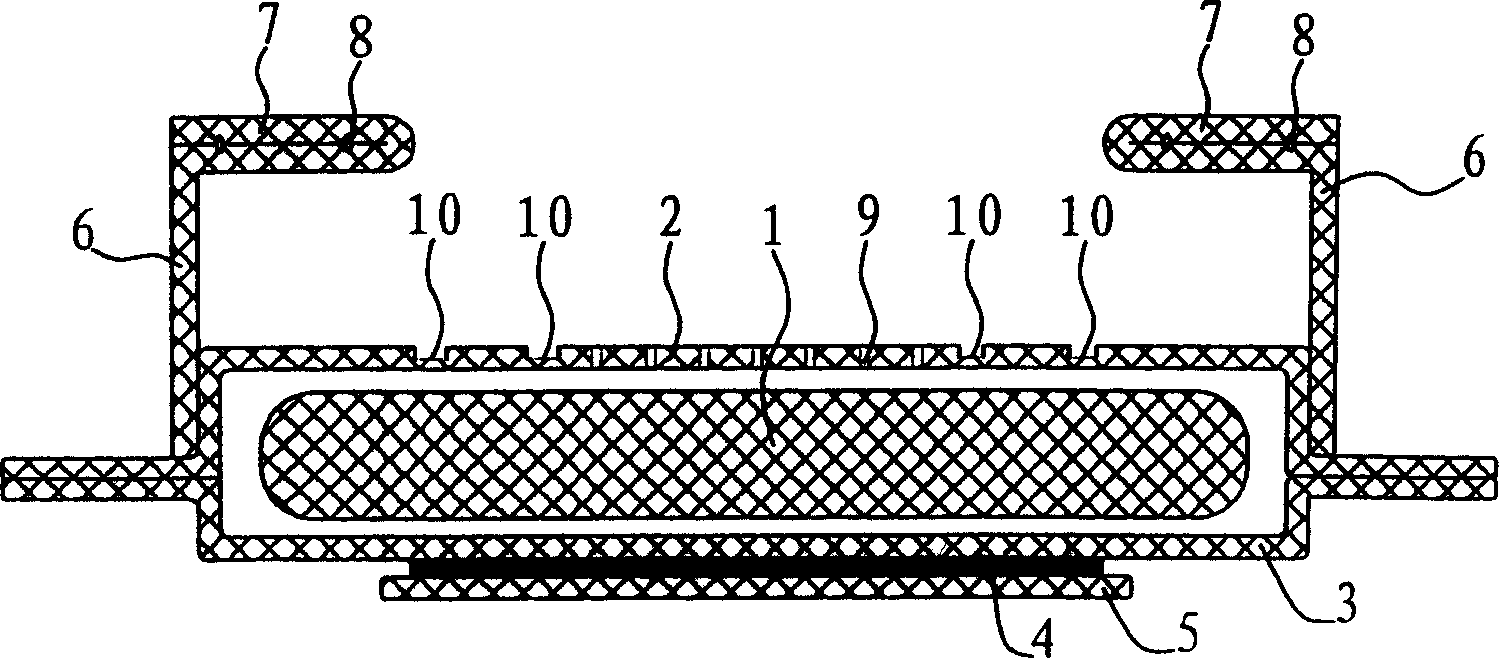

Multifunctional health mattress

InactiveCN104605671AImprove microcirculationImprove actual functionsStuffed mattressesSpring mattressesHuman bodyVitality

The invention discloses a multifunctional health mattress. The multifunctional health mattress is composed of a surface layer (9), a wool composite layer (1), an elastic fibre layer (2), a gasket body (10), medicine bags (3), magnetic blocks (4), massage columns (5), tourmaline negative ion particles (6), far infrared radiation blocks (7) and functional block seats (8), wherein the medicine bags (3) comprise taxus chinensis, phoebe zhennan, folium artemisiae argyi, saffron crocus, osmanthus fragrans, tourmaline and other traditional Chinese medicinal material substances, and through the body temperature of a human body and the heat preservation performance of the gasket body (10) made from a polyethylene foaming material, a thermogenetic effect of the mattress can be used for exciting the exertions of the properties of natural plants and traditional Chinese medicinal materials in the medicine bags (3) and the emission of a natural and aromatic smell, activating negative ion release and far infrared radiation, promoting the micro-circulation of the human body, adjusting the internal functions of the human body, enhancing the cell viability and the vitality, reinforcing the body immunity, improving the various defective conditions of the body, improving the sleep quality of people, so as to achieve the health function of body building.

Owner:湘西自治州众心梦生物科技有限公司

Anti-aging weight-losing and skin-tightening essence

InactiveCN111297753ASolve saggingImprove firmnessCosmetic preparationsToilet preparationsArginineButanediol

The invention provides an anti-aging weight-losing and skin-tightening essence which comprises the following ingredients in percentage by mass: 3 to 5 percent of butanediol, 1 to 3 percent of glycerin, 0.05 to 0.2 percent of hyaluronic acid, 0.5 to 2 percent of betaine, 0.5 to 1.5 percent of biosaccharide gum-1 solution, 0.5 to 1.5 percent of a mixture of hydrolyzed collagen and euglena gracilis polysaccharide, 0.1 to 0.5 percent of arginine, 0.1 to 0.5 percent of p-hydroxyacetophenone, 0.02 to 0.1 percent of caprylhydroxamic acid solution, 1.75 percent of a skin conditioner, 0.35 percent of athickening agent and 0.05 percent of a chelating agent. The mixture of hydrolyzed collagen and euglena gracilis polysaccharide is used, and enters the epidermal layer through the skin to realize targeted reticular energy release; elastic fiber cells, glial cells and epithelial cells are fast and continuously activated; the metabolic growth regeneration is accelerated; the elasticity is enhanced;the problem of skin looseness and sagging is solved; and the effect of improving the skin tightness is achieved. The anti-aging weight-losing and skin-tightening essence also uses the hydroxyacetophenone, and has anti-oxidization capability on the skin; the activity of COX-2 can be inhibited; the skin oxidization is delayed; and the luster is maintained.

Owner:济南霜叶红生物科技有限公司

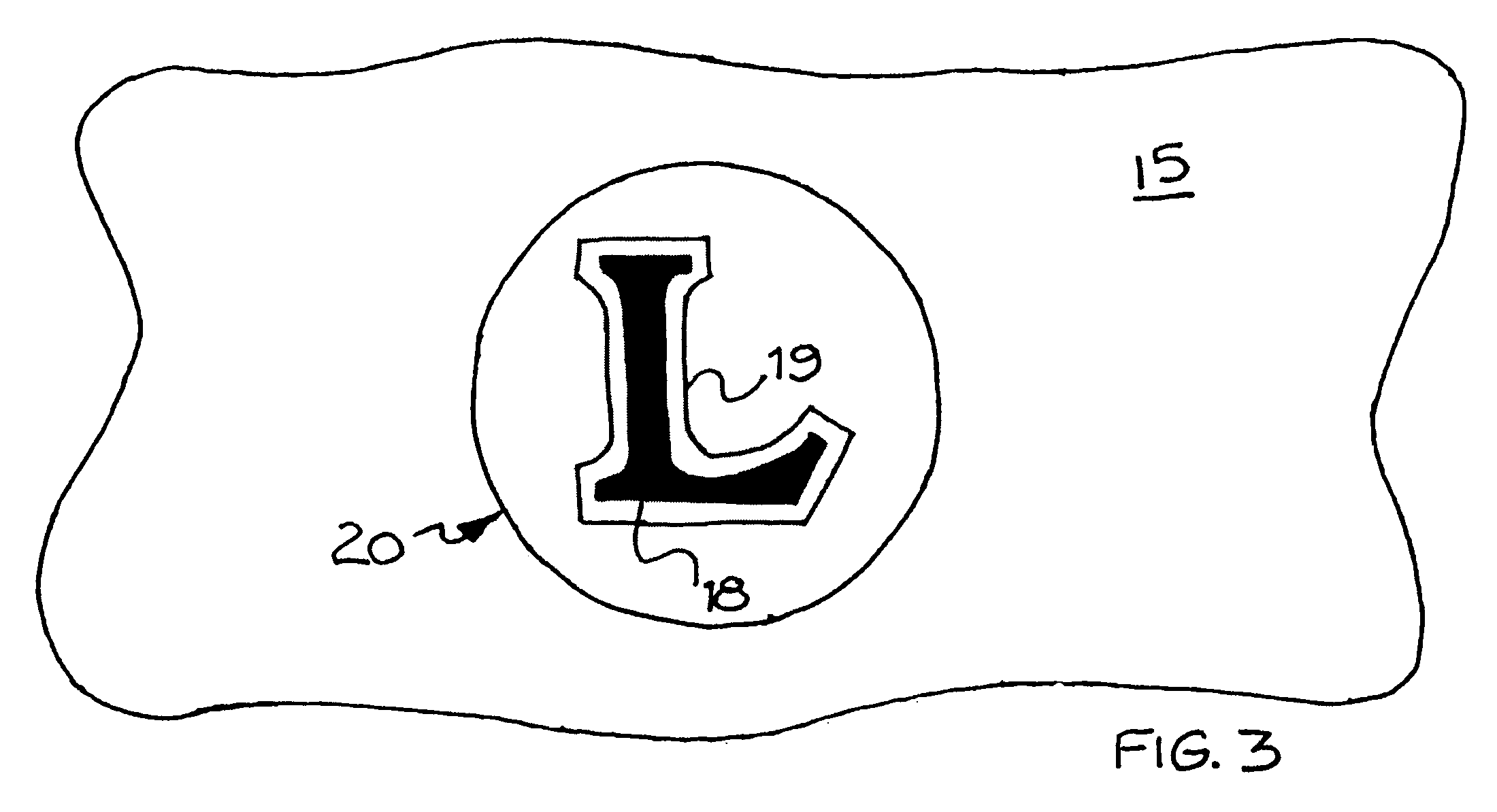

Heat activated applique with upper stretch fabric layer

ActiveUS8765257B2Easy to cutEasily bonded to itselfSynthetic resin layered productsDyeing processThermoplasticYarn

A heat activated applique for apparel and other textile products, and particularly those made out of stretch fabrics (typically knit or woven fabrics) comprised of synthetic or natural fiber yarns constructed with spandex fibers and yarns. The applique includes an upper stretchable fabric layer bonded to a substrate by a thermoplastic adhesive. The stretchable fabric layer is a knit or woven fabric with spandex and polyester or nylon threads, and the thermoplastic adhesive is a urethane-based thermoplastic adhesive with stretch and recovery characteristics. The applique can be layered to provide a three-dimensional characteristic, embossed or etched to provide a surface texture, and adorned with direct printing or sublimation dye. The applique may be easily heat-sealed to a garment or other textile.

Owner:LION BROS CO INC

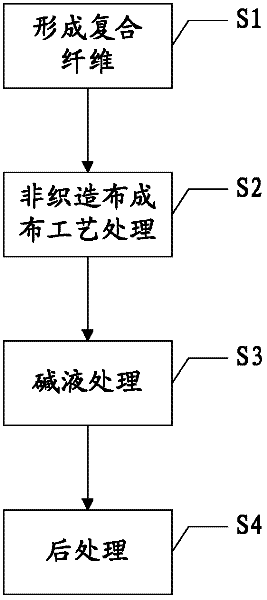

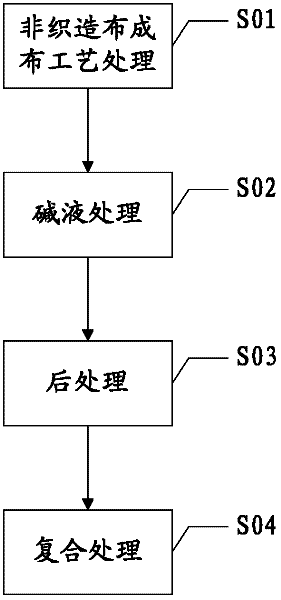

Elastic non-woven fabric, production method thereof and elastic product

ActiveCN102230256AImprove breathabilityNot easy to pillingNon-woven fabricsVegetal fibresElastic fibresCompound matrix

The invention discloses an elastic non-woven fabric, a production method thereof and an elastic product. The production method comprises the steps of: sequentially performing alkali liquid processing and post-processing for a compound non-woven fabric, or sequentially performing the alkali liquid processing and the post-processing for a general non-woven fabric and compounding with an elastic object to obtain the elastic non-woven fabric; the material of the compound non-woven fabric contains compound fibres; compound matrixes of the compound fibres include cellulose fibres and elastic fibres; and the material of the general non-woven fabric contains cellulose fibres. The elastic non-woven fabric containing the cellulose fibres, produced by the invention, has elasticity and shape memory, and has the advantages of good ventilation and difficult ball formation, so that the quality of the elastic non-woven fabric or the elastic product is improved; and the application field of the cellulose fibres is widened; for example, the elastic non-woven fabric can be used for producing medical dressings, such as elastic bondages and the like, for producing elastic materials, such as elastic belts and the like, and for producing semi-durable and durable clothes.

Owner:WINNER MEDICAL CO LTD +2

Hydrophilic skin-friendly non-woven fabric

InactiveCN105714477AGood water permeabilityImprove breathabilityAbsorbent padsNon-woven fabricsElastic fibresPolyester

The invention discloses a hydrophilic skin-friendly non-woven fabric. The hydrophilic skin-friendly non-woven fabric comprises a first spun-bonded layer, a second spun-bonded layer and an elastic fibre layer which is positioned between the first spun-bonded layer and the second spun-bonded layer, wherein the elastic fibre layer is connected with the first spun-bonded layer and the second spun-bonded layer in a hot melting manner; the upper surface of the first spun-bonded layer is coated with a super soft polyester fibre layer; a bamboo cotton fibre layer is adhered to the lower surface of the second spun-bonded layer. In the mode, the hydrophilic skin-friendly non-woven fabric disclosed by the invention is soft and breathable, higher in water permeability, static electricity interference resistant, harmless to human physiology, high in breathability, excellent in skin-friendly touch sense and high in hydrophilic performance, can prevent bacteria from proliferation, and has an excellent sterilizing effect.

Owner:WUXI IMIX NON WOVEN TECH CO LTD

Method of external constructing tissue engineering blood vessel

ActiveCN1651572AScientific construction processHumanize the build processTissue cultureOn/in organic carrierSmooth muscleFiber

A process for in vitro configuration of histoengineered blood vessel and its smooth muscle are disclosed. The resultant histoengineered blood vessel has better elasticity, bright lustre and dense elastic fibres.

Owner:上海组织工程研究与开发中心

Method for changing fabric structure

ActiveCN110760963AIncrease the length of the floating zoneReduce broken endsWeft knittingDrafting machinesYarnFiber

The invention provides a method for changing a fabric structure, and belongs to the field of textile. The method includes: blending polymer filaments, elastic fiber filaments and fiber rovings to obtain white-ground composite core-spun yarns; weaving the yarns to obtain a fabric; and subjecting the obtained fabric to local heat treatment. Based on the characteristic of heat shrinkage of the polymer filaments, the heat treatment enables the polymer filaments in the white-ground composite core-spun yarns to be heated and shrunk, the yarns are shrunk, and then the fabric is driven to be shrunk, so that the density of the fabric is increased; based on the characteristic of heat melted adhesion of the polymer filaments, the heat treatment enables melt bonding fixation to occur at the overlap ofthe yarns. Therefore, the heat-treated area of the fabric loses elasticity, the fabric structure is compact, and the non-heat-treated area still keeps elasticity; the heat treatment helps change thestructure of the fabric, and improve the mechanical properties, pilling resistance and other properties of the fabric.

Owner:WUHAN TEXTILE UNIV

Pant-type absorbent article and a method for producing pant-type absorbent articles

InactiveUS20130240123A1Improved tensile strength in the elastic parts of the pant chassisIncrease resistanceLaminationLamination apparatusElastic fibresThin membrane

Owner:ESSITY HYGIENE & HEALTH AB

Process for producing modified PET/PTT elastic fiber

ActiveCN102127821AAdvanced and reasonable production technologySpinning process is stableArtificial filament physical treatmentFilament/thread formingElastic fibresYarn

The invention discloses a process for producing a modified polyethylene terephthalate / polytrimethylene terephthalate (PET / PTT) elastic fiber, relates to a process for producing a modified elastic fiber, and mainly aims to solve the problems of spinning instability and the like of a product produced by the conventional process. The method comprises the following steps of: tackifying PTT slices and PET slices in a ratio of 40:60; adding the PET slices into a screw extruder for extruding and melting, and heating in five areas; adding the PTT slices into the screw extruder for extruding and melting, and heating in three areas; and mixing a PET melt in a PET melt distributing pipe and PTT fed by a PTTa melt distributing pipe in a weight ratio of 90:10, producing by the conventional process to obtain a partially oriented yarn (POY) bobbin yarn semi-finished product, and showing elasticity by using a draw winder to obtain a draw textured yarn (DTY) finished product. The process has the advantage that: the modified PET / PTT elastic fiber which has spinning stability and high elastic recovery property can be produced.

Owner:辽宁际华新材料制造有限公司

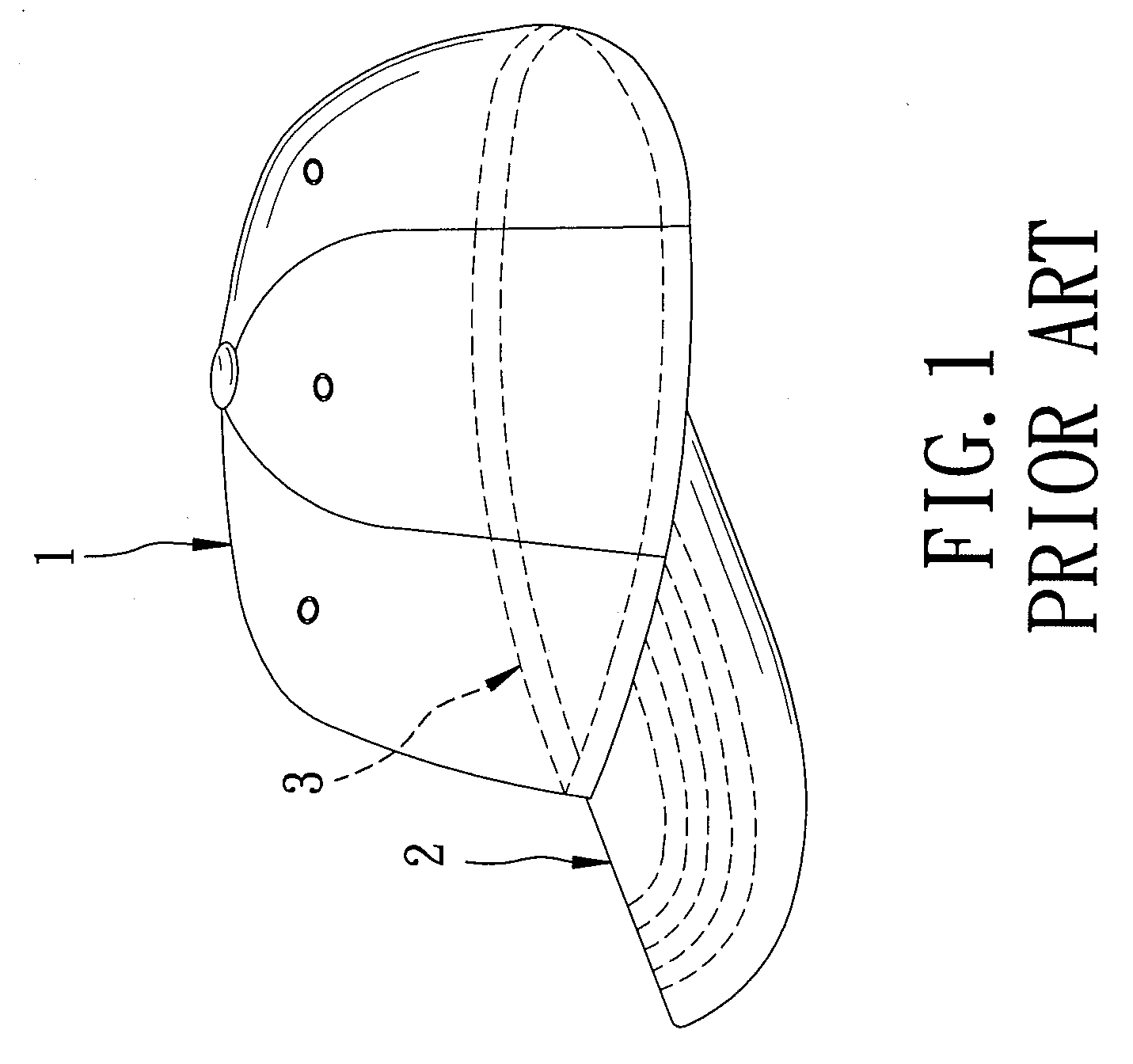

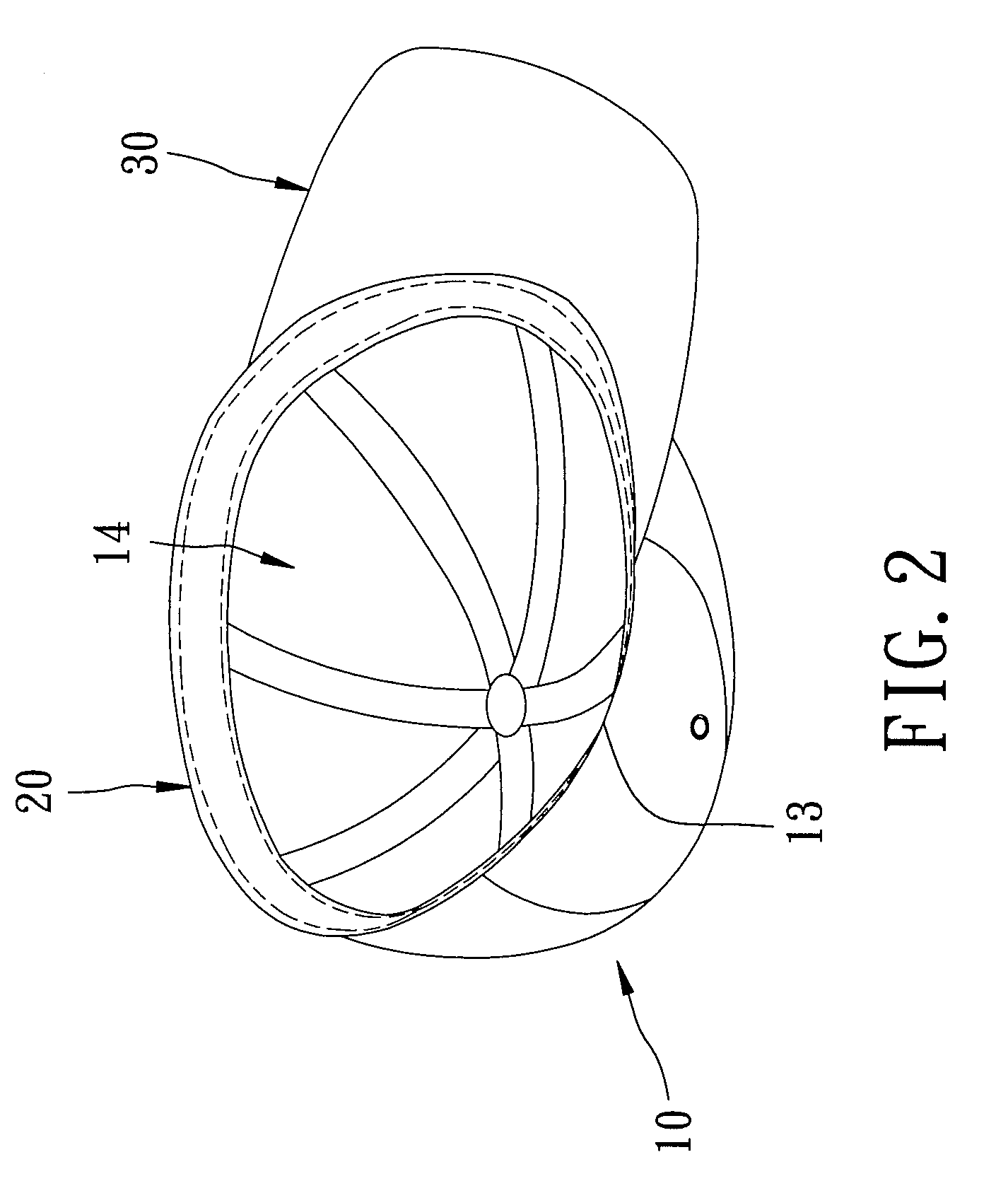

Moisture-absorbable hat

InactiveUS20100162465A1Effectively absorb perspirationOvercomes drawbackHatsHeadwear capsYarnElastic fibres

A moisture-absorbable hat includes: a crown made of a woven fabric including warp and weft textured charcoal fiber yarns, warp and weft non-charcoal fiber yarns which are not elastic and are not textured, and weft elastofiber yarns, the elastofiber yarns extending along a circumferential direction of the crown; and a sweatband attached to and extending along a circumferential open end of the crown and including warp and weft textured charcoal fiber yarns, and weft elastofiber yarns.

Owner:CHEN CHUNG SEN

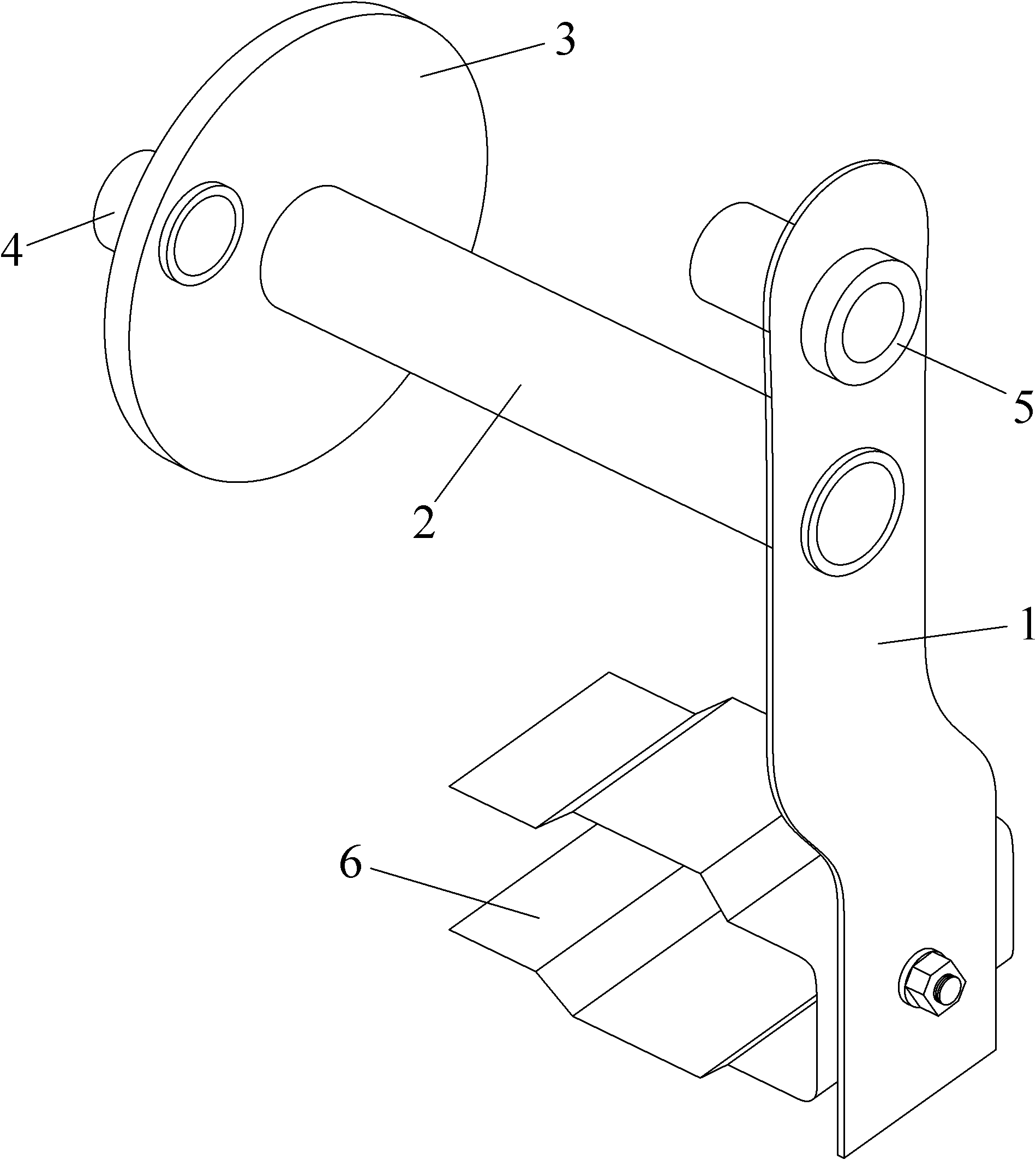

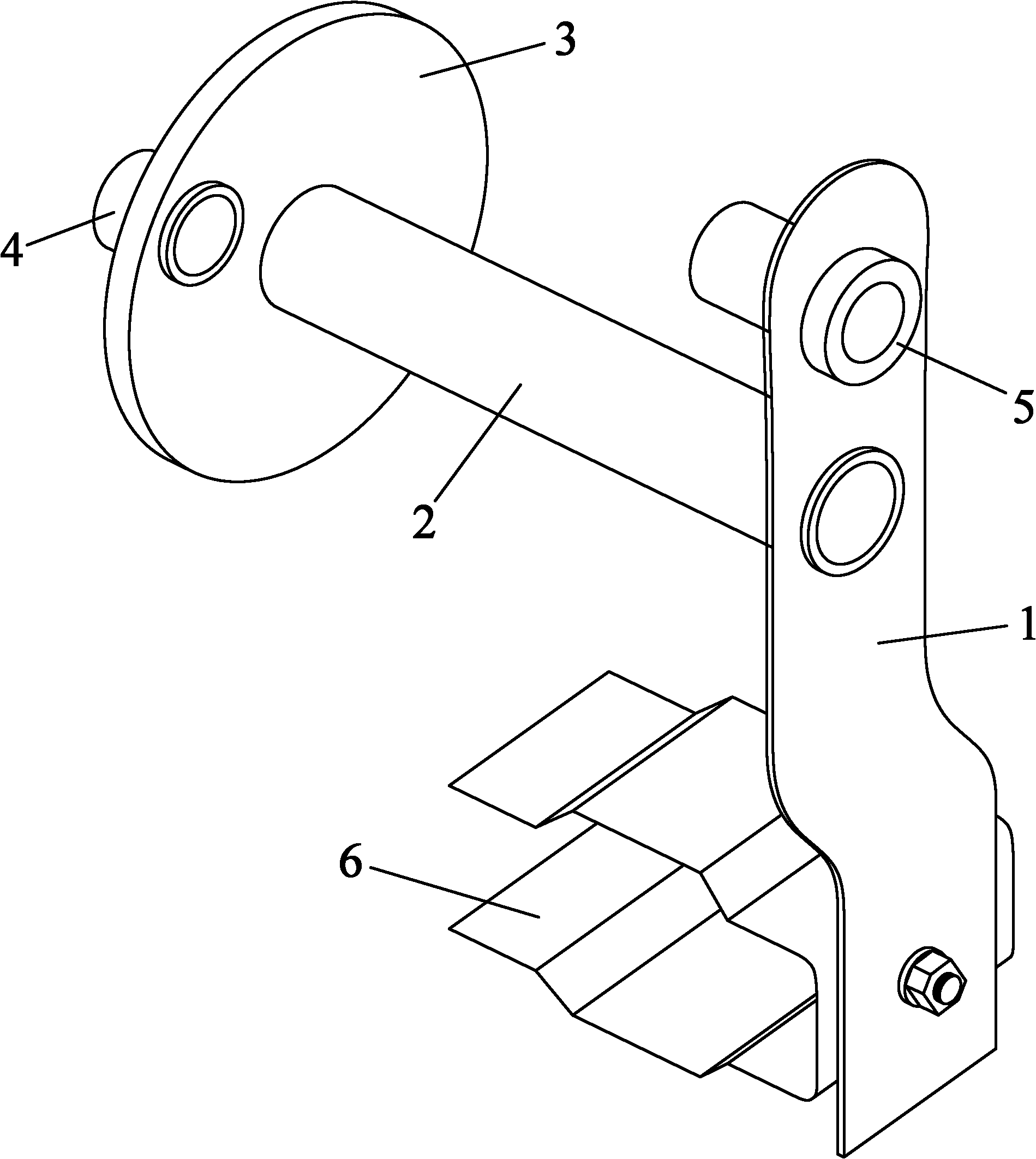

Knitting method for strong-twist non-elastic single jersey and yarn anti-knotting machine of knitting loom

The invention discloses a knitting method for strong-twist non-elastic single jersey and a yarn anti-knotting machine of a knitting loom. The knitting method comprises the following steps: a, twisting a yarn to reach the twist degree of 1800-2000 by a yarn twisting device; b, placing left twist and right twist of the twisted yarn on a yarn frame at intervals; and c, introducing the twisted yarn passing through the yarn anti-knotting machine on the yarn frame into the knitting loom to knit the strong-twist non-elastic single jersey. The cloth has cloth mark effect of the left and right twists, has preferable flexibility and ventilation property, has flexibility which is superior to that of the elastic fiber cloth, and is convenient to wear. The yarn anti-knotting machine is fixed on the yarn frame; the middle of a supporting plate is fixed with one shaft, and other end of the shaft is provided with a disk; the upper part of the supporting plate is provided with a yarn outlet porcelain mouth; and the disk is provided with a yarn inlet porcelain mouth. Tensile force of a twisting yarn is increased when the twisting yarn reels the yarn on the shaft, thus avoiding occurrence of knot tying of the twisting yarn, and adjusting the tensile force of the twisting yarn at the time of reeling the yarn on the shaft so as to adapt to the yarns with different twist degrees.

Owner:绍兴维格网络科技有限公司

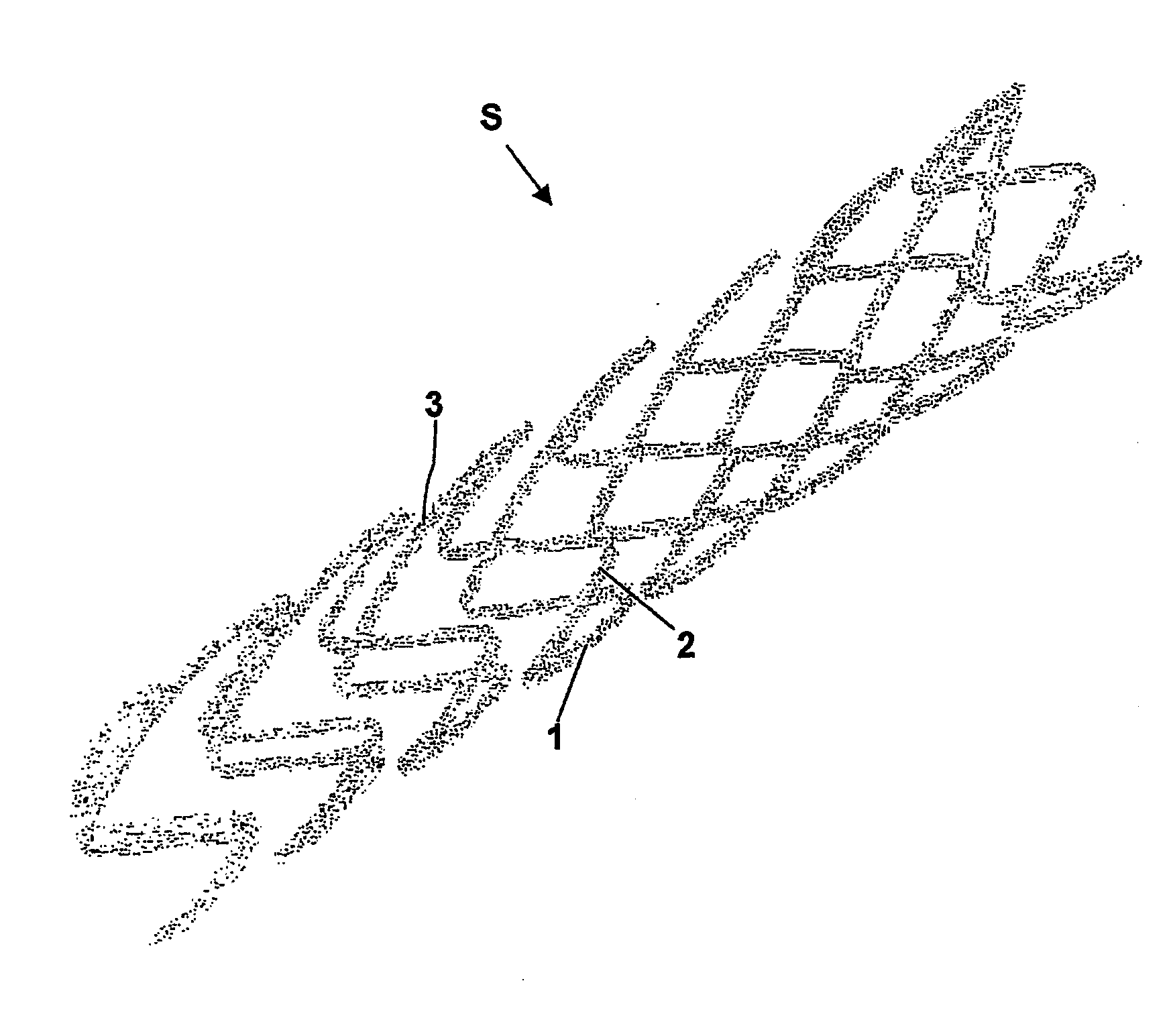

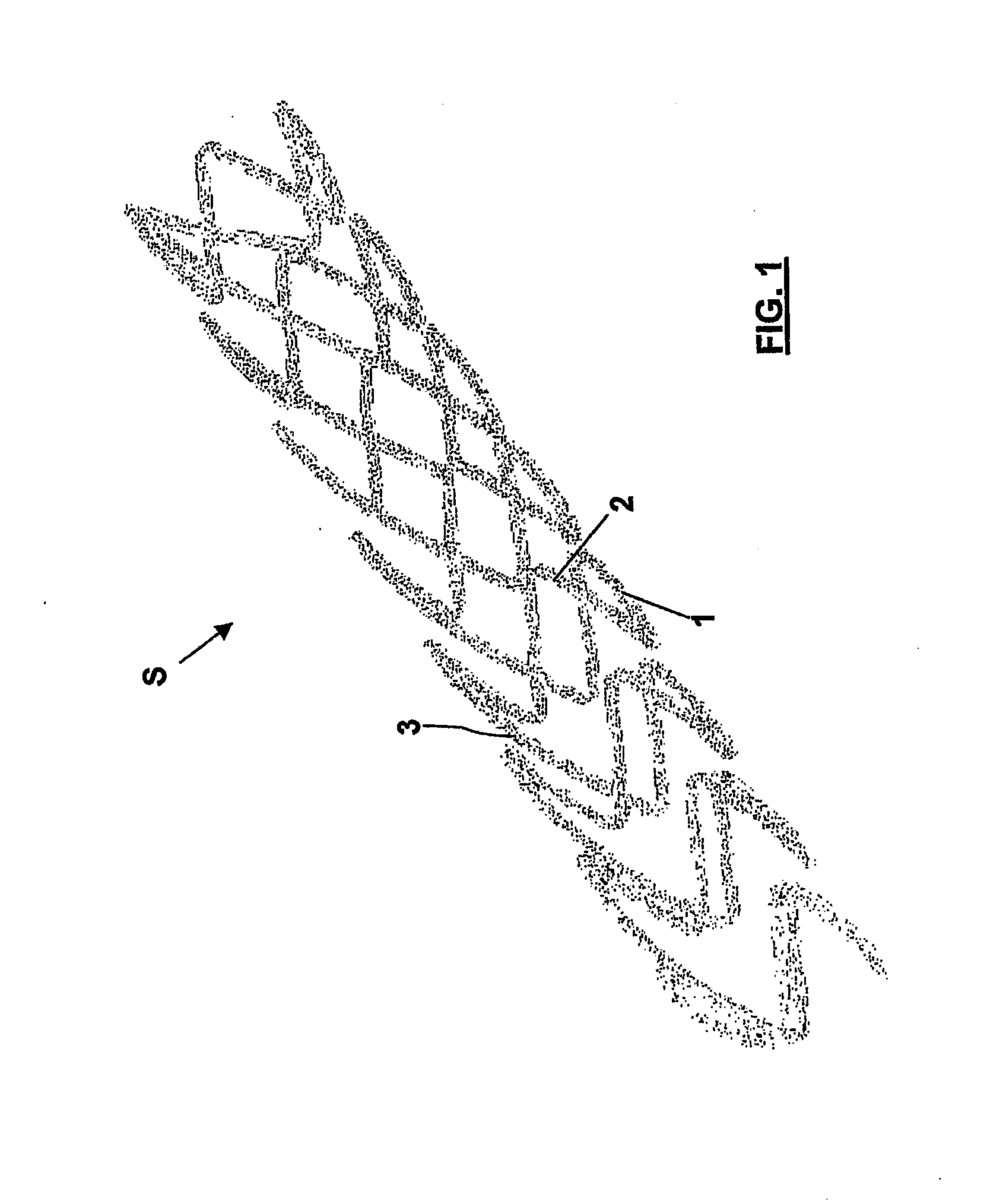

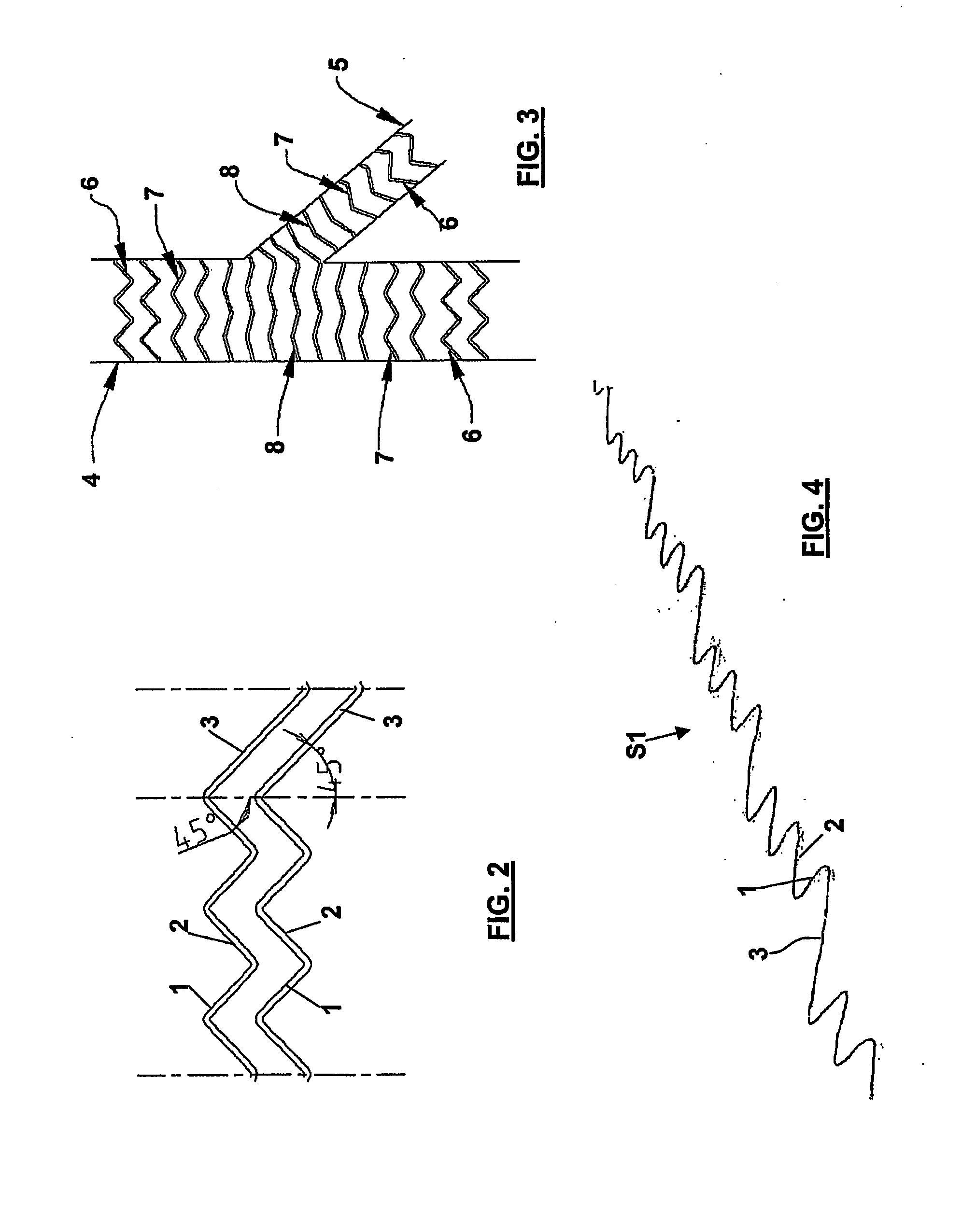

Endovascular prosthesis and relating manufacturing procedure

An endovascular prosthesis is described, in the shape of a cylindrical spiral, and comprising: one or more multiple elements each of which with a sinusoidal shape composed of first sections with a substantially rectilinear development (peaks), defining corresponding levels, and being connected to one another through second sections with a substantially rectilinear development (connection segments); the peaks (1, 2) and the connection segments (3) have an orientation that substantially follows the natural orientation of the elastic fibres of the artery.

Owner:I B S INT BIOMEDICAL SYST

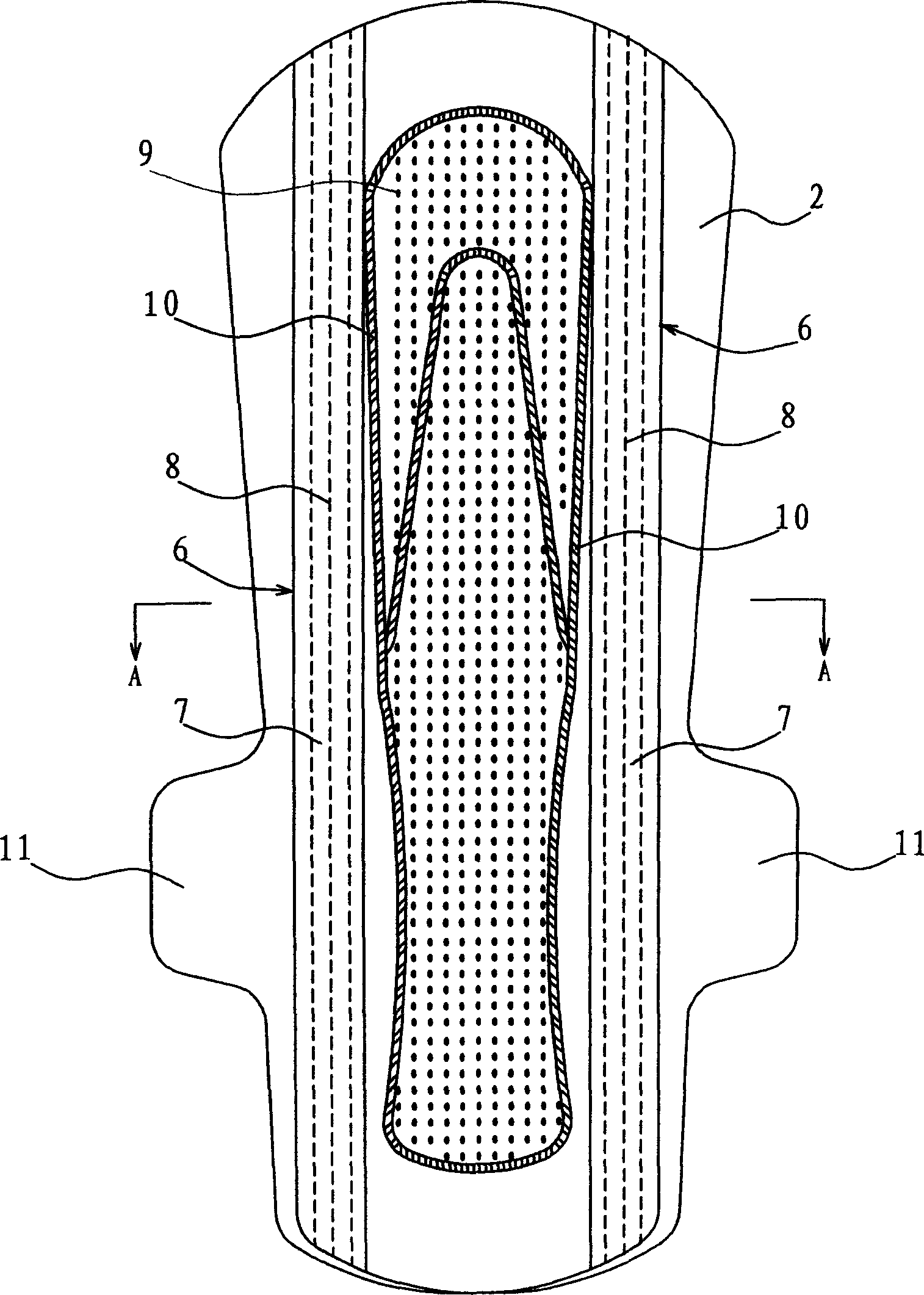

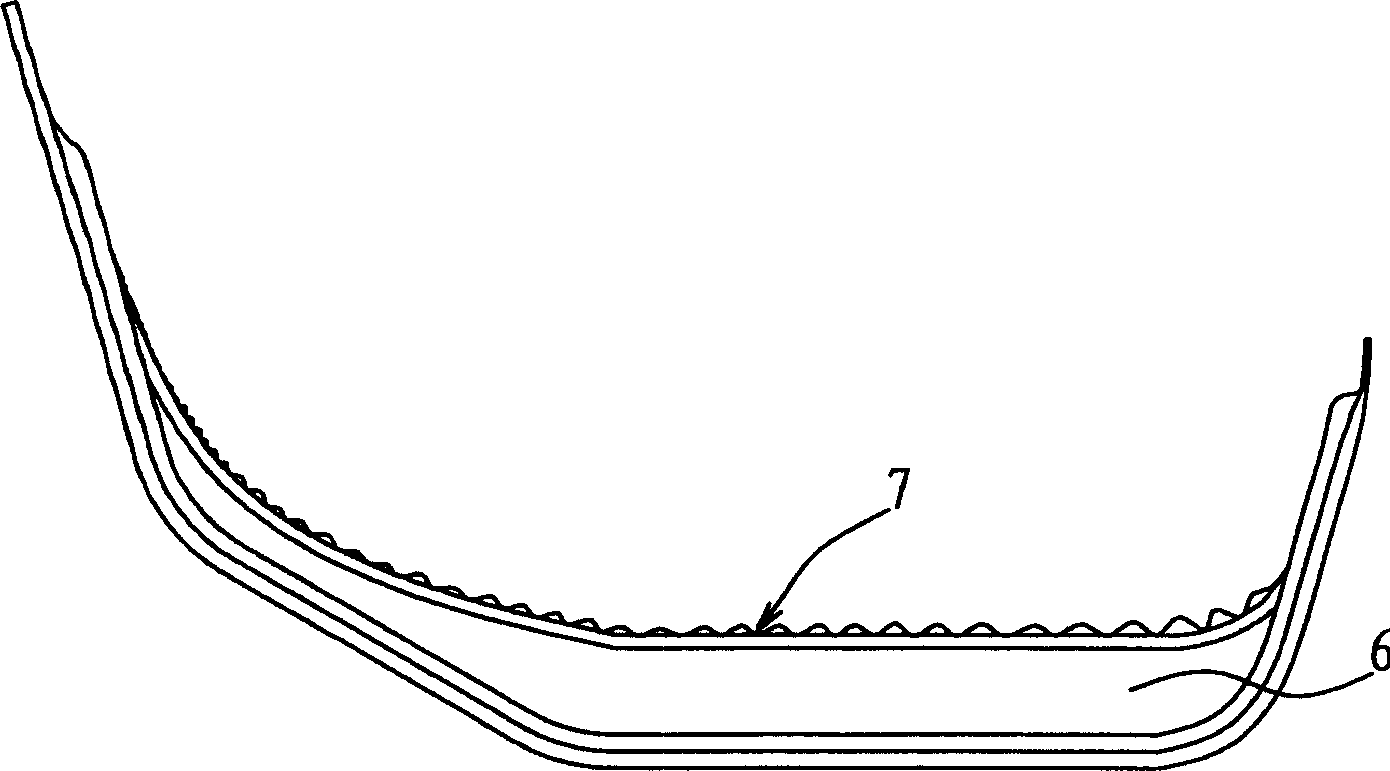

Women sanitary napkins

InactiveCN1559369AEffective stickingPrevent folding and deformationAbsorbent padsBaby linensElastic fibresEngineering

A sanitary napkin for women is composed of a liquid absorbing core, a liquid-permeable internal layer, an impervious bottom film, an adhesive layer on the external surface of said bottom film, a parting paper on said adhesive layer, and two sealing sides which are convex and contains at least one elastic fibre for each.

Owner:HANGZHOU CREDIBLE SANITARY PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com